Patents

Literature

279 results about "Carbon filler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing conductive composite material by utilizing synergistic reaction of conductive filling material

InactiveCN101240091AImprove efficiencyImprove electrical performanceNon-conductive material with dispersed conductive materialFiberCarbon fibers

A preparation of electric conductive composite by synergism of conductive filler, particularly relates to a preparation of electric conductive composite by synergism between carbon nano-tube and conductive carbon filler. The preparation is characterized by using processing apparatus for high-molecular material to melt mix and granulate after mixing polymer, carbon nano-tube, carbon black, black lead, carbon fiber according to a definite ratio. The preparation is simple to operate, easy for application in industry, can further produce electric conductive composite with great electric conductivity and combination property, which can be widely used in automobile, electric and electronic apparatus, office equipment, industrial mechanism, and can satisfy and expand need of high-molecular materials in various application fields.

Owner:TSINGHUA UNIV

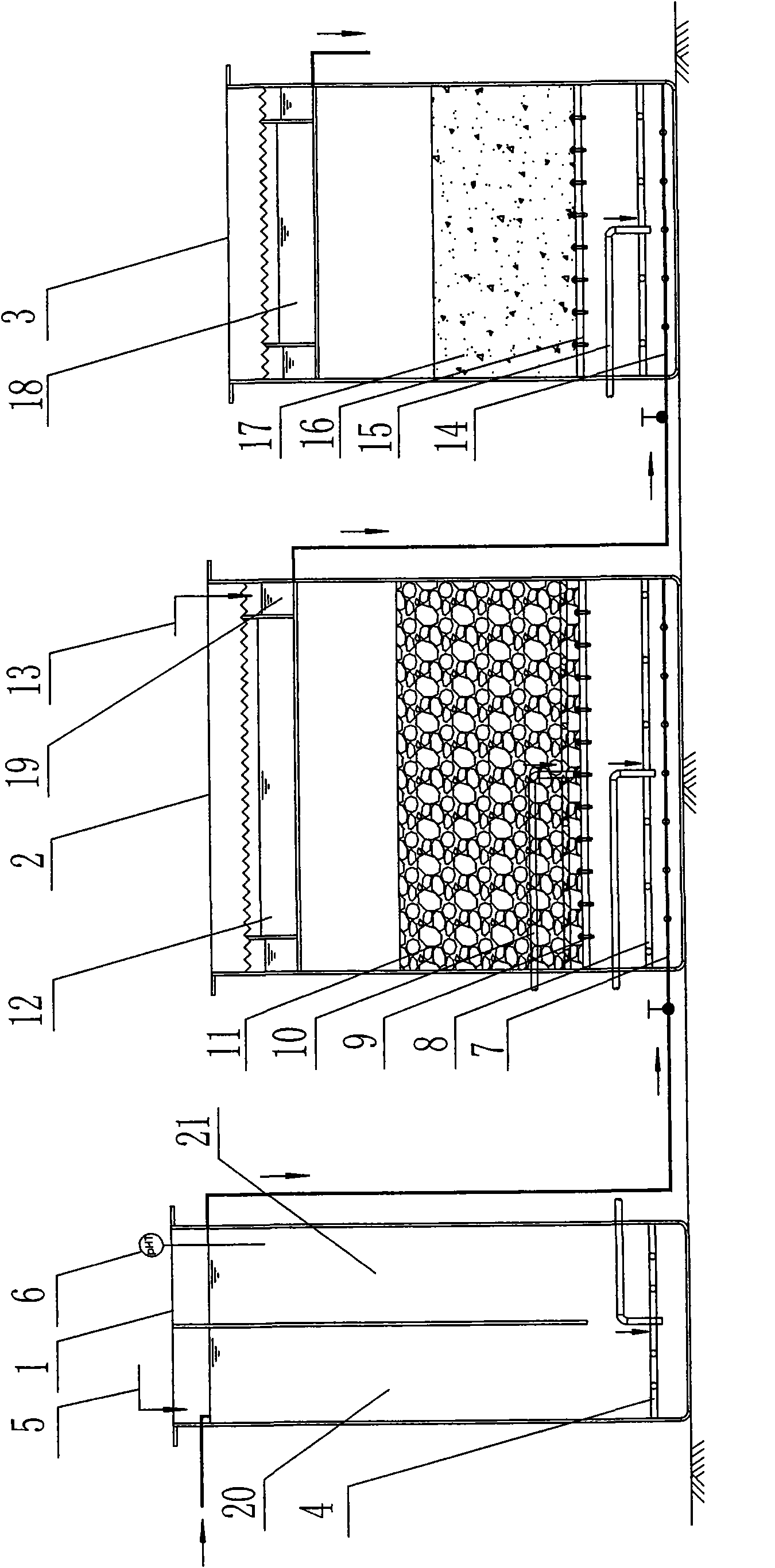

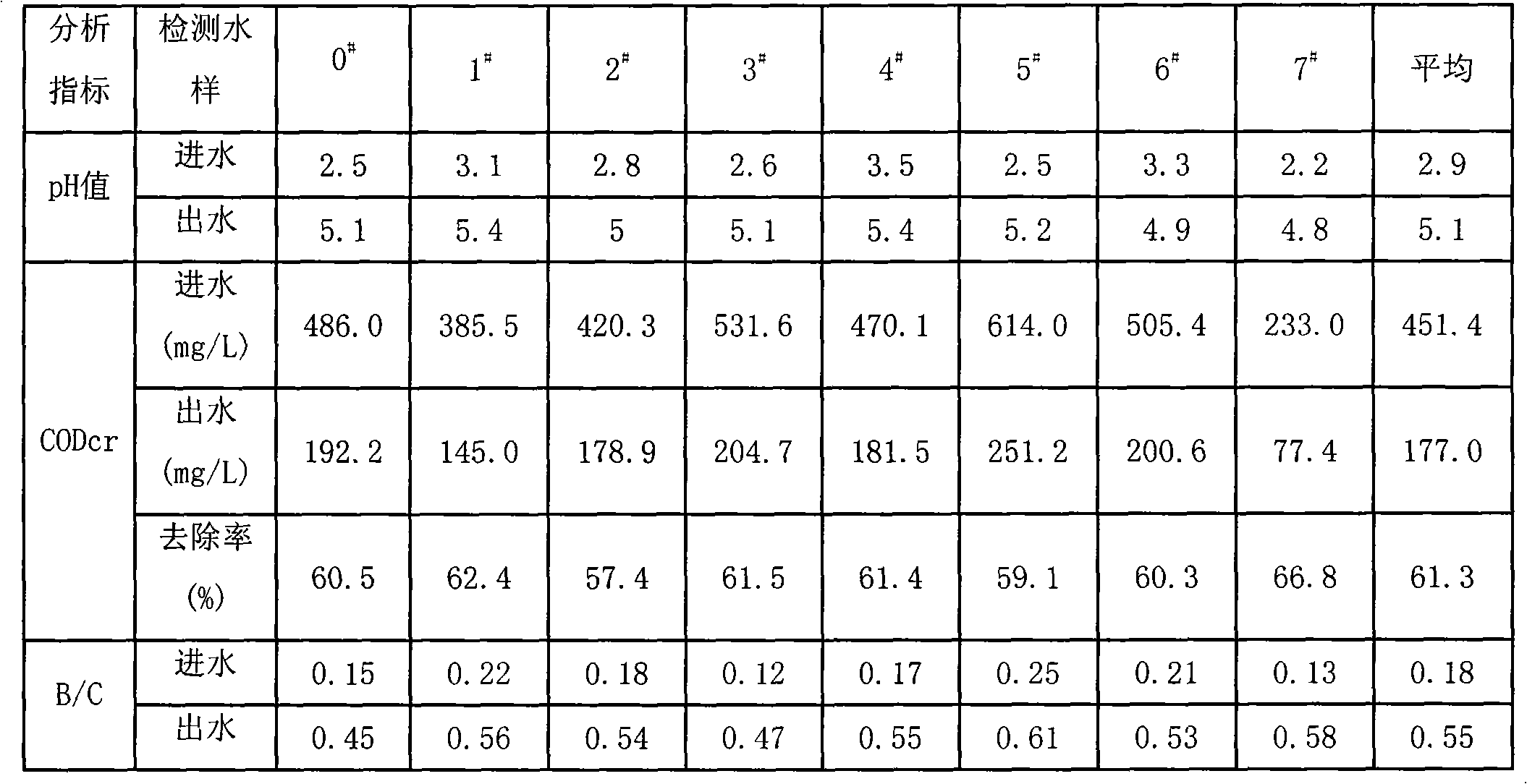

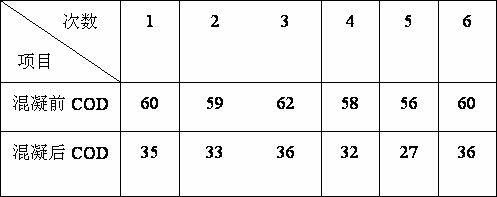

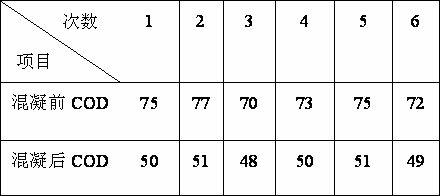

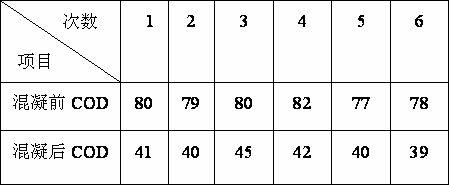

Method and device for multicomponent oxide pretreatment of organic electroplating waste water

InactiveCN101591082AImprove biodegradabilityGood water conditionsWaste water treatment from metallurgical processMultistage water/sewage treatmentPretreatment methodElectrolysis

The invention relates to a method and a device for multicomponent oxide pretreatment of organic electroplating waste water, which belong to the technical filed of electroplating waste water treatment in the environment engineering. The pretreatment method is characterized in that organic electroplating waste water is sequentially subjected to acidity adjustment, ferrum-carbon micro-electrolysis reaction and Fenton oxidation reaction. The corresponding device comprises a pH adjusting tank, a ferrum-carbon micro-electrolysis bath and a Fenton oxidation pond; an acid-alkali feeding device and a pH controller which are in link control are arranged above the pH adjusting tank; the middle low part of the ferrum-carbon micro-electrolysis bath is paved with a ferrum-carbon filler layer, while the bottom is provided with a micro-electrolysis bath perforation water distribution pipe; a hydrogen peroxide feeding device is arranged above the ferrum-carbon micro-electrolysis bath; the bottom of the Fenton oxidation pond is provided with a Fenton oxidation pond perforation water distribution pipe; and the middle lower part of the Fenton oxidation pond is provided with a granular active carbon catalytic carrier layer. The method and the device obviously improve the capability of biochemistry, simultaneously perform oxidation reaction to remove mostly organic pollutants and create favorable water inlet condition for subsequent coagulating sedimentation, air flotation and biochemical treatment.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

