Automatic feeding assembling and transmitting device for electronic elements

A conveying device and automatic feeding technology, applied in the direction of electrical components, electrical components, etc., can solve problems such as low efficiency, workers are susceptible to corrosion and pollution, and achieve the effect of improving production efficiency, saving manpower and material resources, and realizing automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention are described in detail below.

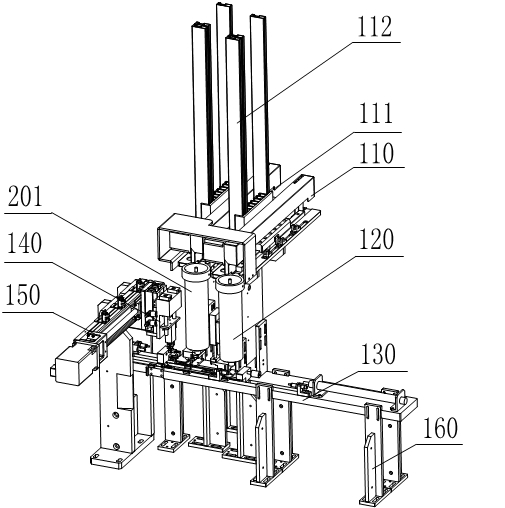

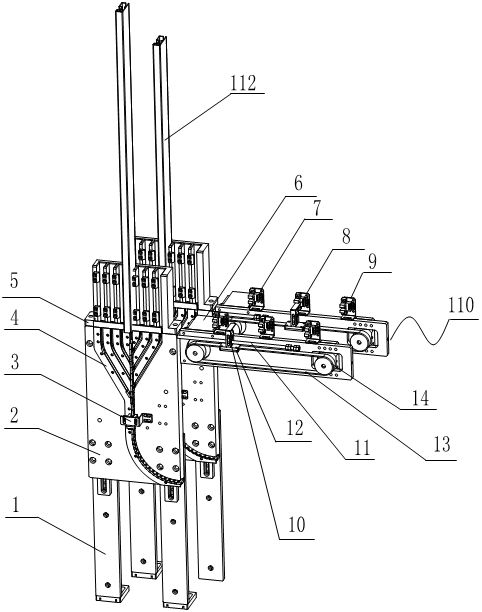

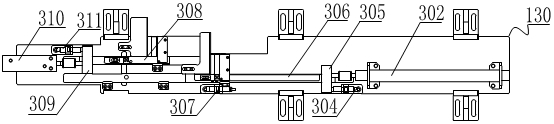

[0033] The electronic component automatic feeding assembly transportation device of the present invention is mainly aimed at the electronic components that need to be installed by dispensing, mainly power components; the installation of dispensing includes installation for dispensing and fixing or heat conduction, and the device of the present invention mainly includes Automatic feeding module 110, automatic gluing module 120, positioning transfer module 130, clamping pick-and-place module 140, and delivery transfer module 150, such as figure 1 shown.

[0034] The above-mentioned modules are fixed on the platform or bracket according to the working cooperation process, figure 1 Shown in the figure only shows the positional relationship, and does not show its platform or support. In actual production, the device of the present invention can be set on various platforms or supports; wherein, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com