Patents

Literature

596results about "Moving conduit heat exchangers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for high shear gas-liquid reactions

InactiveUS20050033069A1Superior and economical and efficientImprove responseRotary stirring mixersTransportation and packagingGas liquid reactionChemical reaction

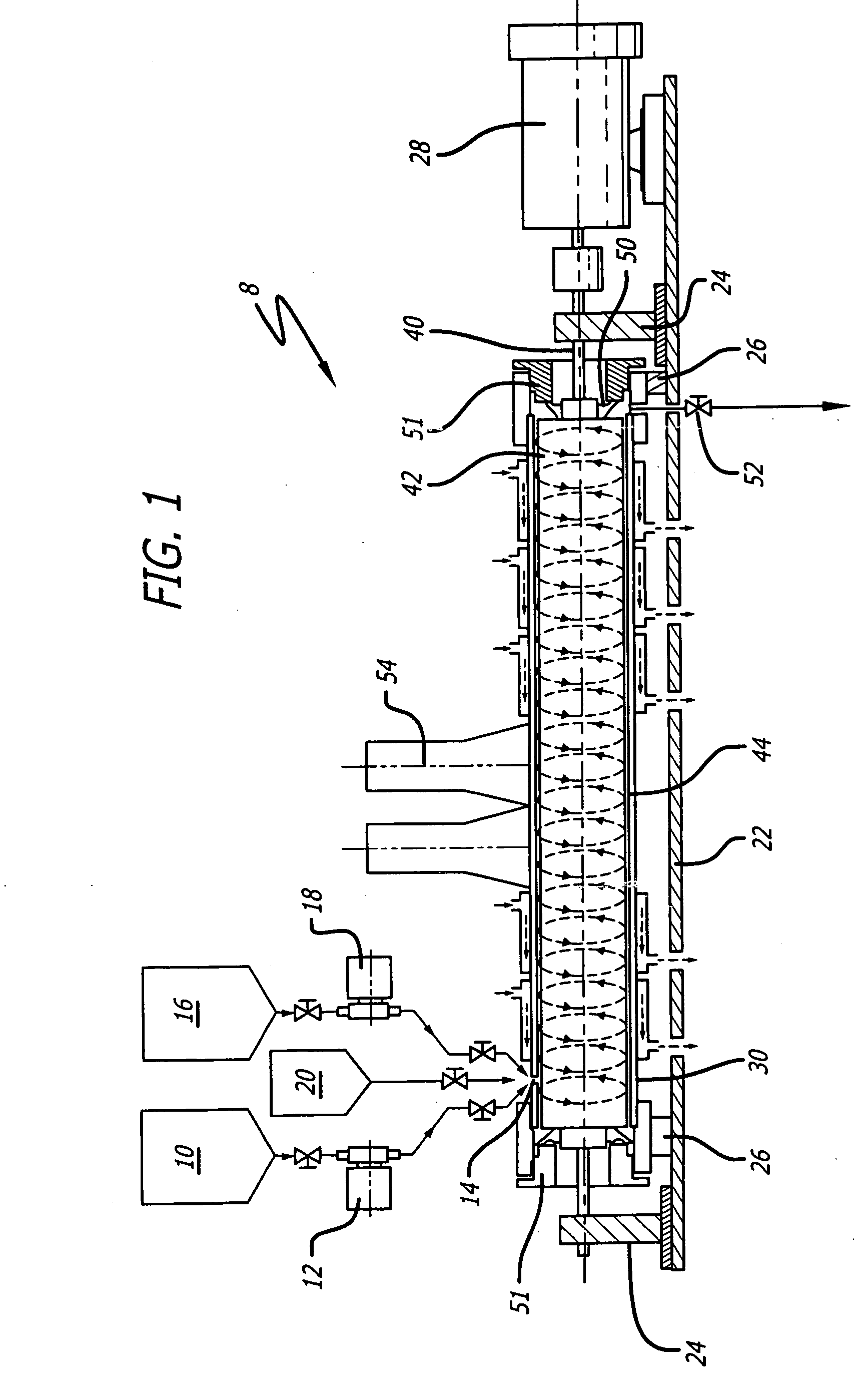

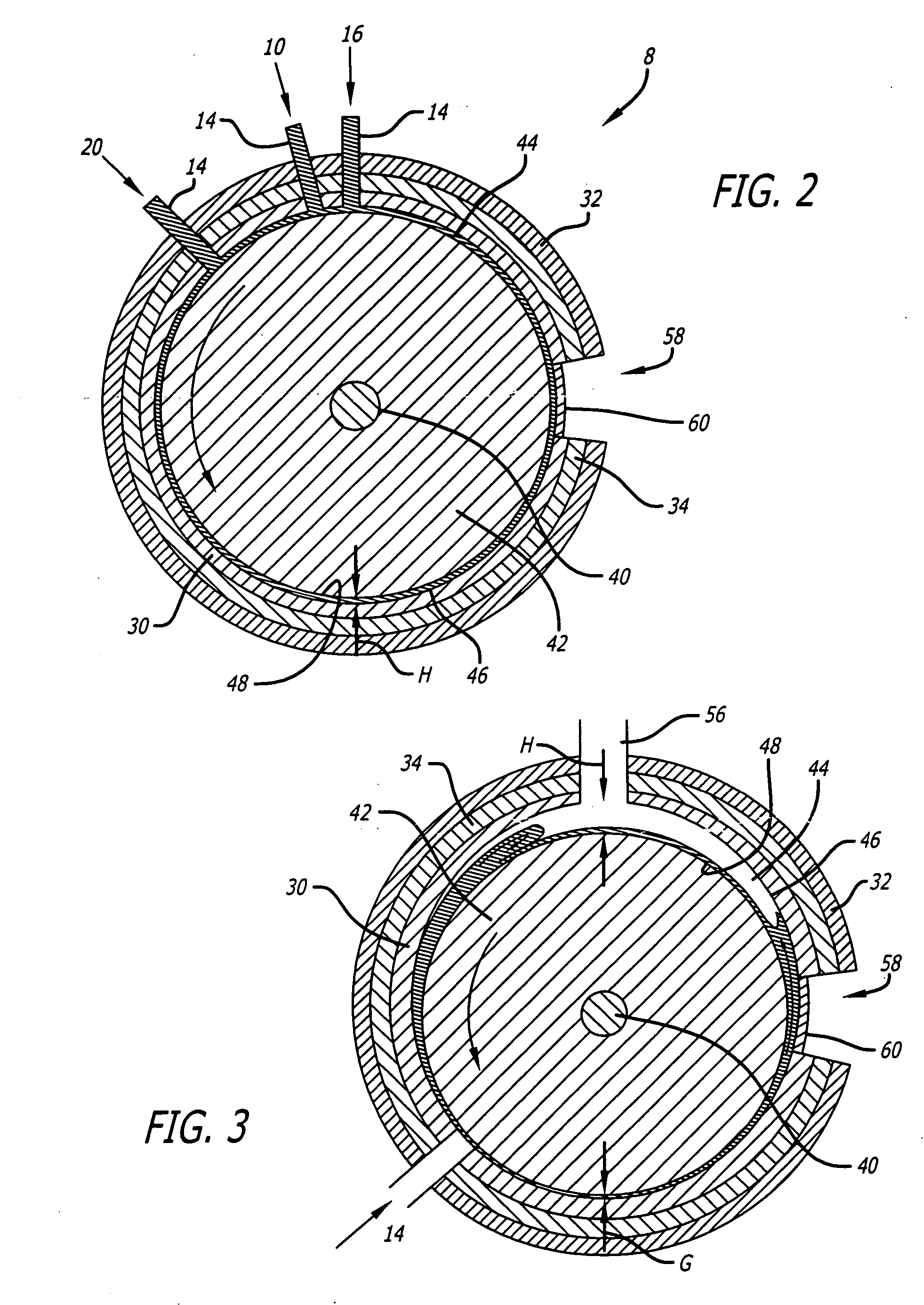

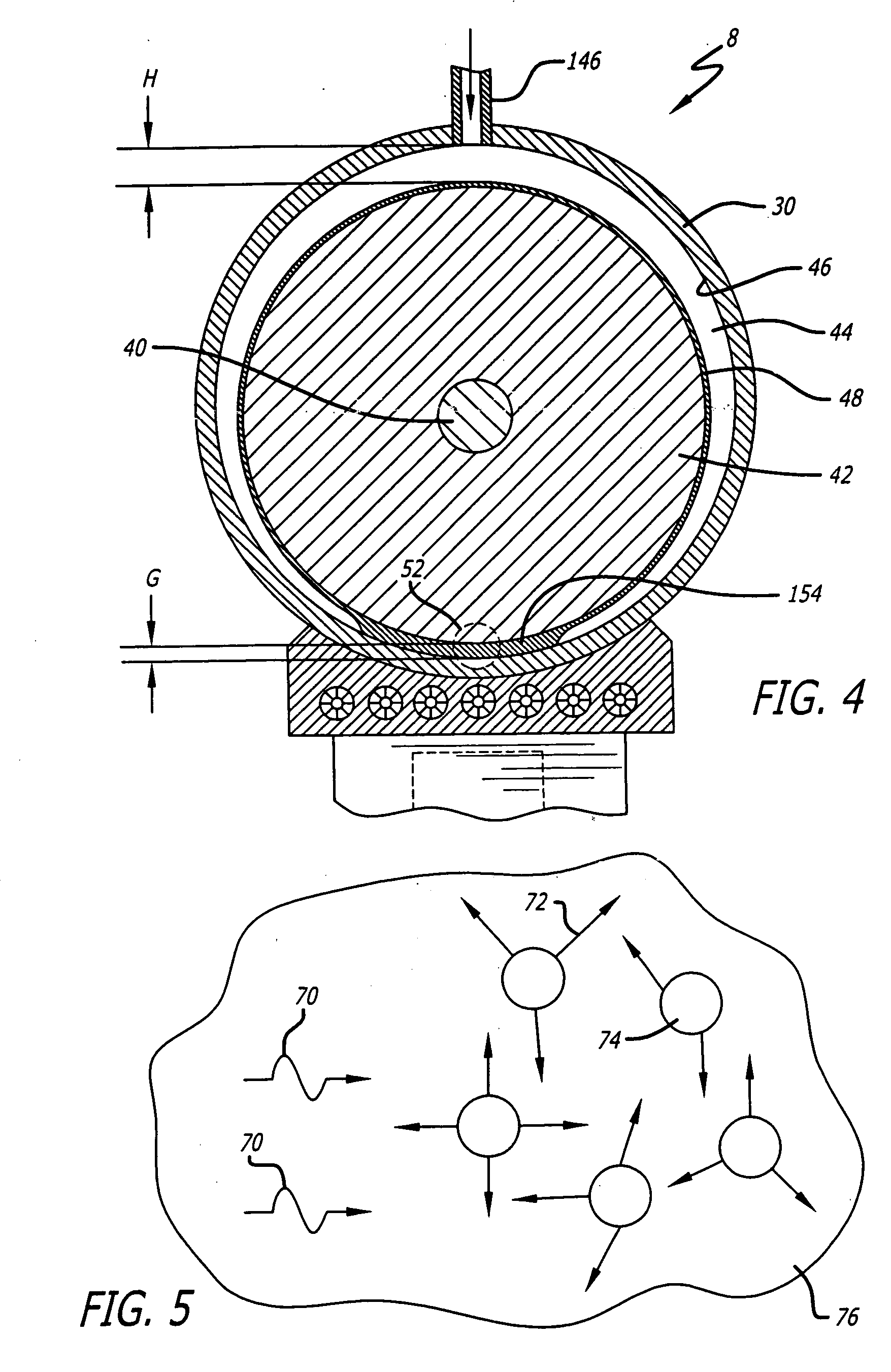

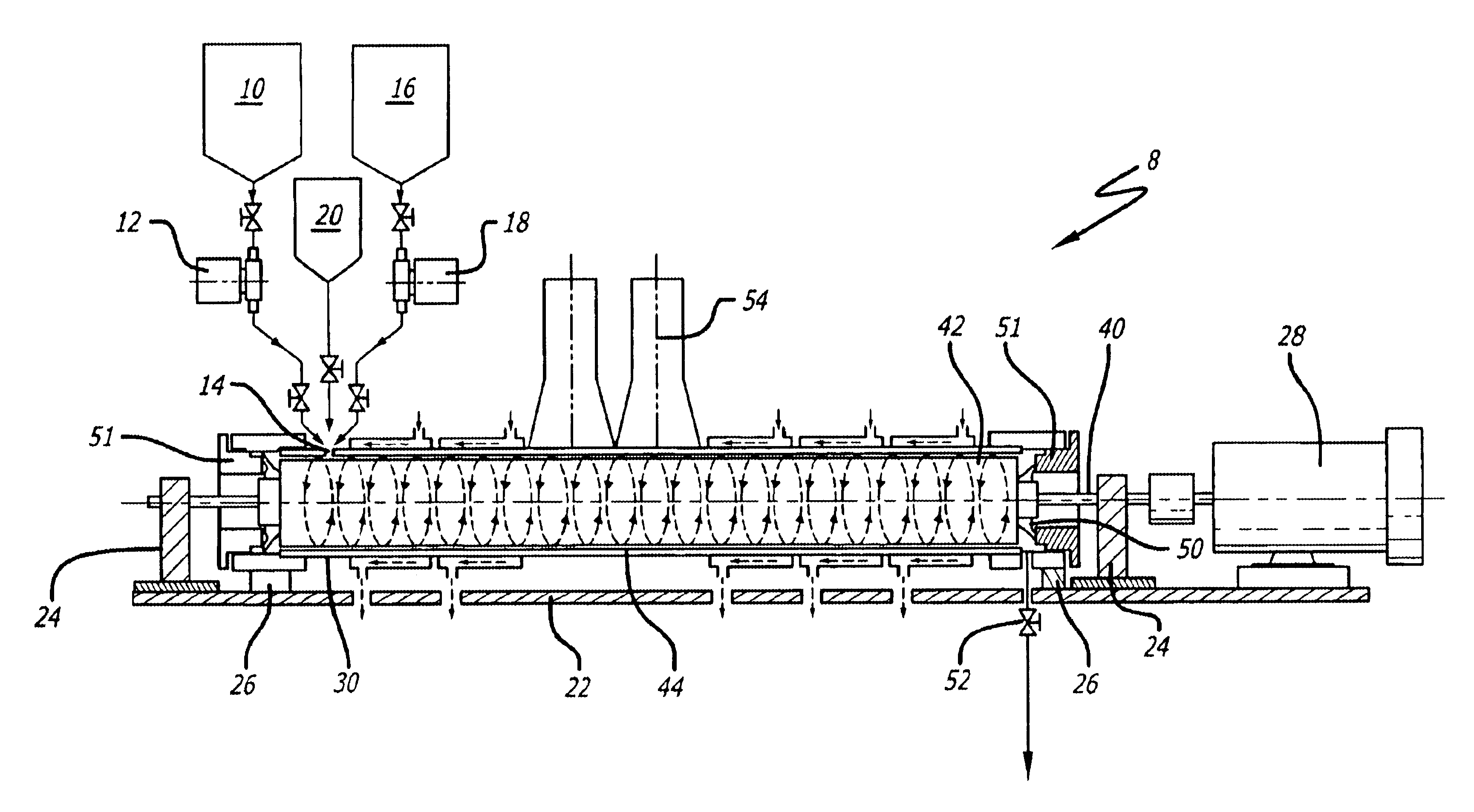

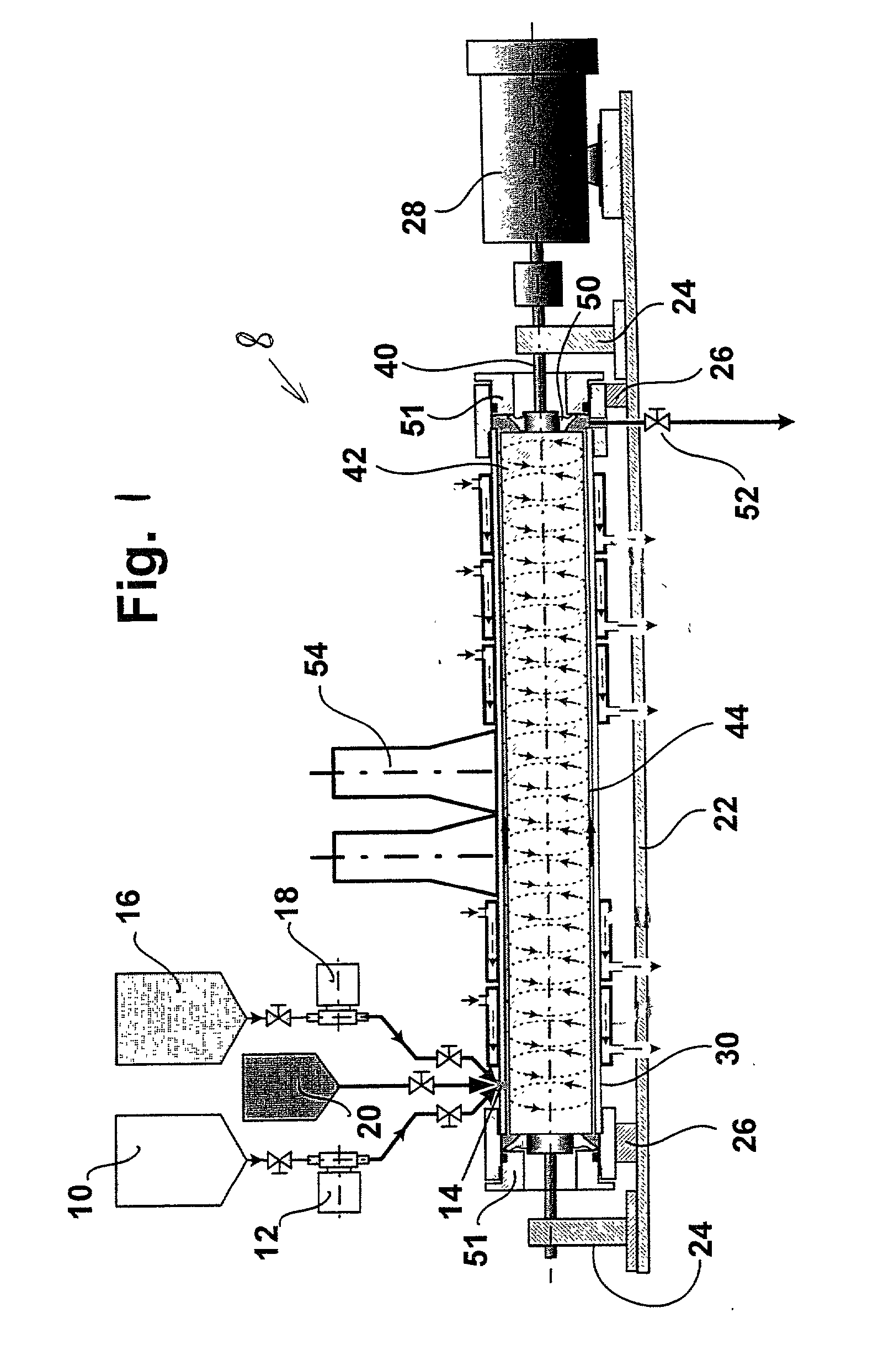

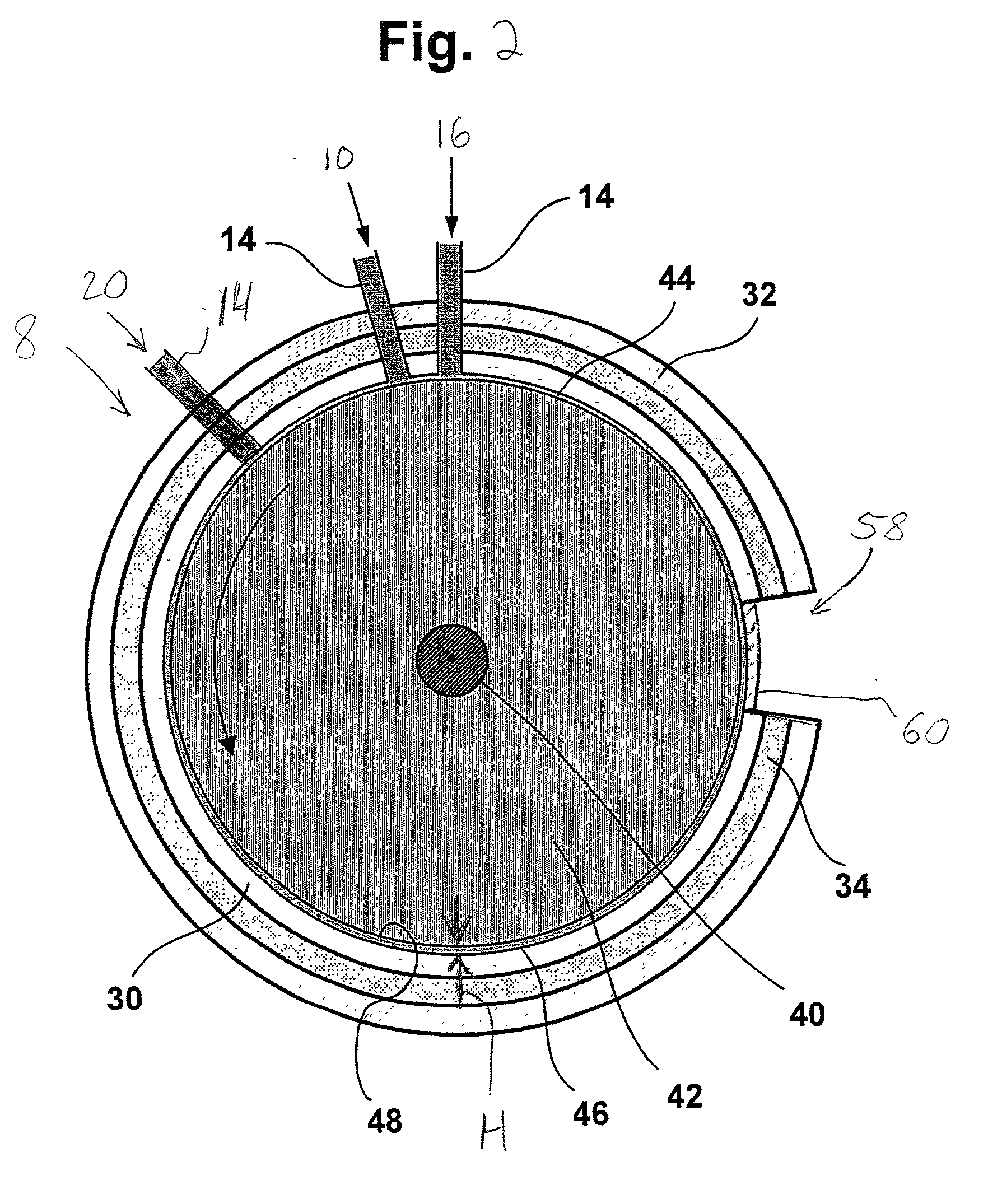

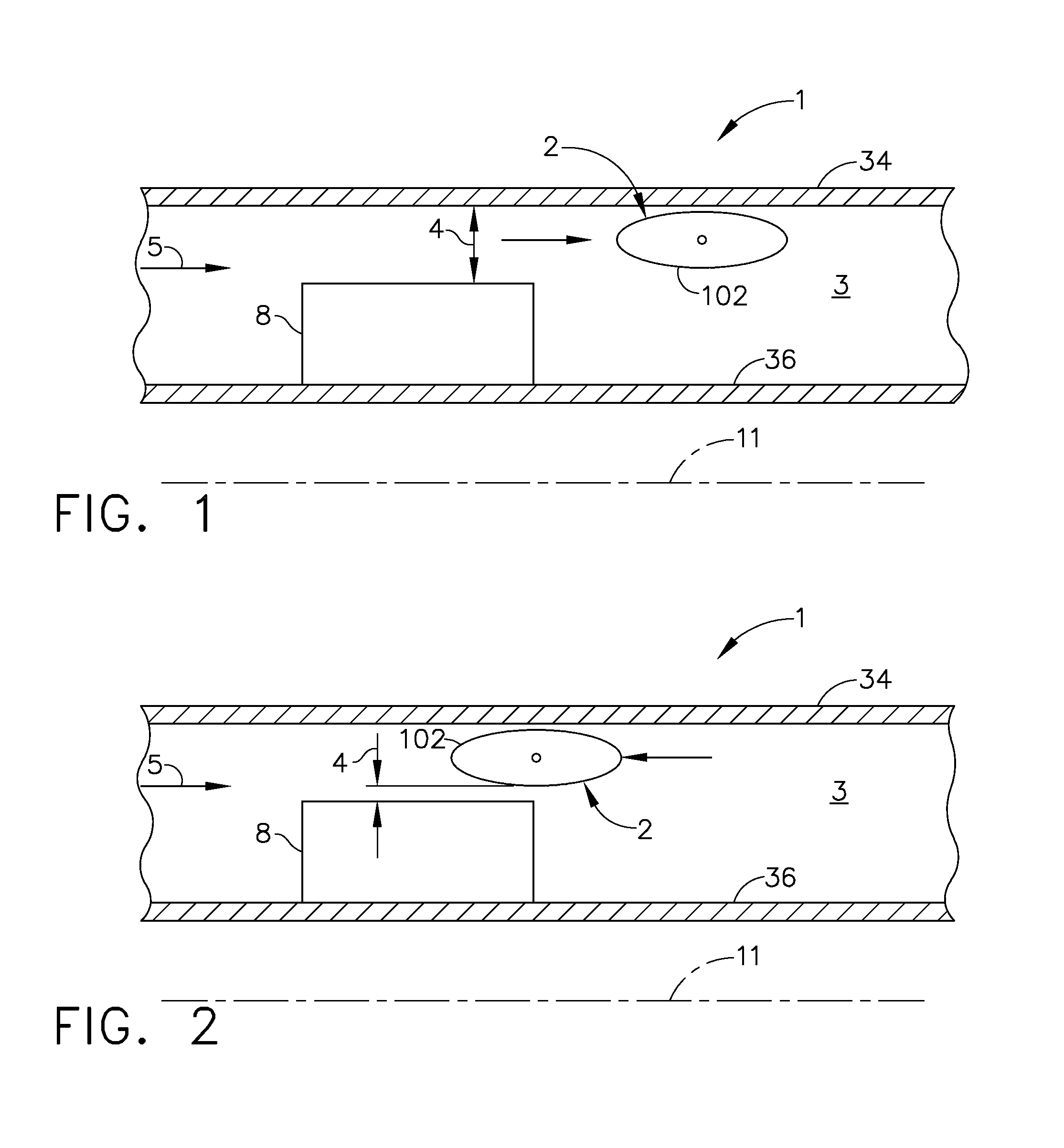

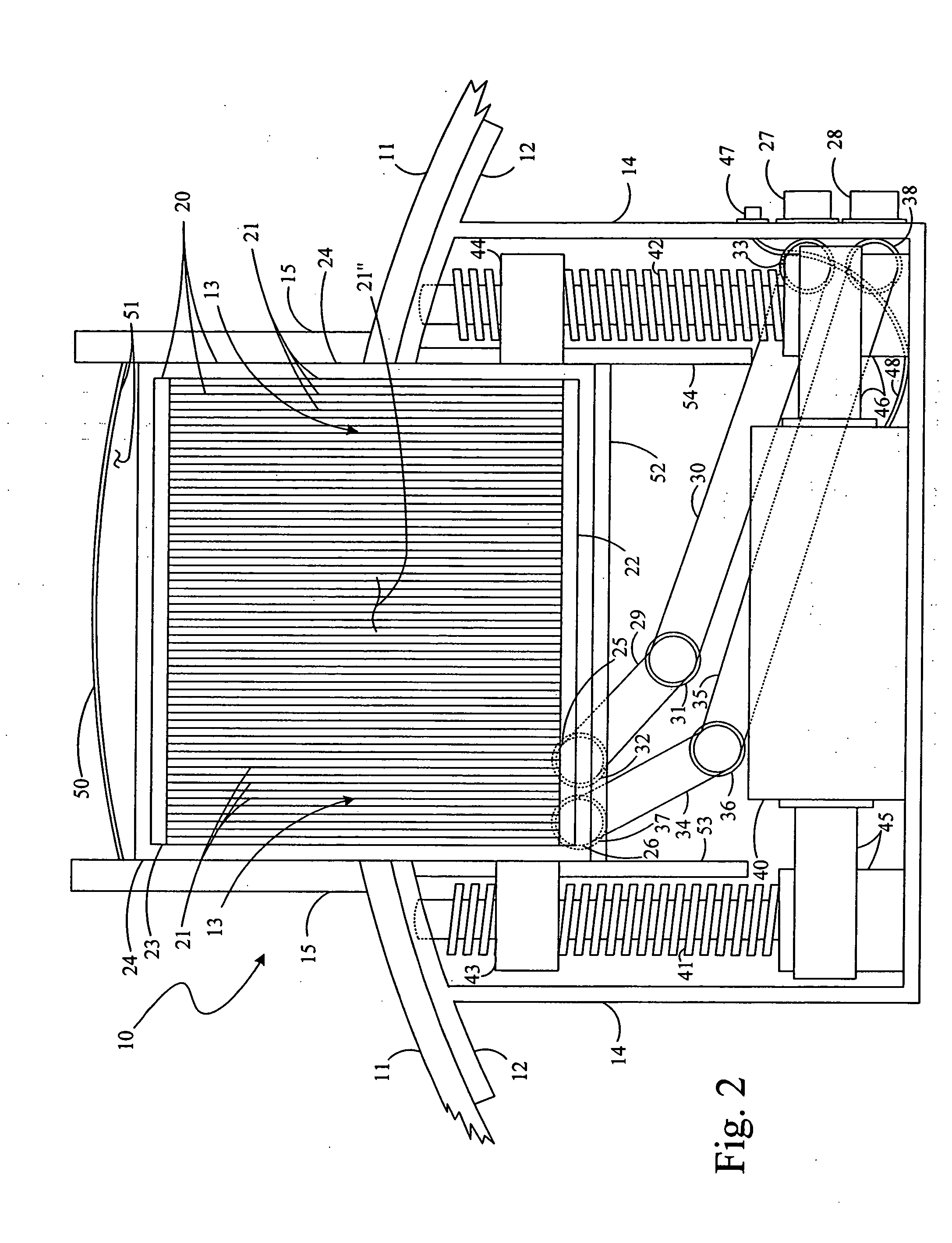

A process for performing a chemical reaction between a plurality of chemical reactants in the presence of a catalyst, with at least a first reactant in a liquid phase and at least a second reactant in a gas phase, the first and second reactants mixing at least by interdiffusion. The process comprises supplying the reactants to a passage defined by a first surface and a second surface and optionally moving at least one of the first surface and second surface relative to each other. The reactants their mixture or reaction products form respective boundary layers against the first and second surfaces and the radial spacing between the first surface and second surface is equal to or less than the back-to-back radial thicknesses of the boundary layers.

Owner:323 TRUST +1

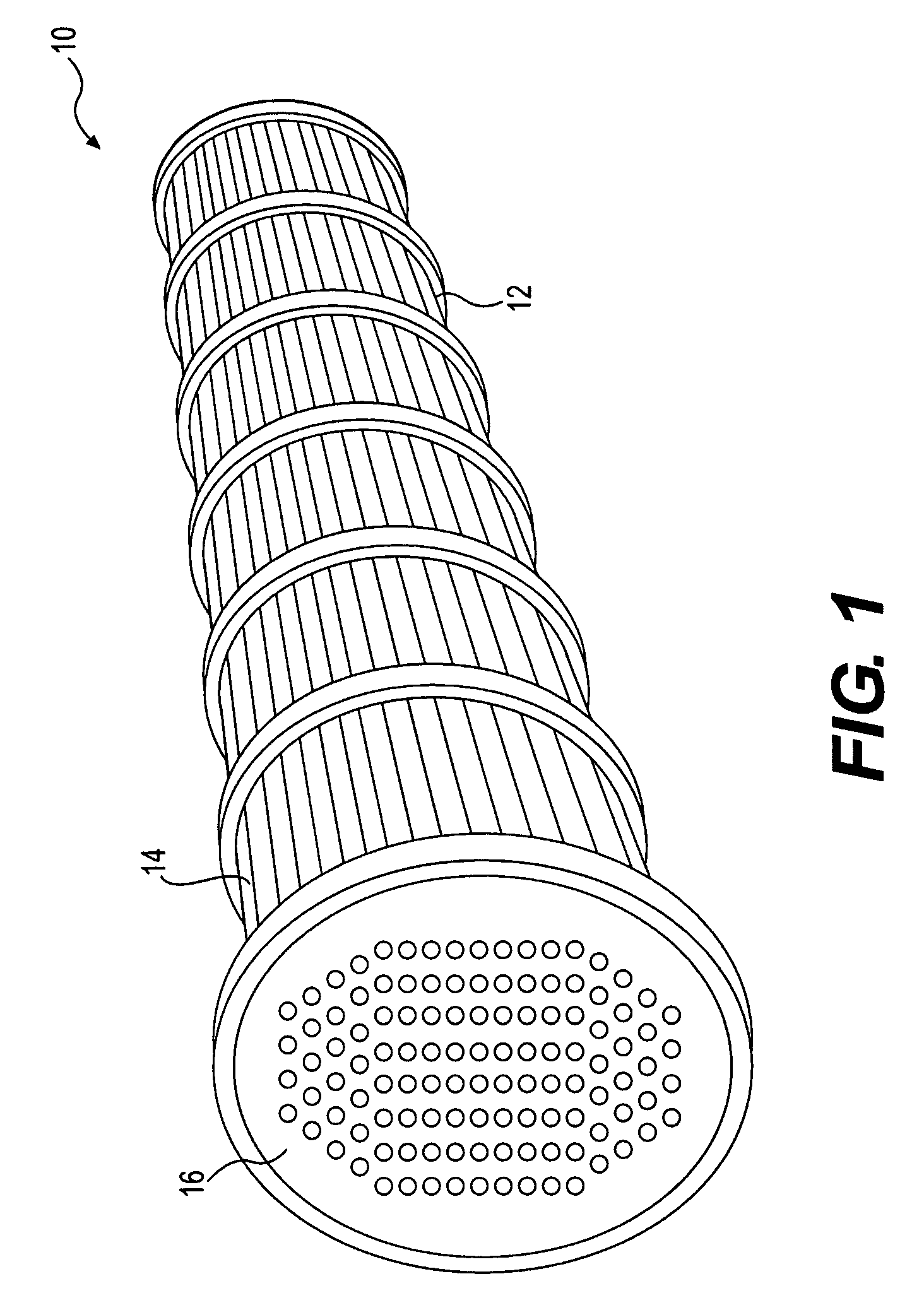

Process for high shear gas-liquid reactions

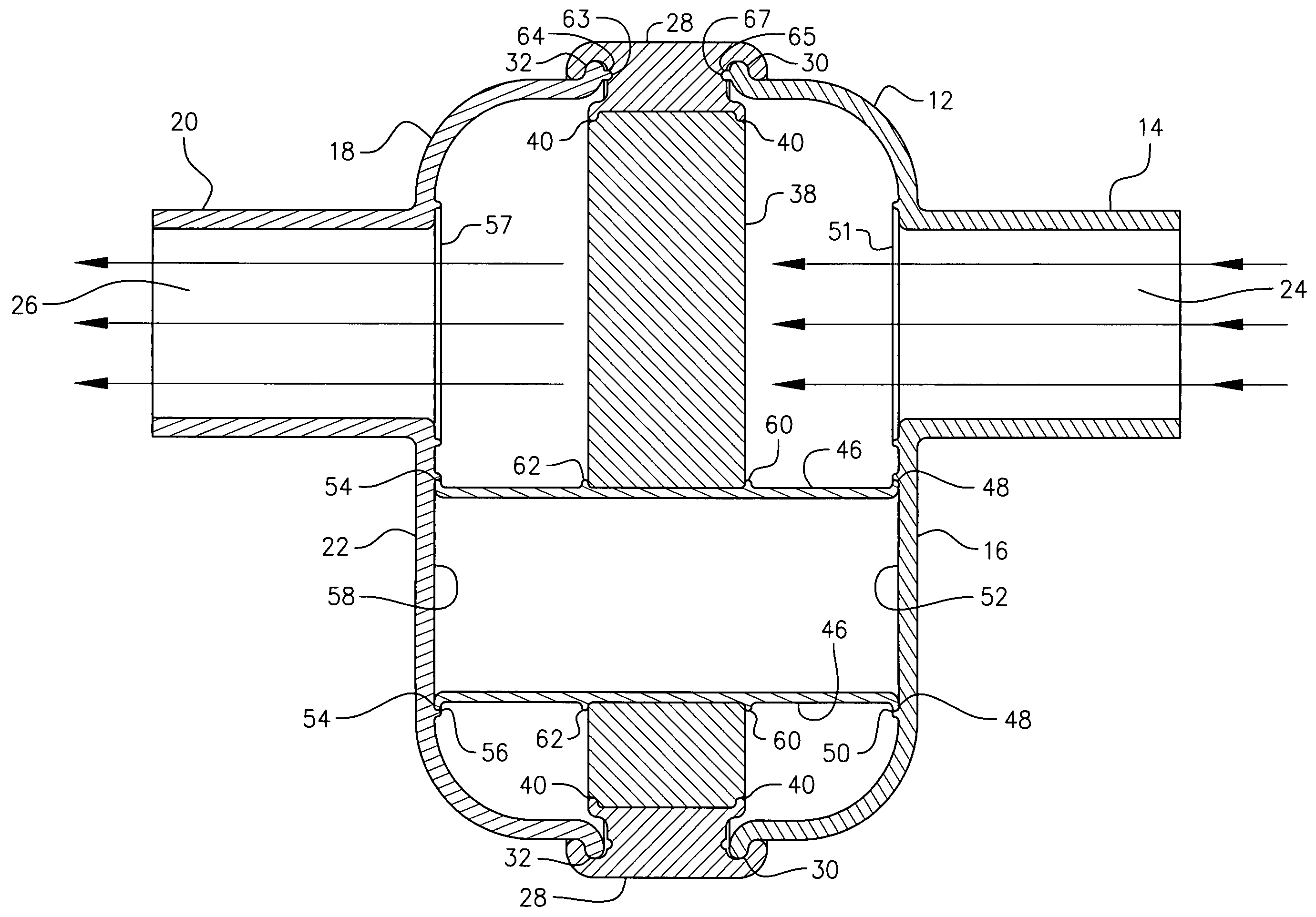

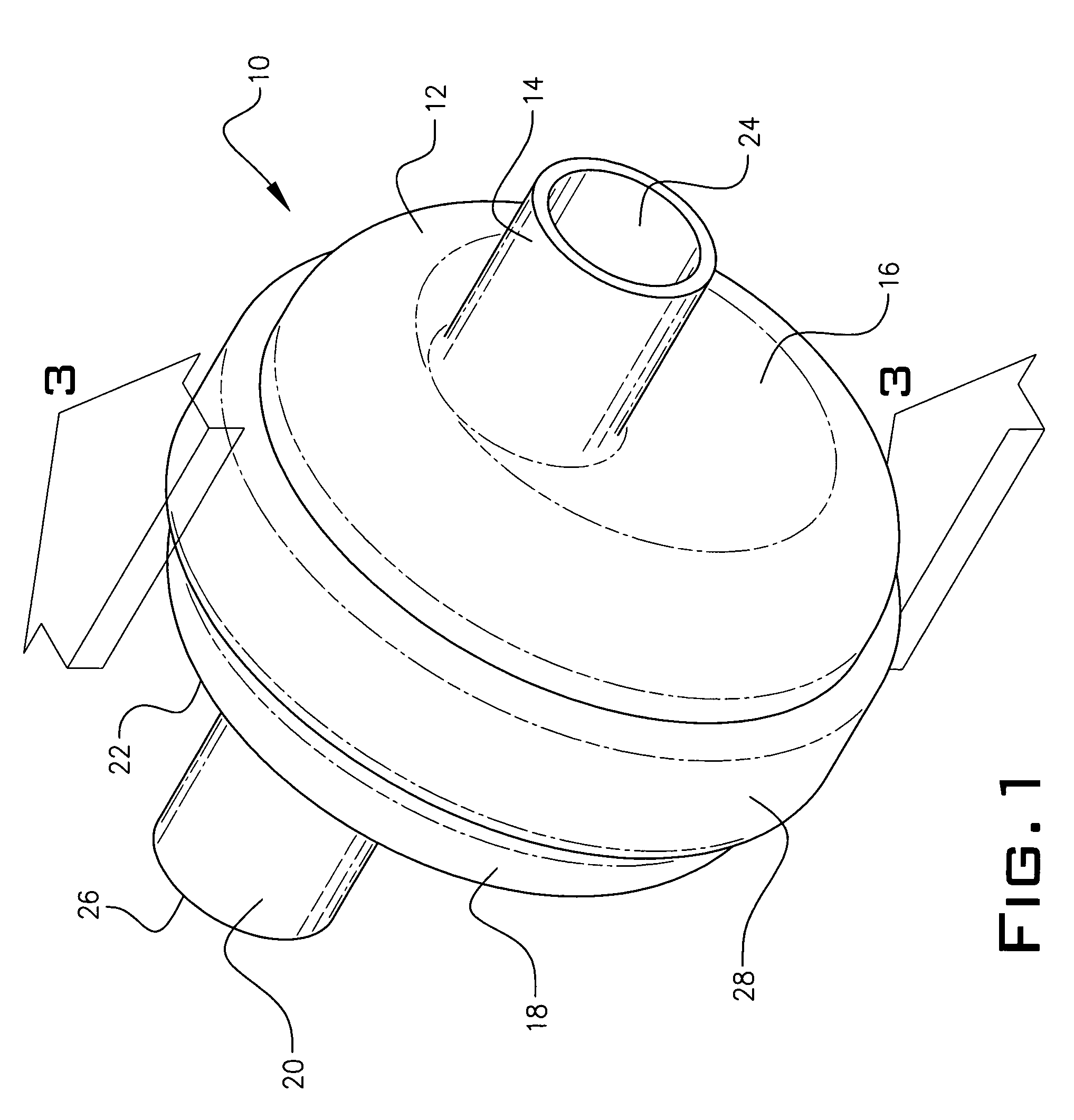

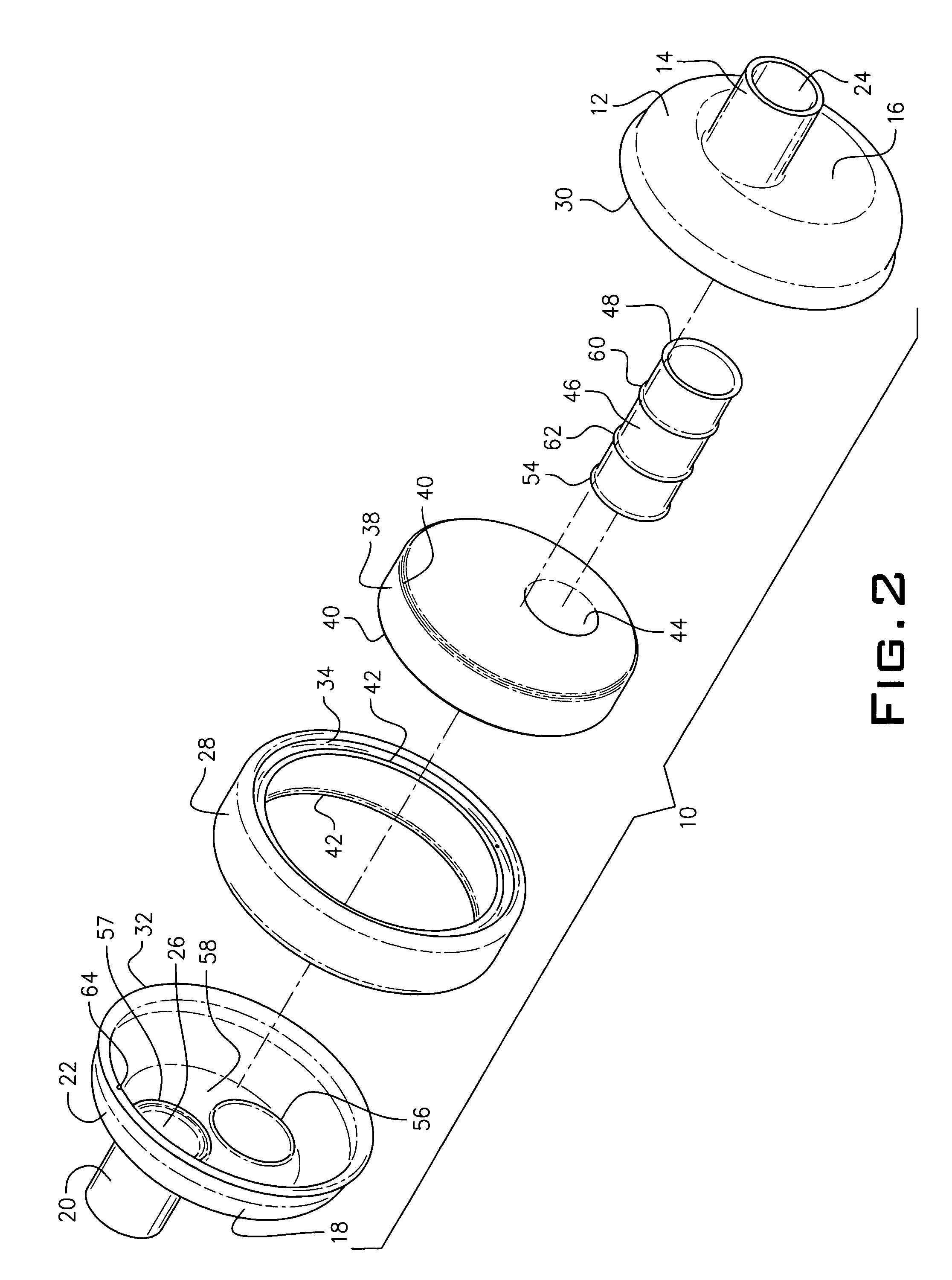

A reactor produces a gas-in-liquid emulsion for providing increased interfacial contact area between the liquid and the gas for improved reaction of the gas with the liquid, or more rapid solution or reaction of a difficulty soluble or immiscible gas in or with a liquid. The reactor is suitable for a continuous or batch type process. Rotor and stator cylindrical members are mounted for rotation relative to one another and have opposing surfaces spaced to form an annular processing passage. The gap distance between the opposing surfaces and the relative rotation rate of the cylindrical members are such as to form a gas-in-liquid emulsion of the gas in the liquid. The liquid and gas pass through the processing passage, changing into the gas-in-liquid emulsion.

