Patents

Literature

34results about How to "Good effect of crushing soil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

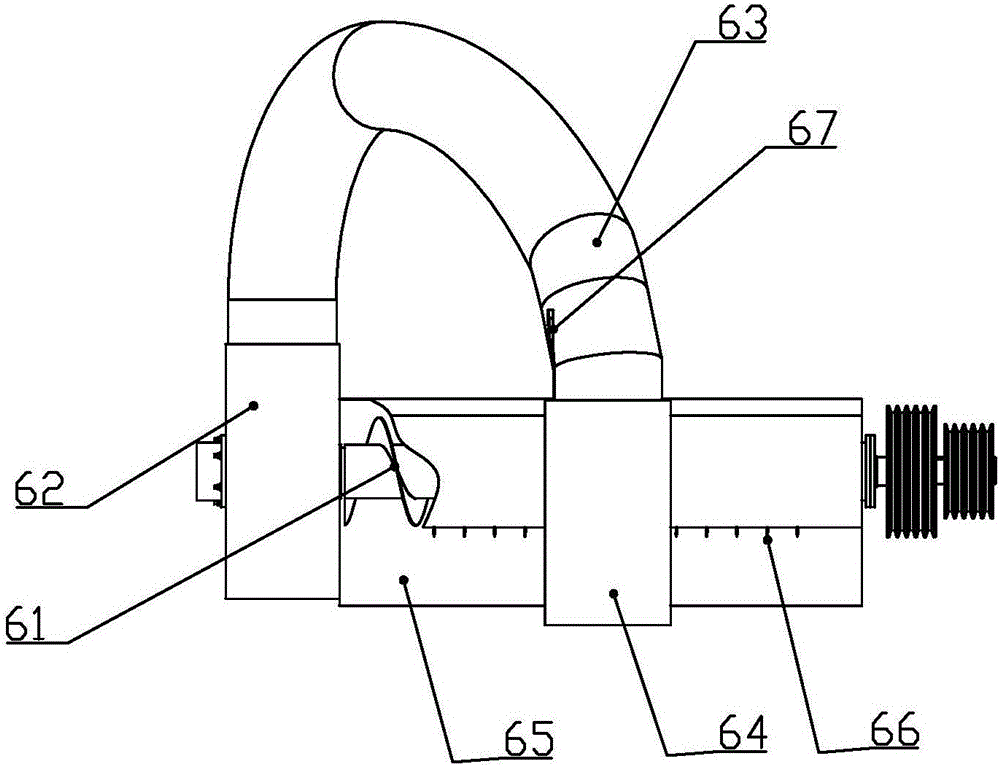

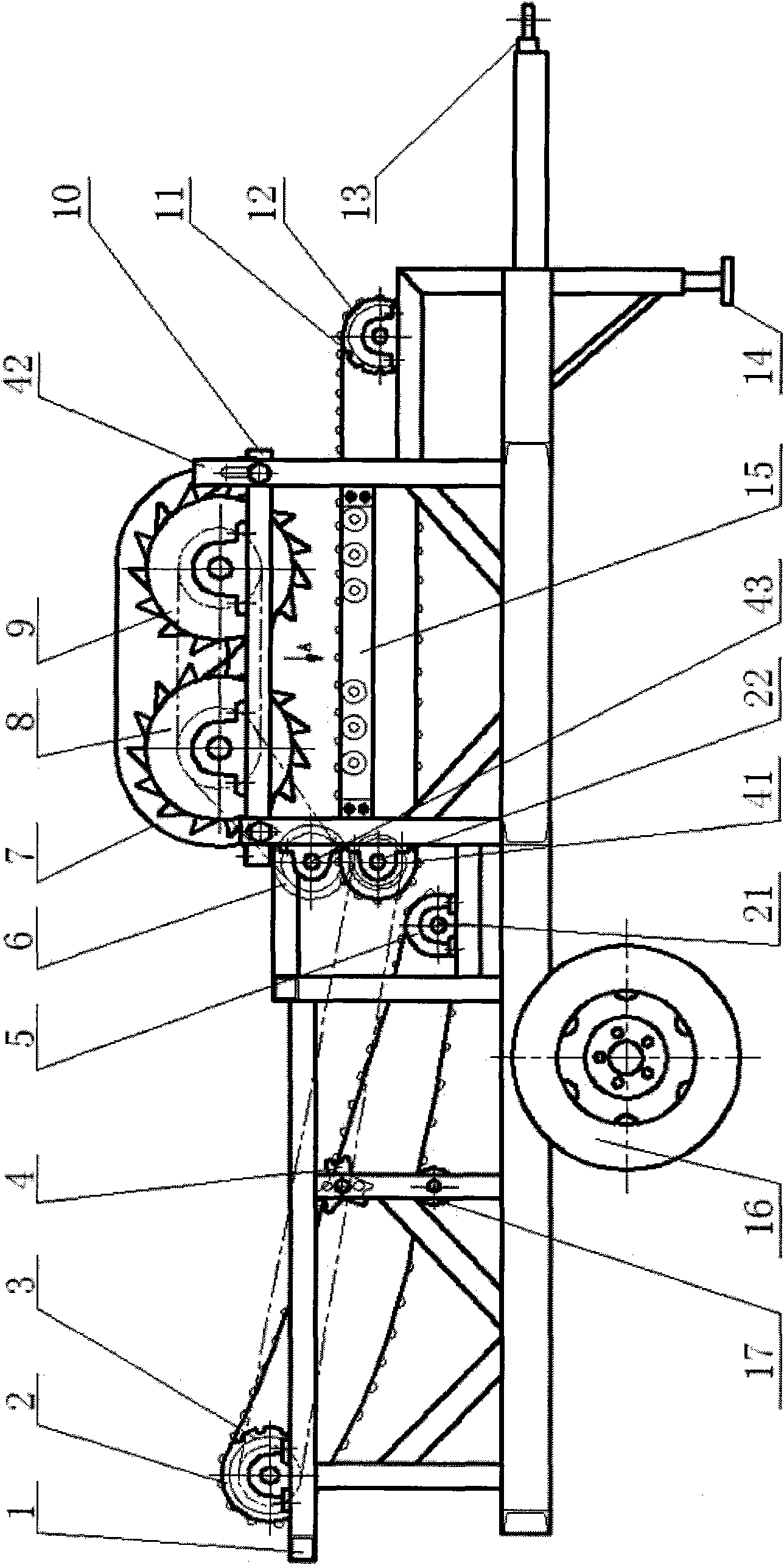

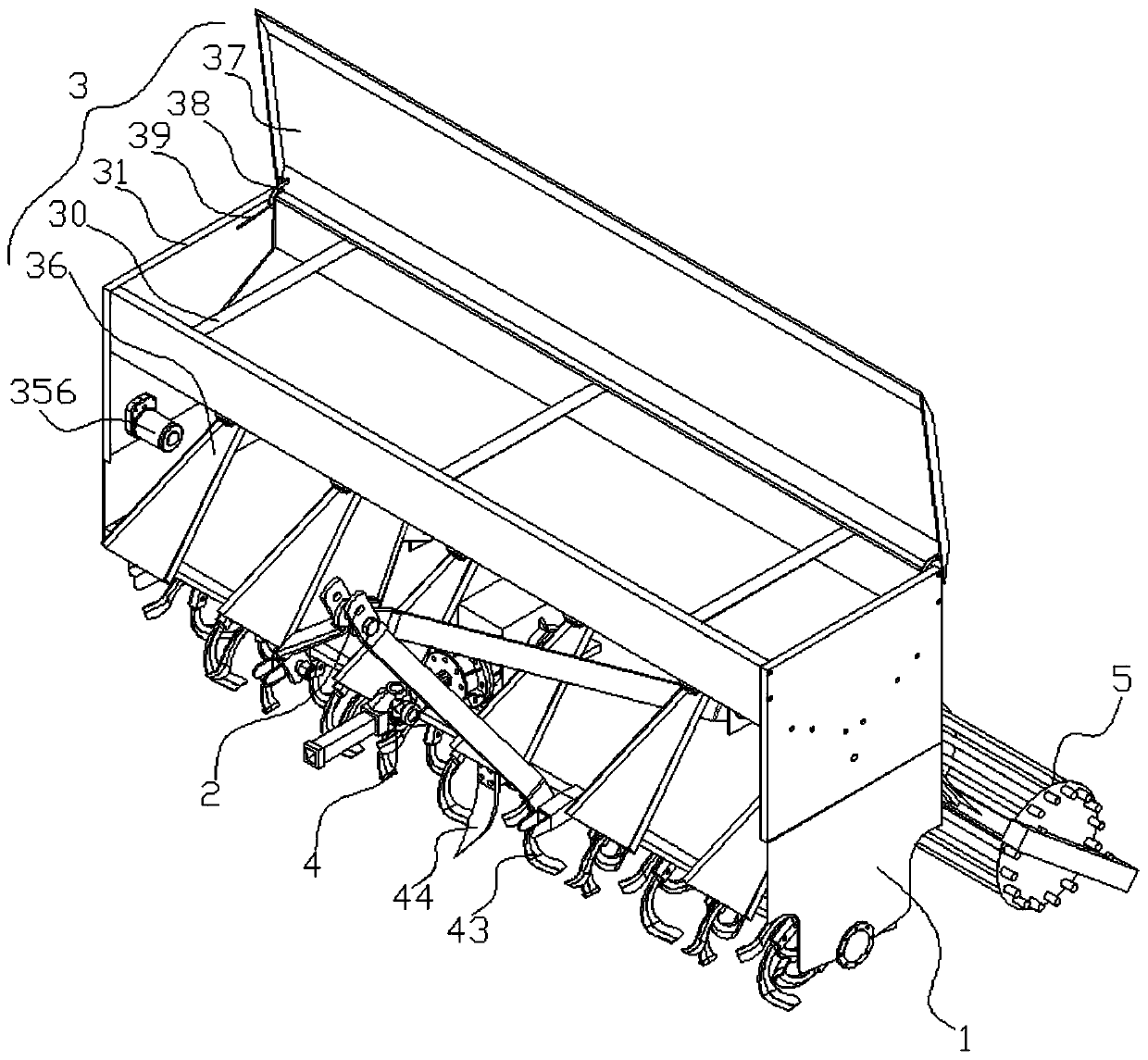

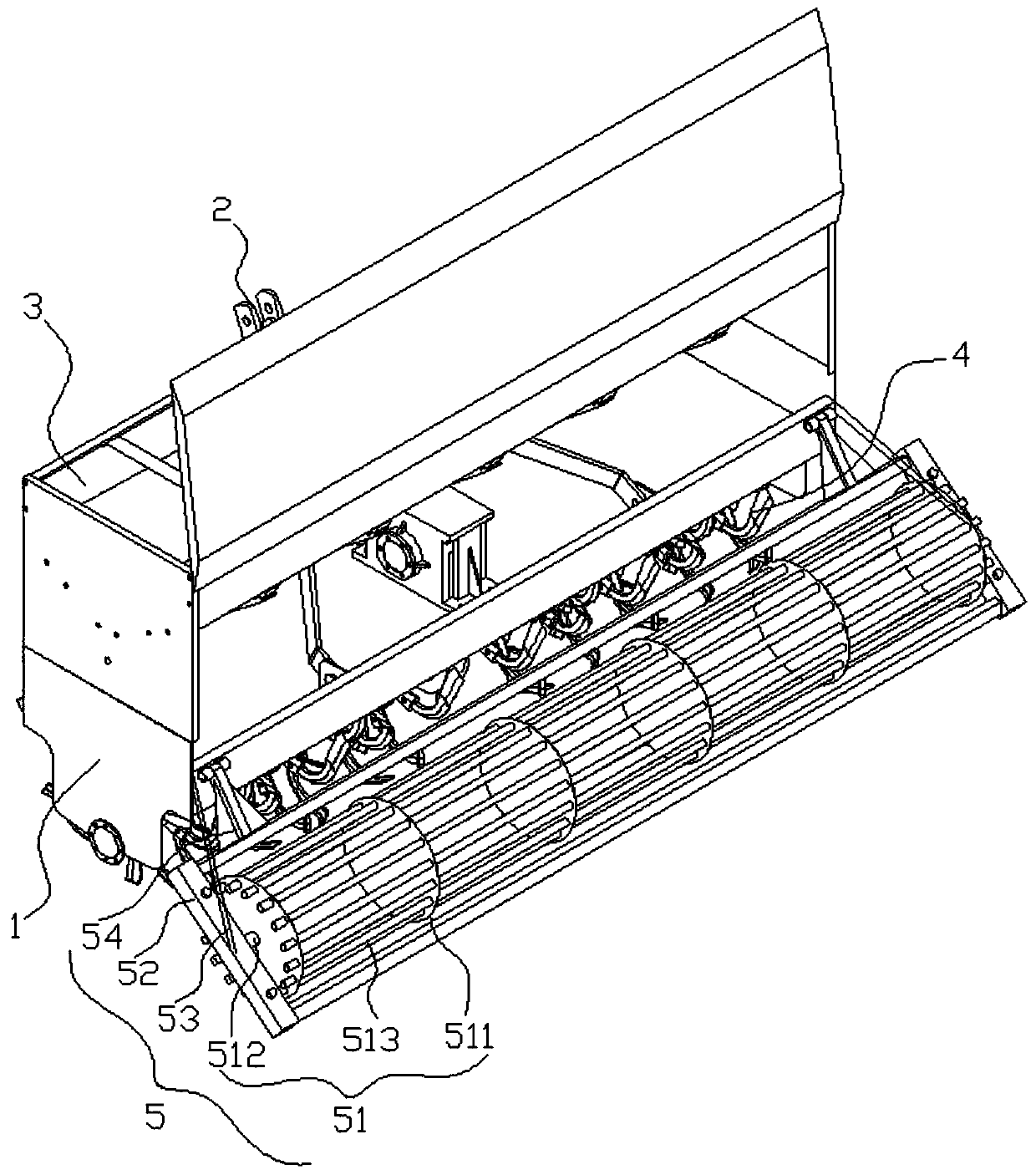

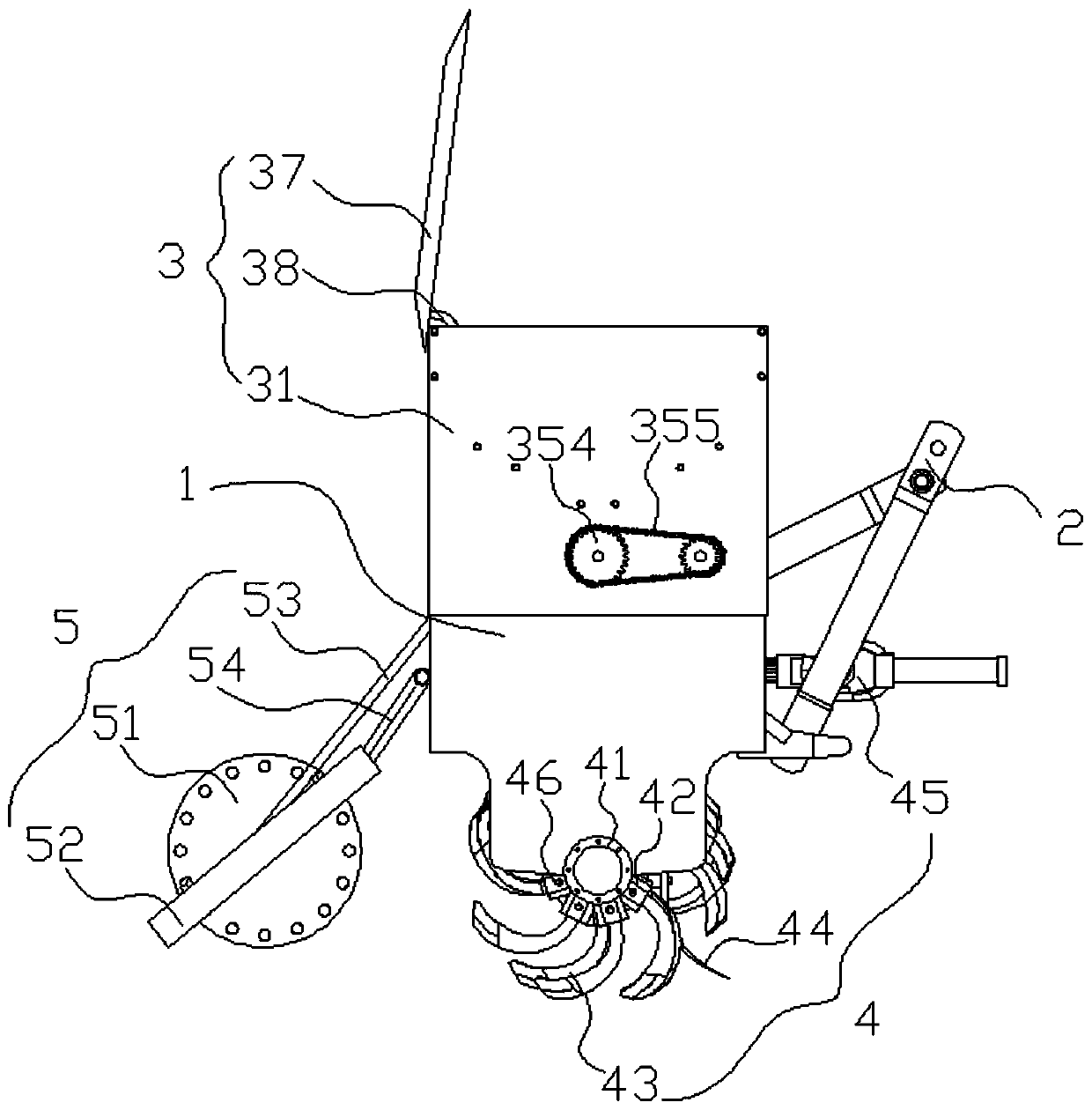

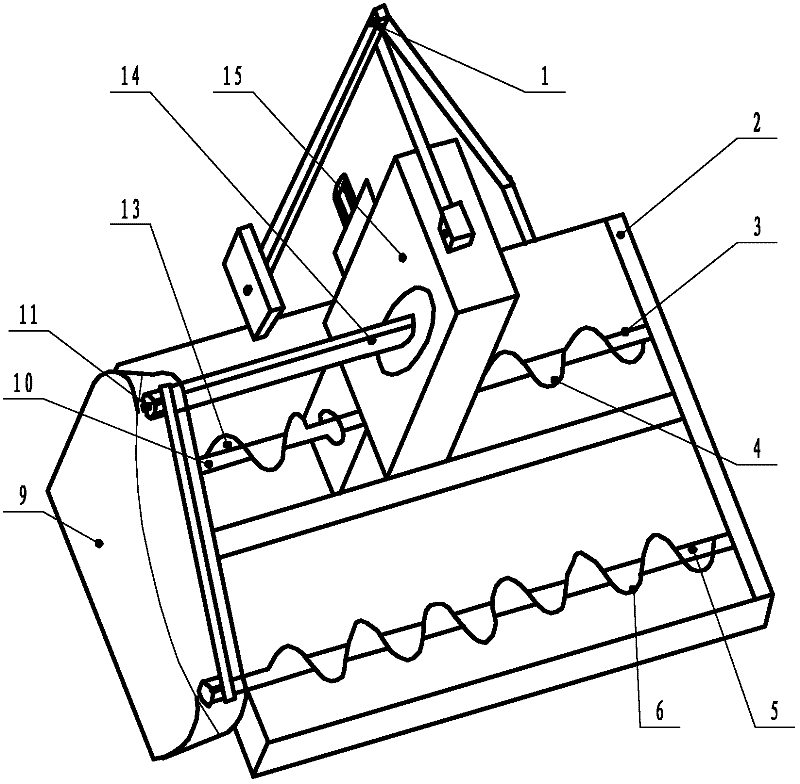

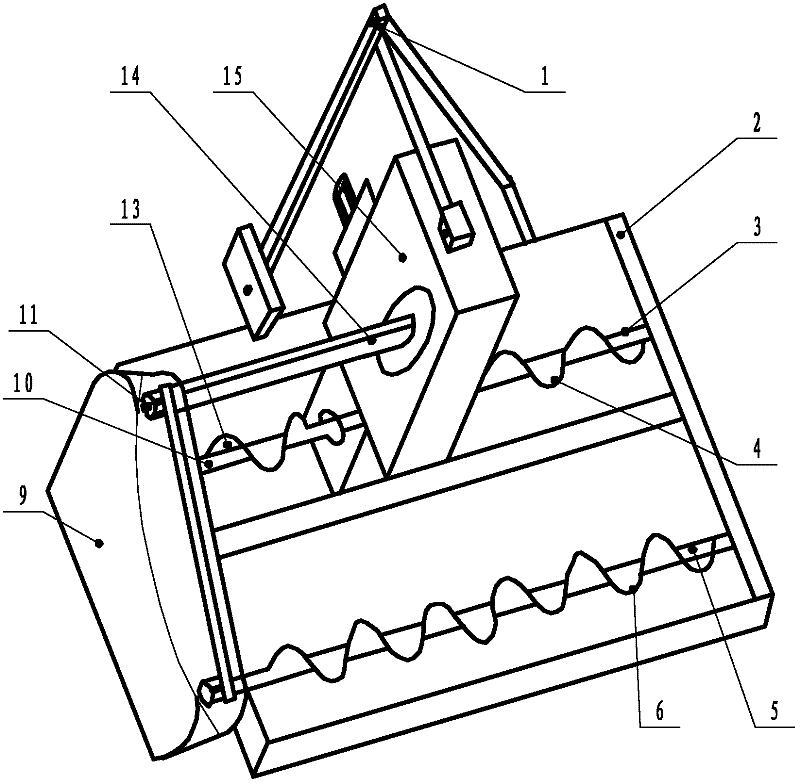

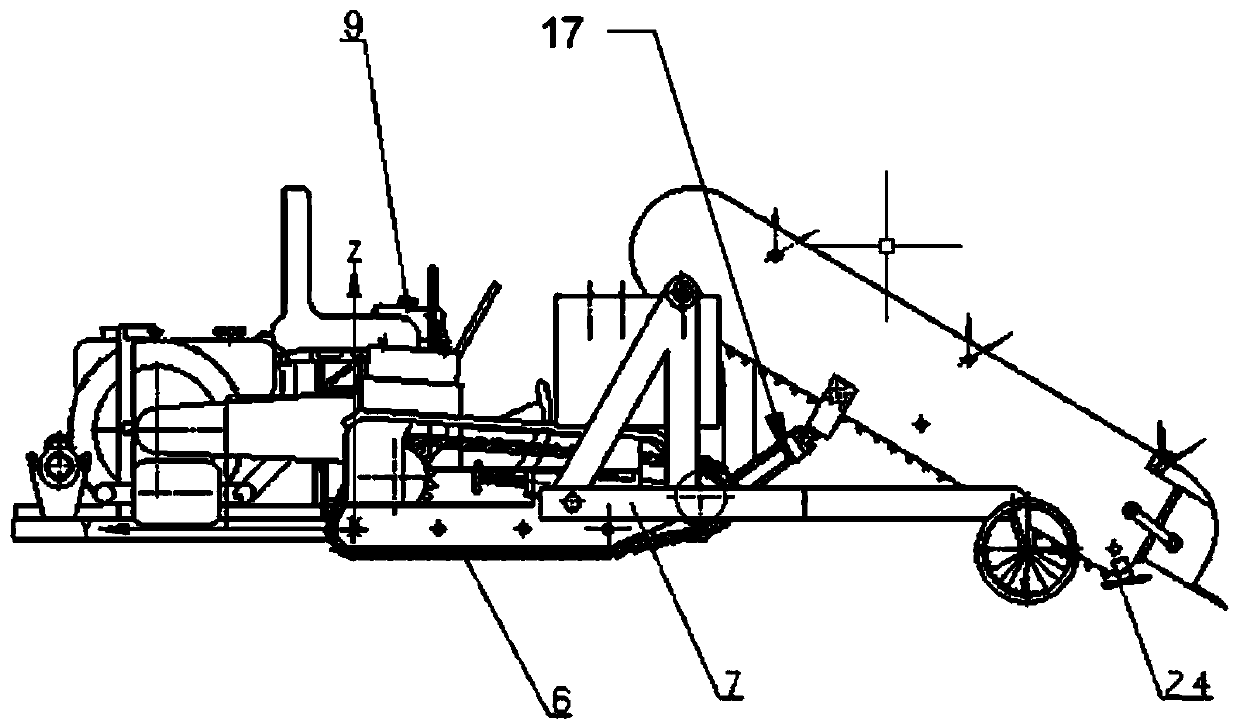

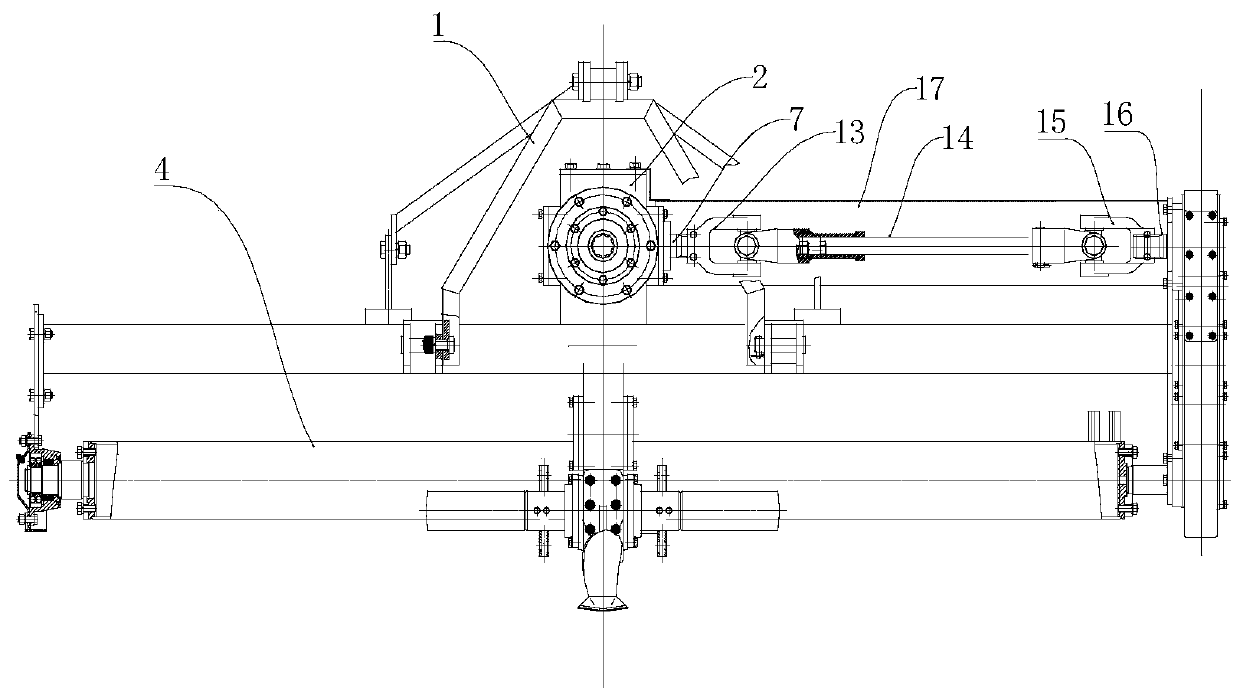

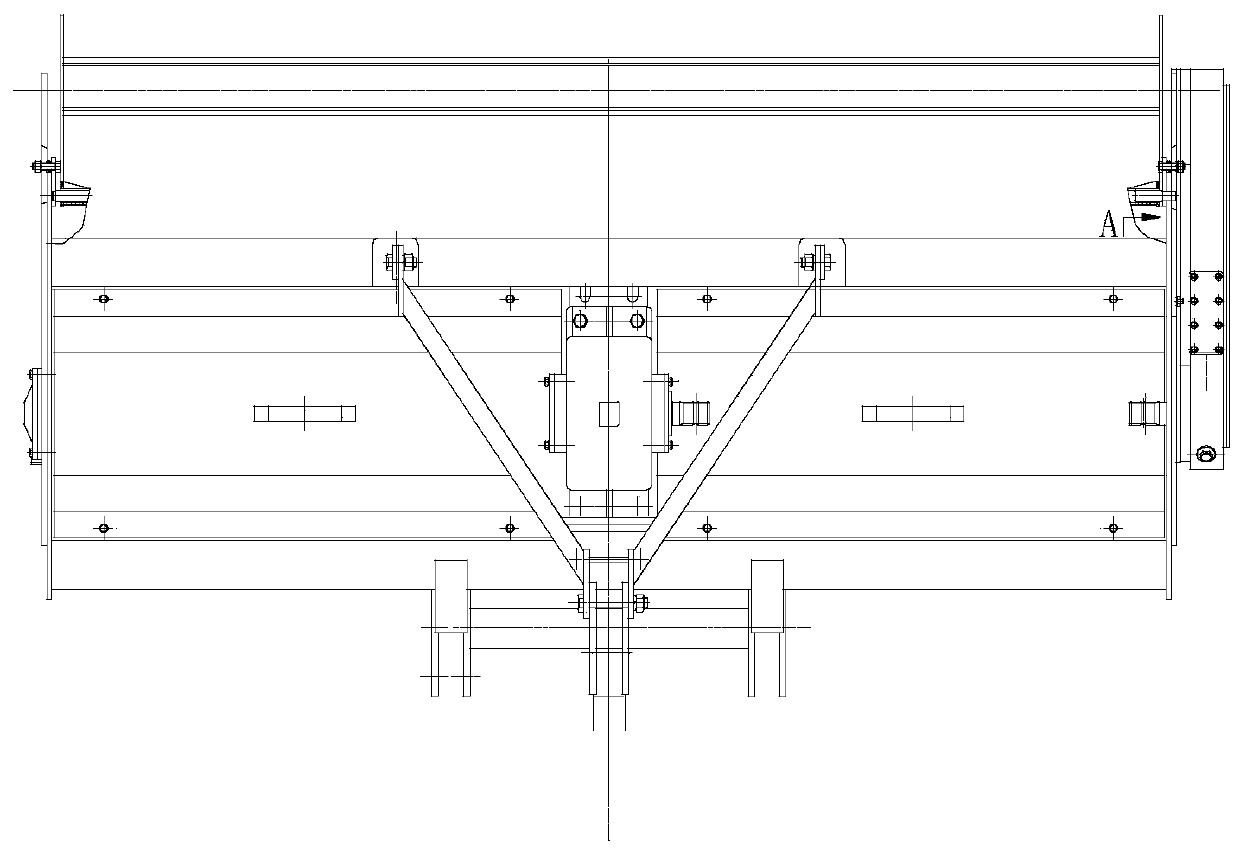

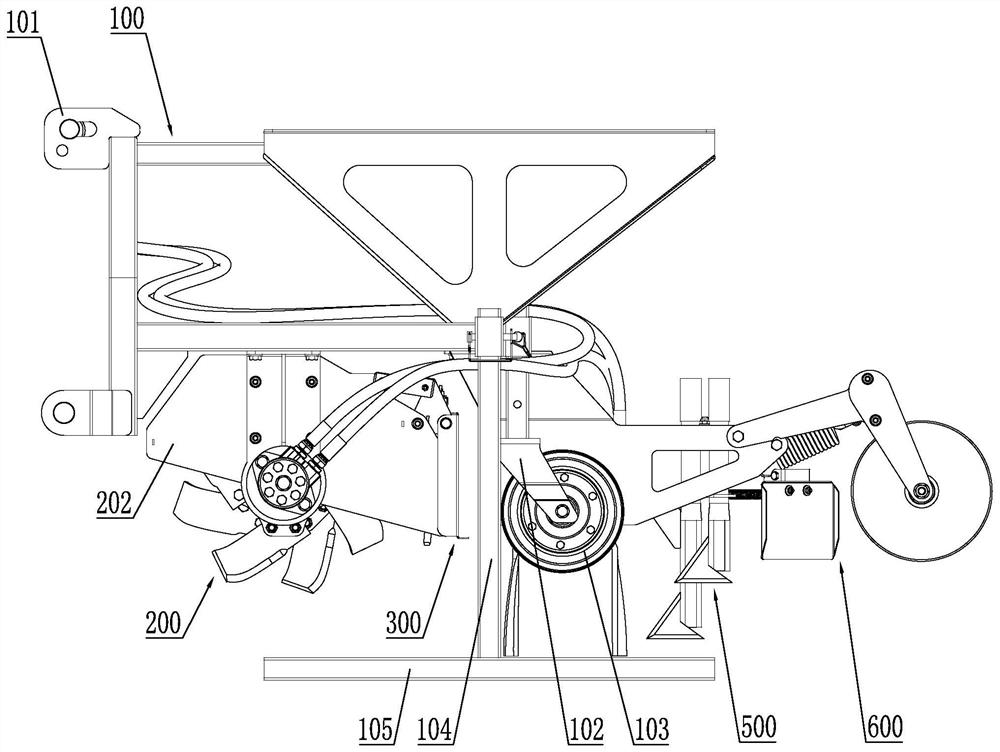

Pneumatic straw deep-burying returning machine

ActiveCN106717477AReduce energy consumptionGood effect of crushing soilMowersAgriculture gas emission reductionDevice formSoil porosity

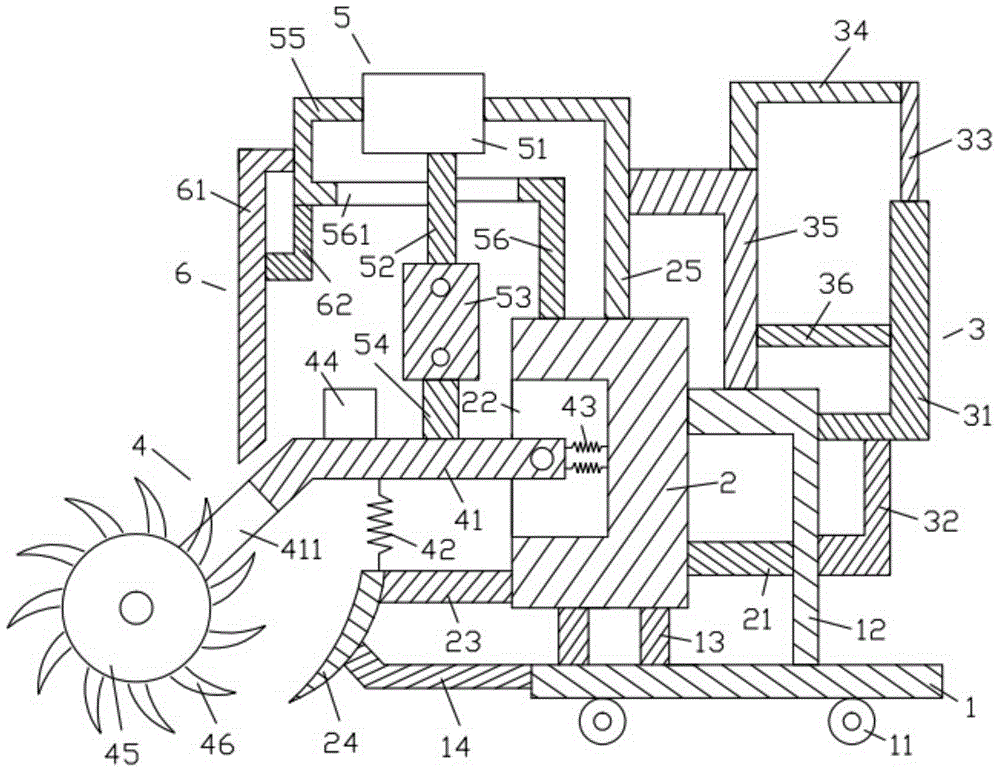

The invention belongs to the field of agricultural tillage and land preparation machinery, relates to a pneumatic straw deep-burying returning machine and aims to functionally realize gas-phase and solid-phase material conveying under blowing pressure and pneumatically convey crushed straws with stubble cleaned to furrows made by furrowers to realize straw deep-burying returning. The pneumatic straw deep-burying returning machine integrally and structurally comprises a frame, a transmission system, a stubble cutting device, a picking and crushing device, a conveying assembly, a furrowing device, an earthing device, a compacting device and depth rollers and the like. A pneumatic conveying device which is a key part is arranged in rear of the picking and crushing device and comprises a screw, a fan, a conveying pipeline, a discharging pipeline and the like. A furrowing device is designed and mounted under the screw and the discharging pipeline, and the compacting device, the earthing device formed by left and right earthing shovels and the like are sequentially mounted in rear of the discharging pipeline. The problem of excessive straw incineration in autumn is effectively solved, and straw deep-burying returning, soil porosity improving, soil water permeability improving, waterlogging preventing, drought resisting and soil organic matter increasing are realized.

Owner:SHENYANG AGRI UNIV

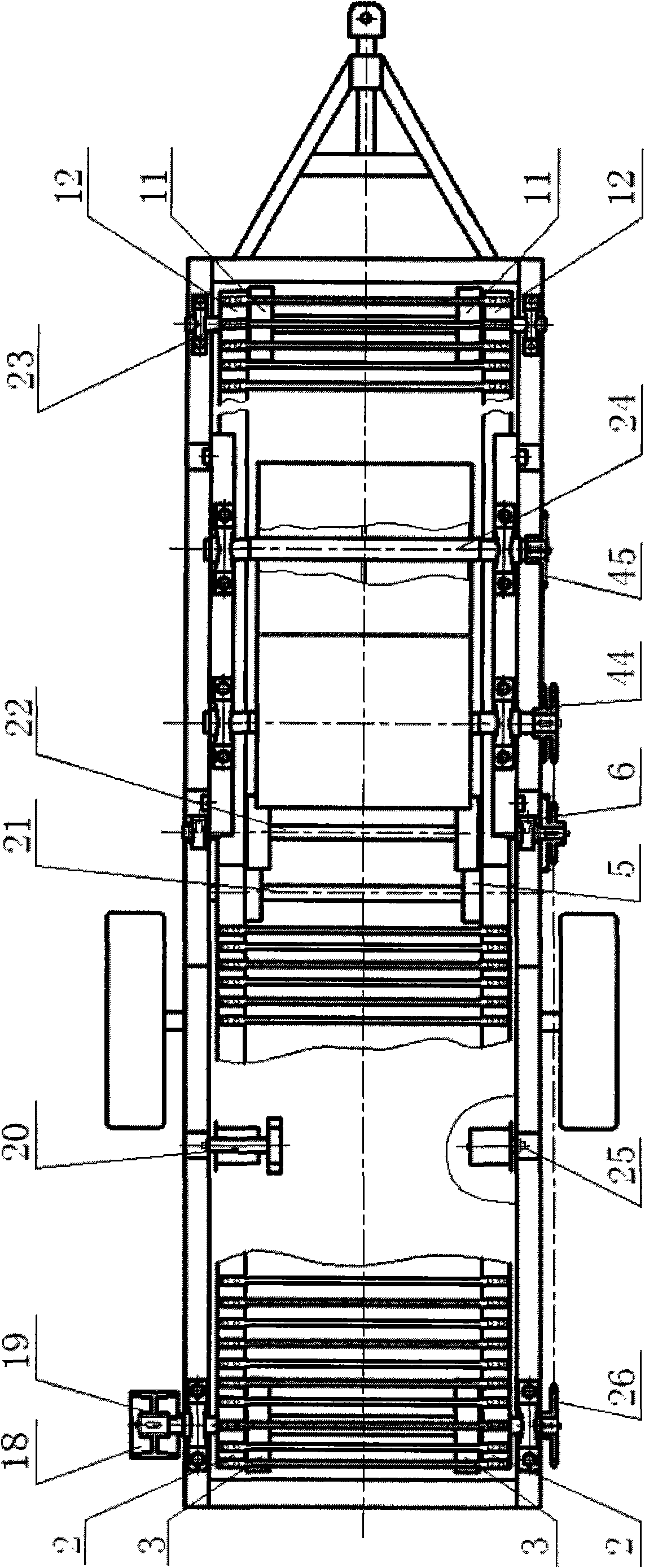

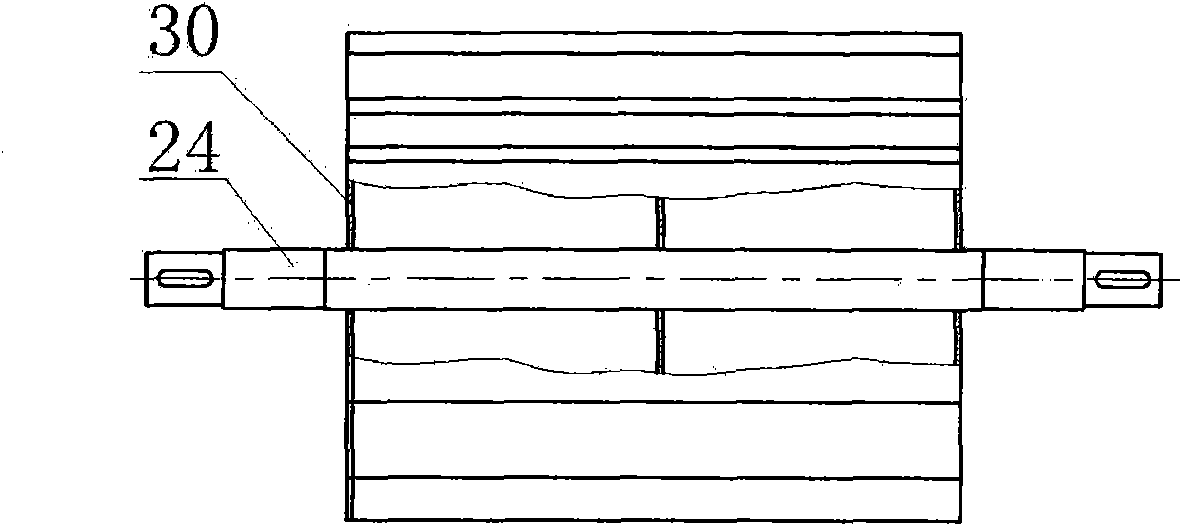

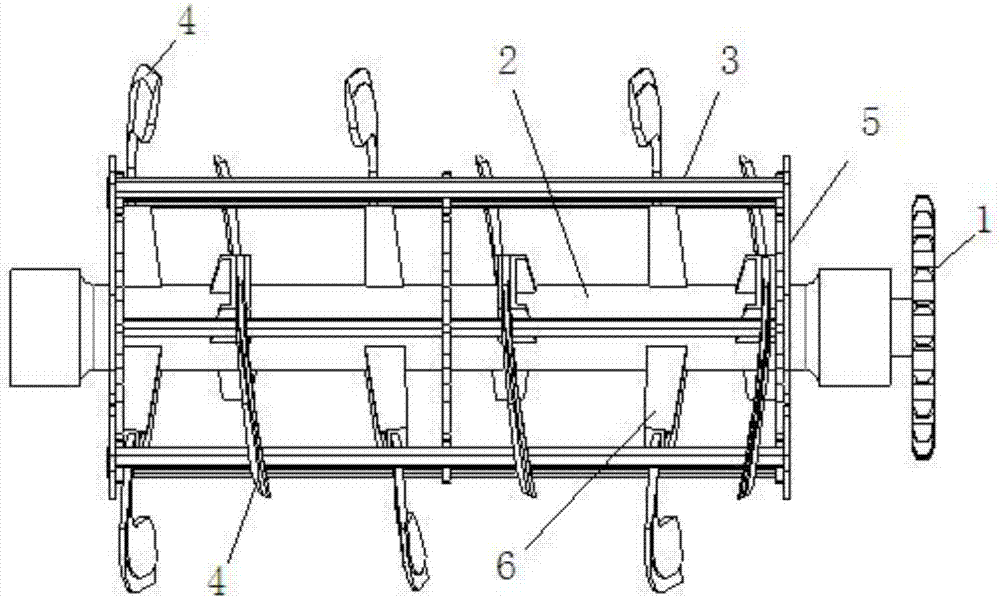

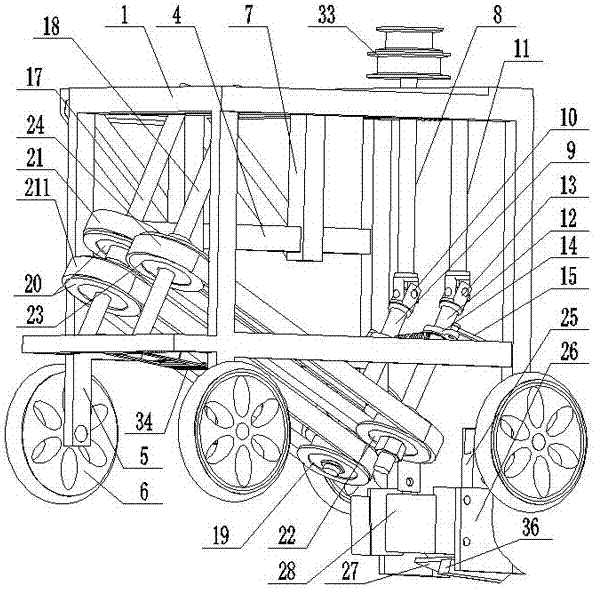

Corn rootstalk soil removal machine

The invention discloses a corn rootstalk soil removal machine. The machine comprises a frame, a double-drum rolling and breaking device, a belt open link chain conveying and feeding mechanism, an open link chain dithering and separating mechanism and a drive system, wherein, the double-drum rolling and breaking device comprises a rear rolling drum, a front rolling drum, two angle iron supports, two roller supports, four channel steel upright columns and six support rollers; the double-drum rolling and breaking device is arranged on the right end of the frame; the open link chain dithering and separating mechanism is arranged on the left end of the frame; the belt open link chain conveying and feeding mechanism is arranged below the rear rolling drum and the front rolling drum; the drive system connects corresponding parts together through a chain wheel, a gear and a chain; the front rolling drum and the rear rolling drum are arranged between the two angle iron supports to form rotary connection; two ends of the two angle iron supports are fixedly connected with the four channel steel upright columns; the six support rollers are arranged between the two roller supports to form rotary connection; and the vertical distance from the vertex of rolling teeth to the six support rollers is 50-70mm.

