Full automatic bead threader

A threading machine, fully automatic technology, applied in jewelry, clothing, applications, etc., can solve the problems of low production efficiency and large labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

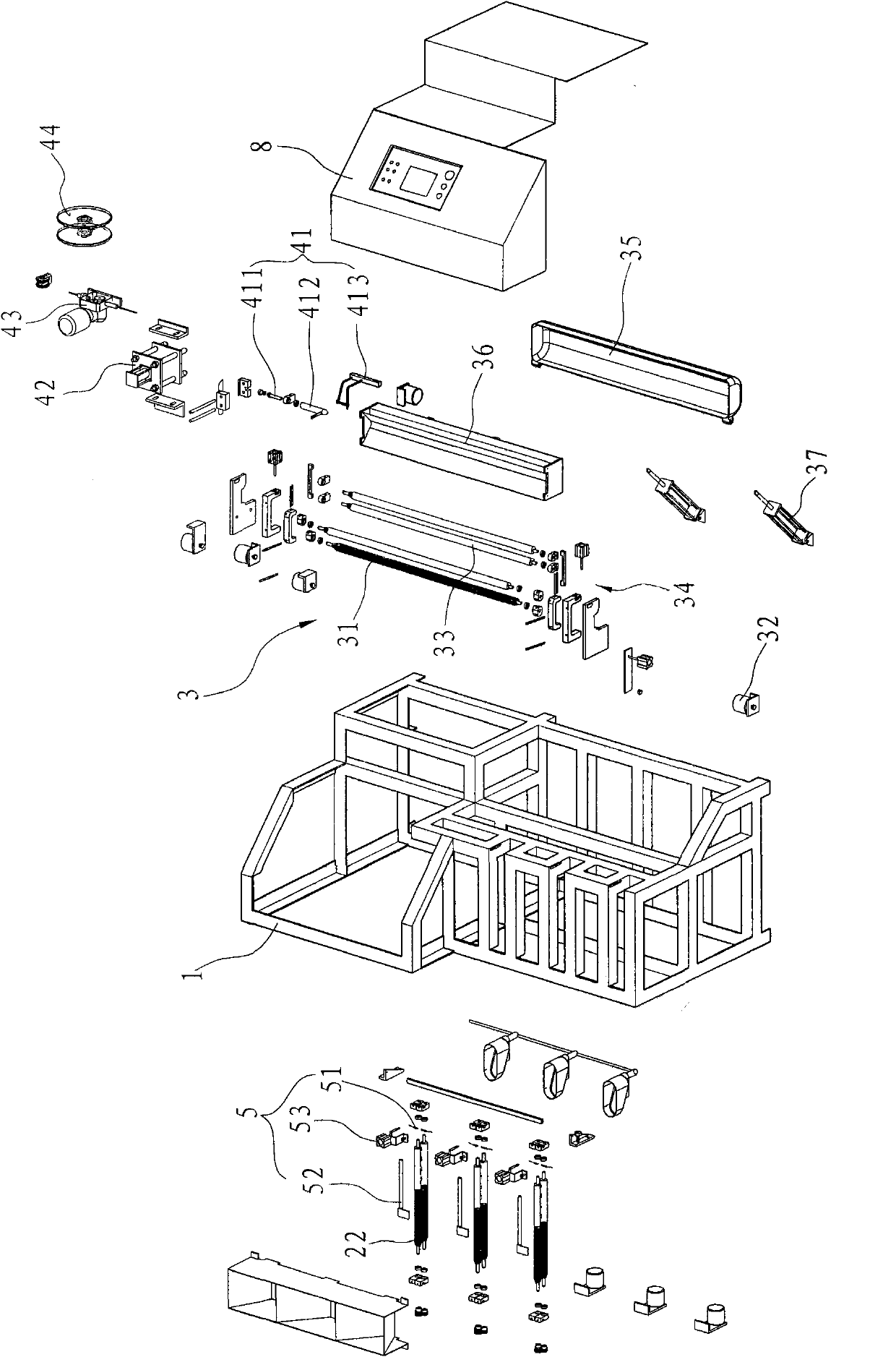

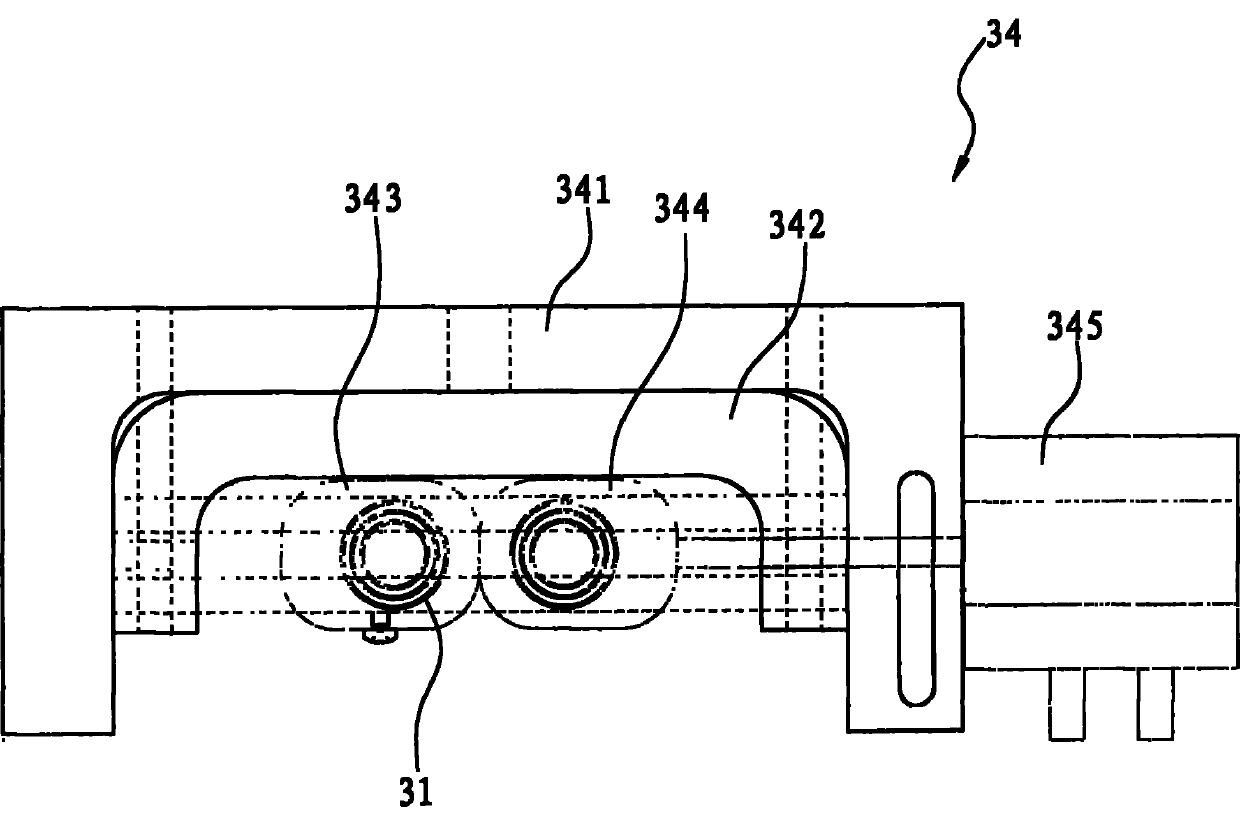

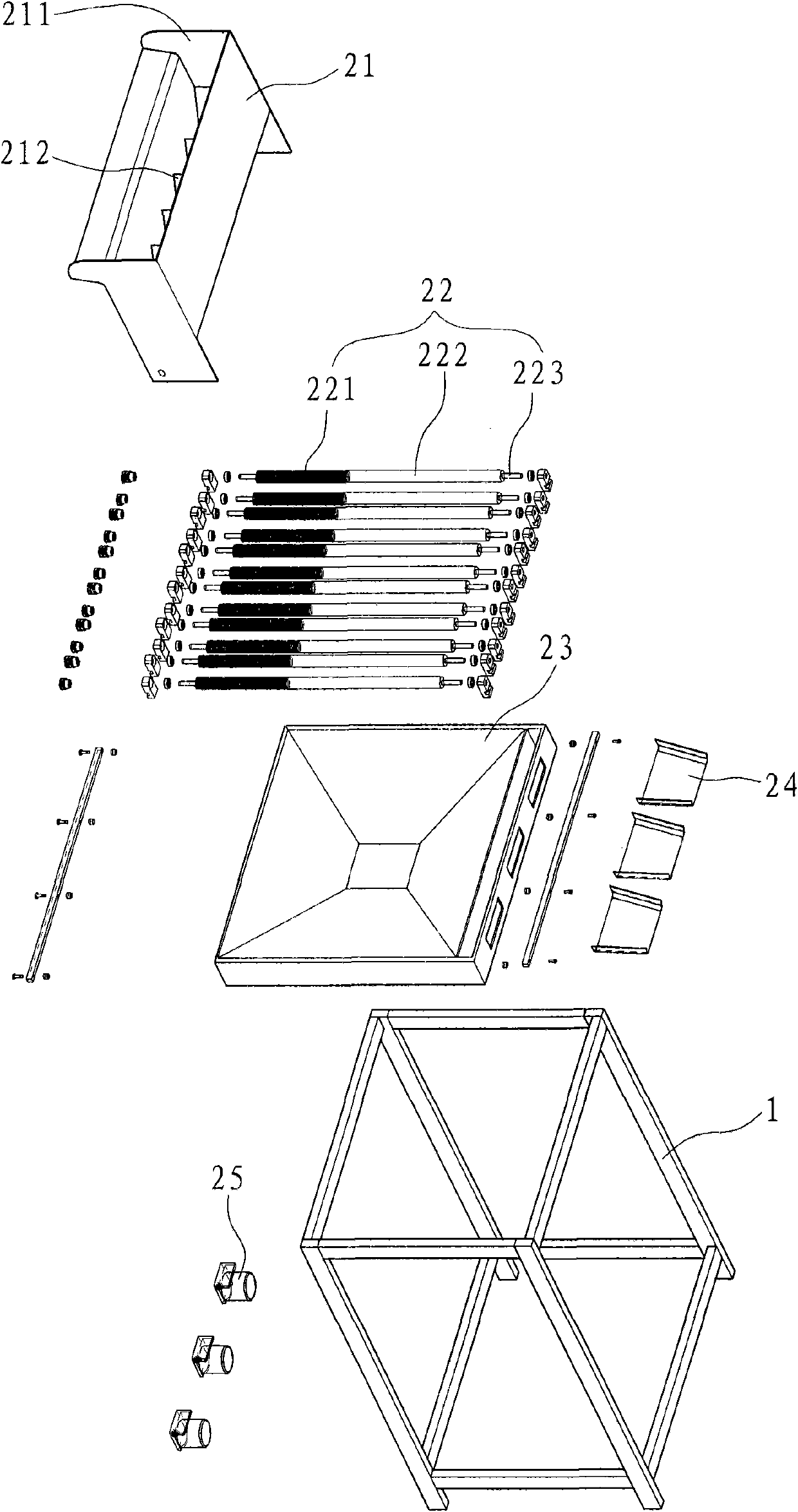

[0066] Such as figure 1 As shown, it shows a preferred embodiment of a full-automatic bead threading machine 100 related to the present invention, which includes a frame 1, a screening mechanism 2, an array mechanism 3, a threading mechanism 4 and a control mechanism (not shown in the figure) shown), the frame 1 is used as the bearing part of the whole automatic bead threading machine 100, the screening mechanism 2, the array mechanism 3, the threading mechanism 4 and the control mechanism are all arranged on the frame 1, and the screening mechanism 2 is located in the array above the mechanism 3, and is used to reject the unqualified beads 6 and transport the qualified beads 6 to the array mechanism 3 one by one. The screening mechanism 2 is also provided with a quantity control unit 5, which performs individu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com