Patents

Literature

168results about How to "Large cooling capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air conditioner with control of compressor

ActiveUS6955060B2Increase capacityLarge cooling capacityAir-treating devicesCompression machines with non-reversible cycleRotation velocityEngineering

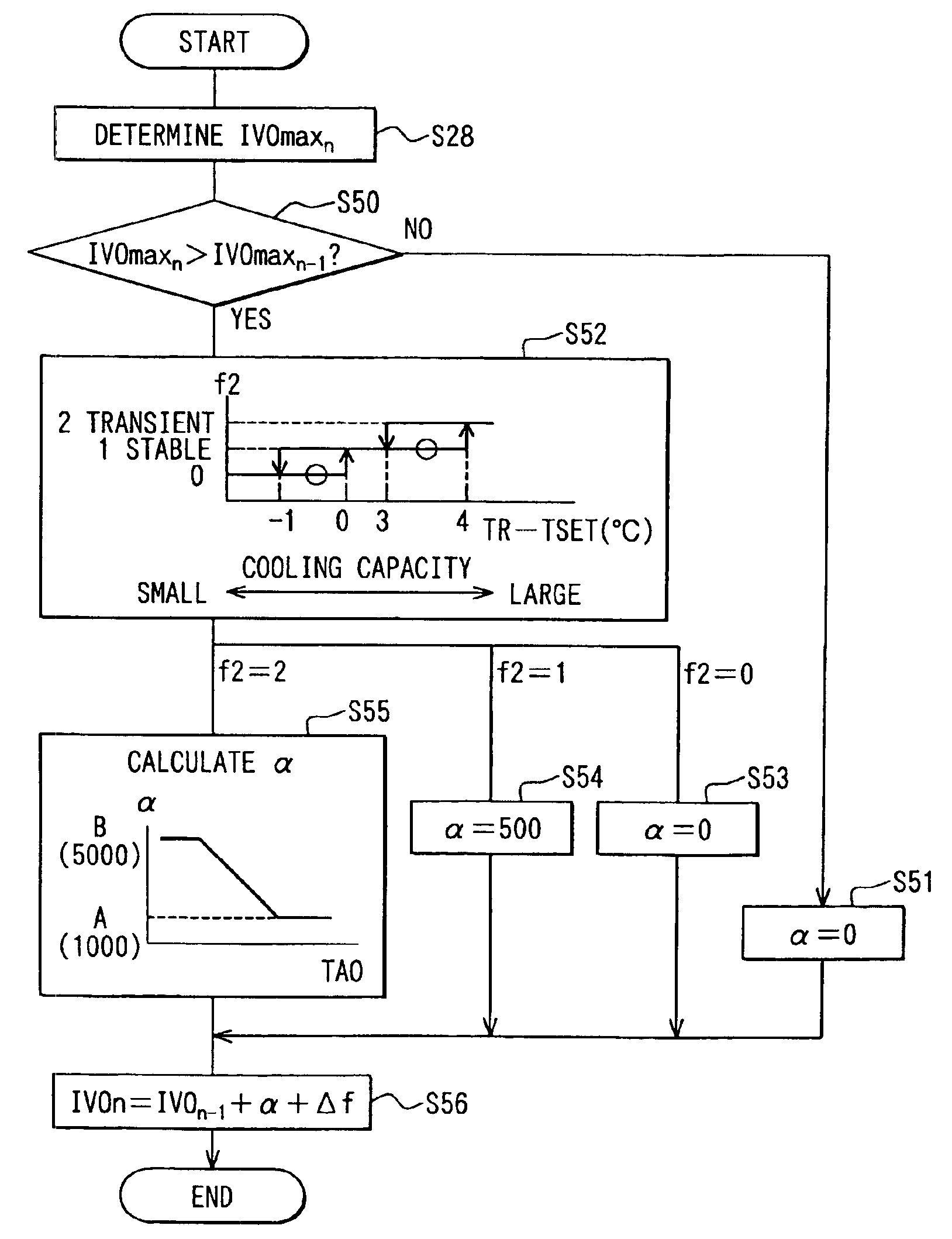

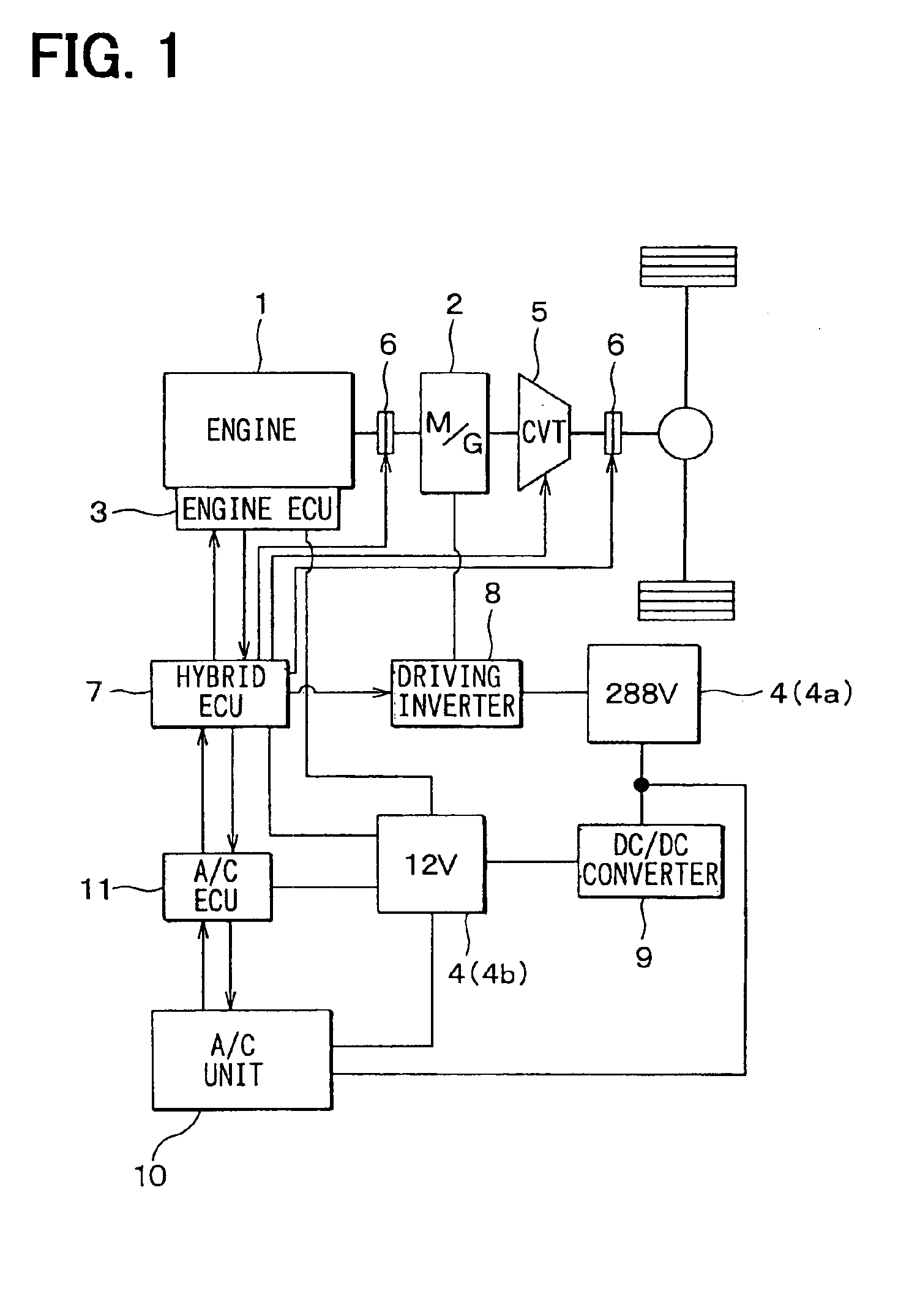

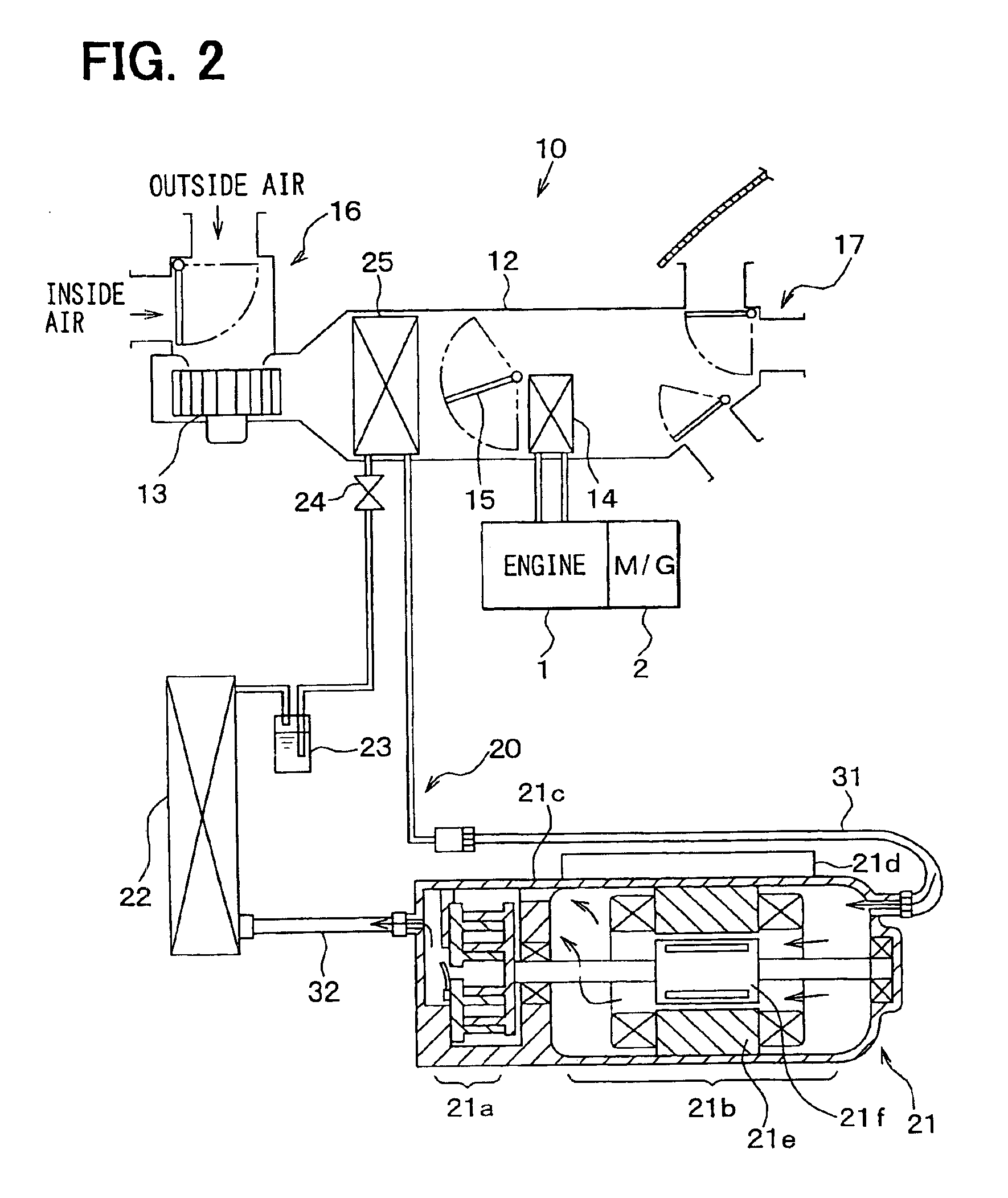

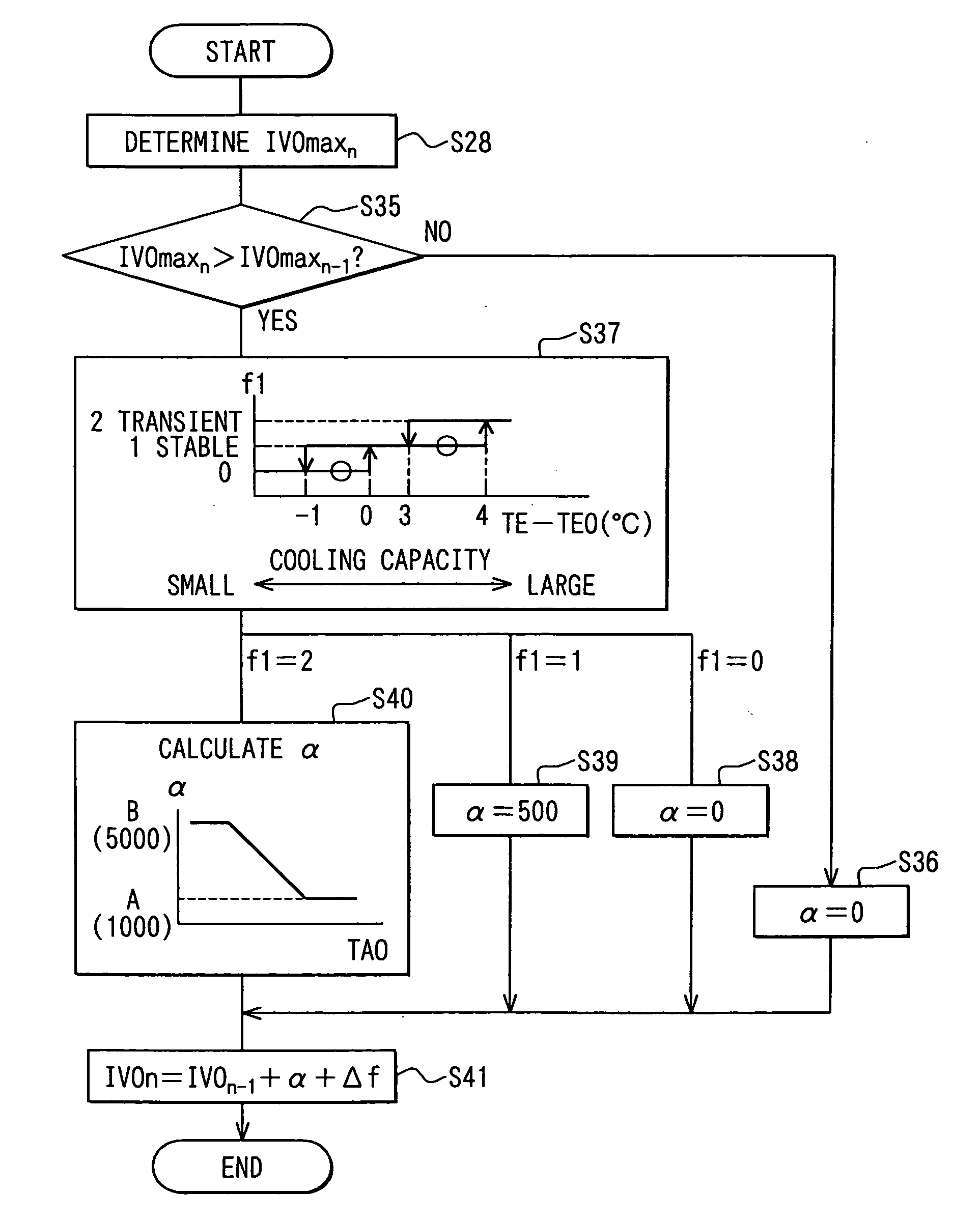

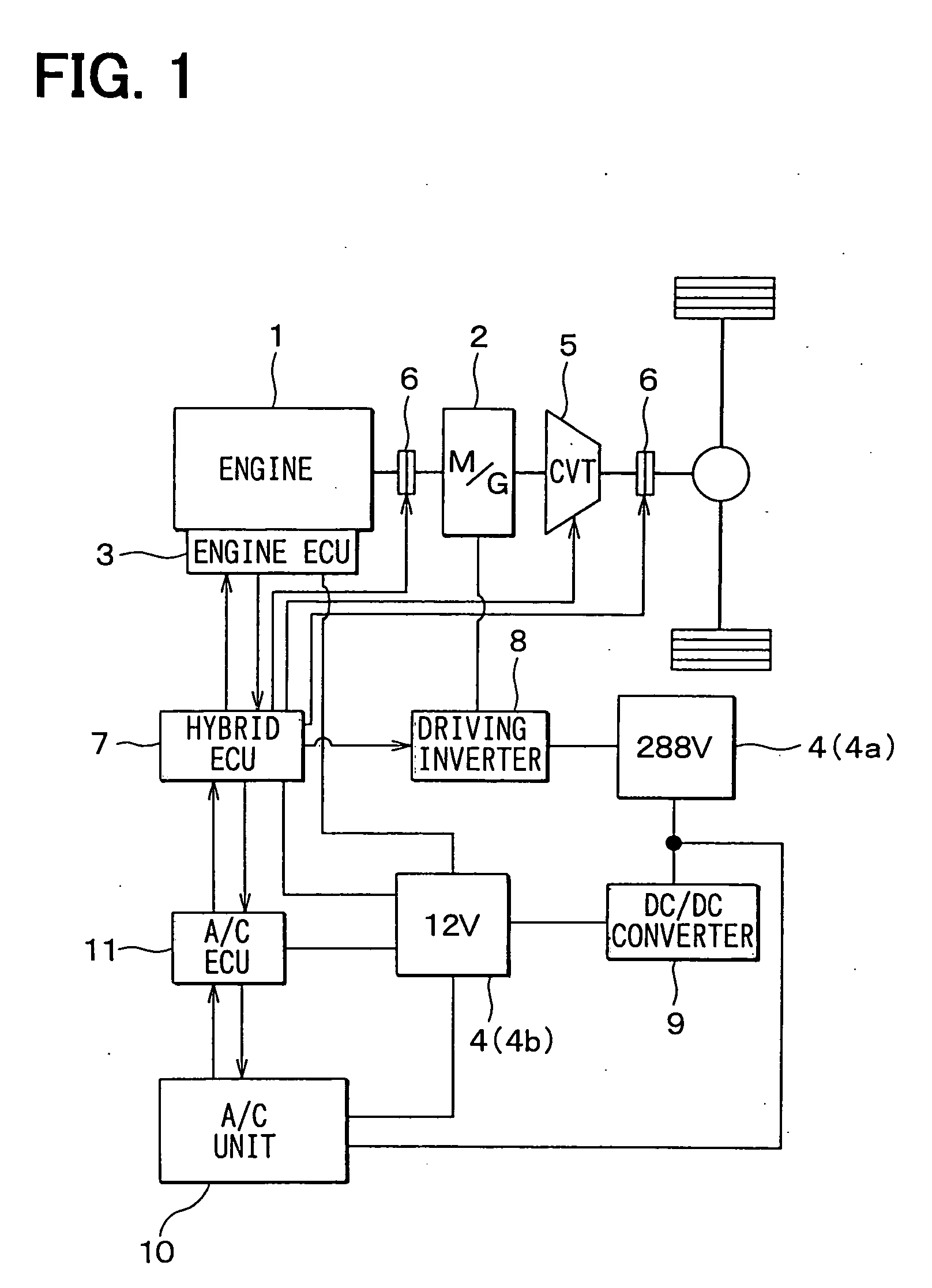

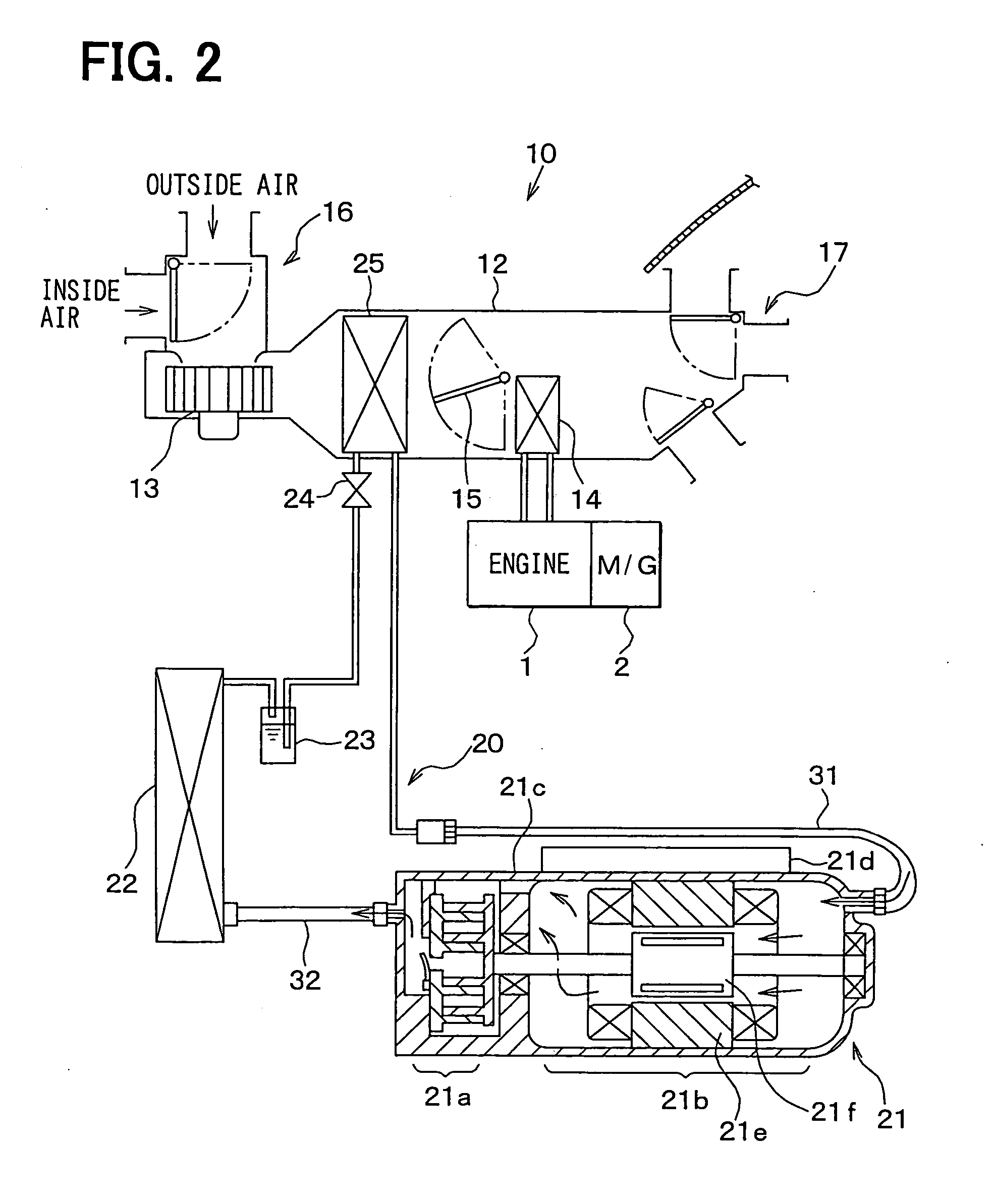

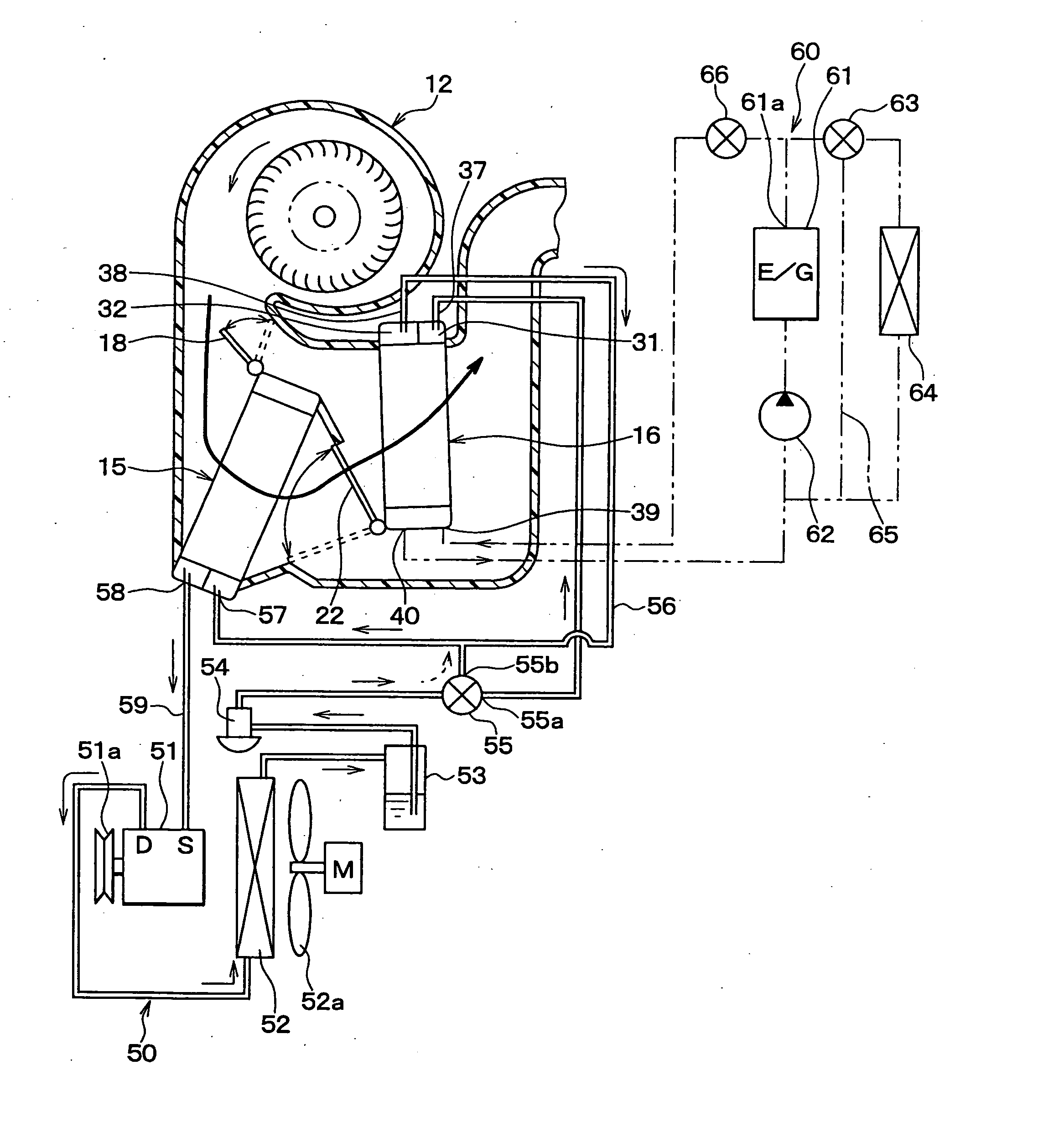

In an air conditioner, a target compressor rotation speed is determined based on a target air temperature, which represents an air conditioning load, when an electric compressor is started from a stop state. Thus, an evaporator air temperature can be approximated to a target evaporator air temperature, more quickly as compared with a control method where an incremental rotation speed is added to a present rotation speed of the electric compressor, that is, 0 rpm. Accordingly, a large cooling capacity can be obtained for a short time period. Thus, an air temperature in a compartment can be quickly reduced to a comfortable temperature, when the air conditioner is started, for example.

