Patents

Literature

552results about How to "Avoid fouling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

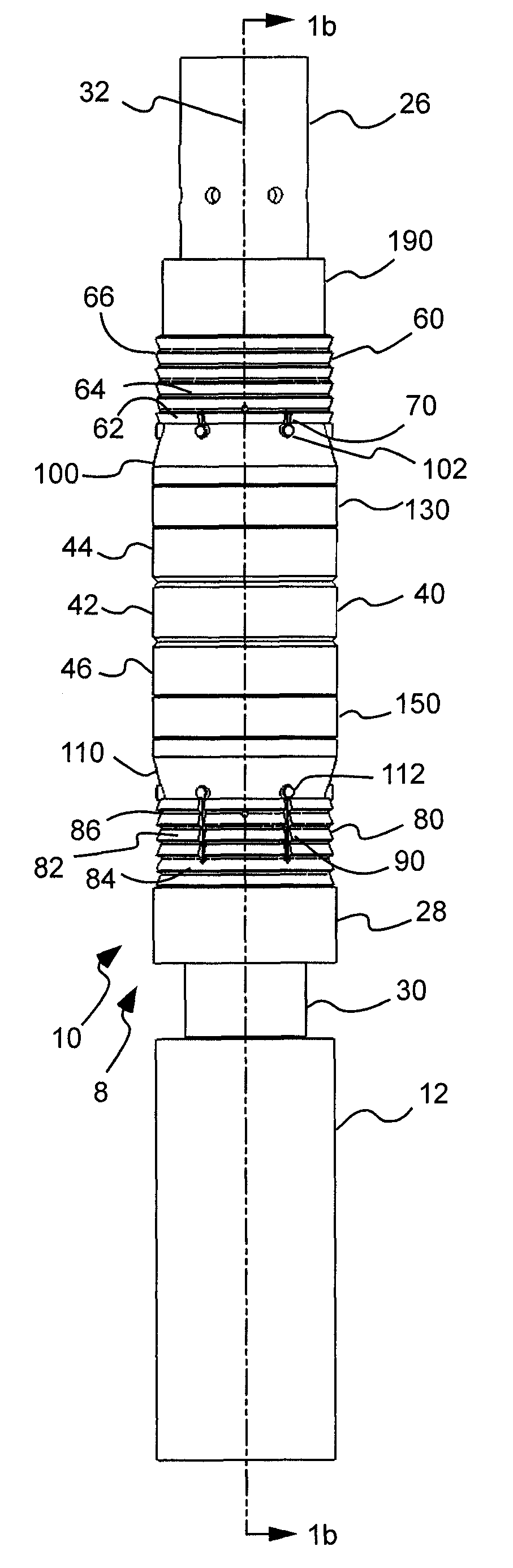

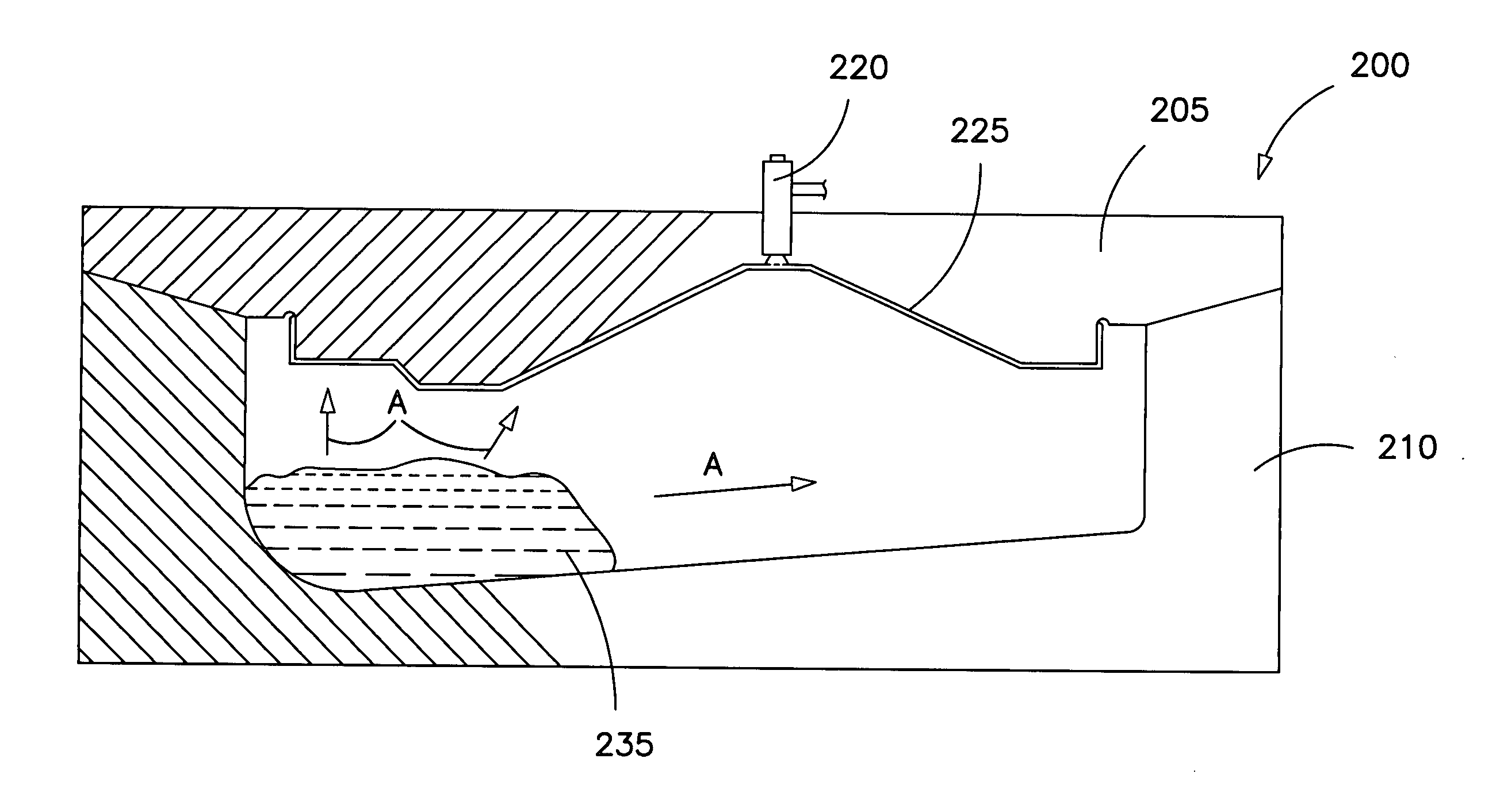

Downhole tool with exposable and openable flow-back vents

InactiveUS7900696B1Avoid contaminationAvoid damageFluid removalSealing/packingEngineeringMechanical engineering

Owner:EXCELIS INC +1

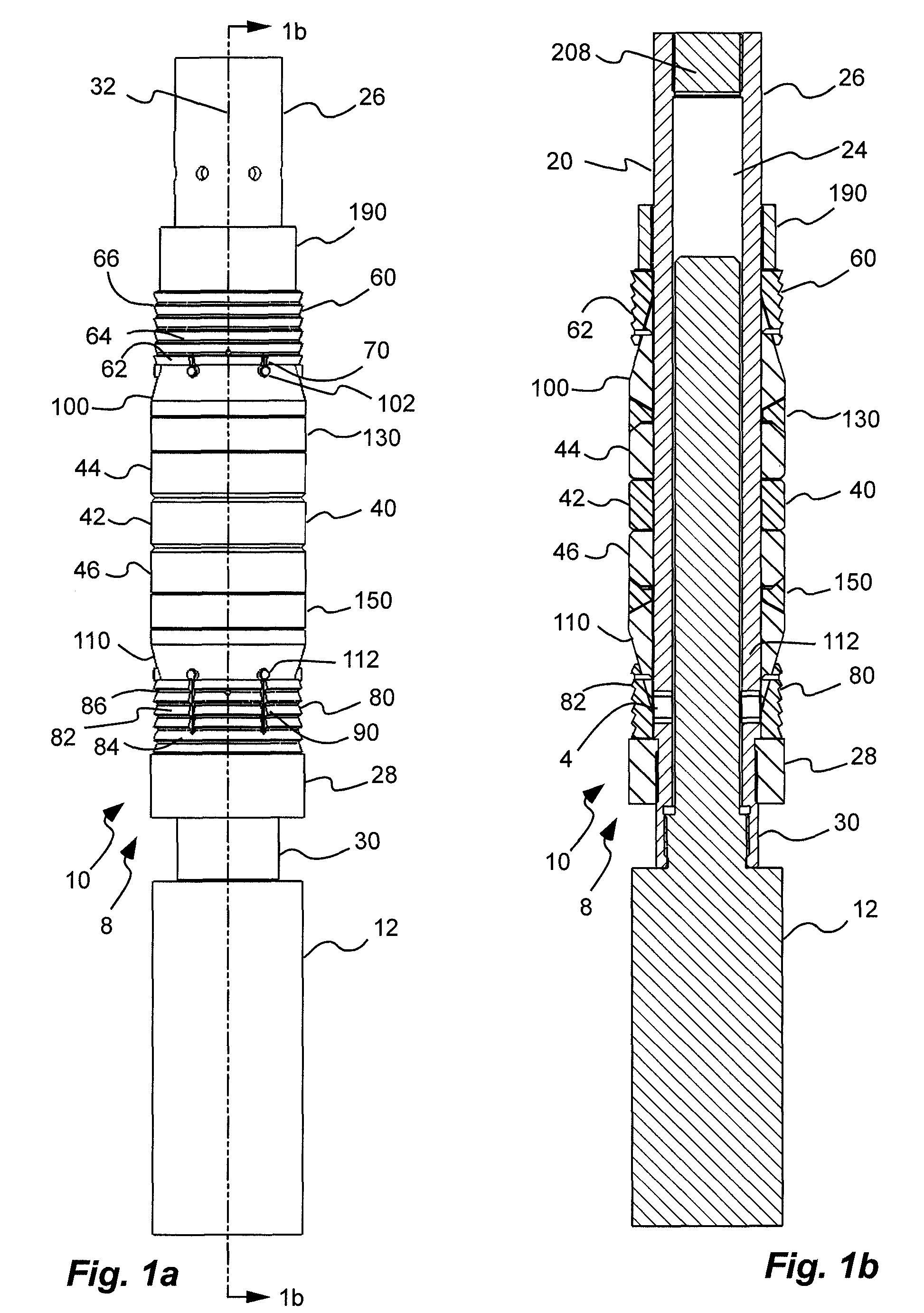

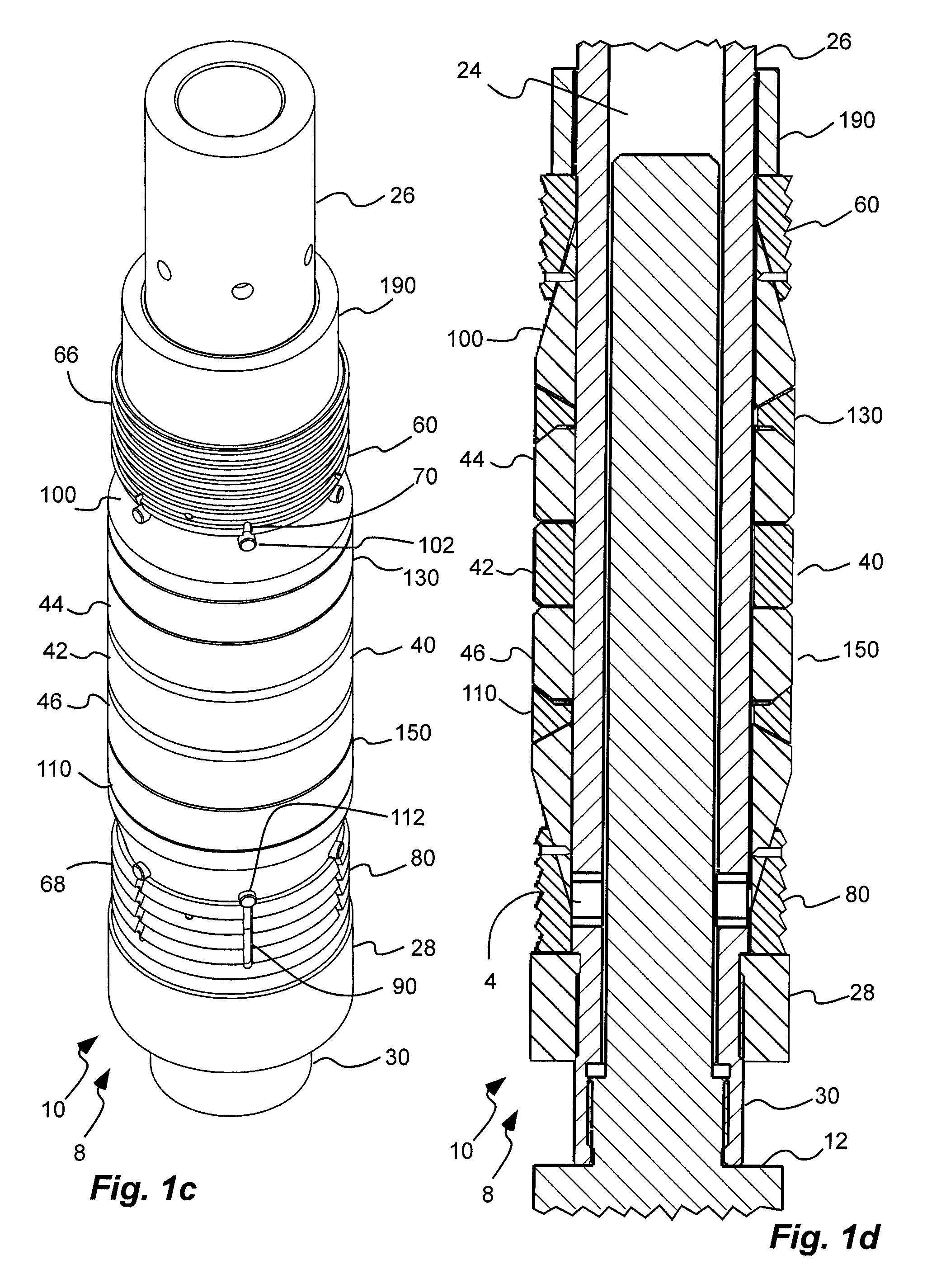

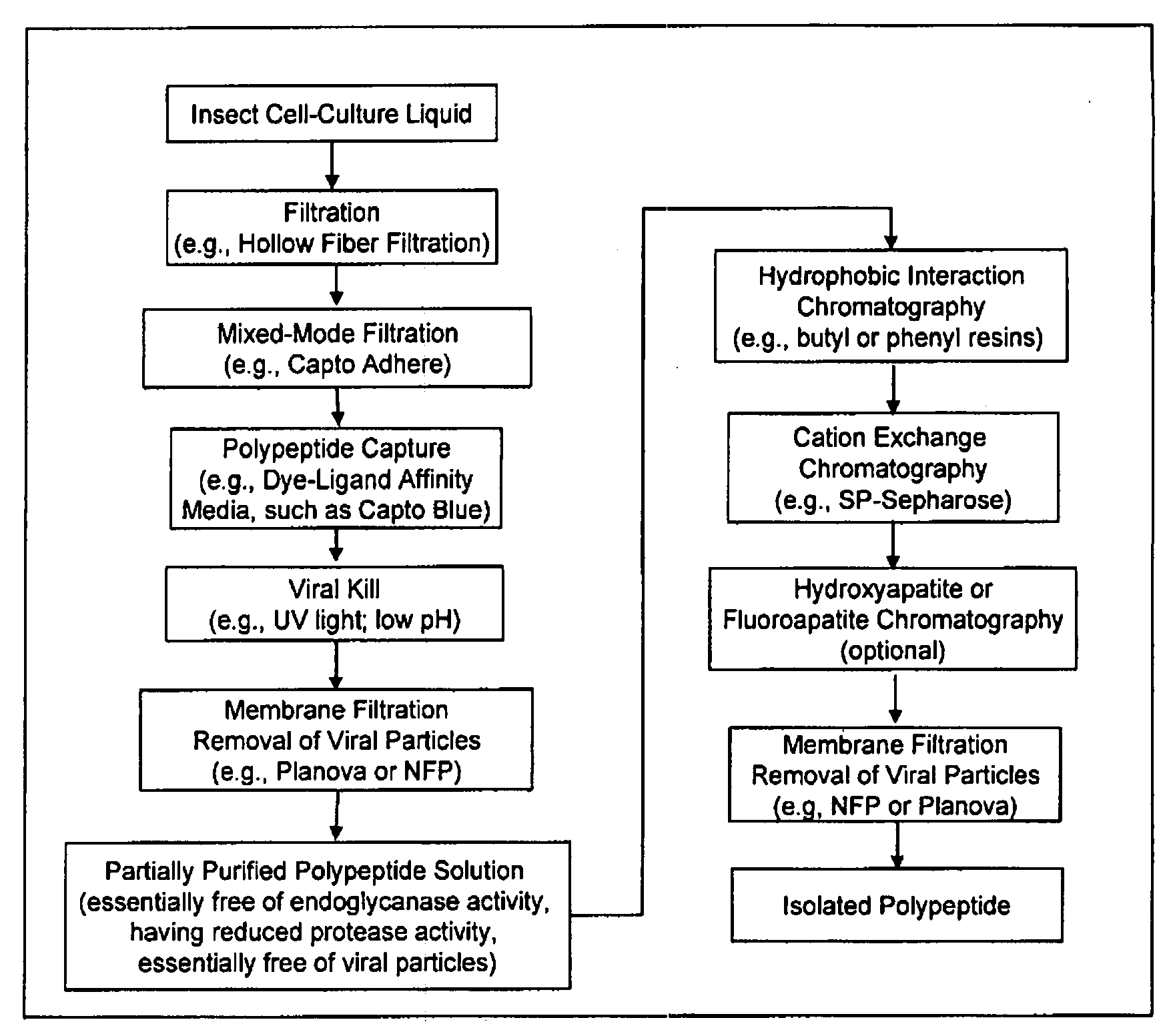

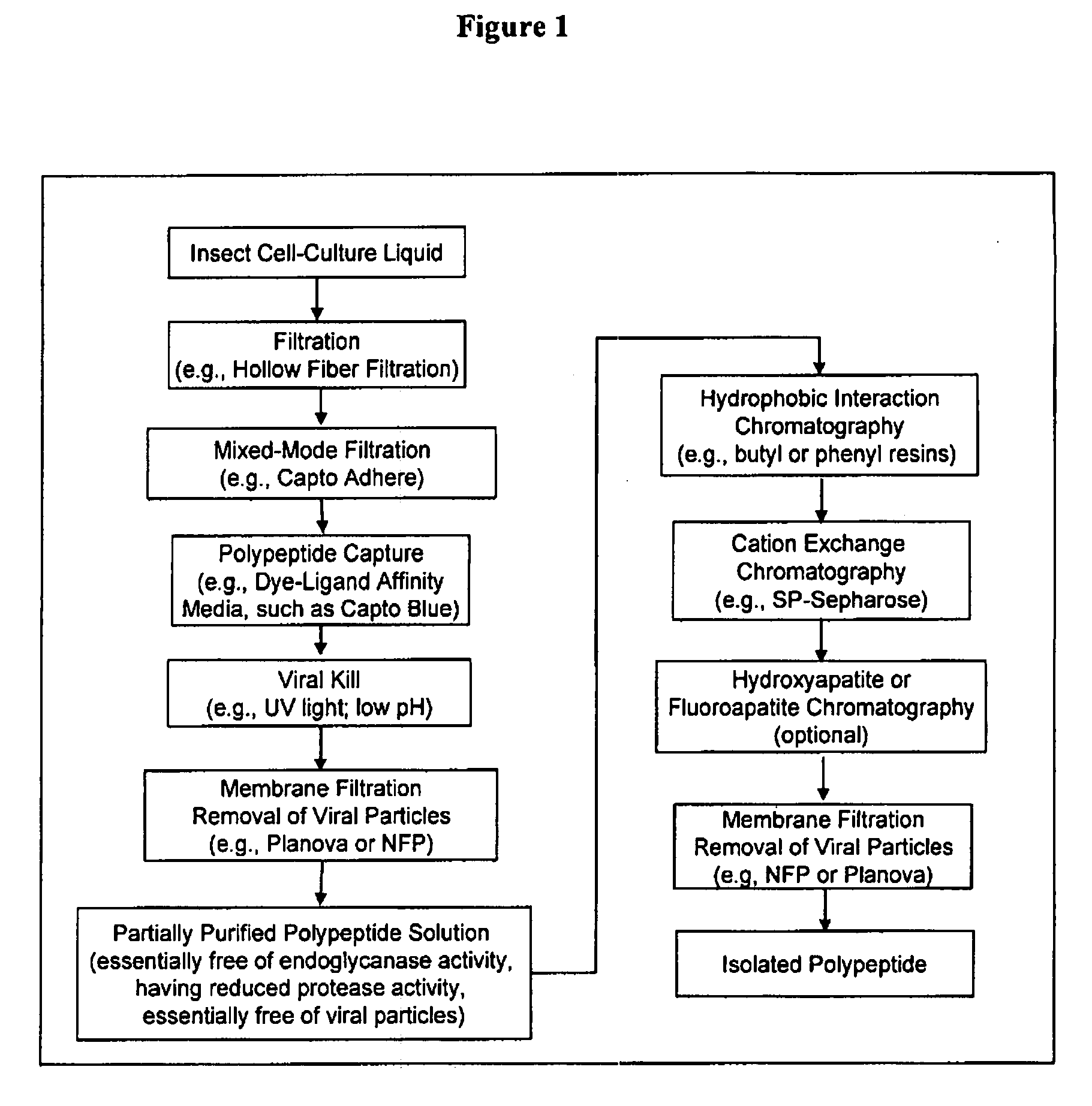

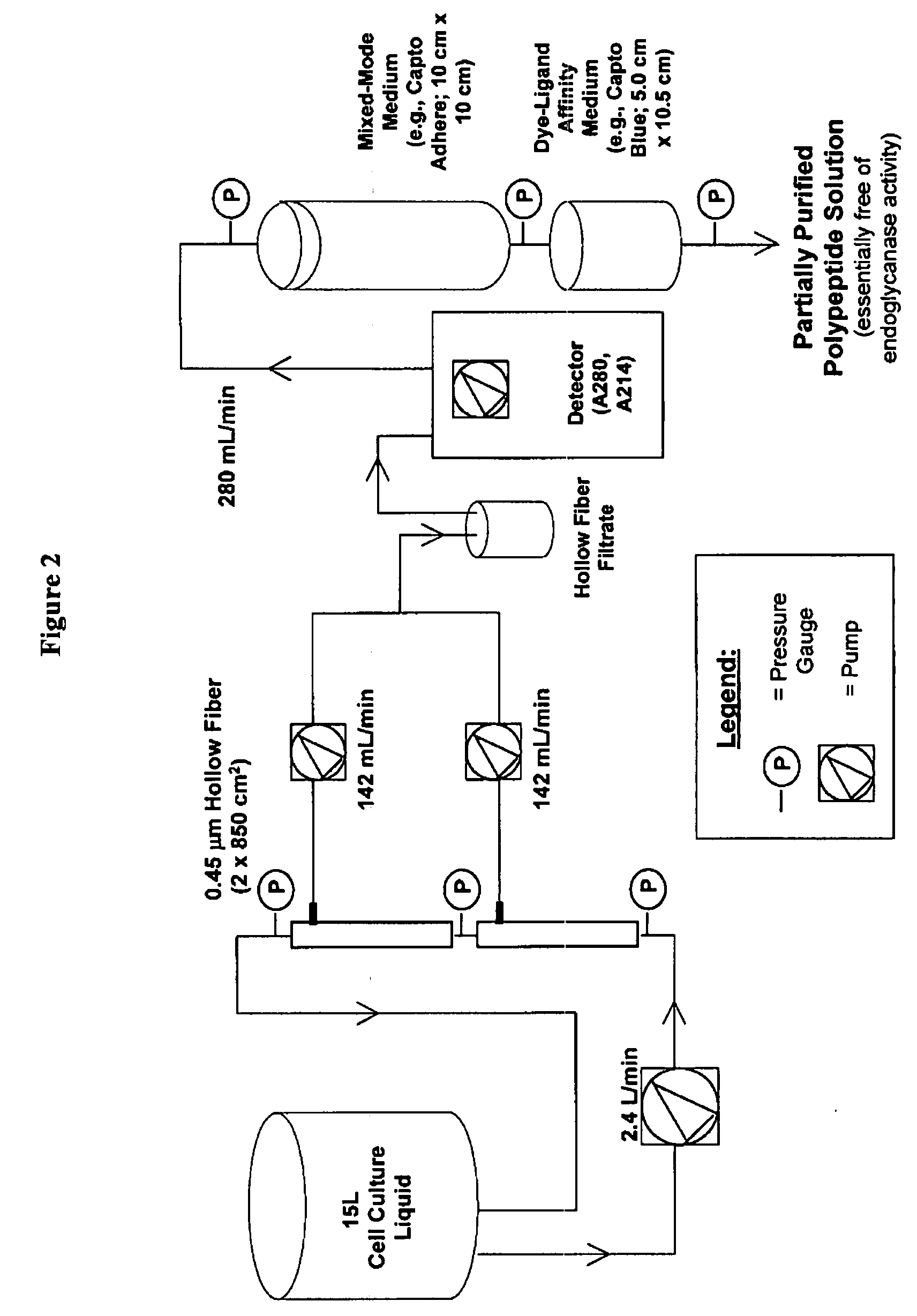

Manufacturing process for the production of polypeptides expressed in insect cell-lines

InactiveUS20080207487A1Promote recoveryReduce manufacturing costPeptide/protein ingredientsDepsipeptidesFiberCulture fluid

The present invention provides a manufacturing method for polypeptides that are produced in insect cells using a baculoviral expression system. In one example, the insect cell culture is supplemented with a lipid mixture immediately prior to infection (e.g., one hour prior to infection). The polypeptides are isolated from the insect cell culture using a method that employs anion exchange or mixed-mode chromatography early in the purification process. This process step is useful to remove insect-cell derived endoglycanases and proteases and thus reduces the loss of desired polypeptide due to enzymatic degradation. In another example, mixed-mode chromatography is combined with dye-ligand affinity chromatography in a continuous-flow manner to allow for rapid processing of the insect-cell culture liquid and capture of the polypeptide. In yet another example, a polypeptide is isolated from an insect cell culture liquid using a process that combines hollow fiber filtration, mixed-mode chromatography and dye-ligand affinity in a single unit operation producing a polypeptide solution that is essentially free of endoglycanase and proteolytic activities. In a further example, the isolated polypeptides are glycopeptides having an insect specific glycosylation pattern, which are optionally conjugated to a modifying group, such as a polymer (e.g., PEG) using a glycosyltransferase and a modified nucleotide sugar.