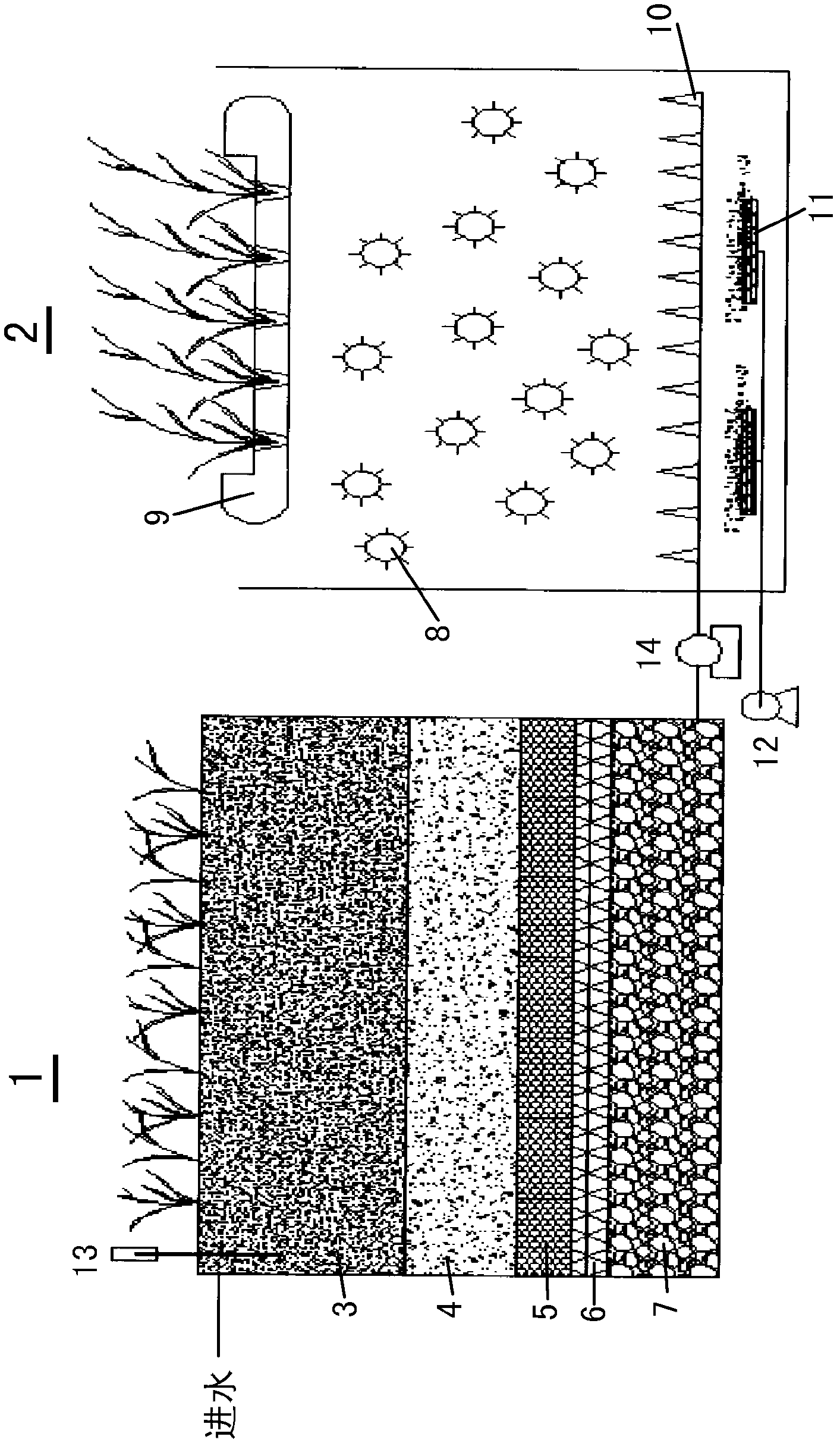

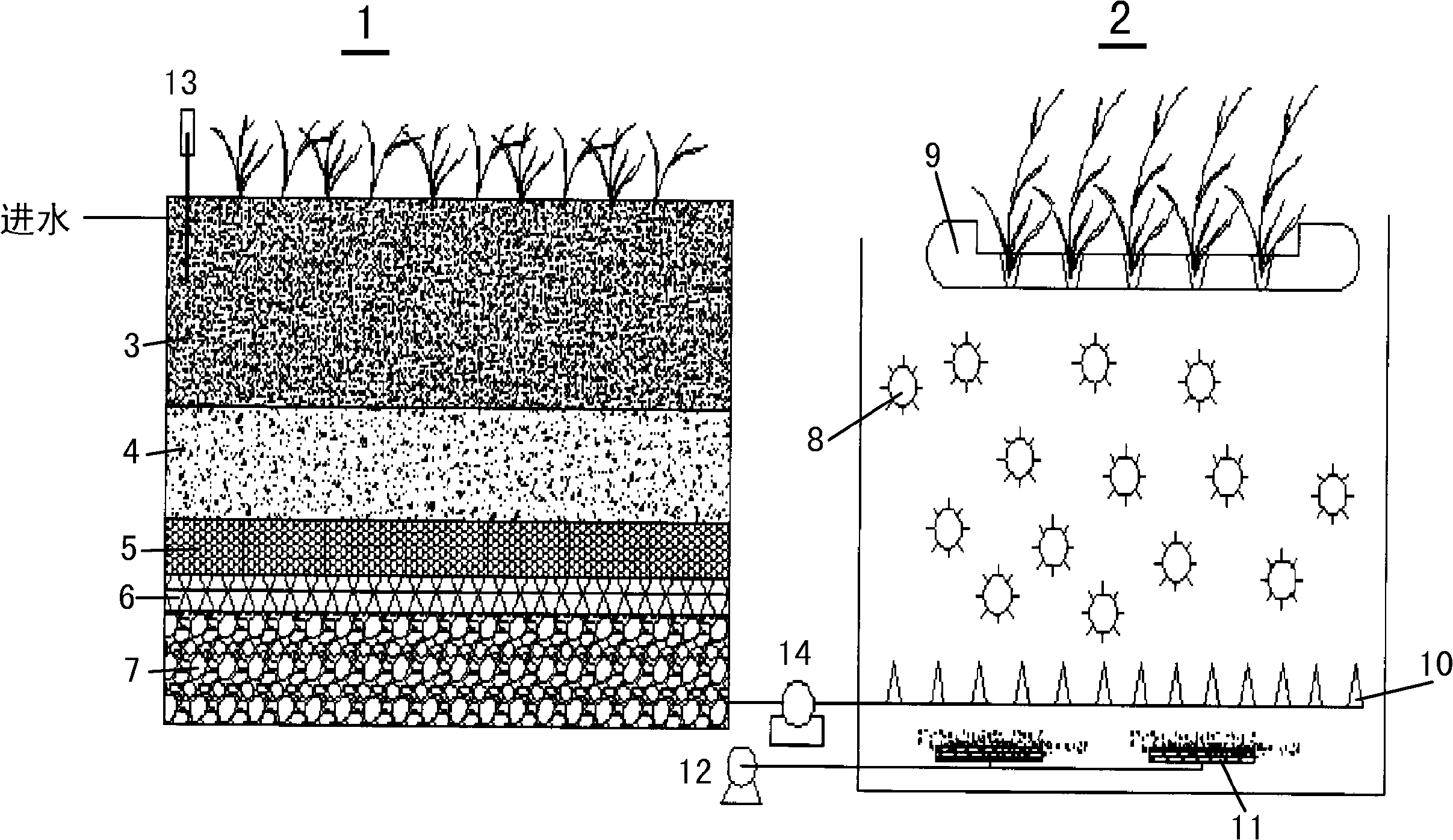

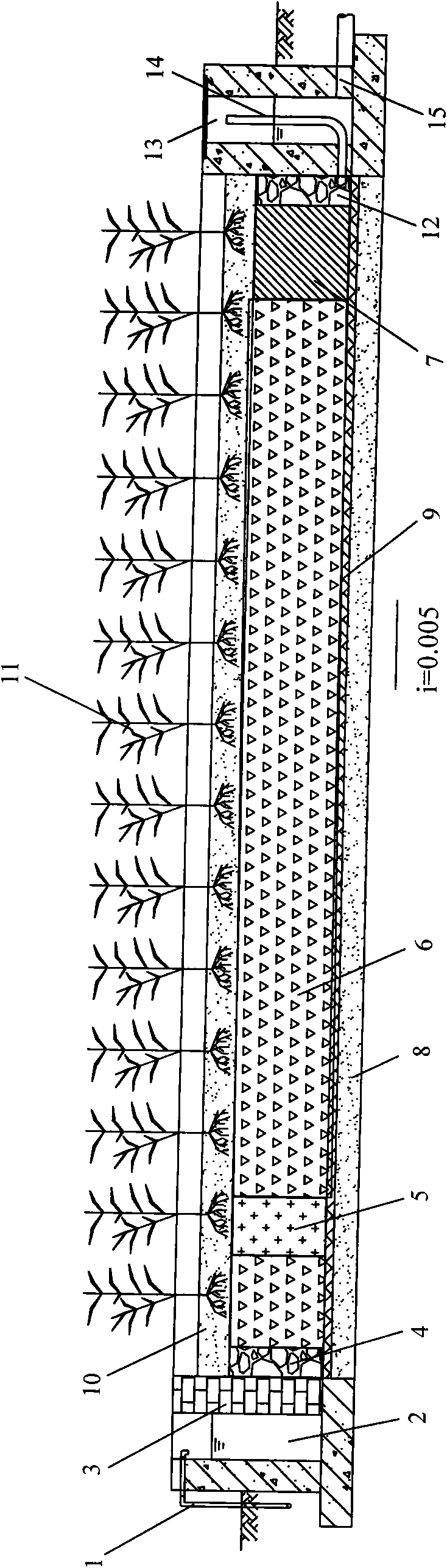

Soil remediation and sewage purification integrated ecological treatment device

ActiveCN102557348APrevent leakageSimple repairContaminated soil reclamationMultistage water/sewage treatmentConstructed wetlandMolecular sieve

The invention relates to a soil remediation and sewage purification integrated ecological treatment device. In the device, constructed wetland is surface flow constructed wetland and sequentially comprises a surface soil layer, a deep treatment layer, a draining layer, a filter layer and a water guide layer from top to bottom, wherein the surface soil layer is composite soil formed by mixing soilinfected by heavy metal, a zeolite molecular sieve and bentonite; the deep treatment layer is iron carbon filler; the draining layer is gravel; the filter layer is non-woven fabric; upper and lower layers of gravel fillers are paved on the water guide layer and the middle part of the water guide layer is separated by the non-woven fabric; an alkaline injection device is arranged at the water inlet end of the constructed wetland and used for controlling the pH value of the constructed wetland and preventing the heavy metal in the constructed wetland from being separated out; an aeration disc is arranged at the bottom of an integrated ecological pool; a water distributor is arranged above the aeration disc; flowing fillers are filled in the integrated ecological pool; an artificial ecological floating bed is floated on the surface of the pool; and a water outlet of the constructed wetland is connected with the integrated ecological pool through a pressure pump. The device performs soil remediation and sewage purification and makes the soil remediation process simple and practical.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

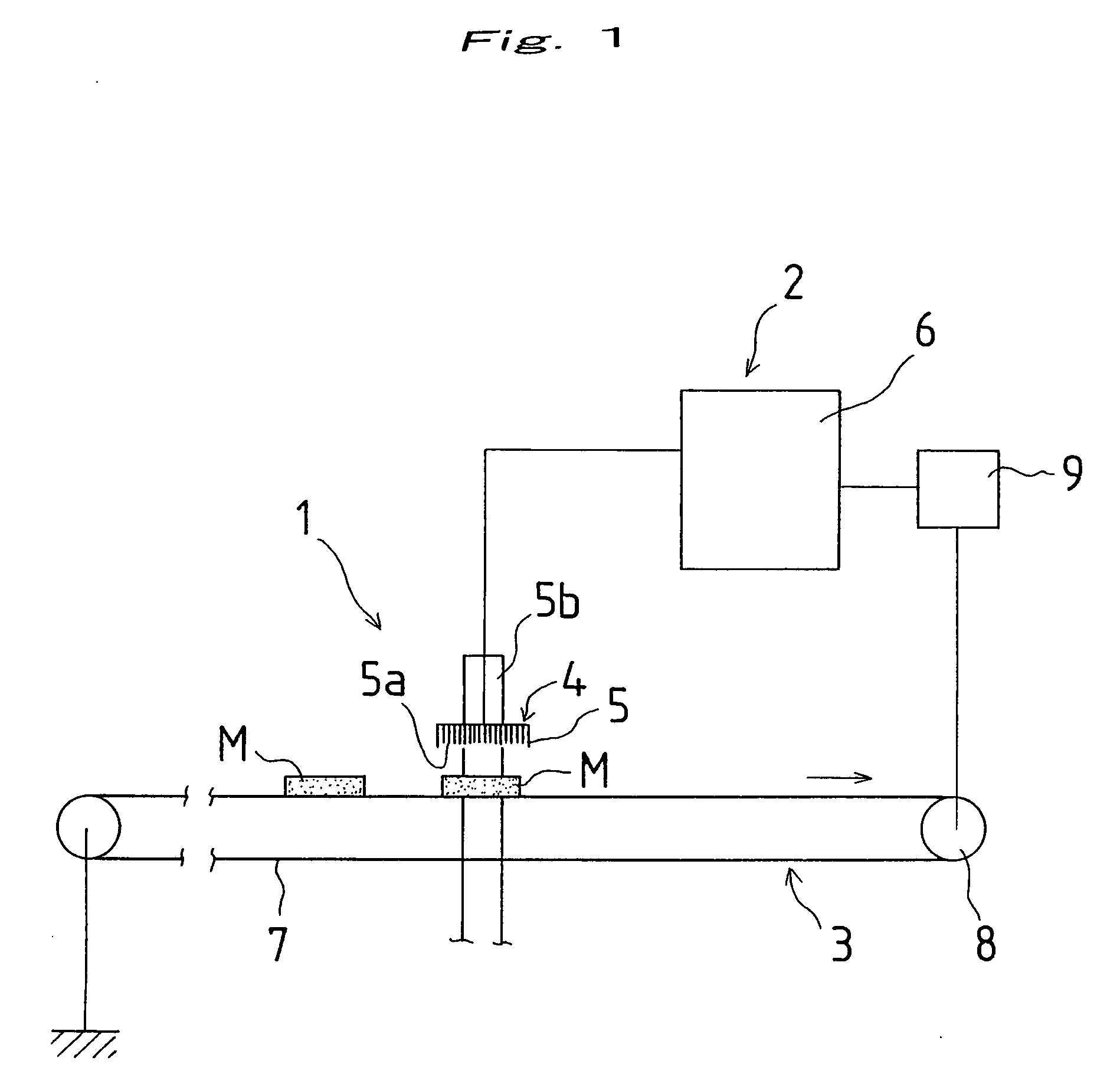

Separator for fuel cell, process for production thereof, and solid polymer type fuel cell using said separator

InactiveUS6881512B2Improve reliabilityGenerates crackSolid electrolytesFuel cells groupingFiberFuel cells

A separator for fuel cell, formed using a base material obtained from a composition comprising at least a binder, a powdery carbon filler having an average particle diameter of 10 nm to 100 μm, and a short fiber having an average fiber length of 0.03 to 6 mm, in which composition the amount ratio of the above three components is such that the amount of the powdery carbon filler is 200 to 800 parts by weight and the amount of the short fiber is 10 to 300 parts by weight, both per 100 parts by weight of the binder.

Owner:NISSHINBO IND INC

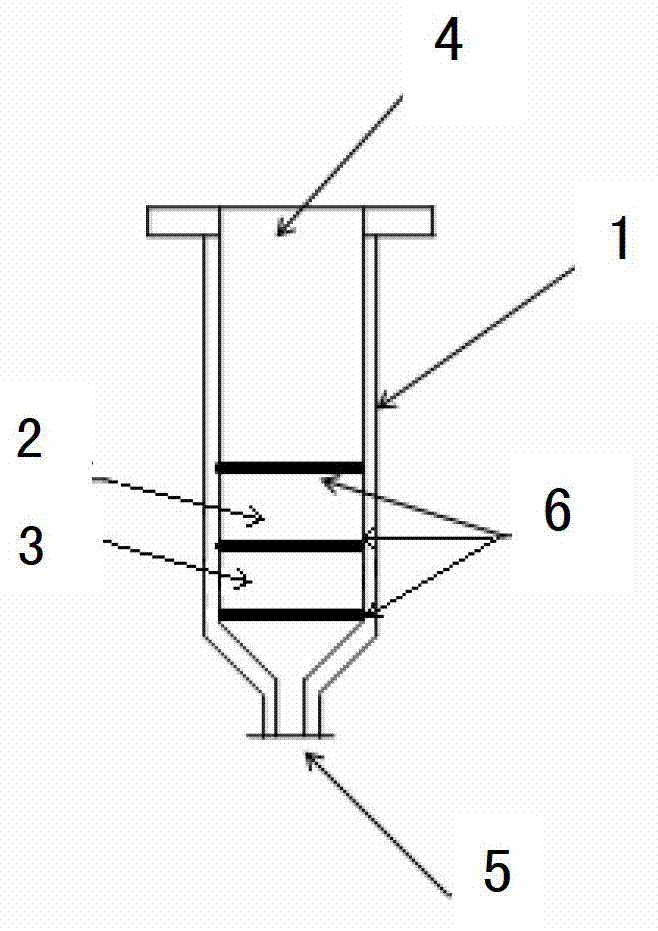

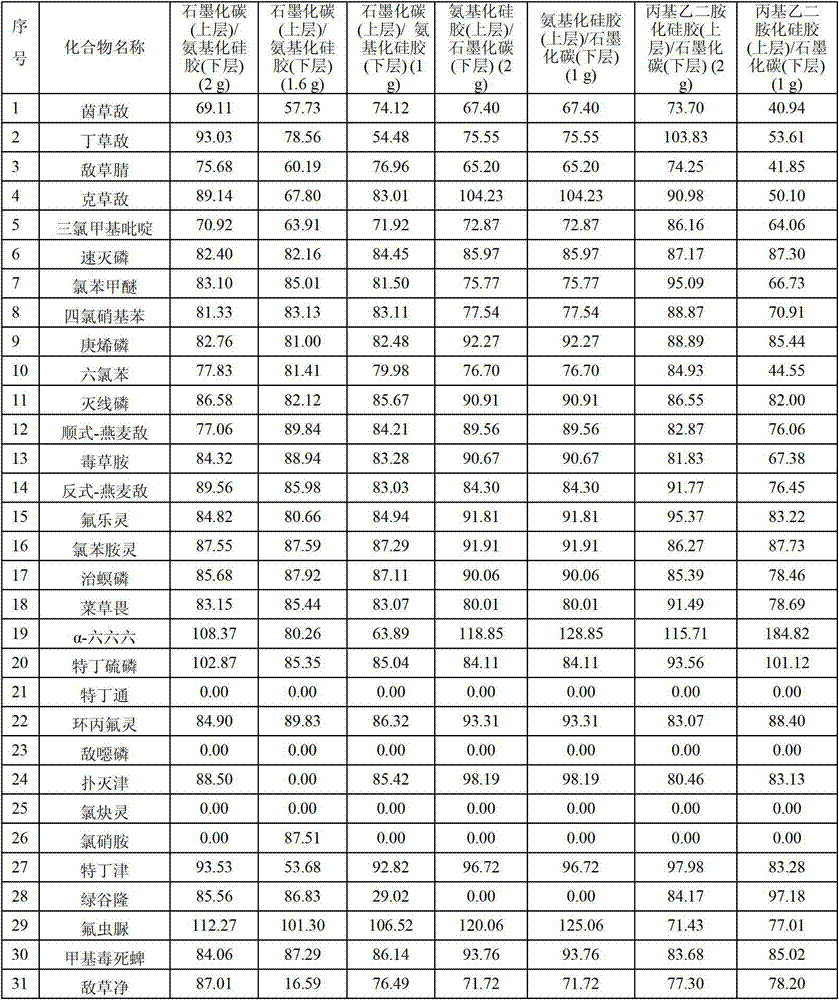

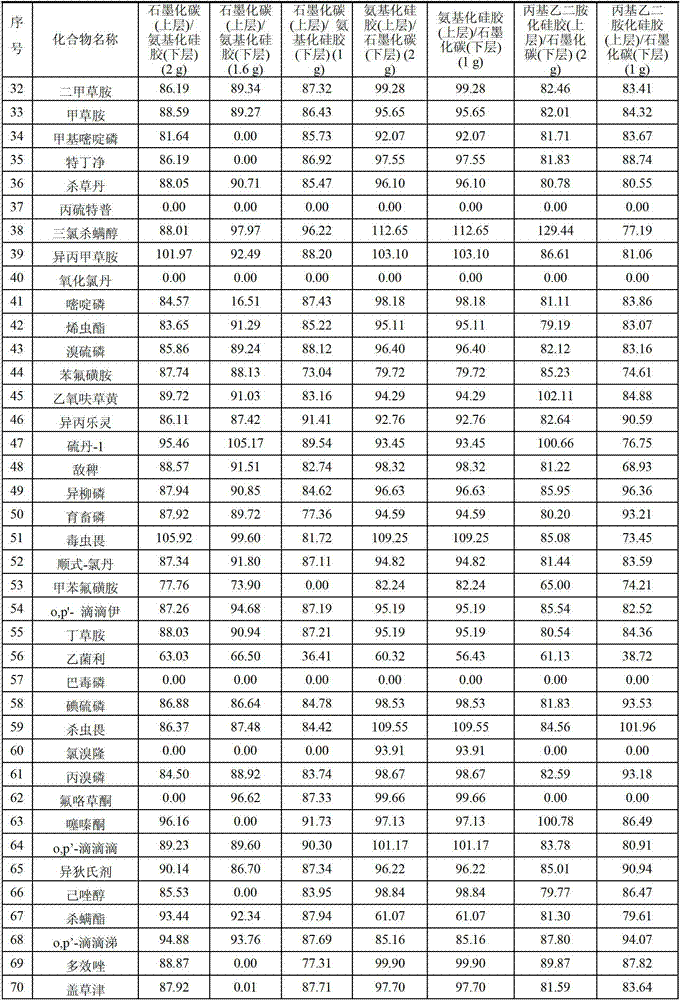

Tea solid phase extraction column and sample pretreatment method for testing pesticide residues in tea leaves