Owner:DENSO CORP

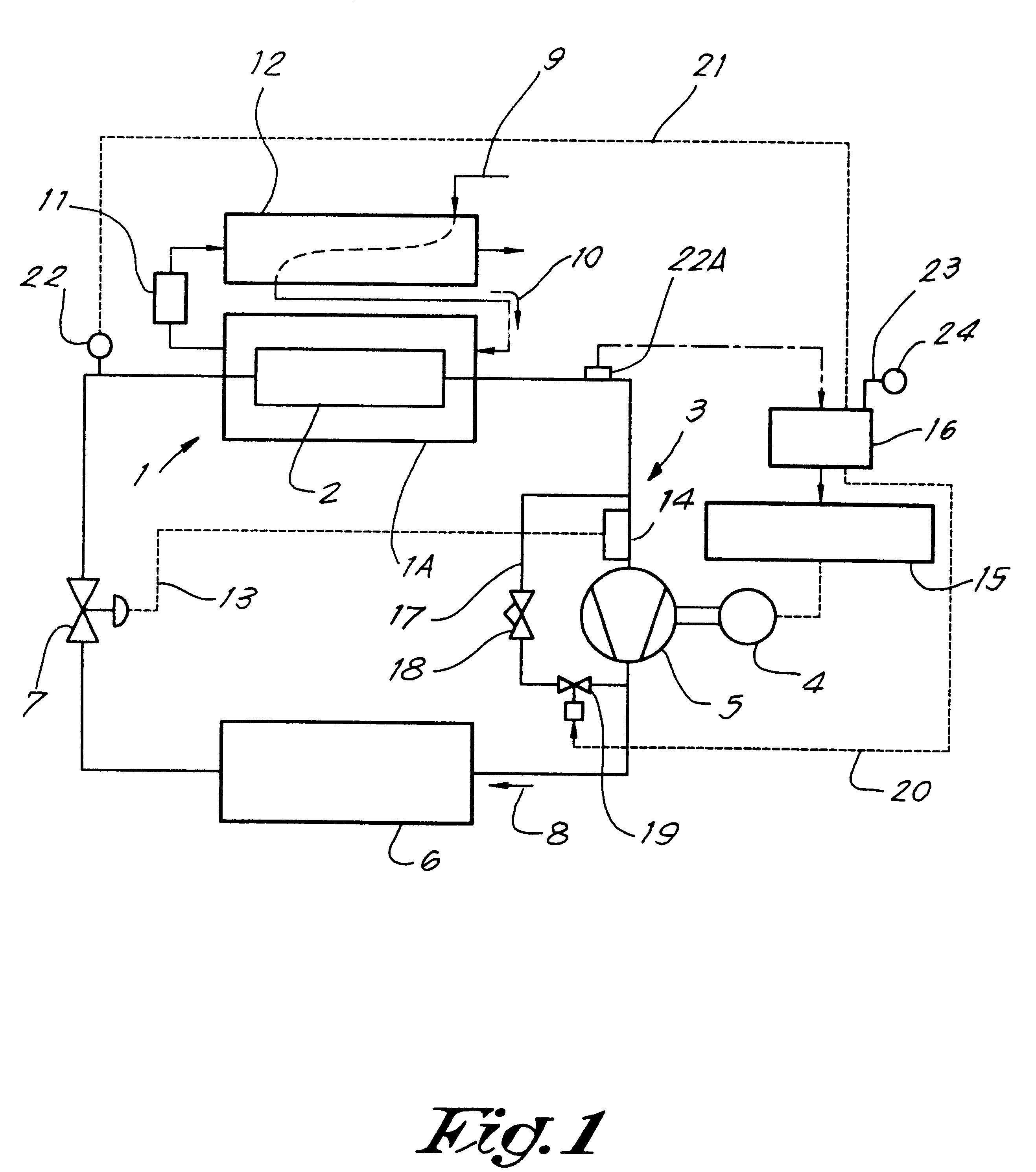

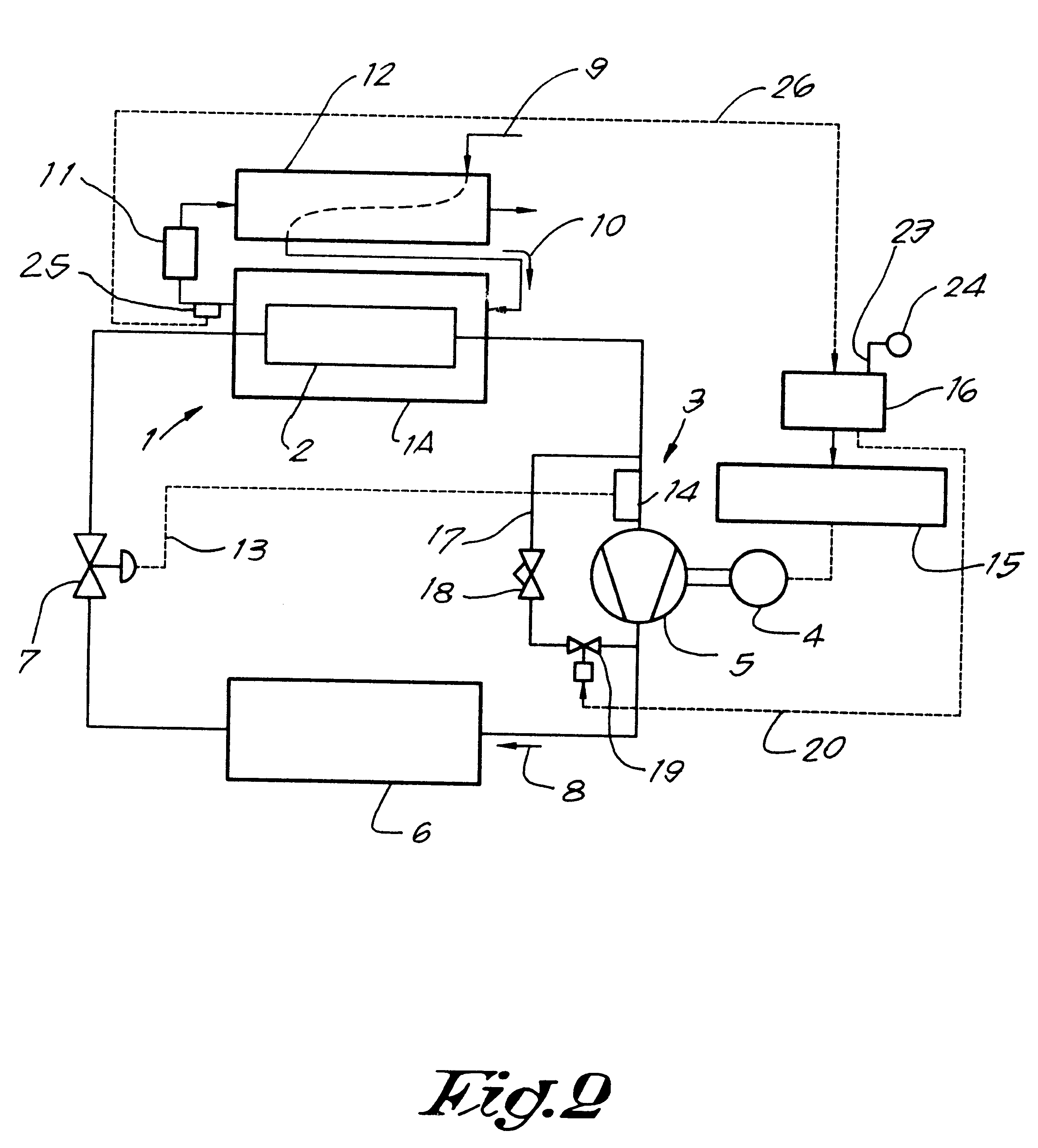

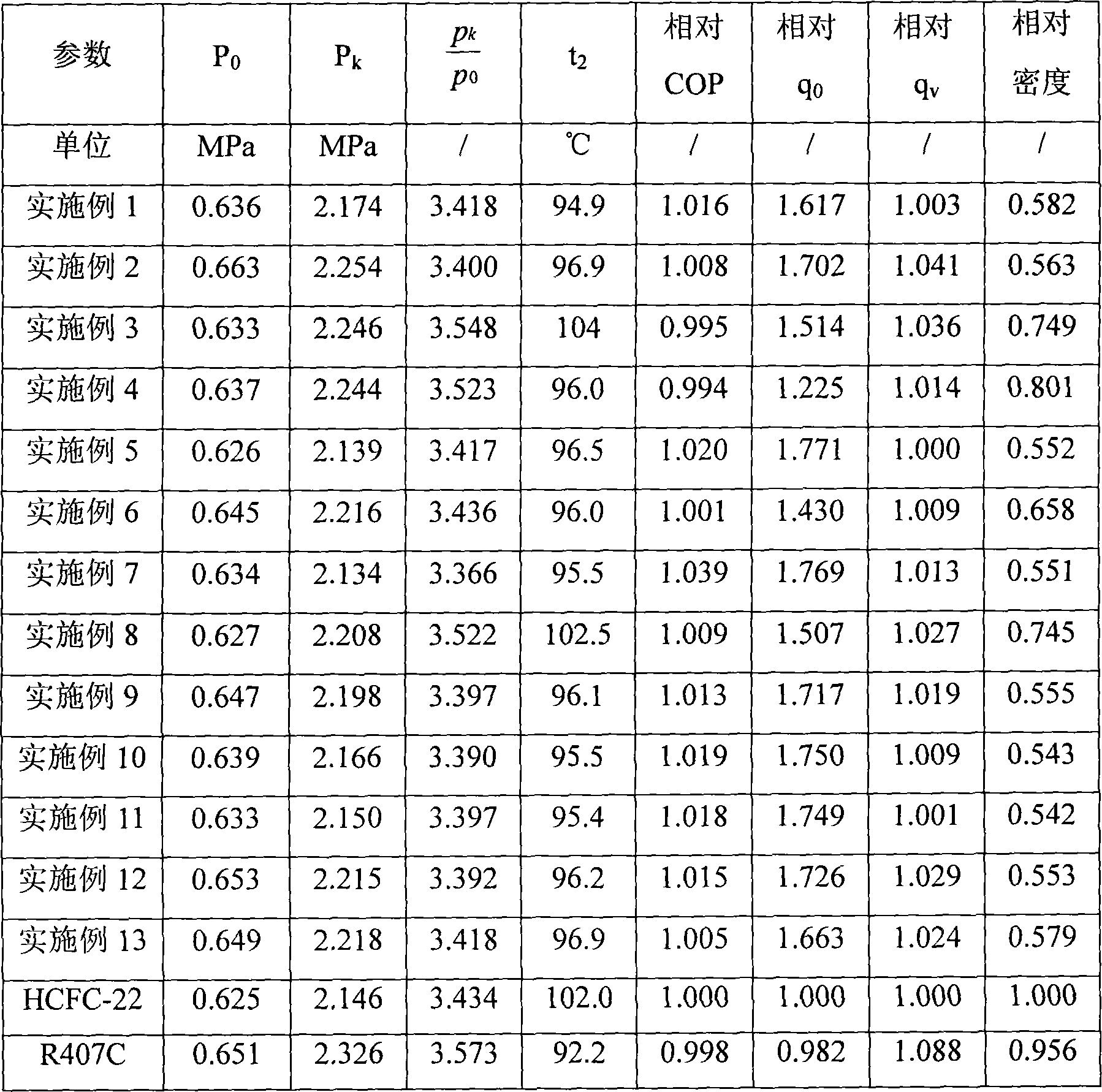

Device and method for performing a dehumidifying operation

InactiveUS6393850B1Large massLarge cooling capacityCompression machines with non-reversible cycleDispersed particle separationEngineeringHeat exchanger

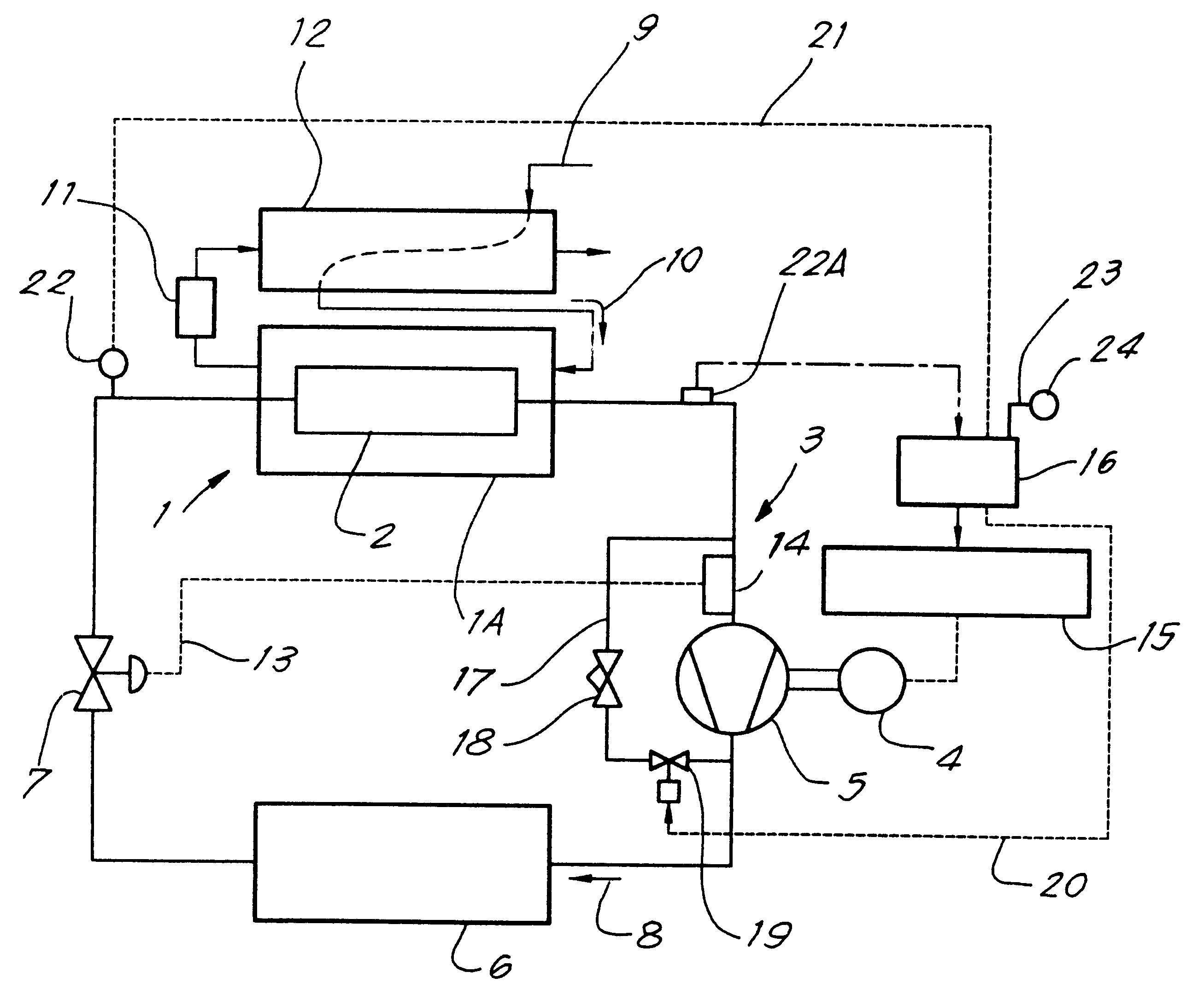

The invention relates to a device for cool-drying, comprising a heat exchanger (1), the primary part of which is the evaporator (2) of a cooling circuit (3) which further comprises a compressor (5) driven by an electric motor (4) being bridged-over by means of a bypass (17) with therein a bypass-closing element (18) and an open / closed closing element (19). The secondary part (1A) of the heat exchanger (1) forms part of a conduit (9) for the gas and, at the outlet of this heat exchanger (1), a liquid separator (11) is disposed. The device comprises means (15) for regulating the speed of the motor (4), which means are controlled by means of a control device (16) in function of the value measured by the measuring means (22, 22A).

Owner:ATLAS COPCO AIRPOWER NV

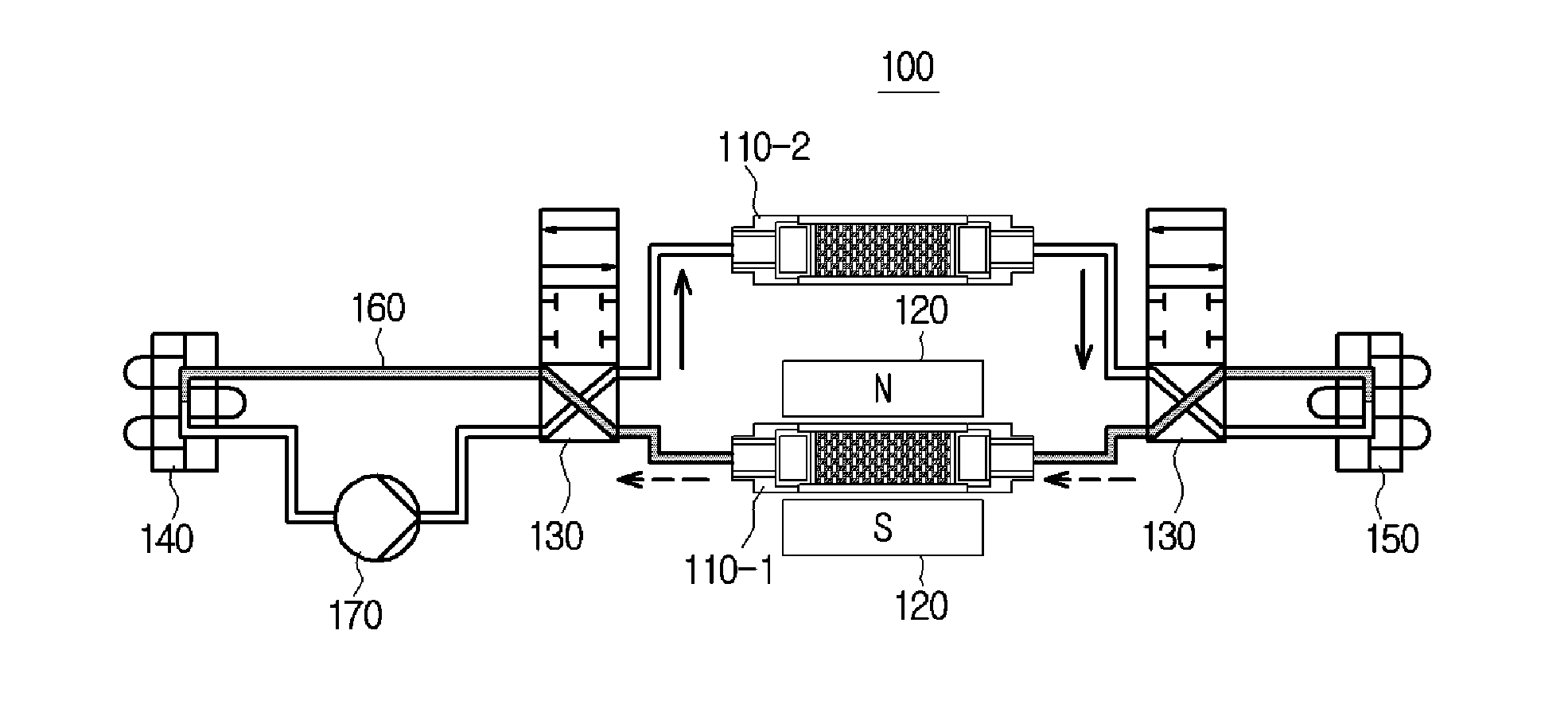

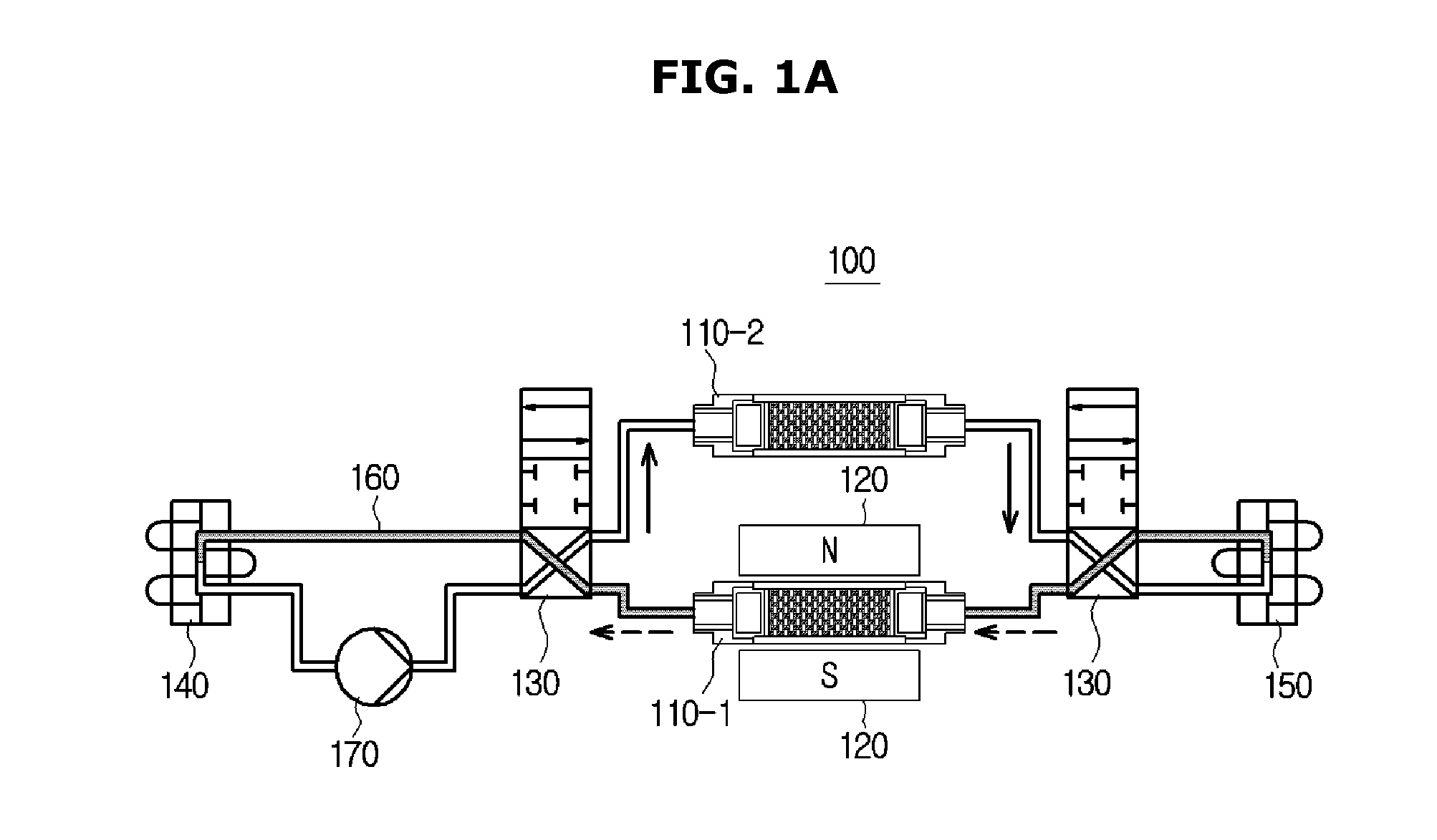

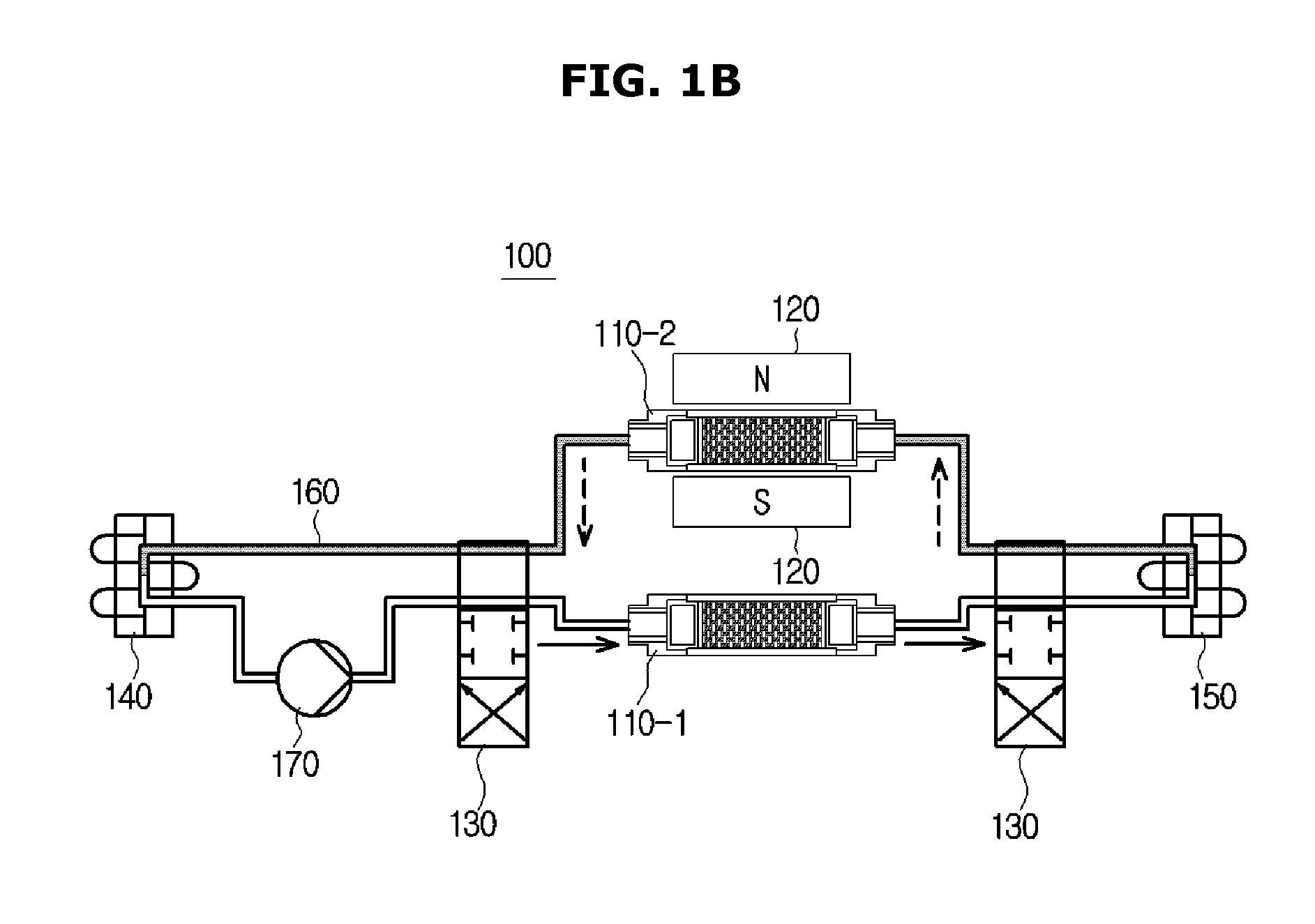

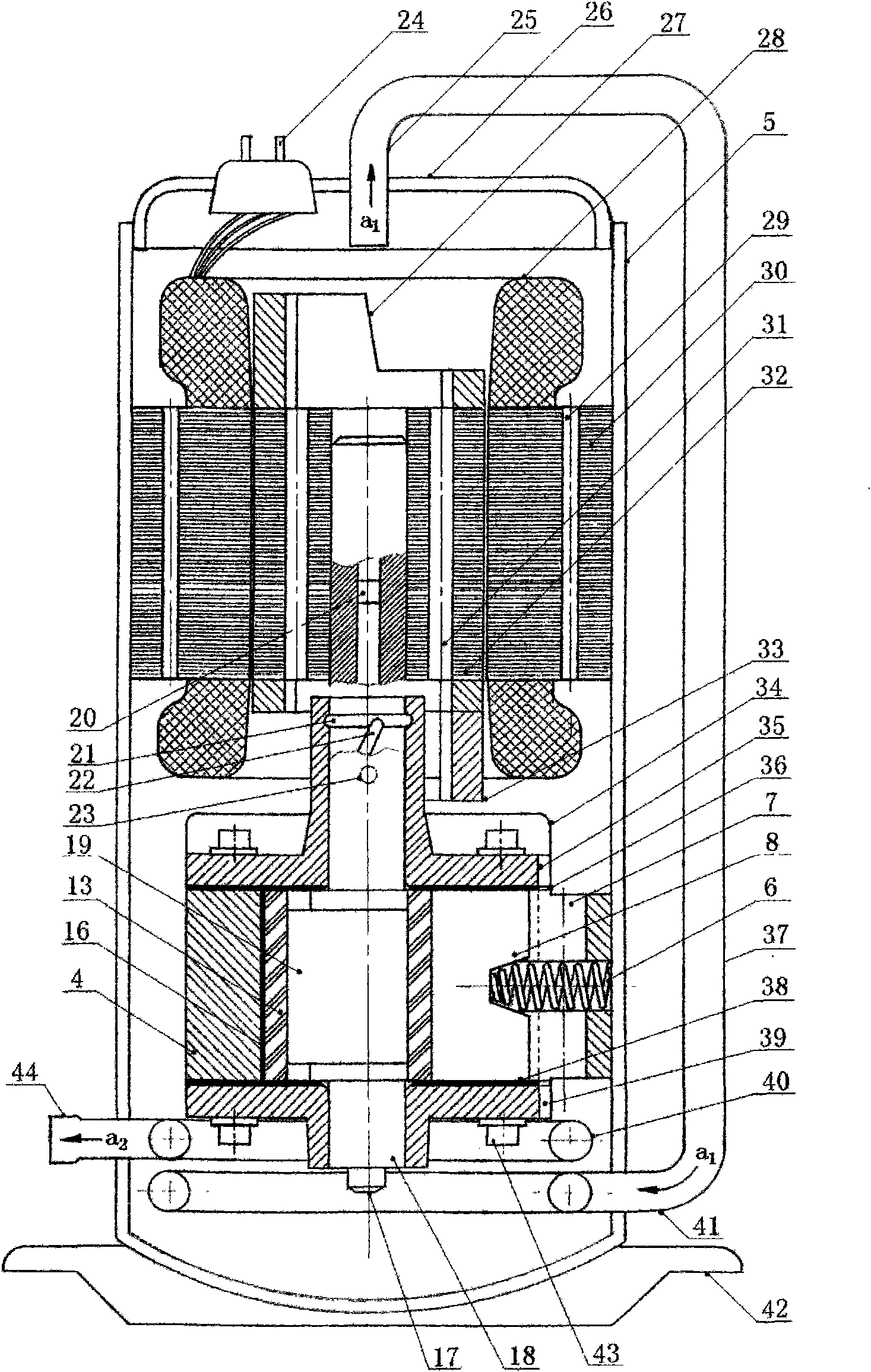

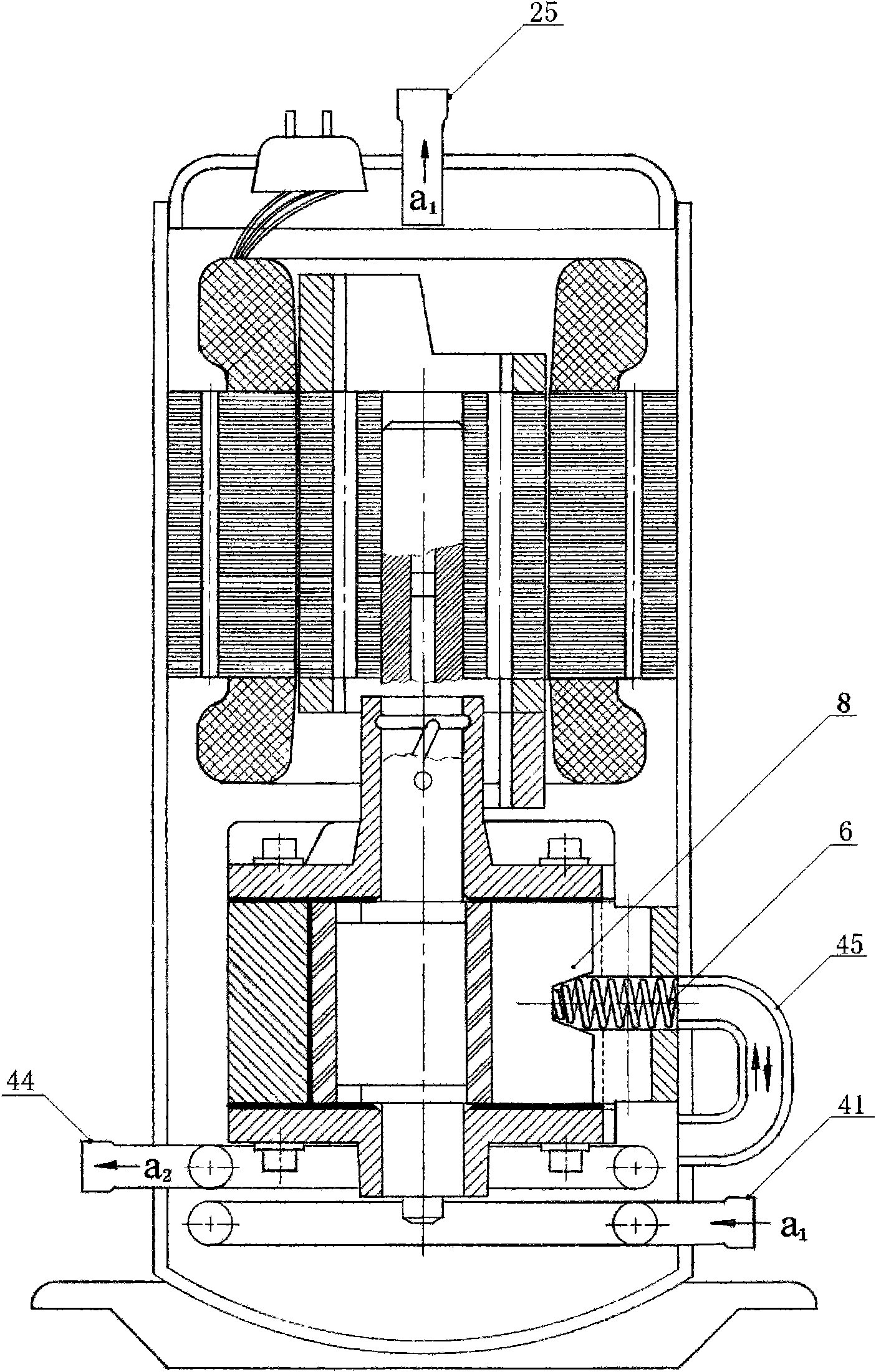

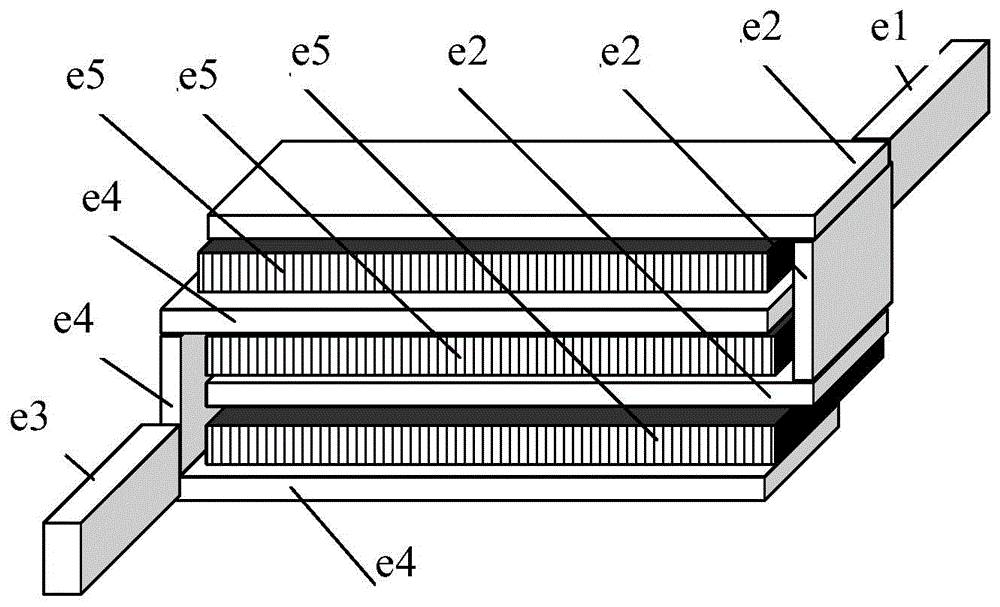

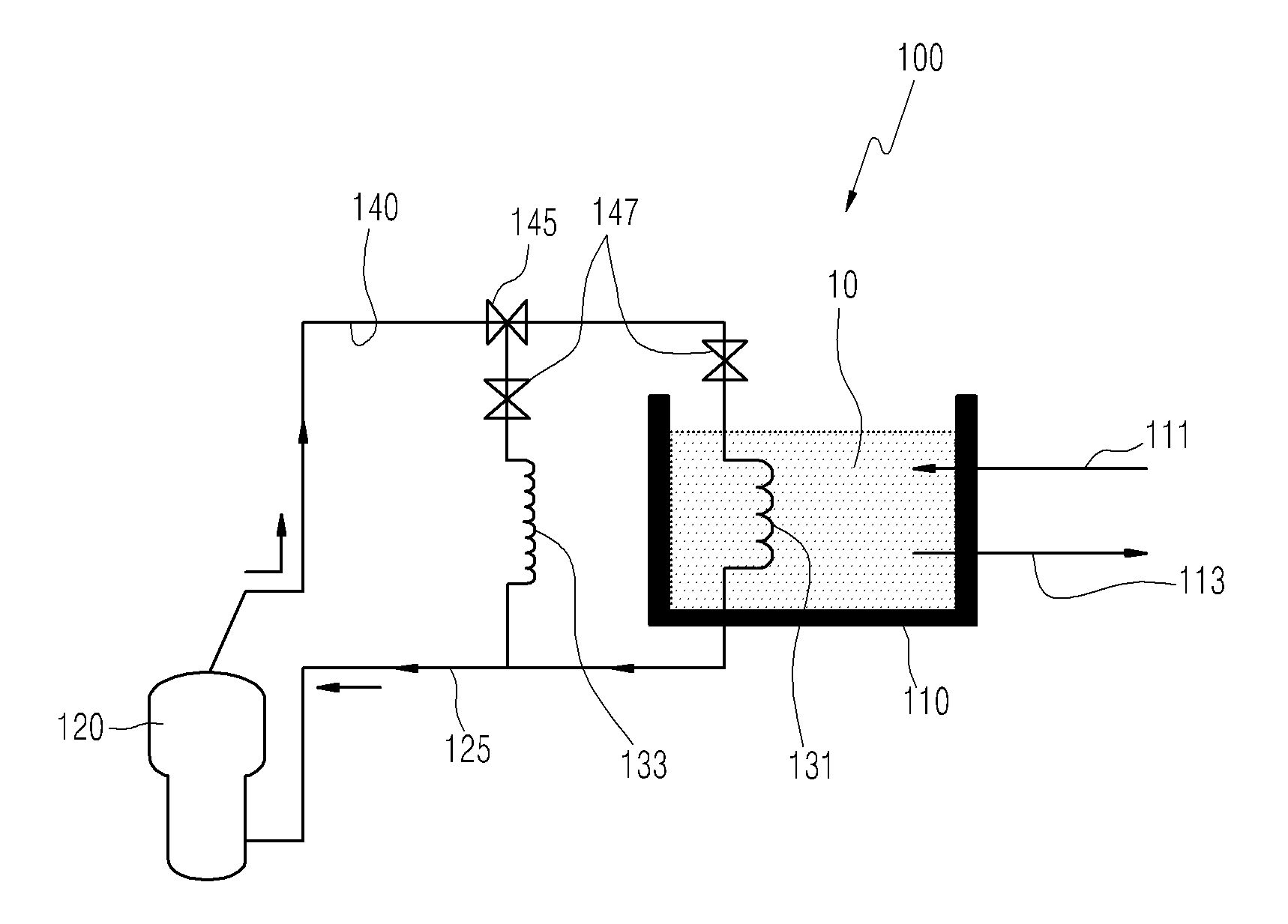

Magnetic regenerator unit and magnetic cooling system with the same

ActiveUS20150267943A1Large cooling capacityHigh efficiencyMagnetic materialsMachines using electric/magnetic effectsHeat transfer fluidEngineering

A terminal may be provided with a magnetic regenerator unit using a magnetocaloric effect of magnetocaloric materials and a magnetic cooling system having the same. By a circular magnetic regenerator structure capable of evenly flowing heat transfer fluid and magnetic field and the flow of the heat transfer fluid being changed in the same way, and a magnetic band having a relative permeability, similar to a relative permeability of the magnetic regenerator, high efficiency of a flux generator may be obtained while reducing torque of a rotator. Power consumption for driving may be reduced due to the reduction of the cogging torque, and the magnetic band may be manufactured at a low cost by using inexpensive iron powder.

