Patents

Literature

209 results about "Petrochemical wastewater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the petrochemical industry, the wastewater may contain high amounts of free and emulsified oil. Ecologix offers its propietary mobile Integrated Treatment Systems (ITS) to remove suspended solids, dissolved metals and hydrocabon from the wastewater.

High-temperature resistance polyamide composite membrane and preparation method thereof

InactiveCN103111195AImprove high temperature resistanceGood acid and alkali resistanceSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolymer scienceIndustrial waste water

The invention discloses a high-temperature resistance polyamide composite membrane and a preparation method thereof. The high-temperature resistance polyamide composite membrane is composed of a non-woven fabric layer, a porous supporting layer and a polyamide layer, wherein a porous supporting membrane material is prepared by adding one or more of a solubility high-temperature resistance polymer P1 and a commodity polymer P2 for preparation of a porous membrane material to a certain solvent and a pore-foaming agent and at least contains the P1. The polyamide composite membrane prepared by the method has very good high-temperature resistance performance and can be widely applied to water treatment composite membrane treatment devices needing to run at a high temperature in industries such as industrial wastewater treatment, petrochemical wastewater treatment, food, medicines and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

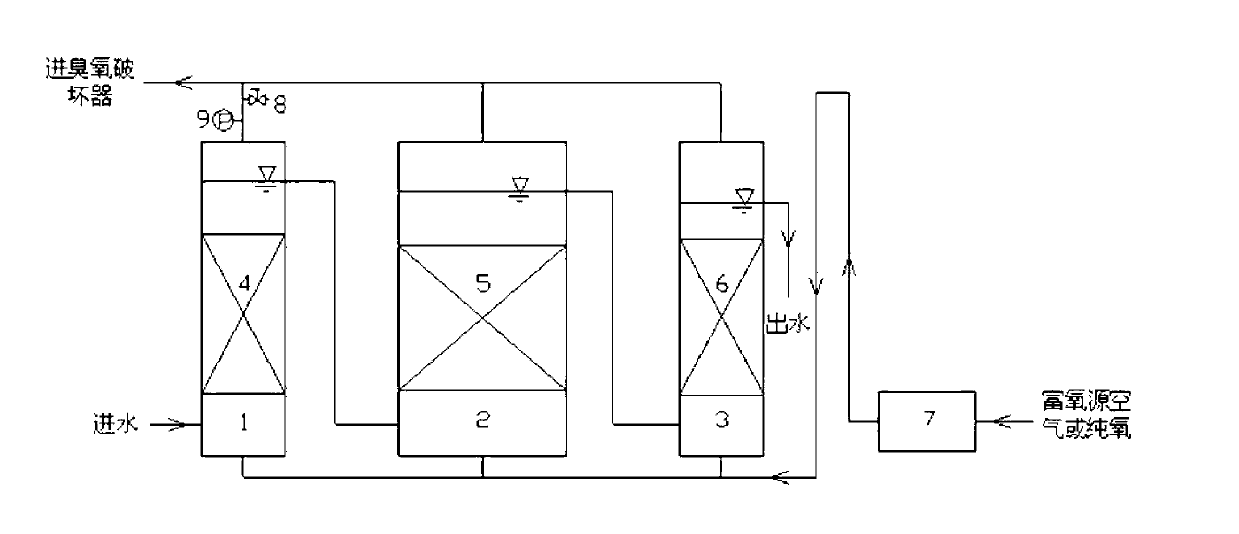

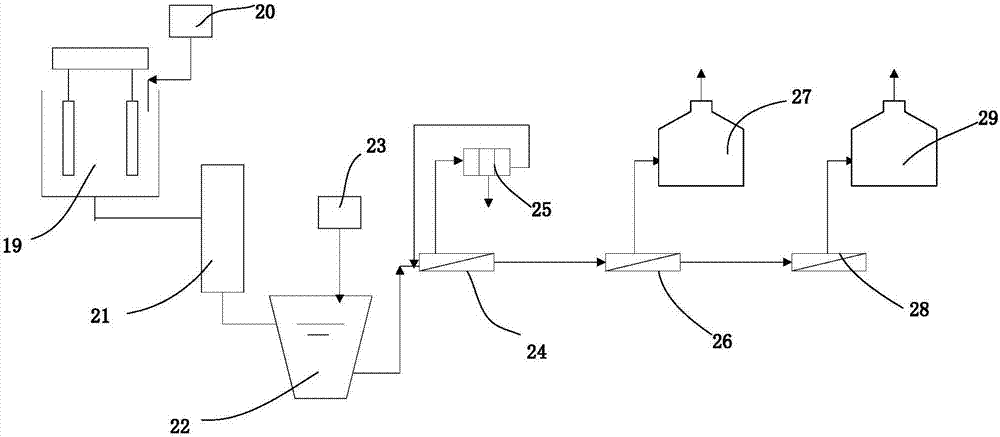

Process method for performing advanced treatment on petrochemical wastewater through catalytic ozonation

ActiveCN103274514AIncrease mass transfer rateIncrease the dissolved concentrationWater/sewage treatment by oxidationPorosityCatalytic oxidation

The invention discloses a process method for performing advanced treatment on petrochemical wastewater through catalytic ozonation. The method is characterized by comprising the following steps of: allowing petrochemical wastewater to sequentially flow through a pre-oxidation tower, a catalytic oxidation tower I and a catalytic oxidation tower II, and respectively filling high-porosity inert filler, activated aluminum oxide-based catalyst and granular active carbon in three towers, wherein the pre-oxidation tower operates under pressure. The ozone is prepared by an oxygen-enriched source or oxygen source ozone generator, and tail gas in the tower is collected and treated in a unified mode.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

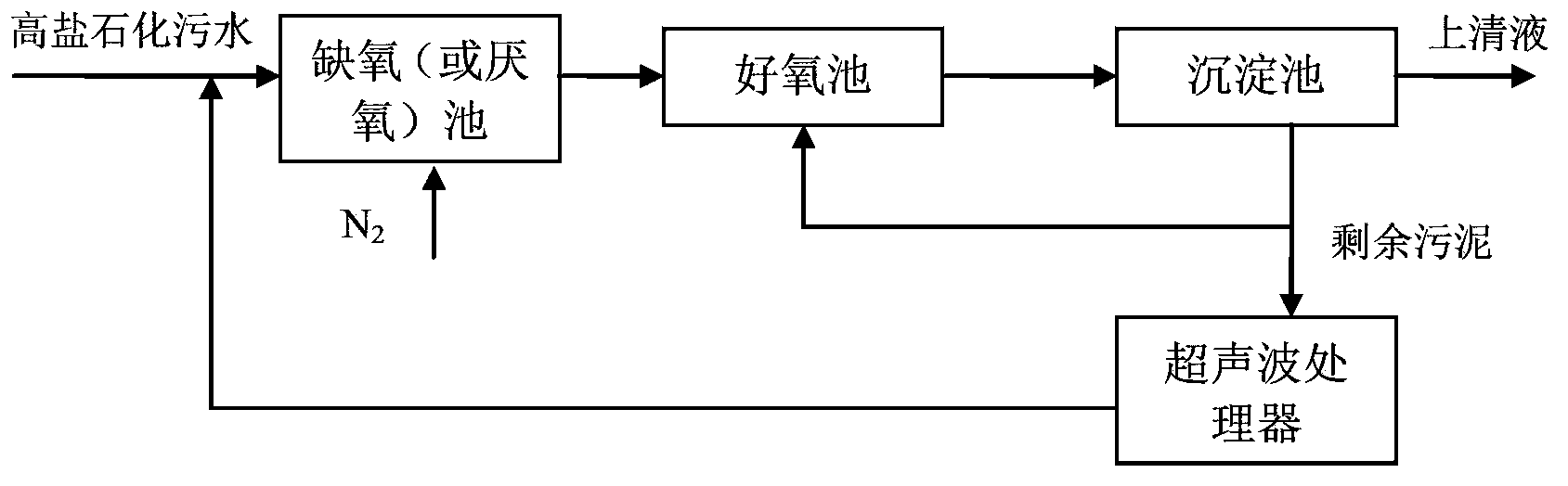

Method and apparatus for removing sulfate in high-salt petrochemical wastewater

ActiveCN103771670AImprove biodegradabilityImprove dehydration effectSludge treatmentTreatment with aerobic and anaerobic processesSulfate-reducing bacteriaSludge

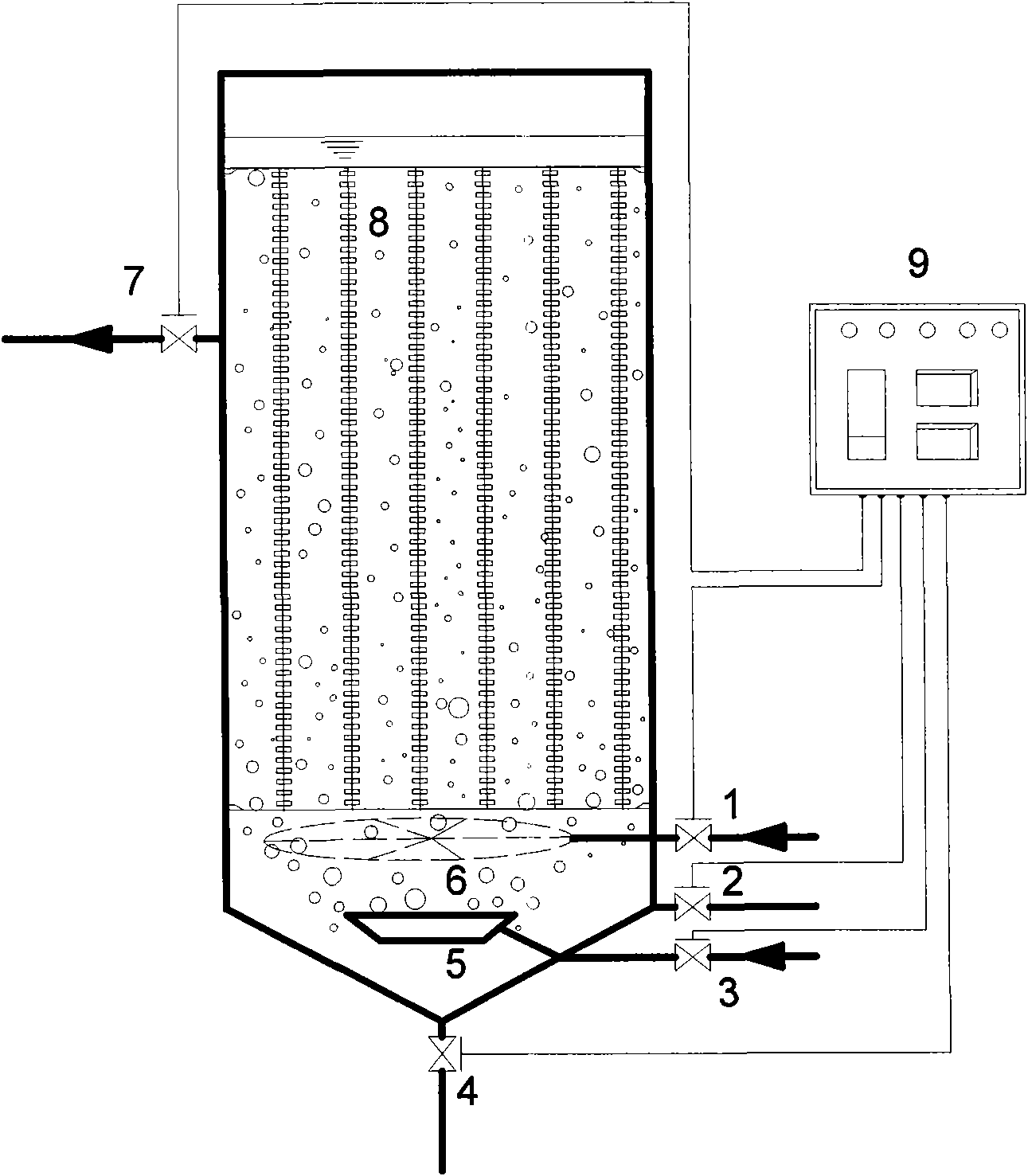

The invention relates to a removing method and a removing apparatus for sulfate in high-salt petrochemical wastewater, and belongs to the technical field of wastewater treatment. According to the present invention, in order to provide a method with characteristics of low cost, simpleness, convenience and high sulfate removal rate, and an apparatus thereof, according to the principle of conversion of sulfate into hydrogen sulfide with sulfate reducing bacteria, residual sludge produced by a high-salt petrochemical wastewater treatment system precipitation tank is subjected to ultrasonic wave degradation through an ultrasonic wave treatment, the obtained sludge or sludge supernatant and high-salt petrochemical wastewater are mixed, and then enter an anoxic tank or anaerobic tank so as to provide a carbon source for the sulfate reducing bacteria, and a blowing removing manner under a N2 solution is adopted to remove the hydrogen sulfide so as to reduce inhibition effects of hydrogen sulfide and other sulfides on the sulfate reducing bacteria; and the sulfate reduction can be effectively promoted, the sulfate removal rate can be increased, the calcium sulfate scaling tendency can be reduced, the maintenance period and the service life of the equipment can be prolonged, and the system stability is increased.

