Heat exchanger for fermentation tank

a technology of heat exchanger and fermentation tank, which is applied in the direction of biochemistry apparatus and processes, stationary tubular conduit assemblies, stationary conduit assemblies, etc., can solve the problems of uniform temperature control, unfavorable quality of beer produced, and formation of undesired sub-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

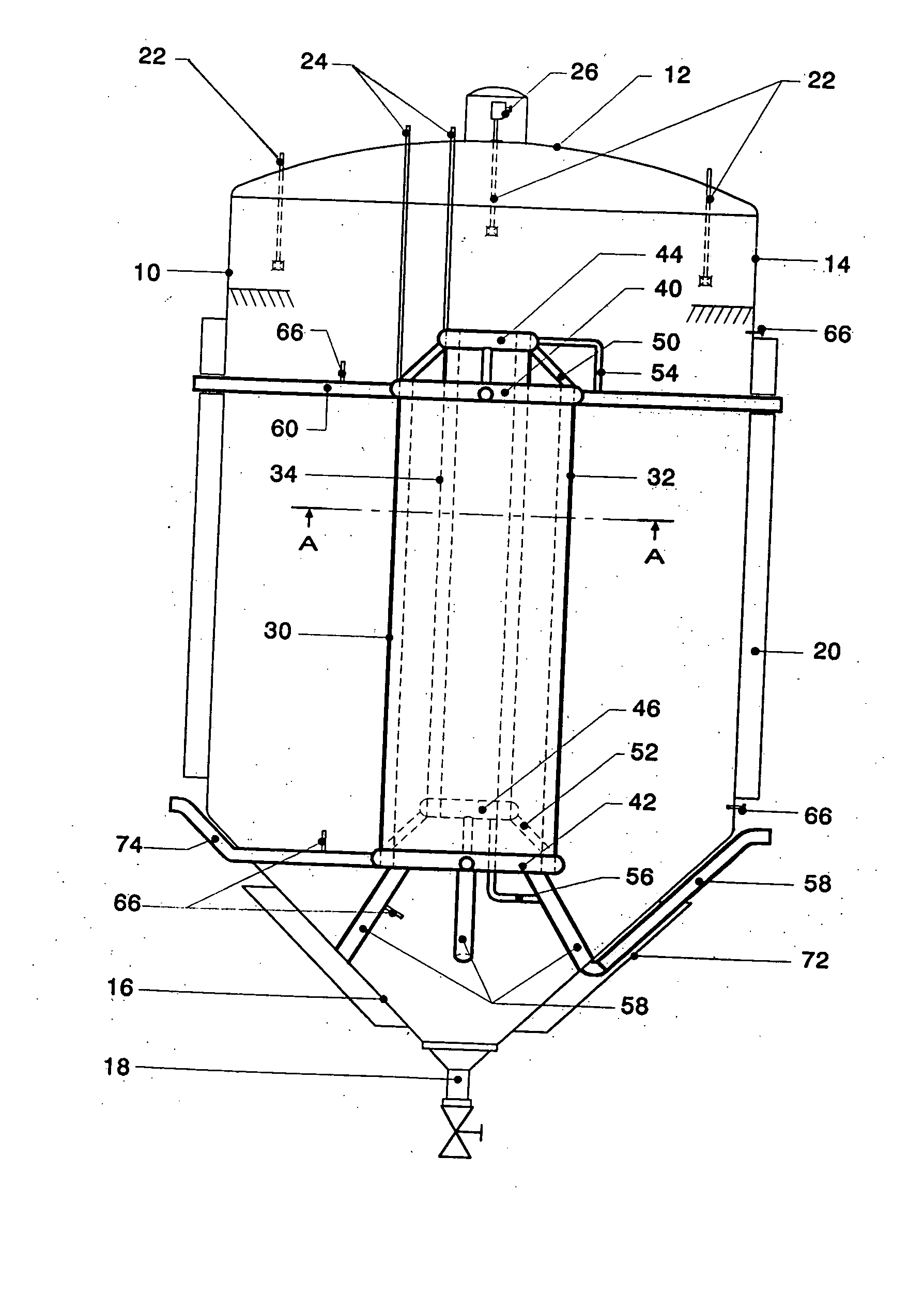

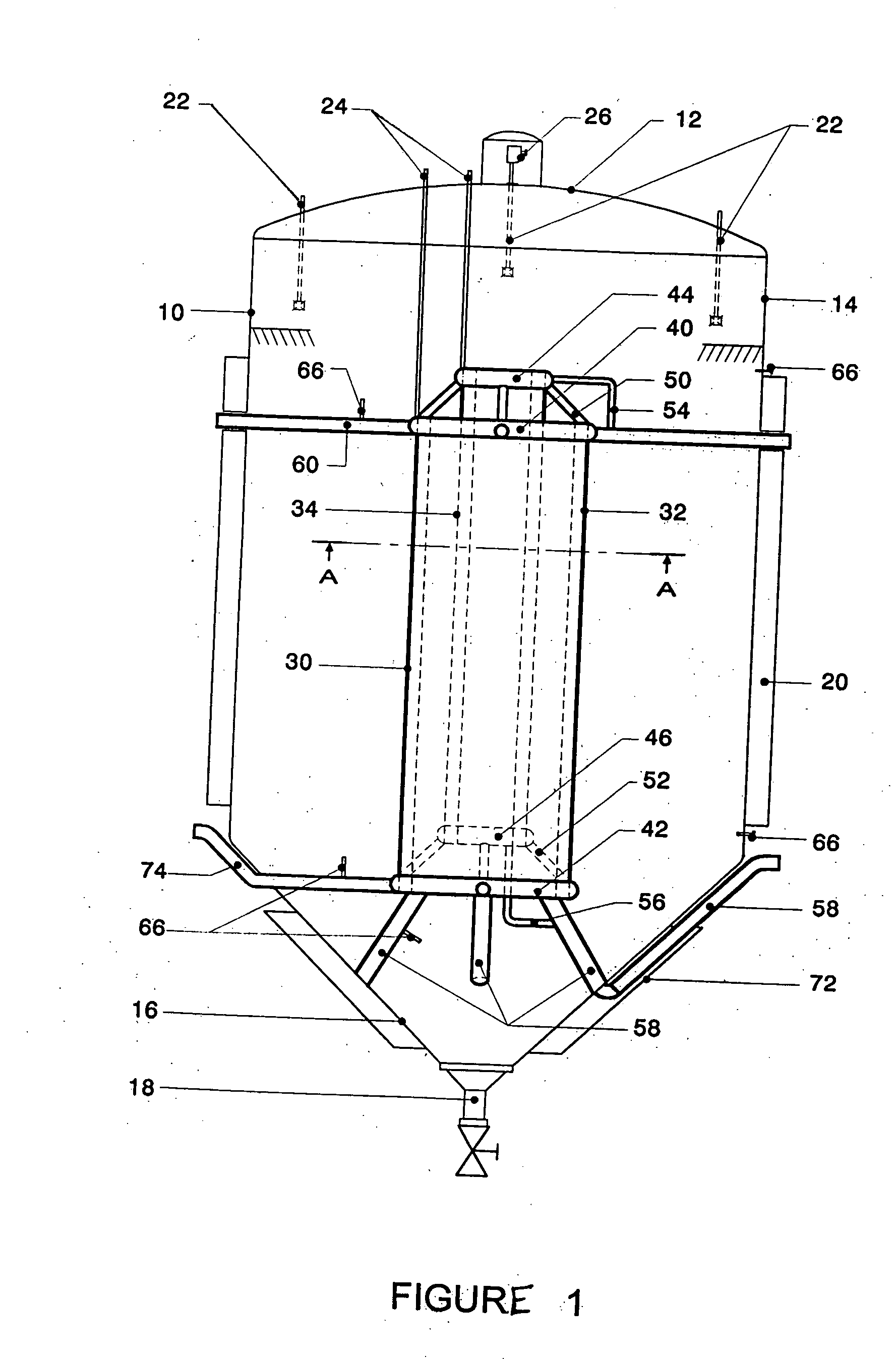

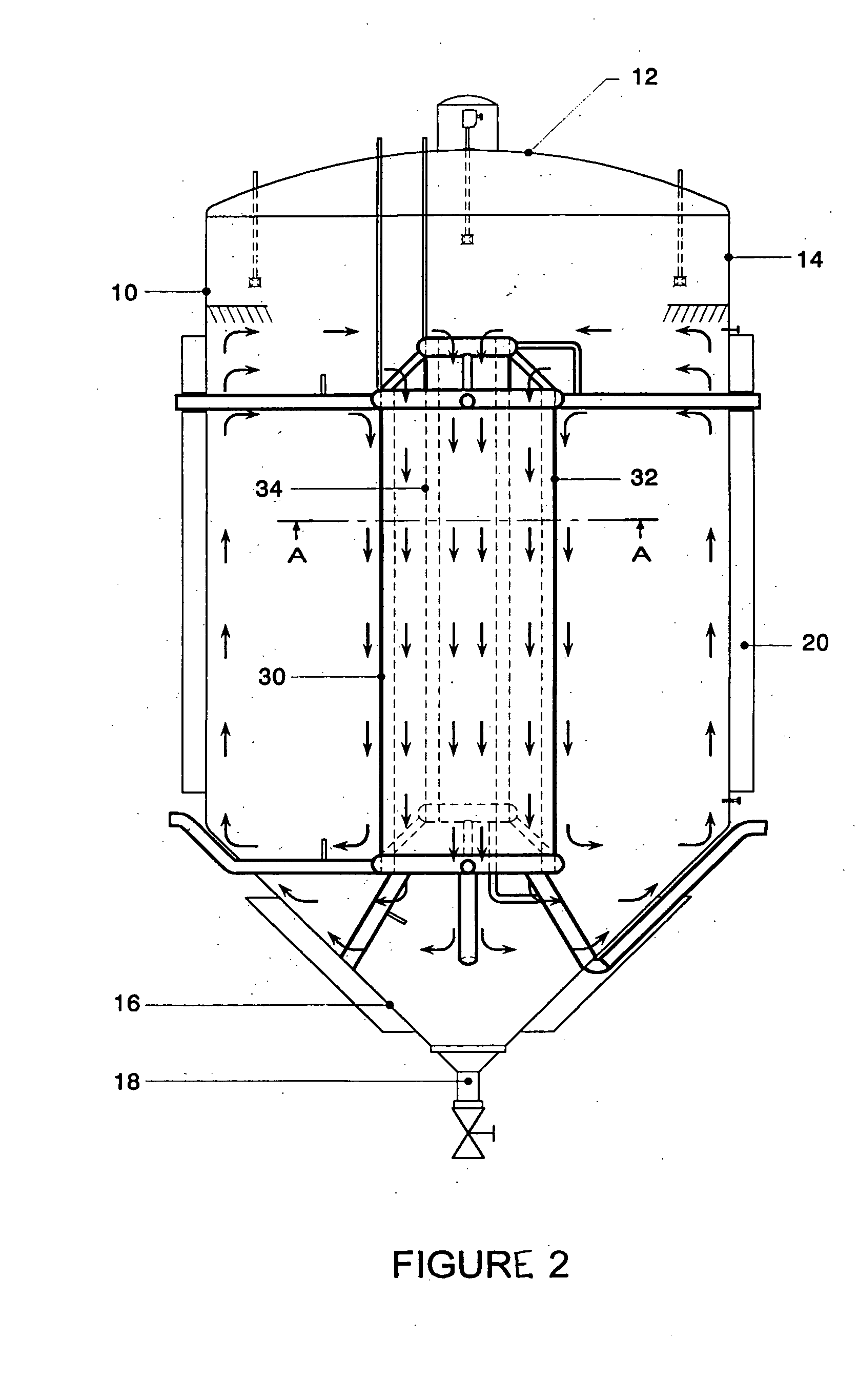

[0041] As referring to said figures and following same nomenclature of reference signs shown, this invention consists of an internal vertical heat exchanger 30, to be installed inside a tank 10, three main sections are underlined from the latter: an upper, dome cap 12, whose function will be to maintain sufficient space as to store gases formed during fermentation process; a cylindrical body 14, whose function will be to contain beer wort to carry out fermentation process, whose exothermal reaction requires cooling and also to cool the beer after fermentation, to do so a cooling jacket 20 may be fitted on external wall, the whole fermentation tank is usually isolated in order to decrease heat losses toward environment and, the conic-shaped bottom 16, with variable design angle, whose function will be to receive and store deposited particles, which are finally extracted by a lower valve 18, same as wort and beer after separating deposits.

[0042] Inside fermentation tank 10, a heat ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com