Patents

Literature

41results about How to "Increase the reflux ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

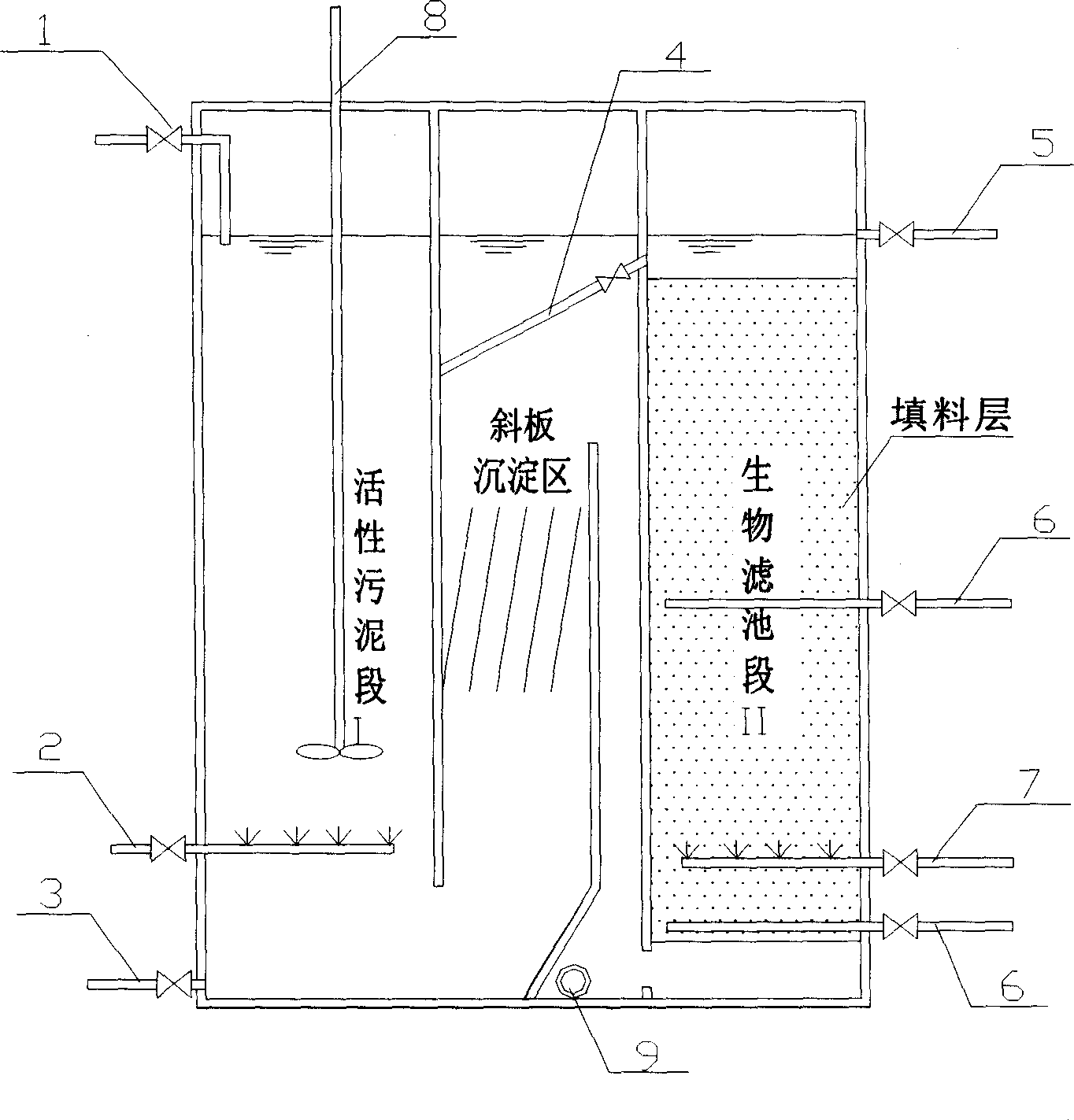

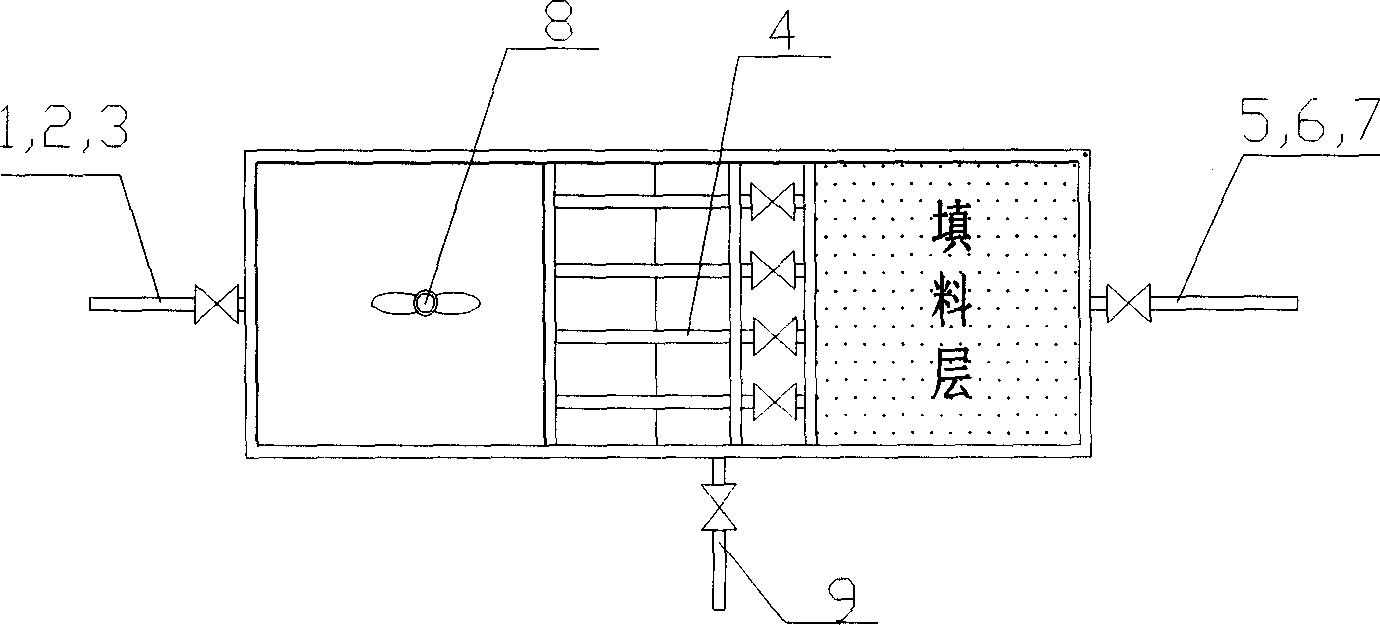

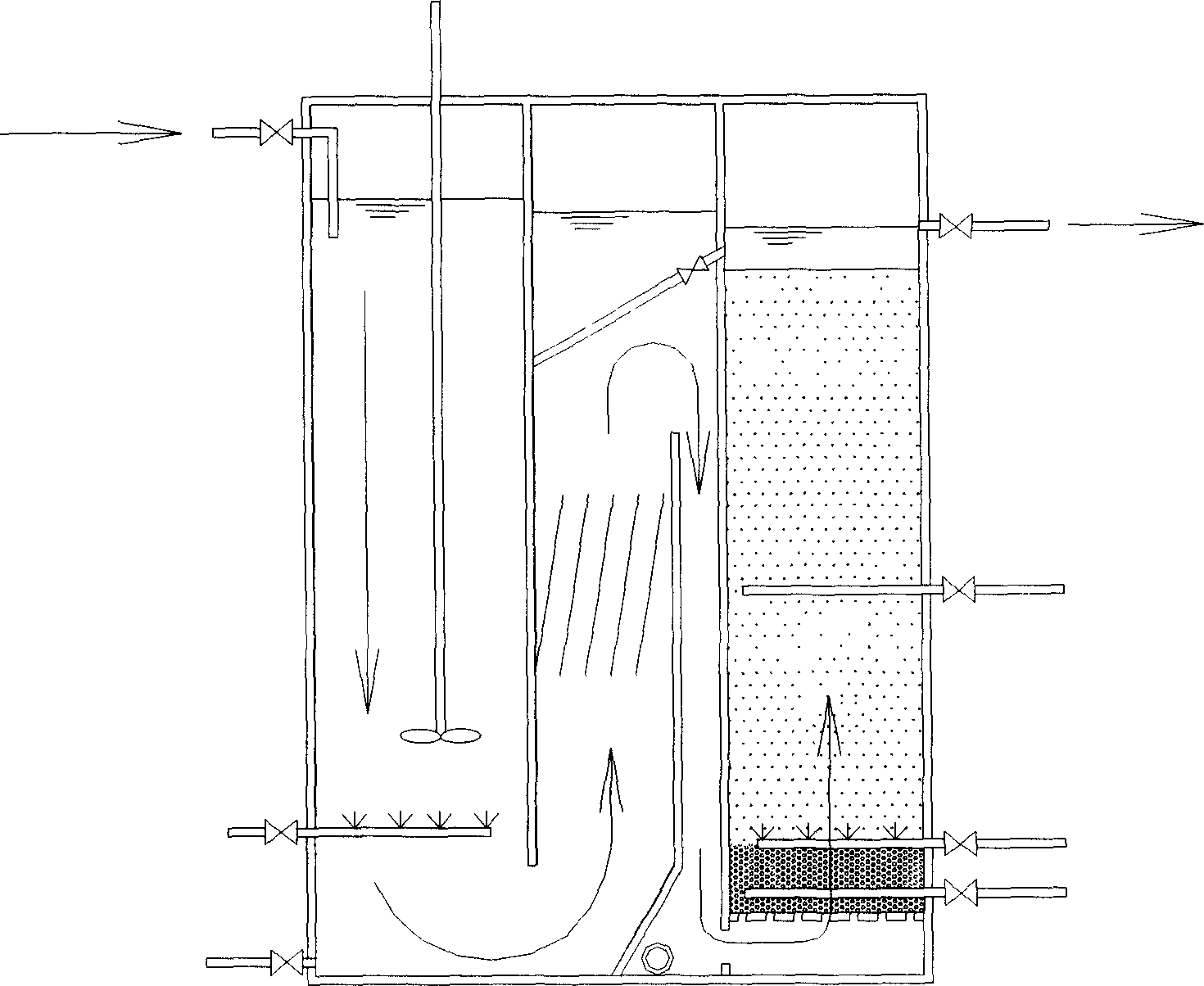

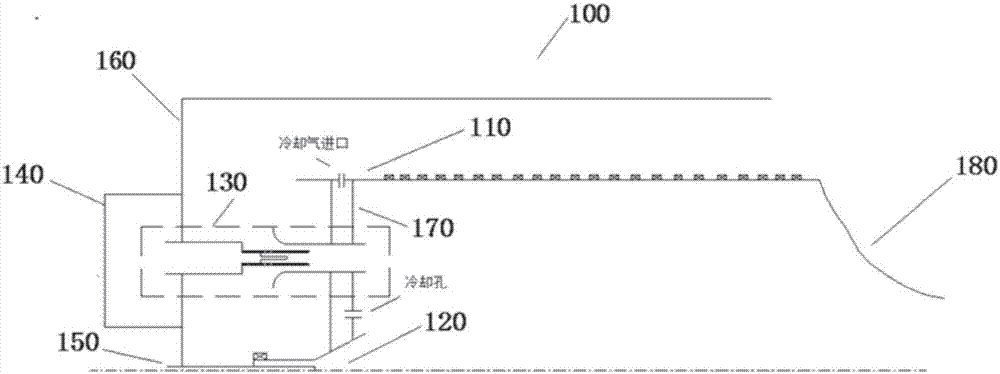

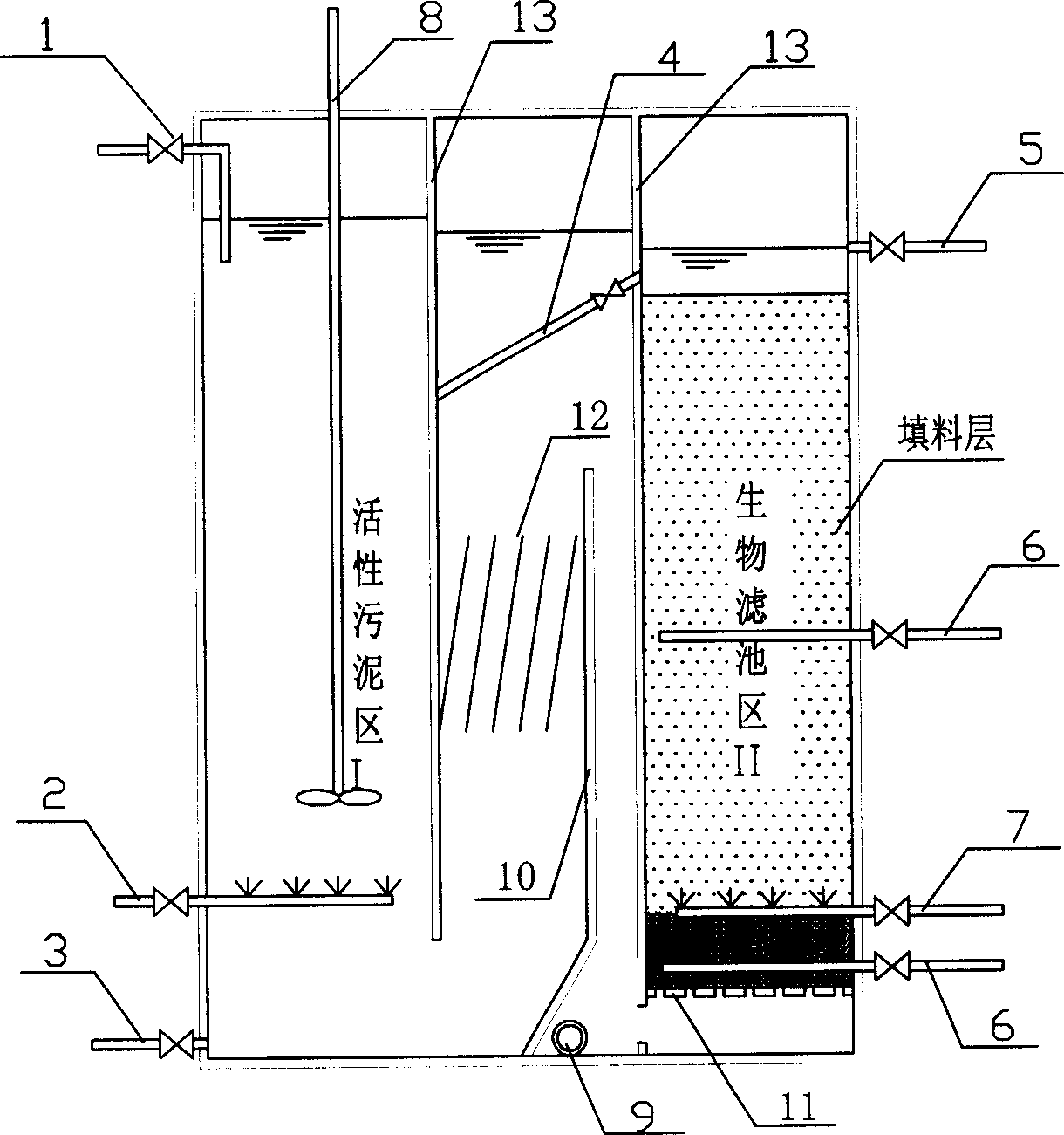

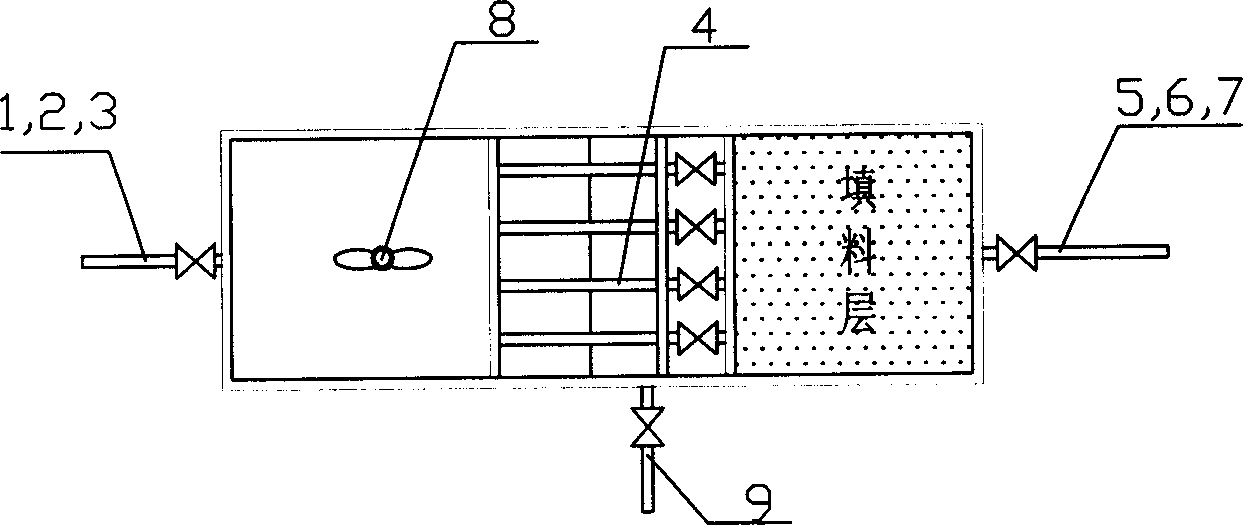

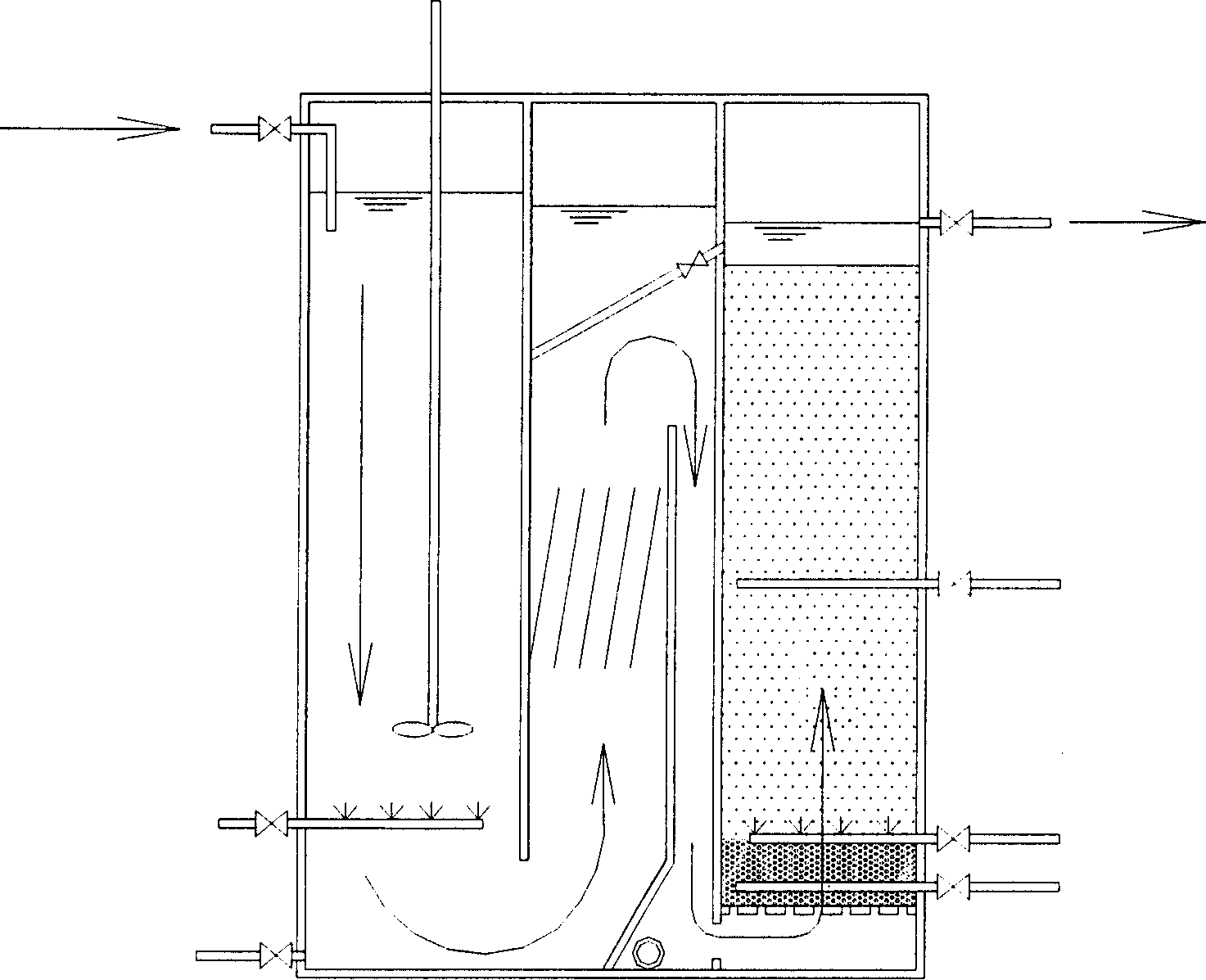

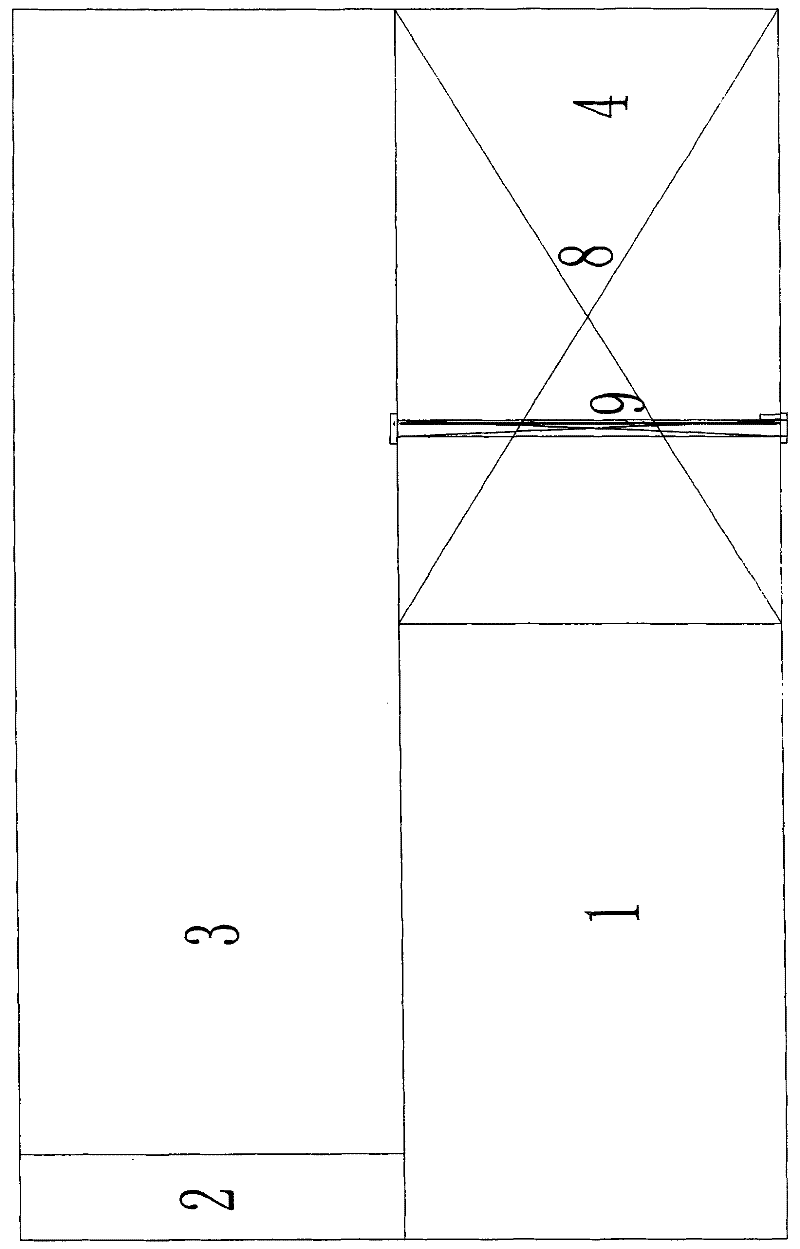

Sewage treatment method using active sludge-biological filtering pond revere flow and integral device

