Circulating fluidized bed advanced treatment equipment for industrial wastewater

A circulating fluidized bed and advanced treatment technology, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems that restrict the popularization and application of Fenton oxidation method, low equipment operation efficiency, high cost of wastewater treatment, etc., to achieve easy automatic design and improve utilization rate , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation.

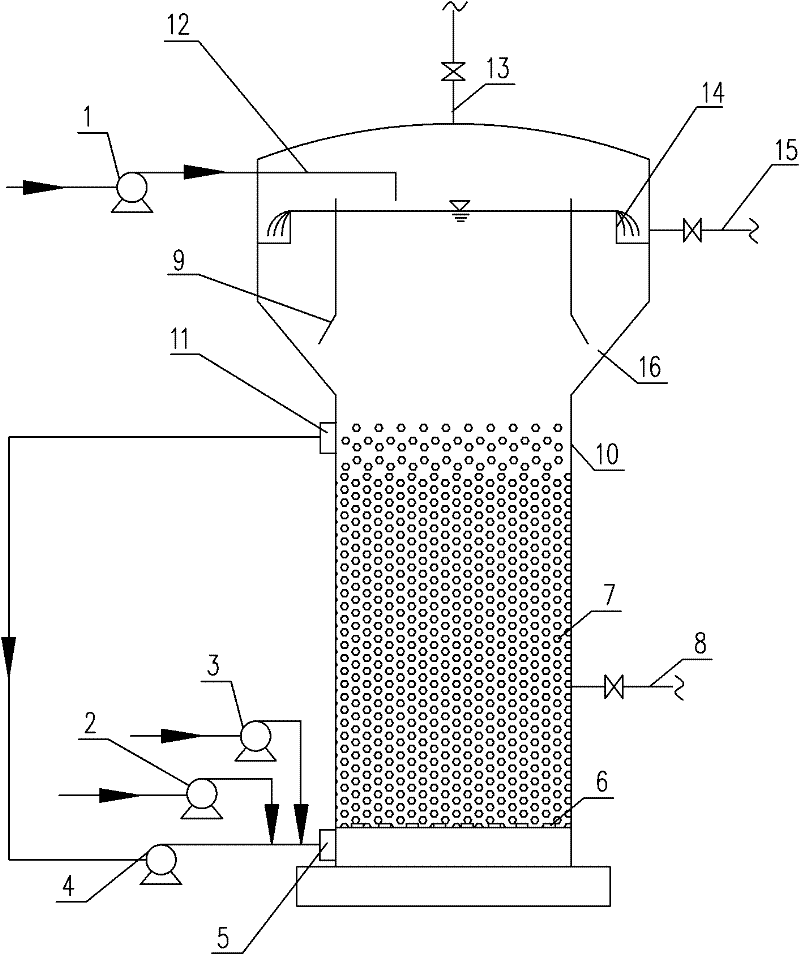

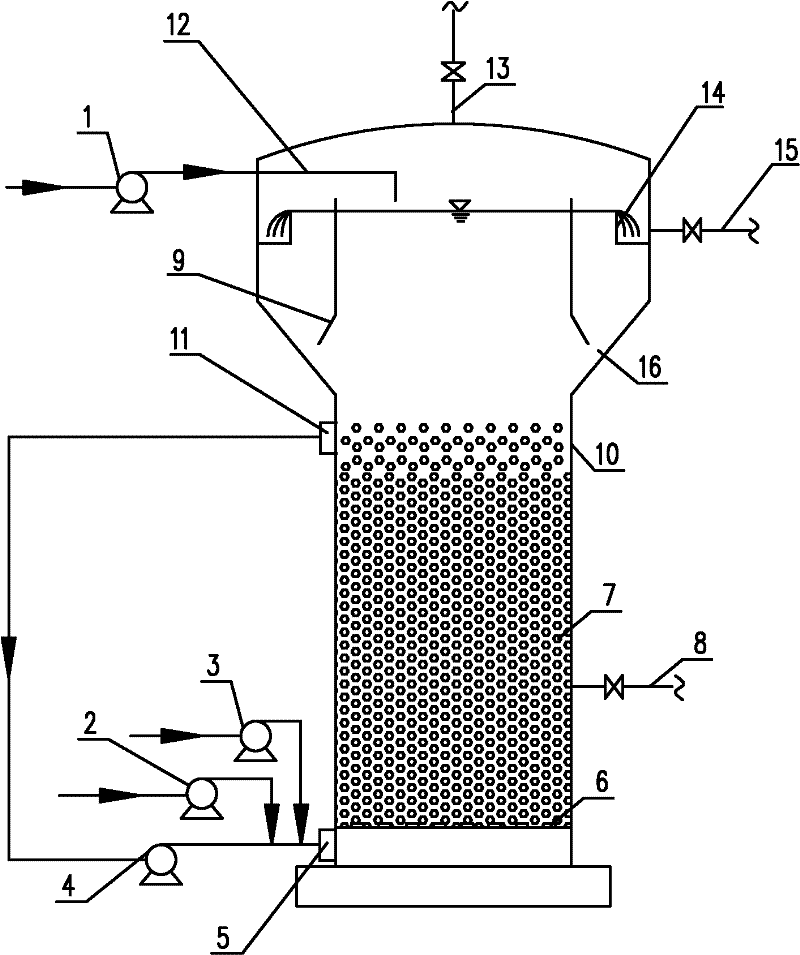

[0038] The industrial wastewater circulating fluidized bed advanced treatment equipment shown in the figure has a cylindrical tank body 10 for the Fenton oxidation reaction of wastewater. There are three functional areas in the tank body 10, and the three functional areas are sequentially arranged from bottom to top. It is the circulating water distribution area, the FeOOH crystallization area and the gas-water separation area.

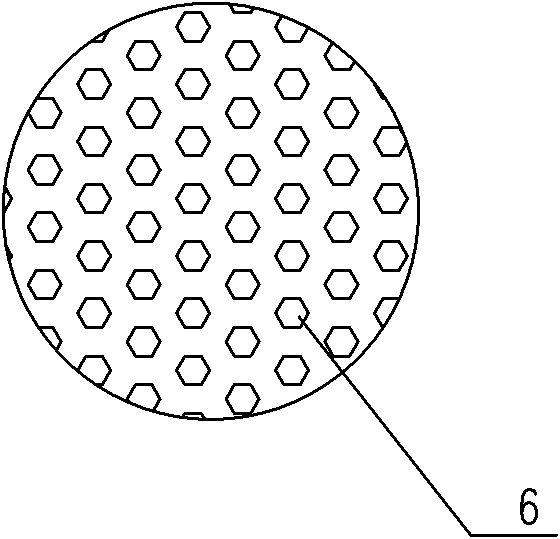

[0039] A water distributor 6 is installed on the top of the circulating water distribution area. The preferred water distributor 6 adopts a porous plate, which is simple and practical in structure. The opening ratio of the porous plate is controlled within the range of 12% to 15%. field needs. There is a circulating water inlet 5 on the tank wall of the circulating water distribution area, and the circul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com