Owner:JILIN UNIV

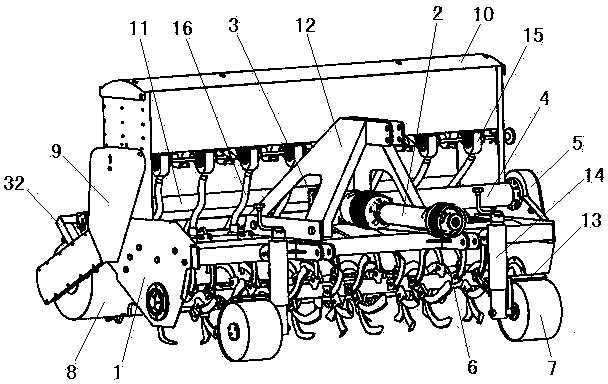

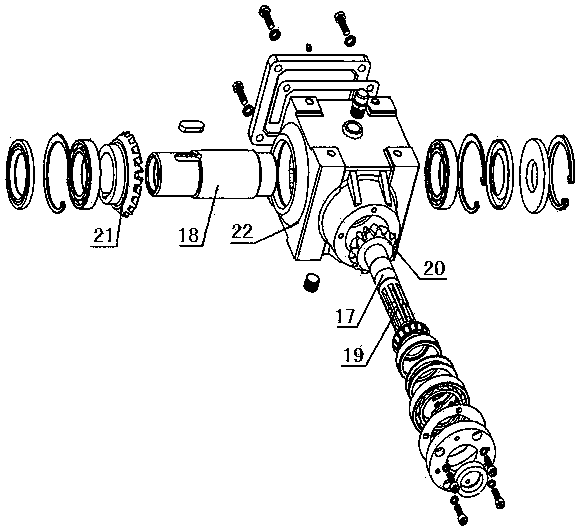

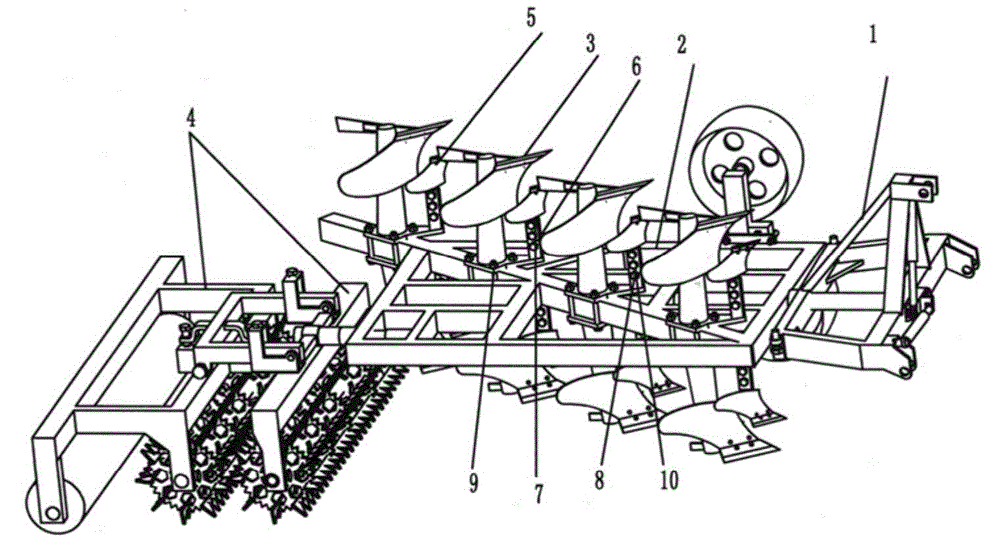

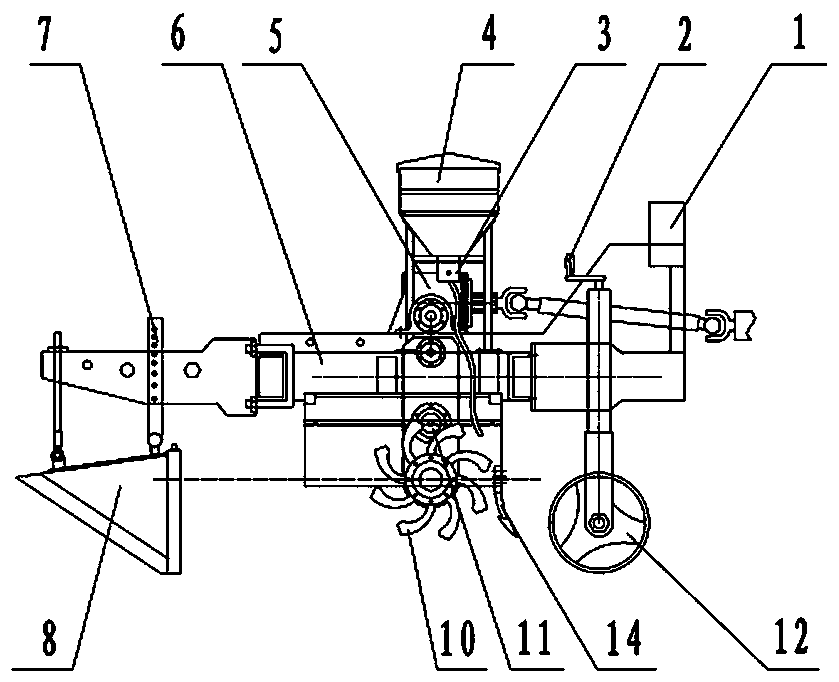

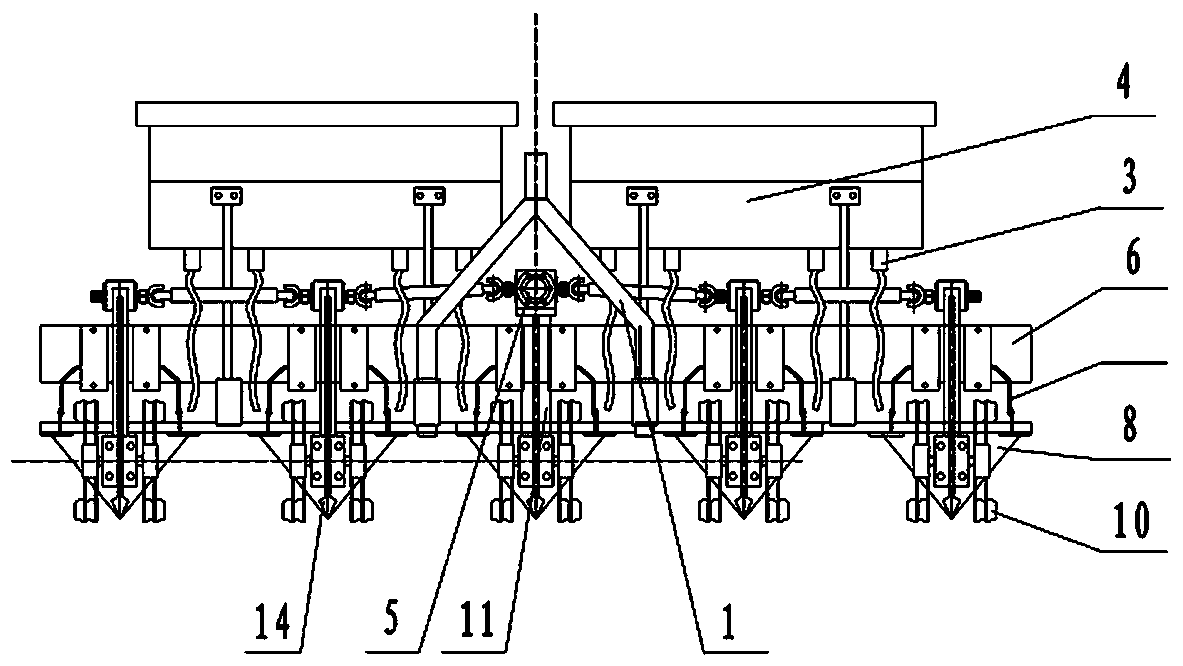

Novel rotary-tillage fertilizing seeder

InactiveCN103749018AEasy to disassemble and maintainConvenient tillage depth adjustmentSpadesAgricultural machinesSeederDrive shaft

The invention relates to a novel rotary-tillage fertilizing seeder which comprises a frame. A central transmission case which is in transmission connection with a tractor power output shaft through a transmission shaft is arranged in the middle front portion of the frame; a side transmission case which is in transmission connection with the central transmission case through a hexagon input shaft is arranged on one side of the frame; a rotary tillage cutter shaft assembly driven through the hexagon input shaft of the side transmission case is disposed on the lower front side of the frame; two depth-limited wheel assemblies are symmetrically disposed in the front of the frame, a suppression wheel assembly is disposed in the rear of the frame, a sprocket-wheel case in transmission connection with the suppression wheel assembly is arranged on the other side of the frame, and a seed fertilizer case in transmission connection with the sprocket-wheel case is arranged in the rear of the frame. The novel rotary-tillage fertilizing seeder has the advantages of simple structure, manufacture easiness, convenience in installation, no leakage, good suppression effect, high transmission efficiency, long service life and the like.

Owner:黄宗筹

Fertilization, rotary tillage, compacting and crushing integrated machine

PendingCN110073747AEasy to removeImprove work efficiencySpadesFertiliser distributersCouplingAgricultural engineering

The invention provides a fertilization, rotary tillage, compacting and crushing integrated machine, comprising a fertilization mechanism, a rotary tillage mechanism and a compacting mechanism; the fertilization mechanism comprises a fertilizer tank, the bottom of the fertilizer tank comprises a front bottom and a rear bottom, and the front bottom and the rear bottom are connected to form a V shape; a fertilizer discharging port is arranged at the joint between the front bottom and the rear bottom, a fertilizer discharging device is arranged at the lower side of the fertilizer discharging port,and a spreading plate is arranged at the lower side of the fertilizer discharging device; the rotary tillage mechanism comprises a cutter roller, a cutter mount fixedly arranged on the cutter roller,a rotary blade mounted on the cutter mount and a depth control cutter mounted on a rack, the cutter roller is connected to a coupling; the compacting mechanism comprises a compacting roller and a compacting roller mounting frame, the compacting roller mounting frame is hinged to the rack, and the two ends of the compacting roller mounting frame are respectively connected to the rack through chains. The operations of fertilization, rotary tillage, compacting and crushing is completed by the same equipment at the same time, the working efficiency is improved and the advantages of simple structure, reasonable design and simple operation are realized.

