Patents

Literature

256 results about "Sand separator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

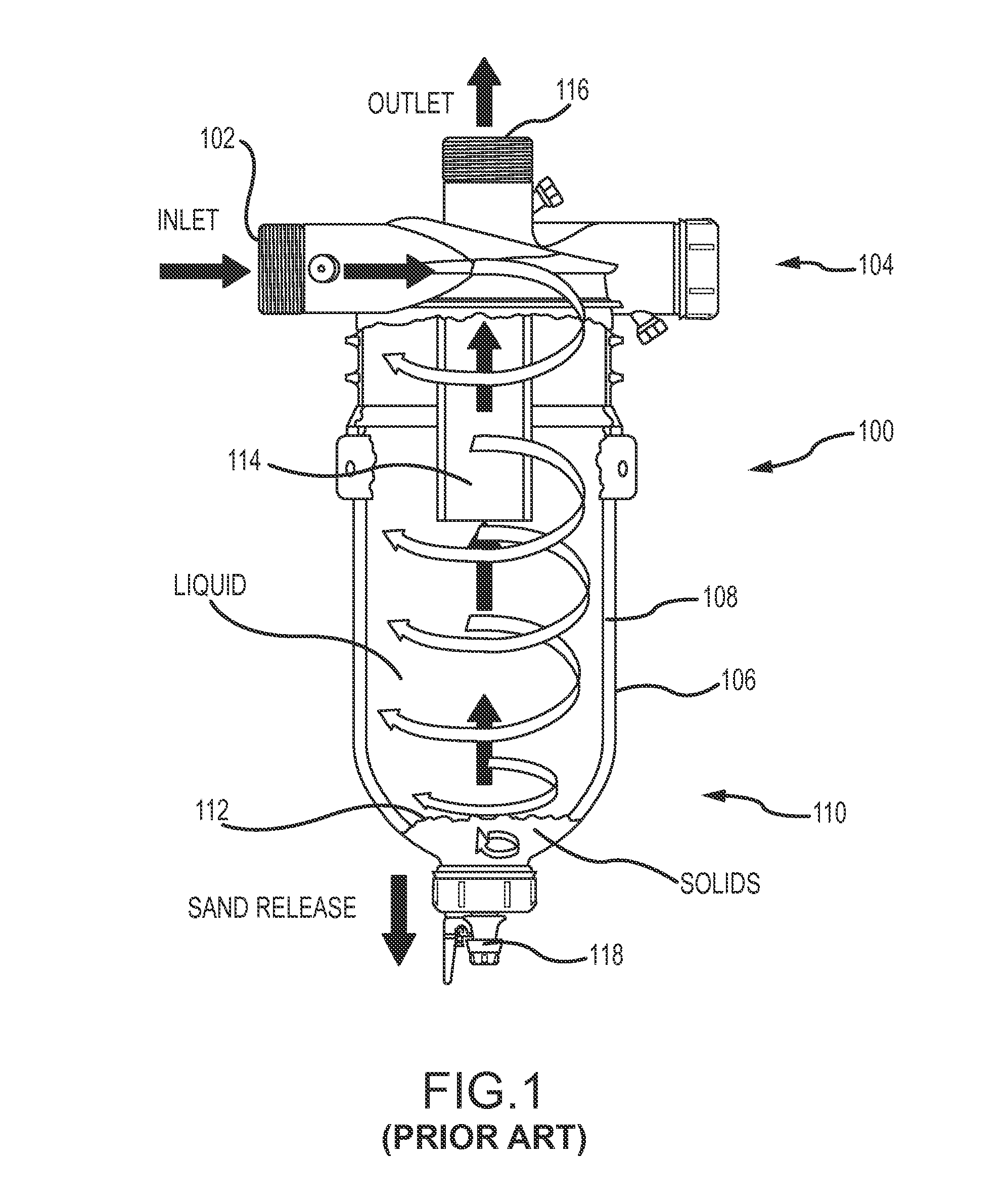

A sand separator is a device that separates sand or other solids from water. One version of sand separator utilizes centrifugal force to separate sand or other heavy particles out of the water. The separated material drops down into a tank or reservoir where it can be removed later or in the case of in-well separators, the separated sand drops into the bottom of the well. It is not a true filter, since there is no physical barrier to separate out the particles, but it is often used upstream of a filter to first remove the bulk of the contaminant, where the filter does the final cleaning. This type of design reduces the time required to flush and clean the filter.

Spherical sand separators

ActiveUS7785400B1Shorten speedPromote resultsCombination devicesLiquid degasificationInterior spaceProcess engineering

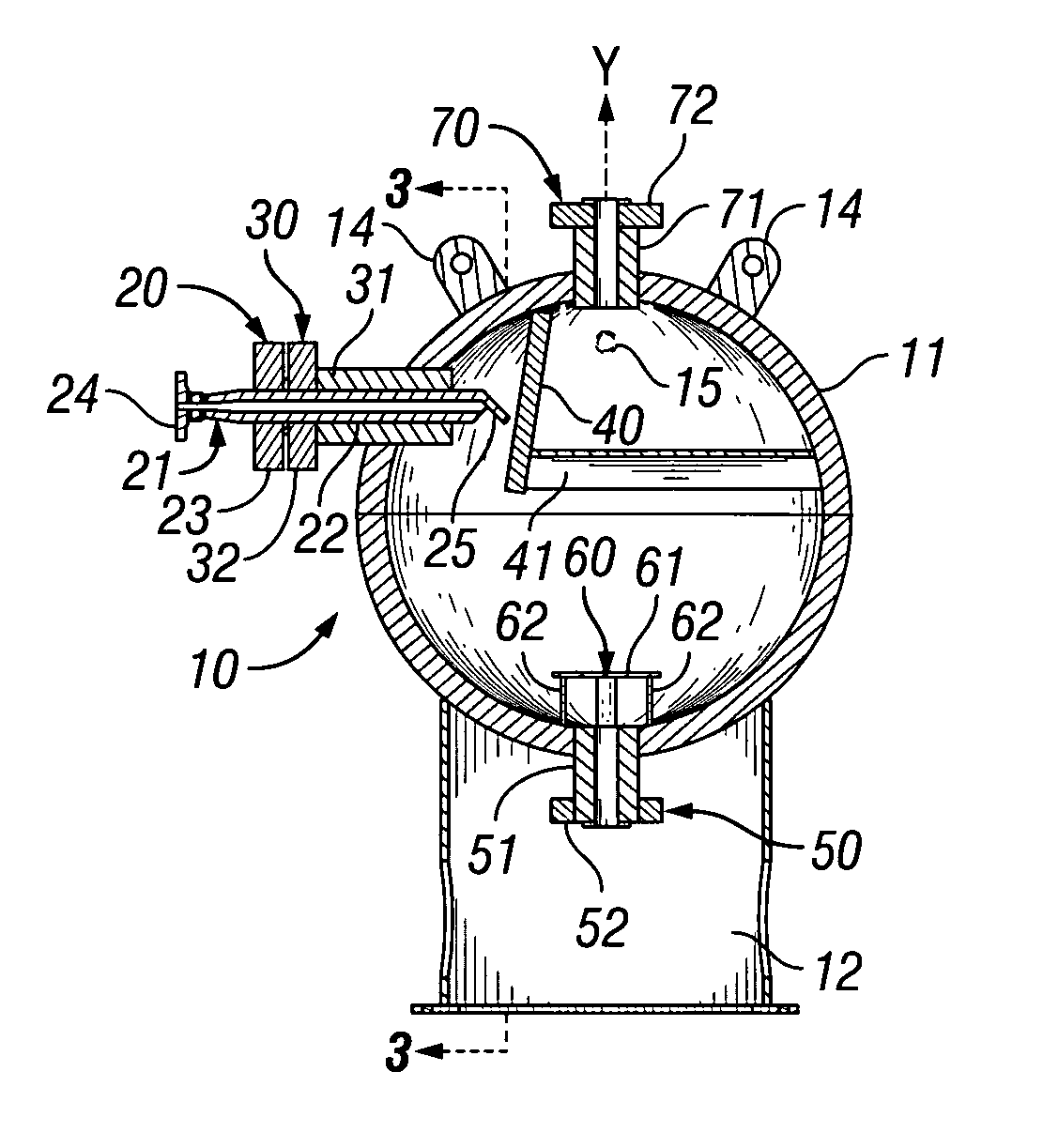

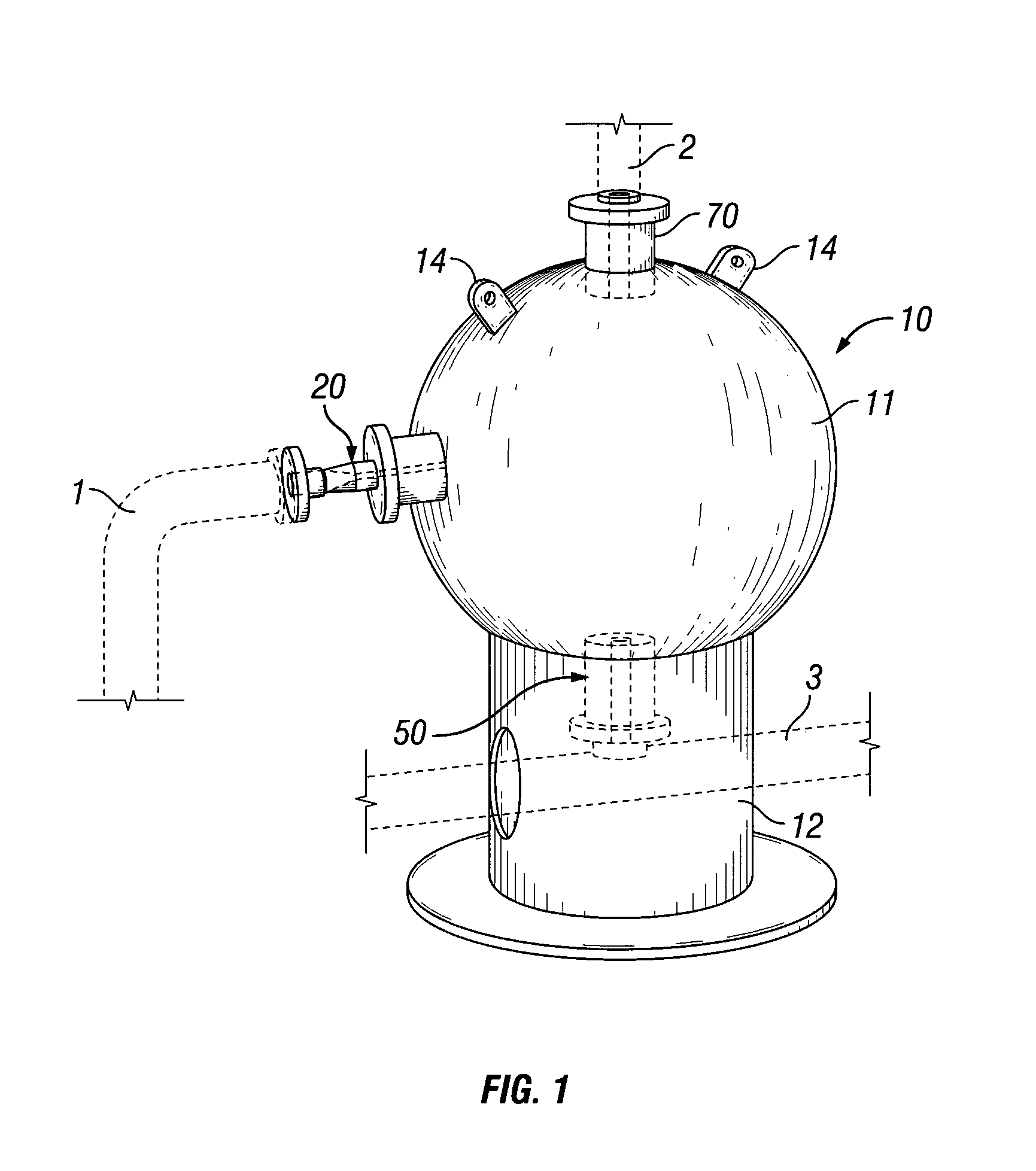

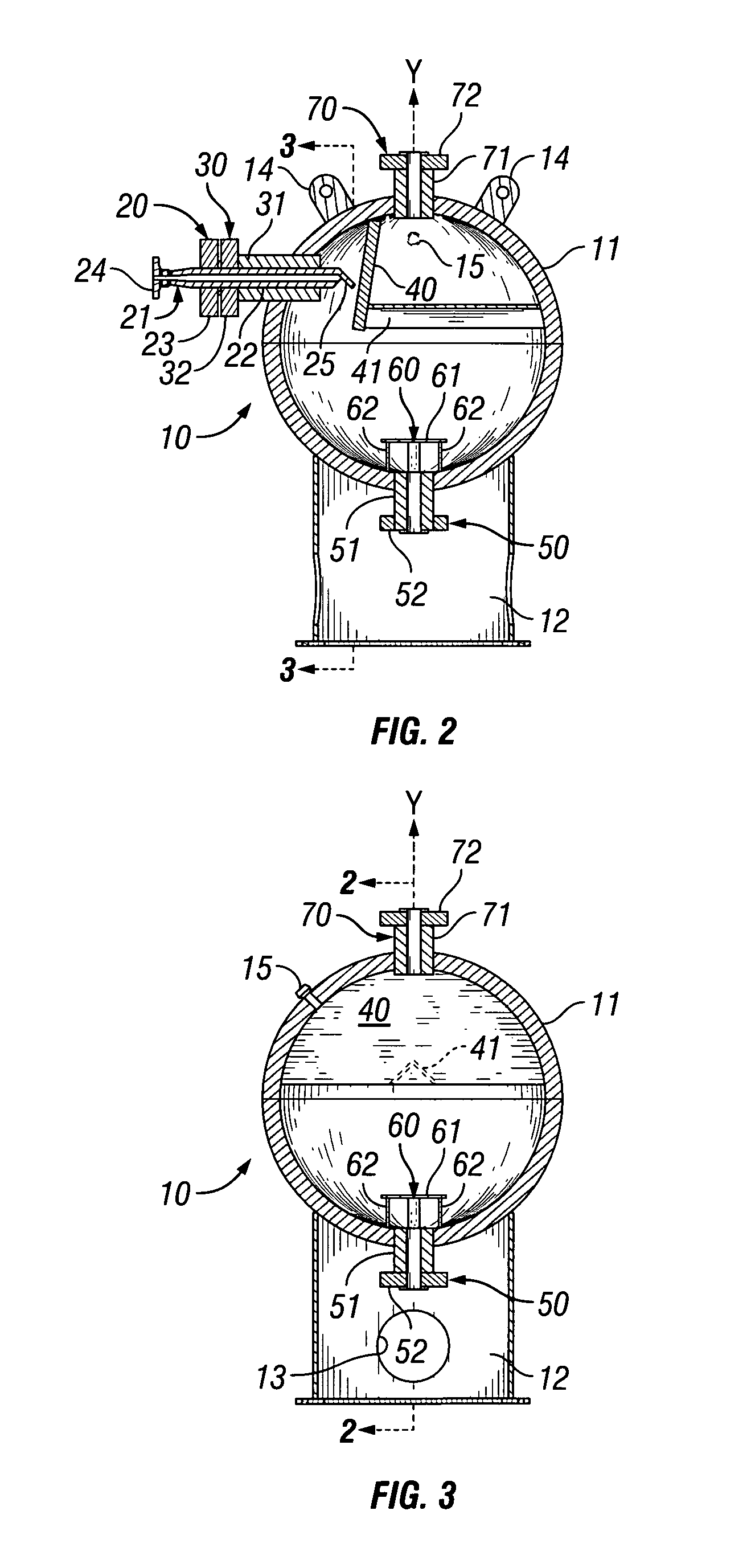

An apparatus for separating natural gas from production streams comprising a liquid dispersion of water, sand, and natural gas is provided for. The separator comprises a vessel having an interior surface defining a spherical interior space. The interior space allows a production stream introduced therein to experience a velocity drop sufficient to allow separation of the natural gas from the sand and water components. The separator also comprises a stream inlet port in the vessel, a liquid drain in the lower end of the vessel, and a gas outlet port at the upper end of the vessel remote from the stream inlet port. A baffle is mounted in the interior of the vessel in the path of the production stream between the stream inlet port and the gas outlet port. The baffle is effective to spread and direct a high pressure production stream introduced into the interior space via the stream inlet port downward toward the liquid drain.

