Patents

Literature

71results about How to "Good for work efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

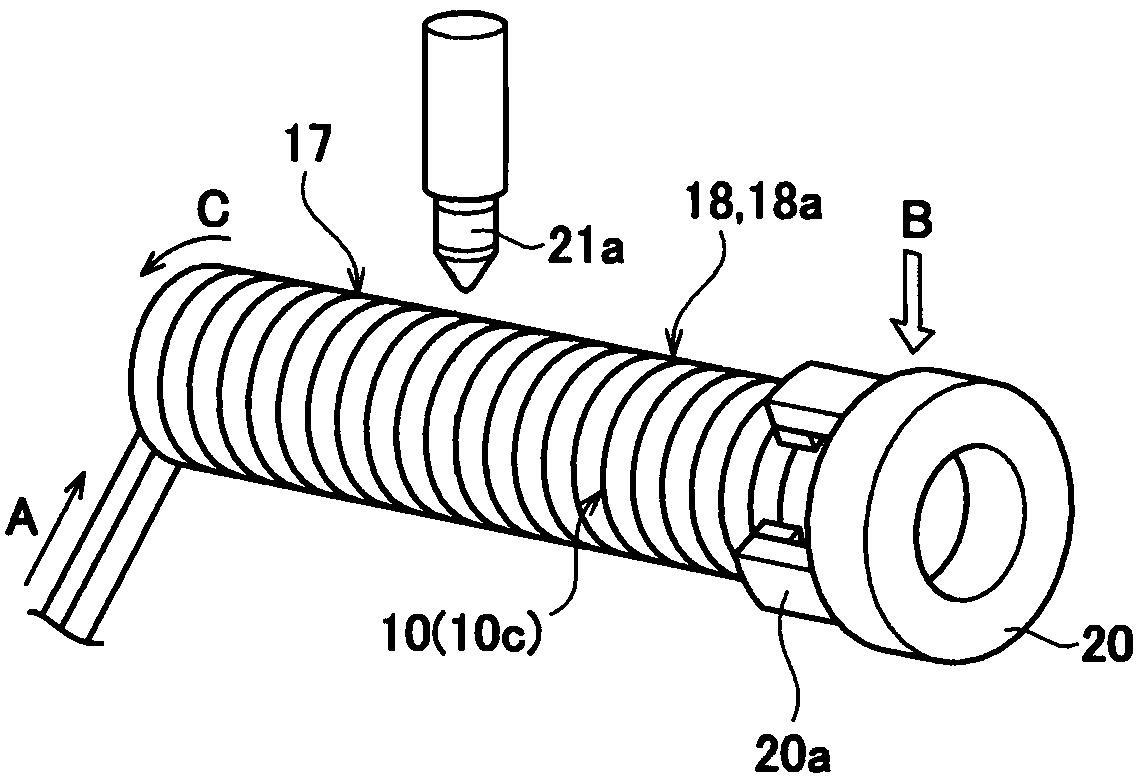

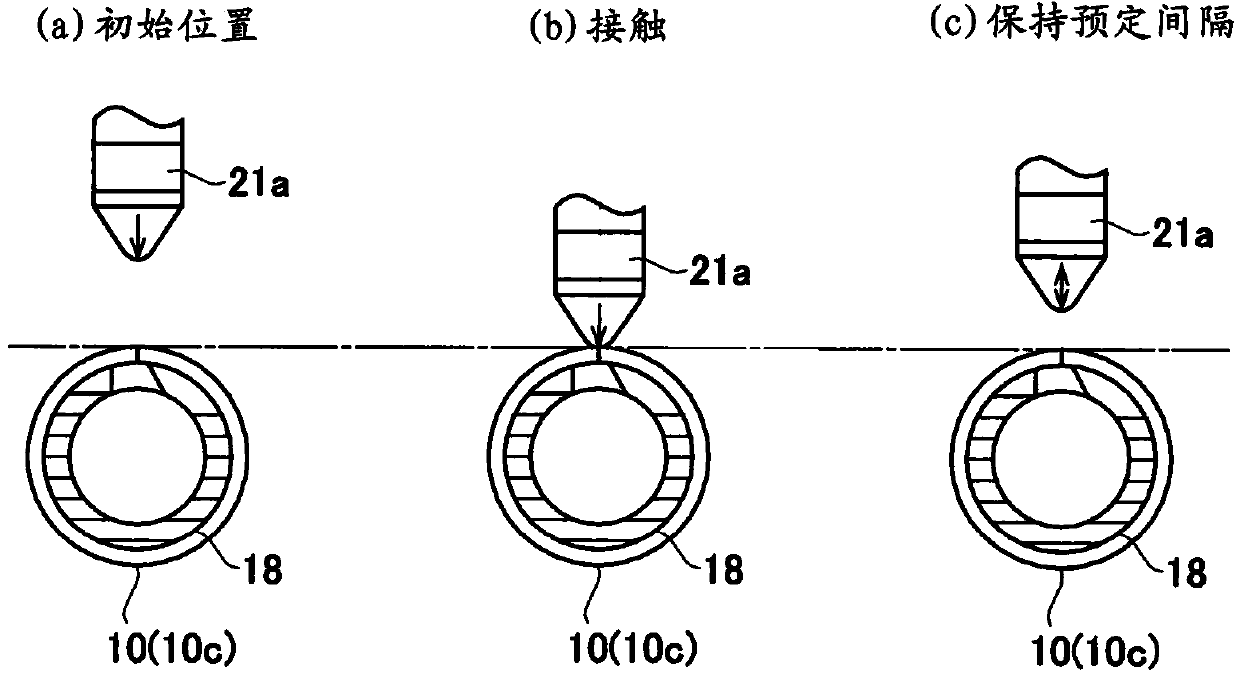

Method for bending metal material, bending machine, bending-equipment line, and bent product thereof

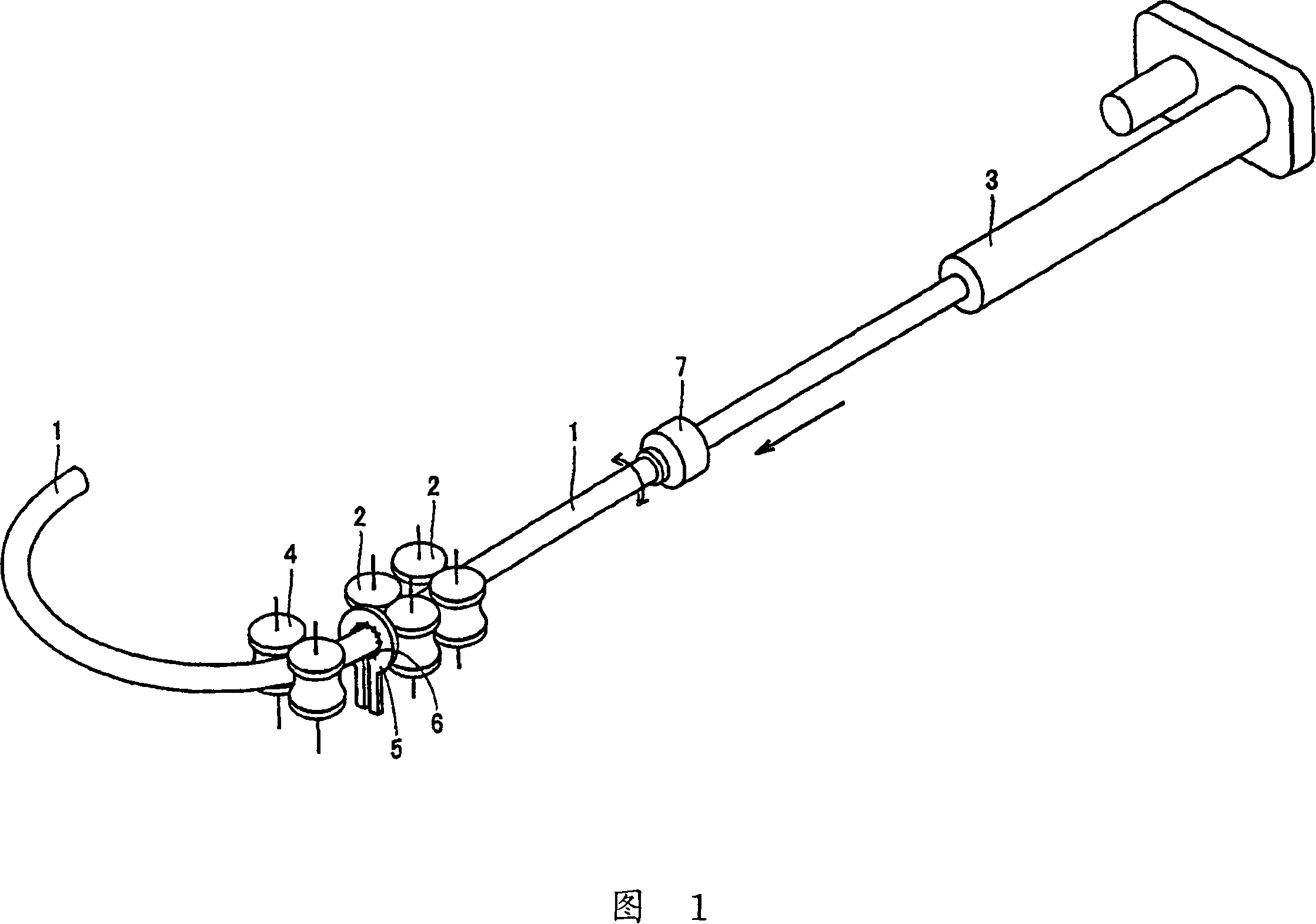

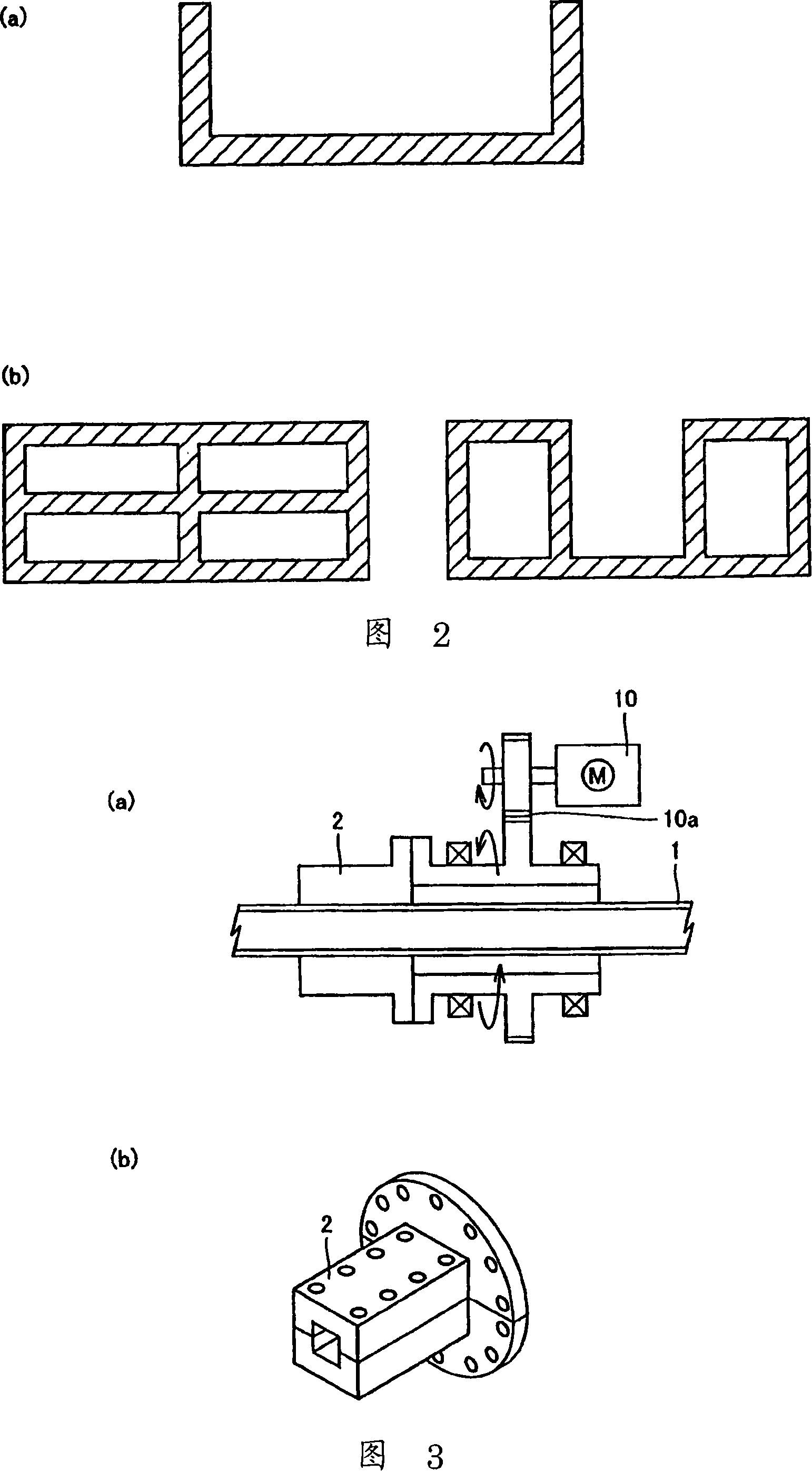

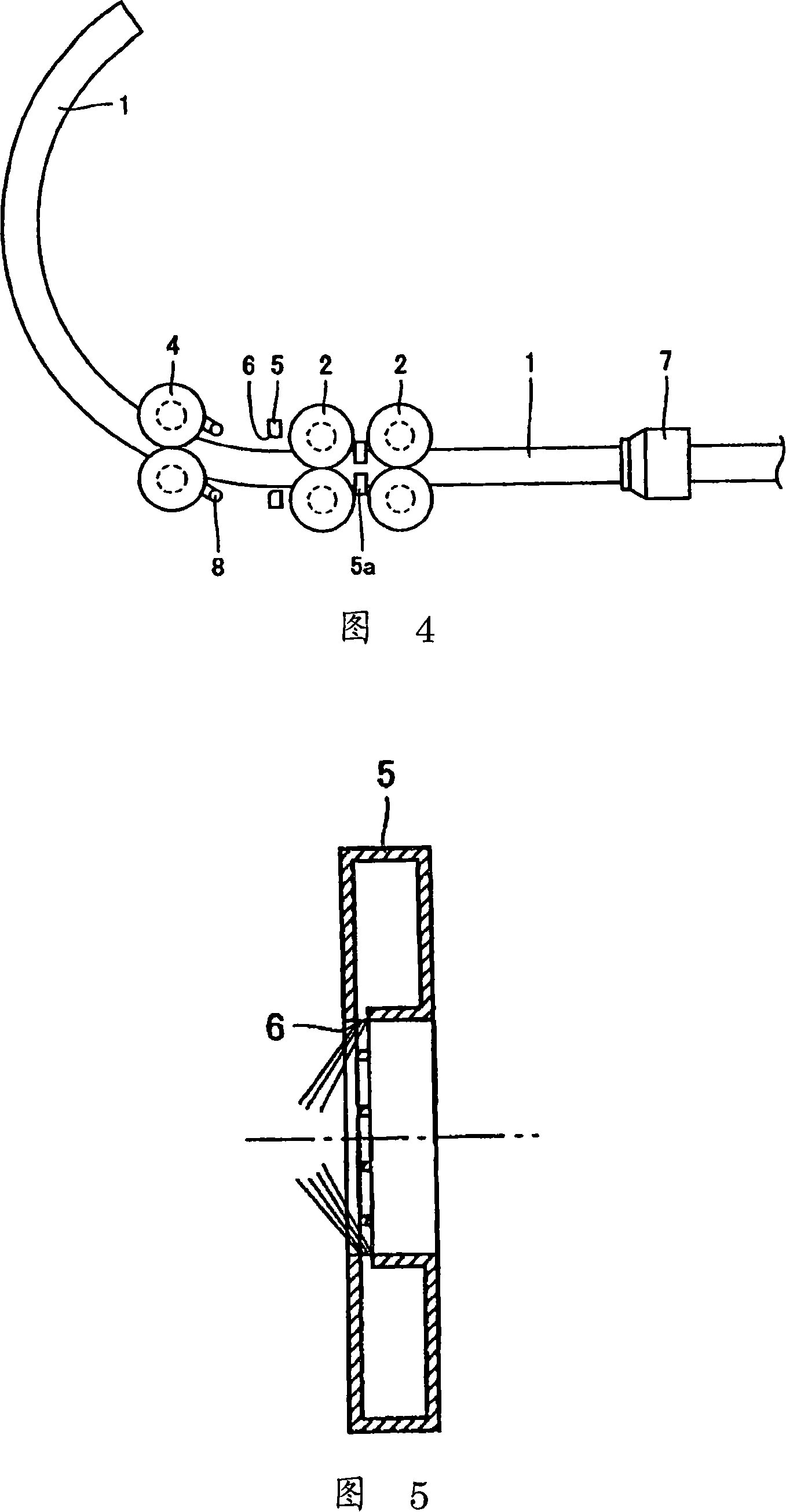

A method of push-through bending processing for a metal material, comprising, while sequentially or continuously extruding a material to be processed from the upstream side, carrying out bending processing thereof on the downstream side, wherein the metal material is clamped by means of mobile roller dies and under controlling of the position and / or moving speed of the mobile roller dies, heated at a temperature range permitting local plastic deformation and permitting quench hardening by means of heating means and cooling means disposed on the periphery of the metal material, followed by application of a bending moment and quenching. Further, there are provided a relevant bending processing apparatus and bending processing equipment line. Even in the event of processing to achieve continuous bending involving two-dimensionally different bending directions, or continuous bending involving three-dimensionally different bending directions, of the metal material, and even in the event of requirement of bending processing for a metal material with greater strength, a metal material with high shape fixability and uniform hardness distribution can be obtained efficiently at low cost. Accordingly, wide application thereof can be found as an increasingly sophisticated automobile part bending processing technology.

Owner:NIPPON STEEL CORP +1

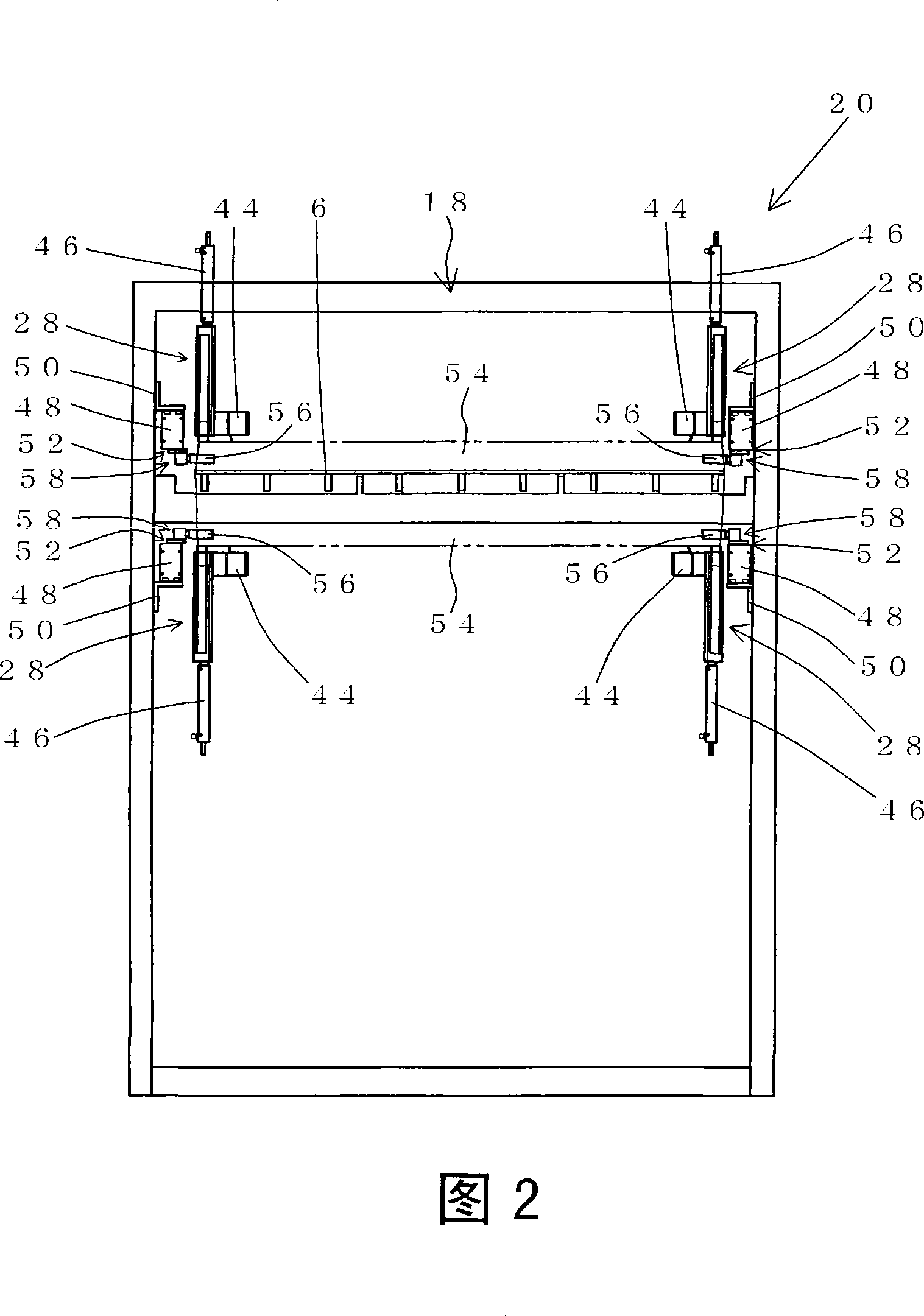

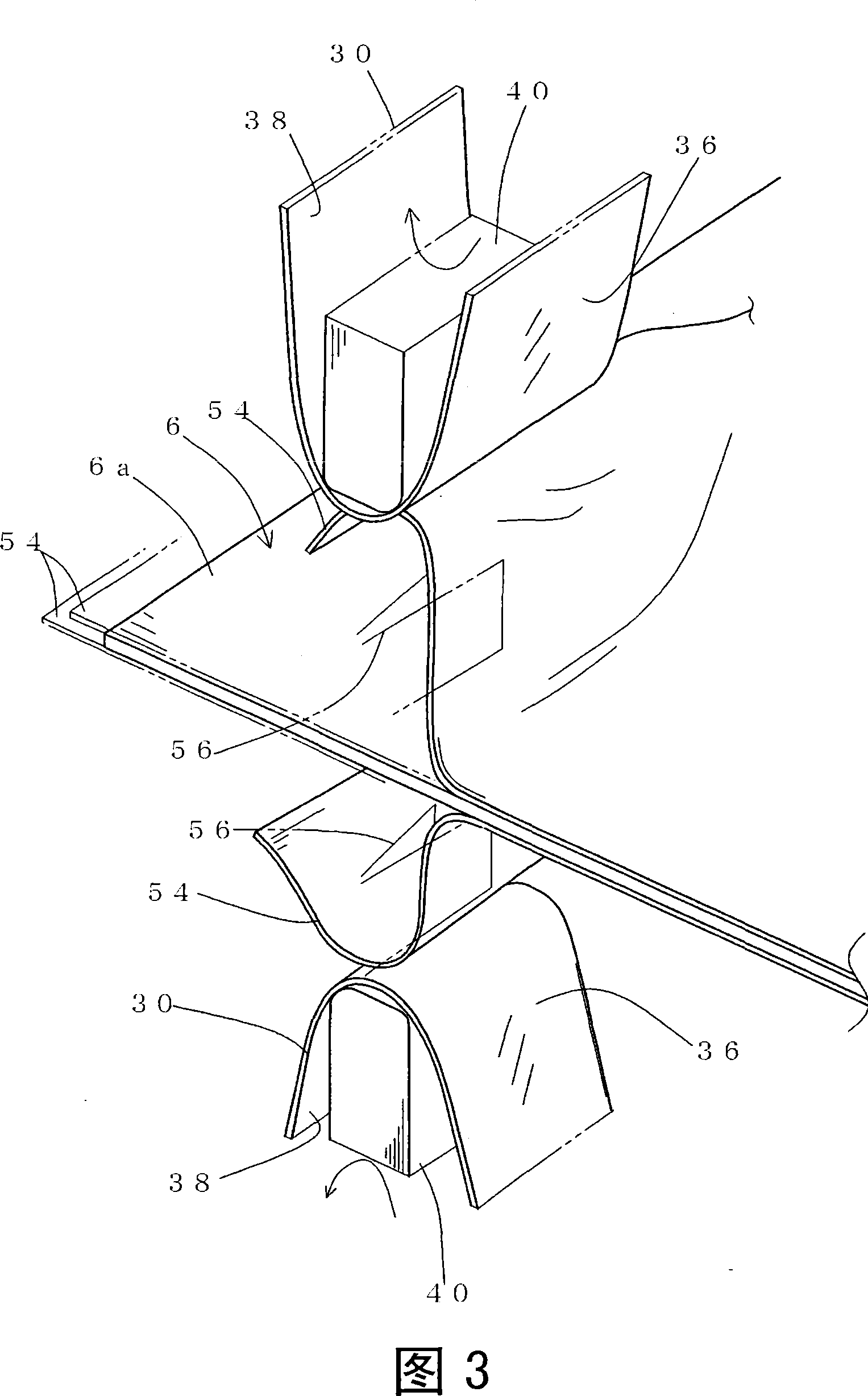

Method and device for peeling off film

InactiveCN1980847AReliable strippingReduce consumptionAdhesivesNon-linear opticsTectorial membraneActuator

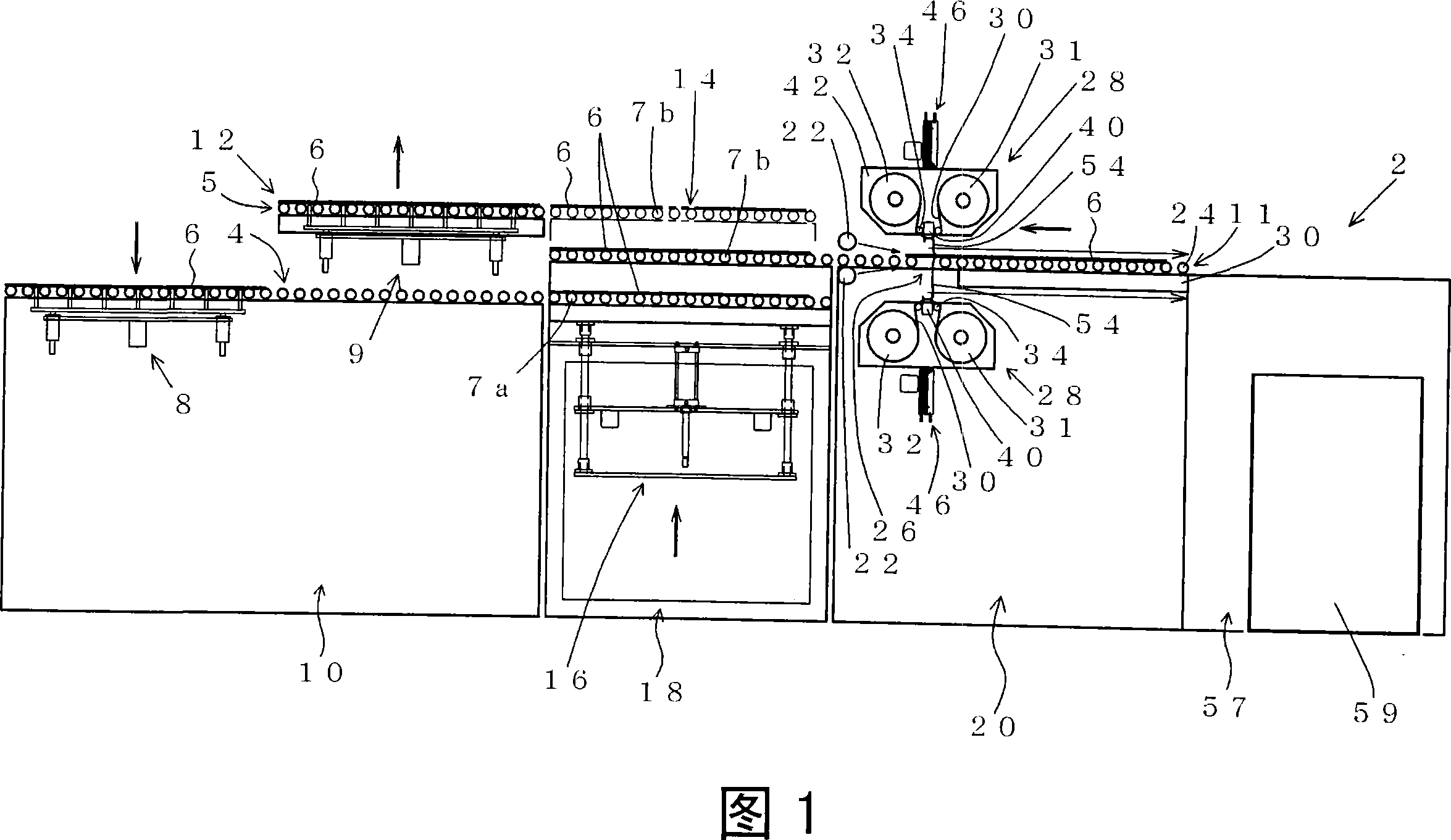

A method and a device for peeling off a film. The device comprises an adhesive tape (30) positioned near the end part of a glass substrate (6) having a protective film (54) stuck on the front and rear surfaces thereof and a peeling head (40) pressing the adhesive face (38) of the adhesive tape (30) against the glass substrate (6). The device also comprises an actuator (46) partly peeling off the protective film (54) from the glass substrate (6) by pulling off the adhesive tape (30) adhered to the end part of the protective film (54) from the surface of the glass substrate (6). In addition, the device comprises a film chuck device (58) holding the end part of the peeled protective film (54), and the protective film (54) held by the film chuck device (58) is peeled off by driving the glass substrate (6) by a roller conveyor (4).

