Patents

Literature

238results about "Fluidised bed heat exchangers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

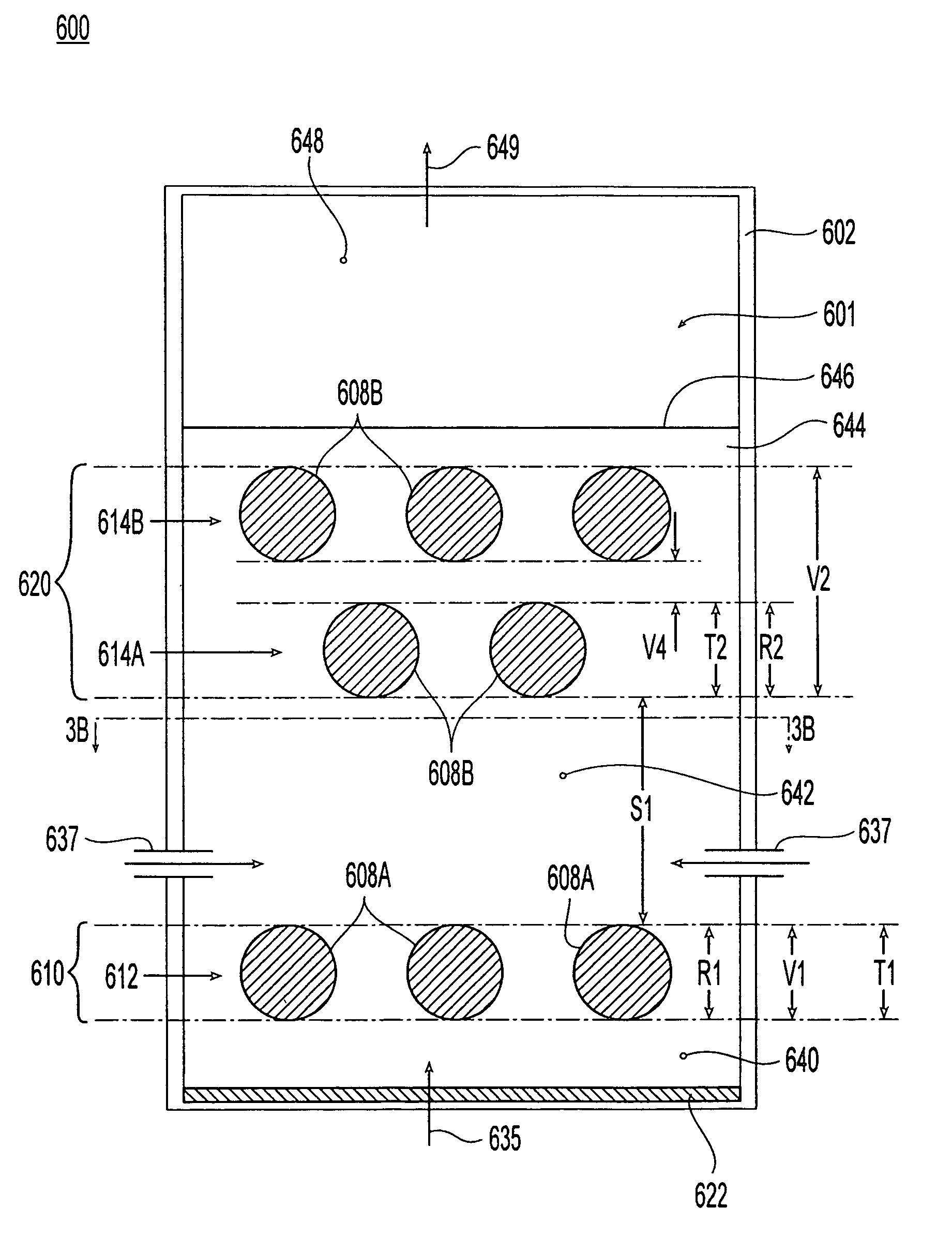

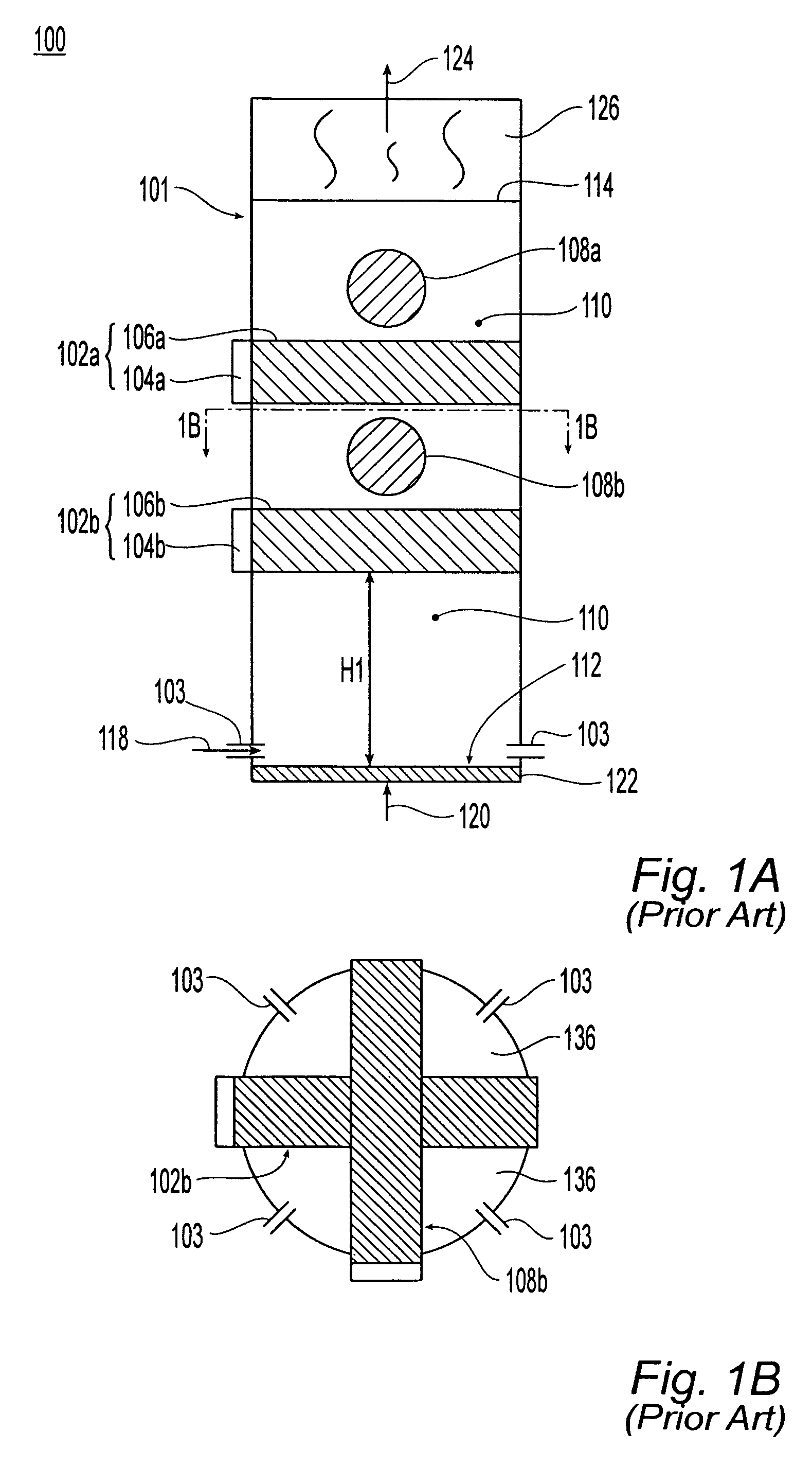

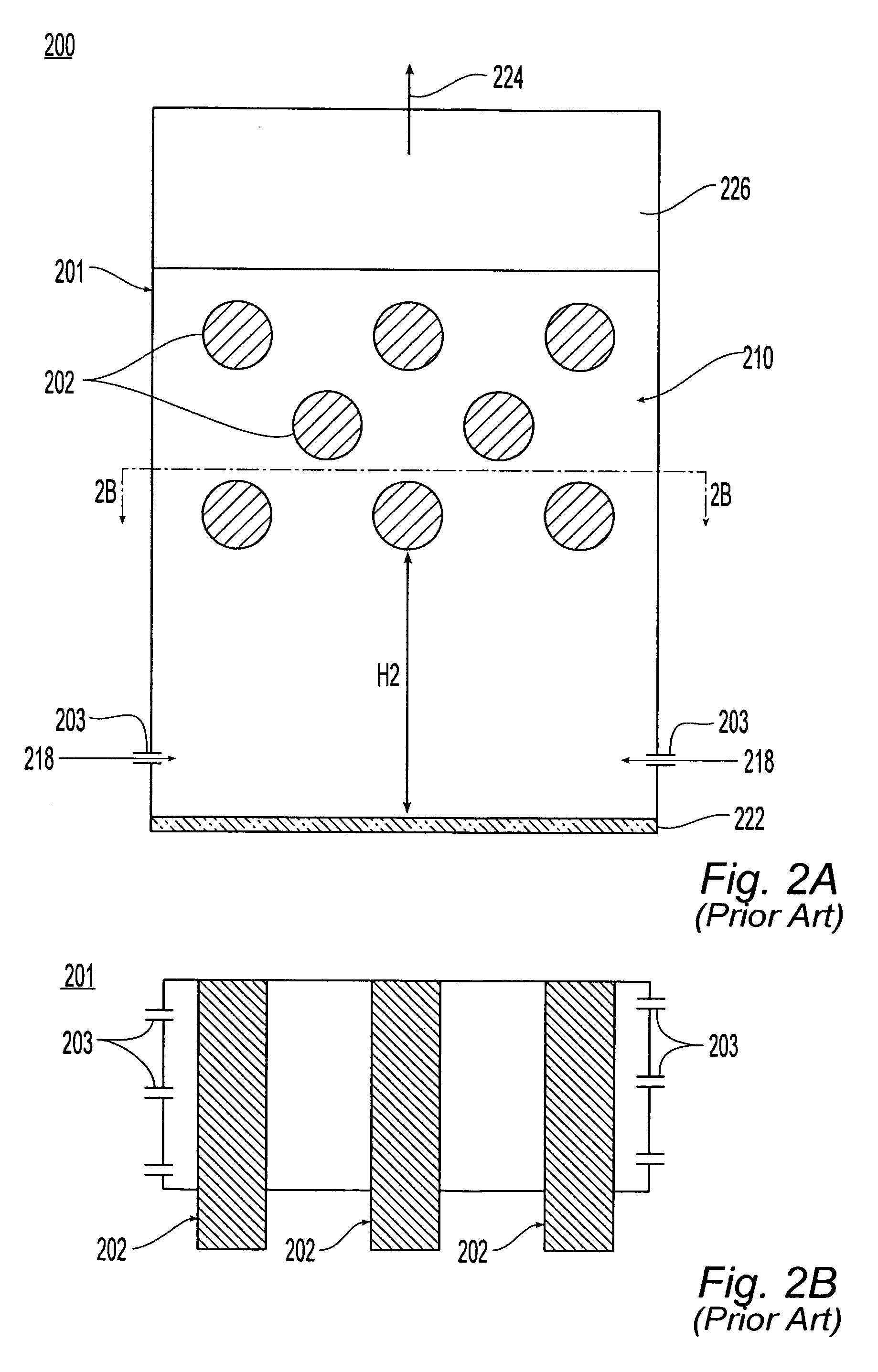

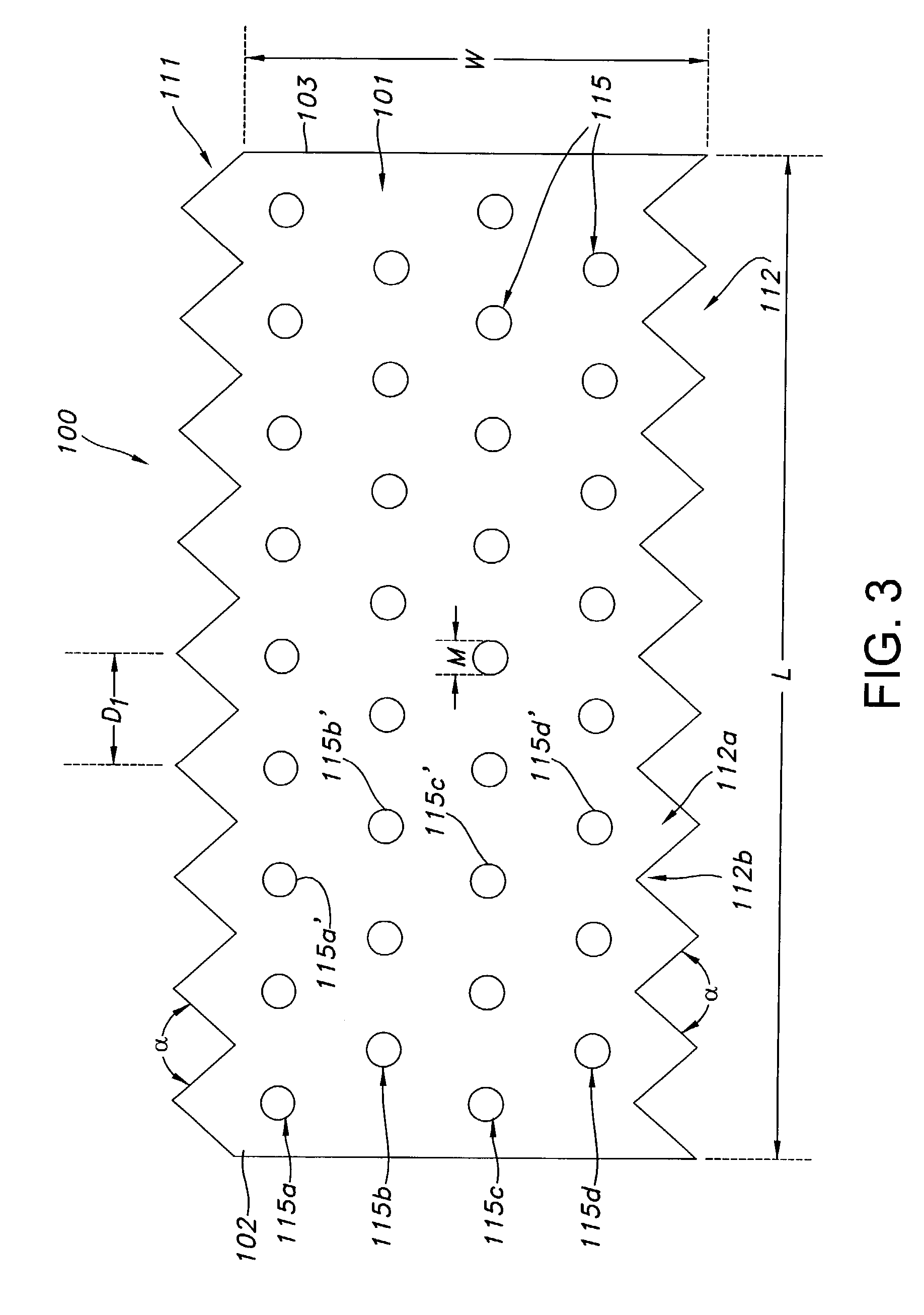

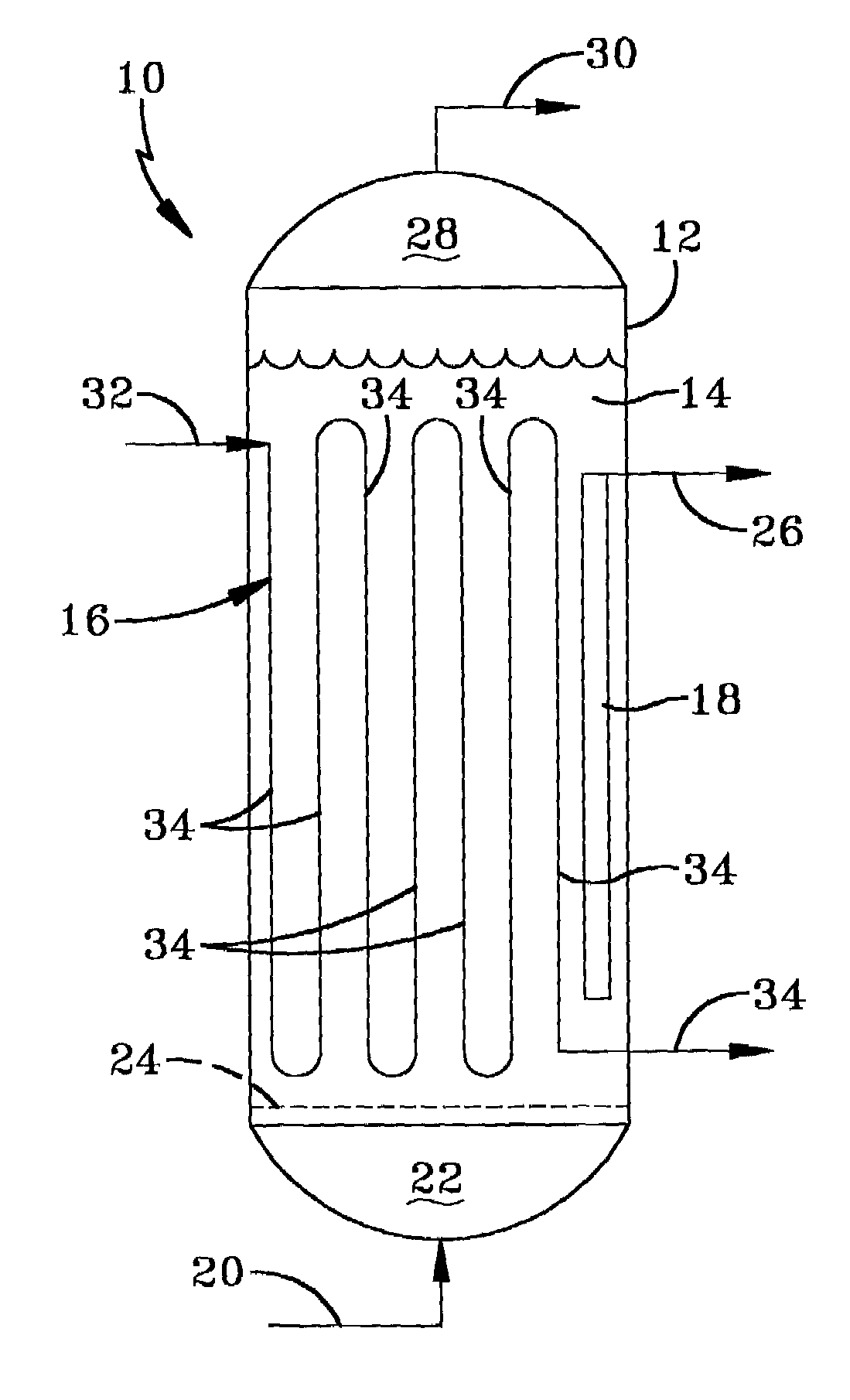

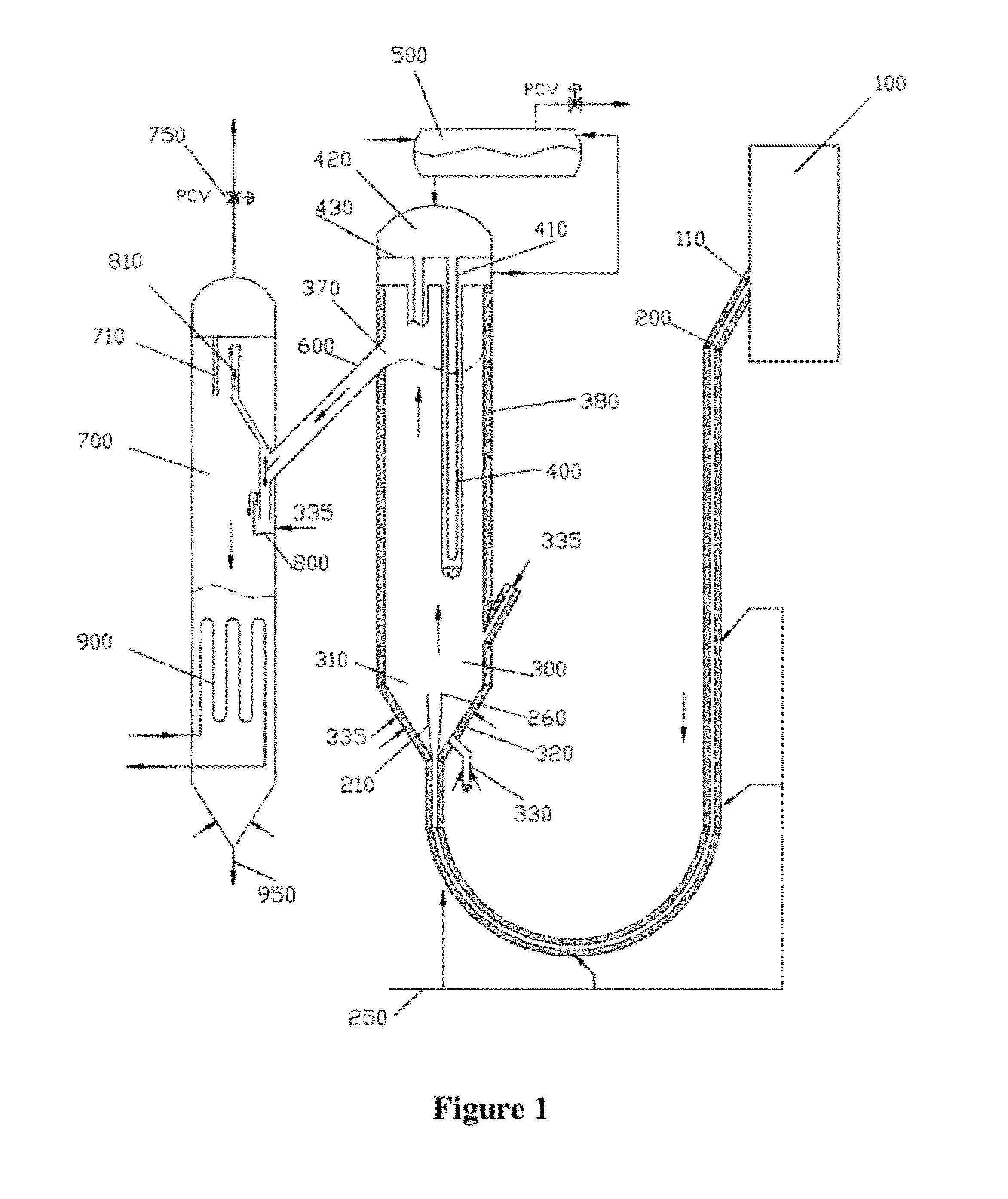

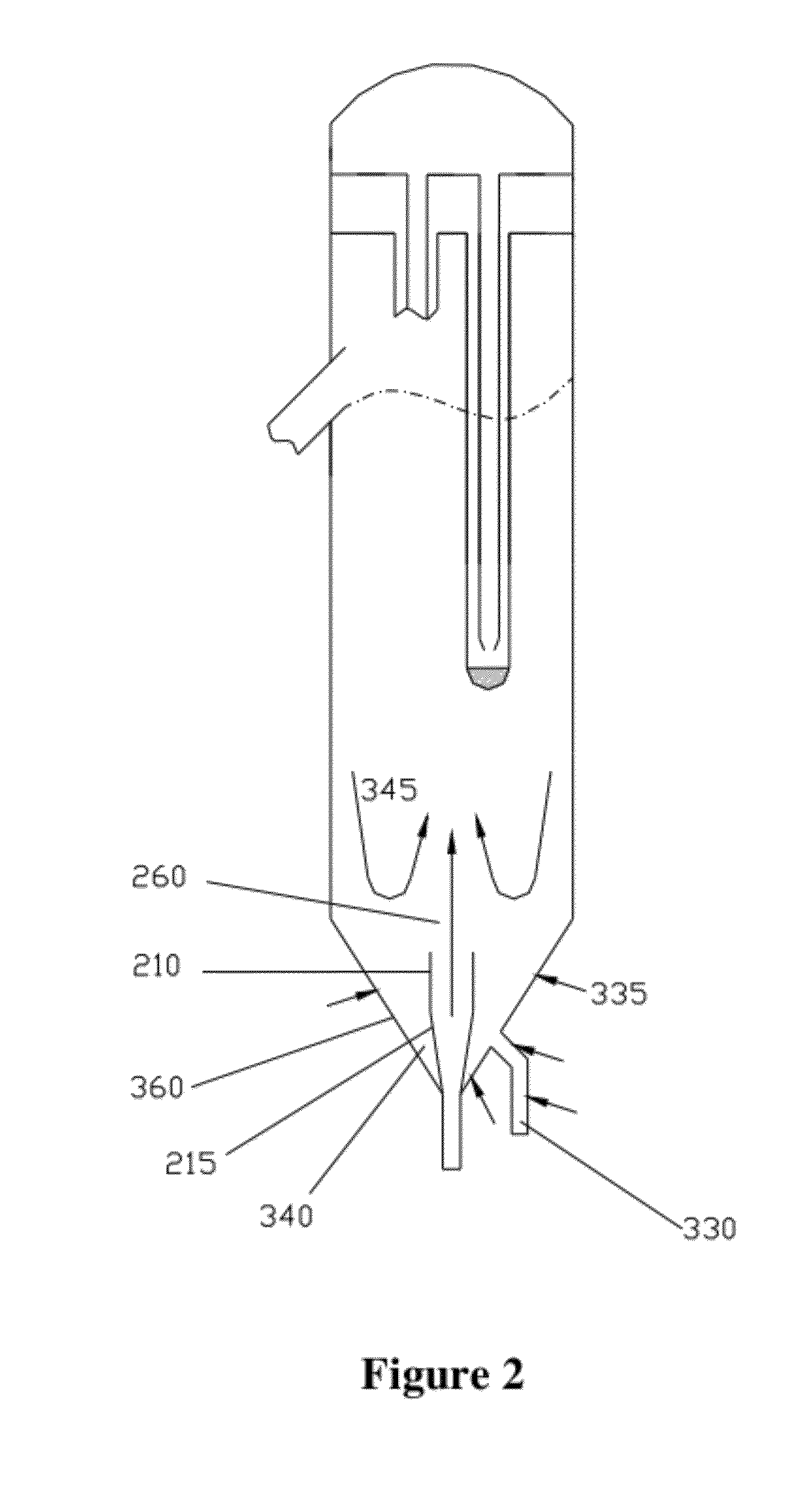

Fluid bed reactor having vertically spaced apart clusters of heating conduits

A fluid bed reactor is configured to process a reactive material to form one or more products. The reactor includes a reaction vessel defining a compartment configured to receive the reactive material. A first cluster of heating conduits at least partially occupies the compartment and extends over a first vertical extent within the compartment. A second cluster of heating conduits partially occupies the compartment and extends over a second vertical extent within the compartment. The first cluster of heating conduits is vertically below the second cluster of heating conduits and spaced apart therefrom by a first separation distance. Feedstock inlets are configured to introduce the reactive material into a region that is vertically between the first and second clusters of heating conduits. The heating conduits in the first cluster have a first thickness while the heating conduits in the second cluster have a second thickness. The first separation distance is at least as great as the smaller of the first and second thicknesses.

