Patents

Literature

33results about How to "Improve wastewater treatment efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

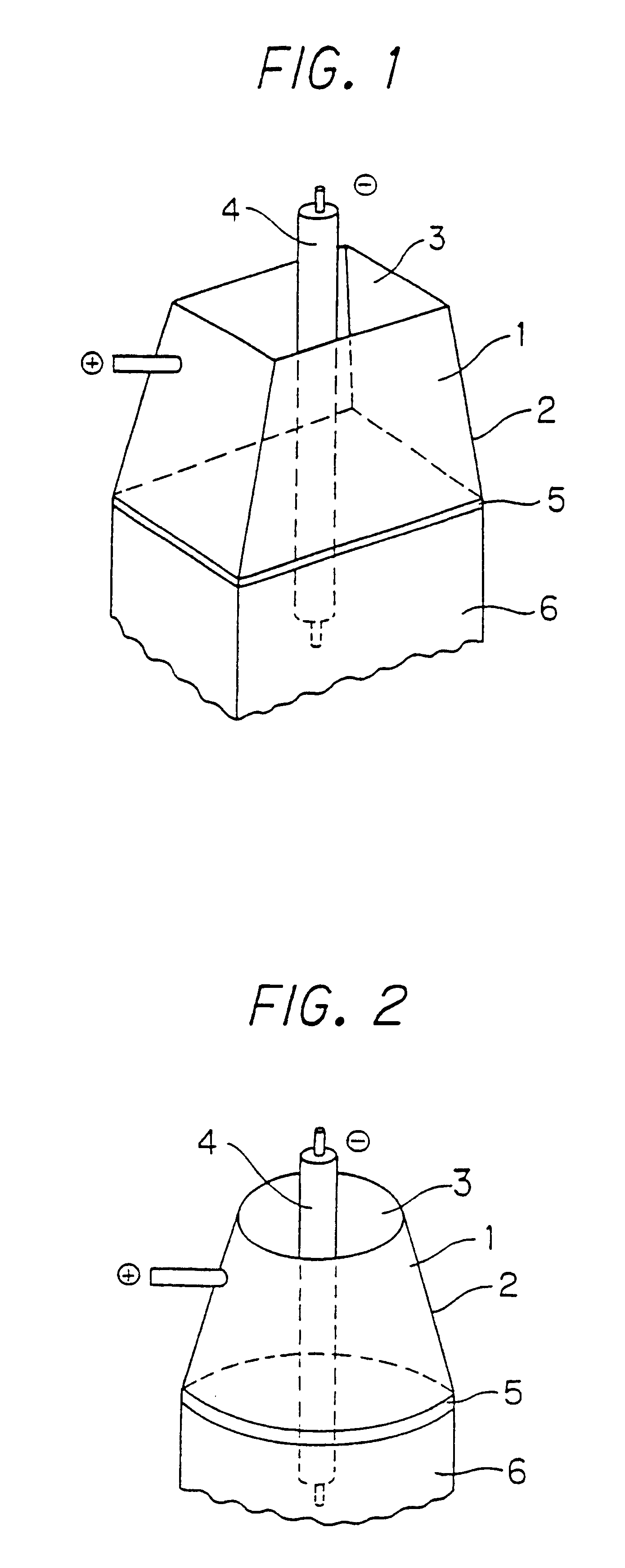

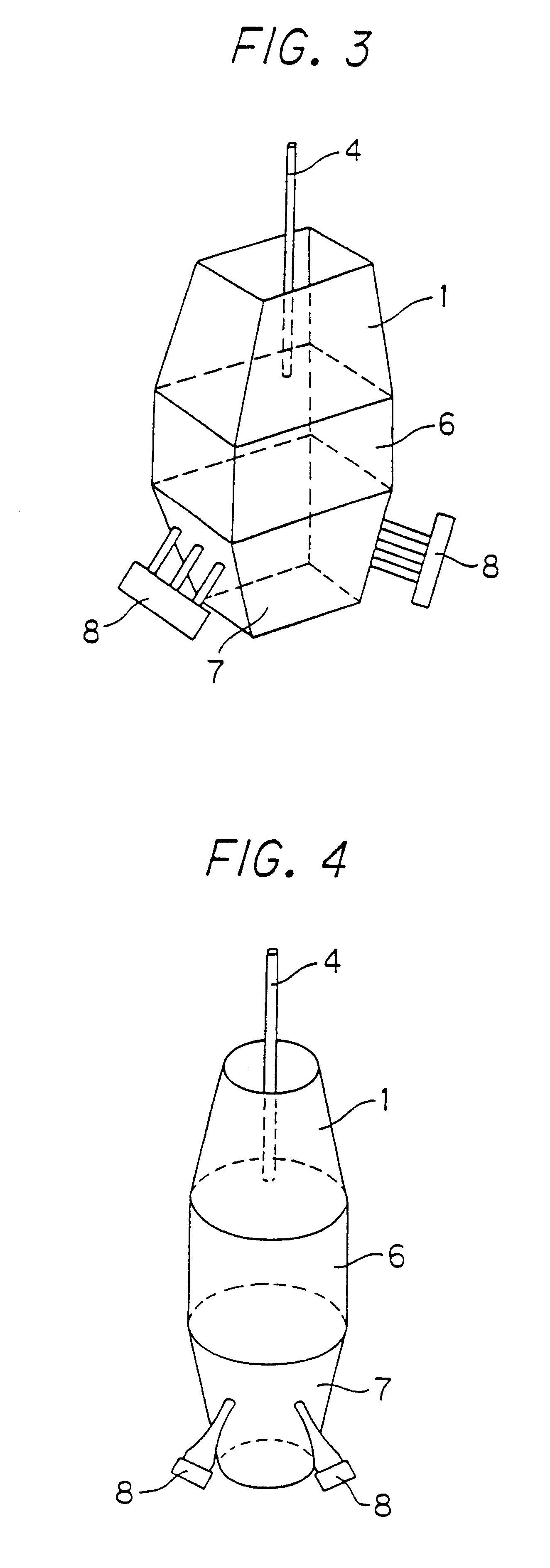

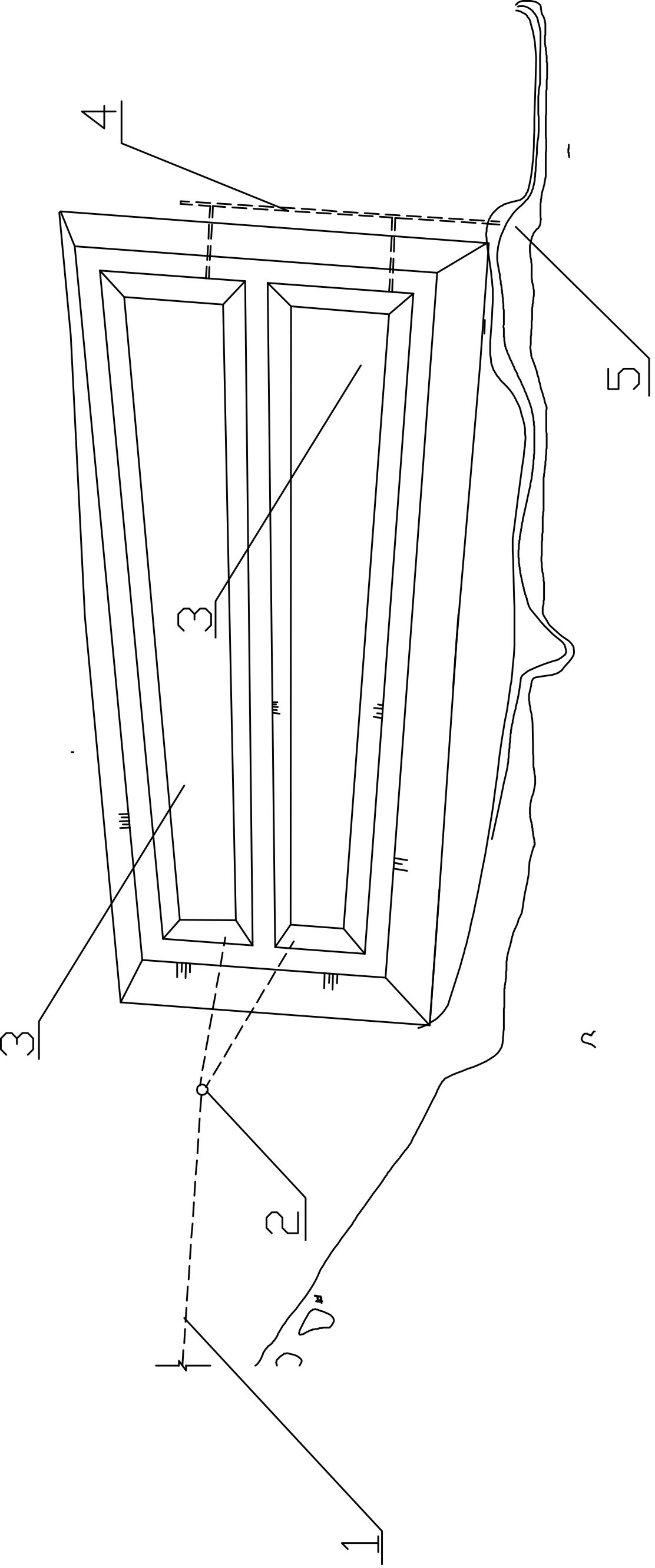

Method and apparatus for treatment of organic matter-containing wastewater

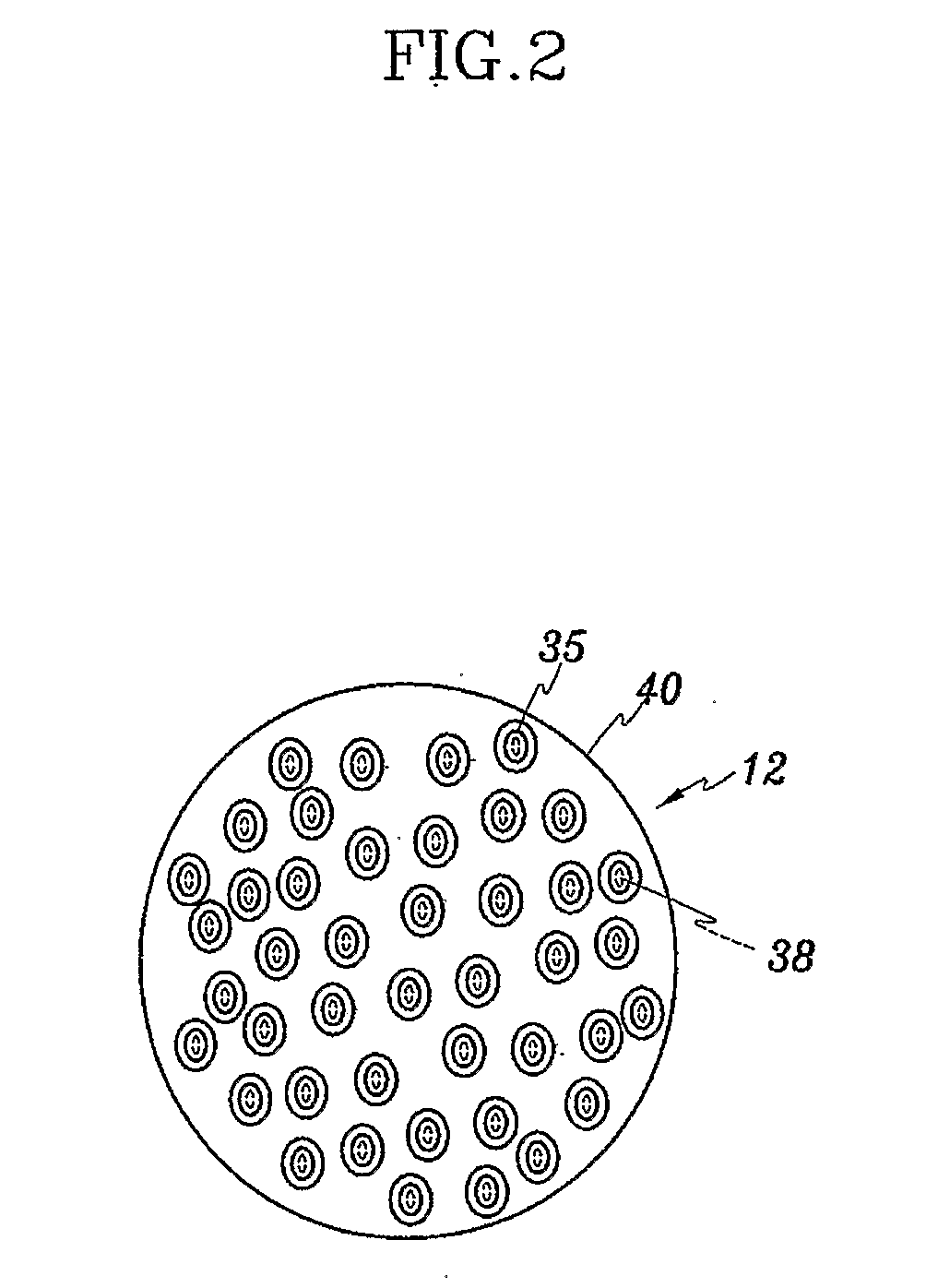

InactiveUS6547951B1Improve efficiencyImprove abilitiesCellsLiquid separation by electricitySurface layerWave form

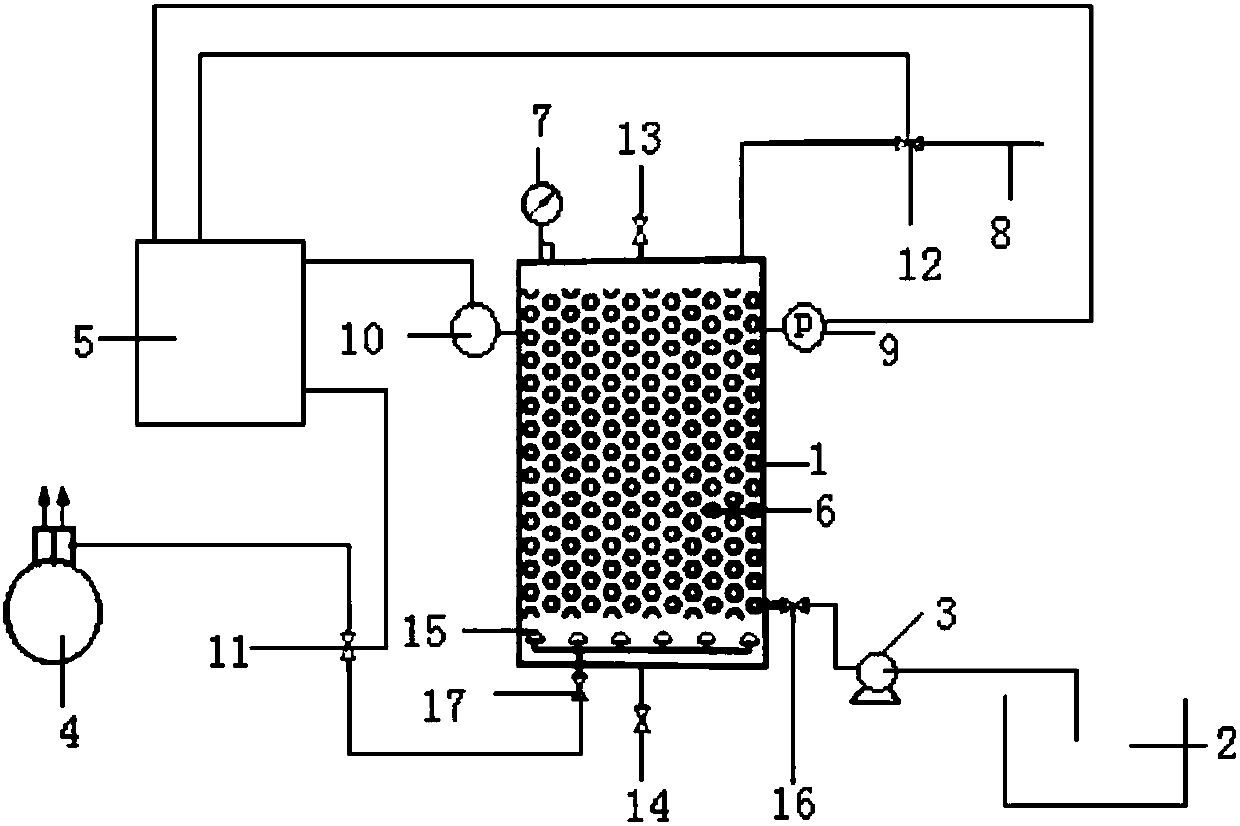

Disclosed is a novel method for treatment of wastewater containing organic contaminant materials by oxidatively decomposing the contaminant materials by a radical reaction involving hydroxyl radicals. The method comprises passing the wastewater through a wastewater treatment conduit (6) comprising a straightly tubular member (6) and a radical generating part consisting of a truncated pyramidal or conical tubular member (1) having an inner surface layer of titanium dioxide to serve as a positive electrode and connected to the upstream end of the straightly tubular member and a negative electrode rod (4) coaxially held relative to the truncated tubular member and applying a pulsed DC voltage having a rectangular wave form at a specified frequency. The efficiency of wastewater treatment can be improved by providing an ultrasonic part consisting of a truncated tubular member similar (7) to the above and connected to the downstream end of the straightly tubular member and an ultrasonic vibrator (8) mounted thereon to emit pulsed ultrasonic waves.

