Patents

Literature

33results about How to "Reduce the number of entry times" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

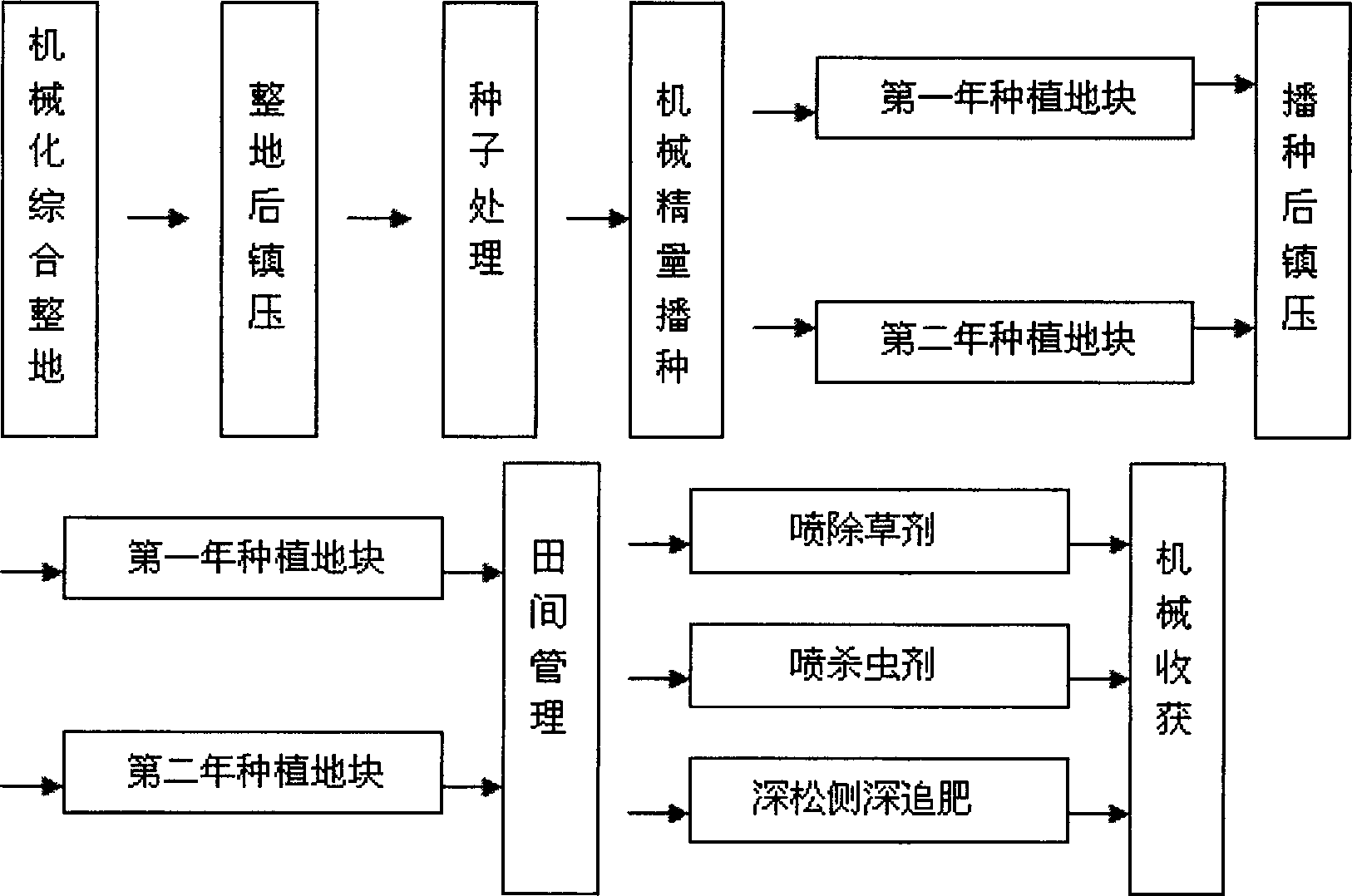

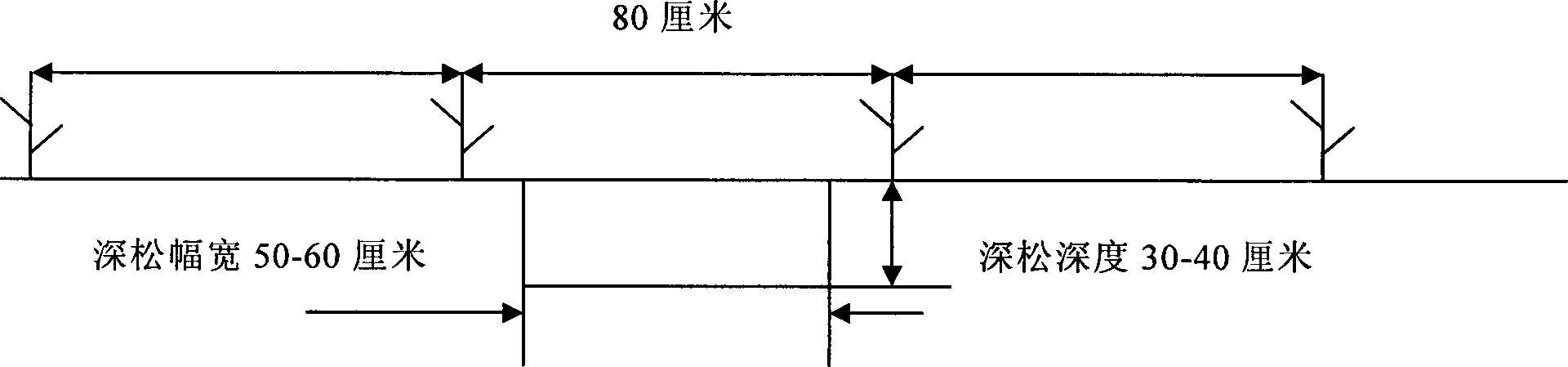

Wide-row flat planting protective tillage planting method for maizes

InactiveCN102396333AReduce runoffReduce churnSeed and root treatmentAgriculture gas emission reductionEvaporationScarification

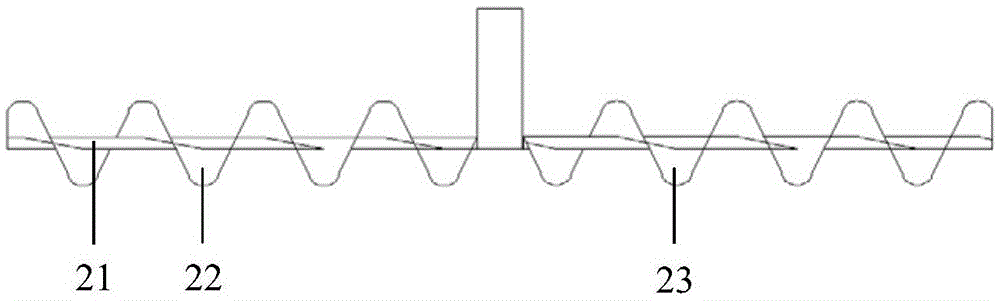

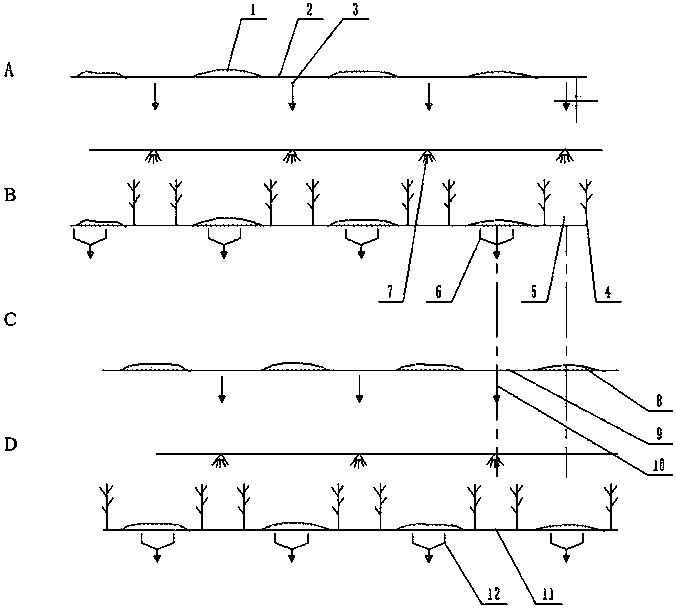

The invention relates to a planting method for crops, in particular to a wide-row flat planting protective tillage planting method for maizes. The planting method comprises the following seven steps of: performing land preparation, sowing, rolling after sowing, weeding by pesticides, subsoiling mechanically and performing side deep fertilizing, preventing and controlling diseases and insect pestsand harvesting mechanically. In the planting method, the conventional 60-centimeter uniform ridge planting mode is changed into a flat planting mode of 80-centimeter row pitch and 20-centimeter row spacing, and ventilating and light-transmitting space of the crops is increased; the conventional shallow intertillage and shallow fertilization mode is changed into a mechanical deep scarification anddeep topdressing mode, namely the conventional three-shovel three-time intertillage management and shallow fertilization operation is changed into one-time deep scarification and deep topdressing operation, so operation links are reduced, and the production cost is reduced; the conventional sowing mode is changed into a zero-tillage sowing mode, so the evaporation of soil moisture is reduced, andthe capacity of drought resistance and soil moisture conservation is improved; the conventional mode that harvested low stubbles are crushed to return to a field into a mode that mechanically-harvested high stubbles are rotten naturally to return to the field; and before sowing, seeds are processed by using a plasma seed processing technology to improve the germination percentage of the seeds.

Owner:梨树县农机技术推广总站

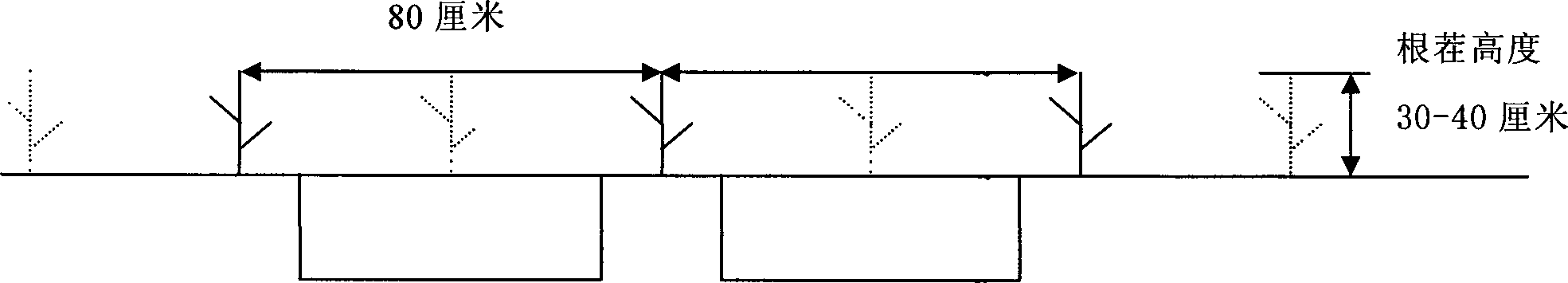

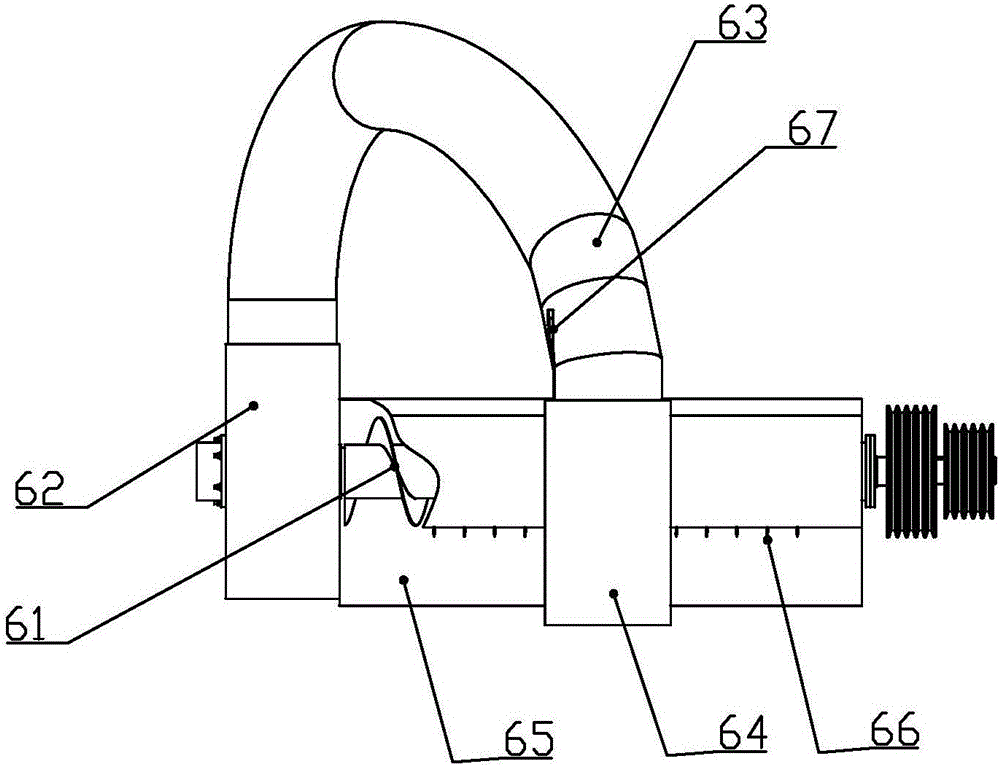

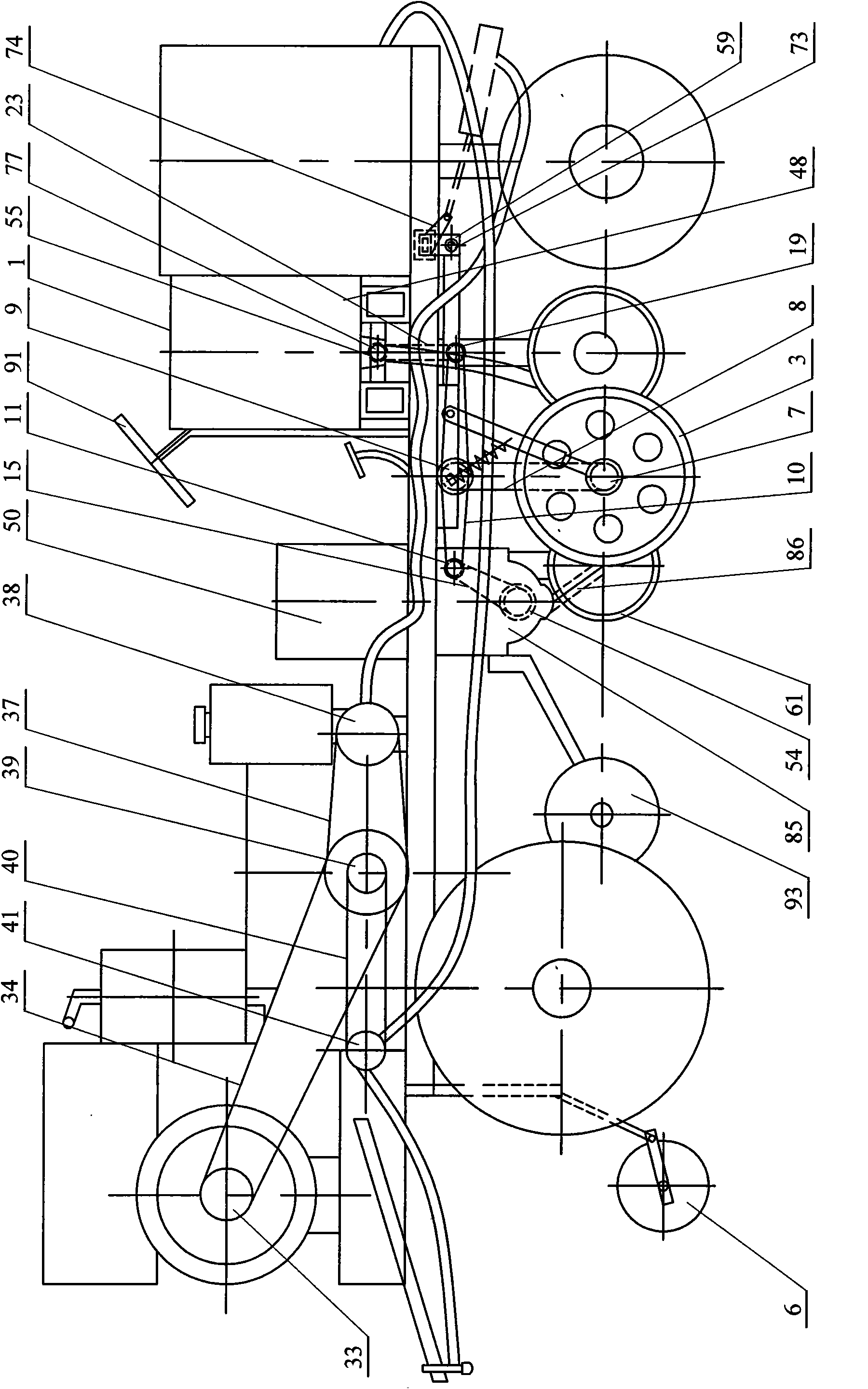

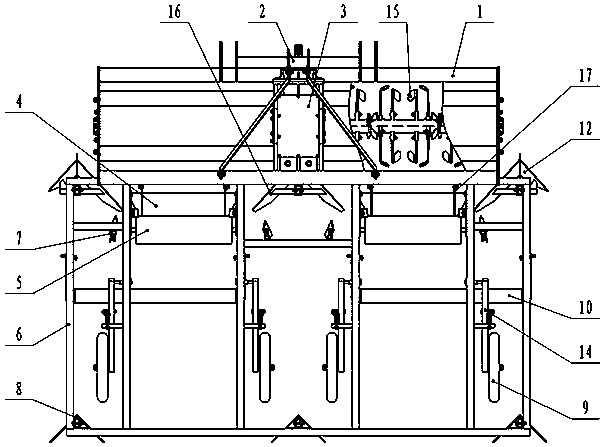

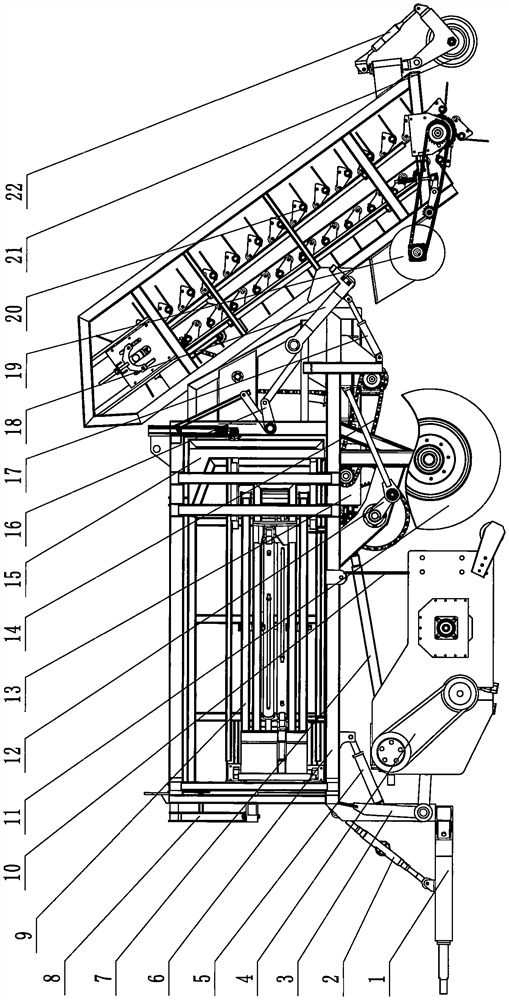

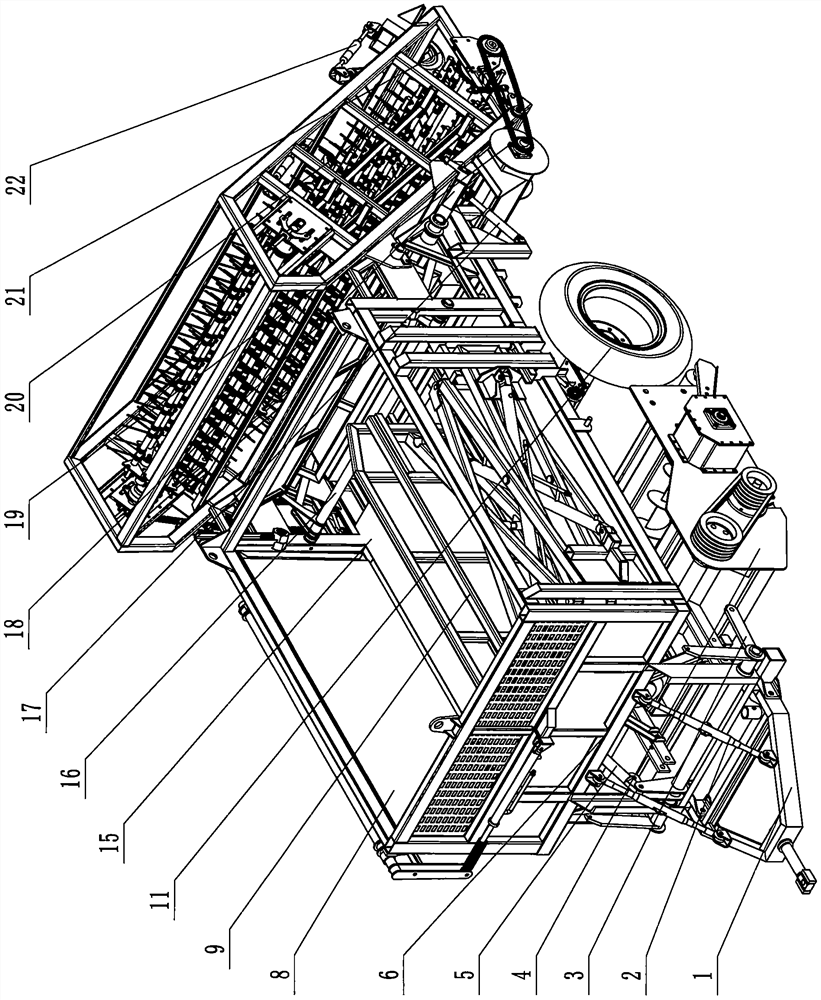

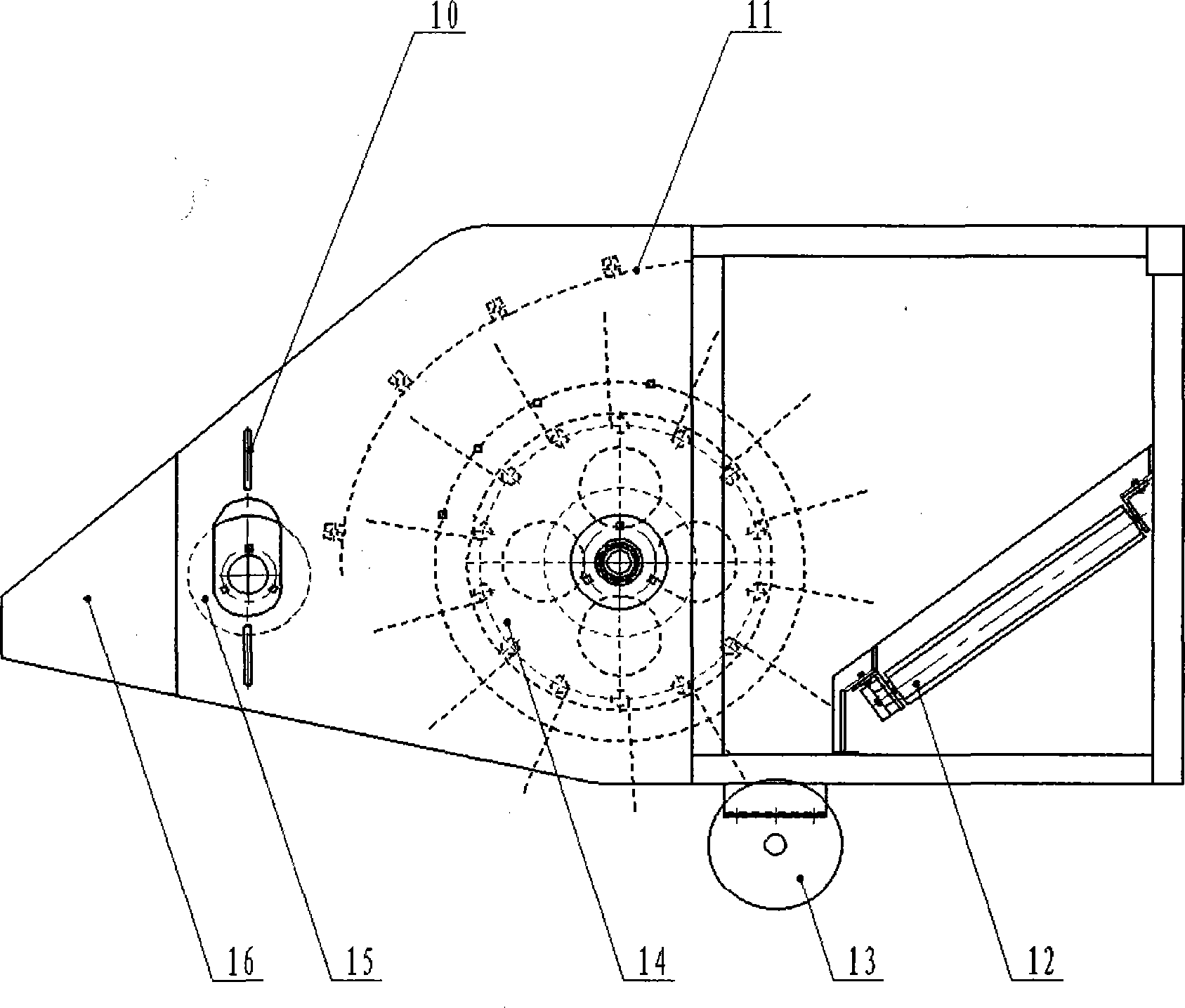

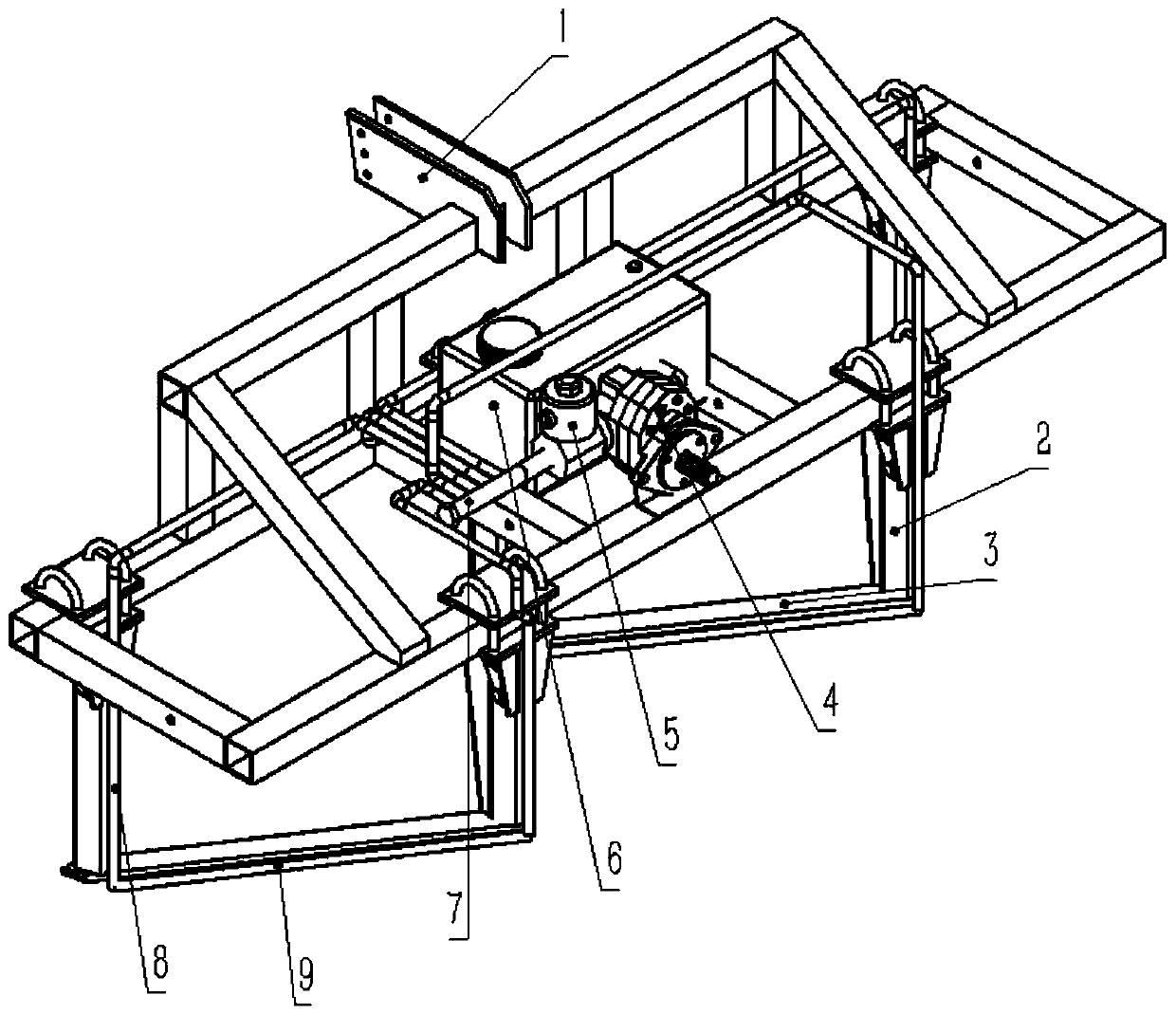

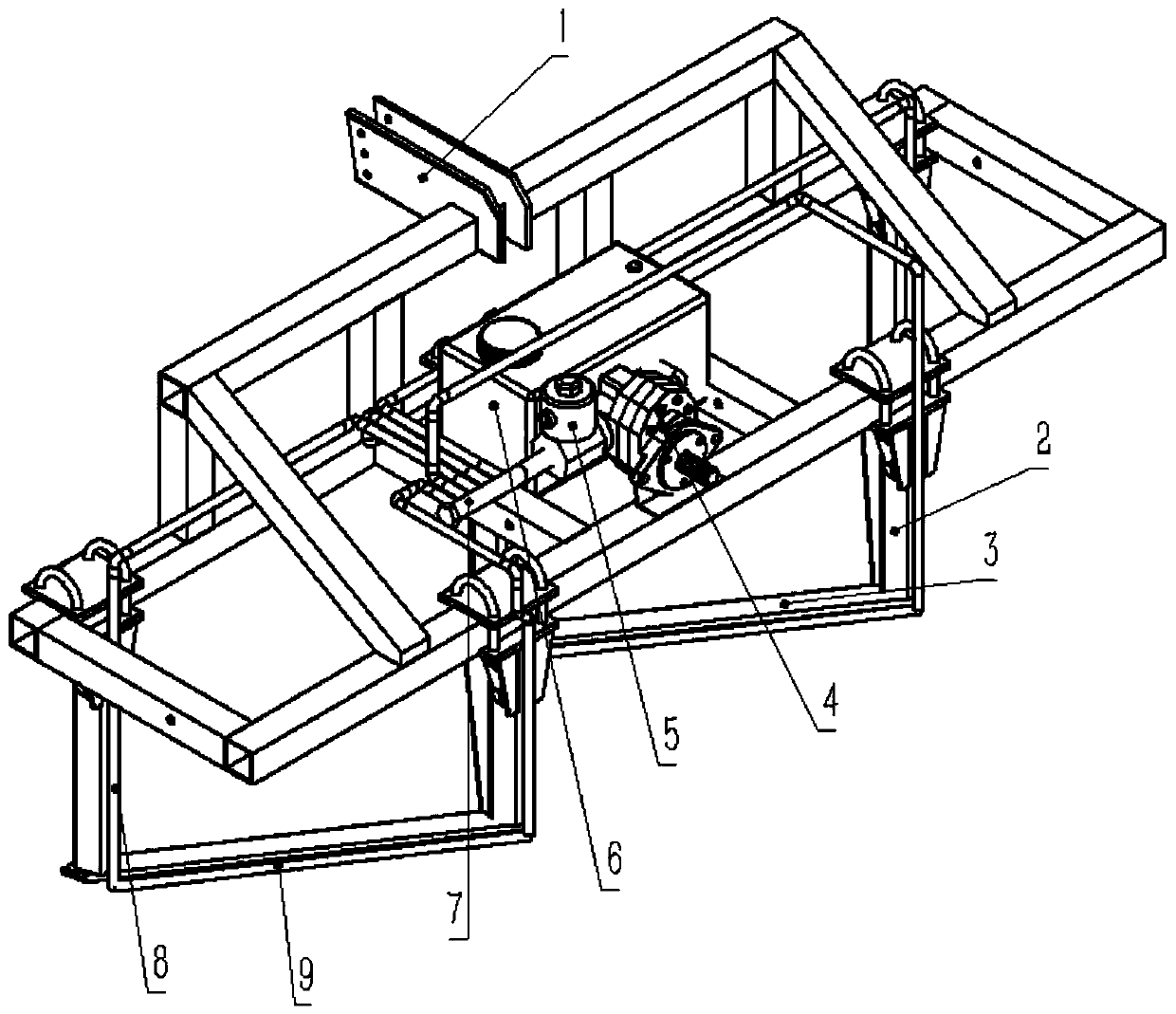

Pneumatic straw deep-burying returning machine

ActiveCN106717477AReduce energy consumptionGood effect of crushing soilMowersAgriculture gas emission reductionDevice formSoil porosity