Owner:SAMSUNG ELECTRONICS CO LTD +1

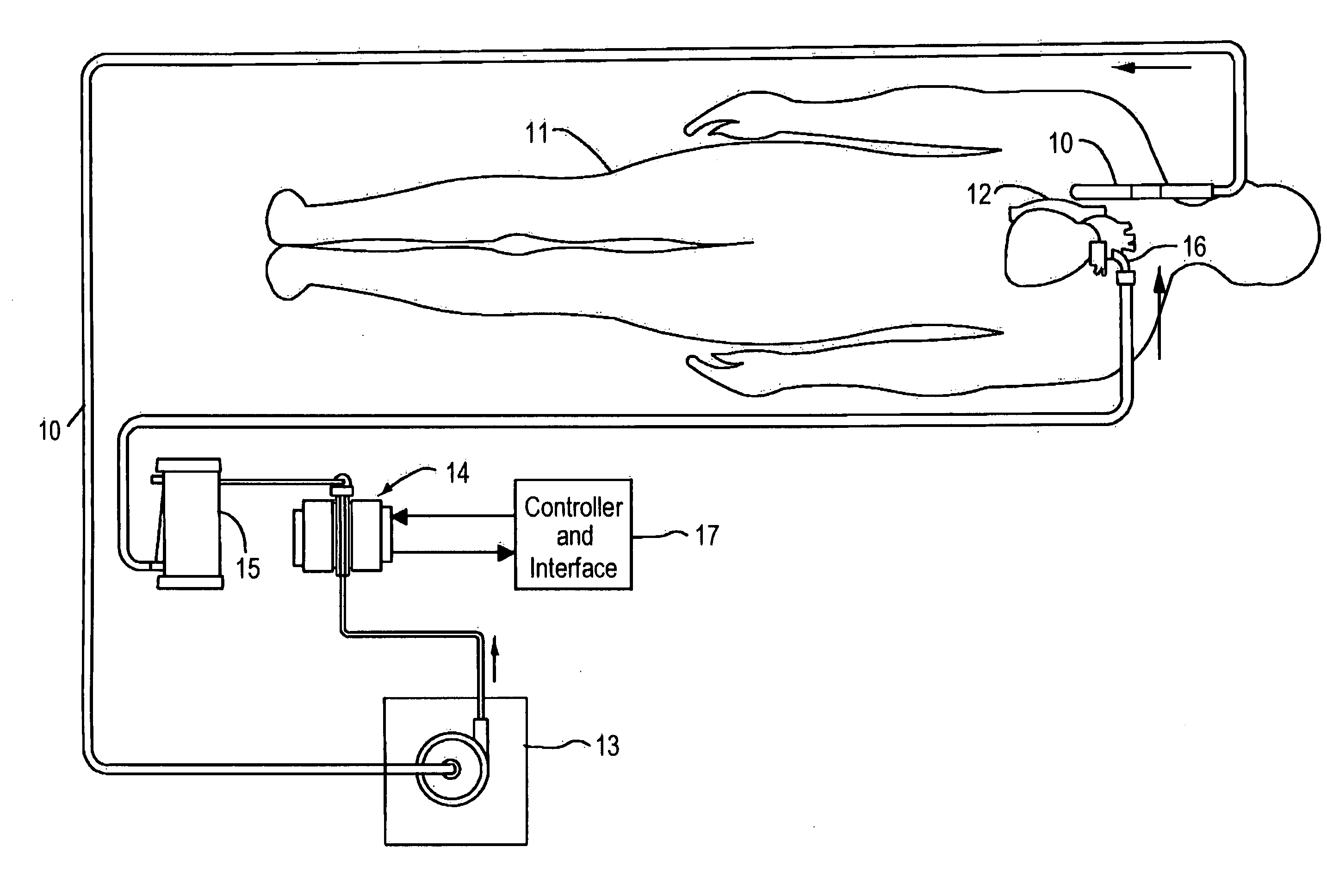

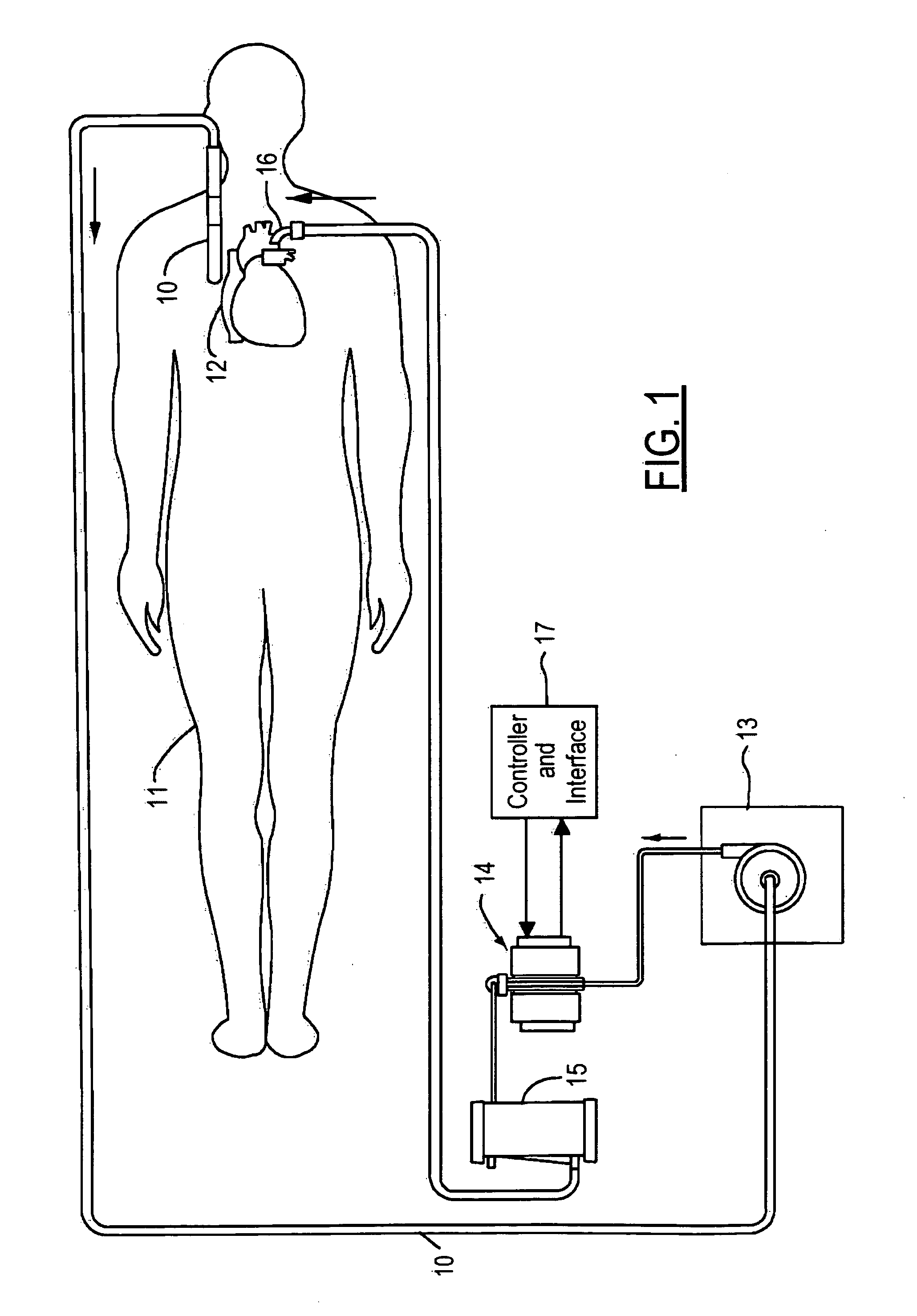

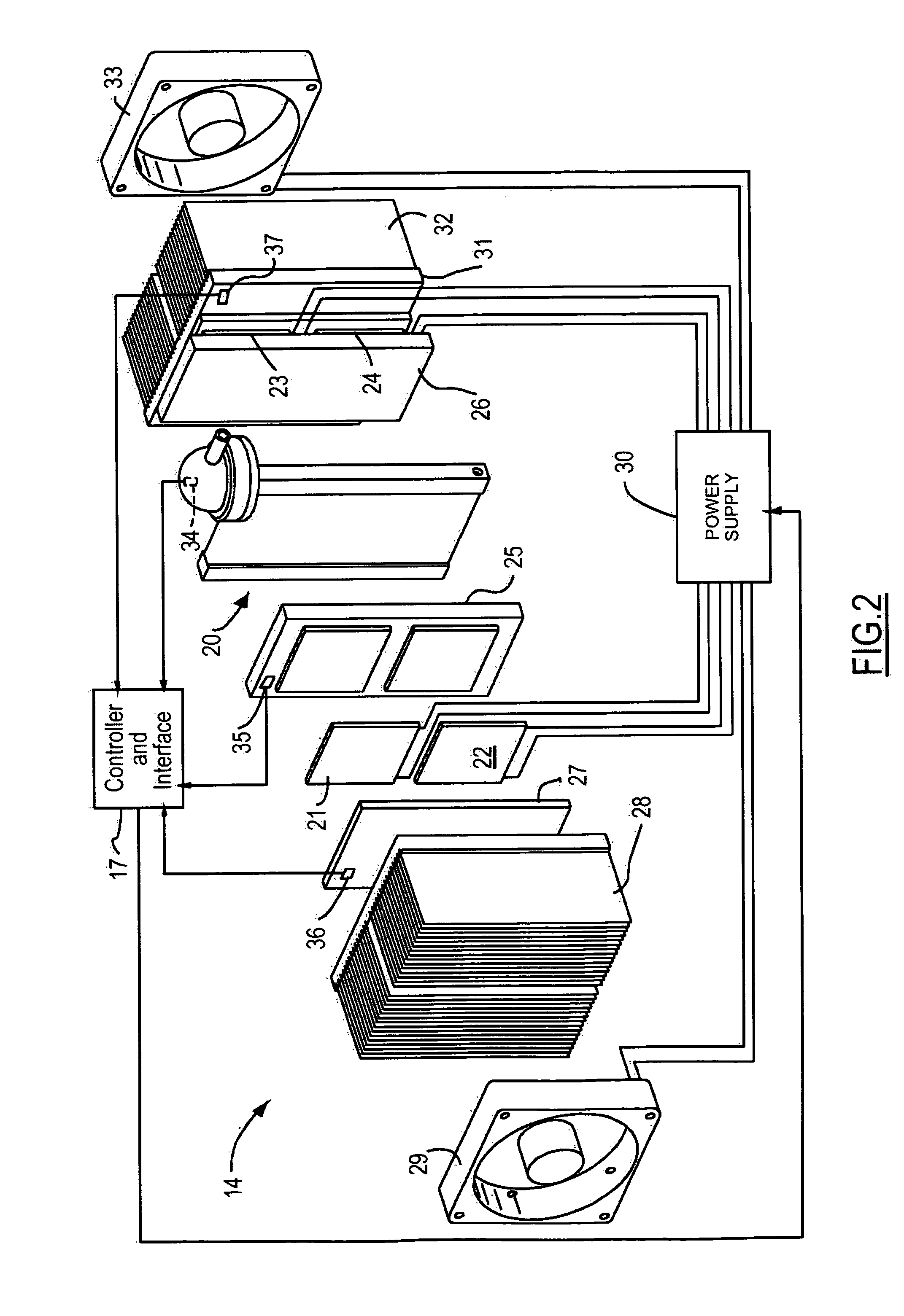

Thermoelectric temperature control for extracorporeal blood circuit

ActiveUS20080031773A1Improve efficiencyReduce blood volumeMedical devicesSuction devicesTemperature controlTemperature difference

A waterless blood heater / cooler device directly controlling temperature of blood flowing through an extracorporeal blood circuit. A thermoelectric module is coupled to a supply voltage to generate a temperature difference. A heat exchanger cassette comprising a core and first and second laminar flow guides is in thermal contact (directly or indirectly) with the thermoelectric module. The cassette has a plurality of tubes for carrying parallel channels of the blood. The first and second laminar flow guides provide an inlet and an outlet for coupling to the extracorporeal blood circuit and respective intermediate chambers for receiving respective ends of the tubes in order to guide the blood to and from respective tubes in a substantially laminar flow.

Owner:TERUMO CARDIOVASCULAR SYST CORP

Air conditioner with control of compressor

ActiveUS20040206102A1Increase capacityLarge cooling capacityAir-treating devicesCompression machines with non-reversible cycleRotation velocityEngineering

In an air conditioner, a target compressor rotation speed is determined based on a target air temperature, which represents an air conditioning load, when an electric compressor is started from a stop state. Thus, an evaporator air temperature can be approximated to a target evaporator air temperature, more quickly as compared with a control method where an incremental rotation speed is added to a present rotation speed of the electric compressor, that is, 0 rpm. Accordingly, a large cooling capacity can be obtained for a short time period. Thus, an air temperature in a compartment can be quickly reduced to a comfortable temperature, when the air conditioner is started, for example.

Owner:DENSO CORP

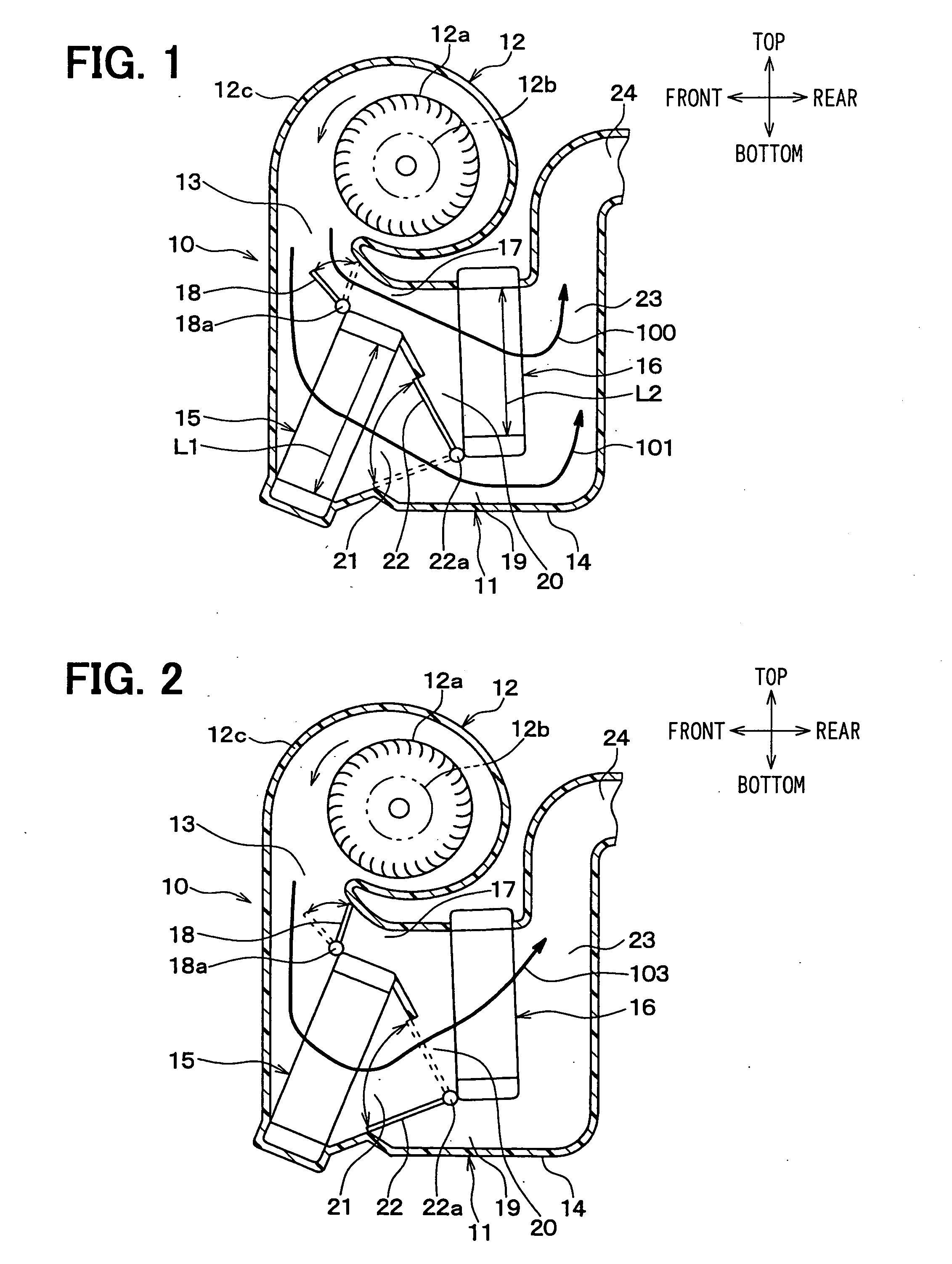

Vehicle air conditioner

InactiveUS20050115704A1Easy to set upSmall sizeAir-treating devicesRailway heating/coolingEngineeringAir conditioning

In a vehicle air conditioner, a cooling heat exchanger for cooling air is arranged in the air conditioning case, and a cooling / heating switching heat exchanger is arranged at a downstream air side of the cooling heat exchanger in the air conditioning case. A first bypass passage is provided at one side of the cooling heat exchanger in the air conditioning case, so that air flows through the first bypass passage while bypassing the cooling heat exchanger. A second bypass passage is provided at one side of the cooling / heating switching heat exchanger in the air conditioning case on an opposite side of the first bypass passage with respect to the first heat exchanger, so that air flows through the second bypass passage while bypassing the cooling / heating switching heat exchanger. Accordingly, a size of the air conditioner can be effectively decreased while a maximum cooling capacity can be sufficiently obtained.

Owner:DENSO CORP

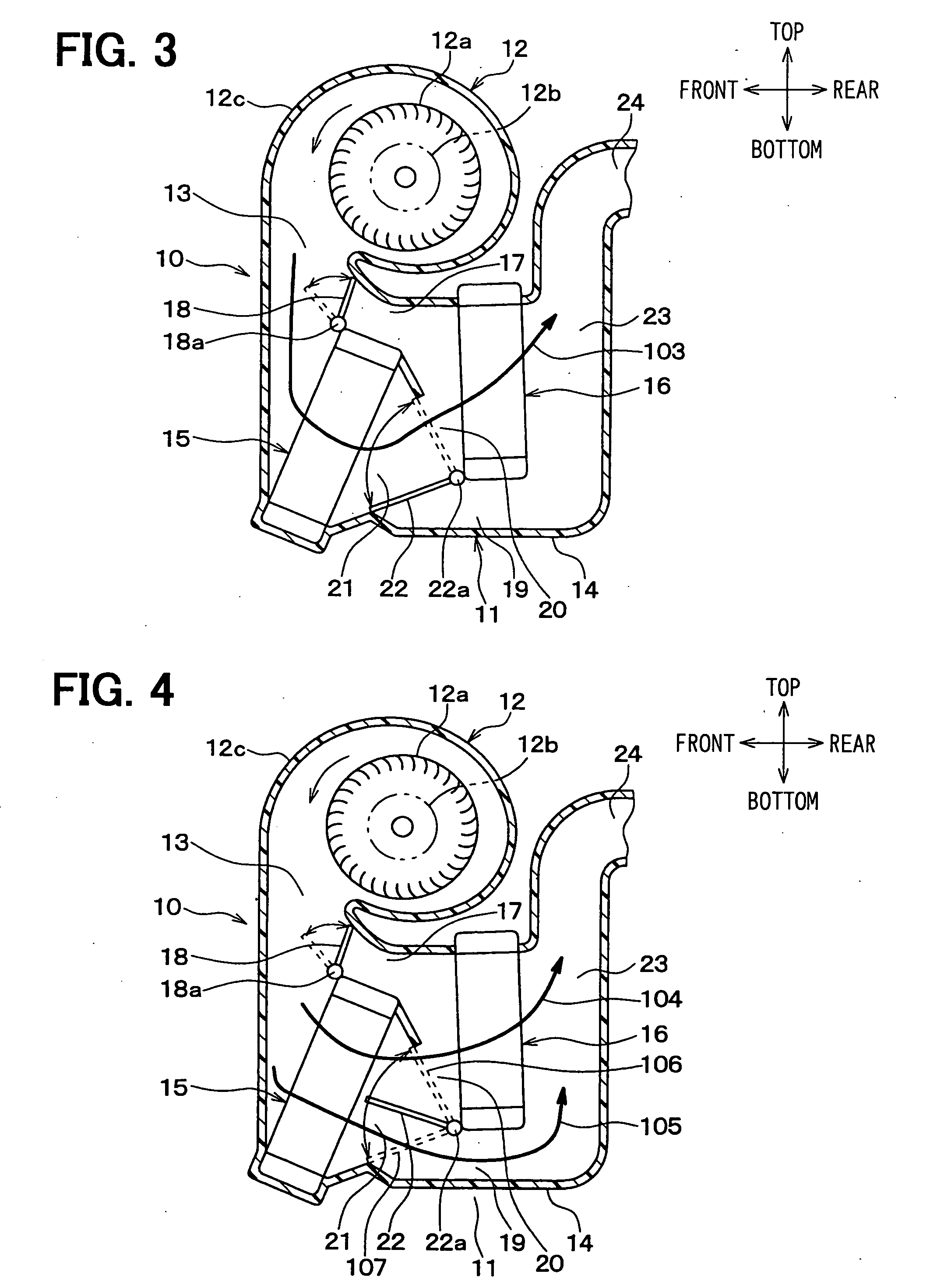

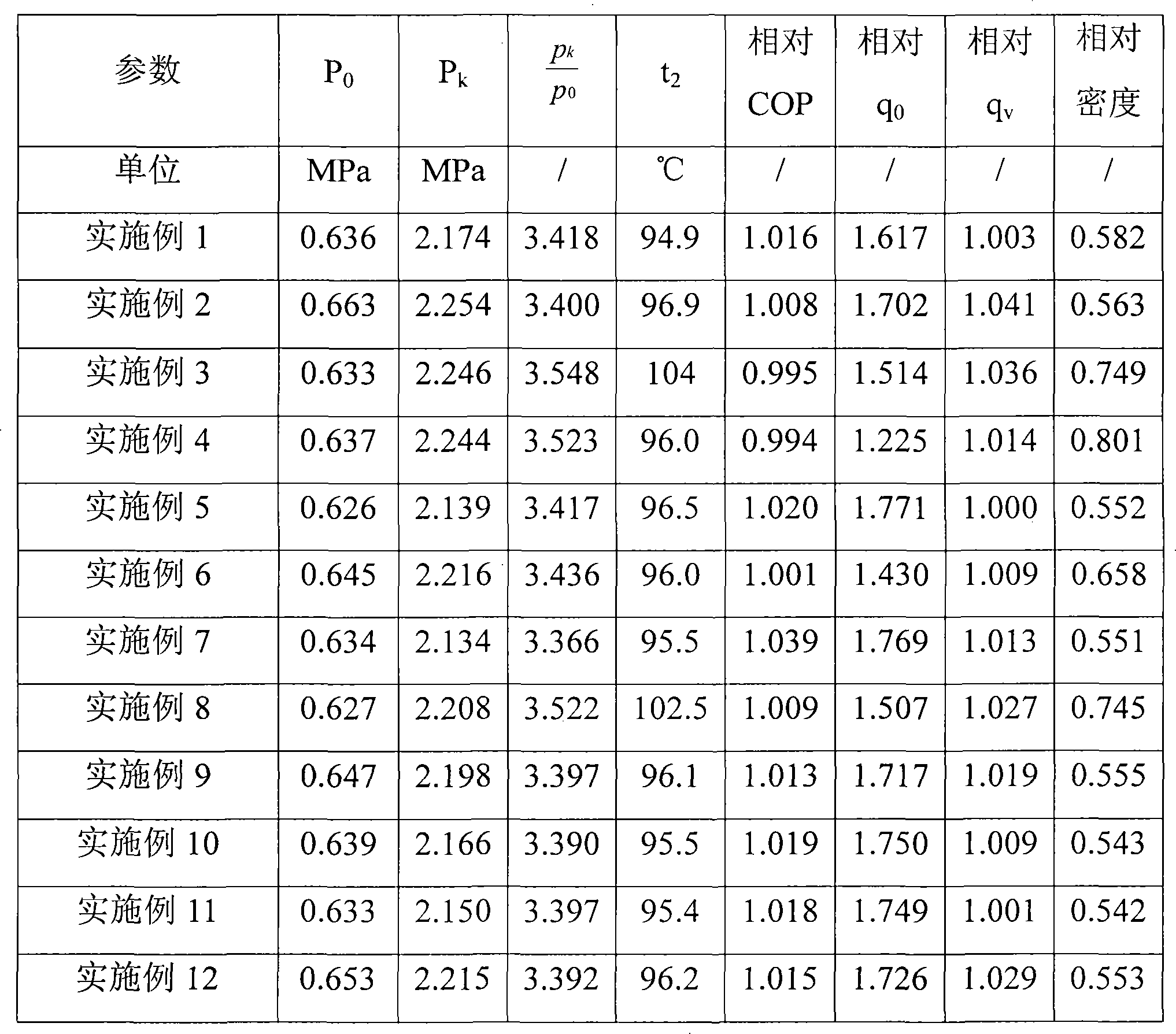

Environment-friendly type refrigerant

InactiveCN101157849AEnvironmentally friendlyMeet environmental protection requirementsChemical industryHeat-exchange elementsBusiness efficiencyVolumetric Mass Density

An environmental-friendly refrigerant, used in equipments such as refrigerators, air-conditions, and heat pumps, etc., is directly in place of the HCFC-22 refrigerant technology field, and consists of components A, B, and C. The component A is one of ethyl fluoride or 1, 1-difluoroethane or the mixture of the two according to any proportion. The component B is Difluoromethane. The component C is one of isobutane, normal butane, propane and propylene or mixture of two or more of the chemicals according to any proportion. The invention overcomes the disadvantages of the prior art of alternative refrigerant and the deficient compatibility between HCFC-22 compressors and lube, as well as the high GWP. The invention provides a refrigerant with good environment performance, the thermal parameters of which is similar to that of HCFC-22. The invention can be used directly in the former system of HCFC-22, as well as the HCFC-22 compressor and lube. The unit volume refrigerating capacity is great while the density is small, thus reducing the mass of using and increasing the energy efficiency ratio, as well as saving resources. The refrigerant can be a long-term substitute of HCFC-22.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH

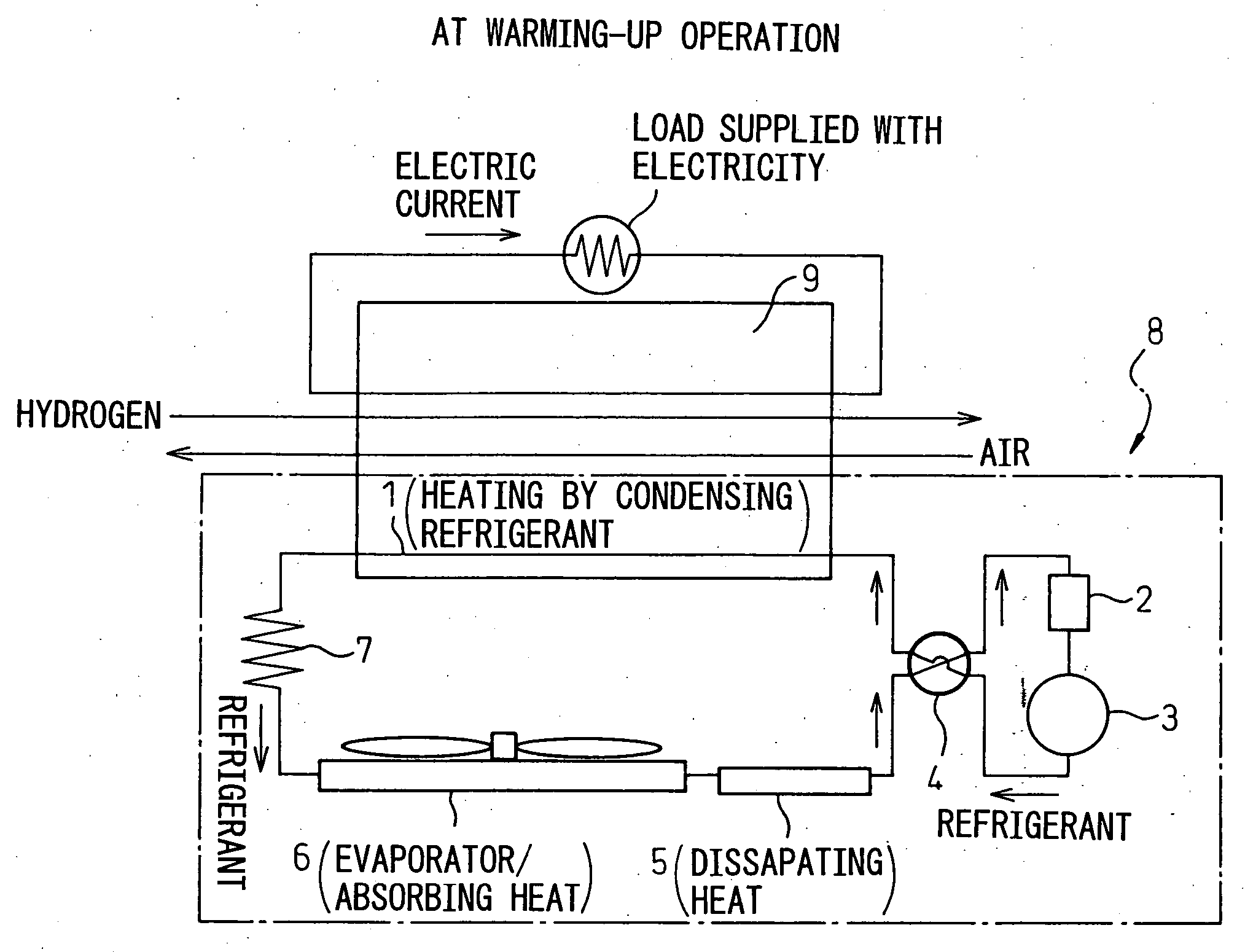

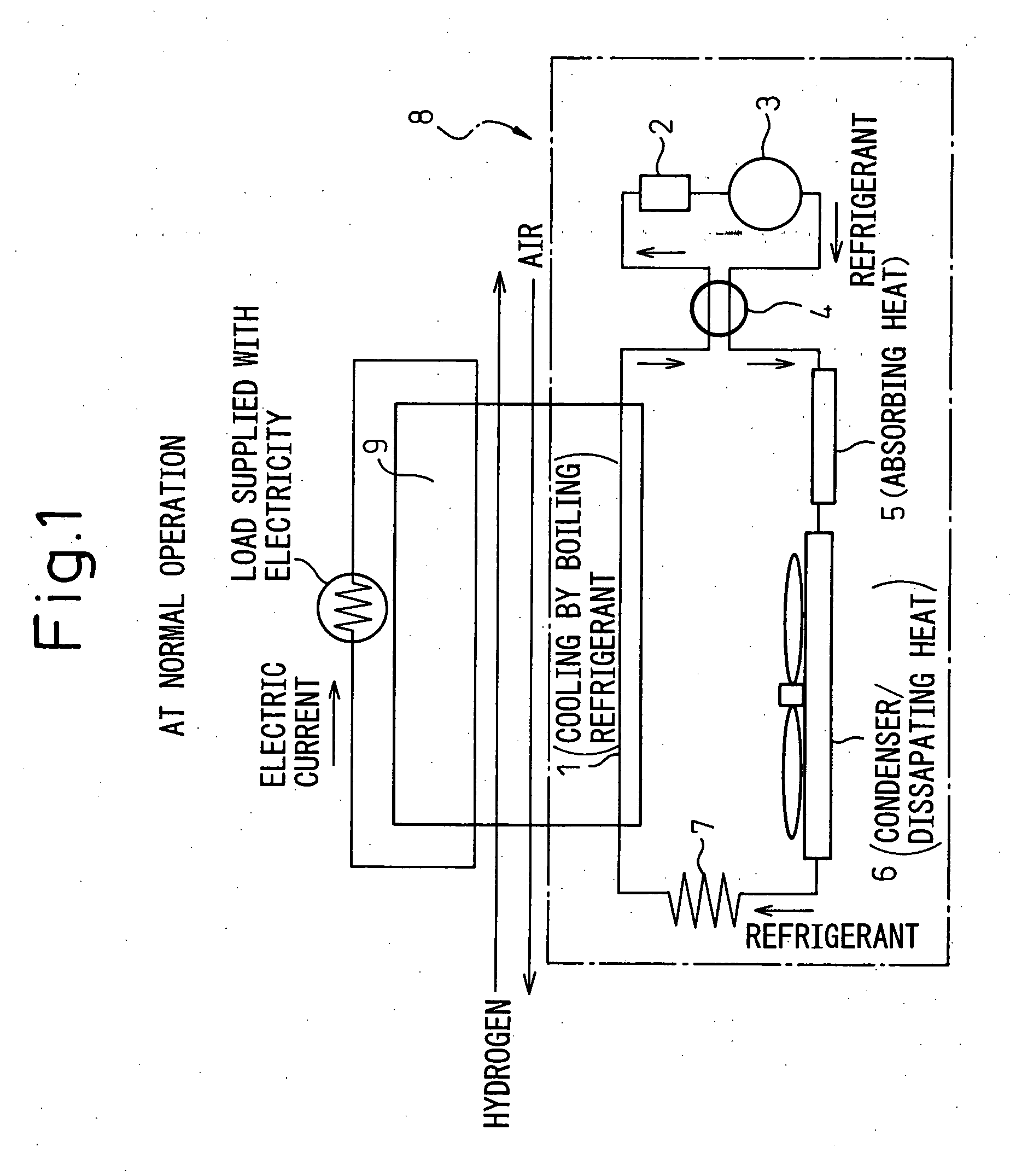

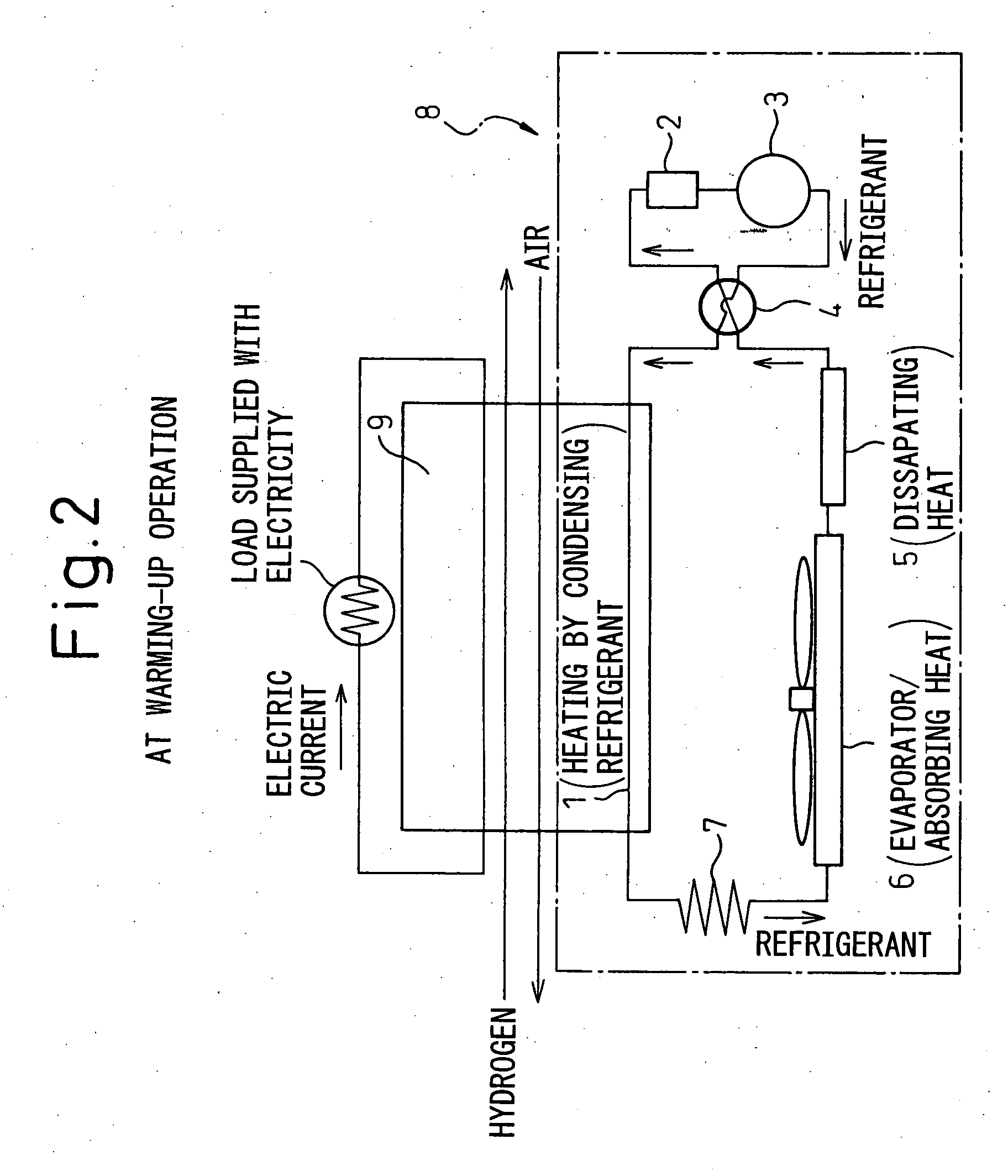

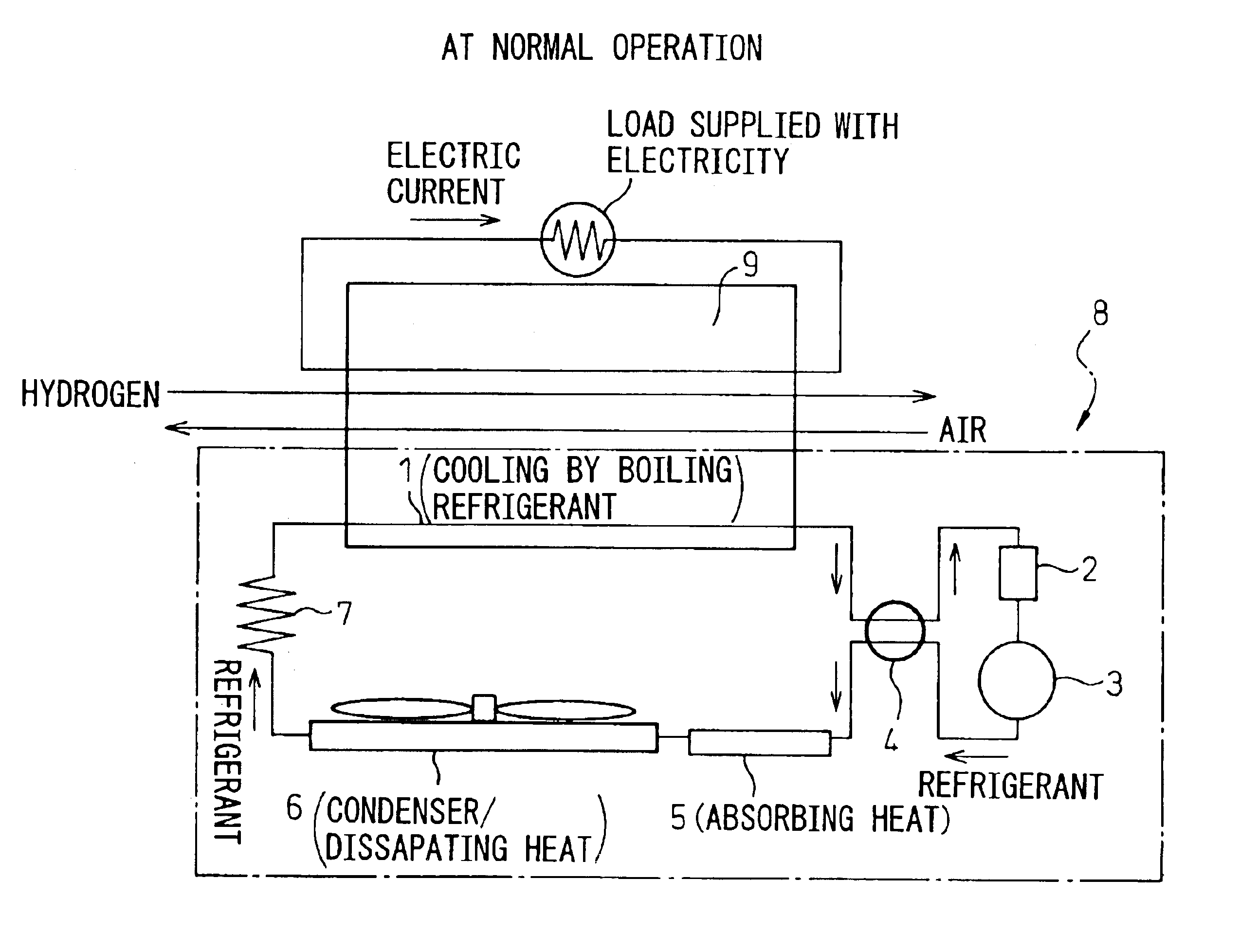

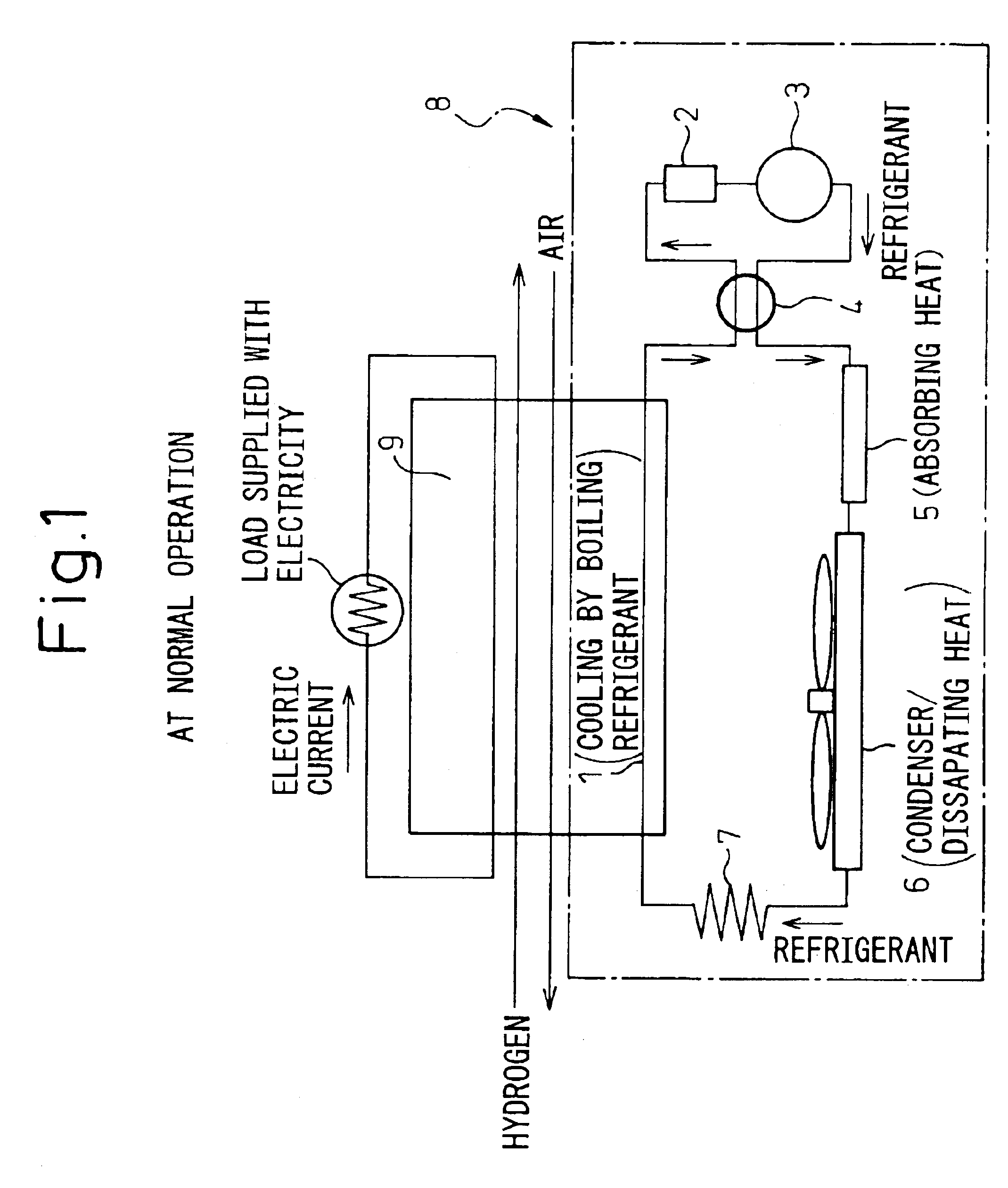

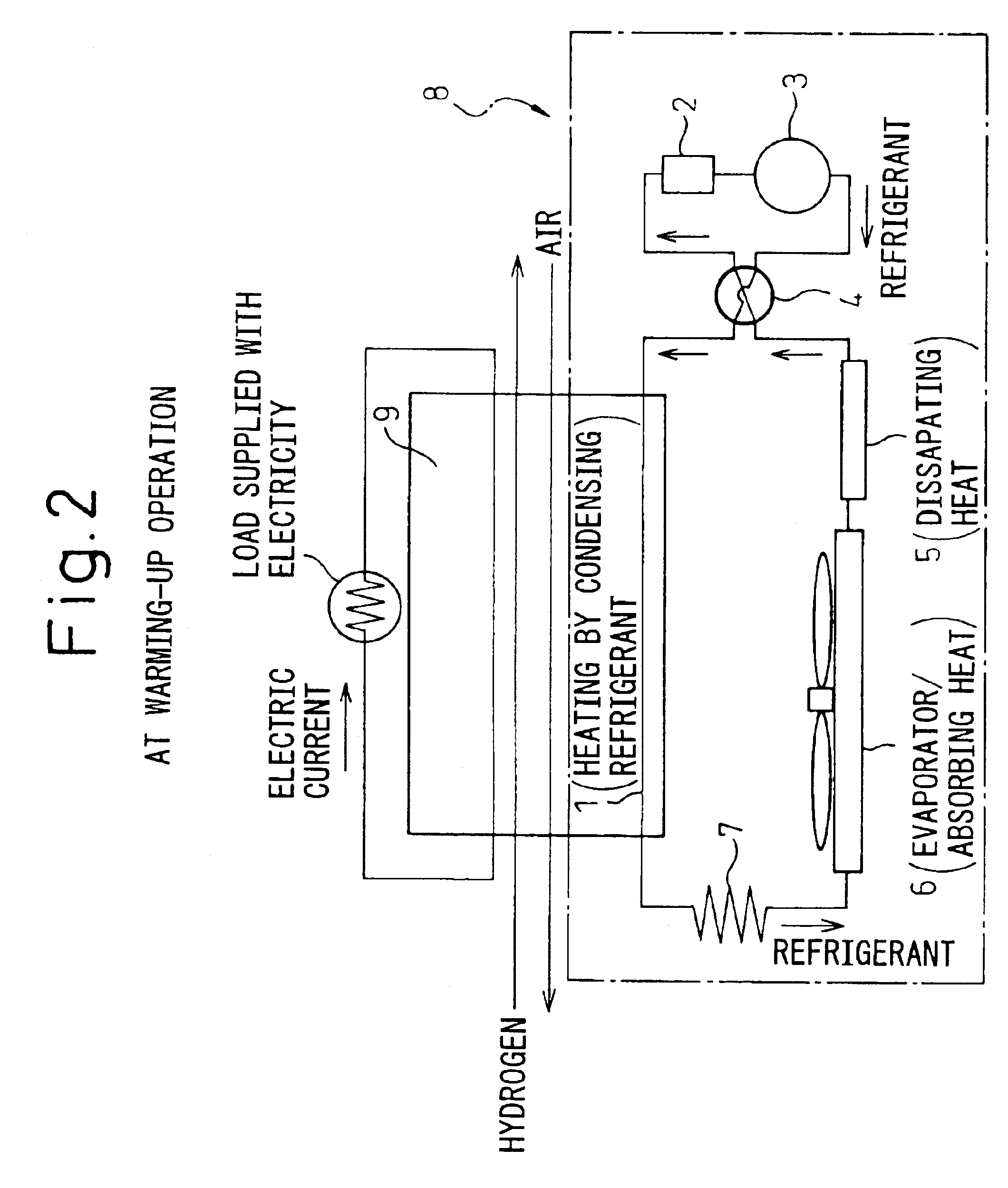

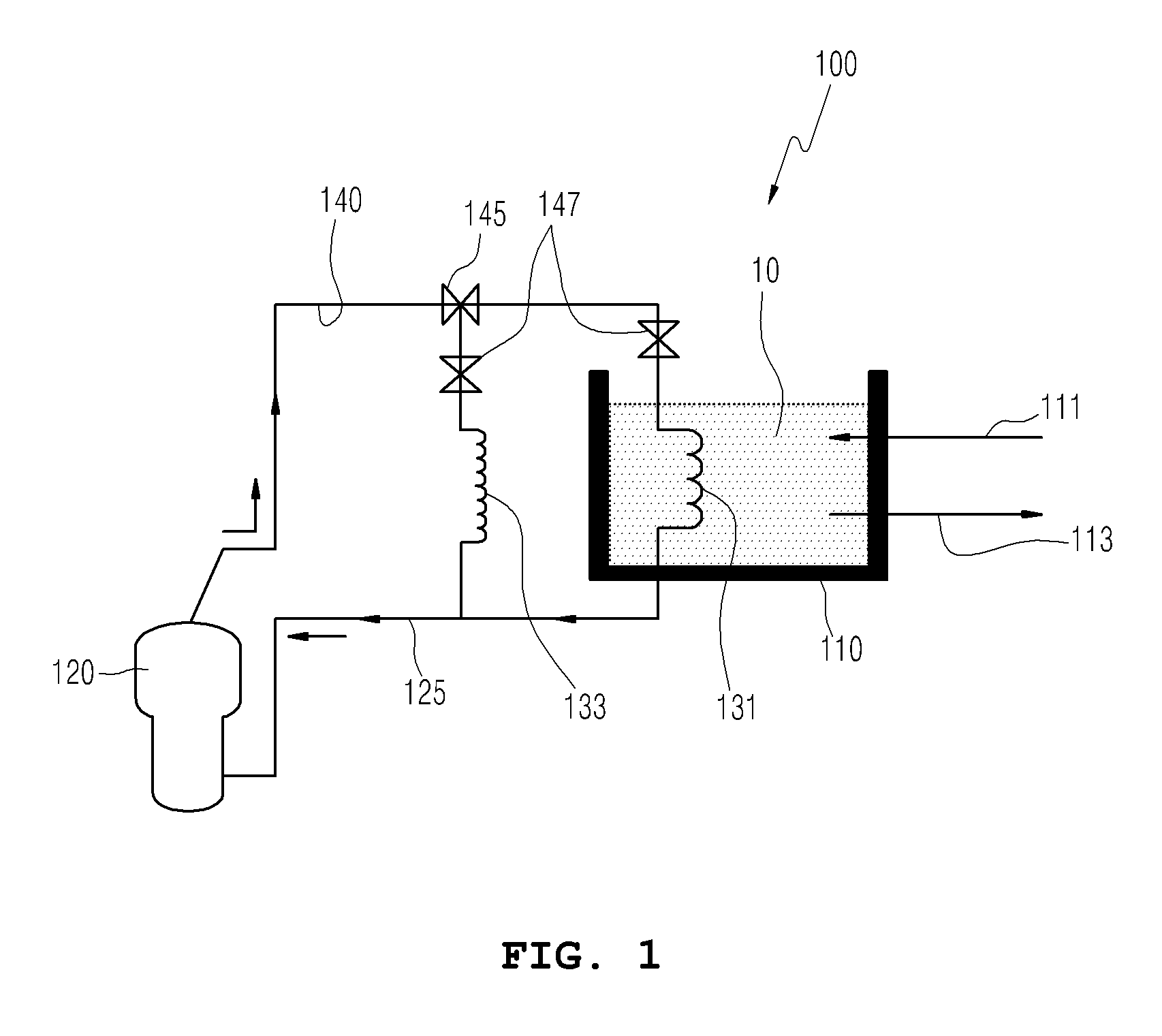

Cooling apparatus for fuel cell utilizing air conditioning system

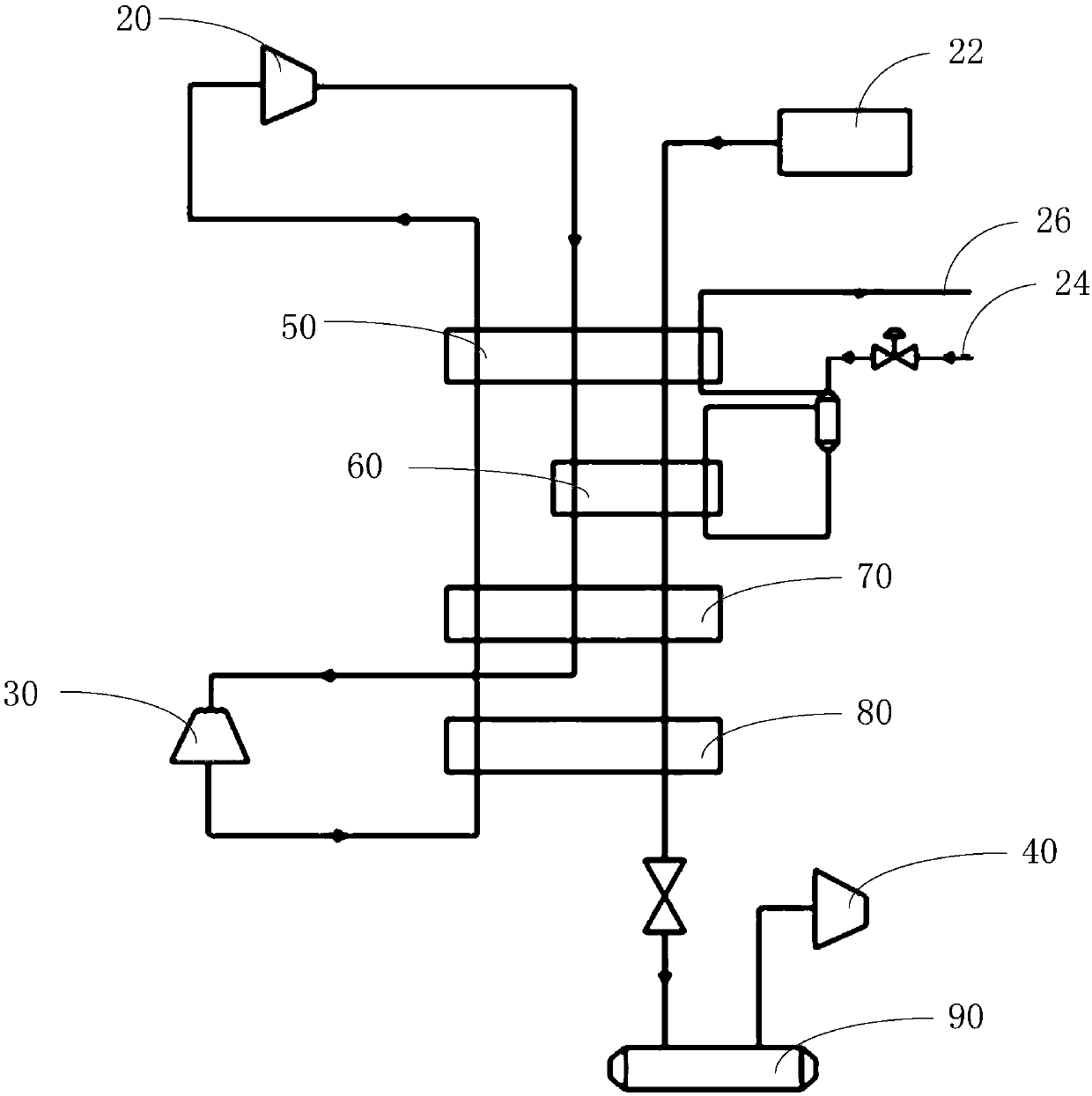

InactiveUS20050022550A1Efficient assemblyGuaranteed to workFuel cell heat exchangeDomestic refrigeratorsFuel cellsFour-way valve

A cooling circuit of a cooling apparatus for a fuel cell comprises a compressor for compressing a gaseous refrigerant, an external heat exchanger arranged on the downstream side of the compressor and for liquefying the compressed refrigerant, a pressure-reducing means arranged on the downstream side of the external heat exchanger, and an accumulator for storing the refrigerant which cools a fuel cell stack main body. The stack main body is connected to the cooling circuit between the pressure-reducing means and the accumulator and a four-way valve is arranged between the compressor and the external heat exchanger, and between the stack main body and the accumulator in the cooling circuit, and the four-way valve introduces the refrigerant from the compressor to the external heat exchanger during the cooling operation, and introduces it to the stack main body during the warming-up operation.

Owner:DENSO CORP

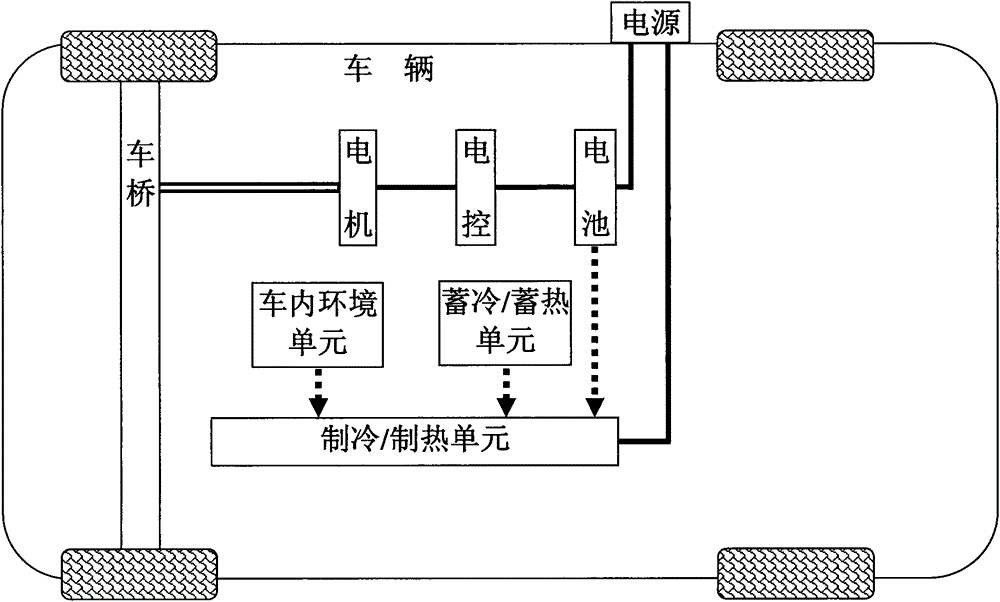

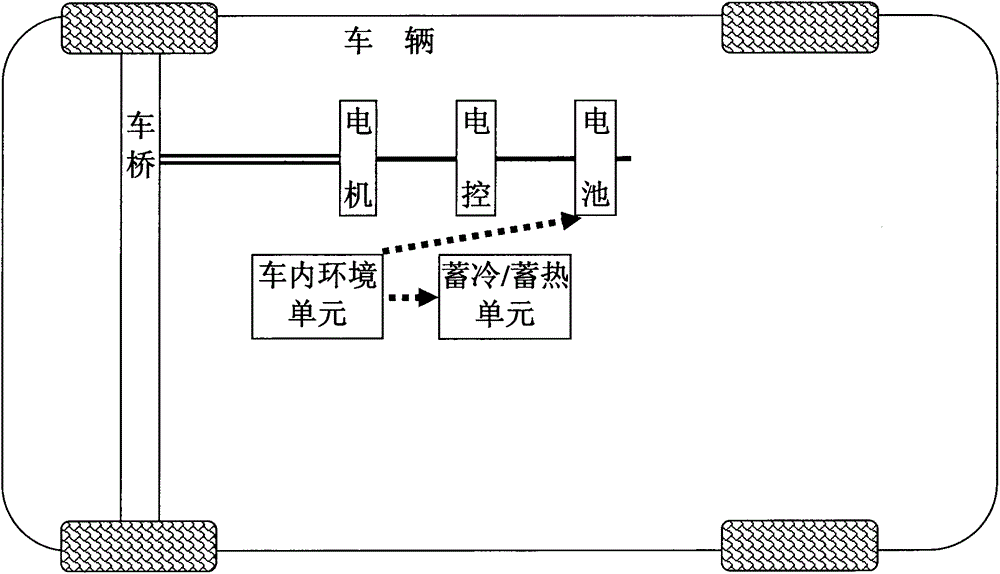

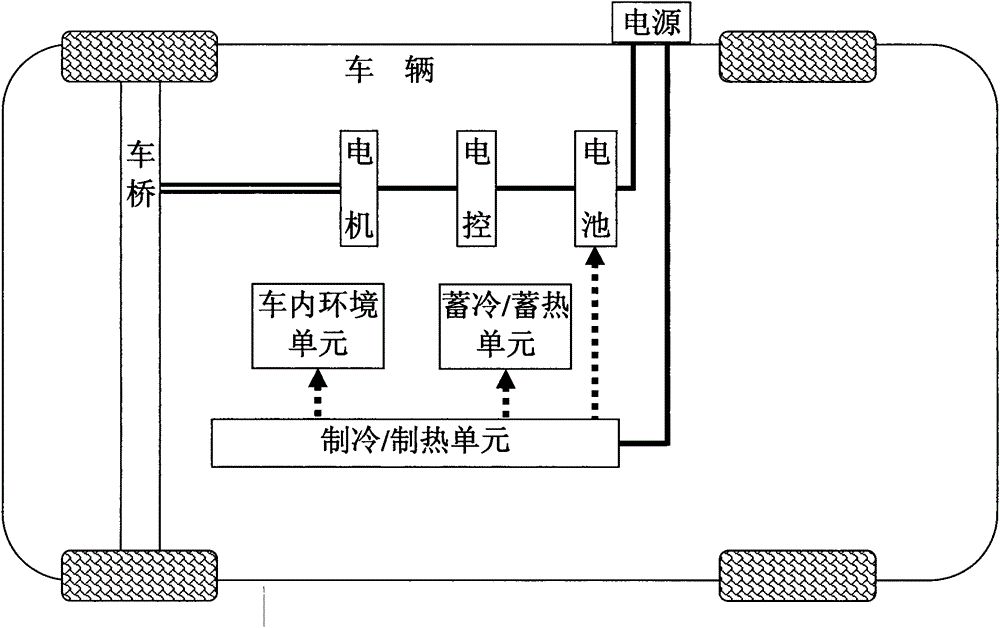

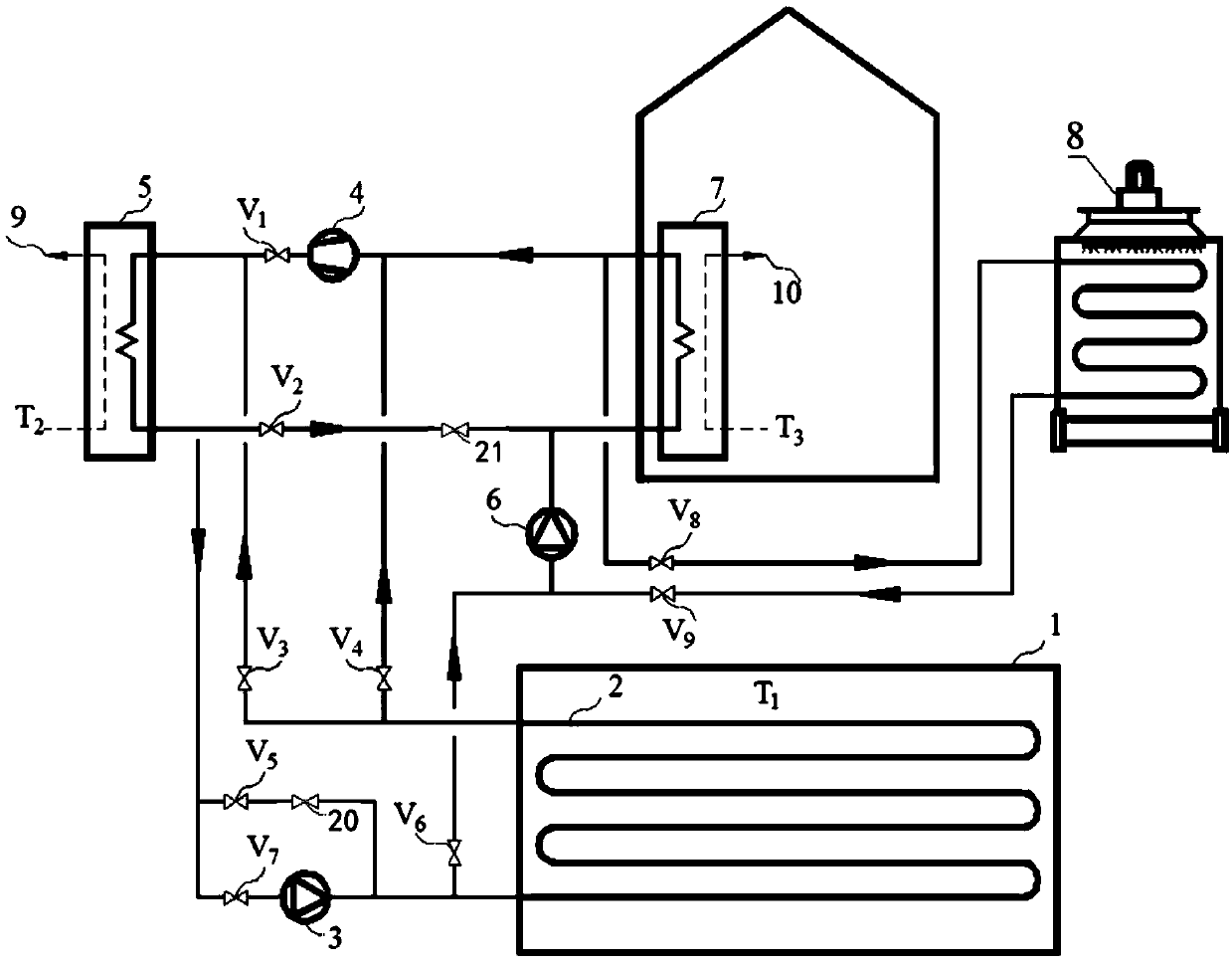

Method for regulating temperature of electric car

InactiveCN105196828AMeet the requirements of air conditioningLarge cooling capacityAir-treating devicesVehicle heating/cooling devicesRemote controlFast charging