Owner:SHARP KK

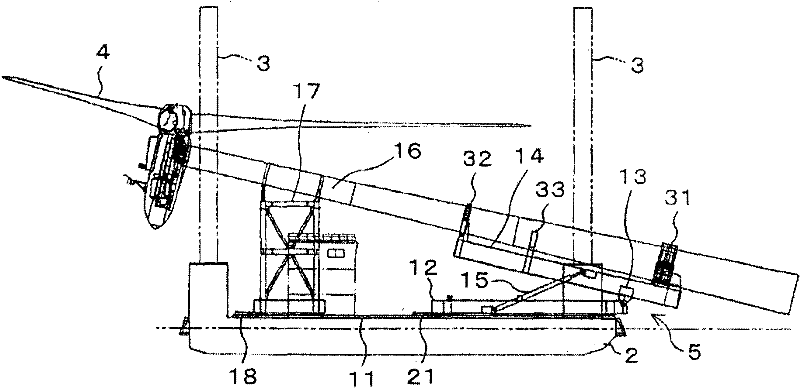

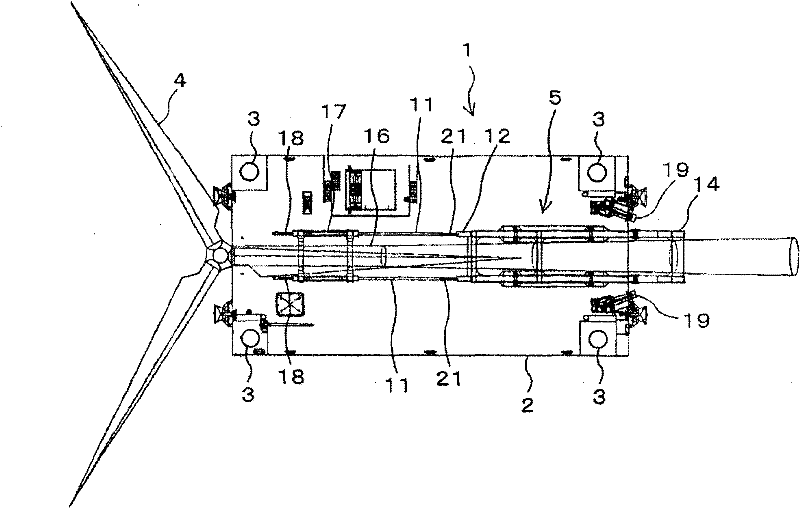

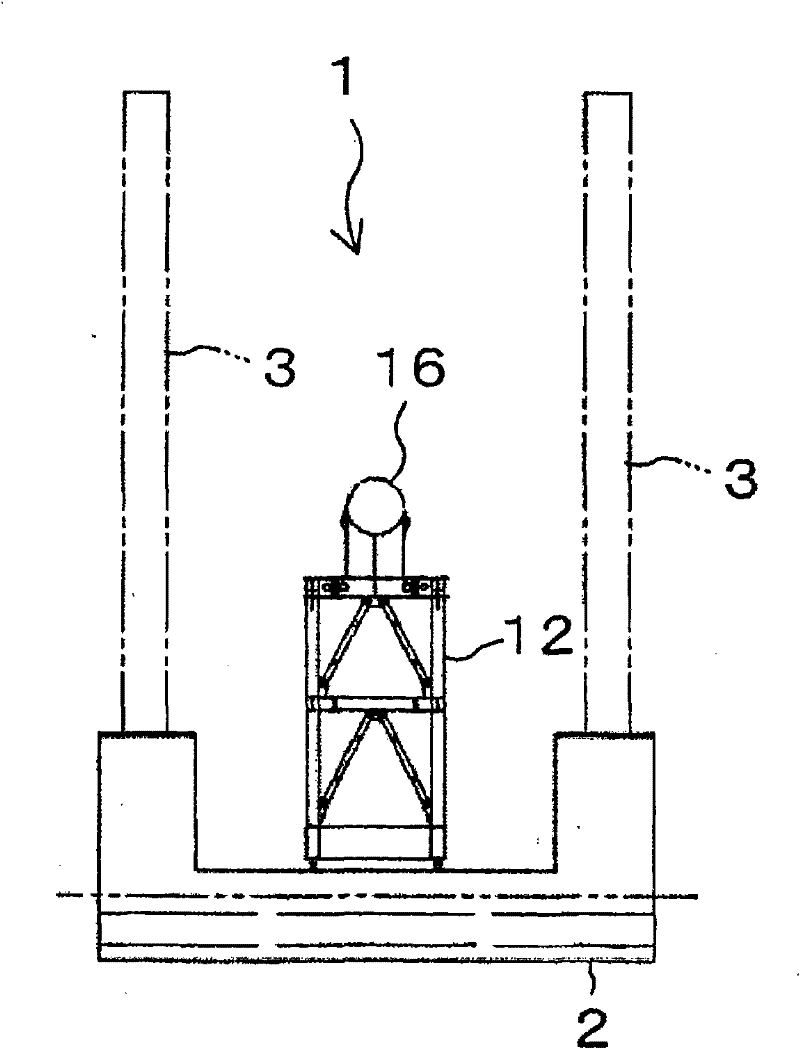

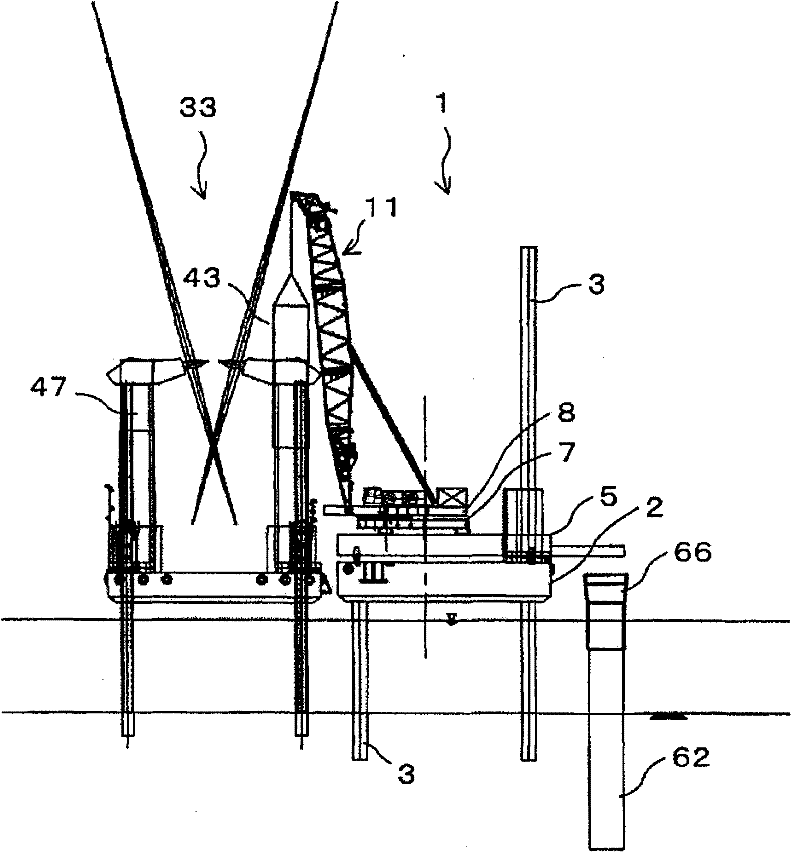

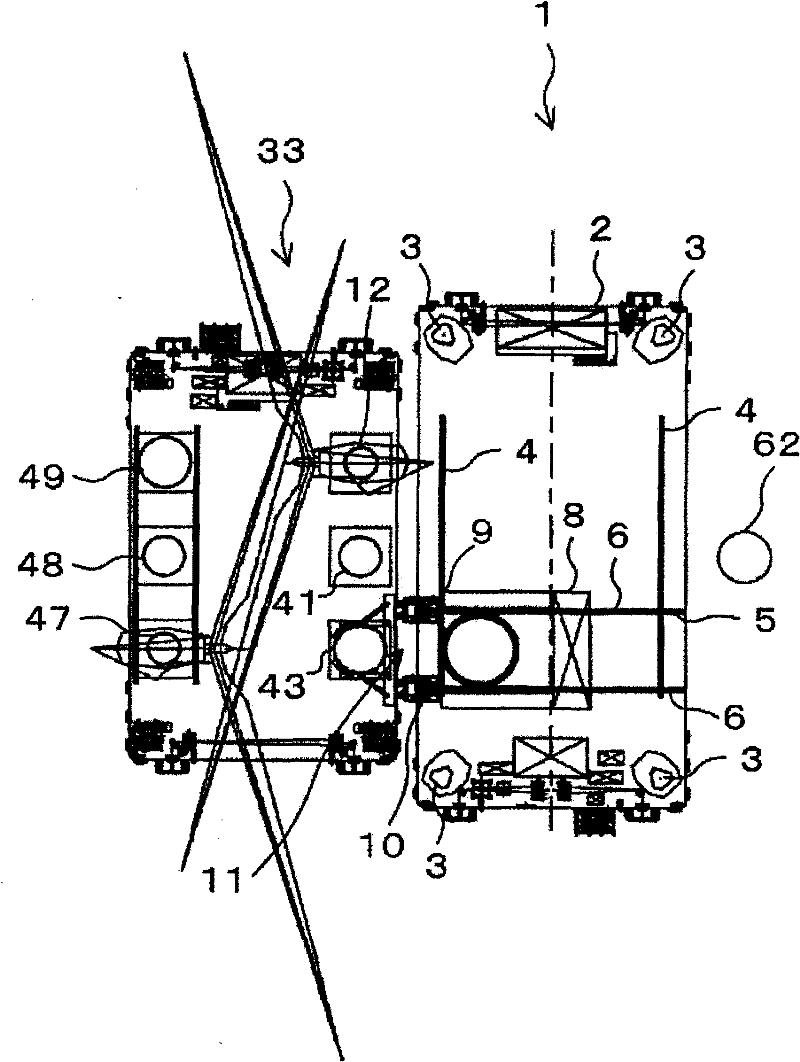

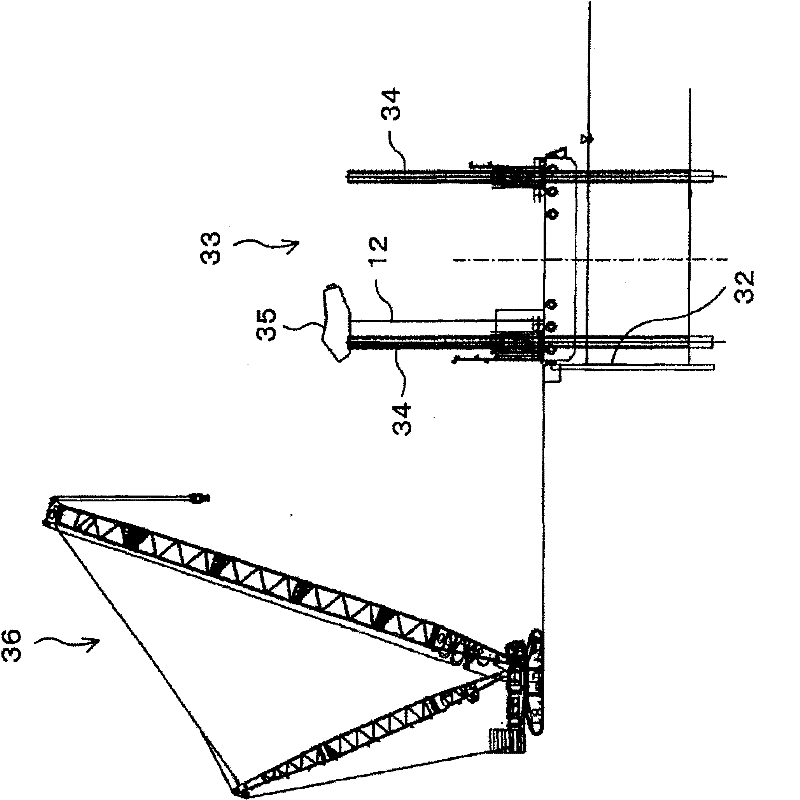

Deck ascent and descent type worktable ship and construction method of shore wind power generation facility using the same

A deck ascent and descent type worktable ship comprises a platform body, and a plurality of columns which causes the platform body to ascend and descend randomly by means of an oil jack jacking system. The deck of the platform body is provided with an erecting device which causes a single pile or tower integrated windmill to form a support movably on the deck of the platform body. Furthermore the single pile or tower integrated windmill can be randomly lifted from a falling-over state or an inclination falling-over state. The erecting device comprises a base frame and a supporting guide frame. The base frame can randomly move on a guide rail which is laid on the deck of the platform body. The supporting guide frame is supported by the base frame through a bracket according to a mode of lifting randomly. Furthermore the single pile or tower integrated windmill can be detached randomly. At severe sea and weather conditions of outer sea, the on-sea wind power generating devices such as the single pile or tower integrated windmill can be loaded, conveyed and lifted, thereby providing the deck ascent and descent type worktable ship which has the following advantages: high operation efficiency, high stability and high safety.

Owner:DAIICHI KENSETSU KIKO +1

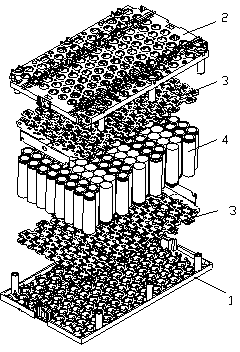

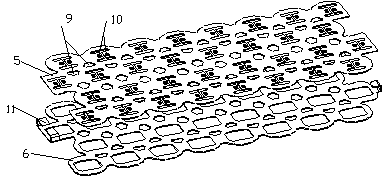

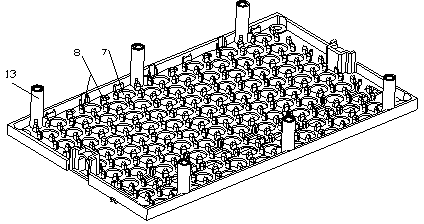

Large capacity battery pack structure and assembly method thereof

ActiveCN104134769ACompact structureFacilitate production and assembly operationsAssembling battery machinesElectrode carriers/collectorsComposite electrodeBattery pack

The invention discloses a large capacity battery pack structure; a battery component is arranged between a first battery clamping plate and a second battery clamping plate, composite electrode pieces are arranged between the first battery clamping plate and battery component positive and negative end surfaces and the second battery clamping plate and the battery component positive and negative end surfaces, first conductive layers of the composite electrode pieces connect battery monomers of the battery component in series and in parallel, second conductive layers of the composite electrode pieces are fixedly connected with the first battery clamping plate and the second battery clamping plate; an assembly method includes the following steps: respectively arranging the composite electrode pieces in the first battery clamping plate and the second battery clamping plate; arranging the battery component; fixedly connecting the first battery clamping plate and the second battery clamping plate; and connecting the composite electrode pieces and positive and negative electrodes of each battery monomer by welding. In the way, the large capacity battery pack structure can bear large current discharge, has the advantages of simple structure, good stability, and strong anti shock and anti vibration ability, no additional work fixture is needed for fixing the composite electrode pieces, the operation is simple, and the assembly cost is low.

Owner:CHANGZHOU GLOBE CO LTD

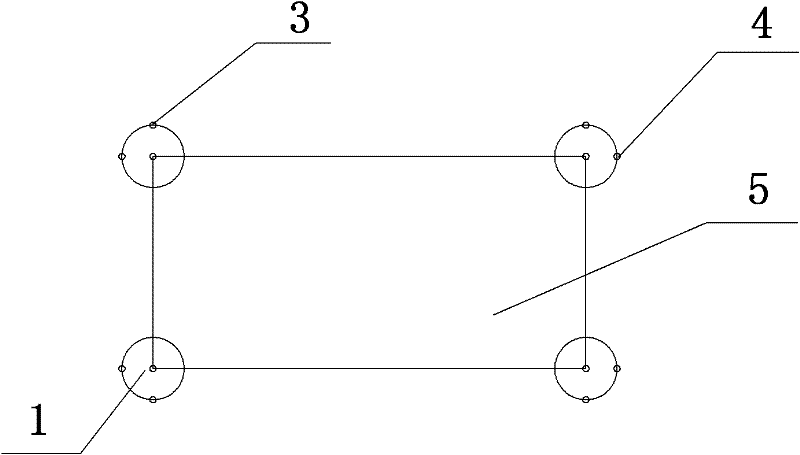

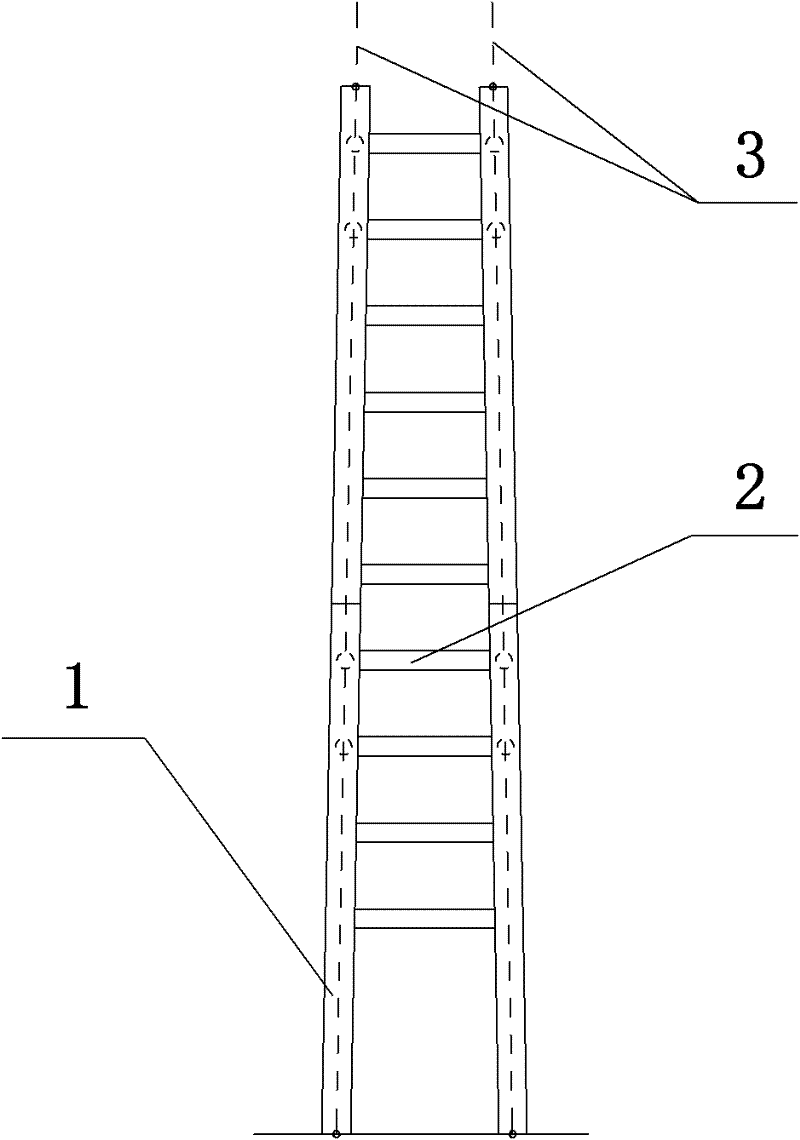

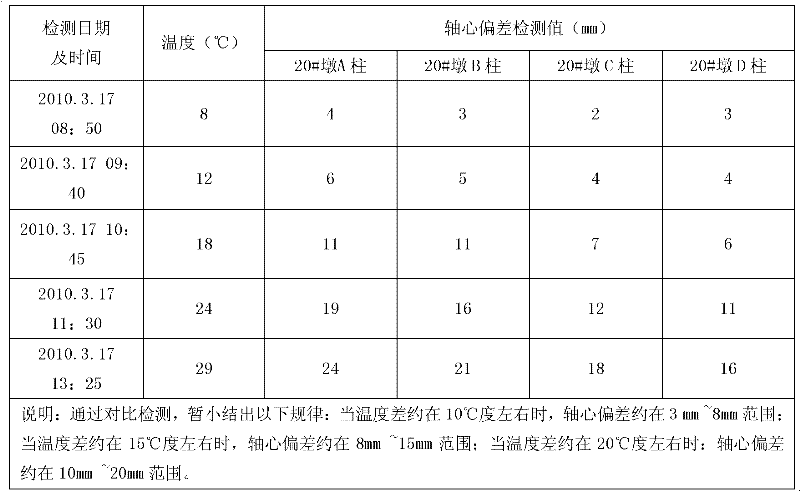

Measurement control method for field installation of steel tube lattice pier

ActiveCN102251476AMeet Design Control RequirementsWon't hurtAngles/taper measurementsBridge structural detailsSurvey PersonnelSteel tube

The invention discloses a measurement control method for field installation of a steel tube lattice pier. The steel tube lattice pier is composed of four upright steel tubes, a transverse-connecting truss is arranged along the height of the pier, and a connecting ventral tube is arranged between the upright steel tubes; the steel tube lattice pier is conveyed to the pier site to carry out field installation in the form of steel tube section units processed in advance and the transverse-connecting truss; the steel tube section unit is composed of two longitudinal A-shaped frame steel tubes anda cross brace through connection; and in the process of installation, the steel tube section units are positioned by using a measurement control method which is based on a 'three-dimensional coordinate control method' and supplemented by a 'double-axis control method'. By using the method disclosed by the invention, the axis deflection of the pier body caused by environment factors, manual operations and improper constructions can be effectively eliminated, the setting-out precision and the operating efficiency are high, the needs of installation of lattice pier studs and cross braces are satisfied, and the surveying personnel and instruments are not hurt by falling objects, therefore, the method has practical applicability.

Owner:CHINA RAILWAY 23RD BUREAU GRP THIRD ENG CO LTD

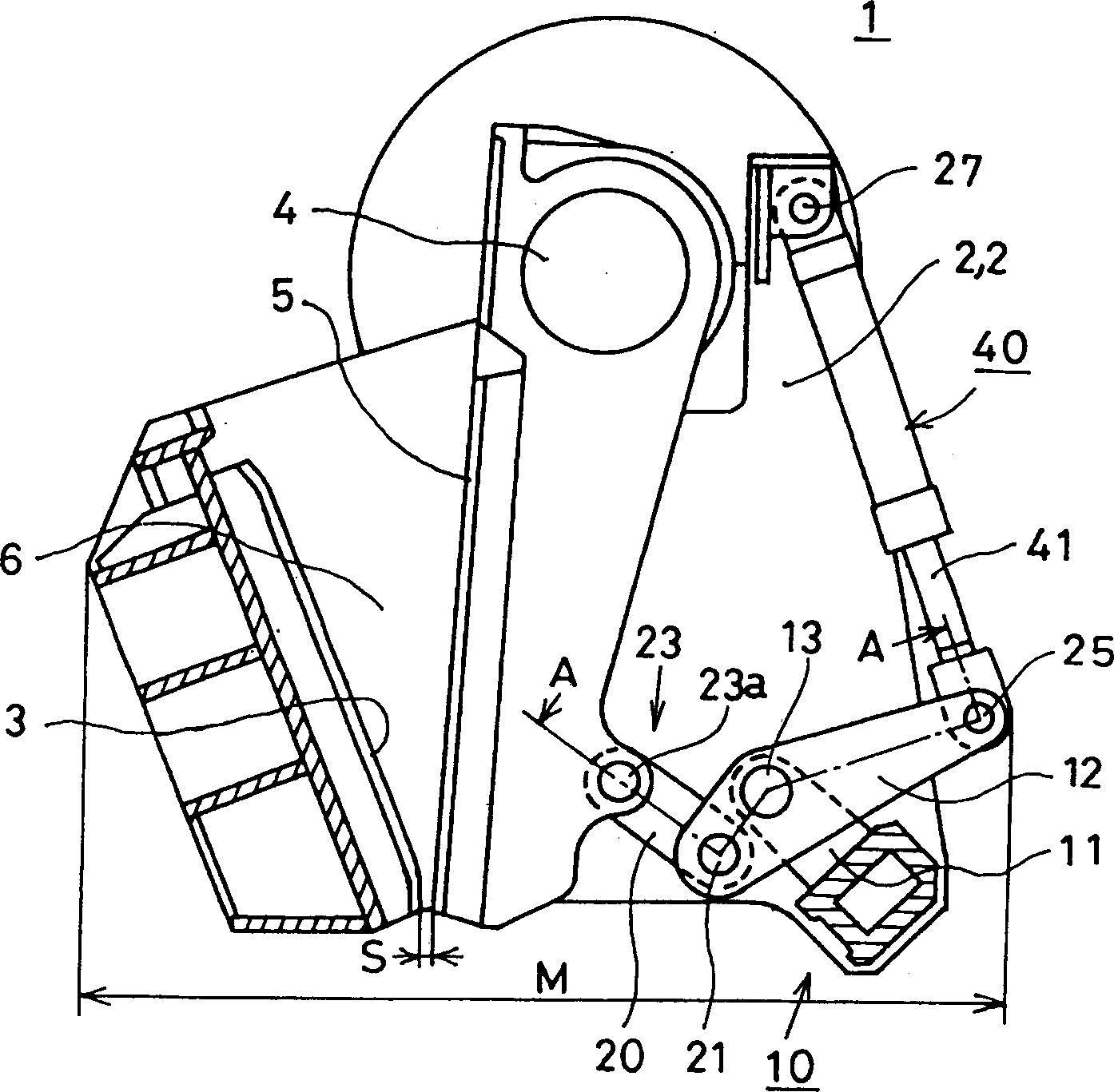

Jaw crusher

A compact and light-weight jaw crusher, in which life span of parts enduring abrasion is long, and an outlet clearance of a crushing chamber is easily adjusted, is provided. For this purpose, the jaw crusher includes a stationary jaw (3) fixedly provided at a frame (2), a movable jaw (5) which is provided to oppose the stationary jaw and attached swingably with an eccentric drive shaft (4), a movable jaw load receiving section (10) attached to the frame, and a coupling joint (23) which is a connecting member for connecting a lower portion of the movable jaw and the movable jaw load receiving section and swingably connects the lower portion of the movable jaw and the movable jaw load receiving section.