The invention belongs to the field of agricultural tillage and land preparation machinery, relates to a pneumatic straw deep-burying returning machine and aims to functionally realize gas-phase and solid-phase material conveying under blowing pressure and pneumatically convey crushed straws with stubble cleaned to furrows made by furrowers to realize straw deep-burying returning. The pneumatic straw deep-burying returning machine integrally and structurally comprises a frame, a transmission system, a stubble cutting device, a picking and crushing device, a conveying assembly, a furrowing device, an earthing device, a compacting device and depth rollers and the like. A pneumatic conveying device which is a key part is arranged in rear of the picking and crushing device and comprises a screw, a fan, a conveying pipeline, a discharging pipeline and the like. A furrowing device is designed and mounted under the screw and the discharging pipeline, and the compacting device, the earthing device formed by left and right earthing shovels and the like are sequentially mounted in rear of the discharging pipeline. The problem of excessive straw incineration in autumn is effectively solved, and straw deep-burying returning, soil porosity improving, soil water permeability improving, waterlogging preventing, drought resisting and soil organic matter increasing are realized.

Owner:SHENYANG AGRI UNIV

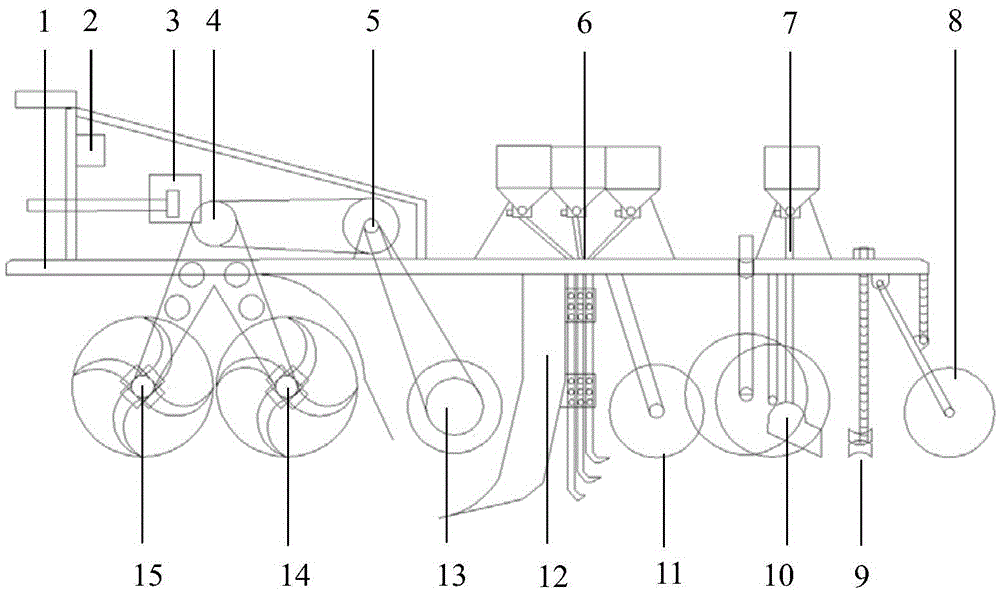

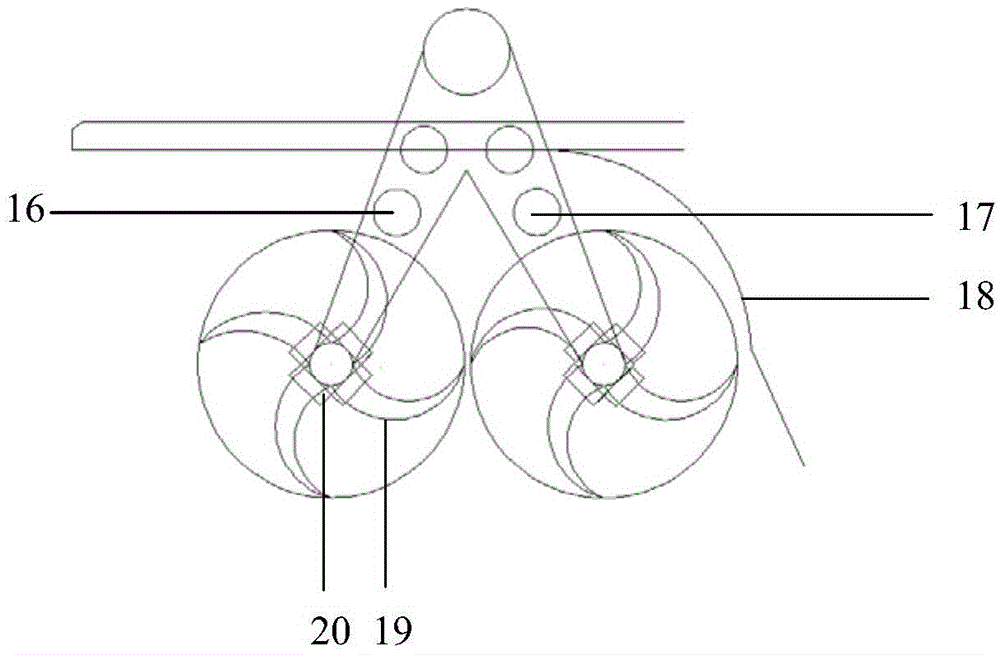

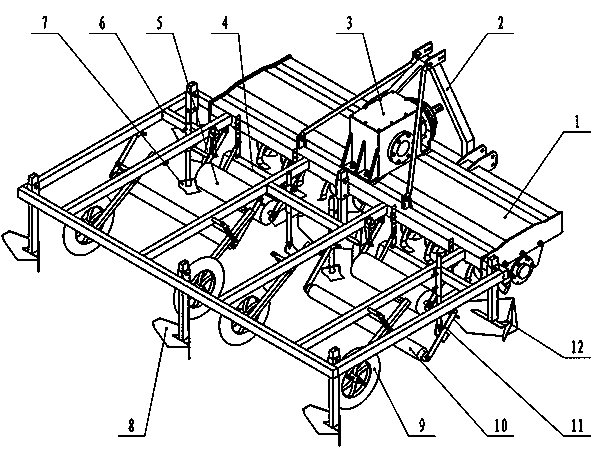

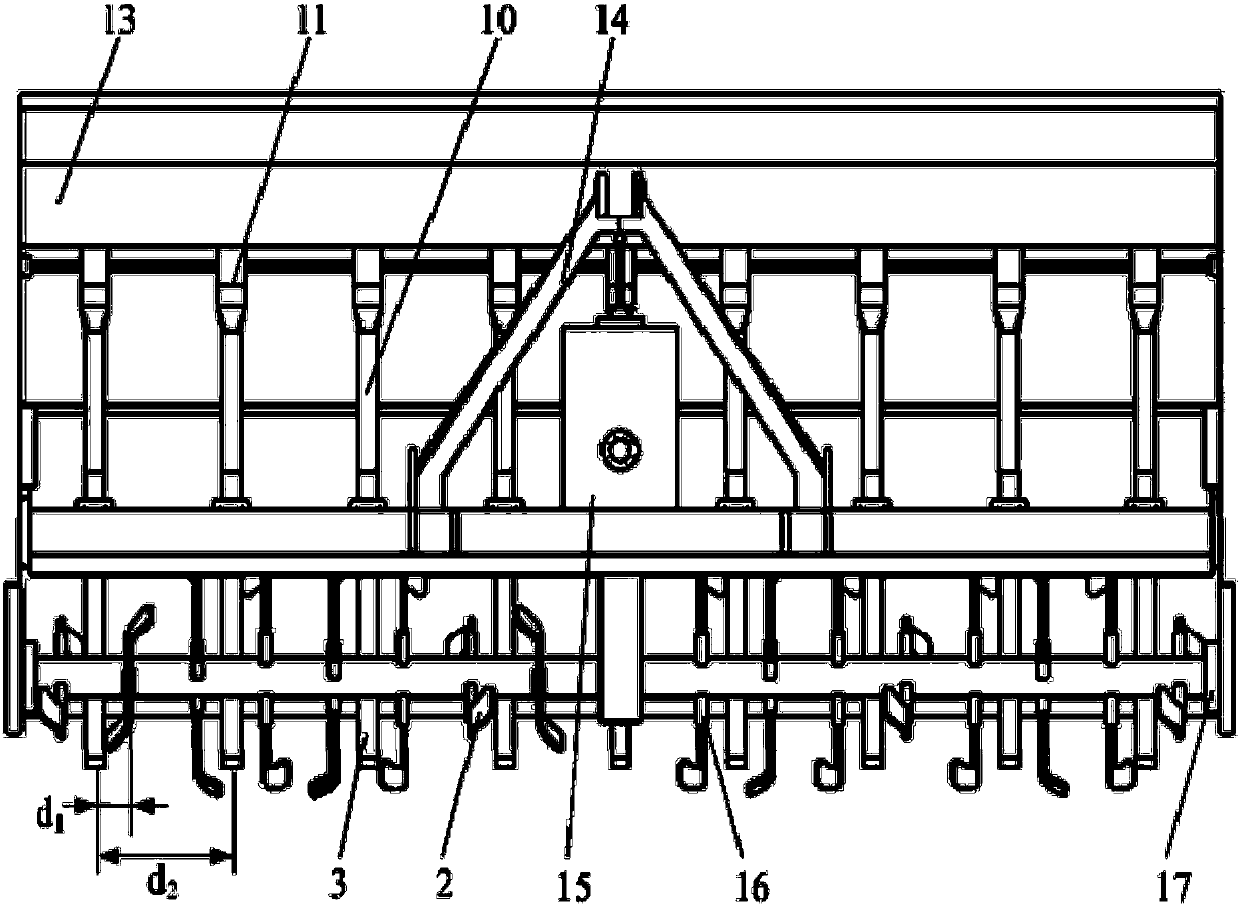

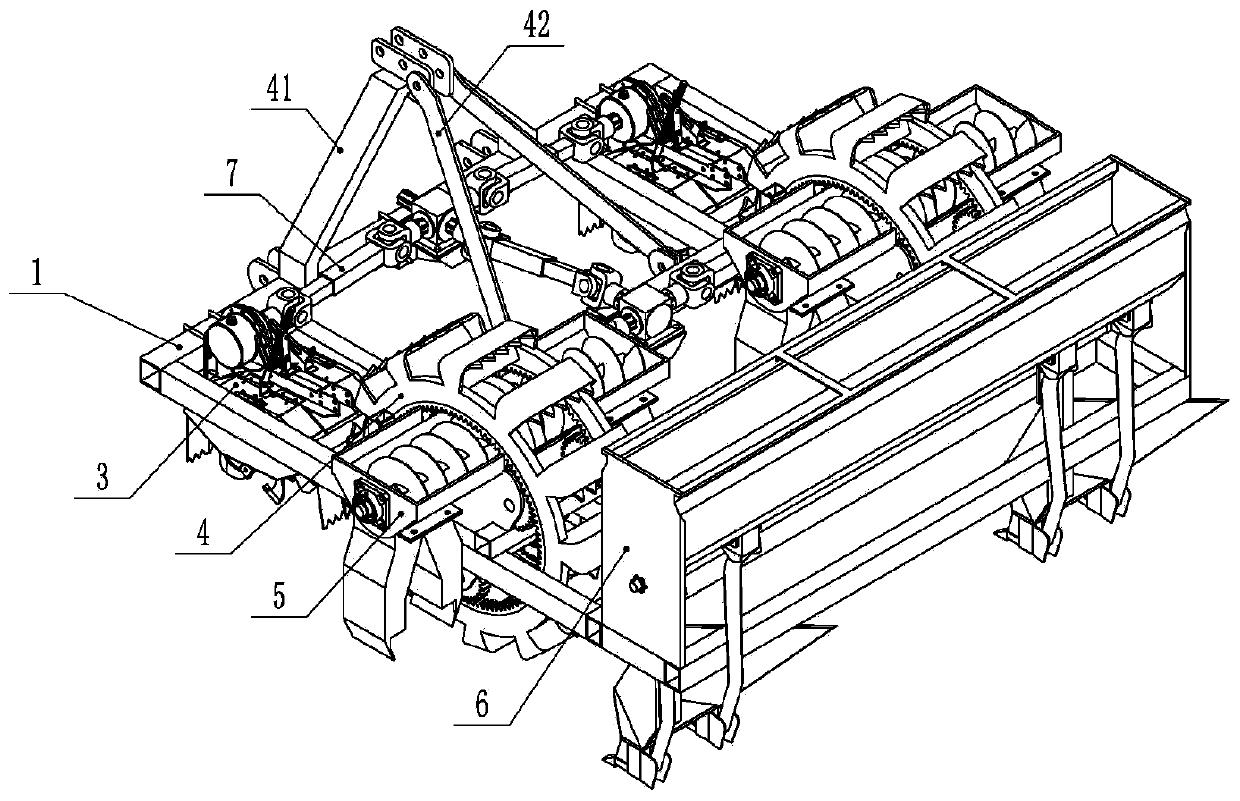

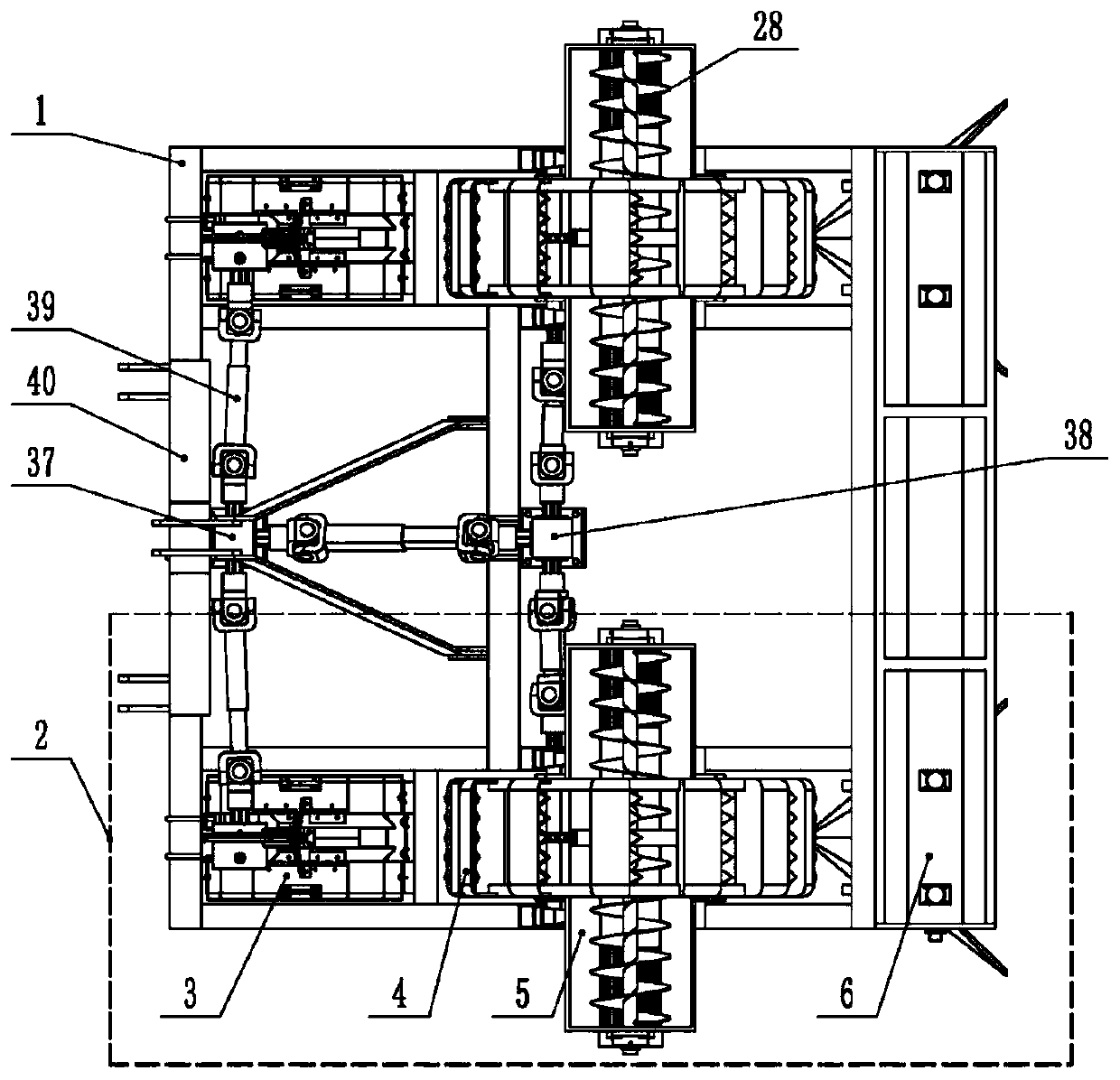

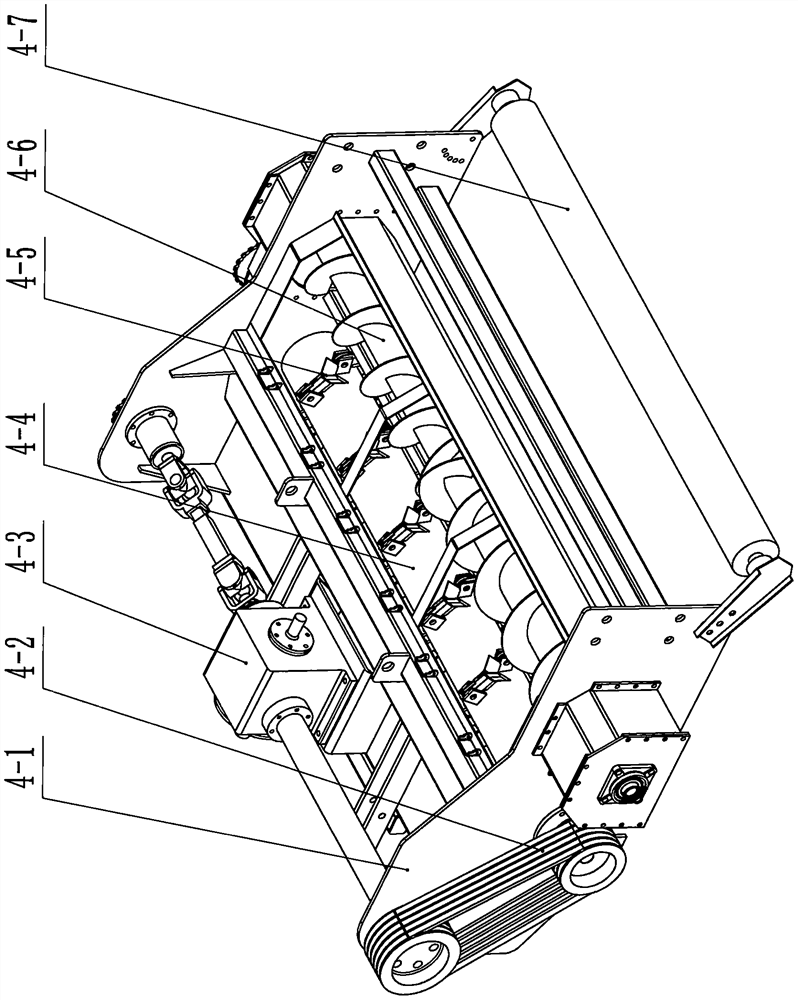

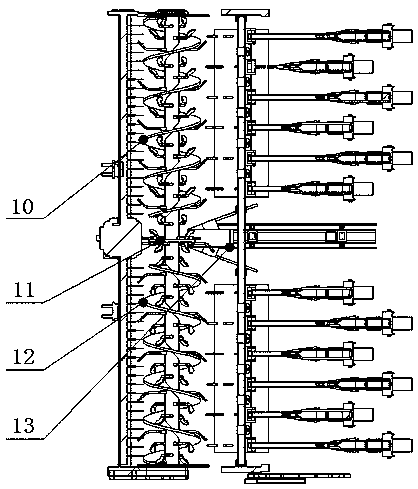

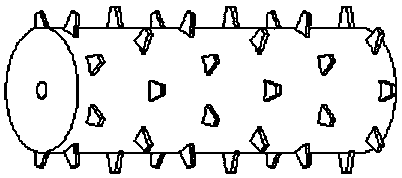

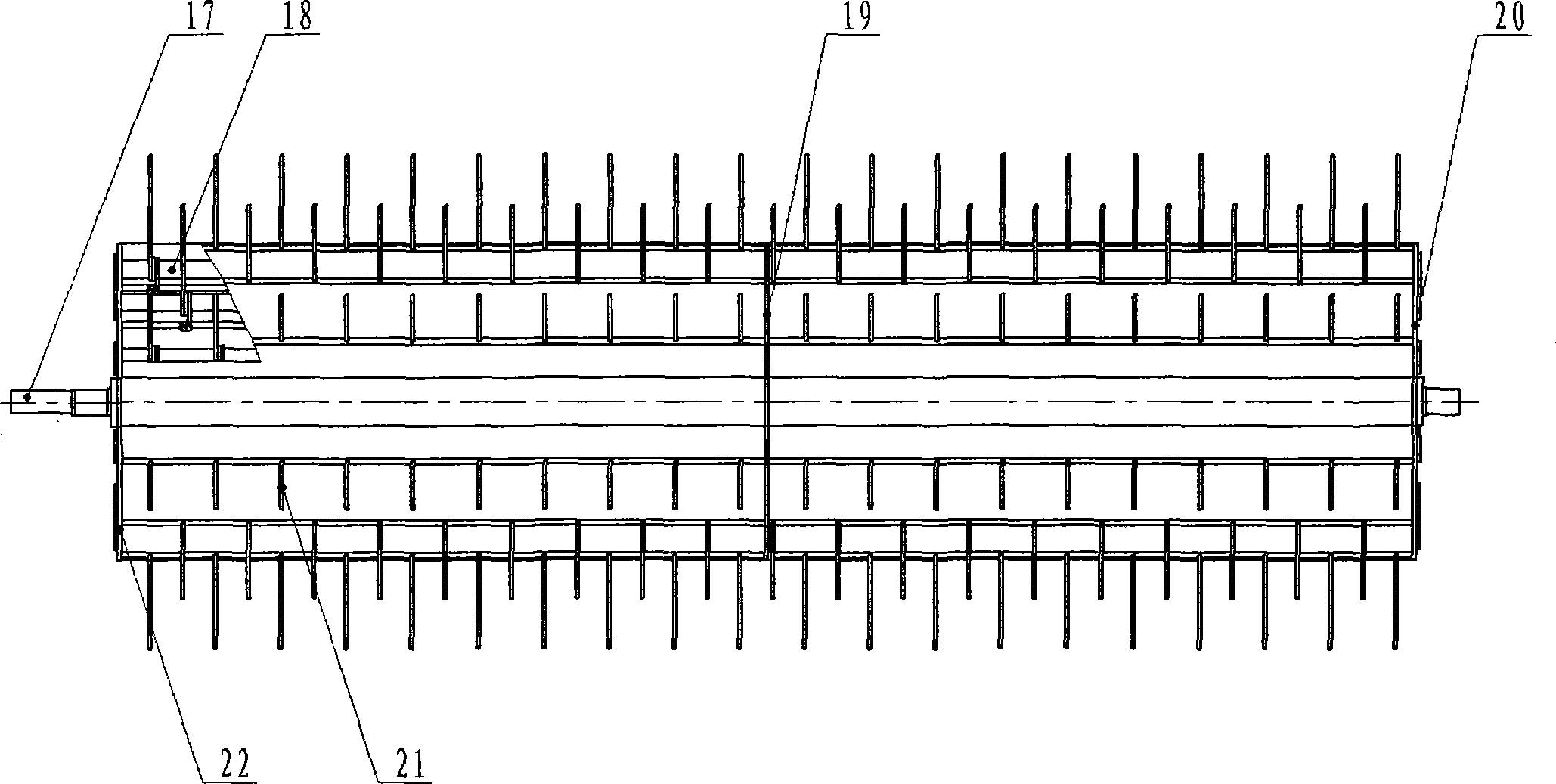

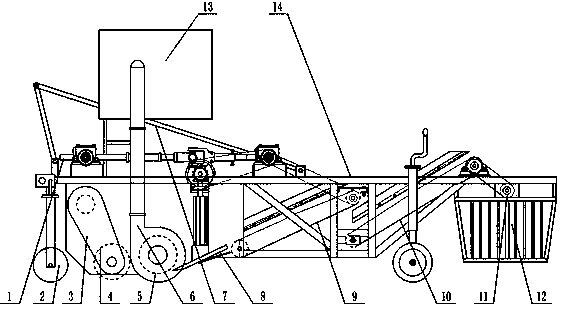

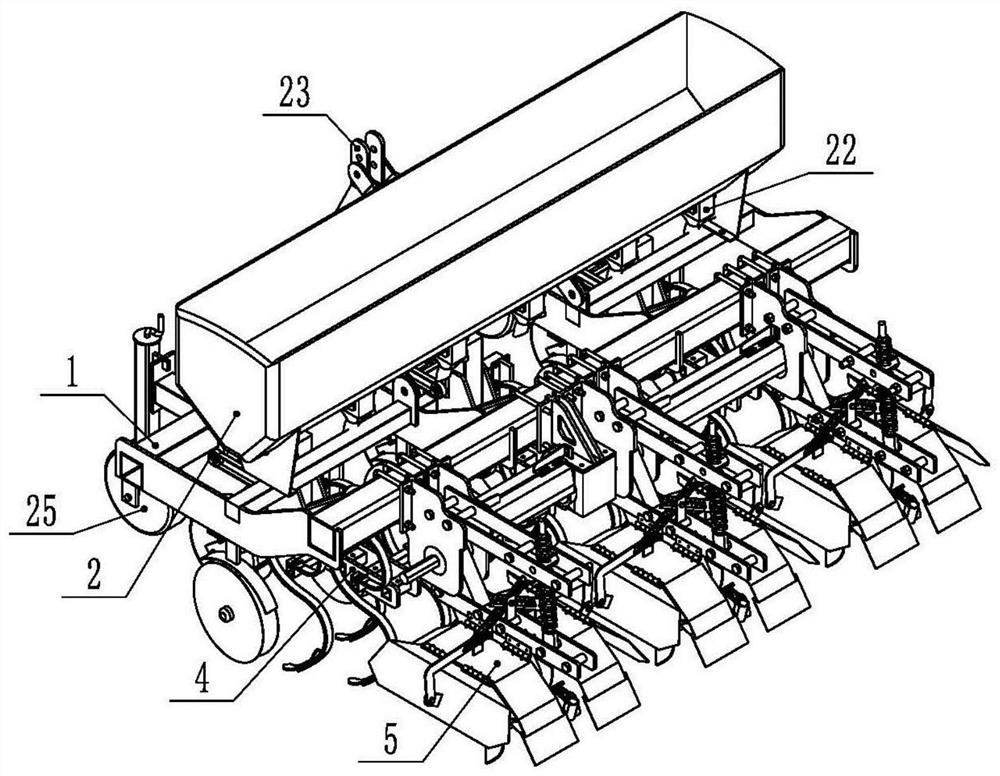

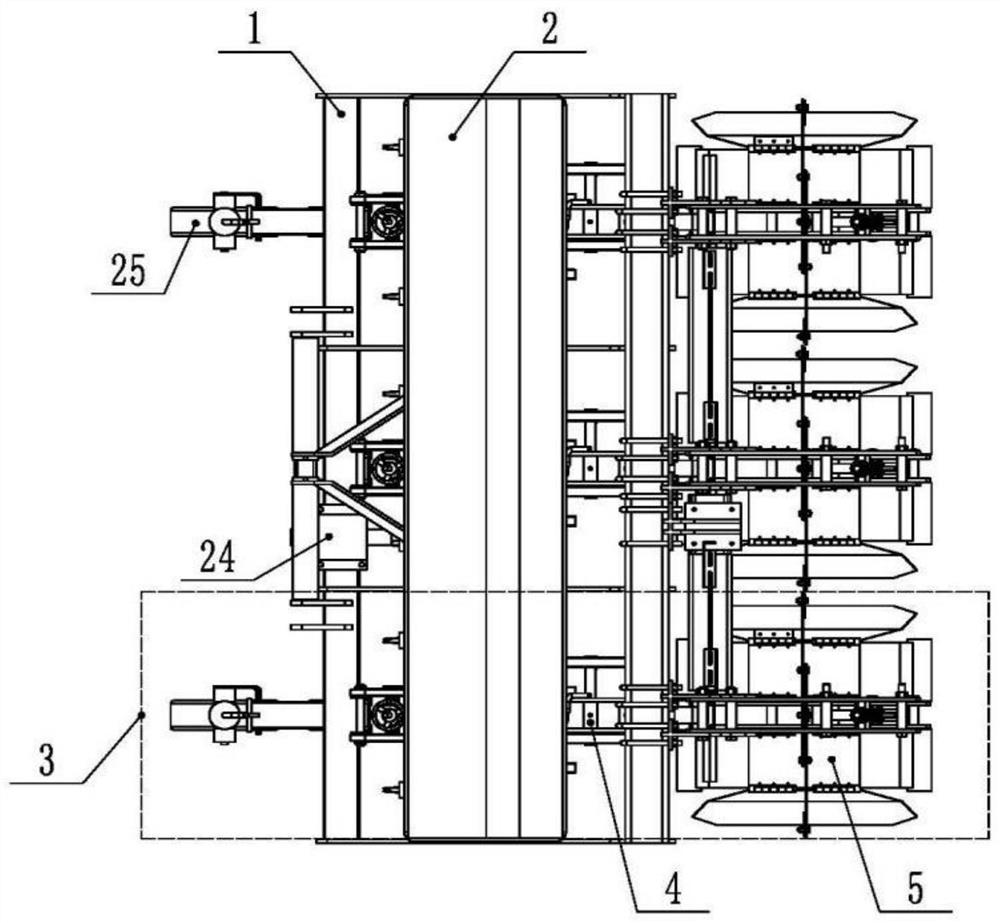

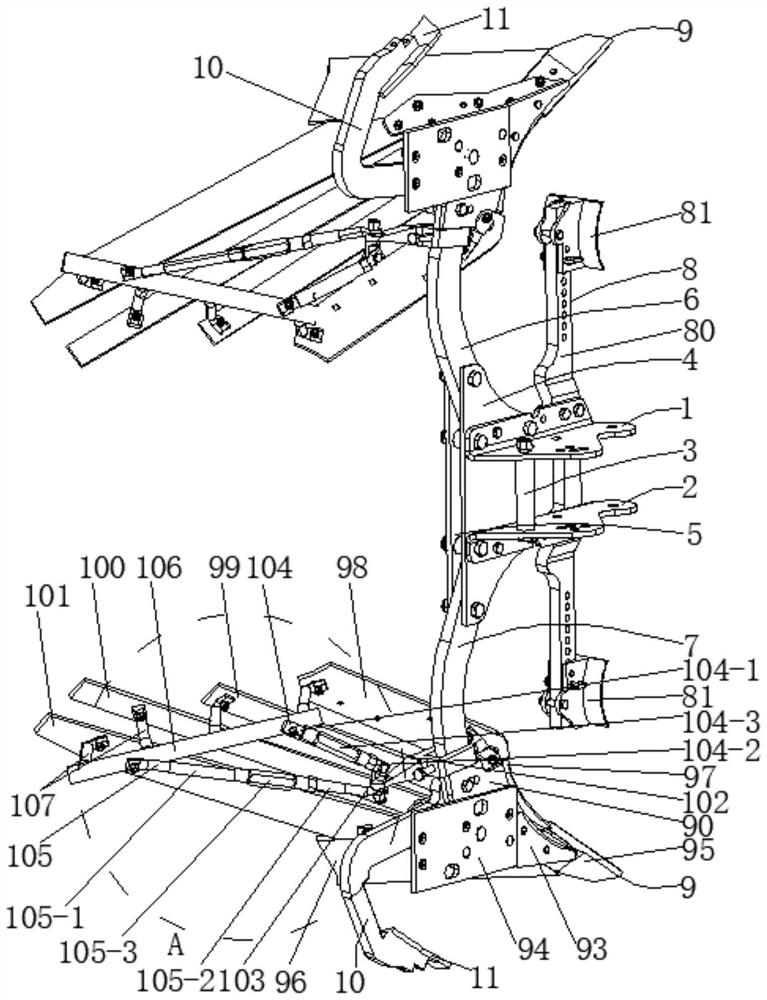

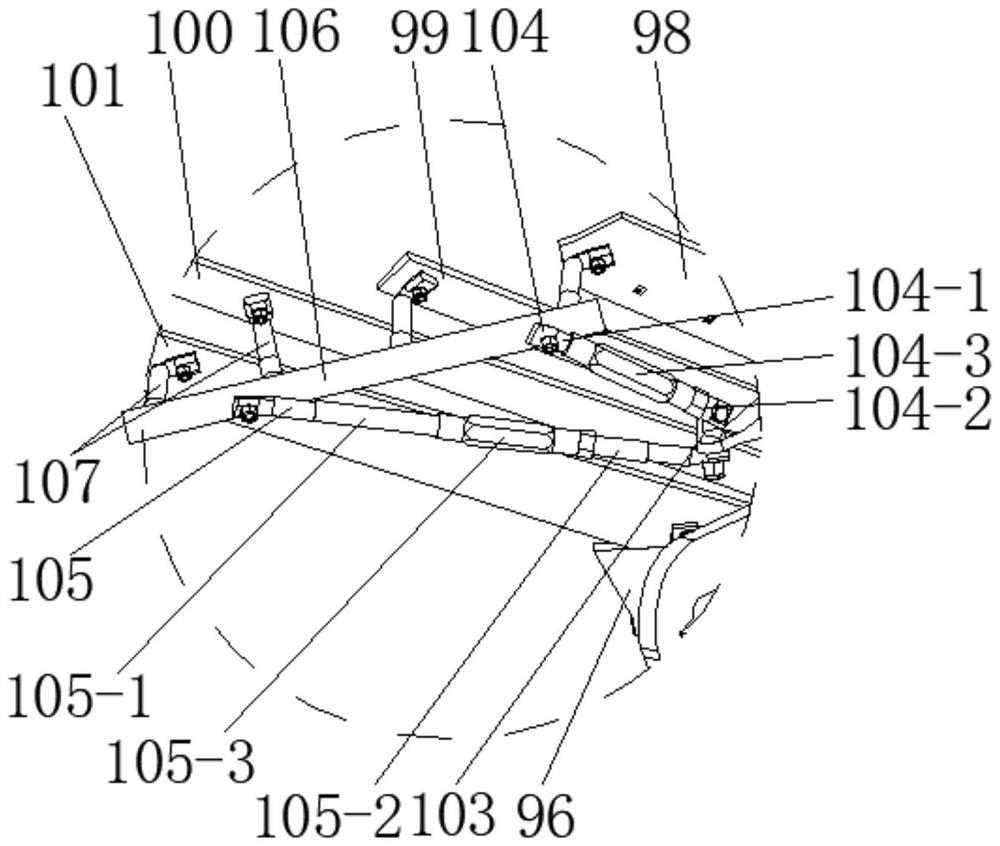

Broad-seedling-width precision sowing machine with functions of double rotary tillage and proportional layering fertilization

ActiveCN105557102AImprove blending uniformityImprove the quality of field returnSpadesSaving energy measuresAnti jammingTerra firma

The invention relates to a broad-seedling-width precision sowing machine with functions of double rotary tillage and proportional layering fertilization. The precision sowing machine comprises a suspended rack, a gearbox, a double-shaft rotary tillage device assembly, an anti-jamming spiral land leveler, a proportional layering fertilization device assembly, a rolling cage harrow, a broad-seedling-width strip sowing device assembly, a cylindrical heavy roller, and a proportional layering fertilization and precision sowing intelligent control system; and the precision sowing machine can sequentially finish operations in links of double rotary tillage for land preparation, spiral blade land leveling for jamming prevention, proportional layering fertilization, land leveling and rolling before sowing, broad-seedling-width precision sowing, rolling after sowing and the like in one time. According to the precision sowing machine, the broad-seedling-width sowing can be realized and a twice throwing and unique multilayer comb strip decentralizing and seed uniformizing structure is adopted, so that seeds can be uniformly distributed in a relatively broad seedling width (8-10cm) range and the space layout structure of seedlings is remarkably improved; and the relationship between a group and an individual is coordinated and a reasonable crop group is created, so that a solid foundation is laid for high yield.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Total collecting and covering no-tillage operation method for corn straw

InactiveCN111226709AAvoid pollutionIncrease organic matterCereal cultivationAgriculture gas emission reductionAgricultural engineeringInsect pest

The invention discloses a total collecting and covering no-tillage operation method for corn straw, and belongs to the field of agriculture. The total collecting and covering no-tillage operation method comprises the steps of step 1, selecting land blocks; step 2, treating straw; step 3, collecting straw in rows; step 4, performing deep scarification in autumn; step 5, performing no-tillage sowing; step 6, performing reduced application of herbicides; step7, performing deep scarification at the seedling stage; and step 8, managing diseases and insect pests, so as to form a crop rotation mode for alternative operations in two years for a straw mulching leisure zone and an agrarian zone. According to the total collecting and covering no-tillage operation method, the problem between total straw returning to fields and sowing can be effectively solved, the rate that the protective cultivation straw is returned to the fields is increased to 100%, the method has obvious operations for preservation of soil moisture for north in spring, the sowing effect and the rate of emergence are guaranteed, the yield increment effect is obvious, straw returning to fields can protect the black lands, and the method is a strong measure for constructing agricultural sustainable development.