Owner:THERMOCHEM RECOVERY INT

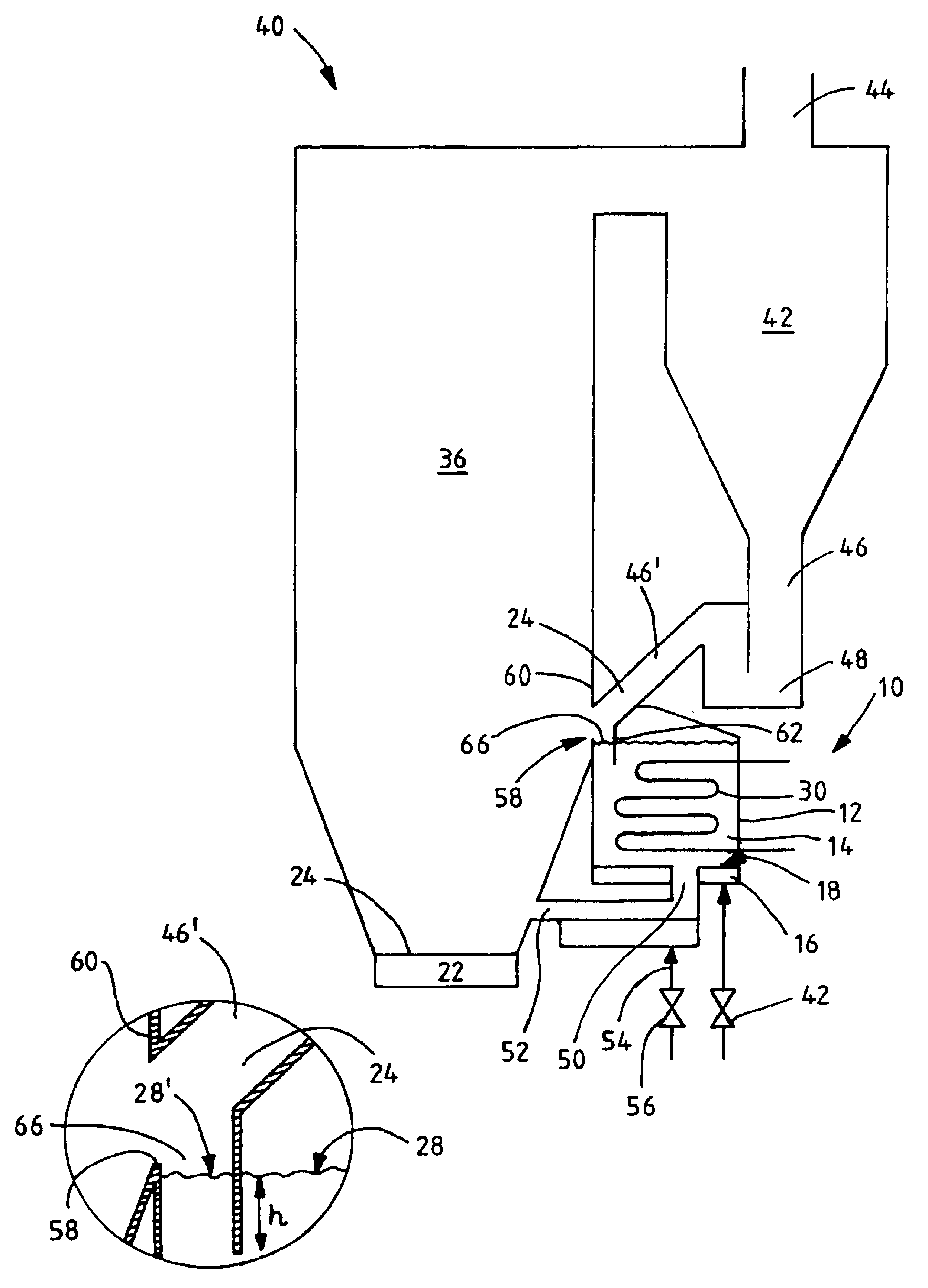

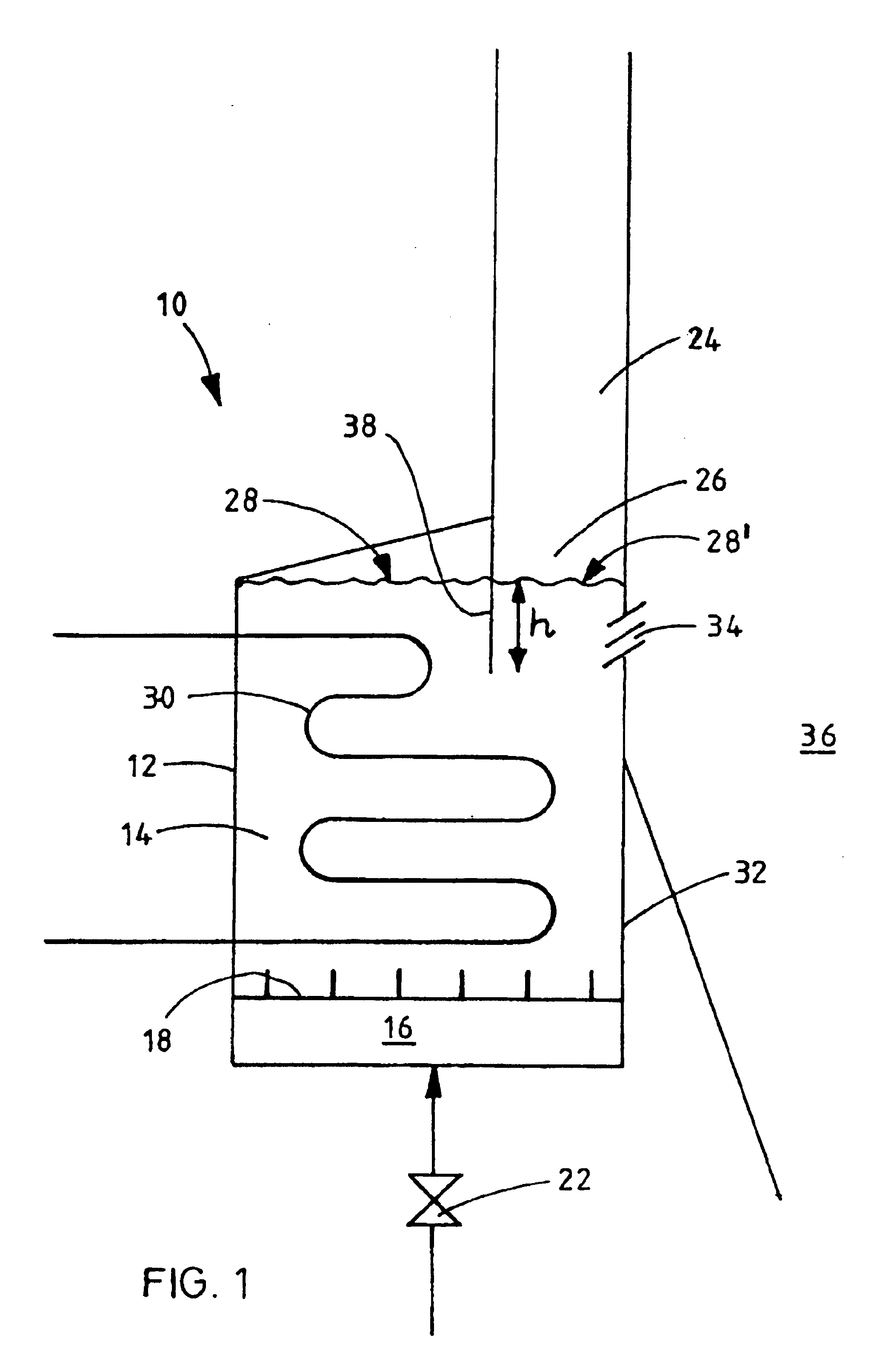

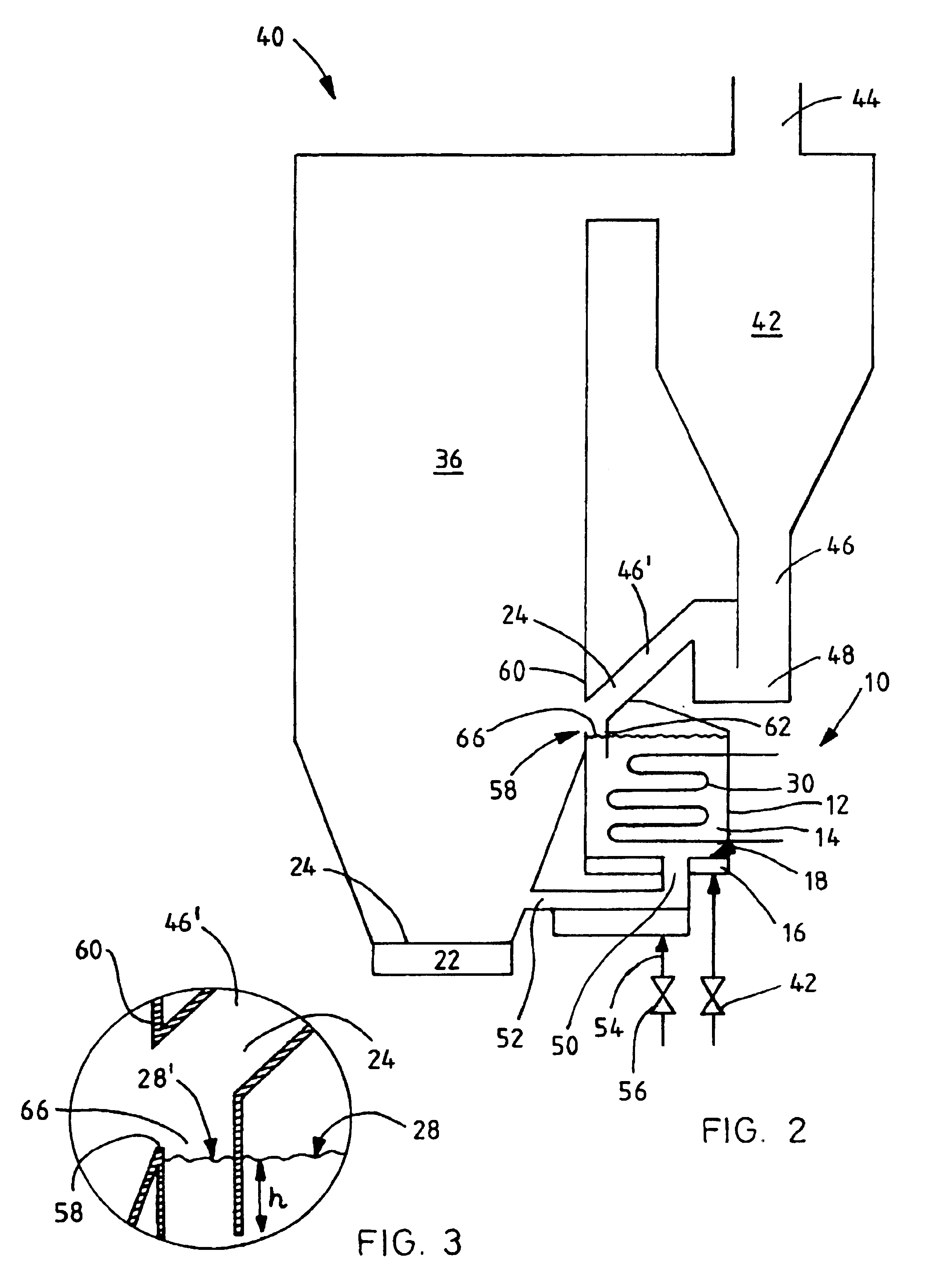

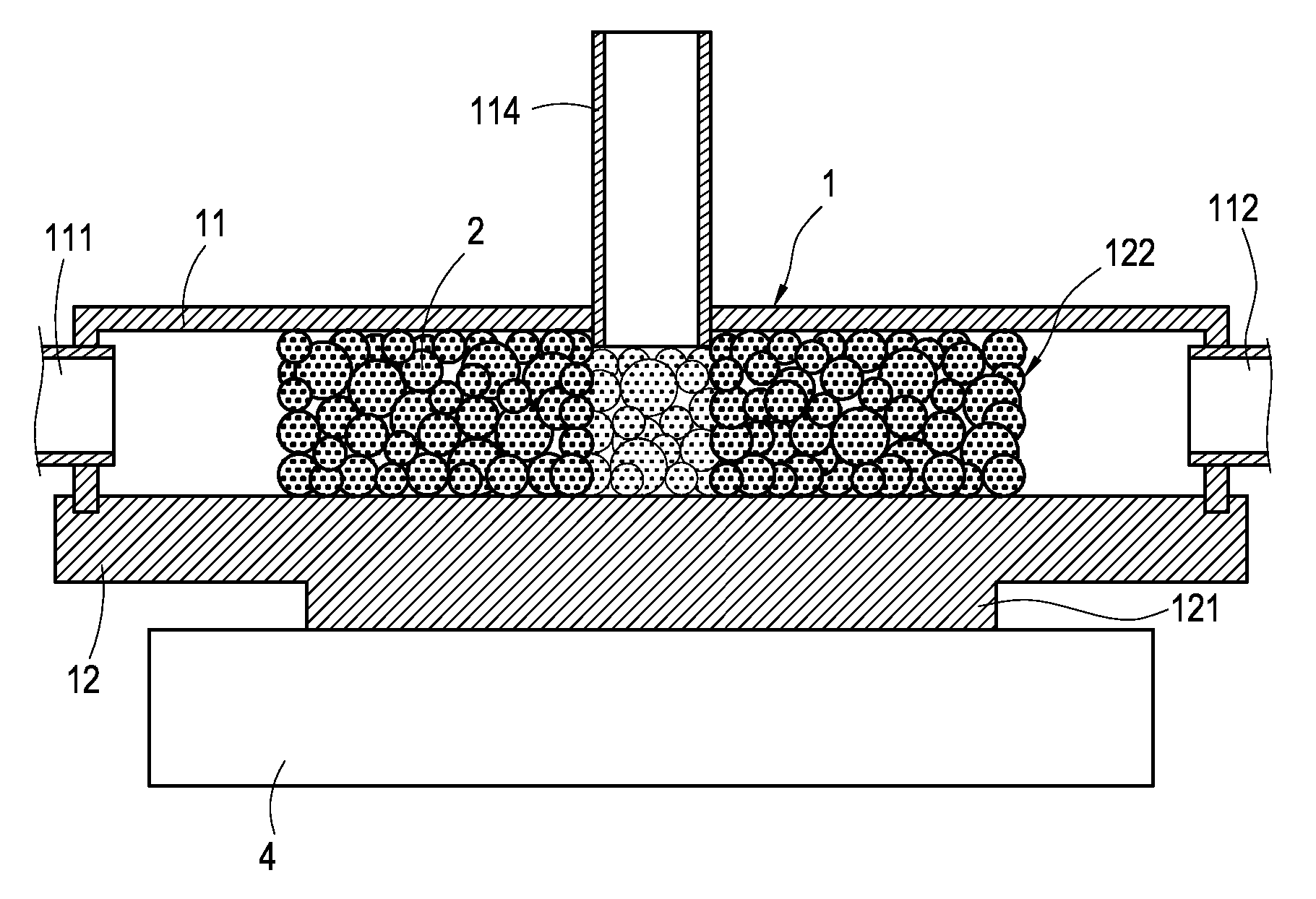

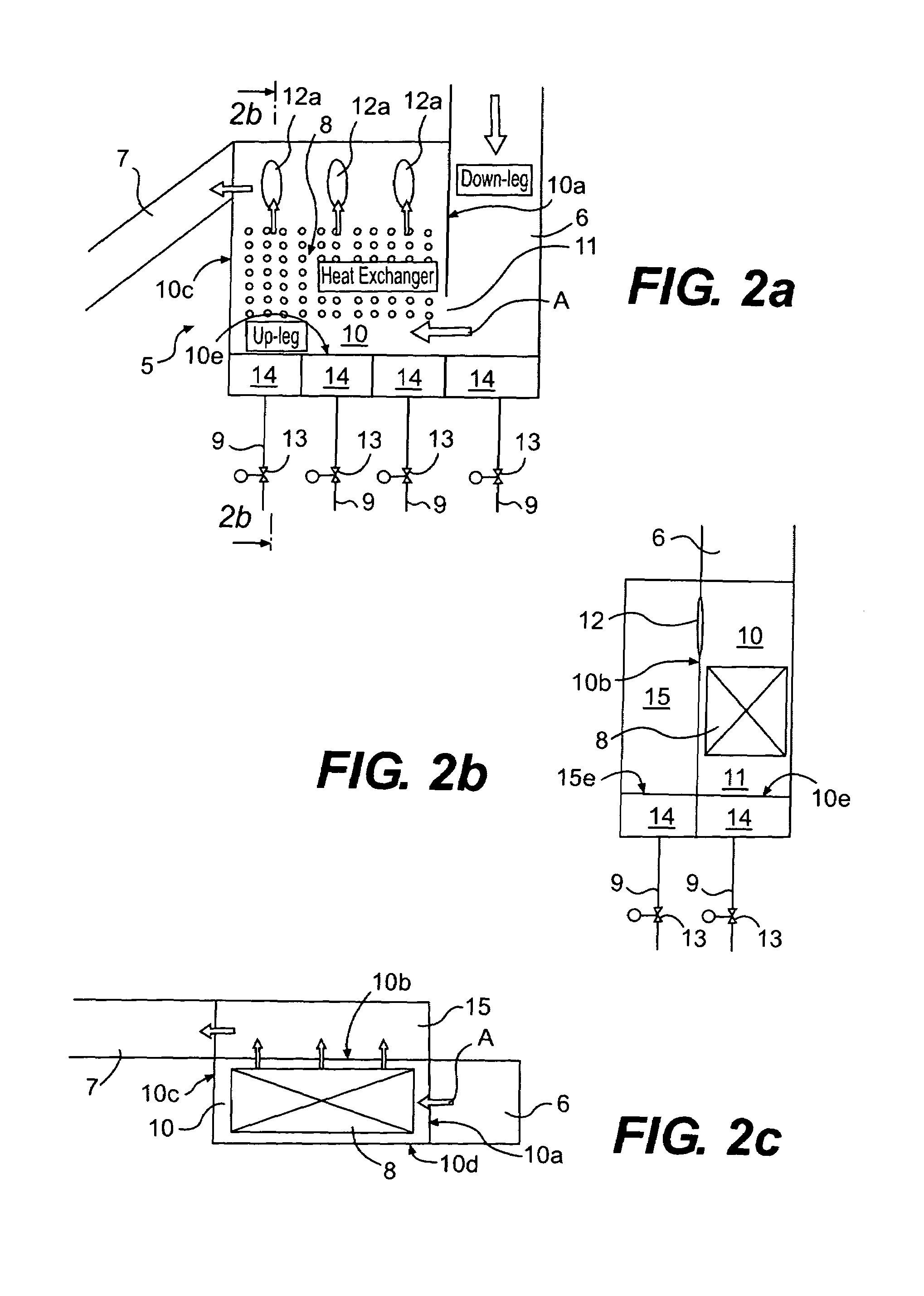

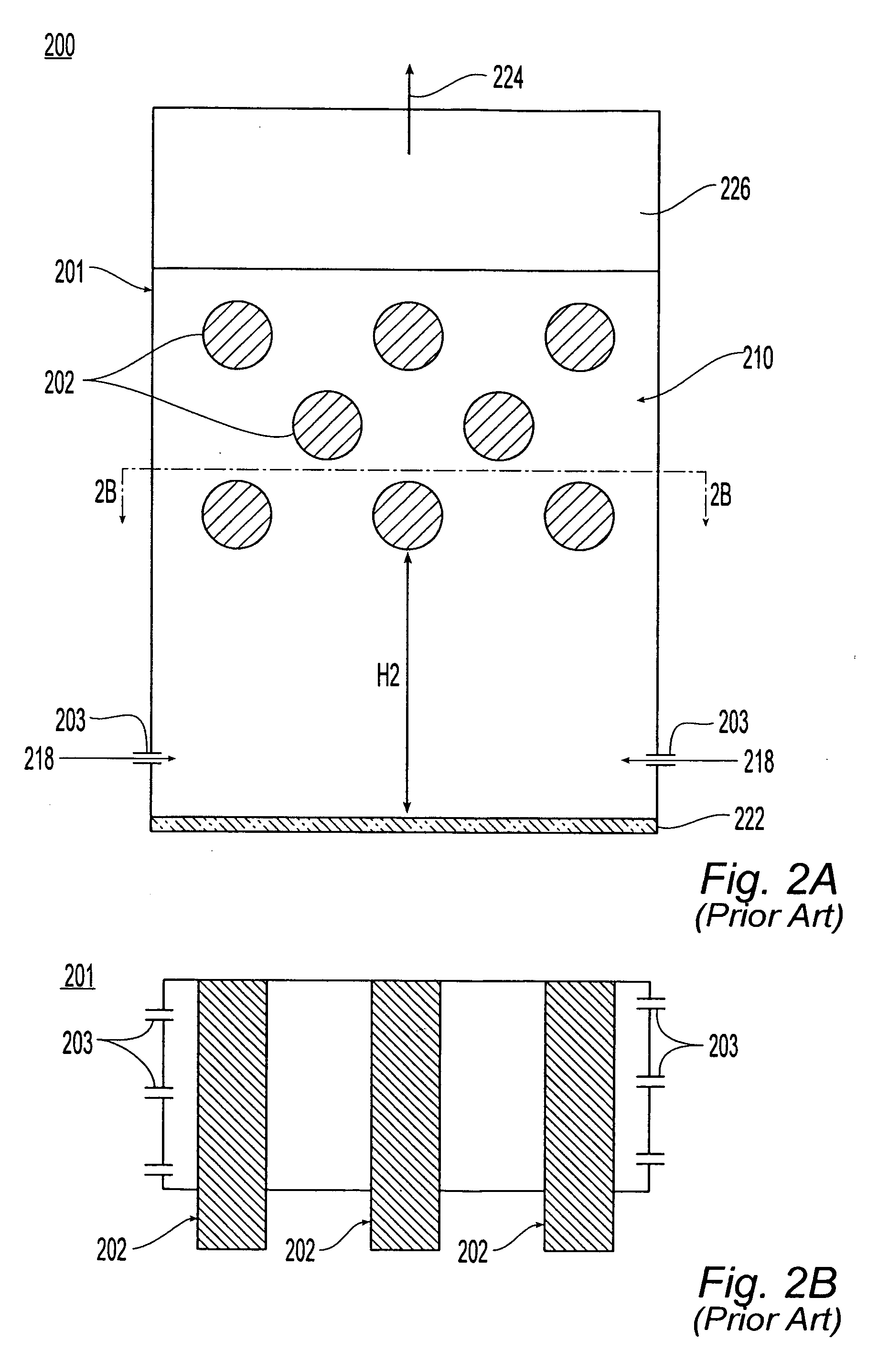

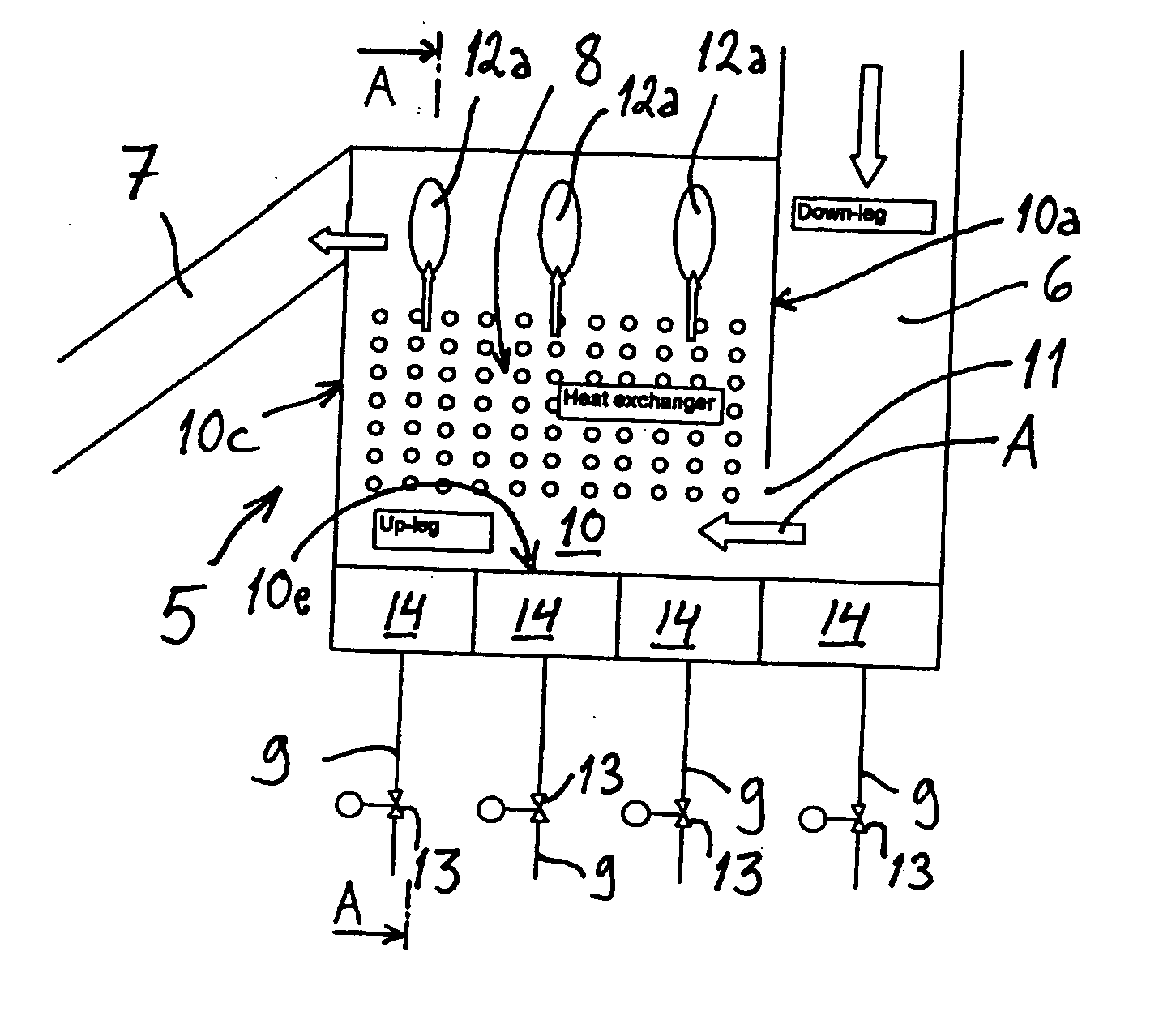

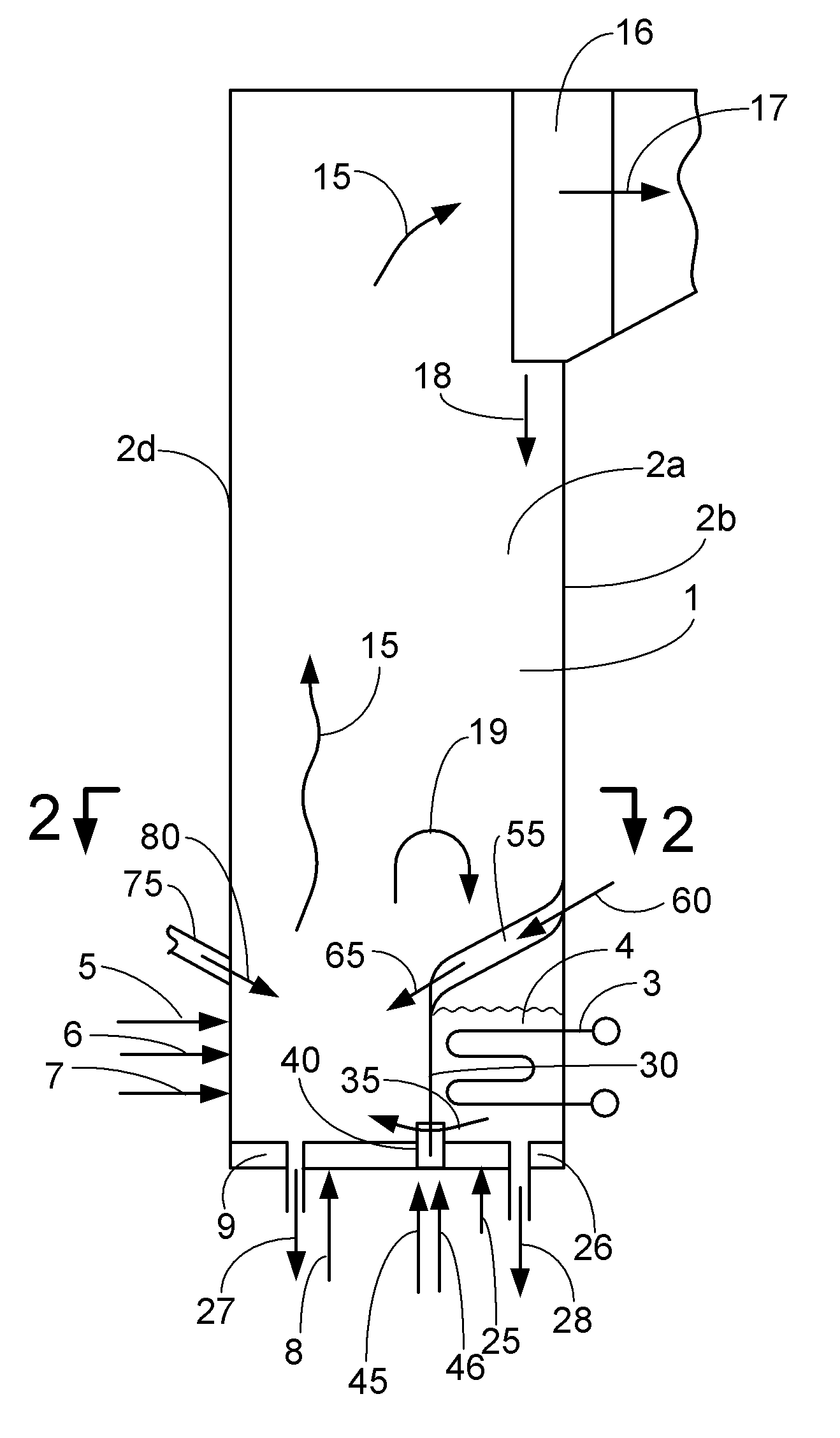

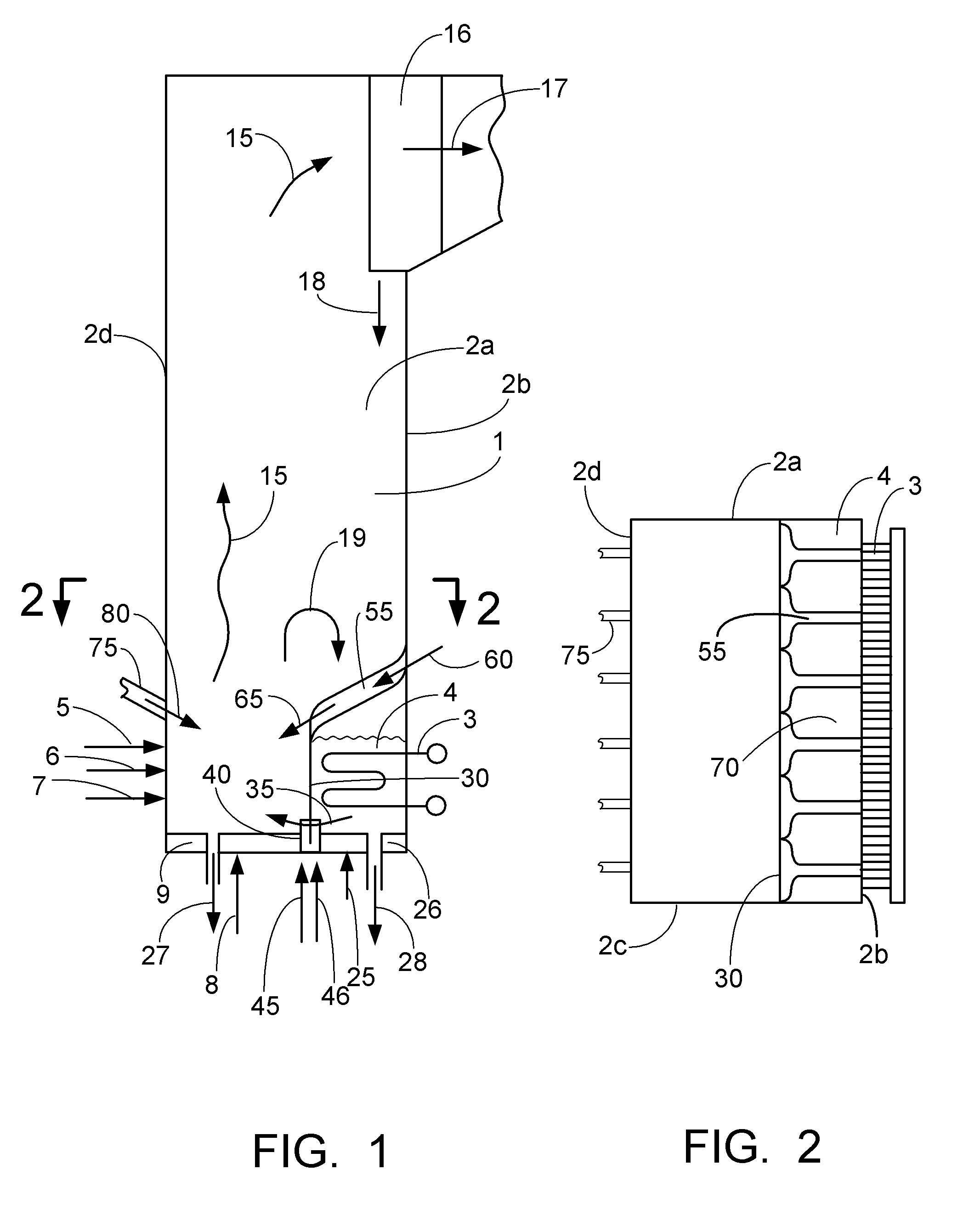

Method and apparatus in a fluidized bed heat exchanger

InactiveUS6962676B1Easy to adjustEfficient and wide-ranging adjustment of heat transferFluidized bed combustionFluidised-bed furnacesFluidized bedEngineering

A method and an apparatus in a fluidized bed heat exchanger including a heat exchange chamber having a fluidized bed of solid particles, heat transfer surfaces, an inlet, and an outlet. Particles are fed through the inlet onto the upper surface of the bed of solid particles by a guiding channel. The guiding channel, which extends from above the upper surface of the bed of solid particles to the surface thereof, or to below the surface, passes the solid particles to the restricted area of the surface. The outlet is formed in the area of the guiding channel to remove particles from the area delimited by the guiding channel. Uncooled particles can thus be removed from the heat exchange chamber.

Owner:FOSTER WHEELER ENERGIA OY

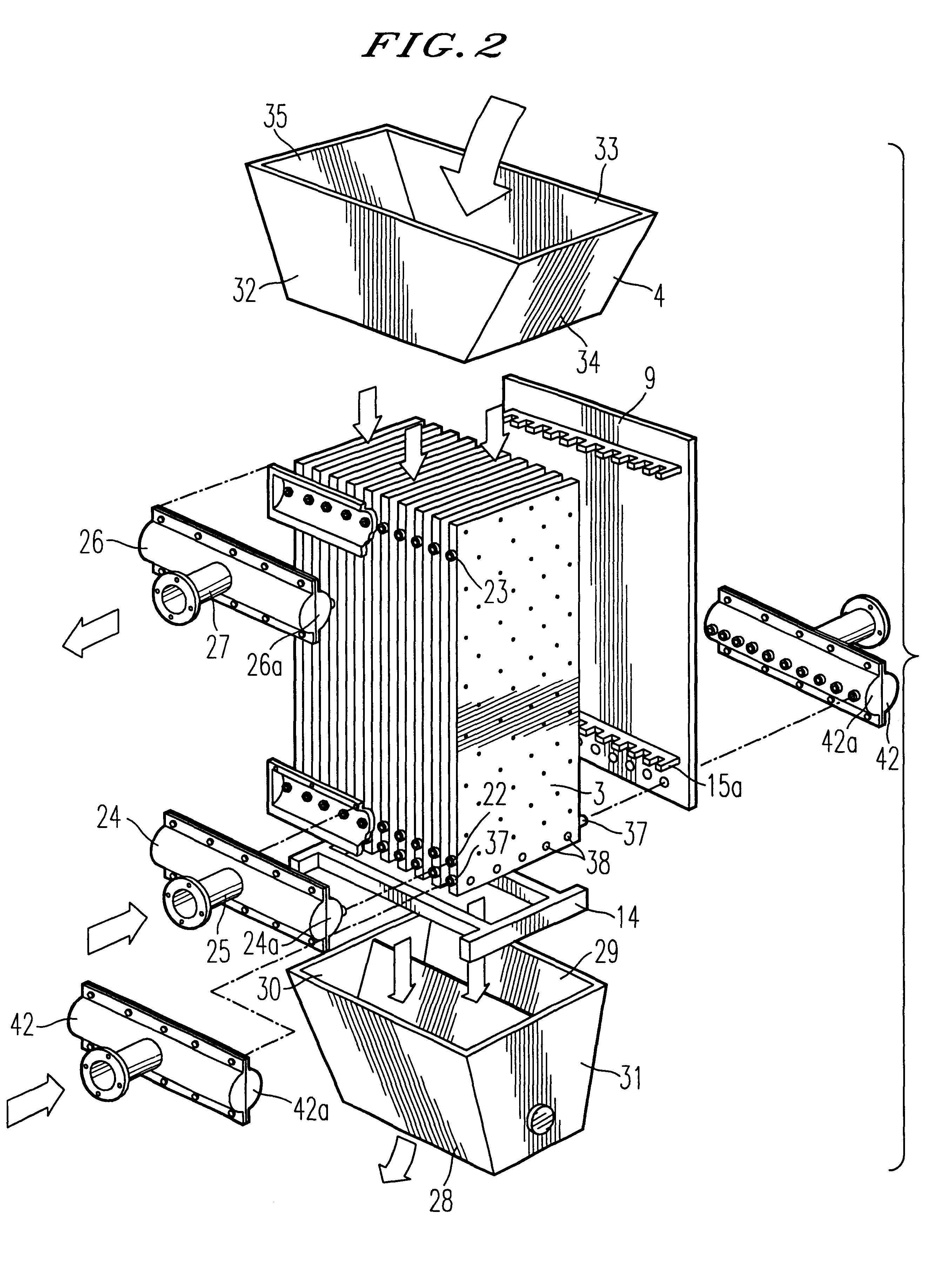

Moving bed dryer

InactiveUS6328099B1Drying solid materials with heatFluidised bed heat exchangersProduct gasSolid particle

Free-flowing solid particles are dried in a moving bed dryer by passing the particles adjacent to a heat exchanger plate containing a heated fluid while passing a dehumidified gas into the solid particles from a gas flow manifold in the heat exchanger plate.

Owner:MISSISSIPPI CHEM

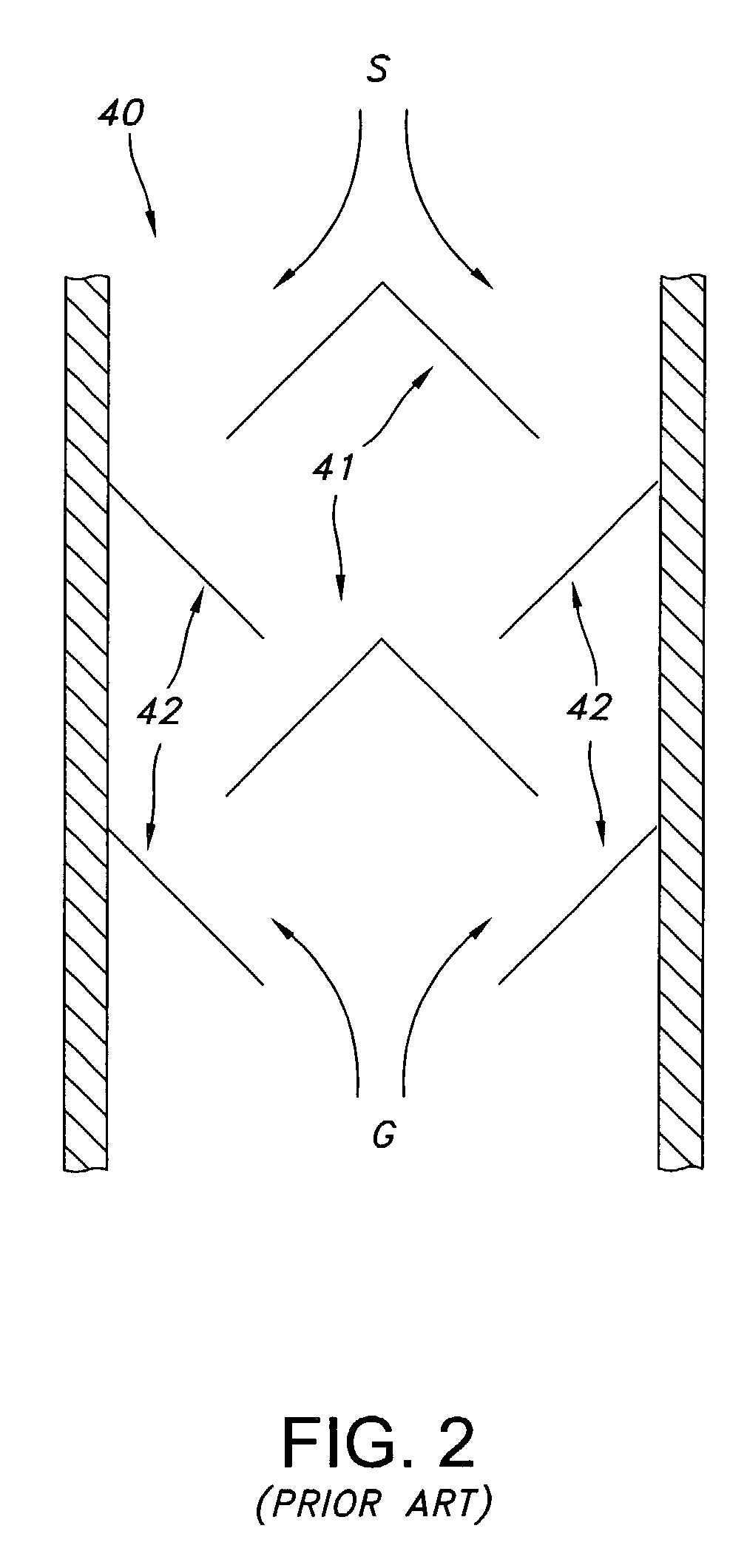

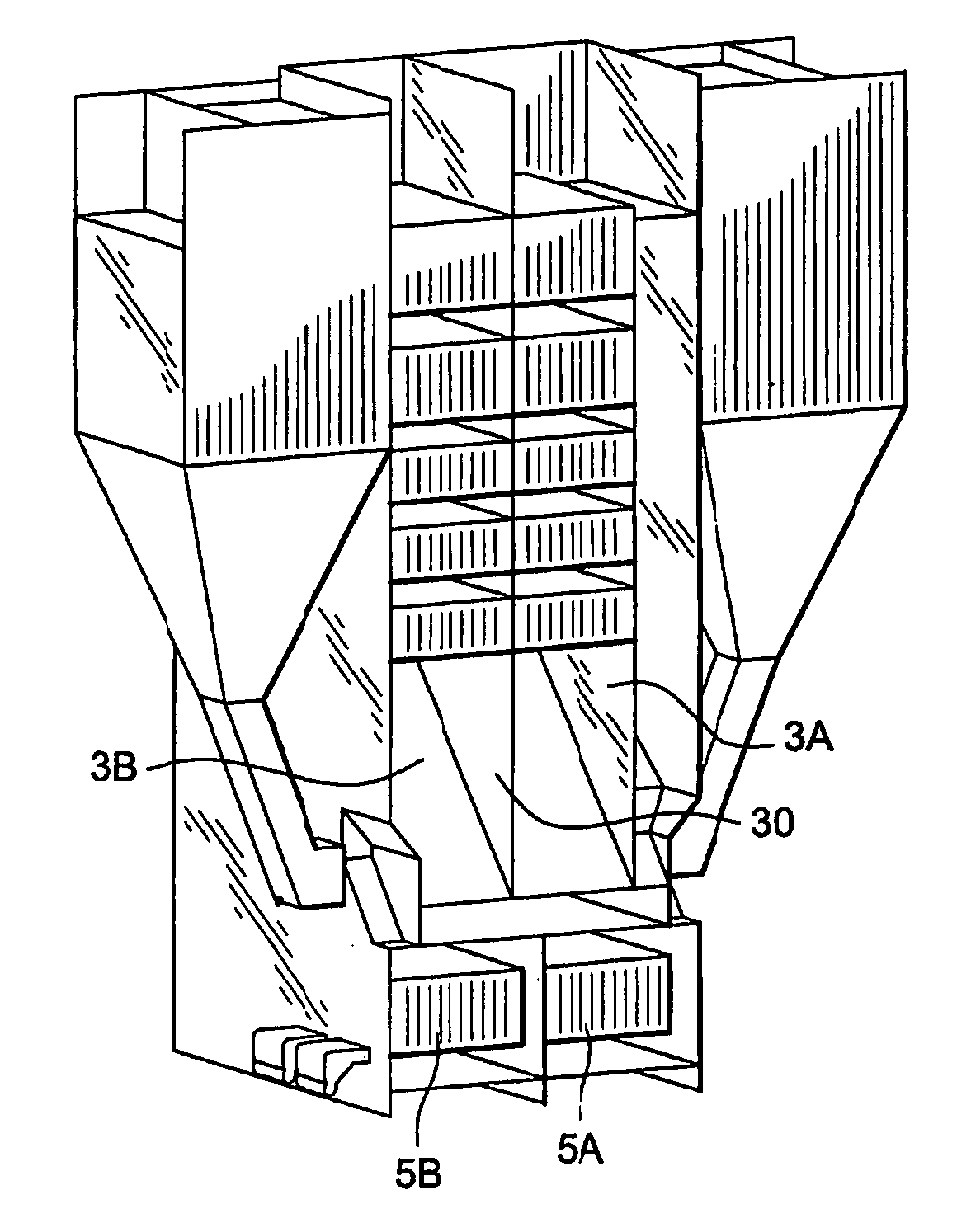

Apparatus for countercurrent contacting of gas and solids

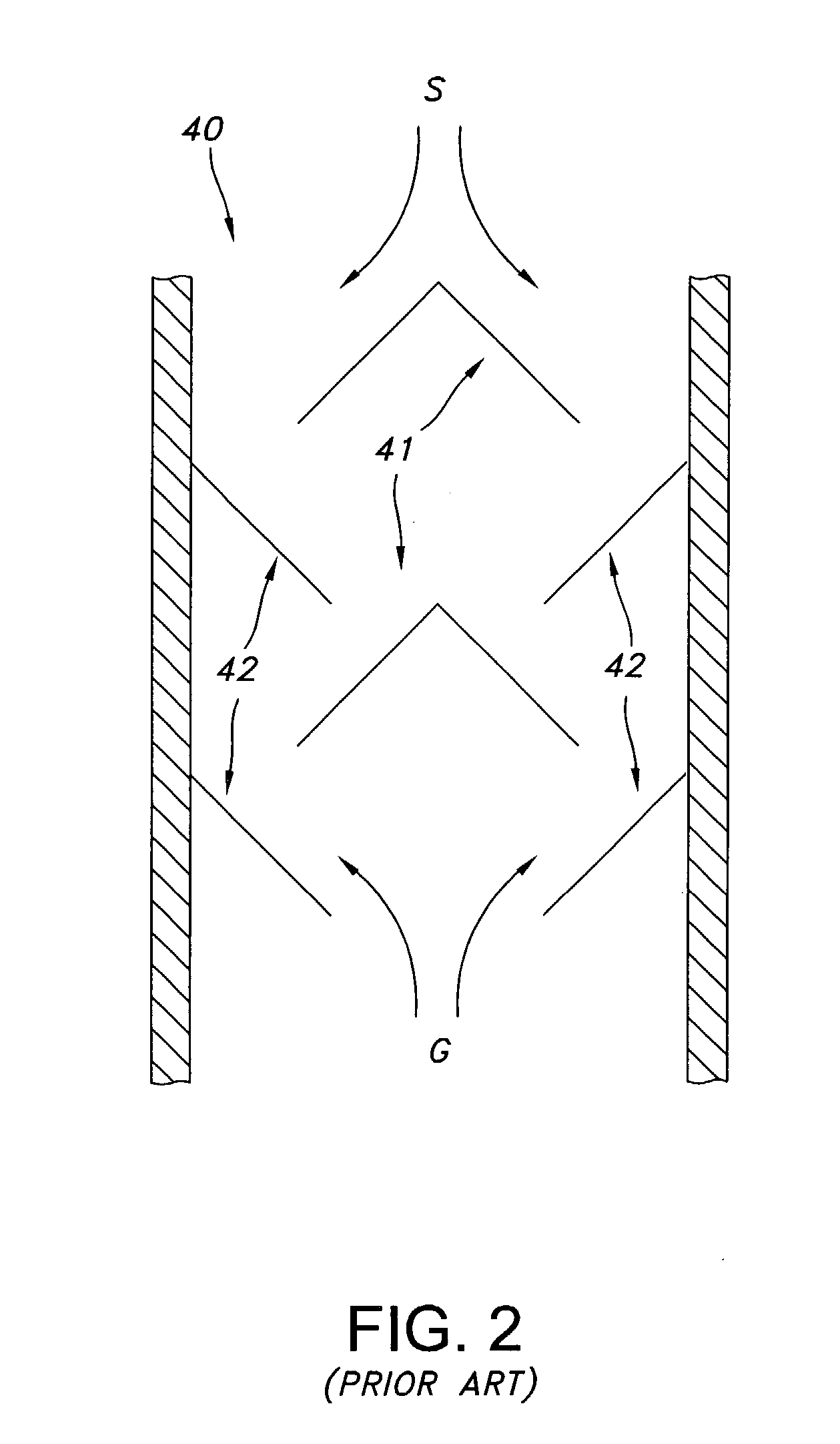

ActiveUS7179427B2Efficient mass transferPrevent channelingCatalytic crackingSynthetic resin layered productsCounter flowSolid particle

An apparatus for the countercurrent contacting of a gas and downflowing solid particles includes a housing and a plurality of baffles positioned within the housing. The baffles are arranged in at least first and second vertically spaced levels in successively lower position, each of the first and second levels including a row of at least two baffles oriented parallel to one another and inclined from horizontal so as to facilitate movement of the solid particles and provide the maximum area for flow. Baffles are oriented so as to laterally shift the direction of downflowing particles transversely as the particles move from one level to the next lower level and avoid channeling of the phases. The number of baffles, length and spacing is optimized to provide maximum interfacial area for interaction between the phases.

Owner:LUMMUS TECH INC

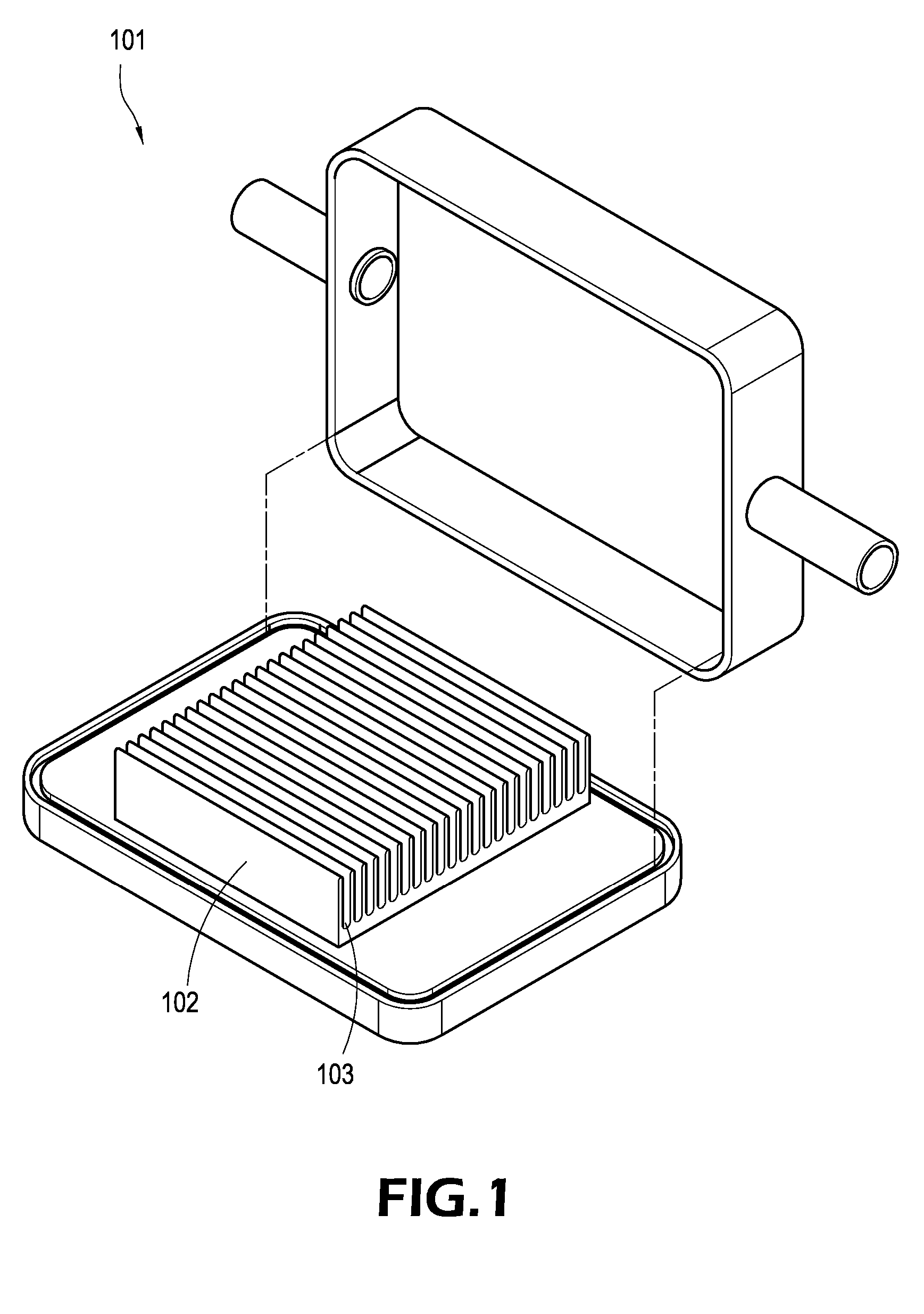

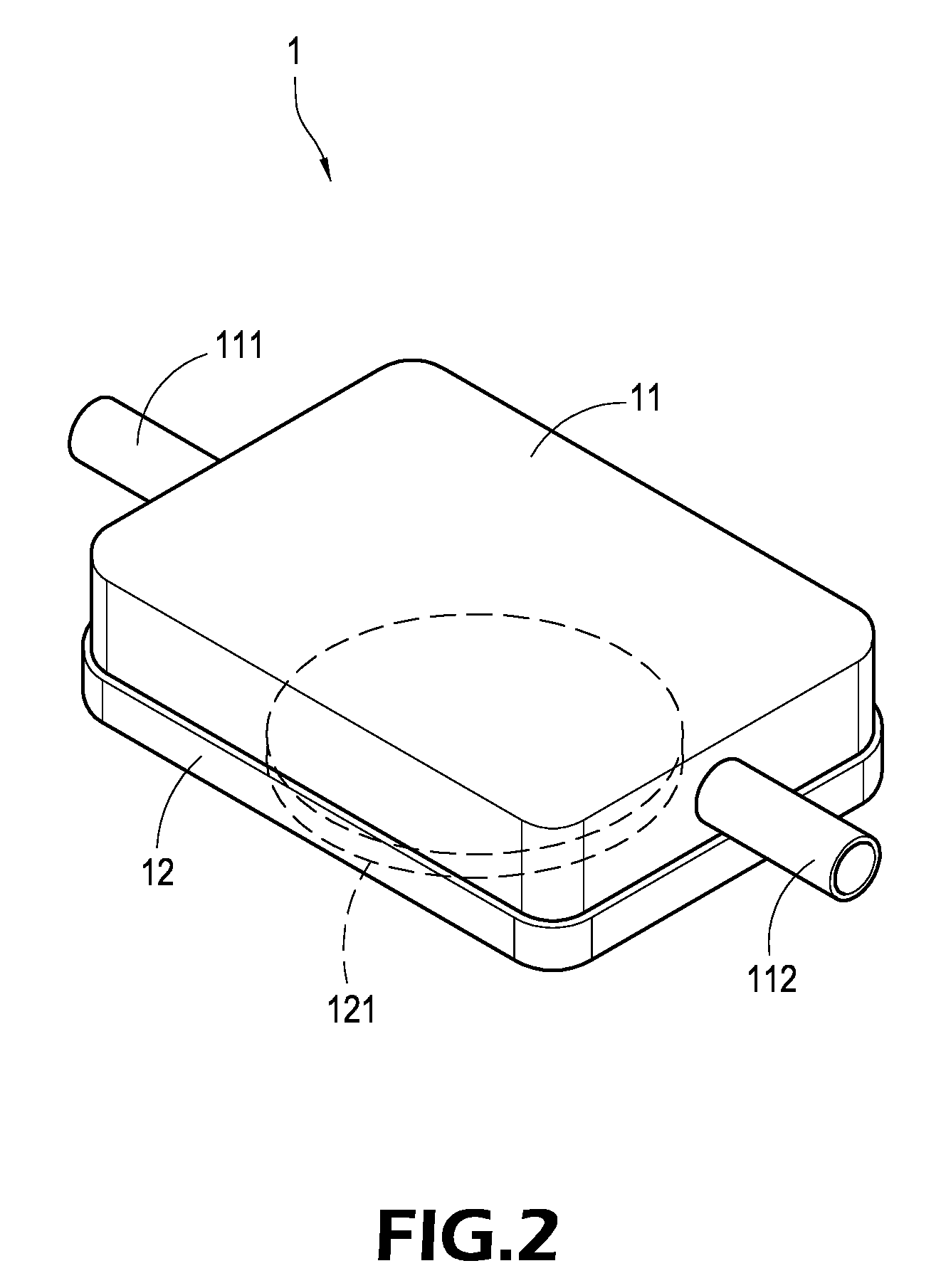

Manufacturing Method of Water Block

InactiveUS20080105413A1Increase of stay timeImprove cooling effectHeat transfer modificationFluidised bed heat exchangersHeat conductingWater block

A porous microchannel structure adopts a first casing and a second casing to form a water block. Water inlet and outlet pipes are extended from both ends of the first casing respectively. The second casing has a porous microchannel structure made by sintering a heat conducting powder and formed on an internal side of the second casing. The second casing has a contact surface on its external side for absorbing and conducting a heat source to the porous microchannel structure, such that a coolant can flow from the water inlet pipe into the water block. The porous microchannel structure produces turbulent flows to the coolant, so as to extend the staying time of the coolant in the water block, and allow the coolant to fully exchange heat with the porous microchannel structure and flow out from the water outlet pipe.

