Patents

Literature

34 results about "Rectisol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rectisol is the trade name for an acid gas removal process that uses methanol as a solvent to separate acid gases such as hydrogen sulfide and carbon dioxide from valuable feed gas streams. By doing so, the feed gas is made more suitable for combustion and/or further processing. Rectisol is used most often to treat synthesis gas (primarily hydrogen and carbon monoxide) produced by gasification of coal or heavy hydrocarbons, as the methanol solvent is well able to remove trace contaminants such as ammonia, mercury, and hydrogen cyanide usually found in these gases. As an acid gas and large component of valuable feed gas streams, CO₂ is separated during the methanol solvent regeneration.

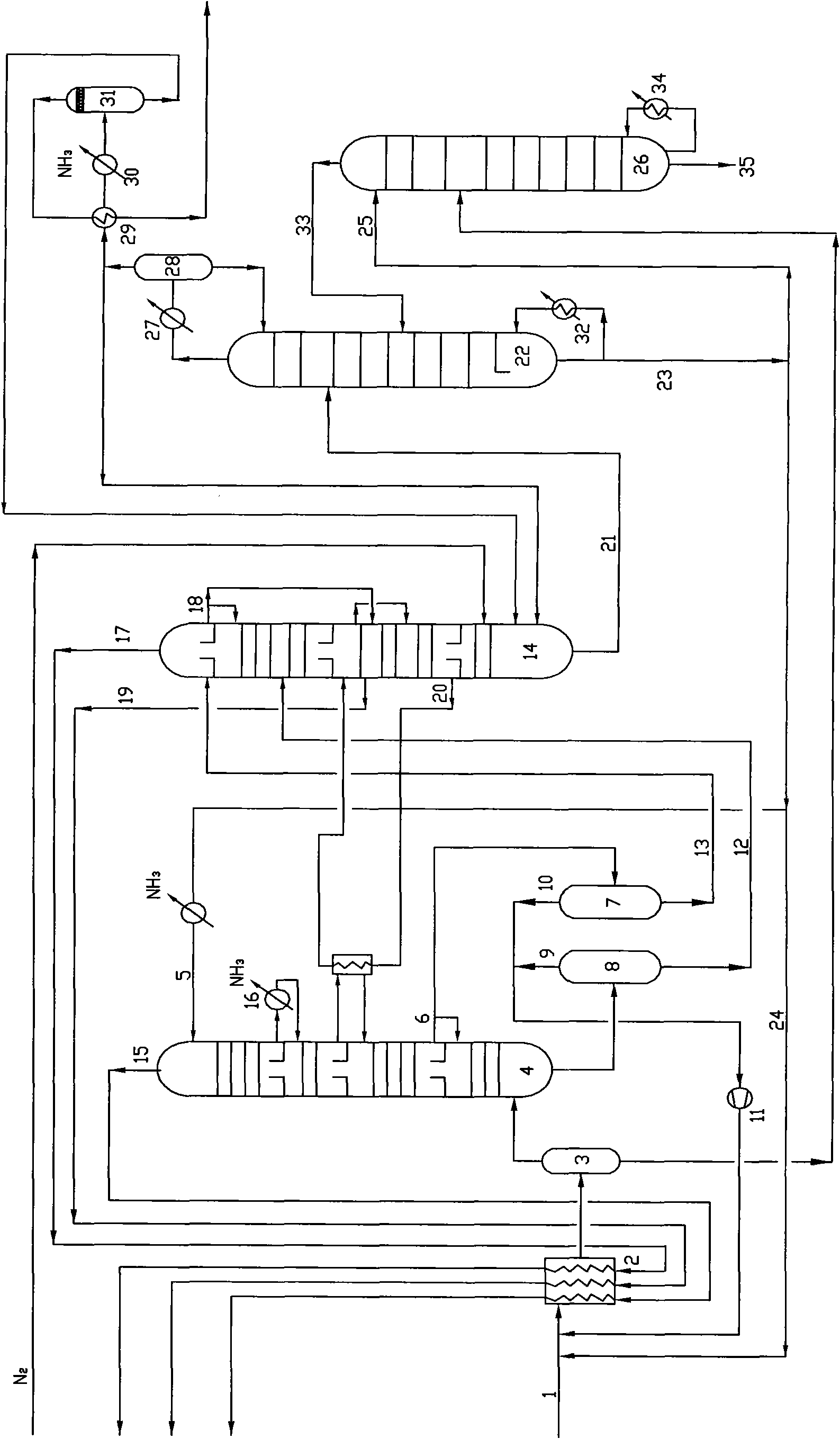

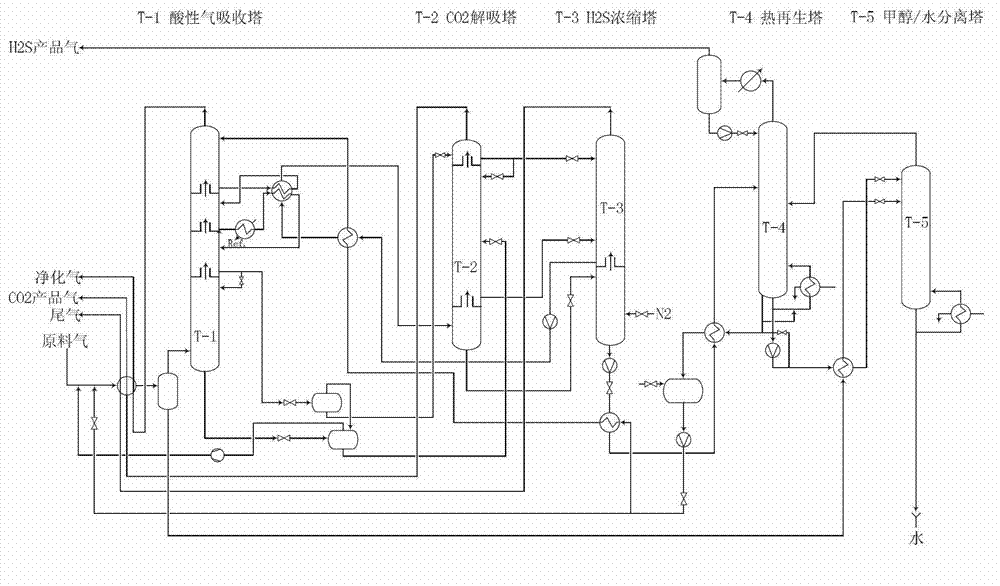

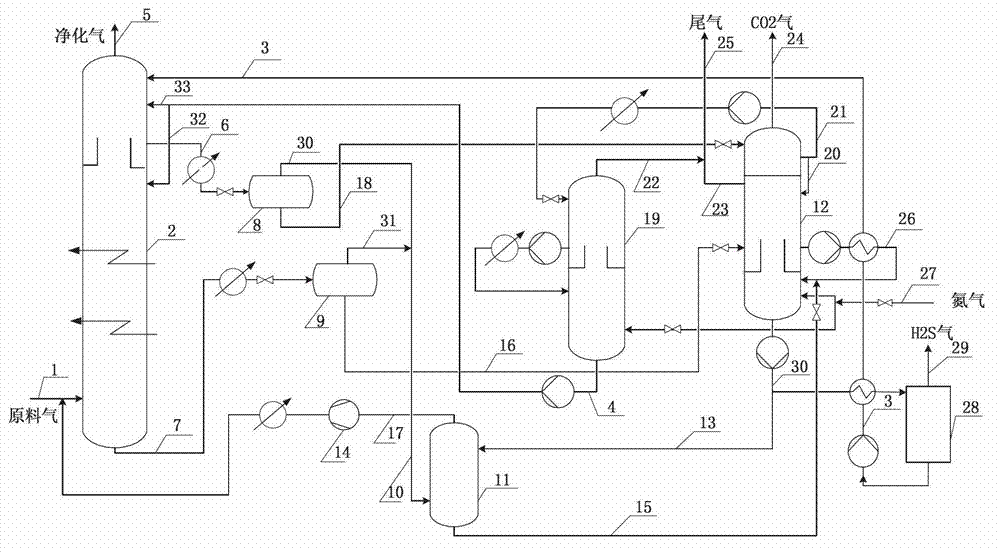

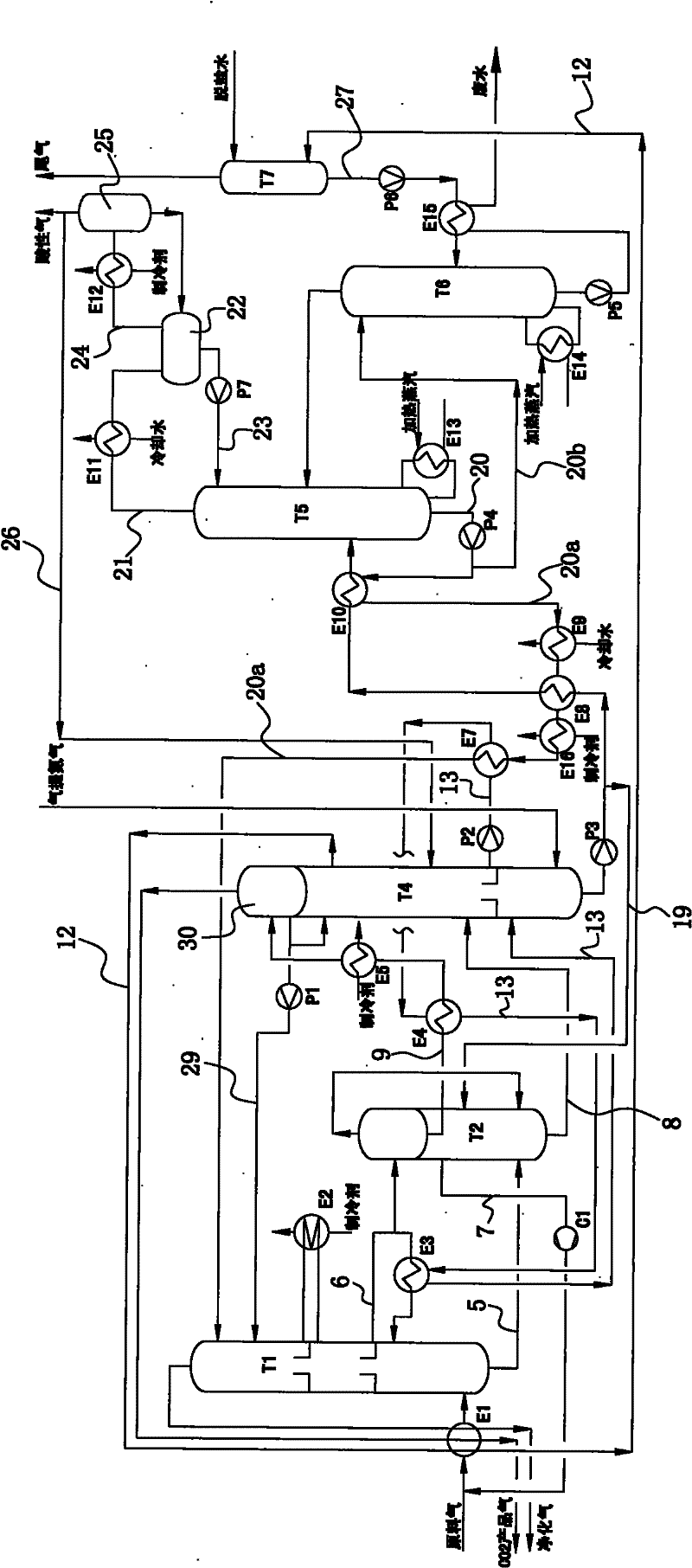

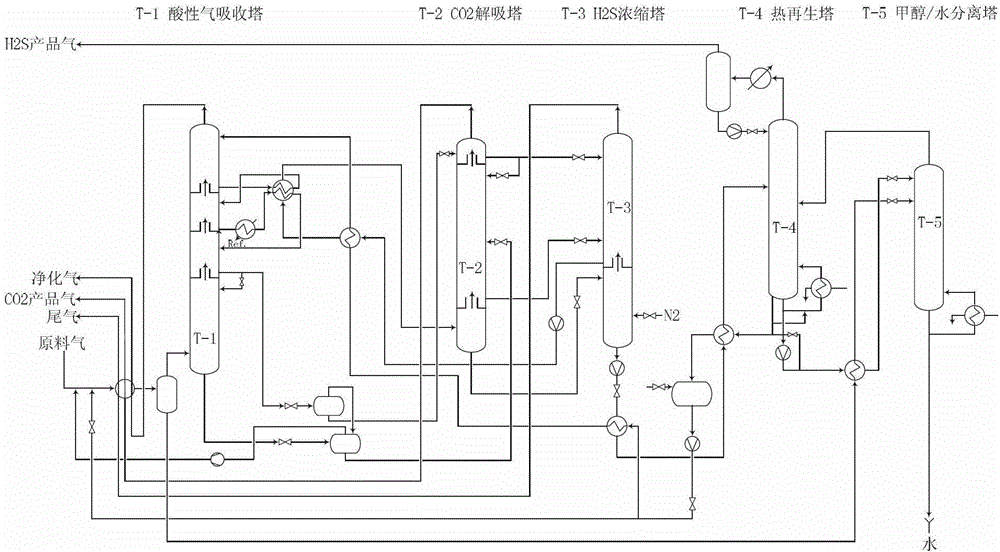

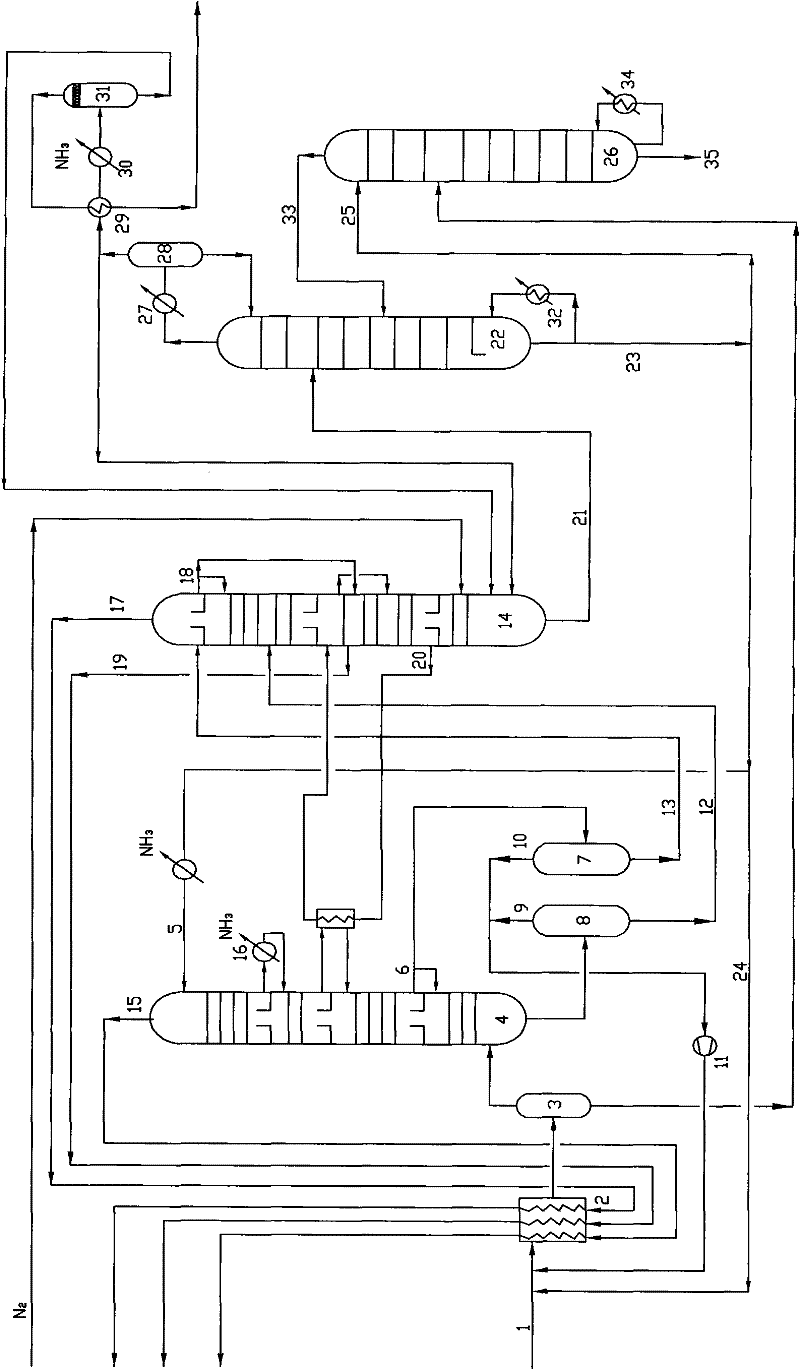

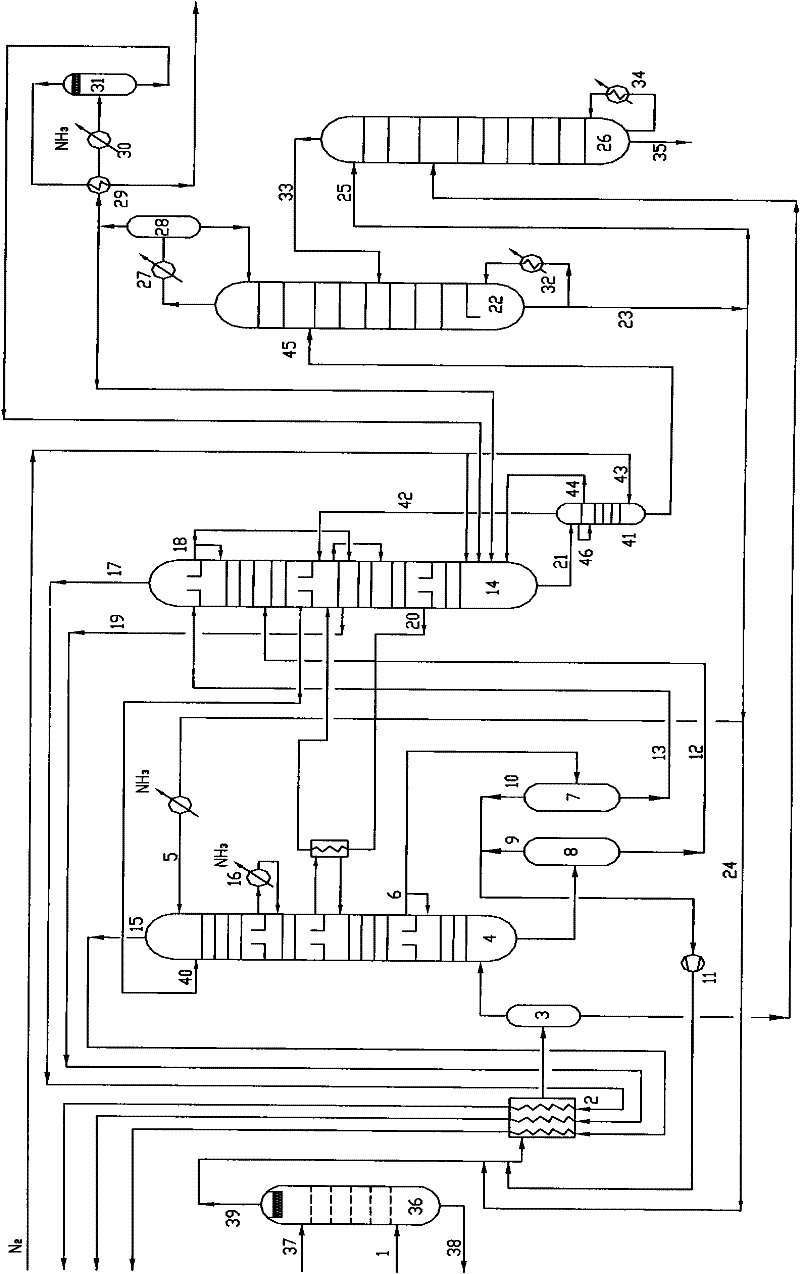

Process for removing acid gas with low-temperature methanol solution

ActiveCN101874967AReduce ammonia contentSolve the blockageDispersed particle separationBy absorptionIncreased carbon dioxideProduct gas

