Main drive gear of numerical control right-angle plate shearing machine

A shearing machine and main drive technology, applied in shearing machine equipment, shearing device, metal processing equipment and other directions, can solve the problems of difficult to ensure accuracy, slow adjustment speed, environmental pollution, etc., to achieve compact device structure, reduce Energy consumption, the effect of eliminating the cooling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

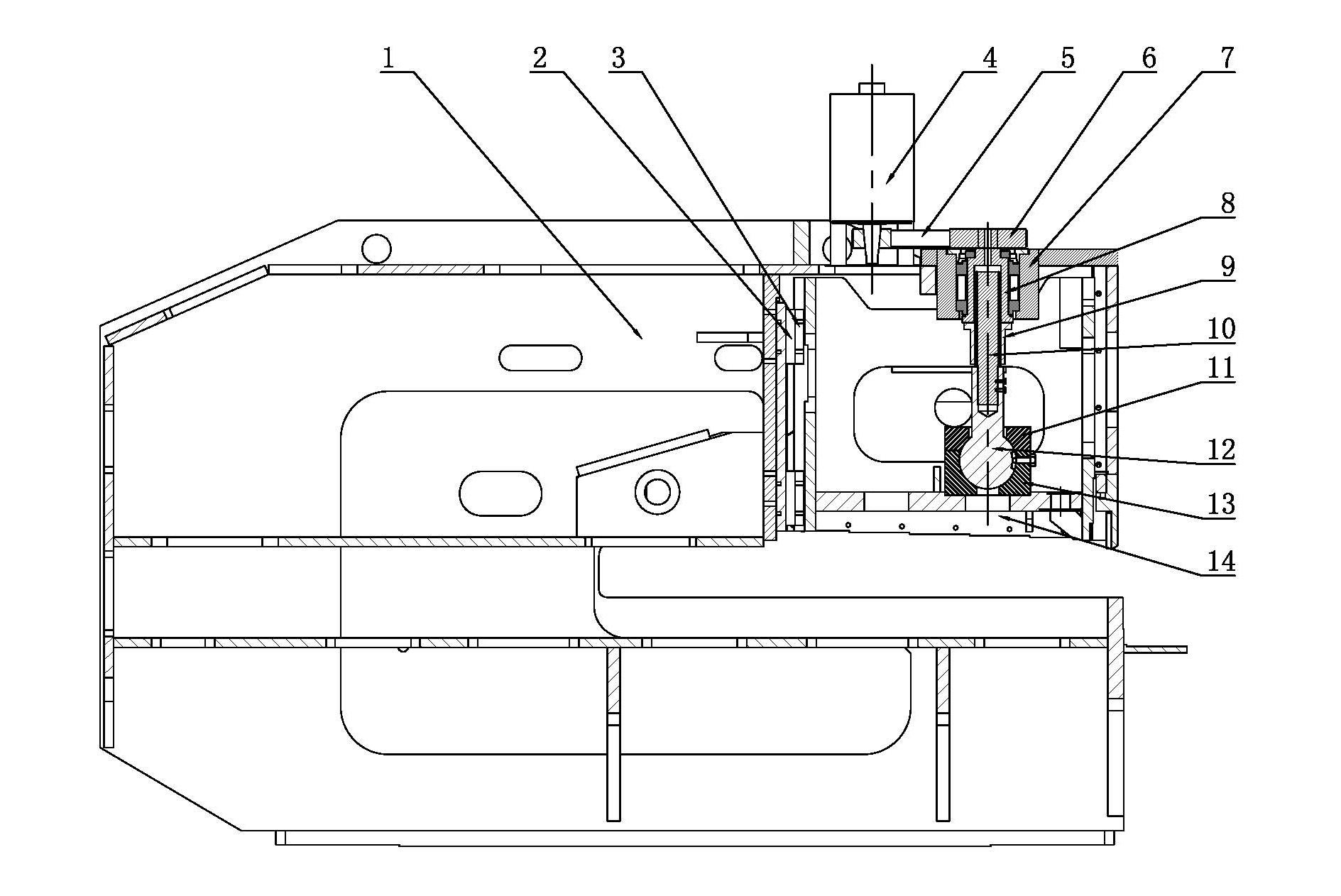

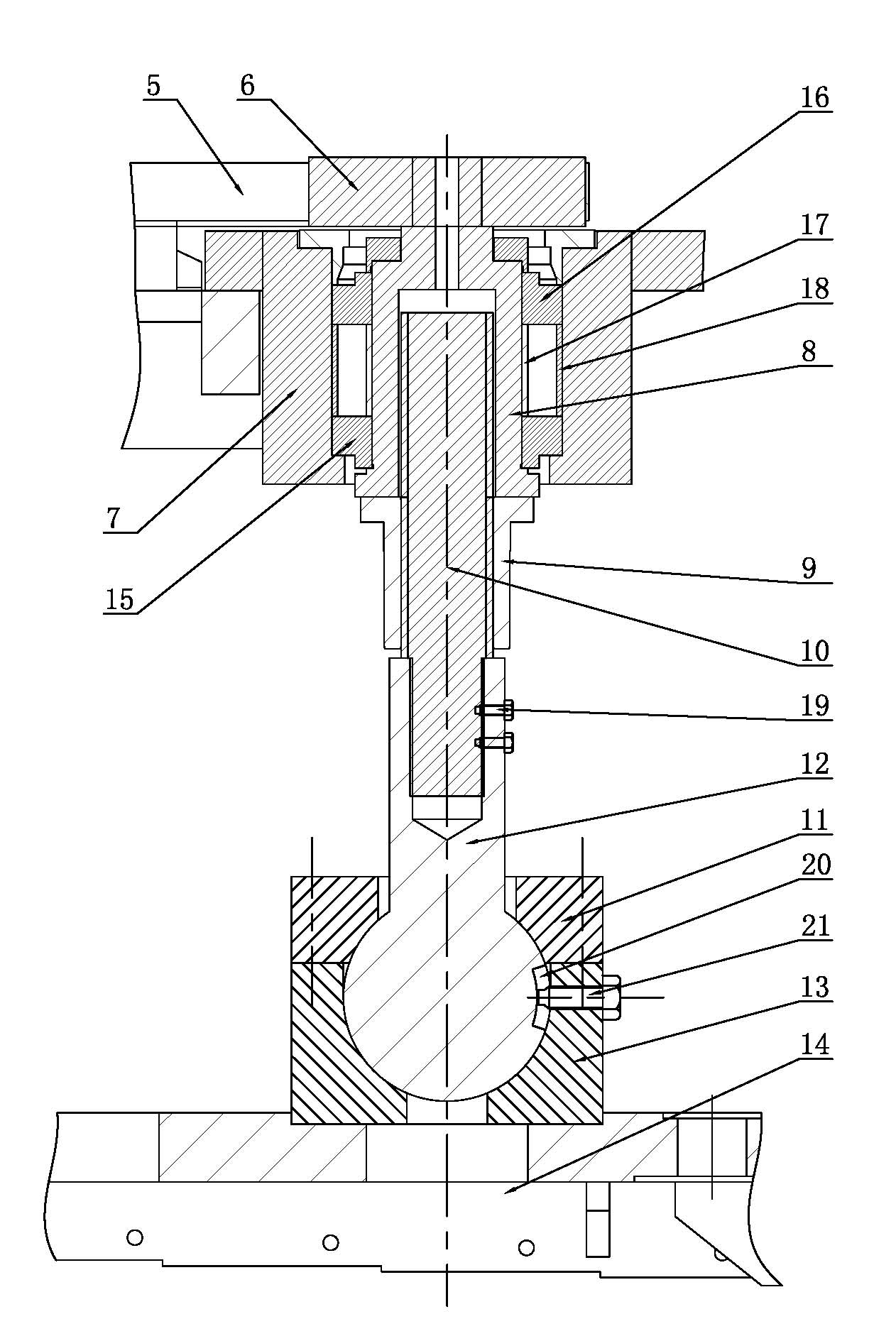

