Patents

Literature

679results about How to "Avoid quality hazards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

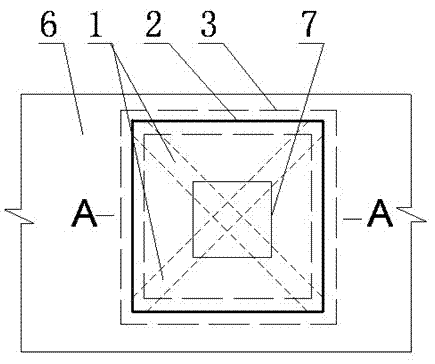

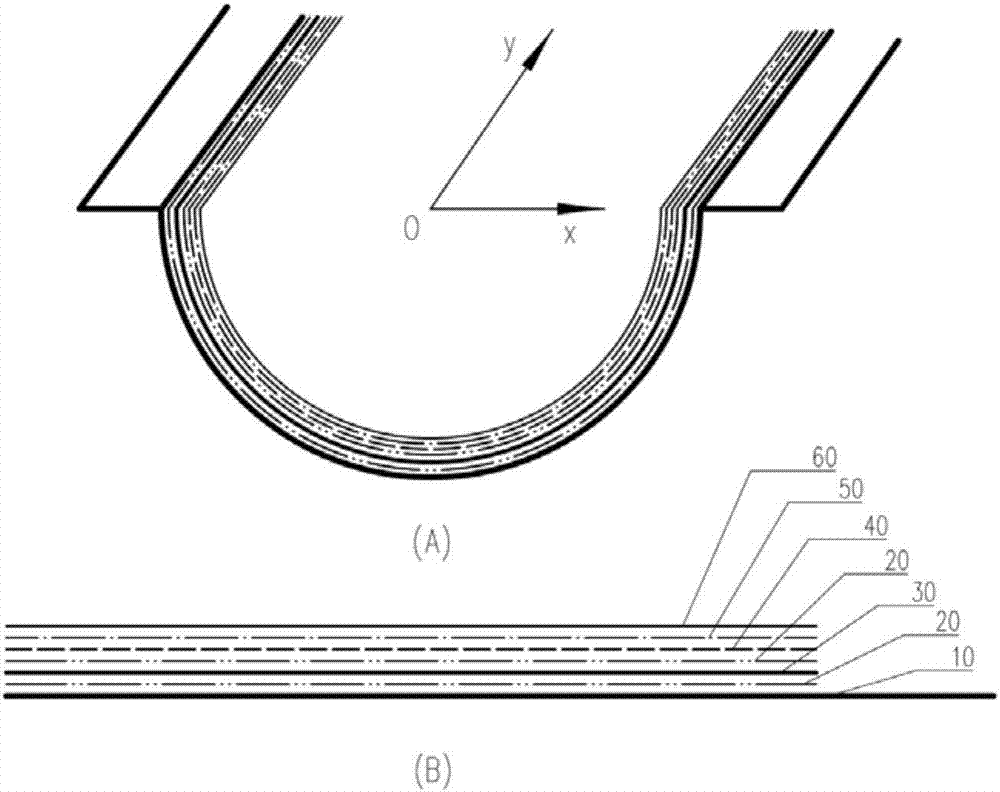

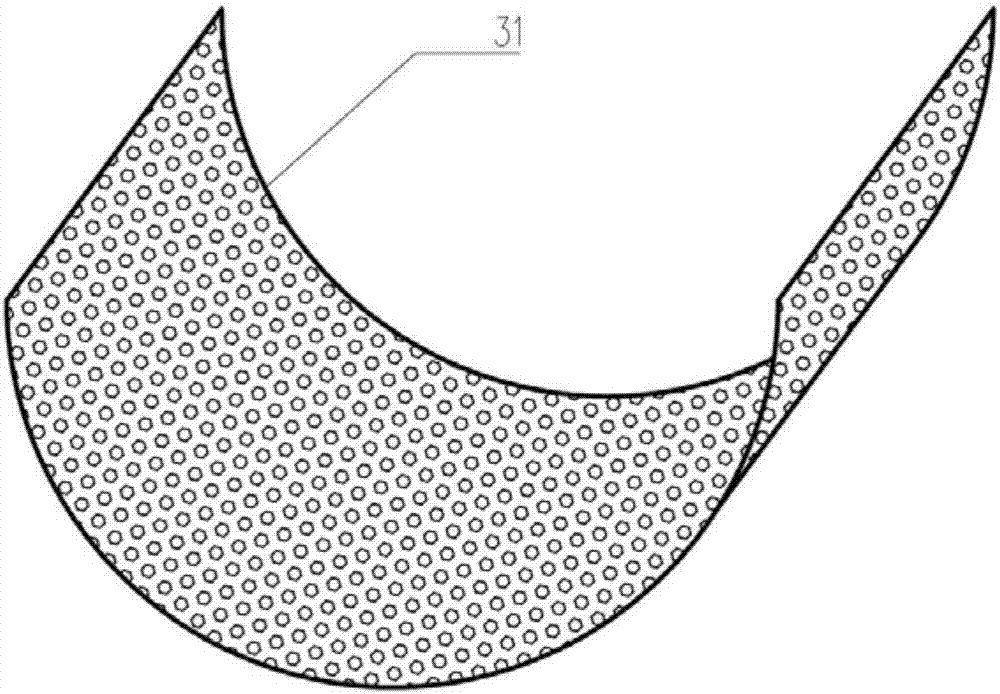

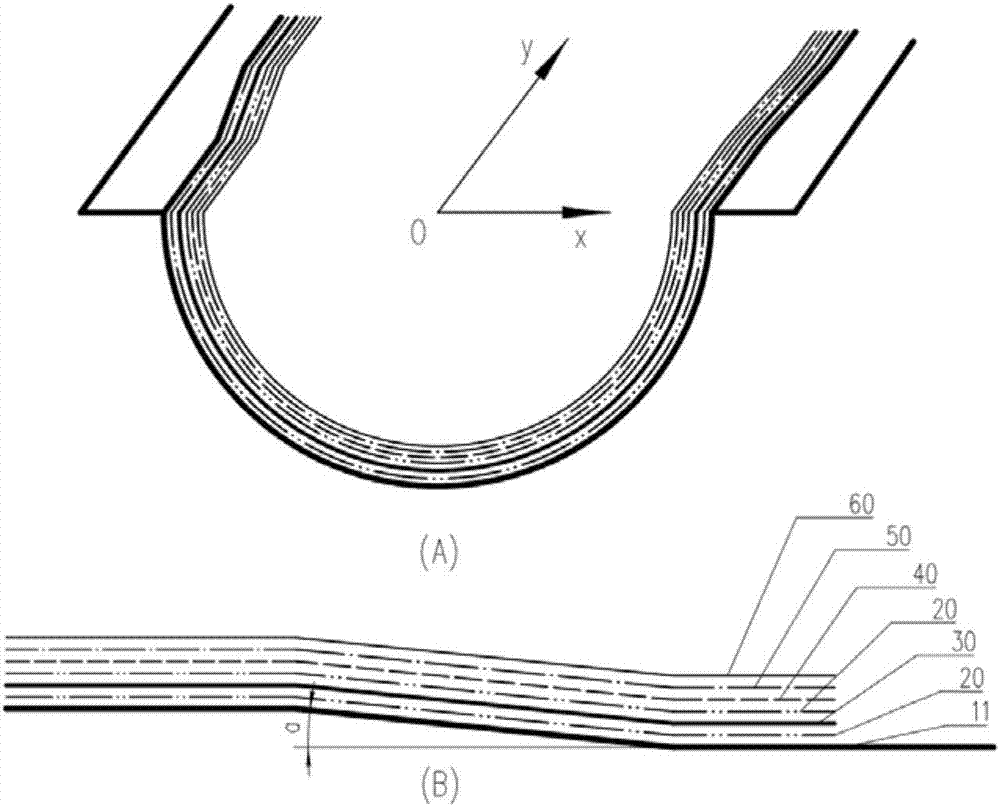

Machining method of thin-wall honeycomb core material curve machining molded surface

ActiveCN106903357AImprove milling efficiencyImprove machining accuracy and surface qualityWorkpiecesMilling equipment detailsThin walledHoneycomb