Owner:吴忠市伊禾农机作业服务有限公司

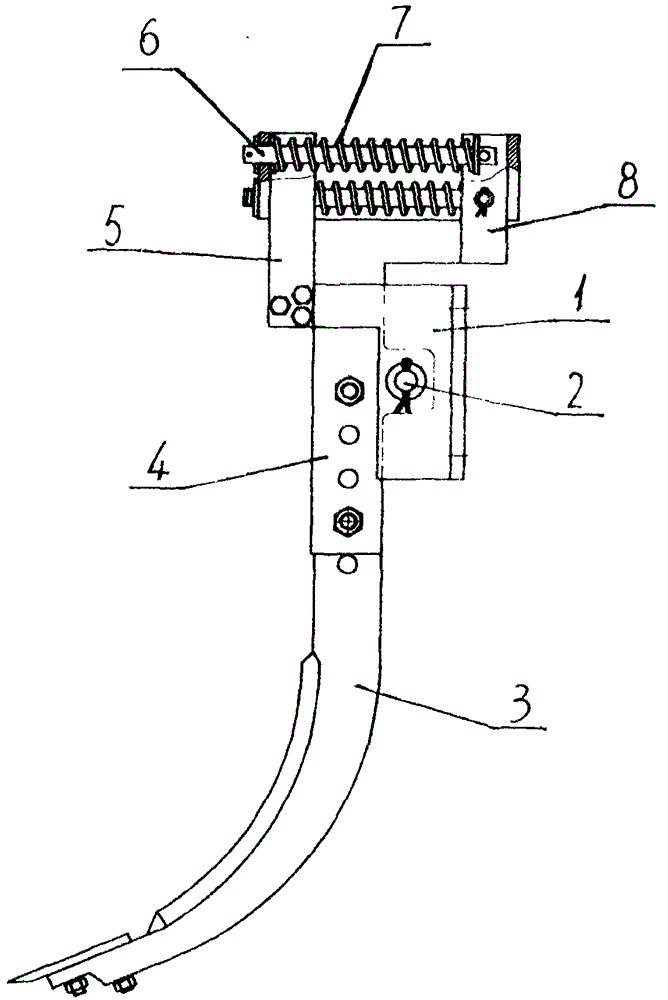

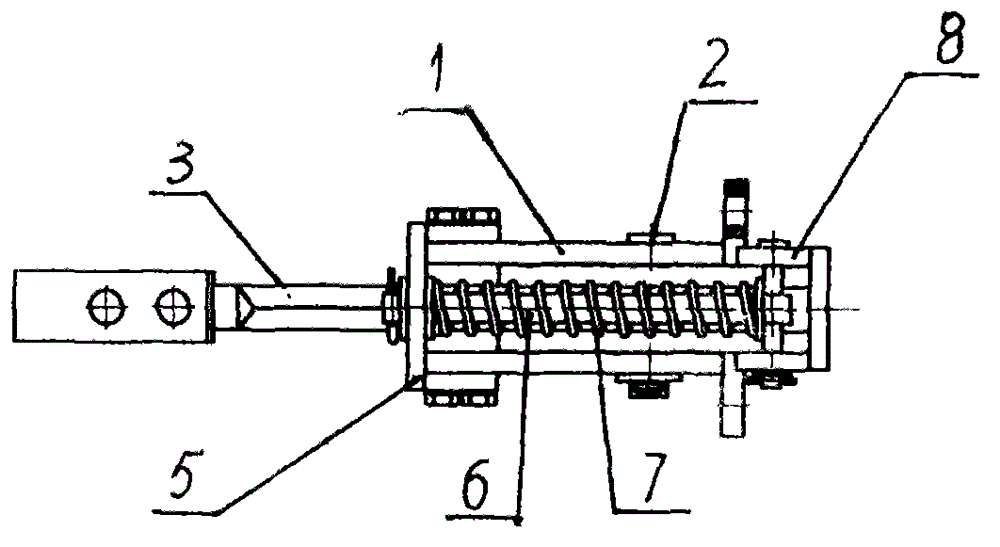

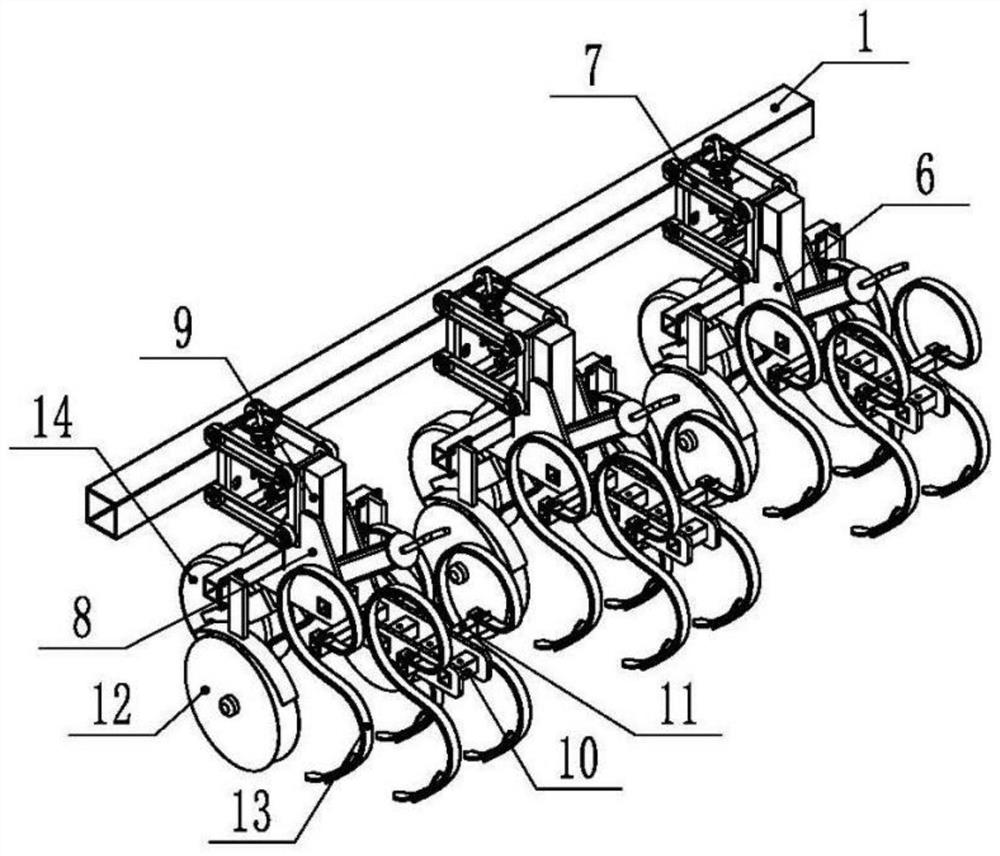

Elastic vibratory deep scarification unit

InactiveCN102907195ASimple structureReduce manufacturing costSoil-working equipmentsScarificationAgricultural engineering

The invention discloses an elastic vibratory deep scarification unit, which belongs to agricultural machinery. A shovel seat is arranged on an assembly rack through a pin shaft; a deep scarification and soil crushing assembly is assembled on the shovel seat; a spring pressure plate is fixedly arranged on the rear part of the upper end of the deep scarification and soil crushing assembly; a spring positioning plate is fixedly arranged on the upper part of the front end of the assembly rack; the front part of a spring shaft is inserted in the spring positioning plate in an axial movable manner; the rear end part of the spring shaft is hinged with the spring pressure plate; a pressure spring is sleeved on the spring shaft; and front and rear end faces of the pressure spring are contacted and matched with the spring positioning plate and the spring pressure plate respectively. The elastic vibratory deep scarification unit has the advantages of simple structure, low manufacturing cost, stable work, small traction resistance, high reliability, good deep scarification and soil crushing effects and wide application range.

Owner:黑龙江省农业机械运用研究所

Rotary machine

InactiveCN102257892AImprove flatnessGood effect of crushing soilTilling equipmentsDrive shaftTransmitted power

The invention provides a rotary tiller, which belongs to an agricultural machine. It solves the problems of poor tillage effect, low efficiency, and time-consuming and labor-intensive problems of the rotary tiller in the prior art. It mainly includes frame, suspension device, box assembly, front left cutter shaft, front right cutter shaft, drive shaft on the box assembly, left-rotary tiller and front right cutter shaft respectively. Right-handed tiller, one side of the box assembly is provided with a side box assembly and a rear through knife shaft, and the front upper part of the side box assembly is provided with an output shaft, and the output shaft and the transmission on the box assembly The shaft is connected, the rear through knife shaft is connected with both sides of the frame, the rear through knife shaft is provided with a rear rotary tiller, and the output shaft transmits power to the rear through knife shaft through a power transmission mechanism. The invention is mainly used for field operations.

Owner:孙传东

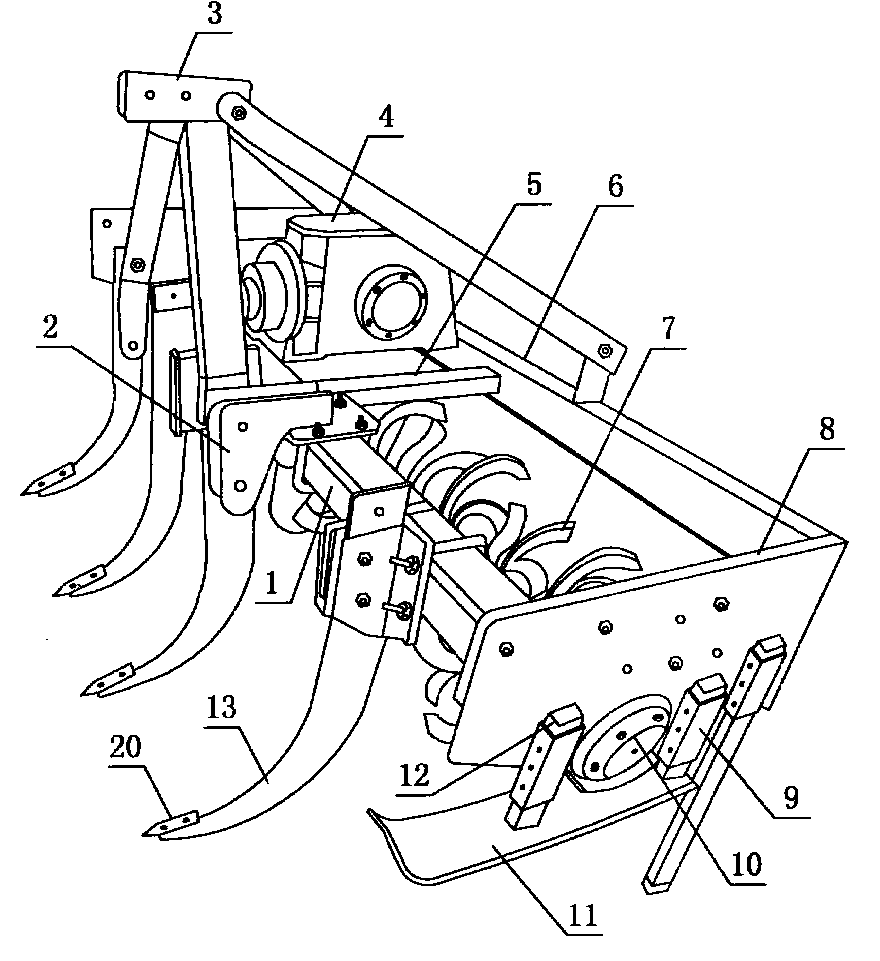

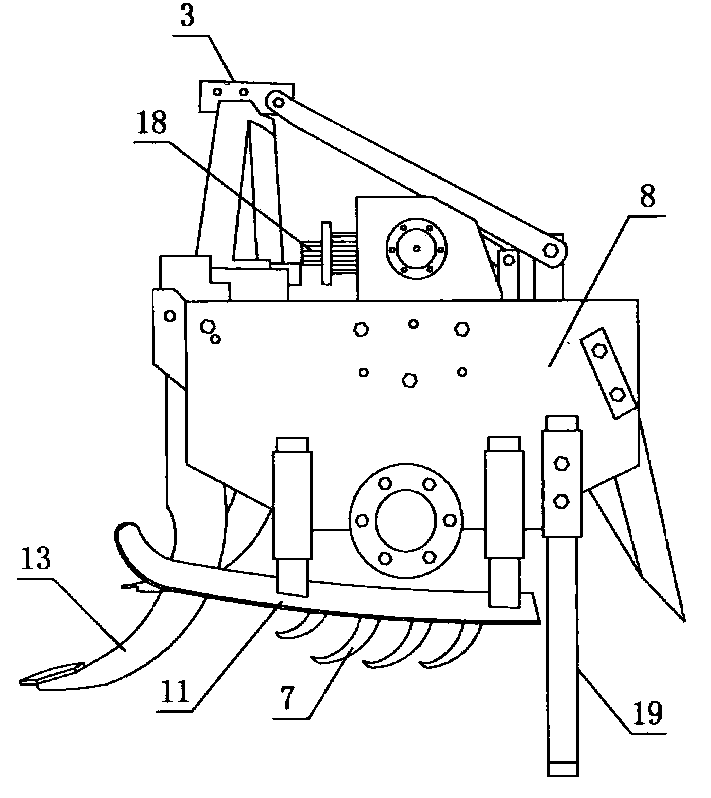

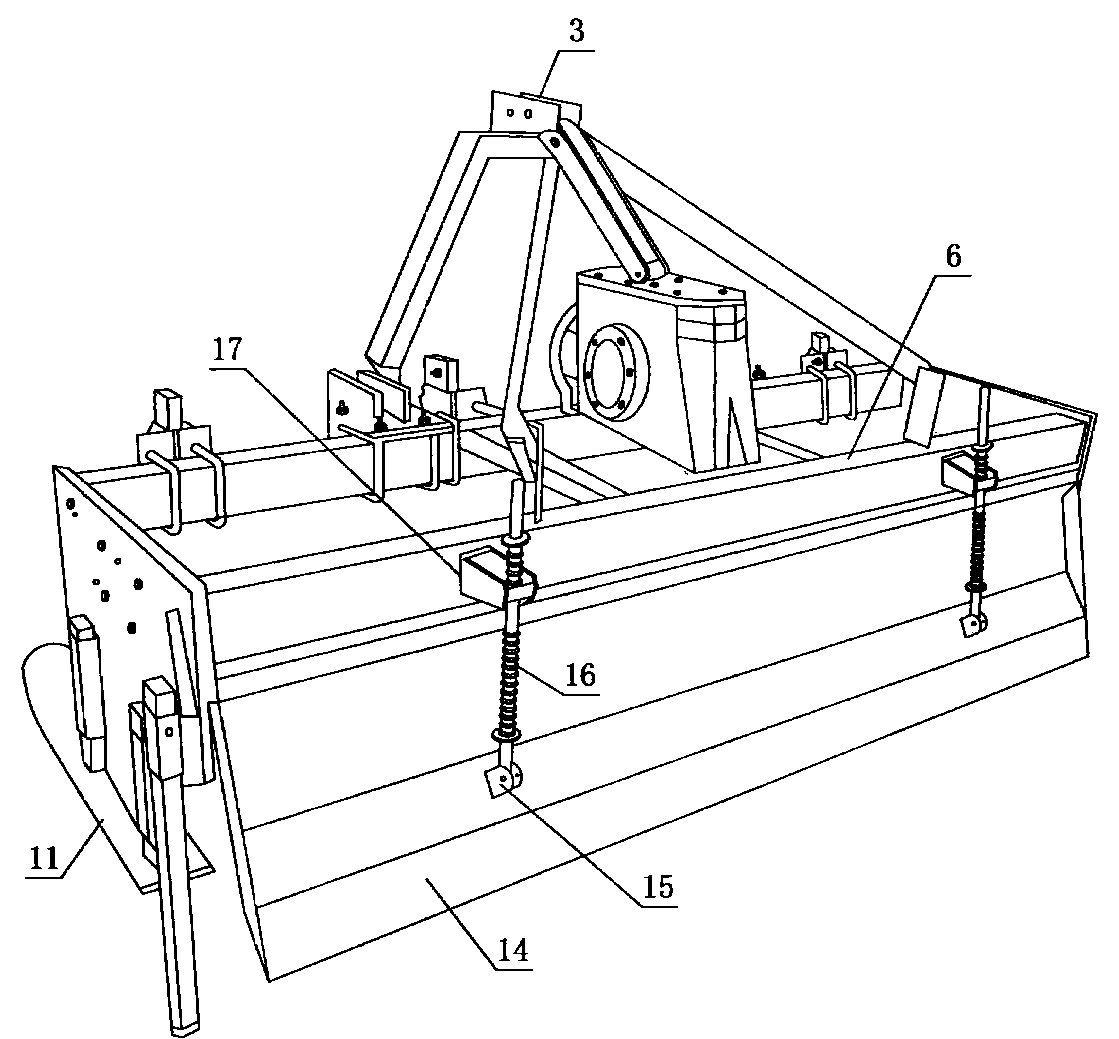

Multifunctional deep scarification soil preparation combined machine

InactiveCN103348791AOvercoming uneven defectsSimple structureSpadesPloughsDrive shaftAgricultural engineering

The invention discloses a multifunctional deep scarification soil preparation combined machine. A front cross beam is arranged at the front end of a frame; a back cross beam is arranged on the back side of the front cross beam; two fixing connecting boards are arranged at the left end and the right end of the front cross beam and the back cross beam respectively; a left vertical beam and a right beam are arranged at the middle parts of the front cross beam and the back cross beam; subsoilers are arranged at the front end of the front cross beam; a gearbox is mounted above the vertical beams; a lifting support is arranged at the upper end of the gearbox; a hanging plough shaft is arranged at the middle lower ends of the fixing connecting boards; hanging plough gears are arranged on the hanging plough shaft; the hanging plough shaft is mounted on the fixing connecting boards at the left end and the right end through shaft sleeves; a driving gear is arranged at the lower end of the gearbox; a corresponding passive gear is arranged on the hanging plough shaft at the bottom end of the driving gear; the passive gear is meshed with the driving gear; a power input shaft is arranged at the front end of the gearbox; the power input shaft is connected with a power transmission shaft at the back end of a dragging machine; the dragging machine provides motive power to drive the gearbox to operate. The combined machine is simple in structure, reasonable in design, good in soil crumbling property and high in land leveling efficiency.