Owner:323 TRUST

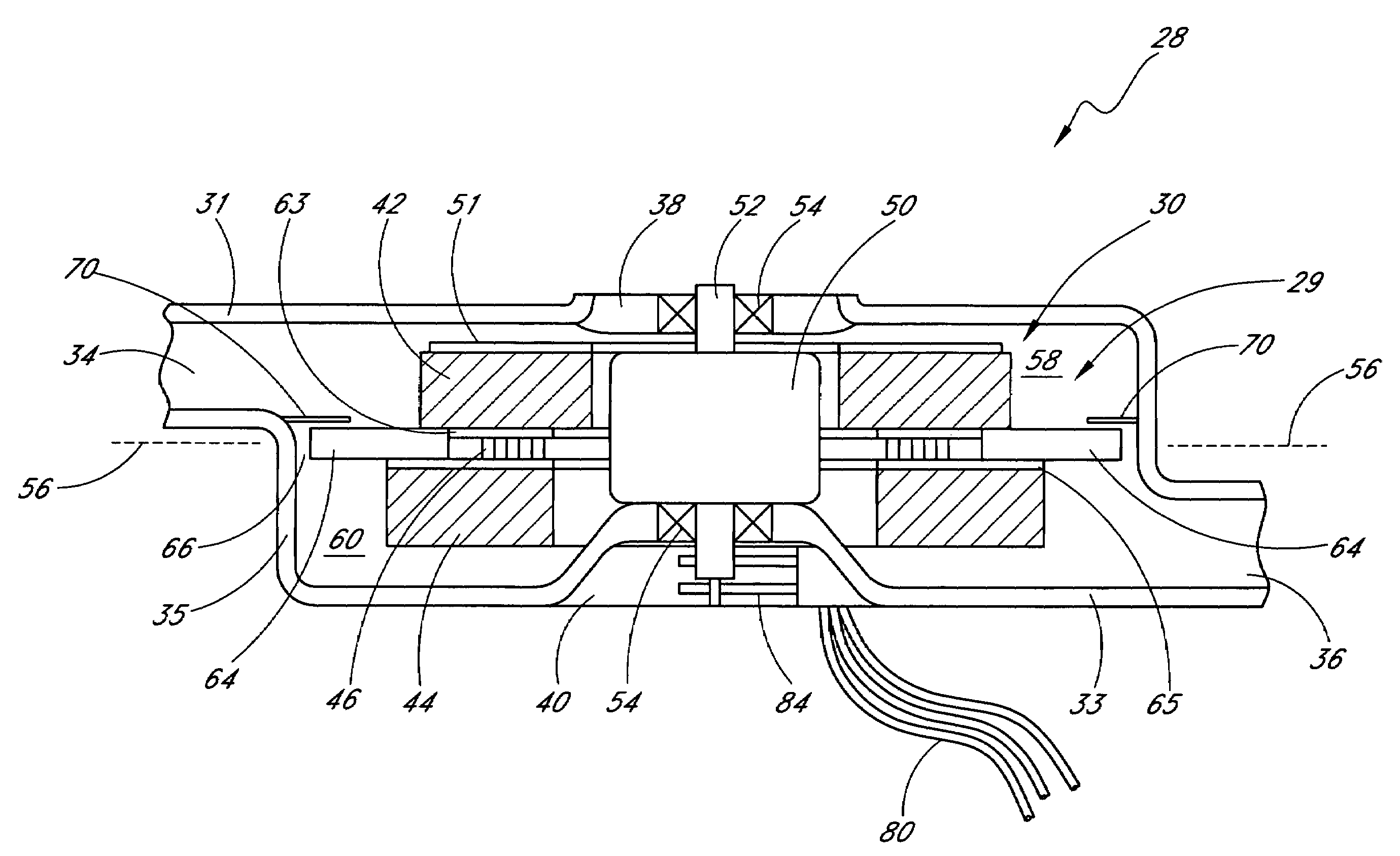

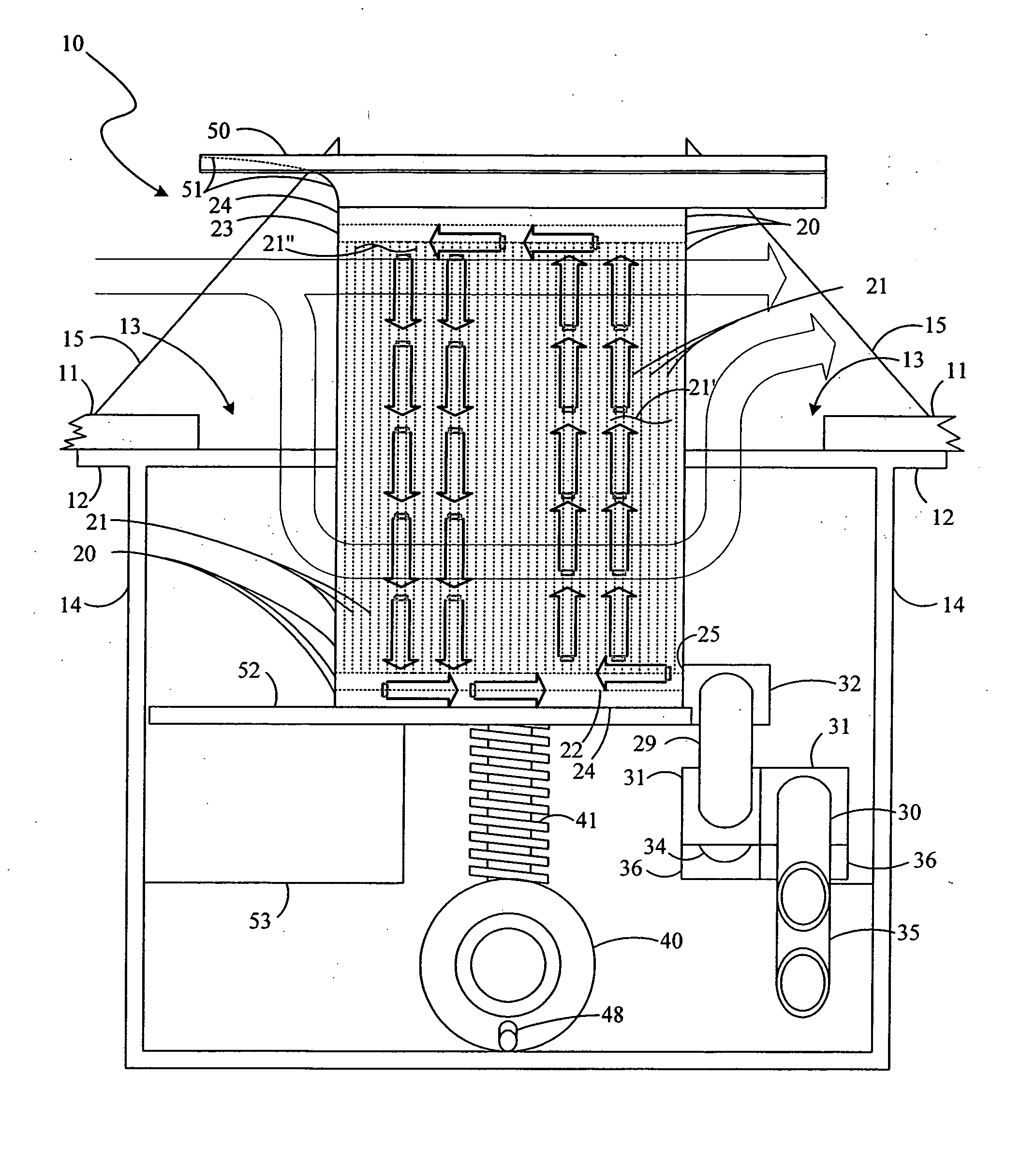

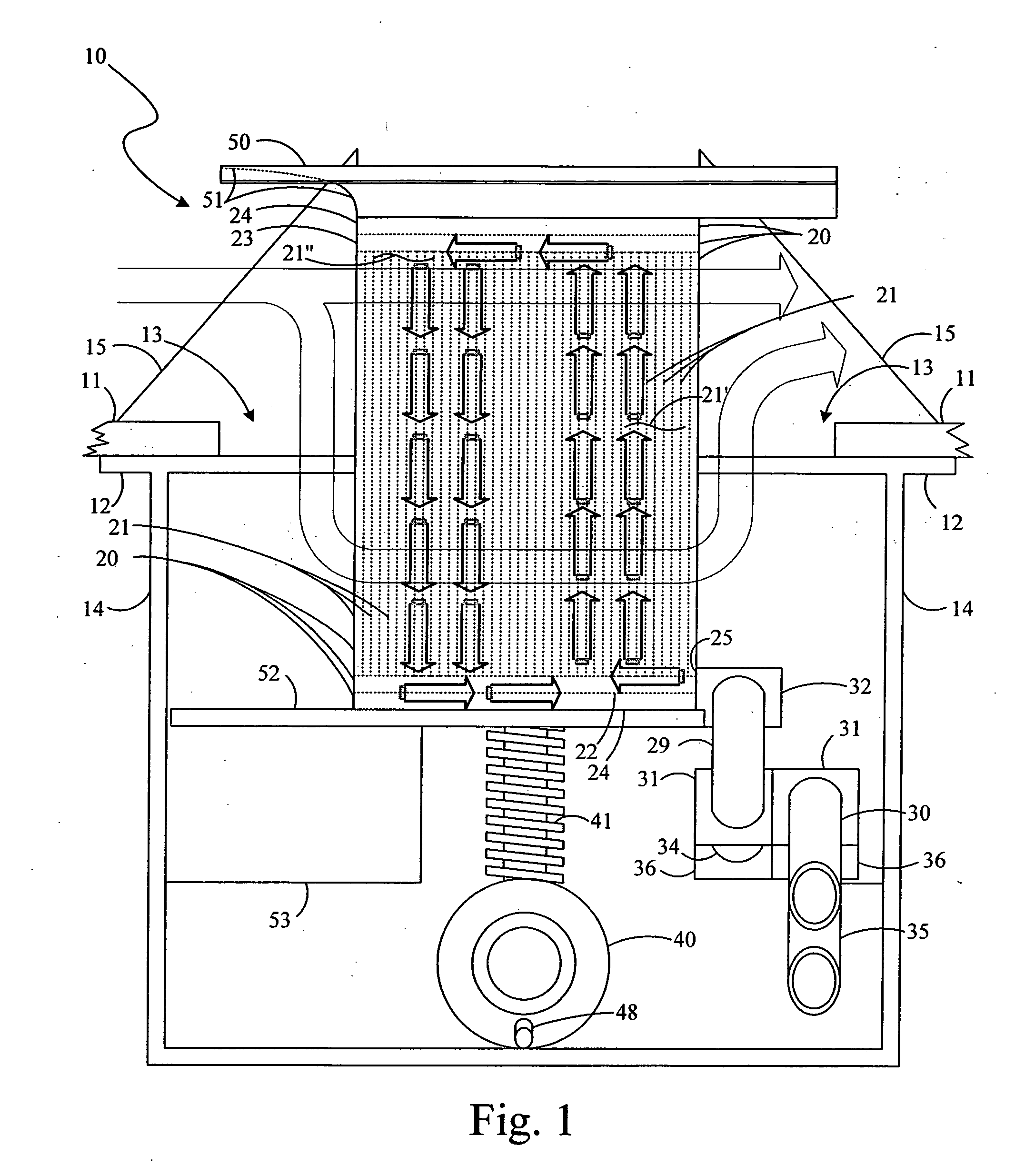

Thermoelectric heat exchanger

Disclosed is a system for thermally conditioning and pumping a fluid. The system includes a thermoelectric heat exchanger having a thermoelectric device configured to pump heat. Heat exchangers are provided for transferring heat to and from the thermoelectric device and for generating a fluid flow across the thermoelectric device. The conditioned fluid may be placed in thermal communication with a variety of objects, such as a vehicle seat, or anywhere localized heating and cooling are desired. Thermal isolation may also be provided in the direction of flow to enhance efficiency.

Owner:GENTHERM INC

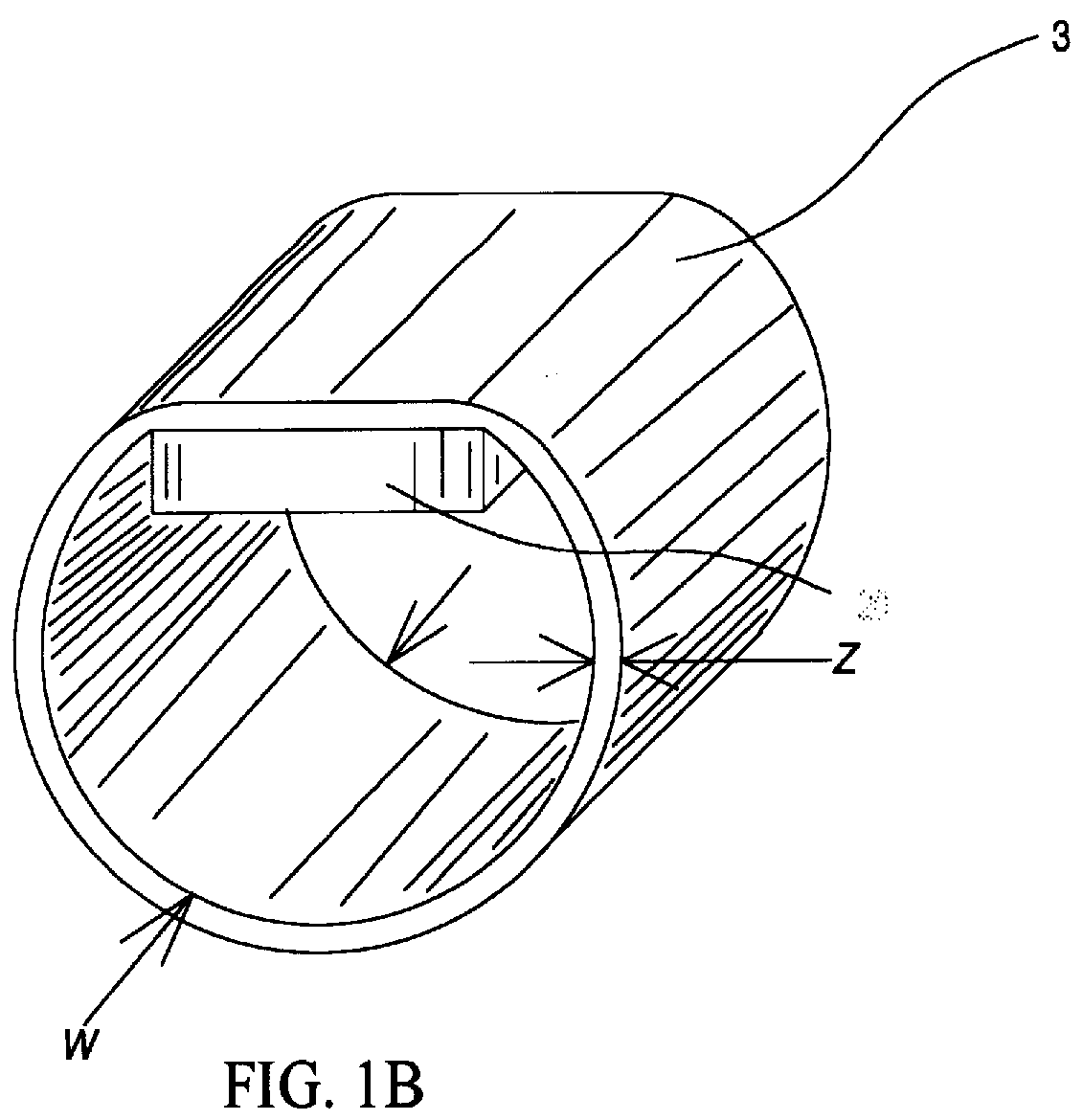

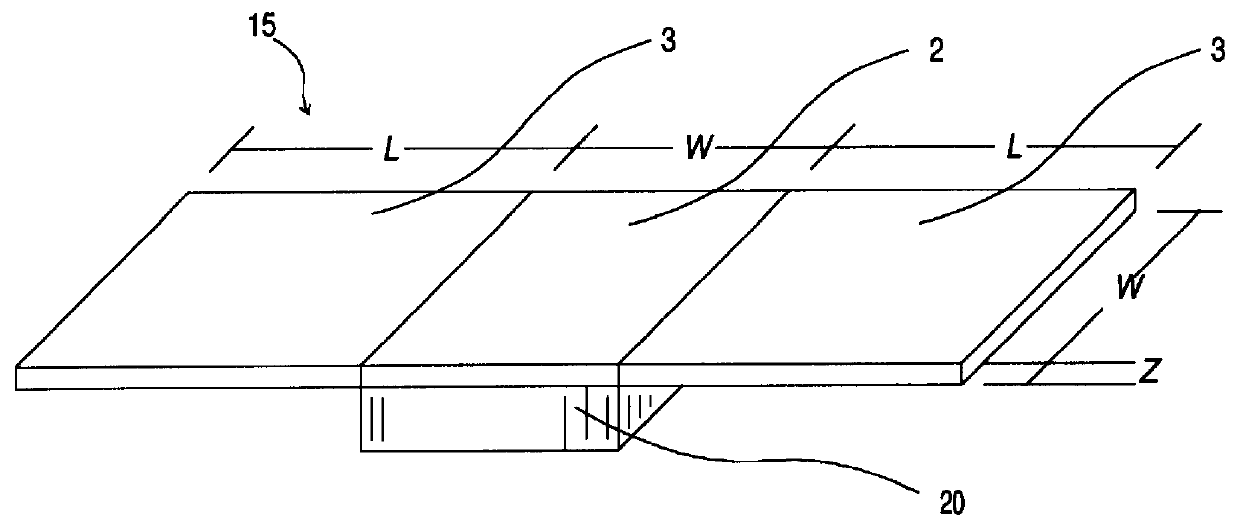

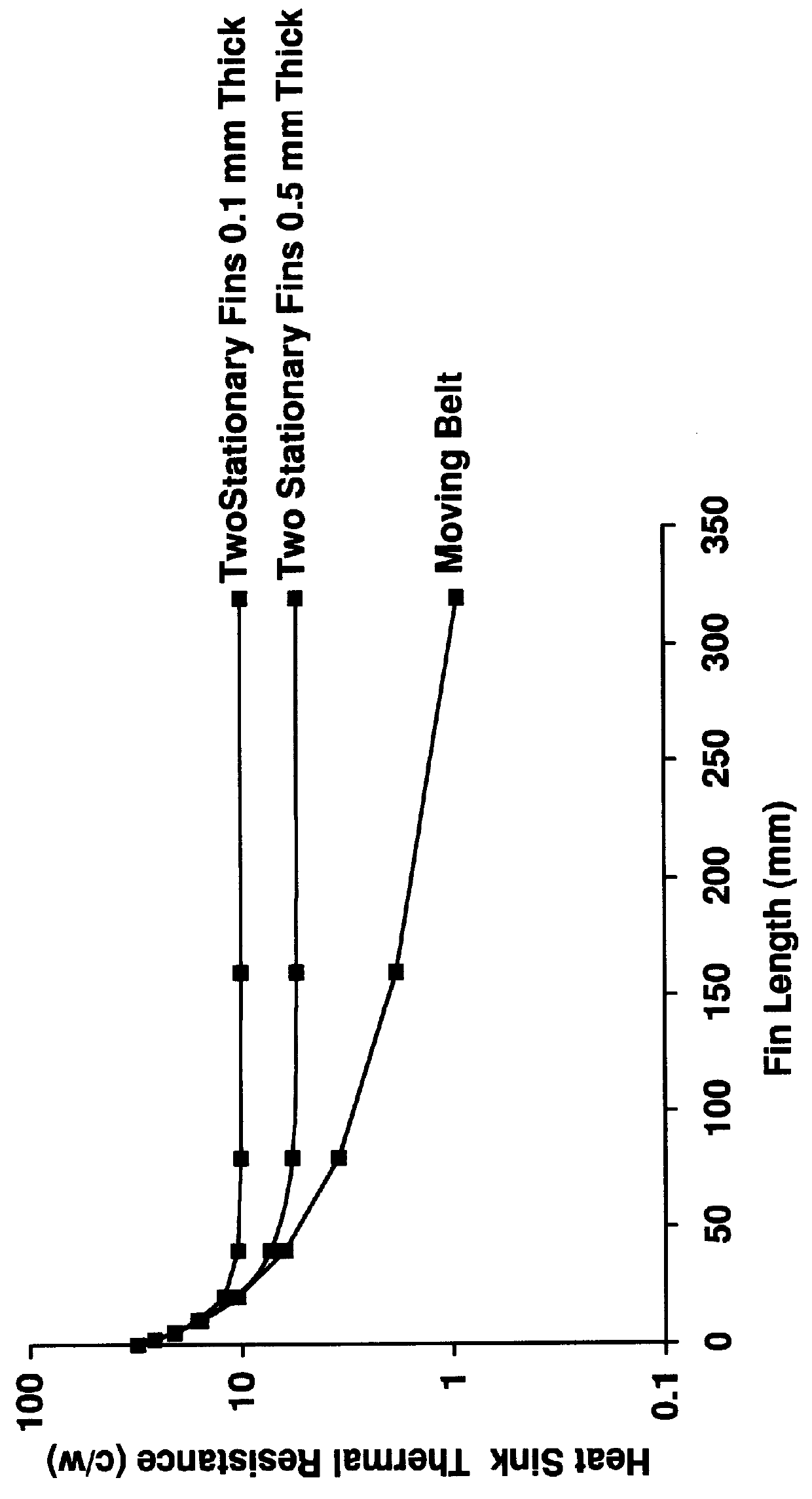

Method and apparatus for cooling an electronic device

A heat dissipation apparatus for cooling one or more electronic devices. The apparatus utilizes a moving heat sink a portion of which is in contact with the device to be cooled. The moving heat sink may be in the form of a rotating disk, moving belt or strip. The heat sink may be made from various materials such as metals or plastics.

Owner:IBM CORP

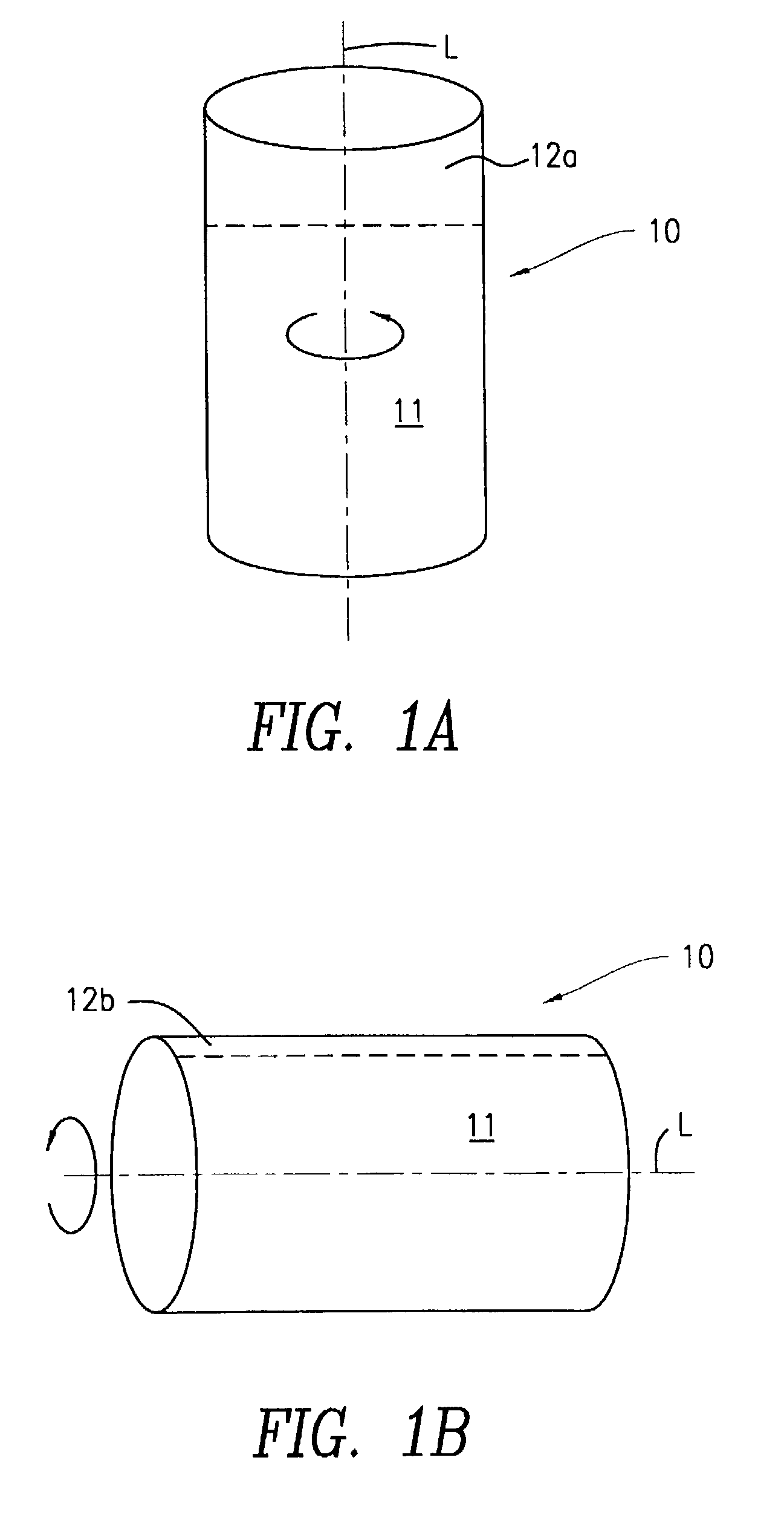

Rapid fluid cooling and heating device and method

InactiveUS20020124576A1Increase surface areaGreat frictional contactFrozen sweetsContainer filling methodsIce creamElectrical and Electronics engineering

A method and device for rapidly changing at least one of the temperature and the state of a liquid in a container is provided. The container is rapidly rotated about its longitudinal axis. A source of a thin film of a medium having a different temperature than the liquid in the container is provided to thermally affect the container while rotating the container. The container is positioned at an angle to the horizontal of less than 45°, and the position of the container with respect to the thin film source is controlled by angling the axis of the container skewed from the axis of the rotating mechanism. The device can be used to cool liquids such as beverages, warm liquids such as infant formula, and / or make ice cream.