Owner:CHINA PETROLEUM & CHEM CORP

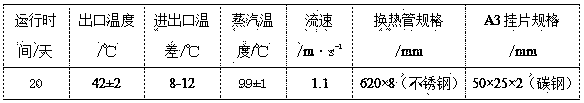

Device and method for dehydrating heavy sump oil

ActiveCN103396830AContinuous dehydrationSimple structureDewatering/demulsification with mechanical meansLong term treatmentsSewage

The invention discloses a device and a method for dehydrating heavy sump oil, which belongs to the technical field of petrochemical wastewater treatment. The method has the characterized by comprising the following steps of leading out sump oil in a tank area and entering the sump oil into a Y-shaped filter; filtering, boosting via a booster pump, and then entering the sump oil into a steam heat exchanger (1), and heating to 80-130 DEG C; then introducing the sump oil in a vortex dehydrator (2), and separating the sump oil into a low-water-content sump oil phase and a low-oil-content sewage phase, and entering the low-water-content sump oil phase into a coalescence dehydrator (4), further dehydrating to obtain low-water-content oil, and leading the low-water-content oil out of the device, and meanwhile, entering the low-oil-content sewage phase into a vortex oil remover (3), separating the low-oil-content sewage phase into a high-water-content sump oil phase and a sewage phase, discharging the sewage phase, and cyclically performing a dehydration treatment on the high-water-content sump oil phase. According to the device and the method, the continuous performance of dehydration for heavy sump oil is realized, deep dehydration and deep oil removal are performed simultaneously, and non-thorough parts can be cyclically dehydrated and separated; the device and the method are low in energy consumption, convenient to operate, high in dehydration rate, strong in adaptability to heavy sump oil with various water contents and dirt contents, and suitable for performing a long-term treatment on a large amount of heavy sump oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

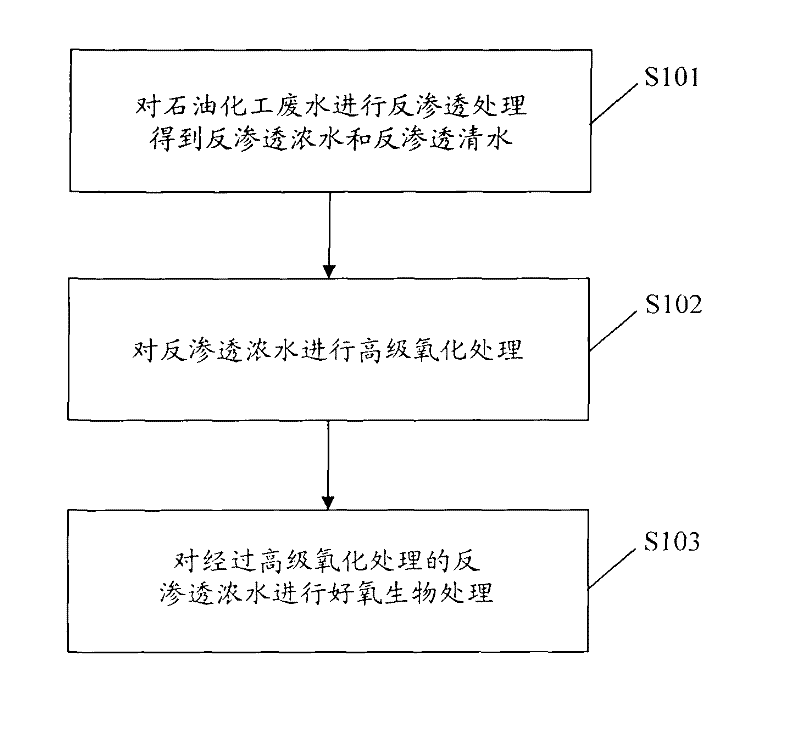

Process for treating petrochemical wastewater

InactiveCN102452766AImprove biodegradabilityImprove water qualityMultistage water/sewage treatmentAdvanced oxidation processEmission standard

The invention discloses a process for treating petrochemical wastewater. The process comprises the following steps of: performing reverse osmosis treatment on the petrochemical wastewater to obtain reverse osmosis concentrated water and reverse osmosis clear water; performing advanced oxidation treatment on the reverse osmosis concentrated water; and performing aerobic biological treatment on the reverse osmosis concentrated water subjected to advanced oxidation treatment. By the process for treating the petrochemical wastewater, a multi-process section series-connected treatment method is adopted, the biochemical degradability of the wastewater is improved by an advanced oxidation process, the effect of improving water quality can be relatively effectively achieved through aerobic biological treatment, and the petrochemical wastewater treated by the scheme meets the emission standard.

Owner:SHANGHAI CHEM IND PARK SINO FRENCH WATERDEV

Biomembrane treatment method of two-step wet-spun acrylic fiber wastewater

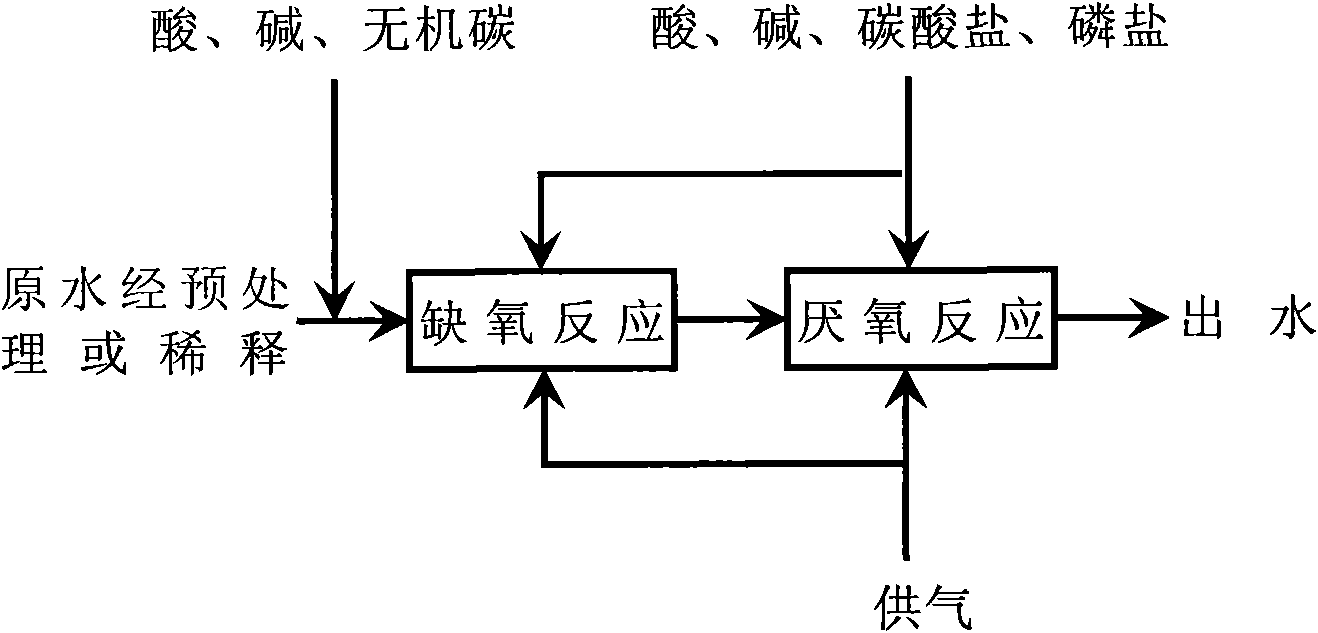

InactiveCN102070240AEasy to handleLess sludgeTreatment with aerobic and anaerobic processesWaste water treatment from textile industryChemical oxygen demandSpinning

The invention relates to a biomembrane treatment method of two-step wet-spun acrylic fiber wastewater. In the method, anaerobic reaction and aerobic reaction are adopted. Being treated by the method, the DMAC two-step wet-spun acrylic fiber wastewater, originally having the following technical indexes: 500-1,000mg / L of COD (chemical oxygen demand), 75-100mg / L of NH4-N, 50-100mg / L of DMAC (dimethyl acetamide), 0-120mg / L of acrylonitrile and pH of 6.0-9, have the following technical indexes: not more than 250mg / L of COD, not more than 4mg / L of NH4-N, not more than 2mg / L of DMAC, not more than 2.0mg / L of acrylonitrile and pH of 6.0-9. The method provided by the invention has the following advantages: the excess sludge is less, the process flow is short, and the method is suitable for treating the mixed wastewater in the two-step wet spinning production taking DMAC as a solvent as well as for treating the wastewater in spinning production adopting other solvents, the wastewater containing acrylonitrile and partial printing and dyeing, spinning and petrochemical wastewater.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

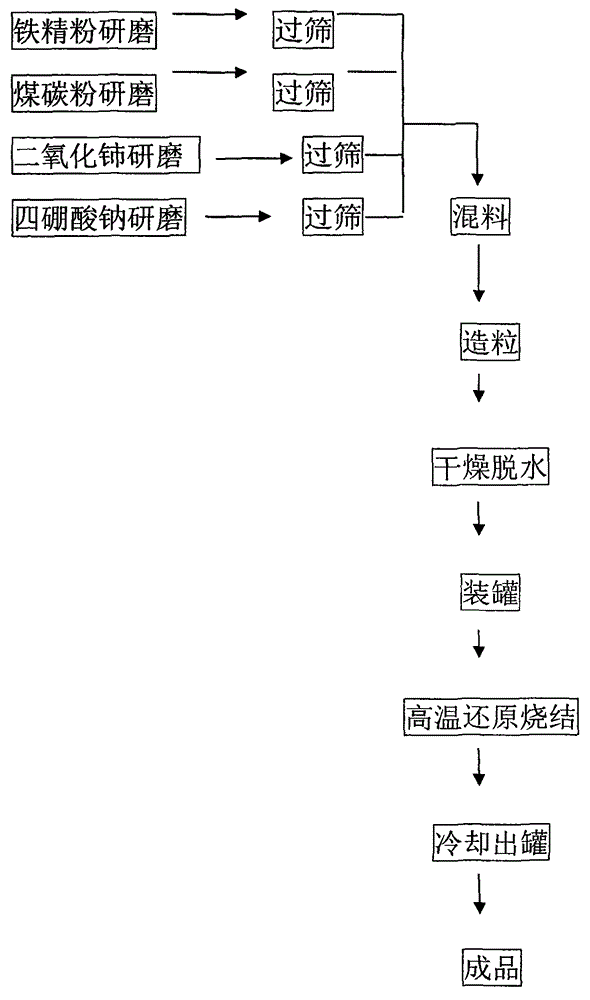

Spherical catalytic microelectrolytic environment-friendly material and preparation method therefor

InactiveCN105084470AImprove reaction speedGood removal effectWater/sewage treatmentHigh concentrationChemical oxygen demand

The invention relates to a spherical catalytic microelectrolytic environment-friendly material and a preparation method therefor. Aiming at the defects such as low reaction speed, low COD (Chemical Oxygen Demand) removal ratio, easiness in passivating and the like of the existing iron-carbon microelectrolytic materials, a special catalyst is added during the production of the spherical catalytic microelectrolytic environment-friendly material disclosed by the invention, the spherical catalytic microelectrolytic environment-friendly material is mainly prepared from 78-88wt.% of zero-valence active iron, 10-14wt.% of carbon, 1-5wt.% of catalyst and 1-3wt.% of auxiliary materials, is an iron, carbon and catalyst integrated composite spherical material and is prepared from fine iron powder, coal, the catalyst and a sintering agent through carrying out grinding and sieving, carrying out mixing and pelletizing, carrying out drying and canning, carrying out high-temperature reduction sintering and carrying out cooling and can discharging, wherein the catalyst is special compounded ceria, and the sintering agent is sodium tetraborate. During the treatment of a variety of high-concentration and toxic wastewater such as pharmaceutical wastewater, coking wastewater, petrochemical wastewater and the like, the reaction speed and COD removal ratio of the spherical catalytic microelectrolytic environment-friendly material are increased by 20-30% through the catalyst compared with those of the ordinary iron-carbon microelectrolytic materials.

Owner:GUANGZHOU S SUNNY ENVIRONMENTAL PROTECTION TECH CO LTD

Microorganism nutrient agent for sewage treatment

InactiveCN104630126ANo pollution in the processVarious nutrientsMicrobiology processesBiological water/sewage treatmentCelluloseSucrose

The invention discloses a microorganism nutrient agent for sewage treatment. The nutrient agent is prepared from the following raw materials in percentage by mass: 15-70% of potato powder, 10-20% of cane sugar, 5-40% of cellulose, 0.5-2% of monopotassium phosphate, 0.5-2% of sodium ammonium, 0.5-3% of ammonium sulfate, 0.5-2% of magnesium sulfate heptahydrate, 0.5-2% of magnesium nitrate, 0.5-2% of calcium chloride, 0.5-4% of ferrous sulfate, 2-15% of peptone and 0.5-8% of oleic acid. As starch and cellulose are taken as main components and are combined with a great amount of organic and inorganic elements, the microorganism nutrient agent can be used for acclimating microorganisms in living wastewater and petrochemical wastewater and used for adjusting microorganism death caused by various insufficient nutrition components or ratio disorder, and has the advantages of being low in price, easy to obtain, free of pollution and rich in nutrition component.

Owner:陕西绿邦环保科技有限公司

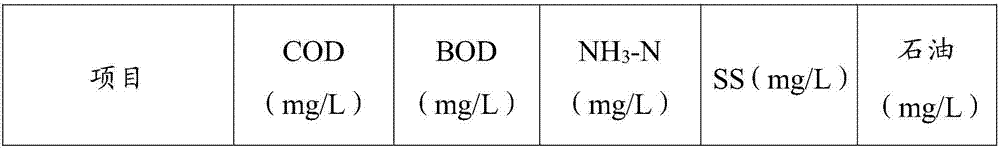

Treatment method of petrochemical wastewater

ActiveCN107117767AReduce usageSmall footprintWaste water treatment from quariesFatty/oily/floating substances removal devicesFlocculationBiological filter

The invention discloses a treatment method of petrochemical wastewater, which comprises the steps of oil separation treatment, air floatation treatment, advanced oxidization, flocculation treatment, solid-liquid separation treatment, biological treatment, and sterilization and disinfection. According to the treatment method of the petrochemical wastewater, most petroleum pollutants in the wastewater are treated by oil separation and air floatation, and then residual petroleum pollutants are removed by petroleum hydrocarbon degrading bacteria loaded on biological porous ceramic powder filled in a biological filter, so that the wastewater meets a discharge standard. In addition, most organic pollutants and partial NH3-N are removed by the advanced oxidization, and then residual NH3-N is removed by aerobic, anoxic and anaerobic regions formed by a biological filler filled in the biological filter, so that the concentration of various pollutants in the wastewater treated by the treatment method meets a standard discharge requirement.