Owner:安徽兆鑫集团汽车有限公司

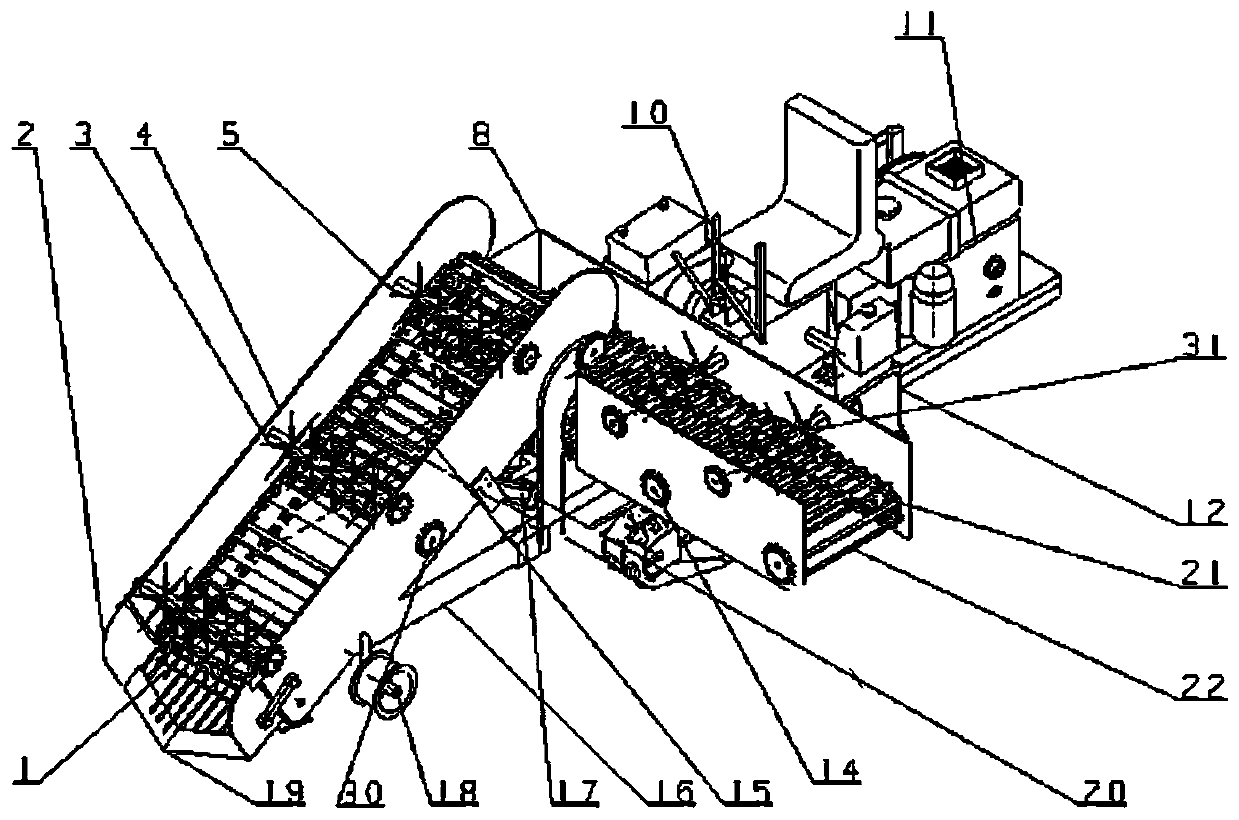

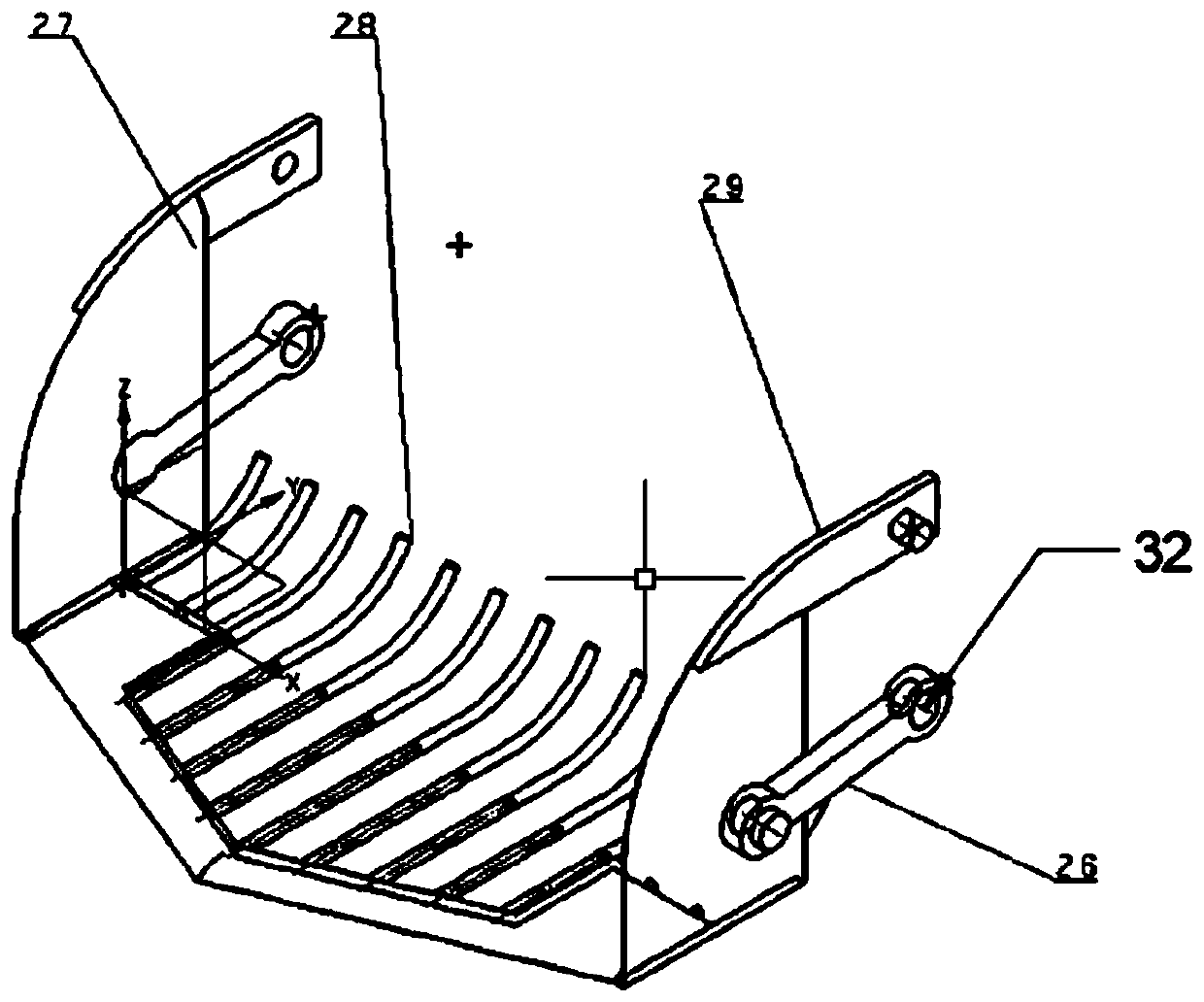

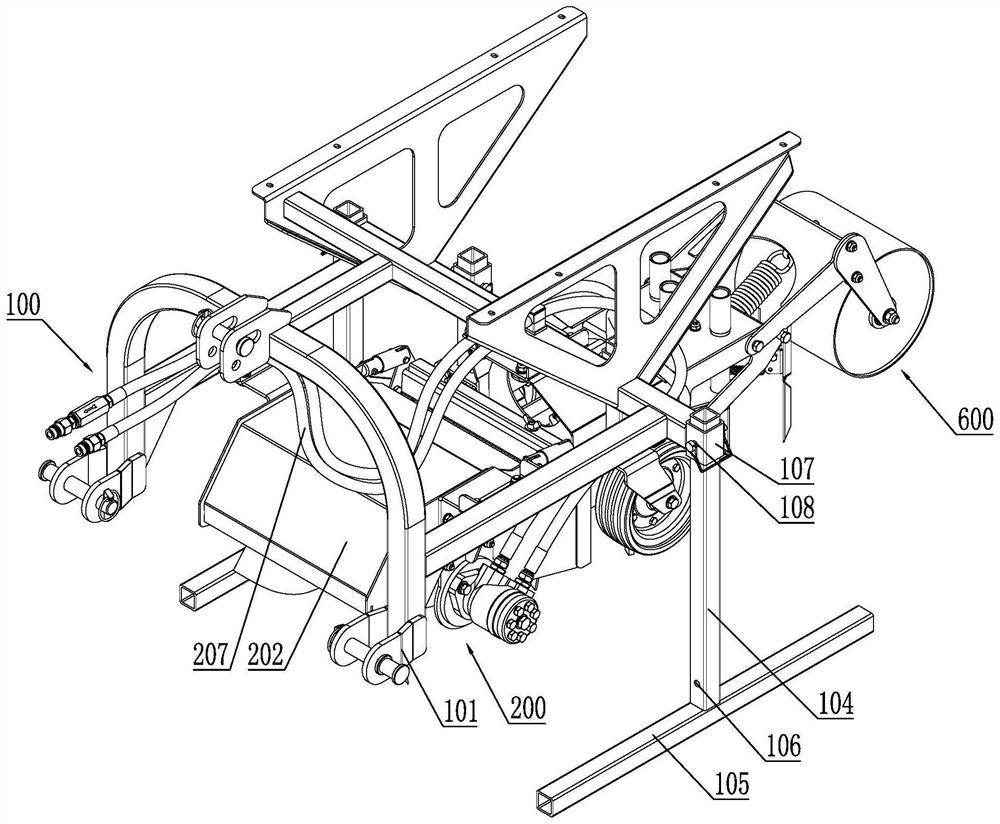

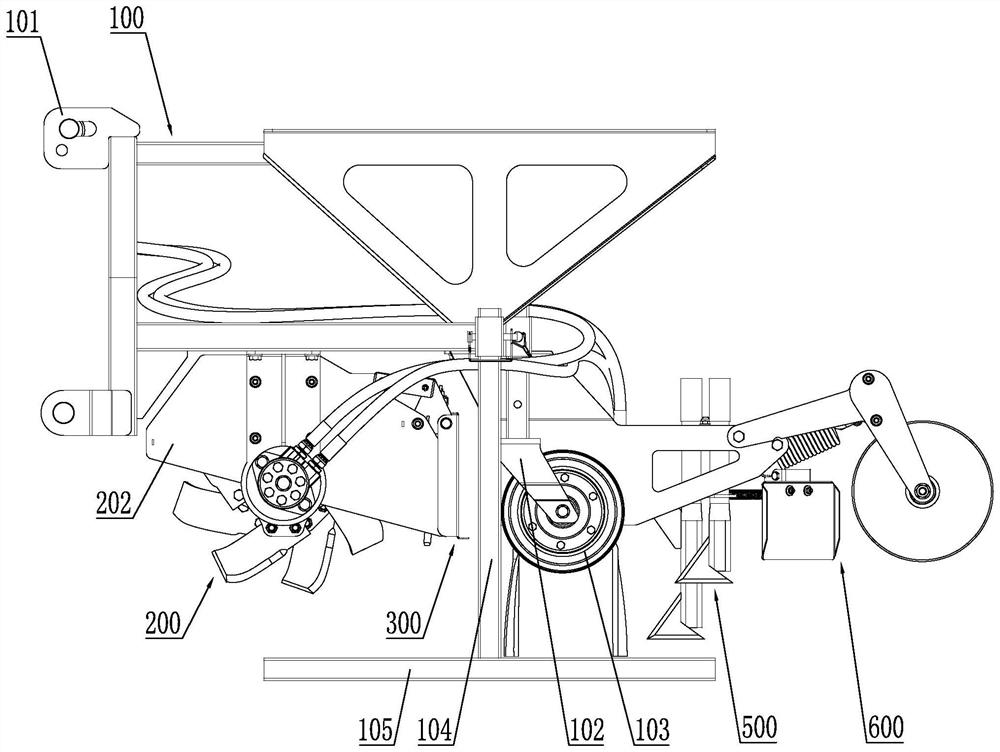

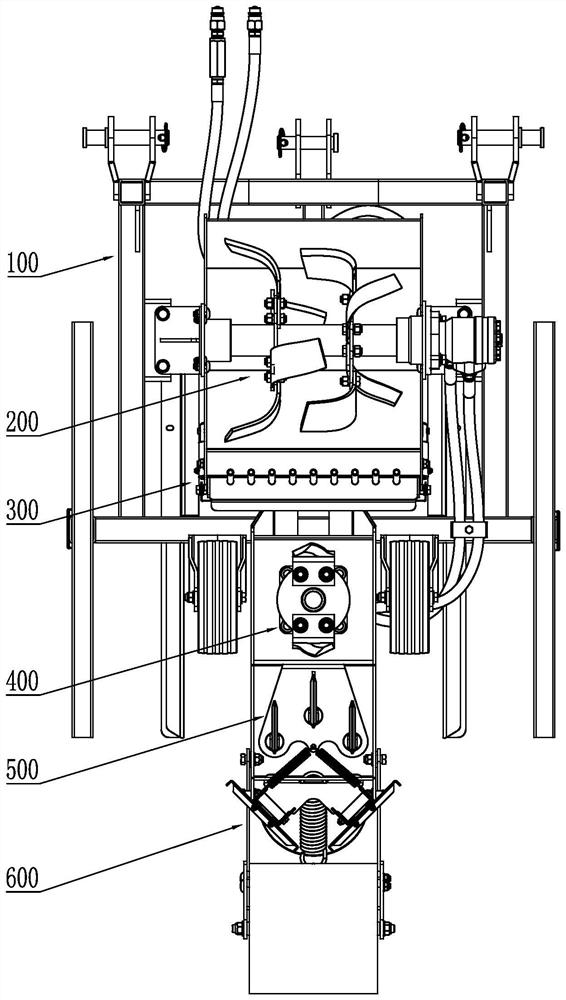

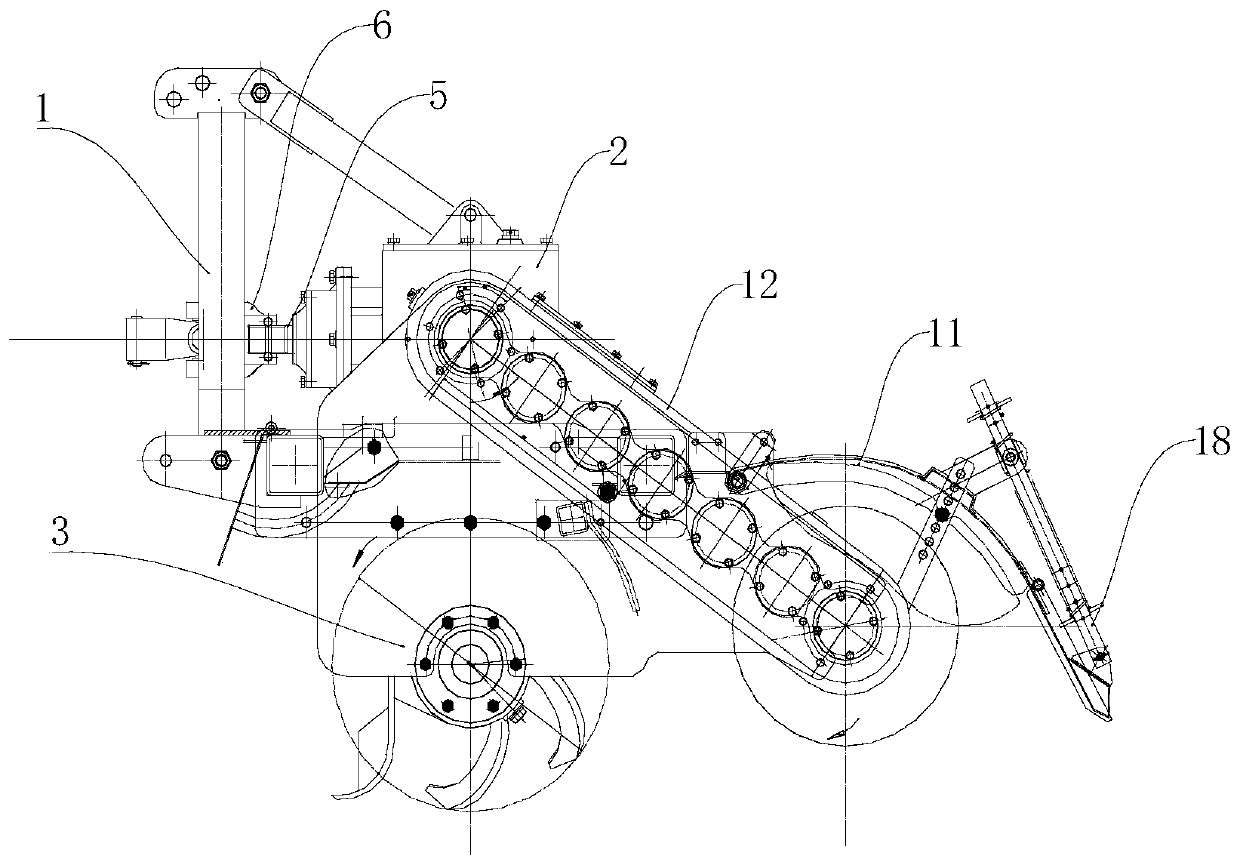

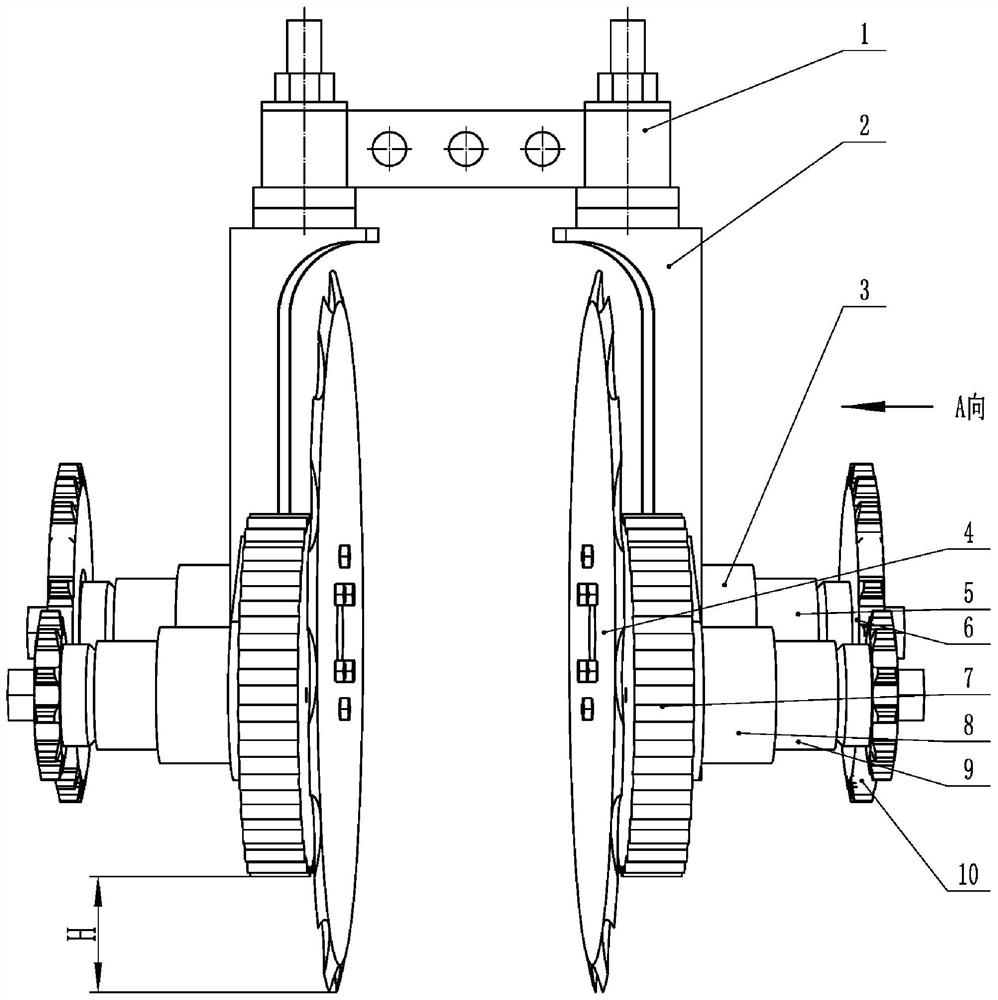

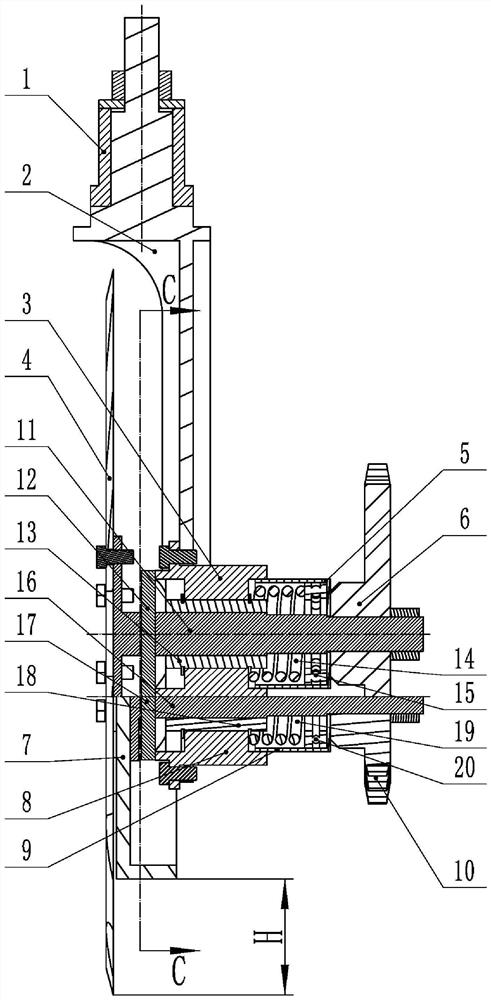

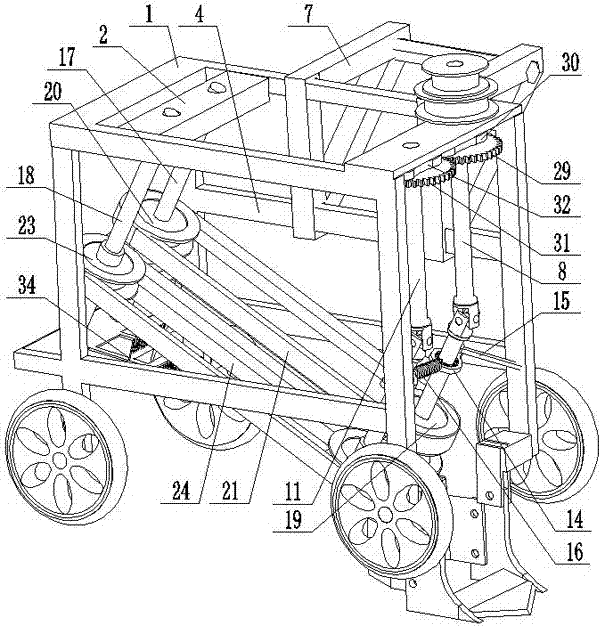

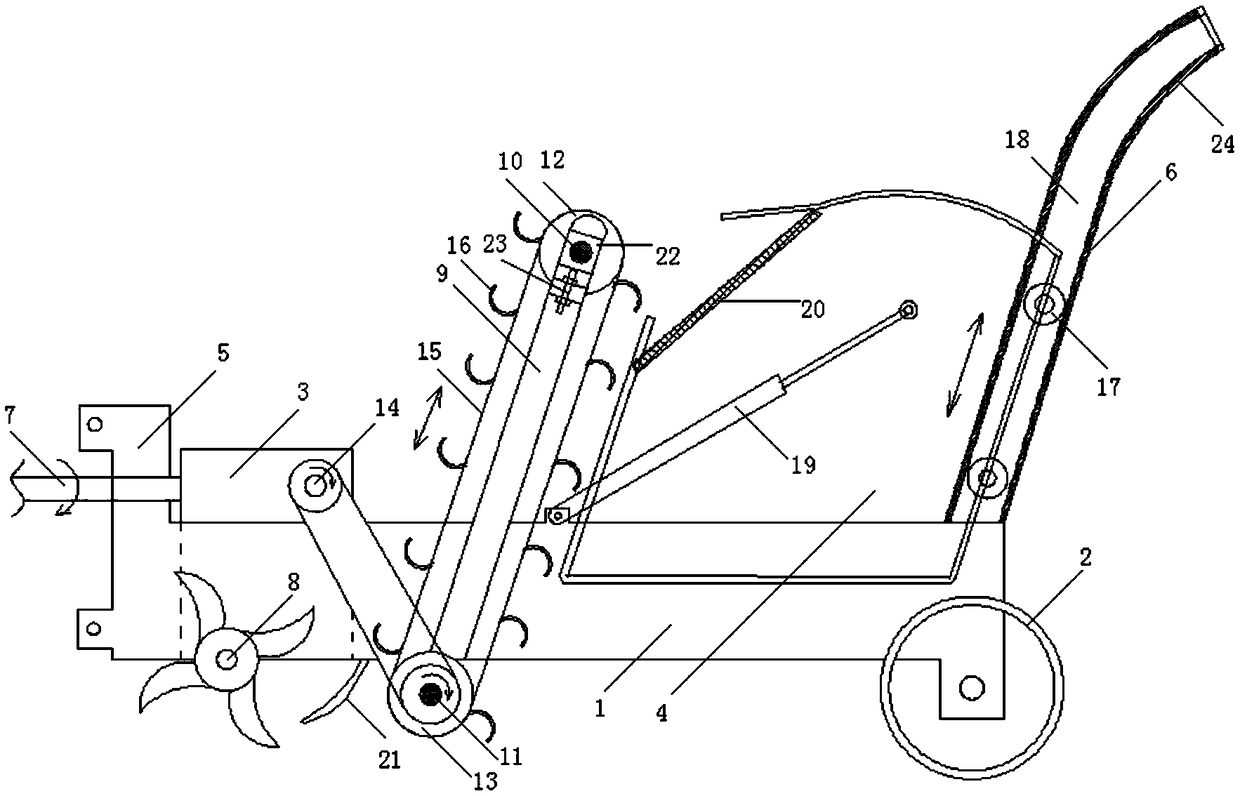

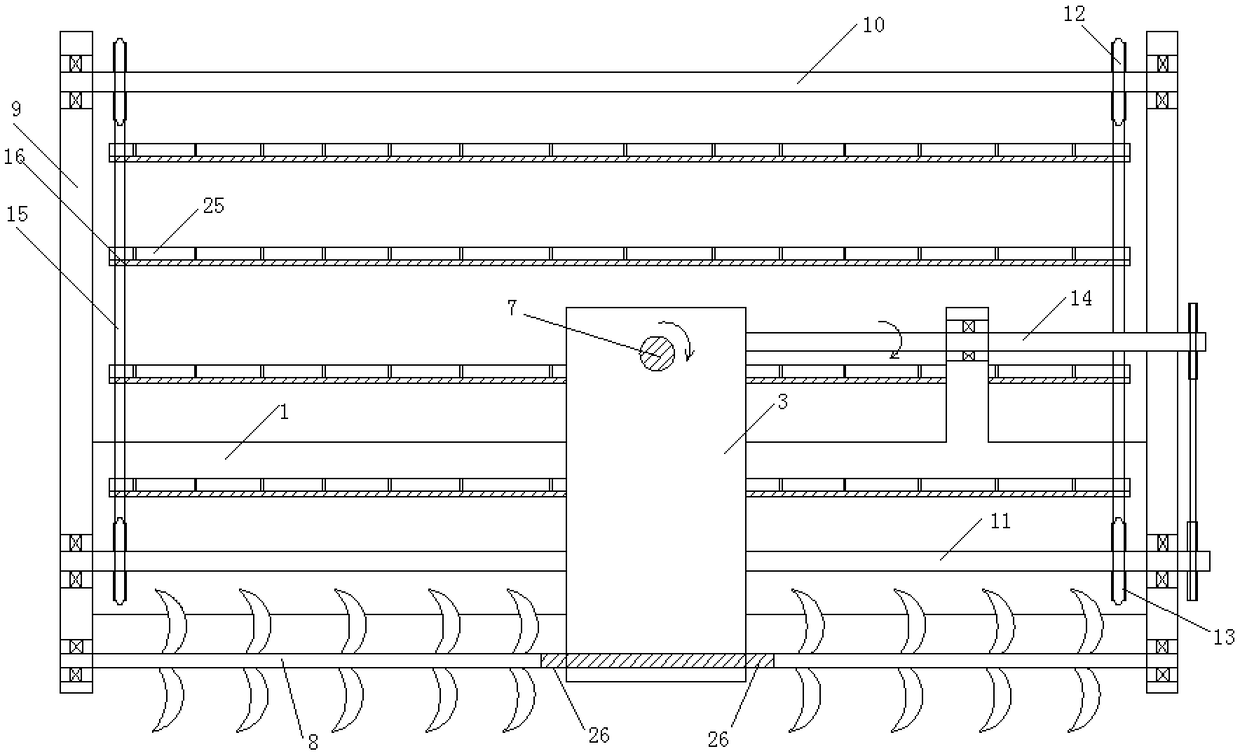

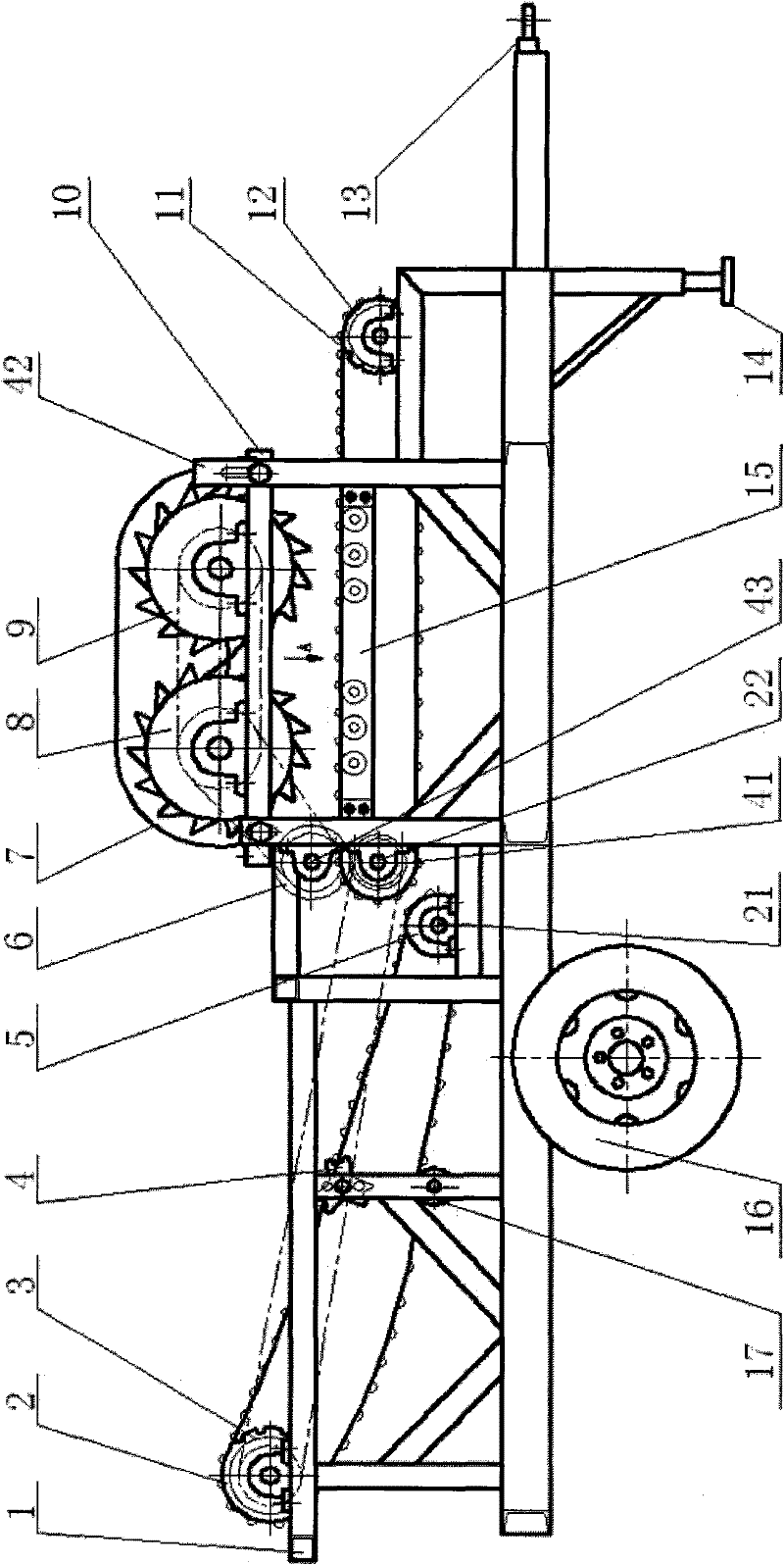

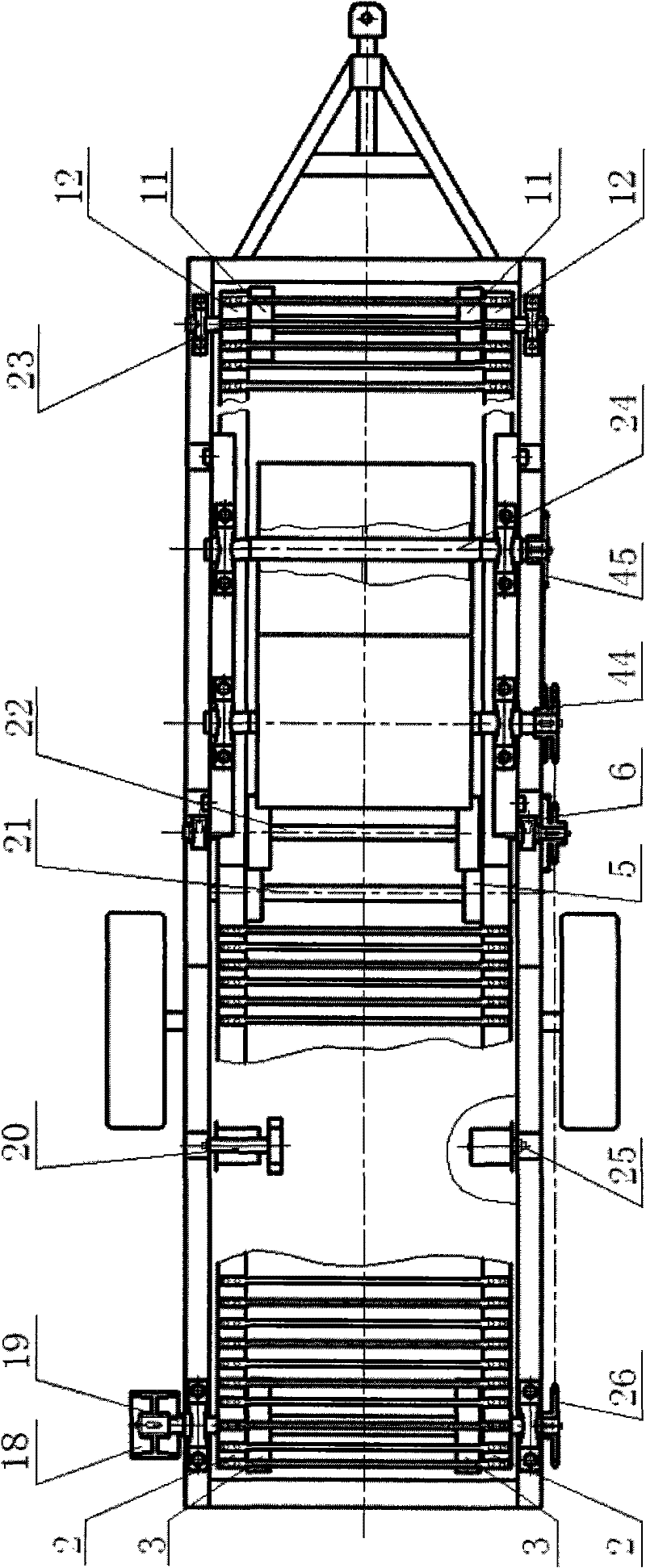

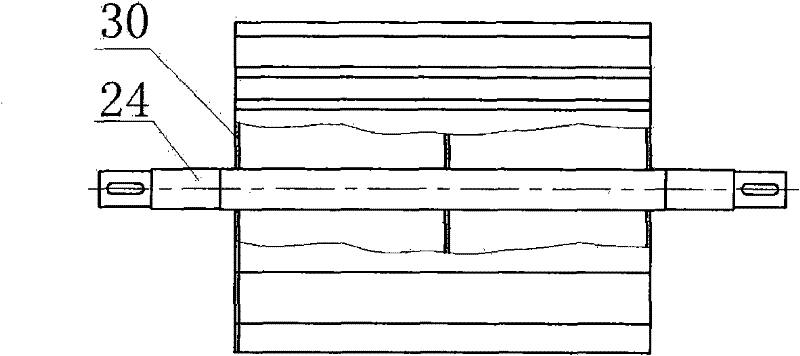

Small self-propelled full-width seedling lifting harvester

PendingCN111512764AImprove terrain adaptabilityConducive to the harvesting of Ophiopogon japonicusDiggersAgricultural scienceAgricultural engineering