InactiveCN1657443AEasy to handleGuaranteed uptimeSustainable biological treatmentBiological water/sewage treatmentActivated sludgeReflux

Owner:CHONGQING UNIV

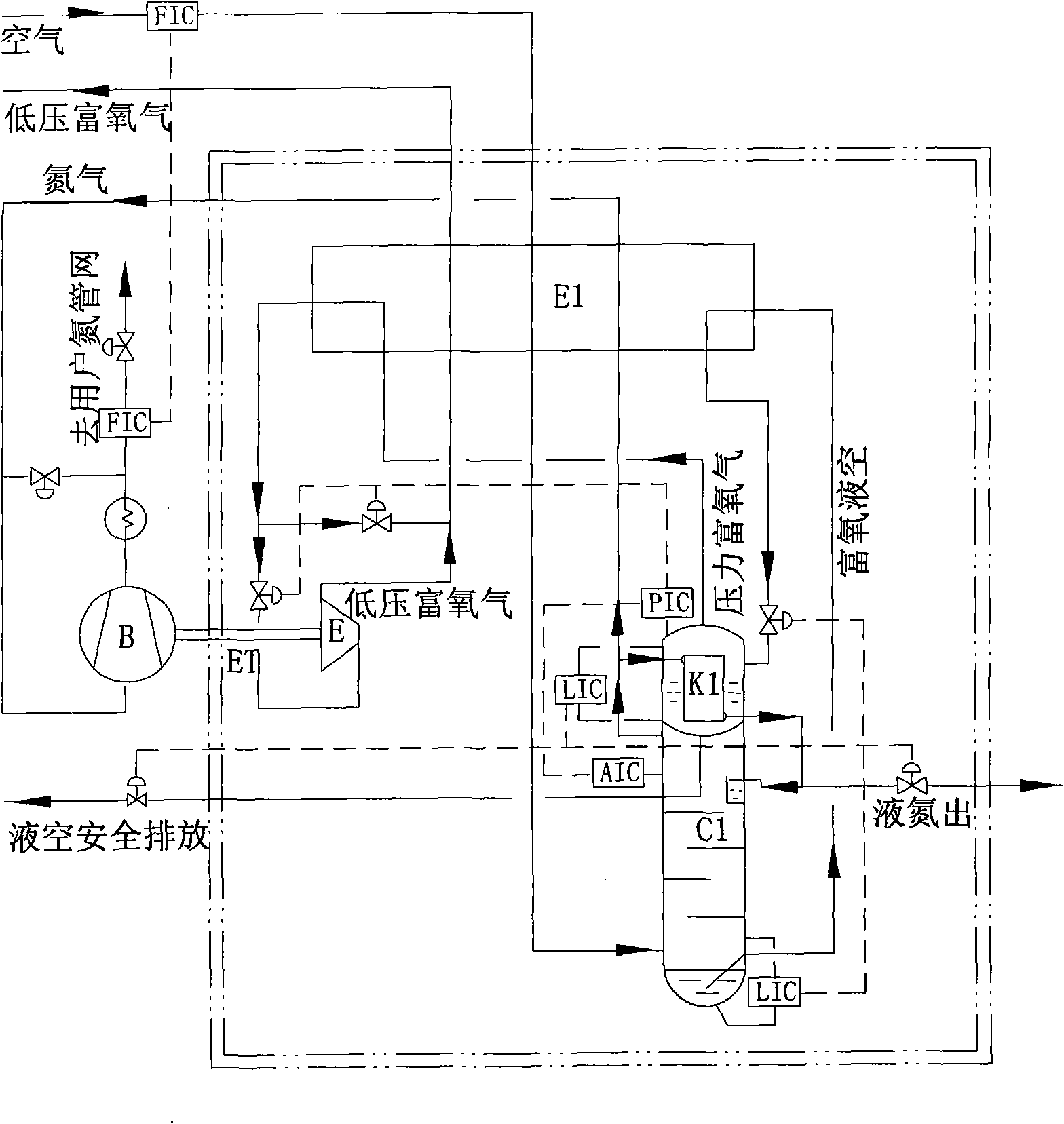

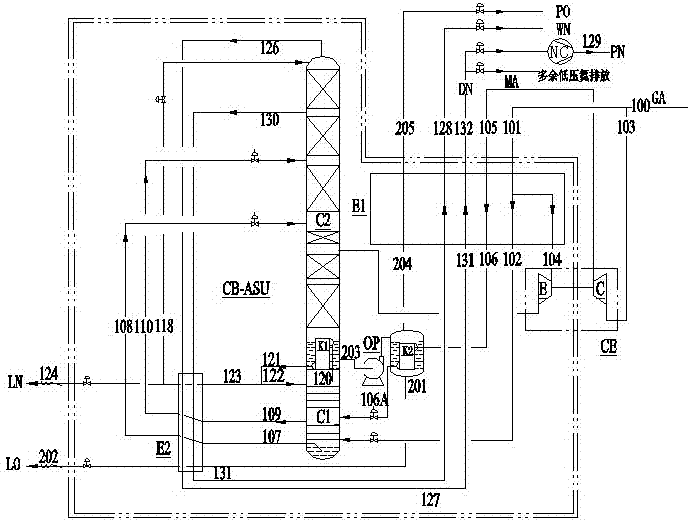

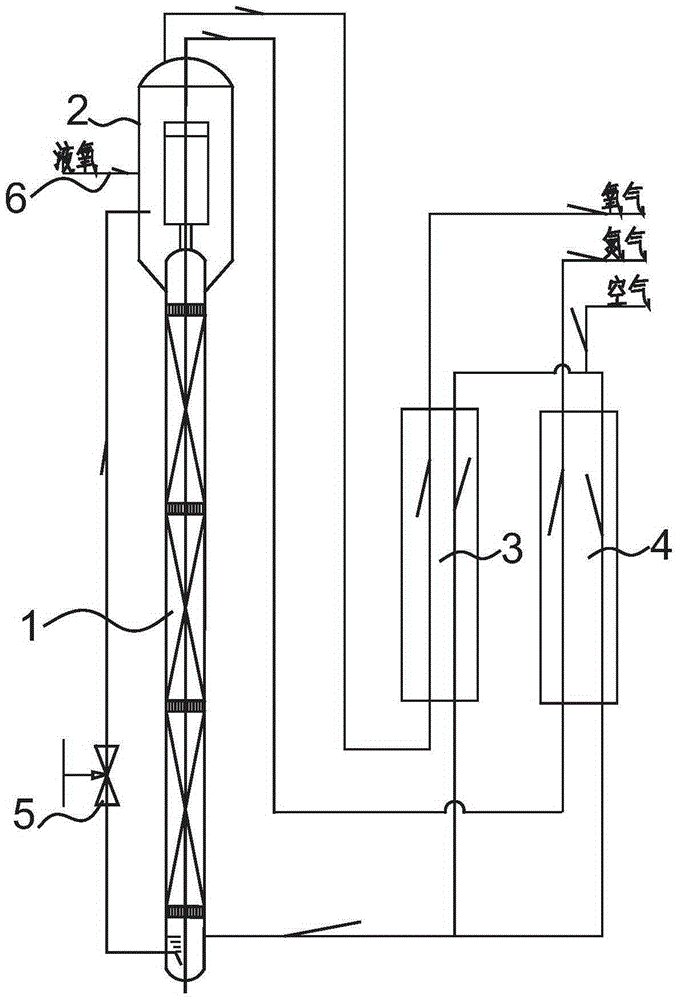

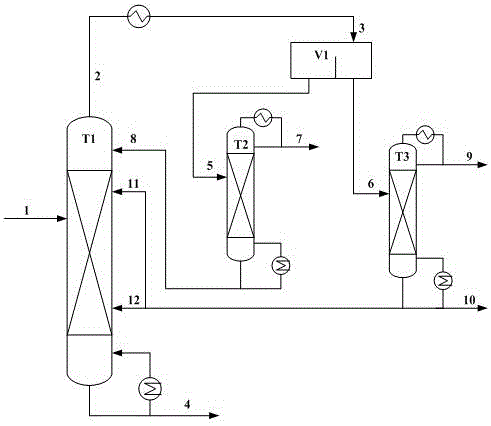

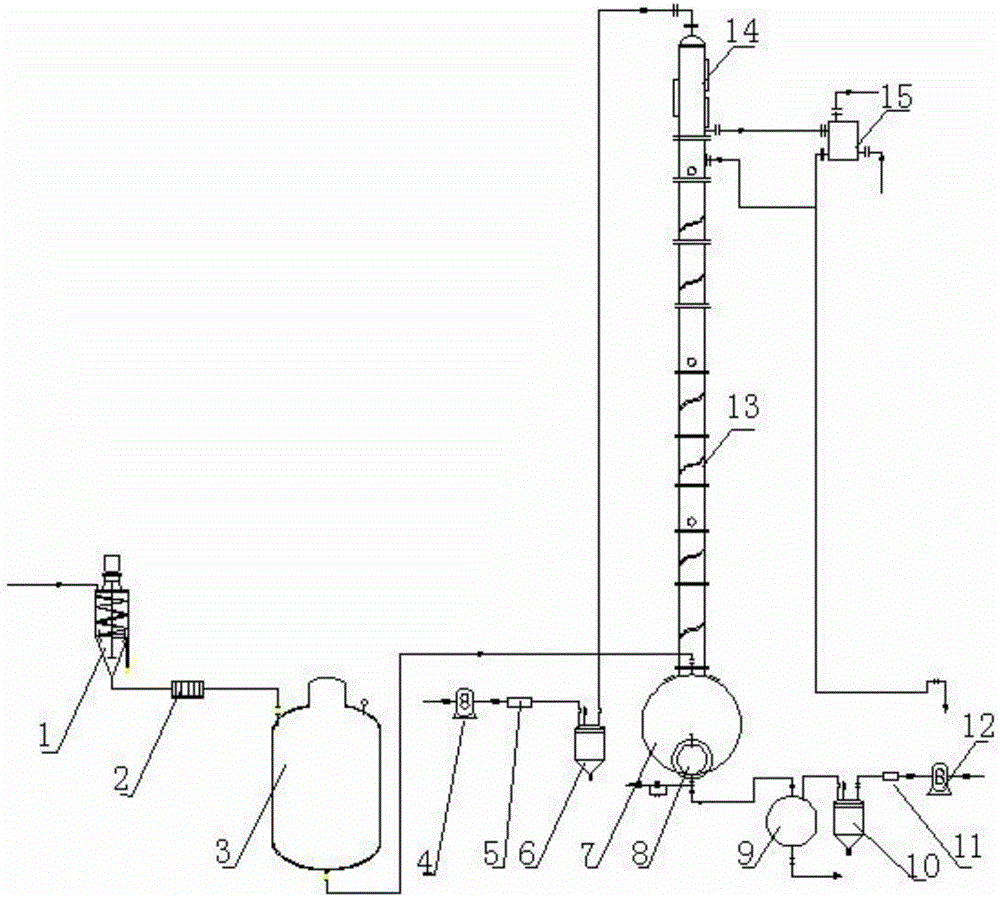

Low-energy consumption nitrogen production method and apparatus

ActiveCN101492156ARaise the inlet temperatureFull recoveryNitrogen purification/separationSolidificationOxygenNitrogen gas

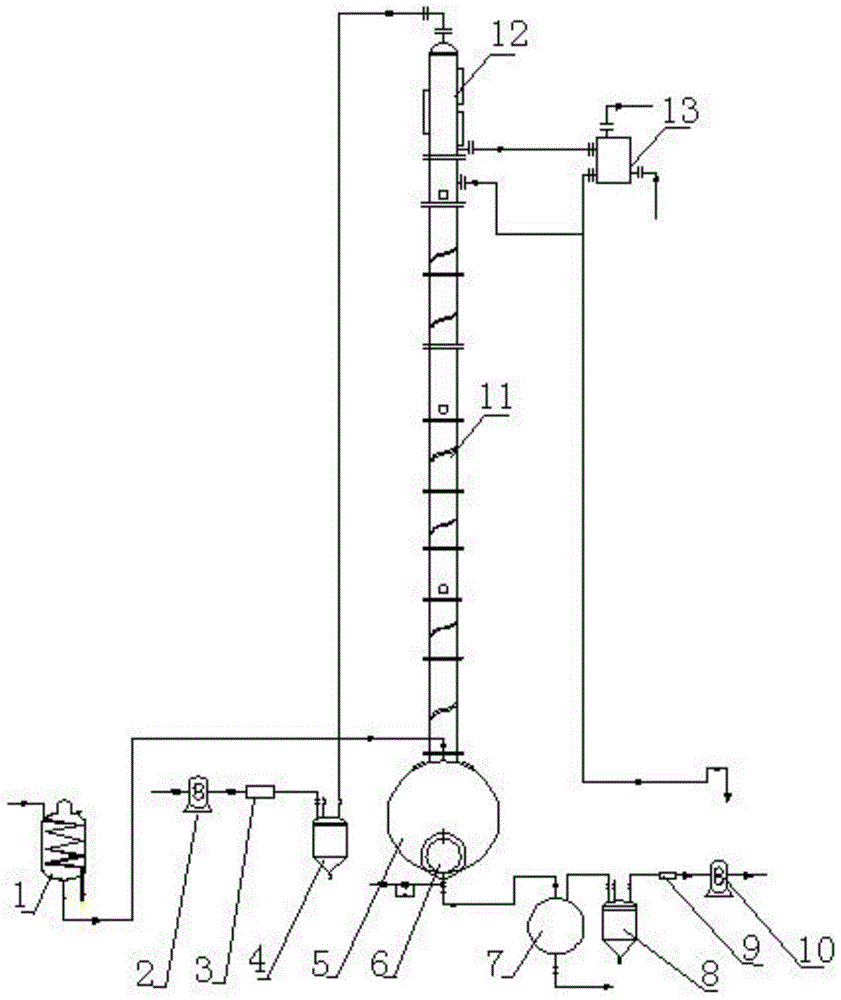

The invention relates to a method and a device for preparing nitrogen in low energy consumption. The method comprises that: the nitrogen is obtained on the top of a rectifying tower after the air is cooled, and one part of the nitrogen is condensed into liquid nitrogen, wherein one part of the liquid nitrogen is taken as a product liquid nitrogen and the rest liquid nitrogen is taken as a backflow liquid to return the top of the tower; the other part of the nitrogen enters a heat exchanger, is heated again to normal temperature and pressurized by a pressure-increasing end of an expander, and is sent into a user nitrogen conveying pipe network; the liquid air rich in oxygen is obtained on the bottom of the tower, enters the heat exchanger, is supercooled by cold fluid and throttled, and enters a condenser / evaporator as a cold source to carry out heat exchange with the nitrogen; the vaporized air rich in oxygen enters the heat exchanger, is heated again, and enters the expander for expansion refrigeration; and the low-pressure air rich in oxygen after the expansion enters the heat exchanger, and is heated again and led out. The method increases the pressure of the nitrogen through work outputted by the expansion of the air rich in oxygen, and reduces pressure discharge of a compressor so as to reduce energy consumption; the liquid air is subjected to heat exchanging and supercooling by various cold fluid such as the low-pressure air rich in oxygen, the nitrogen, the pressurized air rich in oxygen, and the like, so the humidity content of the air is reduced to improve extraction yield, the energy consumption is reduced by 15 to 23 percent, the water consumption is reduced by 14 to 22 percent, and the economic benefit is significant.

Owner:四川空分设备(集团)有限责任公司

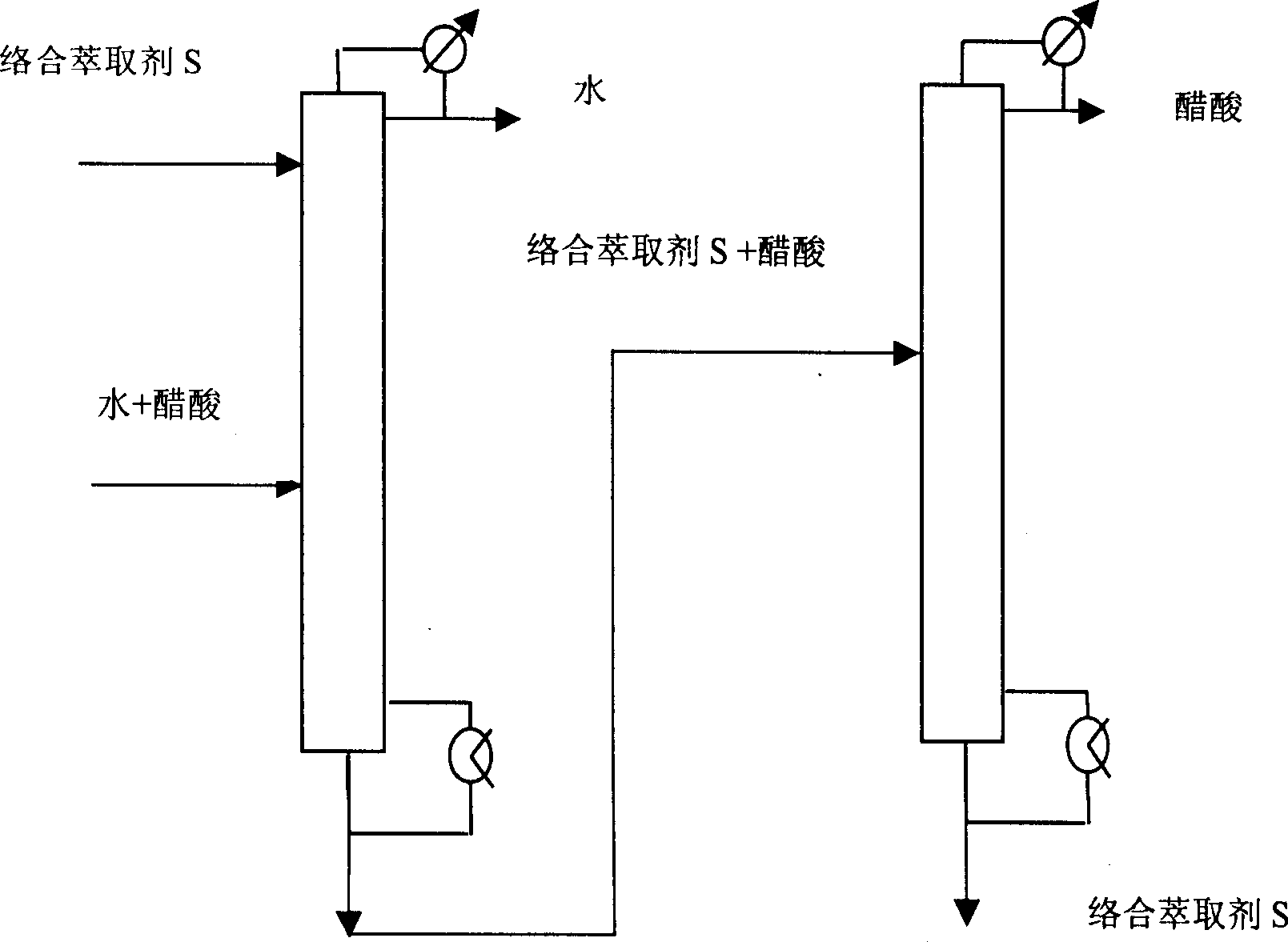

Method for separating acetic acid and water by complexation extraction and rectification

InactiveCN1405137AIncrease relative volatilityImprove energy savingCarboxylic compound separation/purificationTheoretical plateAcetic acid

THe invention provides a method for separating acetic acid and water by complexation, extraction and rectification process. Said invention utilizes the acting force between organic alkali and acetic acid, which is stronger than that of water, and greatly raises the relative volatilities of acetic acid and water so as to separate them. In the fractionating recrtifying tower with 10-50 theoretical plates it adopts tertiary amine organic alkali as complexation extracting agent, under the condition of normal pressure (or reduced pressure), its solvent ratio is 0.5-5 and refluxing ratio is 0-5, the water whose mass fraction is greater than 99.7% can be obtained from tower top, and in the solvent recovering tower with 5-40 the oretical plates, under the condition of reduced pressure and refluxing ratio of 0.5-5 the acetic acid whose mass fraction is greater than 95.0% can be obtained.

Owner:BEIJING UNIV OF CHEM TECH

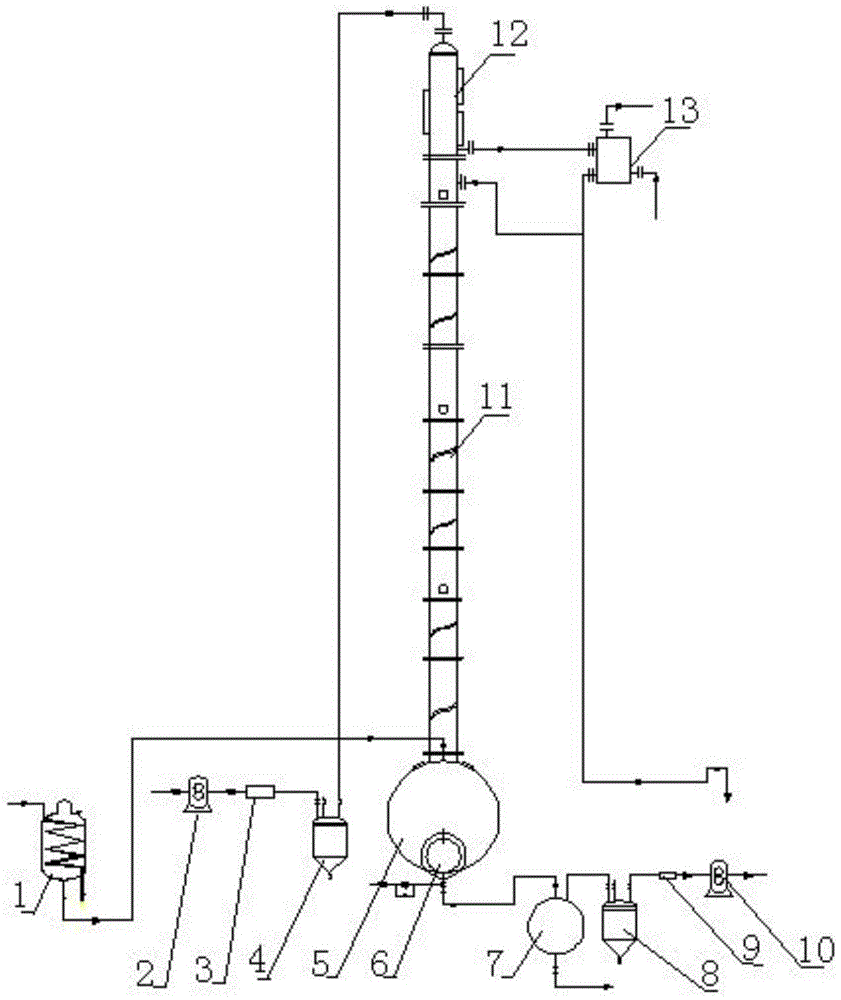

Method for continuously separating alpha-pinene and beta-pinene from turpentine

ActiveCN104130093ARealize continuous operationIncrease the reflux ratioDistillation purification/separationRefluxDistillation

The invention relates to a method for continuously separating alpha-pinene and beta-pinene from turpentine. The method comprises the following steps: raw materials are subjected to a preheating treatment; a packed tower vacuum rectification process is carried out; alpha-pinene is collected with a reflux ratio of 8:1-10:1; a middle fraction is slowly collected with a reflux ratio of 20:1-30:1; beta-pinene is collected with a reflux ratio of 8:1-15:1; and when distillation is finished, while the rectification tower is not cooled and the vacuum state is not relieved, discharge is realized through the pressure difference between a tower kettle and a residual liquid tank. Therefore, intermittent distillation continuous operation is realized. With the method provided by the invention, the content of obtained alpha-pinene can be 98%, and the content of obtained beta-pinene can be 95%.