Owner:COOLER MASTER CO LTD

Methods for reducing the formation of by-products in the production of recombinant polypepticles

ActiveUS20040101449A1Efficient mass transferPrevent channelingCatalytic crackingFluidised-bed furnacesSolid particleMechanical engineering

An apparatus for the countercurrent contacting of a gas and downflowing solid particles includes a housing and a plurality of baffles positioned within the housing. The baffles are arranged in at least first and second vertically spaced levels in successively lower position, each of the first and second levels including a row of at least two baffles oriented parallel to one another and inclined from horizontal so as to facilitate movement of the solid particles and provide the maximum area for flow. Baffles are oriented so as to laterally shift the direction of downflowing particles transversely as the particles move from one level to the next lower level and avoid channeling of the phases. The number of baffles, length and spacing is optimized to provide maximum interfacial area for interaction between the phases.

Owner:LUMMUS TECH INC

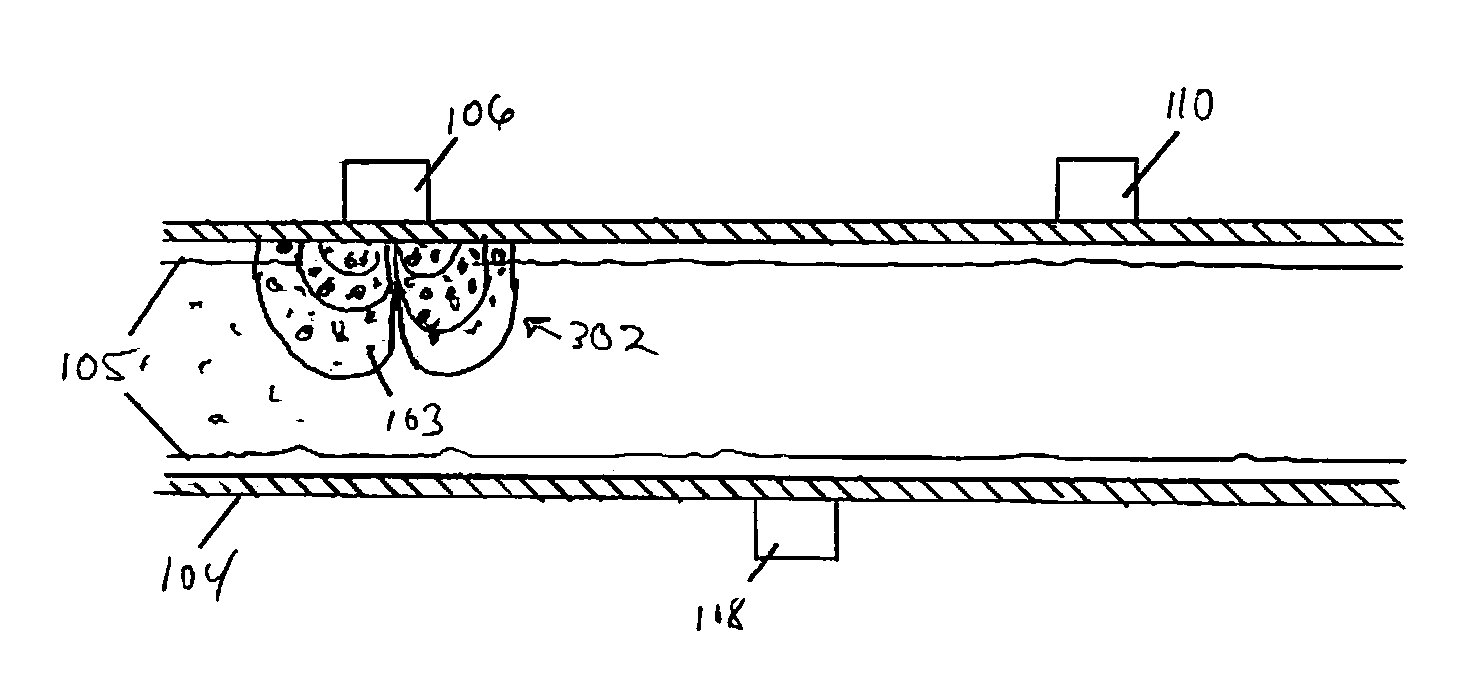

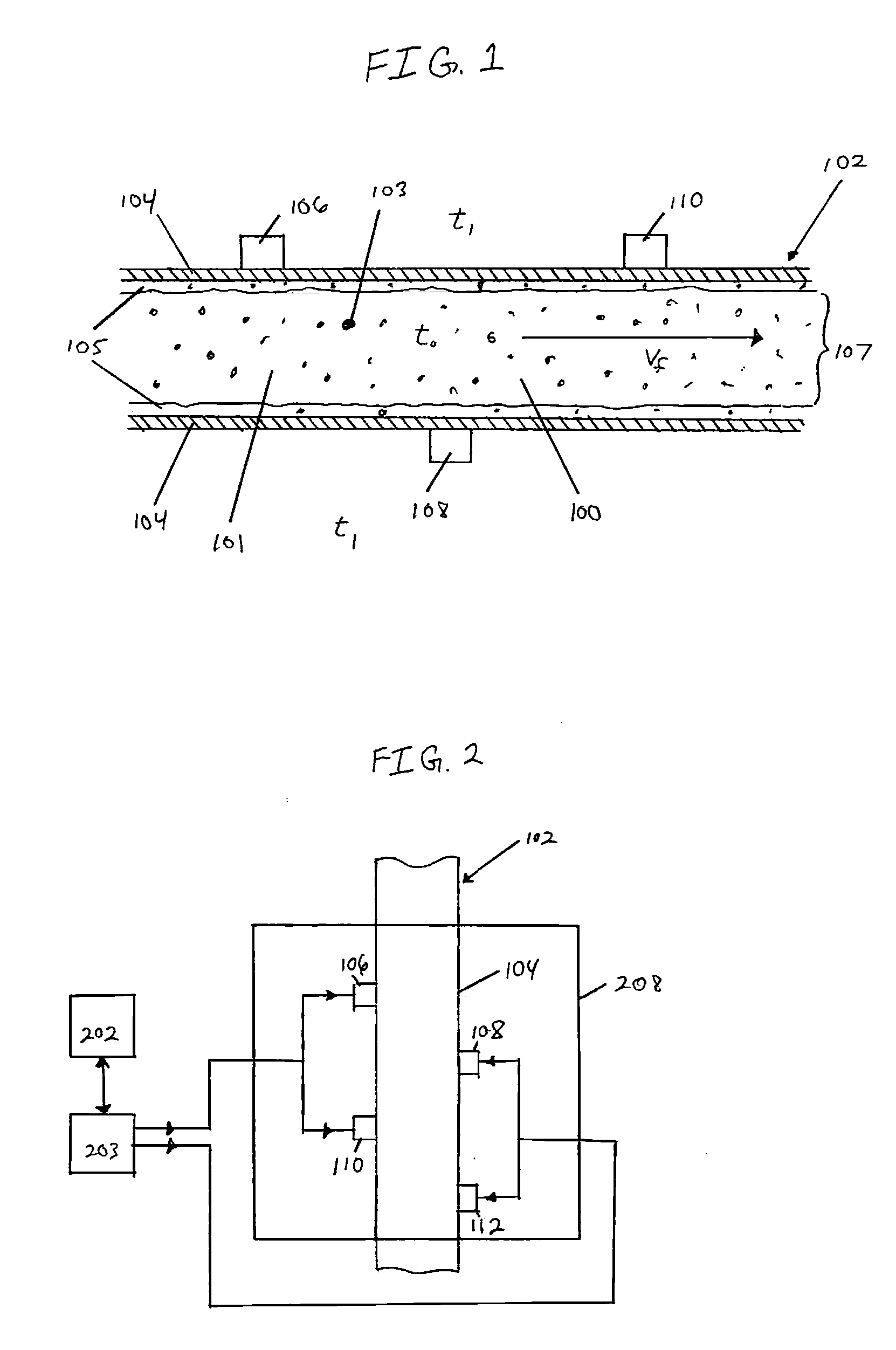

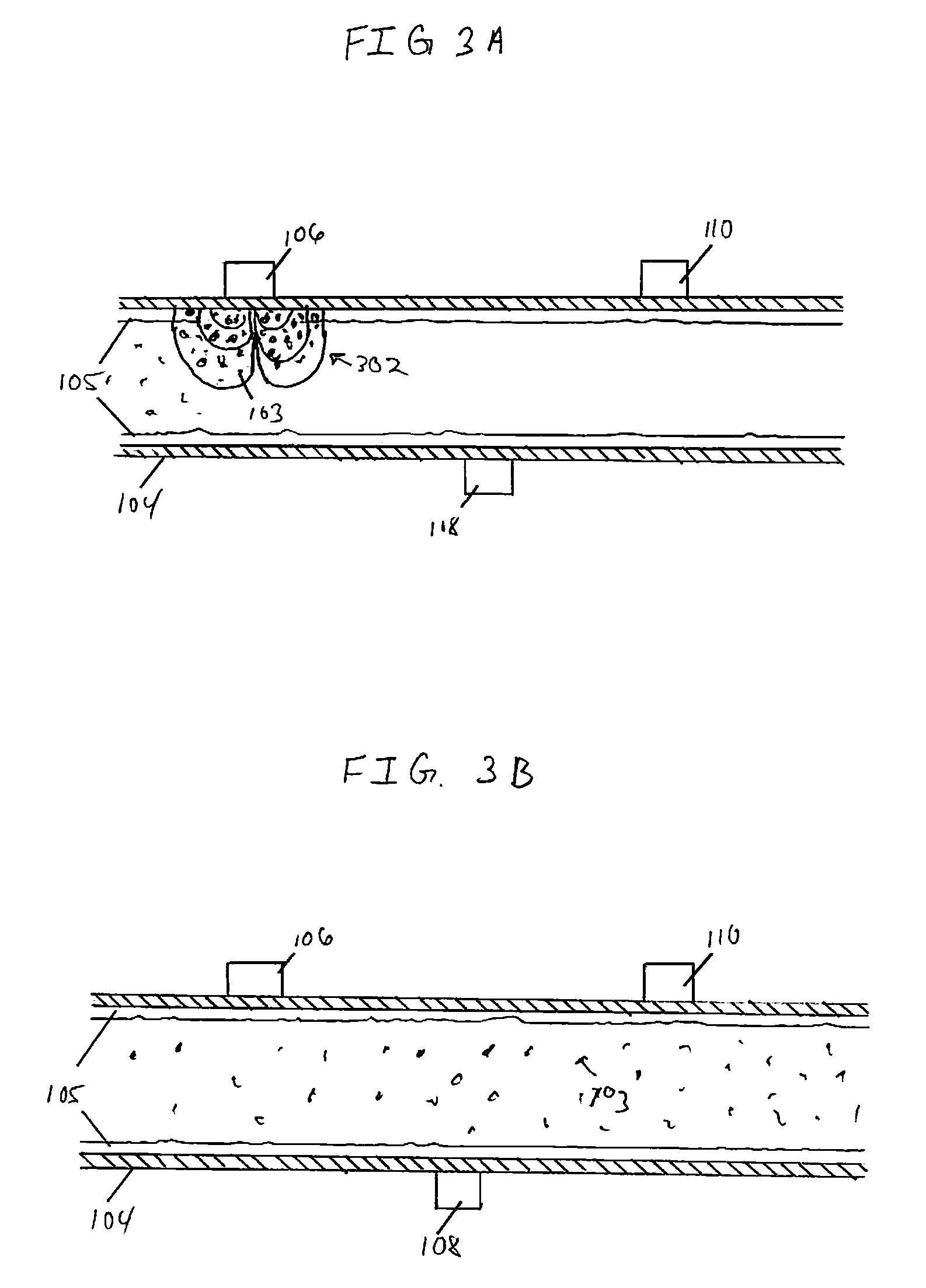

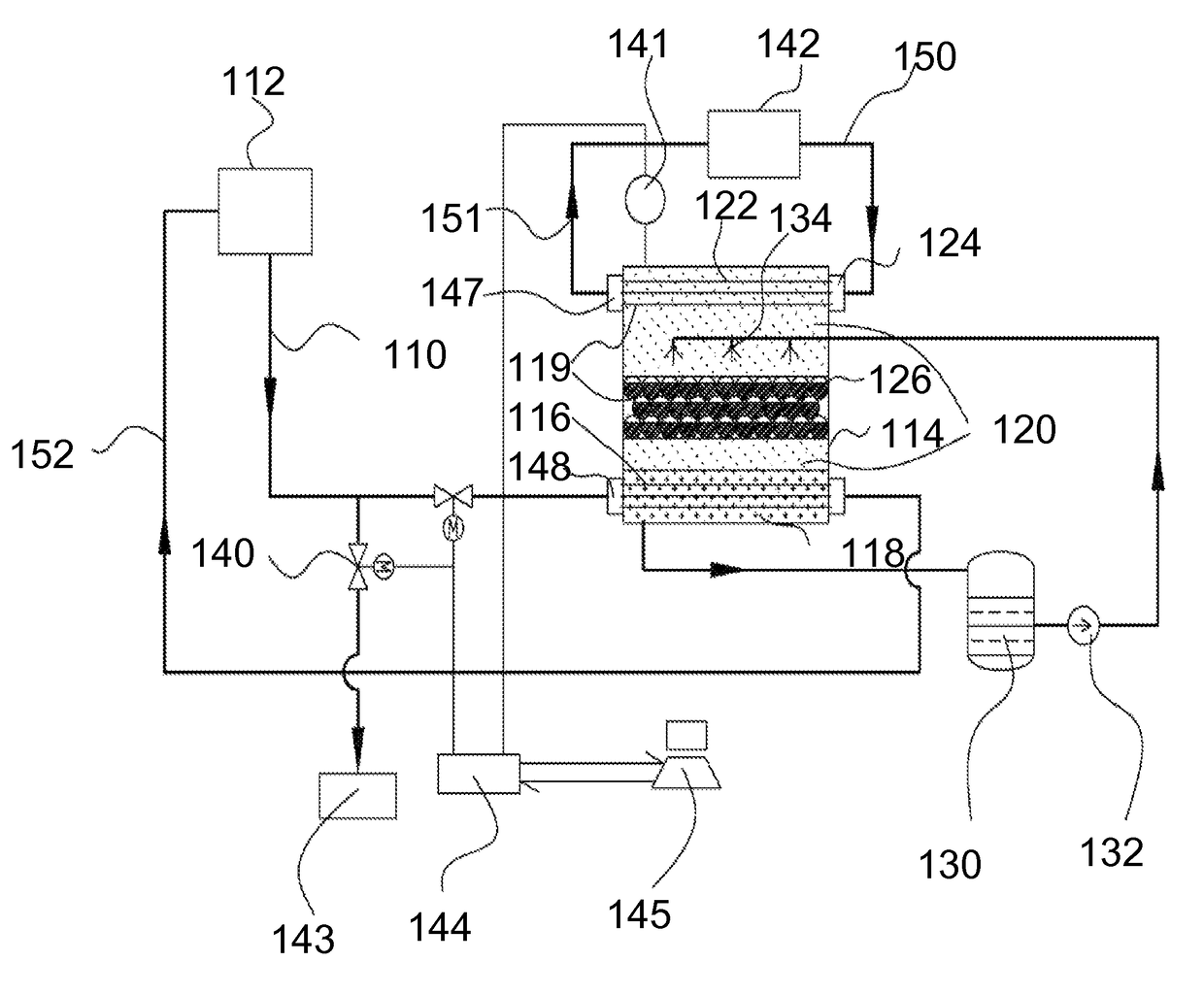

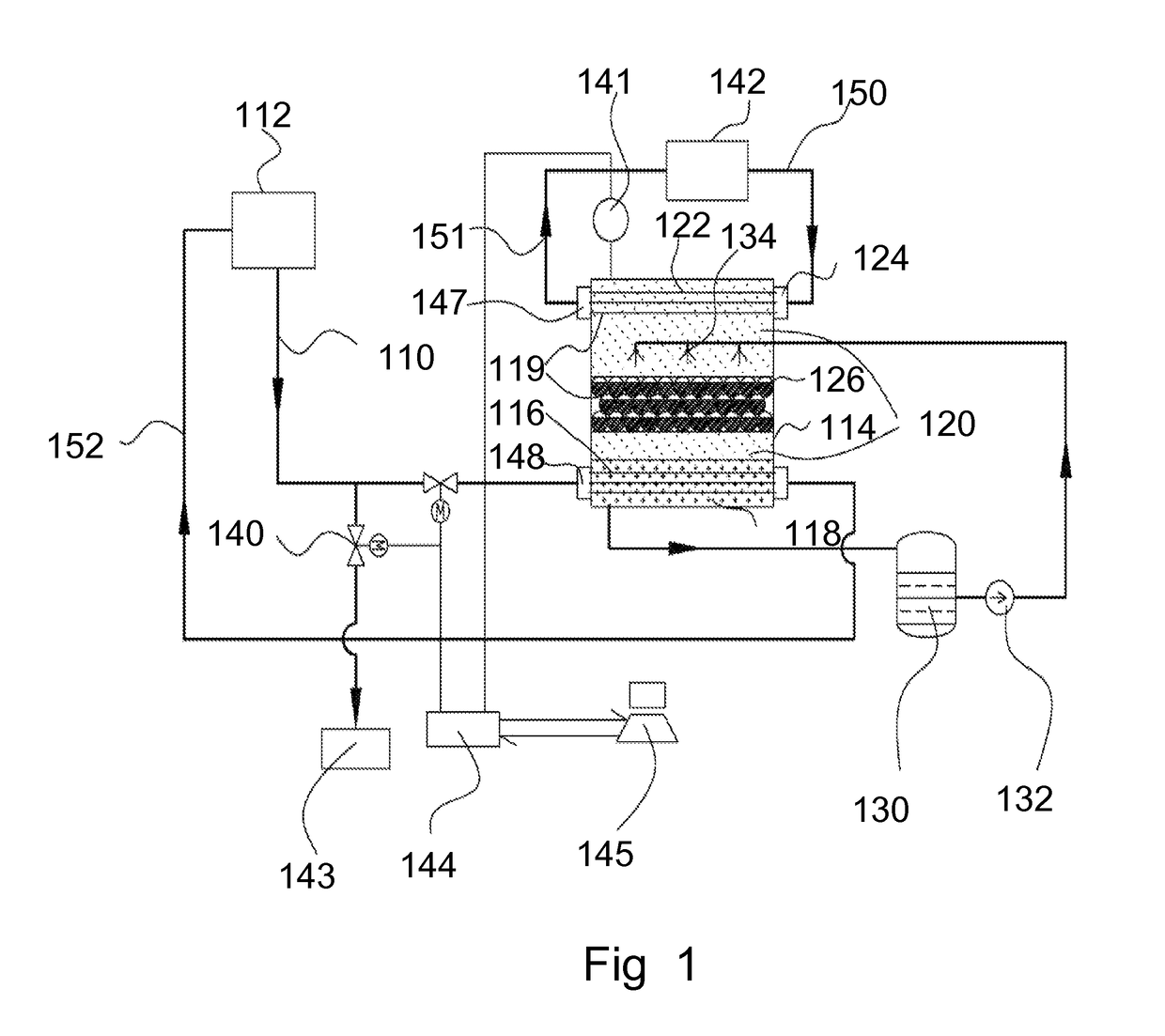

System and method for convective heat transfer utilizing a particulate solution in a time varying field

InactiveUS20070039721A1Improve thermal conductivityImprove conductivitySemiconductor/solid-state device detailsSolid-state devicesParticulatesEnhanced heat transfer

A system combines the thermal conductivity characteristics of certain solids with the high specific heat values of appropriate fluids to enhance the overall heat transfer characteristics of a heat exchanger. The system comprises a fluid channel disposed in a heat exchanger unit with a slurry as the convective heat transfer medium. The slurry comprises an appropriate fluid with field reactive particles suspended therein. Field emitters are located along the walls of the fluid channel whereby the distribution of particles within the slurry is manipulated to achieve enhanced heat transfer characteristics.

Owner:UNITED STATES OF AMERICA

Sewage heat exchange device for large-diameter shell-tube type fluidized bed

InactiveCN102759289AImprove heat transfer efficiencyAnti-dirtCorrosion preventionHeat exchange apparatusSolid particleVolumetric Mass Density

The invention discloses a sewage heat exchange device for a large-diameter shell-tube type fluidized bed, which is provided with a sewage passageway and a clear water passageway, wherein an area for carrying out heat exchange through the tube wall exists between the sewage passageway and the clear water passageway. The sewage heat exchange device is characterized in that the sewage passageway is positioned in the heat exchange area, and a large-diameter pipeline with the diameter of 50-120mm is selected as a sewage pipeline; in addition, a solid particle introducing port is arranged at a water inlet of the sewage large-diameter passageway, and a solid particle storing and conveying assembly is connected to the rear end of the solid particle introducing port, wherein the diameters of the solid particles are 2-8mm, and the volume fraction of the solid particles is 2-8 percent; and the density of the solid particles is more than that of sewage. The sewage heat exchange device disclosed by the invention thoroughly overcomes the defects that a heat exchange is blocked by sundries and the heat exchange property is poor in the utilization of sewage or surface water cold and hot sources, can provide cold and hot sources for a heat pump, can be also used for cooling circulating water of large-size equipment or used for occasions, such as heating, air-conditioning and domestic water and has remarkable environment-friendly economic benefits.

