Zero discharge process for high-salt wastewater discharged from titanium dioxide production

A high-salt, titanium dioxide technology, used in water softening, water/sewage treatment, general water supply saving, etc., to ensure normal and stable operation, improve system water production rate, reduce investment and operating energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Titanium dioxide production discharges high-salt wastewater zero-discharge process, the operation steps are as follows:

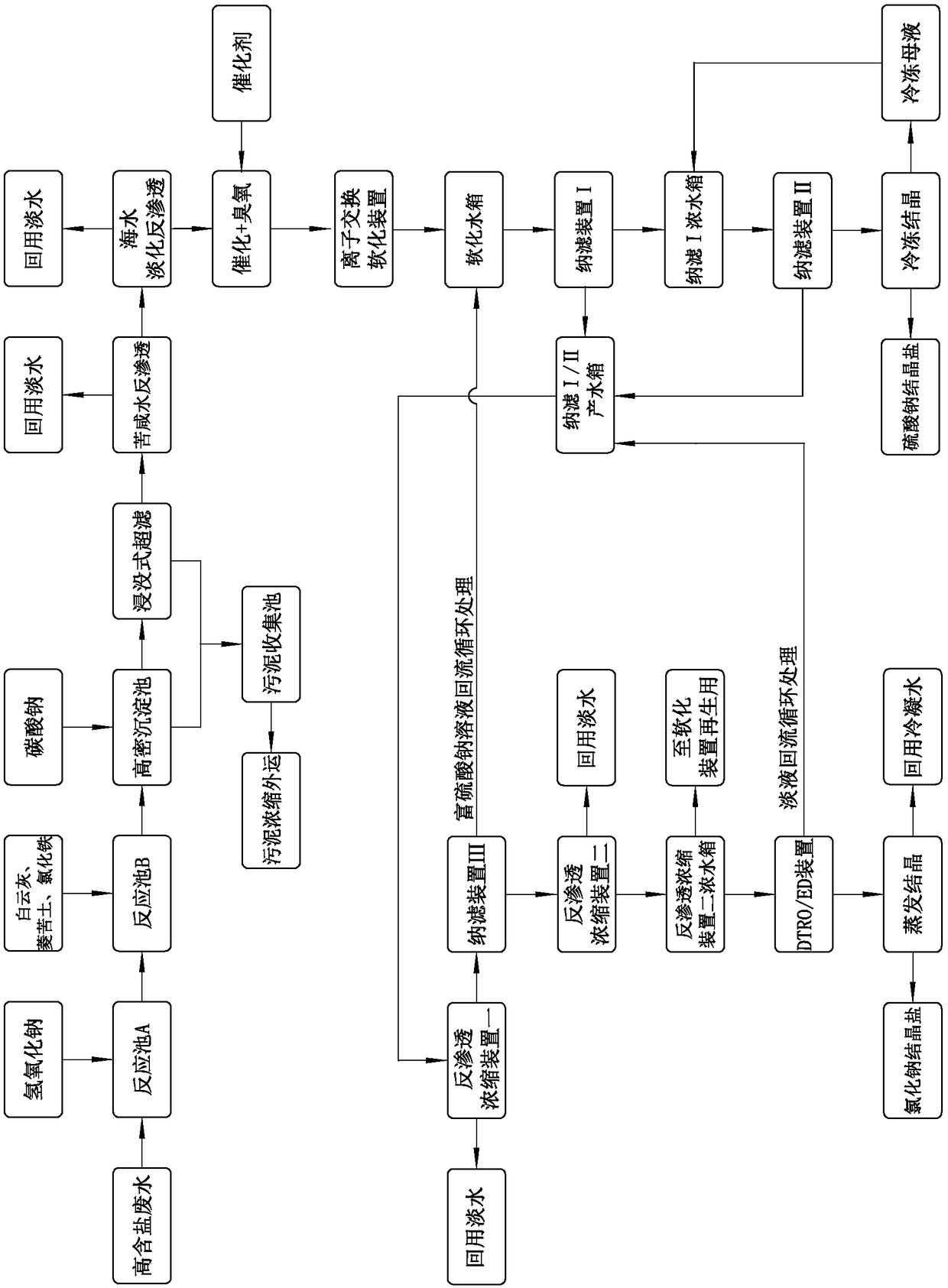

[0029] High-salt wastewater → silicon removal by magnesium agent → chemical softening → high-density precipitation → immersion ultrafiltration → brackish water reverse osmosis membrane concentration → seawater reverse osmosis membrane concentration → catalytic oxidation COD reduction → ion exchange softening → multi-stage nanofiltration Salt separation → high pressure reverse osmosis membrane concentration → DTRO / ED electrodialysis concentration → evaporation crystallization / freeze crystallization.

[0030] In the process of desiliconization by magnesium agent, add sodium hydroxide to adjust the pH value to 10.1-10.3, and then add 2-3 times the amount of magnesia or dolomite with silicon content in the wastewater to form insoluble magnesium silicate particles , and then add ferric chloride or ferrous sulfate, control the temperature of the wastewater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com