Owner:KOMATSU LTD

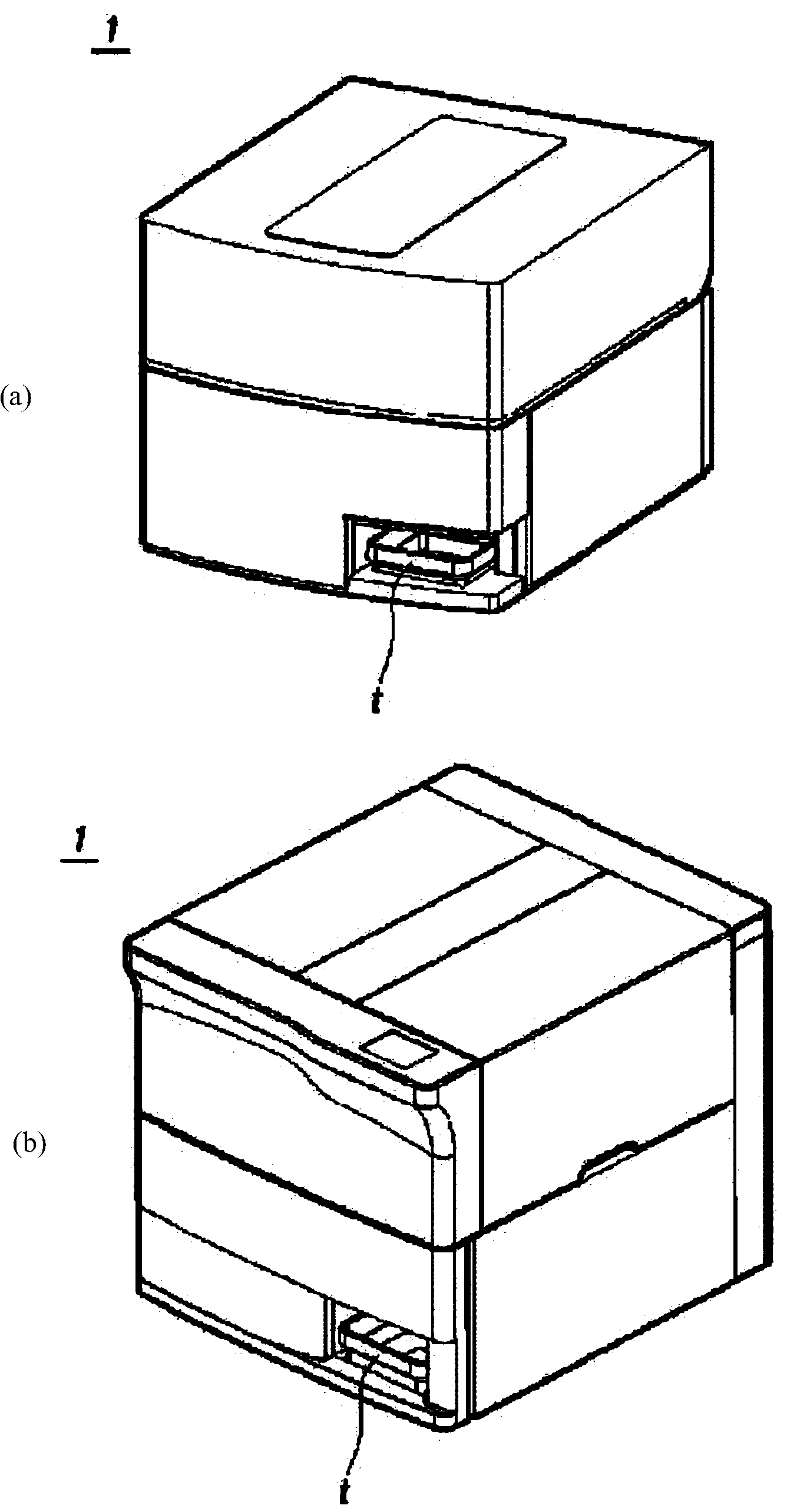

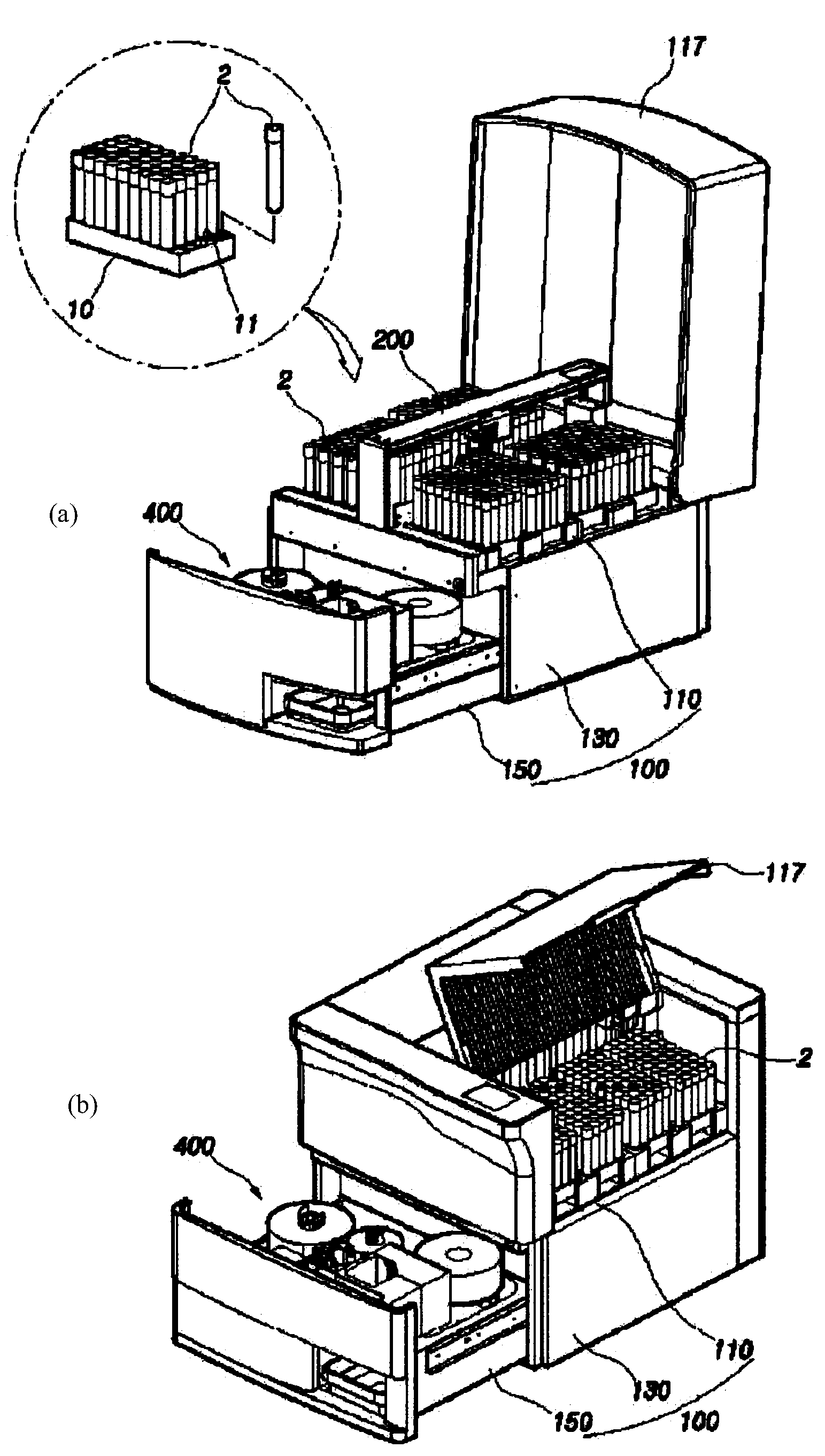

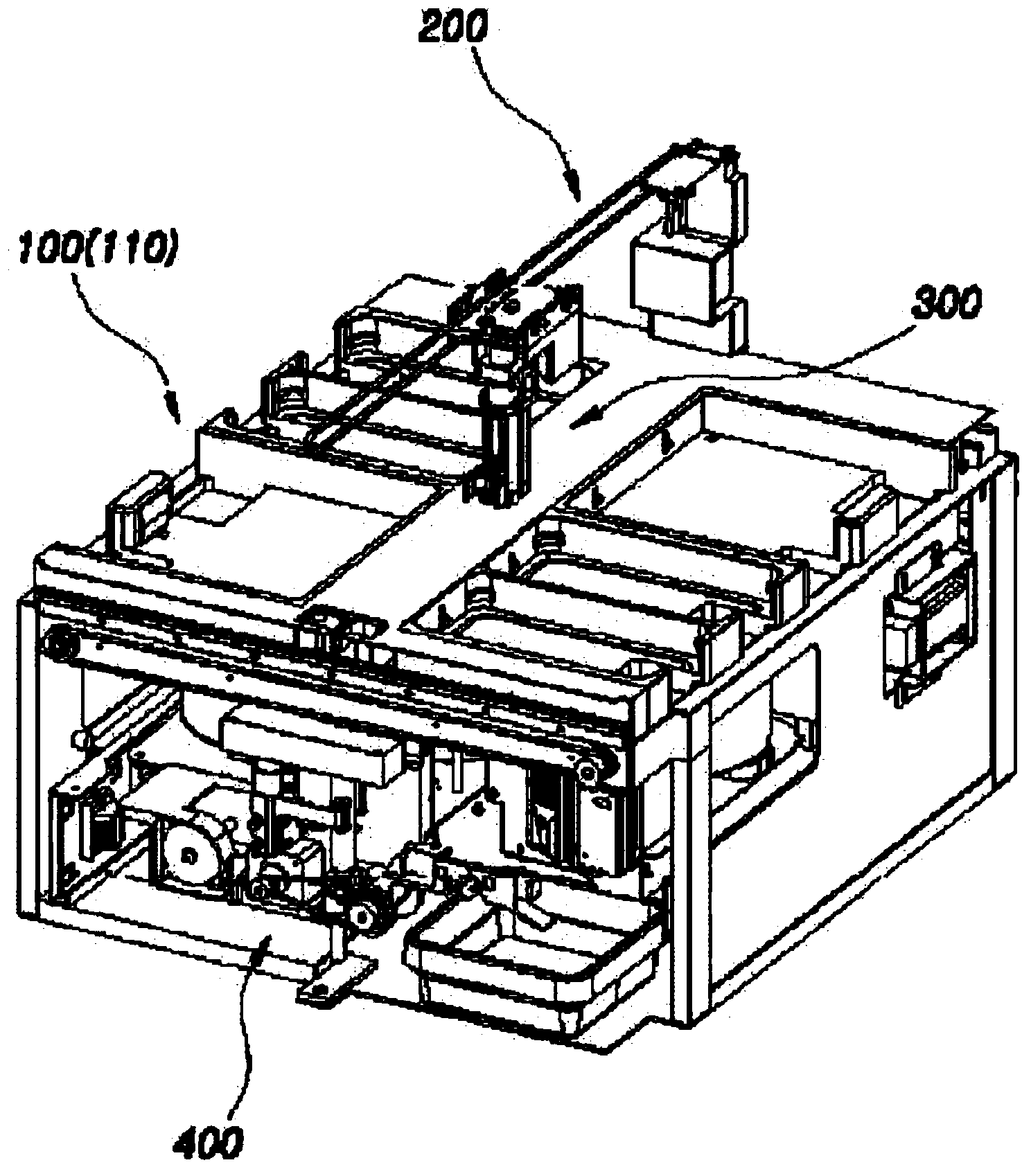

Test tube gripper, test tube labeling unit, and test tube preparing apparatus including the same

Owner:ENERGIUM CO LTD

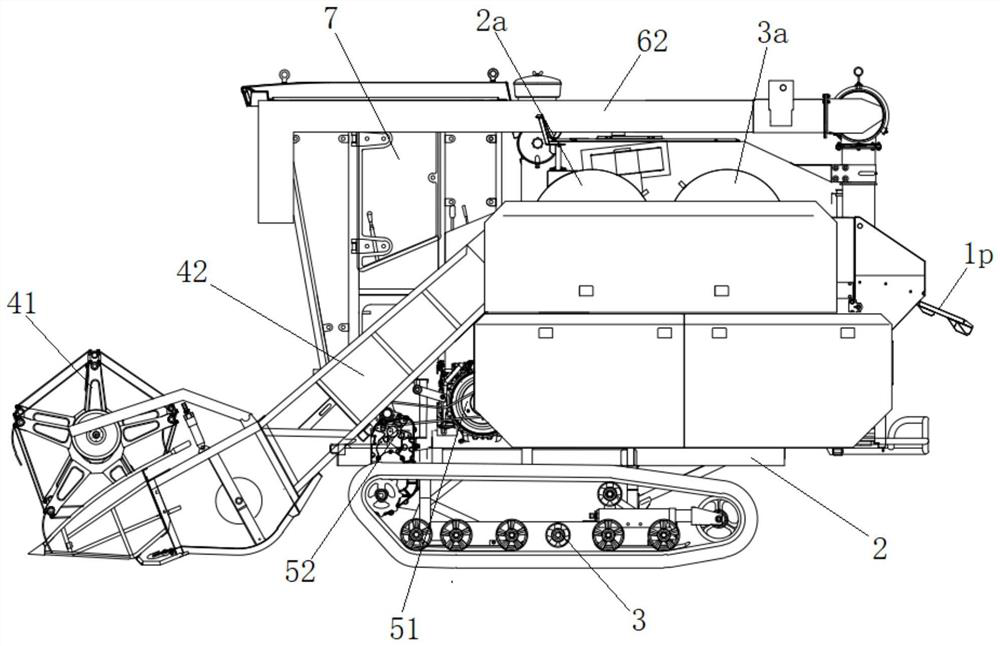

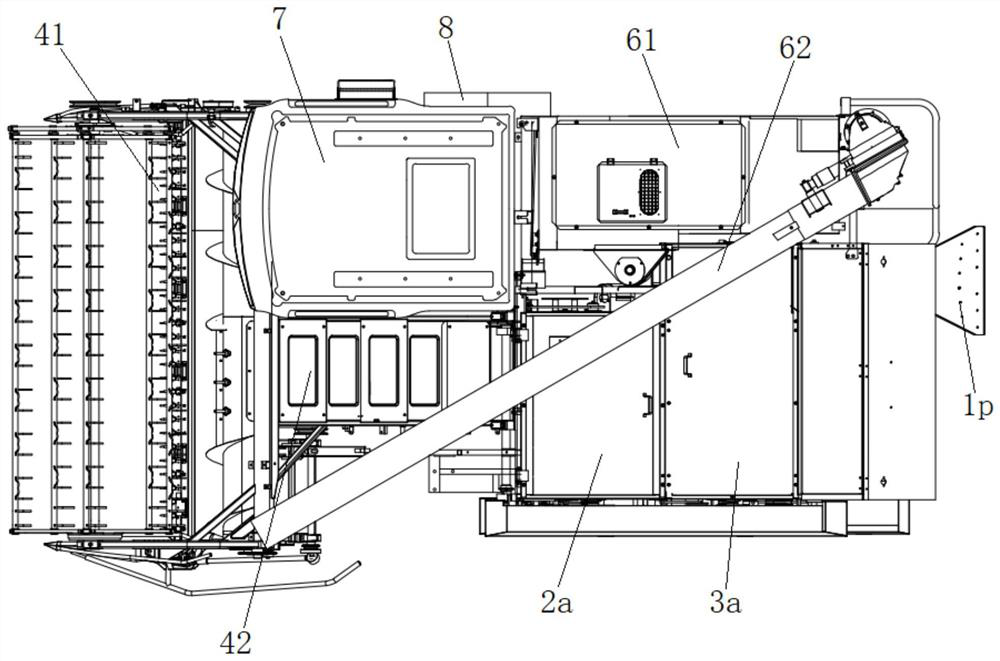

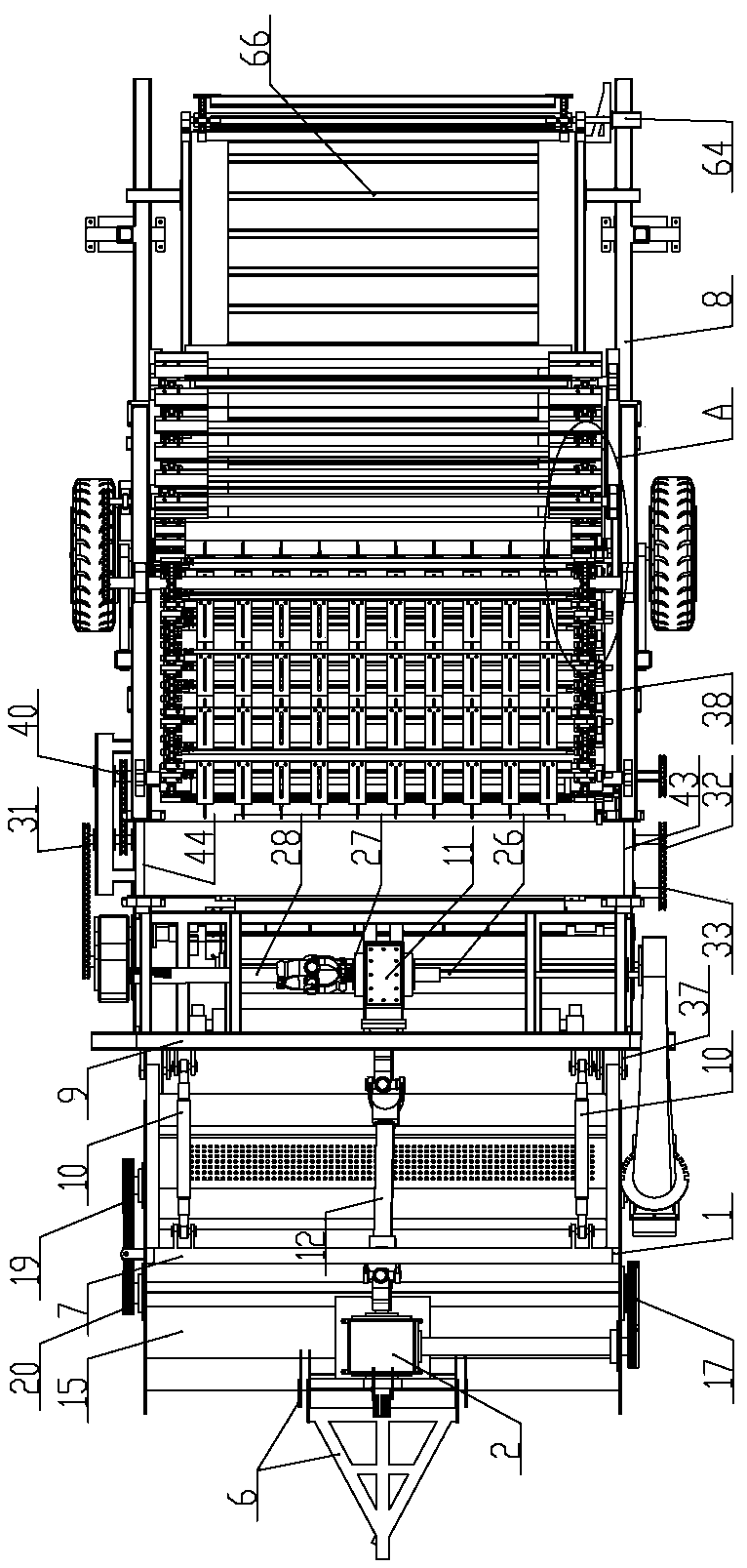

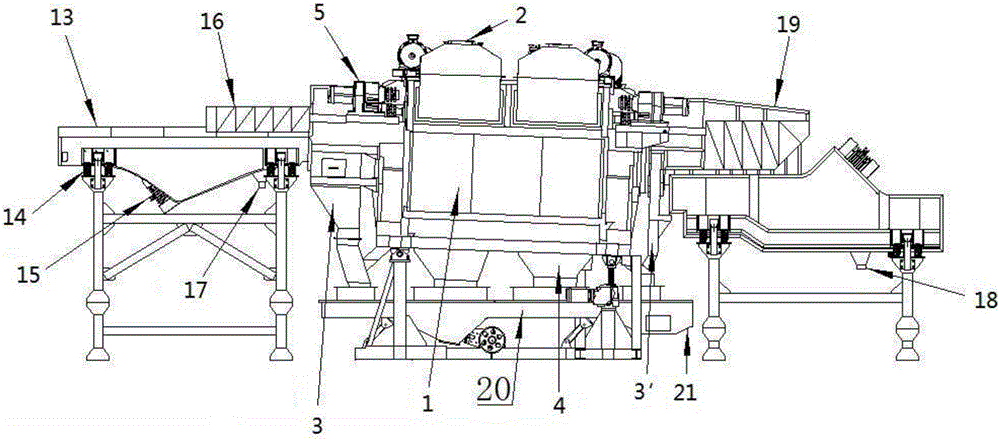

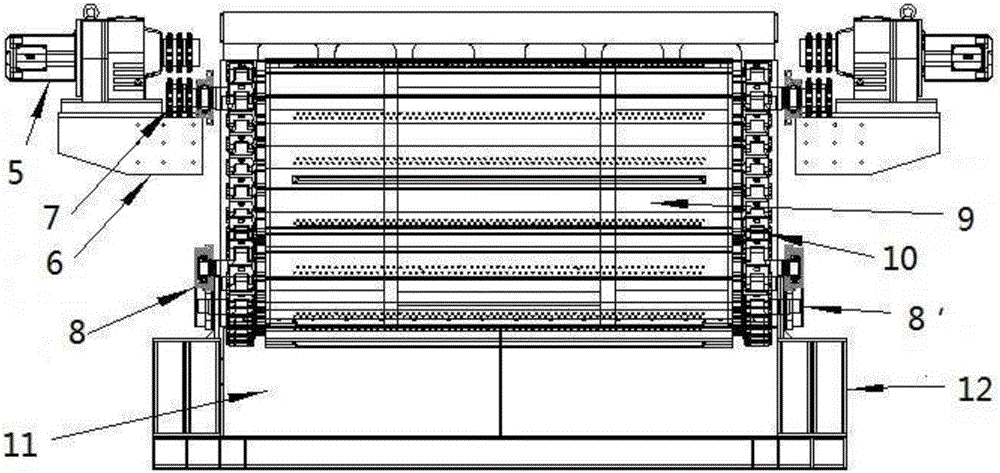

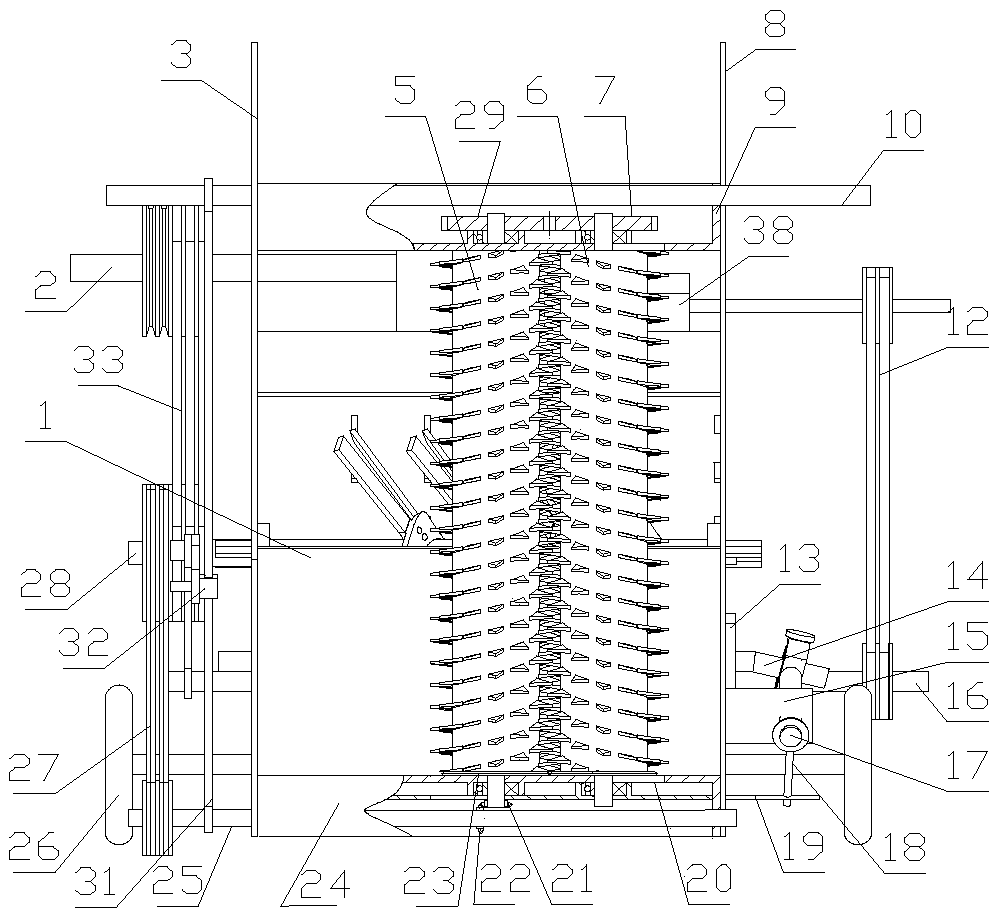

Combine harvester

PendingCN112690086ASmooth feedingGuaranteed stabilityMowersThreshersAgricultural engineeringGrain storage

The invention provides a combine harvester. A feeding port is formed in the middle of a frame, so that a connecting port between a crop conveying structure communicated with the feeding port and a header is located at the position, close to the middle, of the header, and crops are fed into the connecting port from the two sides of the header more evenly; and meanwhile, a scattering structure is arranged close to a grain storage assembly, the crops enter from the middle of the front end of the harvester and are partially scattered out from the middle of the tail end of the harvester through the n-shaped threshing direction of a double-helix threshing conveying system, and the stability of the gravity center of the combine harvester is guaranteed. A cleaning transmission system is arranged at the outer side of a threshing system, centralized transmission is achieved, and installation and debug are convenient. The whole harvester is compact in structure, small in occupied space, high in maneuverability and remarkable in operation efficiency, and the gravity center is always kept stable in the empty operation and harvesting operation process.

Owner:JIANGSU WORLD AGRI MACHINERY

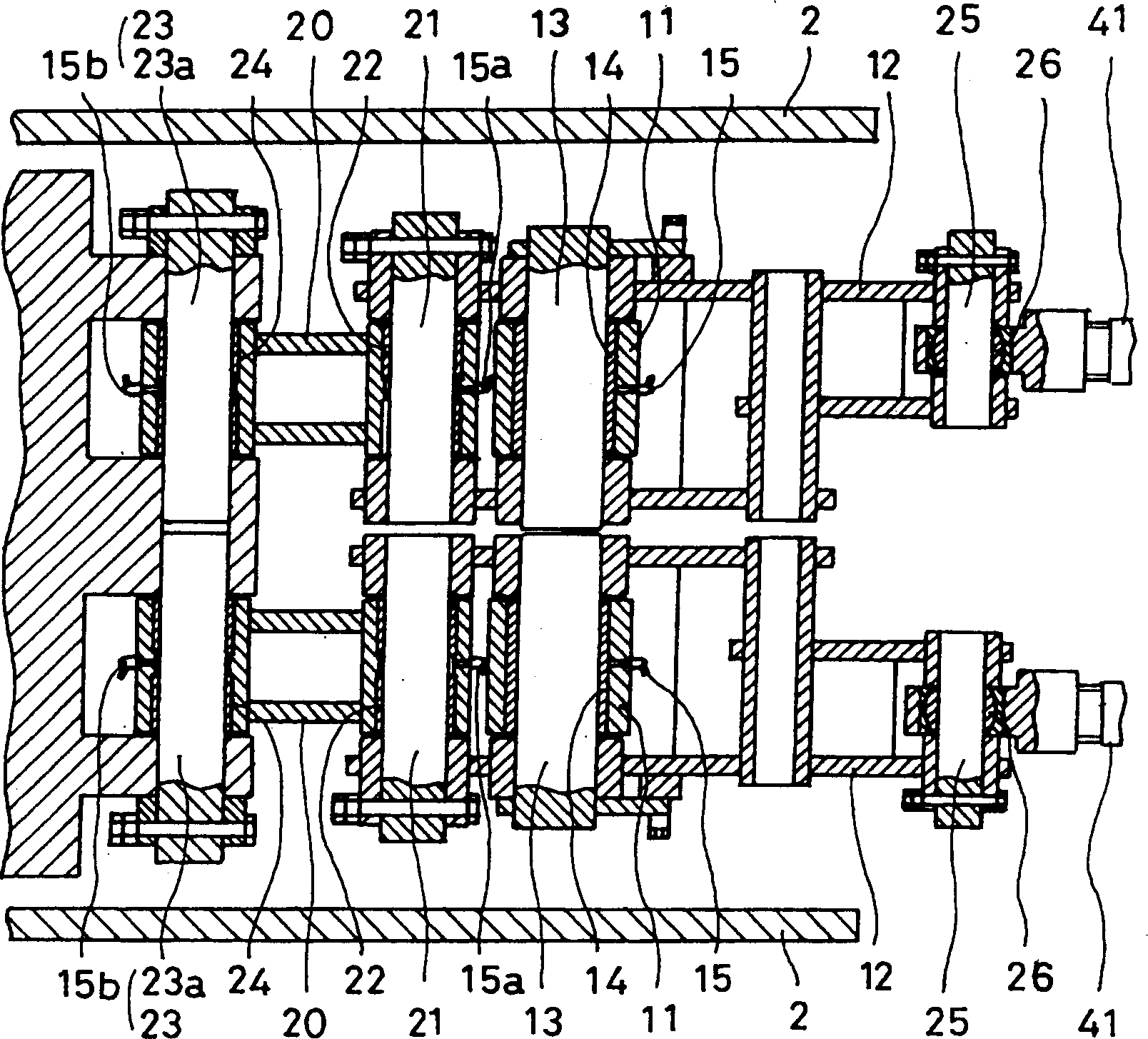

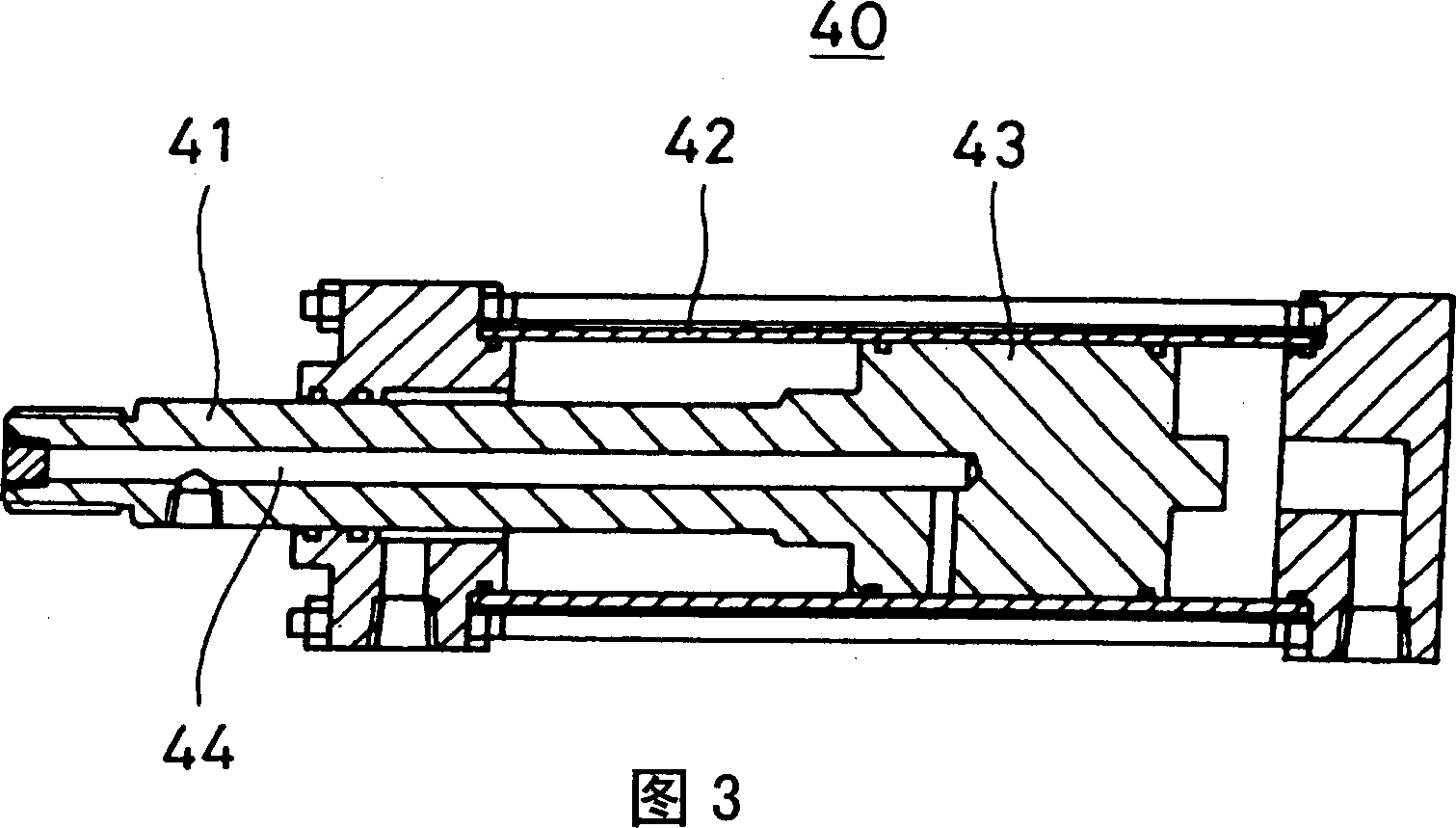

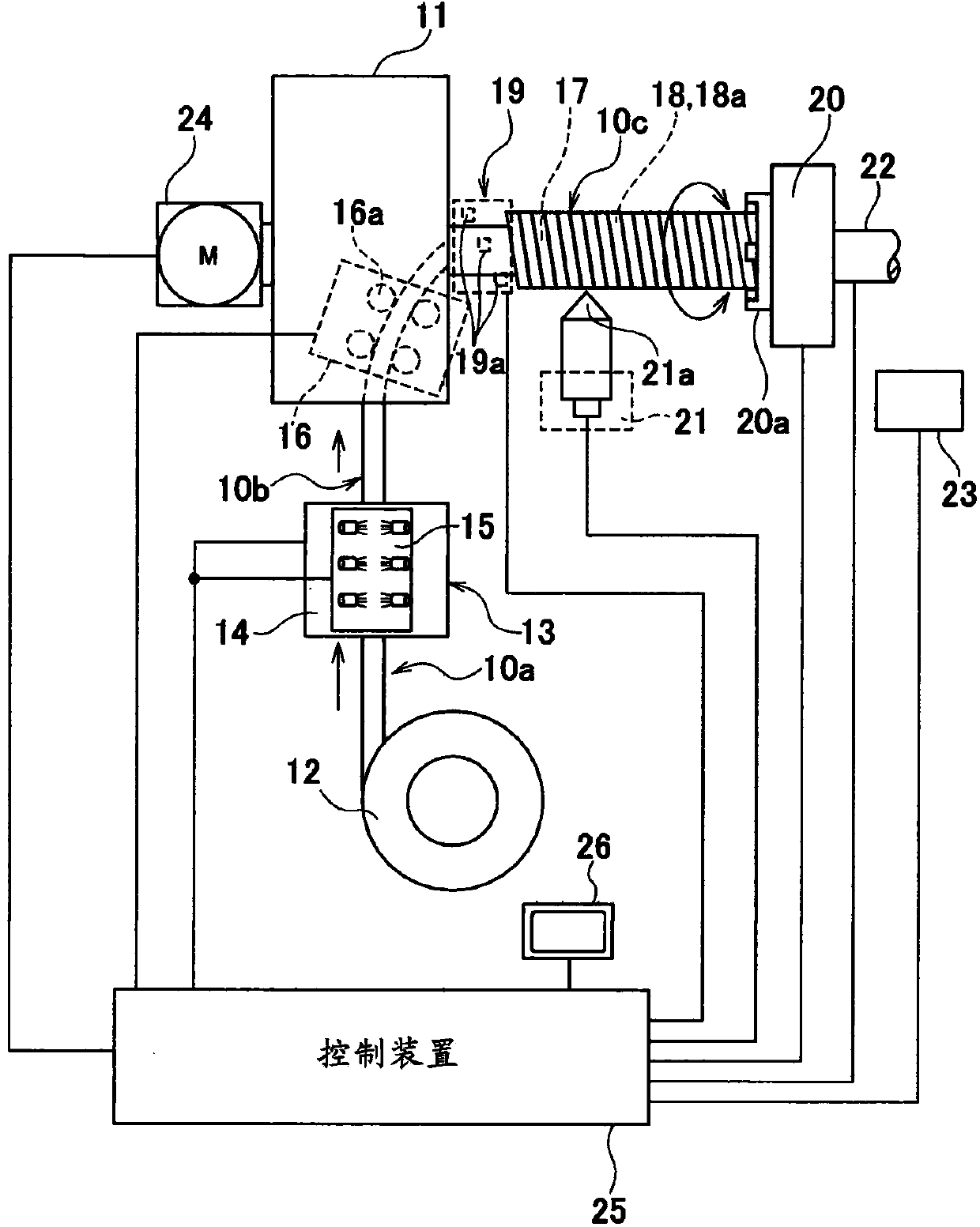

Interlock tube manufacturing method and manufacturing device therefor

InactiveCN104185515AGood precisionGood working efficiencyExhaust apparatusSilencing apparatusMechanical engineeringControl unit

The manufacture of interlock tubes, wherein: tubes, with a circular cross-section or the number of corners in the cross-section being similar to a circle, are easily formed with high precision and without loosening; processability during cutting, etc. is excellent; and the device itself has excellent work efficiency. Interlock tubes are manufactured with excellent work efficiency, etc. by: winding a metal band helically on a winding mandrel, the cross-section of which is circular or a shape in which the number of corners in the cross-section is similar to a circle; installing a fastening chuck on the tip end of the winding mandrel so as to allow free release and fastening; and rotating and synchronizing so as to prevent loosening of the metal band on the basis of commands from a computing / control unit, which integrates the operations of the various units.