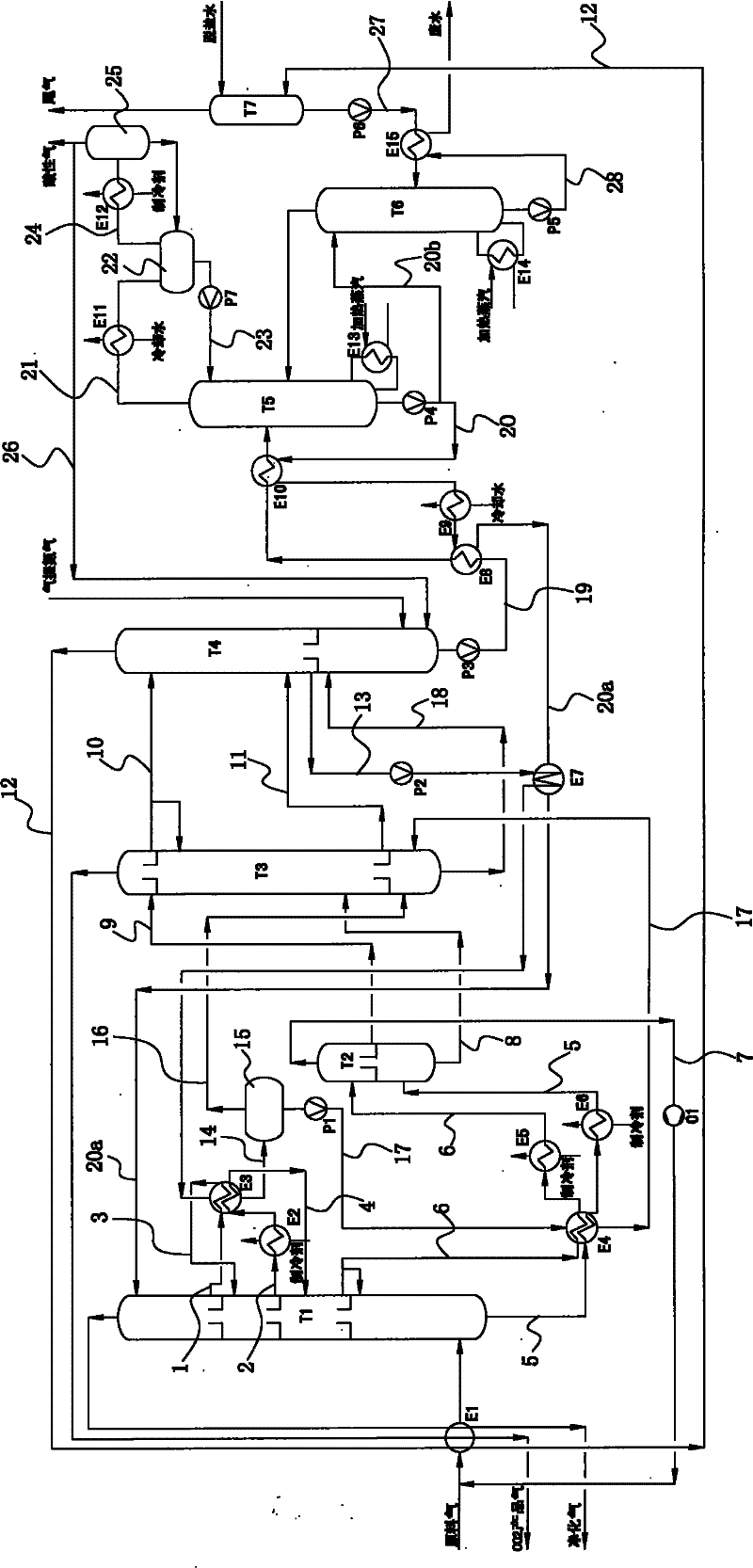

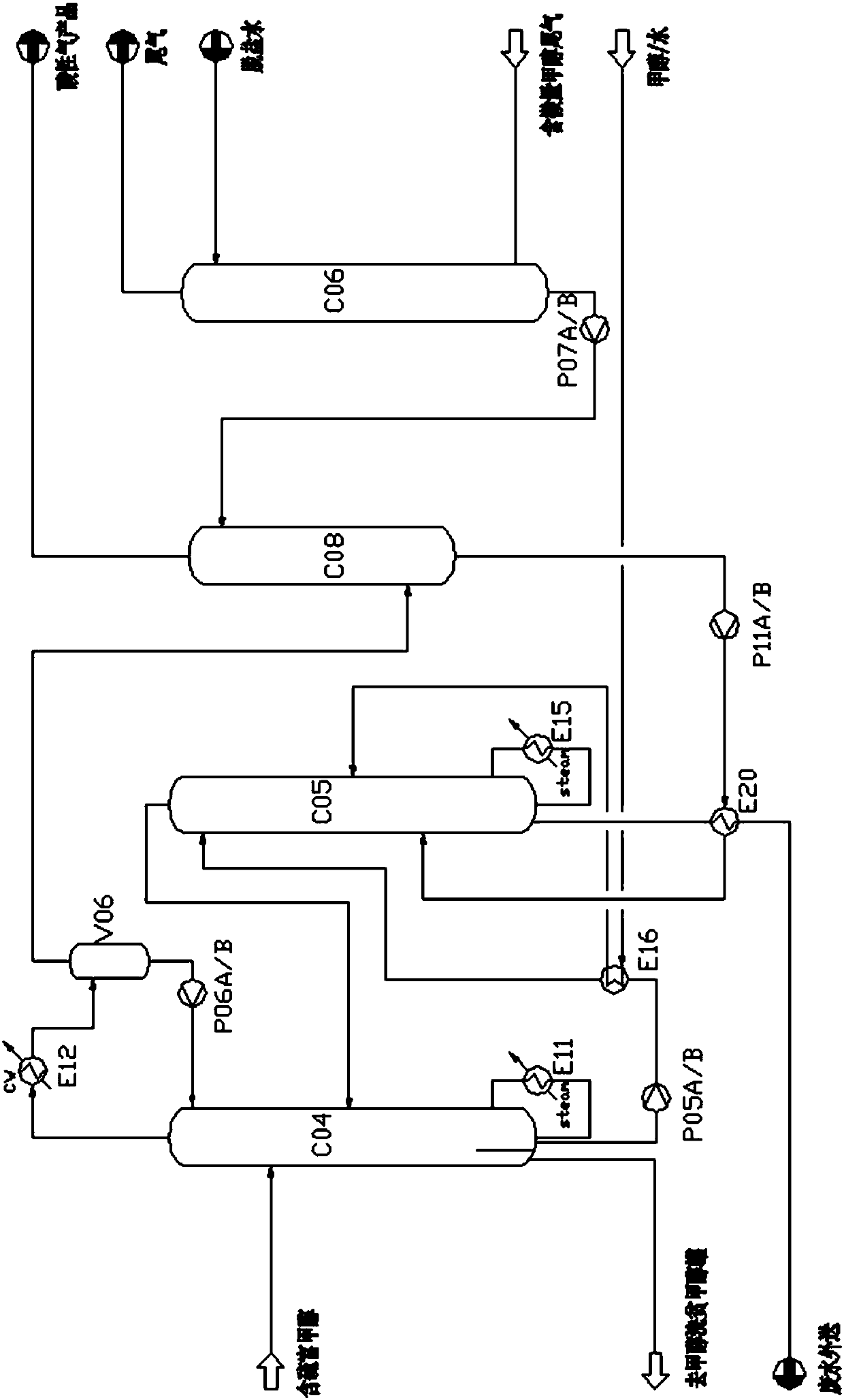

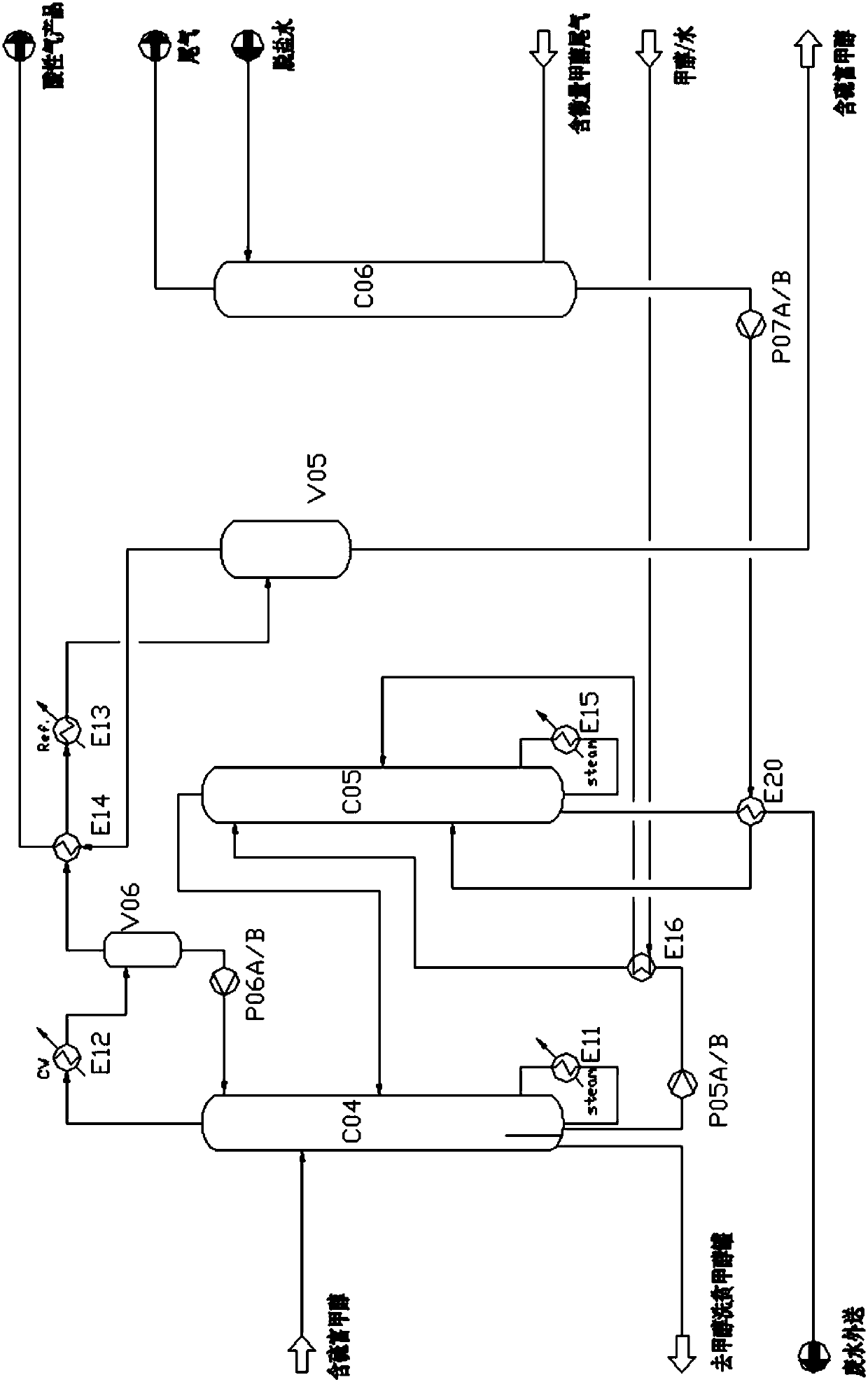

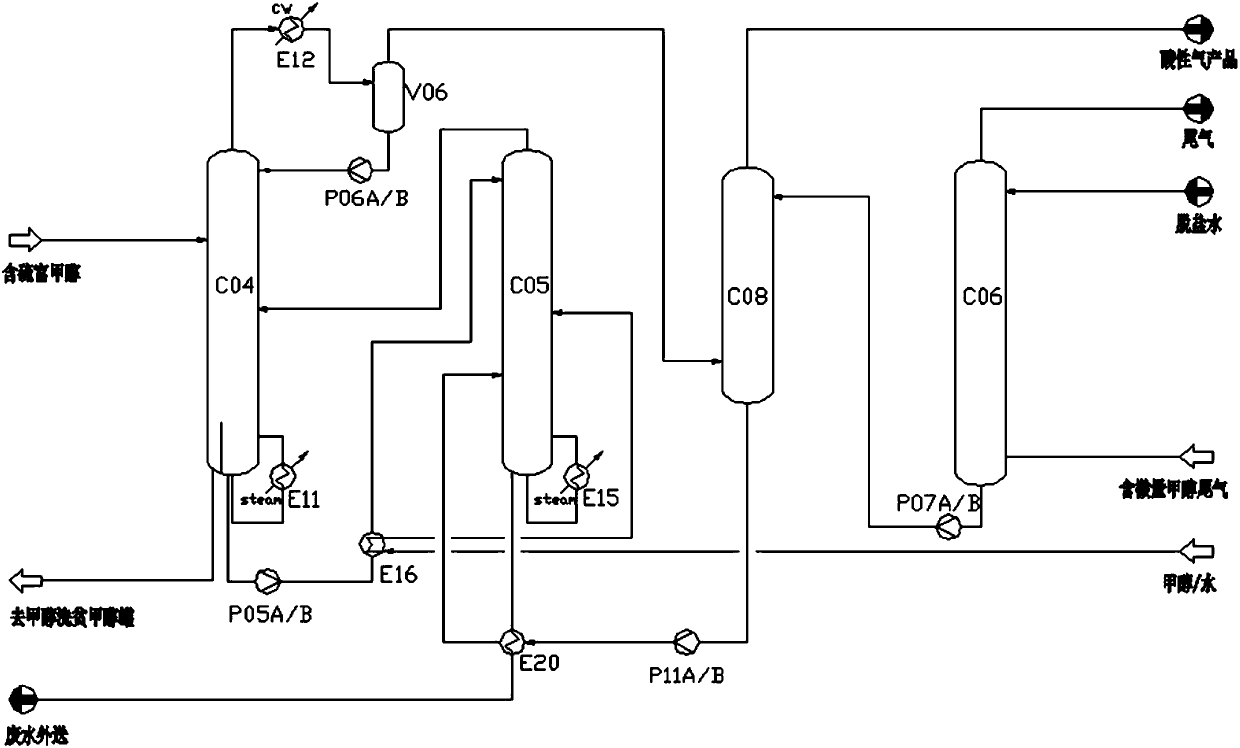

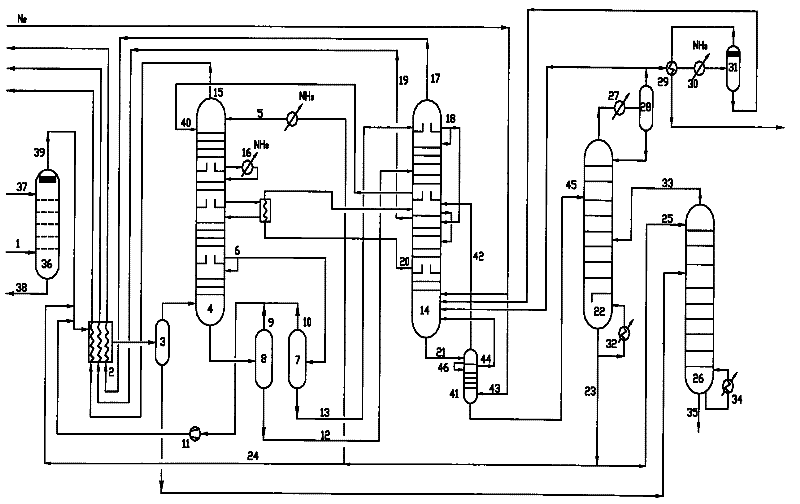

The invention relates to a process for removing an acid gas with a low-temperature methanol solution, solving the problem that a low-temperature rectisol plant enriches ammonia and has lower recovery rate of CO2, lower concentration of H2S in acid gases and large solution circulating volume in the traditional process. The process comprises feed gas preprocessing, desulfuration and decarbonization by an absorption tower, CO2 analysis and gas stripping and hydrogen sulfide concentration by a desorber, regeneration by a heat regenerator and deficient methanol separation by a methanol / water separation tower, wherein the feed gas is conveyed into an ammonia scrubber for deamination and preprocessing. The process can reduce the ammonia enrichment in the low-temperature rectisol plant, increase the recovery rate of CO2, improve the concentration of H2S in acid gases, reduce the circulating volume of the solution and ensure the quality of purified gas products.

