Patents

Literature

93results about How to "Mixed strongly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

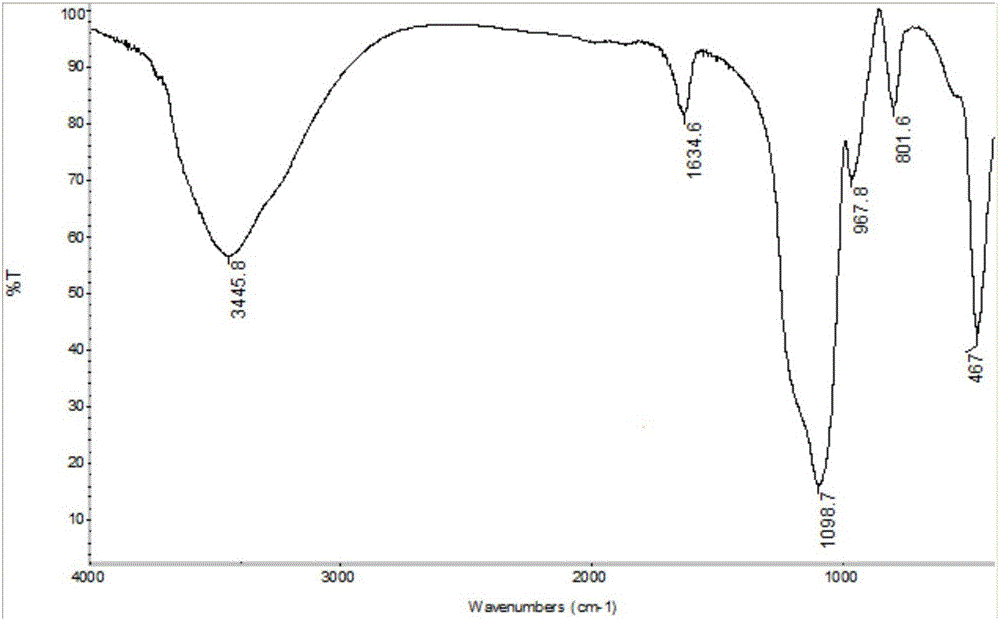

Magnesium cementitious composition

InactiveUS20070017418A1Reduce shrinkReduce crackingSolid waste managementCeramicwareFiberAdditive ingredient

A cementitious product for applications such as stucco, plaster coating, fireproof coatings, casting / molding applications and flooring. The product is a blend of magnesium oxide and magnesium chloride. Suitable fillers such as bottom ash, fly ash, clinker and other pulverized materials may be added. Fibrous materials, foaming agents and surfactants may also be added to achieve product characteristics for specific application. Processes for blending the selected ingredients are also disclosed.

Owner:DENNIS ANDREW C

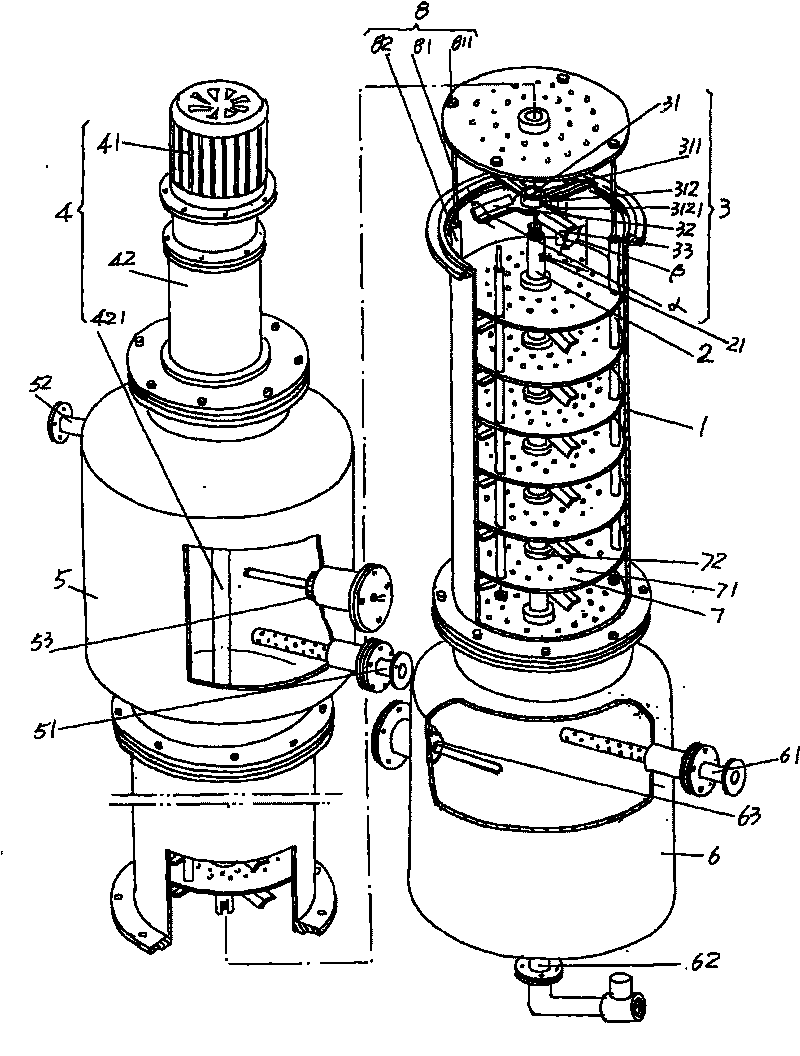

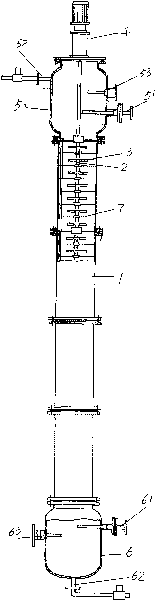

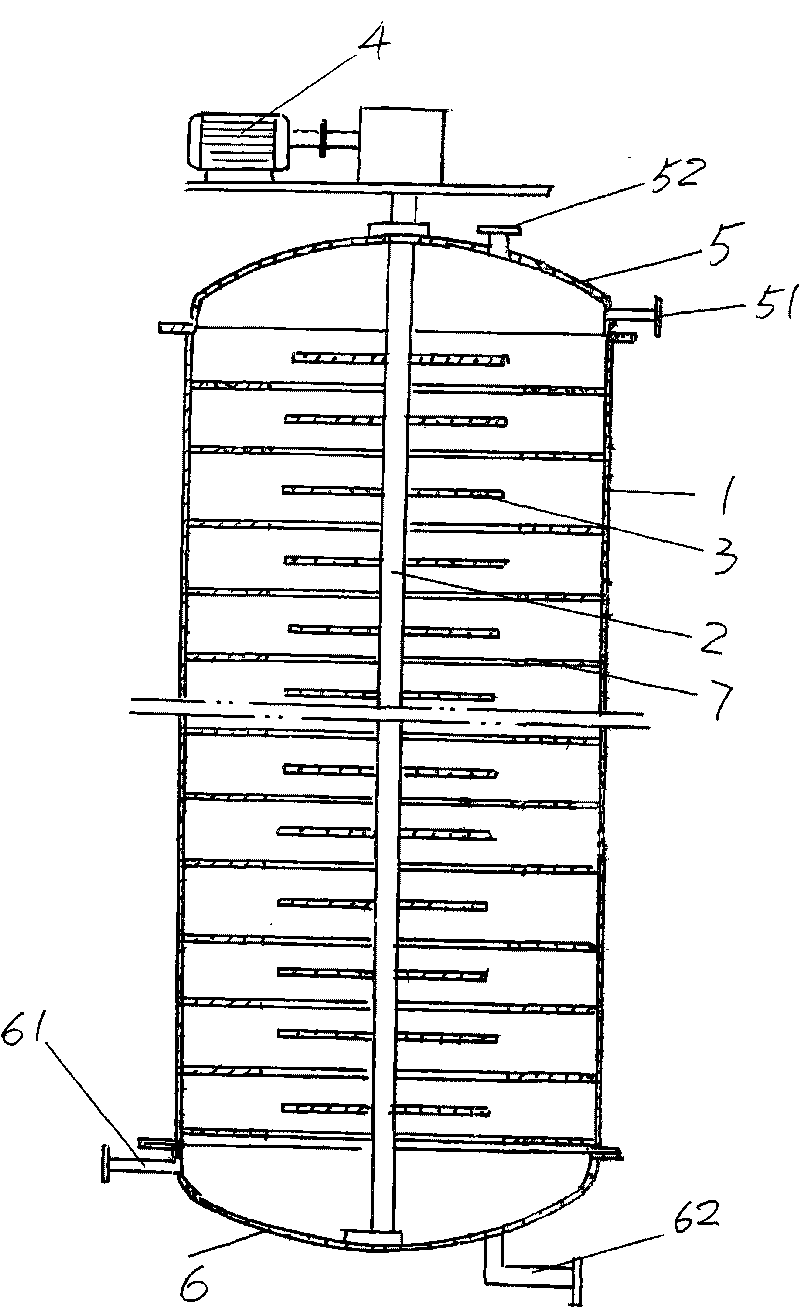

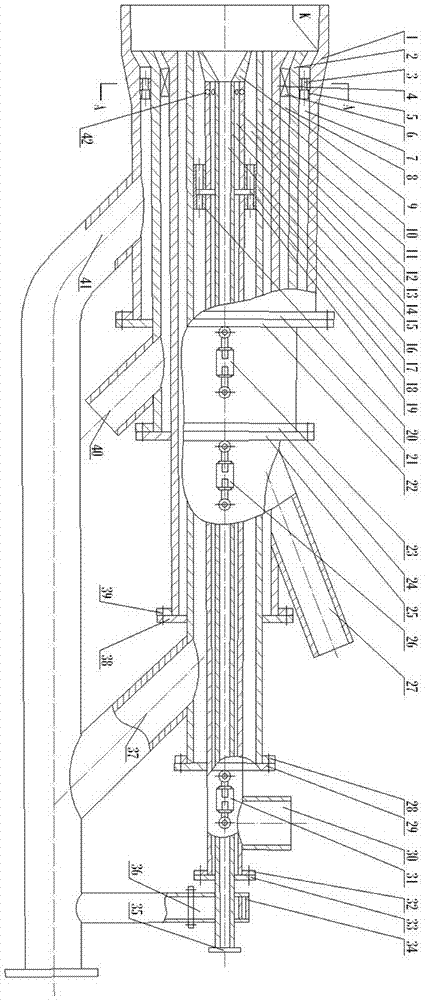

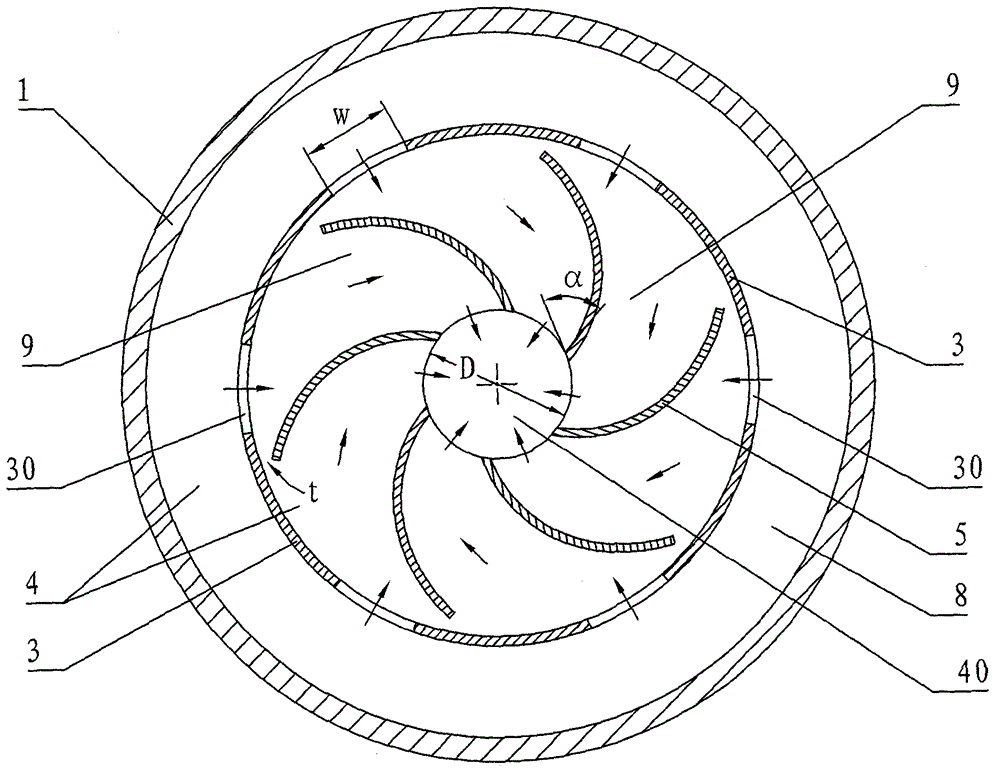

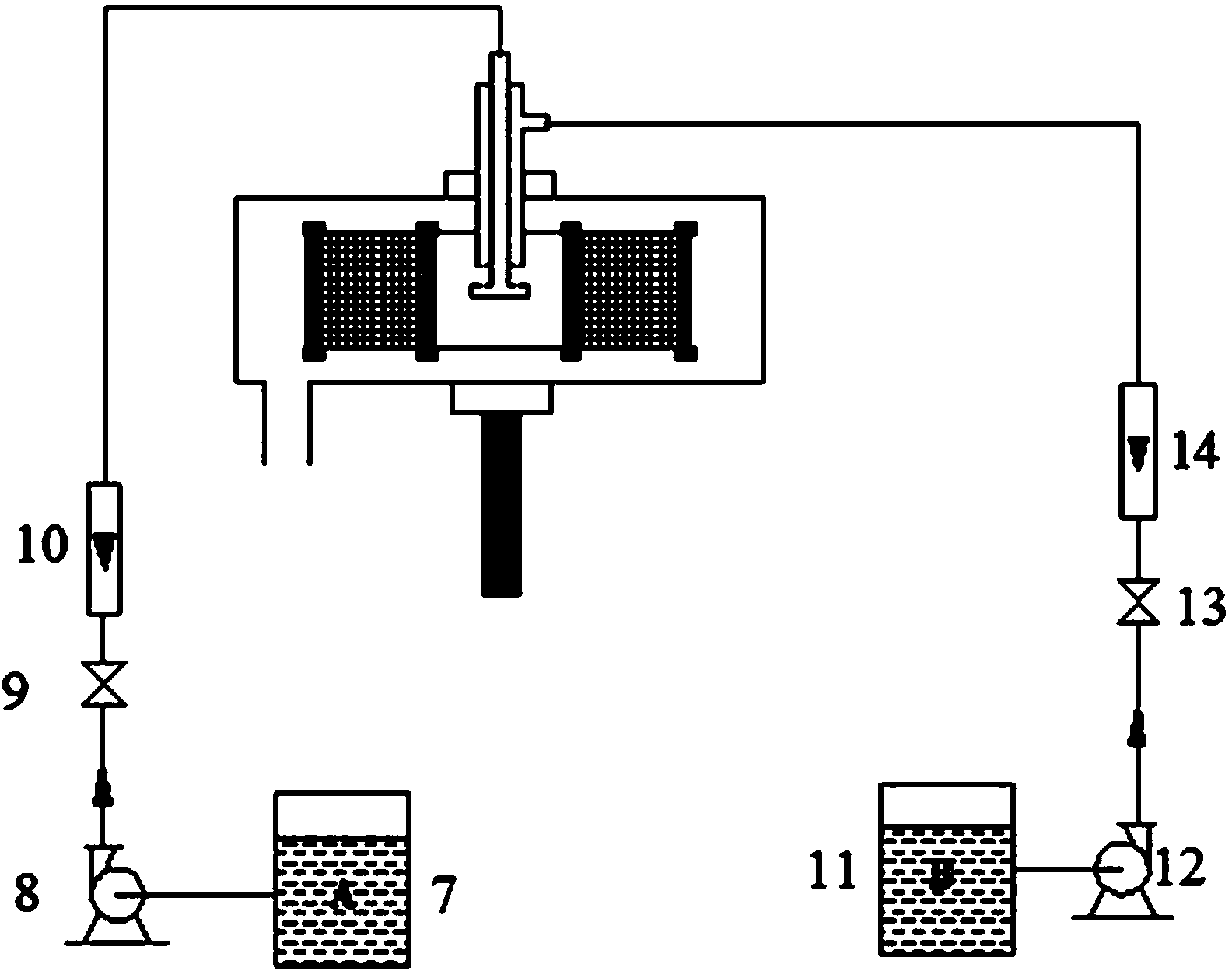

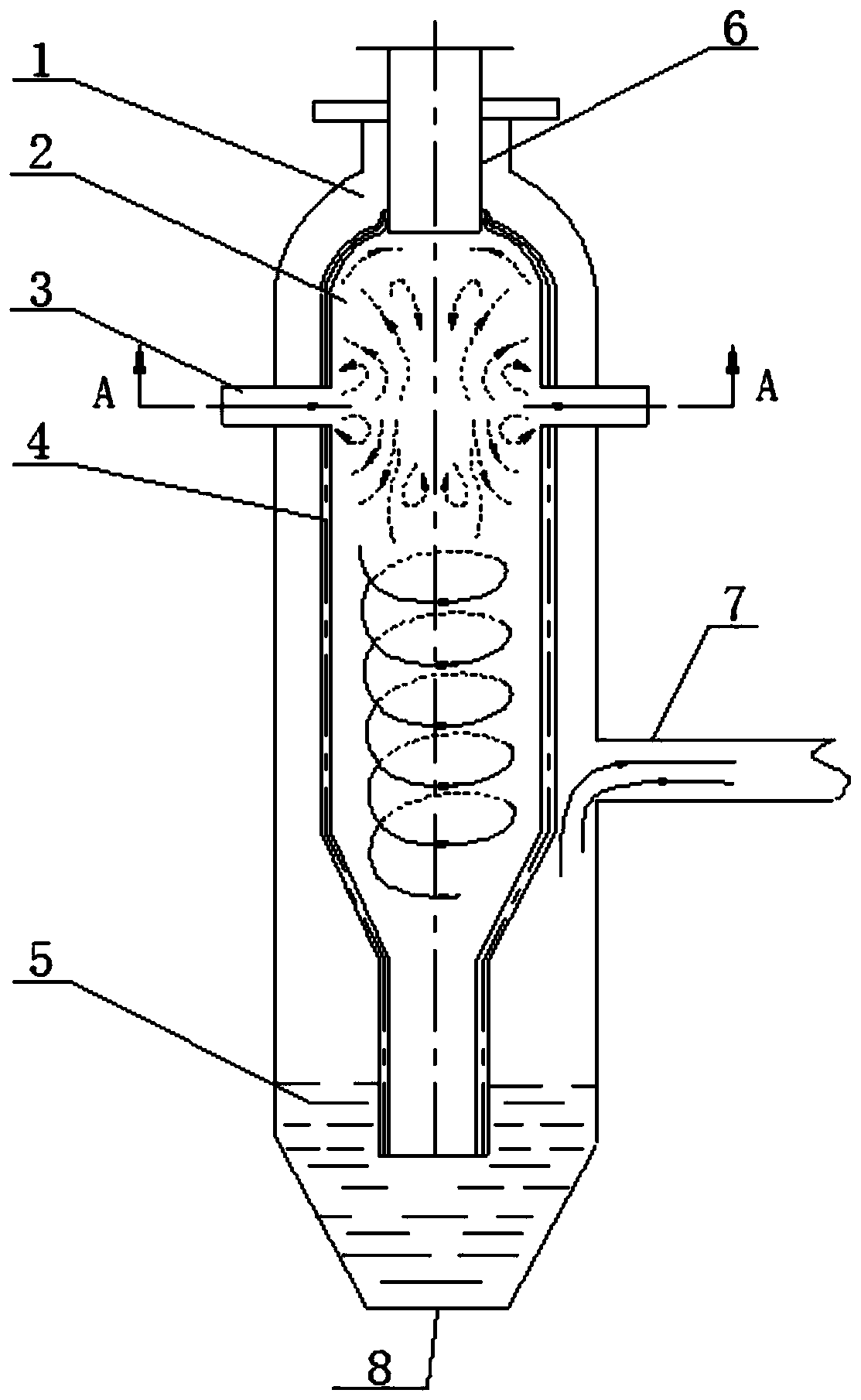

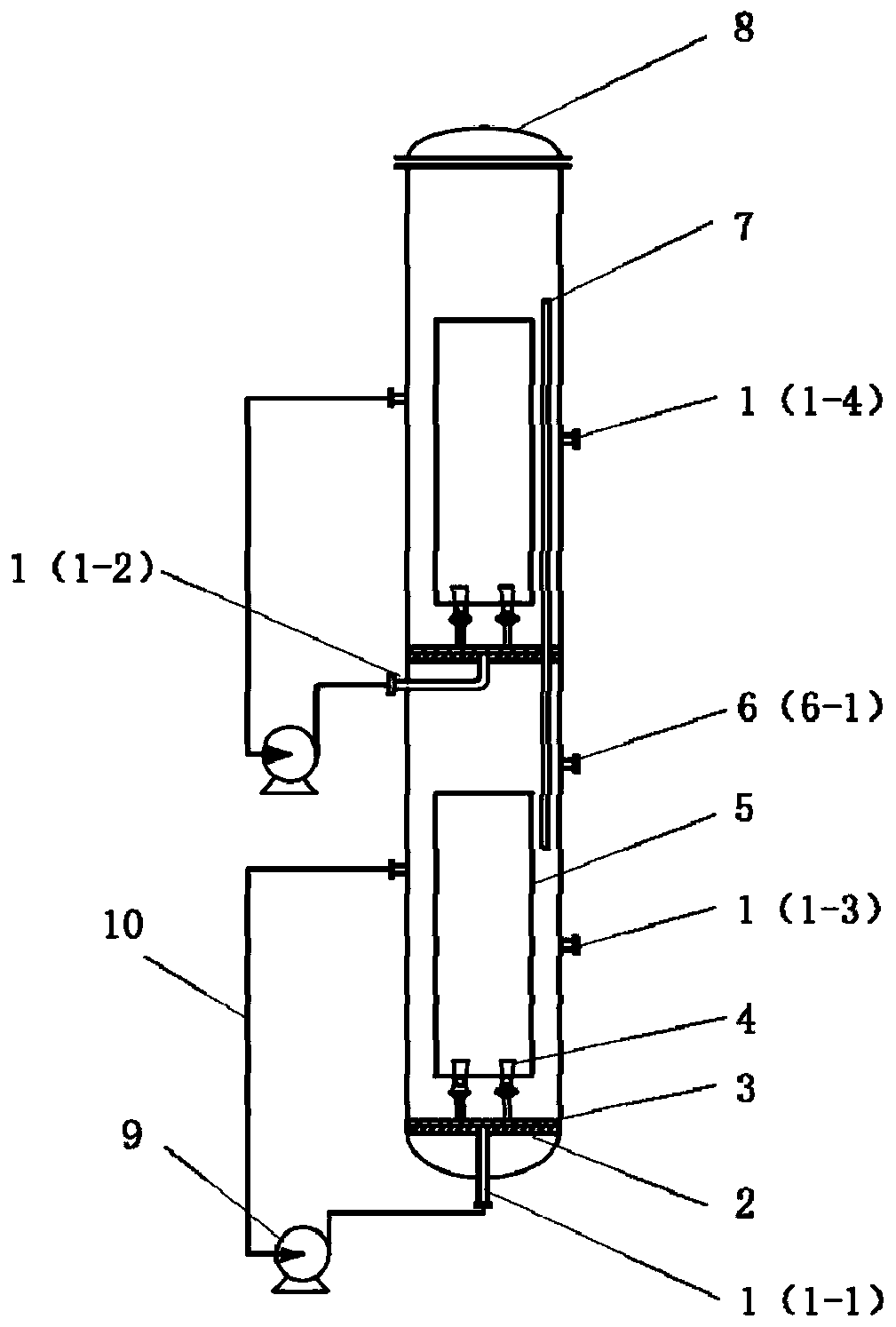

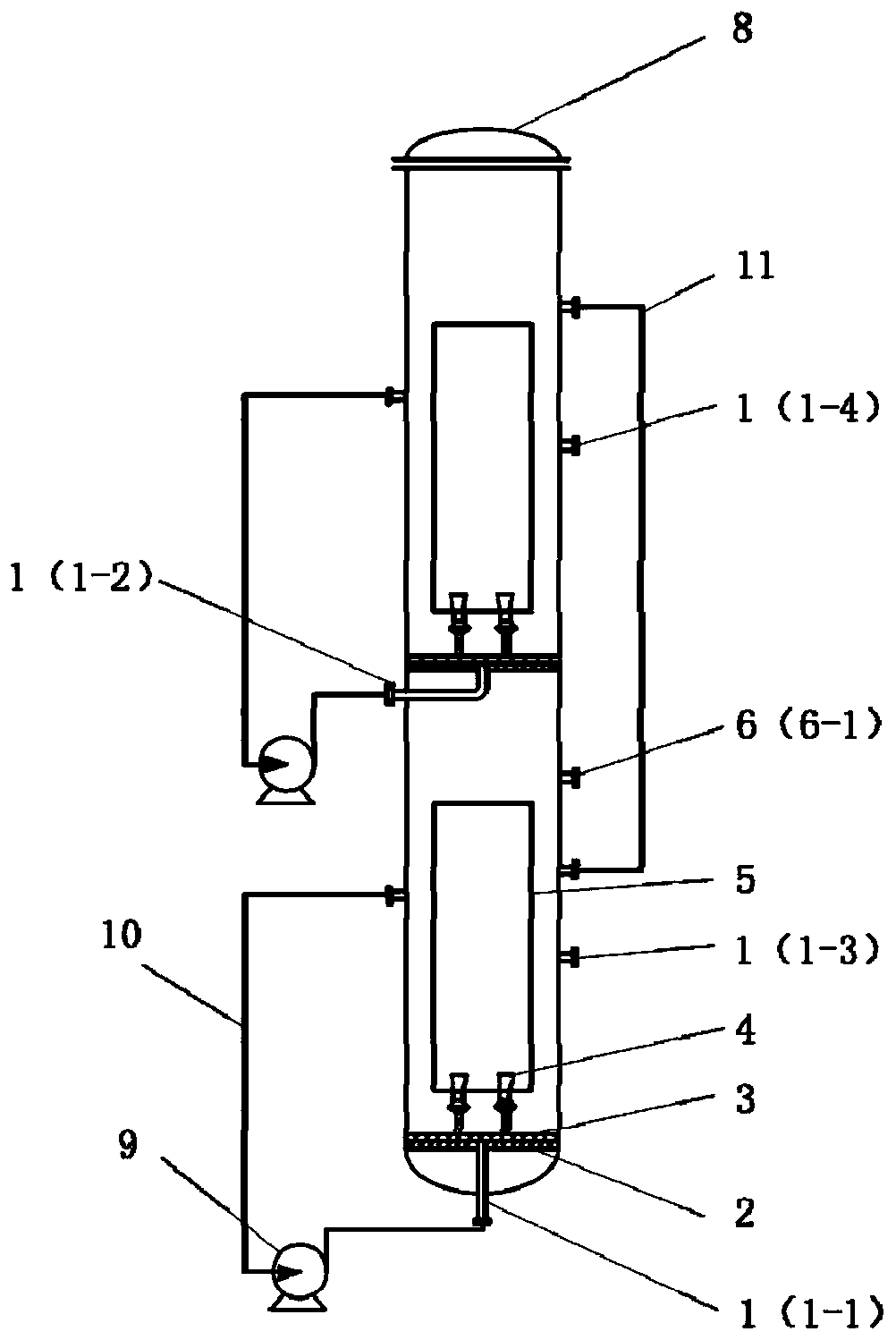

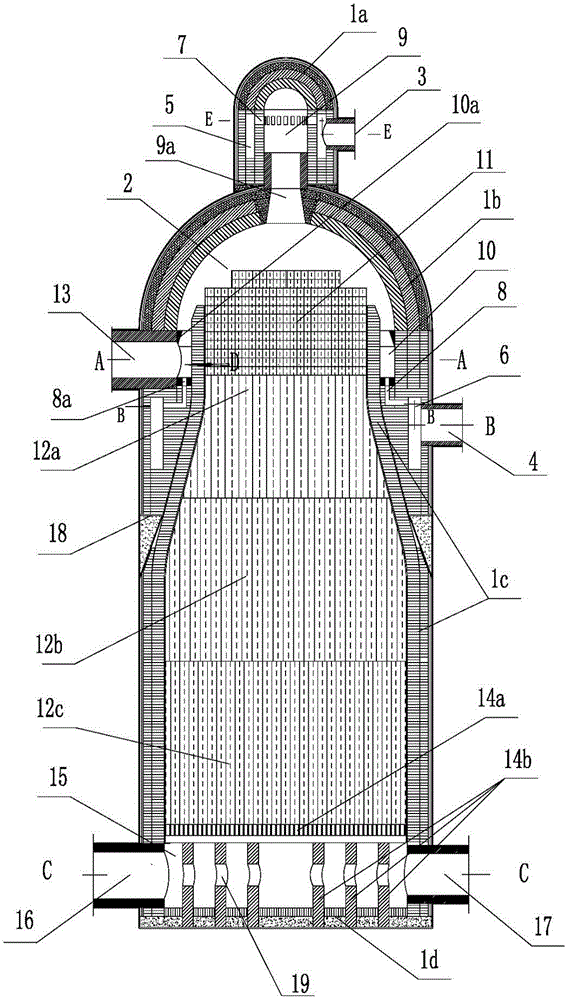

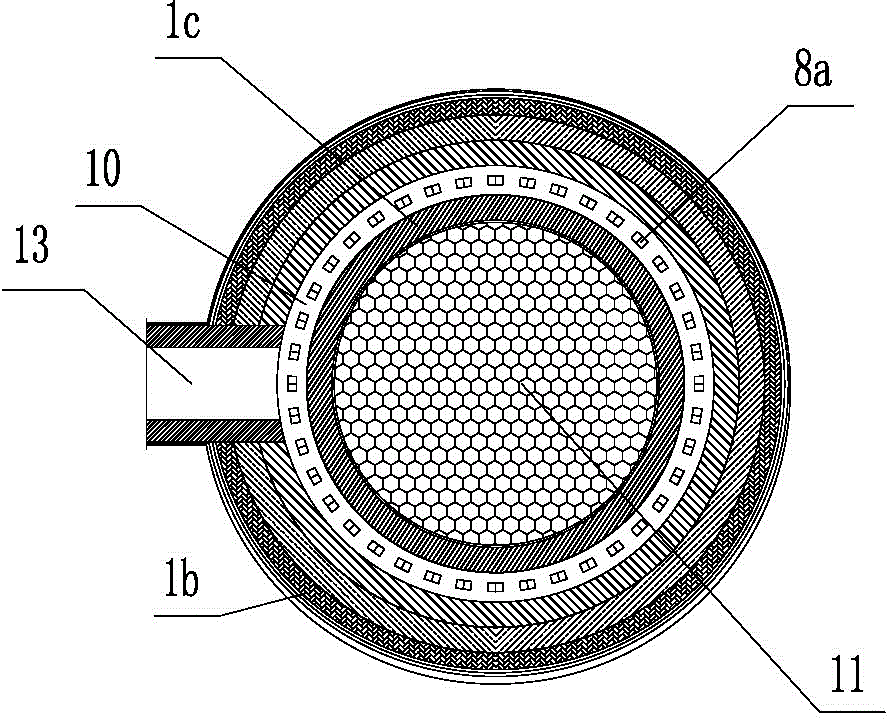

Turntable extracting tower

The invention relates to a turntable extracting tower belonging to the technical field of separation equipment of pharmaceutical chemicals and comprising a tower body, a rotating shaft, a rotator, a power mechanism, an upper sedimentation tank with a heavy phase lead-in interface and a light phase lead-out interface, a lower sedimentation tank with a light phase lead-in interface and a heavy phase lead-out interface, and a separation disc distributed with separation disc through holes on the surface, wherein the rotator comprises a blade holder, a first blade and a second blade; the blade holder is fixed on the rotating shaft; the first blade and the second blade are formed on the blade holder and are arranged at intervals; and the first inclination angle of the first blade and the second inclination angle of the second blade face to opposite directions. The invention can avoid axial backmixing, enhance the interstage mixing effect, ensure the mass transfer of two phases in the tower, meet industrialized production requirements, simplify the structure and save the energy for driving the rotating shaft to rotate.