Owner:DAISHIN DESIGN CORP

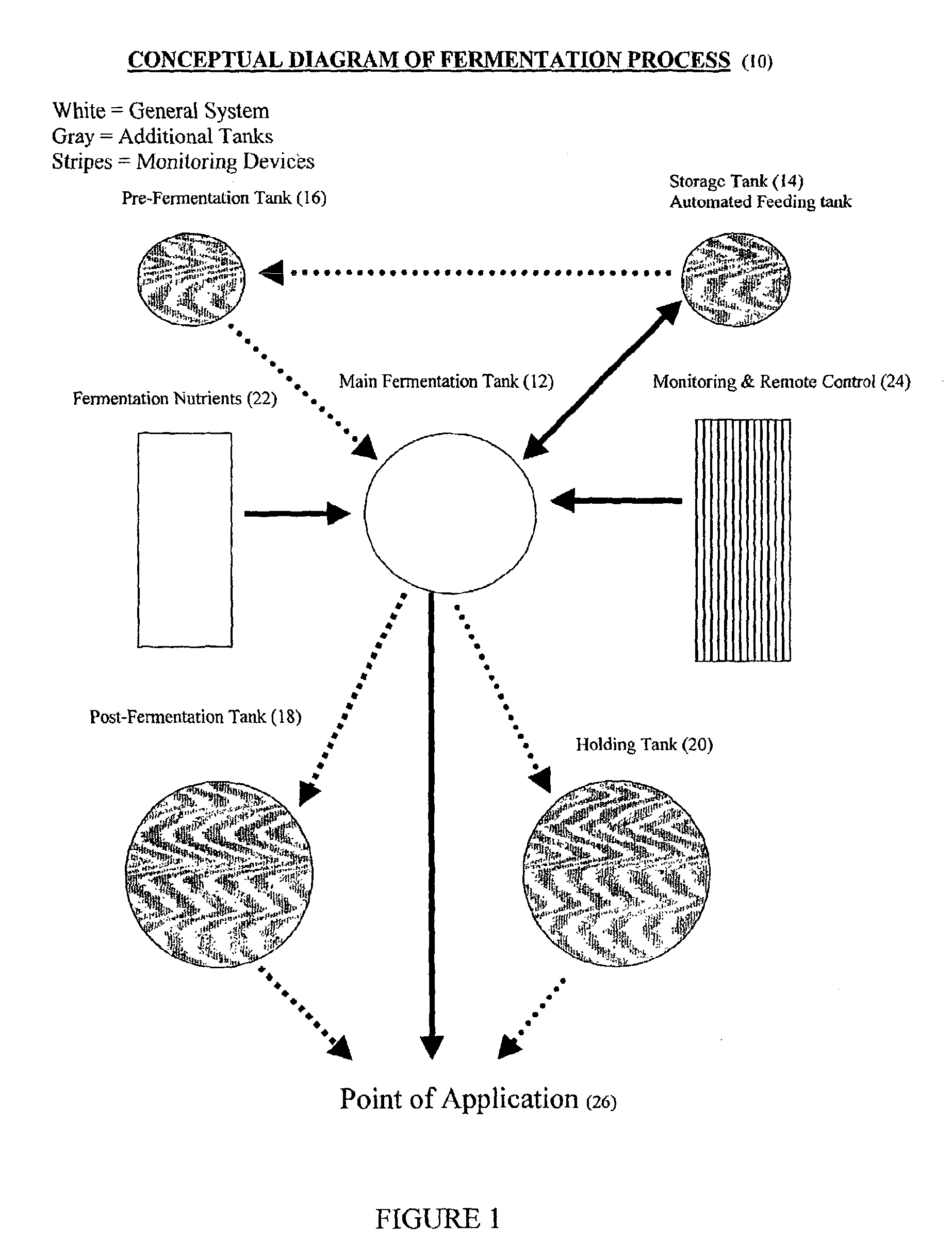

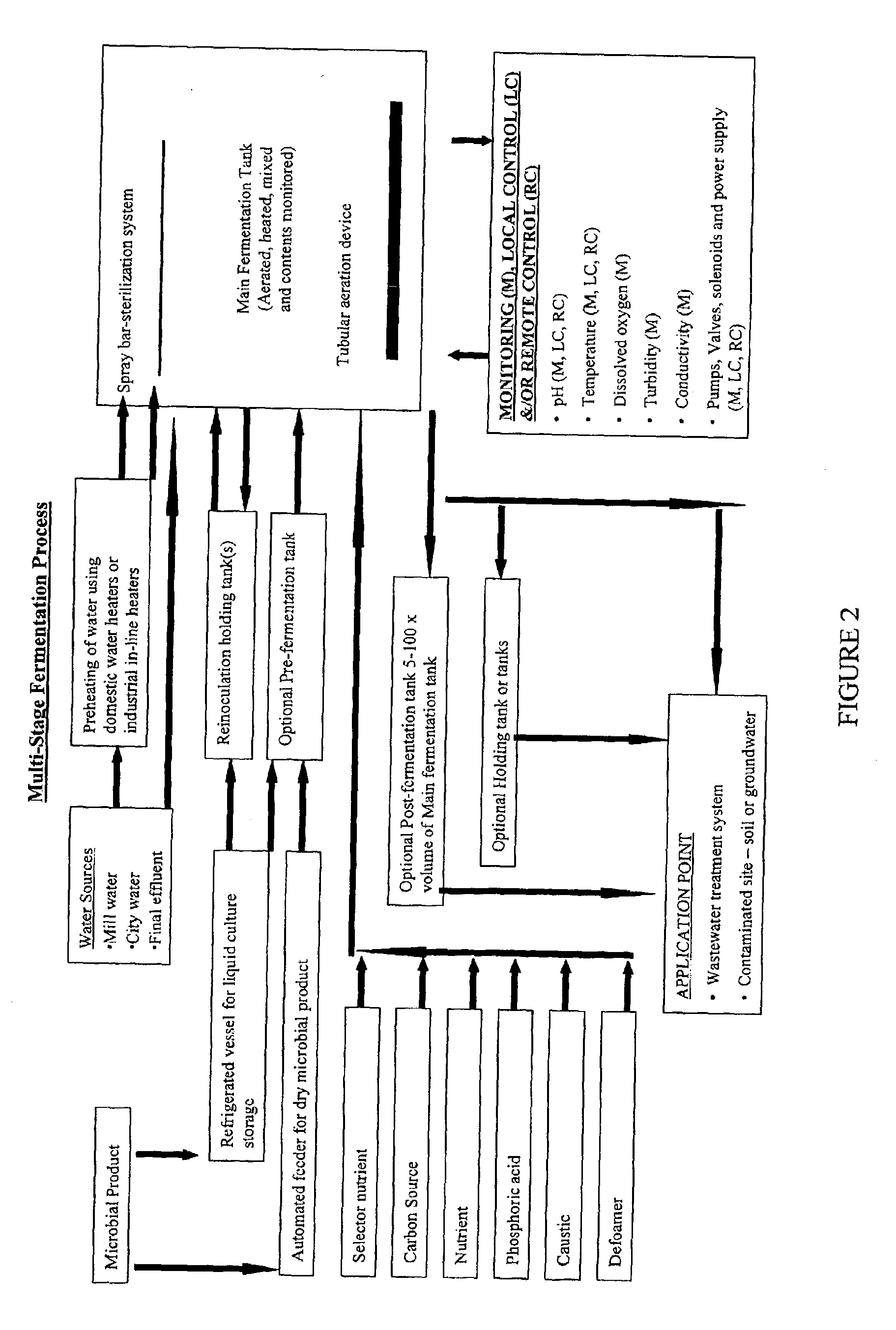

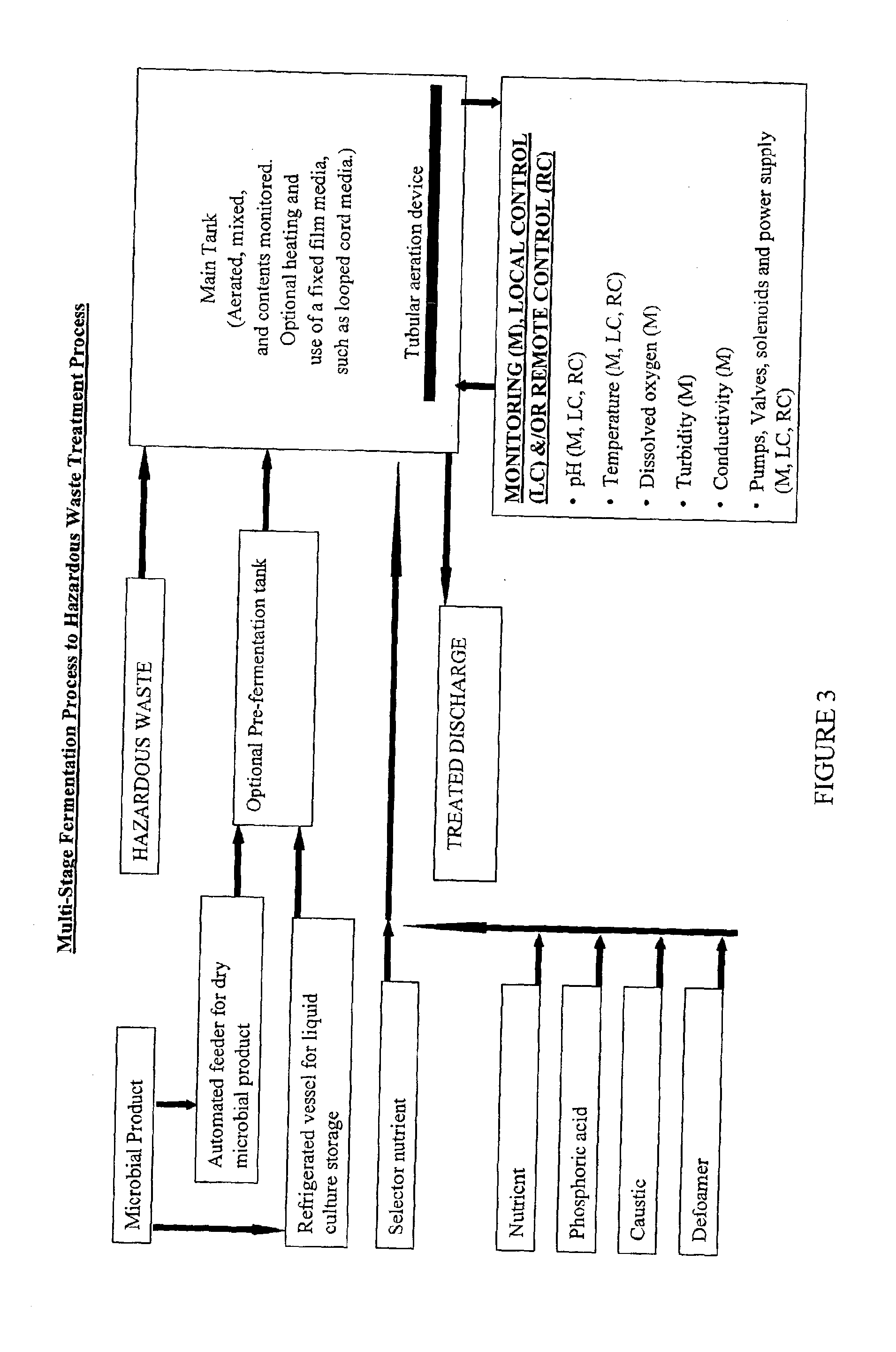

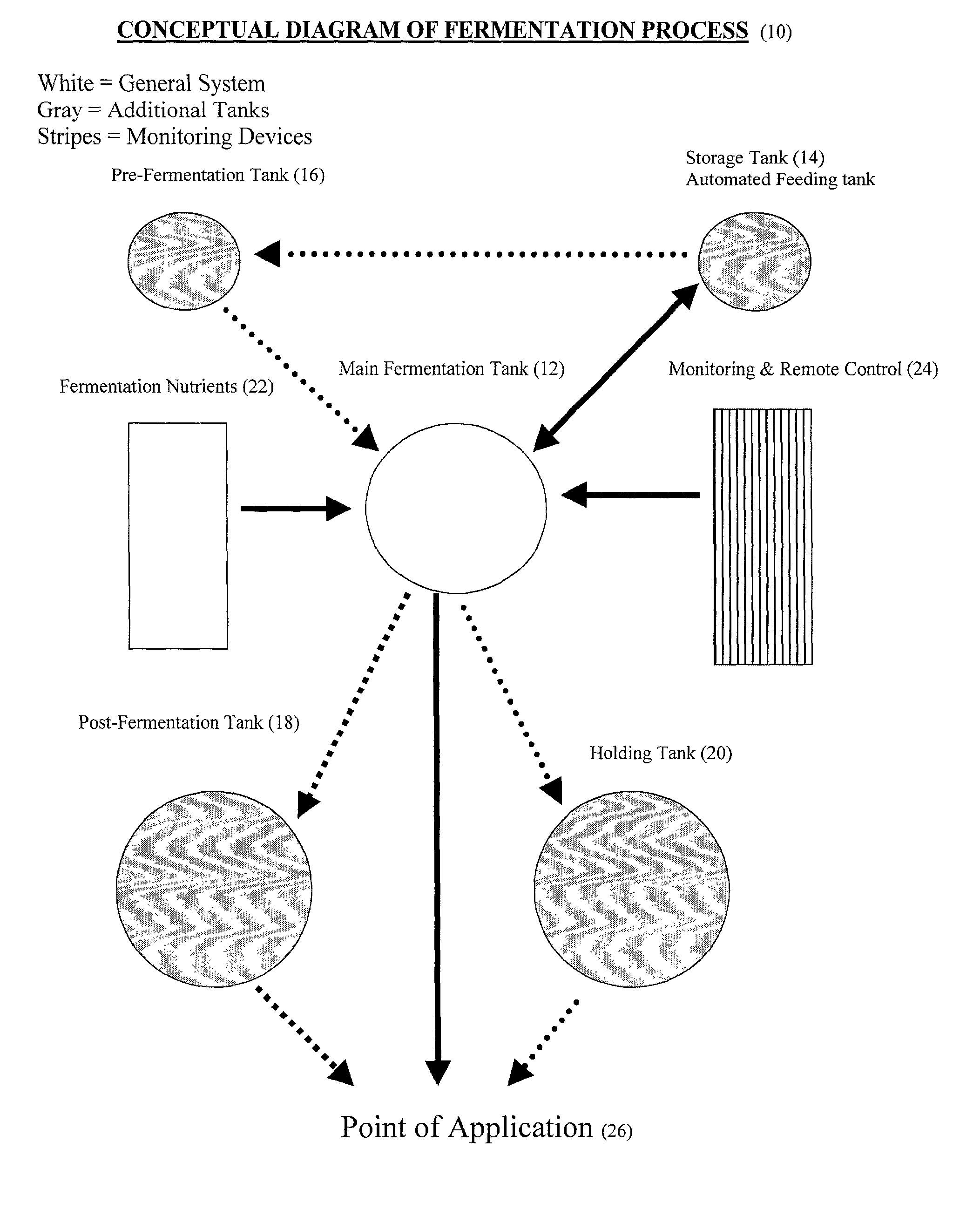

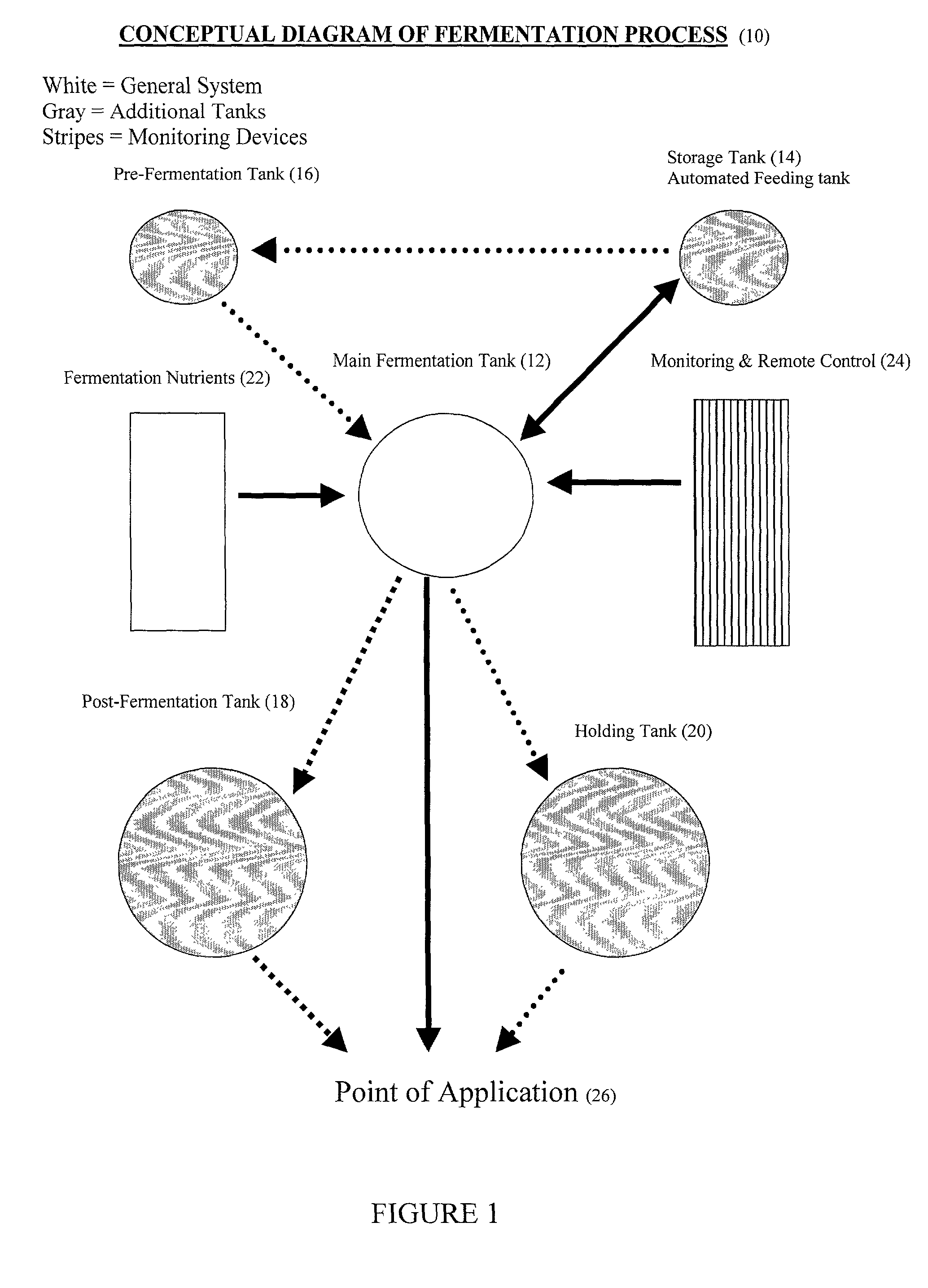

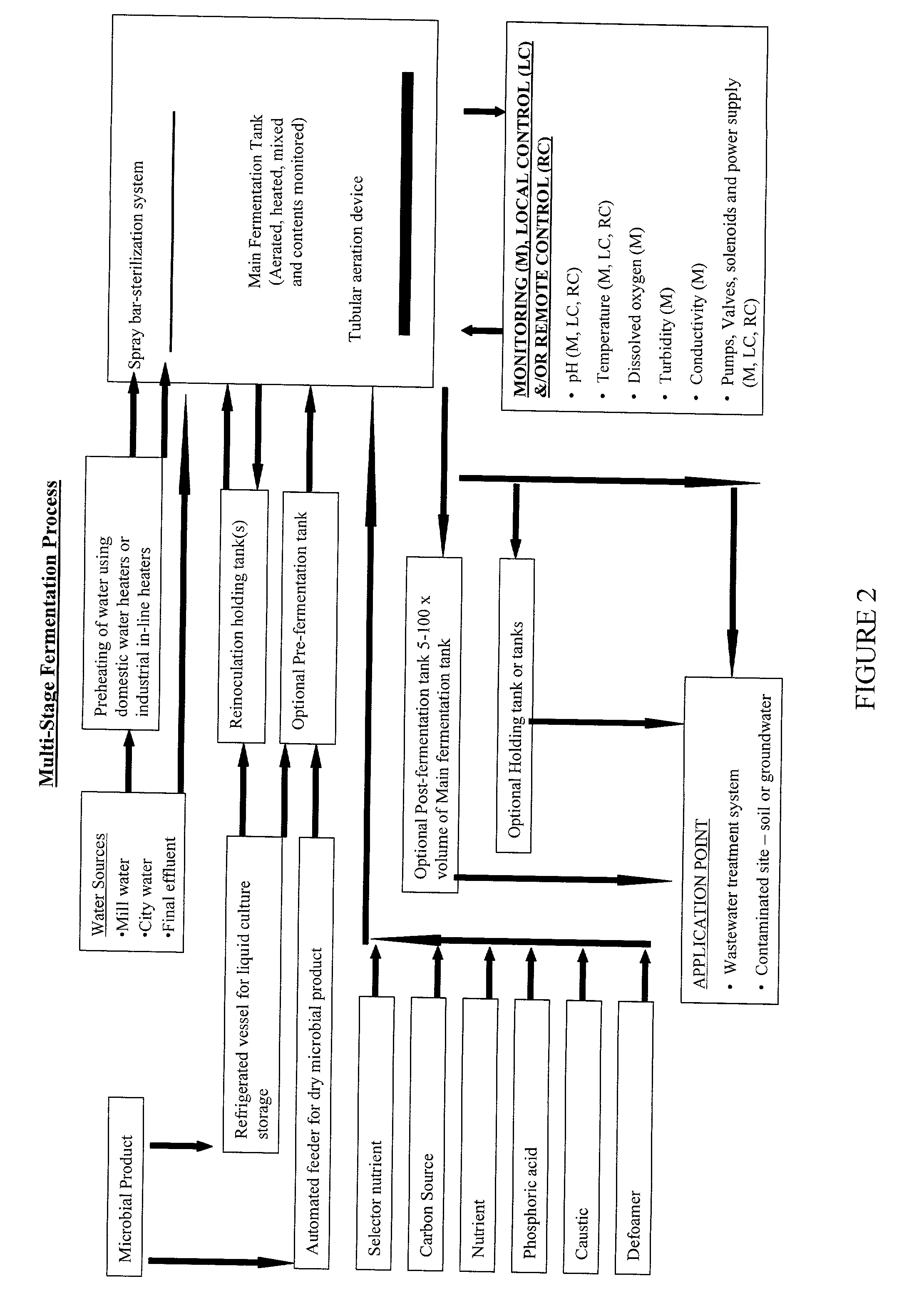

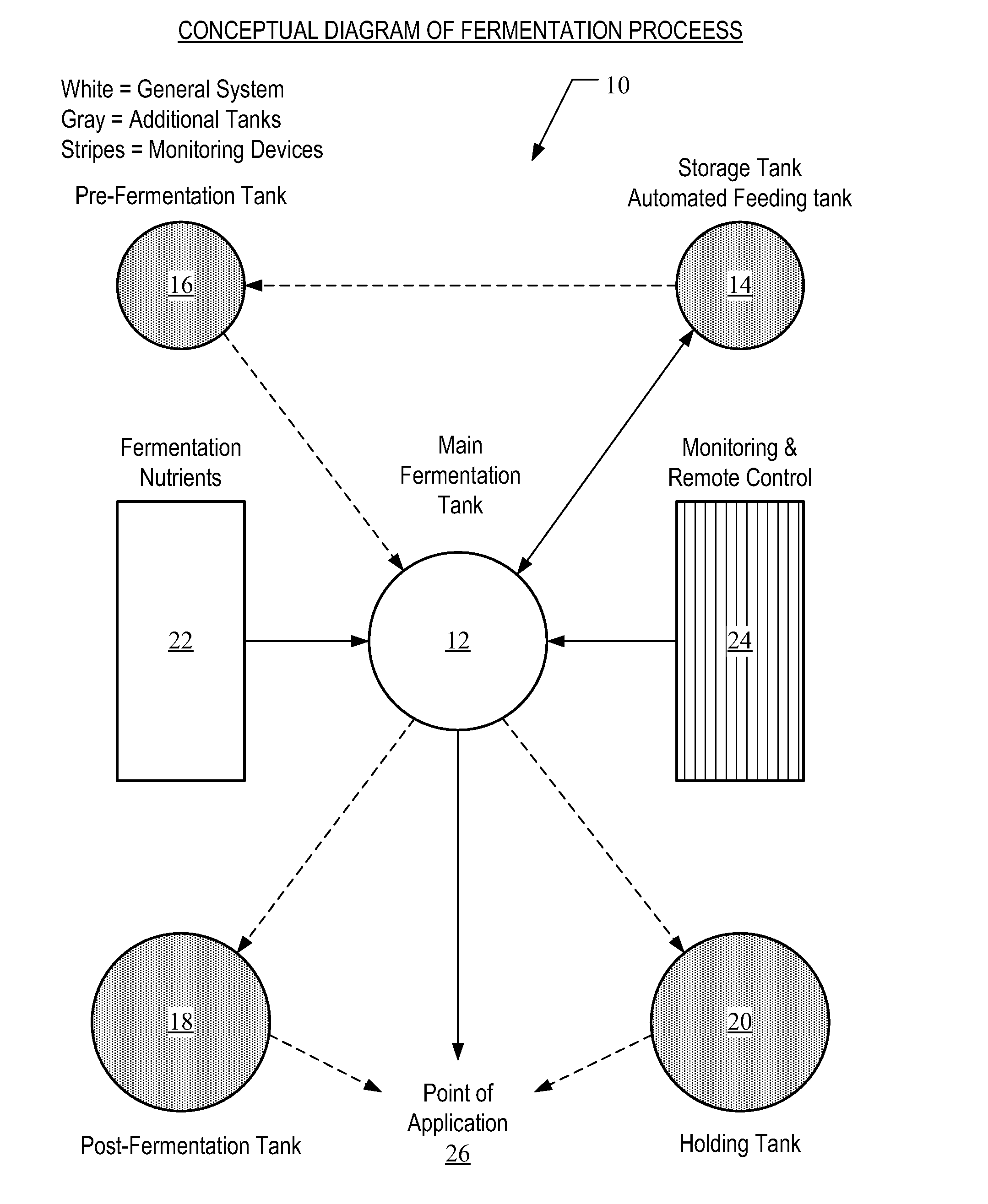

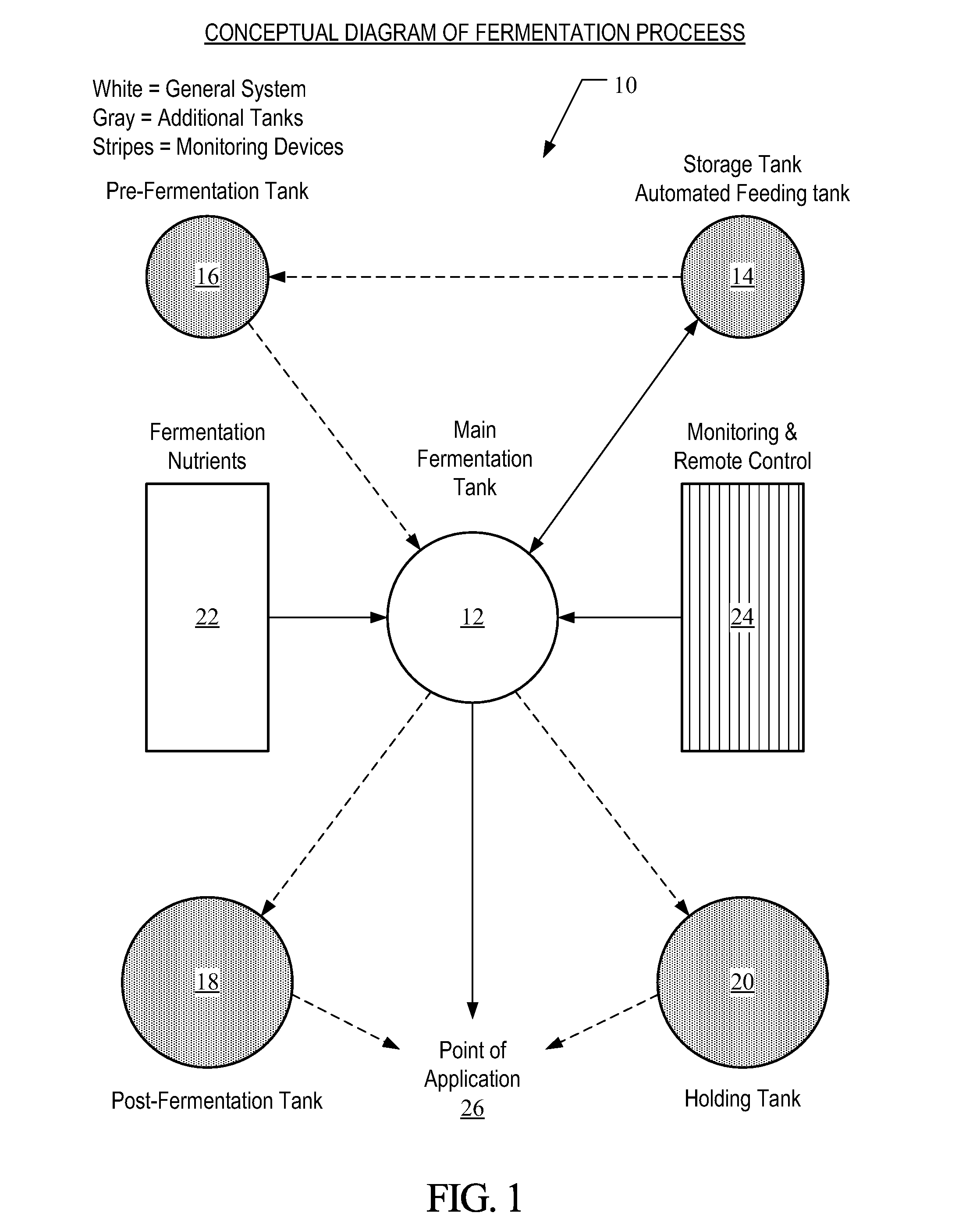

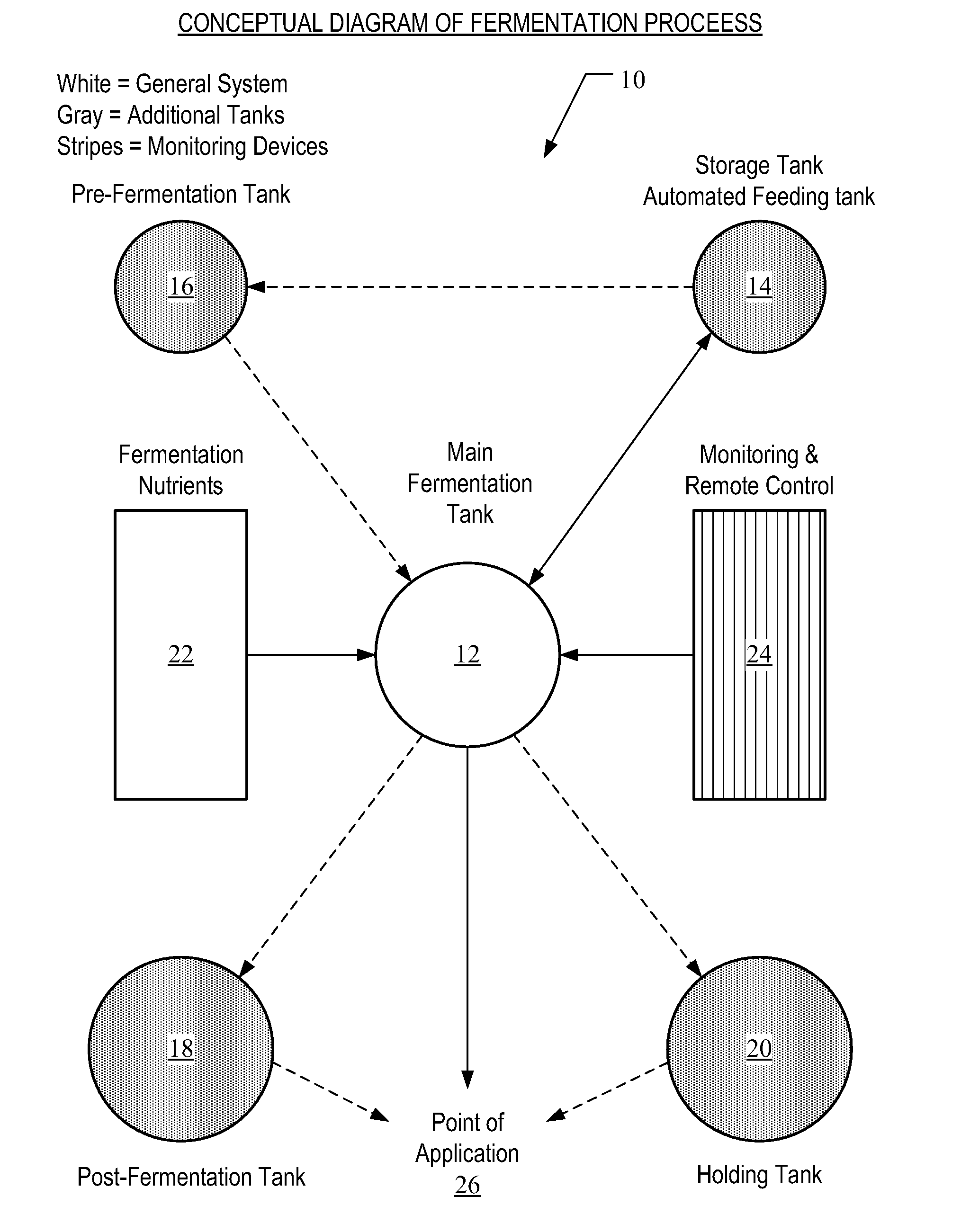

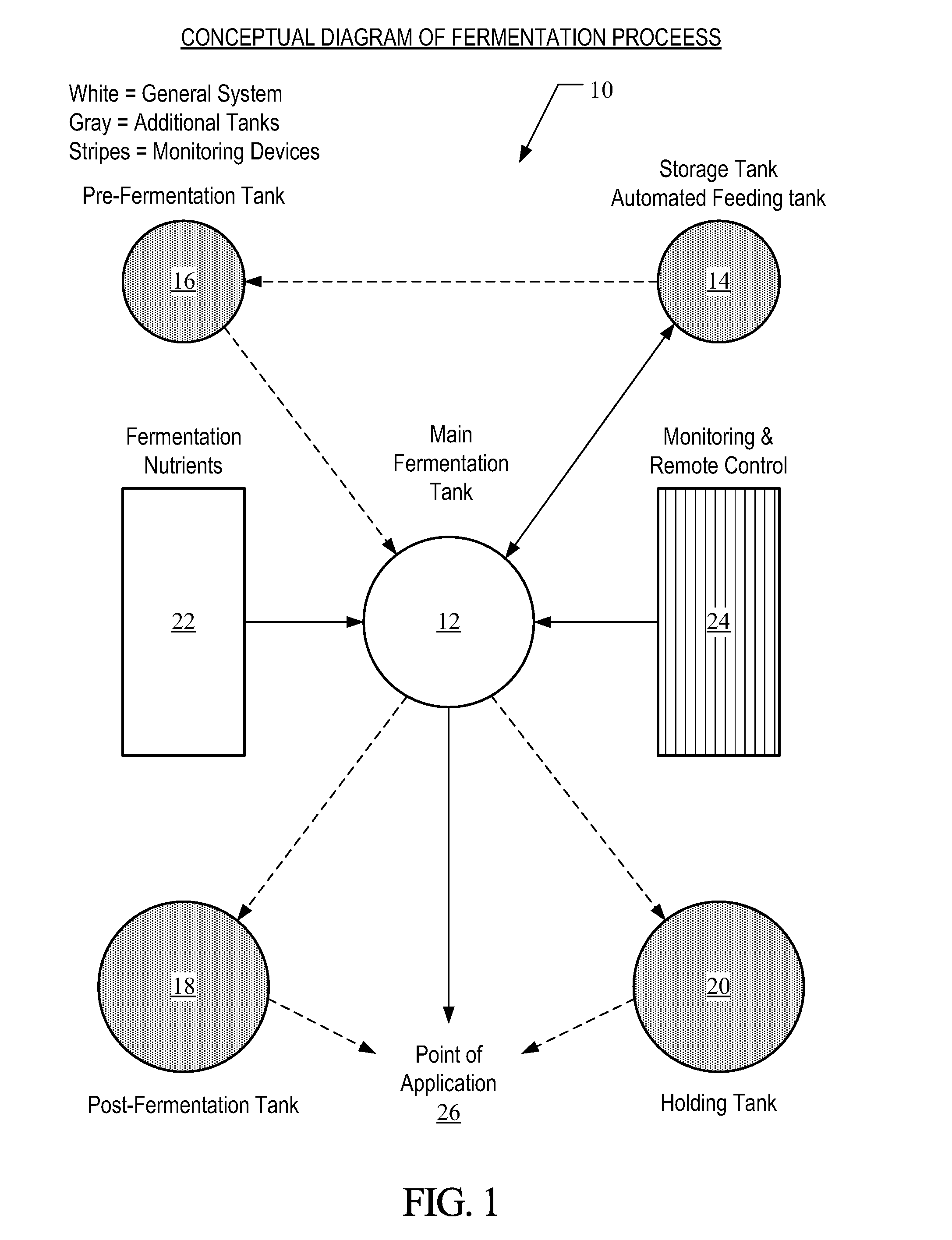

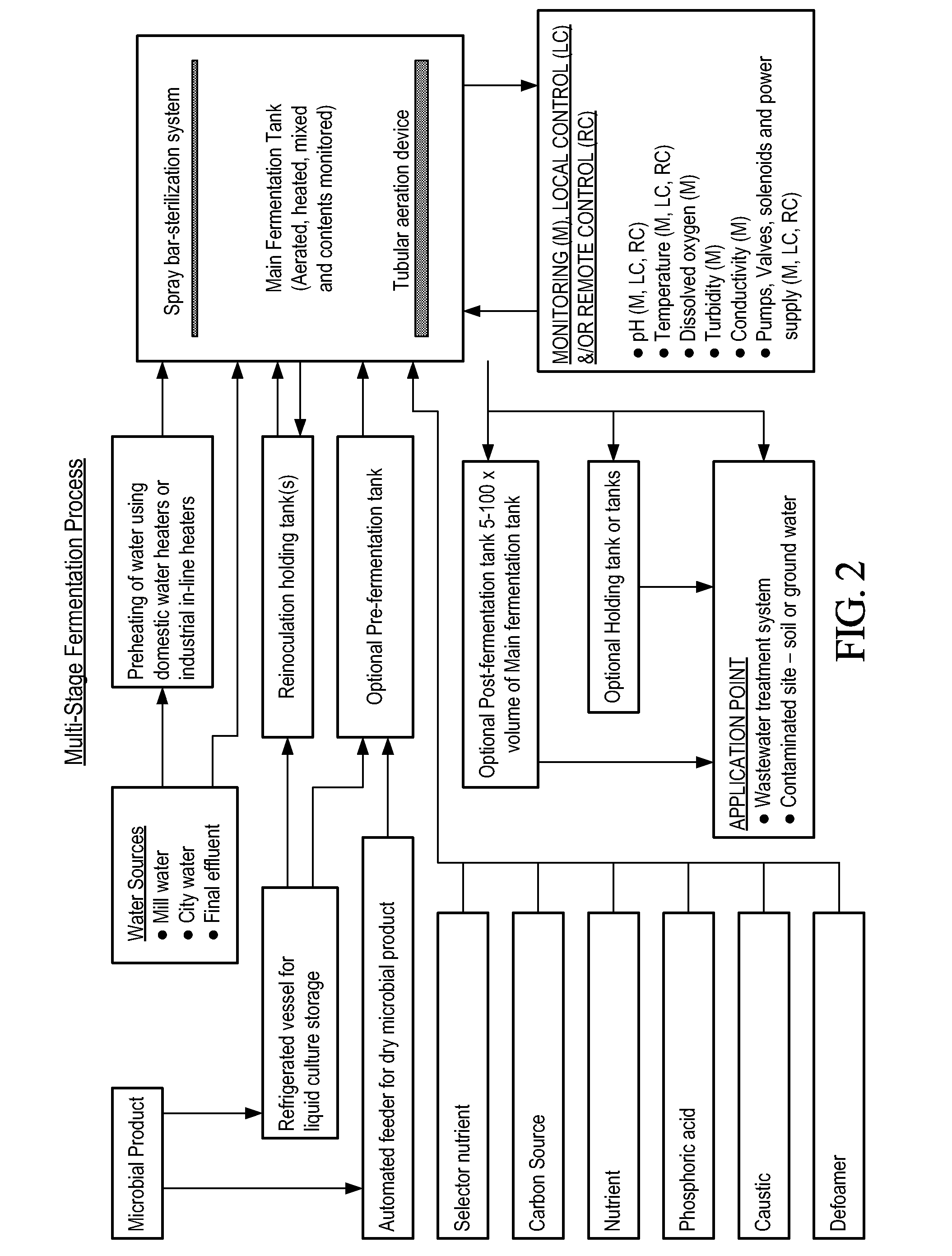

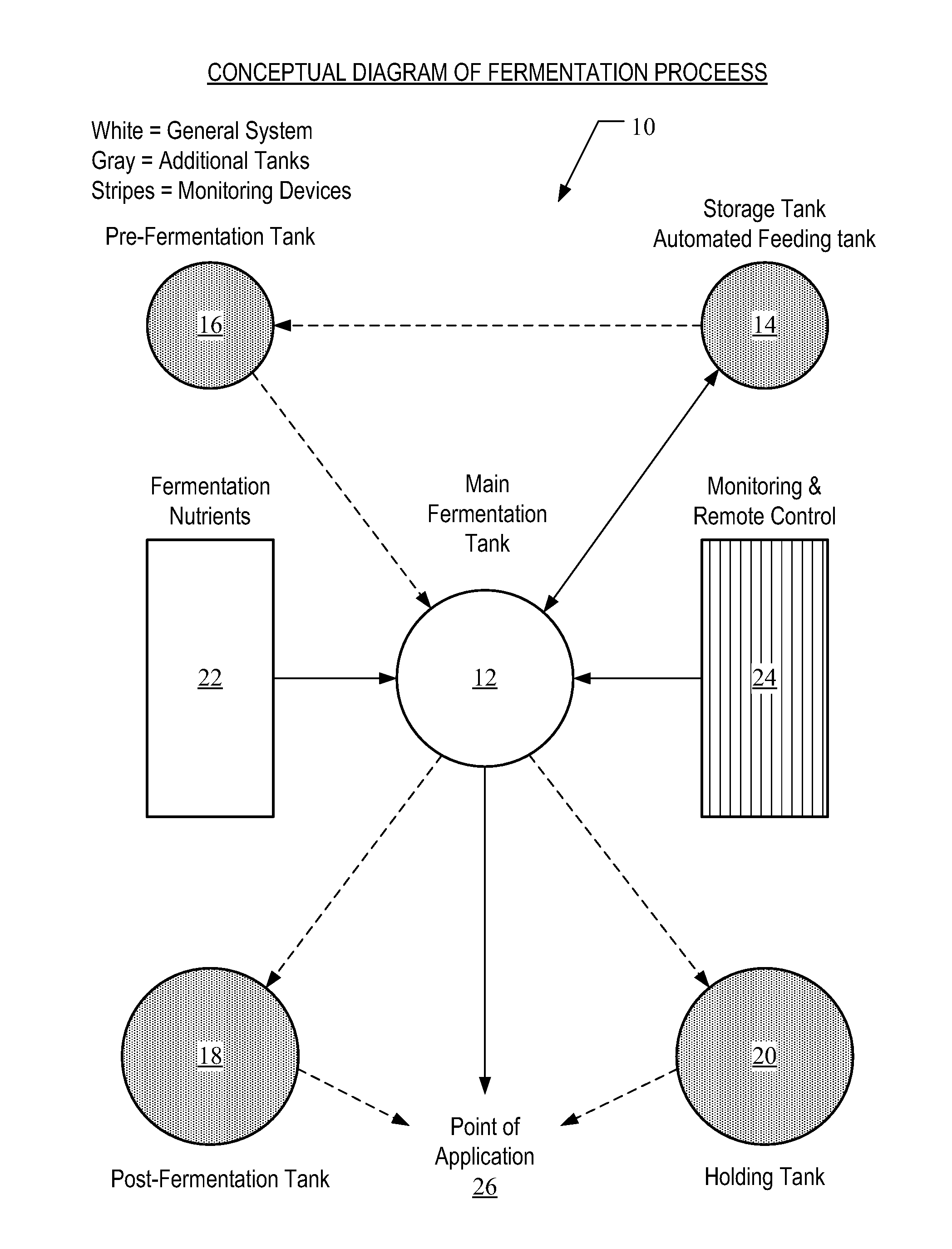

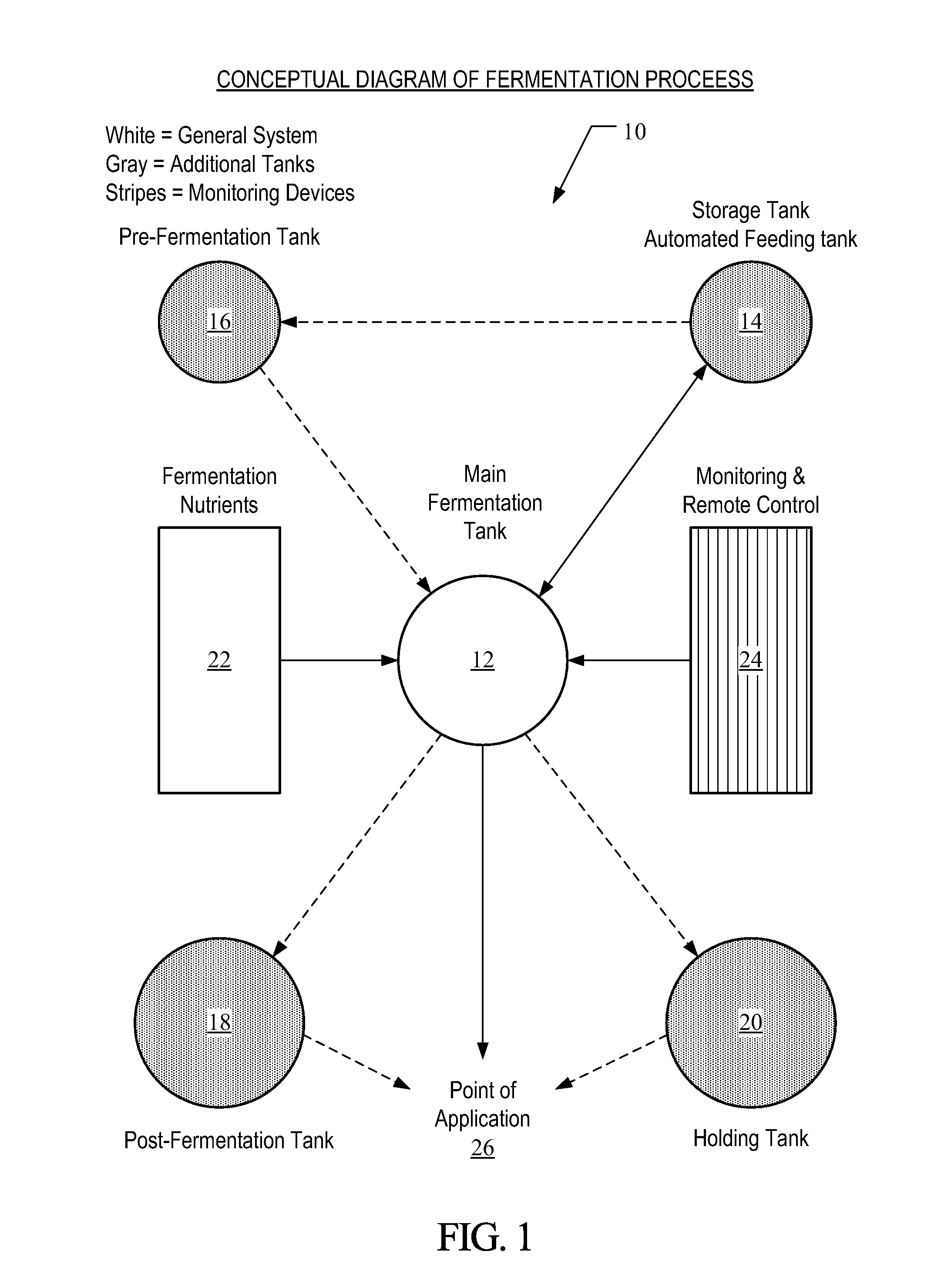

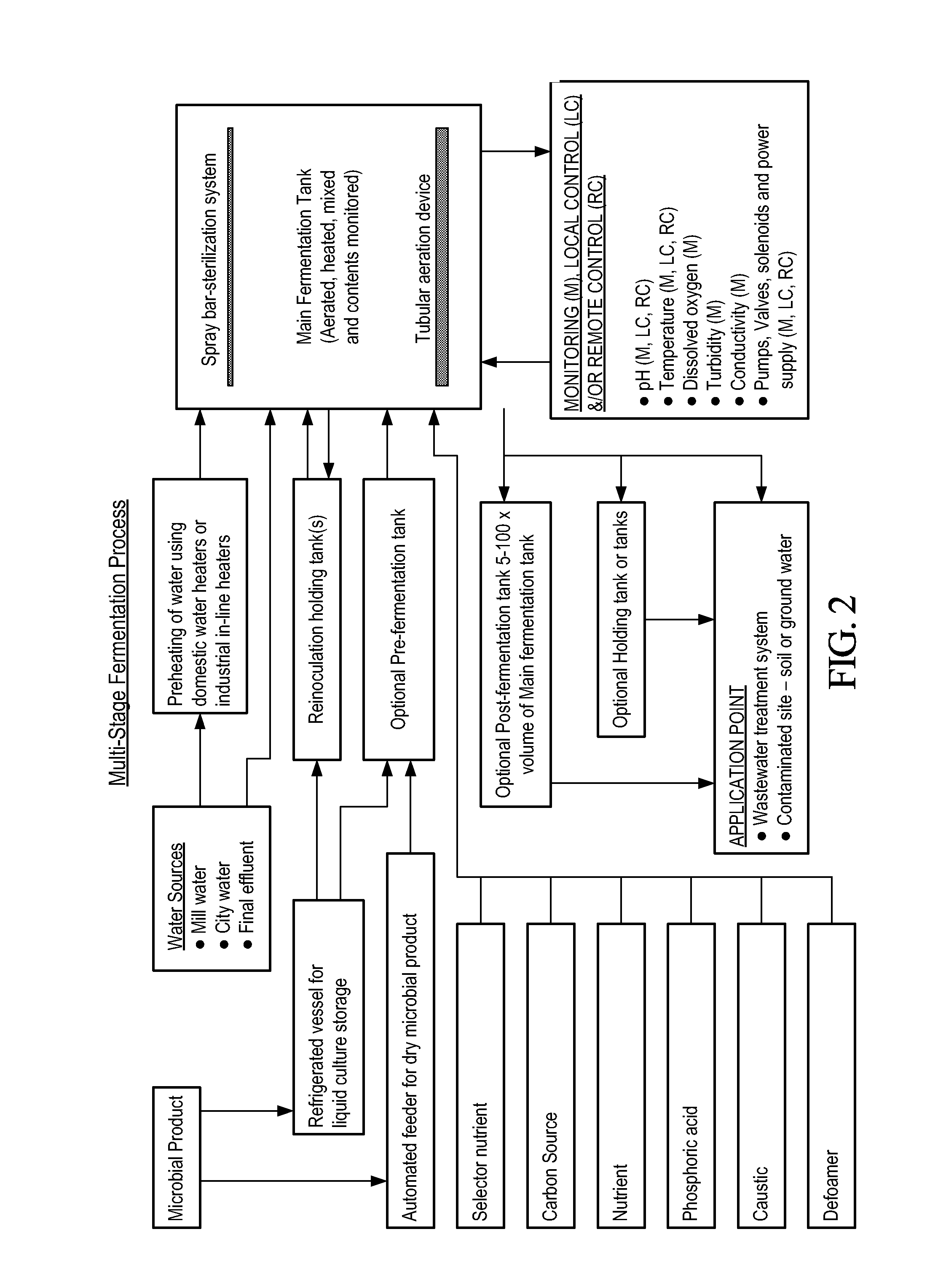

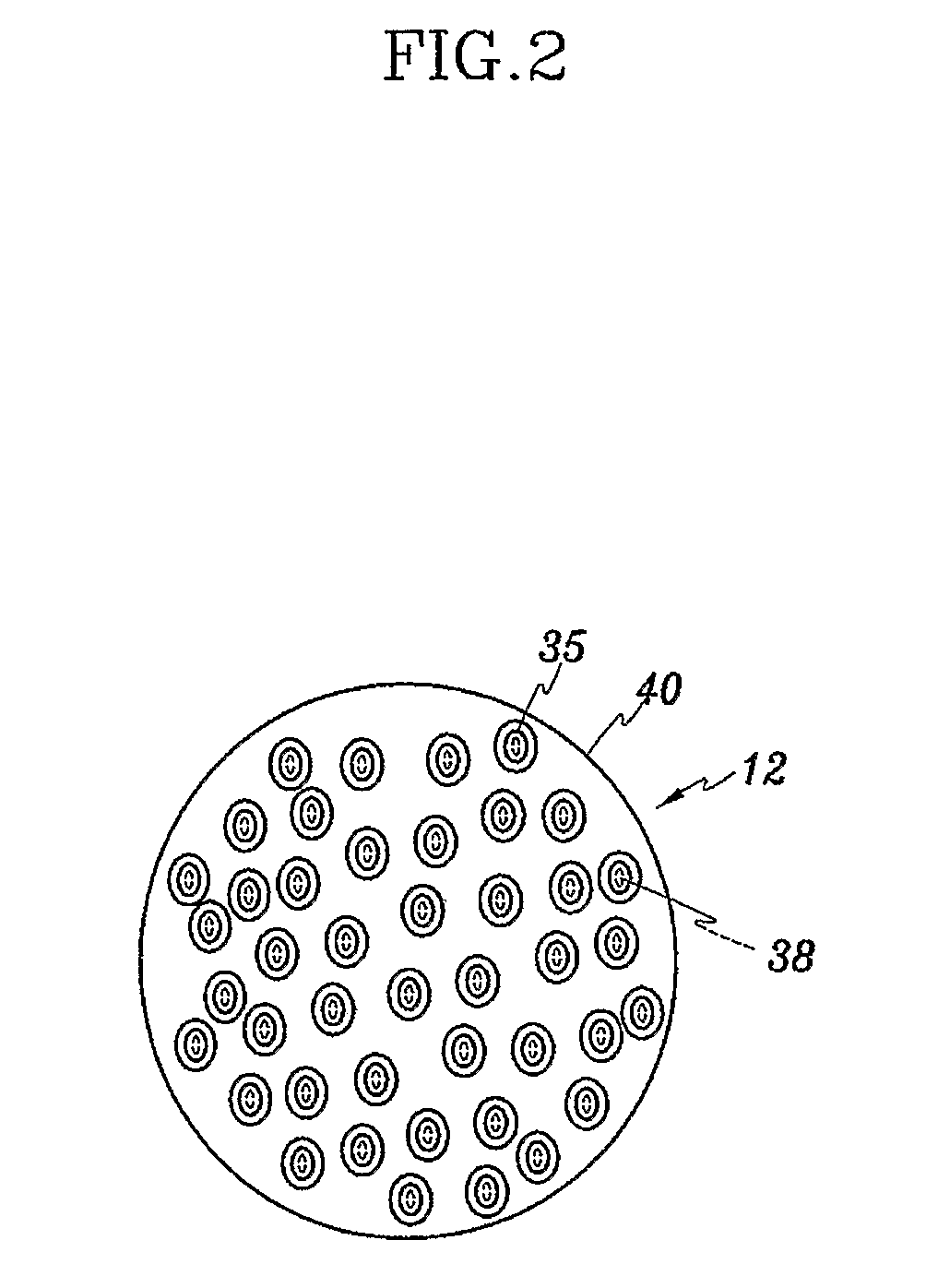

Fermentation systems, methods and apparatus

ActiveUS20030190742A1Eliminate needImprove wastewater treatment efficiencyWater treatment parameter controlWater treatment compoundsOrganismal ProcessWastewater

The present invention relates to apparatus, methods, and applications for treating wastewater, and more particularly to biological processes for removing pollutants from wastewater. This invention further relates to apparatus and methods for growing microbes on-site at a wastewater treatment facility, and for economically inoculating sufficient microbes to solve various treatment problems rapidly

Owner:ADVANCED INNOVATORS INC

Fermentation systems, methods, and apparatus

InactiveUS20020117445A1Eliminate needImprove wastewater treatment efficiencyWater treatment parameter controlTreatment using aerobic processesOrganismal ProcessWastewater

The present invention relates to apparatus, methods, and applications for treating wastewater, and more particularly to biological processes for removing pollutants from wastewater. This invention further relates to apparatus and methods for growing microbes on-site at a wastewater treatment facility, and for economically inoculating sufficient microbes to solve various treatment problems rapidly.