Owner:GUANGXI FORESTRY RES INST

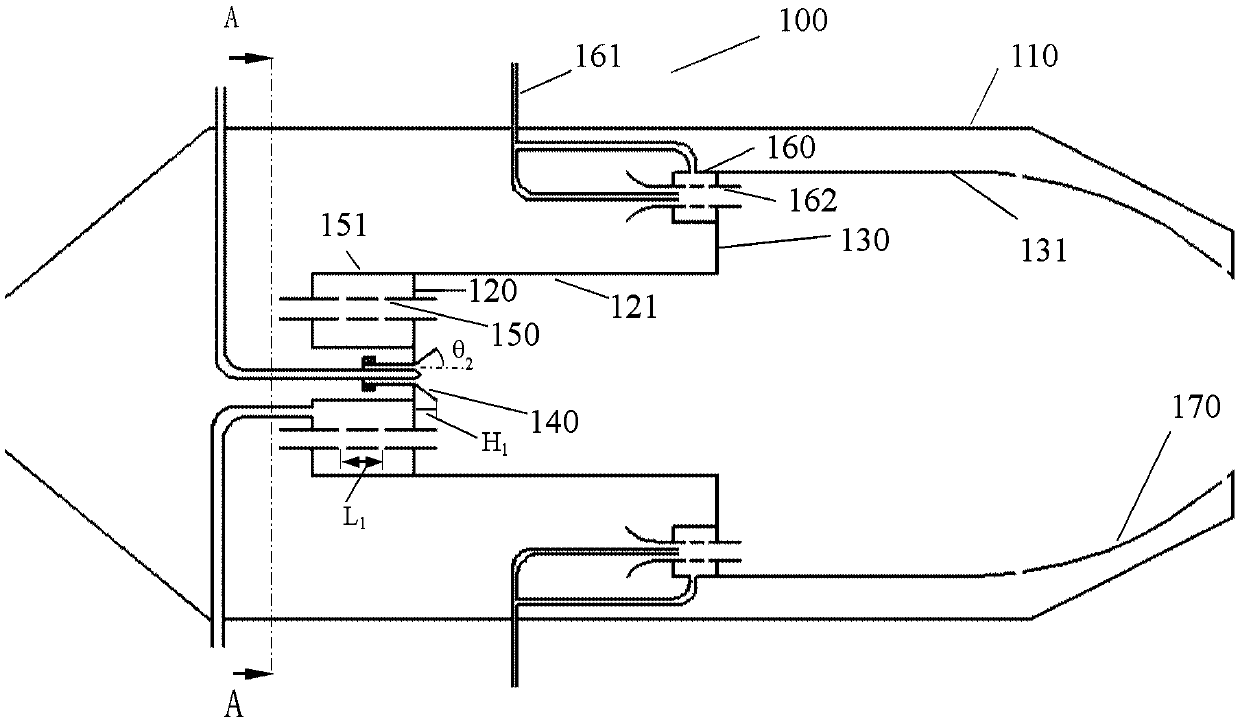

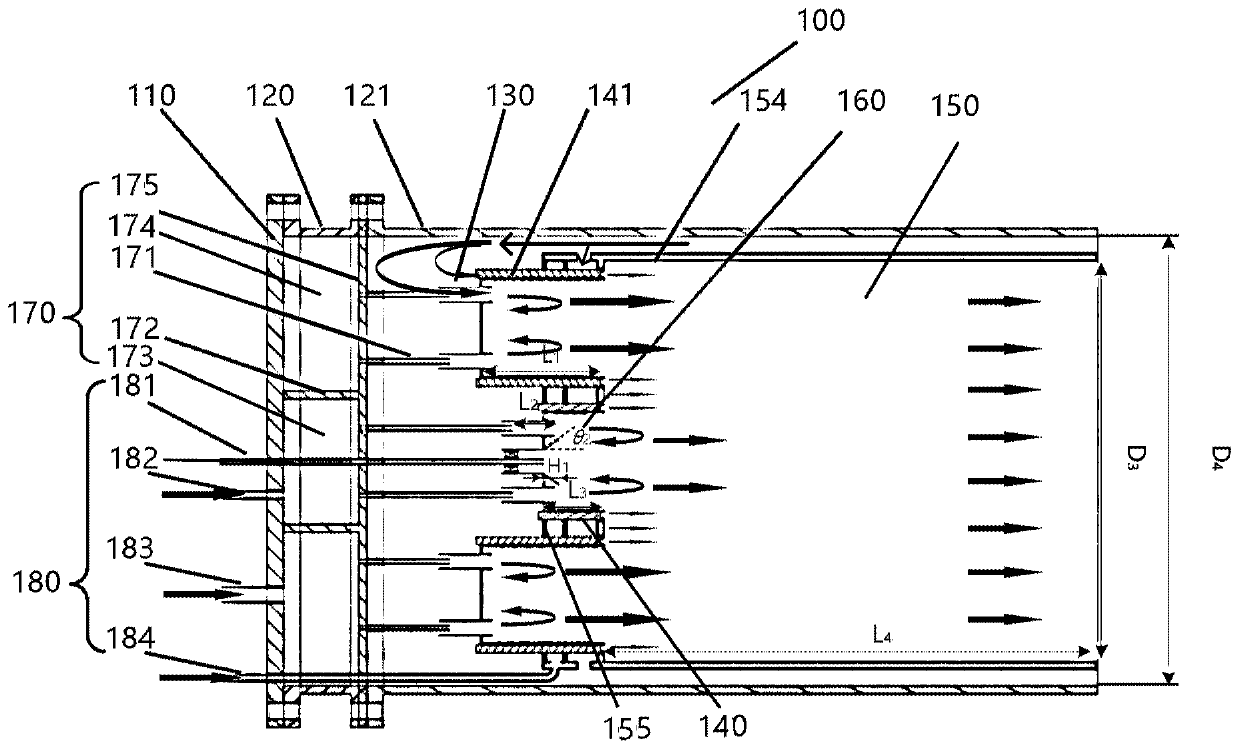

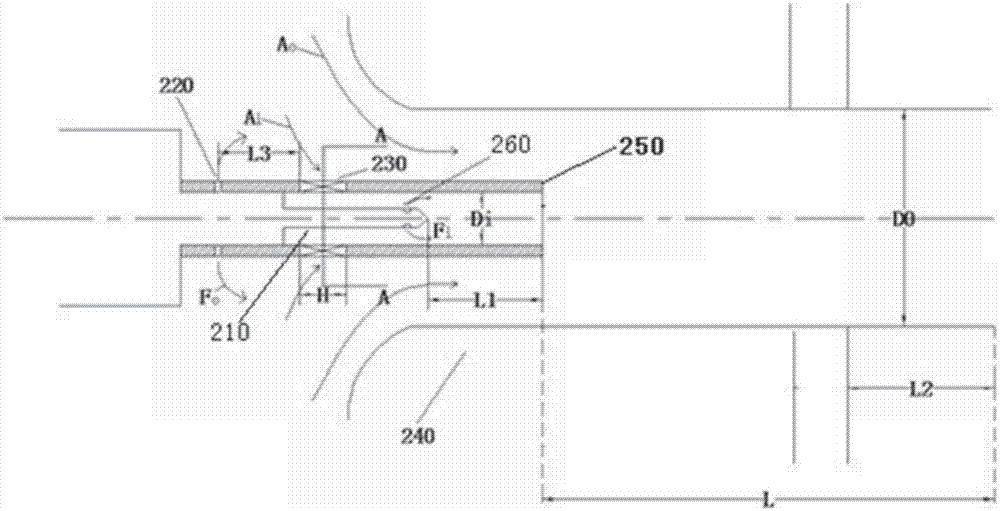

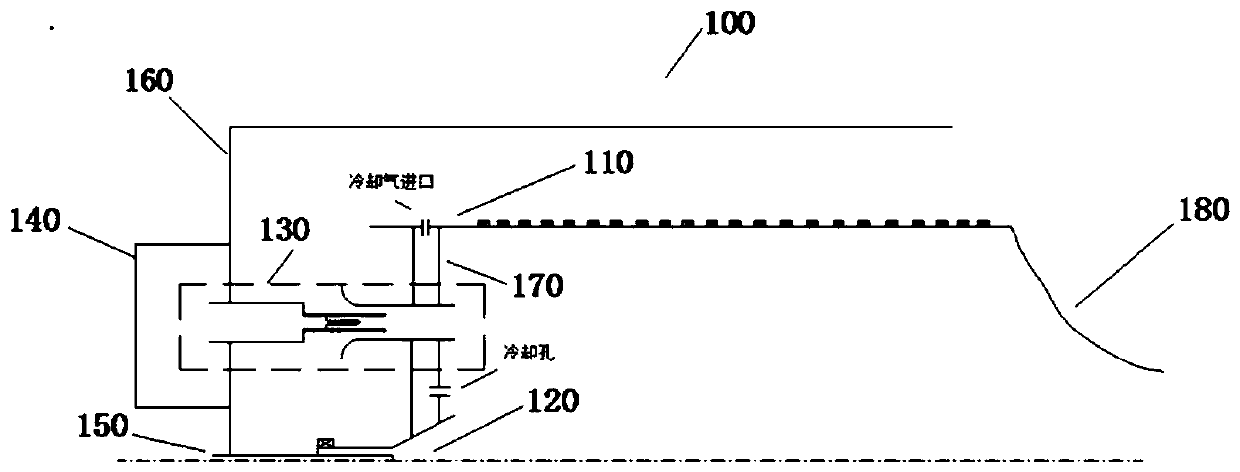

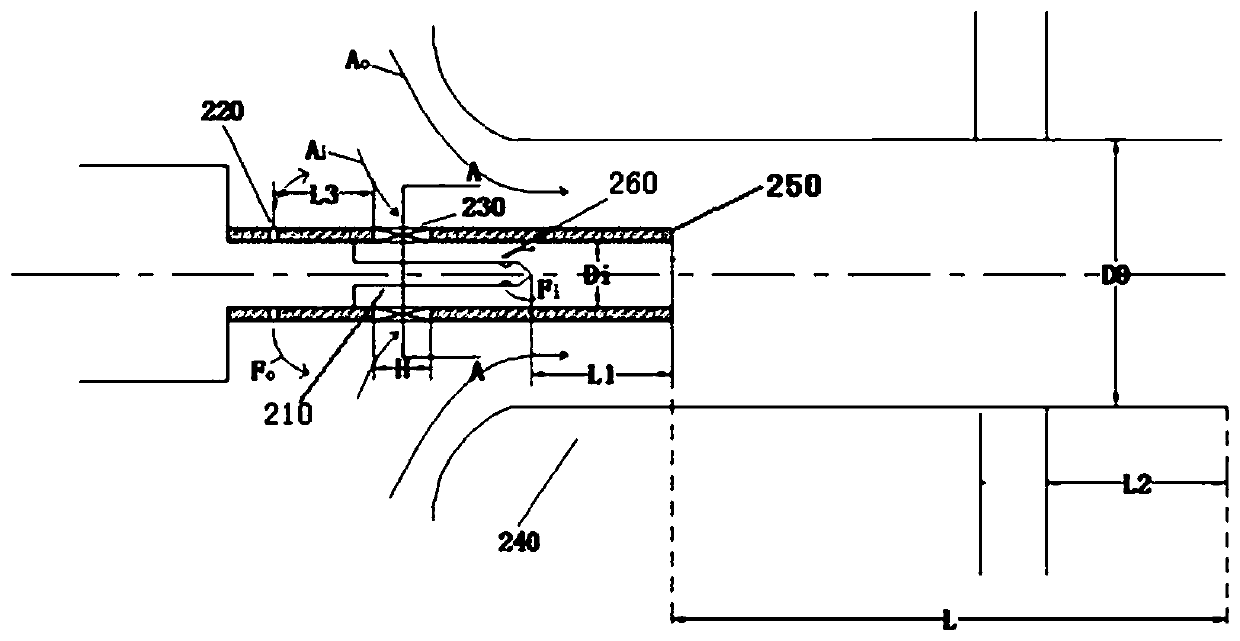

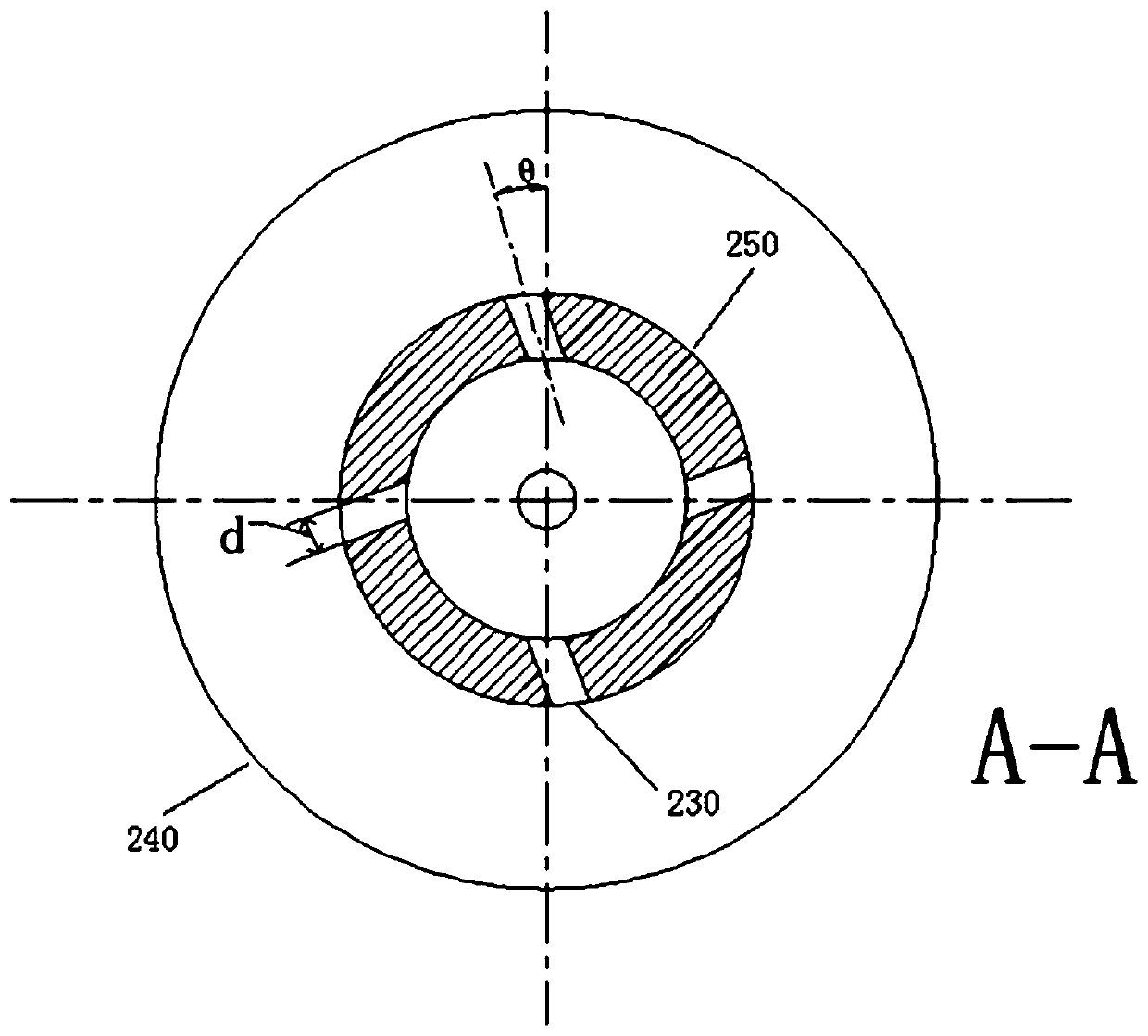

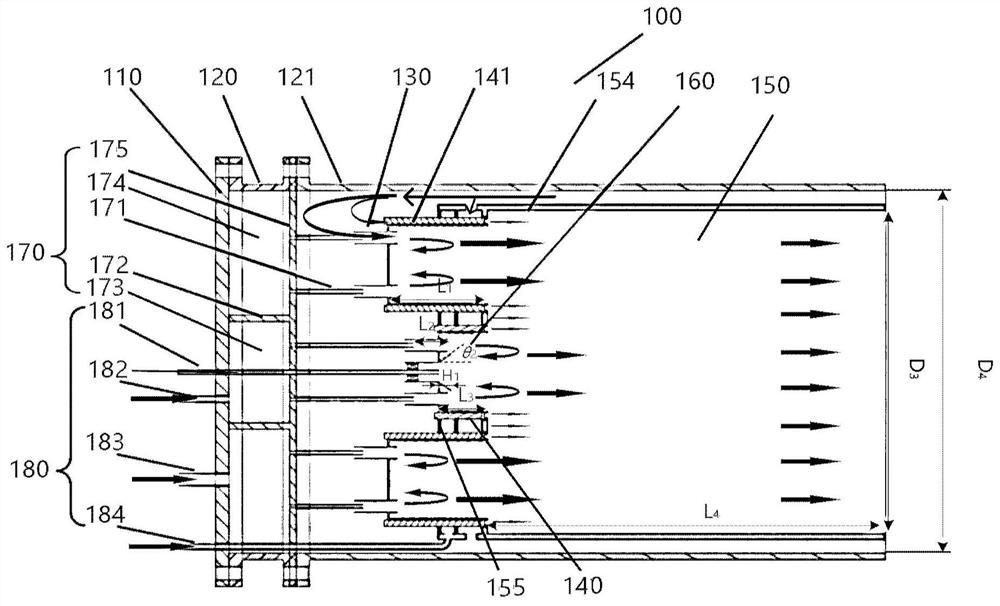

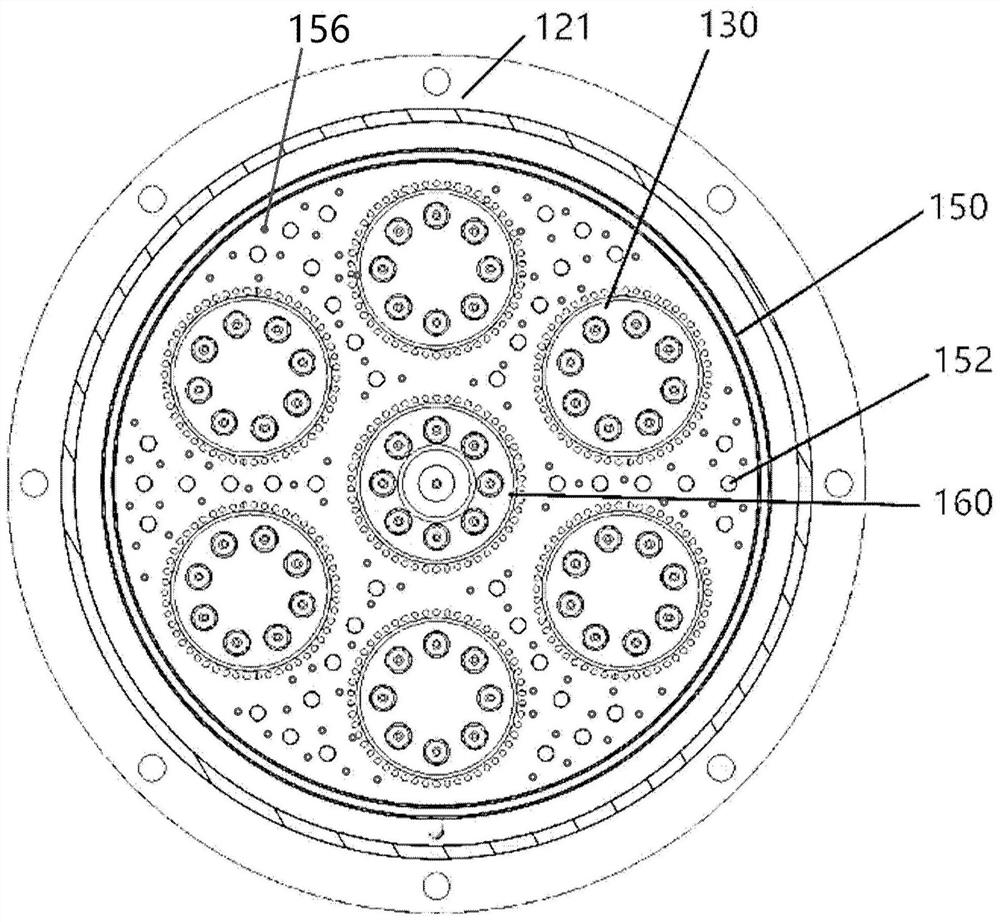

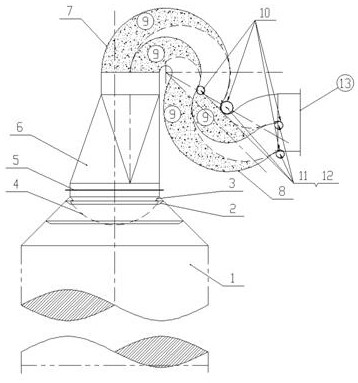

Axial grading combustion chamber of gas turbine and control method of axial grading combustion chamber

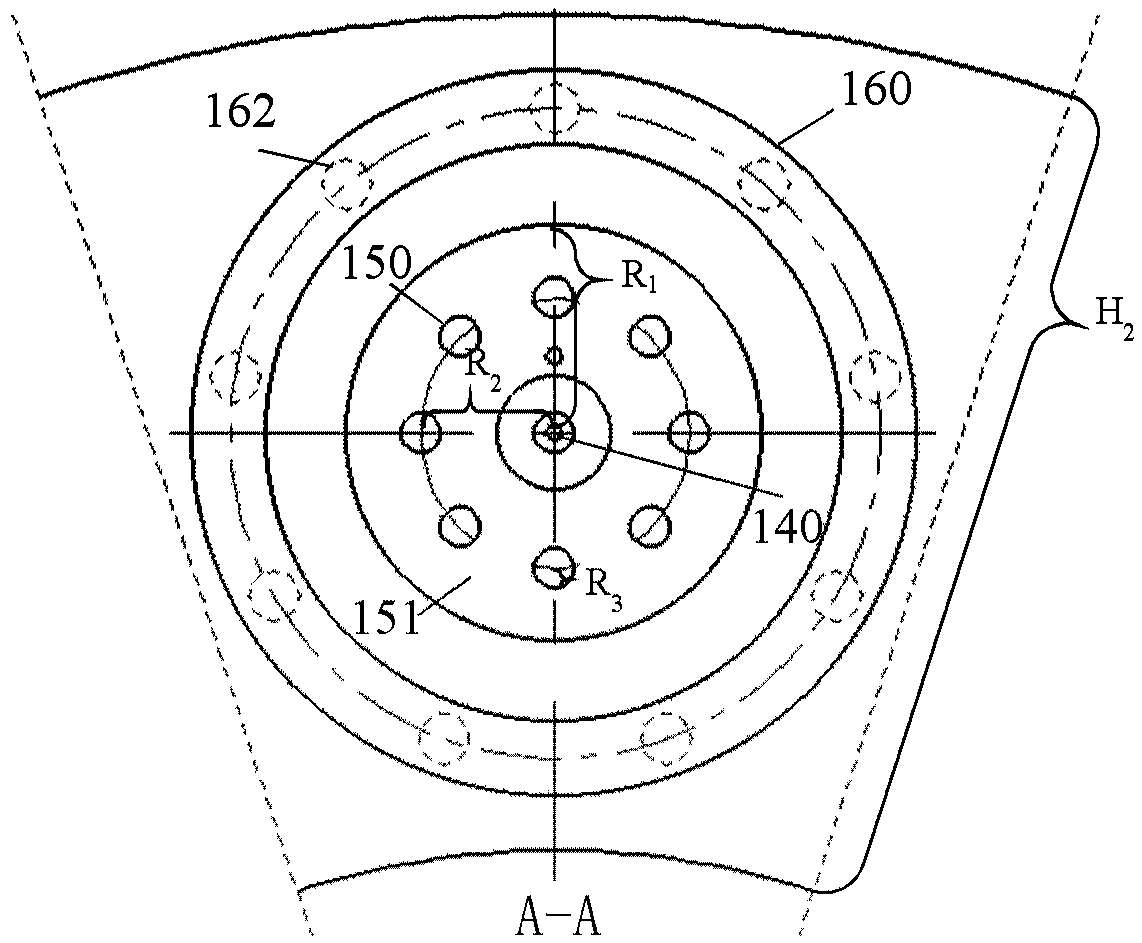

ActiveCN110878948AIncrease the reflux ratioStable combustionContinuous combustion chamberNitrogen oxidesCombustion chamber