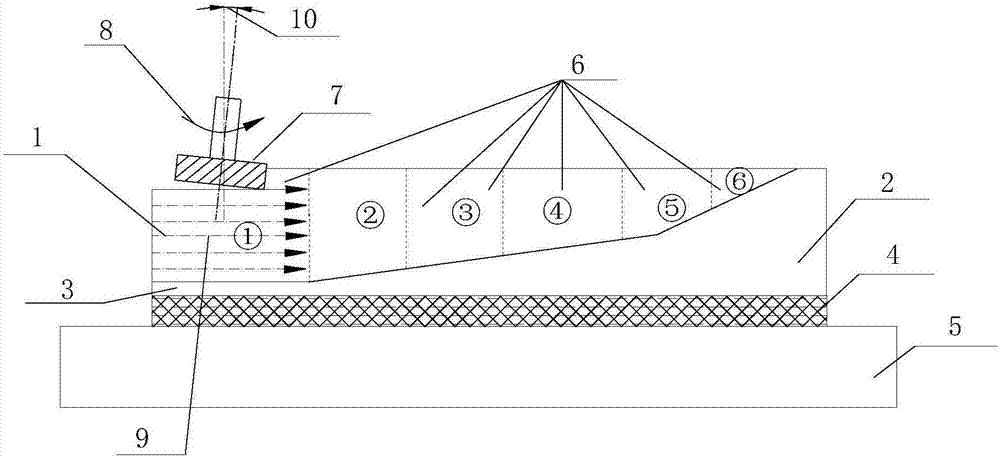

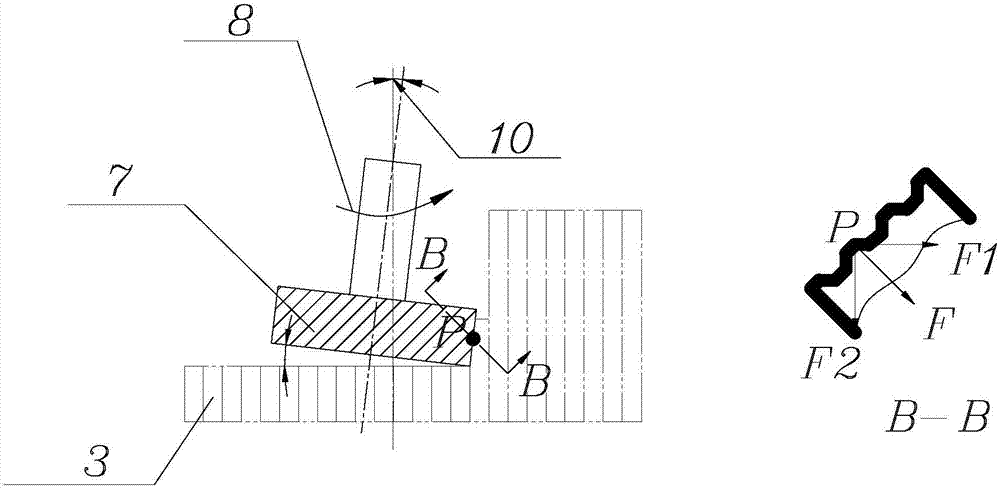

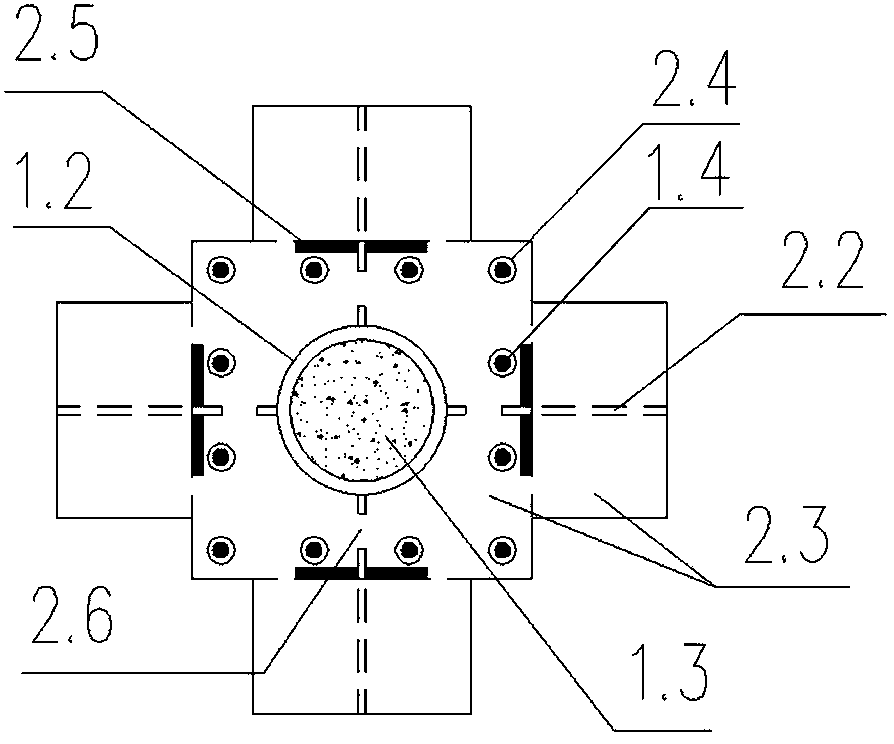

The invention discloses a machining method of a thin-wall honeycomb core material curve machining molded surface, and aims to provide a honeycomb machining method with high milling efficiency and capable of prolonging the life of a special honeycomb combined milling tool. The machining method is realized through the following technical scheme: when a double sided tape fixing state at the earlier stage of honeycomb machining is good, the special honeycomb combined milling tool with a conical disc return milling tool is changed for cutting; the rotating direction of the special honeycomb combined milling tool is changed; the conical disc return milling tool for feeding by a wedged angle of 30-45 degrees through high-speed rotation is used for cutting roughing; according to an anticlockwise tool rotating mode in the tool rotating direction, the downward pressure is applied to a honeycomb thin-edge area (1) through anticlockwise rotation; the part, easy to be pulled and damaged, of the thinnest honeycomb edge of the honeycomb bottom cutting profile is firstly machined; and after the honeycomb thin-edge area (1) of a NOMEX honeycomb part blank is machined, the sequential gradient machining is performed in (2-6) thickness direction of the thick-edge area cutting profile layer by layer, and the other parts are machined.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