Owner:SAND SEPARATORS

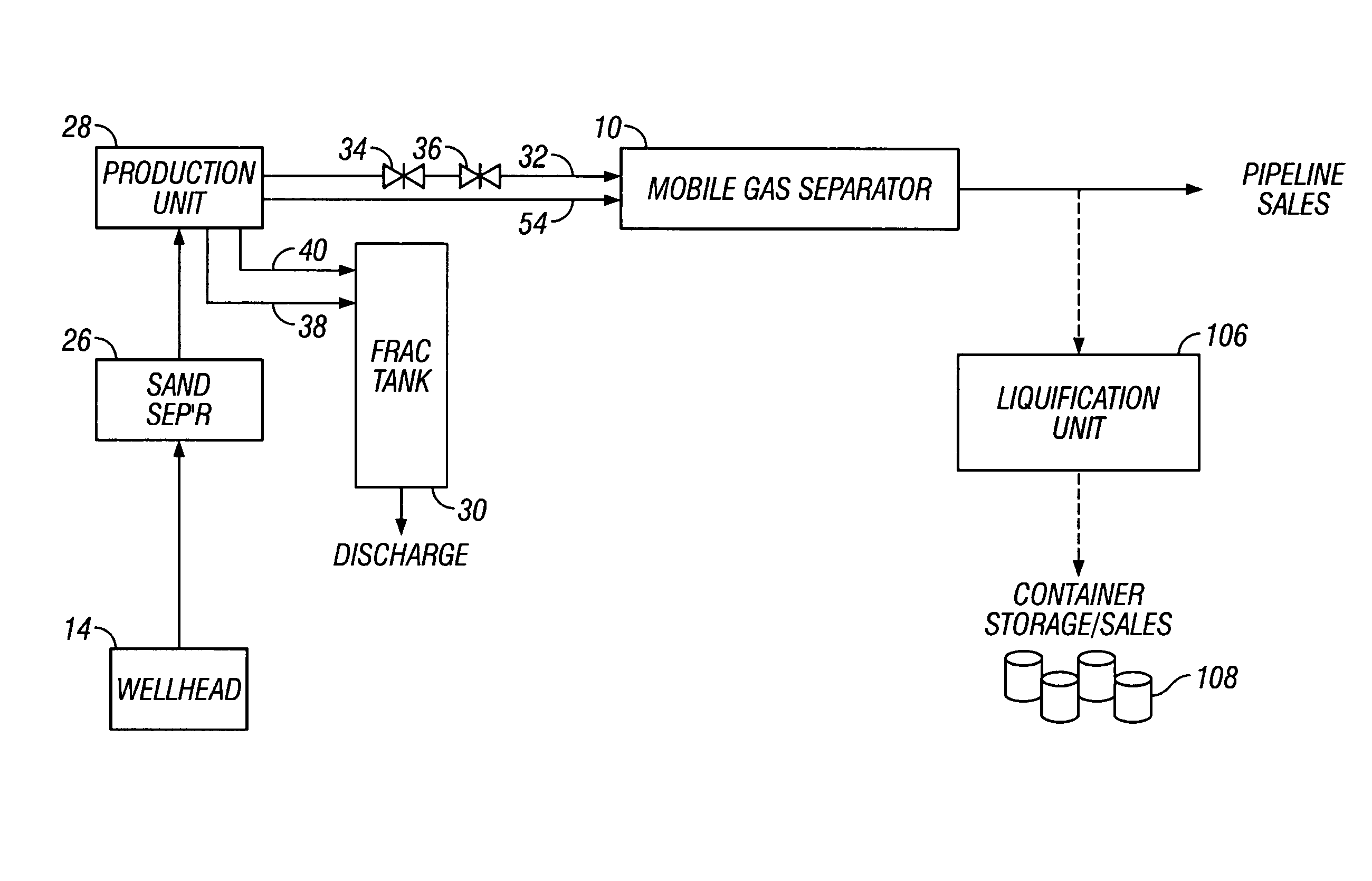

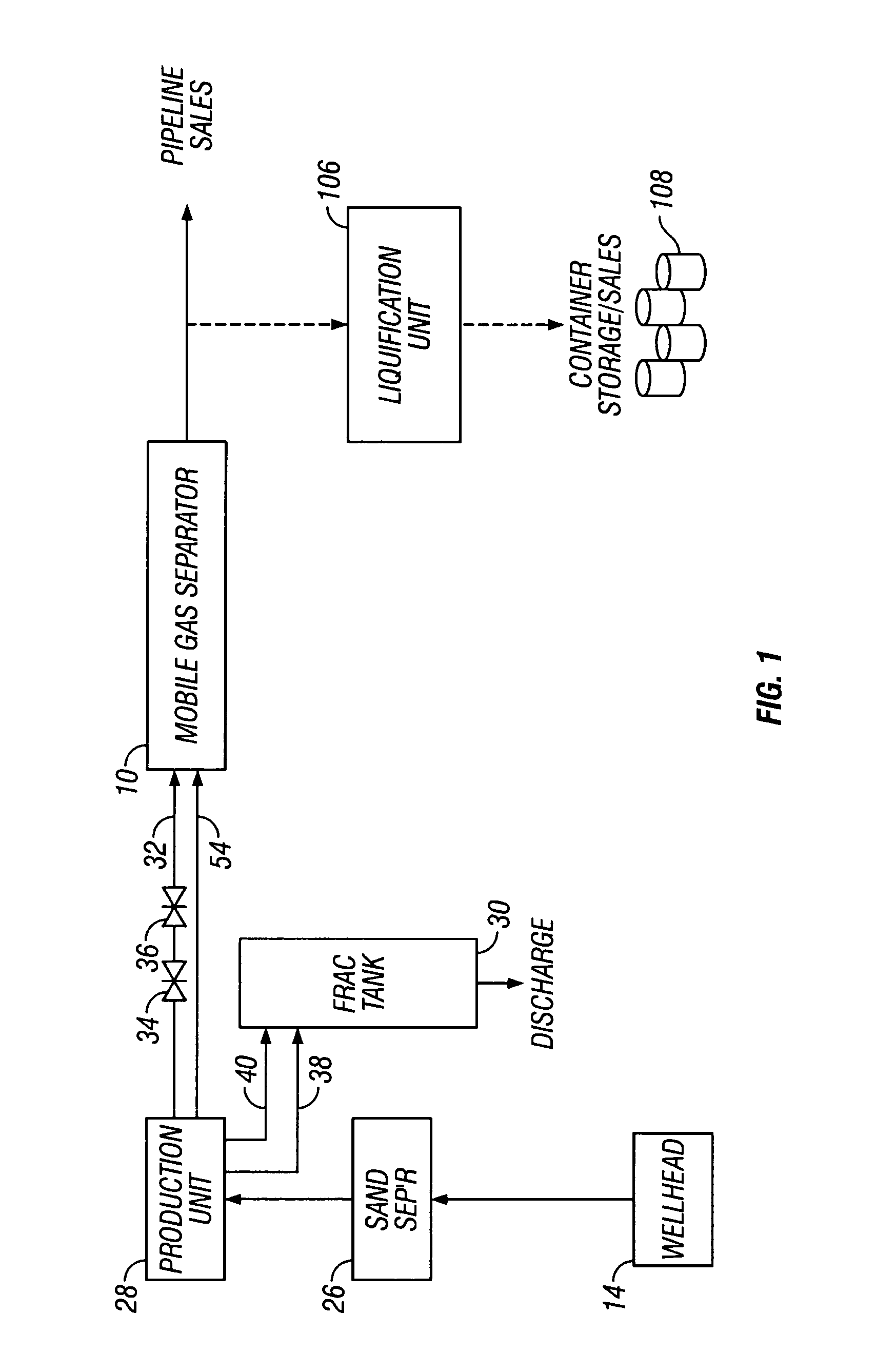

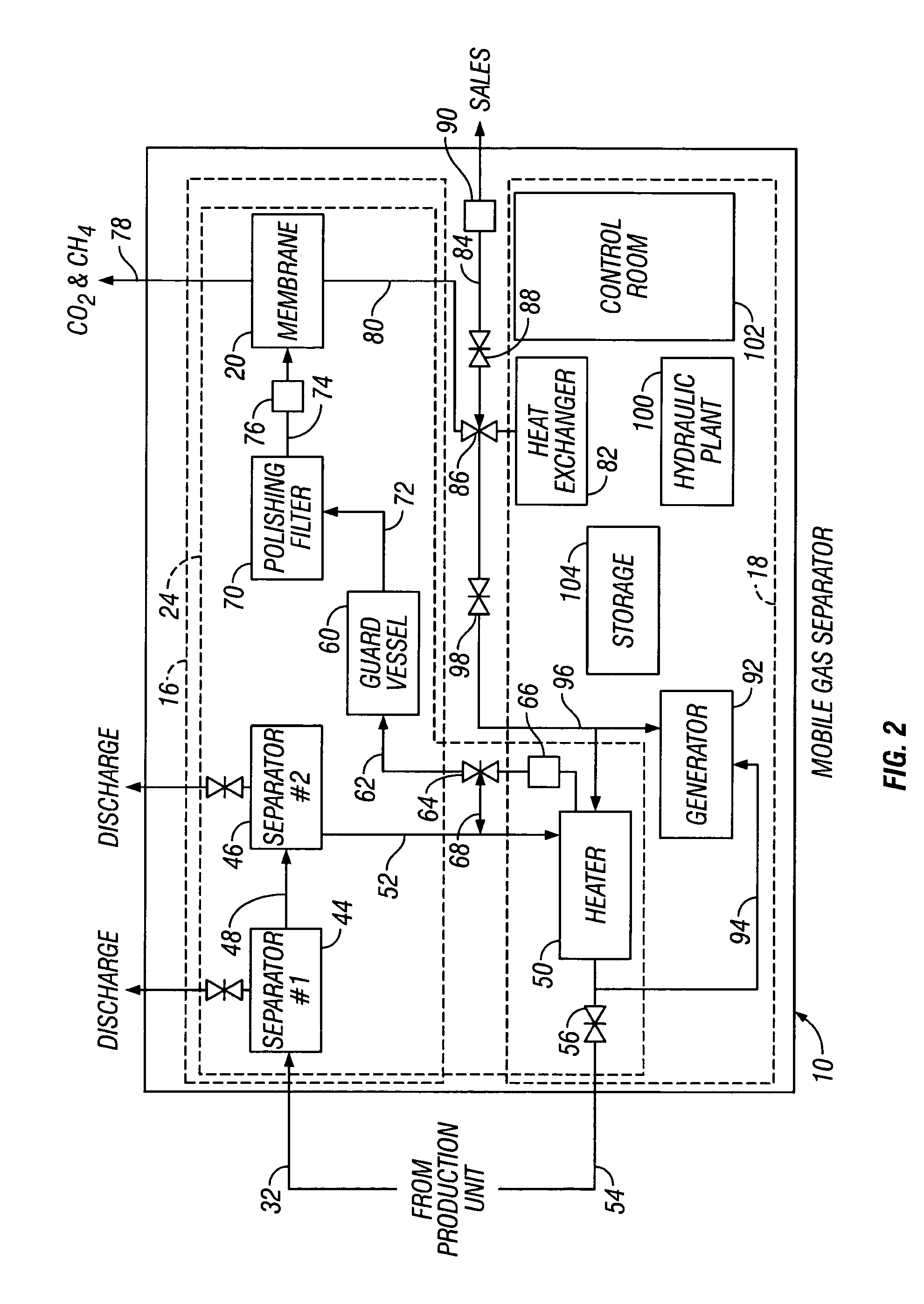

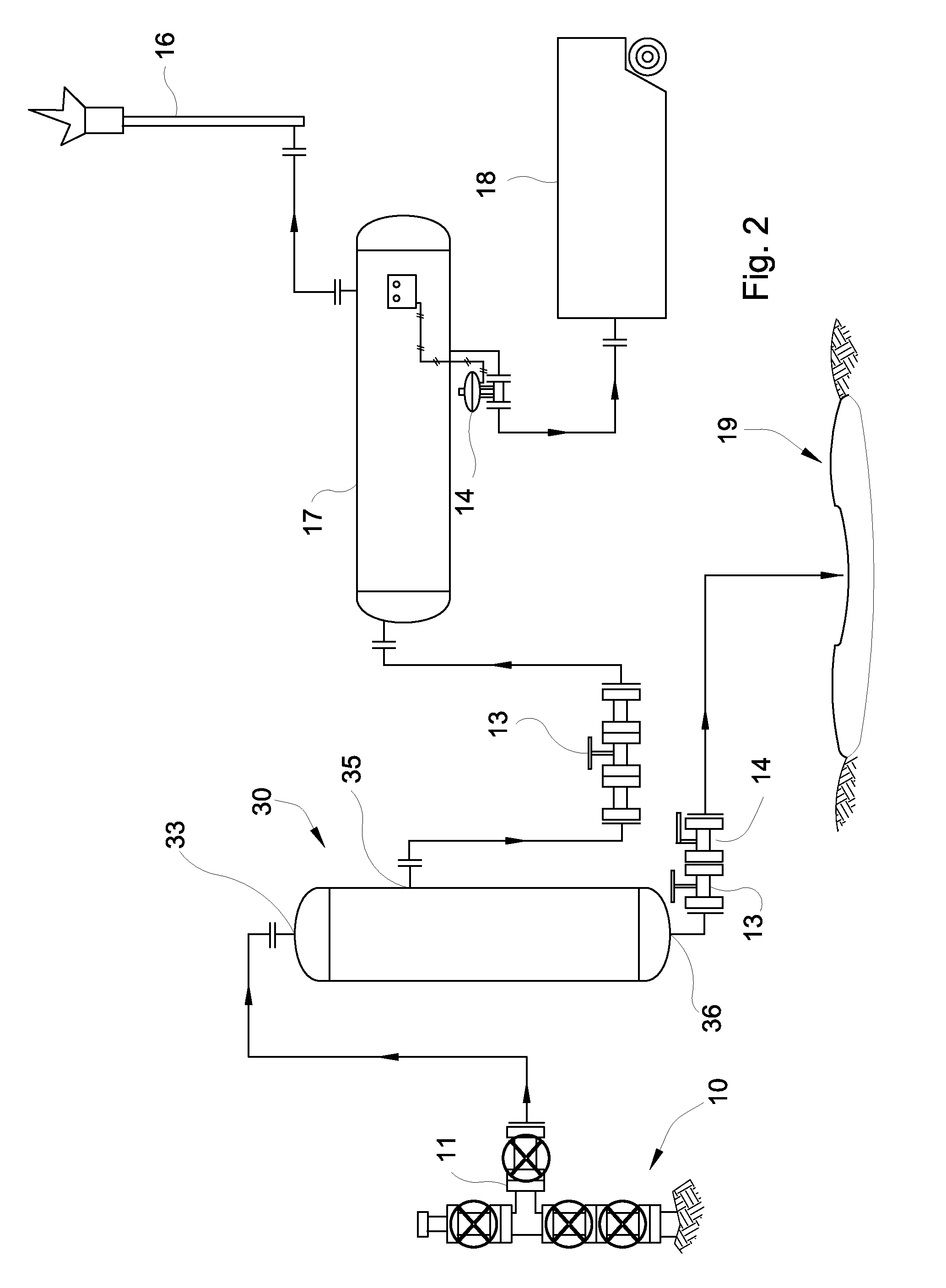

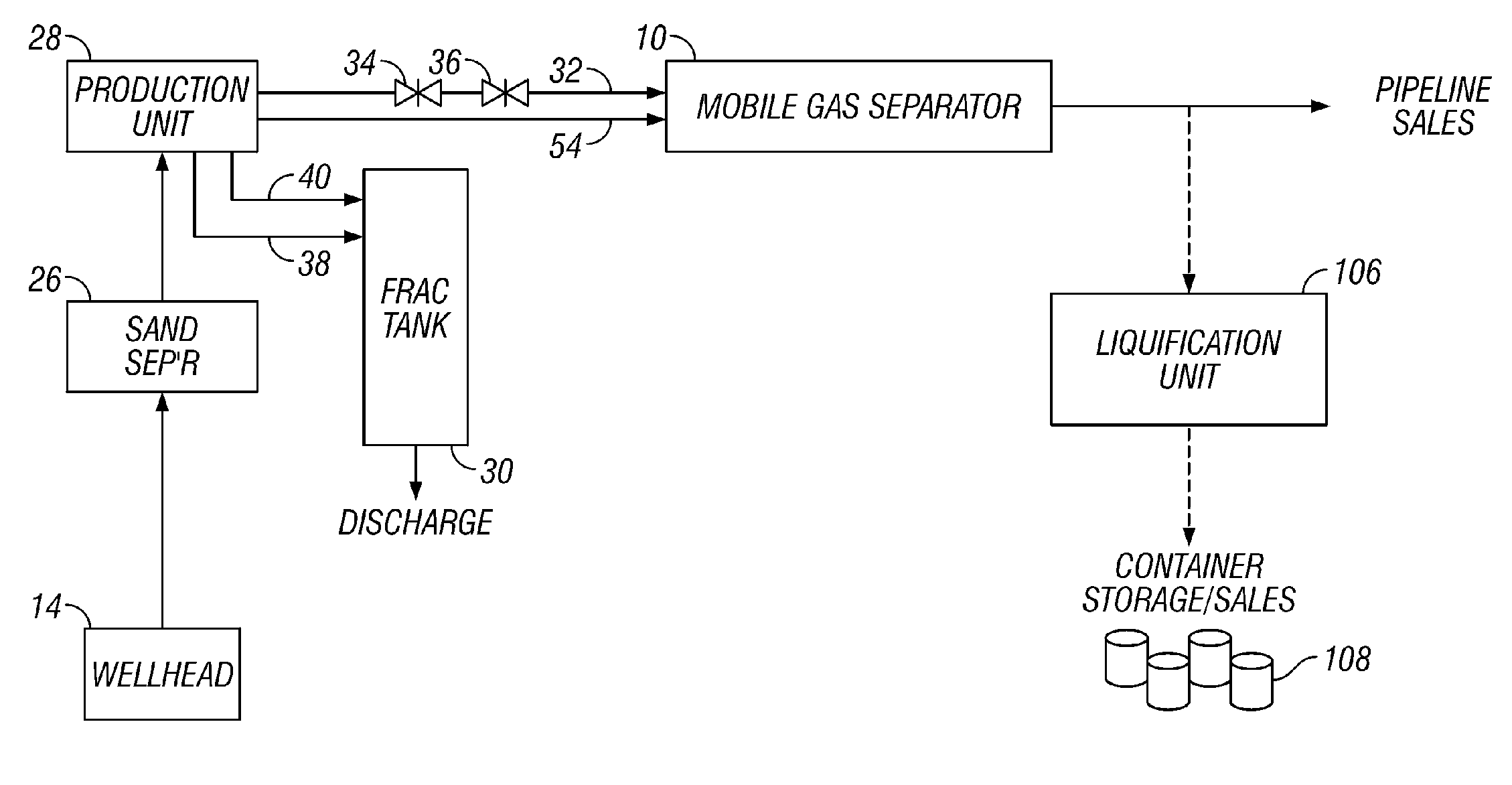

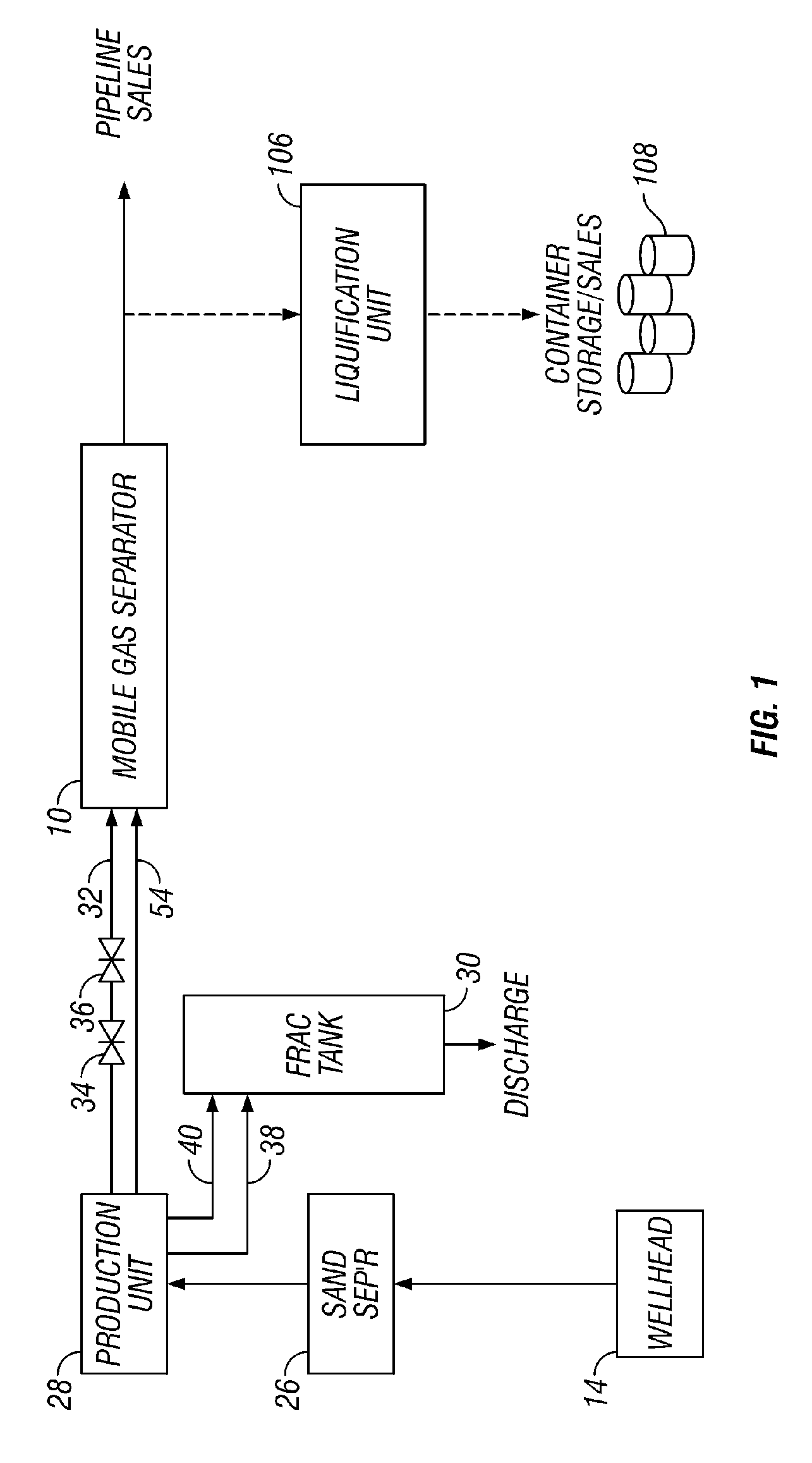

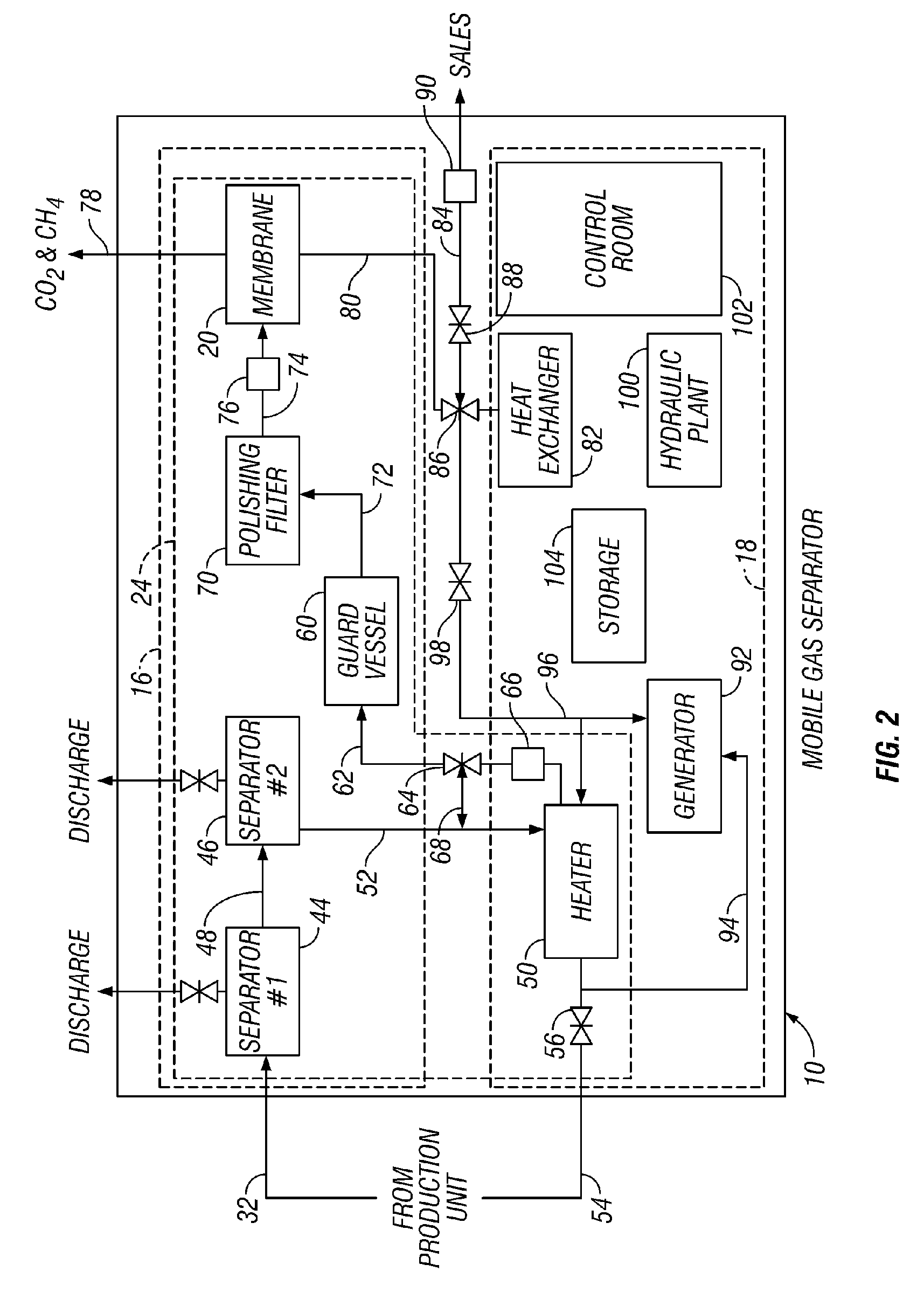

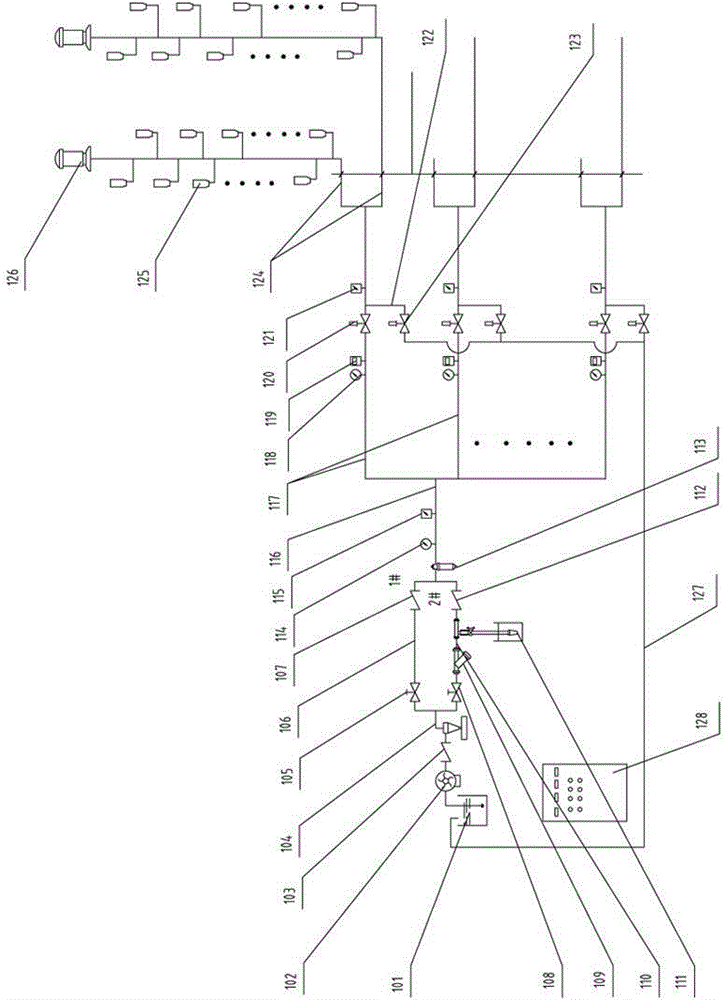

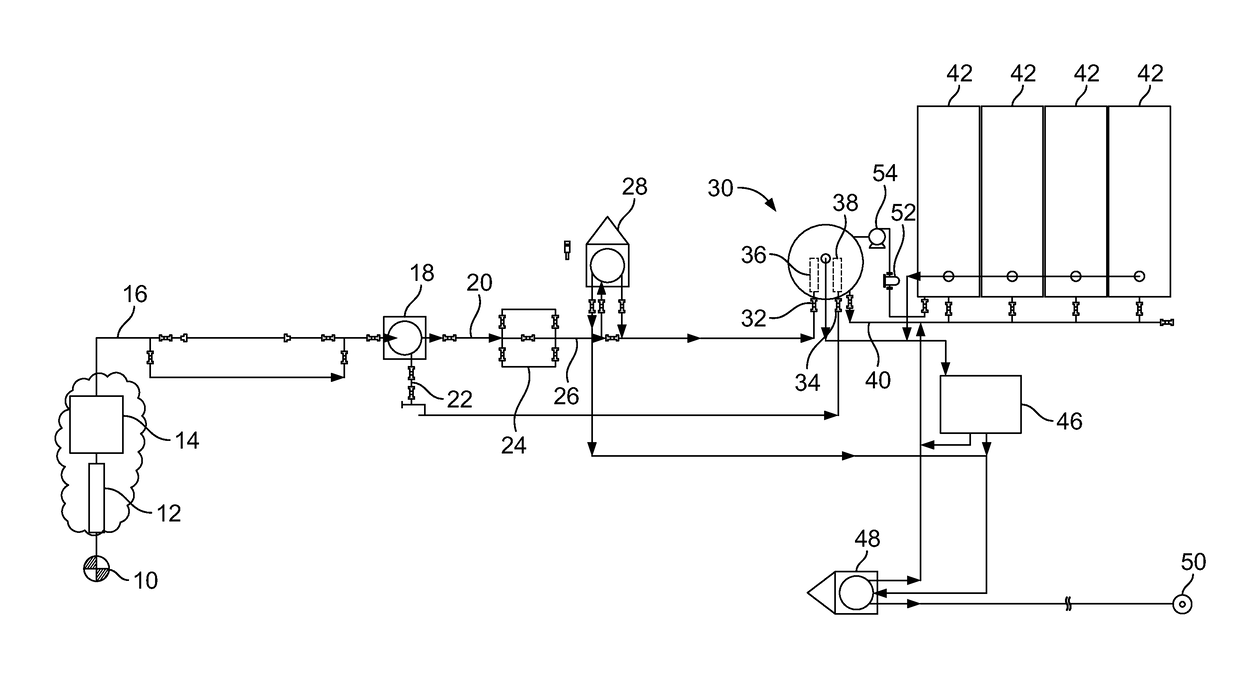

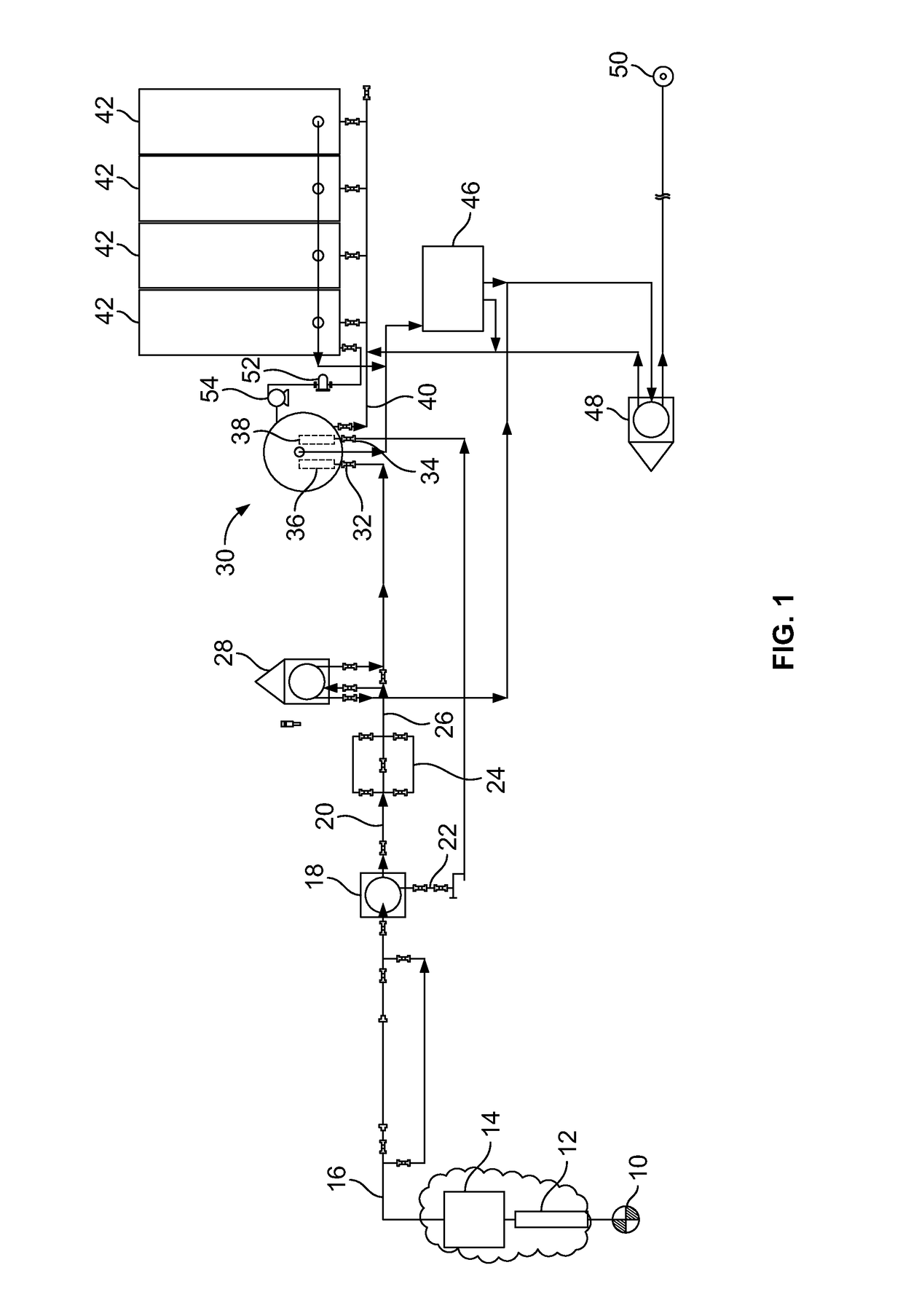

Mobile gas separator system and method for treating dirty gas at the well site of a stimulated well

A method and mobile system for cleaning dirty gas from a newly stimulated gas well. The entire system is supported on a trailer or other mobile support so that it can be driven from well site to well site for short-term, post-stimulation use only. The system comprises a gas separator, such as a membrane separator. The system also includes a pretreatment assembly for preparing the gas for the gas separator. The pretreatment assembly may include separators, a heater, a guard vessel and a polishing filter. A chiller or heat exchanger cools the treated gas to a marketable temperature. A generator and a hydraulics plant provide power to the system. Each mobile system will be designed to treat gases with widely different operating conditions varying from well to well.

Owner:STRAHAN RONALD L

Oil, water and gas separator for swaying service

InactiveUS7008546B2Easy to processImprove performanceLiquid separation auxillary apparatusFluid removalProduct gasDynamic equilibrium

A cylindrical vertical oil, water and gas separator that incorporates the known advantage of a horizontal flow path, when utilizing the force of gravity to separate a mixture of flowing fluids into distinct laminar layers, while providing a means for maintaining the dynamic equilibrium of the disparate layers of the fluids even when the oil, water and gas separator is swaying back and forth as might happen if the oil, water and gas separator is installed on the deck of a ship.

Owner:EDMONDSON TECH HLDG

Flow Back Recovery System

InactiveUS20120012309A1Inhibition releaseLiquid degasificationSeparation devicesProcess engineeringEngineering

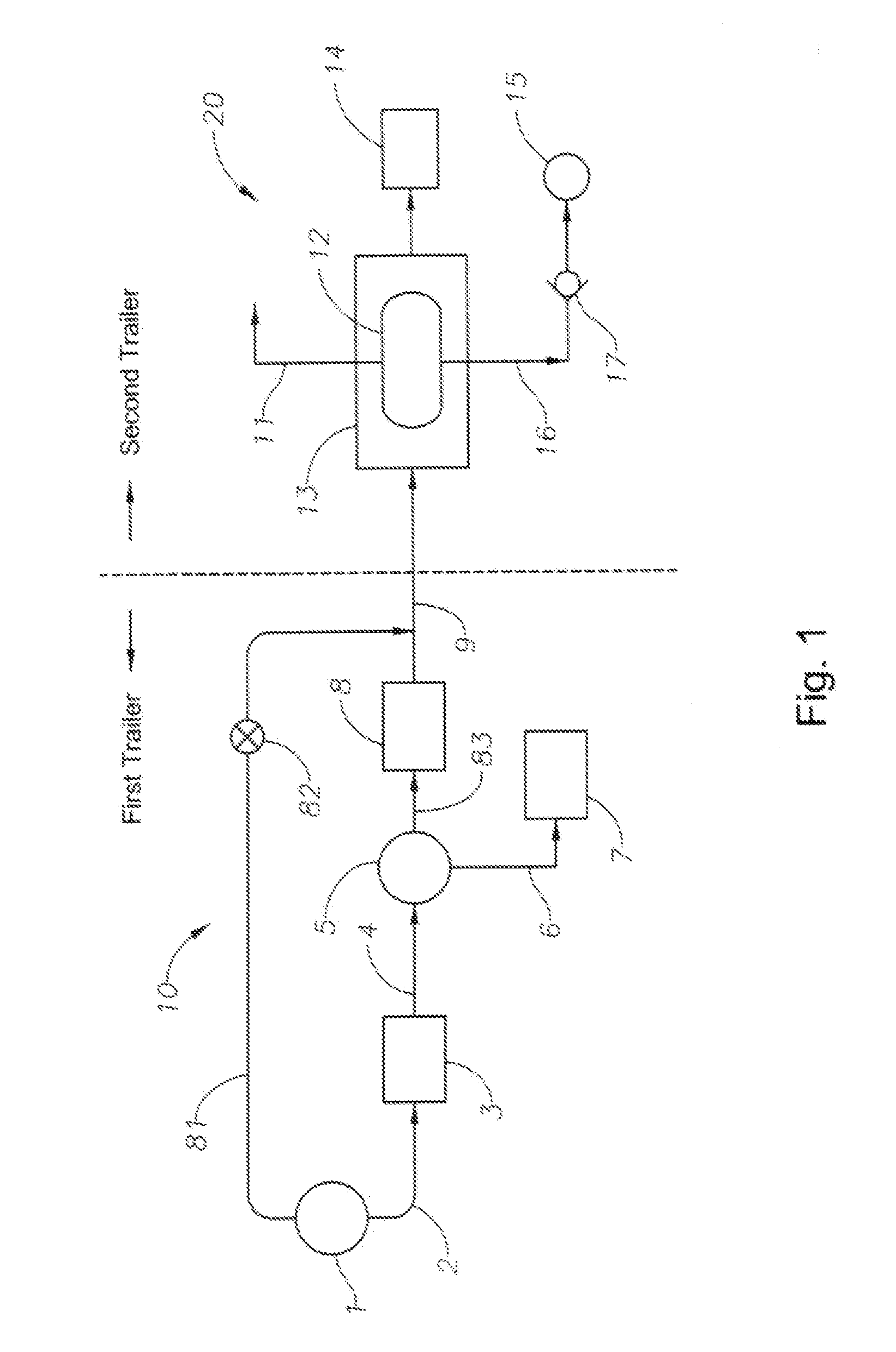

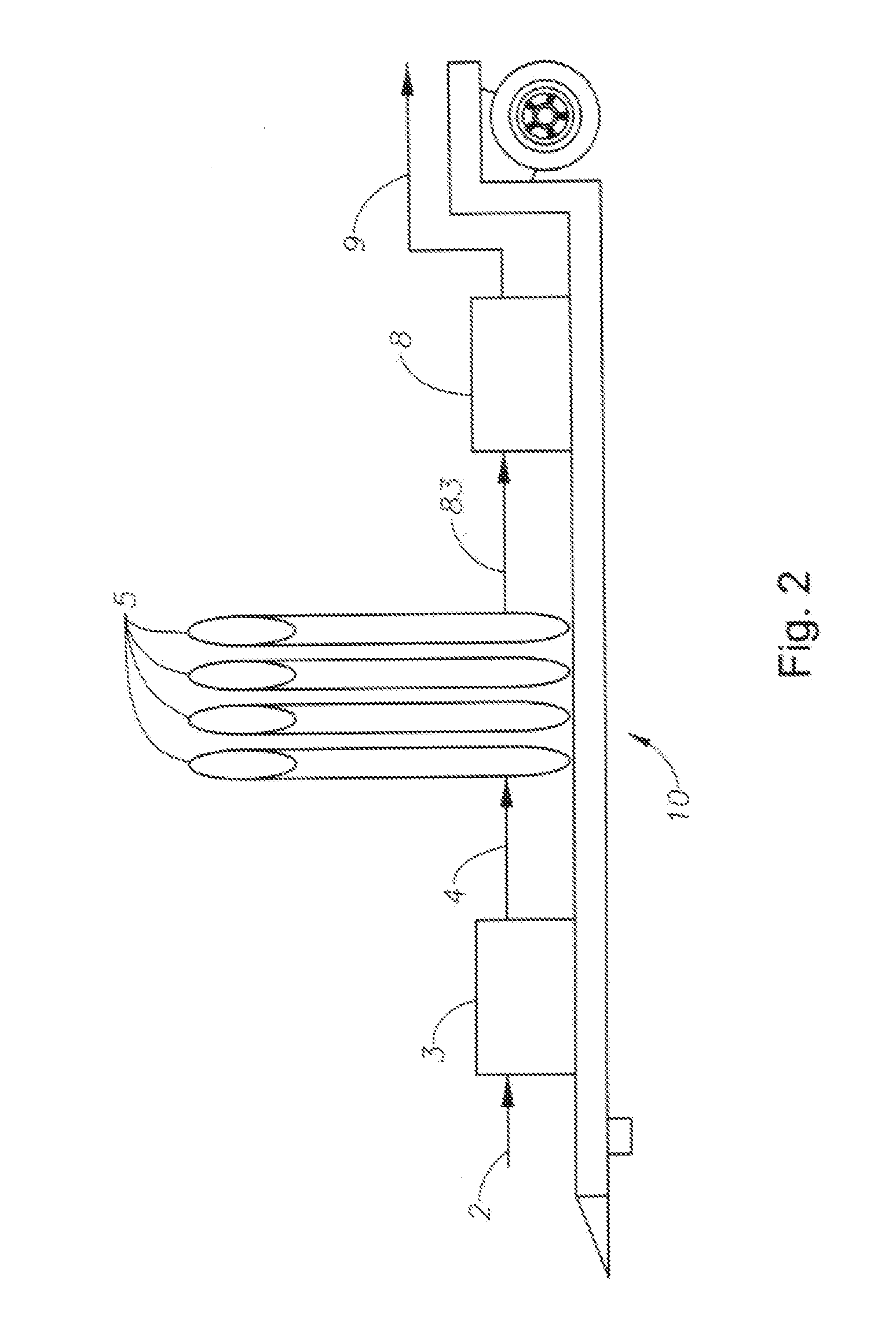

A system and method for processing flow back from an oil or gas well after a fracturing or other well treatment process includes a first trailer having a high pressure filter, a sand separator, and a choke manifold and a second trailer including a gas separator and holding tanks for water and oil. Each trailer may be equipped with a drip or catch pan to confine any leakage of liquid that may occur.