The invention discloses a method for regulating the temperature of an electric car, and belongs to the field of car heating and cooling. The method aims at fundamentally solving the problems that an electric car air conditioner consumes electric energy of a battery, and the battery is short in high-temperature service life, low in low-temperature capacity and low in charging speed. In the parking process, an outer power source supplies power to a refrigerating / heating unit, the cold end or hot end of the refrigerating / heating unit is connected with a car inside environment unit, a cold storage / heat storage unit and a battery and refrigerates / heats the car inside environment unit, the cold storage / heat storage unit and the battery, and the hot end or cold end is connected with a chassis car body outside component for heat radiation or absorption. In the car running process, the cold storage / heat storage unit or the battery releases heat cold or heat into the car inside environment unit. Water is adopted as a medium of the cold storage / heat storage unit. Braking kinetic energy is recycled through an axle and allows the refrigerating / heating unit to continue to carry out refrigerating or heating . The method is used for the electric car and the like, and a remote control unit can enable the temperature in the car to be comfortable and achieve cold and heat storage in advance through the operating unit. When the air conditioner operates, the electric energy of the battery is rarely used. The battery can be helped to be fast charged, the service life is prolonged in summer, and the capacity of the battery is increased in winter. The electric car can be popularized to regions with various climates more easily.

Owner:宋旦

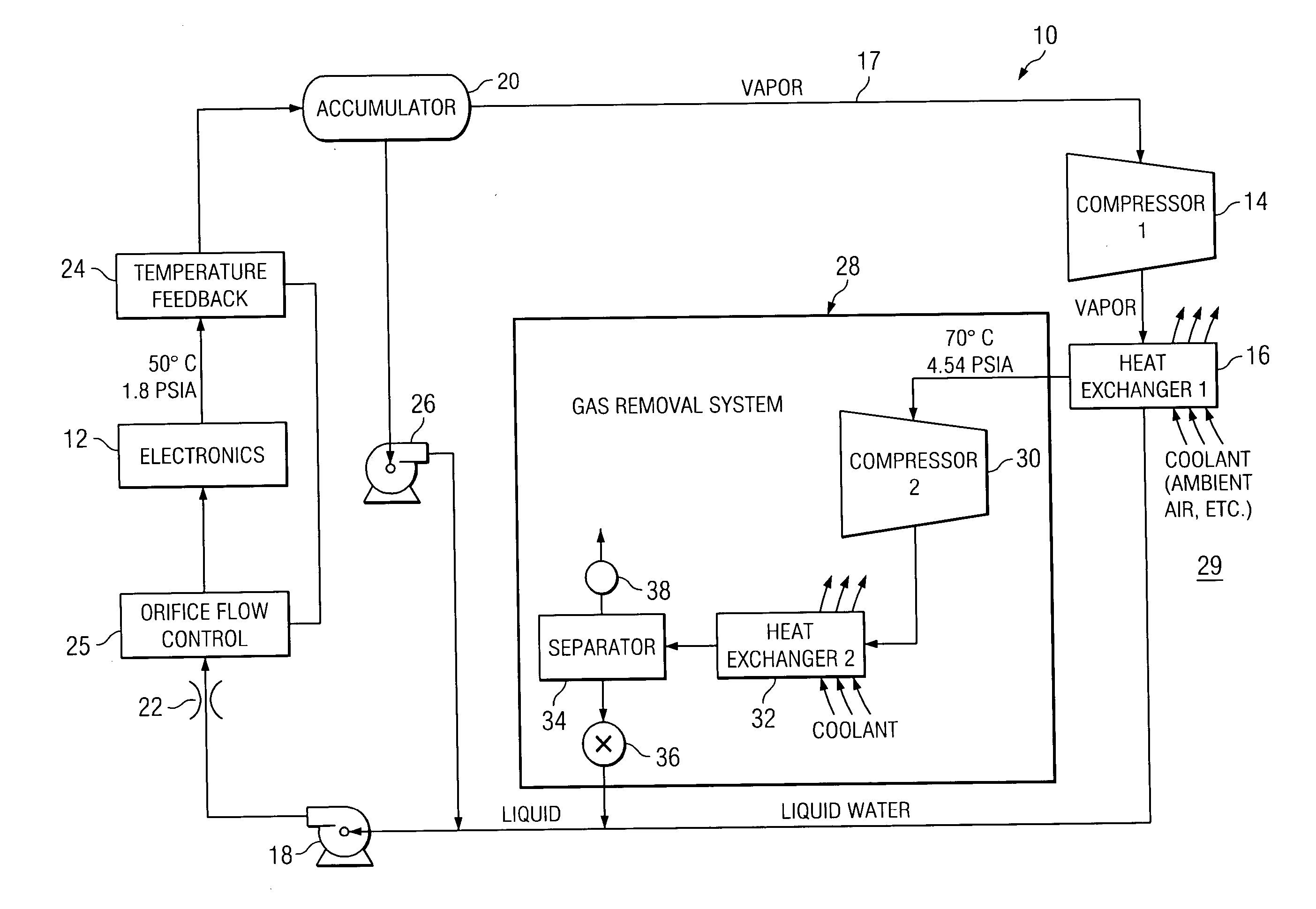

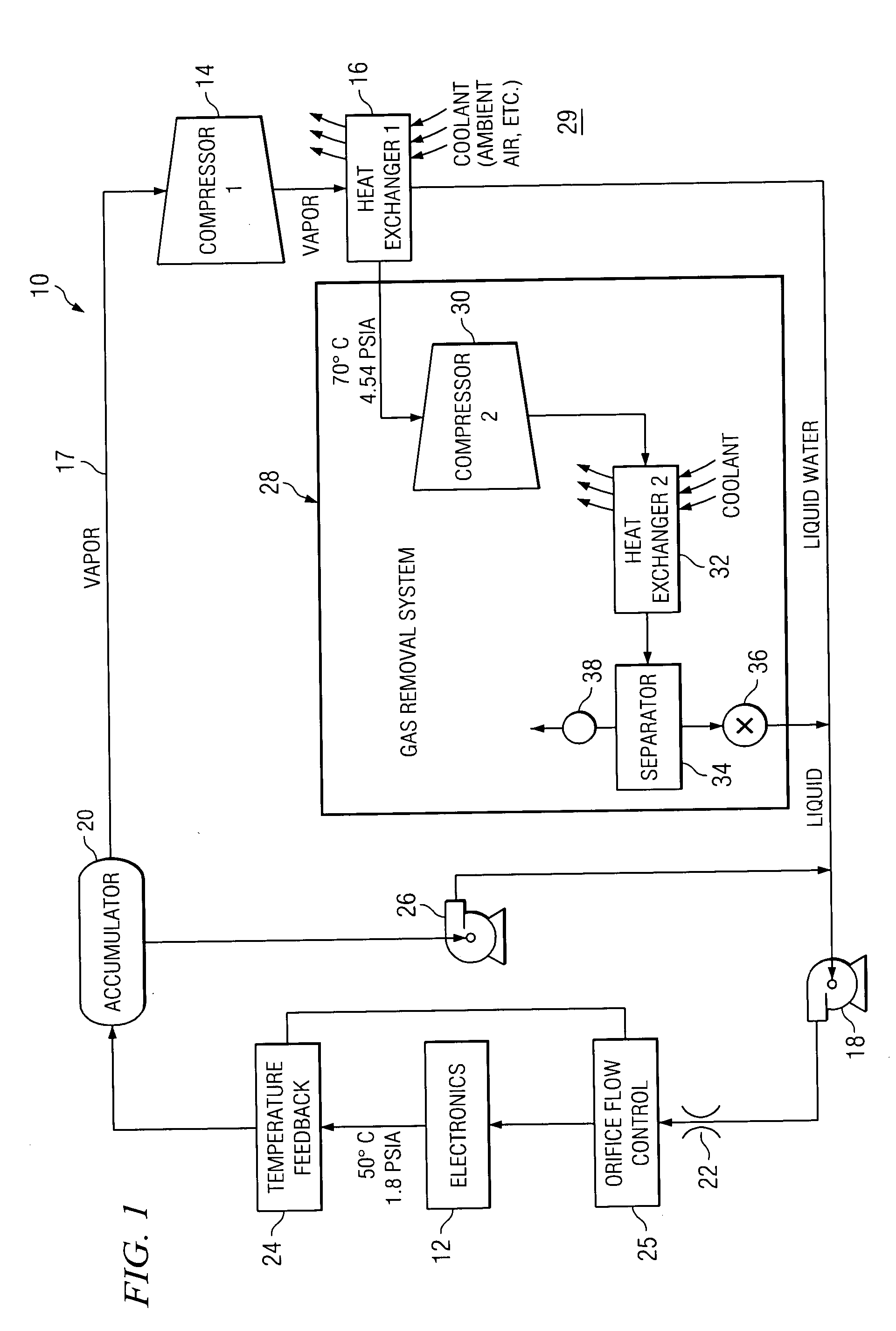

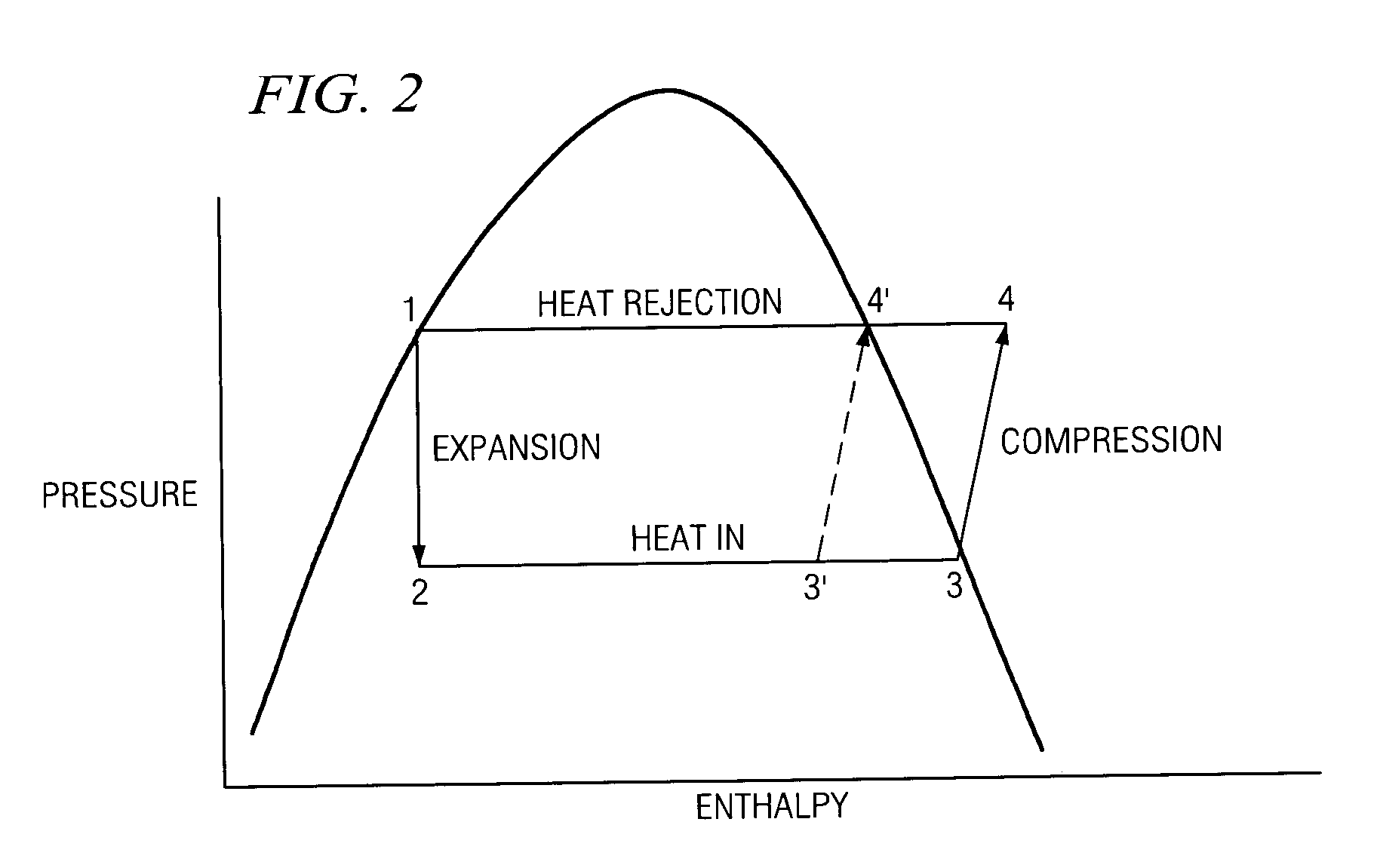

Sub-ambient refrigerating cycle

InactiveUS20050274139A1Large cooling capacityLess powerCompression machines with non-reversible cycleRefrigeration componentsDecreased pressureAmbient pressure

According to one embodiment of the invention, a method for cooling heat-generating structure disposed in an environment having an ambient pressure includes providing a fluid refrigerant and reducing a pressure of the refrigerant to a first sub-ambient pressure at which the refrigerant has a boiling temperature less than a temperature of the heat-generating structure. The method also includes bringing the refrigerant at the first sub-ambient pressure into thermal communication with the heat-generating structure, so that the refrigerant boils and vaporizes to thereby absorb heat from the heat-generating structure. The method further includes increasing a pressure of the vaporized refrigerant above the first sub-ambient pressure to a second sub-ambient pressure.

Owner:RAYTHEON CO

Gas liquefaction system

PendingCN107940895ARaise the minimum temperatureLarge cooling capacitySolidificationLiquefactionProcess engineeringFluid phase

A gas liquefaction system comprises a compressor unit, a precooling heat exchanger, a multistage intermediate turbine precooling unit, a first heat exchanger, a final-stage turbine expander, a secondheat exchanger, a throttle valve and a cryogenic liquid storage tank. The second heat exchanger is arranged between the throttle valve and the cryogenic liquid storage tank. The gas liquefaction system comprises a to-be-liquefied gas circuit, a refrigeration working medium circulating process and a precooling working medium circulating loop. According to the gas liquefaction system, under the samesystem power consumption, the final-stage turbine expander expands under the high temperature by changing the liquefaction process form of the cryogenic end so as to obtain the greater cooling capacity; compared with a traditional helium refrigeration hydrogen liquefaction system, a stage of second heat exchanger is further additionally arranged after throttling of the throttle valve so that thedryness of the liquefied gas can be further decreased to zero, full liquid phase running of an outlet pipeline of the second heat exchanger is ensured, the safe effect is achieved, and the equipment cost is saved; and the lowest temperature of the whole gas liquefaction system is improved, improving of the system efficiency is facilitated, and energy sources are saved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

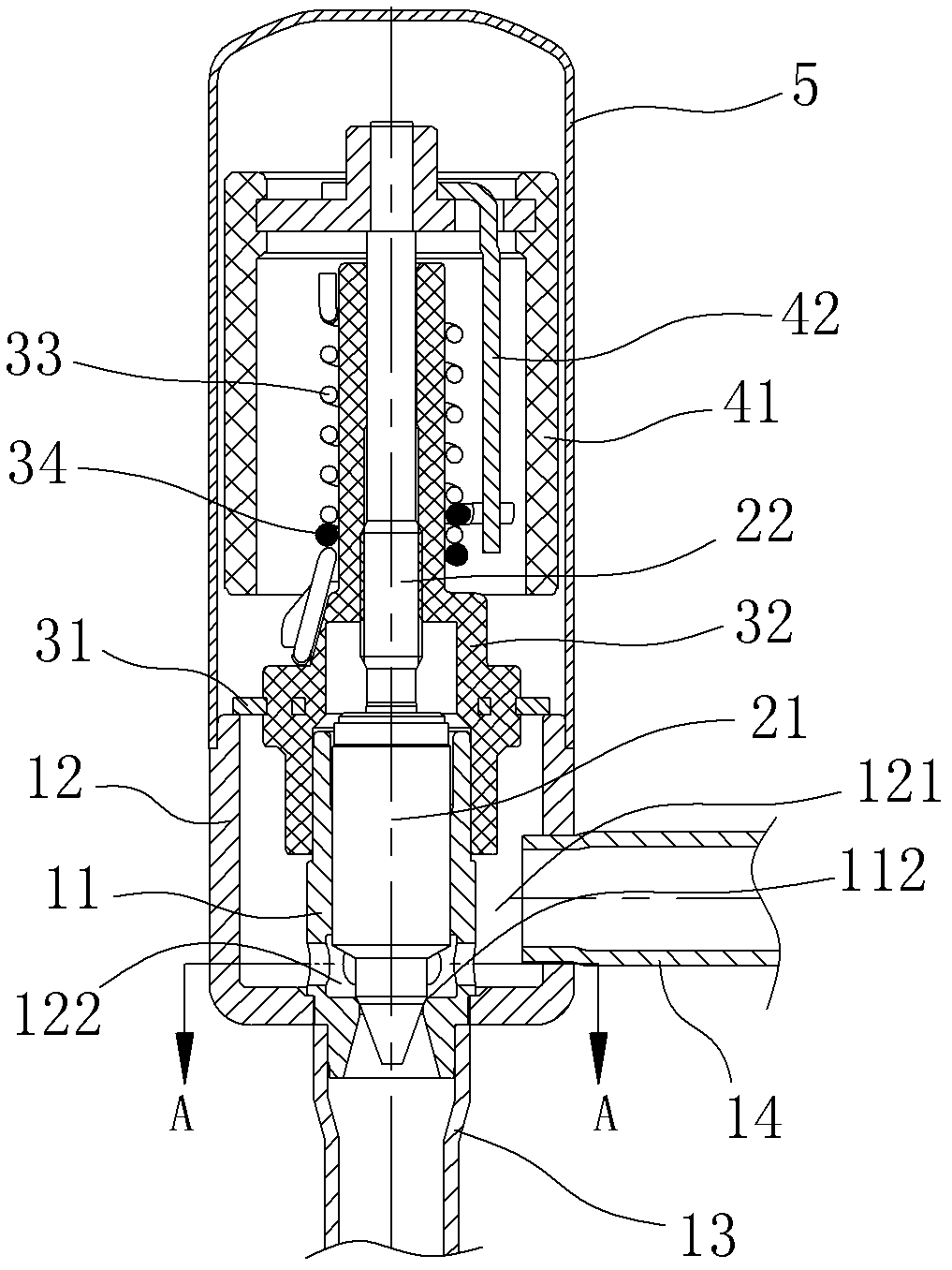

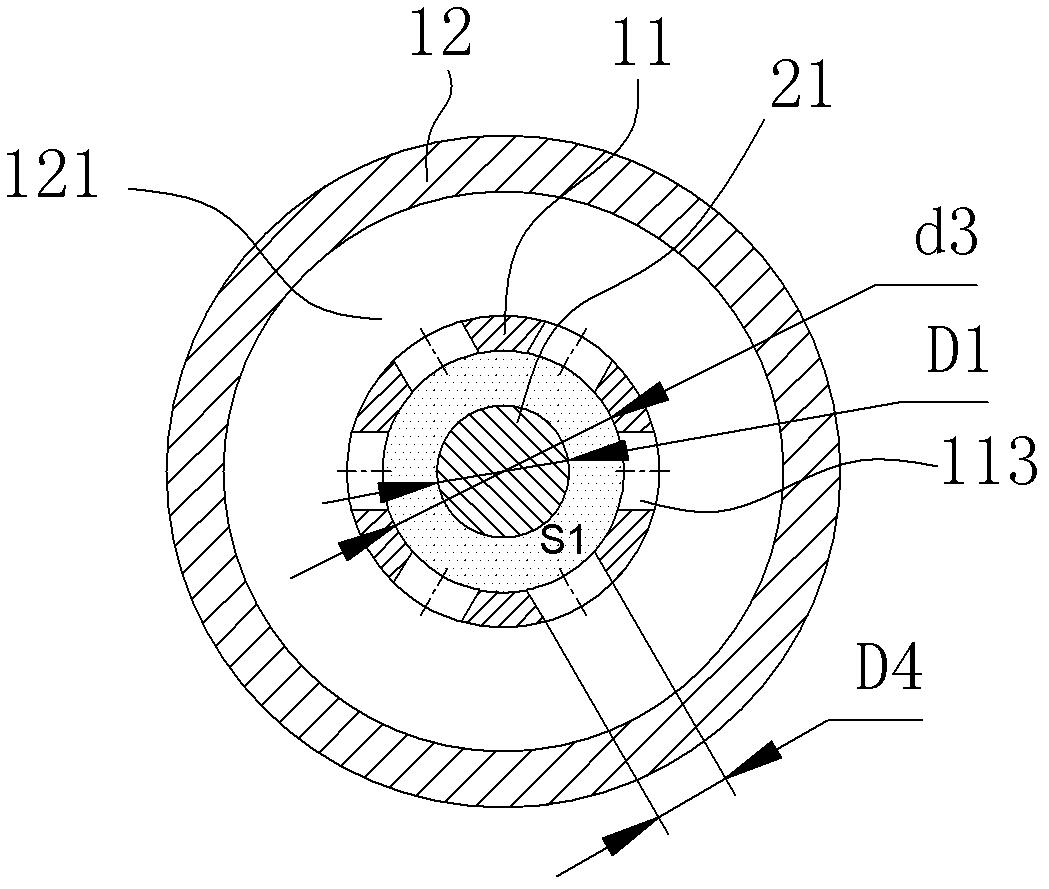

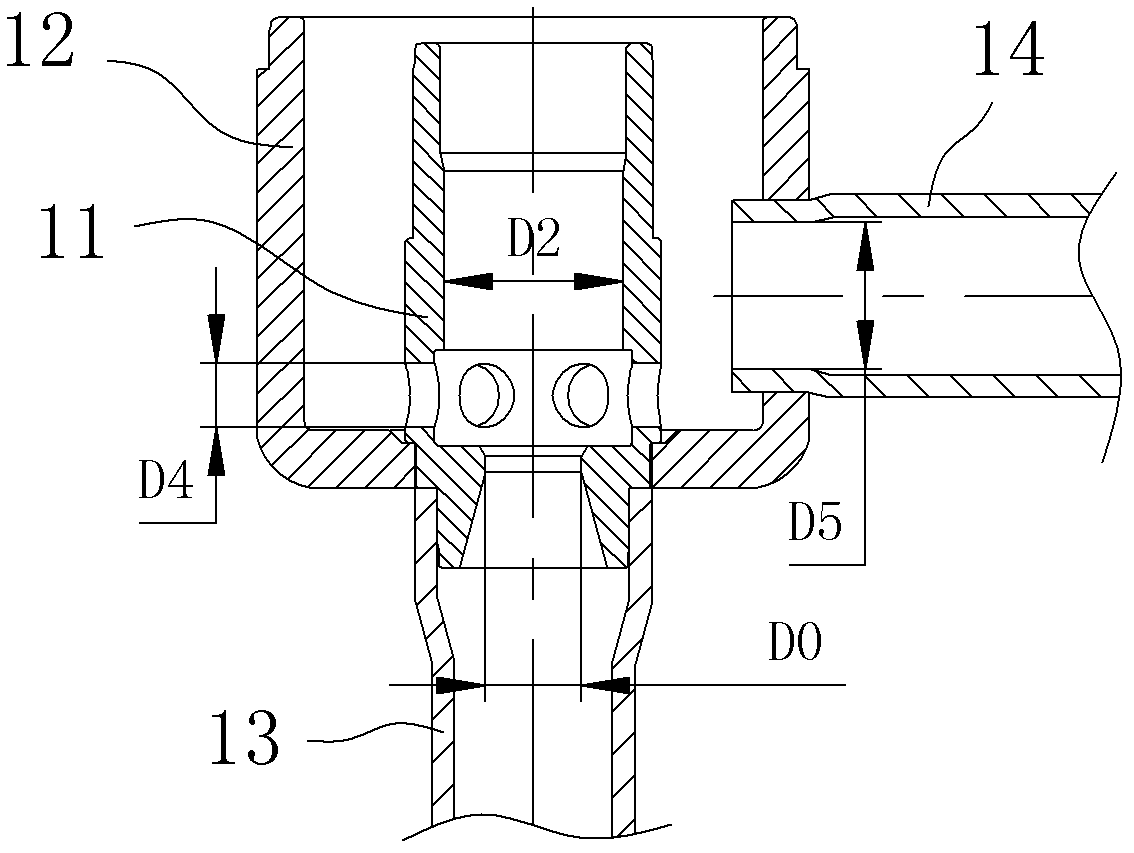

Motorized valve

ActiveCN103133701AAvoid sudden stressPrevent mutagenesisOperating means/releasing devices for valvesLift valveEngineeringControl valves

The invention relates to the technical field of control valves, in particular to a motorized valve for adjusting flow rate of fluid. The motorized valve comprises a valve seat assembly. The valve seat assembly comprises a valve seat provided with a first valve cavity and a valve core seat fixed on the valve seat and provided with a valve opening. A second valve cavity for the fluid to circulate is arranged in the valve core seat. The first valve cavity and the second valve cavity are communicated through a communication portion. The valve core seat is further provided with a guiding section matched with a valve needle, and the inner diameter of the guiding section is smaller than that of the second valve cavity. According to the motorized valve, the second valve cavity with the inner diameter larger than the guiding section of the valve needle is arranged in the valve core seat, and the motorized valve can contain large refrigeration volume under the condition that the appearance and the size of the motorized valve are not changed. In addition, a circulation sectional area ratio of each circulation portion in a flow channel is configured so that mutating of pressure in the flow channel is avoided, the mutating phenomenon when refrigerant circulates is avoided, and noise of the refrigerant is avoided.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Hydrogen liquefying device and method

ActiveCN107014151AReduce energy consumptionSimple processSolidificationLiquefactionLiquid hydrogenChemistry

The invention discloses a hydrogen liquefying device. The hydrogen liquefying device comprises a hydrogen intake pipe, a heat exchanger A, a heat exchanger B, a heat exchanger C, a flash tank and a liquid hydrogen storage tank for communicating in sequence. The invention further discloses a hydrogen liquefying method, comprising the following steps: (S1) hydrogen is precooled; (S2) orthohydrogen and parahydrogen are converted and liquefied; (S3) one part of liquid hydrogen serves as supercooled gas to input back into the heat exchanger C; (S4) hydrogen steam and the liquid hydrogen are separated by the flash tank; and the liquid hydrogen is prepared and stored; and (S5) unliquefied hydrogen is recovered. The hydrogen liquefying method is simple in flow, flexible in adjustment, reliable in work, convenient to maintain and low in energy consumption.