Owner:NOVO NORDISK AS

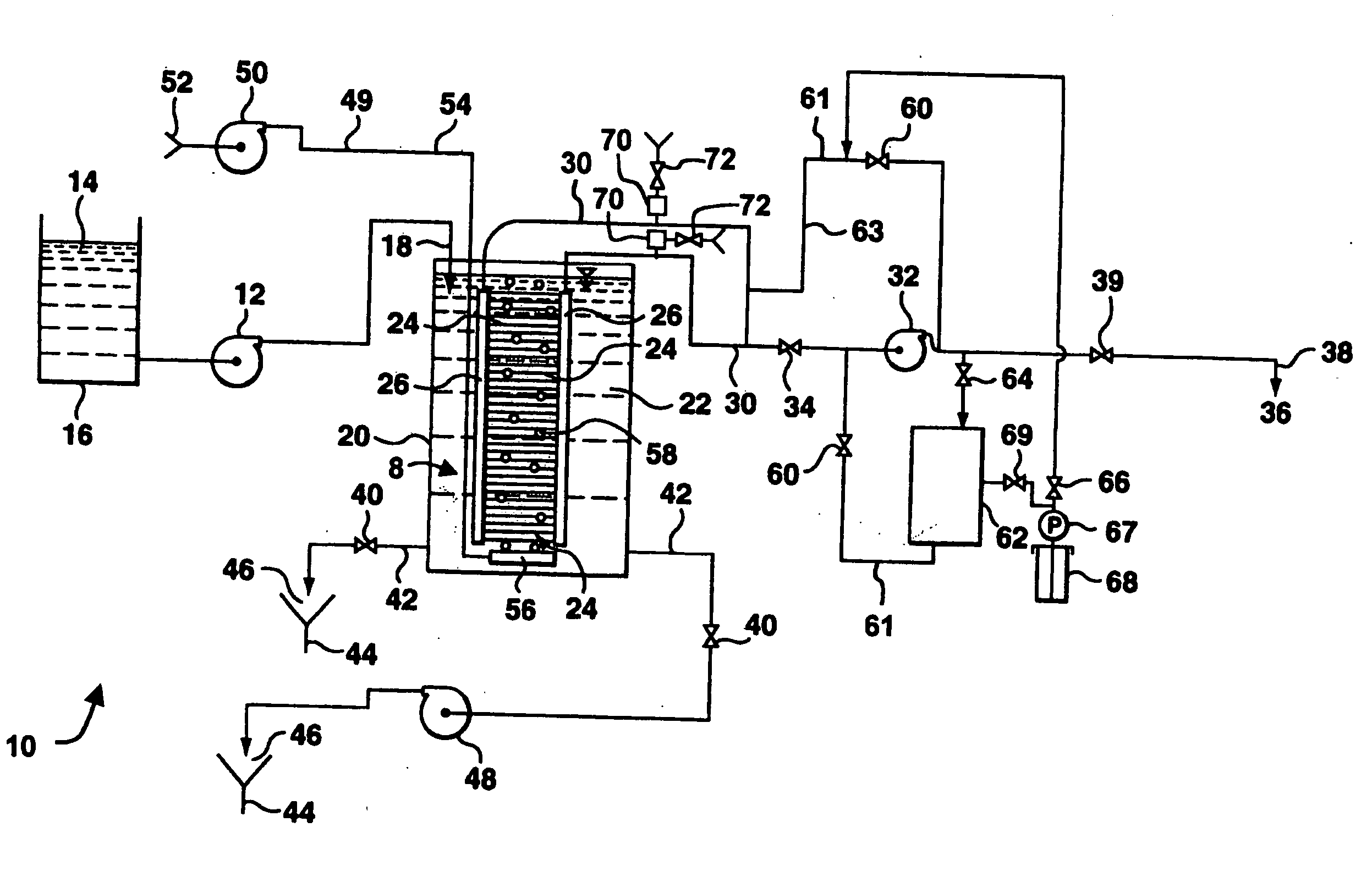

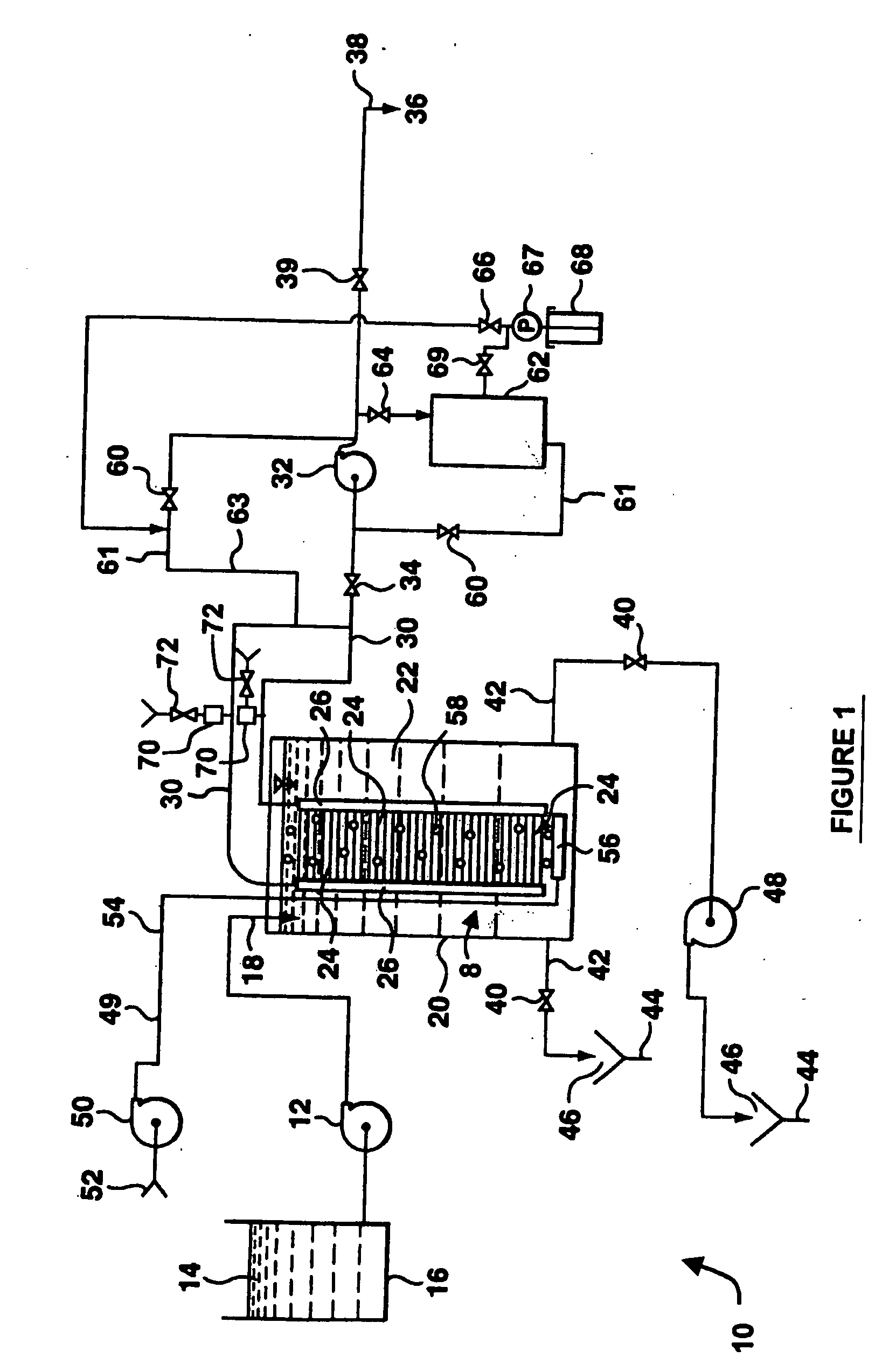

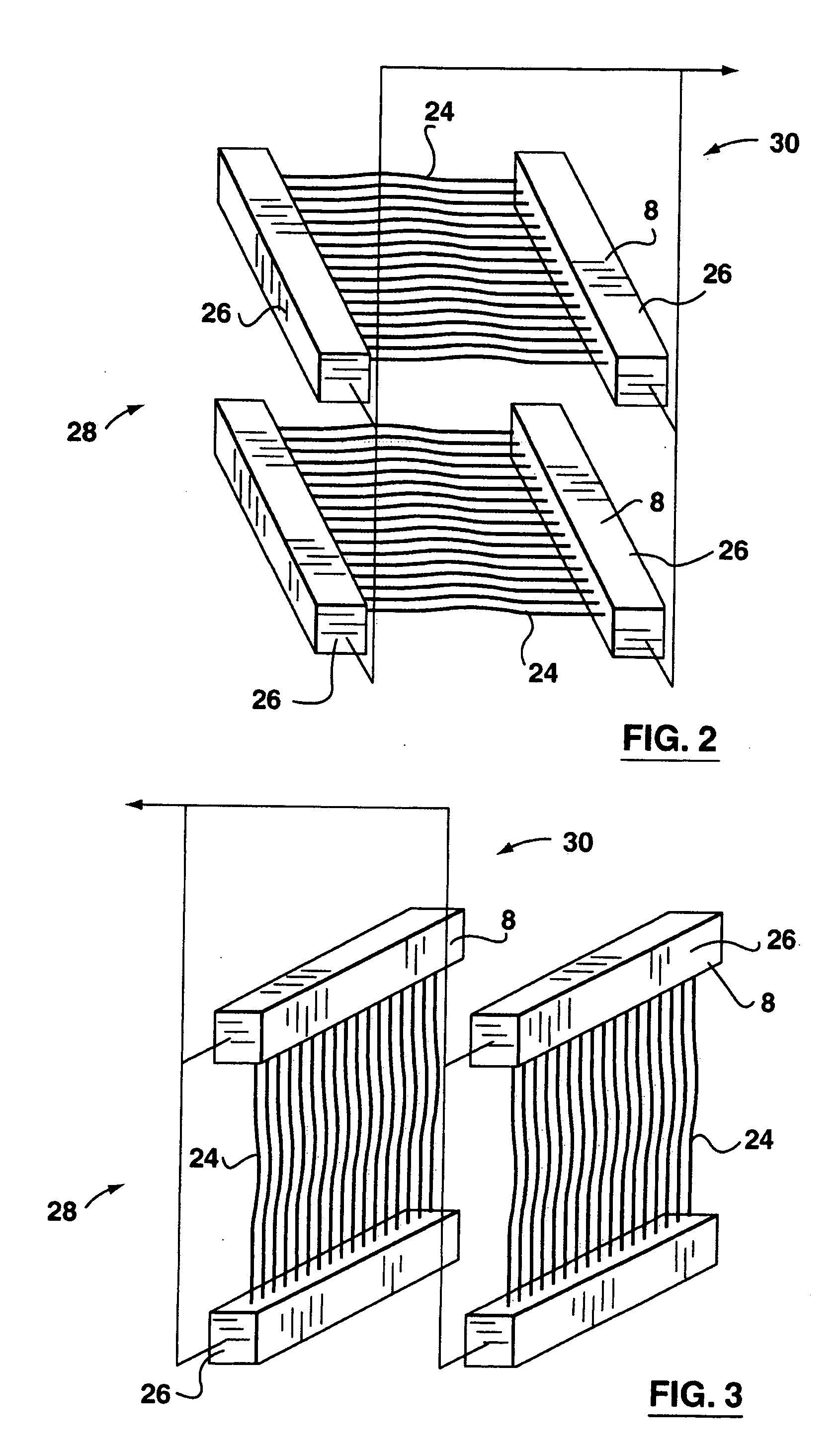

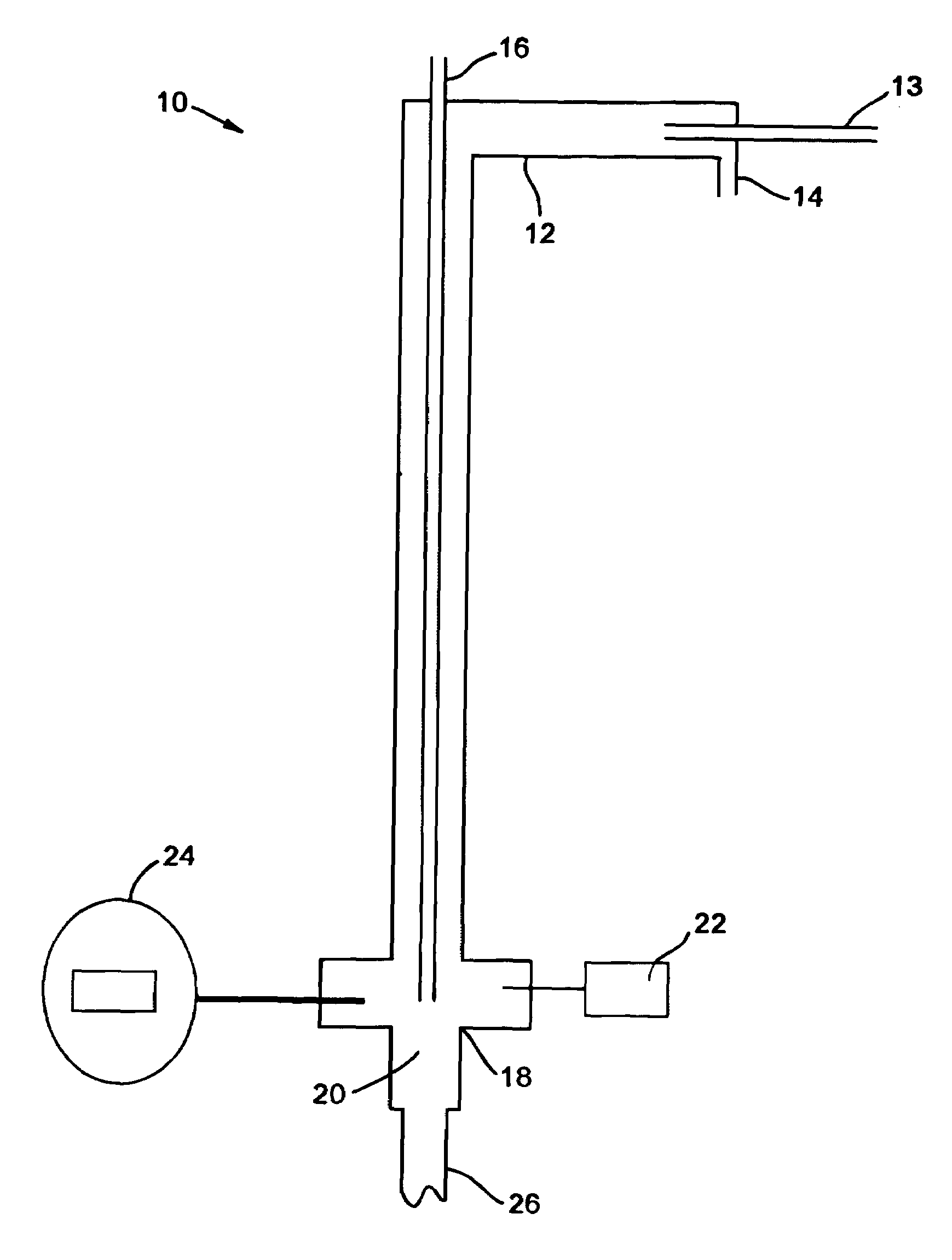

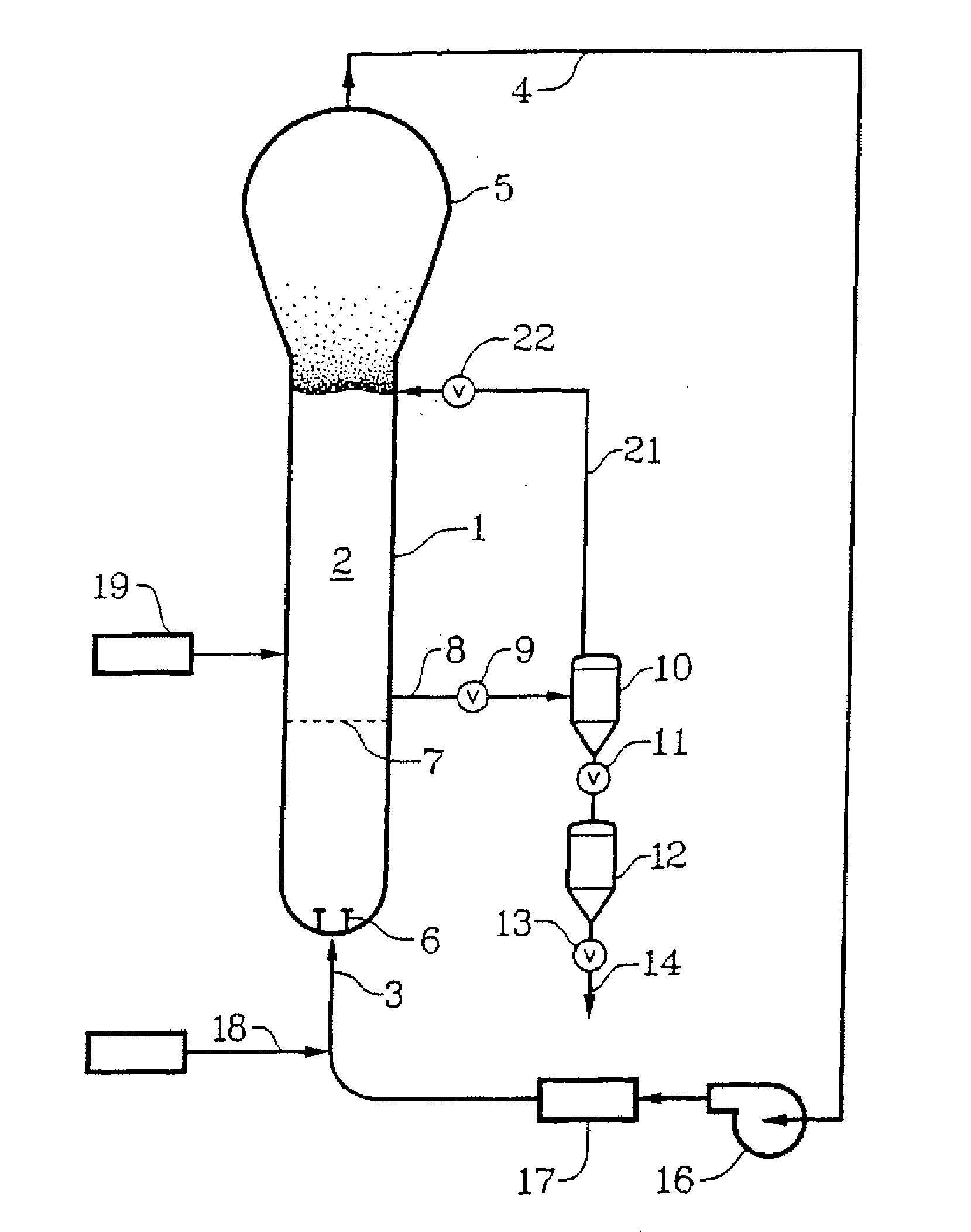

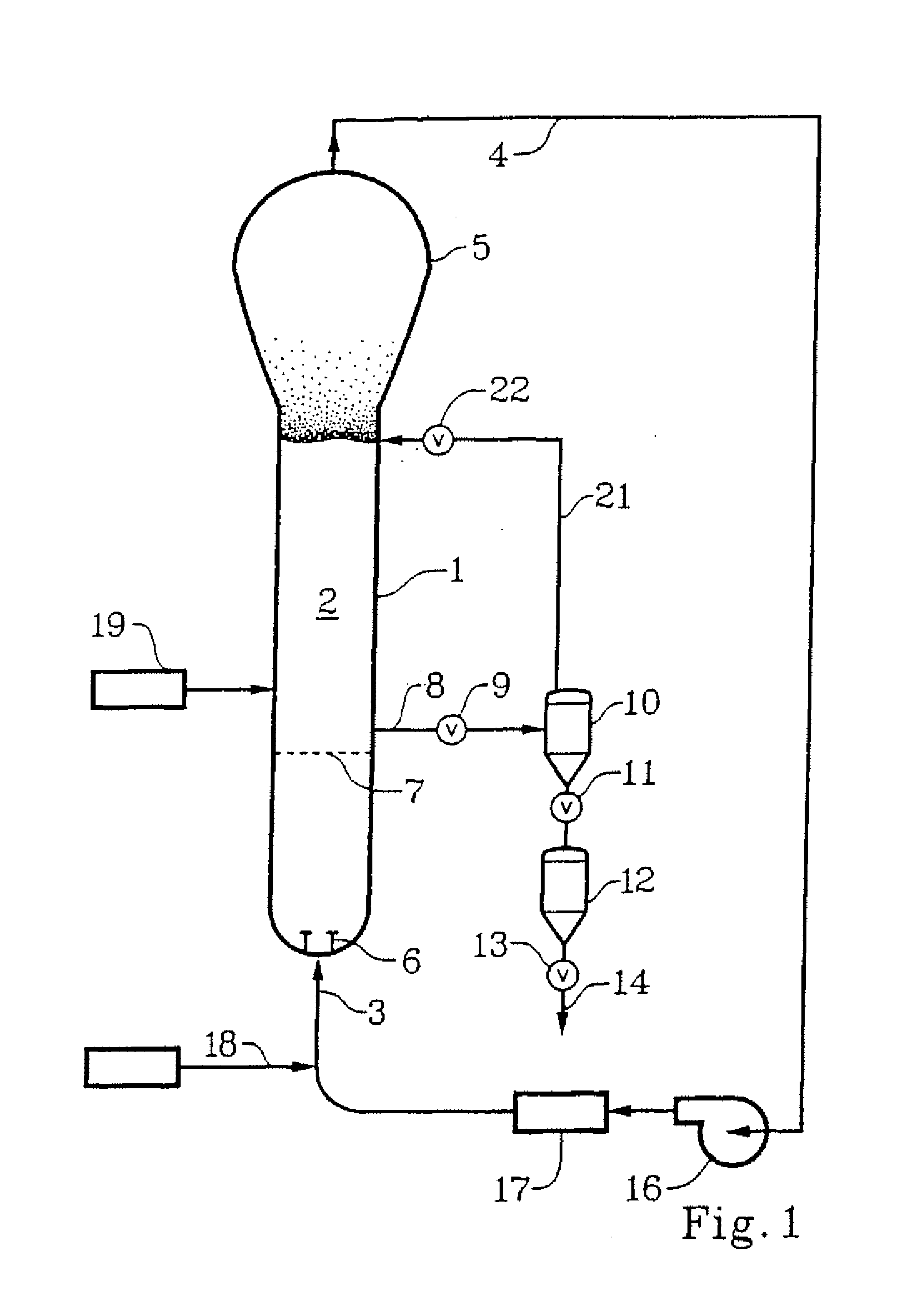

Water filtration using immersed membranes

A process and apparatus is described for filtering water with immersed membranes. In a batch process, permeate is withdrawn while the flow of feed is reduced or stopped at the end of a permeation cycle. The water level is reduced to a level where a portion of the membranes are exposed to air before draining the tank. In this or another process, the level of liquid is reduced to correspond with an area of the membrane fibers having an accumulation of solids. Aeration is provided for a period of time with the liquid at this level to dislodge at least a portion of the solids from the membranes. In these or other processes, the tank is partially drained between cycles to deconcentrate the tank, aeration is provided during backwashing and intermittently while permeating, and / or retentate is withdrawn from the tank during a portion of a permeation step.

