Process for treating petrochemical wastewater

A technology for petrochemical and wastewater treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of poor biodegradability of organic matter and inability to effectively remove organic pollutants, etc. problems, to achieve the effect of improving biodegradability and water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

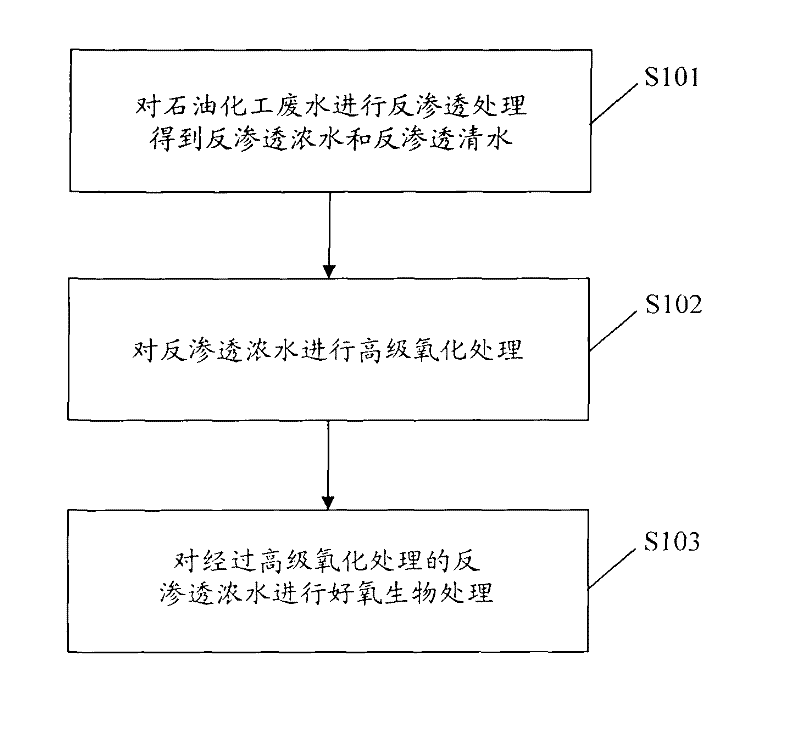

[0015] refer to figure 1 Shown, the present invention discloses a kind of petrochemical wastewater treatment process, comprises the following steps:

[0016] S101. Perform reverse osmosis treatment on the petrochemical wastewater to obtain reverse osmosis concentrated water and reverse osmosis clean water. Reverse osmosis is a kind of reverse migration movement of osmosis, and it is a separation method that separates the solute in the solution from the solvent by means of the selective interception of the semi-permeable membrane under the pressure drive. The reverse osmosis process can remove impurities such as inorganic ions, bacteria, viruses, organic matter and colloids in raw water. In one embodiment, the reverse osmosis treatment in step S101 includes using pressure to drive petrochemical wastewater through a semi-permeable membrane, wherein the semi-permeable membrane has permeable pores with a pore size of 5-10 angstroms. The reverse osmosis clean water obtained in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com