Measurement sensor for information regarding inside of mold

A technology for measuring sensors and internal information, applied in the configuration of indicating equipment/measuring equipment, manufacturing tools, casting and molding equipment, etc., can solve problems such as difficult measurement of vacuum degree, achieve high operating efficiency, reduce installation costs, and reduce operating time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

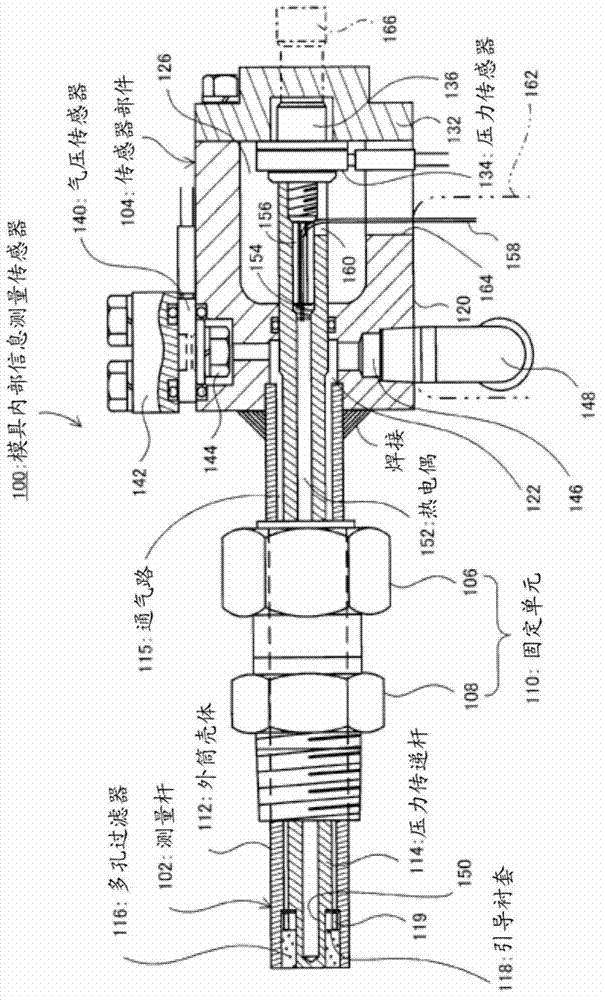

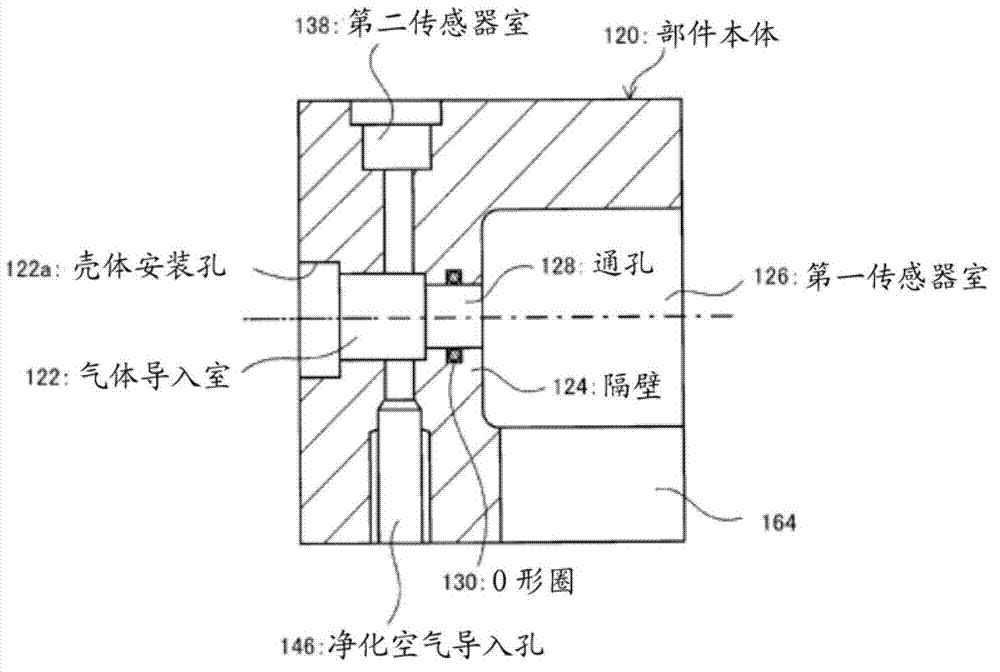

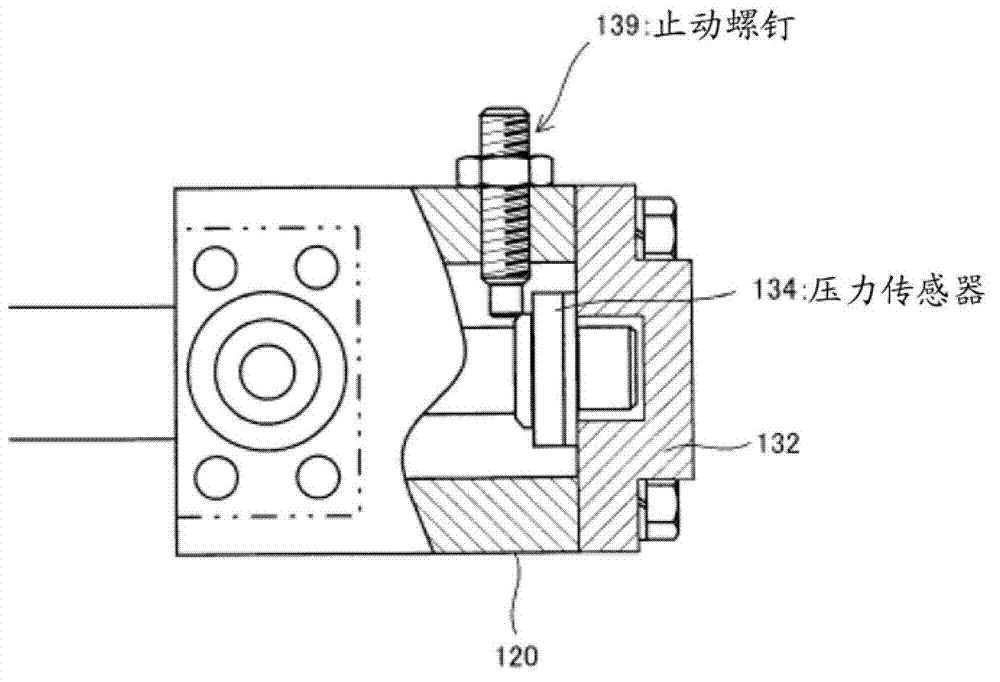

[0042] Embodiments of the sensor for measuring the internal information of the mold of the present invention will be described in detail below with reference to the accompanying drawings.

[0043] Figure 1~Figure 5 Representing the mold internal information measuring sensor 100 of the first embodiment, figure 1 is a vertical cross-sectional view of the mold internal information measurement sensor 100, figure 2 is a sectional view of the sensor part body, image 3 is a partial cut-away top view of the sensor component, Figure 4 yes figure 1 right side view of the , Figure 5 It is a schematic sectional view showing the state of being mounted on a mold.

[0044] The mold internal information measurement sensor 100 of this first embodiment can be mounted on the movable mold 1 a (or the fixed mold 1 b ) of the mold. Therefore if Figure 5 As shown, the movable casting mold 1a is perforated to provide mounting holes 8 reaching the mold cavity 2 from the back thereof. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com