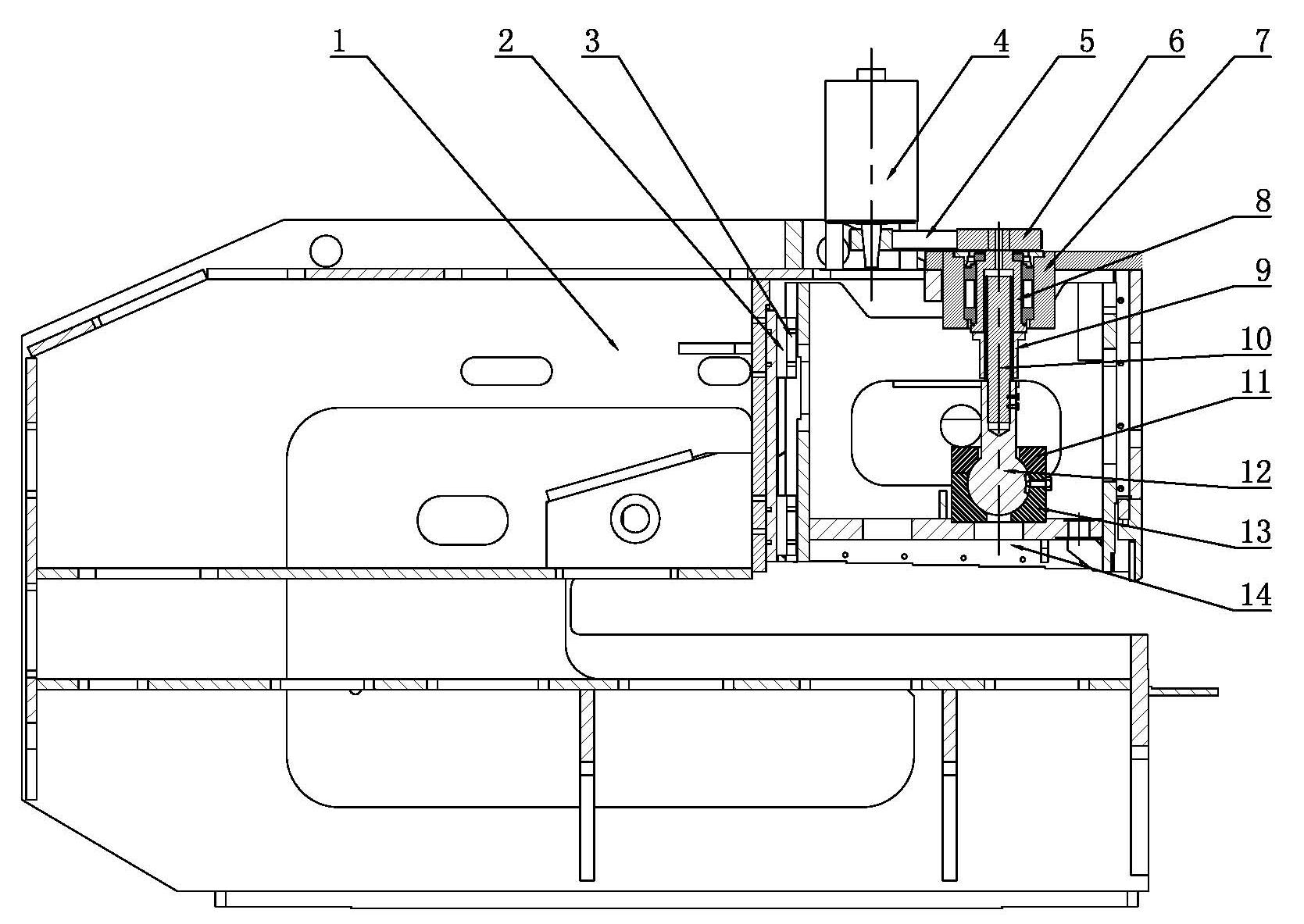

[0015] Such as figure 1 with 2 As shown, it is the main transmission mechanism of the CNC right-angle shearing machine, which mainly includes a fuselage 1. The guide rail slider mechanism set upright on the fuselage 1 is connected with the upper tool rest 14. The guide rail slider mechanism is composed of mutually matched guide rails 2 and The slider 3 is composed of the guide rail 2 fixed on the fuselage 1, the slider 3 is fixed with the upper tool holder 14; the servo motor 4 and the bearing seat 7 are installed on the fuselage 1, and the output shaft of the servo motor 4 passes through the timing belt 5 and The synchronous pulley 6 is connected to the upper end of the hollow support shaft 8, the support shaft 8 is installed on the bearing seat 7 through the upper bearing 16 and the lower bearing 15, and an inner spacer 17 and an outer spacer are arranged between the upper bearing 16 and the lower bearing 15 18. The support shaft 8 is connected with the ball screw kinematic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com