Owner:EXPRESS ENERGY SERVICES OPERATING LP

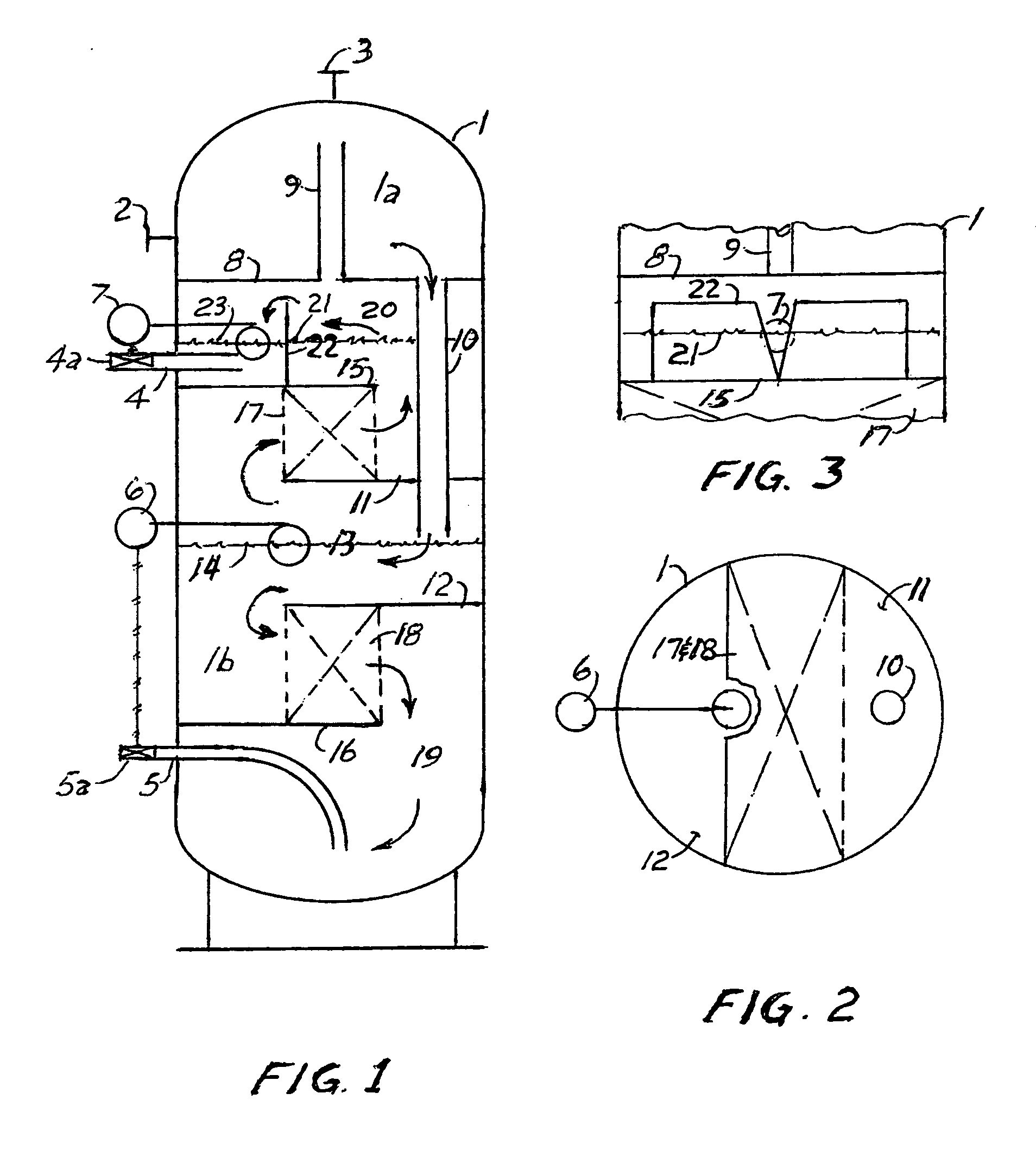

Sand separator for petroleum and natural gas wells

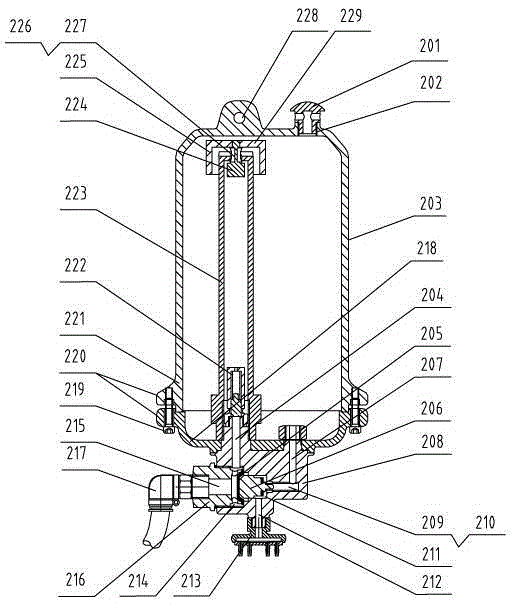

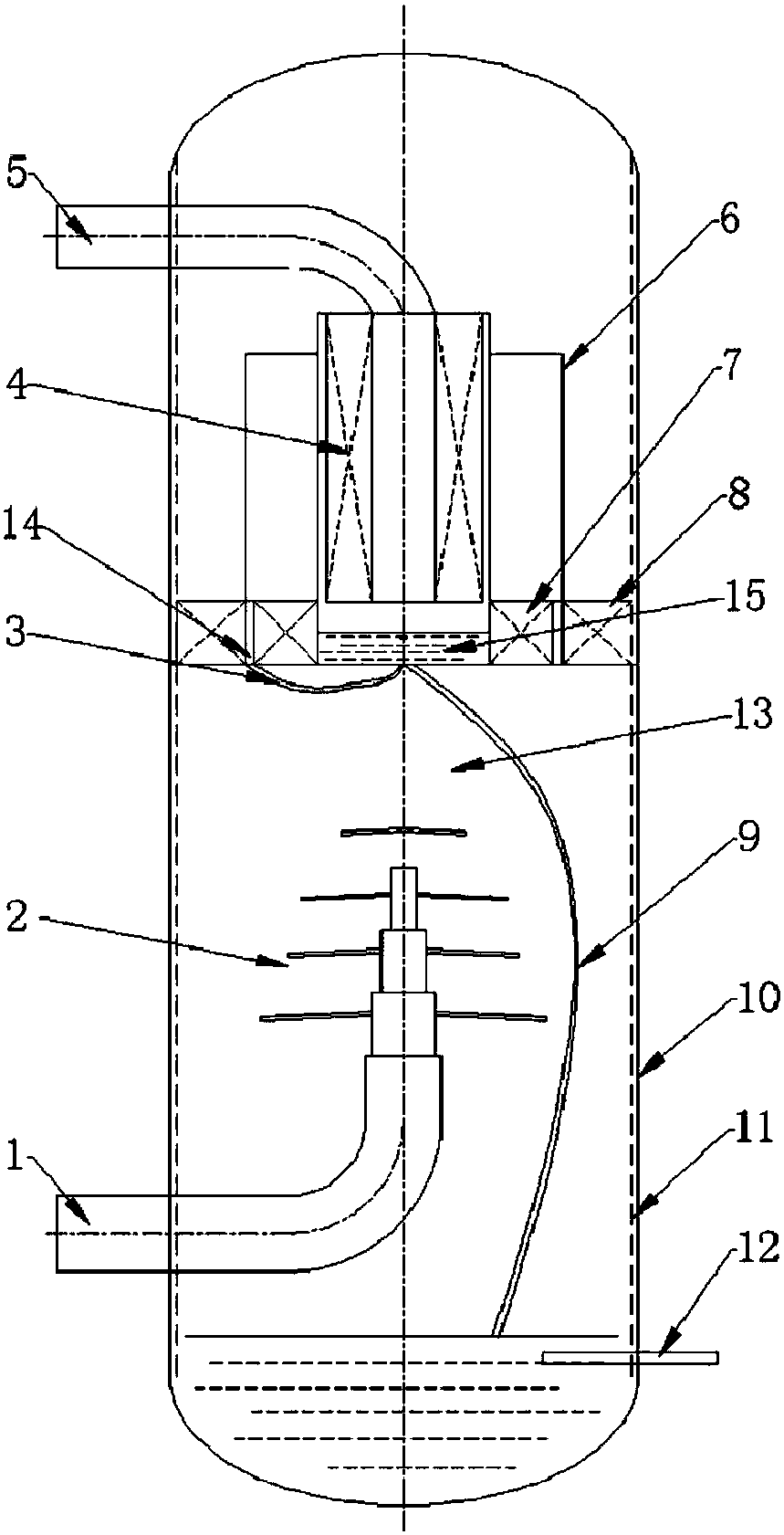

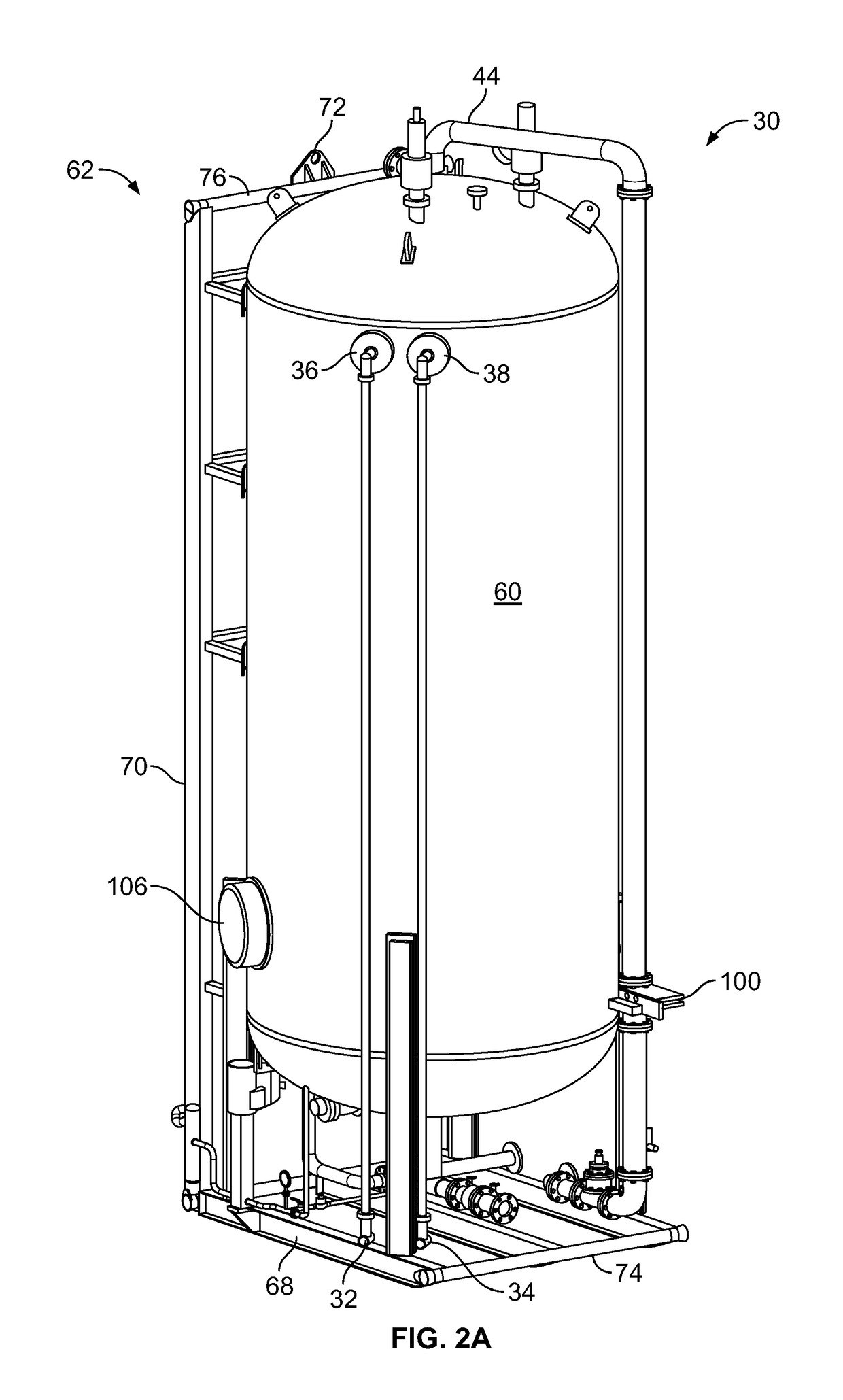

ActiveUS8623221B1Shorten speedLight weightLiquid degasificationSettling tanks feed/dischargeFracturing fluidOil and natural gas

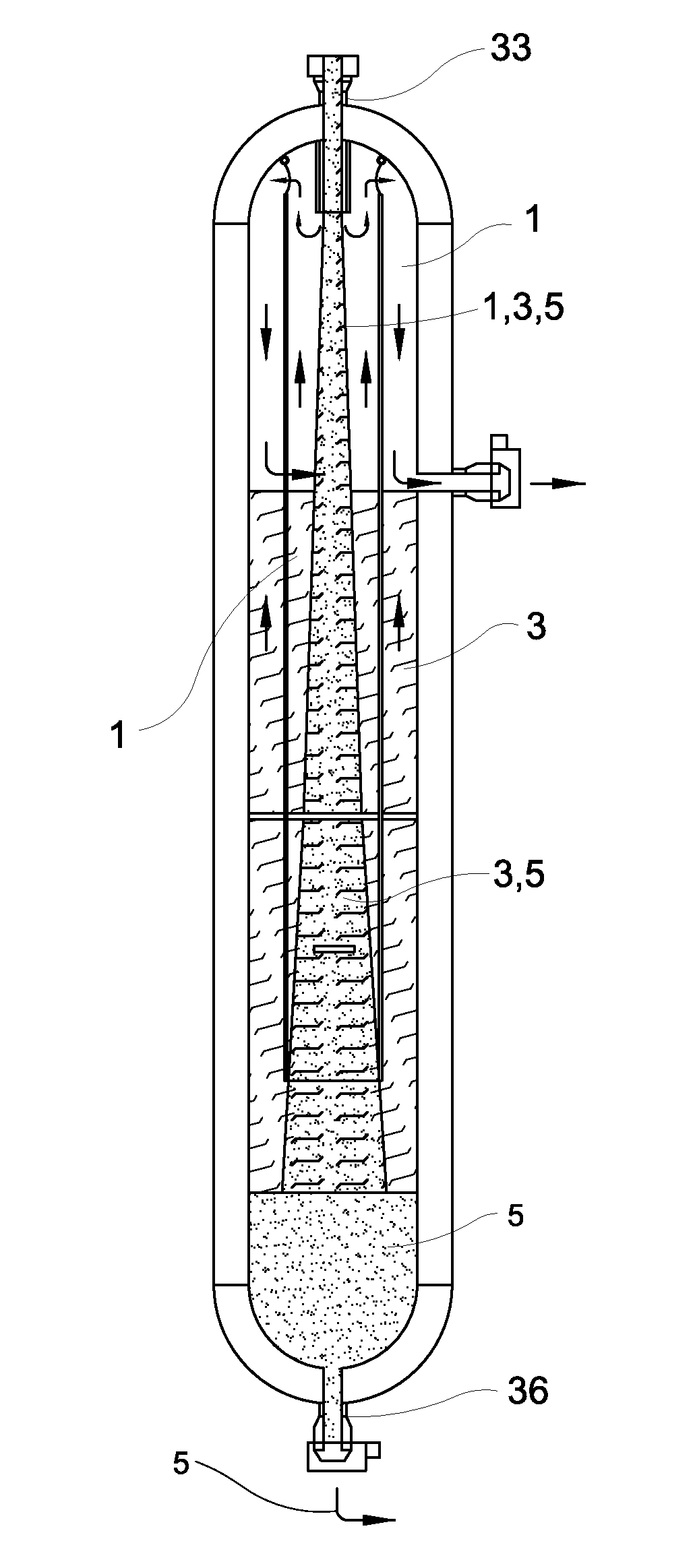

A sand separator for capturing sand and rock debris from recovered natural gas fracturing fluid includes a cylindrical, high-pressure-rated vessel disposed vertically and immediately downstream of the gas wellhead. High pressure fracturing fluid enters the top of the separator into an inner flue extending coaxially downward to terminate a spaced distance above the bottom of the vessel. Transverse baffles spaced apart along the length of the flue extend through the flue to the inner walls of the vessel to keep the flue centered within the separator. As the fluid enters the separator, openings through the flue near the vessel inlet permit lighter weight and gaseous constituents to escape the fluid and bypass the flue, thereby reducing the velocity of the fluid remaining inside the flue. As the remaining fluid falls to the bottom of the vessel, it further slows as it reverses direction to rise between the flue and the vessel walls. At the bottom of the vessel, sand and rock debris precipitates out of the slowed fluid and accumulates above a clean-out valve by which the debris periodically may be removed. The gas and fluid recombine relatively free of sand and rock debris and exit the vessel at one or more outlet ports through the vessel walls. The sand separator functions in both exploration and production wells for both petroleum and natural gas.

Owner:BOYD KEITH L +2

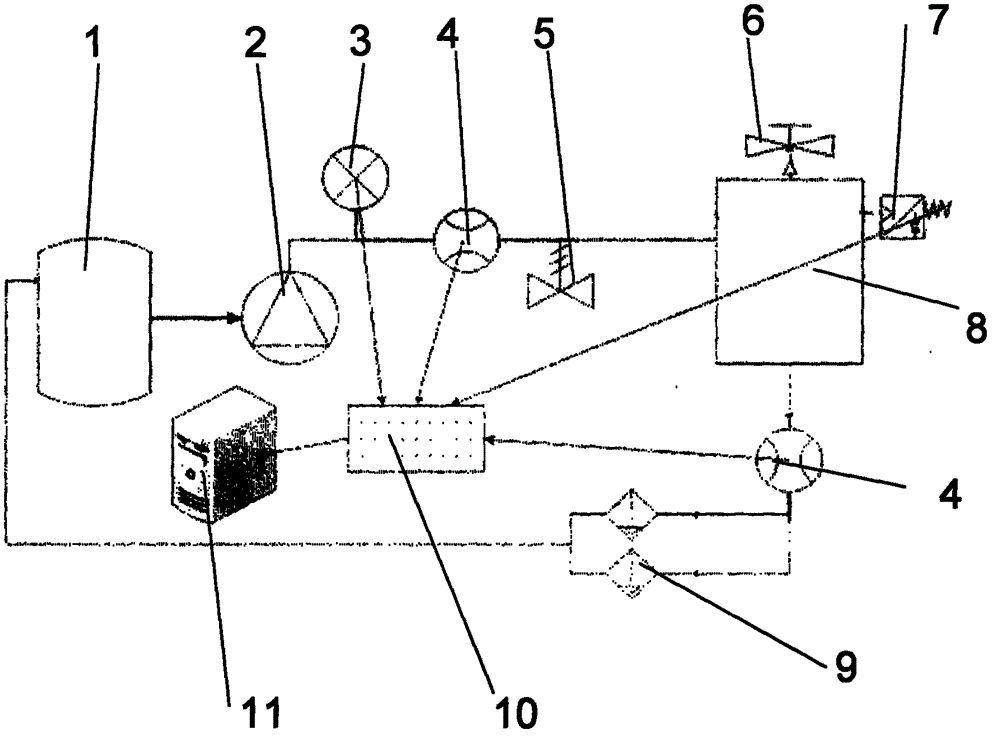

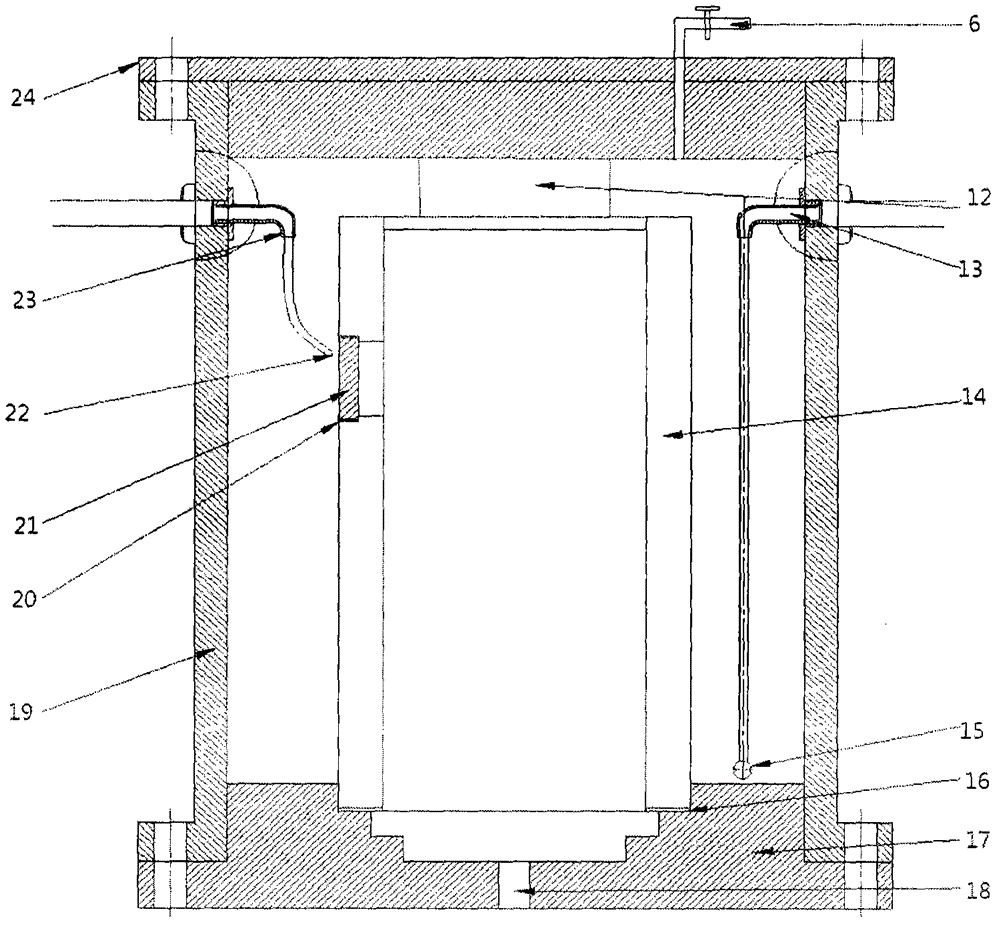

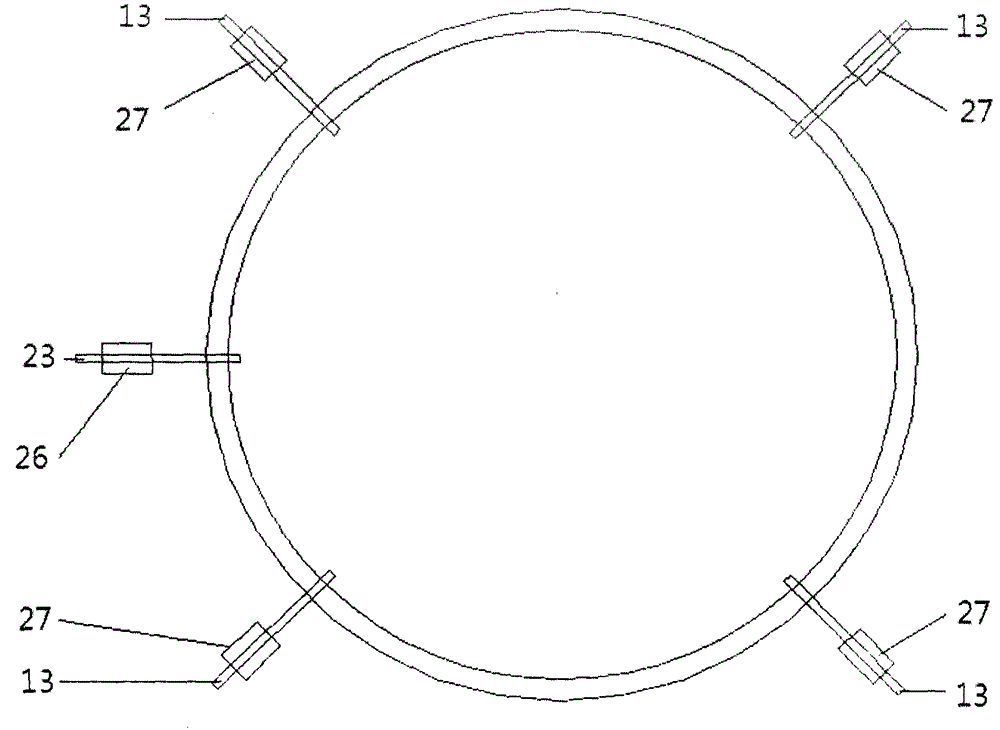

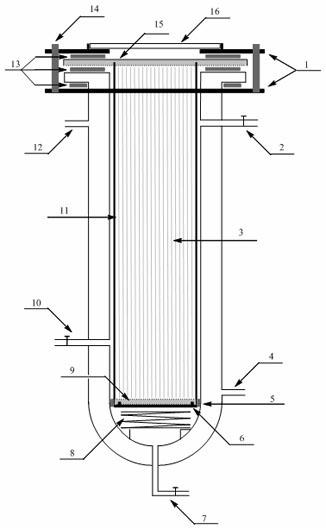

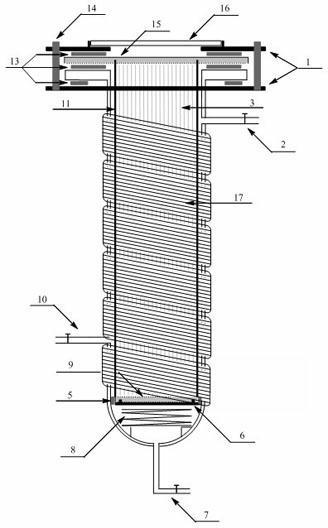

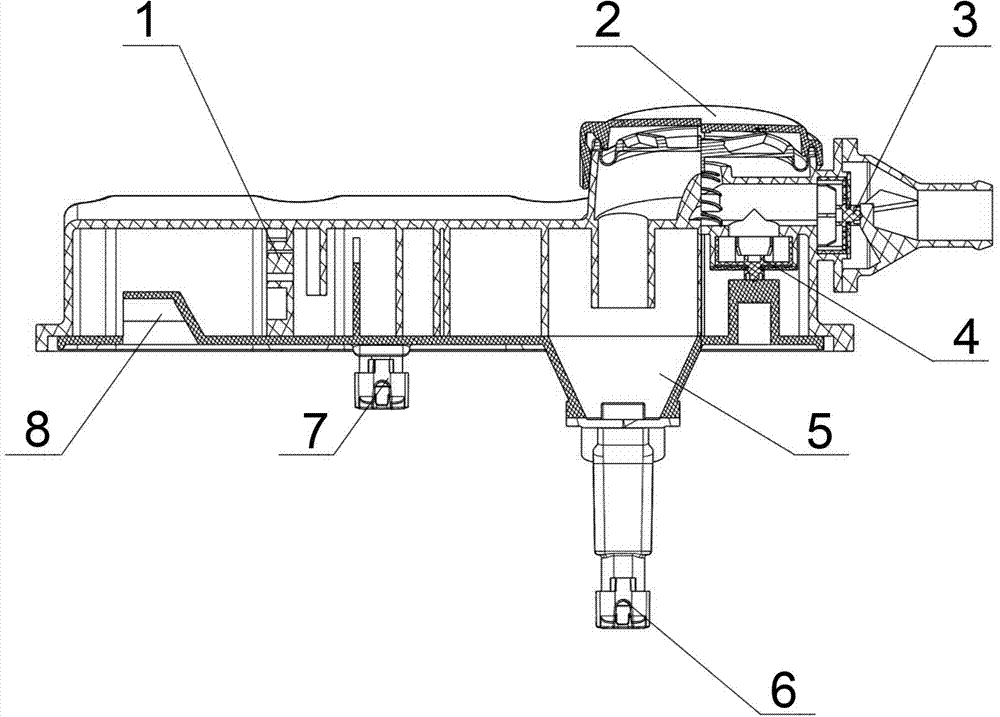

Method for evaluating erosion rate of sand control pipe and its special-purpose apparatus

InactiveCN104897510AWeighing by removing componentMaterial analysis using radiation diffractionExhaust valveErosion rate

