Large box type high-temperature material heat exchanger

A high-temperature material, heat exchanger technology, applied in the direction of heat exchanger type, indirect heat exchanger, mobile duct heat exchanger, etc. Poor fluidity and other problems, to achieve the effect of high material cooling intensity, increase material flow cross-sectional area, and increase material cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

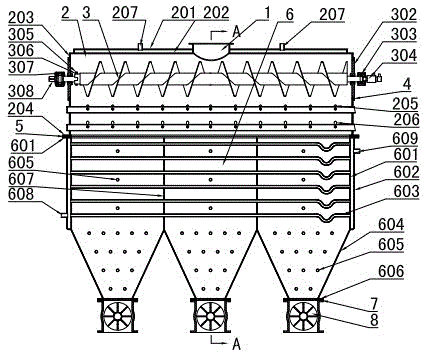

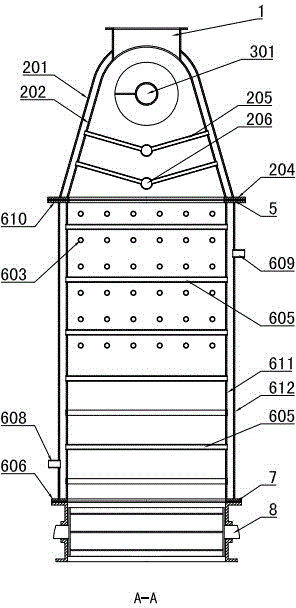

[0031] Embodiment 1: Refer to Figure 1-2, the large box-type high-temperature material heat exchanger is composed of a feed inlet 1, a water-cooled box cover 2, a water-cooled screw distributor 3, a heat exchange box 6 and an impeller discharge valve 8. The heat exchange box 6 is a rectangular shell enclosed by two inner end plates 601 at both ends and two inner plates 611 at both sides. The upper end of the rectangular shell is provided with the upper flange 610 of the heat exchange box, and the lower end is provided with three closing-type hoppers composed of two inner plates 611 and six oblique sealing plates 604, and one The lower flange 606 of the heat exchange box. An outer end plate 602 is arranged on the outer side of the two inner end plates 601, and the two outer end plates 602, the two inner end plates 601 and the upper flange 610 of the heat exchange box together form two closed end water chambers. An outer plate 612, two outer plates 612, two inner plates 611, ...

Embodiment 2

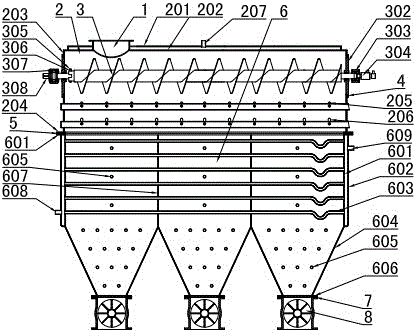

[0038] Embodiment 2: refer to image 3 The difference between this embodiment and Embodiment 1 is that: the feed port 1 of the large-scale box-type high-temperature material heat exchanger is located at one end of the water-cooled tank cover 2; When working, the material enters one end of the water-cooled box cover 2 from the feed port 1, and then moves to the other end of the water-cooled box cover 2 under the rotation of the spiral blade of the water-cooled spiral body 301, and at the same time moves downward by gravity to make the material uniform Fill the heat exchange box6. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com