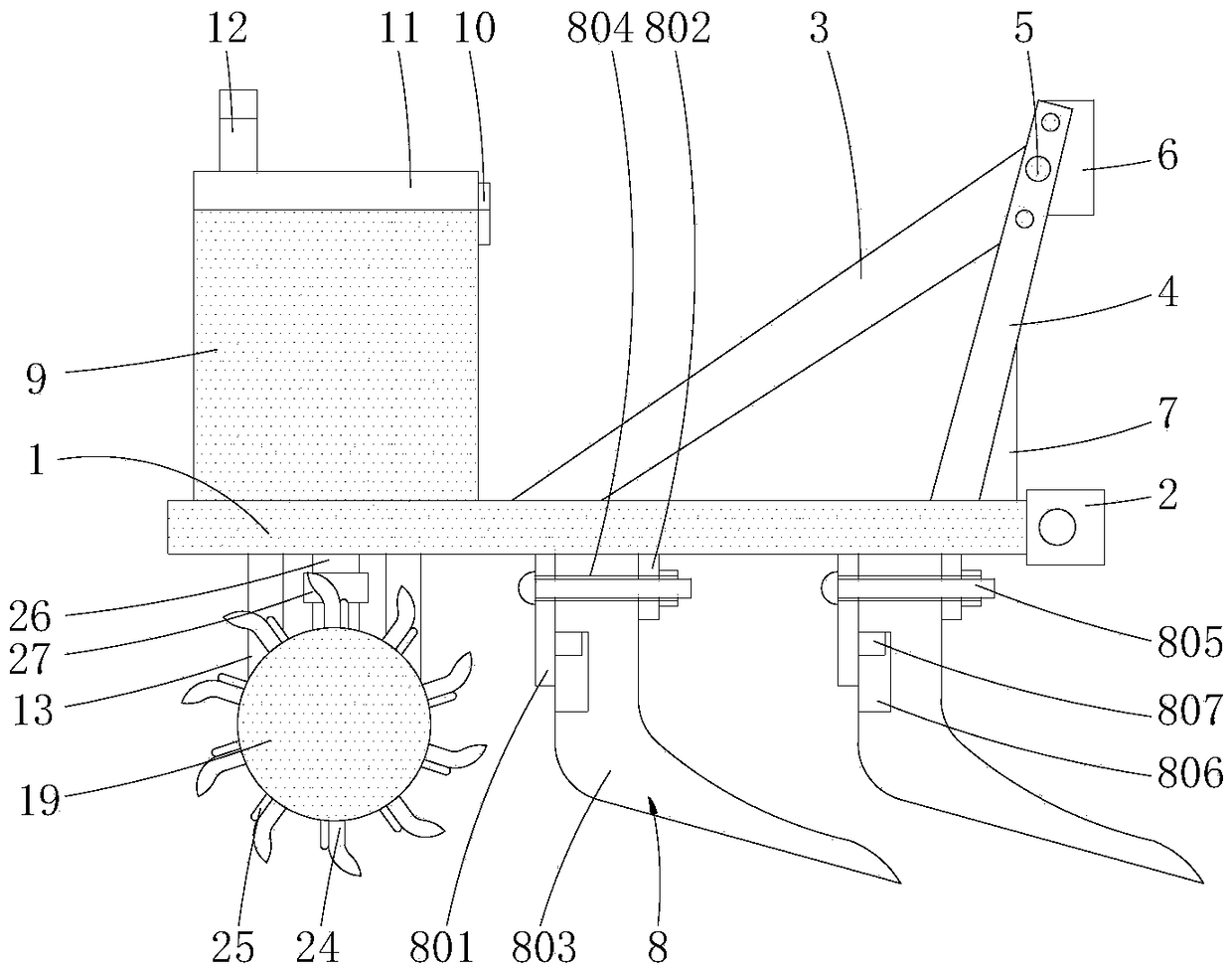

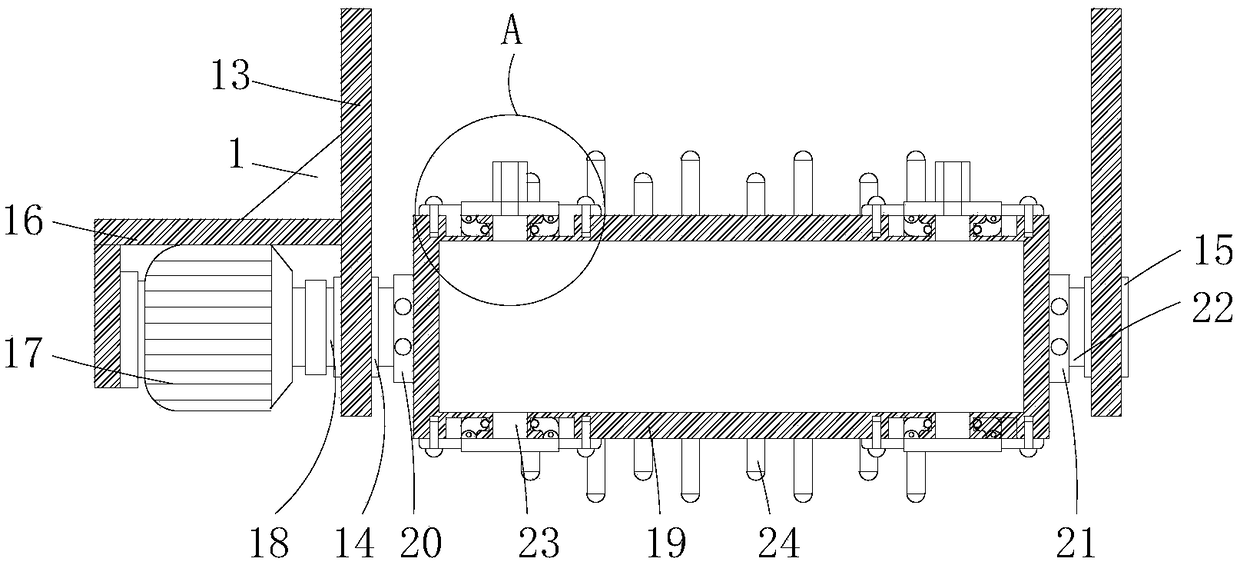

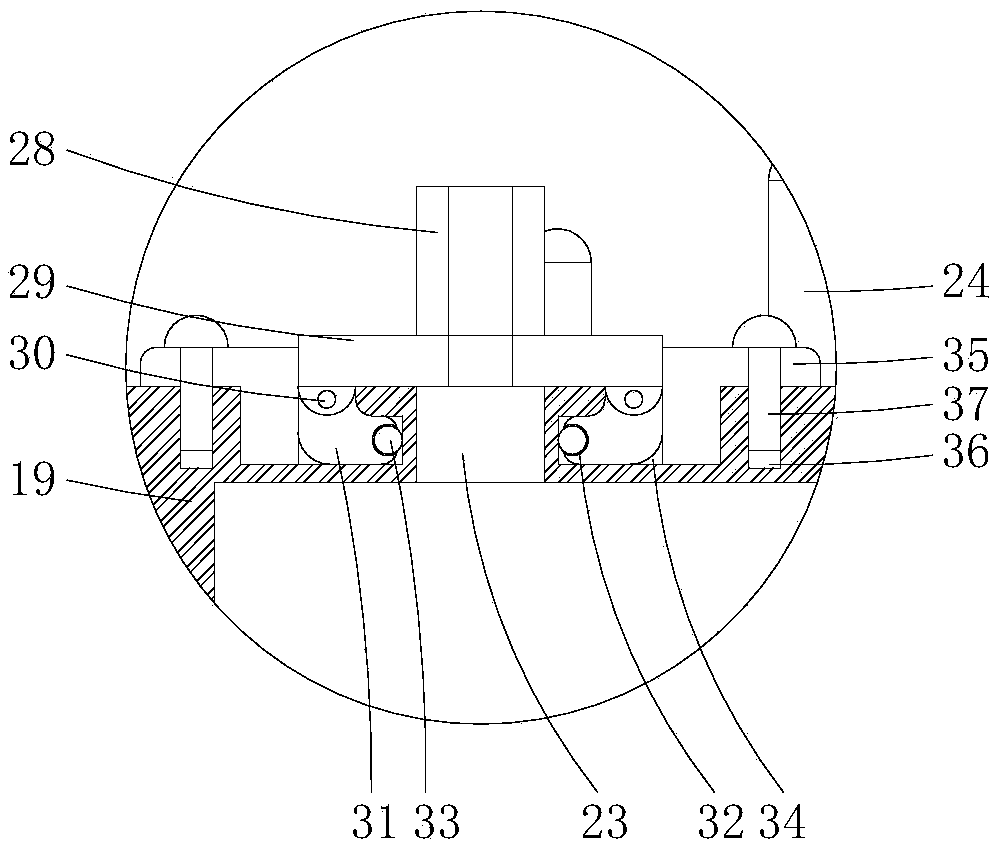

The invention relates to the technical field of traditional Chinese medicine processing, in particular to a small self-propelled full-width seedling lifting harvester. The harvester comprises a rack (20), a walking device (12), an excavating device (2), a conveying device (4), a depth limiting wheel (18), a screening device (8) and a collecting device (22). The conveying device (4) comprises conveying device side plates, a conveying chain plate (15), a first vibrating wheel (30), a toothed soil crushing roller (3), a supporting frame (7), a supporting frame (16), a rolling soil crushing roller(1) and a secondary toothed soil crushing roller (5). The depth limiting wheel (18) is rotationally connected to the front ends of the left conveying device side plate and the right conveying deviceside plate. The screening device (8) comprises screening device side plates, a screening chain plate (21), a second vibrating wheel (14) and a soil removing mechanism. The collecting device (22) is located at a discharging end of the screening chain plate (21). The harvester can adapt to growth characteristics of Ophiopogon japonicus, meet harvesting requirements of Ophiopogon japonicus, save manpower and material resources, and improve labor production efficiency.

Owner:CHINA AGRI UNIV +1

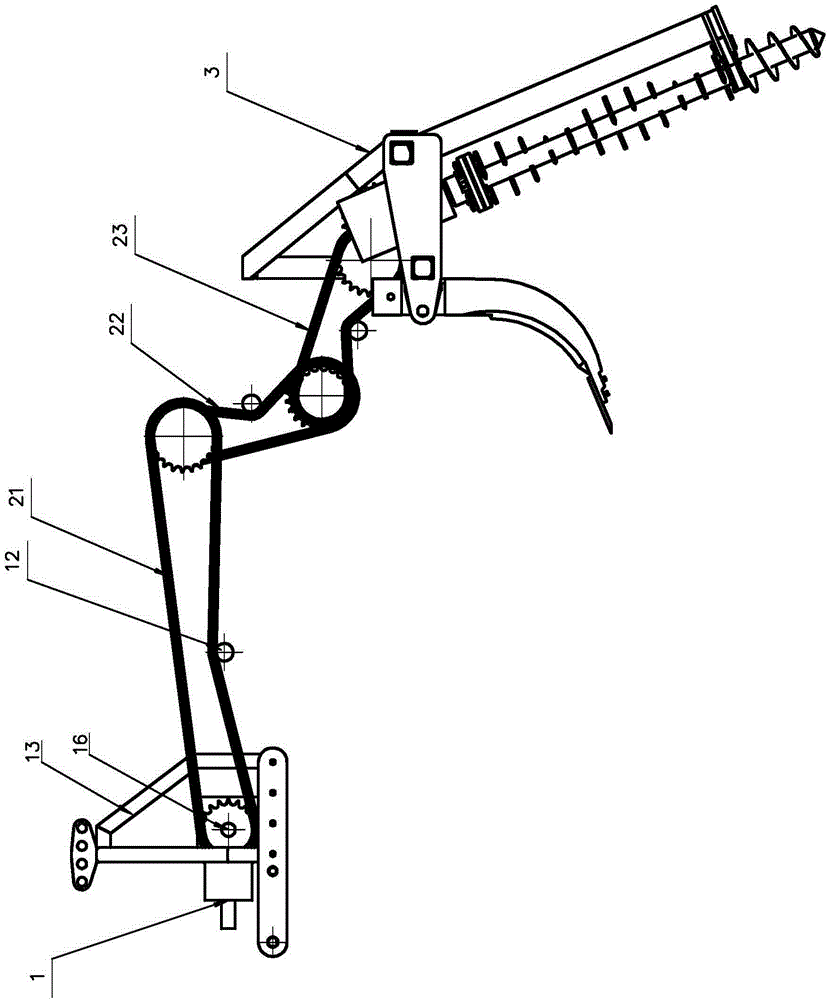

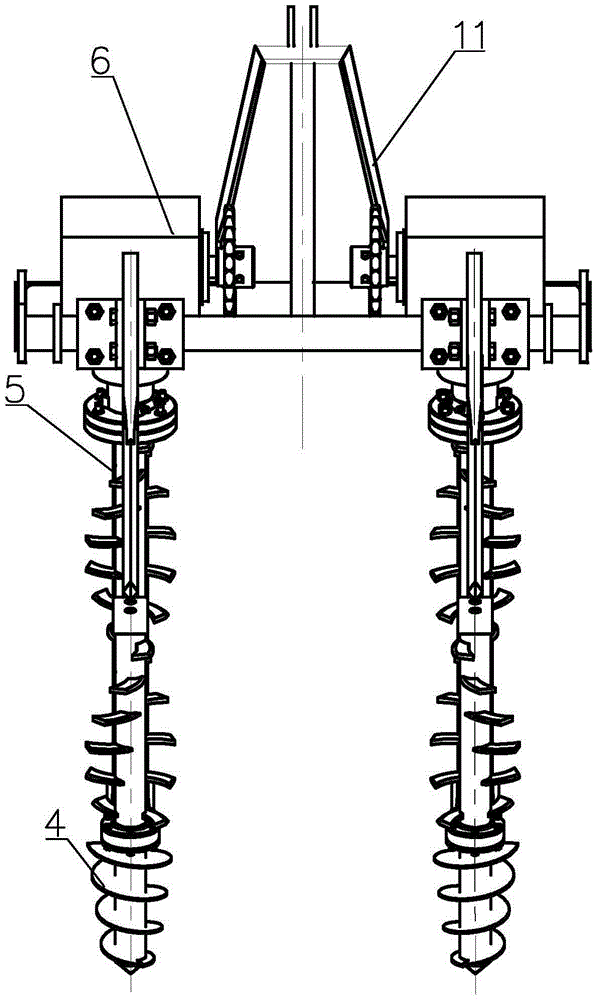

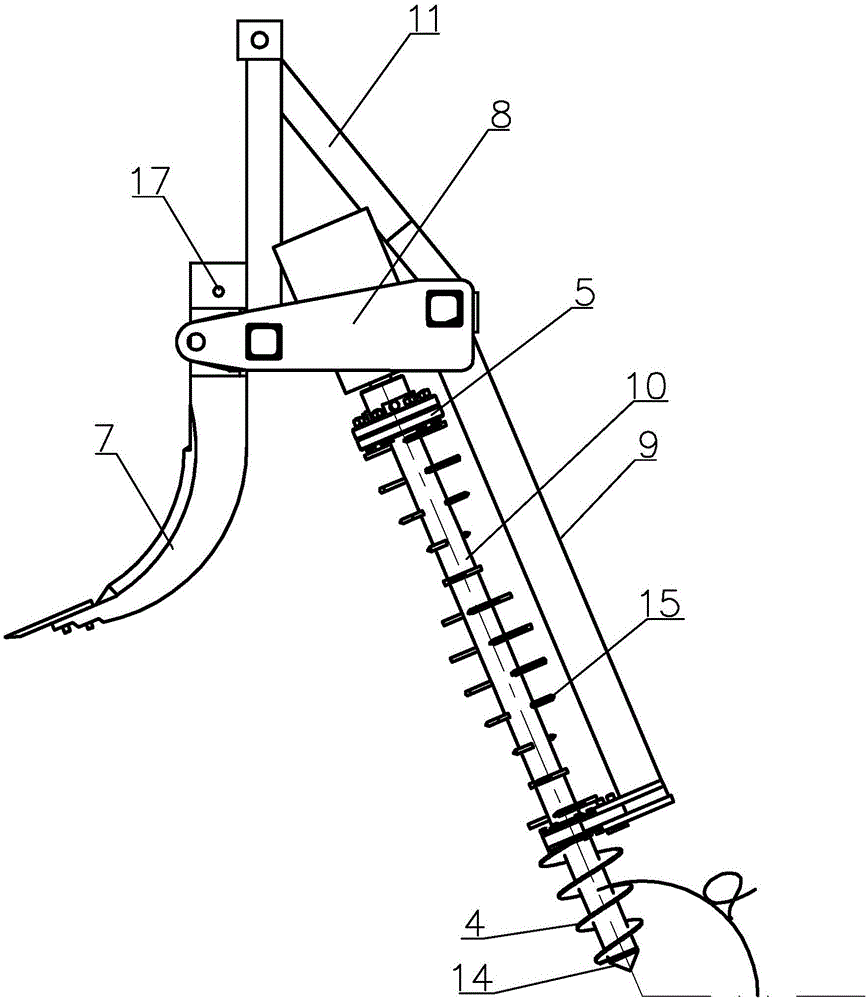

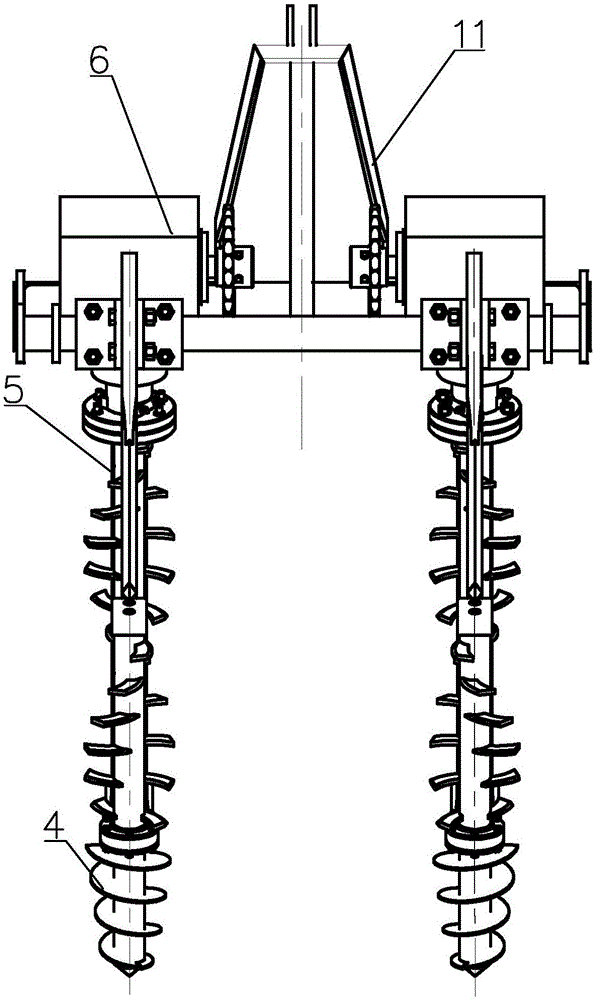

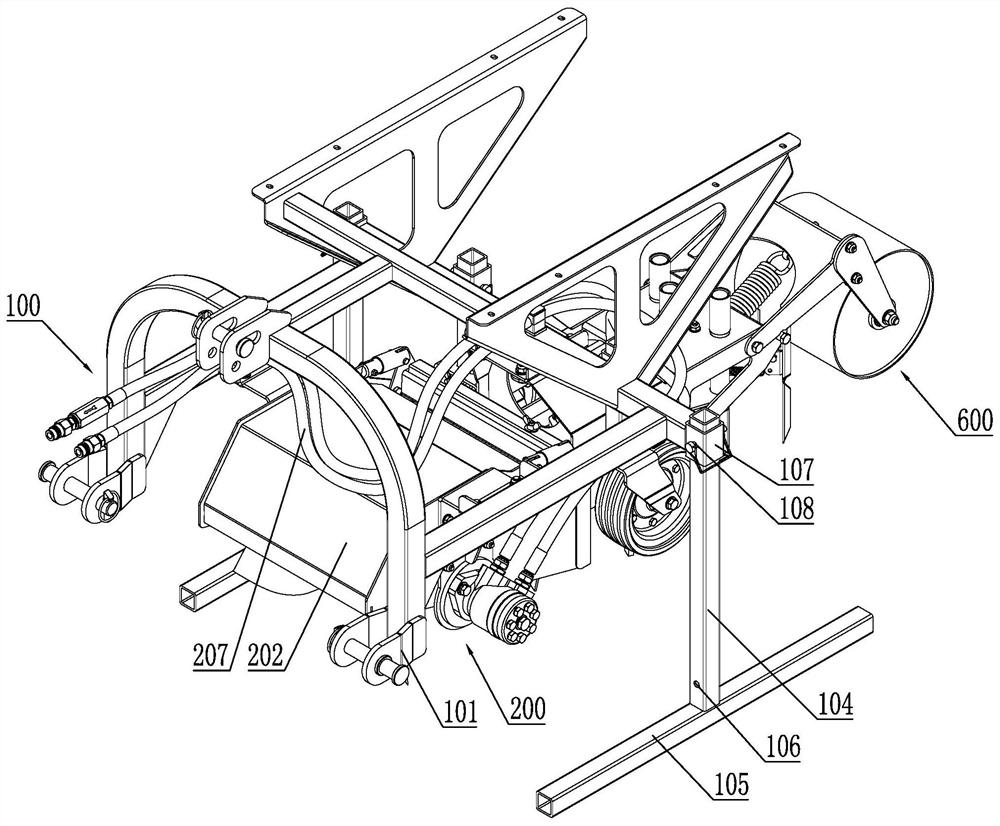

Deep-rooted crop soil preparation machine

The invention provides a deep-rooted crop soil preparation machine and belongs to the technical field of farm machinery. The deep-rooted crop soil preparation machine comprises a rack, a transmission mechanism, at least one set of a soil preparation device and a subsoiler, wherein the soil preparation device which is oblique to the ground is mounted at the rear operation end of the rack; the subsoiler is mounted at the front operation end of the rack; the soil preparation device and the subsoiler are located on the same horizontal line; a ditching shaft of the subsoiler is connected with one end of the transmission mechanism by a driving box on the ditching shaft and the other end of the transmission mechanism is connected with a traction machine. A machine tool composed of the soil preparation device and the subsoiler is matched to operate to reach deep-rooted crop soil preparation. The upper part of the soil preparation device is provided with a ditching cutter assembly and the lower part of the soil preparation device is provided with a diameter-changing spiral packing auger; a drill bit is arranged at an operation tail end and is easily buried in soil. The ditching cutter assembly is composed of a plurality of bent blades which are spirally arrayed; the rotary tracks of the bent blades are overlapped so as to guarantee that an omission phenomenon does not occur when the blades are used for crushing the soil. A ditching shaft buttress beam on the ditching shaft can guarantee that the upper and lower parts are coaxial and the deformation amount is reduced.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI +1