Owner:WUHUAN ENG

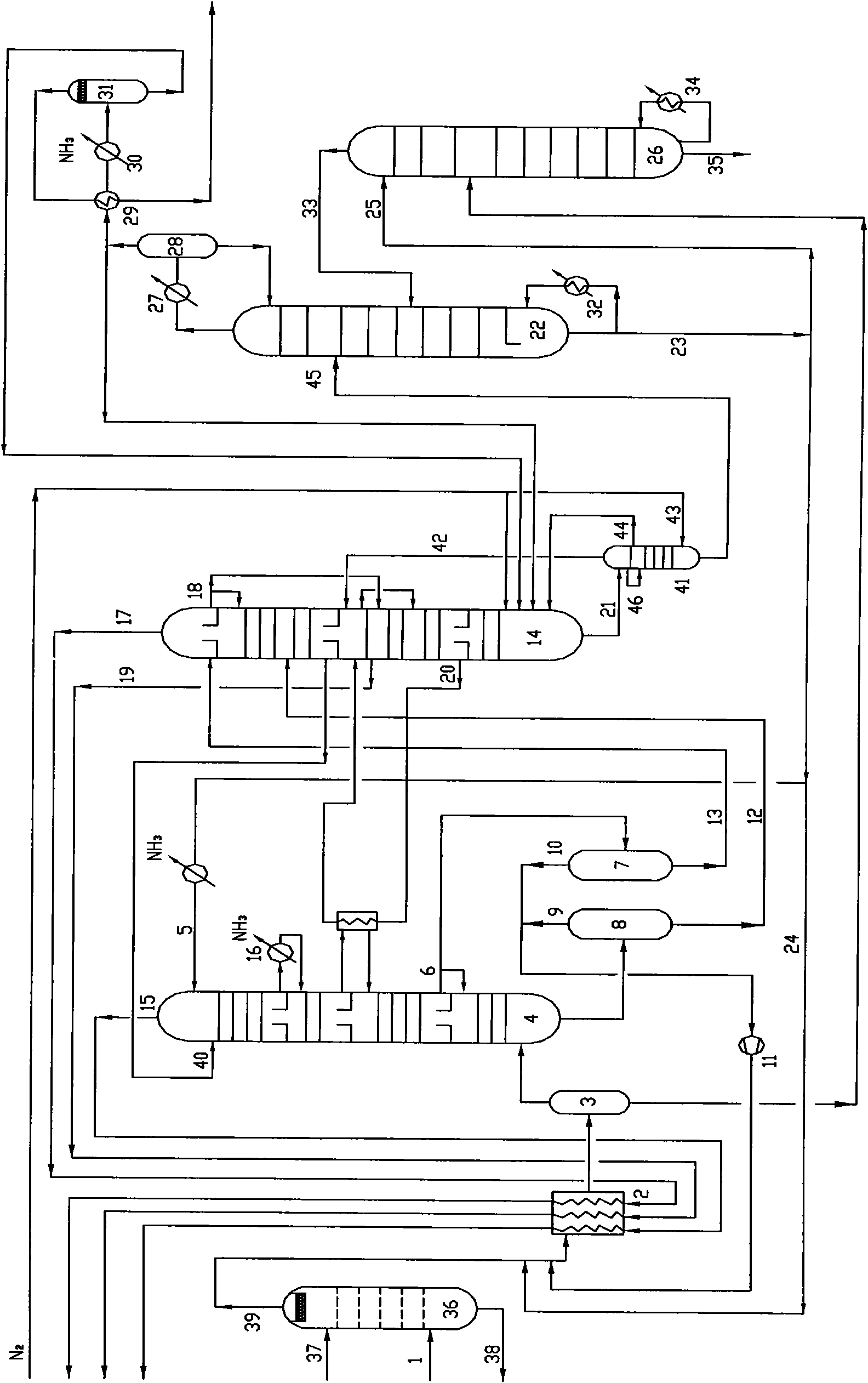

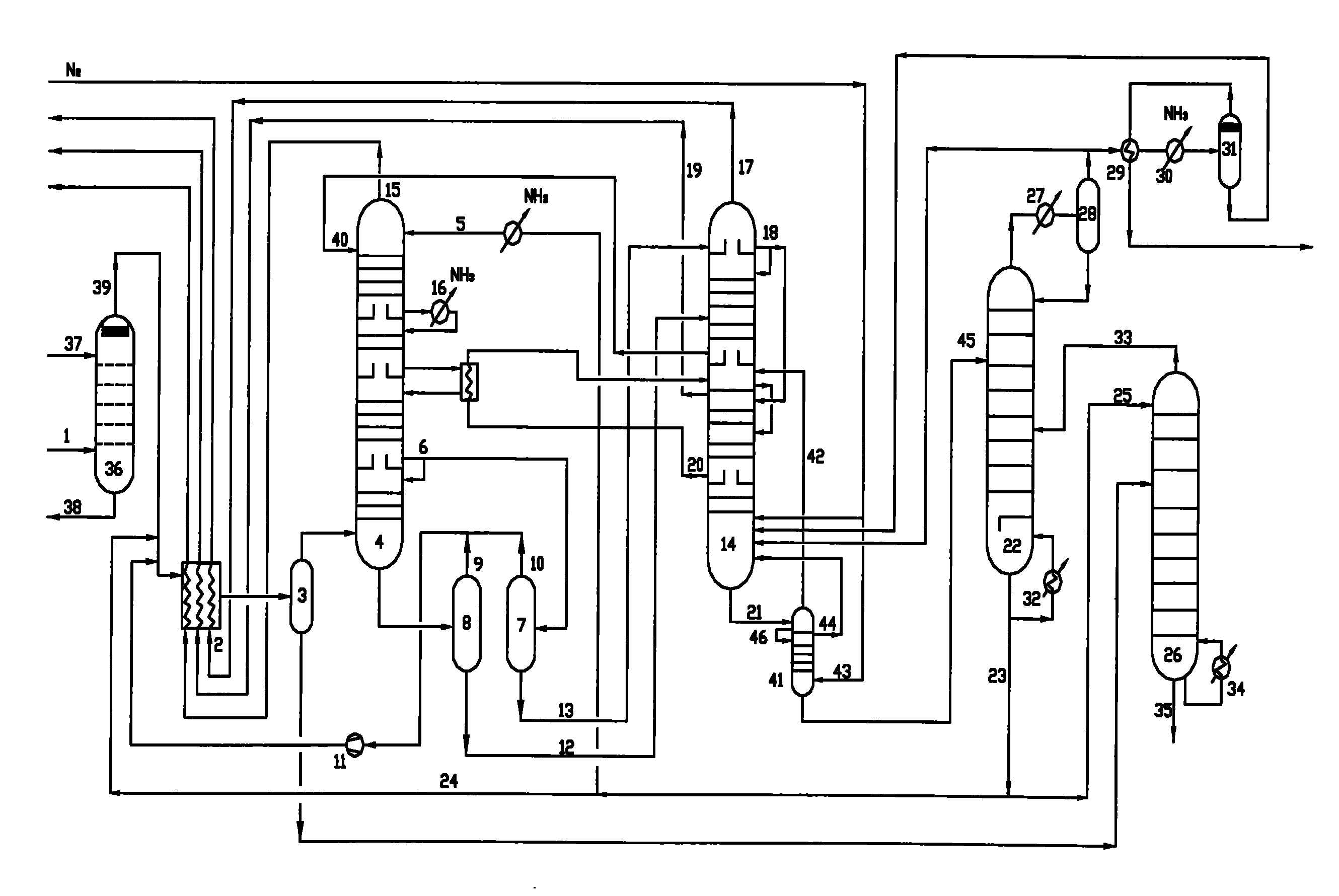

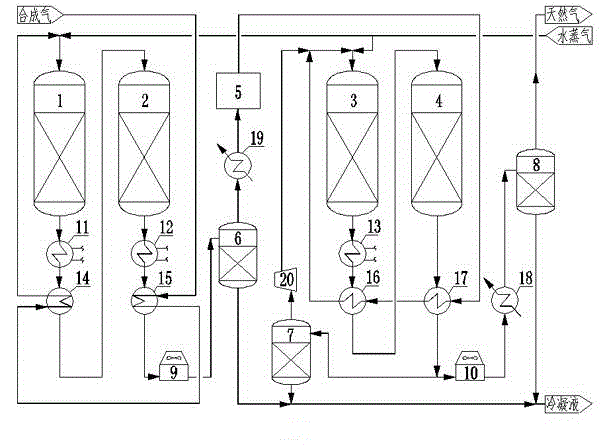

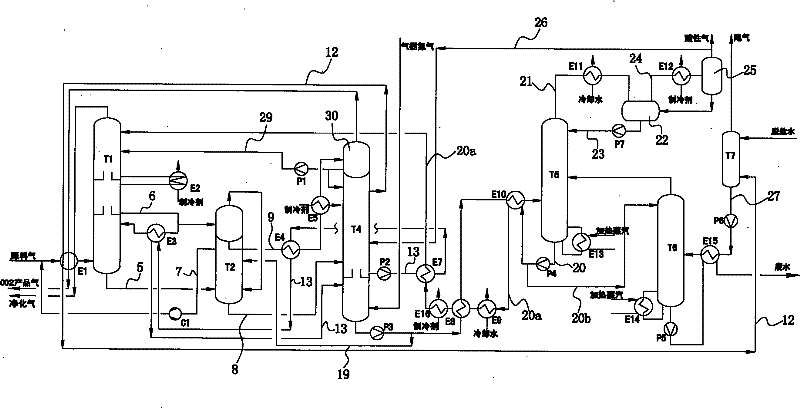

Energy-saving one-step rectisol method

ActiveCN102806000AAvoid the effects of minimum temperatureReduce loadDispersed particle separationAir quality improvementSulfideTower

An energy-saving one-step rectisol method belongs to the technical field of gas purification. The method is characterized in that two or three desulfuration segments of an absorption tower employ a sulfur-free semi-lean solution for absorption; intersegment coolers are adopted; the desulfuration segments can remove sulfide and approximately 50-60% of CO2 from virgin gas simultaneously; only one decarbonization segment of the absorption tower is adopted; a lean solution is used at the top of the tower, and the sulfur-free semi-lean solution is added; flash steam is absorbed by a sulfur-containing semi-lean solution in the medium-pressure flash evaporation process; after most of CO2 in the flash steam is absorbed, the solution is delivered to a lower tower of an H2S concentrating tower for gas stripping; a sulfur-free methanol solution gas stripping tower is additionally adopted and divided into one or two segments; solutions at the segments are heated appropriately before entering the tower; and the sulfur-free semi-lean solution is delivered to the absorption tower after the gas stripping. The energy-saving one-step rectisol method has the effects and benefits that the number of plates of the absorption tower is reduced by about 20%, the tower diameter is shortened, the circulation volume of a methanol lean solution is reduced, the regeneration load of a rich solution is also reduced, the energy consumption of a device is saved by about 30%, and the device investment is saved.

Owner:DALIAN JIACHUN GAS PURIFICATION TECH DEV

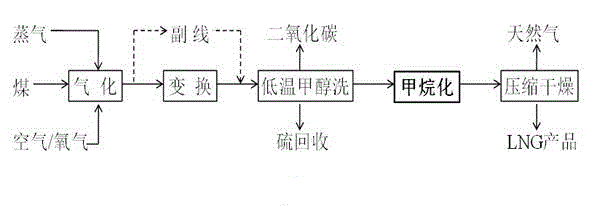

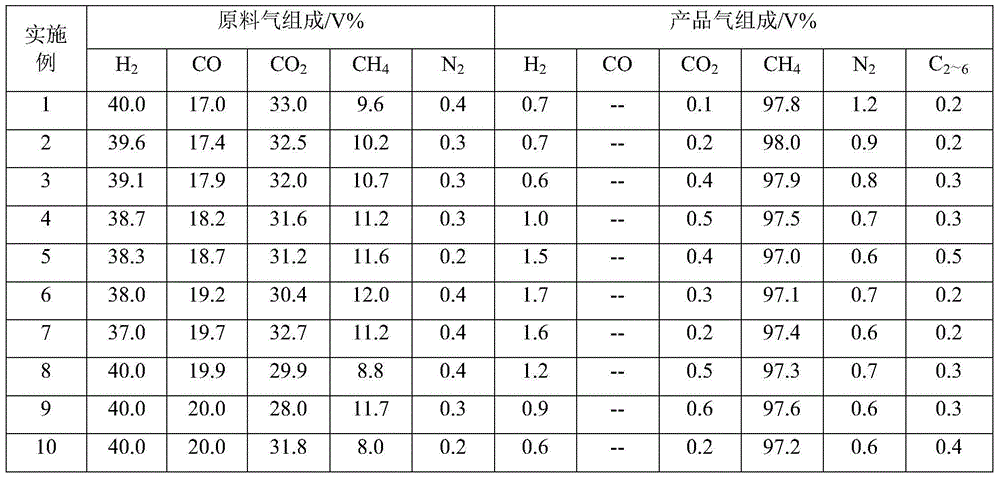

Process for preparing substitute natural gas through sulphur-tolerant methanation of coal synthesis gas

ActiveCN104164262AWith characteristicsHave made significant progressGaseous fuelsMethanationWater vapor

The invention provides a process for preparing substitute natural gas through sulphur-tolerant methanation of coal synthesis gas. The process is characterized in that the synthesis gas enters sulphur-tolerant methanation reactors I and II in sequence, and the mixed gas of the synthesis gas and water vapor enters a rectisol system so as to remove the impurities such as CO2, H2S and the like in the gas after undergoing sulphur-tolerant shift and sulphur-tolerant methanation reaction on a molybdenum-based bifunctional catalyst and then undergoes methanation reaction in methanation reactors I and II in sequence under the action of Ni-based methanation catalysts, thus obtaining the natural gas product. The process has the advantages of simple process flow, small equipment investment, low comprehensive energy consumption and excellent natural gas products.

Owner:SEDIN ENG +1

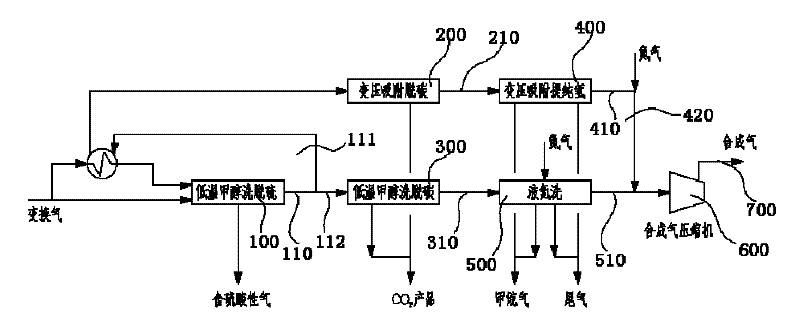

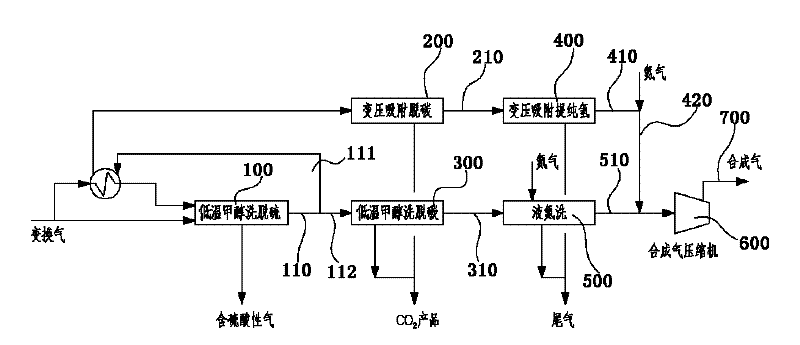

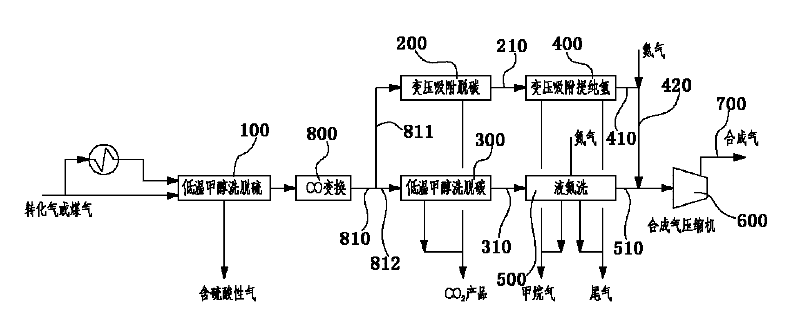

Method for increasing yield of rectisol and/or liquid oxygen wash greatly and saving energy through pressure swing adsorption technique and device thereof

InactiveCN102173380AAvoid remodelingEmissions have no effectHydrogen separationChemical industryGas compressorLiquid hydrogen

According to a method disclosed in the invention for increasing yield of rectisol and / or liquid oxygen wash greatly and saving energy through pressure swing adsorption technique, the desulfurized gas or transformed gas is divided into two branches. One branch enters a pressure swing adsorption decarburization device for decarburization, and the other branch enters a low-temperature methanol carbon washing device for decarburization. The decarburized gas after decarburization of the voltage swing adsorption decarburization device enters a voltage swing adsorption hydrogen purification device for obtaining hydrogen product, and a hydrogen-nitrogen synthesis gas is obtained after allocating the nitrogen. The decarburized gas after decarburization of the voltage swing adsorption decarburization device enters a liquid hydrogen washing device, and the hydrogen-nitrogen synthesis gas is obtained after purification. After mixing the two branches of hydrogen-nitrogen synthesis gas and compressing the mixture in a synthesis gas compressor, the compressed gas enters an ammonia synthesis period. The invention also discloses a device for realizing the method. A yield increase amplitude which is higher than 50% can be realized according to the invention.

