LED lamp band

A technology for LED strips and lamp beads, which is applied to the loss prevention measures of lighting devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve the problems of complex production process, many production steps, and difficult processing, etc. Fewer production processes, precise line layout, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

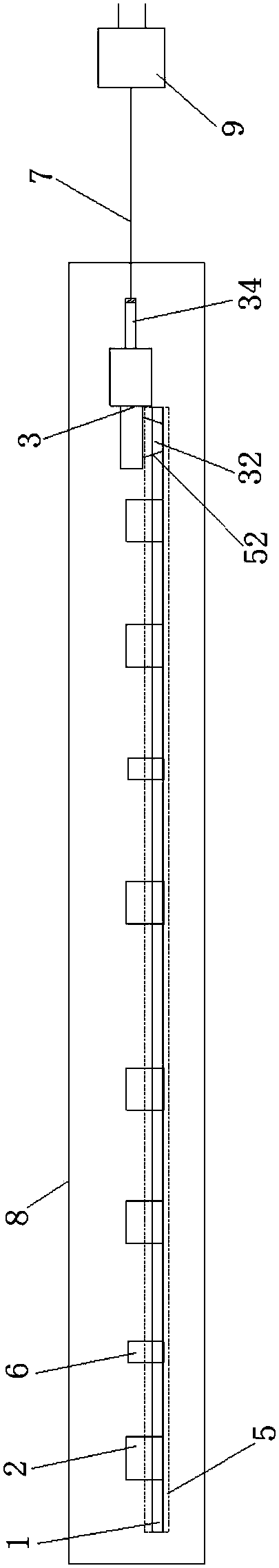

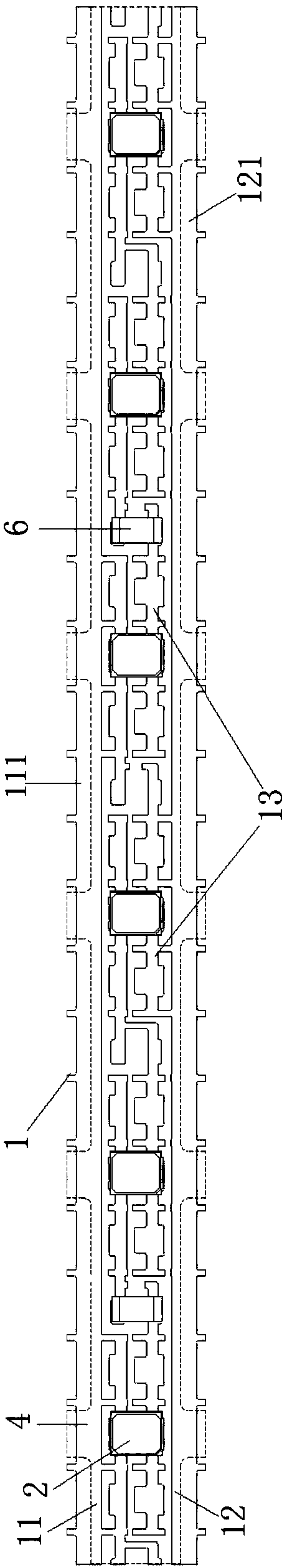

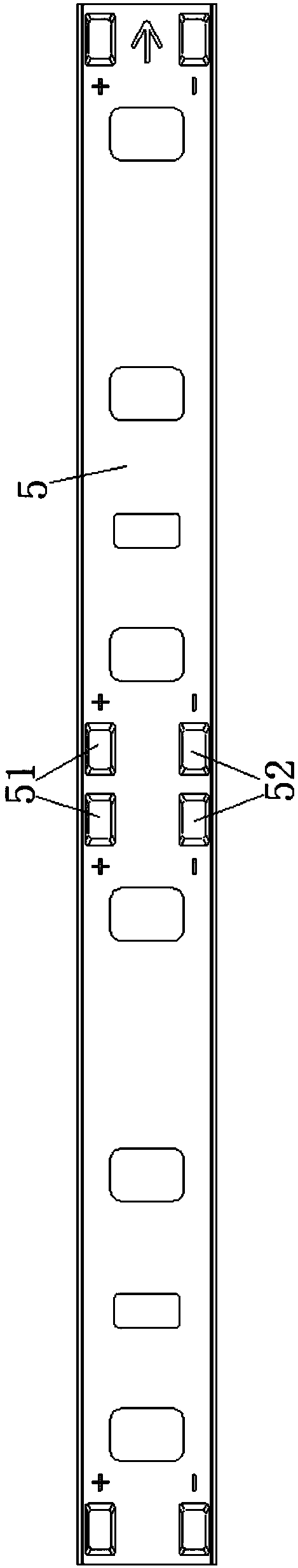

[0031] Such as Figure 1 to Figure 4 As shown, an LED light strip includes a line strip 1, a lamp bead 2, a conversion plug 3, a power cord 7, and a packaging jacket 8. The line strip 1 is integrally stamped and formed by a bendable conductive metal strip. The belt 1 is provided with two first power supply lines 11 and second power supply lines 12 arranged in parallel directions, and a plurality of component lines 13 connected in parallel between the first power supply lines 11 and the second power supply lines 12, Each of the component lines 13 is provided with a plurality of lamp bead installation areas arranged at equal intervals along the longitudinal direction of the line strip 1 and can be connected in series by the lamp beads 2. The lamp beads 2 are mounted on the lamp on the bead mounting area.

[0032] The circuit belt 1 in the present invention is integrally punched and formed by a bendable conductive metal belt. The overall circuit layout is accurate and stable, an...

Embodiment 2

[0042] Compared with Embodiment 1, the main difference is that when the output voltages of the first power supply line 11 and the second power supply line 12 are greater than the sum of the rated voltages of the lamp beads 2 of each element line 13, the The LED light strip further includes a resistance element 6 mounted on the element line 13 and connected in series with the lamp bead 2 of the same element line 13 . By setting the resistance element 6, it can act as a voltage divider to prevent the actual voltage of the lamp bead 2 from being higher than the rated voltage, thereby damaging the lamp bead 2, and avoiding potential safety hazards caused by long-term use.

[0043] The transparent insulating film 4 covers the entire outer surfaces of the element circuit 13 , the lamp bead 2 and the resistance element 6 and part of the outer surfaces of the first power circuit 11 and the second power circuit 12 . Since there are many disconnected or punched areas between the compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com