Owner:WHITEMAN G ROBERT

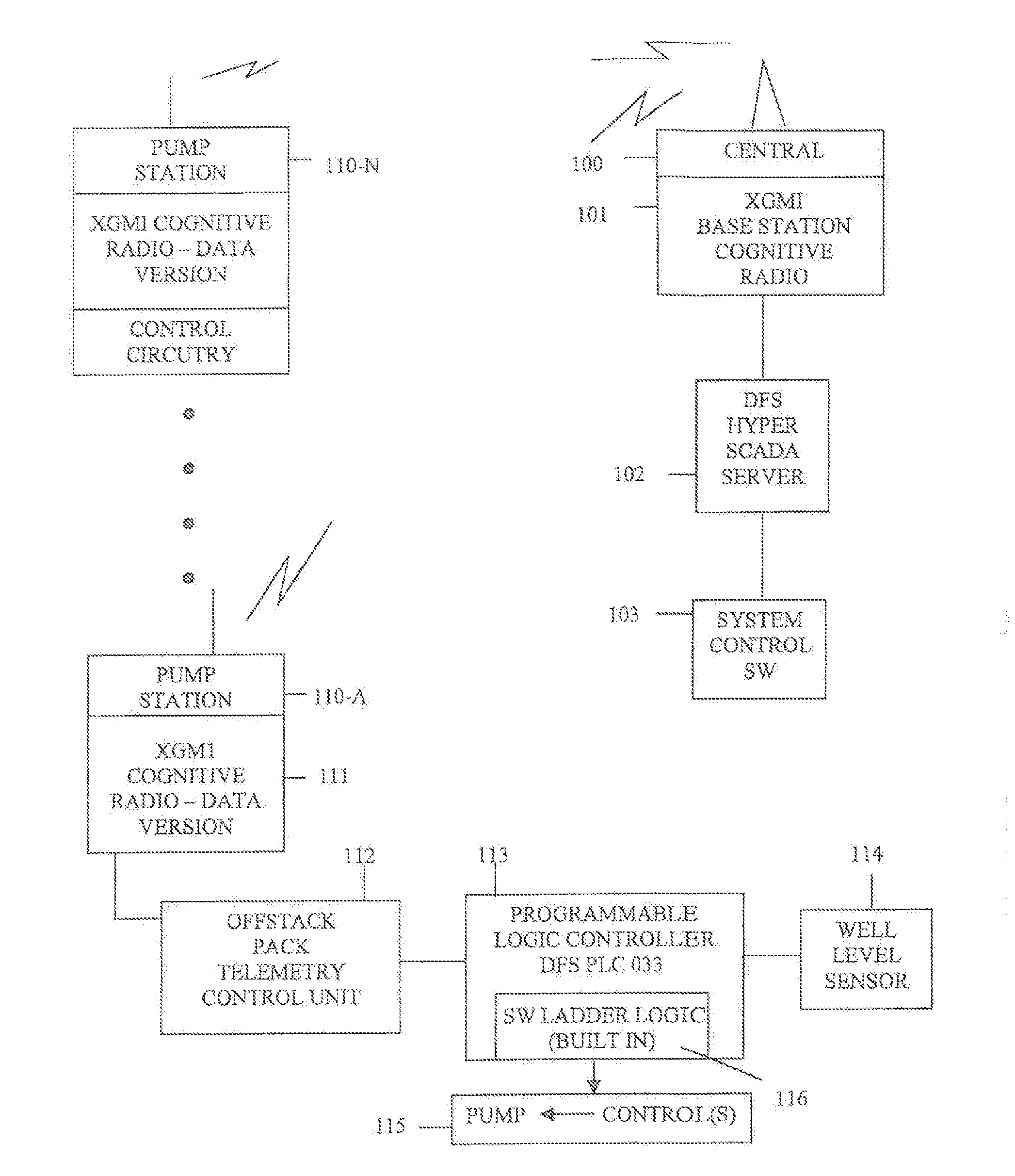

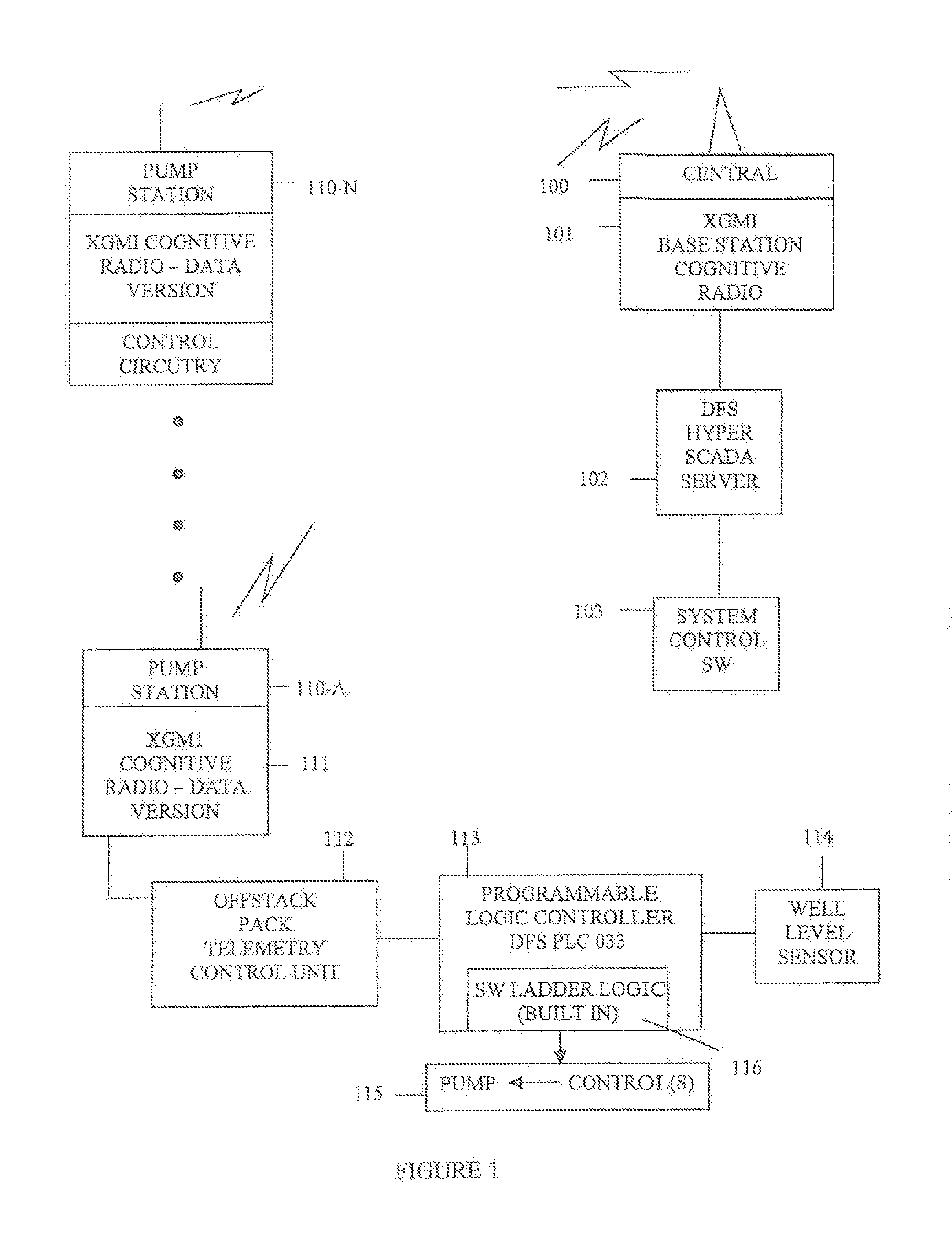

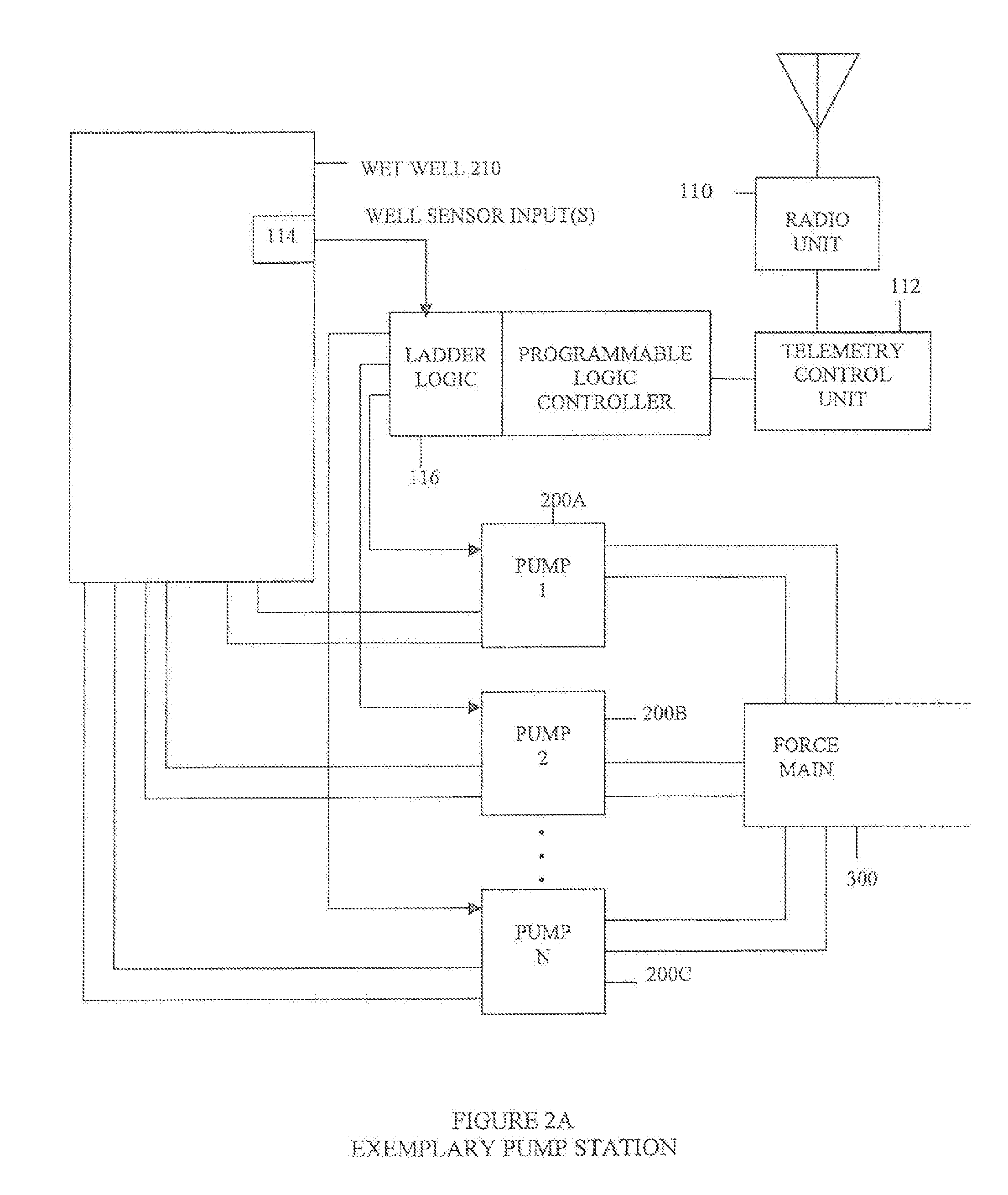

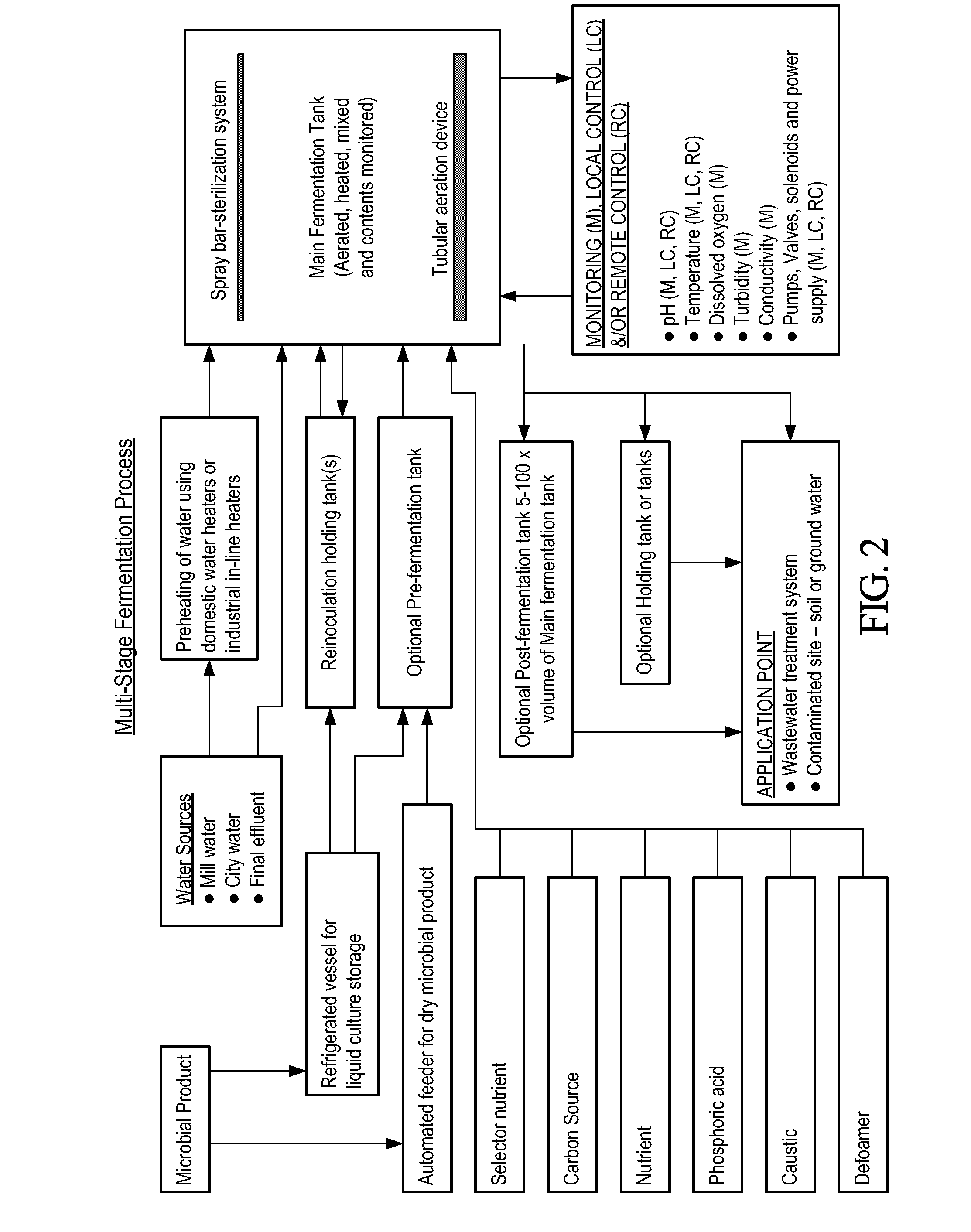

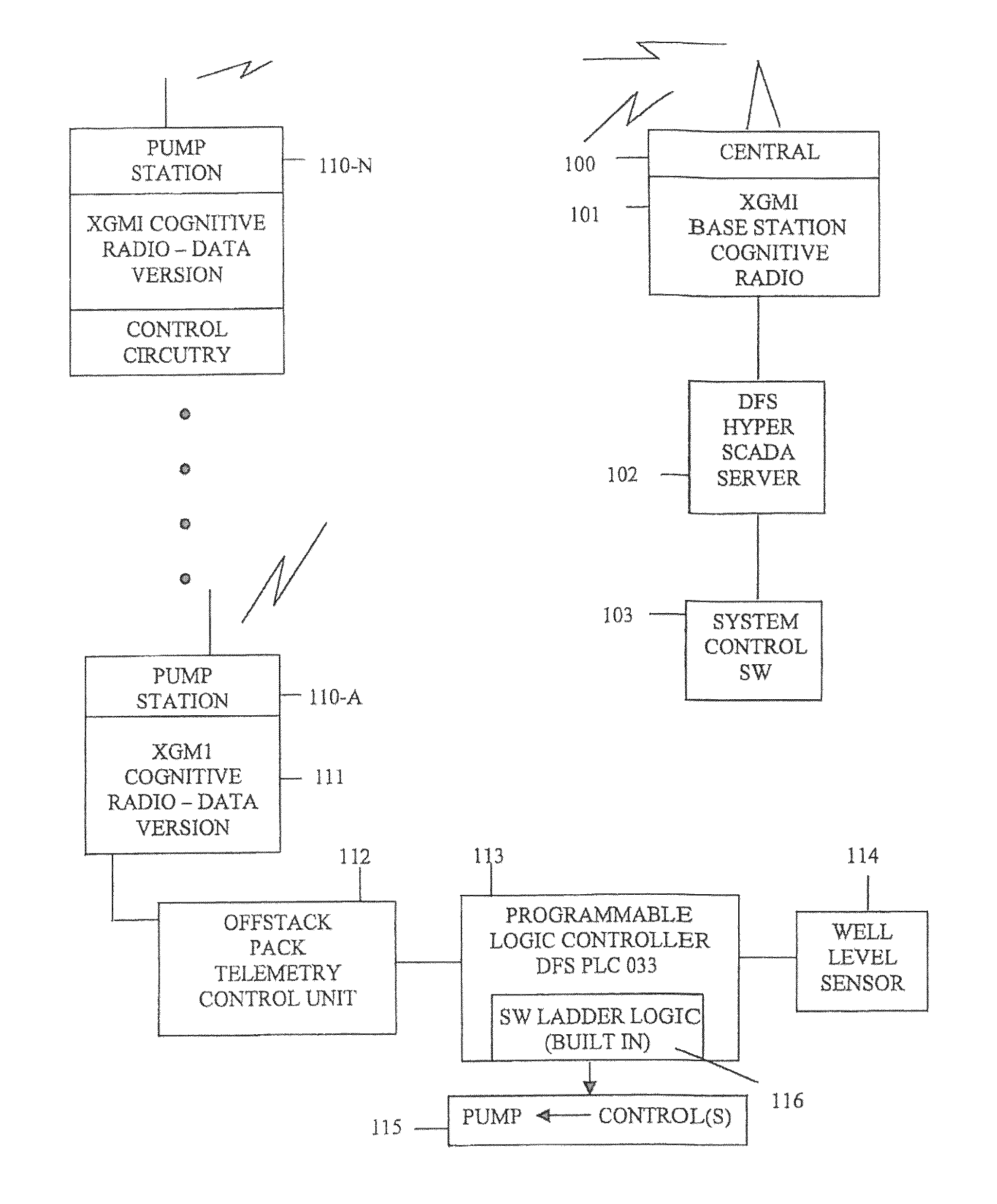

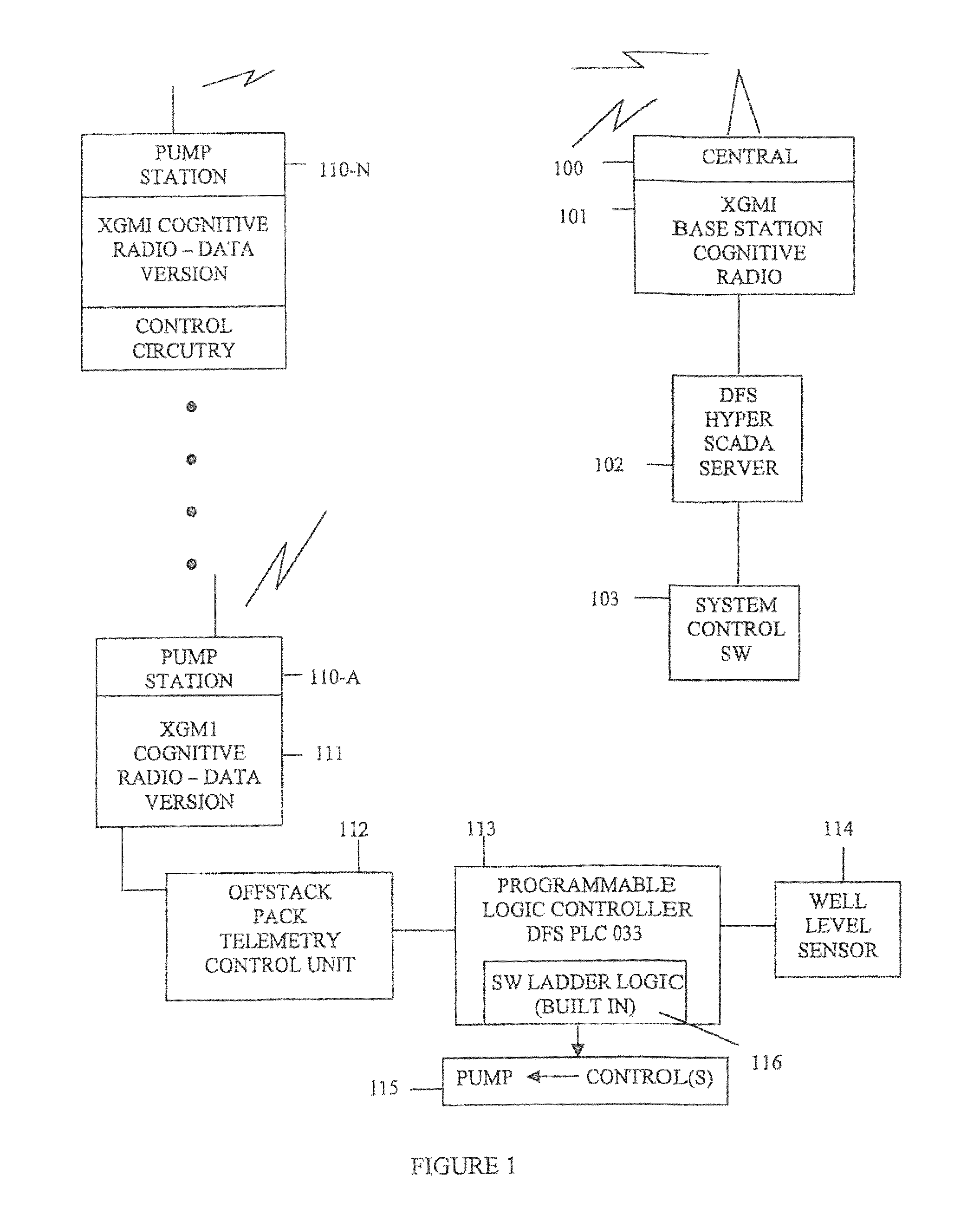

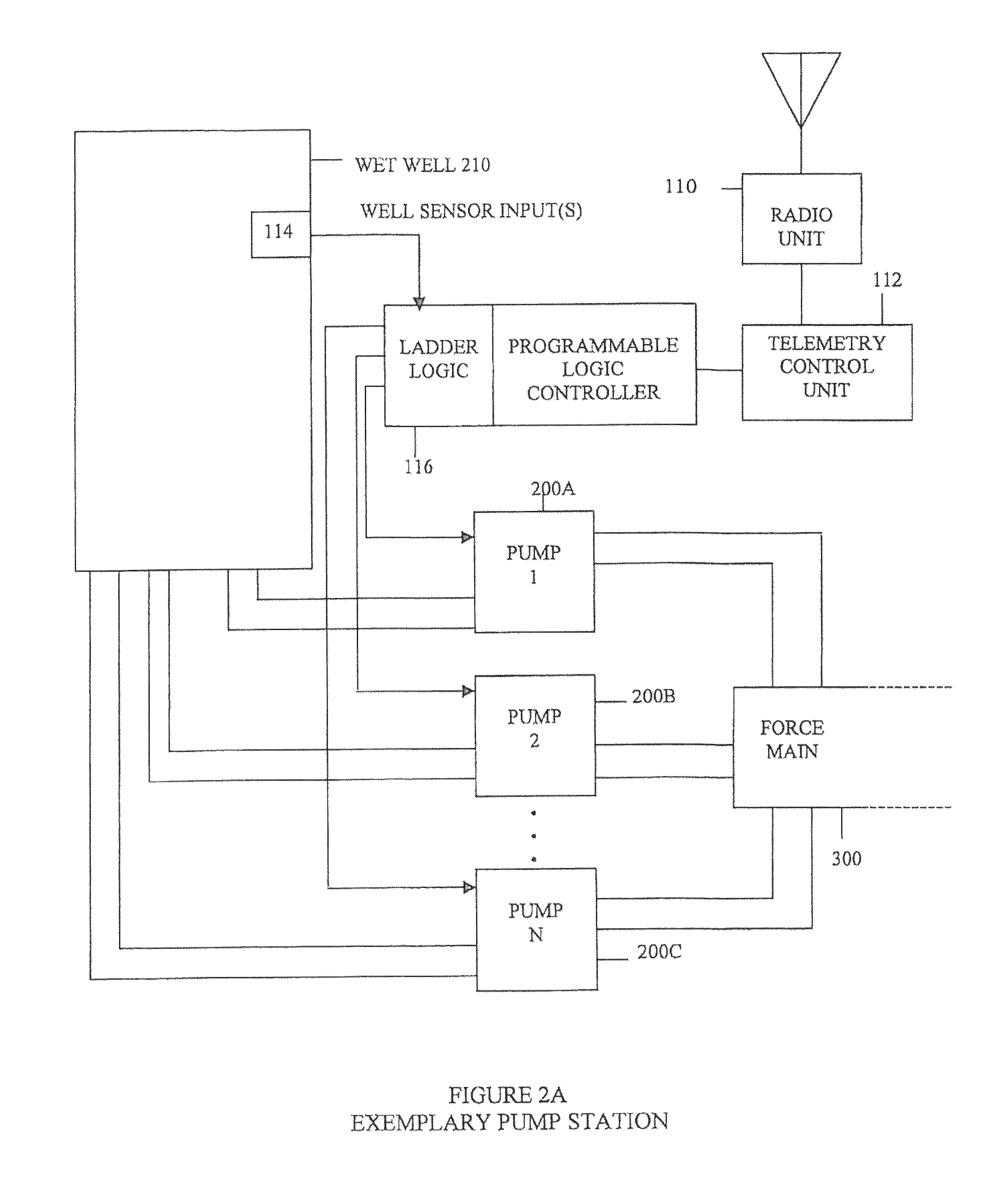

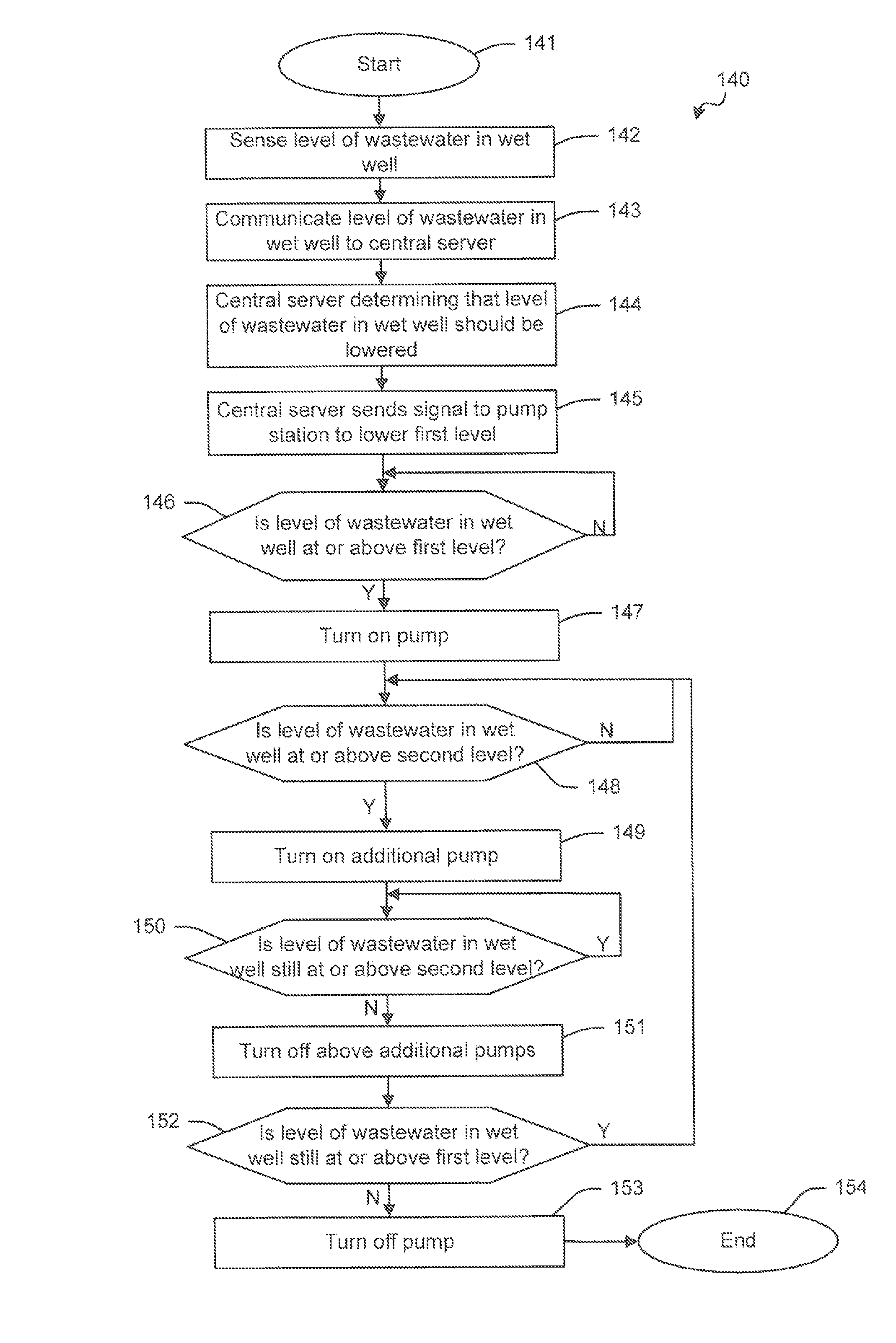

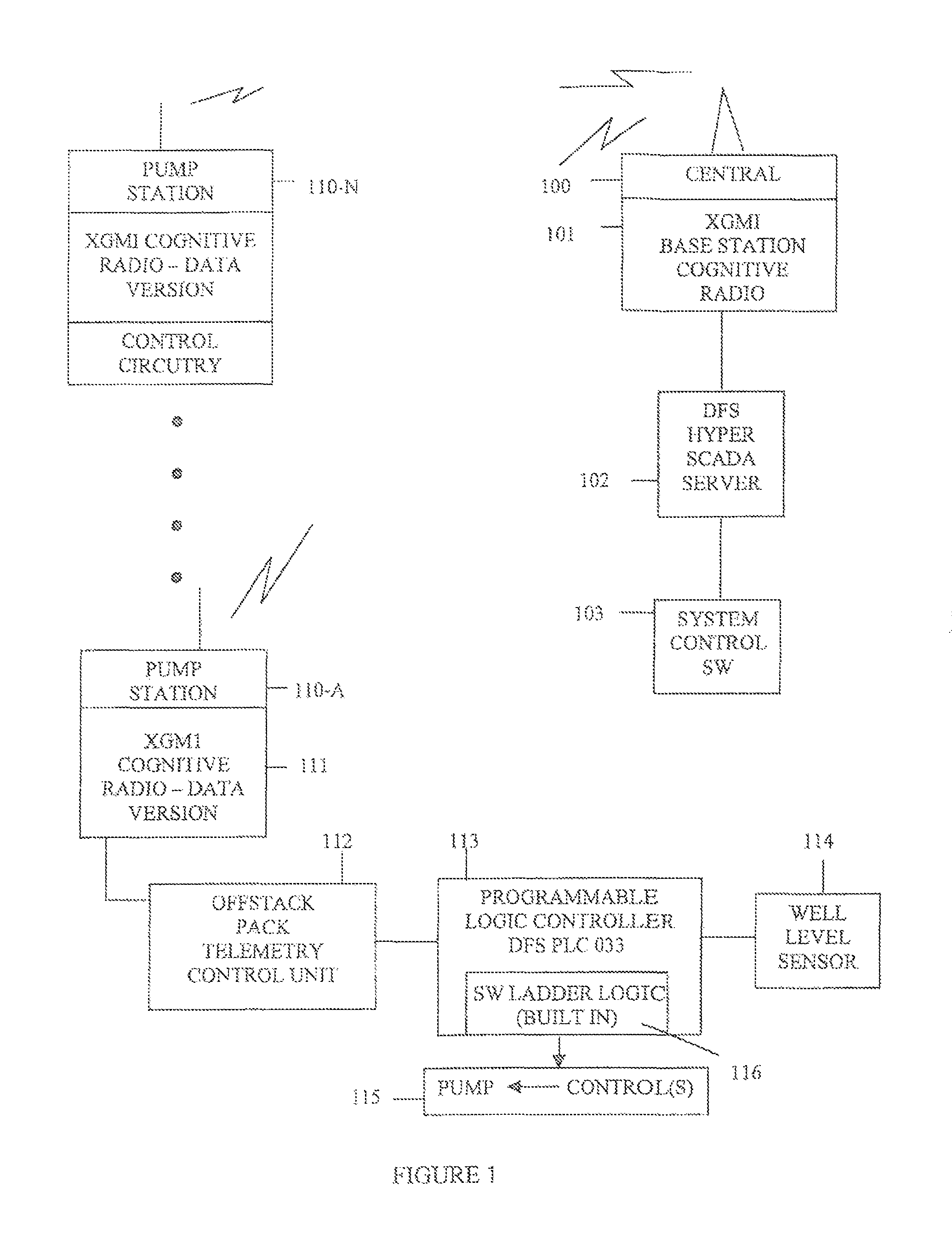

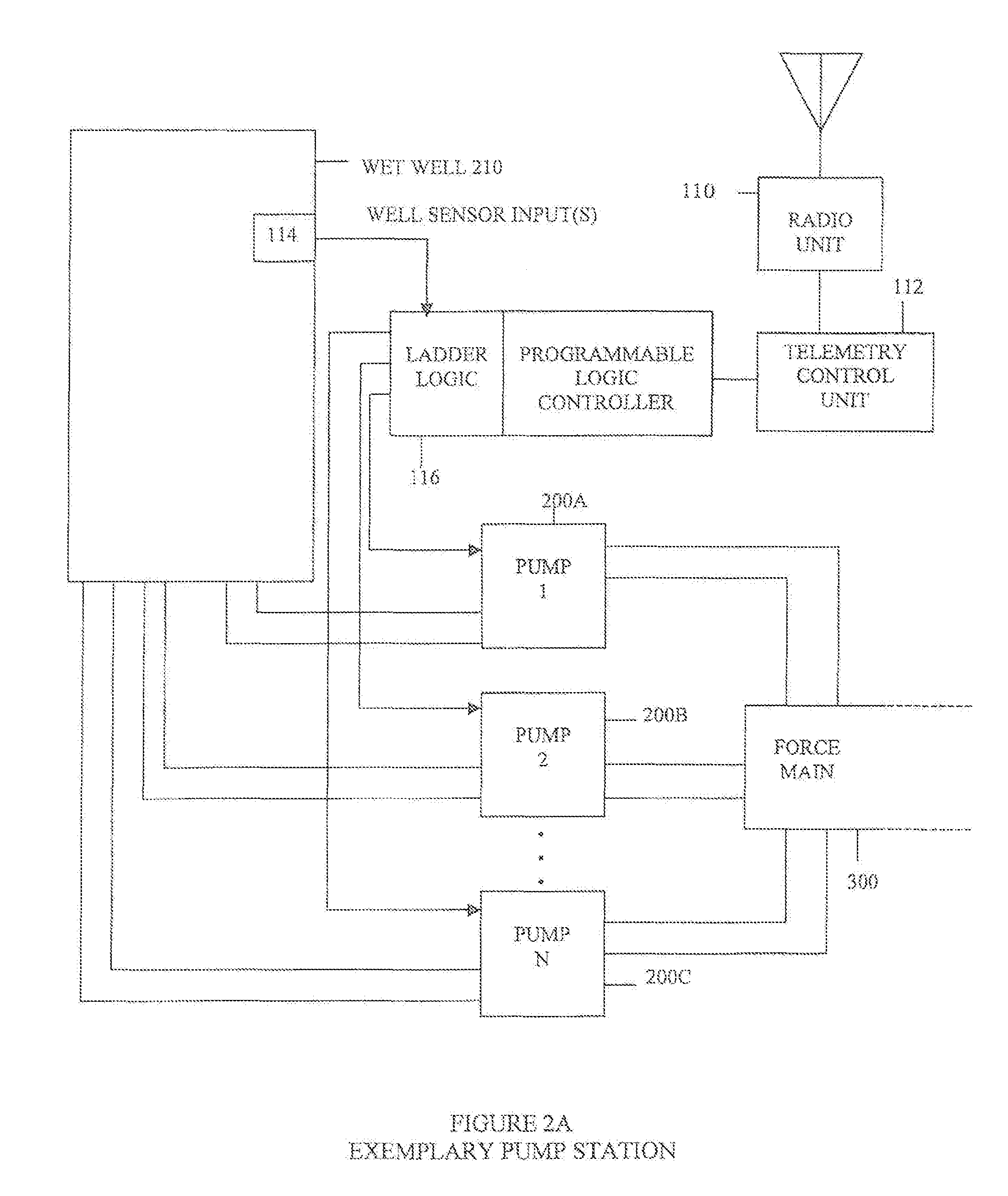

Fluid flow management system and associated methods

ActiveUS20120222994A1Efficient deliveryEasy to useTesting/calibration apparatusBiological treatment regulationFluid managementFlow management

A system is provided to control fluid flow in a wastewater treatment system. The wastewater treatment system may include a wastewater treatment plant and a main that connects a plurality of pump stations to the wastewater treatment plant. Each of the plurality of pump stations may include a wet well and a pump carried by the wet well to pump the wastewater. The system may include a central server and a sensor in communication with the central server to sense a level of wastewater within the wet well. The pump may be moved to an on position when the level of the wastewater in the wet well is at or above a first level. The level of wastewater within the wet well may be systematically manipulated responsive to the central server to control the fluid flow in the wastewater treatment system. The system advantageously enhances fluid management in a wastewater treatment system, increases life span of the wastewater treatment plant, and saves energy associated with running pumps at the pump stations of the wastewater treatment system.