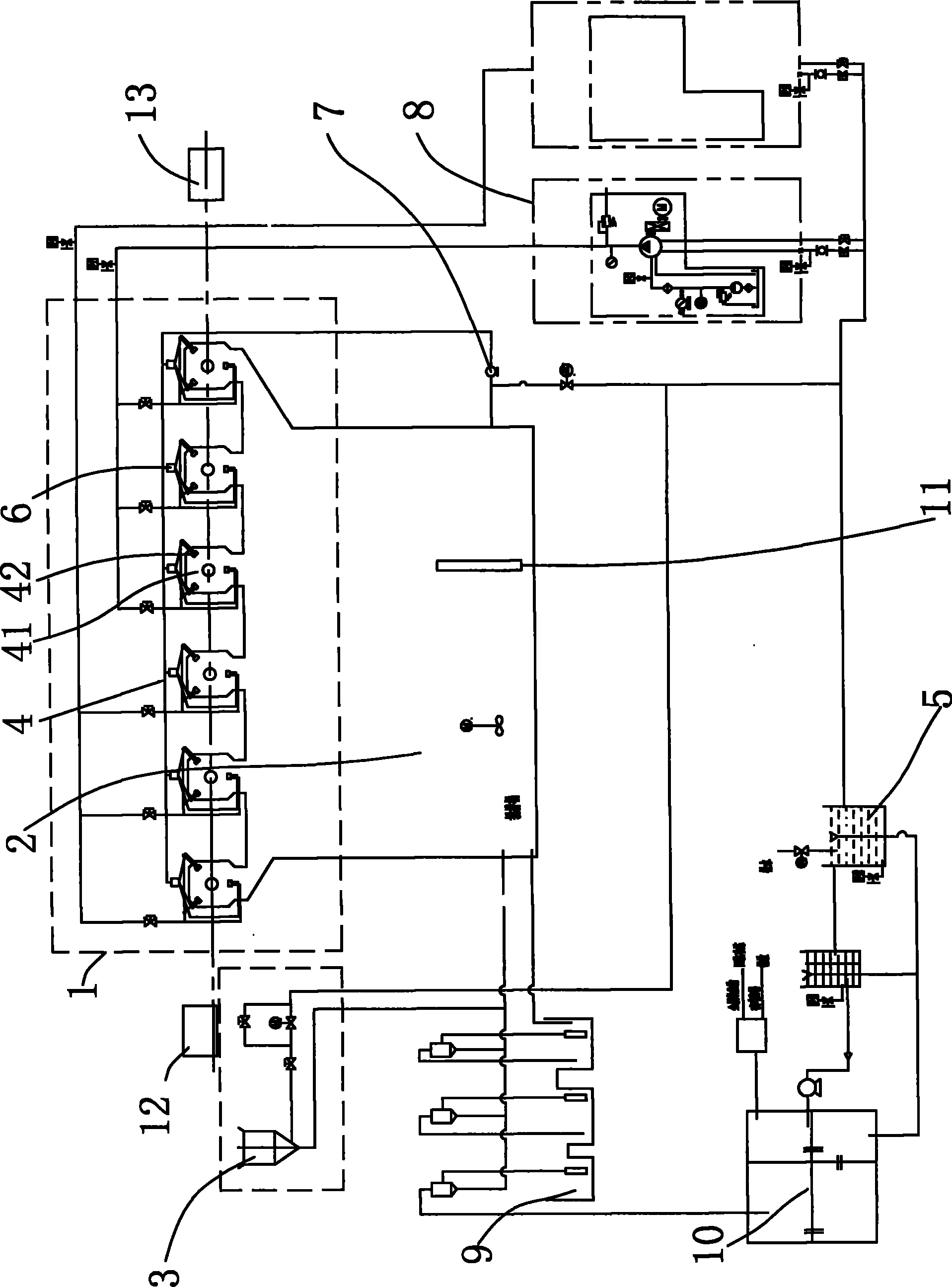

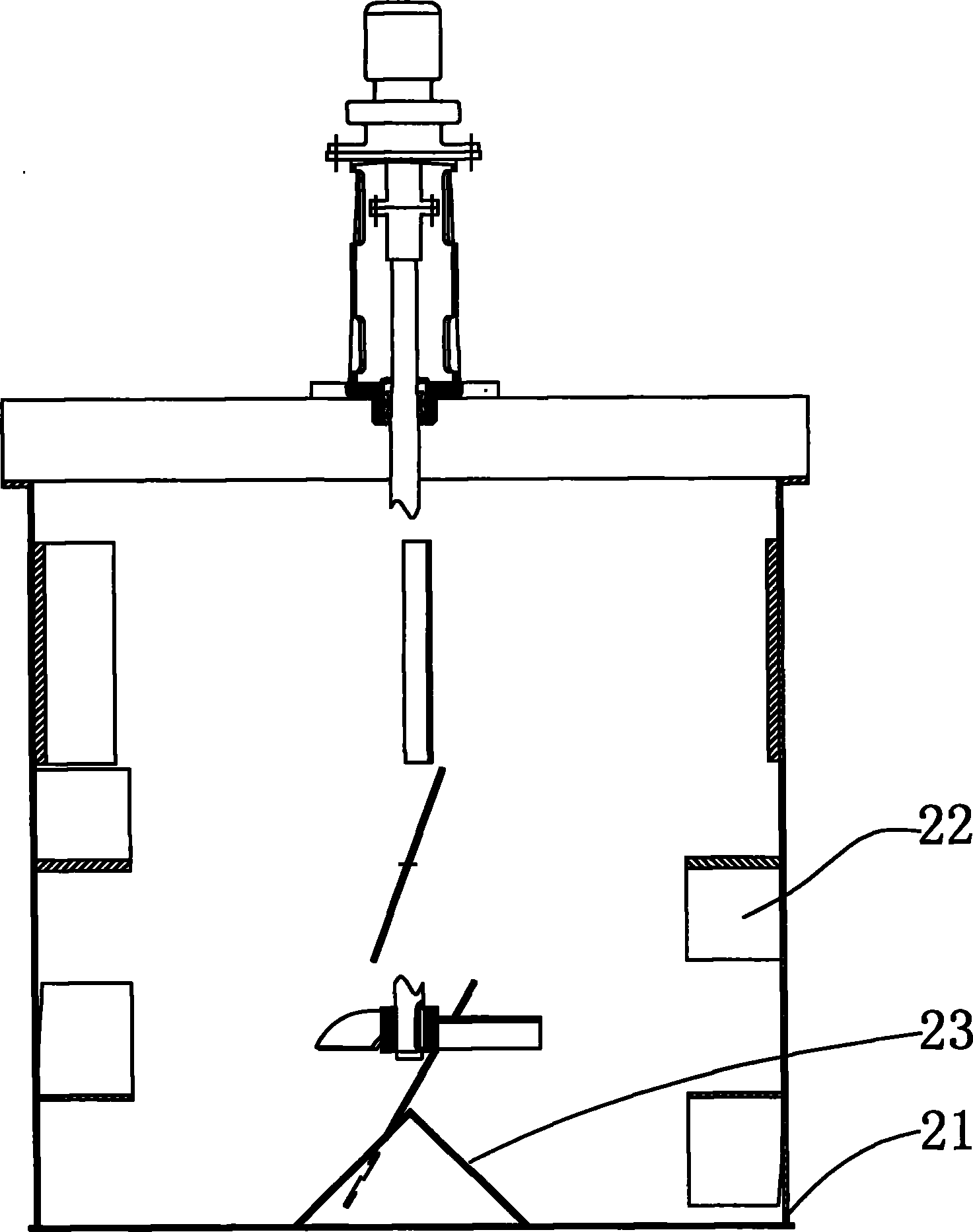

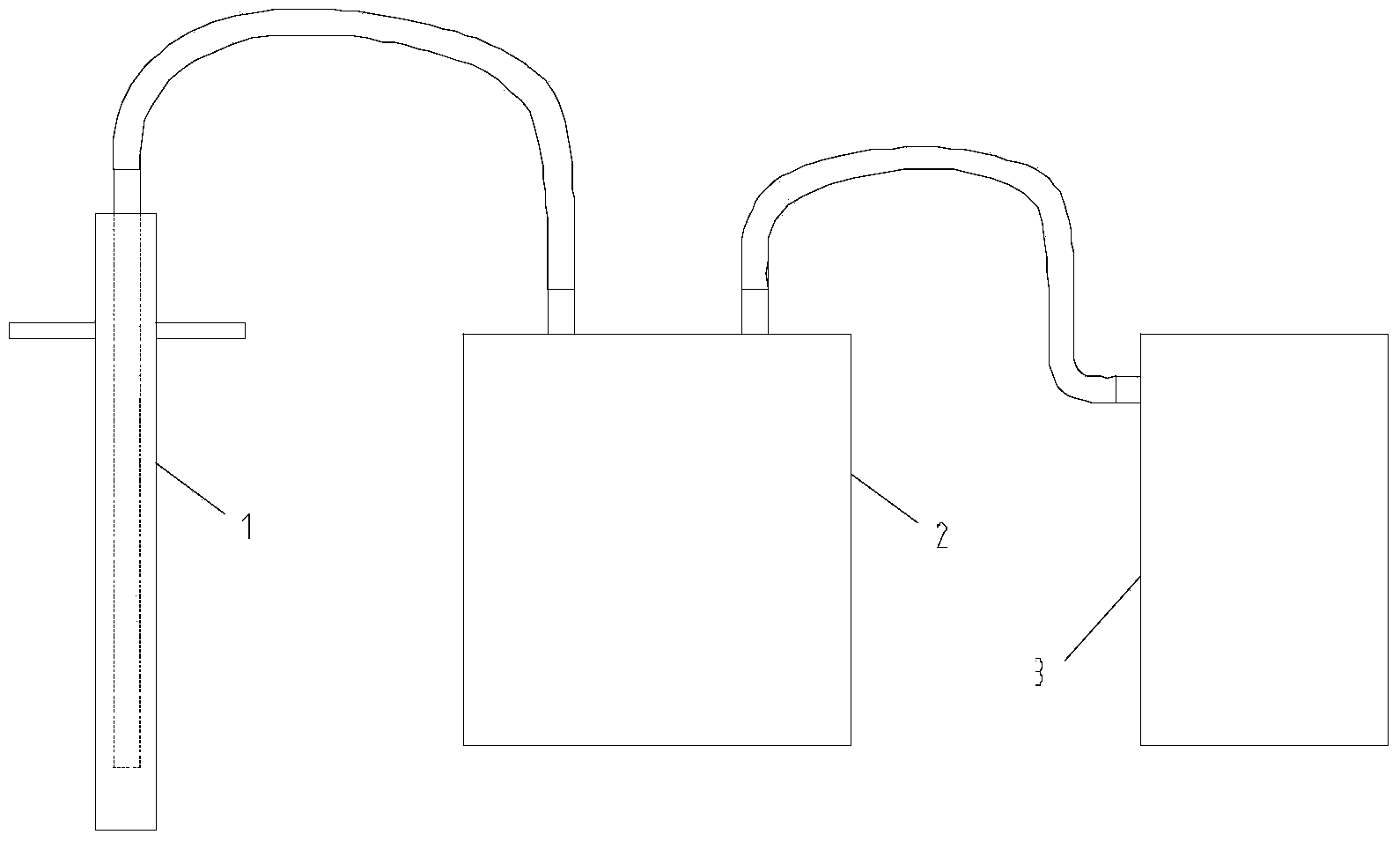

The invention relates to a method for evaluating erosion rate of a sand control pipe and its special-purpose apparatus, which is characterized in that the on-site screen casings are used for processing to screen casing sheets for experiments. According to the invention, change of sand control pipe precision can be evaluated by a laser granularity analysis on sand from different periods of experiment process, erosion rate of the screen casing under specific reservoir condition and production condition can be evaluated according to the mass change of the screen casing sheet before and after the experiment, and finally the erosion rate and the usage life of the screen casing can be predicted. For solving the problems, a technical scheme is characterized in that the special-purpose apparatus is a whole set of fluid circulation apparatus, which comprises a circulation solution storage pot 1, a high pressure pump 2, a pressure gage 3, a flow monitor device 4, a safety exhaust valve 6, a pressure transducer 7, an enclosed autoclave body 8, an oil-sand separator 9, and a data acquisition system 10. According to the special-purpose apparatus, an erosion stand 14, a cleaning nozzle 22 and a sand washing nozzle 15 are arranged in the enclosed autoclave body 8.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

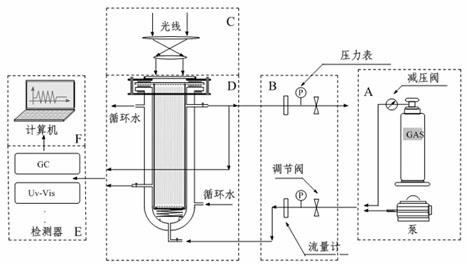

Titanium dioxide photo-catalytic micro-reactor

InactiveCN102580651ARaise the ratioSmall attenuationEnergy based chemical/physical/physico-chemical processesReaction layerFiber

The invention discloses a titanium dioxide photo-catalytic micro-reactor, characterized in that in the reactor, the lower ends of fibers are supported on a porous glass sand separator through a porous glass sheet, the upper end is fixed with a translucent sheet, the bottom of the reactor is provided with an air inlet pipe, and the side of the reactor is provided with a testing port and an injection port. According to the invention, the ratio of effective catalytic surface area to reactive volume is raised, the incident mode of a light source is changed into an internal reflection mode from a traditional external reflection mode, thus the attenuation after the light passes through the solution is reduced, and the utilization rate of the light is raised; compared with TiO2 nano-particles, the TiO2 nanotubes used as the photoreaction catalyst have higher catalysis catalysis effect; and compared with traditional coating modes, the reaction layer obtained by the catalyst layer of the photoreaction unit is more uniform, compact and firm.

Owner:NORTHWEST UNIV

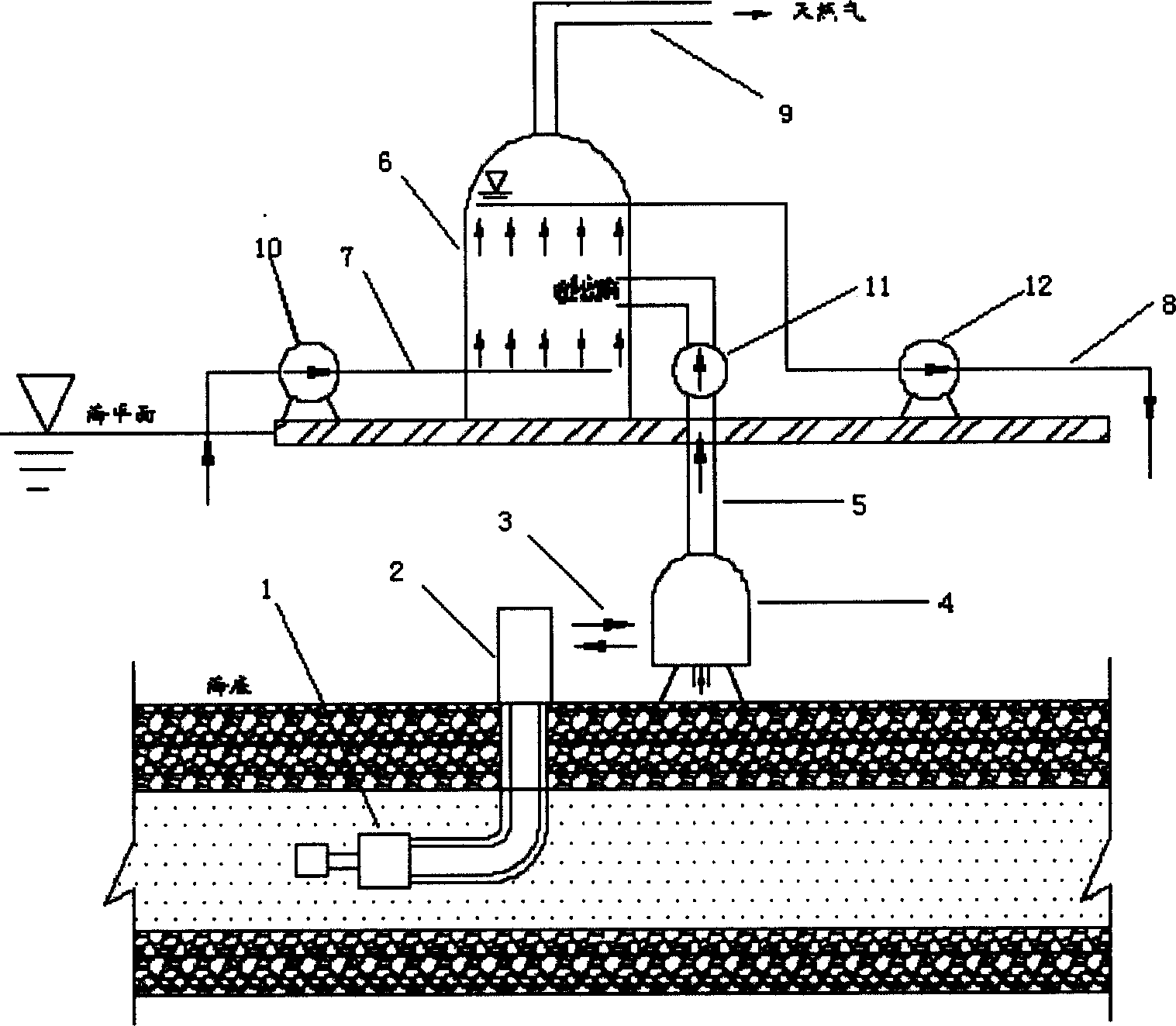

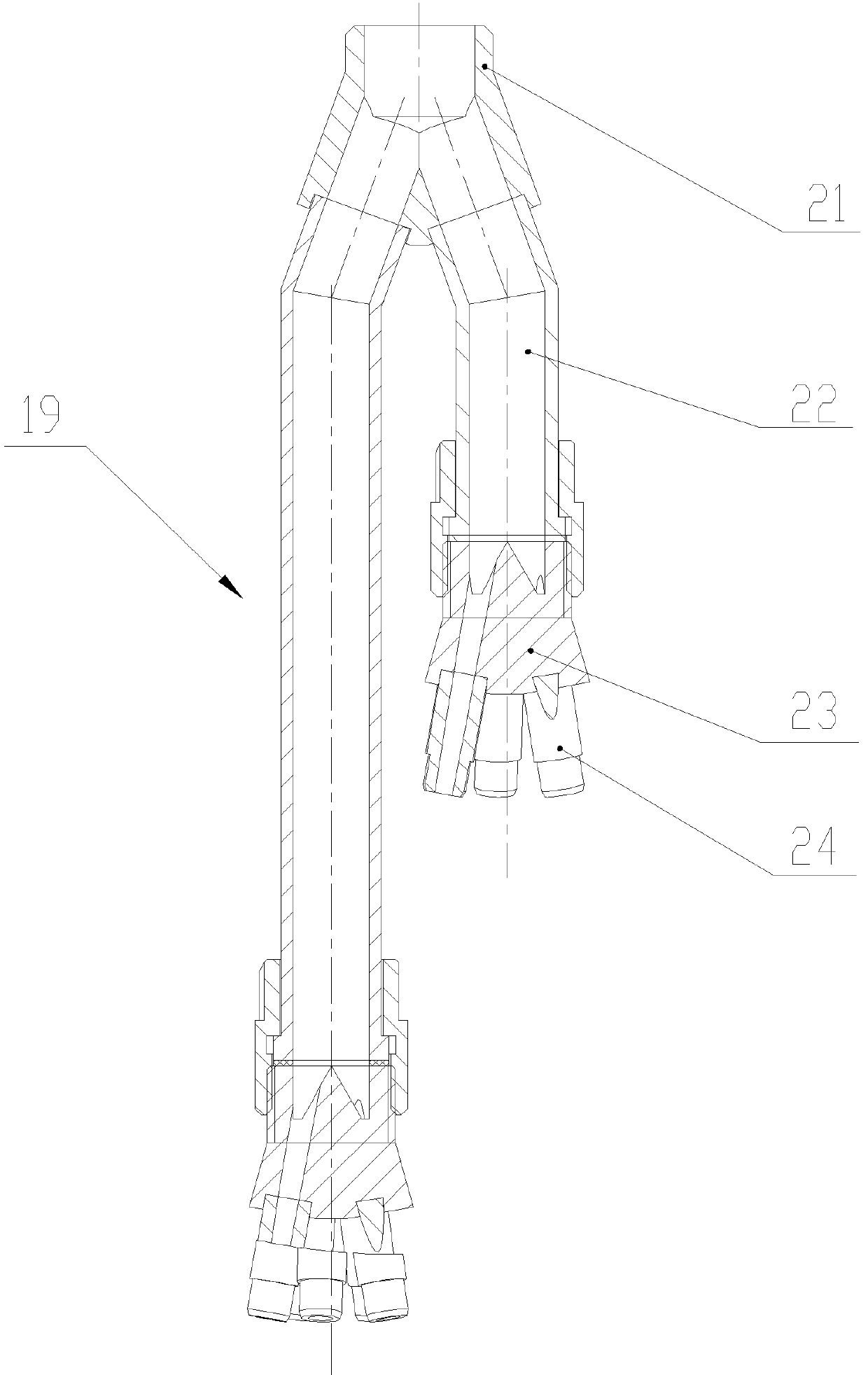

Method and device for sea natural gas hydrate production

The invention discloses a kind of marine natural gas hydrate drilling device and equipment. The method incldues the following steps: exploit the natural gas hydrate layer in the sea floor; separate the silt in the sea floor through silt separating equipment, then transmits the mixture of natural hydrate, resolved gas and water into the resolving device on the sea-level; channel the sea water with higher temperature into the resolving device on to resolve natural gas hydrate; channel out the resolved natural gas and sea water separately. The device includes drilling facility, silt separating equipment, hydrate resolving device and natural gas leadingo ut pipeline, etc. The method and device of the invention well overcome the drawbacks of the existing method for exploiting marine natural gas hydrate, its equipment is simple, operation is easy, cost is low, working efficiency is high, and can apply to extensive exploitation of marine natural gas hydrate.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

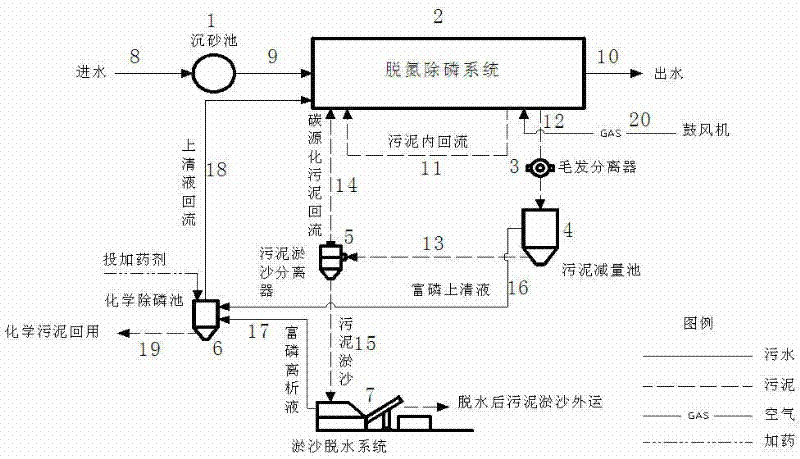

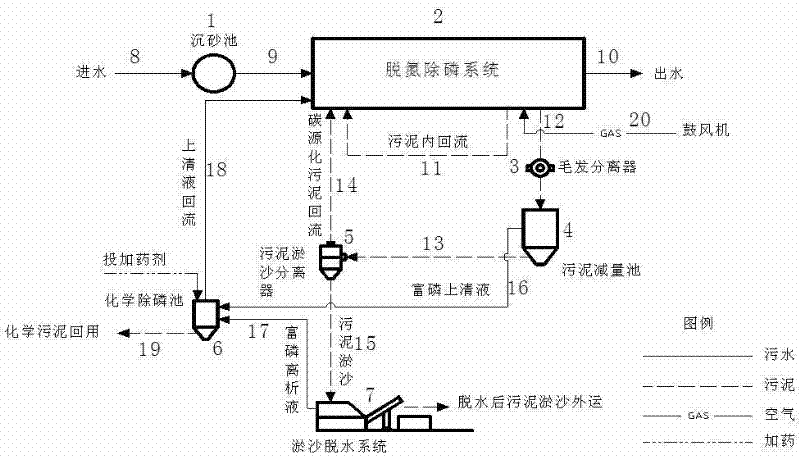

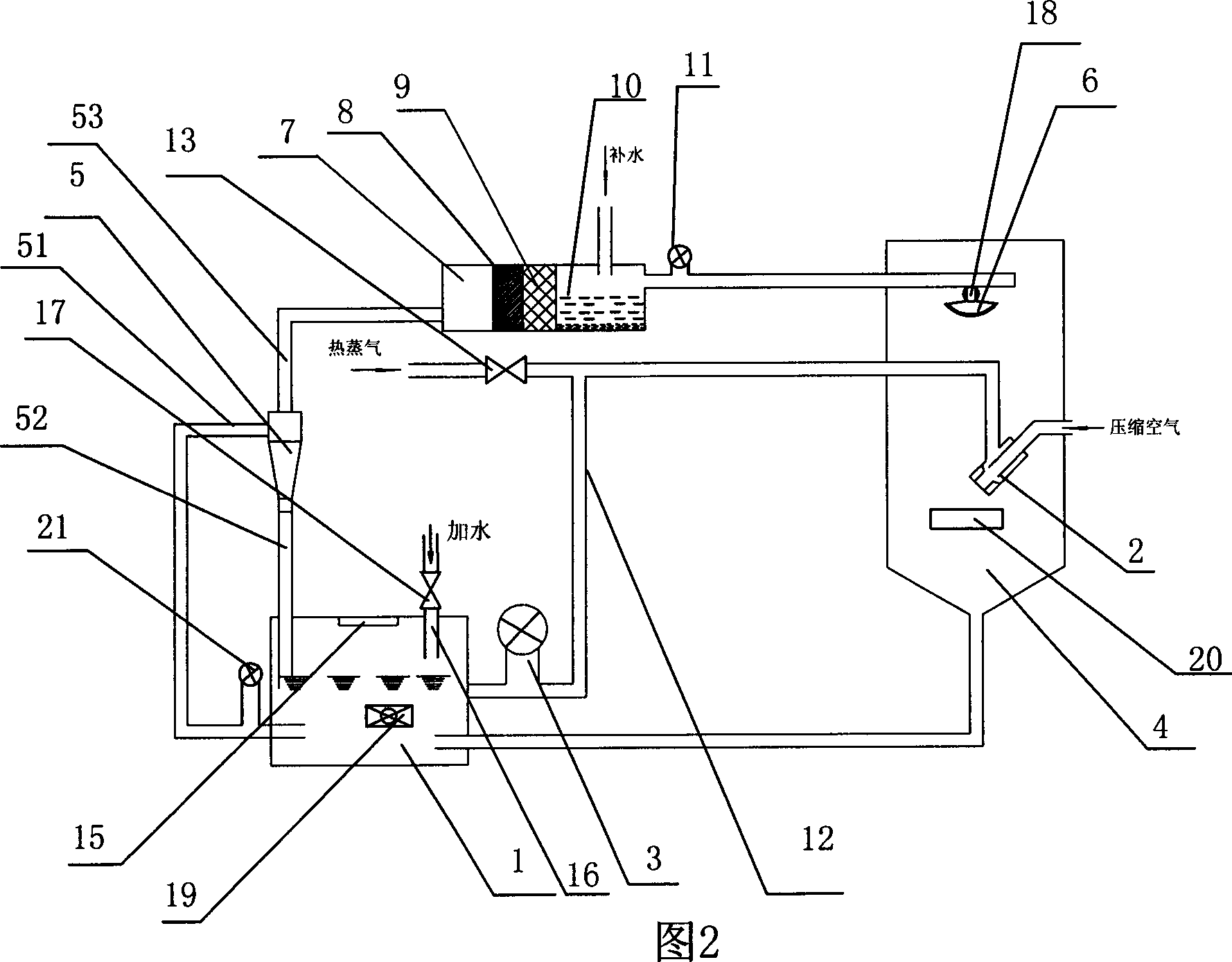

Bypass sludge reduction and silt separation and denitrification and dephosphorization waste water treatment system and method

InactiveCN102241462AImprove biological treatment efficiencyAvoid accumulationSludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesMixed liquor suspended solidsWater treatment system

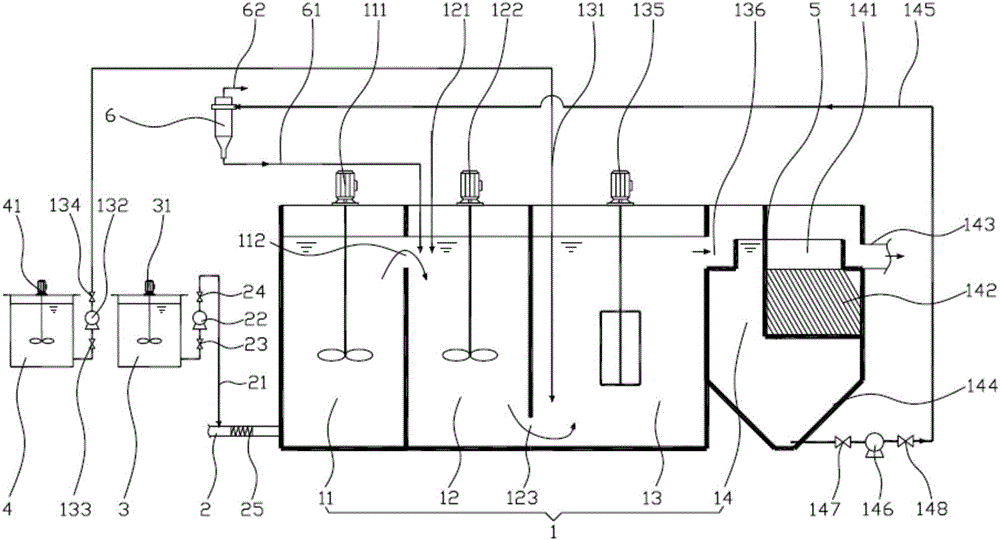

The invention provides a bypass sludge reduction and silt separation and denitrification and dephosphorization waste water treatment system and a bypass sludge reduction and silt separation and denitrification and dephosphorization waste water treatment method for solving the frequency problems of high sand content in incoming water, low volatile suspended solid (VSS) / mixed liquor suspended solids (MLSS), inadequate carbon source and the like in the conventional denitrification and dephosphorization process. The system consists of a main waste water treatment system having denitrification and dephosphorization functions and a bypass system, wherein the main waste water treatment system comprises a grit chamber and a waste water treatment system having denitrification and dephosphorization functions; and the bypass system consists of a hair separator, a sludge reduction pool, a sludge and silt separator, a silt dewatering system and a chemical dephosphorization system. In the invention, by discharging the sludge and silt and retaining slit organic matters, the silt is prevented from depositing in the waste water treatment system and the VSS / MISS ratio of the sludge in a biochemical reaction pool is improved. By returning the sludge recycled as a carbon source, a carbon source is provided for the main waste water treatment system. By applying chemical dephosphorization in the embedded bypass system, the phosphorus in urban waste water can be removed and recycled chemically at low cost.

Owner:CHONGQING UNIV

Mobile gas separator system and method for treating dirty gas at the well site of a stimulated gas well

Owner:STRAHAN RONALD L

Method and equipment for removing scale on metal wires or metal bars by grinding material water jet

The invention discloses a method for removing scale on metal wires or metal bars by grinding material water jet, which comprises the following steps: 1) preparing a grinding material by mixing sand and water in a preset proportion; 2) pumping the prepared grinding material into a splitter by a mortar pump and then allowing the prepared grinding material to enter a jetting cavity; and simultaneously, pressurizing the water by a high-pressure pump to change the water into high-pressure water and convey the water into the jetting cavity, and impacting the grinding materials by taking the high-pressure water as motive power to remove scale through jetting. Special scale removal equipment provided by the method comprises a mixing tank positioned below a scale removal box, an automatic fluidifying and sanding-up device for sanding up sand to the mixing tank, a jetting device and a water box, and also comprises a sand separator positioned in the scale removal box, a high-pressure pump for generating the high-pressure water and the mortar pump for conveying the grinding materials to the sand separator. The grinding materials are impacted by taking high-pressure water as the motive power to remove the scale on the metal wires or the metal bars, and the method and the equipment have the advantages of improving the working efficiency effectively, relieving the labor strength of workers, along with quick cleaning speed, difficult blocking of sprayers, good scale removal effect, no damage to metal matrixes and no environmental pollution.

