Method for realizing rapid internal dumping of metal strip mine hillside mining

A technology of mine slope and open-pit, which is applied to the field of slope mining in metal open-pit mines to achieve rapid inward drainage, which can solve the problems of large height difference between adjacent mining areas and the inability to quickly inward drainage due to the age of inner drainage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

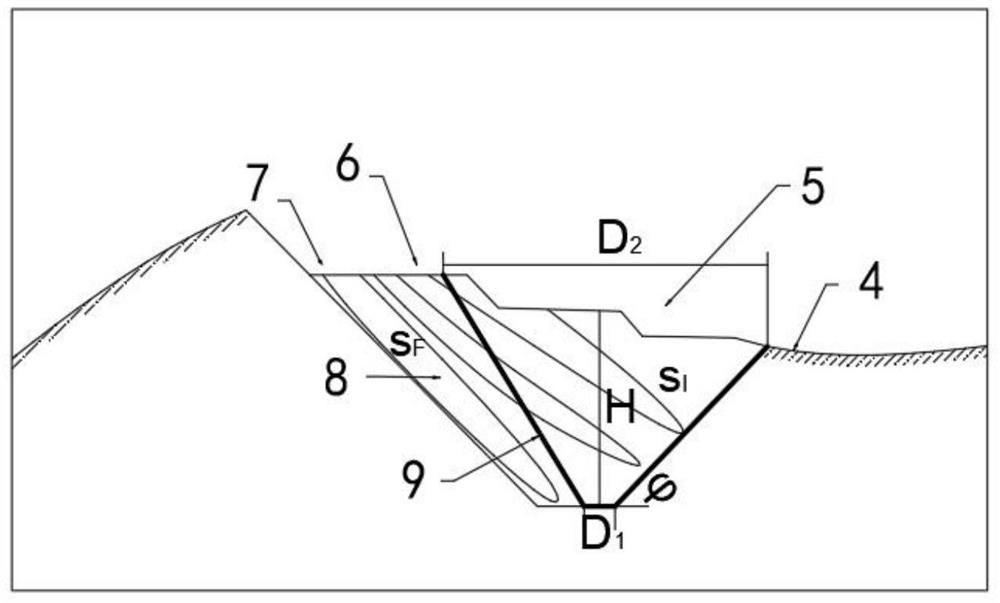

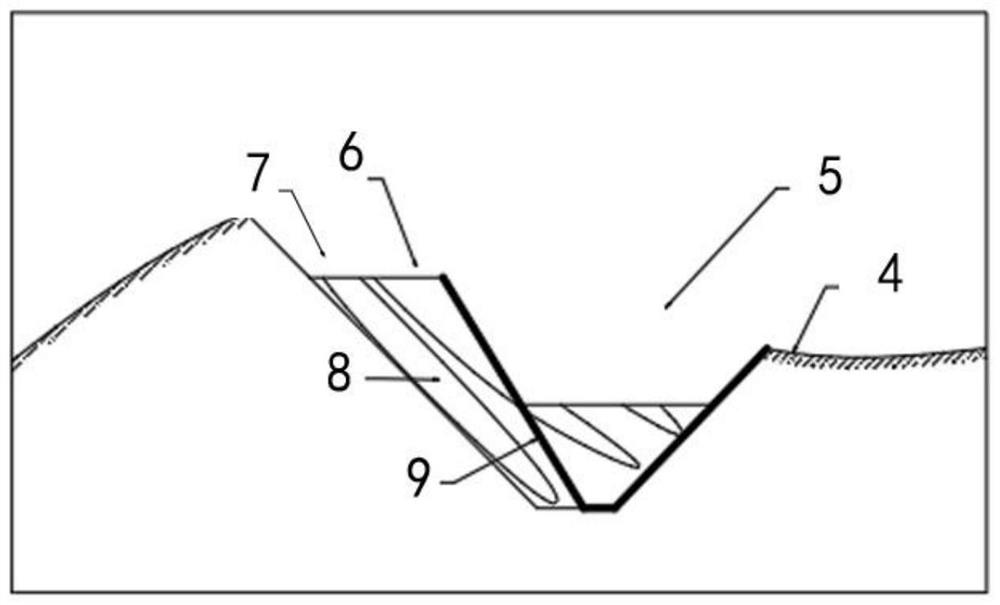

[0043]In this embodiment, internal drainage is carried out for a large-scale open-pit mine mined at the stage of turning from a hillside to a deep depression. The temporary non-working platform in this embodiment is a safety platform or a transportation platform for stope operations, and rocks are discharged by means of external drainage.

[0044] A method for realizing rapid internal drainage in hillside mining of a metal open-pit mine, comprising the following steps:

[0045] step 1:

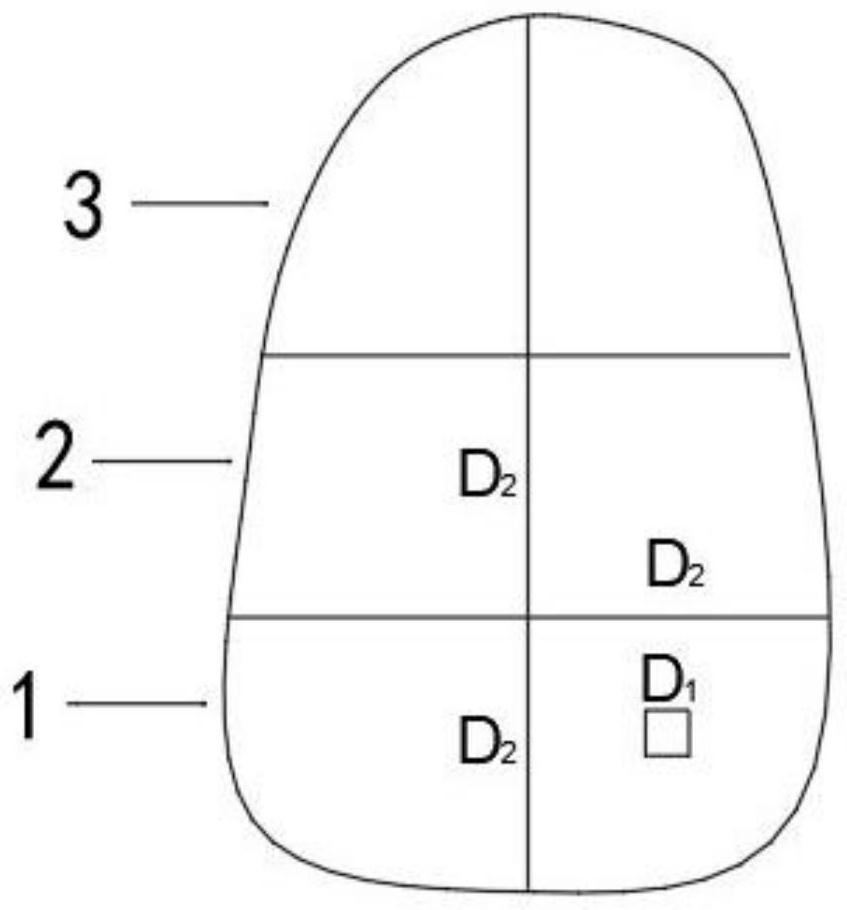

[0046] like figure 1 As shown, in the slope mining stage of metal open-pit mines, the open-pit stope is divided into the first sub-mining area, the second sub-mining area and the third Separate mining area, select the shallowest sub-area of the open pit as the first sub-mining area, and divide the foot of the hillside of the first sub-mining area into the initial mining area, and determine the specific initial mining area according to the minimum distance of the single mining area range, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com