ActiveCN103111091AImprove adsorption capacityReduce adsorptionComponent separationSolid sorbent liquid separationPretreatment methodMetabolite

Owner:天津博纳艾杰尔科技有限公司

Artificial wetland with combined fillers and treating process thereof

ActiveCN102079579AGood at removingGood removal effectWater contaminantsWaste water treatment from metallurgical processConstructed wetlandTreatment effect

The invention provides an artificial wetland with combined fillers for the advanced treatment of the effluent coking wastewater of iron and steel enterprises, which sequentially comprises a water inlet area, a wetland processing unit area and a water outlet area, wherein the wetland processing unit area sequentially comprises a gravel filler section, an iron carbon filler section and a manganese sand filler section; and a soil covering layer and wetland plants are arranged on the surface of the wetland. By using iron carbon, manganese sand and gravels as combined fillers and using emerging plants (such as cattail, Scirpus tabernaemontani, Thalia dealbata, reed and the like) having large biomass, salinization resistance and high metal and organic substance adsorptive power as a composite plant bed, the invention forms a horizontal subsurface flow artificial wetland. Thus, when industrial waste water moves into the artificial wetland, pollutants can be removed on the basis of a series of physical, chemical and biological interaction among the fillers, plants and microorganisms. The process provided by the invention has high pollutant shock load resistance and good treatment effect. Besides, the outlet water is stable, and main indexes of the outlet water can meet the Reuse of Urban Recycling Water-Water Quality Standard for Industrial Uses (GB / T 19923-2005). Thus, the outlet water can be recycled as circulating cooling water for steel enterprises.

Owner:BAOSHAN IRON & STEEL CO LTD +1

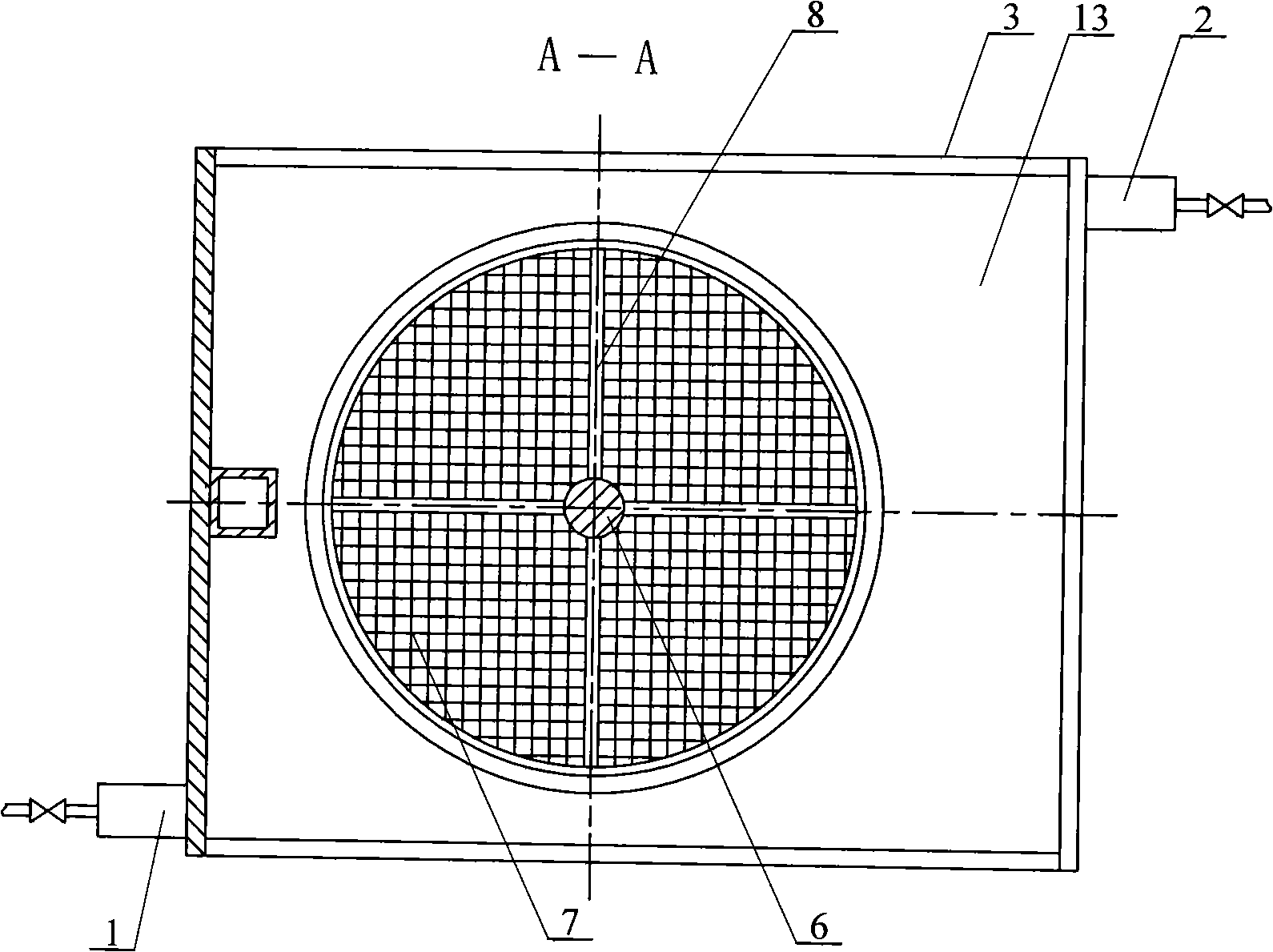

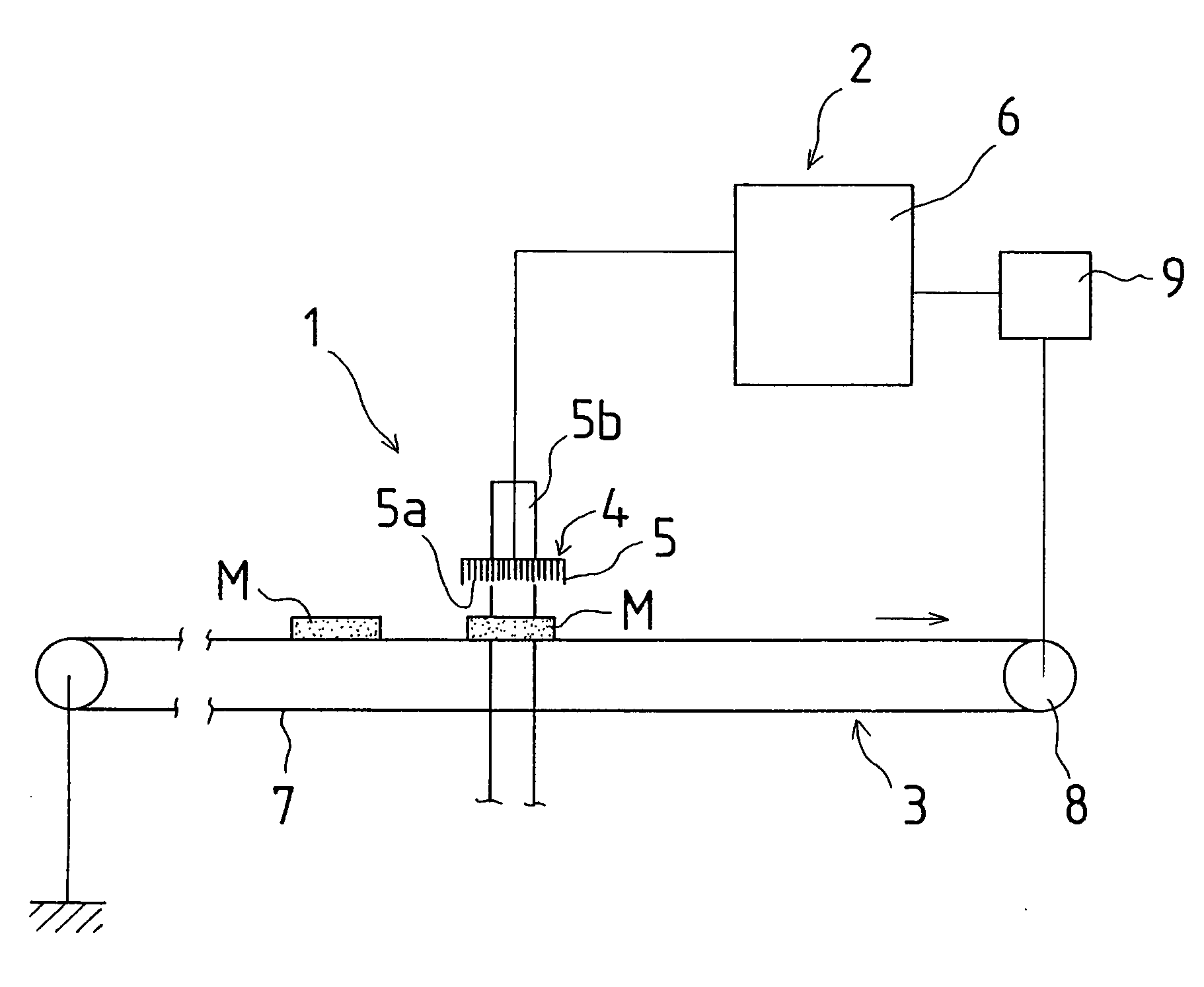

Microelectrolysis-fenton oxidizing reaction device

ActiveCN103663802AReduce the additional amountPlay a catalytic roleMultistage water/sewage treatmentWater/sewage treatment by oxidationElectrochemical responseElectrolysis

The invention belongs to the technical field of sewage treatment, and in particular relates to a microelectrolysis-fenton oxidizing reaction device. The oxidizing reaction device comprises a wastewater supply device, and a hollow-out reactor made of anti-corrosive materials; a barrel body of the reactor is internally divided into a fenton oxidizing reaction area, a microelectrolysis reaction area and a flocculoreaction area from bottom to top; the microelectrolysis reaction area is full of iron-carbon fillers. The device also comprises a draining device arranged at the upper side of the reactor. The draining device is convenient for draining the treated wastewater to the outside of the oxidizing reaction device. The microelectrolysis-fenton oxidizing reaction device has the advantages that the microelectrolysis technology and the fenton oxidizing technology are integrated, so that the effective space of the reactor can be furthest utilized, i.e.,, the electrochemical reaction and the oxidization-reduction reaction can be carried out synchronously within the effective space of every independent unit device, therefore, the wastewater treatment process can be greatly simplified, the impact of various factors on wastewater treatment operation can be reduced, the purification performance of unit equipment in wastewater treatment can be improved, and as a result, an ideal treatment effect can be obtained.

Owner:安徽南风环境工程技术有限公司

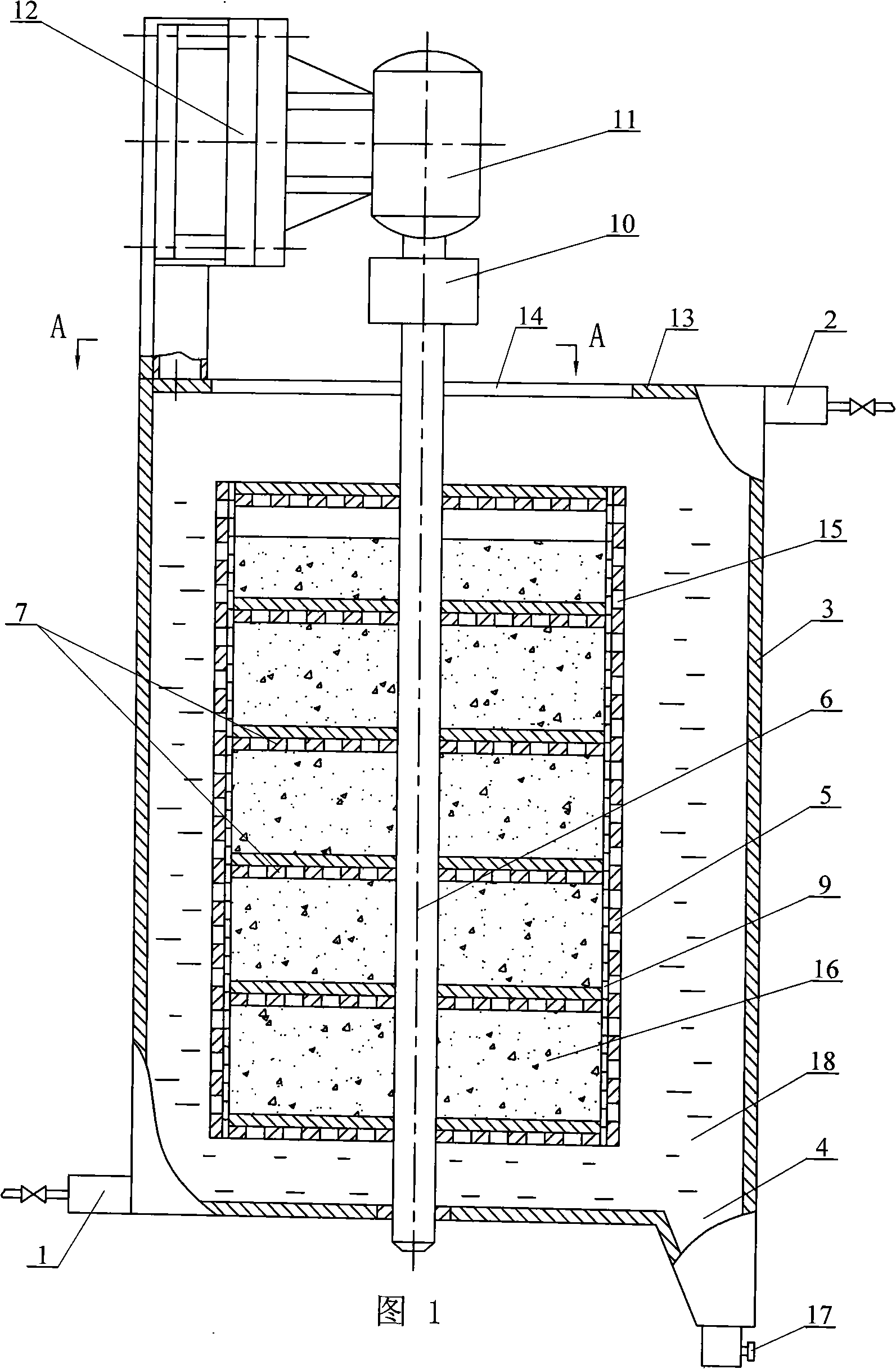

Highly effective pretreatment apparatus for refractory dyeing waste water

InactiveCN101302052AImprove biodegradabilityExtended pathWater/sewage treatmentWaste water treatment from textile industryHigh concentrationElectrolysis

The invention relates to a high-efficient pretreatment device for an undegradable dye printing wastewater, which relates to an industrial wastewater pretreatment device. The invention solves the problems that the prior iron-carbon micro-electrolysis method for treating the dye printing wastewater has channeling and short flow caused by the blocking and hardening of fillers and has difficult operation, large energy consumption, etc. in backwashing by adopting mechanical stirring or air compression. A rotary cylinder body is arranged inside a reactor; an input end of a rotating shaft is connected with an output end of an electromotor by a speed governor; an output end of the rotating shaft is arranged inside an axle hole of the bottom end face of the reactor; a set of netty clapboards are arranged on the rotating shaft and inside the rotary cylinder body; a sludge discharge groove is arranged on the reactor; a plurality of pores are arranged on the outer wall of the rotary cylinder body; and the rotary cylinder body is provided with iron-carbon fillers inside. The high-efficient pretreatment device has simple operation, small power consumption, high reaction efficiency and good pretreatment effect and can effectively carry out pretreatment aiming at the undegradable, high-concentration and high-chroma dye printing wastewater, thereby substantially reducing the concentration of organism and effectively improving the biodegradability of wastewater.