Owner:青海省化工设计研究院有限公司

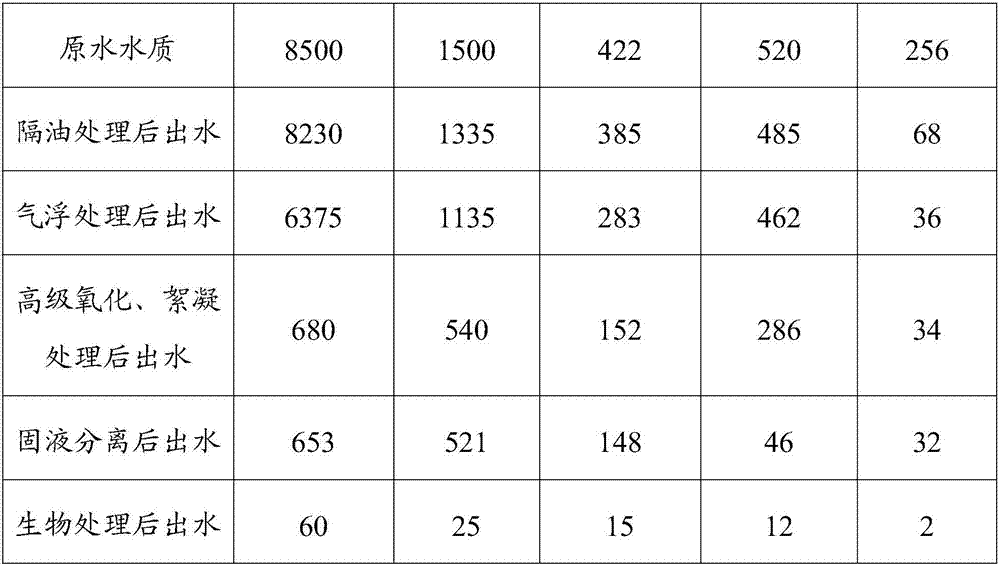

Petrified waste water treatment process

InactiveCN101318754ASimple technologyLow running costFatty/oily/floating substances removal devicesMultistage water/sewage treatmentOil processingSocial benefits

The invention relates to a process for treating petrochemical wastewater. The process comprises a plurality of working procedures and implementation steps such as oil removal by a sloping plate, advection oil separation, pressure floatation, primary floatation by a gas-liquid reaction, biotreatment, secondary floatation, neutralization and filtration and scum and sludge treatment. The process has simple equipment technology, easy implementation and low operating expense; and the process is utilized to rapidly treat wastewater produced in the process of petroleum processing with high efficiency and recycle oil products, thereby effectively reducing environmental pollution and achieving good economical and social benefits.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

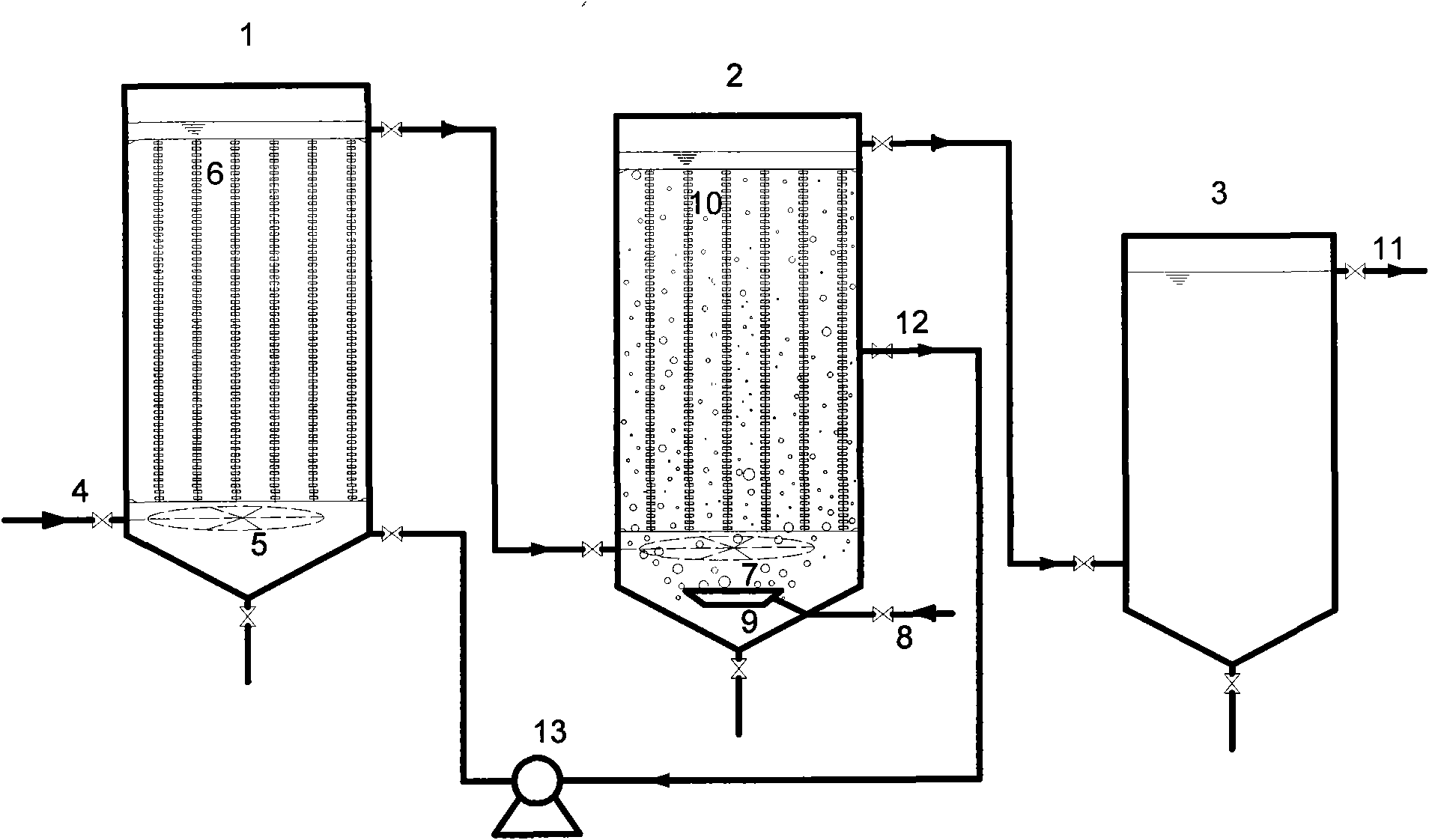

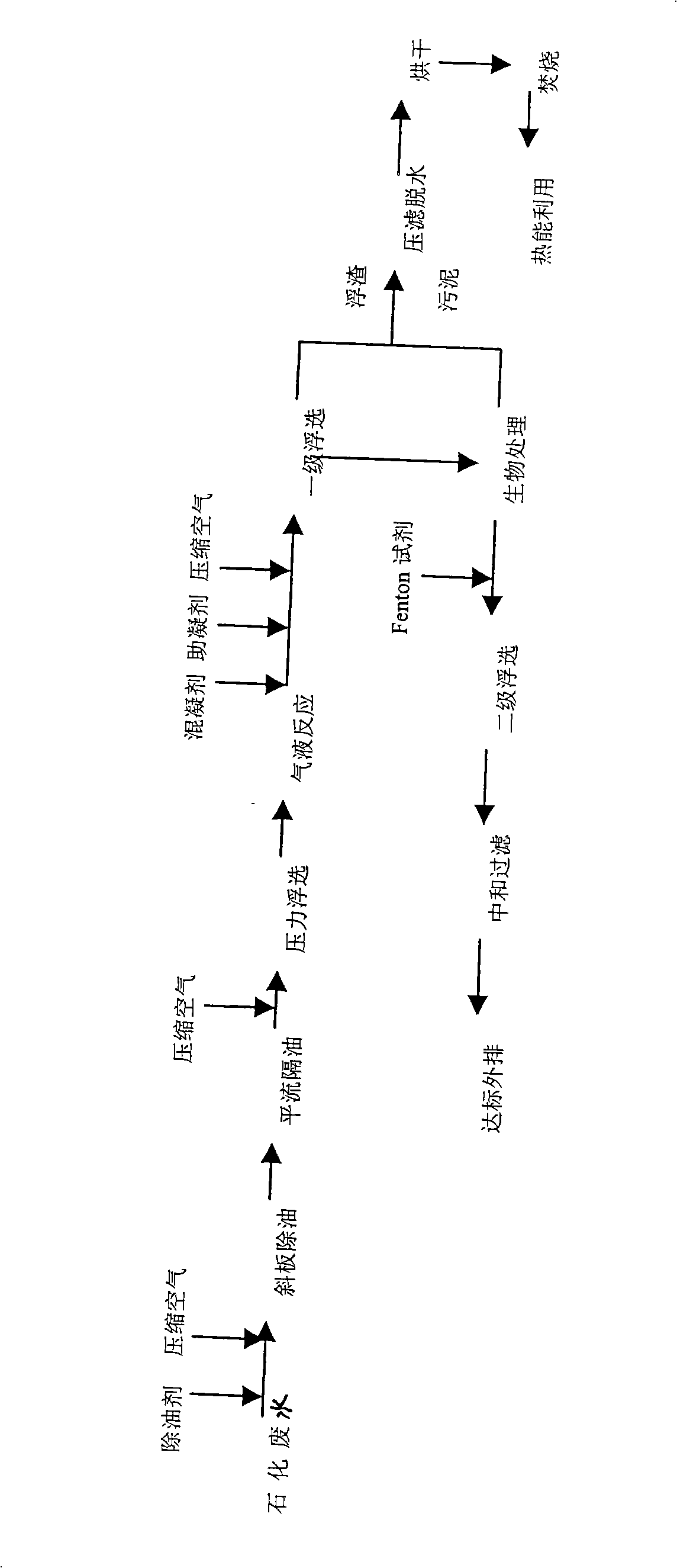

Device and method for treating petrochemical wastewater by using anaerobic hydrolysis acidification-A/O biological membrane method

ActiveCN104230114AImprove biodegradabilityGood removal effectMultistage water/sewage treatmentAeration rateSludge

The invention discloses a device and a method for treating petrochemical wastewater by using an anaerobic hydrolytic acidification-A / O biological membrane method. The method comprises the following steps: controlling the aeration rate through introducing air into a hydrolytic acidification pool, so that the hydrolytic acidification is in an anaerobic hydrolytic acidification state; arranging a settling pool at the tail section of the hydrolytic acidification pool to carry out sludge backflow, enabling liquid supernatant to enter an A / O biological membrane reactor, filling a porous plastic ball carrier filled with polyurethane foam at the O section, enabling outlet water to enter a secondary settling pool so as to carry out sludge-water separation, refluxing the sludge to the O section and discharging the liquid supernatant. The device and the method have the benefits that the petrochemical wastewater is treated by using the method at a normal temperature, acid and base do not need to be added to regulate a pH value, the reduction of sulfate in the petrochemical wastewater can be effectively restrained, the generation of H2S is reduced, and the corrosion of metal equipment is reduced; a whole wastewater processing system is high in efficiency and reliable in operation and is particularly suitable for upgrading and reconstruction of an existing petrochemical wastewater treatment plant.

Owner:TSINGHUA UNIV

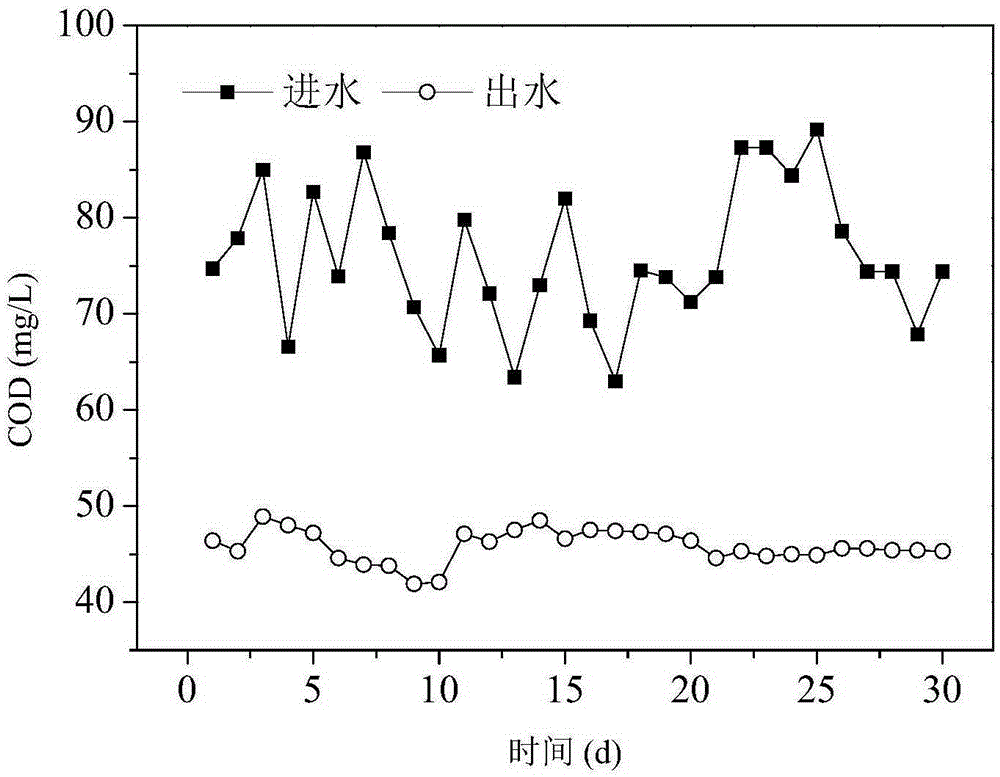

Method for using ozone-immobilized biological activated carbon for realizing deep treatment of industrial wastewater

InactiveCN101786686ADepth processing worksExtended service lifeWater/sewage treatment by sorptionWater/sewage treatment by oxidationUltrafiltrationWater quality

The invention discloses a method for using ozone-immobilized biological activated carbon for realizing the deep treatment of industrial wastewater and relates to a deep treatment method of the industrial wastewater. The method can solve the problems that the existing industrial wastewater deep treatment processes have the common defects of greater investment, unstable process operation, unstable treatment effect and incapability of meeting environmental protection requirements, thereby causing difficult deep treatment of the industrial wastewater; and the method can also solve the problem that the adoption of the ozone-immobilized biological activated carbon technology is not applicable to the industrial wastewater deep treatment. The method comprises the following steps: 1) leading outlet water of pre-treatment to enter into a contact oxidation tower, and carrying out ozone aeration; 2) injecting the outlet water from the contact oxidation tower into an immobilized biological activated carbon tank; and 3) leading the outlet water from the immobilized biological activated carbon tank to enter into an ultrafiltration water tank for completing the method. The method can effectively carry out the deep treatment of the wastewater, reduce the cost, stabilize the process operation and stabilize the treatment effect, thereby being applicable to the deep treatment processes of petrochemical wastewater, printing and dyeing wastewater, coking wastewater and other types of wastewater and leading the water quality COD of the outlet water to be lower than 50mg / L.