Owner:SHANGHAI INT ENG CONSULTING

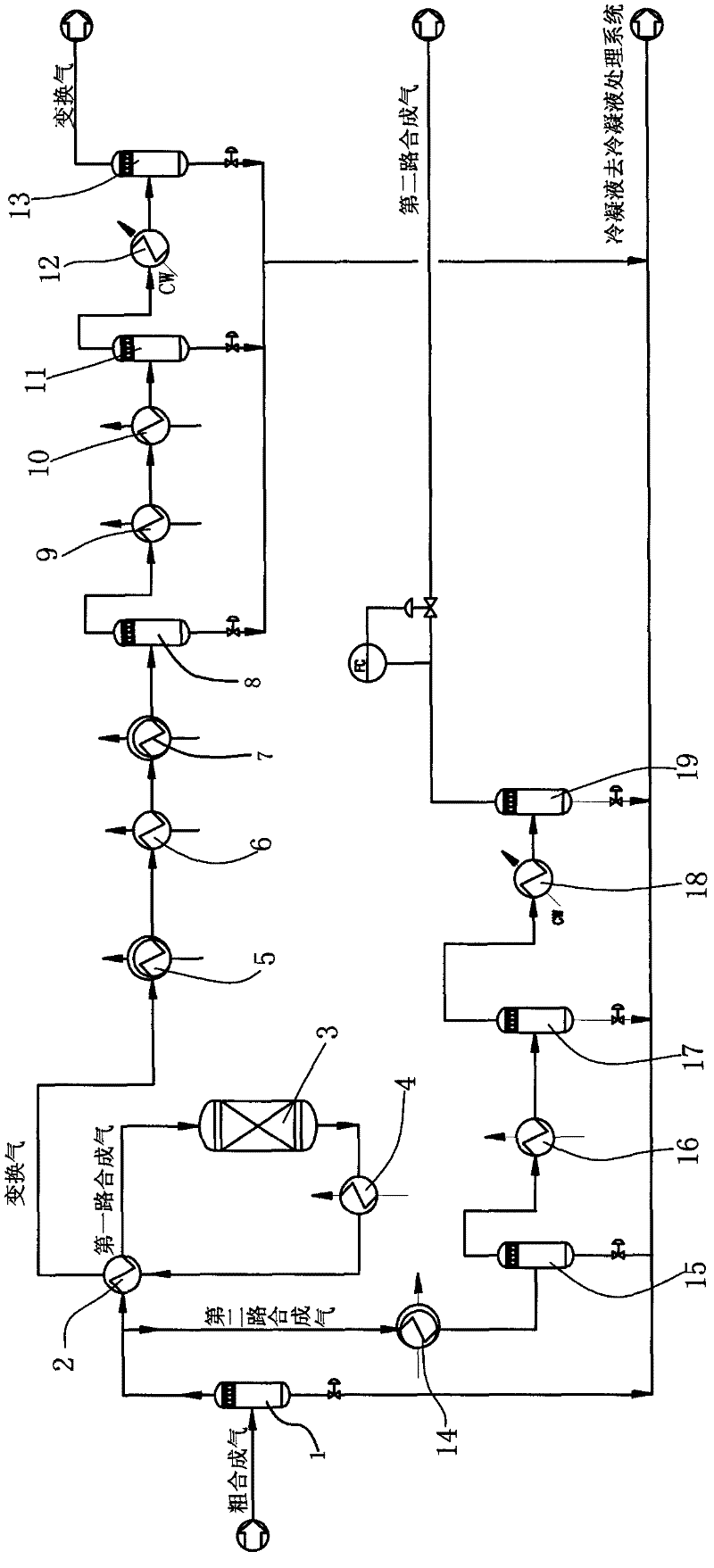

Method for controlling CO/H2 molar ratio in coal to methanol purification device

InactiveCN102225740APrecise control of gas distribution requirementsPrecise control of CO contentHydrogen separation using liquid contactVapor–liquid separatorGas phase

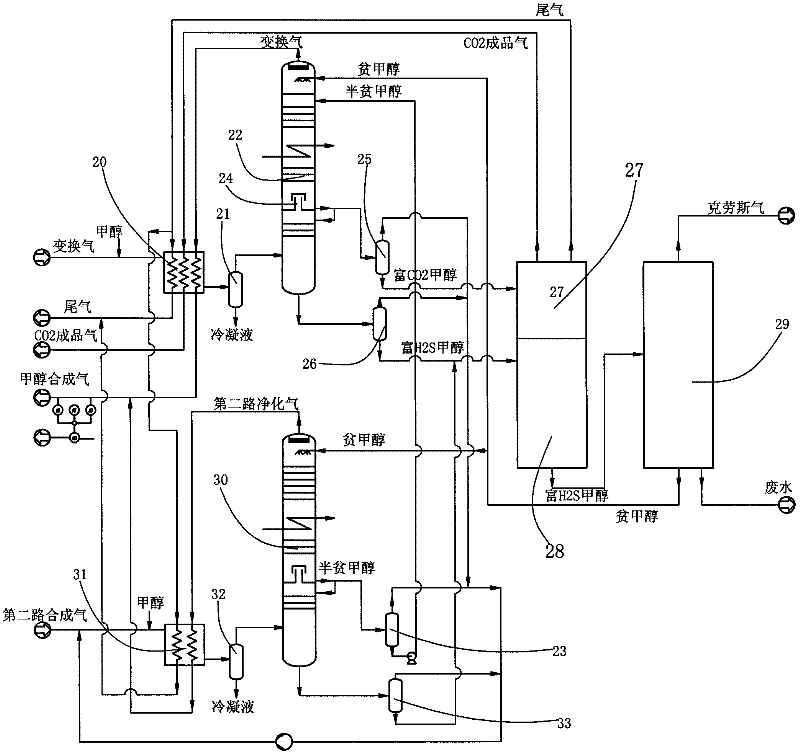

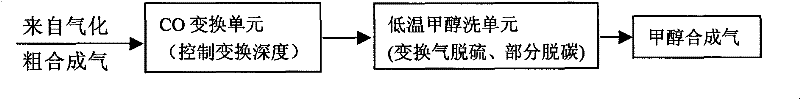

The invention relates to a method for controlling the CO / H2 molar ratio in a coal to methanol purification device. The method is characterized by comprising the following steps: (1) feeding rough synthesis gas from a gasification unit into a gas-liquid separator, performing gas-liquid separation, and dividing the separated gas phase into two paths, namely a first path of synthesis gas and a second path of synthesis gas, wherein the flow ratio of the first path of synthesis gas to the second path of synthesis gas is 1:(0.58-0.85); (2) performing heat exchange on the first path of synthesis gas, and performing CO conversion in a CO conversion unit to obtain converted gas; (3) performing heat exchange on the converted gas until the temperature of the converted gas is less than or equal to 50 DEG C, separating out a liquid phase, performing low-temperature rectisol in a first absorption tower to obtain a first path of purified gas, performing heat exchange on the second path of synthesis gas until the temperature of the second path of synthesis gas is less than or equal to 50 DEG C, separating out a liquid phase, and performing low-temperature rectisol in a second absorption tower to obtain a second path of purified gas; and (4) merging the first path of purified gas and the second path of purified gas to obtain methanol synthesis gas. By utilizing the method, a perfect CO / H2 mole ratio can be obtained, the energy consumption of the device is low, and the purpose of reinforcing the operability of the device can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +2

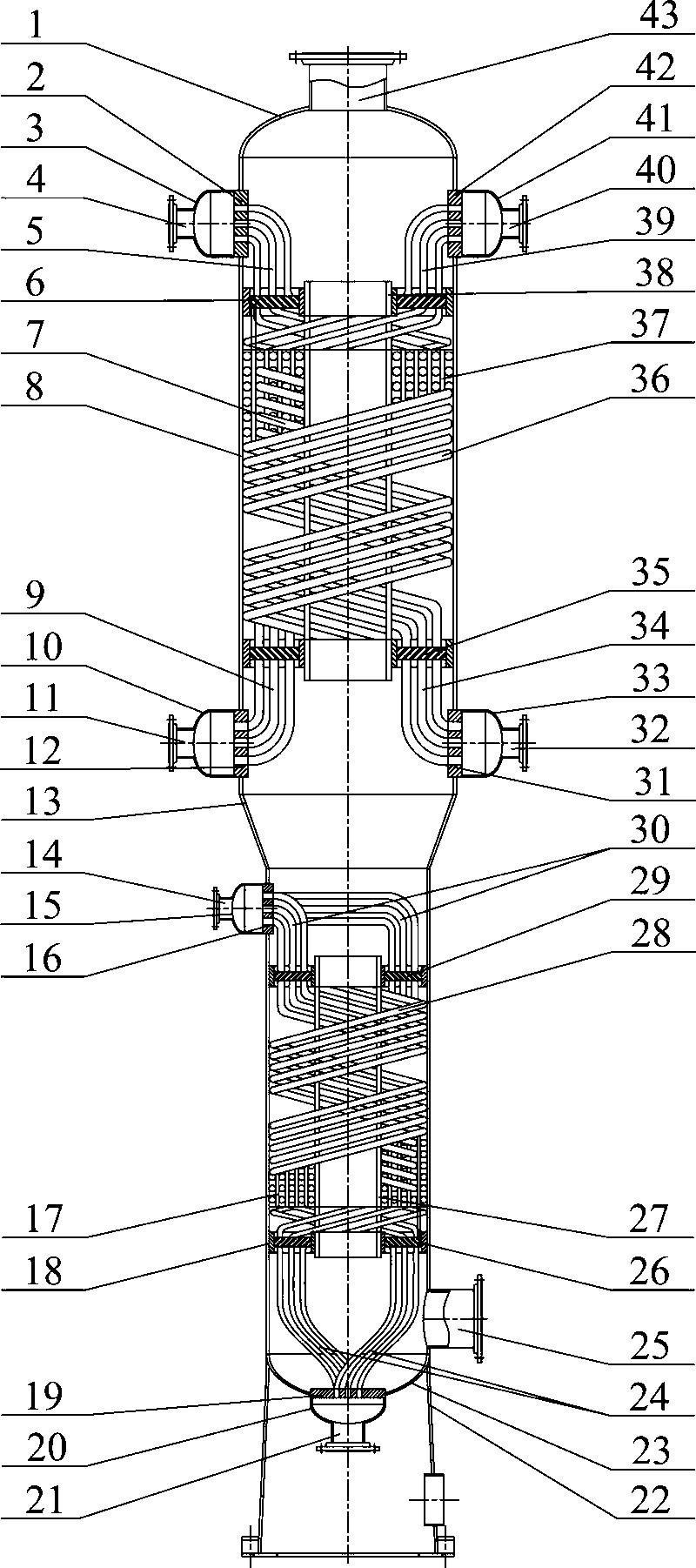

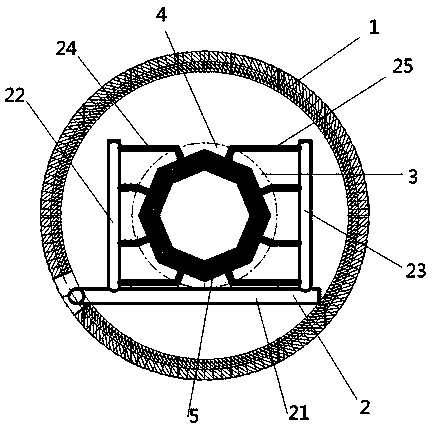

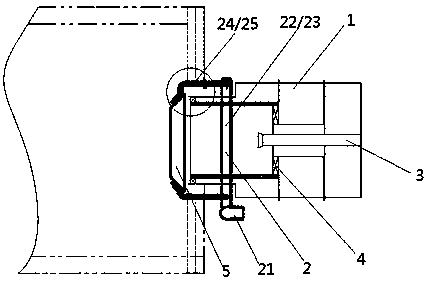

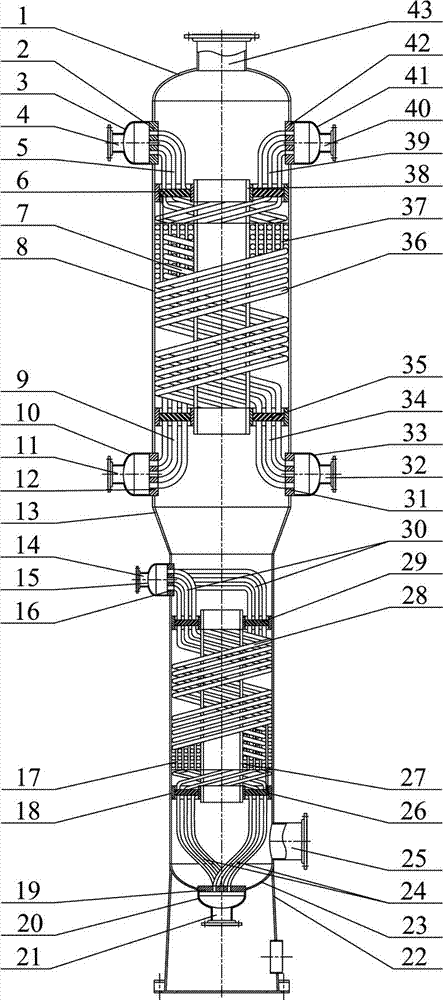

Low-temperature spiral wound heat exchanger for non-converted gas cooler

InactiveCN103017573AReduce in quantityCompact structureChemical industryStationary tubular conduit assembliesDouble tubeSystems research

The invention discloses a low-temperature spiral wound heat exchanger for a non-converted gas cooler, and is mainly applied to the coal chemical industry fields of coal based syngas, coal-to-methanol, and the like, and the technical fields of the rectisol process comprising low-temperature gas purification and low-temperature liquefaction separation, and the like. The low-temperature spiral wound heat exchanger is tower spiral wound heat exchange equipment with the combination of single-fluid and double-fluid, achieving the purpose of precooling non-converted feed gas by process cold gas by mainly utilizing rectisol process off-gas and low-temperature syngas to precool the non-converted feed gas. According to the low-temperature spiral wound heat exchanger for the non-converted gas cooler, disclosed by the invention, the basic structure and the heat exchange process calculation method of a compound spiral wound heat exchanger combining a single-tube-bundle spiral wound heat exchanger and a double-tube-bundle spiral wound heat exchanger for the non-converted gas cooler are systematically researched, the method of introducing the moderate temperature cold source at the middle section and combining the single-fluid and double-fluid spiral wound heat exchangers up and down is adopted, and the entry points of multi-fluid heat exchange at different potential temperatures are improved, so that the heat exchange efficiency is enhanced, the heat exchange area is saved, and the size of the heat exchanger is reduced.

Owner:张周卫

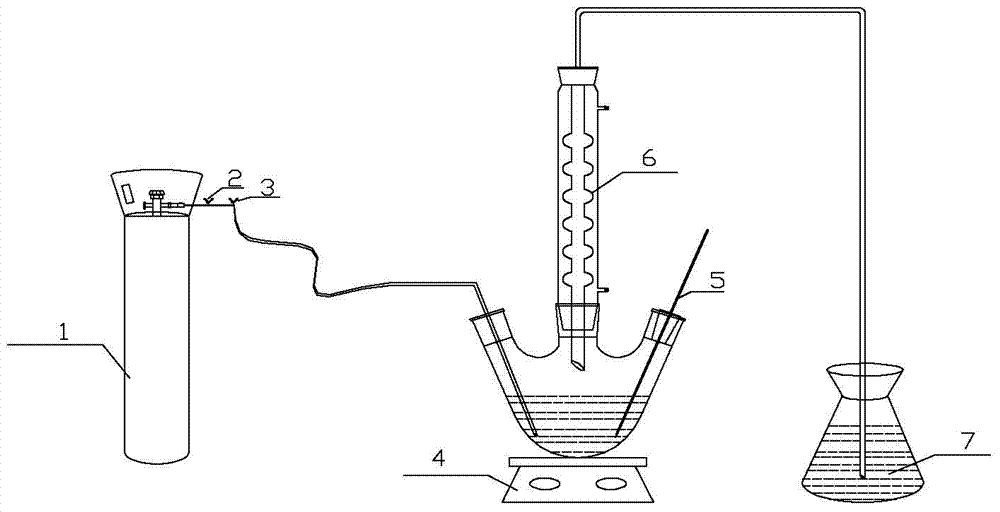

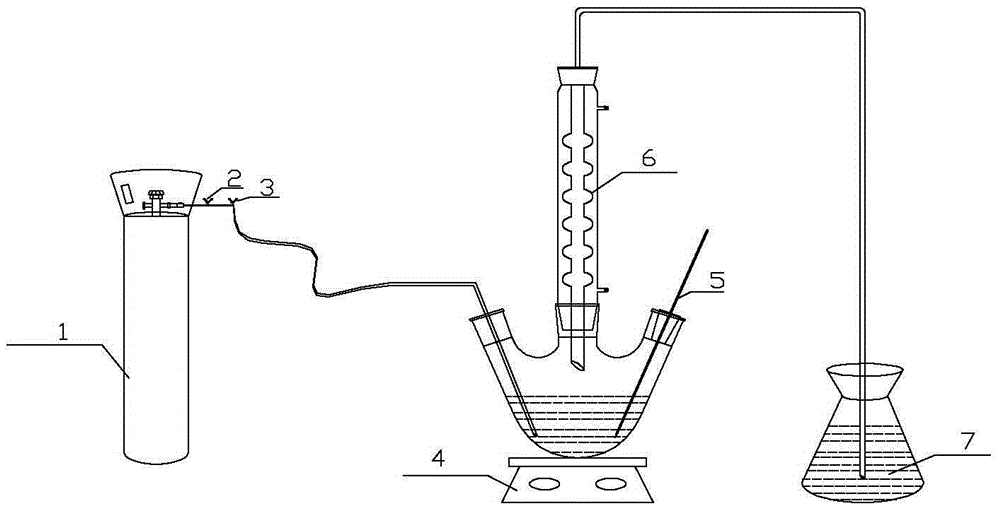

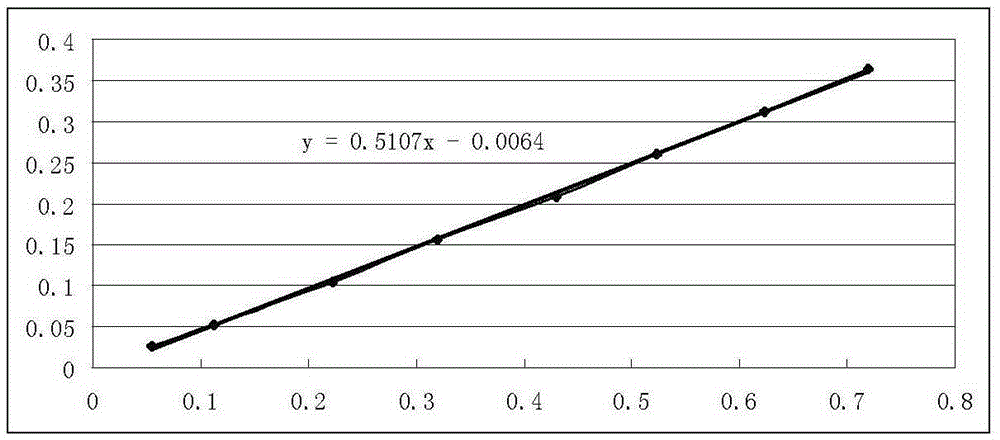

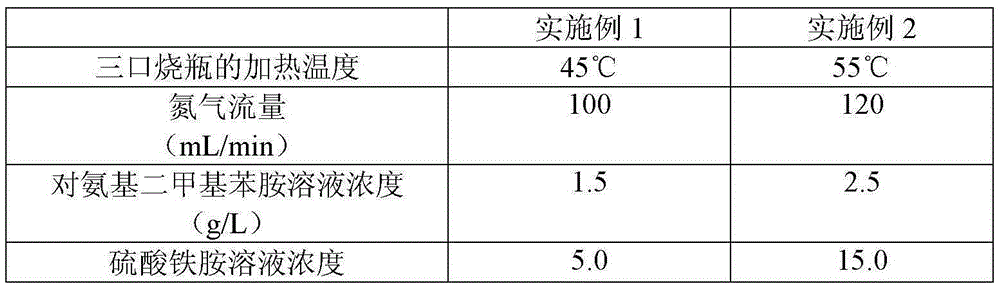

Measurement method for hydrogen sulfide content of methanol solution and application of measurement method

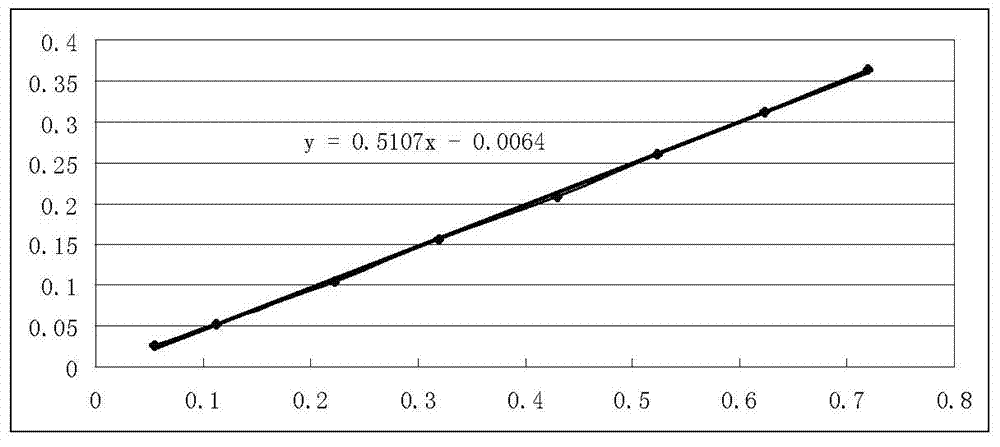

ActiveCN103499540ADetermining povertyGuaranteed absorptionColor/spectral properties measurementsAbsorption capacityPhysical chemistry