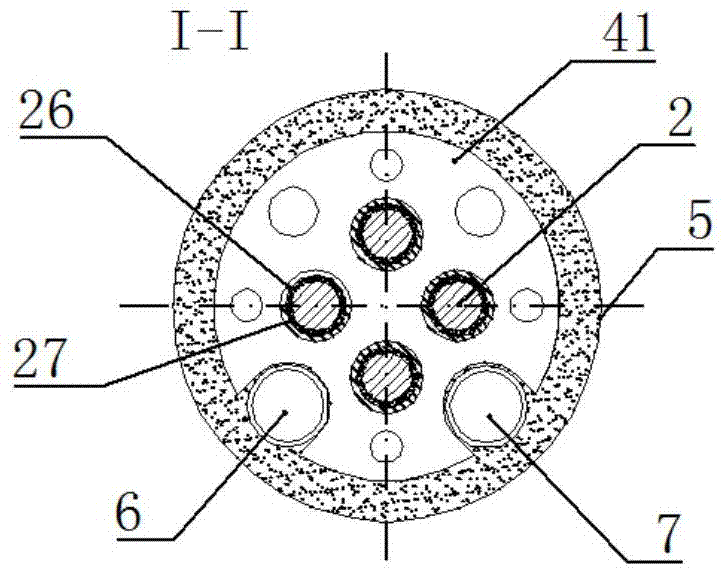

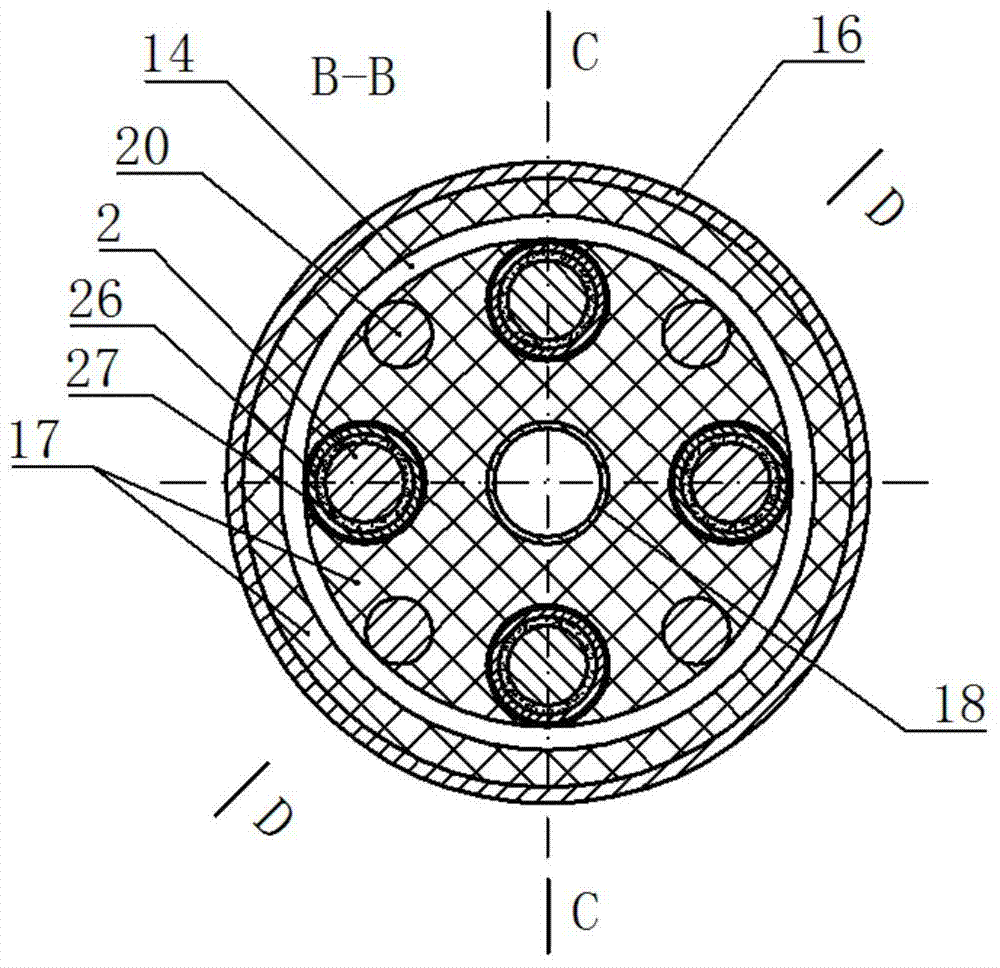

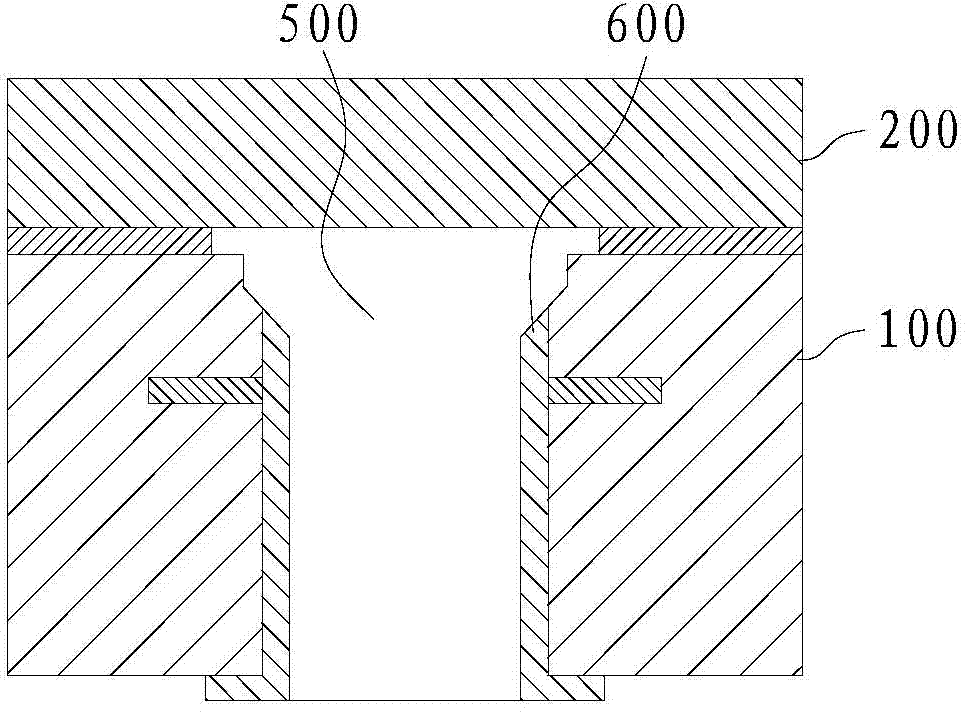

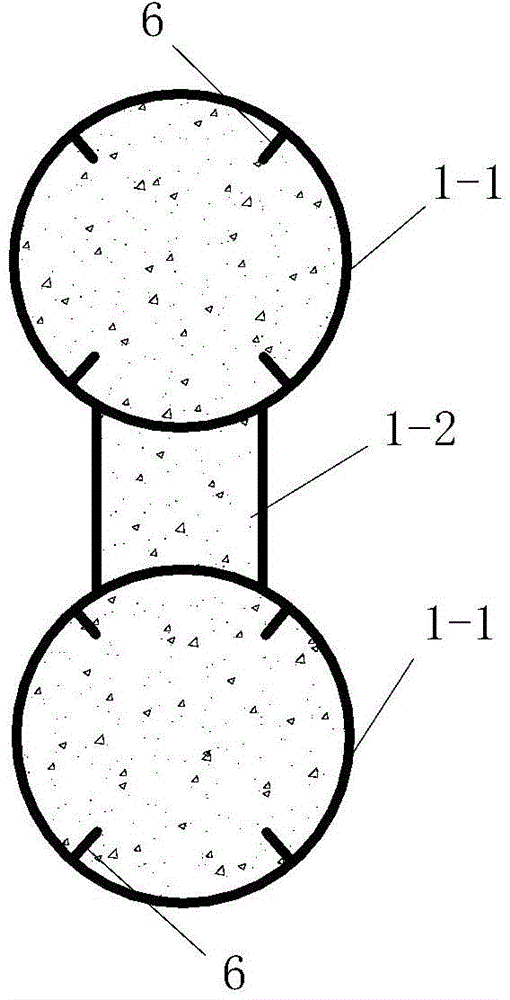

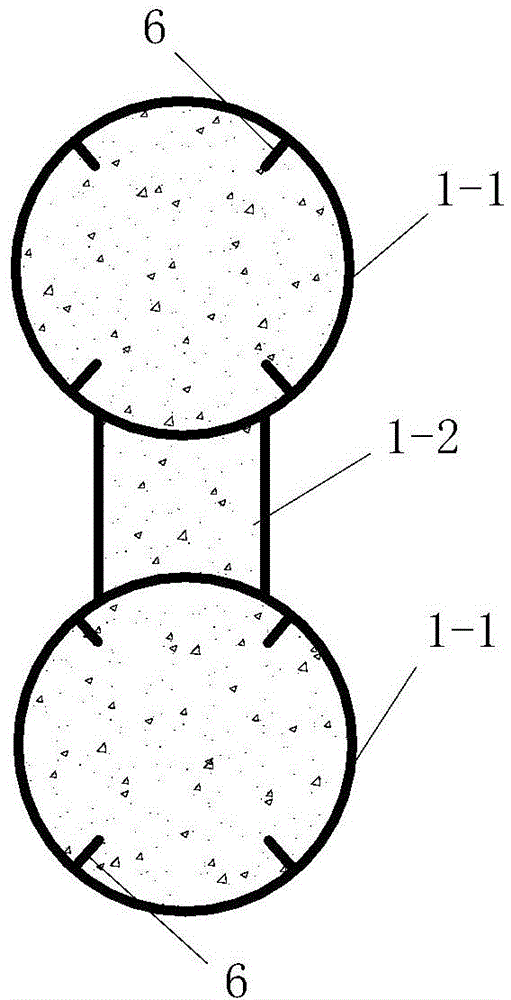

Compound-type prestressed anchor cable structure and construction method thereof

ActiveCN104775428AThe reverse self-locking function generatesImprove anti-corrosion performanceExcavationsBulkheads/pilesPre stressFree state

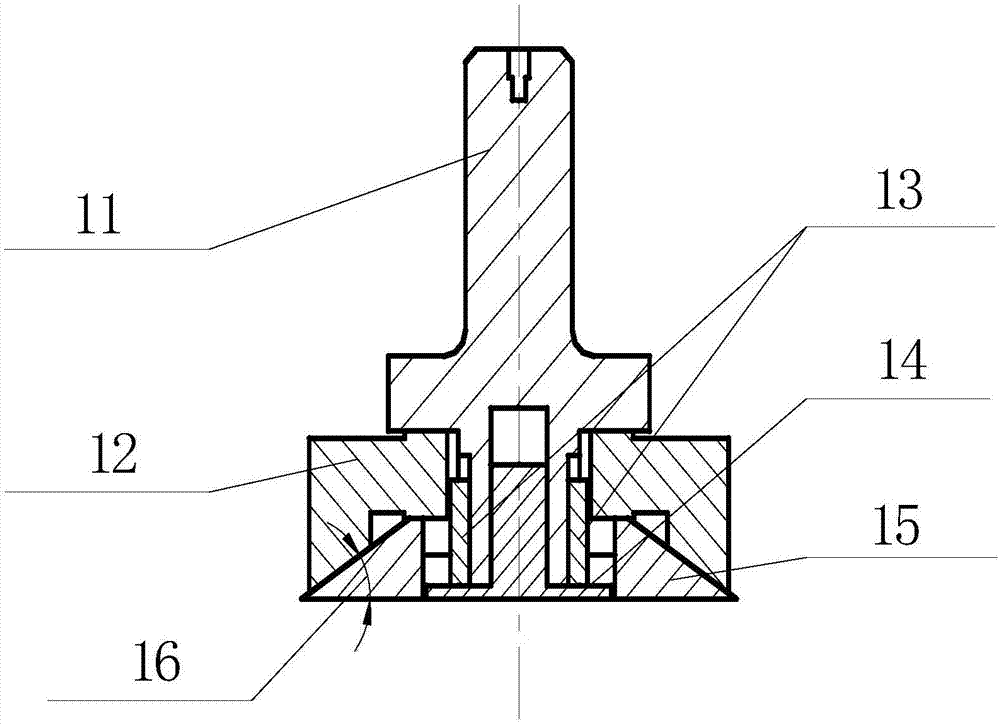

The invention relates to a compound-type prestressed anchor cable structure. The compound-type prestressed anchor cable structure comprises a prefabricated inner anchor head, a free section, an outer anchoring section and an anchor head part, wherein the prefabricated inner anchor head is provided with steel strands in a penetrating manner; the prefabricated inner anchor head is manufactured in a factory; the prefabricated inner anchor head and the steel strands are adhered to the bottom of a drill hole by using a grouting body; the upper part of the drill hole is the free end, which is at a free state, of each steel strand; the outer anchoring section is arranged at an opening of the drill hole; the anchor head part is arranged outside the opening of the drill hole and is fixed with the top end of each steel strand. The compound-type prestressed anchor cable structure is characterized in that the prefabricated inner anchor head is arranged on the bottom of the drill hole; the outer anchoring section is arranged between the upper end of the free section and the opening of the drill hole; grouting by the grouting body is carried out by three times, wherein the first grouting is stopped in the middle of the free section, fracturing grouting is adopted in the second grouting process to form the anchoring section, and the third grouting is carried out after a grout body of the anchoring section reaches an age and has the capability of stretching the steel strands, namely, the outer anchoring section is subjected to grouting, and except that the steel strand of the free section is at a free state, the steel strands of the inner anchor head and the outer anchoring section are adhered with the grouting body to form the compound-type prestressed anchor cable with the prefabricated inner anchor head and the outer anchoring section.