Owner:SHOWA RASENKAN SEISAKUSHO

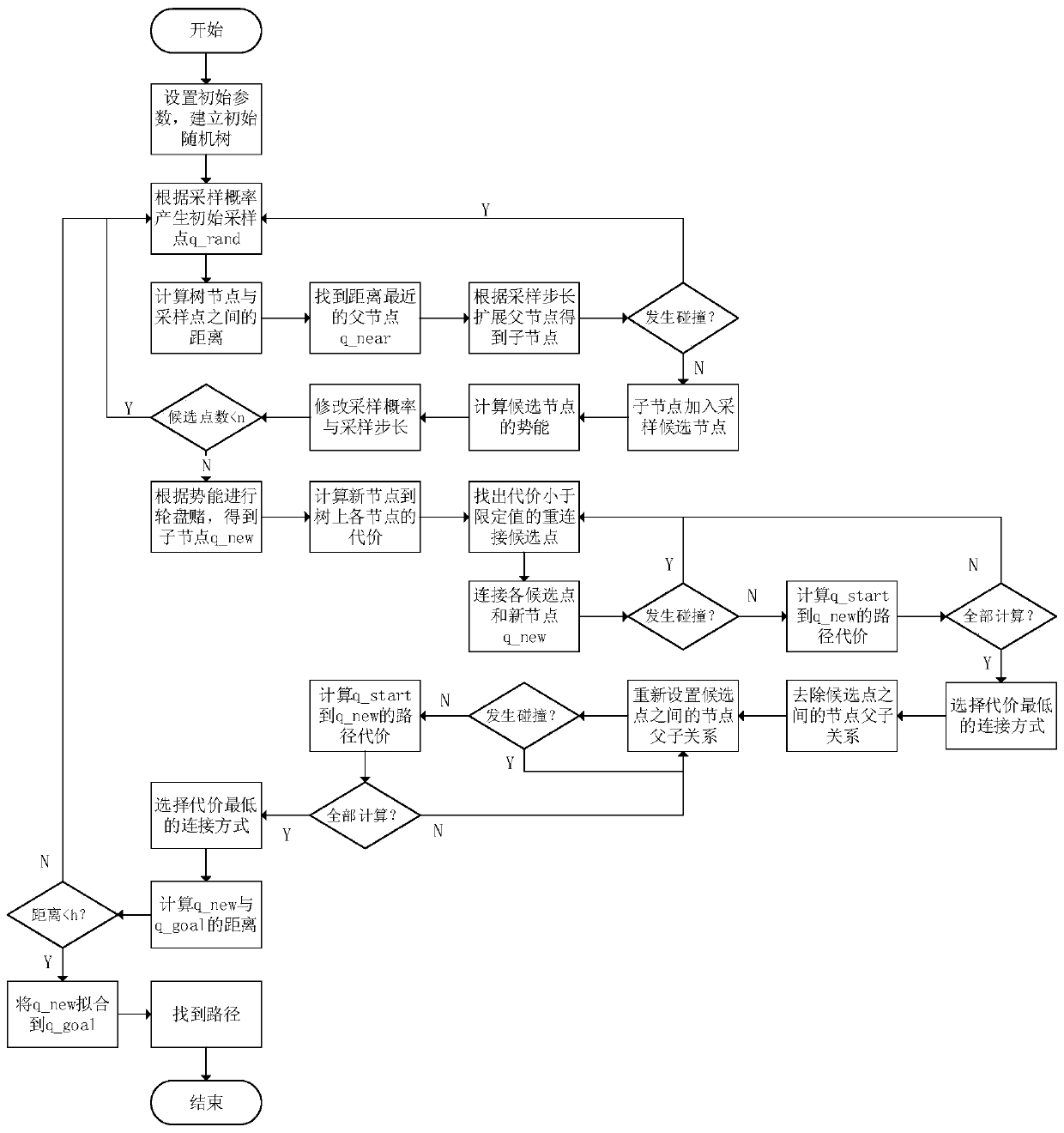

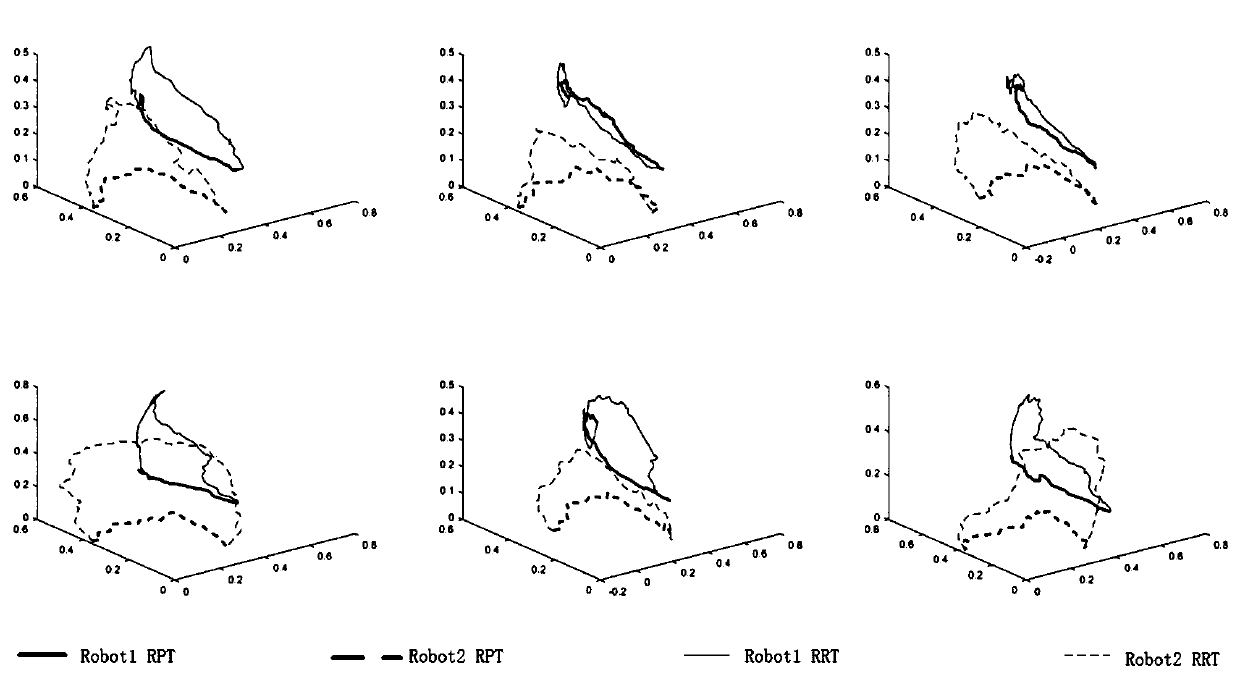

Path planning method of double-mechanical-arm collaborative assembly operation

ActiveCN110181515AOptimize the connection methodImprove sampling qualityProgramme-controlled manipulatorDynamic modelsPotential difference

The invention provides a path planning method of double-mechanical-arm collaborative assembly operation. The path planning method comprises the following steps that a kinematics model and a dynamics model of the double-mechanical-arm operation are established; initial parameters are set, initial sampling is carried out, the distance between a tree node and a sampling point is calculated, and a nearest tree node is found to serve as a parent node; a candidate sampling point is added if no collision occurs; the potential energy of the sampling point is calculated, and roulette selection is performed according to the reciprocal of the potential energy to obtain the sampling point; the point with the cost less than r is added into a heavy connection point, the cost of the path formed by connecting the sampling point with the heavy connection points is calculated, and the connection mode of the shortest cost is selected to determine connection parent node of the sampling point; the connection mode with the lowest cost is selected to re-establish the parent-child relation of the node; the sampling point is replaced by using a target point when the potential difference between the sampling point and the target point is smaller than h, and a random tree is finished; and a planning path is determined according to the parent-child relation of the node of the random tree. According to thepath planning method of the double-mechanical-arm collaborative assembly operation, the high-quality path with short end movement distance, short operation time and low mechanical arm energy consumption can be planned.

Owner:ZHEJIANG UNIV OF TECH

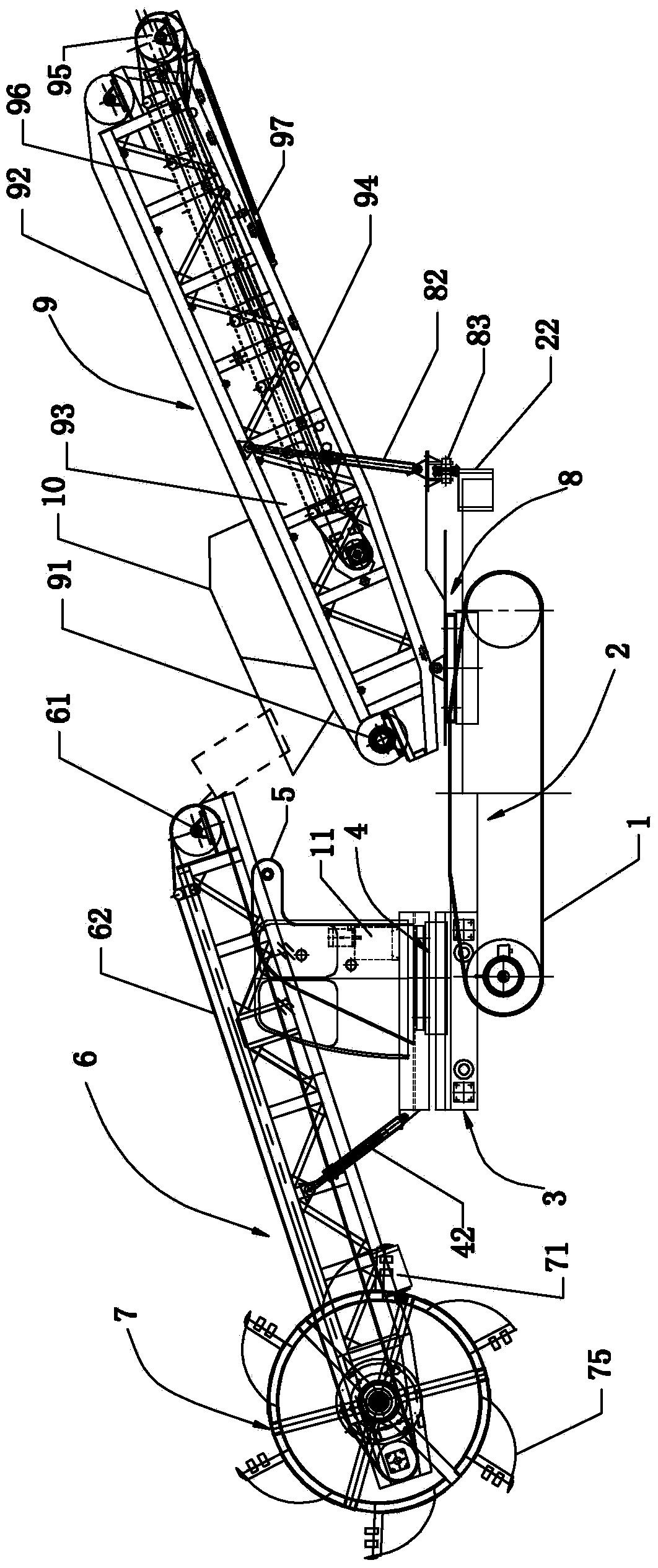

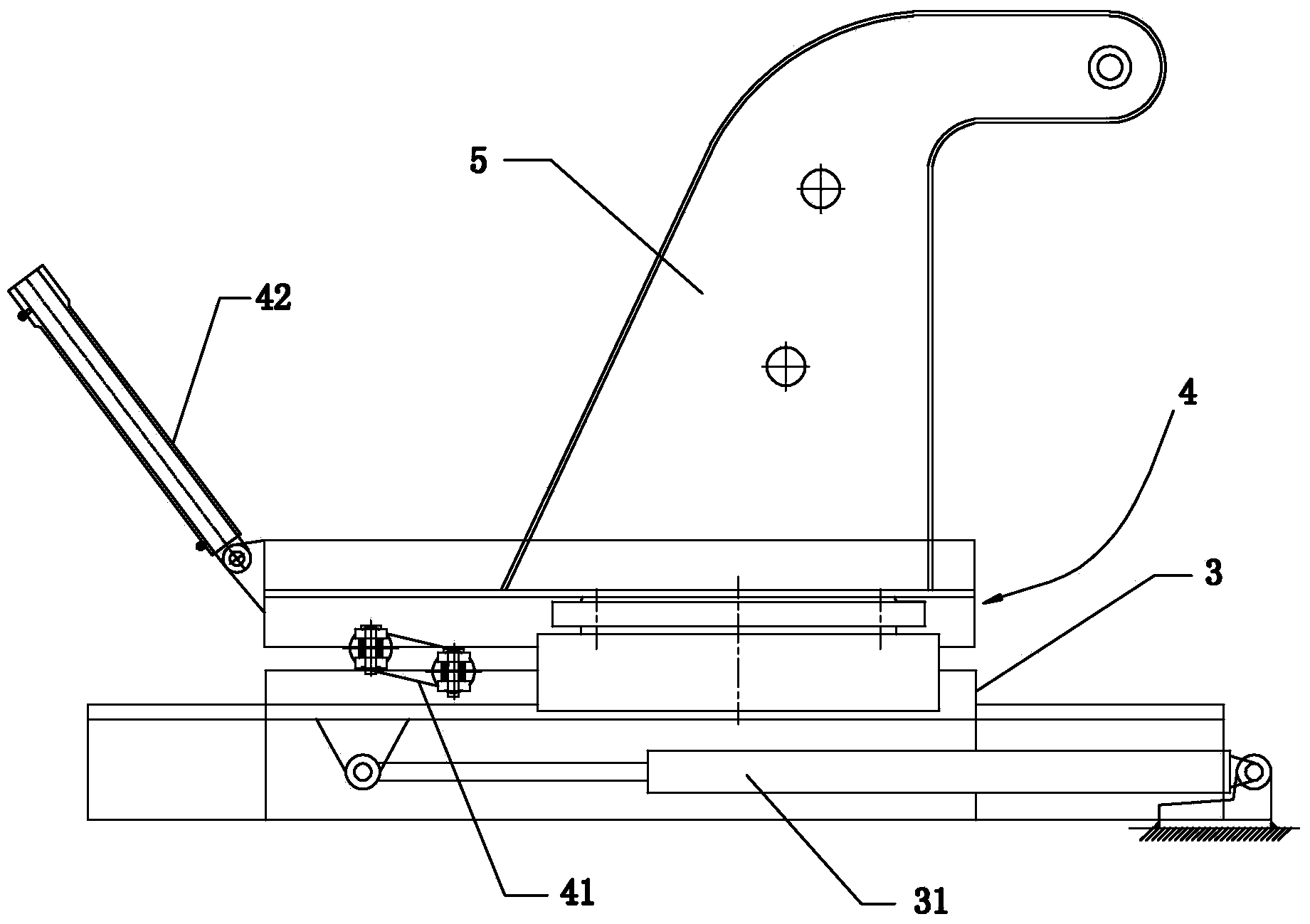

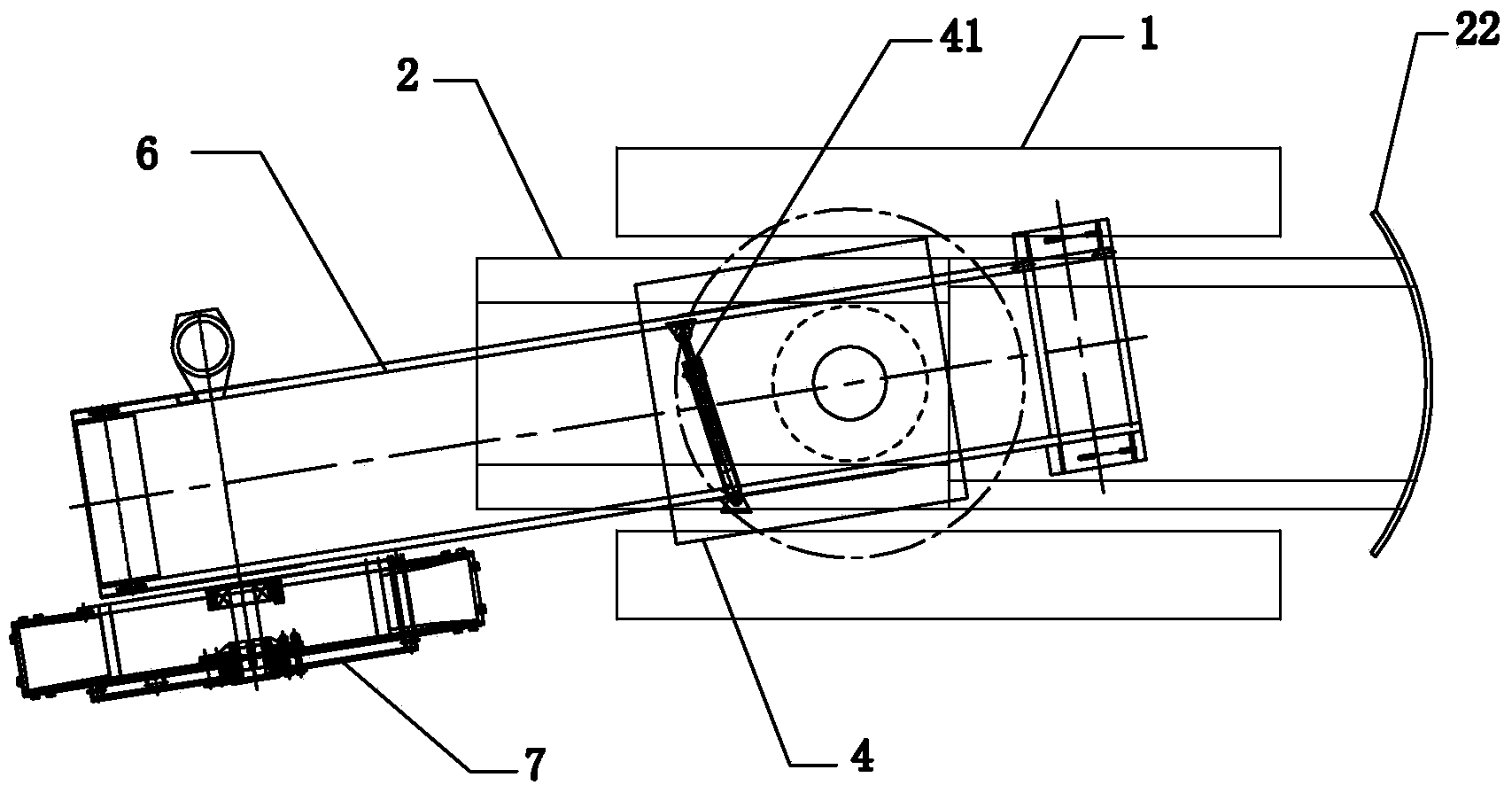

Bucket-wheel reclaimer

The invention belongs to the technical field of stacker reclaimers, particularly relates to a bucket-wheel reclaimer. The bucket-wheel reclaimer comprises a chassis, a sliding box is arranged at one end of the chassis in a sliding manner, a rotating seat is arranged on the sliding box in a rotating manner, a support is fixedly arranged on the rotating seat, a material reclaiming arm is hinged on the support, a first material conveying rail is arranged on the material reclaiming arm, material reclaiming bucket wheels are connected with the first material conveying rail, a third hydraulic cylinder is arranged on the rotating seat, a slewing bearing is arranged at the other end of the chassis in a rotating manner, an output arm is hinged on the slewing bearing, a second material conveying rail is arranged on the output arm, a material conveying hopper is arranged at the upper end of the output arm, and a fifth hydraulic cylinder is arranged on the slewing bearing. The chassis can be adjusted flexibly, the material reclaiming arm and the output arm can be moved backward and frontward, leftward and rightward, and can be lifted up and down, and are flexible to adjust, material reclaiming, material unloading and material loading scope is expanded, working efficiency is increased, and the bucket-wheel reclaimer is widely adaptable to truck loading of materials in bulk in the areas of mines, coal yards and the like and particularly adaptable to small working areas.

Owner:WEIFANG YIHONG HEAVY MACHINERY

Deck-liftable operation platform and construction method for marine wind power generation facility

InactiveCN102191767AGood working efficiencyGood stabilityArtificial islandsWaterborne vesselsRotary stageTransverse axis

A deck-liftable operation platform comprises the following components: a platform body which forms a rectangular shape in plane view; a plurality of columns which are provided at four corner parts of the platform body through a mode of random insertion and extension in a vertical direction are allowed, while a hydraulic jack jacking system causes the platform body to move liftably; a walking cross beam which can randomly move on two walking rails that are laid in a long axis direction of the deck of the platform body; a moving operation trolley which is provided on the walking cross beam and can randomly move in a moving track that is laid in the long axis direction of the deck of the platform body; a suspension rod rotation platform which is rotatably provided on the moving operation trolley; and two suspension rods which are provided in a left-and-right direction and forms a pair for being mounted on the suspension rod rotation platform. Therefore the deck-liftable operation platform with high operation efficiency, high stability and high safety is provided.