Owner:CHANGCHUN AGRI MACHINERY

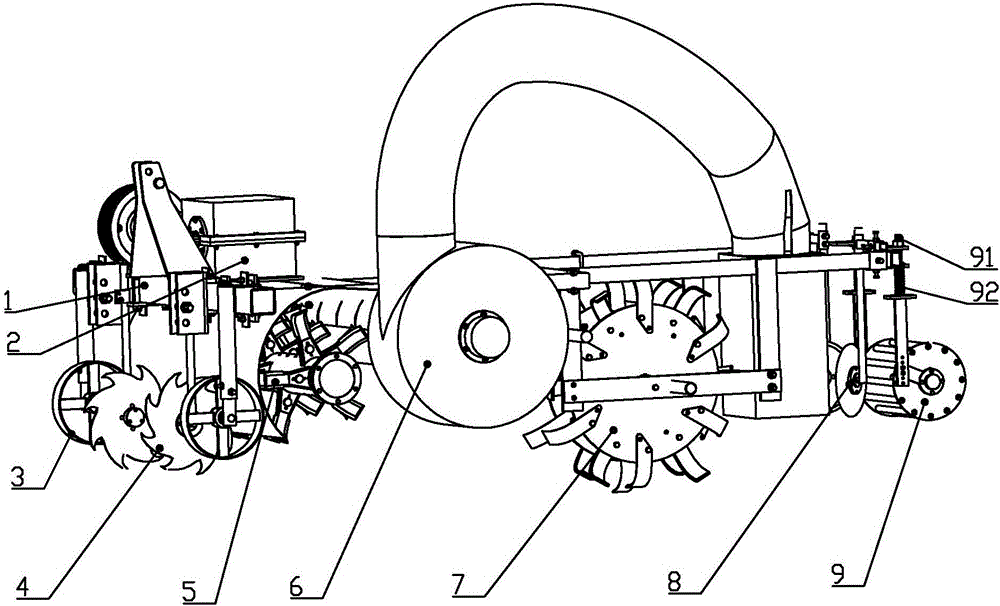

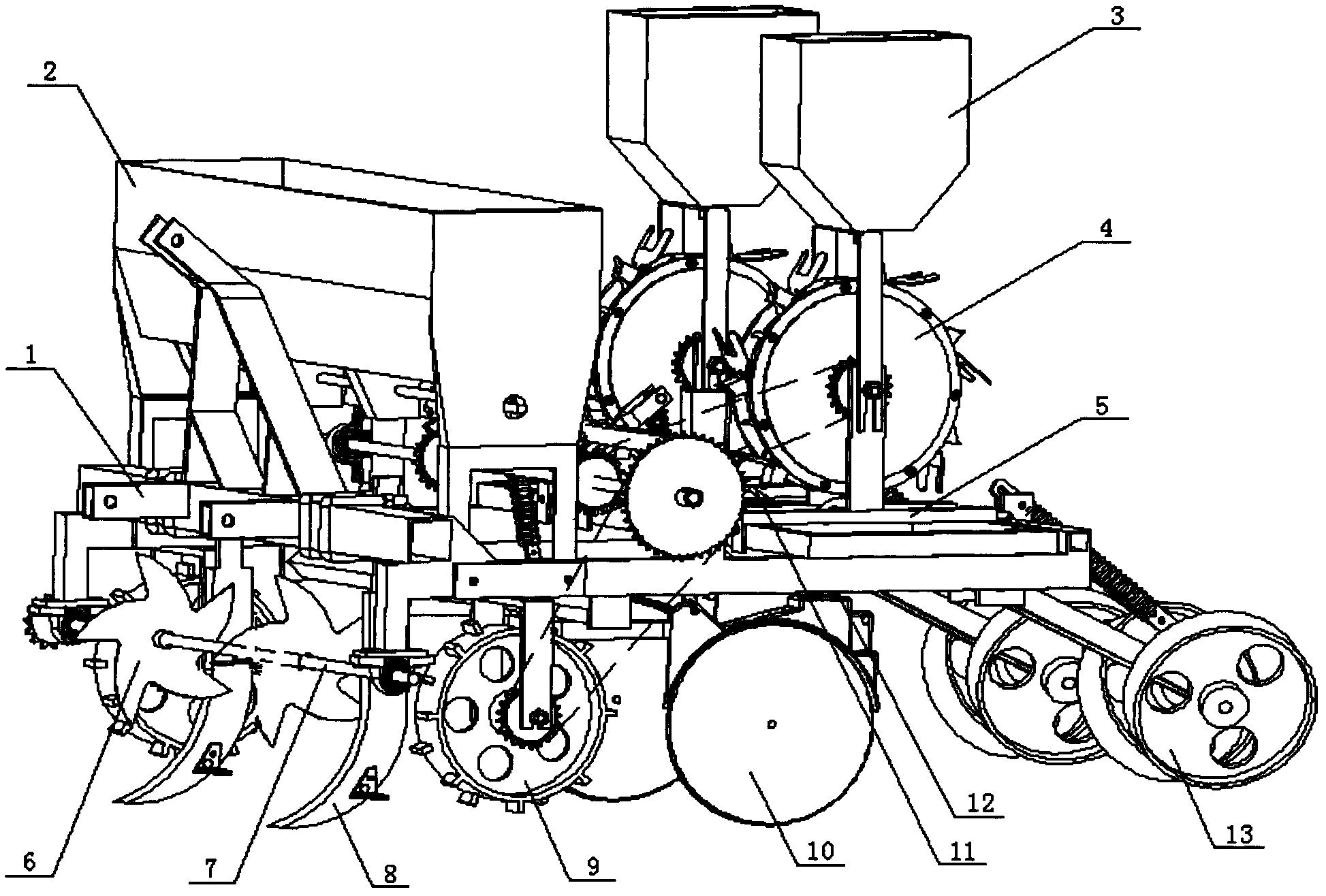

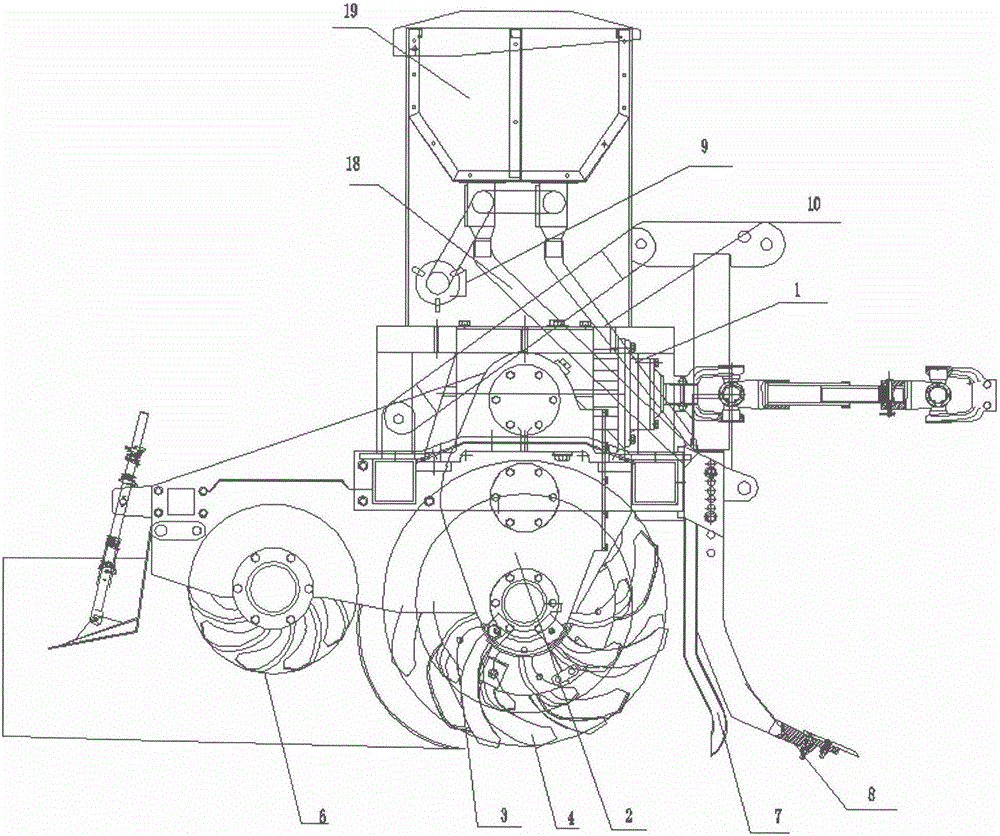

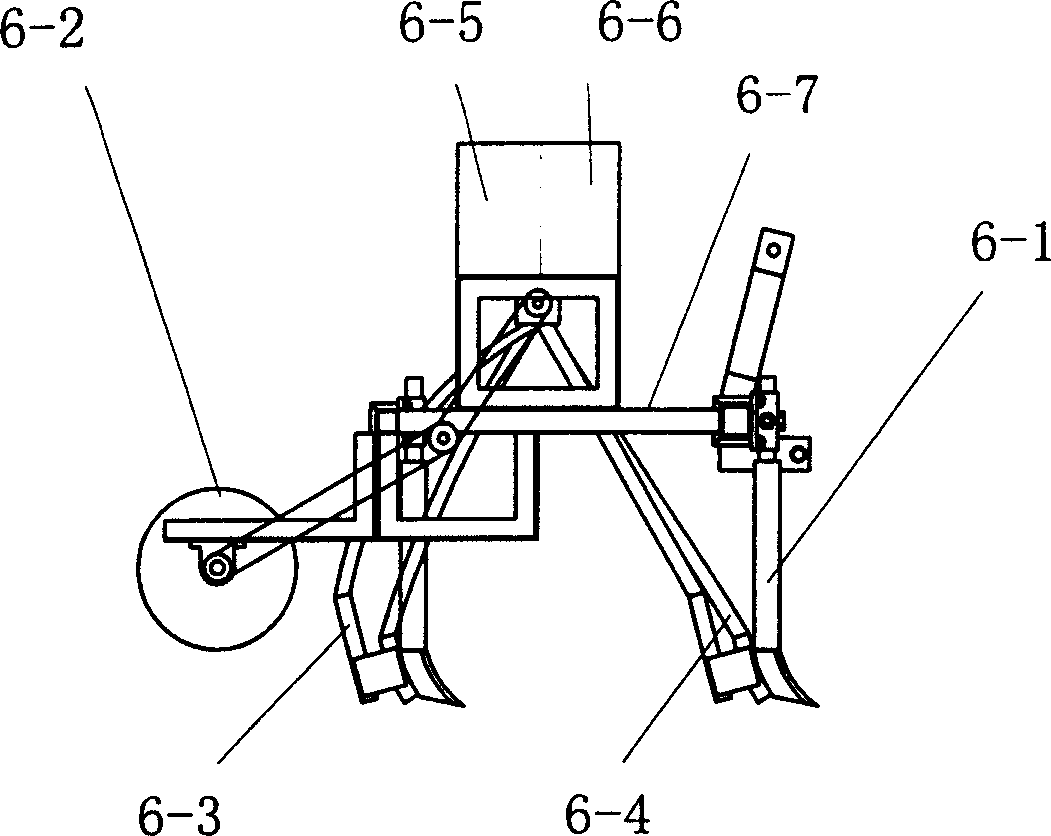

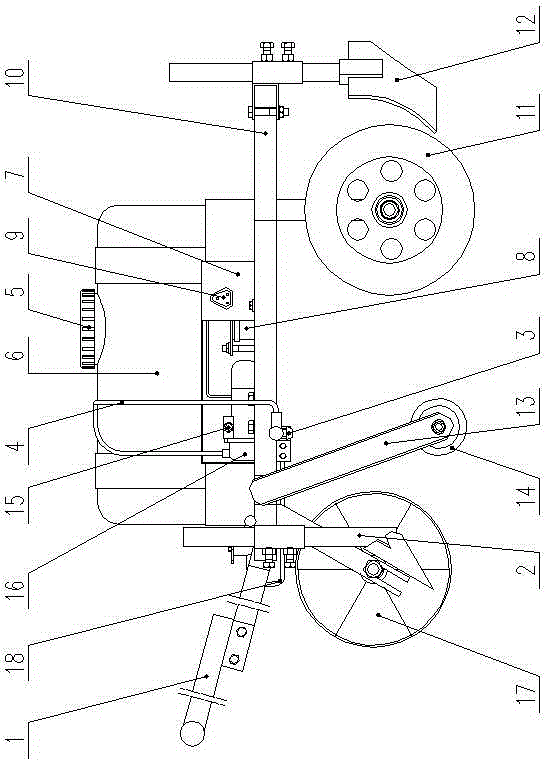

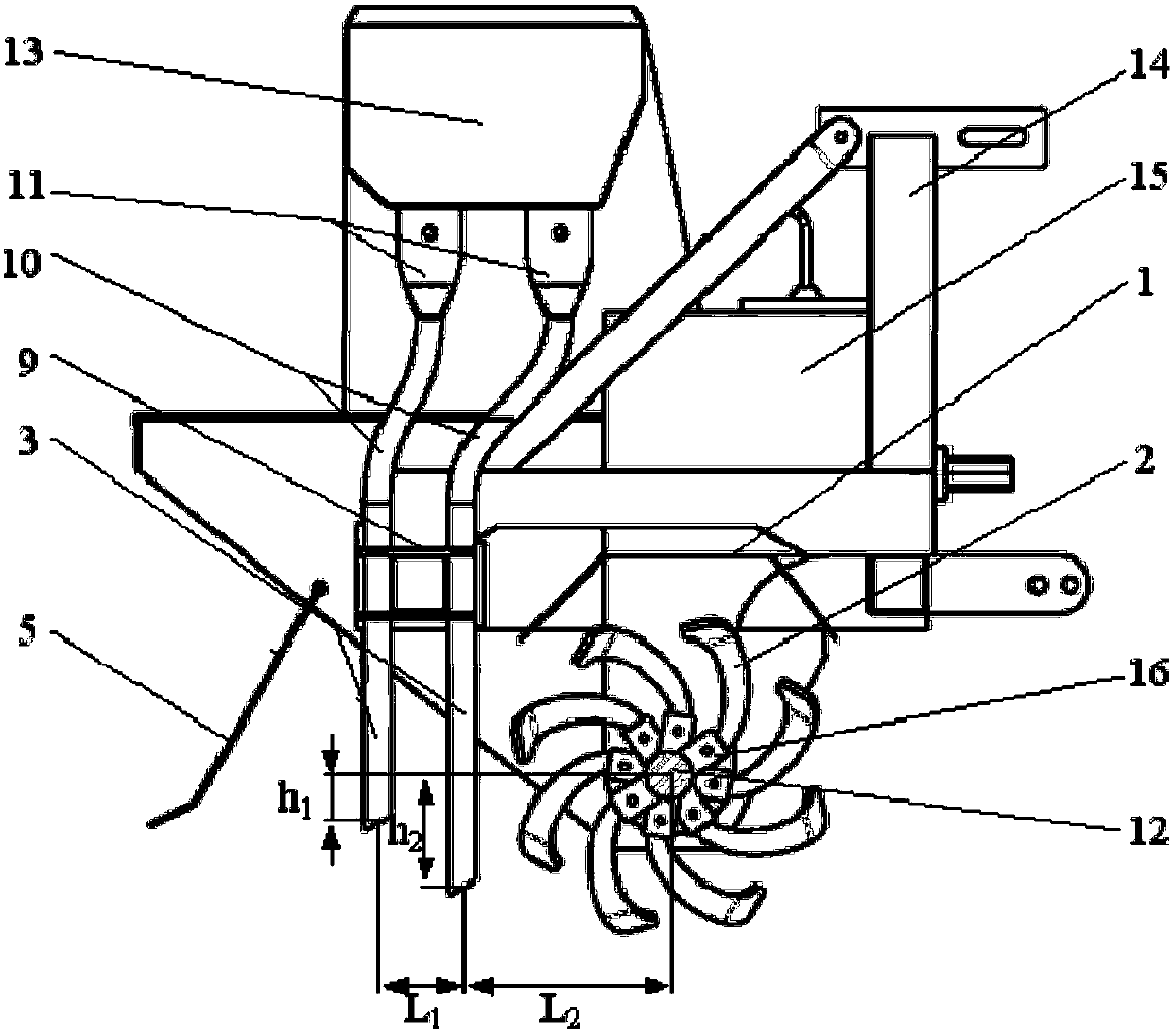

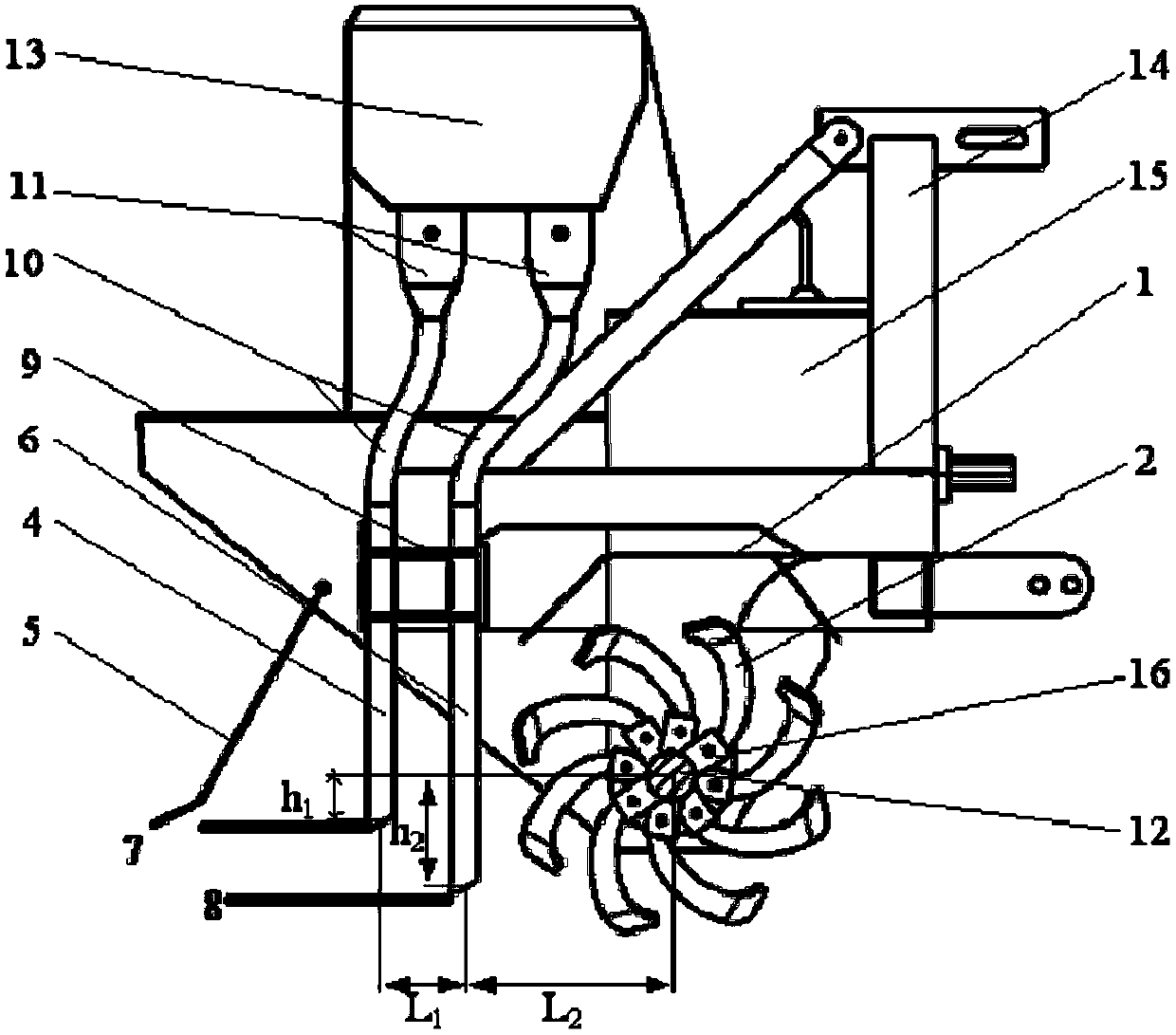

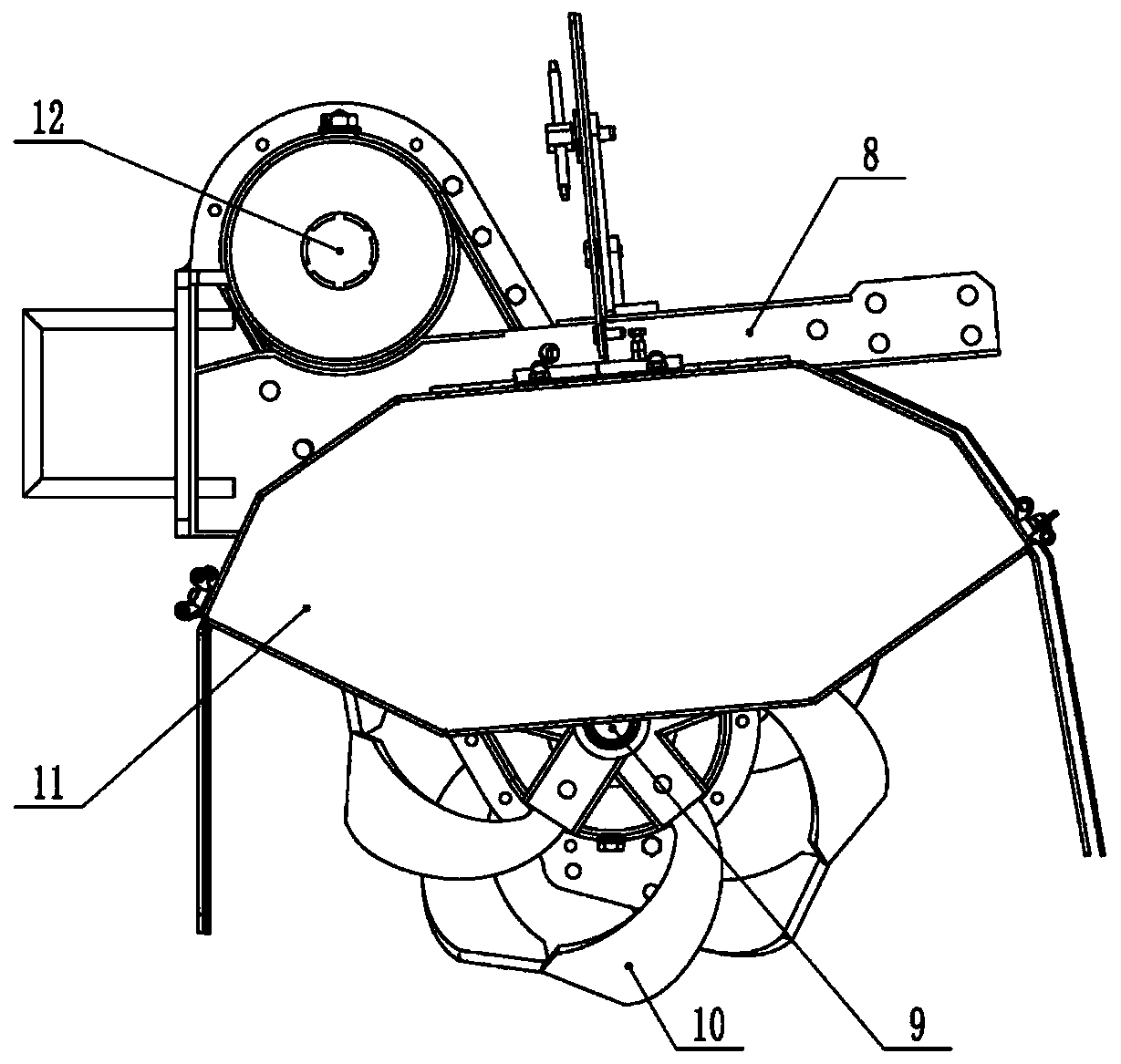

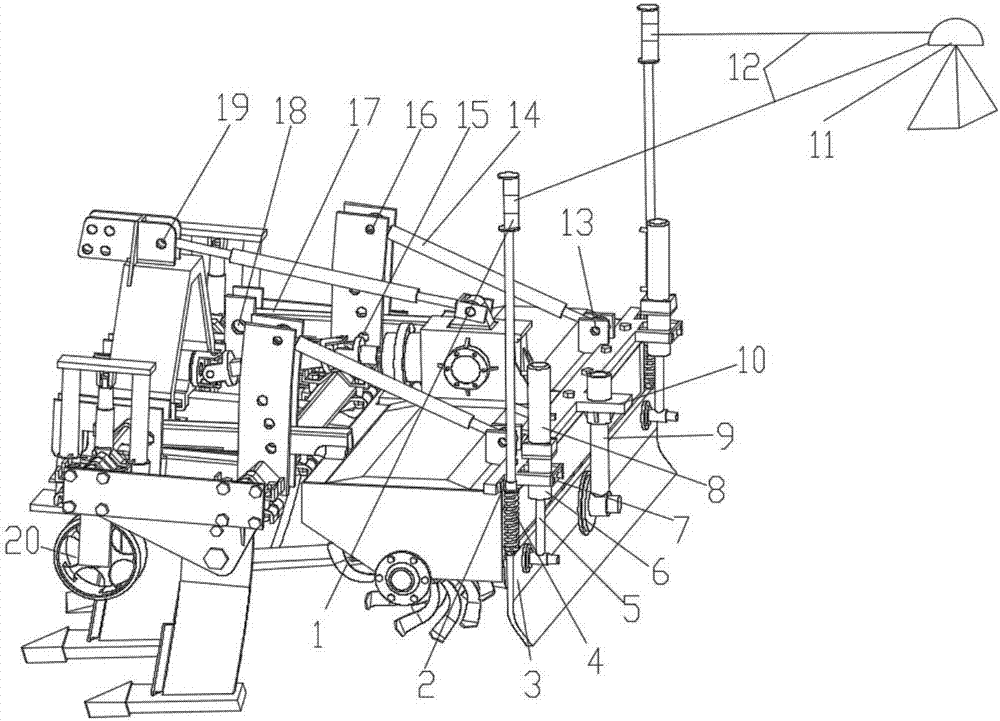

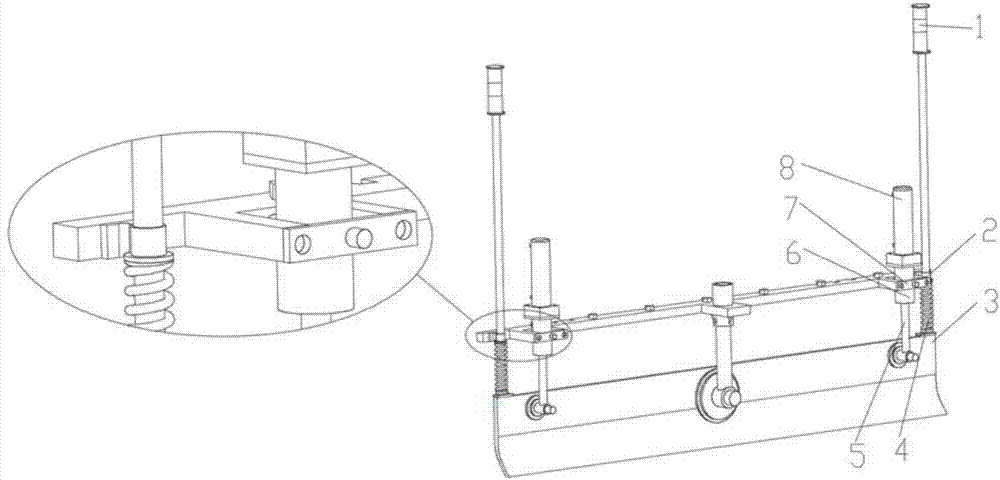

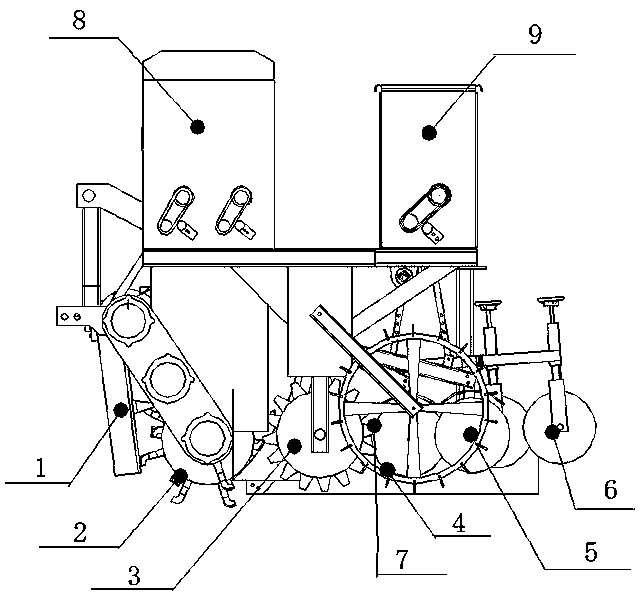

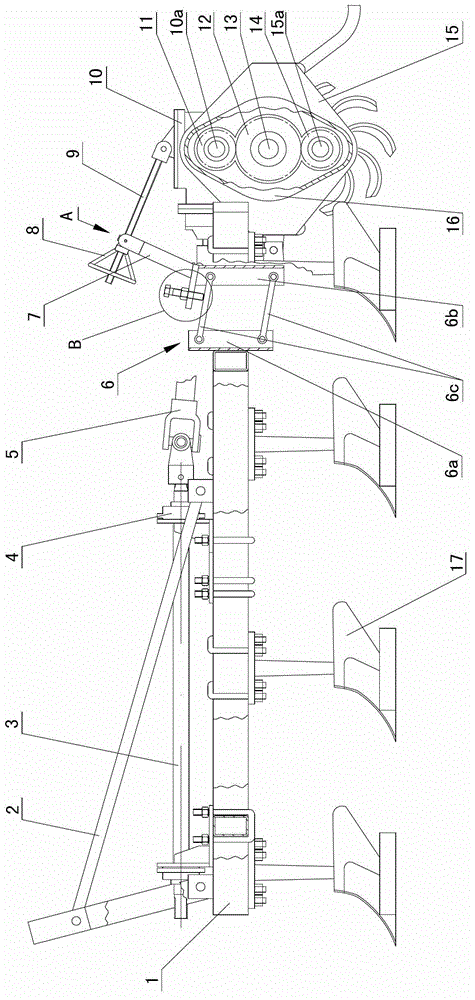

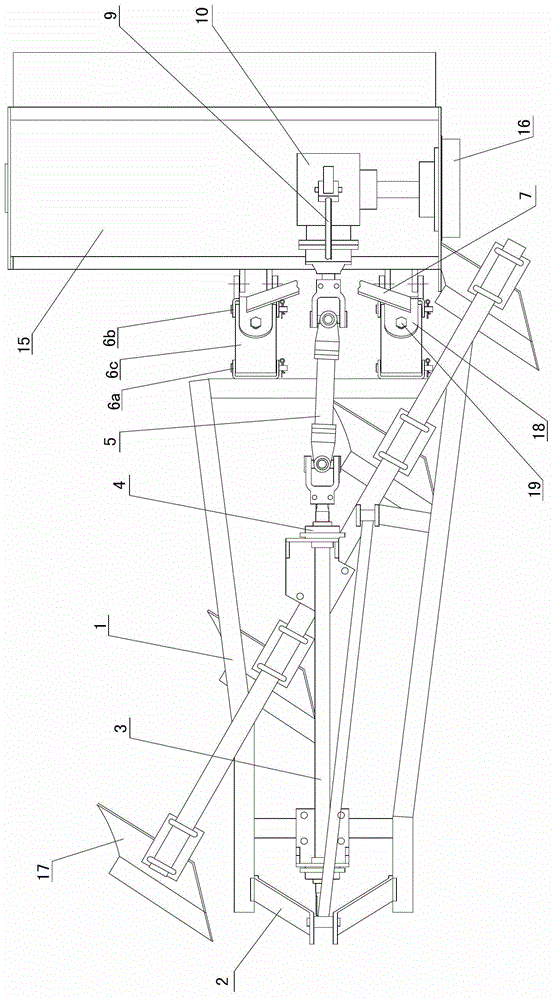

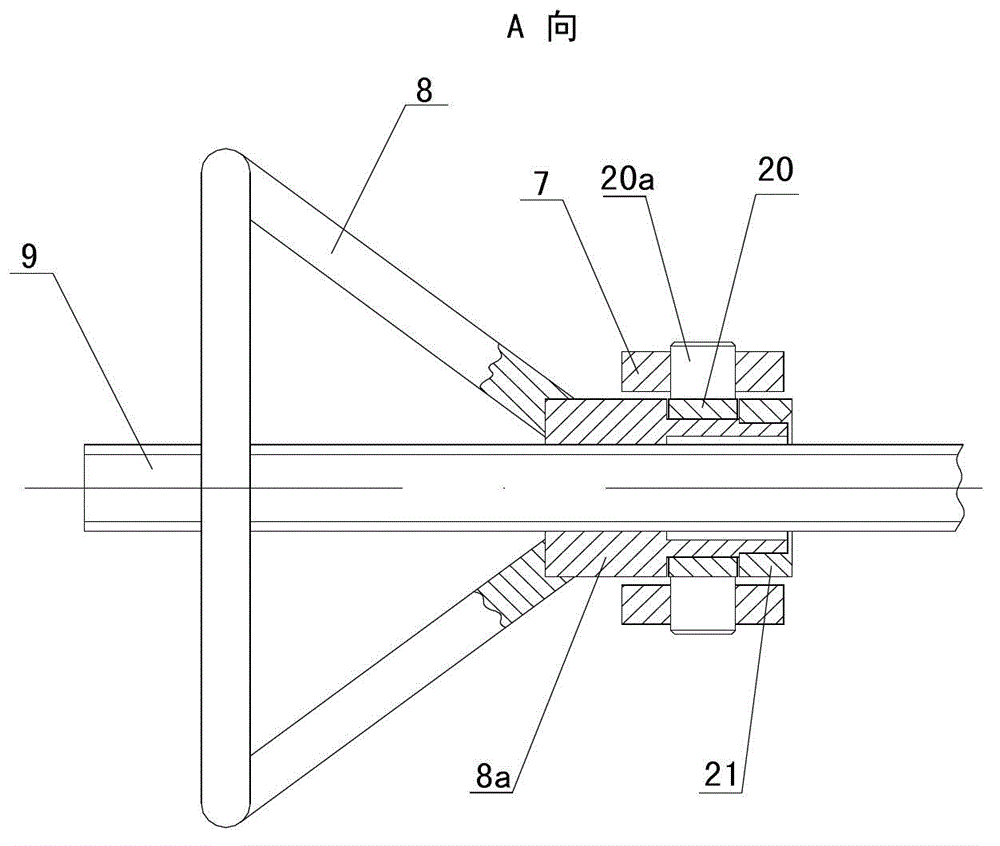

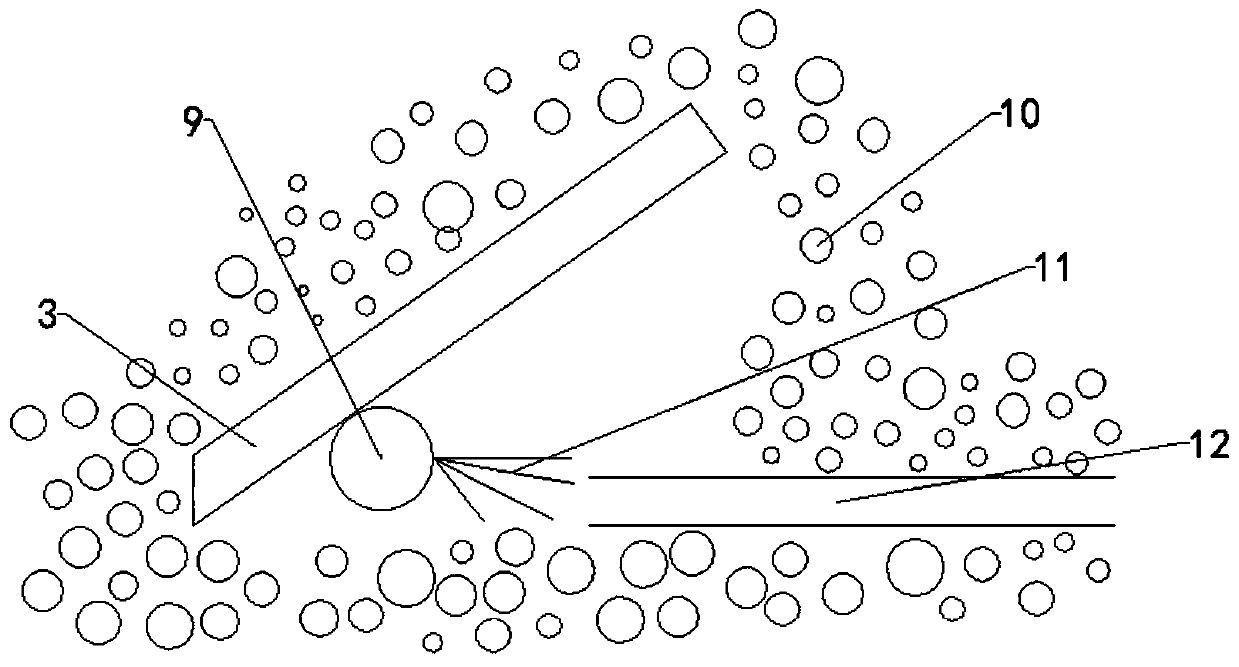

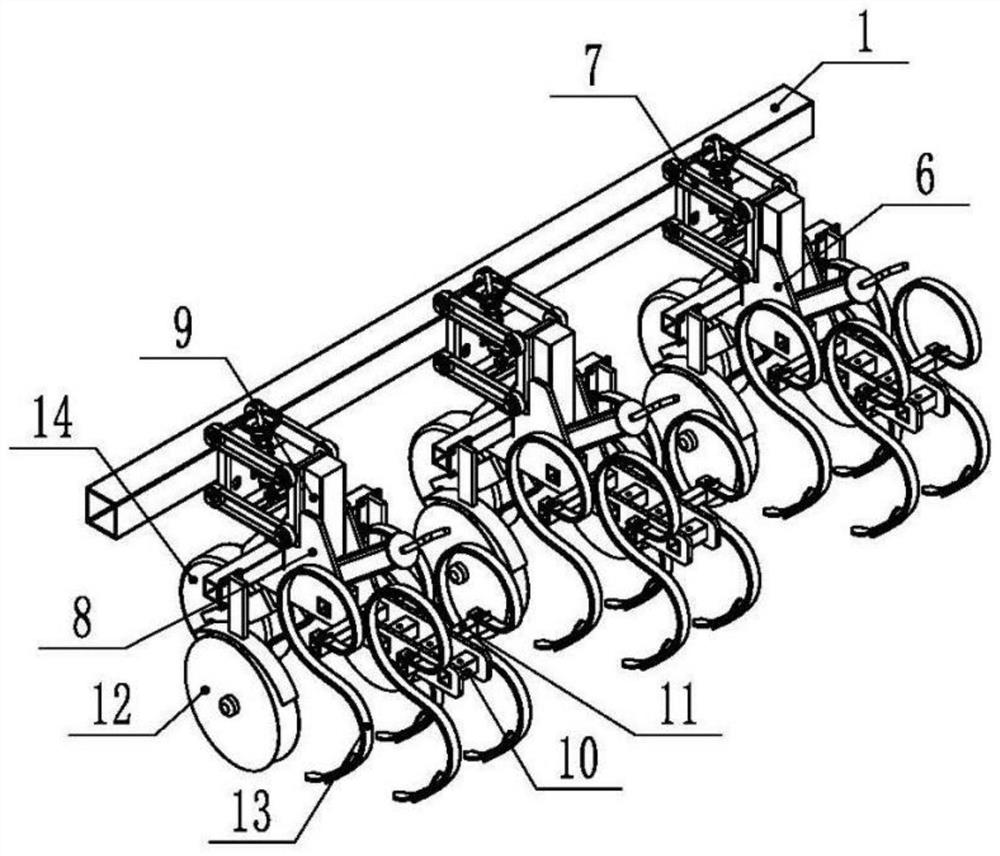

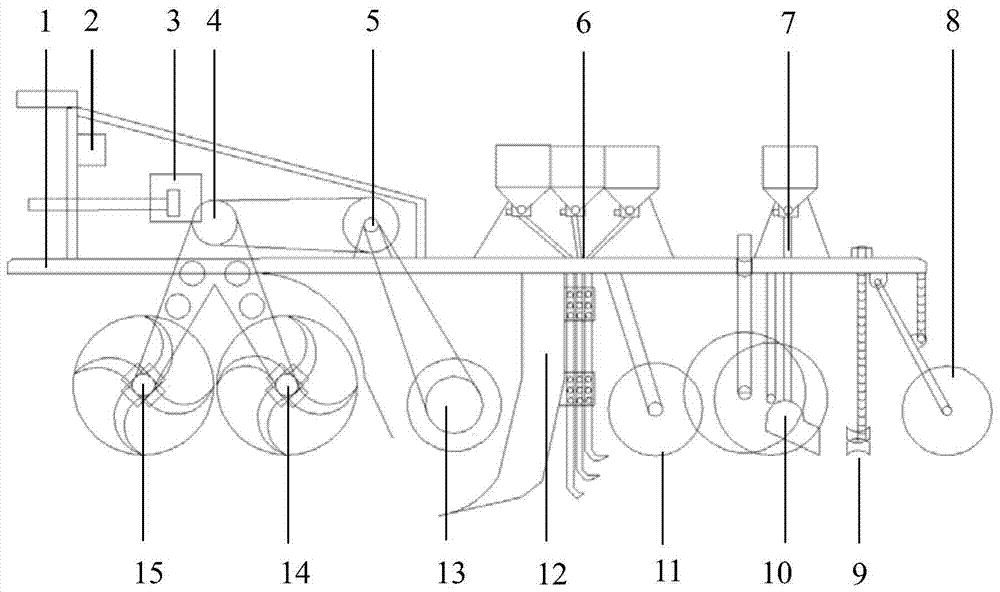

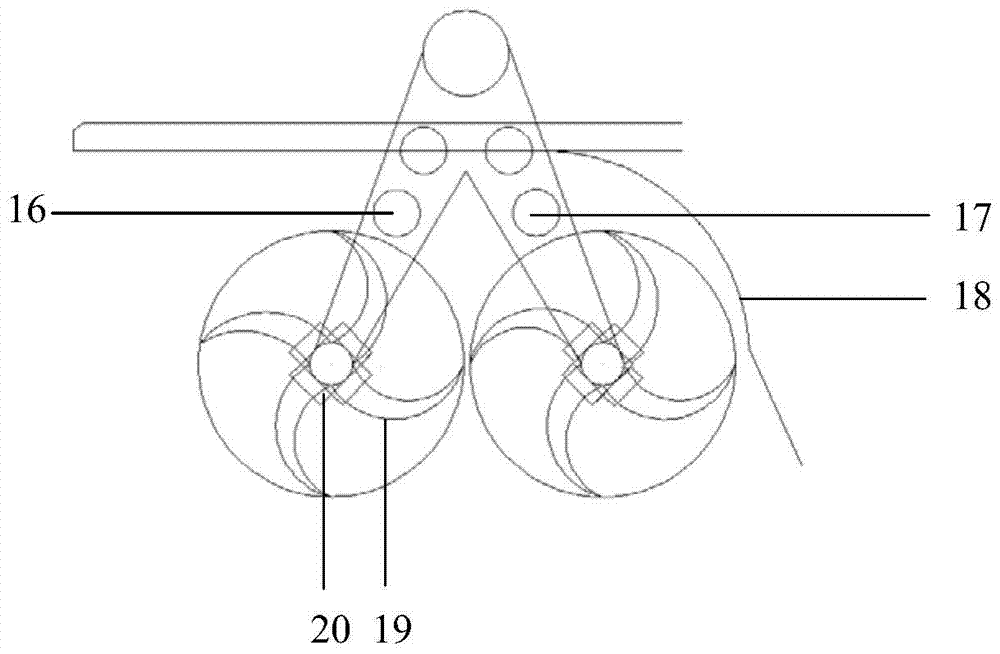

Active anti-blockage type zero-tillage precision seed planter

The invention relates to a corn zero-tillage seed planter capable of completing operations of stubble breaking, ditching, fertilizing, earthing, compacting, etc., belonging to the technical field of agricultural machinery. The zero-tillage seed planter comprises a machine frame (1), a fertilizer box (2), a seed box (3), a precision seed metering device (4), a bracket (5), anti-blockage blades (6), a shaft (7), a cutting edge stubble