Owner:DALIAN UNIV

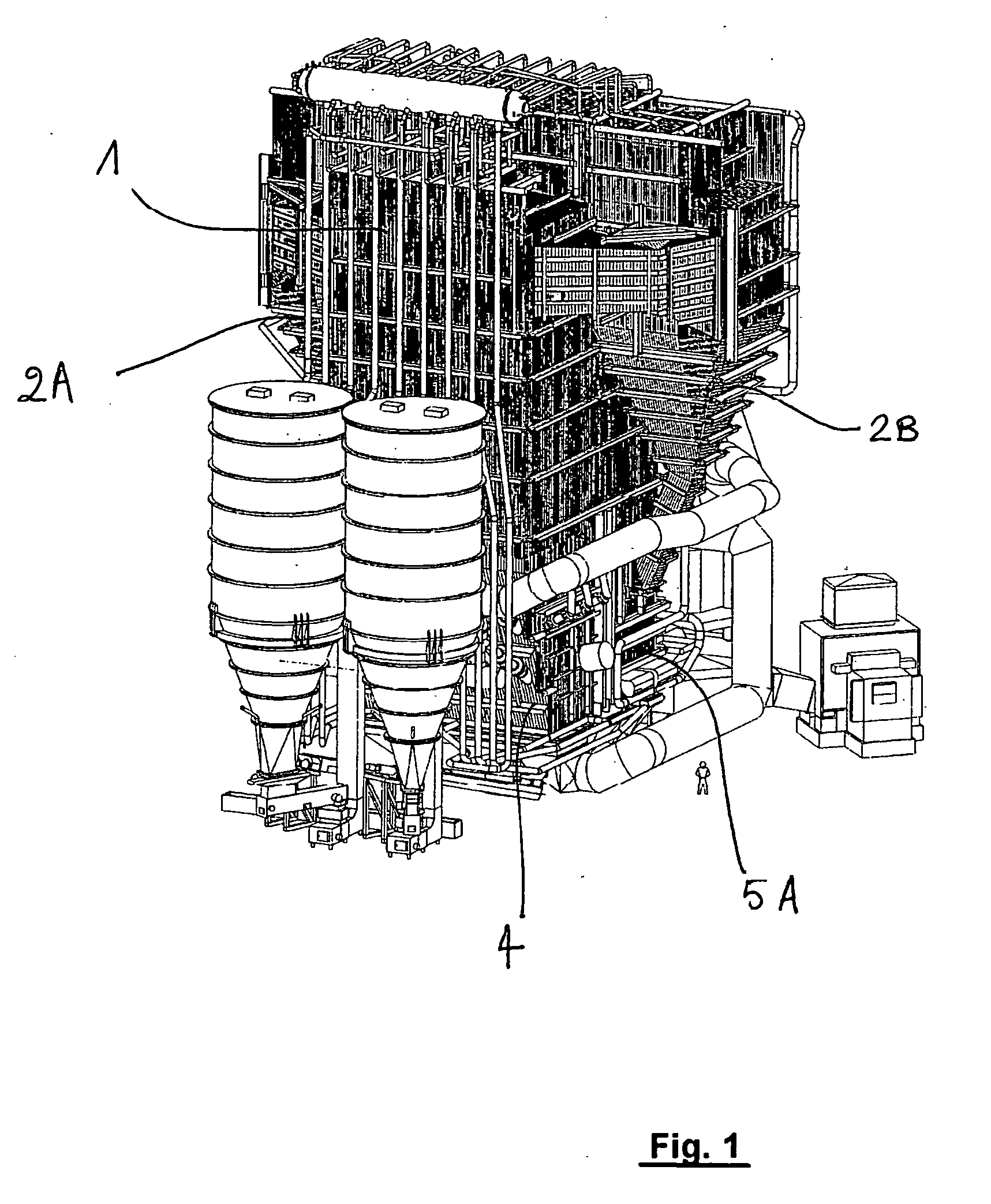

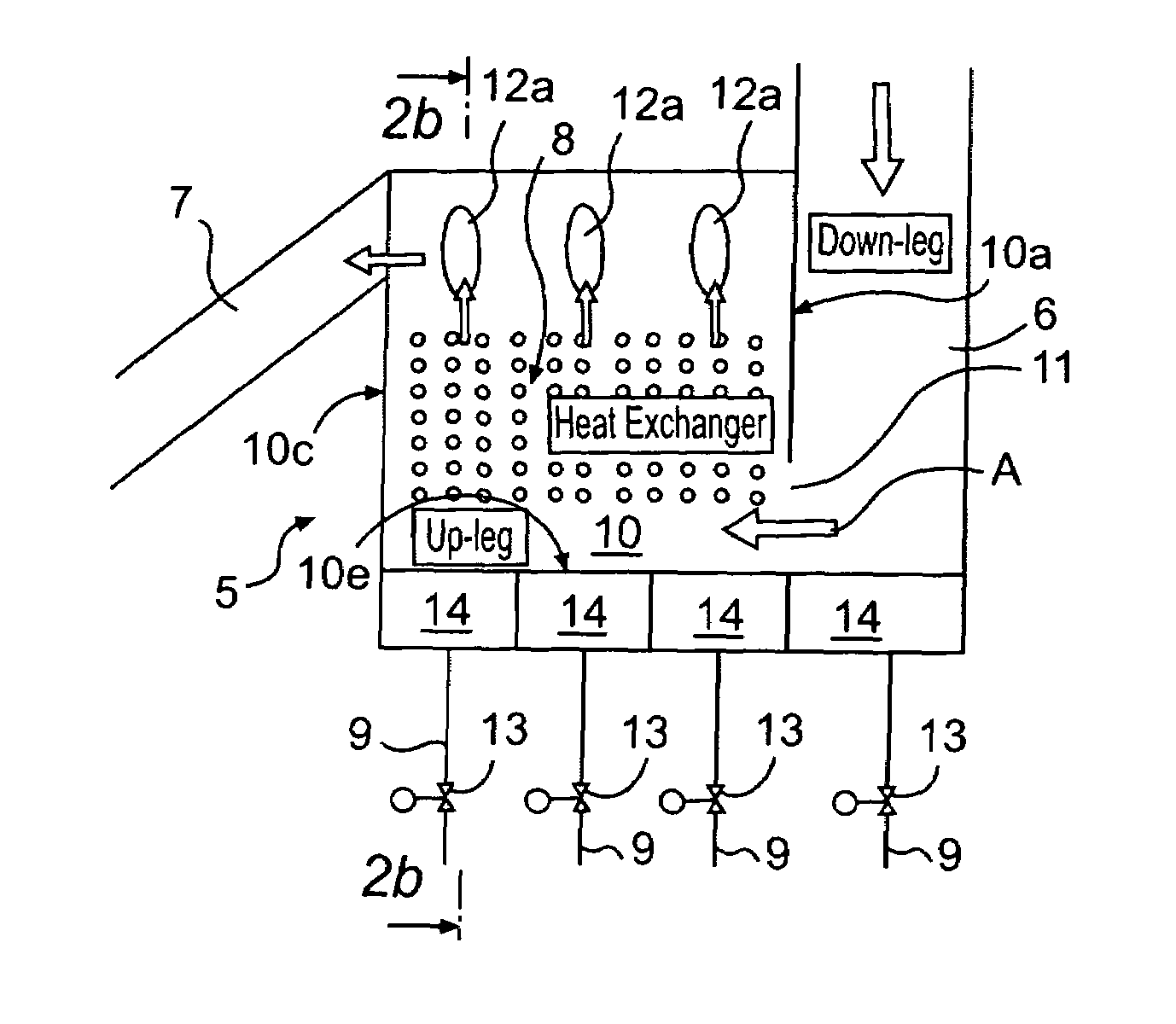

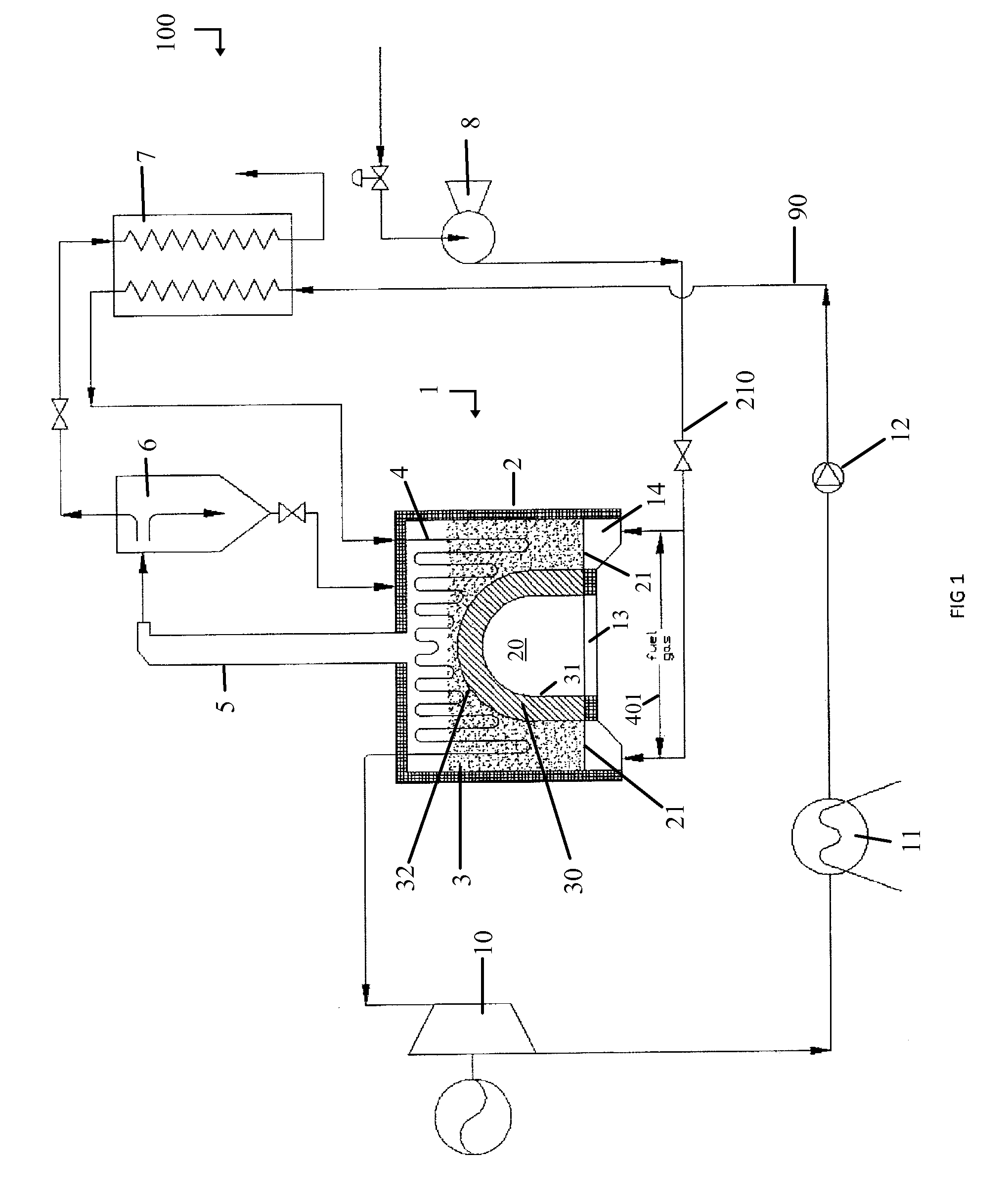

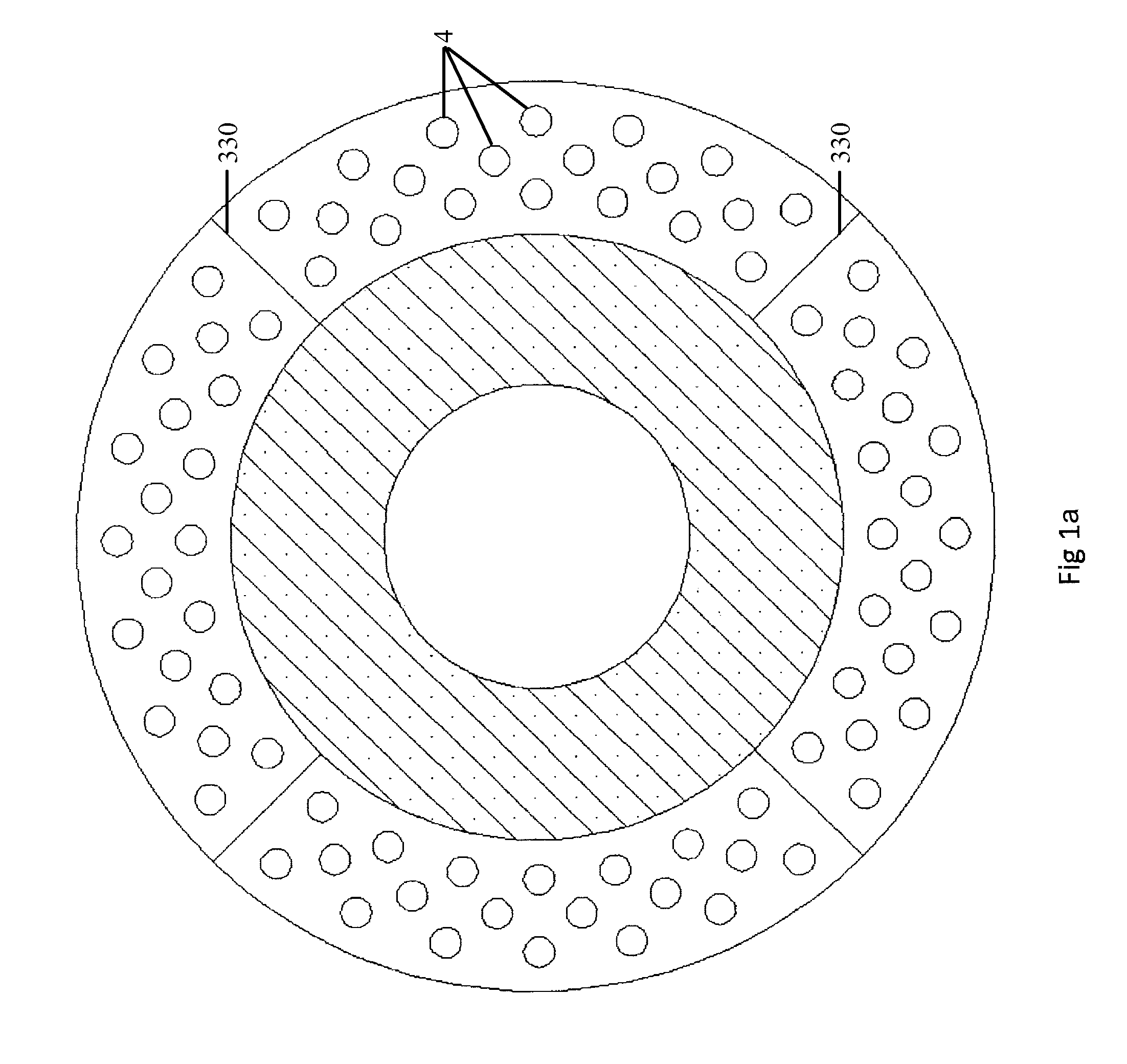

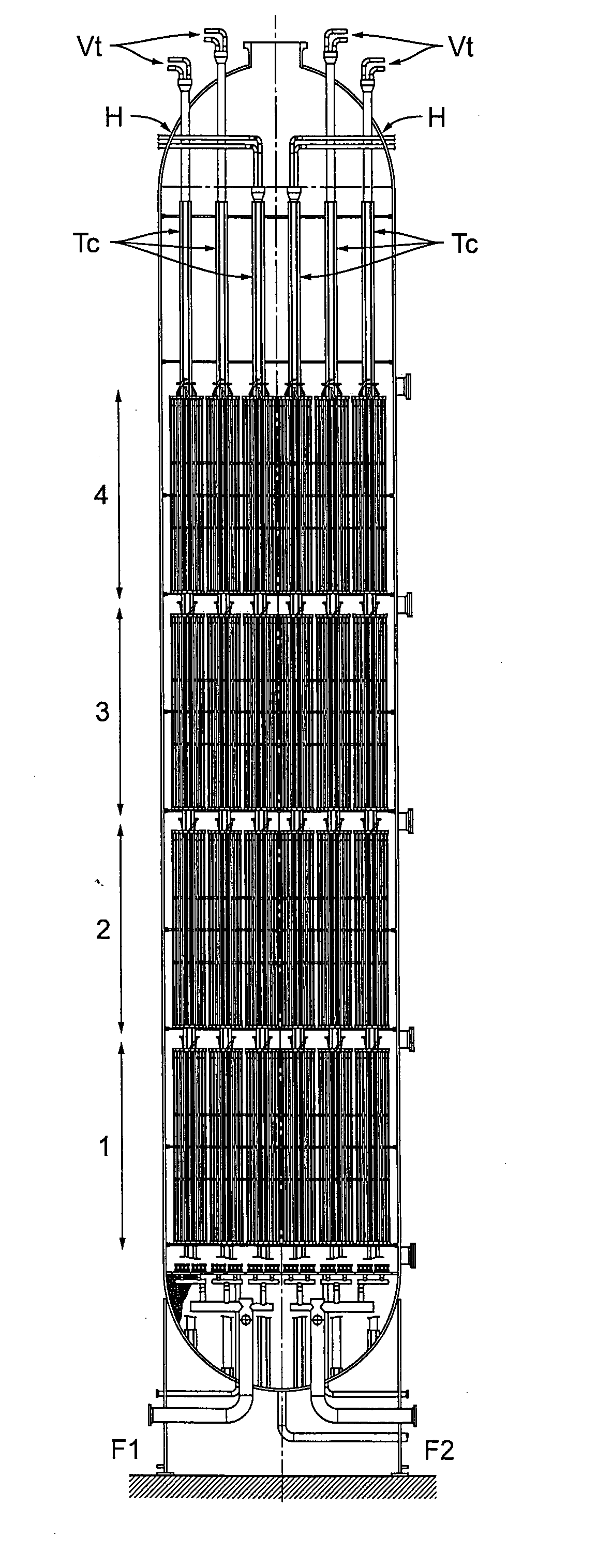

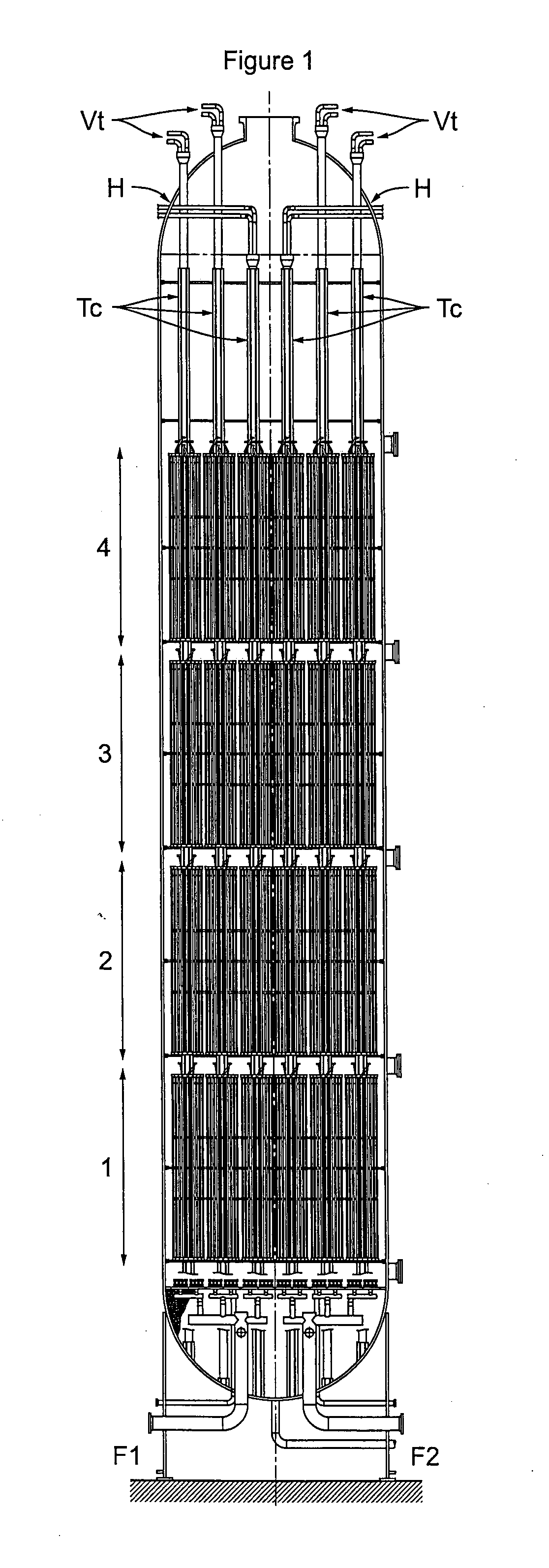

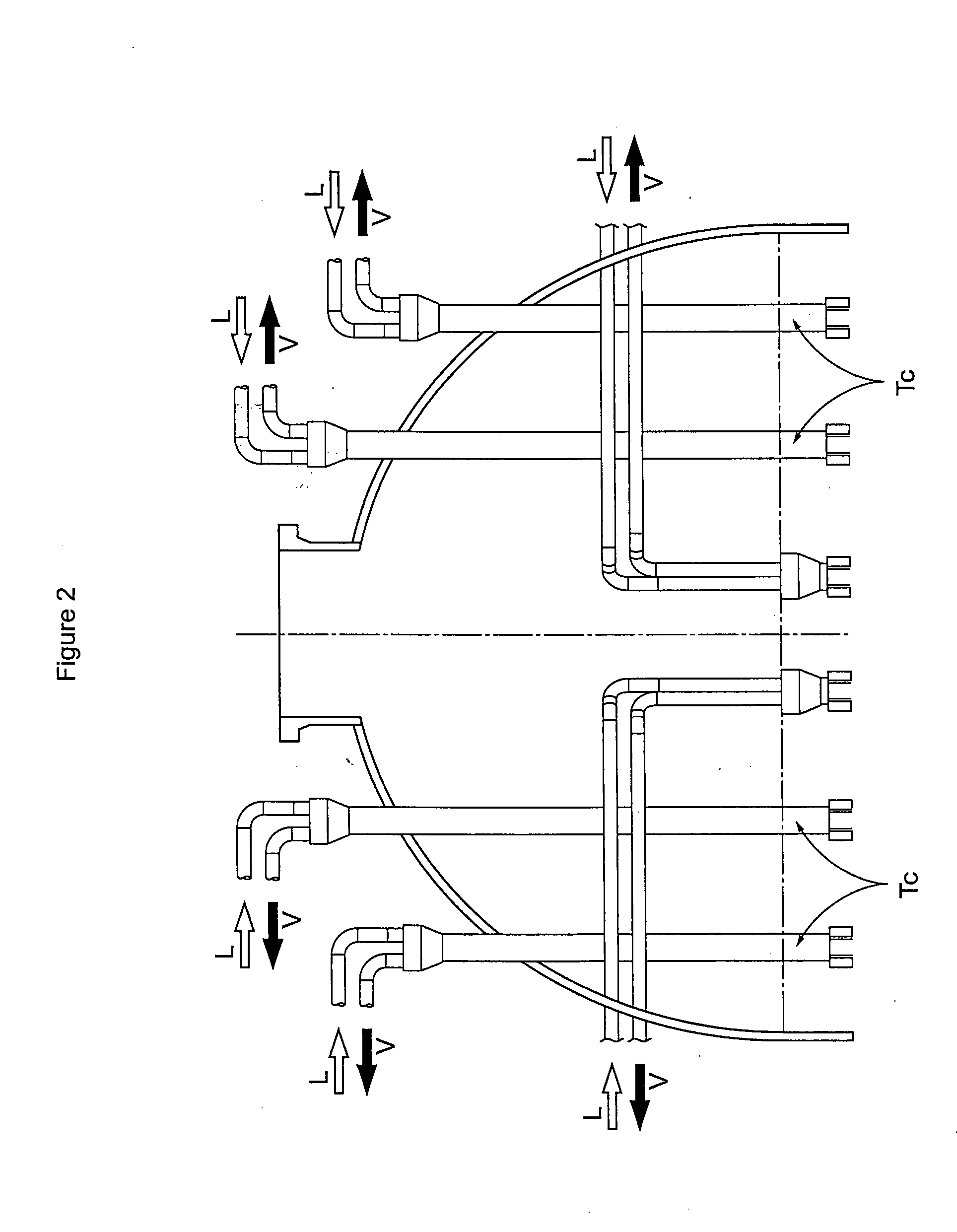

Circulating fluidized bed reactor with a convertible combustion method

InactiveUS20070079773A1Easy to operateFluidized bed combustionSteam/vapor condensersCombustionFlue gas

The invention relates to a circulating fluidized bed reactor designed to be fed with air and convertible to operate with an oxygen-rich mixture, comprising a reaction chamber (1) horizontally bounded by vertical walls, at least two centrifugal separators (2A, 2B) and a heat recovery element called a heat exchanger cage (3), a reactor also comprising means for introducing a fluidization gas into the reaction chamber using at least one wind box (4) placed under the reaction chamber, and for maintaining a circulating fluidized bed of particles in said chamber, means for transferring gas which must be dedusted from the chamber to the separators, means for discharging the particles separated from the separators and means for transferring the dust-free gases from the separators to the exchanger cage. According to the invention: said reaction chamber comprises at least one partially internal vertical partition wall (10) forming two subchambers (1A, 1B) communicating together and each communicating with at least one separator, said exchanger cage (3) comprises a partially internal vertical partition wall (30) forming two subcages (3A, 3B) communicating together and each communicating with at least one separator, these partition walls being arranged in order to create a passage for the flow of the flue gases into one of said subchambers and into one of said subcages corresponding to operation by oxygen feed in the reaction chamber.

Owner:GENERAL ELECTRIC TECH GMBH

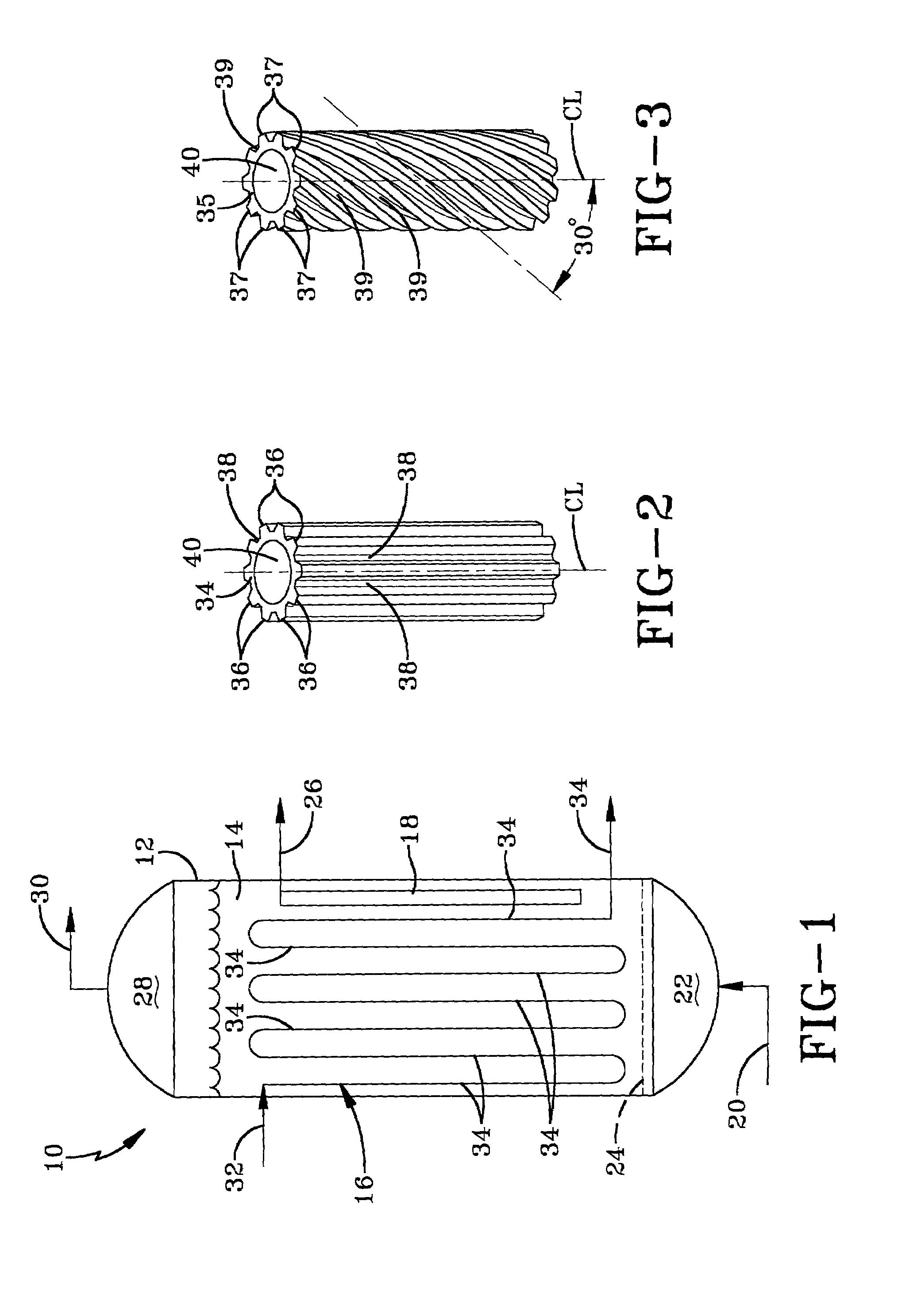

Increased heat exchange in two or three phase slurry

Ribbed heat exchange tubes in which the aspect ratio of the ribs is less than 5, provide greater indirect heat exchange than conventional heat exchange tubes with or without fins, when used in a slurry comprising a liquid phase, in which is dispersed flowing gas bubbles or particulate solids and flowing gas bubbles. The ribs, and typically also the longitudinal axis of the heat exchange tubes, are aligned in a direction parallel to, or spirally along the gas bubble flow direction. This is useful to increase either (i) the productivity of a slurry Fischer-Tropsch hydrocarbon synthesis reactor without an increase in the temperature in the reactor or (ii) increasing the production of higher molecular weight hydrocarbons by reducing the reaction temperature at a given feed conversion.

Owner:EXXON RES & ENG CO

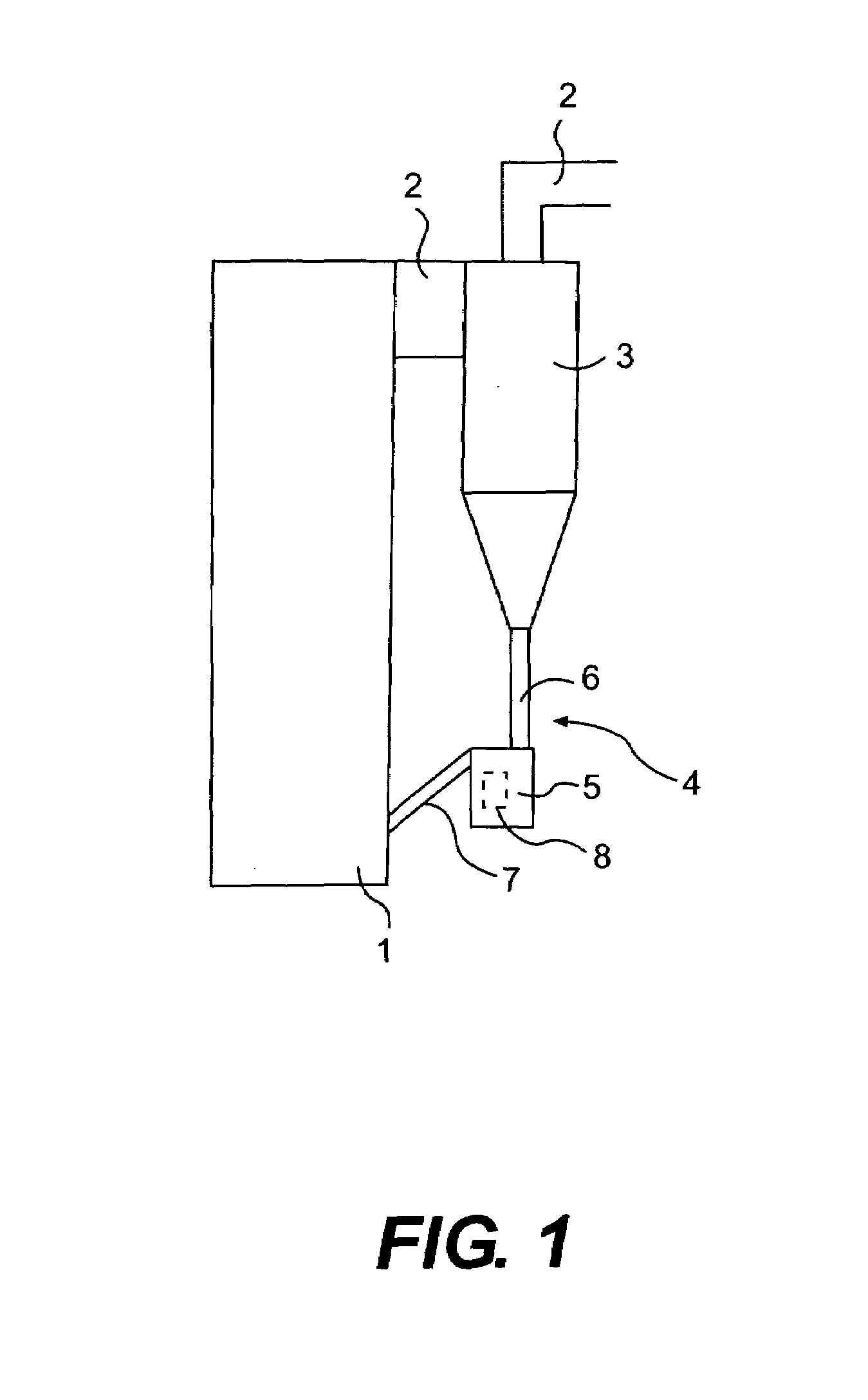

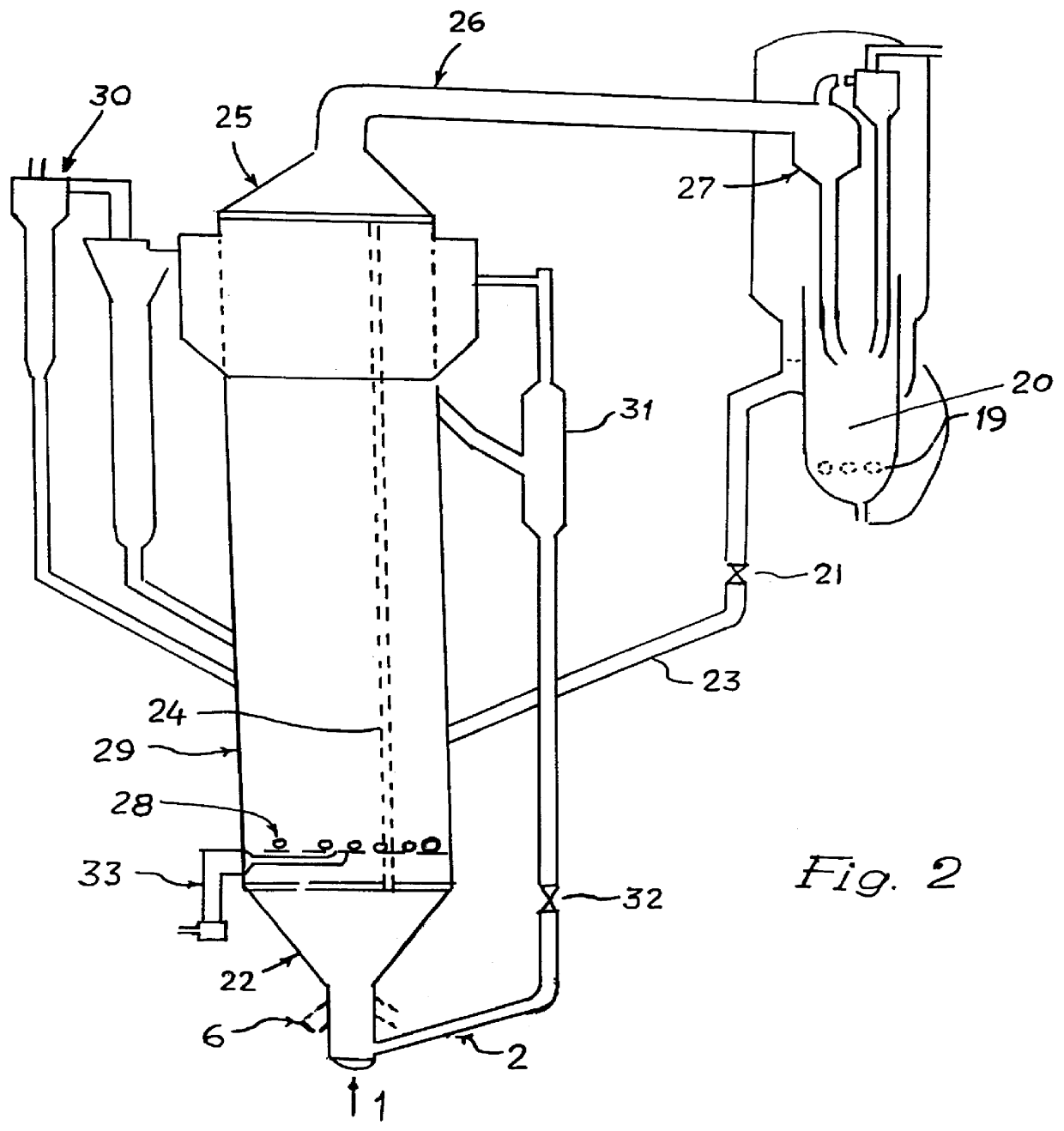

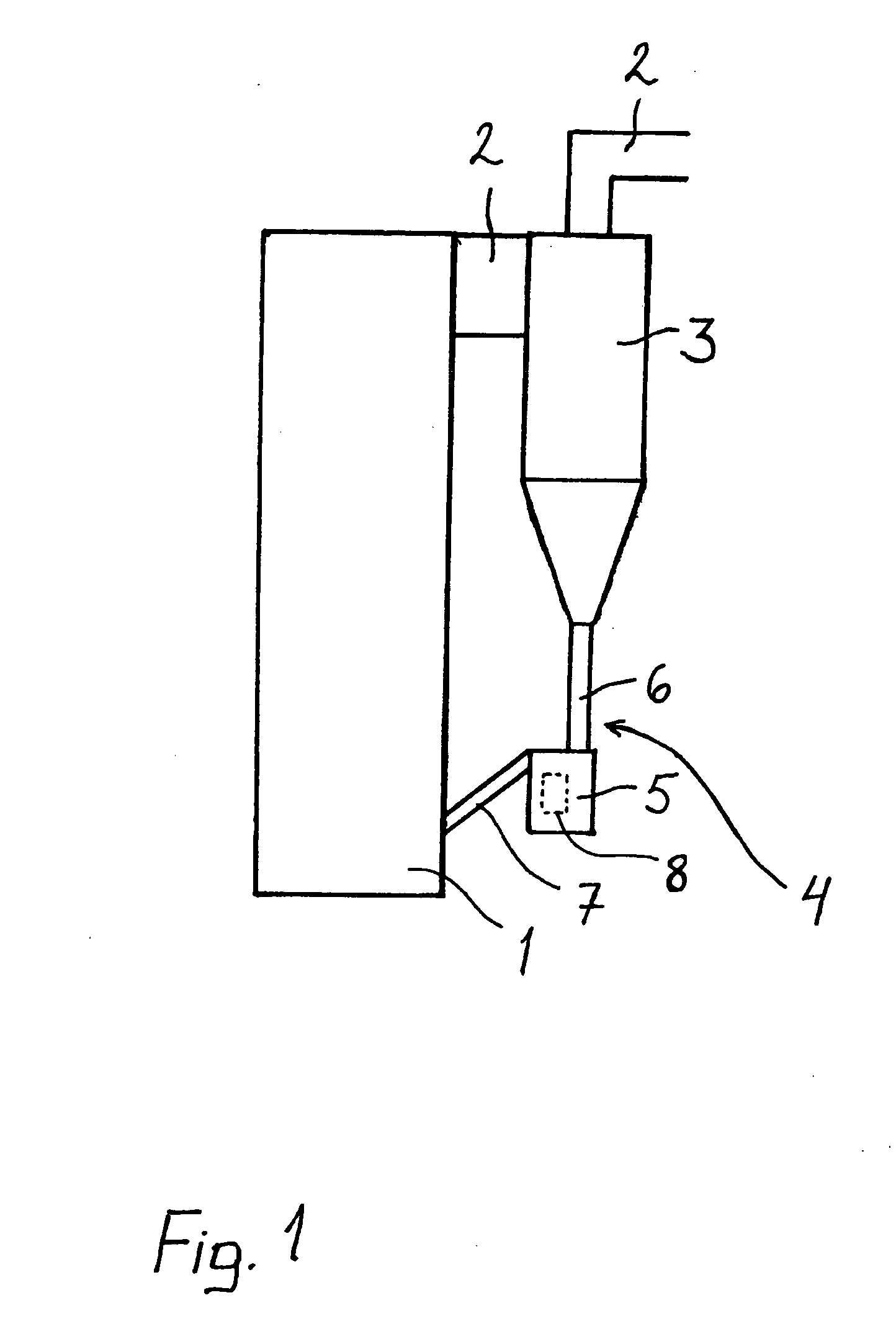

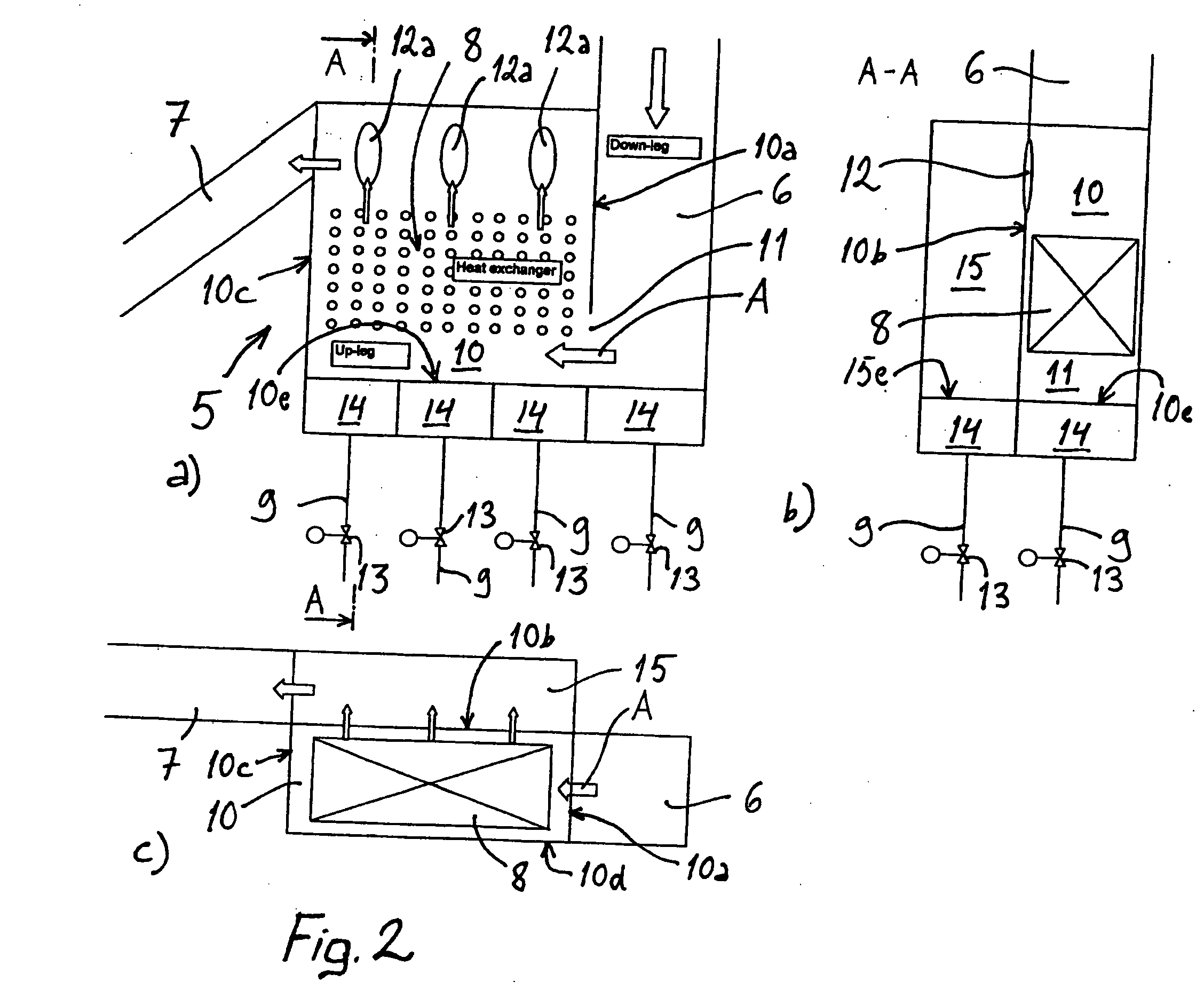

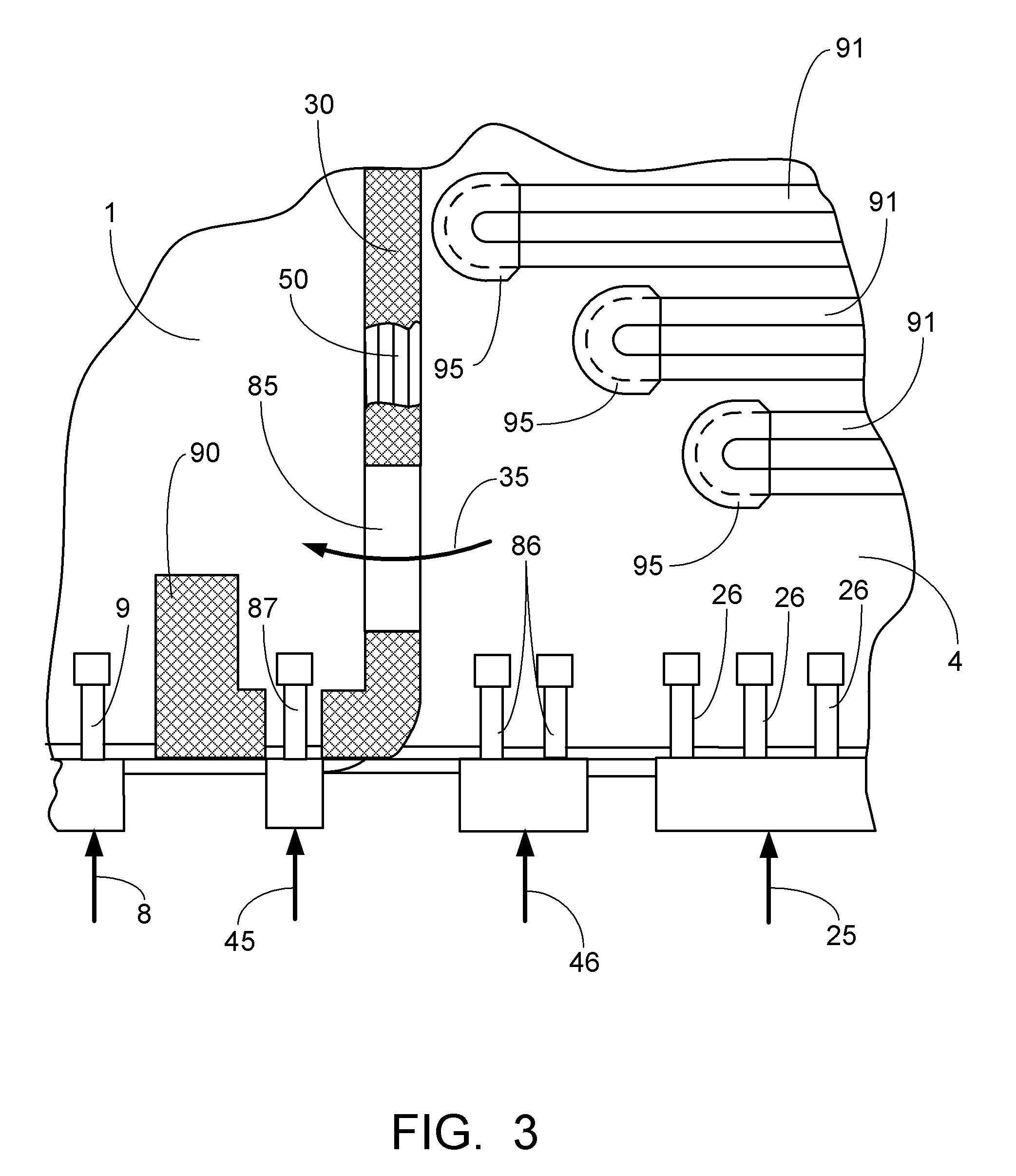

Circulating fluidized bed boiler

InactiveUS7194983B2Easy to integrateFluidized bed combustionIncinerator apparatusPlate heat exchangerFluidized bed

A circulating fluidized bed boiler including a furnace, a separator which is connected to the furnace to separate fluidized bed material from a flow leaving the furnace, as well as a return duct between the separator and the furnace to return the separated fluidized bed material into the furnace. The return duct includes a loop seal equipped with a heat exchanger and a supply of fluidizing medium and having an inlet and an outlet, which open into a chamber including the heat exchanger, i.e. a heat exchanger chamber, and are situated at different heights, the outlet being connected through a return conduit to the furnace. The flow cross-section area of the outlet is at an angle to the flow cross-section area of the inlet in such a way that the fluidized bed material is transferred in the heat exchanger chamber in lateral direction with respect to the inlet direction of its inlet flow. The heat exchanger chamber includes individually controllable fluidizing means at different locations in the direction of the horizontal dimension of the flow cross-section area of the outlet.