The invention discloses a measurement method for hydrogen sulfide content of a methanol solution and application of the measurement method. The measurement method comprises the following steps of constructing an absorbancy-hydrogen sulfide content standard curve; preparing a methanol solution to be measured into a sample to be measured; testing the sample to be measured through a spectrophotometer to obtain an absorbancy value of the sample to be measured; and obtaining a hydrogen sulfide content of the sample to be measured from the absorbancy-hydrogen sulfide content standard curve according to the measured absorbancy value. The hydrogen sulfide content of the methanol solution can be obtained by constructing the absorbancy-hydrogen sulfide content standard curve, preparing the methanol solution to be measured into the sample to be measured, measuring the absorbancy value of the sample to be measured and obtaining the result. The method is applied to liquid in actual production, so that the hydrogen sulfide content of a 'rectisol' solution can be measured accurately and conveniently, and therefore, the deficiency of the methanol solution can be determined, and the absorption capacity of the methanol solution in a purification process is guaranteed.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

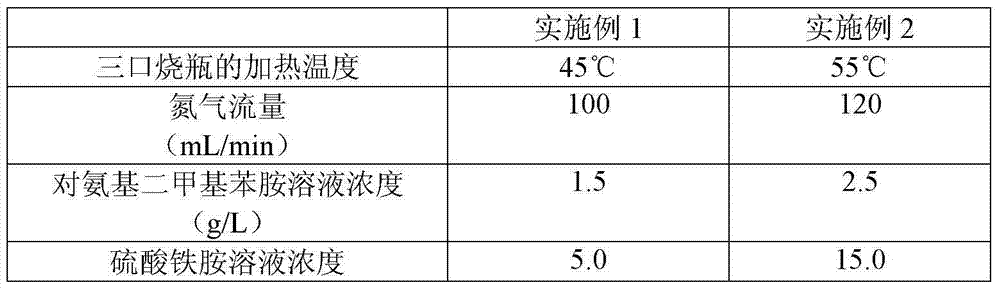

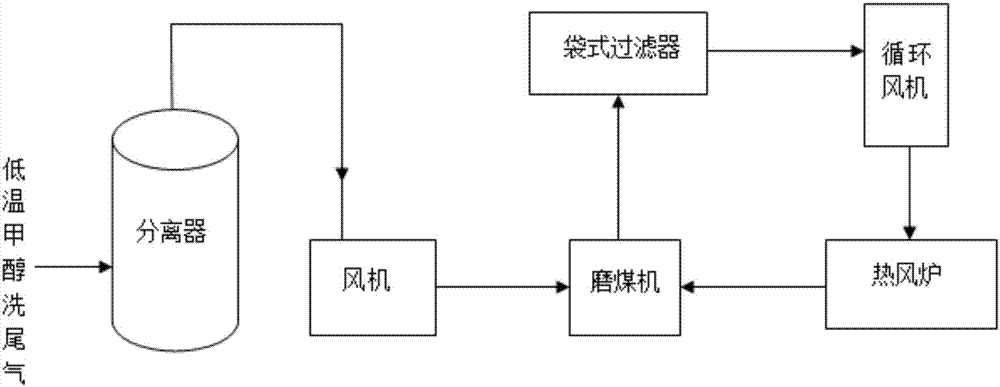

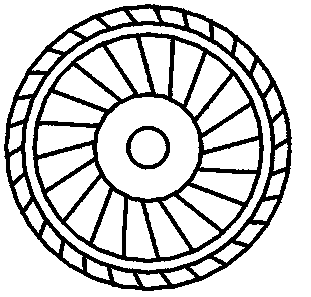

Rectisol tail gas recovery system and method and their application

ActiveCN106984099ASimple processFew process parameters are easy to adjustEngine sealsDispersed particle separationNitrogenProcess engineering

The invention discloses a Rectisol tail gas recovery system and method and their application and solves the problem that Rectisol tail gas treatment is high in cost. The technical process is simple, the main parameter is fan outlet pressure, and process parameters to be controlled are few and easy to adjust; Rectisol vented tail gas replaces seal nitrogen in a coal mill, the waste is utilized, resources are saved, and the investment in Rectisol tail gas treatment is lowered. According to the technical scheme, the Rectisol tail gas recovery system comprises a tail gas source, a separator, a fan and a coal mill, drops are removed from the tail gas source via the separator, the tail gas source is pressurized via a fan and is delivered to a sealed air passage in the coal mill so as to arrive at sealing, and the tail gas source is a Rectisol tail gas source.

Owner:LUXI CHEM GRP

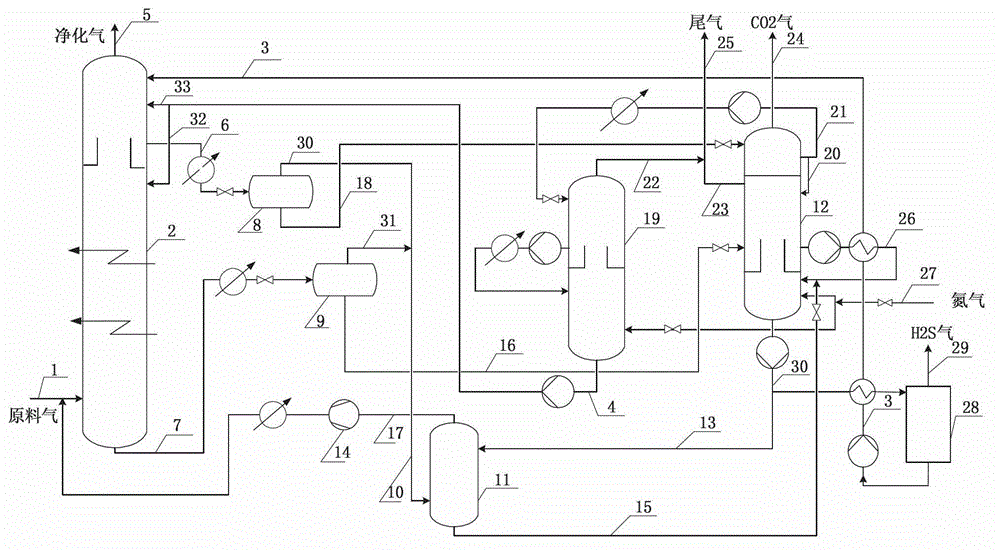

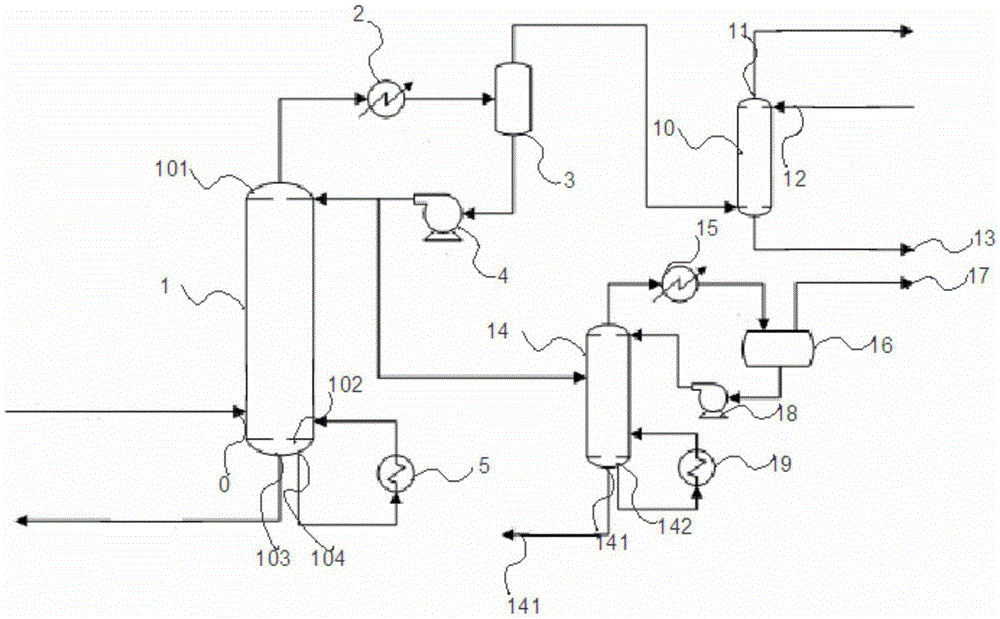

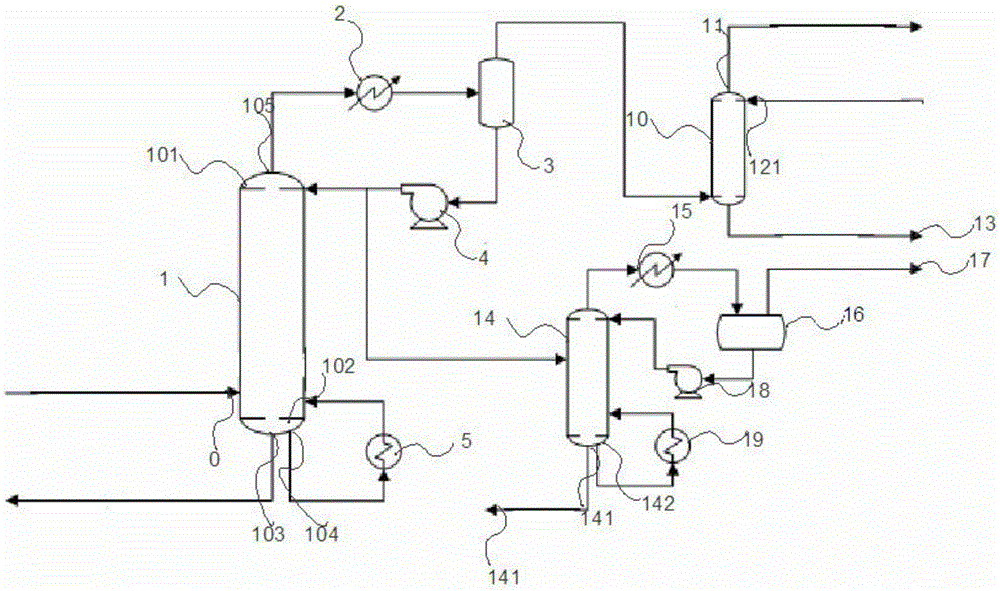

Split-flow rectisol device

ActiveCN101590356BReduce complexityLess investmentDispersed particle separationMethanol waterDistillation