Owner:四川蜀道装备科技股份有限公司

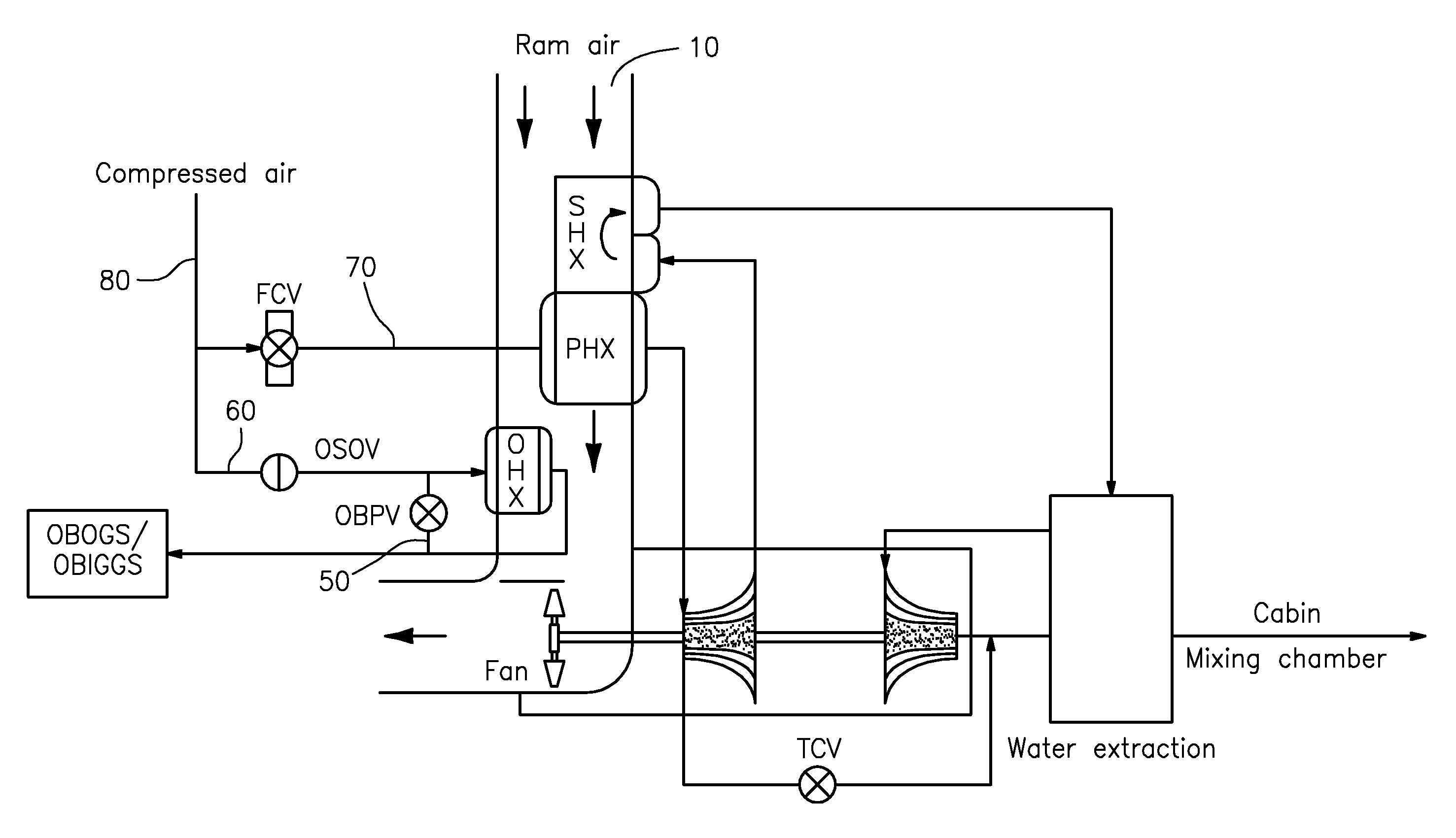

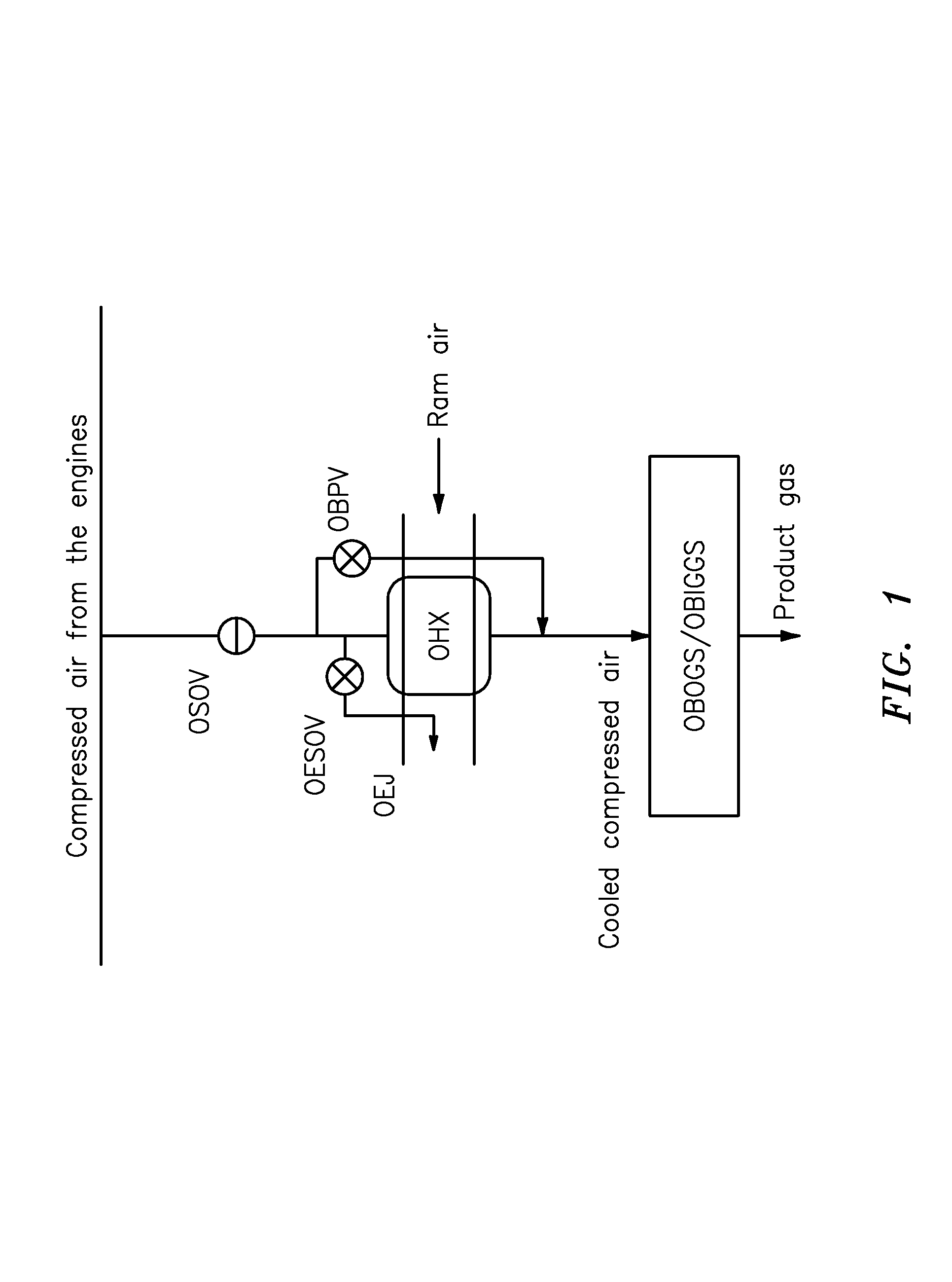

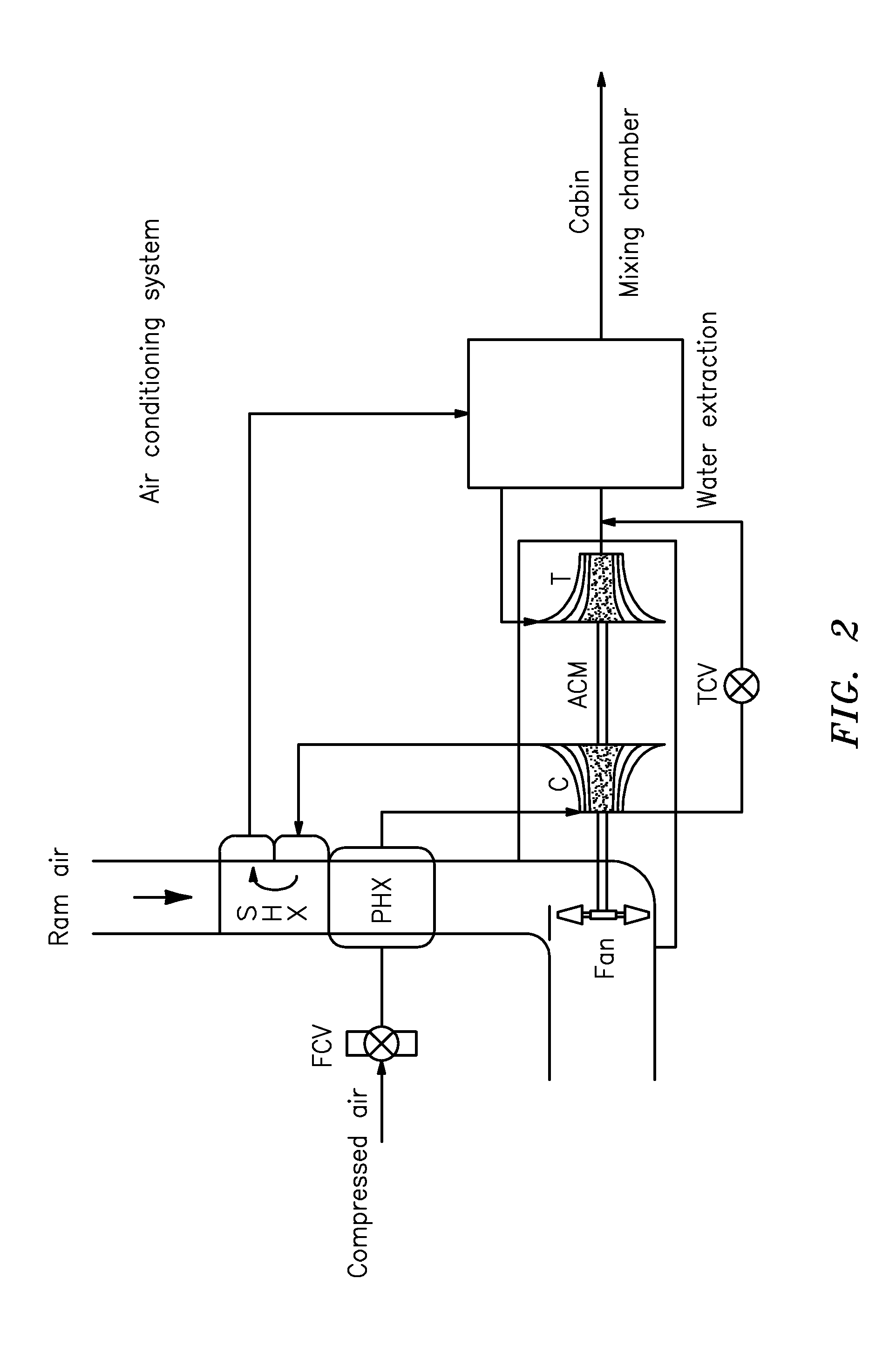

System for the preparation of compressed air

ActiveUS7845188B2Reduce weightSpace minimizationAircraft power plant componentsAir-treatment apparatus arrangementsEngineeringAir conditioning

A method and a system for the preparation of compressed air having a heat exchanger (system heat exchanger) which is in communication with a pressure source on the inlet side on the compressed air side and which is in communication with a system or unit on the outlet side on the compressed air side which is to be supplied with cooled compressed air and including at least one heat exchanger (air conditioning system heat exchanger) which is in communication with a pressure source on the inlet side on the compressed air side and which is in communication with additional components of an aircraft air conditioning system on the outlet side on the compressed air side. Provision is made for the system heat exchanger and the at least one air conditioning system heat exchanger to have a common inlet for supply with ram air or environmental air and for the system heat exchanger to be connected on its outlet side on the compressed air side via a closable line to the line system on the compressed air side in communication with the at least one air conditioning system heat exchanger or to the at least one air conditioning system heat exchanger itself.

Owner:LIEBHERR AEROSPACE LINDENBERG

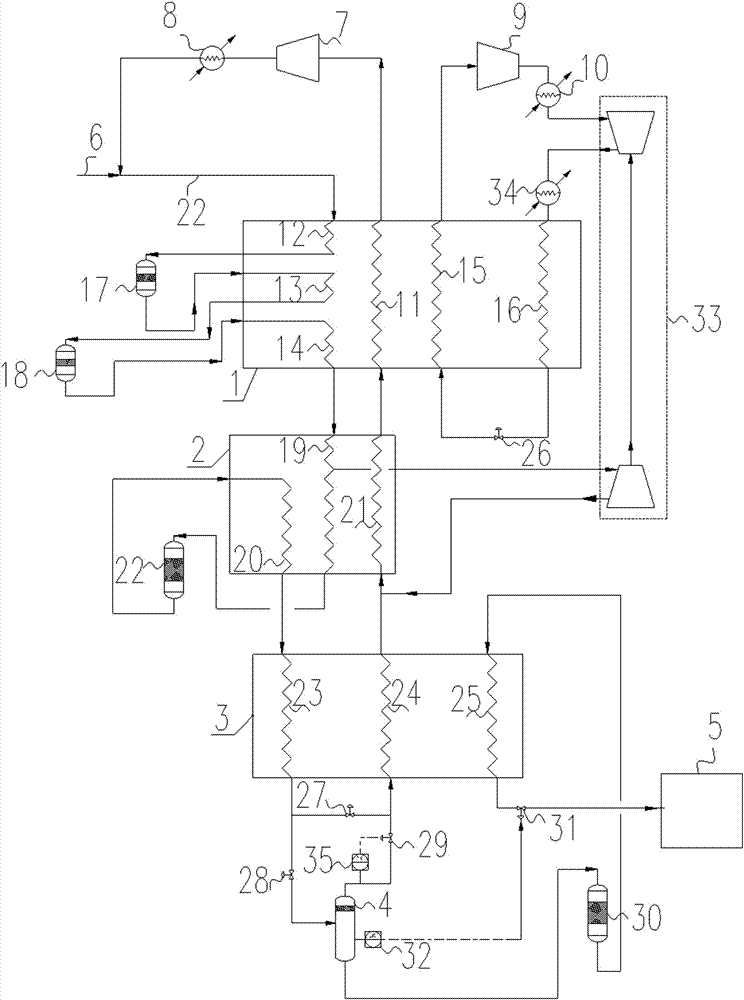

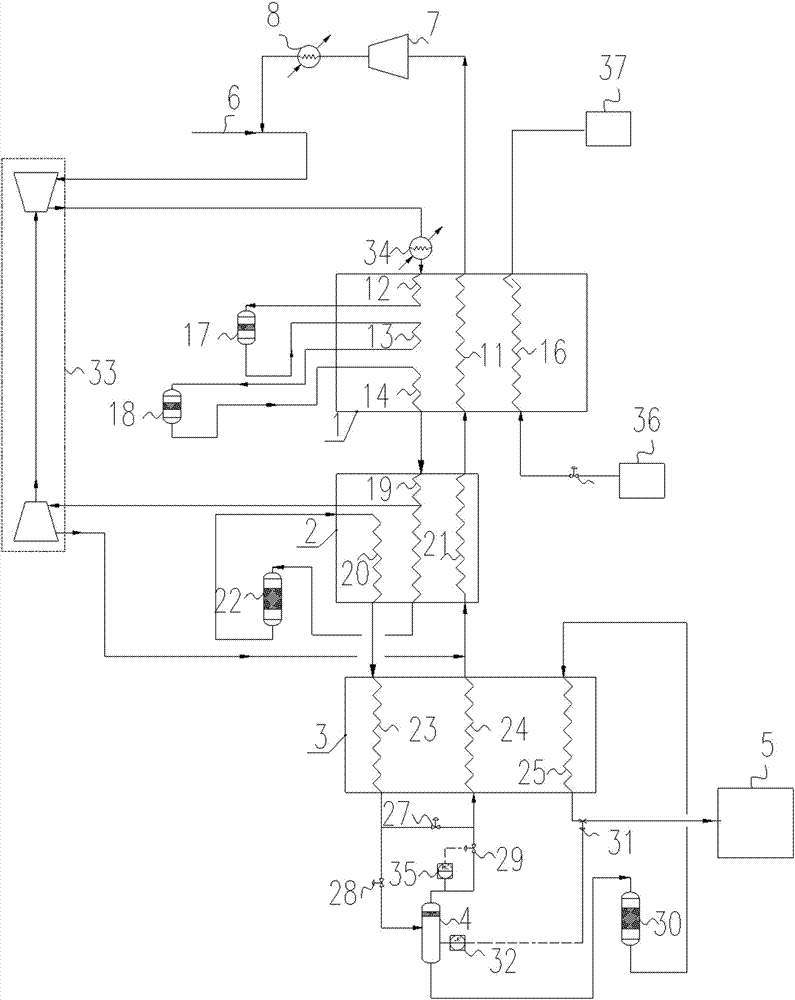

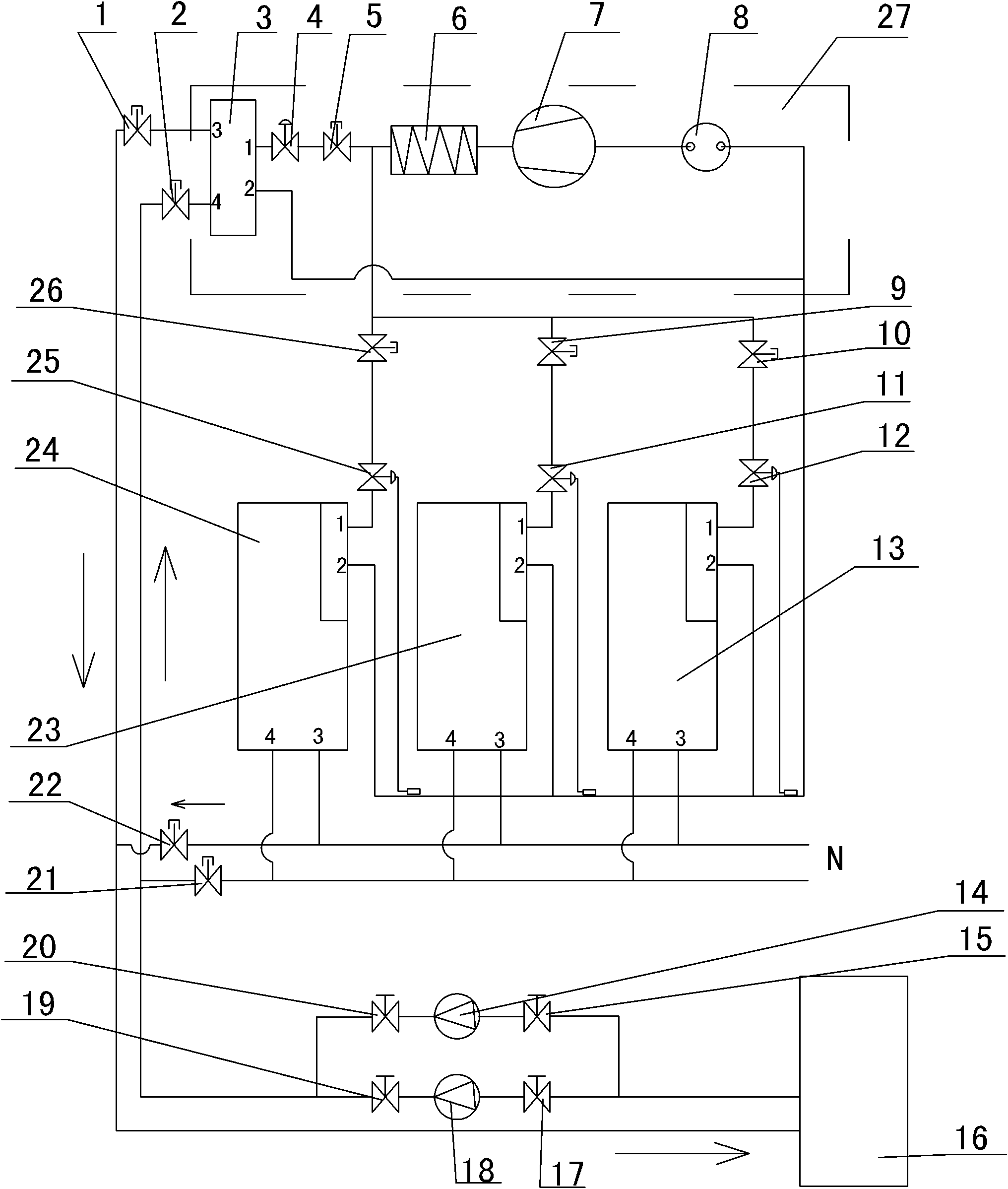

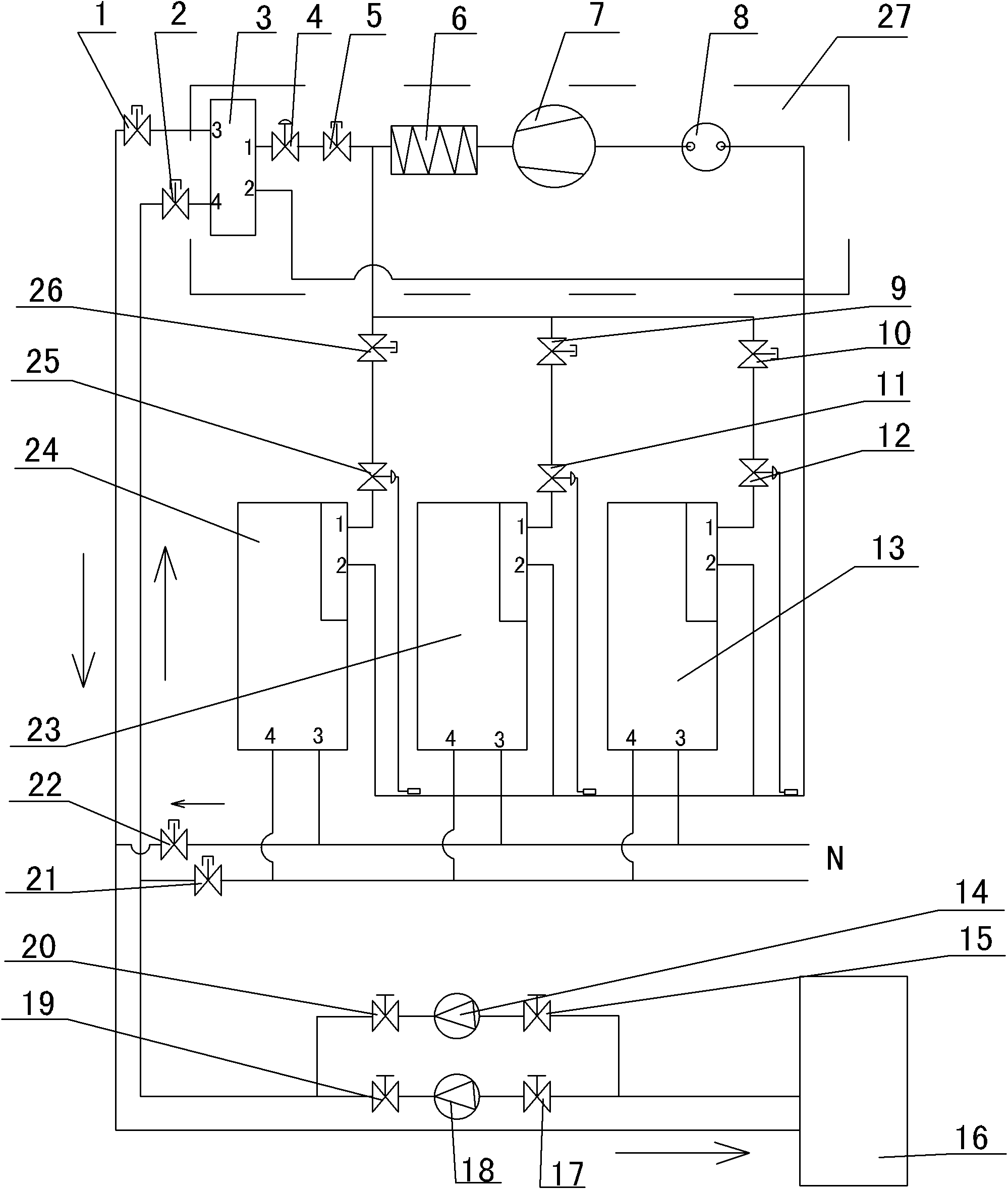

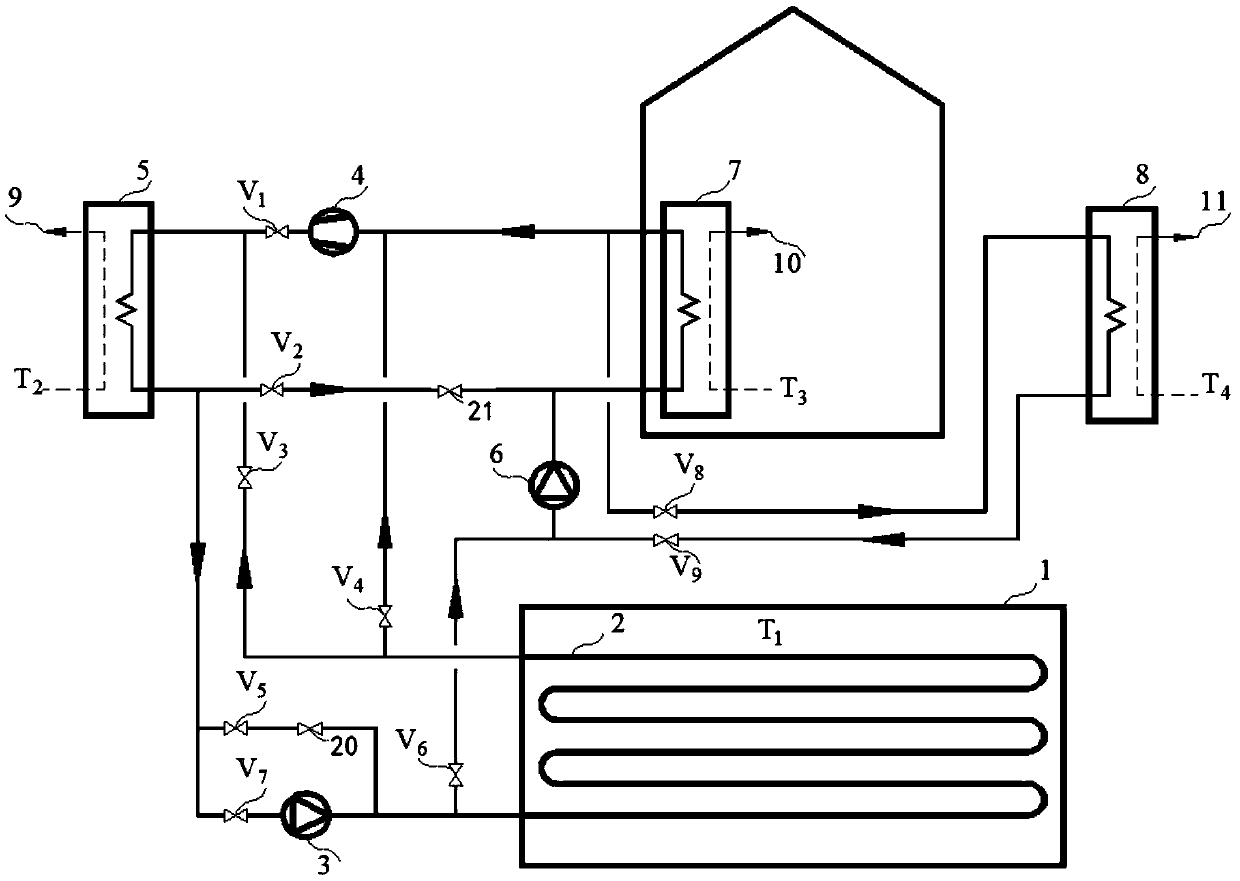

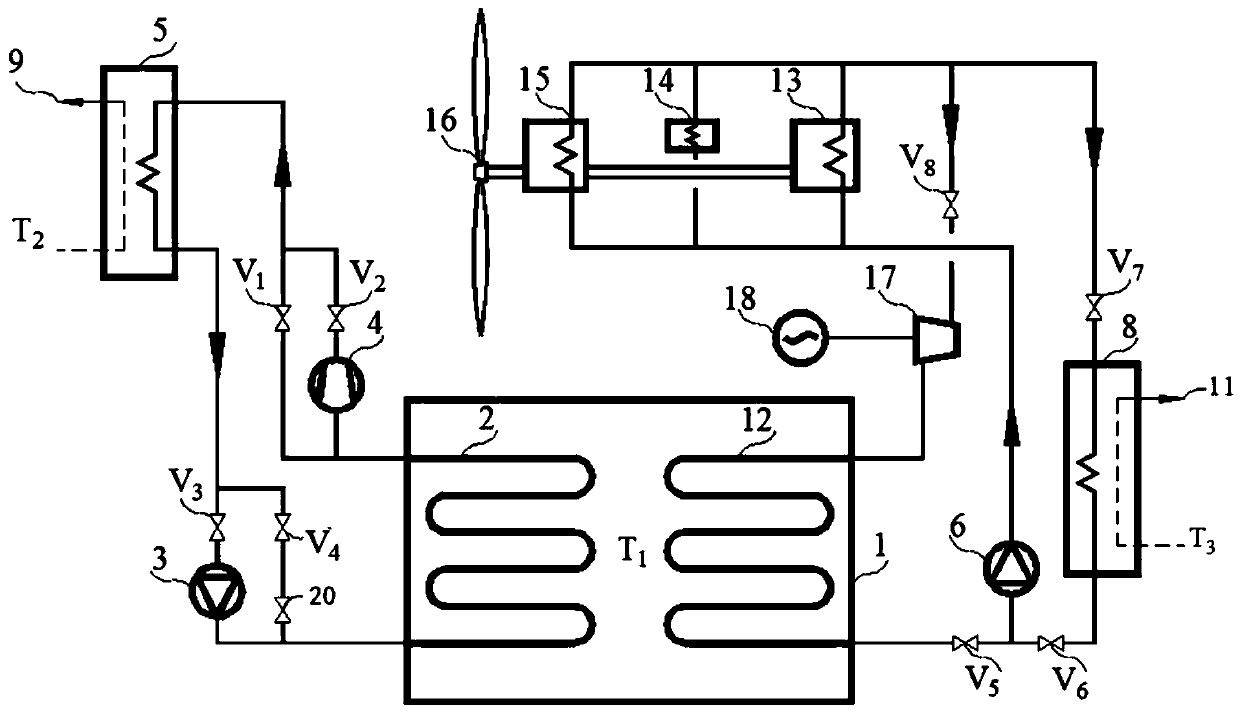

Intelligent control system for direct evaporation type multi-heat-exchange-system ice cold storage air conditioner

InactiveCN102506492ALarge unit cooling capacityLarge cooling capacitySpace heating and ventilation safety systemsLighting and heating apparatusEngineeringIntelligent control system

The invention discloses an intelligent control system for a direct evaporation type multi-heat-exchange-system ice cold storage air conditioner, which belongs to the field of ice cold storage air conditioners. The intelligent control system comprises an air conditioner main unit and ice tanks, wherein one end of the condenser (6) of the air conditioner main unit is connected with the first end of an evaporator (3) through a pipe, a first electromagnetic valve (5) and a first thermal expansion valve (4), and the other end of the condenser (6) is connected with the first ends of a plurality of groups of parallelly connected ice tanks by pipes; the second ends of the plurality of groups of parallelly connected ice tanks are connected with the other end of a vapor and liquid separator (8) by pipes; the third ends of the plurality of groups of ice tanks are connected in parallel and connected to the pipe of a first reversing electromagnetic valve (1) by pipes and a third reversing electromagnetic valve (22); the fourth ends of the plurality of groups of ice tanks are connected in parallel and are connected to a pipe of a second reversing electromagnetic valve (2) by pipes and a fourth reversing electromagnetic valve (21); and the first reversing electromagnetic valve (1) and the second reversing electromagnetic valve (2) are connected with an air conditioner tail end unit (16). The intelligent control system requires small investment and achieves a good energy-saving effect.

