Manufacturing Method of Water Block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical characteristics, features and advantages of the present invention will become apparent in the following detailed description of the preferred embodiments with reference to the accompanying drawings. However, the drawings are provided for reference and illustration only and are not intended for limiting the scope of the invention.

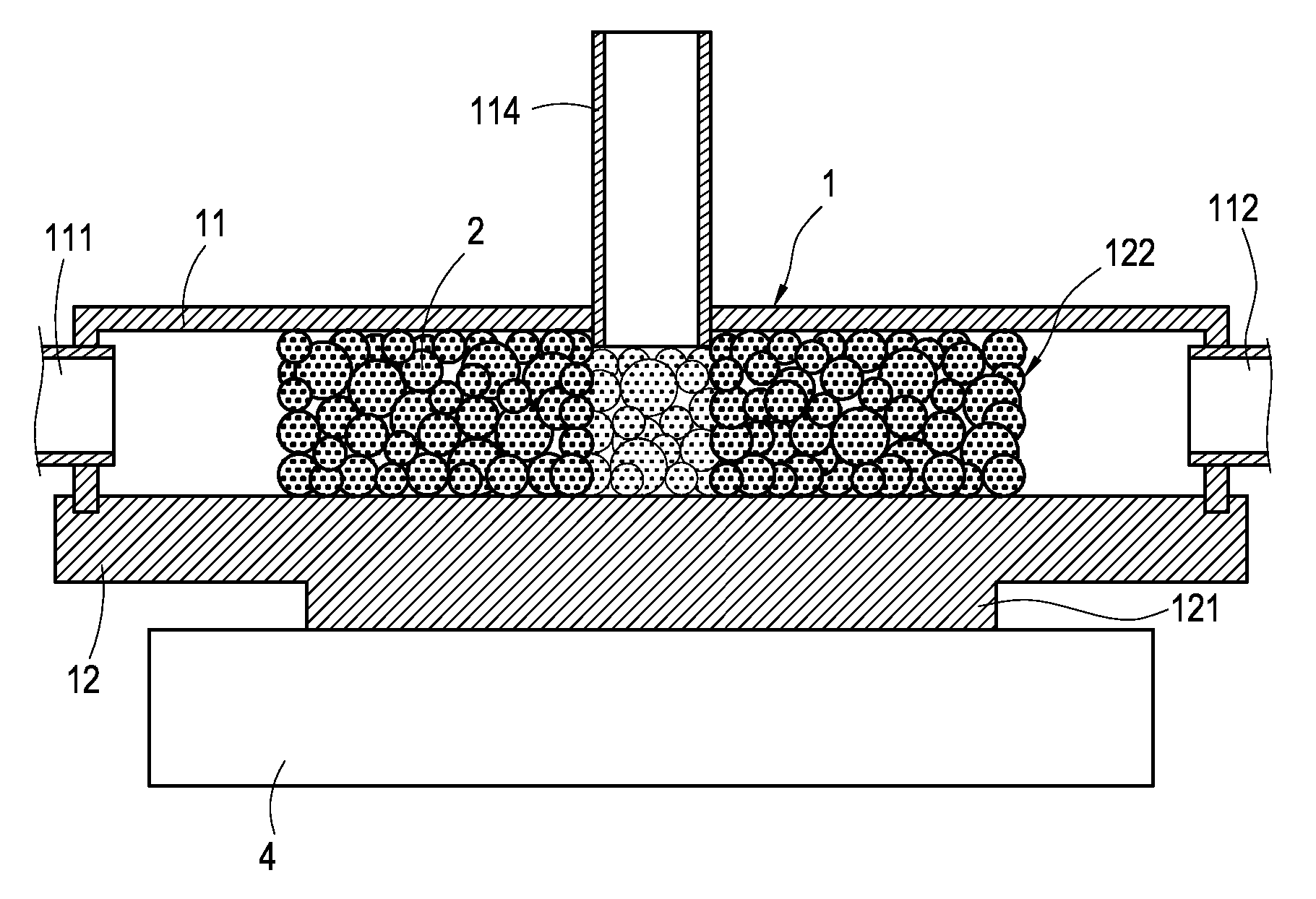

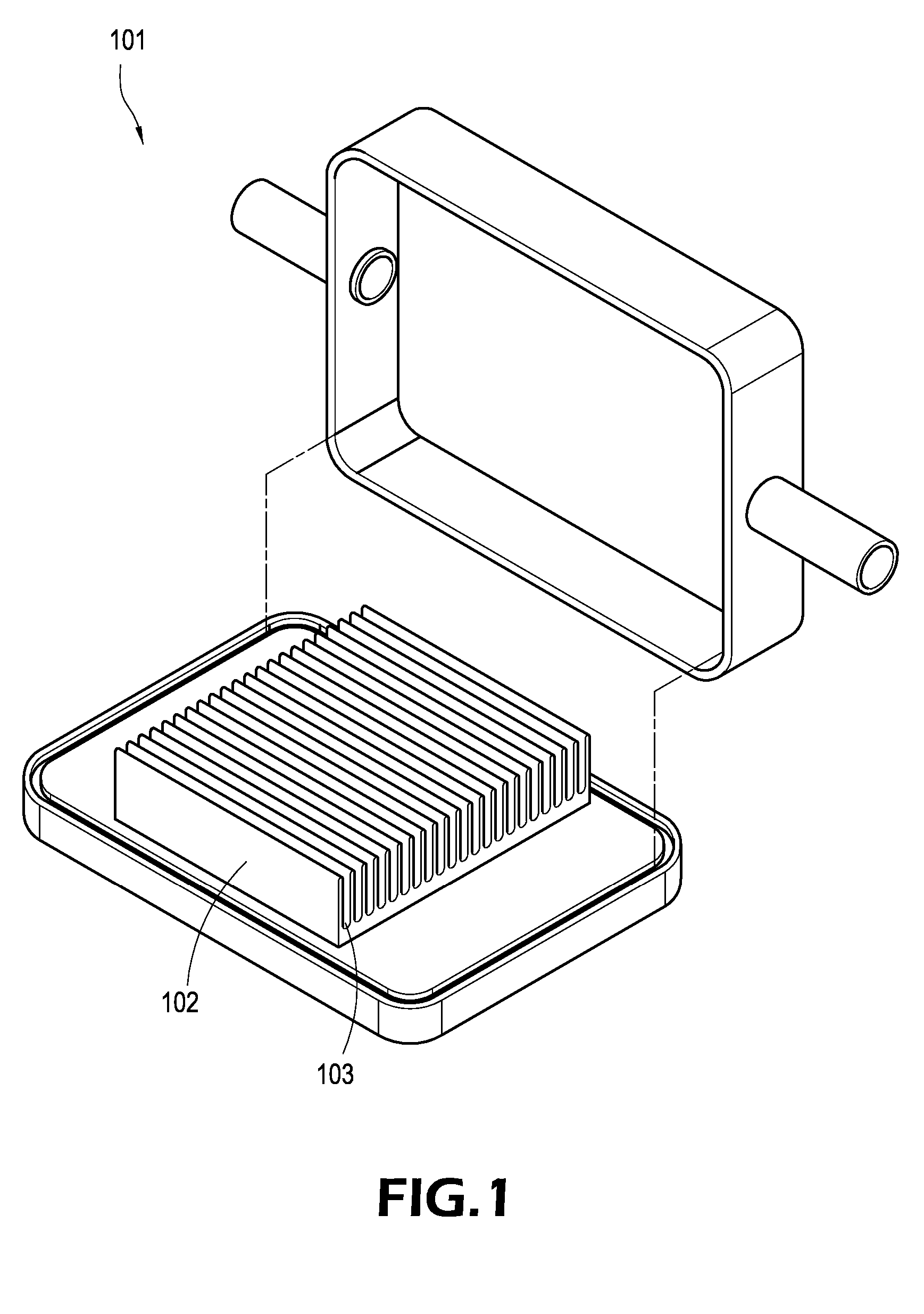

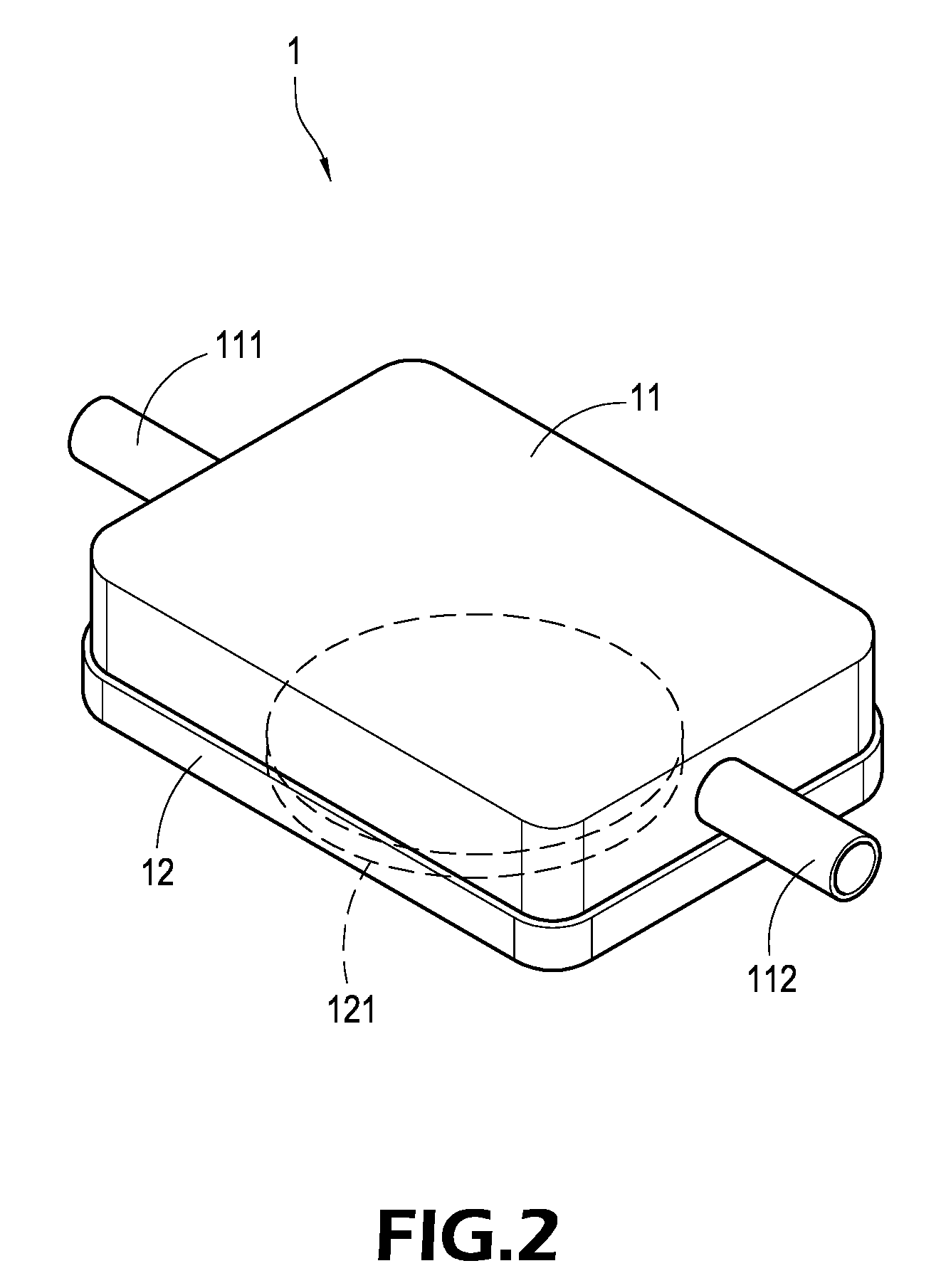

[0030] Referring to FIG. 2, a water block body 1 of the invention comprises a first casing 11 and a second casing 12 engaged with each other to form a hollow sealed box body, and the shape of the water block body 1 can be varied appropriately according to different requirements. The first casing 11 and the second casing 12 of this embodiment are cuboids (but not limited to such arrangement) made of a metal material or a ceramic material. The first casing 11 and the second casing 12 are coupled by soldering, riveting or binding. In addition, the first casing 11 has a water inlet pipe 111 and a water outlet pipe 112 extended outward (or u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com