Ammonia spraying and mixing system for coal-fired flue gas SCR denitration technology

A kind of technical equipment, coal-fired flue gas technology, applied in the direction of lighting and heating equipment, dispersed particle separation, chemical instruments and methods, etc., can solve the problems that cannot reduce the difficulty of ammonia injection adjustment, increase installation costs, increase system pressure drop, etc., Achieve the effect of optimizing the mixing effect of ammonia nitrogen, reducing energy loss, and improving the mixing intensity of vortex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

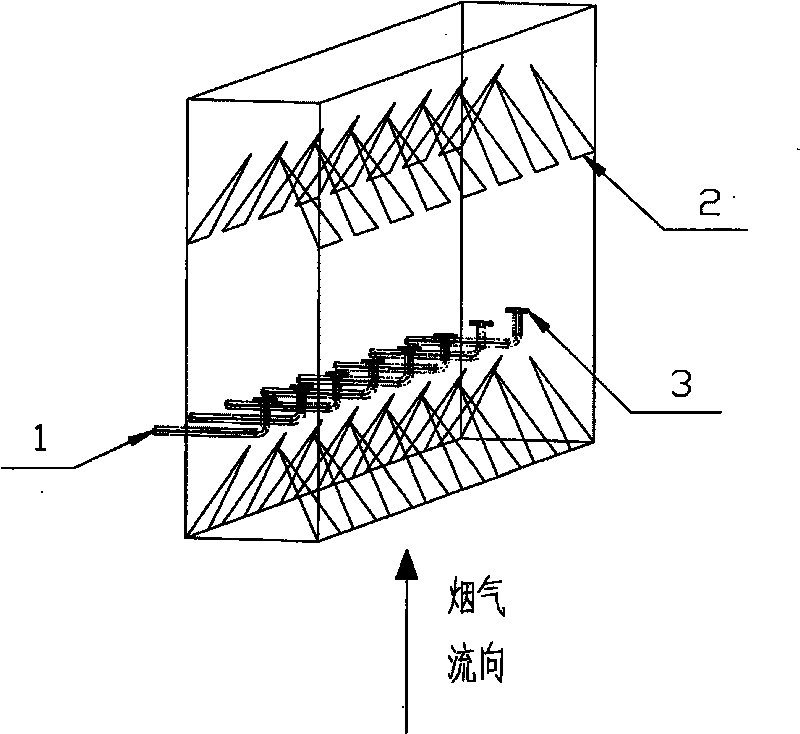

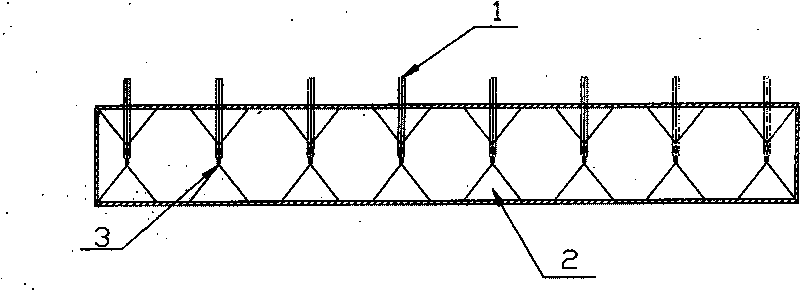

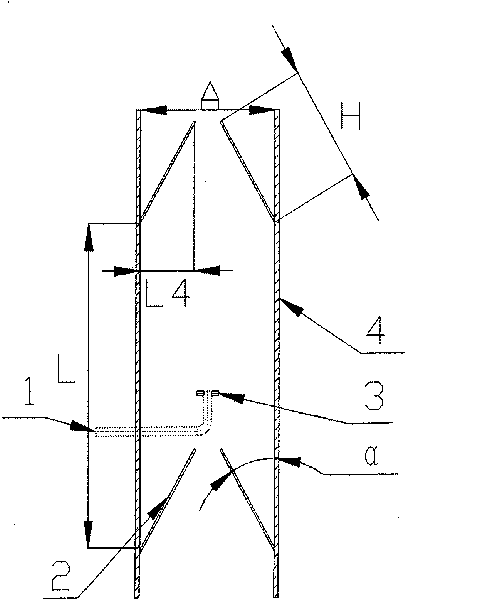

[0016] As shown in the figure, the ammonia injection mixing system used for coal-fired flue gas SCR denitrification technology equipment includes a flue, a reductant ammonia injection pipe 1, a longitudinal vortex generator 2, and a two-way nozzle 3. There are 5~ 20 reducing agent ammonia injection pipes 1, the end of each reducing agent ammonia injection pipe 1 is provided with a two-way nozzle 3, and the upstream and downstream flue walls of the two-way nozzle 3 are provided with a longitudinal vortex generator 2, and the longitudinal vortex generator 2 is composed of two rows of uniformly and symmetrically arranged longitudinal vortex generating element groups fixed on the two walls of the flue. Each row of longitudinal vortex generating element groups is composed of a plurality of longitudinal vortex generating elements. Into 30 ° ~ 60 ° angle.

[0017] Each reductant ammonia injection pipe 1 has a separate flow control system.

[0018] The shape of the longitudinal vorte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com