Cooling system for a farm machine

a technology for cooling systems and farm machines, applied in the direction of stationary tubular conduit assemblies, stationary cooling apparatus, stationary conduit assemblies, etc., can solve the problems of engine overheating, subsequent performance loss, and inability to ensure a sufficiently high filtering degree of grille-like openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

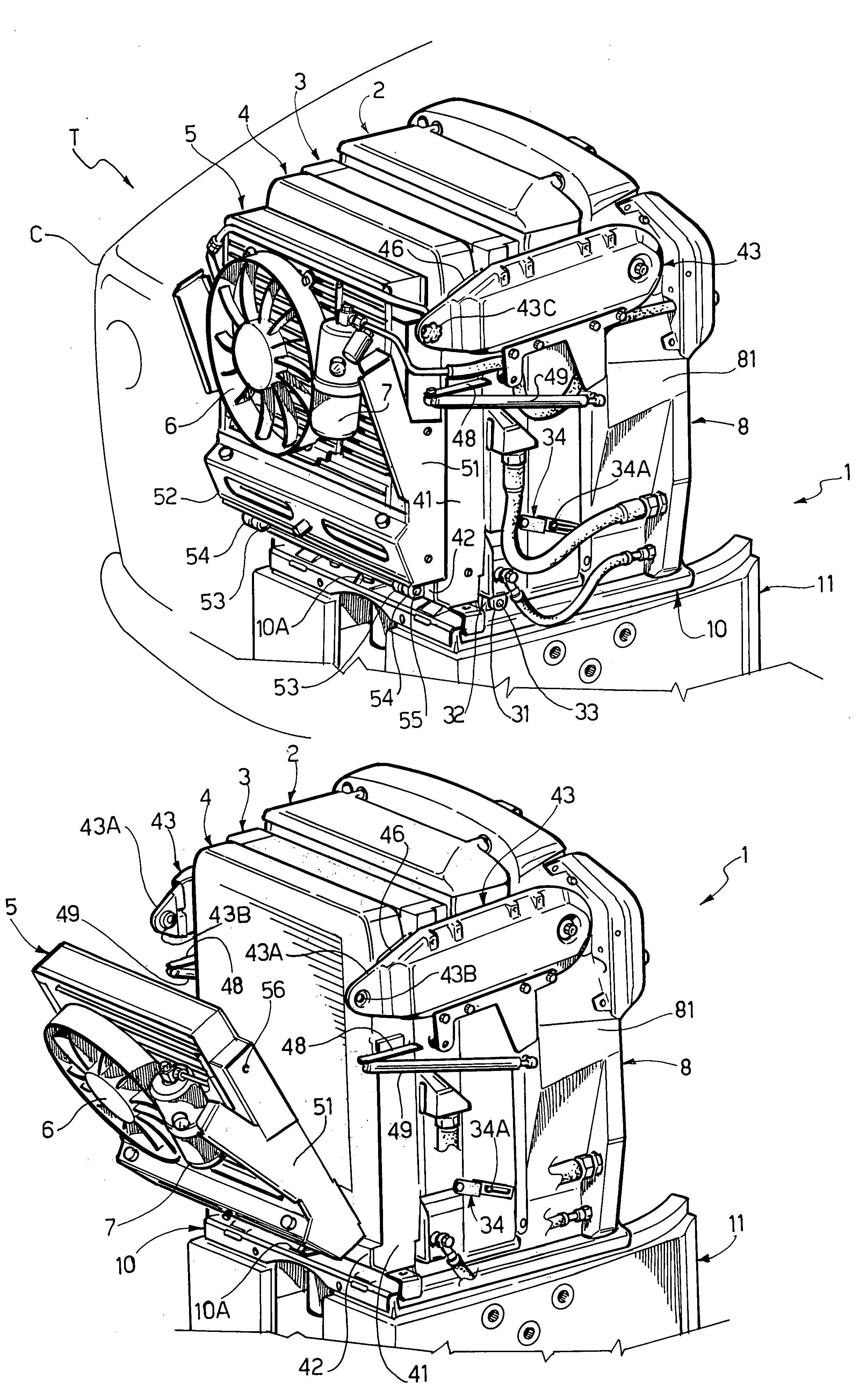

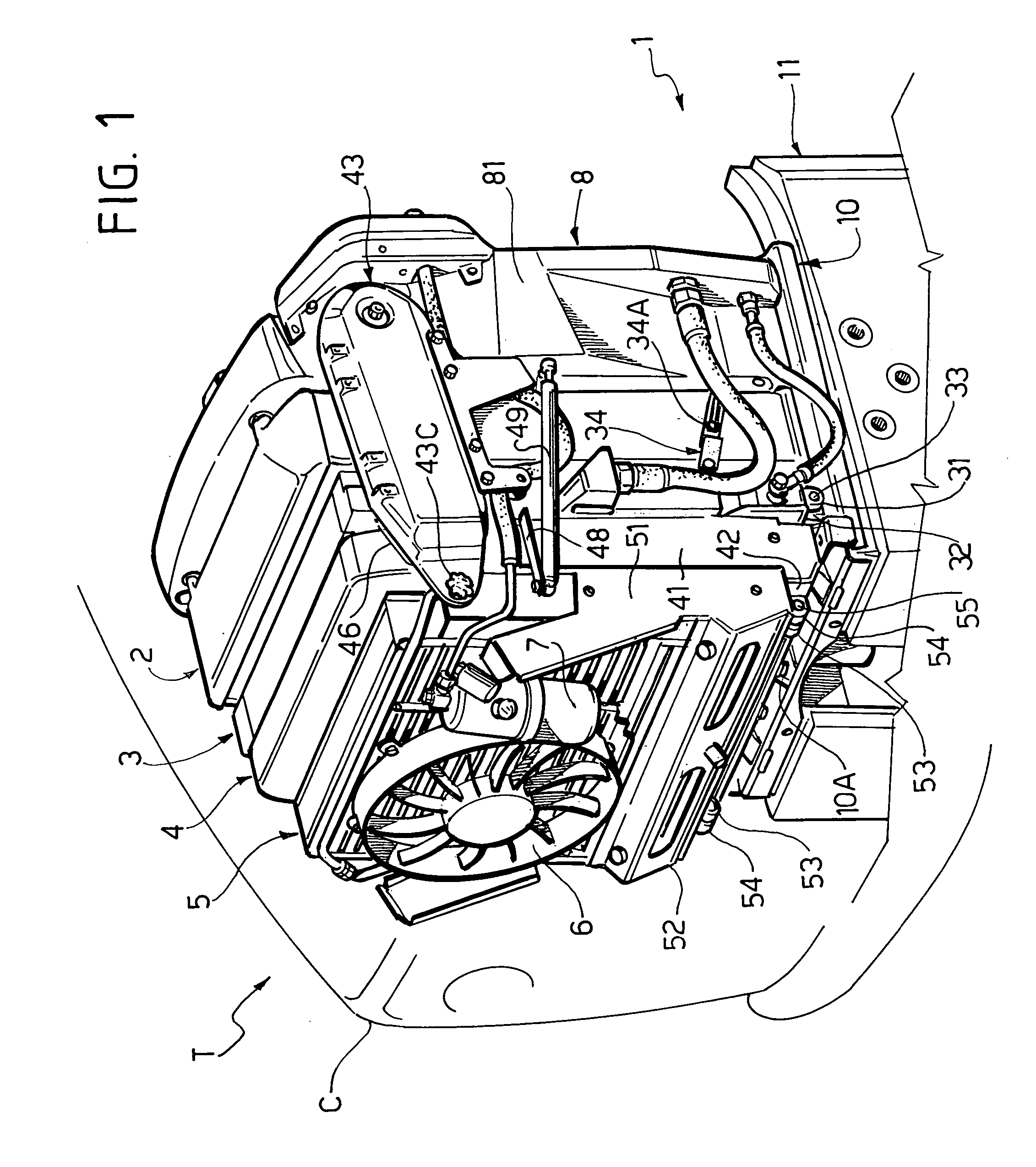

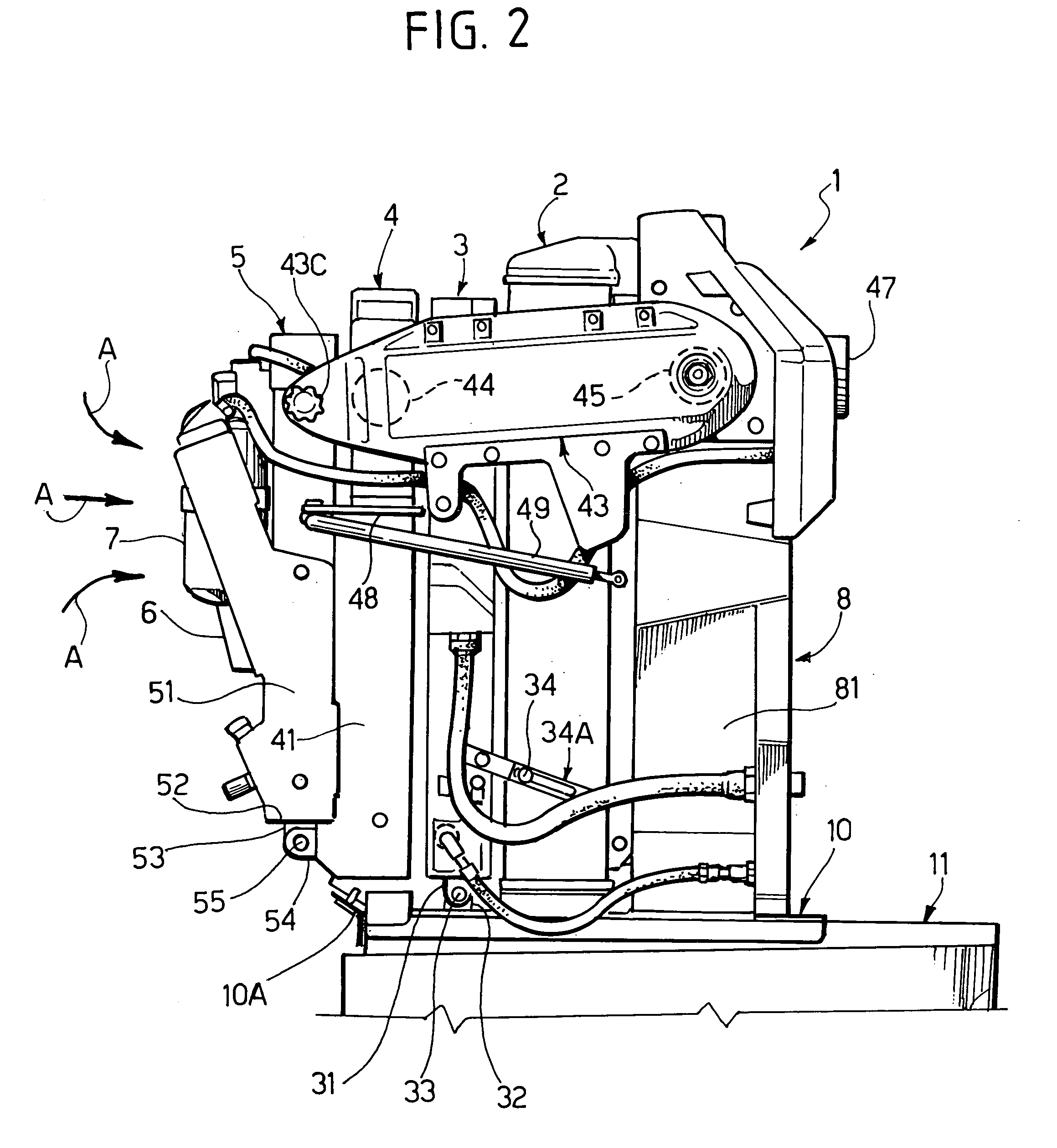

[0016]With reference to FIG. 1, T indicates the front portion of a farm tractor, comprising a bonnet C housing the internal combustion engine of the tractor, not shown. The present invention relates specifically to a farm tractor, but obviously it may also be applied to other types of farm machines, such as for instance combine-harvesters and the like.

[0017]The hood C is provided with grille-like openings, not shown, for inlet and outlet of a cooling air flow. A heat exchange assembly, globally referred to with number 1, is housed in the front portion of the bonnet C. The heat exchange assembly 1 comprises an engine radiator 2, a gearshift oil radiator 3, a radiator 4 of an intercooler system, and a radiator 5 belonging to an air conditioning unit of the tractor cabin; the radiator 5 is associated in quite a conventional way with a respective fan 6 and a de-hydrating filter 7. As can be seen in particular in FIG. 2, the various radiators 2–5 of the assembly 1, globally prism-shaped,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com