breaking opener (8), ground wheels (9), a double-disc opener (10), a duckbilled unfolding device (11), a seed receiving box (12), and earthing compacting wheels (13). During the working, the ground wheel at one side drives a chain wheel to drive the fertilizer device, the fertilizer falls into a ditch opened by the cutting edge stubble breaking opener, the ground wheel drives the anti-blockage blades to rotate so as to cut straws and weeds in a sliding way, the ground wheel at the other side drives the precision seed metering device by means of chain drive so as to force to open a duckbill to discharge the seeds, then the seeds fall into the ditch by the seed receiving box and a seed discharge pipe so as to realize secondary precision seed discharge, and the seeds are then earthed and compacted by the compacting wheels, in this way, the operations of stubble breaking, ditching, fertilizing, earthing, compacting, etc. are completed.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

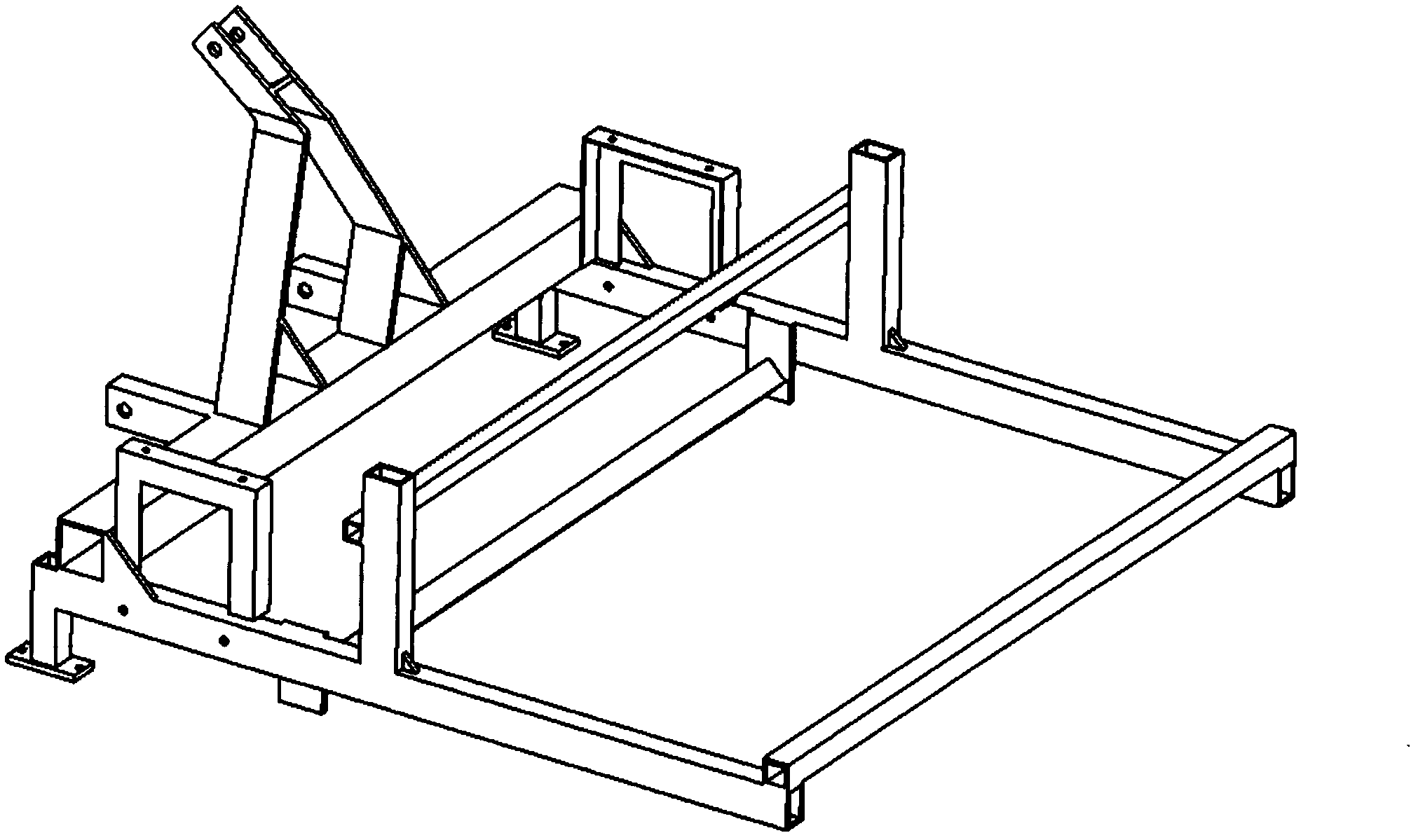

Machine and tool with combined operations of deep scarification, rotary tillage, ditching and intelligent fertilization

PendingCN106416482AReasonable structureHigh degree of mechanizationSpadesSaving energy measuresMotor speedScarification

