Intertillage fertilization machine for potato and underground tuber crops

A technology for underground tubers and potatoes, applied to agricultural machinery and implements, shovels, plows, etc., can solve the problems of small seedbeds, difficulties in sowing, intertillage and harvesting, etc., achieve good seedbeds, reduce the amount of herbicides used, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

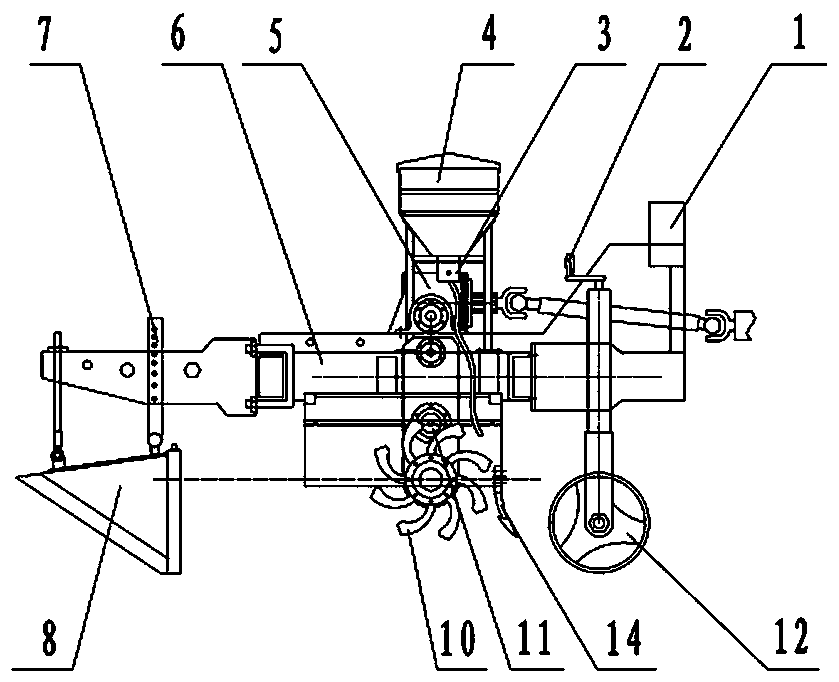

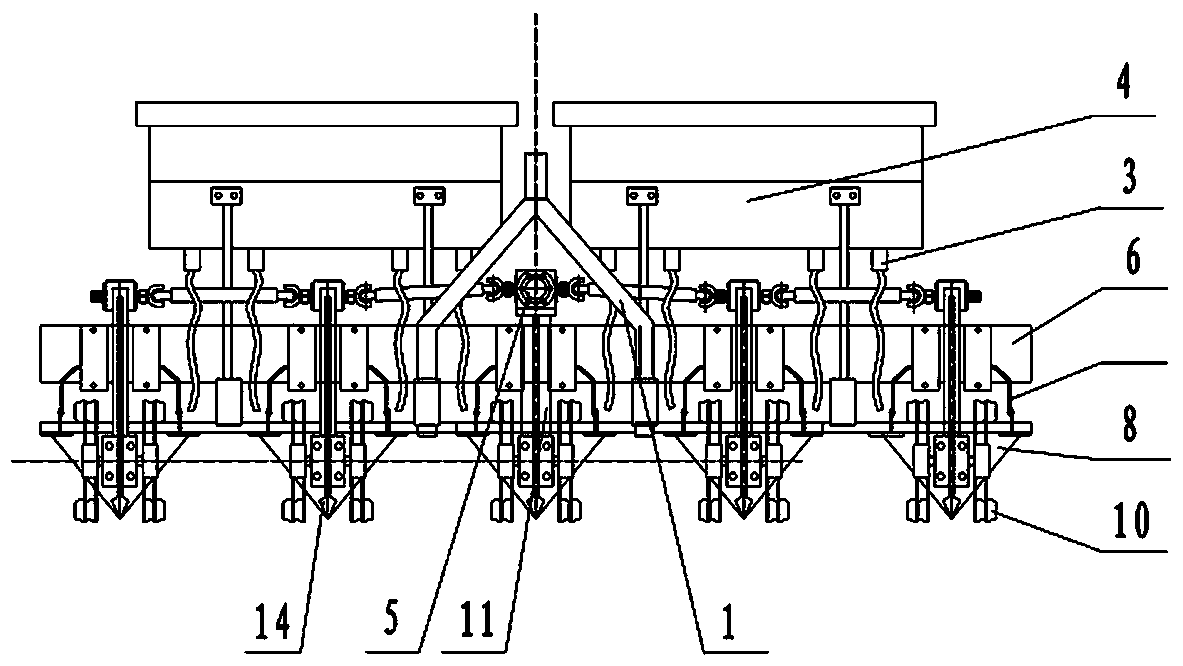

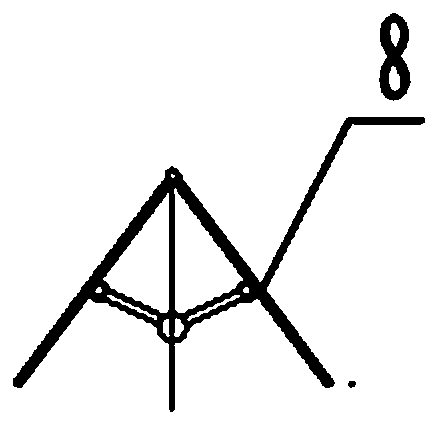

[0017] As shown in the figure, a kind of cultivating and fertilizing machine for potatoes and underground tuber crops of the present invention includes: frame 6, traction suspension frame 1, main gearbox 5, auxiliary gearbox 11, ditch opener 14, soil cutter 10, shaping Plate 8, ground wheel 12 and fertilizer box 4, the traction suspension frame is fixedly arranged on the front end of the frame, the main gearbox is fixedly arranged on the frame, and two auxiliary gearboxes are respectively fixedly arranged on the frame on both sides of the main gearbox. The gearbox drives the auxiliary gearboxes on both sides through the bevel gear, transmission shaft and coupling respectively. The opener is screwed and fixed on the box body of the auxiliary gearbox. Knife, the shaping plate is fixedly arranged at the rear end of the frame, the ground wheel is screwed and fixedly arranged below the frame, and the fertilizer box is fixedly arranged above the frame.

[0018] The shaping plates ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com