Artificial wetland with combined fillers and treating process thereof

A technology of artificial wetland and combined filler, which is applied in metallurgical wastewater treatment, sustainable biological treatment, biological water/sewage treatment, etc., can solve problems that are rarely reported, achieve good removal effect, good growth environment, and reduce head loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

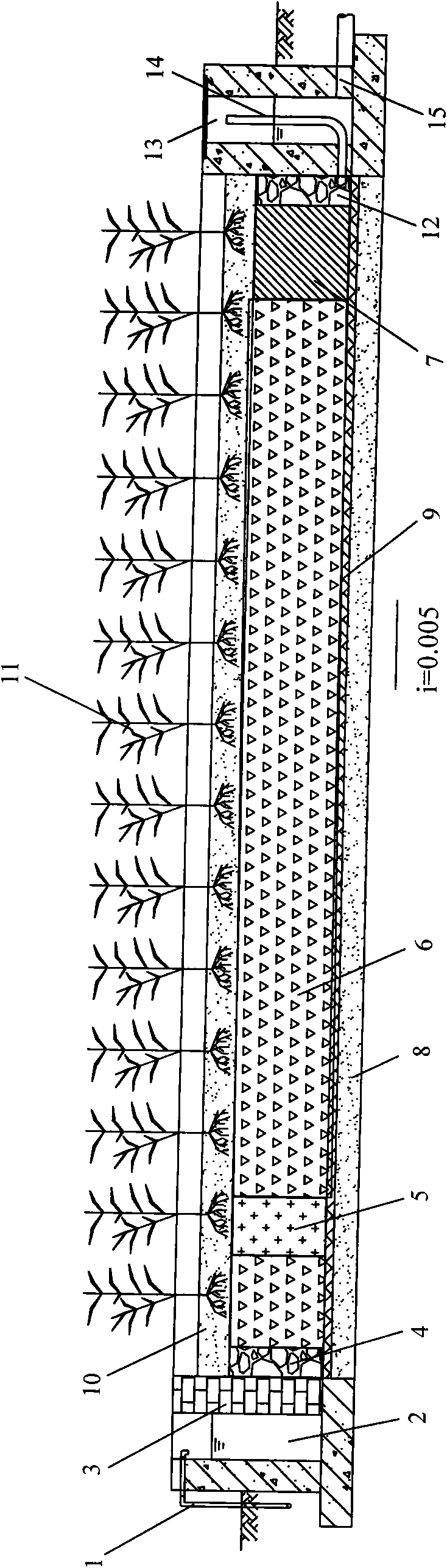

[0043] Such as figure 1 As shown, the composite filler artificial wetland of the present invention sequentially includes the water inlet area A, the wetland treatment unit area B, and the water outlet area C;

[0044] Wherein, the water inlet area A of the wetland includes a water inlet pipe 1, a water inlet tank 2, a water inlet flower wall 3, and a pebble rectification area 4;

[0045] Wetland treatment unit area B includes iron-carbon packing section 5, gravel packing section 6, and manganese sand packing section 7 in sequence; the wetland structure also includes bottom gravel sand cushion layer 8, anti-seepage layer 9, and combined packing from bottom to top. layer (iron-carbon filler 5, gravel filler 6, manganese sand filler 7), original soil covering layer 10, and wetland plants 11.

[0046] The structure of the outlet area C includes a pebble rectification area 12, an outlet water collection tank 13, an outlet pipe 14 with adjustable outlet water level, and a wetland o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com