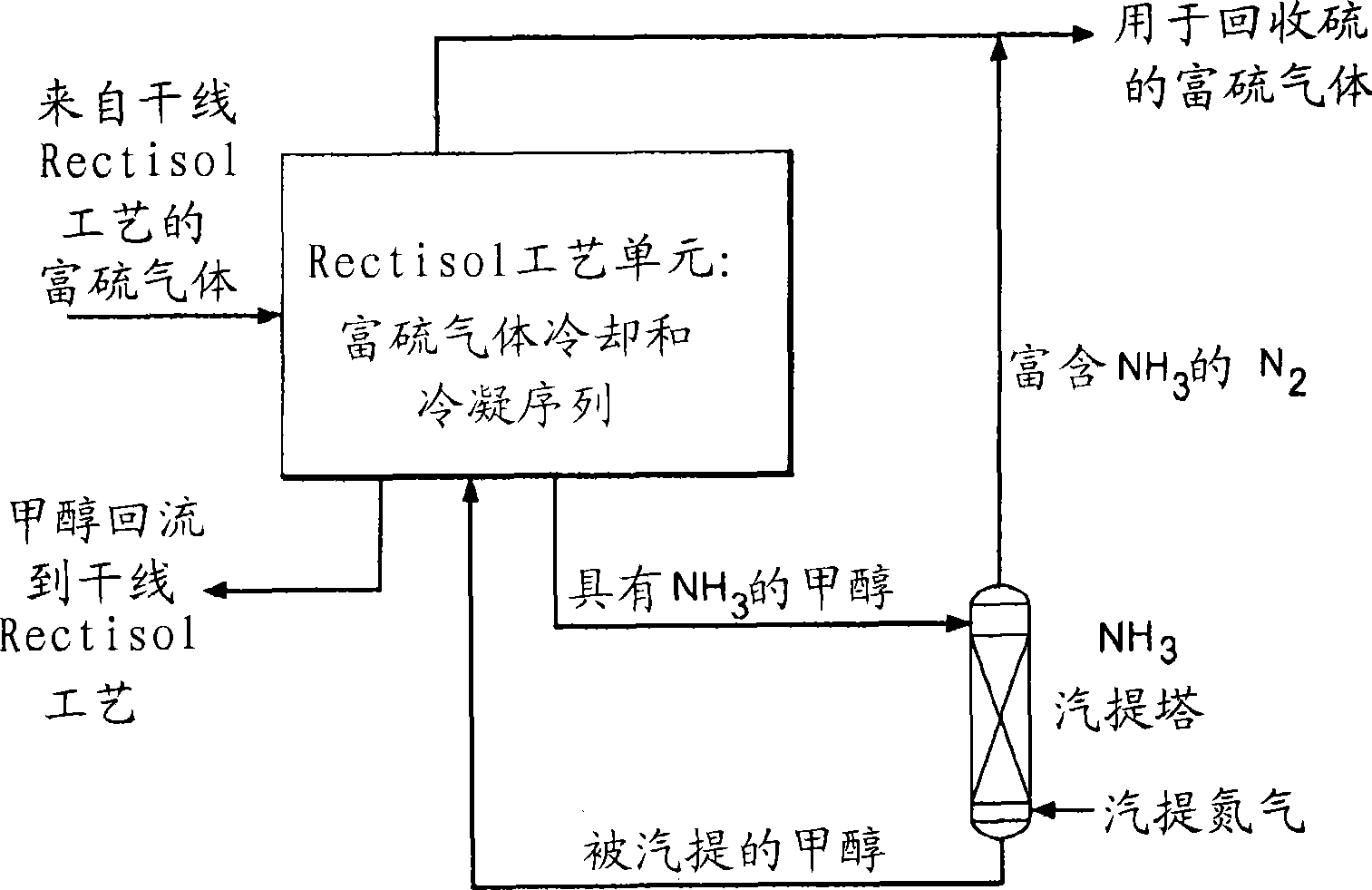

Method for removing ammonia from a methanol containing stream

A methanol, liquid flow technology, applied in separation methods, chemical instruments and methods, ammonia preparation/separation, etc., can solve problems such as corrosion and process problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The following examples are based on gas flows produced in a commercial industrial process and simulated in ASPEN according to conventional methods using a proprietary thermodynamic package. The ammonia removal rate is sufficient to reduce fouling of Rectisol process equipment.

[0024] Base:

[0025] Feed stream to Rectisol unit 112MMSCFD (60F standard conditions)

[0026] Total flow of Claus unit 2.5MMSCFD (60F standard condition)

[0027] Methanol feed to the stripper 1.5GPM

[0028] N of the stripper 2 Stripping gas 13000SCFH (60F standard condition)

[0029] Level 8.0

[0030] Total NH removed 3 0.281bmol / hr

[0031] %NH in the stripper 3 Remove 40.4%

[0032] %HCN removal in the stripper 32.9%

[0033] Stream summary:

[0034] flow incoming liquid

Embodiment 2

[0036] The following example represents the same ammonia mass removal rate as in Example 1: 0.281 bmol / hr. In this example, however, the liquid methanol feed rate to the stripper was doubled, and the nitrogen stripping stripping flow was adjusted to maintain the same mass removal rate. Although the liquid feed rate doubles, the required N 2 The stripping flow was down 27%. The percent ammonia removal (relative to mass removal) decreased from 40.4% in Example 1 to 20.8% in Example 2. This example illustrates that a stripper can be optimized in different ways to achieve a predetermined removal rate, depending on the most important variables in a given plant.

[0037] Base:

[0038] Feed stream to Rectisol unit 112MMSCFD (60F standard conditions)

[0039] Total flow of Claus unit 2.5MMSCFD (60F standard condition)

[0040] Methanol feed to the stripper 3.0GPM

[0041] N of the stripper 2 Stripping gas 9500SCFH (60F standard condition)

[0042] Theoretical progression 8.0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com