Owner:SHANGHAI INT ENG CONSULTING

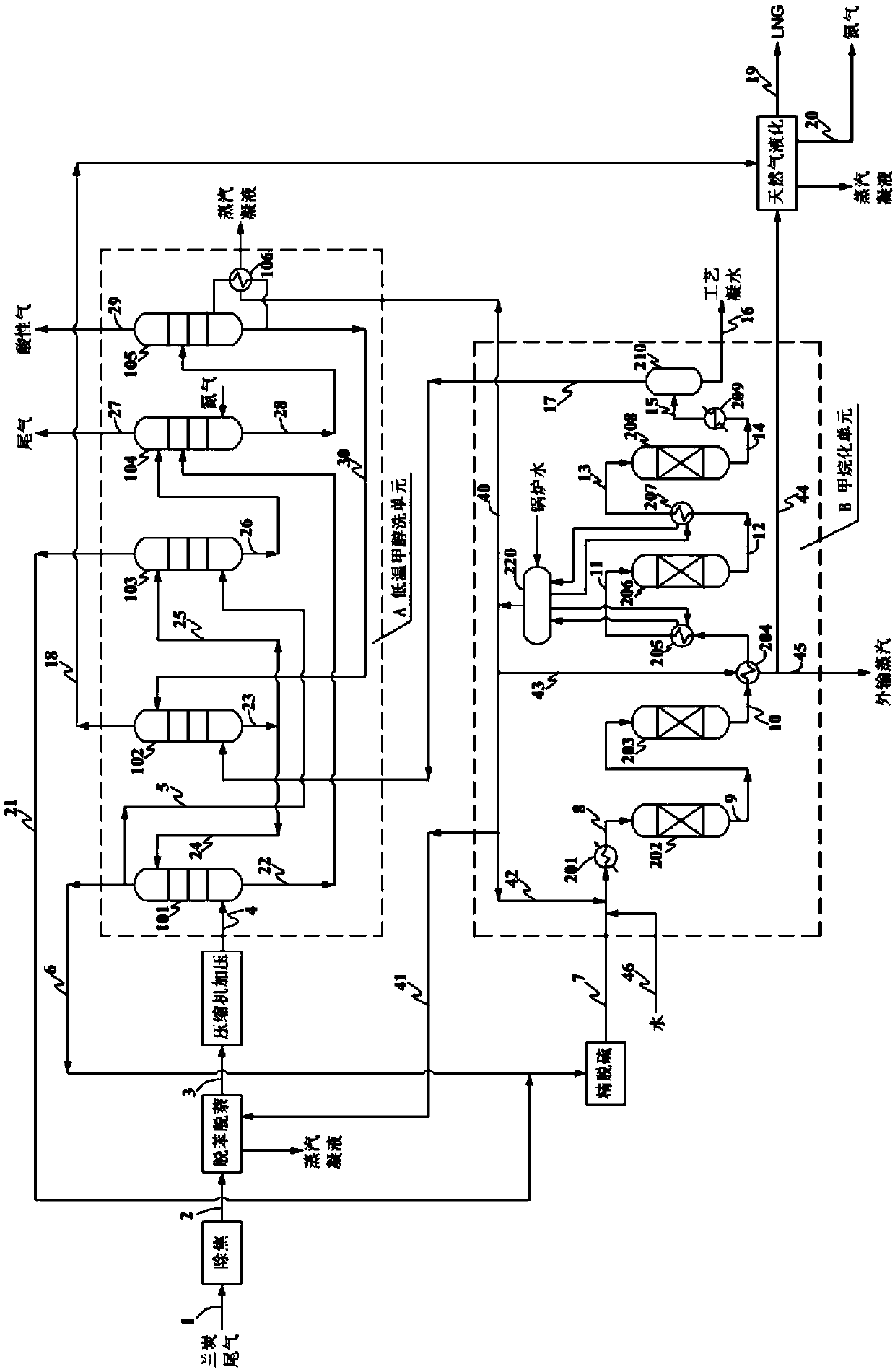

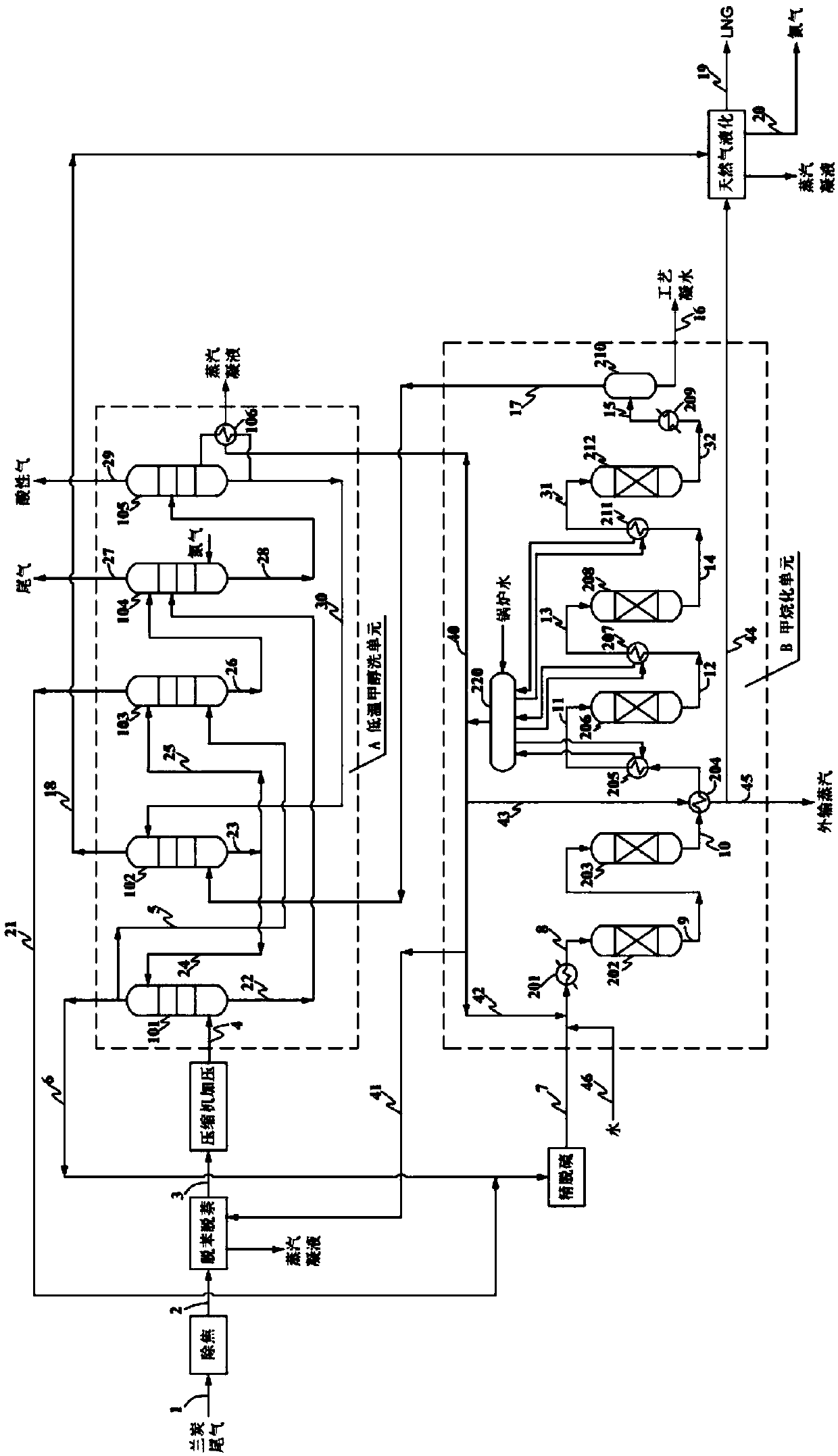

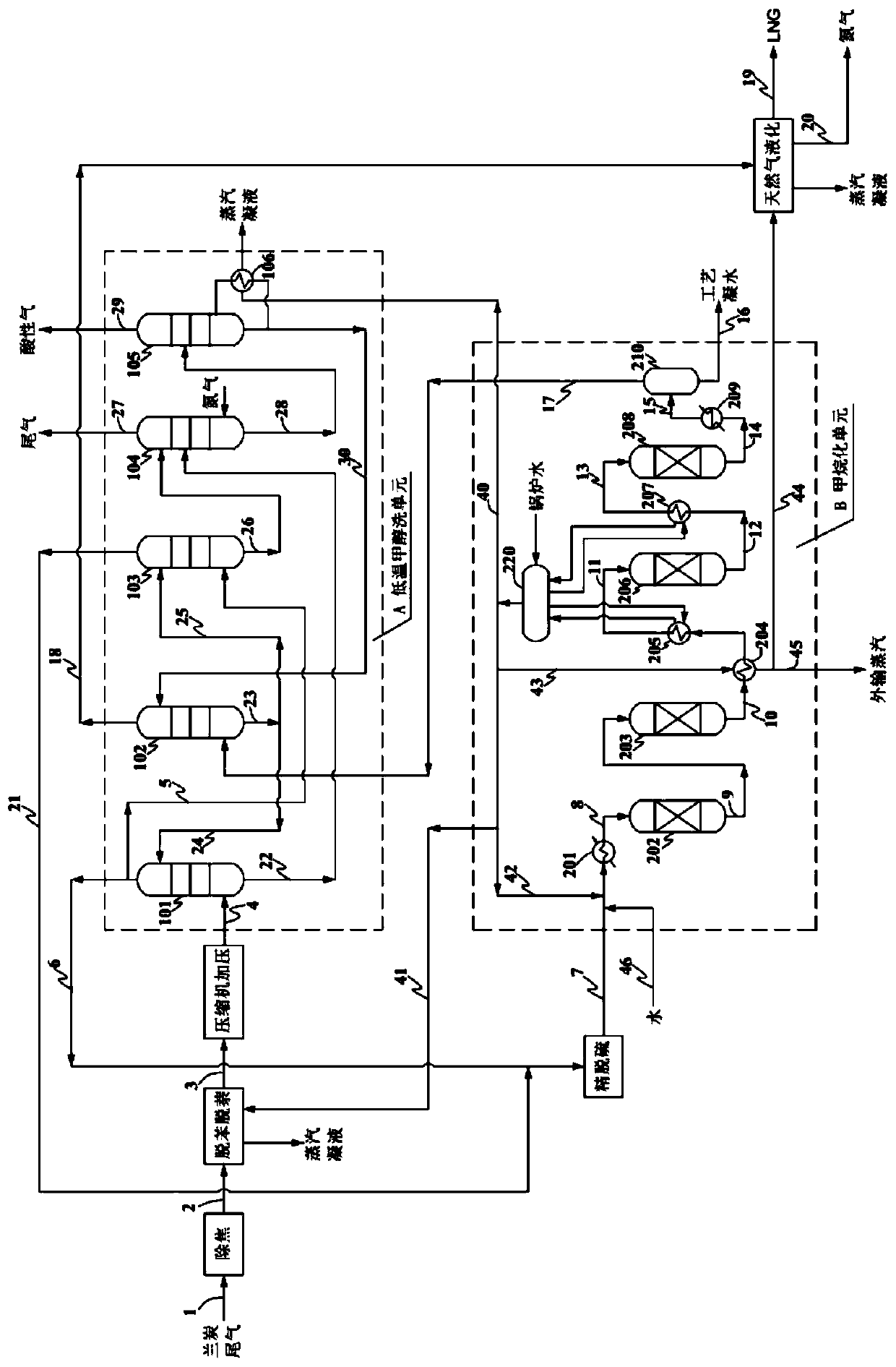

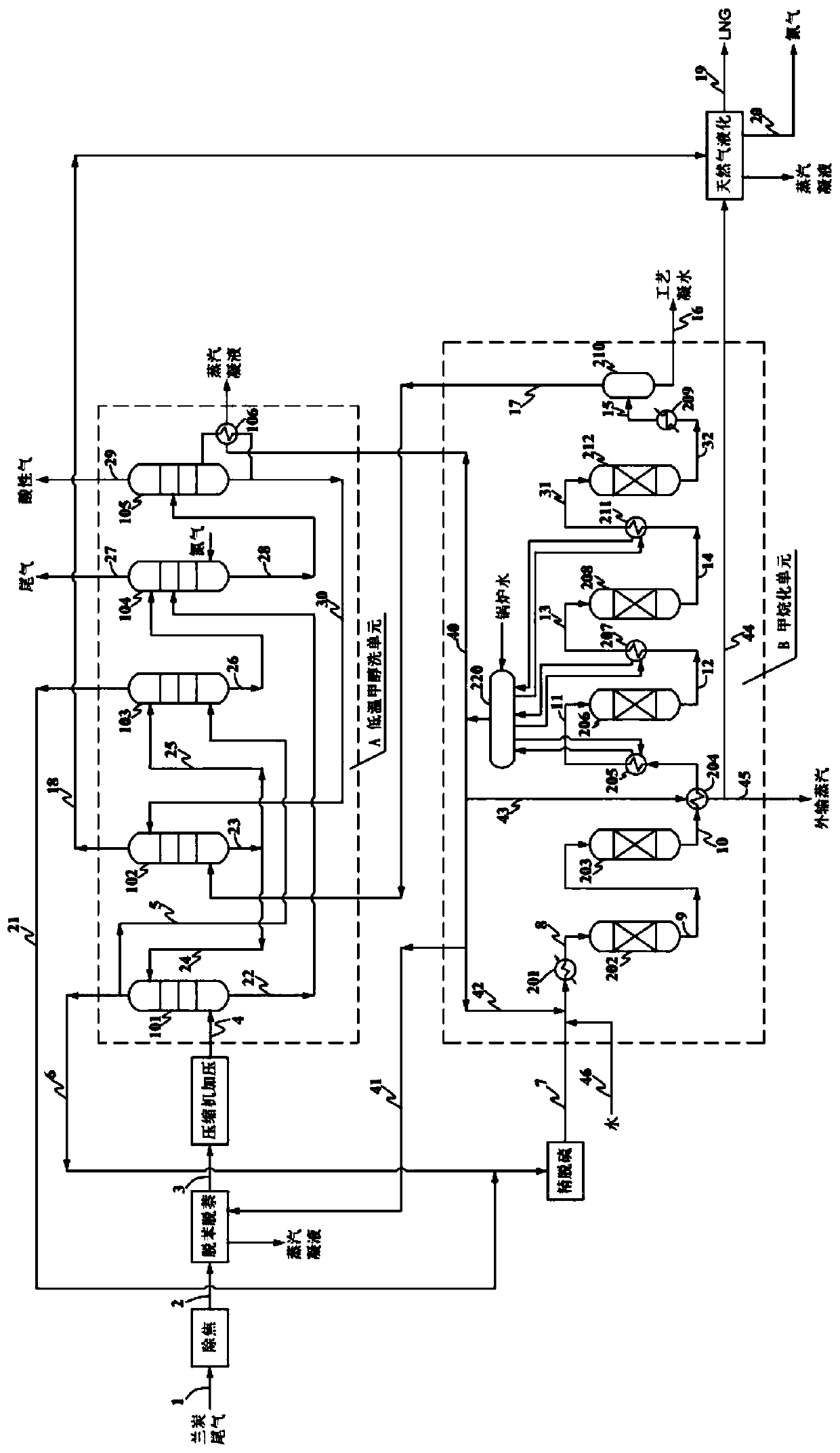

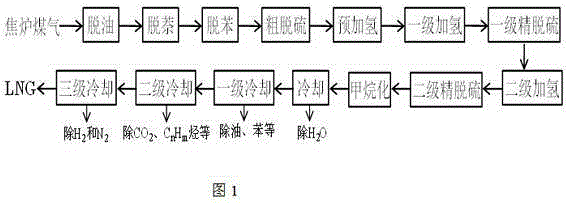

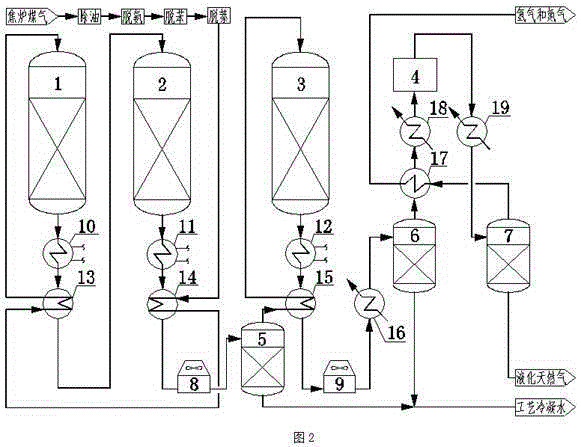

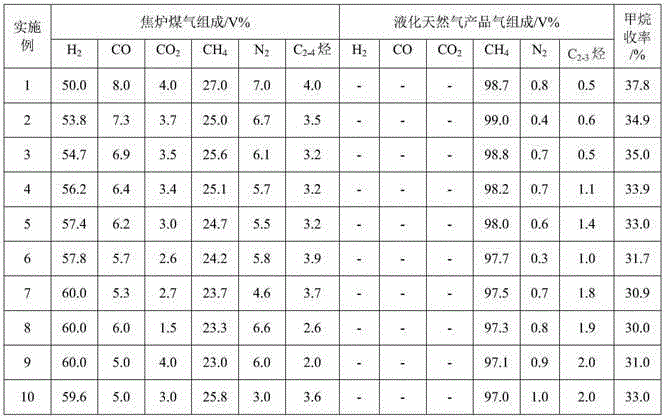

Method for preparing liquefied natural gas from semi-coke tail gas

The invention relates to a method for preparing liquefied natural gas from semi-coke tail gas. The method includes: firstly, after decoking and benzene and naphthalene removal of semi-coke tail gas, and sending to a rectisol unit for purification and desulfurization; then, mixing the desulfurized semi-coke tail gas with high-methane gas, jointly sending into a methanation unit for methanation to obtain a crude methane gas product, sending into the rectisol unit for purification and decarbonization; finally, performing cryogenic separation to remove nitrogen to obtain liquefied natural gas. Compared with the prior art, the method has advantages that by semi-coke tail gas treatment through the rectisol unit and the methanation unit, circulation absorbing agent consumption is sharply reduced,and energy consumption and system CH4 loss in a decarbonization process are reduced; in addition, by adoption of recovered CH4-rich gas and injection of water and / or system self-produced water vaporinto the methanation unit, methanation reaction temperature rise can be controlled so as to guarantee a methanation process against temperature runaway; moreover, heat balance of a whole system can beeffectively realized in the whole process, and economy in preparation of LNG (liquefied natural gas) from the semi-coke tail gas is improved.

Owner:WISON ENG

Rectisol hydrogen sulfide treatment device

PendingCN110314540AReduce or eliminate surrounding odorImprove the ecological environmentDispersed particle separationGas contaminants removalSorbentNitrogen

The invention discloses a rectisol hydrogen sulfide treatment device in the technical field of chemical production. The device comprises a hydrogen sulfide concentration tower, a pipeline for tail gasfrom the hydrogen sulfide concentration tower to a heat exchanger, a nitrogen pipeline, a pipeline from a hydrogen sulfide adsorption tower to a torch and a hydrogen sulfide adsorption tower pressuregauge, wherein the upper portion of the hydrogen sulfide concentration tower is connected with the pipeline for the tail gas from the hydrogen sulfide concentration tower to the heat exchanger, and the pipeline for the tail gas from the hydrogen sulfide concentration tower to the heat exchanger is connected with a tail gas outlet of the hydrogen sulfide concentration tower and an inlet of the heat exchanger. The device is characterized in that the tail gas discharged by the hydrogen sulfide concentration tower of a rectisol system of a methyl alcohol device is discharged to a torch system after being treated by the hydrogen sulfide concentration tower instead of being directly discharged to the torch system; a hydrogen sulfide adsorption technology is adopted to remove hydrogen sulfide inthe tail gas, the treatment process is adsorbent adsorption, it is achieved that the final hydrogen sulfide content in the tail gas is 1ppm or below, odor around a plant is reduced or eliminated, theecological environment of the production device is actively improved, and the economical practicability is stronger.

Owner:河南开祥精细化工有限公司

Method of recovering methanol from acidic gas in Rectisol unit

InactiveCN109701363AHigh recovery rateReduce cooling consumptionDispersed particle separationHydroxy compound separation/purificationPhysical chemistryRectisol

The application discloses a method of recovering methanol from acidic gas in a Rectisol unit. The recovery process aims to the methanol in the acidic gas in the Rectisol unit, wherein wastewater fromthe bottom of a tail gas washing column is employed to wash the acidic gas, thus selectively absorbing methanol under low pressure at normal temperature to recover the methanol. The method not only increases recovery rate of methanol and reduces cost, but also reduces consumption of cooling capacity of the unit and avoids accumulation of impurities, such as hydrocarbons, organo-sulfur and the like.

Owner:DALIAN JIACHUN GAS PURIFICATION TECH DEV

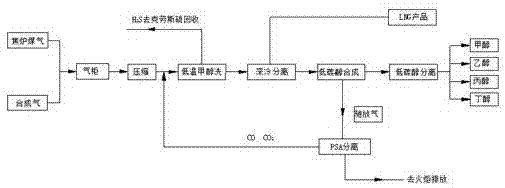

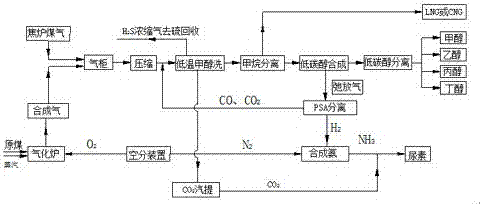

Coke oven gas and synthesis gas production process of low-carbon alcohol and by-product natural gas

ActiveCN105152859BIncrease profitImprove efficiencyOrganic compound preparationGaseous fuelsAlcohol productsHigh carbon dioxide

A process of coke oven gas and synthesis gas to produce low-carbon alcohol and by-product natural gas is to mix coke oven gas and synthesis gas to form crude raw material gas, which is compressed and washed with low-temperature methanol, and the released hydrogen sulfide is recovered by Claus sulfur removal, The removed carbon dioxide is discharged at high altitude; the raw material gas washed and purified by low-temperature methanol is subjected to cryogenic separation, and the extracted methane is produced into LNG products. , the gas is separated by PSA. After the separation, it mainly includes CO and H2 and returns to the low-temperature methanol washing cycle. The other gases after separation are sent to the flare for combustion and emission as purge gas. The separated liquid phase products enter the low-carbon alcohol separation to obtain low-carbon alcohol products. The invention has the advantages of improving the utilization rate of the raw material gas, diversifying the products and regulating the excess production capacity.

Owner:SEDIN ENG

Energy-saving one-step rectisol method

ActiveCN102806000BReduce loadEfficient use ofDispersed particle separationAir quality improvementProduct gasSulfide

An energy-saving one-step rectisol method belongs to the technical field of gas purification. The method is characterized in that two or three desulfuration segments of an absorption tower employ a sulfur-free semi-lean solution for absorption; intersegment coolers are adopted; the desulfuration segments can remove sulfide and approximately 50-60% of CO2 from virgin gas simultaneously; only one decarbonization segment of the absorption tower is adopted; a lean solution is used at the top of the tower, and the sulfur-free semi-lean solution is added; flash steam is absorbed by a sulfur-containing semi-lean solution in the medium-pressure flash evaporation process; after most of CO2 in the flash steam is absorbed, the solution is delivered to a lower tower of an H2S concentrating tower for gas stripping; a sulfur-free methanol solution gas stripping tower is additionally adopted and divided into one or two segments; solutions at the segments are heated appropriately before entering the tower; and the sulfur-free semi-lean solution is delivered to the absorption tower after the gas stripping. The energy-saving one-step rectisol method has the effects and benefits that the number of plates of the absorption tower is reduced by about 20%, the tower diameter is shortened, the circulation volume of a methanol lean solution is reduced, the regeneration load of a rich solution is also reduced, the energy consumption of a device is saved by about 30%, and the device investment is saved.