Owner:JIANGSU SHAJIABANG CHEM EQUIP

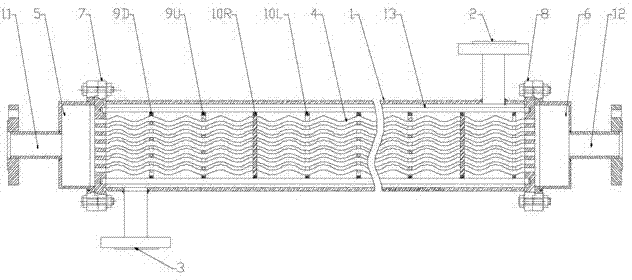

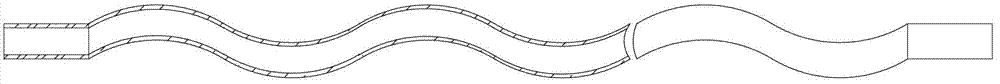

Deflecting fence type square heat exchanger with waved tube

InactiveCN103047882AMixed stronglyImprove heat transfer effectHeat exchanger casingsStationary tubular conduit assembliesEngineeringVenturi effect

The invention provides a deflecting fence type square heat exchanger with a waved tube. The heat exchanger comprises a case, a heat exchange tube, an upper tube plate and a lower tube plate, wherein the case, the upper tube plate and the lower tube plate form airtight space, an airtight upper head is arranged on the left side of the upper tube plate, an airtight lower head is arranged on the right side of the lower tube plate, a tube-side inlet is arranged on the upper head, a tube-side outlet is arranged on the lower head, the heat exchange tube is installed in the airtight space, two ends of the heat exchange tube are installed in the upper tube plate and the lower tube plate respectively and communicated with the upper head and the lower head respectively, a tube-side outlet tube is arranged on the right of the upper tube plate on the case, a tube-side inlet tube is arranged on the left of the lower tube plate, and a deflecting fence for supporting the heat exchange tube is mounted in the case and comprises a deflecting ring and a support rod installed in the deflecting ring. According to the heat exchanger, vortex flow and the Venturi effect can occur when shell pass fluid flows through the square deflecting fence, so that the shell pass fluid can obtain good turbulent current conditions, dead flow zones and leakage current losses when the fluid flows across tube bundles are reduced, and heat exchange on the shell side is strengthened.

Owner:HARBIN ENG UNIV

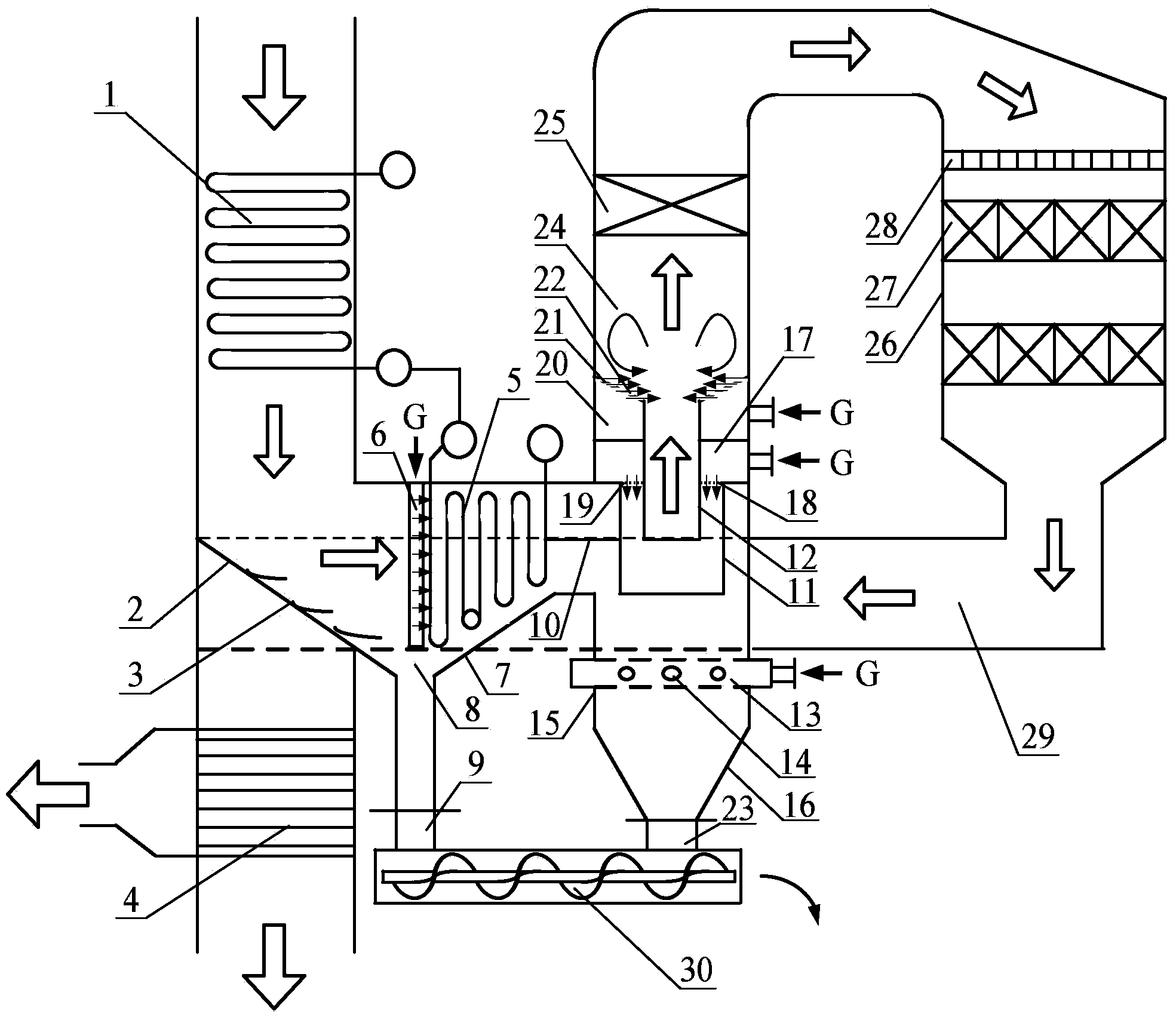

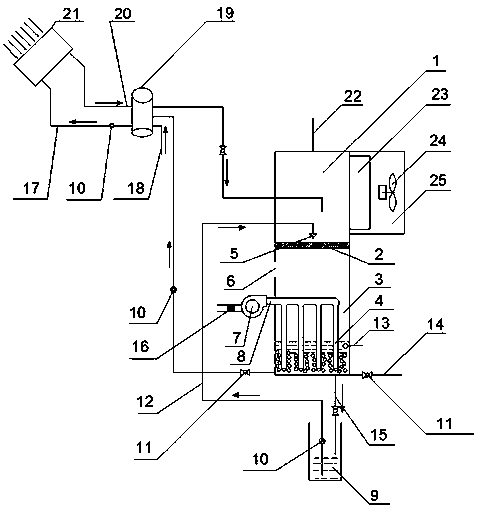

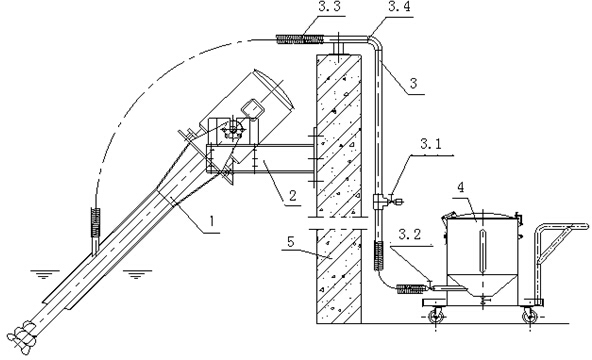

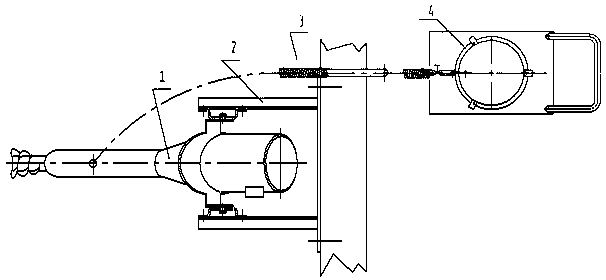

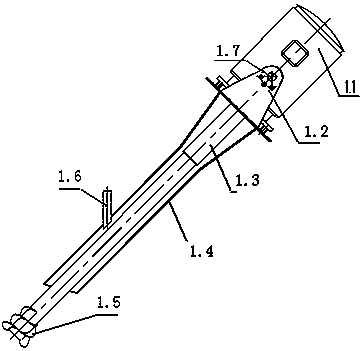

SCR denitration device and denitration method applicable to middle and small-size boilers

The invention discloses a SCR (Selective Catalytic Reduction) denitration device and a denitration method applicable to middle and small-size boilers. Through structural transformation of an economizer inside a vertical flue, a part of a heated surface is preserved, the other part of the heated surface is moved to a horizontal section of the flue, the rest flue is partitioned in an inclined manner so as to be used for elicitation and introduction of the denitration device; a two-stages dedusting ammonia injection system is arranged so as to mix fume with ammonia, the mixture passes through a catalyst preserved layer and enters a SCR reactor for catalysis reaction, most part of NOx is transformed into N2, the fume after denitration is elicited out from two sides of the lower part of the reactor, enters the flue from two sides of a side wall of the flue at the tail part, and is finally discharged outside the flue through an air pre-heater. The SCR denitration device meets the requirement on the space where the denitration flue needs to be pulled out and led in when the SCR denitration device is additionally arranged on the middle and small-size boilers, sufficient, rapid and effective mixing of ammonia and fume inside a low narrow flue is achieved, and the SCR denitration device has the advantages that the denitration system is compact in structure, high in efficiency, low in catalyst abrasion, and the like.

Owner:SOUTHEAST UNIV

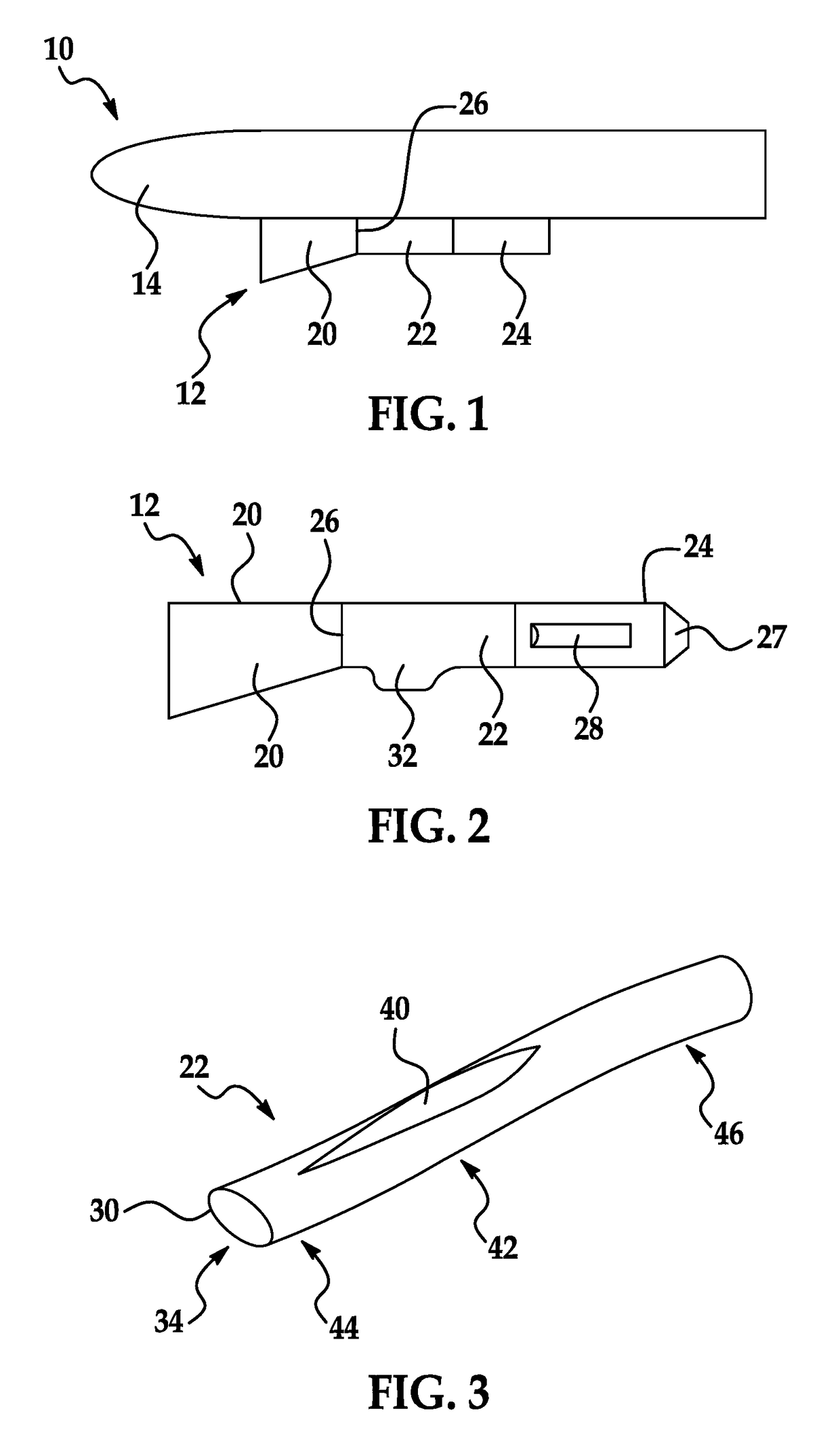

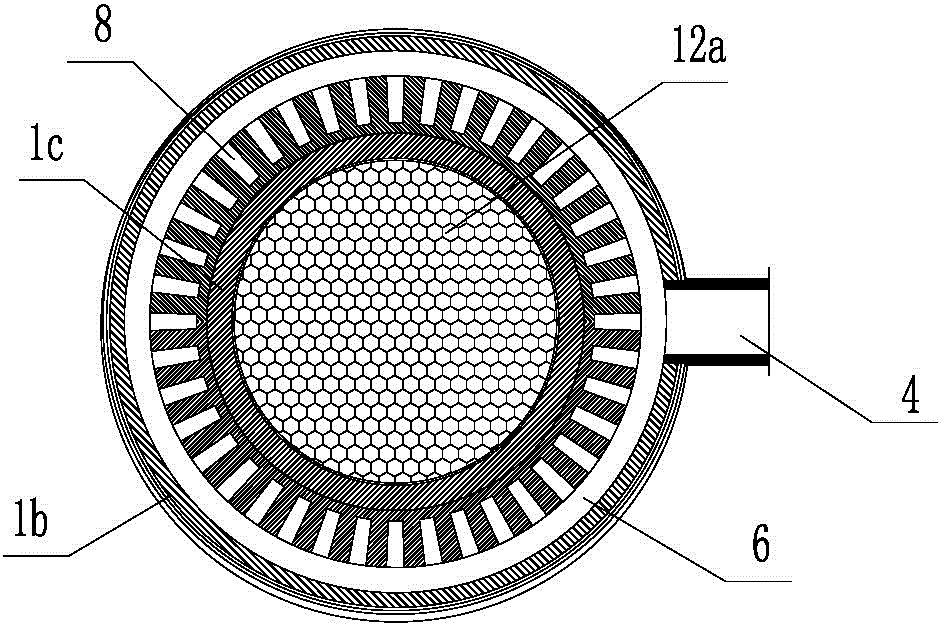

Exhaust system mixing device

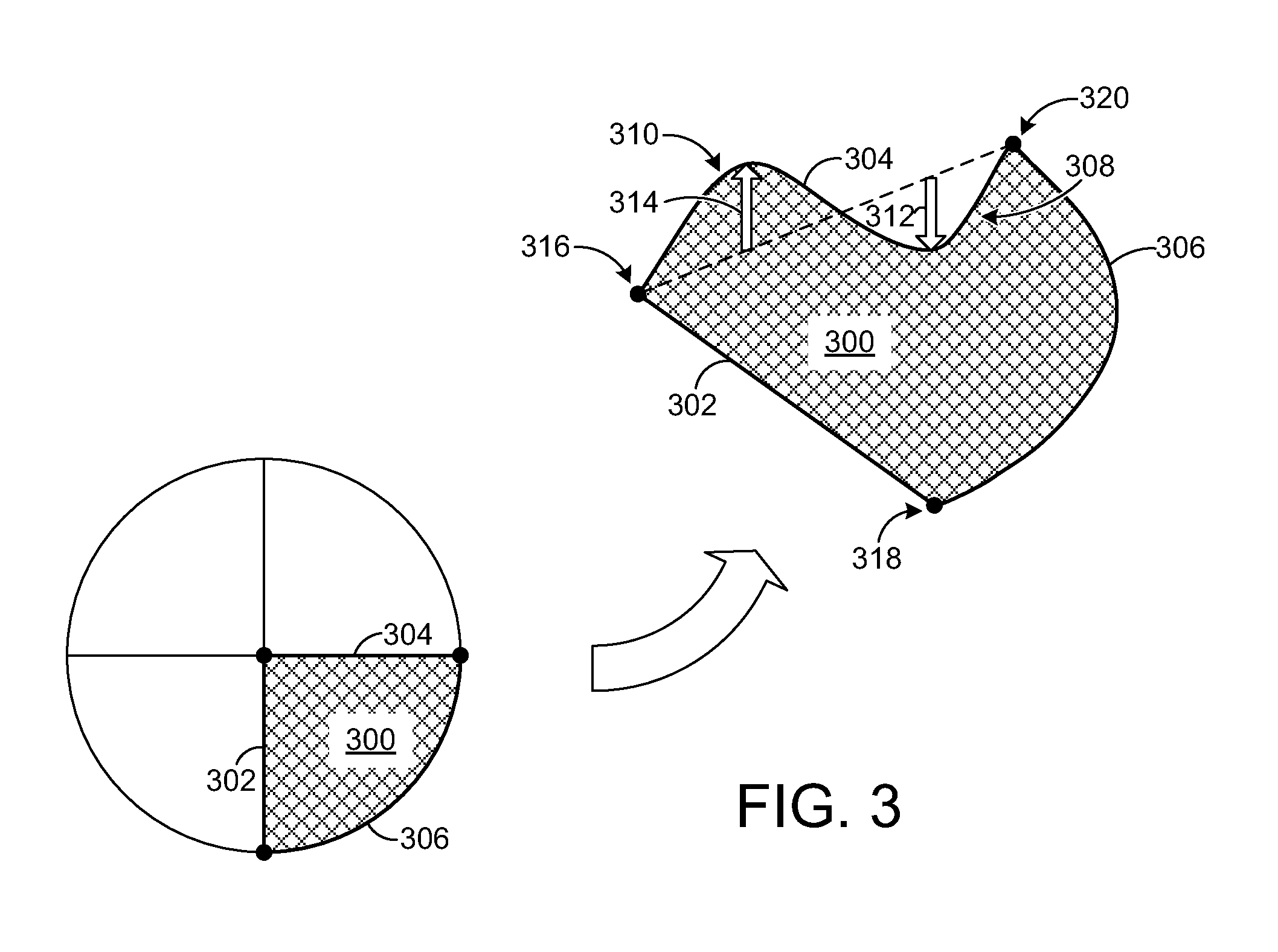

InactiveUS20110131959A1Reduced effectivenessWell mixedInternal combustion piston enginesFlow mixersCircular discEngineering

A mixing device comprises a circular disc of fin sections positioned so as to create openings in the inner and outer regions of the mixing device that generate oppositely rotating flows of exhaust gas. Each fin section may be identical, and may be created by a stamping process. The smooth surface of each fin section reduces creases, and thus, is less prone to urea buildup.

Owner:FORD GLOBAL TECH LLC

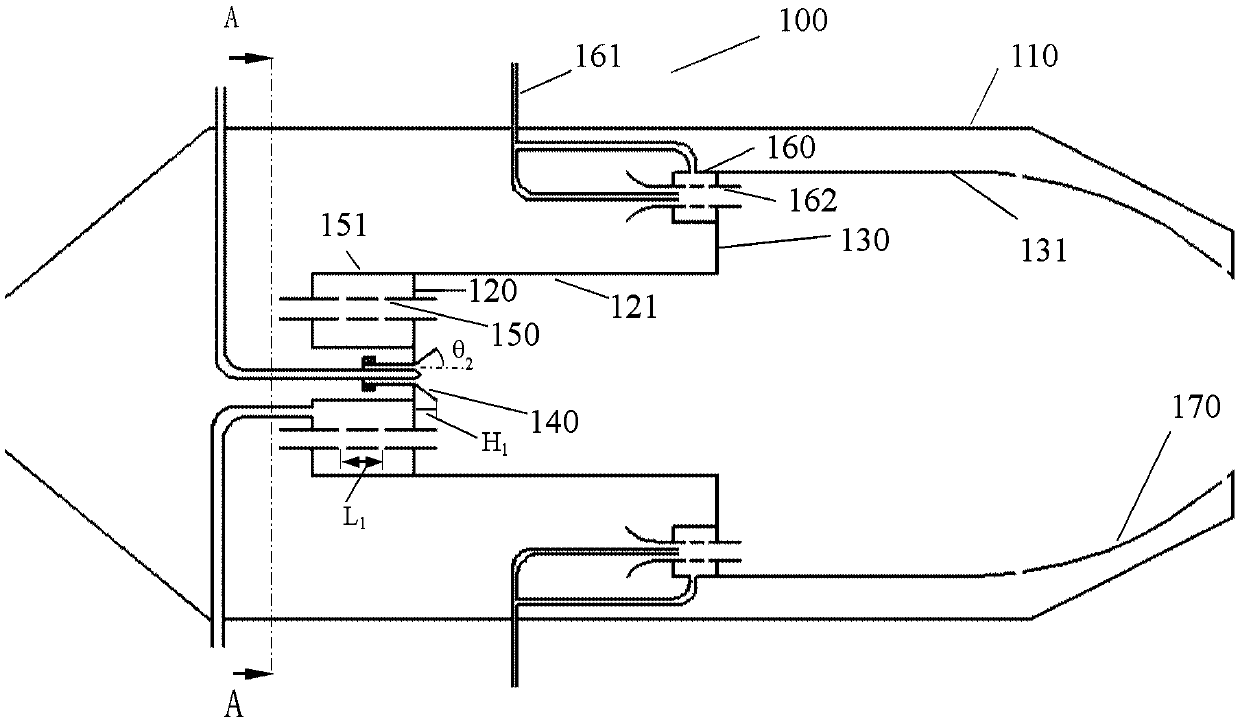

High-temperature smoke generator and control method thereof

ActiveCN110836383AReduce oxygen concentrationReduce the temperatureContinuous combustion chamberCombustion chamberNitrogen oxides

The invention provides a high-temperature smoke generator and a control method thereof. A duty nozzle assembly is arranged at the center of a combustion chamber head baffle, and a premixing nozzle assembly is uniformly distributed on the combustion chamber head baffle in the circumferential direction. An annular air channel is formed between the outer wall of a combustion chamber and a combustionchamber flame tube, and an airflow rate distributing adjusting valve is arranged at an annular channel inlet. High-speed jet flow of premising nozzles forms entrainment backflow in the middle of the combustion chamber, and through a smoke internal circulation mechanism, the forming amount of nitrogen oxide in the combustion chamber is decreased. The outer wall surface of the combustion chamber flame tube is provided with a fin structure to enhance cooling of air in the annular channel to the flame tube. The tail of the combustion chamber flame tube is provided with a plurality of rows of mixing holes, by reasonably distributing the hole diameter and the position of the mixing holes, smoke and mixed air are sufficiently mixed, and accordingly, the uniformity of the outlet smoke temperatureand component distribution is ensured. The high-temperature smoke generator cooperates with the airflow rate adjusting valve, so that effective adjusting of the outlet smoke temperature is achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