Owner:HARBIN INST OF TECH

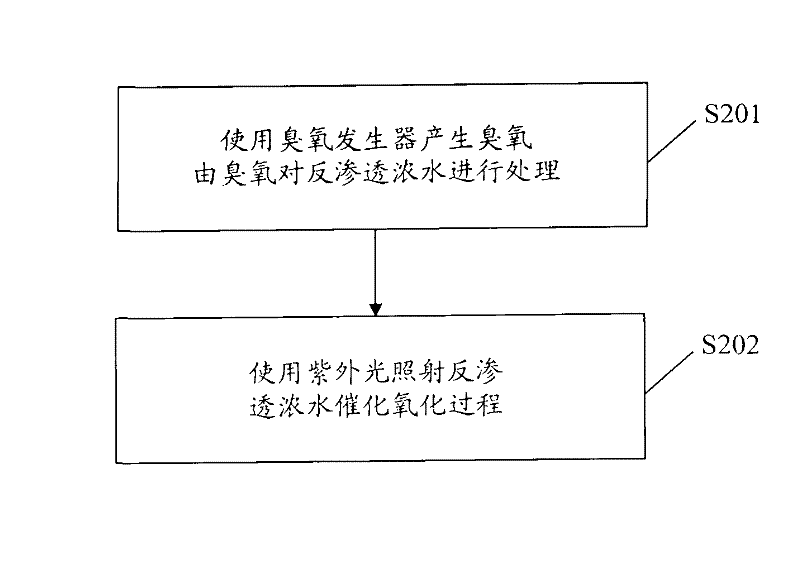

Method for treating reverse osmosis concentrates of petrochemical wastewater

ActiveCN102126781ASimple methodEasy to handleWater/sewage treatment by oxidationTreatment effectRetention time

The invention provides a method for treating reverse osmosis concentrates of petrochemical wastewater. The method comprises the following steps: in the presence of a supported metal oxide catalyst, feeding ozone into the reverse osmosis concentrates of the petrochemical wastewater to carry out oxidation reaction, wherein the dosage of ozone is 70-100g / m<3>; the hydraulic load of the catalyst bed is 2-5m3 / m<3>.h; the empty tower retention time is 12-20 minutes; the effluent COD is reduced below 50mg / L; the catalyst is formed by using a carrier to support reactive metal oxides; the carrier is selected from activated aluminium oxide or activated carbon; and the reactive metal oxides derive from one or more of manganese nitrate and copper nitrate. By utilizing the complex phase catalytic oxidation method to treat the reverse osmosis concentrates of the petrochemical wastewater with ozone, the method is simple and practical, the cost is low, the method has better treatment effect and the effluent COD can meet the requirement of the emission index.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-salt waste water treatment method

ActiveCN104609621AEfficient use ofSimple methodSeawater treatmentWater/sewage treatment bu osmosis/dialysisSalt-wastingEvaporation

The invention discloses a high-salt waste water treatment method. According to the high-salt waste water treatment method, concentration of high-salt waste water is carried out via membrane distillation; an obtained membrane distillation concentrated water is taken as a driving liquid of forward osmosis; the membrane distillation concentrated water is diluted via continuous concentration of forward osmosis feeding liquid collateral circulation raw water, when the concentration of the diluted membrane distillation concentrated water is equal to a certain concentration, the membrane distillation concentrated water is recycled to a membrane distillation unit for concentration treatment; and the above steps are repeated, so that deep concentration of the high-salt waste water is realized, and water of the high-salt waste water and forward osmosis raw water is recycled as far as possible. The high-salt waste water treatment method can be used for processing high-salt waste water, and can also be used for concentration treatment of river water, brackish water, seawater, surface water, municipal wastewater, petrochemical wastewater, landfill leachate, and solutions containing medicines and protein. No impressed pressure or little impressed pressure is needed for treatment; the high-salt waste water treatment method is simple and convenient; operation is simple; and operation cost is low compared with multiple-effect evaporation.

Owner:CHINA PETROLEUM & CHEM CORP +1

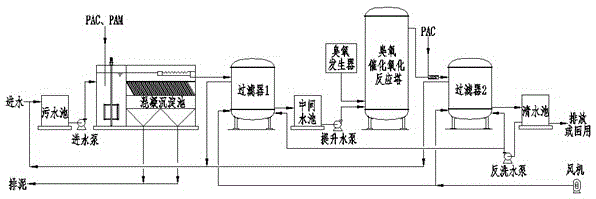

Petrochemical wastewater advanced treatment method

ActiveCN105060633AAvoid the problem of narrow adaptationIncrease profitMultistage water/sewage treatmentFlocculationFiltration

A petrochemical wastewater advanced treatment method includes the following steps: a, discharging secondary treatment effluent of petrochemical wastewater into a sewage pool, ascending the effluent into a coagulation sedimentation tank by a water inlet pump, at the same time, adding a flocculant PAC and a flocculant PAM to the coagulation reaction pool, determining the PAC adding quantity to be 10-30 mg / L and the PAM adding quantity to be 0.2-0.8 mg / L according to water quality conditions of the petrochemical wastewater, after sedimentation, allowing the effluent to enter a primary filter, filtering to remove residual suspended solids, and allowing the effluent after filtration to flow into a middle water pool; b, sending the wastewater in the middle water pool to a catalytic oxidation reactor by a lifting pump with the residence time of 0.5-1.5 h, feeding water and simultaneously adding ozone with the ozone adding quantity of 20-50 mg / L, and carrying out a catalytic oxidation reaction; and c, allowing the effluent of the catalytic oxidation reactor to self-flow through a pipeline mixer, adding the flocculant PAC in the pipeline mixer with the PAC adding quantity of 2-4 mg / L, allowing the wastewater after mixing to enter a secondary filter, carrying out micro-flocculation and filtration treatment, allowing clear water after filtration to enter a clear water pool, and meeting requirements of discharge or reuse.

Owner:PENYAO ENVIRONMENTAL PROTECTION

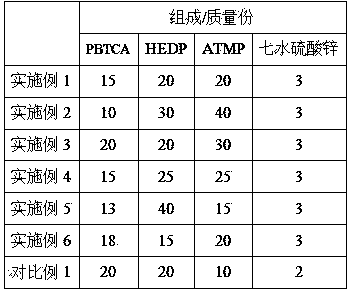

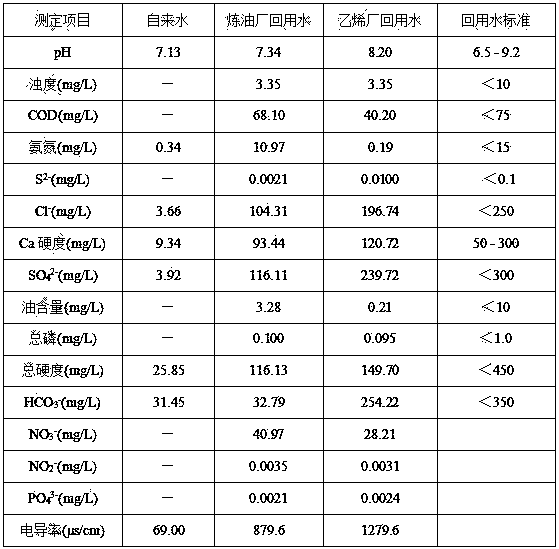

Composite slow-release scale inhibitor suitable for petrochemical wastewater reusing circulating water system

ActiveCN104230015AComply with corrosion rate less than 0.075 mm/a anti-corrosion requirementsAdd lessScale removal and water softeningAqueous corrosionPhosphate

The invention discloses a composite slow-release scale inhibitor suitable for a petrochemical wastewater reusing circulating water system. The composite slow-release scale inhibitor comprises 2-butane phosphate-1,2,4-tricarboxylic acid, hydroxy ethylidene diphosphonic acid, amino trimethylene phosphonic acid and zinc sulfate. After the composite slow-release scale inhibitor is adopted, by virtue of dynamic simulation experiment on oil refinery reuse water, the water quality inhibition rate is 86.18%; by virtue of the dynamic simulation experiment on ethylene plant reuse water, the water quality inhibition rate is 86.44%, and the scale inhibiting rate is 87.42%; the corrosion rate is reduced to 0.0168 mm / a and 0.0091 mm / a, which meets the anticorrosion requirement that the corrosion rate of China petrochemical circulating cooling water is less than 0.075 mm / a. Compared with the traditional polyphosphate carboxylate composite slow-release scale inhibitor, the composite slow-release scale inhibitor disclosed by the invention has the advantages of small addition amount and good corrosion inhibition effect and scale inhibition.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

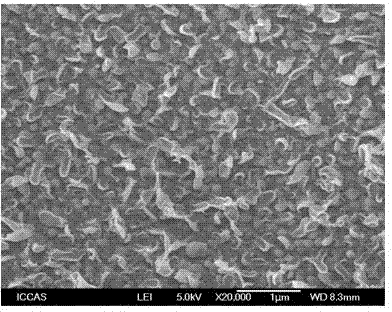

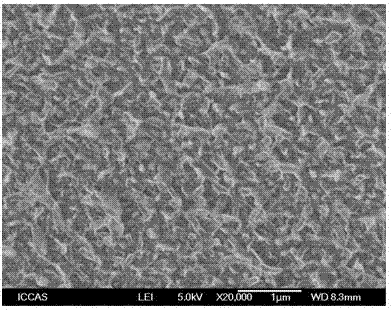

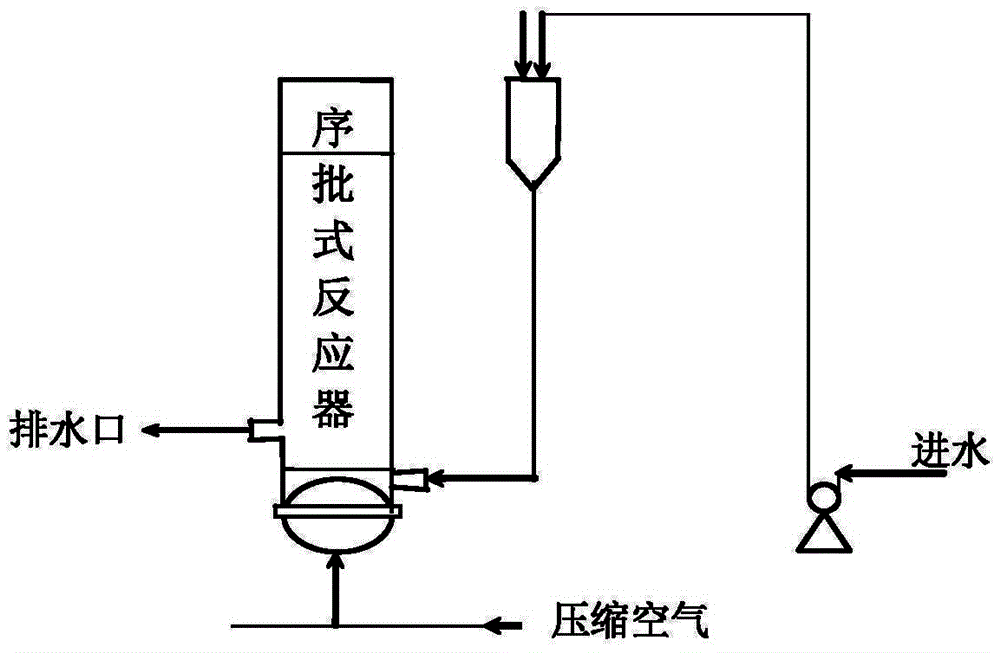

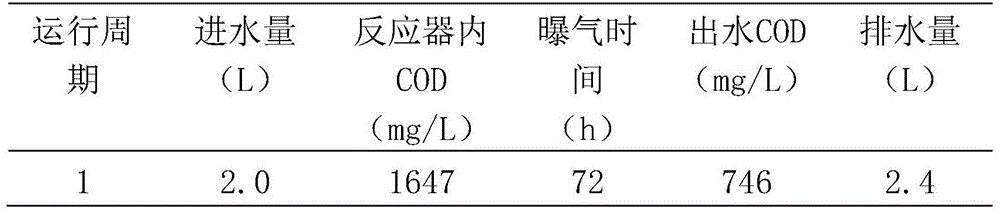

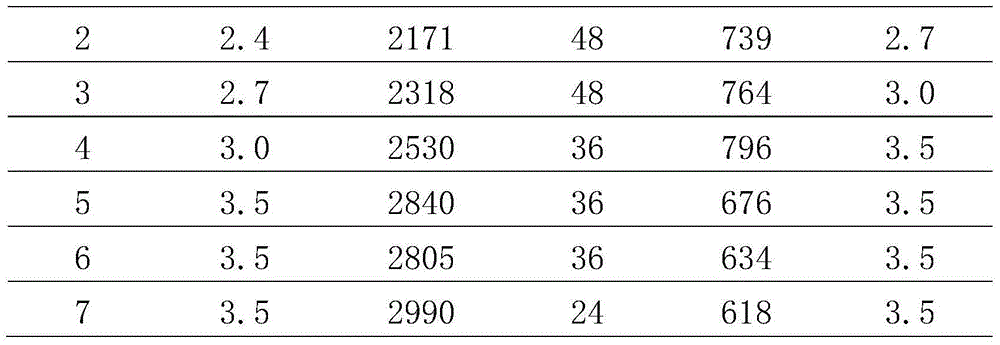

Aerobic granular sludge culture method

ActiveCN104556362ASalt tolerantWith impact resistanceNature of treatment waterSustainable biological treatmentActivated sludgeSequencing batch reactor

The invention relates to an aerobic granular sludge culture method. The aerobic granular sludge culture method comprises the following steps of 1, inoculating a sequencing batch reactor with activated sludge, 2, adjusting a pH value of petrochemical wastewater to be treated by sulfuric acid and pumping the petrochemical wastewater with an adjusted pH value into the reactor, 3, carrying out aeration by an aeration device laid on the bottom of the reactor so that the activated sludge and the petrochemical wastewater are mixed and undergo a full reaction, 4, stopping aeration and carrying standing for sludge-water separation, and 5, discharging a certain amount of water by a water outlet of the reactor and periodically repeating the steps of 2 to 5 in the reactor. The aerobic granular sludge culture method utilizes the petrochemical wastewater to carry out aerobic granular sludge culture. The cultured aerobic granular sludge has salt resistance, impact resistance and high-density organic load resistance, can be directly used for treatment on high-salt, high-COD and strong basic petrochemical wastewater, solves the bottleneck problem of use of aerobic granular sludge in petrochemical wastewater treatment and further widens an aerobic granular sludge technology application scope.