Owner:KVAERNER POWER OY

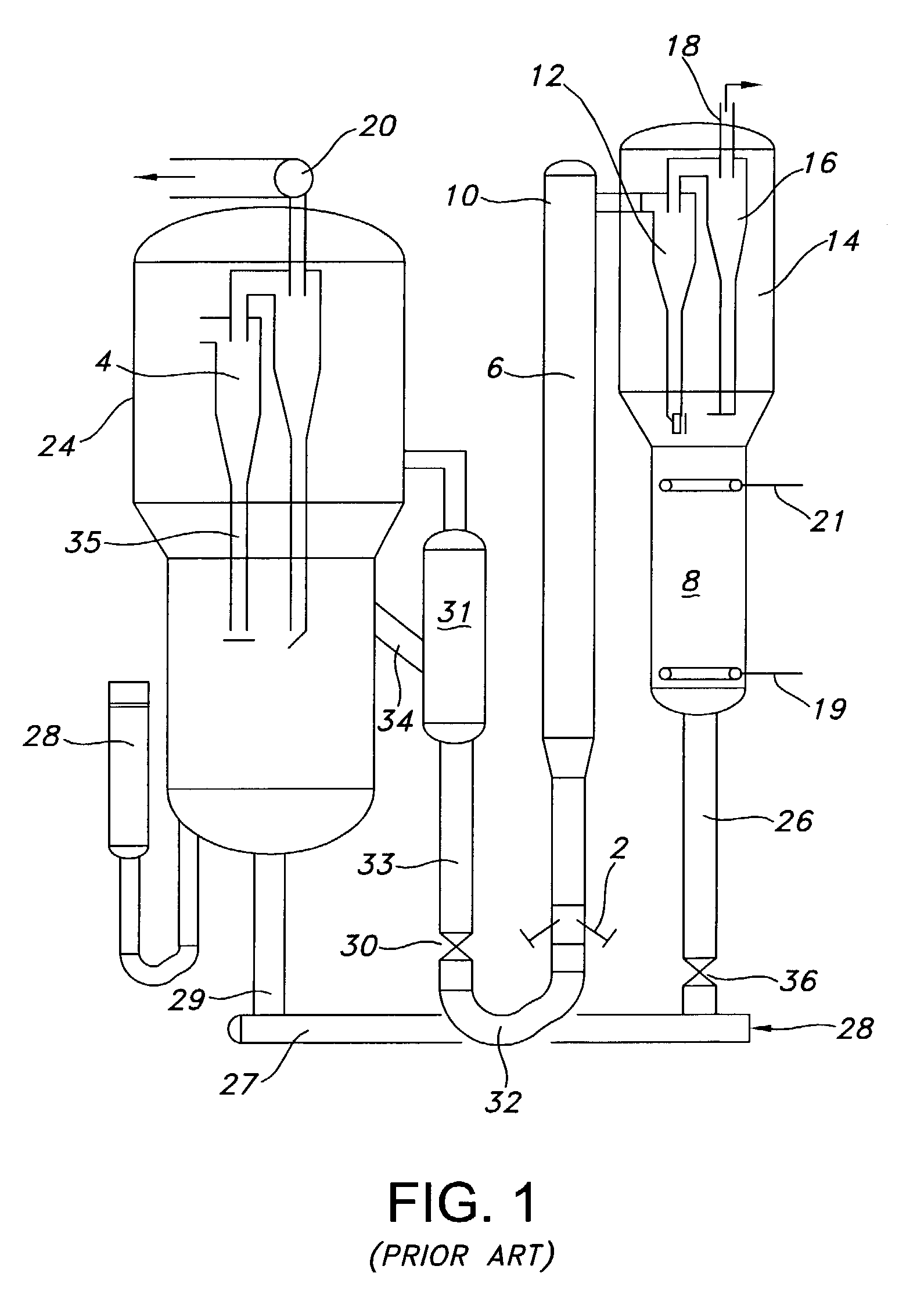

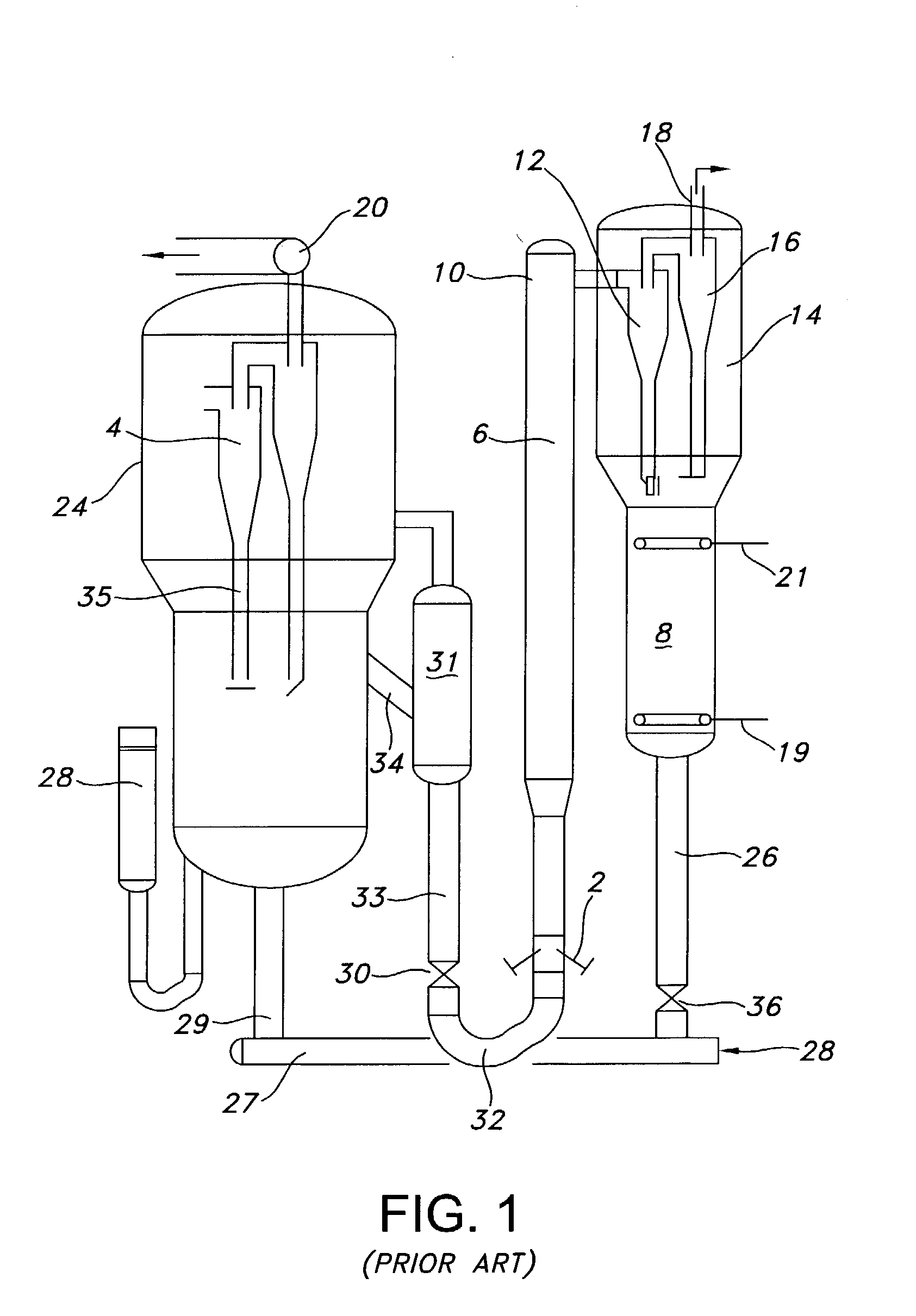

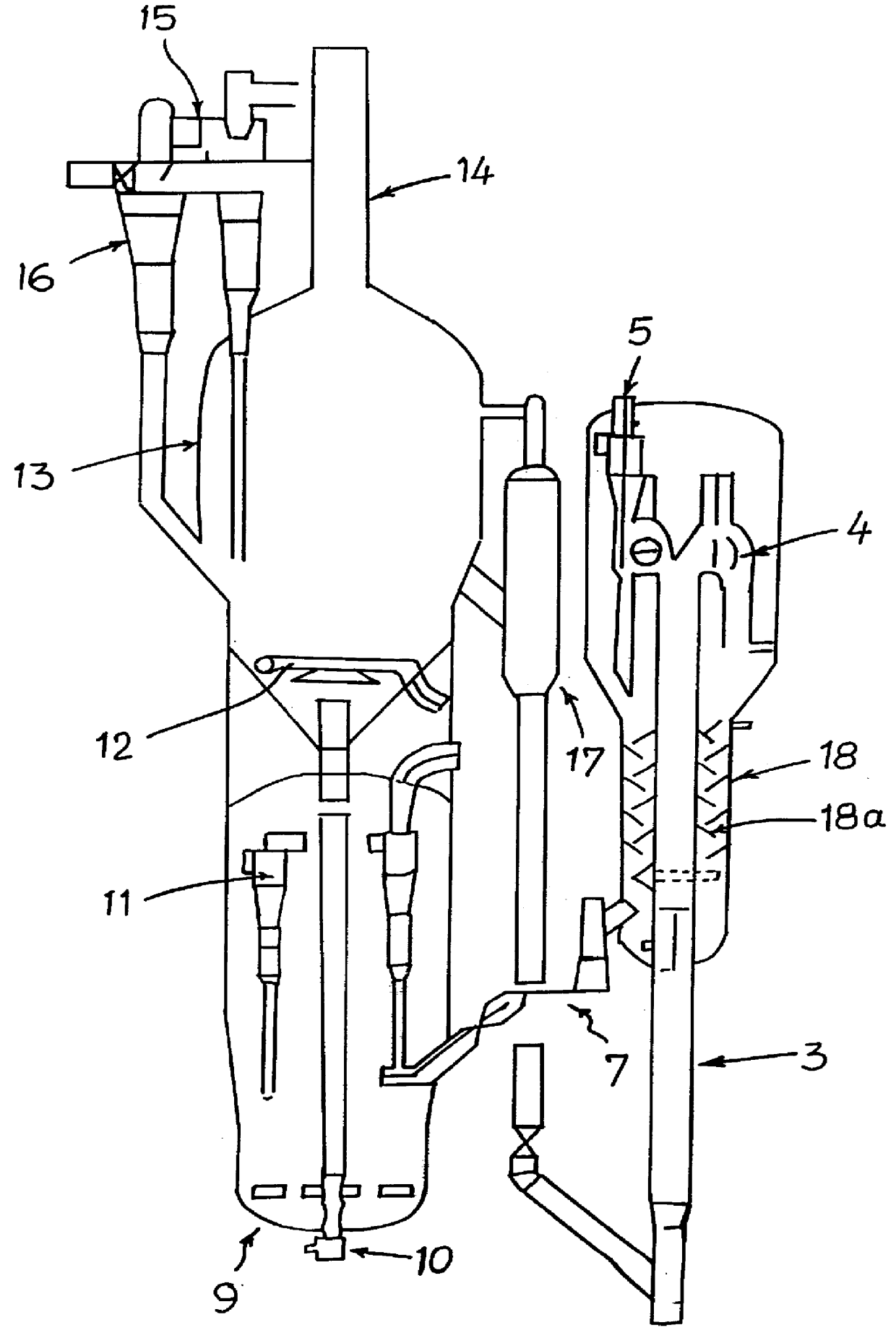

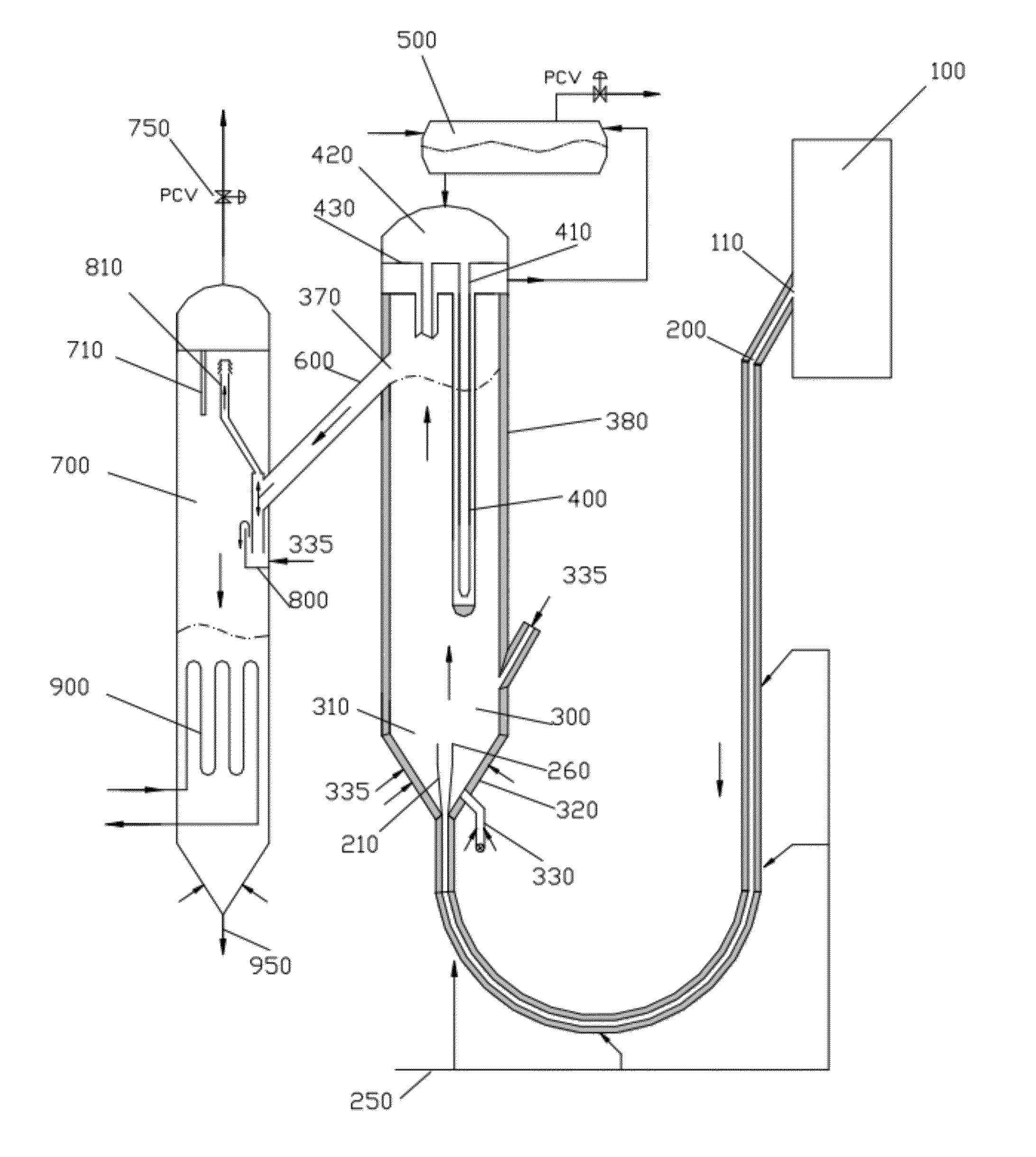

Fluidized catalytic cracking apparatus

A fluidized catalytic cracking apparatus for catalytically cracking a heavy hydrocarbon feed to lighter products includes a regenerator shell for heating spent catalyst, the regenerator shell having a bottom riser for introduction of the heavy hydrocarbon feed, a catalyst, and steam, and from which flows a stream, the bottom riser having a distributor for allowing the stream from the bottom riser to be distributed into a plurality of reaction tubes positioned within the regenerator shell; a catalyst separator connected to an upper end of the regenerator shell; a stripper connected to the catalyst separator to cause a stripping of the catalyst and the spent catalyst feed to the regenerator shell; and an air inlet provided in the regenerator shell so as to cause a combustion within the regenerator shell.

Owner:INDIAN OIL CORPORATION

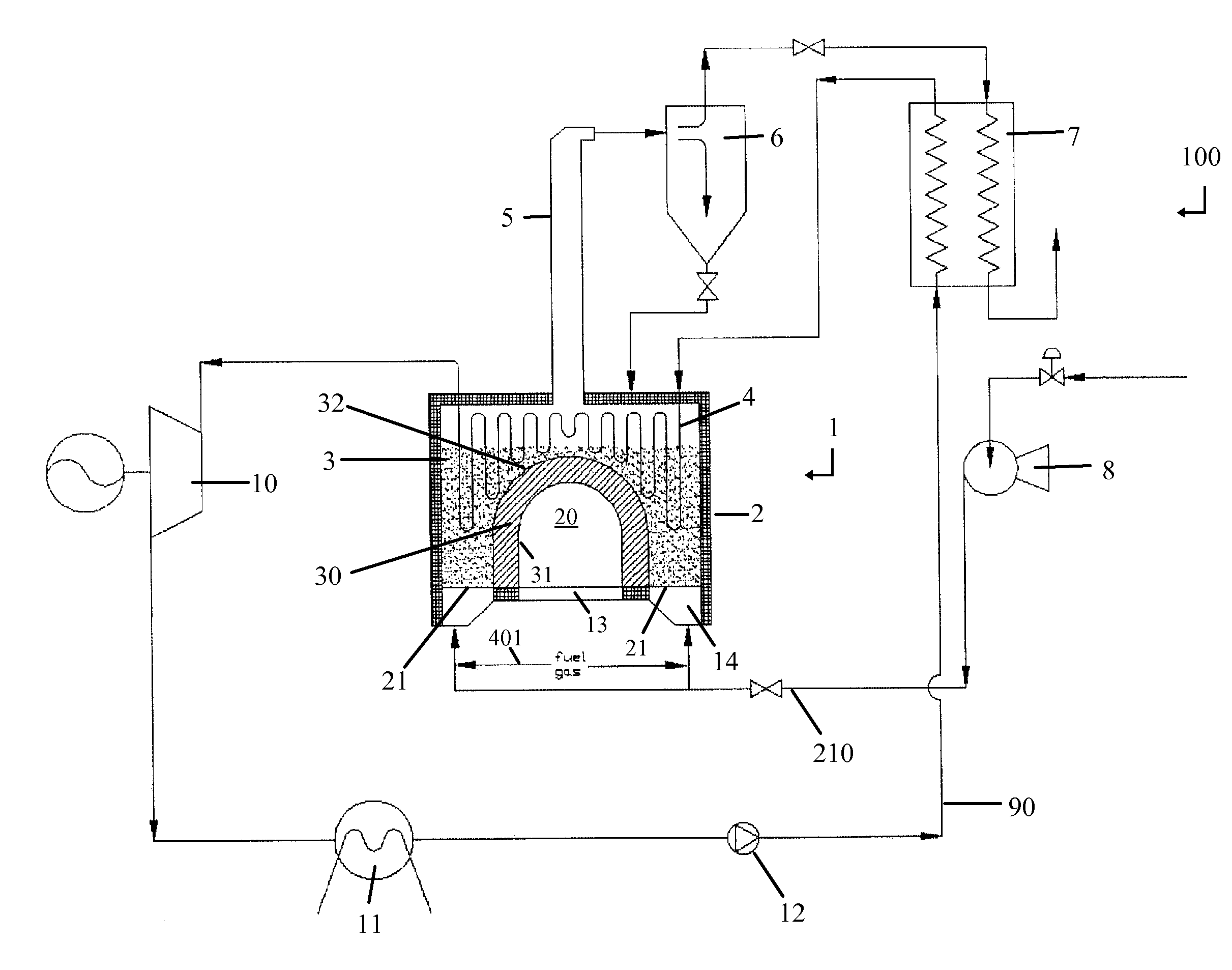

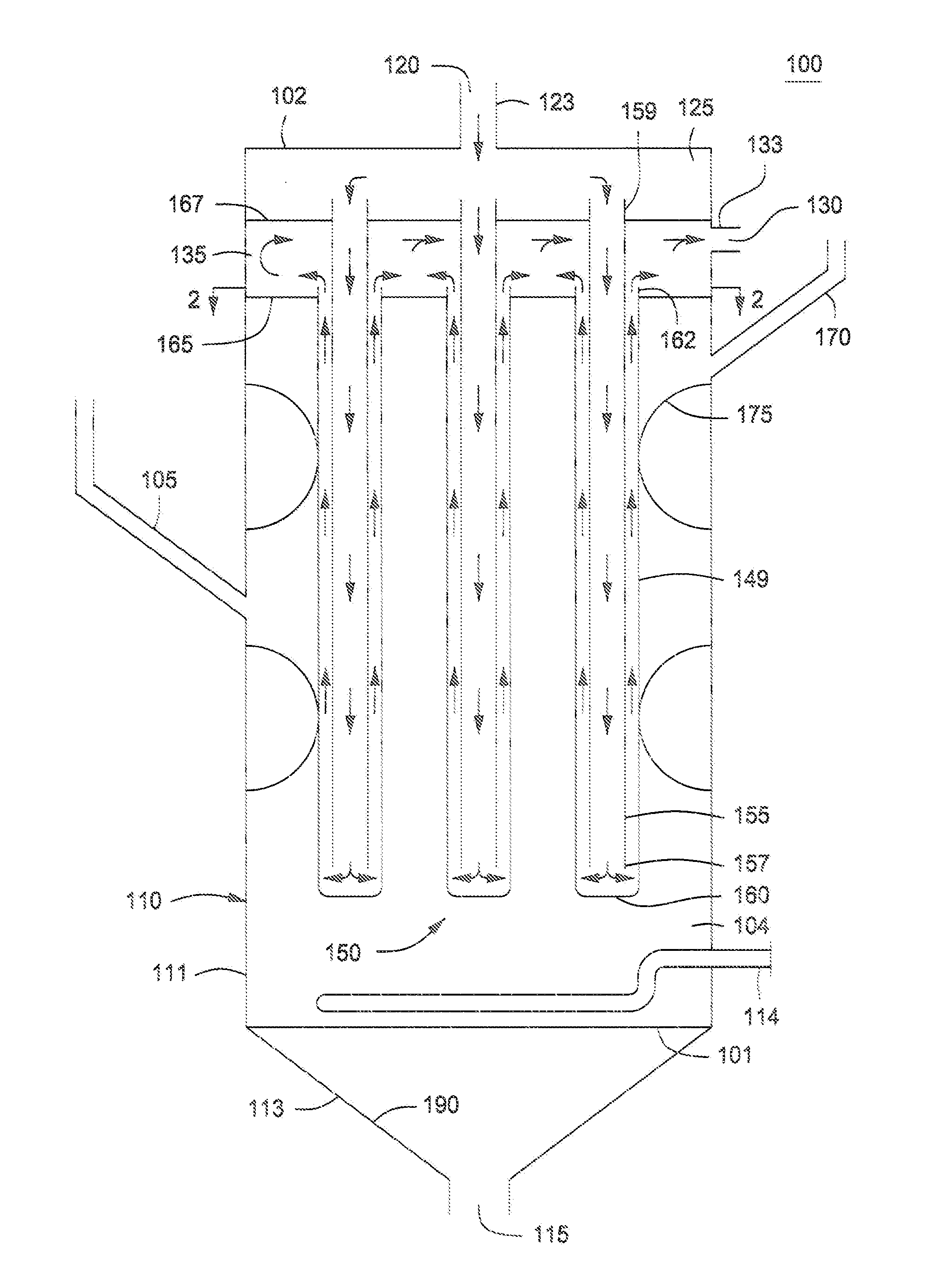

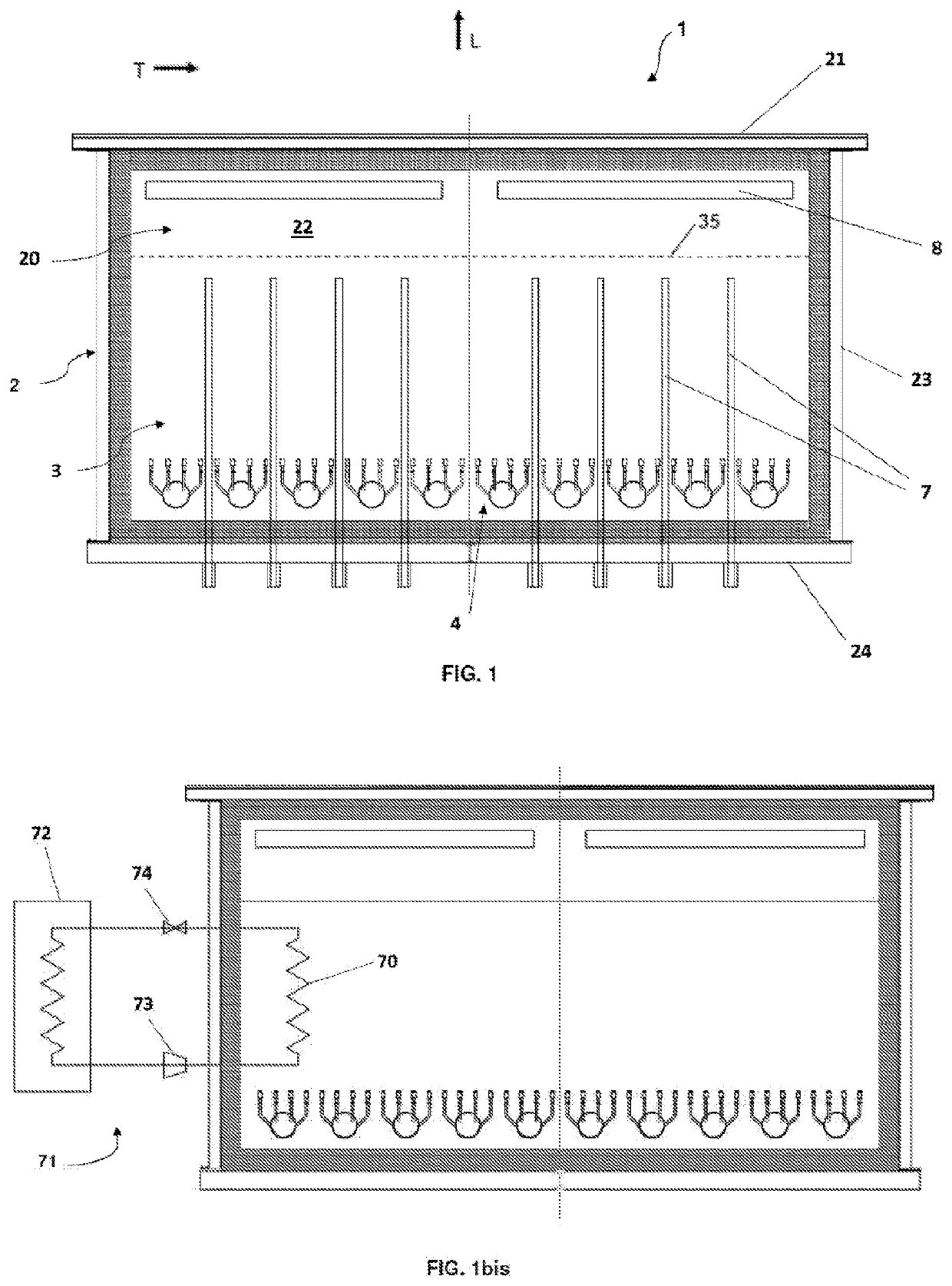

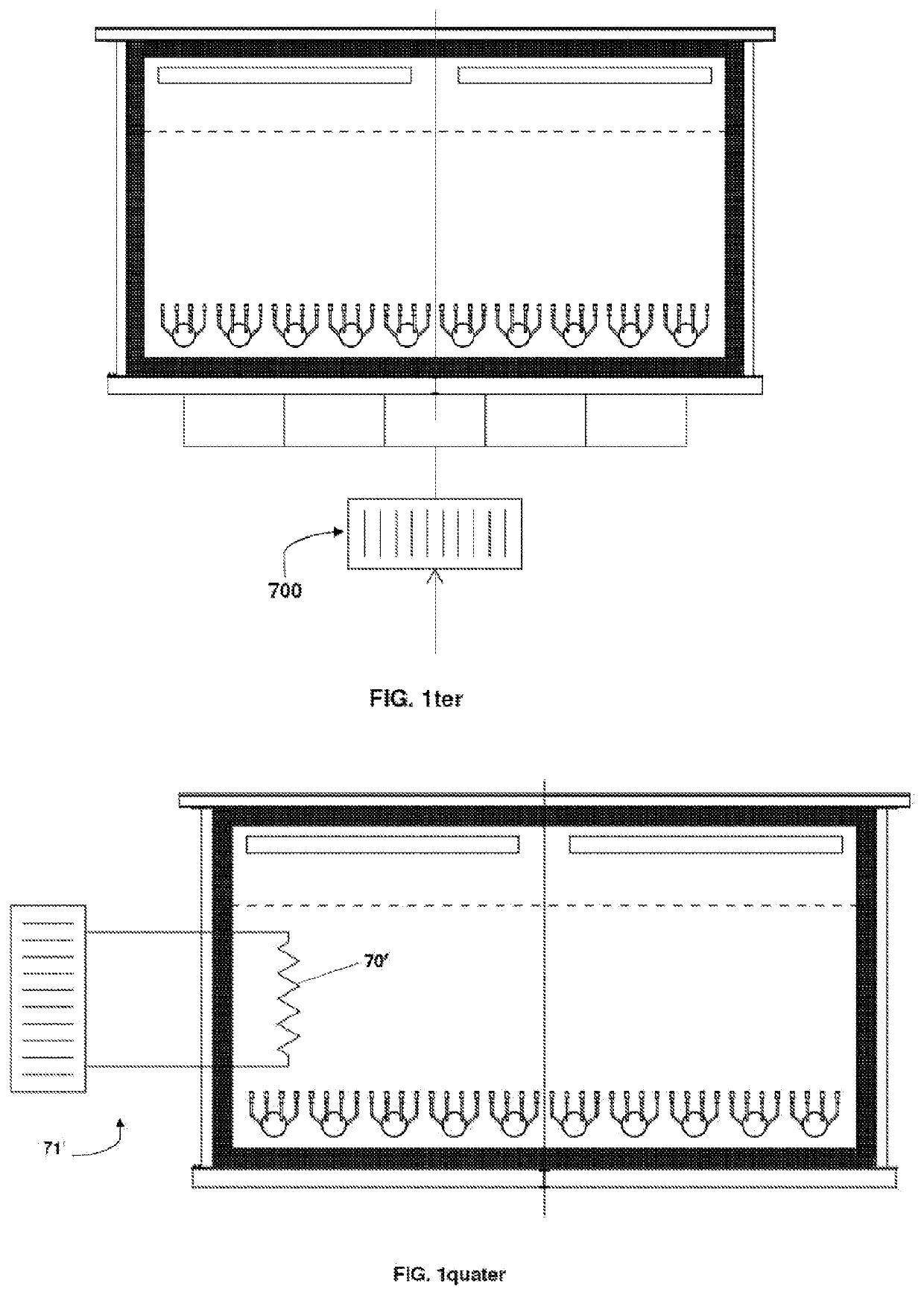

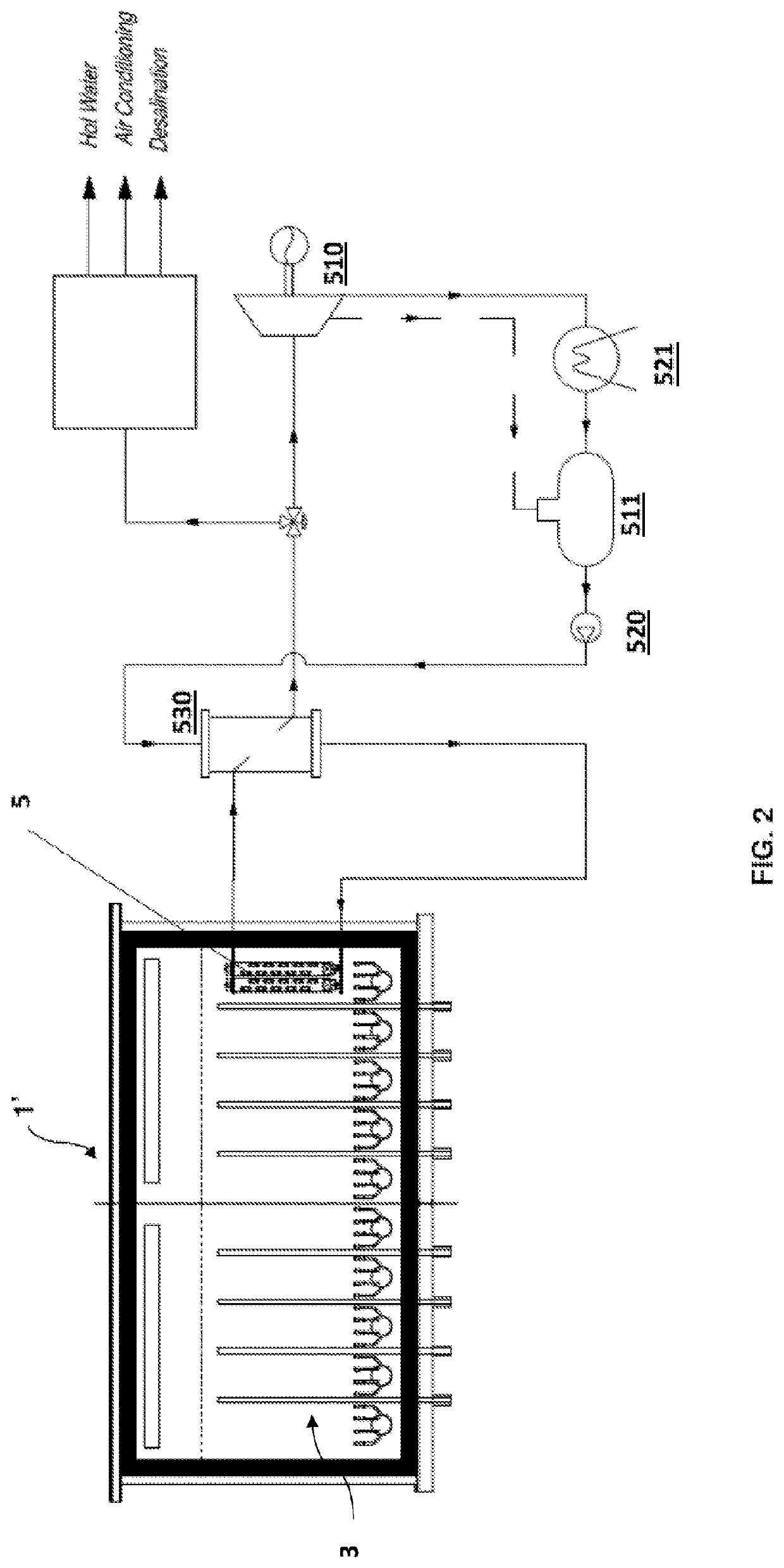

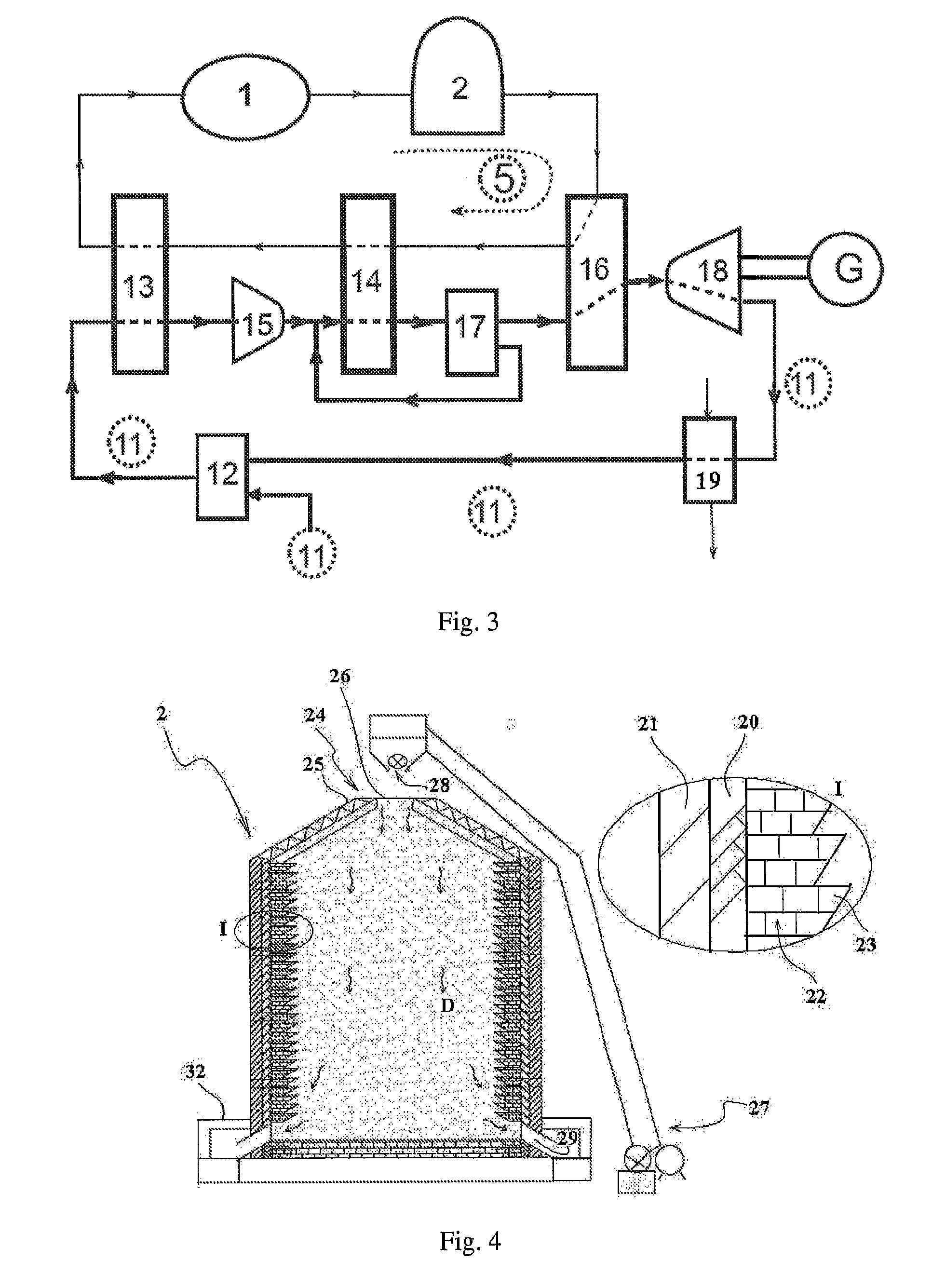

Device and method for storage and transfer of thermal energy originated from solar radiation based on fluidization of a bed of particles

ActiveUS8960182B2Minimize thermal stressImprove heat exchange efficiencySolar heating energySolar heat devicesThermal energyEngineering

A device for storage and conveyance of thermal energy for an energy production system apt to receive solar radiation and based on the use of a modular fluidizable granular bed and a heat exchanger associated thereto is described.