Owner:DAIICHI KENSETSU KIKO +2

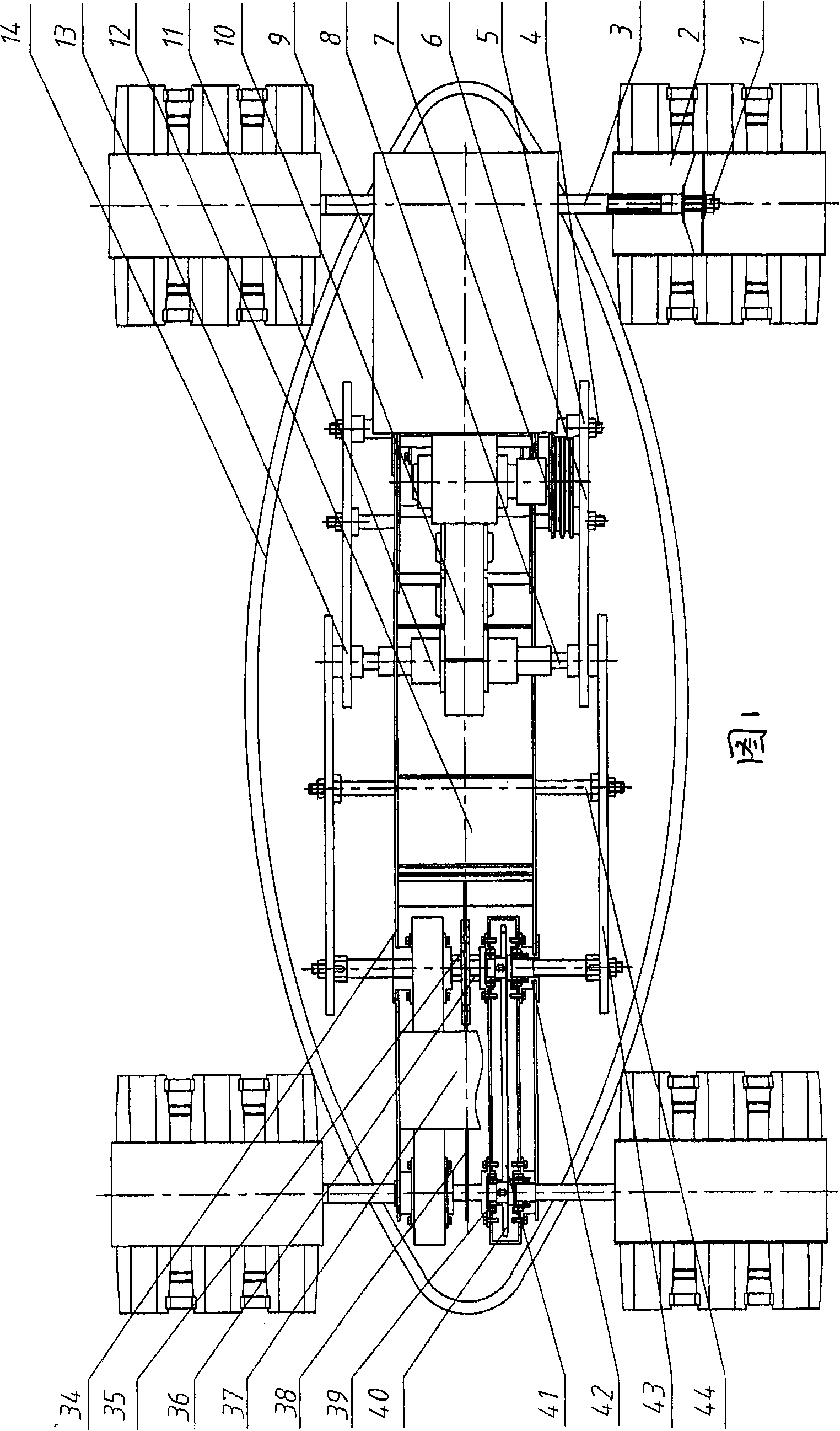

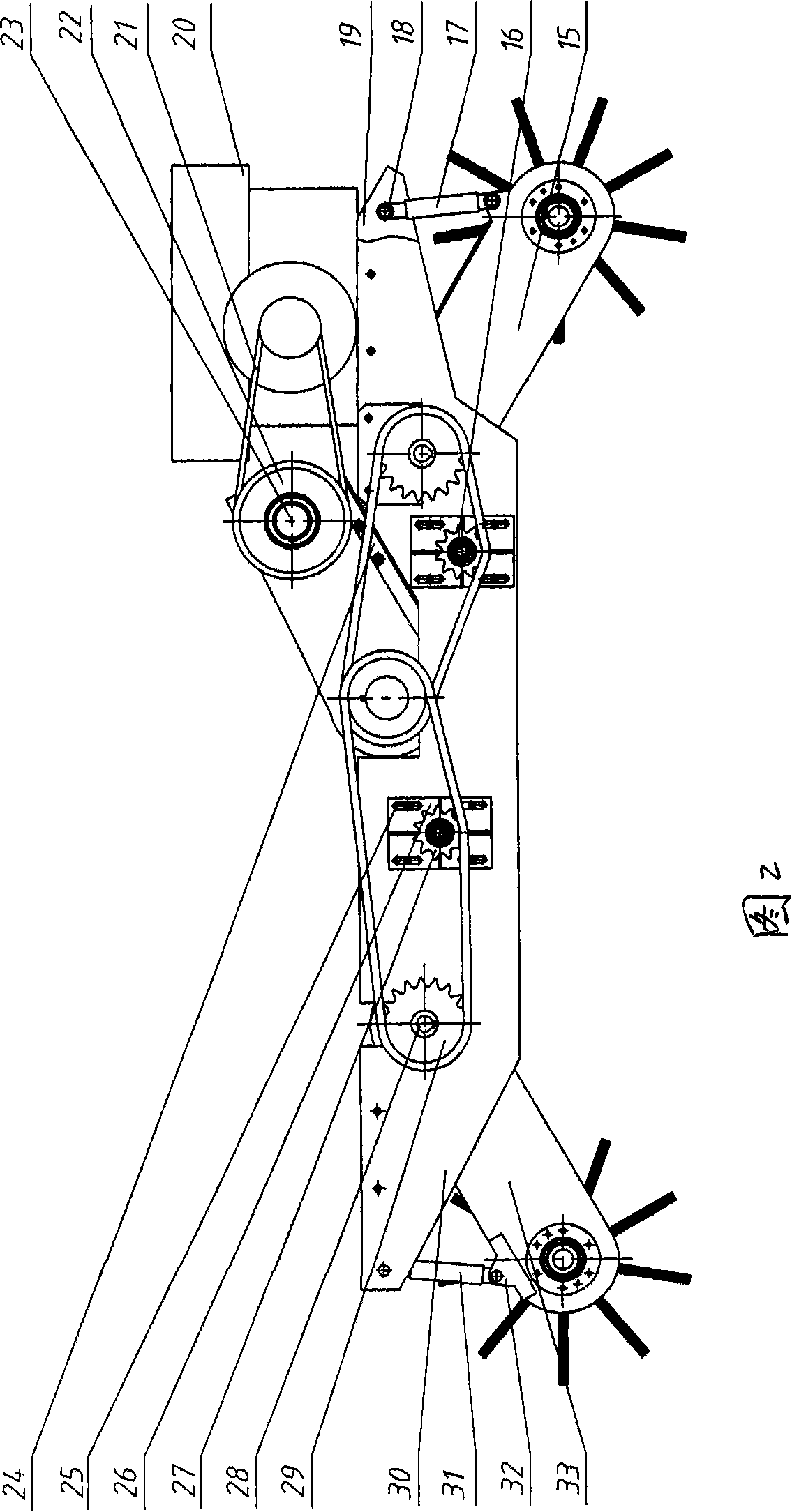

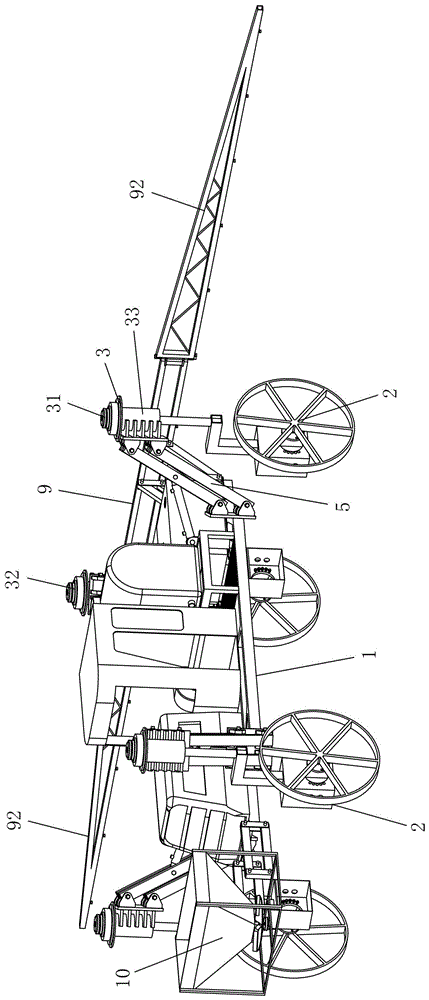

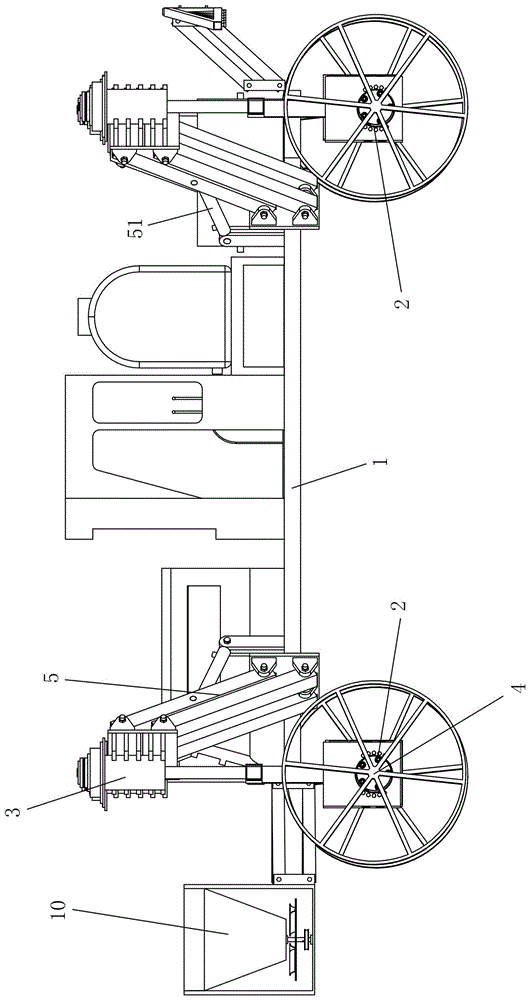

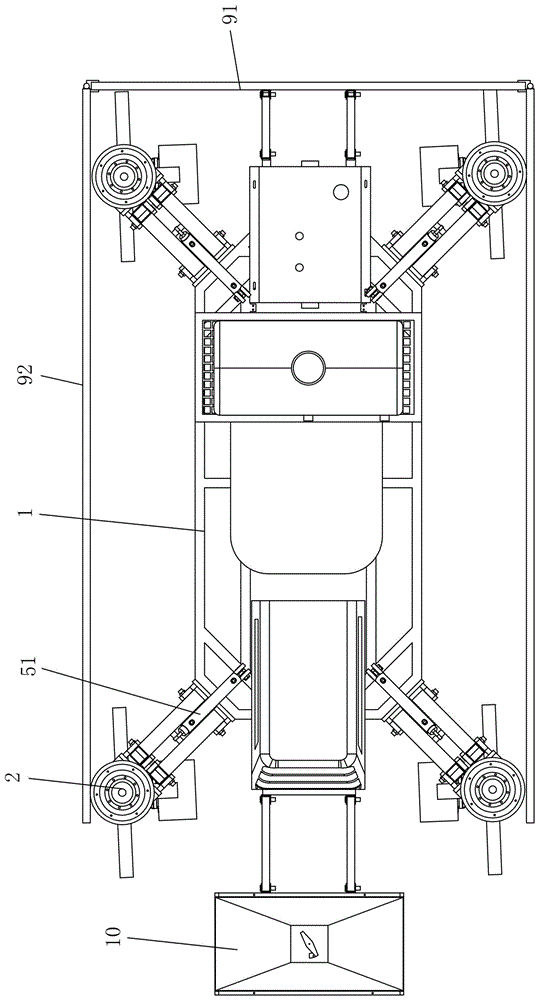

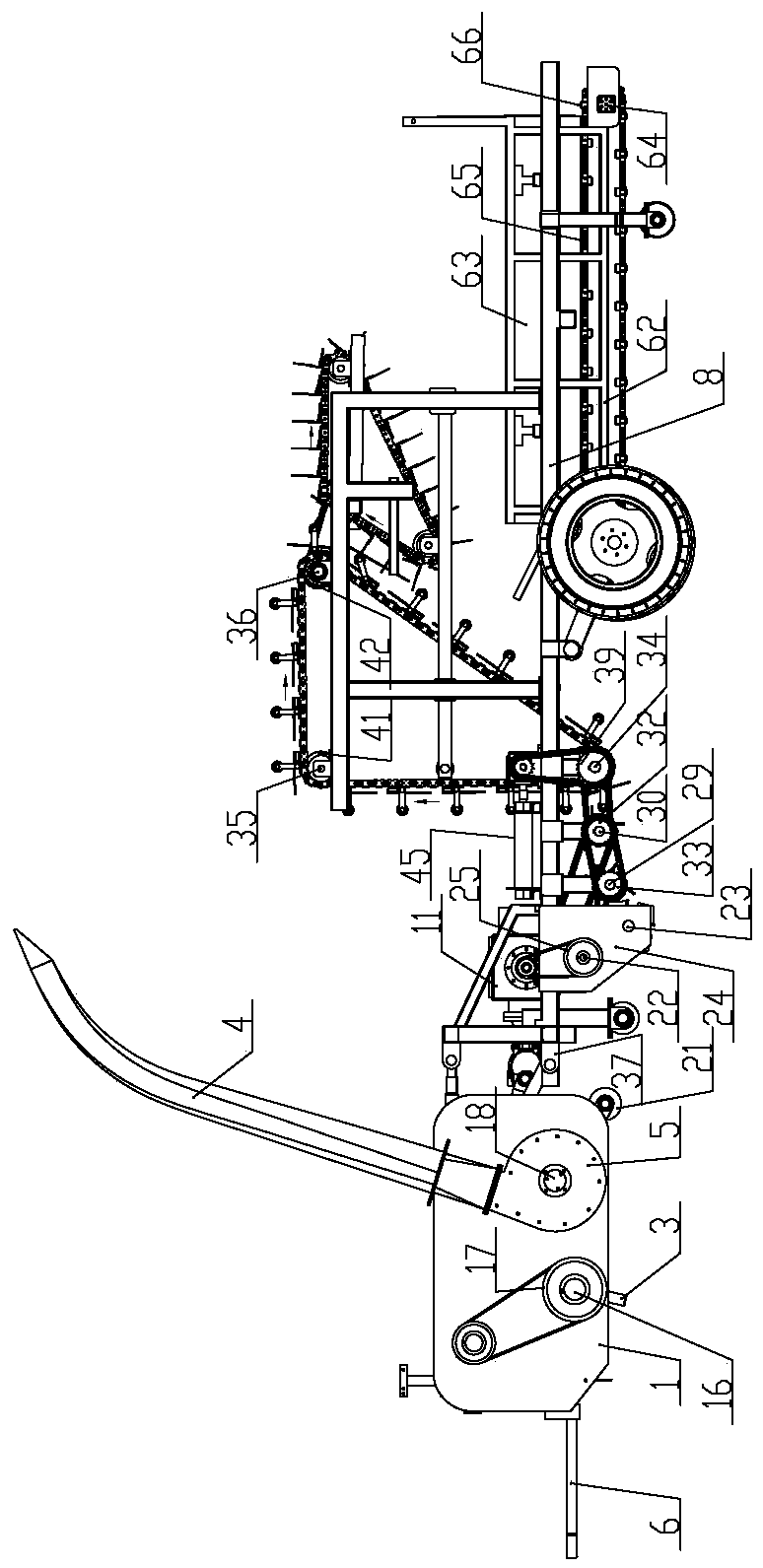

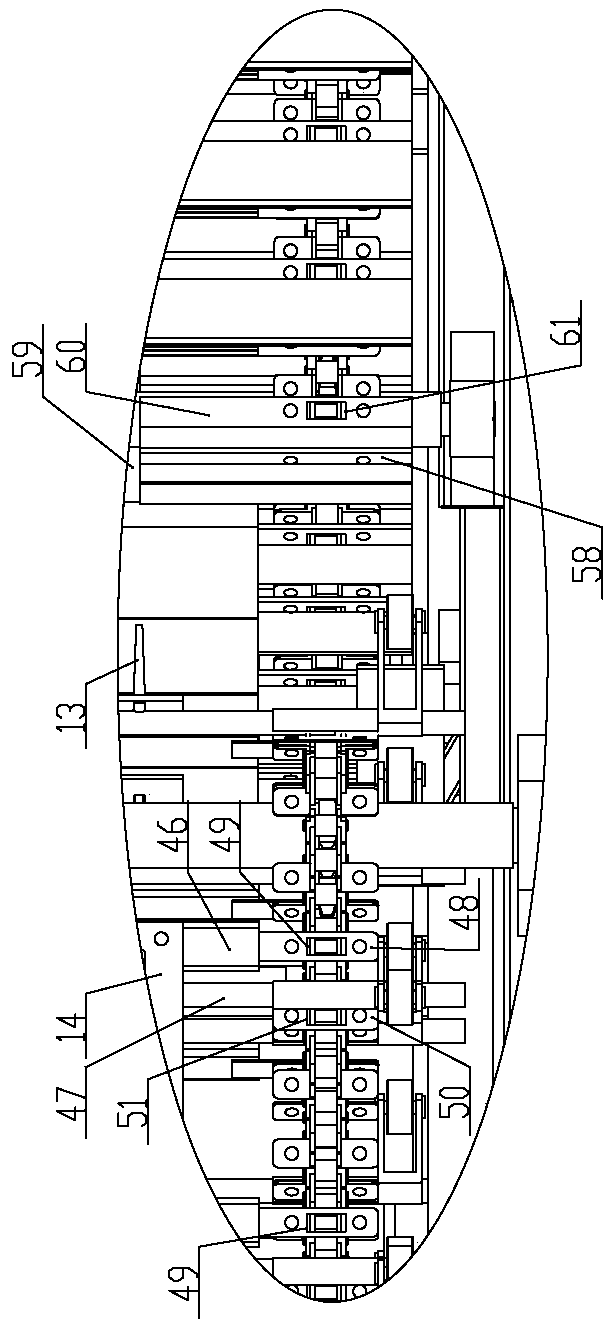

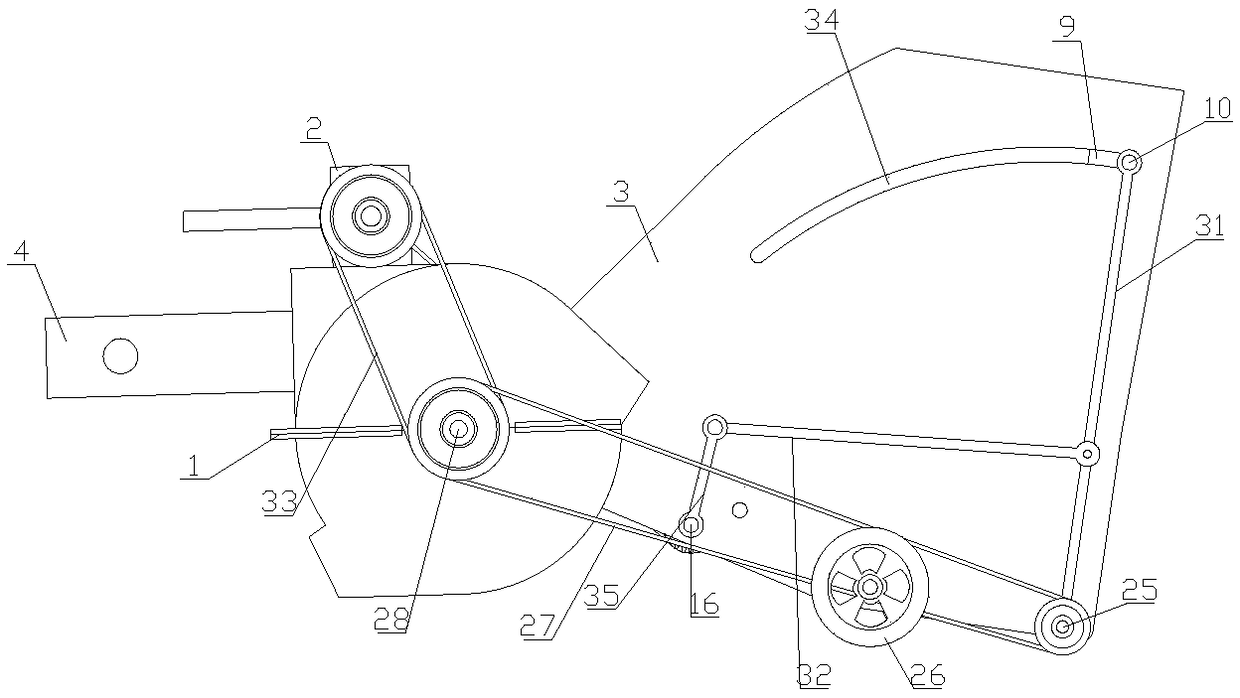

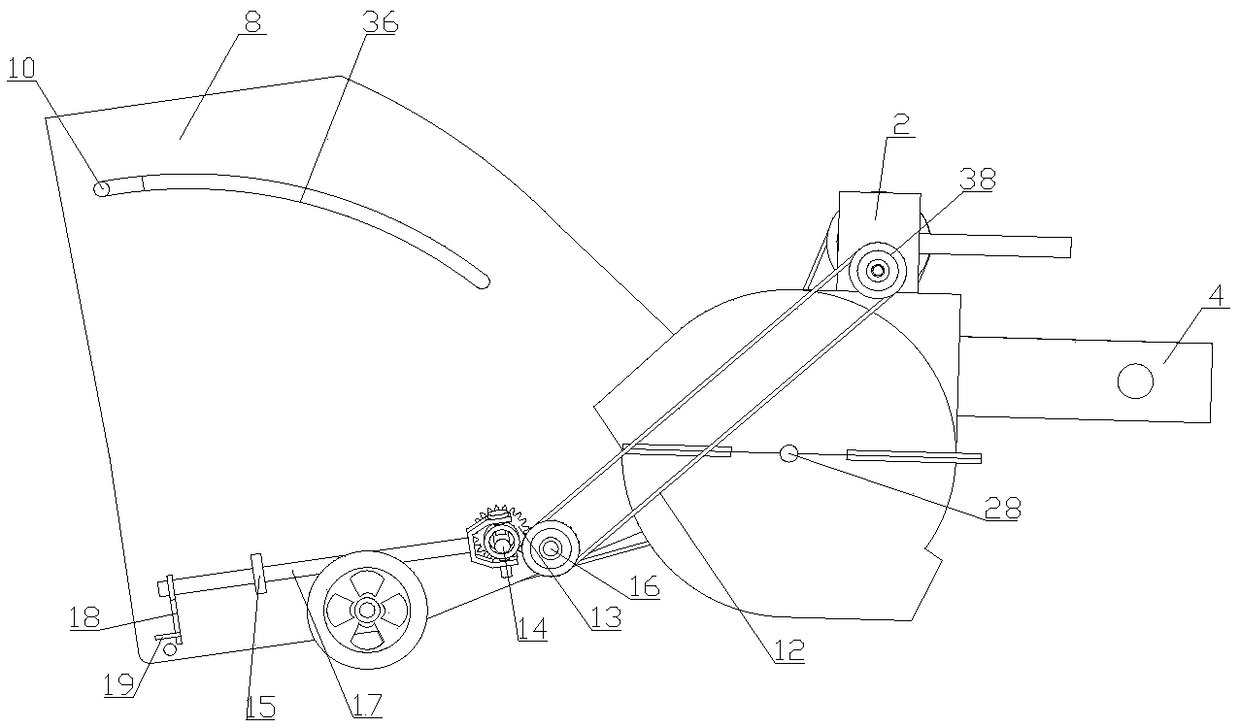

Multifunctional ship type farming machinery

InactiveCN101156511AAvoid destructionNot easy to slipAgricultural machinesAgricultural undercarriagesTransfer caseAutomatic control

The invention discloses a multifunctional boat shaped cultivating machine, which includes a boat body (14), a frame (30), a motor (20), a belt (21), a gear box (10), left and a right output shafts of the gear box (8), a double-linkage output chain wheel of the gear box (13), front and a rear transfer-cases (33, 15), a cultivator tool (2), and a transfer-case output shaft (3). The frame (30) is arranged on the boat body (14), the front and the rear of the frame (30) are provided with four transfer-cases (33, 15), the double-linkage output chain wheel of the gear box (13) is arranged on the separate left and right output shafts of the gear box (8). The outer chain wheel of the double-linkage output chain wheel of the gear box (13) is connected with an input chain wheel (29) of the front transfer-case (33) through a chain (43), and the inner chain wheel is connected with the input chain wheel (5) of the rear transfer-case (15) through a chain (6). The cultivator tool (2) is arranged on output shafts of the front and the rear transfer-cases. The invention has the advantages that the structure is simple, the operation is convenient, the plowing depth can be controlled automatically, and the working efficiency and the operation quality of the cultivating machine can be improved greatly.

Owner:HUNAN AGRICULTURAL UNIV

High-ground-clearance full-hydraulic parameter adaptive multifunctional plant protection machine

ActiveCN106665541AFree turnIncrease flexibilityInsect catchers and killersHydraulic motorControl engineering

The invention provides a high-ground-clearance full-hydraulic parameter adaptive multifunctional plant protection machine. The machine comprises a rack with four walking parts, and a mating system. Each walking part is provided with an independent hydraulic type steering assembly, an independent hydraulic type walking assembly, an independent hydraulic type lifting assembly, a steering hydraulic system, a walking hydraulic system and a lifting hydraulic system. The hydraulic walking assemblies comprise walking wheels and walking two-way hydraulic motors. A one-in-four flow distributing and collecting valve of each walking hydraulic system comprises a first oil port and four second oil ports communicated with the first oil port, wherein the first oil port is connected with one oil inflow and outflow port of a closed variable pump, one work oil port of each of the four walking two-way hydraulic motors is connected with the other oil inflow and outflow port of the closed variable pump, and the other work oil ports of the four walking two-way hydraulic motors are correspondingly connected with the four second oil ports. The plant protection machine is convenient to control and adjust, good in work stability, compact in structure, complete in function, high in flexibility, wide in application range and high in work efficiency.

Owner:HUNAN AGRICULTURAL UNIV

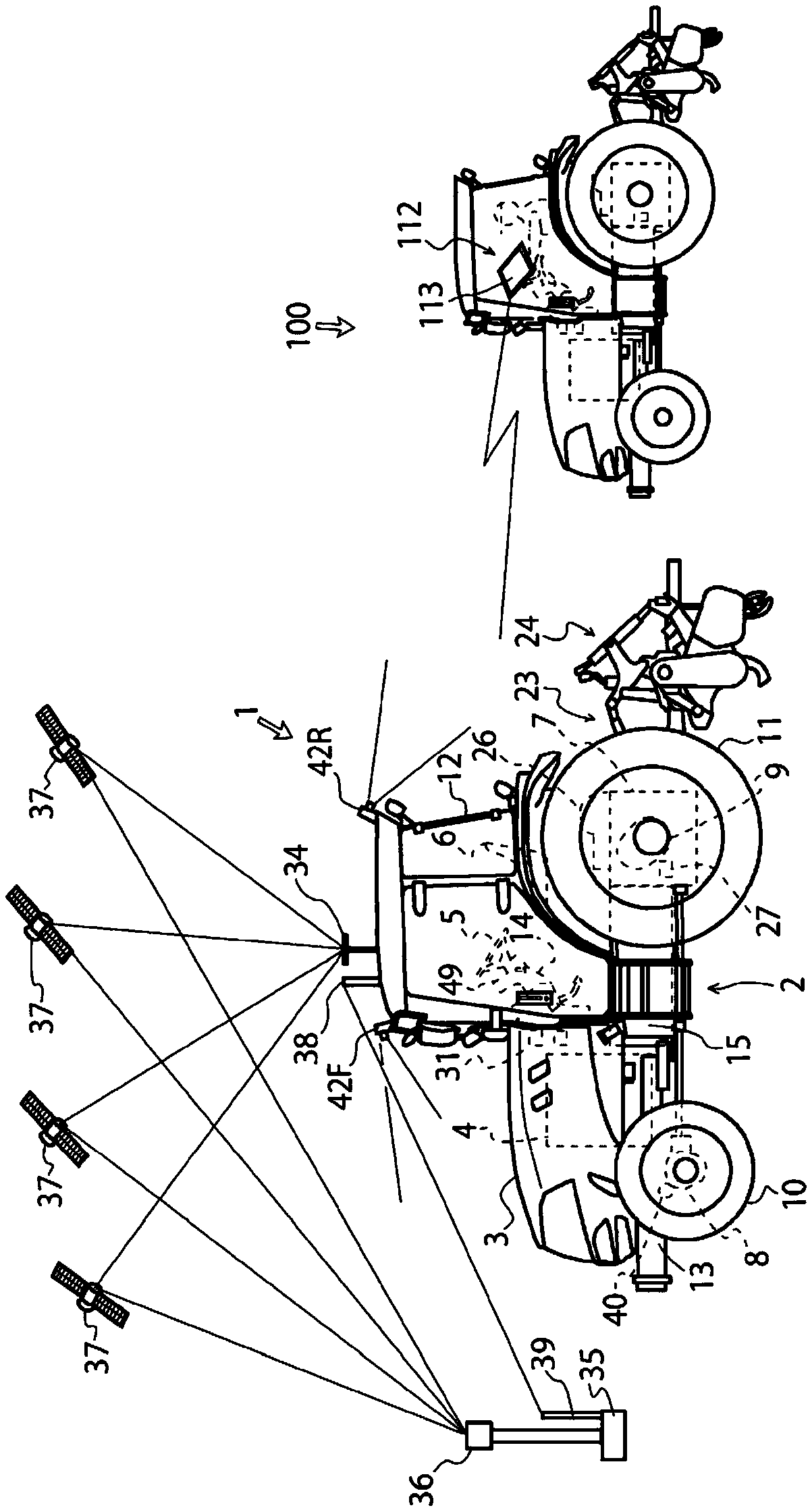

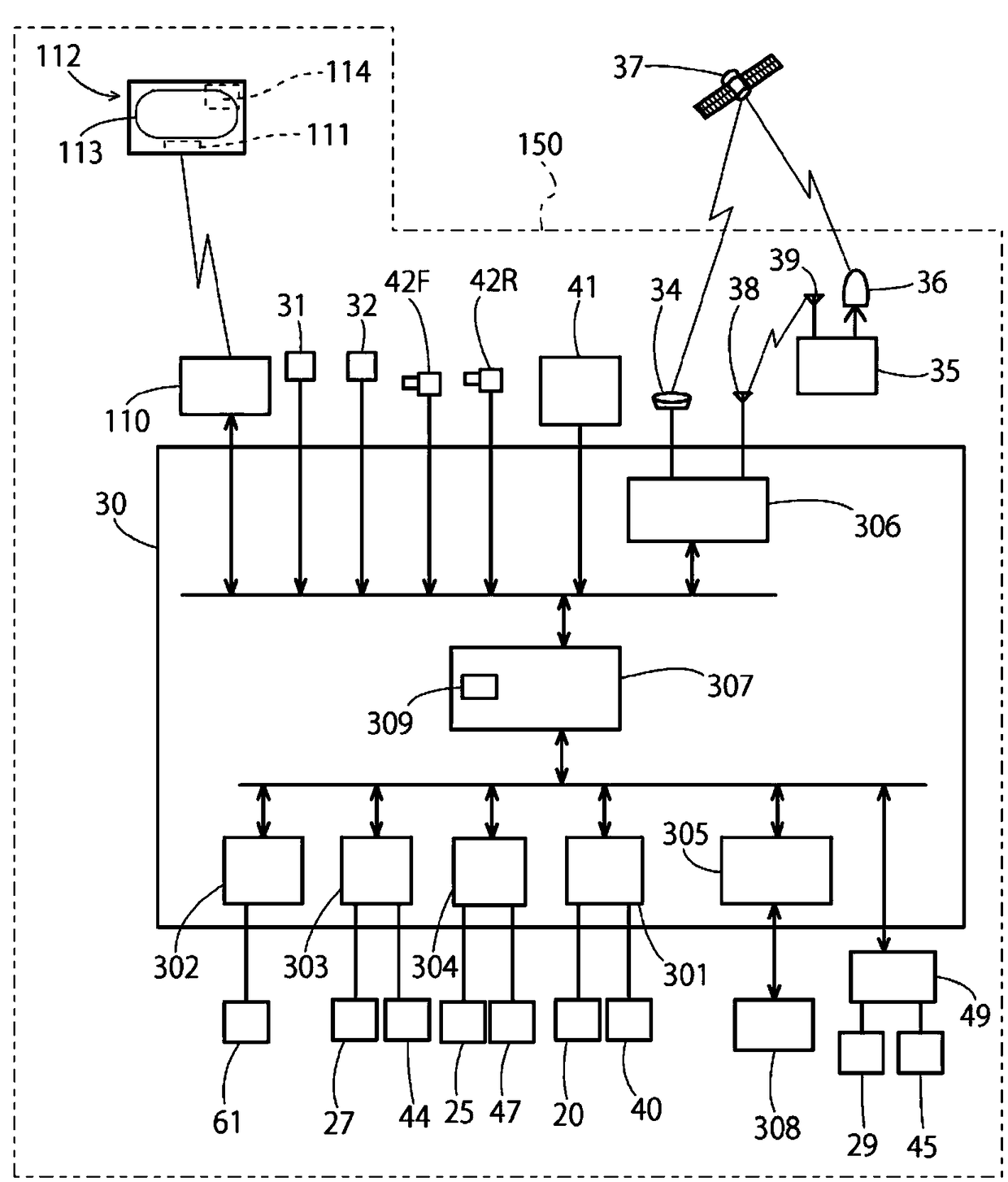

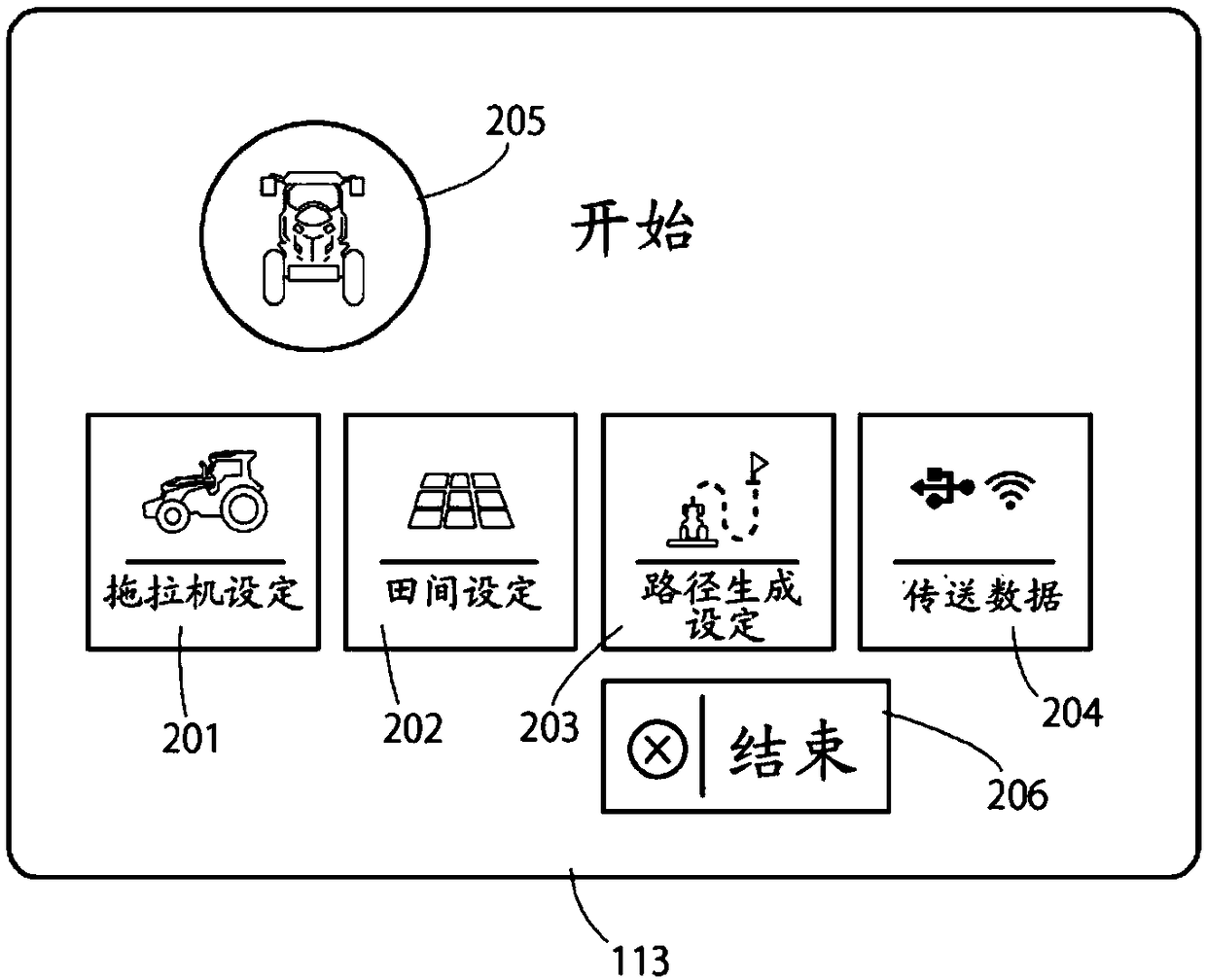

Work vehicle and travel region specification device

ActiveCN108777935AGood for work efficiencyPrevent mistakeAutonomous decision making processGuiding agricultural machinesMobile antennasControl engineering

The purpose of the present invention is to reduce the burden of an operation for disposing an autonomous-travel work vehicle in a work start position, and to improve work efficiency. An autonomous travel work vehicle 1 is provided with: a vehicle body 2; a work machine 24 mounted on the vehicle body 2; a mobile GPS antenna 34 with which it is possible to detect position information of the vehiclebody 2; a memory 309 with which it is possible to store a farm field H in which the vehicle body 2 is caused to travel; a control unit 30 with which it is possible to control the travel of the vehiclebody 2 within the farm field H, and the work by the work machine 24; and a remote operation device 112 for generating a route R of the vehicle body 2 in the farm field H. The farm field H includes awork region HA that includes a work route Ra in which the work is performed by the work machine 24, and headlands HB that are set at the periphery of the work region HA, and when the start of the workby the work machine 24 in the headland HB is ordered, the control unit 30 causes the vehicle body 2 to travel from the current position Z of the vehicle body 2 to a work start position Sw, after which the work can be started by the work machine 24.