Owner:THE COOPER UNION FOR THE ADVANCEMENT OF SCI & ART

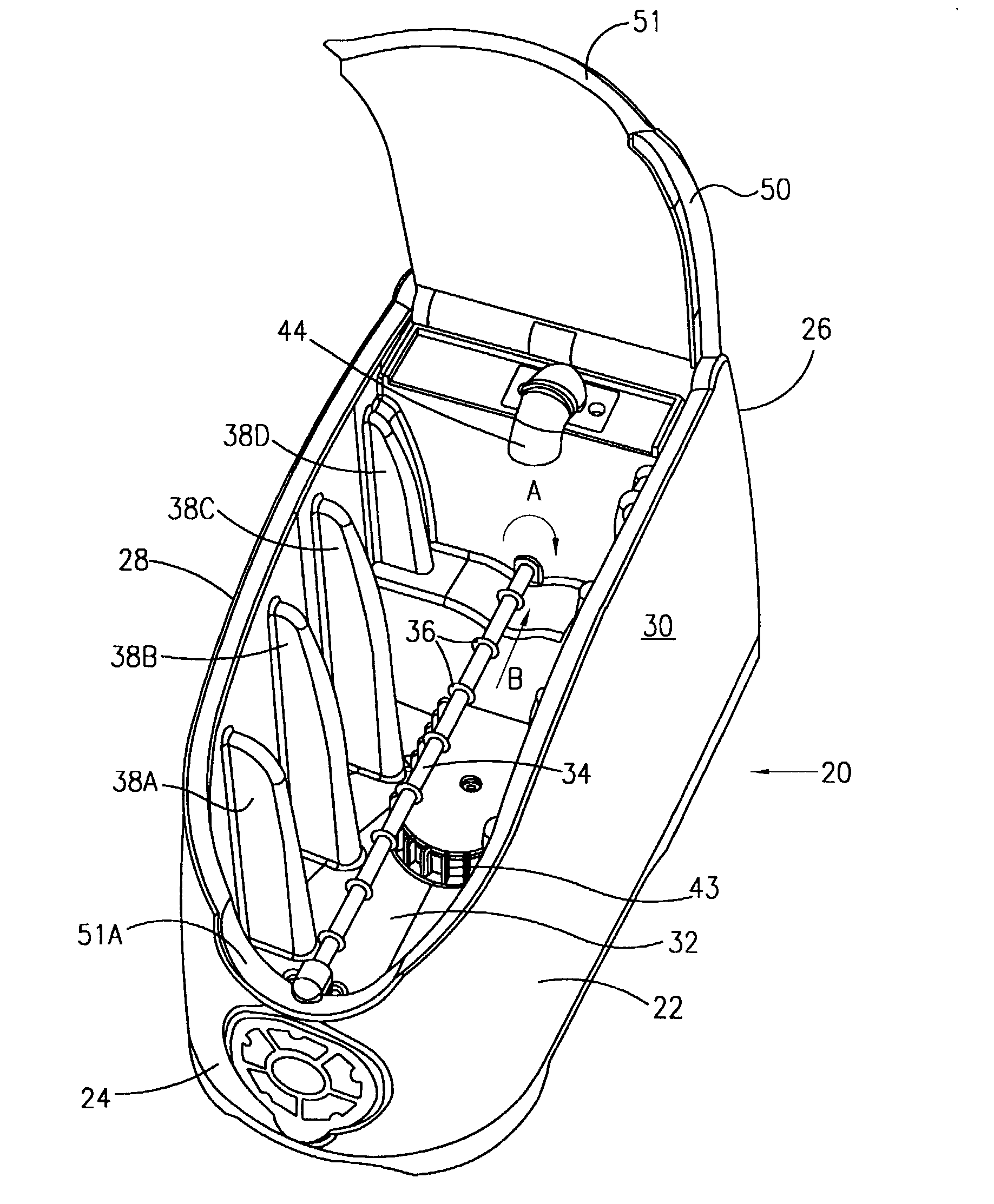

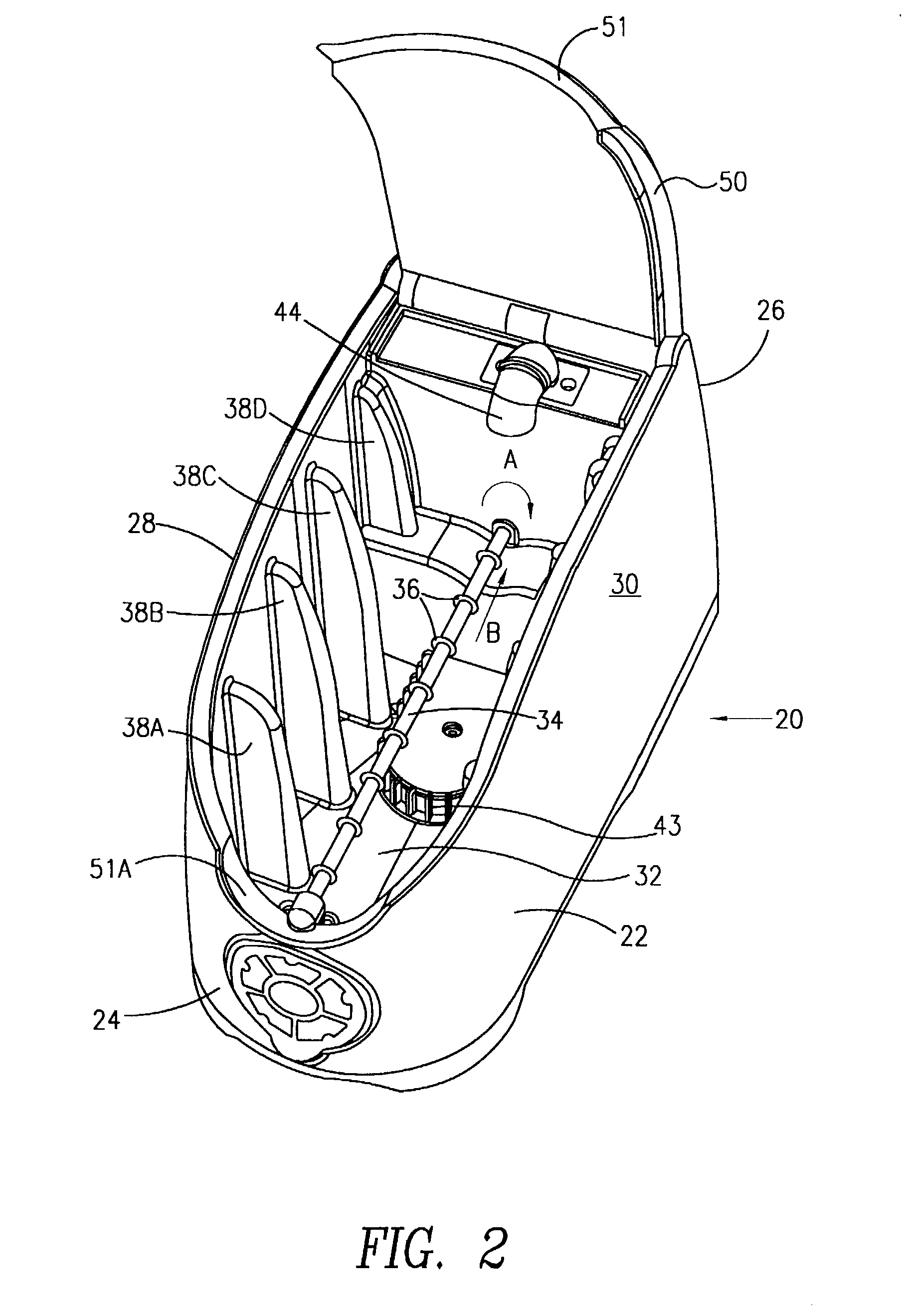

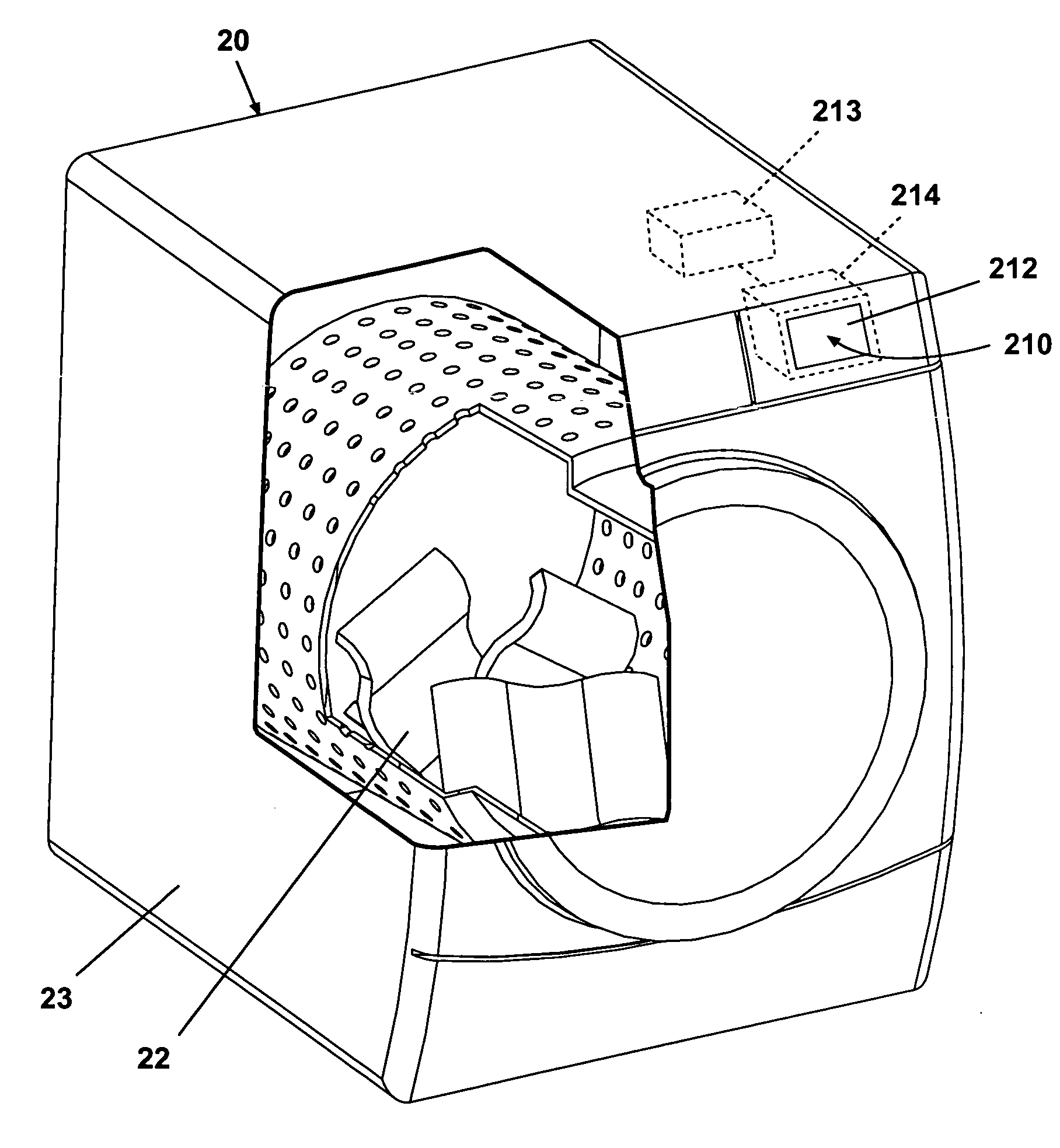

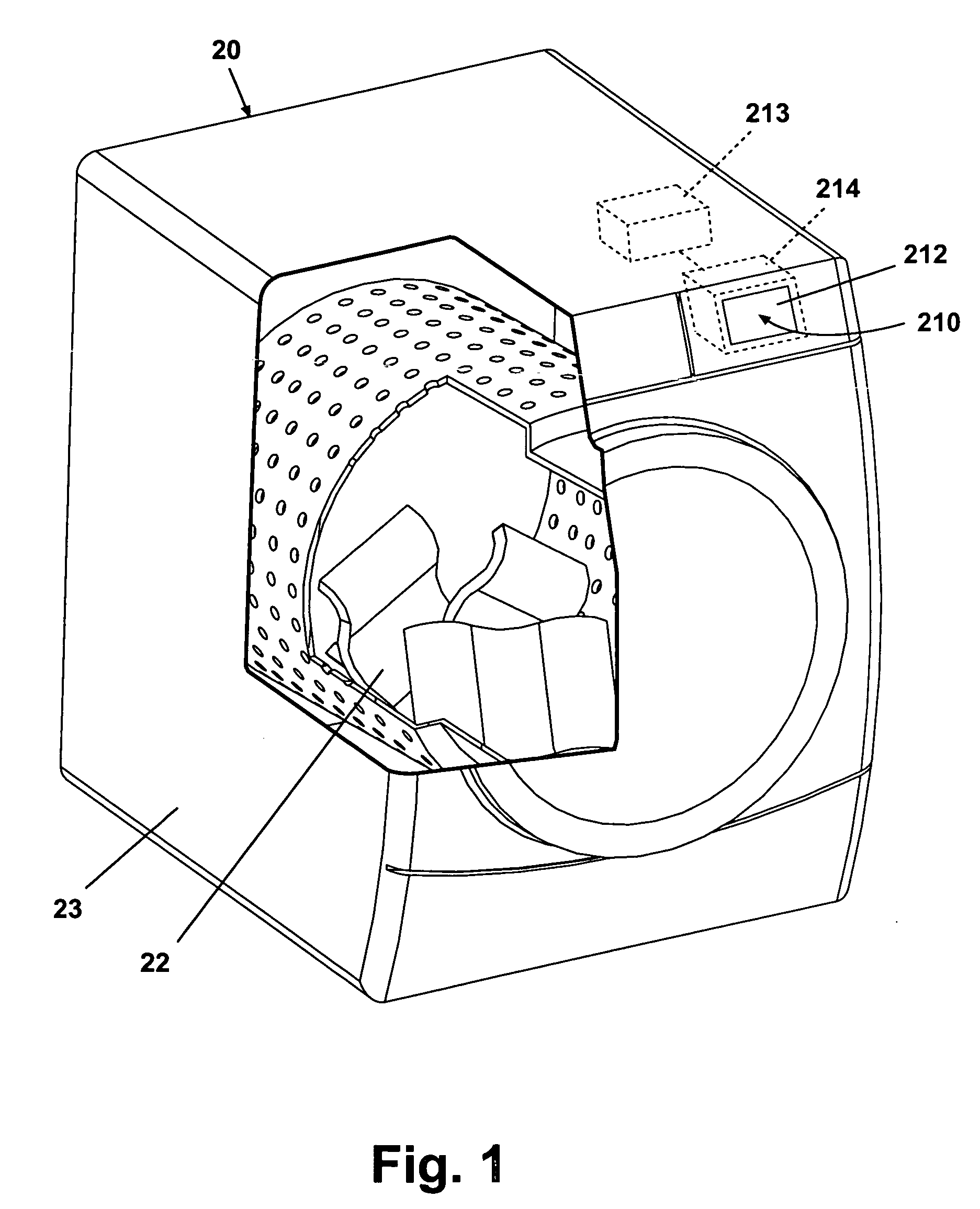

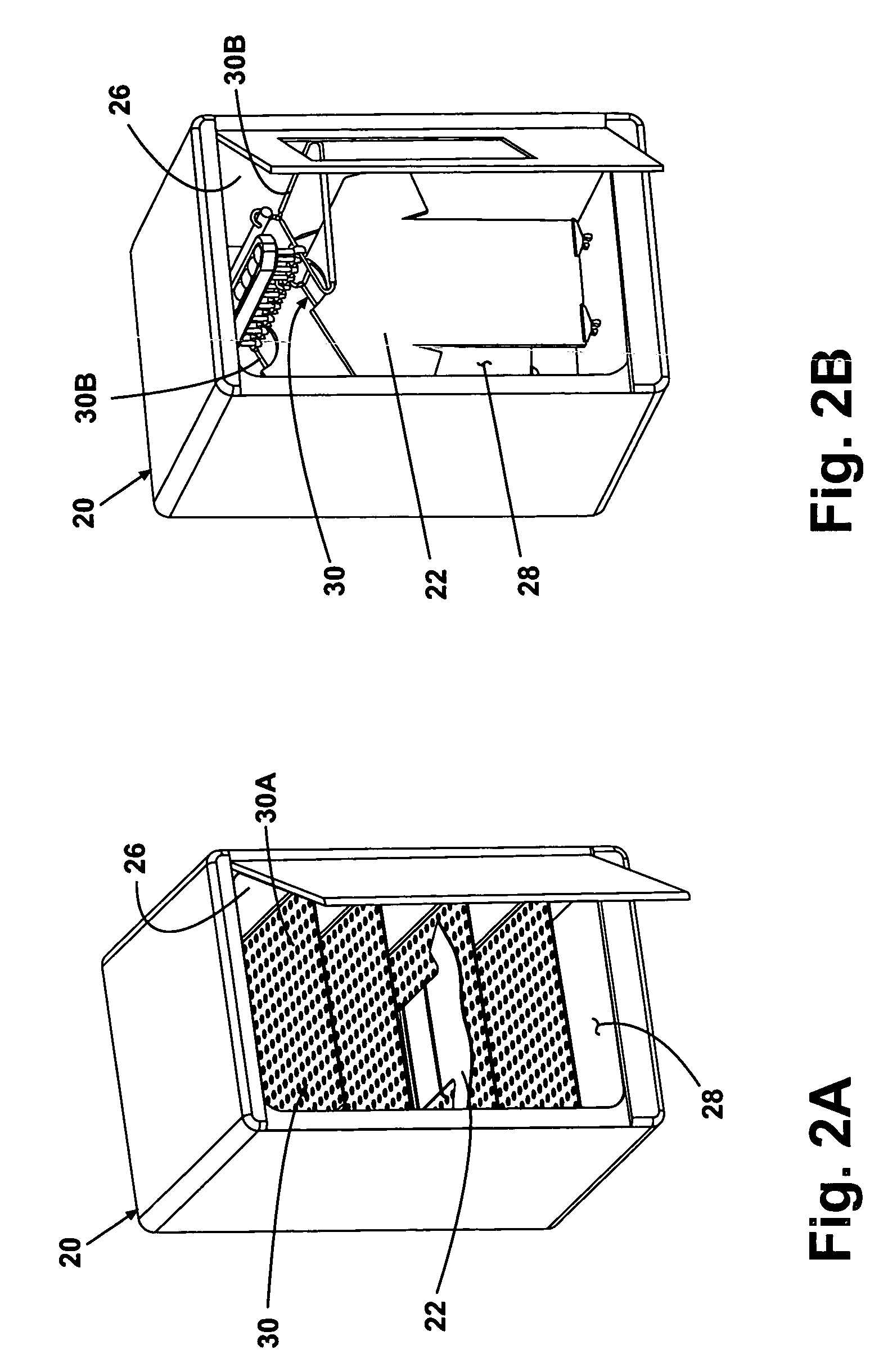

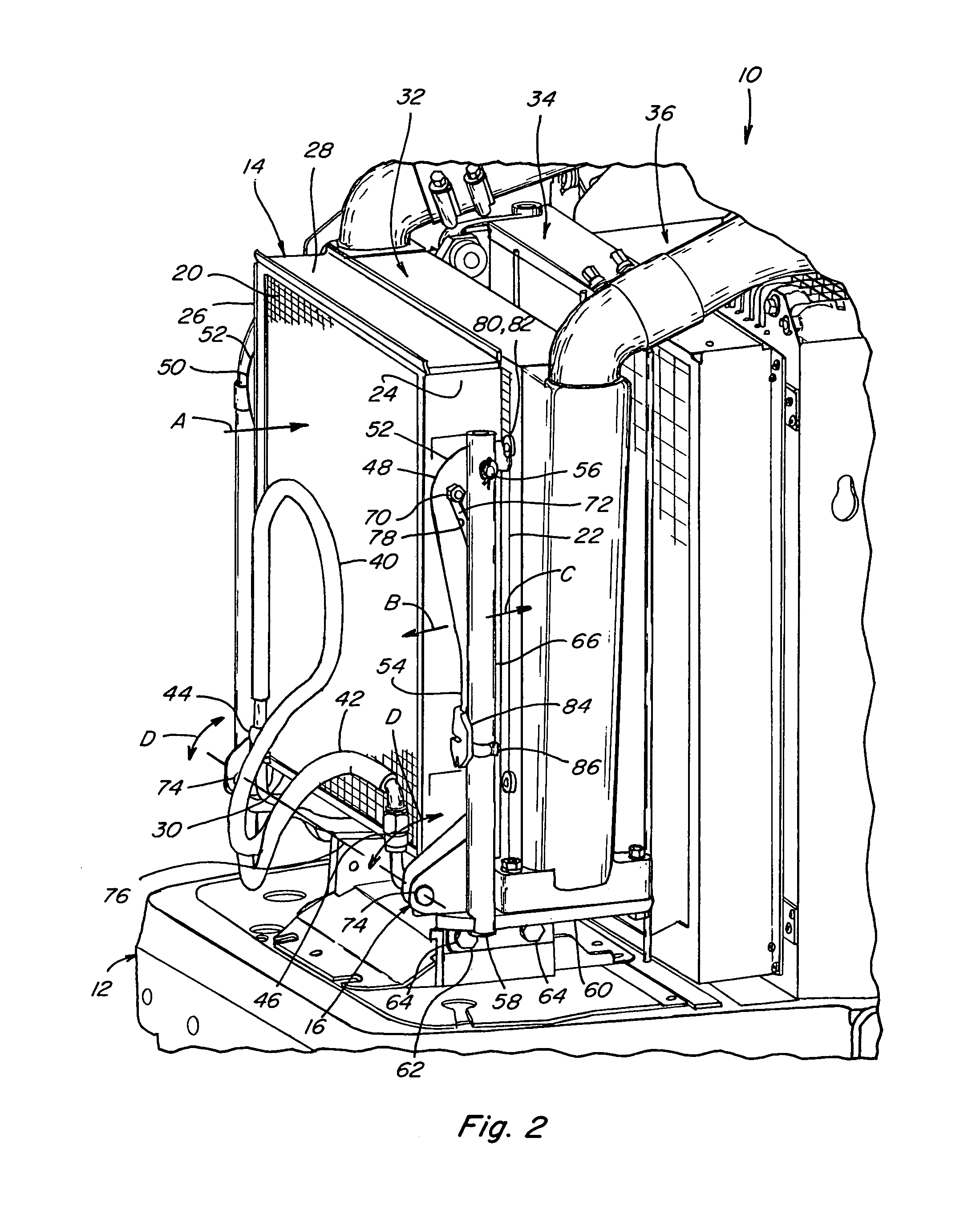

Nebulizer system for a fabric treatment appliance

A nebulizer assembly for use in a fabrics revitalizing system having a fabric treatment chamber comprises a fluid reservoir configured to contain a fluid; an air flow channel in fluid communication with the fluid reservoir; a mist generator configured to generate a mist in the fluid reservoir; and a fan in fluid communication with the air flow channel to draw air through the air flow channel and transport the mist to the interior of the fabric treatment chamber. The nebulizer assembly can include a transitional assembly that communicates the nebulizer assembly with the fabric treatment chamber.

Owner:WHIRLPOOL CORP

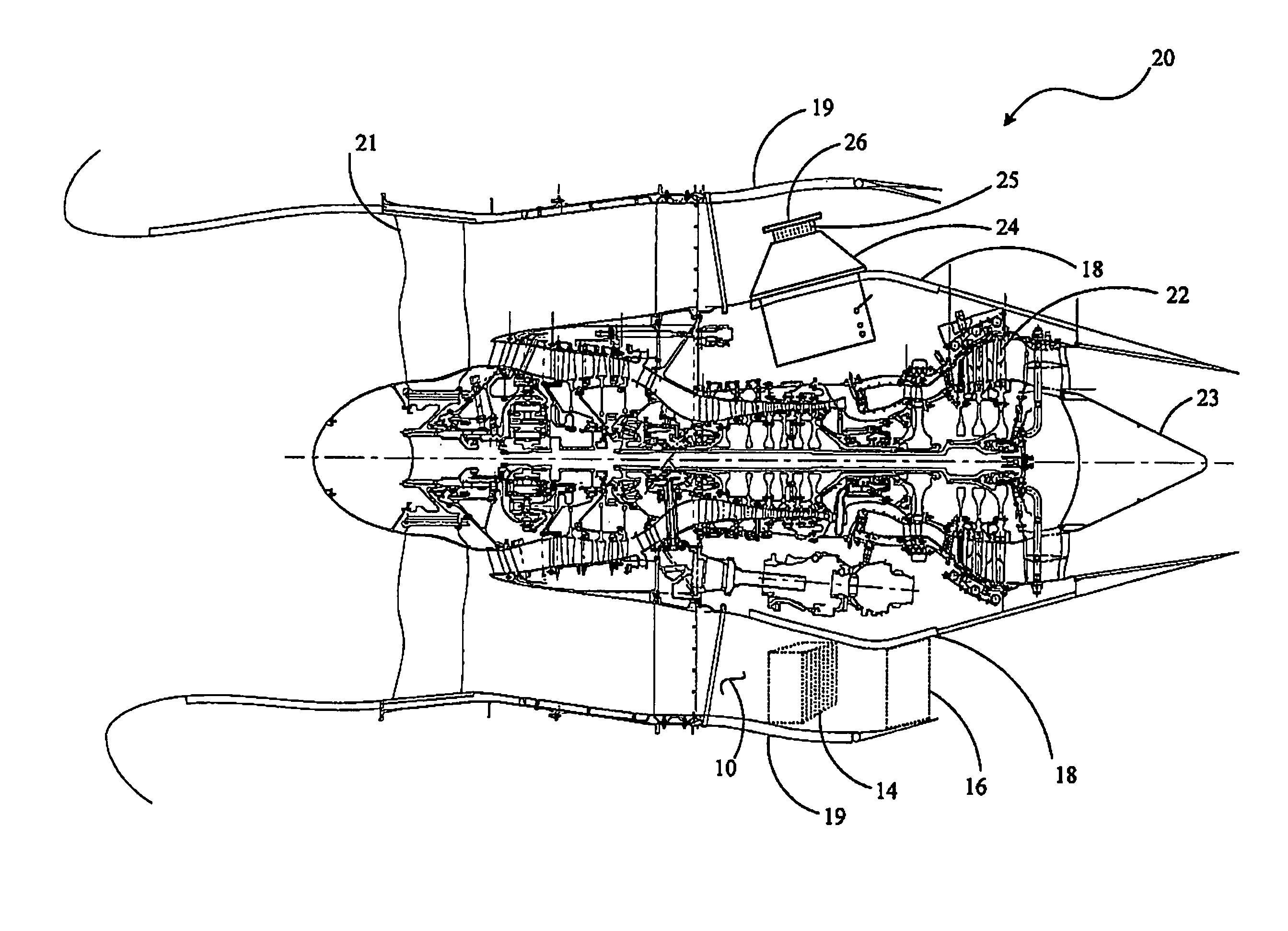

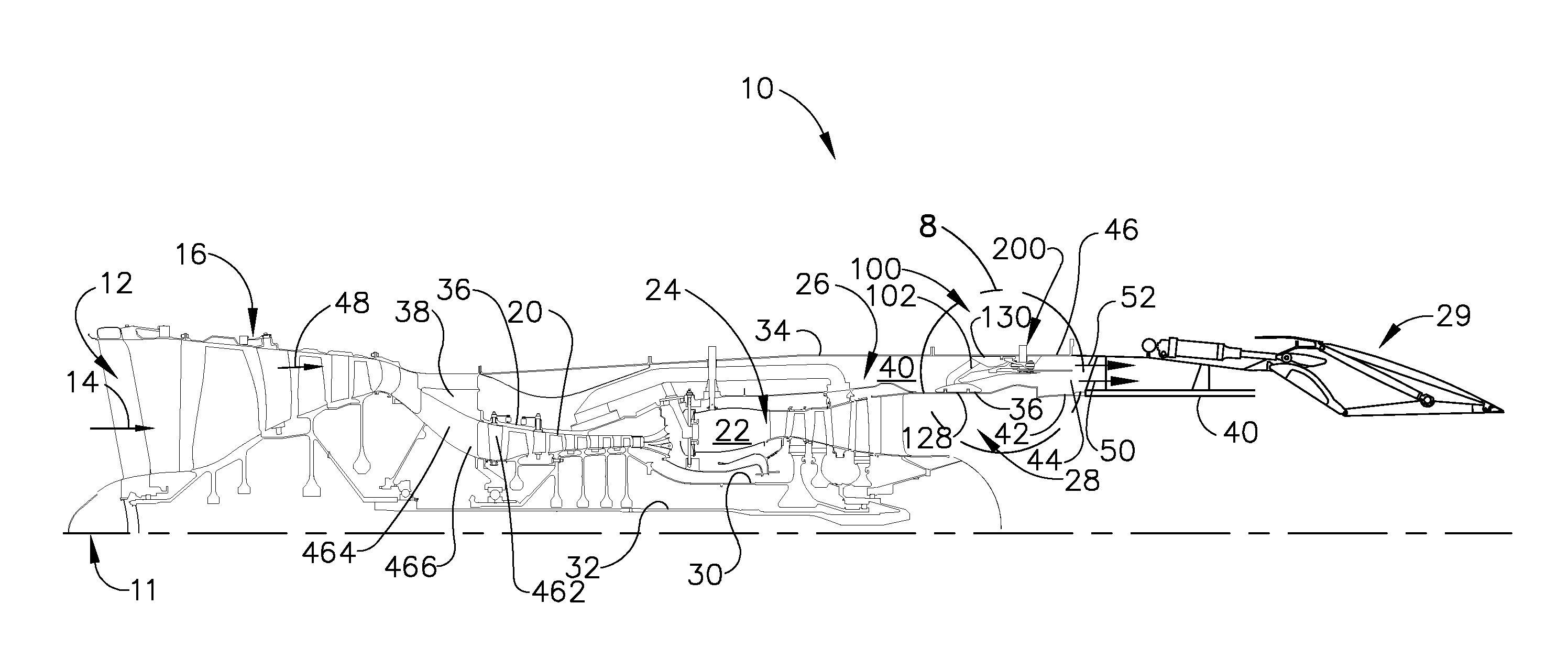

Thermal management system for turbofan engines

A heat exchange system for use in operating equipment in which a working fluid is utilized needing a heat exchange system to provide air and working fluid heat exchanges to cool the working fluid at selectively variable rates in airstreams. The system comprises a plurality of heat exchangers including a first heat exchanger in the plurality of heat exchangers that is mounted with respect to the equipment so as to permit corresponding portions of the airstreams to pass through the core thereof during at least some such uses of the equipment. Also, a second heat exchanger is mounted with respect to the equipment so as to selectively permit corresponding portions of the airstreams to pass through the core thereof during such uses of the equipment. A core actuator is mounted with respect to the second heat exchanger to selectively increase or reduce the passing of those corresponding portions of the airstreams through the core.

Owner:RTX CORP

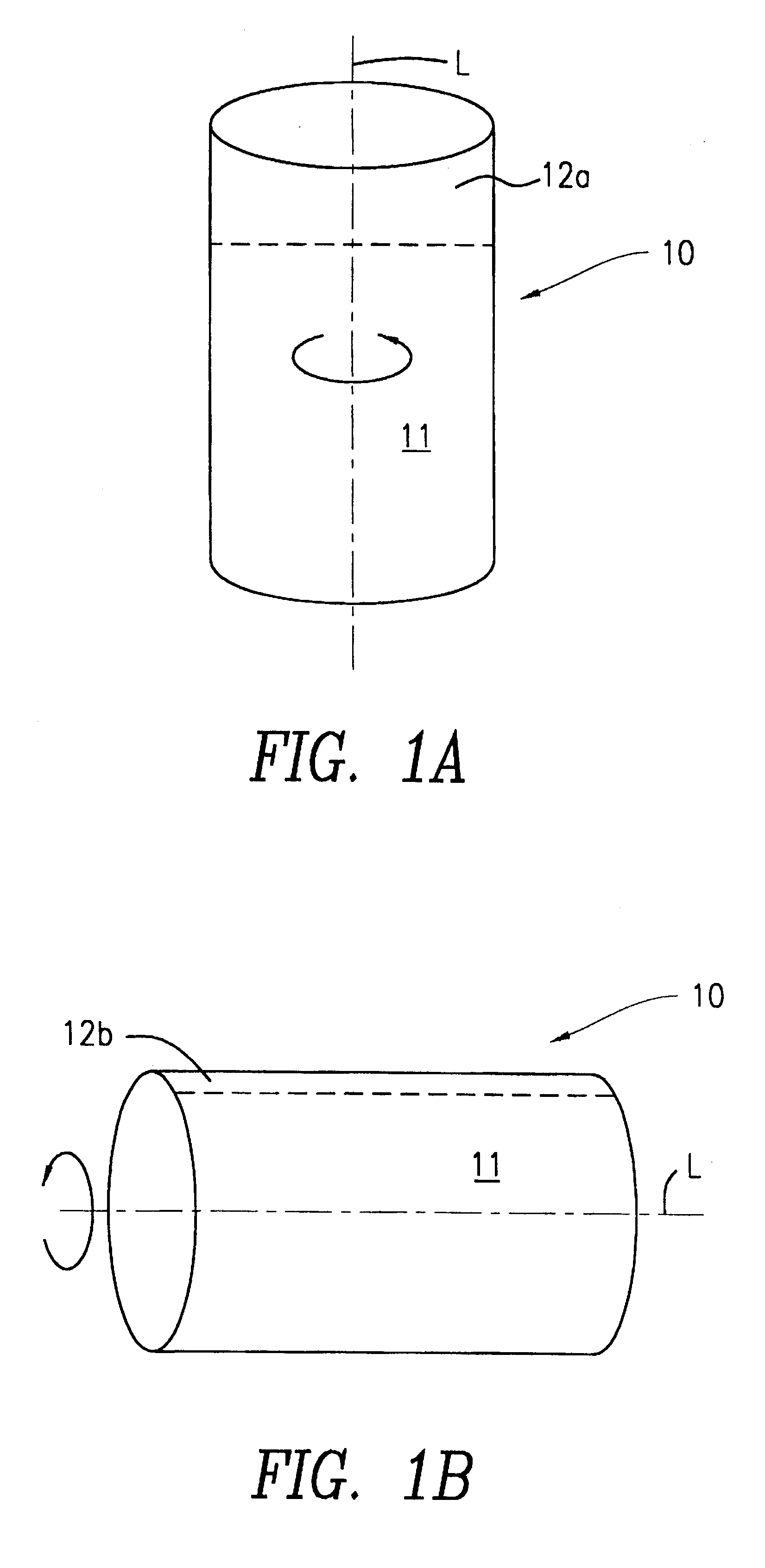

Rapid fluid cooling and heating device and method

InactiveUS6662574B2Rapid coolingIncrease surface areaFrozen sweetsDomestic refrigeratorsIce CreamsThin membrane

A method and device for rapidly changing at least one of the temperature and the state of a liquid in a container is provided. The container is rapidly rotated about its longitudinal axis. A source of a thin film of a medium having a different temperature than the liquid in the container is provided to thermally affect the container while rotating the container. The container is positioned at an angle to the horizontal of less than 45°, and the position of the container with respect to the thin film source is controlled by angling the axis of the container skewed from the axis of the rotating mechanism. The device can be used to cool liquids such as beverages, warm liquids such as infant formula, and / or make ice cream.

Owner:THE COOPER UNION FOR THE ADVANCEMENT OF SCI & ART

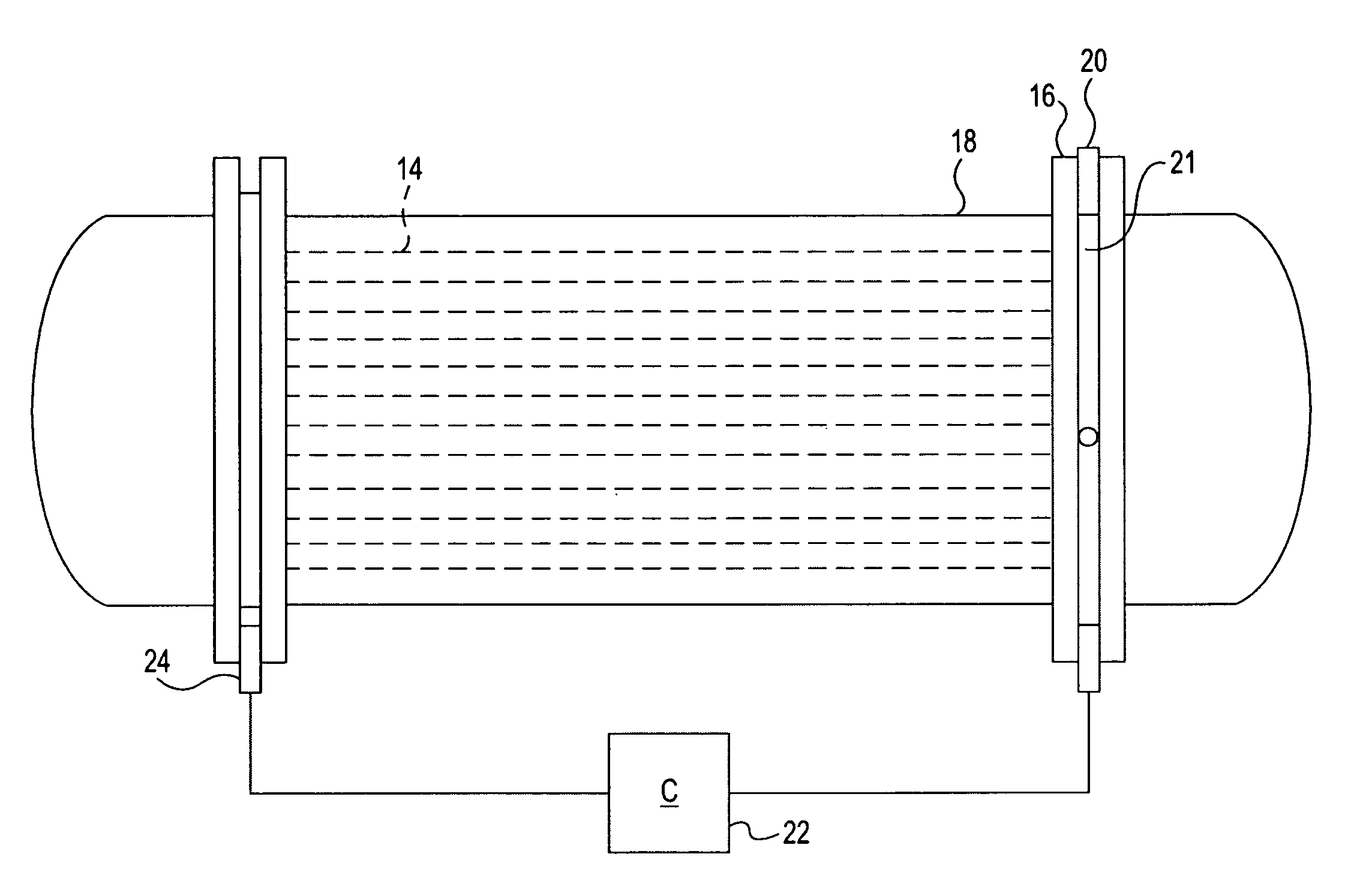

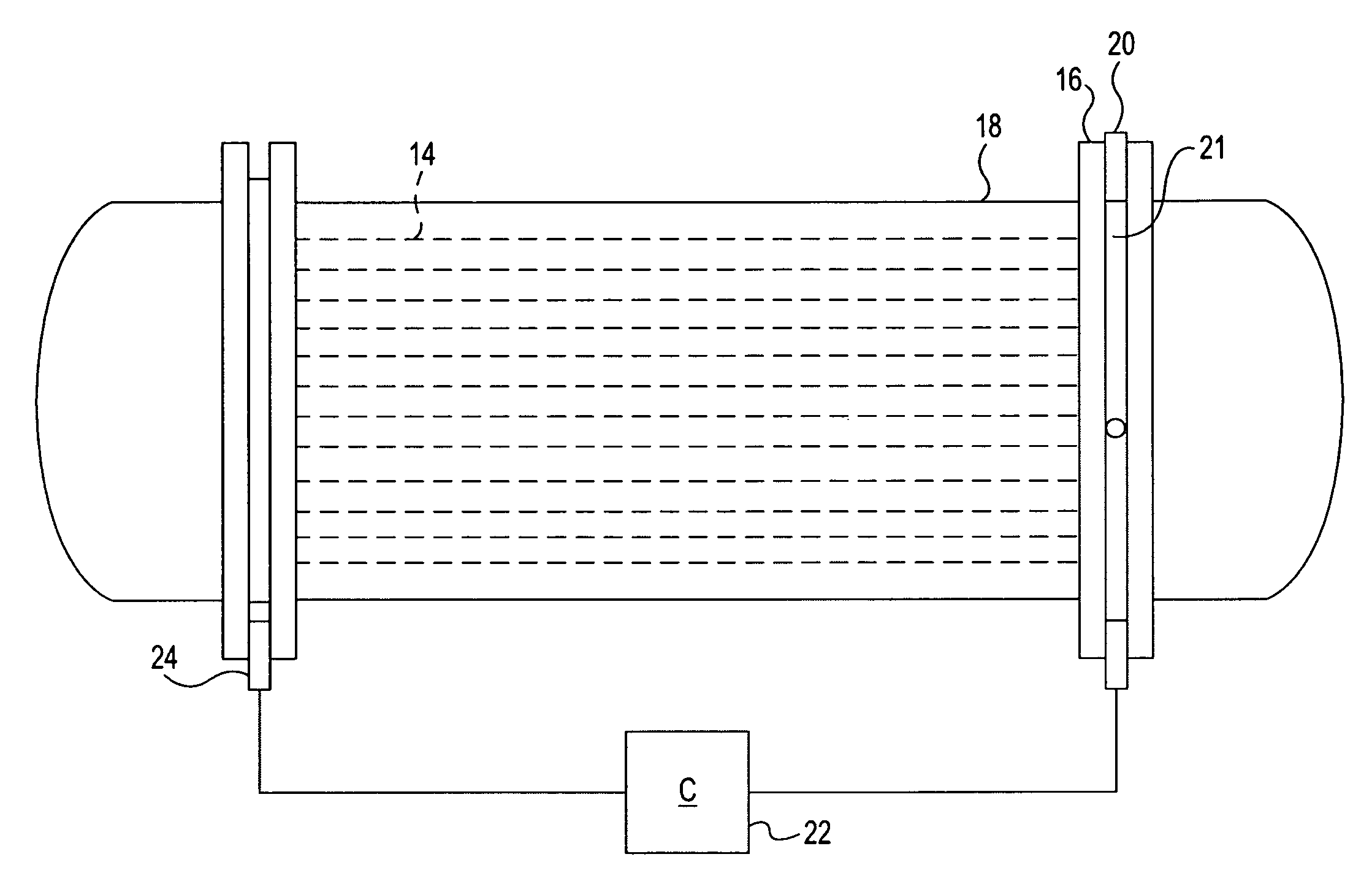

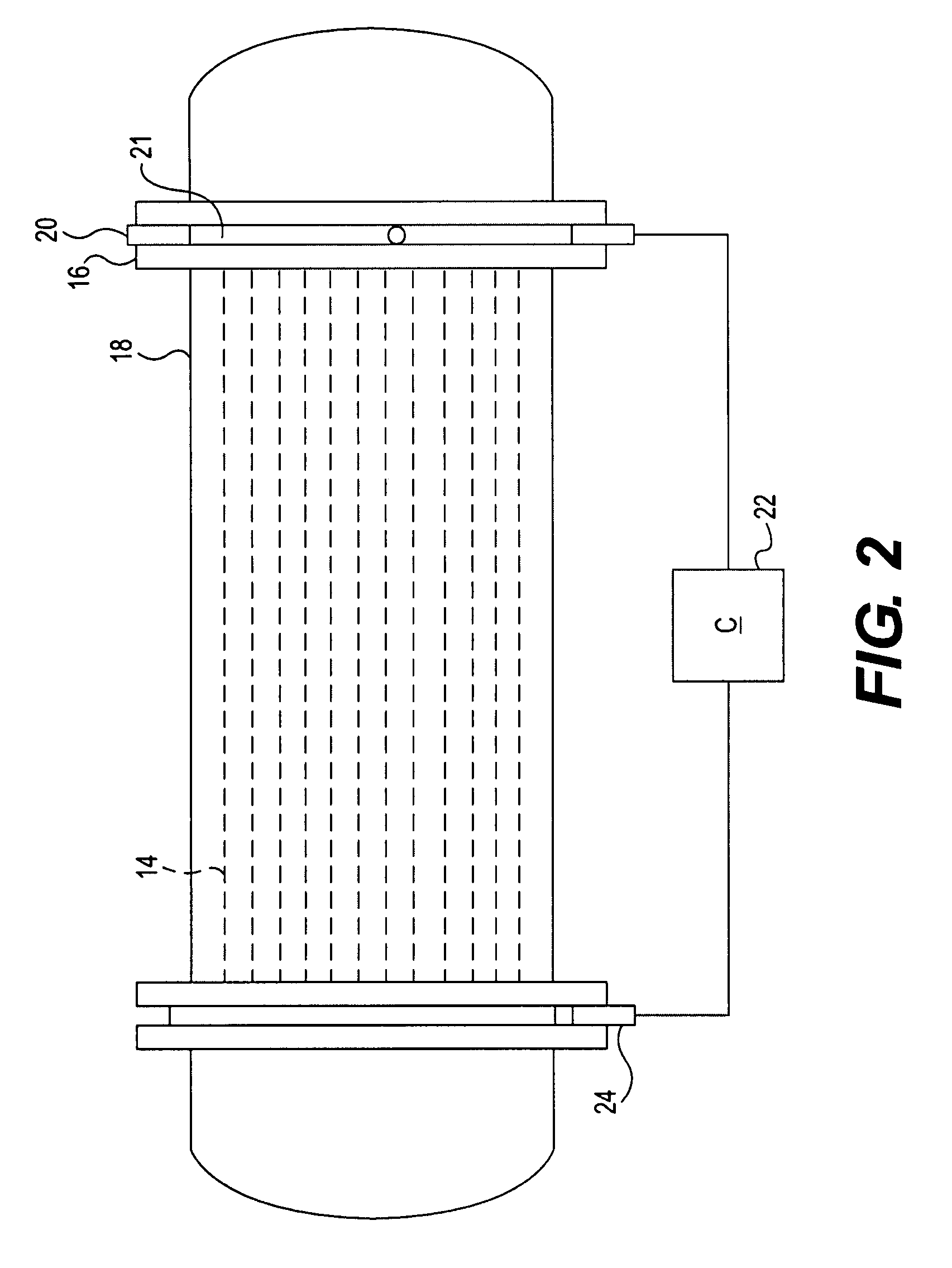

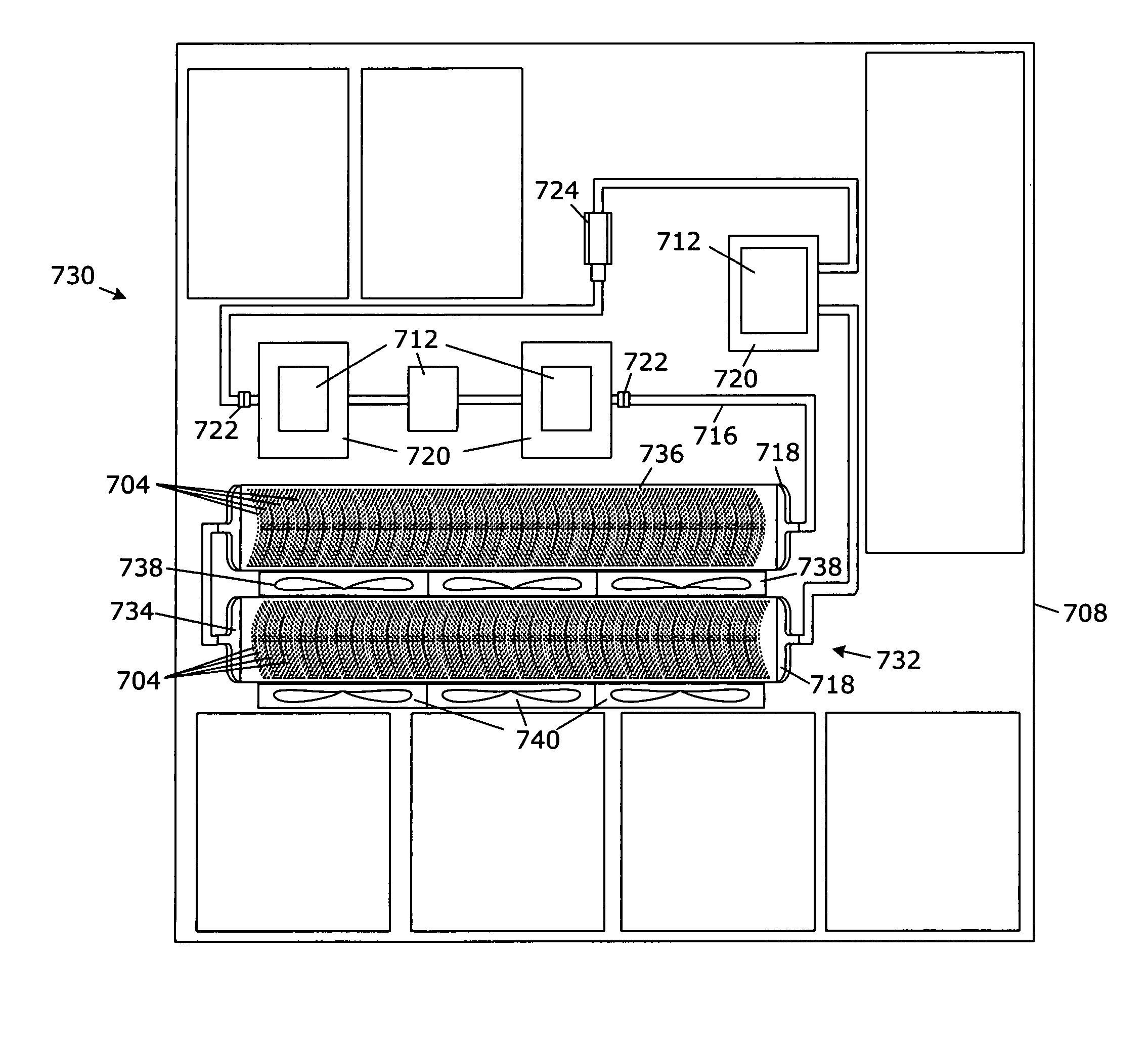

Mitigation of in-tube fouling in heat exchangers using controlled mechanical vibration

InactiveUS20070267176A1Reduce dirtCombustion processCorrosion preventionPlate heat exchangerEngineering

Fouling of heat exchange surfaces is mitigated by a process in which a mechanical force is applied to a fixed heat exchanger to excite a vibration in the heat exchange surface and produce shear waves in the fluid adjacent the heat exchange surface. The mechanical force is applied by a dynamic actuator coupled to a controller to produce vibration at a controlled frequency and amplitude output that minimizes adverse effects to the heat exchange structure. The dynamic actuator may be coupled to the heat exchanger in place and operated while the heat exchanger is on line.