Owner:SHANGHAI HANFU AIR TREATMENT EQUIP

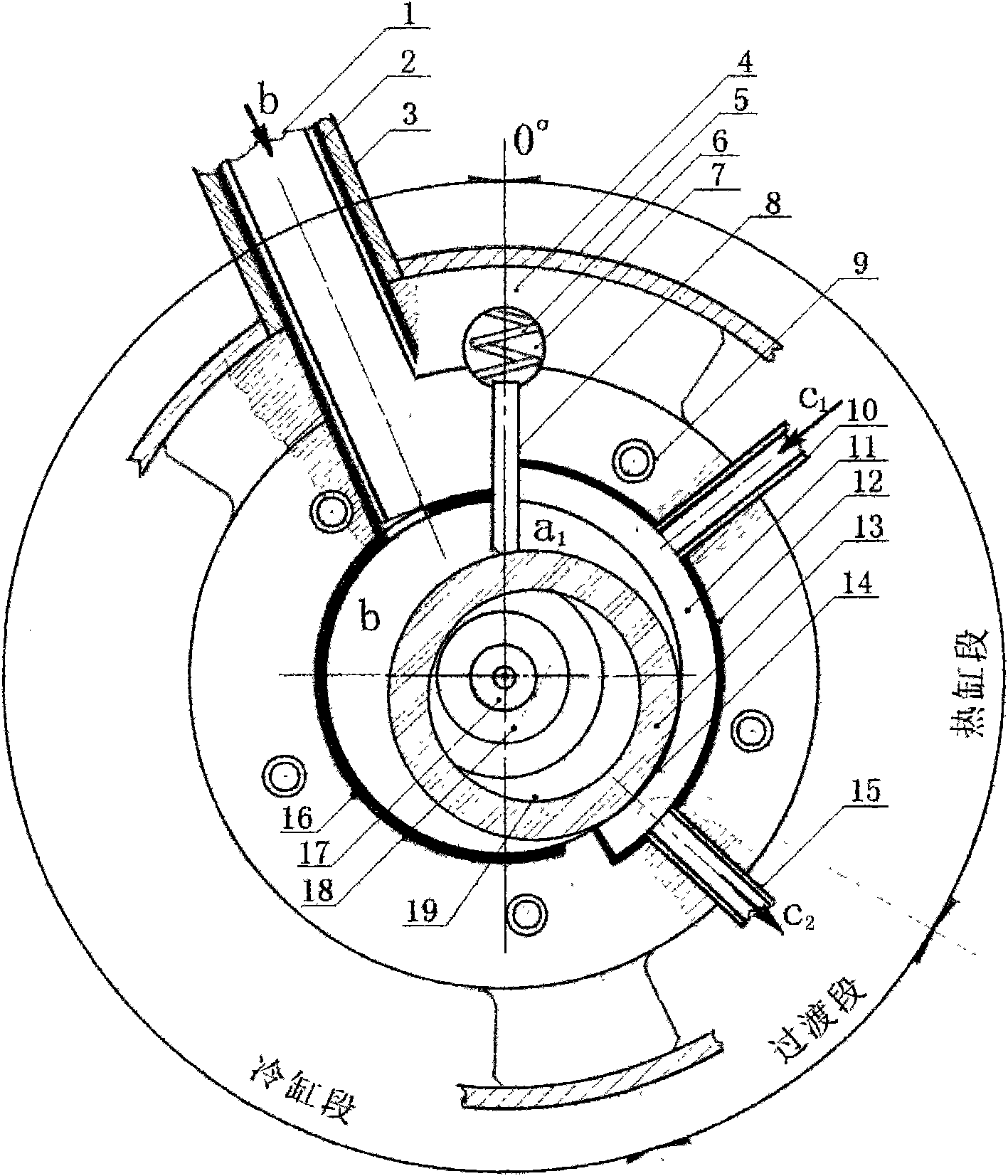

Cooling cylinder compression cycle of rotor-type compressor

InactiveCN101576083ALower subcooling temperatureReduce condensation loadRotary piston pumpsRotary piston liquid enginesRefrigeration compressorSuction force

The invention relates to a cycling system for improving the efficiency of a cooling compressor, cooling cylinder compression cycle for short. The cooling cylinder compression cycle of a rotor-type compressor is mainly realized in four aspects: a. cooling cylinder compression, i.e. performing low-temperature cooling to a compression strong-heat-release cylinder wall surface (defined as a heat cylinder and others are cooling cylinders), coating heat insulating ceramic on the surfaces of a tongue piece and a rolling rotor, pushing compression heat release to a cooled heat cylinder, and increasing the area of the heat cylinder or reduce the rotational speed so as to fully discharge the compression heat release and prevent the discharged gas from overheating and then to reduce the compression net work and the condensation load; b. cooling cylinder gas suction, i.e. performing the isolation of gas phase from heat insulation to high-pressure gas discharge, the cooling and heat cylinders, upper and lower covers and a gas suction pipe, and ensuring the low-temperature characteristic of a gas suction chamber by means of continuous gas suction and heat cylinder cooling so as to obtain greater cold energy; c. oil way improvement, i.e. increasing the gas-suction force; and d. recovery gas discharge overheating and motor heat releasing, for purposes of heating and compensating absorptive lubricant, wherein an absorbent has low partial pressure and strong absorption capability on the surfaces of the cooling cylinders so that the cold energy is further increased and the compression work is further reduced.

Owner:童夏民

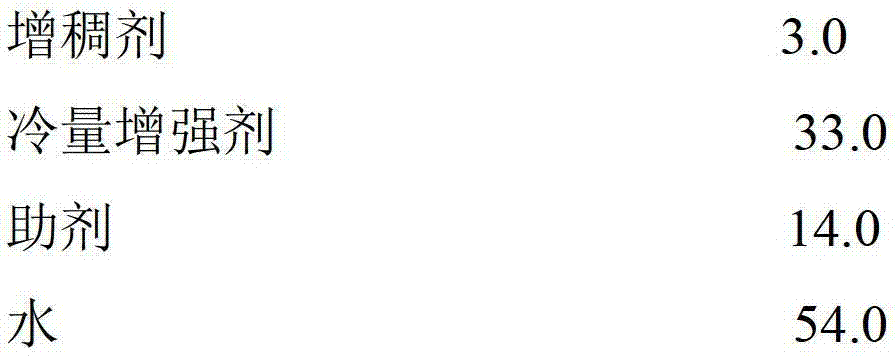

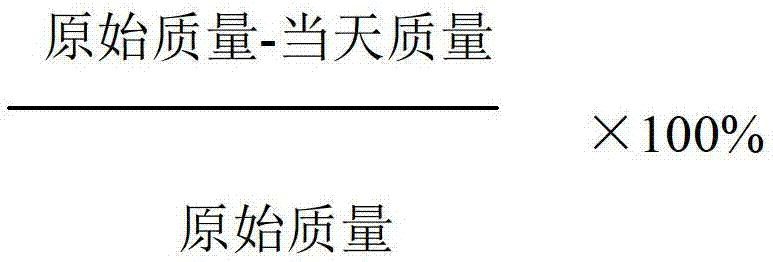

Cold-storage agent and preparation method thereof

ActiveCN102443379AWide variety of sourcesEasy to prepareHeat-exchange elementsEdible oilSodium nitrite

The invention discloses a cold-storage agent and a preparation method thereof. The cold-storage agent comprises the following components by weight percent: 2%-20% of polyacrylate, 2%-20% of edible oil, 2%-20% of vinyl acetate copolymer, 2%-20% of starch, 2%-16% of sodium nitrite and the balance of water. The preparation method comprises the following steps: firstly, correctly weighing polyacrylate, edible oil, vinyl acetate copolymer, starch, sodium nitrite and water according to the proportion and then adding into a mixer; heating to 32-40 DEG C, stirring for 1-2 hours for evenly mixing the former components, cooling to 20-24 DEG C, so that the mixture is of a jelly shape; and packaging with a plastic bag or plastic box. The cold-storage agent has good cold-storage effect, large cold-storage amount and long cold-storage period as well as energy conservation and emission reduction; and the preparation method is simple, has wide raw material source and low cost, is safe and reliable, and can be repeatedly used.

Owner:SUZHOU ANTEK INDAL

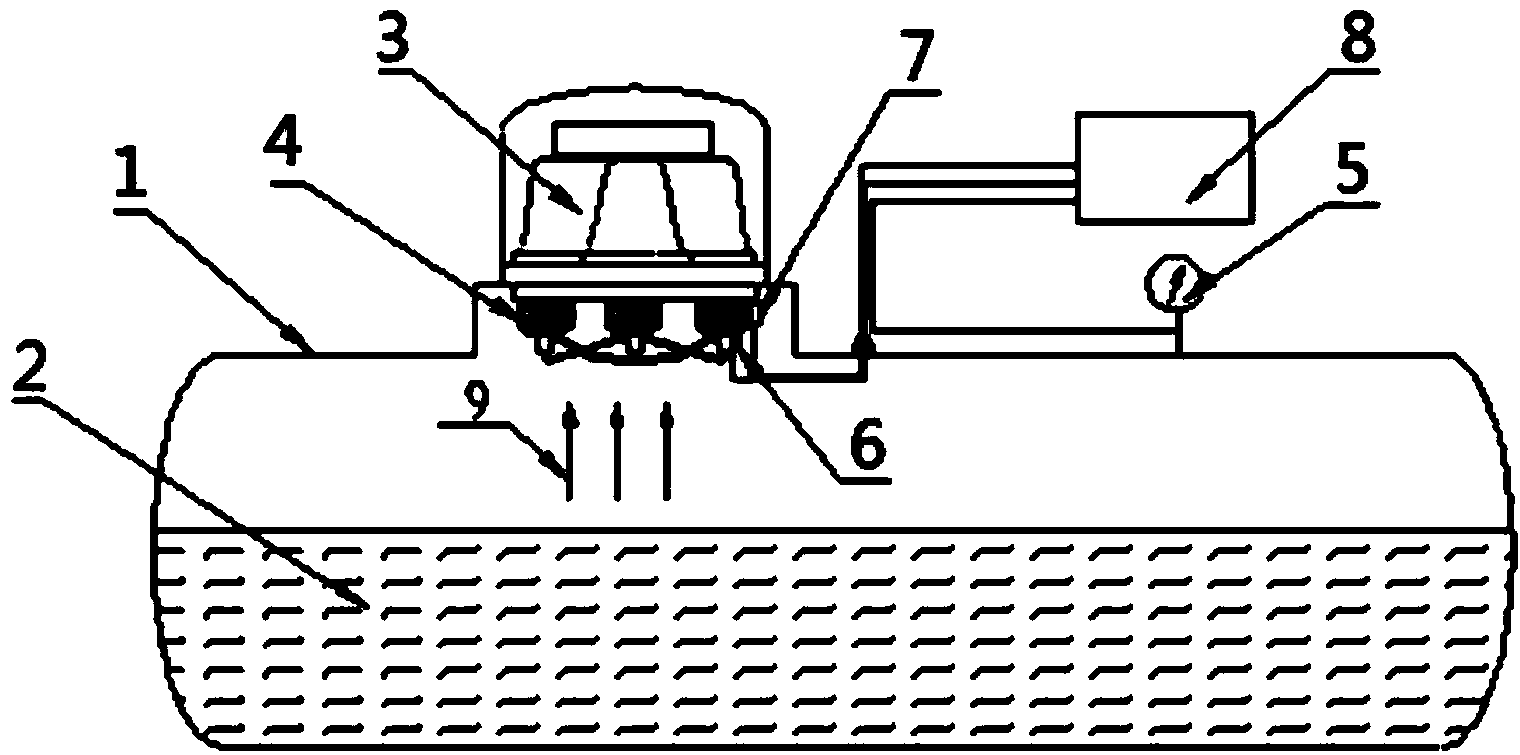

Small skid-mounted evaporation gas reliquefaction and recovery device for liquefied natural gas

InactiveCN103759496ALow cooling temperatureLarge cooling capacitySolidificationLiquefactionRefrigerated temperatureControl system

The invention provides a small skid-mounted evaporation gas reliquefaction and recovery device for liquefied natural gas. The small skid-mounted evaporation gas reliquefaction and recovery device comprises a cryogenic storage tank (1), a regenerative cryo refrigerator (3), an externally-finned condensing heat exchanger (4), a pressure testing device (5), a temperature testing device (6), a heating device (7) and a control system (8). Real-time monitoring and stepless regulation can be performed on cryogenic temperature and output cold of the cryo refrigerator according to requirements on actual pressure and heat loads inside the cryogenic storage tank, and zero consumption of an LNG (liquefied natural gas) storage tank system can be realized; pumpless circulation of gas liquid flow inside the device can be realized by relying on self differential pressure and gravity; the small skid-mounted evaporation gas reliquefaction and recovery device is low in system energy consumption, compact in structure, simple in technology process, high in reliquefaction efficiency and low in operation and maintenance costs, and skid mounting of the device can be realized.

Owner:SHANGHAI JIAO TONG UNIV +1

Fruit and vegetable e-commerce cold-chain fresh-keeping container

PendingCN111184060ATemperature implementation experienceRegulate microcirculationFruit and vegetables preservationDomestic cooling apparatusCold chainMicro environment

The invention relates to a fruit and vegetable e-commerce cold-chain fresh-keeping container which comprises an outer-layer container, an inner-layer container, a sealing cover and a low power consumption internal circulation fan, wherein the inner-layer container is arranged inside the outer-layer container with a gap; the outer-layer container and the inner-layer container share one same sealingcover; a lifting handle is manufactured at the upper part of the sealing cover; the sealing cover tightly seals and covers the inner-layer container and the outer-layer container simultaneously; boththe material and the internal structure of the container cover are identical to those of the outer-layer container; on the inner side of the inner-layer container, a fresh-keeping adjusting assemblyis mounted at a ventilation window corresponding to the fan; the fresh-keeping adjusting assembly is a frame; the frame is made of a net and is opened front and back; a front opening corresponds to the ventilation window; an NO slow release block, a plant essential oil slow release block and a 1-mcp slow release block are placed in the fresh-keeping adjusting assembly from top to bottom in sequence; and an adsorption block is mounted inside the ventilation window corresponding to a sealing gate. Due to addition of slow release materials, environments in sub-containers can be adjusted, meanwhile, real-time gas regulation and control on micro environments in the containers can be implemented, and purposes of gas adjustment and corrosion prevention and environment protection and security canbe achieved.

Owner:大有作为(天津)冷链设备有限公司

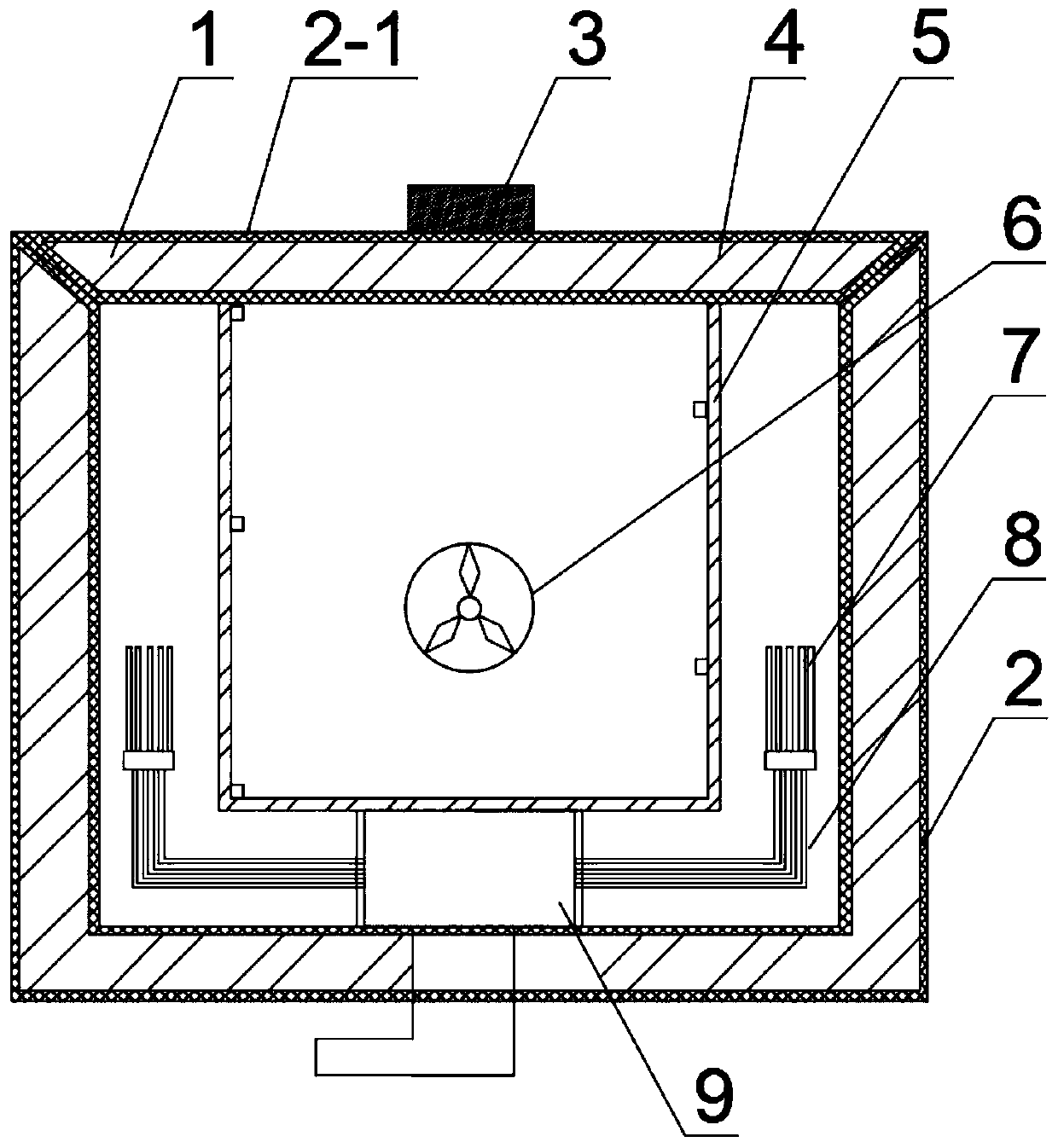

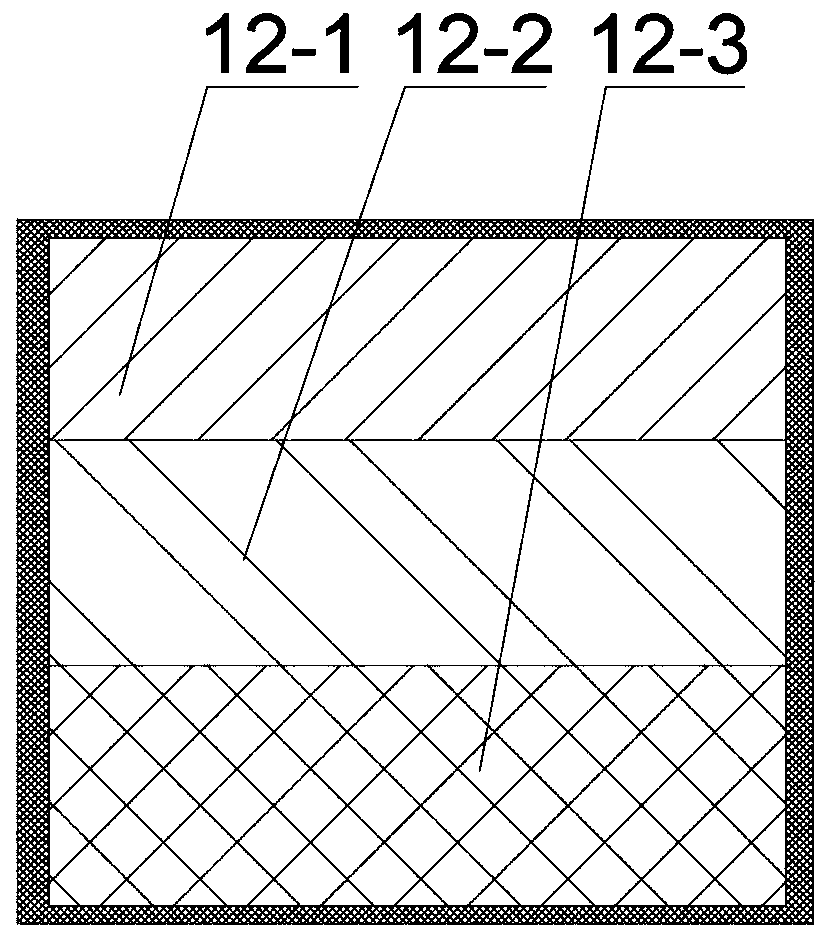

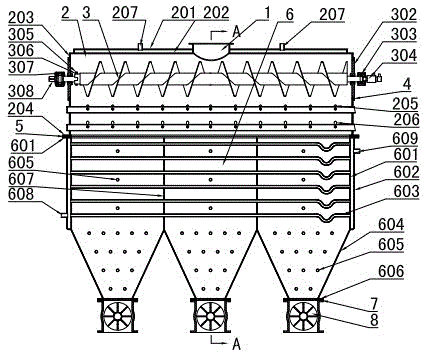

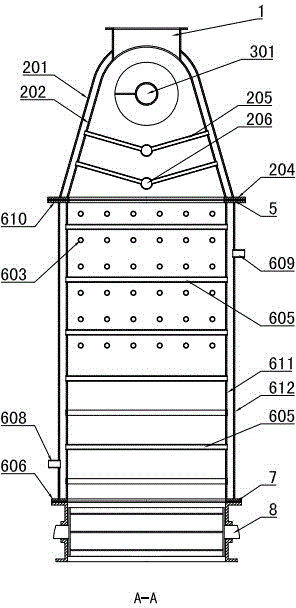

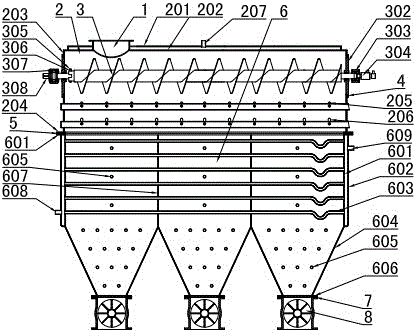

Large box type high-temperature material heat exchanger

ActiveCN104697371ALarge flow cross-sectional areaLarge cooling capacityMoving conduit heat exchangersImpellerEngineering

The invention provides a large box type high-temperature material heat exchanger, and belongs to the field of high-temperature solid material cooling equipment. The large box type high-temperature material heat exchanger is characterized by sequentially comprising a water cooling box cover (2), a heat exchanging box (6) and necking-down type hoppers from top to bottom, wherein a water cooling jacket is arranged on a wall of the water cooling box cover (2); end water cavities and / or side water cavities are formed in the wall of the heat exchanging box (6) and the walls of the necking-down hoppers; a plurality of heat exchanging pipelines are respectively arranged in the water cooling box cover (2), the heat exchanging box (6) and cavities of the necking-down type hoppers; a feeding opening (1) is formed in the upper portion of the water cooling box cover (2); a water cooling spiral distributor (3) which can convey and cool down materials is arranged in the water cooling box cover (2); the necking-down type hoppers are arranged side by side; and an impeller discharging valve (8) is arranged at an outlet of the bottom of each necking-down type hopper. The large box type high-temperature material heat exchanger is large in material cooling amount, low in energy consumption and long in service life; and abrasion of heat exchanging components is small.

Owner:SHANDONG UNIV OF TECH

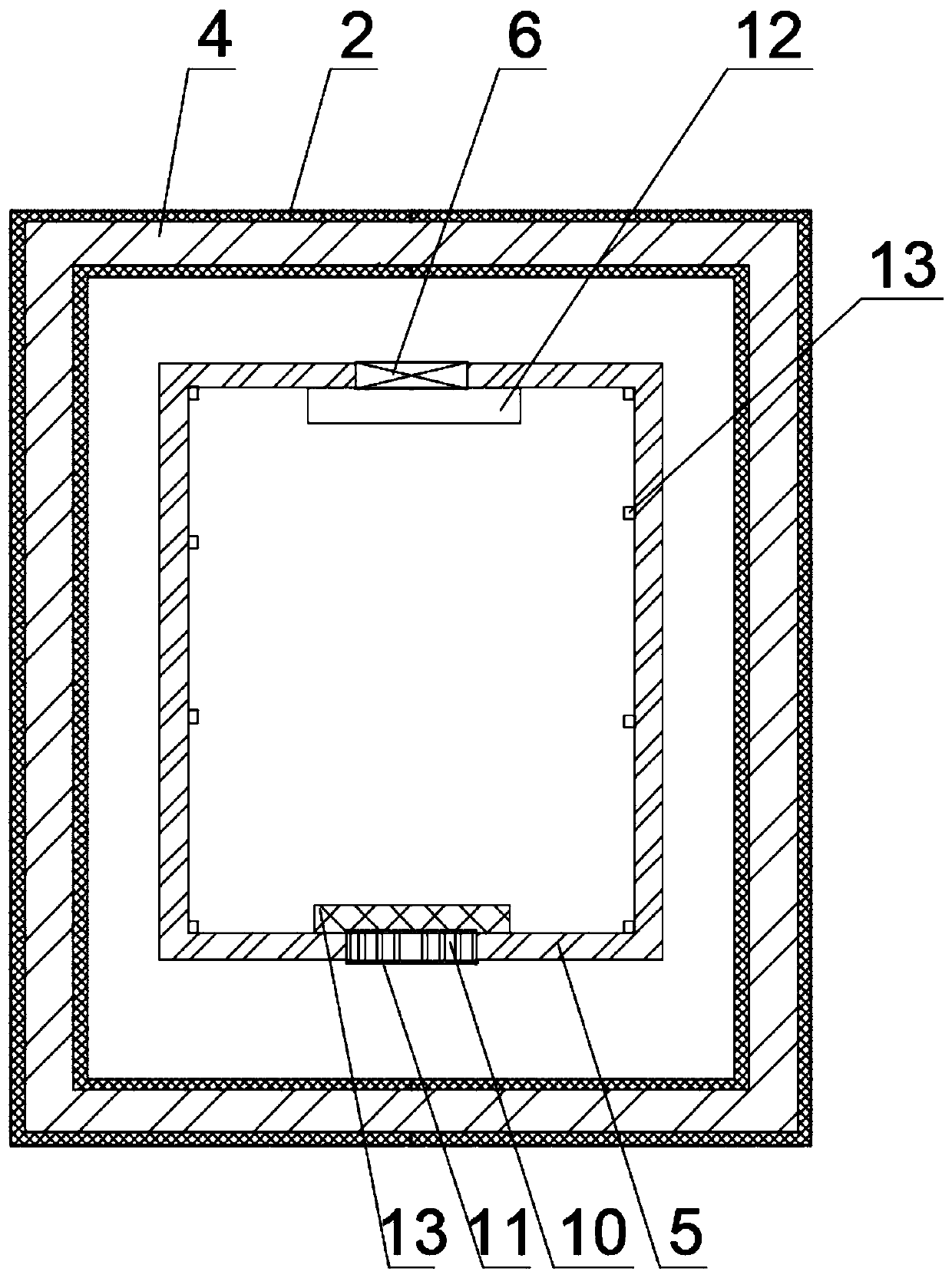

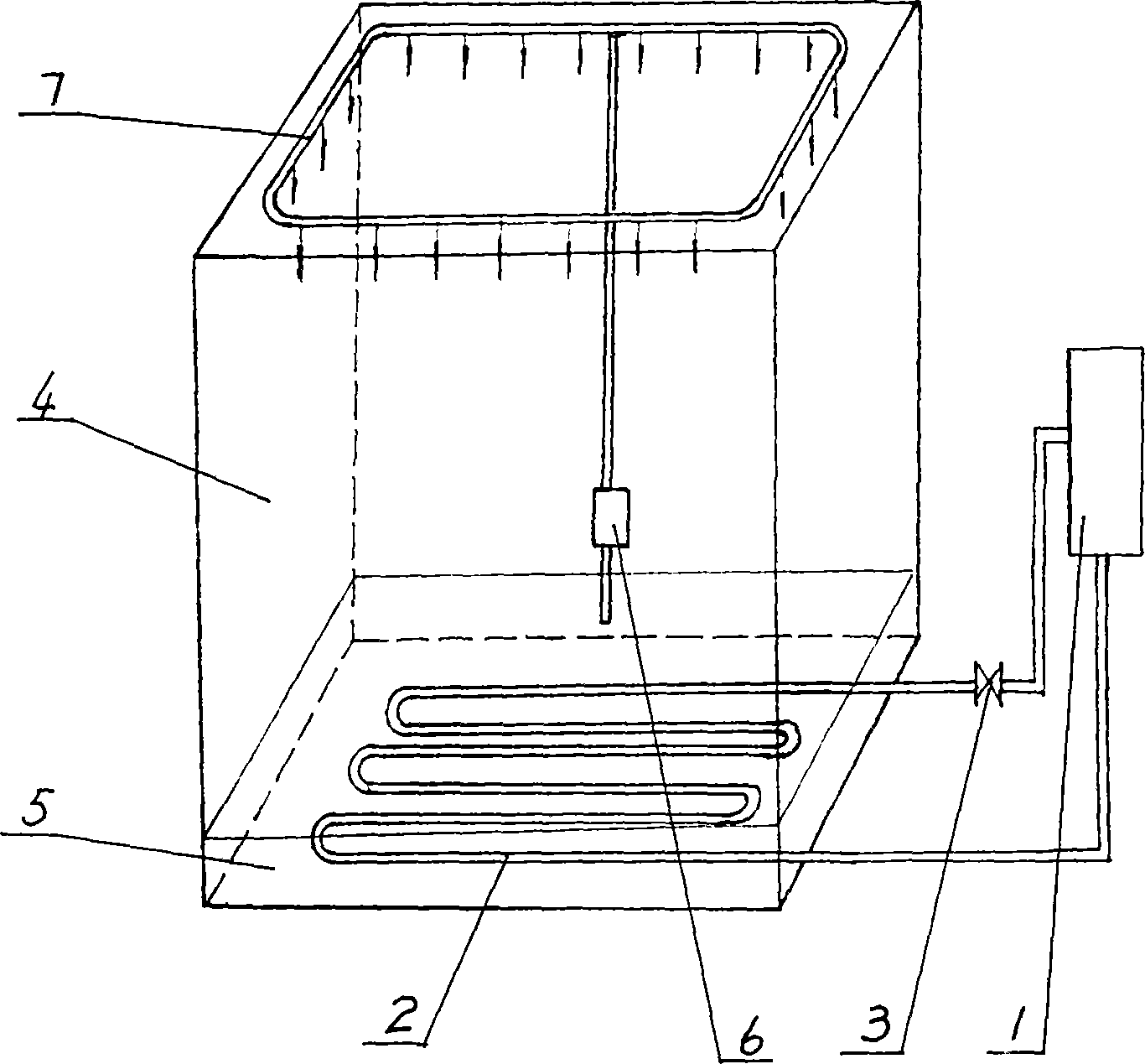

Frostless ice house

InactiveCN101196361AReduce switching timesReduce the temperatureLighting and heating apparatusStationary refrigeration devicesRefrigeration compressorHigh humidity

A small and medium frostless refrigeratory for keeping fresh of farm and sideline products is provided, which comprises a refrigeration compressor unit (1), a vaporize comb (2) and a reducing valve (3). The vaporize comb (2) is communicated with the refrigeration compressor unit (1) to form circulation, which is provided with the reducing valve (3); the vaporize comb (2) is arranged in a shallow pool (5) at bottom of a refrigeratory (4); the shallow pool (5) is internally provided with secondary refrigerant. The refrigeratory (4) is also internally arranged with a circulating pump (6) and a cascade device of a shower (7). The refrigeration compressor unit (1) sends the refrigerant to the vaporize comb (2) through the reducing valve (3) and the refrigerant can return to the refrigeration compressor unit (1) after absorb heat; the circulating pump (6) sends the secondary refrigerant to the shower (7) to spray in the refrigeratory (4). The invention is characterized in that: the cold volume is completely exchanged in the refrigeratory, so the invention has no dissipation and lose, large cold volume storage and is able to maintain a relative constant temperature of the refrigeratory, thereby reducing the times for opening and closing the refrigeration compressor, saving energy, prolonging the service life of the equipment, having no forest and high humidity, etc.

Owner:SHANDONG INST OF POMOLOGY

Cooling apparatus for fuel cell utilizing air conditioning system

InactiveUS7086246B2Reduce power consumptionImprove fuel efficiencyFuel cell heat exchangeDomestic refrigeratorsFuel cellsFour-way valve

A cooling circuit of a cooling apparatus for a fuel cell comprises a compressor for compressing a gaseous refrigerant, an external heat exchanger arranged on the downstream side of the compressor and for liquefying the compressed refrigerant, a pressure-reducing means arranged on the downstream side of the external heat exchanger, and an accumulator for storing the refrigerant which cools a fuel cell stack main body. The stack main body is connected to the cooling circuit between the pressure-reducing means and the accumulator and a four-way valve is arranged between the compressor and the external heat exchanger, and between the stack main body and the accumulator in the cooling circuit, and the four-way valve introduces the refrigerant from the compressor to the external heat exchanger during the cooling operation, and introduces it to the stack main body during the warming-up operation.

Owner:DENSO CORP

Environmental protection type refrigerant

ActiveCN101235275AEnvironmentally friendlyMeet environmental protection requirementsChemical industryHeat-exchange elementsButeneAtmospheric ozone

The invention discloses a novel environment-friendly refrigerant, which is formed by a first component, difluoromethane, penta-fluoroethane and hydrocarbon component, wherein the first component is one of fluoroethane and 1, 1-difluoroethane, hydrocarbon component is the combination of one or more than one of isobutene, normal butene, propane and propylene. The refrigerant whose ODP is zero, which does not damage atmospheric ozone layer, and largely reduces GWP value compared with HCFC-22 and current substitutes R407 C and R410A, and has excellent environment-friendly property. The refrigerant whose thermal property is equivalent to HCFC-22 can be directly used in a system which originally uses HCFC-22, can reduce charge amount and increase energy effect ratio, and has the advantages of saving resources and energy. The refrigerant can be used as long-term substitute of HCFC-22, which provides a reliable technology which is easy to be popularized and applied and can take effect rapidlyfor the global to cope with climate warming.