Owner:MAGALDI IND SRL

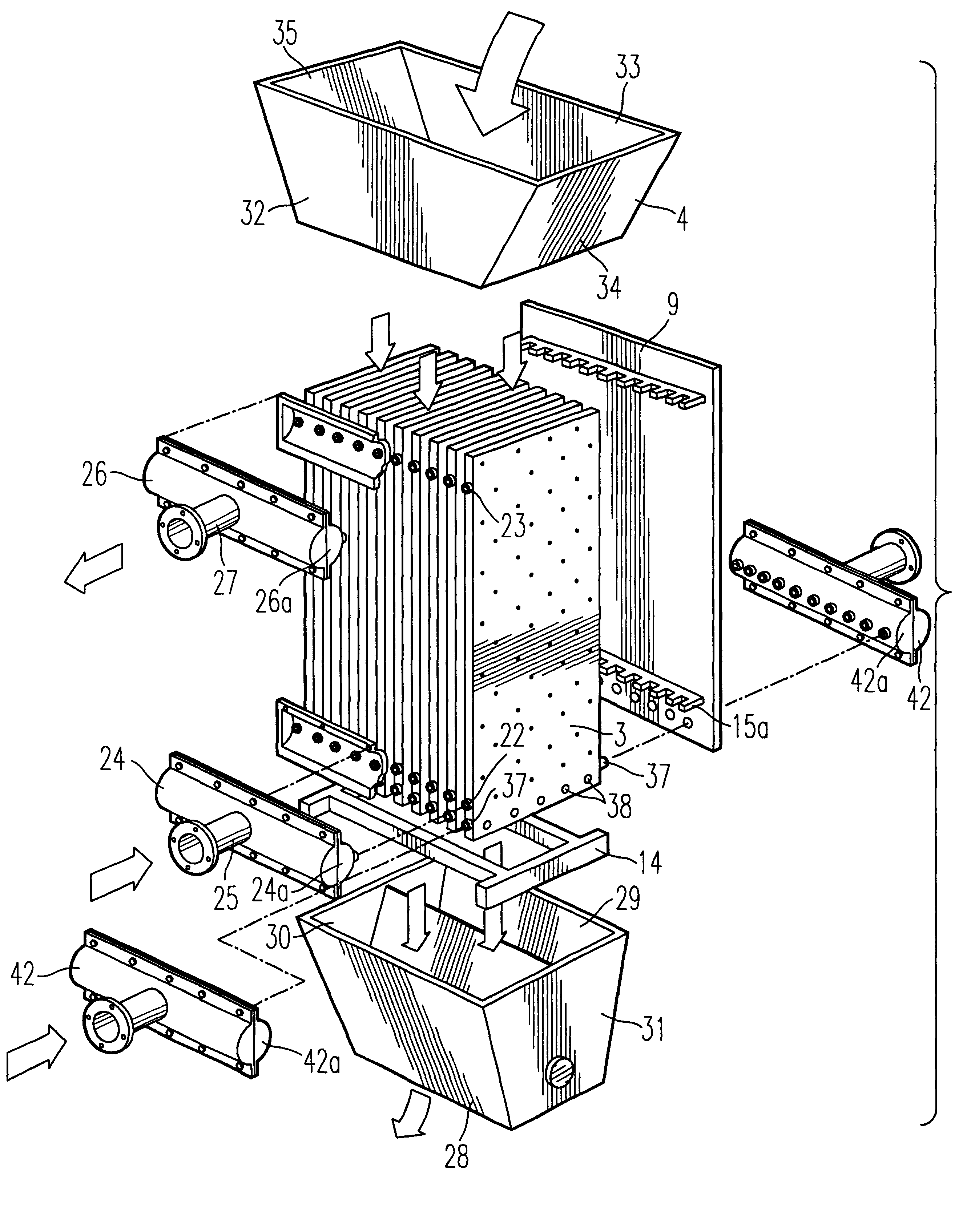

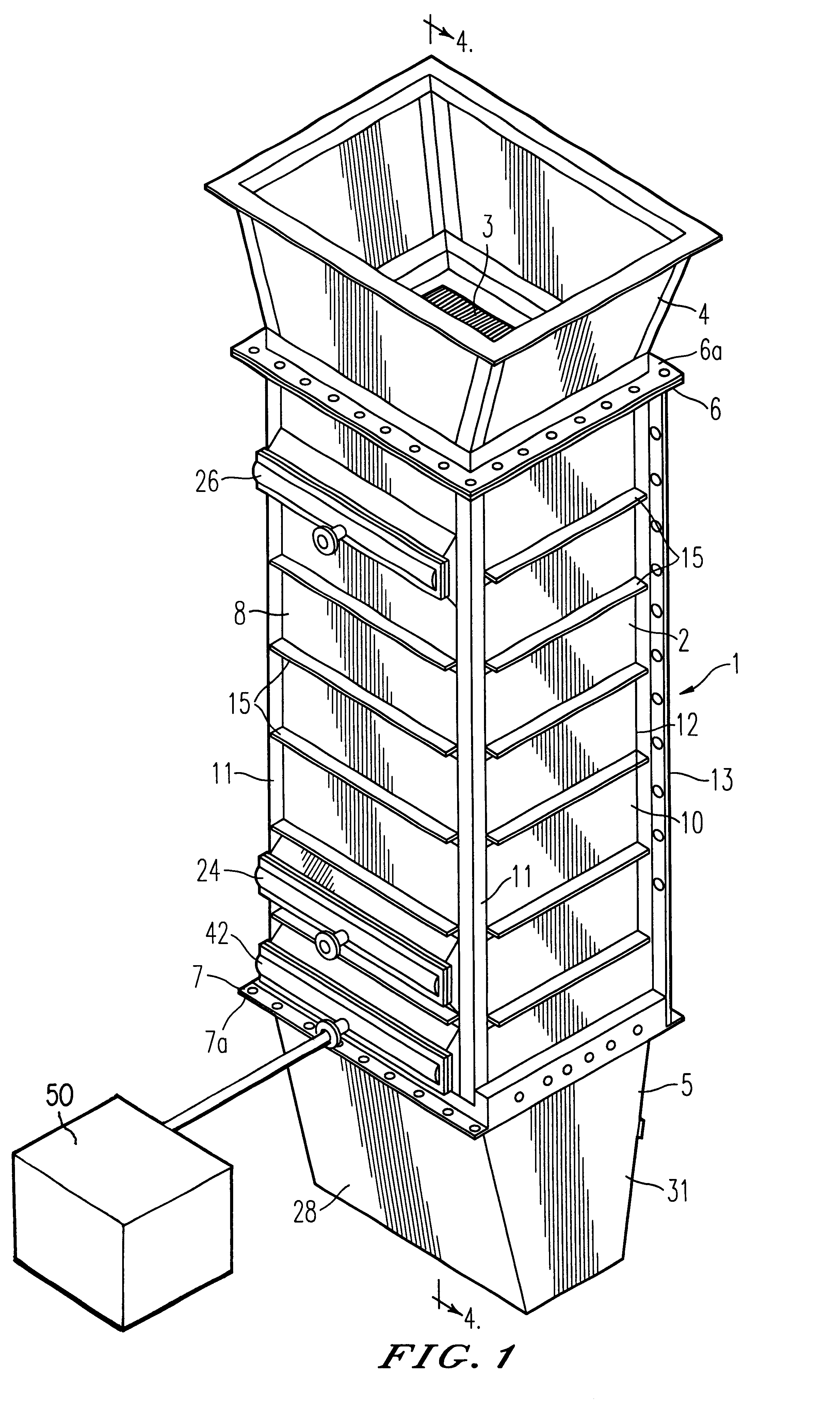

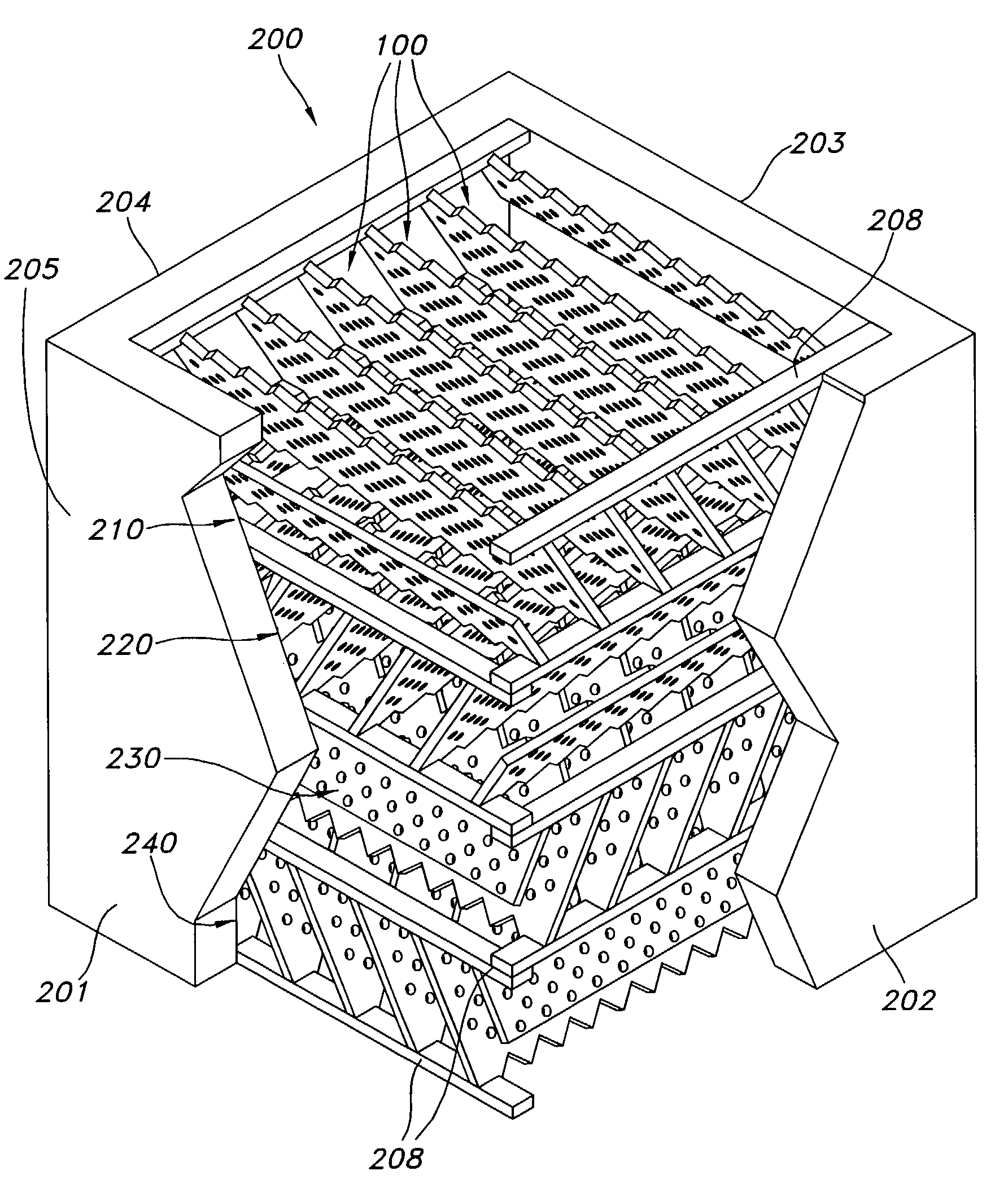

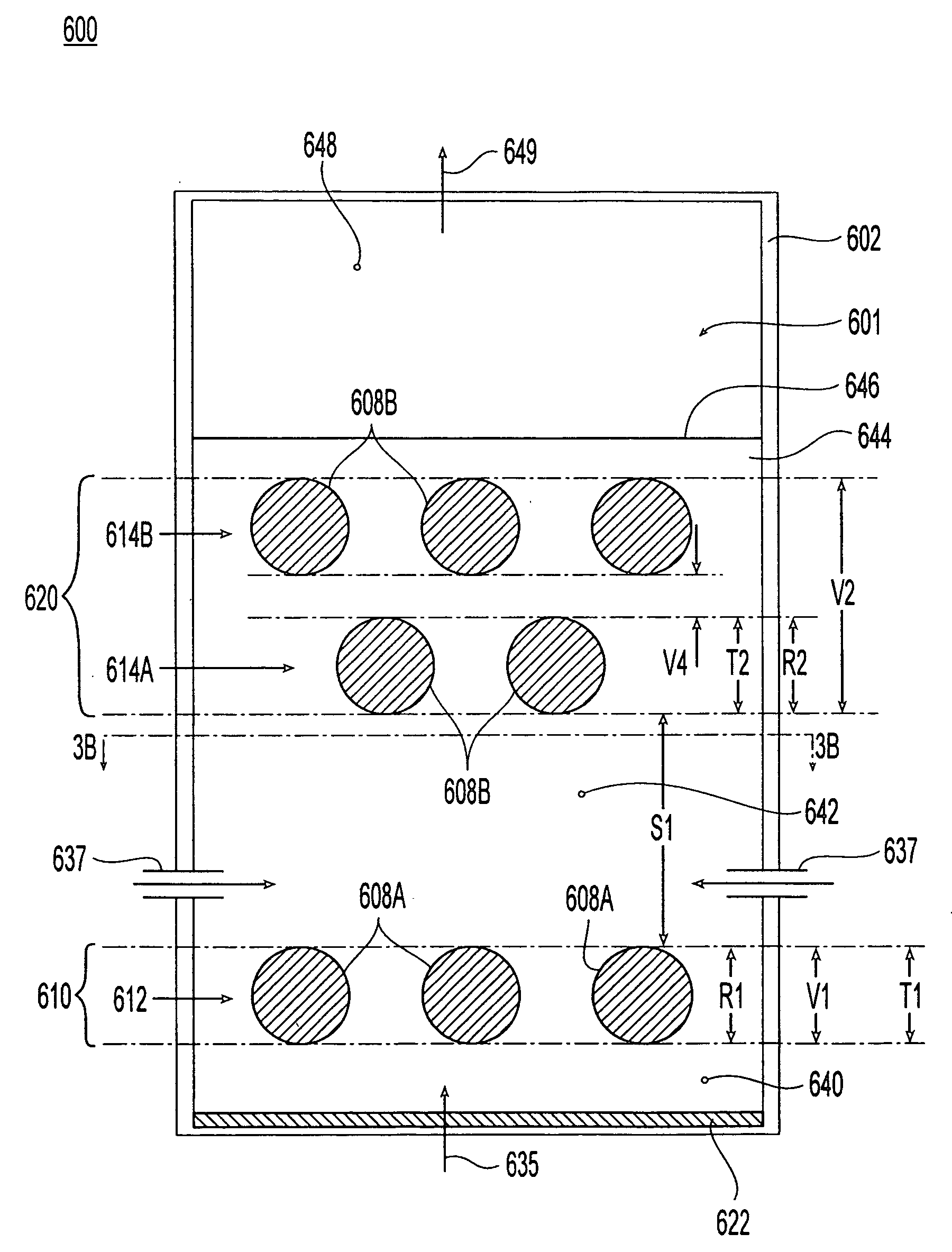

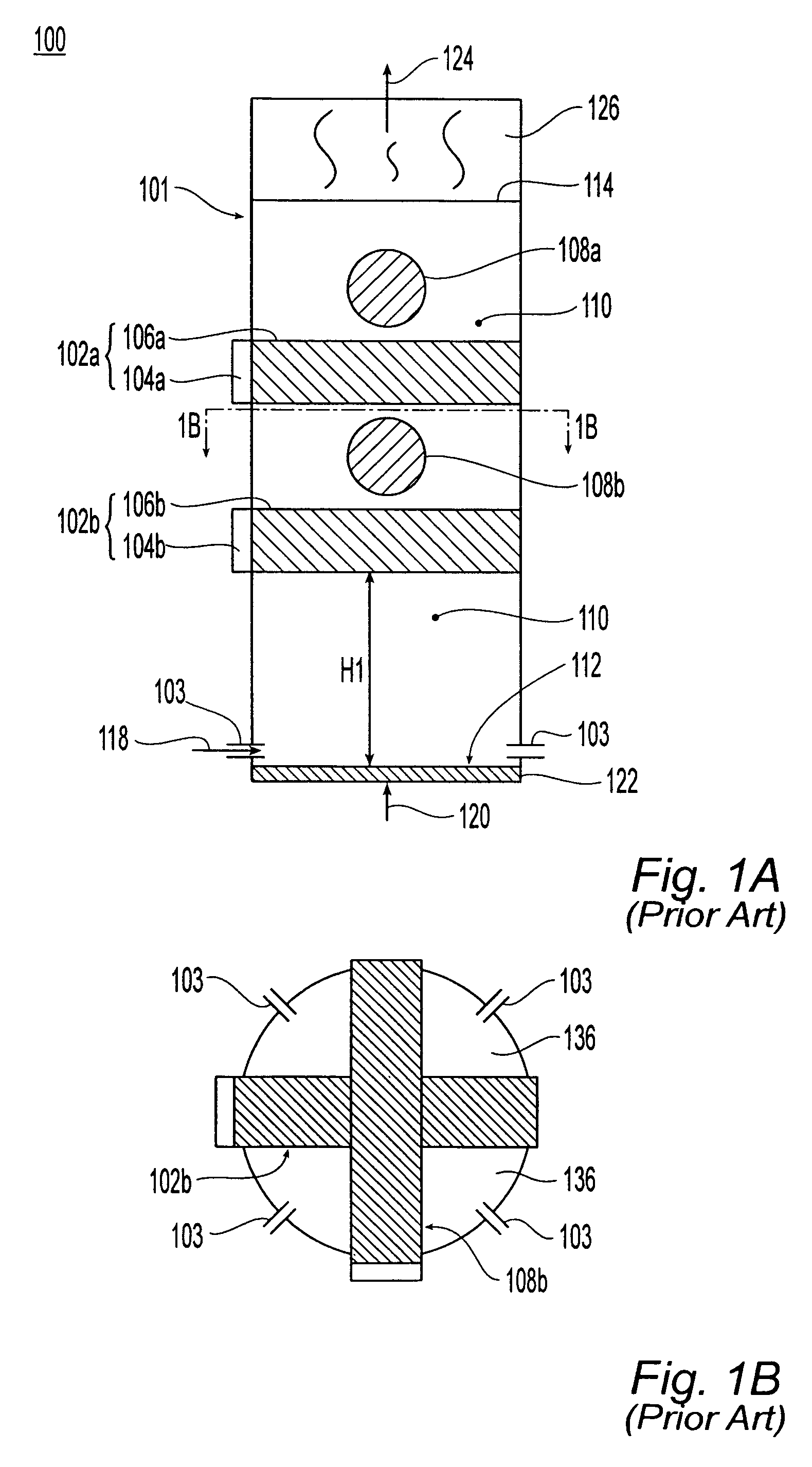

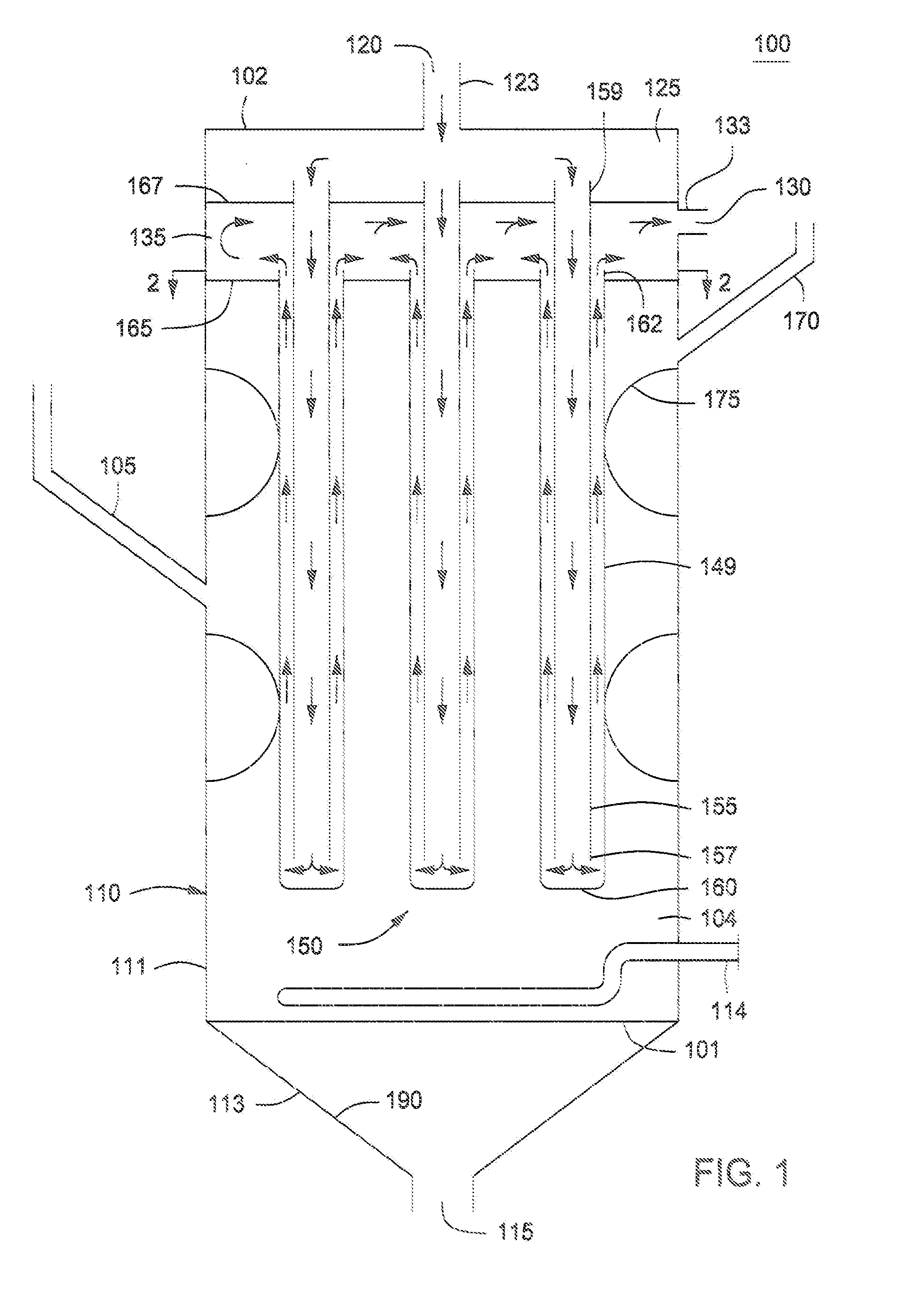

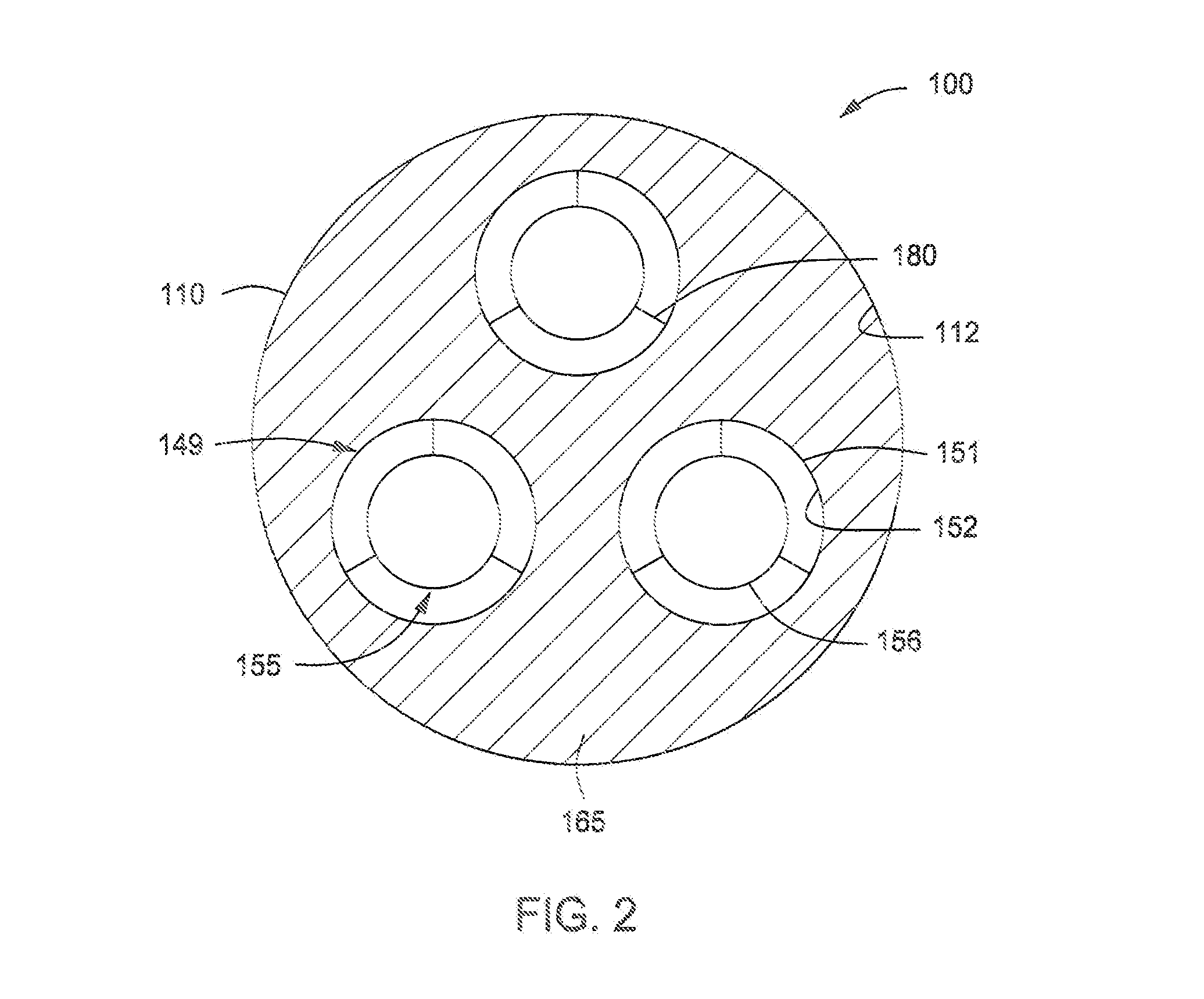

Fluid bed reactor having vertically spaced apart clusters of heating conduits

A fluid bed reactor is configured to process a reactive material to form one or more products. The reactor includes a reaction vessel defining a compartment configured to receive the reactive material. A first cluster of heating conduits at least partially occupies the compartment and extends over a first vertical extent within the compartment. A second cluster of heating conduits partially occupies the compartment and extends over a second vertical extent within the compartment. The first cluster of heating conduits is vertically below the second cluster of heating conduits and spaced apart therefrom by a first separation distance. Feedstock inlets are configured to introduce the reactive material into a region that is vertically between the first and second clusters of heating conduits. The heating conduits in the first cluster have a first thickness while the heating conduits in the second cluster have a second thickness. The first separation distance is at least as great as the smaller of the first and second thicknesses.

Owner:THERMOCHEM RECOVERY INT

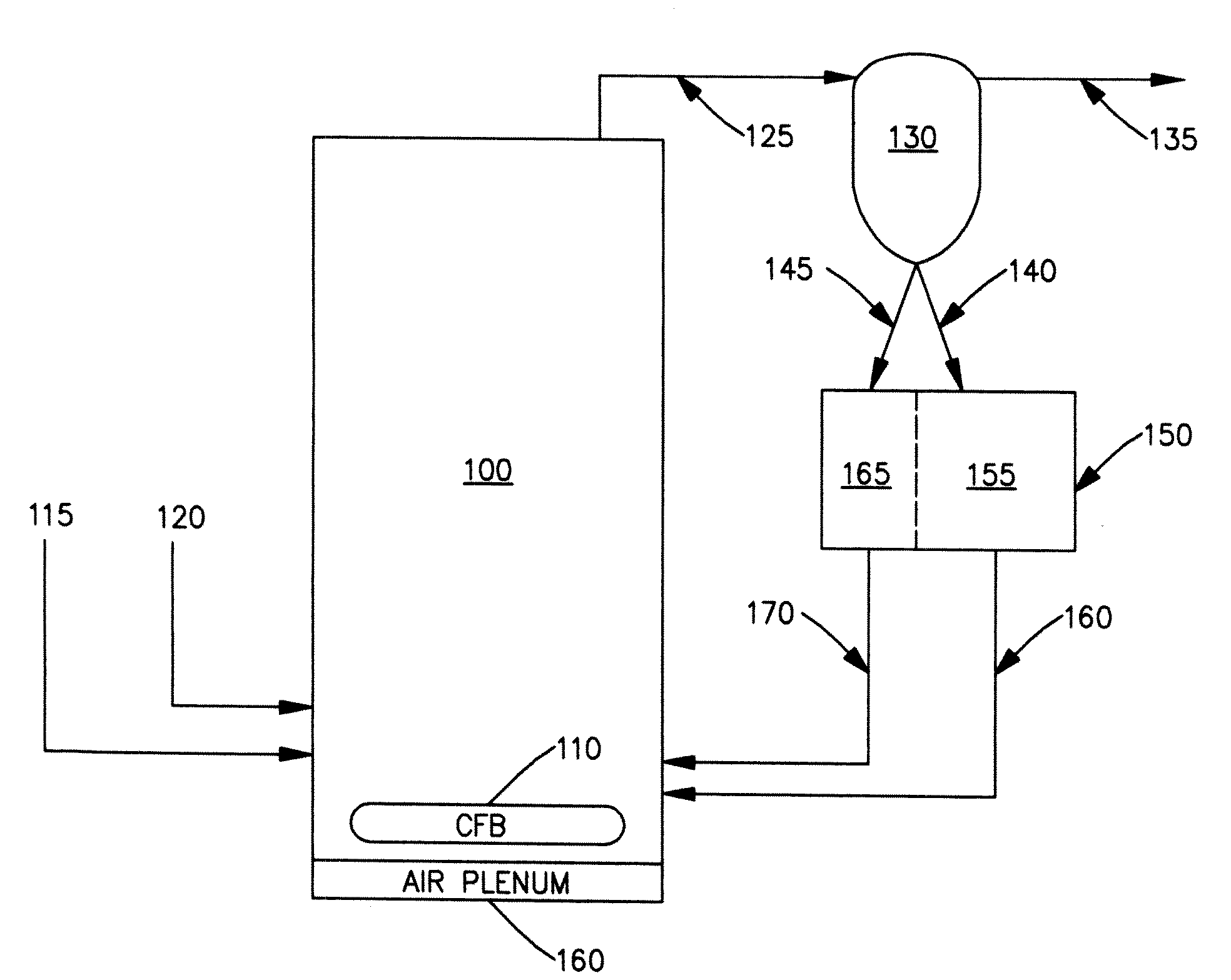

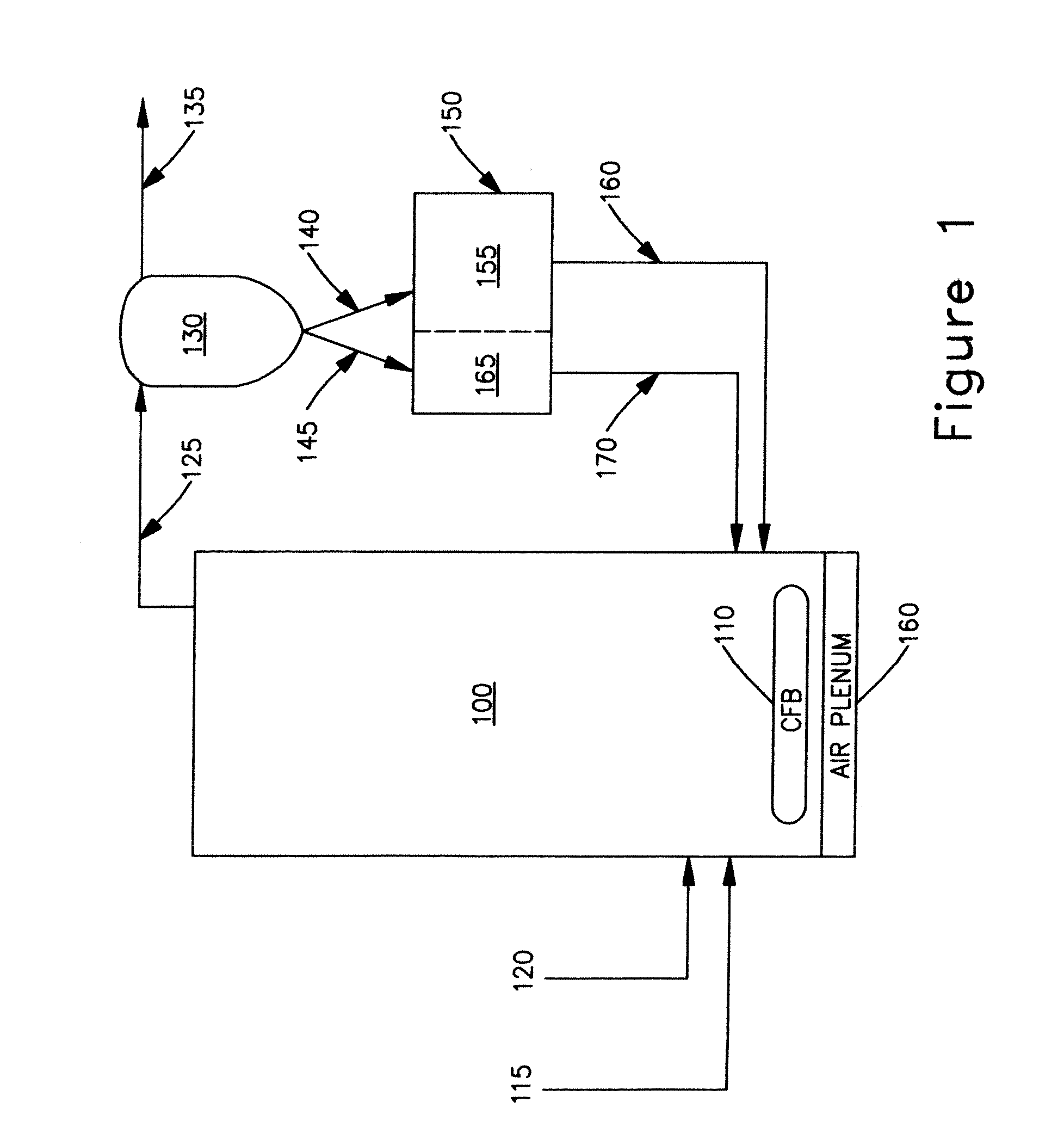

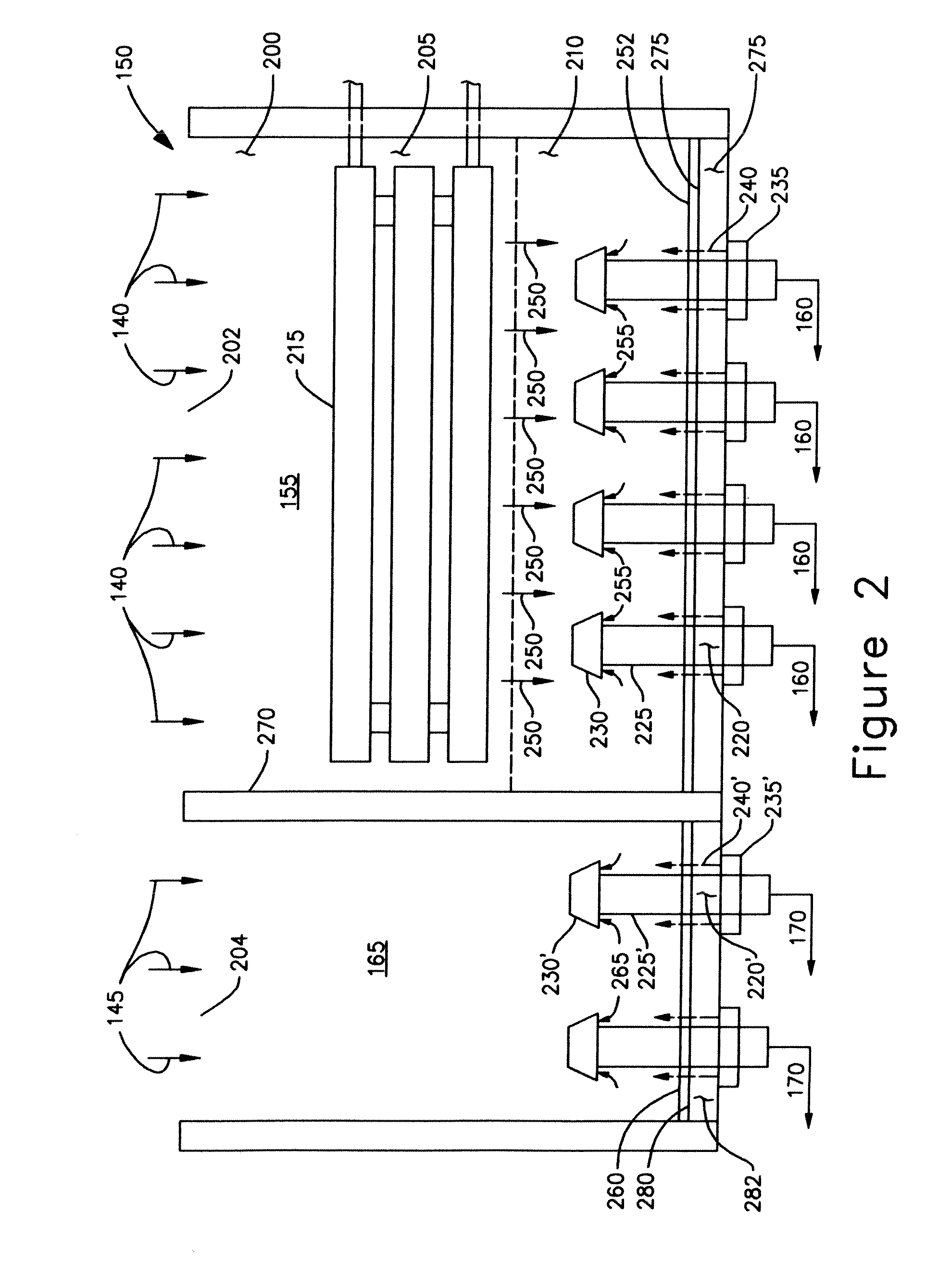

Moving bed heat exchanger for circulating fluidized bed boiler

ActiveUS20090151902A1Avoid Insufficient SealingSimple technologyFluidized bed combustionStationary tubular conduit assembliesWorking fluidFluidized bed

A moving bed heat exchanger (155) includes a vessel having an upper portion (200), a lower portion (210) with a floor (272) including a discharge opening therein, and an intermediate portion (205). The vessel directs a gravity flow of hot ash particles (140) received thereby from the upper portion (200) through the intermediate portion (205) to the floor (272) of the lower portion (210) of the vessel, where the hot ash particles (140) are collected. Tubes in the intermediate portion (205) of the vessel direct a flow of working fluid in a direction substantially orthogonal to the direction of the gravity flow of the hot ash particles (140) through the intermediate portion (205) of the vessel such that heat from the hot ash particles (140) is transferred to the working fluid thereby cooling the hot ash particles (140).

Owner:GENERAL ELECTRIC TECH GMBH

Supercritical fluid fluidized intensified heat diffusion method and its heat diffusion working medium and applications

InactiveCN101285657AReduce thermal resistanceWide operating temperature rangeFluidised bed heat exchangersEnhanced heat transferEngineering

The invention discloses a fluidization enhanced heat transfer method and a fluidization multiphase heat transfer medium. The heat transfer process is enhanced by adding particles inside a supercritical flow body. The technique can be widely applied to an air conditioner, a heat pump, a heat pipe, the heating, the cooling of an internal-combustion engine, an electronic device and the cooling of a power device, raises the energy utilization rate of the whole system, improves the heat control of the system and increases the thermal management ability.

Owner:李建民

Circulating fluidized bed boiler

InactiveUS20060000425A1Easy to integrateFluidized bed combustionIncinerator apparatusPlate heat exchangerFluidized bed

A circulating fluidized bed boiler including a furnace, a separator which is connected to the furnace to separate fluidized bed material from a flow leaving the furnace, as well as a return duct between the separator and the furnace to return the separated fluidized bed material into the furnace. The return duct includes a loop seal equipped with a heat exchanger and a supply of fluidizing medium and having an inlet and an outlet, which open into a chamber including the heat exchanger, i.e. a heat exchanger chamber, and are situated at different heights, the outlet being connected through a return conduit to the furnace . The flow cross-section area of the outlet is at an angle to the flow cross-section area of the inlet in such a way that the fluidized bed material is transferred in the heat exchanger chamber in lateral direction with respect to the inlet direction of its inlet flow. The heat exchanger chamber includes individually controllable fluidizing means at different locations in the direction of the horizontal dimension of the flow cross-section area of the outlet.

Owner:KVAERNER POWER OY

Ash And Solids Cooling In High Temperature And High Pressure Environment

ActiveUS20120031584A1Avoid interferenceEnsure sufficient separationFluidized bed combustionCorrosion preventionSolid particleHigh pressure

Disclosed are cooling and depressurization system equipment, arrangement and methods to cool solid particles from a coal gasifier operating at high temperature and pressure. Ash from the coal needs to be continuously withdrawn from a circulating fluidized bed gasifier to maintain the solids inventory in the gasifier. The system disclosed enables use of conventional materials of construction for heat transfer surfaces. The supports for the cooling surfaces are located on the lower temperature upper section of the primary cooler. The cooled solids along with the fluidizing gas exits the primary cooler to a secondary receiving vessel where the solids can be further cooled by conventional means. The fluidizing and entrained gas entering the secondary vessel is filtered and vented through a vent pressure control valve. The column of cooled solids in the secondary vessel is depressurized by a continuous depressurization system to low pressures which are sufficient for conveying the solids to silos for disposal. The system and methods proposed are equally applicable to many high temperature, high pressure processes that require cooling and depressurization of process solids.

Owner:THE SOUTHERN CO

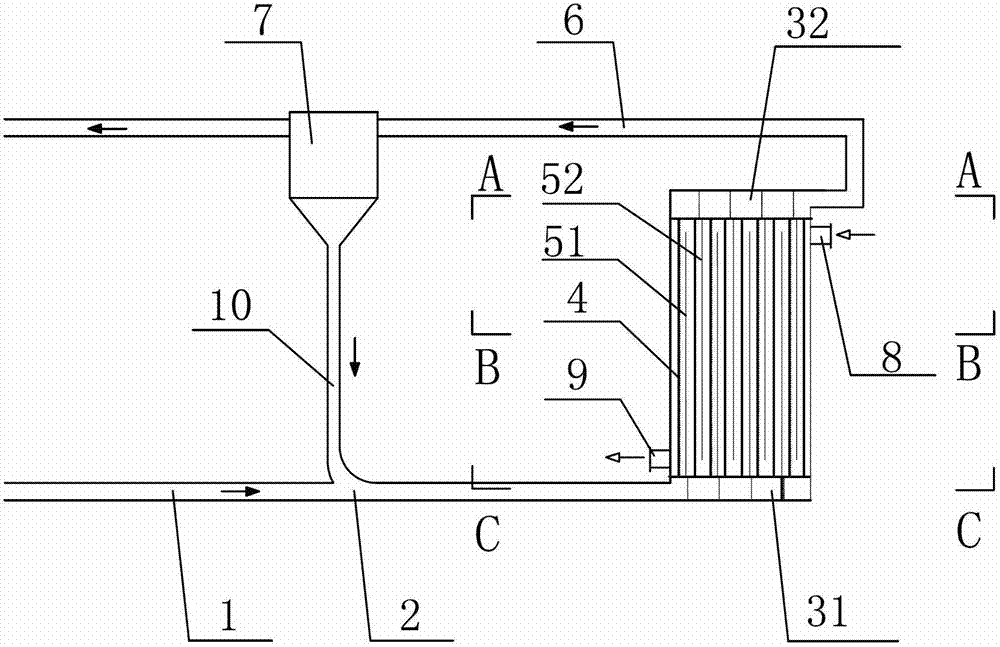

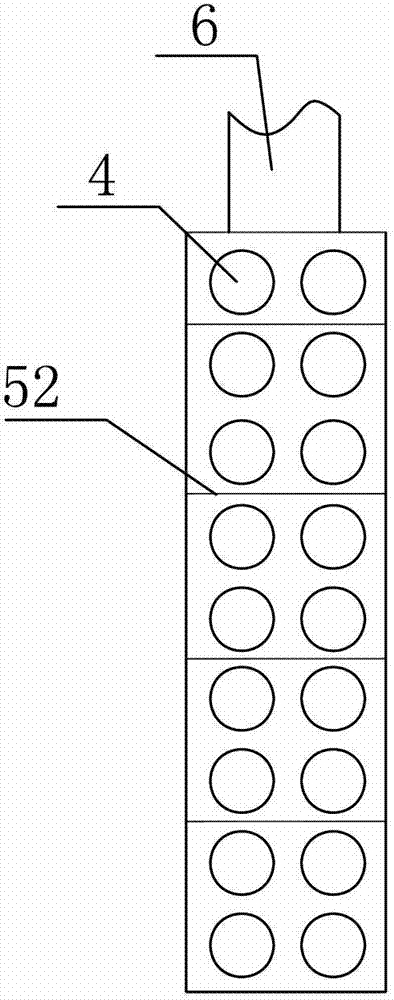

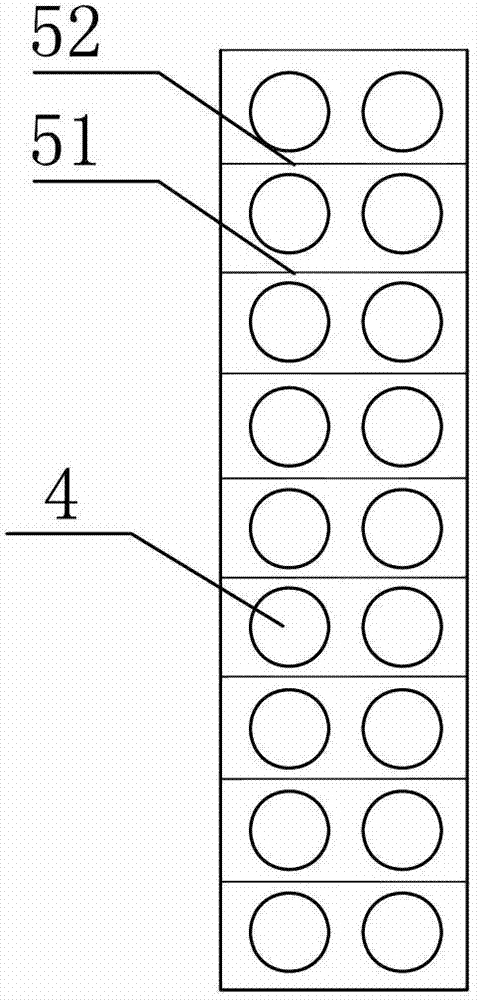

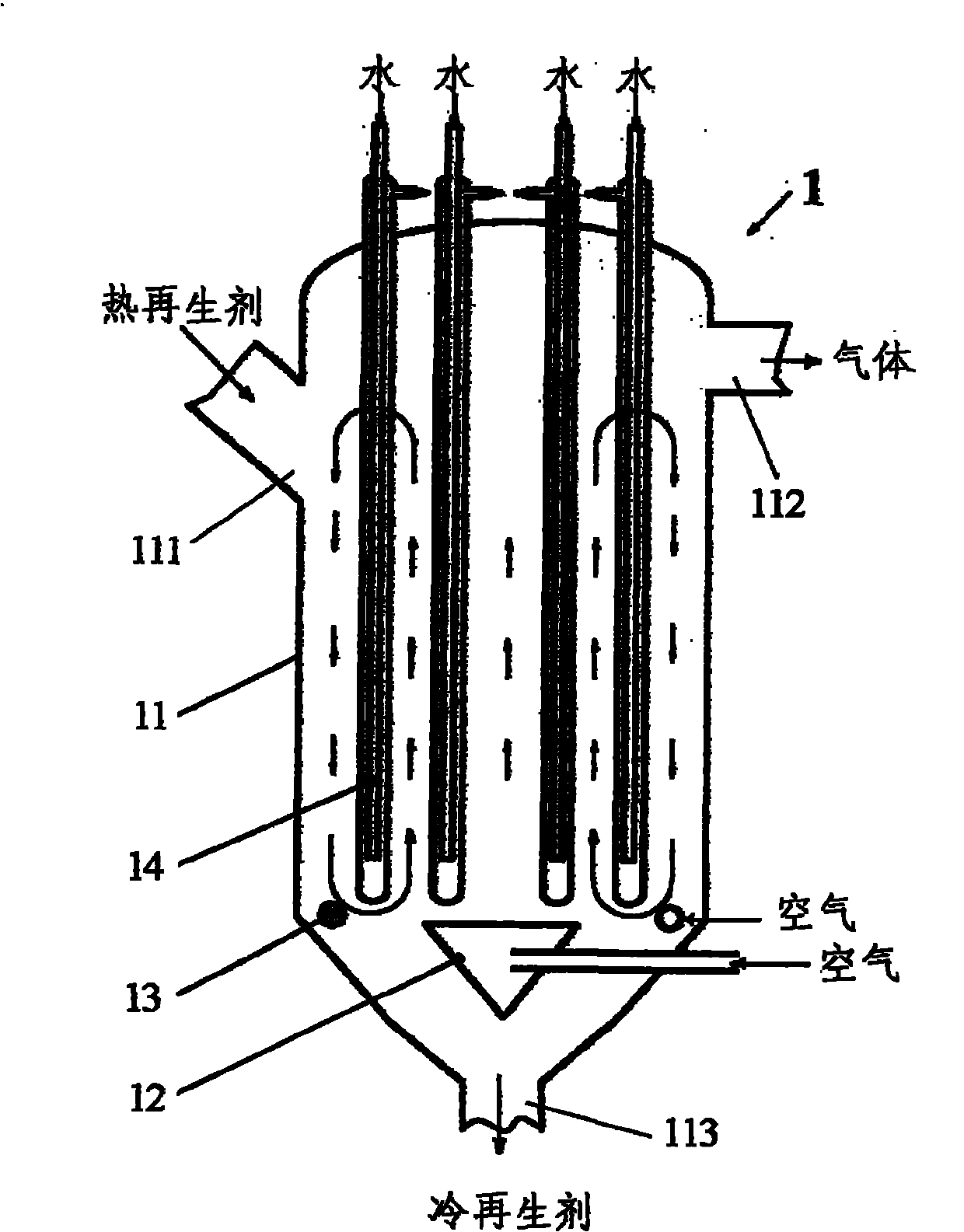

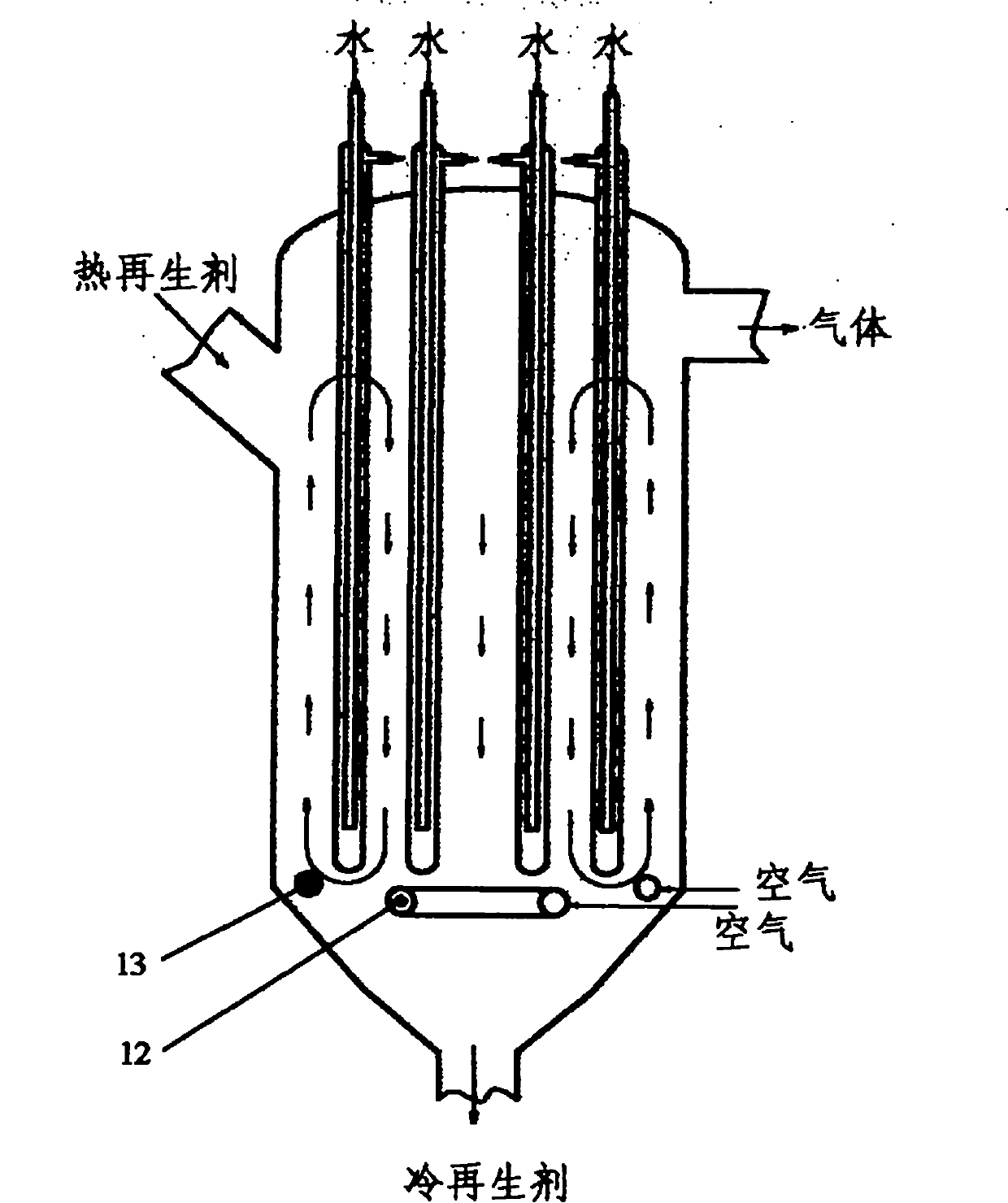

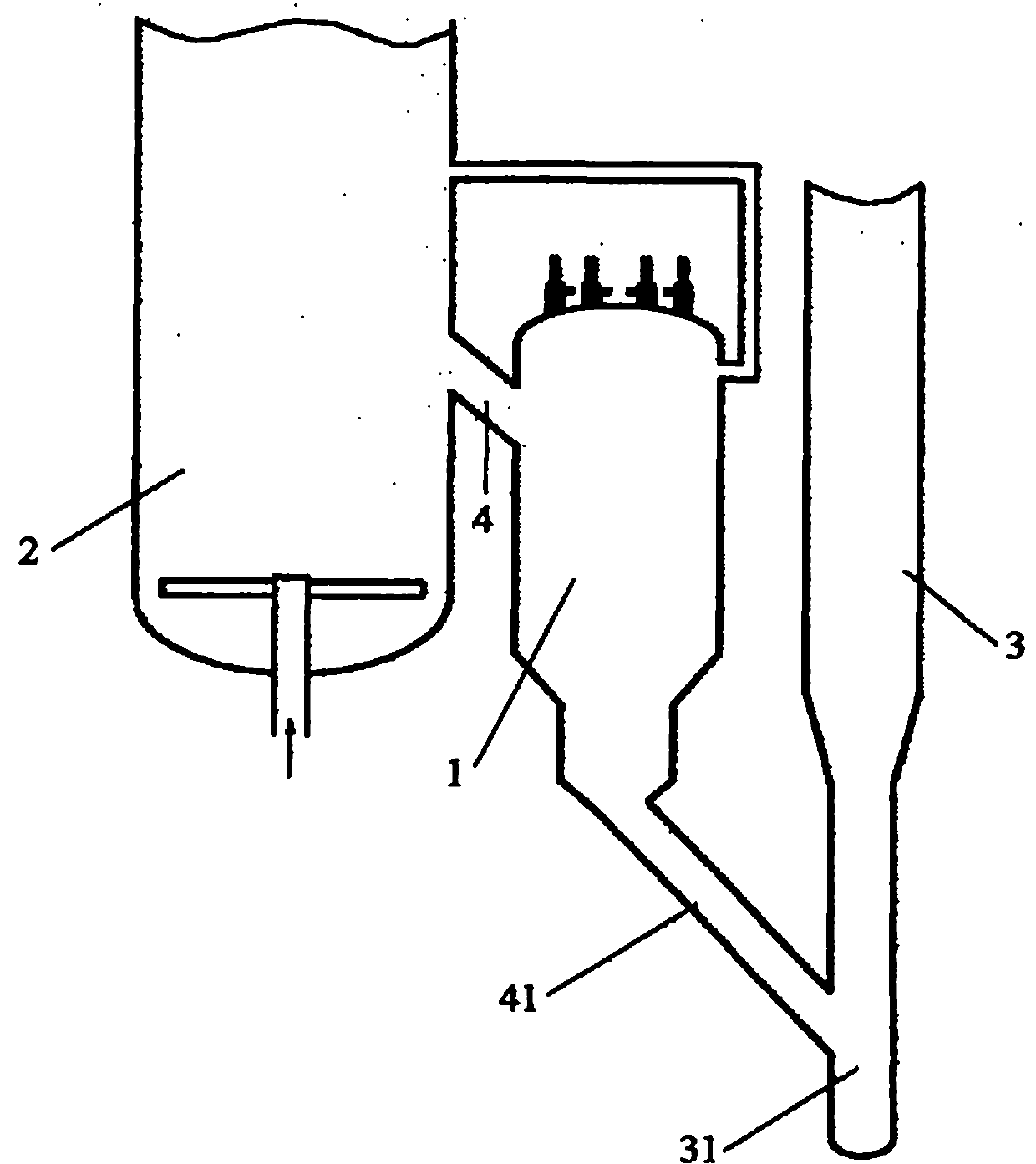

Forced internal recirculation type external cooler for catalytic cracking catalyst

ActiveCN101769694AHigh heat extraction efficiencyMixing Intensity ChangesStationary conduit assembliesFluidised bed heat exchangersPtru catalystEngineering

The invention provides a forced internal recirculation type external cooler for a catalytic cracking catalyst. At least two gas distributors are arranged at the internal bottom of the cooler, and each gas distributor is accessible to fluidized gas independently and can control the gas flow. A plurality of cooling tubes in vertical arrangement are arranged above the gas distributors. Apart from the gas distributors, the cooling tubes and matched fixed parts thereof, no additional components are arranged in the cooler. By controlling the different gas flows of at least two gas distributors, the superficial gas velocity and the bed density in different cross section areas in the cooler are caused to be different and the internal circulation of particles in a bed is strengthened, so the update velocity of the particles on a heat transfer wall is improved and the heat transfer efficiency of the particles and the wall is effectively improved. The cooler has the advantages of simple structure, high heat transfer efficiency and flexible regulation, and can also be used as a themosistor for a catalytic cracking regenerant. In addition, the invention also provides a catalytic cracking device containing the cooler and a catalytic cracking method.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Storing and transport device and system with high efficiency

ActiveUS20130042857A1Minimize thermal stressImprove heat exchange efficiencySolar heating energySolar heat devicesThermal energyEngineering

A device for storage and conveyance of thermal energy for an energy production system apt to receive solar radiation and based on the use of a modular fluidizable granular bed and a heat exchanger associated thereto is described.