Owner:YANMAR POWER TECHNOLOGY CO LTD

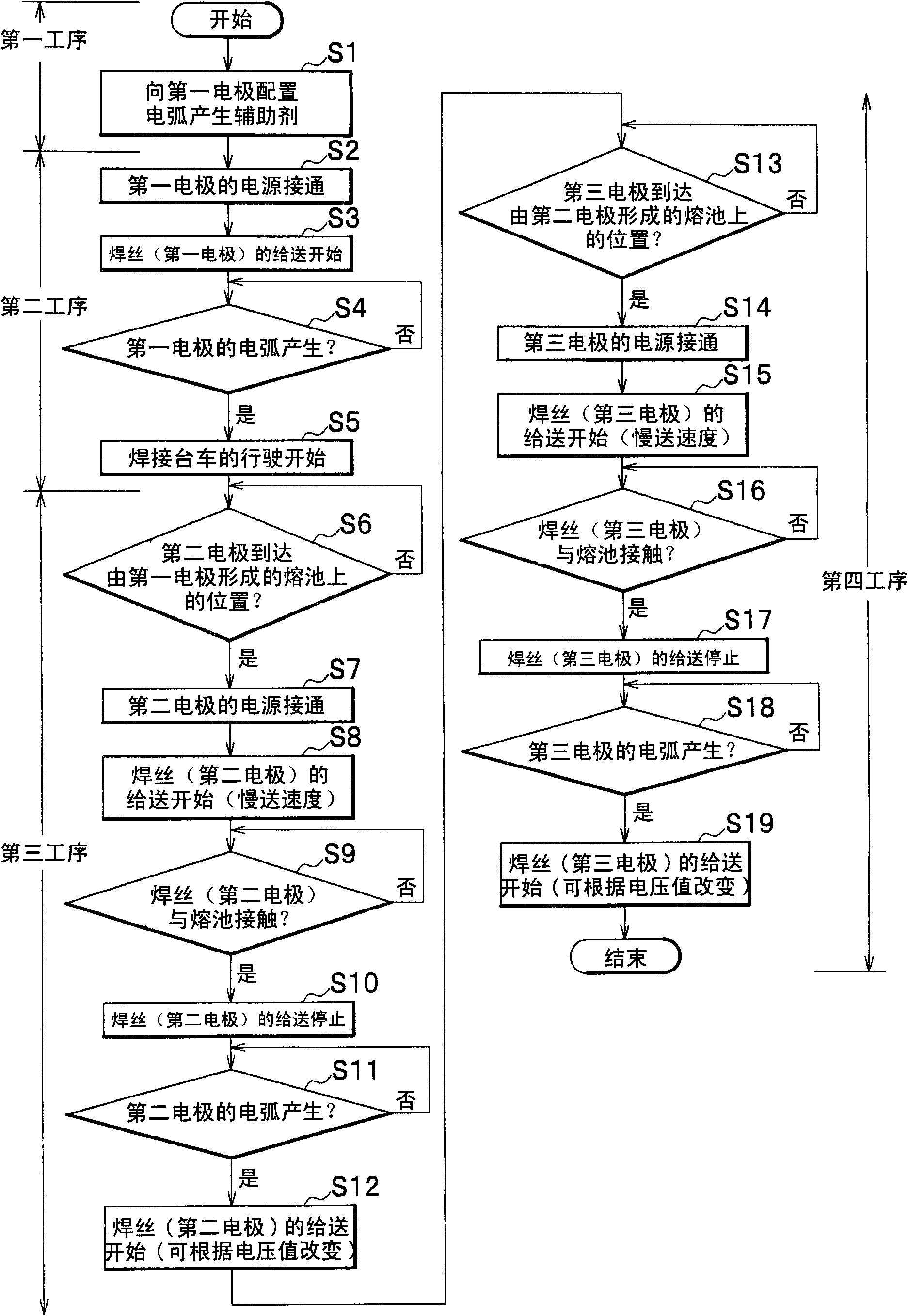

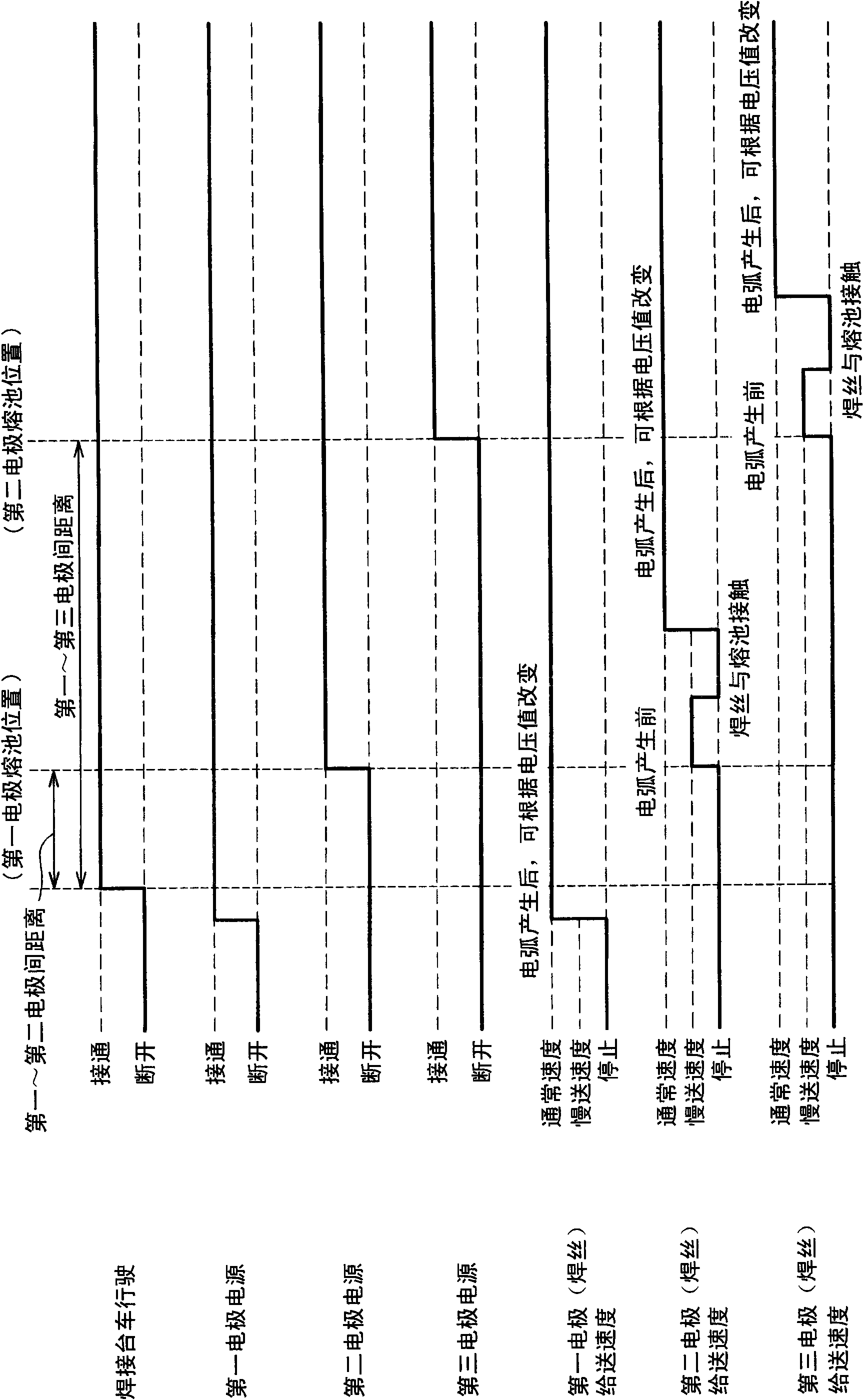

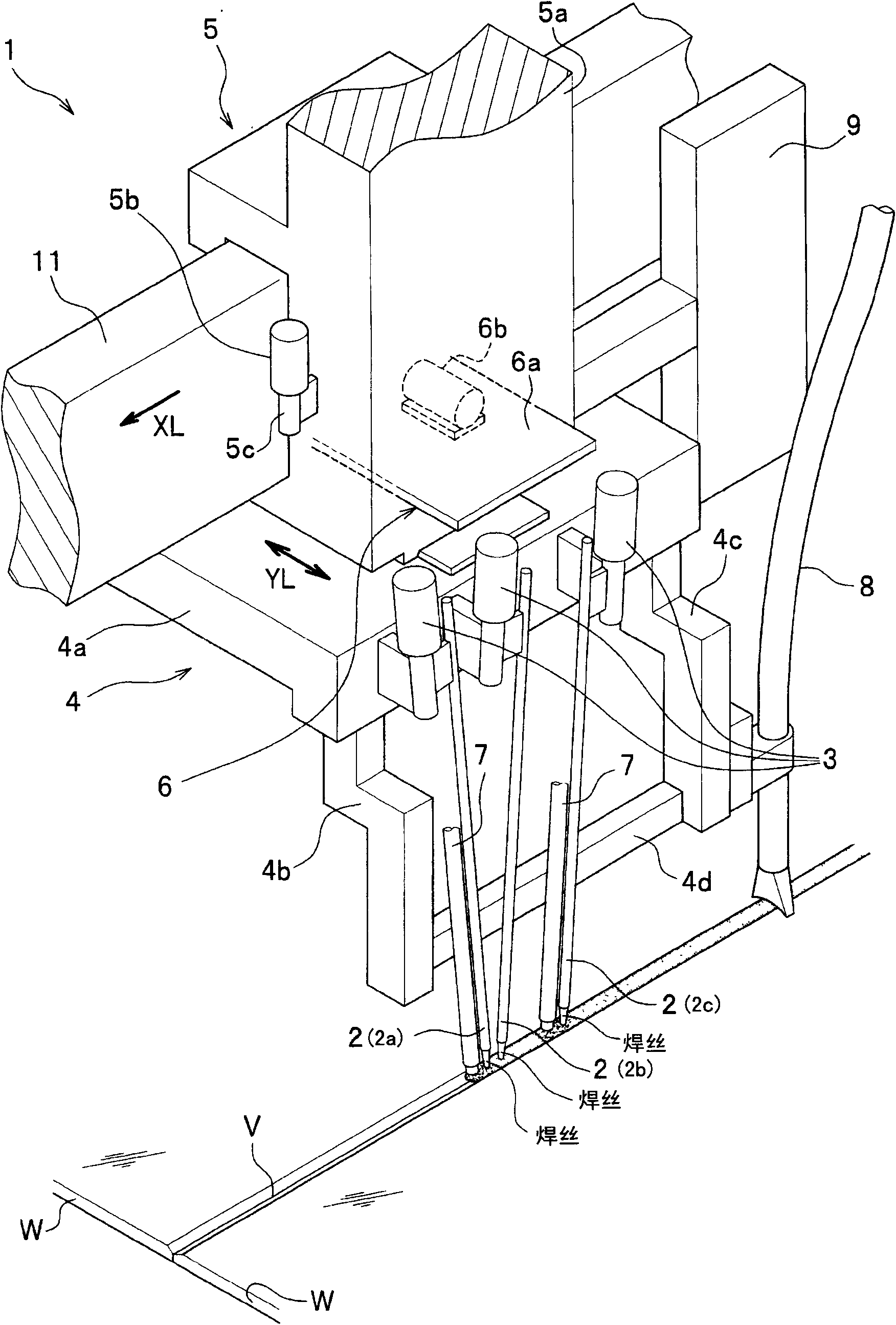

Arc-starting method for multi-electrode single-side welding device and multi-electrode single-side welding device

The invention provides an arc-starting method for a multi-electrode single-side welding device and a multi-electrode single-side welding device, the method is characterized by comprising: a first procedure configuring an electric arc generating auxiliary agent to a first electrode; a second procedure making the first electrode generate an electric arc and then immediately making a welding trolley travel; a third procedure performing control in three stages comprising a first stage making a second electrode generate an electric arc on a molten bath and feeding solder wires as the second electrode at a low speed, a second stage making the feeding stop, and a third stage performing feeding at a common speed changeable according to change of the voltage value of the solder wires; a fourth procedure making electrodes after a third electrode generate electric arcs on the molten bath, and furthermore, controlling feeding of the solder wires as electrodes after the third electrode via the one-to-three three stages. Via the method, automation of arc-starting can be realized, and the use amount of the electric arc generating auxiliary agent can be reduced.

Owner:KOBE STEEL LTD

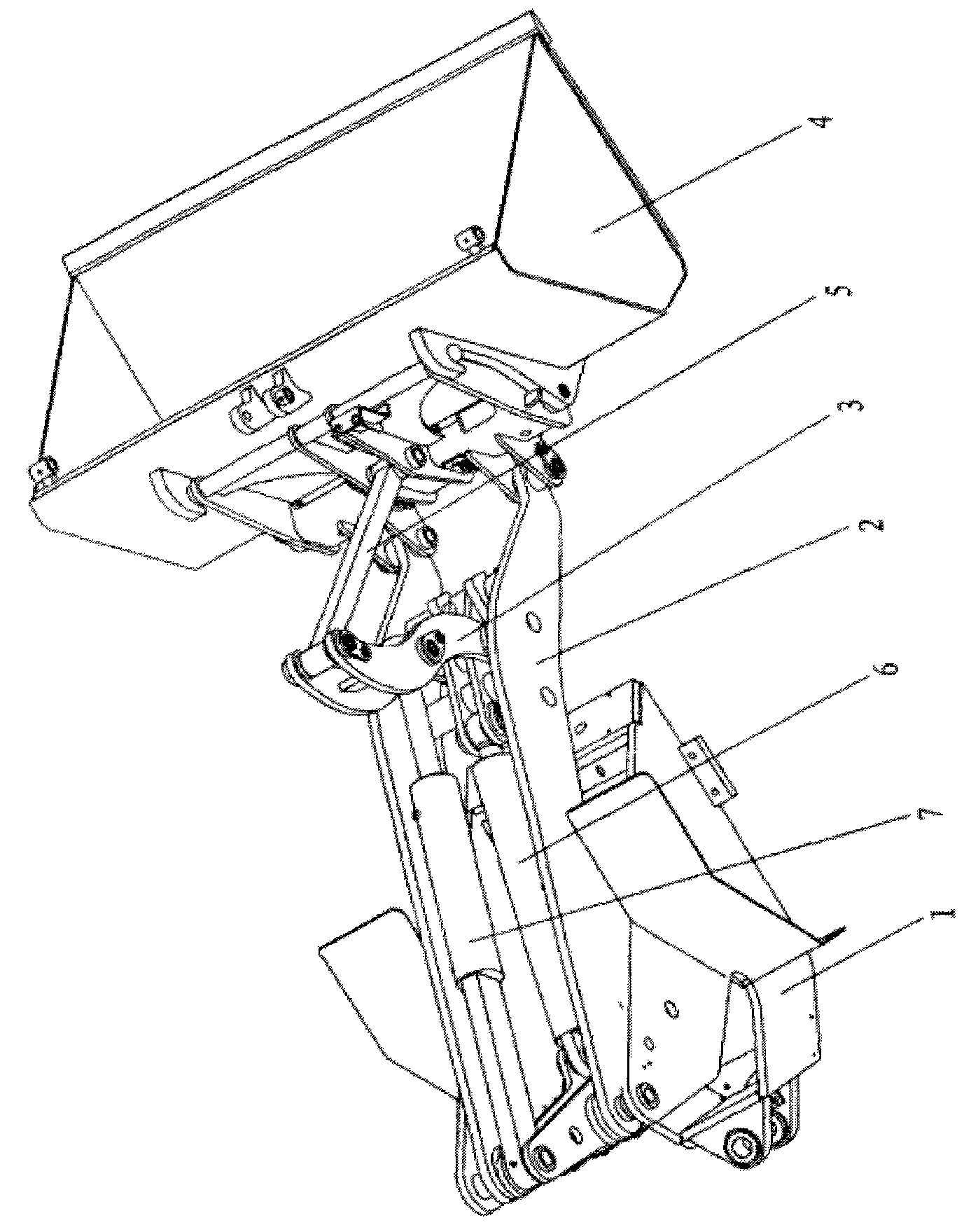

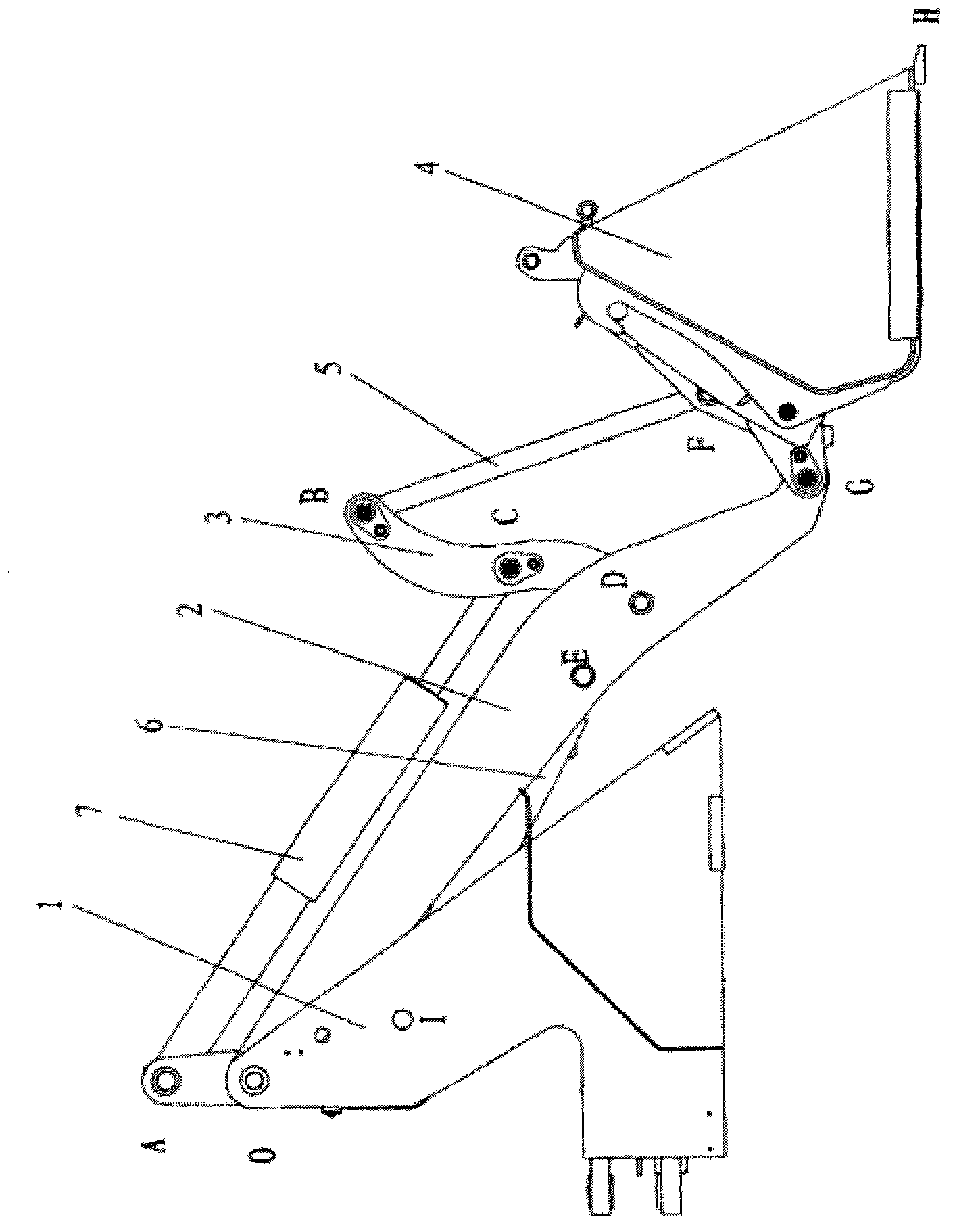

Bucket connection mechanism of small loading machine

InactiveCN103806480ABig breakout forceDigging materials fastMechanical machines/dredgersVehicle frameUltimate tensile strength

The invention discloses a bucket connection mechanism of a small loading machine. The connection mechanism comprises a front frame, a movable arm, a rocker arm, a bucket, a pull rod, a movable arm oil cylinder and a rotating bucket oil cylinder. The connection mechanism adopts reasonable proportional relations for linear distances of multipile hinge points among the movable arm, the rocker arm, the bucket, the pull rod, the movable arm oil cylinder and the rotating bucket oil cylinder, so that the strength and the stability of the movable arm are increased, all components are arranged reasonably in the space, the movable arm and the front frame are free from the problem of interference, the breakout force of the loading machine is larger, materials are shoveled faster, and the loading machine has the better working performance and the better working efficiency.

Owner:QINGDAO LUDA PROJECT MACHINE MFR

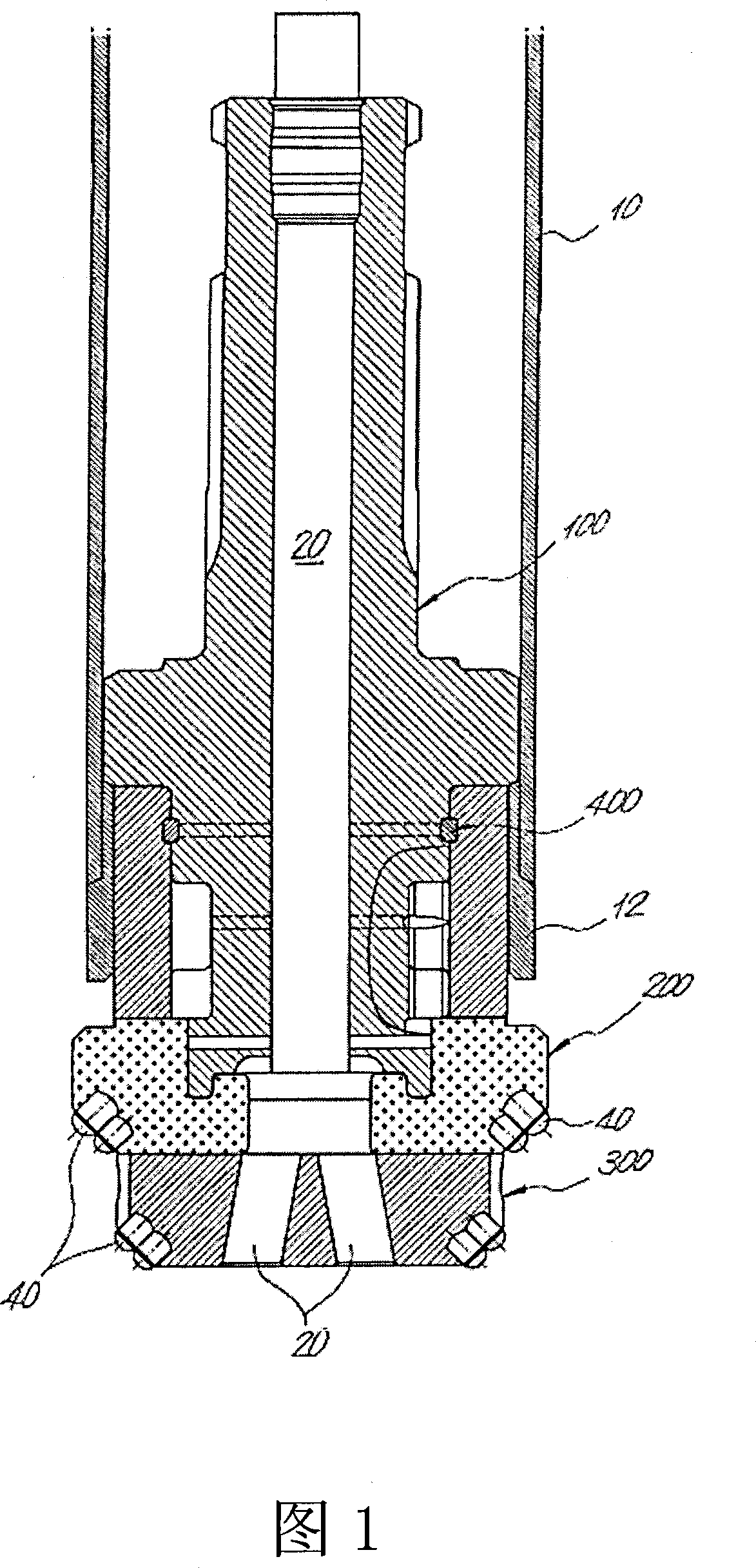

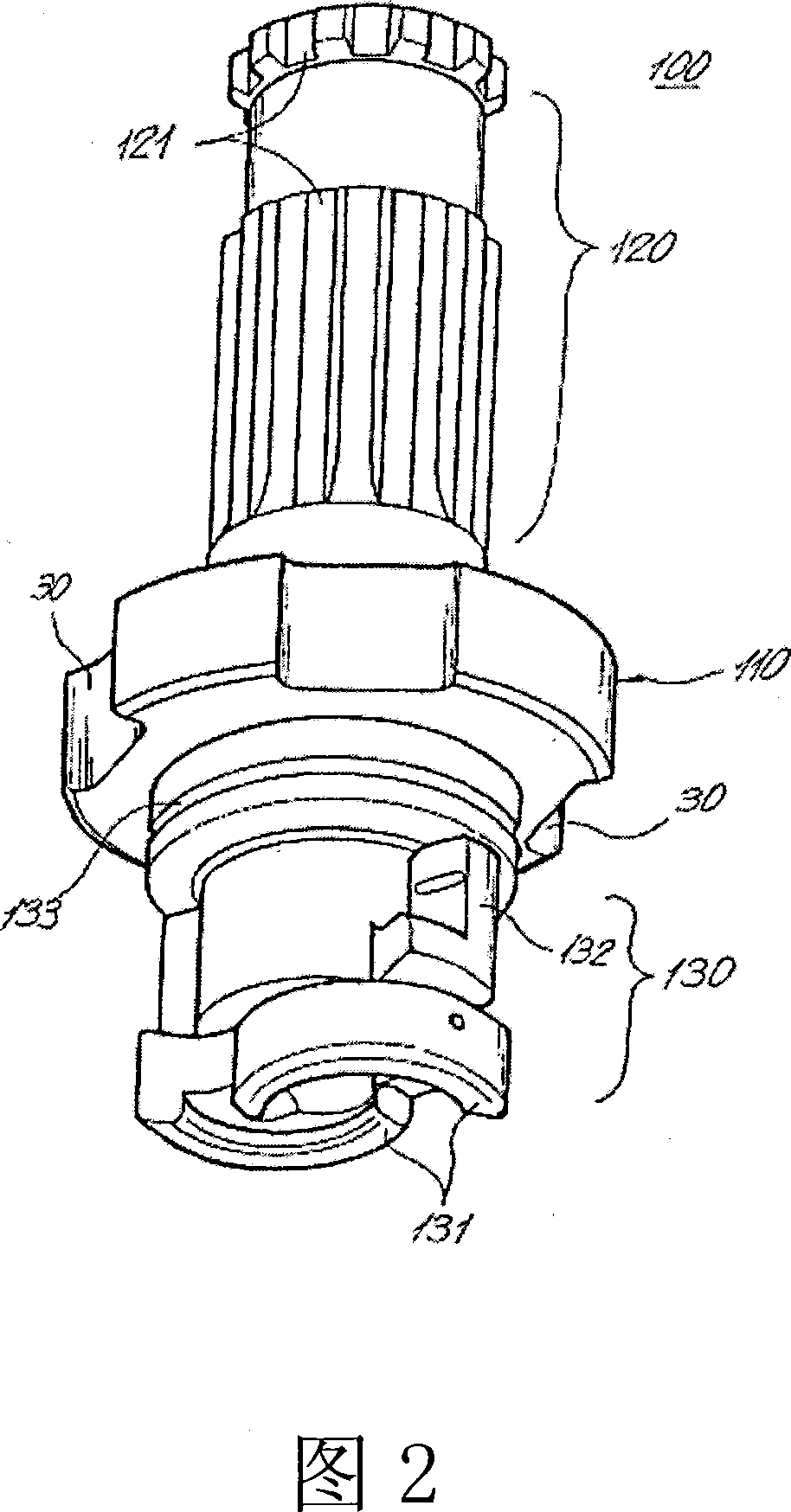

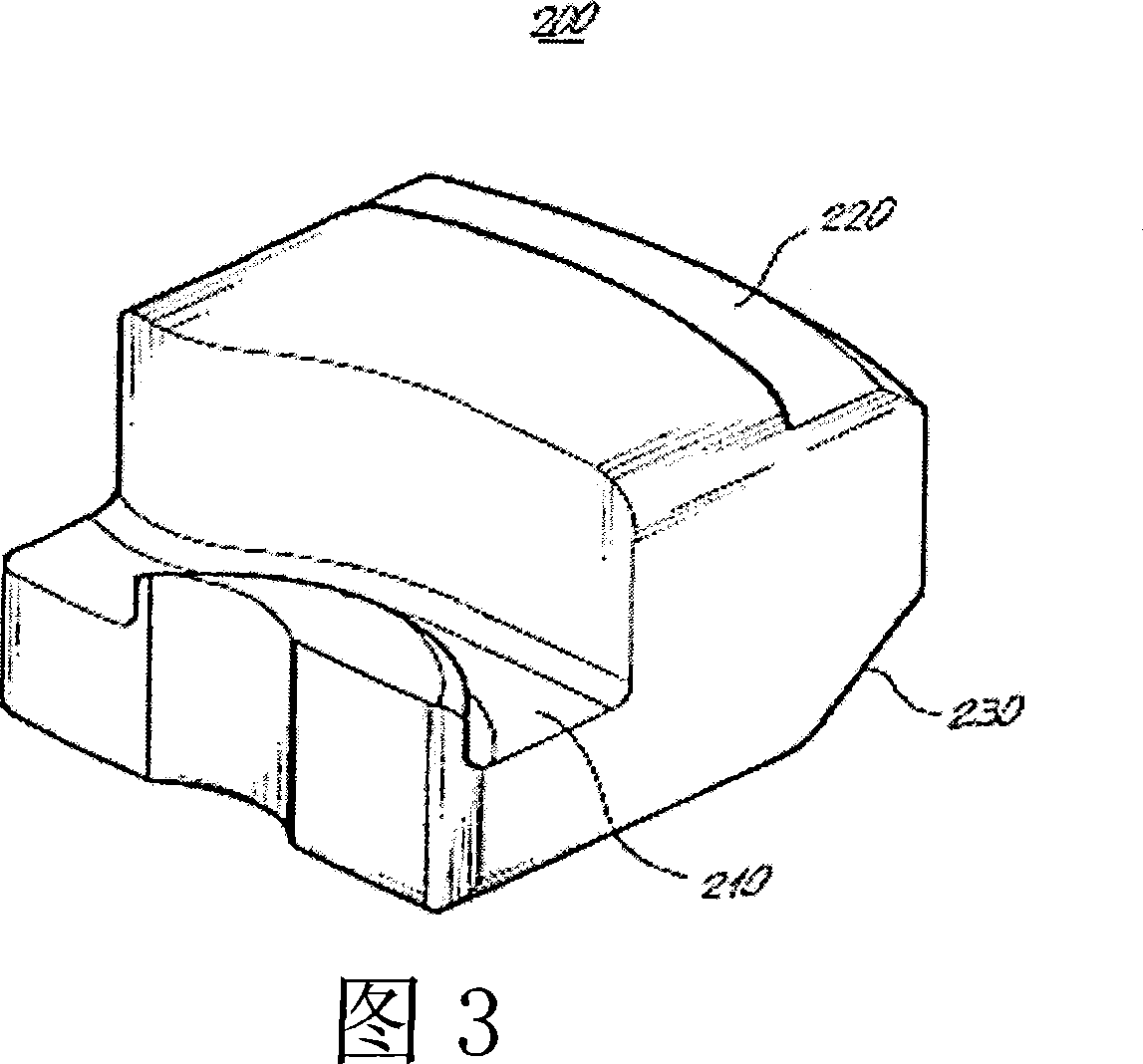

A drilling apparatus having in-line extending wings and driving method thereof

InactiveCN101010481AEasy loadingEasy to unfoldDrill bitsReciprocating drilling machinesEngineeringMechanical engineering

The present invention relates to a borehole drilling apparatus with in-line extending wings and driving method thereof. The drilling apparatus comprises a guide device rotating while moving upwardly and downwardly in a casing to fit into aborehole, extending wings for extending the diameter of adriUedhole, the pilot bit linking the lower portion of the guide deviceto strike the bottom of the borehole, wherein spiral projections formed at a lower surface of the guide device slidably engage with guide grooves formed at a side of the extending wings to each other, and a window is formed at a side of the pilot bit for advancing and retracting the extending wings so that they can spread and return linearly from the center of the pilot bit.