The invention discloses an axial grading combustion chamber of a gas turbine and a control method of the axial grading combustion chamber. The axial grading combustion chamber comprises a combustion chamber structural assembly, a first-stage premixed jet nozzle assembly, a first-stage on-duty nozzle assembly and a second-stage premixed jet nozzle assembly. A head baffle of a first-stage combustionchamber and a front wall of a combustion chamber case form a head part of the combustion chamber, and the first-stage on-duty nozzle assembly is arranged in the center of the head part of the combustion chamber; the first-stage premixed jet nozzle assembly is arranged on a circumference of the head part of the combustion chamber by taking the center of the head part of the combustion chamber as acircle center; and the second-stage premixed jet nozzle assembly is positioned on a circumference of a head baffle of a second-stage combustion chamber by taking an axis of a flame tube of the first-stage combustion chamber as a circle center. According to the axial grading combustion chamber provided by the invention, through grading injection of fuel, residence time of the fuel in a high-temperature region is shortened while combustion efficiency is ensured, and two-stage soft combustion is realized, so that emission of nitrogen oxide by the combustion chamber of the gas turbine is greatlyreduced, and an outlet temperature of the combustion chamber can be further improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

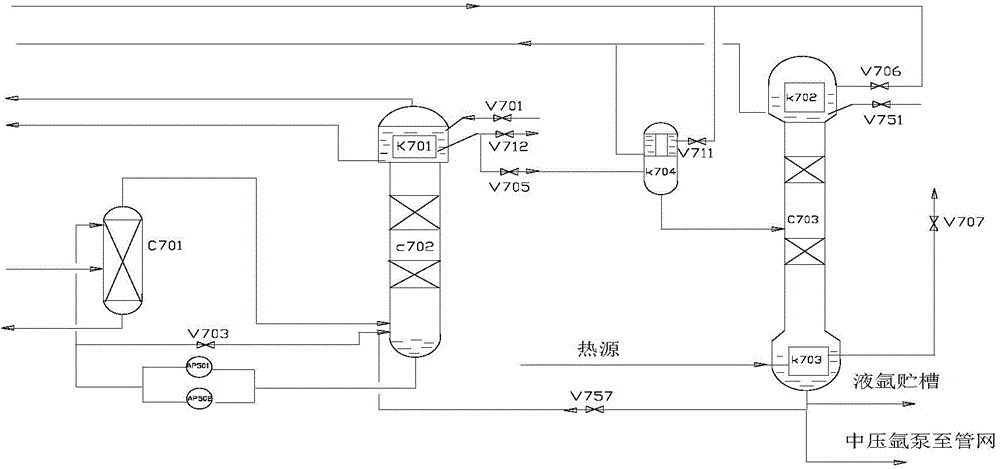

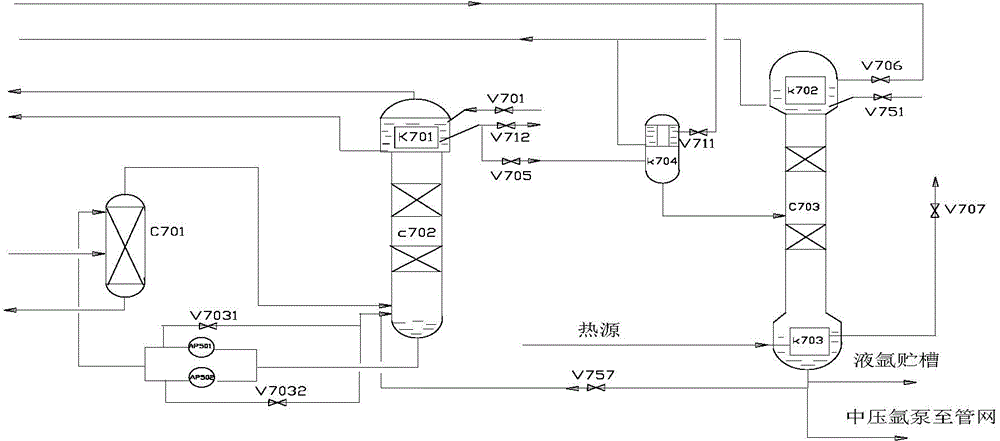

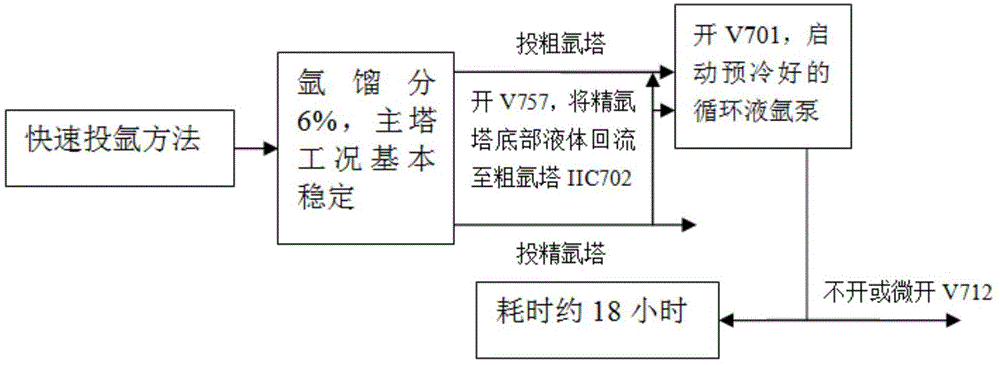

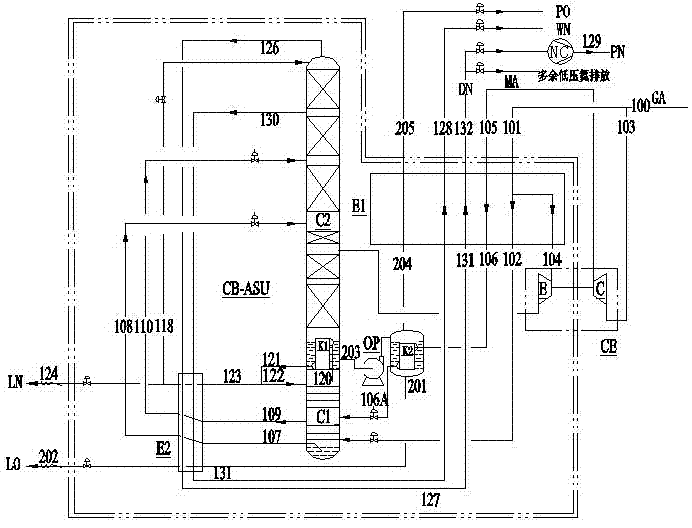

Quick argon feeding method for air separation device

ActiveCN104019631AIncrease the reflux ratioImprove utilization efficiencySolidificationLiquefactionLiquid argonAir separation

The invention belongs to the technical field of air separation. A quick argon feeding method for an air separation device comprises the following steps: 1) closing a coarse argon emptying valve (V712) after the air separation device stops for a short period, and quickly stopping a circulating liquid argon pump; 2) starting the air separation device, and opening a coarse argon condenser throttling valve (V701) of after an argon fraction of a main tower reaches 6 percent; 3) starting the circulating liquid argon pump to enable liquid argon at the bottom of a coarse argon tower II (702) to enter a coarse argon tower I (C701); 4) respectively opening a coarse argon liquefier adjustment valve (V711), a fine argon condenser adjustment valve (V706) and a technical argon adjustment valve (V705), and fully opening a fine argon emptying valve (V751) to enable a fine argon tower to work; 5) opening a backflow valve (V757) to enable liquid argon at the bottom of the fine argon tower (C703) and liquid condensed by a fine argon condenser (K702) to re-participate in rectification. The quick argon feeding method is conductive to improving the backflow ratio of the coarse argon tower II, shortening the argon tower adjustment time and accelerating concentration of argon.

Owner:LAIWU IRON & STEEL GRP

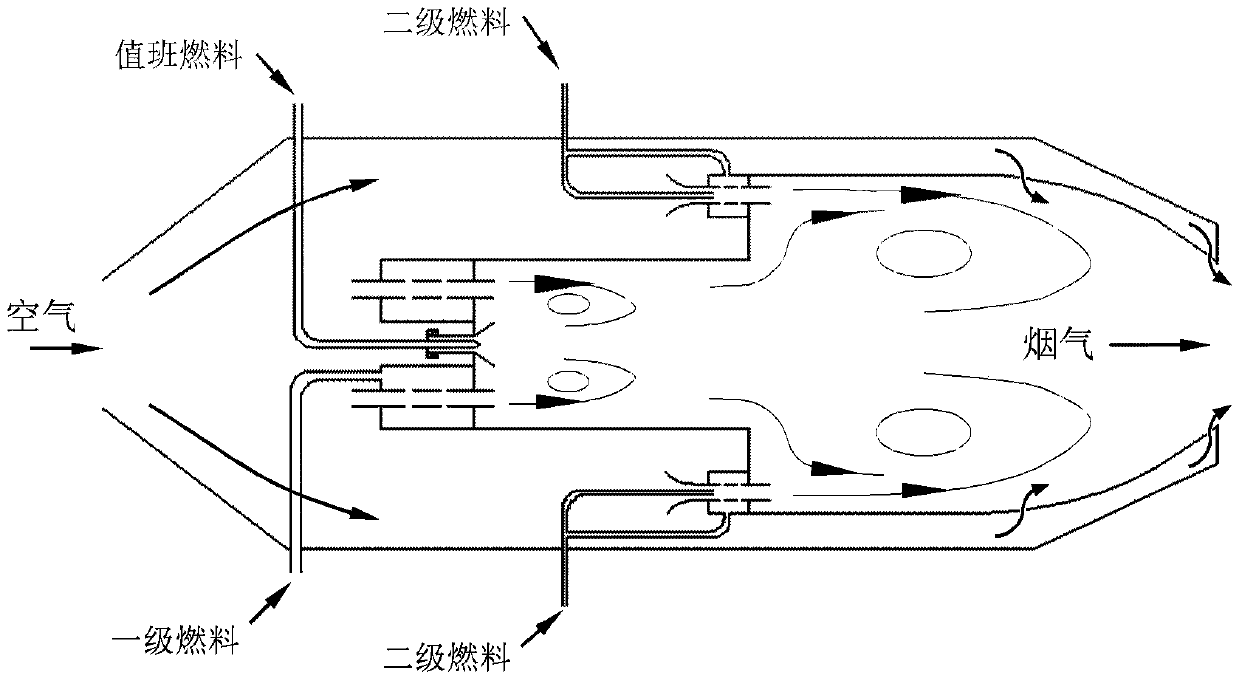

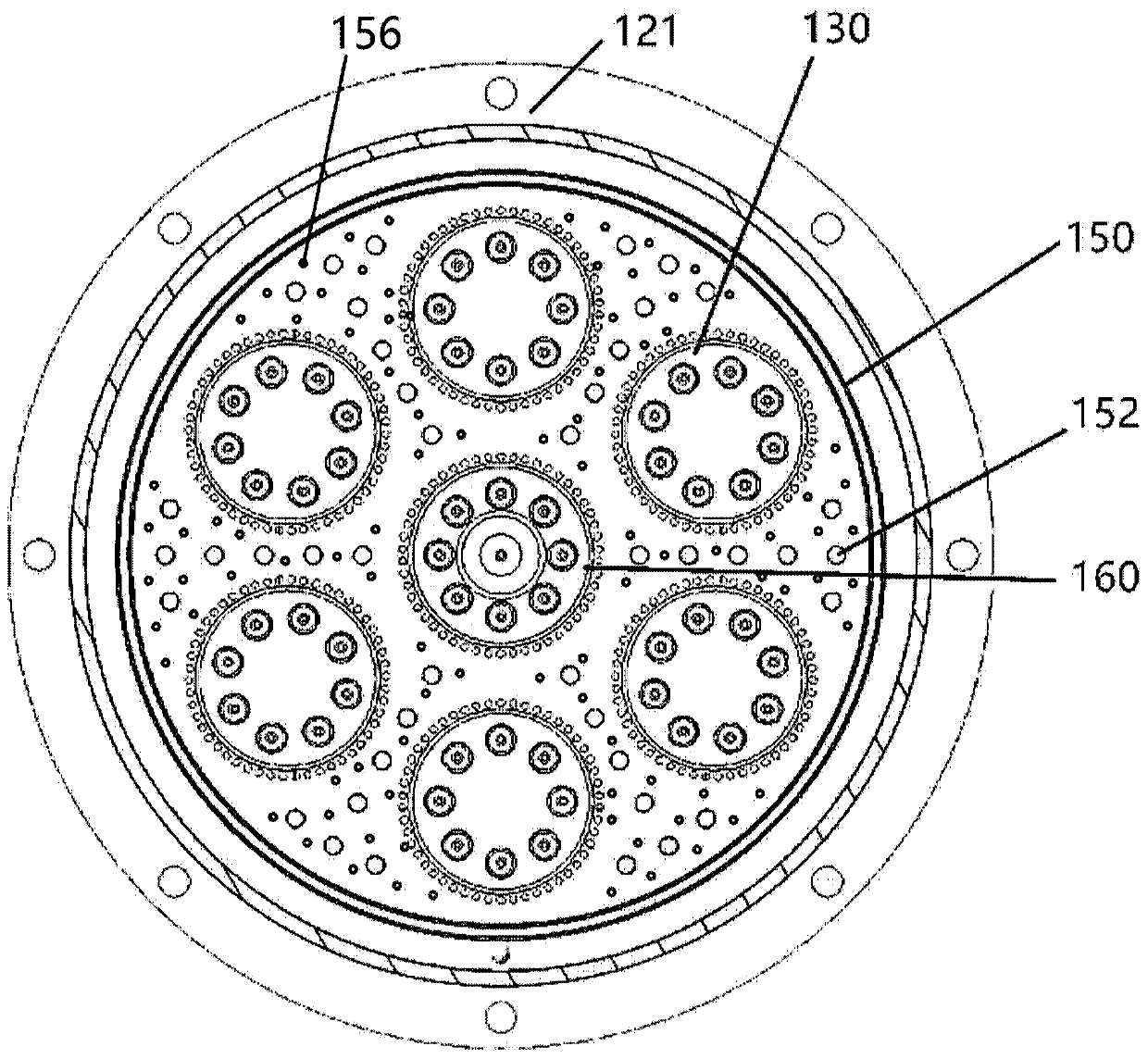

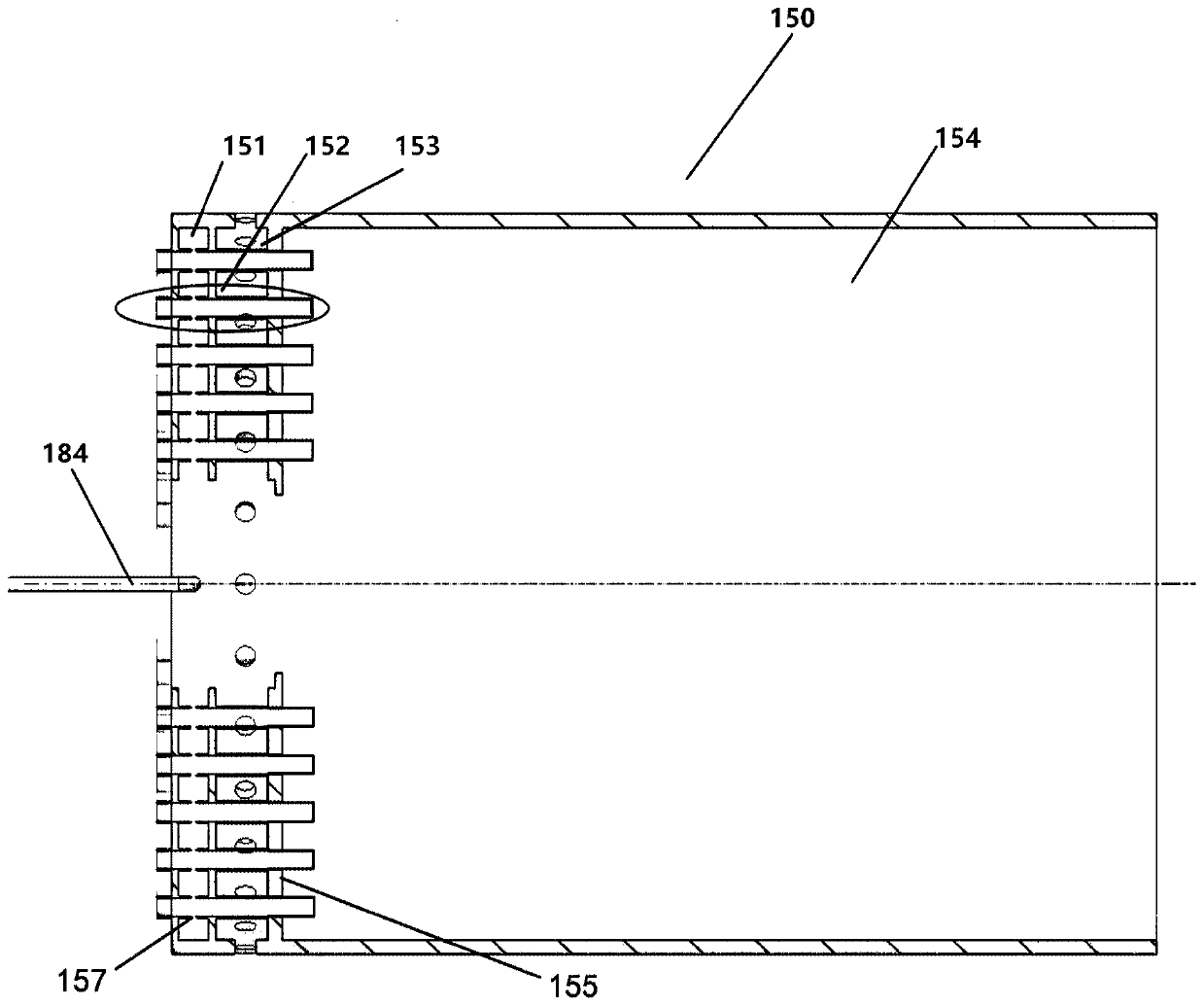

Mild combustion chamber of gas turbine

ActiveCN110631049AMixed stronglyIncrease the reflux ratioContinuous combustion chamberRefluxCombustor

The invention relates to a mild combustion chamber of a gas turbine. The mild combustion chamber comprises a premixed mild combustor, a first guide shell, a second guide shell, a secondary combustionchamber and a mild combustor on duty. Through array-type distribution of the mild combustors, the space of the mild combustion chamber of the gas turbine is fully utilized, the flue gas reflux ratio is increased, a partial mild combustion condition is easier to establish, and full-zone mild combustion of a combustion zone is realized; by means of radial staging, the requirement of regulation within a wide operating condition range is met; and as the mild combustor on duty, the premixed mild combustor and micro-mixing nozzles are different in axial position, axial staging of combustion is realized; the load regulation requirement is met; the uniformity of outlet temperature of the mild combustion chamber of the gas turbine is increased; pressure loss is reduced; full-zone high flue gas reflux ratio of mild combustion is realized; and the requirements of low emission within the wide operating condition range and efficient and stable operation are met.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

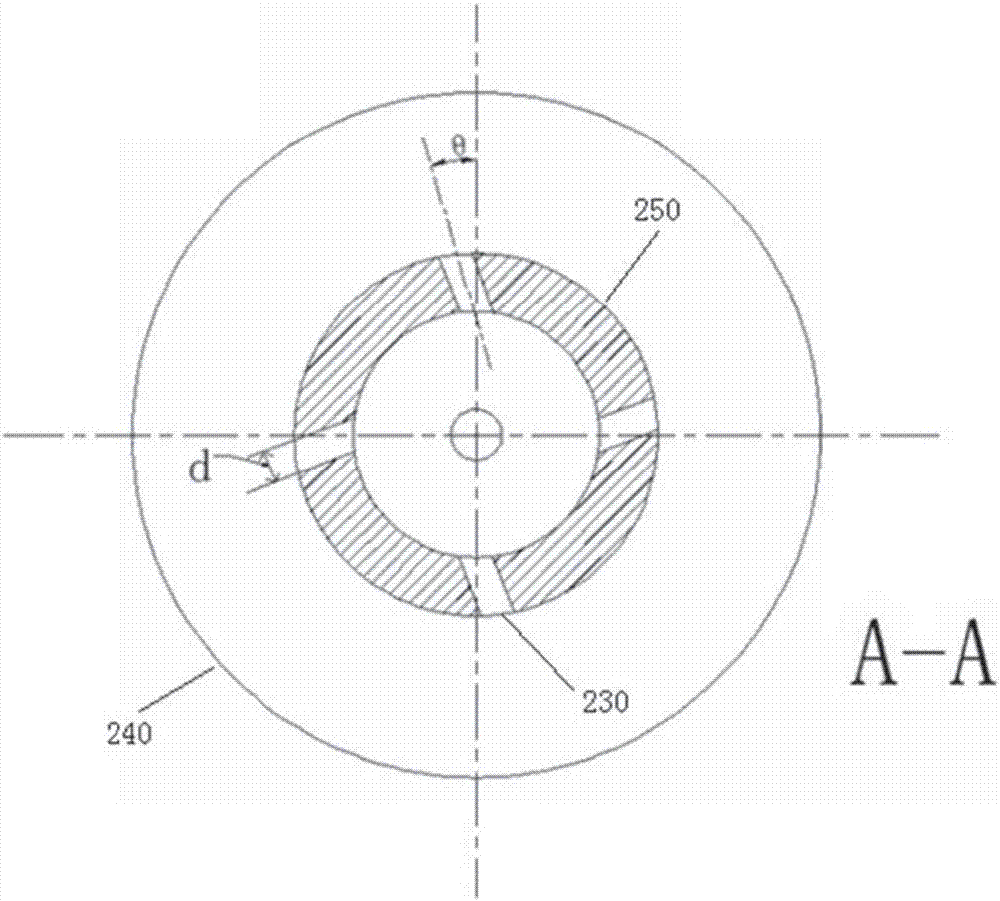

Jet nozzle of mild combustion chamber of gas turbine

ActiveCN107990353AGuaranteed combustion efficiencyAvoid shockContinuous combustion chamberRefluxUltrasound attenuation

A jet nozzle of a mild combustion chamber of a gas turbine comprises a fuel inside nozzle, a fuel outside spray hole, multiple rotational flow groove channels, an outside pipeline and an inside pipeline. The mixing uniformity of fuel and air at a jet nozzle outlet is improved, the outside fuel-air equivalence ratio is relatively low, flame root lifting is facilitated, too-early ignition does not occur easily, jets of the jet nozzle belong to weak rotational flows, the overall pressure loss is relatively low, the axial speed is not prone to attenuation, and increase of the smoke reflux ratio ofthe combustion chamber is facilitated.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

