Three-dimensional knitted side boundary device and use method thereof

A three-dimensional weaving and sideline technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of low work efficiency and complex structure, and achieve the effect of high work efficiency, small number of structures and correct coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

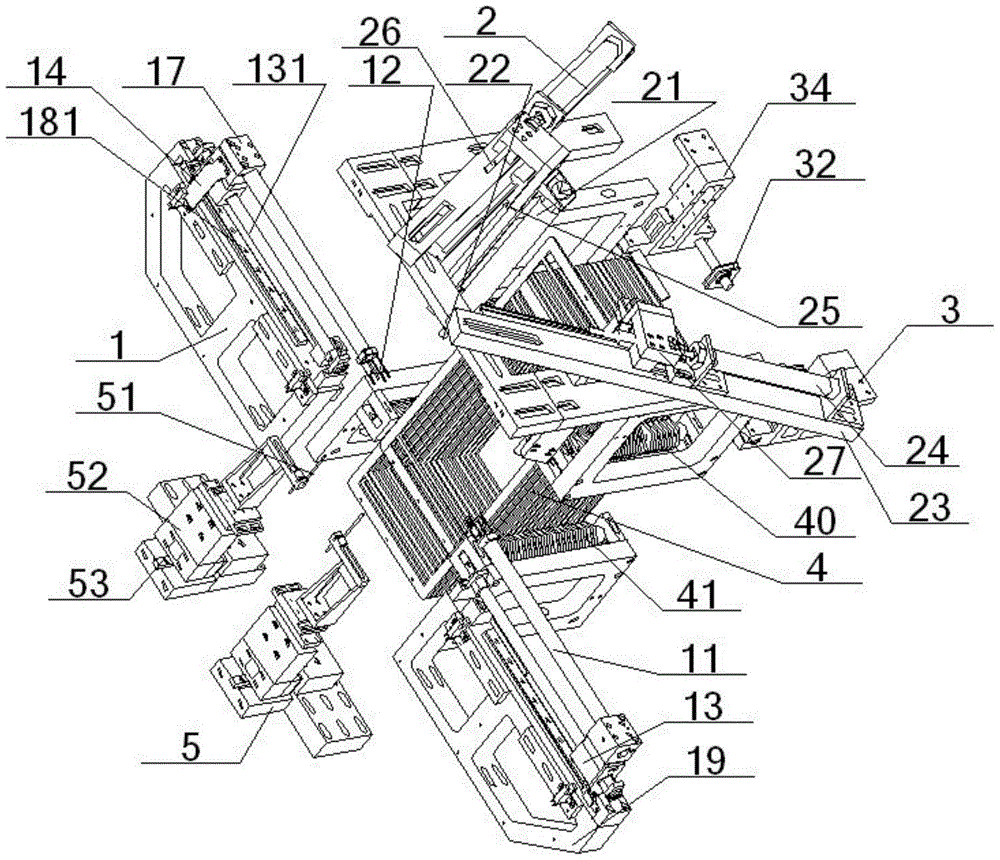

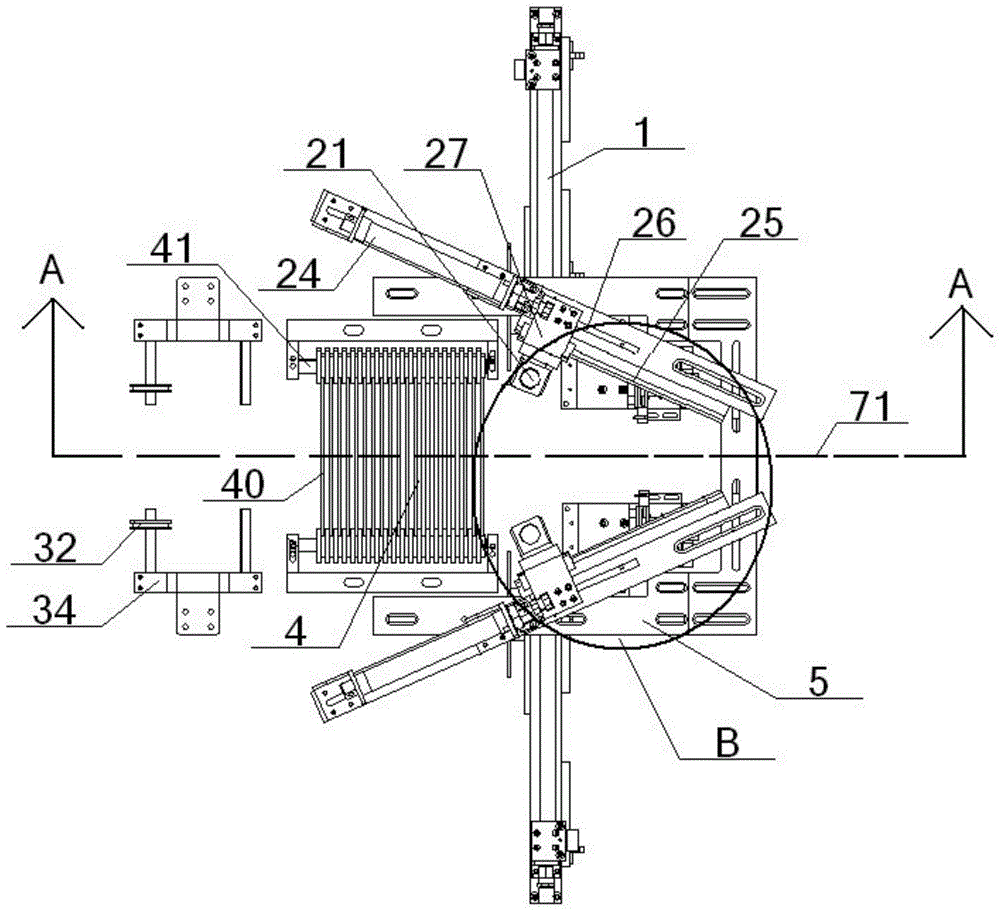

[0065] see figure 1 – Figure 13 , a three-dimensional weaving edge device, comprising a weft insertion mechanism 1, a weft thread sliding mechanism 2, an opening mechanism 4, and a weft thread fixing mechanism 5, the number of the weft insertion mechanism 1, the weft thread sliding mechanism 2, and the weft thread fixing mechanism 5 are two, The two weft sliding mechanisms 2 are symmetrically arranged with the horizontal central axis 71 as the line of symmetry, and the two weft insertion mechanisms 1 are symmetrically arranged with the horizontal central axis 71 as the line of symmetry. The connecting line between the two weft insertion mechanisms 1 and the weft insertion The travel lines of the mechanism 1 are coincident, and the two weft fixing mechanisms 5 are symmetrically arranged with the horizontal central axis 71 as the line of symmetry; the opening mechanism 4 includes a plurality of heald frames 40 arranged side by side and parallel to each other. The side of frame...

Embodiment 2

[0071] Basic content is the same as embodiment 1, the difference is:

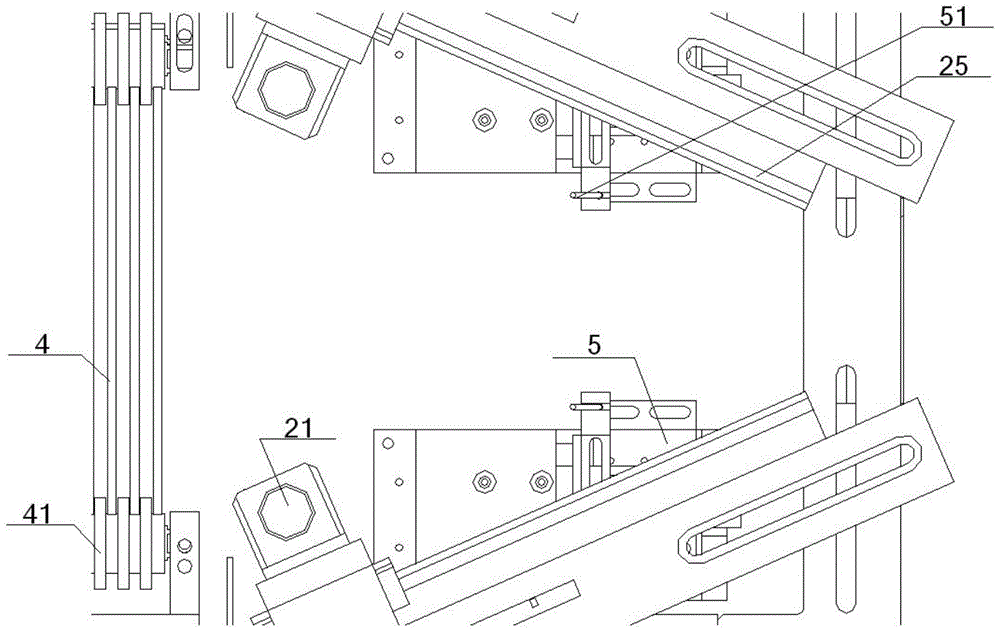