Owner:HARBIN INST OF TECH

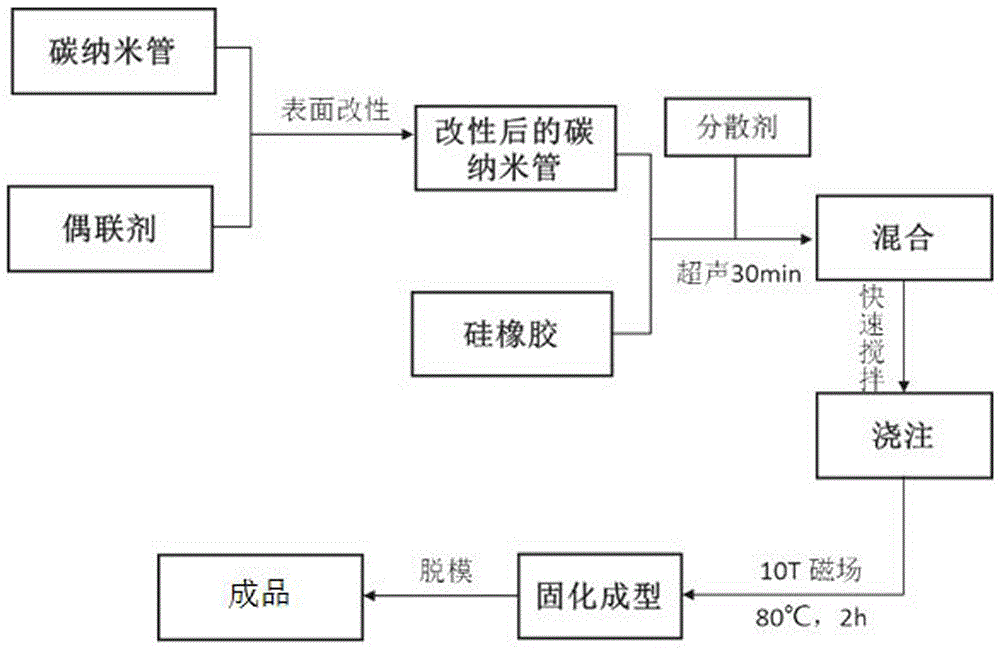

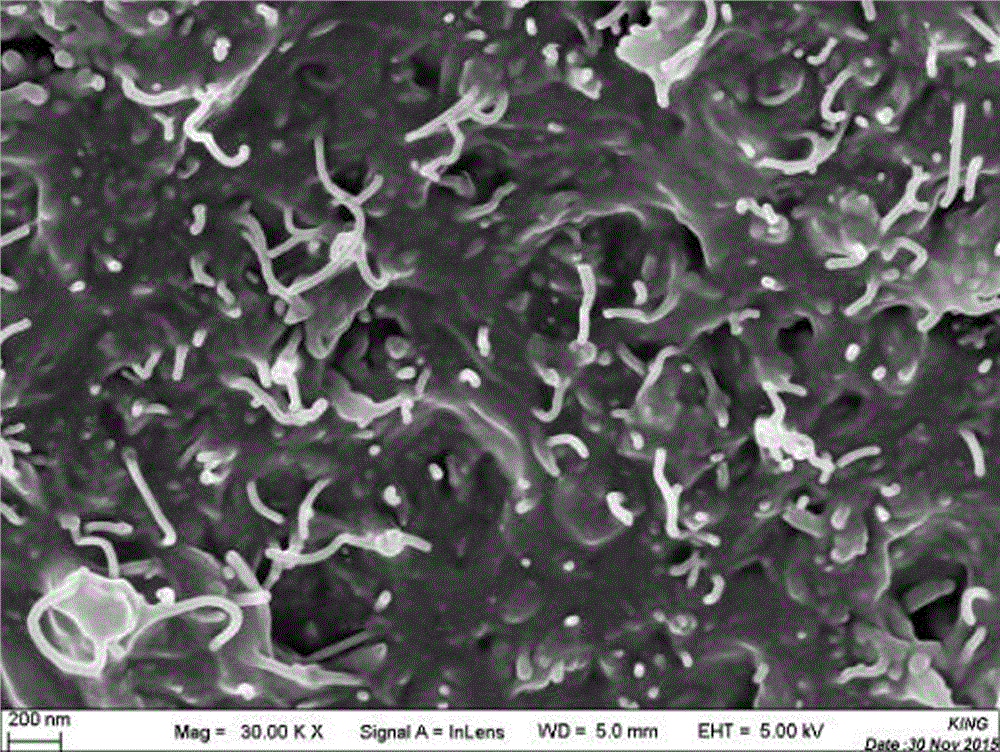

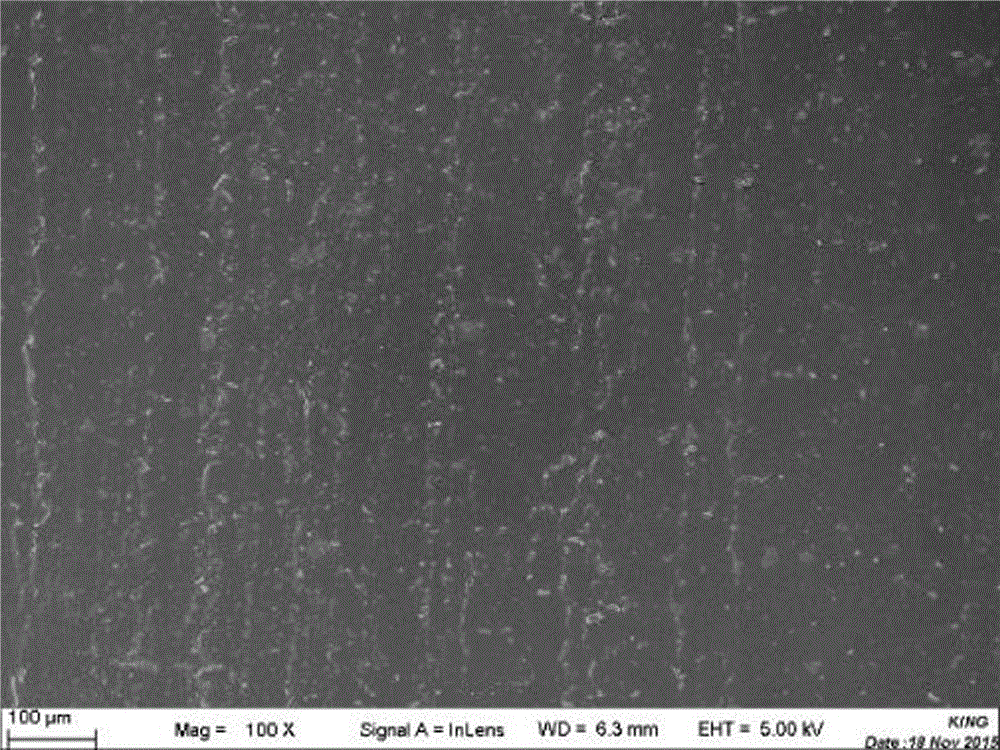

Method for preparing thermally conductive composite material with directivity

The invention discloses a method for preparing a thermally conductive composite material with directivity in order to solve the heat dissipation problem of conventional materials and traditional technology electronic components. The method comprises the following steps that: a carbon material accounting for 0.1 to 15wt% of a thermally conductive silicone rubber composite material forms an anisotropic thermally conductive path in a polymer matrix under the action of a strong magnetic field, and the thermally conductive composite material mainly comprises a thermally conductive carbon filler of carbon nanotubes or graphenes or a mixture thereof and a silicone rubber matrix; the carbon material is ultrasonically dispersed and poured into a mold to be molded by curing under the action of the strong magnetic field, so that the carbon nanotubes or graphenes form chain structures to be arranged in the matrix, thus generating the thermally conductive composite material with directivity. The method provided by the invention has the advantages of simple and safe operation and short preparation period, the carbon material without a magnetic function is regularly arranged in structure under the action of the strong magnetic field to form an anisotropic composite material, and the thermal conduction has directivity.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

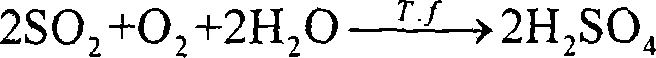

Method for removing sulfur-dioxide in smoke by bamboo-carbon filler biological drip filtering tower

InactiveCN101073745AHigh removal rateImprove sulfur recoveryDispersed particle separationAir quality improvementSulfateSulfur

The invention is concerned with a method to remove sulfur dioxide of gas and smoke through bio-trickling filter tower with bamboo-carbon filler. The nutrient source spray on the filling inside the tower form the top of bio-trickling filter tower and run into the filling from up to down and enter the circulation gutter on the bottom of tower, then go back to the top of tower by circulation gutter. Meanwhile the gas and smoke with sulfur dioxide enter form the bottom of tower, during the rising process, it is cleaned by the bio-film with fixed desulfuration bacteria and discharged form the top of tower. The filling is the pretreatment bamboo-carbon and it is fit for getting Ferrous Sulfate desulfuration byproduct. The bamboo-carbon owns developed holes and strong adsorption ability to form steady and high active bio-film and to remove the sulfur dioxide. It has wide application future to callback sulfur with low cost.

Owner:NANJING UNIV

High-thermal conductivity insulated carbon filler, high-thermal conductivity insulated epoxy resin composite material and preparation method thereof

The invention discloses a high-thermal conductivity insulated carbon filler, a high-thermal conductivity insulated epoxy resin composite material and a preparation method thereof. The high-thermal conductivity insulated carbon filler is prepared from carbon material powder, an insulating modifier, a surfactant, an organic solvent, water and a pH regulator by virtue of a sol-gel method. The high-thermal conductivity insulated epoxy resin composite material is prepared by the following steps: further uniformly mixing the prepared high-thermal conductivity insulated carbon filler with an epoxy resin and a curing agent, performing hot press molding, and curing, thereby obtaining the composite material. The prepared carbon filler is high in thermal conductivity, high in insulating property and high in dispersity, the epoxy resin composite material with high insulating property and high thermal conductivity can be prepared, and the performance requirements of the conventional electronic products on the heat-conducting insulated plastics can be met. In addition, the carbon filler and the epoxy resin composite material are simple in preparation method, low in cost, safe and environment-friendly, and the industrial production requirements are met.

Owner:HUNAN UNIV

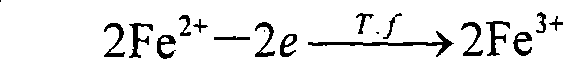

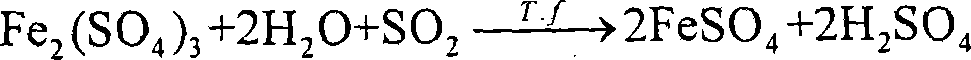

Conductive Resin Composition

InactiveUS20070205401A1Improve conductivityLow water absorptionNon-metal conductorsConductive materialPolyesterPolyamide

Disclosed is a conductive resin composition containing a polyamide, a polyphenylene ether, a polyester and a conductive carbon filler. The resin composition has attained excellent conductivity by being added with a small amount of the conductive carbon filler, while being excellent in fluidity and surface luster. Also disclosed is a molded body formed from such a resin composition.

Owner:ASAHI KASEI CHEM CORP

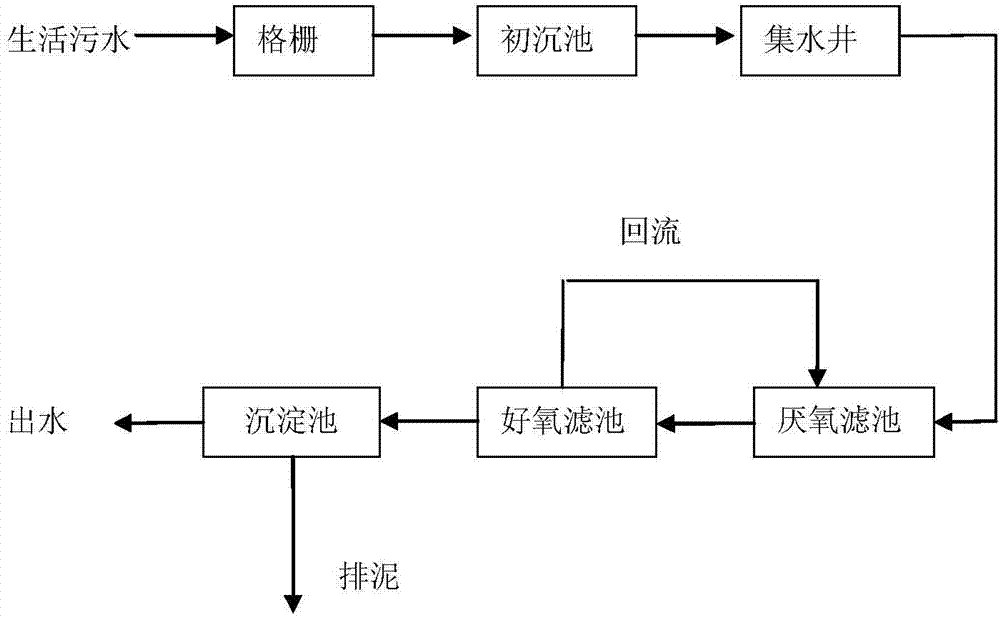

Biochemical simultaneous phosphorus and nitrogen removal method of domestic sewage