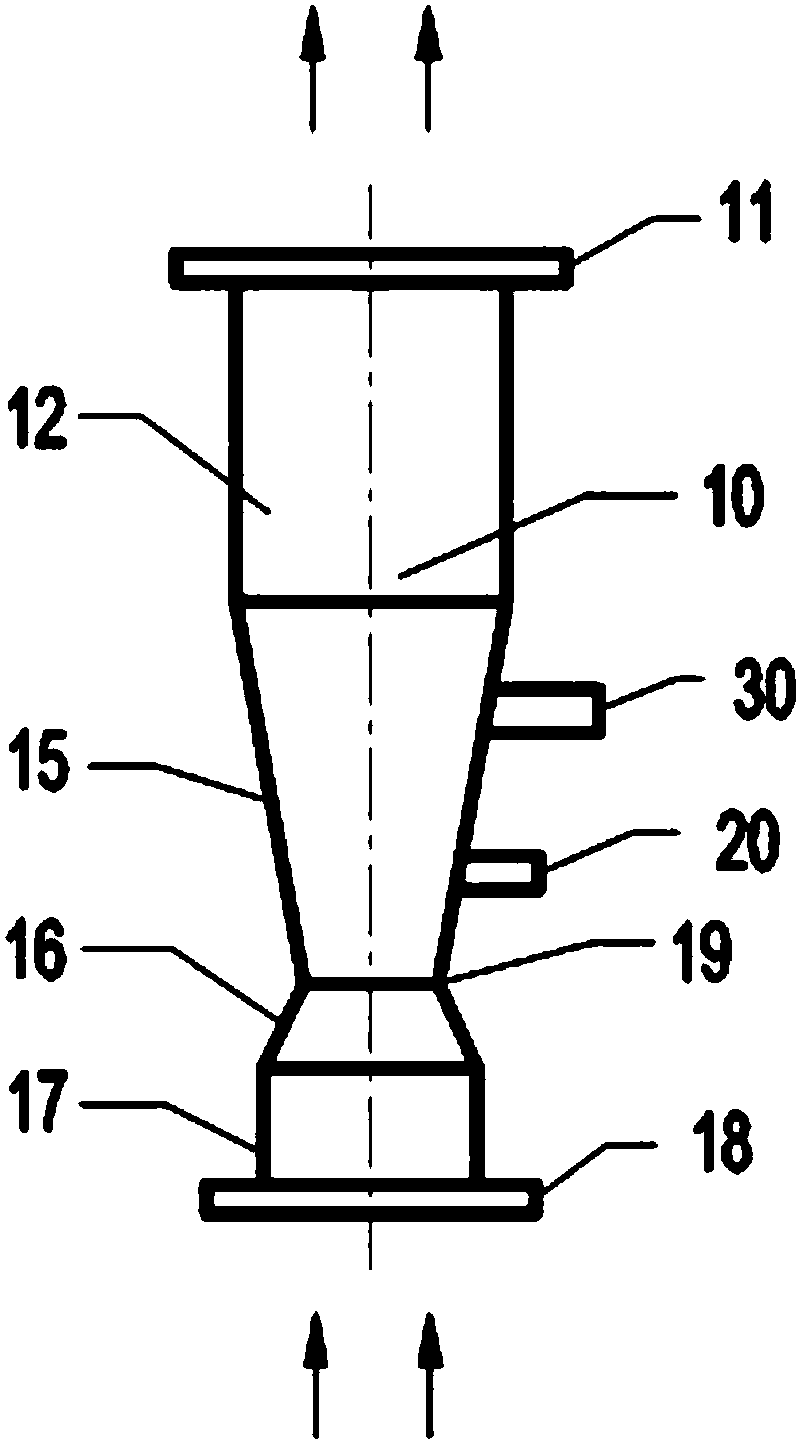

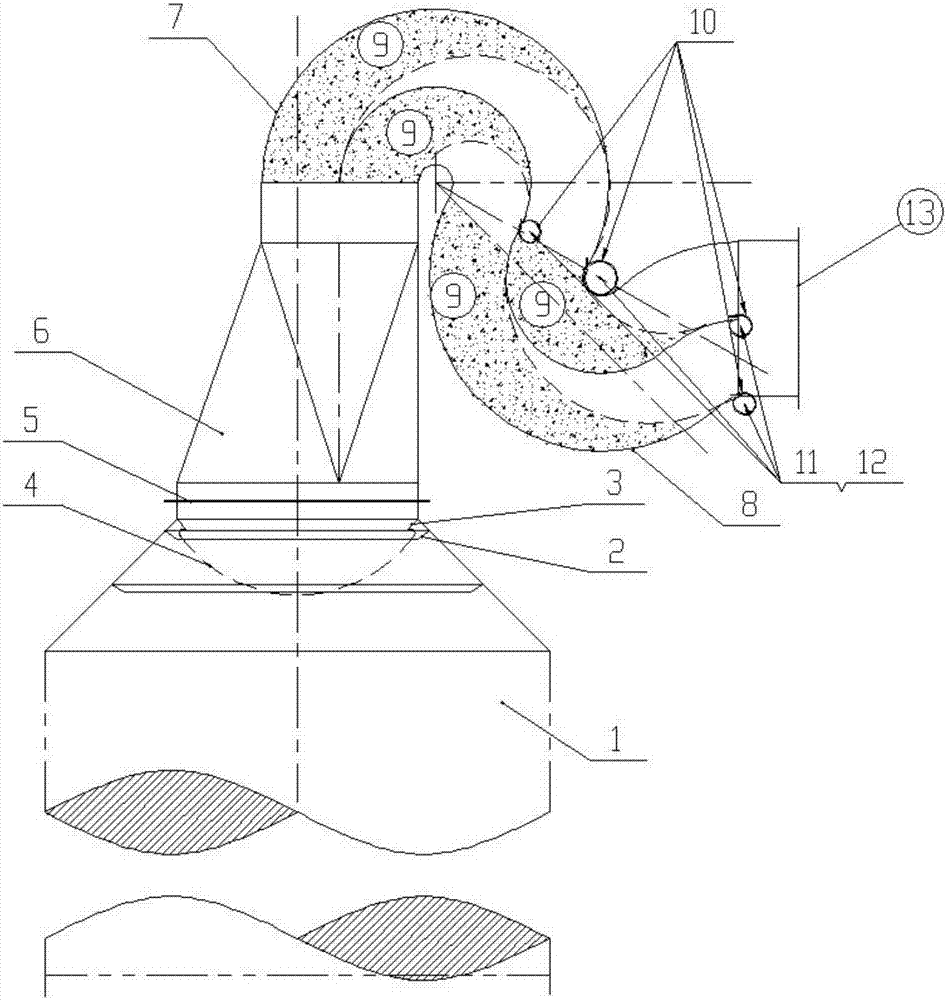

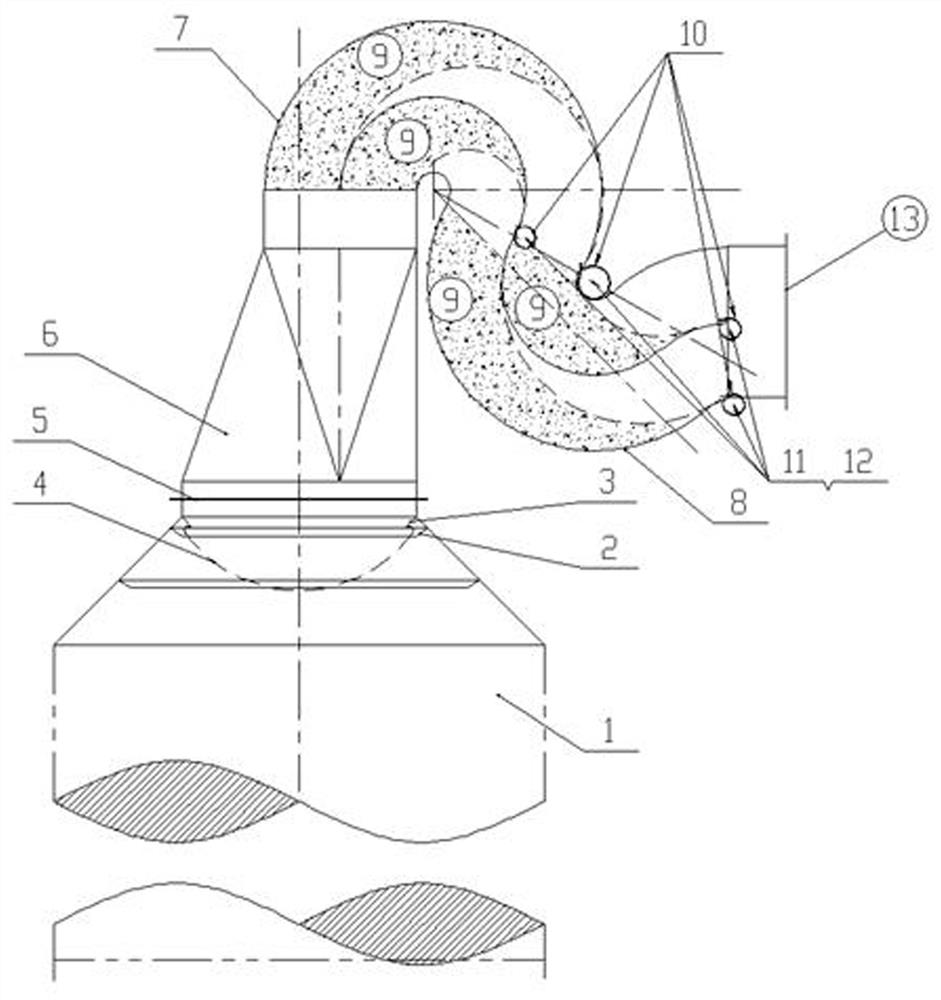

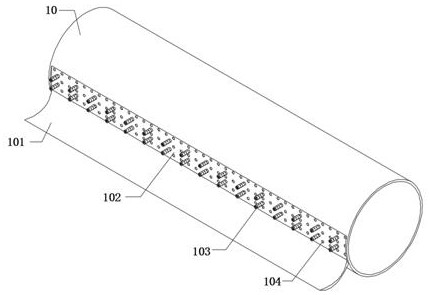

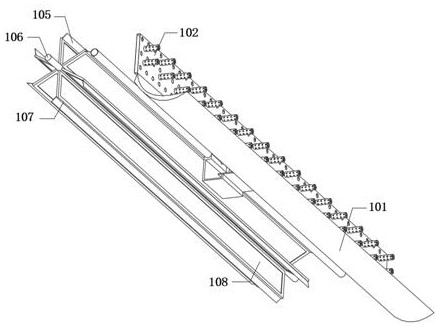

Powder conveying device and application thereof

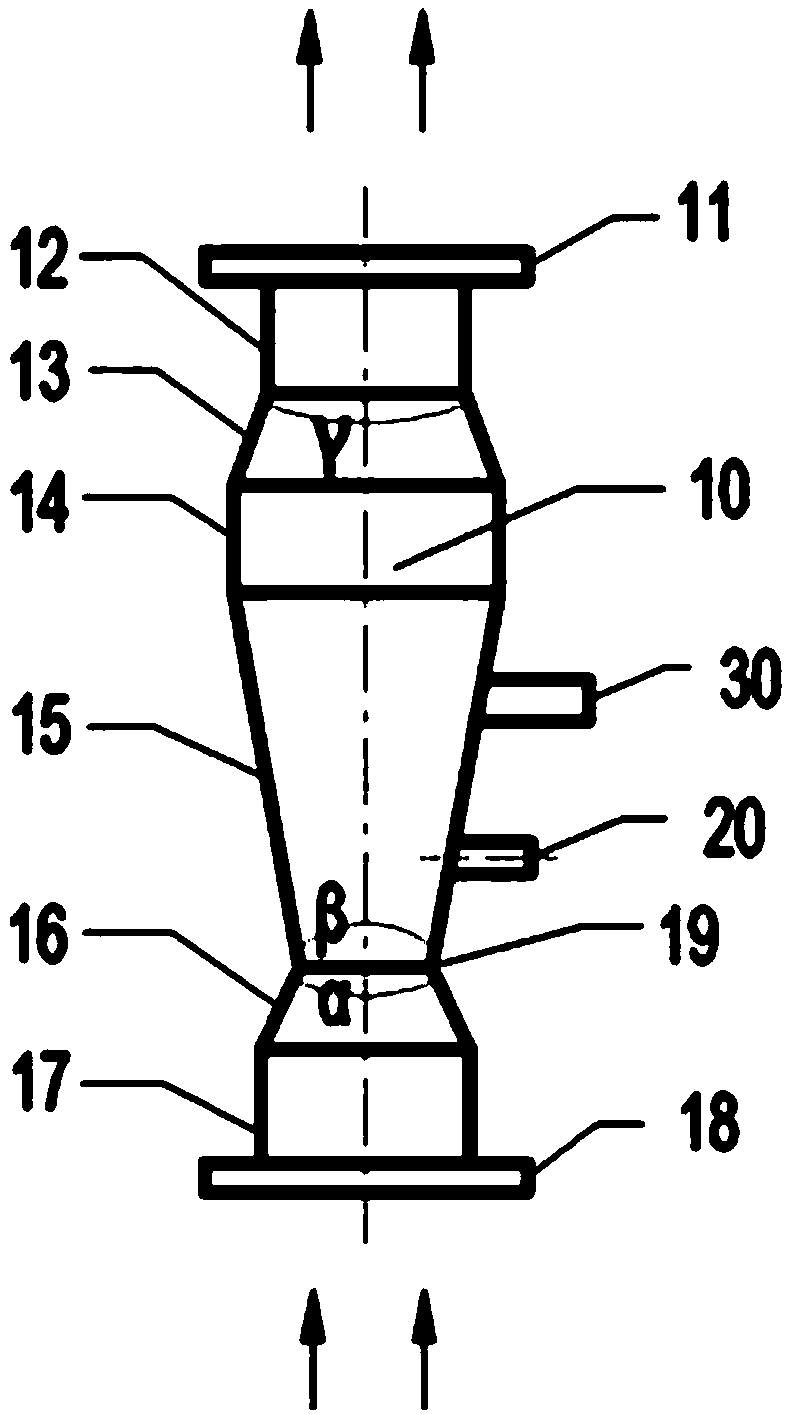

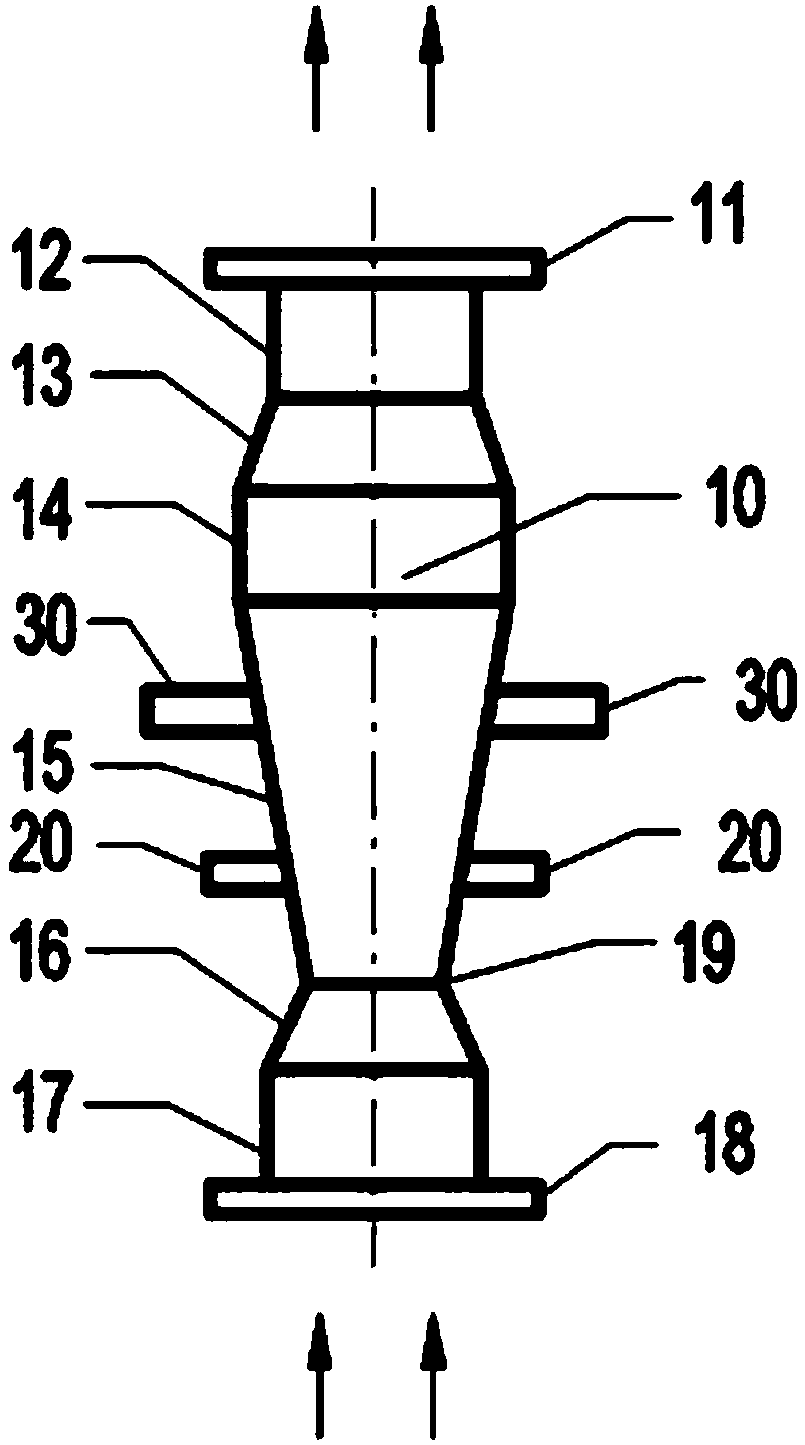

PendingCN107555178AThere will be no falling phenomenonSmall pressure dropBulk conveyorsFlangeEngineering

The invention discloses a powder conveying device and an application thereof, belonging to the field of pneumatic conveying. The powder conveying device comprises a lifting pipeline, a feeding pipeline and a purging pipeline, wherein the lifting pipeline sequentially comprises a lower flange, a lower straight section, a lower contraction section, an expansion section, a middle straight section, anupper contraction section, an upper straight section and an upper flange from bottom to top; the feeding pipeline is arranged on the expansion section and is connected to the lifting pipeline; the axis of the feeding pipeline is perpendicular to the axis of the lifting pipeline; the purging pipeline is arranged on the expansion pipeline and is connected to the lifting pipeline; and the purging pipeline is located right above the feeding pipeline. The powder conveying device solves the technical problems of the powder conveying device in the prior art that a material dropping phenomenon easilyoccurs, and the pressure drop is large. The powder conveying device is capable of fully mixing powder and gas, has small pressure drop in a conveying process, is simple and operates stably and reliably.

Owner:KEDA MAS CLEAN ENERGY +1

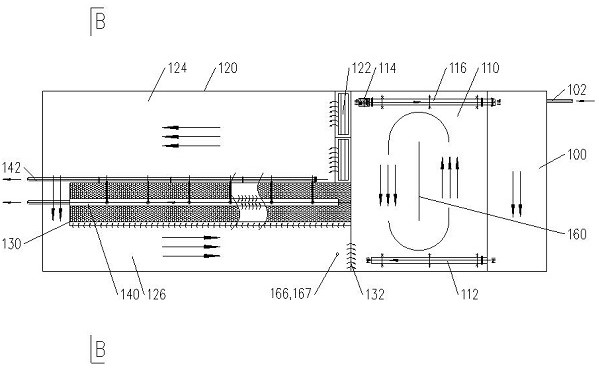

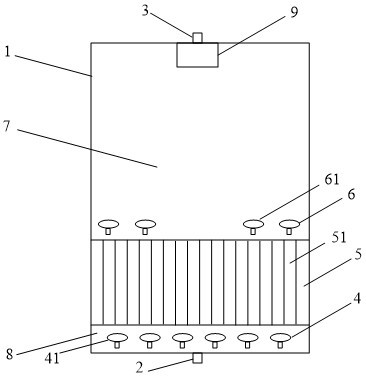

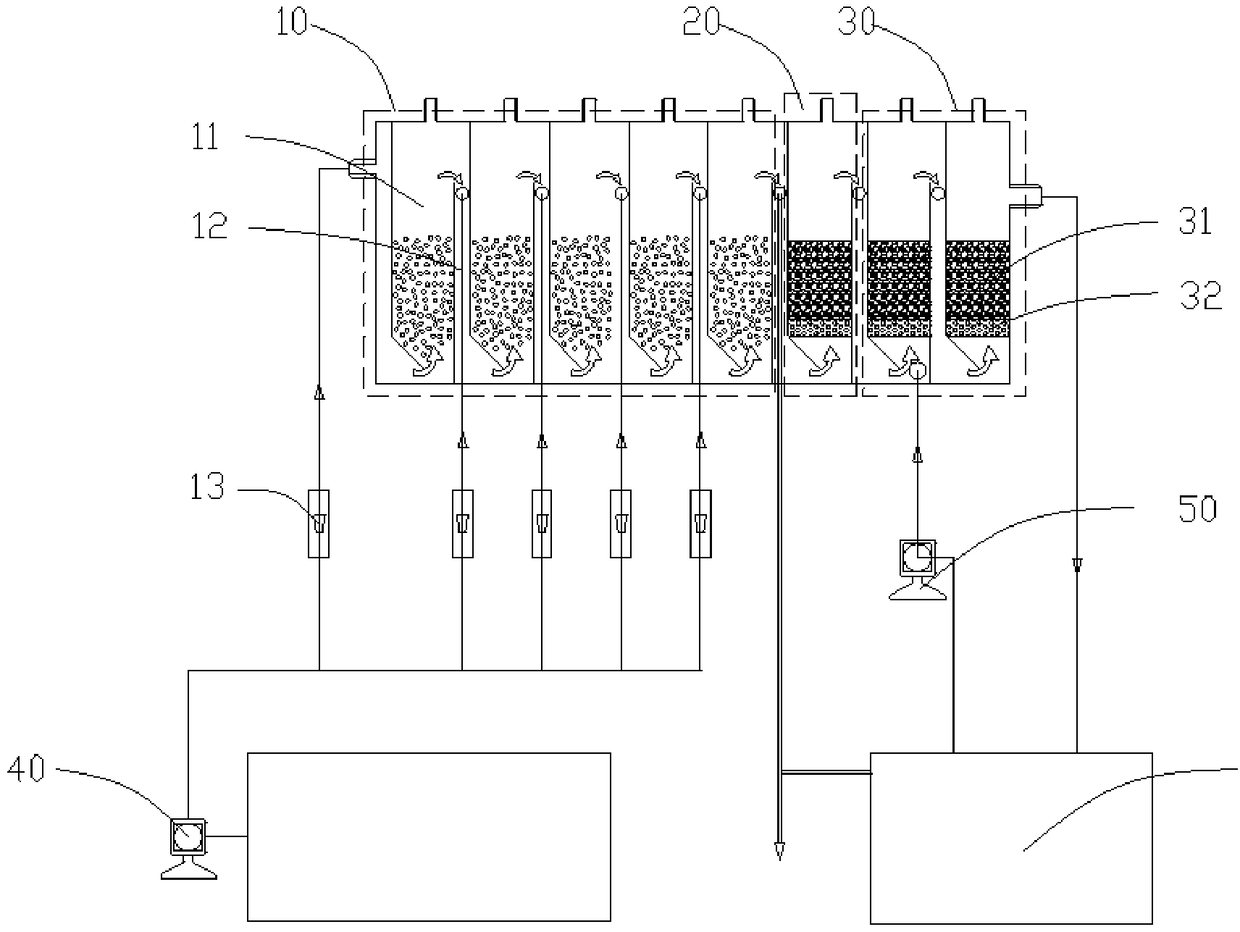

Improved A2O biochemical reaction system and sewage treatment method

ActiveCN114604970ACompact layoutSmall footprintWater treatment parameter controlWater contaminantsSludgeSewage

The invention relates to the technical field of sewage biochemical treatment, and provides an improved A2O biochemical reaction system and a sewage treatment method.The improved A2O biochemical reaction system comprises at least one anaerobic zone, at least one anoxic zone, at least one aerobic zone and at least one three-phase separator; the three-phase separator is arranged in the aerobic zone and is in sealed connection with the bottom of the aerobic zone, and the three-phase separator is suitable for dividing the aerobic zone into a first aerobic zone and a second aerobic zone. By adopting an integrated pool type structure, the occupied area is saved, the use of a high-efficiency reflux device is facilitated, the reflux energy consumption is reduced, and the nitrogen and phosphorus removal effect of the whole process can be obviously improved. The three-phase separator can automatically fall separated nitrified sludge back to the tail end of the second aerobic zone, the nitrified sludge flows back to the anoxic zone along with nitrified sludge mixed liquor, sludge backflow and internal backflow of the nitrified sludge mixed liquor can be combined into a whole, a set of backflow system is saved, a control point is reduced, operation is simpler, and operation, maintenance and management are convenient.