Owner:EXXON RES & ENG CO

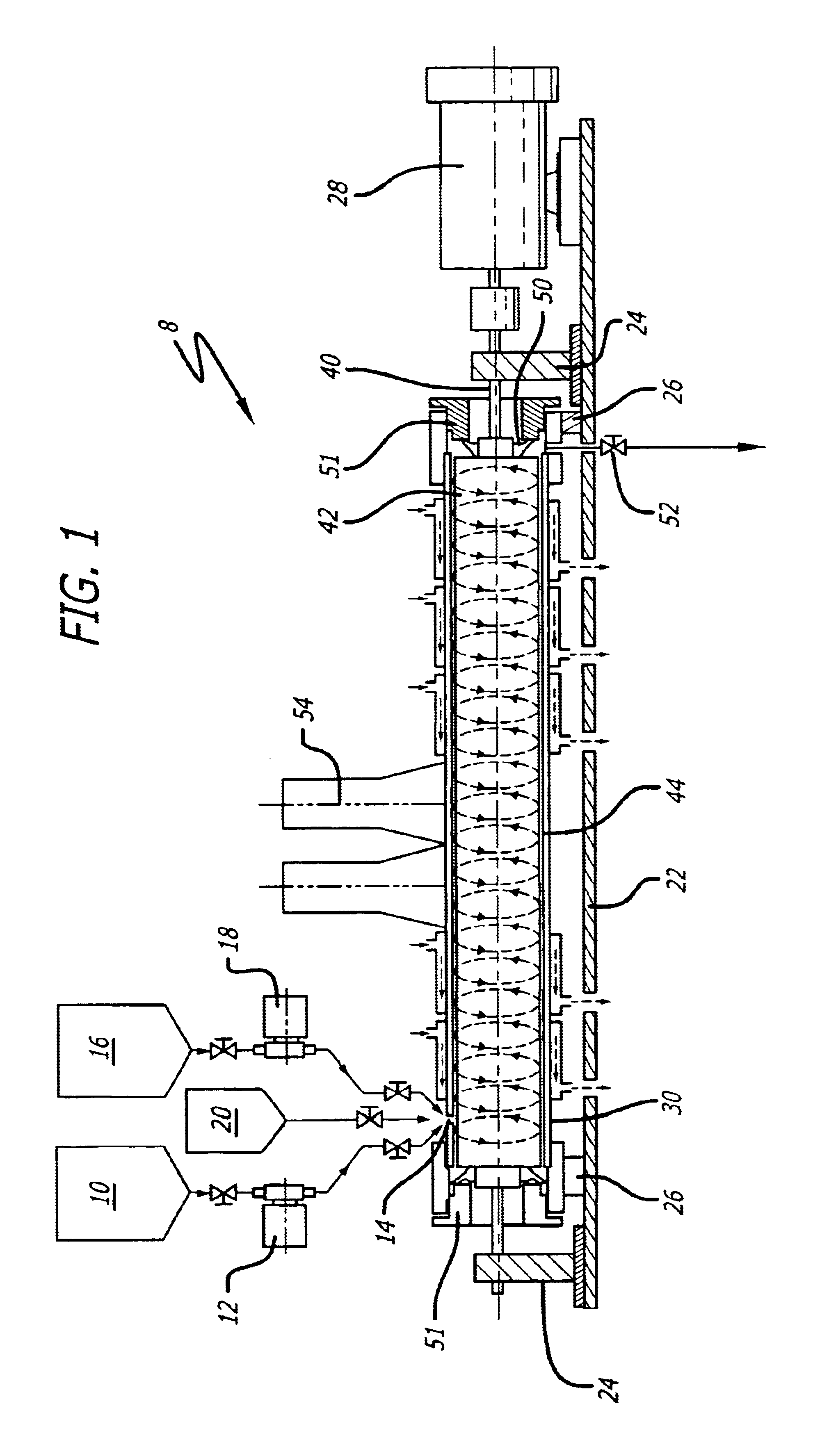

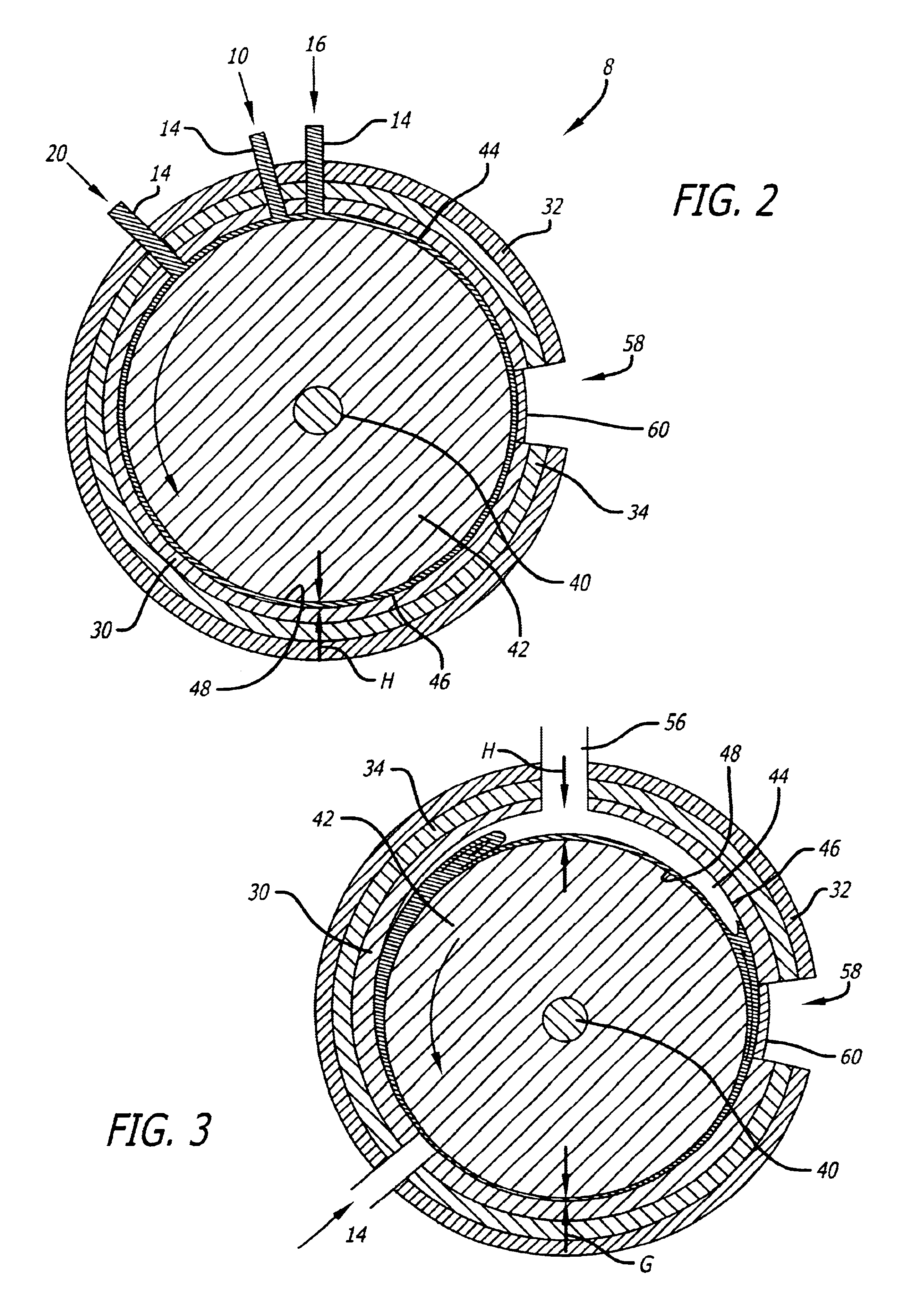

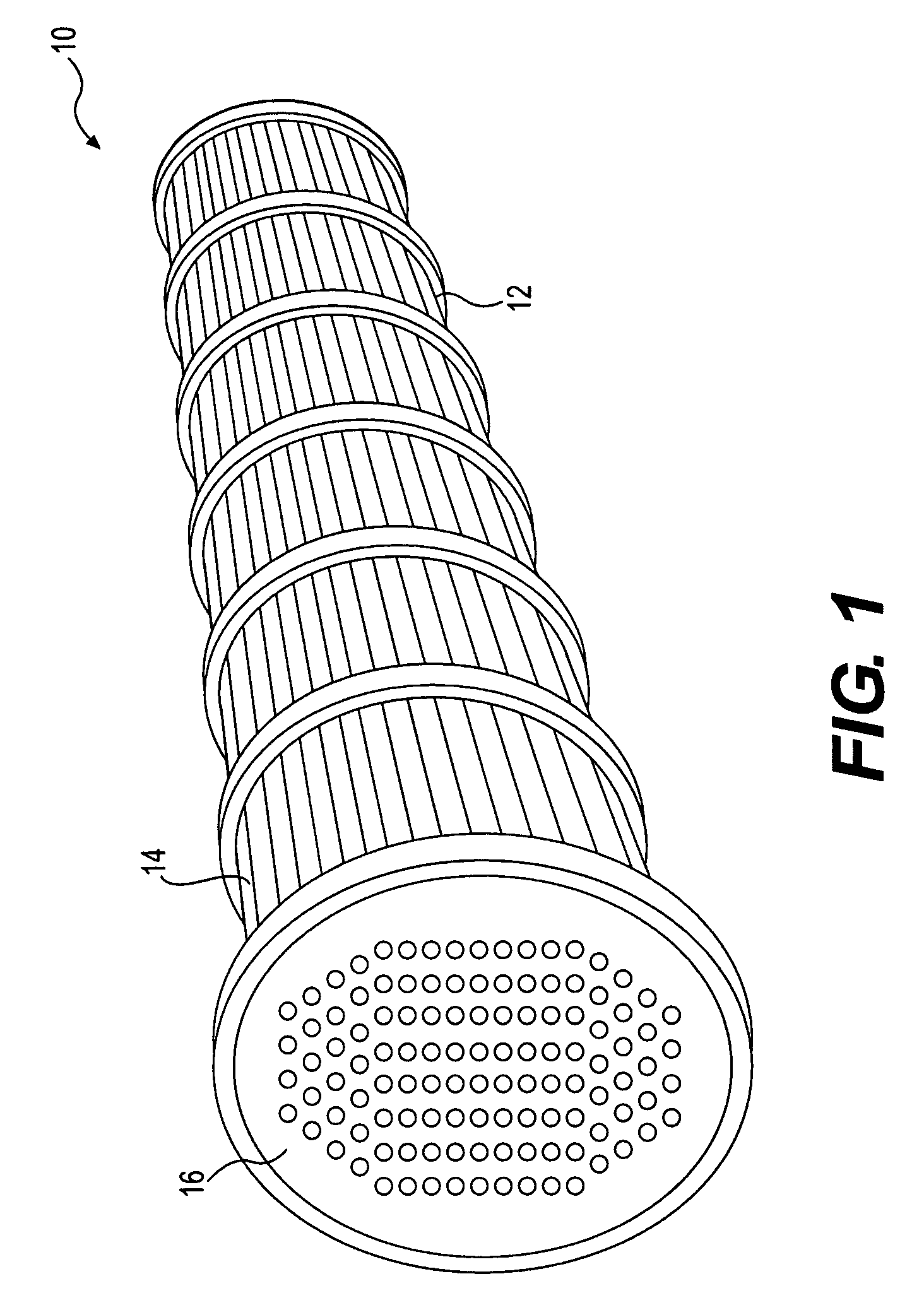

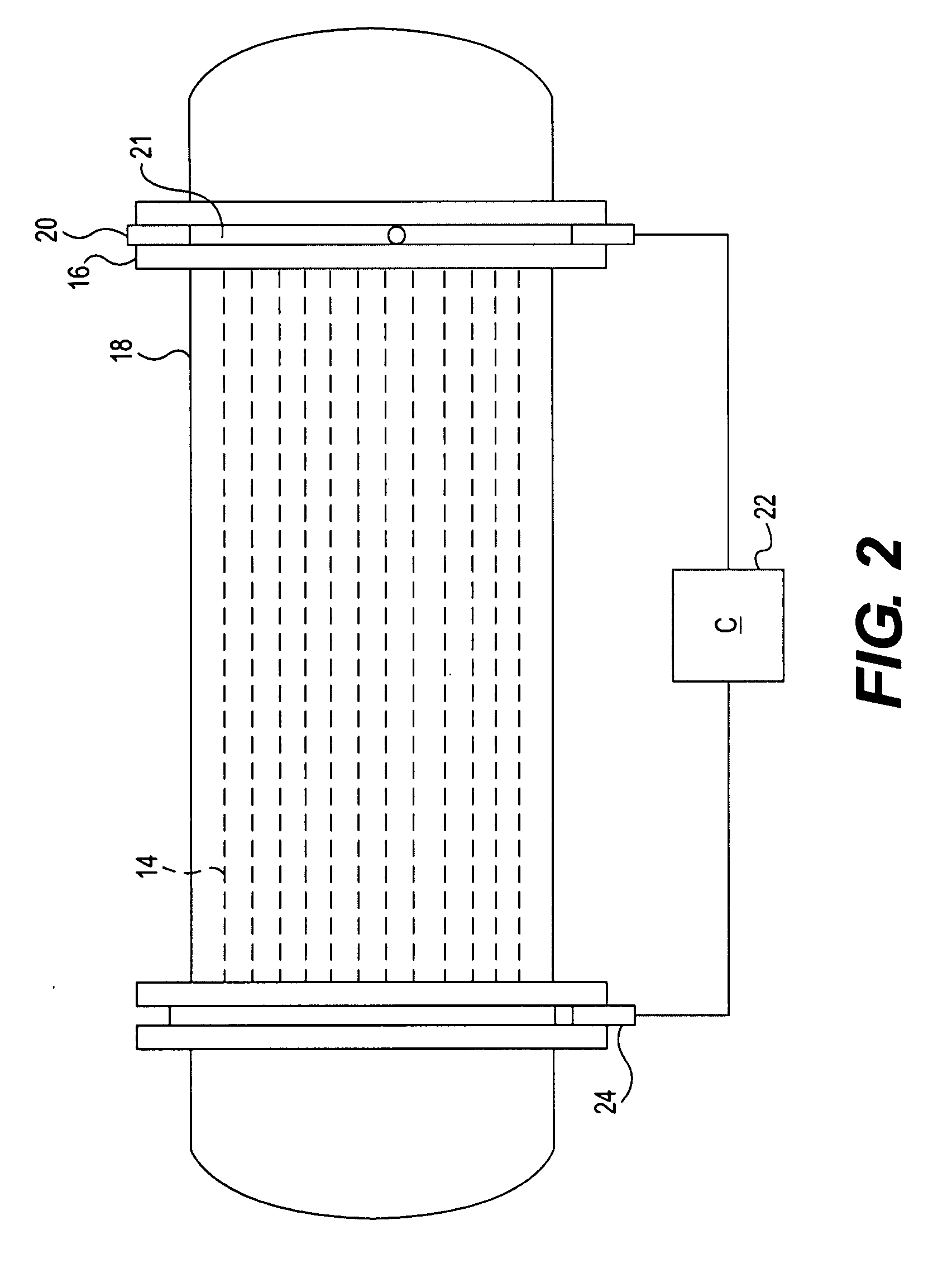

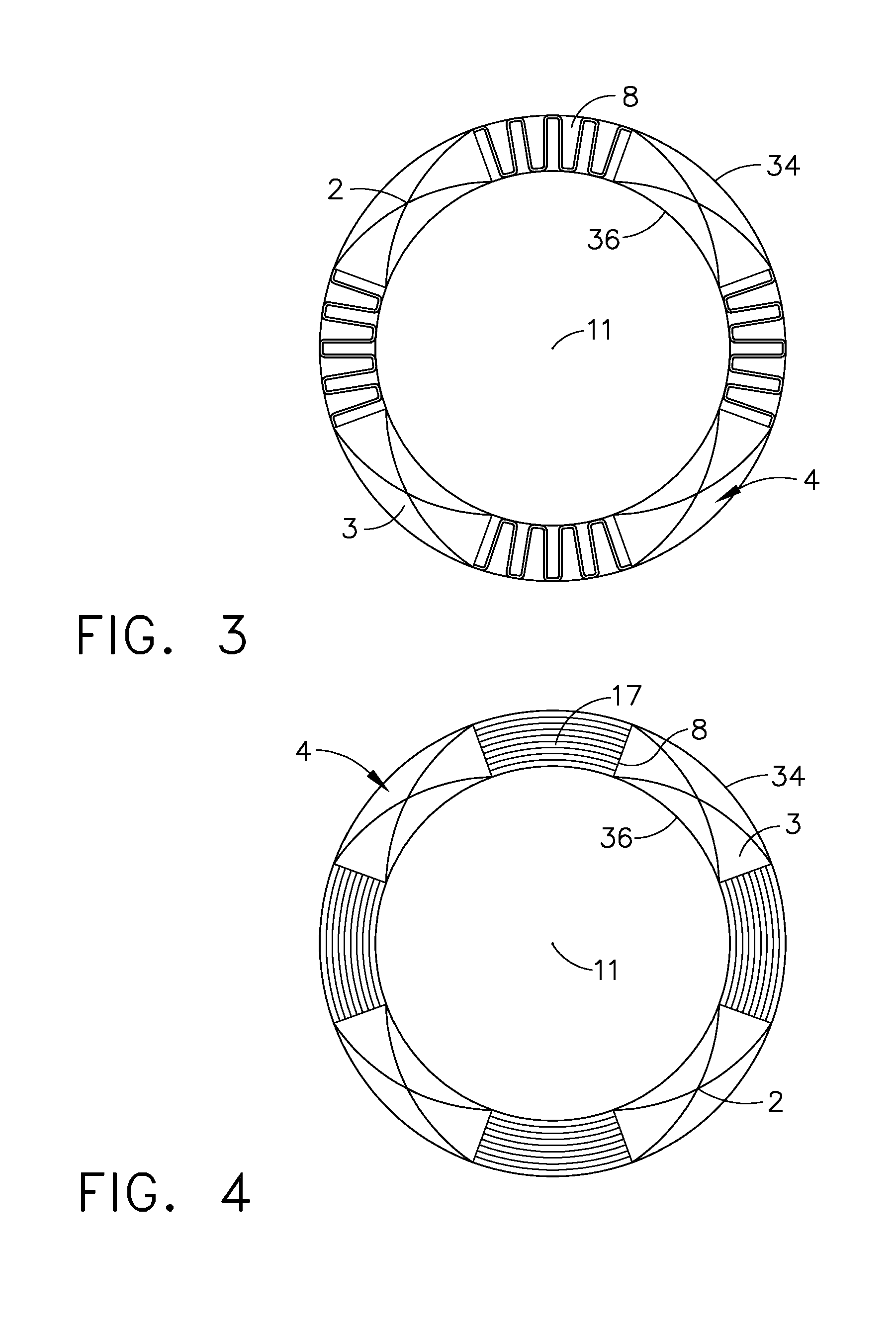

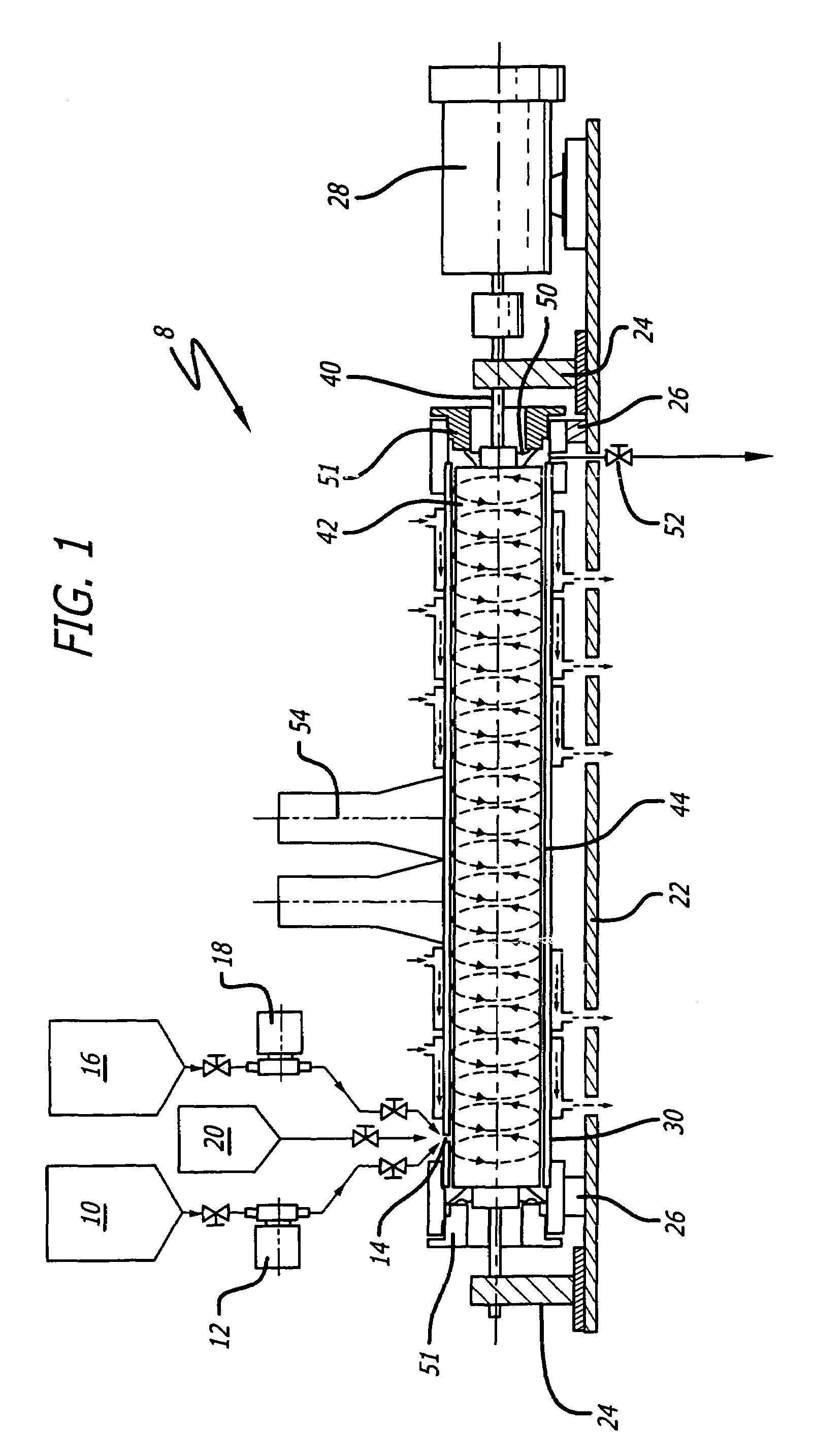

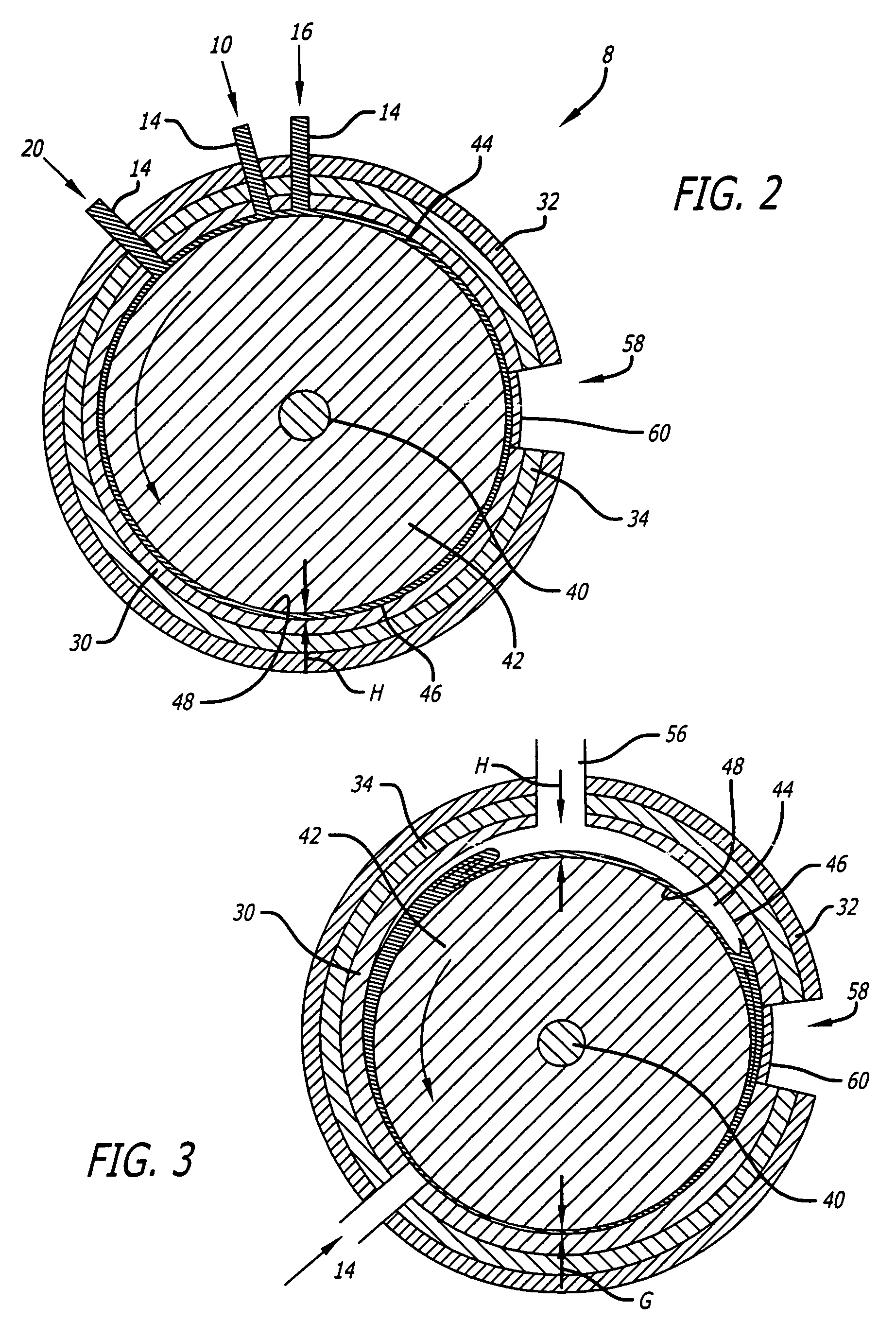

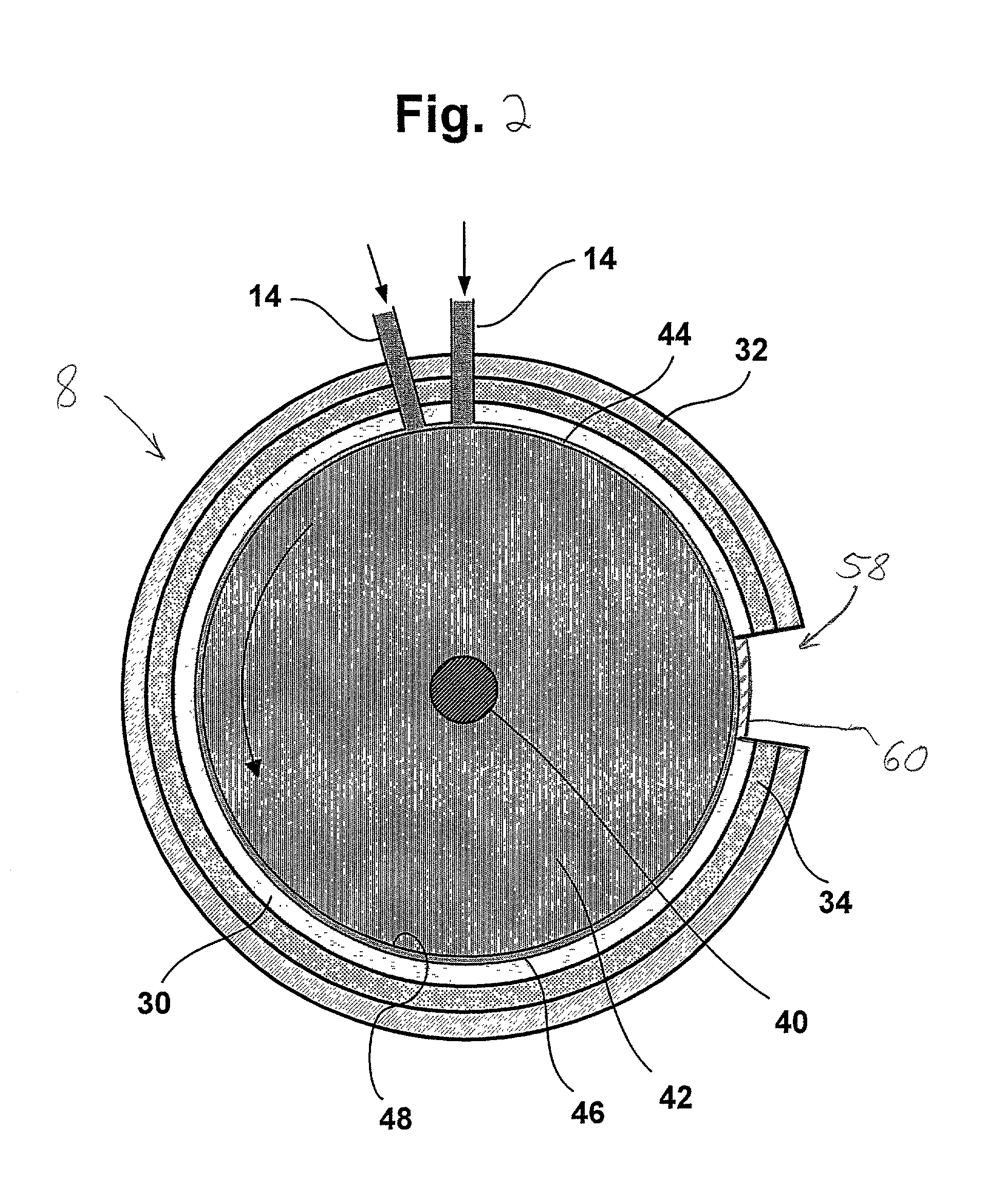

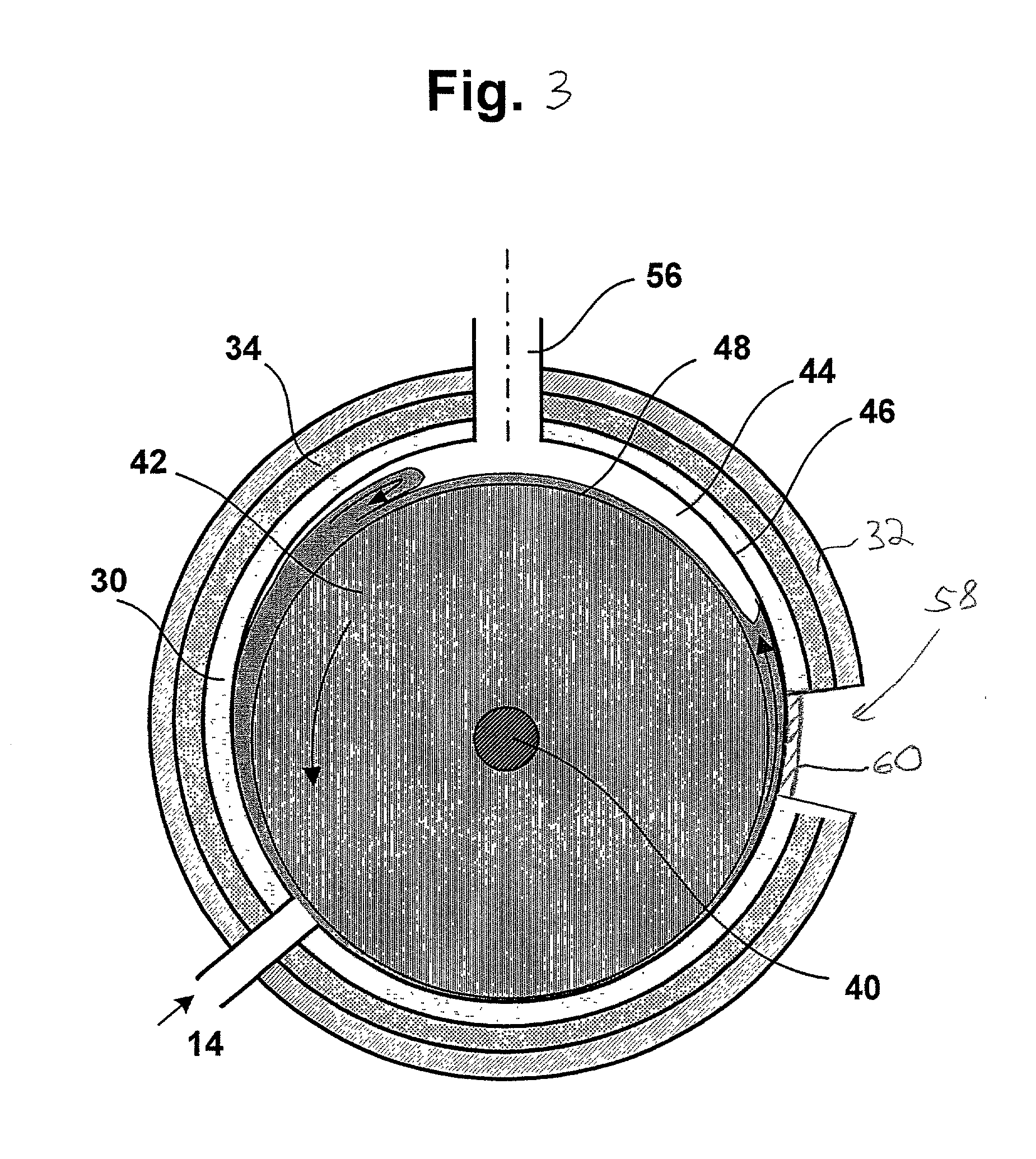

Process for high shear gas-liquid reactions

A reactor produces a gas-in-liquid emulsion for providing increased interfacial contact area between the liquid and the gas for improved reaction of the gas with the liquid, or more rapid solution or reaction of a difficulty soluble or immiscible gas in or with a liquid. The reactor is suitable for a continuous or batch type process. Rotor and stator cylindrical members are mounted for rotation relative to one another and have opposing surfaces spaced to form an annular processing passage. The gap distance between the opposing surfaces and the relative rotation rate of the cylindrical members are such as to form a gas-in-liquid emulsion of the gas in the liquid. The liquid and gas pass through the processing passage, changing into the gas-in-liquid emulsion.

Owner:323 TRUST

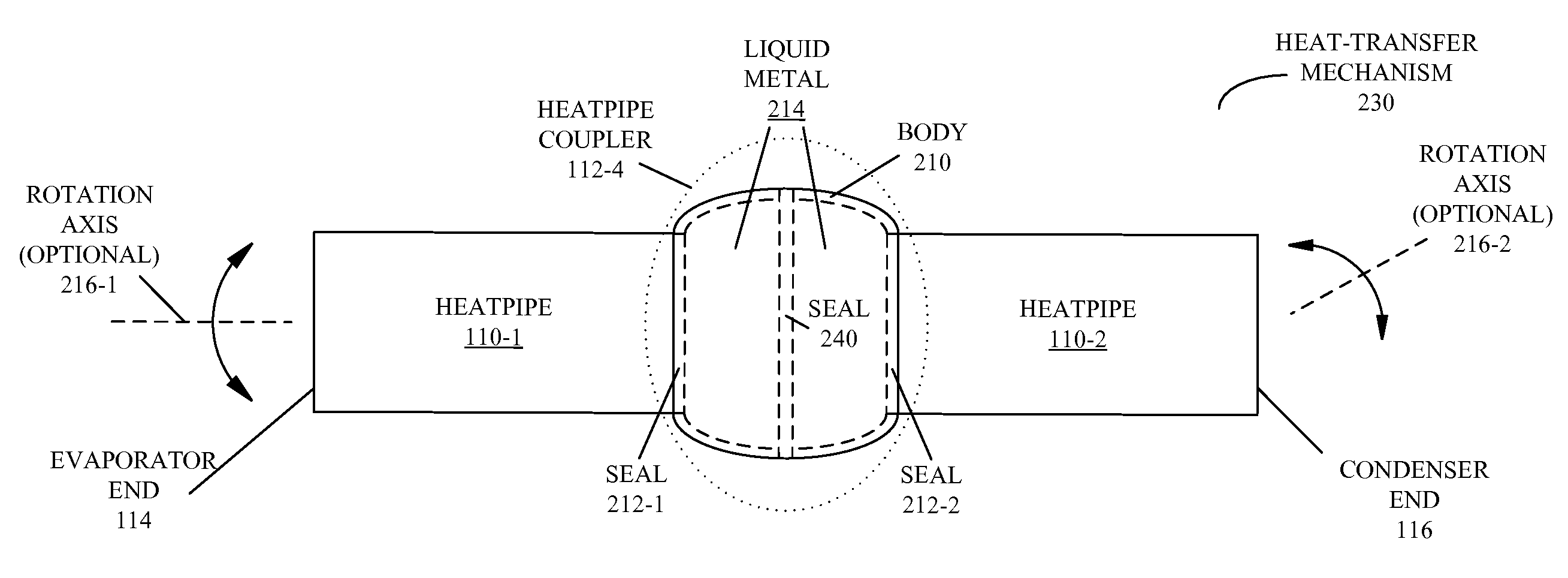

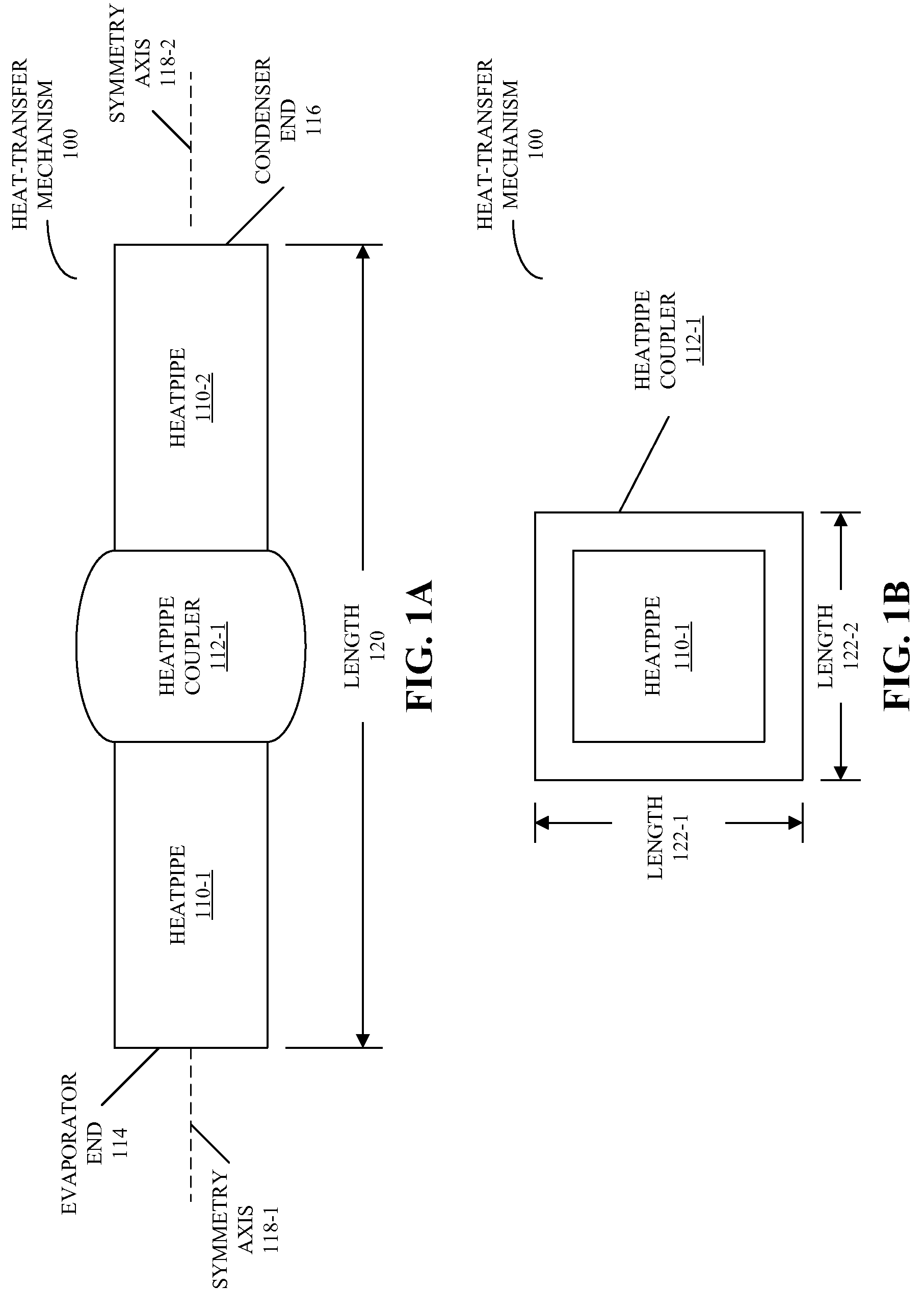

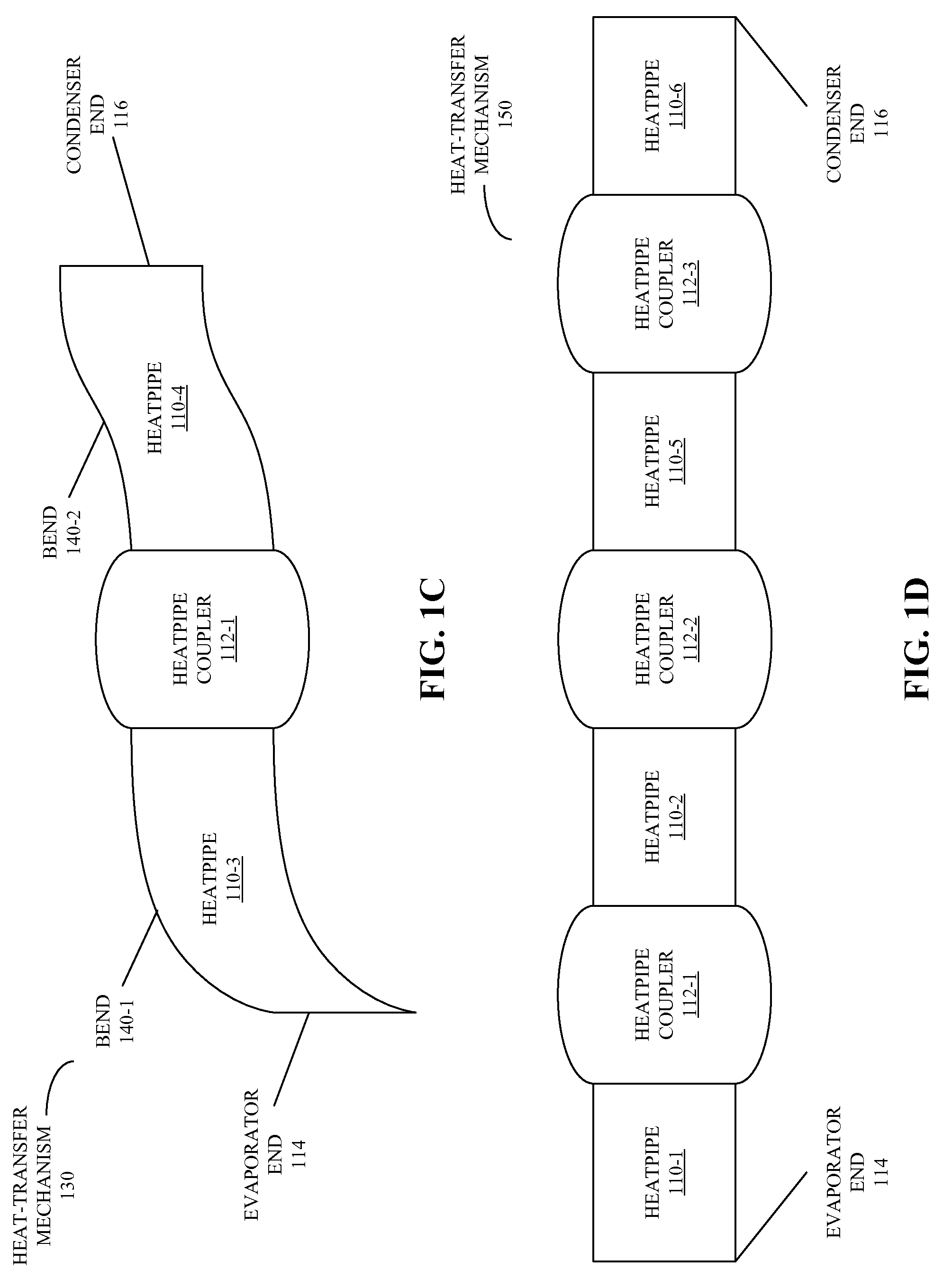

Heat-transfer mechanism including a liquid-metal thermal coupling

Embodiments of a heat-transfer mechanism are described. This heat-transfer mechanism includes a first heatpipe having a first end and a second end, and a second heatpipe having a third end and a fourth end. Moreover, a heatpipe coupler is thermally coupled to the second end of the first heatpipe and the third end of the second heatpipe. This heatpipe coupler includes a housing surrounding a cavity and a liquid metal contained within the cavity, thereby providing a thermal path from the first end of the first heatpipe, which is configured to couple to a condenser, to the fourth end of the second heatpipe, which is configured to couple to an evaporator.