Owner:CHINA PETROLEUM & CHEM CORP +1

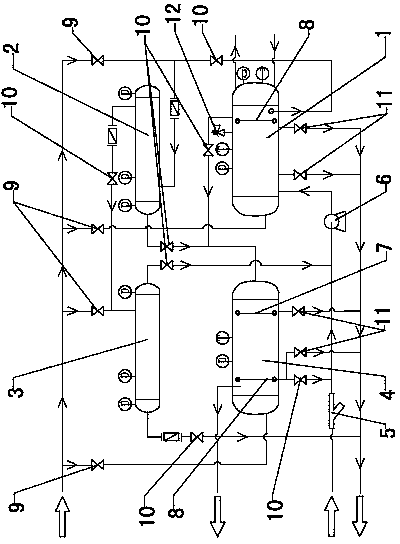

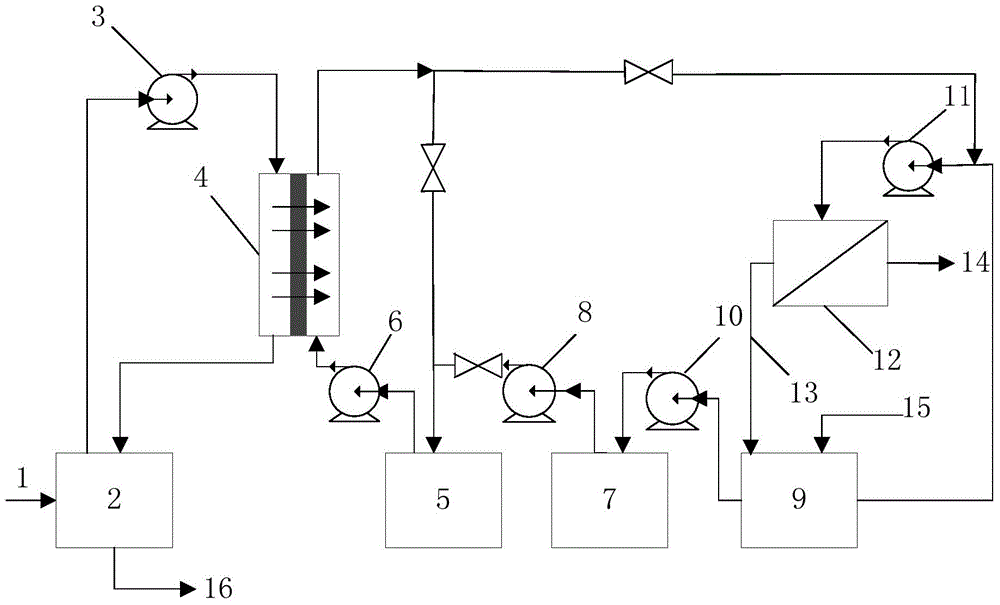

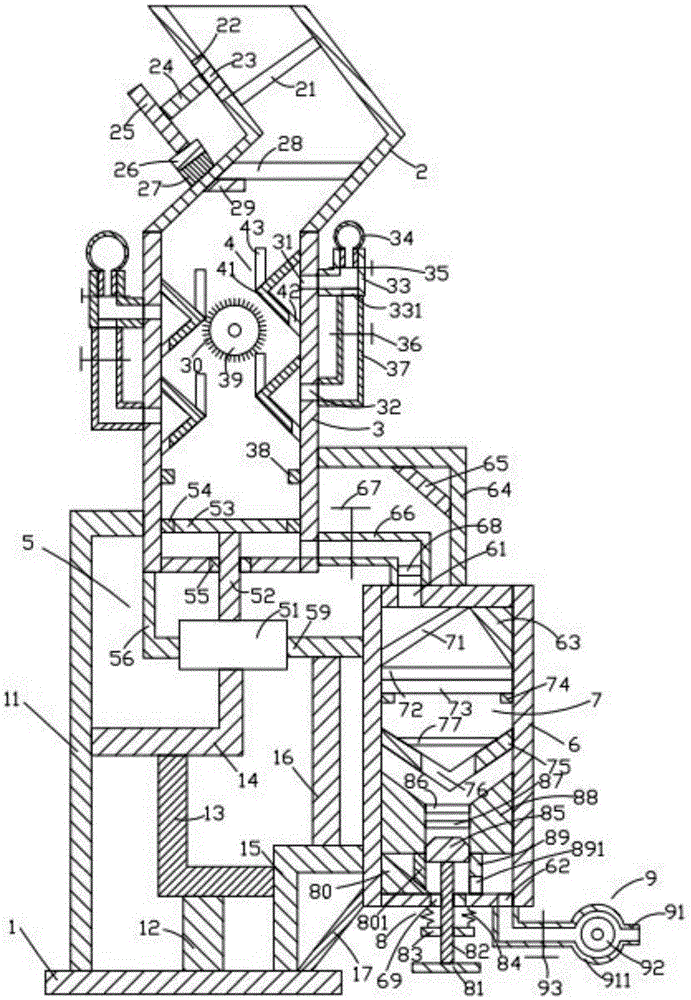

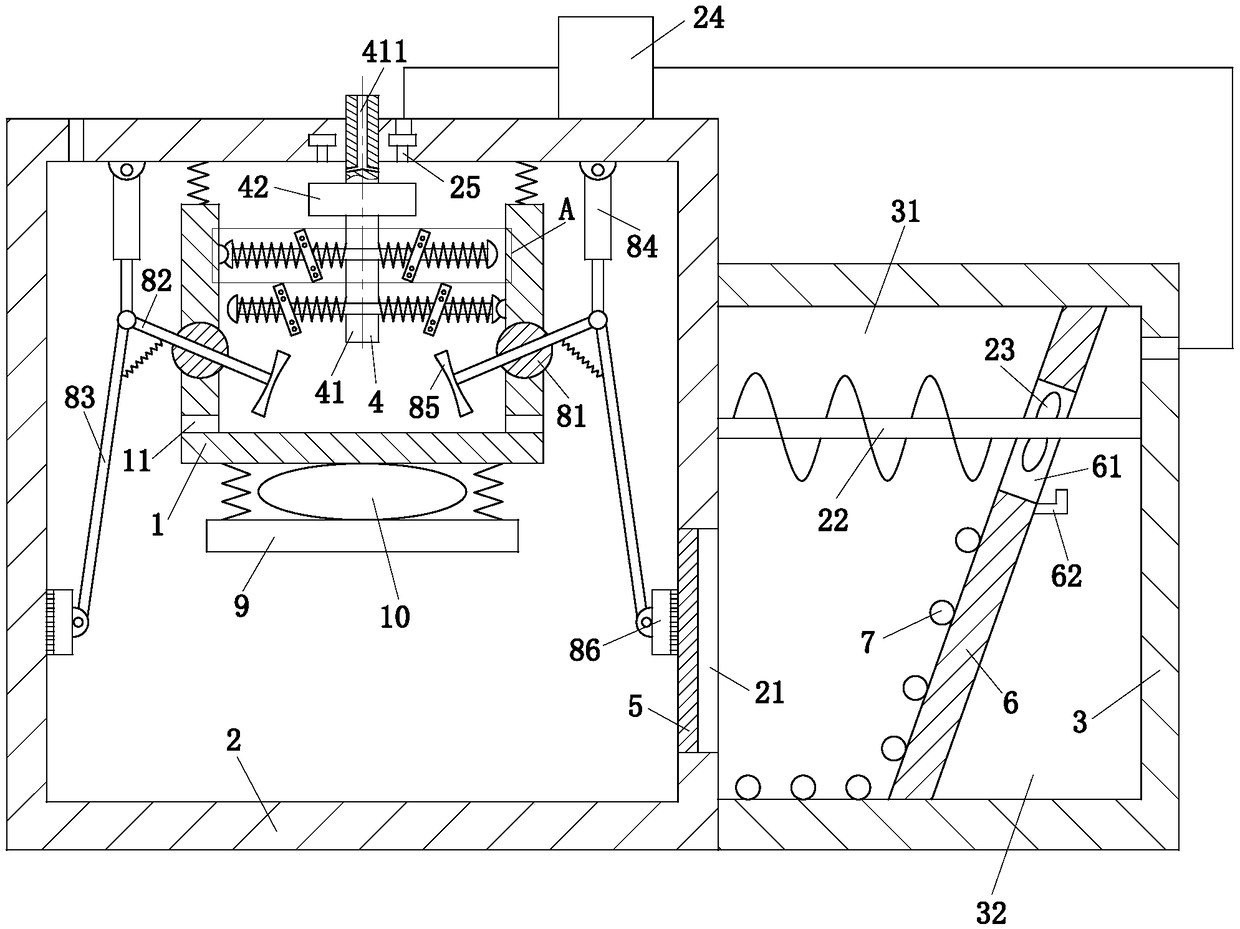

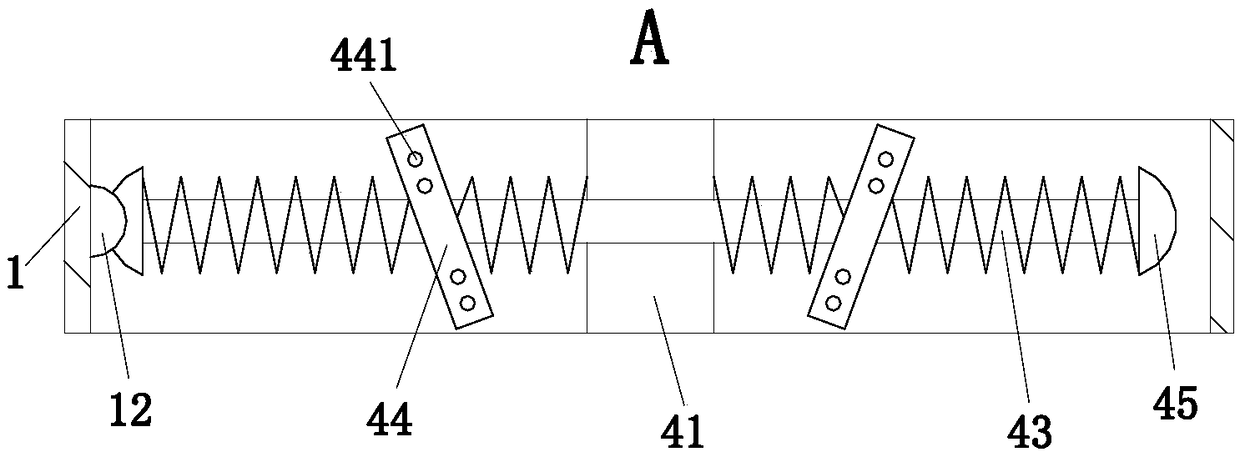

Petroleum and petrochemical wastewater recycling and treating device

InactiveCN105330083ASimple structureEasy to useWater contaminantsBiological treatment apparatusBristleSewage

The invention provides a petroleum and petrochemical wastewater recycling and treating device which comprises a bottom plate, a feeding frame, a first frame body, first purification devices, an air cylinder device, a second frame body, a second purification device, a blocking device and a discharging device. The bottom plate is provided with a first bracket, a first supporting rod, a second bracket, a third bracket, a fourth bracket, a second supporting rod and a first inclined rod. The feeding frame is provided with a first filtering mesh, a first through hole, a first blocking block, a first connection rod, a first holding rod, a first magnet, a second magnet, a second filter mesh and a first fixing block. The first frame body is provided with first through holes, second through holes, first pipes, air bags, first valves, second pipes, second valves, first positioning blocks, first rollers and bristles. Each first purification device comprises a fist isolation frame, a fourth through hole and a third filtering mesh. The air cylinder device comprises an air cylinder, a first push rod, a first blocking plate and a first sealing ring. By means of the petroleum and petrochemical wastewater recycling and treating device, petroleum and petrochemical wastewater can be effectively purified and treated, and treatment efficiency is high.