Owner:BEIJING BOHUITE ENVIRONMENTAL TECH CO LTD

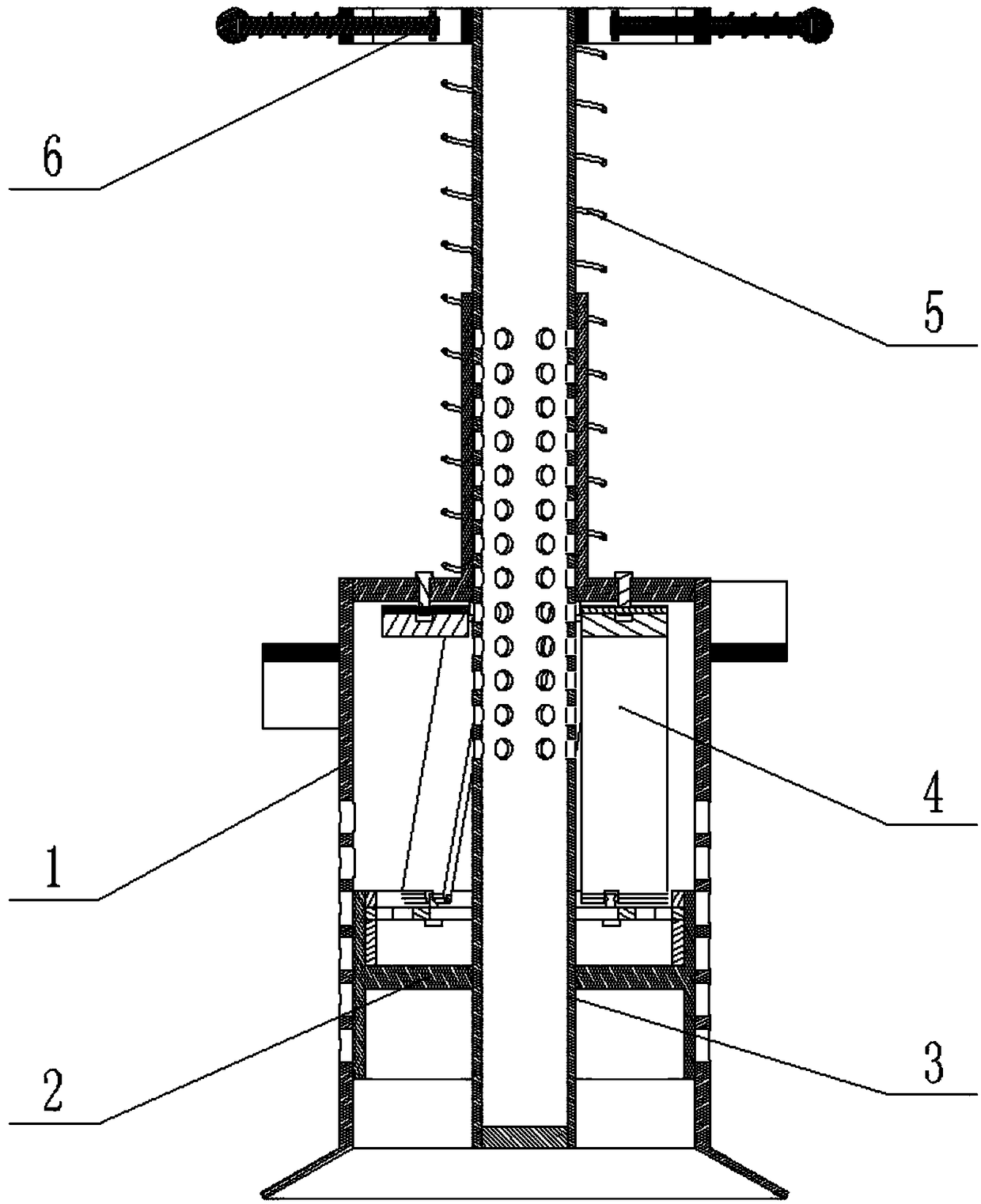

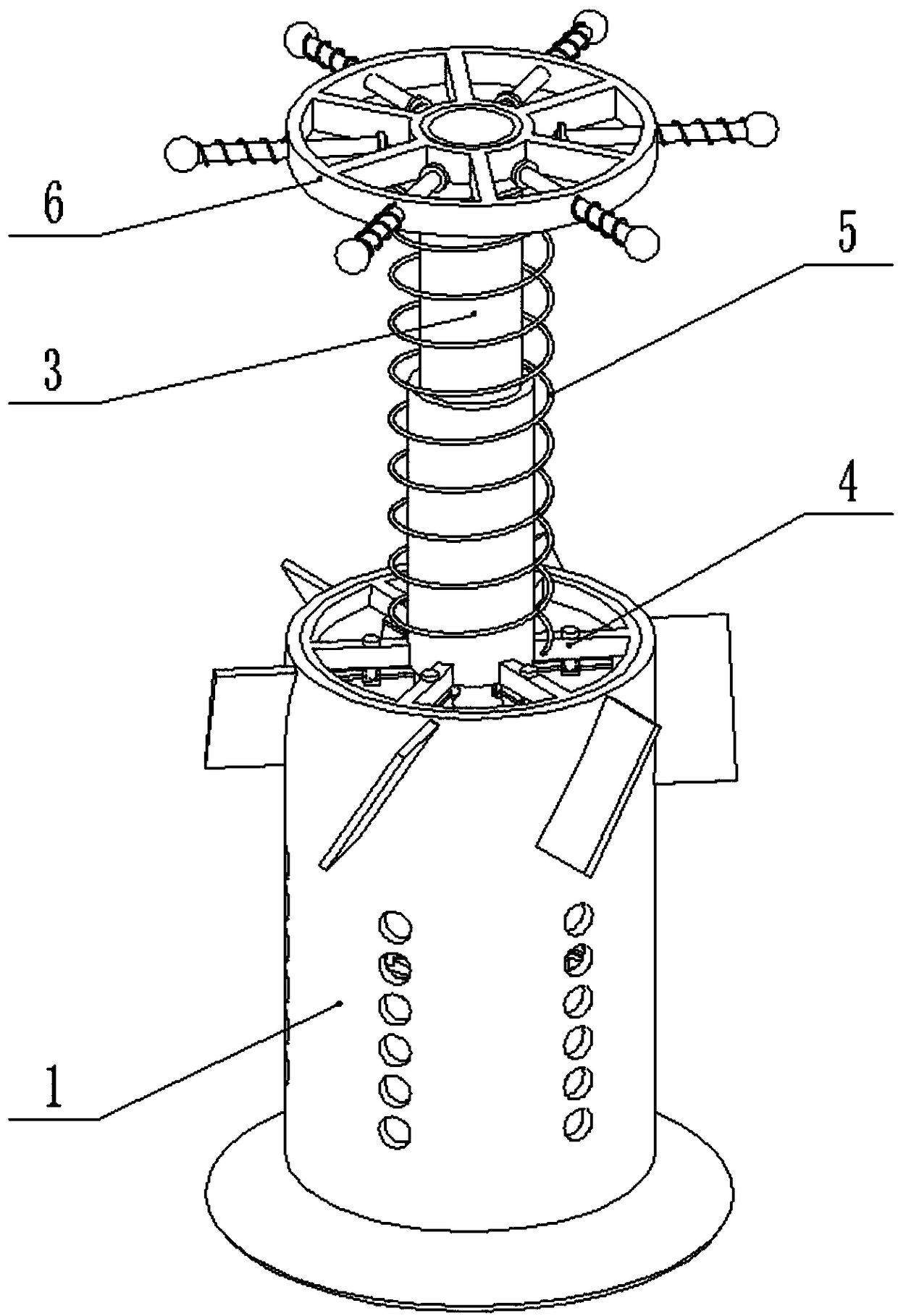

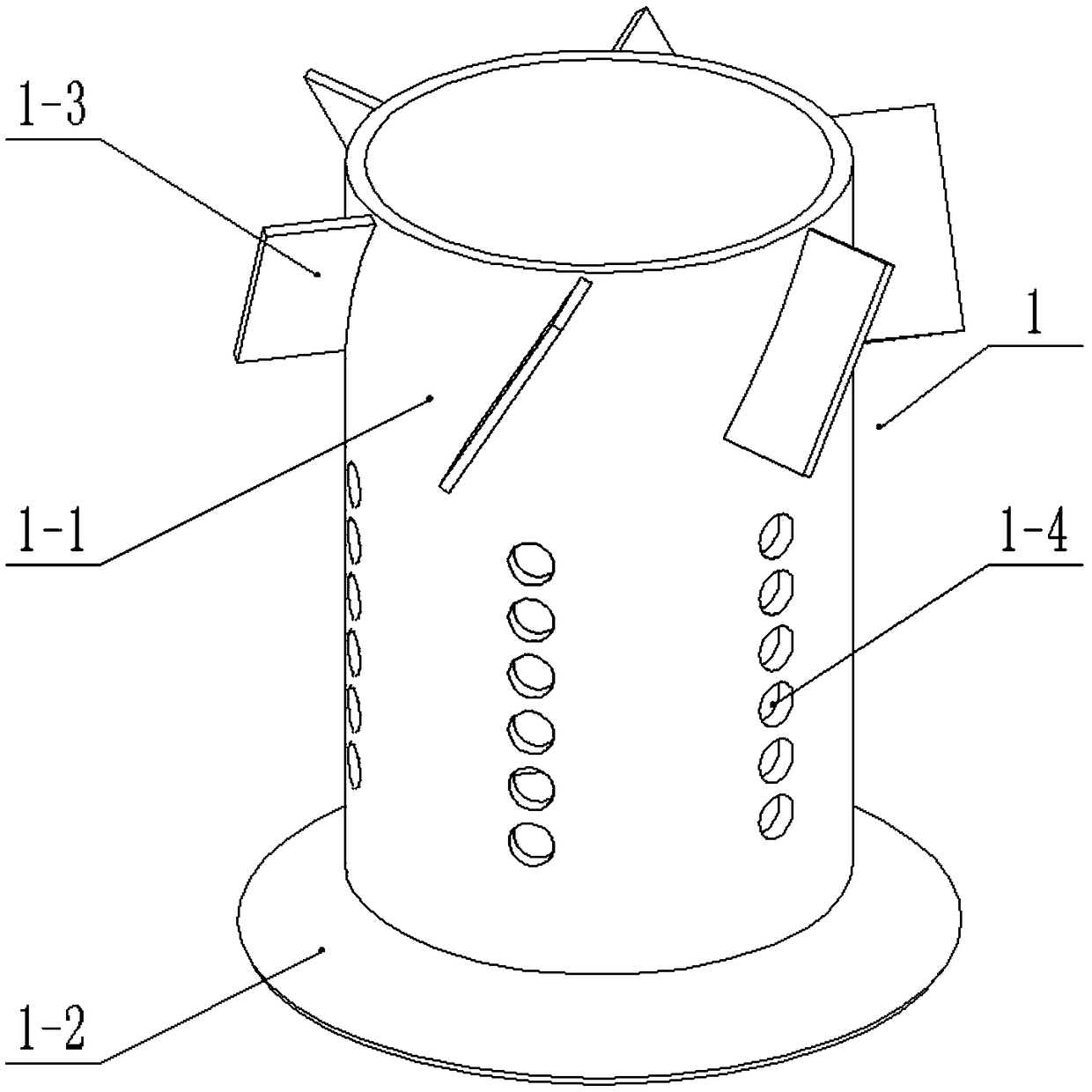

Emulsification treatment equipment for medium viscous crude oil viscosity reduction

The invention relates to the technical field of crude oil viscosity reduction treatment, in particular to emulsification treatment equipment for medium viscous crude oil viscosity reduction. The emulsification treatment equipment comprises a stirring sleeve, an oil sealing sleeve, a viscosity reducer conveying pipe, an internal rotation assembly, a spring and a fixing device. The oil sealing sleeve is slidably connected into the stirring sleeve and fixedly connected to the viscosity reducer conveying pipe, and the lower end of the internal rotation assembly is rotationally connected to the oilsealing sleeve. The middle end of the internal rotation assembly is fixedly connected to the stirring sleeve, and the internal rotation assembly is slidably connected to the viscosity reducer conveying pipe. The fixing device is fixedly connected to the upper end of the viscosity reducer conveying pipe, and the spring is arranged between the internal rotation assembly and the fixing device. The emulsification treatment equipment can rotate during oil liquid flowing, and oil liquid is mixed with an emulsifier or an viscosity reducer advantageously; and the conveying flow rate of the emulsifieror the viscosity reducer can be increased when the viscosity of the oil liquid is large, the backflow proportion of the oil liquid is increased, the inclination angle of inner stirring blades can bedecreased, and flowing resistance of the oil liquid is reduced.

Owner:山东天厚石油科技有限责任公司

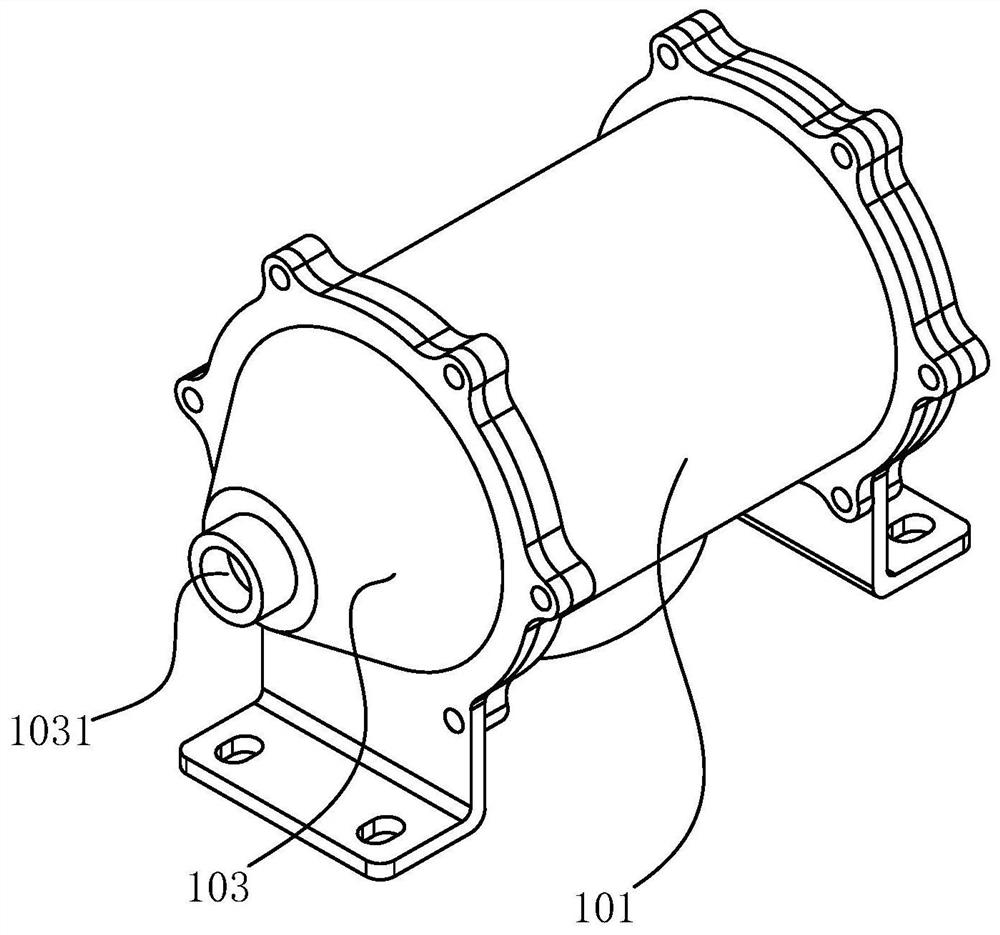

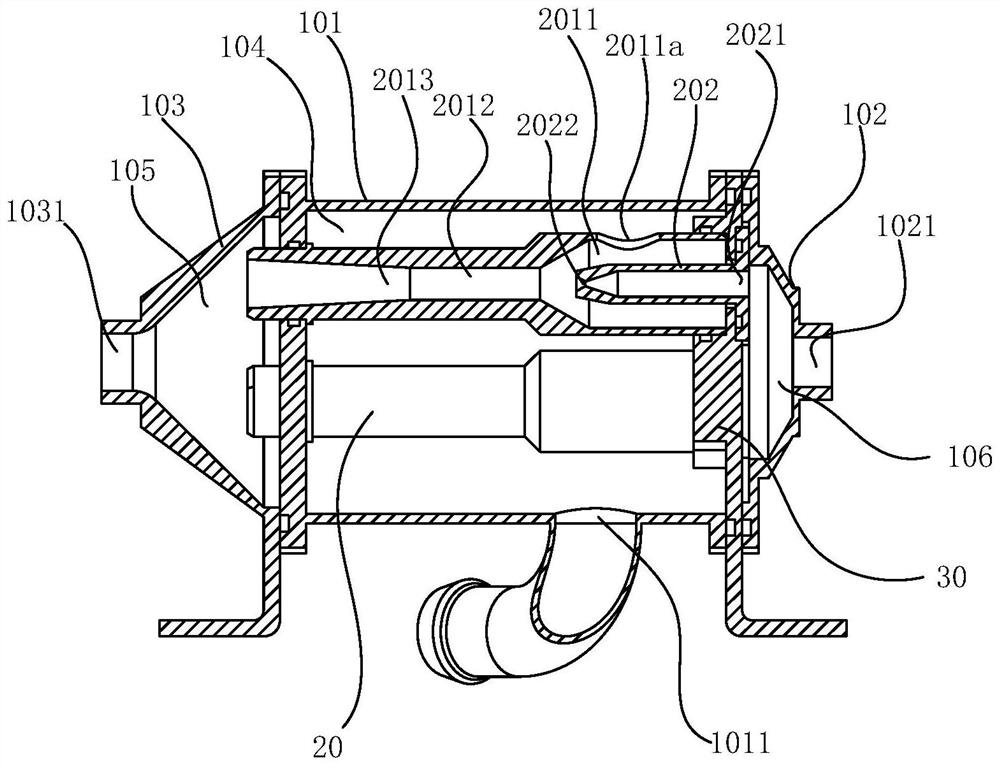

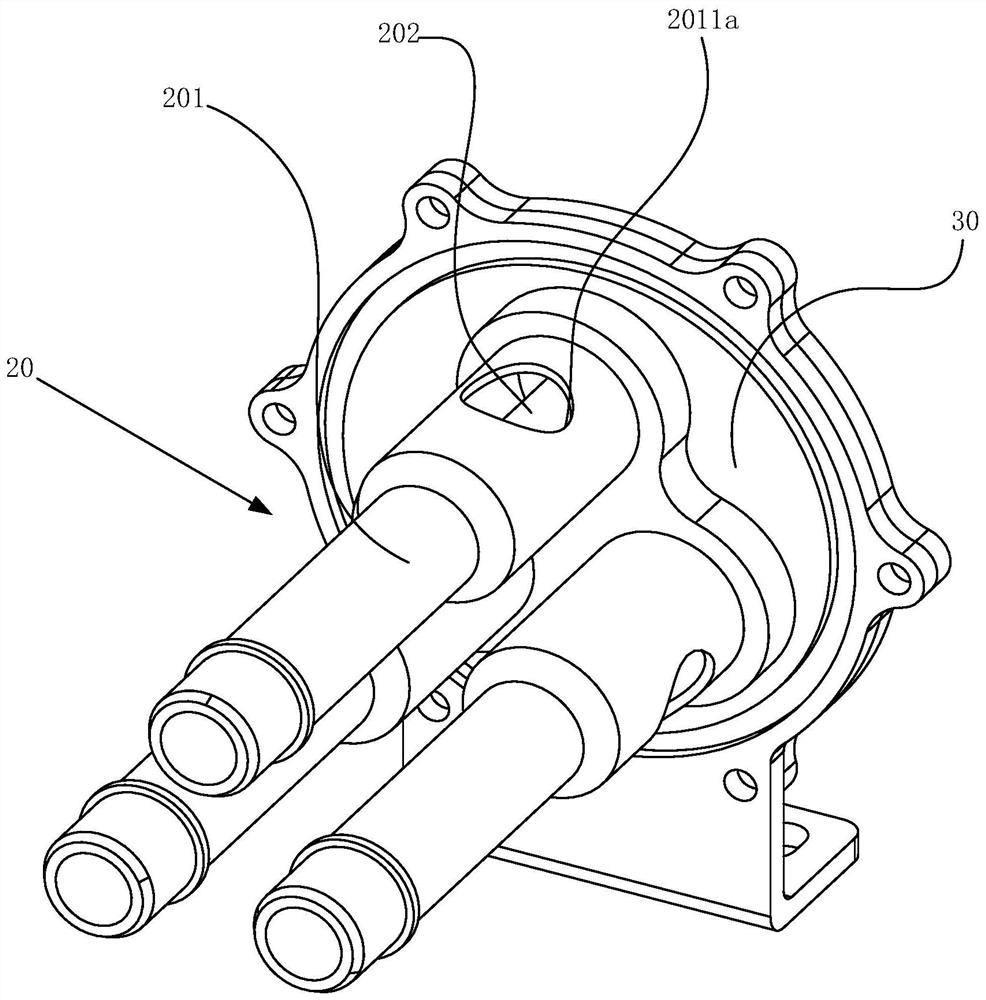

Ejector and fuel cell system comprising same

PendingCN113437327AIncrease the reflux ratioHigh trafficFuel cell auxillariesMultiple injectionInjector

The invention discloses an ejector and a fuel cell system comprising the same. The ejector is used in the fuel cell system and comprises a shell, a first cavity and a second cavity which are spaced from each other are arranged in the shell, and a backflow gas inlet for backflow gas to enter and a gas outlet for mixed gas to flow out are formed in the shell; the backflow gas inlet is communicated with the first cavity, and the gas outlet is communicated with the second cavity; the ejector further comprises a plurality of ejection assemblies, all the ejection assemblies are arranged in the shell and are used for ejecting the backflow gas in the first cavity, and one end of each ejection assembly extends into the second cavity and is communicated with the second cavity. The multiple injection assemblies are arranged in the shell, so that the flow and pressure of an injection gas of the whole injector are increased, meanwhile, the reflux ratio of the reflux gas is increased, and then the flow of the mixed gas of the injection gas and the reflux gas is increased. In addition, the length of the single ejection assembly can be reduced, and therefore the size of the ejector can be reduced.

Owner:SHANGHAI ELECTRICGROUP CORP

Urban sewage oxidation treatment technology

InactiveCN105884123AIncrease the reflux ratioIncrease the external reflux ratioMultistage water/sewage treatmentFiltrationOxidation zone

The invention discloses an urban sewage oxidation treatment technology which comprises the following steps of: incoming water, coarse-screen filtration, fine-screen filtration, sedimentation in a grit chamber, sedimentation in a primary sedimentation tank, oxidation treatment in an A2 / C oxidation ditch, secondary sedimentation treatment, disinfection treatment and effluent, wherein the oxidation ditch in the oxidation treatment in an A2 / C oxidation ditch comprises an anaerobic zone, anoxic zone and an oxidation ditch zone; the phosphorus absorption staying time in the anoxic zone is 30-55min; the mixed liquid staying time in the anaerobic zone is 1-1.8h; an underwater stirrer is arranged in the anaerobic zone; and a surface aerator is arranged in the oxidation ditch. By adopting the oxidation treatment technology disclosed by the invention, the outer reflux ratio and the maximum mixed-liquid reflux ratio can be increased so as to improve the phosphorous removal and nitrate return efficiency and quality.

Owner:宋正兴

Method for continuously separating α-pinene and β-pinene from turpentine

ActiveCN104130093BRealize continuous operationIncrease the reflux ratioDistillation purification/separationDistillationTurpentine

The invention relates to a method for continuously separating alpha-pinene and beta-pinene from turpentine. The method comprises the following steps: raw materials are subjected to a preheating treatment; a packed tower vacuum rectification process is carried out; alpha-pinene is collected with a reflux ratio of 8:1-10:1; a middle fraction is slowly collected with a reflux ratio of 20:1-30:1; beta-pinene is collected with a reflux ratio of 8:1-15:1; and when distillation is finished, while the rectification tower is not cooled and the vacuum state is not relieved, discharge is realized through the pressure difference between a tower kettle and a residual liquid tank. Therefore, intermittent distillation continuous operation is realized. With the method provided by the invention, the content of obtained alpha-pinene can be 98%, and the content of obtained beta-pinene can be 95%.