Owner:DALIAN JIACHUN GAS PURIFICATION TECH DEV

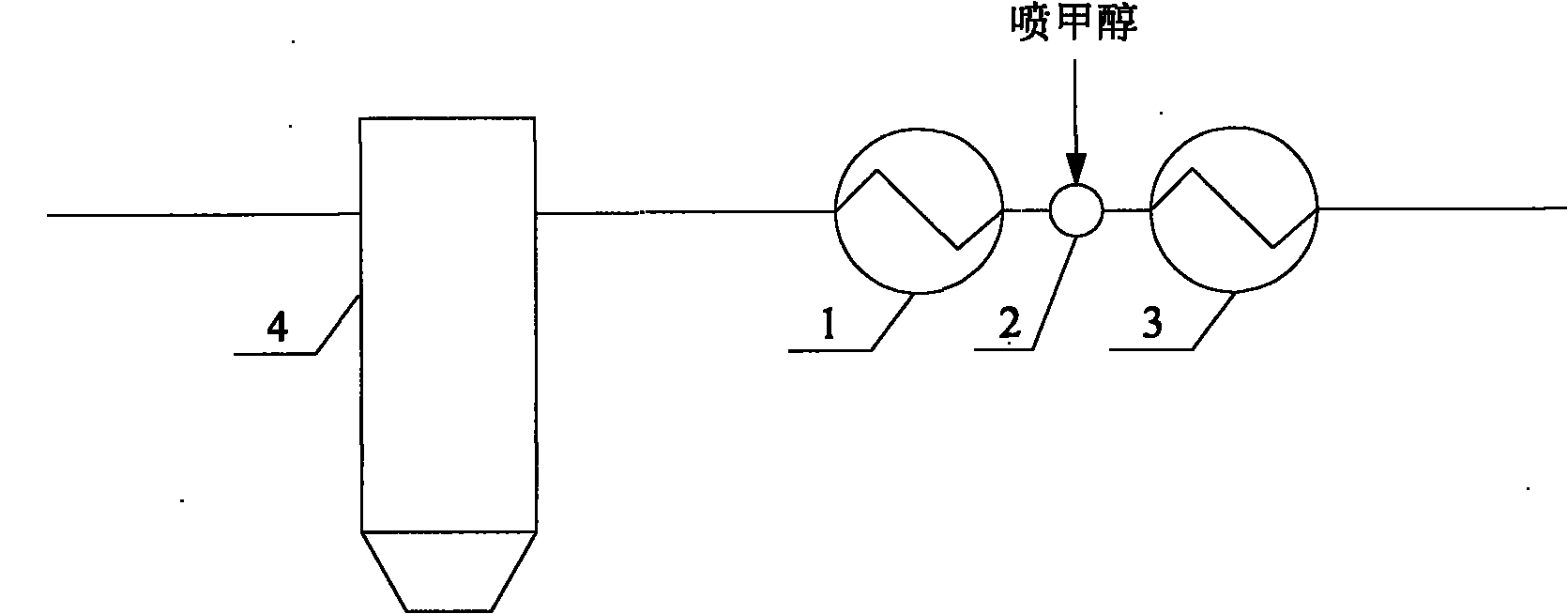

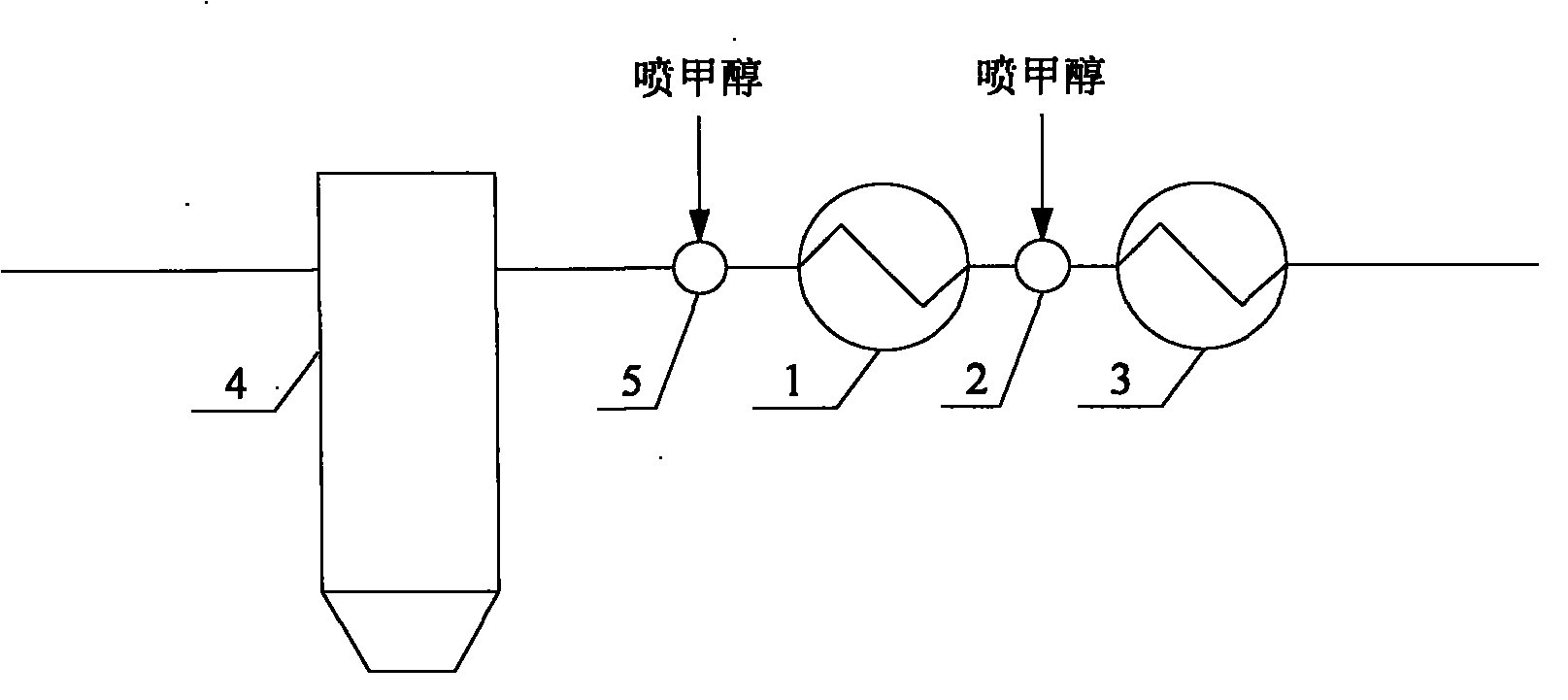

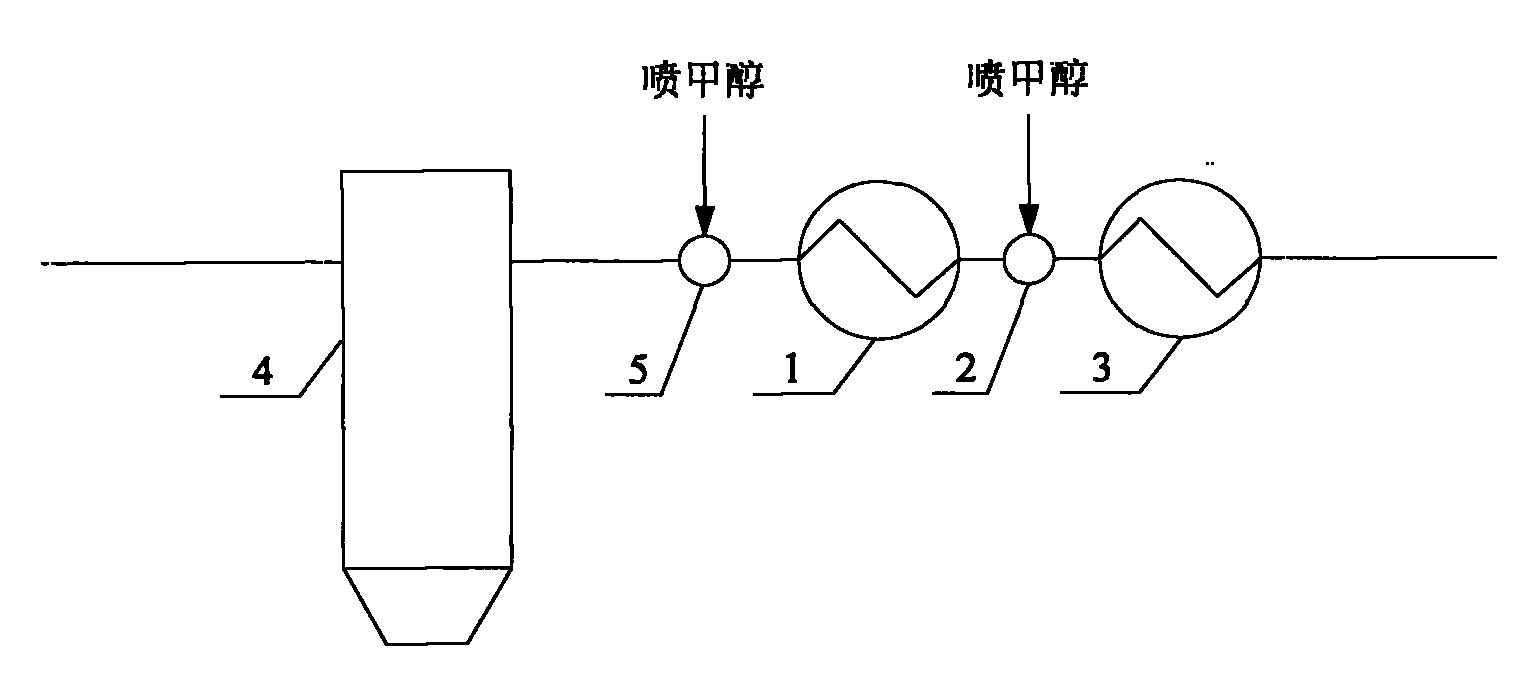

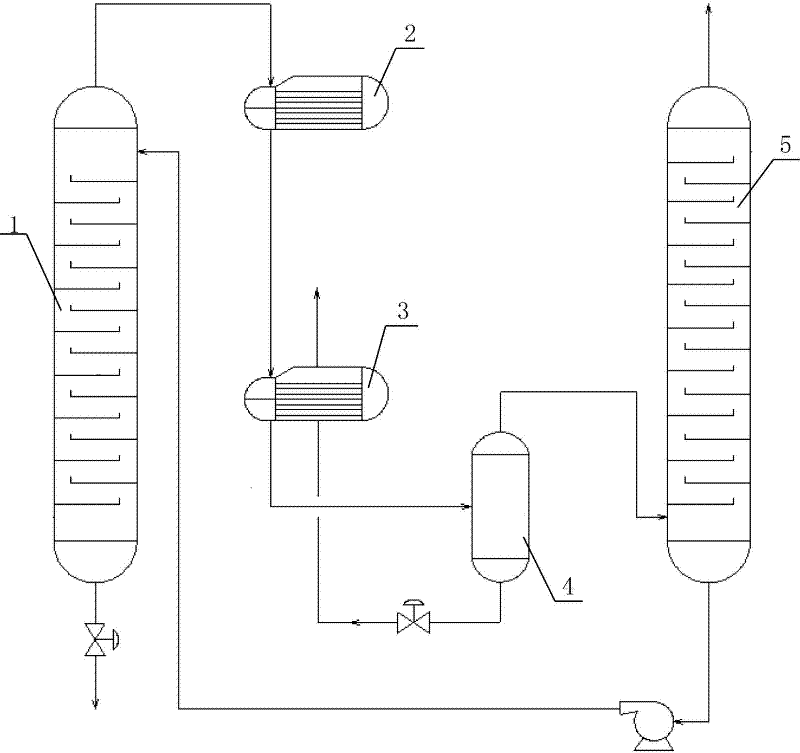

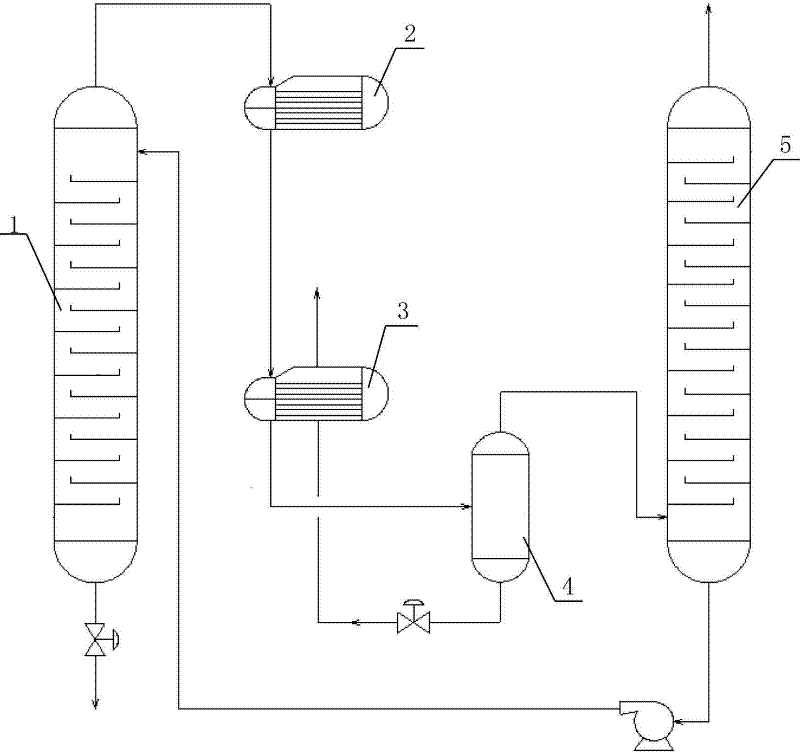

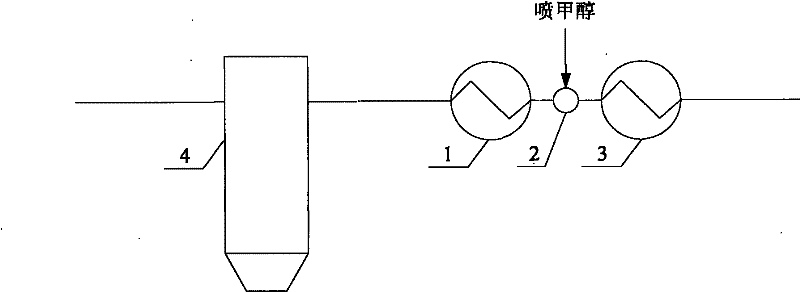

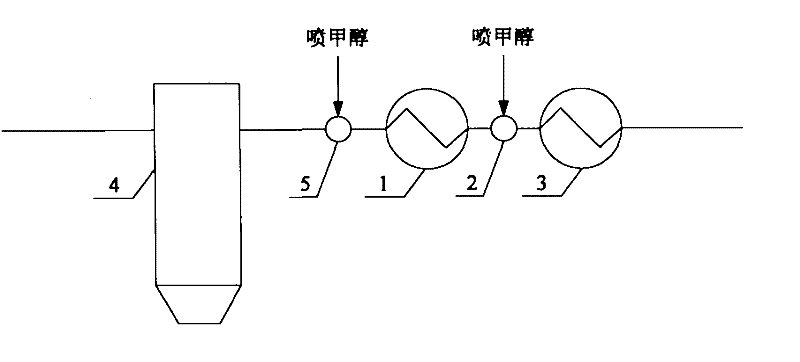

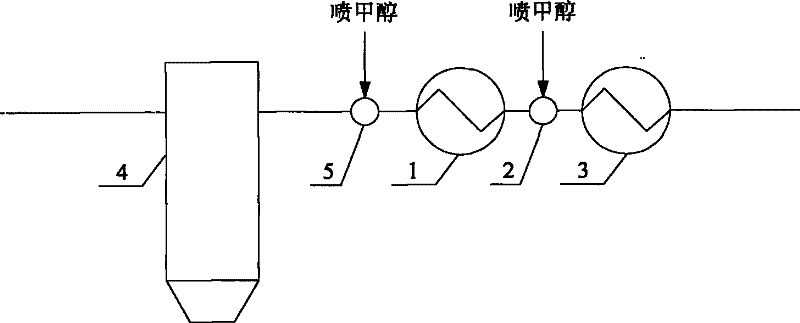

Low-temperature rectisol process and device

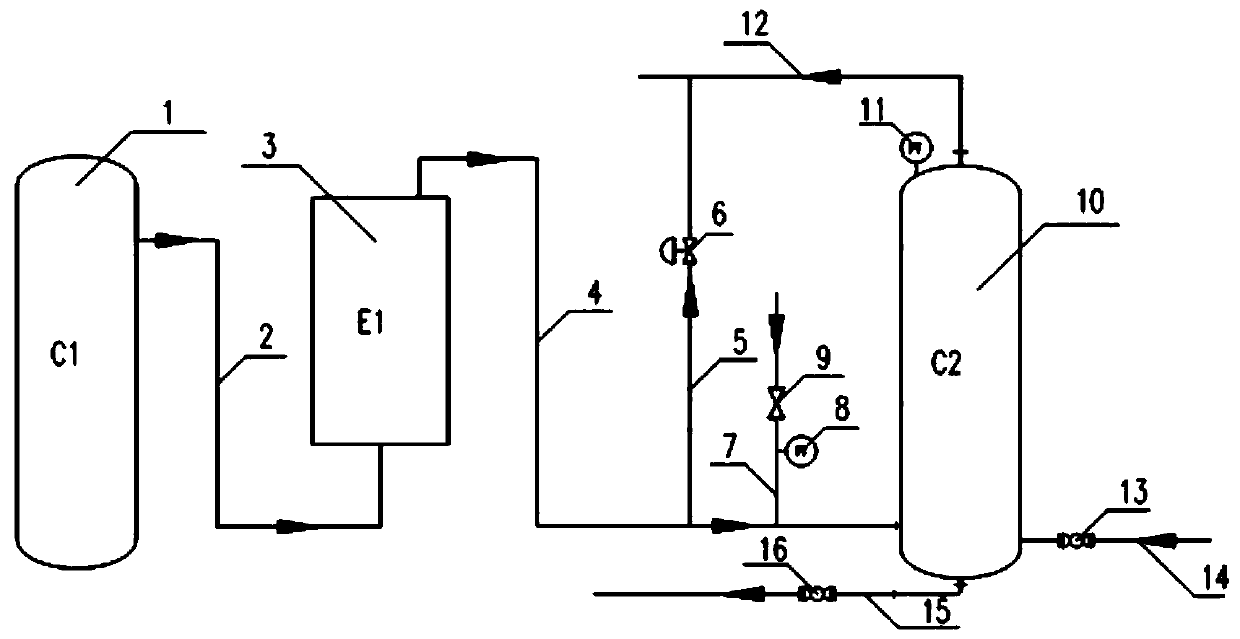

InactiveCN101773764ALowering the freezing pointGood yieldDispersed particle separationCombustible gas purificationAlcoholGas phase

The invention provides a low-temperature rectisol process, comprising the following steps: a) injecting methyl alcohol solution into untreated gases; b) cooling the untreated gases in which methyl alcohol solution is injected; and c) injecting the methyl alcohol solution into the cooled untreated gases again. The invention also provides a low-temperature rectisol device, comprising a second jet bubbler, a first heat exchanger and a first jet bubbler, wherein the second jet bubbler injects the methyl alcohol solution into the untreated gases, the first heat exchanger cools the untreated gases in which the methyl alcohol solution is injected, and the first jet bubbler injects the methyl alcohol solution into the cooled untreated gases again. The low-temperature rectisol process provided by the invention injects the methyl alcohol solution into the untreated gases before cooling to ensure that methyl alcohol is atomized and blended into gaseous phase, and the freezing point of the untreated gases is lowered; when cooling, moisture in the untreated gases has small possibility of condensing, so that the phenomenon that tube bundles are blocked in the heat exchanger can not appear, and gas output does not decrease.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM

Method for producing low-carbon alcohol and co-producing natural gas and urea with syngas and coke oven gas

ActiveCN105061264BReduce manufacturing costIncrease profitUrea derivatives preparationOrganic compound preparationLiquid productAlcohol products

A method for syngas and coke oven gas to produce low-carbon alcohol and co-produce natural gas and urea is to mix crude synthesis gas and coke oven gas to form a raw material gas that satisfies the hydrogen-carbon ratio of low-carbon alcohol synthesis; the raw material gas is washed with methanol at low temperature, The released hydrogen sulfide is desulfurized and recovered, and the removed carbon dioxide is purified by CO2 stripping; the raw material gas washed with low-temperature methanol is subjected to methane separation, and the released methane is made into LNG or CNG, and the pure gas after methane separation is used for synthesis of low-carbon Alcohol reaction, the gas obtained as purge gas enters the PSA for separation, the separated gas mainly includes CO, CO2 and CH4, etc., and returns to the low-temperature methanol washing cycle, and the separated H2 and N2 obtained by air separation are reacted to synthesize ammonia to obtain synthetic ammonia; after purification CO2 reacts with synthetic ammonia to synthesize urea to produce urea products; the obtained liquid phase products are separated from low-carbon alcohols to obtain low-carbon alcohol products. The invention has the advantage of improving the utilization rate of raw gas.

Owner:SEDIN ENG

A device and method for treating low-temperature methanol washing ammonium crystallization and purifying barren liquid methanol

ActiveCN104140852BAvoid cloggingAchieve recyclingCombustible gas purificationGas phaseDiammonium carbonate

The invention discloses a device for treating low temperature methanol washing ammonium crystallization and purifying barren solution methanol and a method for treating low temperature methanol washing ammonium crystallization and purifying barren solution methanol by virtue of the device. The device comprises a thermal regeneration tower of which the top is not provided with a low-temperature condenser, wherein a gas outlet formed in the top of the thermal regeneration tower is communicated with a gas phase separator by virtue of a water cooler, a gas phase outlet of the gas phase separator is communicated with a methanol water-washing tower; the bottom of the gas phase separator is provided with a liquid phase outlet communicated with a liquid phase delivery pipeline, the liquid phase delivery pipeline is divided into two paths, one of which returns back to the top of the thermal regeneration tower and the other is communicated with a methanol-ammonium separation tower. According to the device and the method, by adopting the normal temperature water washing manner, the problems that the condenser and the pipeline arranged on the top of the thermal regeneration tower are blocked by the crystallization of ammonium carbonate in the traditional flow process is solved and the problem of the treatment of intermittent pollution discharge methanol is further solved and thus barren solution methanol is purified and the methanol consumption is reduced.