Owner:ZENON TECH PARTNERSHIP

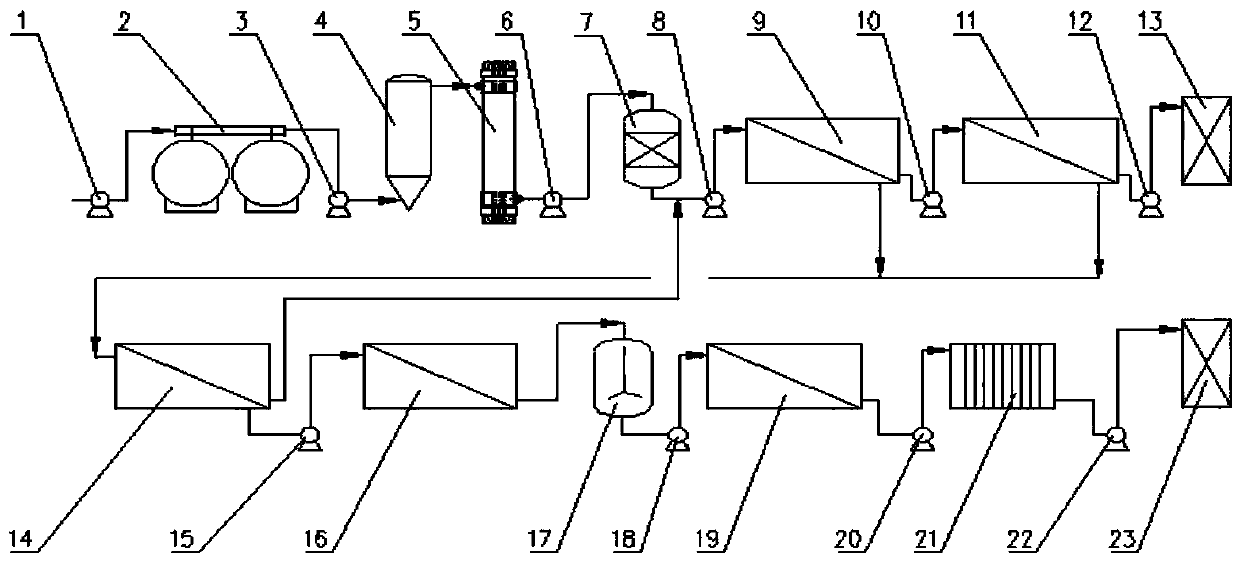

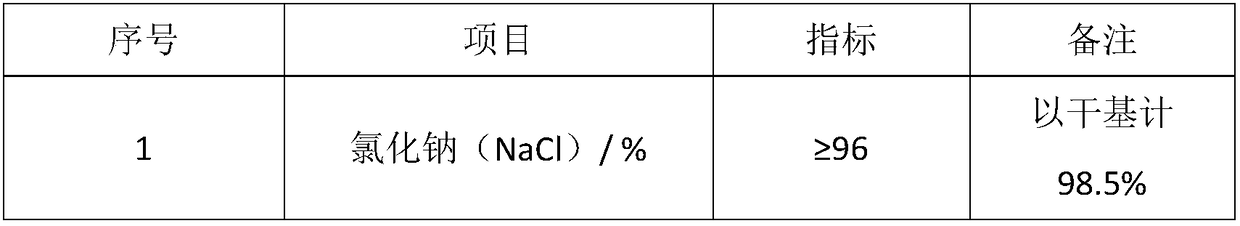

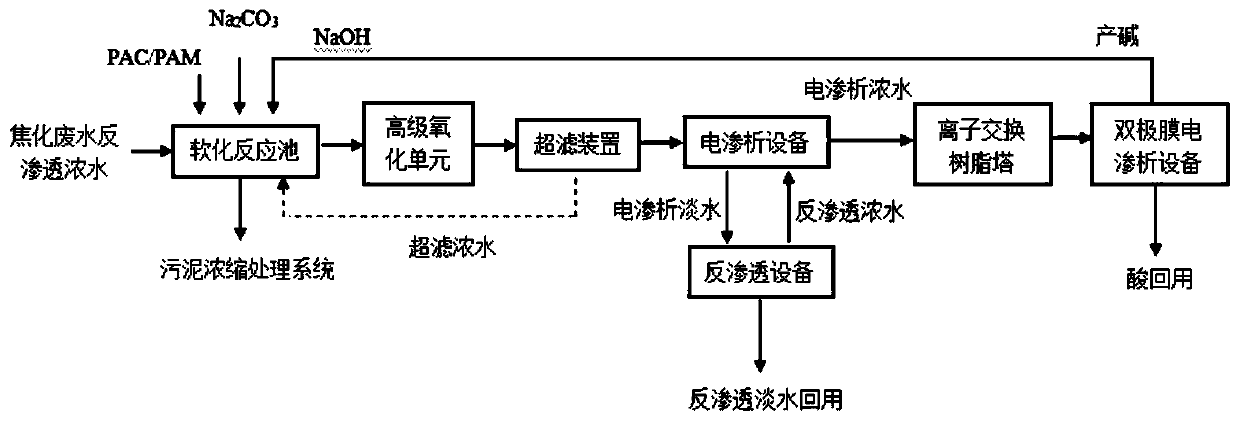

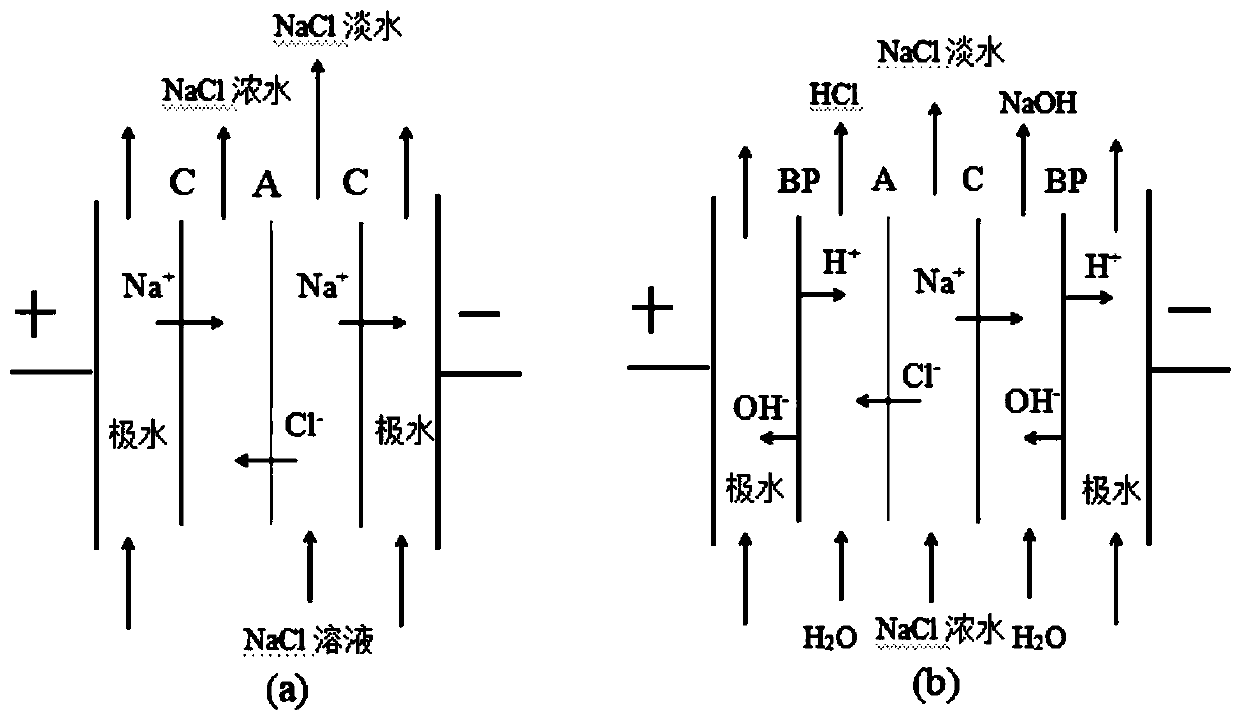

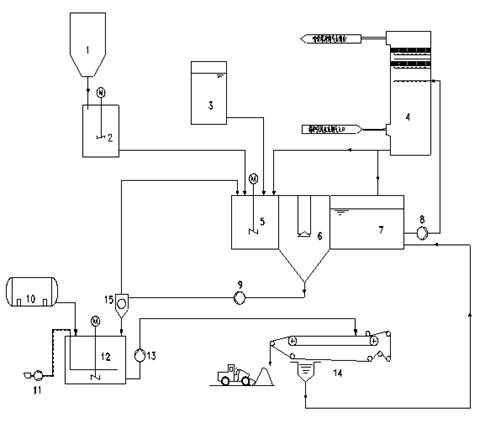

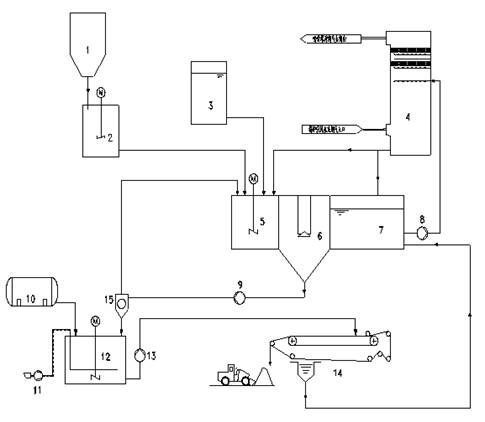

Coking wastewater membrane concentration salt separation zero-emission treatment system and coking wastewater membrane concentration salt separation zero-emission treatment method

InactiveCN110734178AAvoid foulingGuaranteed uptimeSpecific water treatment objectivesChemical industryFiltrationReverse osmosis

The invention belongs to the technical field of water treatment, and particularly relates to a coking wastewater membrane concentration salt separation zero-emission treatment system and a coking wastewater membrane concentration salt separation zero-emission treatment method. The method comprises: coking wastewater pretreatment, wherein the coking wastewater pretreatment comprises full-automaticsand filtration, active carbon adsorption regeneration, ultra-filtration and softening; membrane salt separation and concentration treatment, wherein the membrane salt separation and concentration treatment comprises low-pressure nano-filtration, high-pressure nano-filtration, purification nano-filtration and reverse osmosis treatment; and concentration treatment, fluorine and silicon removal, electrodialysis concentration and evaporative crystallization, wherein an industrial-grade sodium chloride product with a purity of more than 92% is obtained, a sodium sulfate concentrated solution enters a freezing crystallization device to generate mirabilite, the mirabilite is heated and melted and then enters an evaporation crystallization, centrifugation and drying system, and an industrial-grade sodium sulfate product with a purity of more than 95% is obtained. According to the invention, with the system and the method, the zero discharge of coking wastewater is achieved, and the process technology is an innovative coking wastewater zero discharge process at home and abroad.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

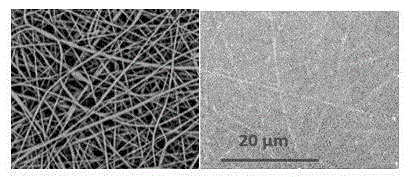

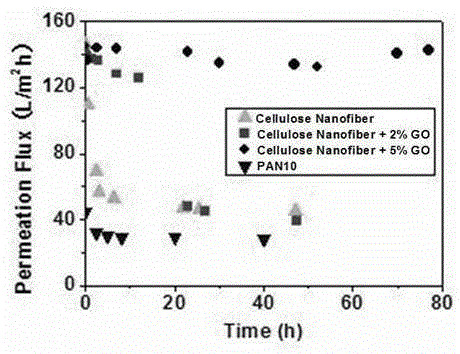

Cellulose nanofiber-graphene oxide hybridized composite ultrafiltration membrane and preparation method thereof

ActiveCN105396466AExtended service lifeImprove pressure resistanceUltrafiltrationWater/sewage treatment bu osmosis/dialysisFiberCellulose

The invention relates to a cellulose nanofiber-graphene oxide hybridized composite ultrafiltration membrane and a preparation method thereof. The cellulose nanofiber-graphene oxide hybridized composite ultrafiltration membrane structurally comprises at least one cellulose nanofiber and graphene oxide hybridized filtering layer, and at least one micro-filtration membrane supporting layer or electrostatic spinning nanofiber supporting layer. The composite ultrafiltration membrane has the good anti-pollution scaling property and pressure-resistant property when being used in oil-water separation process; compared with a commercial membrane, the composite ultrafiltration membrane has water flux 2-10 time that of the commercial membrane under a condition of same reject rate.

Owner:BEIJING UNIV OF CHEM TECH

Reverse osmosis separating membrane with excellent antiscaling nature, method for mfg. same

InactiveCN1401417AGood antibacterial propertiesAvoid foulingMembranesPhysical/chemical process catalystsNanoparticleReverse osmosis

A reverse-osmosis separating membrane with high resitance to scale deposit is prepared through hydrolyzing Ti compound in acidic aqueous solution to generate TiO2 nanoparticles, dispersing them in anaqueous solution (pH=1-6 or 9-13), and dipping the reverse-osmosis separating membrane in it for fixing said TiO2 nanoparticles on it.

Owner:SAEHAN INDS CO LTD

Method used for processing waste water after vanadium precipitation

ActiveCN102531221AEasy to handleAvoid pollutionMultistage water/sewage treatmentAmmonium sulfatesEvaporationSodium sulfate

The invention provides a method used for processing waste water after vanadium precipitation. The processing method leads the waste water after vanadium precipitation to process in a straight line in a whole processing system, the waste water after vanadium precipitation flows unidirectionally in the whole process of putting into a segregation processing, thereby not only being capable of avoiding pollution of the waste water on environment, also being capable of avoiding problems such as equipment scaling blockage, erosion and the like brought by circular process after enrichment of different ions in a crystal residual liquid, and observably improving the waste water treatment ability of a system. The waste water carries out a first crystal and a second crystal after evaporation concentration, is capable of comparing a sodium sulfate constituent and an ammonium sulfate constituent in fully segregation sinking vanadium waste water, and recovers to obtain sodium sulfate crystal and ammonium sulfate crystal with higher purity.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Zero emission treatment method of high-salinity wastewater

ActiveCN105502787AAdvantages of zero-discharge treatment methodsReduce processing costsTreatment involving filtrationMultistage water/sewage treatmentPositive pressureReverse osmosis

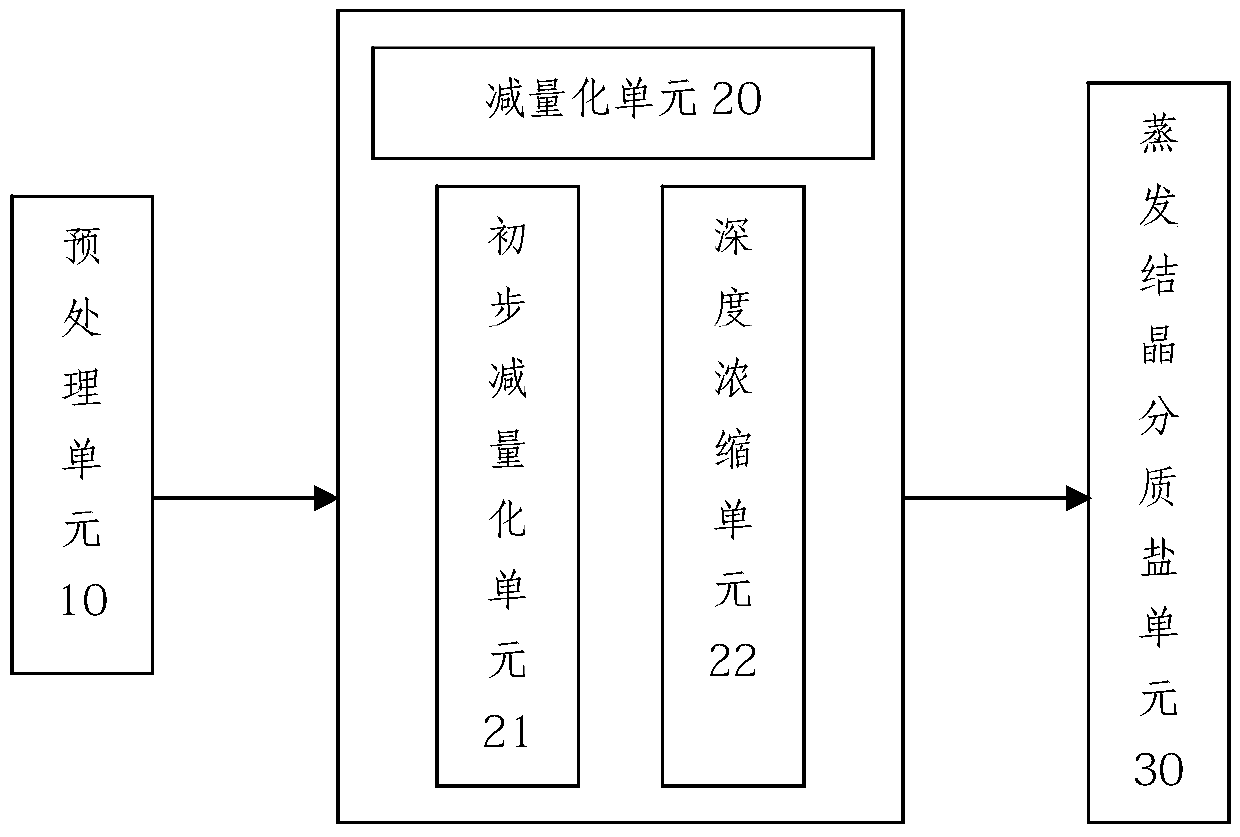

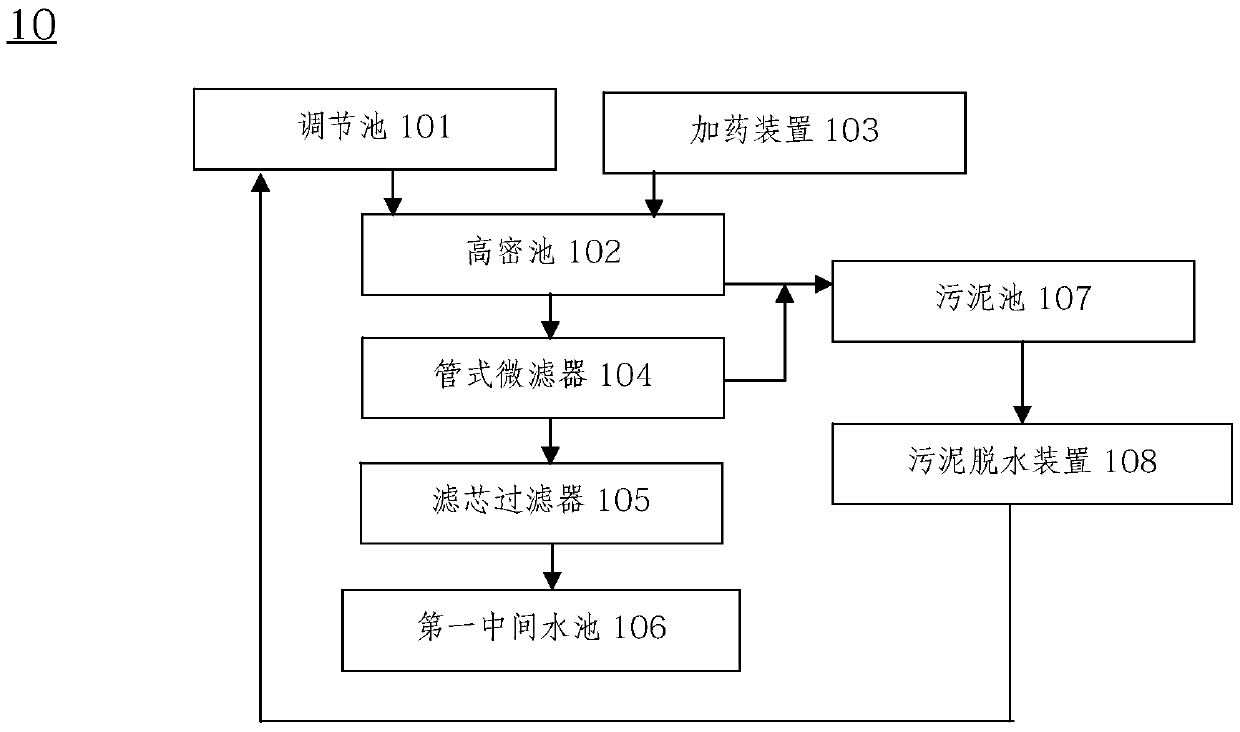

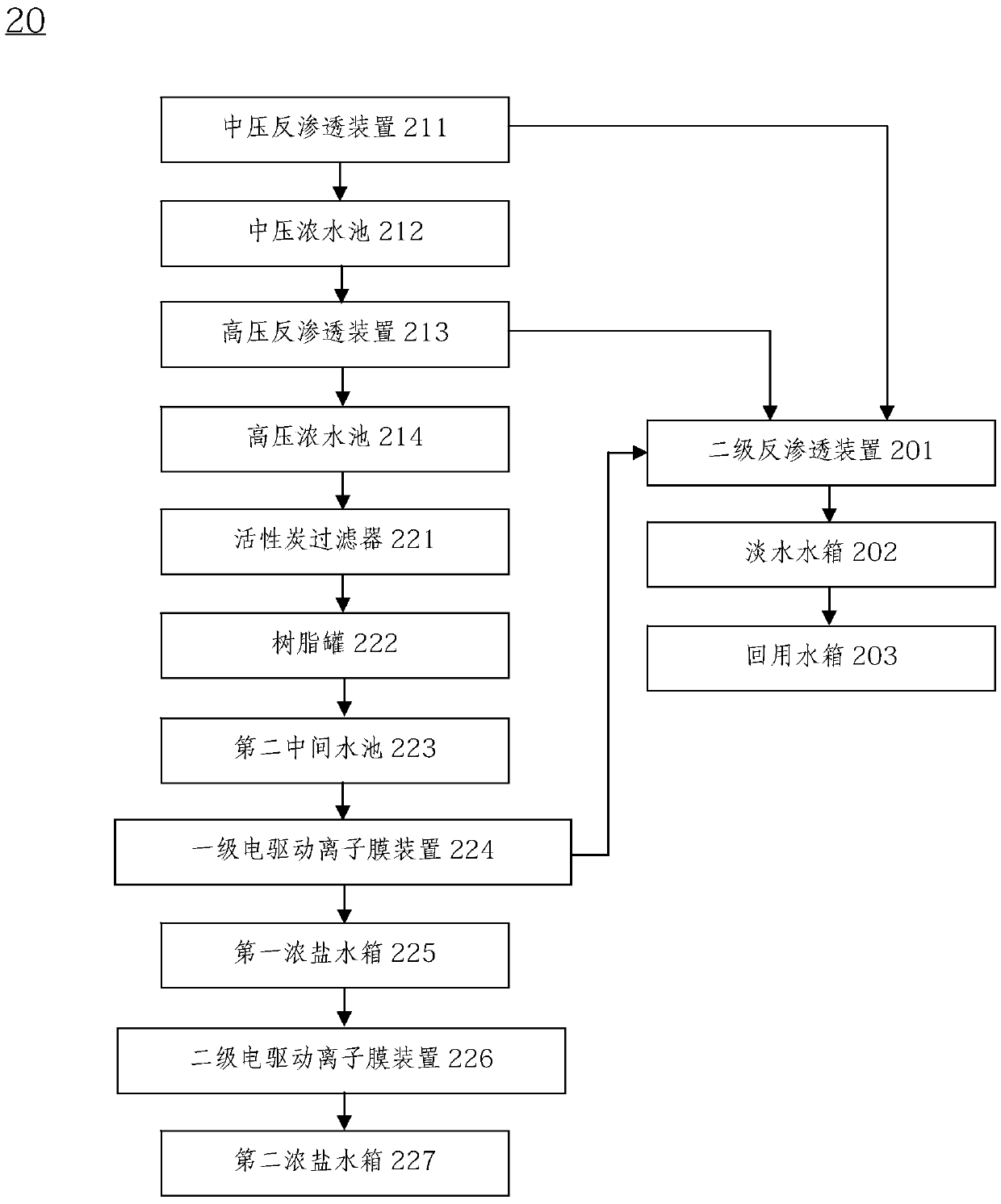

The invention relates to a zero emission treatment method of high-salinity wastewater. The method comprises a pre-treatment technology of wastewater, a reduction technology of the wastewater and an evaporative crystallization technology of the high-salinity wastewater, wherein the pre-treatment technology is implemented as follows: a flocculation and / or sedimentation chemical agent is added, heavy metal ions, hard ions and organic substances in the high-salinity wastewater are removed from a chemical reactor, and the pH of the wastewater is adjusted until the wastewater is alkaline; the reduction technology is implemented as follows: the pretreated wastewater is subjected to preliminary reduction treatment through a medium-pressure reverse osmosis device and a high-pressure reverse osmosis device to form high-pressure reverse osmosis concentrated water, the high-pressure reverse osmosis concentrated water is subjected to deep concentration treatment through a primary electric drive ionic membrane device and a secondary electric drive ionic membrane device, high-salinity concentrated water is obtained through concentration, and producing water in the reduction process is recovered to a recycling water tank; the evaporative crystallization technology is implemented as follows: salts in the high-salinity concentrated water are recovered under the negative pressure or micro-positive pressure condition through a nitrate evaporative crystallization device and a salt evaporative crystallization device, and sodium sulfate and sodium chloride are formed.