Owner:铁科检测有限公司 +1

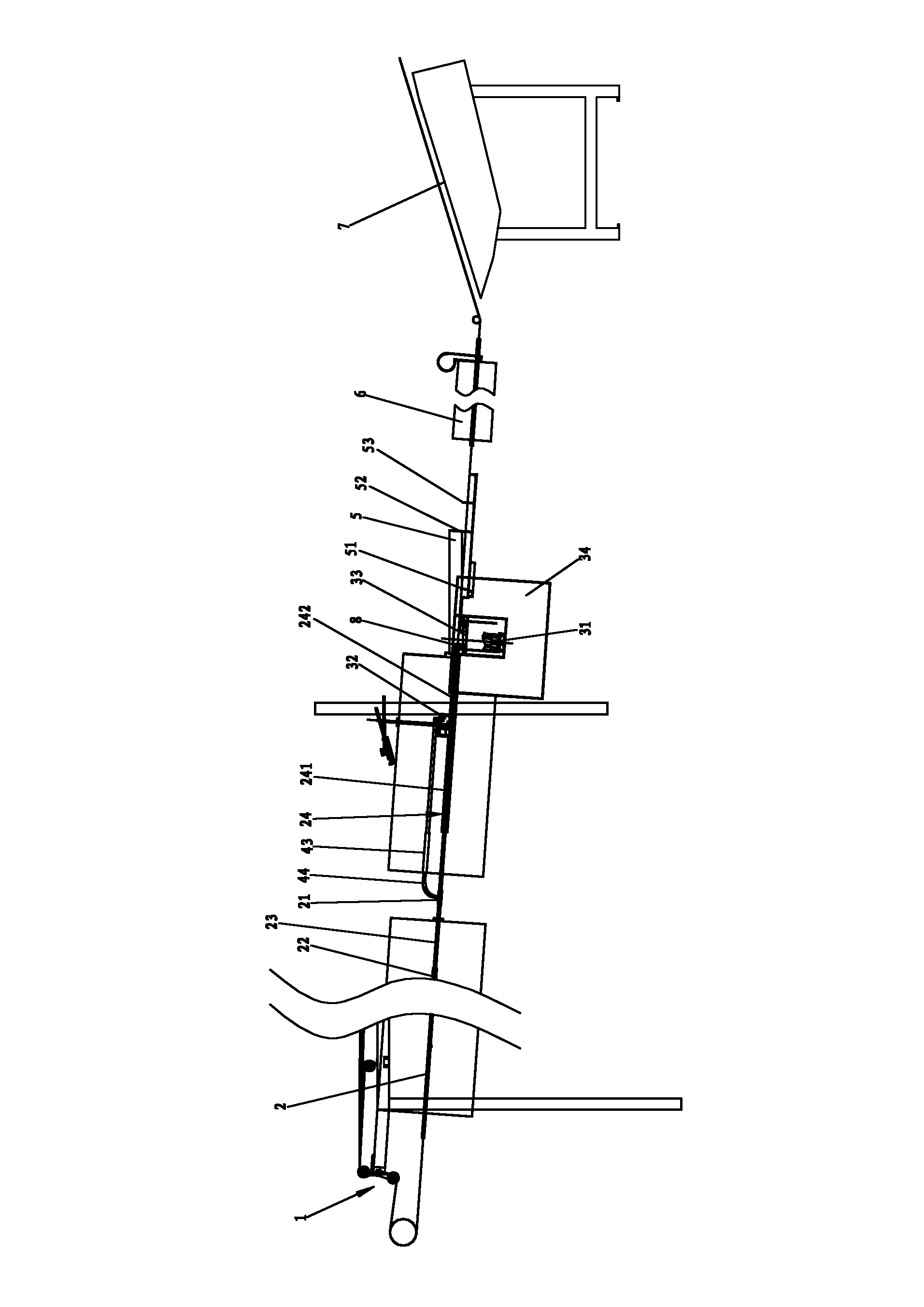

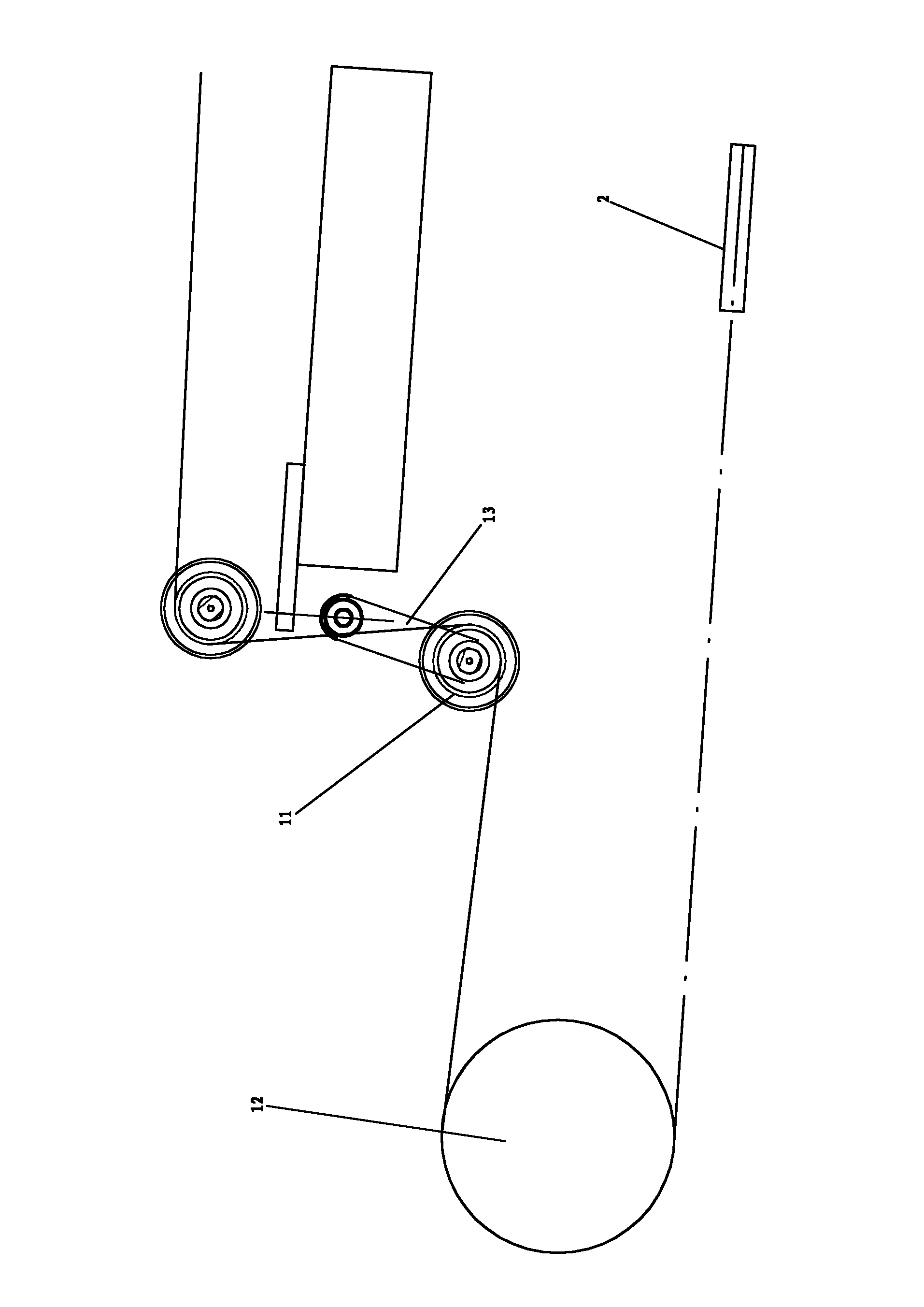

Circulating tin plating process and device

The invention relates to the technical field of tin plating of copper wires, in particular to a circulating tin plating process and device. The circulating tin plating process comprises the following steps of: setting speed and stabilizing speed and tension in a tension buffer area; annealing in a high-temperature annealing area at high temperature; initially cooling in an annealing and cooling area; pre-plating tin in an inlet tin heating area; finally plating tin in an outlet tin heating area; scraping residual tin by using a tin plating mold for sizing; protecting reducing gas to deoxidize liquid tin and protecting a wire rod from being oxidized; cooling a hot plated tin wire with water; scraping water on the tin-plated wire with rubber; scraping water and possible tin beads by using a mold; drying residual water by using a drier; cooling the tin-plated wire to room temperature by using a cooling wind scoop; and rolling into a finished product, and the like. By adopting the circulating tin plating process, the product quality of the tin-plated wire is ensured, use of a soldering flux causing pollution can be avoided, noble rare earth metals are avoided or reduced, a large amount of electric energy is saved, waste of tin dross is reduced, operation is simplified and concealed danger of quality is reduced.