Owner:SHANGHAI INT ENG CONSULTING

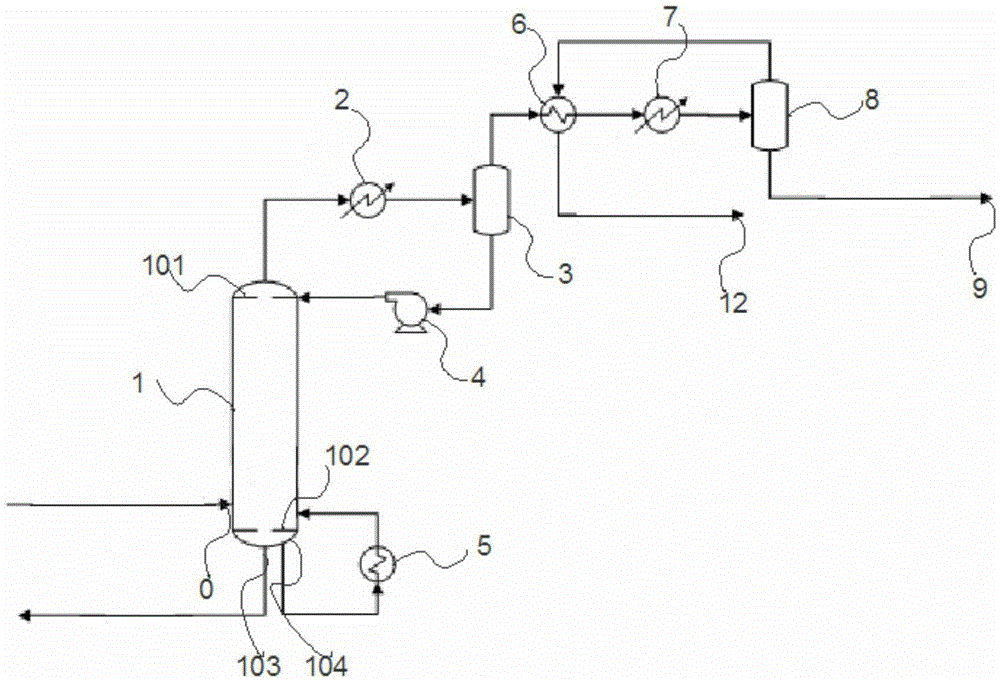

Improved low-temperature rectisol and improved low-temperature rectisol device

InactiveCN102517097ALower carbon dioxide levelsReduced Methanol RecycleCarbon compoundsGas purification by non-gaseous materials condensationCo2 absorptionNitrogen

Provided are an improved low-temperature rectisol method and an improved low-temperature rectisol device. Hydrogen sulfide and carbon dioxide in process gas are removed respectively in two absorbing towers, and the process gas is cooled between two towers so that part of carbon dioxide is liquefied and separated. The two towers absorb hydrogen sulfide and carbon dioxide respectively. Part of carbon dioxide is liquefied and separated by cooling the process gas after hydrogen sulfide is removed through the hydrogen sulfide absorbing tower so that content of carbon dioxide in the process gas is reduced, and content of carbon dioxide in the process gas entering the carbon dioxide absorbing tower is correspondingly reduced. The method can effectively reduce dimensions of a low-temperature rectisol pipeline and equipment, reduces methanol circulating quantity, equipment investment and production running costs are reduced, air-lift nitrogen dosage is reduced, and more pure-state carbon dioxide facilitating application and treatment is obtained.

Owner:李德全 +1

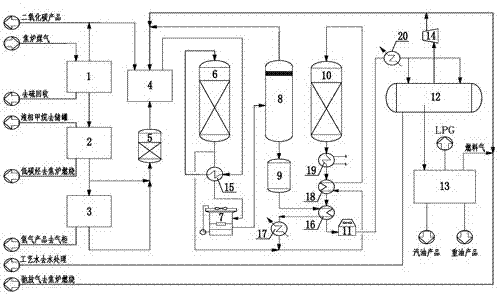

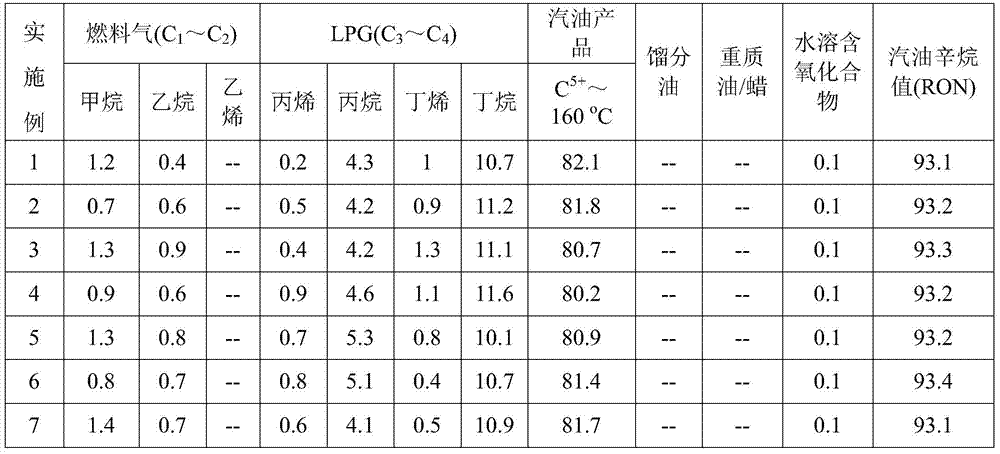

A coke oven process for synthesizing gasoline from methanol and co-producing natural gas and hydrogen

ActiveCN105062591BHigh economic valueIncrease annual profitGaseous fuelsLiquid hydrocarbon mixture productionGas compressorOil phase

Owner:SEDIN ENG

Process for removing acid gas with low-temperature methanol solution

ActiveCN101874967BReduce ammonia contentSolve the blockageDispersed particle separationBy absorptionIncreased carbon dioxideMethanol

The invention relates to a process for removing an acid gas with a low-temperature methanol solution, solving the problem that a low-temperature rectisol plant enriches ammonia and has lower recovery rate of CO2, lower concentration of H2S in acid gases and large solution circulating volume in the traditional process. The process comprises feed gas preprocessing, desulfuration and decarbonizationby an absorption tower, CO2 analysis and gas stripping and hydrogen sulfide concentration by a desorber, regeneration by a heat regenerator and deficient methanol separation by a methanol / water separation tower, wherein the feed gas is conveyed into an ammonia scrubber for deamination and preprocessing. The process can reduce the ammonia enrichment in the low-temperature rectisol plant, increase the recovery rate of CO2, improve the concentration of H2S in acid gases, reduce the circulating volume of the solution and ensure the quality of purified gas products.

Owner:WUHUAN ENG

A kind of method for producing liquefied natural gas from blue carbon tail gas

The invention relates to a method for preparing liquefied natural gas from semi-coke tail gas. The method includes: firstly, after decoking and benzene and naphthalene removal of semi-coke tail gas, and sending to a rectisol unit for purification and desulfurization; then, mixing the desulfurized semi-coke tail gas with high-methane gas, jointly sending into a methanation unit for methanation to obtain a crude methane gas product, sending into the rectisol unit for purification and decarbonization; finally, performing cryogenic separation to remove nitrogen to obtain liquefied natural gas. Compared with the prior art, the method has advantages that by semi-coke tail gas treatment through the rectisol unit and the methanation unit, circulation absorbing agent consumption is sharply reduced,and energy consumption and system CH4 loss in a decarbonization process are reduced; in addition, by adoption of recovered CH4-rich gas and injection of water and / or system self-produced water vaporinto the methanation unit, methanation reaction temperature rise can be controlled so as to guarantee a methanation process against temperature runaway; moreover, heat balance of a whole system can beeffectively realized in the whole process, and economy in preparation of LNG (liquefied natural gas) from the semi-coke tail gas is improved.

Owner:WISON ENG

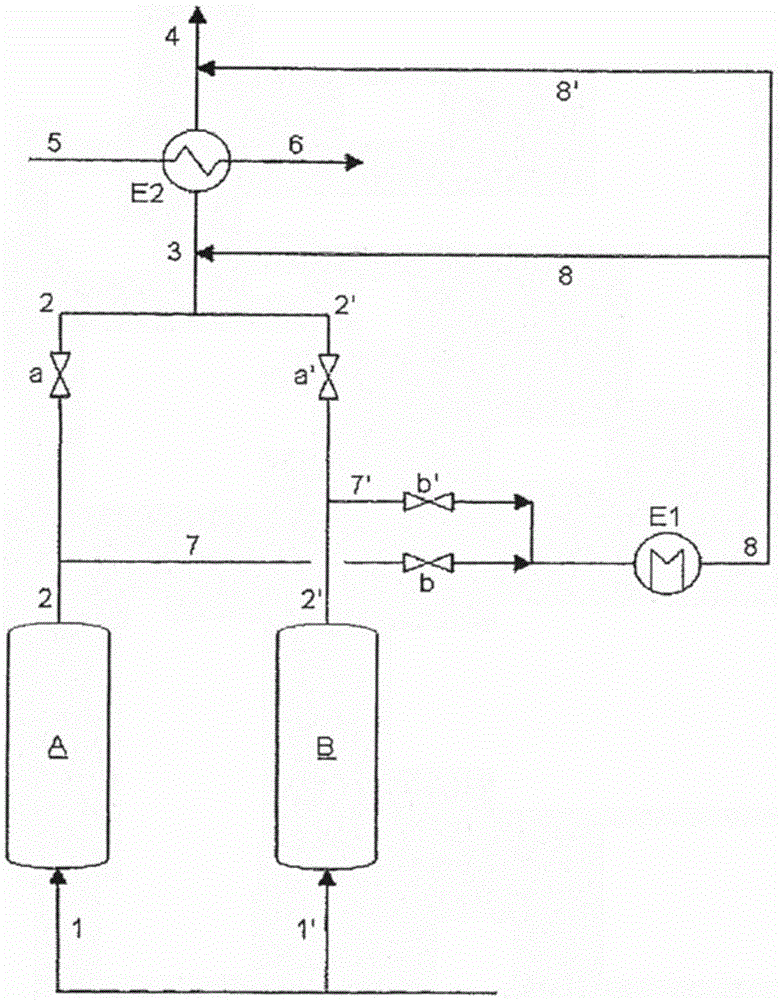

Adsorption method

The method involves carrying out the cooling of the regenerated adsorbent (A,B) to the adsorption temperature with a partial stream of the gas mixture to be analyzed at the end of the regeneration phase. The partial flow of the main stream or the partial stream is deducted, cooled and supplied to the combined stream before or after heat exchange with a medium. The combined flow serves the cooling of the feed gas to be supplied to the Rectisol(RTM: Acid gas removal process) process.

Owner:LINDE AG

Burner for rectisol incinerator

PendingCN110594761AMixed stronglyCombustibility optimizationIncinerator apparatusGaseous fuel burnerCombustorProduct gas

The invention discloses a burner for a rectisol incinerator, and belongs to the field of burners. The technical problem to be solved is to provide the burner for the rectisol incinerator that the structure is simple, the control of fuel gas and other gas gases is independent, mixing is carried out after the gas enters the burner, potential safety hazards can be eliminated, gas does not cross, andthe safety coefficient is high. According to the technical scheme adopted for solving the technical problem, the burner for the rectisol incinerator comprises a furnace barrel, wherein a secondary fuel gas inlet pipe is arranged at the front part of the furnace barrel, a primary nozzle is arranged at the rear part of the furnace barrel, other gas inlet pipes are arranged between the primary nozzleand the secondary fuel gas inlet pipe, the outlet of the secondary fuel gas inlet pipe is divided into a plurality of nozzles which are annularly arranged, an annular wind shield is arranged at the outlet of each nozzle, and each annular wind shield is a conical wind shield. The burner for the rectisol incinerator can be widely applied to the field of burners.

Owner:SHANXI ALEX ENVIRONMENTAL PROTECTION TECH

A system, method and application of low-temperature methanol scrubbing tail gas recovery and utilization

ActiveCN106984099BSimple processFew process parameters are easy to adjustEngine sealsDispersed particle separationNitrogenProcess engineering

The invention discloses a Rectisol tail gas recovery system and method and their application and solves the problem that Rectisol tail gas treatment is high in cost. The technical process is simple, the main parameter is fan outlet pressure, and process parameters to be controlled are few and easy to adjust; Rectisol vented tail gas replaces seal nitrogen in a coal mill, the waste is utilized, resources are saved, and the investment in Rectisol tail gas treatment is lowered. According to the technical scheme, the Rectisol tail gas recovery system comprises a tail gas source, a separator, a fan and a coal mill, drops are removed from the tail gas source via the separator, the tail gas source is pressurized via a fan and is delivered to a sealed air passage in the coal mill so as to arrive at sealing, and the tail gas source is a Rectisol tail gas source.

Owner:LUXI CHEM GRP

Low-temperature spiral wound heat exchanger for non-converted gas cooler

InactiveCN103017573BReduce in quantityCompact structureChemical industryStationary tubular conduit assembliesDouble tubeEngineering

The invention discloses a low-temperature spiral wound heat exchanger for a non-converted gas cooler, and is mainly applied to the coal chemical industry fields of coal based syngas, coal-to-methanol, and the like, and the technical fields of the rectisol process comprising low-temperature gas purification and low-temperature liquefaction separation, and the like. The low-temperature spiral wound heat exchanger is tower spiral wound heat exchange equipment with the combination of single-fluid and double-fluid, achieving the purpose of precooling non-converted feed gas by process cold gas by mainly utilizing rectisol process off-gas and low-temperature syngas to precool the non-converted feed gas. According to the low-temperature spiral wound heat exchanger for the non-converted gas cooler, disclosed by the invention, the basic structure and the heat exchange process calculation method of a compound spiral wound heat exchanger combining a single-tube-bundle spiral wound heat exchanger and a double-tube-bundle spiral wound heat exchanger for the non-converted gas cooler are systematically researched, the method of introducing the moderate temperature cold source at the middle section and combining the single-fluid and double-fluid spiral wound heat exchangers up and down is adopted, and the entry points of multi-fluid heat exchange at different potential temperatures are improved, so that the heat exchange efficiency is enhanced, the heat exchange area is saved, and the size of the heat exchanger is reduced.

Owner:张周卫

A method for preparing liquefied natural gas by sulfur-resistant methanation of coke oven gas

Owner:SEDIN ENG +1

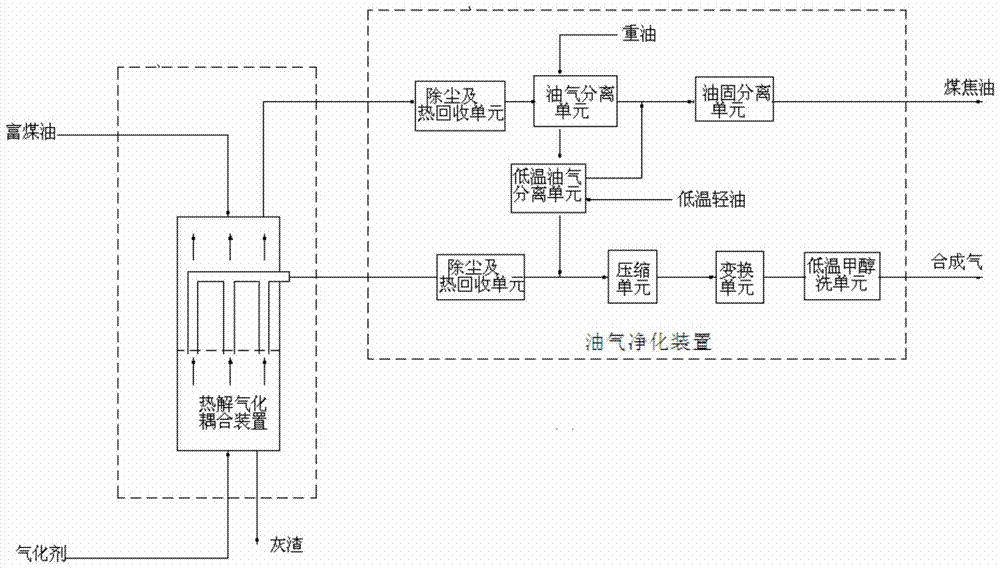

Method for producing coal tar and synthesis gas from oil-rich coal using pyrolysis gasification coupling device and oil gas purification device

ActiveCN105018155BNo need for external heatingRealize separate purification treatmentCombustible gas purificationCombustible gas productionWater dischargeCoal dust

The invention discloses a method for producing coal tar and synthetic gas from oil-rich coal using a pyrolysis gasification coupling device and an oil gas purification device. The oil-rich coal is used as a raw material, and the pyrolysis gas and crude oil are firstly obtained through the pyrolysis gasification coupling device. Syngas, to realize the separate collection of two gases in the same device. Then, in view of the problems of difficult oil and gas separation, low recovery rate of coal tar, and large amount of waste water, an oil and gas purification device was set up to recover coal tar through dust removal and heat recovery, oil and gas separation, oil-solid separation, and low-temperature oil and gas separation to obtain coal Tar products, improve the recovery rate of coal tar, and reduce the waste water discharge in the separation process. At the same time, the synthesis gas is further purified through conversion, low-temperature methanol washing and other units to obtain synthesis gas products.

Owner:HUALU ENG & TECH

Method for cleaning methanol fine filter in low-temperature methanol washing device

ActiveCN104436870BEasy to cleanExtended use timeFilter regenerationBiochemical engineeringPhosphoric acid

Owner:GUIZHOU TIANFU CHEM

Low-temperature rectisol process and device

InactiveCN101773764BLowering the freezing pointGood yieldDispersed particle separationCombustible gas purificationAlcoholGas phase

The invention provides a low-temperature rectisol process, comprising the following steps: a) injecting methyl alcohol solution into untreated gases; b) cooling the untreated gases in which methyl alcohol solution is injected; and c) injecting the methyl alcohol solution into the cooled untreated gases again. The invention also provides a low-temperature rectisol device, comprising a second jet bubbler, a first heat exchanger and a first jet bubbler, wherein the second jet bubbler injects the methyl alcohol solution into the untreated gases, the first heat exchanger cools the untreated gases in which the methyl alcohol solution is injected, and the first jet bubbler injects the methyl alcohol solution into the cooled untreated gases again. The low-temperature rectisol process provided by the invention injects the methyl alcohol solution into the untreated gases before cooling to ensure that methyl alcohol is atomized and blended into gaseous phase, and the freezing point of the untreated gases is lowered; when cooling, moisture in the untreated gases has small possibility of condensing, so that the phenomenon that tube bundles are blocked in the heat exchanger can not appear, and gas output does not decrease.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM

Determination method and application of hydrogen sulfide content in methanol solution

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com