Owner:BGT GRP CO LTD

Production of gaseous chloramine

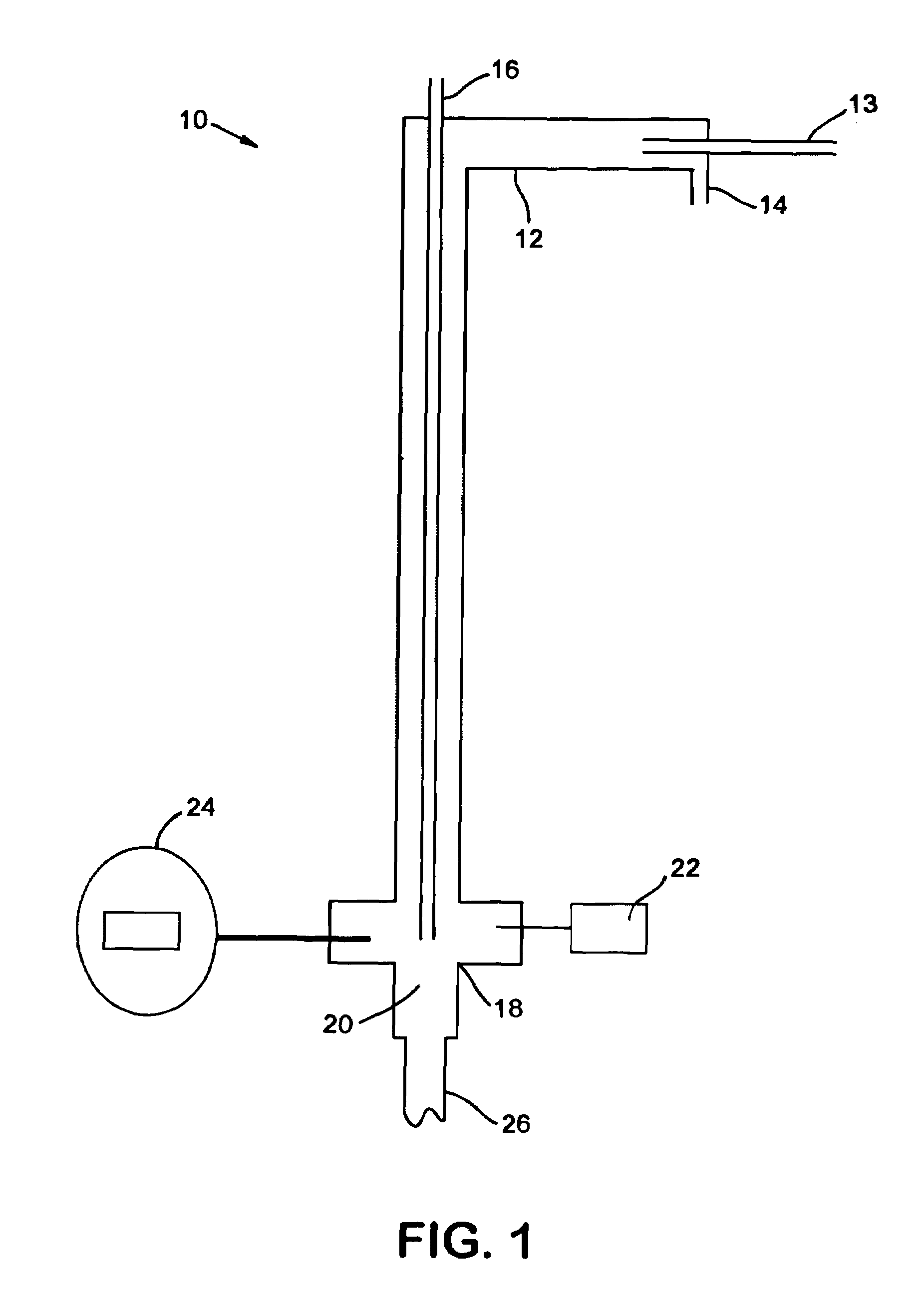

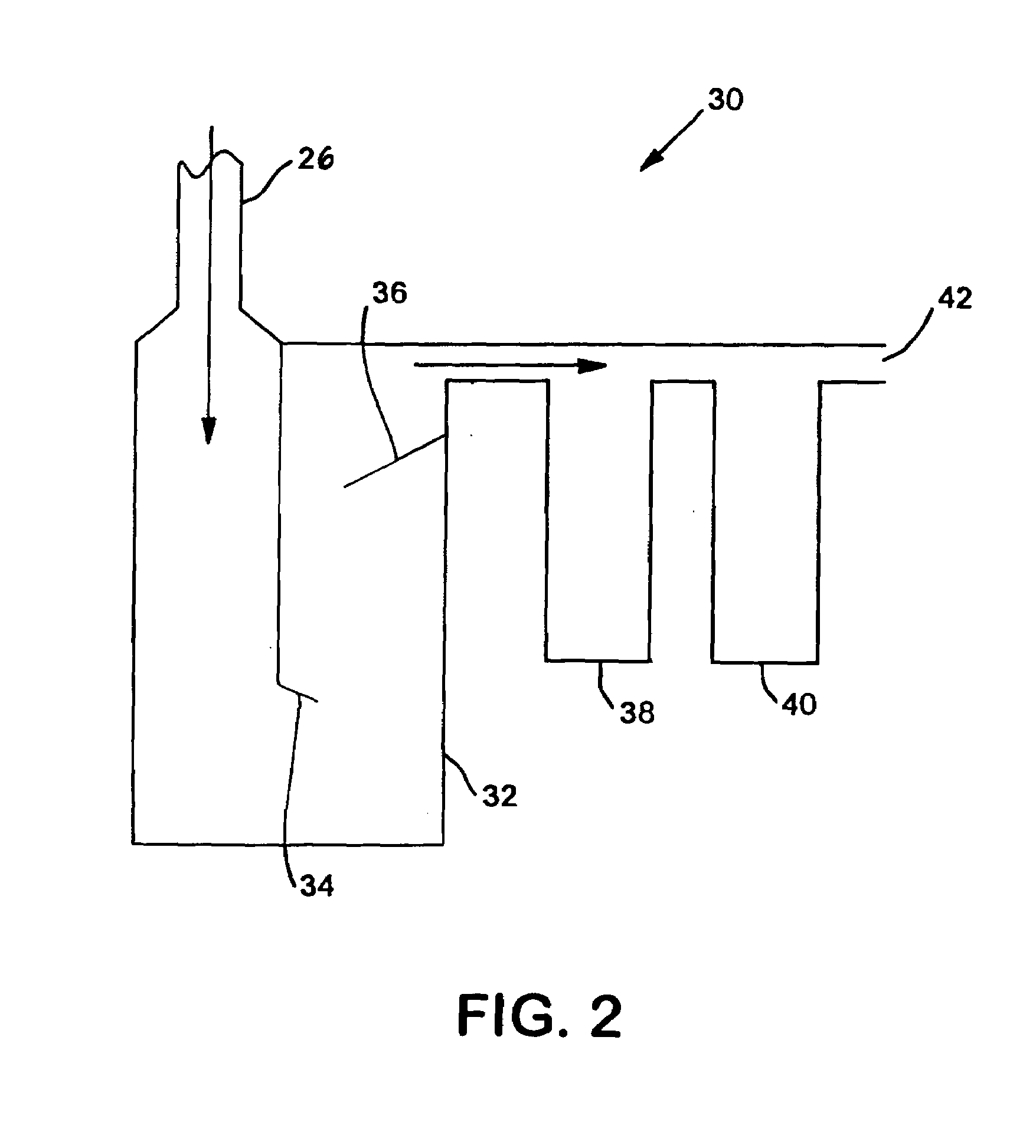

InactiveUS7070751B2Prevent scalingSimple streamlined designCombination devicesExhaust apparatusChloramine BGas phase

The present invention provides a reactor for the gas-phase reaction of commercially available gases in the presence of an inert carrier gas to form product gas. The reactor has a streamlined, compact configuration and at least one solids collection and removal system downstream of the reactor, where solids are efficiently removed from the product gas stream, leaving high purity product gas. The removal system allows for a simple reactor design, which is easy to clean and operates continuously over longer periods of time.

Owner:BRISTOL MYERS SQUIBB CO

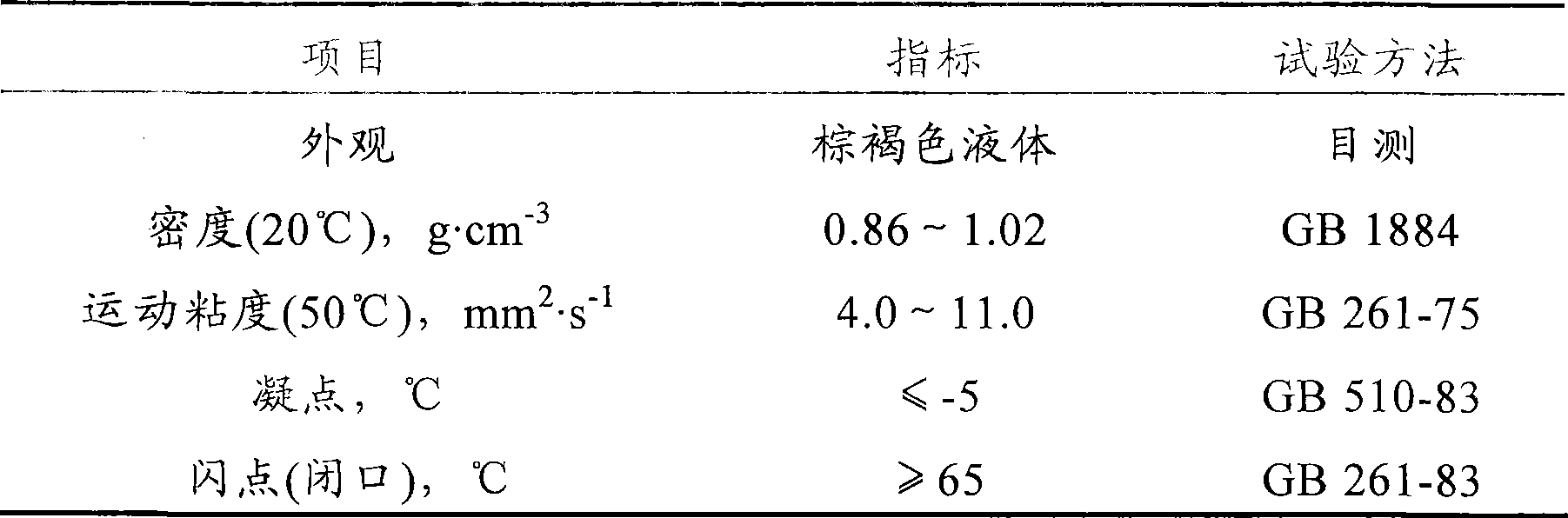

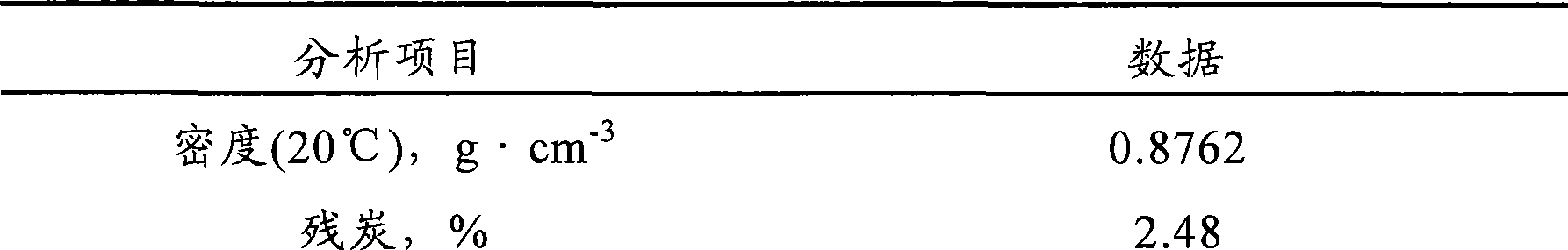

Catalytic cracking multifunctional strengthened additive

The invention provides multifunctional catalytic cracking strengthening additive which comprises a rare earth organic compound, heteropoly acid (and salt thereof), chemical inhibitor, solvent, and the like and has the functions of resisting oxidation and preventing from scorch, dispersing, increasing the acid center, passivating the metal, and the like. When being added into a catalytic cracking lifting pipe reactor, the multifunctional catalytic cracking strengthening additive can inhibit the generation of secondary reaction such as thermal cracking reaction, dehydrogenation condensation reaction, and the like, reduces the generation of side products of net gas, coke, hydrogen, and the like, and improves the yield coefficients of products with high added values, such as liquid gas (especially propylene), gasoline and diesel. The catalytic cracking strengthening additive has the function of metal deactivator and can replace the metal deactivator, therefore, the metal deactivator needs not to be added after the catalytic cracking strengthening additive is added. The invention has the function of resisting oxidation and preventing from scorch, can inhibit a lifting pipe and a settling vessel from being coked and prevent a reaction system from scale deposit, thereby being multifunctional catalytic cracking strengthening additive.

Owner:河北鑫泰精细化工有限公司

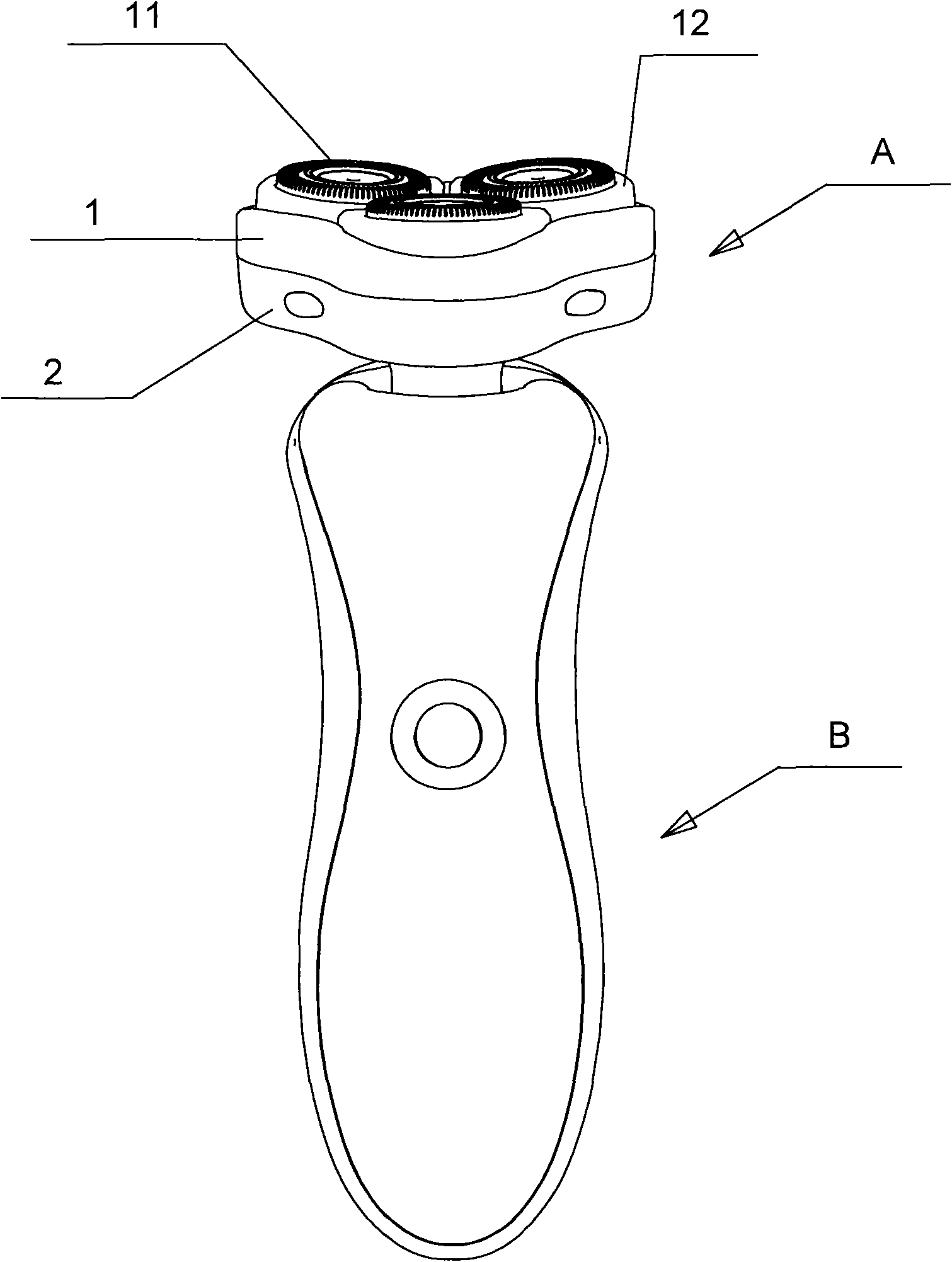

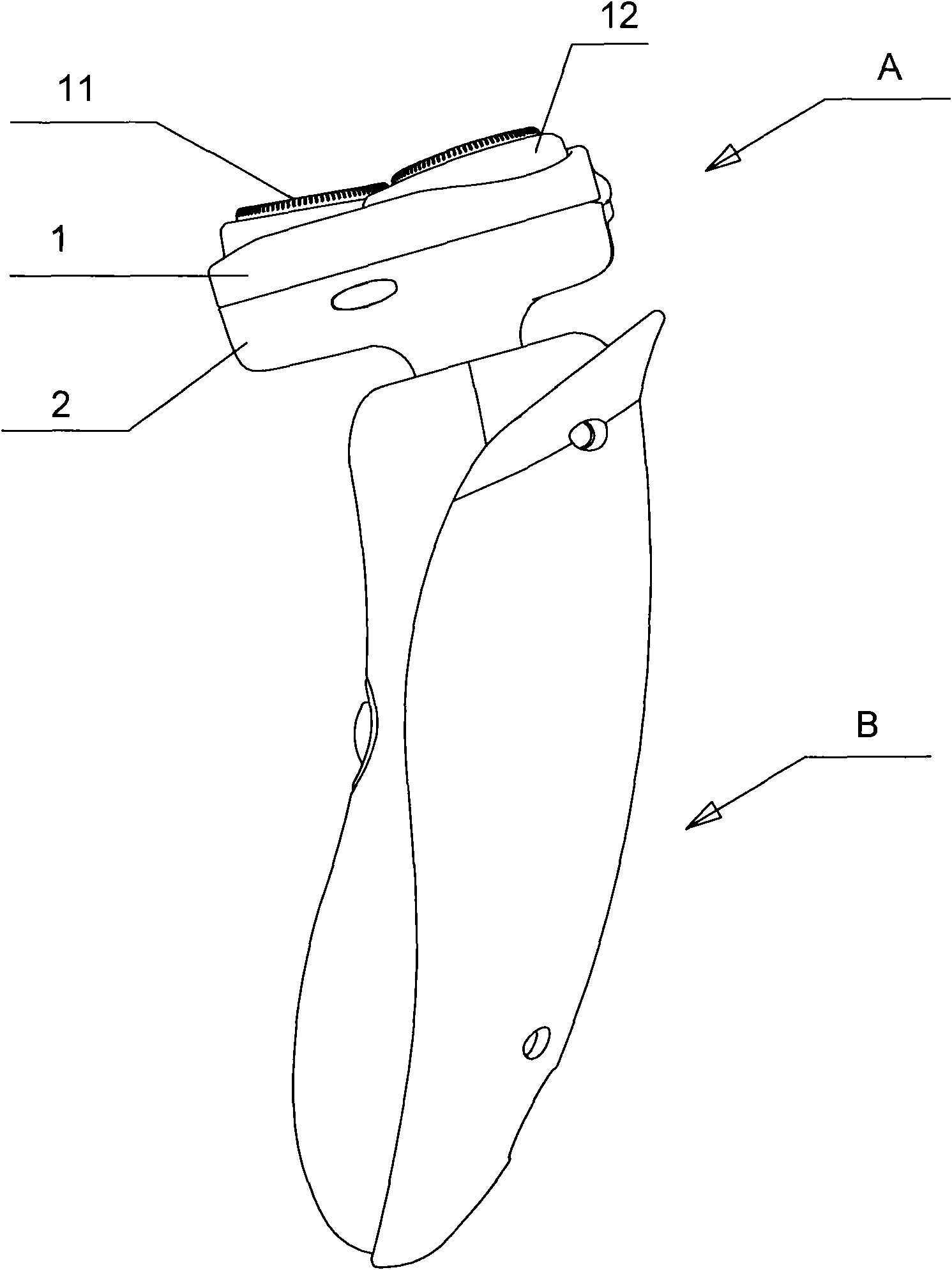

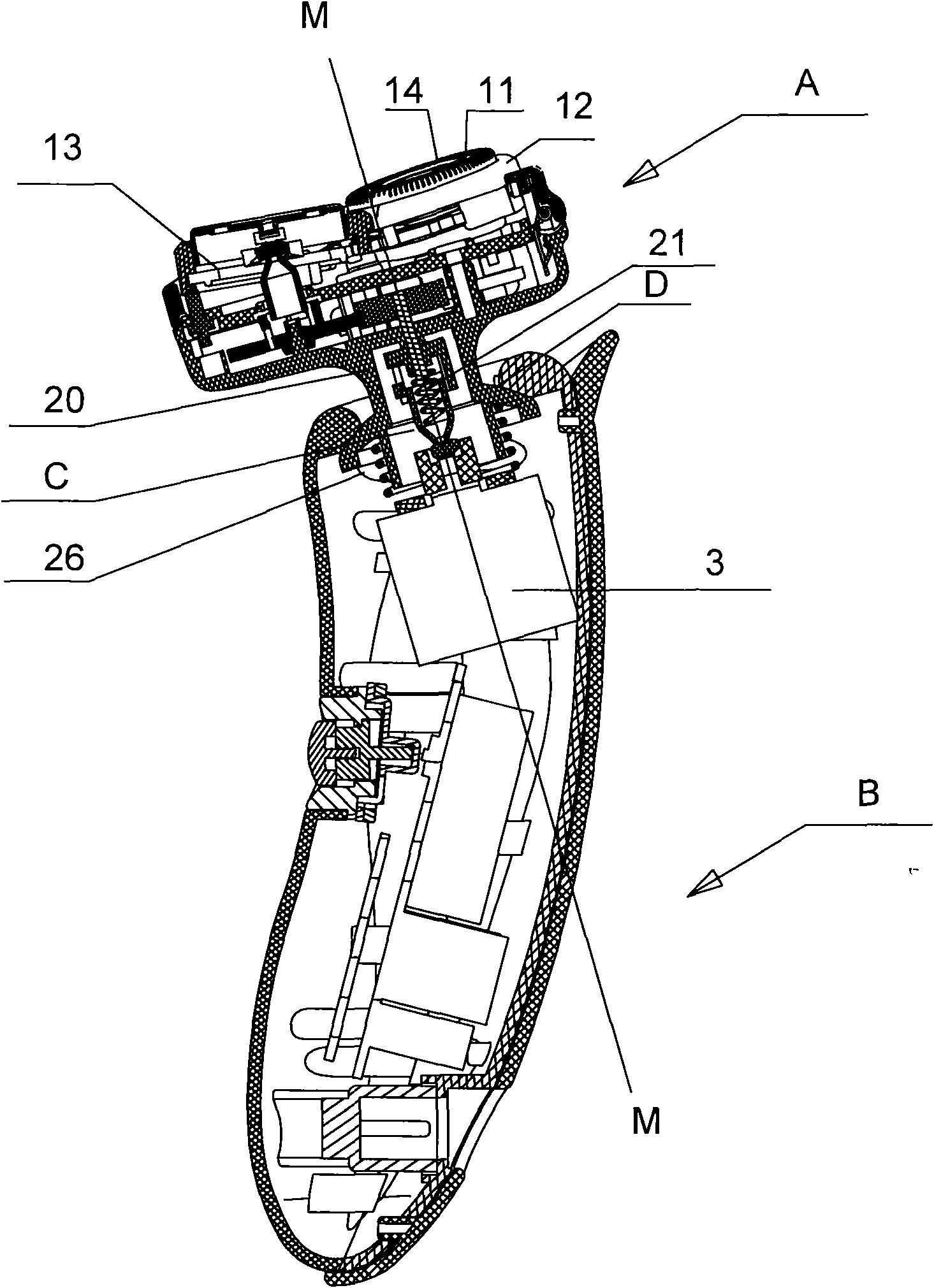

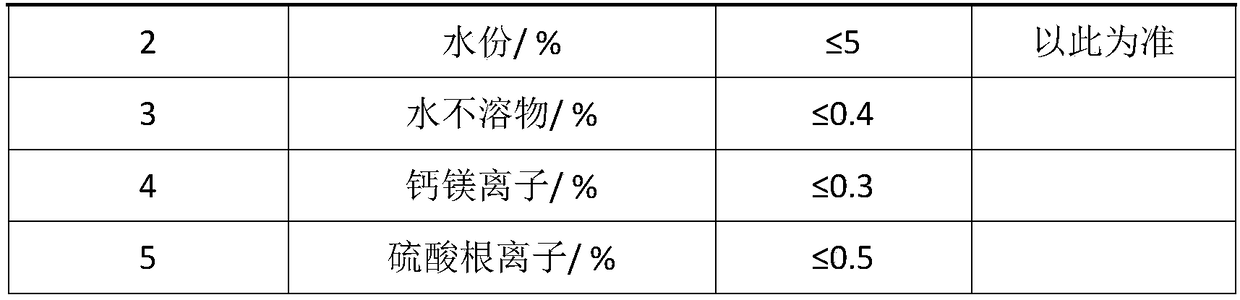

Rotary type shaver with head part capable of omnidirectionally floating

The invention relates to a rotary type shaver with a head part capable of omnidirectionally floating, which belongs to a personal care product. The prior rotary type shaver with a floatable shaving surface has the defects that are not easily overcome in shaving speed and shaving comfort level. The rotary type shaver with the head part capable of omnidirectionally floating comprises the head part and a body, wherein the head part comprises a screen head and a screen head seat and is in structural connection with the body through the screen head seat; the screen head is provided with at least one shaver set and also provided with an attaching surface and a shaver seat supporting piece which are matched with the shaver set; the shaver set comprises an outer cutter which forms a shaving surface and an inner cutter which can be driven and perform rotary movements relative to the outer cutter; the screen head seat of the head part is connected with the body through an elastically combined connection mechanism which comprises a shaver shaft component and a supporting spring; meanwhile, a screen head seat shell and a body shell realize the structure inosculation through the same curvatureswhich are mutually matched and the same radius concave and convex spherical surfaces so as to ensure that the head part can float omnidirectionally relative to the body, thus a user can obtain fast and comfortable shaving feelings.

