Axial grading combustion chamber of gas turbine and control method of axial grading combustion chamber

A technology of gas turbines and secondary combustion chambers, applied in combustion methods, combustion chambers, continuous combustion chambers, etc., can solve problems such as increased emissions, increased CO emissions, and unstable combustion, so as to increase outlet temperature and increase the proportion of flue gas return flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

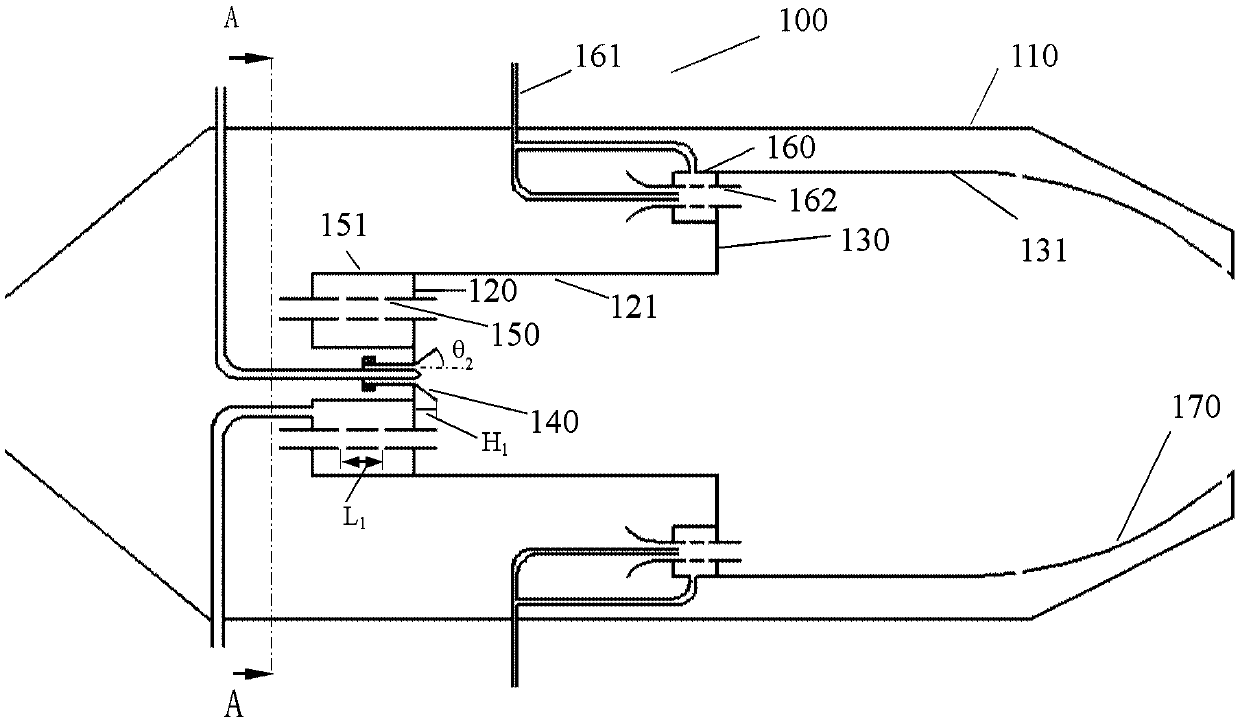

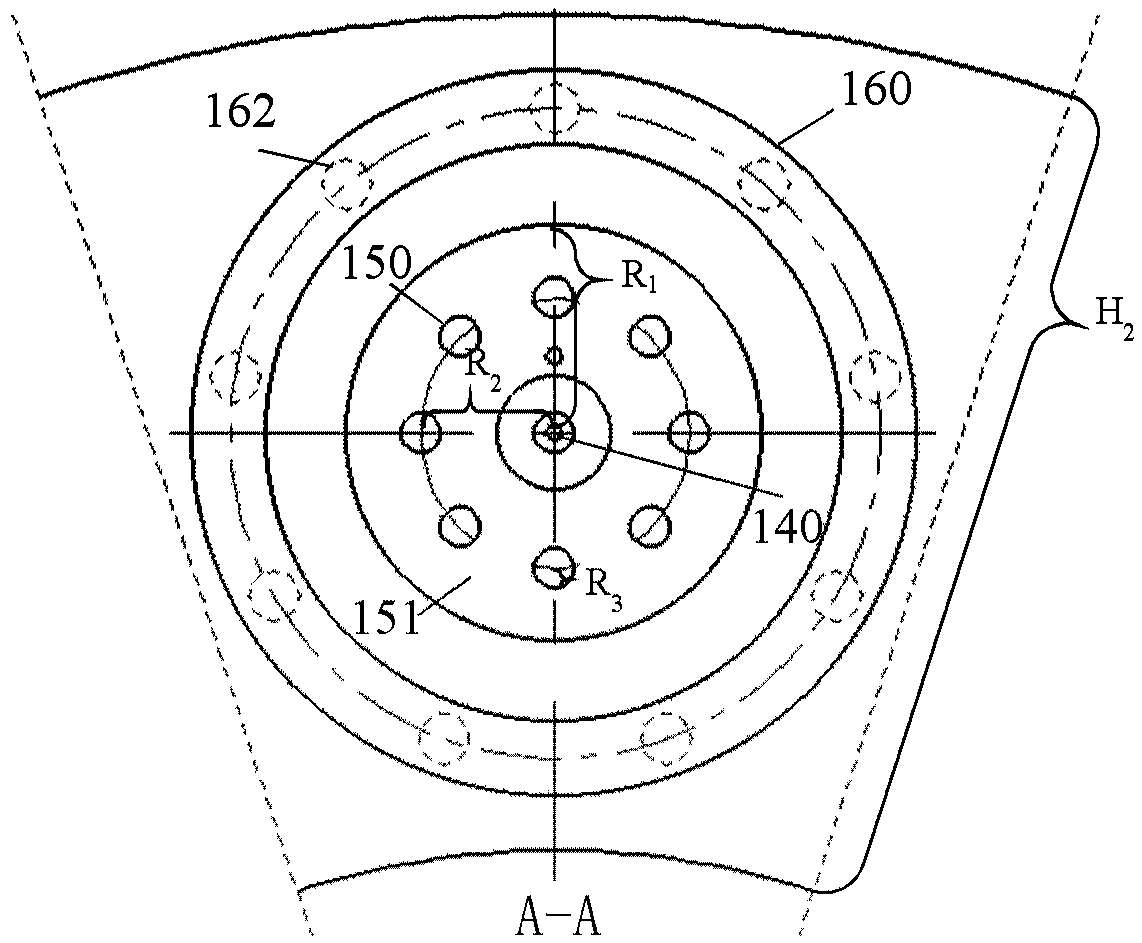

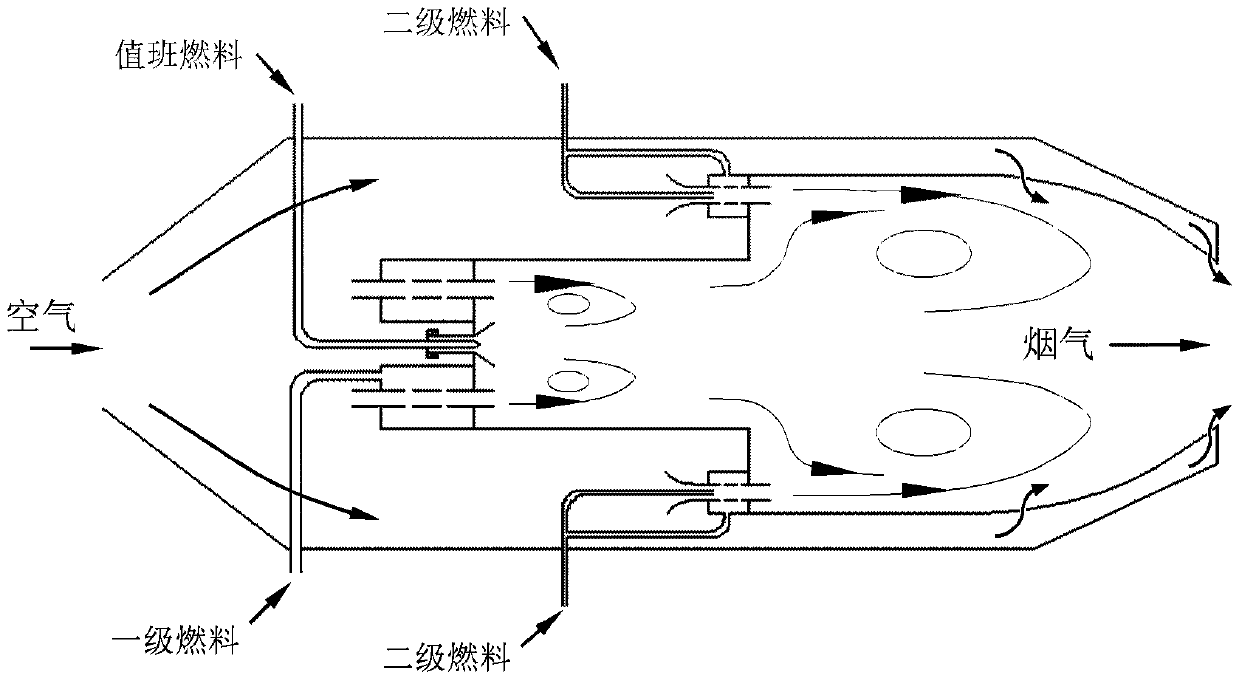

[0051] The present invention forms two-stage high-efficiency low-pressure drop reflux inside the combustion chamber through the first and second-stage high-speed jet entrainment reflux, which promotes the mixing of unburned matter and flue gas, so that the combustion zone maintains a high-temperature and low-oxygen atmosphere and forms a Two-stage soft burn. Therefore, the residence time of fuel in the high temperature zone is reduced, and the emission of nitrogen oxides is reduced. At the same time, because the secondary unburned gas is directly burned in the high-temperature flue gas, it has good combustion stability and burnout efficiency, and can achieve a wide load adjustment range. Therefore, under the premise of ensuring combustion efficiency and combustion stability, the present invention can realize rapid response to burnout load, and can realize extremely low emission of nitrogen oxides in a wider load range.

[0052] In order to make the object, technical solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com