Owner:林秉德

Separable residual plastic film recovery device of straw returning machine

PendingCN110495267ASolve the problem of power mismatchAvoid cloggingCuttersGatherer machinesEngineeringPlastic film

The invention relates to the technical field of agricultural residual plastic film recovery machines, and discloses a separable residual plastic film recovery device of a straw returning machine. Theseparable residual plastic film recovery device comprises a film collecting machine body and a separable straw returning device which is located at the front end of the film collecting machine body. The straw returning device comprises a returning rack, a returning gearbox and a straw smashing device with a flailing knife. The separable residual plastic film recovery device is reasonable and compact in structure and convenient to use; the separable residual plastic film recovery device is connected with the straw returning device through a returning connecting frame, a film collecting connecting frame and adjusting pull rods and can be conveniently separated from the straw returning device. Convenience is brought for a user to a select a tractor with large horsepower or medium horsepower for work, and the problem that power of a tractor and power of a residual plastic film recovery device are not matched is effectively solved. Besides, by forming impurity removal holes and replacing chain wheels with pulleys, the equipment can solve the problem of chain hole blockage caused by residual plastic film so that a spike tooth chain belt can efficiently and continuously work, the applicability is high, the residual film recovery effect is good, the equipment work efficiency is high, and the separable residual plastic film recovery device has the advantages of being safe, capable of saving labor, simple, convenient to use and efficient.

Owner:张朝书

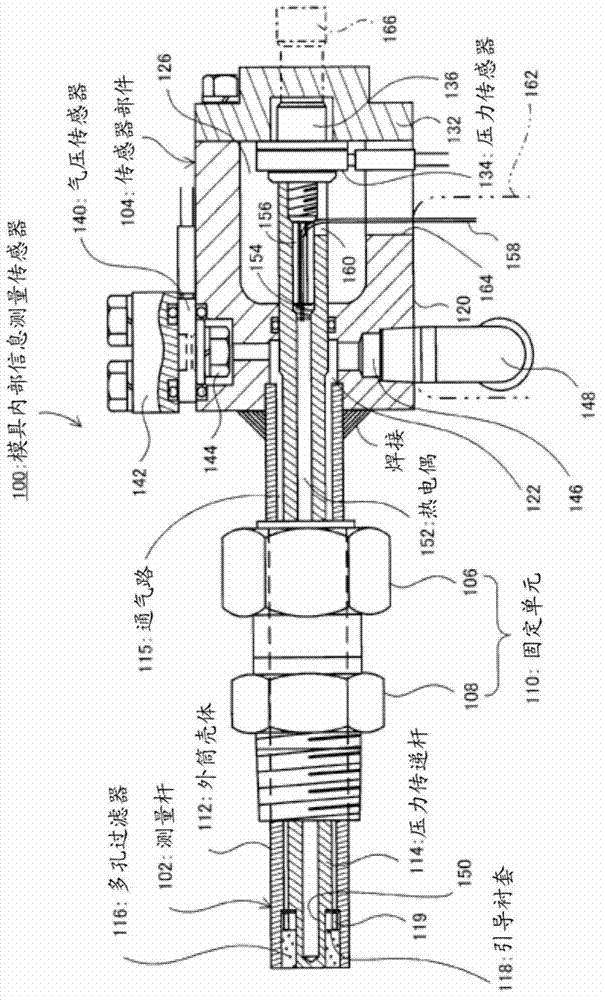

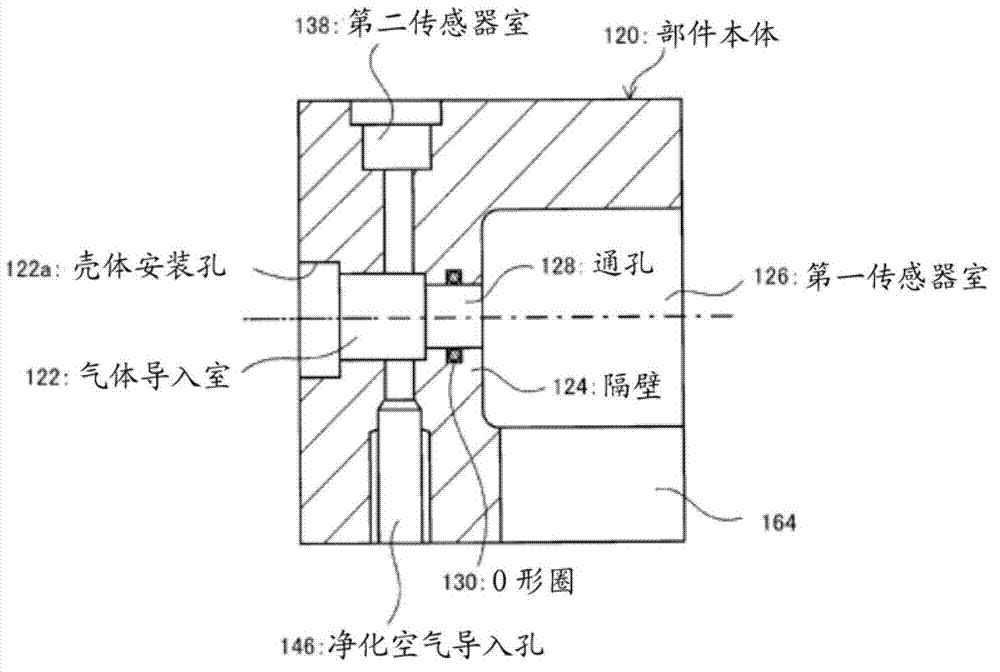

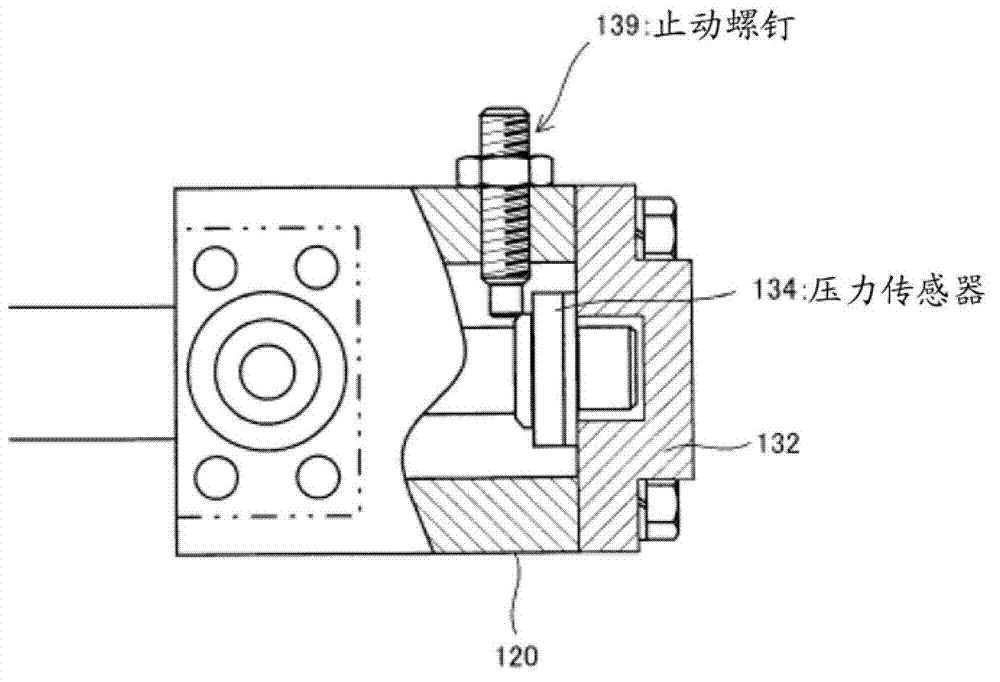

Measurement sensor for information regarding inside of mold

InactiveCN102892532AMonitor pressure drop rateMonitoring Quality ManagementFoundry mouldsFoundry coresPressure transmissionDie casting

Disclosed is a sensor which detects information from a die-casting mold and which determines the quality of a molded product. The sensor detects the gas pressure within a cavity by being provided with: a rod-shaped casing which can be attached to an attachment hole that is drilled on a molding die and that opens to the cavity; a porous filter which is disposed on the tip of the rod-shaped casing, has a tip surface that can conform to the mold cavity surface, and which can separate gas from a melt; an introduction chamber to which the cavity gas is introduced from the porous filter; and a gas pressure sensor which detects the pressure within the gas introduction chamber. The sensor detects the melt pressure within the cavity by being provided with: a pressure transmission rod which is inserted into the rod-shaped casing, can move along the axial direction thereof, and has a tip surface that can conform to the mold cavity surface; and a pressure sensor which faces the rear end of the pressure transmission rod and is fixed and held thereto. Moreover, the sensor detects the melt temperature within the cavity by being provided with a temperature sensor which is attached to a small hole formed on the center of the pressure transmission rod, and which comprises a thermocouple that has a detecting end disposed on the small hole on the side of the tip of the rod.

Owner:DIRECT 21

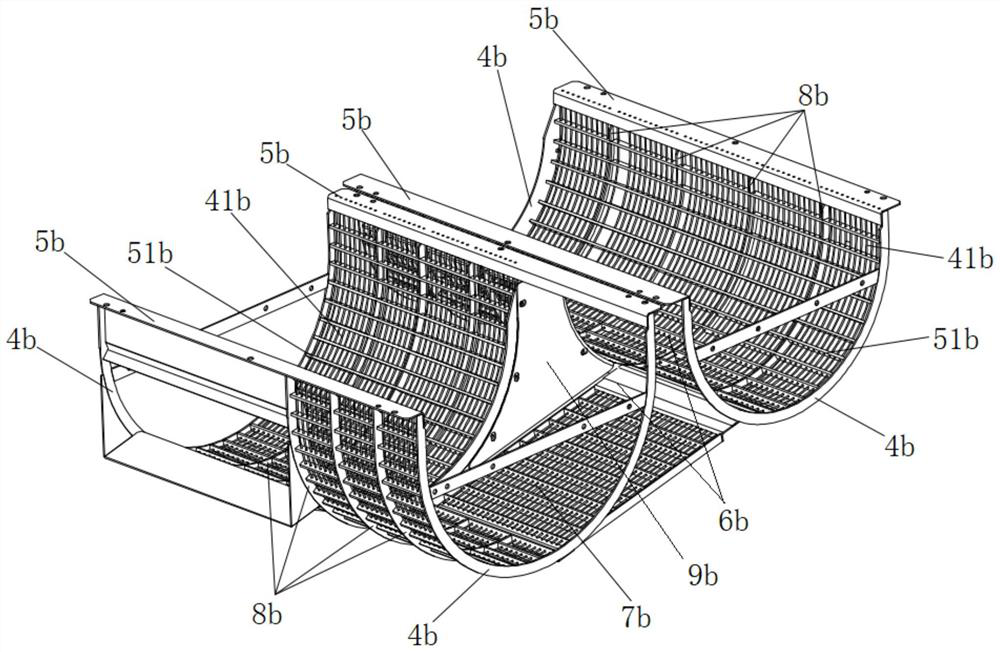

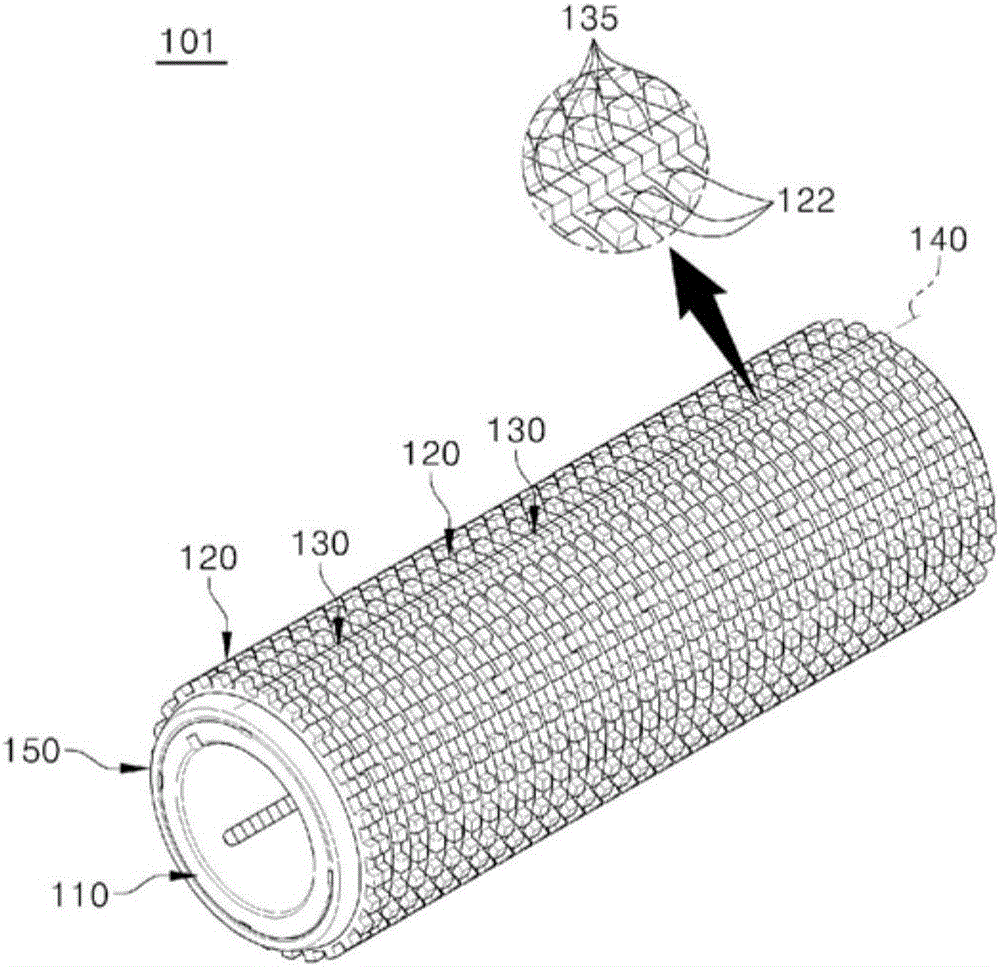

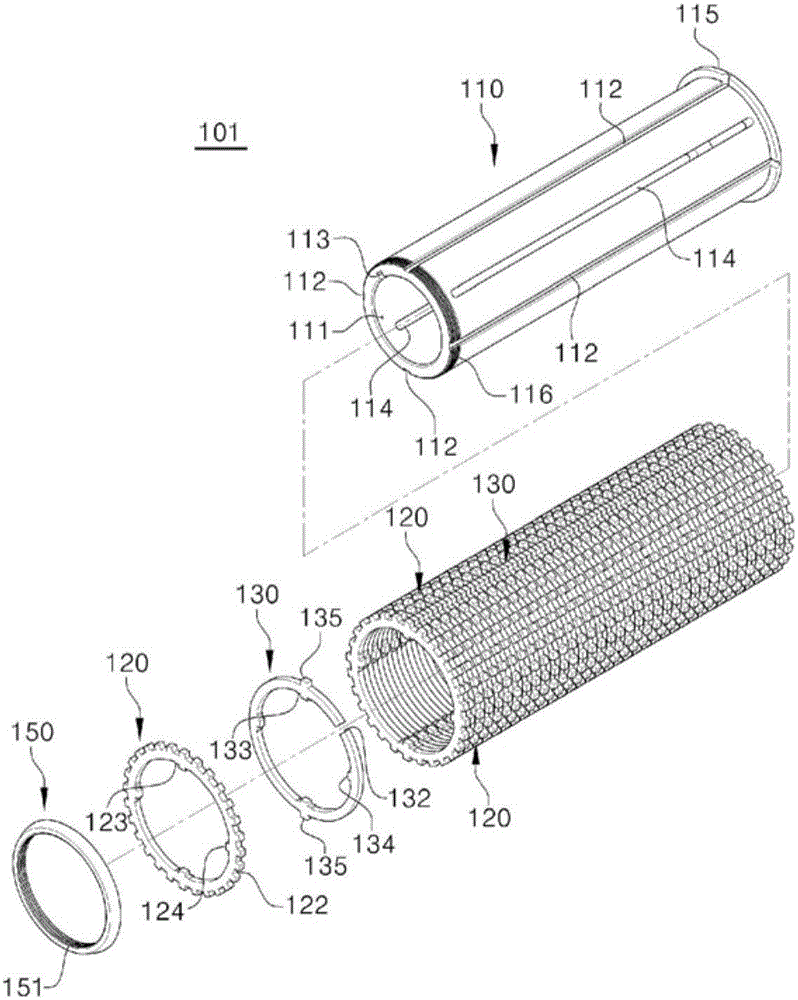

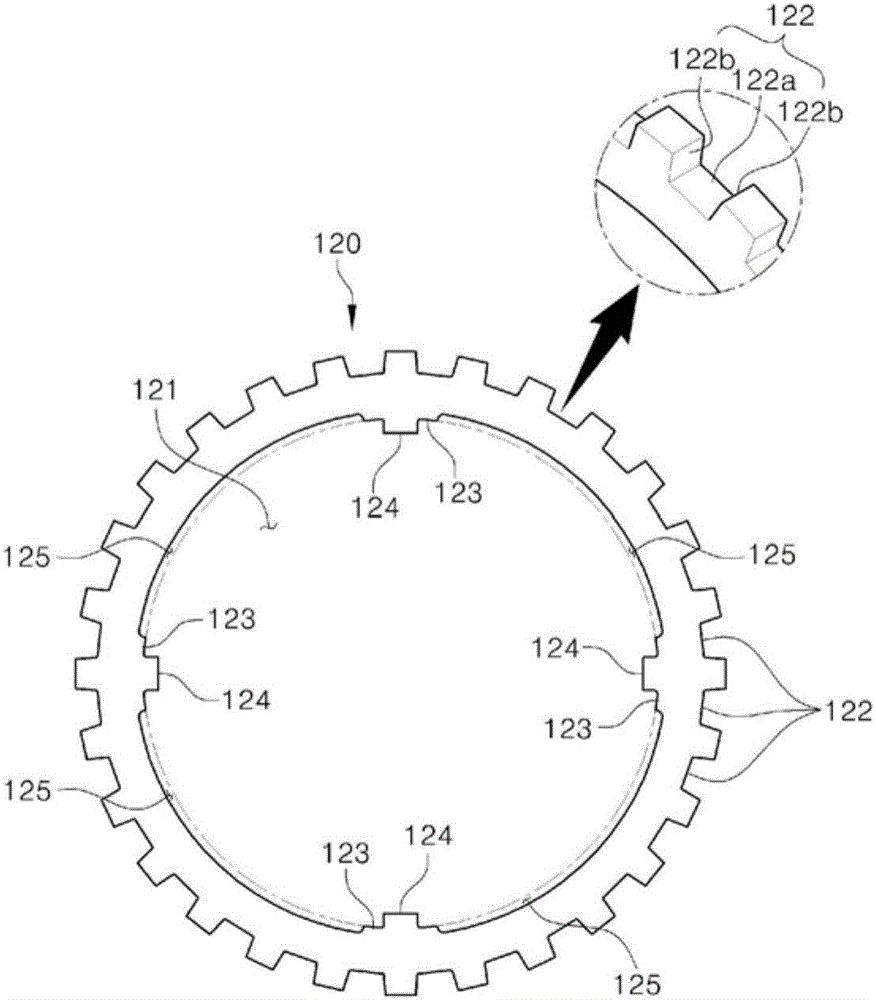

Cutting ring assembly for rice mill

InactiveCN106457253APressurized delivery is effectiveWon't breakGrain huskingGrain polishingEngineeringRice grain

The present invention relates to a cutting ring assembly for a rice mill in which a spacing ring including at least one or more inducing protrusions is alternately disposed between cutting rings to smoothly and forcibly transfer rice grains in the direction of a discharge hole of the rice mill without damaging the rice grains. The cutting ring assembly for the rice mill according to the present invention includes a support shaft having a hollow cylindrical shape and in which at least one key groove is formed in each of an inner circumferential surface and an outer circumferential surface in a longitudinal direction, a plurality of cutting rings coupled to the support shaft, and a plurality of spacing rings coupled to the support shaft and disposed between the cutting rings. Also, the cutting rings have a ring shape having a predetermined thickness and a plurality of channel-shaped cutting passages, which connect both side surfaces of the ring to each other so that rice bran is cut while the rice grains pass therethrough, in an outer circumferential surface thereof, and a key groove connection protrusion formed in an inner circumferential surface thereof is inserted and coupled to the key groove formed in the outer circumferential surface of the support shaft. Also, the spacing rings have a ring shape having a predetermined thickness and includes at least one inducing protrusion in an outer circumferential surface of the spacing ring, and a key groove connection protrusion formed in an inner circumferential surface of the spacing ring is inserted and coupled to the key groove formed in the outer circumferential surface of the support shaft.

Owner:セノンテックリミテッド

Crawler type shot blasting device

InactiveCN105690275AImprove processing efficiencyHigh degree of automationAbrasive machine appurtenancesAbrasive blasting machinesMechanical engineeringSand separator

A crawler type shot blasting device comprises a shot blasting chamber. A shot blasting unit is arranged above the shot blasting chamber. The shot inlet of the shot blasting unit is connected with the shot outlet of a shot-sand separator. A steel crawler which transversely inclines is arranged in the shot blasting chamber. An inlet rotary drum and an outlet rotary drum which are coordinated with the steel crawler to convey shot are arranged on two sides of the shot blasting chamber. The shot blasting device further comprises a shot blasting chamber angle adjusting mechanism. The shot blasting chamber angle adjusting mechanism comprises a support and a worm gear and worm mechanism above the support, an inner thread is machined on the worm gear central hole of the worm gear and worm mechanism, a connecting support block is connected to a screw matched with the worm gear in a threaded manner, and the shot blasting chamber is located on the connecting support block. The shot blasting device is good in operation efficiency, good in operation environment, time saving and labor saving.

Owner:SHANDONG KAITAI SHOT BLASTING MACHINERY

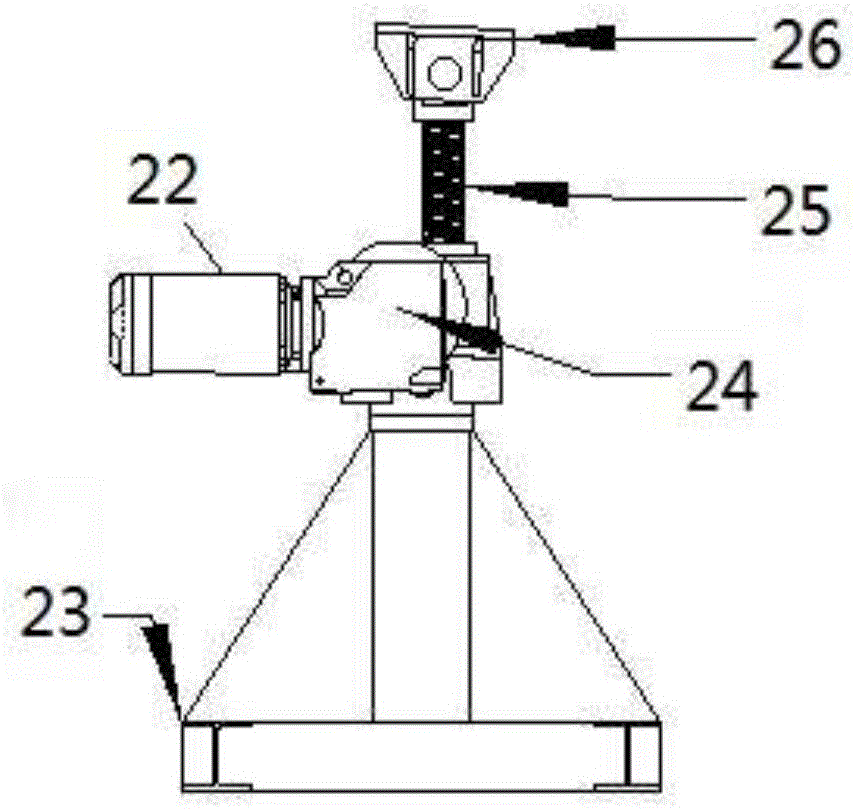

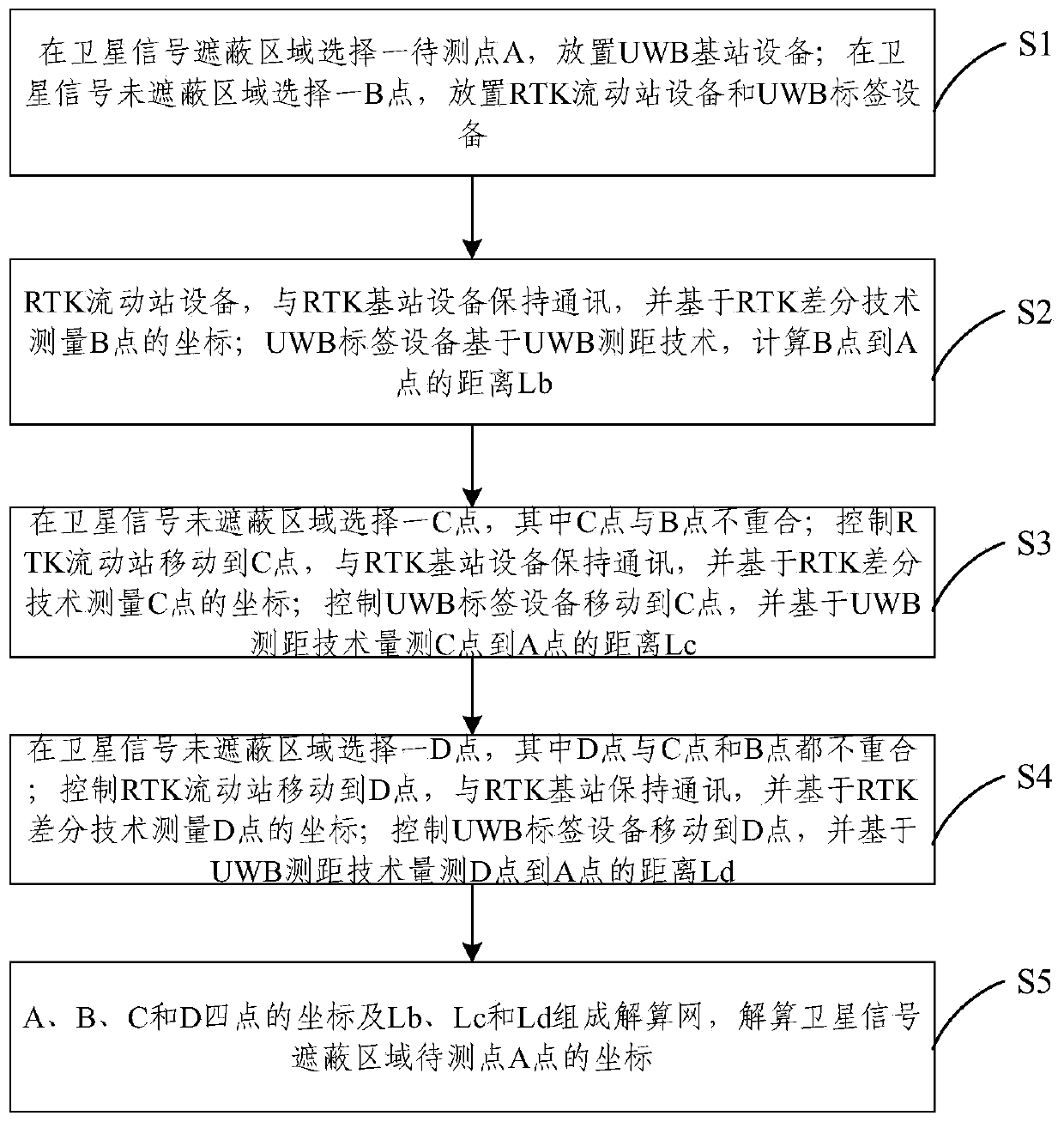

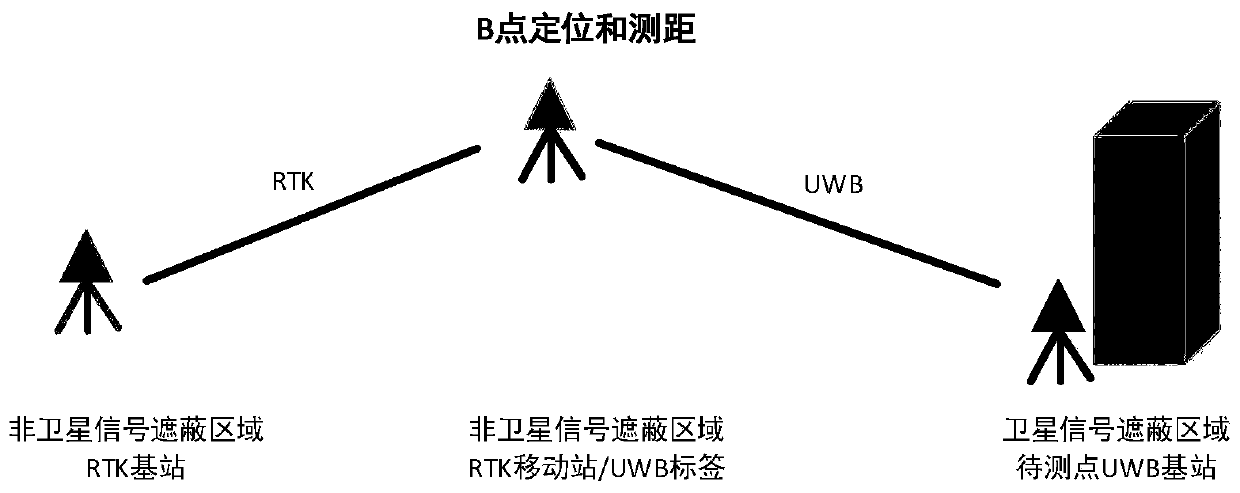

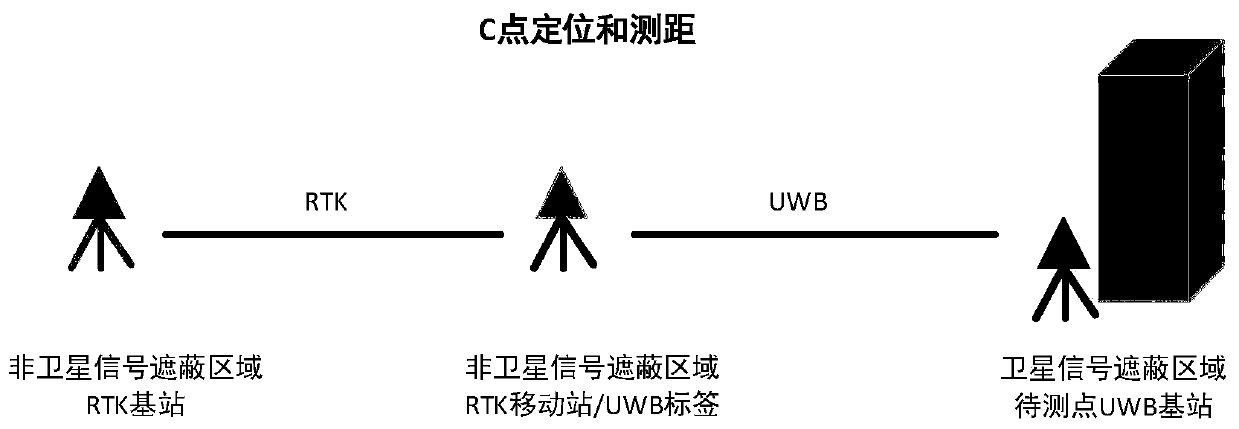

RTK/UWB combined mapping method and system for satellite signal shielding area

InactiveCN110554418ASolve mapping problemsGood working efficiencySatellite radio beaconingUsing reradiationSatelliteAutomation