Owner:SINOCHEM LANTIAN +1

Green mixed refrigerant

InactiveCN102516946ALow ODPImprove thermal performanceHeat-exchange elementsDifluoroethyneEngineering

The invention discloses a green mixed refrigerant, comprising 20-60 wt% of 2,3,3,3-tetrafluoro propylene or trans-1,3,3,3-tetrafluoro propylene, 5-30 wt% of 1,1-difluoroethane or 1,1,1,2-tetrafluoro ethane, and 35-60 wt% of difluoromethane. The preparation method is characterized by physically mixing the above ingredients according to corresponding ratio at normal temperature. According to the invention, because the volume refrigerating capacity of the green mixed refrigerant is very close to that of HCFC-22 and the condensation pressure of the green mixed refrigerant is lower than that of R410A, the green mixed refrigerant can be directly filled in existing refrigeration, air-conditioning or heat pump sets which use HCFC-22; and when HCFC-22 is replaced, the components and pipeline of the system have no need of redesigning. The green mixed refrigerant can be an alternative refrigerant to HCFC-22 and R410A.

Owner:JIMEI UNIV

Brown beech mushroom refrigeration cold-insulation agent and preparation method thereof

InactiveCN103194178ALow freezing pointLowering the freezing pointHeat-exchange elementsFruits/vegetable preservation by freezing/coolingGlycerolBeech

The invention discloses a brown beech mushroom refrigeration cold-insulation agent and a preparation method thereof, wherein the cold-insulation agent is formed by combining a thickening agent formed from soluble chitosan and soluble starch with a cooling capacity reinforcing agent formed from ethanol and glycerol by adding auxiliaries formed from soluble amine or amine salt and soluble acetate and water. The brown beech mushroom refrigeration cold-insulation agent disclosed by the invention is not iced at low temperature; the limited space of a packaging box can be effectively utilized; the transportation cost is reduced; a better effect is played in a long time; good flowability is still kept at minus 30 DEG C; due to addition of the auxiliaries, the cooling capacity storage amount is further increased; the cold-insulation agent disclosed by the invention is low in use amount and also has the advantages of being low in corrosivity and environmental influence; and in addition, if packaging is leaked, effective components of the cold-insulation agent have good effects on fresh keeping and growth of products.

Owner:DALIAN POLYTECHNIC UNIVERSITY

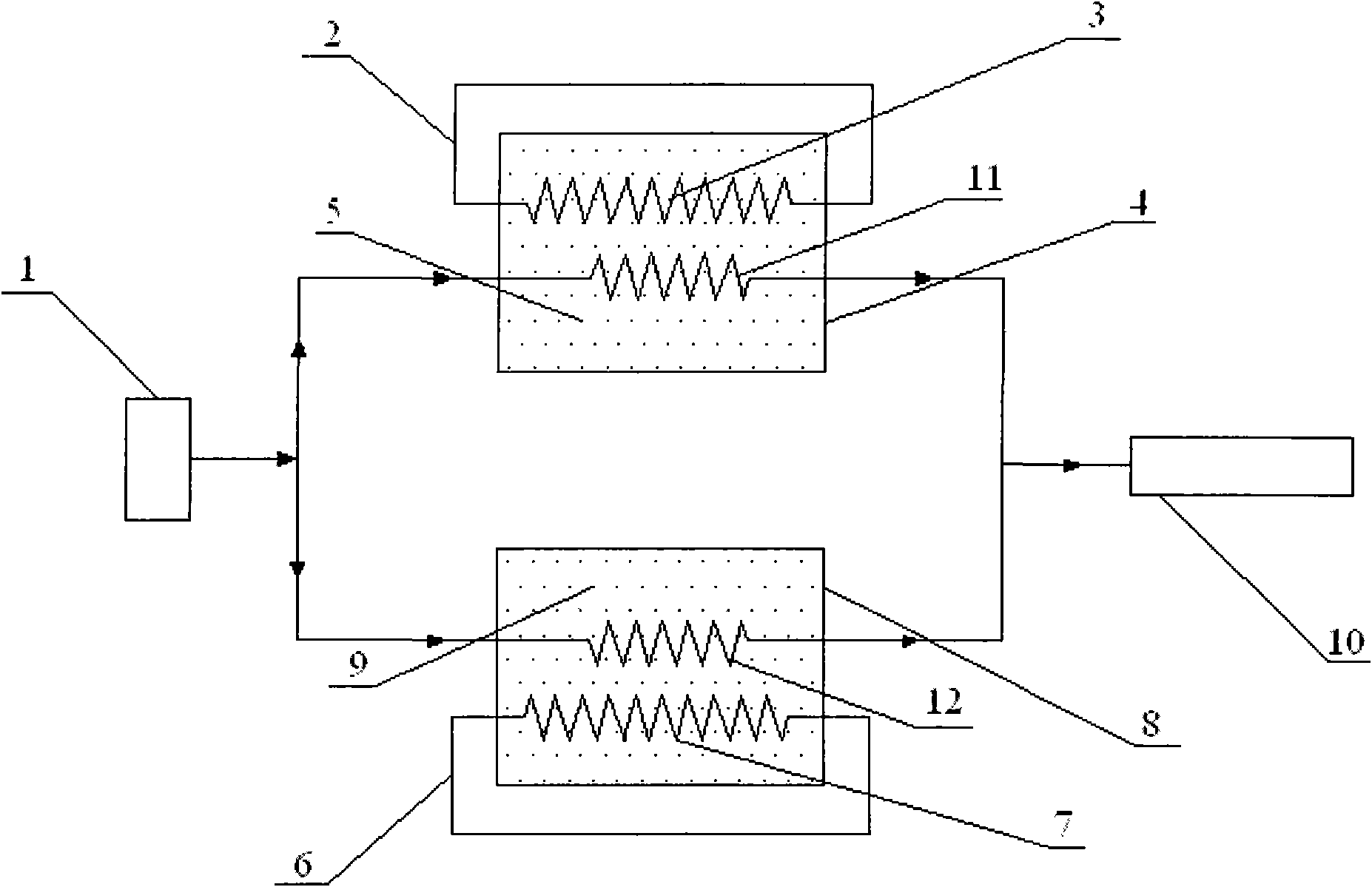

Cold and hot ablation apparatus with cold and heat accumulation devices

InactiveCN101554338AReduce noiseCooling load peak dropSurgical instruments for heatingSurgical instruments for coolingEngineeringRefrigerant

The invention discloses a cold and hot ablation apparatus with cold and heat accumulation devices, the apparatus comprises a refrigerant container, a gas main and a cold / heat probe or a conduit, wherein the refrigerant container is connected with the gas main which is divided into two pipelines, one pipeline is connected with a gas inlet cold pipe, the other pipeline is connected with a gas inlet hot pipe, and the gas inlet cold pipe passing through a cold-accumulating heat exchanger is jointed with the gas inlet hot pipe passing through a heat-accumulating heat exchanger into one gas inlet pipe which is then is connected with the cold / heat probe or the conduit. One way of refrigerant in the refrigerant container used by the apparatus is pre-cooled firstly by the cold-accumulating heat exchanger, and then the refrigerant is used for cooling and freezing pathologically changed tissues through the cold / heat probe or the conduit.. The other way of refrigerant passes through the heat-accumulating heat exchanger and then heats the cold / heat probe or the head part of the conduit so that the temperature of the pathologically changed tissues is quickly reduced or the frozen pathologically changed tissues are molten, and then a series of inreversible injuries can be generated so as to achieve the aim of eliminating pathological changes.

Owner:ACCUTARGET MEDIPHARMA (SHANGHAI) CO LTD

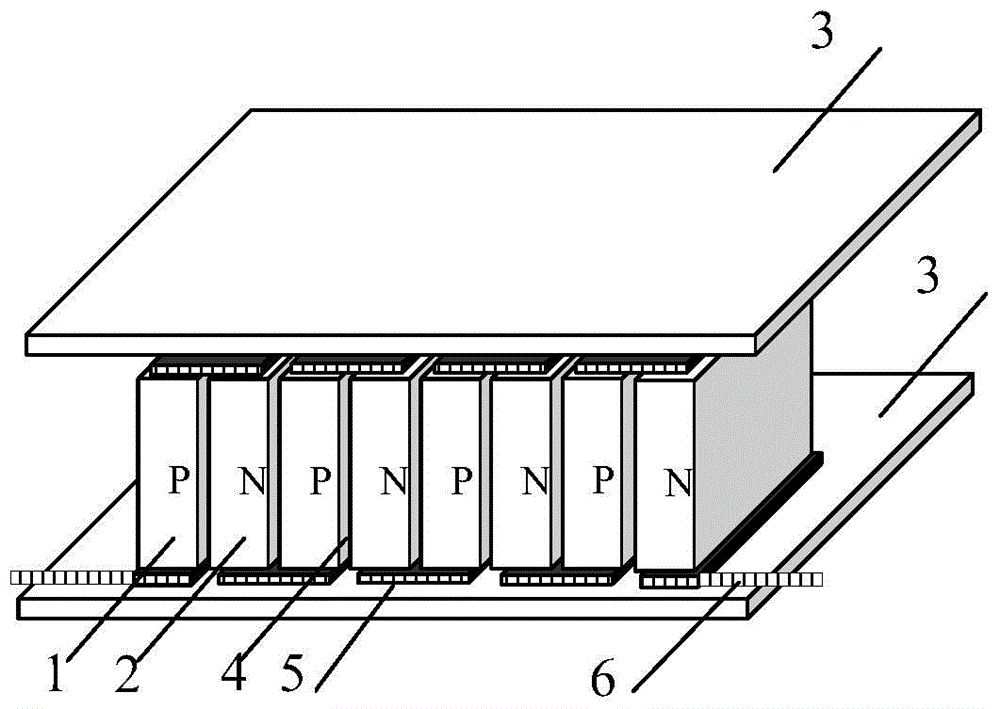

Thermopile and automobile exhaust waste heat generation and refrigeration device employing same

InactiveCN104576912AEliminate the disadvantages of temperature dropSave spaceAir-treating devicesThermoelectric device with peltier/seeback effectElectricityThermopile

Various types of automobile exhaust waste heat generation devices at present are complex in process, high in cost, low in integration level, large in size and low in heat-electricity conversion efficiency. The invention discloses a thermopile which is high in integration level, simple in structure, low in cost and high in reliability; the invention also discloses an automobile exhaust waste heat generation and refrigeration device employing the thermopile as a core part for generation and refrigeration. P-type thermocouple arms formed in the shape of a rectangular cylinder and N-type thermocouple arms are arranged in a staggered manner. A heat-insulation and insulting film material is arranged between the adjacent thermocouple arms in an attaching manner for isolation, so that the convection of air is eliminated, the defect of the reduction of the temperature difference between cold and hot surfaces caused by radiation is overcome, and the heat-electricity conversion efficiency is improved. The electric connection between the thermocouple arms is achieved through flexible heat-conduction and electric-conduction materials, so that a thermal stress is alleviated, the adverse effect of the thermal stress on a product is eliminated, and the problem that the reliability and the service life of the product are affected seriously, caused by the deformation and cracking of the thermopile and falling of welding spots between the thermocouple arms which are caused by the thermal stress, is solved.

Owner:张红碧 +1

Seasonal cold-accumulation all-year cooling system and operating method thereof

ActiveCN109579176ALarge cooling capacityFreeze protection is not necessaryMechanical apparatusLighting and heating apparatusElectricity priceNuclear engineering

The invention discloses a seasonal cold-accumulation all-year cooling system and an operating method thereof, and belongs to the technical field of air conditioners. The system comprises a primary cold-accumulation loop, a secondary cold-accumulation loop, a cold-release cooling loop, a natural cooling loop and a refrigerating cooling loop. In winter, equipment is cooled by the natural cooling loop, and the primary cold-accumulation loop and the secondary cold-accumulation loop generate low-temperature cold energy to store during power consumption valley in winter. In summer and transition seasons, the equipment is cooled by the cold-release cooling loop, and the refrigerating cooling loop is reserved in summer. The seasonal cold-accumulation all-year cooling system utilizes a winter valley electricity price to refrigerate and store cold, is great in cold-storage density, is high in quality, and is suitable for cooling various kinds of electronic equipment, wind generating sets, data machine rooms, and the like.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

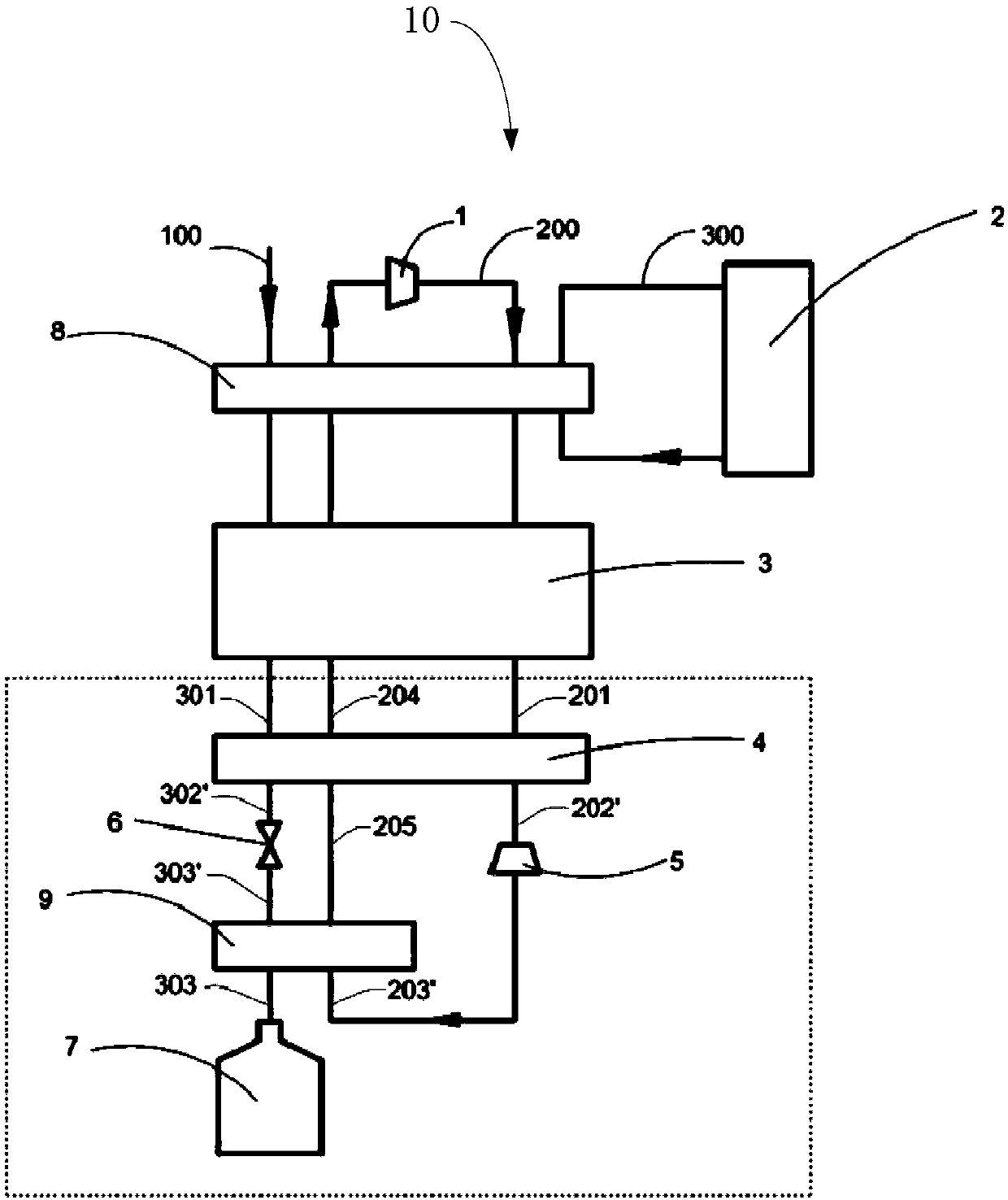

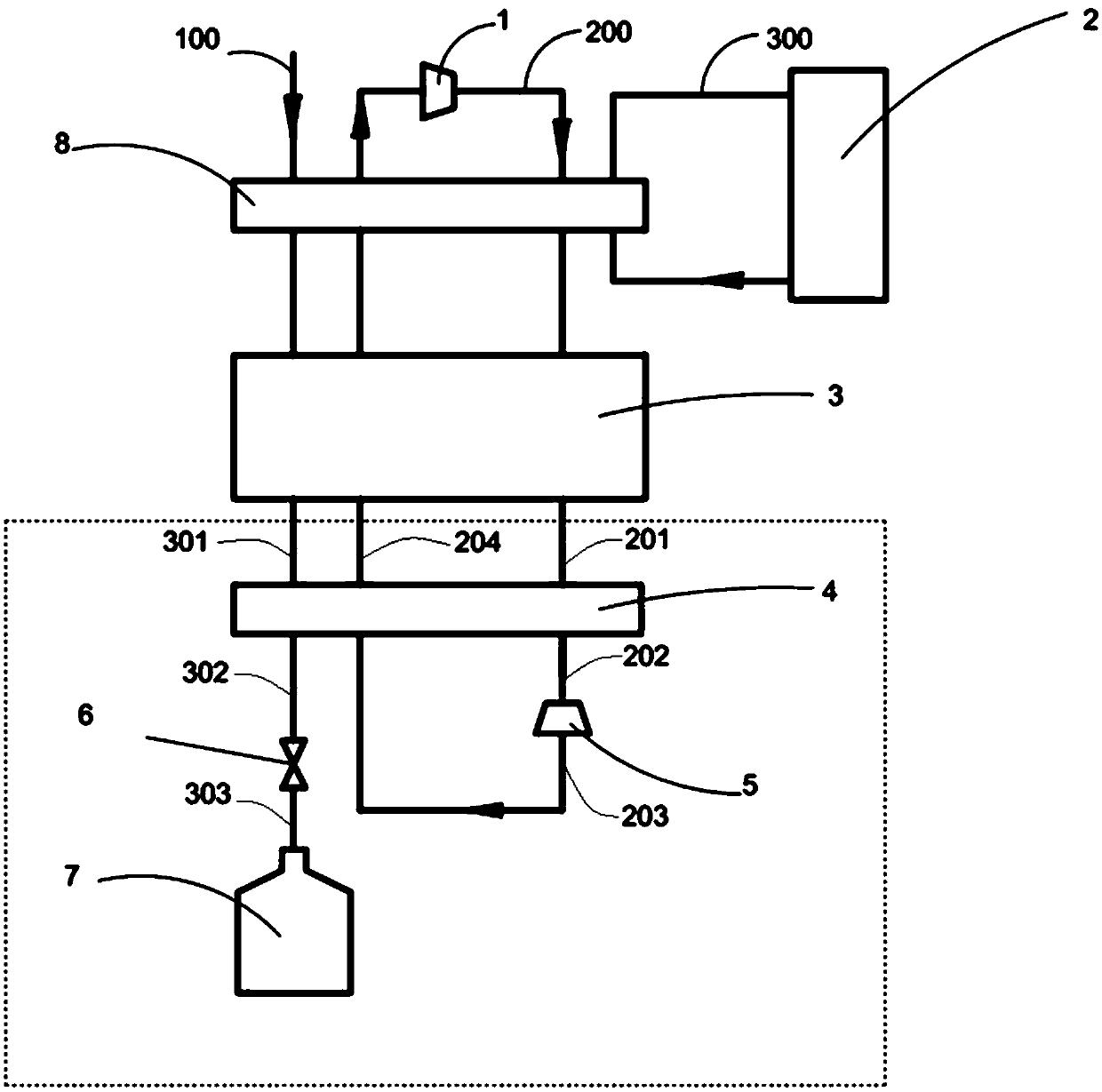

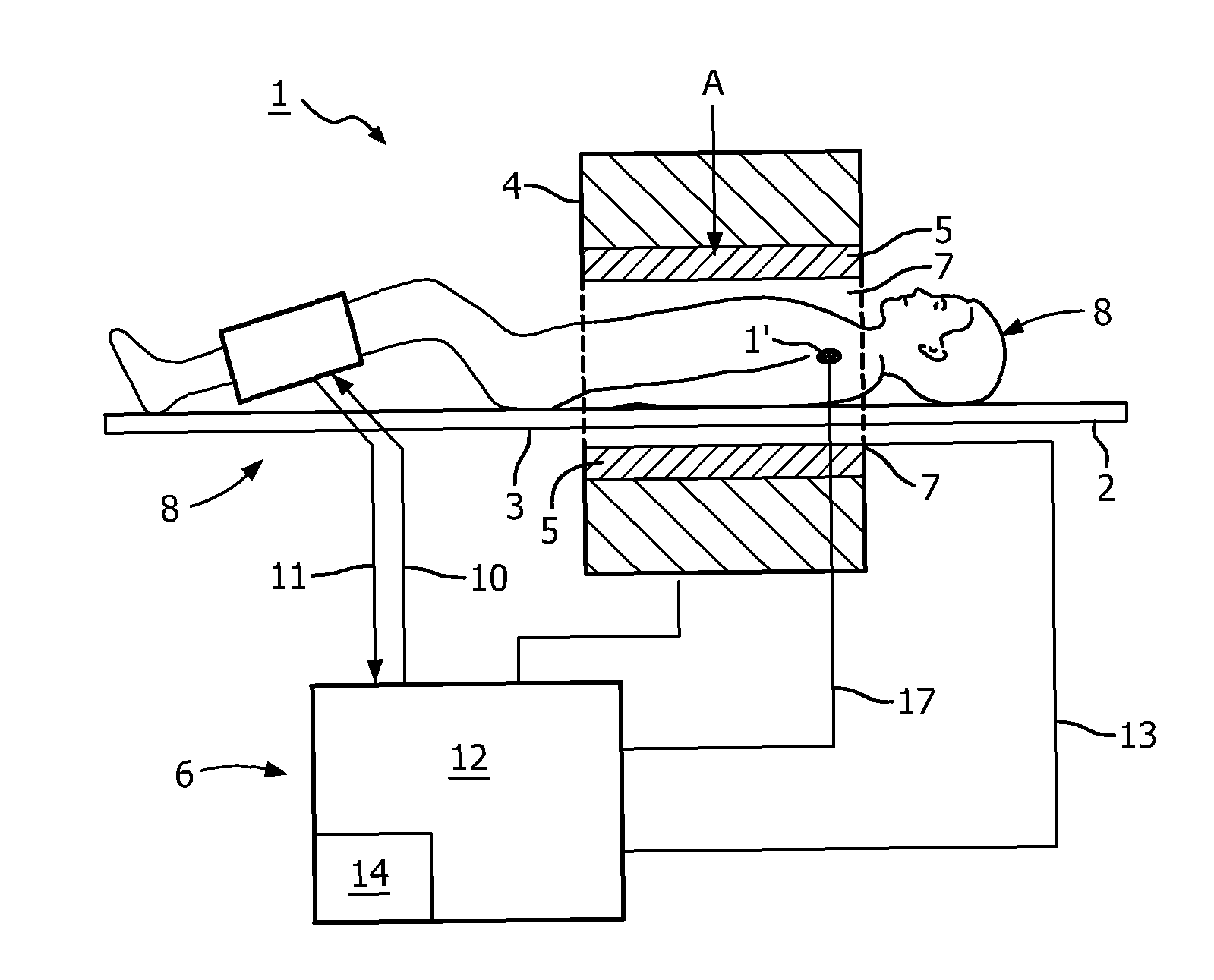

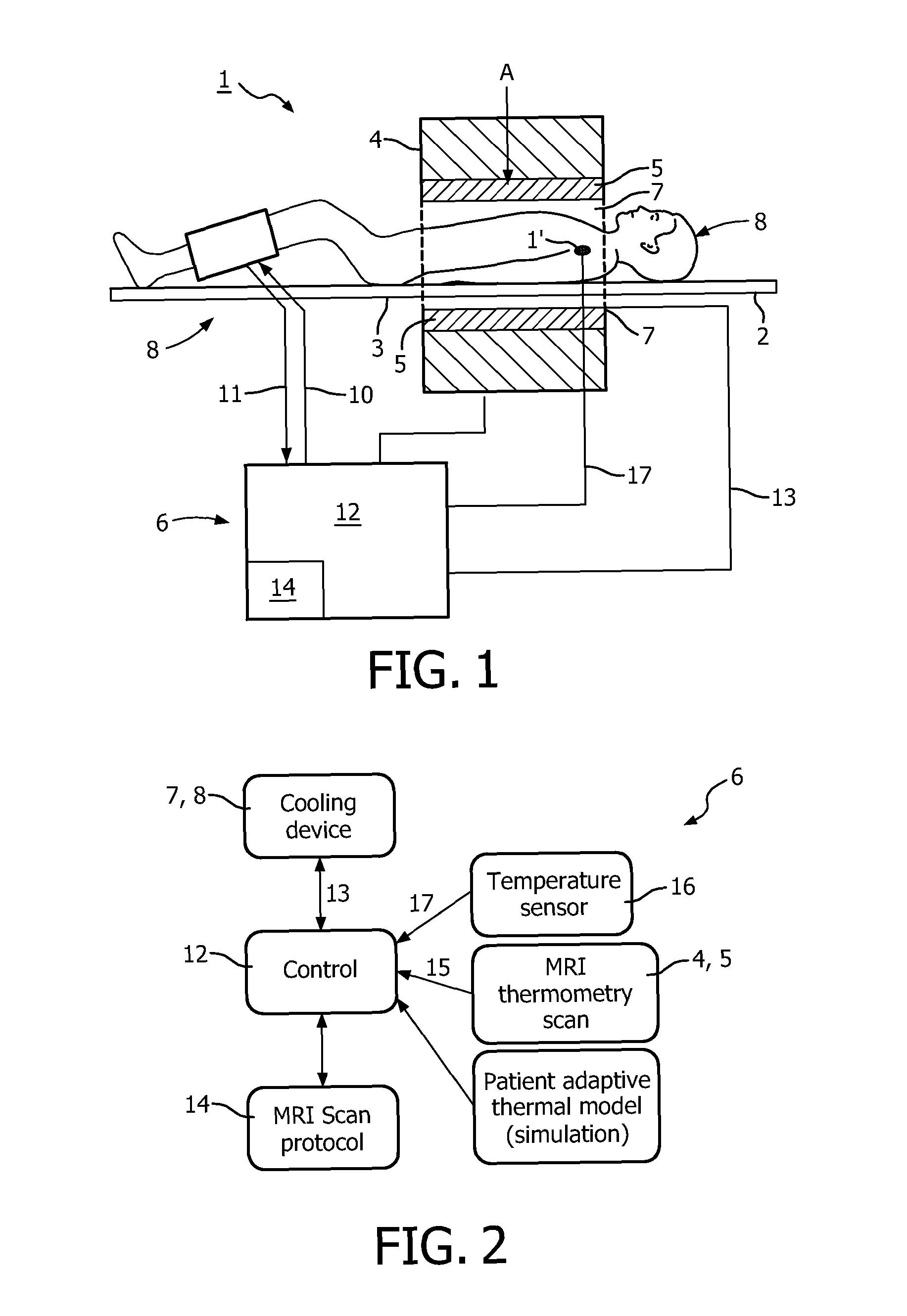

Apparatus and method for mr examination, and temperature control system and method

InactiveUS20140249401A1Improve comfortIncrease quality of imageSurgeryDiagnostic recording/measuringRadio frequencyEngineering

The invention provides an apparatus (1) for magnetic resonance (MR) examination of a subject (S), comprising: an examination region (3) for accommodating the subject (S) during the MR examination; a radio-frequency system (5) for transmission of a radio-frequency (RF) signal or field into the examination region (3) during the MR examination; and a temperature control system (6) for controlling the temperature of the subject (S) in the examination region (3) during the examination. The temperature control system (6) is configured to actively control or regulate an environment of the subject (S), and thereby the temperature or thermal comformt of the subject (S) based upon a detected and / or an expected temperature of the subject (S) during the MR examination. The invention also provides a method of controlling thermal comfort of the subject (S) during an examination of the subject (S) in a MR apparatus (1), comprising the steps of: estimating and / or detecting a temperature of the subject (S) during the MR examination, and actively controlling or regulating the environment of the subject (S) based upon the estimated and / or detected temperature of the subject (S) during the MR examination.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

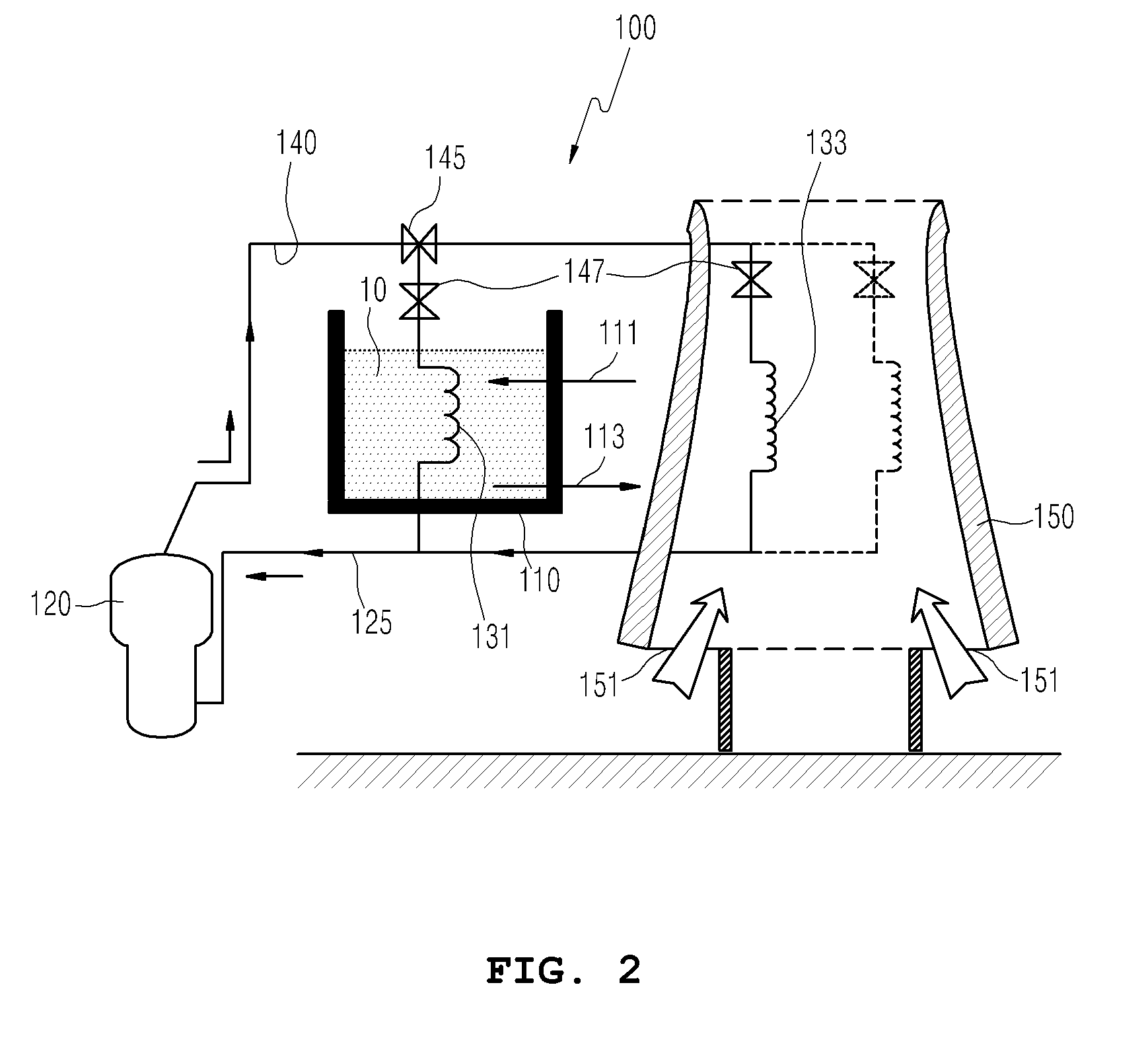

Passive cooling system of nuclear power plant

ActiveUS20130064342A1Small sizeLarge cooling capacityPower plant safety arrangementNuclear energy generationNuclear plantNuclear engineering

A passive cooling system of a nuclear power plant includes a cooling water storage tank configured to store a cooling water therein, a steam generation unit to which the cooling water is supplied from the cooling water storage tank connected thereto, the supplied cooling water being heated to generate a steam, a water cooling heat exchange unit connected to the steam generation unit and provided within the cooling water storage tank, and an air cooling heat exchange unit connected to the steam generation unit and provided outside the cooling water storage tank.

Owner:KEPCO NUCLEAR FUEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com