Owner:APPLE INC

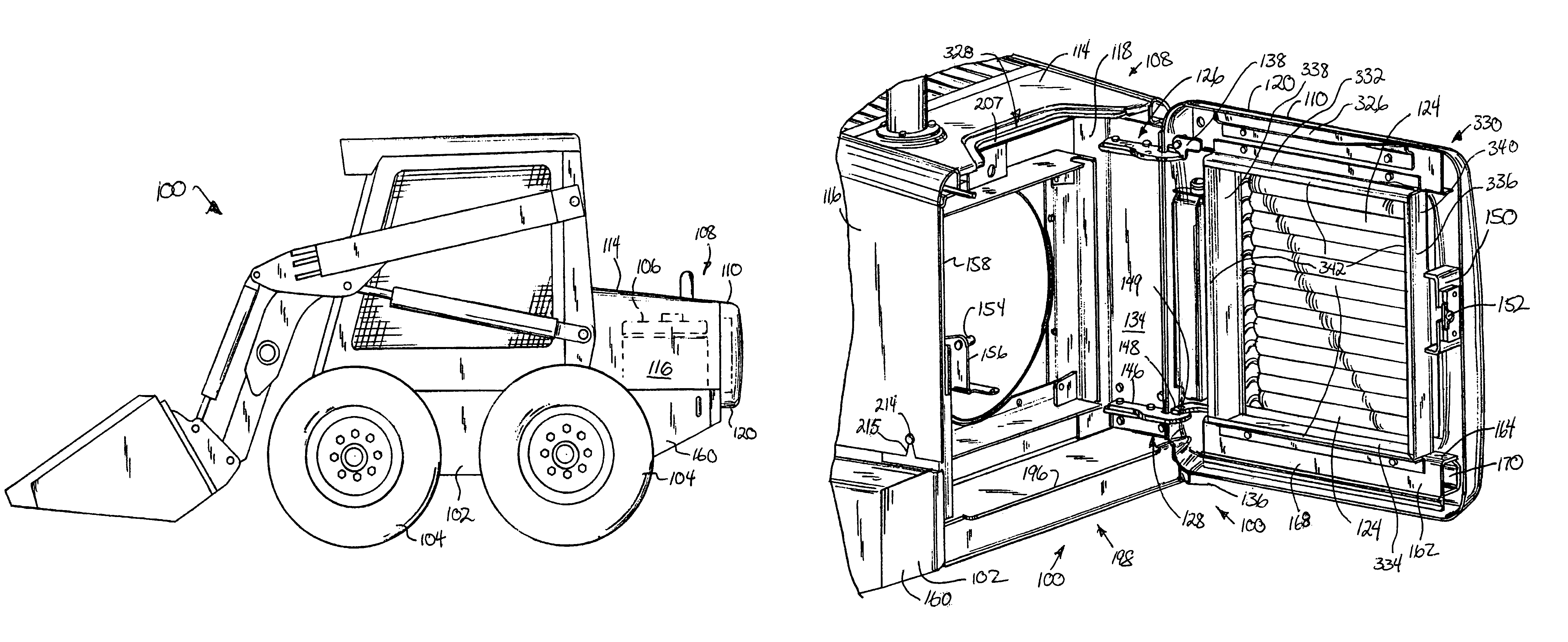

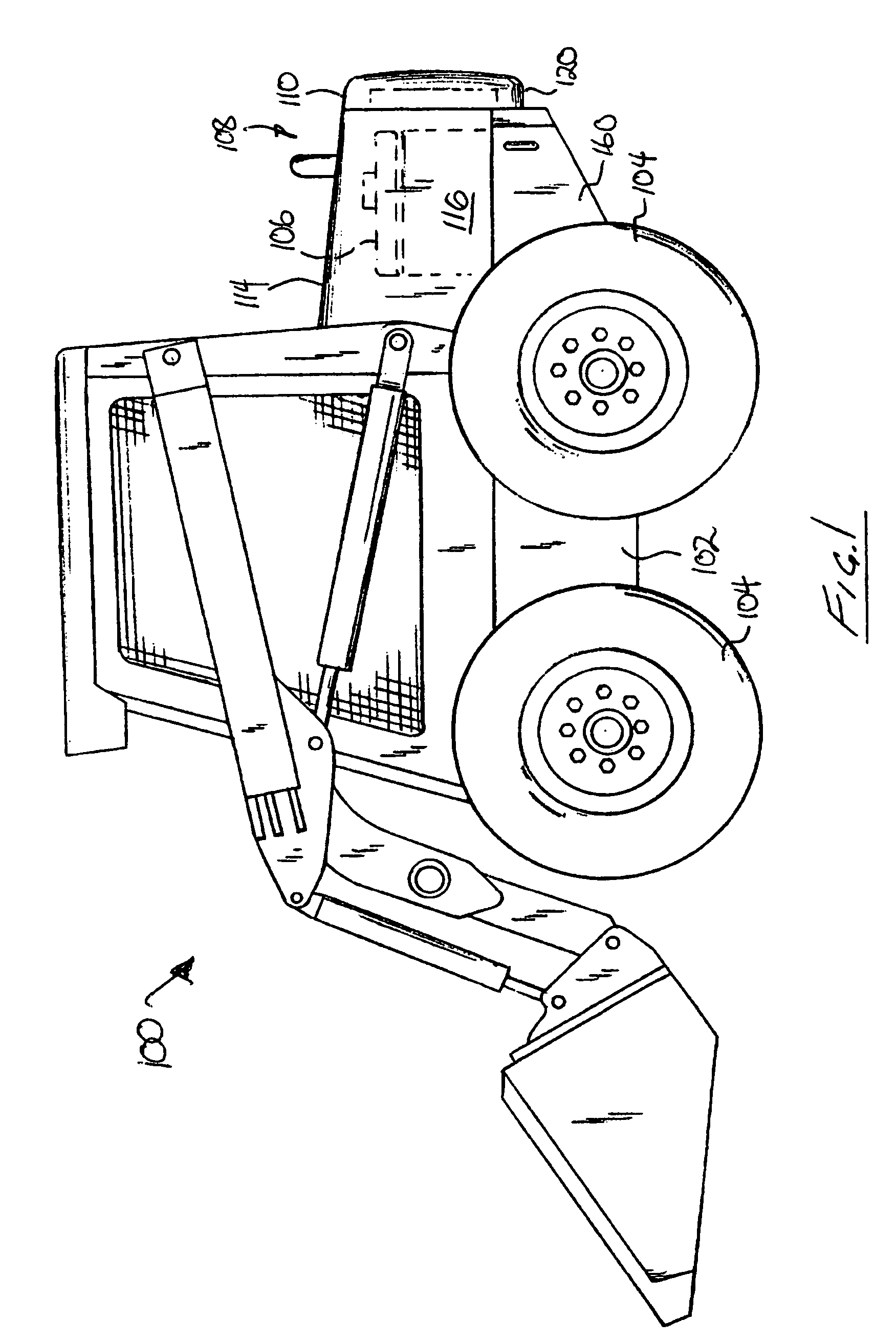

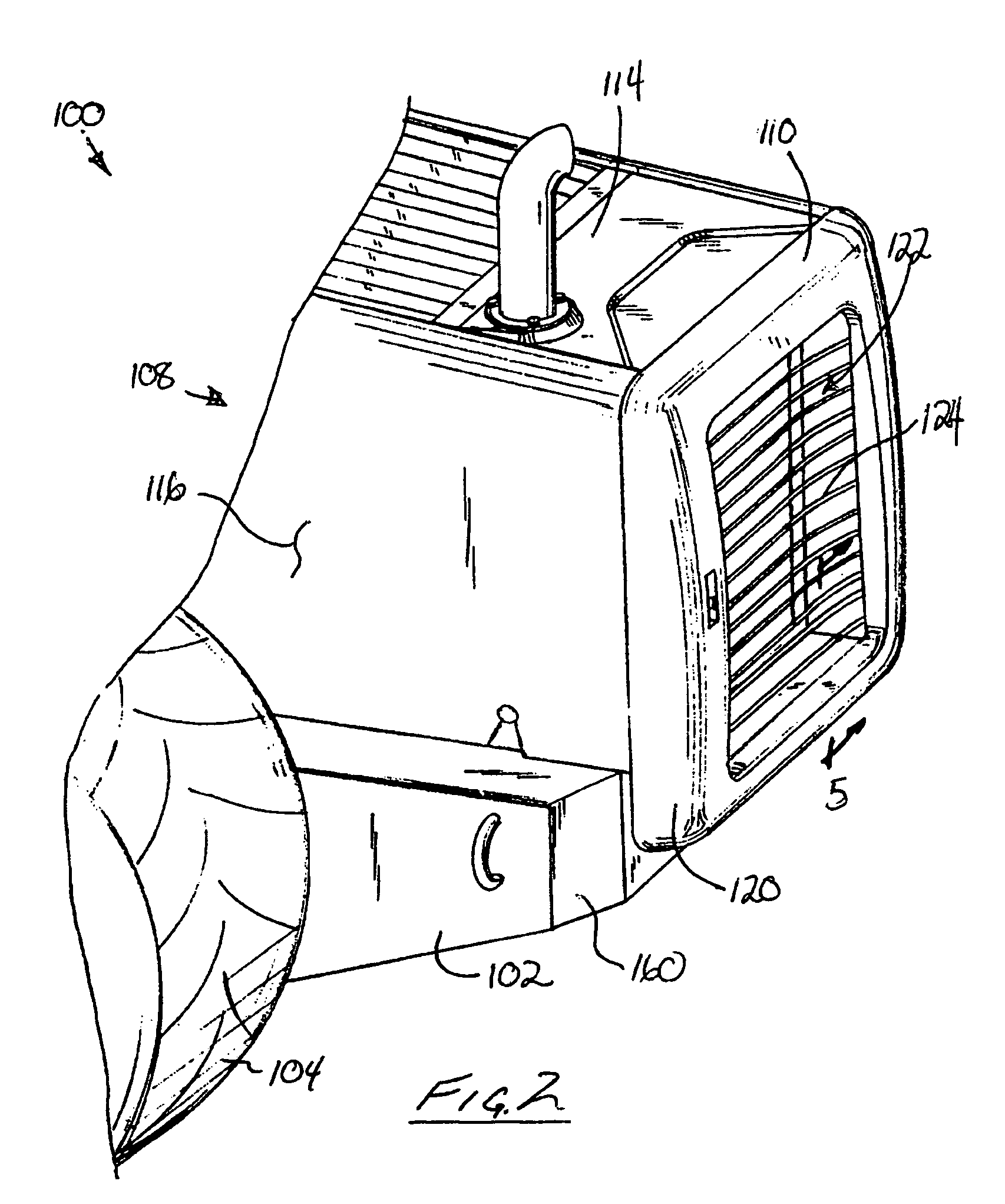

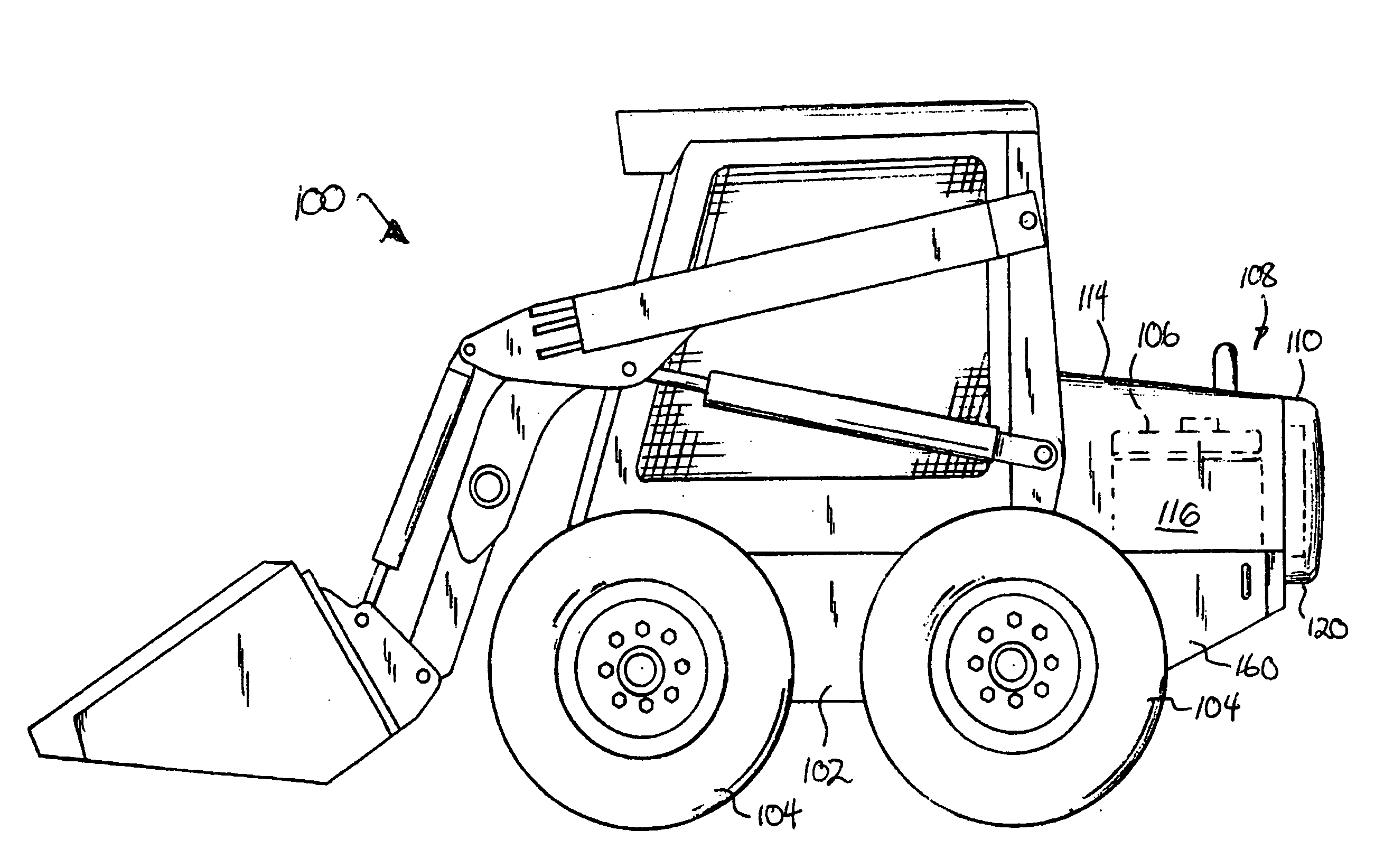

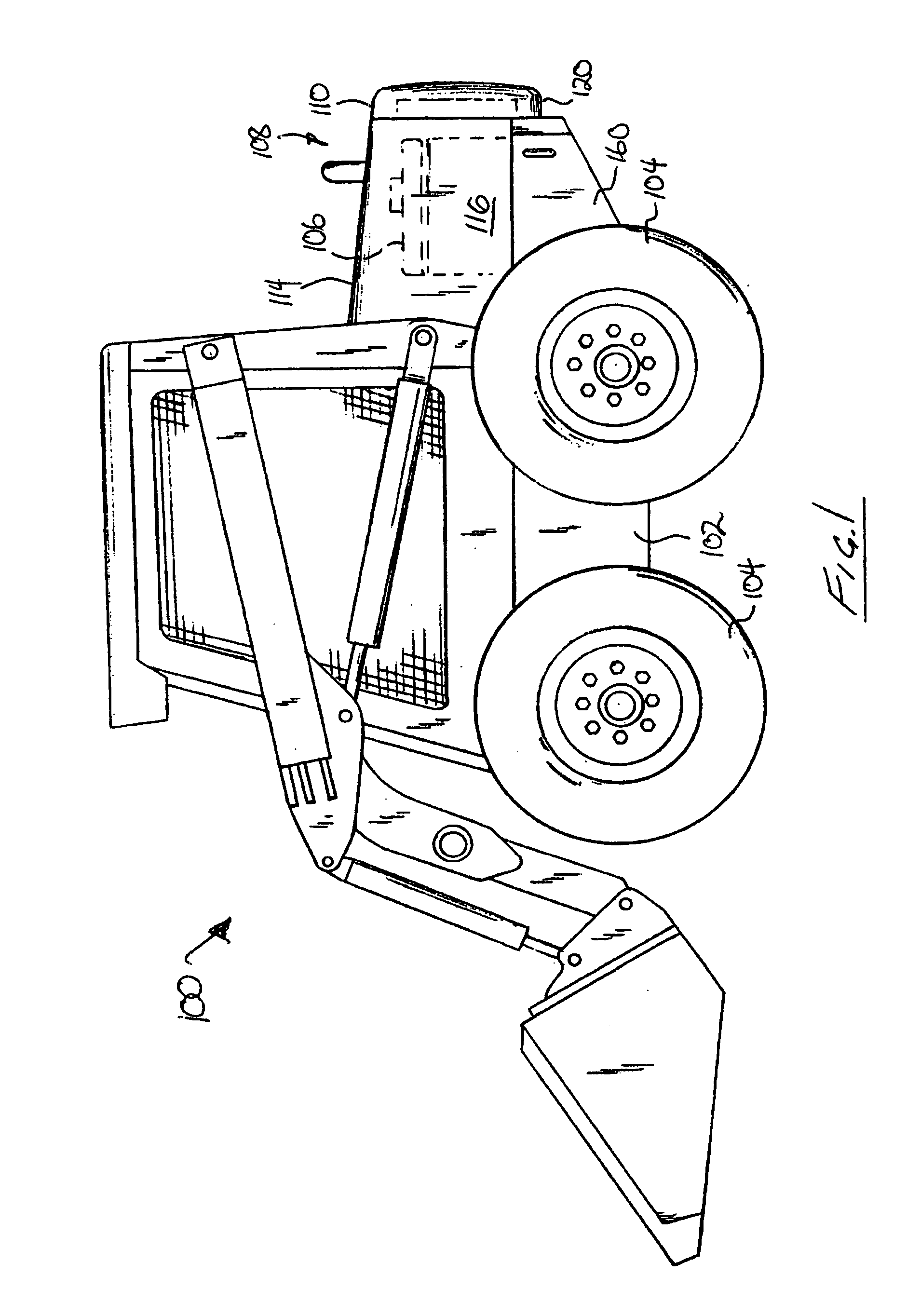

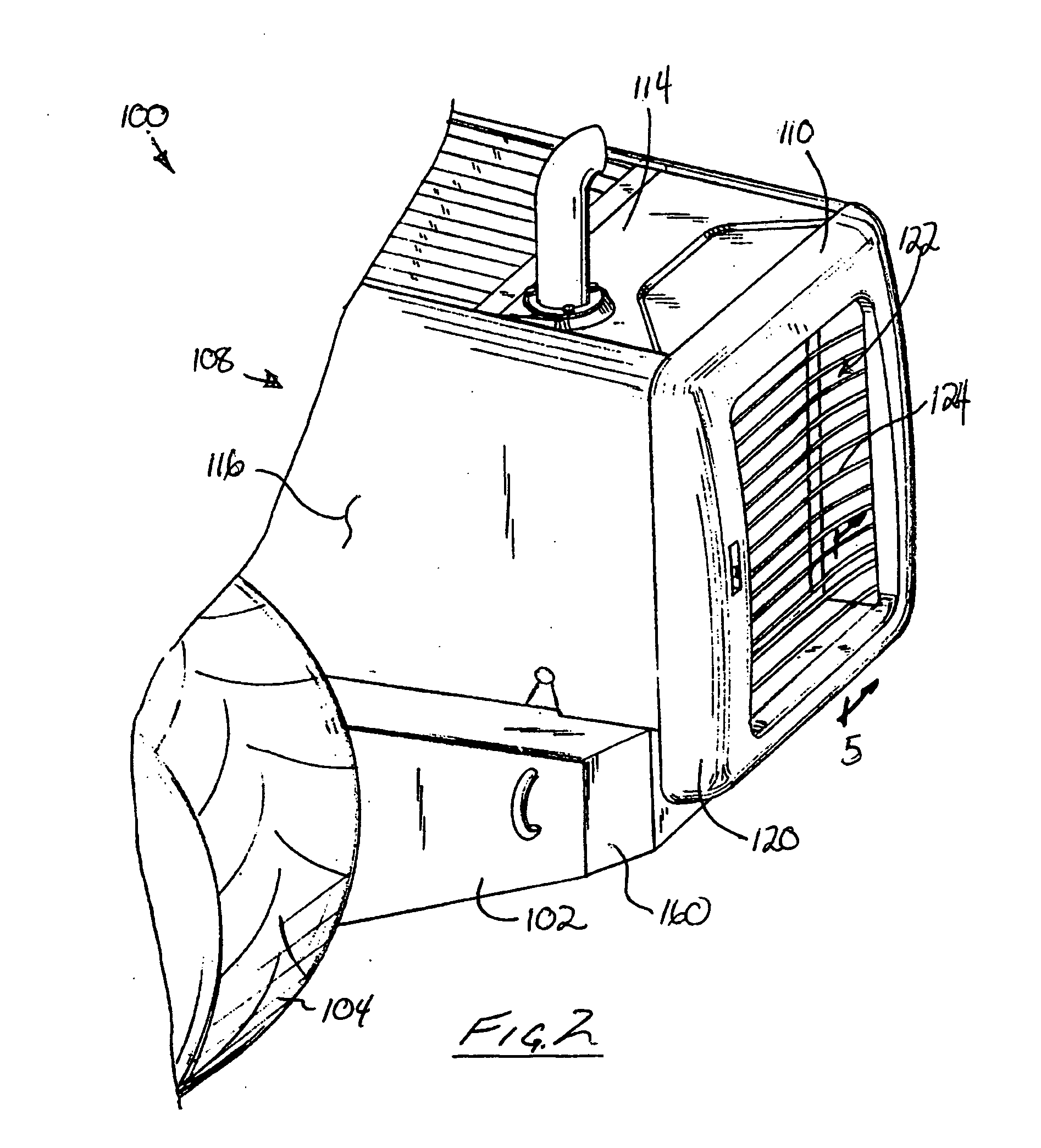

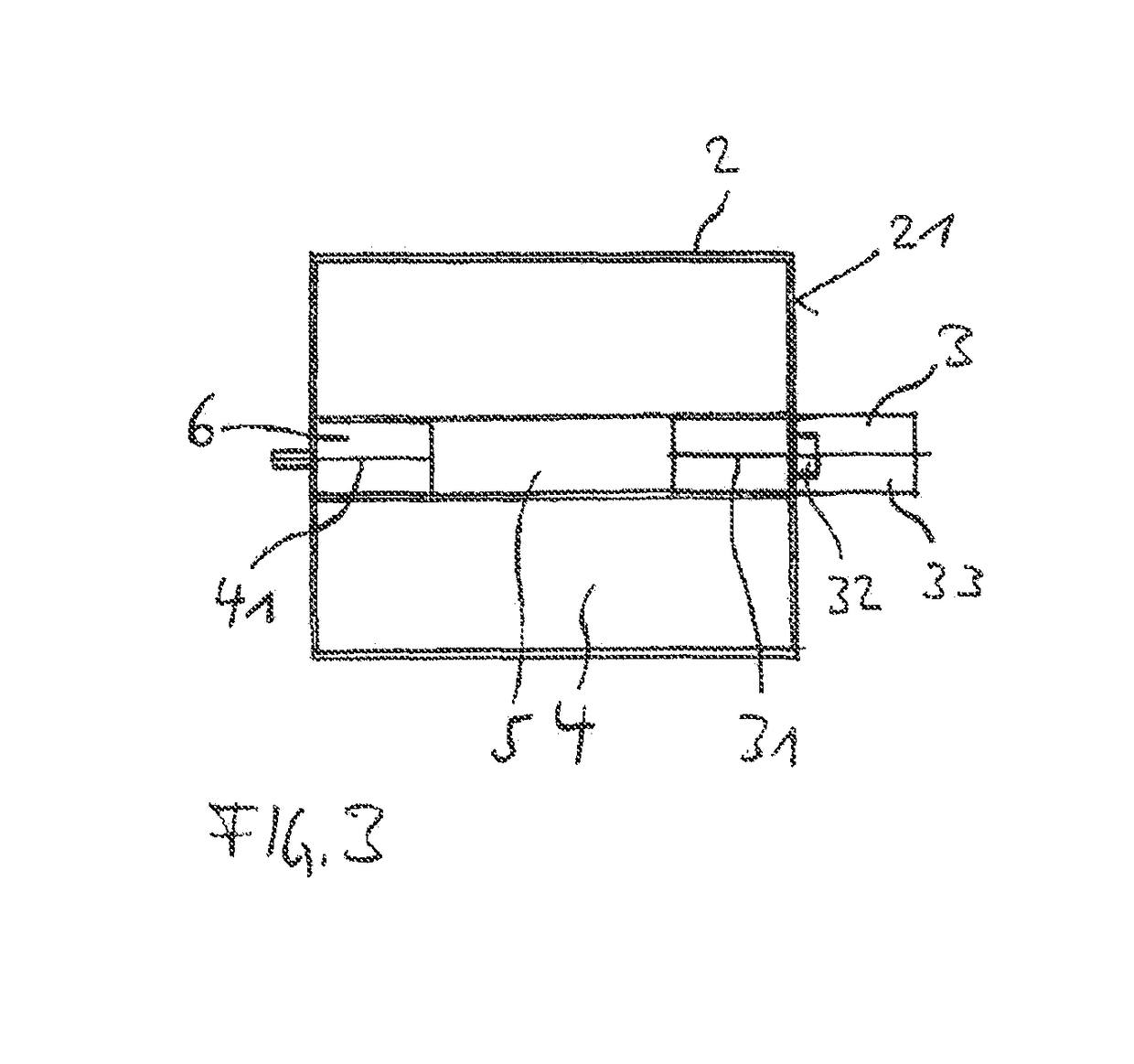

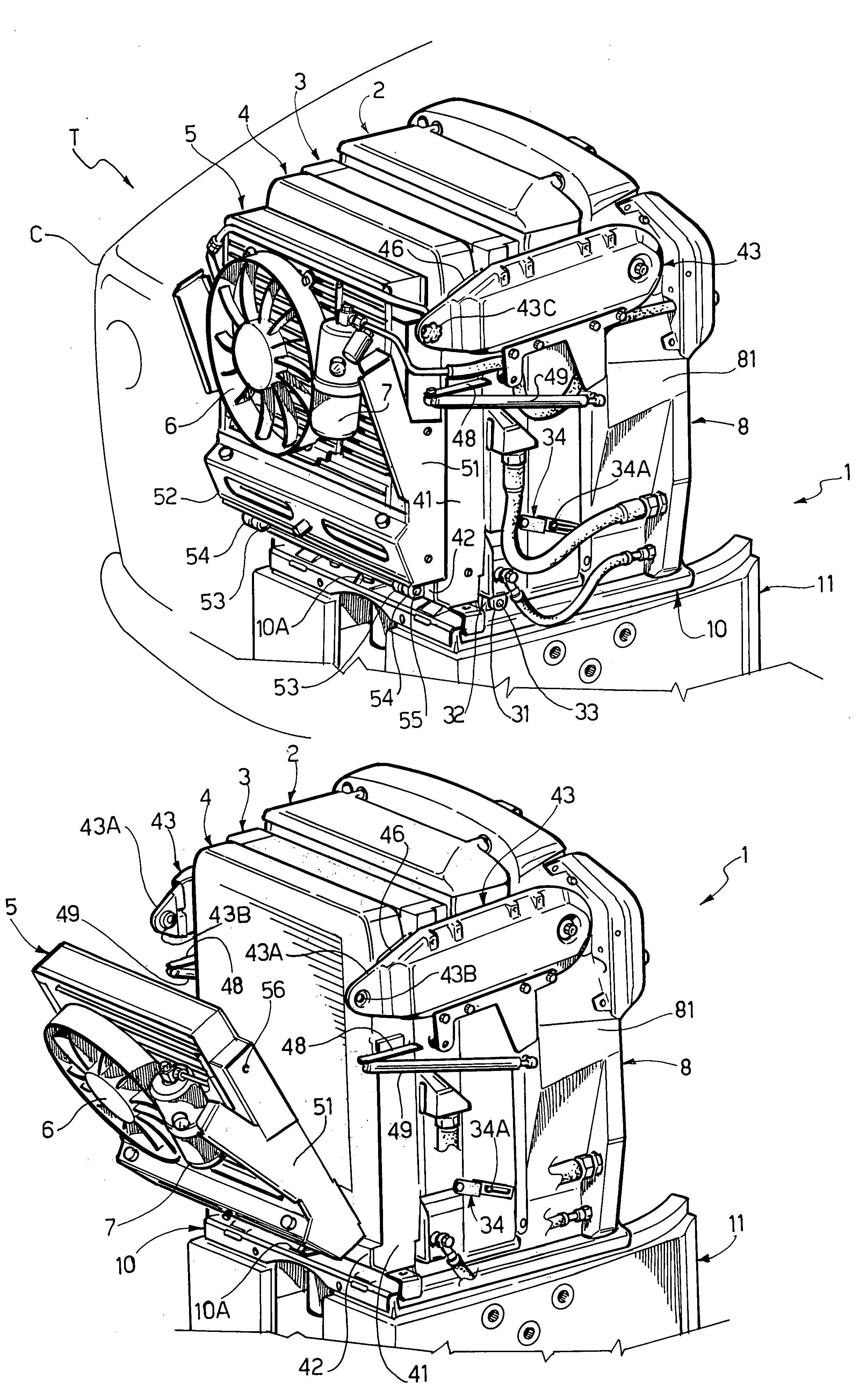

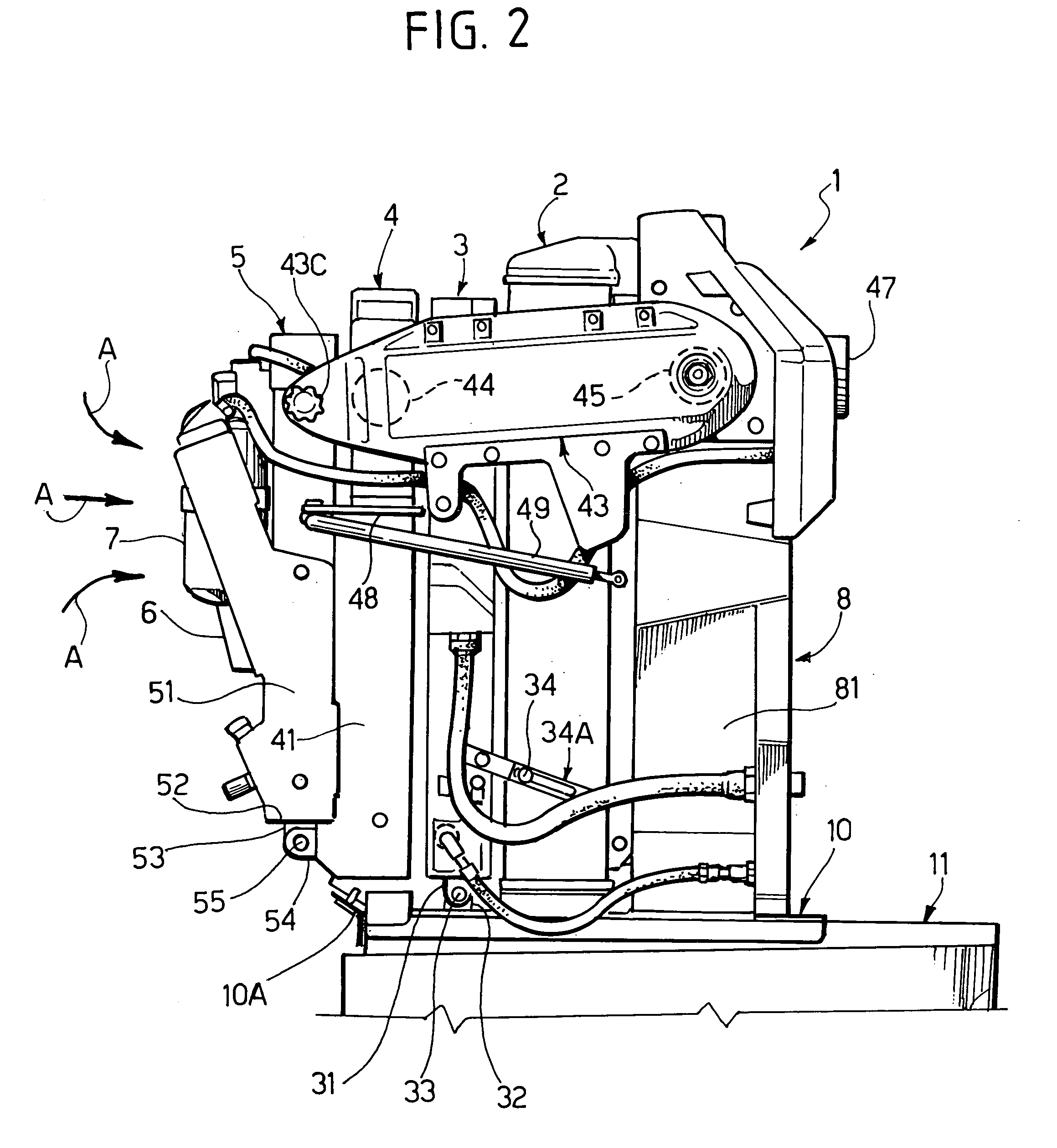

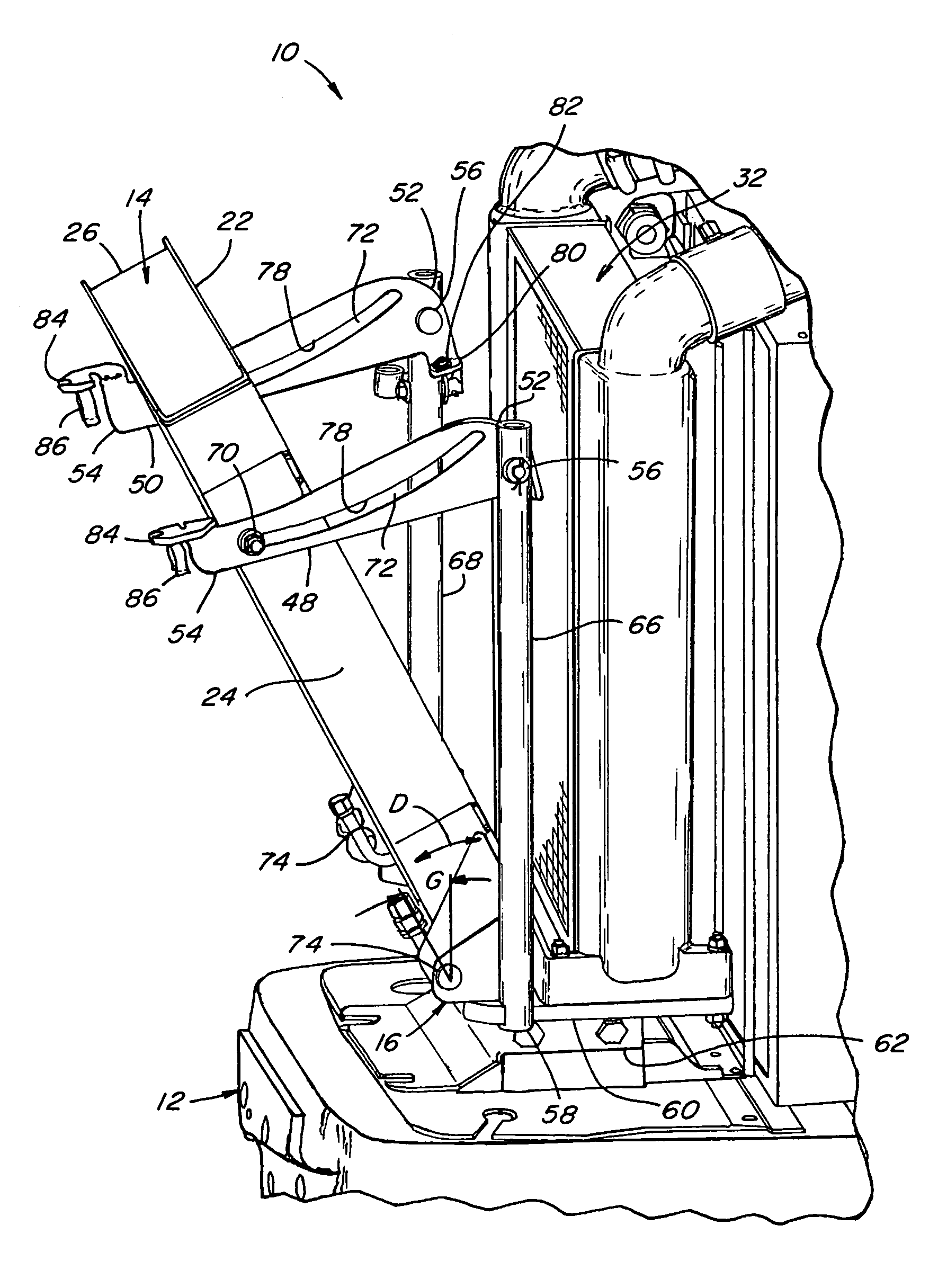

Radiator mounting system

A radiator mounting system for a skid steer vehicle includes an air box with a front wall having an opening sized to receive engine fan blades, an oil cooler disposed in the air box, a radiator; and a radiator frame supporting the radiator that is hingeably coupled to the air box. The radiator has plastic tanks and an aluminum core and the frame extends around the periphery of the radiator.

Owner:BLUE LEAF I P INC

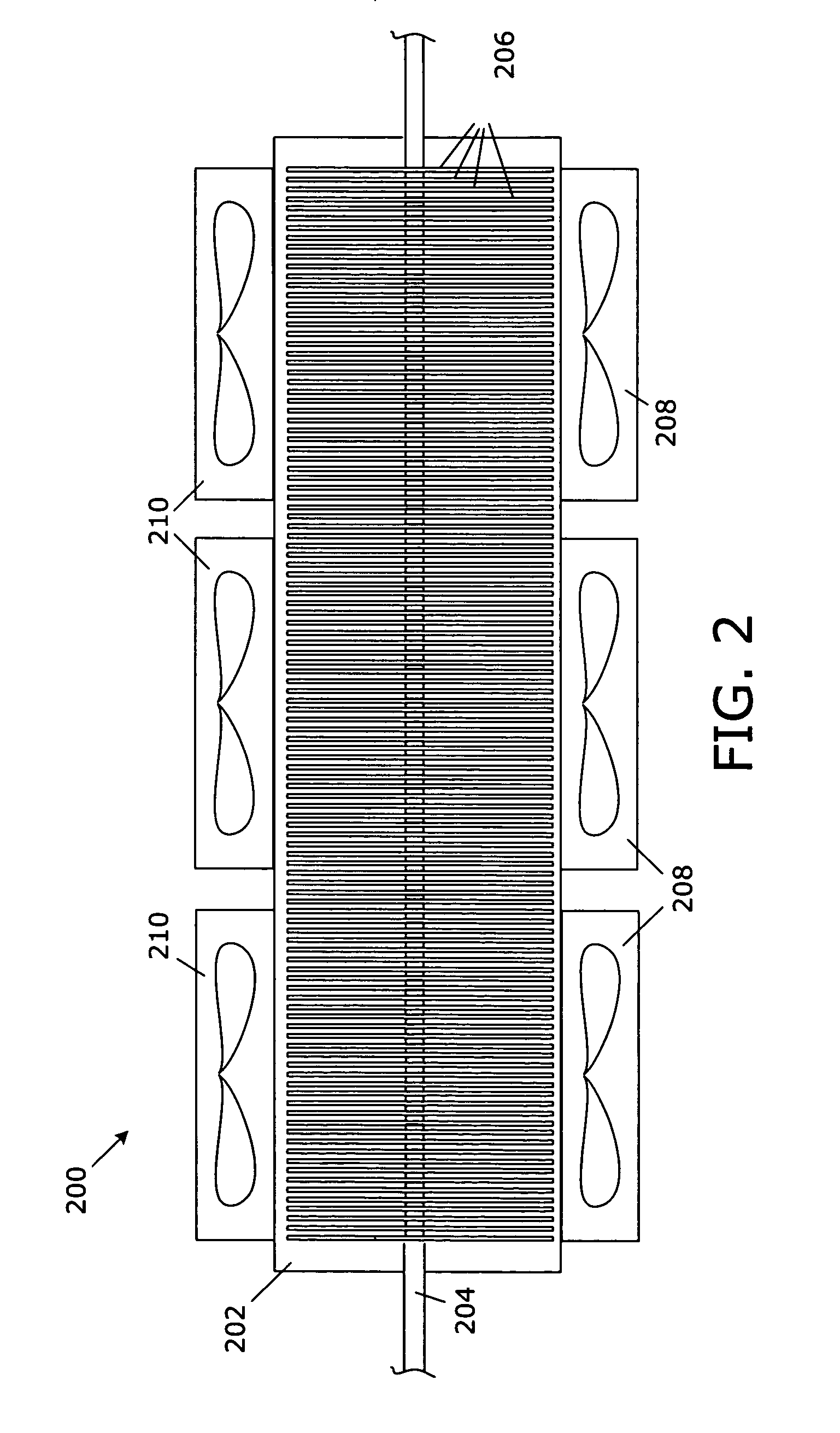

Integrated variable geometry flow restrictor and heat exchanger

ActiveUS20120128467A1Low and reduced performance conflictPump componentsWind motor controlEngineeringAnnular duct

One or more heat exchangers mounted in a duct have heat transfer cooling passages therein and a variable geometry flow restrictor is integral with each of the heat exchangers. An annular slide valve axially translatable within the duct is operable to open and close or vary a variable area between the heat exchangers and one of inner and outer casings bounding the duct. The heat exchangers may be being circumferentially distributed around an annular duct and include radial or circumferentially curved heat transfer tubes or vanes.

Owner:GENERAL ELECTRIC CO

Mitigation of in-tube fouling in heat exchangers using controlled mechanical vibration

Fouling of heat exchange surfaces is mitigated by a process in which a mechanical force is applied to a fixed heat exchanger to excite a vibration in the heat exchange surface and produce shear waves in the fluid adjacent the heat exchange surface. The mechanical force is applied by a dynamic actuator coupled to a controller to produce vibration at a controlled frequency and amplitude output that minimizes adverse effects to the heat exchange structure. The dynamic actuator may be coupled to the heat exchanger in place and operated while the heat exchanger is on line.

