Rototilling-tillage combined machine with secondary plough

A combined operation machine and auxiliary plow technology, which is applied to agricultural machinery and tools, plows, agriculture, etc., can solve the problems of high stubble, incomplete coverage of stubble and weeds, and affecting the quality of sowing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

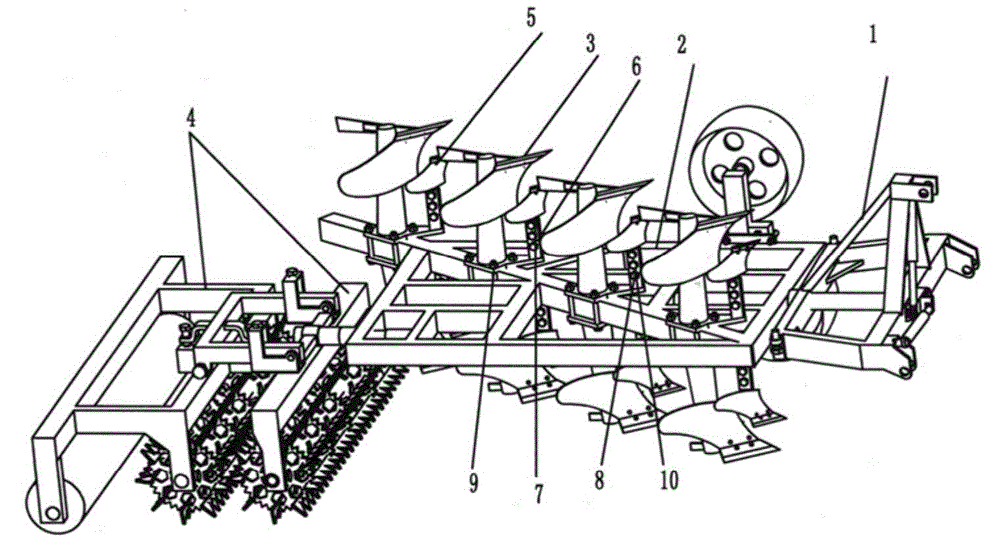

[0016] Such as figure 1 As shown, the combined tillage and tillage operation machine with a pair of plows in this embodiment includes a tillage device and a land preparation mechanical device;

[0017] The cultivating device includes a turning mechanism 1, a plow frame assembly 2, a plow body assembly 3, and a soil preparation mechanical device including a soil preparation mechanical assembly 4, and the crushed soil

[0018] Roller 11 and suppressing roller 12 are patent numbers; ZL201320771613.6 The subordinate technology of the tillage combined operation machine.

[0019] As an improvement to this embodiment, the structural features and innovations of the auxiliary plow body of the present invention are that a section is extended at the front end of the pressure plate 9 of the main plow body 3, and the upper part 6 of the auxiliary plow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com