Owner:GUANGXI FORESTRY RES INST

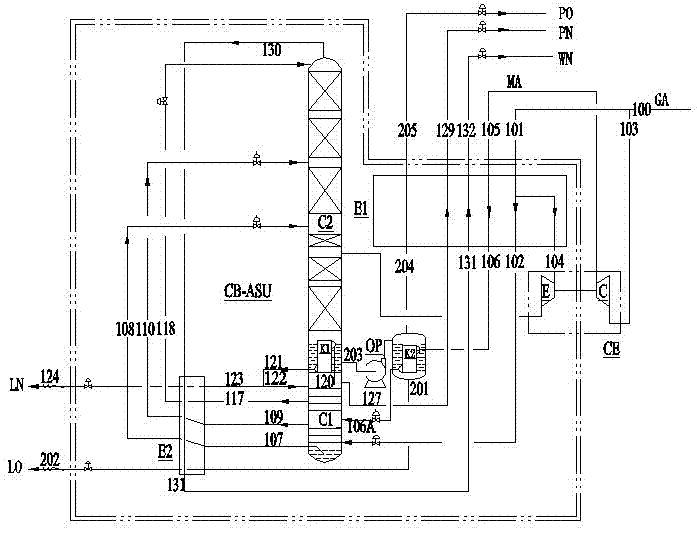

Method and device for producing pressure oxygen by air separation

The invention discloses a method for producing pressure oxygen by air separation. The compressed air is divided into two paths: one path of the compressed air is pressurized to enter a main heat exchanger for cooling, enter an oxygen pressurizer to exchange heat with pressure liquid oxygen to be condensed into a liquid state and enter a lower tower for rectification; and the other path of the compressed air enters the main heat exchanger for cooling and is divided into two parts, and one part of the air is expanded to be fed to an upper tower for rectification. The nitrogen obtained by the lower tower enters a condensing evaporator to be condensed into two parts, namely one part of the nitrogen serving as reflux returns to the lower tower and the other part of the nitrogen is subcooled through a subcooler and divided into two paths. One path of the nitrogen serving as liquid nitrogen is led out, and the other path of the nitrogen enters the top of the upper tower. Dirty liquid air extracted from the lower tower and the obtained liquid air are subcooled through the subcooler, enter the upper tower for rectification once again and pass through the condensing evaporator so as to formliquid oxygen. The liquid oxygen which is pressurized or subjected to liquid oxygen pump pressurization enters the oxygen pressurizer to be evaporated into pressure oxygen and reheated in the main heat exchanger for output. The method for producing the pressure oxygen has the advantages of optimized flow organization, low equipment input cost, and capacity of obviously reducing the energy consumption.

Owner:四川空分设备(集团)有限责任公司

LD-type wet desulfurization special-purpose dust and water removal unit

InactiveCN106984100ASimple structureAvoid easy cloggingDispersed particle separationFlue gasEnvironmental engineering

LD type wet desulfurization dedicated dedusting and water removal unit, applied to the outlet at the center of the top of the desulfurization tower, including water stop and water collection ring, plastic suction port, flue gas transition flue, inlet flange, outer ring, inner ring, gas and water capture The tank, the flushing water pipeline, the return pipe in the return tower area and the outlet flange, the air flow is discharged through the outlet of the desulfurization tower into the shaping suction port, and the air flow is integrated. During this process, a mushroom-shaped inlet flue gas isokinetic line will be formed at the shaping suction port. The flue gas enters a flat rectangular "S" channel, and the channel is divided into double-layer or multi-layer "S" channels with "S"-shaped partitions. Each channel is divided into a positive semicircle (210°) and an anti-semicircle. (150°). It has the advantages of simple structure and not easy to block, and is compatible with the original folding plate demister. The above structure shows that the efficiency of suctioning concentrated wet airflow is significantly higher than that of simply recovering liquid.

Owner:中电国核(北京)节能环保科技有限公司

External cooling type low pure oxygen air separation system and method

InactiveCN105423702AImprove distillation air separation efficiencySave energySolidificationLiquefactionNitrogenEngineering

The invention provides an external cooling type low pure oxygen air separation system and method. The external cooling type low pure oxygen air separation system comprises a lower tower, a condensing evaporator, an oxygen inlet, an oxygen heat exchanger, a nitrogen heat exchanger, a throttle valve and a delivery pipeline; the condensing evaporator is arranged at the top of the lower tower; the throttle valve is arranged on an outer side of the lower tower; liquid oxygen is fed into the condensing evaporator through the oxygen inlet; raw material air is precooled by the heat exchanger to reach a saturation temperature before going into the bottom of the lower tower, and nitrogen in the raw material air rises to the top of the lower tower and goes into the condensing evaporator; one part of the nitrogen exchanges heat with the liquid oxygen in the condensing evaporator and thus is condensed into liquid nitrogen for flowing black, while the other part of the nitrogen is discharged out of the condensing evaporator and reheated by the nitrogen heat exchanger to reach a normal temperature before being recovered; the liquid oxygen is transformed into oxygen that is discharged out of the condensing evaporator and reheated by the oxygen heat exchanger to reach the normal temperature before being recovered; the liquid oxygen staying at the bottom of the lower tower is discharged out of the lower tower and delivered into the condensing evaporator at the top of the lower tower through the delivery pipeline with the throttle valve to serve as a cold source taking part in the heat exchange process.

Owner:XINJIANG TIANCHEN GAS CO LTD

Sewage treatment method using active sludge-biological filtering pond revere flow and integral device

InactiveCN1281519CEasy to handleGuaranteed uptimeSustainable biological treatmentBiological water/sewage treatmentActivated sludgeReflux

Owner:CHONGQING UNIV

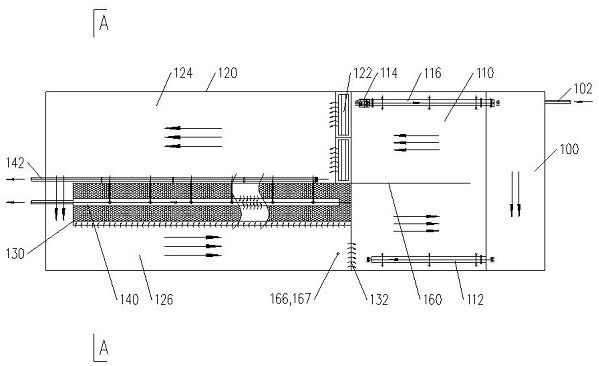

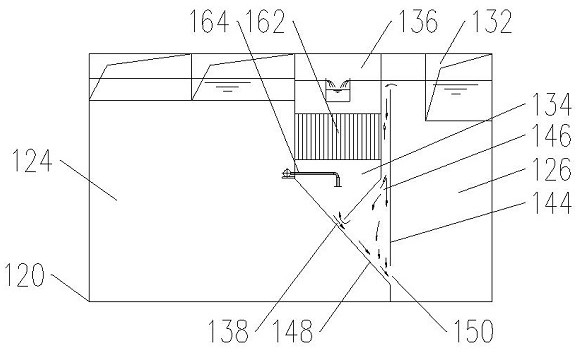

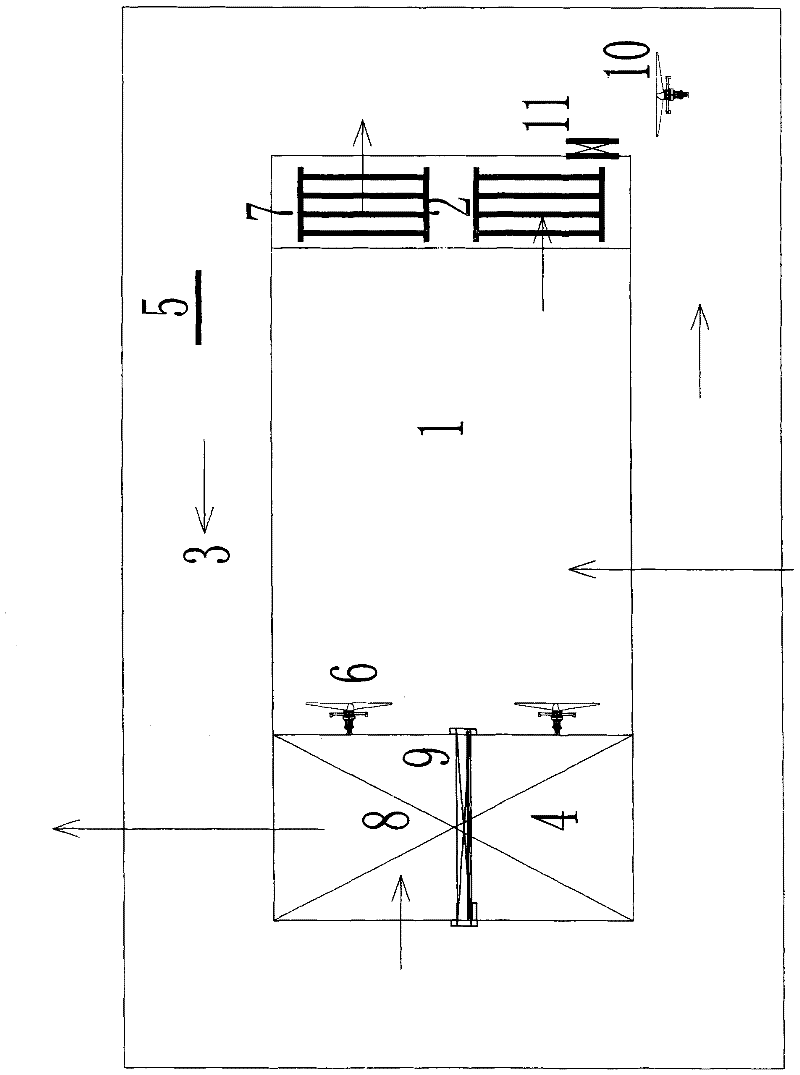

Highly-efficient stable bio-doubling sewage treatment device

ActiveCN102180543BChange layout structureReduce concentration differenceTreatment using aerobic processesBiological treatment apparatusRefluxSludge

The invention discloses a highly-efficient stable bio-doubling process sewage treatment device, which is improvement of a bio-doubling process sewage treatment device. The highly-efficient stable bio-doubling process sewage treatment device is characterized in that: an aerobic aeration area is an annular channel, a water propulsion device is arranged in the annular channel, a water-feeding mix reaction area, a water lifting area and a settlement area are internally arranged at the inner side of the annular channel, and the annular channel is respectively communicated with the settlement area and the water-feeding mix reaction area. According to the pool-type structure, the contradiction between low dissolved oxygen amount and high sludge content required by the bio-doubling process is greatly solved, the requirements on a bio-doubling process for low dissolved oxygen amount and high sludge content can be ensured, thus the practical effect and advantage representation of the bio-doubling process are ensured; two or more loops are formed through treatment, thus the involved devices are conveniently overhauled without running stop, and the reflux ratio is adjustable and high; in addition, a controllable gate or valve is additionally arranged between the lifting area and the annular channel, thus practical running adjustability is improved; and after construction or construction finish of the controllable gate or valve, an aeration device is flexibly added, or started / stopped according to water quality, thus the application expandability of the highly-efficient stable bio-doubling process sewage treatment device is good, and adaptability of the highly-efficient stable bio-doubling process sewage treatment device is strong.

Owner:LINGZHI ENVIRONMENTAL PROTECTION CO LTD +3

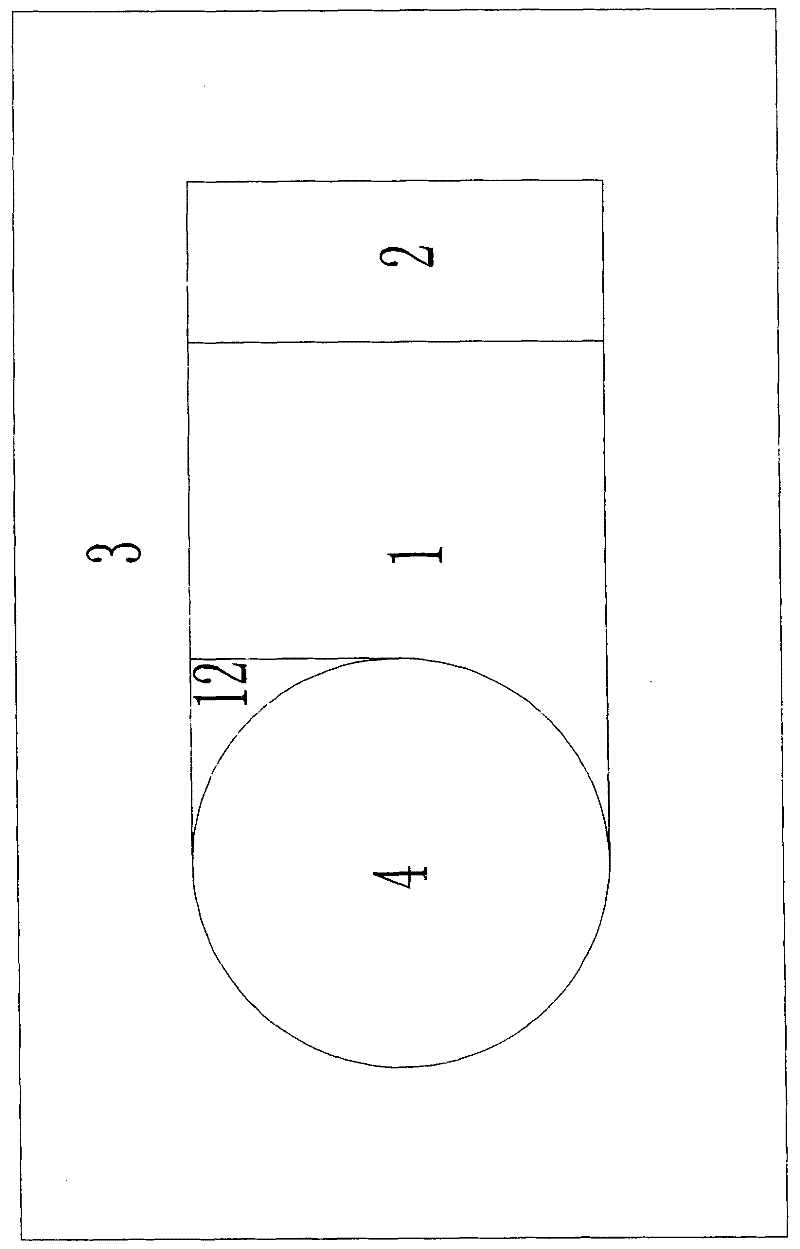

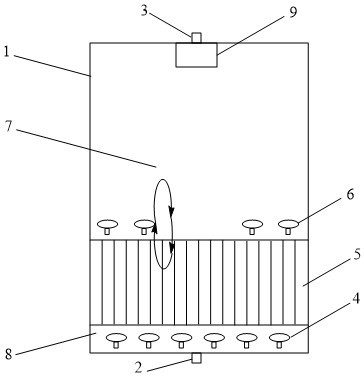

Sewage treatment reactor and treatment method thereof

ActiveCN113896326APromote circulationPromotes synergistic symbiosisTreatment with aerobic and anaerobic processesSewage treatmentWater treatment

The invention relates to a sewage treatment reactor and a treatment method thereof. The reactor comprises a box body, a water inlet pipe and a water outlet pipe, the water inlet pipe is installed at the bottom of the box body, the water outlet pipe is installed at the top of the box body, and an upper-layer aeration assembly, a flow guide assembly and a lower-layer aeration assembly are sequentially arranged in the box body from top to bottom; and the area where the upper-layer aeration assembly is located and the upper part are aerobic areas, and the area where the lower-layer aeration assembly is located is an anoxic area or an anaerobic area. Through the arrangement of a double-layer aeration assembly and a flow guide assembly, mixed liquid in the upper area and the lower area of the reactor can flow back and reach an extremely high reflux ratio, nitrification, denitrification and synchronous nitrification and denitrification reactions can occur in the reactor, accurate regulation and control of dissolved oxygen are assisted, and short-cut nitrification and denitrification, synchronous short-cut nitrification and denitrification and anaerobic phosphorus removal reaction can occur in the reactor, so that the sewage treatment efficiency is greatly improved.

Owner:SHENZHEN QINGYAN ENVIRONMENTAL TECH CO LTD

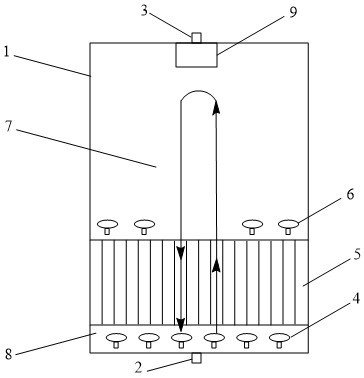

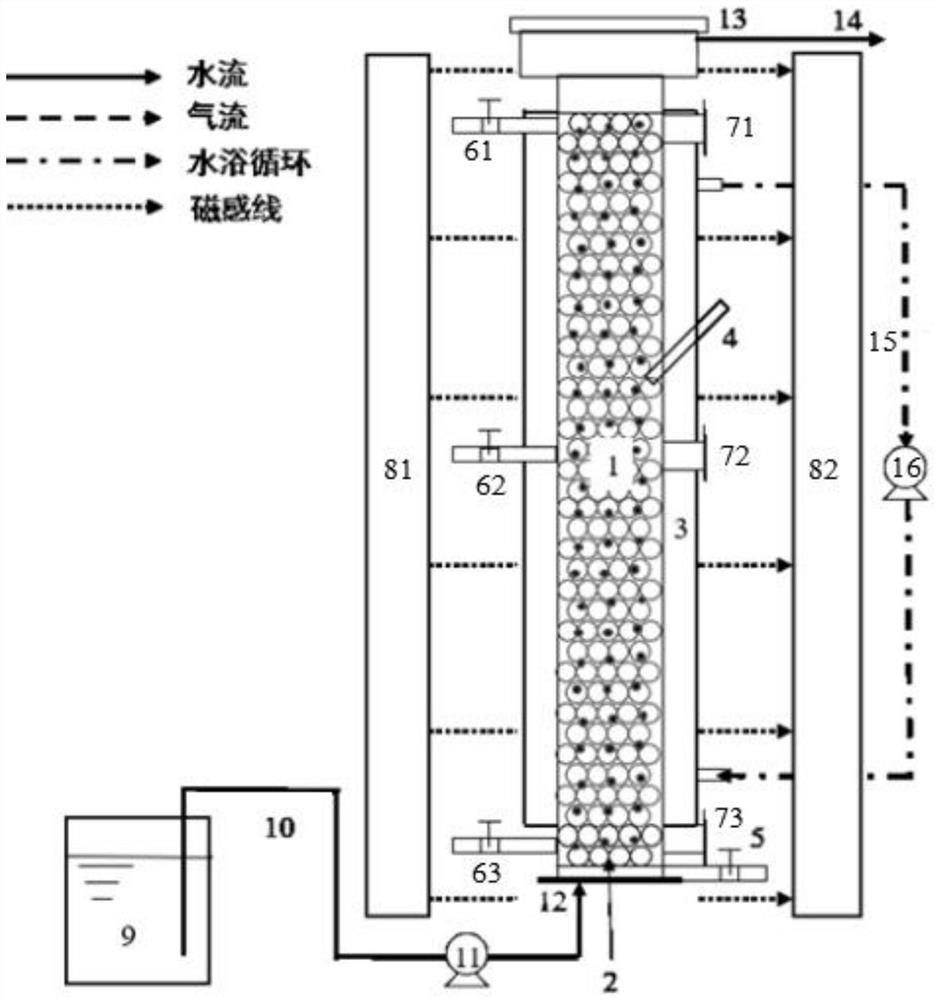

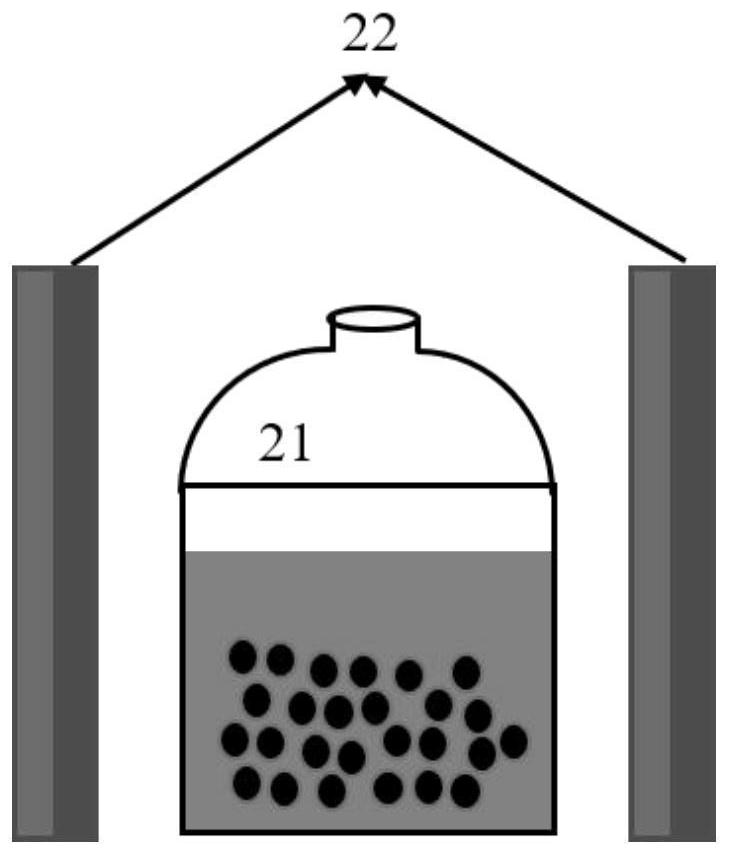

Method and device for removing nitrate nitrogen pollutants by intensifying iron-carbon micro-electrolysis through low-intensity magnetic field

InactiveCN113620413AIncrease the reflux ratioReduce corrosion potentialWater treatment parameter controlTreatment by combined electrochemical biological processesMicrobial inoculationMagnetic field gradient

The invention provides a method and a device for removing nitrate nitrogen pollutants by intensifying iron-carbon micro-electrolysis through a low-intensity magnetic field, and belongs to the technical field of denitrification. Under the action of a low-intensity magnetic field, microorganisms are inoculated on an iron-carbon carrier, nitrate-nitrogen-containing inlet water is introduced, iron-carbon micro-electrolysis corrosion hydrogen evolution and iron-carbon micro-electrolysis autotrophic denitrification are carried out, and nitrate-nitrogen-removed outlet water is obtained. Iron-carbon micro-electrolysis autotrophic denitrification is carried out under the condition of a low-intensity magnetic field, the activity of microorganisms and related enzymes can be improved, the corrosion potential of an iron-carbon carrier can be reduced, the iron-carbon micro-electrolysis corrosion hydrogen evolution rate is increased, the precipitation position and the precipitate attribute can be changed through the Lorentz force and the magnetic field gradient force effect, therefore, the formation of an iron-carbon carrier passivation film is relieved, and the nitrate nitrogen removal effect of microorganisms is effectively improved.

Owner:BEIJING JIAOTONG UNIV

LD type wet desulphurization special dust and water removal unit

InactiveCN111643973ASimple structureAvoid easy cloggingDispersed particle separationThermodynamicsRinse water

The invention discloses a special dust and water removal unit for LD-type wet desulphurization. The device is applied to a central outlet in the top of a desulfurizing tower. The device comprises a water stop and water collection ring, a shaping suction port, a flue gas transition flue, an inlet flange, an outer ring, an inner ring, a gas-water trapping tank, a flushing water pipeline, a tower return area return pipe and an outlet flange. The airflow is discharged from the outlet of the desulfurizing tower and enters the shaping suction port to undergo shaping. In the process, a mushroom-shaped inlet smoke constant-speed line is formed at the shaping suction port, smoke enters a flat rectangular S-shaped channel, the interior of the channel is divided into two layers or multiple layers ofoverlapped S-shaped channels through S-shaped partition plates, and each layer of channel is divided into a positive semicircle (210 degrees) and a negative semicircle (150 degrees). The device has the advantages of being simple in structure and not prone to being blocked, meanwhile, the device is compatible with an original folded plate demister, and it can be seen through the structure that thetreatment efficiency of pumping and concentrating wet airflow is obviously improved compared with pure liquid recovery.

Owner:中电国核(北京)节能环保科技有限公司

A method for optimizing operation of solvent dehydration system in aromatic acid production process

ActiveCN104513150BReduce energy consumptionReduce back flowOrganic compound preparationCarboxylic acid esters preparationRefluxOil phase

Owner:CHINA PETROLEUM & CHEM CORP +1

Jet Nozzles for Gentle Combustion Chambers of Gas Turbines

ActiveCN107990353BImprove mixing uniformityElevate the Flame RootsContinuous combustion chamberRefluxUltrasound attenuation

A jet nozzle of a mild combustion chamber of a gas turbine comprises a fuel inside nozzle, a fuel outside spray hole, multiple rotational flow groove channels, an outside pipeline and an inside pipeline. The mixing uniformity of fuel and air at a jet nozzle outlet is improved, the outside fuel-air equivalence ratio is relatively low, flame root lifting is facilitated, too-early ignition does not occur easily, jets of the jet nozzle belong to weak rotational flows, the overall pressure loss is relatively low, the axial speed is not prone to attenuation, and increase of the smoke reflux ratio ofthe combustion chamber is facilitated.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

A method for continuously separating high-purity longifolene from heavy turpentine

ActiveCN104130096BRealize continuous operationIncrease the reflux ratioDistillation purification/separationAdsorption purification/separationDistillationLongifolene

The invention discloses a method for continuously separating high-purity longifolene from heavy turpentine. The steps of activated clay decoloration and thermal pretreatment are performed on raw materials, and discharging is performed through the pressure different between a tower kettle and a residual liquid tank under the condition of not cooling a rectifying tower or breaking the vacuum, so that energy is saved, and continuous operation of intermittent distillation is realized. The longifolene content of a longifolene product obtained by using the method is greater than 75 percent, and can be up to 95 percent in maximum.