Owner:浙江超人科技股份有限公司

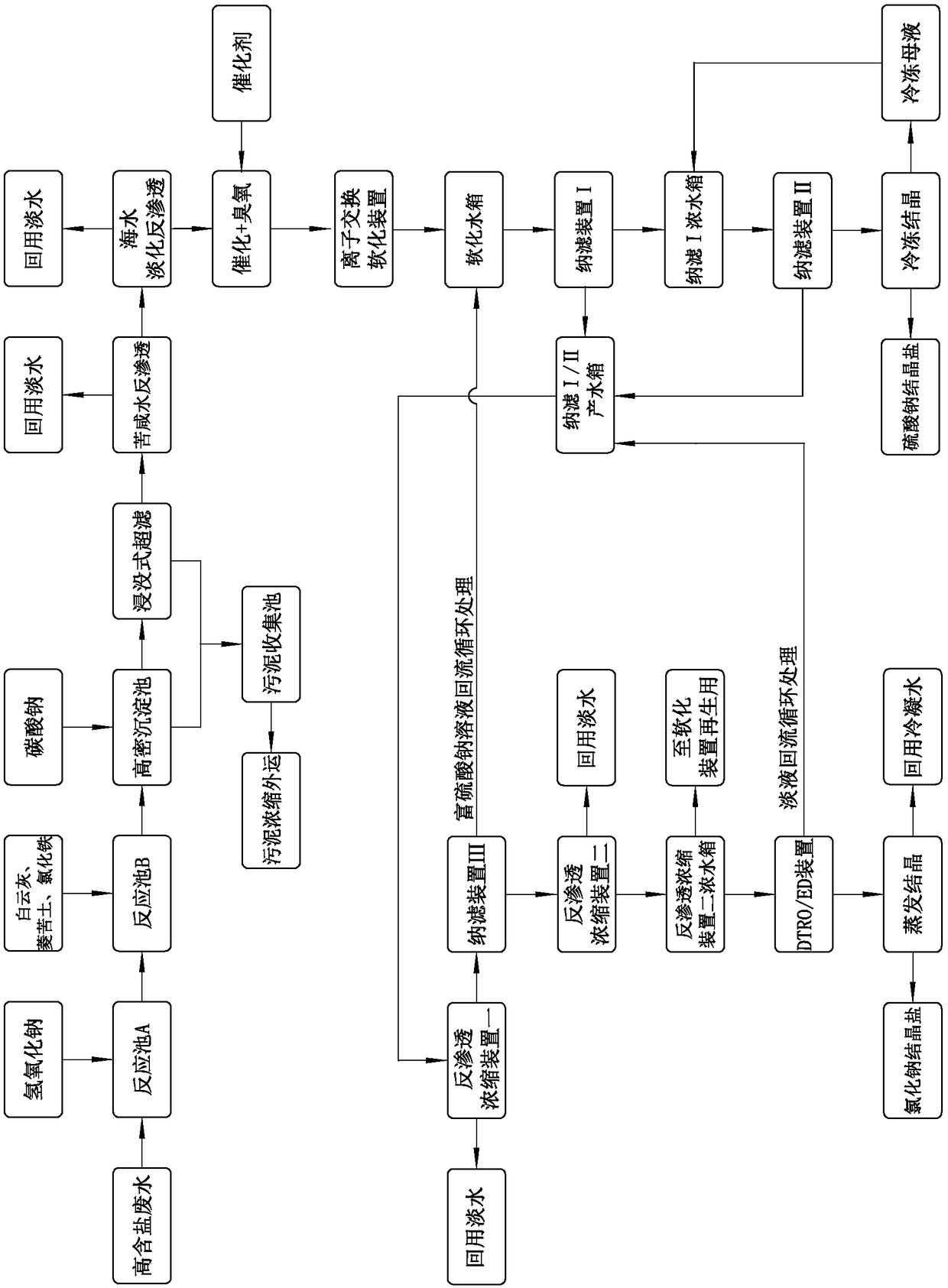

Zero discharge process for high-salt wastewater discharged from titanium dioxide production

ActiveCN108529802AAvoidance of foulingAvoid foulingGeneral water supply conservationWater softeningUltrafiltrationCatalytic oxidation

The invention relates to a zero discharge process for high-salt wastewater discharged from titanium dioxide production, and the steps are as follows: high-salt wastewater, removal of silicon by a magnesium agent, medicinal agent softening, high-density precipitation, immersion-type ultrafiltration, brackish water reverse osmosis membrane concentration, seawater desalination reverse osmosis membrane concentration, reduction of COD by catalytic oxidation, ion exchange softening, multi-stage nanofiltration salt separation, high pressure reverse osmosis membrane concentration, DTRO / ED electrodialysis concentration, and evaporation crystallization / freezing crystallization. The zero discharge process adopts corresponding treatment processes separately, realizes for the first time the zero discharge of the high-salt wastewater of titanium dioxide by a detailed control technology of each specific process in the system, ensures the normal and smooth operation of the system, and recovers a largeamount of fresh water resources and industrial salts. The purpose of resource recycling of the titanium dioxide production wastewater is realized, and on the basis of creating of certain economic benefits, significant environmental and social benefits are reflected.

Owner:SHANDONG YUXIN ENVIRONMENTAL SCI & TECH

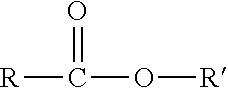

Novel corrosion and scale inhibitor and preparation method thereof

ActiveCN103723843AAvoid foulingPlay a role in corrosion inhibitionScale removal and water softeningEtidronic acidDiethylenetriamine

The invention provides a novel corrosion and scale inhibitor and a preparation method thereof. The novel corrosion and scale inhibitor comprises a corrosion inhibitor, a scale inhibitor and etidronic acid with the mass ratio of (0.1-1):(1-90):(0.1-10), wherein the corrosion inhibitor is a compounded corrosion inhibitor and comprises the following raw materials: oleic acid, diethylenetriamine, a quaternary ammonium reagent, and a compound; the compounded corrosion inhibitor is prepared by the following steps: obtaining imidazoline intermediates through the reaction between the oleic acid and diethylenetriamine; reacting with the quaternary ammonium reagent and obtaining an imidazoline quaternary ammonium salt corrosion inhibitor; finally, adding the compound and compounding to obtain the compounded corrosion inhibitor. The invention further provides the preparation method of the corrosion and scale inhibitor. The novel corrosion and scale inhibitor provided by the invention has the function of inhibiting corrosion and scale simultaneously and can effectively solve the problem of oilfield water scaling in the field of oil fields.

Owner:PETROCHINA CO LTD

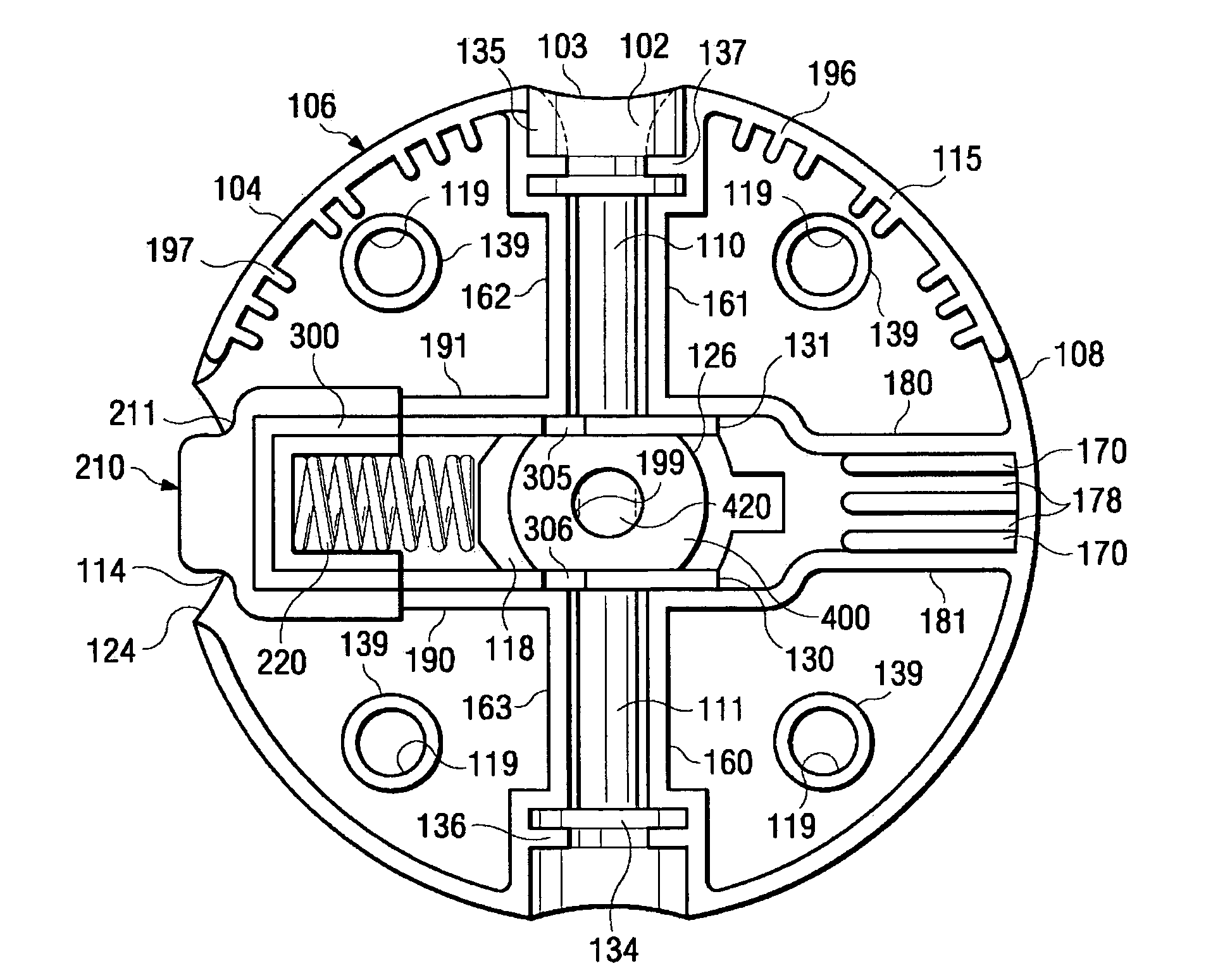

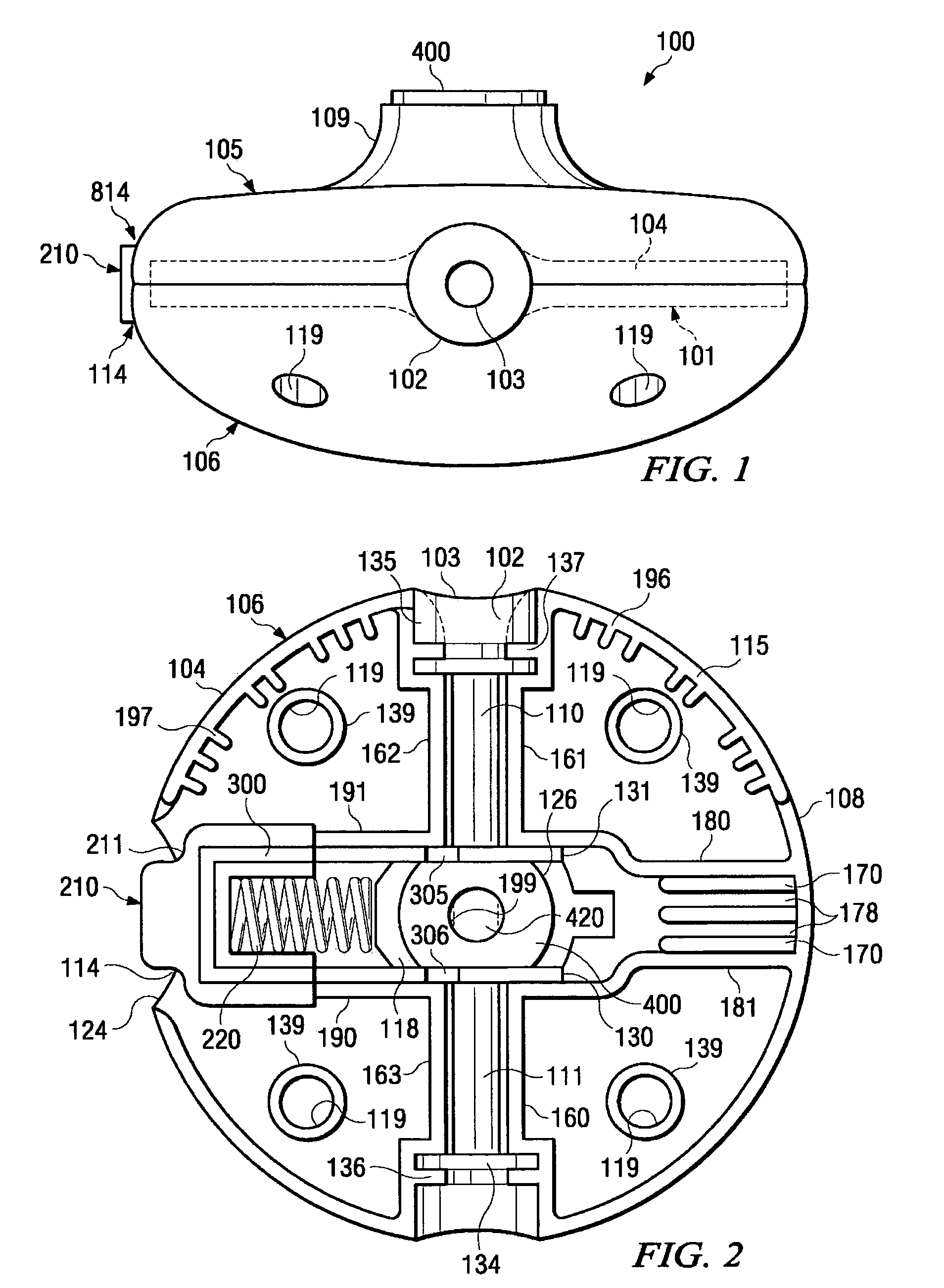

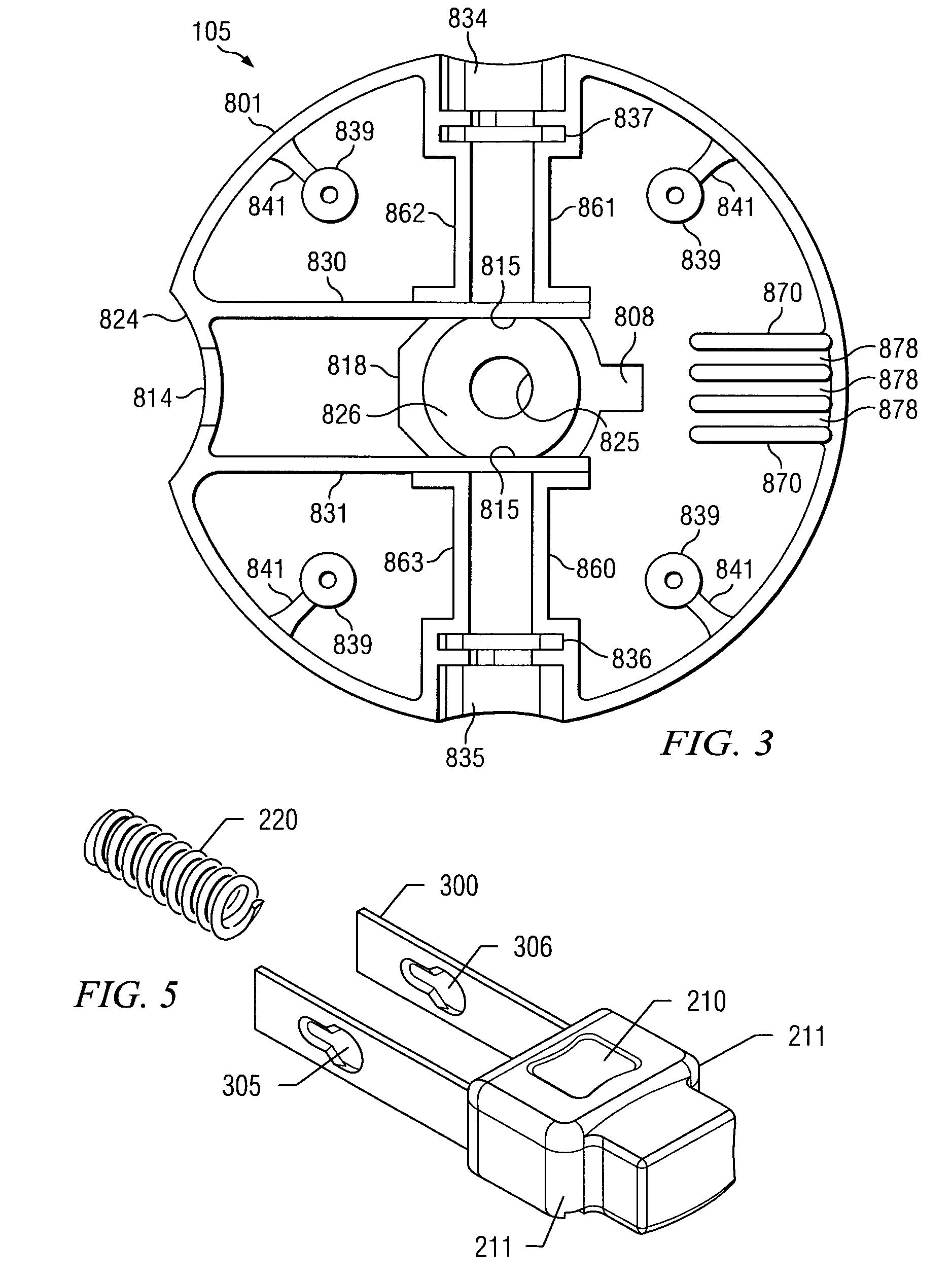

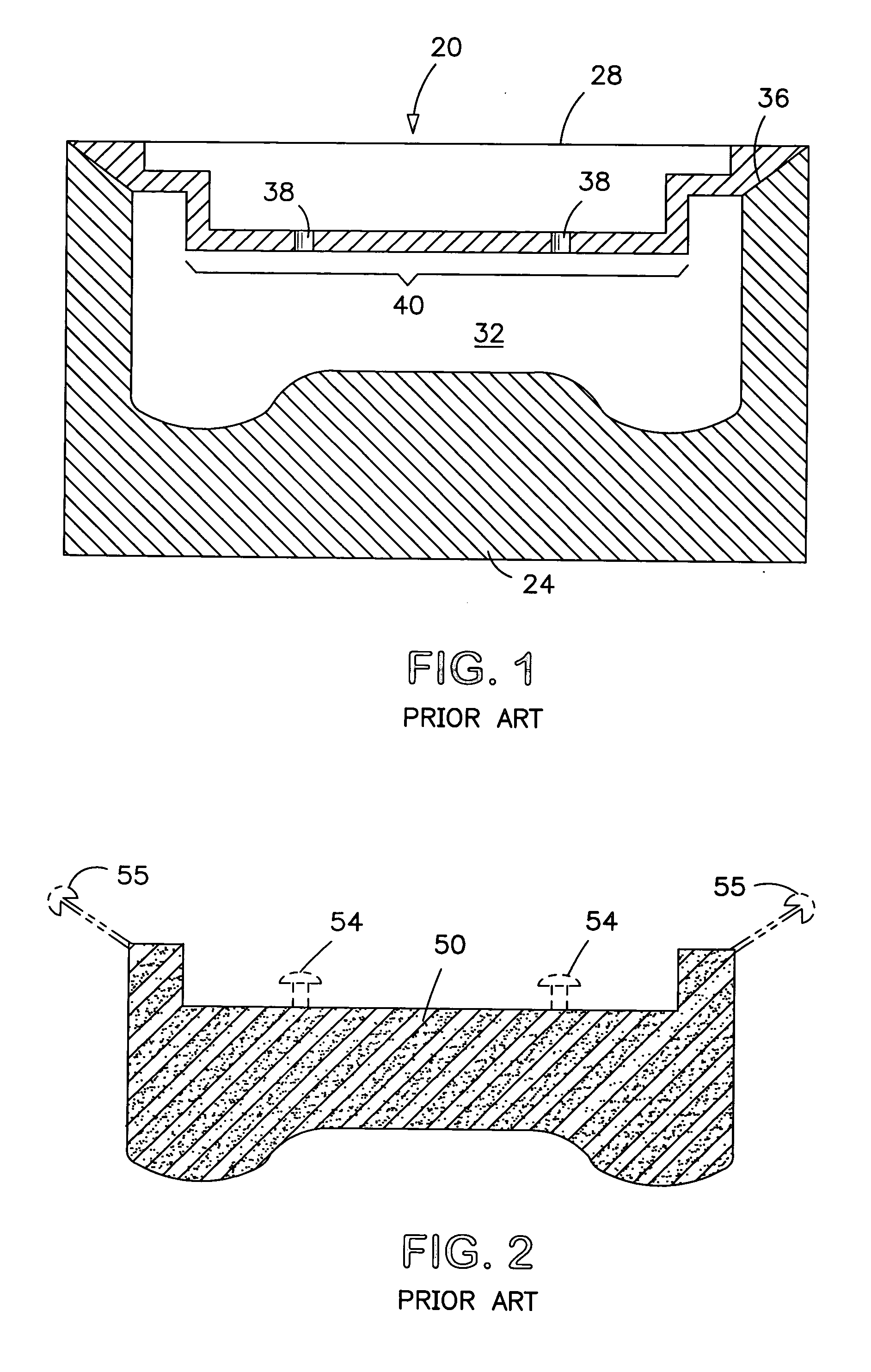

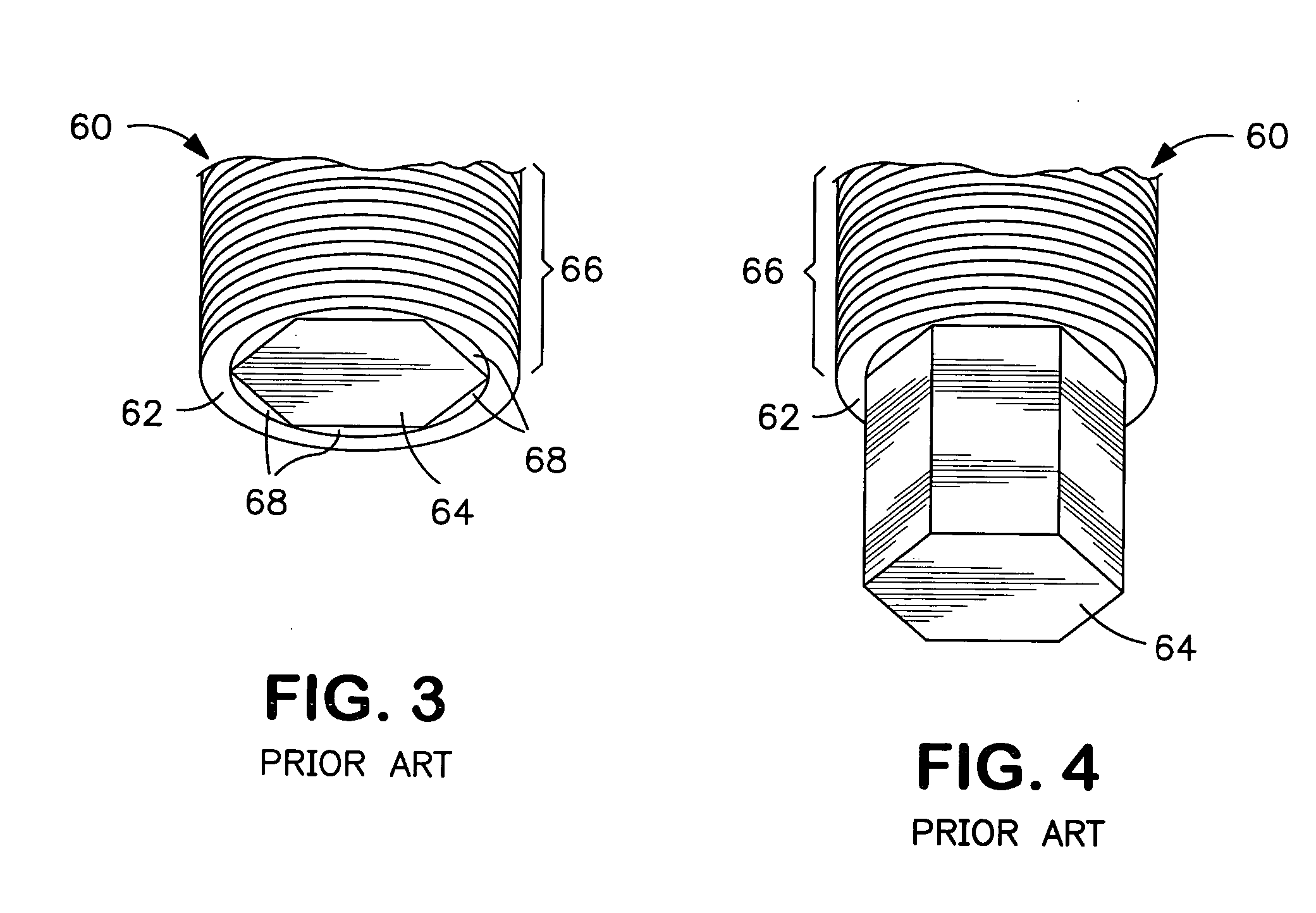

Head for a rotary line trimmer apparatus

InactiveUS7536792B2Prevents excessively acute and sharp bendingPremature damageMowersMetal working apparatusMechanical engineeringKinetic energy

An improved head for a flexible line trimmer apparatus is provided. The improved head includes a metal tubing that extends through the head and surrounds a cutting line of selected length. The tubing is provided with a flared exit portal increasing the efficiency of the head. The contact surface eliminates the possibility of the cutting line fusing to plastic surfaces due to heating caused by friction. The head is surrounded with an interior perimeter counterweight to store kinetic energy on each end having a parabolic surface of revolution concentric with the axis of the tubing. A replaceable cartridge is provided to increase the ease of maintenance and the useful life of the head.

Owner:MOORE MARK R

Method for polymerizing polypropylene

The present disclosure relates to a method for polymerizing polypropylene, optionally with one or more additional comonomers in a gas phase reactor in the presence of a mixed electron donor system comprising at least one selectivity control agent and at least one activity limiting agent. The process involves controlling the polymerization process to ensure that the difference between the reactor temperature and the dew point temperature of the incoming monomer stream is 12° C. or greater.