Owner:MAGALDI IND SRL

Systems and methods of thermal transfer and/or storage

Systems, methods, and computer-implemented embodiments consistent with the inventions herein are directed to storing and / or transferring heat. In one exemplary implementation, there is provided a system for transferring / storing heat comprised of a heat exchange / storage apparatus including a chamber, and a heat input device adapted to heat / provide a vapor into the chamber. Other exemplary implementations may include one or more features consistent with a heat output device through which a working medium / fluid passes, a thermal storage medium located within the chamber, and / or a heat exchange system that delivers a heat exchange medium / fluid to the thermal storage medium.

Owner:BLUELAGOON TECH

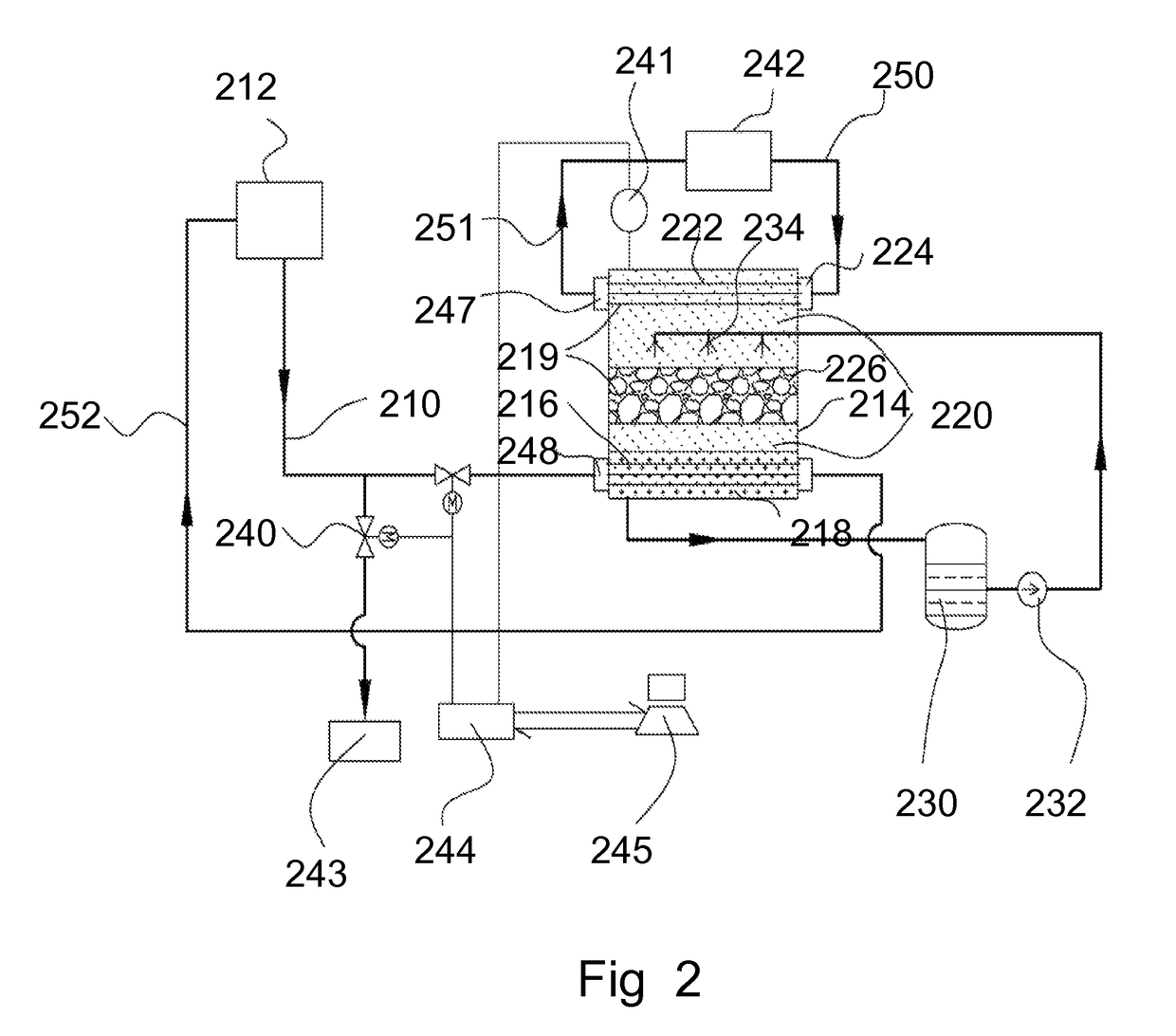

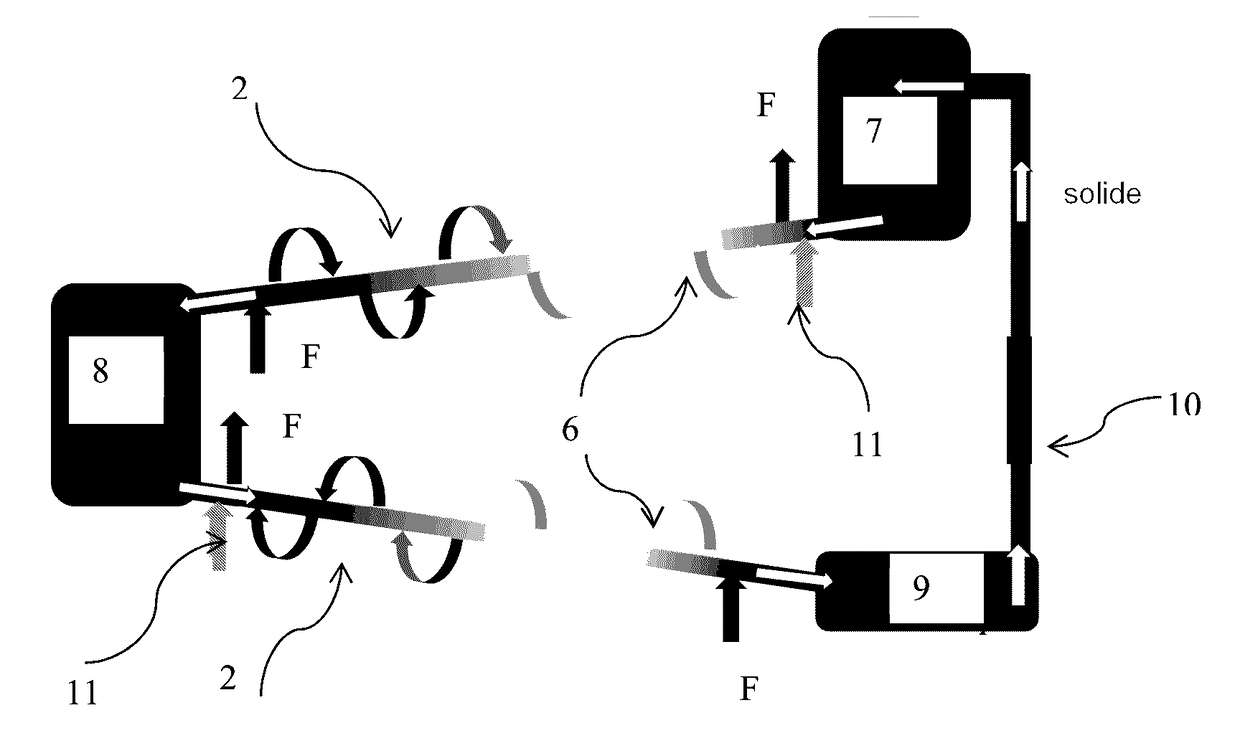

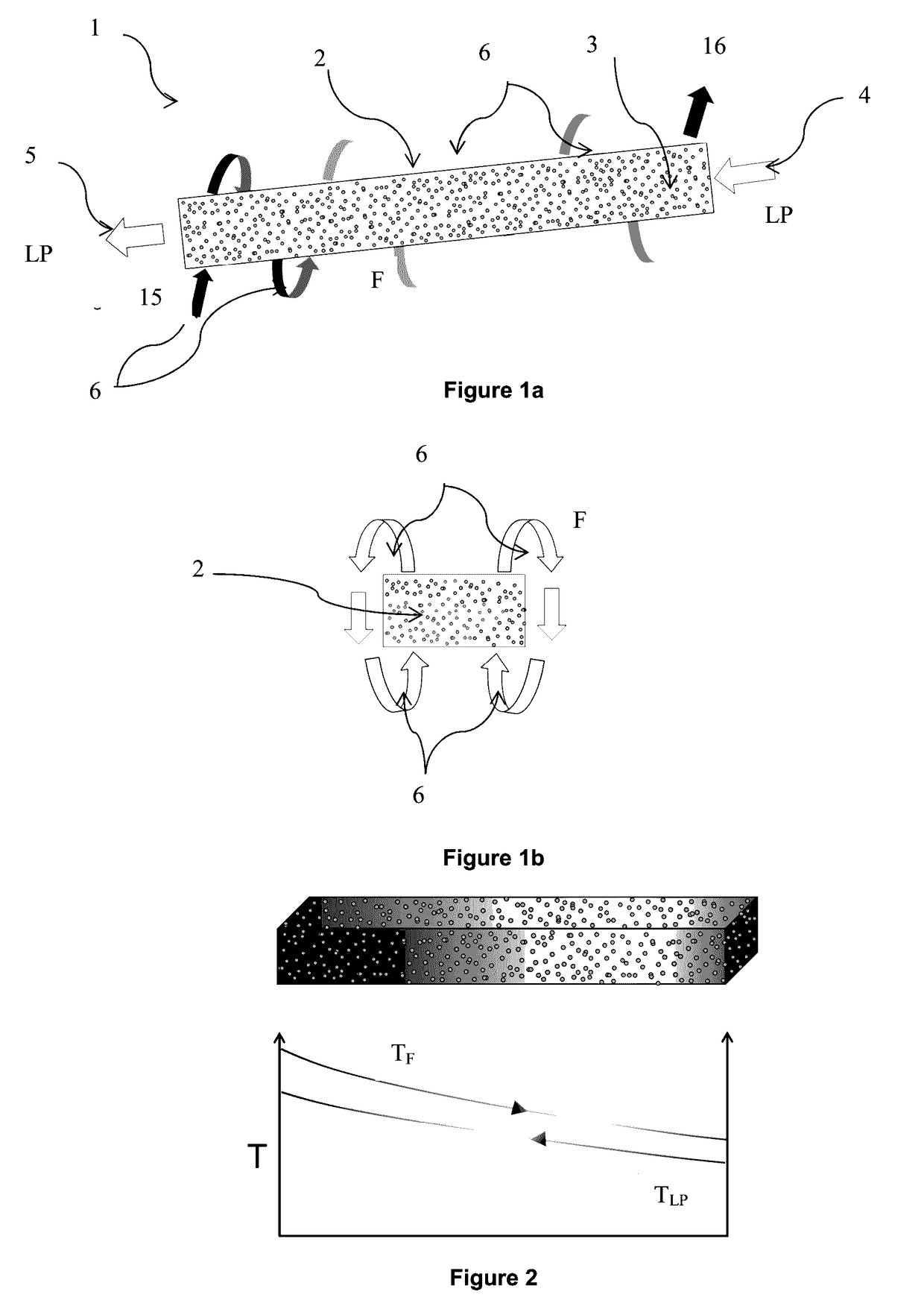

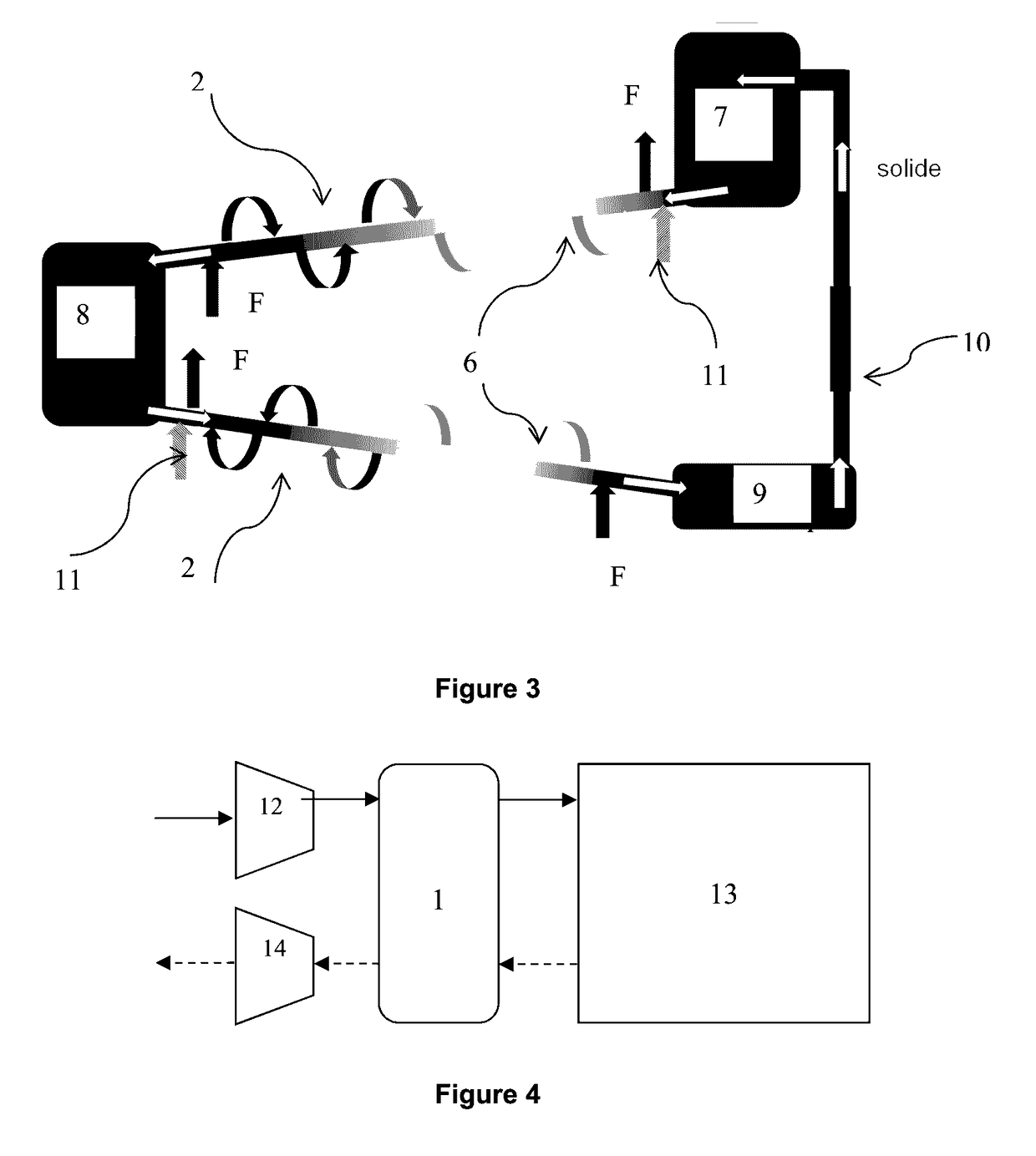

System and method for the crossflow exchange of heat between a fluid and heat storage particles

InactiveUS20170159503A1Reduce disadvantagesHeat storage plantsEngine fuctionsFluidized bedEngineering

The present invention relates to a system and a method for exchanging heat between a fluid (F) and heat storage particles (3). The exchange system comprises an exchange zone (2) in which the fluid (F) and the heat storage particles in a fluidized bed flow as a countercurrent flow and a cross flow. The invention also relates to a compressed gas energy storage and restoration system and method using the heat exchange system.

Owner:INST FR DU PETROLE

Methods and Systems for Cooling Hot Particulates

Methods, systems, and apparatus for cooling particulates are provided. The method can include introducing particulates to a heat exchanger containing a tube bundle having a plurality of tubulars, introducing a coolant to the plurality of tubulars through a coolant inlet, flowing the particulates through the shell side of the heat exchanger, and contacting at least a portion of the particulates with the tube bundle. The method can also include recovering a heated coolant from the coolant outlet and recovering cooled particulates from the particulate outlet. The heat exchanger can include a vessel having an elongated shell having a first end, a second end, one or more sidewalls, a shell side particulate inlet disposed in the one or more sidewalls for receiving particulates, a shell side particulate outlet disposed adjacent the second end for discharging cooled particulates, and a tube bundle including a plurality of tubulars disposed within the vessel.

Owner:KELLOGG BROWN & ROOT LLC

Novel internal exchanger for gas-liquid-solid fluidized bed reactor employing a highly exothermic reaction

InactiveUS20080000622A1Good effectLiquid hydrocarbon mixture productionHeat exchanger casingsNuclear engineeringFluidized bed

The present invention describes a novel type of internal exchanger for a gas-liquid-solid fluidized bed reactor employing a strongly thermal reaction. Said exchanger is modular in concept and comprises a central tube with separations allowing both supply of cooling fluid to the pins of the module and collection of partially vaporized fluid from said same pins.

Owner:INST FR DU PETROLE

In-bed solids control valve

InactiveUS20110073049A1Easy to operateImprove reliabilityFluidized bed combustionIncinerator apparatusBubbling fluidized bedControl valves

A circulating fluidized bed (CFB) boiler comprising a reaction chamber. A bubbling fluidized bed (BFB) is contained within an enclosure within the lower portion of the reaction chamber and contains an in-bed heat exchanger (IBHX) that occupies part of the reaction chamber floor. At least one non-mechanical valve, which includes an opening between the CFB and BFB and independently controlled fluidizing means located both upstream and downstream of the opening, is used to control the heat transfer to the IBHX by controlling the solids discharge from the BFB to the CFB. The elevation of the bottom of the opening is at or above the elevation of the fluidizing means. A flow control barrier may be located downstream of the opening.

Owner:THE BABCOCK & WILCOX CO

Plant and method for accumulation of energy in thermal form

PendingUS20220090827A1Zero environmental impactImprove efficiencySolar heating energyHeat storage plantsThermodynamicsEngineering

A plant for the accumulation and transfer of thermal energy, which plant has an accumulation device of the kind with a bed of fluidizable solid particles. The plant further has for each accumulation device:electric resistor means arranged within the casing and thermally connected with the bed of particles, which electric resistors are configured for transmitting thermal energy generated by Joule effect to the particles and they are fed by exceeding electric energy from wind or photovoltaic source; andheat exchange means, also thermally connected with the bed of particles and which can be selectively actuated to receive thermal energy therefrom,the overall configuration being such that the thermal energy is transferred from the resistor means to the fluidizable solid particles of the bed and from the fluidizable solid particles to the heat exchange means.