Owner:DATA FLOW SYST

Apparatus for treating wastewater

ActiveUS20080210610A1Eliminate needImprove wastewater treatment efficiencyWater treatment parameter controlWater treatment compoundsOrganismal ProcessWastewater

The present invention relates to apparatus, methods, and applications for treating wastewater, and more particularly to biological processes for removing pollutants from wastewater. This invention further relates to apparatus and methods for growing microbes on-site at a wastewater treatment facility, and for economically inoculating sufficient microbes to solve various treatment problems rapidly

Owner:ADVANCED INNOVATORS INC

Fluid flow management through a wastewater level manipulation system and associated methods

ActiveUS8983667B2Efficient deliveryEasy to useBiological treatment regulationPressure pumpsWater levelFluid management

A system is provided to control fluid flow in a wastewater treatment system through wastewater level manipulation. The wastewater treatment system may include a wastewater treatment plant connected to a plurality of pump stations by a main. Each of the plurality of pump stations may include a wet well with a pump therein. The system may include a central server in communication with a sensor to sense a level of wastewater within the wet well. The pump may be automatically moved to an on position when the level of the wastewater in the wet well is at or above a first level and may be automatically moved to an off position when the level of the wastewater in the respective wet well is at or below a pump cutoff level. The central server may systematically manipulate the first level to selectively set the level of wastewater within the wet well.

Owner:DATA FLOW SYST

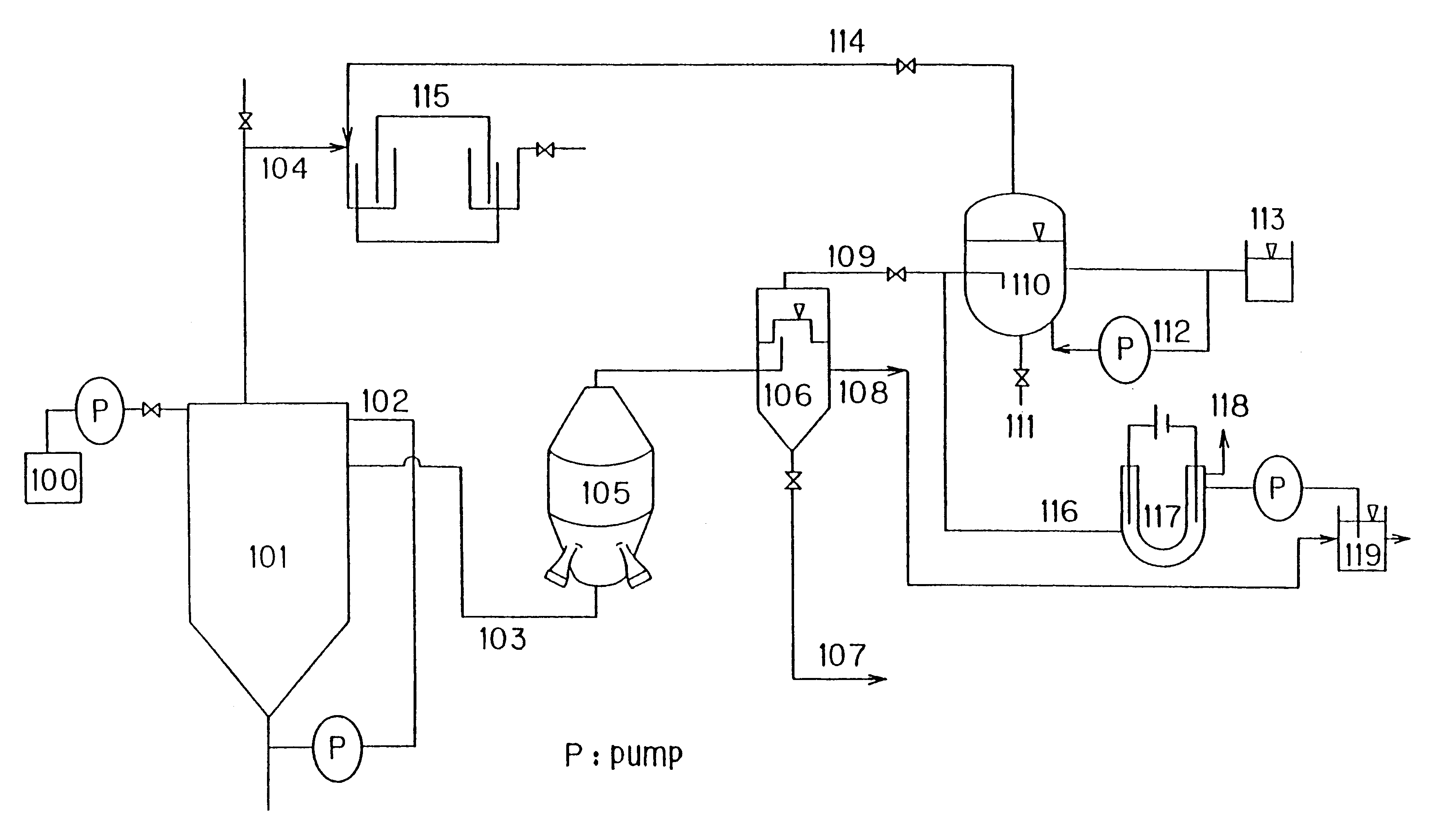

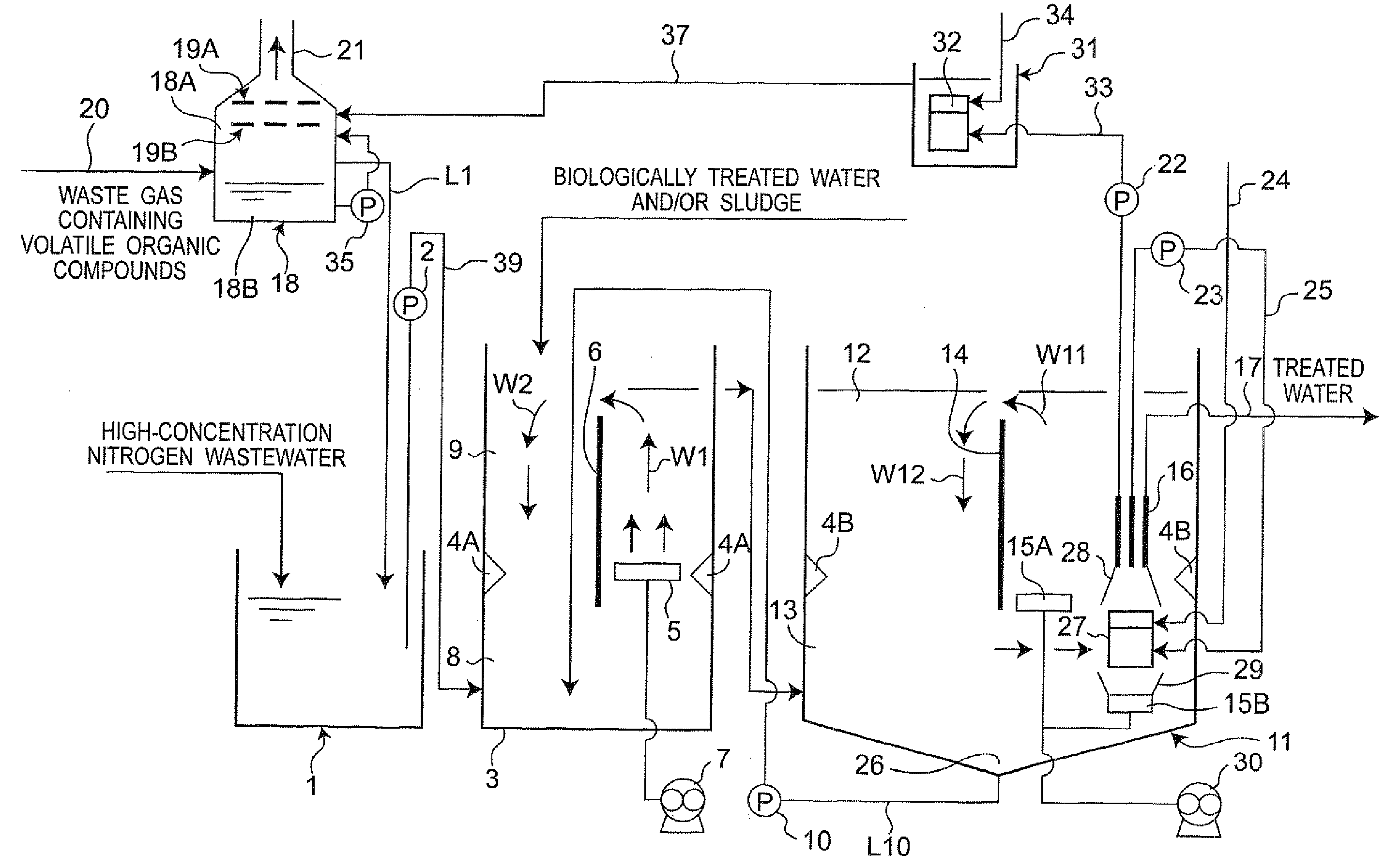

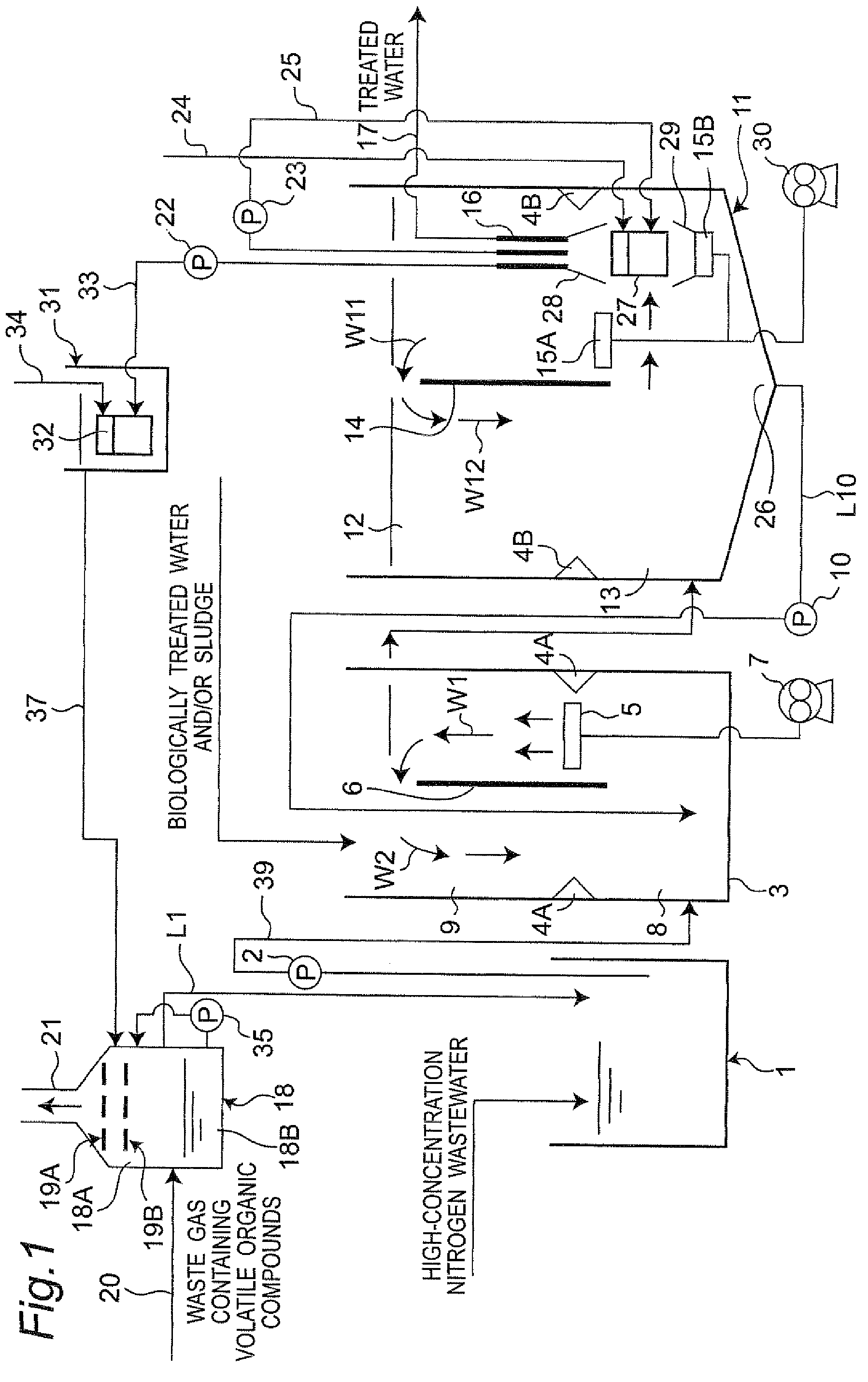

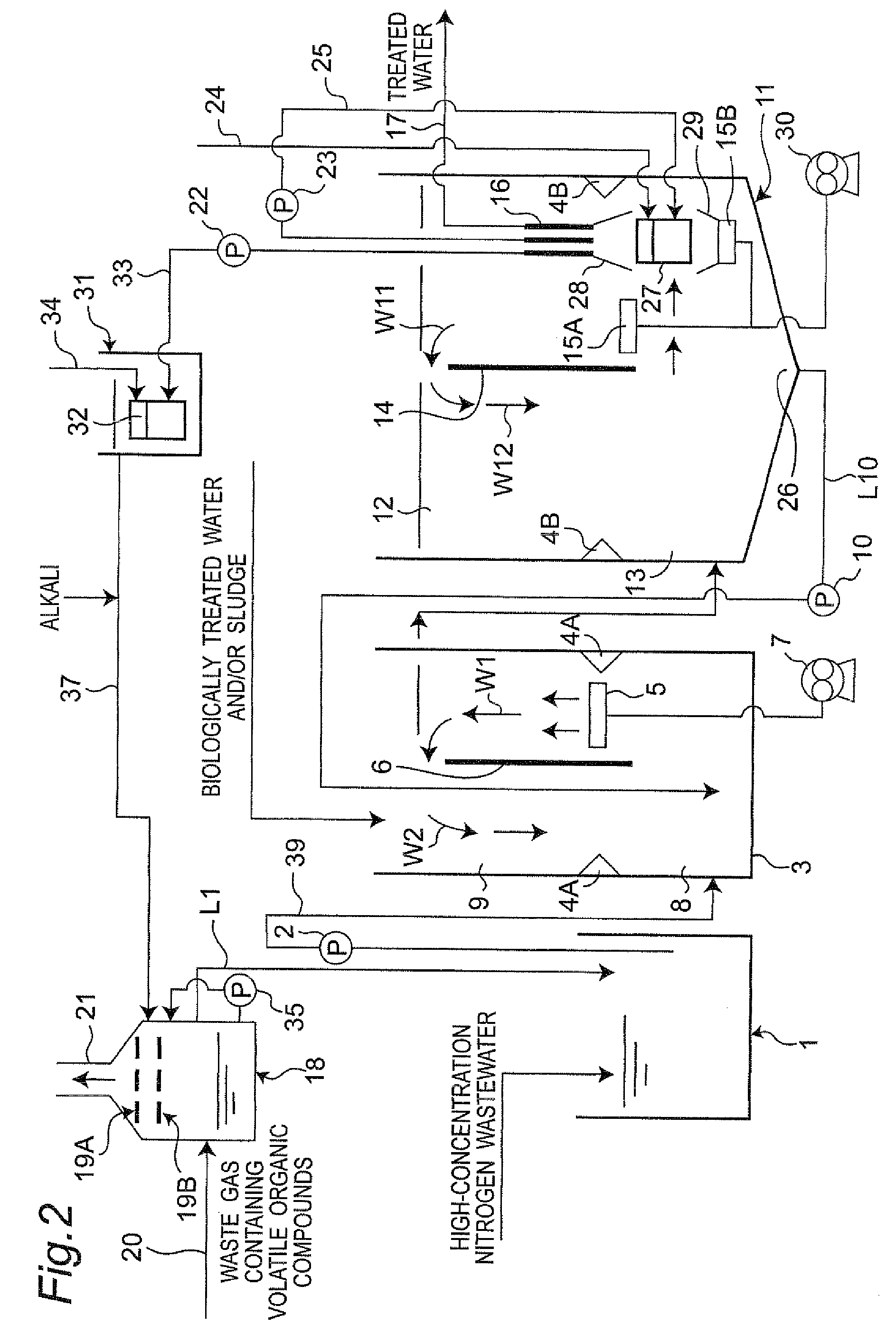

Waste gas/wastewater treatment equipment and method of treating waste gas/wastewater

InactiveUS7691268B2Easy to cleanImprove efficiencyOrganic chemistryTreatment using aerobic processesExhaust fumesHigh velocity

Waste gas / wastewater treatment equipment treats waste gas in a scrubber 18 by using micronanobubble water produced in a micronanobubble reaction vessel 31 as washing water. Waste gas is efficiently cleaned by the substance surface high-velocity cleaning function which micronanobubbles have. The washing water having been used in the waste gas treatment is reused in wastewater treatment in adjustment tank 1, denitrification tank 3 and nitrification tank 11 which constitute a wastewater treatment section. Thus, the micronanobubbles contained in the washing water are utilized in wastewater treatment, so that efficiency of wastewater treatment is enhanced.

Owner:SHARP KK

Fluid flow management system and associated methods

ActiveUS8600568B2Efficient deliveryEasy to useTesting/calibration apparatusLevel controlFluid managementFlow management

A system is provided to control fluid flow in a wastewater treatment system. The wastewater treatment system may include a wastewater treatment plant and a main that connects a plurality of pump stations to the wastewater treatment plant. Each of the plurality of pump stations may include a wet well and a pump carried by the wet well to pump the wastewater. The system may include a central server and a sensor in communication with the central server to sense a level of wastewater within the wet well. The pump may be moved to an on position when the level of the wastewater in the wet well is at or above a first level. The level of wastewater within the wet well may be systematically manipulated responsive to the central server to control the fluid flow in the wastewater treatment system. The system advantageously enhances fluid management in a wastewater treatment system, increases life span of the wastewater treatment plant, and saves energy associated with running pumps at the pump stations of the wastewater treatment system.

Owner:DATA FLOW SYST

Methods and kits for bioremediation of contaminated soil

InactiveUS20080210630A1Eliminate needImprove wastewater treatment efficiencyWater treatment parameter controlTreatment using aerobic processesOrganismal ProcessWastewater

The present invention relates to apparatus, methods, and applications for treating wastewater, and more particularly to biological processes for removing pollutants from wastewater. This invention further relates to apparatus and methods for growing microbes on-site at a wastewater treatment facility, and for economically inoculating sufficient microbes to solve various treatment problems rapidly

Owner:ADVANCED BIOLOGICAL SERVICES INC

Methods of treatment of ground water

InactiveUS20080277338A1Eliminate needImprove wastewater treatment efficiencyWater treatment parameter controlTreatment using aerobic processesOrganismal ProcessBiology

The present invention relates to apparatus, methods, and applications for treating wastewater, and more particularly to biological processes for removing pollutants from wastewater. This invention further relates to apparatus and methods for growing microbes on-site at a wastewater treatment facility, and for economically inoculating sufficient microbes to solve various treatment problems rapidly