Owner:WR GRACE & CO CONN

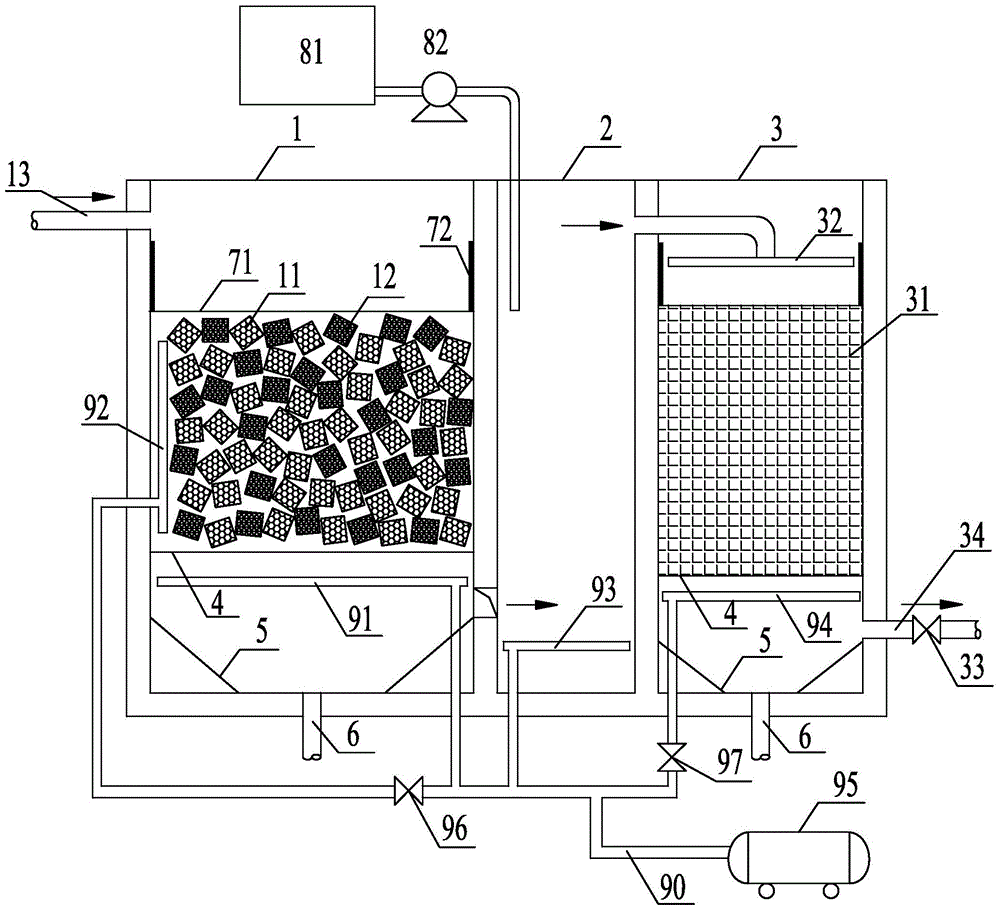

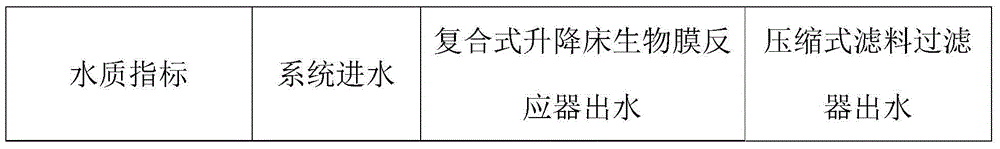

Advanced treatment system and method for municipal domestic wastewater

ActiveCN104591508AReduce friction lossImprove adsorption capacityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationWastewater

The invention relates to an advanced treatment system for municipal domestic wastewater, and in particular relates to an advanced treatment system and method for municipal domestic wastewater. The advanced treatment system for the municipal domestic wastewater comprises a water inlet pipe and a water outlet pipe, as well as a composite lift bed bio-membrane reactor, a flocculation reactor, a compression type filtering material filter, a chemical dosing device and an aerating apparatus, wherein the aerating apparatus is used for ventilating the composite lift bed bio-membrane reactor, the flocculation reactor and the compression type filtering material filter. According to the advanced treatment system for the municipal domestic wastewater, the treatment effect can be improved; the technological process and the structure arrangement are simplified; the management and operation strength is reduced; and the floor area and the operation cost are reduced.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

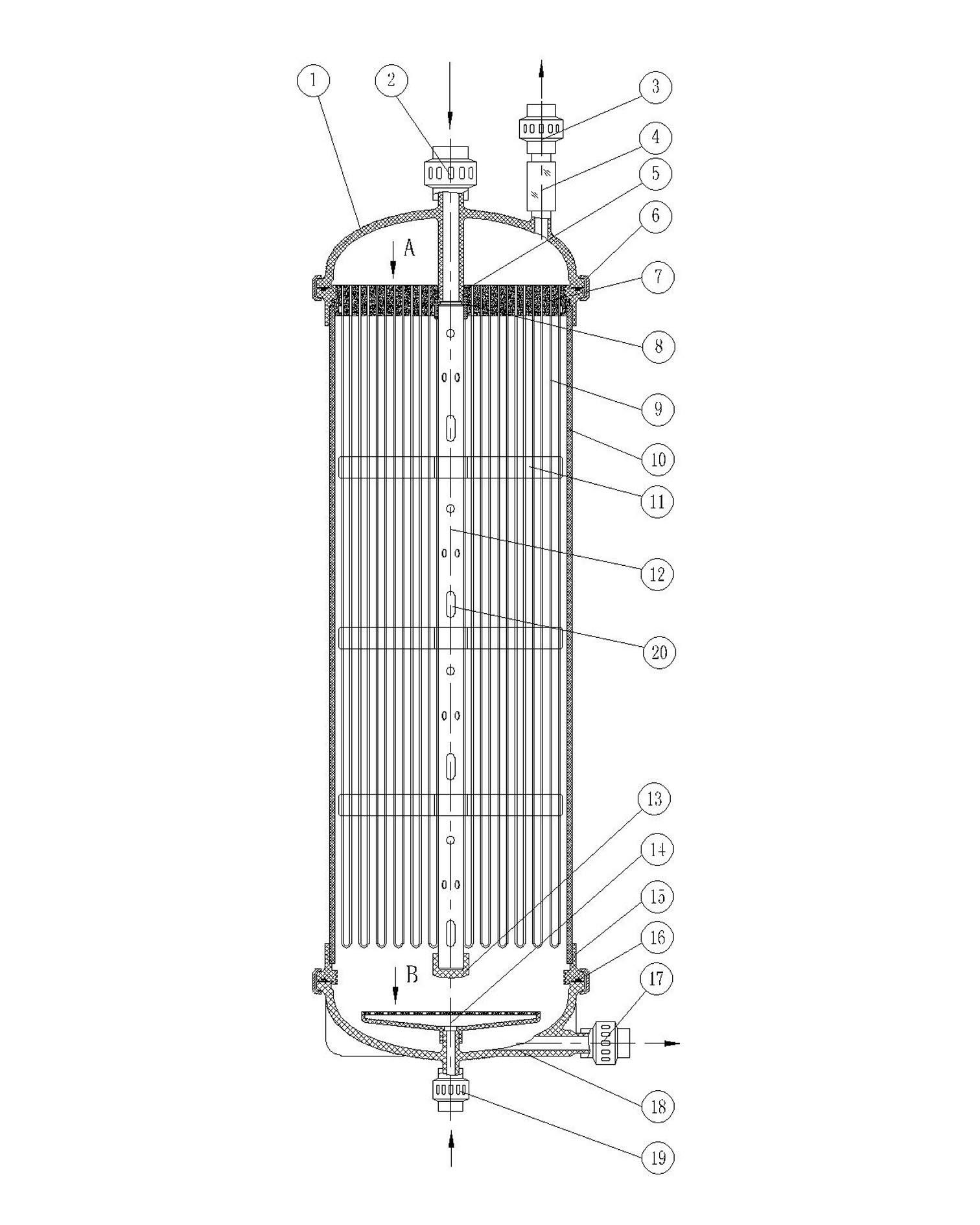

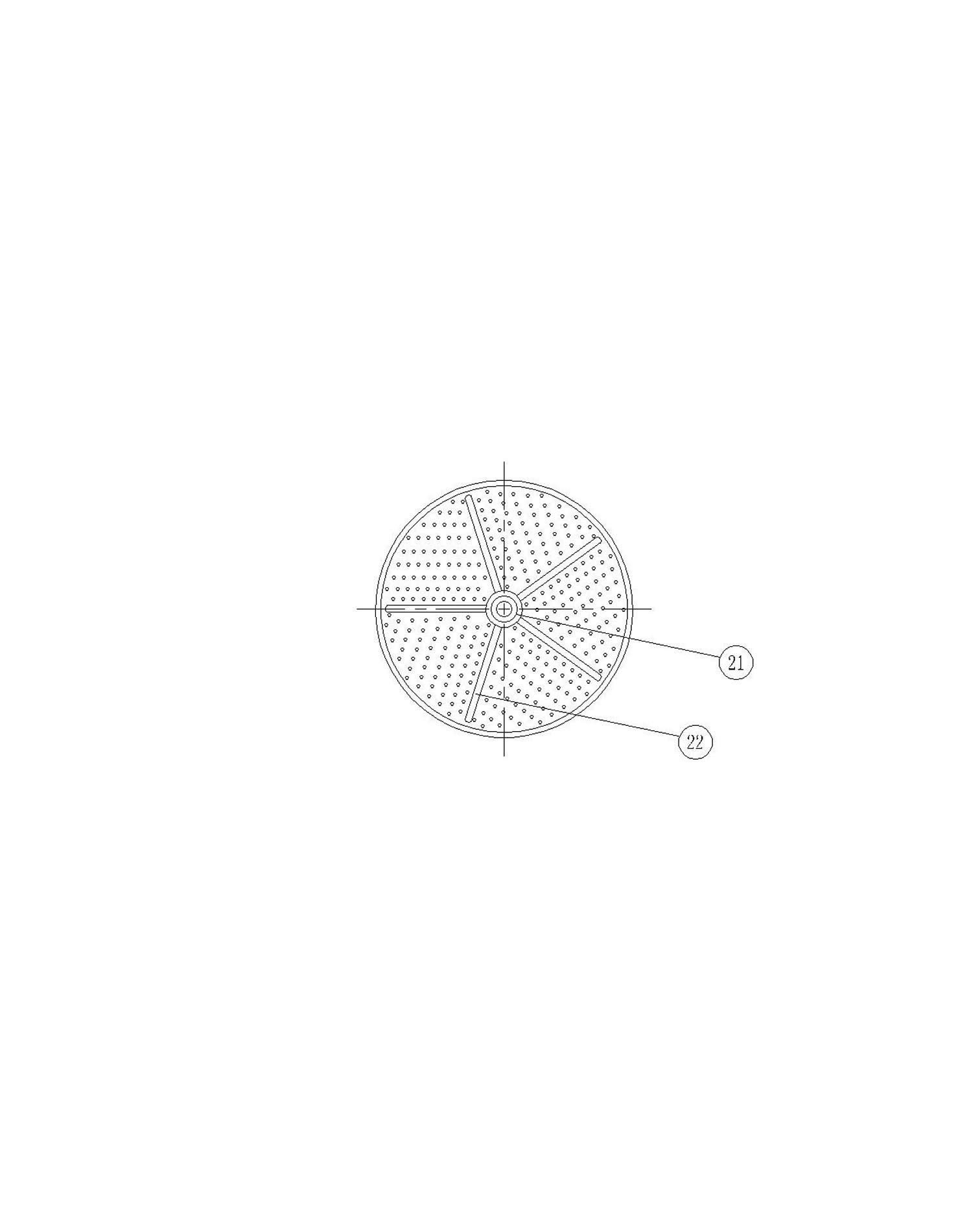

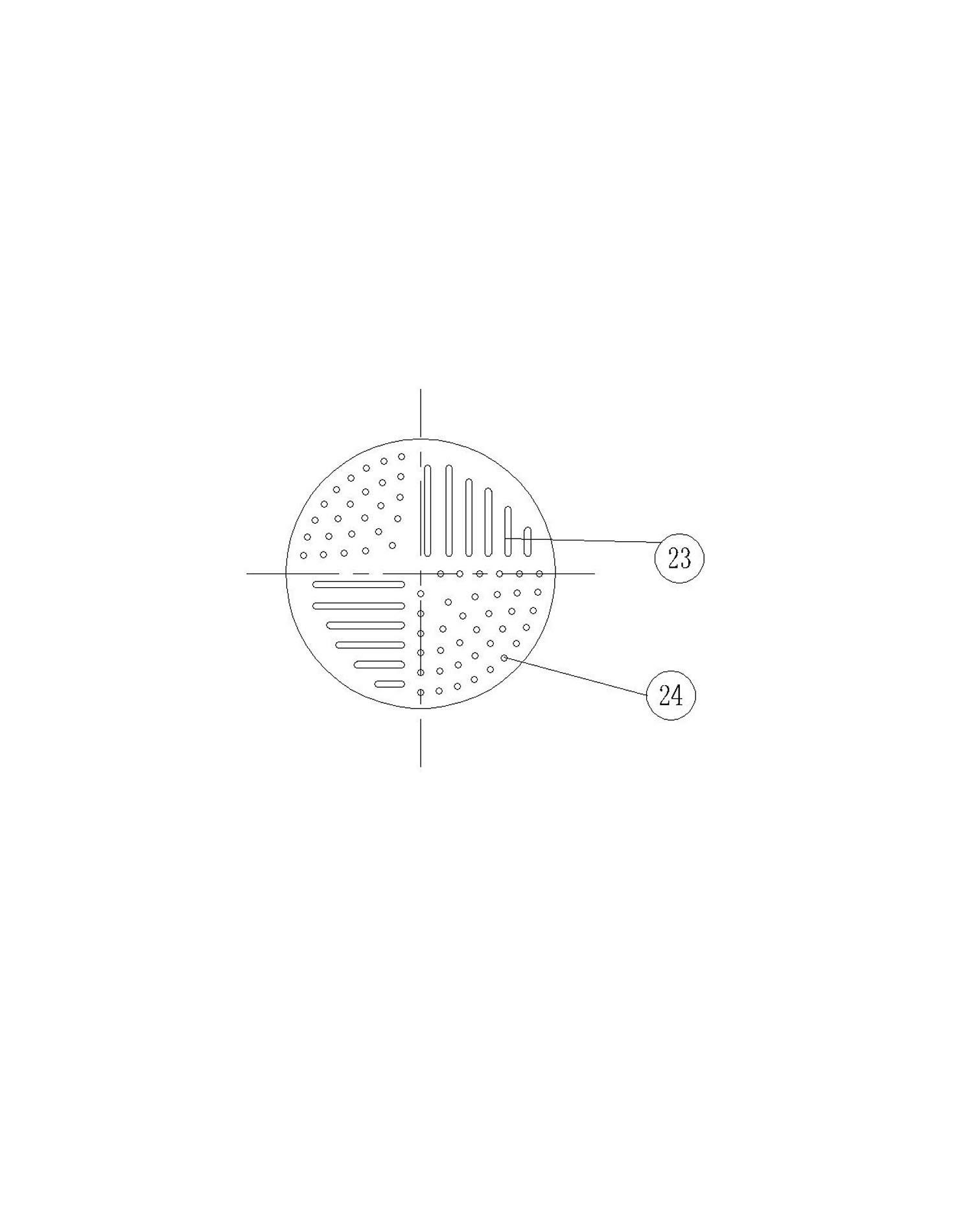

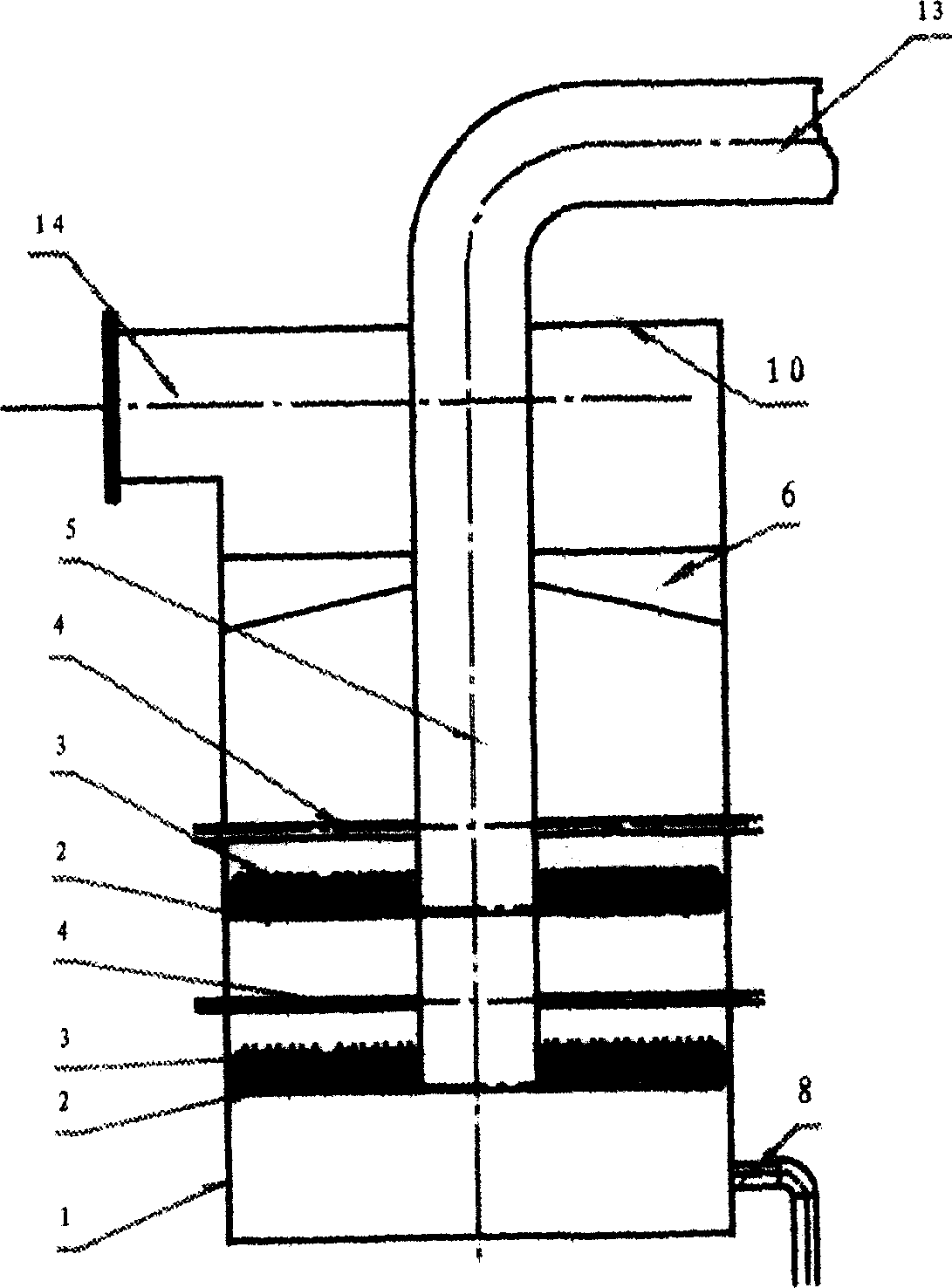

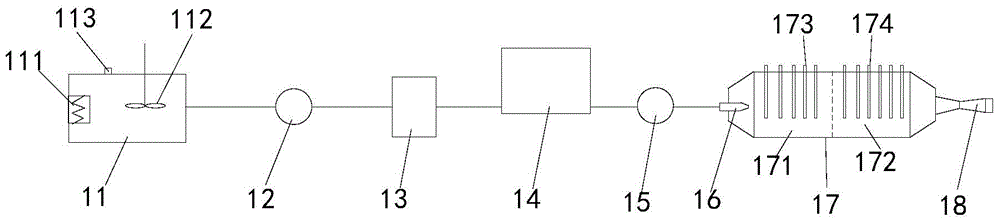

External filtering system for hollow fiber porous membrane bundle and technology thereof

The invention relates to a water processing system and a method of water processing. An external filtering system for a hollow fiber porous membrane bundle comprises a casing, an air inlet, a water inlet and a drain outlet are arranged on the casing, and a frame body and a hollow U-shaped membrane wire are arranged in the casing. The water processing technology corresponding to the water processing system comprises a water producing process and a gas-liquid two-phase washing process. The membrane wire of the external filtering system is not apt to break, and a membrane assembly is long in service life, wash-resisting and good in antifouling effect. The external filtering system and the technology solve the problems that in the prior art, two ends of the membrane wire are fixed, the membrane wire is not apt to shade or vibrate so that vibration washing effect cannot be achieved, stress is not very even, breaking can be generated easily, pollutants are apt to deposit on the root portion of the membrane wire, accordingly service life of the membrane assembly is effected, water quality is not stable, the membrane wire of the water processing system is apt to be blocked, and water processing effect can be influenced.