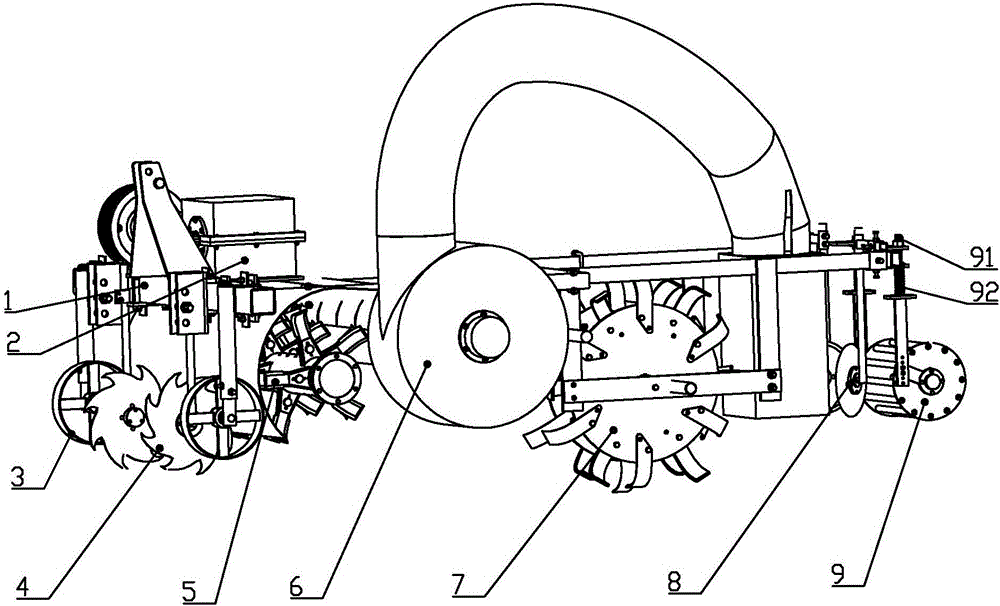

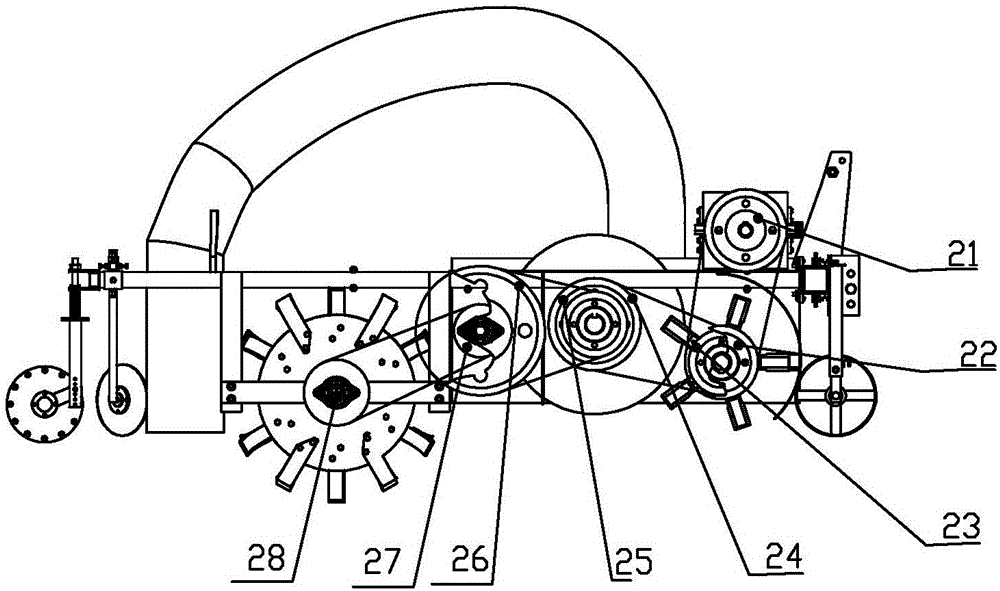

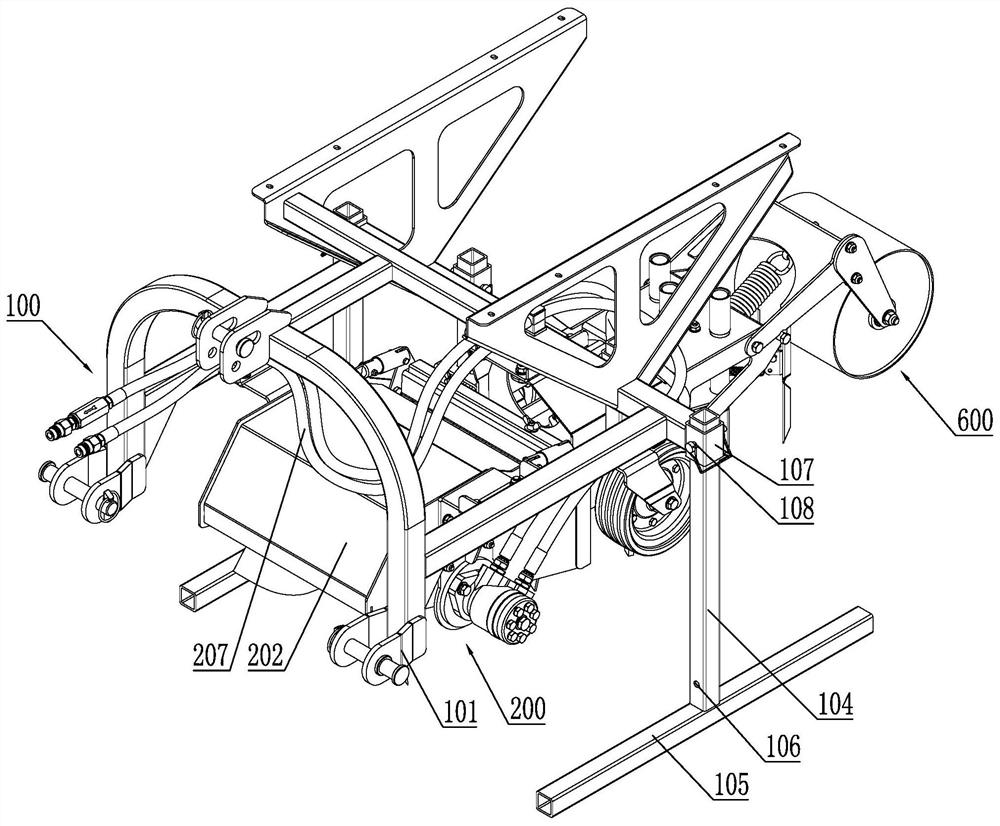

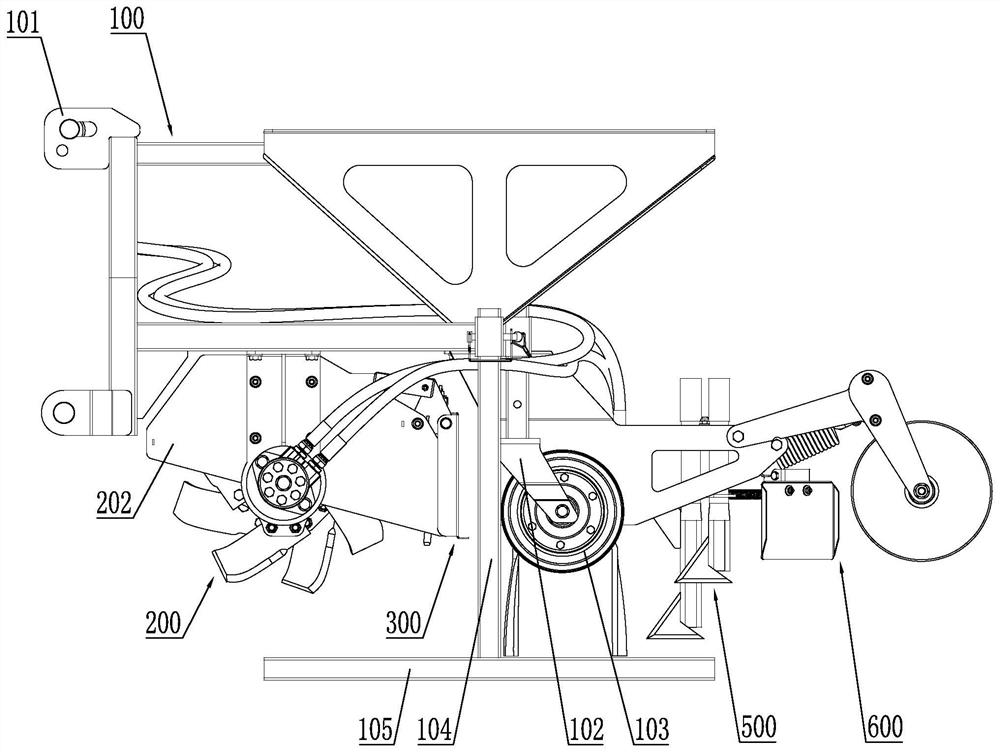

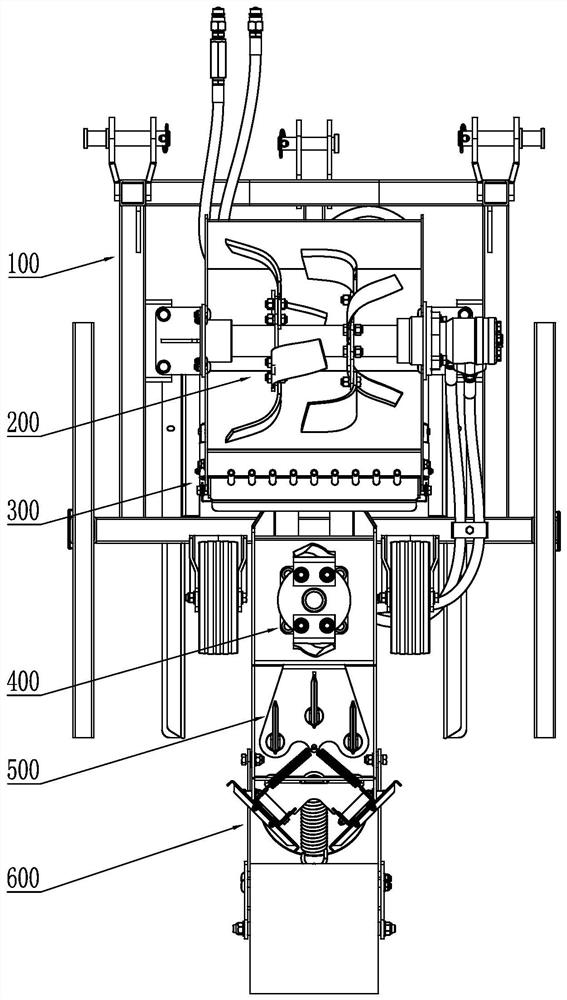

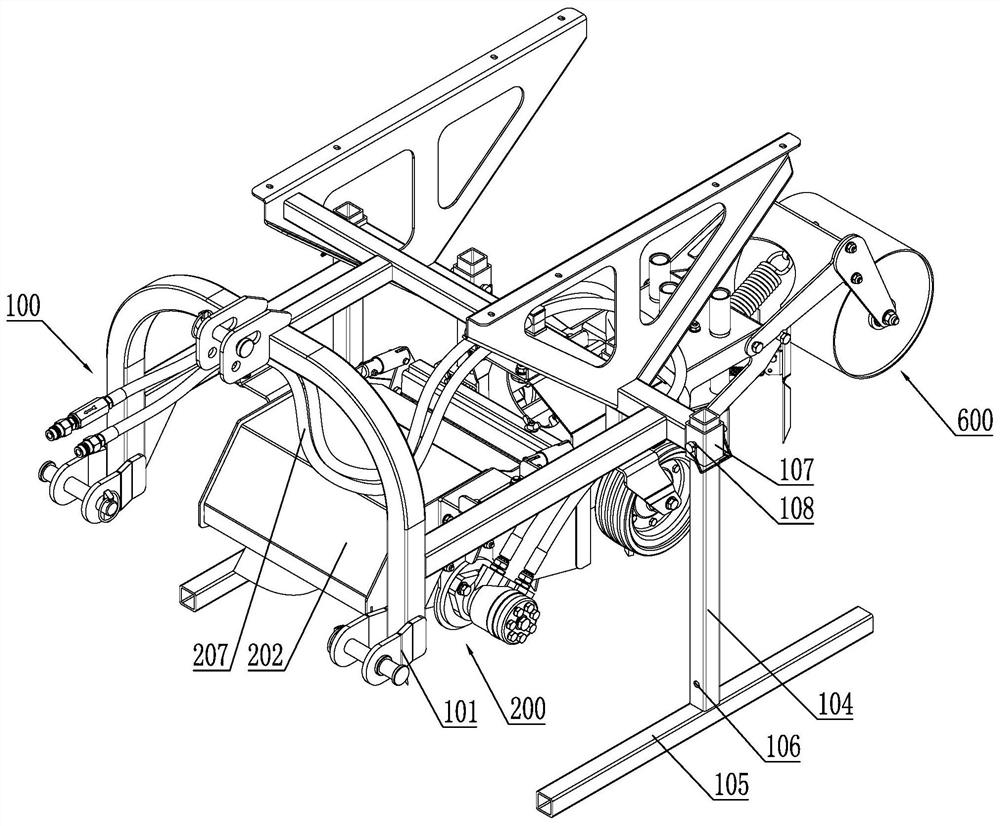

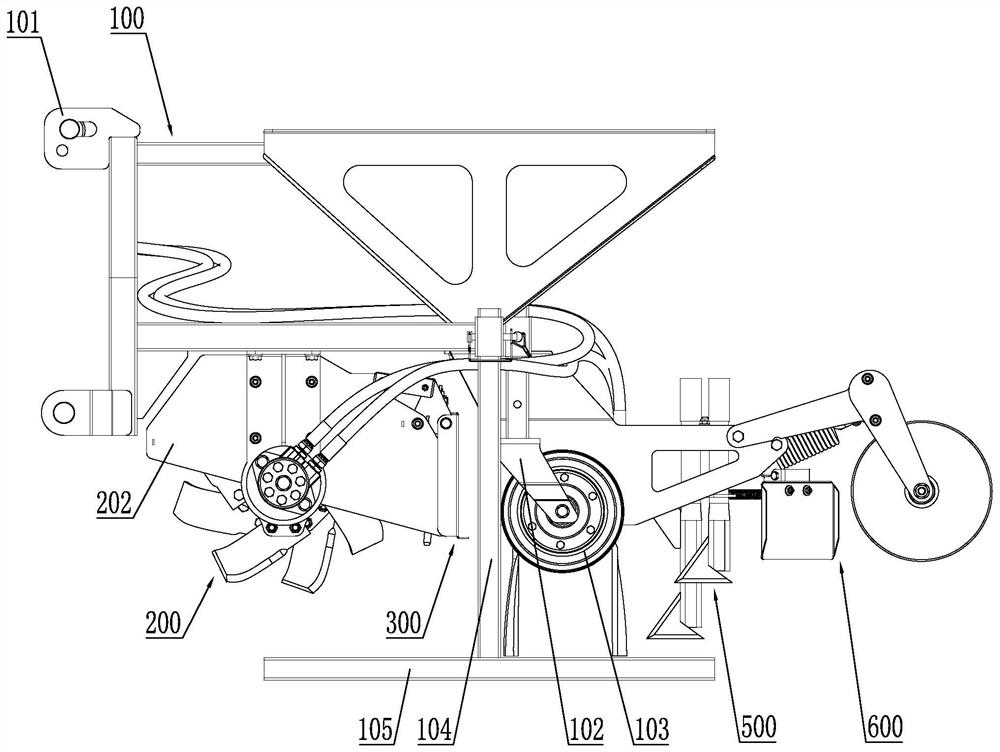

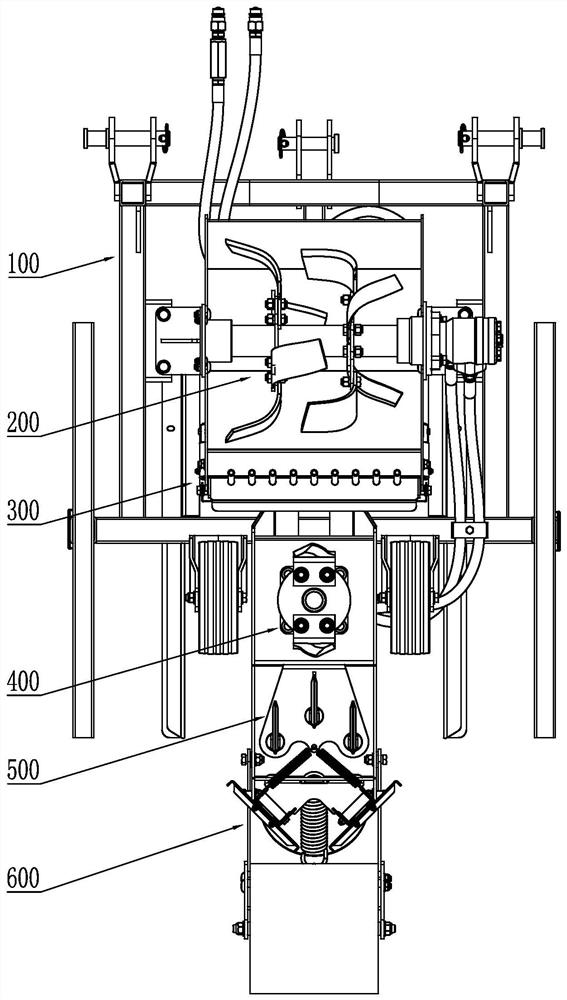

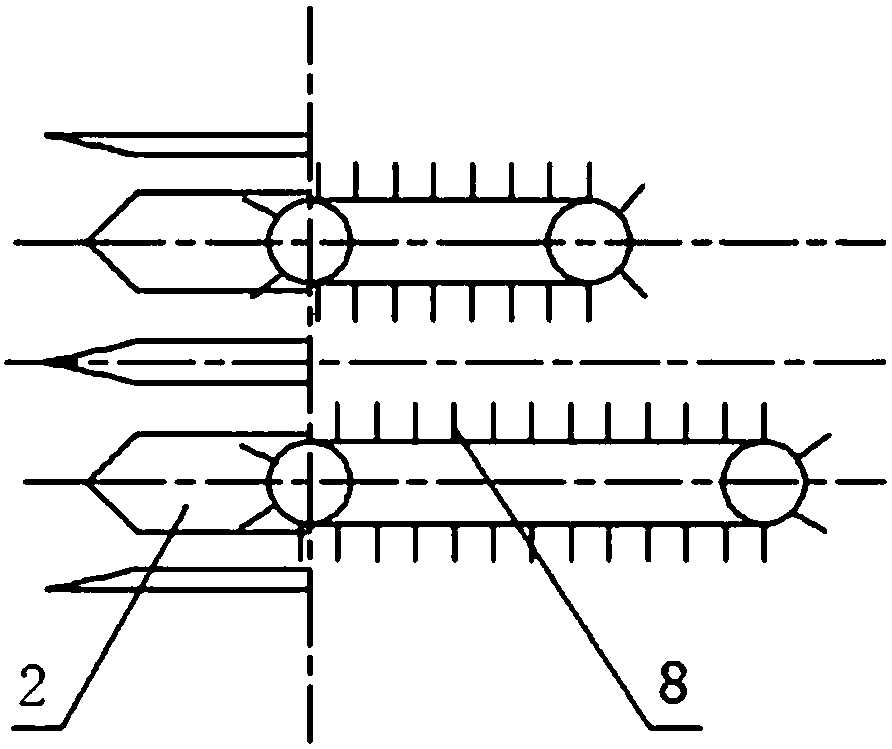

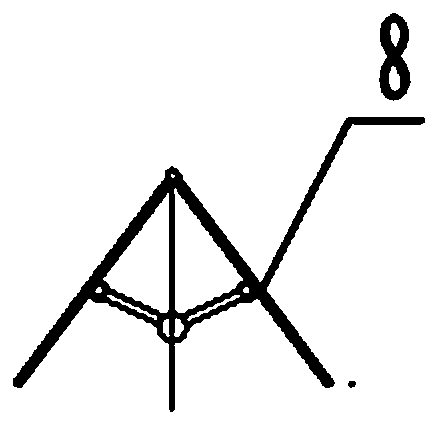

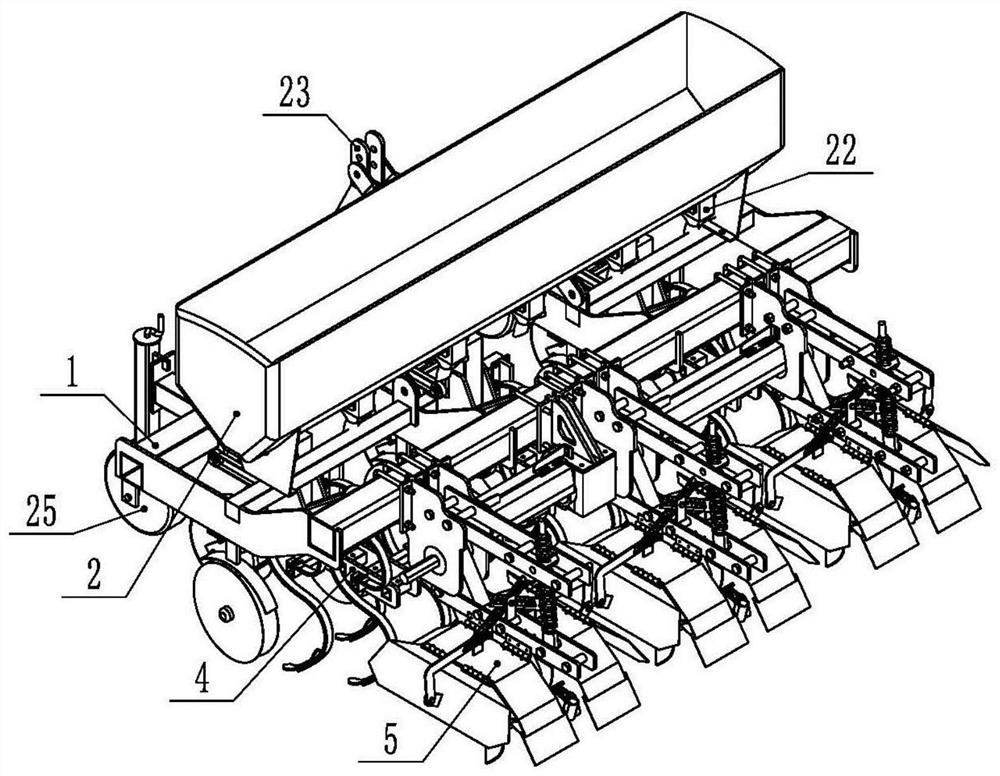

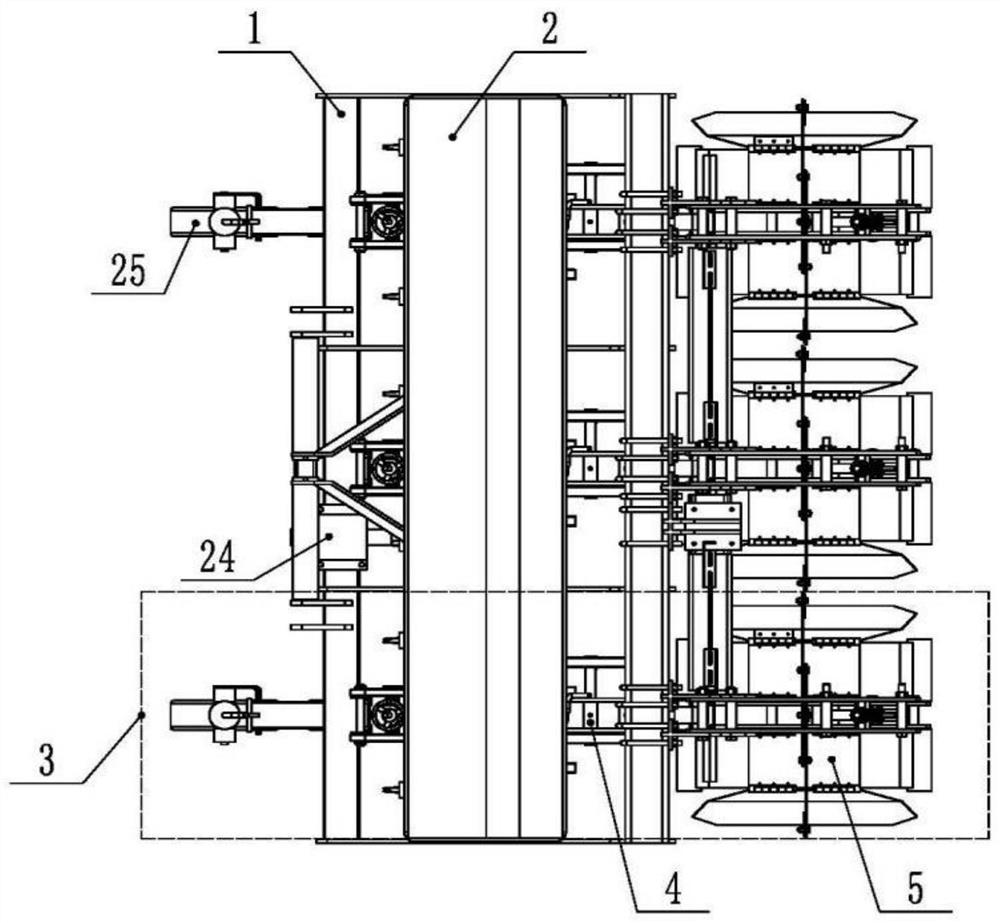

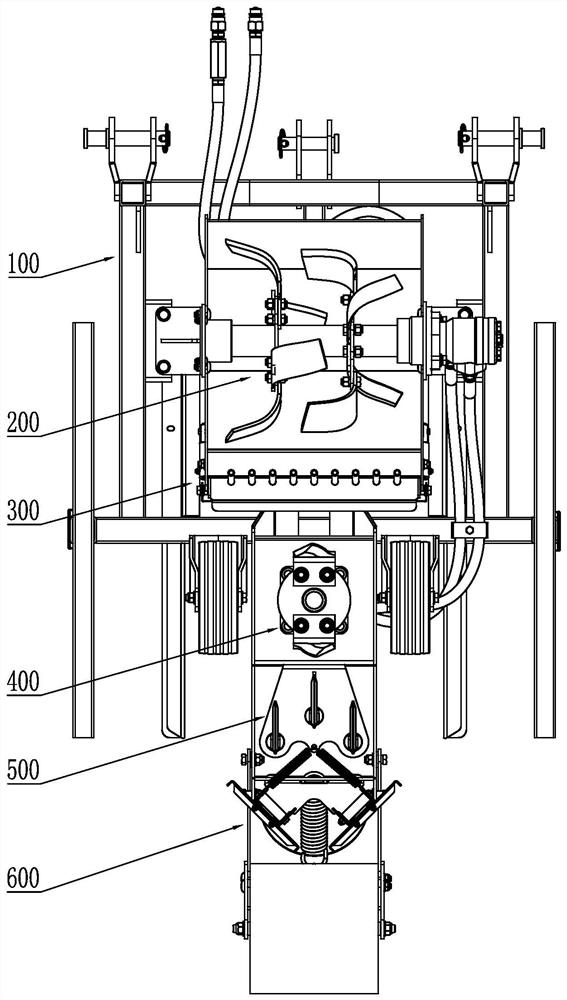

Soil preparation mechanism for wheat drill seeder suitable for sticky and heavy soil of rice stubble field

ActiveCN112544146AThere will be no accumulation, etc.Good effect of crushing soilSpadesPlantingSeederSoil science

The invention discloses a soil preparation mechanism for a wheat drill seeder suitable for sticky and heavy soil of a rice stubble field. The soil preparation mechanism comprises a rack, and a horizontal shallow rotary tillage mechanism, a floating soil crushing and leveling mechanism, a vertical deep stubble cutting mechanism, a ditching, fertilizing and seeding mechanism and a floating soil covering and pressing mechanism are sequentially installed on the rack from front to back; the horizontal shallow rotary tillage mechanism conducts stubble cutting and soil crushing in the advancing direction on shallow soil, then the floating soil crushing and leveling mechanism conducts profiling soil crushing and leveling on the surface layer of the soil, and then the vertical deep stubble cuttingmechanism conducts stubble cutting and soil crushing on the shallow soil and deep soil; and through combined use of the horizontal shallow rotary tillage mechanism and the vertical deep stubble cutting mechanism, an in-situ tillage and soil breaking treatment technical scheme is formed, the rice and wheat crop rotation planting system and agricultural requirements of typical regions of Jiangsu aremet, and high-performance compound seeding operation of the sticky and heavy soil of the rice stubble field is achieved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Rototilling-tillage combined machine with secondary plough

The invention discloses a rototilling-tillage combined machine with a secondary plough. The rototilling-tillage combined machine comprises a plough frame assembly and a plough body. The rototilling-tillage combined machine is technically characterized in that a secondary plough body is mounted in front of a main plough body; in operation, the secondary plough plows over 10 cm stubbles and weeds to the bottom of a trench at first, and then the main plough covers 10 cm below soil at an upper layer, so that the stubbles and weeds are completely covered beneath 10 cm. The structure of the rototilling-tillage combined machine is that one section of the front end of a big plough pillar pressing plate is extended, and the lower face is welded to an upper structure of a secondary plough pillar; the upper part of the structure is provided with an adjusting hole for adjusting height of the lower part of the secondary plough, and the plowing depth of the secondary plough can be adjusted. The rototilling-tillage combined machine with the secondary plough is simple in structure, low in cost, strong in practicability, good in covering performance, good in pulverizing soil, and is scientific and reasonable.

Owner:武文秀

Wheat drill seeder single body suitable for sticky and heavy soil of rice stubble field and planting method

ActiveCN112544147AThere will be no accumulation, etc.Good effect of crushing soilSpadesPlantingSeederSoil science

The invention discloses a wheat drill seeder single body suitable for sticky and heavy soil of a rice stubble field and a planting method. The wheat drill seeder single body comprises a rack, and a horizontal shallow rotary tillage mechanism, a floating soil crushing and leveling mechanism, a vertical deep stubble cutting mechanism, a ditching, fertilizing and seeding mechanism and a floating soilcovering and pressing mechanism are sequentially installed on the rack from front to back; the horizontal shallow rotary tillage mechanism conducts stubble cutting and soil crushing in the advancingdirection on shallow soil, then the floating soil crushing and leveling mechanism conducts profiling soil crushing and leveling on the surface layer of the soil, and then the vertical deep stubble cutting mechanism conducts stubble cutting and soil crushing on the shallow soil and deep soil; then a ditching and fertilizing device ditches and fertilizes at the same time, a ditching and seeding device ditches and seeds at the same time, and the seeding manner of seeding, fertilizing and seeding alternating and shallow seeding and deep fertilizing is achieved; and then, a floating soil covering device performs profiling soil covering on fertilized and sown ditches, and finally, a floating adjustable pressing device performs profiling compaction on the surfaces of the ditches after soil covering, so that high-performance compound seeding operation of the sticky and heavy soil of the rice stubble field is realized.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Plow-harrow soil pulverization device for biological organic fertilizer soil repairing

InactiveCN109328499AImprove repair uniformityPromote growthSpadesPloughsSoil remediationAgricultural engineering

The invention relates to the technical field of soil repairing, and discloses a plow-harrow soil pulverization device for biological organic fertilizer soil repairing. The plow-harrow soil pulverization device includes a support frame and plow-harrow devices, a first connection block is fixedly connected to the right end of the support frame, a connection rod is fixedly connected to the middle ofthe upper surface of the support frame, a support rod is fixedly connected to the right end of the connection rod, a rib plate is fixedly connected to the lower end of the support rod, the lower end of the rib plate is fixedly connected to the support frame, and the plow-harrow devices are arranged at the right end of the lower surface of the support frame. According to the plow-harrow soil pulverization device for biological organic fertilizer soil repairing, by arranging support plates, a first bearing, a second bearing, a fixing frame, a motor, a first rotation rod, a soil pulverization rolling wheel, a first connection plate, a second connection plate, a second rotation shaft, a circular hole, soil pulverization blades and discharging pipes, the soil pulverization effect is good duringplowing; after plowing, the soil pulverization rolling wheel can incidentally pulverize soil, therefore, soil repairing uniformity can be improved, it is convenient for people to use the plow-harrowsoil pulverization device, and after plants are planted, the growth of the plants is promoted.

Owner:中擘土壤环境工程技术(江苏)有限公司

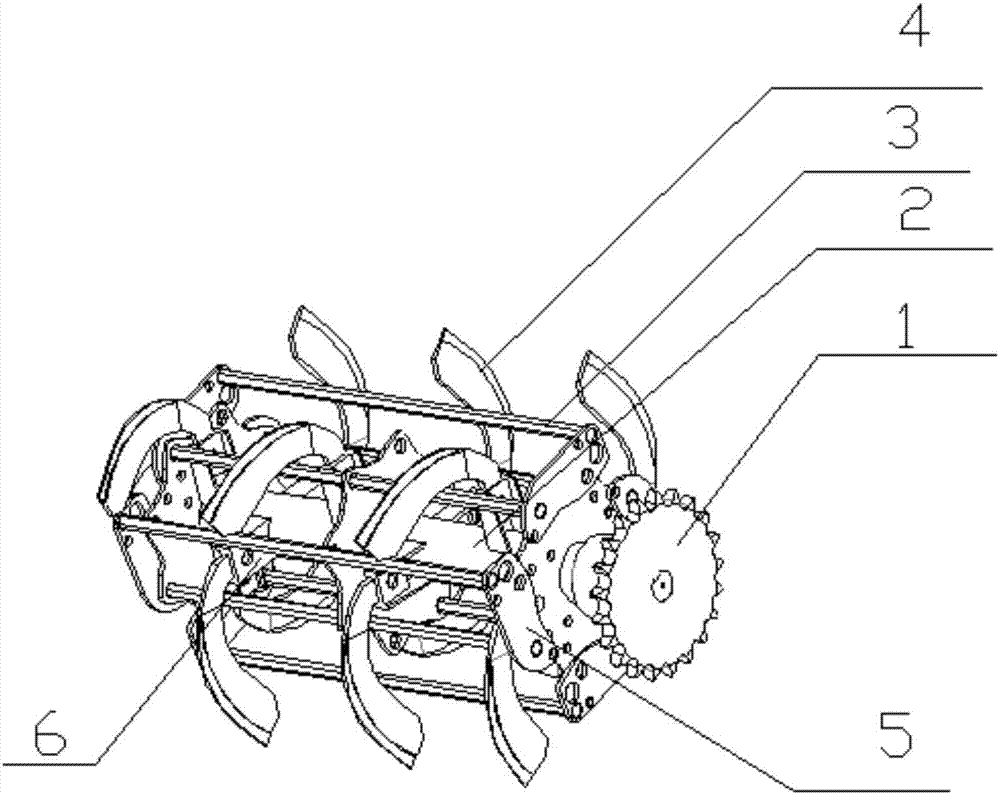

Draw bench knife roll

The invention provides a draw bench knife roll. The knife roll comprises a knife roll driving chain wheel, a knife roll shaft, cross bars and rotary tillage curved knives, the knife roll driving chain wheel is fixedly mounted at one end of the knife roll shaft and used for being connected with a driving device in a transmission mode, and the cross bars are distributed on the outer side of the knife roll shaft in the peripheral direction and are parallel to the knife roll shaft; a mounting embedded plate is vertically fixed to the knife roll shaft, the cross bars are all fixed to the mounting embedded plate, and multiple sets of rotary tillage curved knives are distributed on the outer side of the knife roll shaft in the length direction; each set of rotary tillage curved knives comprises two rotary tillage curved knives totally, the two rotary tillage curved knives of each set are distributed at an angle of 180 degrees, and the rotary tillage curved knives of two adjacent sets of the rotary tillage curved knives are arranged at an angle of 90 degrees in a staggered mode; the knife edge ends of the rotary tillage curved knives all extend out to the outer sides of the cross bars, and the rotary tillage curved knives are fixed to the mounting embedded plate through tool mounting supports. The draw bench knife roll solves the problems that a draw bench manufactured in the existing knife roll mounting mode has loopholes, and the tool is large in bearing stress and easy to damage. The invention belongs to the field of agricultural tobacco machines.