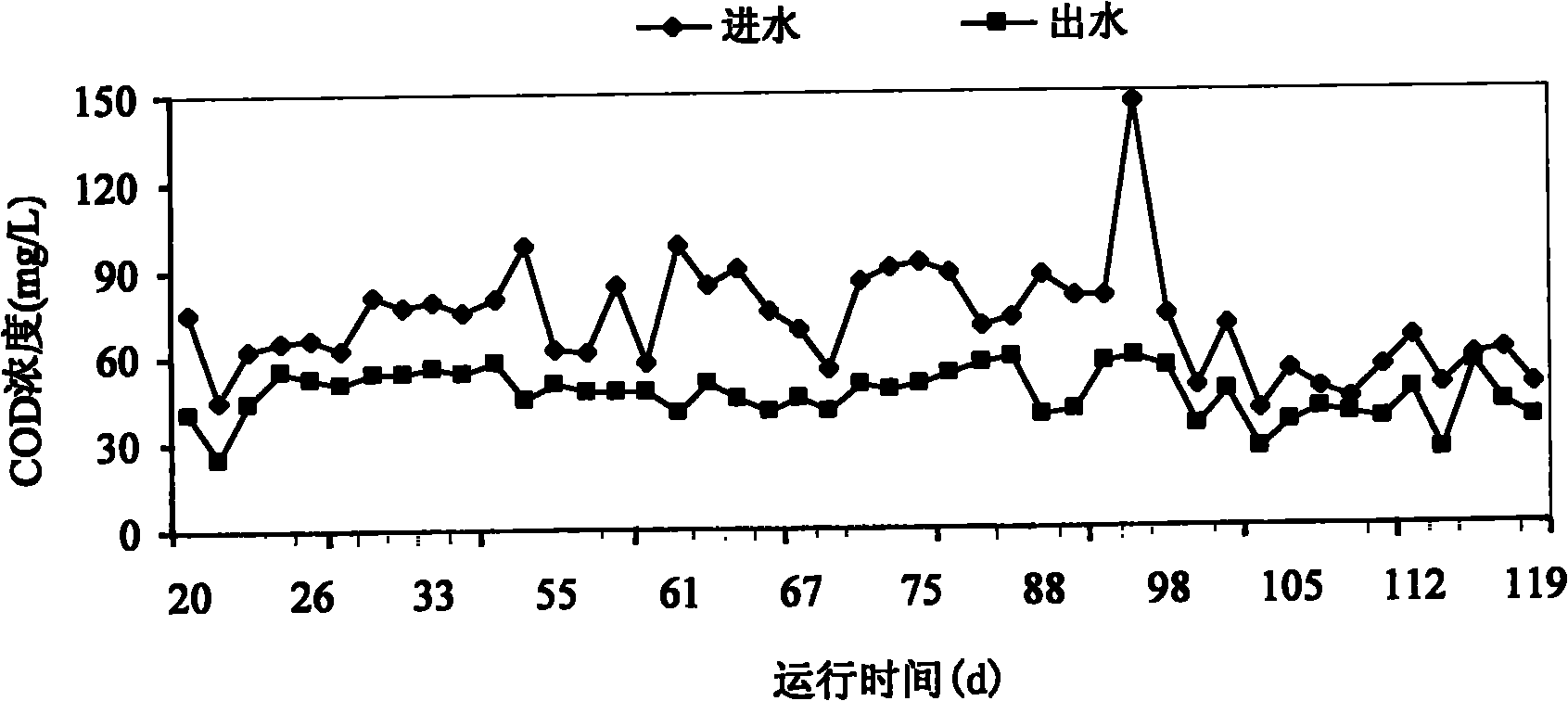

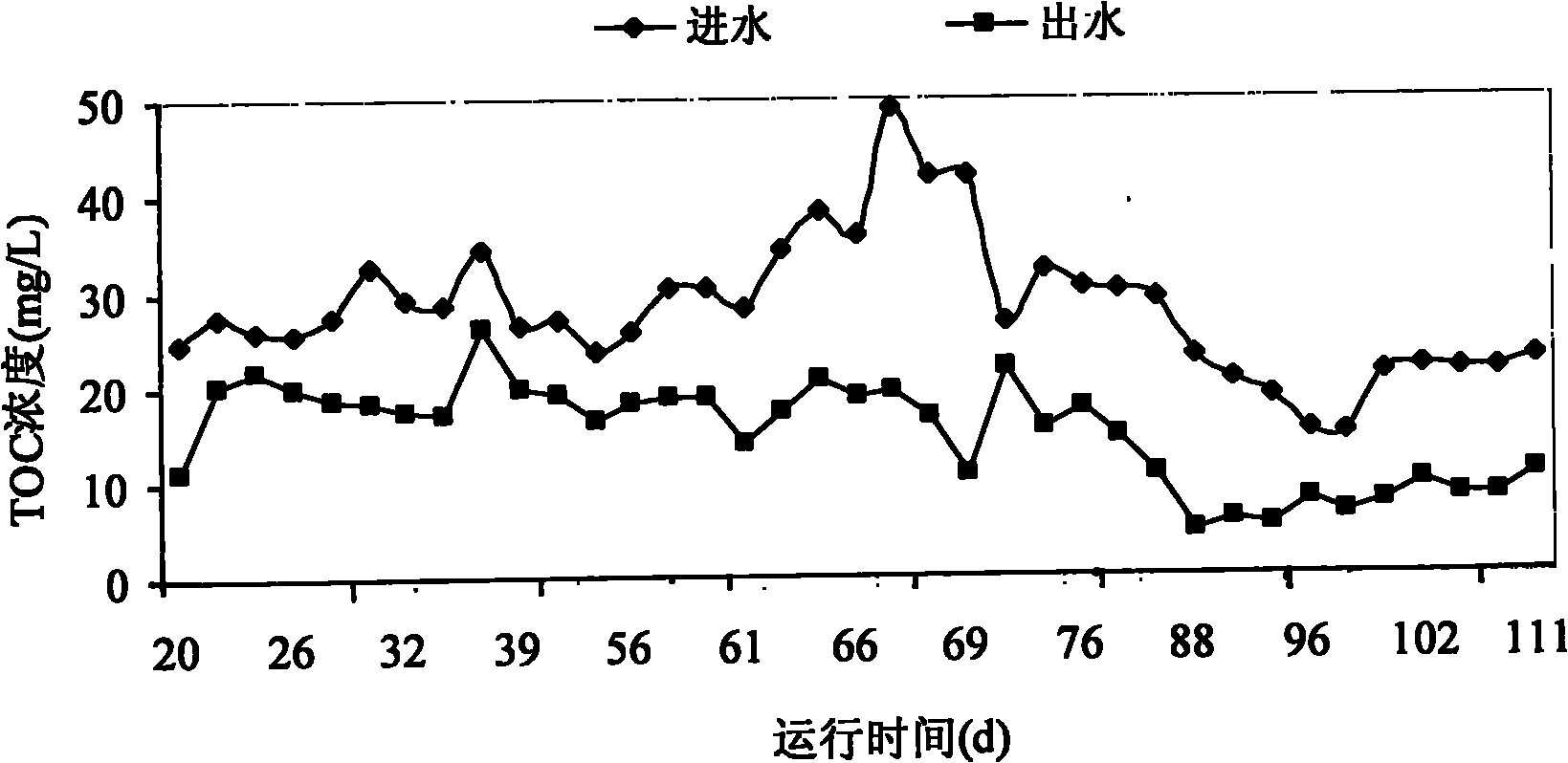

InactiveCN103496787ALess sludgeLow running costTreatment with aerobic and anaerobic processesElectrochemical responseChemical oxygen demand

The invention relates to a biochemical simultaneous phosphorus and nitrogen removal method of domestic sewage. Sewage passes through a grating and a primary settling tank at first so that partial suspended solids are removed, next, the sewage passes through an anaerobic filter tank loaded with iron carbon filler and an aerobic filter tank, the effluent of the aerobic filter tank flows back to the anaerobic filter tank, organic matters in the sewage in the anaerobic state are acidified so that the pH is reduced, an electrochemical reaction is aroused on the surface layer of the iron carbon filler to intensify denitrification, and in the meantime, few ferrous ions (Fe<2+>) are dissolved out; the ferrous ions (Fe<2+>) are oxidized into ferric ions (Fe<3+>) in the aerobic state, the ferric ions react with soluble phosphate radicals in the sewage to generate precipitate, and finally, the sewage enters a sedimentation basin and is gravitationally settled, and then emitted. The biochemical simultaneous phosphorus and nitrogen removal method of domestic sewage, provided by the invention, has the advantages that no reagent needs to be fed independently to remove phosphorus, and only by virtue of the biochemical method, the COD (Chemical Oxygen Demand) in the yielding water is lower than 30 mg / L, TN (Total Nitrogen) in the yielding water is 1.5 mg / L and TP (Total Phosphorus) in the yielding water is 0.2 mg / L, and consequently, the yielding water is up to the class IV water standards of surface water. Furthermore, the biochemical simultaneous phosphorus and nitrogen removal method of domestic sewage is simple in process, and capable of saving investment and operation costs, and thus has a great application value.

Owner:TONGJI UNIV

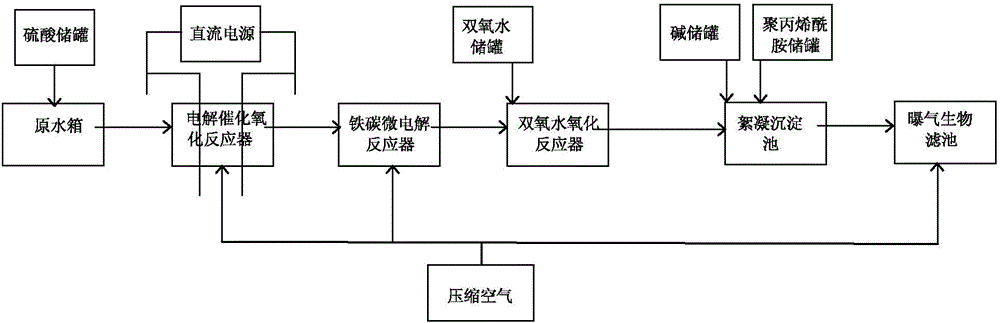

Treatment method for reverse osmosis concentrated water

ActiveCN104556533AImprove oxidation efficiencyLarge specific surface areaTreatment using aerobic processesMultistage water/sewage treatmentElectrolysisReverse osmosis

The invention relates to a treatment method for reverse osmosis concentrated water, in particular to a standard treatment method for the reverse osmosis concentrated water which is produced during sewage reusing. The treatment method comprises the following steps: the pH value of the reverse osmosis concentrated water is regulated to be 2.0-4.0, and electrolytic catalysis oxidation is carried out; water produced from the electrolytic catalysis oxidation is subjected to redox reaction in an electrolytic reactor, which is filled with iron-carbon fillers obtained through sintering of iron and carbon; hydrogen peroxide is then added, so that oxygenolysis is further achieved; the pH value is regulated to be 6.0-8.0, and a flocculant is added for flocculent settling; a supernate obtained from the flocculent settling enters an aeration biological tank, and a co-substrate is added for biological degradation. The COD of the reverse osmosis concentrated water with lower biodegradability, which is obtained through reverse osmosis reusing treatment after standard biochemical treatment, is reduced from 70-200 milligrams per liter to below 50 milligrams per liter, so that the strictest local emission standards can be met.

Owner:CHINA PETROLEUM & CHEM CORP

Glyphosate-producing wastewater treatment integration technology

InactiveCN104609665ATo achieve the purpose of precipitation removalPrevent subsidenceMultistage water/sewage treatmentNature of treatment waterTreatment effectElectrolysis

The invention discloses a gyphosate-producing wastewater treatment integration technology. The technology comprises steps as follows: micro-electrolysis treatment is performed under the aeration condition, toxic and degradation-resistant organic matters in wastewater are oxidized by a Fenton regent comprising hydrogen peroxide and ferrous ions which are by-products produced by ferric carbon filler, after lime is added to effluent and pH is regulated to 8-9, a flocculating agent is added for precipitation, suspended matters and iron-phosphorus precipitates are removed, effluent after precipitation is sent to an upflow anaerobic reactor, and degradation-resistant and toxic organic matters in wastewater are further degraded, removed and transformed, the effluent enters a multi-stage contact oxidation pond and a primary aeration sedimentation tank for biochemical treatment, the treated wastewater is emitted up to standard, and the organic matter removal rate in a pretreatment combination physicochemical technology can be up to 50%. The technology is stable in operation and good in treatment effect, the treatment cost is reduced, and the treated effluent can meet the integrated wastewater discharge standard (GB-8978-1996).

Owner:四川省生态环境科学研究院 +2

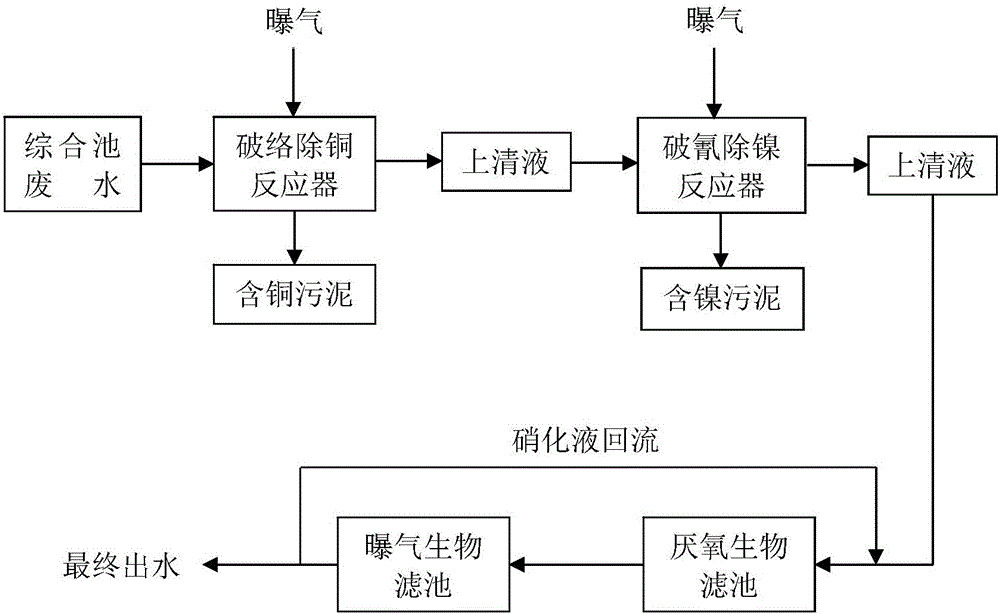

Resourceful treatment and recycling method of circuit board wastewater

InactiveCN105906154AAvoid inhibitionImprove biodegradabilityWater contaminantsMultistage water/sewage treatmentBiological filterMaterials science

The invention relates to a resourceful treatment and recycling method of circuit board wastewater. The resourceful treatment and recycling method comprises the following steps of 1, precipitation breaking and copper removal, wherein pH of the circuit board wastewater is adjusted to 2-4, the circuit board wastewater is put into a precipitation breaking and copper removal reactor filled with ferric carbon filler, an aeration reaction is performed, the pH of outlet water of the reactor is adjusted, a flocculating agent is added, a stirring coagulating reaction is performed, and solid-liquid separation is performed; 2, cyanide breaking and nickel removal, wherein the pH of a supernate obtained in the step 1 is adjusted to 2-4, the supernate is put into a cyanide breaking and nickel removal reactor, and an aeration reaction is performed, the pH of outlet water of the reactor is adjusted to 8-9, a stirring coagulating reaction is performed, and solid liquid separation is performed; 3, filter material biological filter pond treatment, wherein the supernate obtained in the step 2 is added into a filter material biochemical treatment system with a cyanide breaking and nickel removal filter material, cyanide breaking and nickel removal are performed, and the final outlet water is obtained. Compared with the prior art, the method is simple in flow, compact, stable, efficient, low in operation cost, applicable to wastewater with the high heavy metal concentration and particularly suitable for circuit board wastewater treatment, and has the high popularization and application value.

Owner:TONGJI UNIV

Device and process for treating high-concentration organic wastewater containing PVA

PendingCN106145467AReduce CODAchieve emission standardsWater treatment compoundsTreatment involving filtrationHigh concentrationElectrolysis

The invention discloses a device for treating high-concentration organic wastewater containing PVA. The device comprises an iron-carbon micro-electrolysis reaction tank, a sedimentation tank, a Fenton reactor and a clean water tank which are arranged and communicated along a wastewater incoming sequence, a water storage tank is connected with the iron-carbon micro-electrolysis reaction tank through a metering pump, the iron-carbon micro-electrolysis reaction tank is connected with an oxygenator, the bottom of the iron-carbon micro-electrolysis reaction tank is filled with an iron-carbon filler, a stirring device is arranged in the upper portion of the iron-carbon micro-electrolysis reaction tank, and the Fenton reactor is connected with a ferrous sulfate replenishment tank and a hydrogen peroxide replenishment tank through a ferrous sulfate feeding pipe and a hydrogen peroxide feeding pipe. Electro-electrolysis flocculation pretreatment is performed through the iron-carbon micro-electrolysis reaction tank, and then polyacrylamide flocculation treatment is performed further, so that COD of the wastewater is lowered substantially, little particles, metal particles and organic macromolecules PVA dispersed in the wastewater are adsorbed, cost is saved for subsequent Fenton treatment in the Fenton reactor, and up-to-standard emission of the wastewater is realized finally.