The invention discloses a machine and tool with combined operations of deep scarification, rotary tillage, ditching and intelligent fertilization, and belongs to the technical field of agricultural equipment. The machine and tool comprises a machine frame and a tractor, an intermediate gear case and a broadside gear case are arranged on the machine frame, wherein the broadside gear case is connected respectively with a rotary blade shaft and a soil pulverizing blade shaft below the broadside gear; a ditching cutter is arranged on the rotary blade shaft, a power-driven fertilizer apparatus is arranged above the intermediate gear case, a speed adjustable motor in the power driven fertilizer apparatus drives a rear fertilization shaft to rotate through chain drive, a deep fertilization shaft drives the fertilization shaft to rotate through the chain drive and controls fertilizing amount by adjusting motor speed, wherein the motor speed is controlled through a signal control device, and the signal control device is connected with a velocity sensor arranged on the tractor; four fertilizing pipes of the fertilizing pipes are drawn forth from a fertilizer discharging hole and then put on the machine frame, and the other four fertilizing pipe are connected with a deep scarification fertilizing pipe, wherein the deep scarification fertilizing pipe is arranged at a rear part of a subsoiler. The machine and tool is reasonable in structure, can finish operation in one-time the deep scarification, rotary tillage, ditching, plough layer fertilizing and deep fertilizing, lowers frequency for the tractor to enter into the field, thus saving energy and lowering cost.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI +1

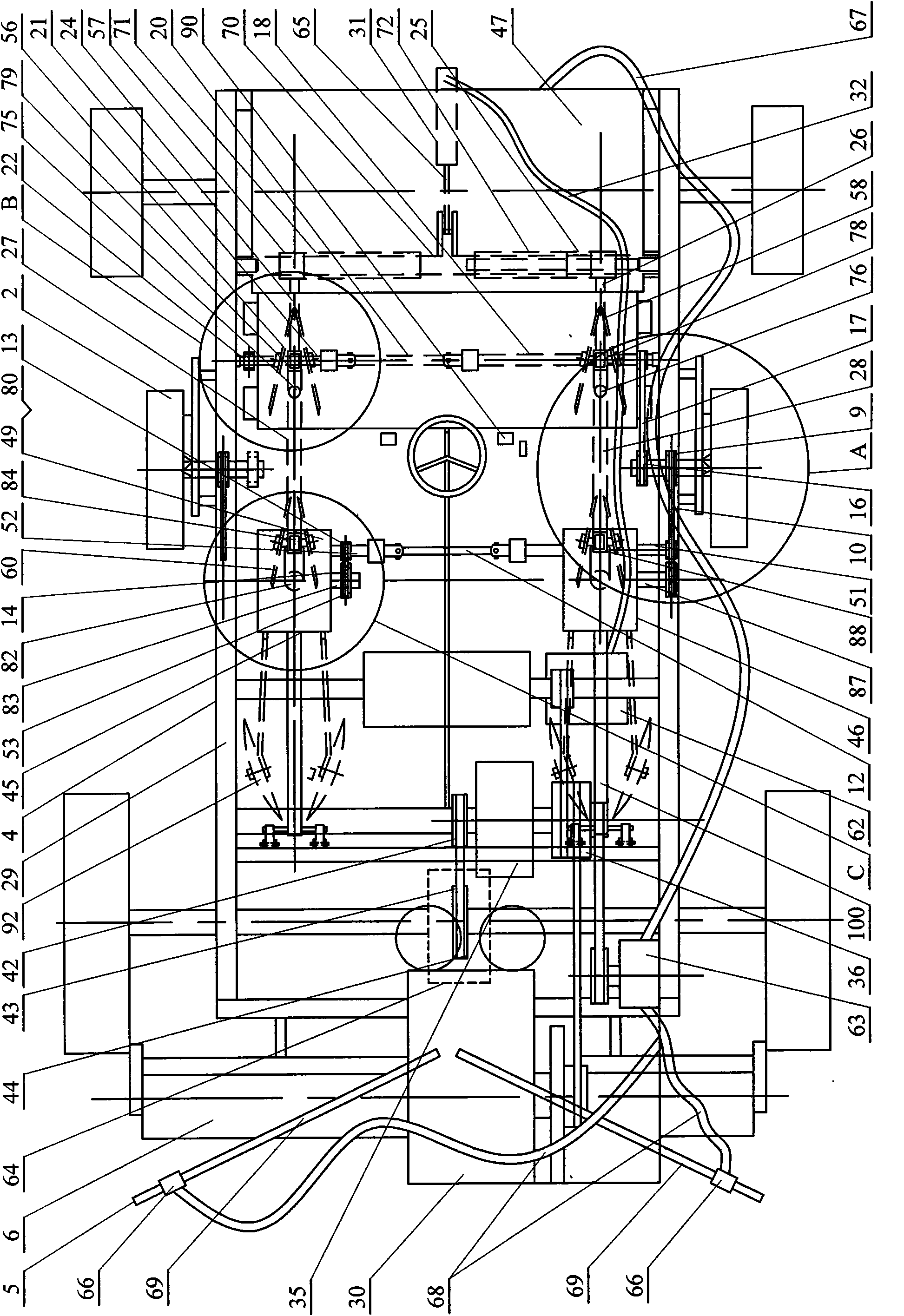

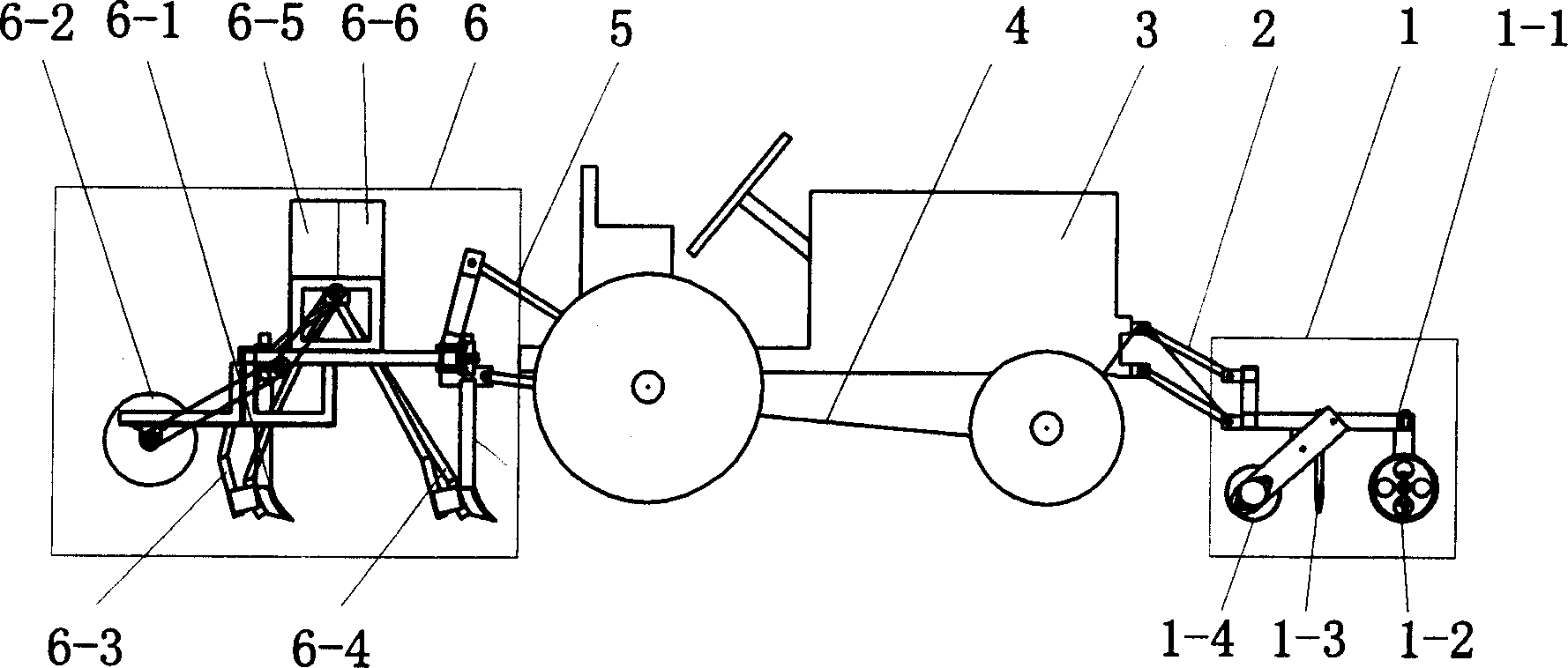

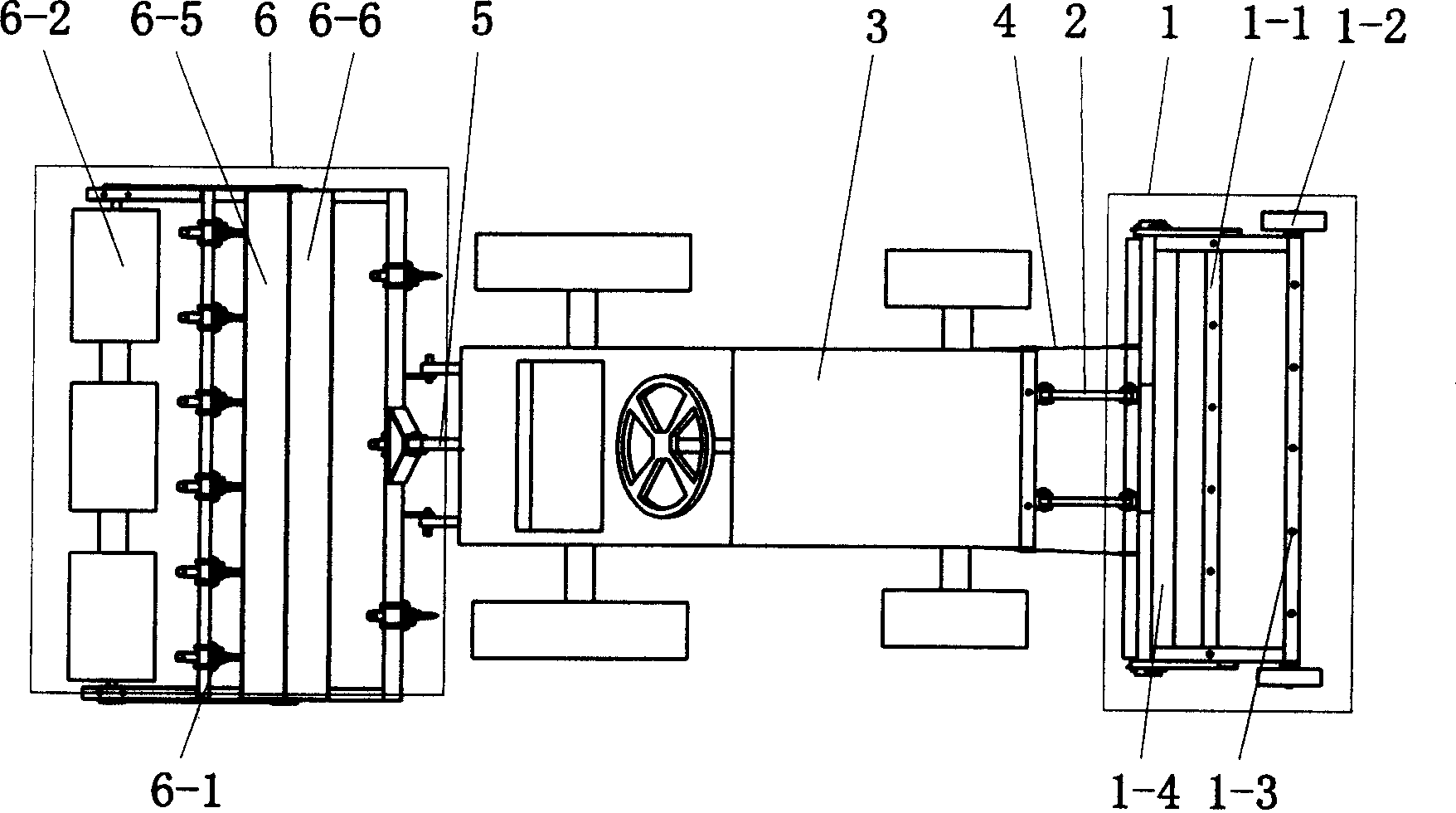

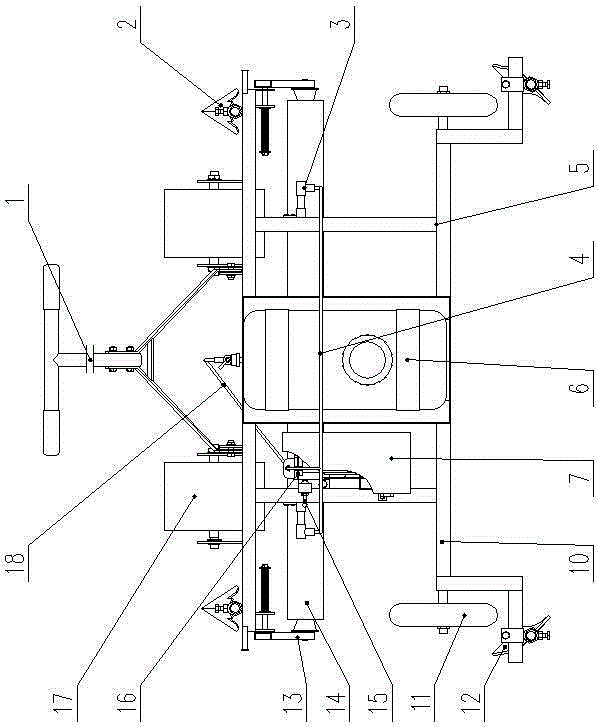

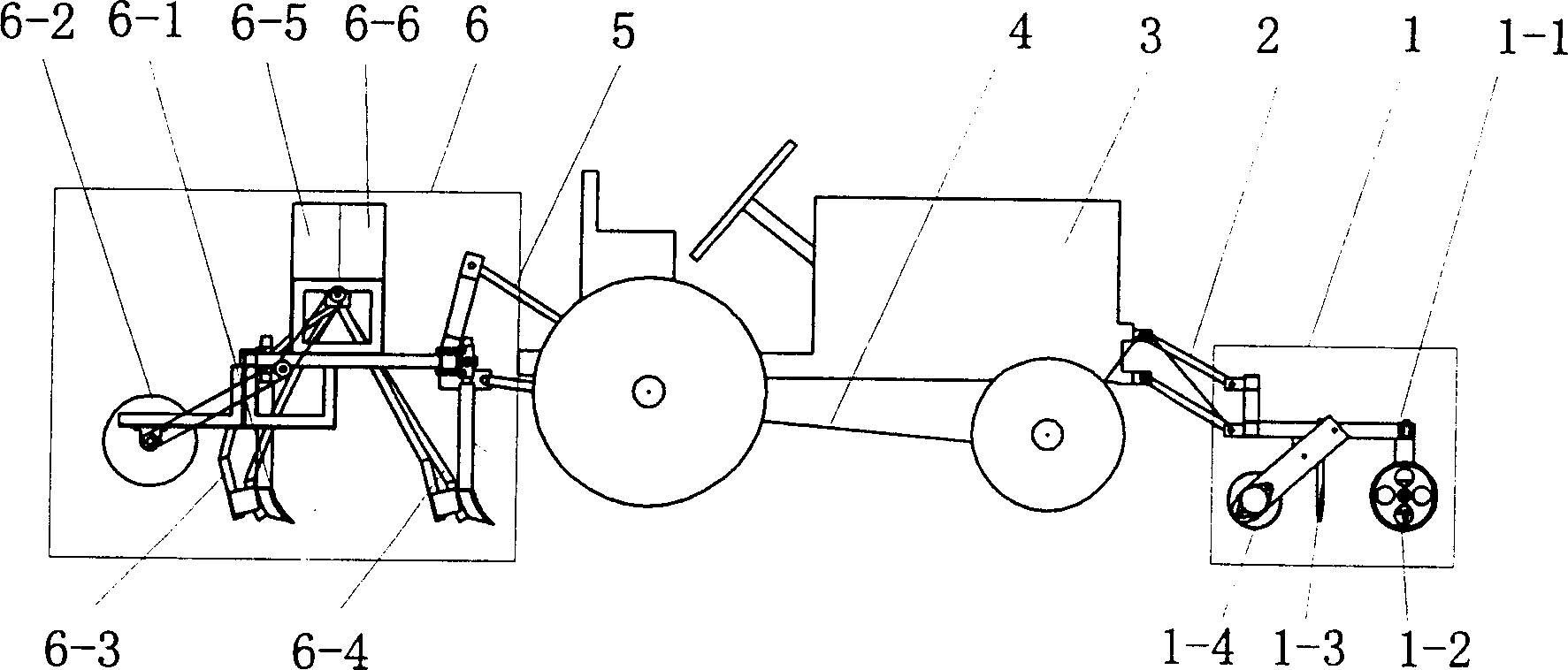

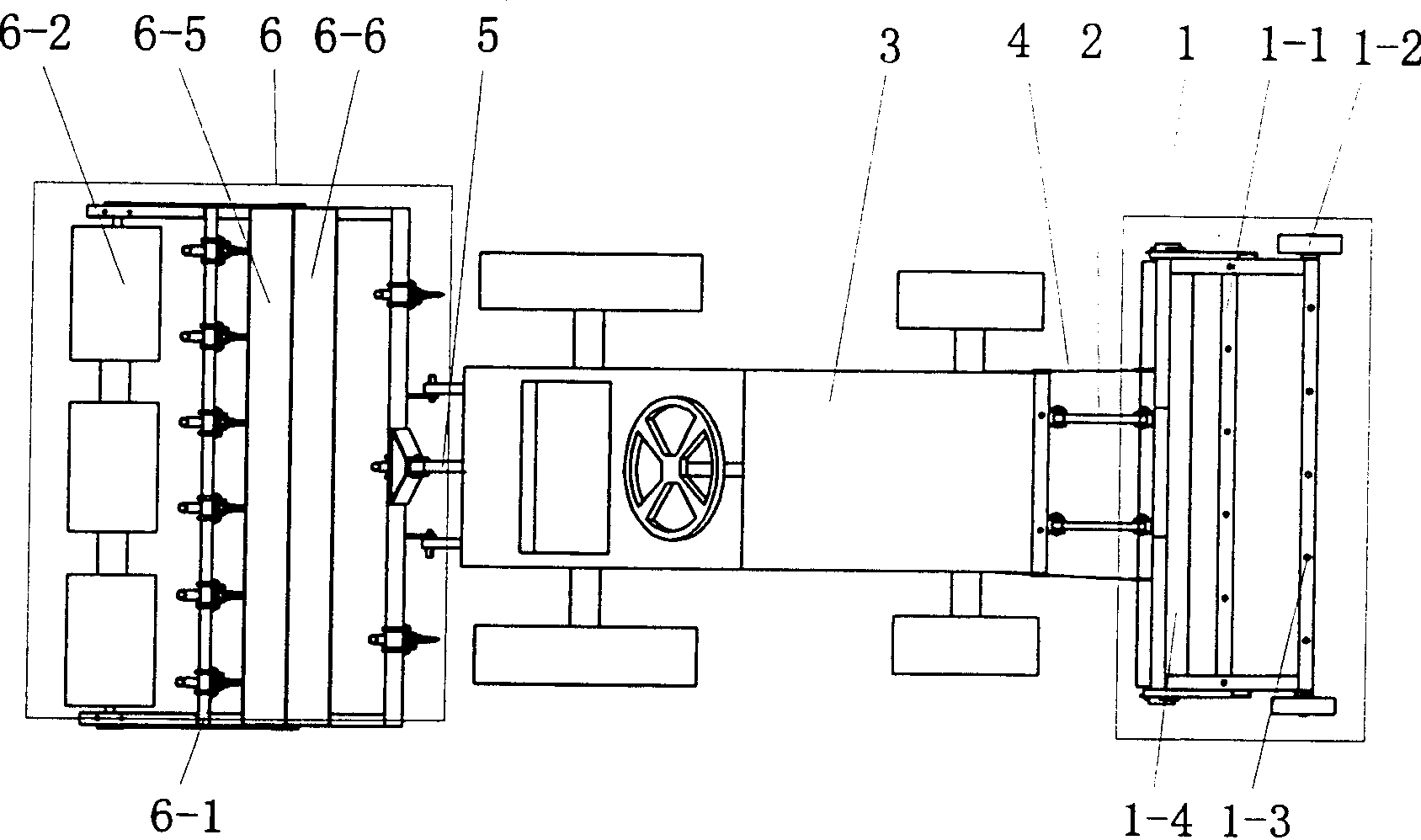

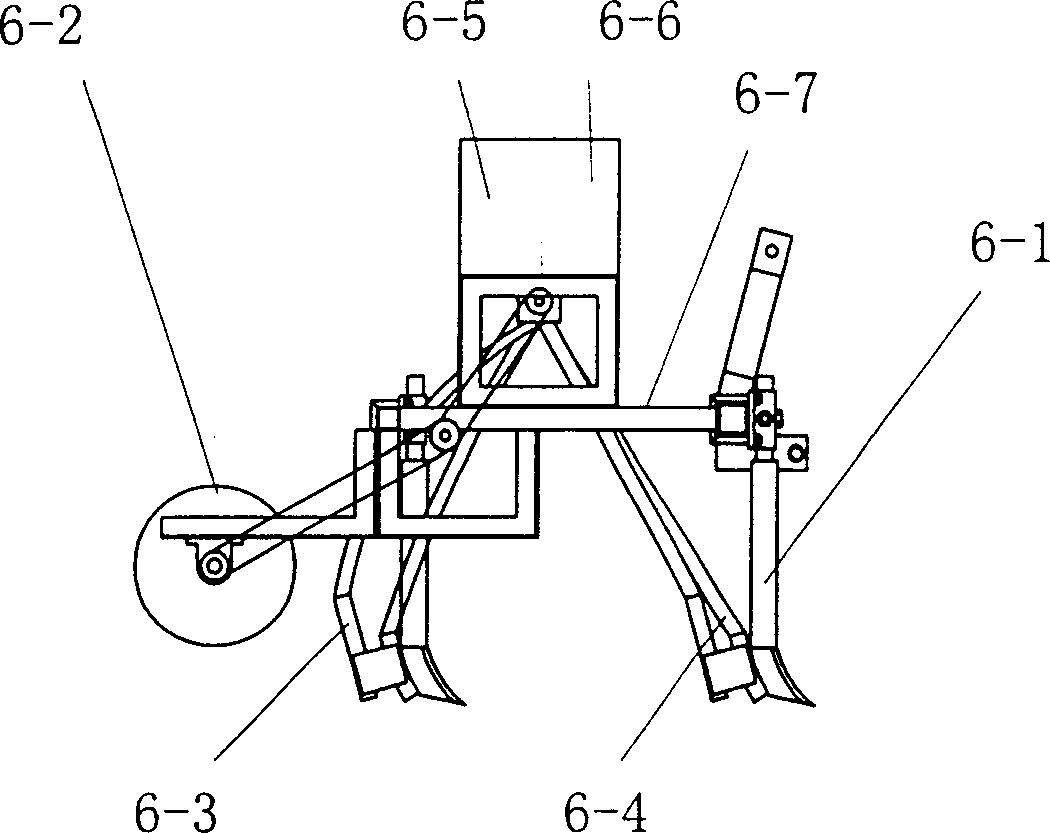

Self-propelled seeding, fertilizing and spraying combined operation machine

InactiveCN101622924ASmall turning radiusReduce the number of entry timesPlantingFurrow making/coveringSeederUniversal joint

The invention discloses a self-propelled seeding, fertilizing and spraying combined operation machine, relating to a seeding, fertilizing and spraying combined operation machine. The existing planting and fertilizing combined operation machine and tractor adopts a split structure, and has no spraying function, thereby having the problems of large turning radius at the edge of a field and high purchase cost for the existing machine. A medical kit, a fertilizer machine, seeders, a compacting device and a spraying rod are arranged along the machine body from front to back; a right travelling wheel is fixedly installed with a drive sprocket wheel which is linked with a second transitional sprocket wheel by a first chain, a second chain and a first transitional sprocket wheel; a right seeder is connected with a left seeder by a first universal joint and drive shaft; a right shaft is connected with a left shaft by a second universal joint and drive shaft; the left shaft is connected with a fertilizer discharging sprocket wheel by a six transitional sprocket wheel and a six chain; and the left and right openers of the fertilizer machine are fixedly connected with the left and right thread bushings of a horizontal position adjusting device by a left and a right front shun beams. The invention integrates the functions of seeding, fertilizing, spraying, compacting and the like with the tractor into a whole, thereby having small turning radius at the edge of the field and low purchase cost for the machine.

Owner:张红波

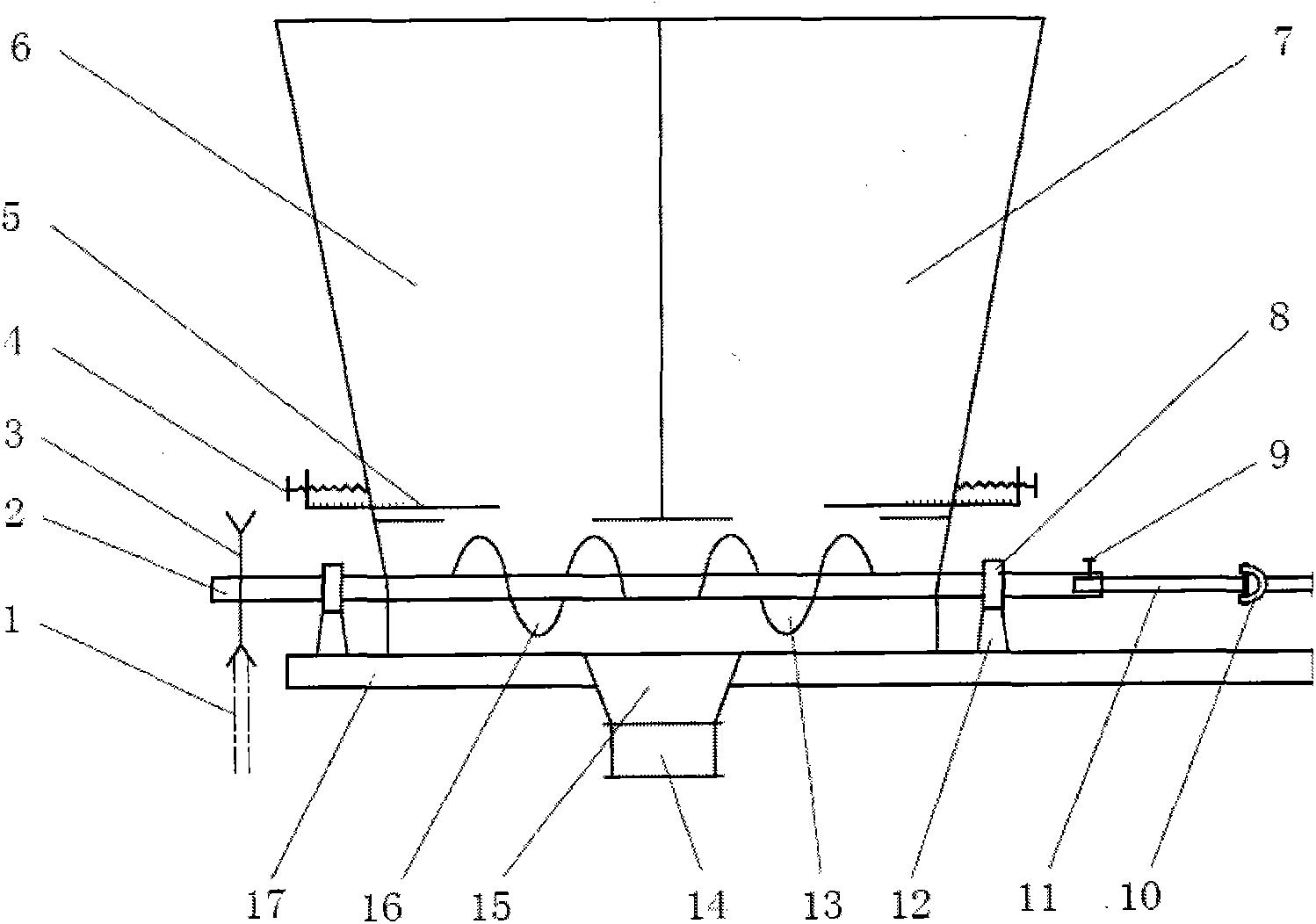

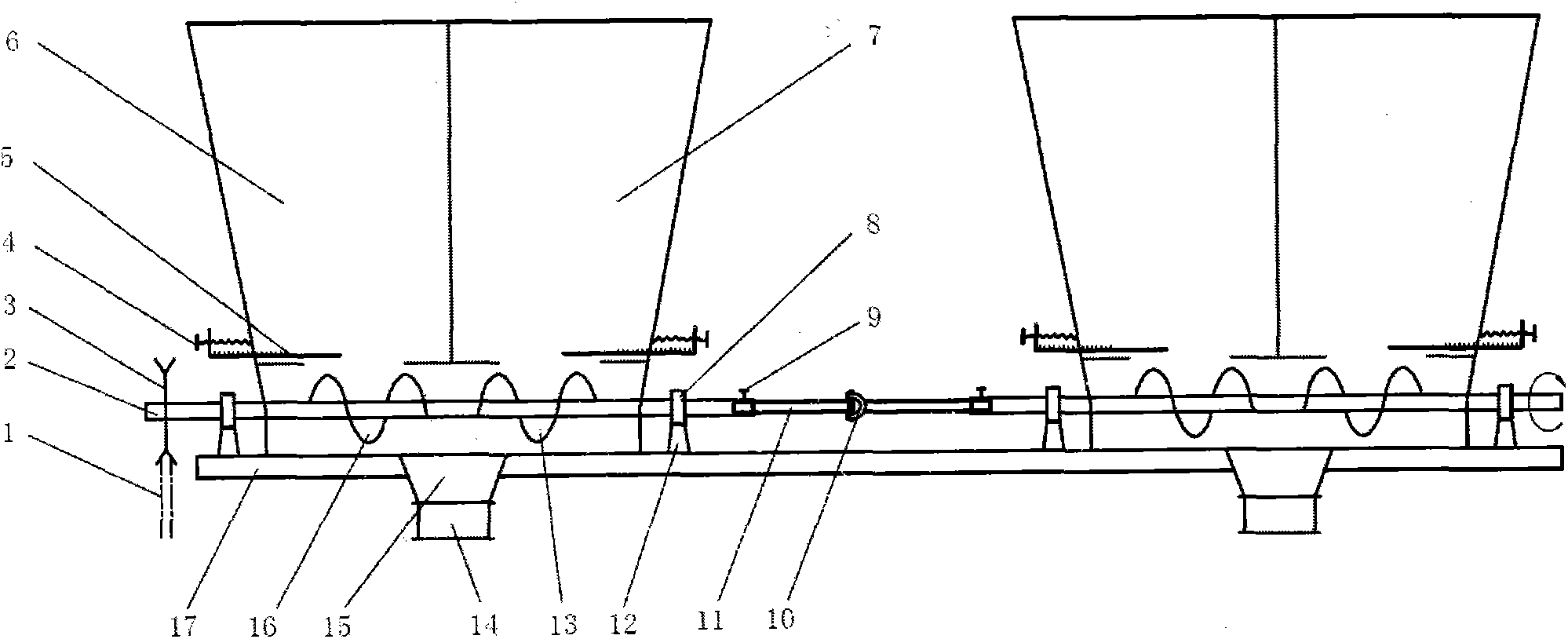

Mechanism for mixing nitrogen fertilizer and phosphorus in ratio and applying mixed fertilizer

InactiveCN104221550AReduce the number of entry timesSmall ditching resistanceFertiliser distributersFertiliser and seeding apparatusPhosphorus fertilizerNitrogen fertilizer

The invention discloses a mechanism for mixing nitrogen fertilizer and phosphorus fertilizer in a ratio and applying mixed fertilizer. The mechanism comprises a rack, a spindle, a left spiral, a right spiral, a nitrogen fertilizer box, a phosphorus fertilizer box, a fertilizer quantity control device, a collector and a mixed fertilizer tube joint, wherein the spindle, the nitrogen fertilizer box and the phosphorus fertilizer box are arranged on the upper part of the rack; the left spiral and the right spiral are fixed on the spindle; the fertilizer quantity control device is arranged at the bottom of the nitrogen fertilizer box and the phosphorus fertilizer box; the collector and the mixed fertilizer tube joint are arranged on the lower part of the rack. According to the mechanism, the nitrogen fertilizer and the phosphorus fertilizer can be mixed according to a ratio and then the mixed fertilizer is applied. The mechanism has the beneficial effects that the fertilizers are uniformly mixed, energy is saved, the operating efficiency is high, and the fertilization quality is stable.