The embodiment of the invention provides an RTK / UWB combined mapping method and system for a satellite signal shielding area. According to the method, high-precision coordinates can be measured by using an RTK positioning mode; for the satellite signal shielding area, point position coordinates of three or more non-satellite signal shielding areas can be obtained by utilizing an RTK technology; then, the distances from RTK positioning points to to-be-solved points in a satellite signal shielding area are measured through the UWB distance measuring technology, and according to the coordinates of the RTK positioning points and UWB distance measuring information, networking can be conducted to solve the coordinates of the to-be-solved points (more than three RTK point position time adjustmentsolving coordinates); the embodiment of the invention has the advantages that the RTK mapping problem of the satellite signal shielding area is solved, the mapping precision is high, the operation efficiency is obviously superior to that of other methods, and meanwhile, the method is easy to practice, simple to operate and relatively high in automation degree.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

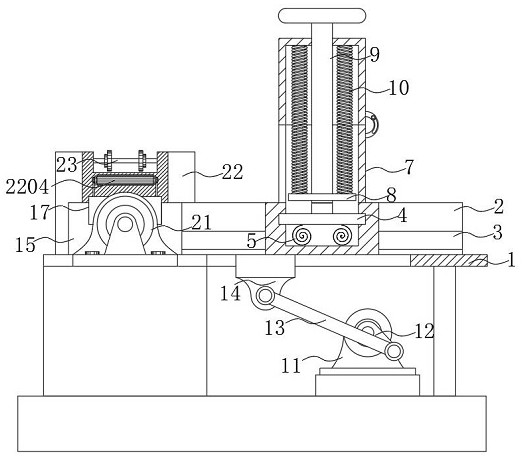

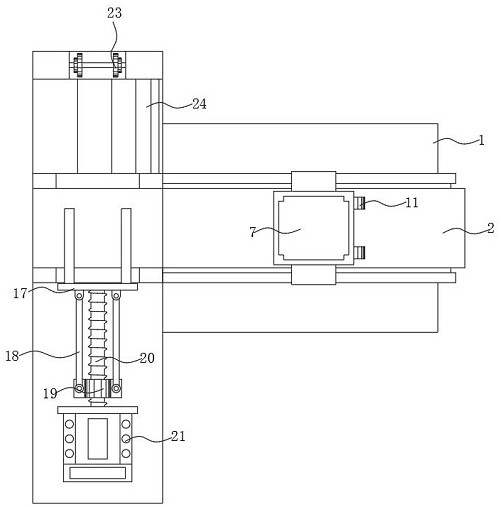

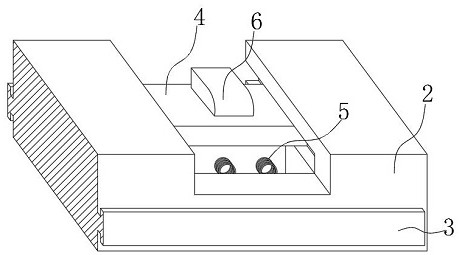

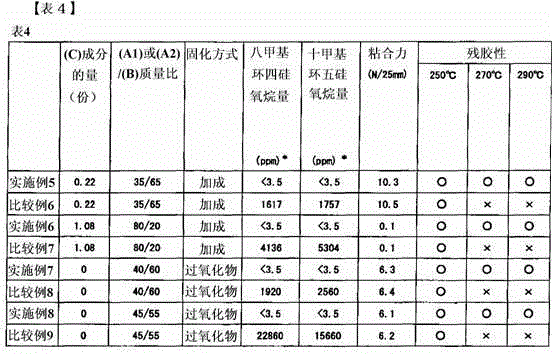

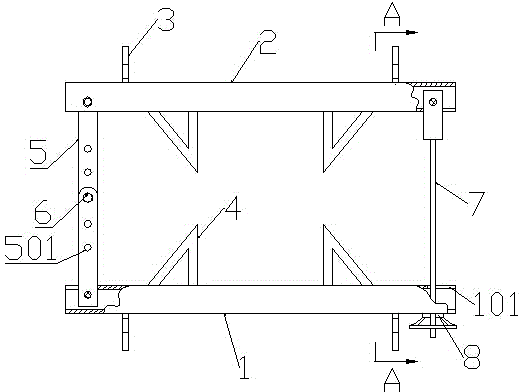

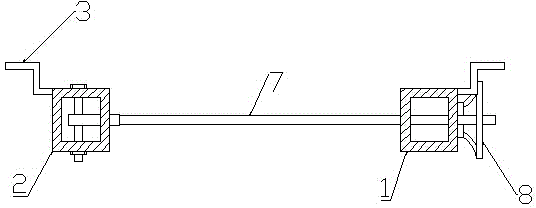

Wireless charger coil provided with automatic winding production processing equipment

InactiveCN112260409AGood for work efficiencyAvoid CatonTransformersCircuit arrangementsElectric machineryWinding machine

The invention discloses a wireless charger coil provided with automatic winding production processing equipment. The wireless charger coil comprises a supporting frame, wherein a flow guide base is installed on the upper surface of the supporting frame, a control motor is installed at the bottom of the supporting frame, an operation table is arranged at the end of the left side of the supporting frame, an adhesive tape winding machine is arranged on the surface, opposite to a pressing and pushing plate, of the operation table, and a discharge port is formed below bottom of the finished surfaceof the adhesive tape winding machine. According to the invention, a clamping and pushing plate and a feeding bin are arranged on the left side and the upper surface of a flow guide base, and a coil bottom support is installed in the flow guide base, so that a coil in the feeding bin can be conveniently pushed into the clamping and pushing plate; and the clamping and pushing plate and the adhesivetape winding machine are oppositely arranged, so that the coil is conveniently pushed into the adhesive tape winding machine to be wrapped, the situation that one device is provided with one worker is avoided so as to reduce personnel operation and inconvenience during coil installation, and the working efficiency of coil wrapping is improved.

Owner:深圳市辉迪机电科技有限公司

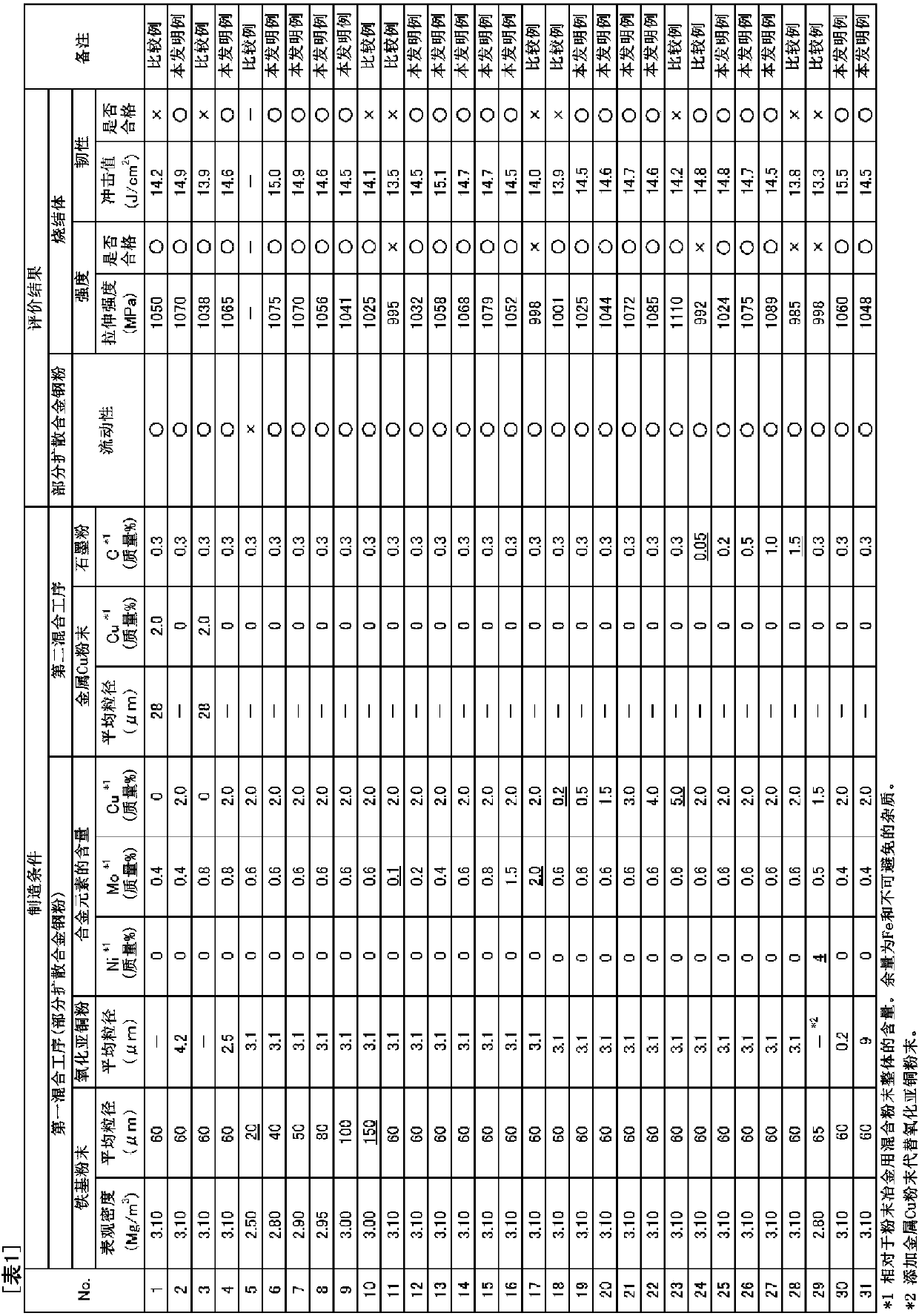

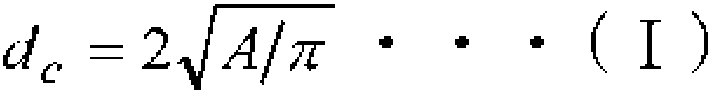

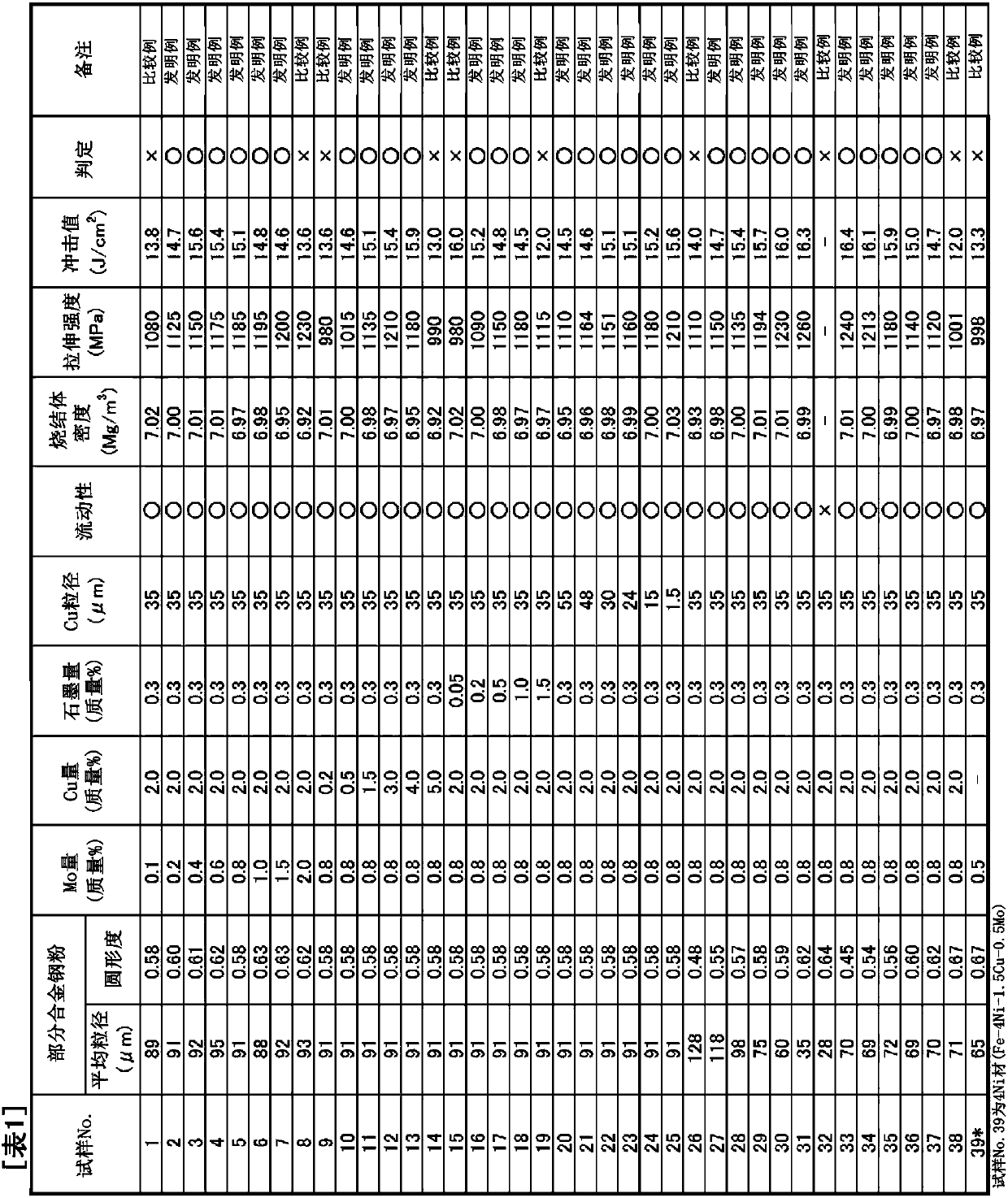

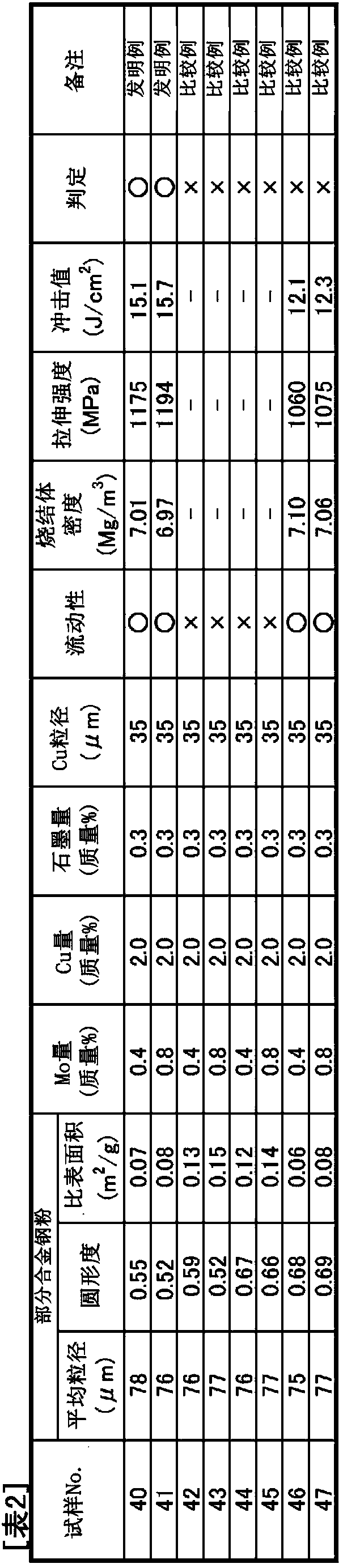

Method for producing mixed powder for powder metallurgy, method for producing sintered compact, and sintered compact

ActiveCN107921531AImprove liquidityHigh strengthTransportation and packagingMetal-working apparatusGraphiteUltimate tensile strength

Provided is a mixed powder for powder metallurgy with which it is possible to obtain a sintered compact that, despite not containing Ni, has an excellent tensile strength and ductility equivalent to or better than those of a sintered compact containing Ni. This method for producing a mixed powder for powder metallurgy includes: a first mixing step, in which a starting material mixed powder is obtained by mixing a Mo-containing powder and a Cu-containing powder into an iron-based powder; a diffusion / adhering step, in which a partially-diffused alloyed steel powder is obtained by diffusing and adhering the Mo and Cu onto the surface of the iron-based powder by heat-treating the starting material mixed powder; and a second mixing step, in which the mixed powder for powder metallurgy is obtained by mixing a graphite powder into the partially-diffused alloyed steel powder. The average grain diameter of the iron-based powder is 30-120 [mu]m. A cuprous oxide powder is used as the Cu-containing powder. The component composition of the mixed powder for powder metallurgy is 0.2-1.5 mass% Mo, 0.5-4.0 mass% Cu, and 0.1-1.0 mass% C, with the remainder comprising Fe and unavoidable impurities.

Owner:JFE STEEL CORP

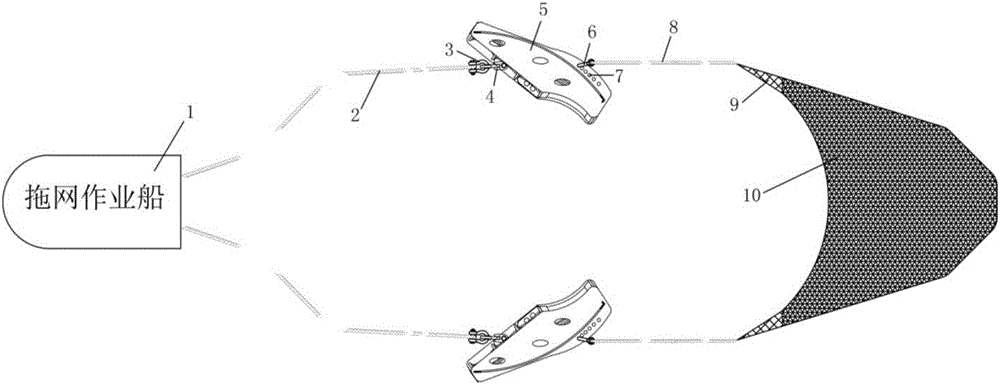

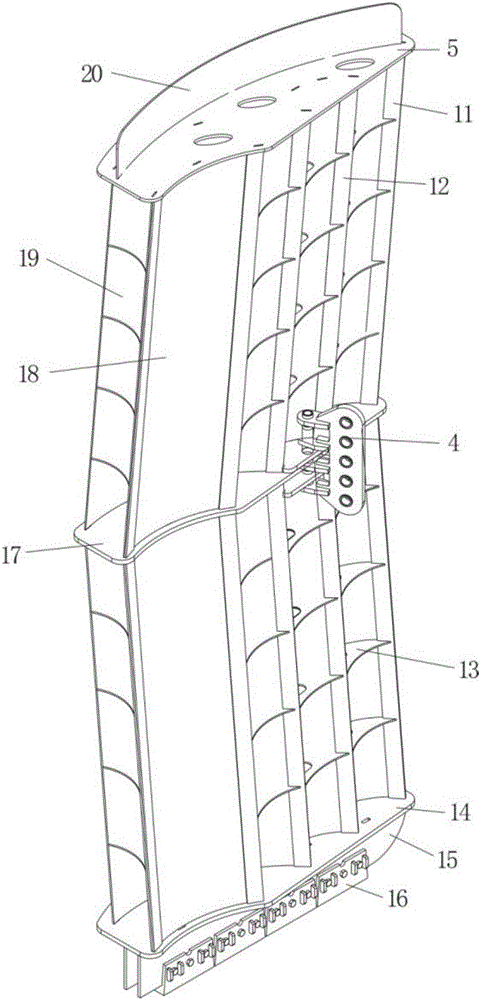

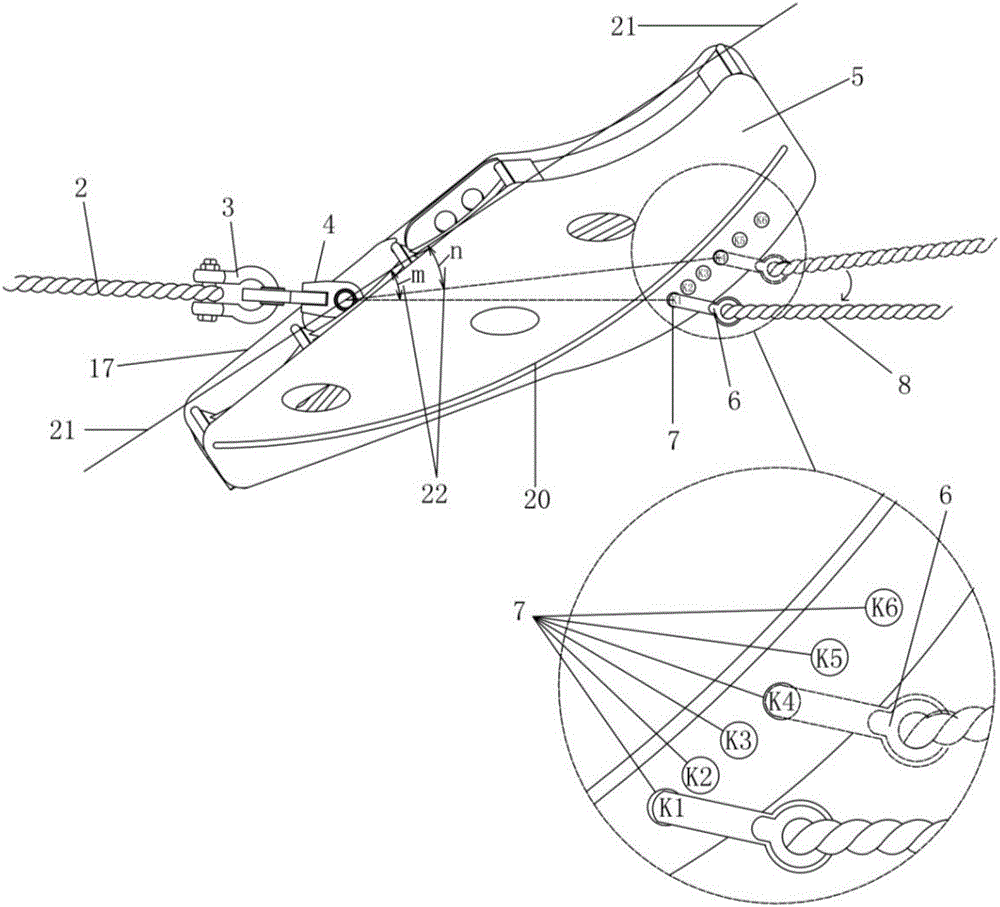

Method for adjusting work attack angle of euphausia superba dragnet horizontal expanding device

ActiveCN105766819AChanging the working water depthAdjustable horizontal expansion forceFishing netsEngineeringEuphausia

A method for adjusting the work attack angle of a euphausia superba dragnet horizontal expanding device adopts a V-shaped cambered surface net plate. The V-shaped cambered surface net plate is characterized in that the aspect ratio of the V-shaped cambered surface net plate is larger than or equal to 2.7, a steel warp pull plate is welded to a middle steel warp plate between a rear diversion plate and a rear main panel, five longitudinally-arrayed steel warp pull holes are formed in the steel warp pull plate, one is selected from the five steel warp pull holes to be connected with steel warp and used for adjusting the tension angle of the net plate, adjusting the inside and outside inclination state of the device in water and changing the working water depth of the horizontal expanding device, the steel warp pull plate is connected with the steel warp through a steel warp detaching buckle, six cross rope pull holes are formed in the rear side of an upper cross rope plate of the V-shaped cambered surface net plate, six cross rope pull holes are correspondingly formed in the rear side of a lower cross rope plate, and an upper cross rope and a lower cross rope of a net sleeve manrope of a dragnet of a trawler are connected with the cross rope pull holes, with corresponding sequencing numbers, of the upper cross rope plate and the lower cross rope plate through cross rope detaching buckles respectively, so the work attach angle is adjusted. The method is suitable for a low-dragging-speed euphausia superba dragnet.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Standing corn stalk front-mounted crushing return-to-field machine

The invention discloses a standing corn stalk front-mounted crushing return-to-field machine, and belongs to the agricultural machinery. The machine mainly comprises a right spiral clamping roller anda left spiral clamping roller which are vertically arranged and opposite in rotation direction, during the process of the right and left spiral clamping rollers holding standing corn stalks to a crushing knife roll assembly on the rear side, while the upper sides of the right and left spiral clamping rolls continuously conduct inclining actions to the rear side, and the left spiral clamping roller also performs lateral reciprocating motion to increase the distance between the left spiral clamping roller and the right spiral clamping roller, which not only improves the clamping and conveying effect on the standing corn stalks, but also avoids the winding and blocking of the clamping rollers caused by the corn stalks. The machine has the advantages of novel structure, reasonable structure,high work efficiency, good work quality, reliable use and strong adaptability.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Mixed powder for powder metallurgy, sintered body, and method of manufacturing sintered body

ActiveCN108025357AImprove liquidityGood working efficiencyTransportation and packagingMetal-working apparatusPowder metallurgyCarburizing

Provided is a mixed powder for powder metallurgy, which, while having a constituent composition that does not contain Ni, a cause of non-uniformity in the metal structure of sintered compacts, and theleading factor behind increased costs of alloy powders, makes it possible to achieve components by sintering compacts of alloyed steel powder, and subsequently subjecting the compacts to carburizing,quenching and tempering, said components having equivalent or superior mechanical properties to components to which Ni has been added. The mixed powder contains a partially diffused alloyed steel powder obtained by diffusion-deposition of Mo on the particle surface of an iron-based powder, in addition to Cu powder and graphite powder. The mixed powder has a constituent composition containing 0.2-1.5 mass% Mo, 0.5-4.0 mass% Cu, and 0.1-1.0 mass% C, with the remainder being made up of Fe and unavoidable impurities, and the partially diffused alloyed steel powder has an average particle diameterof 30-120 [mu]m and a specific surface area of less than 0.10 m2 / g, and the degree of circularity of particles having a diameter of 50-100 [mu]m does not exceed 0.65.

Owner:JFE STEEL CORP

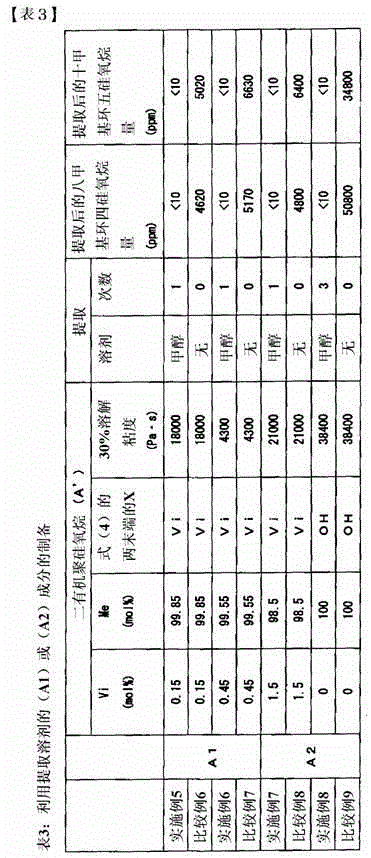

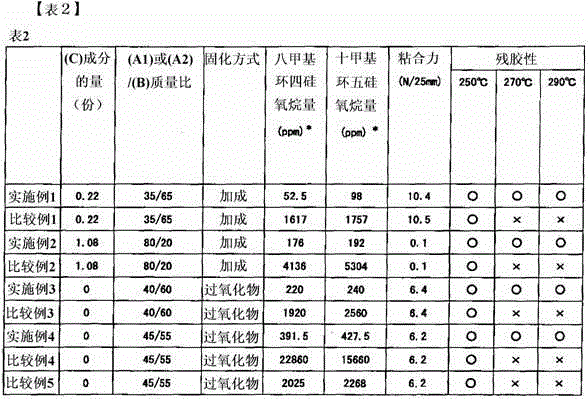

Silicone adhesive composition, method for making the same and adhesive film

InactiveCN104946194AReduce movementLess cleaningFilm/foil adhesivesThin material handlingAntioxidantSilicone adhesive

A purpose of the present invention is to provide a silicone adhesive composition which comprises no antioxidant, has sufficient adhesive and tack properties, has excellent heat resistance and which, in tested use, leaves no adhesive residue. Another purpose is to provide adhesive film and tape having a cured layer obtained from the composition. The invention provides an addition curable or peroxide curable silicone adhesive composition, wherein the addition curable silicone adhesive composition comprises (A1) a diorganopolysiloxane having an alkenyl group and a viscosity at 25 degrees C of 100,000 mPa·s or more, (B) an organopolysiloxane having R 1 3 SiO 0.5 units and SiO 2 units, wherein R 1 is a substituted or unsubstituted, monovalent hydrocarbon group having 1 to 10 carbon atoms, (C) an organohydrogenpolysiloxane having at least three SiH groups, (D) optionally an addition reaction inhibitor, (E) a platinum group metal catalyst for an addition reaction, and (F) an organic solvent, and the peroxide curable silicone adhesive composition comprises (A2) a diorganopolysiloxane having a viscosity at 25 degrees C of 100,000 mPa·s or more and may or may not have an alkenyl group, (B) an organopolysiloxane having R 1 3 SiO 0.5 units and SiO 2 units, wherein R 1 is a substituted or unsubstituted, monovalent hydrocarbon group having 1 to 10 carbon atom, (F) an organic solvent, and (G) an organic peroxide, and components (A1) and (A2) may be accompanied with octamethylcyclotetrasiloxane and / or decamethylcyclopentasiloxane and each content of octamethylcyclotetrasiloxane and decamethylcyclopentasiloxane is less than 0.1 mass %, based on a total amount of component (A1) or (A2), component (B) and octamethylcyclotetrasiloxane and decamethylcyclopentasiloxane.

Owner:SHIN ETSU CHEM IND CO LTD

Cross-arm bracket and method for replacing cross arm through employing same

InactiveCN105490203AReduce labor intensitySimple structureCable installation apparatusScrew threadSteel tube

The invention discloses a cross-arm bracket and a method for replacing a cross arm through employing the same. The cross arm bracket comprises two square steel tubes, and the square steel tubes are provided with a leaning frame. The inner side of each square steel tube is provided with a left jacking frame and a right jacking frame, and corresponding ends of the two square steel tubes are hinged to an upper connection plate and a lower connection plate, which are arranged in a staggered manner, and are provided with a plurality of connection position adjustment holes. The interiors of upper and lower adjustment holes are provided with connection bolts and nuts, and the other sides of the two square steel tubes are provided with screws. The rear ends of the screws are hinged to the rear square steel tube, and one end, corresponding to the screws, of the front square steel tube is provided with gaps. The front parts of the screws are inserted into the gaps, are provided with threads, and are provided with locking nuts through the threads. The distance between the two square steel tubes, corresponding to the end, is adjusted through the locking nuts. The bracket is simple in structure, is convenient to disassemble, is high in work efficiency, is low in labor intensity, is high in safety factor, and can be operated by one person on a rod.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com