Owner:NANJING BAIYUN CHEM ENVIRONMENTAL MONITORING

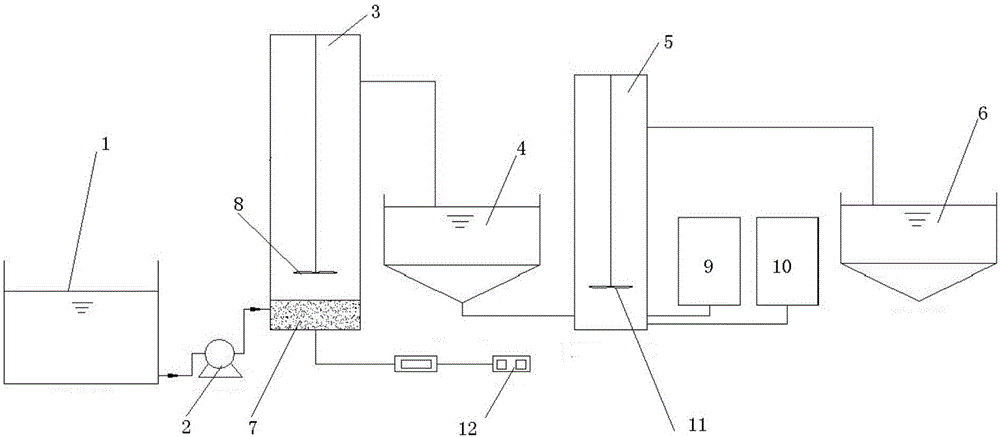

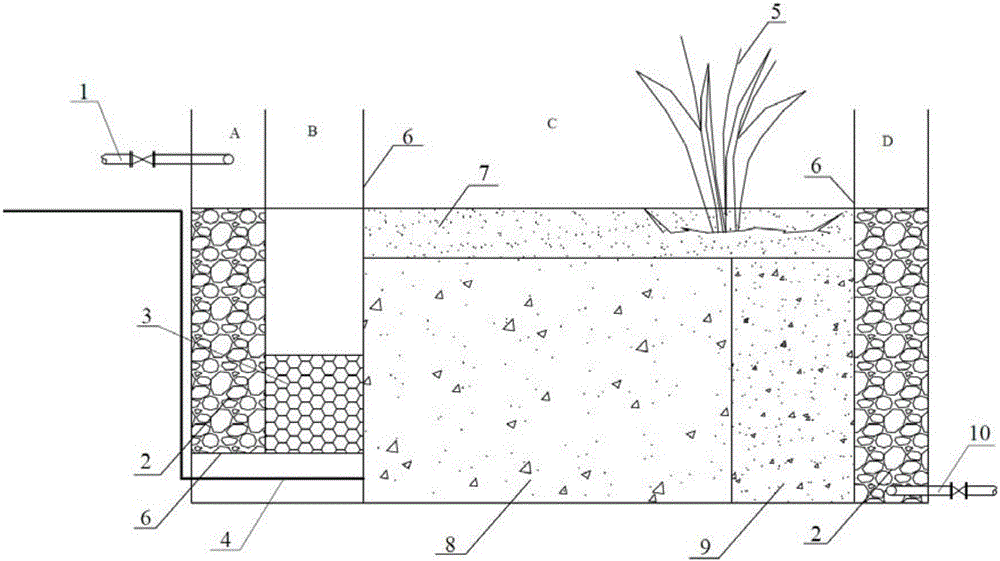

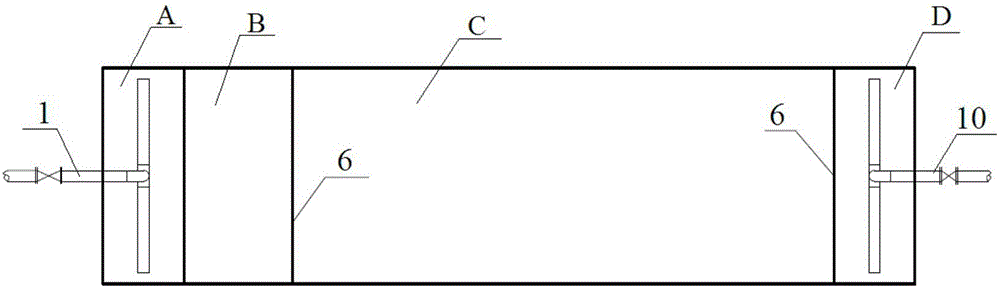

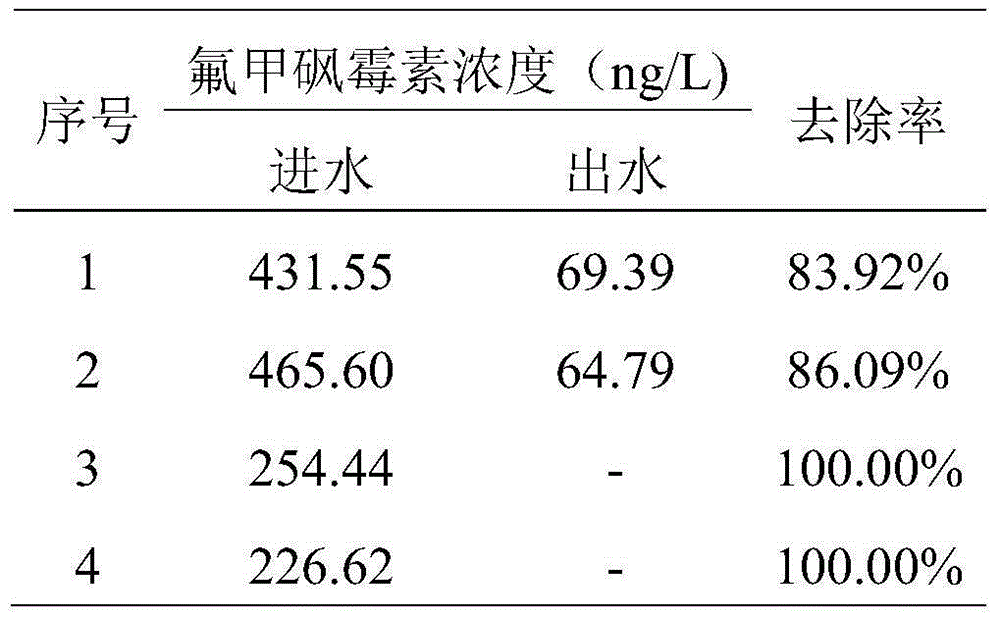

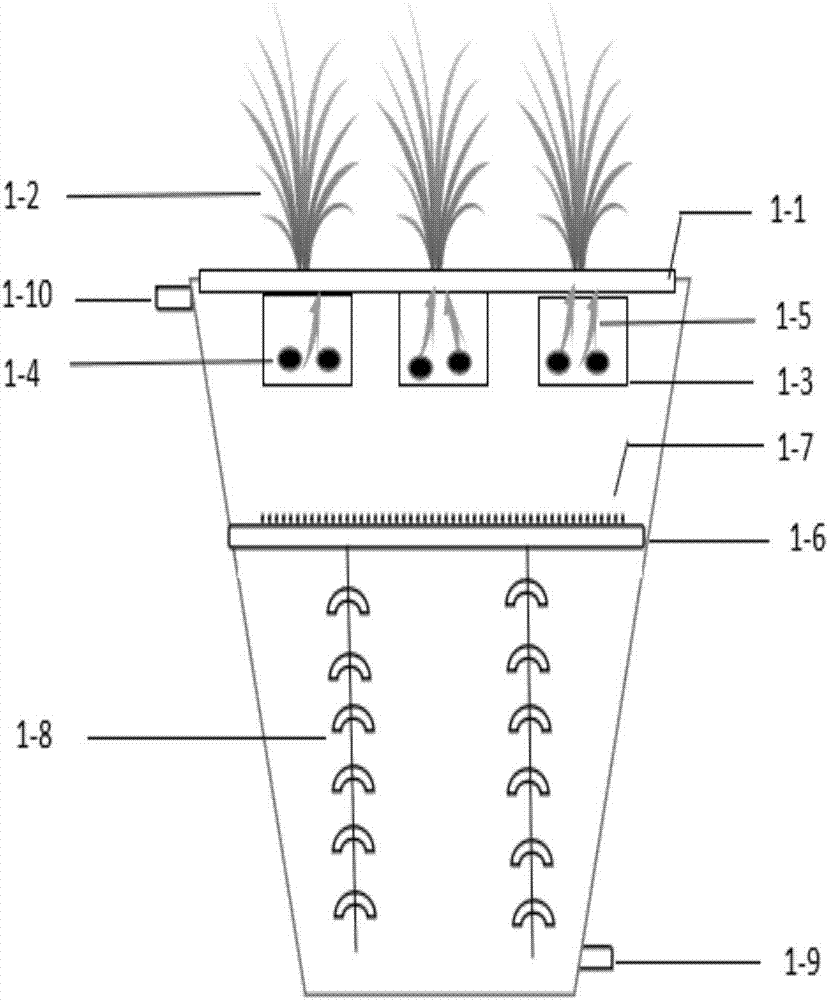

Iron-carbon-base artificial wetland purification system for removing florfenicol in aquaculture

InactiveCN105084655AReduce construction costsLow costWater contaminantsMultistage water/sewage treatmentConstructed wetlandBiological interaction

The invention belongs to the technical field of water treatment, and relates to an iron-carbon-base artificial wetland purification system for removing florfenicol in aquaculture. The system comprises a water inflow area, an iron-carbon microelectrolysis area, a wetland purification area and a water outflow area in sequence. The iron-carbon microelectrolysis area is filled with iron-carbon filler, and an aeration device is arranged below the iron-carbon filler. The wetland purification area comprises a lower filler layer and an upper soil covering layer, the filler layer comprises a gravel filler segment close to the iron-carbon microelectrolysis area and a zeolite filler segment close to the water outflow area, and wetland plants are planted on the soil covering layer. Compared with the prior art, the iron-carbon microelectrolysis area is additionally arranged, antibiotics in aquatic water are removed under the physical, chemical and biological interaction, and meanwhile other types of pollutants are removed as well; the system has the advantages of being low in construction cost, good in purification effect, capable of bringing good ecological benefits, easy and convenient to operate, stable in water outflow and the like, can be applied to purification and cyclic utilization of aquatic water and has great economical and environmental benefits.

Owner:TONGJI UNIV

Resin molded product

InactiveUS20050004269A1Improve conductivityReduce surface resistanceElectric discharge heatingSpecial tyresGraphiteFiber diameter

A resin molded product is provided which exhibits a higher level of electrical conductivity and particularly a lower level of surface resistance than those generally expected from the content of an electrically conductive filler. The resin molded product comprises a matrix of a resin material and an electrically conductive filler dispersed in the matrix, wherein a content of the electrically conductive filler is lower than 20 wt %, and the resin molded product has been subjected to a voltage application process employing a voltage of not lower than 20 kV and lower than a dielectric breakdown voltage of the matrix. The electrically conductive filler is, for example, a fibrous filler such as a fibrous carbon filler or a fibrous graphite filler, and has an average fiber diameter of, for example, 0.002 to 15 μm. The resin molded product typically contains a coloring material dispersed in the matrix together with the electrically conductive filler, and exhibits a color corresponding to the coloring material.

Owner:OSAKA GAS CO LTD

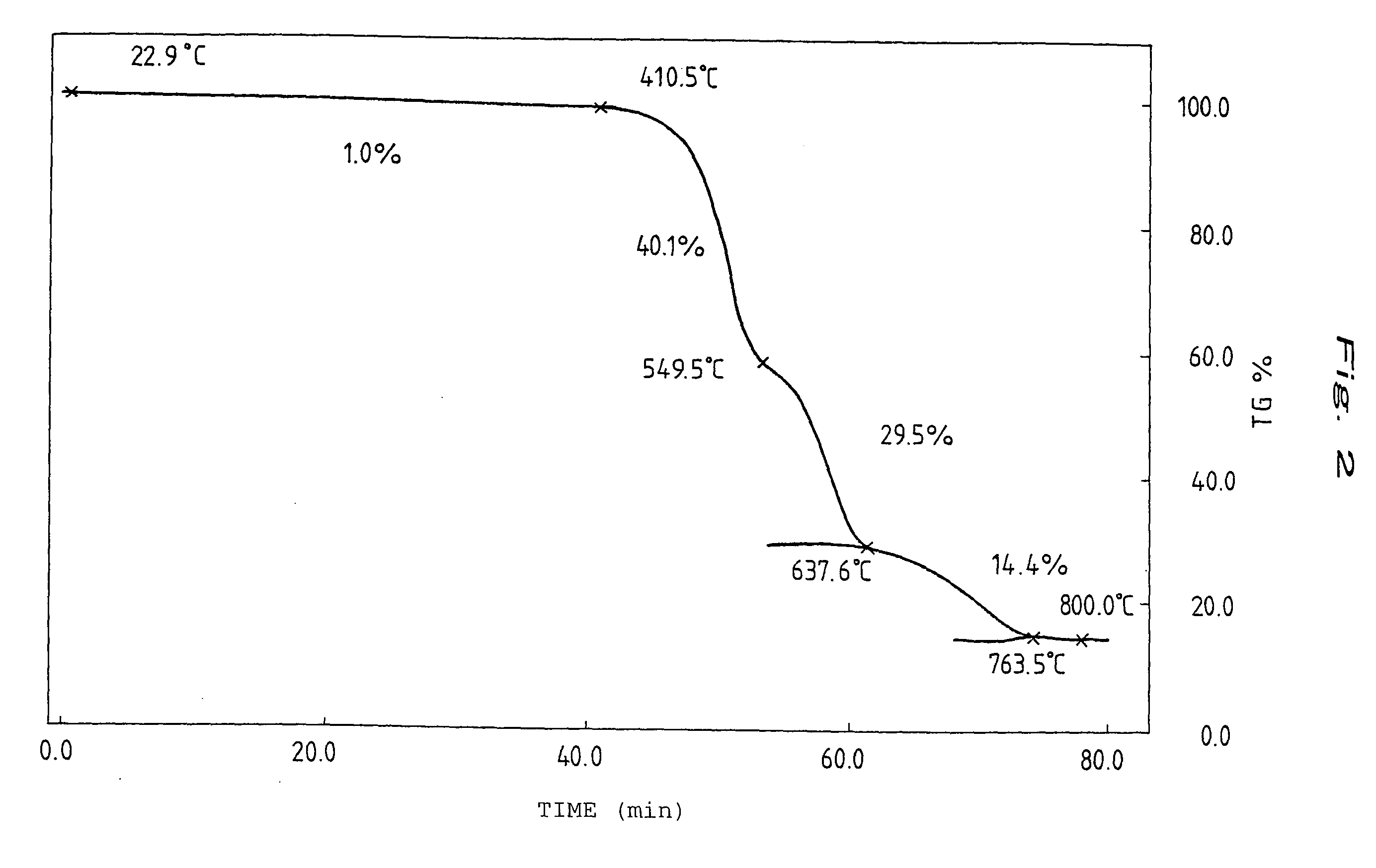

Preparation method of honeycomb-like ozone oxidation catalyst and catalyst prepared through same

ActiveCN105688912ALarge specific surface areaImprove catalytic performanceMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationChemical oxygen demandActive component

The embodiment of the invention discloses a preparation method of a honeycomb-like ozone oxidation catalyst and a catalyst prepared through the preparation method. The preparation method includes the steps that iron carbon filler is smashed, and powder-shaped iron carbon filler is obtained; the powder-shaped iron carbon filler, a forming agent and an adhesion agent are mixed and stirred according to the mass ratio of (6-16): (2-12): (1-4), and a paste mixture is obtained; the paste mixture is subjected to extrusion forming, and a honeycomb-like blank is obtained; the honeycomb-like blank is dried and sintered, the honeycomb-like ozone oxidation catalyst is obtained. The honeycomb-like ozone oxidation catalyst prepared through the scheme has lots of porous channel structures, the specific surface area is large, the catalytic effect is good, when the honeycomb-like ozone oxidation catalyst is adopted for catalyzing ozone to process sewage, the effects is good, the chemical oxygen demand (COD) removing rate of sewage is greatly increased, and the dissolving-out quantity of active components of the catalyst is greatly reduced.

