Corn wheat combine

A technology that combines working machines and wheat, applied in the field of agricultural machinery, can solve the threats to sustainable development such as the effective utilization of renewable resources, affect traffic safety, people's lives and health, increase the number of tractors entering the ground, etc., to improve the quality of work. , Solve the effect of effective return to the field, saving seeds and fertilizers and increasing the yield by a large margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

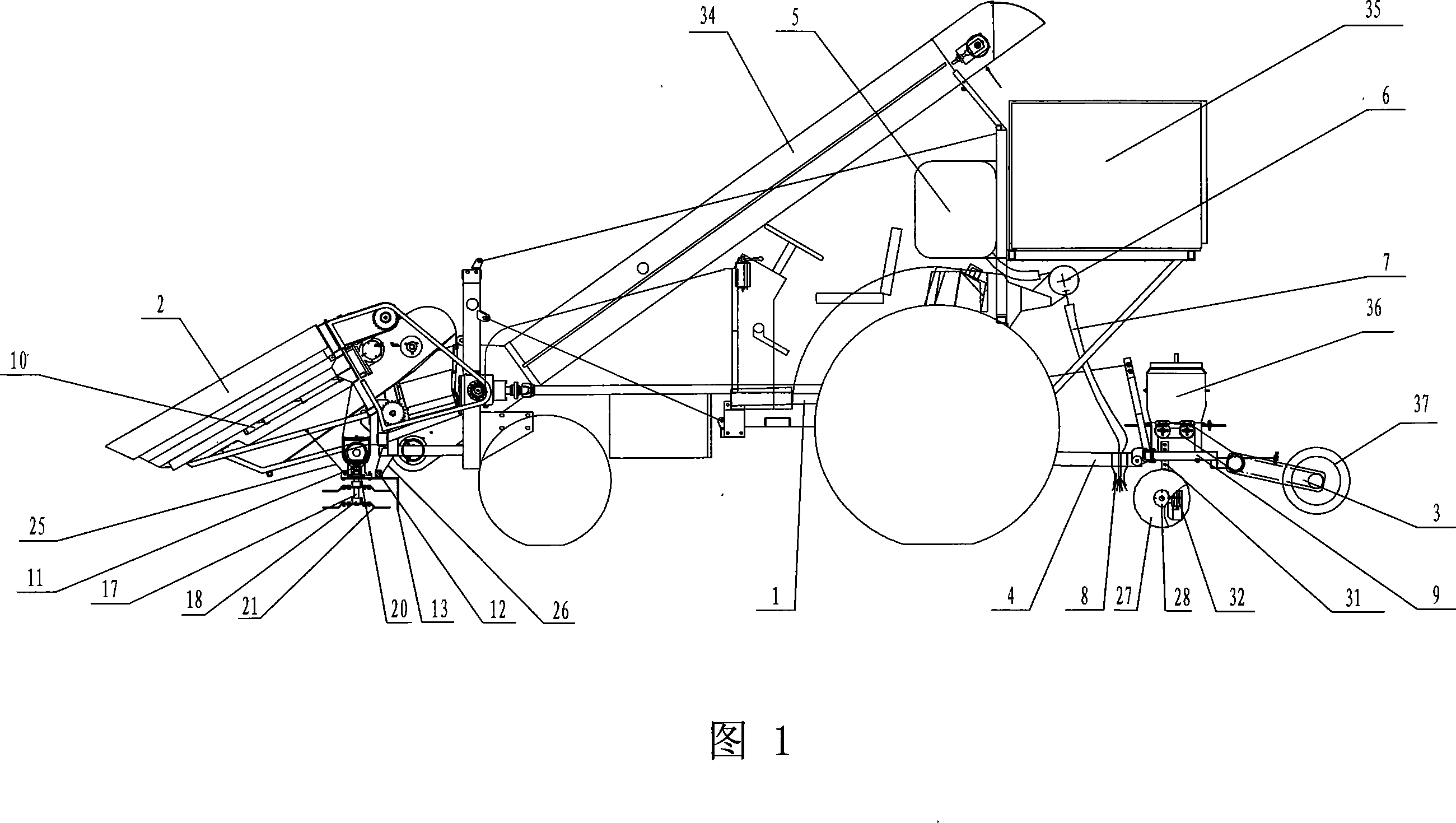