Owner:ZHEJIANG THINK ENERGY TECH

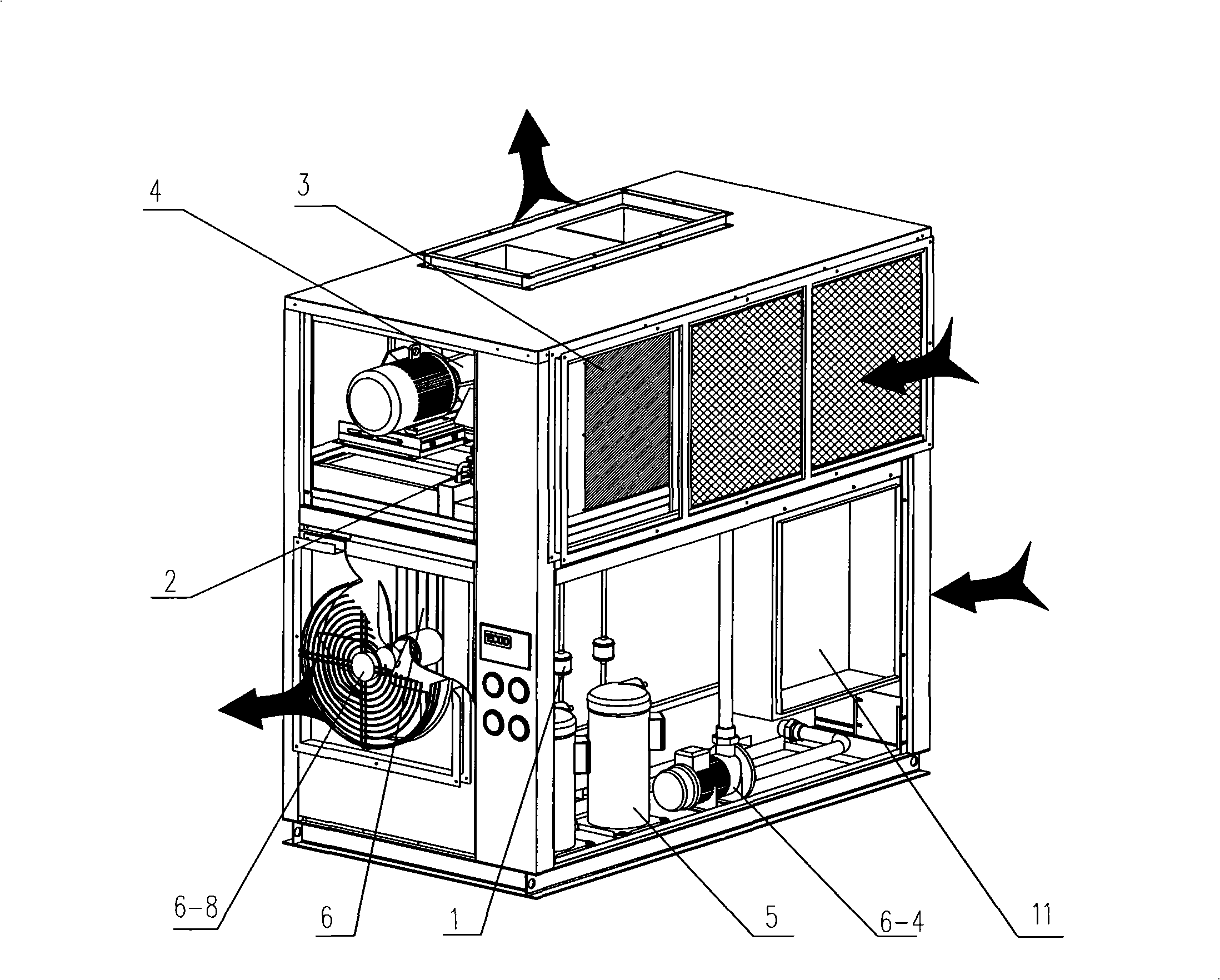

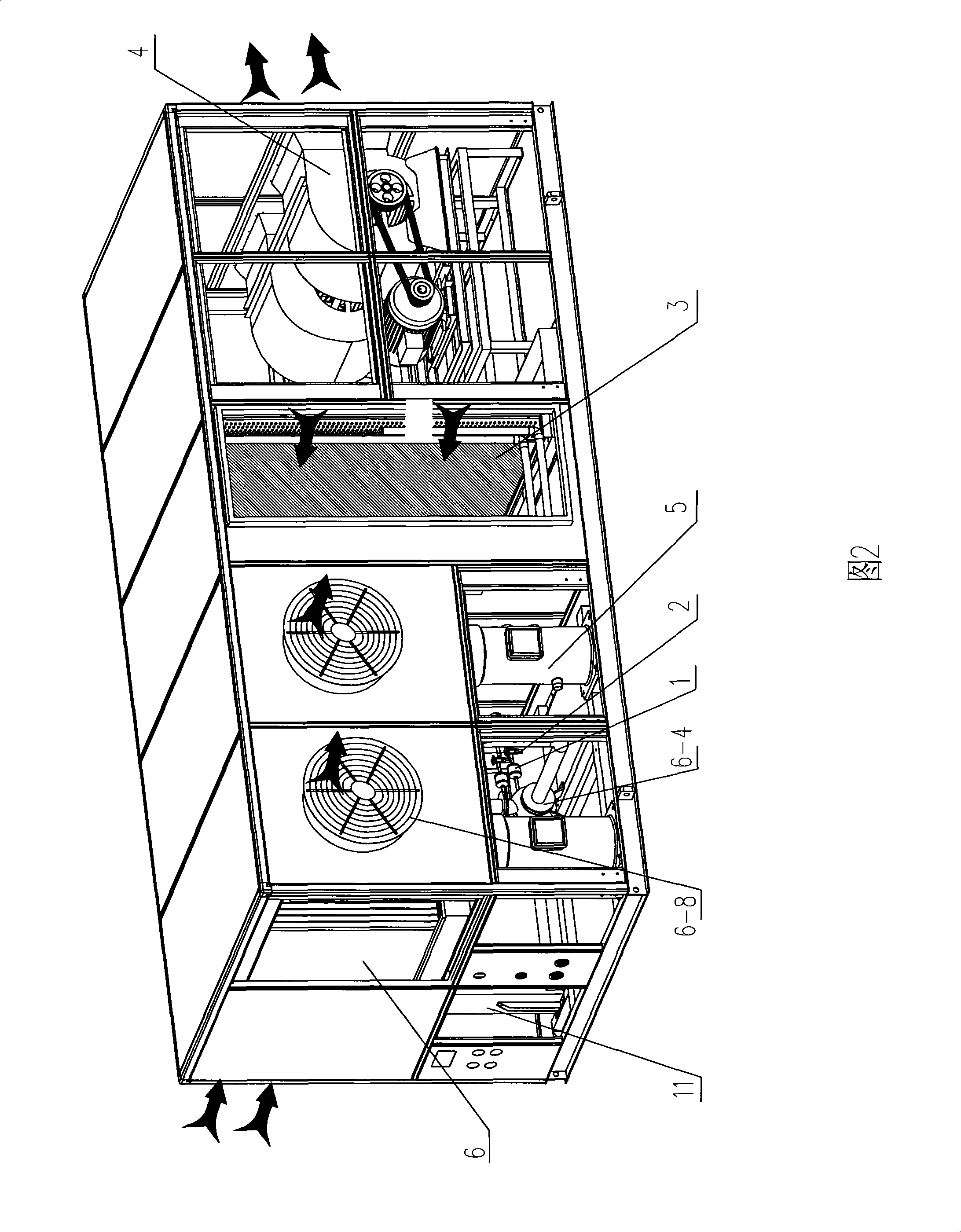

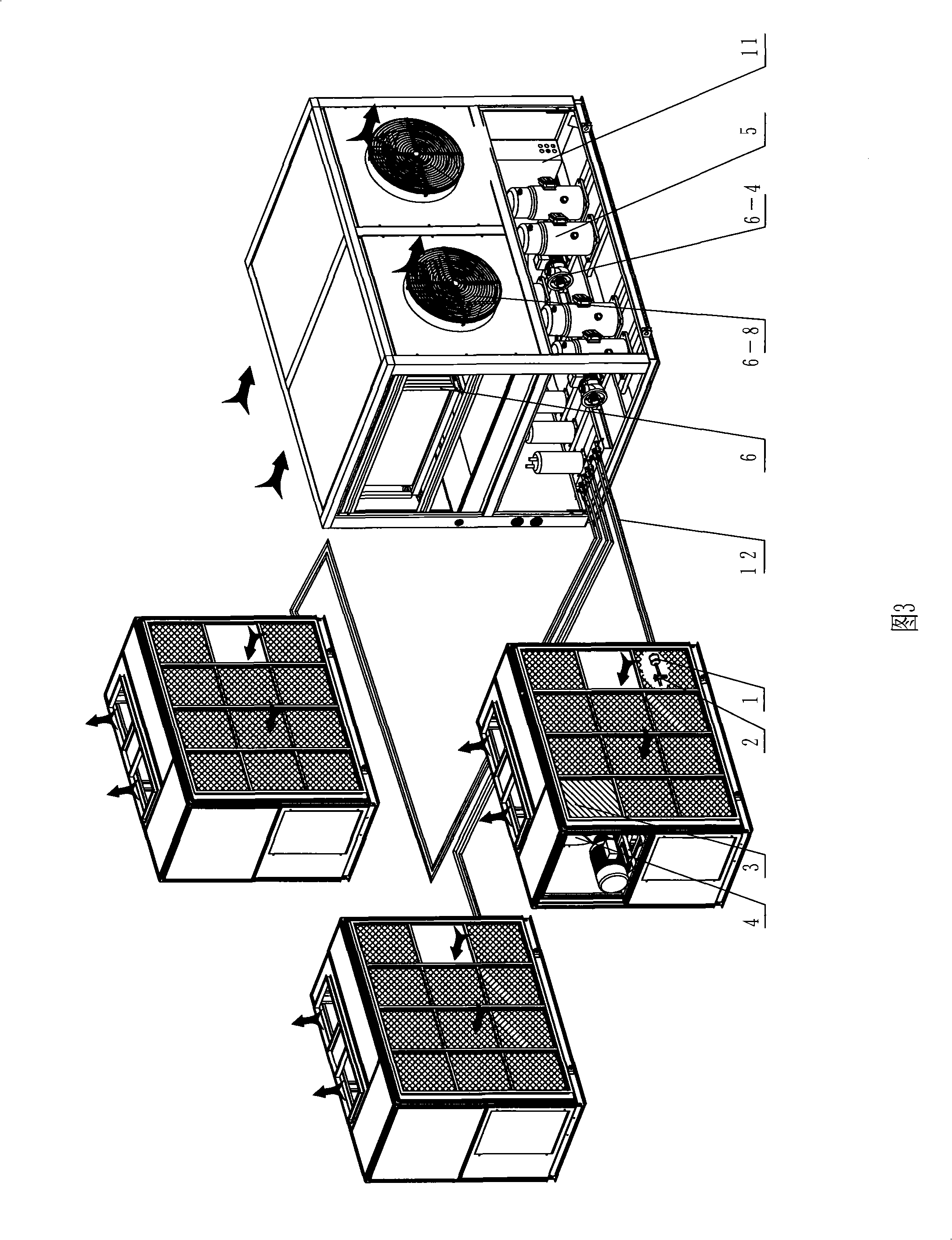

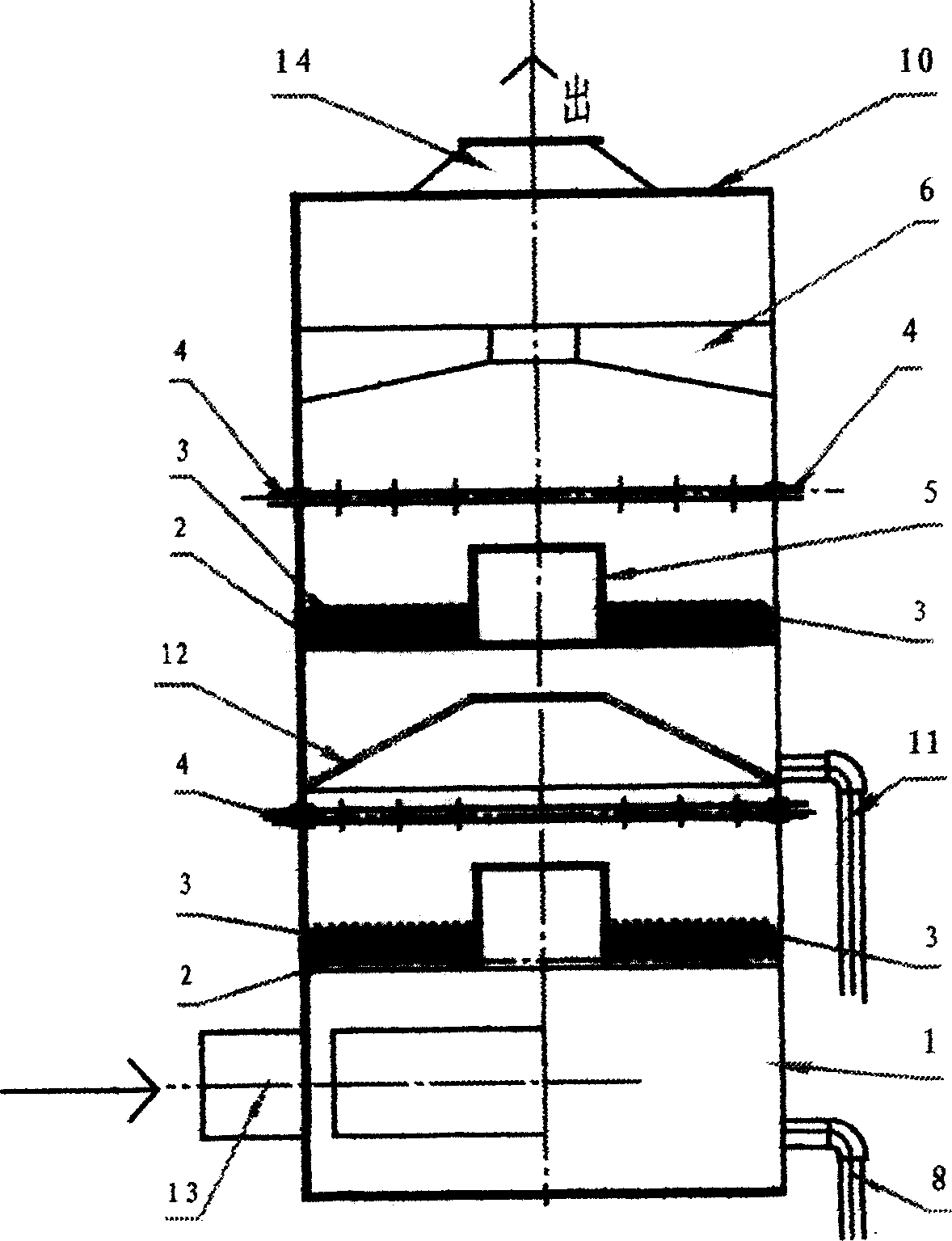

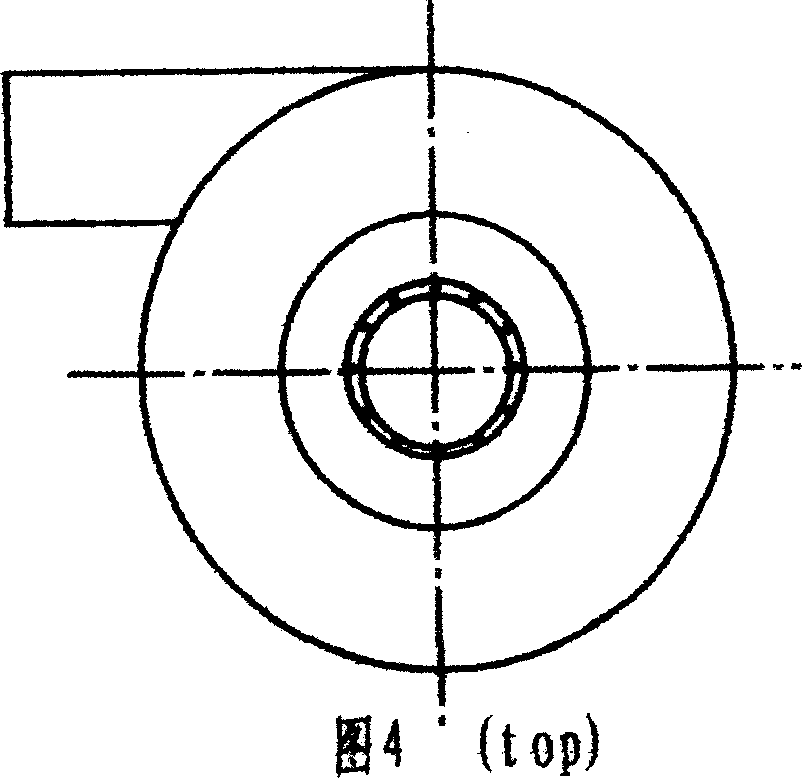

Tube-plate evaporative condensing air-conditioning unit with packing

ActiveCN101514829ARealize heat exchangeAchieve heat transfer performanceEnergy recovery in ventilation and heatingSpace heating and ventilation safety systemsFresh airEvaporation

The invention provides a tube-plate evaporative condensing air-conditioning unit with packing. The unit comprises an evaporation and air supply unit and a compression and condensing unit. The evaporation and air supply unit consists of a drying and filtering device, an expansion valve, an evaporator and a centrifugal fan which are sequentially connected, and the compression and condensing unit is formed by connecting a compressor and a condenser; the condenser is connected with the drying and filtering device, and the compressor is connected with the evaporator; the air-conditioning unit is provided with a condensate recovery system which is formed by connecting a condensate recovering collector of the evaporator with the condenser by a tube or a water pump; and an indoor air supply system of the evaporation and air supply unit consists of an outdoor fresh air inlet of the evaporator, a unit air supply outlet and the centrifugal fan, or consists of the outdoor fresh air inlet of the evaporator, a unit return air inlet, the unit air supply outlet and the centrifugal fan. The tube-plate evaporative condensing air-conditioning unit has high heat exchange efficiency, and can realize maximal energy recovery and reduction of energy consumption and water consumption, effectively solves increased energy consumption resulting from increased fresh air volume of an air-conditioning system and realizes double performance of saving energy and water and health care.

Owner:GUANGZHOU WIDE IND

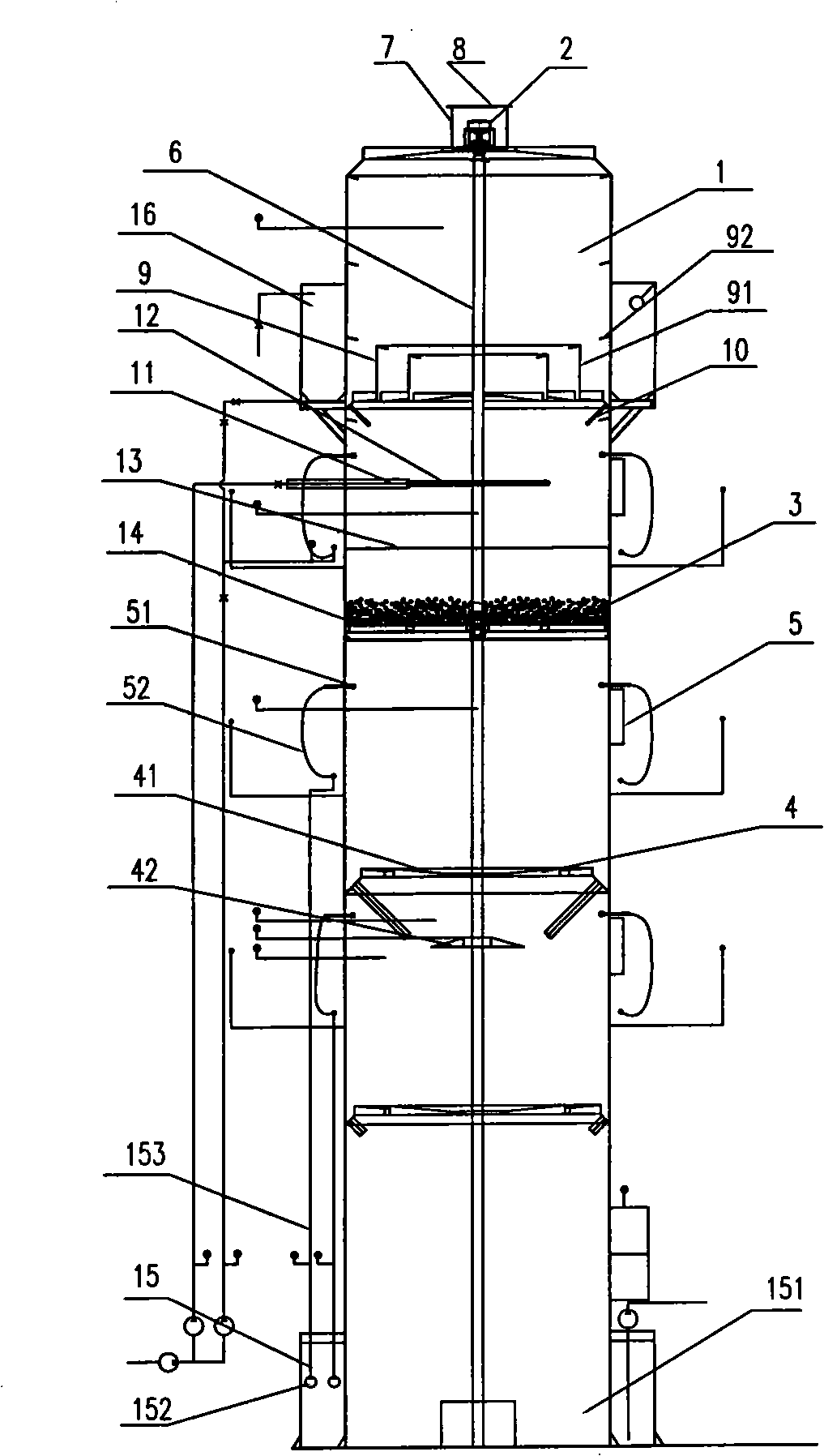

Normal flow filler tower

InactiveCN1748841ASolve a series of difficult problems that seriously affect the mass transfer rateLarge specific surface areaUsing liquid separation agentChemical/physical/physico-chemical processesChemical reactionEngineering

The regular packing tower includes outer cylinder, bearing plate and fluidizing balls, and the bearing plate matching the inner wall of the outer cylinder and has one inner cylinder in the center and baffles. The present invention adopts the technological scheme with fluidizing balls possessing ring rotating orbit to raise the mass transfer rate. The present invention has the advantages of stable running, full utilization of absorbing liquid, high mass transfer effect, capacity of multiple stage shutting and liquid phase treatment, low cost, simple structure, etc. and is suitable for various kinds of mass transfer reaction.

Owner:方达辉

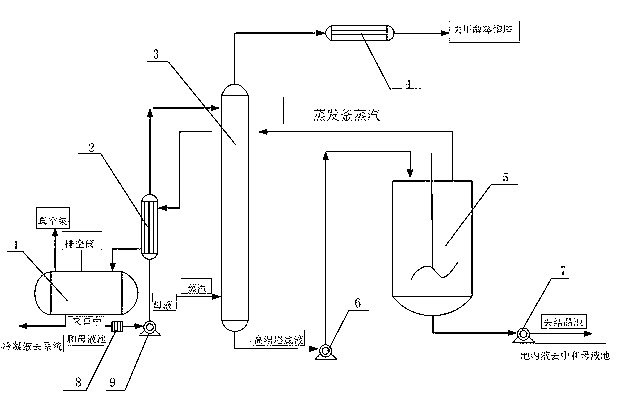

Device and production technology for treating ternary-monomer wastewater and extracting sodium sulfate

ActiveCN103253819AReduce maintenance workloadExtend the life cycleMultistage water/sewage treatmentAlkali metal sulfites/sulfatesThermodynamicsDistillation

The invention discloses a device and a production technology for treating ternary-monomer wastewater and extracting sodium sulfate. The device comprises a plate-and-frame filter press, a mother liquid heat exchanger, a stripping tower and a condenser which are sequentially communicated through a pipeline, wherein the condenser is communicated with a methane distillation tower through the pipeline. The production technology comprises the following steps of: (1) pumping neutralized mother liquid into the plate-and-frame filter press, preheating the mother liquid through the mother liquid heat exchanger, and then pumping the mother liquid into the stripping tower from the top of the stripping tower; (2) pumping steam into the stripping tower from the bottom of the stripping tower, after methane in the mother liquid is brought out by the steam, condensing the steam through the condenser, then entering the methane distillation tower, and separating to obtain methane; (3) pumping liquid at the bottom of a high-temperature tower into an evaporation and concentration kettle to be concentrated, steaming out moisture, and using the steam generated by the evaporation and concentration kettle for heating the mother liquid heat exchanger; and (4) after concentrating a material in the evaporation and concentration kettle, placing the concentrated material in a crystallizing pond, and feeding the mother liquid, Na2SO4.10H2O in which is separated out in the crystallizing pond, into a mother liquid neutralization pond to be reused.

Owner:WEIFANG WORLD CHEM

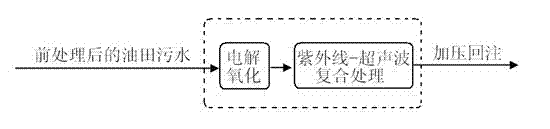

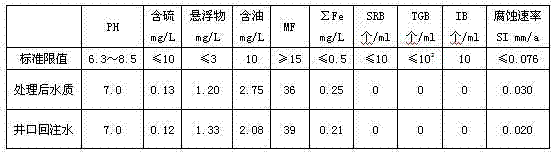

Method for sterilizing oil field sewage by cooperating electrochemical oxidation with ultraviolet and ultrasonic technology

InactiveCN102372386ASterilization is efficient, rapid and durableReduce outputWaste water treatment from quariesWater/sewage treatment by irradiationUltrasonic cavitationElectrolysis

The invention relates to a method for sterilizing oil field sewage by cooperating electrochemical oxidation with an ultraviolet and ultrasonic technology and belongs to treatment of the oil field sewage. The method comprises the following steps of: (1) electrolyzing, wherein available chlorine can be generated from the sewage, the current density is in the range of 5 to 3,000A / m2 and the concentration of the available chlorine is in the range of 0.1 to 40mg / L; (2) carrying out ultrasonic-ultraviolet compound treatment and degerming by cooperating the available chlorine with the ultrasonic cavatition and ultraviolet irradiation, wherein the frequency of ultrasonic waves is in the range of 20 to 500KHz and the wavelength of ultraviolet rays is in the range of 100 to 400nm; and (3) washing aquartz socket tube by cooperating chlorine generated by electrolysis with the chemical cleaning effect of the ultrasonic waves. The method is mainly characterized in that (1) the available chlorine is generated by electrochemical oxidation to carry out primary sterilization; (2) the residual chlorine is cooperated with the ultrasonic cavatition and the ultraviolet irradiation to completely sterilize; (3) after treatment, the residual chlorine in a water body is used to continuously sterlize; and (4) the chlorine generated by electrolysis is cooperated with the ultrasonic cavatition to preventscale from depositing on the surface of the quartz socket tube of an ultraviolet lamp.

Owner:广州金川环保设备有限公司

Filtrating and squeezing process and system for desulphurization wastewater

ActiveCN101456656AReduce moisture contentAvoid foulingSludge treatment by de-watering/drying/thickeningWater storage tankFilter cake

The invention relates to a process and a system for filtering and squeezing wastewater. The system comprises a sludge inlet system, a sludge blow-drying system, a septum squeezing system, a filter cloth cleaning system and a matched electric control system. An outlet of a wastewater pool is communicated with a feed inlet of a feed pump through a feed conveying pipe; a discharge port of the feed pump is respectively communicated with feed inlets at two sides of a filter press through the feed conveying pipe and a feed valve; an outlet of an air compressor is communicated with an air inlet of an air storage tank; an air outlet of the air storage tank is respectively communicated with an air inlet of the filter press through an air pipe and a back flushing valve; the feed conveying pipe between the feed valve and the filter press is provided with a pressure sensor; the signal end of the pressure sensor is connected with the signal end of a PLC controller; an inlet of a press pump is connected with a water storage tank; and an outlet of the press pump passes through a squeezing pipeline and is connected with a main squeezing pipe of the filter press through a tee valve. The process and the system have the following advantages: 1, the process and the system have time conservation, high efficiency and low energy consumption; and 2, the process and the system can effectively squeeze out moisture remained in a filter cake, completely carry out back flushing on materials in a feeding pipeline to a material pool and achieve the aims of cleanness and smoothness of the pipeline.

Owner:HANGZHOU XINGYUAN FILTER TECH

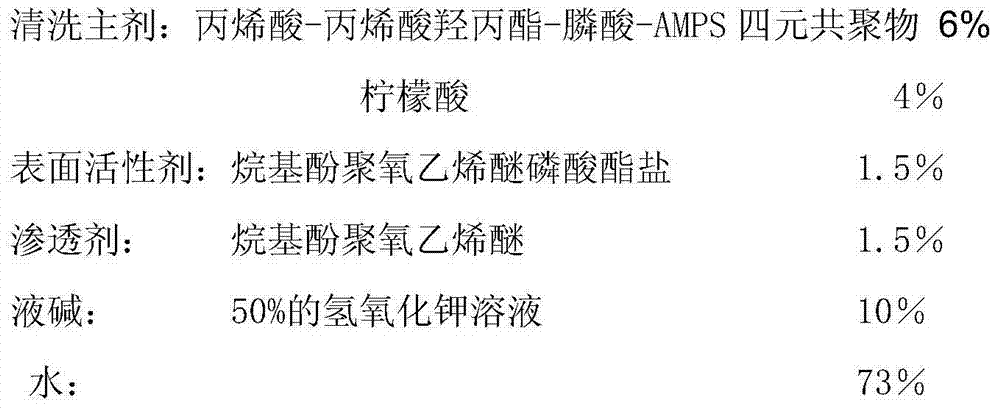

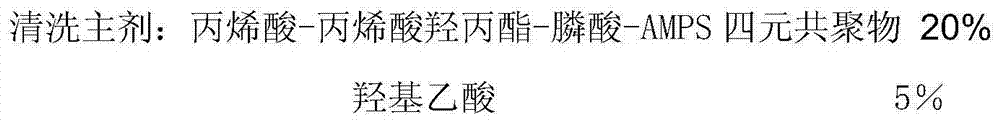

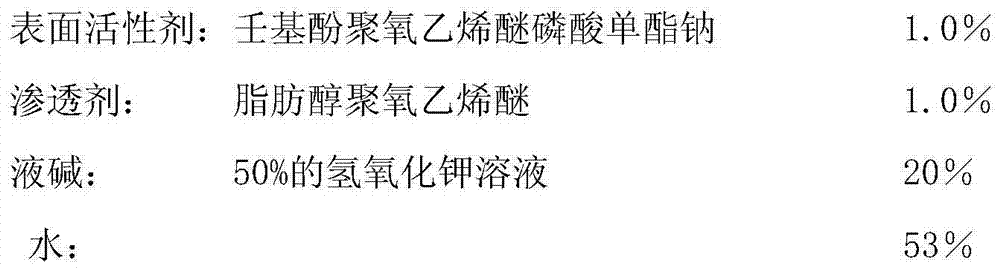

Neutral chemical cleaning agent for eliminating hard scales of air pre-heater of desulfurization system and preparation method of neutral chemical cleaning agent

InactiveCN104745337ANo adverse reactionAvoid foulingSurface-active non-soap compounds and soap mixture detergentsMetasilicateTransmittance

The invention discloses a neutral chemical cleaning agent for eliminating hard scales of an air pre-heater of a desulfurization system and a preparation method of the neutral chemical cleaning agent. The neutral chemical cleaning agent is compounded of a main cleaning agent, a surfactant, a penetrant, caustic soda liquid and water. The cleaning agent has complexing action with aluminum metasilicate and silicate scales on the surface (in contact with the cleaning agent) of the air pre-heater to achieve the purpose of dissolving dirt; by virtue of permeation and swelling, cracks and gaps are generated in an inner structure of a scale layer. The cleaning agent adopts a safe and environmental-friendly neutral scheme and is free of toxicity. The main compound, namely the main cleaning agent, is easily biodegraded so that the environmental problems are avoided; the cleaning agent has the characteristics of quickly removing scales and not corrode a steel frame, not damaging an enameled heat exchange component, not damaging the flak anticorrosive material and the like. When used for cleaning the air pre-heater, the neutral chemical cleaning agent has the beneficial effects that the removal rate of hard scales is 98% or above, and the light transmittance of the air pre-heater reaches 95% or above, and moreover, the heat exchange efficiency of the heat exchange equipment is improved, a vent channel is dredged, and safe and economical operation of the unit is guaranteed.