Owner:周开勇

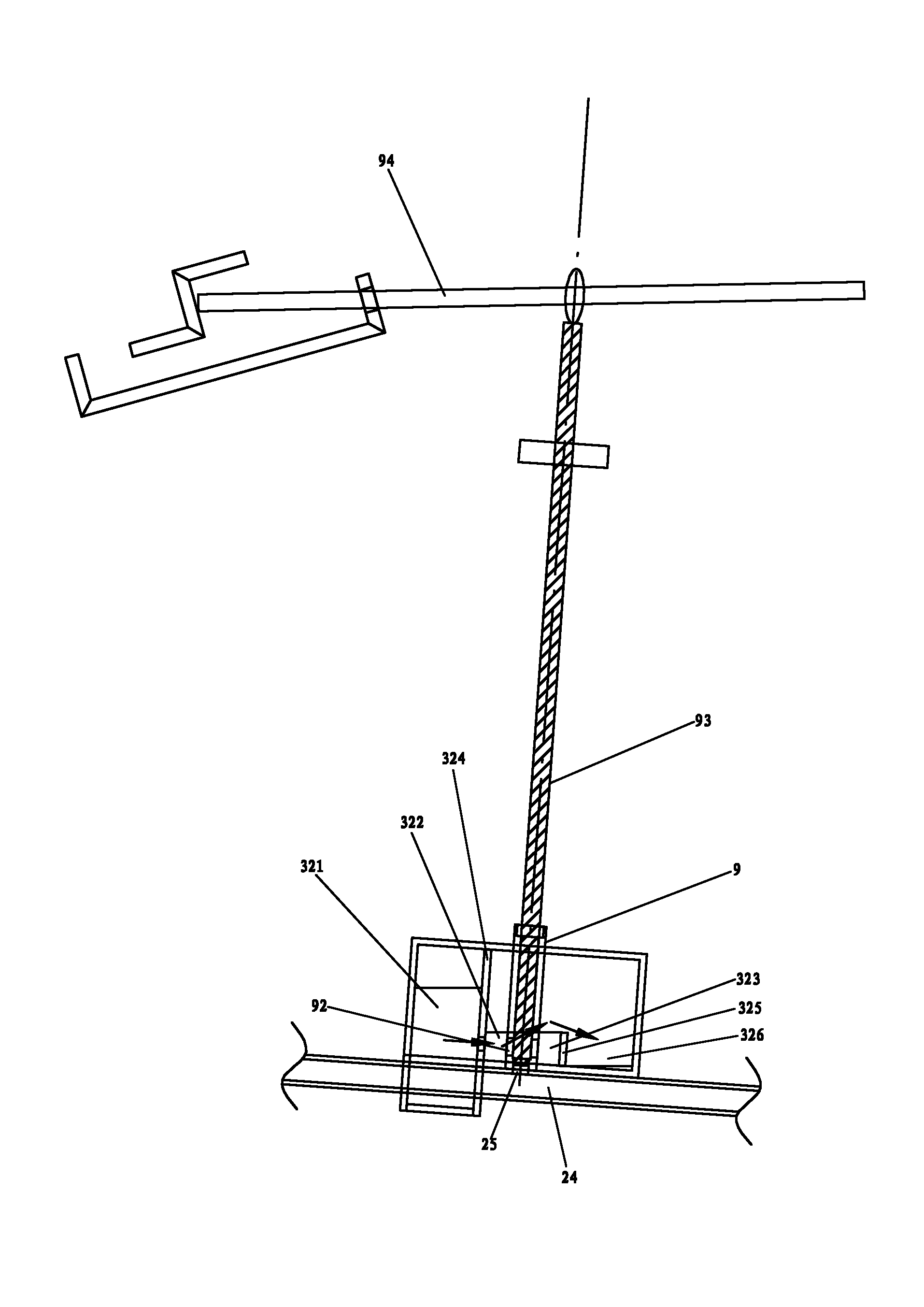

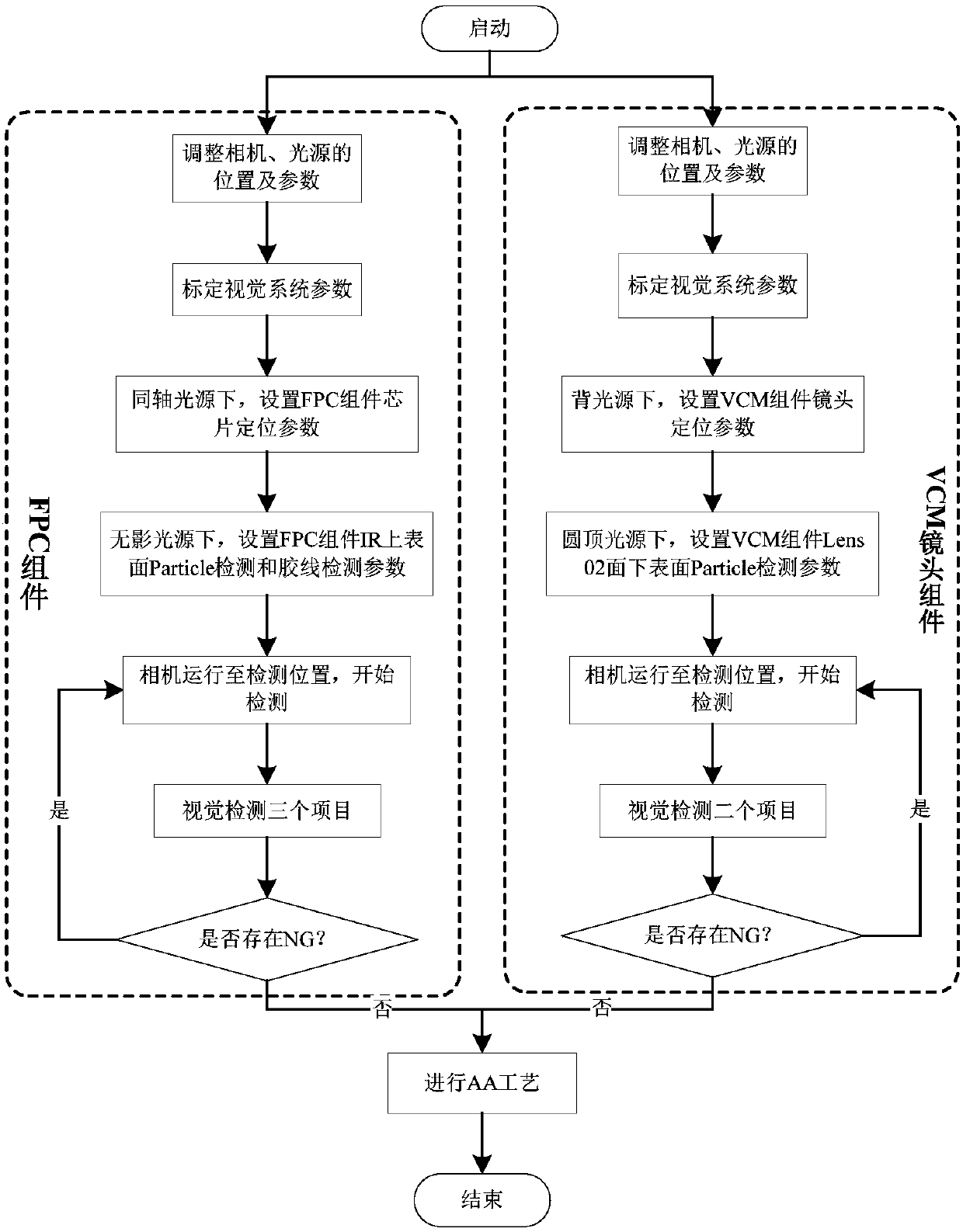

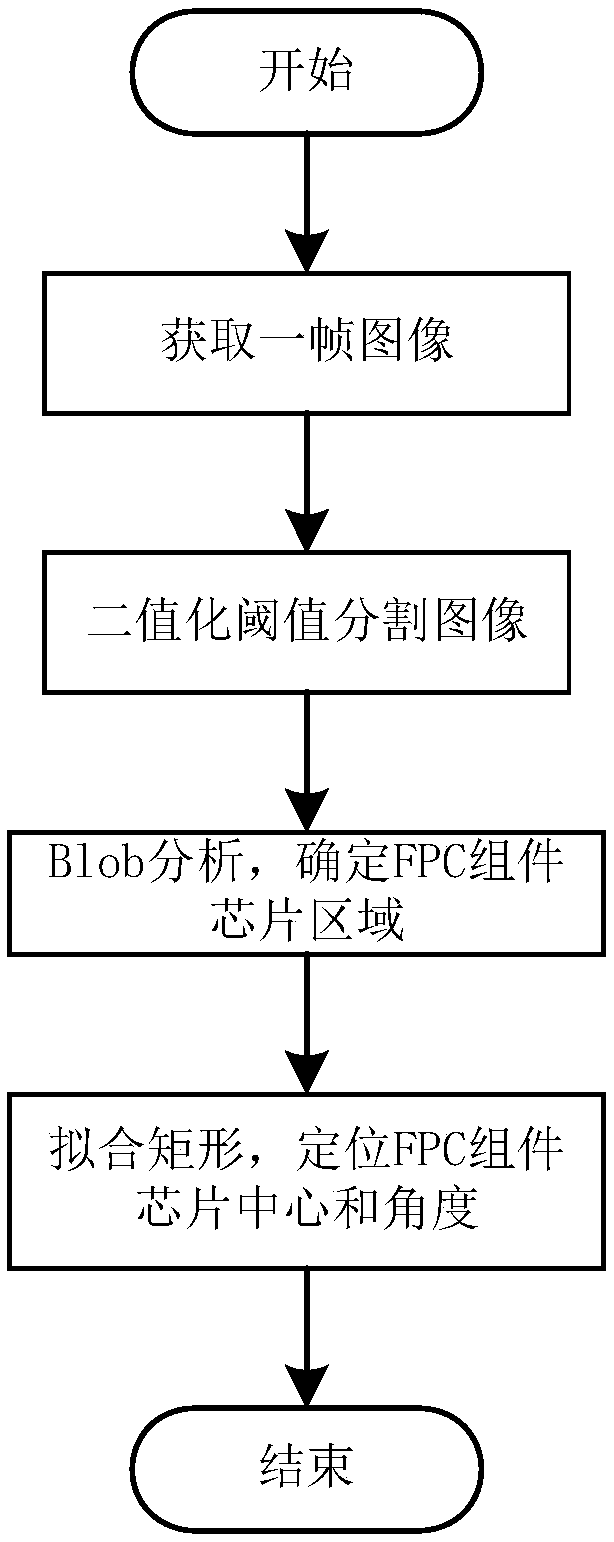

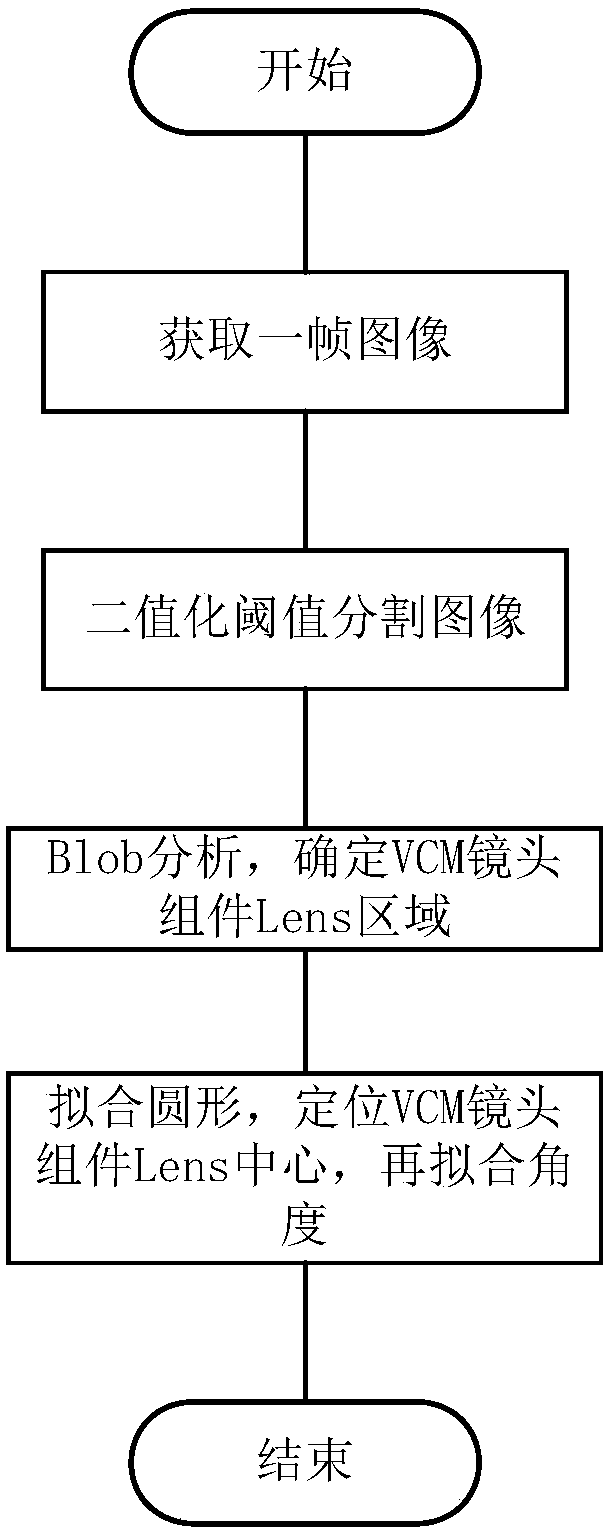

Device detection method

ActiveCN107796825AAccurate locationHelp with assemblyOptically investigating flaws/contaminationIntegrated operationsIrradiation

The invention discloses a device detection method, which comprises the following steps: irradiating the surface of a device for a test by a first light source, taking a photo of the device under the irradiation of the first light source to obtain a first image; according to the first image, positioning the device; irradiating the surface of the device by a second light source, taking a photo of the device under the irradiation of the second light source to obtain a second image; and analyzing the second image to determine whether the device is qualified or not. The provided method can carry out positioned detection and defect detection on a device, the position where the device stays can be accurately positioned, at the same time, the device can be detected to determine whether the deviceis qualified or not, the subsequent operation such as calibration, assembling, and the like, becomes convenient, and the product quality is improved effectively. Moreover, the integrated operation ofpositioning and defect detection is realized, the device does not need to be transmitted between different stations, and the detection efficiency is improved.