Owner:POTEN ENVIRONMENT GRP +2

Catalytic ozone oxidizing method for industrial wastewater deep treatment

ActiveCN104030429ATo overcome the poor catalytic effectOvercome limitationsPhysical/chemical process catalystsWater/sewage treatment by oxidationIndustrial waste waterReducing atmosphere

The invention relates to a catalytic ozone oxidizing method for industrial wastewater deep treatment. The method comprises the following steps: calcining raw material mainly containing iron and carbon in the reducing atmosphere to form iron-carbon filler, wherein the filler finished product is of particle shapes, has a particle diameter phi of 5-15mm, and comprises the following effective components in percentage by weight: 40-65 percent of reduction-state iron, 15-25 percent of carbon, 5-25 percent of transition metal; performing acid and oxidation modifying on the iron-carbon filler: reacting on a table for 0.5-5.0 hours in HNO3 with concentration of 0.5-5mol / L at 30-60 DEG C; forming a filling table by using the modified particles, arranging an ozone distribution device under the filling to form a catalytic zone reaction tank; catalyzing ozone to form an advanced oxidizing method in the neutral condition by using secondary bio-treated effluent as a processing object so as to deep remove organic matters out of the industrial waste water, wherien the hydraulic staying time is controlled to be 20-360min.

Owner:TONGJI UNIV

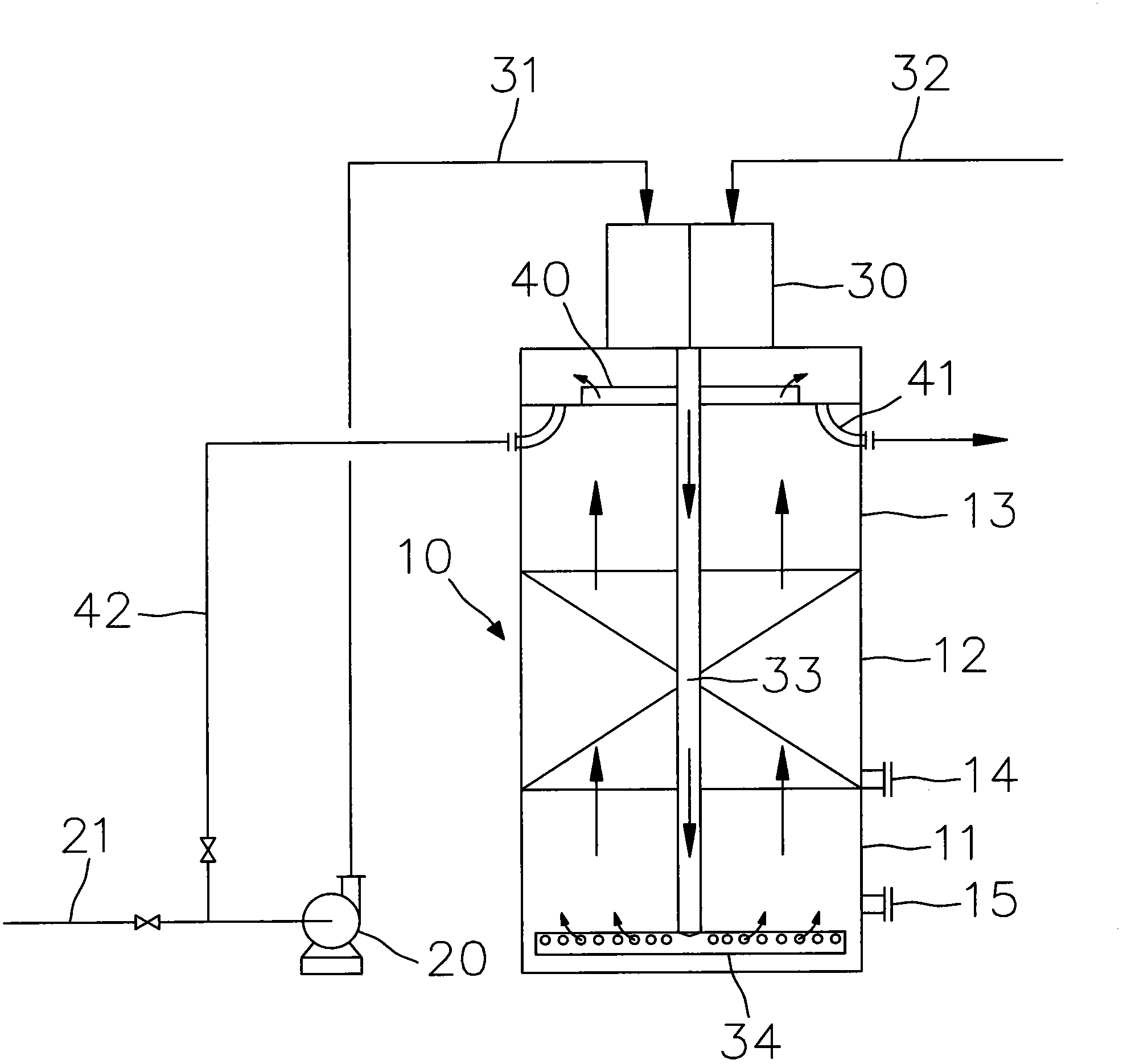

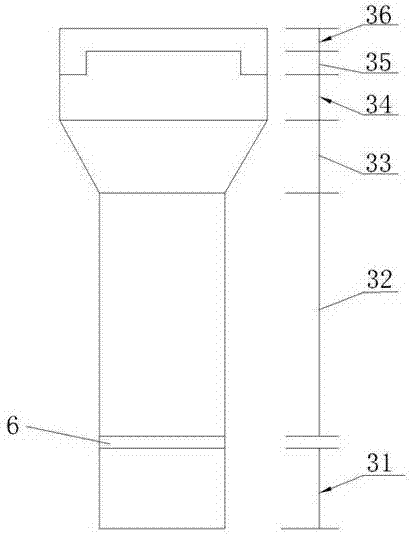

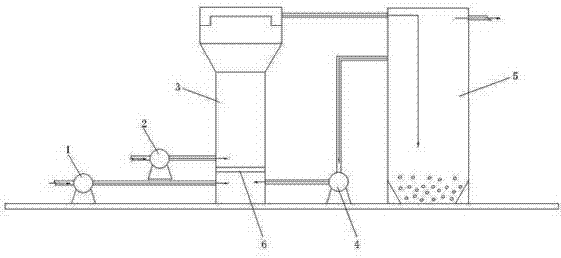

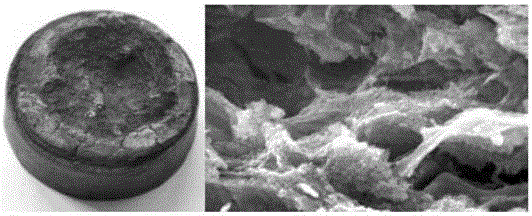

Micro-electrolysis reaction technique of iron carbon filler three-phase circulating fluidized bed and reactor

The invention belongs to the applied technical field of a micro-electrolysis reaction to waste water treatment, particularly relates to a micro-electrolysis reaction technique of an iron carbon filler three-phase circulating fluidized bed and a reactor. The reaction technique comprises the following steps: (a), the waste water enters the lower part of a distributing hole plate of the fluidized bed, an iron carbon filler layer is arranged at the upper part of the distributing hole plate; (b), compressed air enters the upper part of the distributing hole plate at the same time; (c), flow of the waste water is gradually increased, the iron carbon filler layer is formed to be a fluidized suspending layer, pollutant components in the waste water perform the micro-electrolysis reaction on the surface of iron carbon filler; (d), products of the micro-electrolysis reaction are taken out of the fluidized bed by the waste water and then entered a circulating tank to precipitate; (e) the waste water precipitates and separates a product carrying out the micro-electrolysis reaction in the circulating tank, part of flowed water is used as produced water, and part of the flowed water is used as circulating waste water to return to the fluidized bed. In the micro-electrolysis reaction, the invention cannot passivate, harden and block; thus the micro-electrolysis reaction technique of the iron carbon filler three-phase circulating fluidized bed can be widely industrially applied to the waste water treatment of every industry.

Owner:东莞市珠江海咸水淡化研究所

Preparation method of iron-sludge based biological carbon micro-electrolysis filler and application of iron-sludge based biological carbon micro-electrolysis filler to treatment of uranium-containing wastewater

InactiveCN107935129AOvercoming easy hardeningOvercoming the disadvantages of passivationWater/sewage treatmentRadioactive contaminantsElectrolysisSodium Bentonite

The invention relates to a method for treating uranium-containing wastewater through an iron-carbon micro-electrolysis method and preparation of filler. According to a preparation method of iron-sludge based biological carbon micro-electrolysis filler, reducing iron powder and residual sludge-based biological carbon are used as raw materials, sodium silicate or / and bentonite is / are used as a binding agent, and nonferrous heavy metal copper powder and cobalt powder are used as catalysts; the materials are mixed according to a certain ratio, are roasted at high temperature and are sintered to form a regularized iron and carbon micro-electrolysis material. By adopting the method provided by the invention, the defects that existing iron and carbon filler has high cost and is easy to harden andpassivate are overcome; the uranium-containing wastewater is creatively treated by utilizing the iron and carbon micro-electrolysis filler.

Owner:NANHUA UNIV

Efficient composite phase change material and preparation method thereof

InactiveCN108531136AGood effectAdjustable phase change temperatureHeat-exchange elementsStrontium chloride hexahydrateLithium bromide

The invention discloses an efficient composite phase change material and a preparation method thereof. The efficient composite phase change material is composed of 96.5%-75% of a thermal medium; 0.5%-3% of a nucleating agent; 3%-7% of a thickener; 1-15% of a high-efficiency conducting agent; and 0.1%-10% of a melting point regulator. The thermal medium is prepared by mixing one or more aqueous solutions of inorganic salts sodium sulfate, sodium carbonate, calcium chloride, lithium bromide and the like. The nucleating agent is any one of strontium chloride hexahydrate, potassium chloride, sodium tetraborate decahydrate, barium sulfate, or calcium fluoride. The thickener is any one or a mixture of several of the following substances in arbitrary proportion: diatomite, attapulgite, polyacrylamide and carboxymethylcellulose. The high-efficiency conducting agent is: (a) metal filler, (b) carbon filler, or (c) ceramic filler. The melting point regulator is any one of ammonium chloride, ammonium sulfate or ammonium nitrate. The efficient composite phase change material provided by the invention can rapidly play a conduction role in 60s to 180s, and the supercooling degree is 1.5DEG C.

Owner:曹斌斌

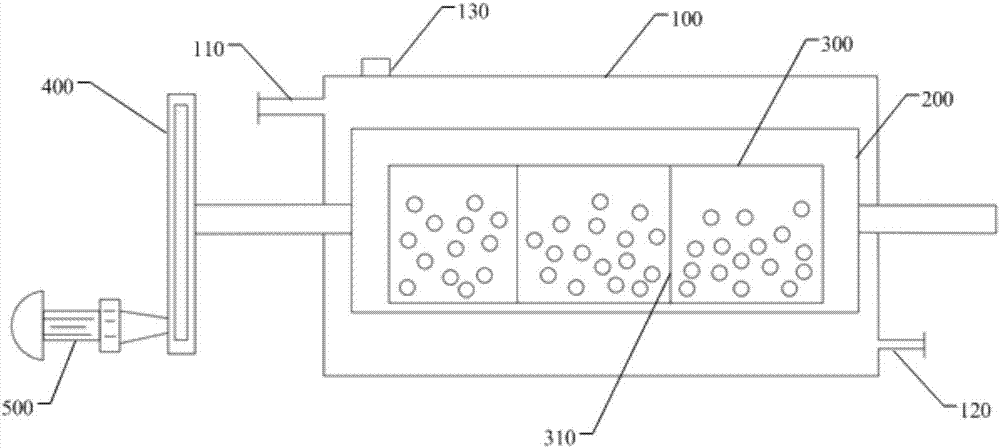

Rotary iron-carbon micro-electrolysis reactor and wastewater treatment method

InactiveCN106976935ANot easy to hardenAvoid easy cloggingWater/sewage treatment using germicide/oligodynamic-processElectrolysisWastewater

The invention provides a rotary iron-carbon micro-electrolysis reactor and a wastewater treatment method, and relates to the technical field of wastewater treatment. The rotary iron-carbon micro-electrolysis reactor comprises a shell with a cover, a water inlet tube, a water outlet tube, an air vent and a rotary drum, wherein the water inlet tube and the water outlet tube are arranged on two sides of the shell; the air vent is formed in the shell; holes are uniformly formed in the rotary drum; the rotary drum is horizontally arranged in the shell; rotating shafts are arranged at two ends of the rotary drum and extend out of the shell; the rotating shaft at one end of the rotary drum is connected with a motor through a transmission device; the rotary drum is provided with a cover body capable of being opened; a barrel which consists of a sieve is arranged in the rotary drum; and an iron-carbon filler is arranged in the barrel. By the rotary iron-carbon micro-electrolysis reactor, the technical problems that a bed body of the traditional fixed bed type micro-electrolysis reactor is easy to cake, the reaction efficiency is low, and fillers are inconvenient to change are solved. According to the reactor, the filler is in full contact with water by a rotary mode, and the filler is prevented from being caked. In addition, the barrel in the rotary drum can be changed to directly change the filler, the rotary iron-carbon micro-electrolysis reactor is convenient to operate, and the reactor which treats wastewater is high in efficiency and good in effect.

Owner:杭州绿夏环境科技有限公司

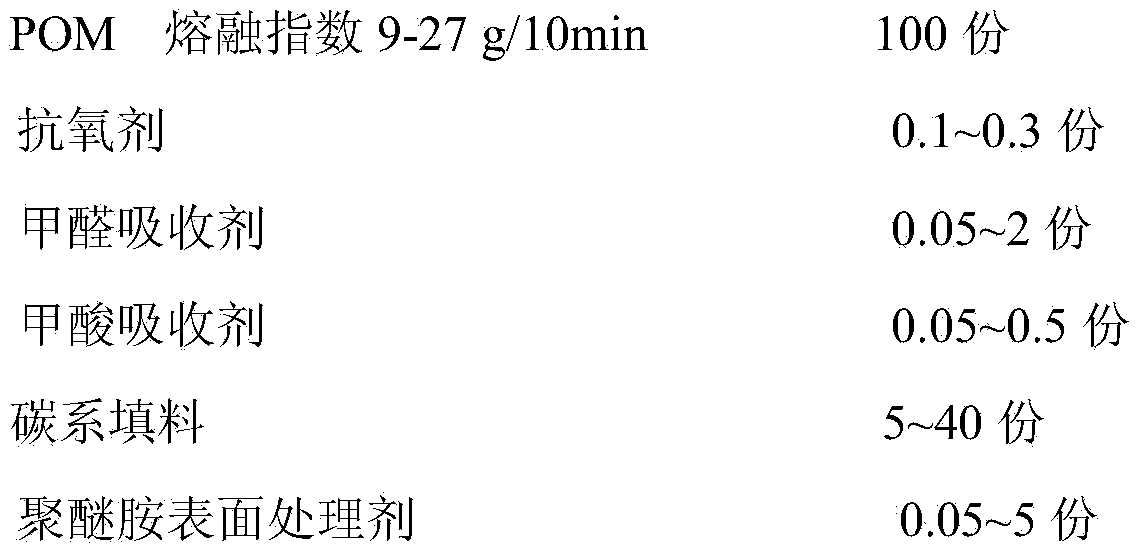

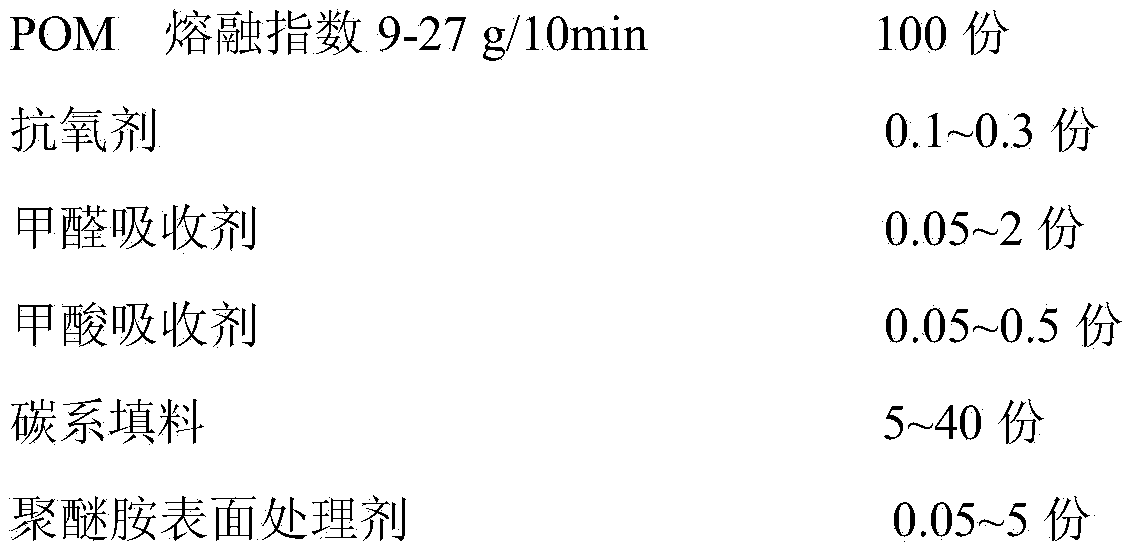

Heat-conducting polyformaldehyde composite material and preparation method thereof

The invention discloses a heat-conducting polyformaldehyde composite material and a preparation method thereof. The method is characterized by comprising the following steps: mixing 100 parts of POM resin, 0.1-0.3 parts of antioxidant, 0.05-2 parts of formaldehyde absorbent, 0.05-0.5 parts of formic acid absorber and 5-40 parts of carbon filler modified with a polyether amine surface treatment agent in a high-speed mixer; fusing and mixing by adopting an exhaust type twin-screw extruder; extruding and pelleting so as to obtain the heat-conducting polyformaldehyde composite material, wherein the screw rotation speed is 50-200r / min, and the barrel temperature is 140-220 DEG C.

