Method for controlling CO/H2 molar ratio in coal to methanol purification device

A purification device and coal-to-methanol technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problem of catalyst bed temperature, reactive CO transformation reaction degree difficult to control, large loading amount, and impossible to optimize Methanol circulation system and other issues, to achieve the effects of stable operation and operation control, avoiding large fluctuations in CO content, and facilitating the use of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

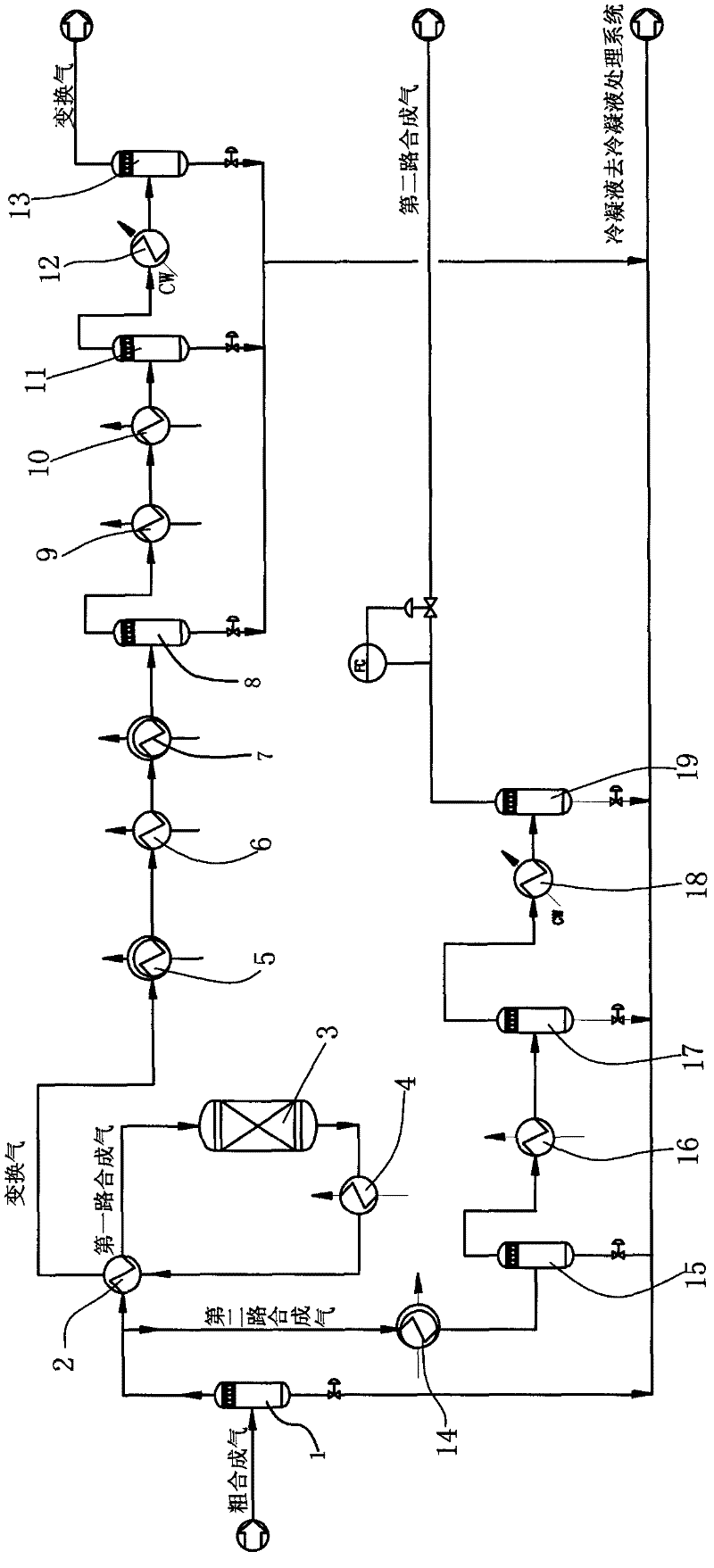

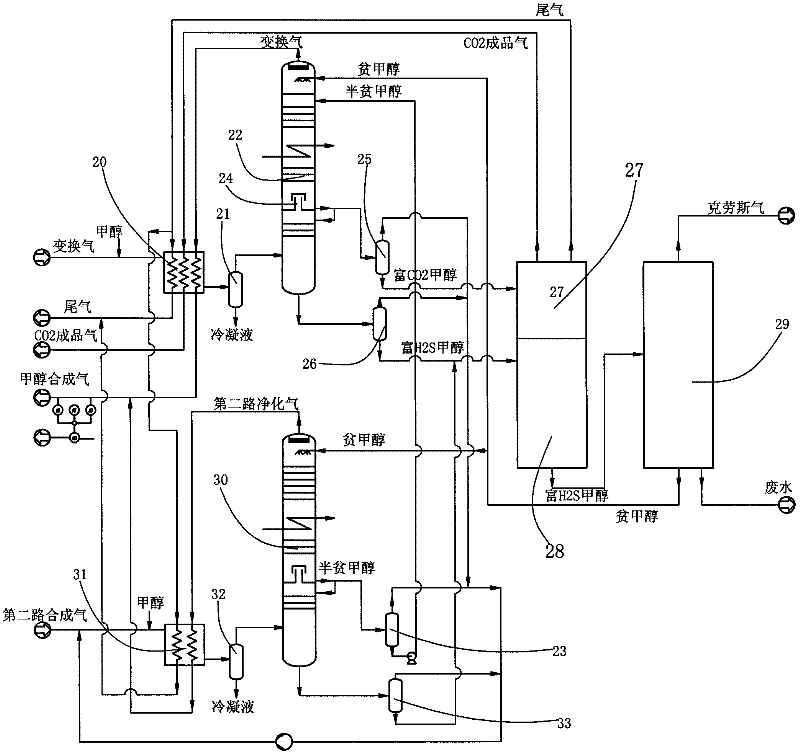

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

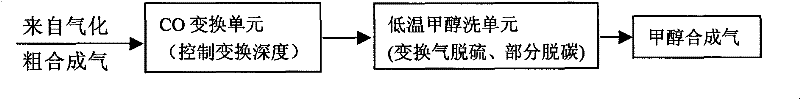

[0023] Such as figure 1 and figure 2 As shown, the CO / H 2 The method of molar ratio is as follows:

[0024] 1. Crude syngas split, CO conversion, two-way syngas heat exchange, the specific steps are as follows:

[0025] The crude synthesis gas from the gasification unit at a temperature of 240°C and a pressure of 62 barg has a molar composition of H 2 O: 58.55%, H 2 : 15.19%, CO: 18.28%, CO 2 : 7.63%, H 2 S: 0.106%, others: 0.244%; the gas-liquid separator 1 at the inlet of the crude synthesis gas sent to the CO conversion unit separates the liquid phase, and the obtained gas phase is divided into two paths, namely, the first synthesis gas and the second Synthetic gas. The flow ratio of the first synthesis gas and the second synthesis gas changes according to different processes: for example, in the process of coal water slurry gasifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com