Owner:ADVANCED INNOVATORS INC

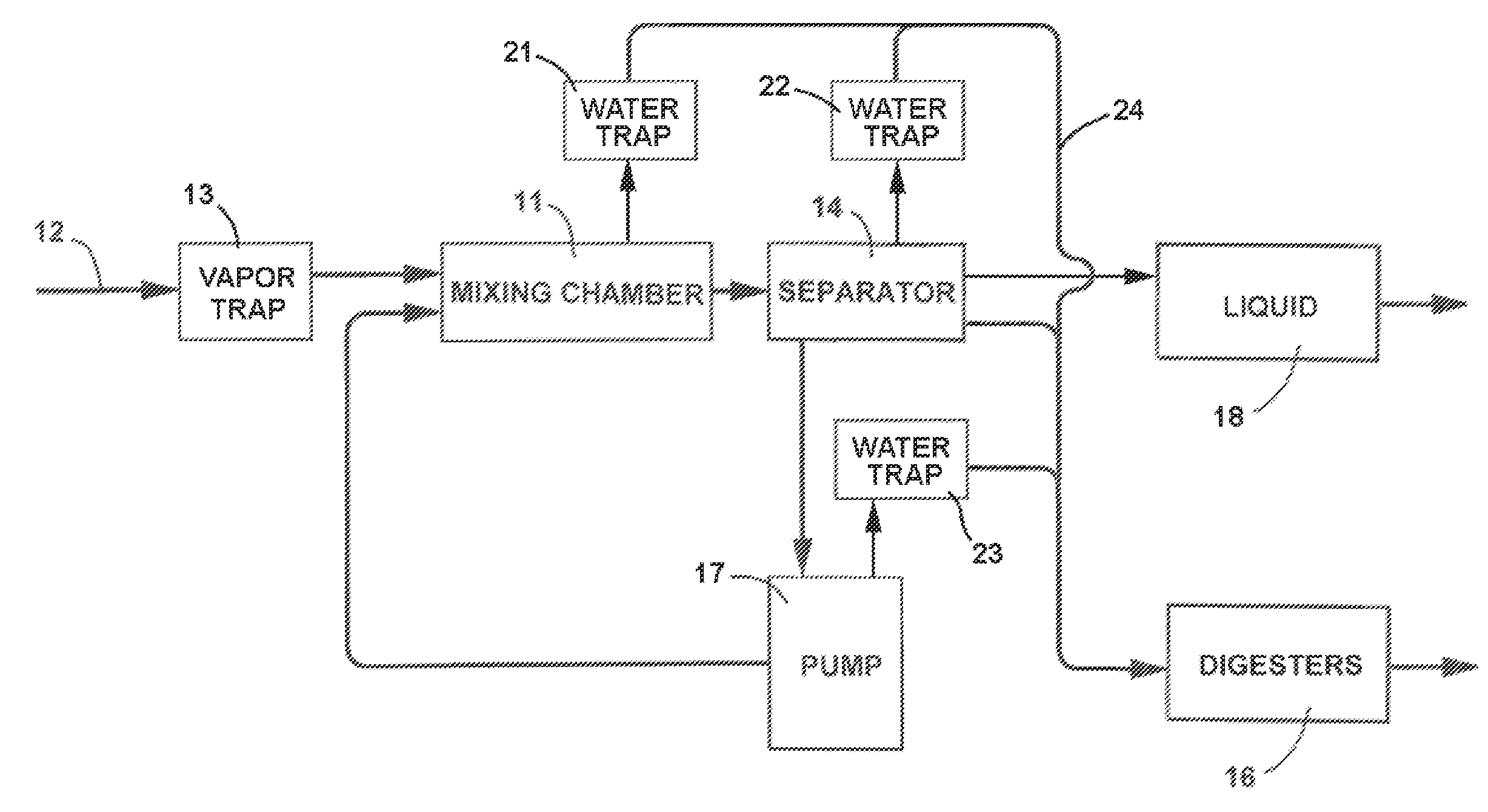

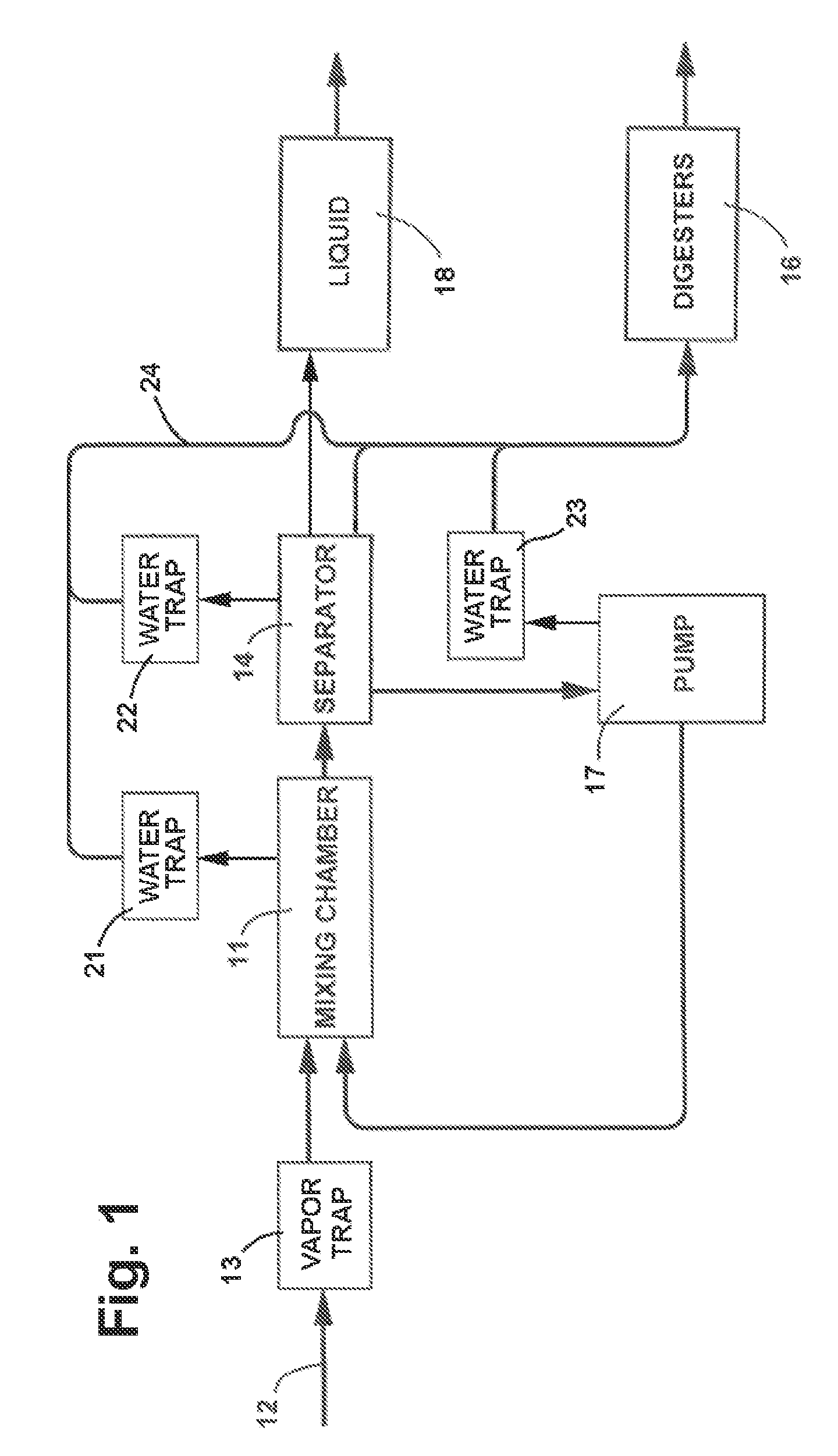

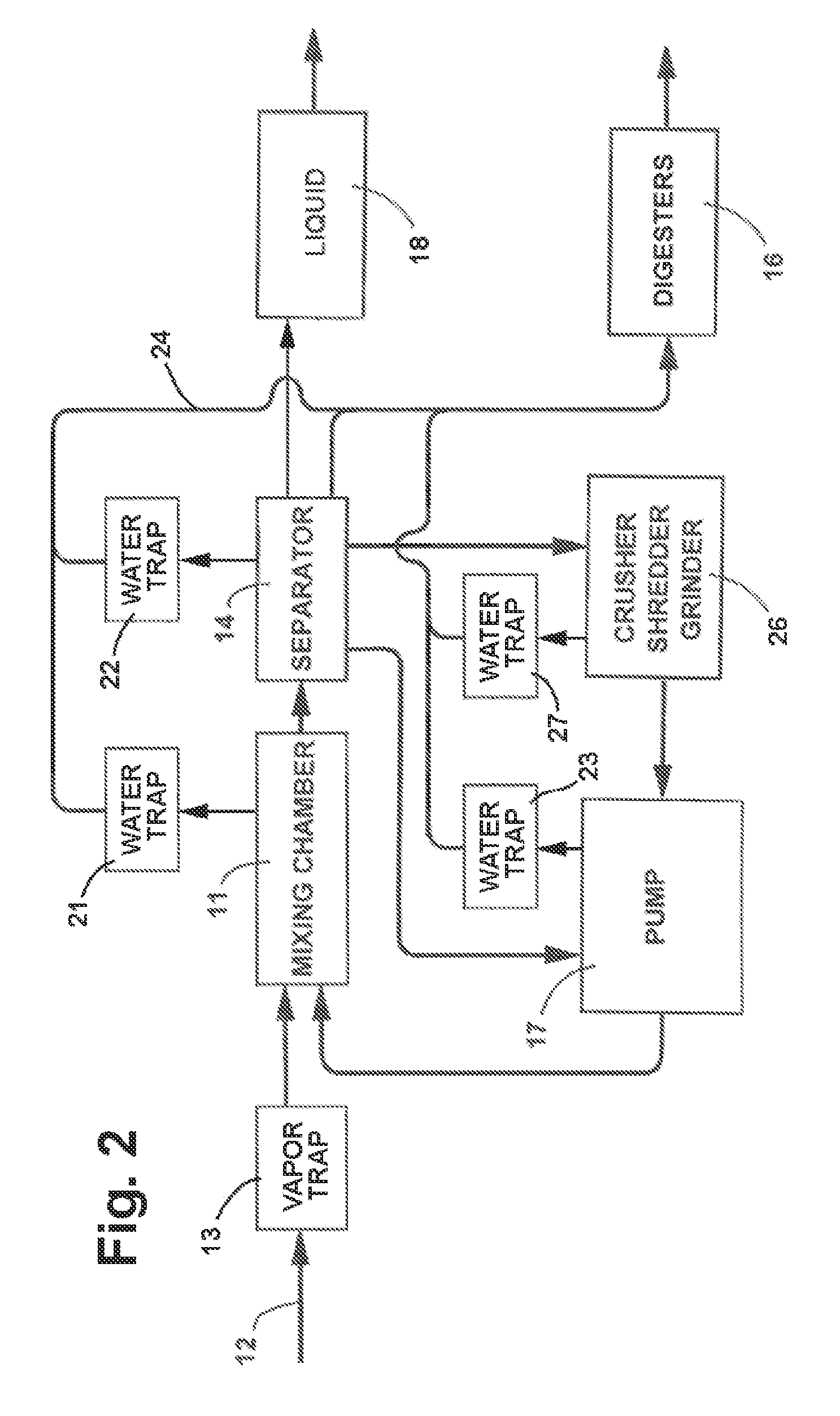

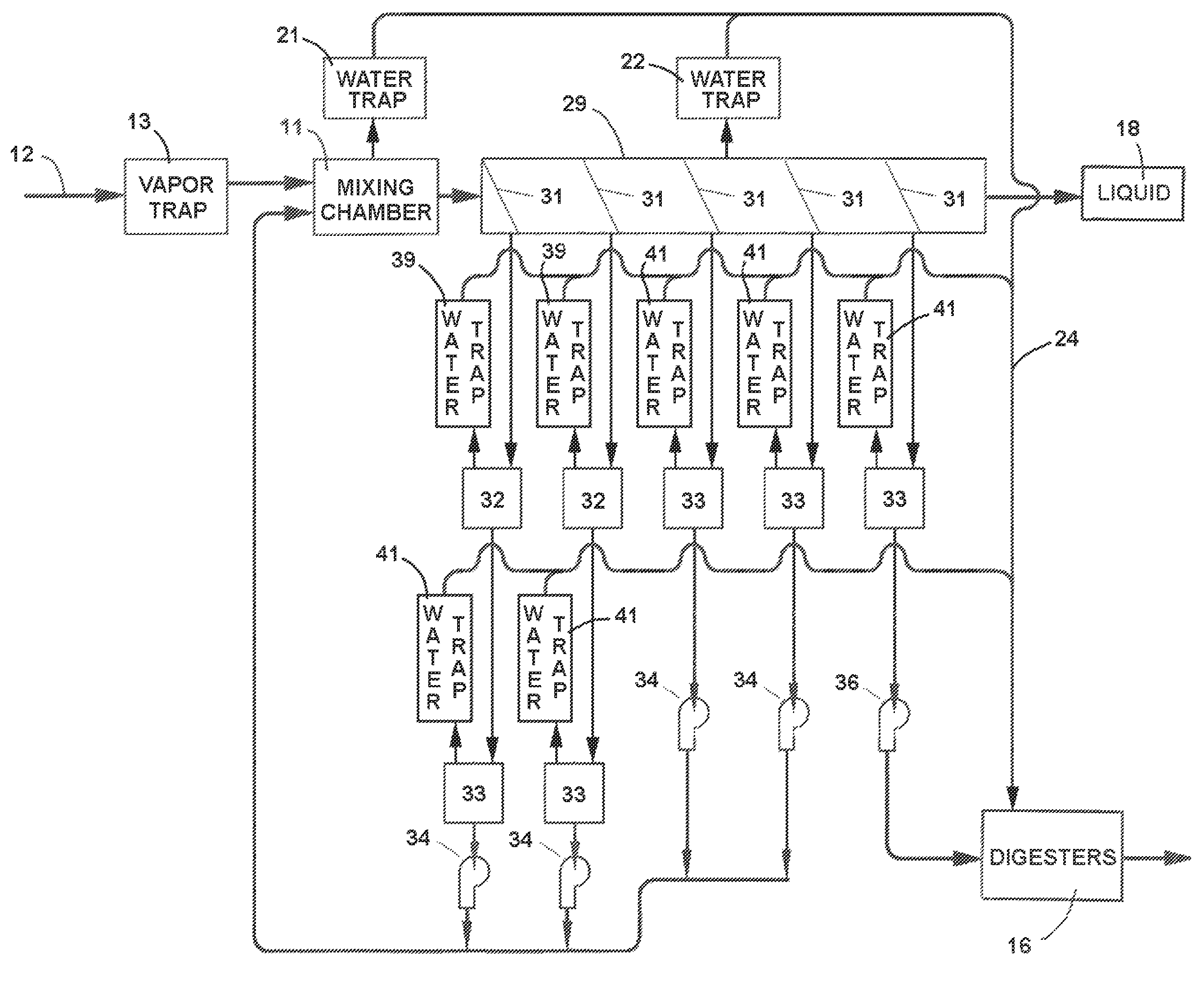

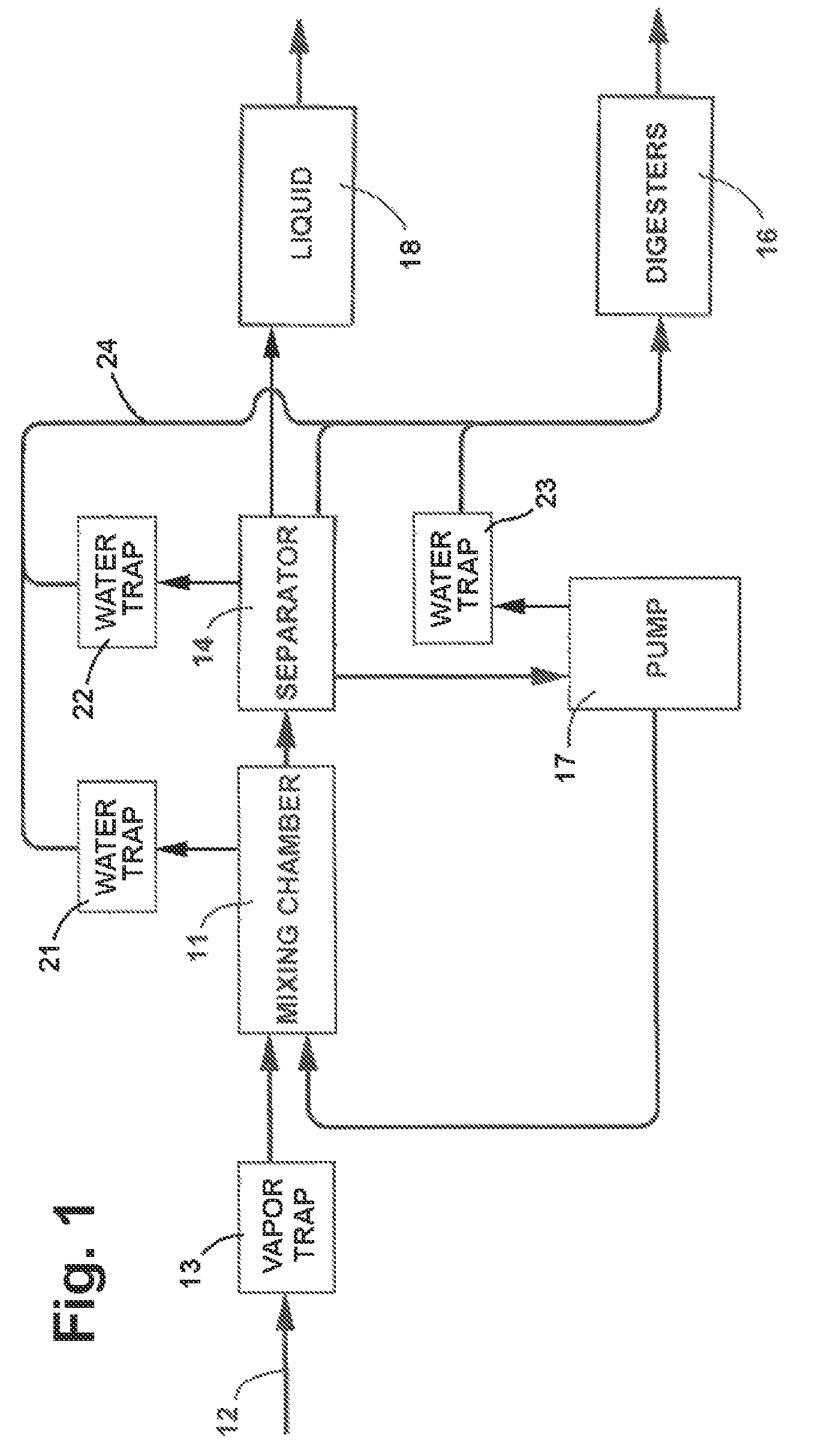

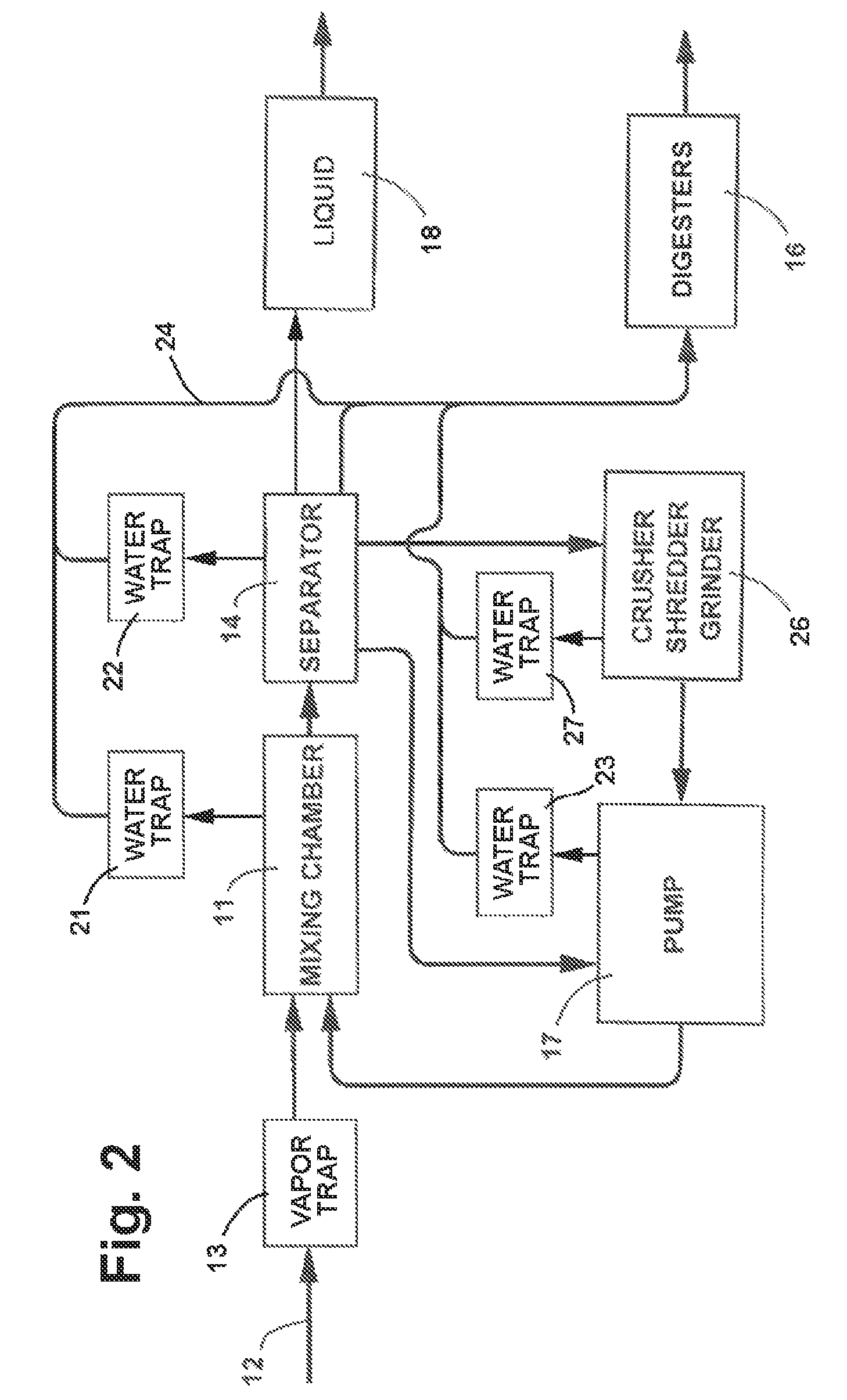

Anaerobic Wastewater Treatment System and Process Utilizing Solids Based Bacterial Colonization (SBBC)

InactiveUS20100213121A1Improve wastewater treatment efficiencyEnhancing growth and colonizing activitySpecific water treatment objectivesLavatory sanitorySolid baseBacterial colonization

Anaerobic Wastewater treatment system and process in which the influent is passed through a mixing chamber and then through a series of filters of progressively smaller size to separate the materials carrying the colonized bacteria from finer solids in the influent and separate the materials according to size in a completely enclosed and flooded environment. The materials from the filters are progressively reduced to a smaller size, the materials of smaller size are returned to the mixing chamber, and new influent is inoculated with the colonized bacteria carried by the materials returned to the mixing chamber.

Owner:MILLER III HERMAN P

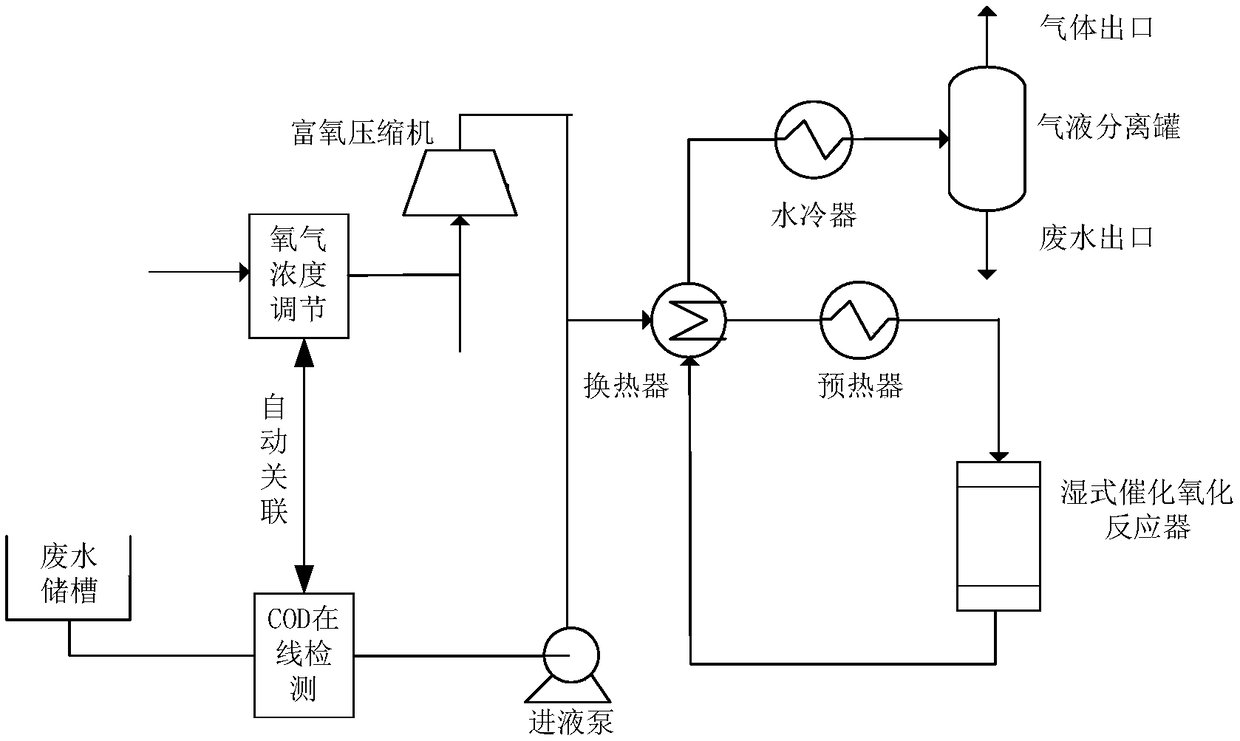

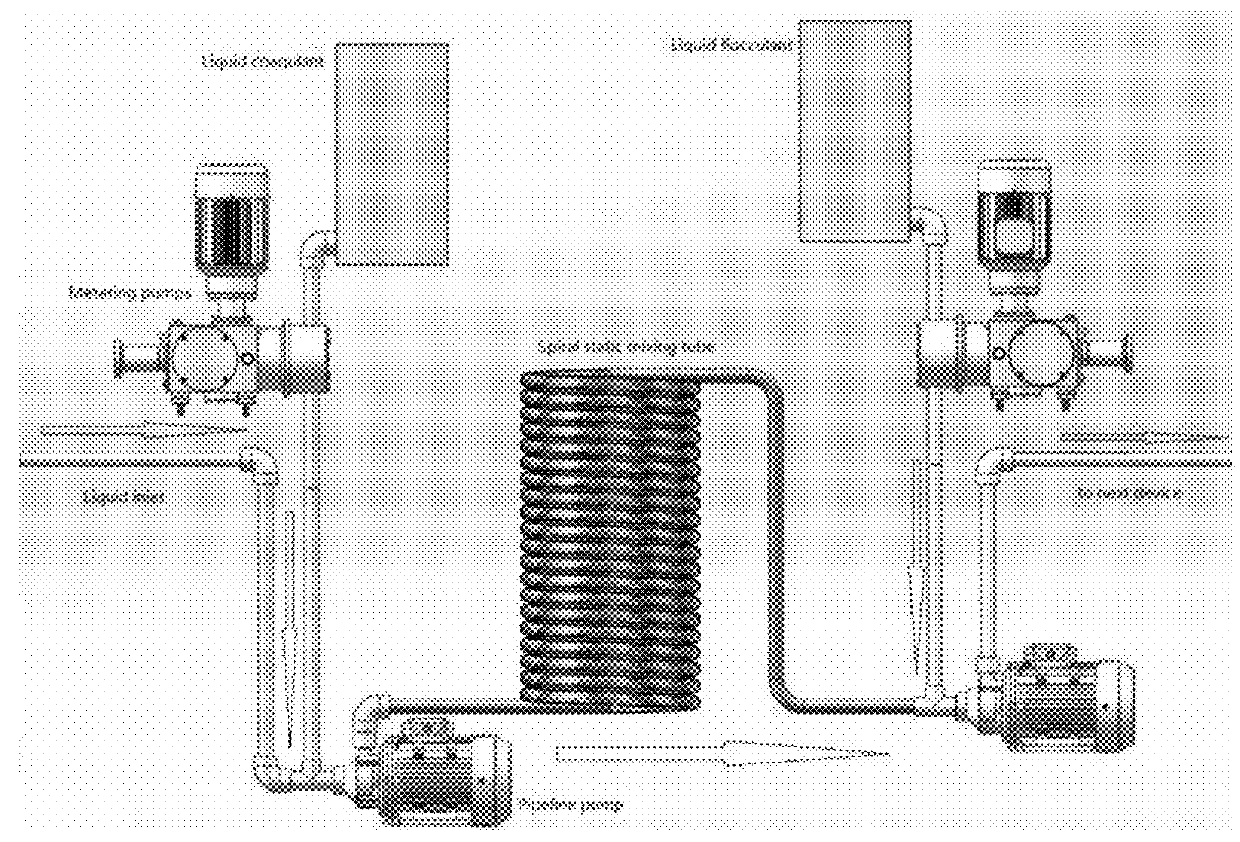

Technology of treating high-concentration organic wastewater with wet type catalytic oxidation

InactiveCN109455808AImprove wastewater treatment efficiencyReduce process energy consumptionWater/sewage treatment by oxidationChemistryCarbon dioxide

The invention discloses a technology of treating high-concentration organic wastewater with wet type catalytic oxidation. The technology comprises the following steps that the technology adopts COD concentration online detection and is automatically correlated to an oxygen concentration regulation device, organic wastewater with the COD content being 10000-50000 mg / L and the liquid space velocityof the wastewater being 0.5-2.5 h<-1> is mixed with enriched oxygen, the device automatically regulates the oxygen volume concentration to be 25-99 percent, water which is sent into a wastewater reactor charged with a catalyst for treatment is directly discharged or sent to a next treatment work section, and tail gas containing nitrogen, oxygen, carbon dioxide and water vapor is directly exhaustedto atmosphere, wherein the space velocity of the enriched oxygen is 34-39 times the liquid space velocity of the wastewater, and the oxygen supply quantity is 1.1-1.2 times the theoretical oxygen demand. The technology disclosed by the invention has the advantages that high-concentration COD in acid or alkaline organic wastewater can be effectively removed.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

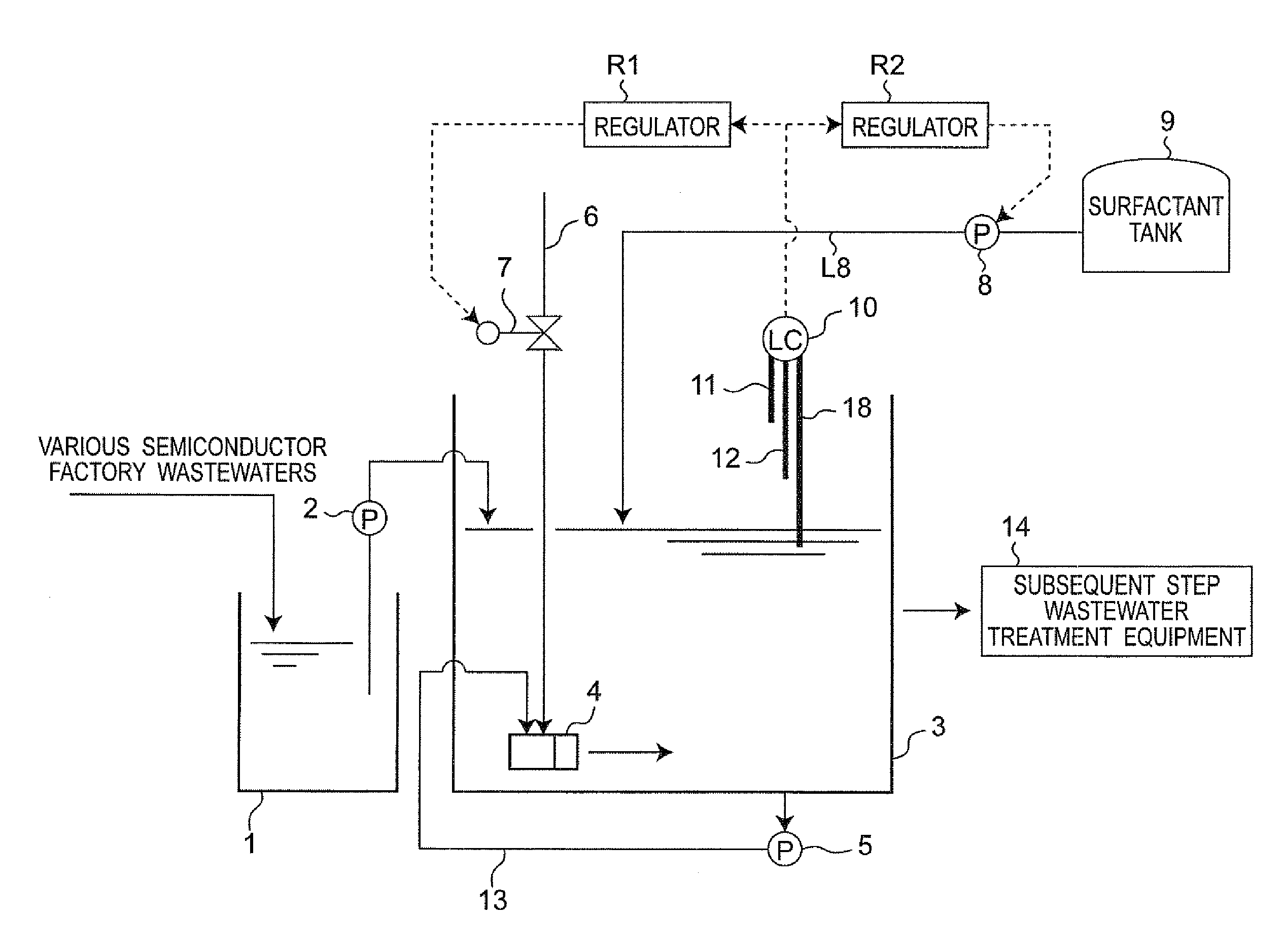

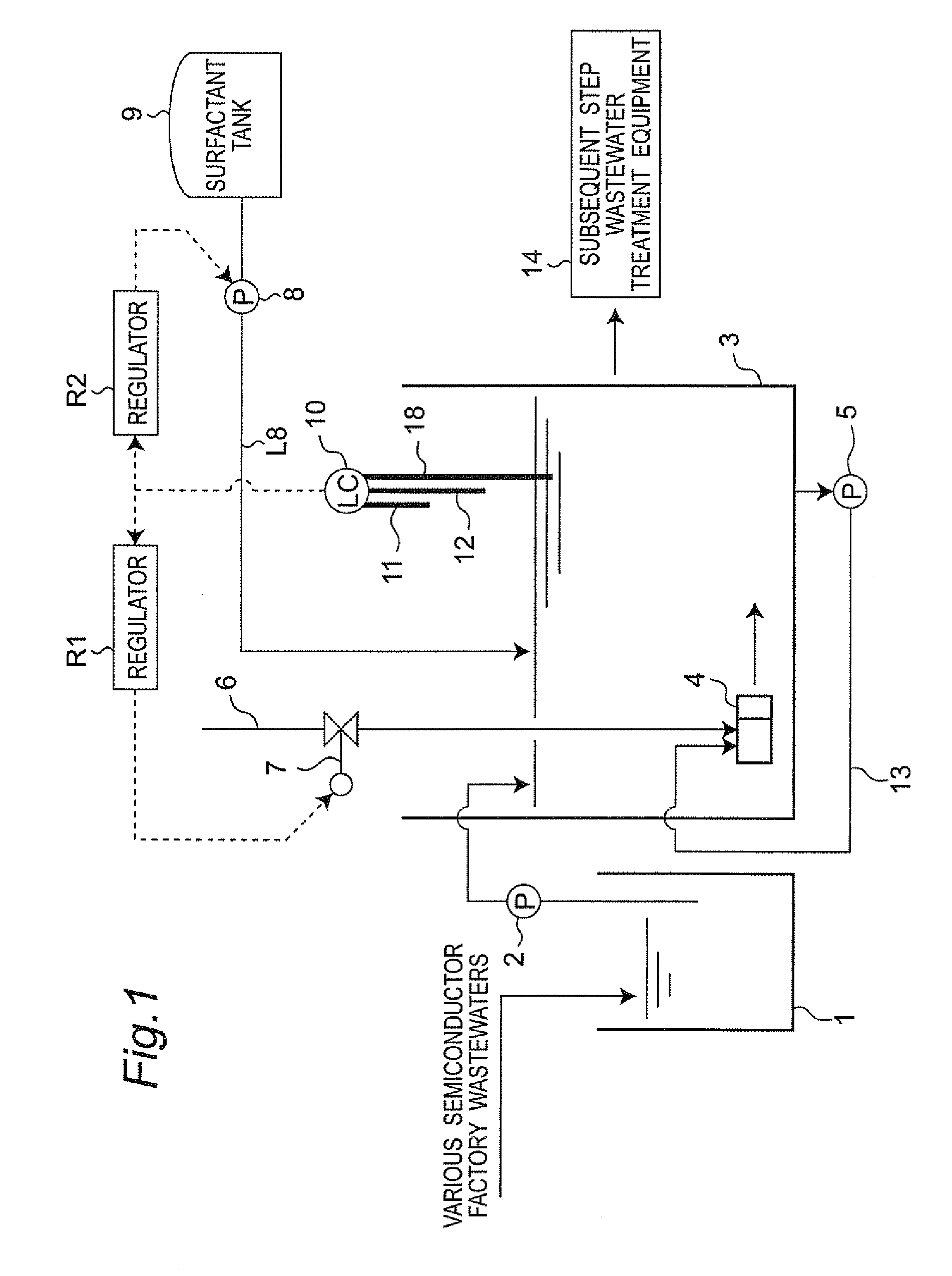

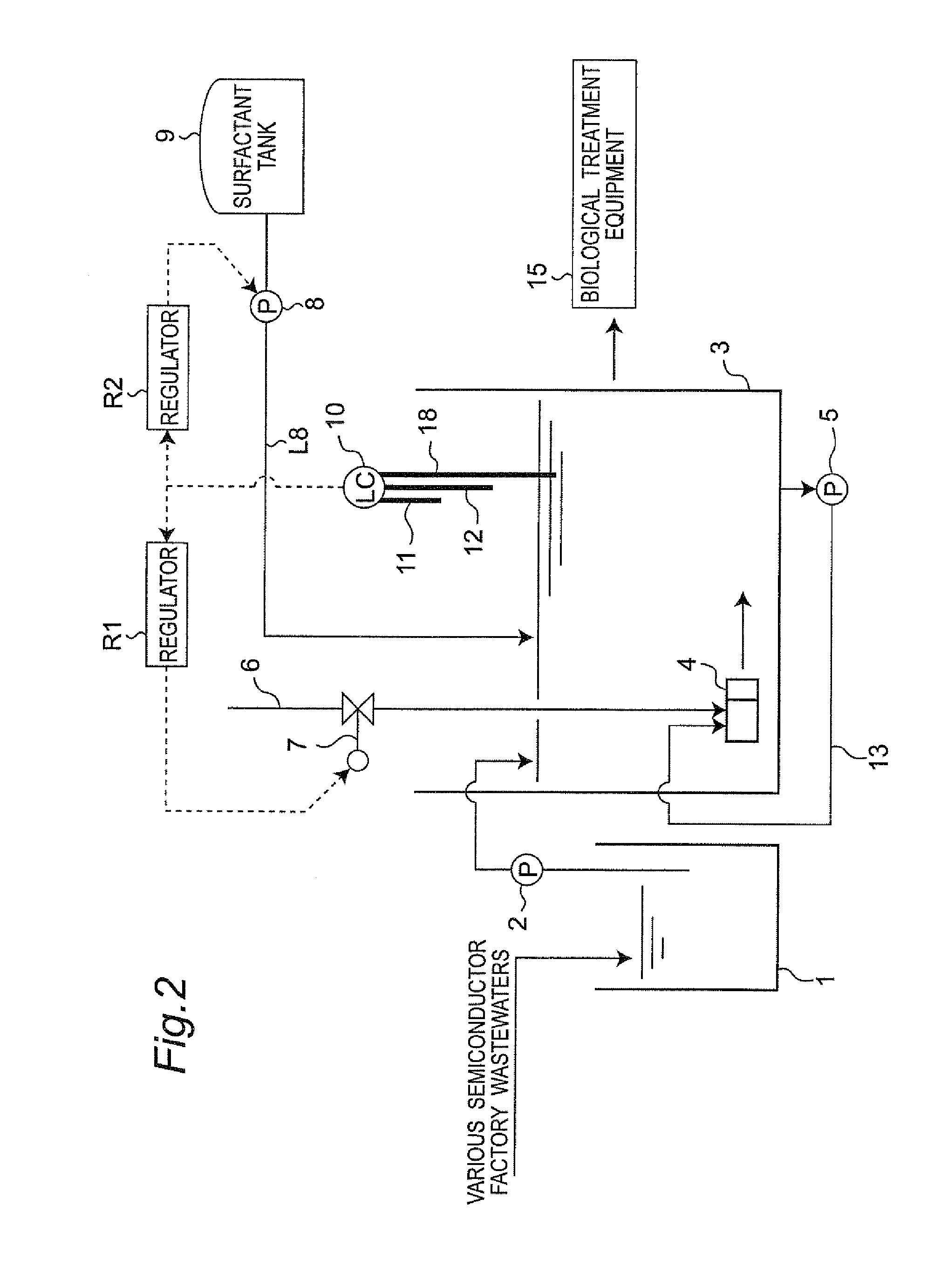

Wastewater treatment equipment and method of wastewater treatment

InactiveUS7578942B2Stable and efficient productionEfficient preprocessingMixing methodsTransportation and packagingTreatments waterSURFACTANT BLEND

In wastewater treatment equipment, a surfactant is added to a micronanobubble reaction vessel 3 by using a surfactant pump 8 and a surfactant tank 9 which constitute a surfactant adding section. Thereby, a micronanobubble generator 4 stably and efficiently produces micronanobubbles in the treatment water as raw water containing the surfactant in the micronanobubble reaction vessel 3. Thus, the micronanobubbles make it possible to efficiently pretreat the wastewater introduced into the micronanobubble reaction vessel. Consequently, it becomes possible not only to enhance efficiency of wastewater treatment but also to reduce a treatment load on wastewater treatment equipment 14 in a step subsequent to the pretreatment. Thereby, scale of the wastewater treatment equipment 14 is reduced.

Owner:SHARP KK

Waste water treatment device

InactiveUS20160332899A1Improve efficiencyExtension of timeTreatment involving filtrationWater/sewage treatment by ion-exchangeIon exchangeTreatment system

There is described an embodiment of a wastewater treatment system comprising a plurality of agitating devices and dosing devices. The agitating devices connect with a tank though a water pipe. The agitation devices are connected through connecting pipes. The treated wastewater is discharged by a blow-off pipe. The dosing devices are installed on the water pipe and the connecting pipes. The dosing devices doses at least one of: a flocculants, a coagulant, a pH adjuster and combination thereof. This embodiment of a wastewater treatment system allows for ion exchange between wastewater and flocculants by using high-speed rotating blades of a pump. Treatment of wastewater is performed with small-sized equipment with high efficiency.

Owner:WATER MAX NANJING ENVIRONMENT TECH CO LTD

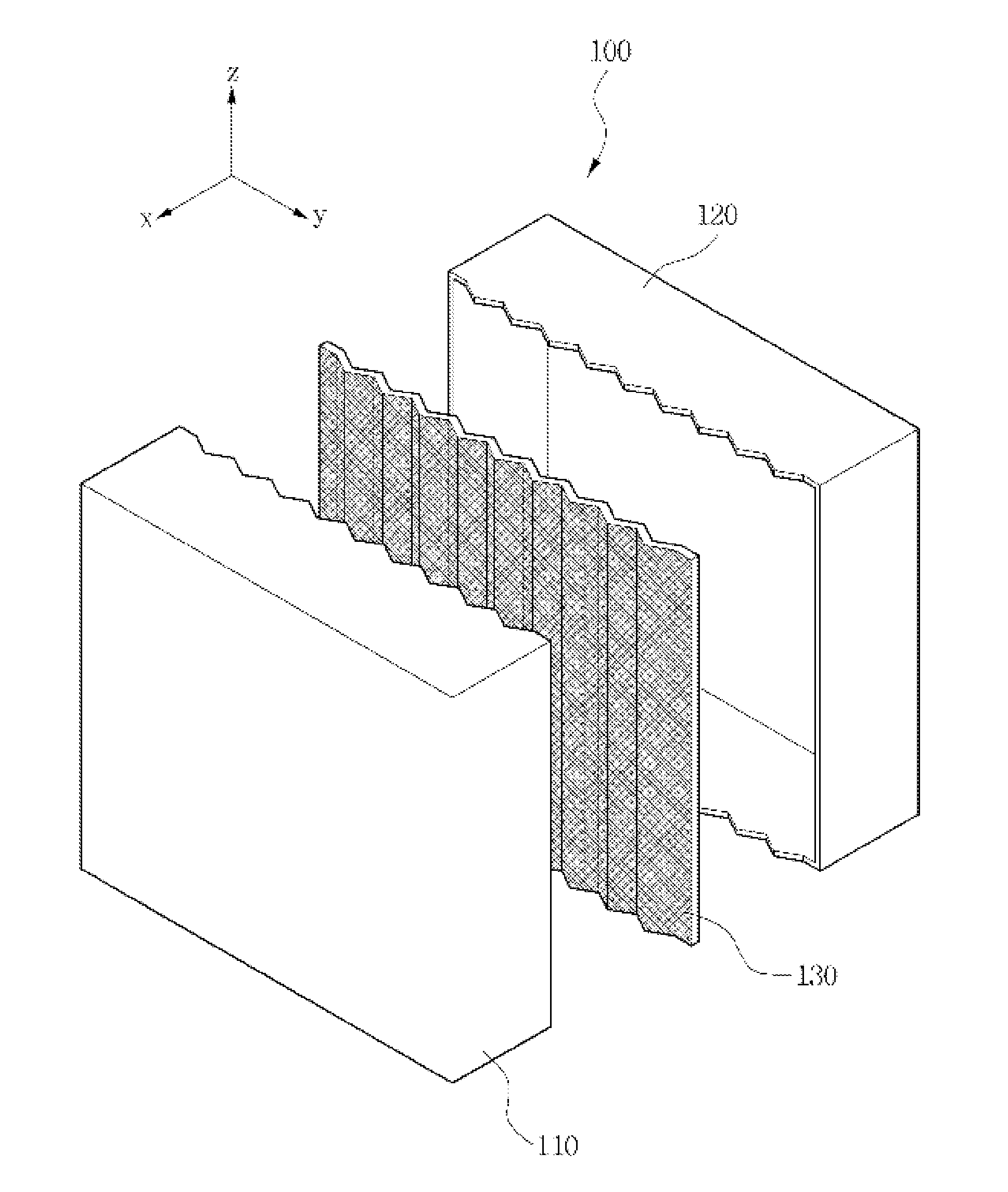

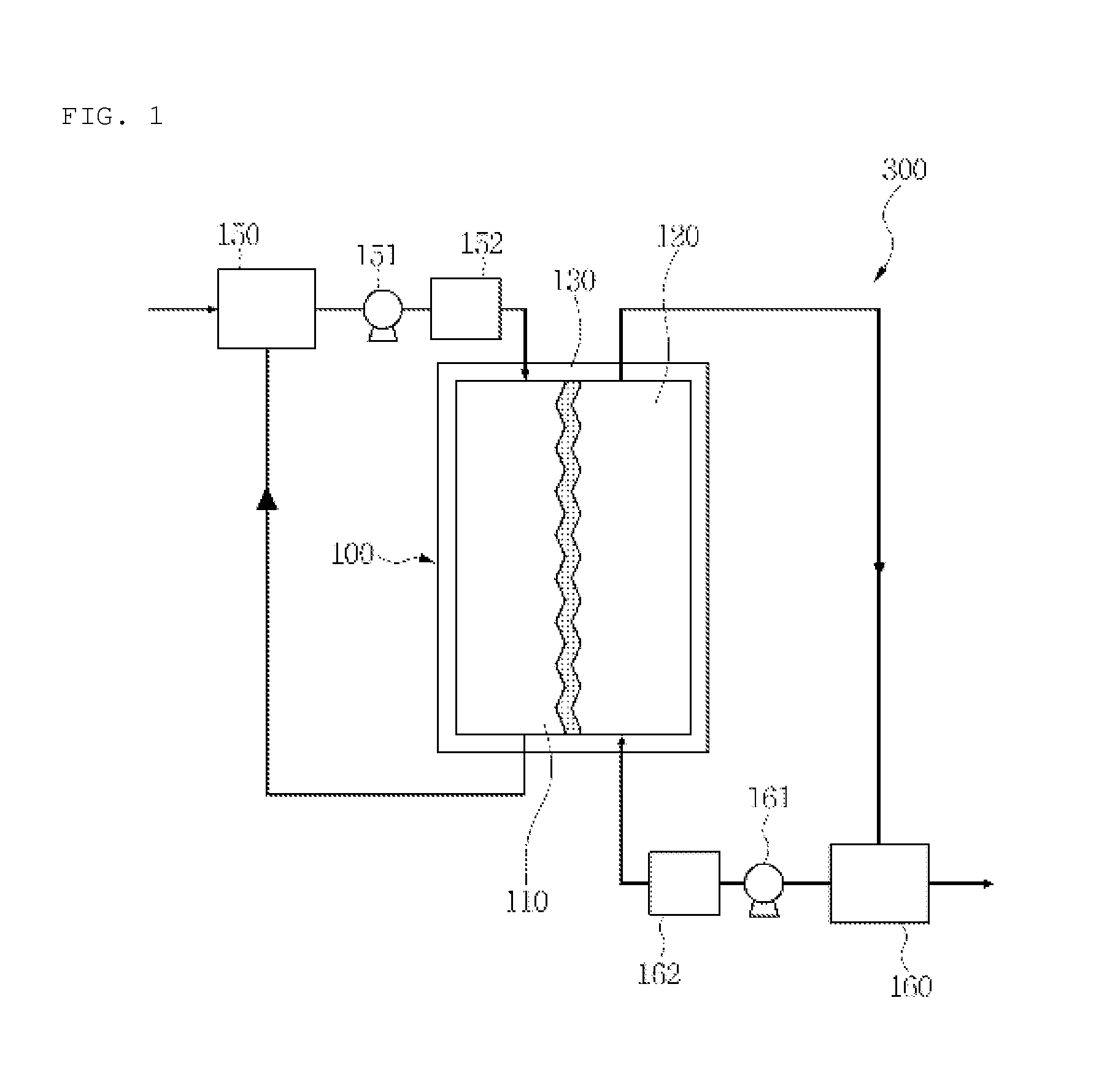

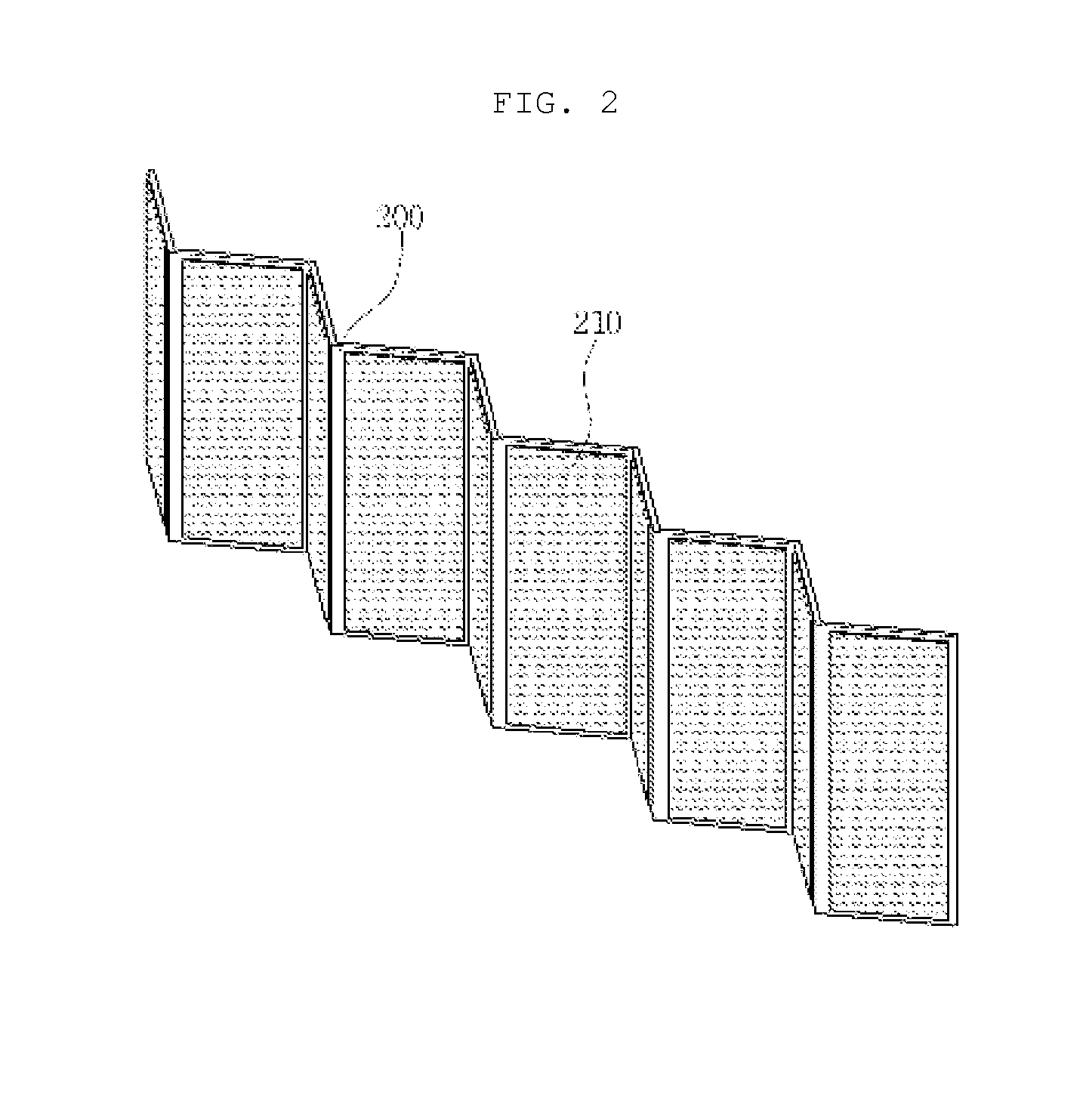

Wastewater treatment module using membrane distillation and wastewater treatment apparatus including the same

InactiveUS20150218018A1Improve wastewater treatment efficiencyImprove efficiencyMembranesSemi-permeable membranesMembrane distillationTreated water

An aspect of the invention relates a wastewater treatment module using a membrane distillation. The wastewater treatment module includes: an inflow-water side including a space for receiving feed water; a treated-water side including a space for receiving treated water, wherein the treated-water side coupled to the inflow-water side; and a separation membrane interposed between the inflow-water side and the treated-water side. The separation membrane has a bent shape.