Owner:GUIZHOU UNIV

Wheat drill unit and planting method suitable for sticky and heavy soil in rice stubble field

The invention discloses a wheat seed drill unit and a planting method suitable for sticky and heavy soil in rice stubble fields. Mechanism, vertical deep stubble breaking mechanism, ditch fertilization and seeding mechanism, floating soil covering suppression mechanism; horizontal shallow rotary tillage mechanism breaks stubble and crushes the shallow soil in the forward direction, and then the floating crushed soil leveling mechanism The soil surface is broken and leveled by profiling, and then the vertical deep stubble breaking mechanism breaks and breaks the shallow soil and deep soil; then the ditching and fertilizing device fertilizes while ditching, and the ditching and seeding device ditches while Seeding realizes the sowing method of sowing-fertilization-sowing interval and shallow sowing and deep fertilization; then, the floating soil covering device performs profiling soil covering on the grooves after fertilization and sowing, and finally the floating adjustable suppression device performs soil covering on the grooves after soil covering The surface is profiled and compacted to realize high-performance compound seeding operations in sticky and heavy soil in rice stubble fields.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Reverse-rotating high-speed vertical-claw double-shaft finished land combined machine

PendingCN110809918AGood effect of crushing soilImprove the crushing effectSpadesTilling equipmentsAgricultural engineeringClay soil

The invention provides a reverse-rotating high-speed vertical-claw double-shaft finished land combined machine which comprises a hanging frame, a middle box, a rotary tiller and a soil breaking knifeshaft, the front end of the middle box is provided with an input shaft for being connected with an output shaft of a tractor, a universal joint for connecting the input shaft with the output shaft ofthe tractor is arranged at the front end of the input shaft, and the middle box is provided with a first output shaft extending out from the side face of the middle box and a second output shaft extending out from the lower end of the middle box; the rotary tiller is fixed on the hanging frame, and the first output shaft is connected with an input shaft of the rotary tiller; two ends of the soil breaking knife shaft are in rotating fit with the hanging frame, a first gear is fixed on the second output shaft and meshed with a gear fixed on the soil breaking knife shaft through a plurality of middle gears, and a plurality of soil breaking knives are arranged on the soil breaking knife shaft. The soil breaking knife shaft is mounted on the hanging frame mounted with the rotary tiller, the soil breaking knives on the soil breaking knife shaft are utilized for soil breaking to break up soil blocks after rotary tillage of clay land, and a dragging plate is utilized subsequently to level theland.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI +1

Combined digging harvester for underground crops

The invention relates to a combined digging harvester for underground crops. The combined digging harvester for underground crops comprises a harvester body, a plowing and vine-pulling unit, and a conveying and soil-breaking unit; the harvester body comprises a bottom plate, a support arranged on the bottom plate and an upper vine-pressing plate arranged on the top of the support, and is used forfixing and supporting; the plowing and vine-pulling unit comprises a plow arranged on the lower end of the front end of the bottom plate, a vine lifter fixed at the front end of the upper vine-pressing plate and arranged above the plow, and a fruit-picking cutter fixed at the front end of the support and the rear of the plow; the inlet of the conveying and soil-breaking unit is arranged corresponding to the rear of the plow, and the conveying and soil-breaking unit comprises a soil-breaking passage and a plurality of soil-breaking wheels arranged on the bottom of the soil-breaking passage. Compared with the prior art, the combined digging harvester for underground crops has the advantages of good practicability, thorough fruit and vine separation, good adaptability, good soil breaking effect, cleanliness and the like.

Owner:SHANGHAI UNIV OF ENG SCI

Intertillage fertilization machine for potato and underground tuber crops

PendingCN108260371AAdjustable to control the depth of entry into the soilAvoid the phenomenon of mixing a large amount of mudSpadesPloughsEngineeringSolanum tuberosum

The invention discloses an intertillage fertilization machine for potato and underground tuber crops. The machine comprises a machine frame, a main gearbox, sub gearboxes, a furrow opener, a soil cutter, a shaping plate and a fertilizer box, wherein two sub gearboxes are respectively and fixedly arranged on the machine frame positioned at the two sides of the main gearbox; the main gearbox respectively transmits the sub gearboxes and the soil cutter; a soil cutter blade cuts a soil layer from back side to front side; the soil is forwards thrown to the cover plate and then falls back into a furrow; the soil then covers the ridges by the shaping plate arranged at the back side, so that the loose shaping is realized; the furrow opener achieves the effect of opening the soil and deepening theculture layer; a space and depth regulation device arranged on the shaping plate can form ridges and build seedling beds before the seeding; during the intertillage, the adjustable culture covering and weeding can be realized. By using the intertillage fertilization machine for potato and underground tuber crops, the land preparation, ridge formation and fertilization are completed in one step; the perfect soil crushing, soil covering, shaping, weeding and topdressing effects are achieved; the best growth environment can be created for the potatoes; the weeding agent consumption is reduced; the work efficiency is improved.

Owner:赵东明

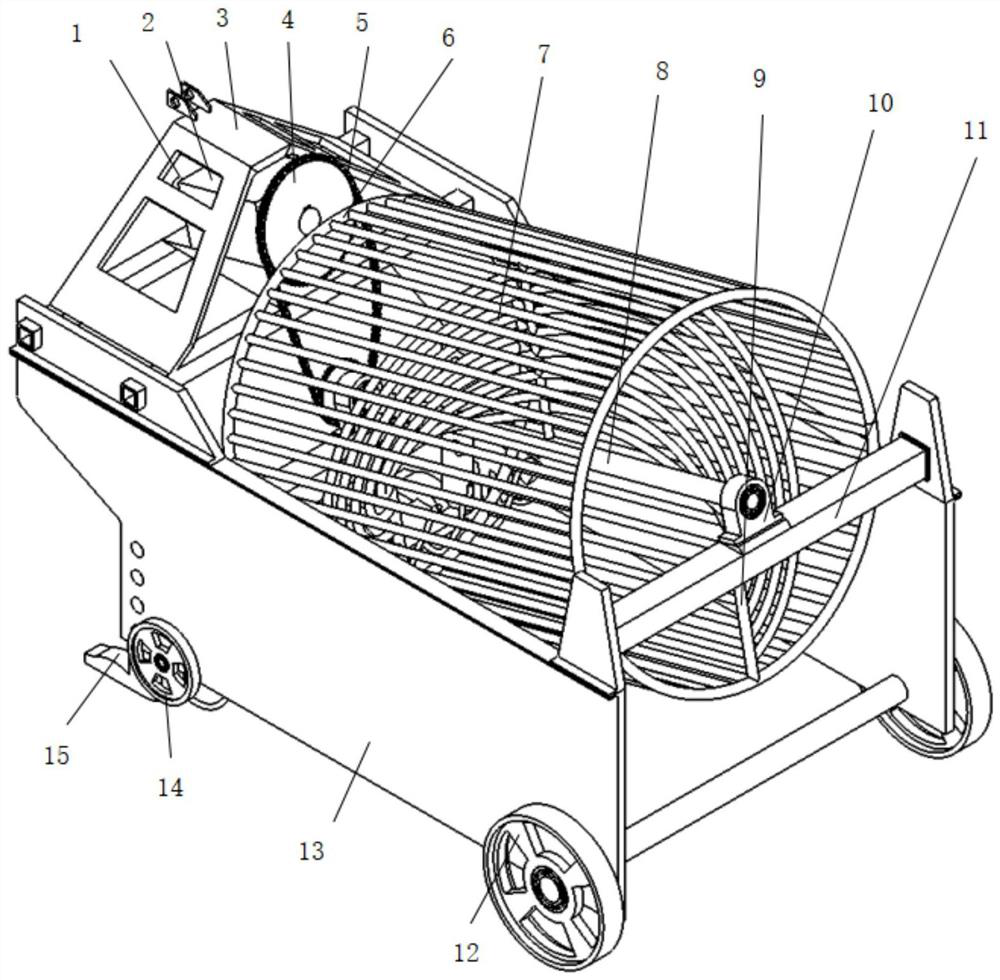

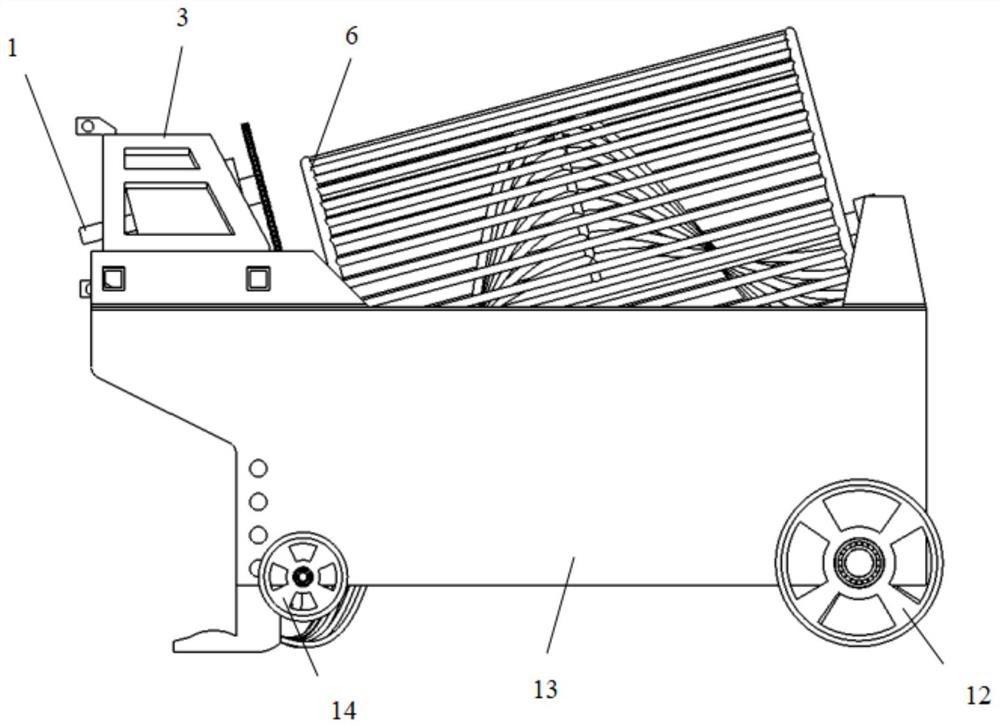

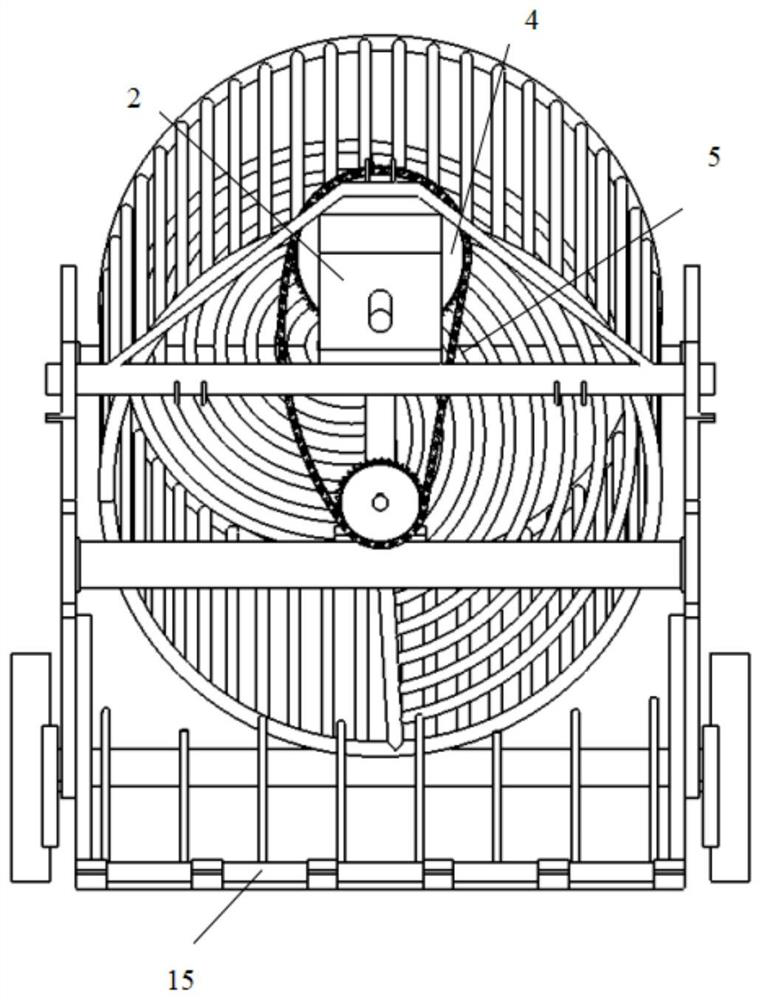

Spiral drum separation type cassava harvester

ActiveCN114223376AImprove machine performanceImprove performance in soilBiofuelsDiggersAgricultural engineeringManihot esculenta

The invention discloses a spiral drum separation type cassava harvester, which belongs to the technical field of agricultural machinery and comprises a transmission device, a cassava and soil separation device, an excavating device, a supporting device and a depth limiting device. The transmission device comprises a transmission shaft; the potato and soil separating device comprises a drum screen and flow guide screen bars, the transmission shaft is arranged on the inner side of the drum screen, the drum screen is of a hollow structure, and the flow guide screen bars are arranged on the inner side of the drum screen and are spirally connected and fixed to the transmission shaft in the axial direction of the conveying shaft; the rotary screen and the transmission shaft both have an inclination angle of 15-25 degrees, and the rotary screen and the flow guide screen bars can be driven by the transmission shaft to rotate together. According to the spiral roller separation type cassava harvester, the designed digging shovel has good soil penetrating performance and soil crushing capacity, a mixture composed of cassava and soil can be dug, the dug mixture can be separated, the spiral roller separation type cassava harvester has the advantages of being simple in structure, convenient to use, good in separation effect, small in cassava root damage and the like, and the spiral roller separation type cassava harvester is suitable for popularization and application. And the potato-soil separation operation efficiency and the overall performance of the cassava harvester can be improved.

Owner:HAINAN UNIVERSITY

Method of cultivation of high-yielding cotton

InactiveCN107027471ASolve outputSolve the survival ratePlant cultivationCultivating equipmentsInsect pestHigh yielding

The invention provides a method of the cultivation of high-yielding cotton, relates to the field of cotton cultivation. The method comprises the steps of 1, selection of land and preparation of site; 2, selection of breed; 3, treatment of seed; 4, configuration of cotton crop and row spacing; 5, seed sowing; 6, management of common field cultivation; 7, crop harvesting. The method of the cultivation of high-yielding cotton solves the problems of low output, low survival rate, weak resistance to insect pests and poor growth of old cotton materials.

Owner:合肥云都棉花有限公司

An agricultural soil crusher

ActiveCN105144872BSimple structureEasy to useClod-crushersAgricultural engineeringAgricultural machinery

An agricultural soil breaking machine comprises a base plate, a body, a holding device, a smashing device, a pushing device and a positioning device, wherein universal wheels, a first rack, a first supporting rod and a first fixing rod are arranged on the base plate; the body is provided with a first cross rod, a first groove, a second cross rod, a bend plate and a second rack; the holding device is formed by a third rack, a fourth rack, a first vertical plate, a fifth rack, a sixth rack and a third cross rod; the smashing device is formed by a rotating rod, a first spring, a second spring, a balancing block, a roller wheel and smashing teeth; the pushing device consists of an air cylinder, a first pushing rod, a connection rod, a second pushing rod, a second supporting rod, and a third supporting rod; one end of the rotating rod is accommodated into the first groove and connected with a body rotating shaft; the lower end of the first spring is fixedly connected with the upper surface of the bend plate; and the upper end of the first spring is fixedly connected with the lower surface of the rotating rod. The agricultural soil breaking machine has obvious soil breaking effect, improved soil breaking effect and enlarges soil breaking use range.

Owner:盐城熔石科技有限公司

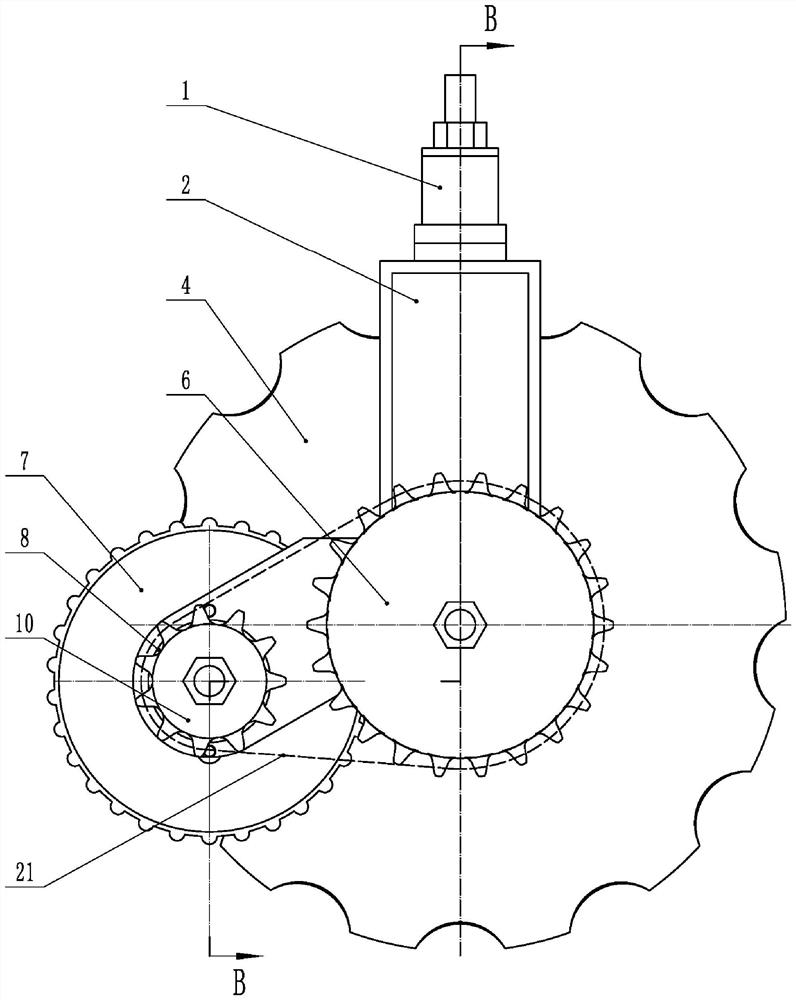

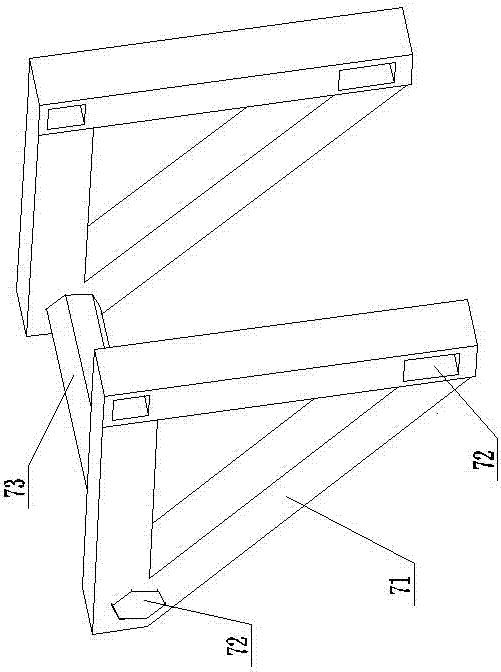

Reciprocating motion extrusion type strip seedbed construction unit

The invention discloses a reciprocating motion extrusion type strip type seedbed construction unit, and belongs to agricultural machinery. According to the reciprocating motion extrusion type strip type seedbed construction unit, hanging arms are symmetrically arranged on a connecting frame at intervals, the hanging arm is provided with a smashing and cutting device for strip seedbed soil, straw and stubble smashing and an operation auxiliary device, the smashing and cutting device for the strip seedbed soil, the straw and the stubble is composed of an end face cam A, a sawtooth disc coulter, a spring seat A, a chain wheel A, a cutter shaft, an ejector rod A, a pressure spring A and a plane thrust bearing A, the operation auxiliary device is composed of an end face gear B, a depth-limiting anti-skid straw pressing wheel, a spring seat B, a chain wheel B, a wheel shaft, an ejector rod B, a pressure spring B and a plane thrust bearing B, a chain is sleeved on the chain wheel A and the chain wheel B; according to a single body of the reciprocating motion extrusion type strip type seedbed construction unit, the strip seedbed soil and the stubbles are cut up through rotation and axial reciprocating motion of the sawtooth disc coulter, meanwhile, the strip seedbed soil is extruded, smashed, gathered and gathered inwards in the opposite direction, the single body has the characteristics of unique and reasonable structure, low power consumption, good constructed strip seedbed quality and high operation efficiency.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

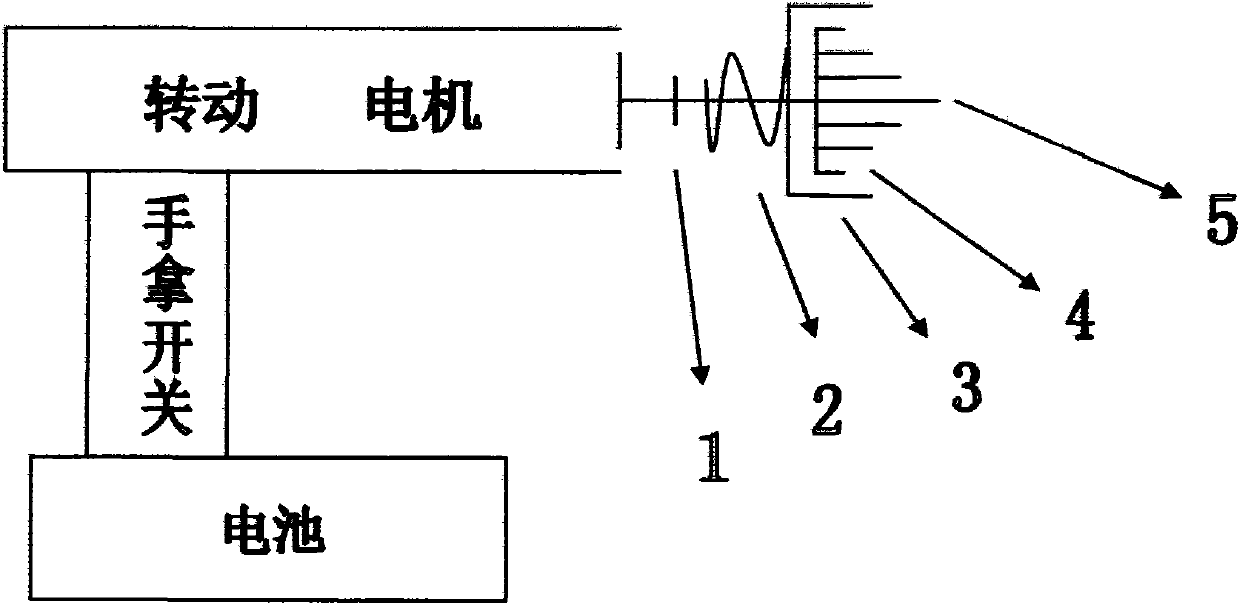

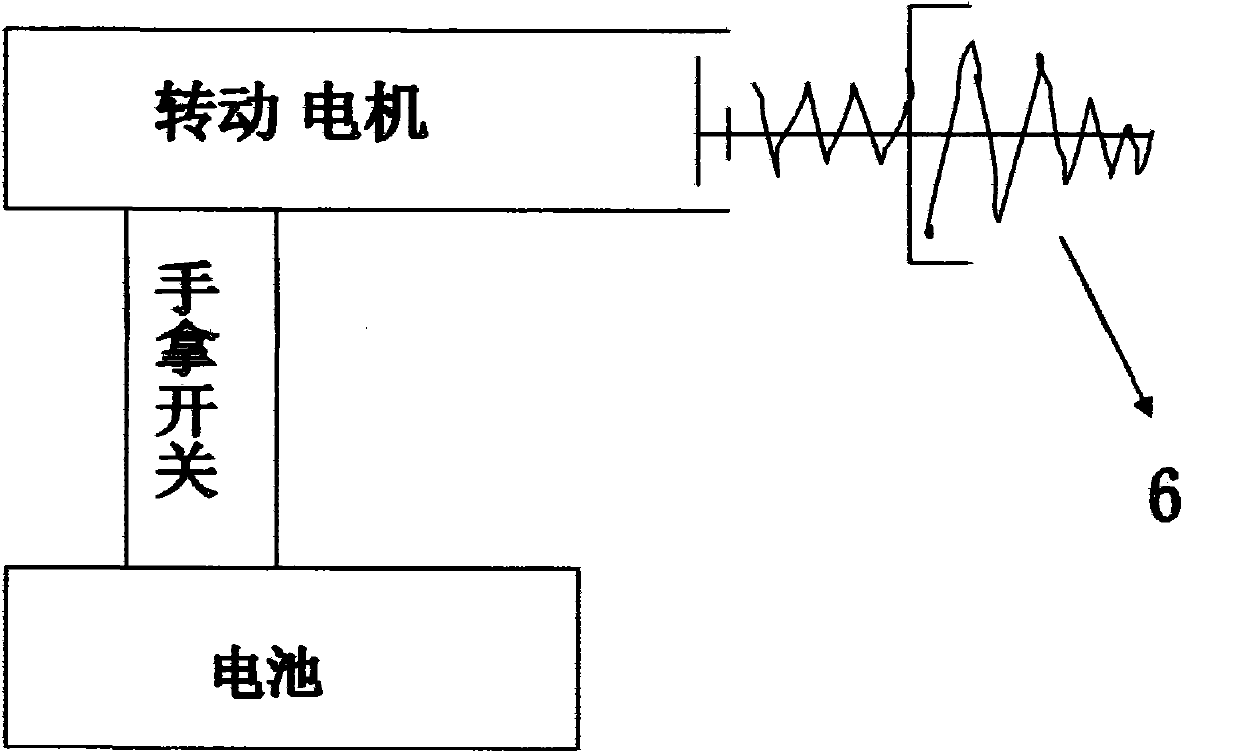

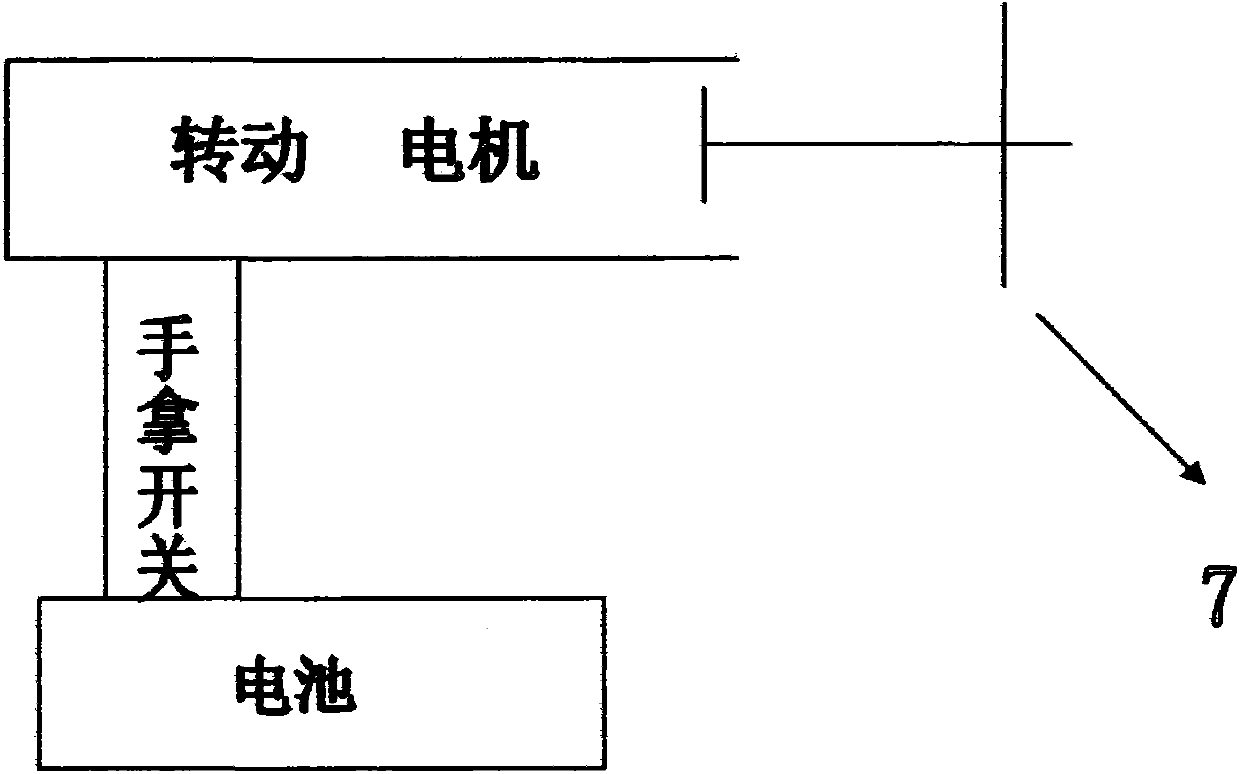

Handheld chargeable type rotary cultivator

The invention discloses a handheld chargeable type rotary cultivator which is mainly applied to agriculture. The rotary cultivator consists of a continuously chargeable battery, a motor and a soil hacking drill bit. When the rotary cultivator is used, the battery is used for supplying power to enable the motor to rotate, the soil hacking drill bit is driven to rotate after the motor rotates, a plurality of cutting blades are fixed on the soil hacking drill bit, the soil can be instantaneously hacked to form caves after the soil hacking drill bit rotates, and the soil is made into powder within seconds. The rotary cultivator is mainly applied to transplanting of various vegetable seedlings, melon seedlings, dibble seeding of seeds, and vegetable garden planting by farmers. The weight of the rotary cultivator is smaller than the conventional shovel.

