Crawler type shot blasting device

A processing device and crawler-type technology, applied in the direction of used abrasive processing devices, abrasives, metal processing equipment, etc., to achieve the effects of improving efficiency, ensuring quality, and prolonging the passing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

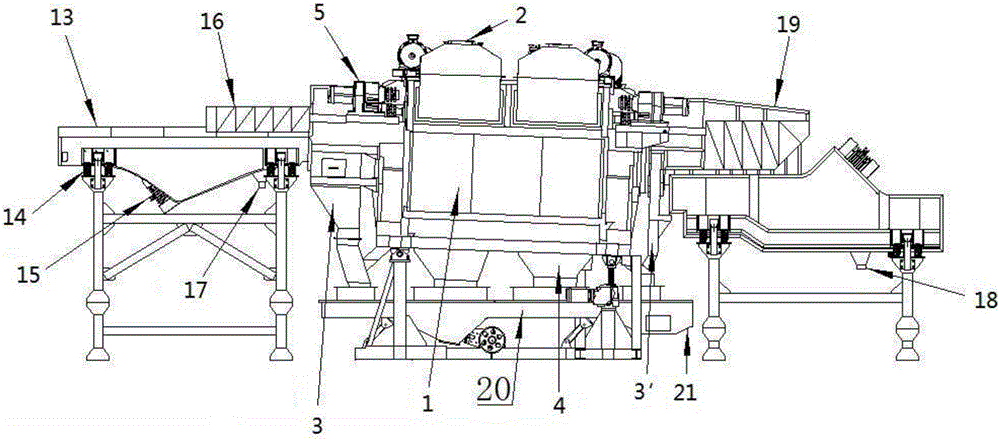

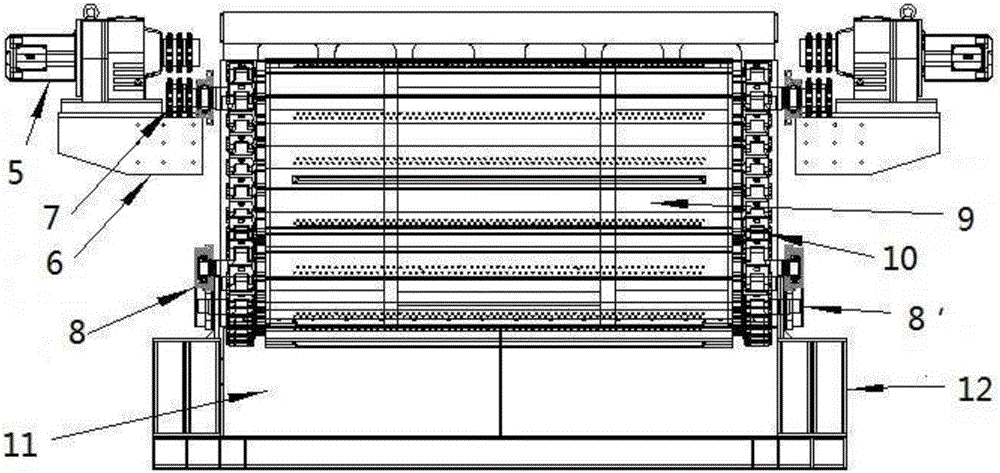

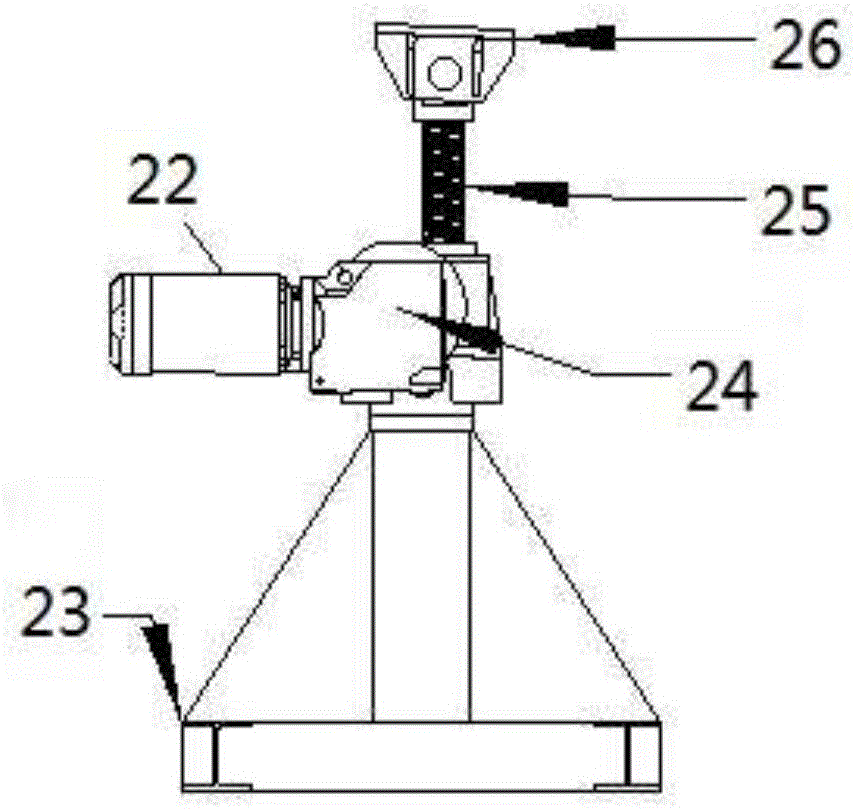

[0016] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. The invention discloses a crawler-type shot blasting treatment device with continuously passing workpieces and adjustable shot blasting chamber angle. Circulation system, pellet and sand separator, dust removal system and observation and maintenance platform.

[0017] Shot blast chamber (see figure 1 and figure 2 ), including chamber door 1, air outlet 2, front sealing device 3, rear sealing device 3', shot bucket 4, crawler motor 5, motor base 6, driving chain shaft 7, inlet roller 8, and outlet roller 8', Steel track 9, chain 10, shot chamber 11, base 12. The drive chain shaft 7 is driven by the crawler motor 5 to rotate, and the drive chain shaft 7 drives the two driven chain shafts to rotate, thereby driving the steel crawler belt 9 to rotate. The workpiece coming in from the inlet drum 8 rolls and advances on the steel track 9, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com