Owner:KOREA INST OF SCI & TECH

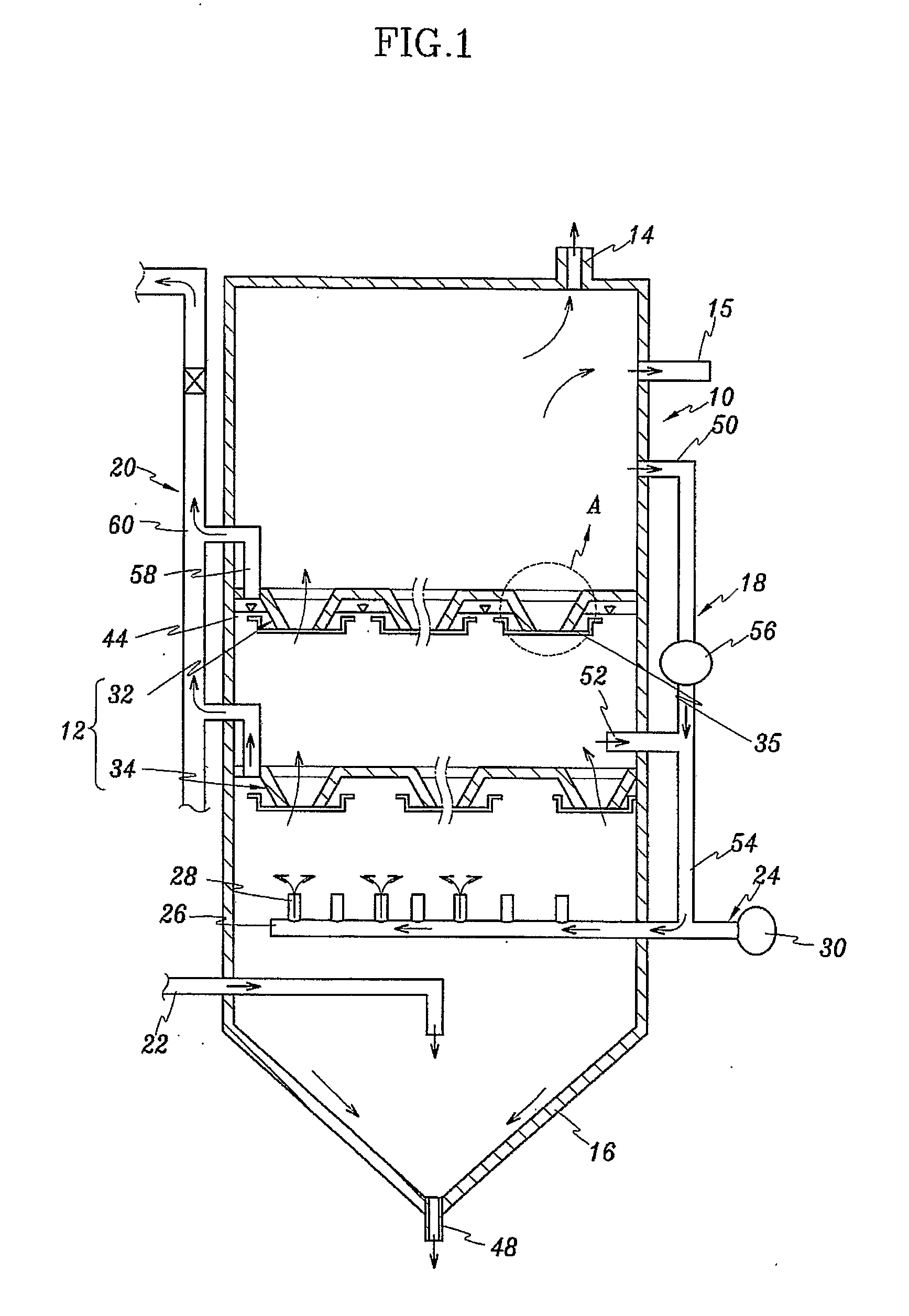

Fluids Fluxion Method and Plant for Wastewater Treatment

InactiveUS20080264840A1Improve wastewater treatment efficiencyPractical and economical and functional and easy in manufactureTreatment using aerobic processesGeneral water supply conservationDraining tubeSludge

A wastewater treatment plant includes a reaction tank connected to an wastewater supply tube and an aeration apparatus to receive wastewater therein, a sludge separation unit dividing an internal space of the reaction tank into upper and lower sections to increase an amount of dissolved oxygen by increasing an contact area of the wastewater and bubbles and to separate relatively light materials by moving low density matters existed on a surface of each section upward in turn, an air exhaust tube mounted on the reaction tank to exhaust bubbles passing through the sludge separation unit out of the reaction tank, a treated water exhaust tube mounted on the reaction tank to exhaust the wastewater that is treated by passing through the sludge separation unit, and a settling tank provided on a bottom of the reaction tank to concentrate and exhaust the settled sludge.

Owner:ECODAYS

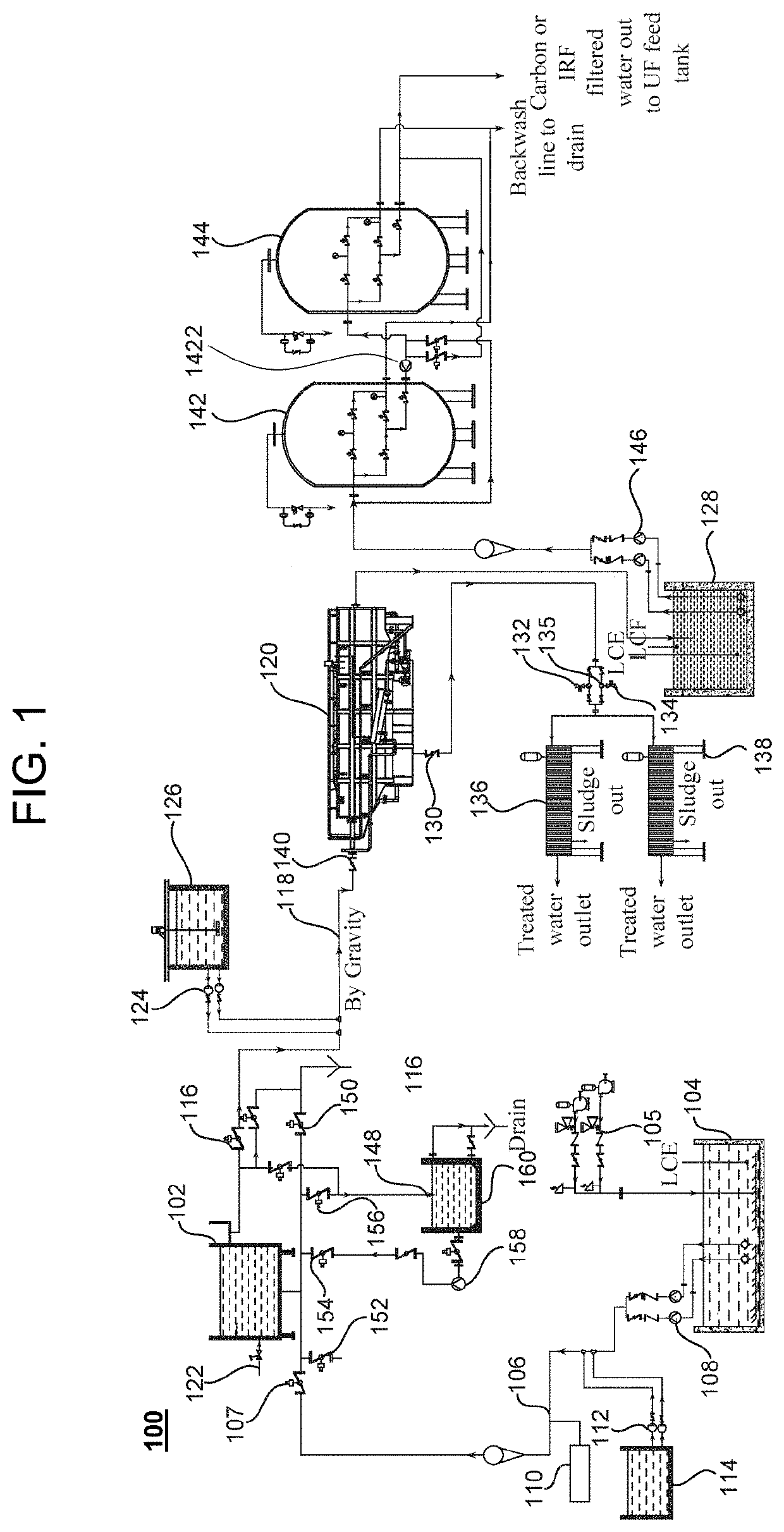

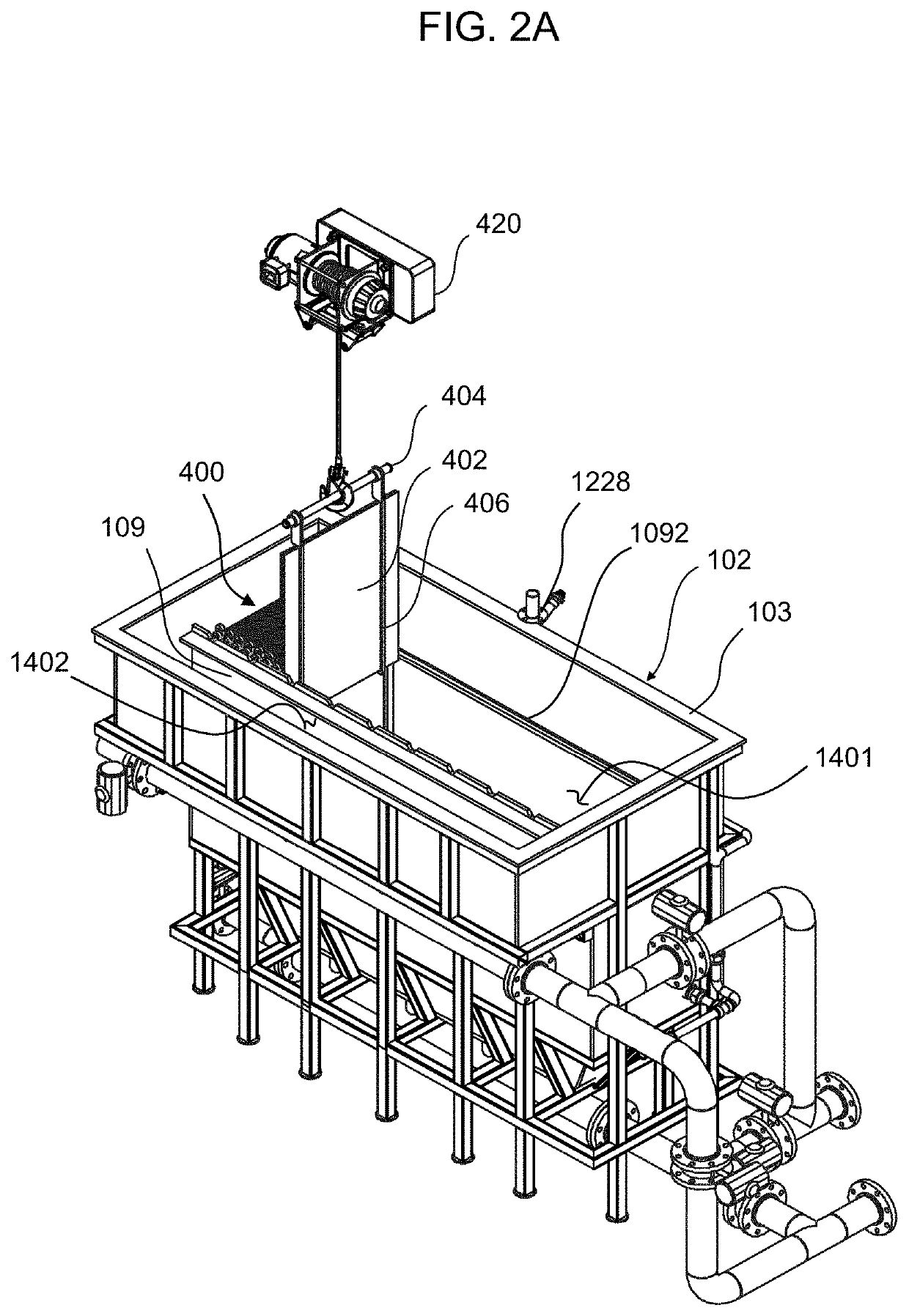

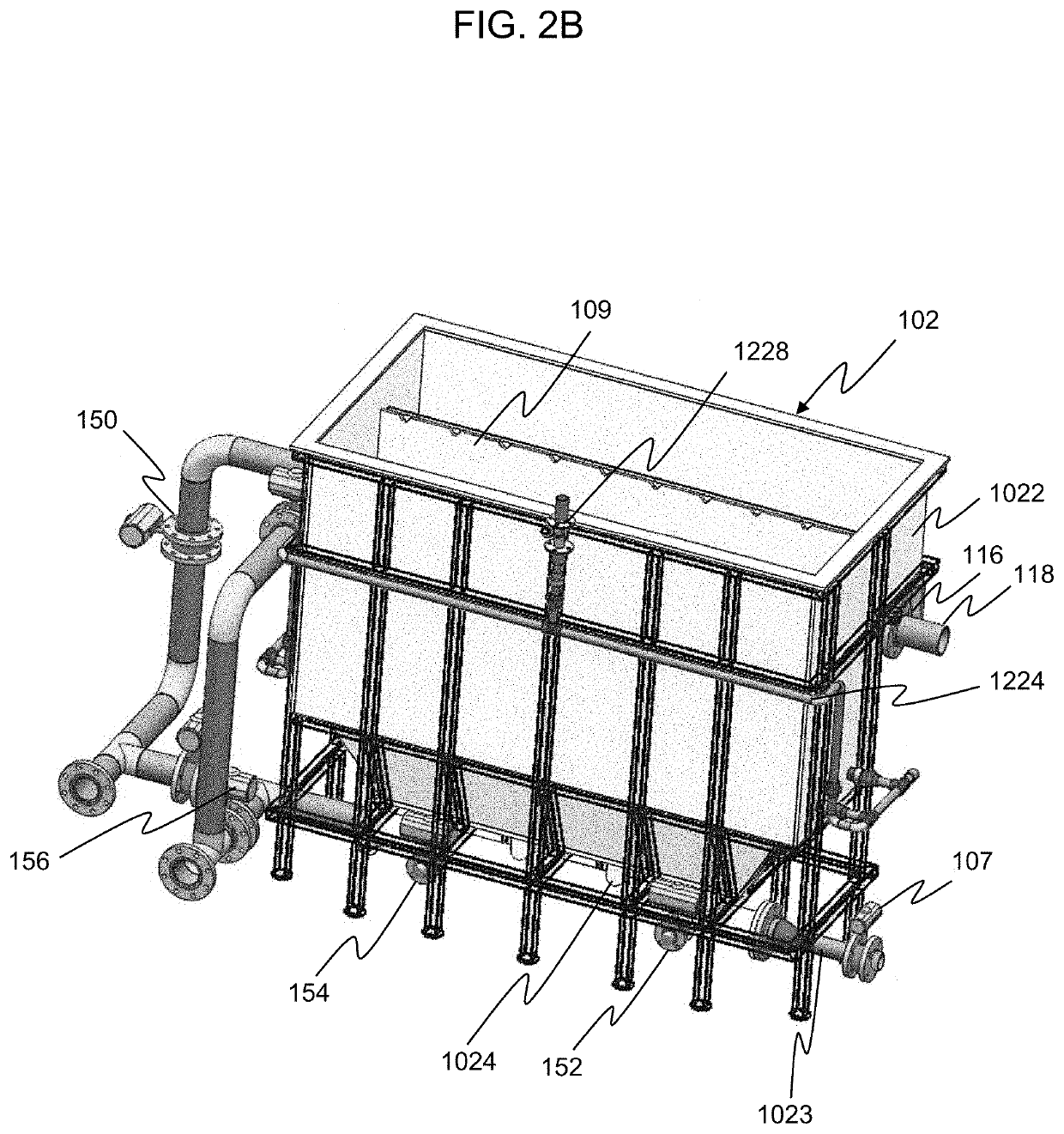

Automated waste water recycling system using advanced electro-coagulation unit

ActiveUS20200095149A1Improve convenienceExtend your lifeSludge treatmentUltrafiltrationElectrocoagulationUltrafiltration

An automated waste water treatment system includes a collection tank constructed to hold waste water, a first flow line connected to the collection tank to output the waste water from the collection tank, an electrocoagulation unit that receives the waste water and outputs the waste water as coagulated waste water to a flow line, a polymer dosage tank to provide a polymer dosage into the flow line where the polymer dosage mixes with the coagulated waste water to produce and output flocculated waste water. A clarifier connected to the flow line receives the flocculated waste water and produces sludge-free waste water and concentrated sludge, a series of filters to output filter-treated water, and an ultrafiltration system that receives filter-treated water and outputs ultrafiltration-treated water to a reverse osmosis system.

Owner:GREEN TECHNO CORP +1

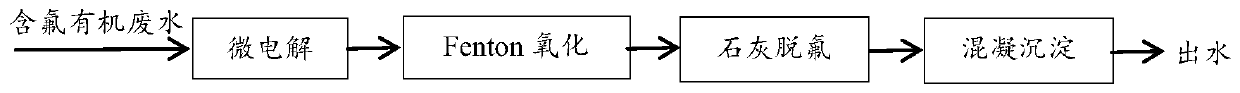

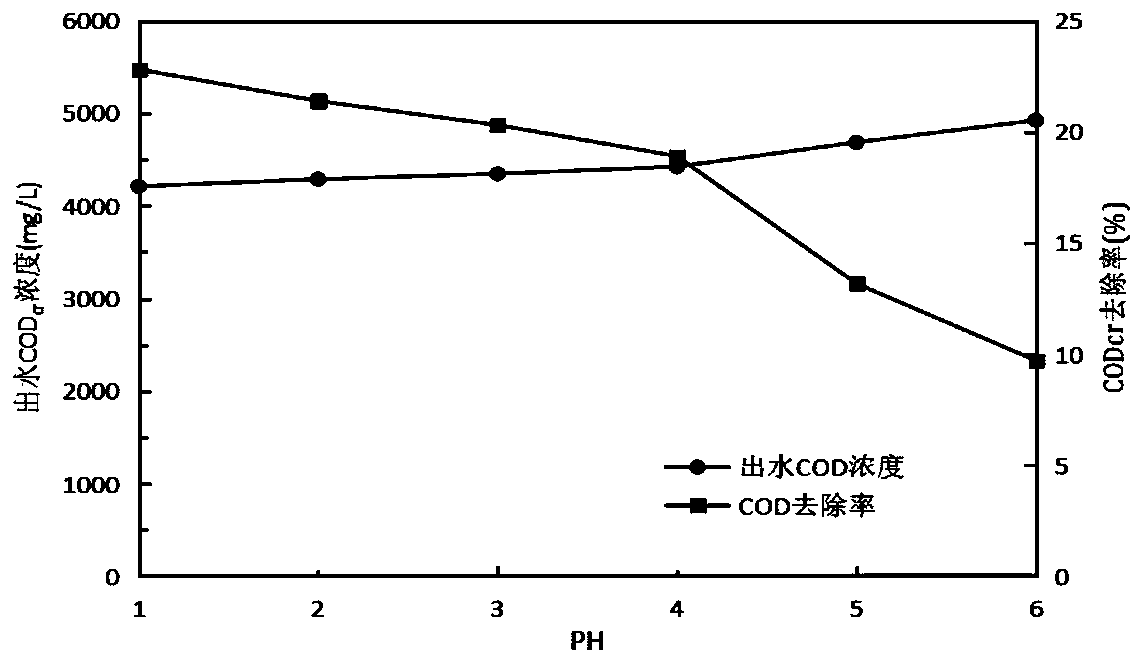

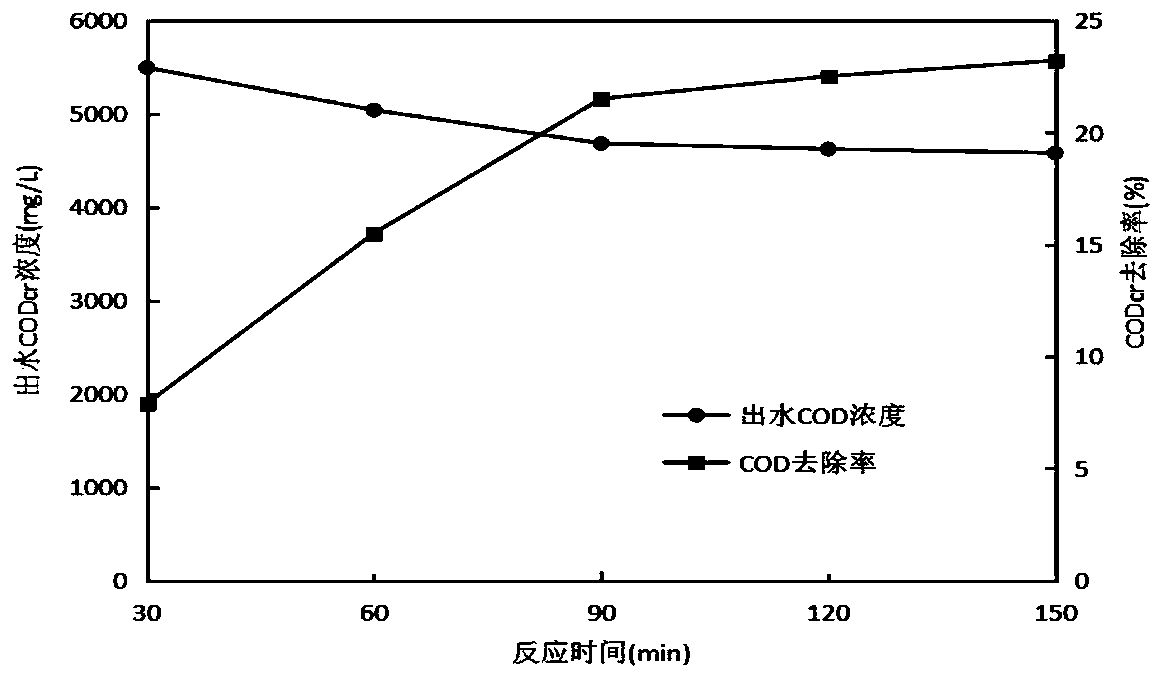

Process for treating chemical fluorine-containing wastewater by combining micro-electrolysis, Fenton and lime coagulation

InactiveCN111499058AImprove wastewater treatment efficiencyHigh removal rateWater contaminantsMultistage water/sewage treatmentAeration rateFenton oxidation

The invention discloses a process for treating chemical fluorine-containing wastewater by combining micro-electrolysis, Fenton and lime coagulation. The process comprises an iron-carbon-Fenton combined experiment and a lime defluorination coagulation experiment, wherein the iron-carbon-Fenton combined experiment comprises an iron-carbon micro-electrolysis experiment and a Fenton oxidation experiment carried out on the basis of iron-carbon micro-electrolysis; the influence of different pH values, reaction time, aeration rate and filler dosage on the CODcr removal effect is studied by the iron-carbon micro-electrolysis experiment, and the CODcr removal effect is studied by different H2O2 dosage, pH and reaction time by the Fenton oxidation experiment; the lime defluorination coagulation experiment comprises the steps: performing lime method defluorination on water subjected to iron-carbon micro-electrolysis defluorination, wherein the F<-> removal effect is achieved by different additionamounts and reaction time; because the lime method defluorination precipitation is fine and the precipitation speed is slow, the influence of different pH values, PAC addition amounts and PAM addition amounts on the removal effect needs to be studied in cooperation with coagulation reaction defluorination and coagulation experiment parts. Under the optimal process conditions, the comprehensive removal rate of COD can reach 88.7%, and the comprehensive removal rate of F<-> can reach 99%.

Owner:LIAONING TECHNICAL UNIVERSITY

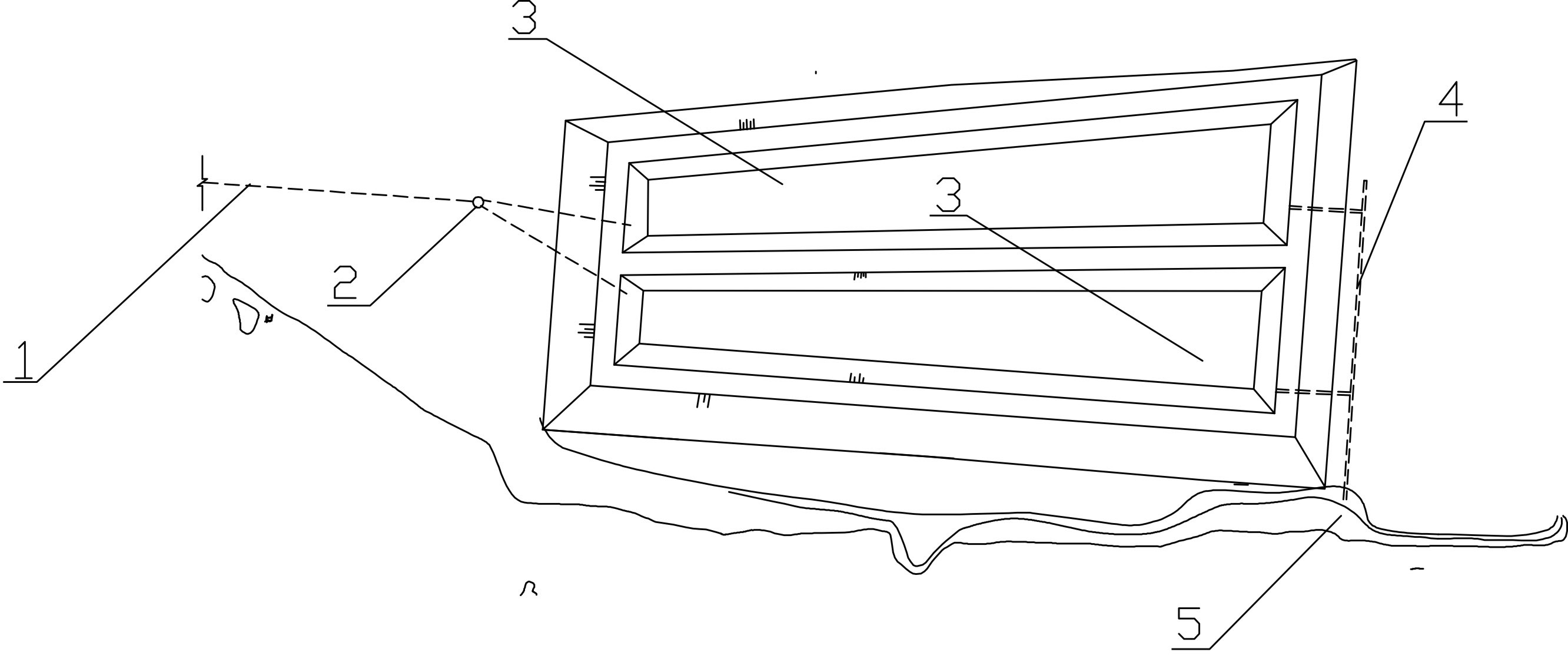

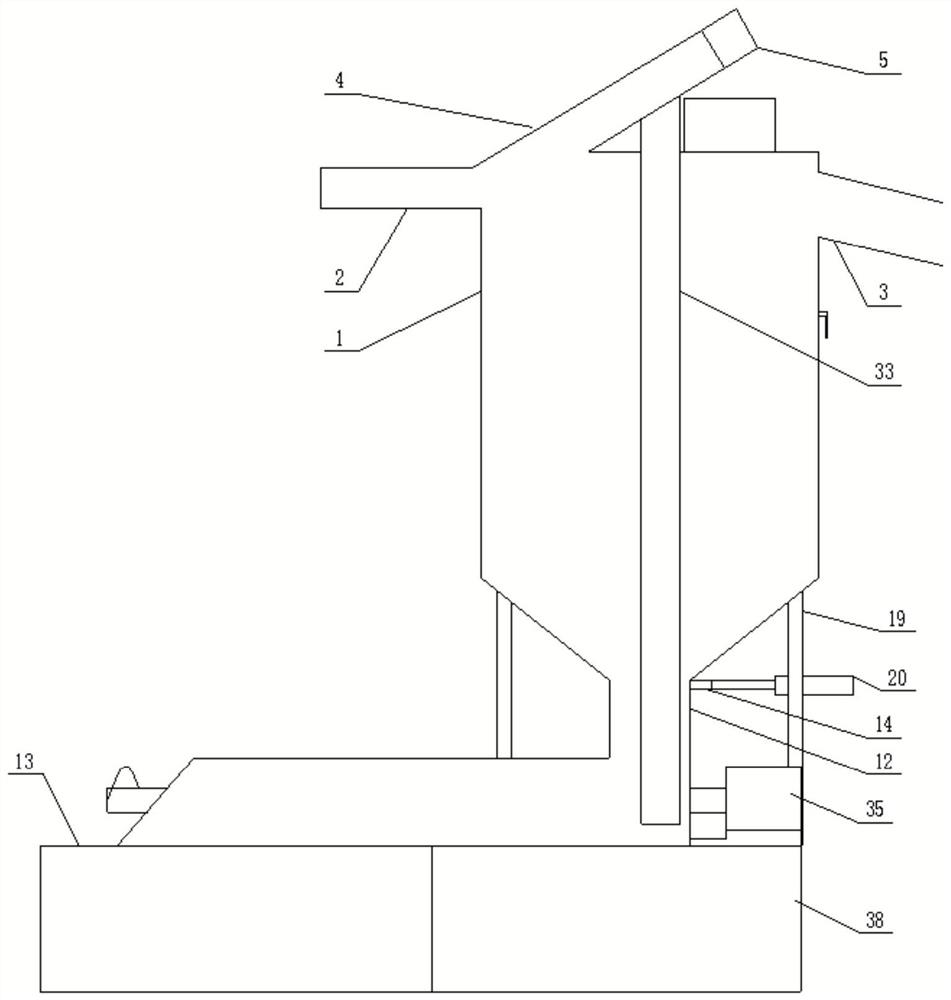

Technological method for processing natural material sandstone processing system waste water

InactiveCN102424460AImprove wastewater treatment efficiencyLow costWater/sewage treatment by flocculation/precipitationSlagRiver water

The invention relates to a technological method for processing natural material sandstone processing system waste water. The method comprises steps that: (1) waste water of natural material sandstone processing systems is gathered, and is delivered into a collected water distributing well by using a trench pipe; the waste water is delivered into a waste water sedimentation tank by the collected water distributing well, and is subject to natural sedimentation; (2) suspended matters in the waste water processed through natural sedimentation in the previous step are settled to the bottom of the waste water sedimentation tank, and a supernatant which reaches a discharging standard is discharged into river water through a water discharging ditch communicating with the waste water sedimentation tank. According to the technological method for processing the natural material sandstone processing system waste water, the waste water sedimentation tank is adopted as a waste slag storing site, such that a mechanical dredging equipment structure of the sedimentation tank is saved; the waste water is continuously processed, and no drying time is required, such that the utilization rate of a unit tank is high; the waste water reaching a discharging standard after processing is not recovered and reused, such that the construction investment of facilities such as a recovering technological pipe and a sedimentation tank is saved. Therefore, the waste water processing efficiency is improved, the cost is reduced, the operation is convenient, and the method is economic and reliable.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG

Method for extracting and refining potassium salt from mica acid production wastewater

InactiveCN110395747ALow input costImprove wastewater treatment efficiencyNature of treatment waterWater/sewage treatment by heatingChemistryDecomposition

The invention relates to the technical field of wastewater treatment, in particular to a method for extracting and refining a potassium salt from mica acid production wastewater. The method for extracting and refining the potassium salt from the mica acid production wastewater comprises the following steps: firstly, concentrating the mica acid production wastewater, and adjusting the heat value and the pH value of the mica acid production wastewater; controlling the temperature of a high-temperature liquid incinerator to be 600-1200 DEG C, spraying the pretreated wastewater into the high-temperature liquid incinerator for high-temperature decomposition, performing high-temperature denitration on generated gas, performing desulfurization, performing absorption, performing water washing treatment, performing emptying, and recycling incineration residues at the bottom of the incinerator; and finally, adding water into the incineration residues for dissolving, performing filtering, performing concentrating, and performing crystallizing to obtain the potassium salt. According to the method provided by the invention, the potassium salt in the wastewater is extracted in the wastewater treatment process, the equipment investment costs of the whole process are low, the wastewater treatment costs are low, the recovery rate of the potassium salt is high, and the purity of the recovered potassium salt is high.