Owner:HUNAN NONFERROUS HEAVY MACHINERY

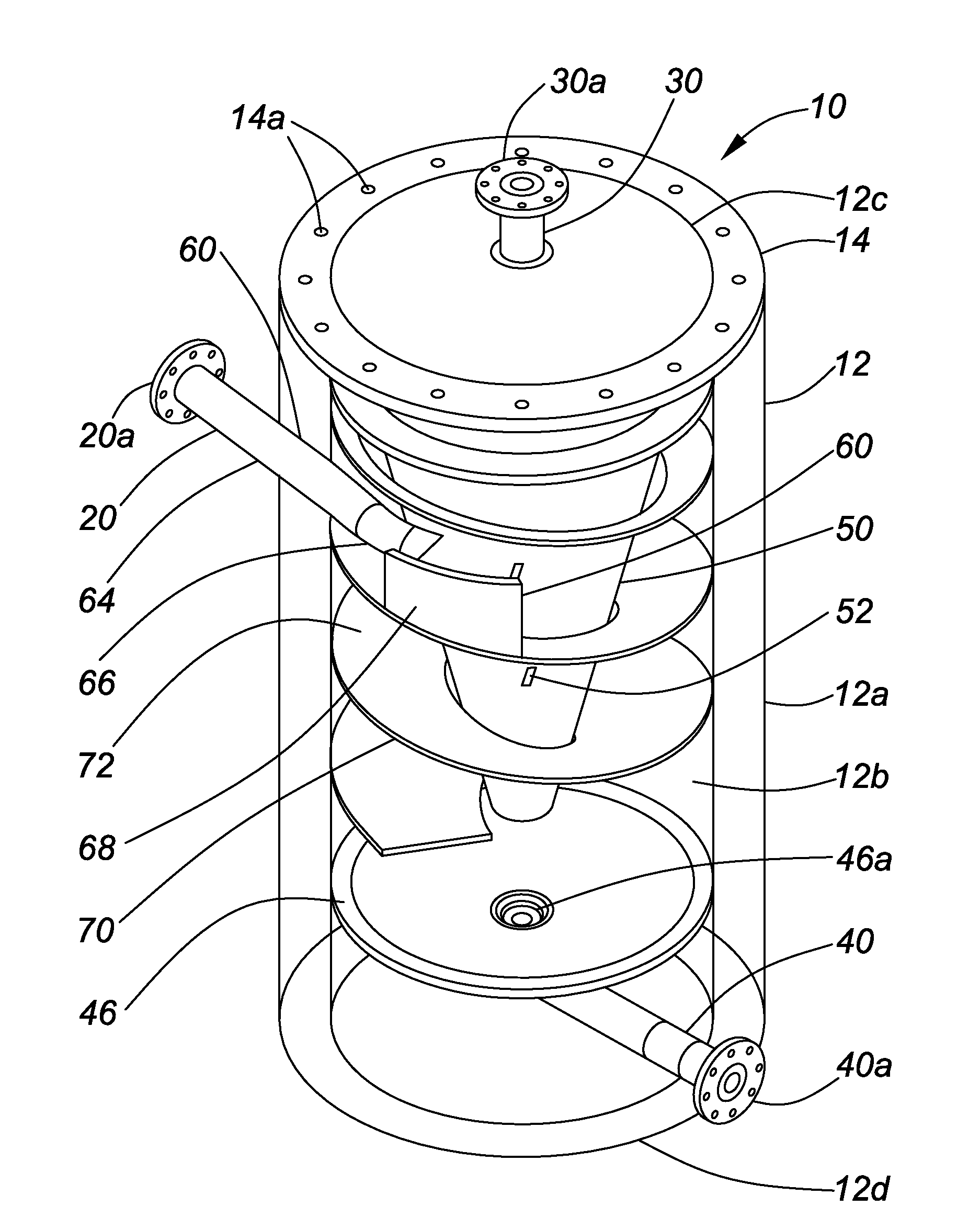

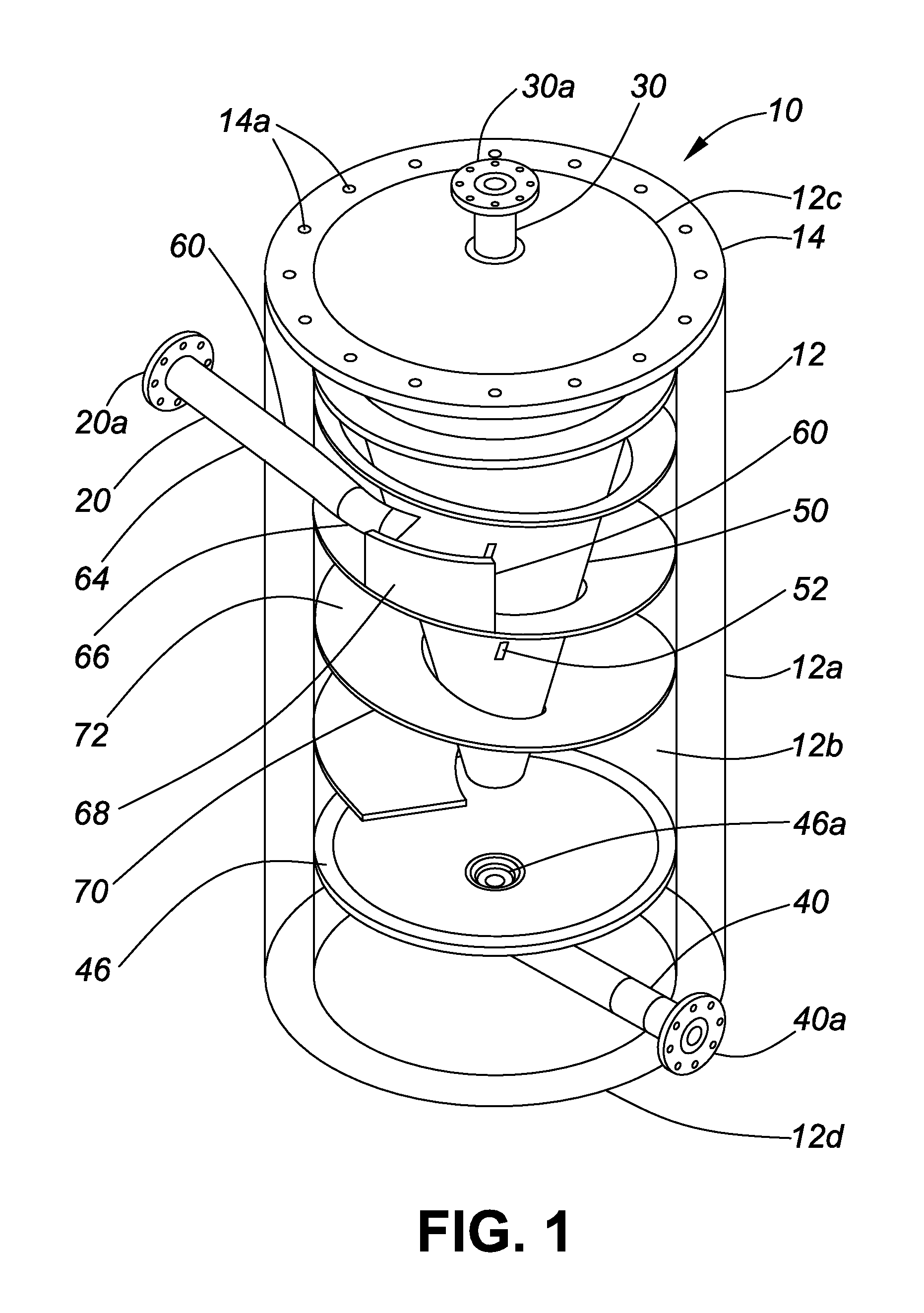

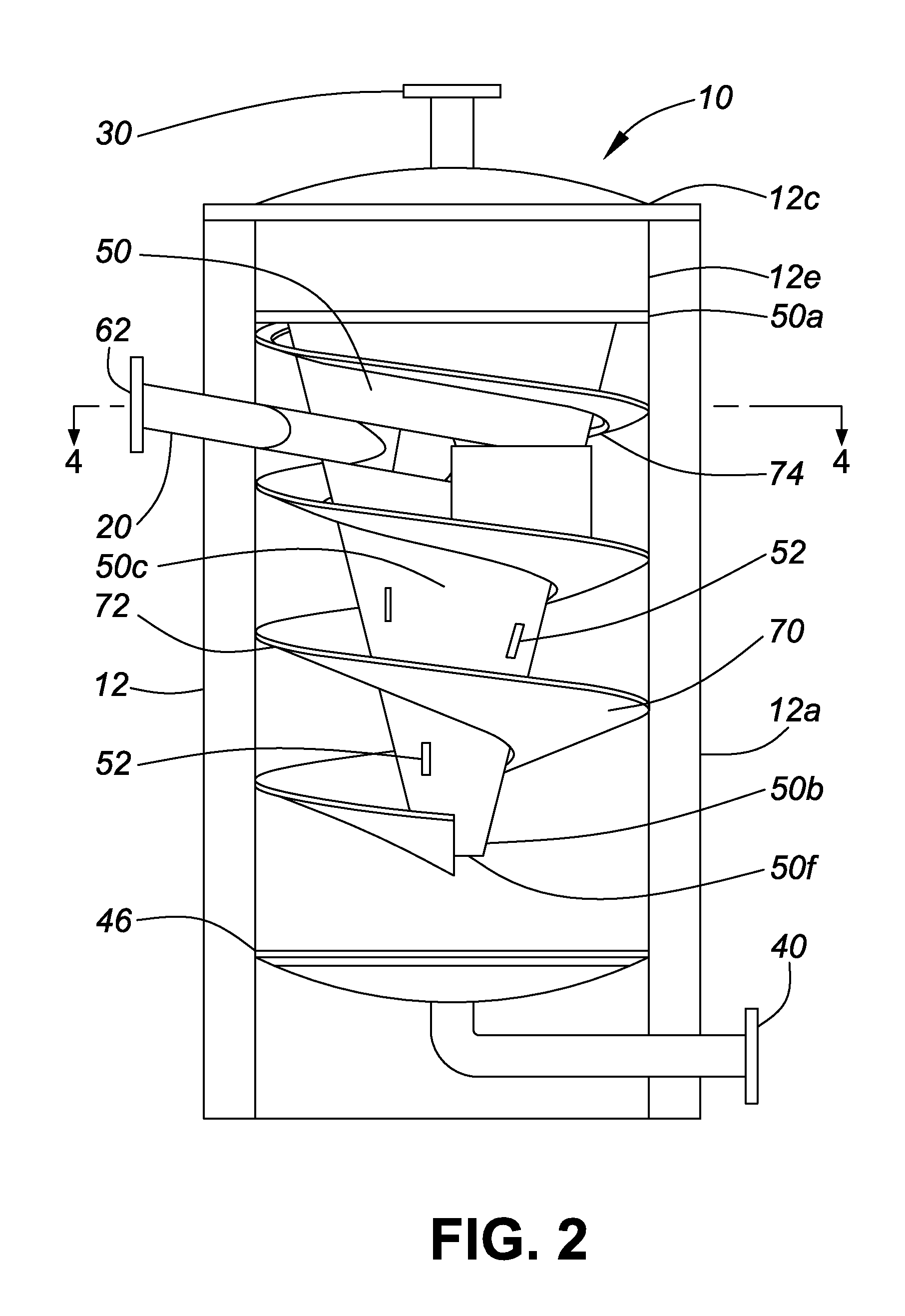

Sand separator

ActiveUS20140243571A1Reversed direction vortexHydrocarbon purification/separationProcess engineeringProduct gas

An apparatus and method for separating a natural gas production stream from hydrocarbon well operations into a gas component and a sand and liquid component is described. More specifically, a sand separator comprising a cylindrical body, a production stream inlet port, a gas outlet port and a solid and liquid drain port is described. The cylindrical body has an inner cavity with an inner cone having one-way gas vents and a stationary auger wrapped around the inner cone. The production stream inlet port includes a pipe having a curved tip that directs the production stream into the body and around the inner cone and stationary auger, causing the production stream to slow down and the components to separate.

Owner:2468042 ALBERTA LTD

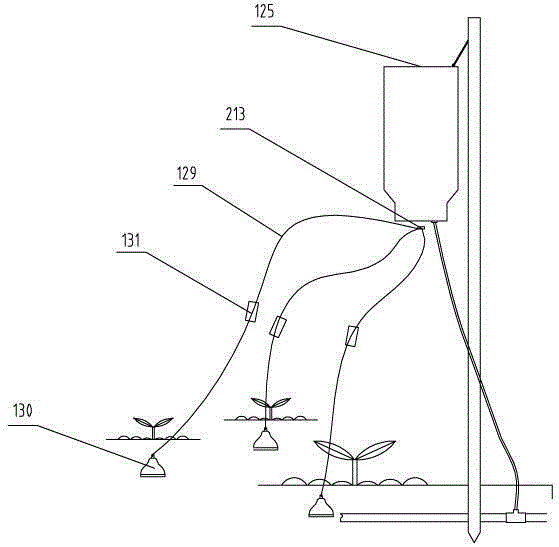

Pulse type intelligent agricultural water-saving drip irrigation pot micro-irrigation system

ActiveCN105265282AGood adjustment spaceClimate change adaptationWatering devicesWater sourceDrip irrigation

Owner:HUBEI FOR LONG PIPE TECH CO LTD

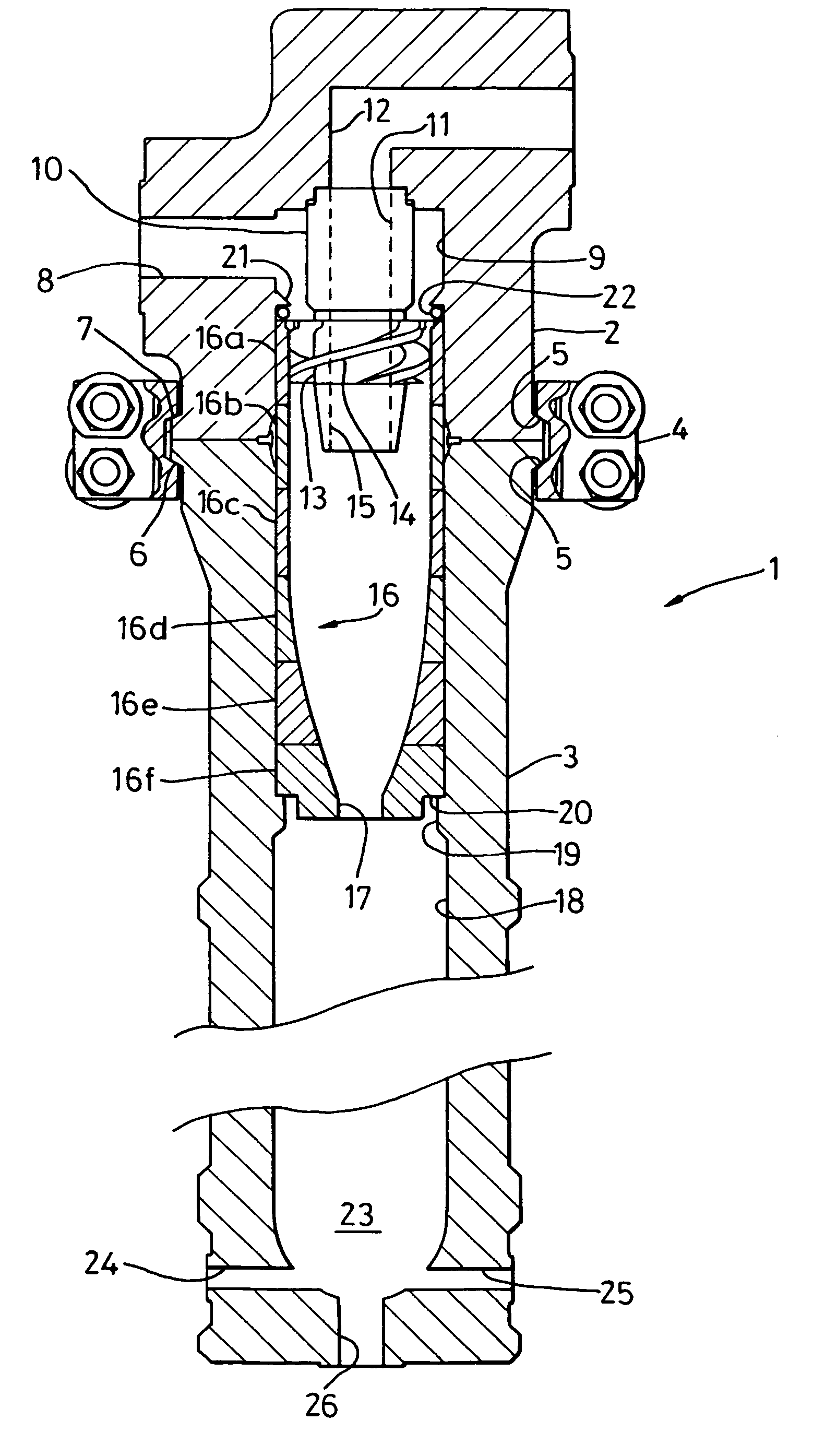

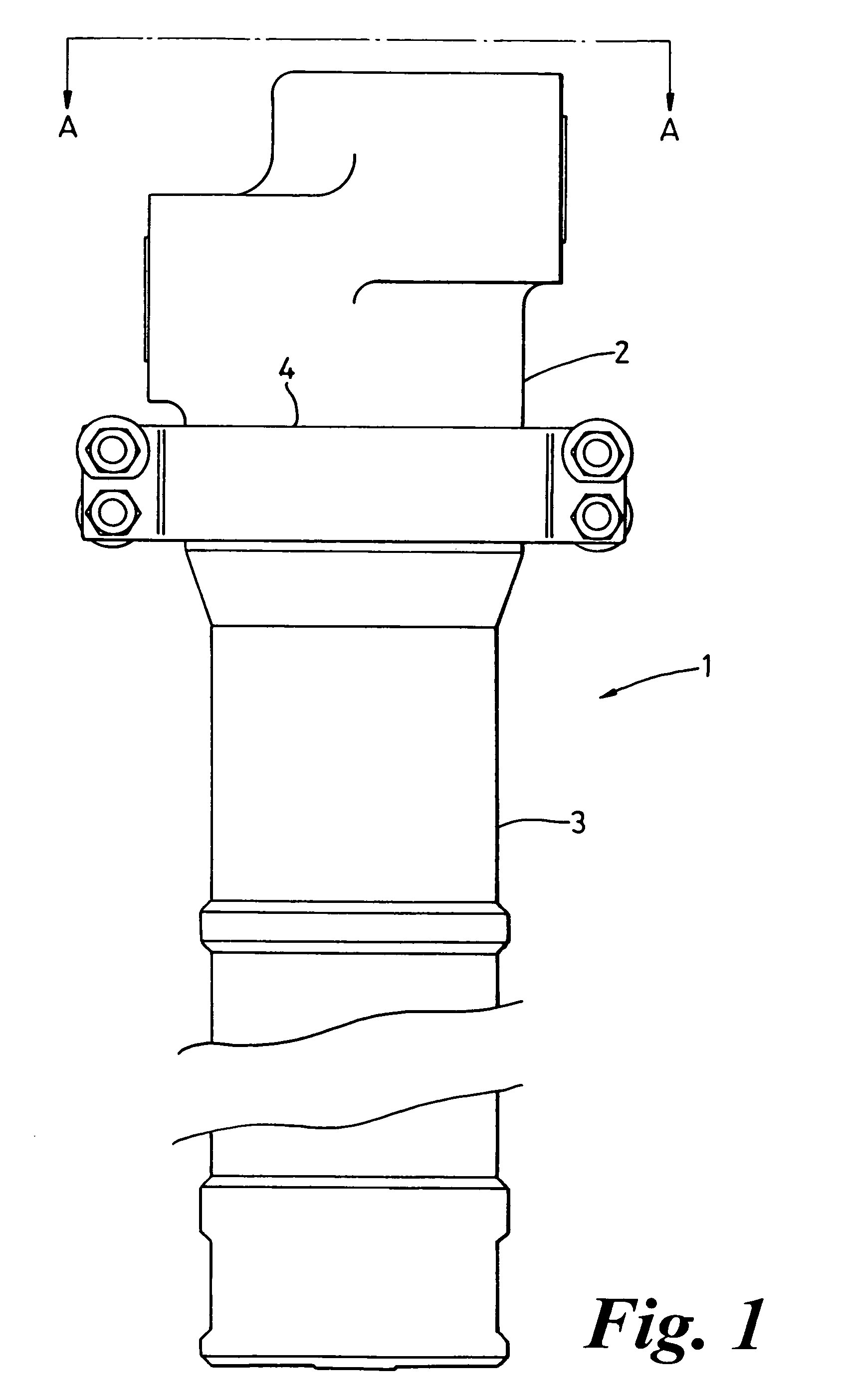

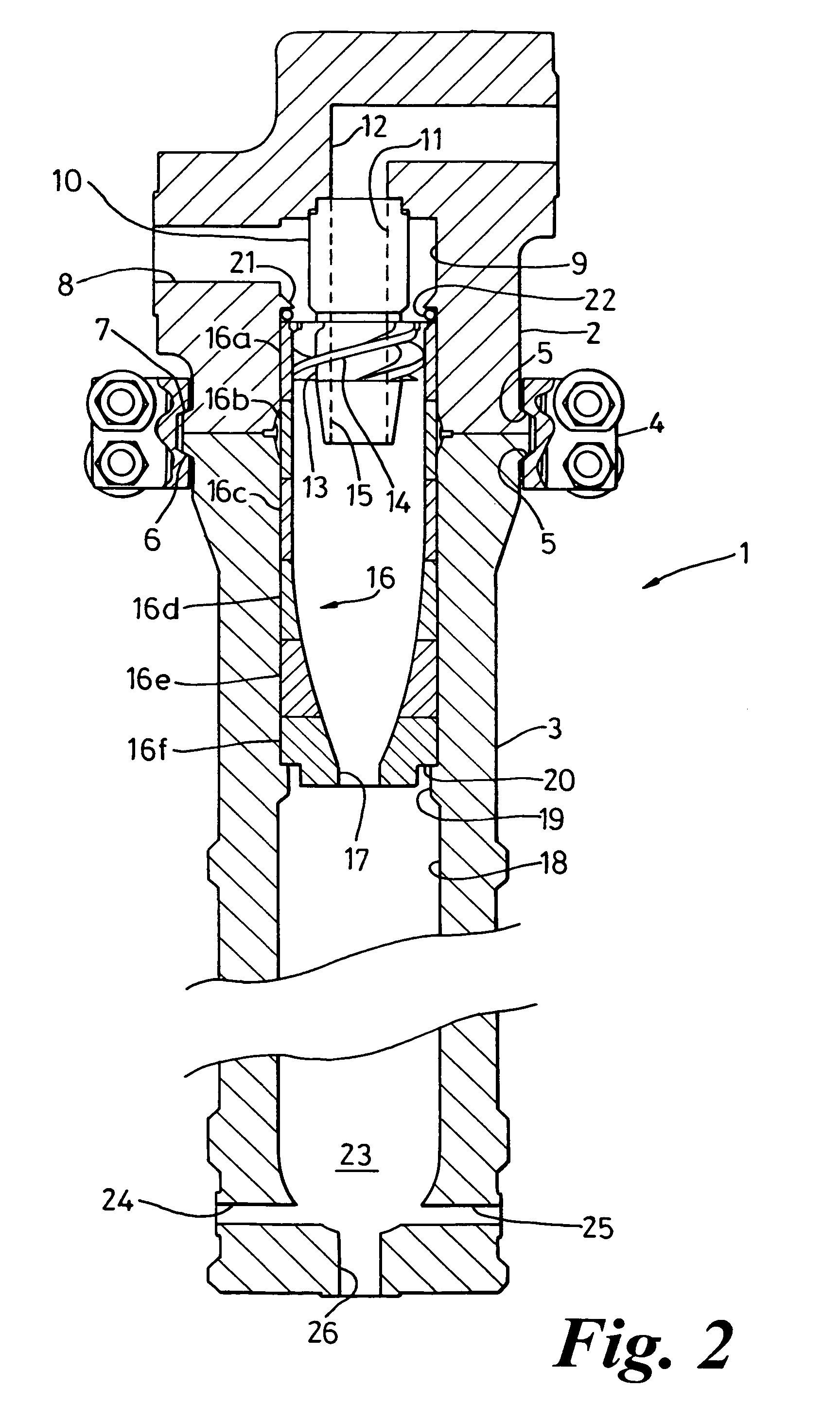

Relating to well head separators

ActiveUS7635430B2Easy to shapeEasy to solveWater/sewage treatment by centrifugal separationReversed direction vortexCycloneParticulates

Well head hydrocyclone separators are typically used for separating particulates from fluids such as gas, oil and water and mixtures thereof. Well head separators are useful to prevent wear and blocking of choke valves, rupture of piping, damage to instruments and to prevent vessels from filling with particulate materials. In the present invention, the cyclone separator assembly includes an inlet, an overflow outlet and a segmented cyclone separator tube.

Owner:AXSIA SERCK BAKER

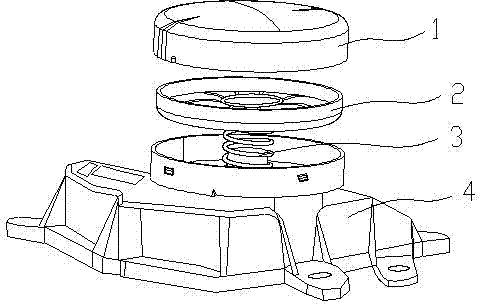

Plastic oil and gas separator with labyrinth type and screw type combined

ActiveCN103939177ALow densityHas the effect of double separationMachines/enginesCrankcase ventillationEconomic benefitsAir separation

The invention relates to a plastic oil and gas separator with the labyrinth type and the screw type combined in order to solve the problems that oil and gas separation efficiency can not be optimized, and the mixture of engine oil and gas can not be completely separated. The plastic oil and gas separator with the labyrinth type and the screw type combined comprises a shell and a clamping cover arranged on the end face of the shell and is characterized in that the shell is of a flat box type structure formed through one-time injection molding, and an oil and gas mixture inlet, an oil return cavity and an air separation cavity are all provided with smooth surfaces; the oil and gas mixture firstly passes through a labyrinth type channel and then passes through a fine separator assembly; the fine separator assembly is provided with a plurality of oil and gas separation holes with screw-type channels; the position where the clamping cover is matched with the shell is provided with an oil and gas separation diaphragm. The plastic oil and gas separator with the labyrinth type and the screw type combined is scientific and reasonable in structure and has good economic benefits and the environmental-friendly working effect, and separated matter can be recycled.

Owner:SHENTONG TECH GRP CO LTD

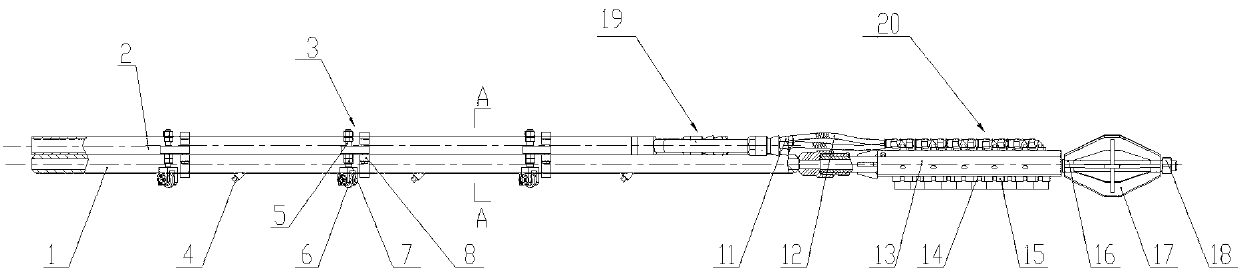

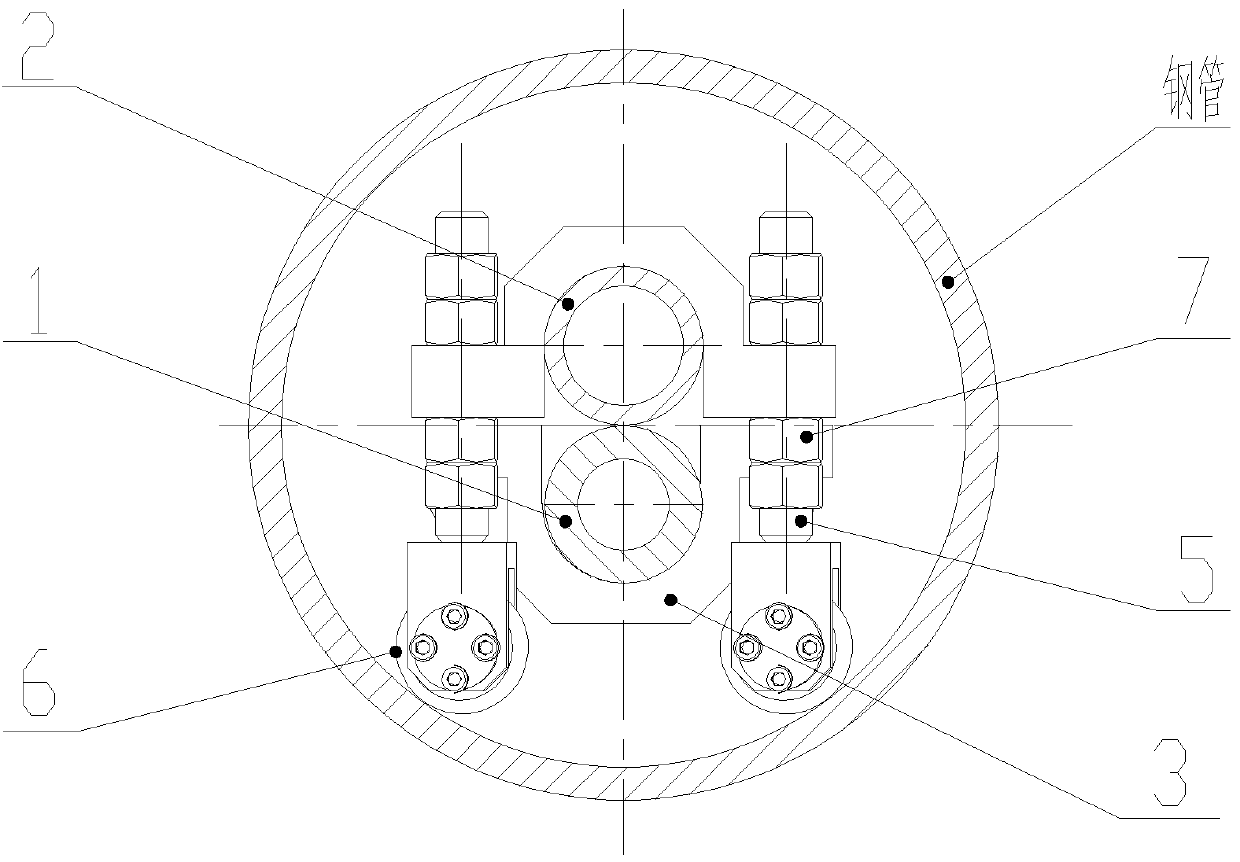

Steel pipe inner wall washing gun

InactiveCN103100982ALarge diameter rangeNo pollution in the processBlast gunsAbrasive feedersRolling resistanceHigh-speed grinding

The invention discloses a steel pipe inner wall washing gun comprising a sand supplying pipe and a high-pressure water supplying pipe located below the sand supplying pipe, wherein the tail end of the sand supplying pipe is connected with a sand separator; the tail end of the high-pressure water supplying pipe is connected with an injection head; the injection head comprises a plurality of independent injection units; and all the injection units are communicated with the sand separator. The sand supplying pipe and the high-pressure water supplying pipe respectively convey mortar and high-pressure water to the injection units; the mortar and the high-pressure water are mixed in nozzles of the injection units to form a grinding material jet flow which moves at a high speed so as to form a linear injection section; and the impact and the washing of the high-speed grinding material injection flow are used so that scales on the inner wall of a steel pipe can be removed in a continuous, efficient and environment-friendly manner. The sand supplying pipe and the high-pressure water supplying pipe are fixed through a pipe clip assembly and a supporting wheel of the pipe clip assembly is contacted with the inner wall of the steel pipe to support a whole de-scaling gun; the de-scaling gun and the inner wall of the steel pipe are in rolling friction, so that the movement resistance is reduced and no barrier exits when the de-scaling gun and the steel pipe move relatively. Furthermore, the height of the supporting wheel is adjustable so as to adapt to the size of the diameter of the steel pipe to be washed.