Owner:付德永

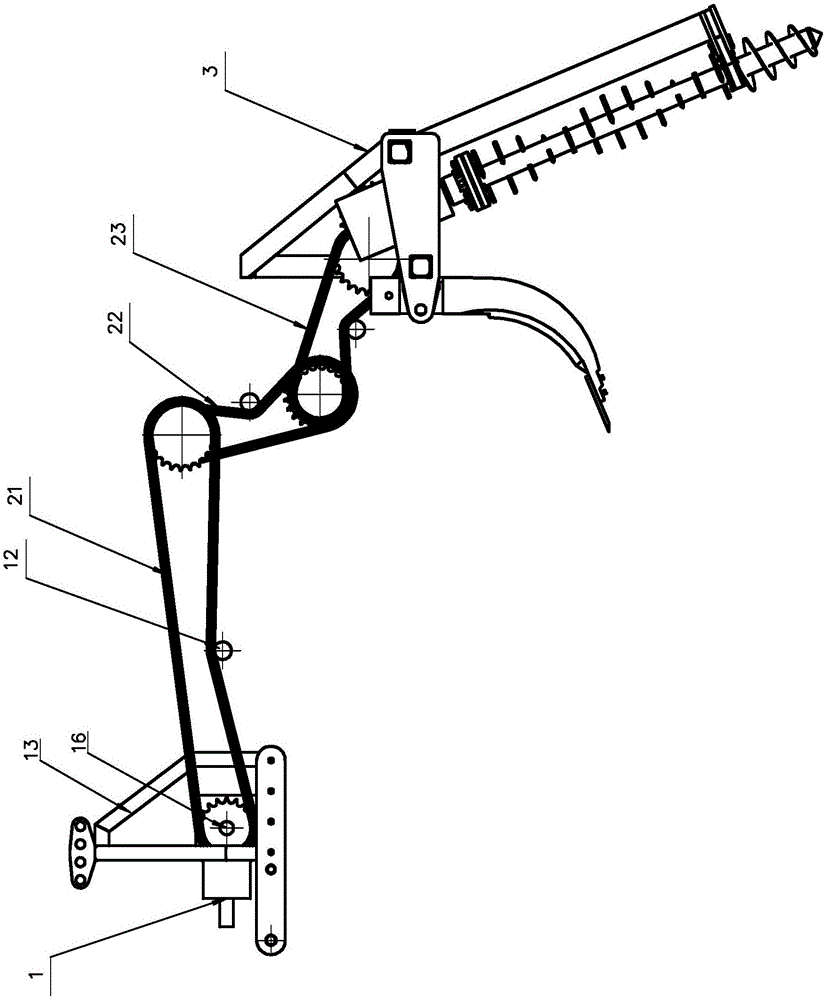

Deep root crop soil preparation machine

The invention provides a deep-rooted crop soil preparation machine and belongs to the technical field of farm machinery. The deep-rooted crop soil preparation machine comprises a rack, a transmission mechanism, at least one set of a soil preparation device and a subsoiler, wherein the soil preparation device which is oblique to the ground is mounted at the rear operation end of the rack; the subsoiler is mounted at the front operation end of the rack; the soil preparation device and the subsoiler are located on the same horizontal line; a ditching shaft of the subsoiler is connected with one end of the transmission mechanism by a driving box on the ditching shaft and the other end of the transmission mechanism is connected with a traction machine. A machine tool composed of the soil preparation device and the subsoiler is matched to operate to reach deep-rooted crop soil preparation. The upper part of the soil preparation device is provided with a ditching cutter assembly and the lower part of the soil preparation device is provided with a diameter-changing spiral packing auger; a drill bit is arranged at an operation tail end and is easily buried in soil. The ditching cutter assembly is composed of a plurality of bent blades which are spirally arrayed; the rotary tracks of the bent blades are overlapped so as to guarantee that an omission phenomenon does not occur when the blades are used for crushing the soil. A ditching shaft buttress beam on the ditching shaft can guarantee that the upper and lower parts are coaxial and the deformation amount is reduced.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI +1

Cotton intertillage fertilization ridging machine

PendingCN111713199AImprove work efficiencyReduce the number of entry timesSpadesPlantingAgricultural scienceUniversal joint

The invention discloses a cotton intertillage fertilization ridging machine. The cotton intertillage fertilization ridging machine comprises a rack, wherein a fertilizer box and a plurality of operation units are arranged on the rack, and each operation unit comprises an intertillage fertilization profiling single body and a rotary ridging mechanism; each intertillage fertilization profiling single body comprises a profiling single body rack connected with the rack through a four-bar linkage profiling assembly and a fertilization furrow opener connected with the corresponding profiling singlebody rack, a plurality of electric fertilizer feeders are arranged on the fertilizer box, and the electric fertilizer feeders communicate with the corresponding fertilization furrow openers; each rotary ridging mechanism comprises a ridging rack and a gearbox, the ridging racks and the gearboxes are fixedly connected with the rack, a transmission shaft, a ridging cutter shaft and a soil crushing housing are arranged on each ridging rack, the transmission shaft is connected with an output shaft of the gearbox and is in transmission connection with the ridging cutter shaft, and a plurality of ridging cutters are arranged on the ridging cutter shaft; the rack is further provided with a gap bridge shaft connected with an input shaft of the gearbox through a universal joint. According to the cotton intertillage fertilization ridging machine, the cotton intertillage ridging operation efficiency is improved.

Owner:滨州市农业机械化科学研究所

A small garlic harvester

A small garlic seedling harvester is provided with a double-sided upper hanging shaft and a single-sided upper hanging shaft on the front beam of the frame. The double-sided upper hanging shaft and the single-sided upper hanging shaft are respectively provided with double-sided gears and single-sided gears. Double-sided cam and single-sided cam; the double-sided upper hanging shaft is connected to the double-sided lower hanging shaft, the single-sided upper hanging shaft is connected to the single-sided lower hanging shaft, and the lower end of the double-sided lower hanging shaft is provided with two double-sided moving pulleys. The lower end of the single-sided lower suspension shaft is equipped with a single Side driving pulley; there is a double-sided fixed shaft and a single-sided fixed shaft on the rear cross member. There are two double-sided fixed pulleys spaced on the double-sided fixed shaft. There is a single-sided fixed pulley on the single-sided fixed shaft; double-sided fixed shaft. There are double-sided upper belts and double-side lower belts on the side moving pulley and the double-sided fixed pulley, and a single-side belt is installed on the single-sided moving pulley and the single-sided fixed pulley; the front end of the frame is equipped with a double-sided moving pulley. Excavating shovel at the front and bottom of the pulley and single-sided moving pulley. The invention has a simple structure, is compact and flexible, and is easy to operate. It successfully fills the technical gap in the mechanization of harvesting garlic seedlings at home and abroad, and makes due contributions to the progress of agricultural mechanization.

Owner:HENAN AGRICULTURAL UNIVERSITY

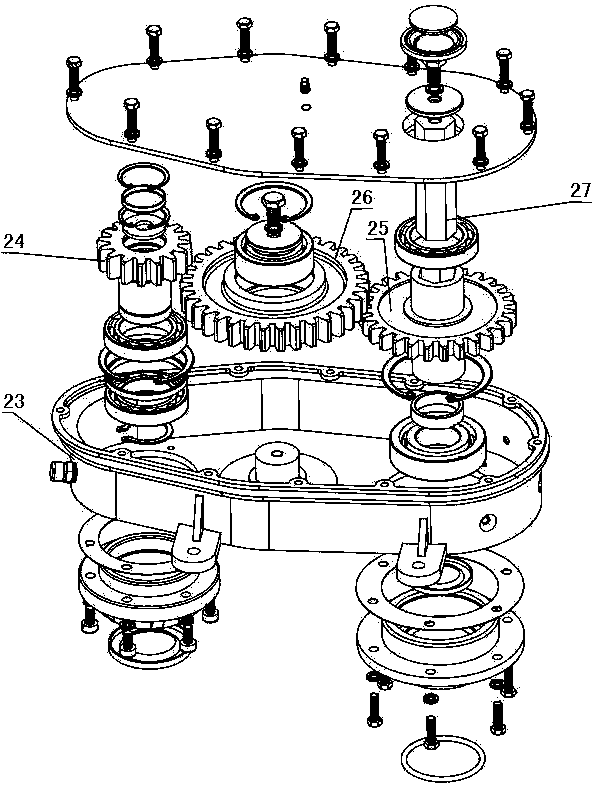

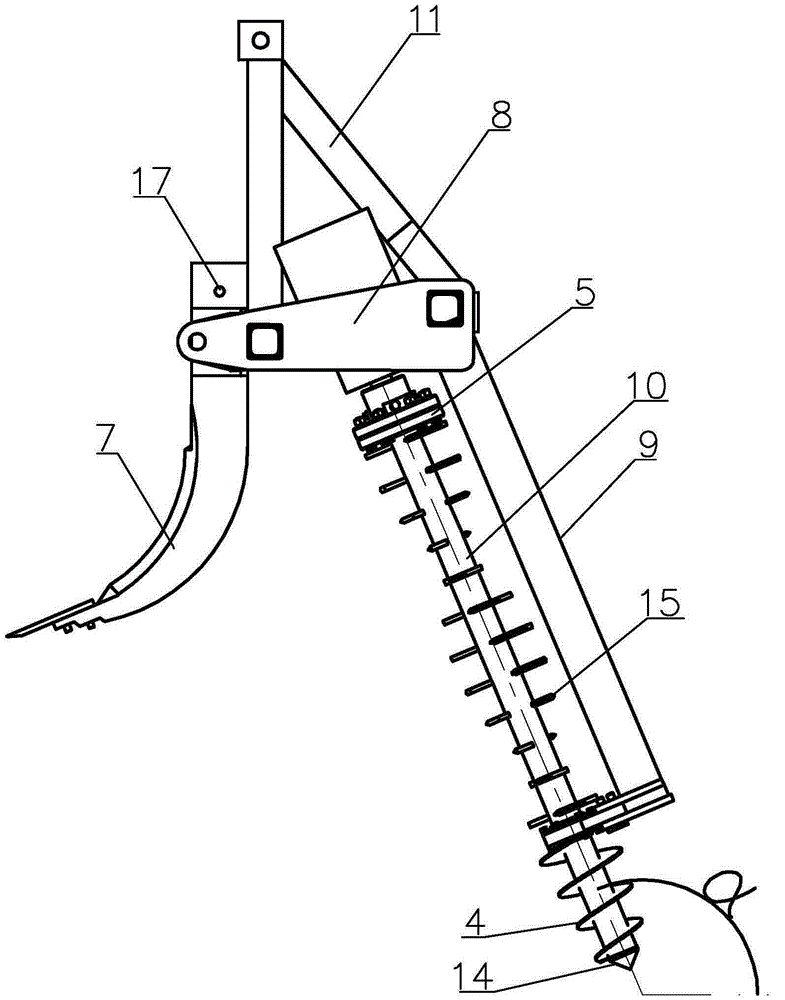

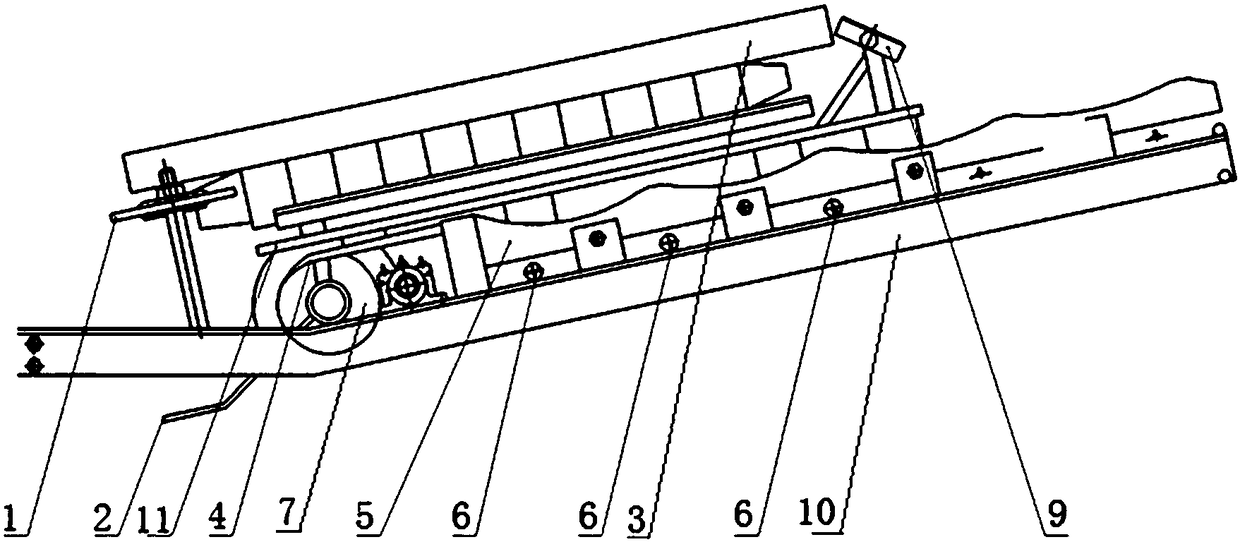

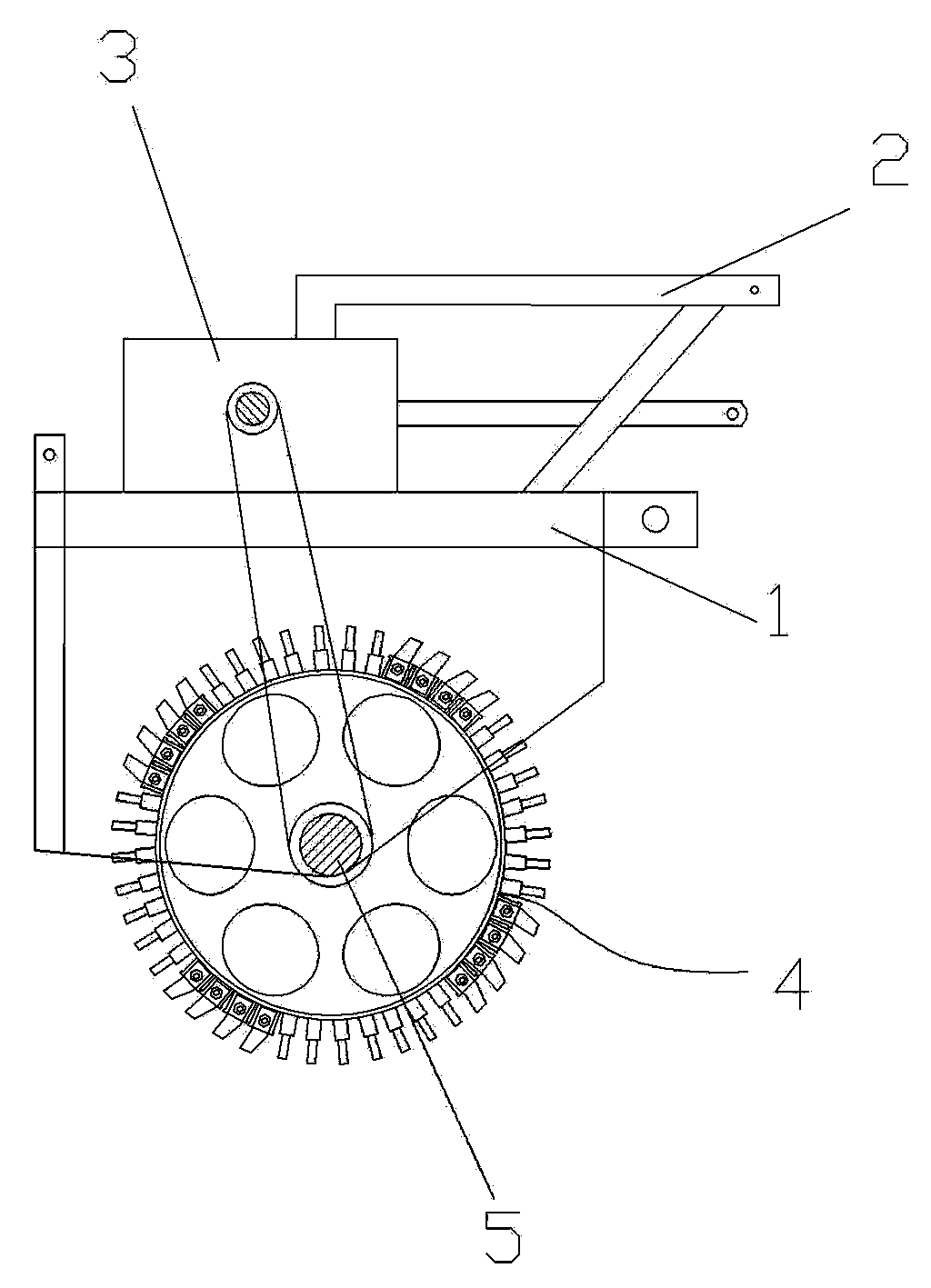

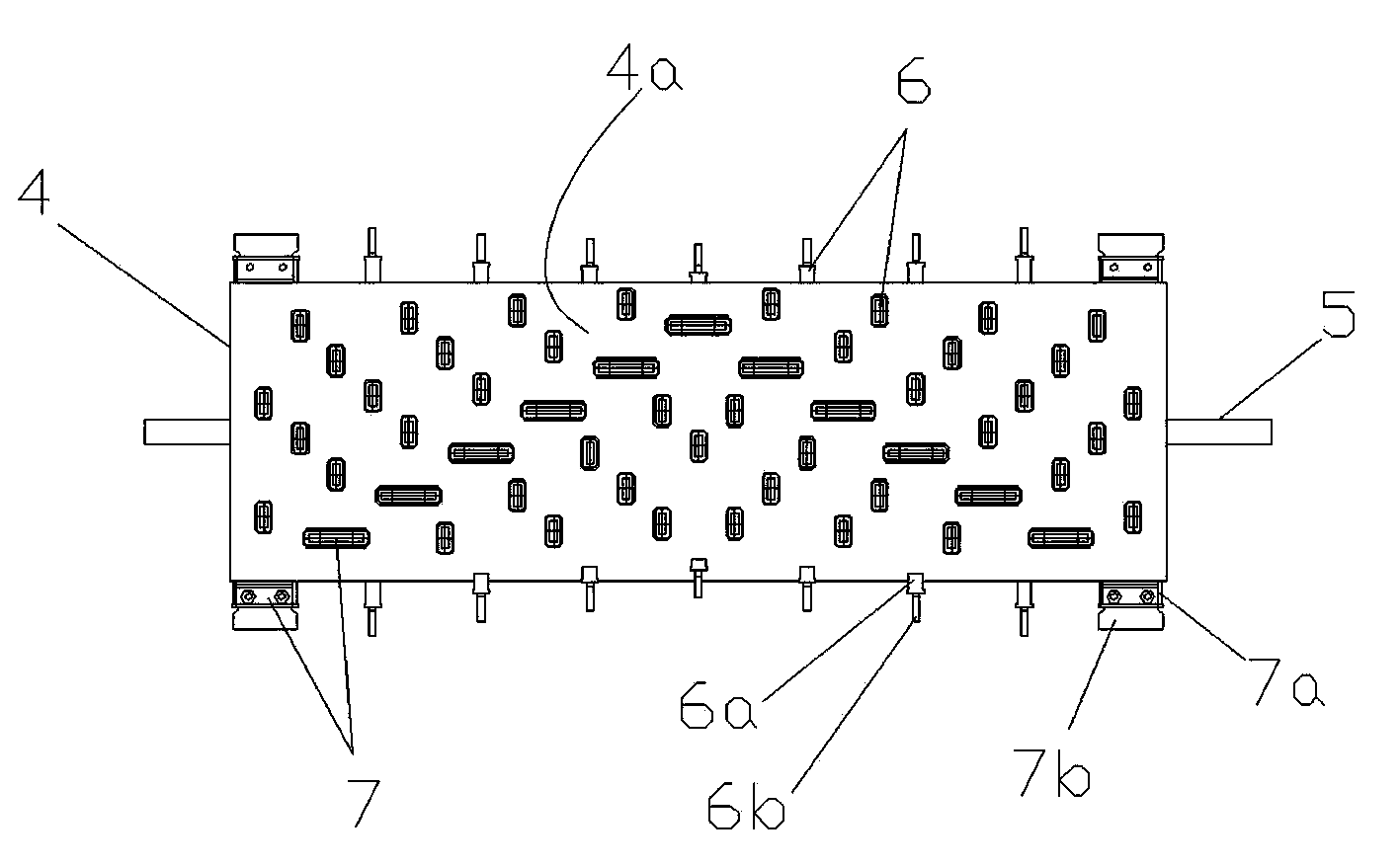

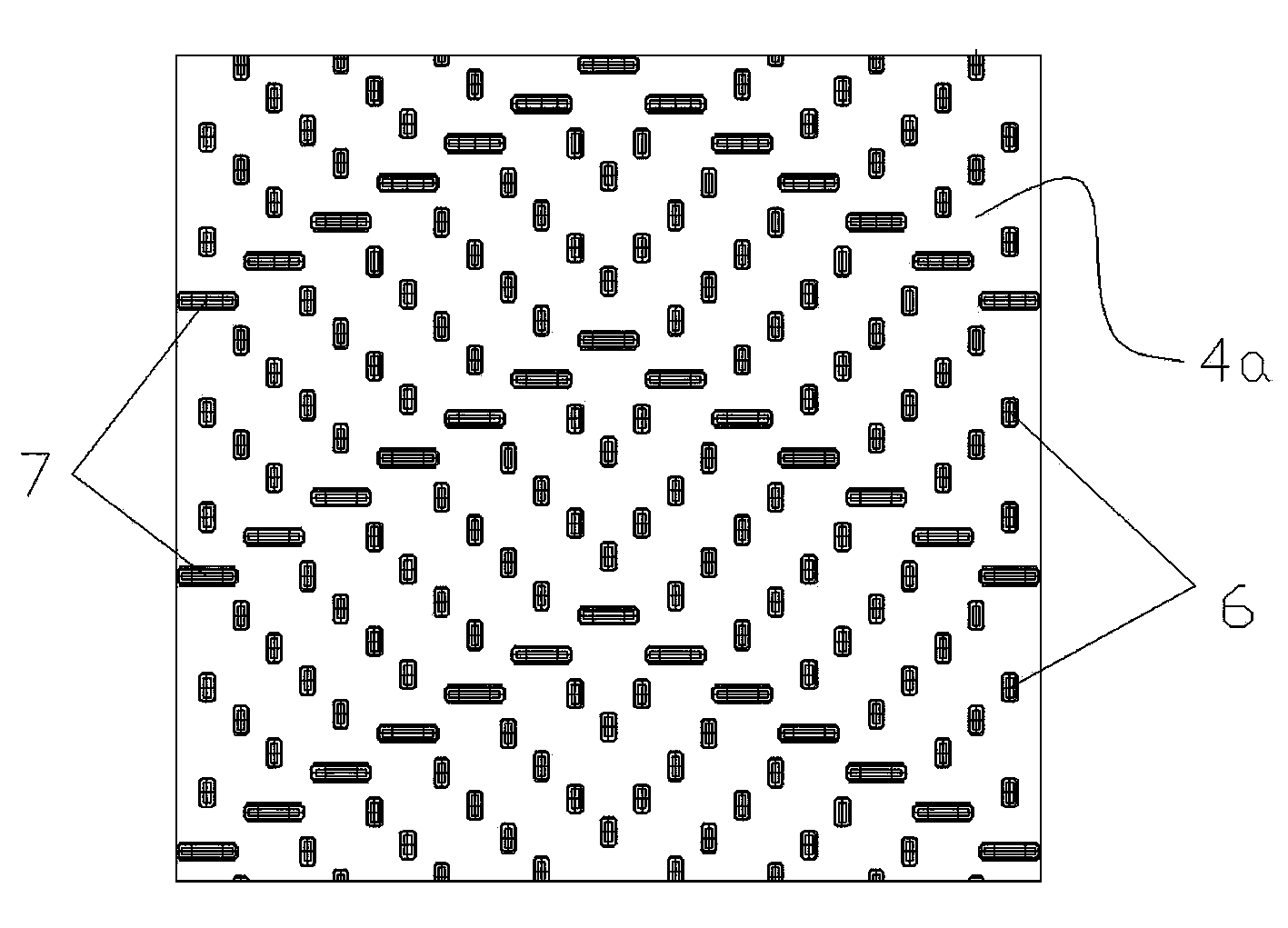

Rotary drum type rotary cultivator

InactiveCN103636304AEasy to operateImprove the efficiency of rotary tillageTilling equipmentsTraction frameMechanical engineering

The invention discloses a rotary drum type rotary cultivator. The rotary drum type rotary cultivator comprises a traction frame (2) and a transmission assembly (3) which are arranged on a machine frame (1) and is characterized by being provided with a rotary drum type rotary cultivation assembly (4), a spindle (5) is arranged on the rotary drum type rotary cultivation assembly (4), two ends of the spindle (5) are connected with the machine frame (1), and the spindle (5) is matched with the transmission assembly (3). The rotary drum type rotary cultivator has the advantages of being convenient to operate, high in rotary cultivation efficiency, good in soil-crushing effect, simple in structure, durable, quick and convenient to maintain and the like.

Owner:ANHUI YUANDA MACHINERY MFG

Integrated agricultural machine for land preparation and soil sifting

InactiveCN108966699AGood effect of crushing soilQuality improvementSpadesSievingDrive shaftAgricultural engineering

The invention discloses an integrated agricultural machine for land preparation and soil sifting, comprising a chassis and traveling wheels. A gearbox assembly is mounted in the front of the chassis;a soil storage tank is arranged in the rear of the chassis; the front end of the chassis is provided with a connection portion connected with a tractor; the rear end of the chassis is provided with arear support that is inclined; an input shaft of the gearbox assembly is in transmission connection with a power system of the tractor; two output shafts in the lower portion of the gearbox assembly are in transmission connection with a cutter shaft; middle supports inclined are arranged on the two sides of the middle of the chassis; the upper and lower ends of the middle supports inclined are fitted with an upper transmission shaft and a lower transmission shaft respectively. The integrated agricultural machine for land preparation and soil sifting is suitable for carrying out land preparation and soil sifting at the same time, so that land preparation and soil sifting quality and efficiency are greatly improved.

Owner:凤台县发群农业机械制造有限公司

Corn rootstalk soil removal machine

The invention discloses a corn rootstalk soil removal machine. The machine comprises a frame, a double-drum rolling and breaking device, a belt open link chain conveying and feeding mechanism, an open link chain dithering and separating mechanism and a drive system, wherein, the double-drum rolling and breaking device comprises a rear rolling drum, a front rolling drum, two angle iron supports, two roller supports, four channel steel upright columns and six support rollers; the double-drum rolling and breaking device is arranged on the right end of the frame; the open link chain dithering andseparating mechanism is arranged on the left end of the frame; the belt open link chain conveying and feeding mechanism is arranged below the rear rolling drum and the front rolling drum; the drive system connects corresponding parts together through a chain wheel, a gear and a chain; the front rolling drum and the rear rolling drum are arranged between the two angle iron supports to form rotary connection; two ends of the two angle iron supports are fixedly connected with the four channel steel upright columns; the six support rollers are arranged between the two roller supports to form rotary connection; and the vertical distance from the vertex of rolling teeth to the six support rollers is 50-70mm.

Owner:JILIN UNIV

Soil preparation mechanism for wheat drill suitable for sticky heavy soil in rice stubble field

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com