External cooling type low pure oxygen air separation system and method

An air separation system and low-purity oxygen technology, which is applied in the field of air separation, can solve the problems of complex equipment settings and high energy consumption, and achieve the effects of saving energy, promoting energy saving of the system, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

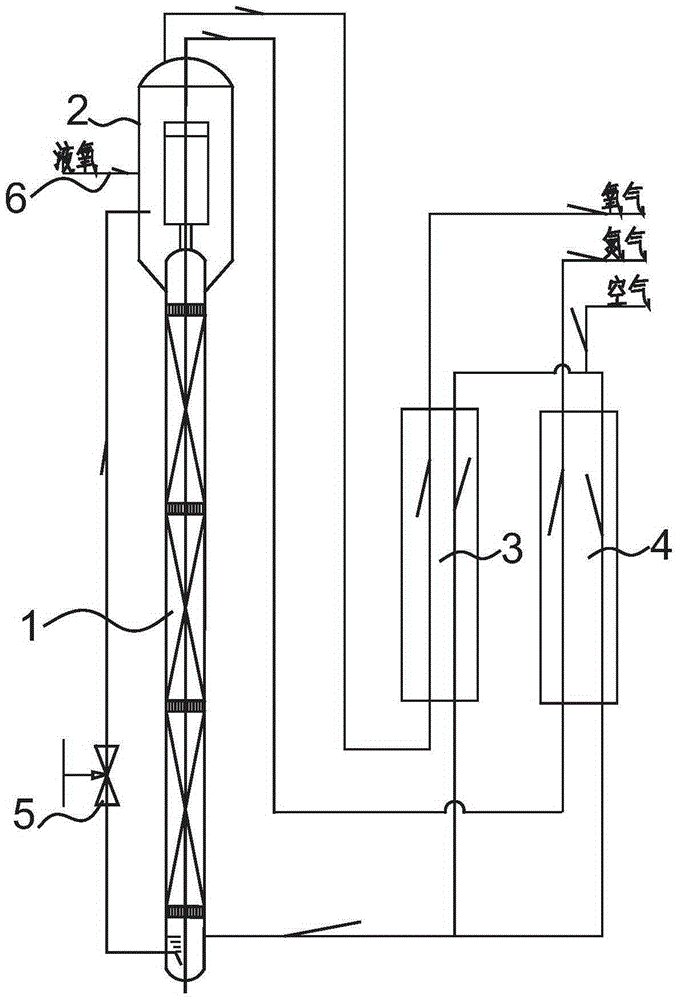

[0027] The embodiment of the external cooling type low-purity oxygen air separation system and method of the present invention will be described with reference to the accompanying drawings.

[0028] figure 1 It is a diagram of the external cooling low-purity oxygen air separation system of this embodiment.

[0029] Such as figure 1 As shown, the air at normal temperature enters the bottom of the lower tower 11 after being pre-cooled to the saturation temperature through the oxygen heat exchanger 3 and the nitrogen heat exchanger 4 respectively. Because the boiling point of nitrogen is lower than the boiling point of oxygen under the same pressure, the liquid nitrogen in the lower tower 1 is converted into nitrogen and the inherent nitrogen in the gas-liquid equilibrium phase rises along the inside of the lower tower 11 to the condensing evaporator 2 at the top of the lower tower 1 .

[0030] Before starting the machine, liquid oxygen can be filled into the condensing evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com