Owner:NORTHWEST A & F UNIV

Mealie whole straw coverage wheat full no-tillage planting method and equipment thereof

The invention provides a method and apparatus for total no-tillage planting operation through blanketing wheat with overall maize stalks, wherein the complete stalks of the harvested maize are pulled down in situ in the field, and the wheat seeds are planted through trench digging between the maize planting rows. The maize complete stalk blanketing wheat no-tillage planting and fertilizer applicator set provided by the invention can realize the operations of upright maize stalk pulling down, combing, wheat seeding, fertilizing, suppressing and stalk compression.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

Manual and animal-powered tractive electric spraying and film laying machine

InactiveCN105191901AReduce rollingReduce pestsPlant protective coveringsInsect catchers and killersAgricultural engineeringInsect pest

A manual and animal-powered tractive electric spraying and film laying machine is composed of a rack, a traction handle, wide depth wheels, furrowing shovels, a spraying system, a shield, a film hanging frame, a film roll, film pressing wheels, covering shovels and the like. The traction handle is installed at the front end of the rack, the wide depth wheels and the furrowing shovels are installed in the front of the rack, the film hanging frame is arranged on the portion, behind the furrowing shovels, of the rack, the film pressing wheels and the covering shovels are installed on the rear portion of the rack, and the spraying device is installed in the middle of the rack. According to the manual and animal-powered tractive electric spraying and film laying machine, traction of power is achieved through manual and animal power, frequency of power machine entering the field is reduced, rolling of the machine on soil is reduced, and looseness of soil is improved; by means of the electric spraying device, spraying of pesticide liquid is completed before film laying is conducted, the combination process of the machine is achieved, frequency of people entering the field is reduced, the work efficiency is improved, the pesticide liquid is prevented from volatilization, the pesticide effect is improved, and weeds and plant diseases and insect pests are reduced; a foldable mode is adopted by the film hanging frame, and the transport performance of the machine and the tools is improved; the wide depth wheels are designed to adopt wide wheels, and pressure of the machine on the soil and operation traction are reduced.

Owner:GANSU TAOHE TRACTOR MFG

Double-ridge shaping efficient environmentally-friendly film placement machine

PendingCN108990439AImprove adaptabilityHigh recovery rateSpadesPloughsAgricultural engineeringPlastic film

The invention provides a double-ridge shaping efficient environmentally-friendly film placement machine. The machine comprises a rotary tillage rack. The lower part of the rotary tillage rack is provided with a rotary cultivator. The rear end of the rotary tillage rack is provided with a plastic film laying rack. Two sides of the front part of the plastic film laying rack are respectively providedwith side ridging shovels. An intermediate ridging shovel is arranged between the two side ridging shovels. The plastic film laying rack between each side ridging shovel and the intermediate ridgingshovel is provided with a shaper. The plastic film laying rack on the rear of the shaper is provided with a ridge top compressing roll. The plastic film laying rack on two sides of the ridge top compressing roll is provided with a film edge furrowing blade. The plastic film laying rack on the rear of the film edge furrowing blade is provided with a mulch roll. Two sides of the rear part of the mulch roll are provided with film pressing wheels. The lower part of the rear part of the plastic film laying rack is provided with a film edge covering blade. The film edge covering blade is used for earthing on two sides of the film on the mulch roll. The ridge top compressing roll can compact a ridge top formed by the shaper, and after plastic film placement, a ridge form is better and the ridge does not easily collapse. The machine solves problems that when an environmentally-friendly film is recovered after crops are harvested, ridge form variation is large, and recovery rate and working efficiency is low.

Owner:GANSU TAOHE TRACTOR MFG

Base fertilizer layered application device and method

InactiveCN107750494AAchieve layered application effectSimple structureSpadesPloughsCombined useEngineering

The invention provides a base fertilizer layered application device and method. According to the device, a plurality of fertilizer discharging pipes of different lengths are arranged in each of layered fertilizing mechanisms; the layered fertilizing mechanisms are arranged between rotary blades and a soil-flattening dragging plate; the rotary blades are located in a soil-baffling cover; and the plurality of layered fertilizing mechanisms are arranged parallel to each other on a frame. The rotary blades mill soil and throws out soil clods, the soil clods are impacted by the soil-baffling coverand the soil-flattening dragging plate, fertilizers are applied to fertilization plough layers of different lengths by the fertilizers discharging pipes of different lengths and are covered by the falling soil clods, and then the soil clods are scrapped to be level by the soil-flattening dragging plate. Through combined usage of the fertilizer discharging pipes of different lengths in the layeredfertilization mechanism and a rotary tillage mechanism, the base fertilizer layered application device and method can realize layered application effect of fertilizers without a deep ditch shovel anda furrow opener, the layered fertilization precision is high, and the base fertilizer layered application device is simple in structure, economic and practicable.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

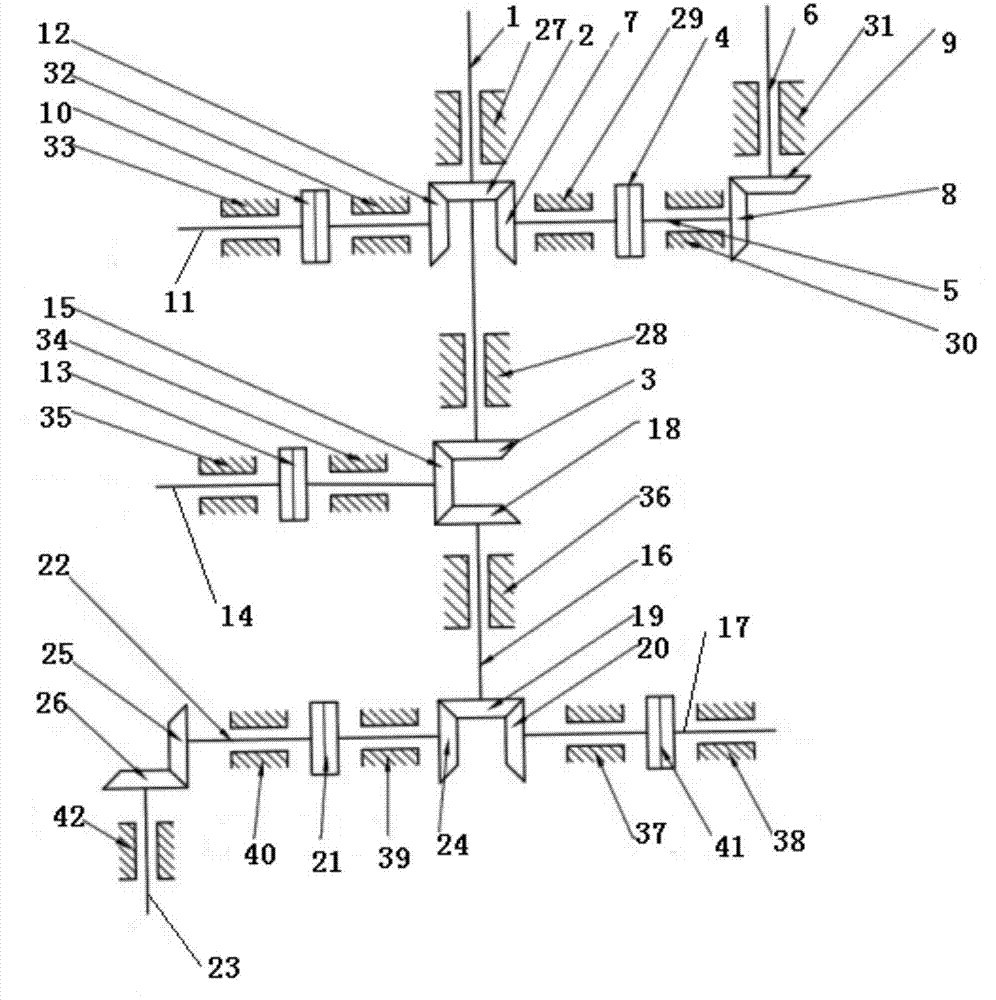

Single-power-input and multi-direction multi-power-output transmission device

InactiveCN107152498AReduce the number of entry timesAvoid damageToothed gearingsGearing detailsEngineeringOutput device

The invention provides a single-power-input and multi-direction multi-power-output transmission device. The transmission device comprises a box body for storing cooling oil, and a power input mechanism and a power output mechanism arranged in the box body; and the power output mechanism comprises a first power output device, a second power output device, a third power output device, a fourth power output device and a fifth power output device. The transmission device can realize the power output in multiple directions of the front part, the back part, the left side, the right side and the abdomen part, and can realize the machine and tool suspension in different positions of the front part, the back part, the left side, the right side and the abdomen part; the first power output device, the second power output device, the third power output device, the fourth power output device and the fifth power output device respectively perform the power on-off control through a first clutch, a second clutch, a third clutch, a fourth clutch and a fifth clutch; and operators can distribute the power to the needed parts through buttons to realize the machine and tool operations.

Owner:ANHUI AGRICULTURAL UNIVERSITY

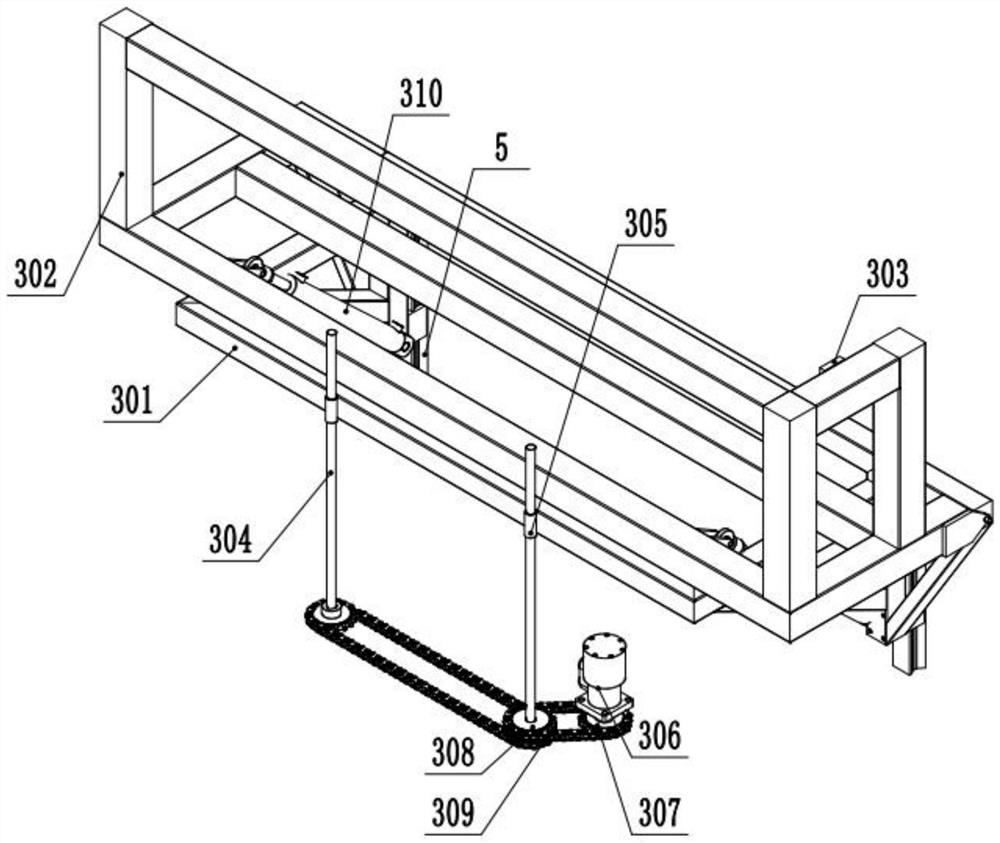

Intertillage, ridging and fertilizing integrated machine for cotton

PendingCN110741759AImprove efficiencyReduce the number of visits and operating costsSpadesSoil-working equipmentsFertilizerAgricultural engineering

The invention discloses an intertillage, ridging and fertilizing integrated machine for cotton. The intertillage, ridging and fertilizing integrated machine comprises a frame and is characterized in that a fertilizer tank and a plurality of operating units are arranged on the frame at intervals, and each operating unit comprises a rotary tillage mechanism, a soil taking mechanism, a soil conveyingmechanism and a ridging and fertilizing mechanism which are sequentially arranged on the frame; each soil taking mechanism comprises a planet gear drive mechanism and a bucket-wheel type soil takingdevice; each soil conveying mechanism comprises a soil conveying tank, a spiral conveying shaft and soil discharge devices, the soil conveying tank is fixedly connected with the frame and penetrates acircular support rack, the spiral conveying shaft is arranged in the soil conveying tank, the soil discharge devices are communicated with the soil conveying tank, and a first spiral blade and a second spiral blade which are opposite in spiral direction are arranged on the spiral conveying shaft; each ridging and fertilizing mechanism comprises a fertilizing furrowing device, an electric fertilizer discharge device and a ridging and fertilizing shovel, the ridging and fertilizing shovel and the fertilizing furrowing device are arranged below the fertilizer tank, and the fertilizer discharge pipe of the electric fertilizer discharge device is connected with the fertilizing furrowing device. By the intertillage, ridging and fertilizing integrated machine for cotton, ridging efficiency during cotton planting is increased.

Owner:滨州市农业机械化科学研究所

Residual film recycling and straw returning combined operation machine

PendingCN111819926AImprove work efficiencyImprove convenienceSpadesCuttersTraction frameProcess engineering

The invention relates to a residual film recycling and straw returning combined operation machine. The machine is composed of a traction frame, a straw smashing device, a main rack, a shear fork typefilm unloading mechanism, walking wheels, a film collecting box, a residual film compacting device, an impurity discharging device, a residual film picking device and a depth limiting tail wheel. Themachine reasonably integrates residual film recycling operation and straw returning operation, belongs to a combined operation machine, and can effectively reduce the land entering frequency of a tractor, relieve harmful compaction of soil and reduce power consumption; the whole operation process is smooth, labor and time are saved, and the working reliability is high; the stacking area after residual film compaction is small, so that subsequent transfer treatment is facilitated; and the residual film recycling rate is relatively high.

Owner:新疆振新民创农业科技有限公司 +1

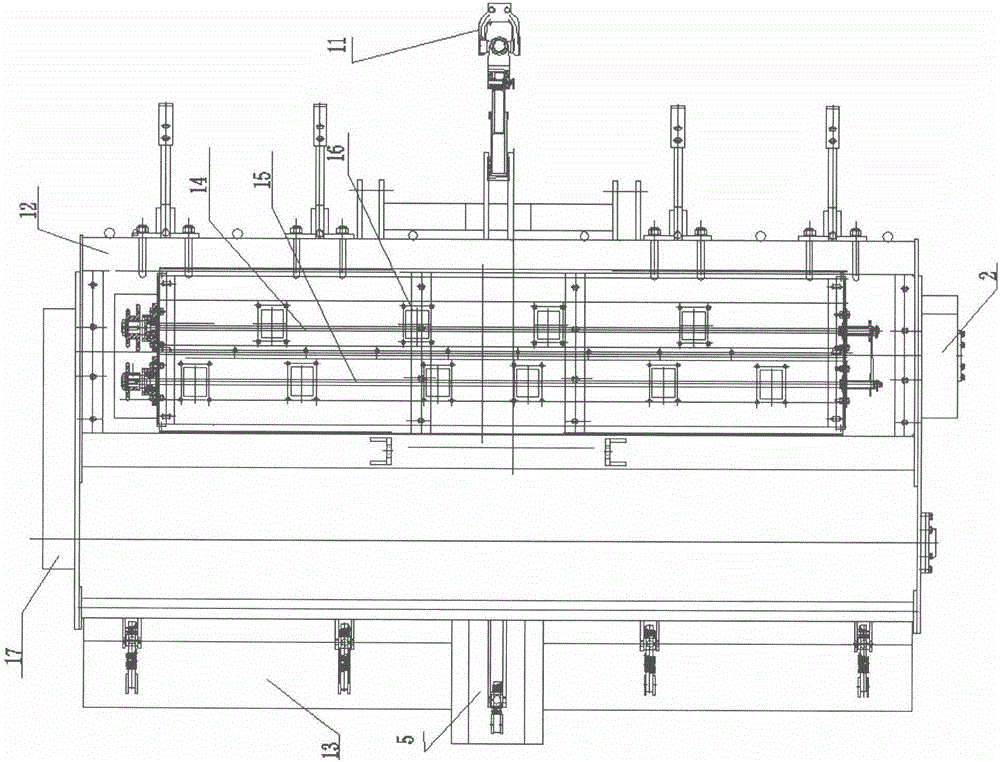

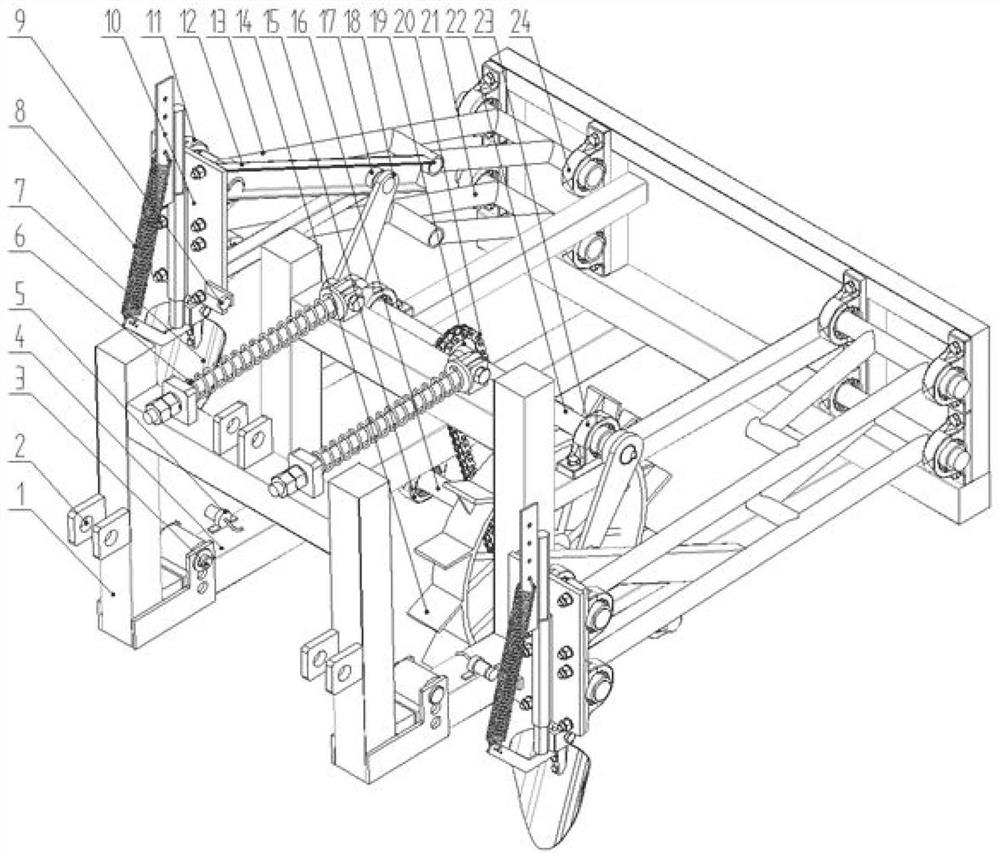

Laser measurement and control subsoiling and rotary tillage and leveling combined machine

InactiveCN107027353APrevent compactionReduce the number of entry timesSpadesPloughsIntegrated operationsEngineering

The invention relates to a laser measurement and control subsoiling and rotary tillage and leveling combined machine. The complete machine comprises a subsoiling device, a rotary tillage device and a laser measurement and control and leveling assembly, wherein the subsoiling device is located in front of the complete machine, the rotary tillage device is mounted at the back of the subsoiling device through a hinge bar, and the laser measurement and control and leveling assembly is mounted at the tail of the rotary tillage device. According to the laser measurement and control subsoiling and rotary tillage and leveling combined machine, subsoiling and rotary tillage and leveling integrated operation can be achieved, multiple operation such as soil subsoiling, surface soil rotary tillage soil pulverizing, stubble cleaning and leveling is finished at one time, and therefore a soil surface reaches a ready-to-sow state, the frequency of land entering of machines and tools is reduced, multiple compaction for soil is avoided, the field operation efficiency is improved, and the depth of the subsoiling and rotary tillage can be regulated according to the demands of agriculture; the laser measurement and control and leveling assembly achieves surface automatic leveling, and the leveling precision is high.

Owner:HEBEI AGRICULTURAL UNIV.