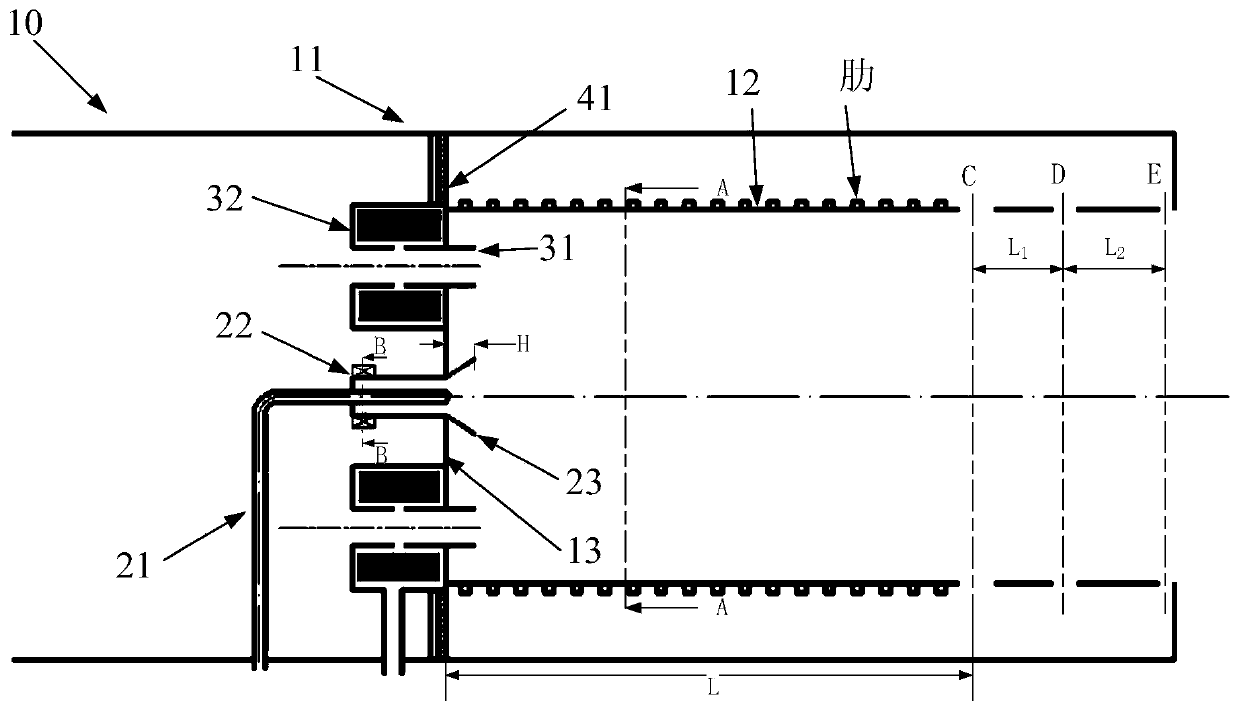

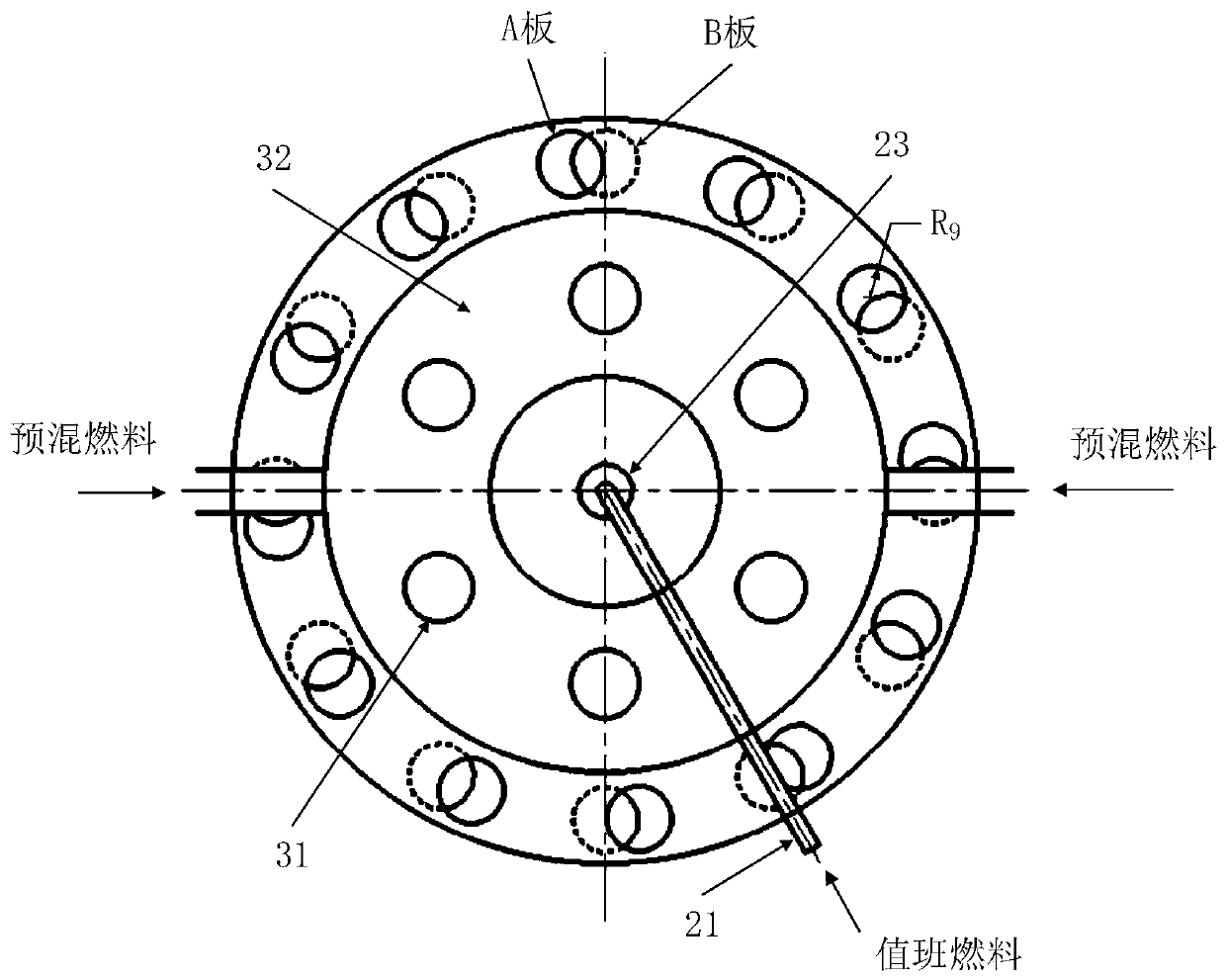

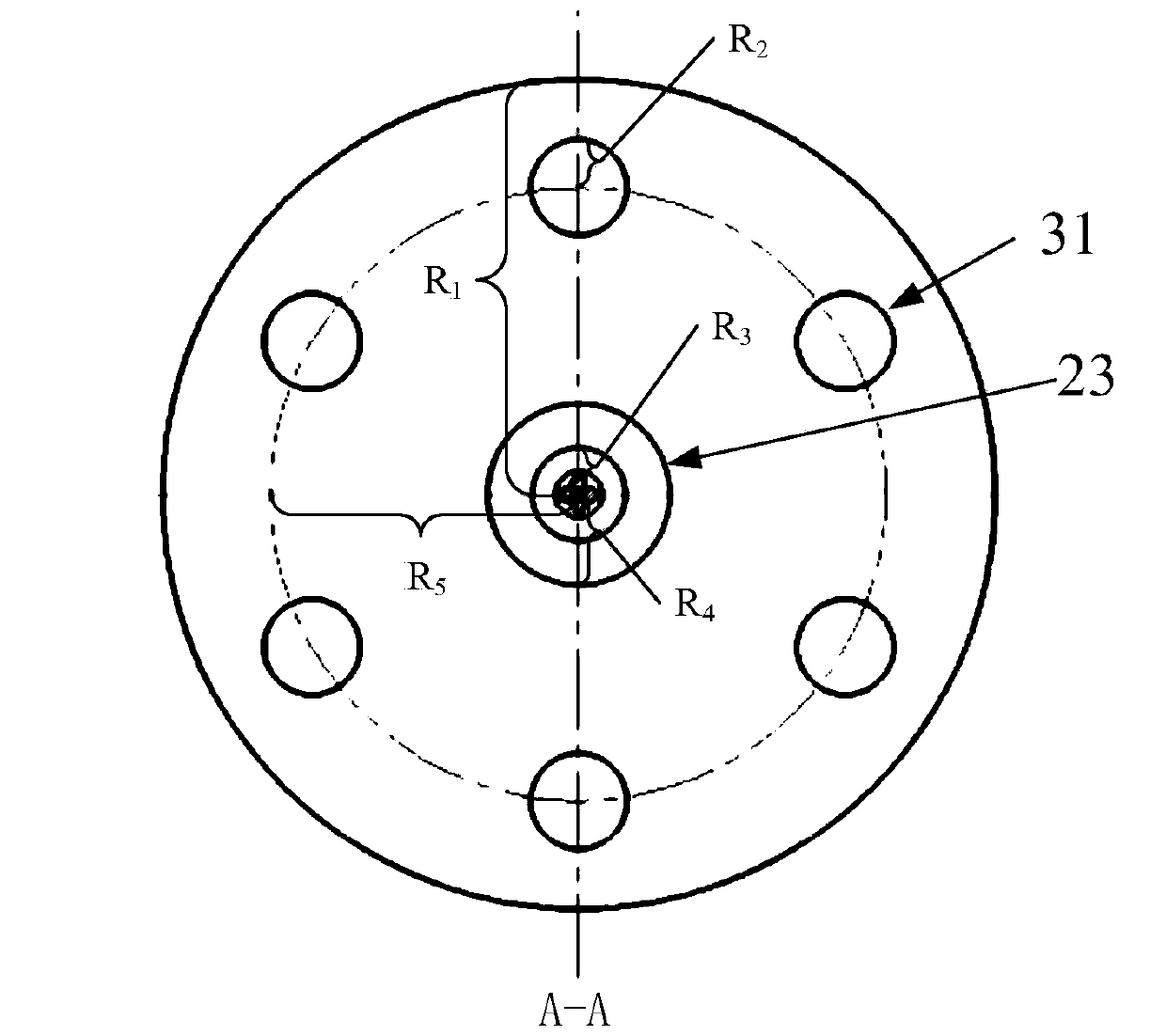

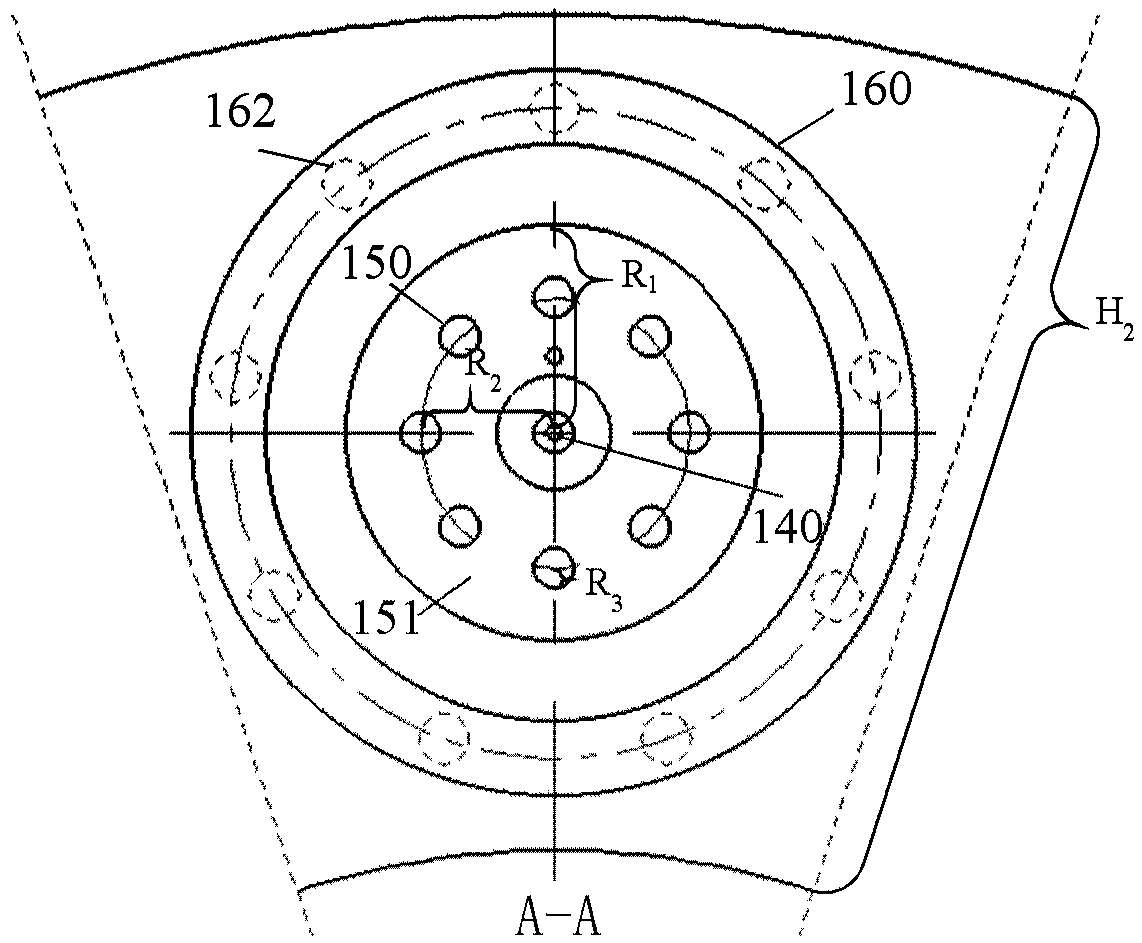

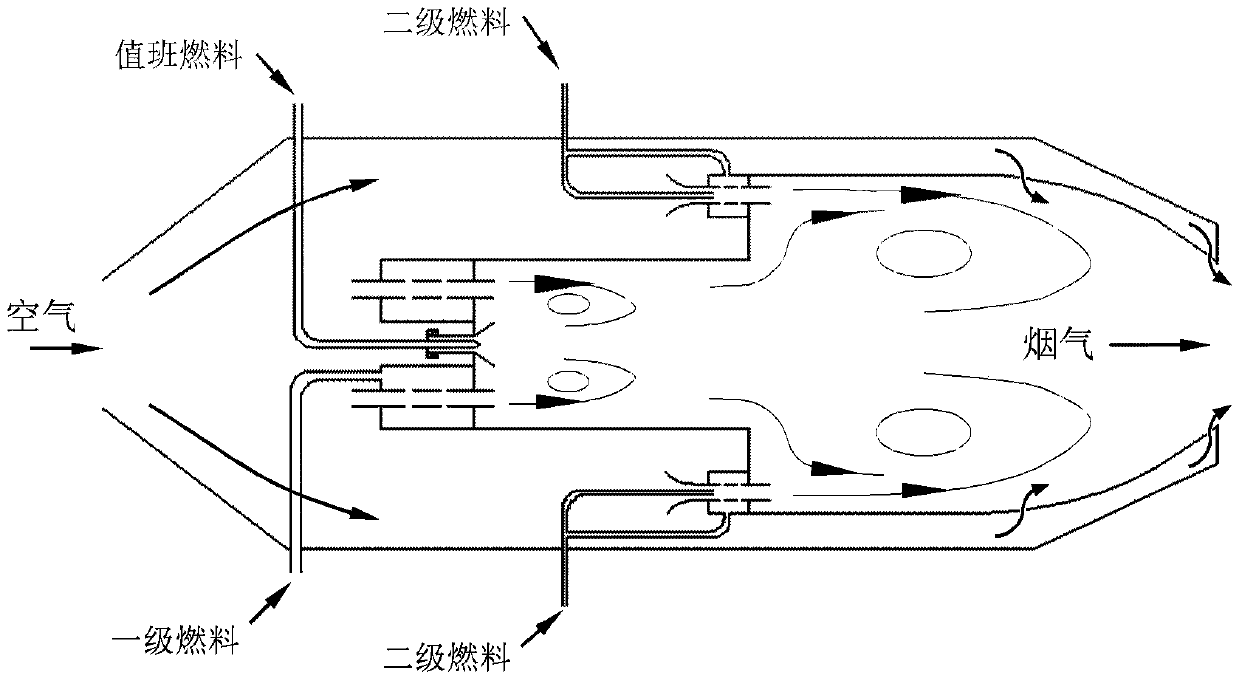

Axial grading combustion chamber of gas turbine and control method of axial grading combustion chamber

ActiveCN110878948AIncrease the reflux ratioStable combustionContinuous combustion chamberNitrogen oxidesCombustion chamber

The invention discloses an axial grading combustion chamber of a gas turbine and a control method of the axial grading combustion chamber. The axial grading combustion chamber comprises a combustion chamber structural assembly, a first-stage premixed jet nozzle assembly, a first-stage on-duty nozzle assembly and a second-stage premixed jet nozzle assembly. A head baffle of a first-stage combustionchamber and a front wall of a combustion chamber case form a head part of the combustion chamber, and the first-stage on-duty nozzle assembly is arranged in the center of the head part of the combustion chamber; the first-stage premixed jet nozzle assembly is arranged on a circumference of the head part of the combustion chamber by taking the center of the head part of the combustion chamber as acircle center; and the second-stage premixed jet nozzle assembly is positioned on a circumference of a head baffle of a second-stage combustion chamber by taking an axis of a flame tube of the first-stage combustion chamber as a circle center. According to the axial grading combustion chamber provided by the invention, through grading injection of fuel, residence time of the fuel in a high-temperature region is shortened while combustion efficiency is ensured, and two-stage soft combustion is realized, so that emission of nitrogen oxide by the combustion chamber of the gas turbine is greatlyreduced, and an outlet temperature of the combustion chamber can be further improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Exhaust system mixing device

InactiveUS8240135B2Reduced effectivenessWell mixedInternal combustion piston enginesFlow mixersCircular discEngineering

Owner:FORD GLOBAL TECH LLC

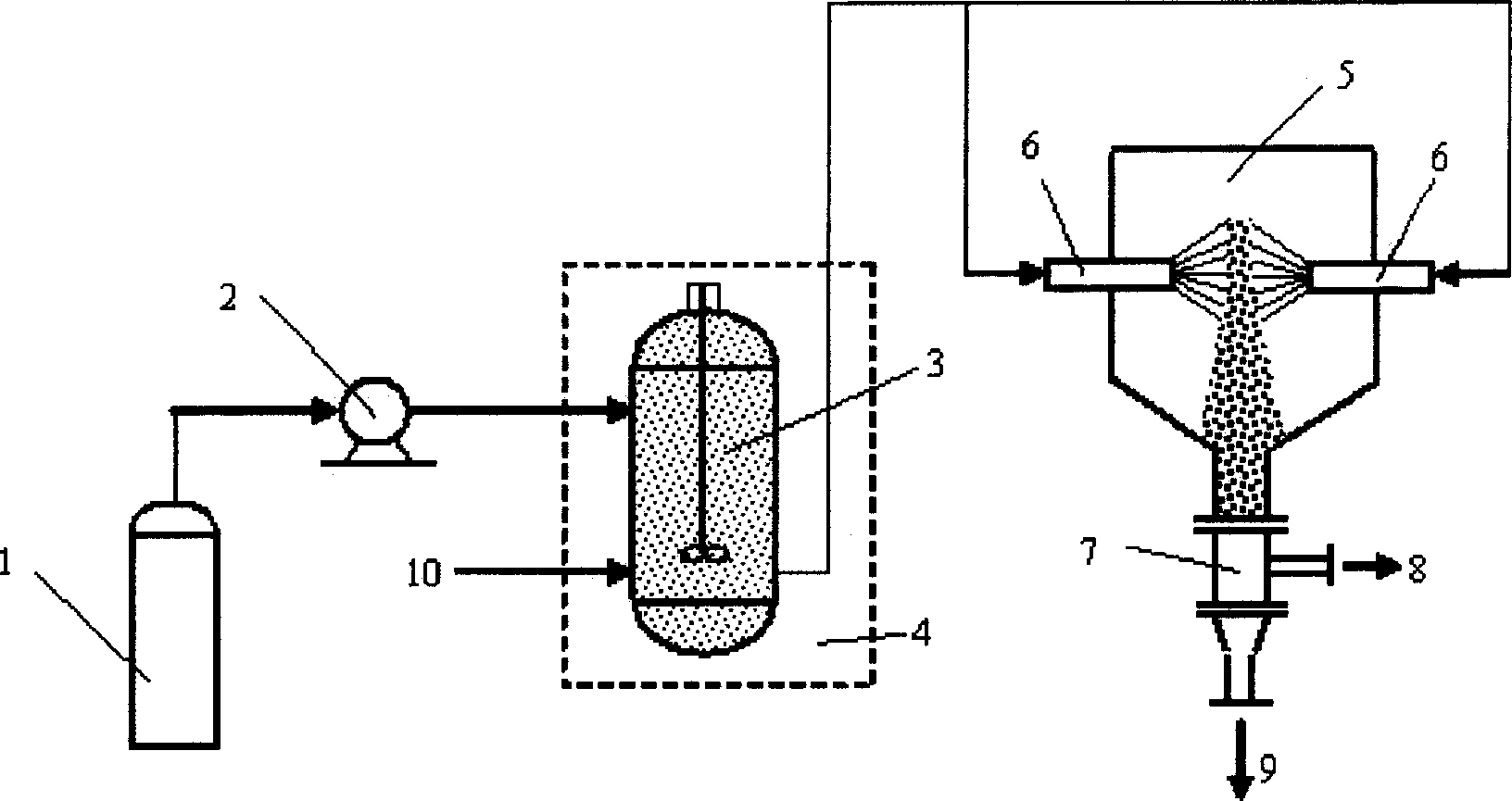

Supercritical impact flow method for wrapping micro granule

InactiveCN1879957AIncrease resistanceReduce resistanceMicroballoon preparationMicrocapsule preparationParticle packingPaper production

The invention relates to a ultra-critical impact flow particle packing method, which is characterized in that: adding the wall material into the mixer to be dissolved into solution; mixing and dispersing the particle uniformly, to form suspension; using a couple of coaxial nozzles to output the wall material to be deposited on the surface of packed particle to form the coat, and separated by the separator to obtain the micro capsule product. The invention can combine the advantages of present packing fluid bed packing method and impact flow method, to be used in food industry, paper production, etc.