Owner:NINGBO SUNNY OPOTECH CO LTD

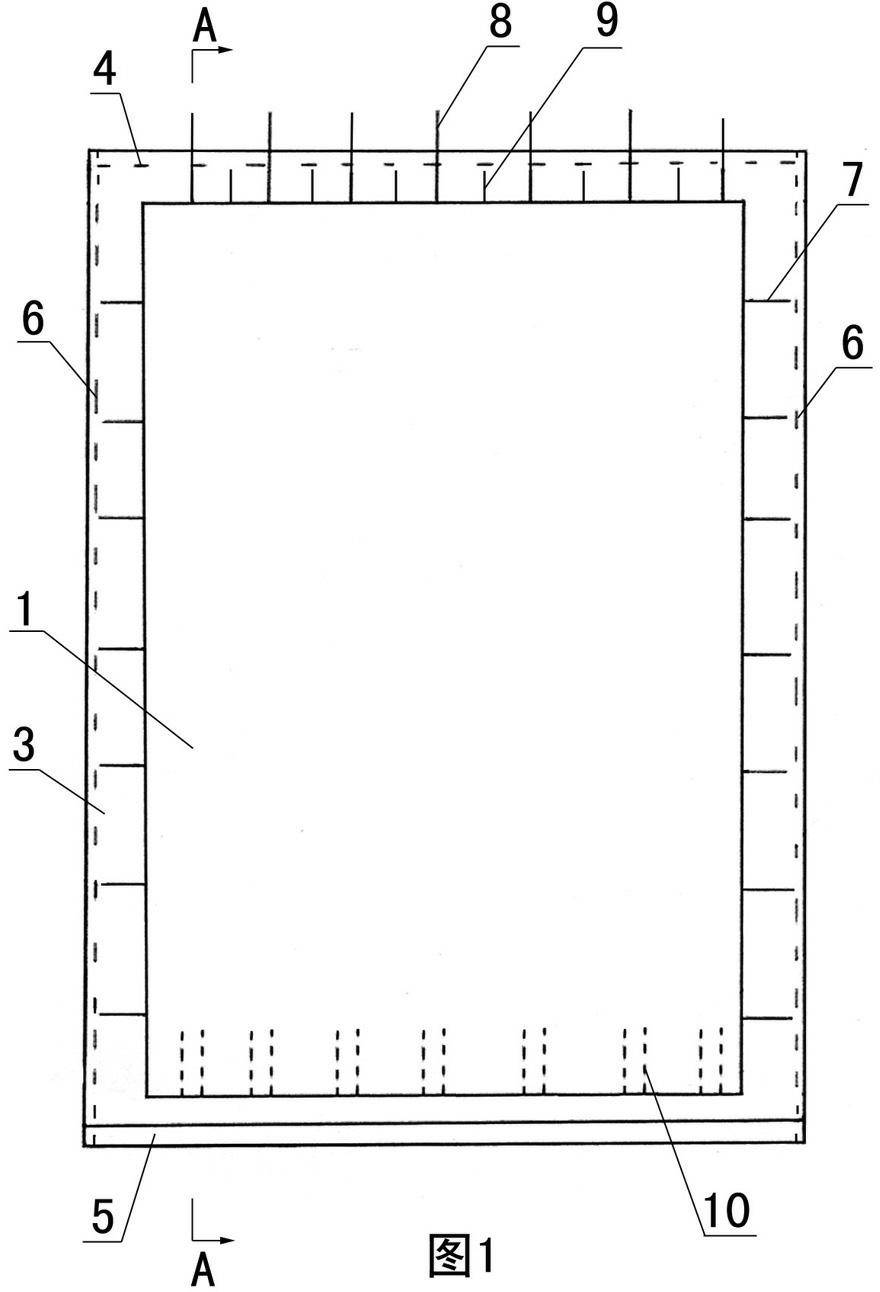

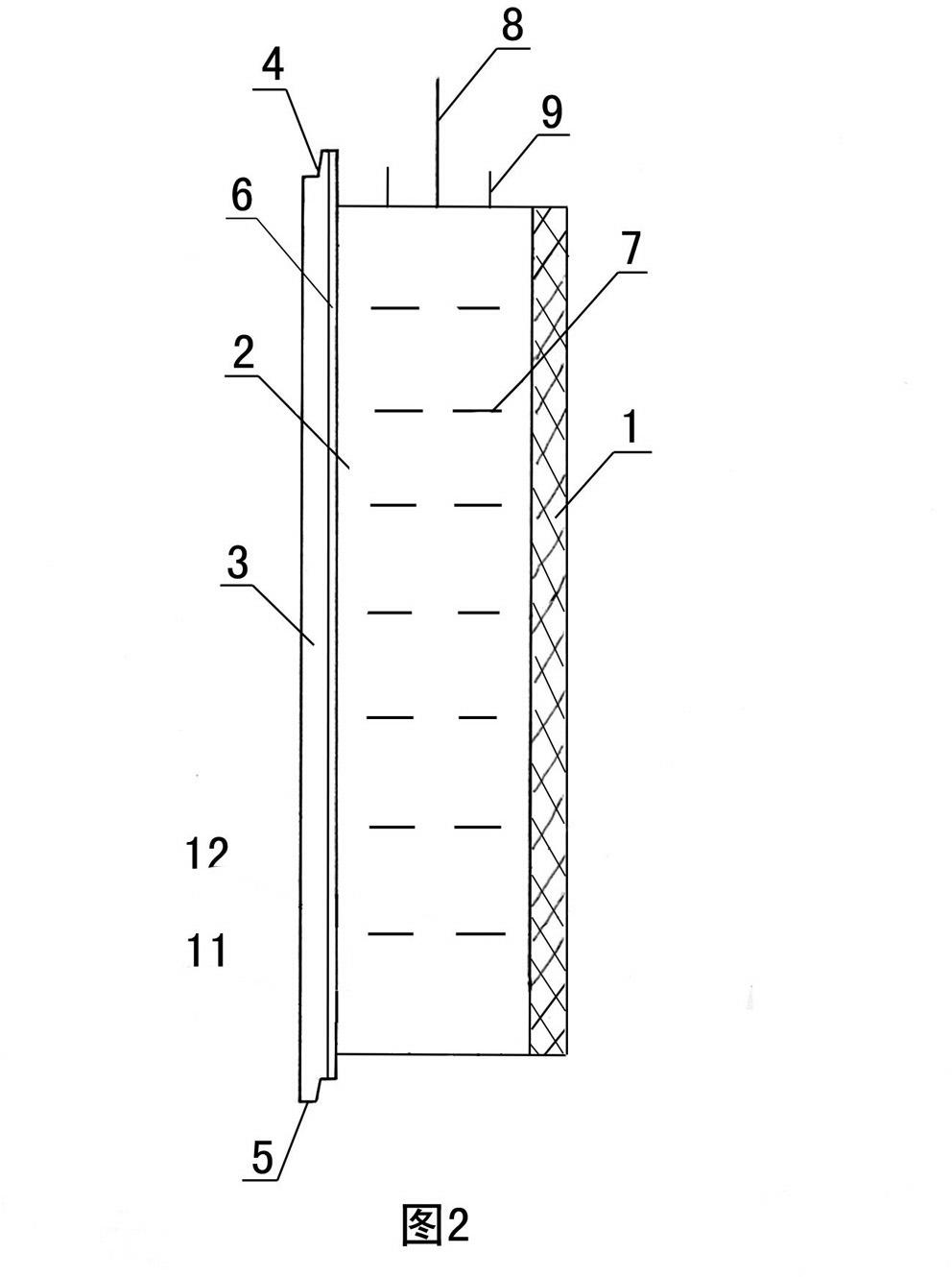

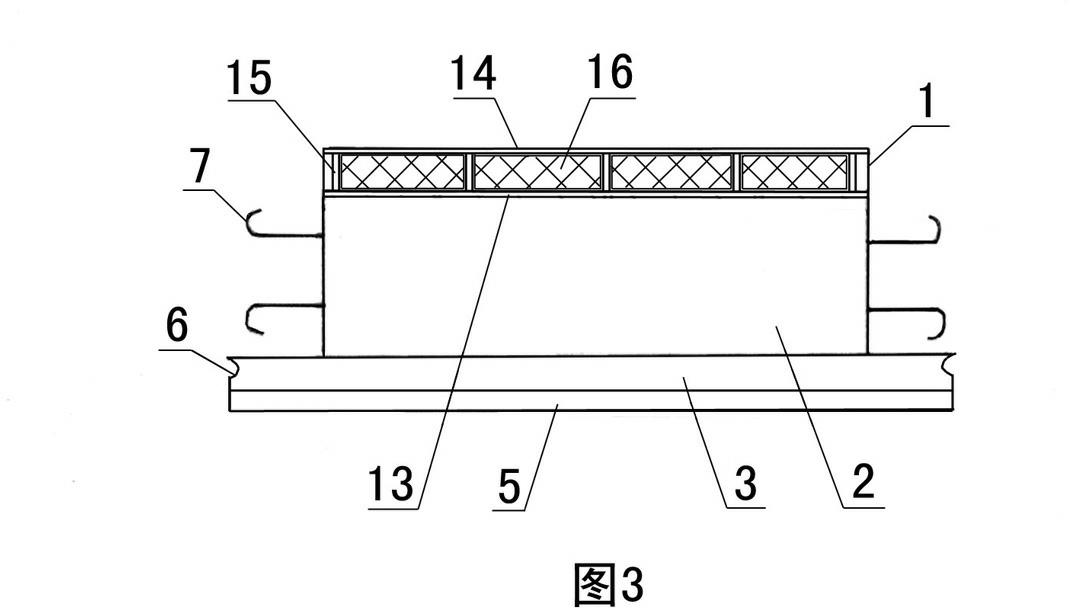

Block type wall system assembled by hoisting and construction method thereof

ActiveCN102505779ASimple construction methodReduce generationWallsClimate change adaptationSurface layerInsulation layer

Disclosed are a block type wall system assembled by hoisting and a construction method thereof. Multiple prefabricated wall board blocks are assembled into a whole, each prefabricated wall board block is provided with a reinforcing mesh concrete layer and a heat insulation layer outside in sequentially, the reinforcing mesh concrete layer consists of a structural layer and an outer surface layer disposed on the outer surface of the structural layer, four edges of the outer surface layer are protruded from four edges of the structural layer, the lower surface of the structural layer is provided with inner reinforcing bar holes corresponding to vertical long reinforcing bars on the lower adjacent prefabricated wall board block, and the heat insulation layer comprises external nonorganic boards, internal nonorganic boards, vertical nonorganic rib plates and fireproof heat insulation rock wool. The wall system is light in weight, simple in structure, convenient in installation and capable of realizing industrialized production. The wall system utilizes the external wall and internal heat insulation structure, the specially-made heat insulation layer and the concrete structural layer are connected quite closely and tightly, and the heat insulation layer is located on the innermost side, so that the probability of wetting due to seepage is reduced greatly.