Owner:GUANGXI FORESTRY RES INST

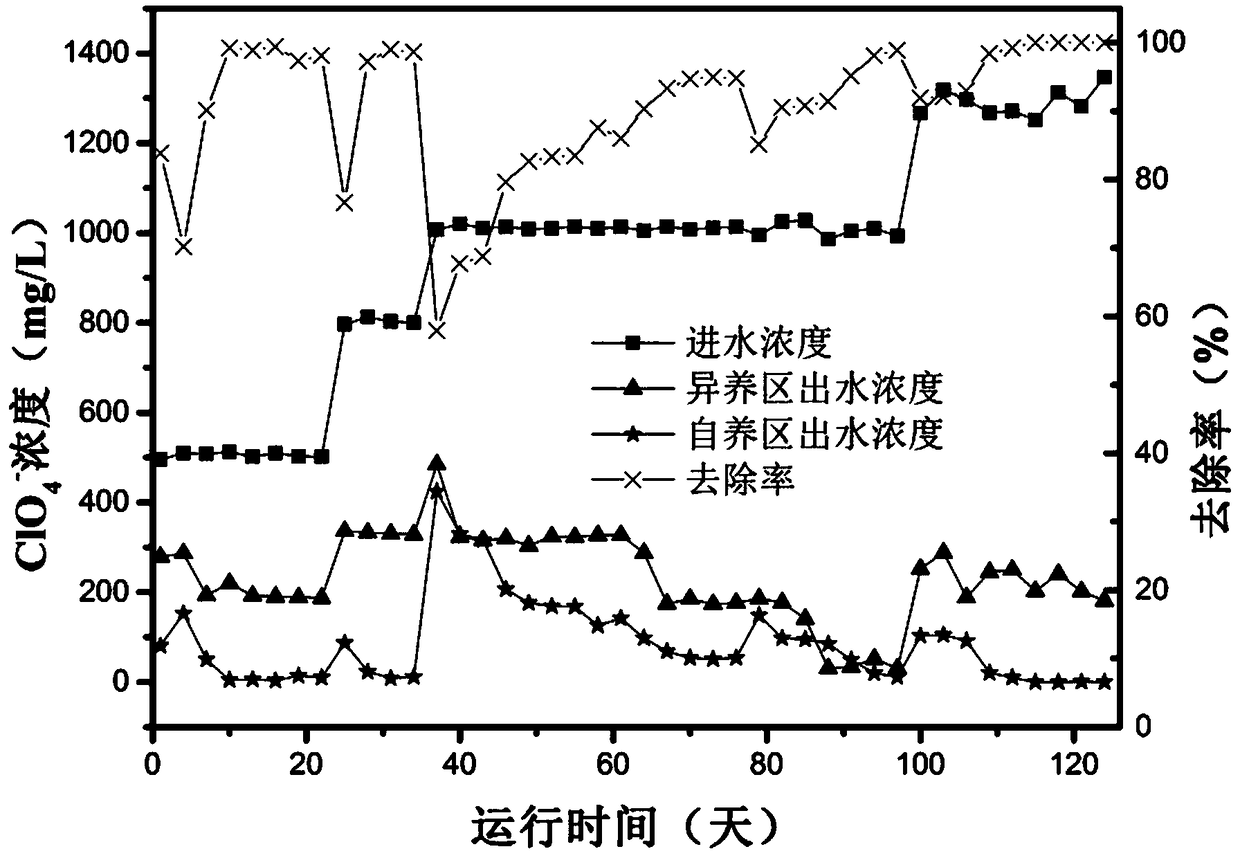

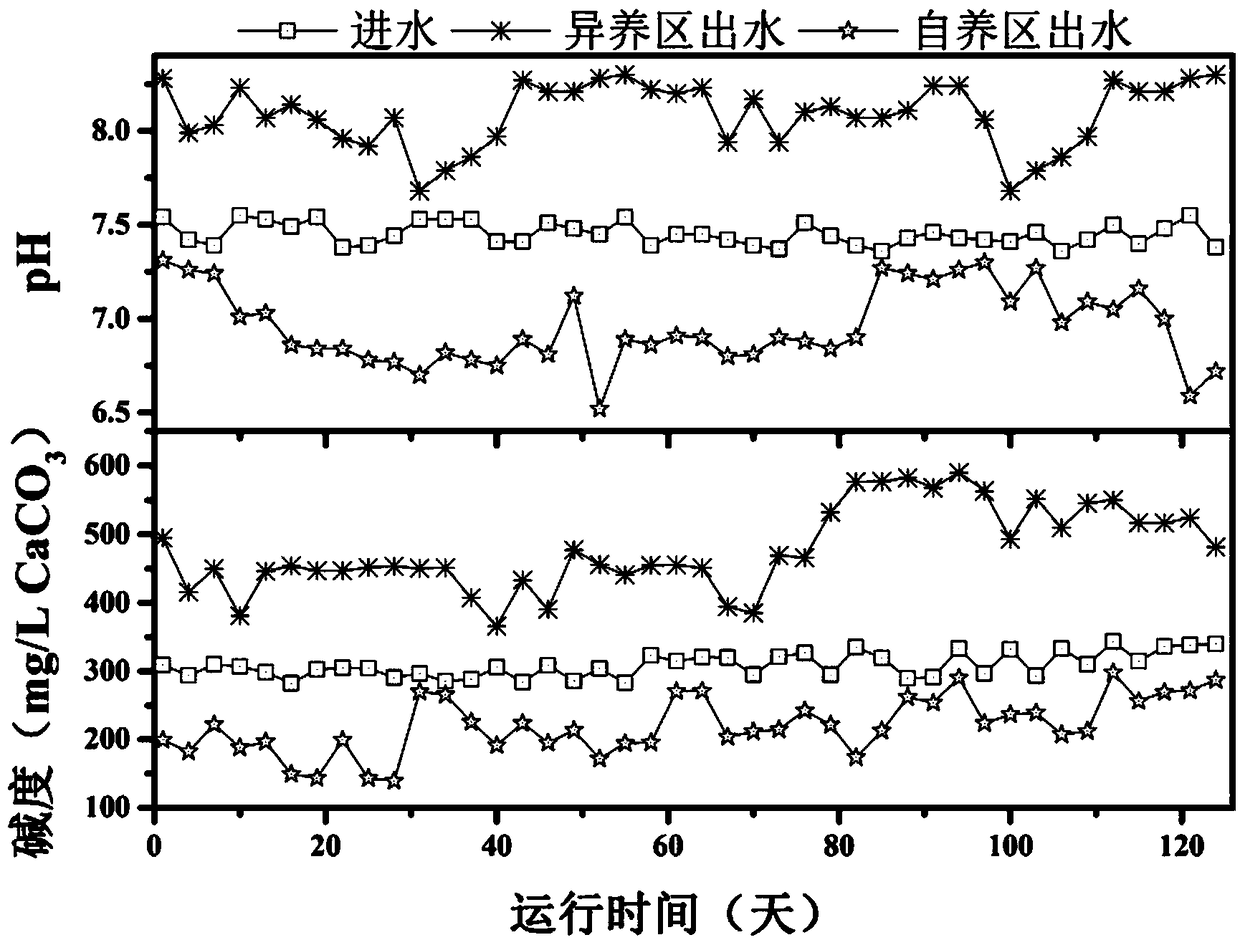

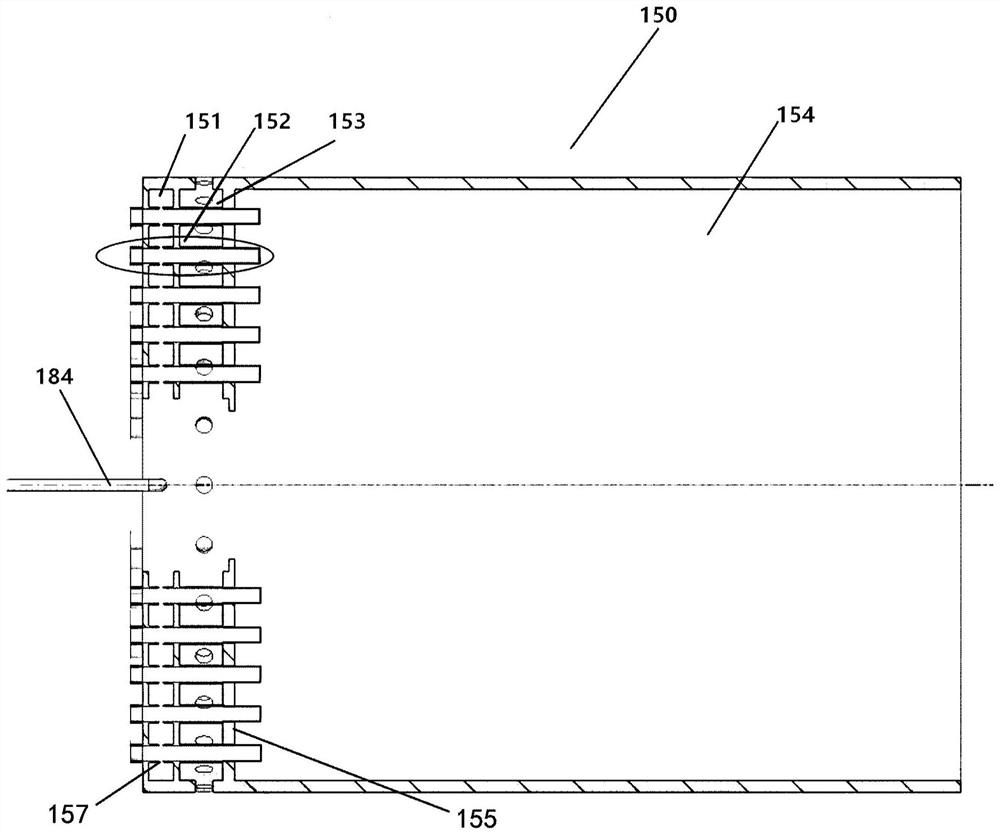

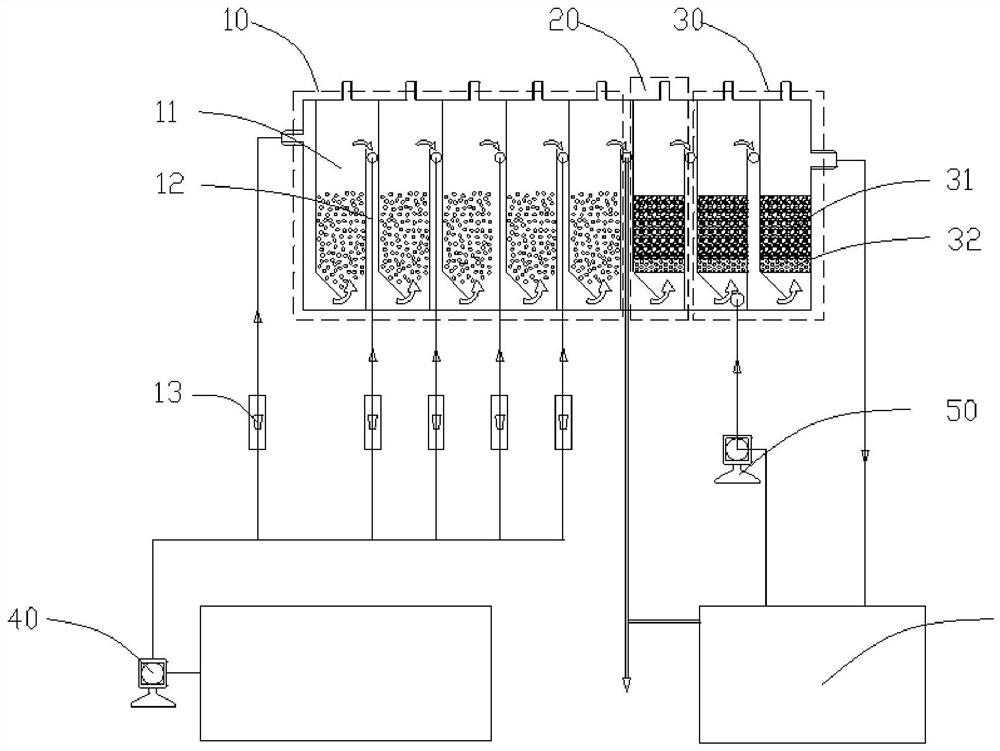

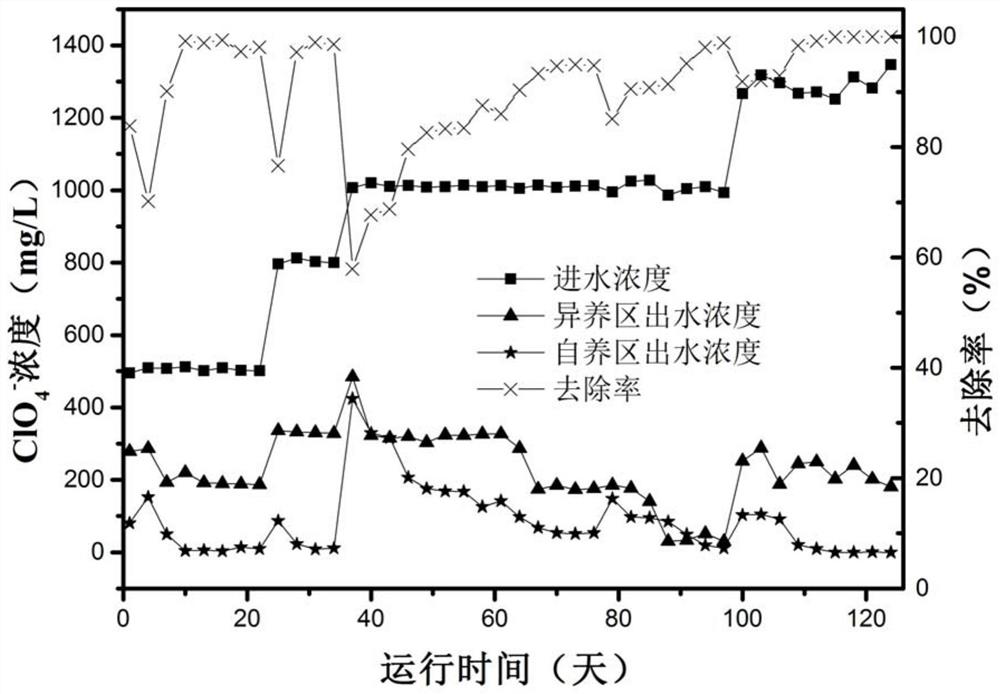

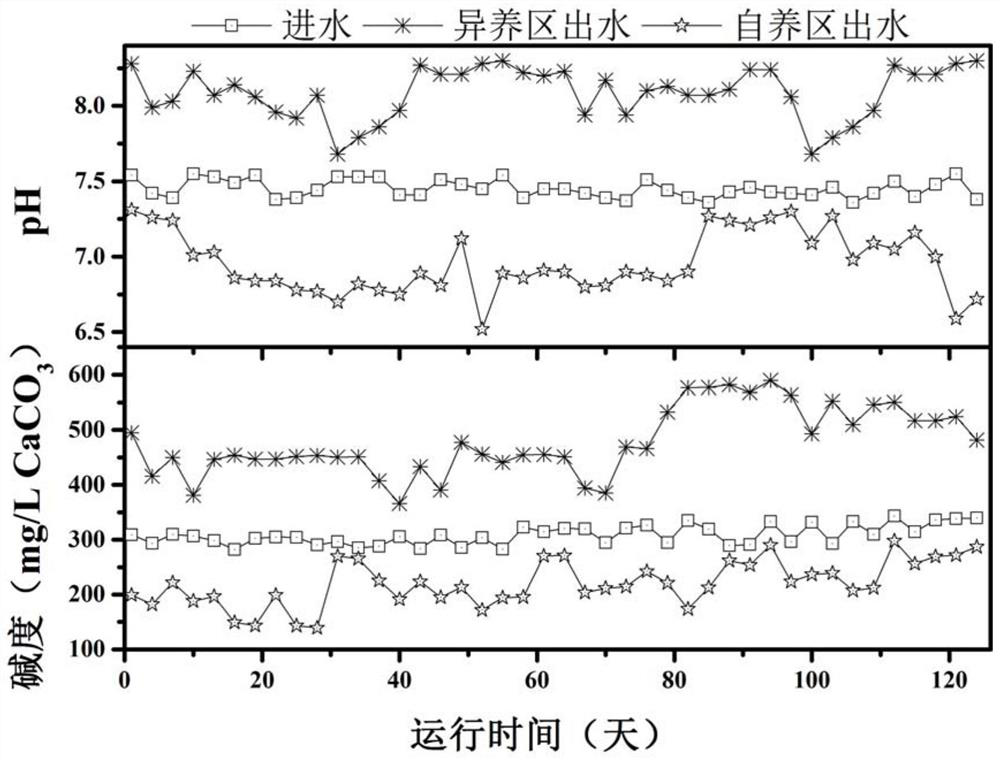

ABR (anaerobic baffled reactor) system and regulation and control method to degrade high-concentration perchlorate wastewater

ActiveCN109133339AEfficient removalEasy loadingWater treatment parameter controlWater contaminantsHigh concentrationSulfur

The invention discloses an ABR (anaerobic baffled reactor) system to degrade high-concentration perchlorate wastewater, comprising: a reactor; and a plurality of baffles vertically arranged in the reactor. The baffles divide the reactor into multiple serial cells; each cell includes a lower flow chamber and an upper flow chamber; the cells are divided into a heterotrophic zone and an autotrophic zone along a flow propelling direction; the upper flow chambers of the heterotrophic zone are each filled with a sludge bed, the lower flow chambers are each provided with an inflow pipe, and a segmented inflow structure is formed; the upper flow chambers of the autotrophic zone are each filled with sulfur particles and quartz sand to form a double-layer filler. The ABR system herein has significant advantage in the treatment of perchlorate wastewater with inharmonious carbon-chlorine ratio.

Owner:TIANJIN CHENGJIAN UNIV

gas turbine soft combustor

ActiveCN110631049BMixed stronglyIncrease the reflux ratioContinuous combustion chamberCombustorCombustion chamber

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

ABR system and control method for degrading high-concentration perchlorate wastewater

ActiveCN109133339BEfficient removalEasy loadingWater treatment parameter controlWater contaminantsPerchlorateSludge

The invention discloses an ABR system for degrading high-concentration perchlorate wastewater, comprising: a reactor; The reactor is divided into a plurality of cells connected in series, and each cell includes a downflow chamber and an upflow chamber; a plurality of the cells are divided into a heterotrophic zone and an autotrophic zone along the direction of water flow; the upflow chamber of the heterotrophic zone Sludge beds are filled respectively, and water inlet pipes are respectively arranged in the downstream chambers to form a segmented water inlet structure; the upstream chambers of the autotrophic zone are respectively filled with double-layer fillers formed by sulfur particles and quartz sand. The ABR system of this application has obvious advantages in the treatment of perchlorate wastewater with uncoordinated carbon-to-chlorine ratio.

Owner:TIANJIN CHENGJIAN UNIV

Dust and water removal unit special for LD type wet desulphurization

PendingCN113856334AIncrease the reflux ratioSimple device structureCombination devicesFlueActivated carbon

The invention belongs to the technical field of design environmental protection, and particularly relates to a dust and water removal unit special for LD type wet desulphurization, and the following scheme is provided: the dust and water removal unit comprises a water stopping and collecting ring, the inner wall of the water stopping and collecting ring is fixedly connected with a shaping suction port, the outer wall of the shaping suction port is fixedly connected with a connecting ring, and the inner wall of the connecting ring is fixedly connected with an inlet flange; an inlet flue gas constant-speed line is arranged on the inner wall of the water stopping and collecting ring, a flue gas transition flue is arranged on the inner wall of the inlet flange, an outer ring is installed on the inner wall of the flue gas transition flue, and an inner ring is arranged in the outer ring. By arranging the flue gas transition flue, the treatment frame, the flow guide cover and the bent activated carbon adsorption plates, after flue gas enters the flue gas transition flue, the flue gas enters the treatment frame through the flow guide cover, and under the sealing and guiding action of the sealing plate, the flue gas can only pass through all the bent activated carbon adsorption plates; and the bent activated carbon adsorption plate prolongs the time that the flue gas is located in the treatment frame, and the flue gas adsorption treatment effect is improved.

Owner:中电国核(北京)节能环保科技有限公司

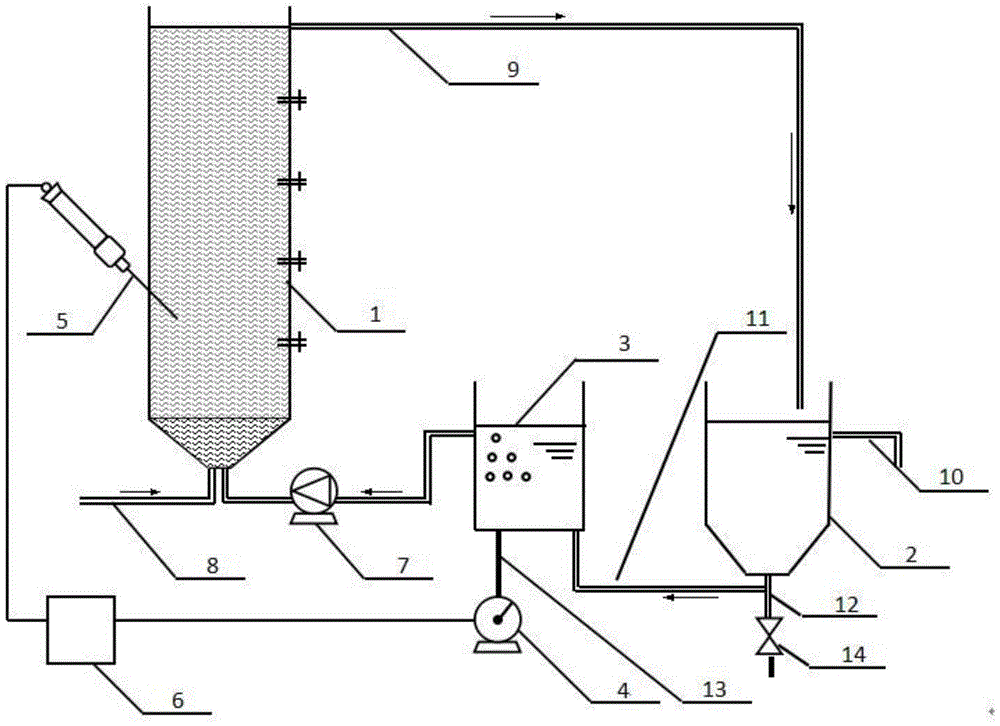

Method for treating pig-raising wastewater by using a micro-aerobic biological treatment device for dry-cleaning pig farm wastewater with low c/n ratio

InactiveCN104591409BCost-effective removalReduce aerationWater contaminantsWaste water treatment from animal husbandryPig farmsAnaerobic respiration

The invention relates to a micro-aerobic biological treatment device for low-C / N-ratio manure dry-collection pig farm wastewater and a method for treating pig farm wastewater, belongs to the technical field of sewage treatment and particularly relates to the micro-aerobic biological treatment device for low-C / N-ratio manure dry-collection pig farm wastewater and a method for treating pig farm wastewater. The micro-aerobic biological treatment device is used for solving the problems of complex process, large investment in infrastructure, high energy consumption and high operating cost since the low-C / N-ratio wastewater treatment technology is not perfect in the prior art. The device comprises a micro-aerobic reactor, a sedimentation tank, a muddy water dissolved oxygen tank, a blower, a dissolved oxygen sensor, an air flow control instrument, a sludge return pump, a micro-aerobic reactor water inlet pipe, a micro-aerobic reactor water outlet pipe, a sedimentation tank water outlet pipe, a sludge return pipe, a residual sludge discharge pipe, an aeration pipe and valves. The method comprises the following step of carrying out micro-aerobic treatment on wastewater through the micro-aerobic reactor so that anaerobic respiration, aerobic respiration, nitrification and denitrification coexist in the treatment system to remove pollutants. The micro-aerobic biological treatment device is used for treating pig farm wastewater.

Owner:HARBIN INST OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com