Owner:DALIAN UNIV OF TECH

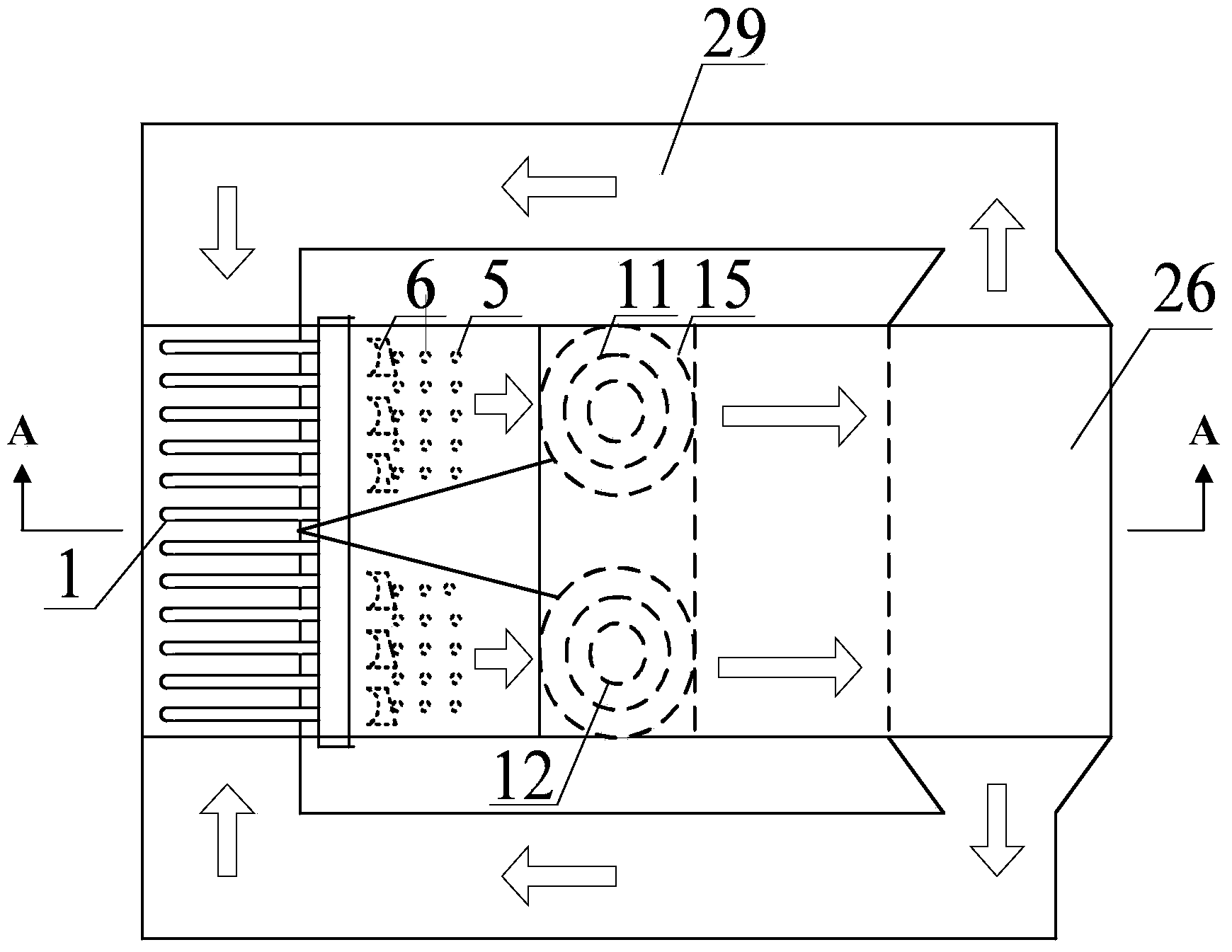

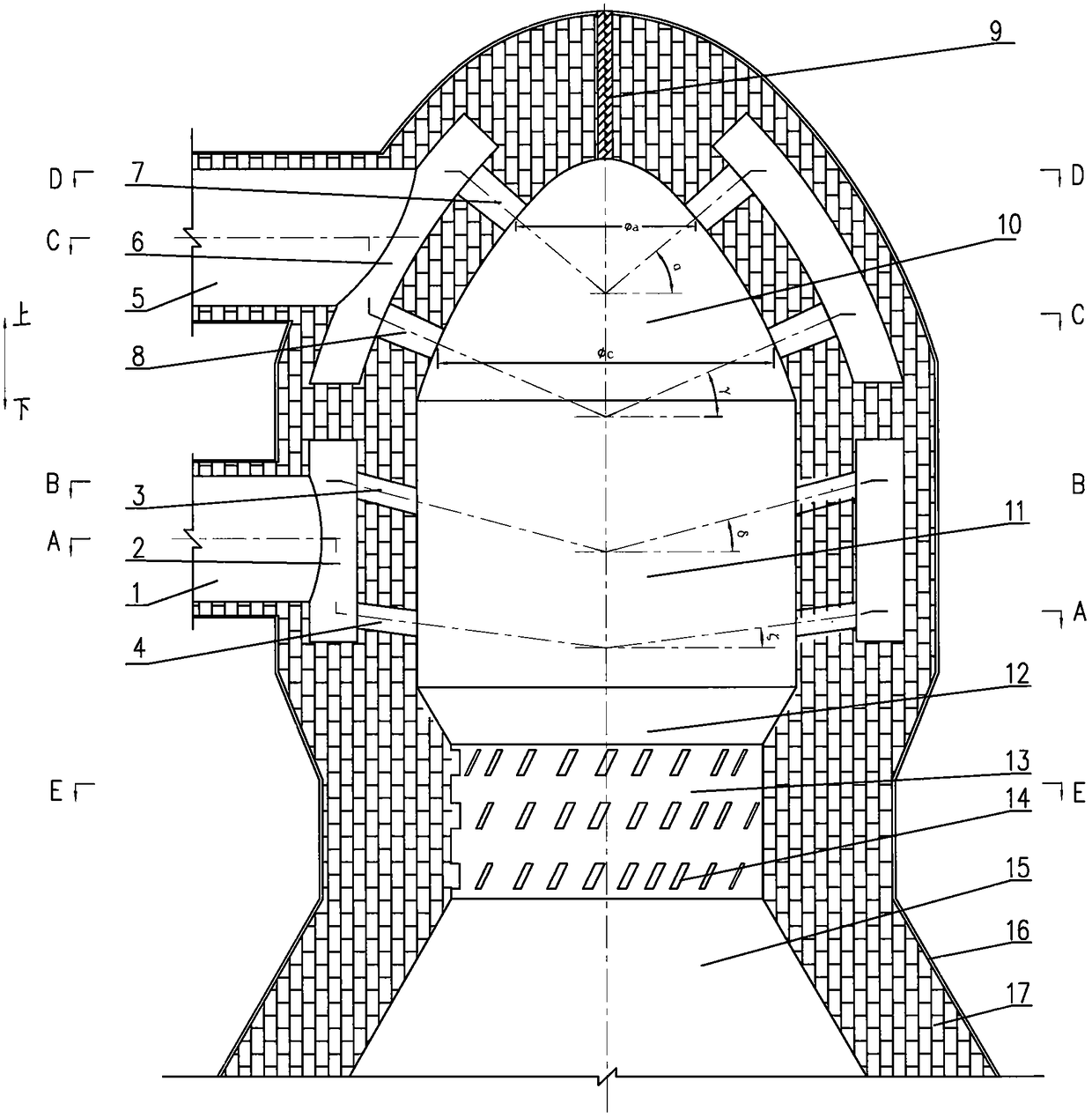

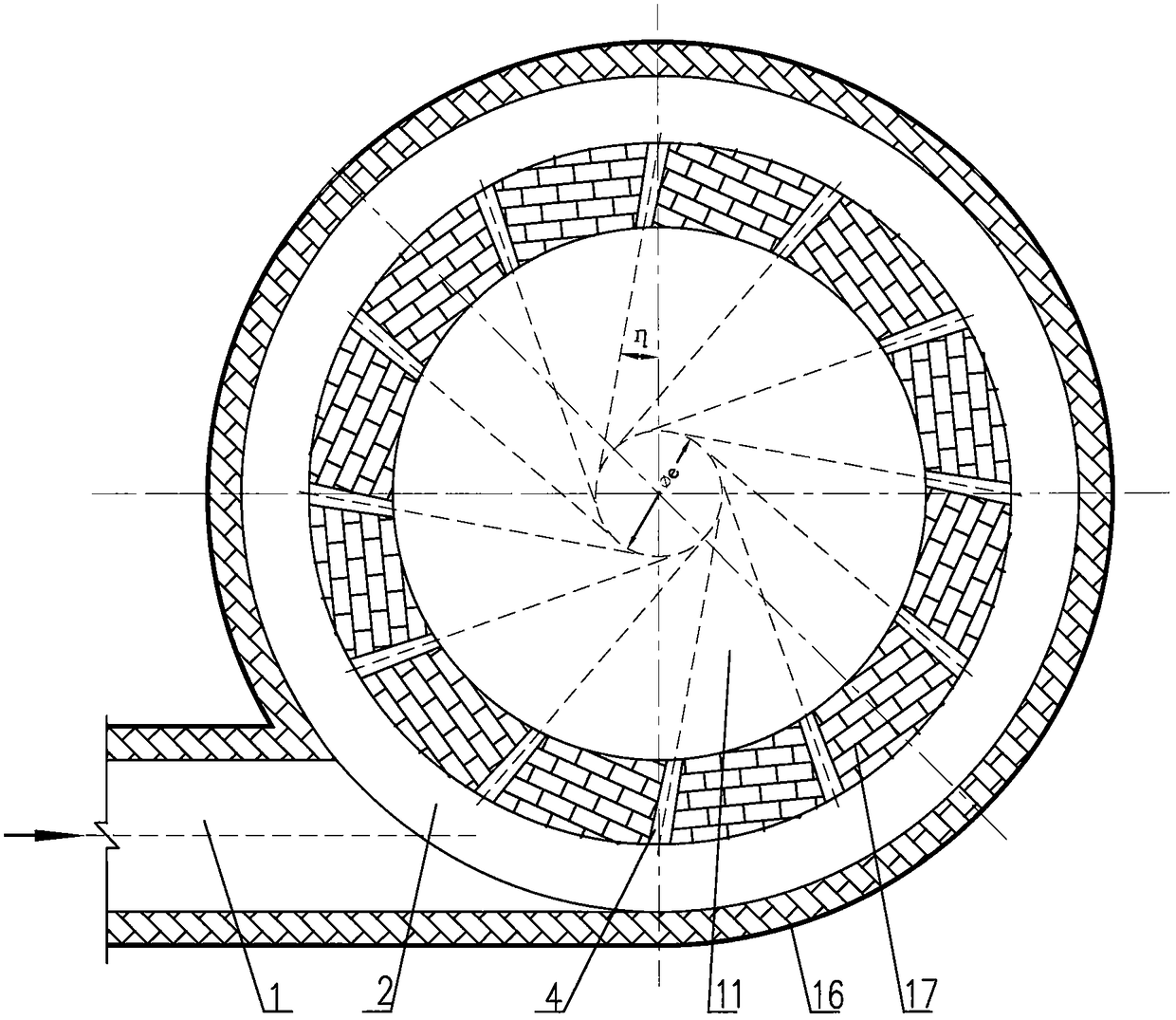

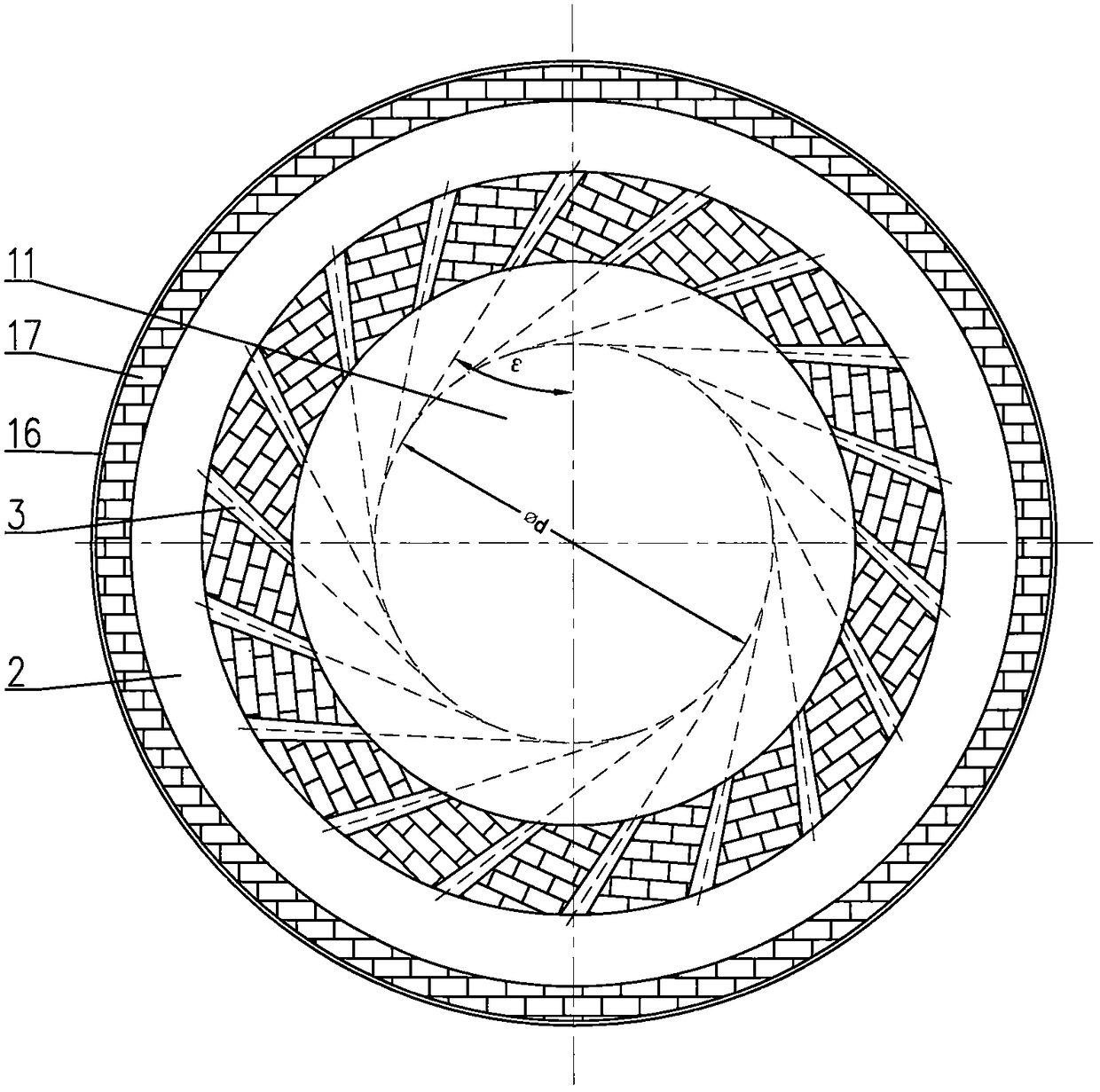

Combustion system improving safety and economical performance of opposite-firing boiler

ActiveCN104990069AIncrease the itineraryMixed stronglyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion systemAir preheater

The invention discloses a combustion system improving safety and economical performance of an opposite-firing boiler. The combustion system comprises a primary fan, a secondary fan, an air pre-heater, a hearth, a plurality of direct-flow overfire-air nozzle, a plurality of first overfire-air nozzles, a plurality of second overfire-air nozzles and a plurality of cyclone burners. By adopting the combustion system, the problems of the opposite-firing boiler that fly ash combustibles are increased, a water-cooling wall is coking, high-temperature corrosion is caused, difference of oxygen amounts at two sides of a hearth outlet is large, the vapor temperature is difficult to control, and the like can be effectively solved.

Owner:XIAN THERMAL POWER RES INST CO LTD

Extruded composite jerky and preparation method thereof

InactiveCN103404881AImprove product qualityQuality improvementFood preservationFood shapingFiberMeat cooking

The invention discloses an extruded composite jerky and a preparation method thereof. The extruded composite jerky is prepared from the following raw materials in parts by weight in an extruded manner by a screw bolt extruding machine: 100 parts of raw meat, 5-7 parts of hydrophilic colloid, 2-20 parts of condiment and 0-30 parts of food ingredients. The preparation method comprises the following steps: ingredient pretreatment: muscle fibers are used as main raw meat, and subjected to meat cooking and crushing; compounding: the cooked and crushed meat, the hydrophilic colloid and the food ingredients are mixed uniformly according to the composition, quality adjusting is performed and a wet basis water content of all materials is controlled within the range of 35-55 percent; extrusion molding: the materials with adjusted quality is formed through extrusion by the screw bolt extruding machine; drying for dehydration: the extruded composite jerky can be obtained after drying. According to the method, the condiment can be added in any one step or two or three steps. The extruded composite jerky is short in production period, low in low manufacturing cost and good in taste; as texture main bodies are mainly formed by the muscle fibers, the ingredients can be added within a wide range.

Owner:GUIZHOU UNIV

Three-dimensional vortex burner

InactiveCN108662581AEasy to adjustAvoid damageNon-combustible gases/liquids supplyGaseous fuel burnerThermal energyNitrogen oxide

The invention relates to a three-dimensional vortex burner and belongs to the technical field of thermal power engineering. The three-dimensional vortex burner is primarily characterized by being provided with an air inlet and a coal gas inlet entering tangentially, a catenary convoluted rectifying room, a primary air nozzle and a secondary air nozzle which are arranged in layers and different indirection and a diversion trench reinforcing throat, so that air is supplied to form conical spiral vortexes to inject the coal gas to fit an extremely low coal gas pressure and staged burning and thick and light burning are achieved to reduce emission of nitric oxide. The three-dimensional vortex burner is full in burning and small in resistance loss, and is particularly suitable for various industrial kilns which are high in power, low in coal gas calorific value, low in coal gas pressure, great in pressure fluctuation and high in demand on emission of nitric oxide. Energy conservation and emission reduction are achieved.

Owner:姜凤山

Normal temperature semi-dry method circulating fluidized bed flue gas desulphurization system and method

ActiveCN104941435AIncrease surface areaExtended stayDispersed particle separationFlue gasFluidized bed

The invention discloses a normal temperature semi-dry method circulating fluidized bed flue gas desulphurization system and a method, which relate to a method for removing sulfur oxides in flue gas discharged from a burning device and a system. The normal temperature semi-dry method circulating fluidized bed flue gas desulphurization system and the method use a circulating fluidized bed as a desulphurization reactor, and are characterized in that slurry with super fine desulfurizer particles is injected into a circulating fluidized bed reactor, circulating material particles are added into the circulating fluidized bed reactor simultaneously, and the circulating material particles in the circulating fluidized bed reactor and desulfurizer slurry are fully collided and contacted, and generate a desulfurization reaction. The normal temperature semi-dry method circulating fluidized bed flue gas desulphurization system and the method can achieve the purpose that desulfurizer equipment and desulfurization reaction process are coupled and the use rate of desulfurizer is obviously improved. Compared with existing semi-dry method flue gas desulphurization prior, the normal temperature semi-dry method circulating fluidized bed flue gas desulphurization system and the method have the advantages of high desulphurization efficiency, simple system structure and low investment and maintenance cost of operation, and can be used for flue gas purification process of industrial boilers and station boilers.

Owner:清义(山西)新材料科技有限公司

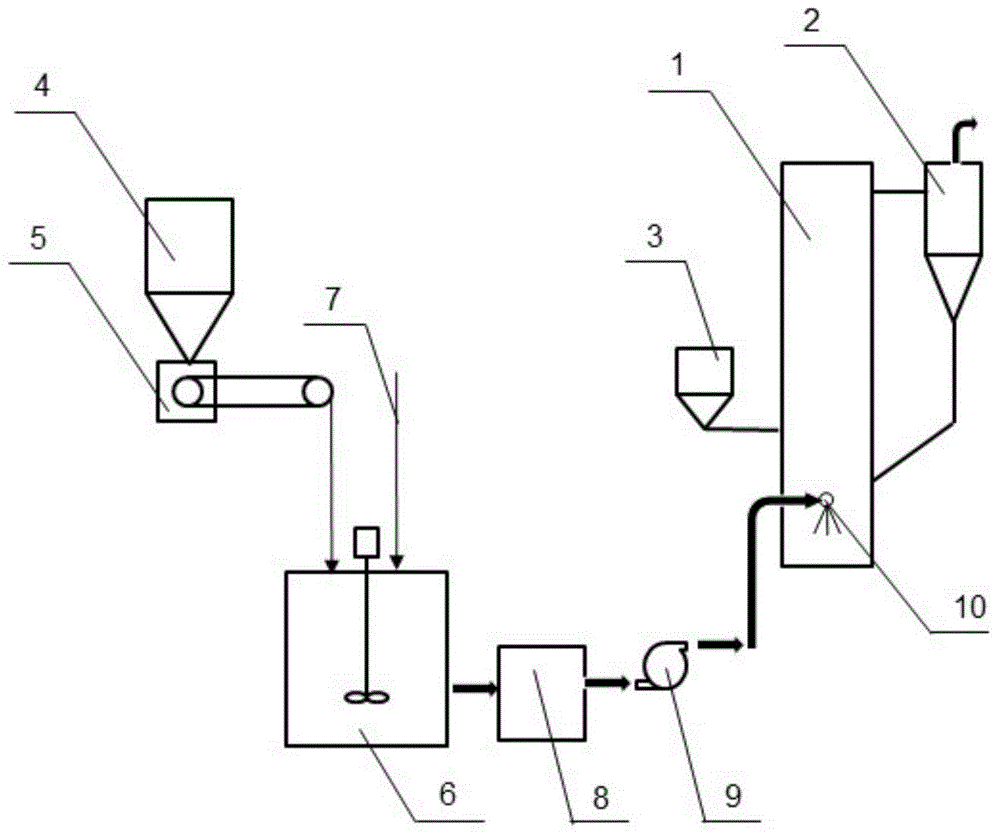

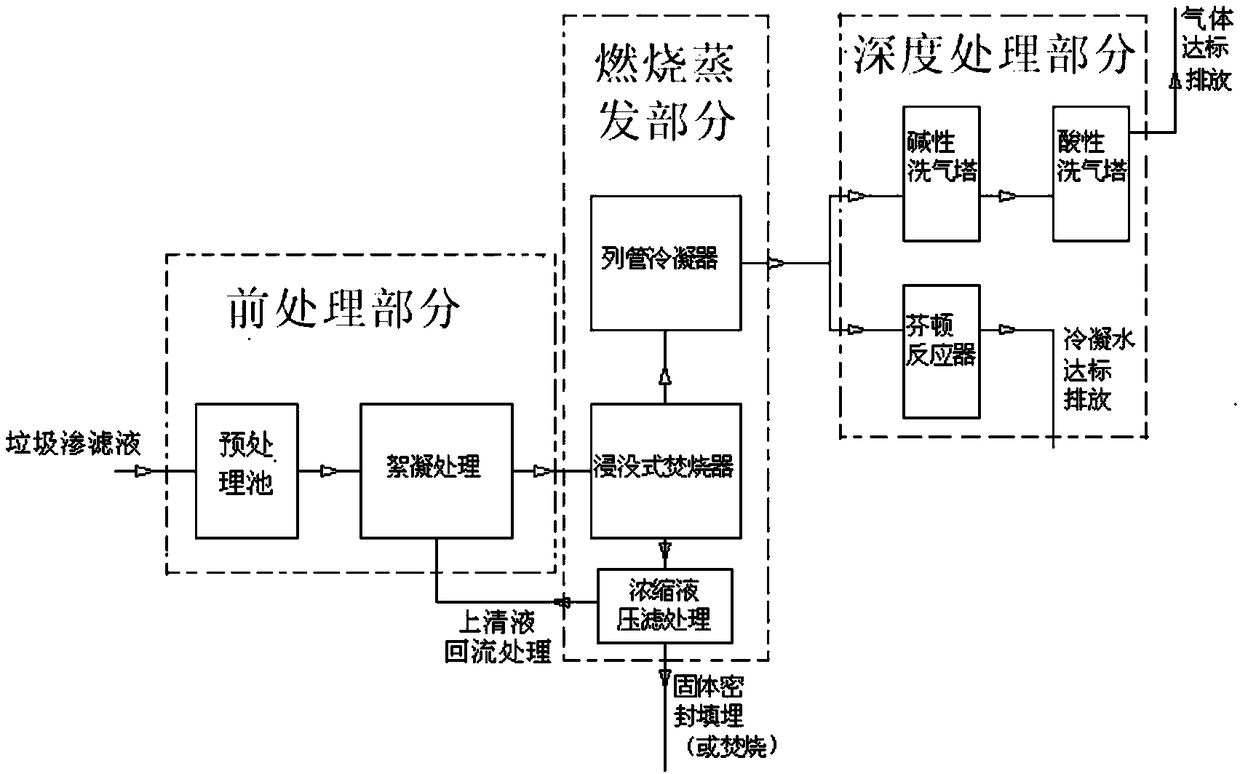

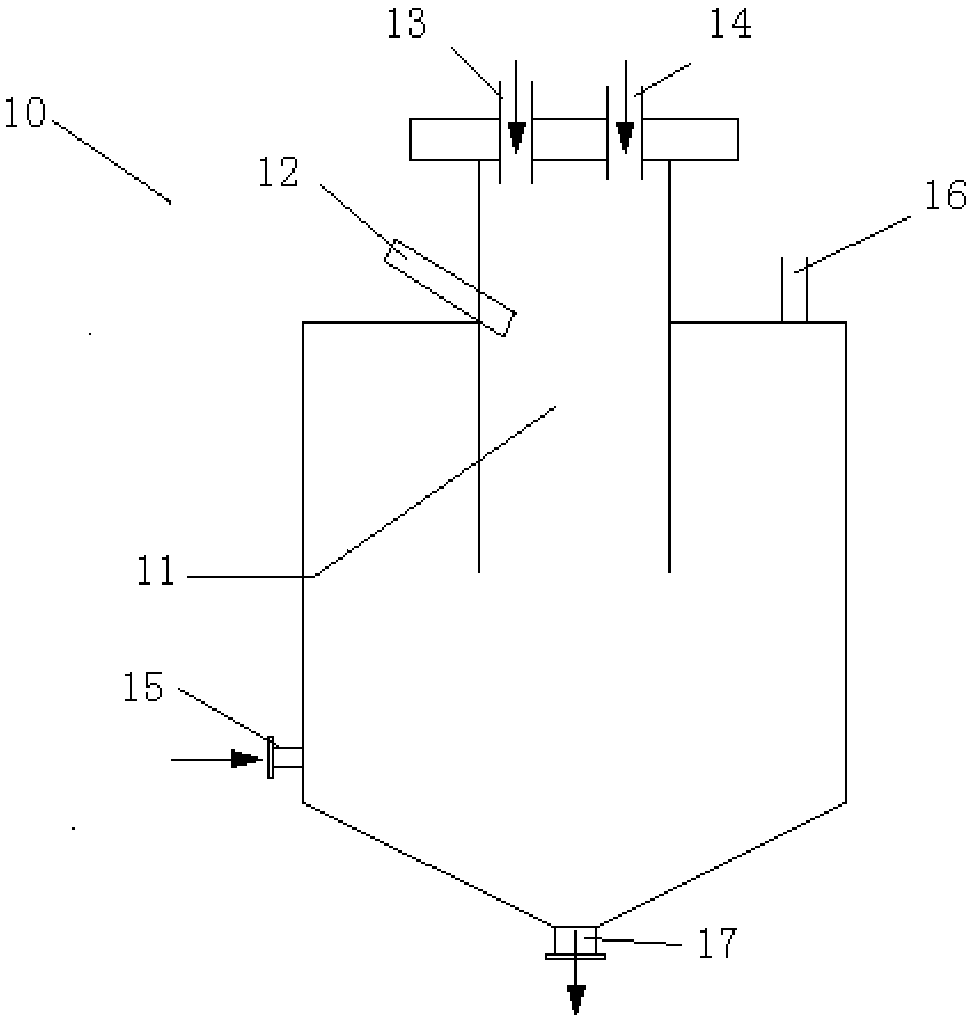

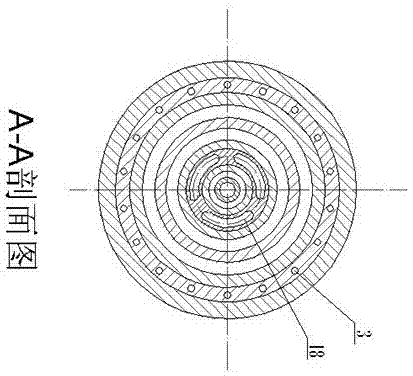

Immersed combustion treatment system for refuse leachate

InactiveCN108609787ALow costIncrease heat transfer areaWater treatment compoundsDispersed particle separationFlocculationCombustion chamber

The invention discloses an immersed combustion treatment system for refuse leachate, which includes: a pretreatment part, which includes a pretreatment tank and a flocculation reaction apparatus communicated therewith; a combustion and evaporation part, which includes an immersed incinerator, a tubular condenser, and a concentrate press filter device, wherein the immersed incinerator is provided with a combustion chamber comprising a fuel gas inlet, a combustion-supporting gas inlet, and an igniter, a steam outlet is disposed on the upper end of the immersed incinerator and the bottom of the immersed incinerator is conical in shape and is provided with a concentrate discharge outlet, after treatment in the flocculation reaction apparatus, a fluid flows into the immersed incinerator, then the tubular condenser is connected to the immersed incinerator through the steam outlet and the concentrate press filter device is connected to the immersed incinerator through the concentrate discharge outlet; a deep processing part, which includes an alkaline gas washing tower, an acidic gas washing tower, and a Fenton reactor, wherein the alkaline gas washing tower is connected to the gas outletof the tubular condenser, the acidic gas washing tower is connected to the alkaline gas washing tower, and the Fenton reactor is connected to a condensate discharge outlet on the tubular condenser.

Owner:BEIJING GREEN USE ENVIRONMENTAL PROTECTION SCI & TECH

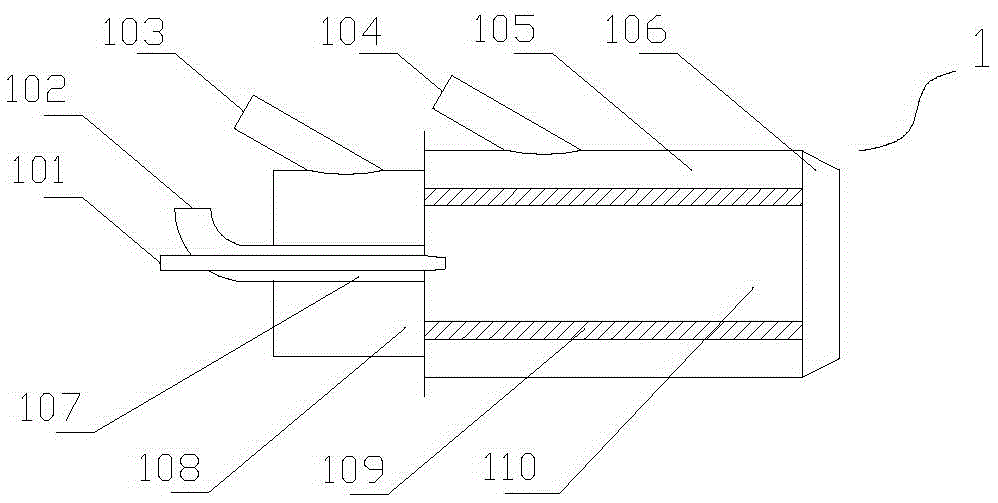

Multichannel rotational flow flame stabilization stepless regulation multifuel combustion combustor

The utility model relates to a multi-channel swirling flow stabilizing flame stepless adjustable mixed combustion burner, which relates to a burner, in particular to a mixed combustion burner using pulverized coal and gas as fuel or a single combustion burner of pulverized coal and gas. It is equipped with a conical ring flame stabilizer in the center of the burner shell, the small head of the flame stabilizer is connected to the central air pipe and the gas pipe, and the outer wall of the gas pipe is connected to a gas mixer. A volute swirler and an adjustment pull rod are arranged on the outer wall of the gas ring joint and the gas pipe at the other end. The outer layer of the gas pipe is equipped with a fire channel, a primary air channel, a secondary air channel and a clean air channel. The secondary air duct and the clean air duct are equipped with swirlers and conical air nozzles respectively. The outer wall of the outlet of the clean air inner pipe and the secondary air inner pipe is made with a cone angle of 15-20° that expands outwards, and the cross-sectional area of the outlet can be changed arbitrarily in the axial direction, and the airflow velocity can be changed. The flame stabilizer can move axially to change the outlet angle of the central air. In this way, the heat load flame shape can be adjusted steplessly, and the combustion temperature can be organically combined with the process conditions. The invention is a pulverized coal and gas burning device with high efficiency, energy saving and low emission of NOx.

