Rotational flow turbulent flue gas purification column

A flue gas purification tower, turbulent ball technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of easy deformation and rupture, complex structure, unfavorable maintenance, etc., and achieves good adaptability and simple operation. , reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

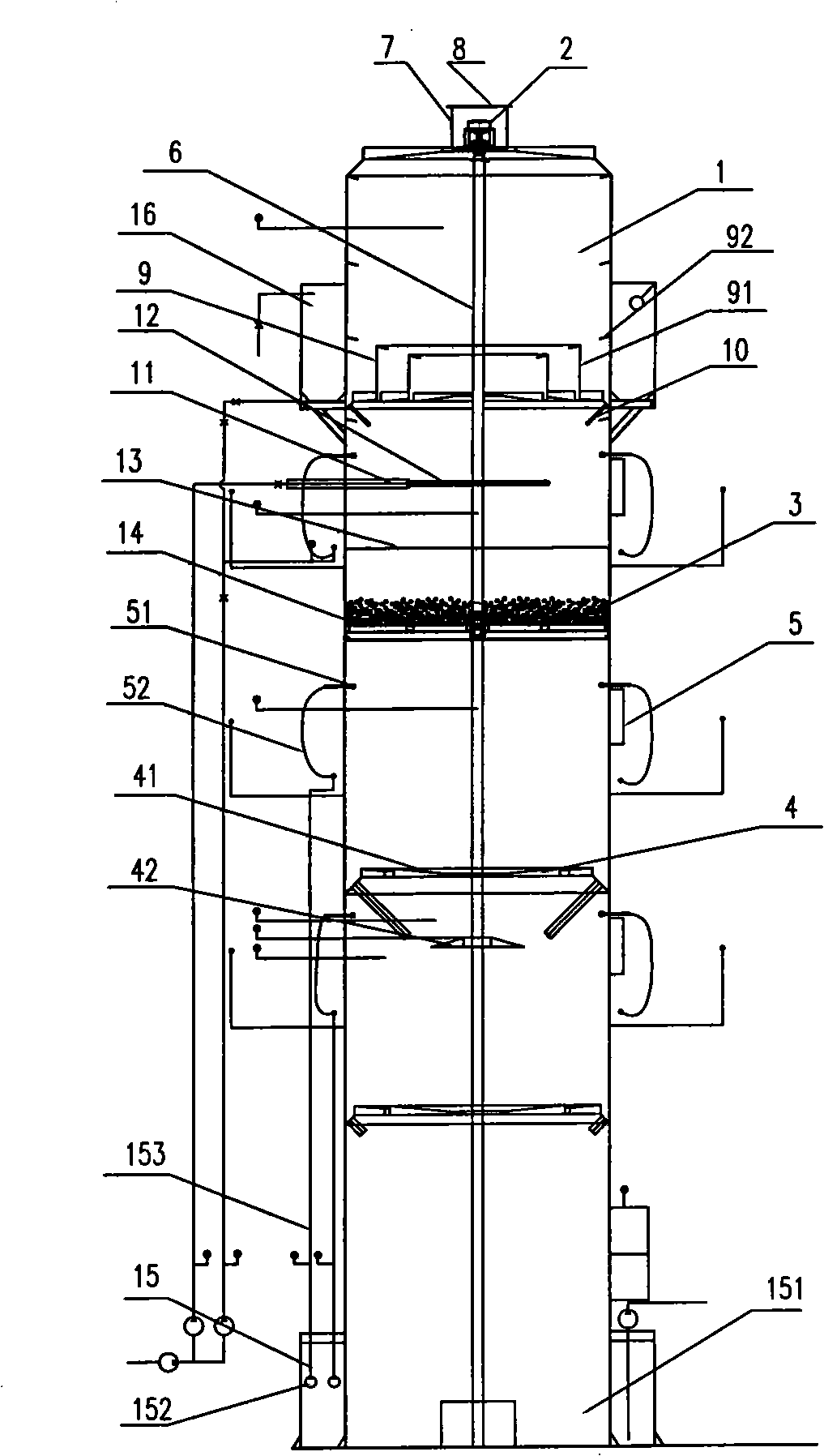

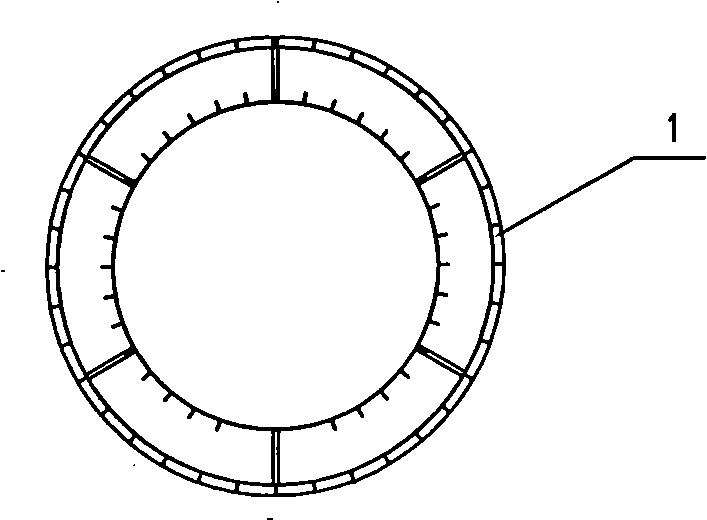

[0020] Such as figure 1 , figure 2 As shown, a swirling turbulent ball flue gas purification tower of the present invention includes a tower body 1, a driving device 2, a turbulent ball layer 3, a swirling plate layer 4 and peripheral equipment 5, and the peripheral equipment 5 includes multiple groups of spray guns 51, soft Pipe 52, quick connector and gate valve, spray gun 51, flexible pipe 52, quick connector and gate valve are placed on the turbulent ball layer 3 and the swirl plate layer 4 respectively. The turbulent ball layer 3 and the swirl plate layer 4 are located in the same tower body 1 and are distributed up and down. The middle part of the turbulent ball layer 3 and the swirl plate layer 4 is vertically provided with a central pipe 6, which is connected to the driving device 2 , the driving device 2 is located on the top of the tower body 1, and is mainly composed of a motor 21 and a transmission assembly 22 connected thereto. A cover tube 7 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com