Hydrogen liquefying device and method

A hydrogen and nitrogen technology, applied in liquefaction, refrigeration, liquefaction, solidification, etc., can solve problems such as difficult maintenance and complicated process, and achieve the effect of easy maintenance, simple process and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

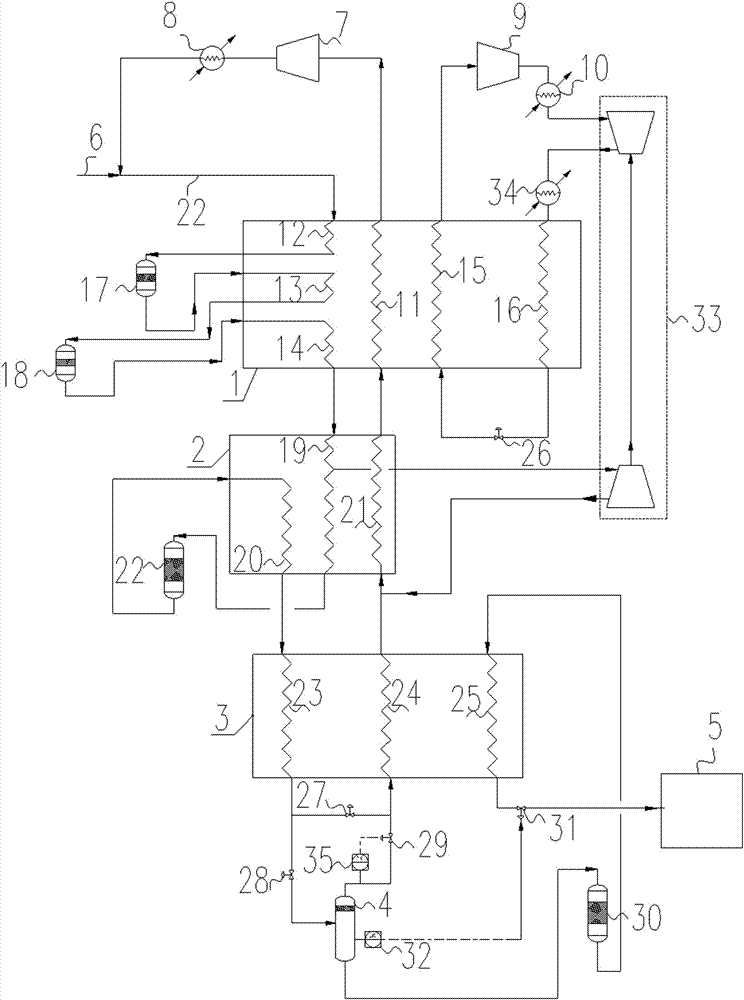

[0032] Such as figure 1 As shown, a device for hydrogen liquefaction, which includes a hydrogen inlet pipeline 6, a heat exchanger A1, a heat exchanger B2, a heat exchanger C3, a flash tank 4 and a liquid hydrogen storage tank 5 connected in sequence, and the heat exchanger Air intake channel A and return channel A11 are provided in A1, intake channel B and return channel B21 are provided in heat exchanger B2, subcooling channel C23 and return channel C are provided in heat exchanger C3, and hydrogen enters Air pipe 6 communicates with the air inlet of air intake channel A, the air outlet of air intake channel communicates with the air inlet of air intake channel B, the air outlet of air intake channel B communicates with the air inlet of supercooling channel C23, and the air outlet of overcooling channel C23 communicates. The gas outlet of the cold channel C23 is connected with the air inlet of the flash tank 4, the liquid outlet of the flash tank 4 is connected with the liqu...

Embodiment 2

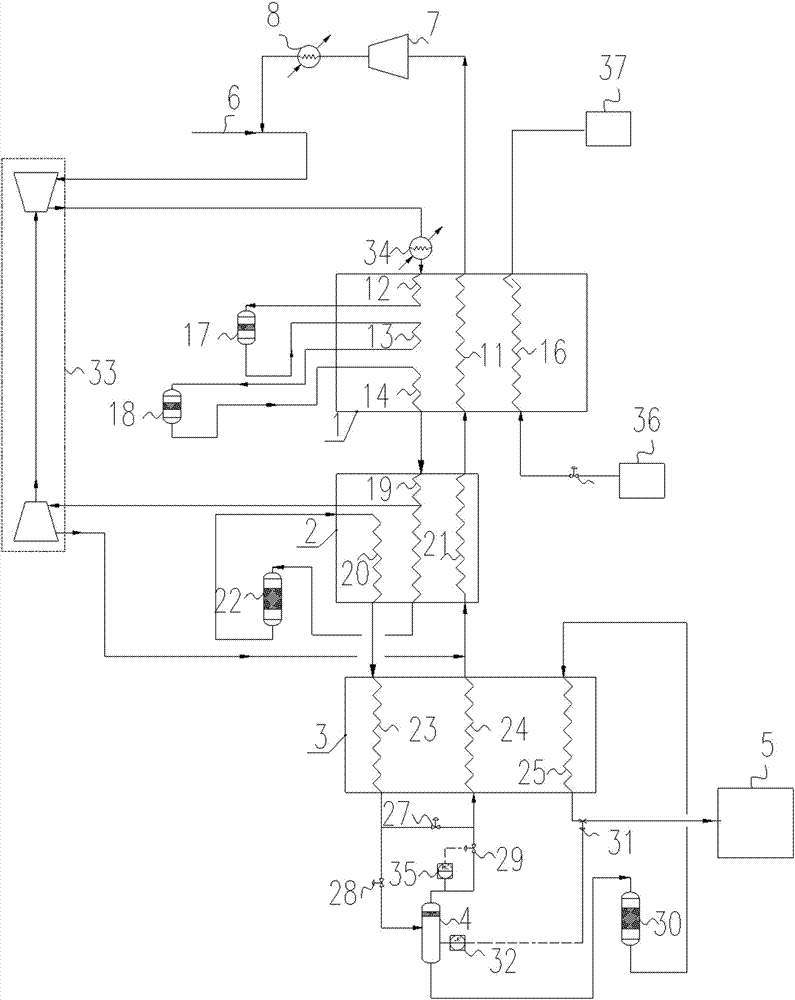

[0044] Such as figure 2 As shown, the difference between the present embodiment and the device in Embodiment 1 is that the hydrogen inlet pipeline 6 communicates with the first pre-cooling passage A12 through the pressurized end of the turbocharger expander 33, and the first pre-cooling passage A12 communicates with the turbocharging end of the turbocharger expander 33. A turbocharged expander cooler 34 is provided between the pressurized ends of the flat booster expander 33, a nitrogen channel 16 is provided in the heat exchanger A1, the inlet of the nitrogen channel 16 is provided with external liquid nitrogen, and the nitrogen channel 16 The outlet is equipped with a nitrogen storage device. By setting the external liquid nitrogen instead of the closed nitrogen refrigeration cycle, the composition of the device is reduced, and the turbocharger expander 33 is used to pressurize the hydrogen before the precooling channel A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com