Owner:山东金城晖瑞环保科技有限公司

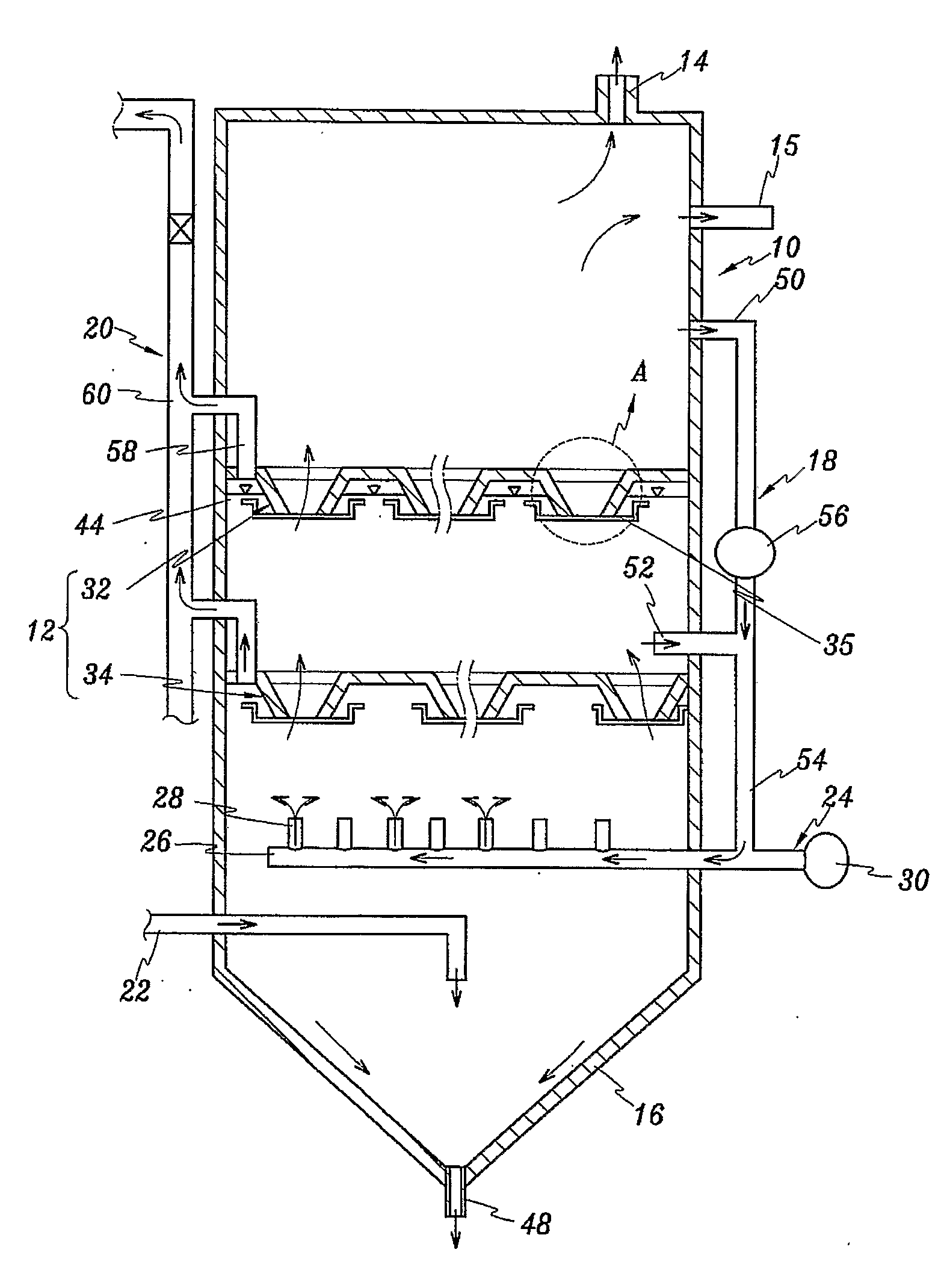

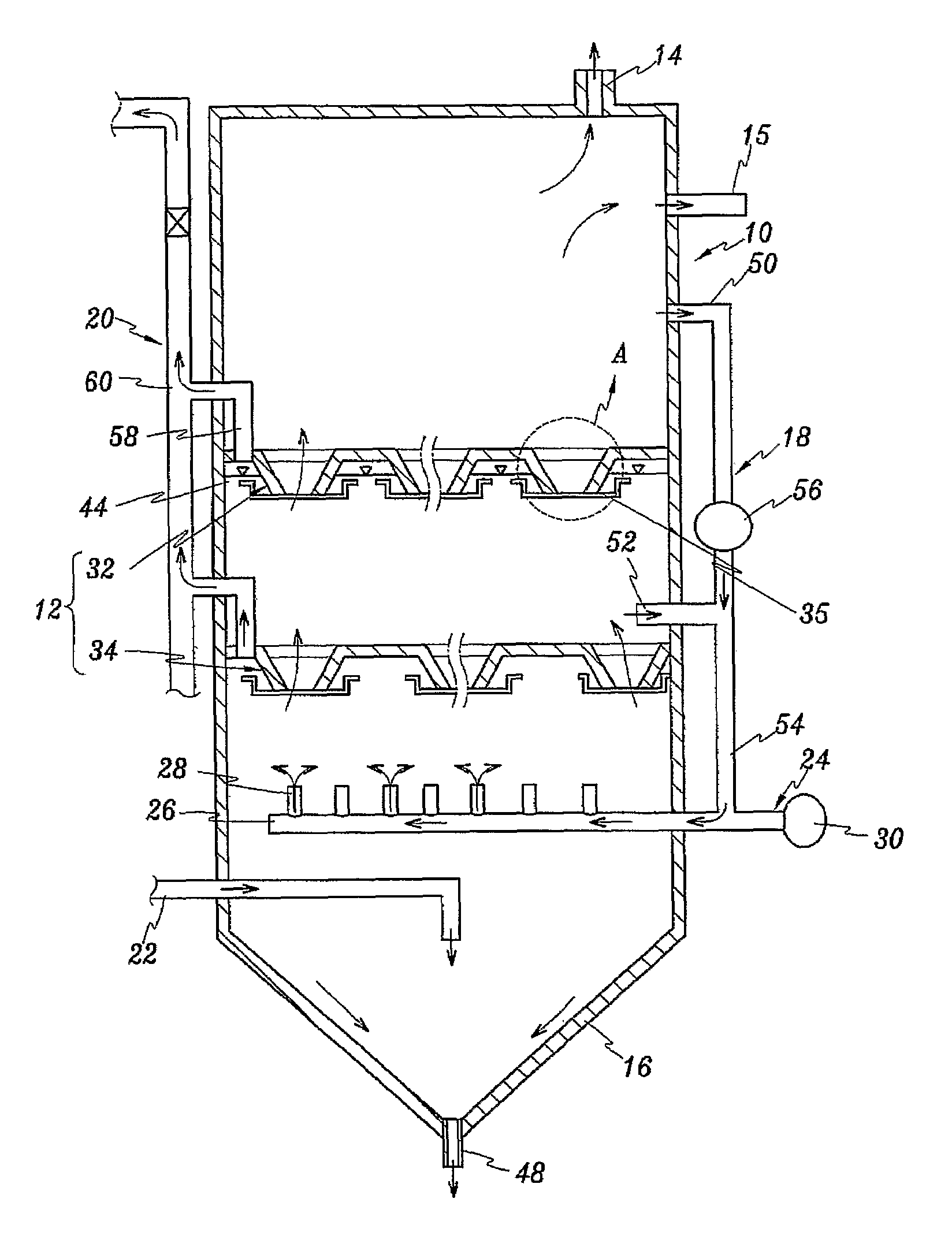

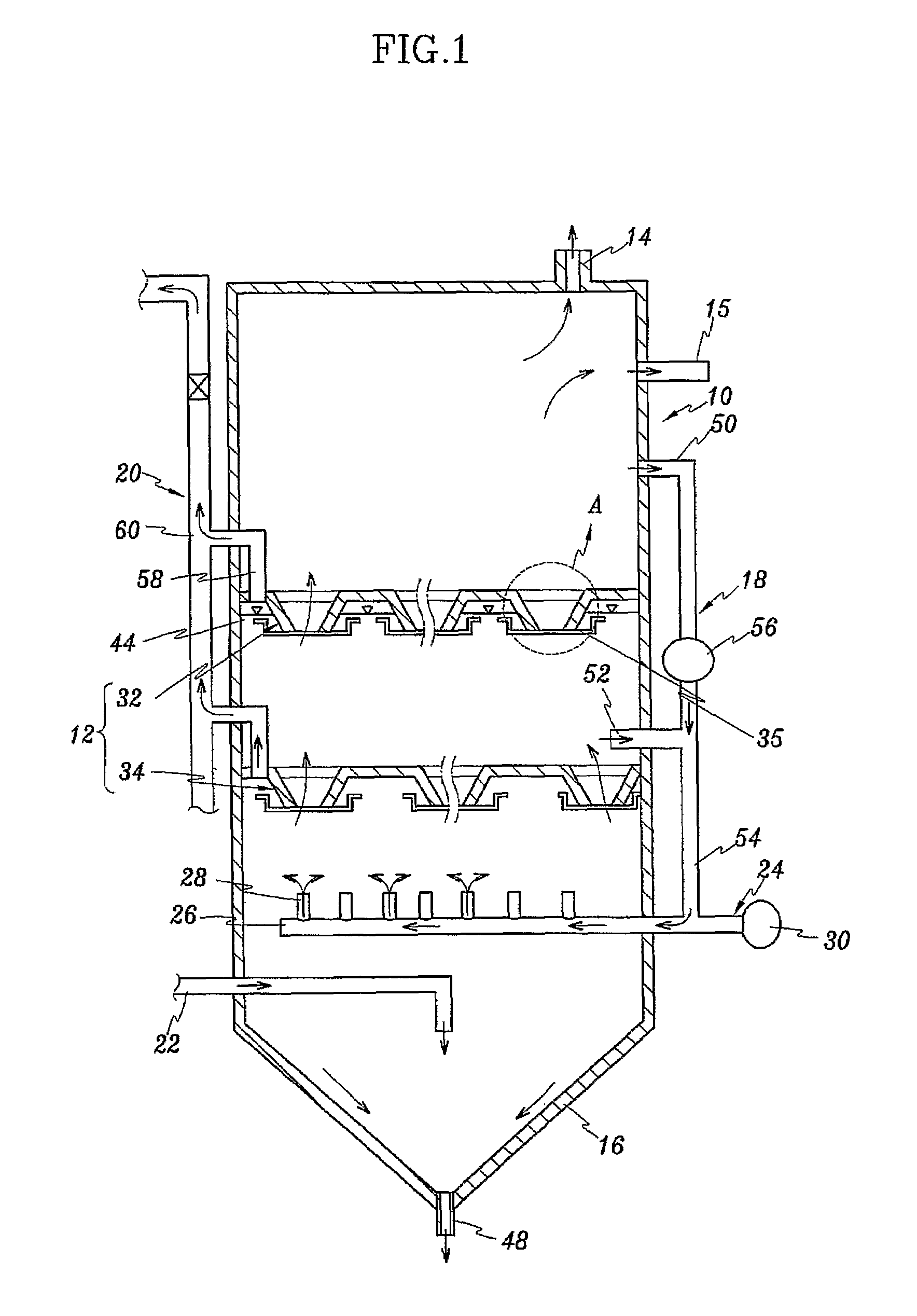

Fluids fluxion method and plant for wastewater treatment

InactiveUS7597801B2Practical and economical and functional and easy in manufactureImprove wastewater treatment efficiencyTreatment using aerobic processesGeneral water supply conservationDraining tubeSludge

A wastewater treatment plant includes a reaction tank connected to an wastewater supply tube and an aeration apparatus to receive wastewater therein, a sludge separation unit dividing an internal space of the reaction tank into upper and lower sections to increase an amount of dissolved oxygen by increasing an contact area of the wastewater and bubbles and to separate relatively light materials by moving low density matters existed on a surface of each section upward in turn, an air exhaust tube mounted on the reaction tank to exhaust bubbles passing through the sludge separation unit out of the reaction tank, a treated water exhaust tube mounted on the reaction tank to exhaust the wastewater that is treated by passing through the sludge separation unit, and a settling tank provided on a bottom of the reaction tank to concentrate and exhaust the settled sludge.

Owner:ECODAYS

Anaerobic wastewater treatment system and process utilizing solids based bacterial colonization (SBBC)

InactiveUS8357297B2Improve wastewater treatment efficiencyEnhancing growth and colonizing activityLiquid degasificationSpecific water treatment objectivesSolid baseBacterial colonization

Anaerobic Wastewater treatment system and process in which the influent is passed through a mixing chamber and then through a series of filters of progressively smaller size to separate the materials carrying the colonized bacteria from finer solids in the influent and separate the materials according to size in a completely enclosed and flooded environment. The materials from the filters are progressively reduced to a smaller size, the materials of smaller size are returned to the mixing chamber, and new influent is inoculated with the colonized bacteria carried by the materials returned to the mixing chamber.

Owner:MILLER III HERMAN P

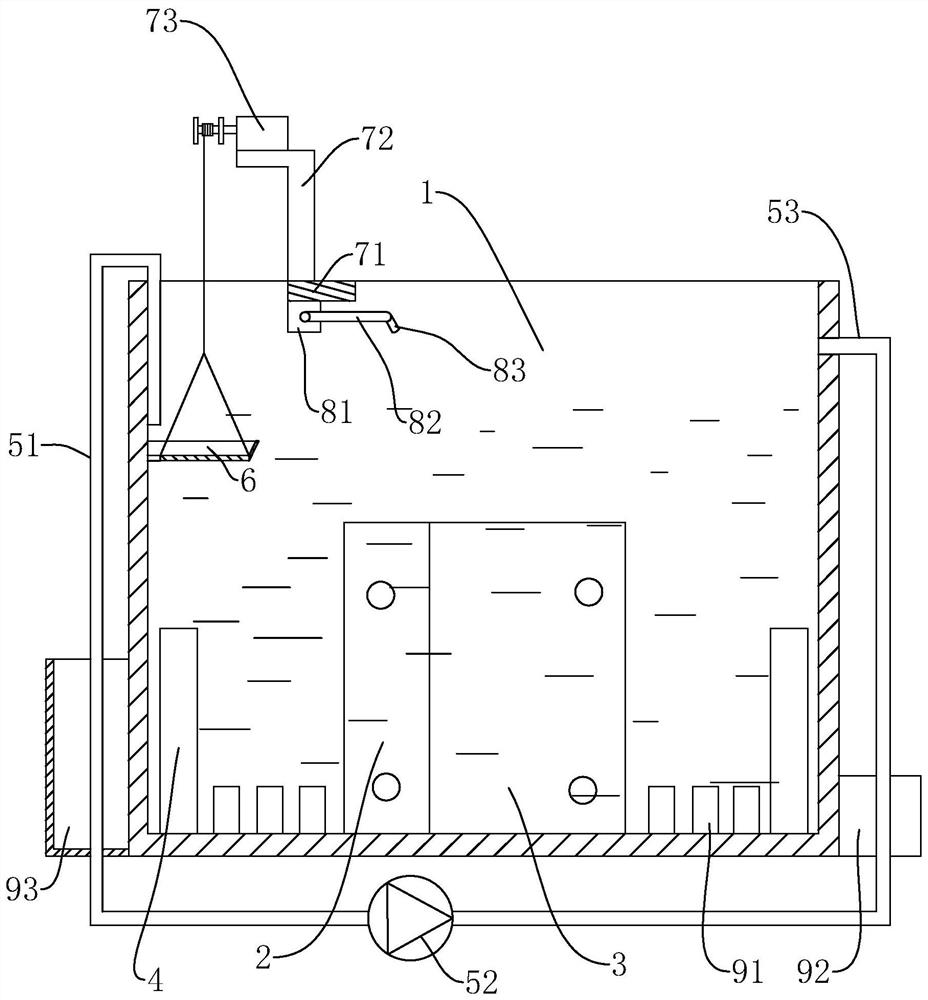

Biochemical reaction equipment with function of increasing oxygen concentration

InactiveCN107686163AIncreased oxygen transfer rateImprove wastewater treatment efficiencyWater treatment parameter controlSustainable biological treatmentChemistrySewage treatment

The invention belongs to the technical field of sewage treatment, and solves the technical problem that the existing biochemical reaction equipment is low in wastewater treatment efficiency. The biochemical reaction equipment with a function of increasing oxygen concentration is characterized by comprising a pressure reaction tank, a water inlet slot, a water inlet pump, an air compressor and a controller. The biochemical reaction equipment has the beneficial effect of being high in wastewater treatment efficiency.

Owner:沈艳

Plug flow reactor for petrochemical wastewater treatment

PendingCN112939120AImprove stabilityImprove wastewater treatment efficiencyNature of treatment waterWater/sewage treatment by heatingProcess engineeringPetrochemical wastewater

The invention provides a plug flow type reactor for petrochemical wastewater treatment, and belongs to the technical field of sewage treatment. The plug flow type reactor for petrochemical wastewater treatment comprises a bottom plate, a plug flow pipeline and a precipitation tank, wherein the upper surface of the bottom plate is fixedly connected with a box body, and a reaction box is arranged on one side of the inner bottom wall of the box body; an inner shell is fixedly connected to the inner wall of the reaction box, supporting rods are fixedly connected to the two sides of the inner wall of the inner shell, and a plug flow pipeline is fixedly connected to one end of each supporting rod. According to the plug-flow reactor for petrochemical wastewater treatment, by arranging a water pump, a plug-flow pipeline, an electric heating column, a material pipe, heat dissipation holes, heat dissipation fiber cotton and a heat control plate; when the reactor is used, petrochemical wastewater can be continuously and stably pumped through the water pump, so that the operation stability of the reactor is higher; the petrochemical wastewater can be spirally propelled after entering the plug-flow pipeline, then the corresponding raw materials can be added in sections through the plurality of material pipes, so that the petrochemical wastewater can be quickly and effectively purified, and the wastewater treatment efficiency is effectively improved.

Owner:西安众昇达科技工程有限公司

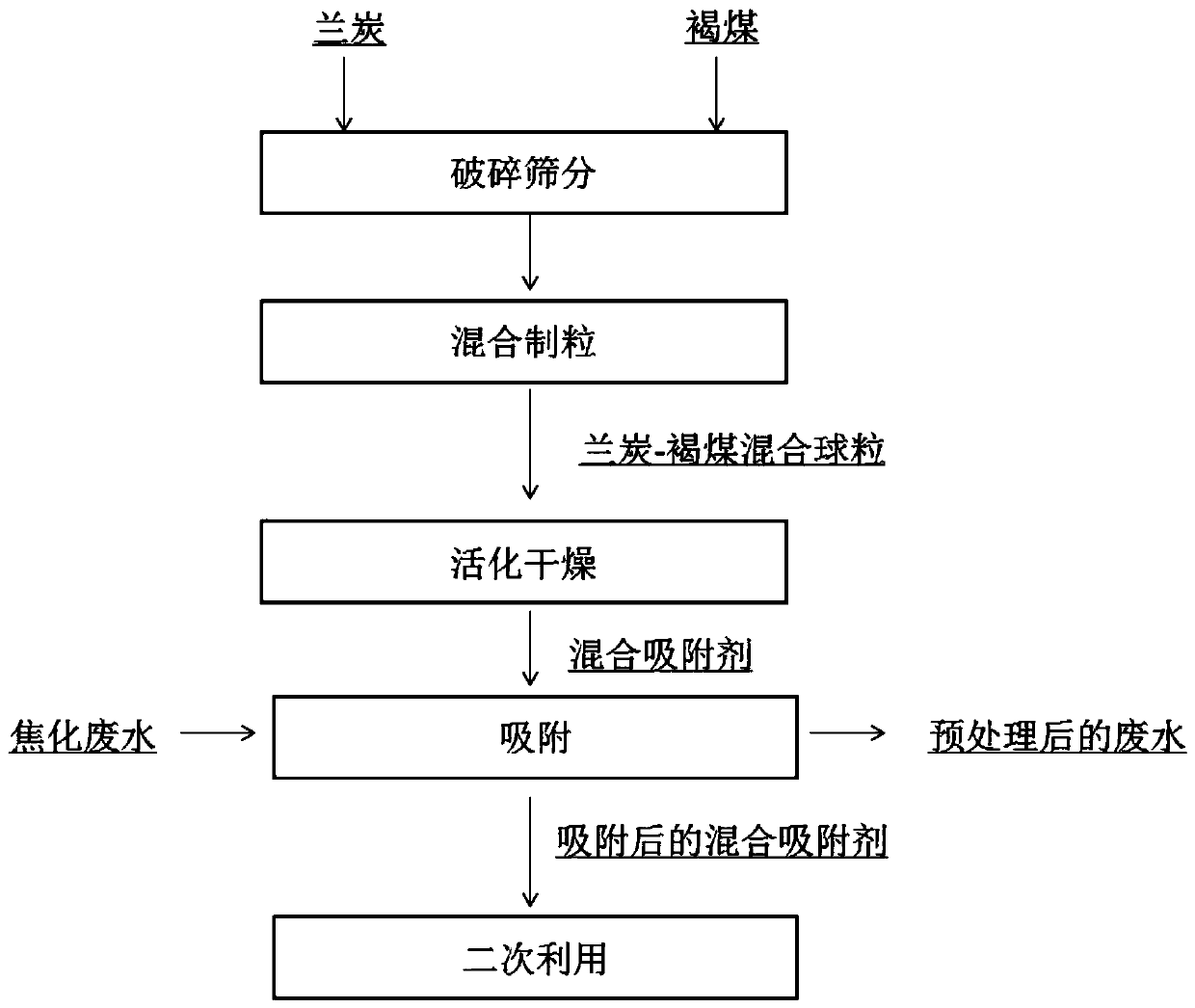

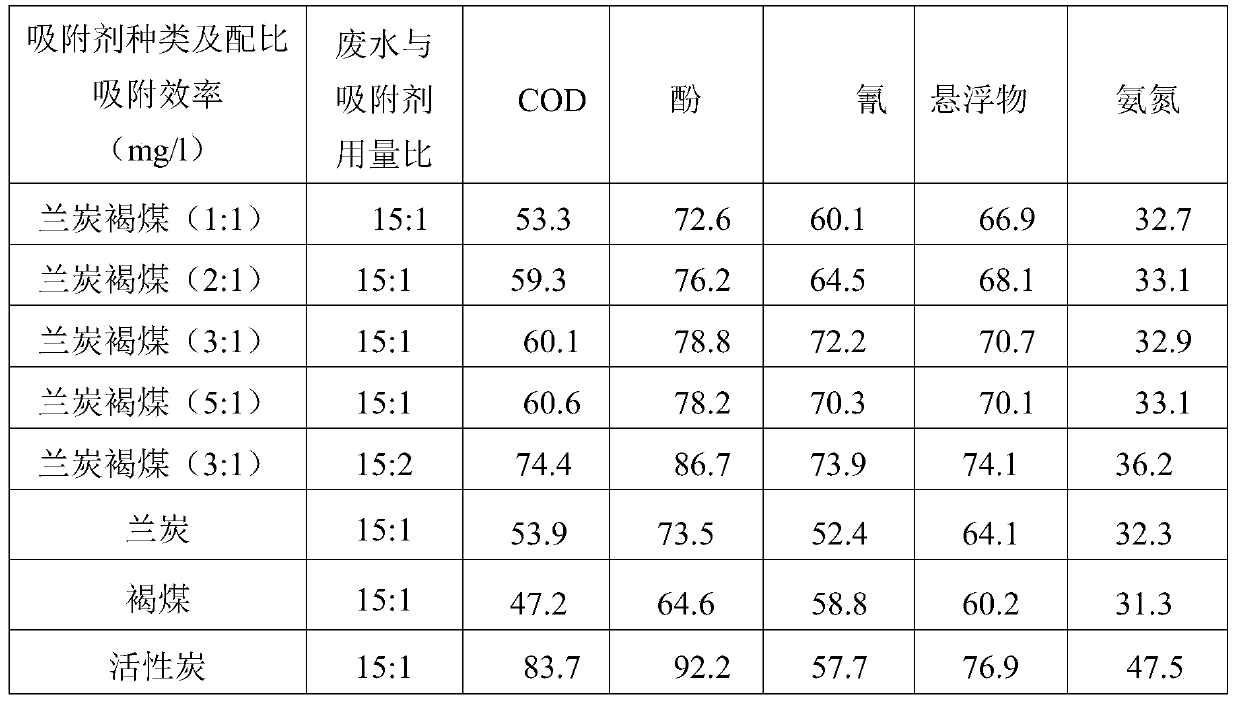

Coking wastewater treatment method with lignite and semi-coke used as novel adsorbent

InactiveCN110252244ALow priceImprove wastewater treatment efficiencyOther chemical processesWater contaminantsChemistryTreatment costs

The invention discloses a coking wastewater treatment method with lignite and semi-coke used as a novel adsorbent, and belongs to the technical field of treatment of coking wastewater. The coking wastewater treatment method with the lignite and the semi-coke used as the novel adsorbent comprises the following steps of (1) crushing the semi-coke and the lignite, and then conducting screening to obtain semi-coke powder and lignite powder with preserved particle size; (2) mixing the semi-coke powder and the lignite powder according to a set ratio for granulation so as to obtain semi-coke-lignite mixed spherical particles; (3) conducting activation and drying treatment on the semi-coke-lignite mixed spherical particles to produce a mixed adsorbent; (4) conducting adsorption operation on coking wastewater by means of the mixed adsorbent; and (5) taking out the humid mixed adsorbent with saturated adsorption, conducting drying to obtain mixed powder, and using the obtained mixed powder as a coking raw material or a sintering process fuel or a blast furnace injection fuel to achieve secondary utilization of the adsorbent. The method is suitable for large-scale treatment of coking wastewater, has a good adsorption effect and is low in cost, secondary utilization of the semi-coke and lignite mixed powder adsorbent is achieved, and the treatment cost of the coking wastewater is greatly reduced.

Owner:CENT SOUTH UNIV

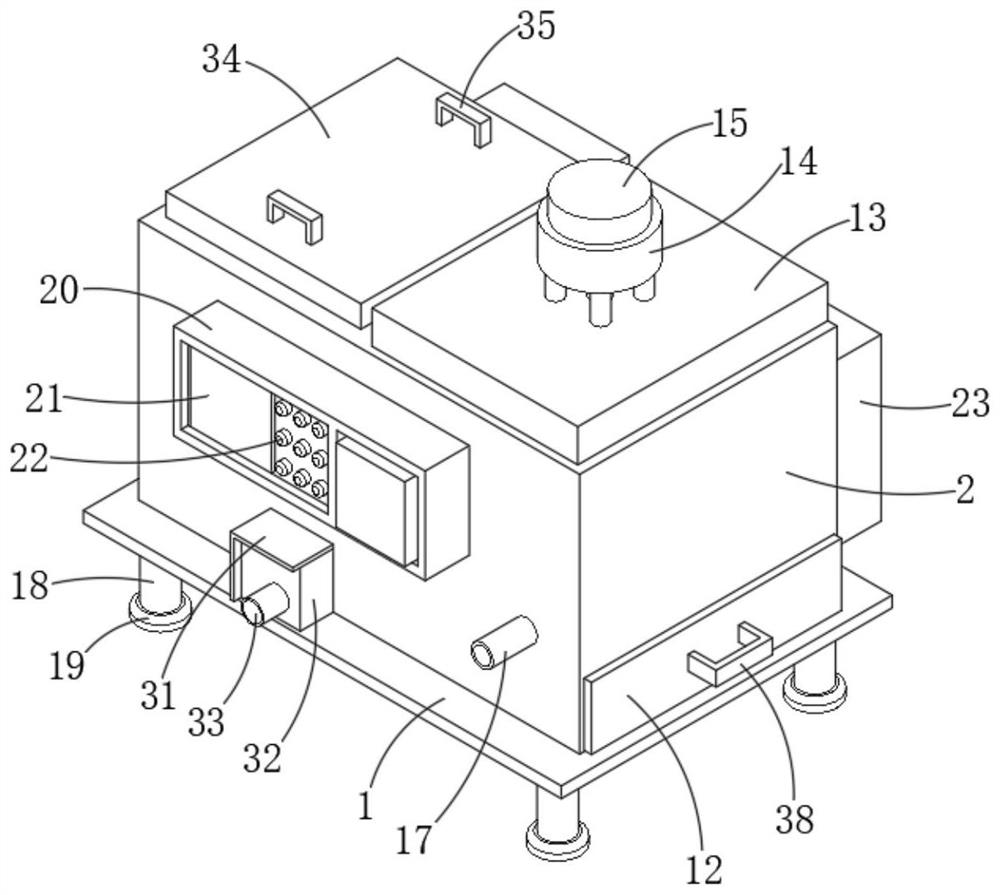

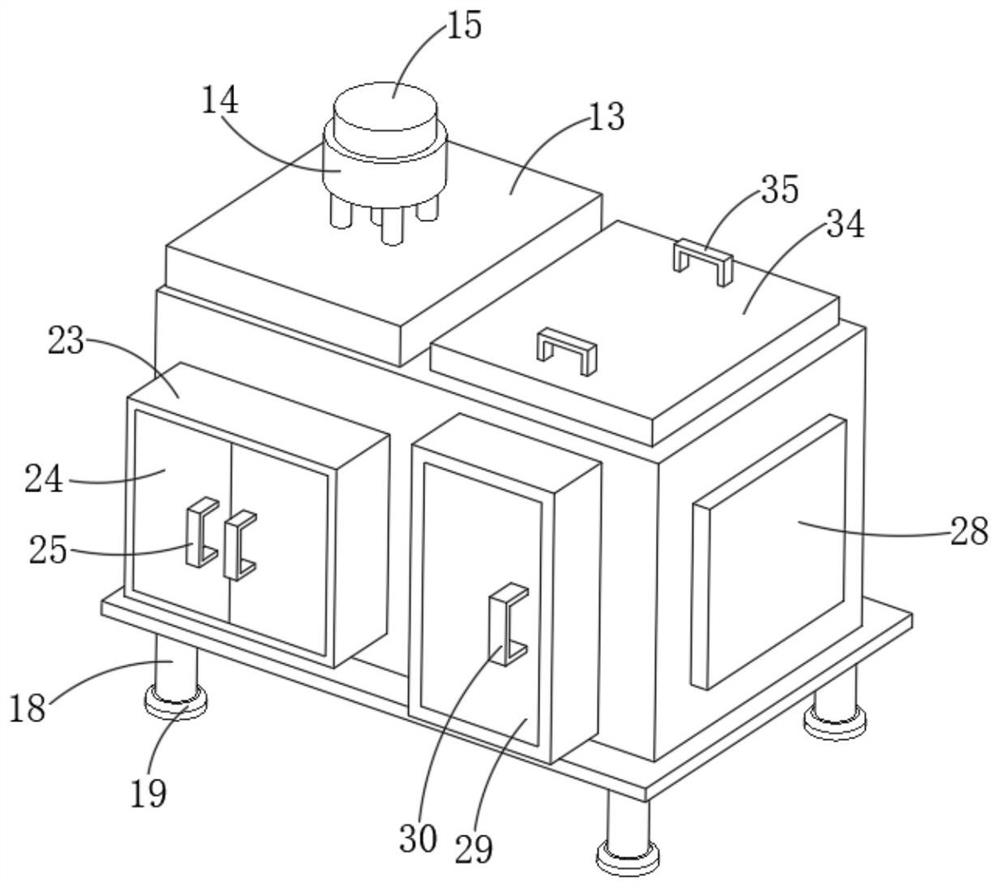

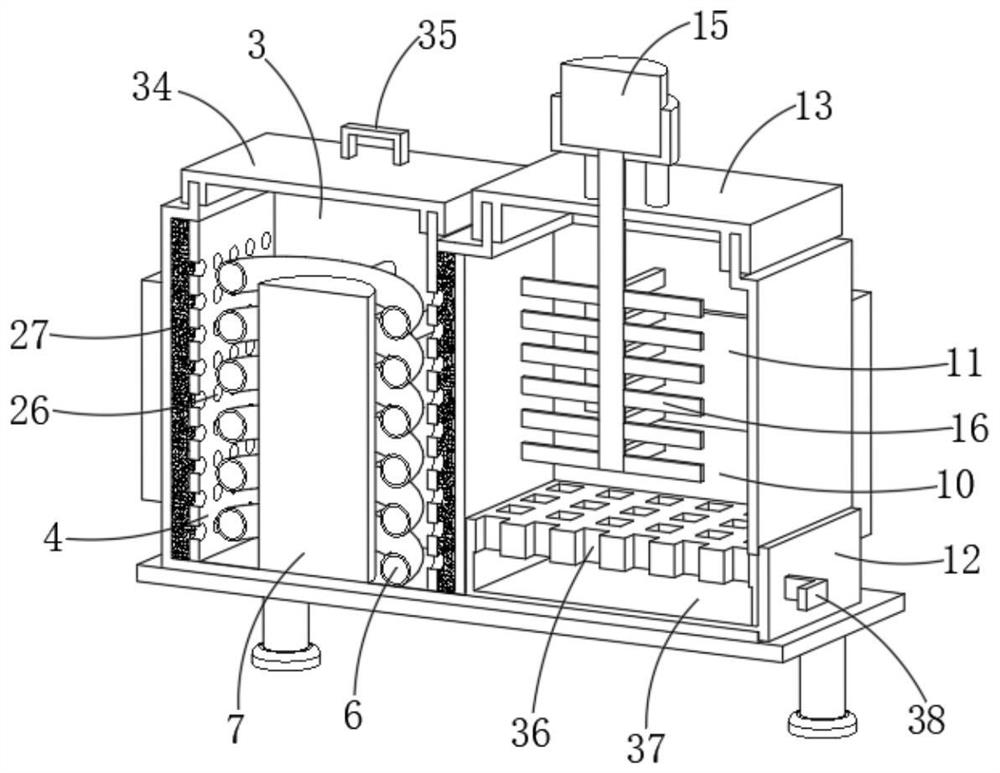

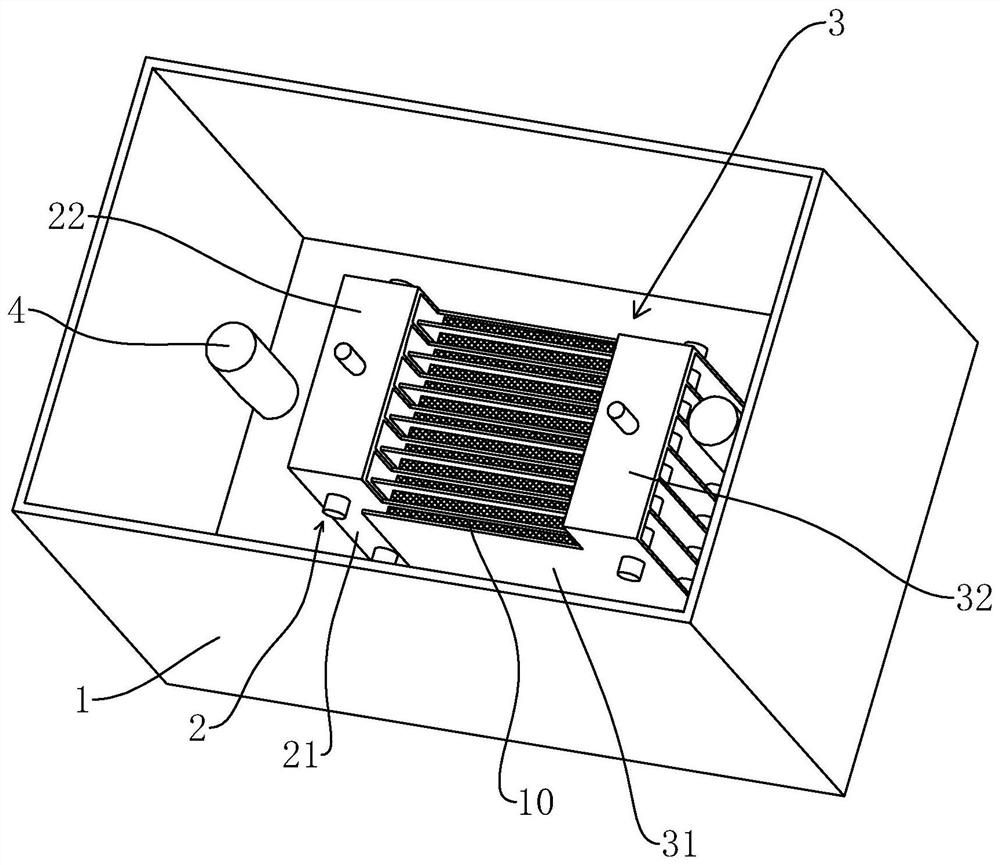

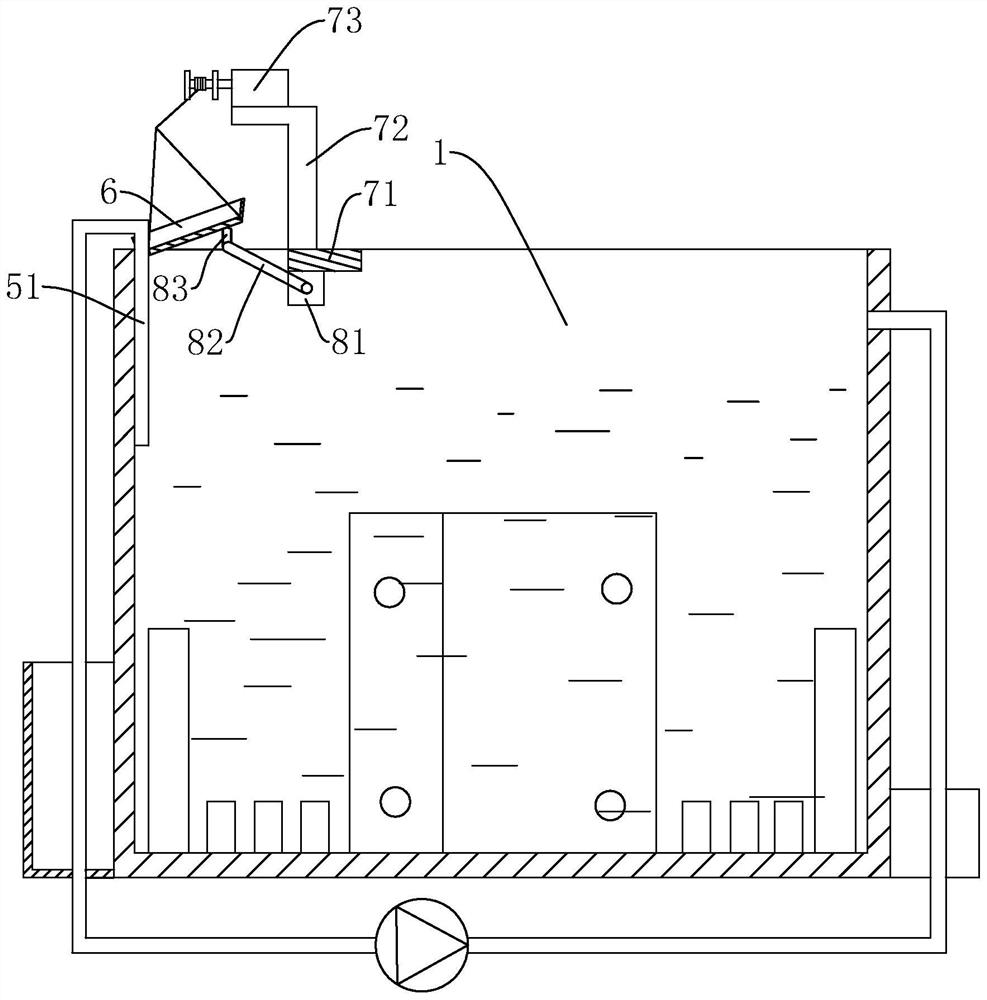

High-chlorine high-ammonia-nitrogen wastewater treatment device with three-dimensional electrode

PendingCN111943329AImprove wastewater treatment efficiencyEasy to cleanWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment apparatusActivated carbonElectrolytic cell

The invention provides a high-chlorine high-ammonia-nitrogen wastewater treatment device with a three-dimensional electrode, which comprises an electrolytic tank, an anode electrode and a cathode electrode; the anode electrode comprises a plurality of anode plates arranged in parallel, the cathode electrode comprises a plurality of cathode plates arranged in parallel, the anode plates are insertedinto the cathode plates and arranged in a staggered manner, and the cathode plates are arranged in a staggered manner. Activated carbon and insulating particles are filled between the anode plate andthe cathode plate according to the volume ratio of 1: 1 to serve as a bipolar third electrode, openings between the anode plate and the cathode plate are sealed through insulating separation nets, and an ultrasonic rod is arranged in the electrolytic tank. The bipolar third electrode can adsorb organic matters, and is not influenced by the adsorption saturation amount in an adsorption and degradation circulation mode; in addition, the effective reaction surface area of the electrolytic cell in unit volume is increased, the mass transfer effect is enhanced, and the wastewater treatment efficiency is improved, so that the generation of short-circuit current is reduced, and the current efficiency is improved. Besides, by arranging an ultrasonic rod, the utilization rate of active groups generated by electrolysis is increased through the ultrasonic effect, and the wastewater treatment efficiency is improved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Wastewater treatment equipment

PendingCN114853111ASimple equipment structureImprove wastewater treatment efficiencyWater treatment parameter controlWater/sewage treatment by irradiationWater tanksWater treatment

The invention provides wastewater treatment equipment, which relates to the technical field of wastewater treatment and comprises a cavity, a water distributor, a flow equalizing plate, an MW-LEP processor and a water tank, wherein the water distributor and the MW-LEP processor are arranged at an interval; the flow equalizing plate is arranged at the bottom of the water distributor; the water tank comprises a first water tank and a second water tank; the first water tank is arranged at the bottom of the cavity; the second water tank is arranged at the top of the water distributor. The wastewater subjected to flow equalization by the water distributor is treated on the basis of the MW-LEP treater, the equipment structure is simple, organic matters in the wastewater are effectively removed by the microwave electrodeless ultraviolet lamp in the MW-LEP treater, and the wastewater treatment efficiency is high.