Owner:HUNAN NONFERROUS HEAVY MACHINERY

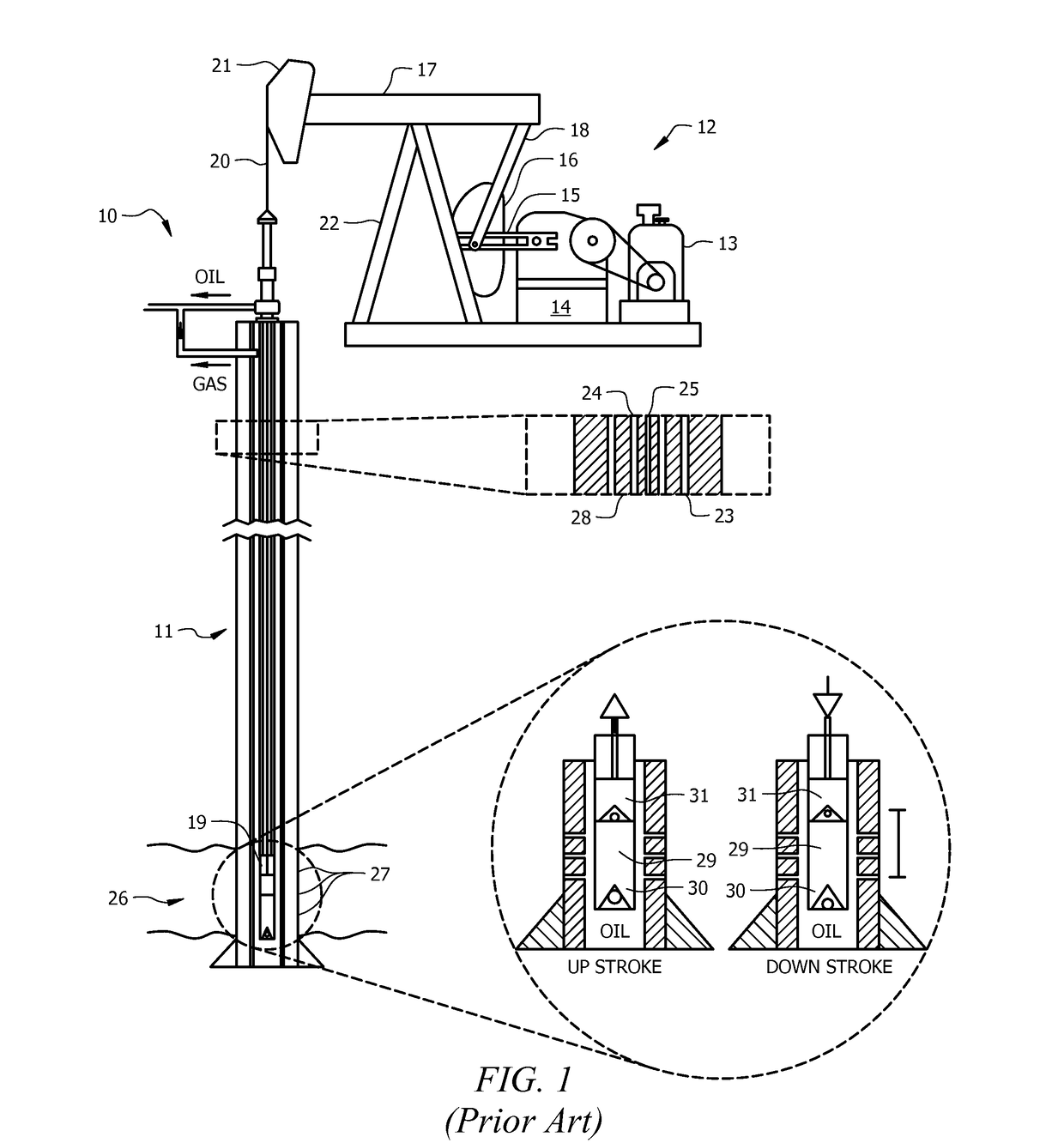

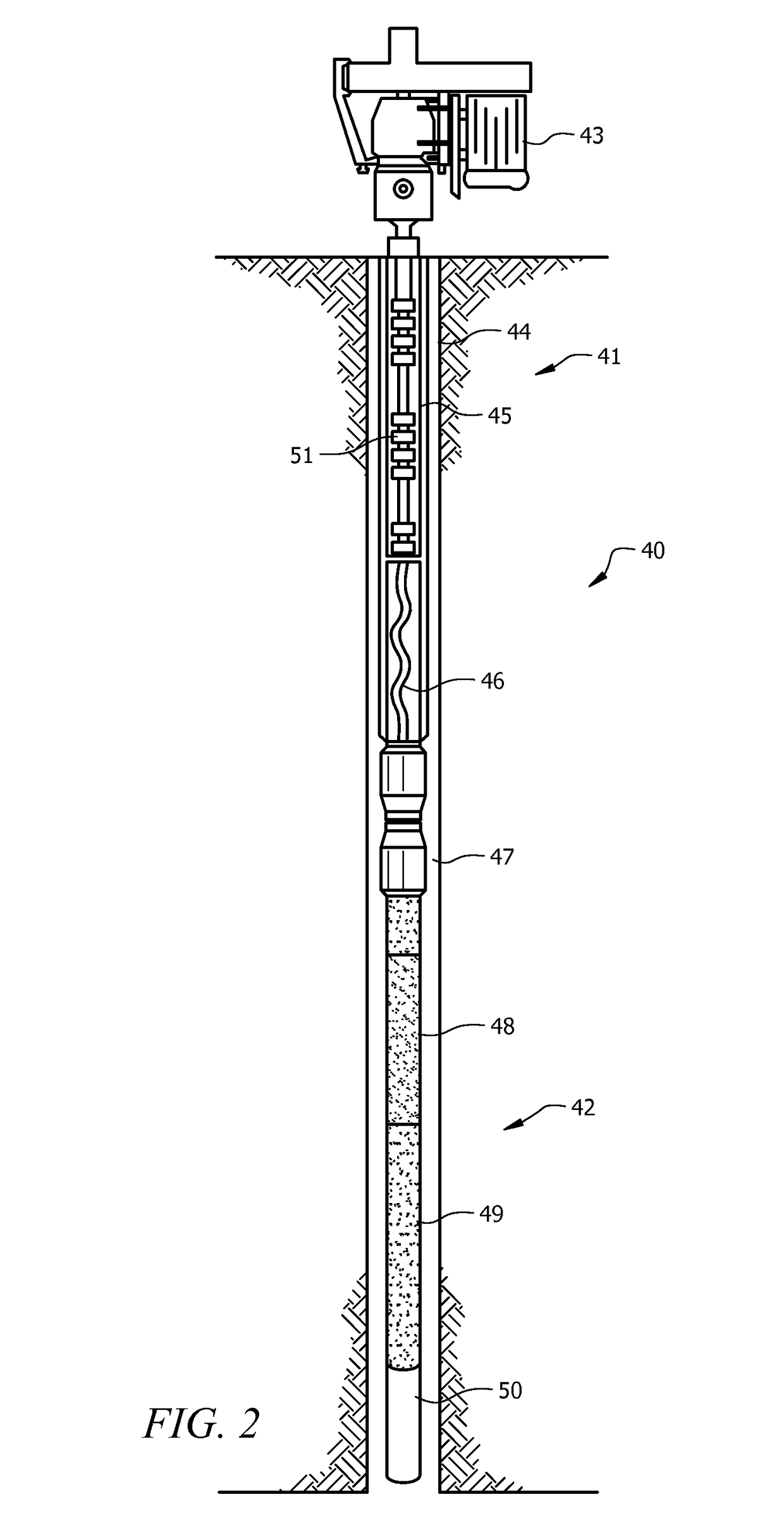

Down-hole gas and solids separator utilized in production hydrocarbons

A particulate separator system and method for petroleum wells are described. An embodiment comprises a two stage separator. A fluid mixture flows into an outer casing that surrounds an inner tube. The first stage comprises a number of baffles that help to separate gas from fluid as the fluid mixture falls downward within the casing. A second stage comprises a widened inner tube and a fin causing the fluid mixture to fall radially around the inner tube and downward. As the mixture gains speed the particulate matter is forced to the periphery of the mixture by centrifugal force. A pump intake on the bottom of the inner tube pulls in the fluid while the particulate matter falls away.

Owner:HARBISON FISCHER

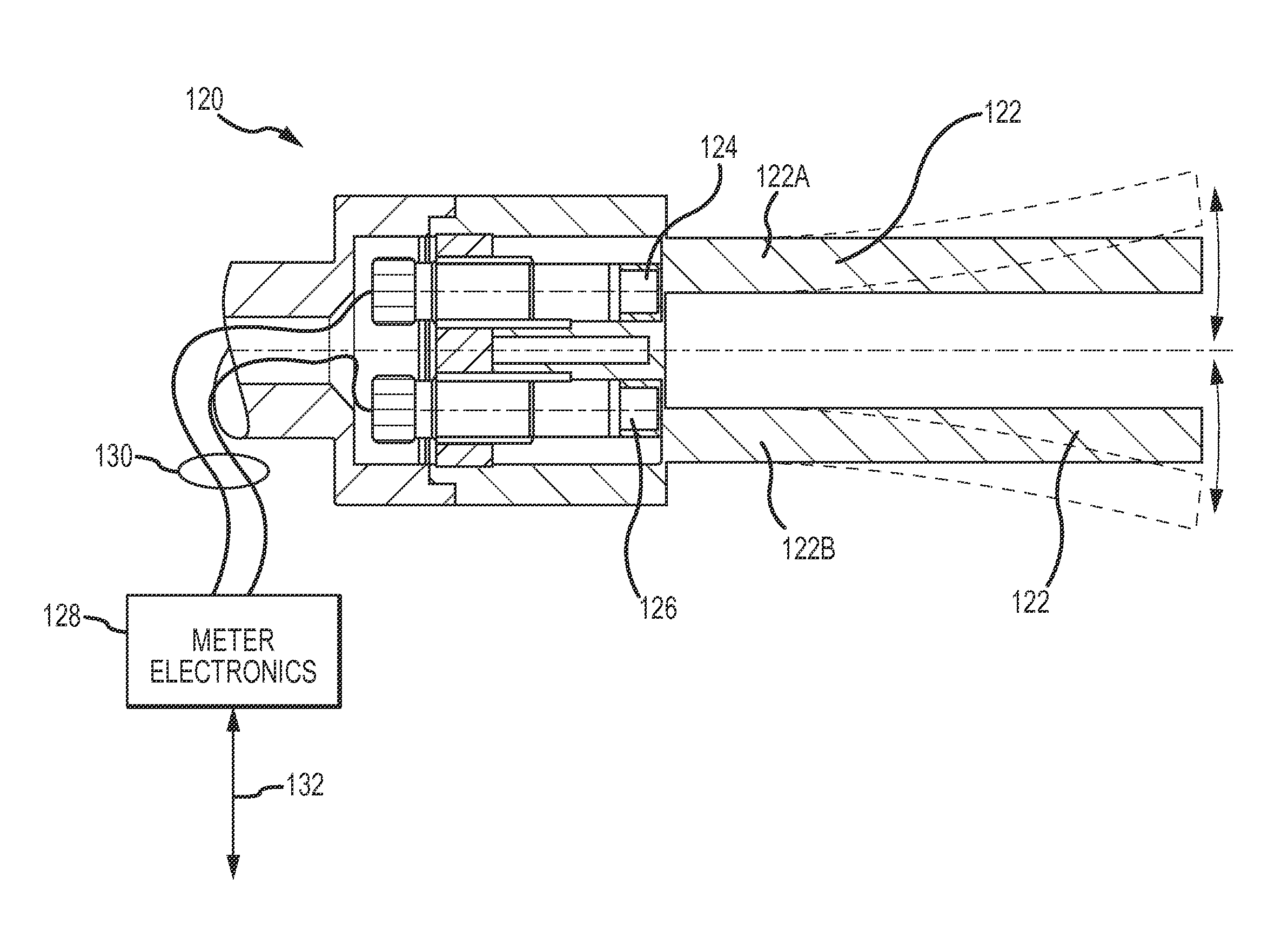

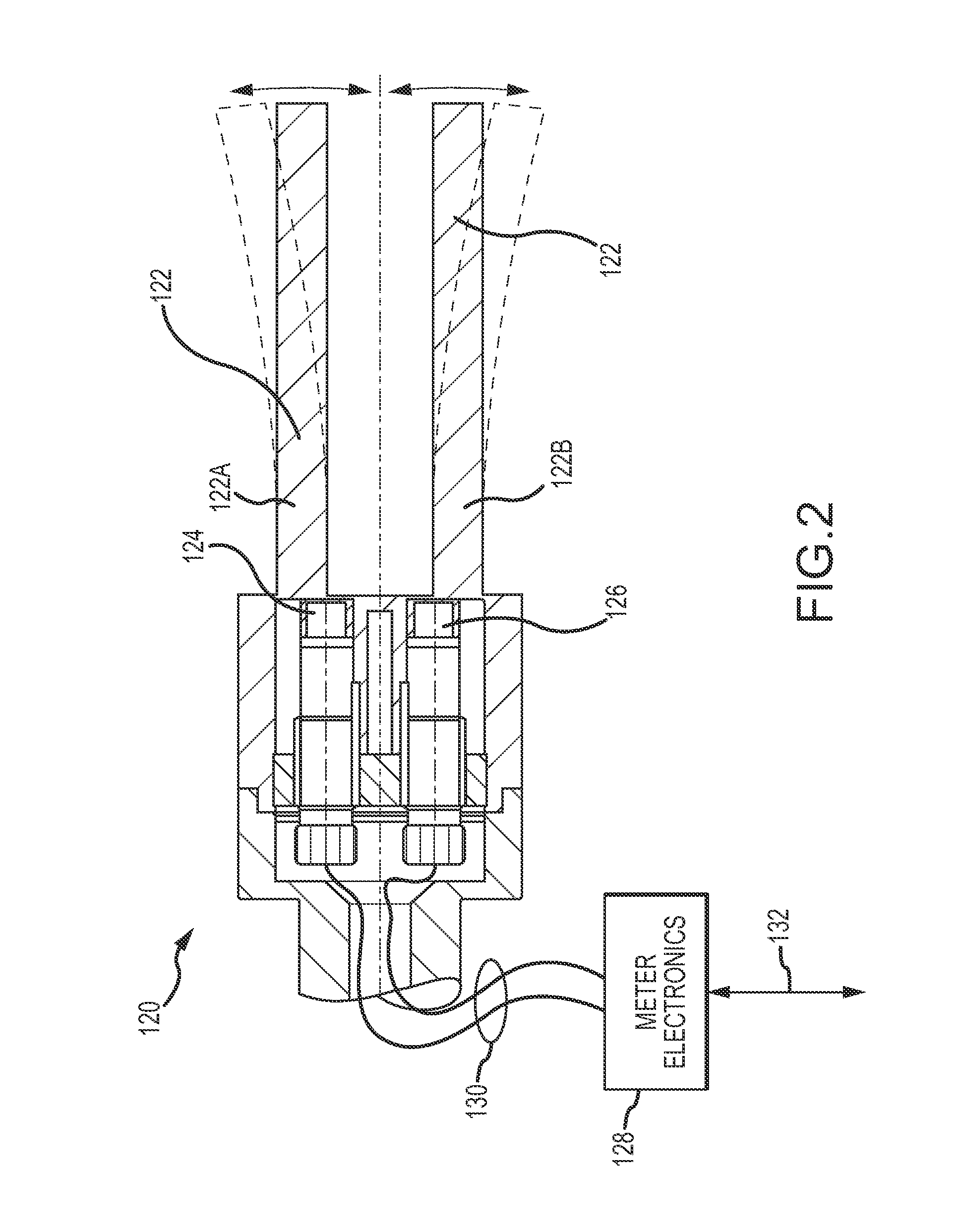

Sand separator interface detection

ActiveUS20160059153A1Settling tanks feed/dischargeWater/sewage treatmentElectricityEnvironmental engineering

A sand separator is provided that includes a separation chamber and a drain. The sand separator comprises a meter in fluid communication with an interior of the separation chamber, wherein the meter is configured to detect a liquid / solid interface. Meter electronics in electrical communication with the meter are configured to receive a signal from the meter indicating the liquid / solid interface.

Owner:MICRO MOTION INC

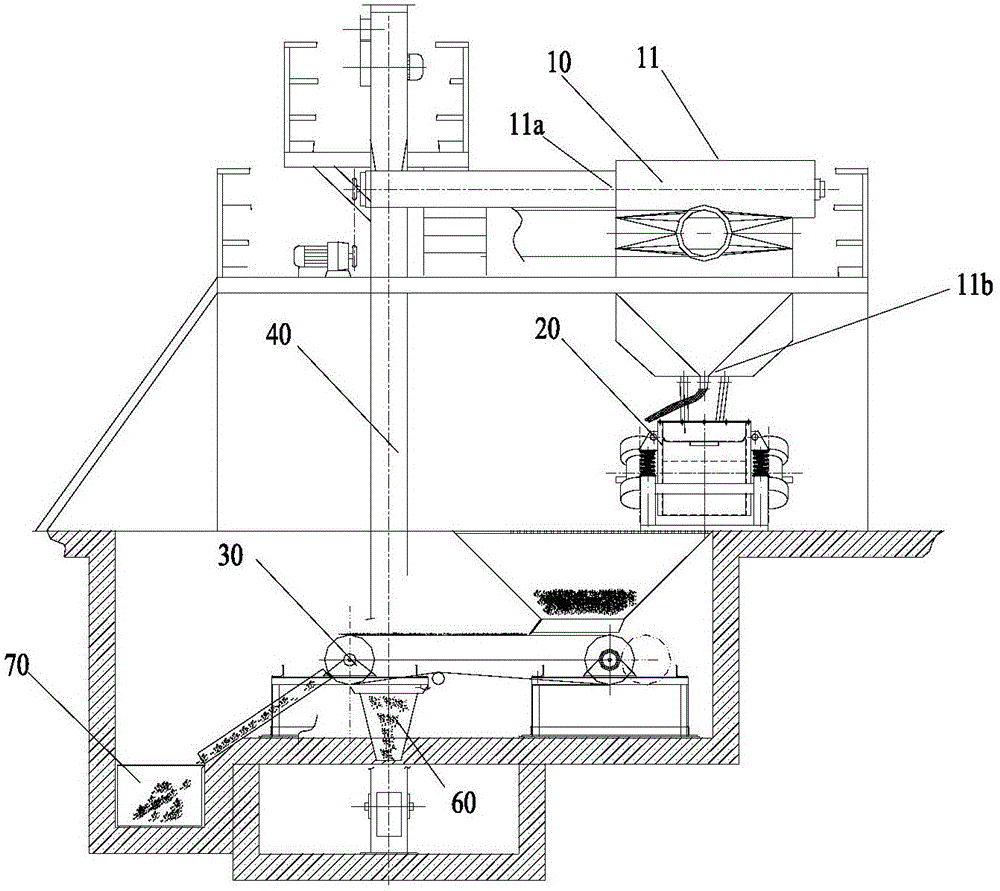

Shot blasting waste recycling system and method

InactiveCN105798781AEfficient recyclingMaximize recoverySievingGas current separationIron powderSand blasting

The invention relates to the field of machining, and discloses a shot blasting waste recycling system and method, wherein the shot blasting waste recycling system comprises a shot-sand separator (10), a vibration screening device (20) and a magnetic separating device (30) which are sequentially arranged, wherein the shot-sand separator (10) is used for separating shots containing pills from the shot blasting waste; the vibration screening device (20) is used for screening the shots into pills and iron-containing ash; and the magnetic separating device (30) is used for separating iron powder from the iron-containing ash. Beneficial resources in the shot blasting waste can be effectively recycled by the following triple separating steps: firstly, carrying out shot-sand preliminary separation on the shot blasting waste by the shot-sand blasting separator; secondly, separating out the pills in the shots by the vibration screening device; and finally, separating out iron-containing resources in screen underflow of the shots by the magnetic separating device, thereby recycling the beneficial resources in the shot blasting waste to a maximum extent.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Novel vertical type oil-gas separator

ActiveCN104713280ALittle resistance lossReduce chargeRefrigeration componentsComing outFriction loss

The invention discloses a novel vertical type oil-gas separator. Oil-gas mixtures enter the oil-gas separator through a bending pipeline, centrifugal separation is formed in the bending pipeline, the oil-gas mixtures form collision separation with the wall surface of a horizontal barrel body after coming out from the bending pipeline, the oil-gas mixtures reversely flow after being collided, after the oil-gas mixtures penetrate through a W-shaped baffling perforated plate and a vertical perforated plate, part of oil drops are caught by the wall surfaces of the baffling perforated plate and the vertical perforated plate, and the oil-gas mixtures pass through a filter screen at uniform flow velocity to be filtered and separated so that the surplus oil drops are separated out. Multiple stages of separating devices are utilized to separate the oil drops out from the oil-gas mixtures, the separating efficiency is not affected by the machine set running state, and on the premise that the separating efficiency is met when a machine set is run at full load, the separating efficiency under other load is also very good; the oil-gas mixtures are very small in resistance loss through collision and filter screen separation; filling of lubricating oil is mainly located on a vertical barrel body section, and the filling volume of the lubricating oil is reduced.

Owner:MCQUAY AIR CONDITIONING & REFRIGERATION WUHAN

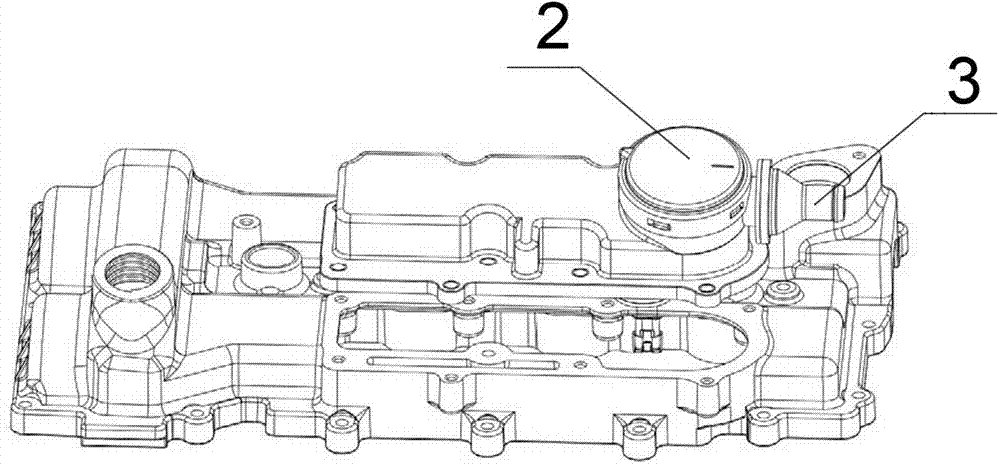

Oil-gas separator

InactiveCN104500174AAchieving compactness requirementsSimple structureMachines/enginesCrankcase ventillationCylinder headProcess engineering

An oil-gas separator comprises a shell, an S-shaped mixed gas channel, a maze structure and a cyclone structure. The shell is mounted on a cylinder head cover and internally provided with the S-shaped mixed gas channel. The maze structure and the cyclone structure are arranged in the shell. The technical scheme includes that a mixed gas inlet of the mixed gas channel is formed in the bottom of one end of the shell, a retainer platform structure is arranged at the mixed gas inlet, the maze structure is arranged between the mixed gas inlet and the mixed gas channel, the cyclone structure is arranged at the tail of the mixed gas channel, oil return control valves are arranged at the bottoms of the mixed gas channel and the cyclone structure, and a gas exhaust end of the cyclone structure is provided with a one-way valve and a PCV (positive crankcase ventilation) valve. In this way, the problems of the conventional oil-gas separator such as poor separating effect, high production cost, low separating efficiency and complicated structure are thoroughly solved.

Owner:BRILLIANCE AUTO

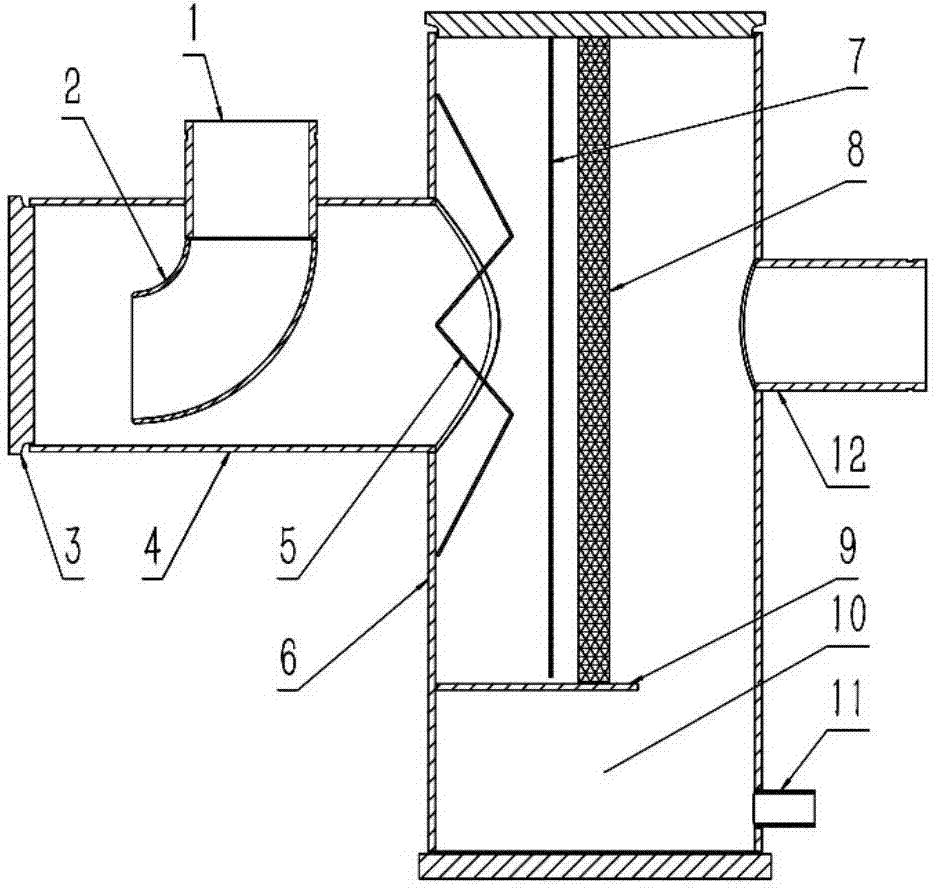

Desert tree planting machine

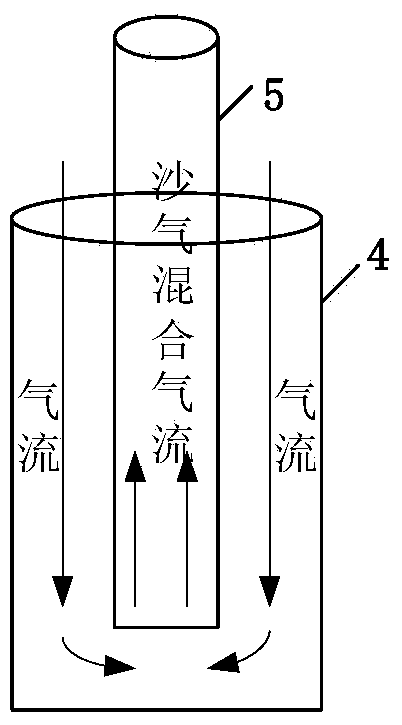

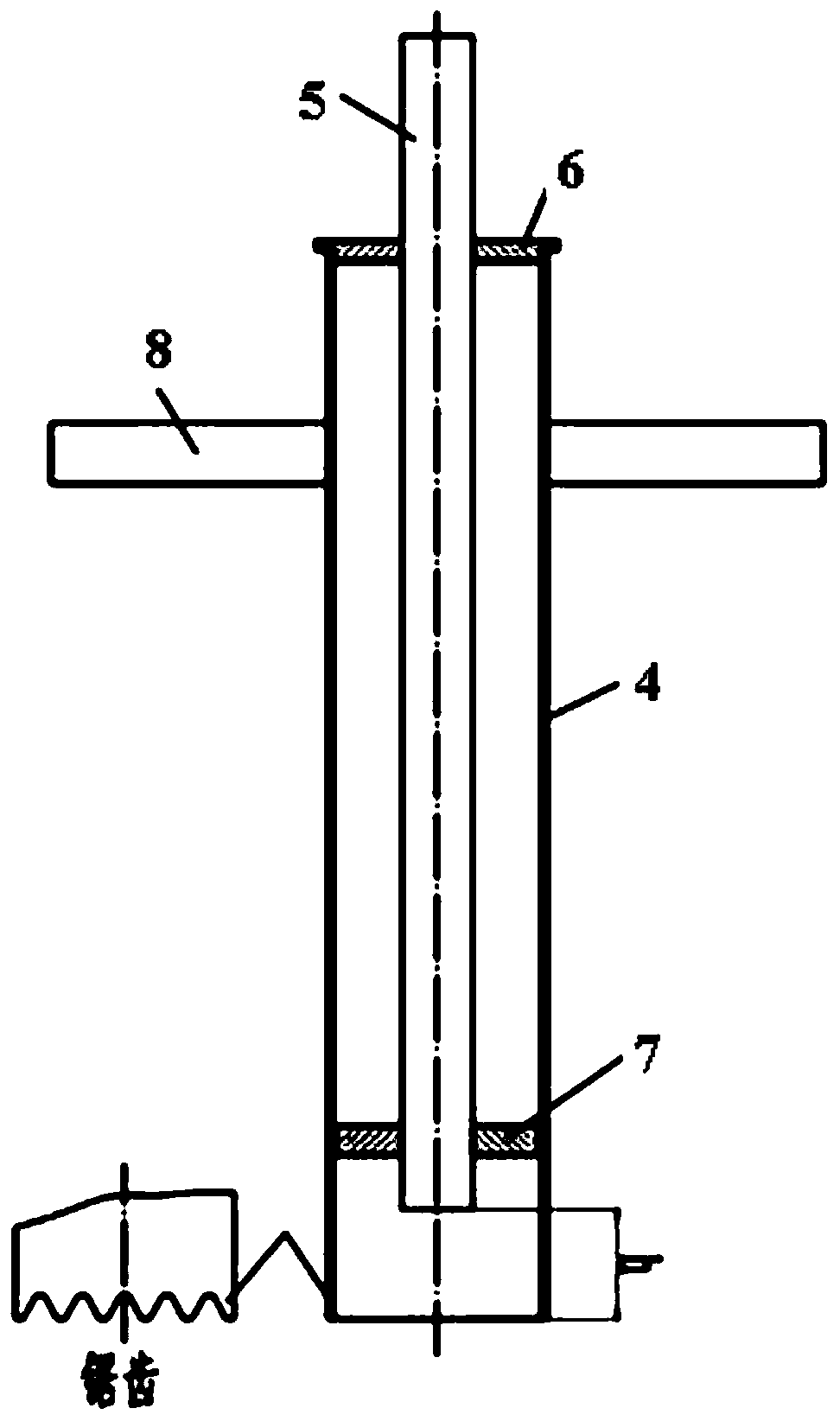

InactiveCN103518587AImprove dust removal effectRealize pneumatic conveyingPlantingVortex flow apparatusEngineeringTree planting

The invention discloses a desert tree planting machine. The desert tree planting machine comprises a split type sand absorbing hole forming device, an air and sand separator and an airflow power device. The split type sand absorbing hole forming device comprises a hole forming pipe and a sand absorbing pipe which are in a cylindrical shape. The sand absorbing pipe is sleeved with the hole forming pipe, and an annular cavity is formed between the sand absorbing pipe and the hole forming pipe. The distance between the bottom of the sand absorbing pipe and the bottom of the hole forming pipe can be adjusted. The air and sand separator comprises a rough filtering chamber and a fine filtering chamber, a partition board is arranged between the rough filtering chamber and the fine filtering chamber, and the upper portion of the rough filtering chamber is communicated with the upper portion of the fine filtering chamber. A sand inlet is formed in the top of the rough filtering chamber, and a sand discharging port I is formed in the bottom of the rough filtering chamber. An air outlet is formed in the top of the fine filtering chamber, and a sand discharging port II is formed in the bottom of the fine filtering chamber. Sand discharging valve ports are formed in the sand discharging port I and the sand discharging port II. The sand absorbing pipe is communicated with the sand inlet. The air outlet is communicated with the airflow power device. The operating principle of the desert tree planting machine is different from the operating principle of machine drilling and a ditcher in the prior art, the desert tree planting machine is simple in structure, and a hole can be formed fast.