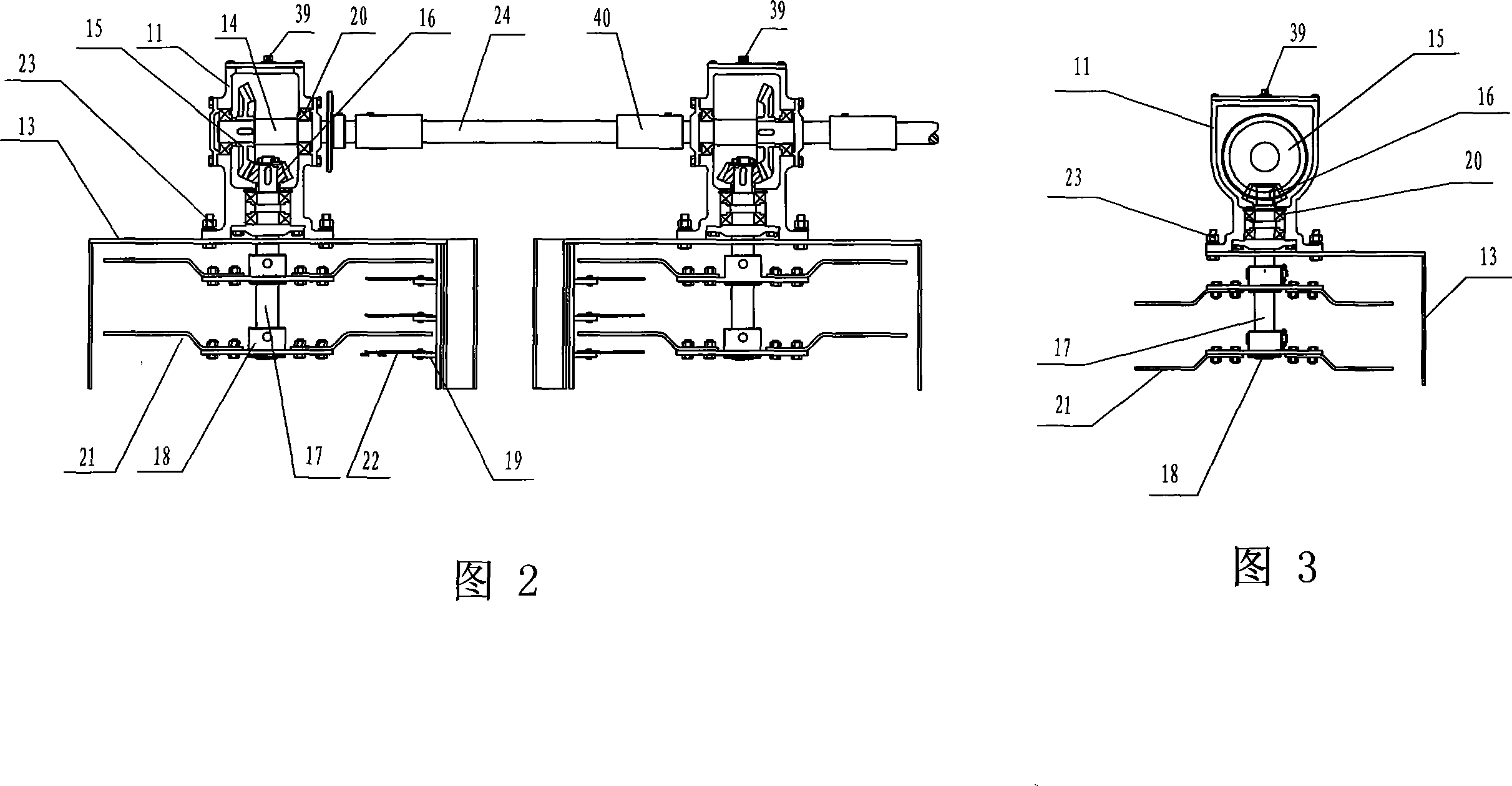

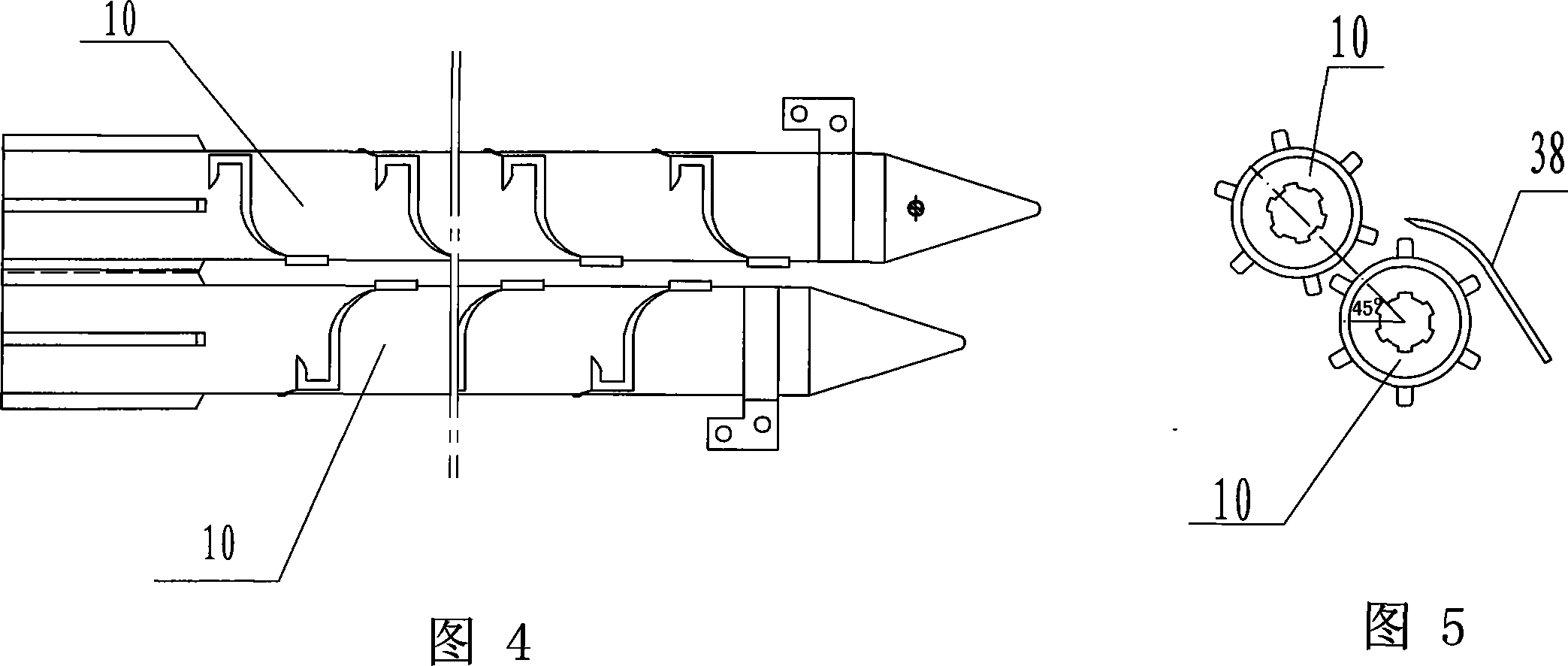

[0024] In the embodiment shown in Figures 1 to 3, the present invention includes four parts: a corn ear harvesting device 2, a straw crushing and returning device, a wheat no-tillage planting device 3 and a chemical spraying device. Among them, the straw crushing and returning device adopts a combined straw crushing and returning device, which is composed of several monomers, each of which includes a gearbox 11, a hood welded body 13 with a hook 12, a transmission shaft 14, and a drive shaft. Bevel gear 15, passive bevel gear 16, 2 cutter heads 18 fixed on the cutter shaft 17 in a horizontal set, 3 fixed cutter seats 19, two pairs of tapered roller bearings 20, 8 moving knives 21 and 3 fixed knives 22 , the transmission shaft 14 is installed in the gearbox 11 through a pair of tapered roller bearings 20, the driving bevel gear 15 is installed on the transmission shaft 14, and the cutter shaft 17 is installed in the lower part of the gearbox 11 through another pair of tapered ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com