Owner:湖北满天星节能环保科技有限公司

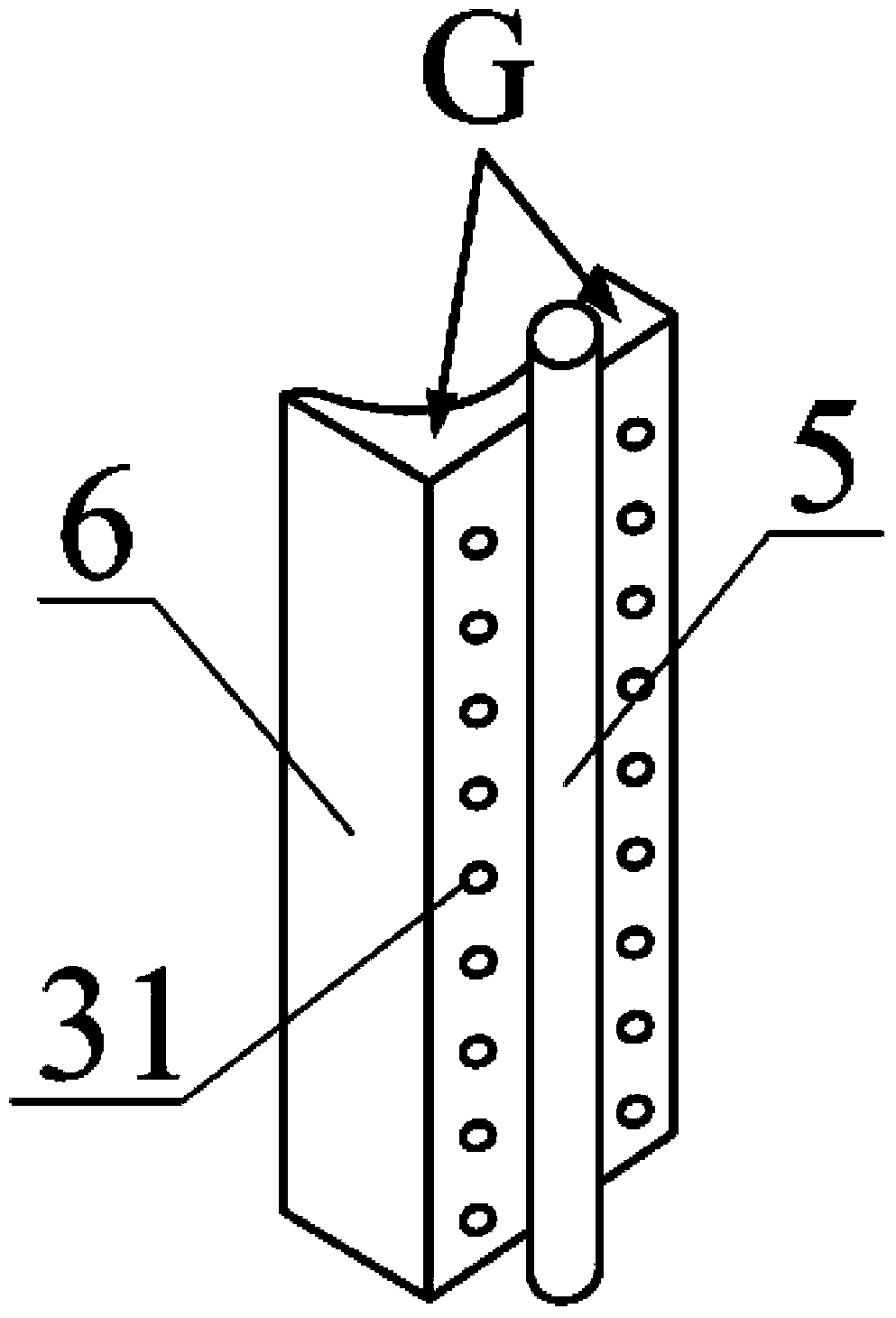

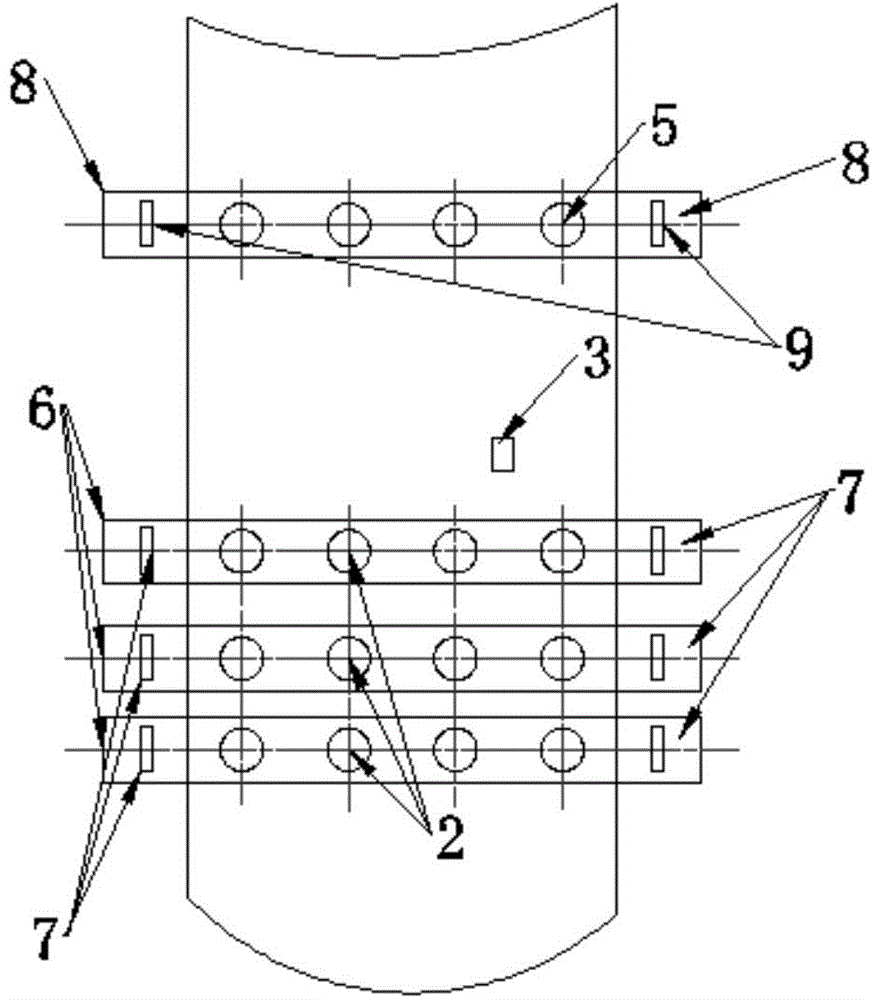

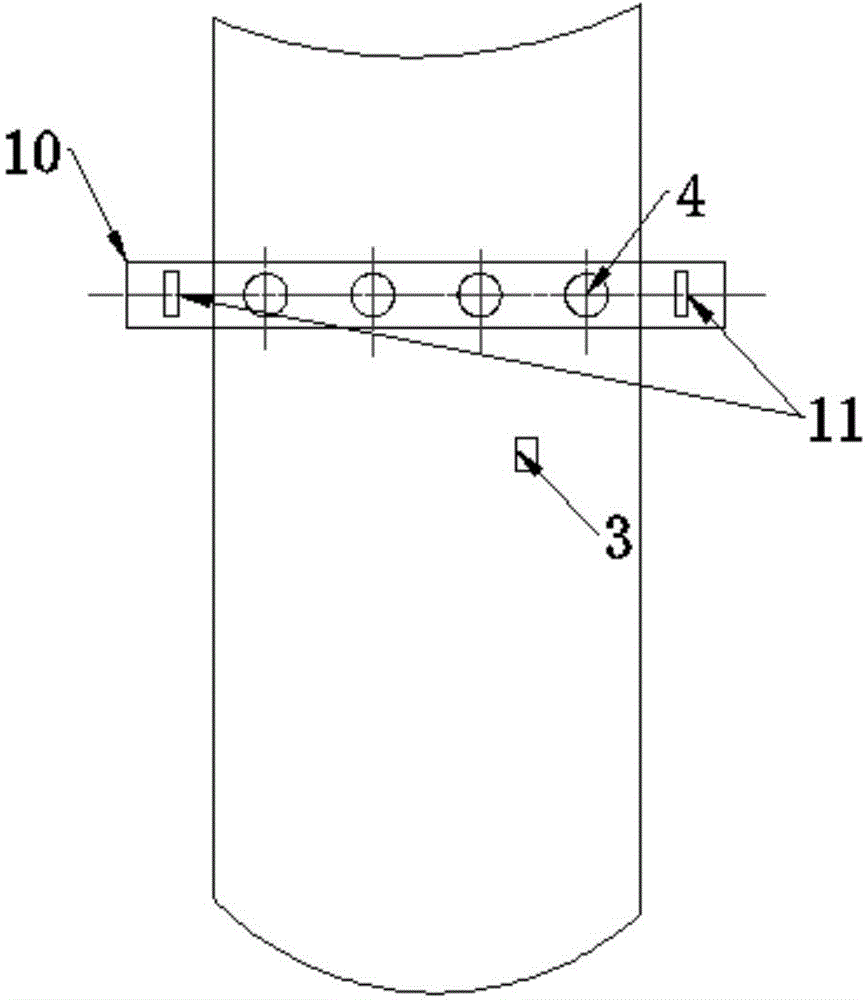

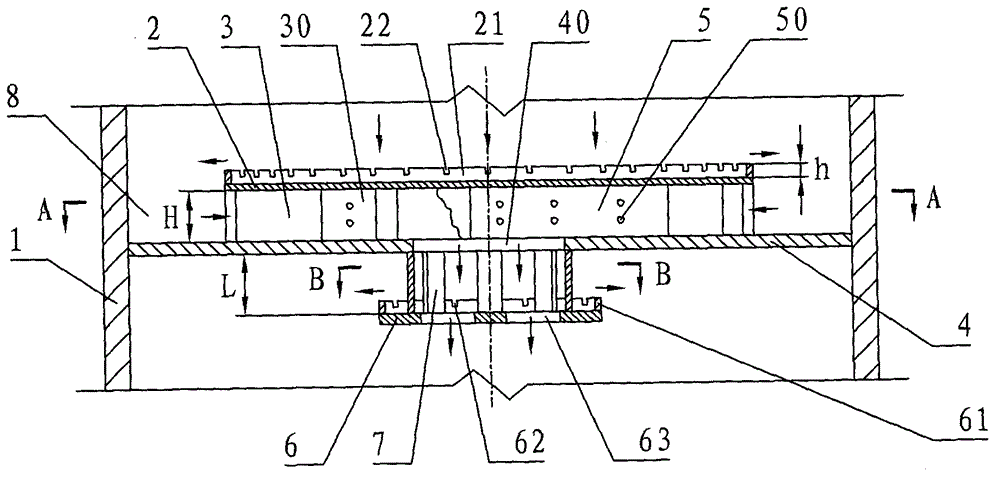

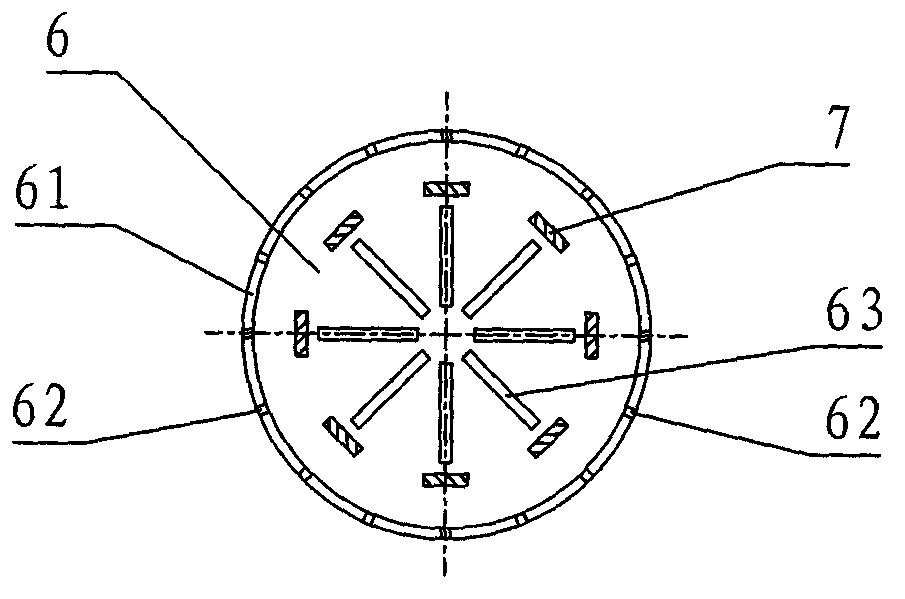

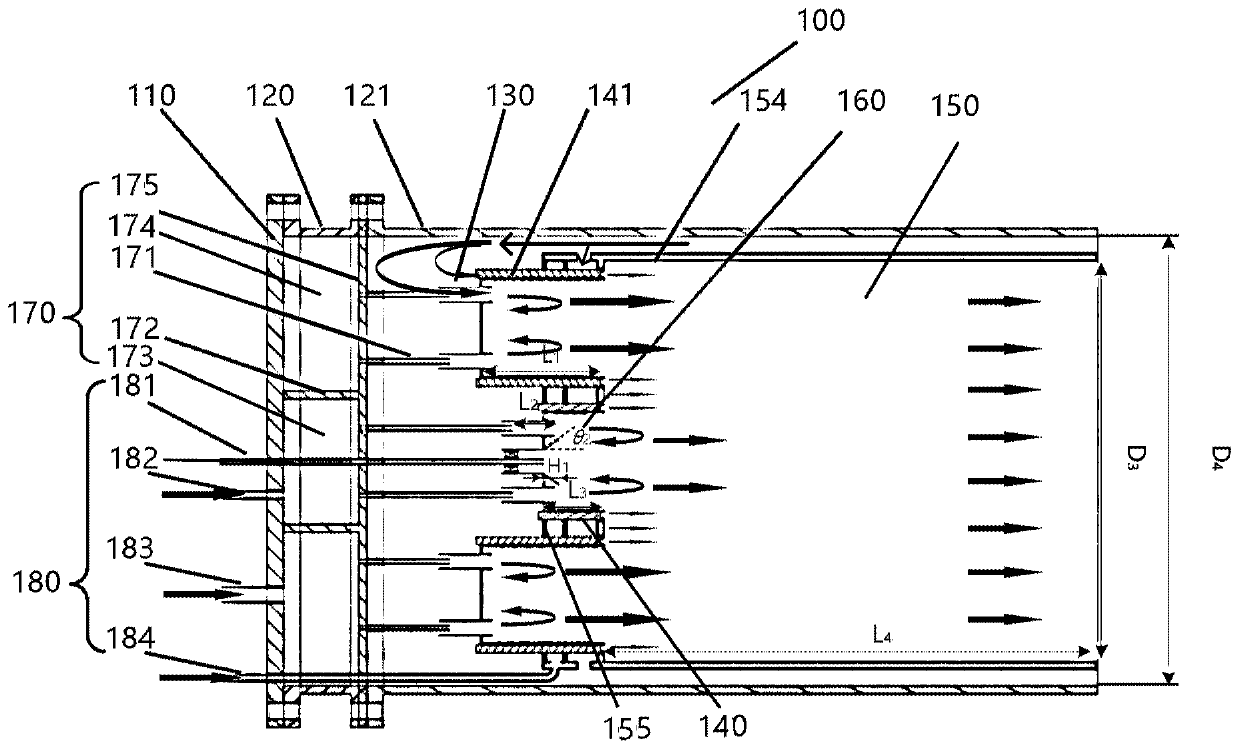

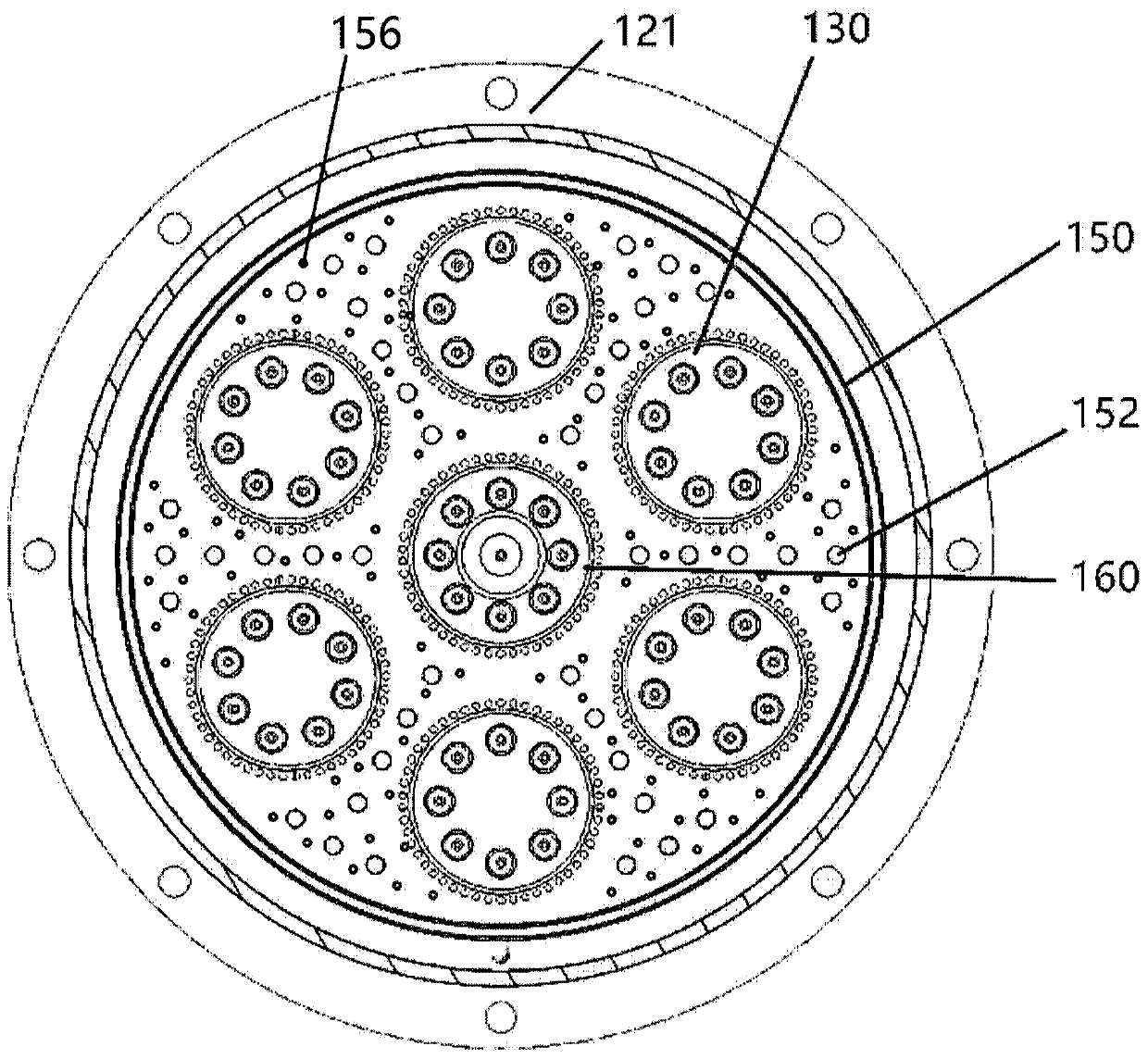

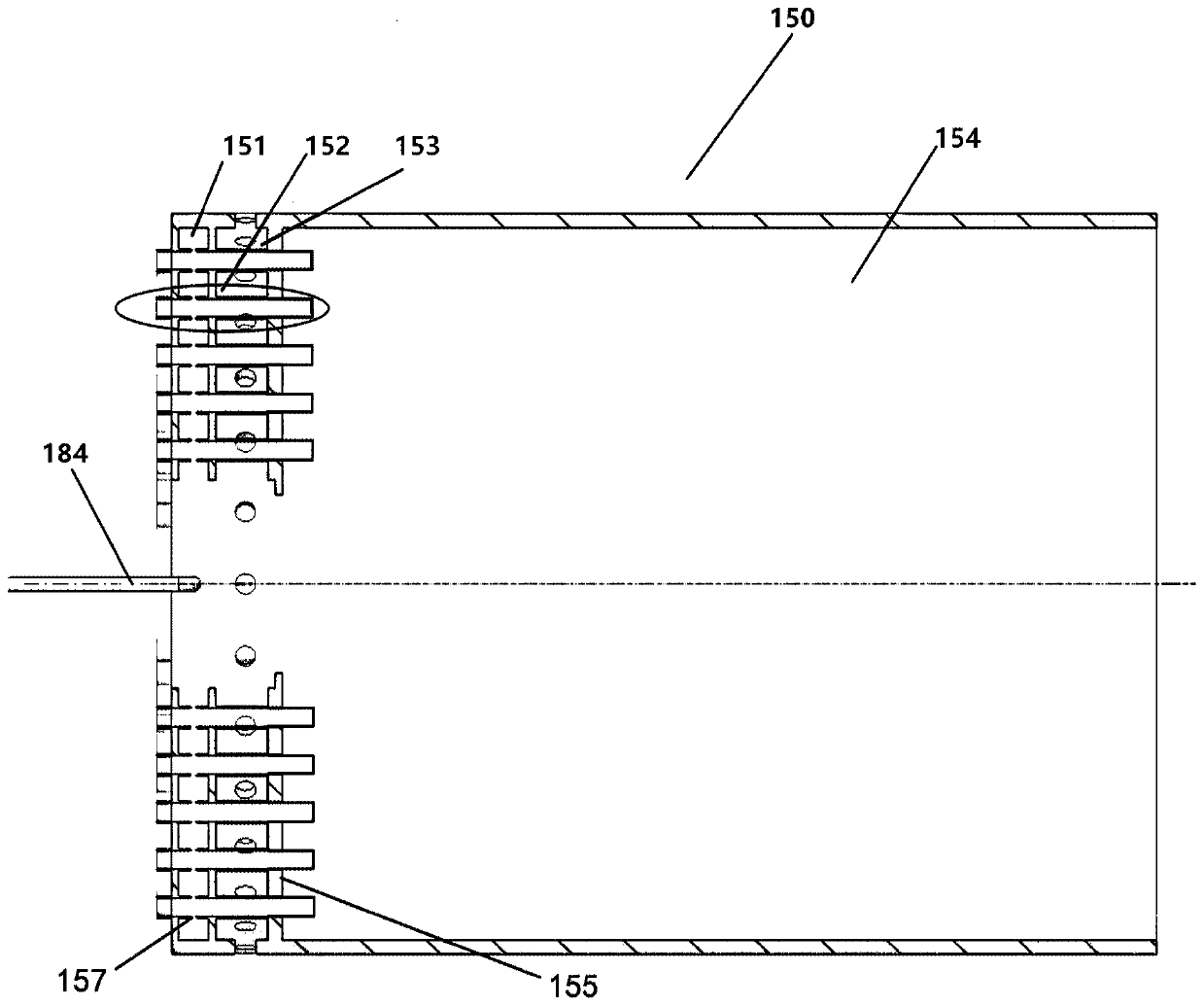

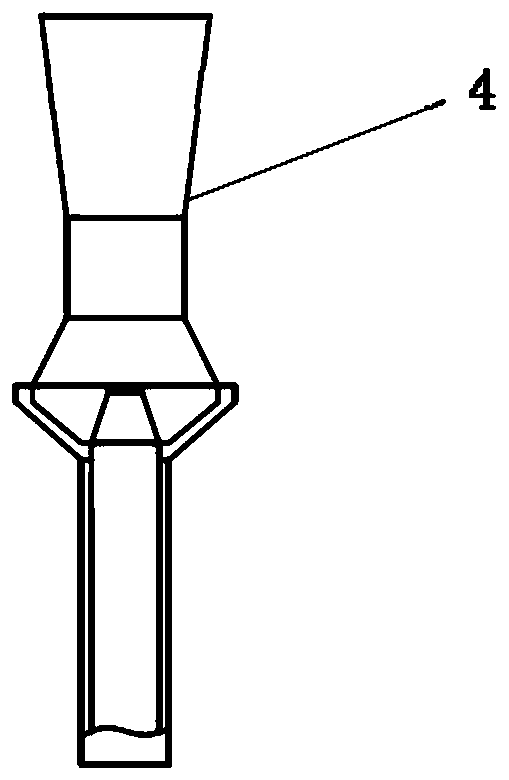

Quench mixer used for hydrogenation reactor

ActiveCN104096517AWell mixedMixed stronglyFlow mixersChemical/physical processesGas phaseEngineering

The invention discloses a quench mixer used for a hydrogenation reactor and aims to solve problems that a mixing effect is poor and a flow resistance of a mixed material flow is large when a quench mixer in the prior art is used for mixing and distributing a mixed material flow having a large amount of gas-phase reactants. The quench mixer is provided with a plurality of rotational-flow plates (5), wherein tops of the rotational-flow plates (5) are connected to a top baffle (2) and bottoms of the rotational-flow plates (5) are connected to a shutoff plate (4). A central hole (40) is formed in the center of the shutoff plate (4). A distribution plate (6) is arranged under the central hole. At least four arc-shaped plates (3) are disposed between the top baffle and the shutoff plate, around an edge of the top baffle and at external ends of the rotational-flow plates. A mixed material flow inlet (30) is arranged between each two adjacent arc-shaped plates. Each rotational-flow plate is arranged at a position corresponding to each mixed material flow inlet. A top baffle folded-edge (21) is disposed at the periphery of the top baffle. A distribution plate folded-edge (61) is disposed at the periphery of the distribution baffle. The quench mixer is mainly used in the hydrogenation reactor used for processing light-weight oil.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