Owner:杨永健 +2

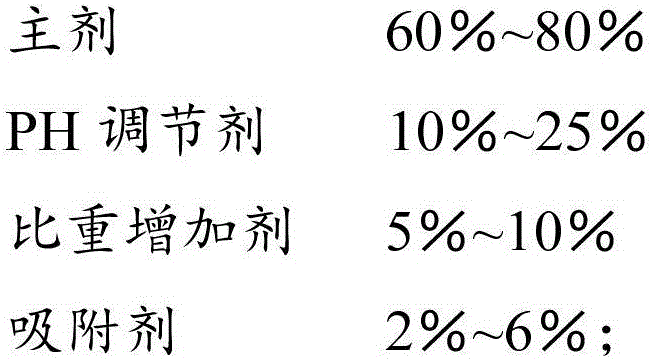

Integrated water treatment device having function of carrier flocculation sedimentation

PendingCN106830252AImpact resistantFlexible designWater/sewage treatment by flocculation/precipitationFlocculationWater quality

The invention discloses an integrated water treatment device having a function of carrier flocculation sedimentation. The device comprises an integrated pool body. The integrated pool body comprises a coagulation tank, a sand addition tank, a flocculation tank and a high speed sedimentation tank. A water inlet pipe is connected to the coagulation tank. The water inlet pipe is used for injecting sewage and a high-efficiency coagulant into the coagulation tank. The upper end of the coagulation tank is communicated with the upper end of the sand addition tank. The sand addition tank is used for adding micro-sand into sewage. The lower end of the sand addition tank is communicated with the lower end of the flocculation tank. The flocculation tank is used for feeding a coagulant aid into the sewage after reaction in the sand addition tank. The upper end of the flocculation tank is communicated with the upper end of the high speed sedimentation tank. The high speed sedimentation tank is used for separating water and alumen ustum particles in the sewage after the reaction in the flocculation tank. The high-speed sedimentation tank is externally connected to a muddy sand separator. The device has the advantages of flexible design, compact structure, small covering area, impact resistance, high treatment efficiency, low cost and strong load capacity, and can be used for purification of black and smelly polluted water and treatment on industrial wastewater having high content of suspended solids.

Owner:SHENZHEN SANLIN BIOTECH ENG

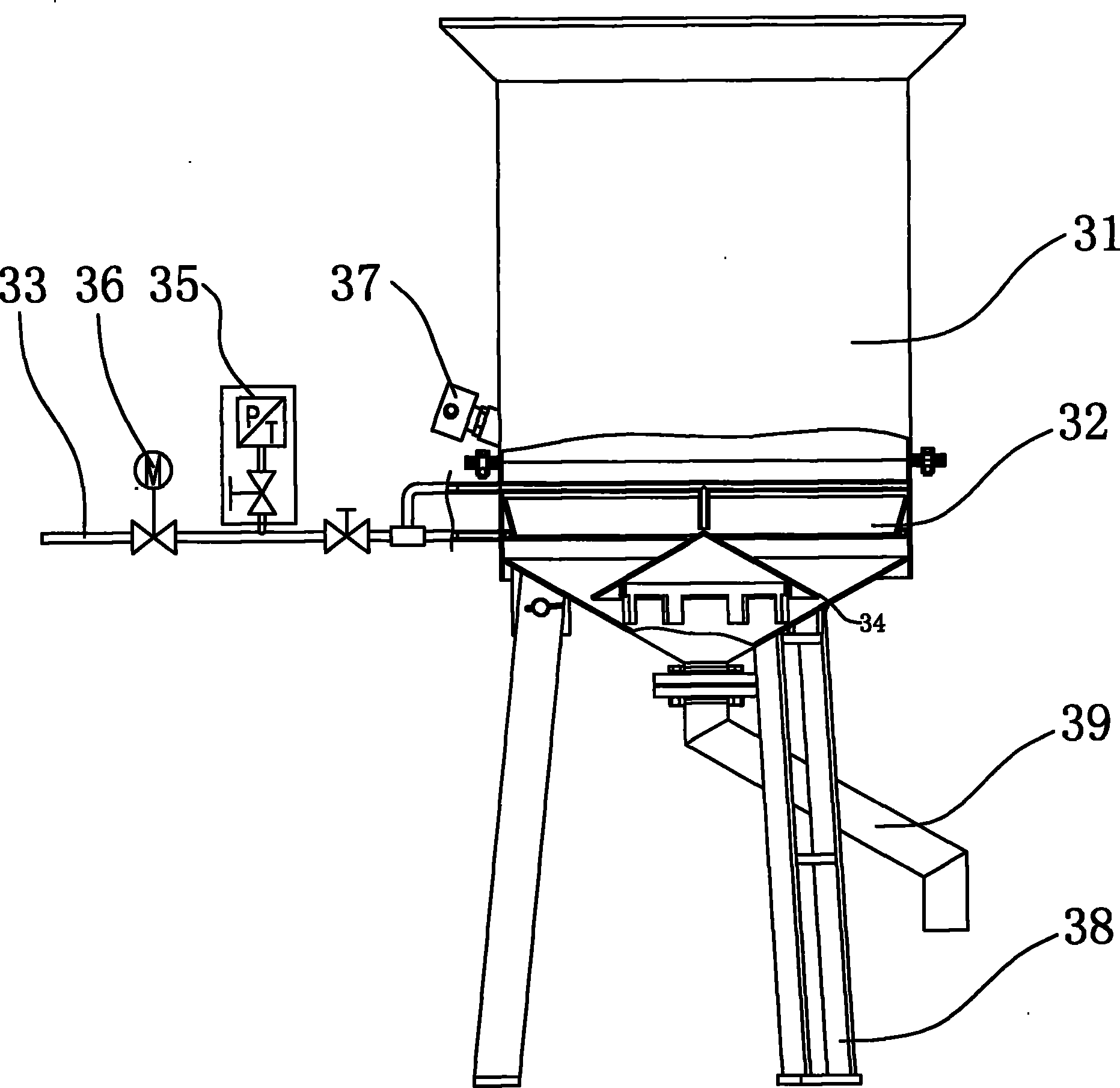

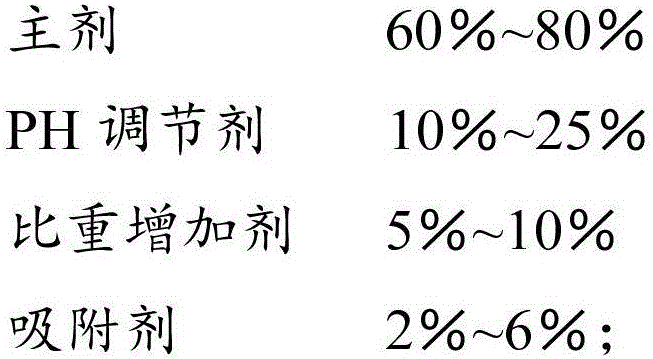

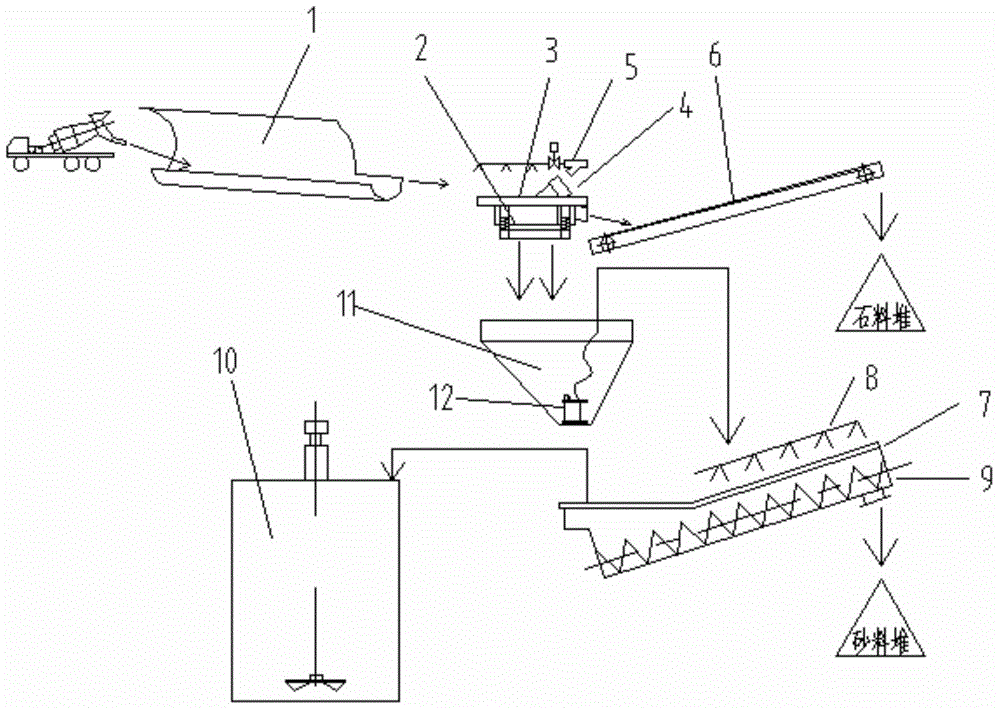

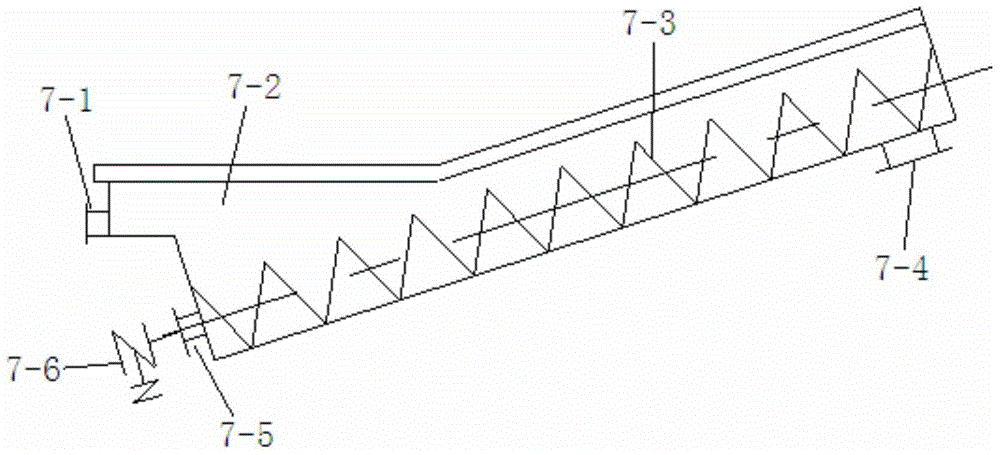

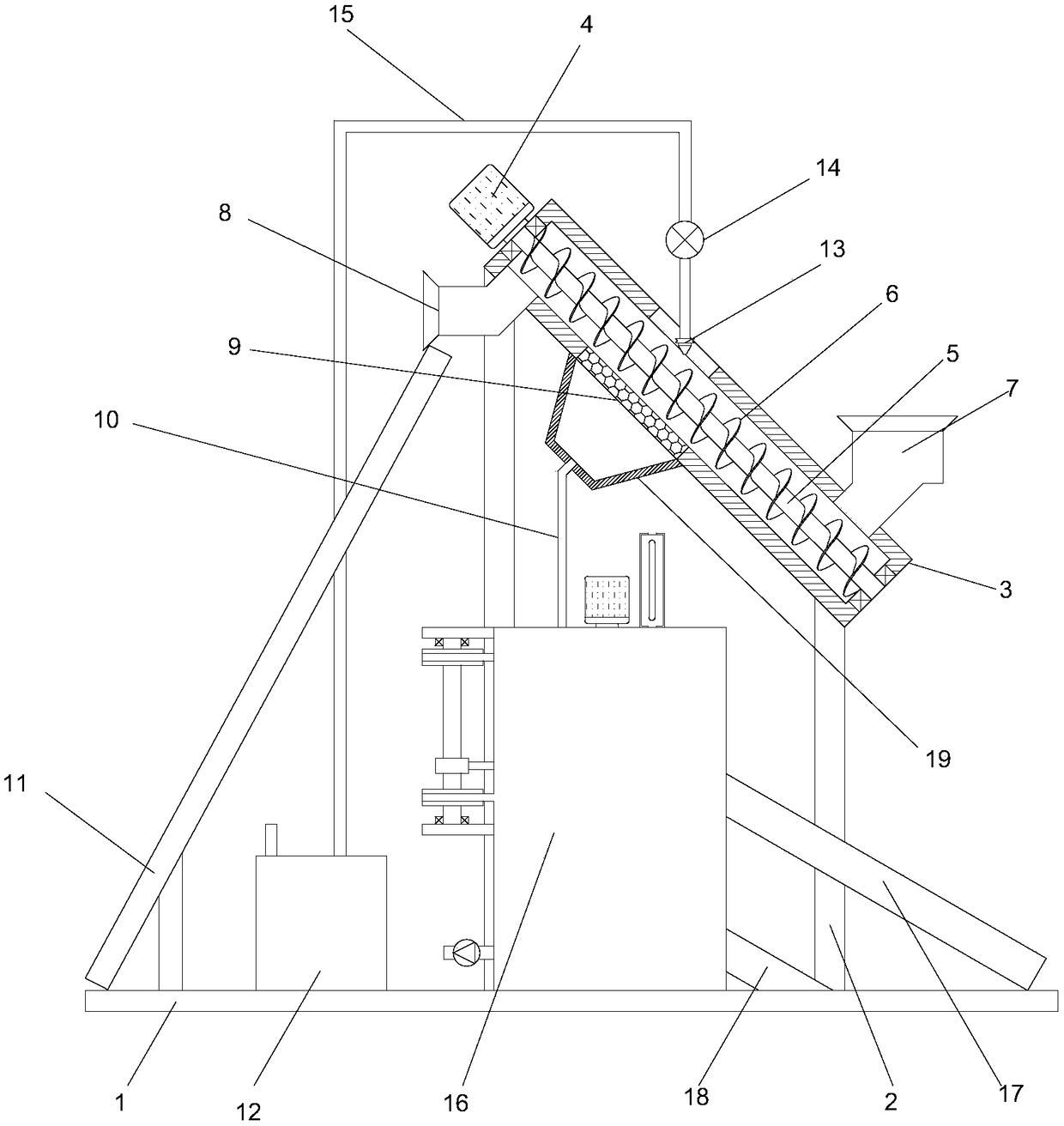

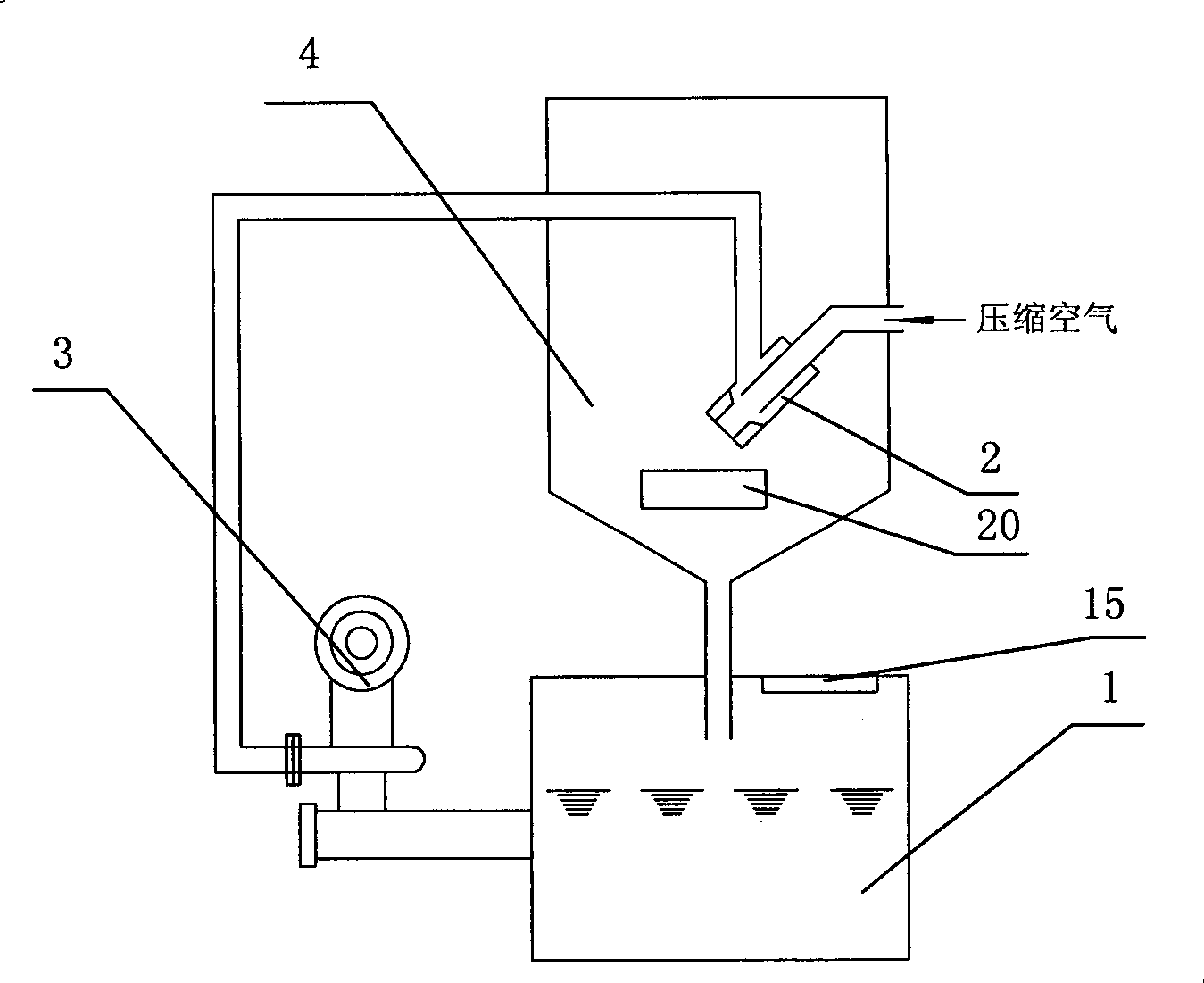

Novel concrete gravel-sand separation device

The invention relates to a novel concrete gravel-sand separation device. The novel concrete gravel-sand separation device comprises a washing tank, a vibrating sieve, a screw sand separator, a mortar pool, a water pump and an agitation pool and is characterized in that the washing tank is connected with the vibrating sieve, residual concrete in an agitating truck is discharged into the washing tank and then flows onto the vibrating sieve which is positioned above the mortar pool, the water pump is positioned in the mortar pool, a discharging port of the water pump is connected with the screw sand separator, a water outlet of the screw sand separator is connected to the agitation pool, and a vibrating motor and a screen are arranged on the vibrating sieve. By means of high-efficiency vibration of the vibrating sieve, sand and gravels in concrete can be thoroughly separated, the separated sand and gravels are flushed by a high-pressure flushing device, and accordingly low mud content and moisture content are realized, and standards of gravel aggregates for building concrete can be met; residual mortar can be recycled directly, and accordingly zero emission of waste residues and waste water of a concrete batching plant is realized truly.

Owner:SHANTUI CHUTIAN CONSTRUCTION MACHINERY CO LTD

Equipment and method for manufacturing high-density large-piece insulating paperboard

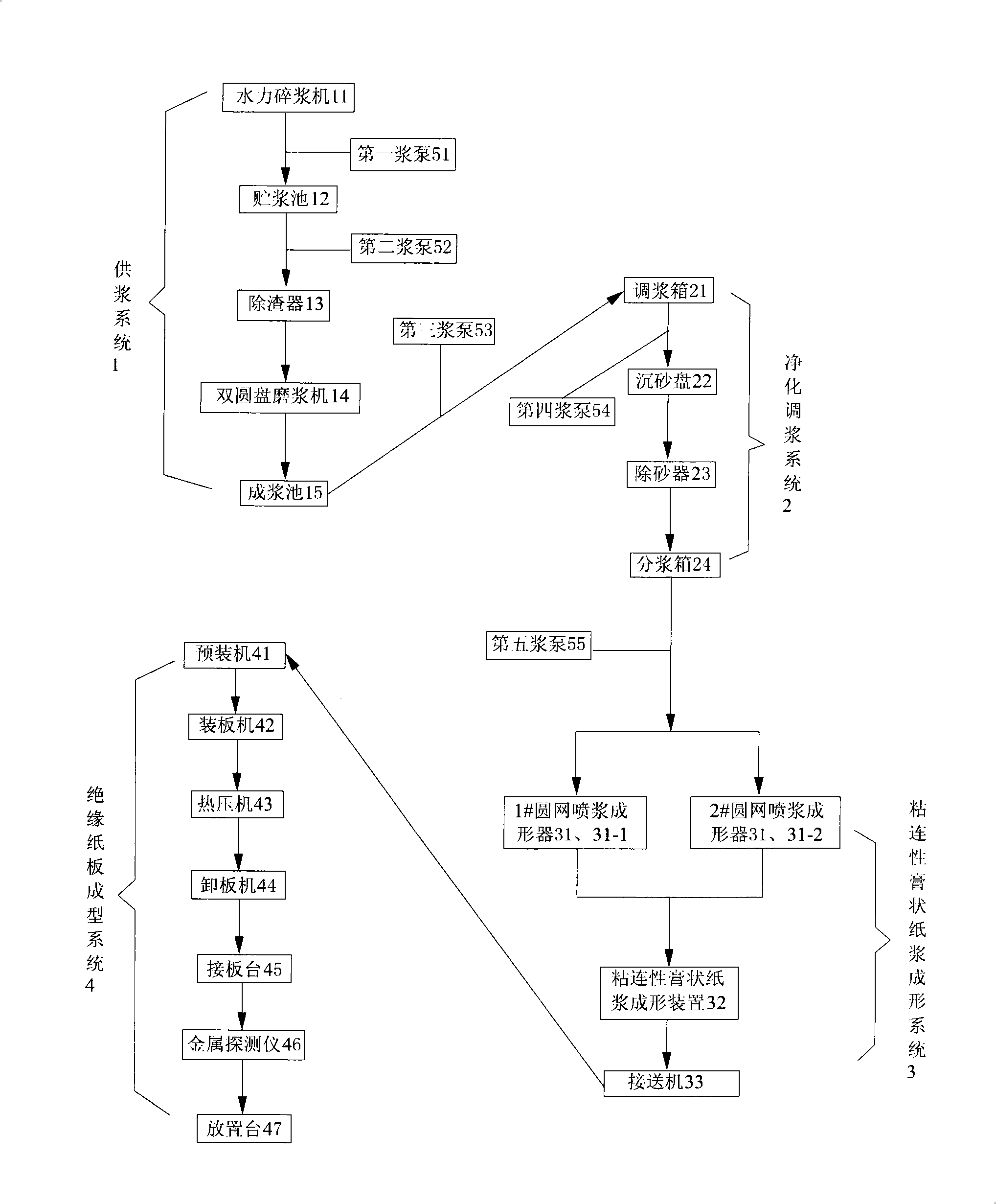

ActiveCN101343844AStrict control of thickness toleranceAvoid quality hazardsPlastic/resin/waxes insulatorsMachine wet endCardboardHigh density

The invention discloses a manufacturing device for a big insulating cardboard with high density as well as a manufacturing method thereof. The device comprises a pulp feeding system, a pulp purifying and adjusting system, an adhesive paste paper pulp forming system and an insulating cardboard forming system. The pulp feeding system comprises a hydraulic pulp kneader, a pulp storage tank, a slag separator, a double-disc pulp grinder and a pulp forming tank which are connected sequentially through pipes. The pulp purifying and adjusting system comprises a pulp adjusting box, a desilting disc, a sand separator and a pulp separating box which are connected sequentially through pipes. The adhesive paste paper pulp forming system comprises a round net pulp spraying former, an adhesive paste paper pulp forming device and a delivering machine. The insulating cardboard forming system comprises a pre-loading machine, a board loading machine, a hot pressing machine, a board unloading machine and a board receiving table. The invention adopts pure wood pulp as a raw material, and a set of advanced devices to manufacture big insulating cardboards with high density, and a gap in the insulating cardboard manufacturing field is filled.

Owner:常州市英中电气有限公司 +1

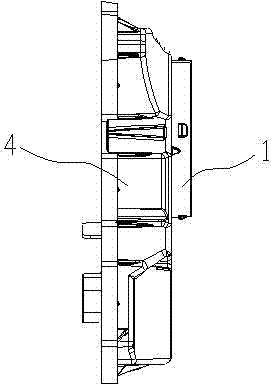

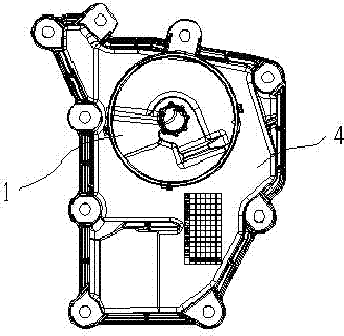

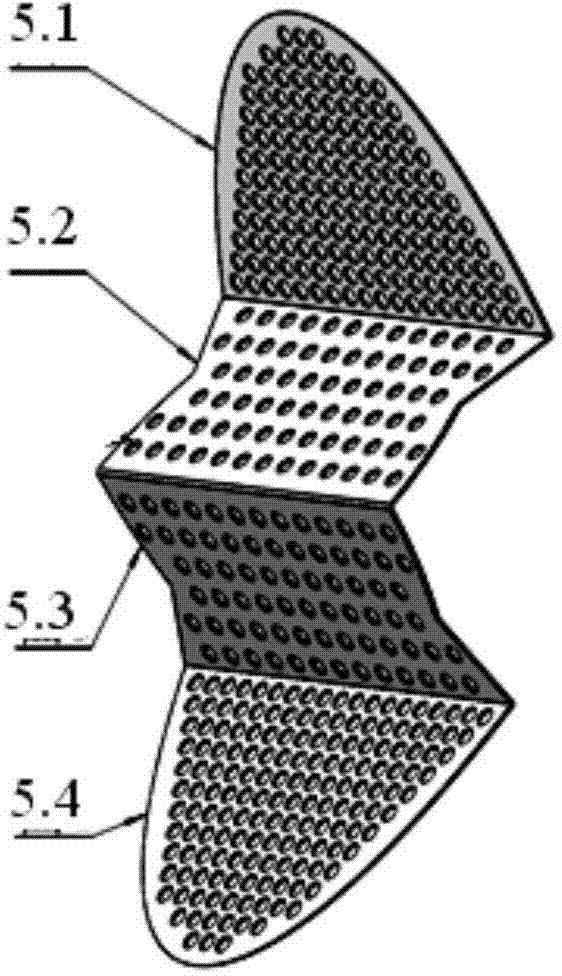

Assembled oil-gas separator and oil-gas separation method thereof

ActiveCN107630818AImprove efficiencyReduce path lengthRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringThin walled cylinder

The invention provides an assembled oil-gas separator and an oil-gas separation method thereof. On the basis that a traditional oil-gas separator is used for performing crude separation through a cyclone separator and performing fine separation through a filter element, an inlet primary separation device and an inertial separation area are additionally arranged, and a single hydrocyclone in the traditional oil-gas separator is changed into an inner hydrocyclone and an outer hydrocyclone which are embedded into each other; and a porous thin-walled cylinder used for preventing secondary entrainment is arranged in a barrel. By adopting the inlet primary separation device and the inertial separation area, the capability of the oil-gas separator for adapting to compressor variable working condition operation is effectively improved; the inner hydrocyclone and the outer hydrocyclone are used for whirling an oil-gas mixture, the lengths of paths for moving of centrifugal separation oil dropsto the wall surface are shortened, the efficiency of a centrifugal separation section is improved, the separation effect of a filter element is indirectly improved, and the service life of the filterelement is prolonged; and since an annular space exists between the porous thin-walled cylinder and the barrel, airflow moving at a high speed is effectively prevented from impacting oil film moving downwards along the surface of the barrel, and the separation efficiency is improved.