Owner:EXXON RES & ENG CO

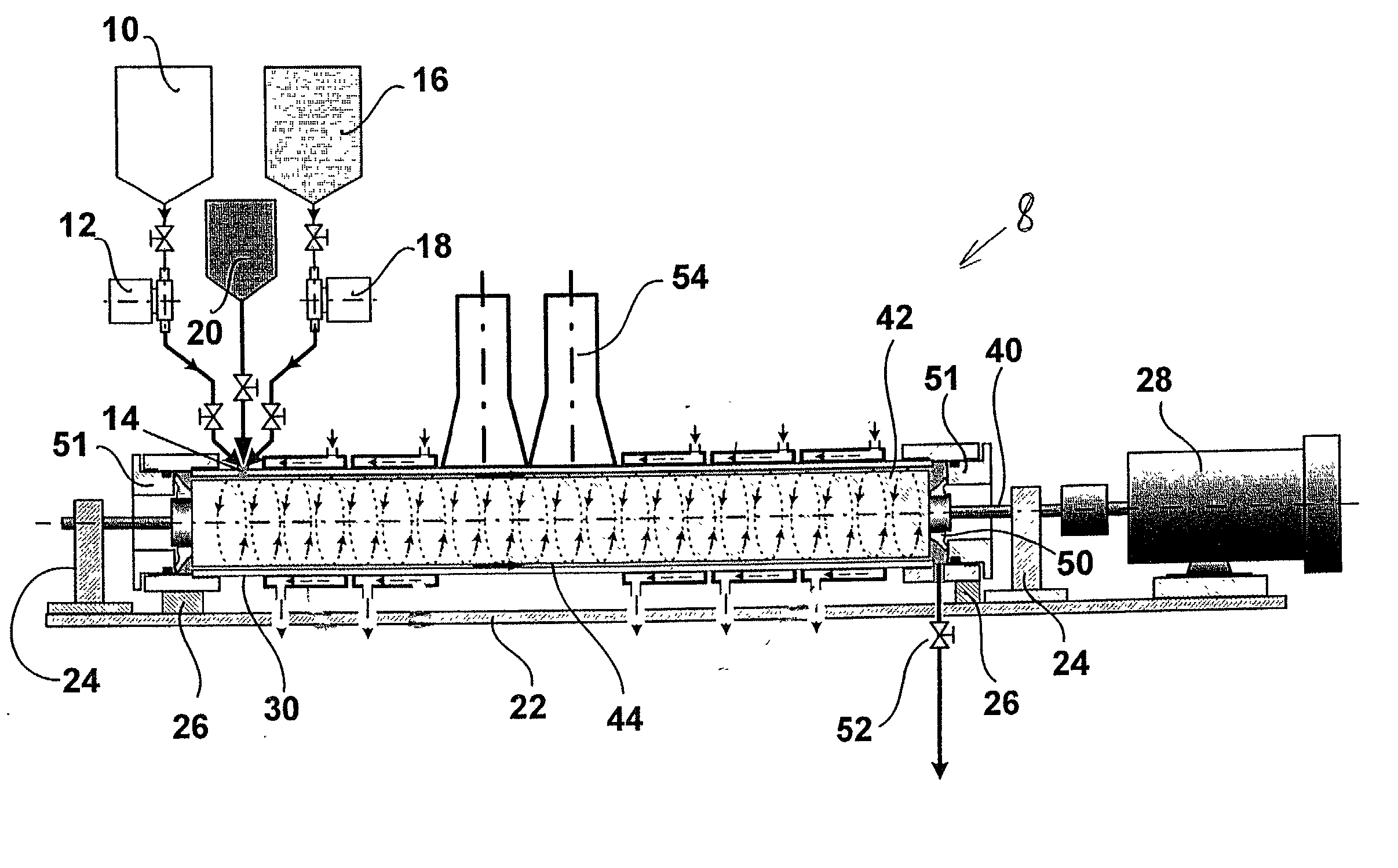

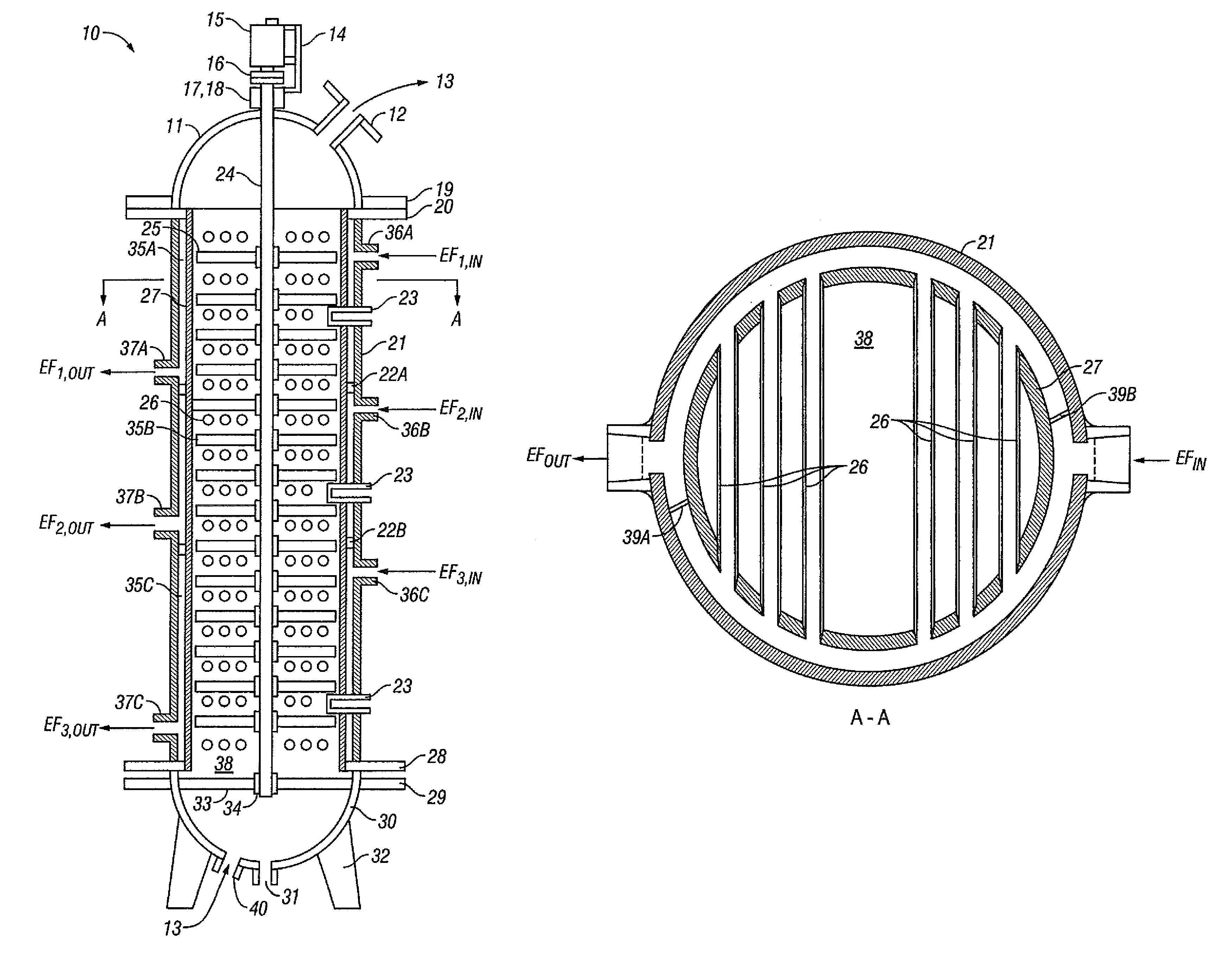

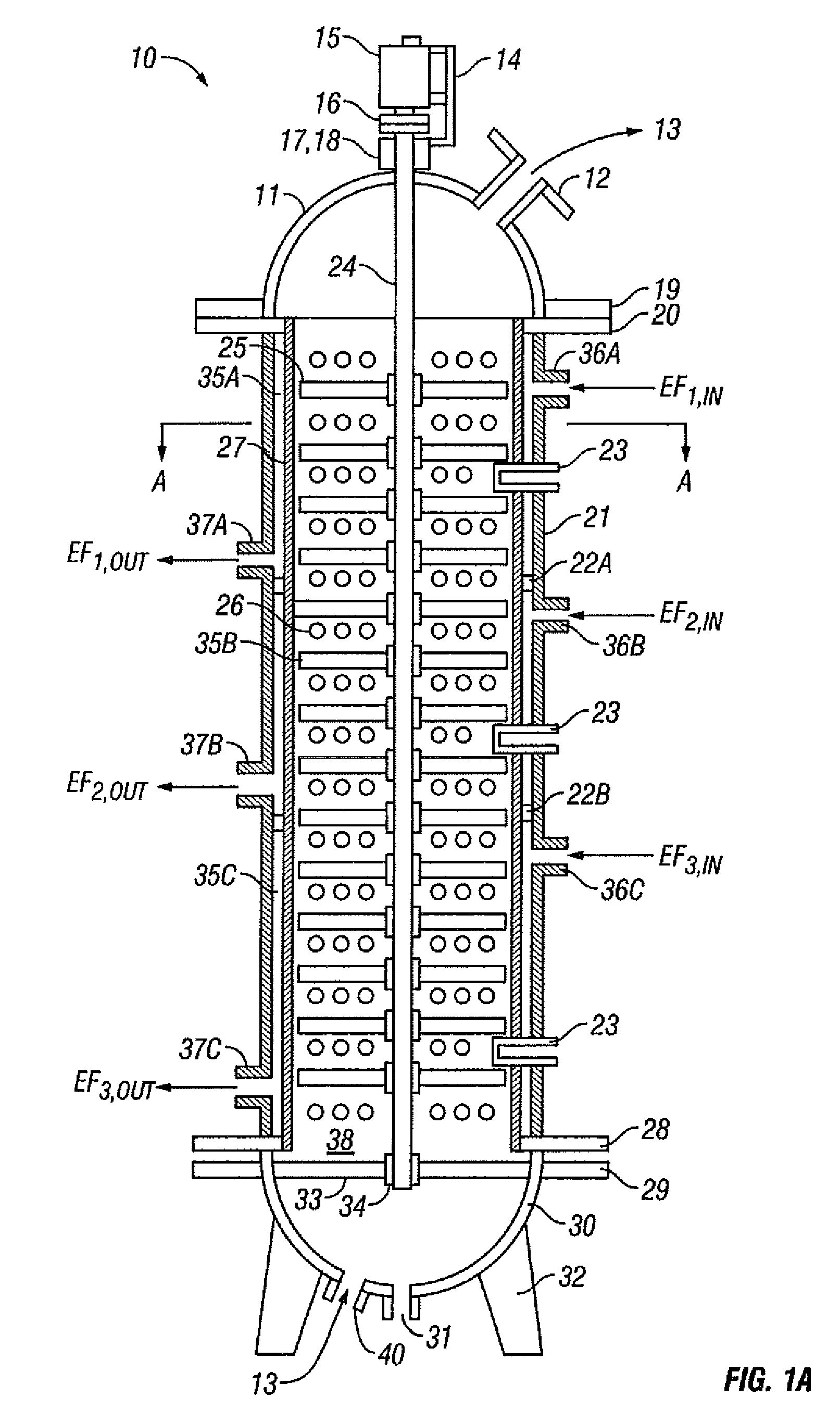

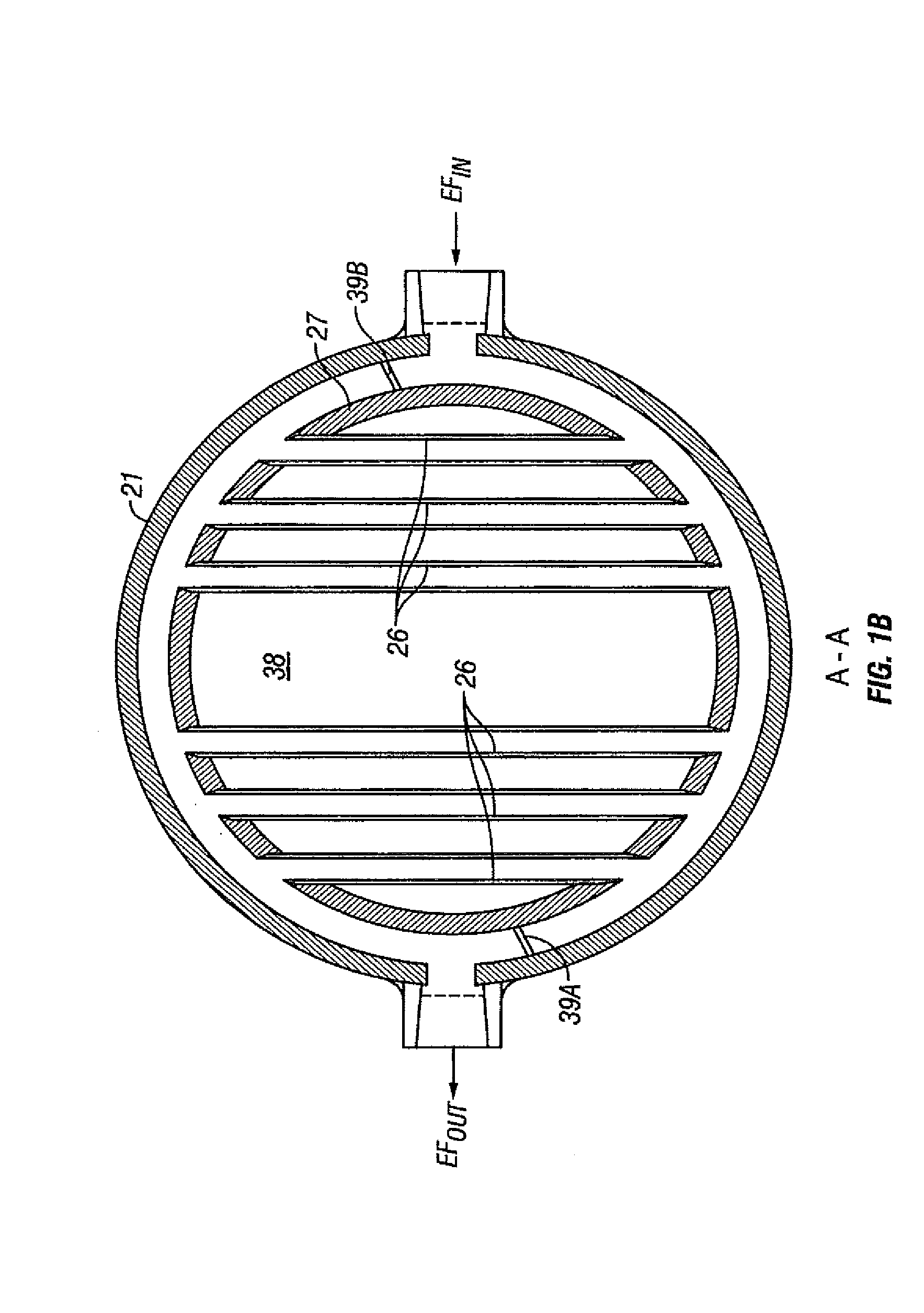

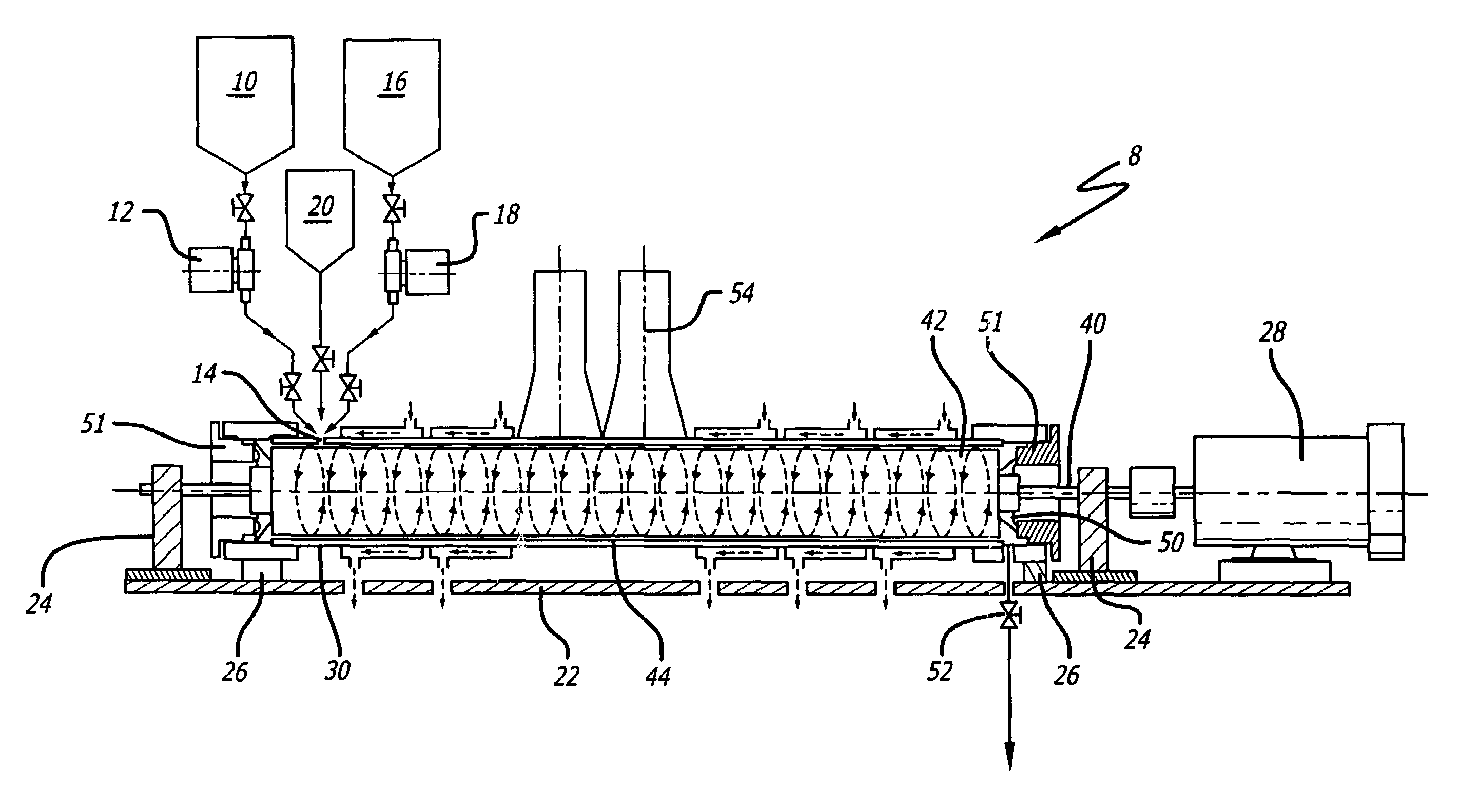

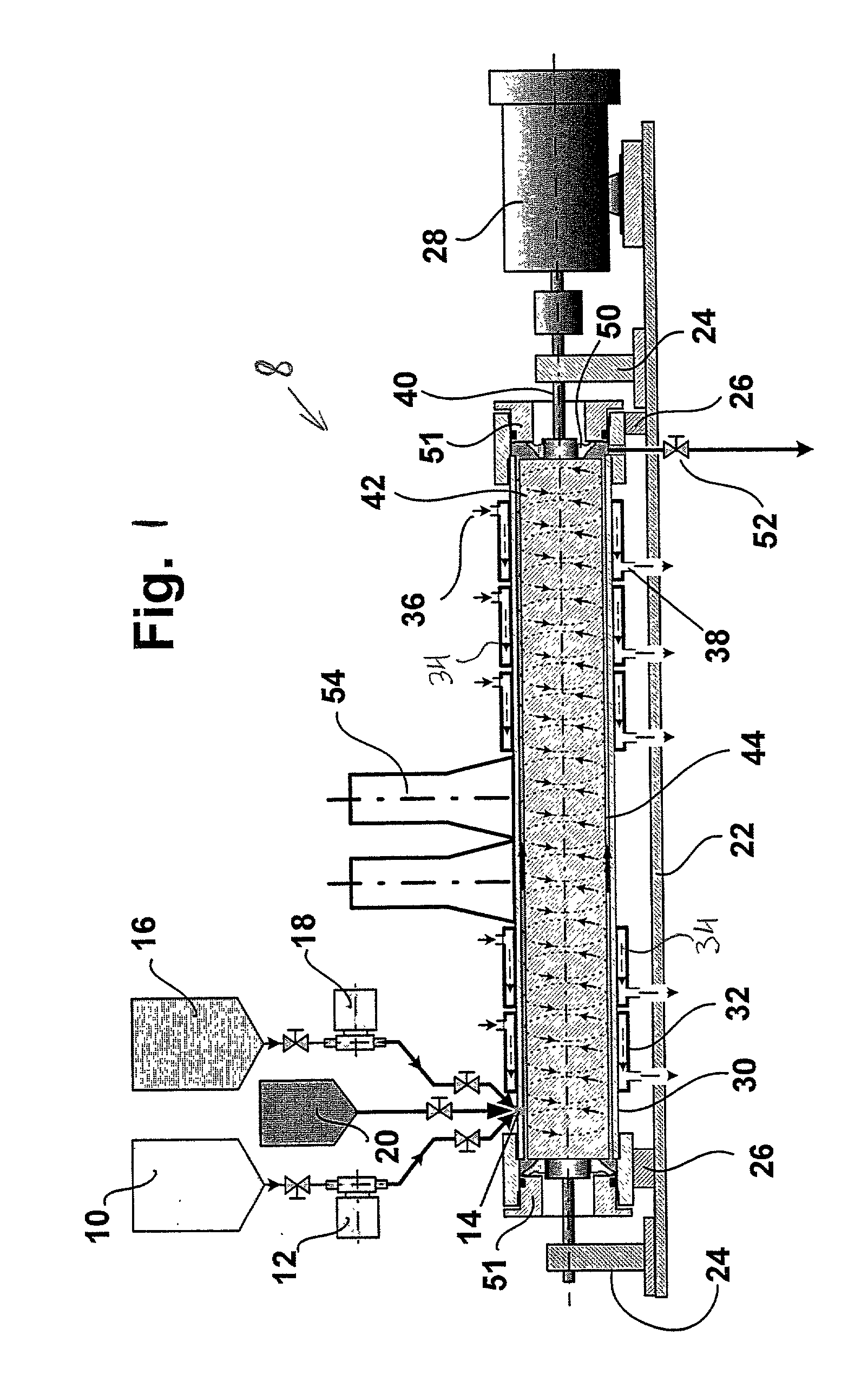

Plug flow reactor and polymers prepared therewith

InactiveUS7511101B2Domestic stoves or rangesSpace heating and ventilationProcess engineeringHigh impact polystyrene

A plug flow reactor having an inner shell 27 surrounded by outer shell 21 and having at least one annular flow passage 35 therebetween can be used to prepare compositions, including polymers. The plug flow reactor also includes inlet port 36, an outlet port 37 and a plurality of exchanger tubes 26 wherein the exchanger tubes are in fluid communication to the at least one annular flow passage. Polystyrene and high impact polystyrene can be prepared using the reactor.

Owner:FINA TECH

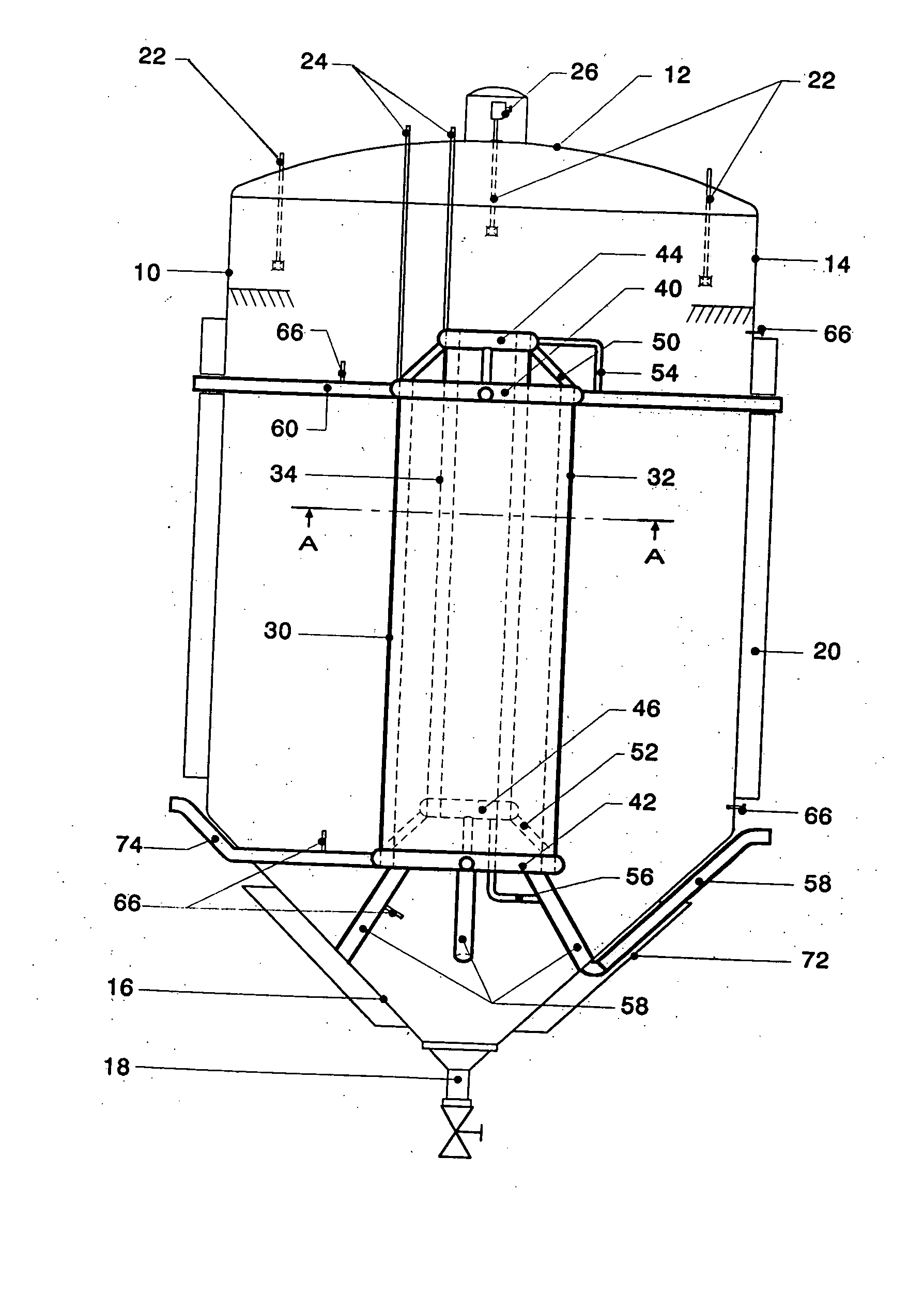

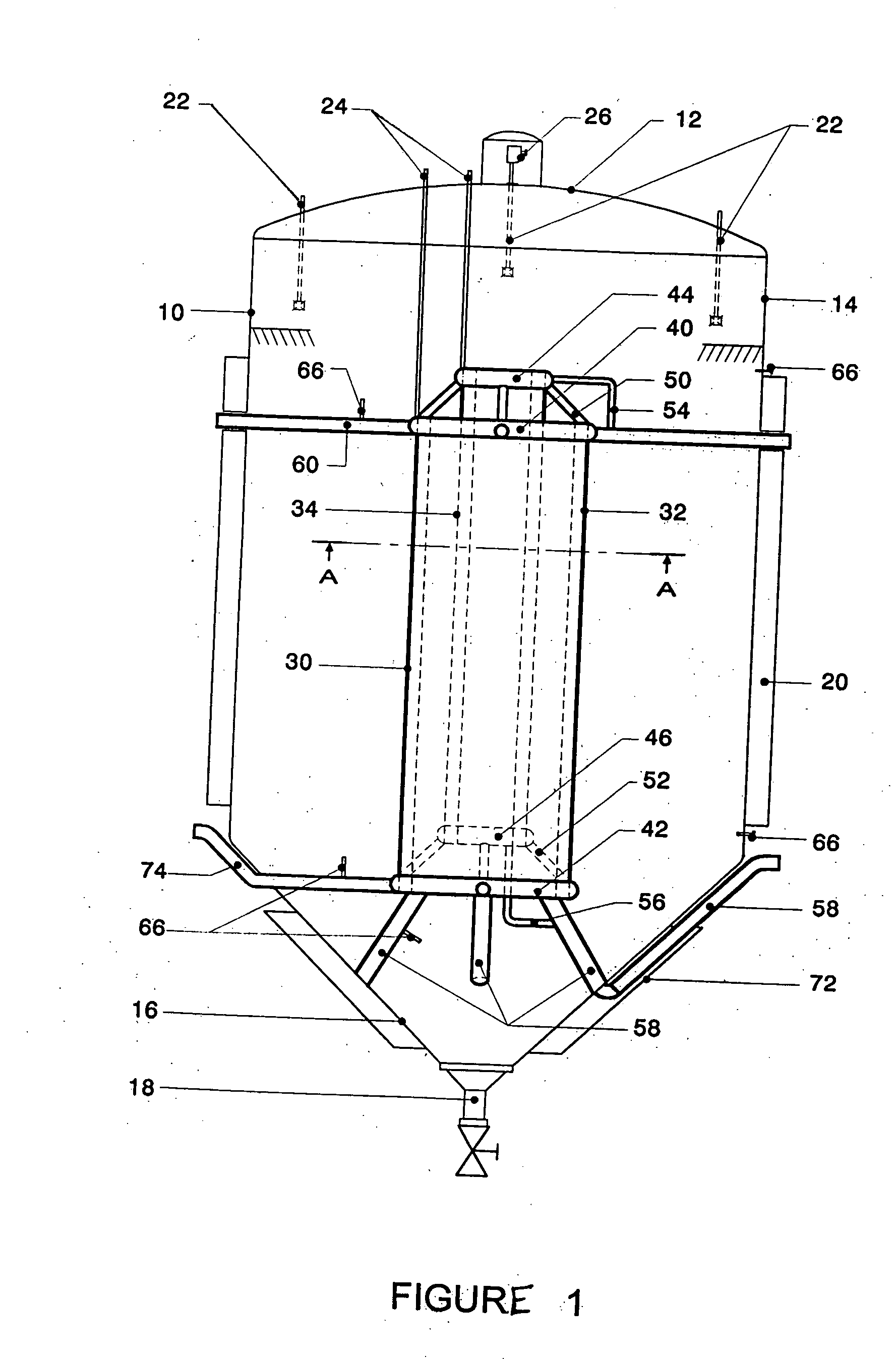

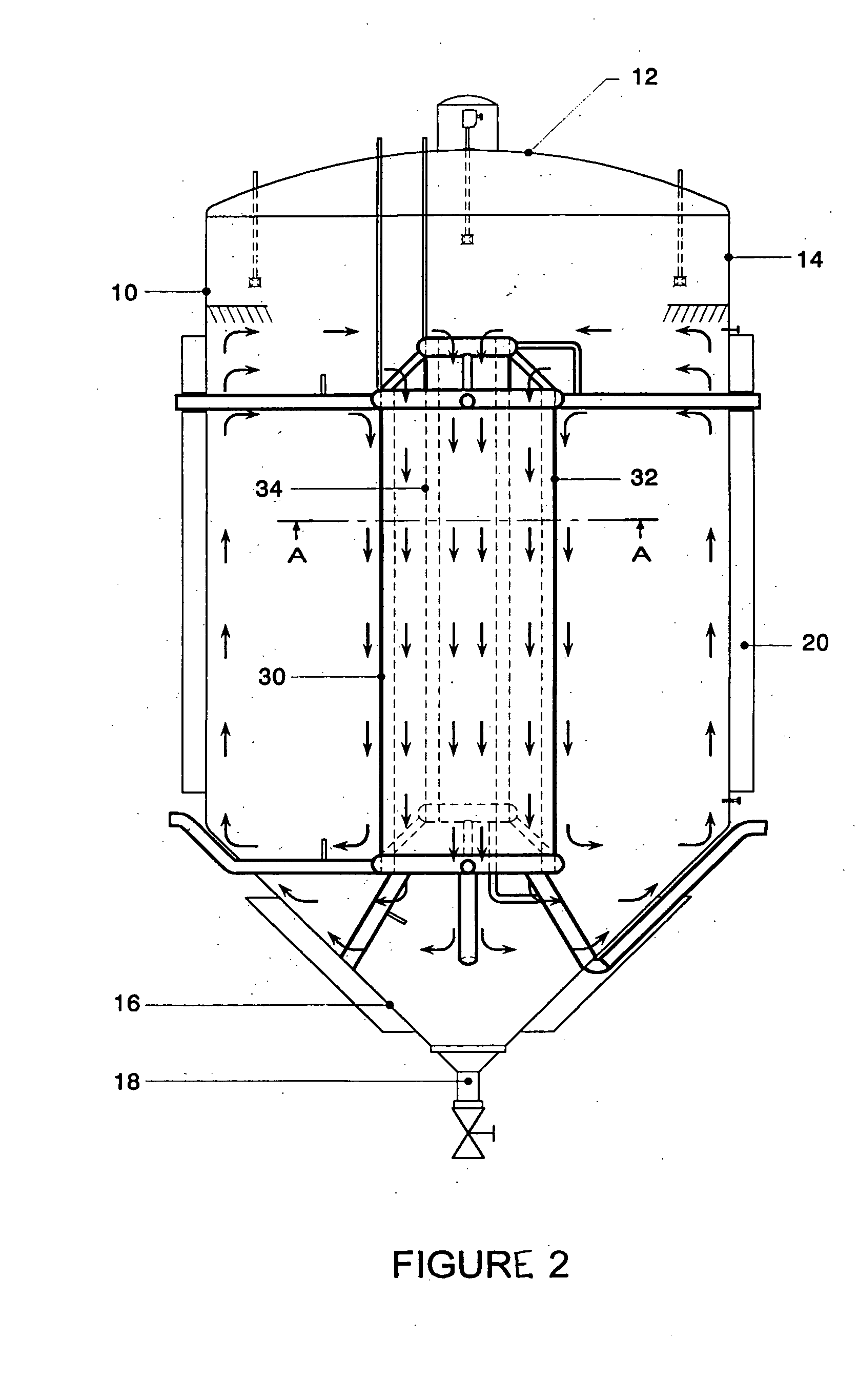

Heat exchanger for fermentation tank

InactiveUS20050077029A1Quality improvementReduce CooldownBeer fermentationWine preparationCoolant flowDouble wall

A device which is used to cool fermentation tanks and which can be used essentially in beer production, cooling and maturation, includes a vertical heat exchanger, which comprises single- or double-wall concentric cylinders and is positioned internally at the center of a tank. The length and capacity of the cylinders differ depending on the size and shape of the tank. A coolant flows through the cylinders in order to cool and to maintain a suitable temperature range. In addition, the double-wall cylinders which form the heat exchanger are interconnected by means of coolant flow and support tubes. Meanwhile, the exchanger is supported by the cone and the walls of the tank by means of tubes which are used for the passage of the coolant and the passage of signals. Moreover, the outer wall and the cone can be provided with a cooling jacket.

Owner:MORALES CERVANTES JOSE +1

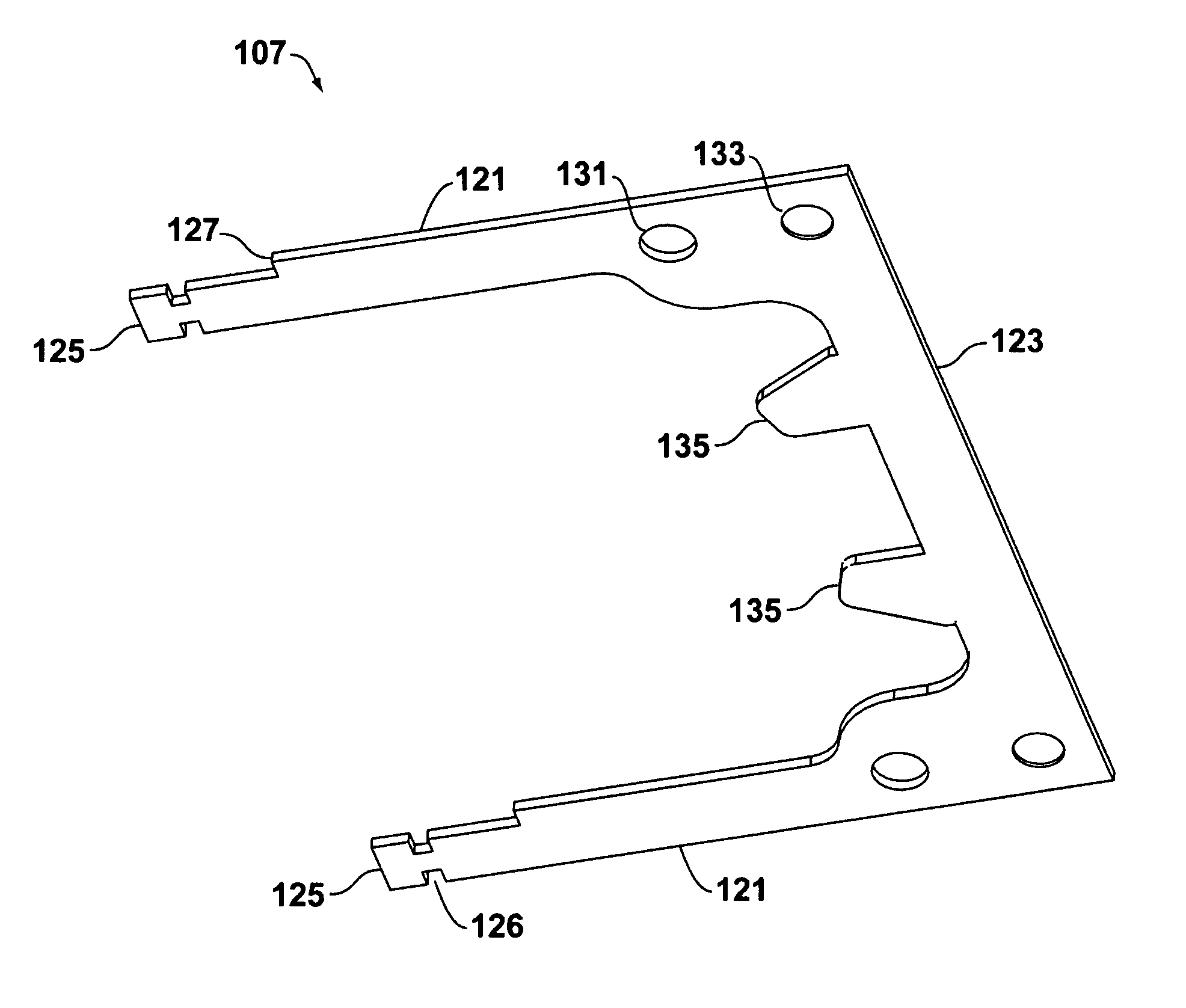

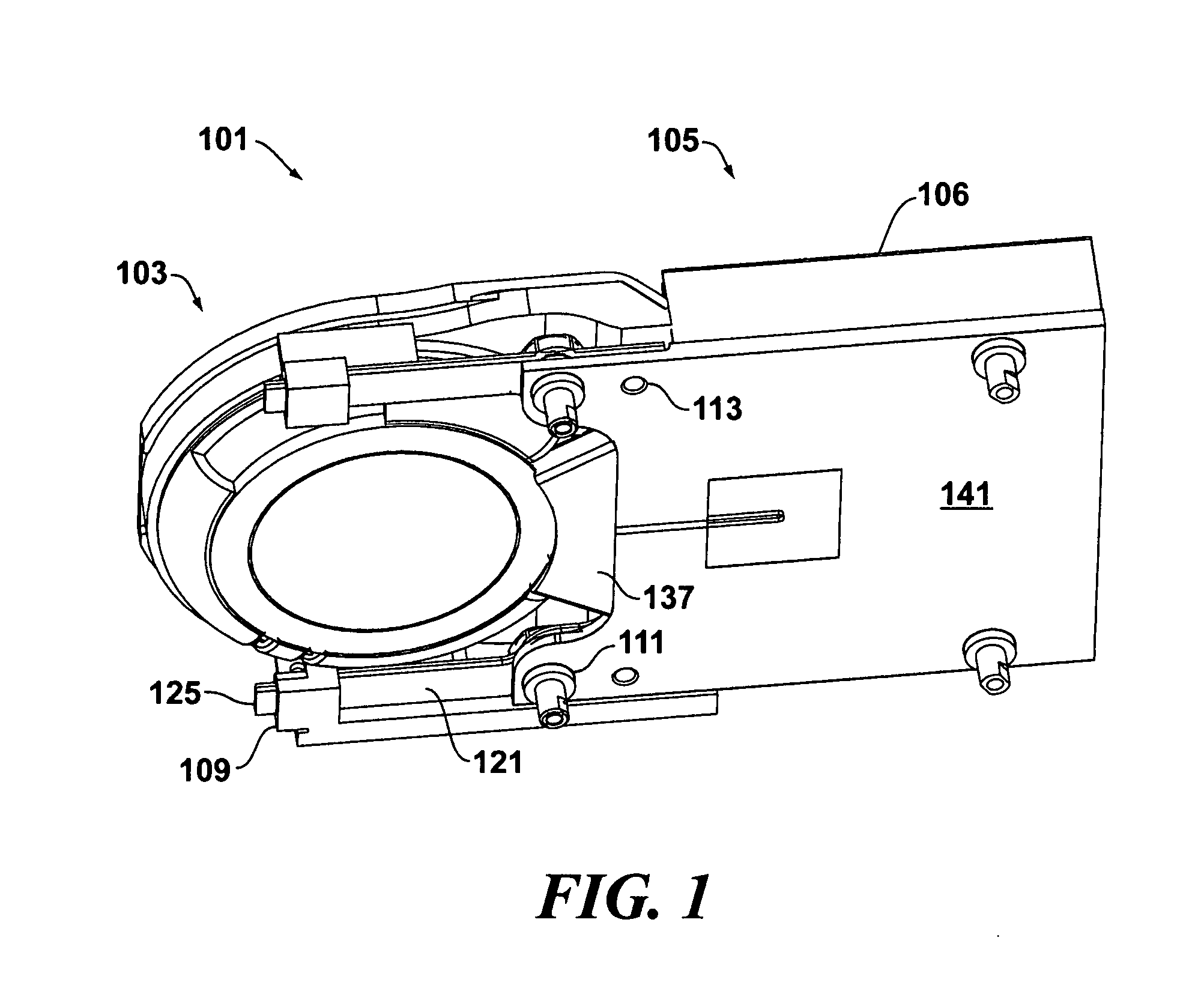

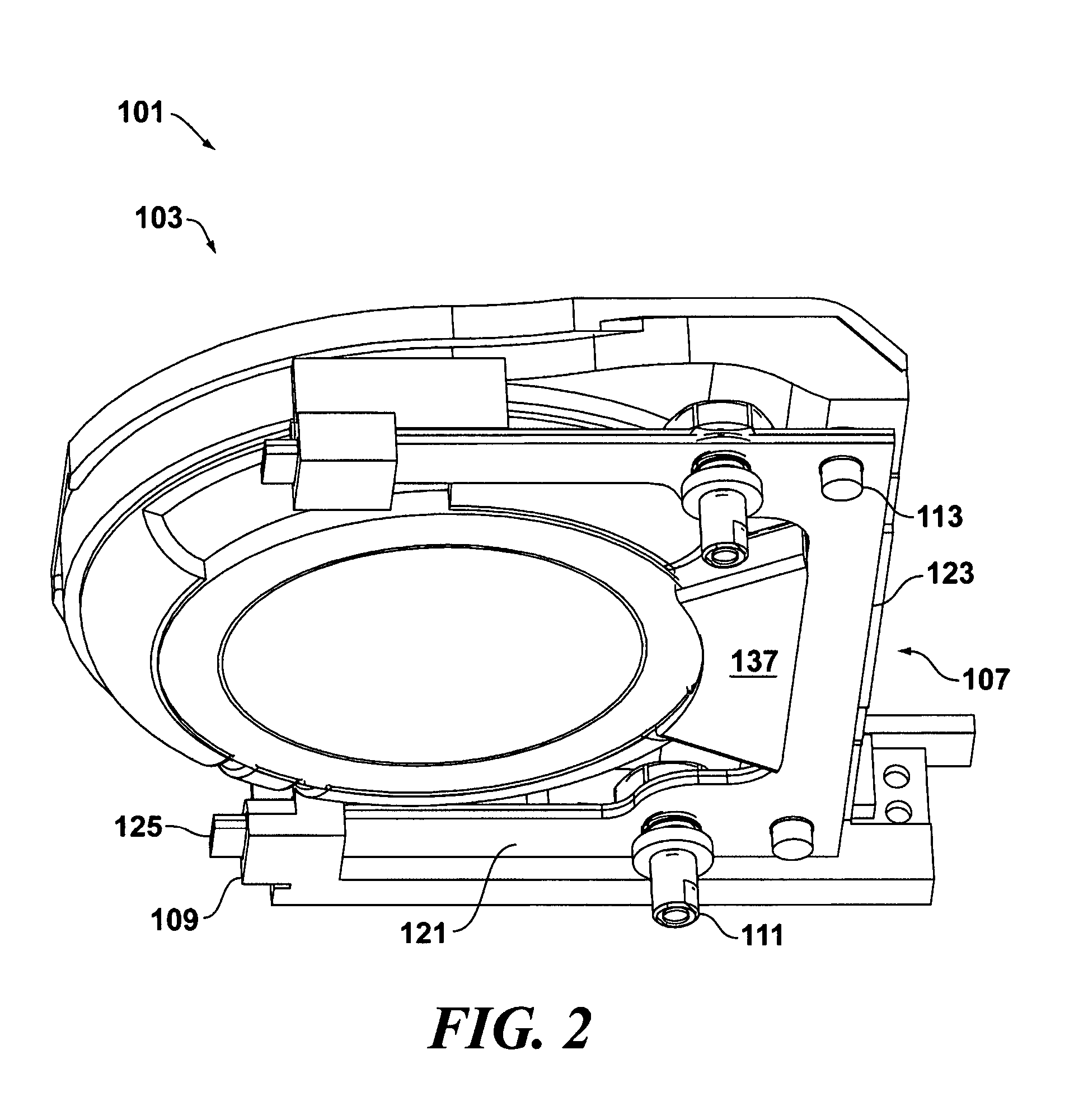

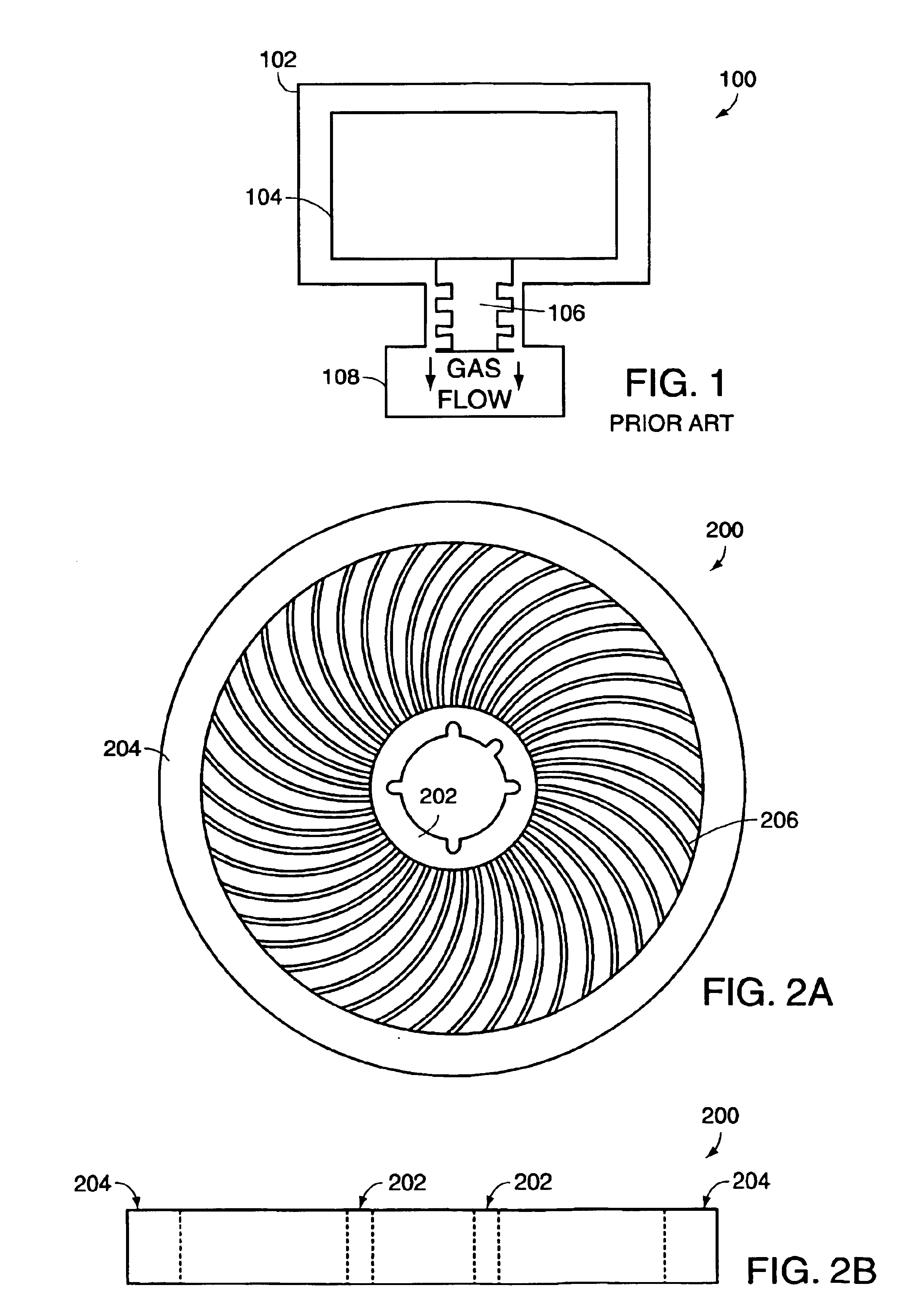

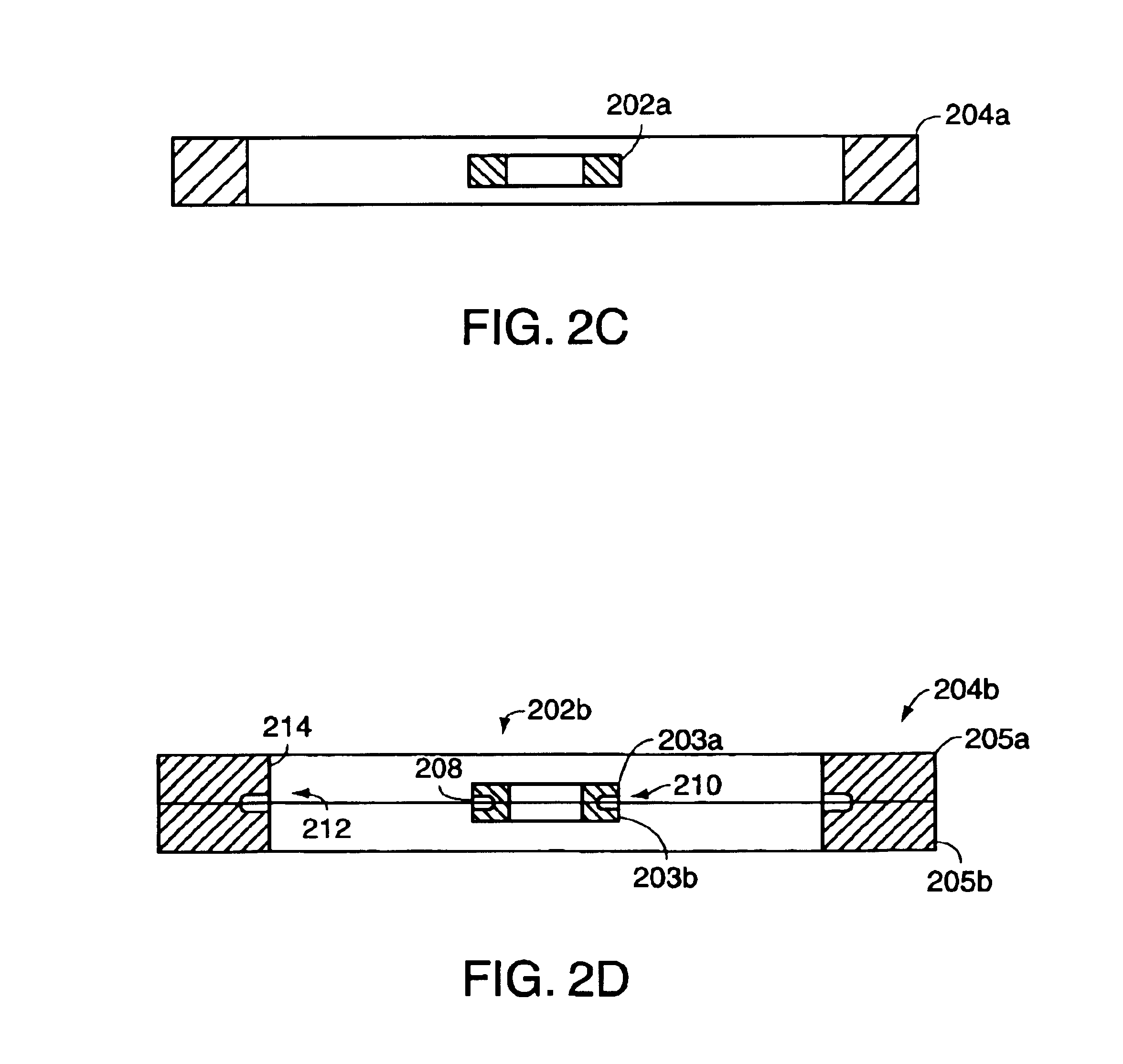

Vibration isolation system for synthetic jet devices

ActiveUS20080006393A1Portable framesSemiconductor/solid-state device detailsEngineeringThermal management system

A thermal management system is provided herein. The system comprises a substrate (141), a synthetic jet ejector (103), and a vibration isolation element (107) adapted to releasably engage said synthetic jet ejector and said substrate.