Owner:MAGALDI POWER SPA

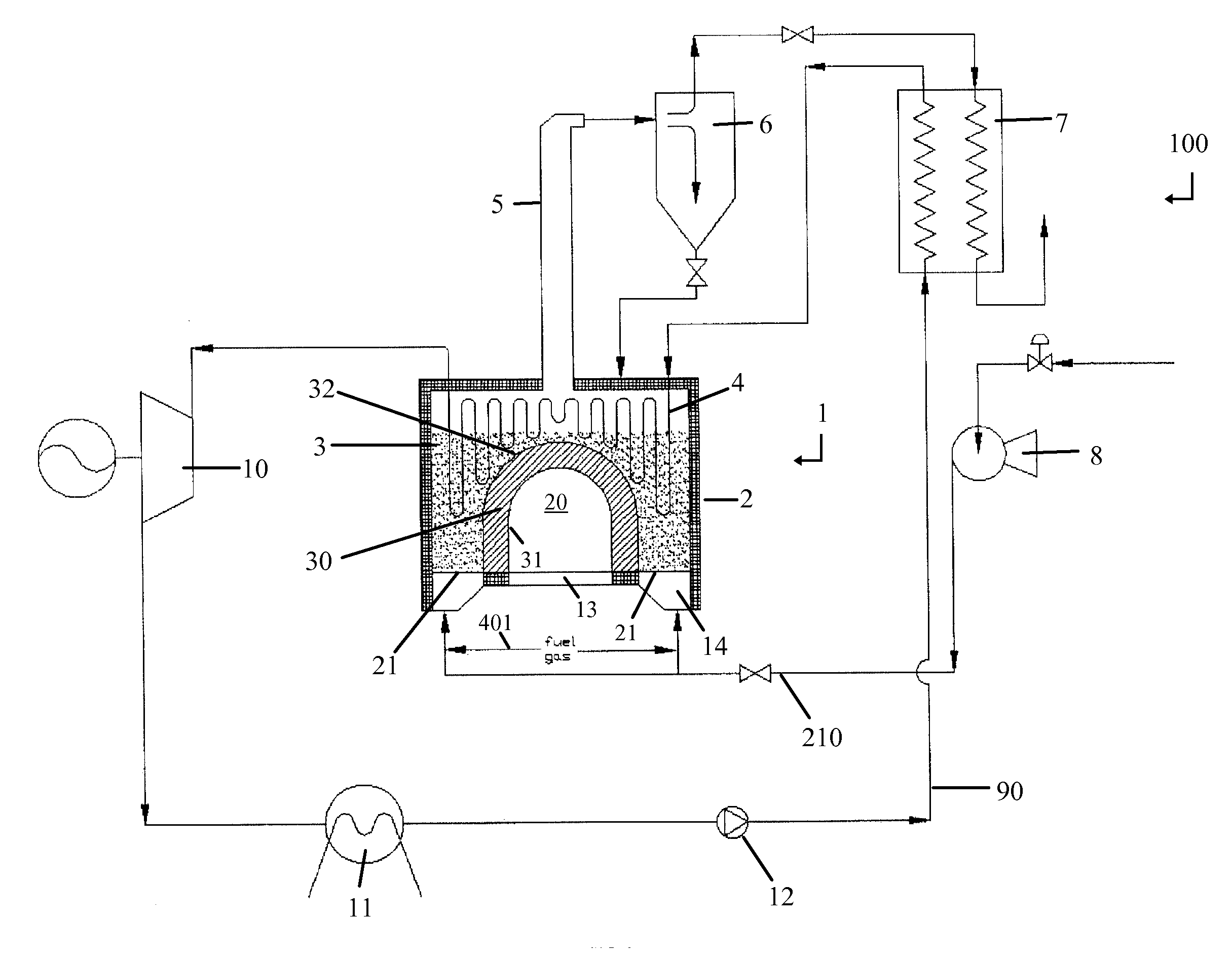

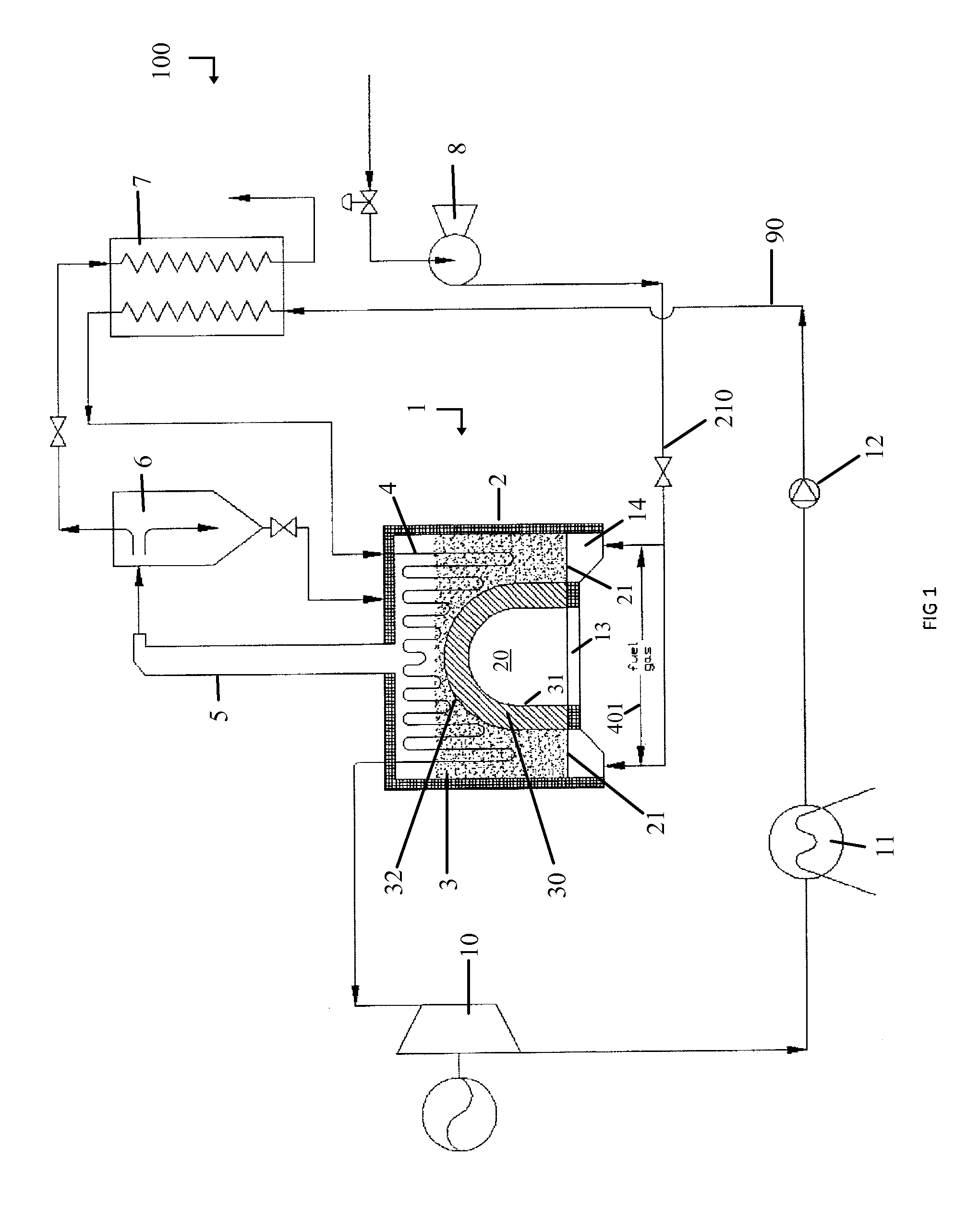

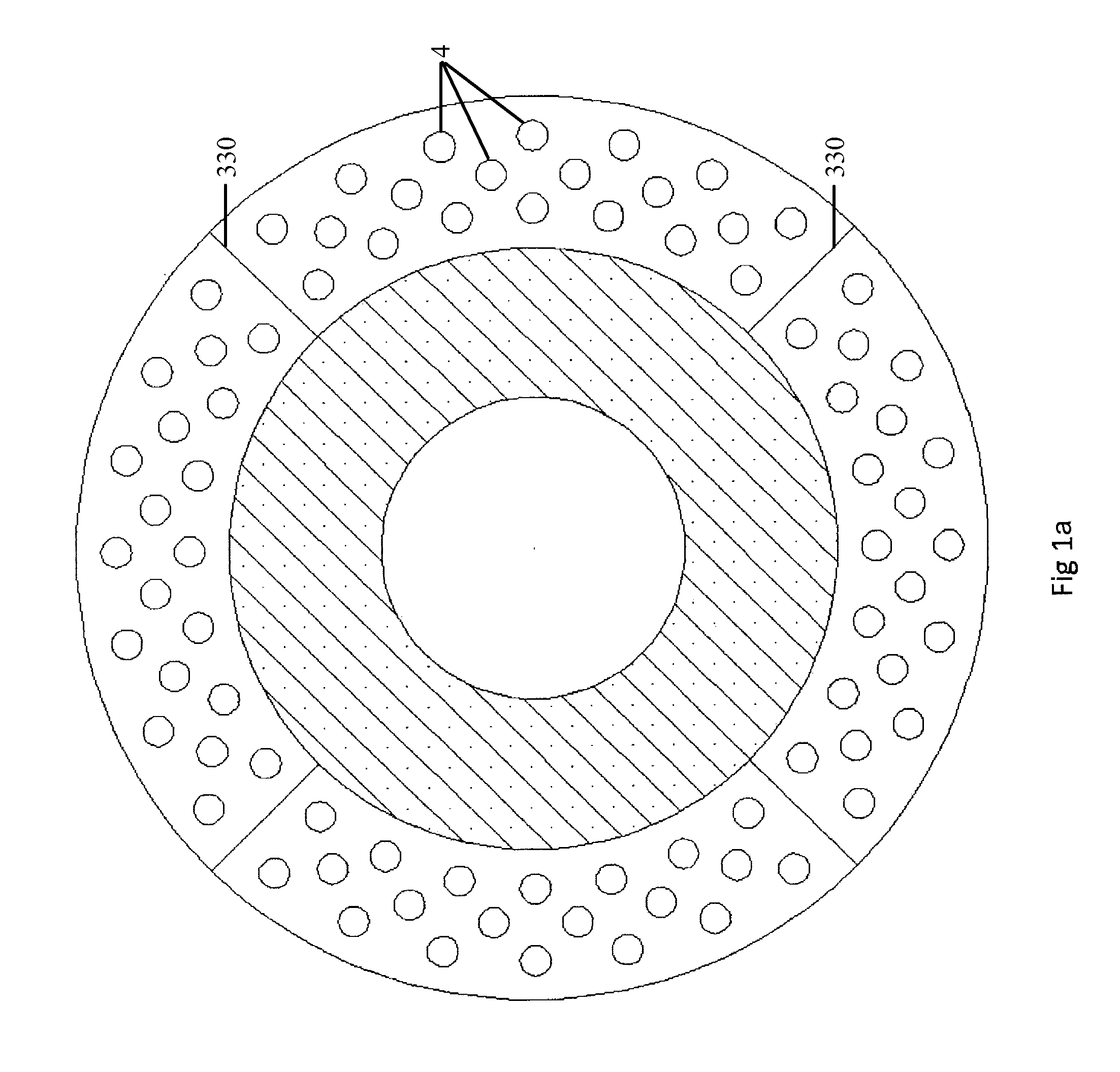

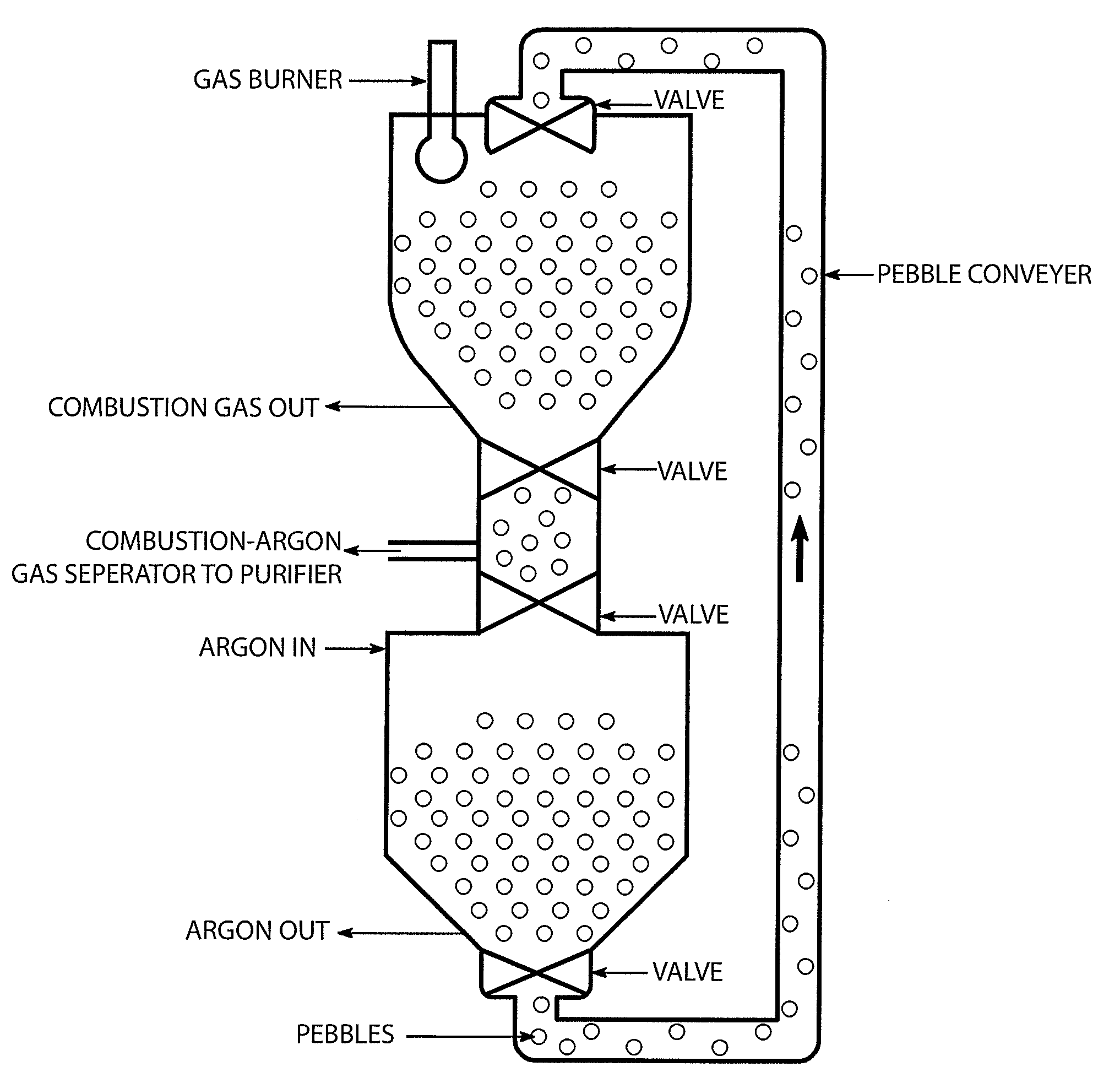

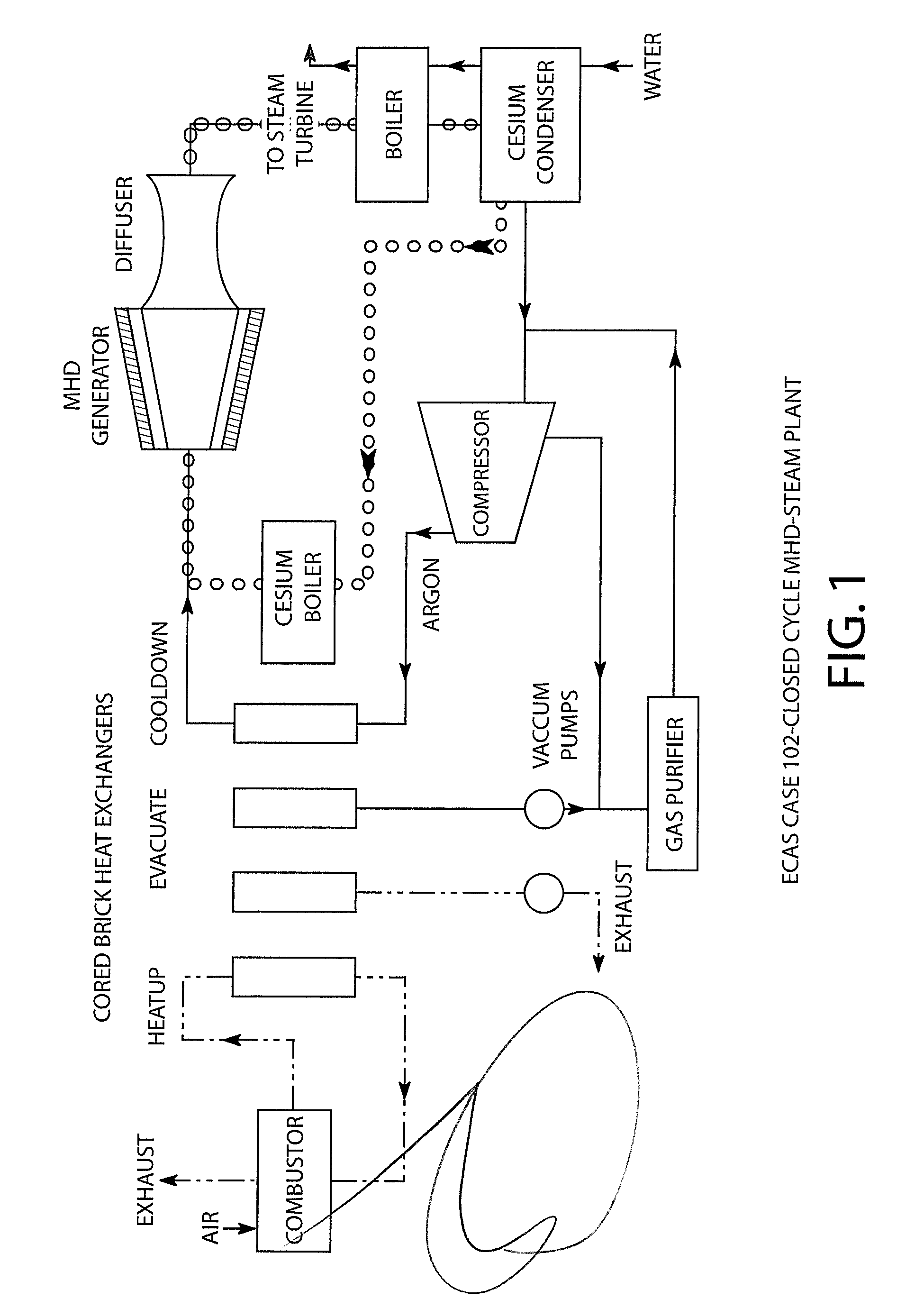

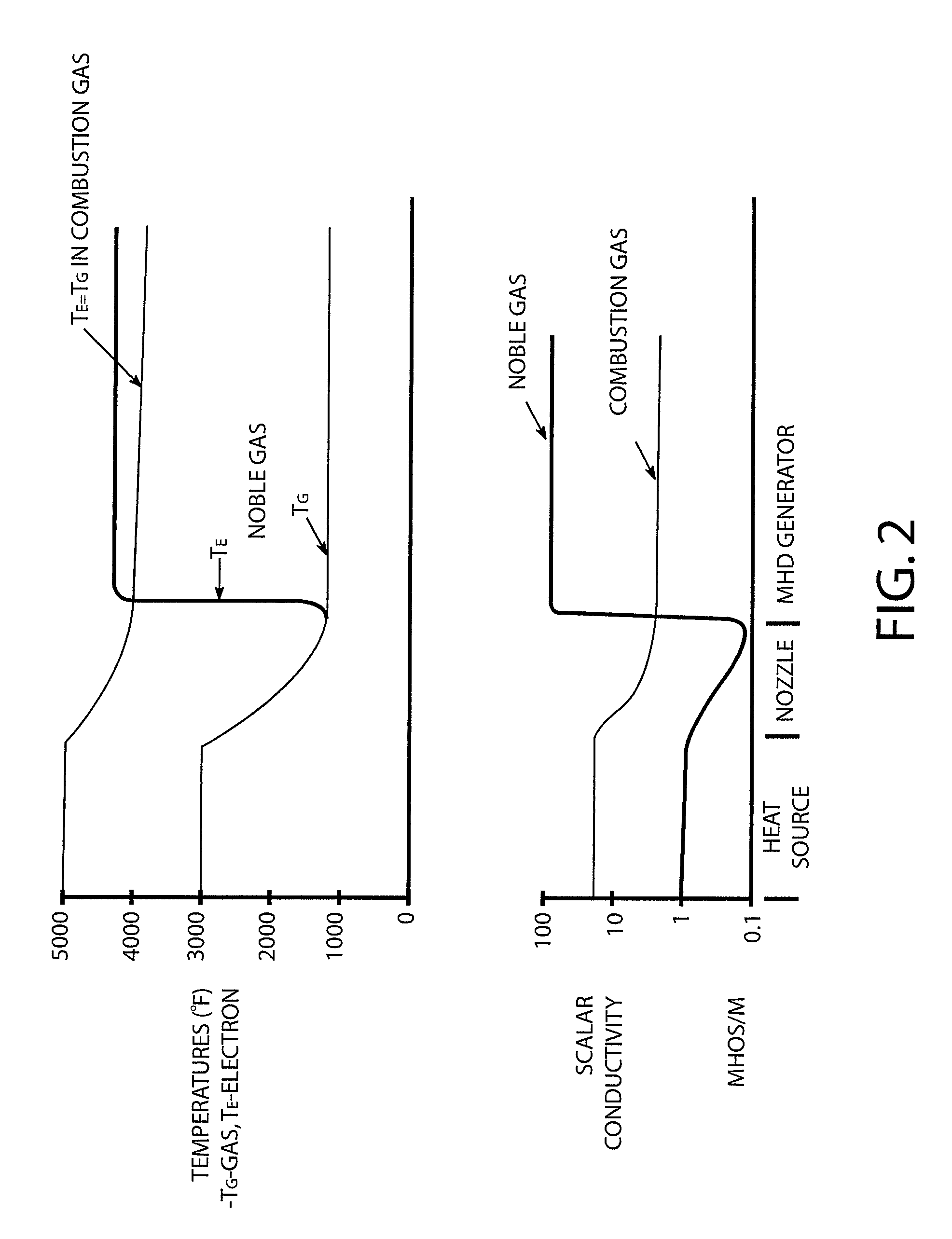

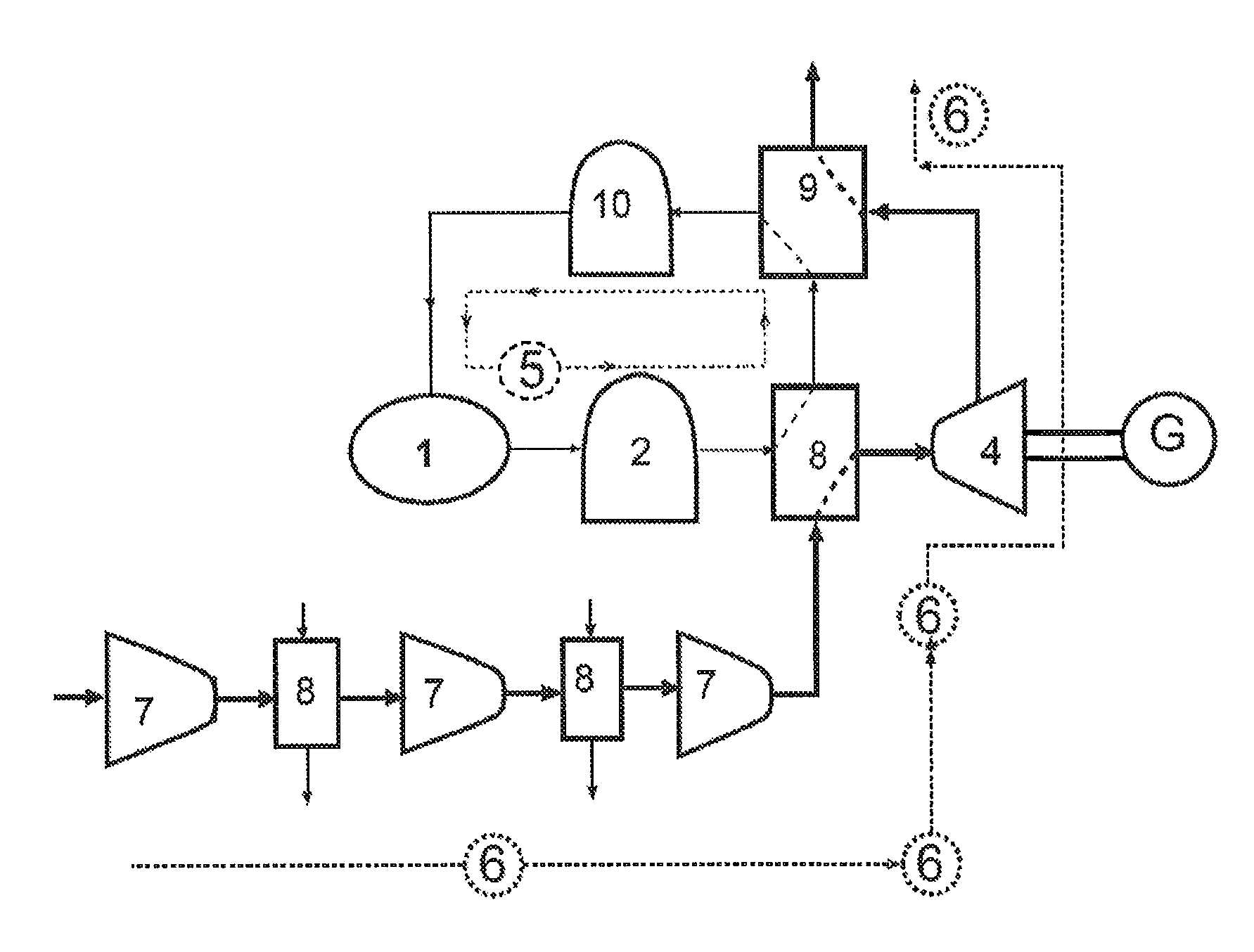

Fossil fuel fired, closed cycle mhd generator in parallel with steam turbine cycle with zero emissions and co2 sequestration

InactiveUS20120137877A1Low costHigh revenue potentialOrganic chemistryNitrogen compoundsNoble gasNuclear engineering

Disclosed is a gaseous fossil fuel fired, indirectly heated, Brayton closed cycle comprising an alkali metal seeded noble gases that is rendered non-equilibrium, electrically conducting in a magnetohydrodynamic (MHD) electric power generator with zero emissions from the combustion products, including physical separation and sequestration of the carbon dioxide (CO2) what is emitted from the fossil fuel, with said cycle combined with a Rankine steam turbine bottoming cycle to compress the noble gas, while another optional new or existing Rankine steam cycle is placed in parallel and separate from the MHD cycle, and it is fired by the solid char remaining if the MHD cycle is fired with the devolatilized coal, and / or with solid coal culm, and / or unburned carbon in coal power plant waste ash, in order to achieve high efficiency at low capital, low operating, and low fuel costs.

Owner:ZAUDERER BERT

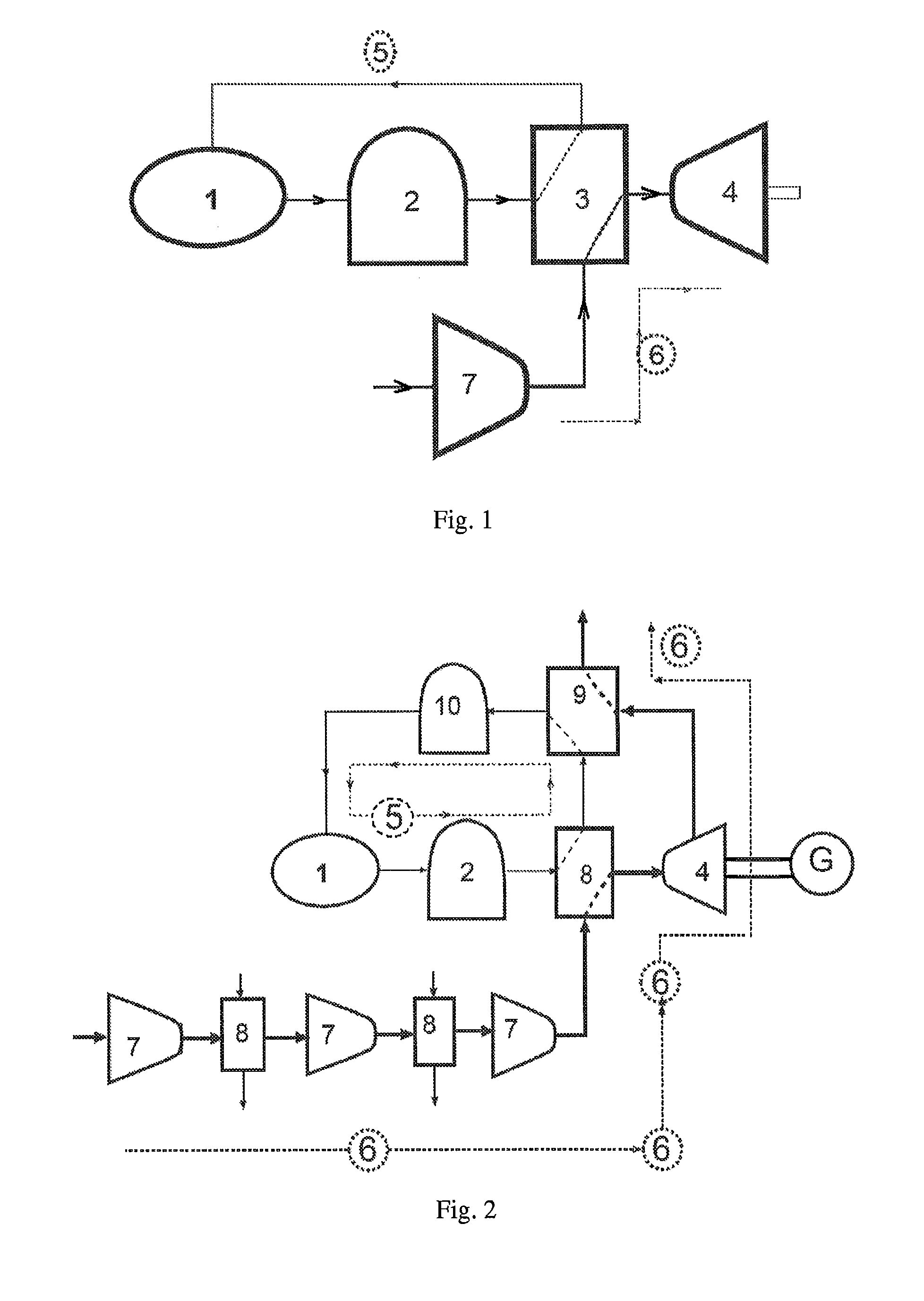

Solar heat storage and high temperature gas generating system with working medium being flowing sand

InactiveUS20140026883A1Good effectLarge scaleSolar heating energySolar heat devicesProcess engineeringHigh pressure

A solar heat storage and high temperature gas generating system comprises a sun-tracking light concentrating device (1), a heat storage tank (2) and a heat exchange device (3), with the working medium being flowing sand (5). The flowing sand (5) is heated by the sun-tracking light concentrating device (1), and is transported into the heat storage tank (2). The flowing sand (5) is exported from the heat storage tank (2) steadily, thereby transferring heat to the high pressure gas or liquid (6) which is to be heated in the heat exchange device (3) and generating high temperature and pressure gas. The system has the advantages of good heat storage effect, large heat storage volume, high heat exchange efficiency and low operation cost.

Owner:CHEN YUQI

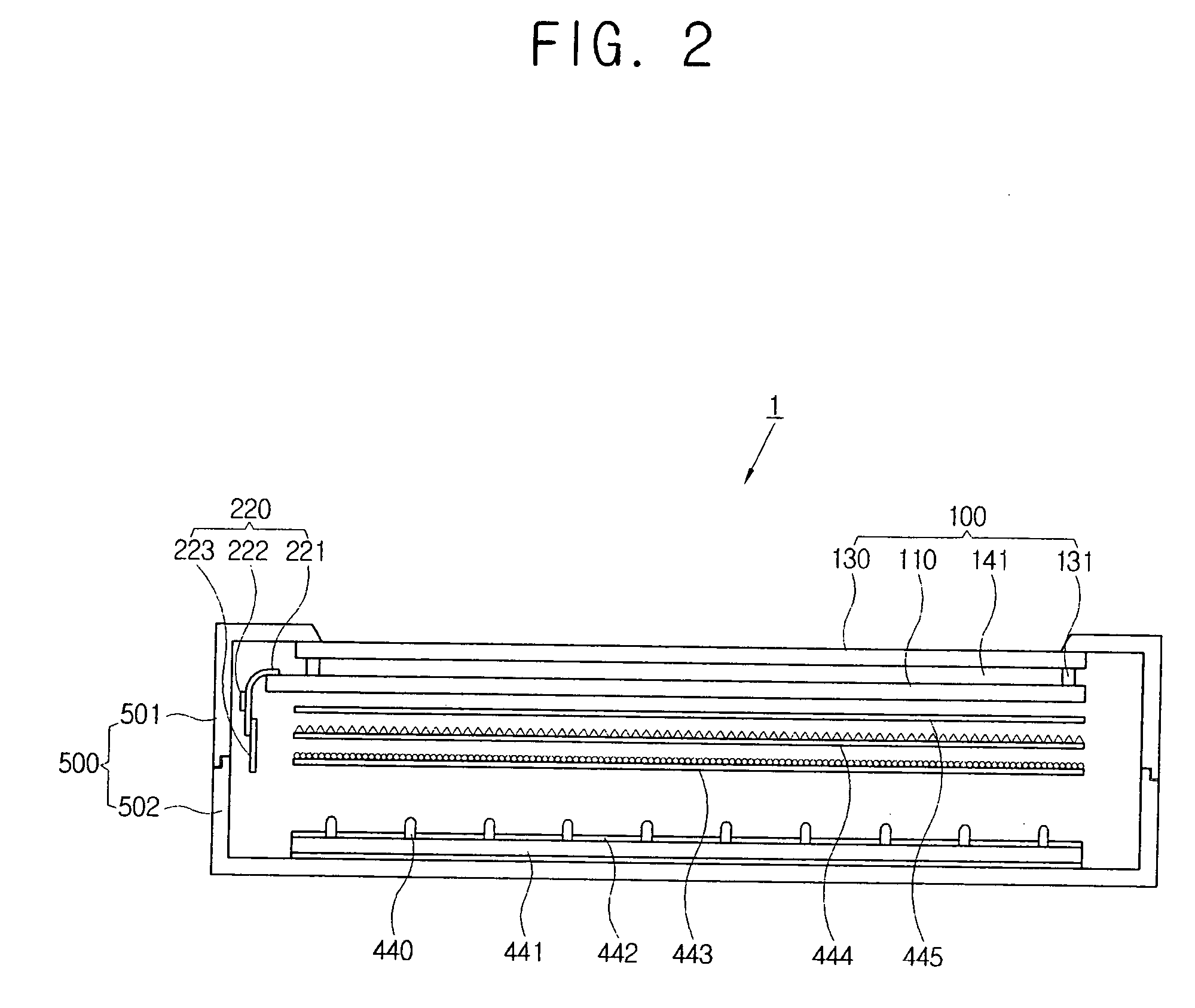

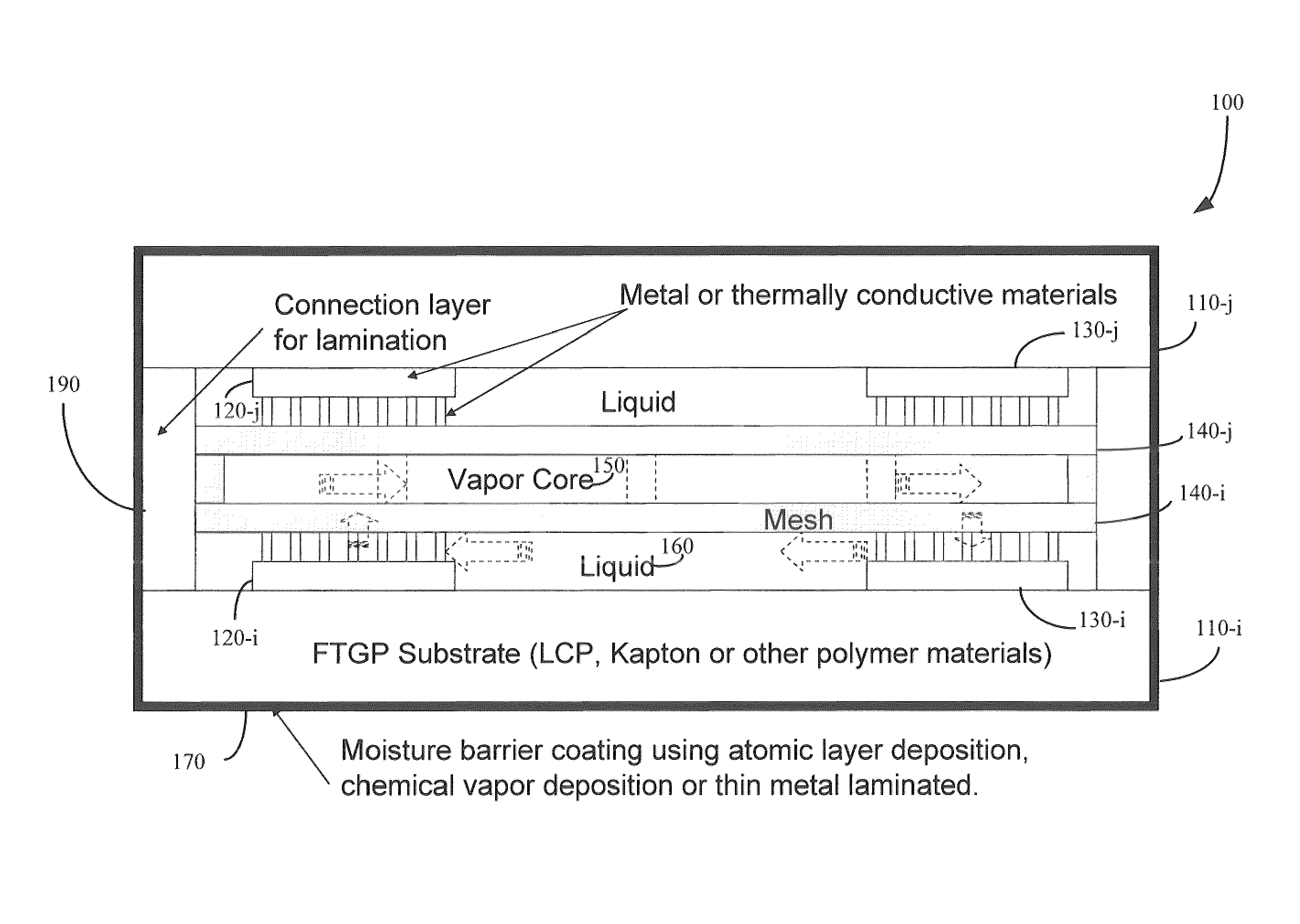

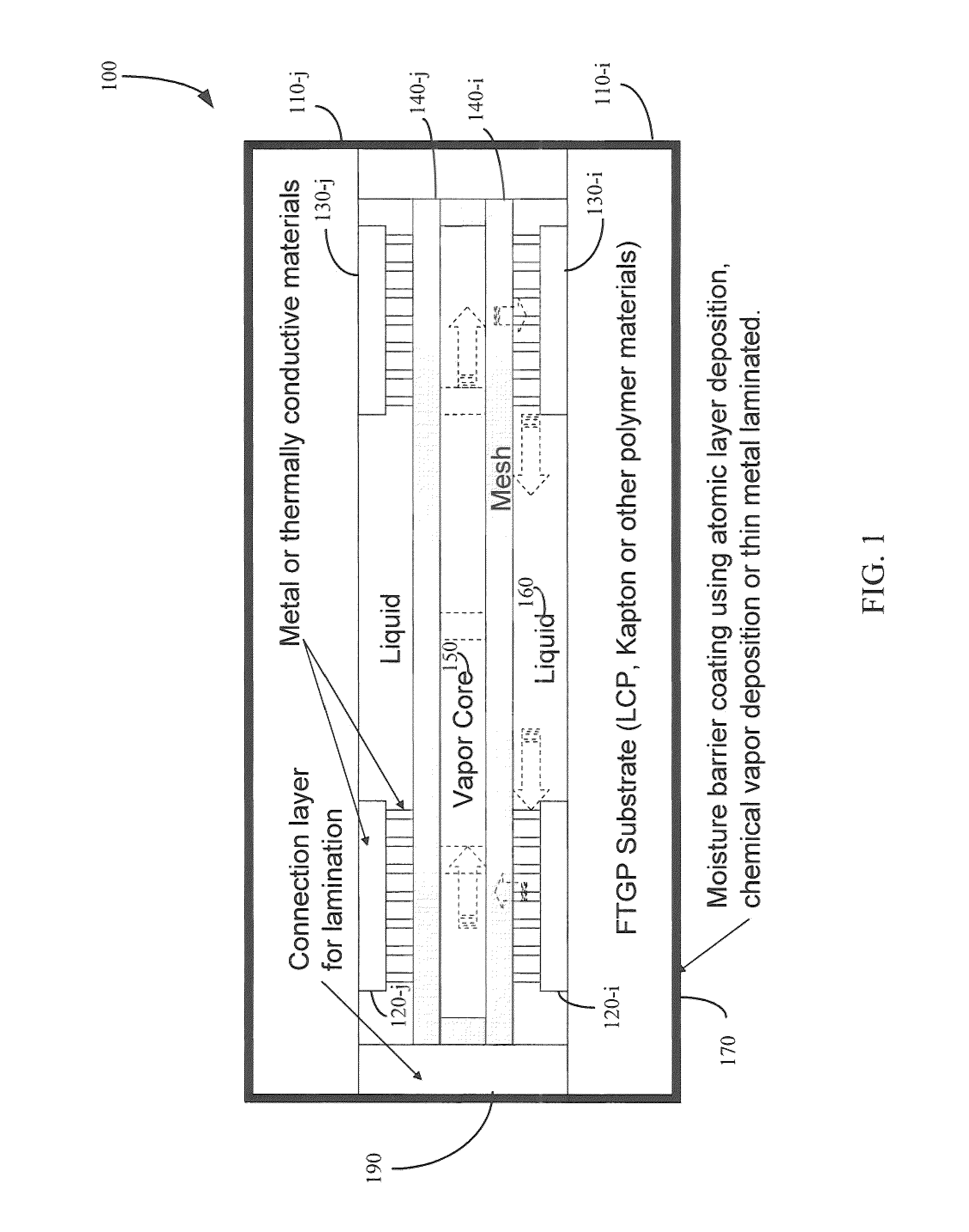

Flexible thermal ground plane and manufacturing the same

ActiveUS9163883B2Improve thermal performanceImprove heat transfer performanceSemiconductor/solid-state device detailsSolid-state devicesGround planeNanomesh

Methods, apparatuses, and systems are disclosed for flexible thermal ground planes. A flexible thermal ground plane may include a support member. The flexible thermal ground plane may include an evaporator region or multiple evaporator regions configured to couple with the support member. The flexible thermal ground plane may include a condenser region or multiple condenser regions configured to couple with the support member. The evaporator and condenser region may include a microwicking structure. The evaporator and condenser region may include a nanowicking structure coupled with the micro-wicking structure, where the nanowicking structure includes nanorods. The evaporator and condenser region may include a nanomesh coupled with the nanorods and / or the microwicking structure. Some embodiments may include a micromesh coupled with the nanorods and / or the microwicking structure.

Owner:KELVIN THERMAL TECH

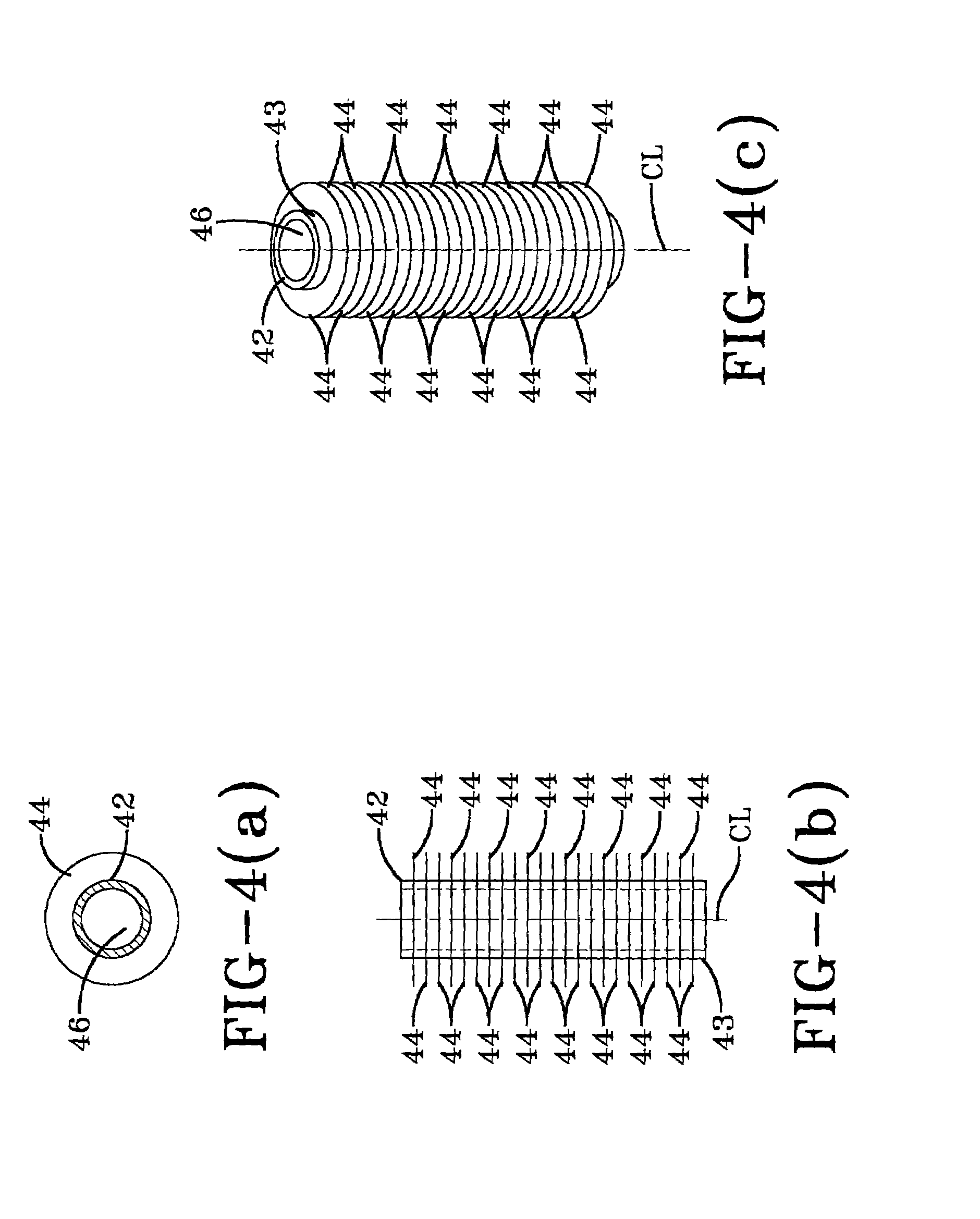

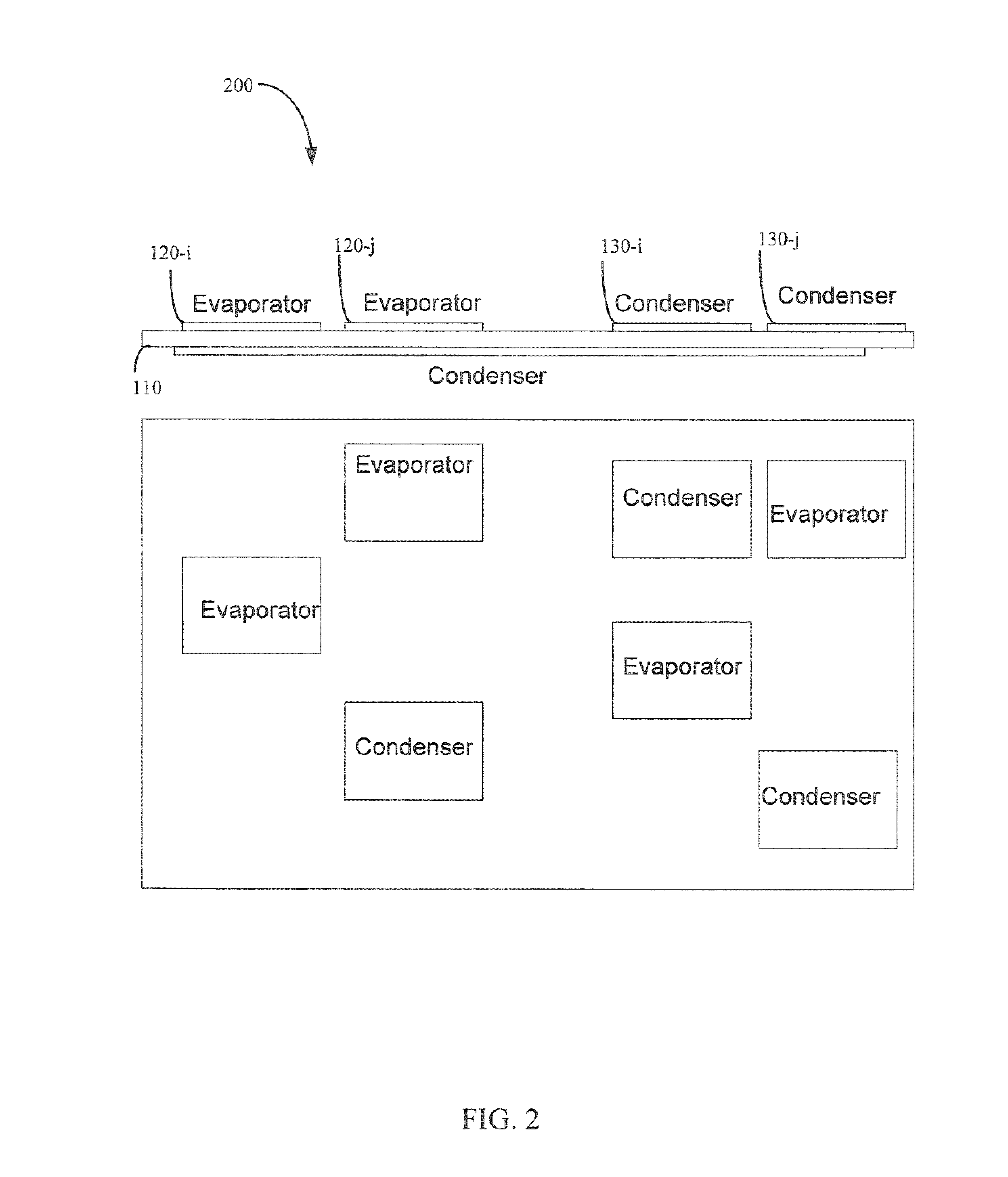

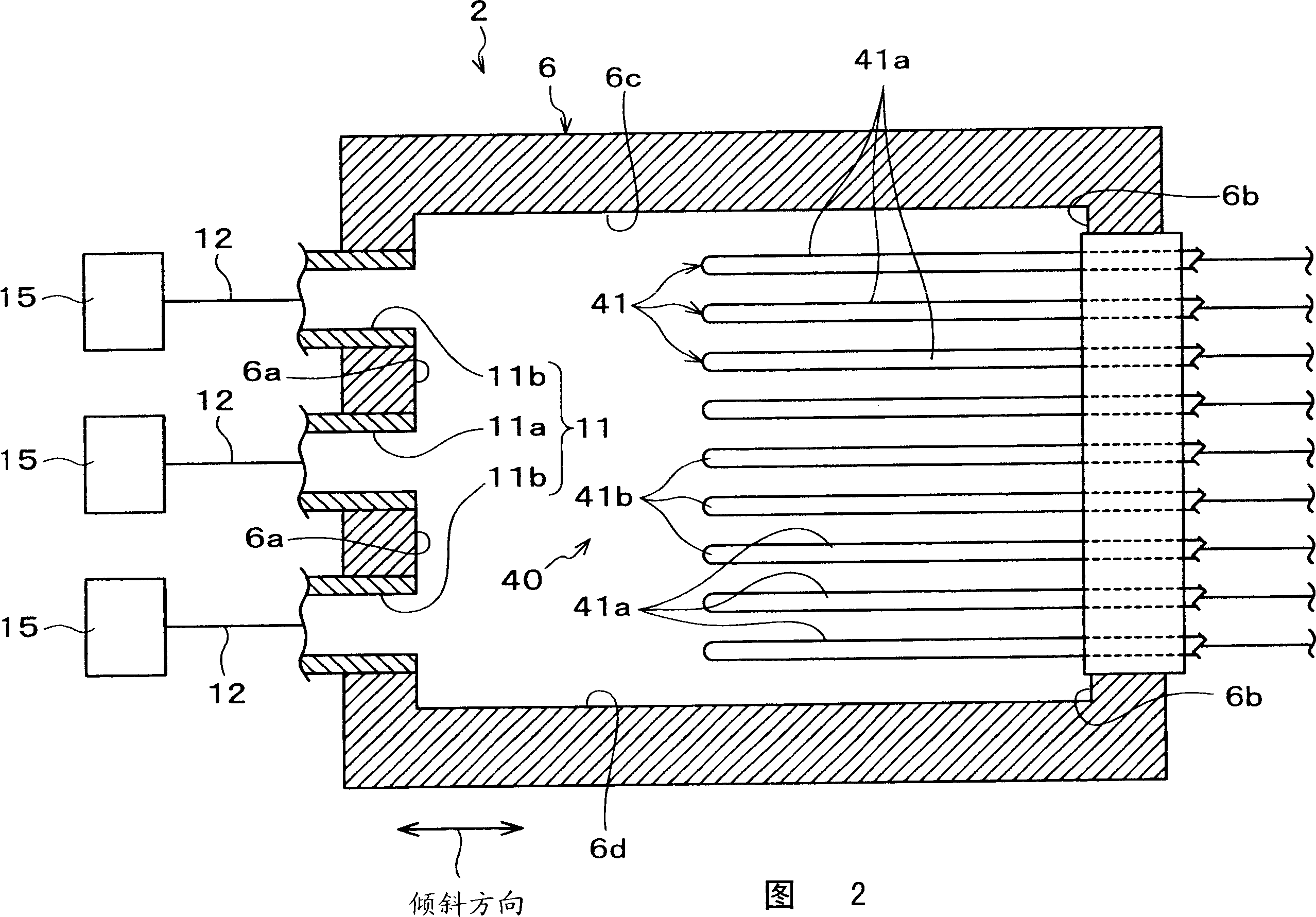

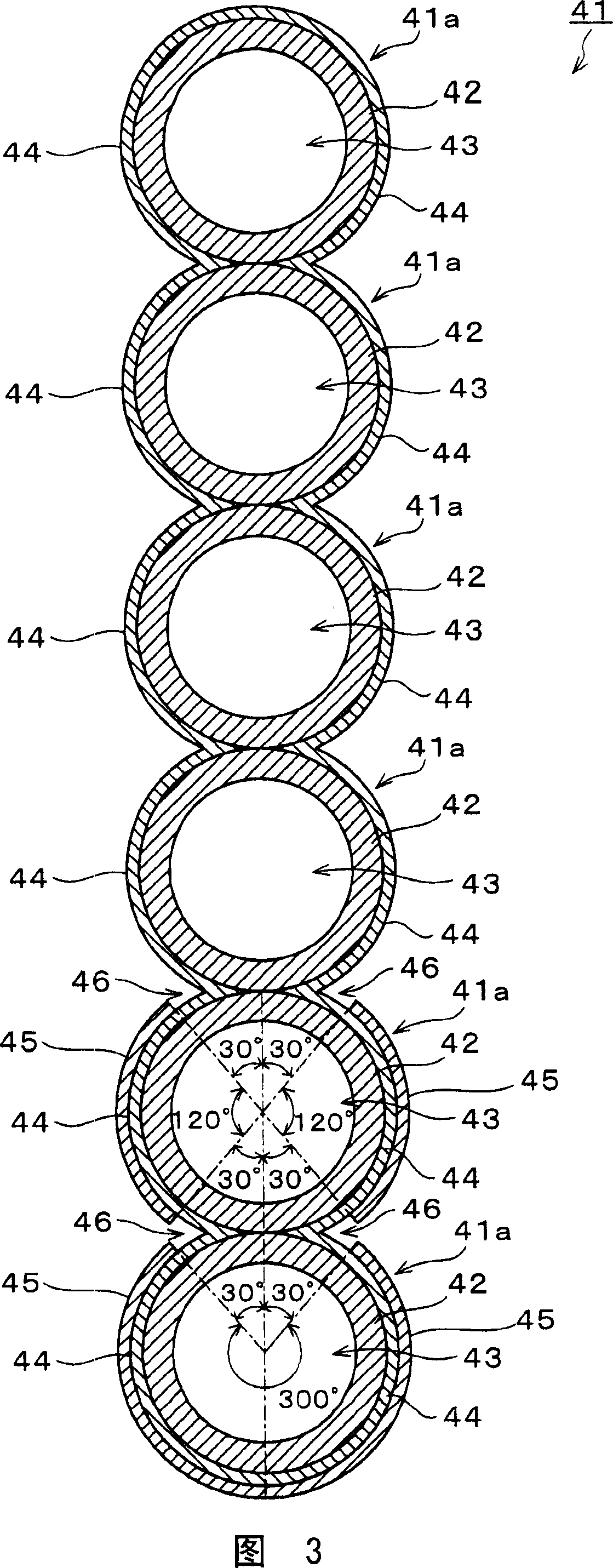

Heat exchanger tube, method of manufacturing heat exchanger tube, and fluidized-bed furnace

InactiveCN1991291AStrong jointEnough durabilityFluidized bed combustionReinforcing meansFluidized bedEngineering

A heat exchanger tube 41 includes: a first cover layer 44 provided on an outer side of a tube main body 42 to partly or completely cover a tube main body 42; and a second cover layer 45 provided on an outer side of the first cover layer 44 to partly or completely cover the first cover layer 44. The first cover layer 44 is formed by overlay-welding a material higher in ductility than the second cover layer 45 to the tube main body 42. The second cover layer 45 is formed by overlay-welding a material higher in hardness than the first cover layer 44 to the first cover layer 44.

Owner:DOWA HLDG CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com