Owner:沈汉杰

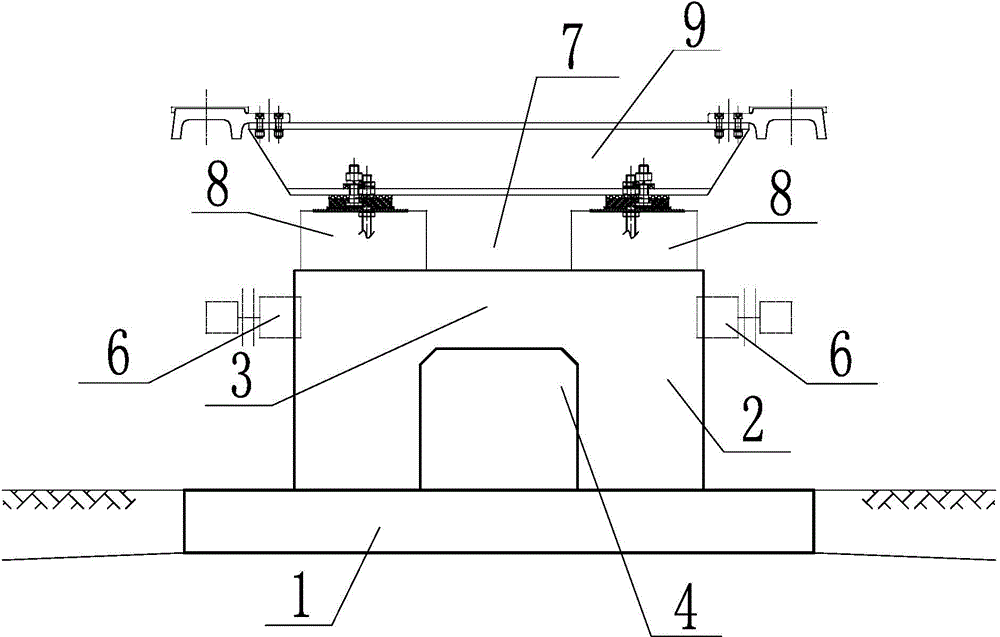

Medium-and-low speed magnetic levitation railway low route continuous arched supporting rail beam structure and construction method

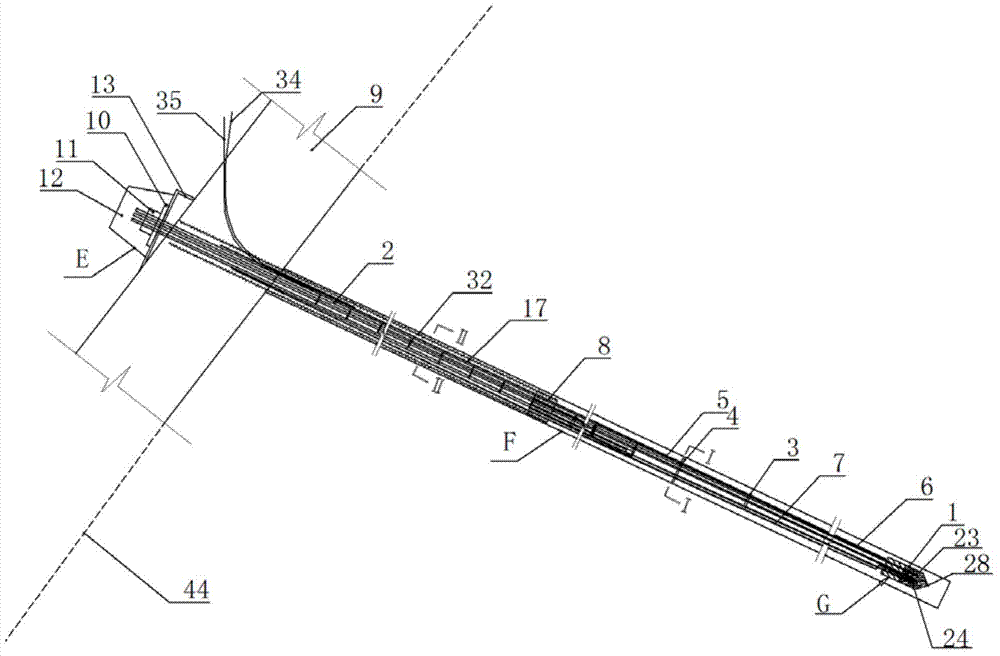

ActiveCN104480803AMeet stability requirementsMeet strength requirementsBallastwayLow speedReinforced concrete

The invention discloses a medium-and-low speed magnetic levitation railway low route continuous arched supporting rail beam structure. The structure comprises a reinforced concrete bottom plate, a rail row, a plurality of rows of track rail supporting tables, a reinforced concrete top plate, flow guide rail brackets and a plurality of reinforced concrete arched posts, wherein a transponder mounting position is arranged between a left track rail supporting table and a right track rail supporting table in each row of track rail supporting tables; the flow guide rail brackets are arranged on the two sides of the reinforced concrete top plate; the reinforced concrete arched posts are arranged on the reinforced concrete bottom plate along the track line direction at equal intervals; the bottom of the reinforced concrete top plate is fixedly connected with the top of each reinforced concrete arched post; the rail row is arranged at the top of the reinforced concrete top plate through the track rail supporting tables; a transverse arch is arranged in each reinforced concrete arched post; a longitudinal arch is formed between every two adjacent reinforced concrete arched posts. The transverse drainage requirement on a low route at a dual-line road section is convenient to meet, and the difficulty on construction of a rail structure on the upper part can be reduced.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