Owner:NUVENTIX

Radiator mounting system

A radiator mounting system for a skid steer vehicle includes an air box with a front wall having an opening sized to receive engine fan blades, an oil cooler disposed in the air box, a radiator; and a radiator frame supporting the radiator that is hingeably coupled to the air box. The radiator has plastic tanks and an aluminum core and the frame extends around the periphery of the radiator

Owner:BLUE LEAF I P INC

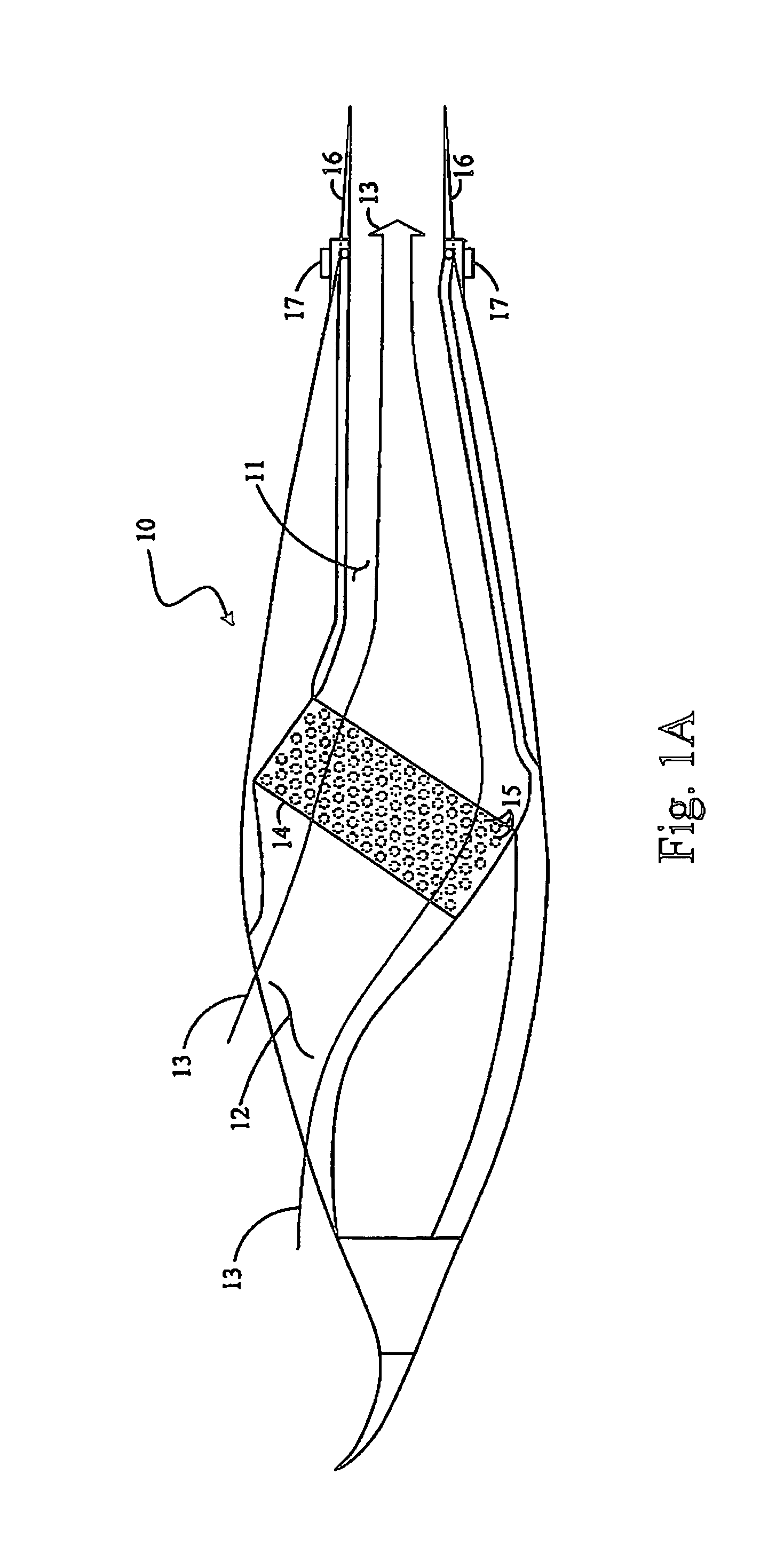

Air-oil heat exchanger

A heat exchange system for use in fluid operated equipment to provide air and working fluid heat exchanges to cool the working fluid in airstreams on a stream side of a wall. An actuator is mounted to be substantially located on a side of the wall opposite the stream side thereof having a positionable motion effector. A heat exchanger core having a plurality of passageway structures therein to enable providing the working fluid to, and removal therefrom. The heat exchanger core is mounted on the motion effector so as to be extendable and retractable thereby through the opening for selected distances into that region to be occupied by the airstreams.

Owner:RAYTHEON TECH CORP

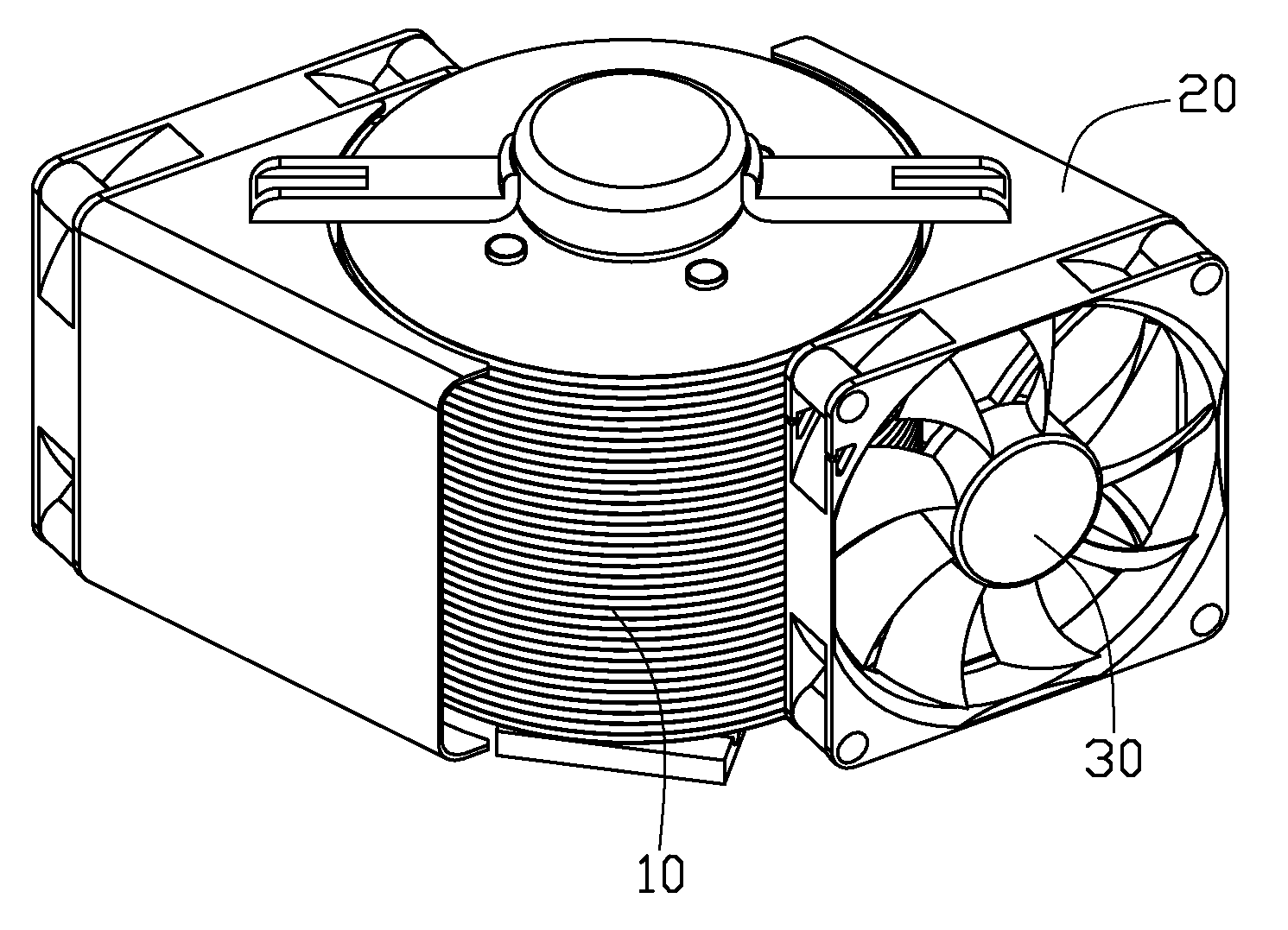

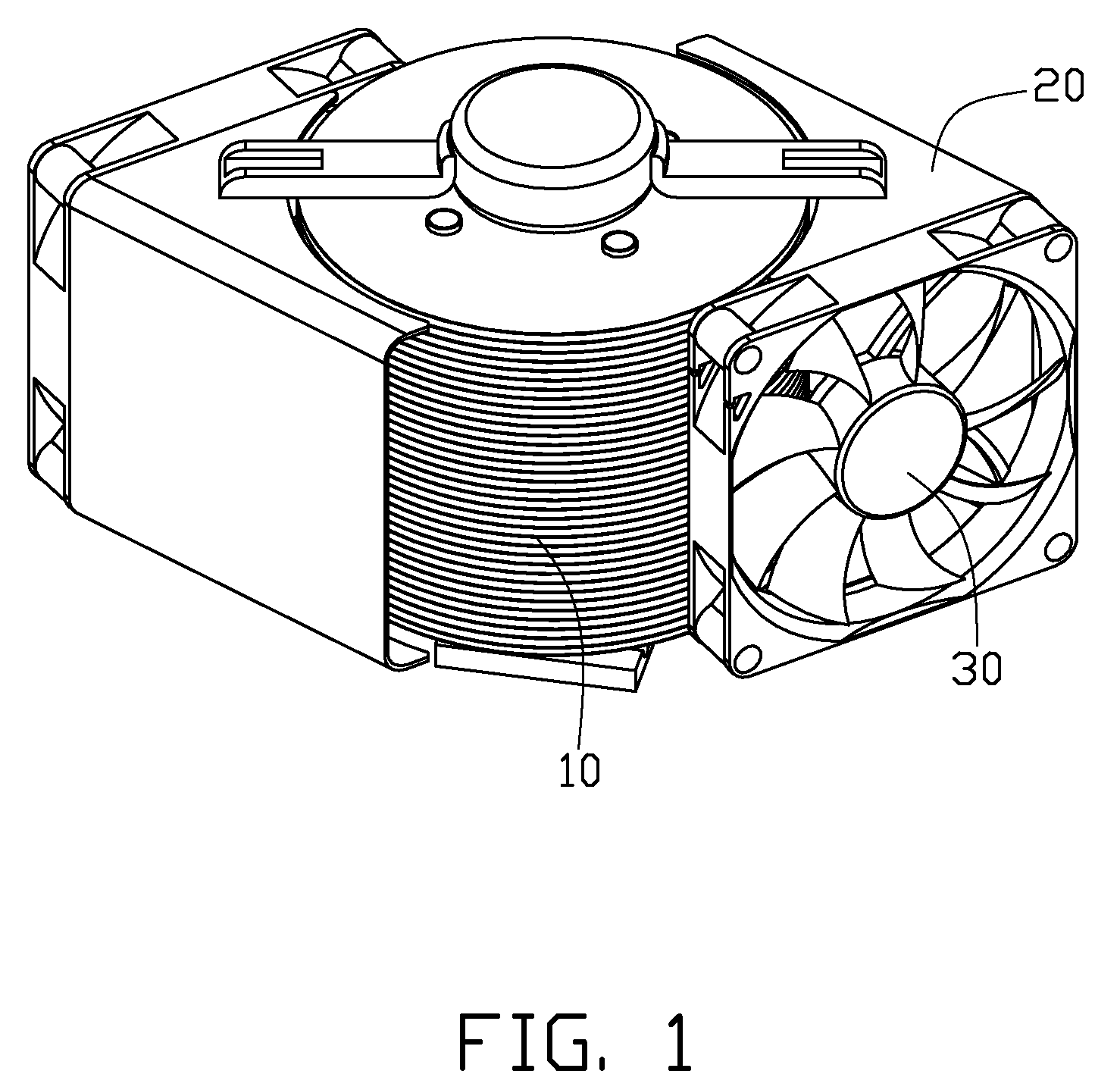

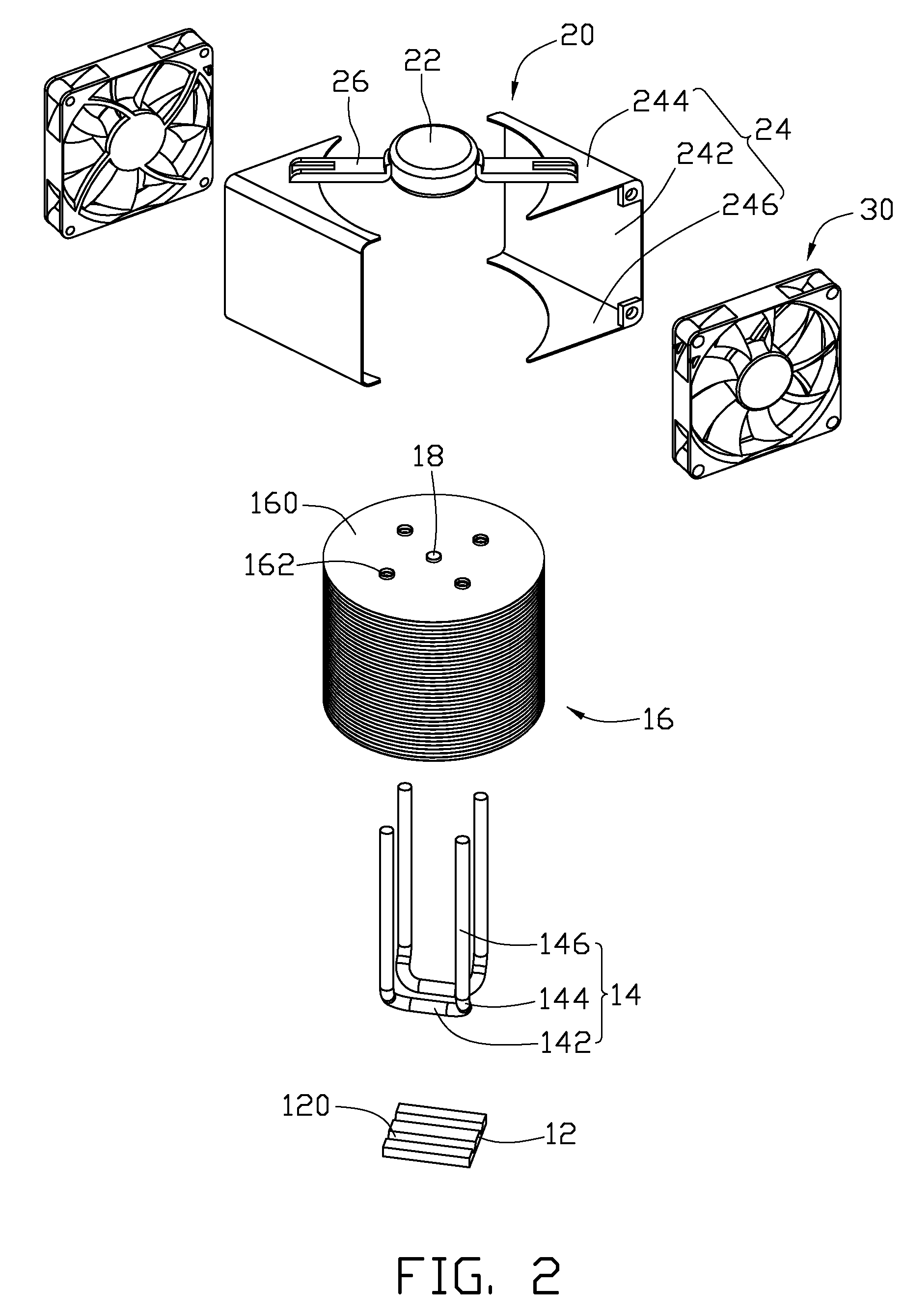

Heat dissipation device

InactiveUS8061411B2Improve cooling efficiencyLow efficiencySemiconductor/solid-state device detailsSolid-state devicesAirflowEngineering

A heat dissipation device removing heat from an electronic device includes a base plate, a fin set in thermal connection with the base plate, a fixing member and two fans. The fixing member includes a driving part coupled to a top of the fin set, two mounting parts located at two opposite sides of a circumference of the fin set and two connecting arms extending outwardly from the driving part and connecting with the two mounting parts. The two fans, respectively mounted on the two mounting parts of the fixing member and located at two opposite sites of the circumference of the fin set, are driven to rotate around the circumference of the fin set by the driving part and generate two streams of airflow which flow through the fin set that are non-intersecting.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

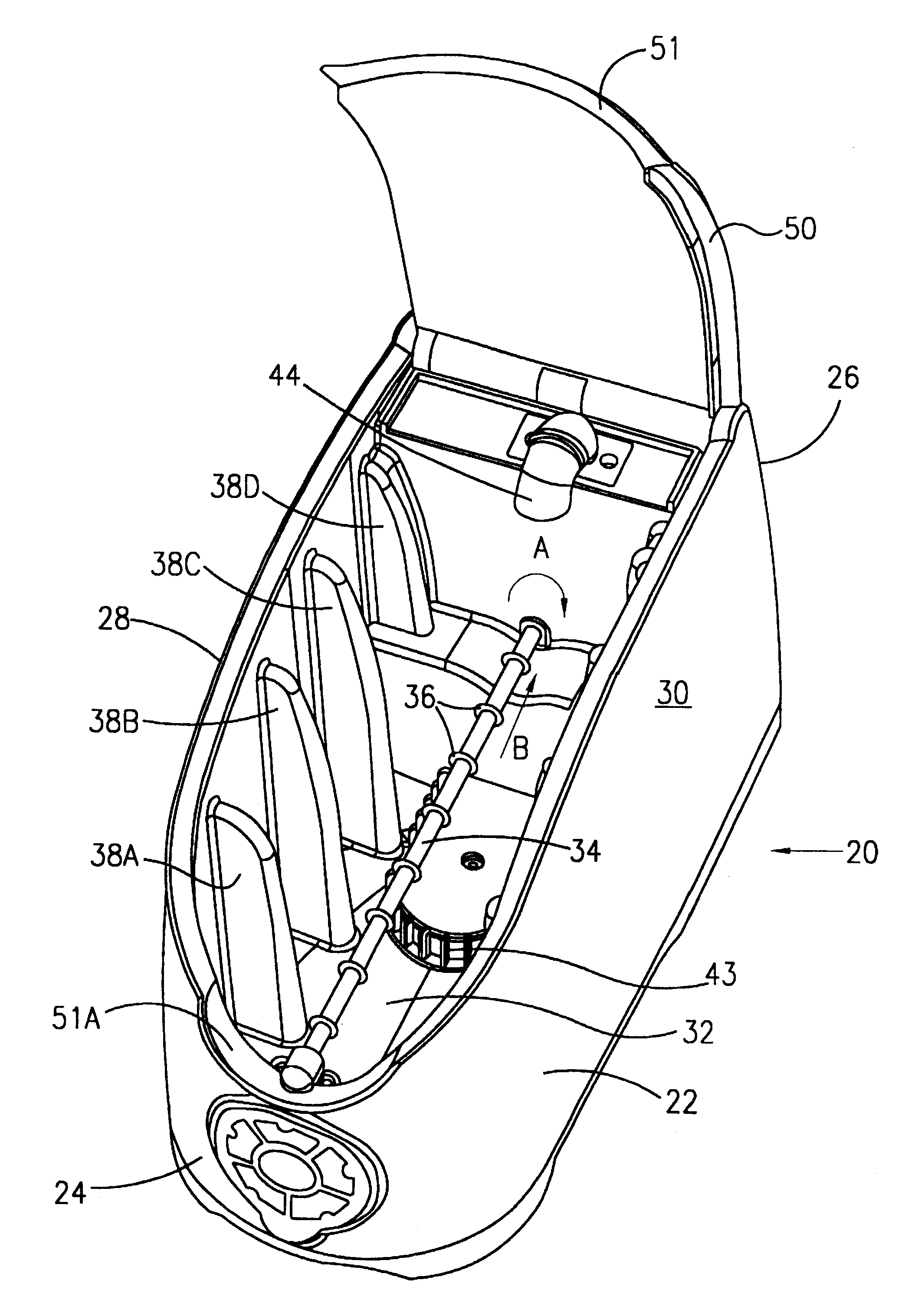

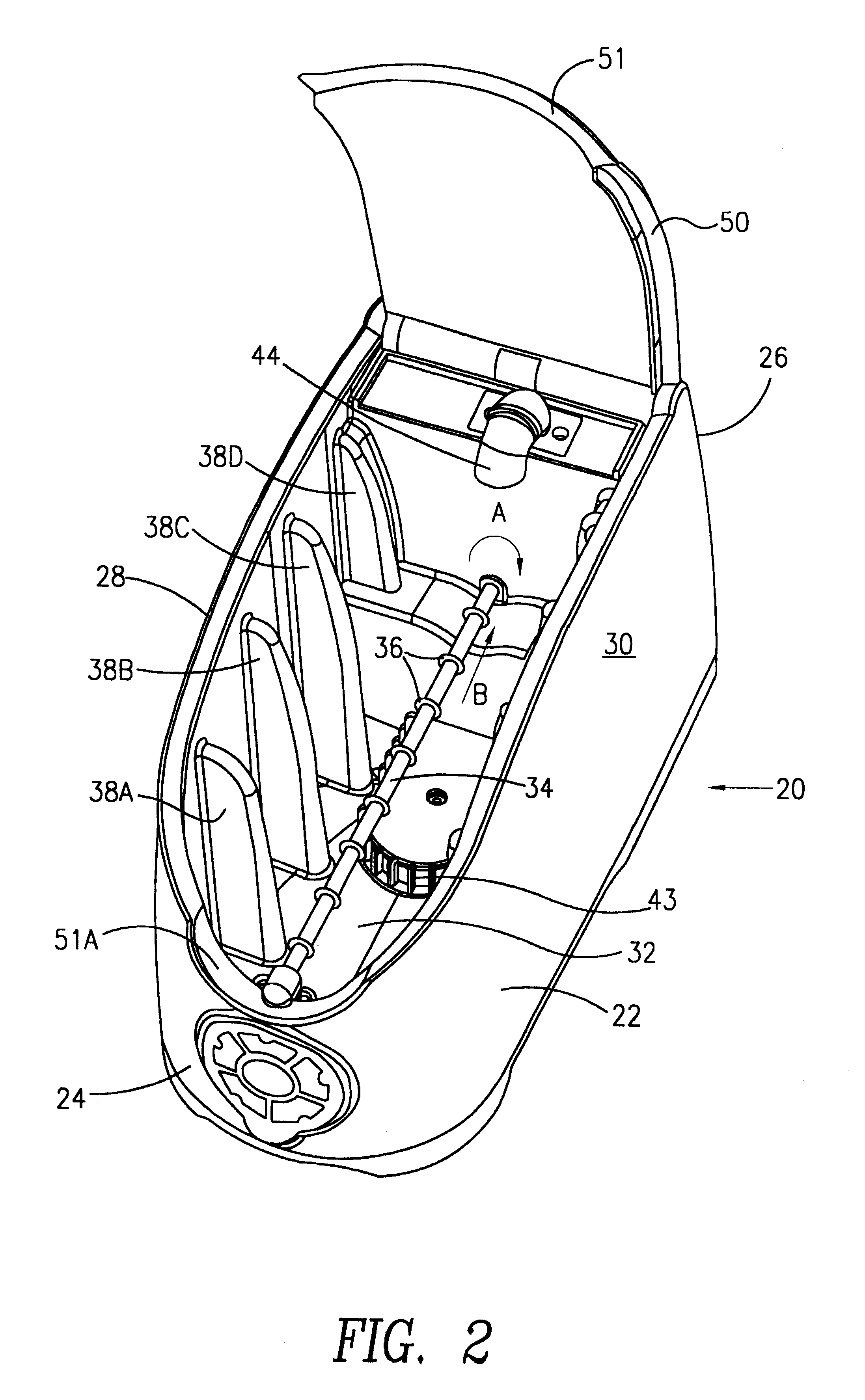

Theremoelectric heat exchanger

InactiveUS20060048518A1Domestic cooling apparatusThermoelectric device with peltier/seeback effectThermal isolationEngineering

Disclosed is a system for thermally conditioning and pumping a fluid. The system includes a thermoelectric heat exchanger having a thermoelectric device configured to pump heat. Heat exchangers are provided for transferring heat to and from the thermoelectric device and for generating a fluid flow across the thermoelectric device. The conditioned fluid may be placed in thermal communication with a variety of objects, such as a vehicle seat, or anywhere localized heating and cooling are desired. Thermal isolation may also be provided in the direction of flow to enhance efficiency.