Owner:SICHUAN UNIV

Combined floating bed device by coupling microorganisms and microelectrolysis and domestic sewage treatment method

InactiveCN107473389AEasy to handleLarge specific surface areaTreatment by combined electrochemical biological processesWater contaminantsExpanded clay aggregateOxygen

The invention provides a combined floating bed device by coupling microorganisms and microelectrolysis and a domestic sewage treatment method, and belongs to the technical field of ecological engineering. The combined floating bed device consists of an upper plant area, a middle substrate area and a lower biofilm carrier area, wherein the upper plant area adopts root-developed and cold-resistant aquatic plants with good effect of adsorbing organic matters in sewage; the middle substrate adopts ion and carbon filler and high-efficiency film-hanging biological ceramsite, the filler is porous inorganic filler with high mechanical strength, large specific surface area, good adsorption property and high film hanging speed, and the stable and high-activity biofilm can be formed at the surface of the filler, so as to treat the organic matter in water at high efficiency; the lower biofilm carrier adopts combined filler, and the combined filler can be easily hung with the film, and can be used for effectively cutting air bubbles, so as to improve the transfer rate and utilization rate of oxygen, and treat the organic matter in the water at high efficiency. The combined floating bed can complete the functions of physical adsorption, chemical oxidization-reduction, electrochemistry, flocculation-precipitation, and film biological treatment.

Owner:UNIV OF SCI & TECH BEIJING

Method for treating petrochemical waste water and biochemical tail water through recycled coagulant

InactiveCN102583679AStrong oxidation abilityIncrease oxidation potentialSludge treatment by oxidationWater/sewage treatment by flocculation/precipitationPetroleumOxidizing agent

The invention provides a method for treating petrochemical waste water and biochemical tail water through a recycled coagulant, relates to a petrochemical waste water and biochemical tail water treatment method and in particular relates to coagulation in the waste water and biochemical tail water treatment method and a coagulation mud oxidation regenerating and recycling. The treatment method comprises the following steps: (1) performing coagulation treatment by using a composite coagulant: adding the composite coagulant and coagulant aid into the petrochemical waste water and performing mud water separation to obtain coagulation precipitate coagulation mud; (2) performing coagulation mud and iron carbon micro-electrolytic reaction: adding iron carbon filler into the coagulation mud, reacting for 0.5 to 3 hours, and acidifying to maintain the pH value of the coagulation mud to be acidic; (3) performing Fenton-like oxidative regeneration of the coagulation mud: directly adding oxidant into the micro-electrolytic water containing a large number of Fe<2+>, coupling with the Fe<2+> in the coagulation mud, and performing Fenton-like oxidation reaction for 0.5 to 3 hours; and (4) recycling the coagulation mud, wherein the coagulation property of the coagulant in the coagulation mud after oxidation is recovered; the coagulation mud can be reused for coagulation of the waste water and then is oxidized again; and the coagulation can be reused.

Owner:CHINA PETROLEUM & CHEM CORP +1

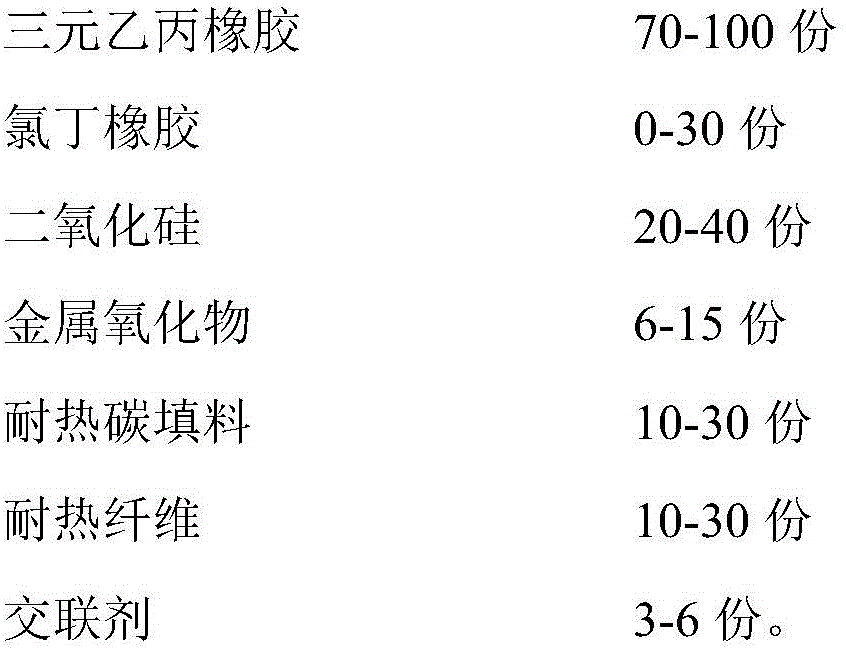

Ablation-resistant rubber type thermal insulation layer and preparation method thereof

The invention discloses an ablation-resistant rubber type thermal insulation layer and a preparation method thereof. Polyphenylene sulfide fiber is used and is matched with other auxiliary agent systems of silicon dioxide, heat-resistant carbon fillers, metallic oxide, aramid fiber and the like, so that the ablation-resistant performance of thermal insulation materials is obviously improved; and 70 to 100 parts of EPDM (Ethylene-Propylene-Diene Monomer), 0 to 30 parts of chloroprene rubber, 20 to 40 parts of silicon dioxide, 6 to 15 parts of metallic oxide, 10 to 30 parts of heat-resistant fillers, 10 to 30 parts of heat-resistant carbon fiber and 3 to 6 parts of cross-linking agents are used for obtaining the ablation-resistant rubber type thermal insulation layer provided by the invention through two-roll open milling and hot pressing vulcanization molding. The ablation-resistant rubber type thermal insulation layer containing the filled polyphenylene sulfide fiber has excellent ablation-resistant performance. The material is applicable to the thermal protection field with high-temperature-ablation-resistant requirements, and is particularly applicable to the technical field of instant high-temperature ablation thermal protection.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

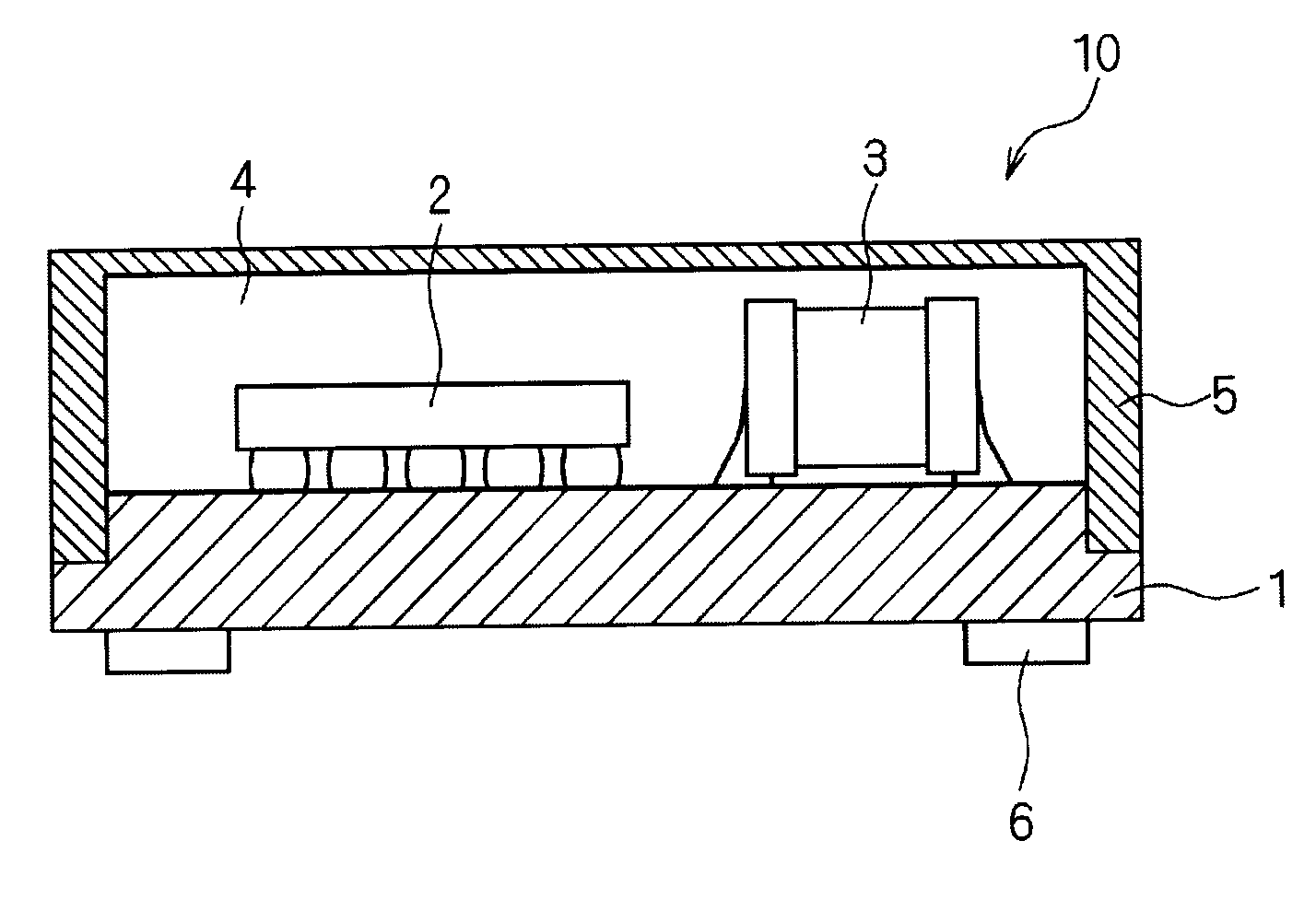

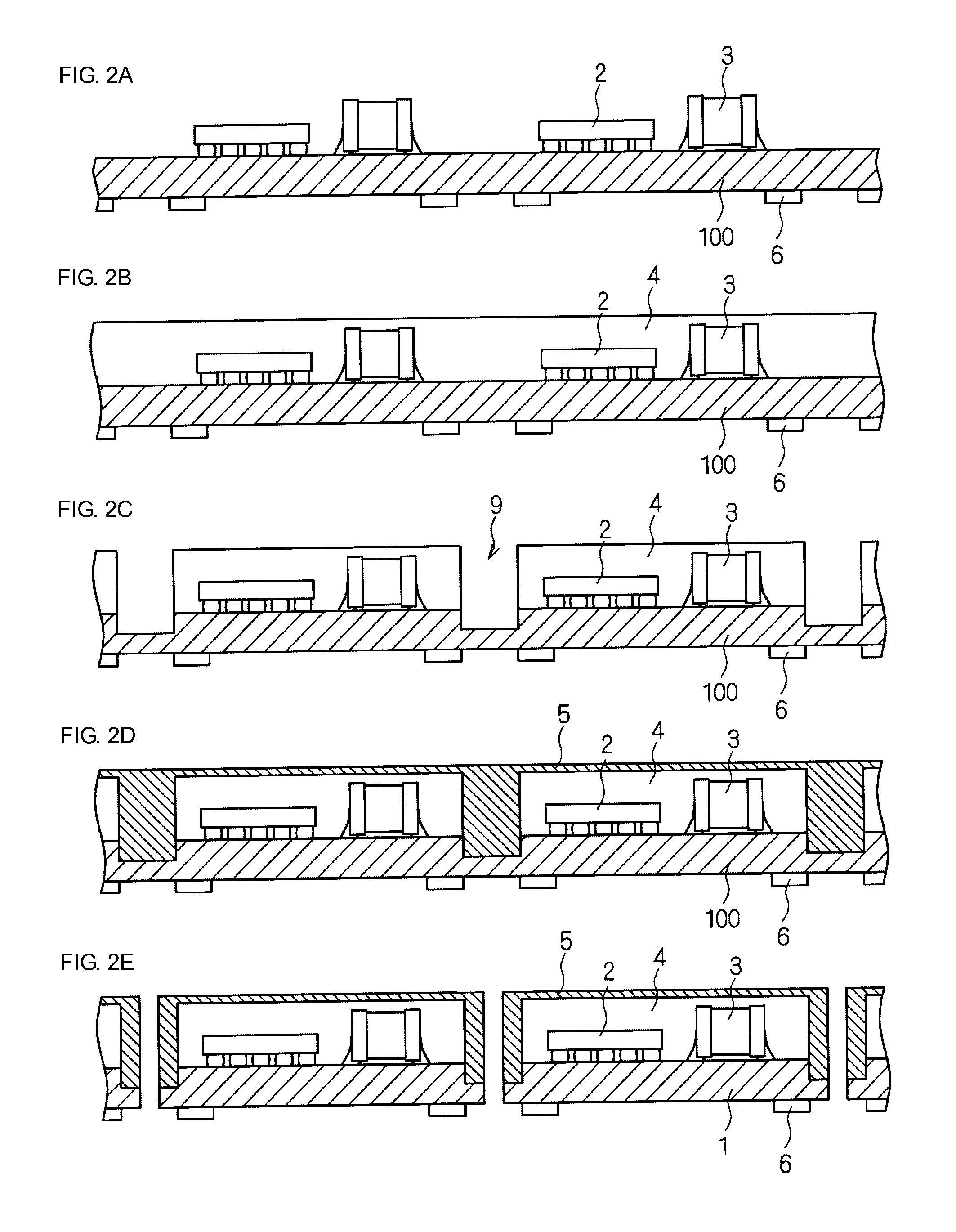

Module board

ActiveUS20140204550A1Suppress interferenceImprove module characteristicCross-talk/noise/interference reductionPrinted electric component incorporationEngineeringElectronic component

A module board includes a base substrate. Electronic components are mounted on a first principal surface of the base substrate. The mounted electronic components are sealed by a sealing resin containing an SiO2 filler. A top surface and side surfaces of the sealing resin are covered with a shield layer containing a carbon filler, which is flat powder, as a conductive component. A terminal electrode is formed on a second principal surface of the base substrate that is disposed opposite to the first principal surface of the base substrate.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com