[0072] The weft sliding mechanism 2 also includes a sliding base 23, a horizontal sliding cylinder 24 and a linear guide rail 25, the top of the sliding base 23 is connected with the bottom of the horizontal sliding cylinder 24, and the output end of the horizontal sliding cylinder 24 is connected to the horizontal push rod 26 The inner end of the horizontal push rod 26 is connected to the top of the vertical support 27, and the inner side of the vertical support 27 is slidably matched with the linear guide rail 25 provided on the inner side of the sliding base 23. The vertical support The outer part of 27 is connected with the inner part of vertical telescopic cylinder 21, and the output end of vertical telescopic cylinder 21 is connected with the top of the vertical push rod 22 that is positioned at directly below it, and the bottom of vertical push rod 22 is provided with The vertical slot 28 is inserted...

Embodiment 3

[0074] Basic content is the same as embodiment 1, the difference is:

[0075]Described sideline device also comprises two latitude anti-band mechanisms 3, two weft anti-band mechanisms 3 are left and right symmetrically arranged with the horizontal axis 71 as the line of symmetry, each weft anti-band mechanism 3 all comprises anti-band lines 31, anti-band rollers 32 and the counterweight 33, one end of the anti-band line 31 is connected with the top of the counterweight 33 after the anti-band roller 32, the middle part of the anti-band roller 32 is connected with the anti-band support 34, and the other part of the anti-band line 31 One end is connected with the fixed frame 35, the position between the anti-belt roller 32 and the counterweight 33 on the anti-belt line 31 coincides with its center of gravity line, and the part between the anti-belt roller 32 and the fixed frame 35 on the anti-belt line 31 The position is parallel to the horizontal central axis 71, and the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com