Owner:GENTHERM INC

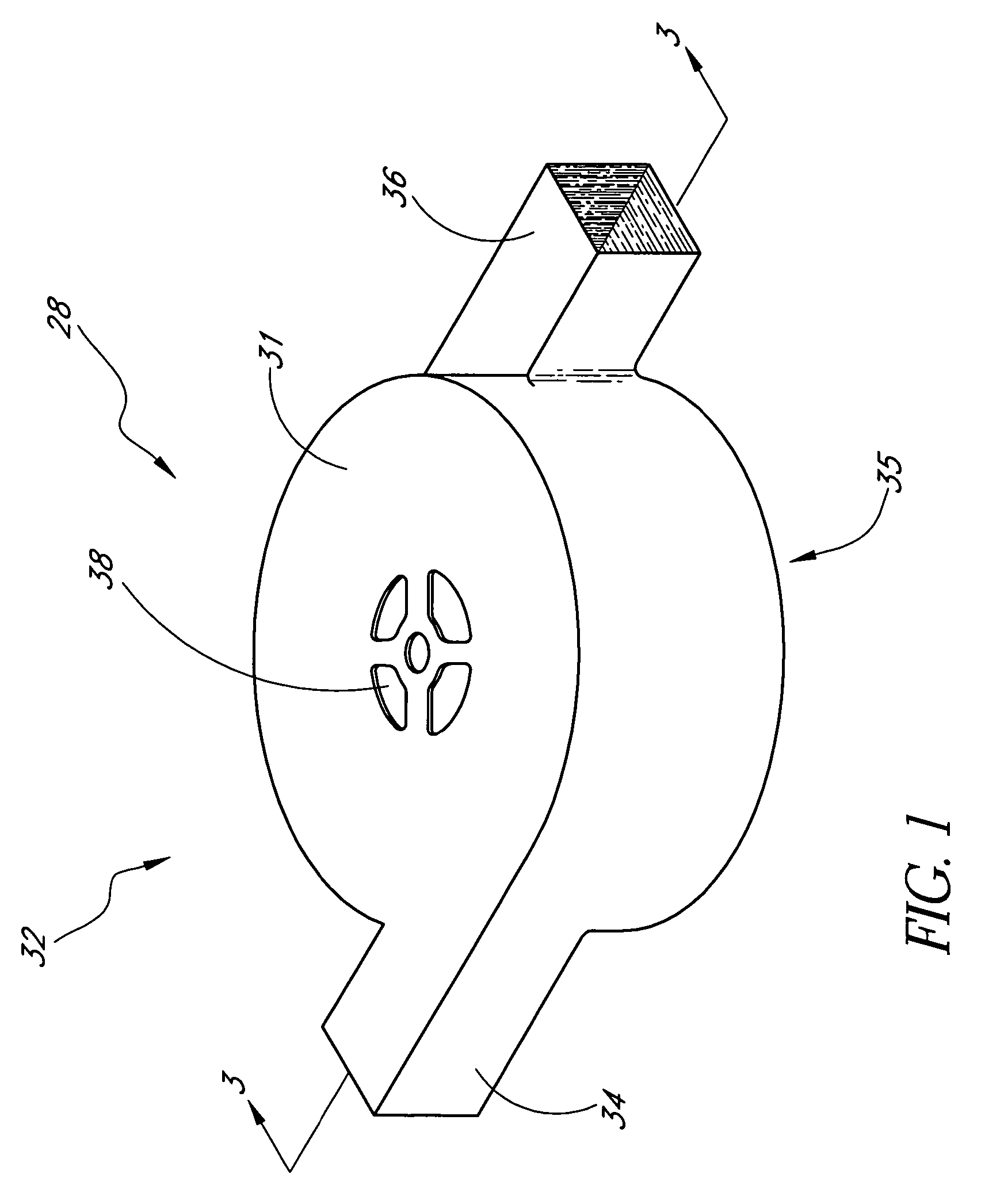

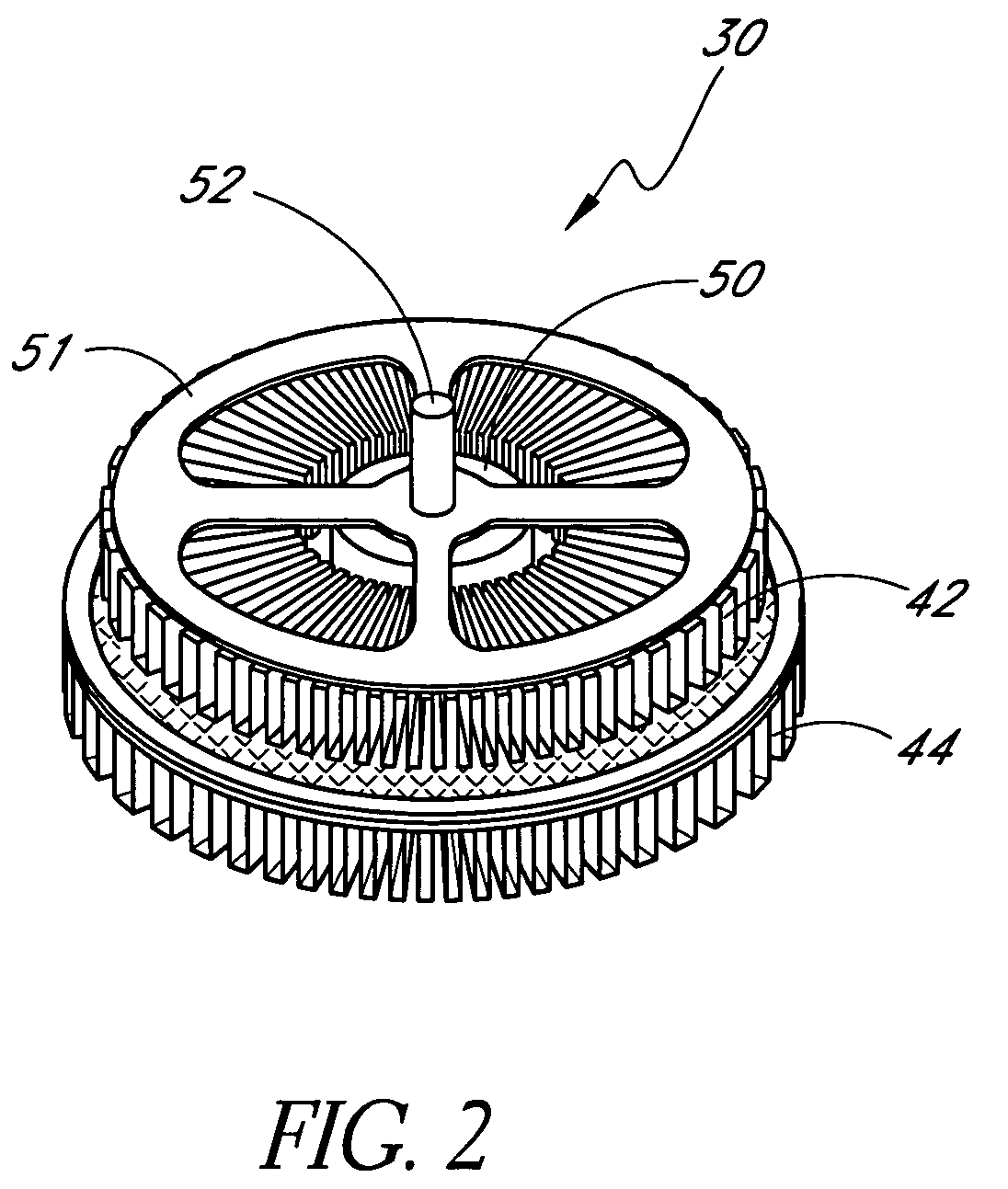

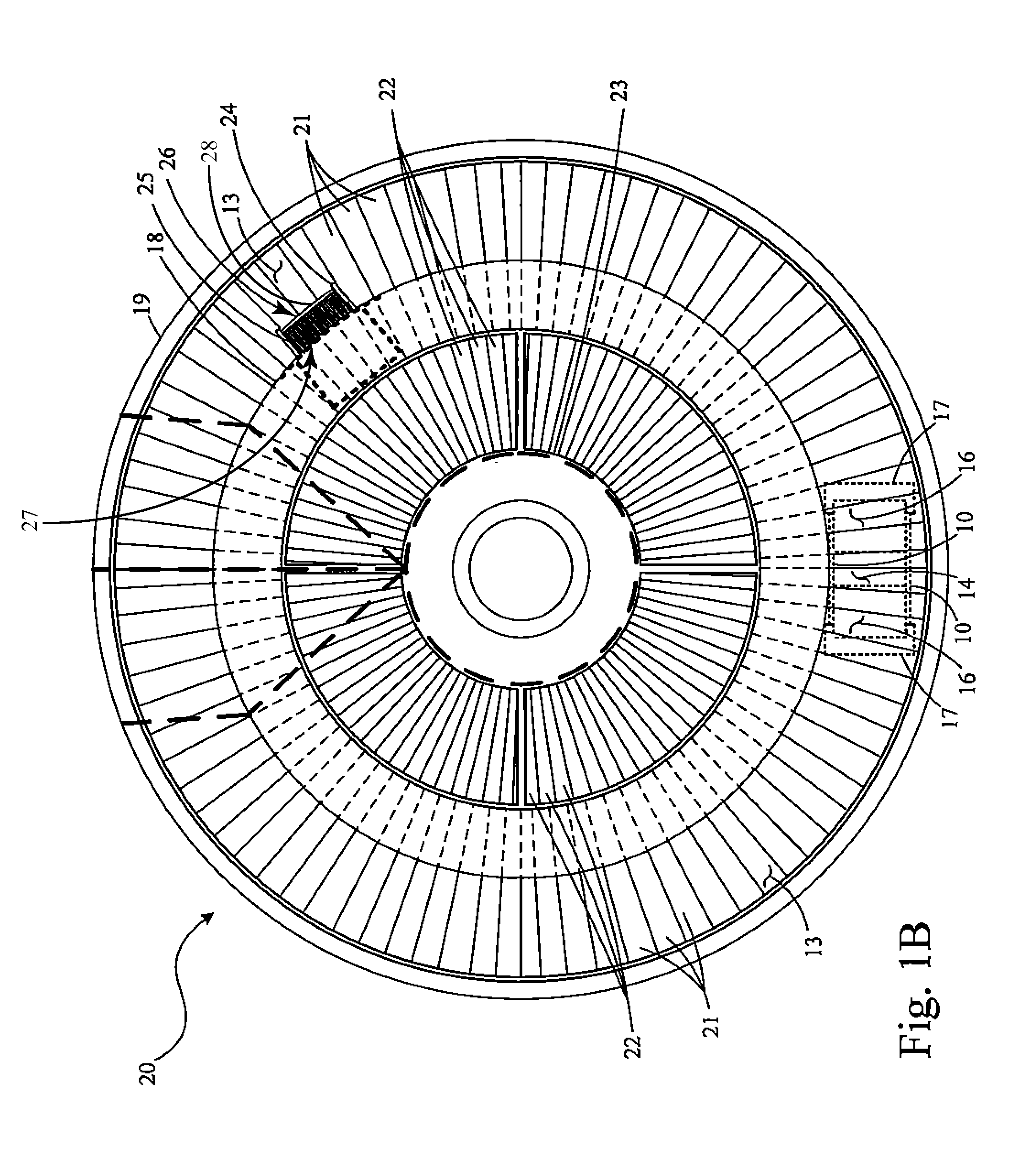

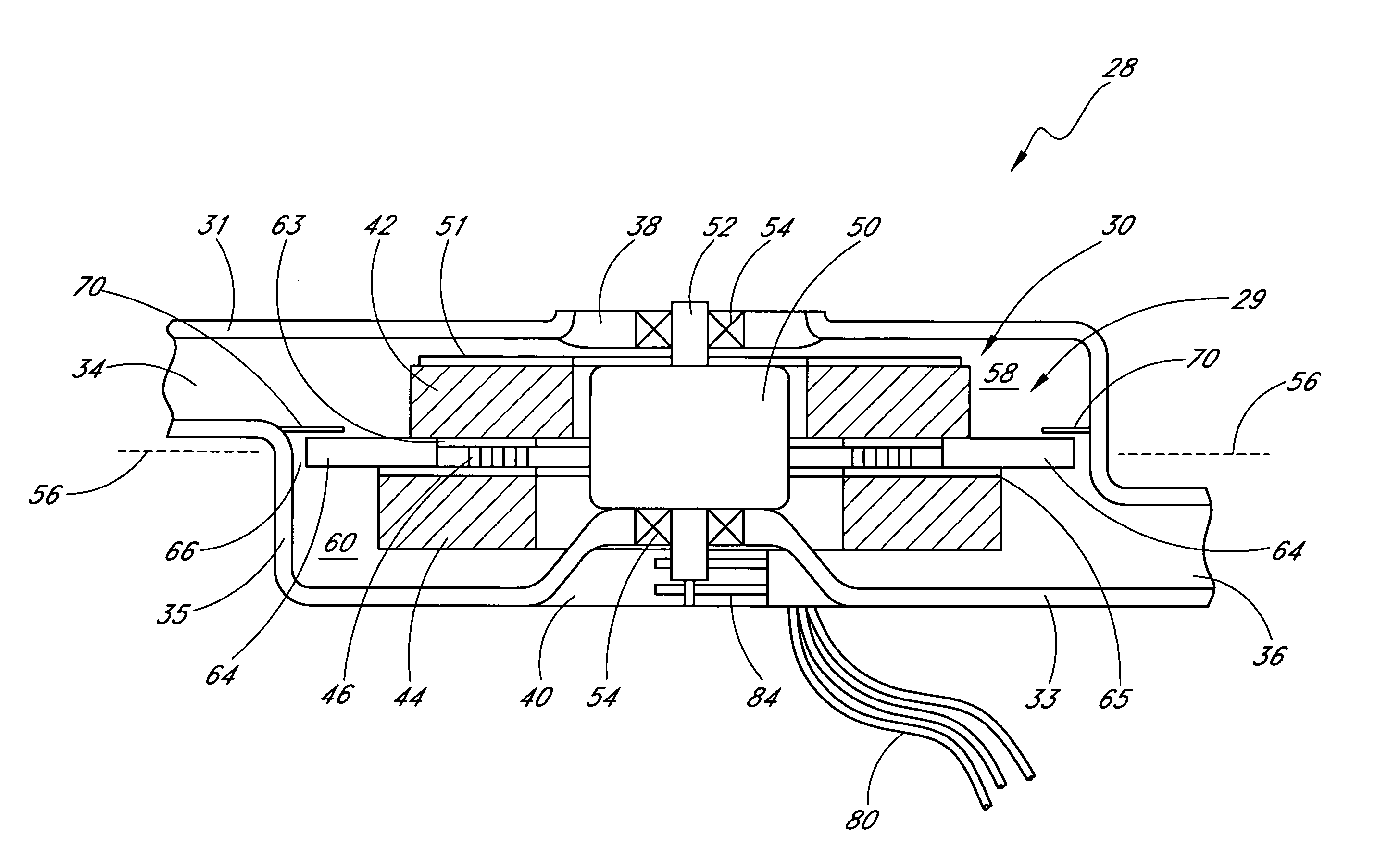

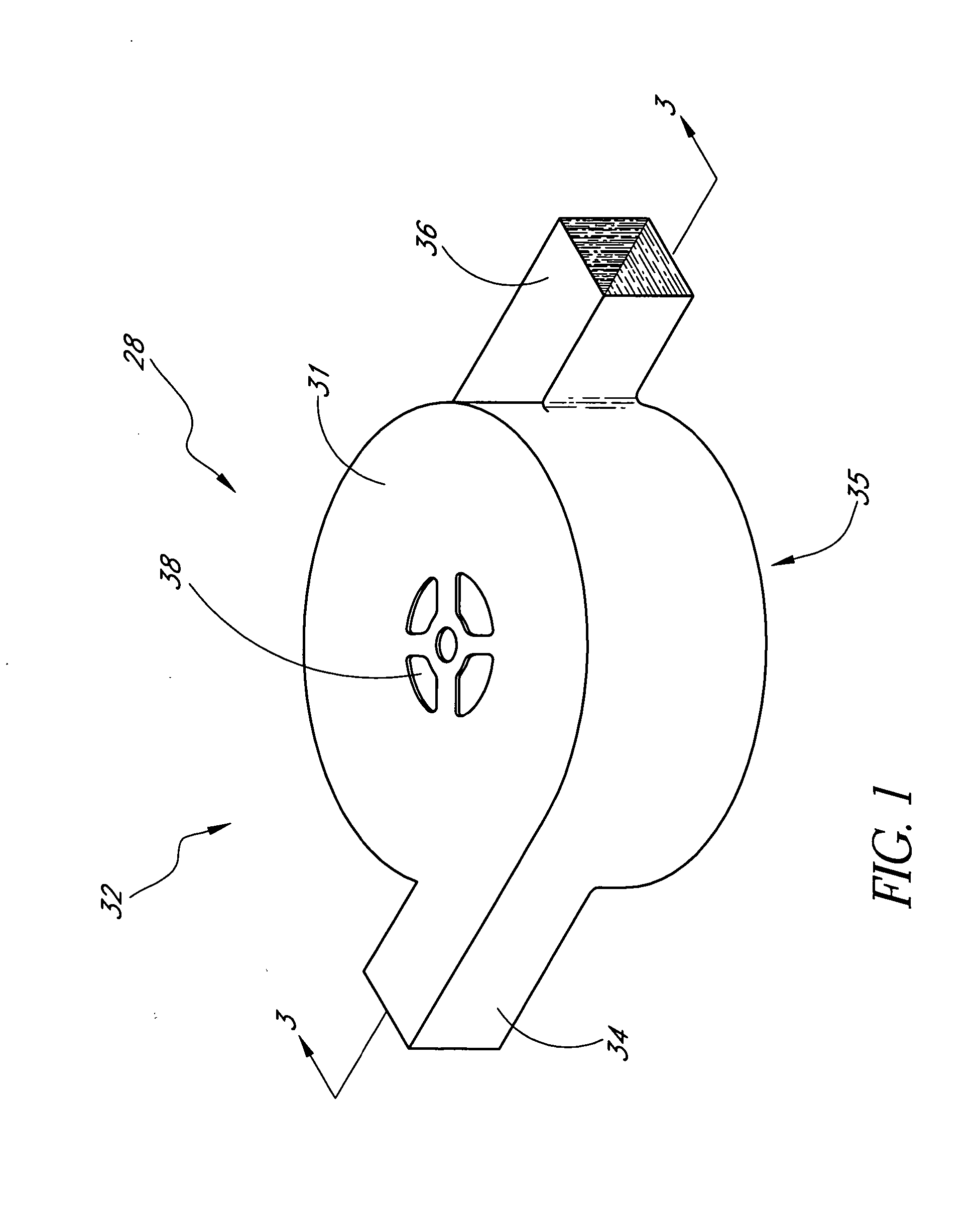

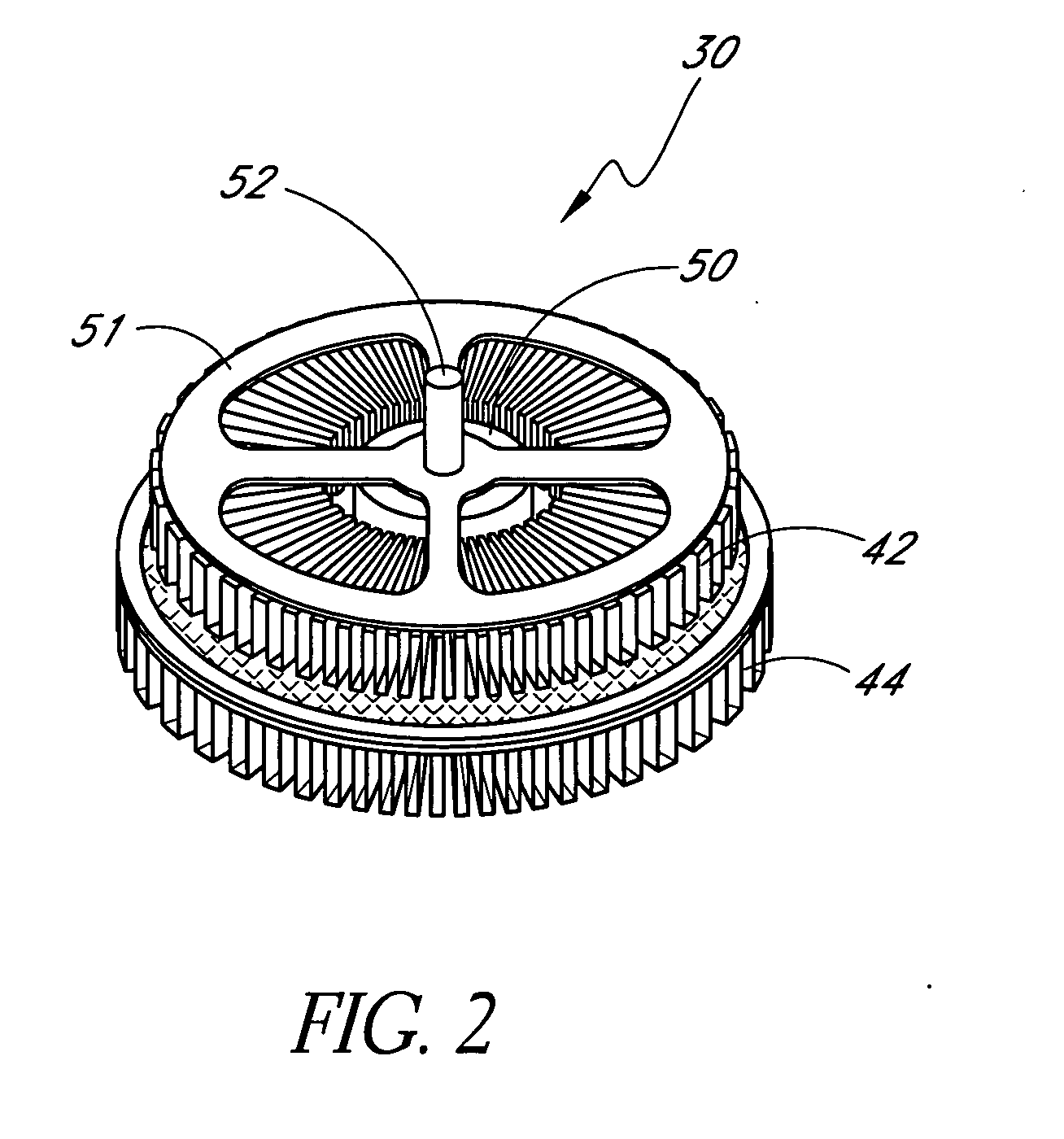

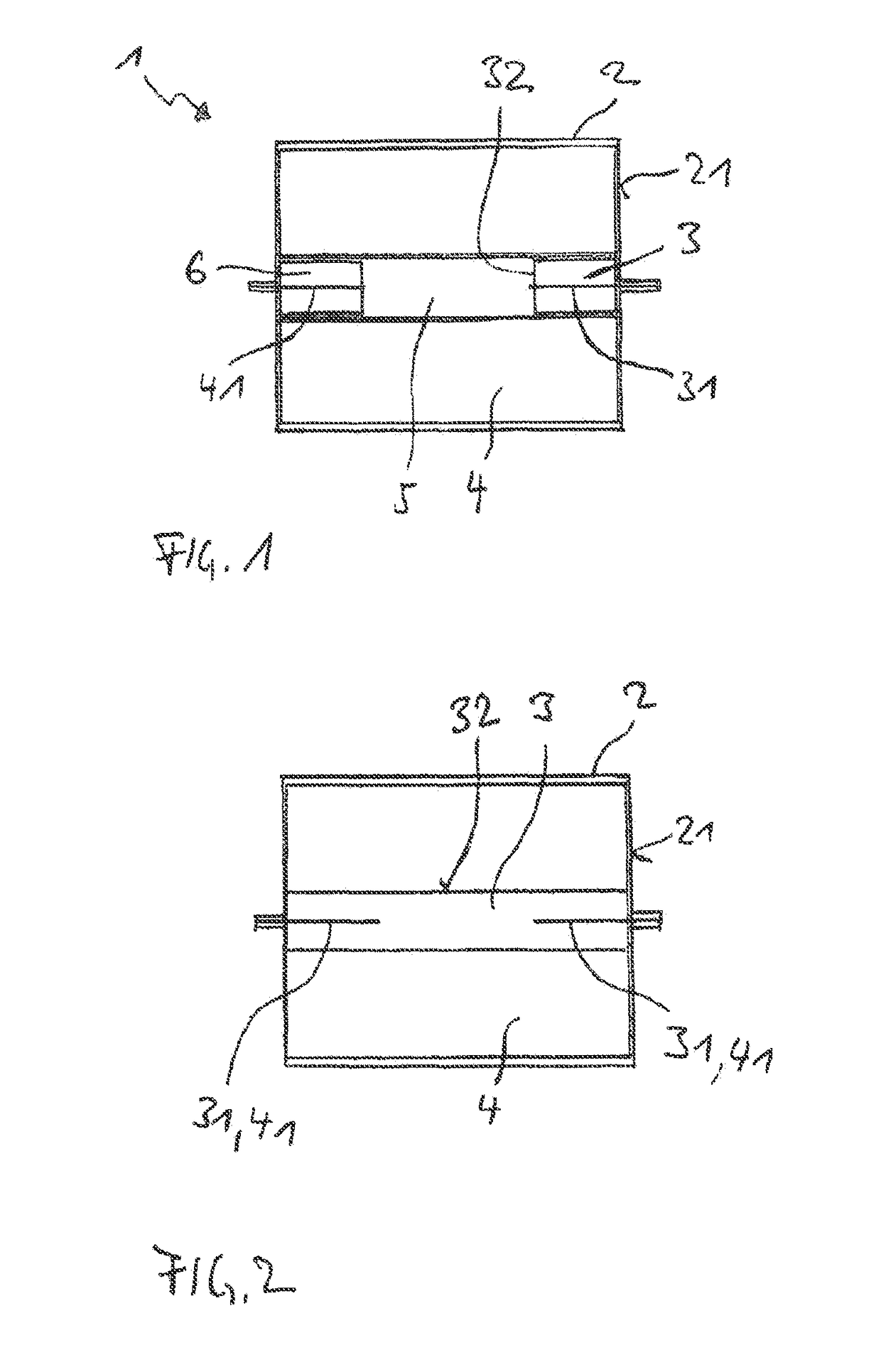

Rotary Heat Exchanger Device

InactiveUS20170328649A1Speed up heat exchangeLower assembly costsEnergy recovery in ventilation and heatingAir treatment detailsEngineeringDrive motor

A rotary heat exchanger device is disclosed. In an embodiment the rotary heat exchanger includes a rotary heat exchanger having a rotary heat exchanger axis of rotation, a drive motor having a stator and a rotor including a rotor axis of rotation and a housing into which the rotary heat exchanger is installed and in which the latter rotates, wherein the rotor axis of rotation and the heat exchanger axis of rotation extend coaxially and the rotor is rigidly connected to the rotary heat exchanger.

Owner:TBM

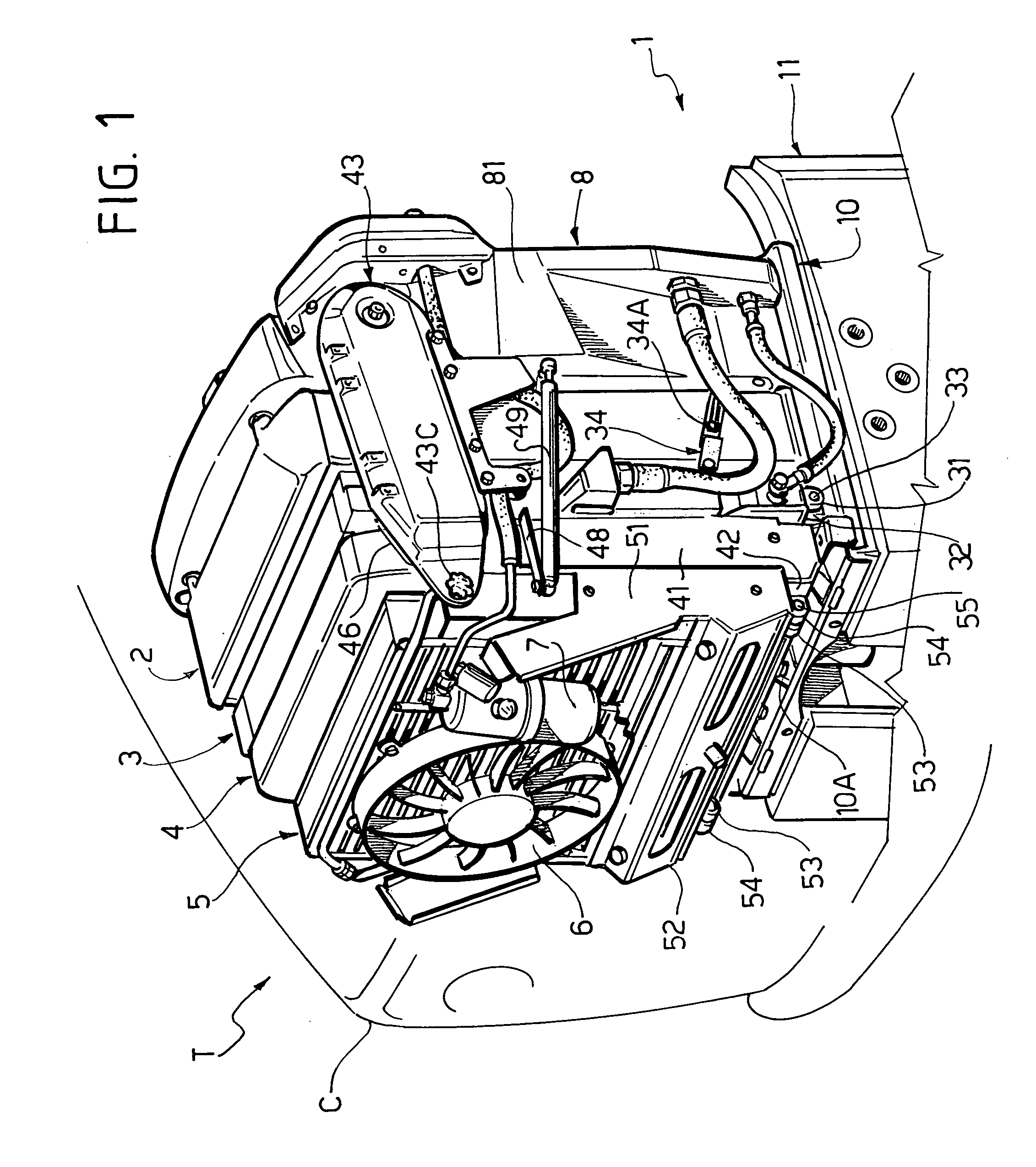

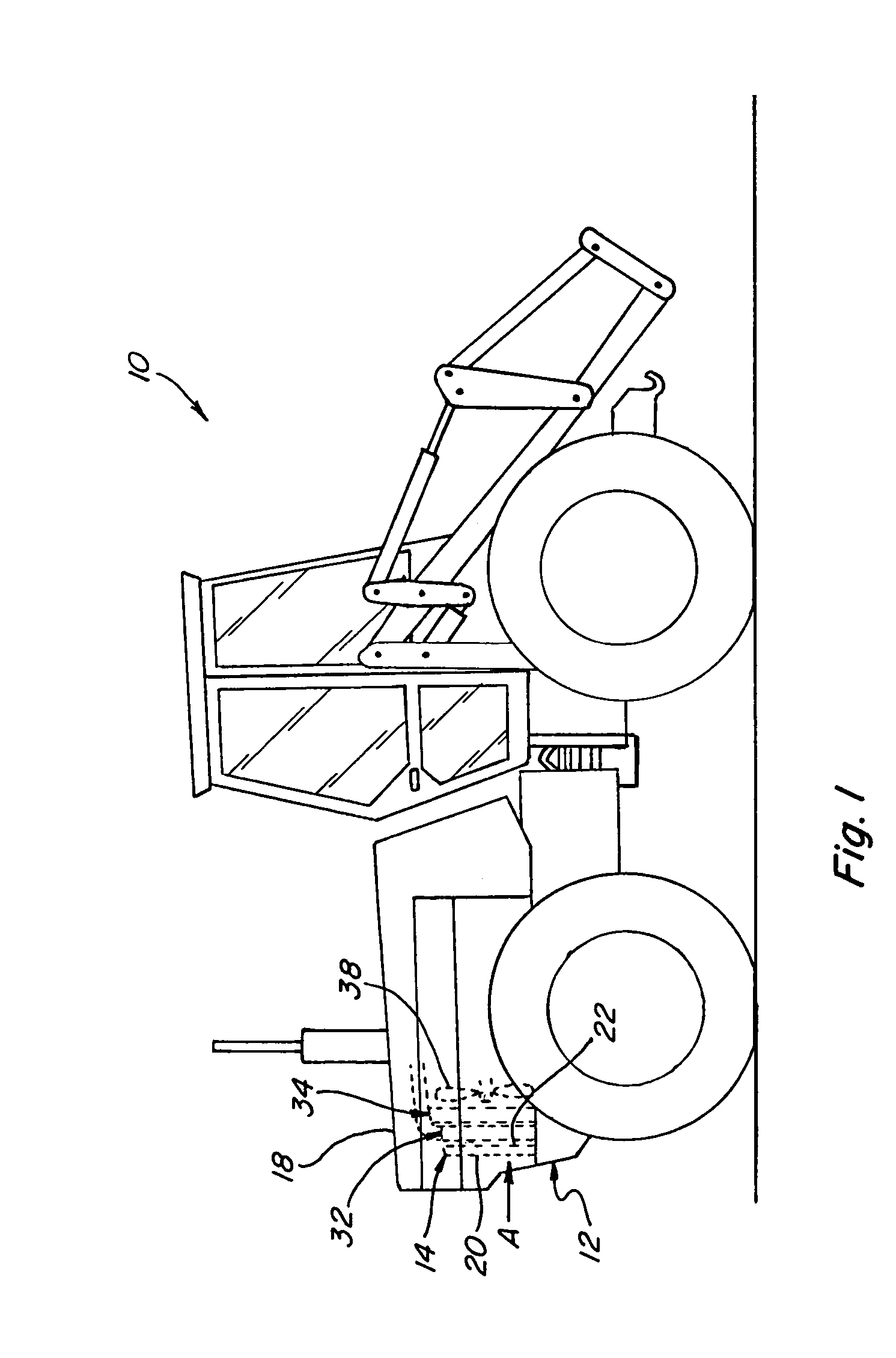

Cooling system for a farm machine

A cooling system for a farm machine comprises a heat exchange assembly (1) having a plurality of radiators (2, 3, 4, 5) arranged one close to the other and so as to be passed through by a same air flow. According to the invention, at least a first radiator (3, 4, 5) can be shifted angularly with respect to a second radiator (2, 3, 4), so as to make cleaning operations for the latter easier.

Owner:SAME DEUTZ-FAHR

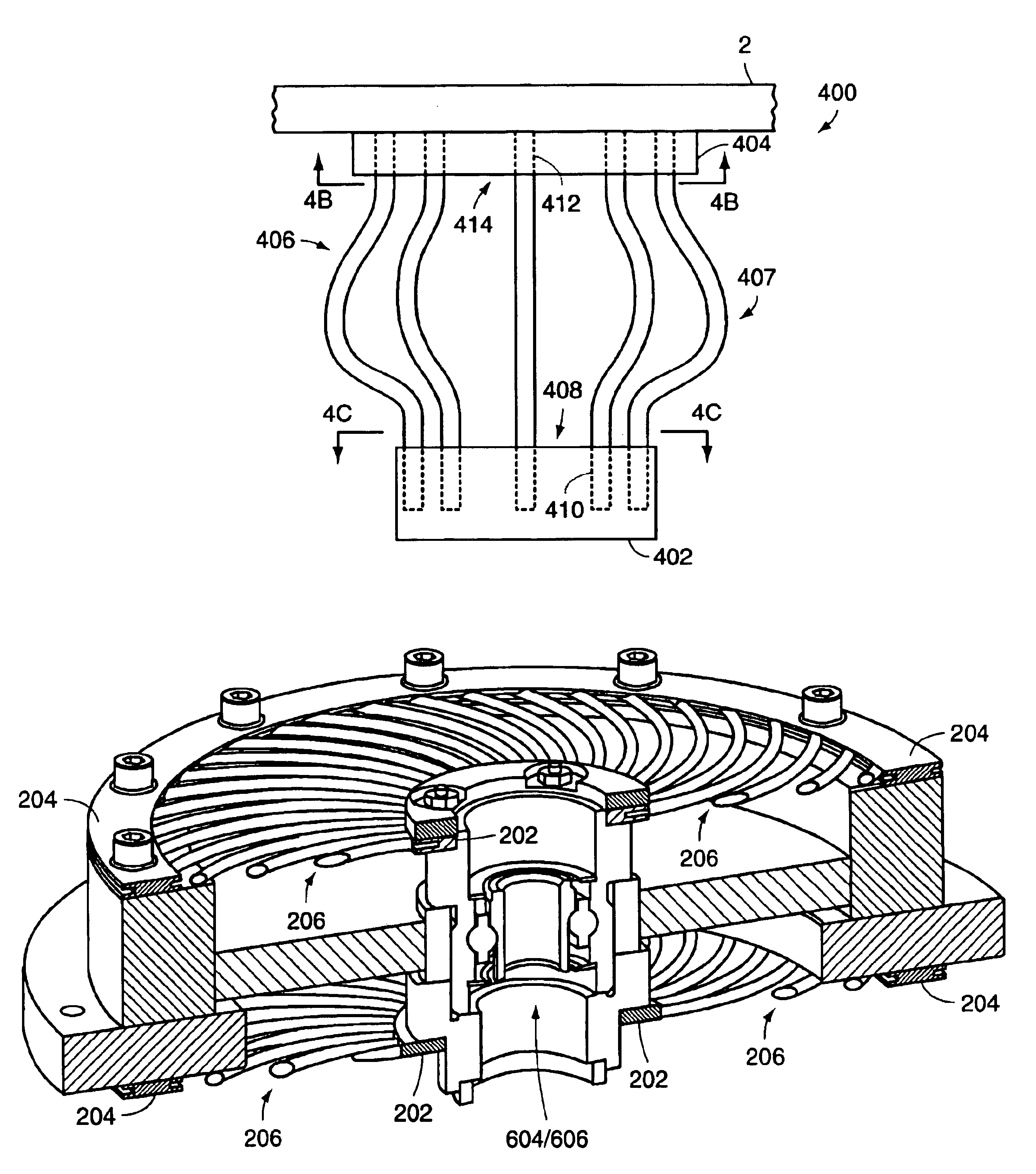

Device for cooling a bearing; flywheel energy storage system using such a bearing cooling device and methods related thereto

Featured is a heat transferring device being configured and arranged so that at least some of the heat energy being generated by a heat producing device, such as the a bearing assembly of a flywheel energy storage system, is communicated directly from the locus of the device directly to a heat sink structure remote from the locus of the device. The heat-transferring device includes one or more flexible thermally conductive members, one end of each being thermally coupled to the heat generating device and the other end of each being thermally coupled to the heat sink. The flexible member also is configured and arranged so as to allow relative motion between the heat generating device and the heat sink in or about one or more directions or axes. The heat-transferring device further includes first and second conductive members that are each configured and arranged to thermally couple each flexible member end to one of the heat producing device and the heat sink.

Owner:BEACON POWER LLC

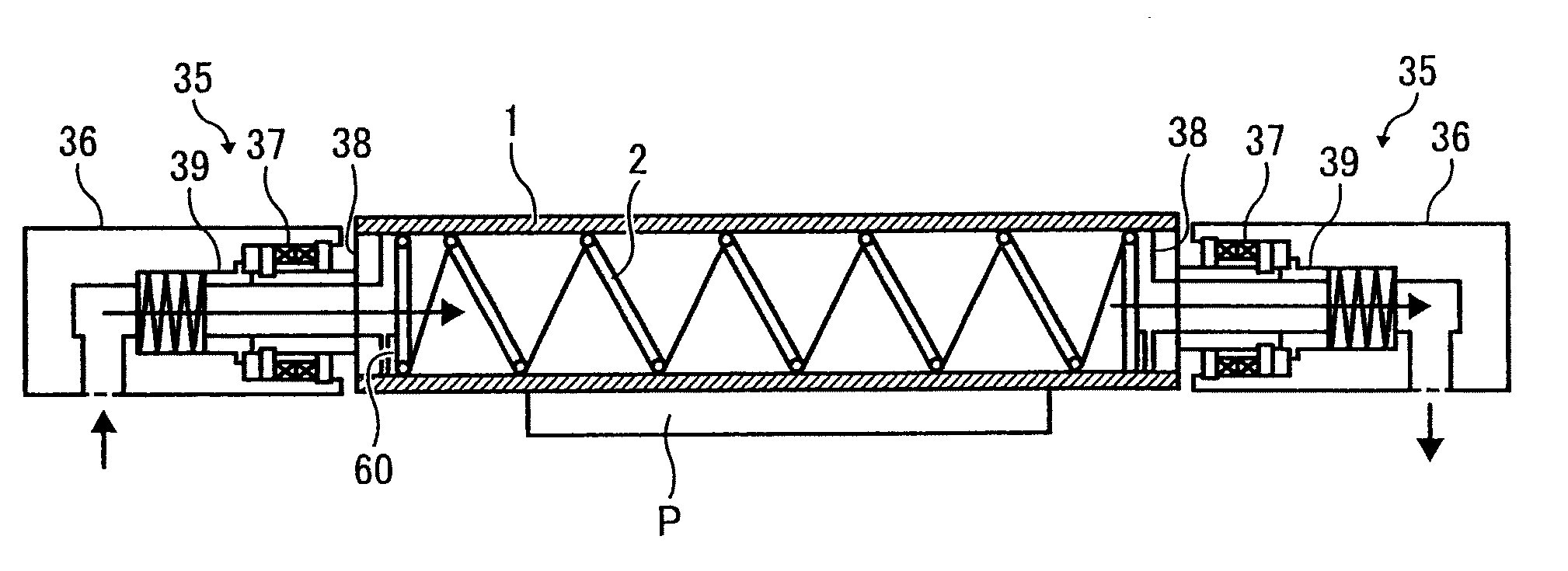

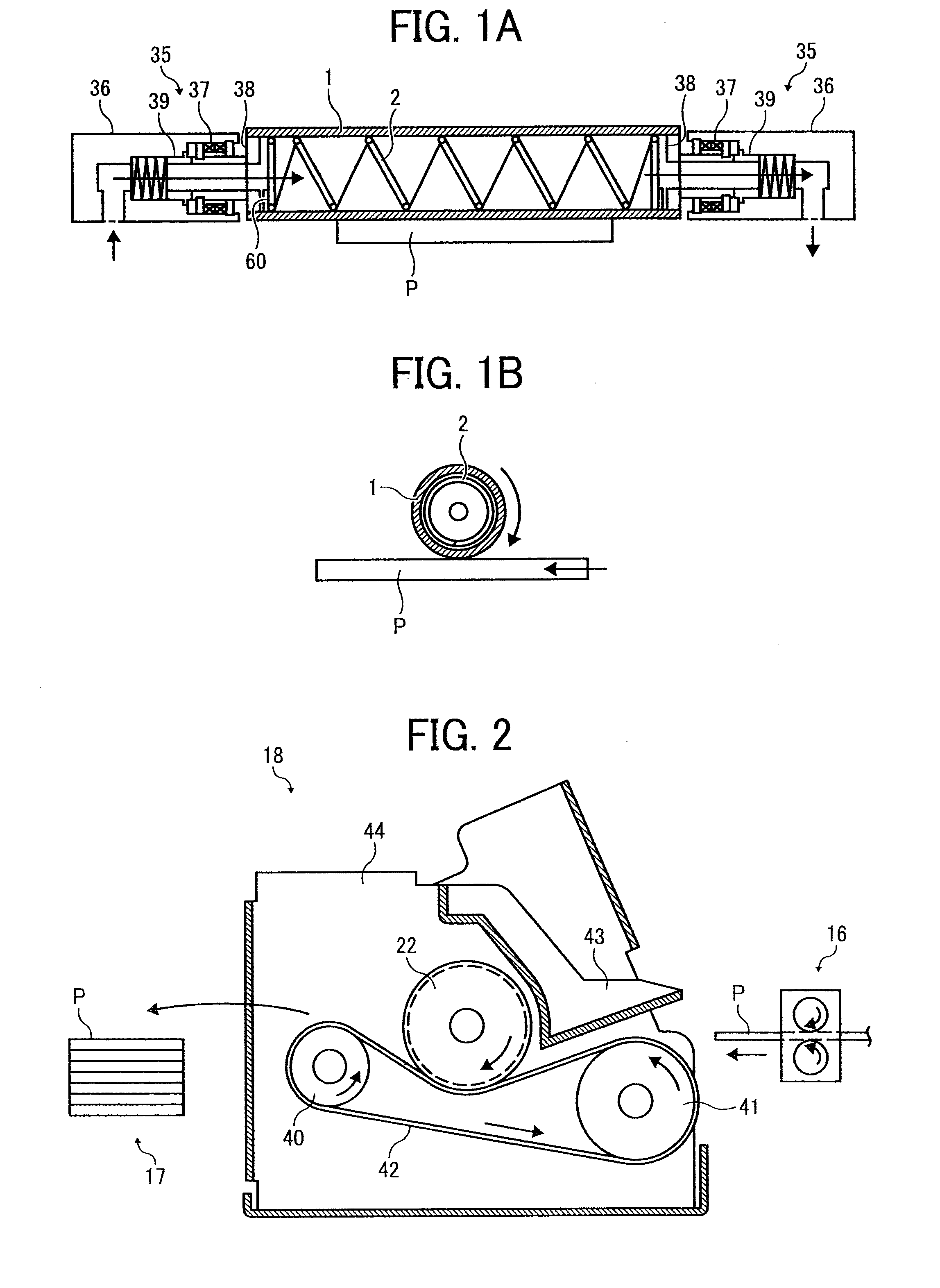

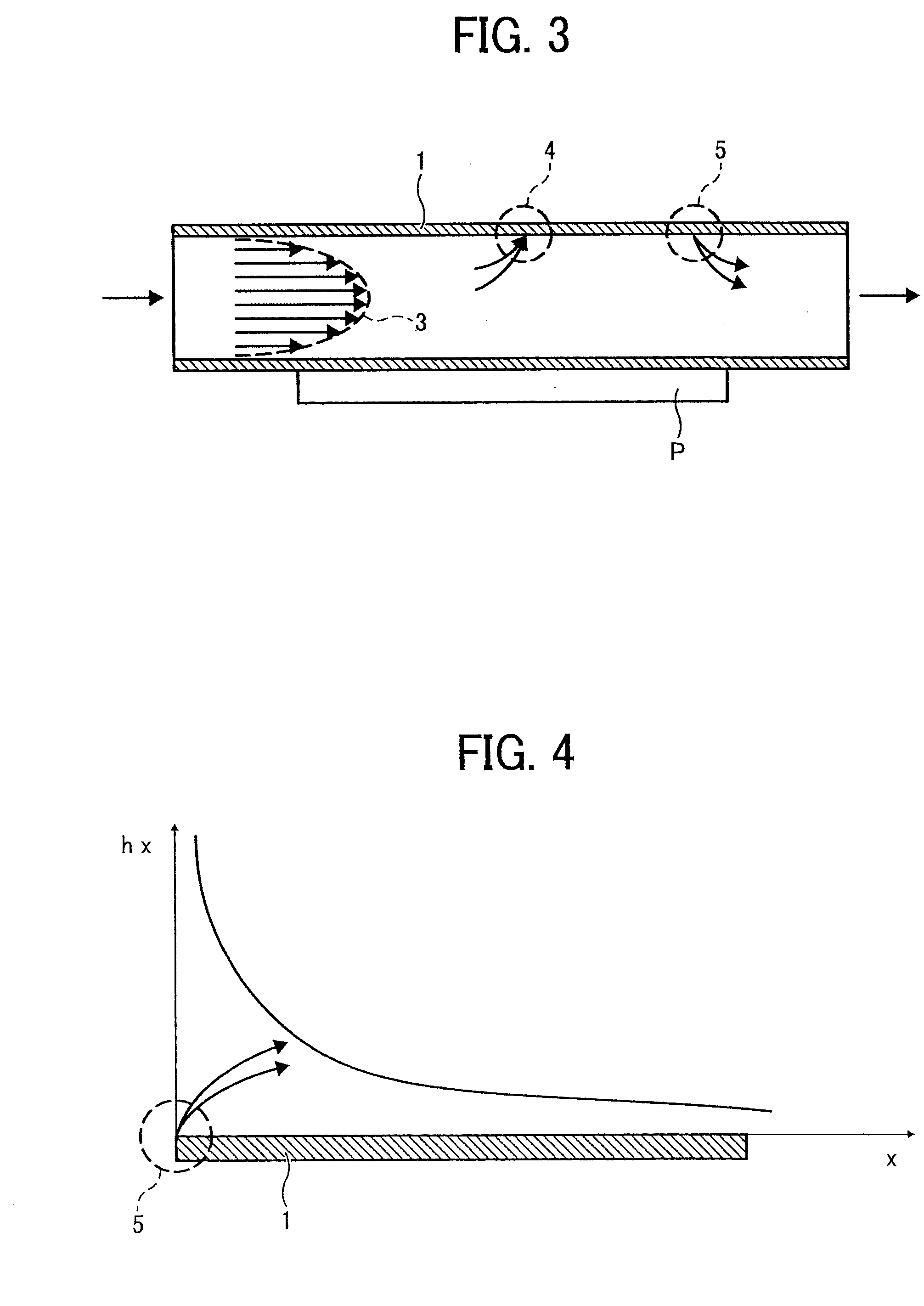

Cooling device

InactiveUS20110030927A1Solve problemsElectrographic process apparatusStationary tubular conduit assembliesCooling downCooling fluid

In a cooling device that includes a cooling roller that comprises a hollow tubular member and a cooling medium transport unit for transporting a cooling liquid to the inside of the cooling roller and contacts a sheet-like member to cool down the paper, a turbulence generating unit that generates turbulence in a cooling liquid is disposed near an inner wall of the outer tube.

Owner:RICOH KK

Process for high shear gas-liquid reactions

InactiveUS7538237B2Improve responseRapid responseRotary stirring mixersTransportation and packagingGas liquid reactionChemical reaction

A process for performing a chemical reaction between a plurality of chemical reactants in the presence of a catalyst, with at least a first reactant in a liquid phase and at least a second reactant in a gas phase, the first and second reactants mixing at least by interdiffusion. The process comprises supplying the reactants to a passage defined by a first surface and a second surface and optionally moving at least one of the first surface and second surface relative to each other. The reactants their mixture or reaction products form respective boundary layers against the first and second surfaces and the radial spacing between the first surface and second surface is equal to or less than the back-to-back radial thicknesses of the boundary layers.

Owner:323 TRUST +1

Apparatus for tilting and securing a heat exchanger

InactiveUS7370690B2Solve the lack of spaceAir-treating devicesVehicle heating/cooling devicesAir conditioningMicro heat exchanger

Apparatus for supporting a heat exchanger such as a condenser of an air conditioning system on a vehicle, for pivotal movement between an operational position and a position angularly related to the operational position, for such purposes as inspection, cleaning, service and maintenance, the apparatus being configured for holding the heat exchanger in the operational position, and for guiding and controlling movement thereof to the tilted position, and holding the heat exchanger in the tilted position.

Owner:BLUE LEAF I P INC

Electromagnetic wave assisted chemical processing

InactiveUS20010030295A1Rotary stirring mixersTransportation and packagingChemical treatmentElectromagnetic electron wave

A window allows the introduction of radiation energy into an annular processing chamber filled with a material to be processed. The chamber is formed from coaxial cylinder members rapidly rotating relative to one another. The chamber can be thin enough so that it is short compared to the penetration depth of the radiation through the material, providing even exposure of the material to the radiation. Also, eddies created in the material by the relative rotation enhances the even exposure. When the material inside the annular processing chamber is opaque, resulting in an insignificant penetration depth, the eddies still insure that the material is evenly exposed to the irradiation.

Owner:KREIDO LAB +1

Heat-moisture exchanger with aerosol by-pass

A first and second housing is joined together by a middle housing rotatable with respect to the first and second housing. The first and second housings have conduits passing through exterior walls and an annular ring on an inside wall together with an annular interior edge rotatably joined to first and second side rim channels of the middle housing. A heat-moisture exchanger material having an annular opening through which a tube passes is mounted within the middle housing so that in a first rotatable position air and moisture passes through the first and second housing conduits directly and in a second rotatable position must pass through the heat-moisture exchange material.

Owner:WALDO JR JAMES V +1

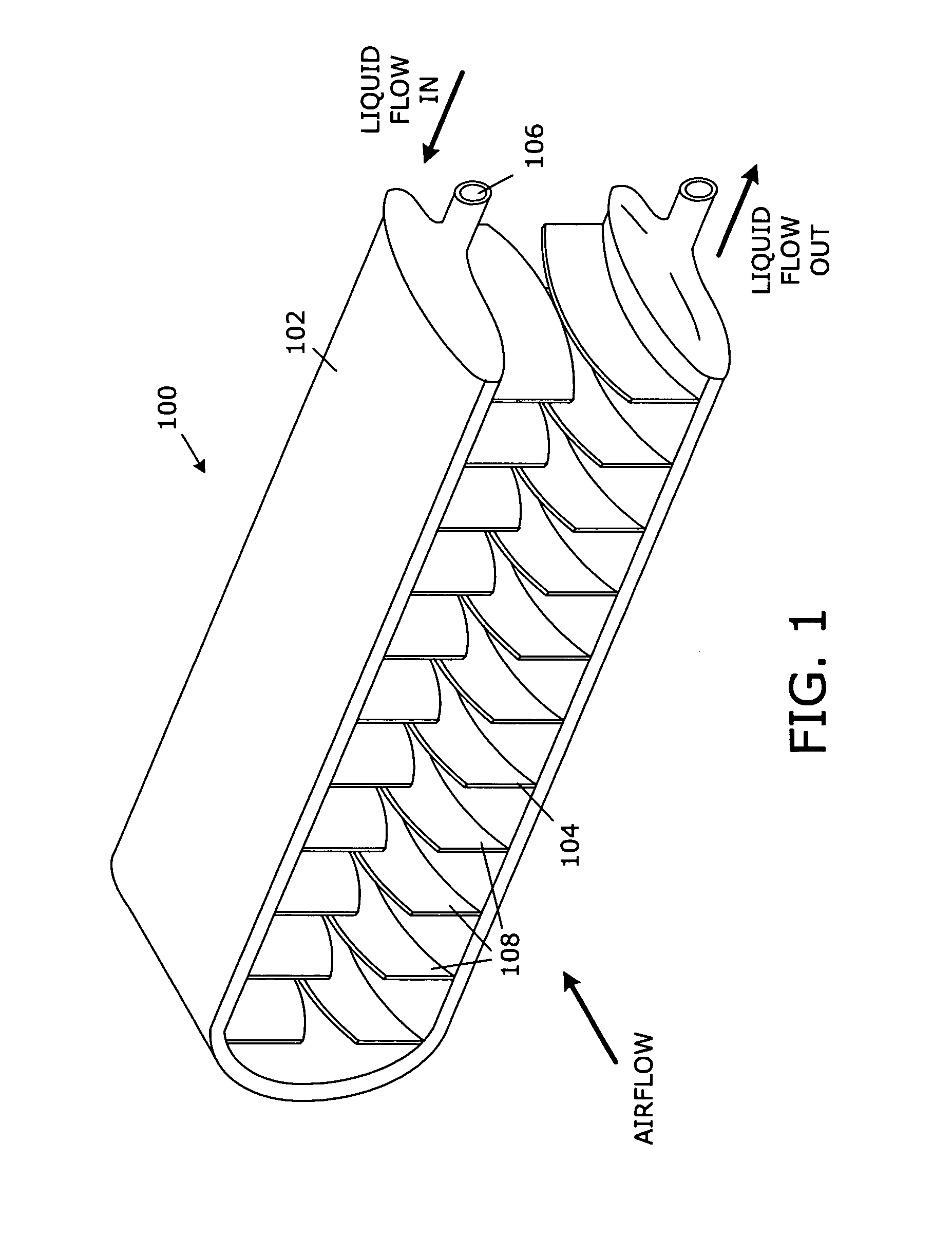

Heat exchanger including flow straightening fins

ActiveUS7142424B2Easy to straightenDomestic cooling apparatusDigital data processing detailsPlate heat exchangerEngineering

A heat exchanger includes a tube, and a plurality of fins coupled to the tube having a curved fan-stator shape that facilitates straightening of airflow from a fan.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

Popular searches

Mixer accessories Printed circuit manufacture Circuit susbtrate materials Moving conduit heat exchangers Water/sewage treatment by irradiation Organic compound preparation Water/sewage treatment with mechanical oscillations Carboxylic preparation by ozone oxidation Chemical/physical/physico-chemical stationary reactors Energy based chemical/physical/physico-chemical processes

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com