Equipment and method for manufacturing high-density large-piece insulating paperboard

An insulating cardboard and high-density technology, which is applied in papermaking, paper machines, insulators, etc., can solve the problems of high-density large-sheet insulating cardboard production equipment and manufacturing methods that have not yet been discovered, and achieve the effect of avoiding hidden dangers in quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

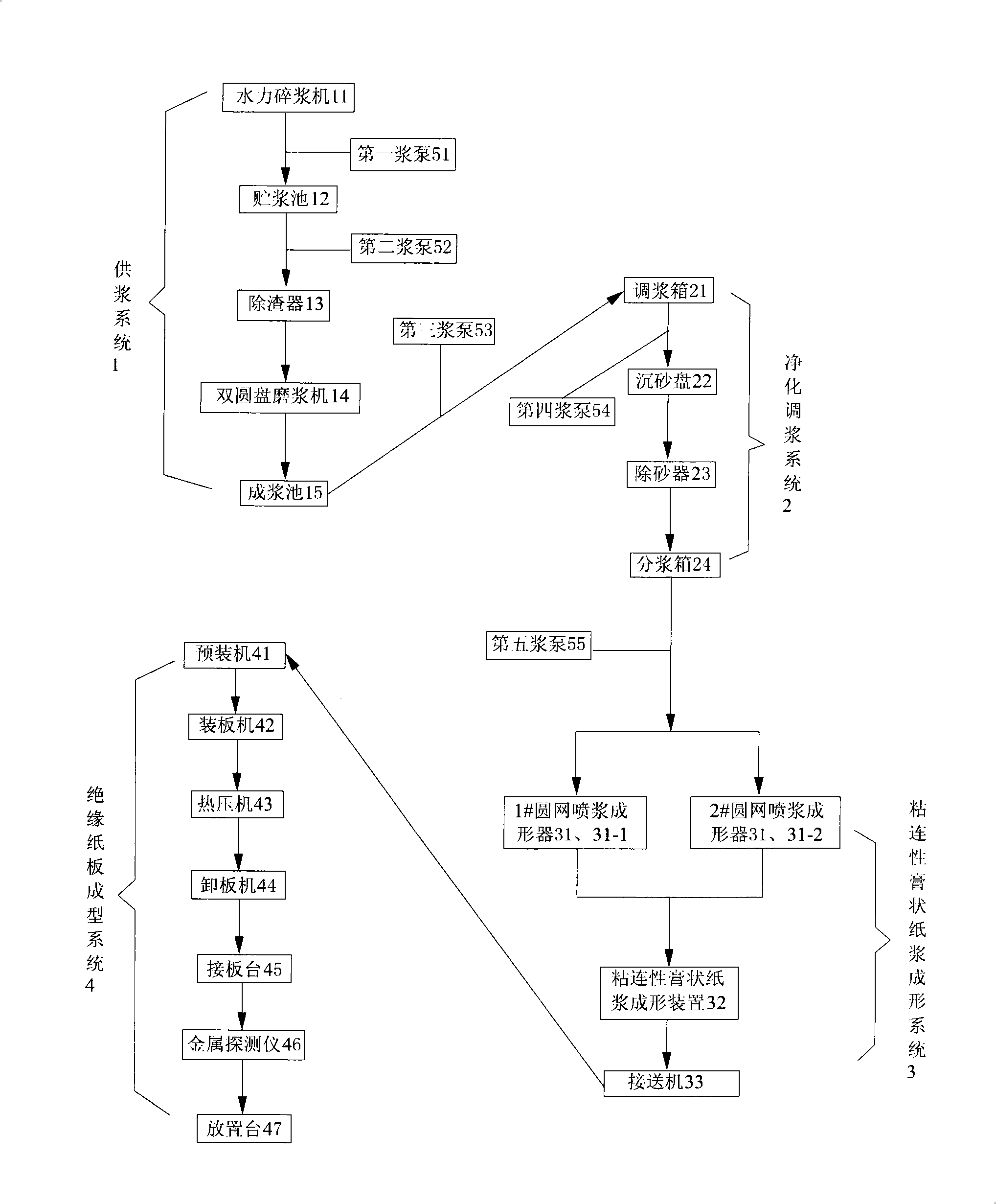

[0028] See figure 1 , The equipment for manufacturing high-density large-sheet insulating paperboard of the present invention includes a pulp supply system 1 , a clean pulp mixing system 2 , an adhesive paste pulp forming system 3 and an insulating paperboard forming system 4 .

[0029] The pulp supply system 1 includes a hydraulic pulper 11 , a pulp storage tank 12 , a slag remover 13 , a double-disc refiner 14 and a pulp tank 15 connected in sequence through pipelines. The hydropulper 11 includes a housing and an agitator. A first pulp pump 51 is connected in series on the pipeline between the hydraulic pulper 11 and the pulp storage tank 12 . A second slurry pump 52 is connected in series on the pipeline between the slurry storage tank 12 and the slag remover 13 . The double-disc refiner 14 of this embodiment is provided with three sets used in series, and each double-disk refiner 14 includes two pairs of refining discs.

[0030] The cleaning slurry mixing system 2 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com