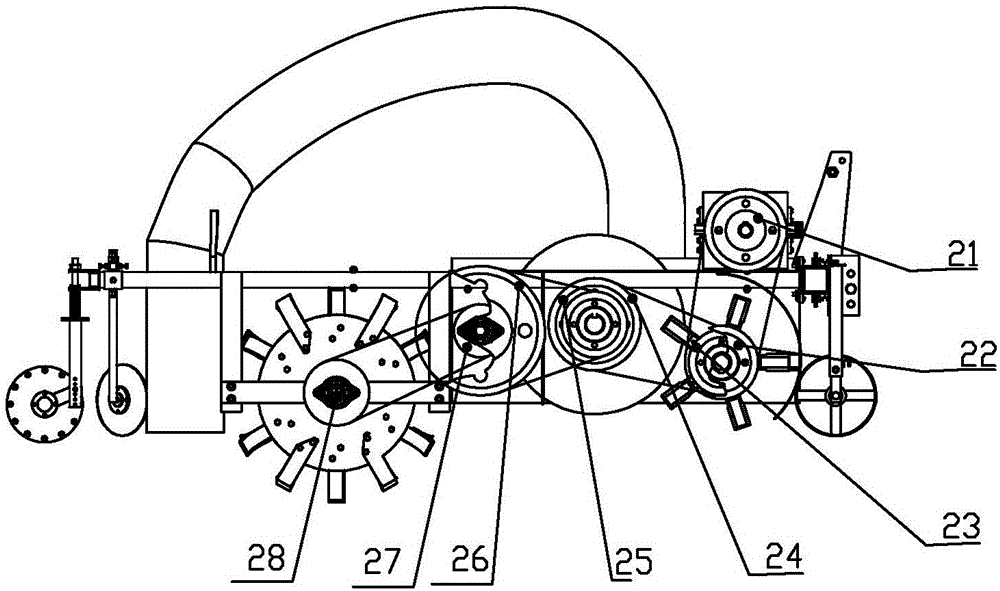

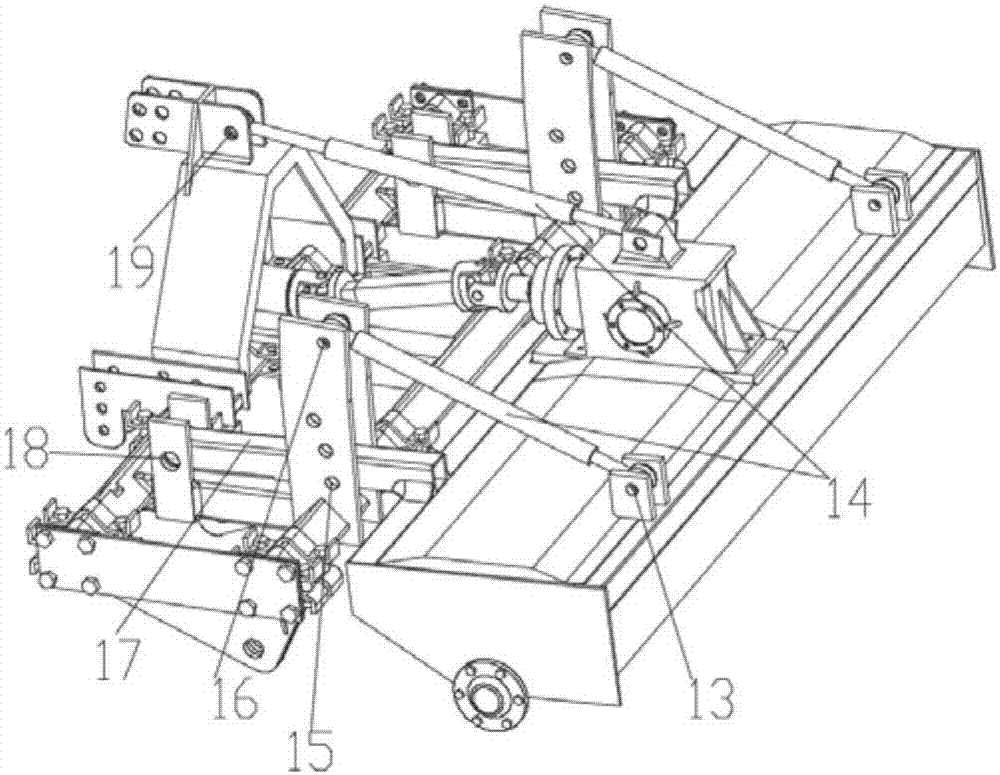

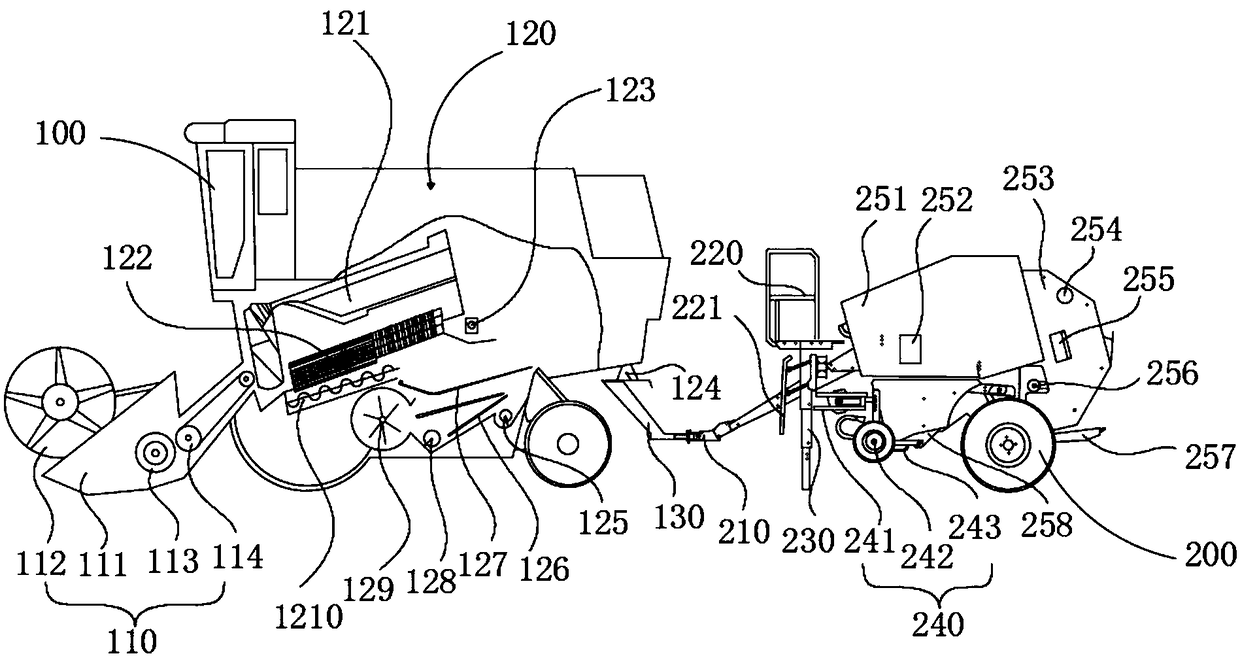

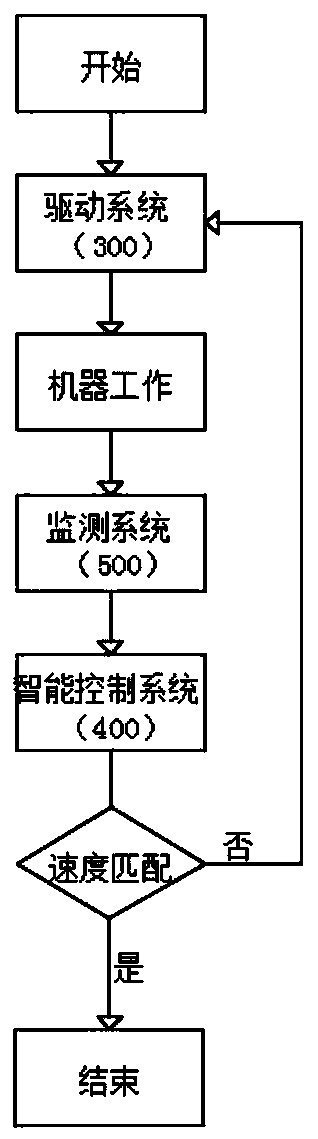

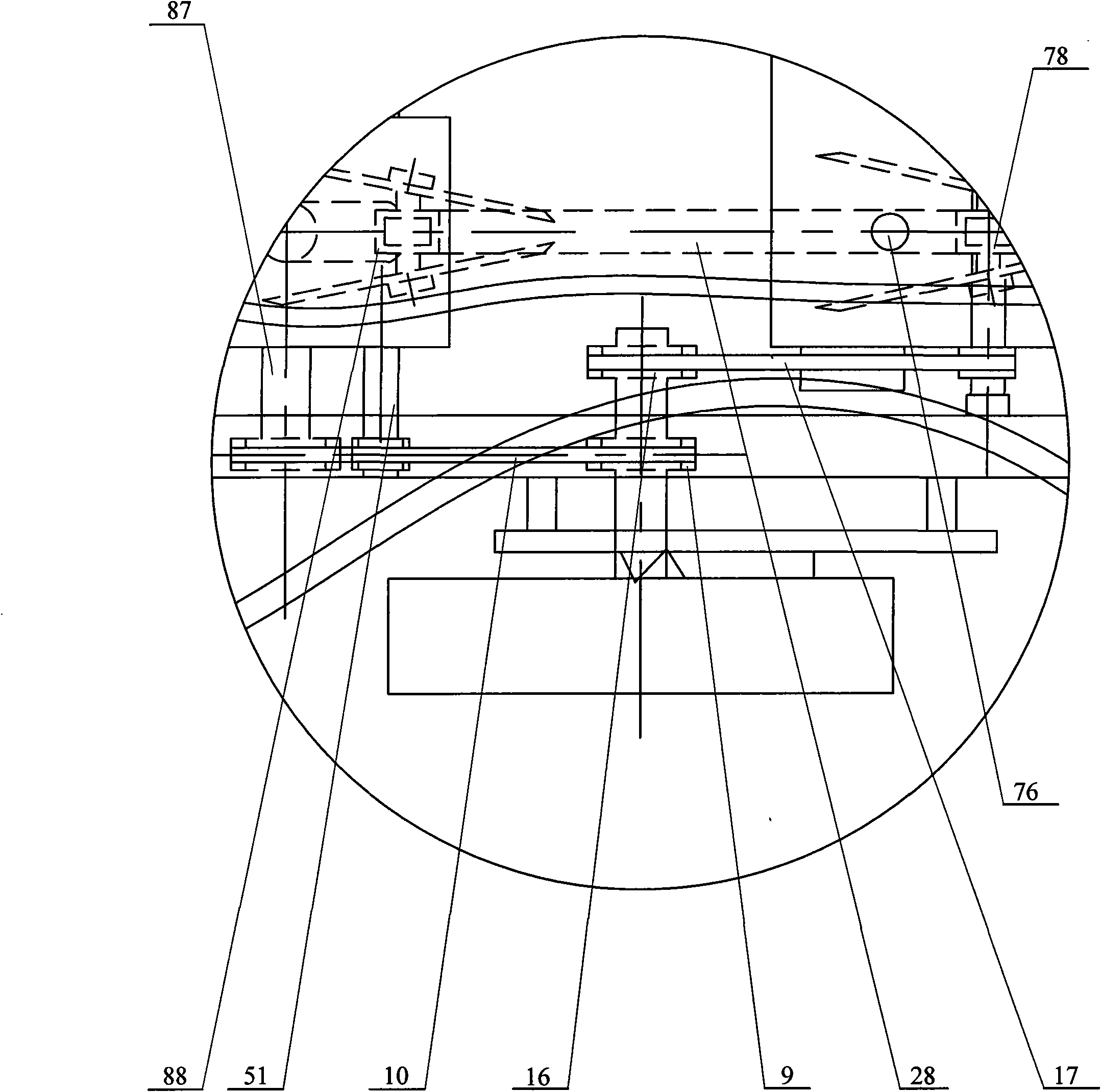

Harvesting bundling combined machine

PendingCN109041756AReduce the number of entry timesReduce soil compaction and formation of secondary compactionMowersAgriculture gas emission reductionAgricultural engineeringCombine harvester

The invention discloses a harvesting bundling combined machine. The combined machine comprises an axial flow drum-type combined harvester and a straw bundling machine, a pulling device is arranged atthe back end of the axial flow drum-type combined harvester, a hanging device is arranged at the front end of the straw bundling machine, and the pulling device is connected with the hanging device. The machine can harvest singly or bundle singly, combine harvesting and bundling steps in the cereal harvesting process, remotely control the work efficiency and work mode of the machine, and reduce the land entering frequencies of the combined machine, therefore the forming of soil compaction and secondary hardening is reduced, the operation harvesting and packaging cost is reduced, the step of burning straw is omitted, and the air is purified.

Owner:北京德邦大为科技股份有限公司

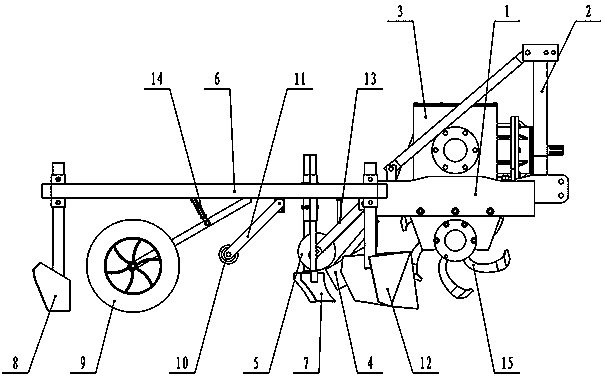

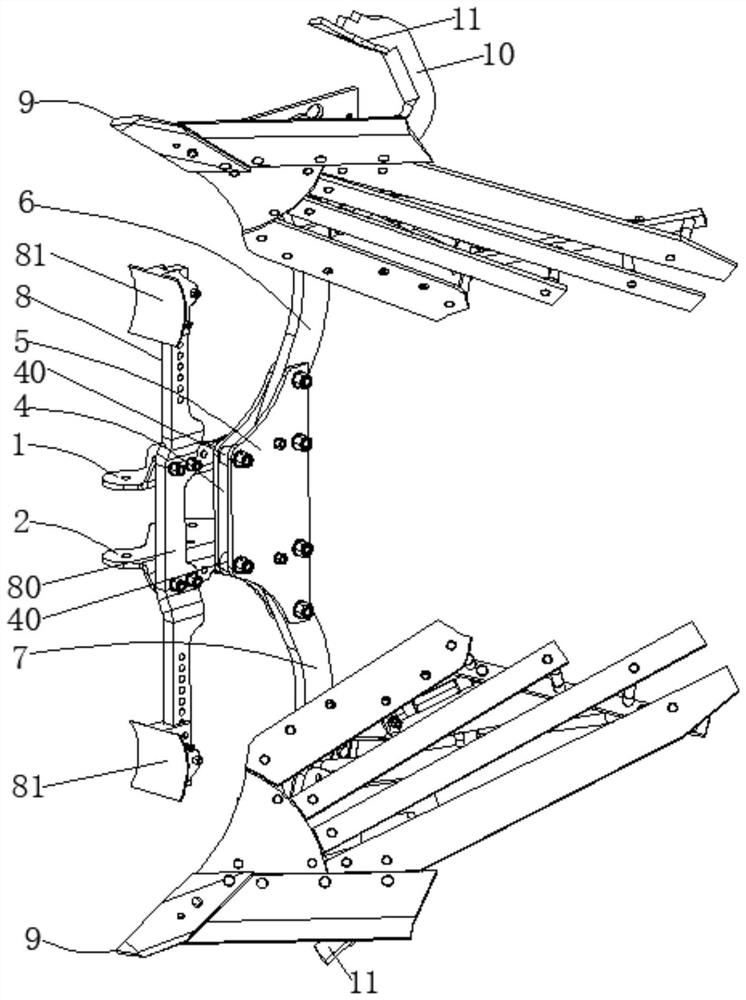

Sowing machine capable of carrying out compacting, reverse rotation, ditching and fertilizing before rotary tillage and straw breaking and working method thereof

PendingCN110393049ASatisfy the requirement of interlaced deep burialReduce the number of entry timesSpadesPloughsAgricultural engineeringTillage

The invention relates to a rice and wheat sowing machine capable of carrying out compacting, reverse rotation, ditching, sowing and fertilizing before rotary tillage and straw breaking sowing. The sowing machine structurally comprises a rack, a soil retaining cover, a reverse-rotating cultivator, a pre-sowing compacting roller, a speed measuring wheel, a double-disc ditcher, a single-hinge profiling compacting mechanism, a double-fertilizer box, a seed box, a reverse-rotating ditching cutter and a ditch protection device. The sowing machine has the advantages that (1) on the basis of meeting the agronomic requirements, the procedures of fertilizing, rotary tillage, straw crushing, ditching, sowing and compacting are completed in field operation at one time, so that the frequency of field operation based on machinery is decreased, and the operation cost is reduced; (2) the pre-sowing compacting roller is arranged for compacting before sowing, the sowing depth can be thus controlled moreeffectively and precisely, and seed emergence and development are facilitated.

Owner:NANJING AGRICULTURAL UNIVERSITY

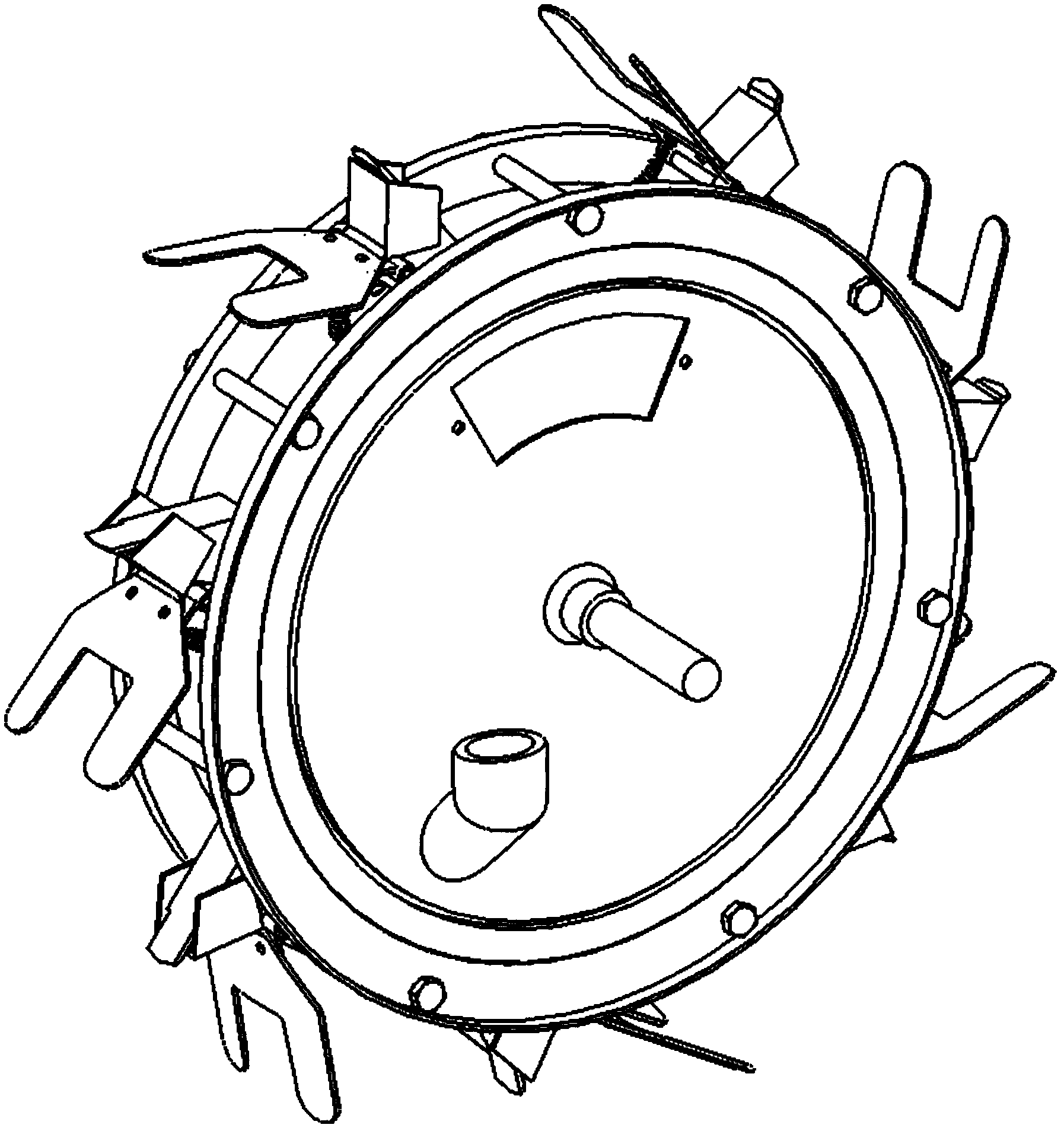

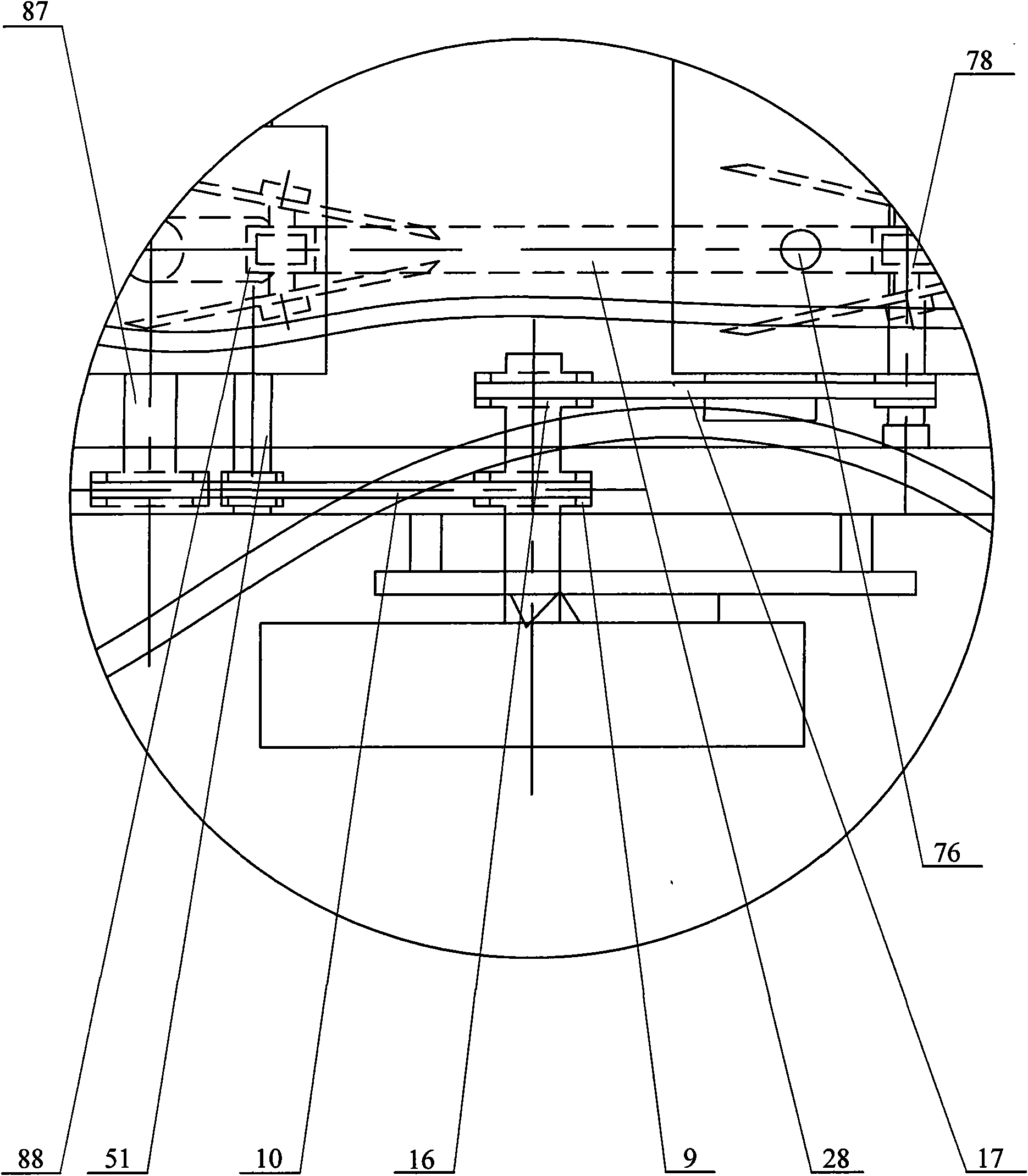

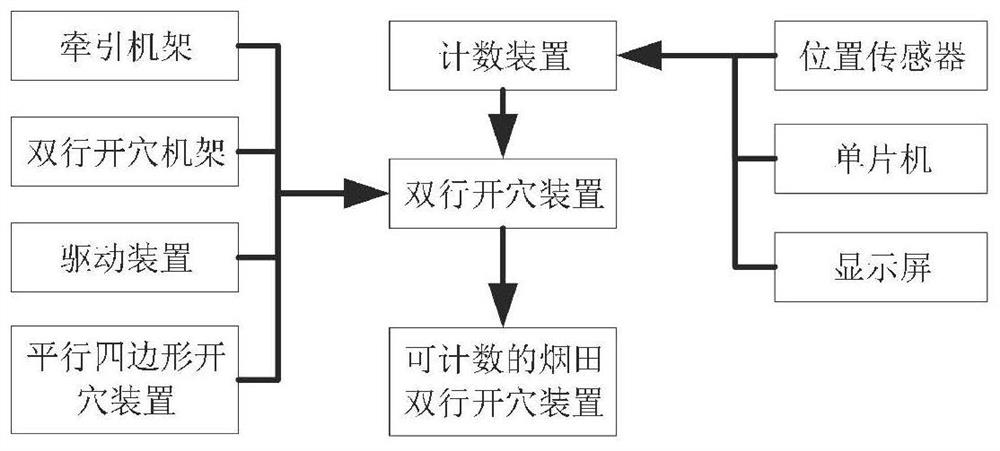

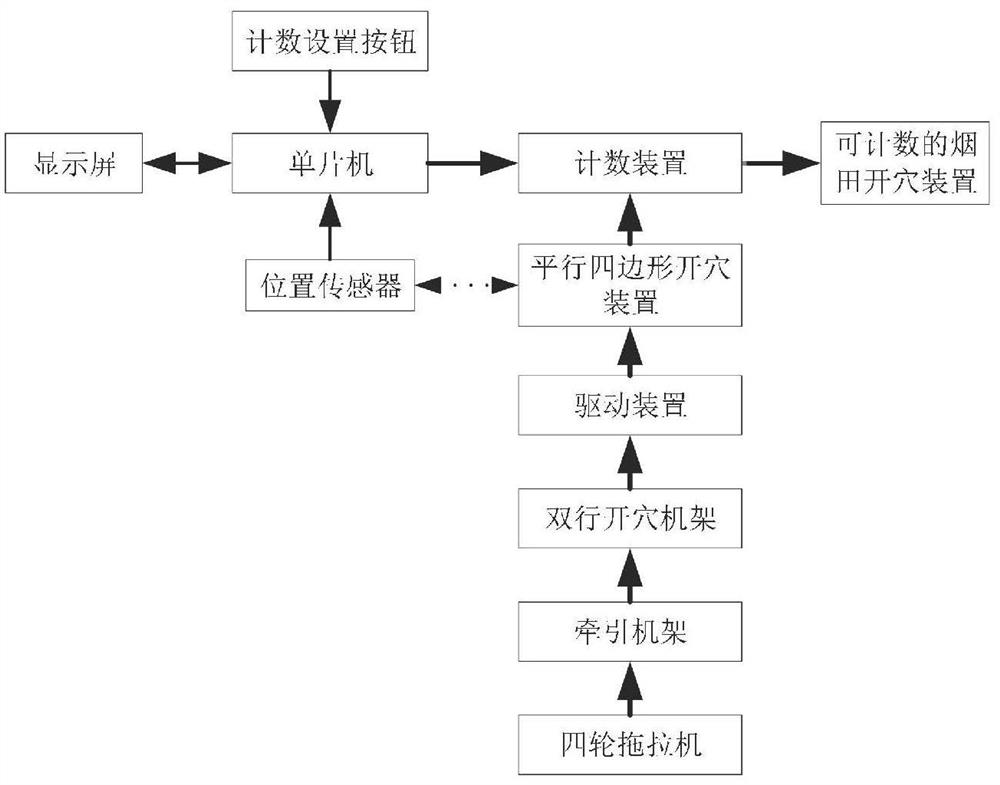

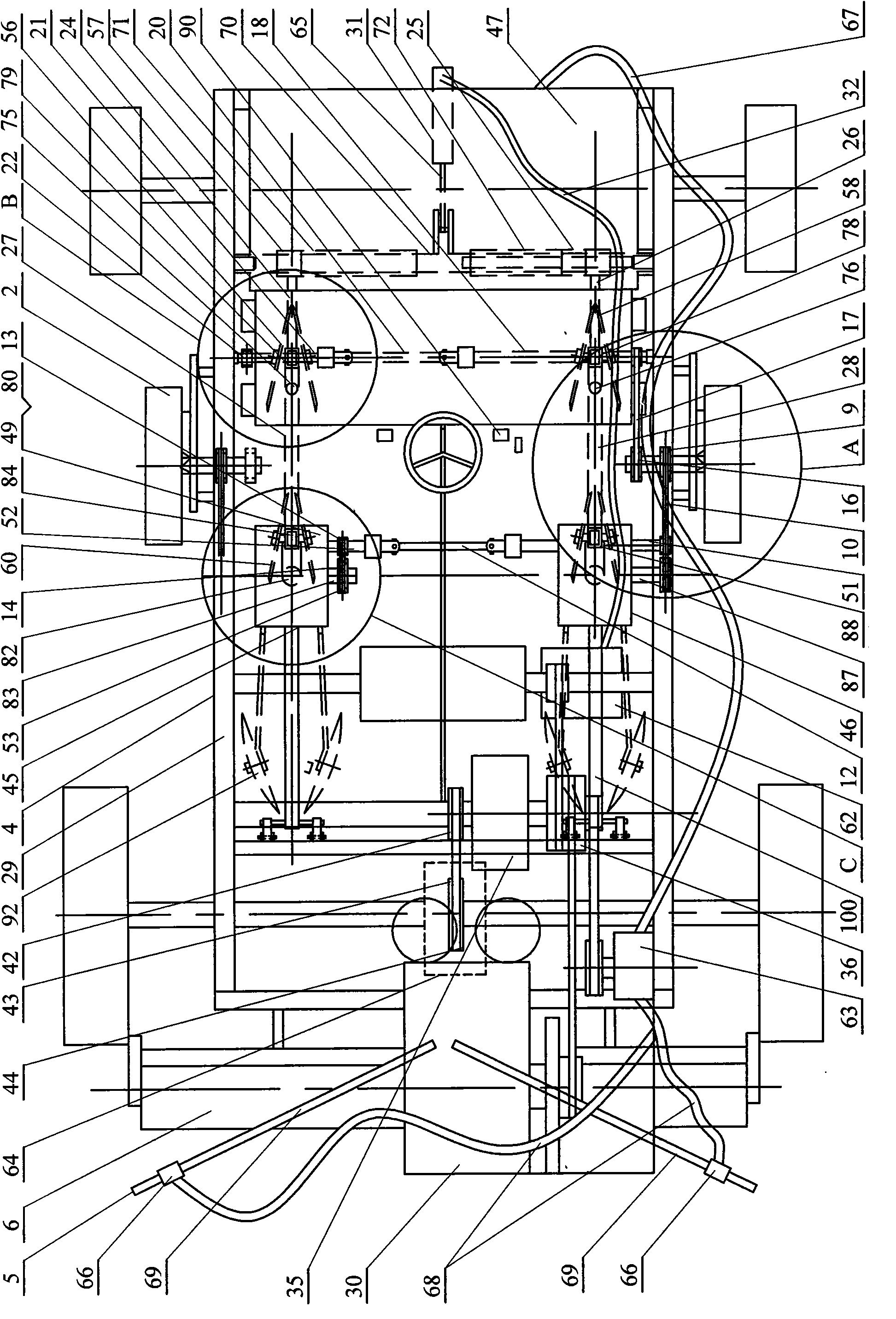

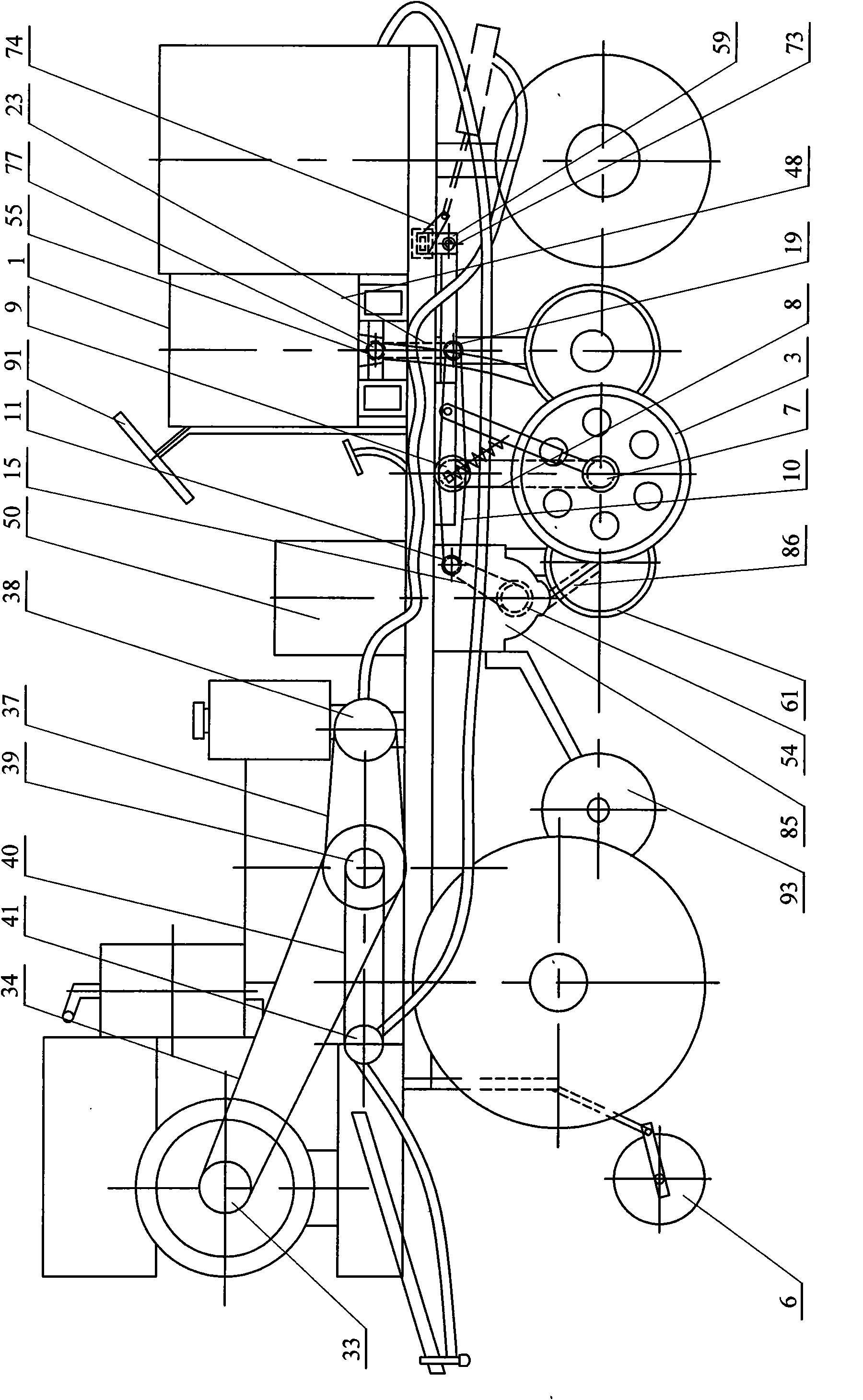

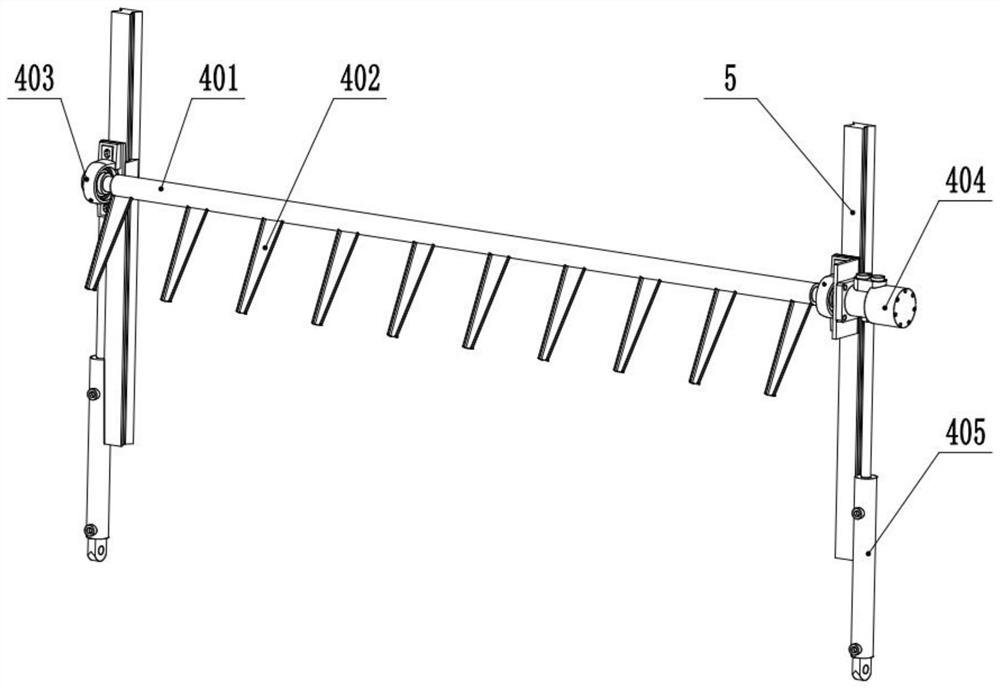

Double-row holing device for tobacco field

ActiveCN111837513AReduce the number of entry timesImprove protectionPlantingFurrow making/coveringDrive shaftAgricultural engineering

The invention discloses a double-row holing device for a tobacco field, and relates to the technical field of agricultural mechanical equipment. The double-row holing device comprises a traction rack,a double-row holing rack, a driving device and holing devices, wherein the traction rack is connected with a traction device; the front end of the double-row holing rack is fixedly connected with thetraction rack, and the driving device is mounted on the double-row holing rack and used for driving the holing devices to perform holing; the driving device comprises a land wheel and a driving shaft; the land wheel is rotationally mounted on the double-row holing rack through a land wheel shaft; a driving chain wheel is mounted on the land wheel shaft, a driven chain wheel is arranged on the driving shaft, and the driving chain wheel is connected with the driven chain wheel through a driving chain; and two ends of the driving shaft are rotationally mounted on the double-row holing rack, andeach of two ends of the driving shaft is connected with a holing device. Two rows of pond holes can be formed at the same time in one stroke, so that the operation efficiency is improved, the field entry frequency of agricultural implements is reduced, and ridges are better protected.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +1

Self-propelled seeding, fertilizing and spraying combined operation machine

InactiveCN101622924BSmall turning radiusReduce the number of entry timesPlantingFurrow making/coveringUniversal jointDrive shaft

The invention discloses a self-propelled seeding, fertilizing and spraying combined operation machine, relating to a seeding, fertilizing and spraying combined operation machine. The existing planting and fertilizing combined operation machine and tractor adopts a split structure, and has no spraying function, thereby having the problems of large turning radius at the edge of a field and high purchase cost for the existing machine. A medical kit, a fertilizer machine, seeders, a compacting device and a spraying rod are arranged along the machine body from front to back; a right travelling wheel is fixedly installed with a drive sprocket wheel which is linked with a second transitional sprocket wheel by a first chain, a second chain and a first transitional sprocket wheel; a right seeder is connected with a left seeder by a first universal joint and drive shaft; a right shaft is connected with a left shaft by a second universal joint and drive shaft; the left shaft is connected with a fertilizer discharging sprocket wheel by a six transitional sprocket wheel and a six chain; and the left and right openers of the fertilizer machine are fixedly connected with the left and right thread bushings of a horizontal position adjusting device by a left and a right front shun beams. The invention integrates the functions of seeding, fertilizing, spraying, compacting and the like with the tractor into a whole, thereby having small turning radius at the edge of the field and low purchase cost for the machine.

