Method for treating petrochemical waste water and biochemical tail water through recycled coagulant

A petrochemical wastewater and treatment method technology, applied in the direction of flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, oxidation treatment of sludge, etc., can solve the problem of waste of metal resources such as iron and other waste, secondary pollution, etc. problems, to achieve the effect of reasonable configuration, strong oxidation ability and good connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Wastewater biochemical tail water of a petrochemical company.

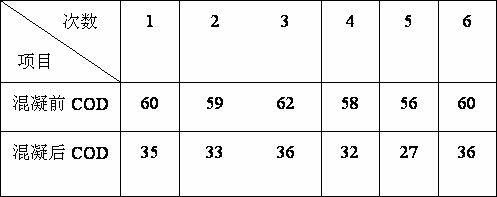

[0017] (1) Coagulation treatment with composite coagulant: Add ferrous sulfate and polyaluminum ferric sulfate in a ratio of 3:7 to the petrochemical wastewater and add composite coagulant and coagulant polyacrylamide to adjust the pH to 3. After the composite coagulant strengthens the reaction, the sewage is separated from mud and water to obtain coagulation sediment coagulation mud. The COD of wastewater before coagulation is 60, the COD of wastewater after coagulation is 37, and the COD of coagulation mud is 2337.

[0018] (2) Iron-carbon micro-electrolysis reaction in concrete mud: Add cast iron chips and activated carbon filler to the concrete mud for 0.5h reaction, the volume ratio of iron-carbon filler is 4:1, and the volume ratio of iron-carbon filler and concrete mud is 1:7 . Sulfuric acid was added during the reaction to keep the pH value of the concrete at 3.

[0019] (3) Fenton oxidation rege...

Embodiment 2

[0024] Wastewater biochemical tail water of a petrochemical company.

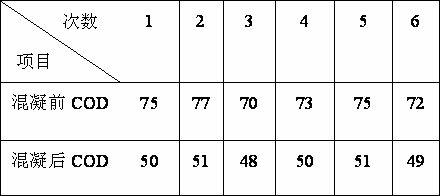

[0025] (1) Coagulation treatment with composite coagulant: Add ferric chloride and polyaluminum ferric chloride in a ratio of 5:5 to the petrochemical wastewater and add composite coagulant and coagulant sodium polyacrylate to adjust the pH to 10. The sewage after the enhanced reaction of the composite coagulant is separated from the mud and water to obtain the coagulation sediment coagulation mud. The COD of wastewater before coagulation is 75, the COD of wastewater after coagulation is 49, and the COD of coagulation mud is 2649.

[0026] (2) Micro-iron-carbon micro-electrolysis reaction in concrete mud: Add cast iron chips and activated carbon filler to the concrete mud for 1 hour reaction, the volume ratio of iron to carbon is 1:5, and the volume ratio of iron-carbon filler to concrete mud is 3:1 . During the reaction, hydrochloric acid was added to keep the pH value of the concrete at 5.

[0027] (3)...

Embodiment 3

[0032] PTA wastewater biochemical tail water of a petrochemical company.

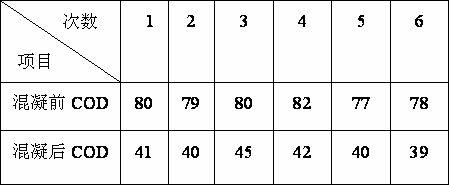

[0033](1) Coagulation treatment with composite coagulant: add aluminum sulfate, polyferric silicon in a ratio of 7:3 to the petrochemical wastewater and add a composite coagulant and coagulant sodium vinyl sulfonate to adjust the pH to 5. The sewage after the enhanced reaction of the composite coagulant is separated from the mud and water to obtain the coagulation sediment coagulation mud. The COD of wastewater before coagulation is 80, the COD of wastewater after coagulation is 42, and the COD of coagulation mud is 3841.

[0034] (2) Iron-carbon micro-electrolysis reaction in concrete mud: add cast iron chips and activated carbon filler to the concrete mud for 2 hours, the volume ratio of iron-carbon filler is 1:1, and the volume ratio of iron-carbon filler and concrete mud is 1:5. Sulfuric acid was added during the reaction to maintain the pH value of the concrete at 4.

[0035] (3) Fenton oxidati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com