Owner:张萍

Process and device for zero discharge treatment of coal chemical wastewater

ActiveCN107311374AEfficient accumulationEfficient accumulation and removalTreatment involving filtrationMultistage water/sewage treatmentSludgeFiltration

The invention relates to a process and device for zero discharge treatment of coal chemical wastewater and belongs to the technical field of water treatment. The process comprises the steps of adding a bio-surfactant into coal wastewater, and then causing the bio-surfactant to undergo electric flocculation treatment; causing electric flocculation sludge to undergo dehydration and incineration treatment; sending water generated by the electric flocculation into an iron carbon microelectrolysis tower for oxidation treatment; adding NaOH and Na2CO3 into the water generated by iron carbon microelectrolysis, and causing calcium and magnesium in salt-containing wastewater to precipitate; sending the obtained wastewater into a ceramic ultrafiltration membrane to be filtered, and sending a concentrated solution of a nanofiltration membrane into a first evaporator for evaporation and crystallization, and obtaining recycled Na2SO4; sending water generated by the nanofiltration membrane into a reverse osmosis membrane for filtration, sending a concentrated solution of the reverse osmosis membrane for evaporation and crystallization, and obtaining recycled NaCl.

Owner:SUZHOU XINER ENVIRONMENTAL TECH CO LTD

Method for treating petrochemical waste water and biochemical tail water through recycled coagulant

InactiveCN102583679AStrong oxidation abilityIncrease oxidation potentialSludge treatment by oxidationWater/sewage treatment by flocculation/precipitationPetroleumOxidizing agent

The invention provides a method for treating petrochemical waste water and biochemical tail water through a recycled coagulant, relates to a petrochemical waste water and biochemical tail water treatment method and in particular relates to coagulation in the waste water and biochemical tail water treatment method and a coagulation mud oxidation regenerating and recycling. The treatment method comprises the following steps: (1) performing coagulation treatment by using a composite coagulant: adding the composite coagulant and coagulant aid into the petrochemical waste water and performing mud water separation to obtain coagulation precipitate coagulation mud; (2) performing coagulation mud and iron carbon micro-electrolytic reaction: adding iron carbon filler into the coagulation mud, reacting for 0.5 to 3 hours, and acidifying to maintain the pH value of the coagulation mud to be acidic; (3) performing Fenton-like oxidative regeneration of the coagulation mud: directly adding oxidant into the micro-electrolytic water containing a large number of Fe<2+>, coupling with the Fe<2+> in the coagulation mud, and performing Fenton-like oxidation reaction for 0.5 to 3 hours; and (4) recycling the coagulation mud, wherein the coagulation property of the coagulant in the coagulation mud after oxidation is recovered; the coagulation mud can be reused for coagulation of the waste water and then is oxidized again; and the coagulation can be reused.

Owner:CHINA PETROLEUM & CHEM CORP +1

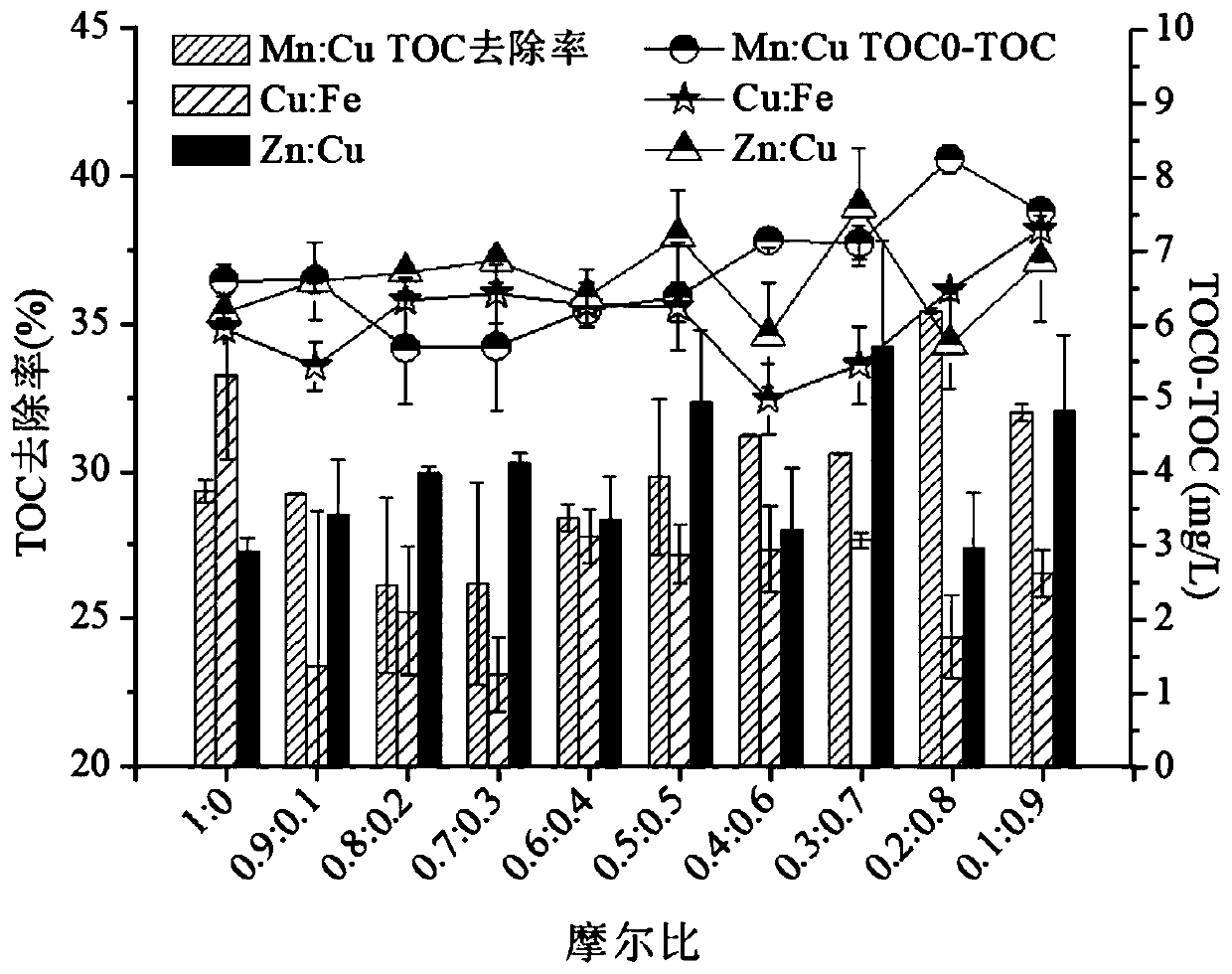

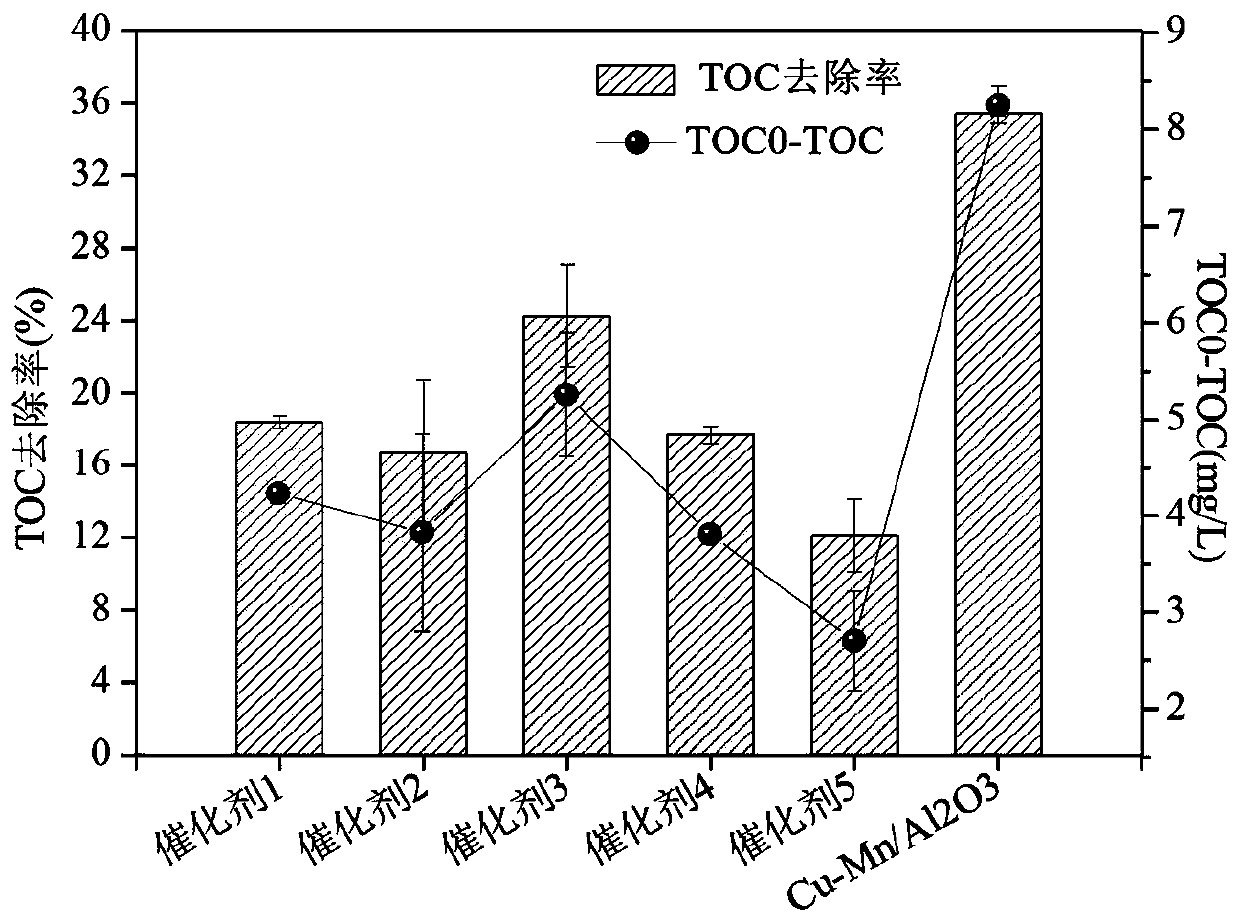

Supported bi-component metal oxide catalyst for advanced treatment of petrochemical wastewater and preparation method thereof

InactiveCN111282577ALarger than surfaceLarge apertureWater contaminantsHeterogenous catalyst chemical elementsPtru catalystProcess engineering

The invention discloses a preparation method of an obligate supported bi-component metal oxide catalytic ozonation catalyst for advanced treatment of petrochemical wastewater. Specifically, the supported metal oxide catalytic ozonation catalyst is prepared from commercially available activated alumina balls through the steps of carrier activation, impregnation liquid preparation, carrier impregnation, catalyst roasting and catalyst cleaning. The method disclosed by the invention is simple, low in cost and easy to prepare, and the prepared catalyst has relatively high removal efficiency on secondary effluent of petrochemical wastewater; and the product has good stability, can be repeatedly used, and has very important meanings for application of a catalytic ozonation technology of a petrochemical sewage treatment plant, energy conservation and consumption reduction.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

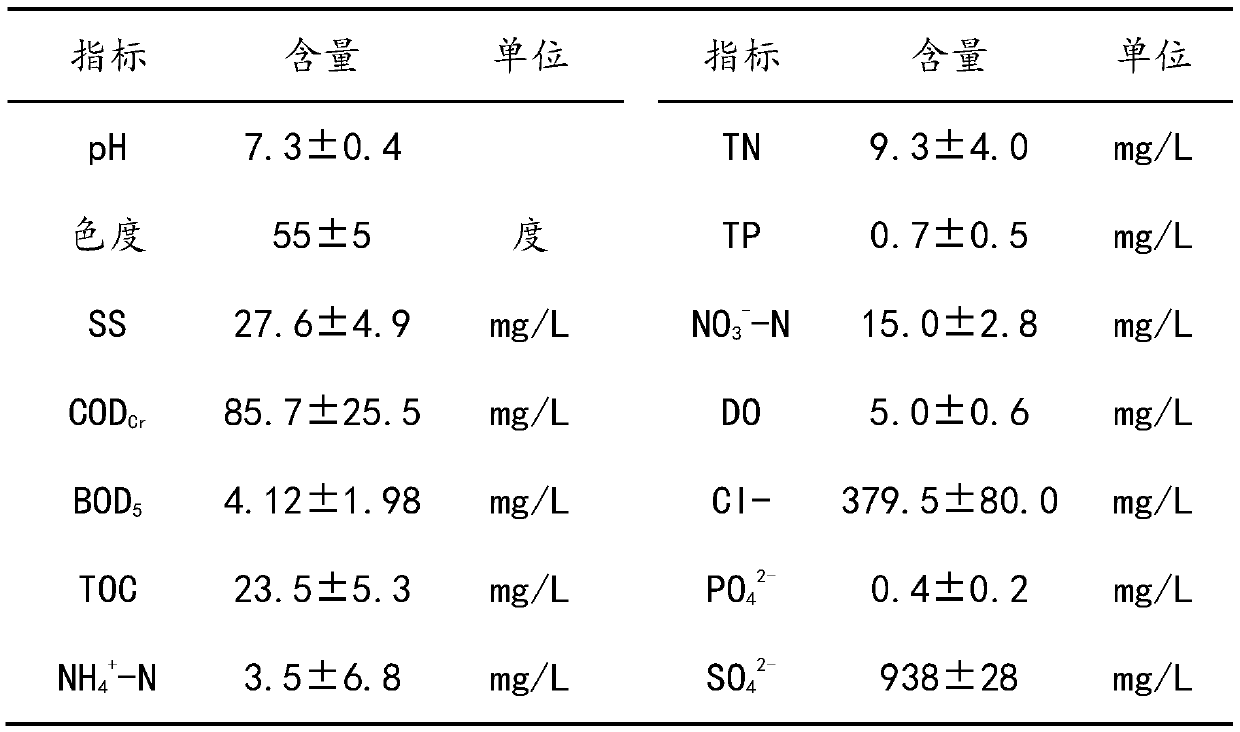

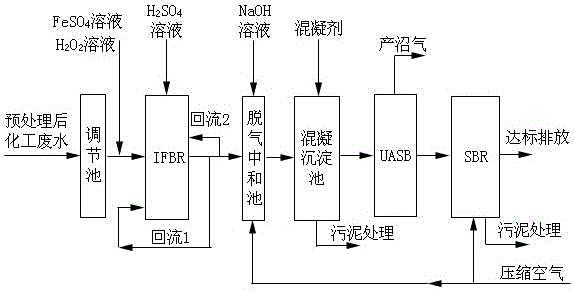

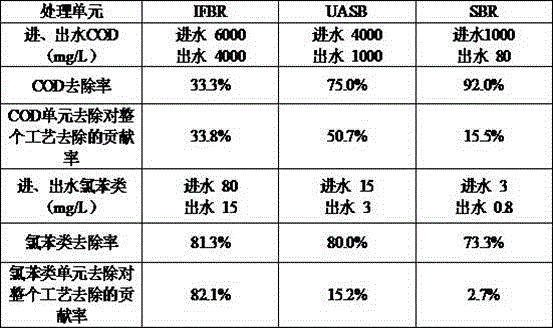

Novel combined process for treating chemical wastewater

InactiveCN105884154AMeet environmental requirementsSimple processWater treatment parameter controlWater treatment compoundsSequencing batch reactorFluidized bed

The invention provides a novel combined process for treating chemical wastewater. The process adopts a regulating tank, an improved Fenton fluidized bed, a degassing neutralizing tank, a coagulative precipitation tank, an up-flow anaerobic sludge bed and an SBR (sequencing batch reactor), wherein the units are connected by a water pipe in sequence to treat the chemical wastewater. The novel combined process has the beneficial effects that the process is optimized and is clear and concise in route; the overall COD (chemical oxygen demand) removal rate is not less than 95%; the removal rate of characteristic organic pollutants is not less than 95%; and the process is convenient to operate and manage, is stable and is low in investment and operating costs.