Owner:张红波

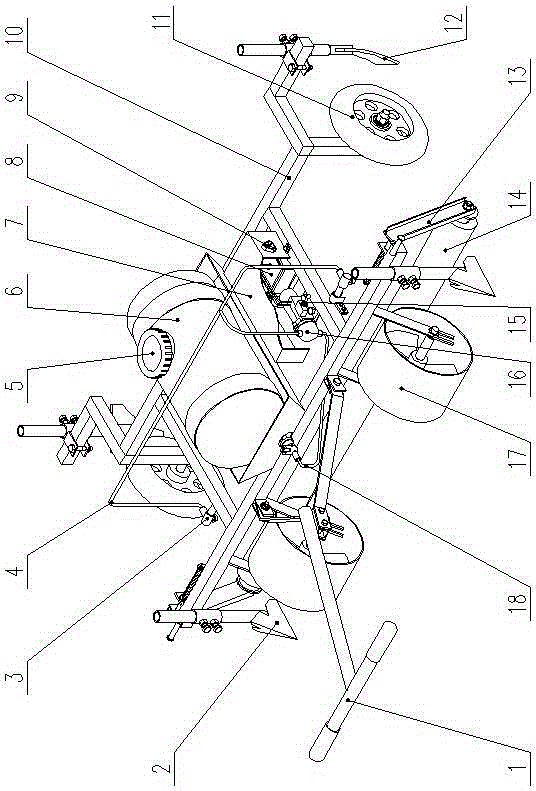

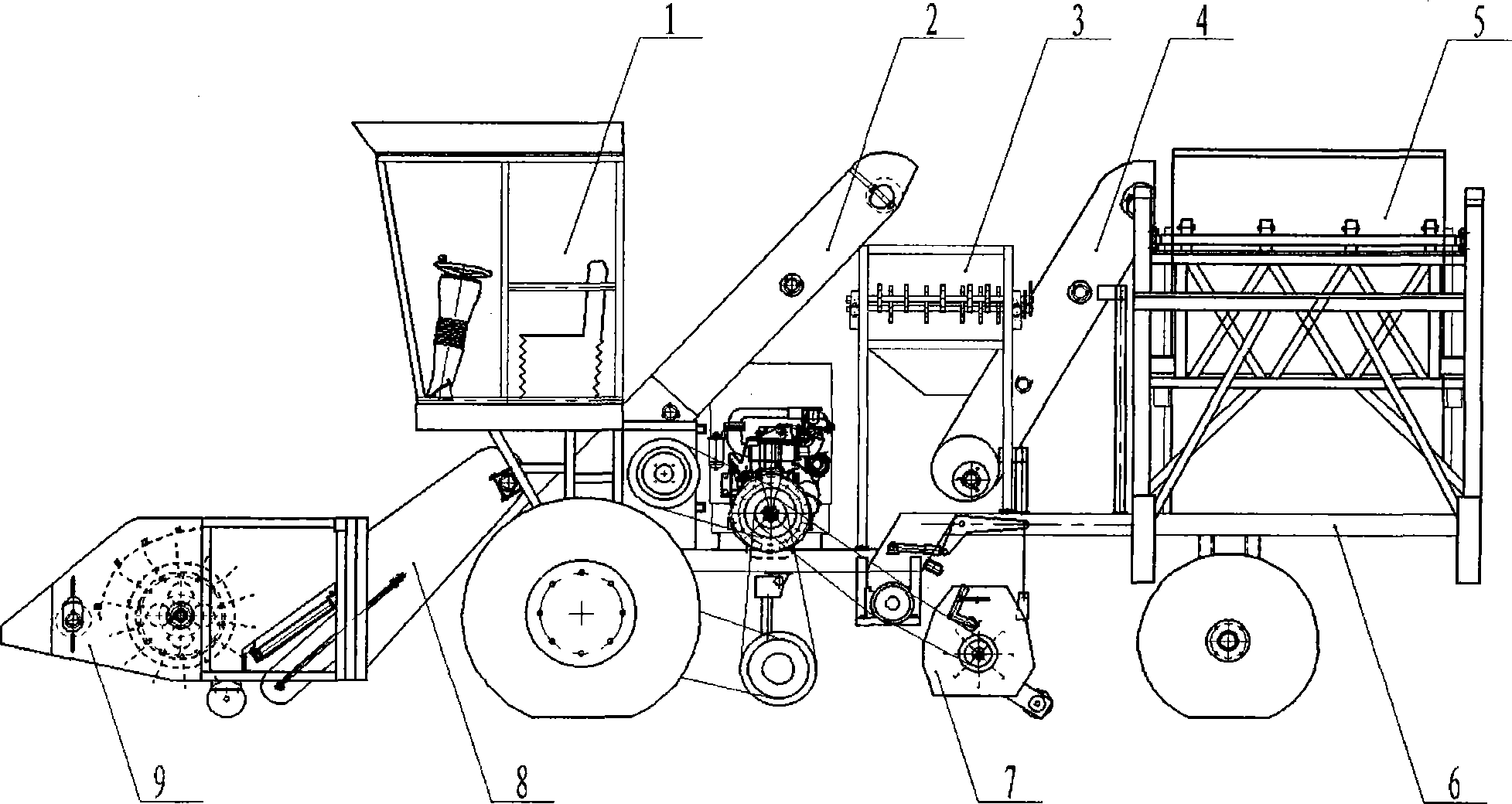

Cotton boll combine harvester

The invention relates to a cotton boll combine harvester. The cotton boll combine harvester comprises a rack (6), a picking device (9), a power control device (1), a first-level conveying device (2), a second-level conveying device (4), a separation device (3), a lifting material box (5) and a cotton stalk recycling device (7), wherein the picking device (9) is arranged at the front end of the rack (6), and is connected with the rack (6) through a gap bridge (8), the separation device (3) is arranged on the top of the middle of the rack (6), the first-level conveying device (2) is installed between the picking device (9) and the separation device (3), the lifting material box (5) is installed on the rear portion of the rack (6), the second-level conveying device (4) is installed between the separation device (3) and the lifting material box (5), and the cotton stalk recycling device (7) is installed at the bottom of the middle of the rack (6). Compared with the prior art, the cotton boll combine harvester can accomplish various types of operation including cotton boll picking, conveying, separation, material collection and cotton stalk recycling at one time, the farming season is ensured, the phenomenon that operation is busy is eliminated, efficiency is high, energy consumption is low, the investment is small, and particularly, compared with single operation, the frequency of the cotton boll combine harvester for entering the field is reduced, and damage to the soil structure is reduced.

Owner:SHIHEZI UNIVERSITY

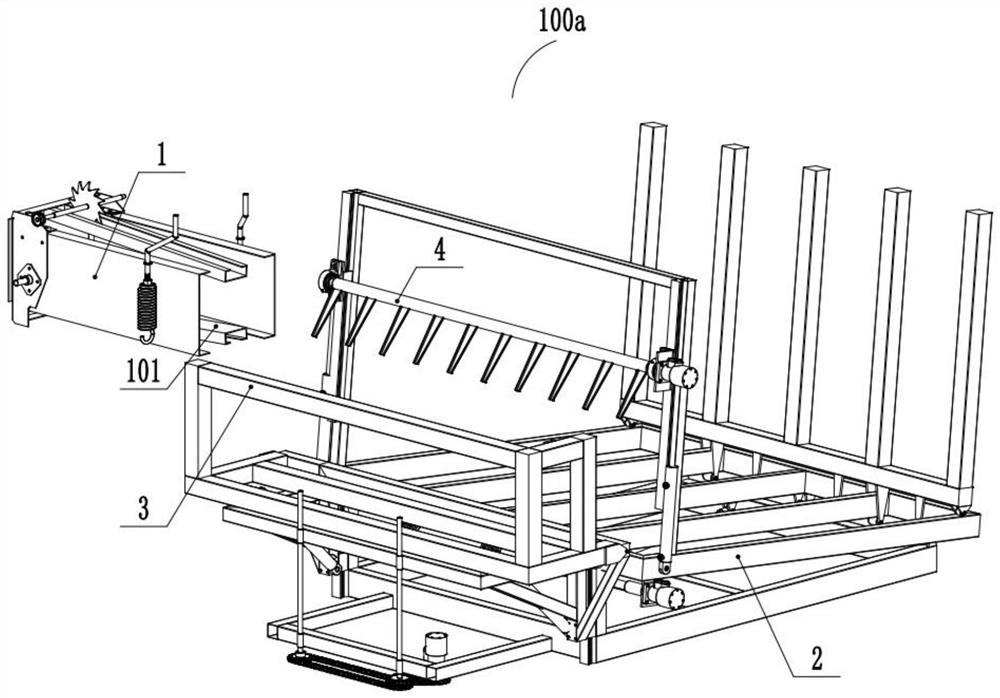

Mealie whole straw coverage wheat full no-tillage planting method and equipment thereof

The invention provides a method and apparatus for total no-tillage planting operation through blanketing wheat with overall maize stalks, wherein the complete stalks of the harvested maize are pulled down in situ in the field, and the wheat seeds are planted through trench digging between the maize planting rows. The maize complete stalk blanketing wheat no-tillage planting and fertilizer applicator set provided by the invention can realize the operations of upright maize stalk pulling down, combing, wheat seeding, fertilizing, suppressing and stalk compression.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

Square bundle collecting device

PendingCN112758698ANeatly stackedReduce the number of entry timesConveyorsStacking articlesClassical mechanicsStructural engineering

The invention discloses a square bundle collecting device which comprises a square bundle discharging unit, a square bundle storage unit, a square bundle conveying unit and a baffle unit. During work, square straw bundles are output from a bundle outlet and gradually pushed to a rotating platform by subsequently-output square straw bundles, after the square straw bundles trigger a contact switch, a movable rack drives the rotating platform to descend, when the bearing face of the rotating platform is flush with a storage platform, the rotating platform turns over, the square straw bundles stacked horizontally in a single layer are turned over to the storage platform, the bundle outlet continues to output the square straw bundles, the rotating platform stacks the square straw bundles stacked horizontally in the single layer to the previous square straw bundles, and stacking of multiple layers of square straw bundles is achieved; and the baffle unit can move up and down, so that the square straw bundles are stacked in order, and when the square straw bundles are stacked to a certain height, a movable baffle moves in the direction away from the square bundle conveying unit so that the storage platform can stack the square straw bundles again until the square straw bundles on the storage platform are stacked in order.

Owner:滨州市农业机械化科学研究所

Film-covered corn straw crushing and collecting type residual film recycling machine

PendingCN108770391AReduce mechanical damageHigh recovery rateGatherer machinesDrive shaftAgricultural engineering

The invention relates to the field of agricultural machinery, in particular to a film-covered corn straw crushing and collecting type residual film recycling machine. The recycling machine comprises atransmission shaft, a straw stubble depth limiting wheel, a transmission device, a cutter shaft assembly, a spiral conveying device, a straw pneumatic lifting assembly, a suspension mechanism, a filmlifting shovel, a primary lifting chain, a secondary lifting chain, a reel assembly, a film sundry box assembly, a straw collecting box and a rack, wherein the straw collecting box, the suspension mechanism and the transmission shaft are arranged at the upper end of the rack; the transmission device is arranged at the lower end of the rack, the straw stubble depth limiting wheel is arranged at the left end of the transmission device, the cutter shaft assembly is arranged at the lower end of the transmission device, the a spiral conveying device and the straw pneumatic lifting assembly are arranged at the right end of the transmission device, the film lifting shovel is arranged at the right end of the straw pneumatic lifting assembly, the primary lifting chain is arranged at the right endof the film lifting shovel, the secondary lifting chain is arranged at the right end of the primary lifting chain, the reel assembly is arranged at the right end of the secondary lifting chain, and the film sundry box assembly is arranged at the lower end of the reel assembly.

Owner:潘卫云

Harrow and plow compound machine

The invention discloses a compound workover rig of a raking plough. A traction frame and a group of plough shares are arranged on a plough rack; a rotary cultivator is arranged behind the plough rack; a pair of parallel four-bar mechanisms is arranged between the plough rack and the rotary cultivator; the rear end of the plough rack is fixedly connected with first support saddles of the pair of parallel four-bar mechanisms; the rotary cultivator is hinged with second support saddles of the pair of parallel four-bar mechanisms; a transmission shaft is supported on the plough rack; a first speed reducer is fixed at the upper part of the rotary cultivator; the transmission shaft is connected to the input shaft of the speed reducer; an output shaft of the speed reducer is connected with a cutter shaft of the rotary cultivator; each parallel four-bar mechanism is provided with a limiting mechanism for controlling the second support saddles to translate downwards; and an adjusting mechanism for adjusting the levelness of the rotary cultivator is arranged between the second support saddles of the two parallel four-bar mechanisms and the rotary cultivator. The compound workover rig of the raking plough is pulled by the tractor; the transmission shaft is coupled to the power output shaft of the tractor; and the plough shares and the rotary cultivator can respectively plow and rake the field in field operation, so that plowing and racking are finished in one-stop operation.

Owner:安徽省淮丰现代农业装备有限公司

In-situ film-forming salt-isolation operation device and method for saline-alkaline land improvement

ActiveCN111165108AReduce the number of entry timesPrevent compactionSoil lifting machinesClimate change adaptationLand improvementSoil science

The invention provides an in-situ film-forming salt-isolation operation device and method for saline-alkaline land improvement. The device comprises a machine frame, an in-situ film-forming module anda high-pressure laminating module; the machine frame is used for supporting and fixing other modules, is in hooking connection or traction with a tractor suspension system, and provides power for other devices; the in-situ film-forming module is used for realizing deep scarification and layering operation on soil; and the high-pressure laminating module is used for spraying laminating liquid. Theoperation method in the invention is as follows: an in-situ film-forming scooper scoops up soil; liquid film liquid is sprayed through a film-forming spray head after scooping; after liquid is solidified, a layer of isolation film is formed; laminating areas are mutually overlapped through S-shaped advancing; a whole isolation film is formed; therefore, isolation of underground salt is realized;and salinization of soil is prevented.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

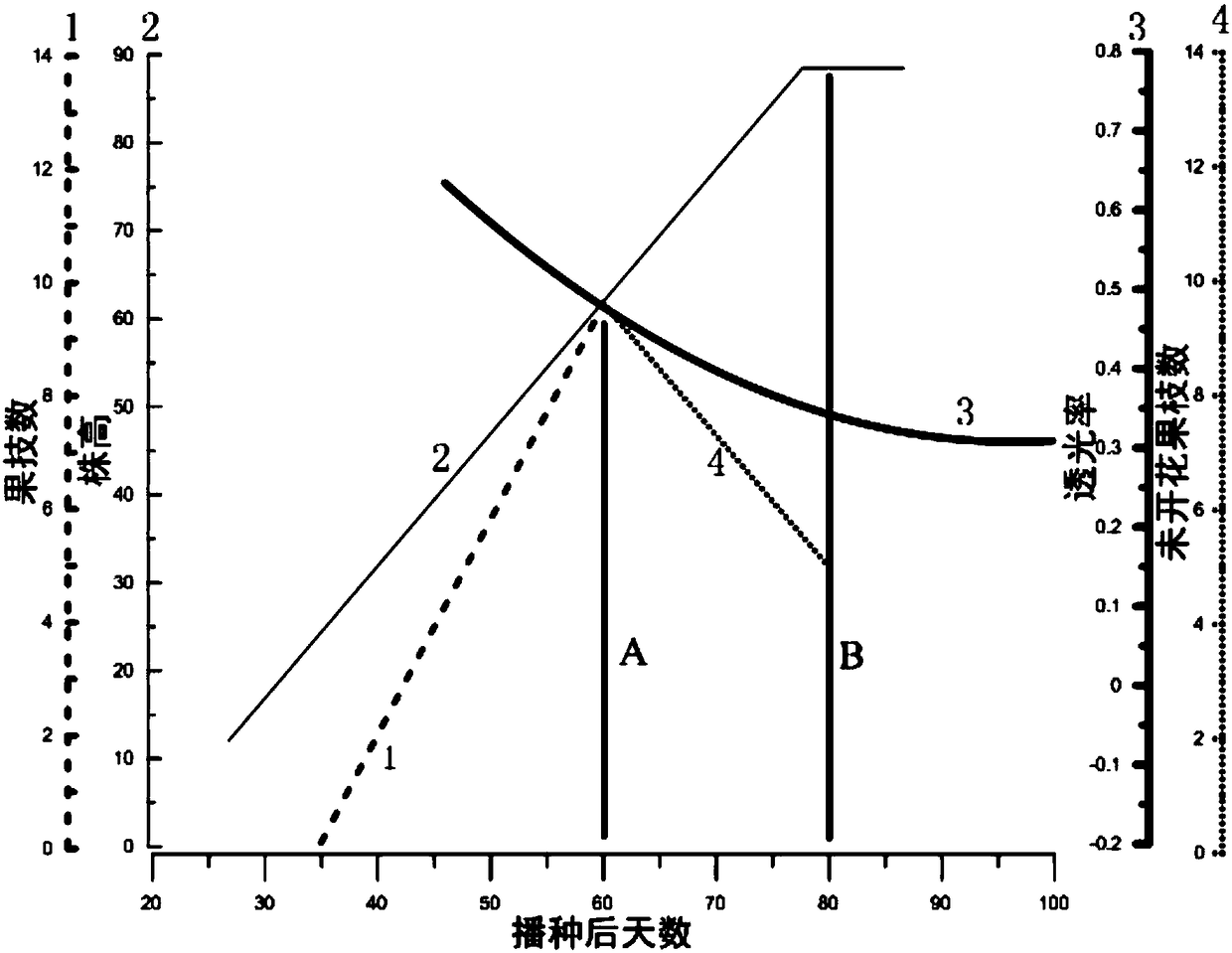

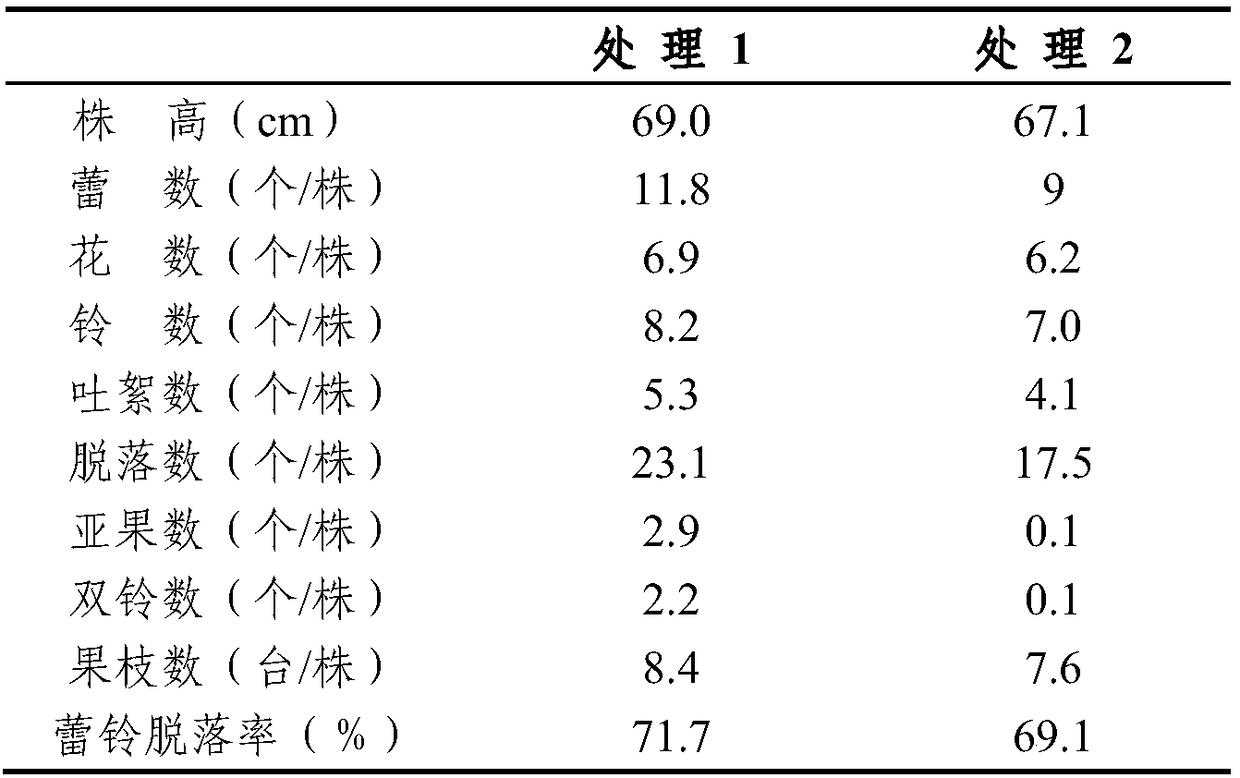

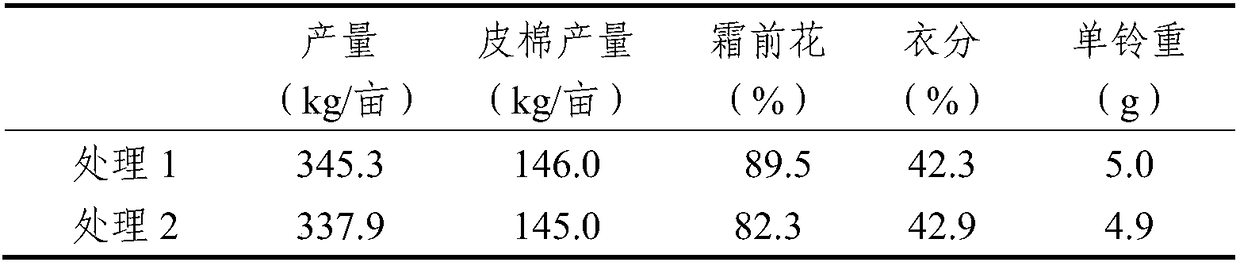

A kind of cotton growth regulator and its preparation method and application

ActiveCN105851021BPromote early maturityPromote differentiationBiocidePlant growth regulatorsAgricultural scienceChemical control

The invention relates to a cotton growth regulating agent and a preparation method and application thereof. Active ingredients of the cotton growth regulating agent include naphthylacetic acid, triacontanol, triodebenzoic acid, 6-BA (6-benzylaminopurine), uniconazole, a dispersing agent, a wetting agent, ethylene glycol, glycerin, gibberellins and indoleacetic acid. The cotton growth regulating agent is capable of promoting cotton precocity and concentrated maturity and can be used by either spraying or drip irrigation, and labor input is effectively reduced. According to cotton standard maturity and plant type regulation reference graphs, cotton growth indexes are inspected to realize quantified regulation in two periods in contrast to a standard plant type and a maturity curve, and adverse influences of risks of cotton yield reduction, runt seedlings and the like caused by spraying of mepiquat chloride in a cotton seedling stage due to improper traditional experience based chemical control can be avoided.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

Cotton intertillage fertilization ridging machine

PendingCN111713199AImprove work efficiencyReduce the number of entry timesSpadesPlantingAgricultural scienceUniversal joint

The invention discloses a cotton intertillage fertilization ridging machine. The cotton intertillage fertilization ridging machine comprises a rack, wherein a fertilizer box and a plurality of operation units are arranged on the rack, and each operation unit comprises an intertillage fertilization profiling single body and a rotary ridging mechanism; each intertillage fertilization profiling single body comprises a profiling single body rack connected with the rack through a four-bar linkage profiling assembly and a fertilization furrow opener connected with the corresponding profiling singlebody rack, a plurality of electric fertilizer feeders are arranged on the fertilizer box, and the electric fertilizer feeders communicate with the corresponding fertilization furrow openers; each rotary ridging mechanism comprises a ridging rack and a gearbox, the ridging racks and the gearboxes are fixedly connected with the rack, a transmission shaft, a ridging cutter shaft and a soil crushing housing are arranged on each ridging rack, the transmission shaft is connected with an output shaft of the gearbox and is in transmission connection with the ridging cutter shaft, and a plurality of ridging cutters are arranged on the ridging cutter shaft; the rack is further provided with a gap bridge shaft connected with an input shaft of the gearbox through a universal joint. According to the cotton intertillage fertilization ridging machine, the cotton intertillage ridging operation efficiency is improved.

Owner:滨州市农业机械化科学研究所

Hydraulic turnover plow with deep scarification function

PendingCN112690051AWith deep loosening functionRealize the soil turning operationSpadesPloughsAgricultural engineeringStructural engineering

The invention discloses a hydraulic turnover plow with a deep scarification function. The plow comprises a plow seat plate I, a plow seat plate II, a seat plate support sleeve, a plow column clamping plate I, a plow column clamping plate II, a plow column I, a plow column II, a small plow component and plow blade components. The plow seat plate I and the plow seat plate II are connected through the seat plate support sleeve, the plow column clamping plate I is connected with the plow seat plate I and the plow seat plate II, the plow column clamping plate II is connected with the plow column clamping plate I, the plow column I and the plow column II are inserted between the plow column clamping plate I and the plow column clamping plate II and connected with the plow column clamping plate I and the plow column clamping plate II respectively, the small plow component is connected with the front end of the plow seat plate I and the front end of the plow seat plate II respectively. Two plow blade components are mounted and are connected with the end parts of the plow column I and the plow column II, the end parts of the plow column I and the plow column II are connected with subsoiling shovels, subsoiling sheets are arranged on the subsoiling shovels, and a tractor operates at one time, so that soil turning and straw burying are completed, the subsoiling operation of a plow pan is also completed, the land entering frequency of the tractor is reduced, the operation efficiency is high, and resources are saved; and therefore, the subsoiling resistance is small, and the tractor traction requirement is low.

Owner:JIAMUSI WODI AGRI MACHINERY MFGCO

Double rotary tillage proportional layered fertilization wide seedling width precision seeder

ActiveCN105557102BImprove blending uniformityImprove the quality of field returnSpadesSaving energy measuresAnti jammingTerra firma

The invention relates to a broad-seedling-width precision sowing machine with functions of double rotary tillage and proportional layering fertilization. The precision sowing machine comprises a suspended rack, a gearbox, a double-shaft rotary tillage device assembly, an anti-jamming spiral land leveler, a proportional layering fertilization device assembly, a rolling cage harrow, a broad-seedling-width strip sowing device assembly, a cylindrical heavy roller, and a proportional layering fertilization and precision sowing intelligent control system; and the precision sowing machine can sequentially finish operations in links of double rotary tillage for land preparation, spiral blade land leveling for jamming prevention, proportional layering fertilization, land leveling and rolling before sowing, broad-seedling-width precision sowing, rolling after sowing and the like in one time. According to the precision sowing machine, the broad-seedling-width sowing can be realized and a twice throwing and unique multilayer comb strip decentralizing and seed uniformizing structure is adopted, so that seeds can be uniformly distributed in a relatively broad seedling width (8-10cm) range and the space layout structure of seedlings is remarkably improved; and the relationship between a group and an individual is coordinated and a reasonable crop group is created, so that a solid foundation is laid for high yield.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com