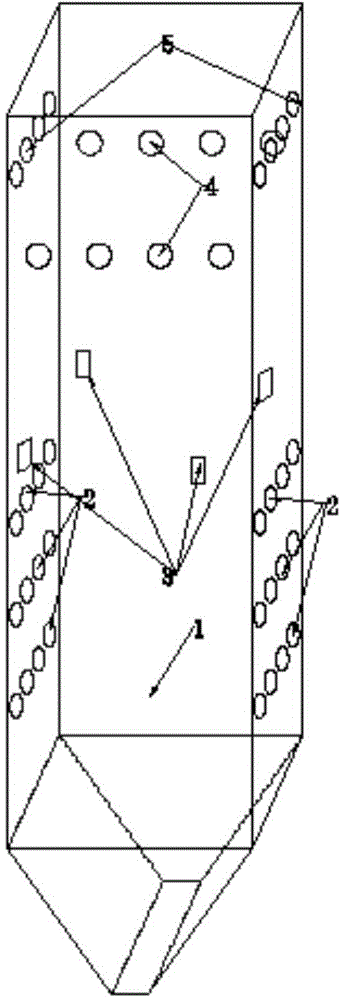

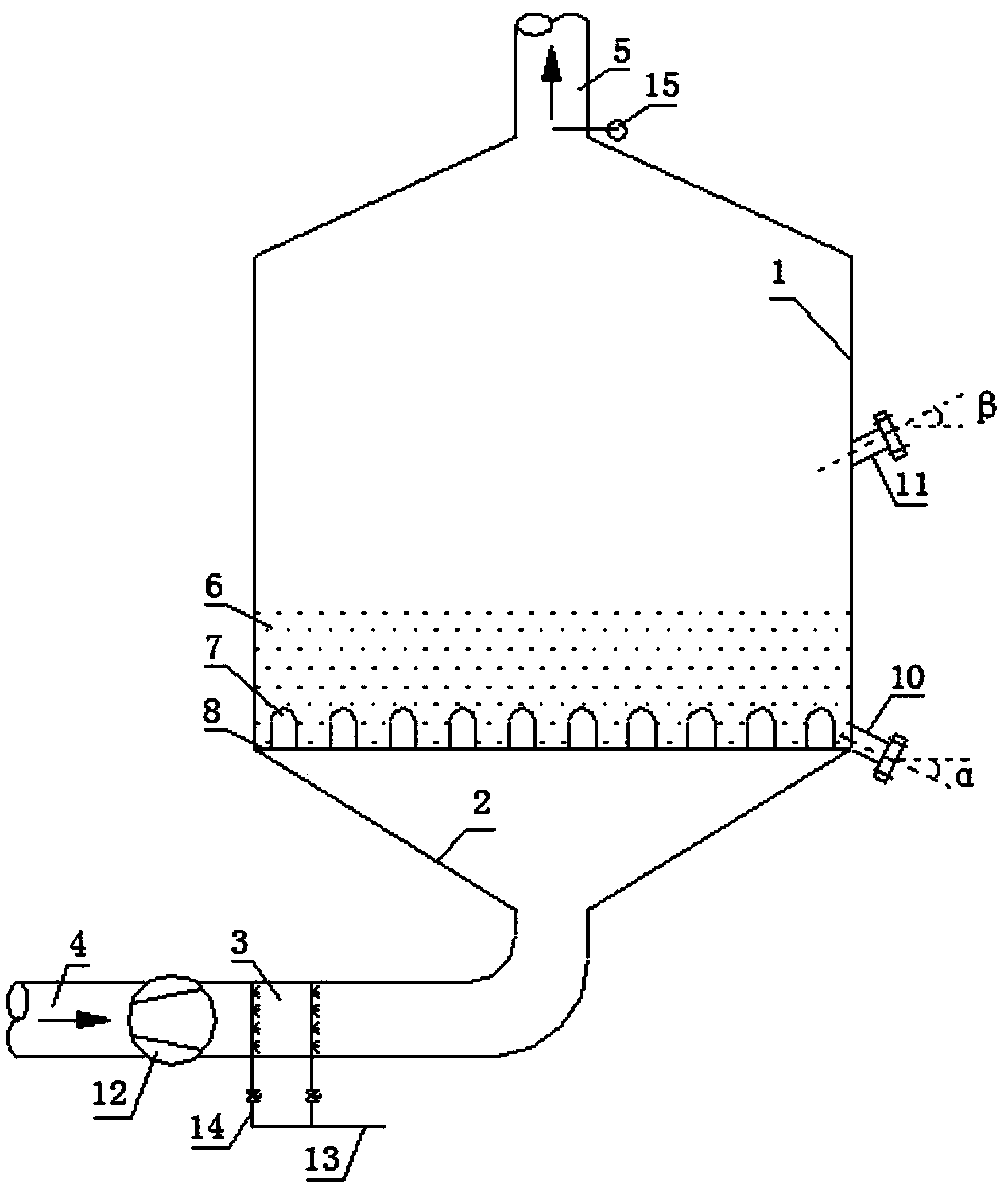

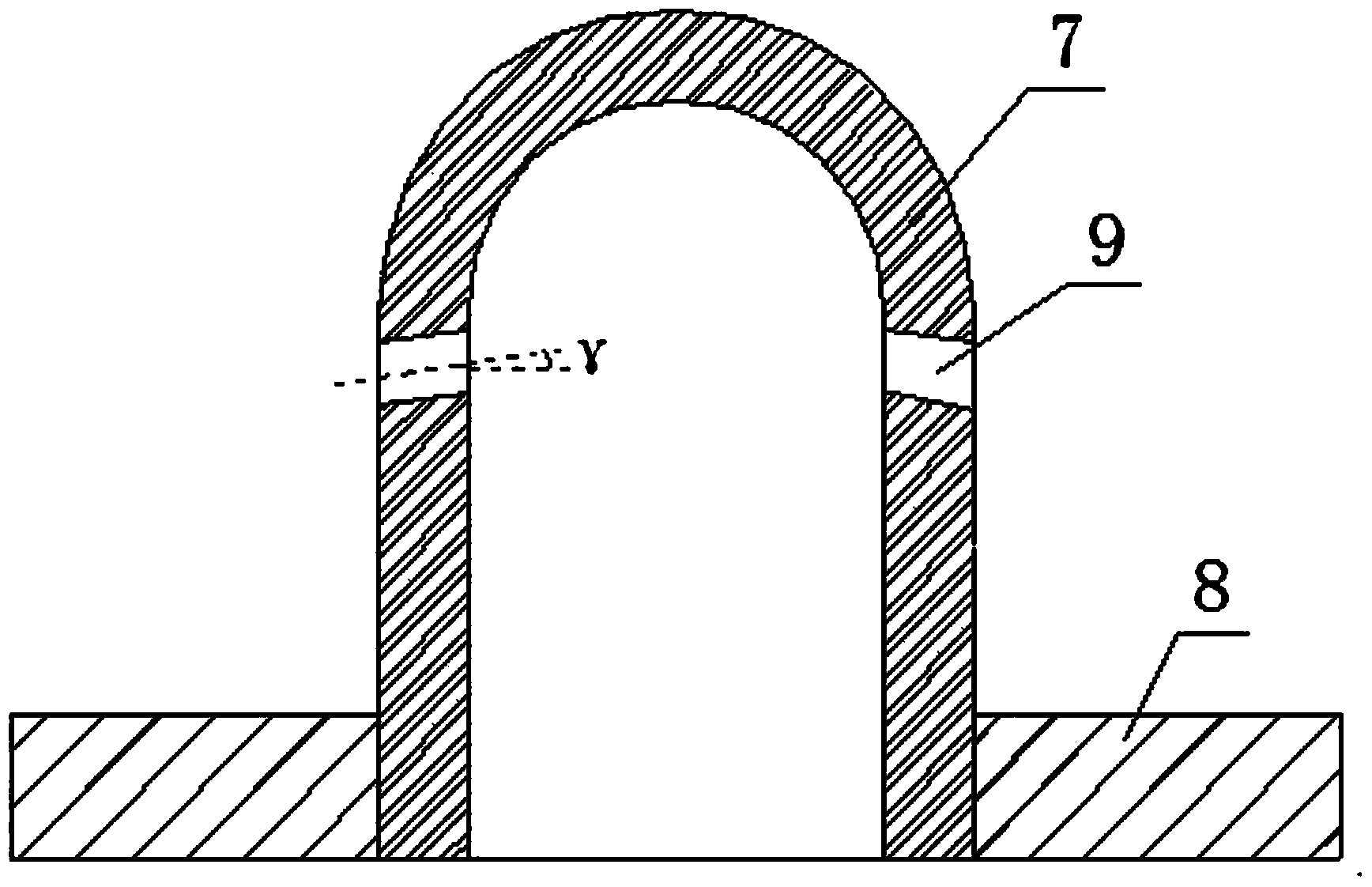

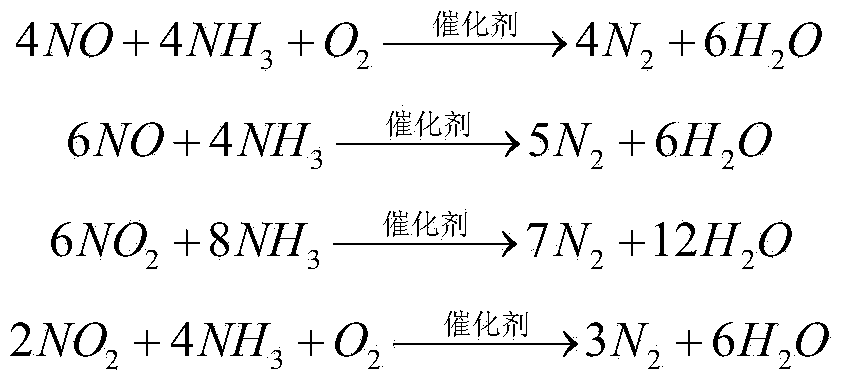

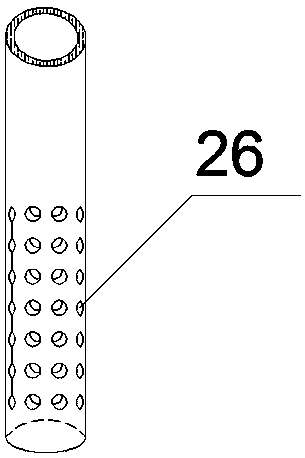

Smoke SCR denitration system for fluidized fuel gas kiln

InactiveCN104056549ALarge specific surface areaMixed stronglyDispersed particle separationIsoetes triquetraEngineering

The invention provides a smoke SCR denitration system for a fluidized fuel gas kiln. The smoke SCR denitration system comprises a reaction chamber and a mixing chamber located below the reaction chamber. An air distributor is arranged between the reaction chamber and the mixing chamber, air caps on the air distributor are ranked in an equilateral triangle mode, and the necks of the air caps are provided with small air cap holes, wherein the included angles between the small air cap holes and the horizontal cross section range from 5 degrees to 15 degrees. Catalyst granules are distributed on the upper surface of the air distributor, carriers of the catalyst granules are ceramic granules with the diameter ranging from 0.1 mm to 5 mm, and coating materials are SCR denitration active materials. The stack height of the catalyst granules is 2 to 6 times that of the air caps. According to the smoke SCR denitration system, the specific surface area of the catalyst granules is large, the catalyst granules continuously circulate vertically and turn over under the effect of mixed airflow flowing upwards and the gravity of the catalyst granules, the catalyst granules more intensively and more completely make contact with and are mixed with smoke / ammonia gas mixed gas in the fluidization process compared with that in traditional technology, the catalysis effect is better, and denitration efficiency is more than 99%.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Mild combustion chamber of gas turbine

ActiveCN110631049AMixed stronglyIncrease the reflux ratioContinuous combustion chamberRefluxCombustor

The invention relates to a mild combustion chamber of a gas turbine. The mild combustion chamber comprises a premixed mild combustor, a first guide shell, a second guide shell, a secondary combustionchamber and a mild combustor on duty. Through array-type distribution of the mild combustors, the space of the mild combustion chamber of the gas turbine is fully utilized, the flue gas reflux ratio is increased, a partial mild combustion condition is easier to establish, and full-zone mild combustion of a combustion zone is realized; by means of radial staging, the requirement of regulation within a wide operating condition range is met; and as the mild combustor on duty, the premixed mild combustor and micro-mixing nozzles are different in axial position, axial staging of combustion is realized; the load regulation requirement is met; the uniformity of outlet temperature of the mild combustion chamber of the gas turbine is increased; pressure loss is reduced; full-zone high flue gas reflux ratio of mild combustion is realized; and the requirements of low emission within the wide operating condition range and efficient and stable operation are met.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

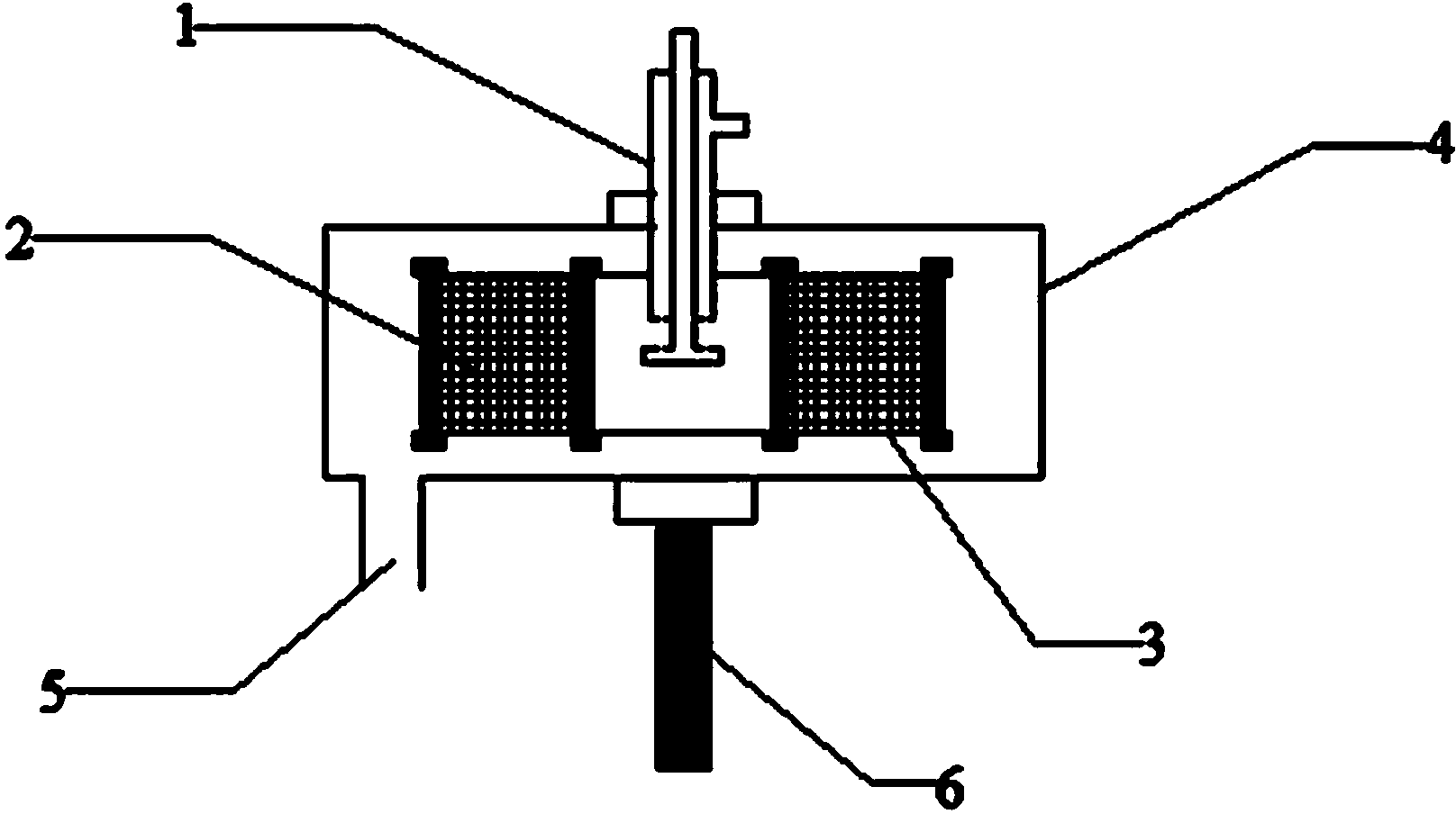

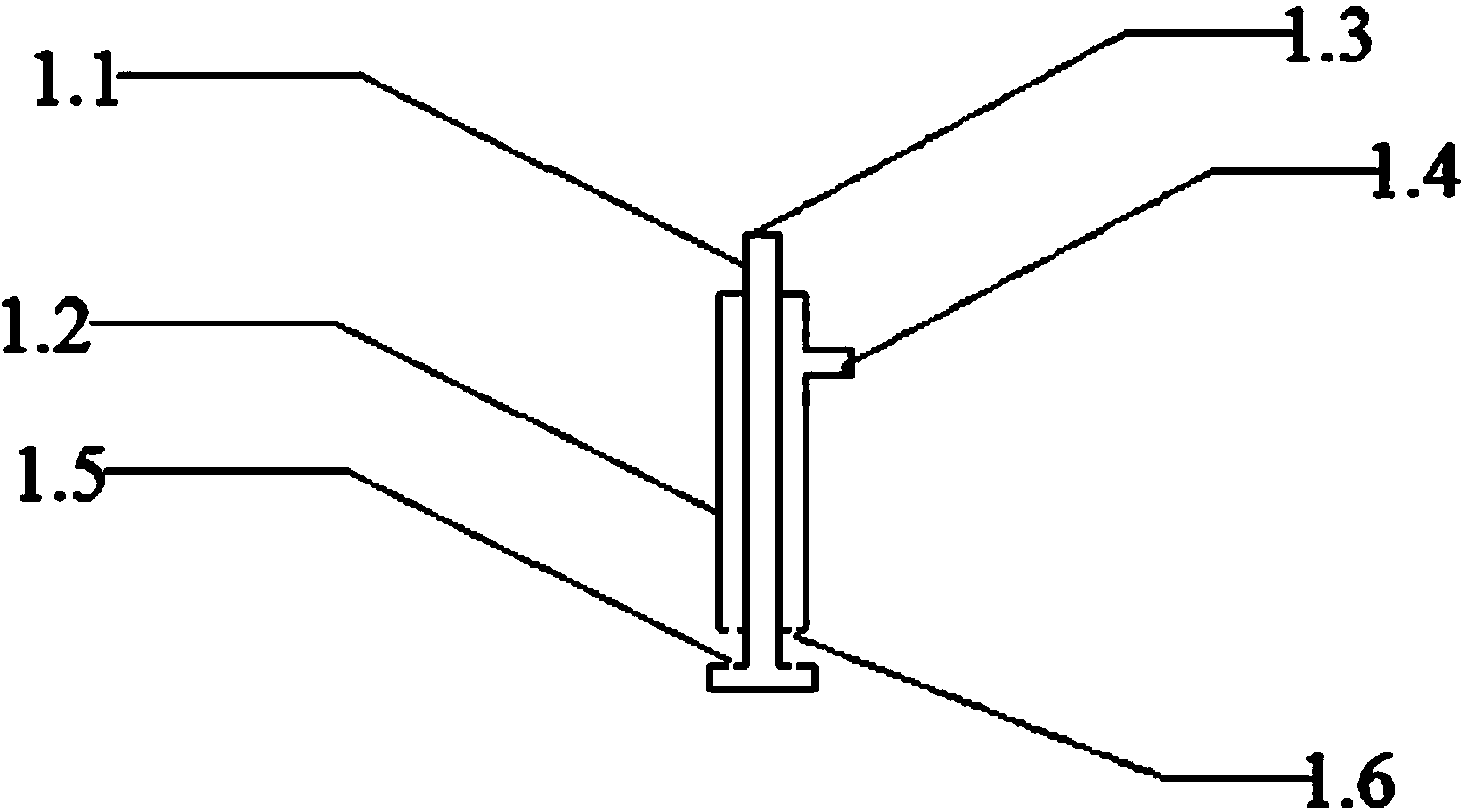

Impinging stream structure and impinging stream and rotary material packed bed device

ActiveCN104226202AReduce settingsReduce lossesChemical/physical/physico-chemical nozzle-type rreactorsFeed devicesEngineeringPipe

The invention belongs to the technical field of devices for intensifying liquid and liquid quick micro mixing reaction, in particular relates to an impinging stream structure and an impinging stream and rotary material packed bed device, and solves the problem that the conventional impinging stream structure is not ideal and nonuniform in mixing effect. The impinging stream structure comprises a main feed pipe and a sleeve which are different in pipe diameter, wherein a plurality of main feed pipe discharge holes are formed in one side, near the sleeve, of the discharging section of the main feed pipe; the bottom of the sleeve corresponds to the discharging section of the main feed pipe; a plurality of sleeve discharge holes in one-one correspondence to the main feed pipe discharge holes in an up and down manner are coaxially formed in the bottom of the sleeve. According to the impinging stream and rotary material packed bed device, the impinging stream structure is arranged in a cavity of a rotor of the rotary material packed bed and is arranged in the axial direction of the rotor. the impinging stream structure and the impinging stream and rotary material packed bed have the advantages that fed feed in different amounts can be uniformly mixed, the reaction is quick, the reaction time is short, and the momentum loss is less, and are particularly suitable for quick reaction of batch feed feeding in different amounts in industry and the reaction system with the certain viscosity character.

Owner:ZHONGBEI UNIV

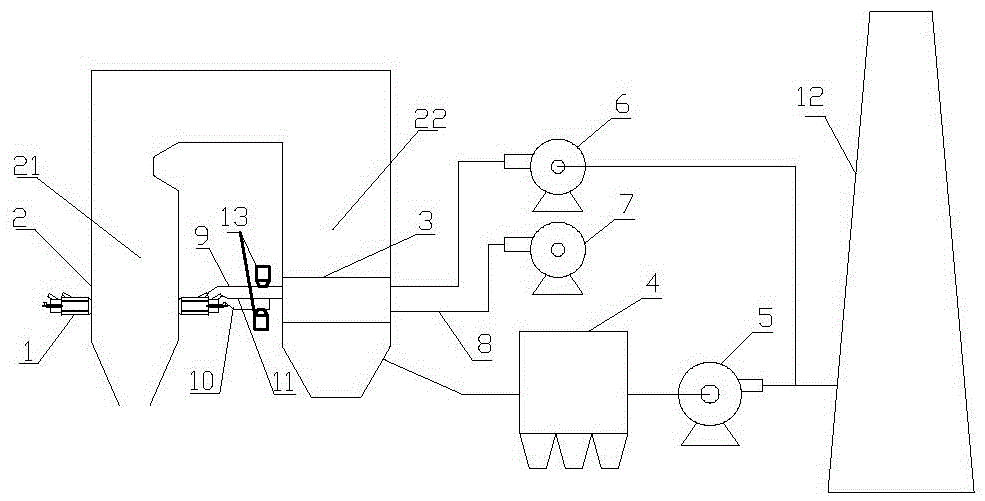

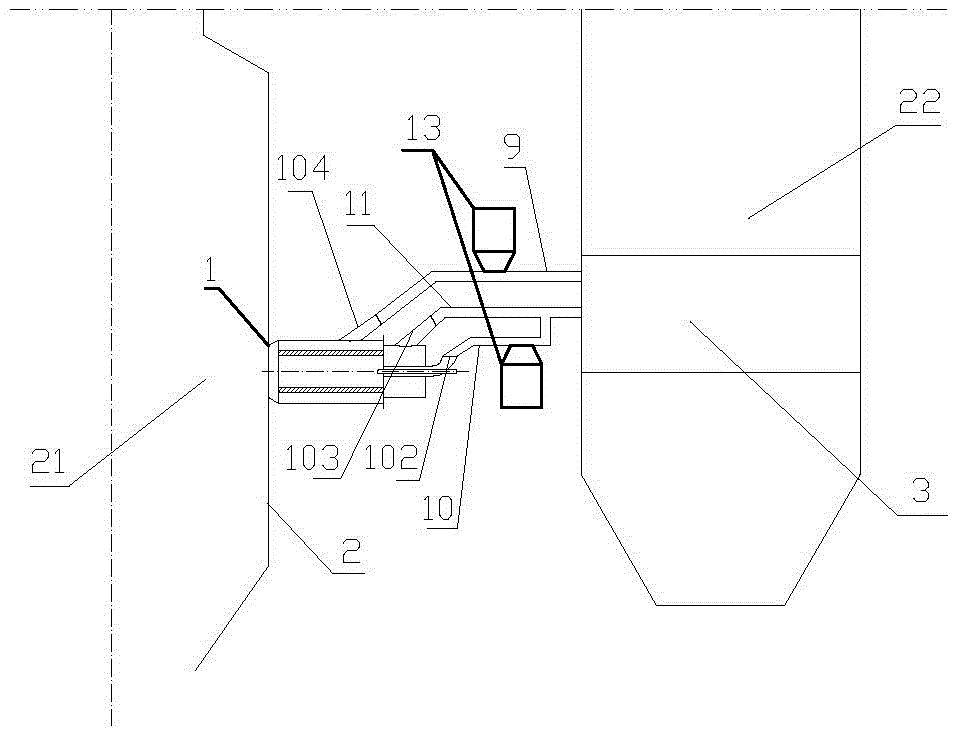

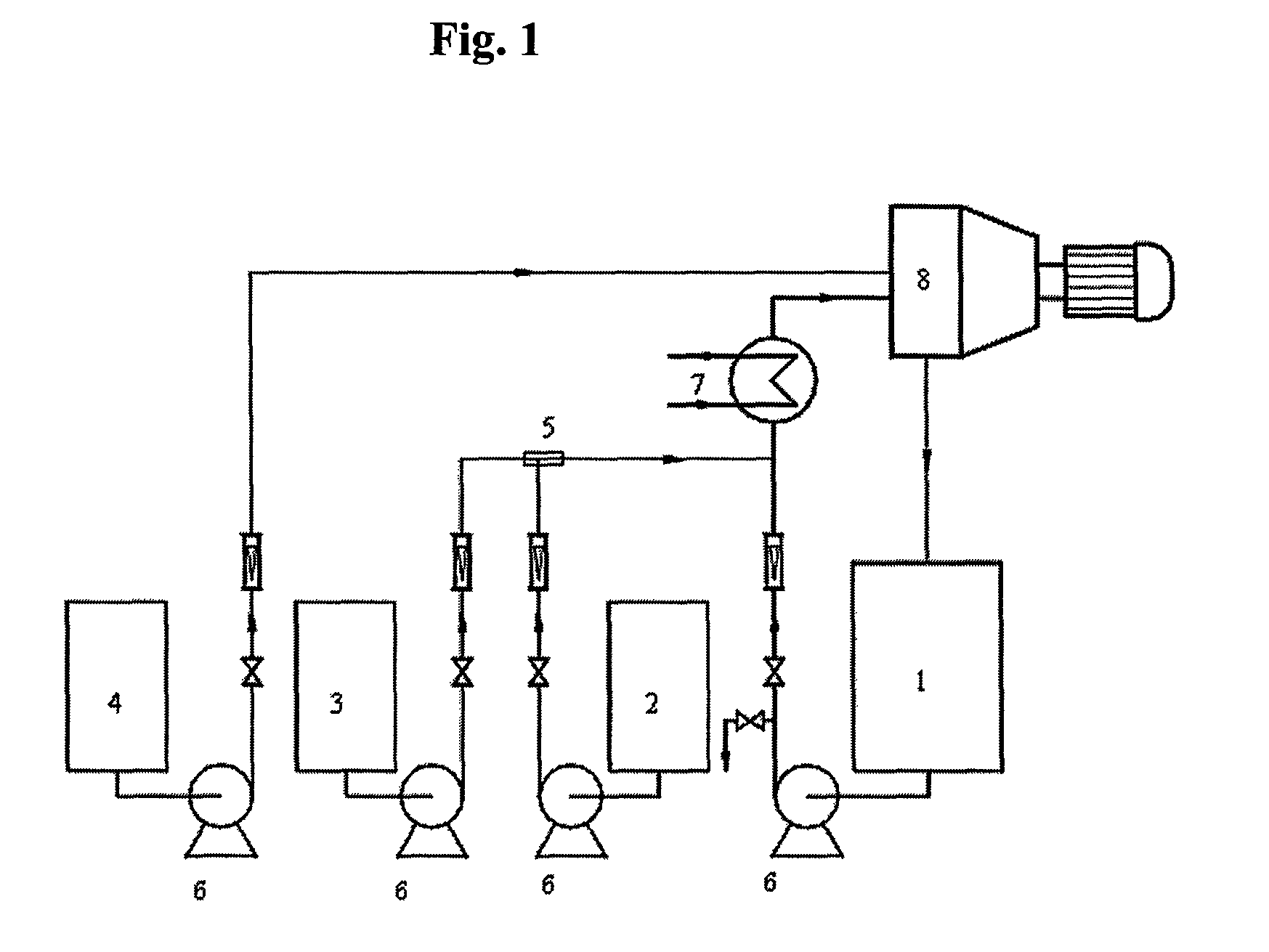

Low NOx pulverized coal combustion system and method

InactiveCN106122945AImprove combustion stabilityIncrease the reaction areaCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCoalProcess engineering

Provided are a low NOx pulverized coal combustion system and method. The low NOx pulverized coal combustion system is characterized by comprising a burner (1), a powder making and supplying system (13), a boiler body (2), an air preheater (3), a dust remover (4), a main induced draft fan (5), a flue gas circulation fan (6), a primary fan (7), a primary air duct (8), a flue gas return tube (9), an inner primary air duct (10), an outer primary air duct (11) and a chimney (12); and the boiler body (2), the dust remover (4), the main induced draft fan (5) and the chimney (12) are sequentially connected. On the premise of improving the combustion stability and efficiency, a strong reducing area of combustion in a boiler is created effectively, the effective staying time of flue gas in the reducing area is prolonged, a certain turbulence degree of pulverized coal exists in a boiler hearth when in an extremely low excess air coefficient, the burn-off rate of combustion products in the boiler is improved, and NOx generated in the combustion process is restrained and reduced; and meanwhile, part of emitted flue gas is circulated, NOx carried in the flue gas is further reduced, and low NOx flue gas emission of the pulverized coal combustion system with high-efficiency combustion is achieved.