Owner:YANCHENG INST OF TECH

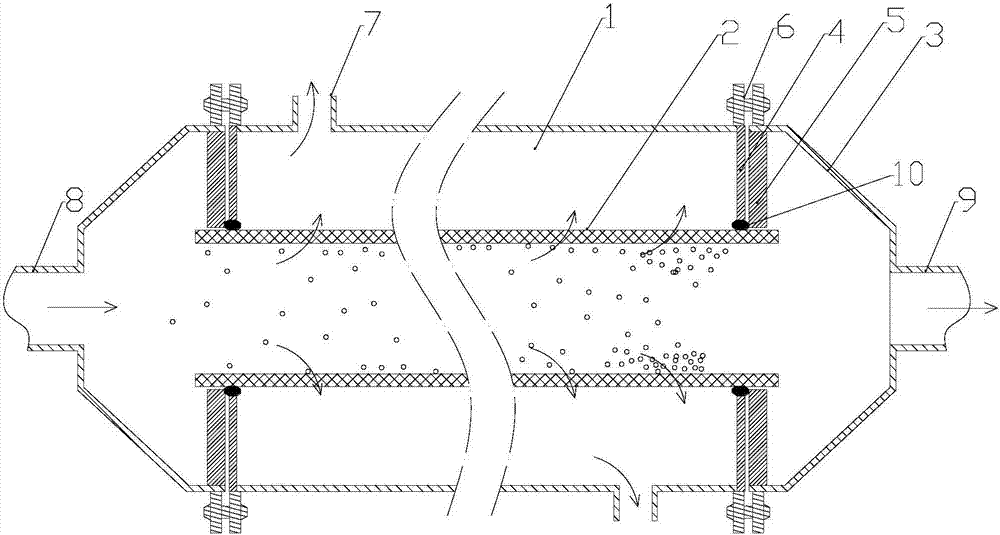

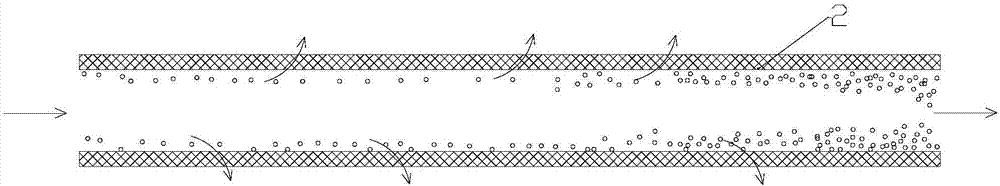

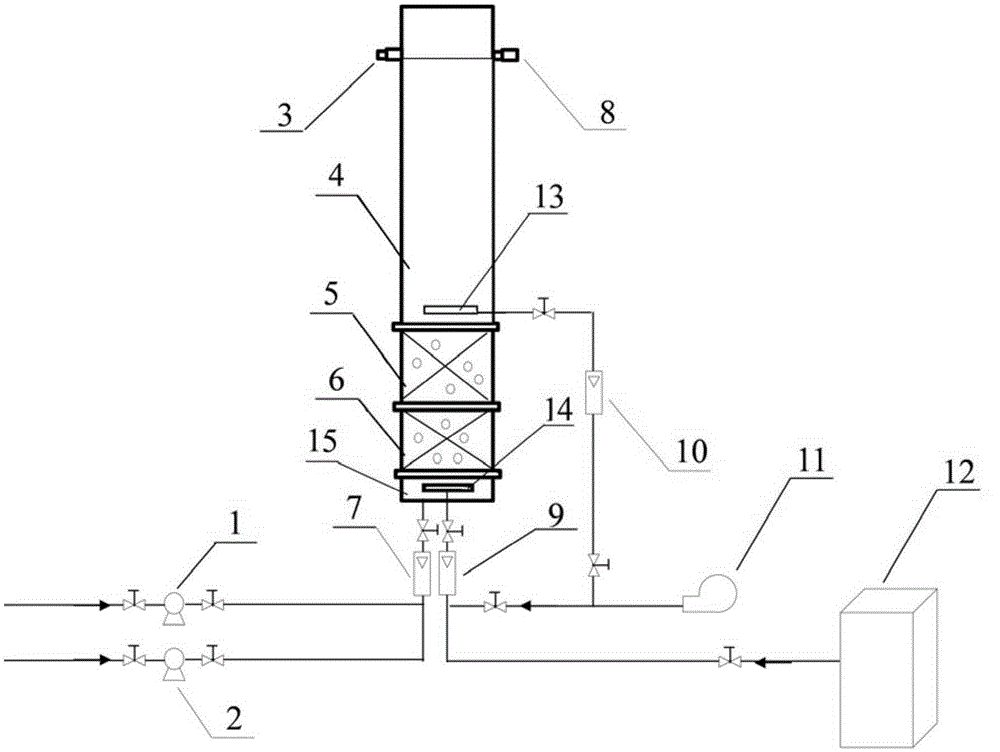

Upflow ozone biological aerated filter device and petrochemical wastewater treatment method

InactiveCN105174432AImprove biodegradabilityCost-effective removalTreatment using aerobic processesSustainable biological treatmentOzone generatorCatalytic decomposition

The invention discloses an upflow ozone biological aerated filter device which comprises an integrated seal tower, an air blower (11) and an ozone generator (12). A water inlet is formed in the bottom of the seal tower, a water outlet (3) is formed in the upper portion of the seal tower, the middle of the seal tower is provided with a treatment area, and the treatment area sequentially comprises an ozone catalytic ozonation area (6), an ozone catalytic decomposition area (5) and a biological aerated filter area (4) from bottom to top. The invention further discloses a petrochemical wastewater treatment method by adopting the upflow ozone biological aerated filter device. According to the upflow ozone biological aerated filter device and the petrochemical wastewater treatment method, the technology is compact, the floor area is small, the treatment efficiency is high, the ozone catalytic decomposition area is filled with manganese sand, and the influence of residual ozone in yielding water of the ozone catalytic ozonation area on the biological aerated filter area can be reduced.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

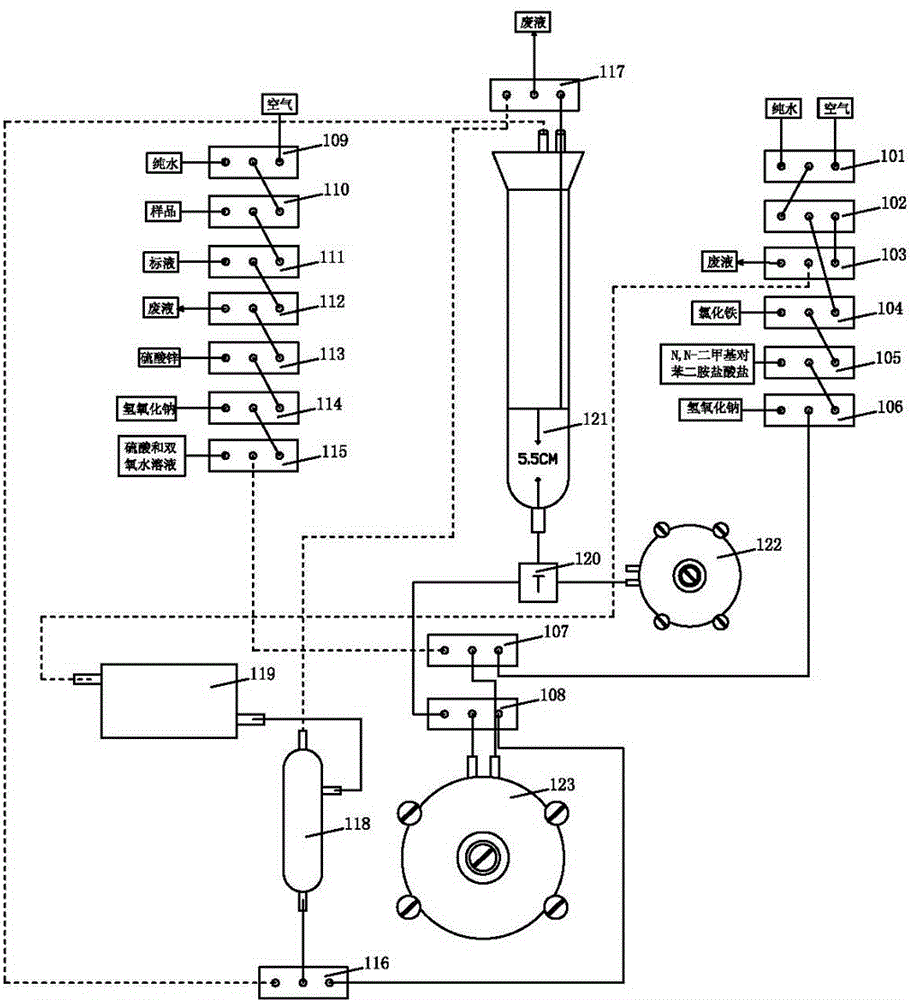

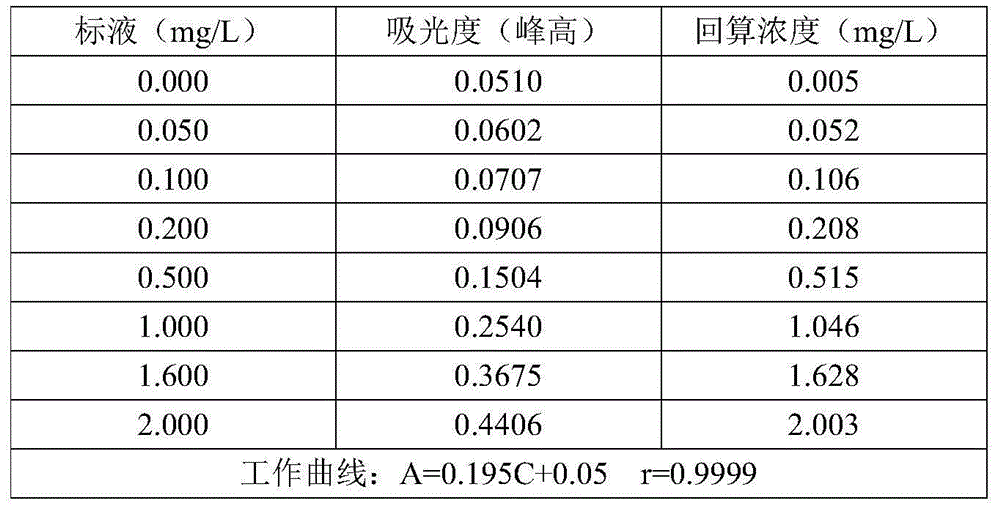

Analyzer and analytical method for soluble sulfides in water sample

ActiveCN104977265AAccurate measurementAuto detect highMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsPeristaltic pumpCuvette

The invention discloses an analyzer for soluble sulfides. The analyzer is characterized by comprising first to seventh three-way valves, an air pump, a peristaltic pump, a mixing tube, a cuvette, a stripping tube, and a T-shaped three-way device. The bottom of the mixing tube is provided with an inlet, and the top and one side of the mixing tube are provided with outlets, respectively. The bottom of the stripping tube is provided with a liquid inlet, and the top of the stripping tube is provided with a liquid outlet and an air outlet. The invention further comprises an analytical method for soluble sulfides in a water sample by adopting the analyzer. When the analyzer for soluble sulfides in the water sample is used for analyzing the soluble sulfides in the water sample, the soluble sulfides in the water sample can be accurately measured, and especially the soluble sulfides in a water sample (such as leather waste water and petrochemical waste water) with relatively complex components or chromaticity itself can be accurately measured. The analyzer has advantages of automatic detection and high measurement accuracy.

Owner:XIAMEN KELUNGDE ENV ENG CO LTD

Application of microbial compound bacteria agent in treatment of petrochemical wastewater and sludge

InactiveCN104310594APromote growthHigh PAH degradation capacityWater contaminantsNature of treatment waterSludgePhosphate

The invention provides an application of a compound microorganism bacterium agent in treatment of petrochemical sewage and sludge. The application comprises the following steps: (1) preparing a biological carrier, to be specific, adding glutaraldehyde to polyphenylene oxide, suspending, stirring, washing, then adding a PBS (Phosphate Buffer Solution) containing CaCl2 and standing; (2) carrying out enlarging cultivation of the compound microorganism bacterium agent; (3) putting the compound microorganism bacterium agent subjected to enlarging cultivation, obtained in the step (2), in the biological carrier prepared in the step (1); and (4) adding the biological carrier loaded with the compound microorganism bacterium agent, obtained in the step (3), to the petrochemical sewage sludge, wherein the compound microorganism bacterium agent continuously increases to a stable period and forms a biological membrane on the surface of the biological carrier, and the biological membrane metabolizes, adsorbs, absorbs, digests and resolves organic pollutants and heavy metals in petrochemical sewage and sludge, so that the petrochemical sewage and sludge are converted into stable harmless materials. Through research, the applicant finds that the compound microorganism bacterium agent can be used for treating the petrochemical sewage and sludge very well.