Owner:SHANGHAI WEILAI ENTERPRISE

Vented mold and method for producing molded article

ActiveUS20050253293A1Effectively actNone is problem freeVehicle seatsTailstocks/centresPolymer scienceEngineering

The invention relates mold, particularly a mold for producing foam articles. In a preferred embodiment, the mold comprises a lid and a bowl releasingly engageable to define a mold cavity, the lid comprising: (i) a vent having a passageway for gas to escape from the mold cavity, and (ii) a plurality of grooves connected to the vent. The use of a plurality of grooves / slots in the mold cavity surface effectively acts as a siphon to draw gas away from the composition to be molded. The plurality of grooves / slots is connected to one or more vents which then allows for escape of the gas from the mold cavity to the exterior of the mold.

Owner:PROPRIETECT LP

Method for recycling and comprehensively utilizing reverse osmosis concentrated water produced after treatment of coking wastewater

InactiveCN111039477AAvoid pollutionAvoid foulingWater treatment parameter controlGeneral water supply conservationHazardous substanceReverse osmosis

The invention discloses a method for recycling and comprehensively utilizing reverse osmosis concentrated water produced after treatment of coking wastewater. In the steel industry, a widely used reverse osmosis process in a coking wastewater treatment technology can produce 70% of high-quality effluent and 30% of reverse osmosis concentrated water. Pollutants in water are intercepted and concentrated by a reverse osmosis membrane, but the pollutants are not removed, so the pollutants are completely concentrated in the reverse osmosis concentrated water. According to a traditional treatment method for reverse osmosis concentrated water produced after treatment of coking wastewater, reverse osmosis concentrated water is used as slag washing water in the iron and steel industry, and toxic and harmful substances can be volatilized under the action of high temperature, which causes conversion of water pollution into gas pollution and leads to a severe environment of a working site. According to the invention, a combined process of pretreatment (bi-alkali softening, advanced oxidation and ultrafiltration)-electrodialysis-reverse osmosis-bipolar membrane electrodialysis is innovatively adopted to realize zero discharge of coking wastewater.

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH

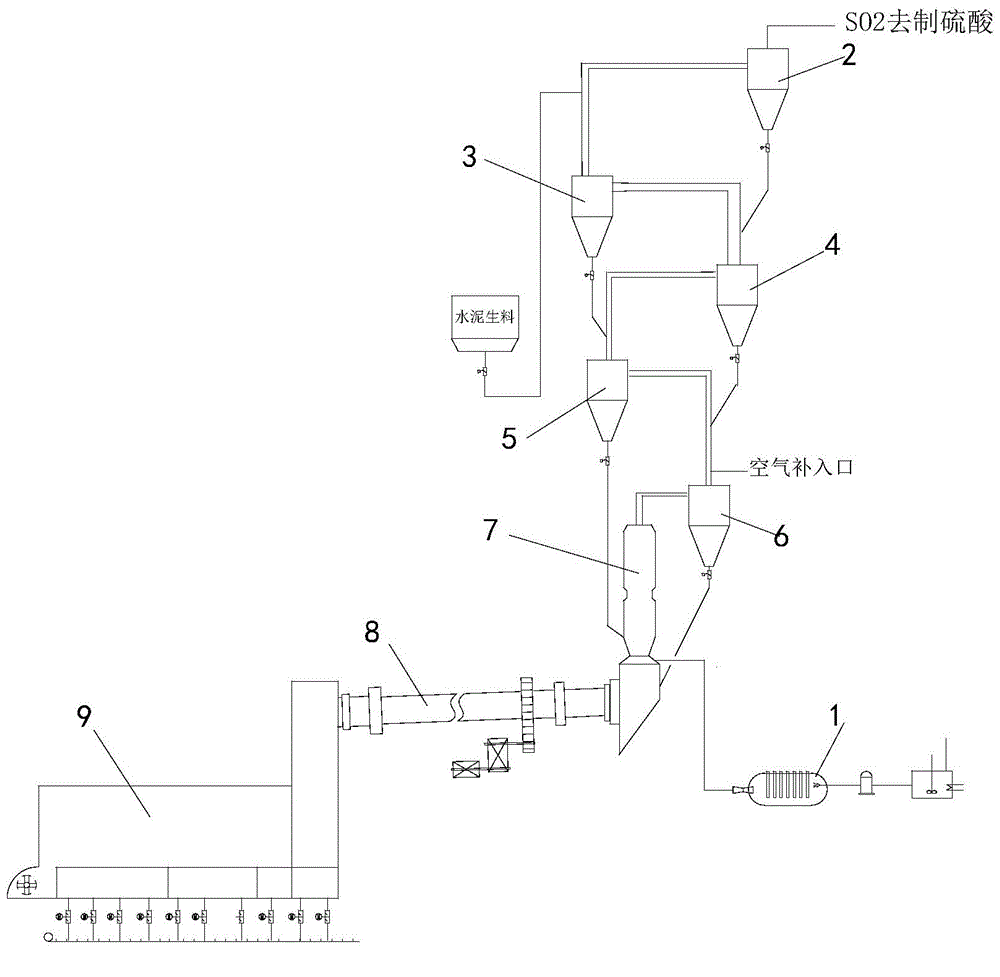

Method for jointly producing sulphuric acid and cement clinker by using sulphur gas to reduce gypsum

ActiveCN104555946APerfect workmanshipAvoid foulingSulfur compoundsClinker productionGypsumExhaust gas

The invention relates to a method for jointly producing sulphuric acid and cement clinker by using sulphur gas to reduce gypsum. The method comprises the steps of preparing high-temperature sulphur gas, proportioning and preheating raw materials, reducing gypsum, preparing cement clinker by using gypsum reduction products, preparing sulphuric acid by using tail gas and the like. The method disclosed by the invention has complete technology, the purity of the sulphur gas component can be kept at 95-100%, maximal conversion efficiency of calcium sulfate in a calcining kiln is effectively controlled by controlling the optimal conversion ratio of calcium sulfate into calcium sulfide in a reduction furnace at 25-27%, and the calcination is convenient to control; and the method has the advantages of simple technological procedure, high practicality of system control indexes, convenient operation and management, low investment of equipment, low energy consumption, high automation degree and the like.

Owner:上海三夫工程技术有限公司

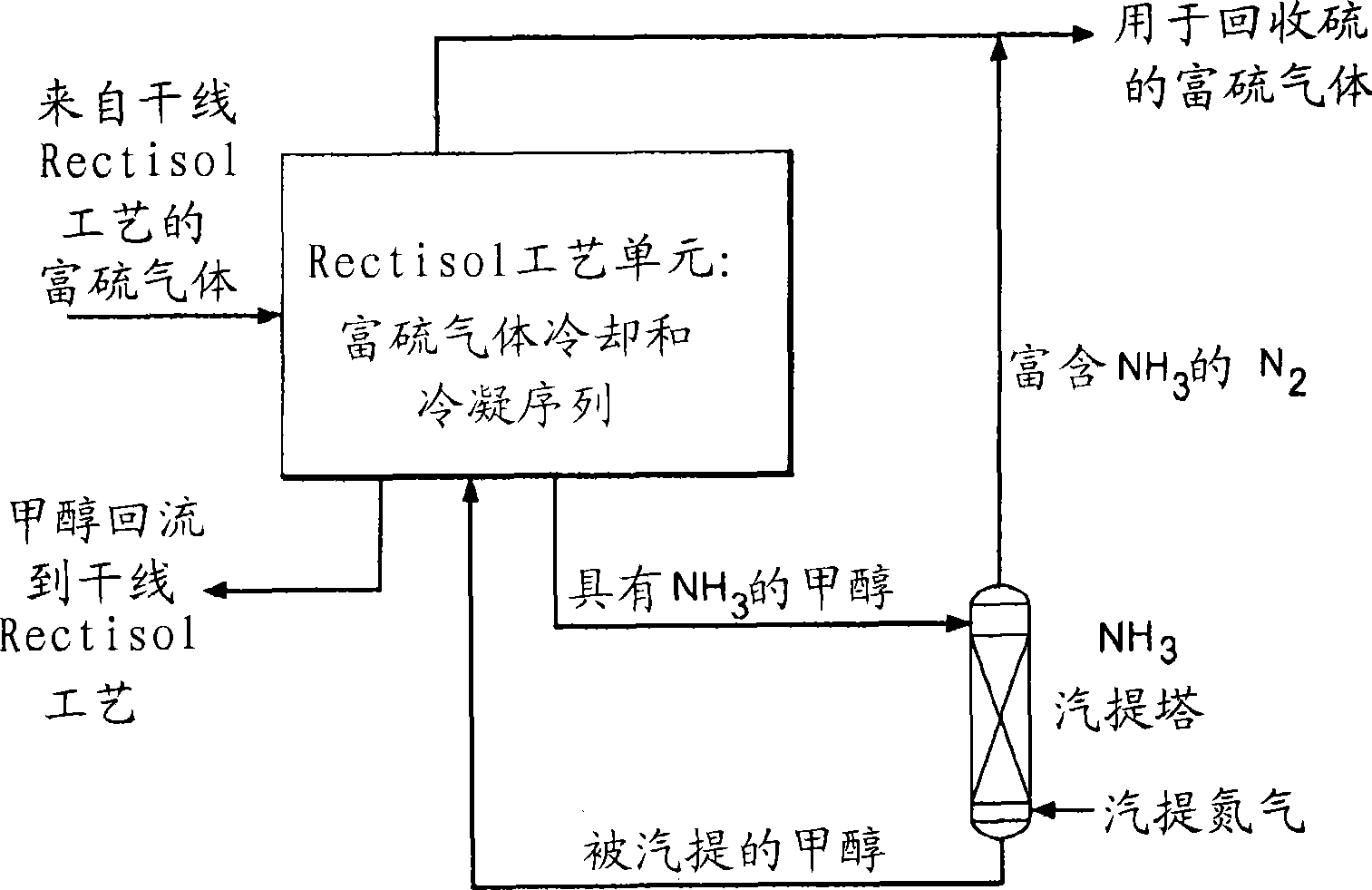

Method for removing ammonia from a methanol containing stream

InactiveCN101497554AAvoid accumulationAvoid gatheringGas treatmentLiquid degasification with auxillary substancesNitrogenNitrogen gas

The invention relates to a method for eliminating ammonia from the stream containing methanol. A stream of liquid methanol containing ammonia and other species is sent to the top of a countercurrent stripping column. The stream is stripped with a flow of ambient-temperature nitrogen or another inert gas. The column can be packed with random dumped packing. The overhead vapor contains ammonia and the liquid exiting the column has a reduced amount of ammonia. Removing ammonia can reduce or prevent fouling or corrosion caused by ammonia (and other compounds).

Owner:AIR PROD & CHEM INC

Rotational flow turbulent flue gas purification column

InactiveCN101318103AAvoid easy cloggingImprove performanceDispersed particle separationFlue gasTower

The invention discloses a rotational flow and turbulent swirl ball flue gas purifying tower, which comprises a tower body, a driving device, a turbulent swirl ball layer, a rotating-stream tray layer and peripheral devices, and is characterized in that the turbulent swirl ball layer and the rotating-stream tray layer are arranged in the same tower body and are distributed up and down; a center pipe is vertically arranged at the middle part of the turbulent swirl ball layer and the rotational flow ply and is connected with the driving device. The rotational flow and turbulent swirl ball flue gas purifying tower can be used for debusting, desulfurizing, demist, washing and cooling the flue gas, has reliable performance, favorable adaptability, high desulfurization efficiency, simple operation, saved cost and convenient the maintenance, also avoids the scale blockage and has good popularization value.

Owner:GUANGDONG OVERLAND CERAMICS CO LTD

A desulfurization process and device of external circulation plus independent oxidation double alkali method

InactiveCN102284239AReduce moisture contentImprove availabilityDispersed particle separationCirculator pumpProcess engineering

The invention belongs to the field of atmosphere environmental protection, and particularly discloses a desulfurization process and device based on out-of-tower circulation and independent oxidization dual-alkali methods. In the process, an out-of-tower circulation process is adopted, wherein an absorption tower is separated from a circulating pool, circulating fluid is extracted by a circulatingpump from the circulating pool which is arranged outside the tower and sprayed into the tower, and smoke rises from the inside of the tower and comes into contact with the circulating fluid to removesulfur dioxide; and the cleaned circulating fluid is drained to the circulating pool through a drainage port at the bottom of the tower, so that the whole out-of-tower circulation process is completed. The desulfurization process has high desulfurization efficiency, long stable operation time, low operation cost and high purity of product gypsum, can be used for effectively preventing the absorption tower from scaling and being blocked, and is suitable for wide popularization and application.

Owner:COAL IND JINAN DESIGN & RES

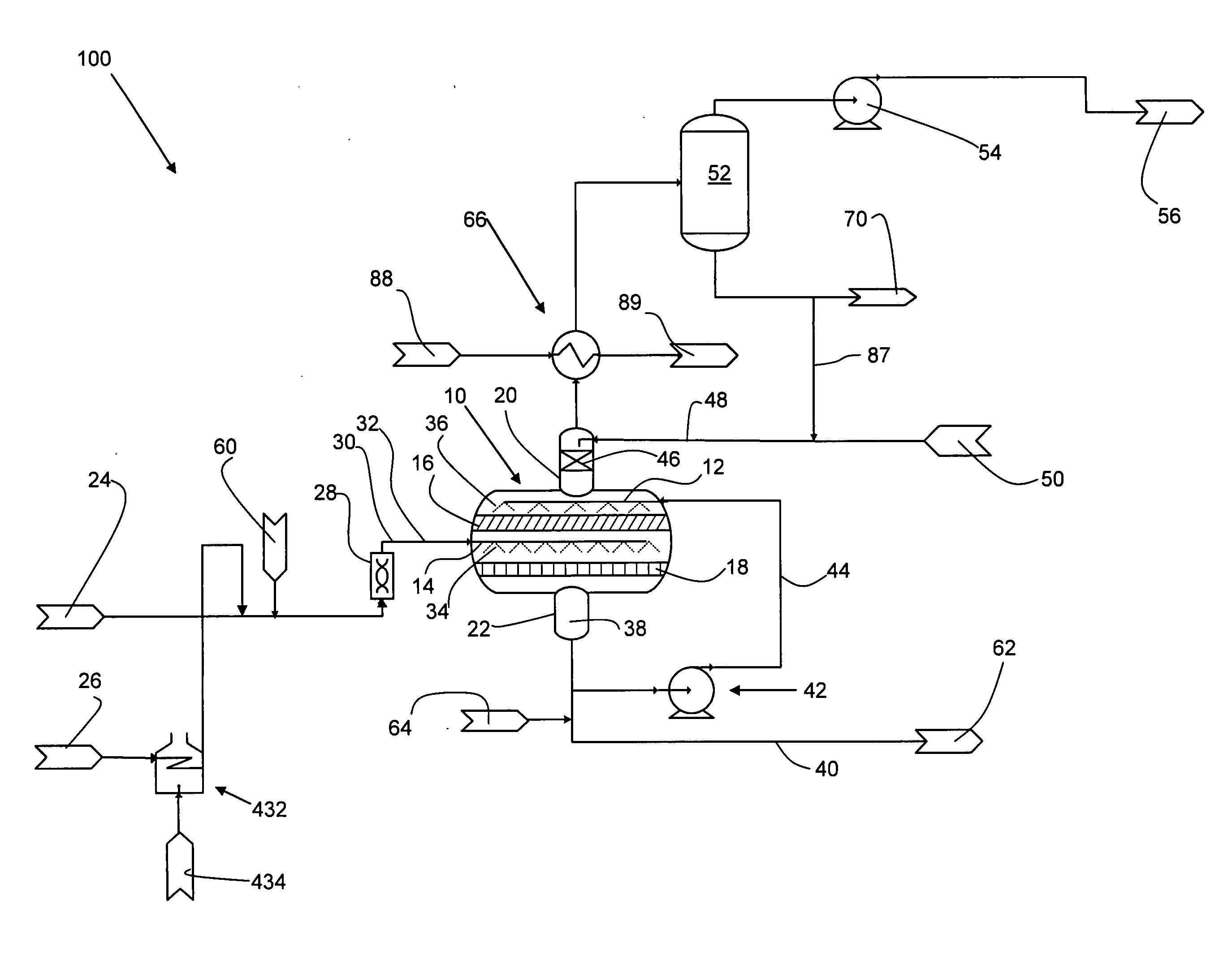

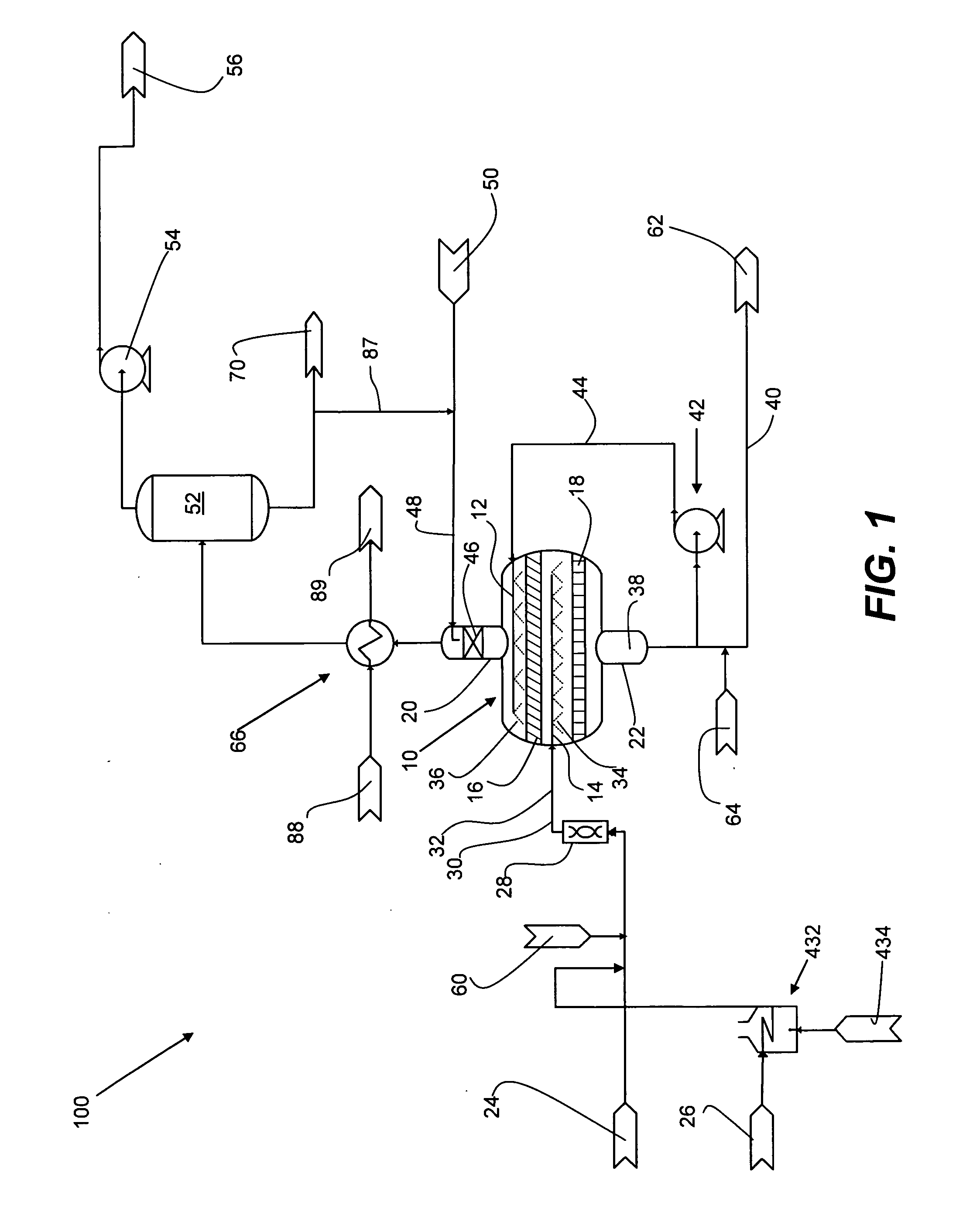

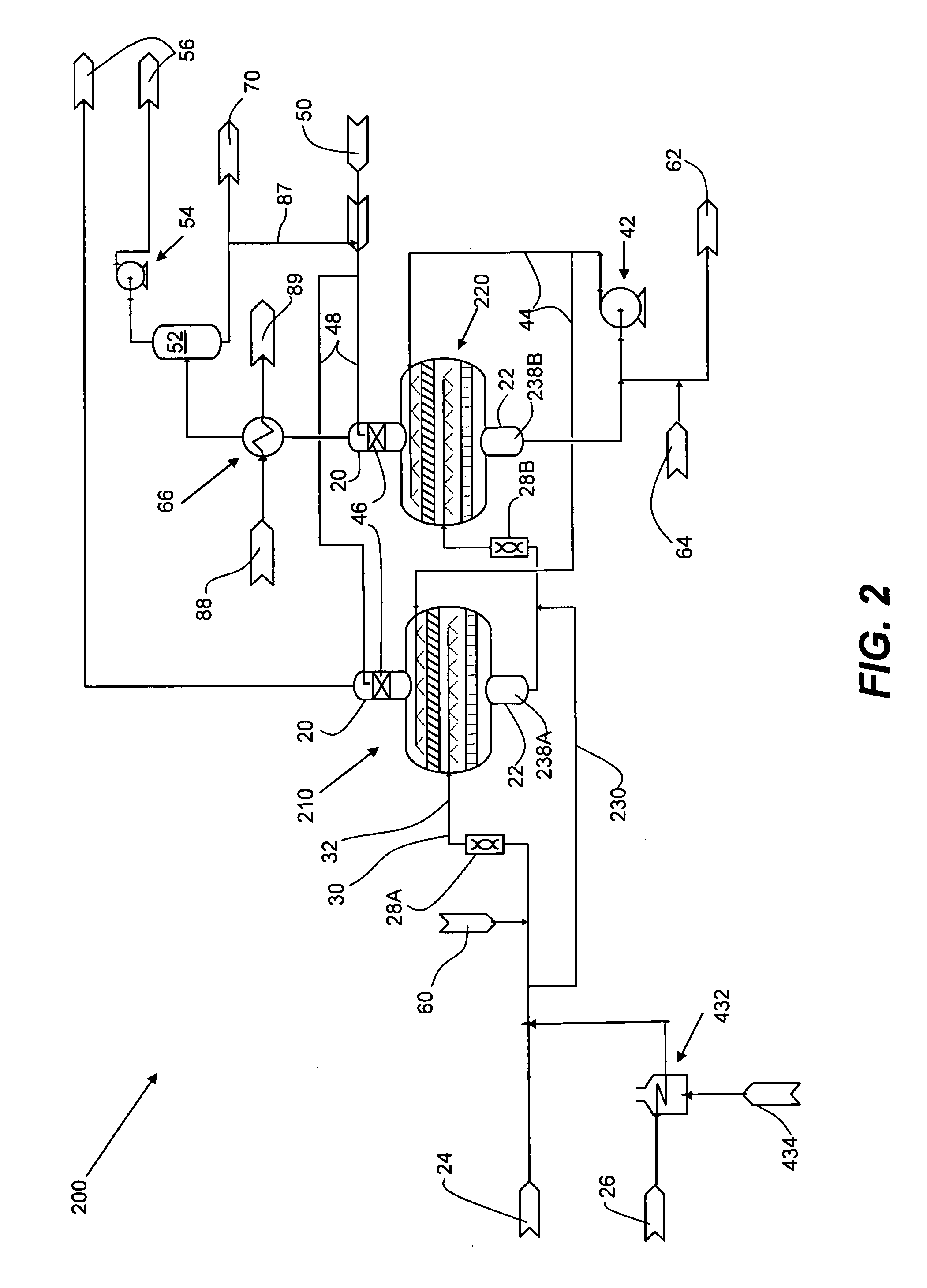

Process and apparatus for removal of oxygen from seawater

ActiveUS20120118154A1Avoid foulingGood removal effectWater treatment parameter controlLiquid degasificationChemistrySeawater

A process and apparatus is provided for reduction of dissolved oxygen content in seawater from about 8 ppm in the feed seawater to about 10 ppb or less. Significant advantages are achieved by: use of a separator in horizontal alignment to provide high gas-liquid contacting area for separation and de-entrainment within the separator, thereby providing higher throughput; and heating seawater to at least 30° C. and up to 60° C., so as to enhance removal of oxygen from seawater; use of once-through fuel gas as stripping gas and its subsequent combustion for heating the seawater provides for high efficiency and reduction of fouling. The combination of these features allows the amount of residual oxygen in deoxygenated seawater to be reduced to below 10 ppb and as low as 2 ppb.

Owner:AMT INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com