Owner:JIANGSU SUNPOWER TECH

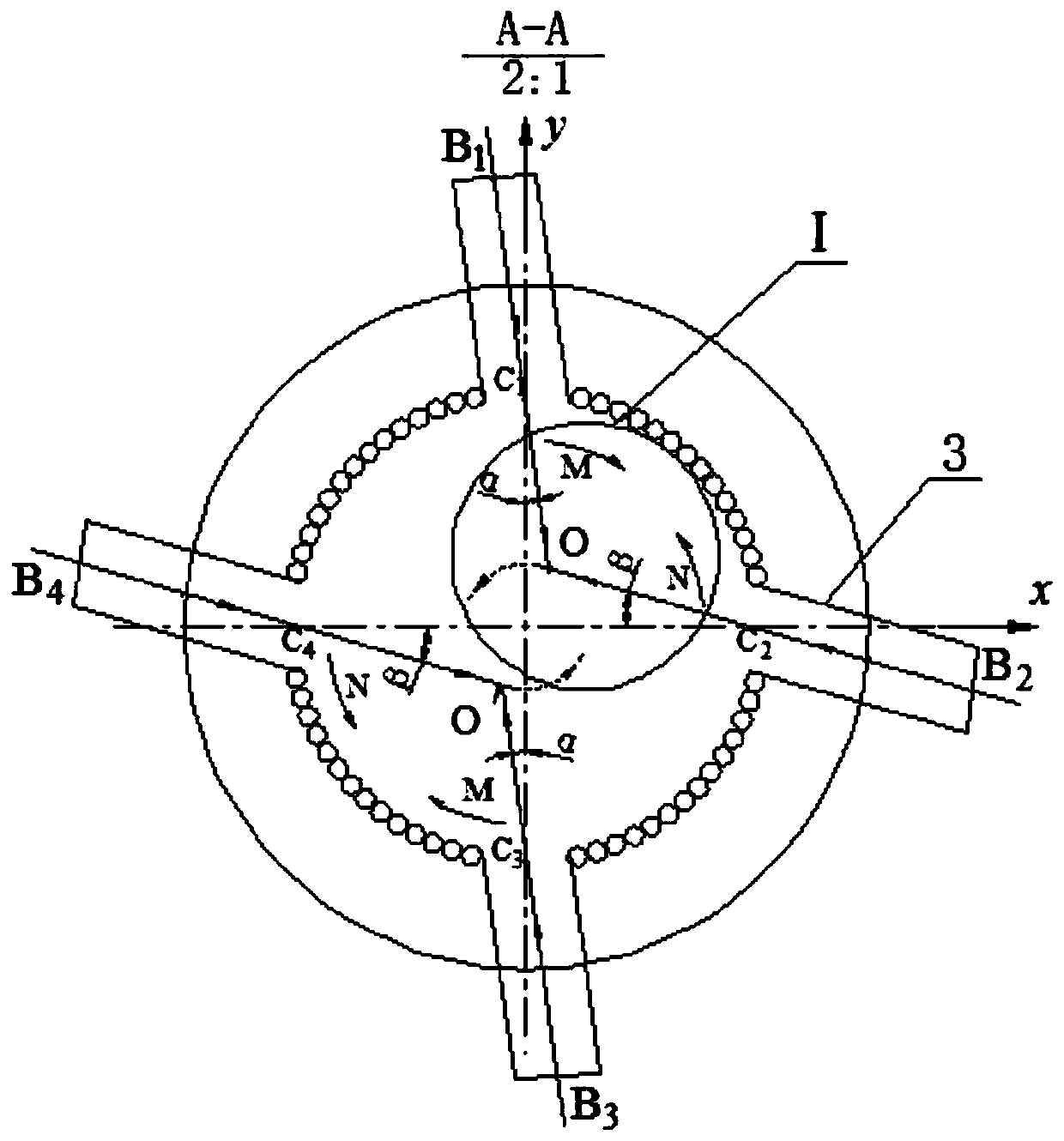

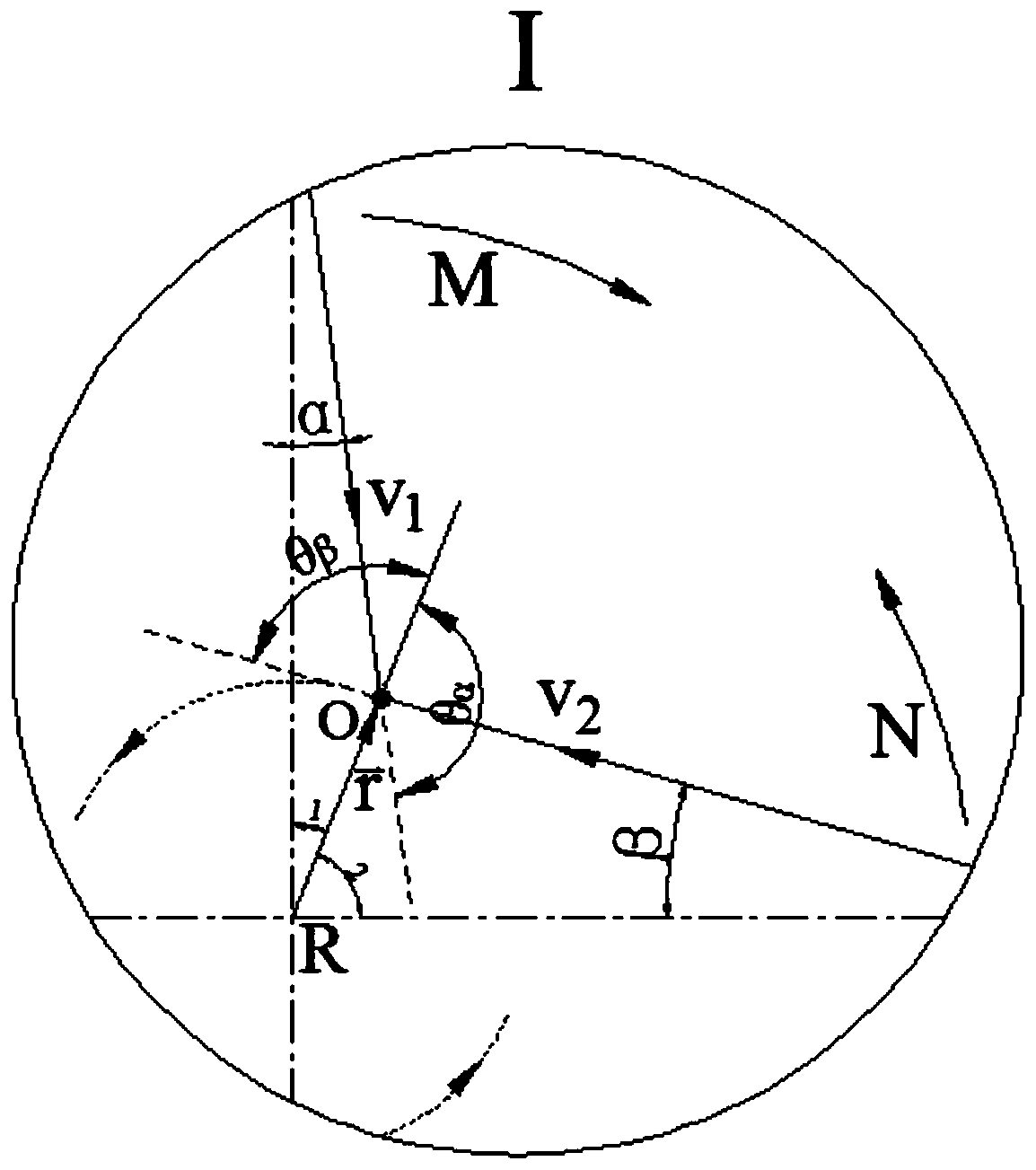

Entrained flow gasifier device with four forward and reverse rotating burners and gasification method

ActiveCN110452737AWell mixedImprove carbon conversionGasification processes detailsGranular/pulverulent flues gasificationSlagEngineering

The invention relates to an entrained flow gasifier device and a gasification method utilizing the device, particularly to an entrained flow gasifier device with four forward and reverse rotating burners and a gasification method, and aims to solve the problems of gasifier water-cooled wall burning loss, low carbon conversion rate and the like caused by unreasonable burner arrangement mode of existing multi-burner entrained flow gasifiers. The entrained flow gasifier device with four forward and reverse rotating burners includes a gasifier body, burners, a water-cooled wall, an igniter burner,a slag tank and a synthesis gas channel. The four burners, i.e. burner B1, burner B2, burner B3 and burner B4 are located on a same horizontal plane, and are evenly distributed along the circumference of the gasifier body in order, the intersection points of center lines and the water-cooled wall surface are C1, C2, C3, and C4 respectively, the center lines of B1 and B2 intersect at point O, andthe center lines of B3 and B4 intersect at point O'; the included angle alpha of C1O and C1C3, and the included angle beta of C2O and C2C4 satisfy that: alpha is greater than 0 and smaller than beta and beta is less than 45 degrees, or beta is greater than 0 and smaller than alpha and alpha is less than 45 degrees. The entrained flow gasifier device provided by the invention is used for the entrained flow gasification field.

Owner:HARBIN INST OF TECH

Method for grinding and scattering solid particles in liquid

InactiveCN101513594AEvenly distributedStrong disturbanceFlow mixersTransportation and packagingSolid particleMaterials science

The invention relates to a method for grinding and scattering solid particles in liquid. In the method, a specially designed machine is adopted for processing liquid containing solid particles; the machine generates vacuoles groups in the liquid by means of mechanical rotation, grinds the solid particles under the massive impact of the vacuole and scattering the particles in the liquid.

Owner:初景涛 +1

Strong mixing reactor

PendingCN111135778ASimple structureMix all phases evenlyFlow mixersTransportation and packagingMechanical engineeringMechanics

A strong mixing reactor relates to a strong mixing reactor suitable for liquid-liquid, liquid-solid and gas-liquid, gas-liquid-solid multiphase reaction processes with relatively low gas quantity. Thereactor is mainly and technically characterized in that energy is carried through liquid external circulation, and the circulation flow in a fluid is amplified in a mode of combined use of a venturimixed flow nozzle and an inner sleeve, so that each phase in the reactor is quickly, uniformly and strongly mixed; through the flow amplification effect of the coupling nozzle and the inner sleeve, mechanical stirring or gas carrying energy is replaced, and strong mixing of multi-phase fluids can be well achieved; and the reactor has the advantages of simple structure, uniform mixing of each phase, uniform particle suspension, high reactor efficiency and large fluid circulation flow in the reactor. According to the reactor, the effect of a multi-kettle series reactor is achieved through a simple structure, continuous operation of multiple reaction steps is achieved in a single reaction tower, the size of the reactor is reduced under the same reaction conversion rate, and the efficiency ofthe reactor is improved.