Owner:LANZHOU PETROCHEM COLLEGE OF VOCATIONAL TECH

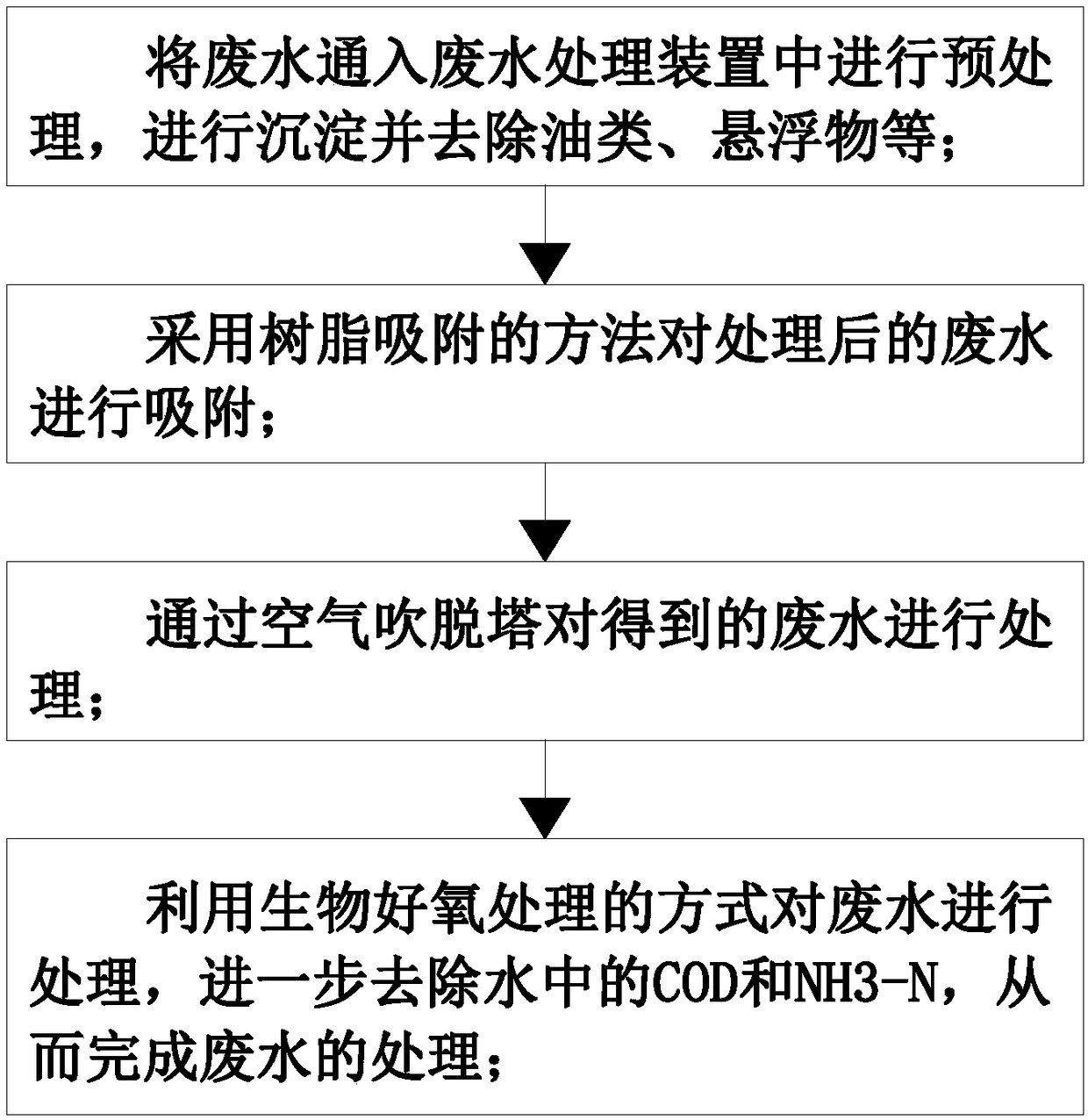

Purification treatment process of coal chemical wastewater

InactiveCN108929001AAchieve recyclingAchieve separationFatty/oily/floating substances removal devicesTreatment using aerobic processesPre treatmentSuspended matter

The invention belongs to the technical field of coal chemical wastewater treatment, and in particular relates to a purification treatment process of coal chemical wastewater. The process includes thefollowing steps: introducing the wastewater into a wastewater treatment device for pretreatment, precipitation and removal of oil, suspended matters, etc.; carrying out adsorption on the treated wastewater by a resin adsorption method; treating the obtained wastewater by an air stripping tower; and treating the wastewater treated by an air stripping tower in a biological aerobic treatment mode tofurther remove COD and NH3-N in water, so as to complete wastewater treatment. The purification treatment process can efficiently treat coal chemical wastewater, has high working efficiency and savesenergy.

Owner:朋仁锋

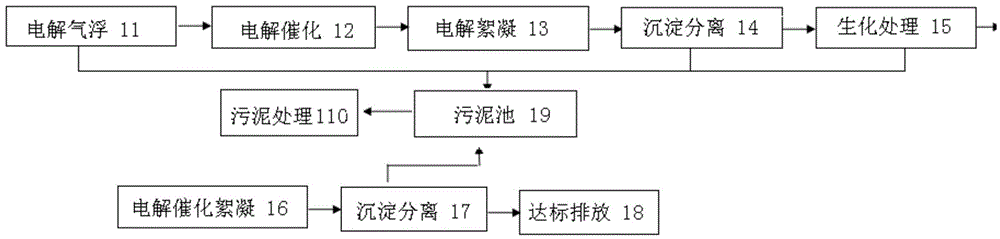

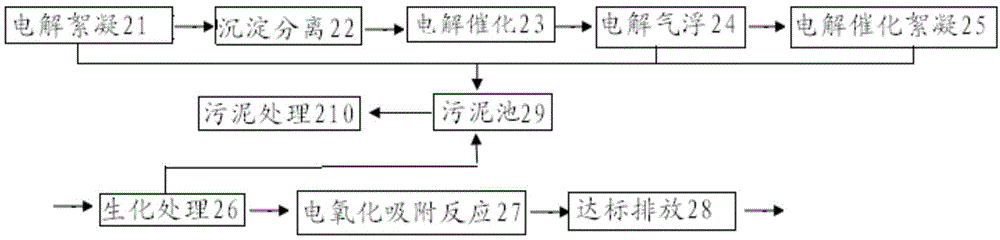

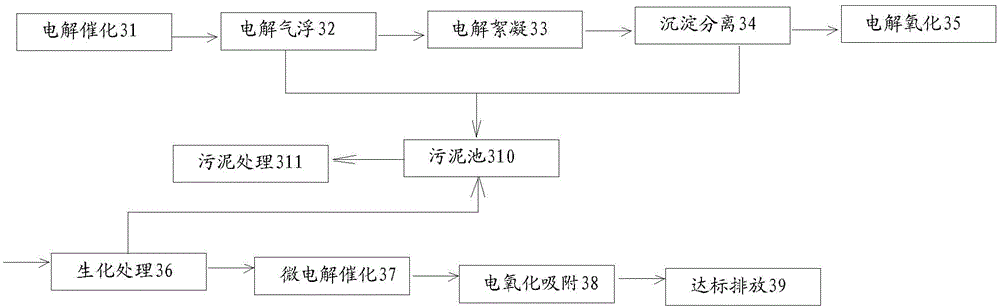

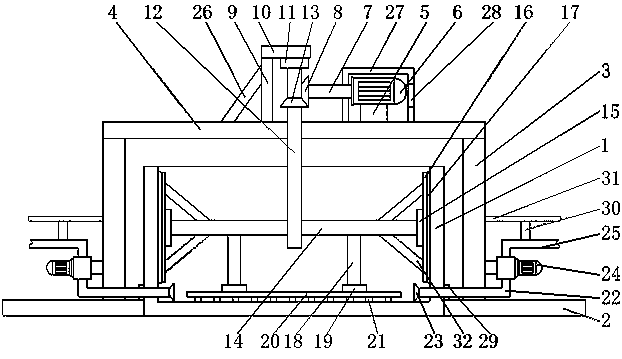

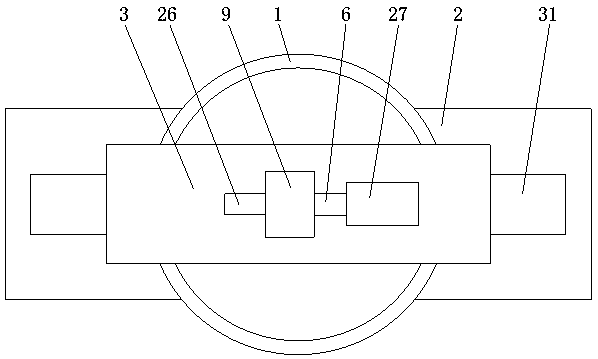

Ternary electrolytic sewage treatment combined process

The invention discloses a ternary electrolytic sewage treatment combined process and application thereof to petroleum and petrochemical wastewater treatment. The process comprises the steps of: successively conducting electrolysis flotation, electrolysis catalysis, electrolysis flocculation, precipitation separation, biological treatment, catalytic electrolysis flocculation and sedimentation separation on highly difficult wastewater, detecting the obtained water, discharging qualified water, and sending the sludge obtained in electrolysis flotation, sedimentation separation, biochemical treatment and precipitation separation to a sludge pool for sludge treatment. The electrolysis combined treatment process provided by the invention is a modular integrated treatment system, which can be combined flexibly according to the specific needs, so as to play the potential advantage of the sewage treatment steps to the greatest and cooperate with each treatment step to complete optimized treatment on various wastewater.

Owner:宋斌英

Genetically engineered bacteria for degrading phenol in petrochemical wastewater

The invention relates a strain of genetically engineered bacteria for degrading phenol in petrochemical wastewater, solving the problem that wild bacterial strains for isolating and identifying phenol in petrochemical wastewater has a low capacity of degrading phenol in the prior art. The genetically engineered bacteria strain is (Bacillus subtilis) dqly-2 which is preserved in China General Microbiological Culture Collection Center as on Dec 20, 2011 as the preservation number of CGMCC No.5619. According to the invention, phenol can be degraded to achieve a concentration of 0.3825mg / L in 96h by the (Bacillus subtilis) dqly-2 at the extreme, and the highest degradation rate of phenol can reach to 96.18%, and the wastewater treated by the (Bacillus subtilis) dqly-2 reaches the national first-degree wastewater discharge standard.

Owner:DAQING BRANCH OF HEILONGJIANG ACAD OF SCI

Petrochemical wastewater treatment sedimentation pool with high convenience in inner wall cleaning

InactiveCN109126221ASolve the problem that it is not easy to clean the inner wallReduce labor intensitySettling tanks feed/dischargeSedimentation settling tanksSludgePulp and paper industry

The invention discloses a petrochemical wastewater treatment sedimentation pool with high convenience in inner wall cleaning. The sedimentation pool comprises a sedimentation pool main body, wherein fixing plates are fixedly connected with the left and the right sides of the sedimentation pool main body; a supporting plate is fixedly connected with the top of each fixing plate; and the tops of thetwo supporting plates are fixedly connected through a connecting plate. The sedimentation pool provided by the invention has the advantages that through cooperation among the fixing plates, the supporting plates, the connecting plate, a cleaning motor, a cleaning rotating shaft, a first gear, a rolling bearing, a rotating shaft, a second gear, first cleaning rods, first cleaning plates, first scrapers, second cleaning rods, second cleaning plates, second scrapers, sludge discharging pipes, sludge discharging heads, sludge pumps and sludge removing pipes, the problem of the conventional petrochemical wastewater treatment sedimentation pool that cleaning of the inner walls is inconvenient is solved; and the inner walls are automatically cleaned, so that the labor intensity of workers is reduced, the cleaning efficiency is improved, and wastewater treatment is greatly facilitated.

Owner:王帅

Advanced treatment technology of petrochemical wastewater

InactiveCN106186552AReduce CODReduce oil contentMultistage water/sewage treatmentNature of treatment waterAluminium hydroxideCalcite

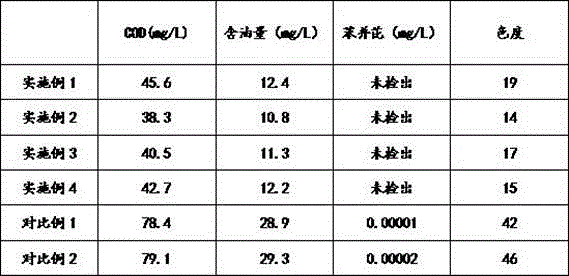

The invention discloses an advanced treatment technology of petrochemical wastewater. A composite treatment agent prepared from modified starch, siliceous carbonate, aluminium hydroxide, polyferric sulfate, polysilicon aluminum sulfate, calcite powder, opal powder, sodium hypochlorite, poly-aluminum calcium chloride, sodium hydroxide caustic soda flakes, glacial acetic acid, 3-Oxo-1-cyclopentanecarboxylic acid, potassium ethylate, pilocarpine and a coagulant aid. The composite treatment agent is matched with corresponding water treatment technologies including adsorption, treatment agent treatment, anaerobic treatment, photo-catalytic oxidation, sodium hypochlorite oxidation, aeration, electric flocculation, electroflotation and the like, so that COD, the oil content, the benzopyrene content and chroma of treated wastewater are obviously reduced, the requirements of environment protection standard can be met, and application prospects are good.

Owner:张伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com