Owner:陕西青朗万城环保科技有限公司

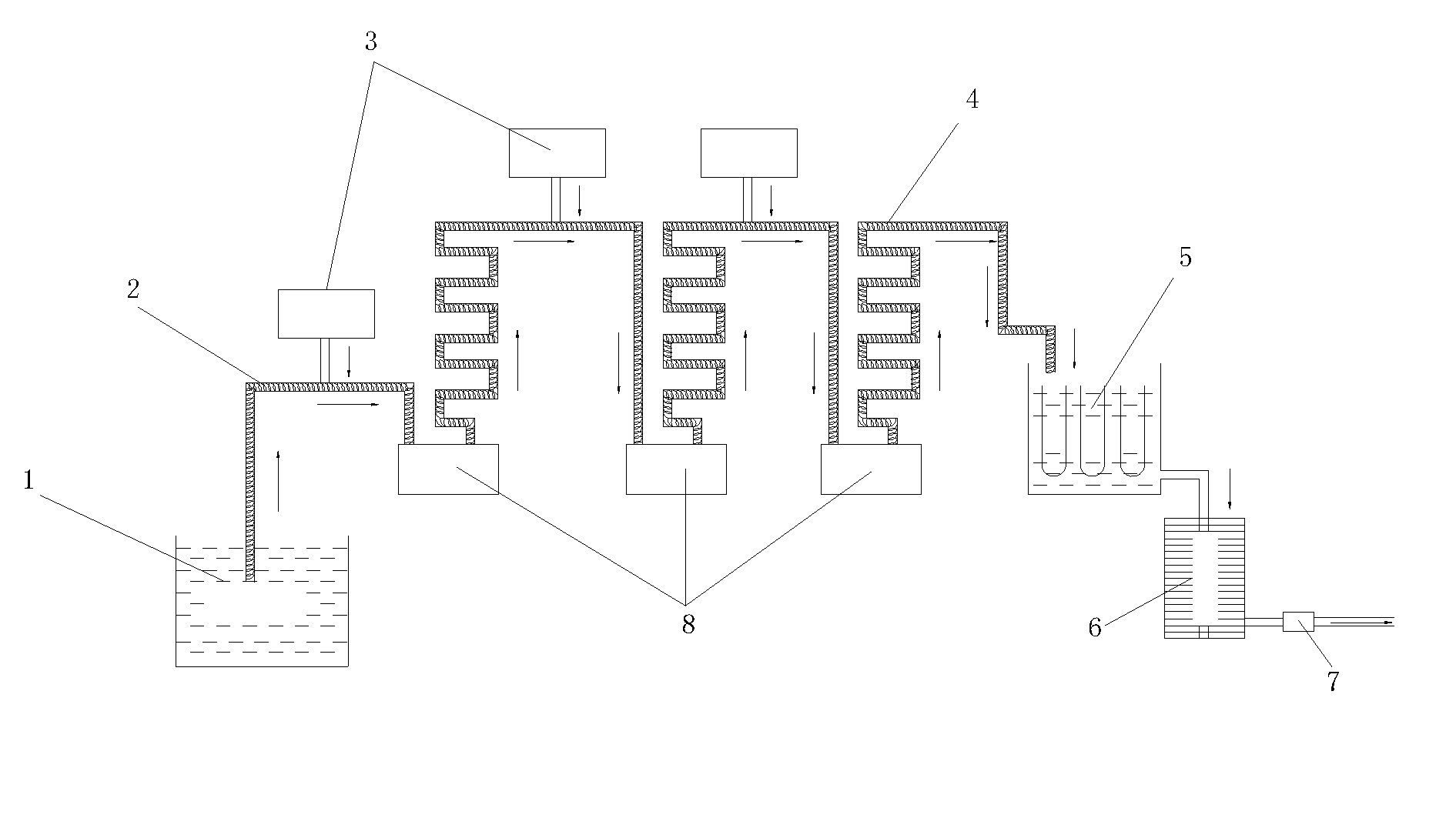

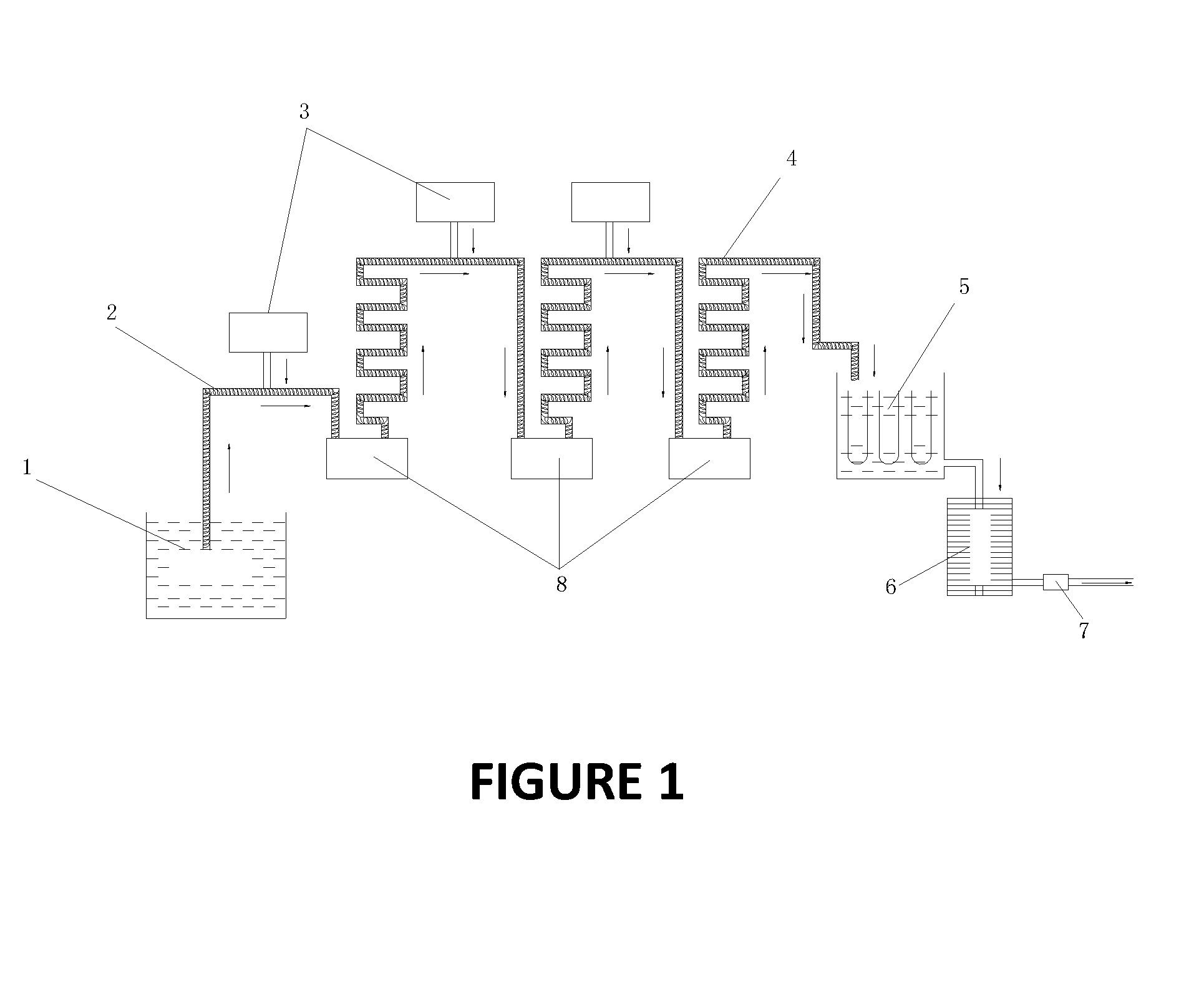

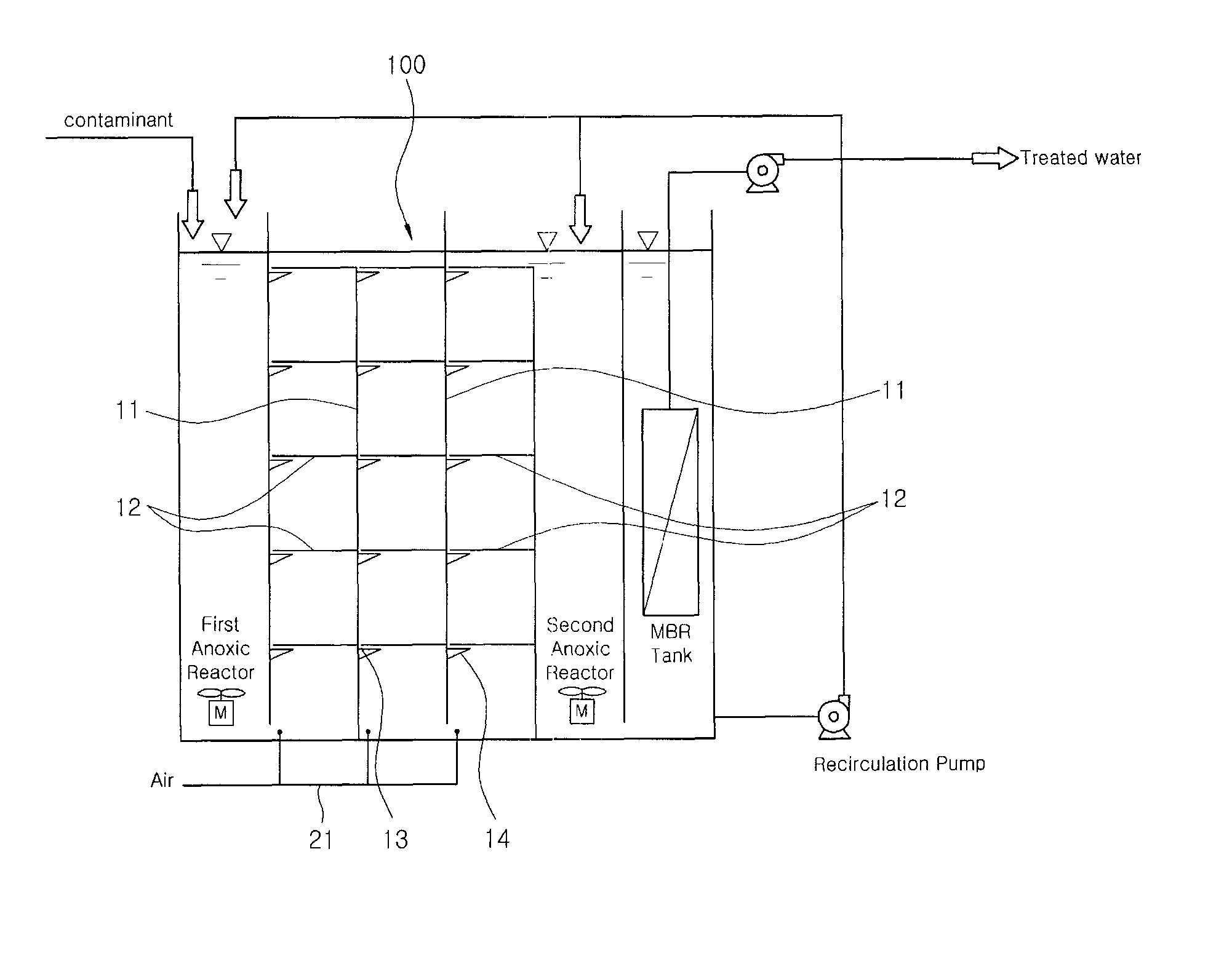

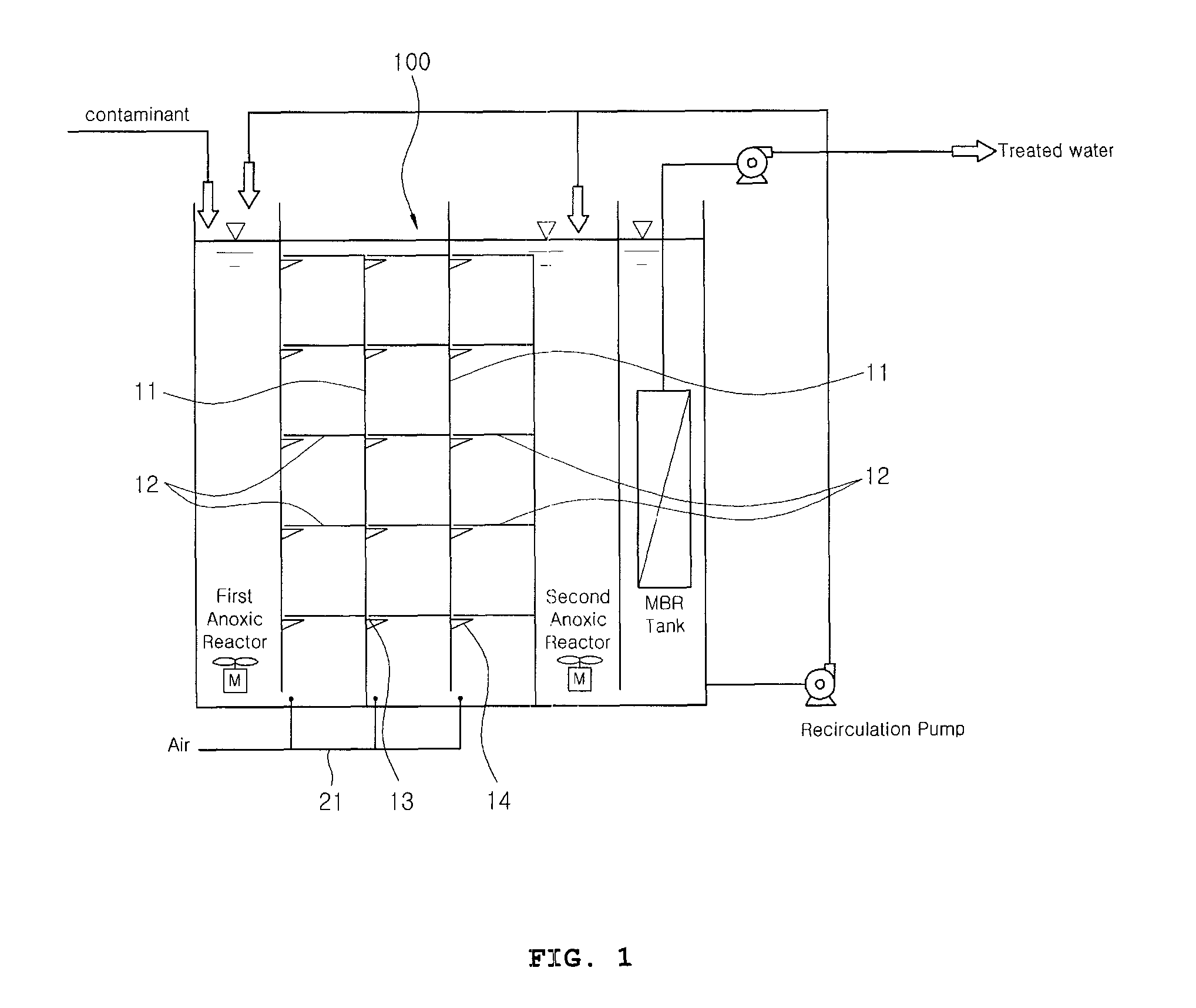

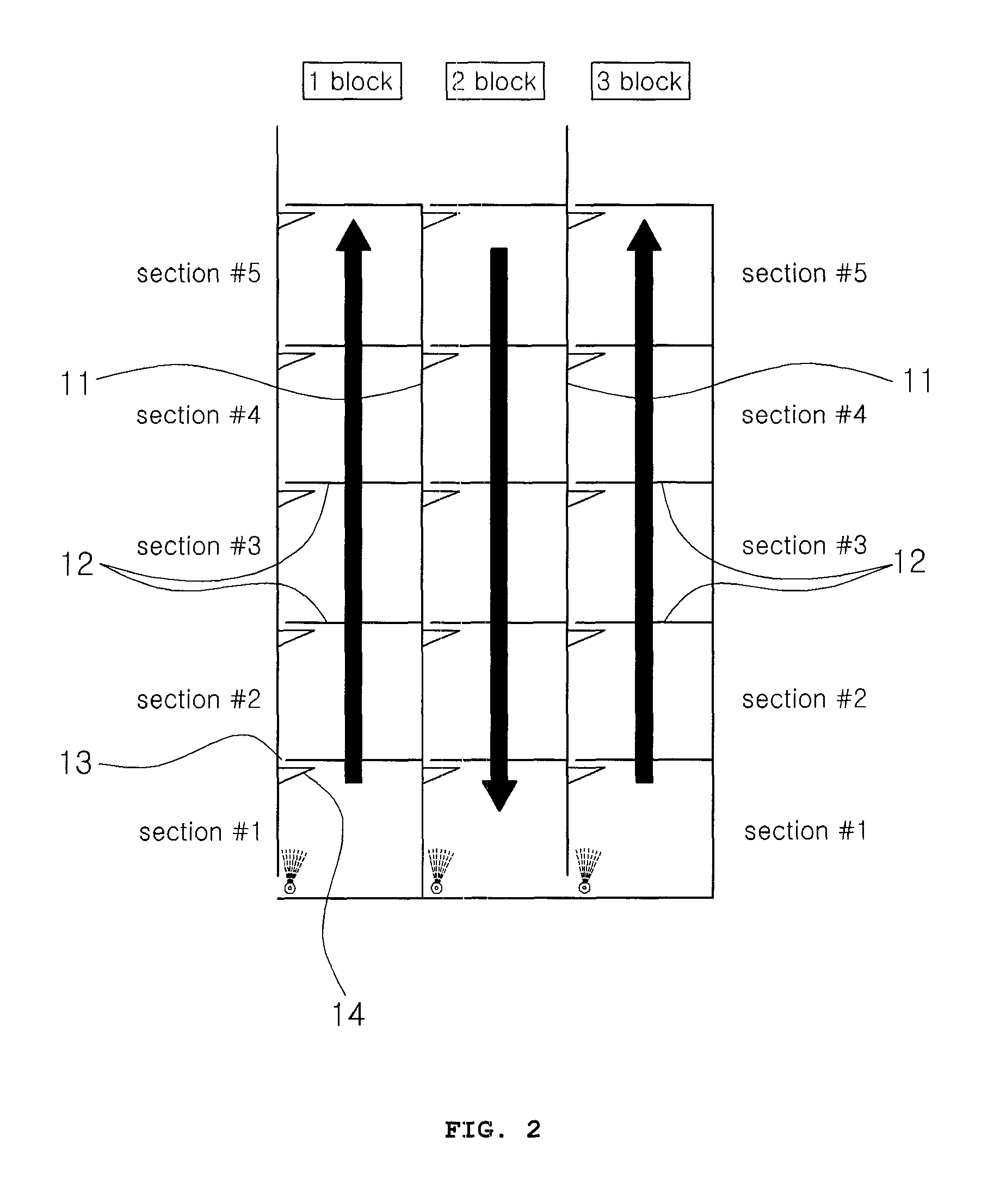

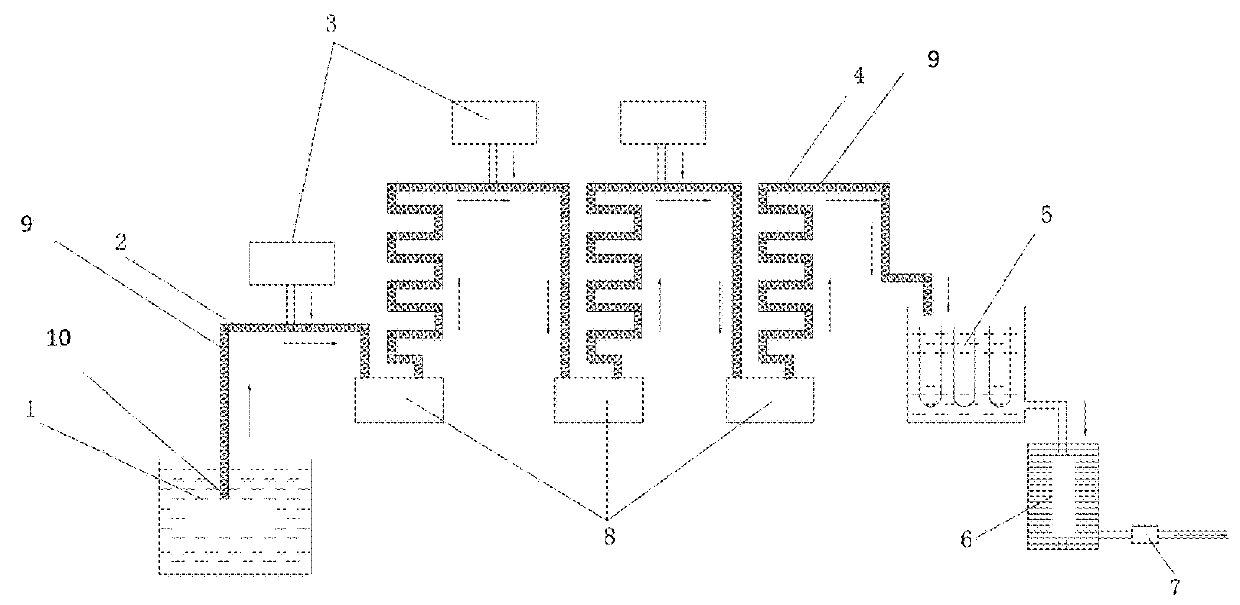

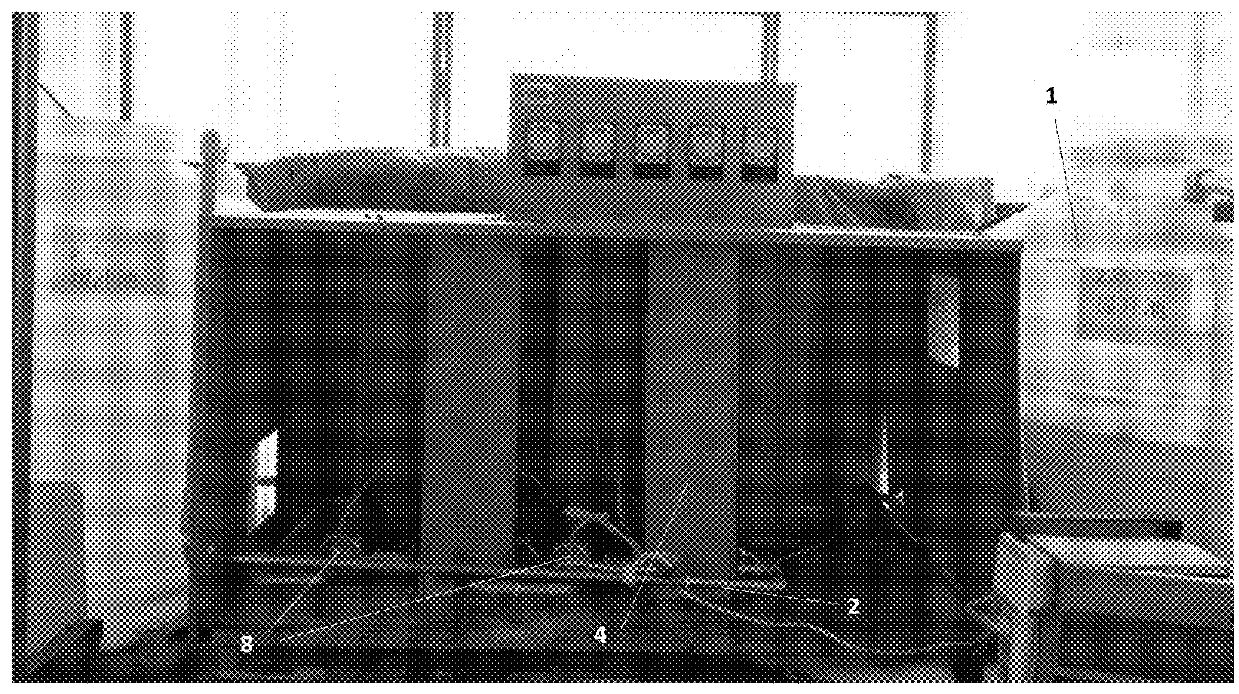

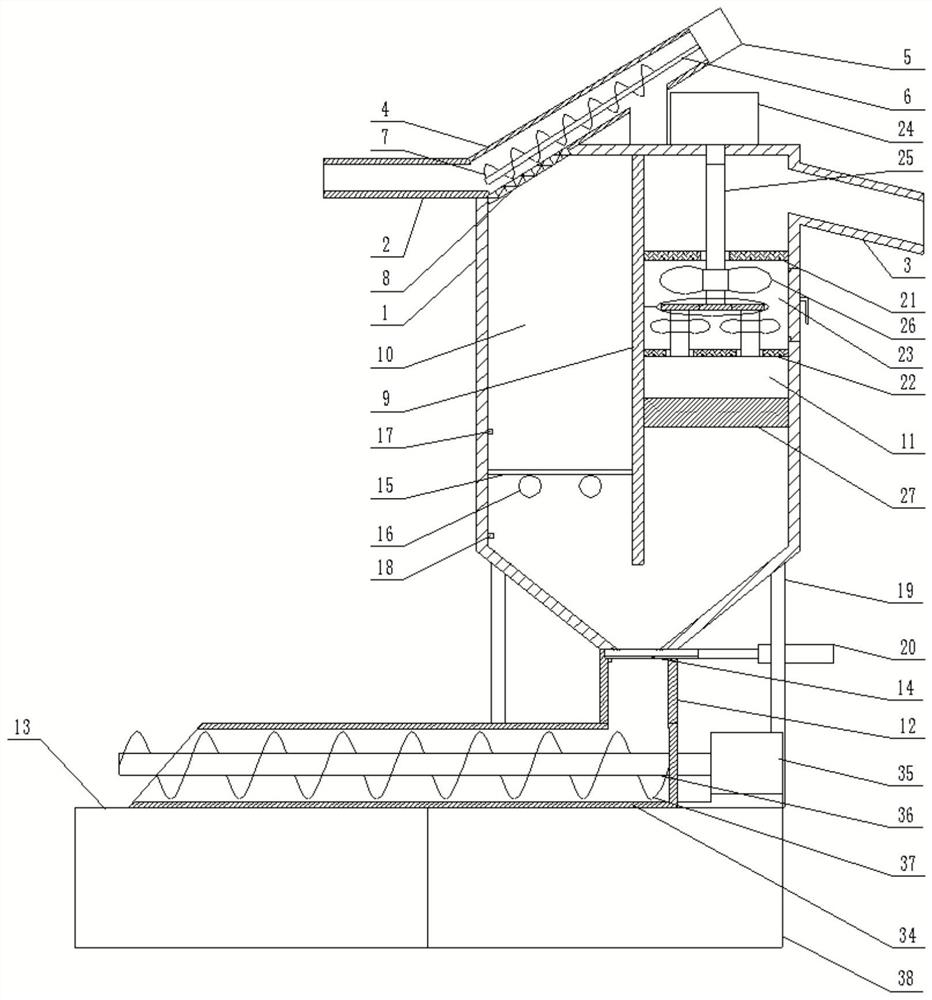

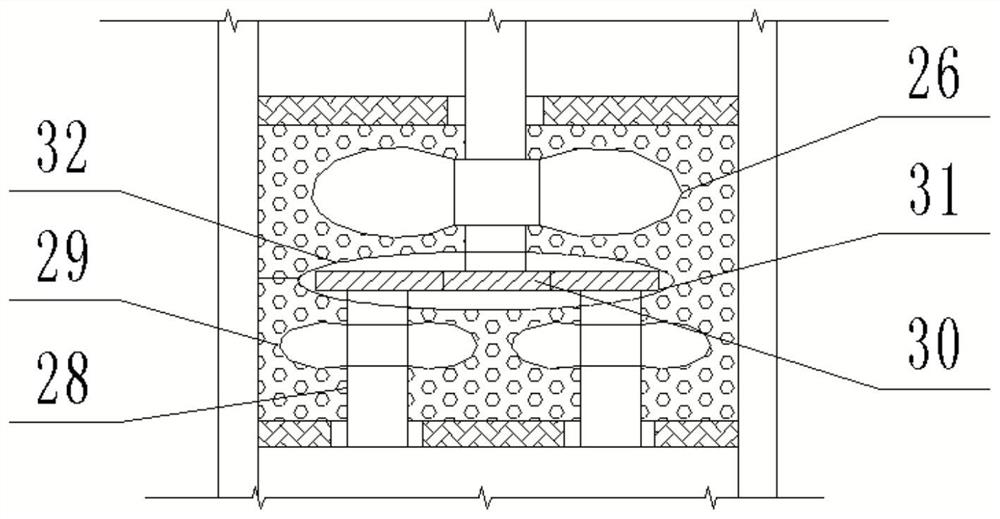

Purification system having vertical multicompartment reactor for organic waste water

ActiveUS8628664B2Increase contact timeImprove wastewater treatment efficiencyTreatment using aerobic processesWater contaminantsContact timeEngineering

Provided is an purification system having vertical multi-compartment reactor for organic waste water, which generates swirling flow in respective sections while circulating wastewater vertically in respective wastewater treatment blocks in the system, so as to considerably increase contact time between air and the wastewater, thus greatly improving wastewater treatment efficiency. According to the system, a size of an aeration tank built in the wastewater purification system may be greatly decreased.

Owner:SEOUL NAT UNIV R&DB FOUND

Waste water treatment device

InactiveUS20180161700A1Improve efficiencyExtension of timeTreatment involving filtrationSedimentation separationSiphonIon exchange

There is described an embodiment of a wastewater treatment system comprising a tank, agitating devices, a water pipe, connecting pipes, dosing devices, a flow-slowing device, and a blow-off pipe. The agitating devices are connected with the tank through the water pipe, the agitating devices being connected therebetween by the connecting pipes. Each one of the agitating devices comprises one of a pump and an agitated tank, the agitating devices mix wastewater and a flocculant together. The dosing devices are provided on the water pipe and the connecting pipes, the dosing devices dose at least one of the flocculant, a coagulant, a pH adjuster and combination thereof to be added in the wastewater treatment system. The flocculant and coagulant are instant dissolving for providing ion exchange between wastewater and the flocculant. Each one of the dosing devices comprises one of a dosing pump and a siphon valve. The pump, the siphon valve or both being free of negative pressure. The flow-slowing device is provided within at least one of the water pipe and the connecting pipes, the flow-slowing device having a flow-restrictive structure. The blow-off pipe discharges treated wastewater.

Owner:WATER MAX NANJING ENVIRONMENT TECH CO LTD

Novel building construction wastewater treatment device

PendingCN114149096AAvoid pipe blockageImprove wastewater treatment efficiencyWater contaminantsTreatment involving filtrationBuilding materialWater treatment

The invention discloses a novel building construction wastewater treatment device which comprises a vertical barrel, a wastewater injection pipe is fixedly mounted on one side of the top of the side wall of the vertical barrel, a water outlet pipe is fixedly mounted on the other side of the top of the side wall of the vertical barrel, a preliminary filtering mechanism is mounted at the joint of the wastewater injection pipe and the vertical barrel, and a precipitation filtering mechanism is mounted at the bottom of the vertical barrel. An adsorption filtering mechanism is mounted in the vertical barrel, the wastewater injection pipe is communicated with a preliminary filtering mechanism, the preliminary filtering mechanism is communicated with a precipitation filtering mechanism, and the precipitation filtering mechanism is communicated with the adsorption filtering mechanism. Large-particle materials, silt fine materials and organic matter are separated from building construction wastewater in a layered mode, the situation that pipeline blockage is caused by the large-particle materials such as gravel materials, and consequently wastewater treatment cannot be conducted or wastewater treatment equipment is damaged is avoided, the wastewater treatment efficiency is effectively improved, the purification quality is improved, and meanwhile, the treatment cost is reduced. Large-particle materials and silt are respectively screened out and are recycled as building materials, so that resources are effectively saved, and the building construction cost is reduced.

Owner:ZHEJIANG TONGJI VOCATIONAL COLLEGE OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com