Owner:TSINGHUA UNIV

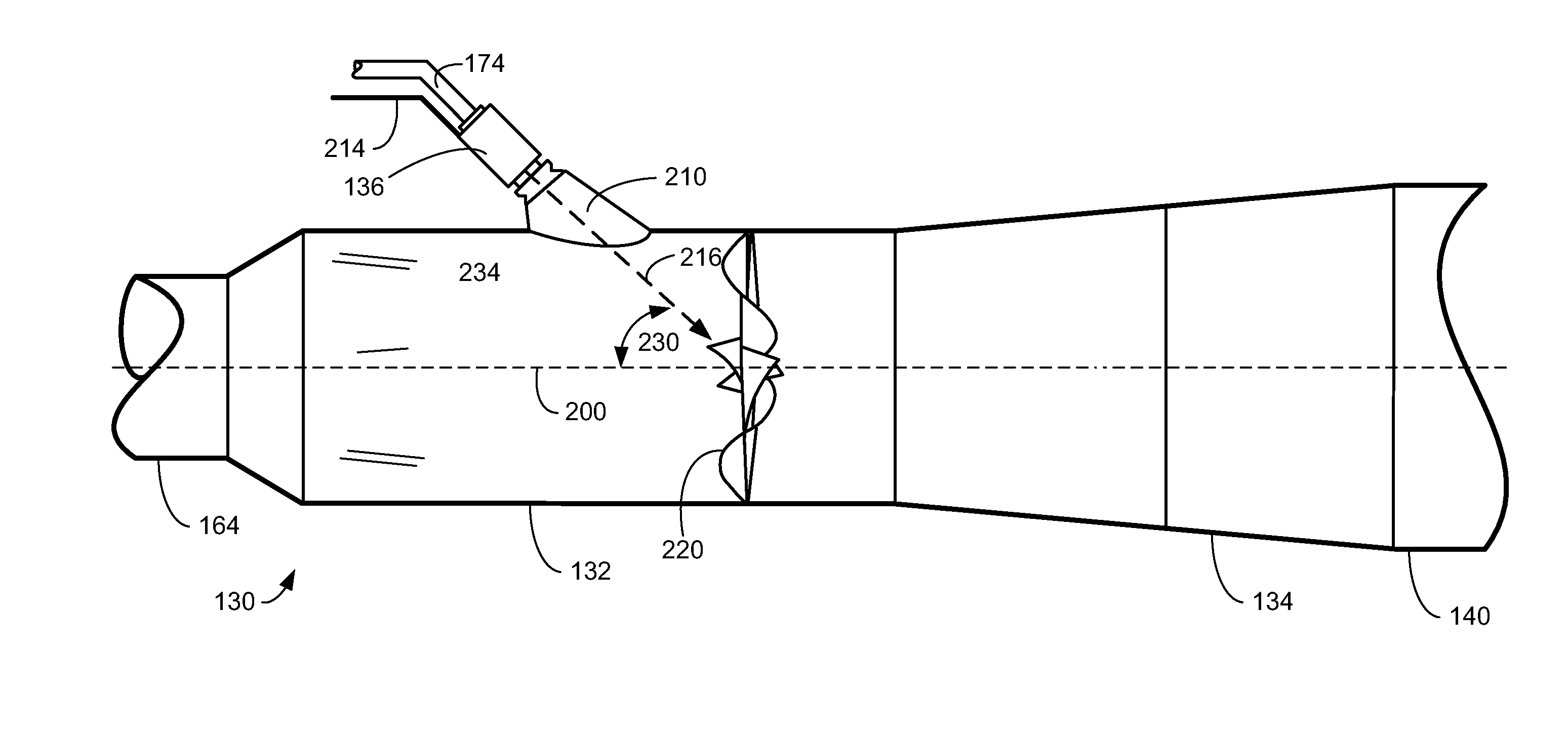

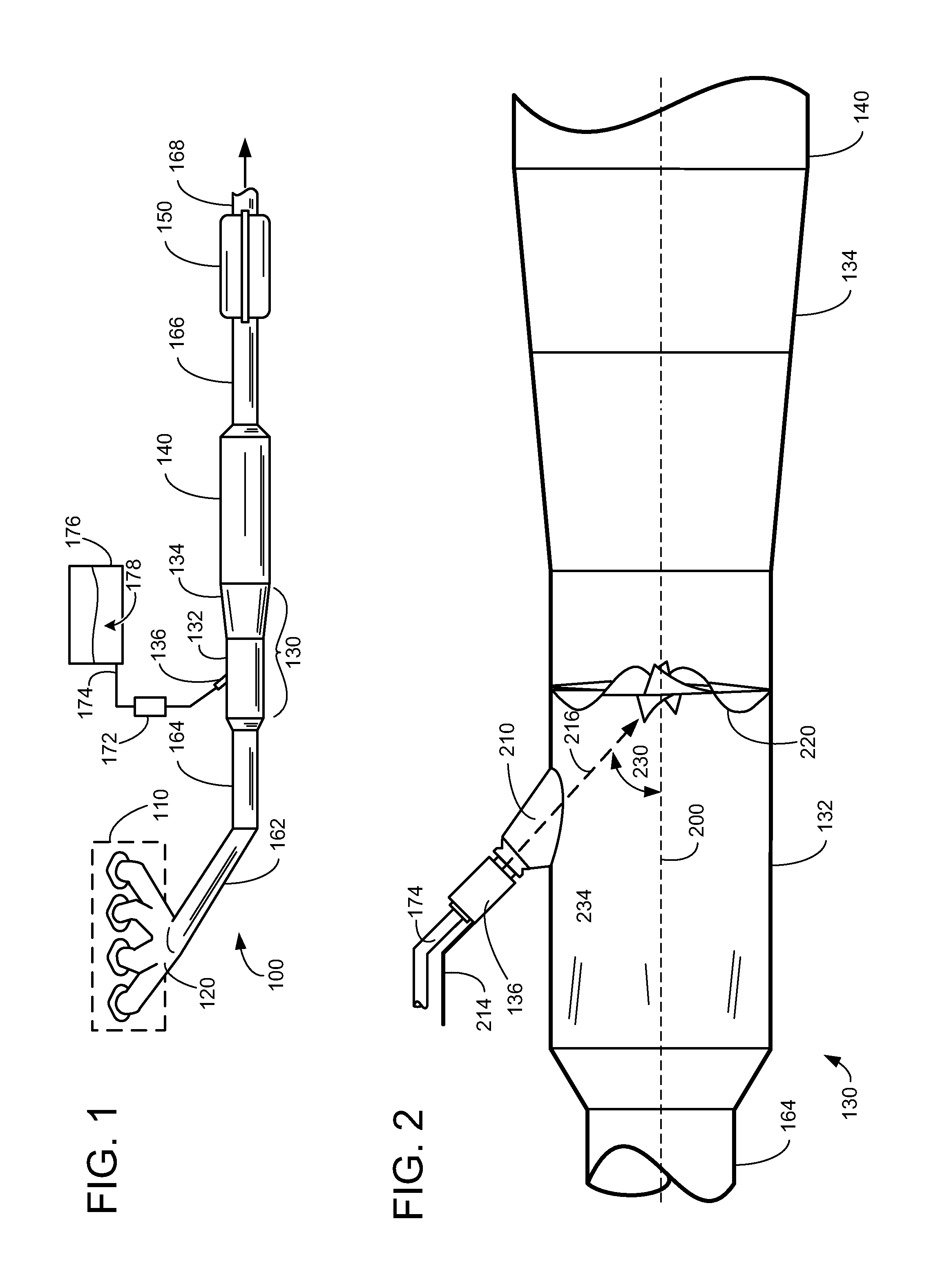

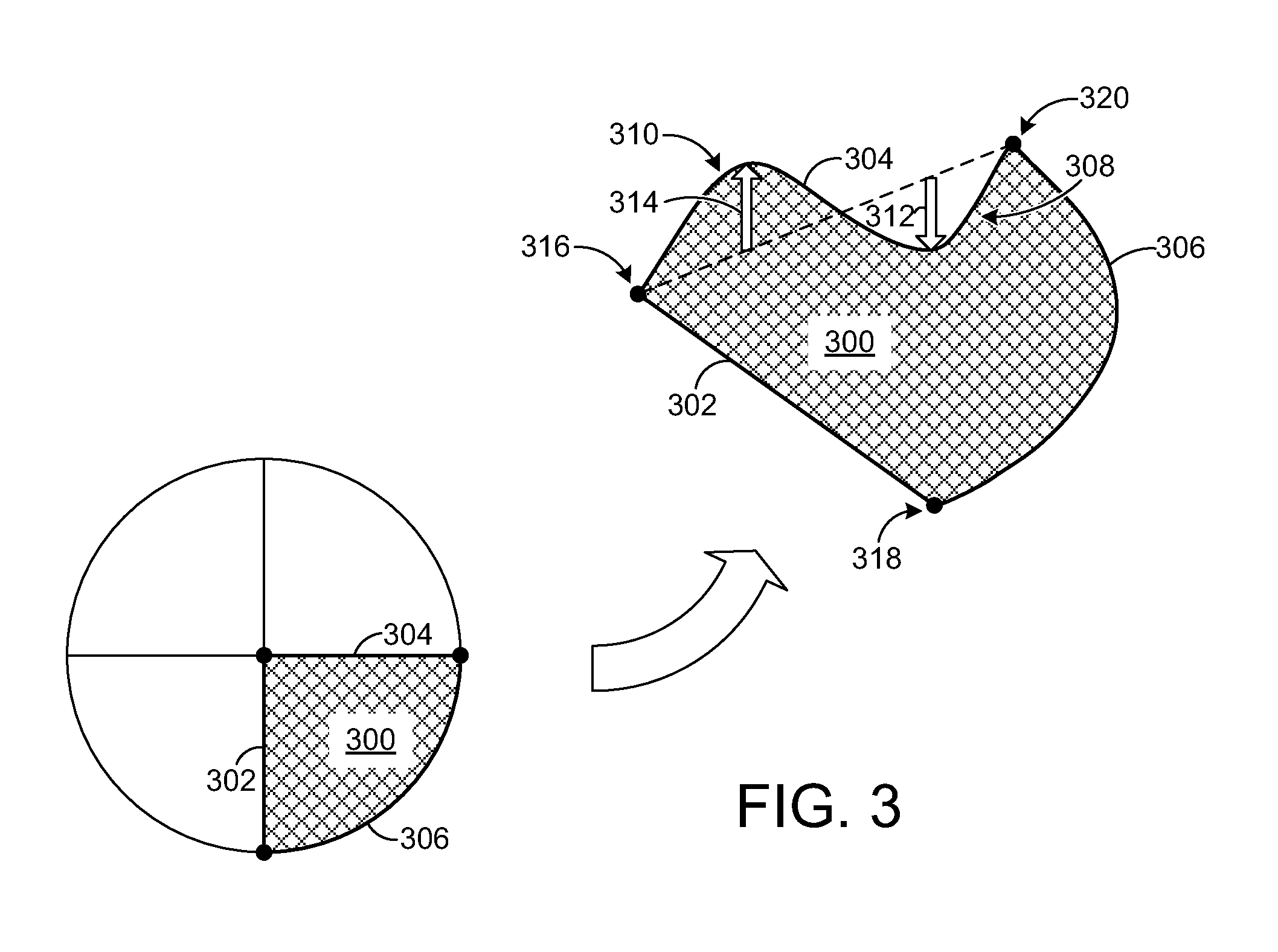

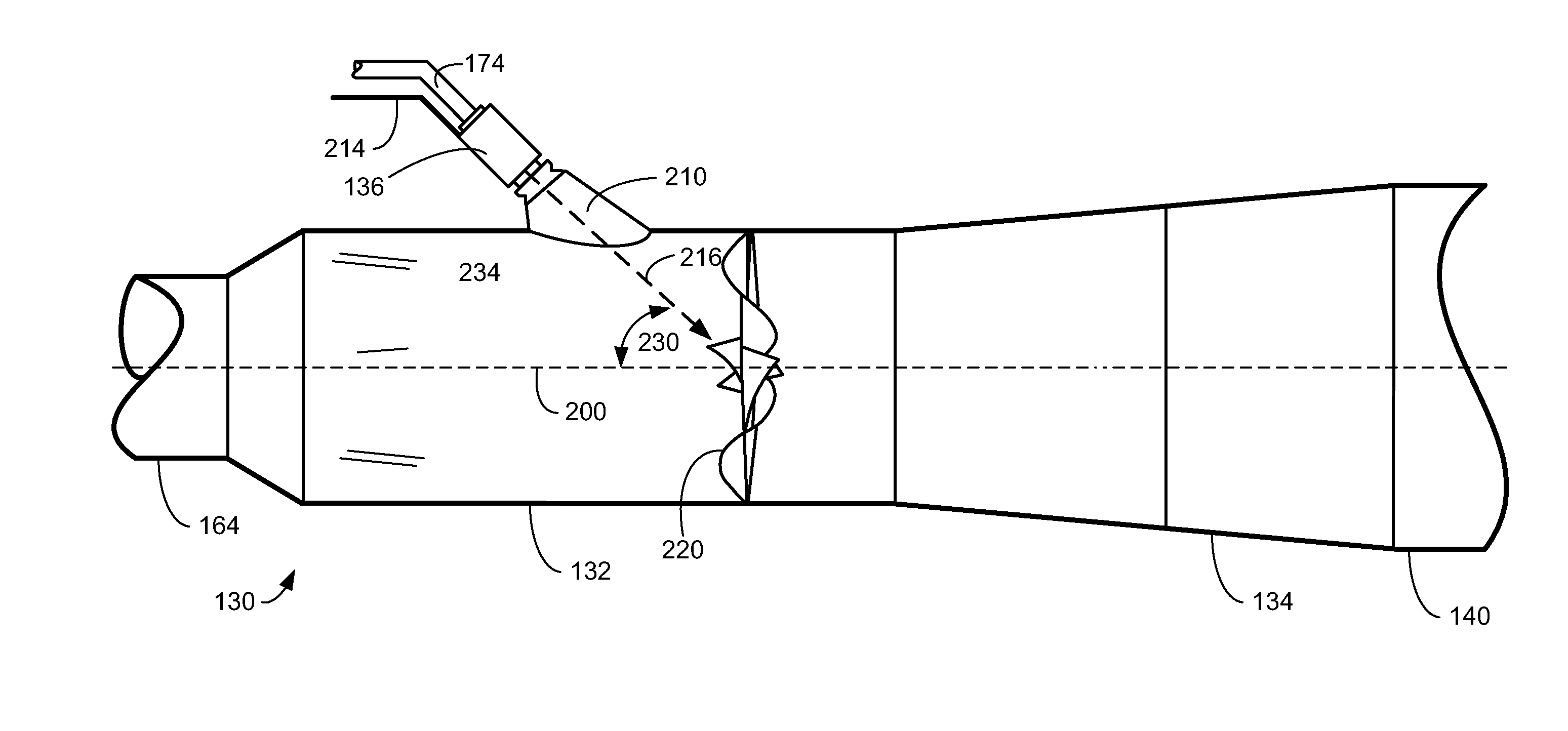

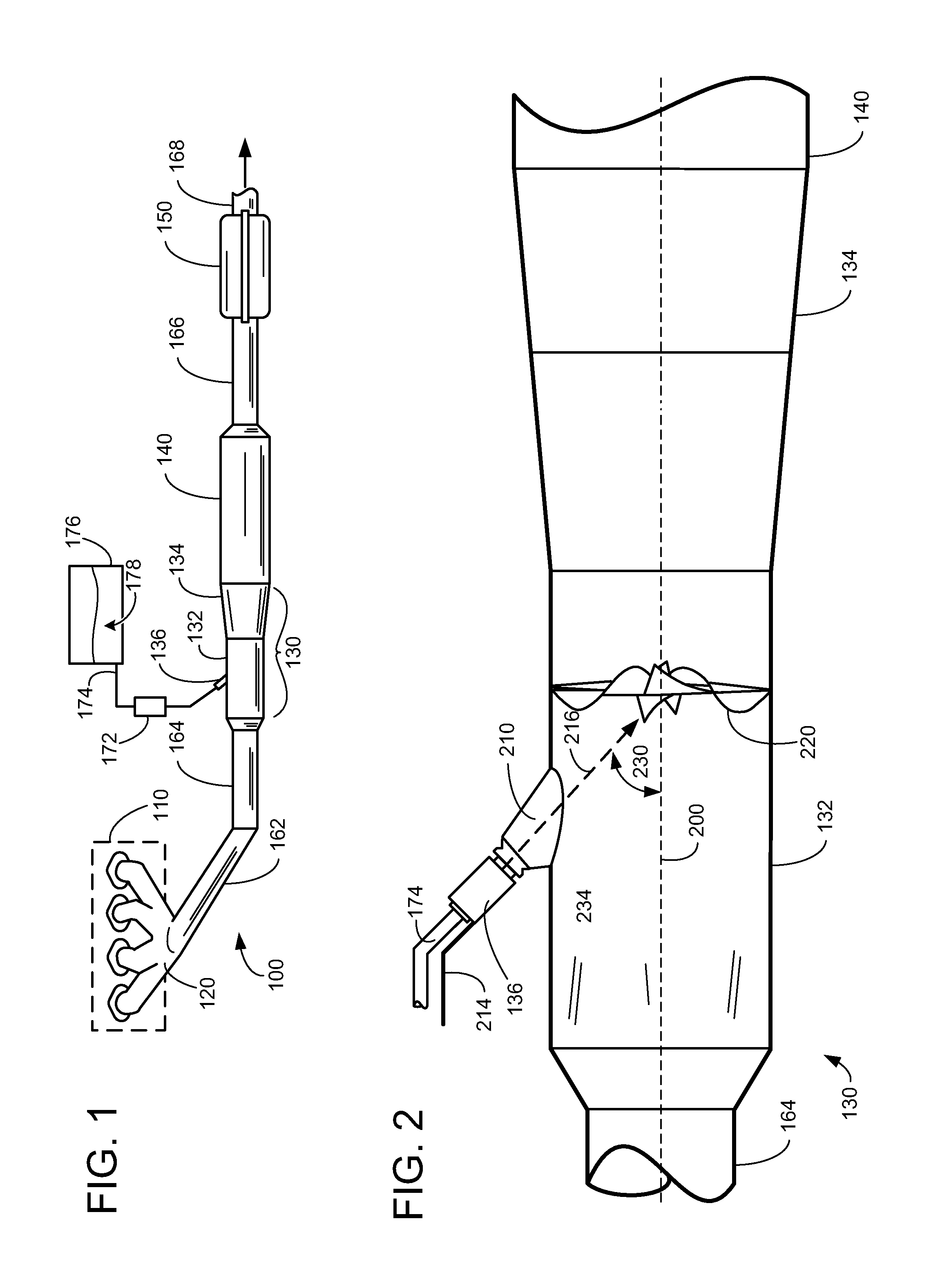

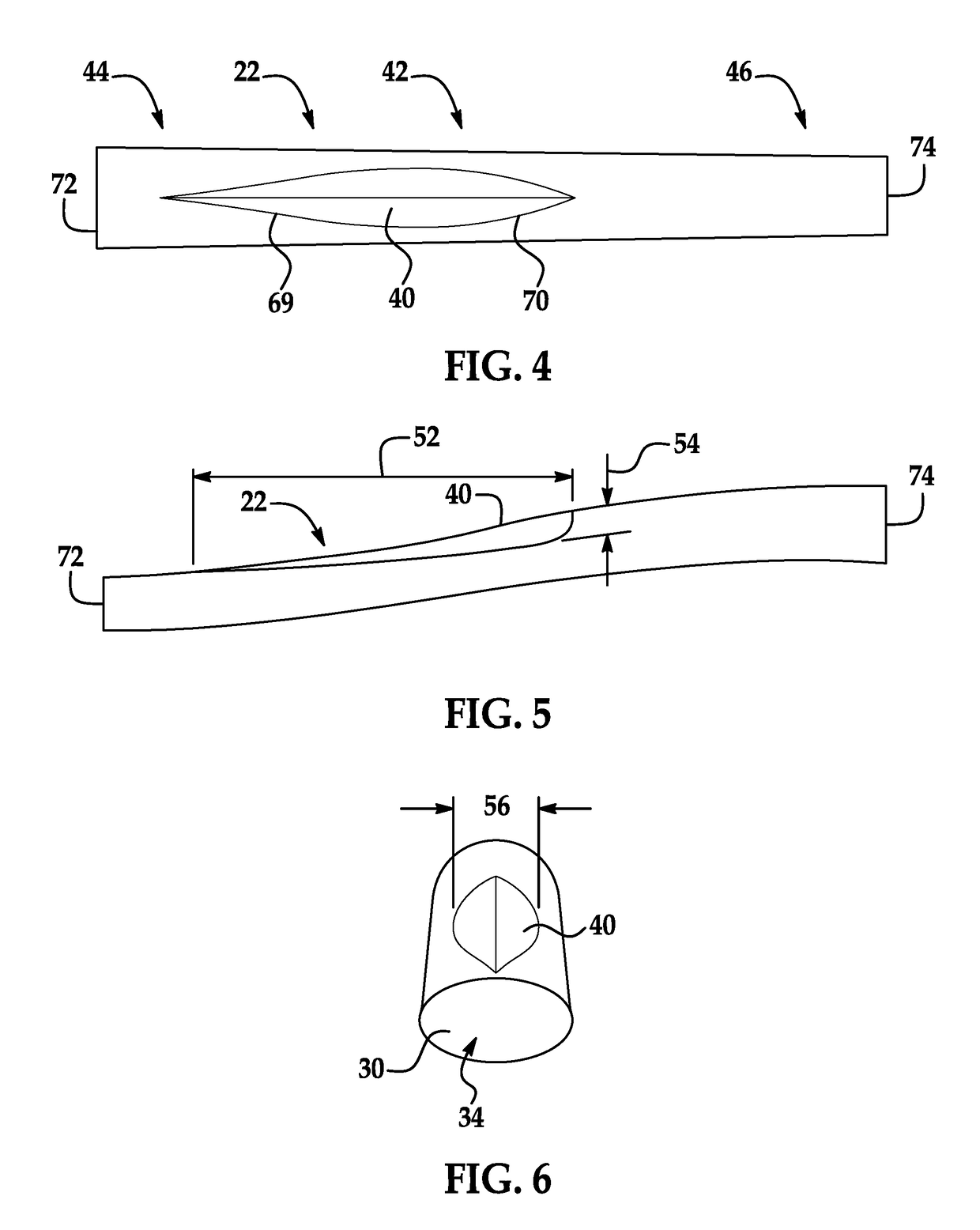

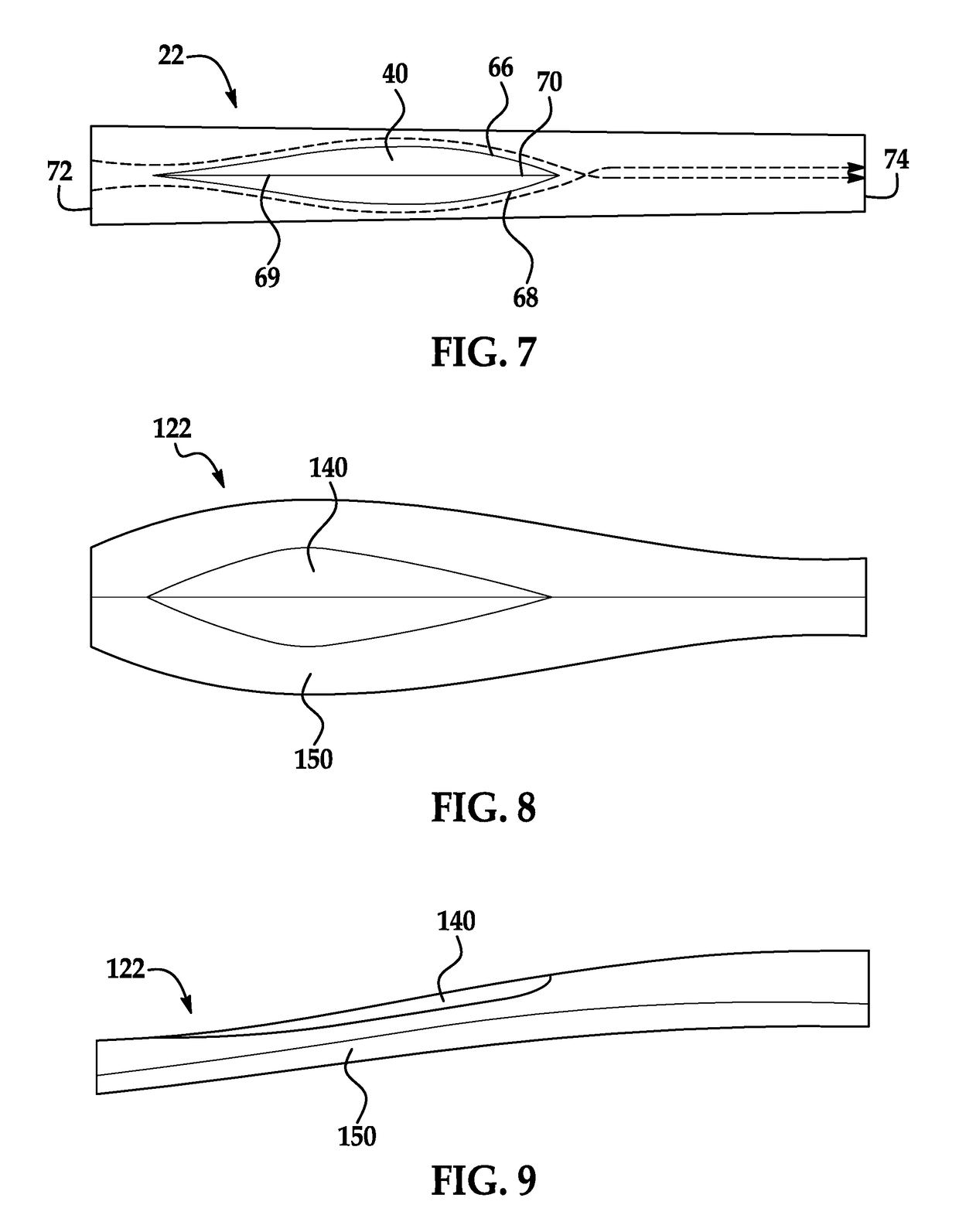

Flight vehicle air breathing propulsion system with isolator having obstruction

ActiveUS20180347462A1Well mixedEnhanced vortex strengthEngine manufactureJet type power plantsCombustorHigh energy

A flight vehicle has a propulsion system that includes an air inlet, an isolator (or diffuser) downstream of the air inlet, and a combustor downstream of the isolator. The isolator includes an obstruction that protrudes inwardly from an inner wall of the isolator, into the flow channel in which air flows through the isolator. The obstruction diverts the flow to either side of it. Downstream of the obstruction the flow on either side of the obstruction comes together again, leading to mixing of the flow, for example including mixing of low energy and boundary layer flow with high energy flow. This mixing of flow may make for a more uniform flow at the exit of the isolator. In addition the obstruction may help fix the location of shocks within the isolator, providing longer flow mixing length in the isolator.

Owner:RAYTHEON CO

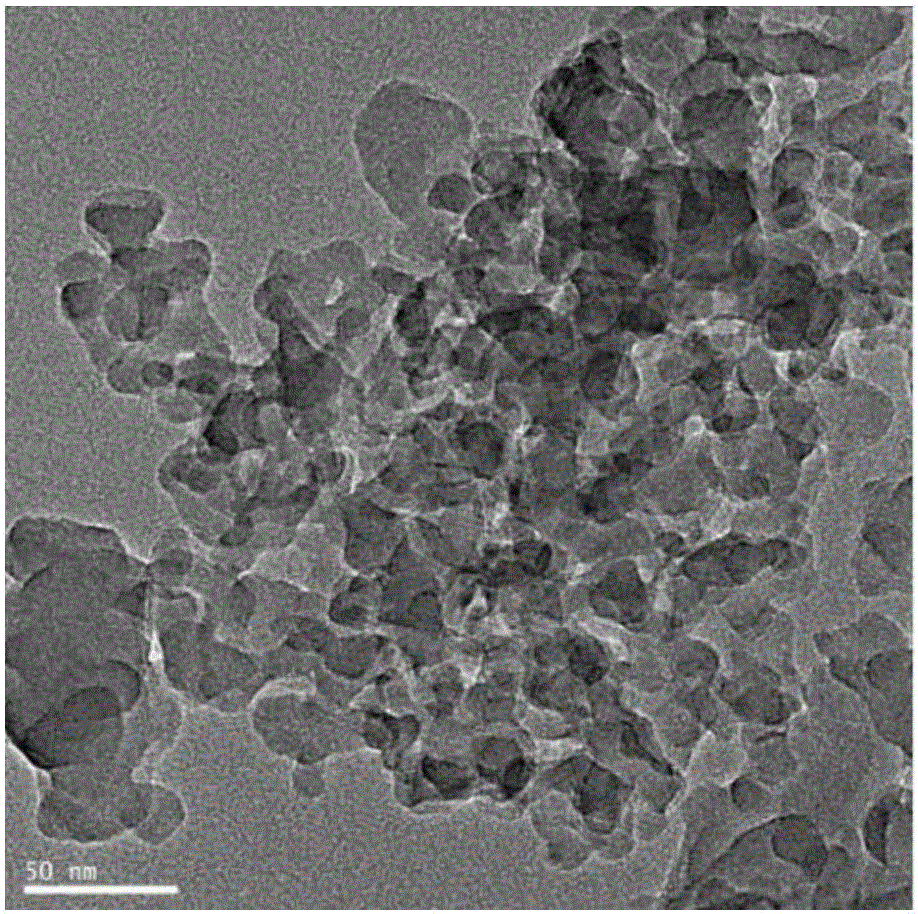

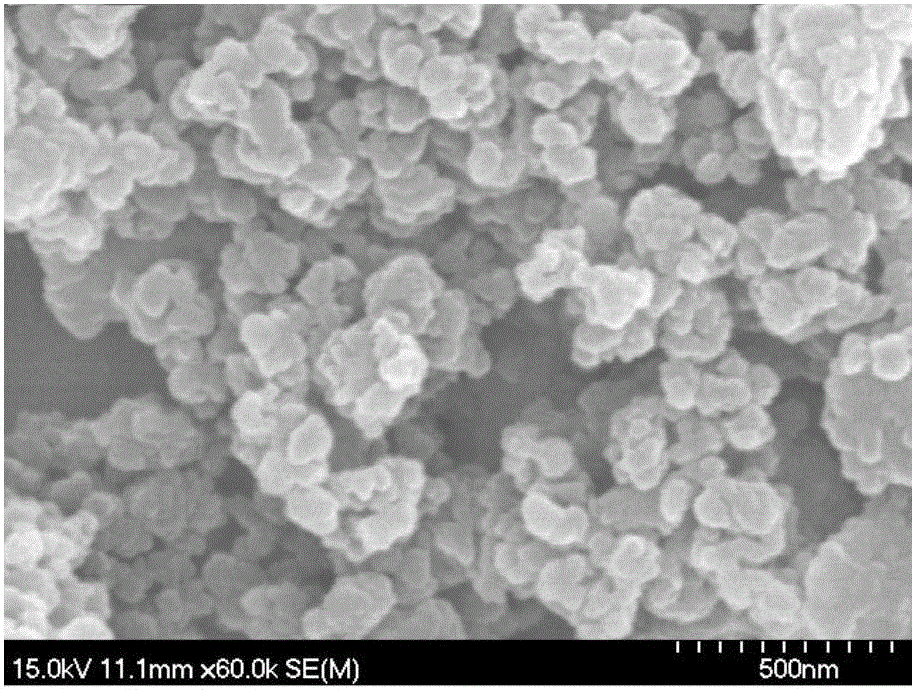

Supergravity gas-liquid precipitation method for preparing silica nanoparticles based on rice hull ash

InactiveCN106629755ARelieve pressureLow costMaterial nanotechnologySilicon compoundsSilica nanoparticlesSilicon dioxide

The invention relates to a supergravity gas-liquid precipitation method for preparing silica nanoparticles based on rice hull ash. The supergravity gas-liquid precipitation method for preparing the silica nanoparticles based on the rice hull ash has the advantages that the rice hull ash is taken as a raw material, a supergravity container substitutes for an acidizing stirring reactor, and a surfactant is added into reaction, so that cost is reduced greatly, acidizing reaction time can be shortened, and both efficiency and product quality can be improved. Silica prepared by the method is high in purity, small in particle size and even in distribution, and can be widely applied to the fields such as catalysts and additives, thereby being promising in prospect.

Owner:ZHEJIANG UNIV OF TECH

Rural bubbling method evaporation cold-hot exchange household air conditioning system

PendingCN110006122AReduce power consumptionLarge temperature differenceSolar heating energyLighting and heating apparatusWater storage tankSolar water

The invention provides a rural bubbling method evaporation cold-hot exchange household air conditioning system. The system comprises an air conditioner outdoor unit and an air box mounted on the air conditioner outdoor unit, the lower portion of the air box communicates with a water storage tank, and a plurality of bubbling pipes are arranged in the water storage tank. The bubbling pipes are connected with an external fan. A porous netty water distributor is arranged between the air box and the water storage tank. A spray nozzle communicating with an underground water well through a pipeline is arranged above the water distributor, the air box communicates with a return water pipe of a solar water heater, and the bottom of the water storage tank communicates with a water inlet pipe of thesolar water heater. According to the rural bubbling method evaporation cold-hot exchange household air conditioning system, when an air conditioner is used for refrigerating and heating, underground water and hot water in the solar water heater are utilized for performing cold-hot exchange with outdoor air, cold-hot exchanging is performed between the air subjected to exchanging and a condenser &an evaporator in the air conditioner outdoor unit, a larger temperature difference can be provided, electric energy consumption of the air conditioner outdoor unit is effectively reduced, the design is reasonable, mounting is easy, existing conditions in rural families can be fully utilized, and a remarkable energy-saving purpose is achieved.

Owner:HENAN UNIV OF URBAN CONSTR

Chemical phosphorus removal medicament adding device for sewage treatment

ActiveCN104045136AImprove suction capacityImprove phosphorus removal efficiencyWater/sewage treatment by flocculation/precipitationChemical storageImpeller

The invention relates to a chemical phosphorus removal medicament adding device for sewage treatment. The device comprises a chemicals adding host machine, a chemicals storage tank and a chemicals conveying pipe connecting the chemicals adding host machine and the chemicals storage tank, wherein the chemicals adding host machine comprises a motor, a main shaft hood and a main shaft which is connected to the motor and placed in the main shaft hood; a spiral impeller is arranged at the lower end of the main shaft, the motor output end is connected with a host machine installation base and is fixed on a pool wall through a frame, the lower end of the main shaft hood is open and the upper end of the main shaft hood is fixedly connected with the host machine installation base in an airtight manner, so that the inner cavity of the main shaft hood becomes a chamber with the upper end closed and the lower end open; a chemicals suction opening is arranged at the lower half section of the main shaft hood; both ends of the medicament conveying pipe are respectively connected with a chemicals outlet of the chemicals storage tank and the lower semi-section of the main shaft hood on the main shaft hood, and chemicals are correctly added through adjustment by virtue of a vacuum degree control valve and a dosage control valve. Different from conventional chemical phosphorus removal methods, the device has the advantages that the chemicals are directly added and the liquid chemicals exported by a plant is added, so that the system for preparing and conveying the liquid chemicals is omitted. The device is simple, convenient and reliable and has a high practical value.

Owner:中节能国祯环保科技股份有限公司

Heat storage body gas and air swirl entrainment pre-mixing combustion hot-blast stove

ActiveCN104962677AIncrease temperatureImprove heat utilizationBlast furnace detailsHeating stovesCombustion chamberEngineering

The invention relates to a heat storage body gas and air swirl entrainment pre-mixing combustion hot-blast stove. The hot-blast stove solves the problems of low mixing rate, non-uniform mixing effects, and low intensity, low temperature and incomplete combustion. A sleeve-type heat storage block is arranged in the wall of a combustion chamber, a gas inlet pipe at the lower part is connected to a gas distribution circuit, a gas main nozzle of the gas distribution circuit is communicated with a gas adjustment nozzle, the gas adjustment nozzle is connected to the bottom of a gas mixing circuit, the top of the gas mixing circuit is provided with an annular adjustment baffle plate, an air inlet pipe of the wall of an air mixing chamber at the top is connected to an air distribution circuit, the air distribution circuit is provided with an air distribution nozzle, the bottom of the air mixing chamber is provided with an air nozzle, the wall is provided with a hot air outlet pipe, the wall of a heat storage chamber is sleeved by the wall of the combustion chamber and is built on the stove bottom, support columns on the stove bottom are provided with a grate, the heat storage block is arranged on the grate, and the lower part of the grate is provided with a flue gas outlet pipe and a cold air inlet pipe. The hot-blast stove has the advantages of uniform mixing, high combustion intensity, uniform air-flow distribution, good heat transfer uniformity and high heat utilization rate.

Owner:陈维汉

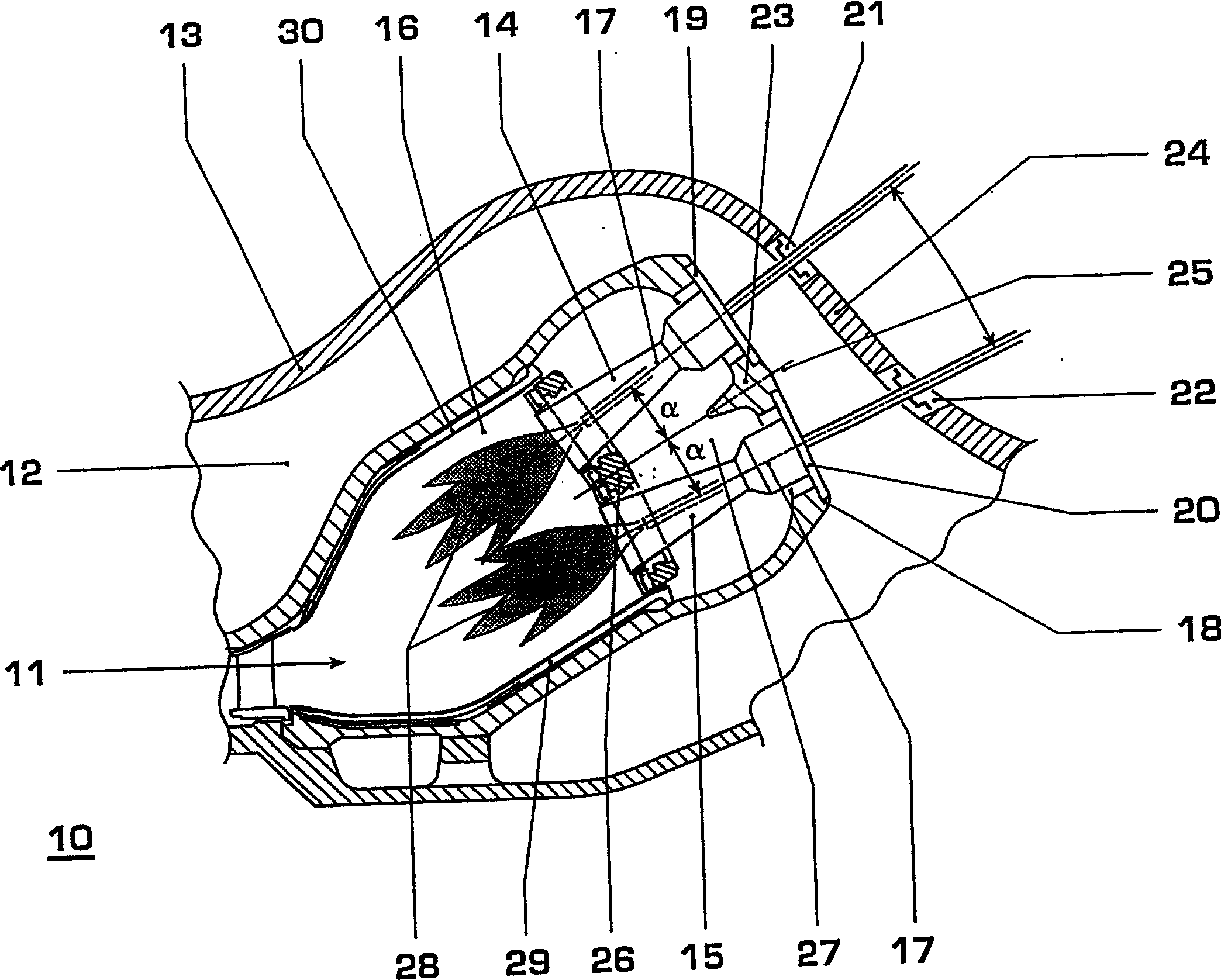

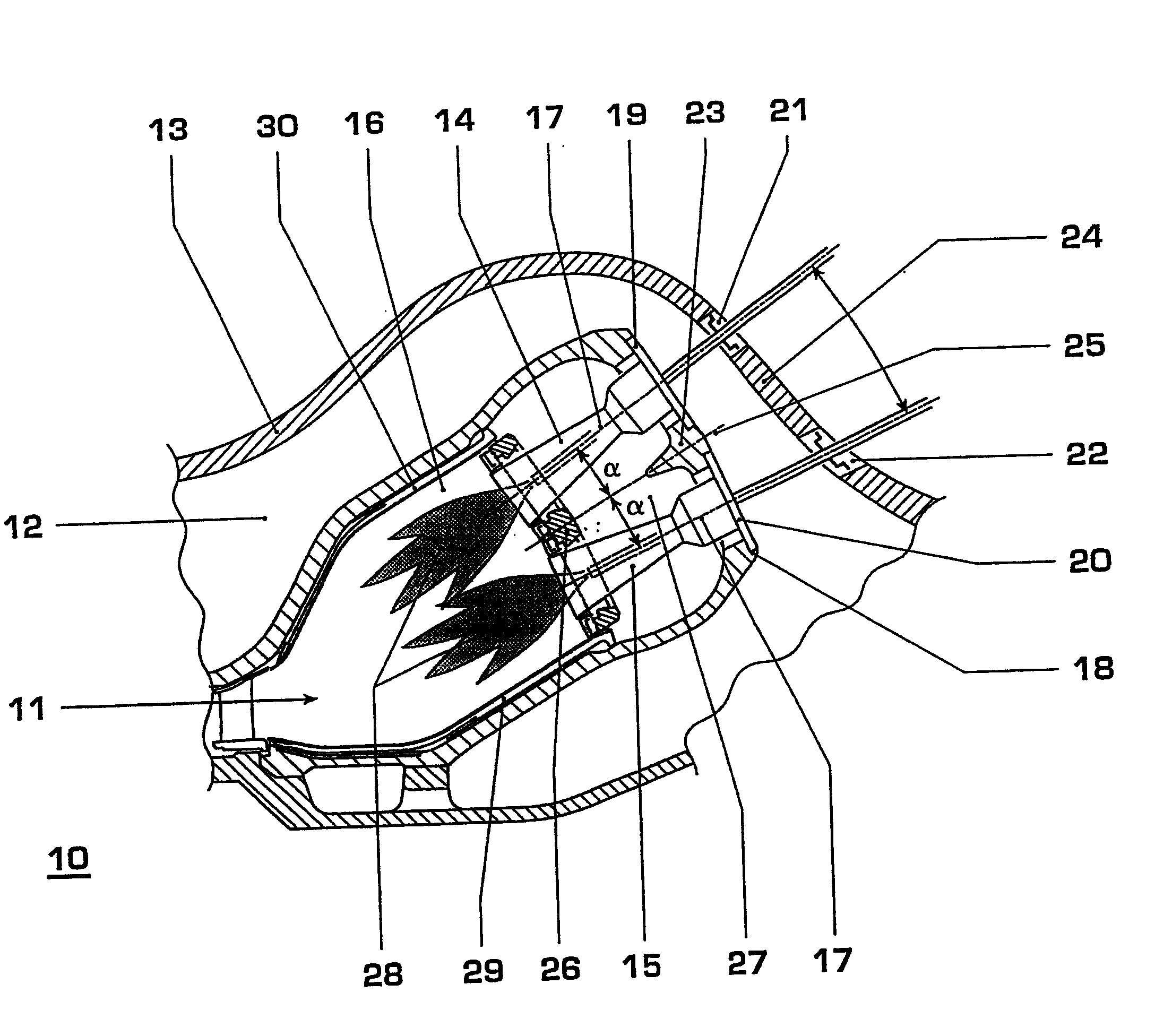

Combustion device for circular combustion chamber in a gas turbine plant

InactiveCN1615417AReduced mechanical weakeningStrong interactionCombustion using gaseous and pulverulent fuelContinuous combustion chamberCombustorCombustion chamber

In a burner arrangement for an annular combustion chamber (11) of a gas turbine (10), a plurality of burners (14, 15) are each arranged in pairs radially one above the other on a concentric ring. In this burner arrangement, the two burners (14, 15) of a burner pair are aligned offset from parallel in such a way that their burner axes (17) approach each other gradually in the direction of flow. This increases the mechanical integrity of the gas turbine housing and optimizes the operation of the combustion chamber.

Owner:ANSALDO ENERGIA SWITZERLAND AG

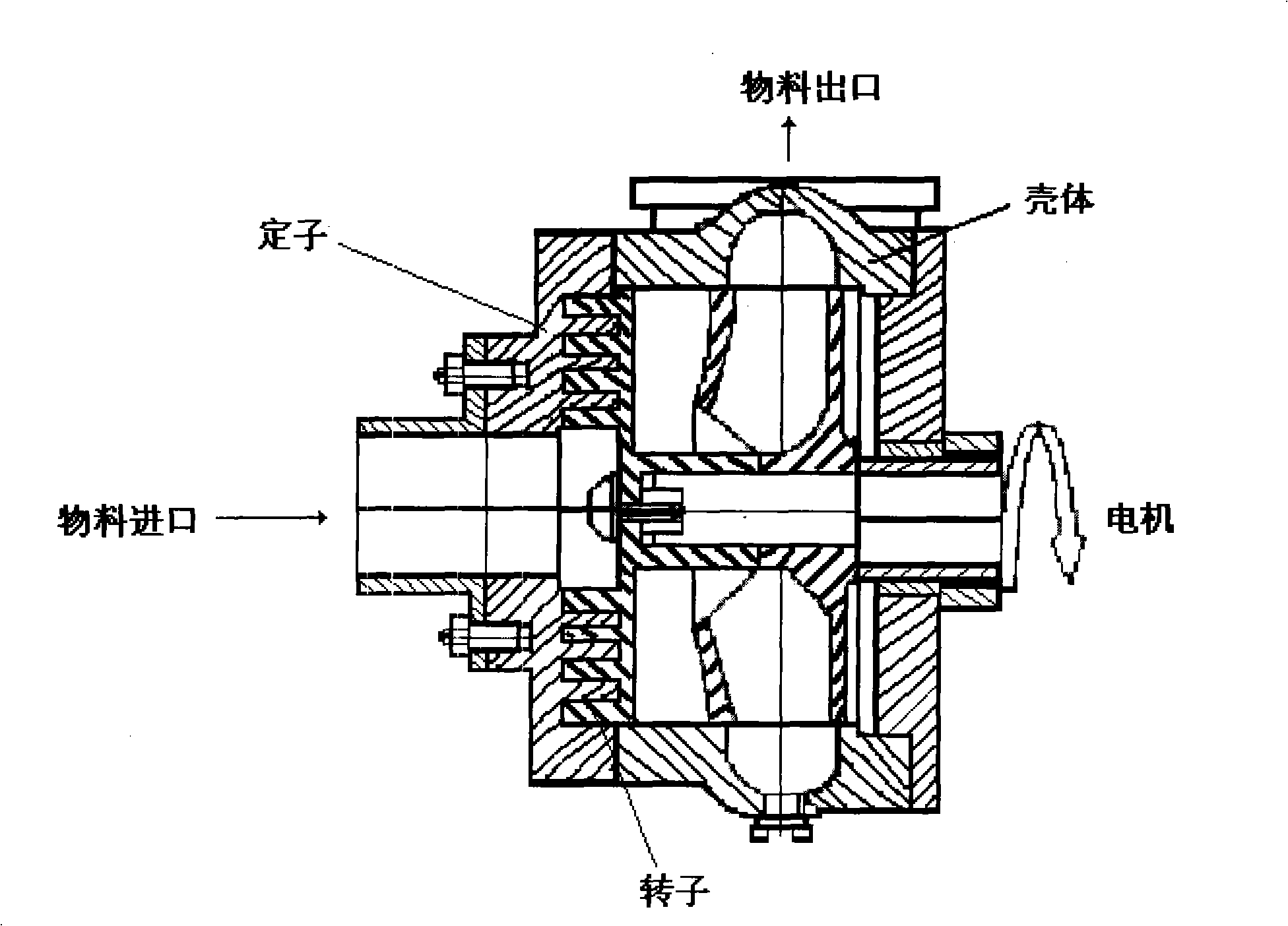

Method of preparing polymethylene-polyphenyl-polyamine

ActiveUS7893301B2Conducive to stable operationLow impurity contentIsocyanic acid derivatives preparationOrganic compound preparationMolecular rearrangementAniline

The present invention provides a method of preparing polymethylene-polyphenyl-polyamine (briefly referred to as polyamine, DAM), in which a high gravity rotating bed is used as the mixing reactor of formaldehyde and aniline hydrochloride, the mixing solution of aniline hydrochloride and circulation solution and the formaldehyde are fed into the high gravity rotating bed reactor proportionally to carry out mixing and condensation reaction under a condition of a very high gravity; the materials leaving the high gravity rotating bed reactor is introduced into a stirred vessel to proceed with the pre-condensation reaction and obtain a condensation solution; and the process steps of heating, molecular rearrangement, neutralization, water washing and purification, etc. are completed to obtain the refined DAM. With the method according to the present invention, the main by-products is obviously reduced in the condensation process, the phenomenon of deposit attaching to the inner walls of circulation pipes and heat exchanger and blockage are prevented in the condensation process, the impurity content is low in the refined DAM, and the subsequent product MDI has a lighter color, the product quality is stable and may be improved to a certain extent.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com