Owner:福建伊普思实业有限公司

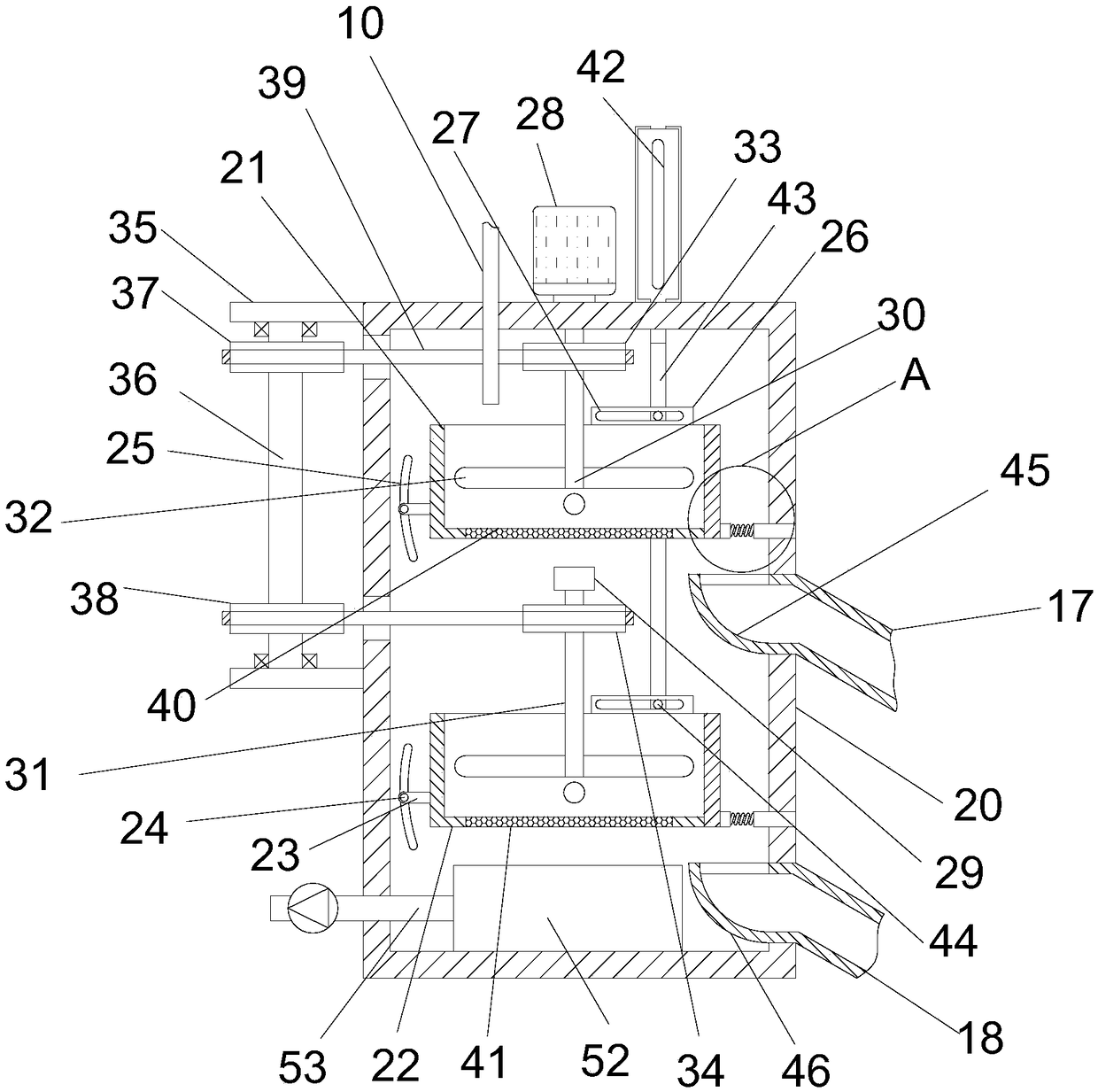

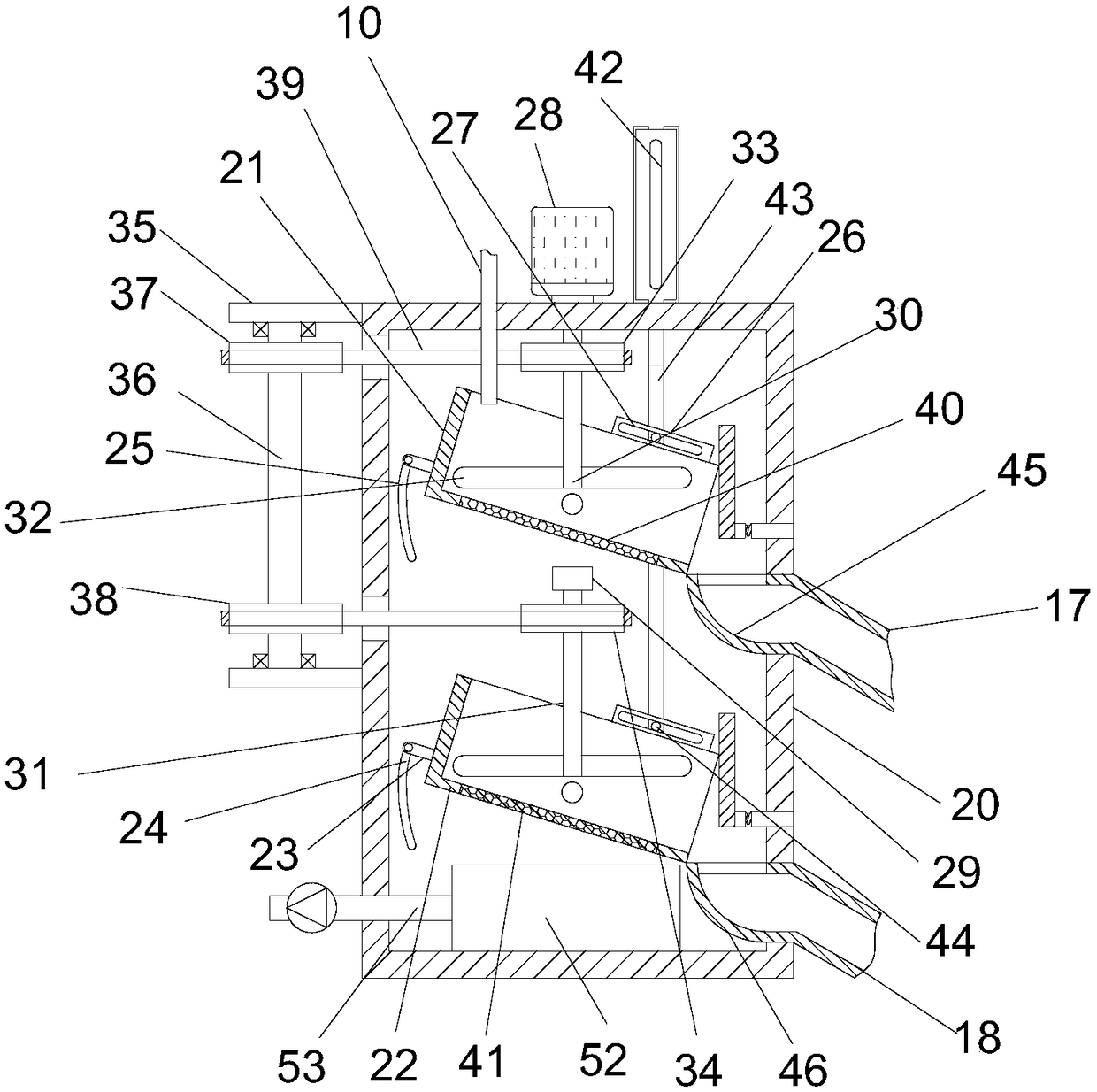

Sandstone separator with fine sand separating device

PendingCN108421711AEasy to separateHigh recovery puritySievingGas current separationFiltrationEngineering

The invention discloses a sandstone separator with a fine sand separating device. The sandstone separator comprises a bottom plate, a supporting column, a sandstone separation module, a fine sand separating device and a cleaning module, wherein the sandstone separation module is used for separating stones and cleaning and recycling the stones by the cleaning module; the fine sand separating deviceis used for separating mortar to obtain coarse sand and fine sand, so that the mortar is completely separated, the fine sand recycling purity is improved, and the fine sand is reutilized; a second motor is started to drive a first stirring shaft to rotate, so that the second stirring shaft is driven to rotate under the actions of a driving guide wheel, a driven guide wheel, a transmission shaft,a first transmission wheel, a second transmission wheel and a belt. The filtered mortar can be stirred under the effects of stirring blades, the filtration is accelerated, the production efficiency isimproved, the automatic sand discharging function is realized under the effects of a cylinder, a push rod, a second pin shaft, a second chute, a baffle, a spring, a sliding column and a sliding sleeve, the manual cost is reduced, and the production efficiency is improved.

Owner:广州臻太机械制造有限公司

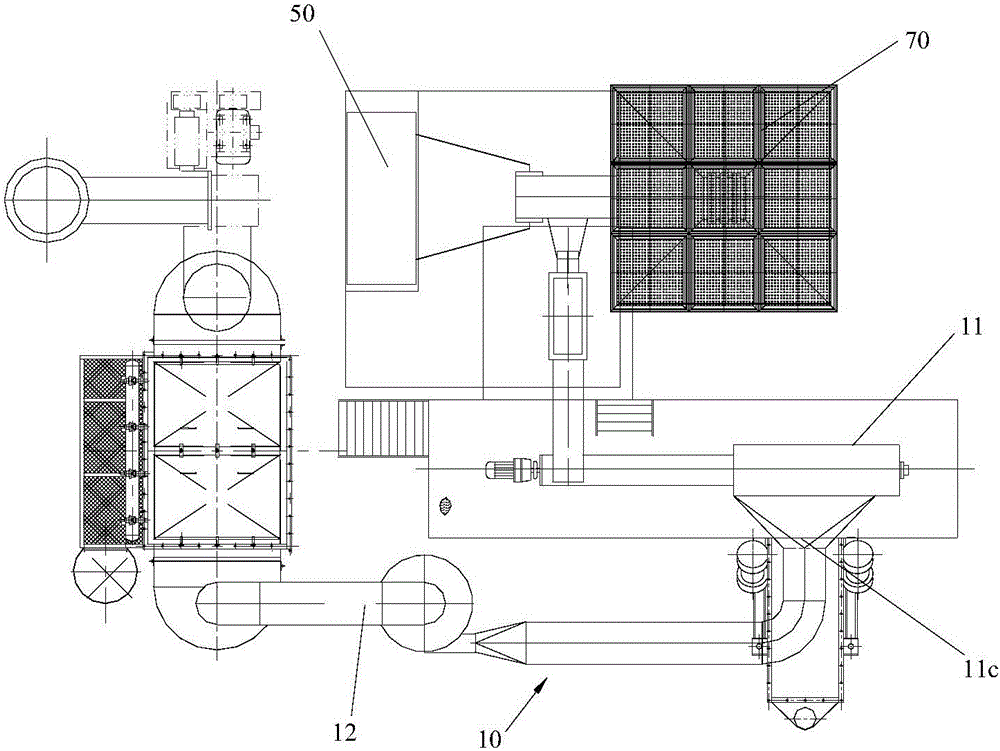

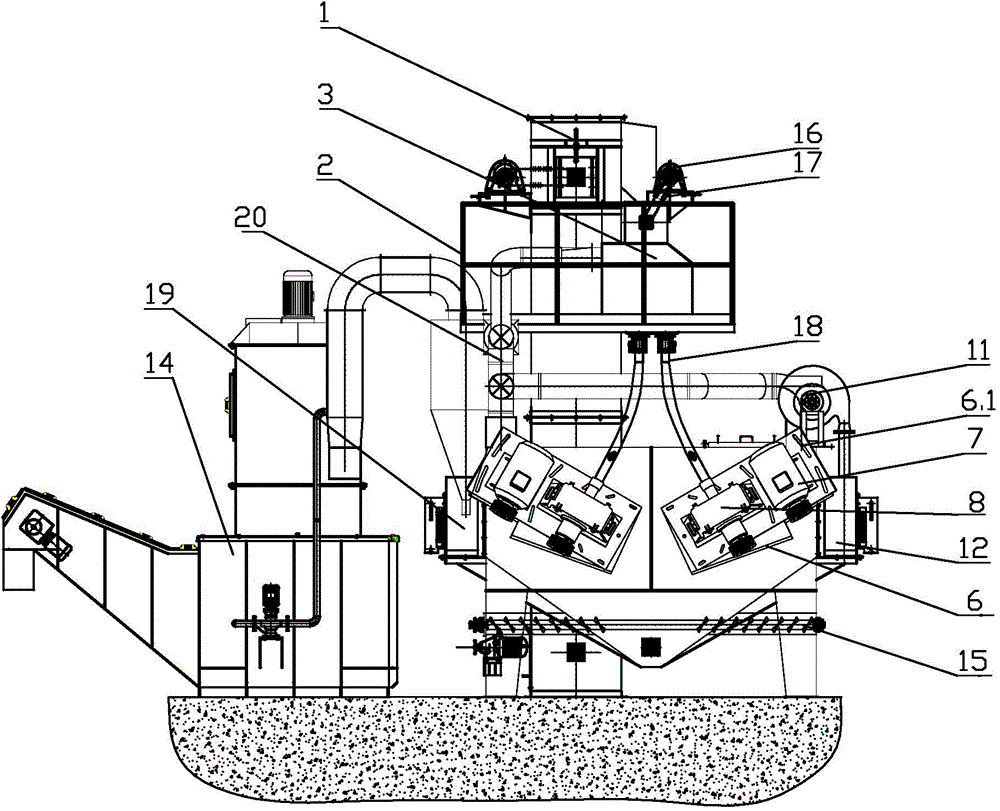

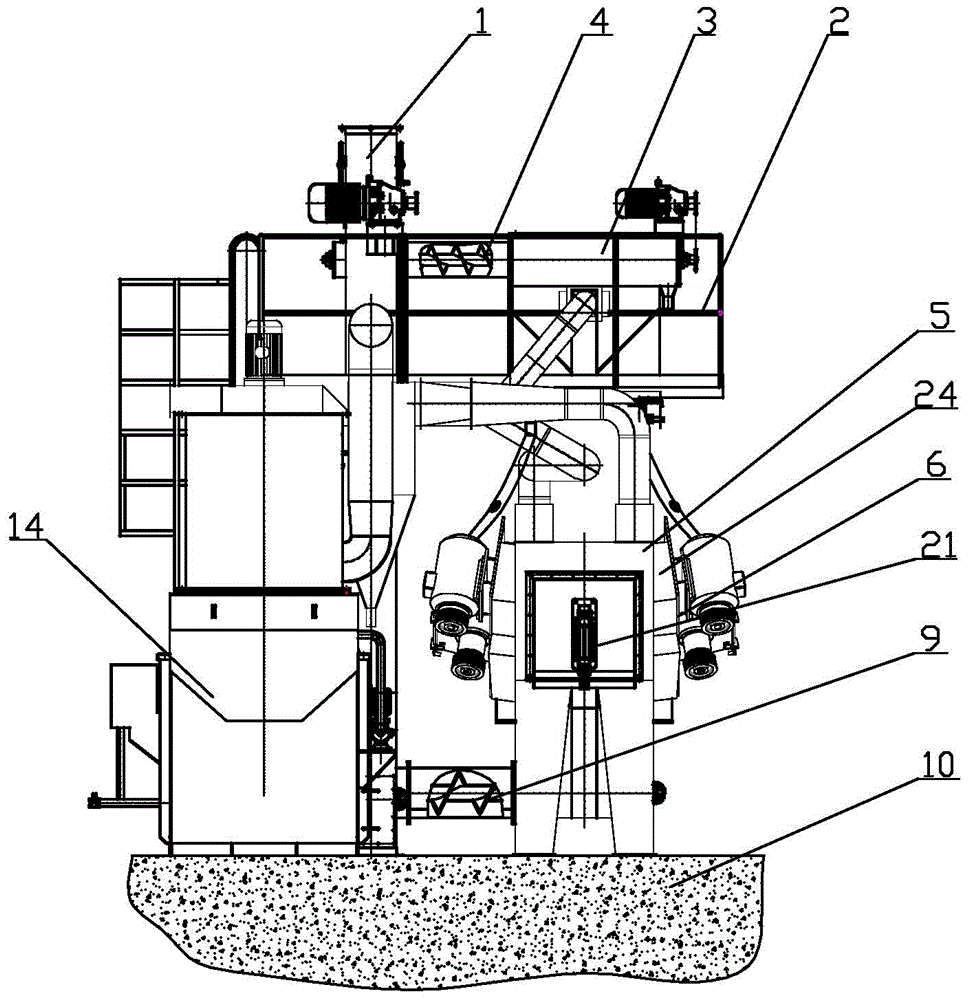

Strip steel through-type shot blasting cleaning machine

ActiveCN104647216AEnsure correct walkingIncrease working areaAbrasive machine appurtenancesAbrasive blasting machinesStrip steelEngineering

The invention relates to a shot blasting cleaning machine and in particular relates to a strip steel through-type shot blasting cleaning machine, belonging to the technical field of shot blasting cleaning equipment. The strip steel through-type shot blasting cleaning machine comprises an elevator, a maintenance platform, a shot-sand separator, an upper screw conveyer, a cleaning chamber body, a lower screw conveyer, a base and a water curtain dust removal device, wherein the cleaning chamber body fixed on the base is formed below the shot-sand separator and is communicated with the water curtain dust removal device by virtue of a dust removal pipe; a dust removal fan is fixed at the upper end of the water curtain dust removal device and is communicated with the water curtain dust removal device; a cyclone dust collector is arranged in the middle of the dust removal pipe; the cleaning chamber body is connected with the lower part of the elevator by virtue of the lower screw conveyer; and a longitudinal auger is arranged in the cleaning chamber body. According to the strip steel through-type shot blasting machine disclosed by the invention, coiled strip steel can be continuously subjected to continuous shot blasting, and the cleaning machine can be applied to cleaning of strip steel with various sizes and specifications and is wide in application range; and moreover, a secondary dust removal system consists of the cyclone dust collector and the water curtain dust removal device, the dust removal effect is excellent, and the environmental pollution degree is low.

Owner:无锡希凯姆机械有限公司

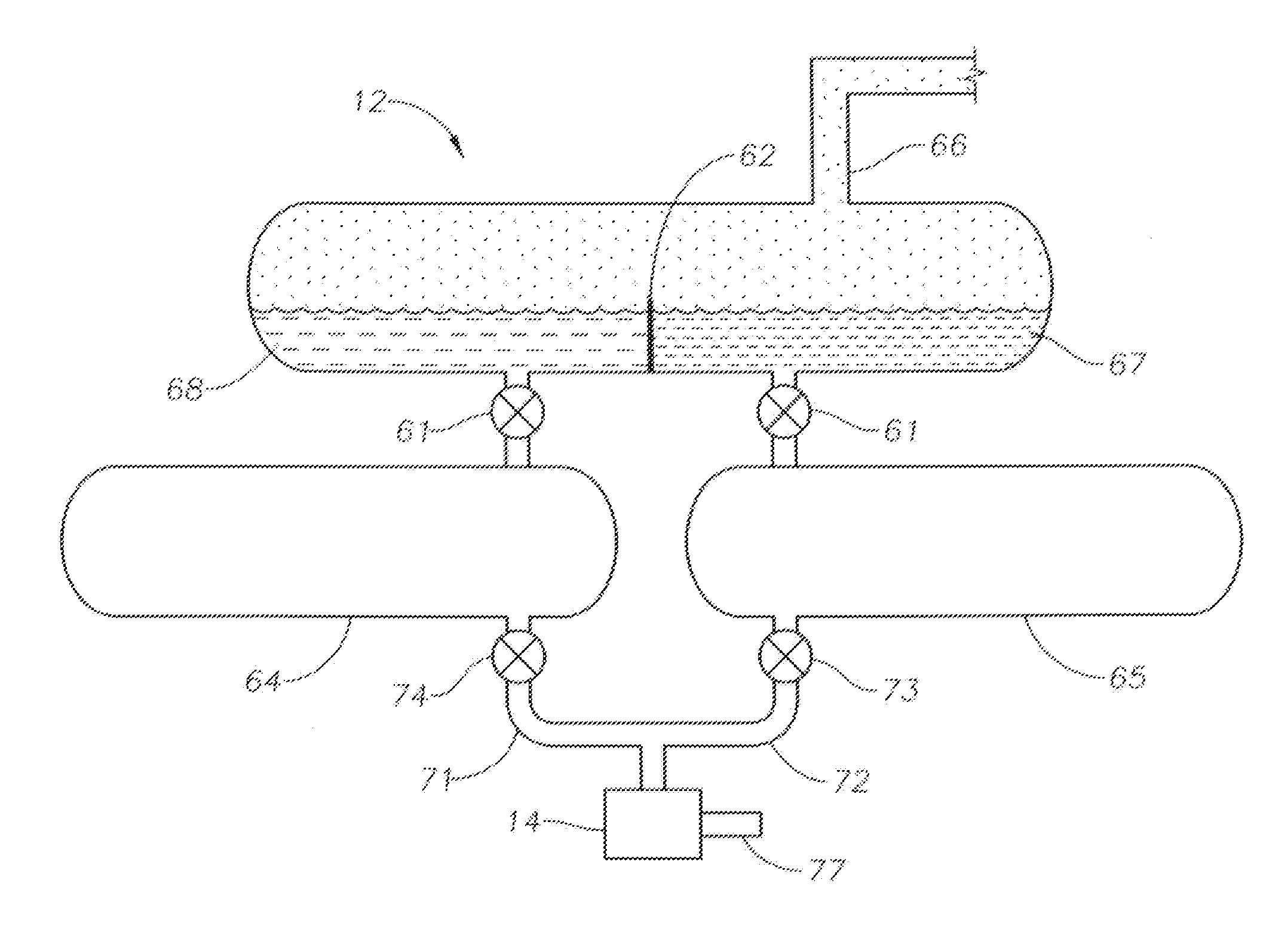

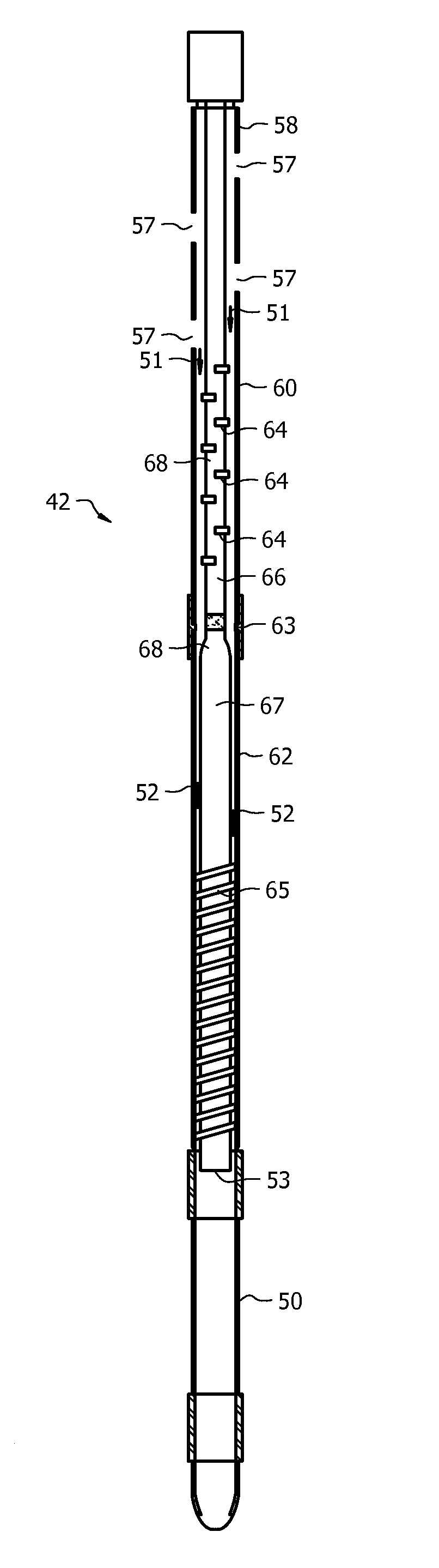

Temporary production system and separator with vapor recovery function

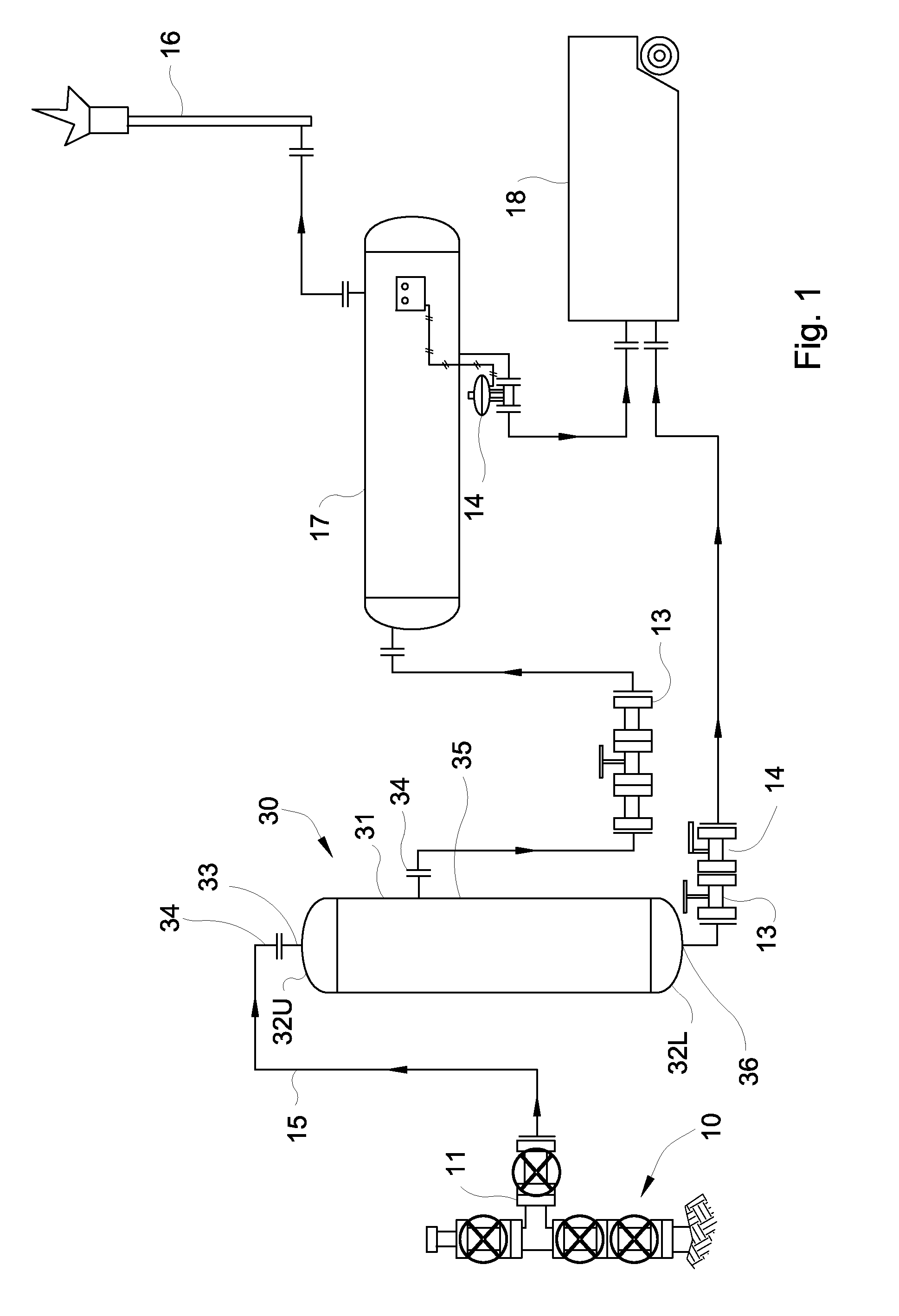

ActiveUS9803459B1Facilitates temporary production of hydrocarbonEnhanced overall recoverySeparation devicesFluid removalProduction lineEngineering

A temporary hydrocarbon well production system receives flow from a hydrocarbon well through a production line connected to the well. The production line flows into a sand separator, which has a fluid outlet connected to a choke manifold and a solids outlet connected to a sand dump line. A transportable and vertical closed separator receives flow through two separate lines from the choke manifold and from the sand dump line, which respectively flow into independent diffusing structures in the closed separator. Gas, vapors, volatile organic compounds, etc. are captured within the closed vessel and are discharged through a vapor discharge line attached to a vapor recovery unit for either further processing or incineration through a flare. A liquid dump line discharges liquids from the closed separator to at least one closed tank.

Owner:PROS

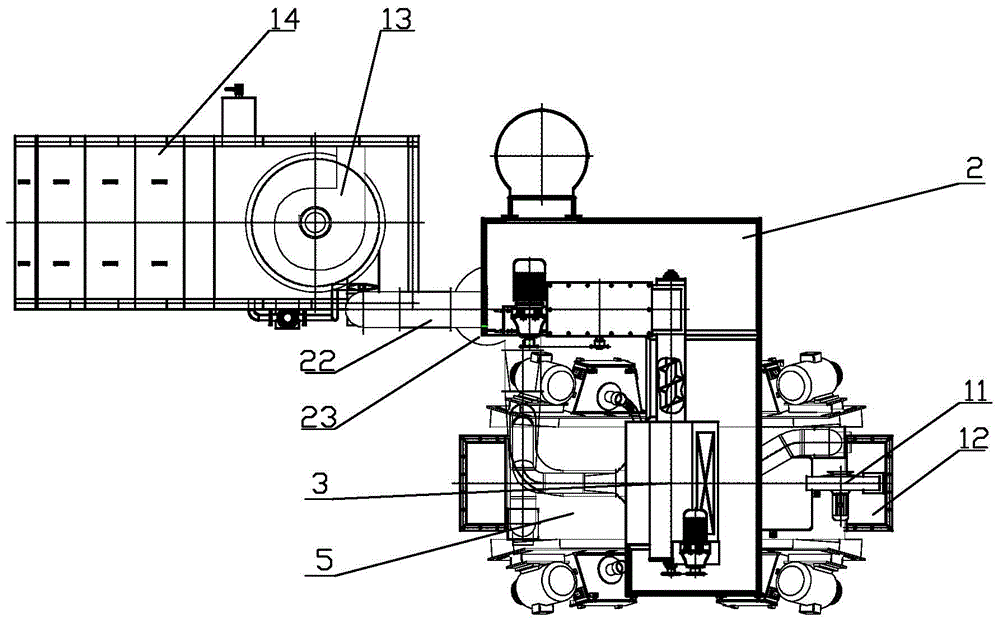

Wet-process spray sand system

InactiveCN101367201AReduce pollutionAvoid wastingAbrasive machine appurtenancesAbrasive blasting machinesSand blastingWastewater

The invention discloses a wet sandblast system which comprises a mortar tank and a sandblasting injector, wherein the mortar tank is provided with a sandblasting pump which sends mortar to the sandblasting injector; the mortar injected by the sandblasting injector flows into a recovery warehouse the outlet of which is communicated with the mortar tank; the recovery warehouse is provided with a cyclone water-sand separator and a spray header; a mortar inlet of the cyclone water-sand separator is communicated with the mortar tank; the mortar tank is provided with a second sandblasting pump which sends the mortar to the cyclone water-sand separator; a sand outlet of the cyclone water-sand separator is communicated with the mortar tank; and a water outlet of the cyclone water-sand separator is communicated with the spray header which is arranged on the upper part of the recovery warehouse. The wet sandblast system has the advantages that a closed loop system is adopted so that waste water in the system can be used repeatedly after processing, and the environmental pollution is reduced; meanwhile, the mortar stuck on the surface of a workpiece is washed away and enters the mortar tank through the recovery warehouse, thereby repeatedly using the mortar, avoiding the waste of he mortar, and reducing the production cost.

Owner:宁波赛盟科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com