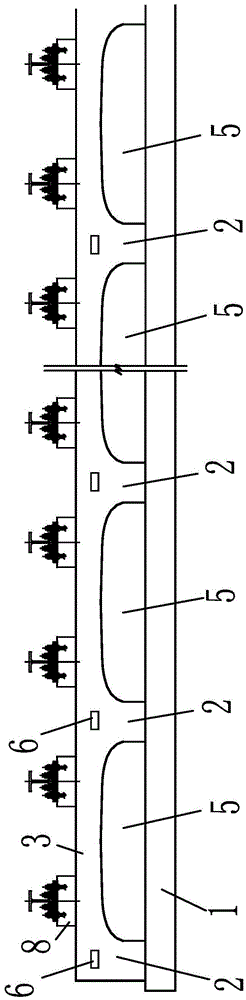

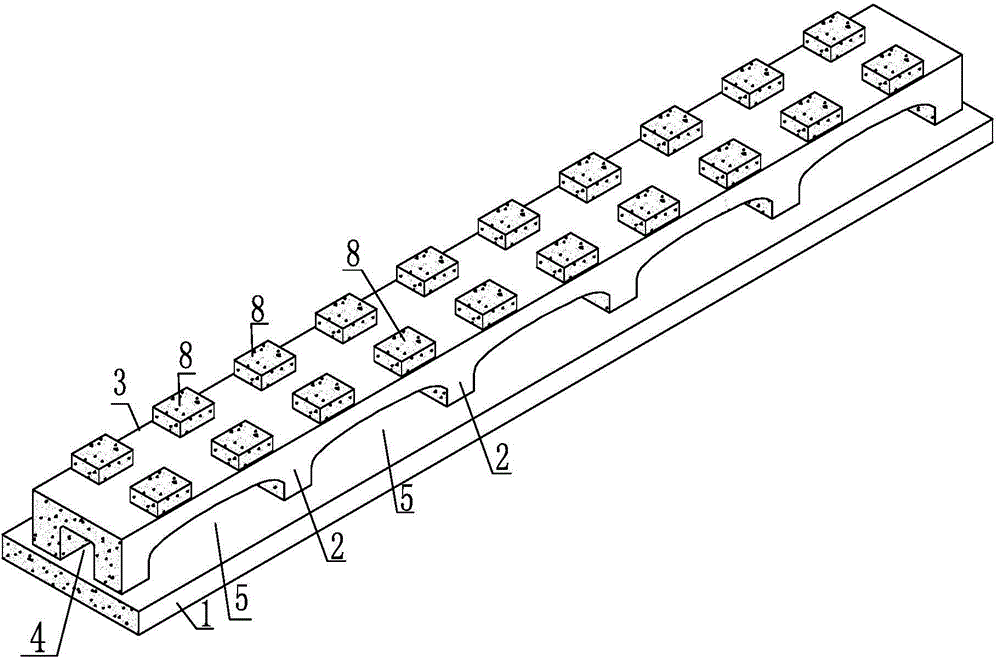

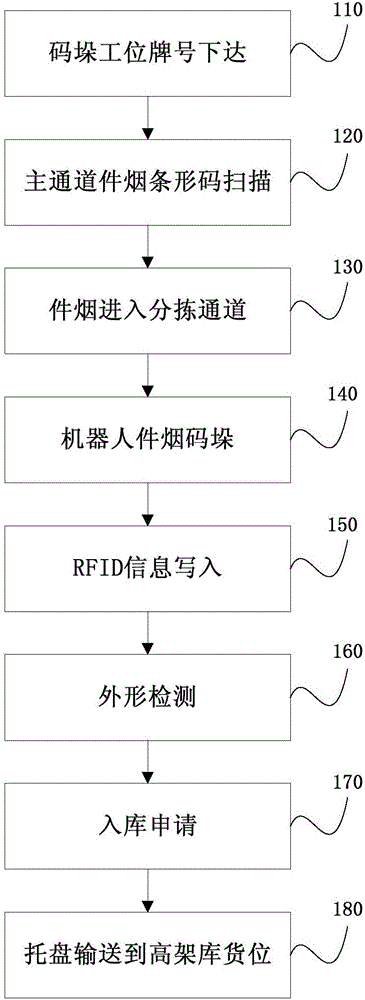

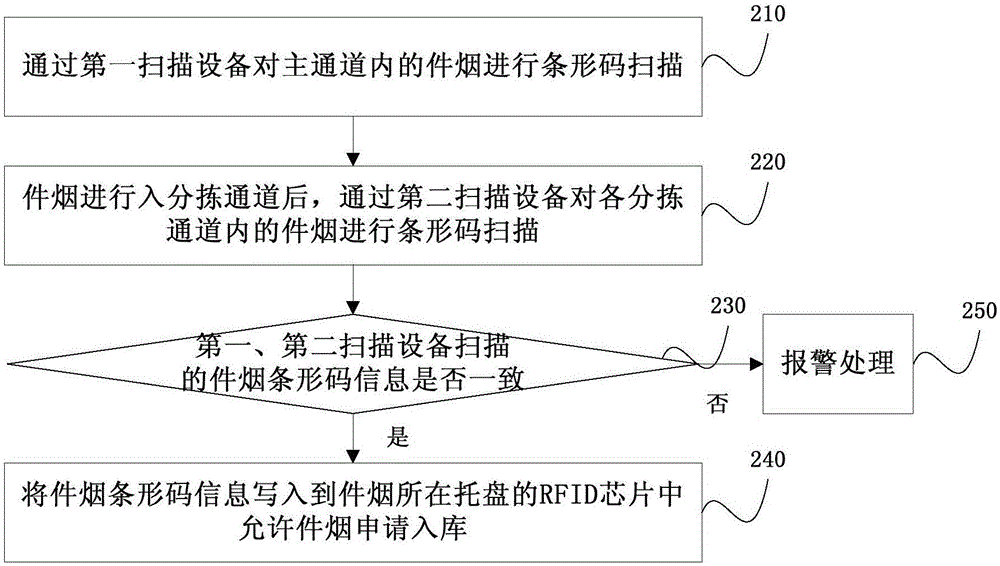

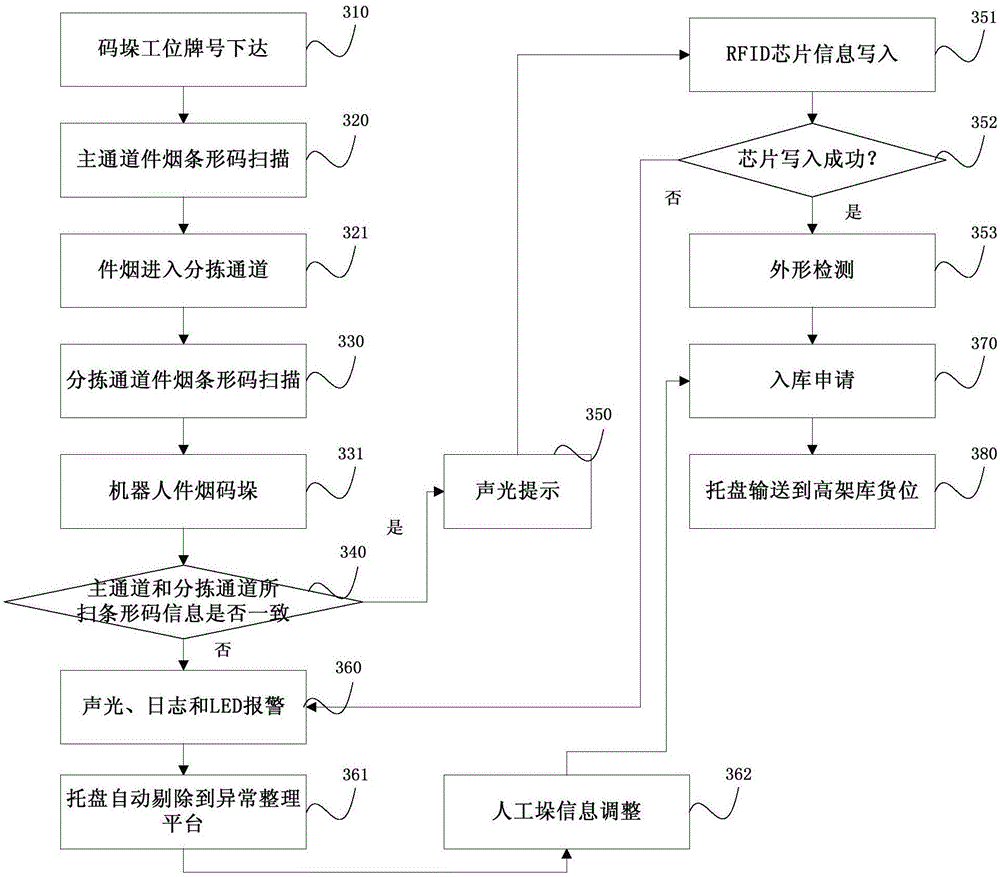

Cigarette product warehousing method and system

PendingCN106529890AImprove accuracyReduce quality hazardsCo-operative working arrangementsLogisticsRadio frequencyMain channel

The invention discloses a cigarette product warehousing method and system, and relates to the field of automatic logistics of cigarette industry products, wherein the method comprises the following steps of: performing barcode scanning of piece cigarettes in a main channel through first scanning equipment; after the piece cigarettes enter sorting channels, performing barcode scanning of the piece cigarettes in the various sorting channels through second scanning equipment; after the piece cigarettes are stacked, judging whether piece cigarette barcode information scanned by the first scanning equipment is the same as piece cigarette barcode information scanned by the second scanning equipment or not; if so, writing the piece cigarette barcode information in a radio-frequency identification RFID chip of a tray, where the piece cigarettes are, and allowing the piece cigarettes to warehouse; and otherwise, giving an alarm. By means of the cigarette product warehousing method and system disclosed by the invention, the self-checking risk of barcodes in the original warehousing process can be avoided; the accuracy of each warehousing piece cigarette barcode is improved; and potential quality hazards can be reduced.

Owner:LONGYAN CIGARETTE FACTORY

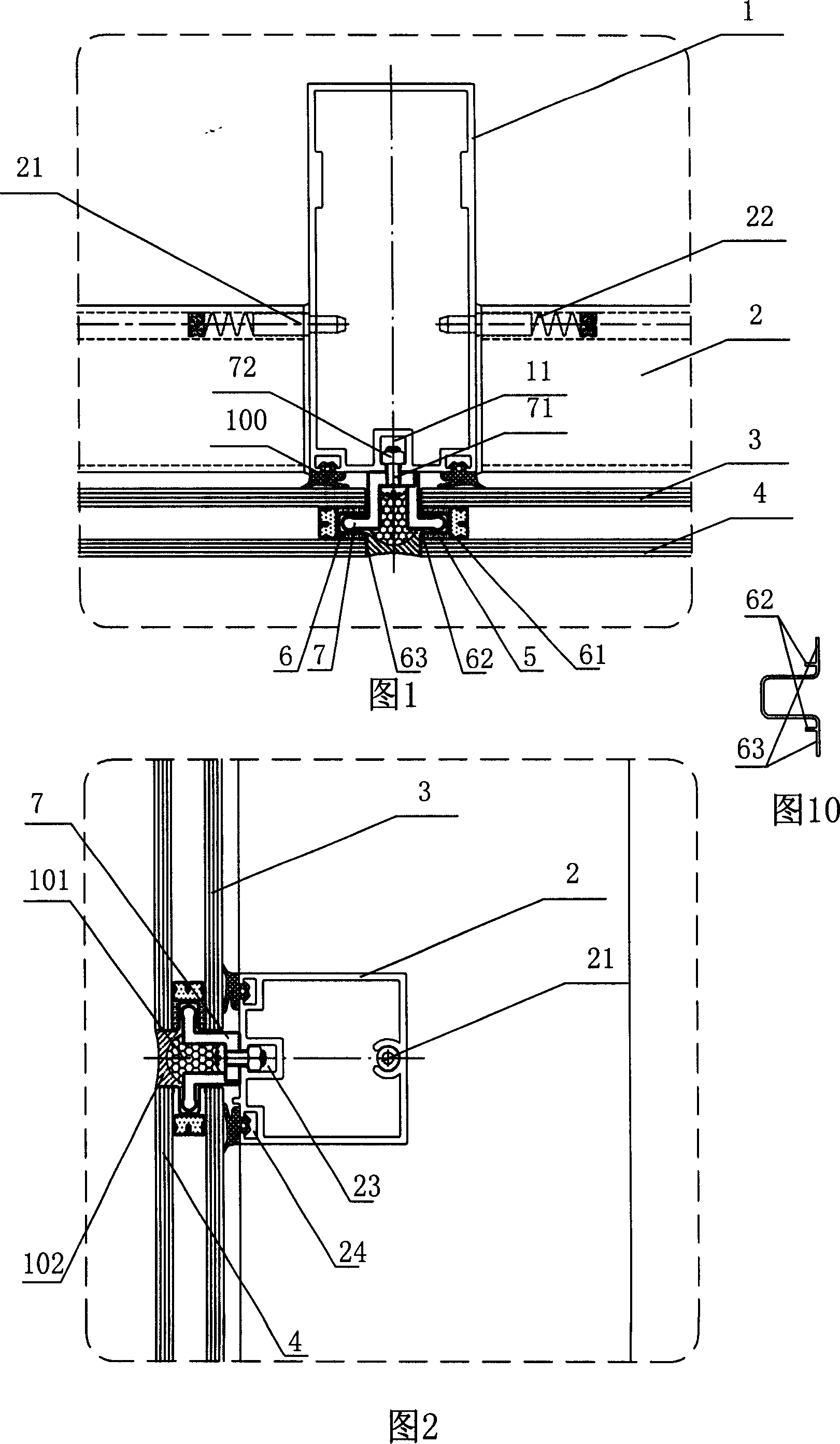

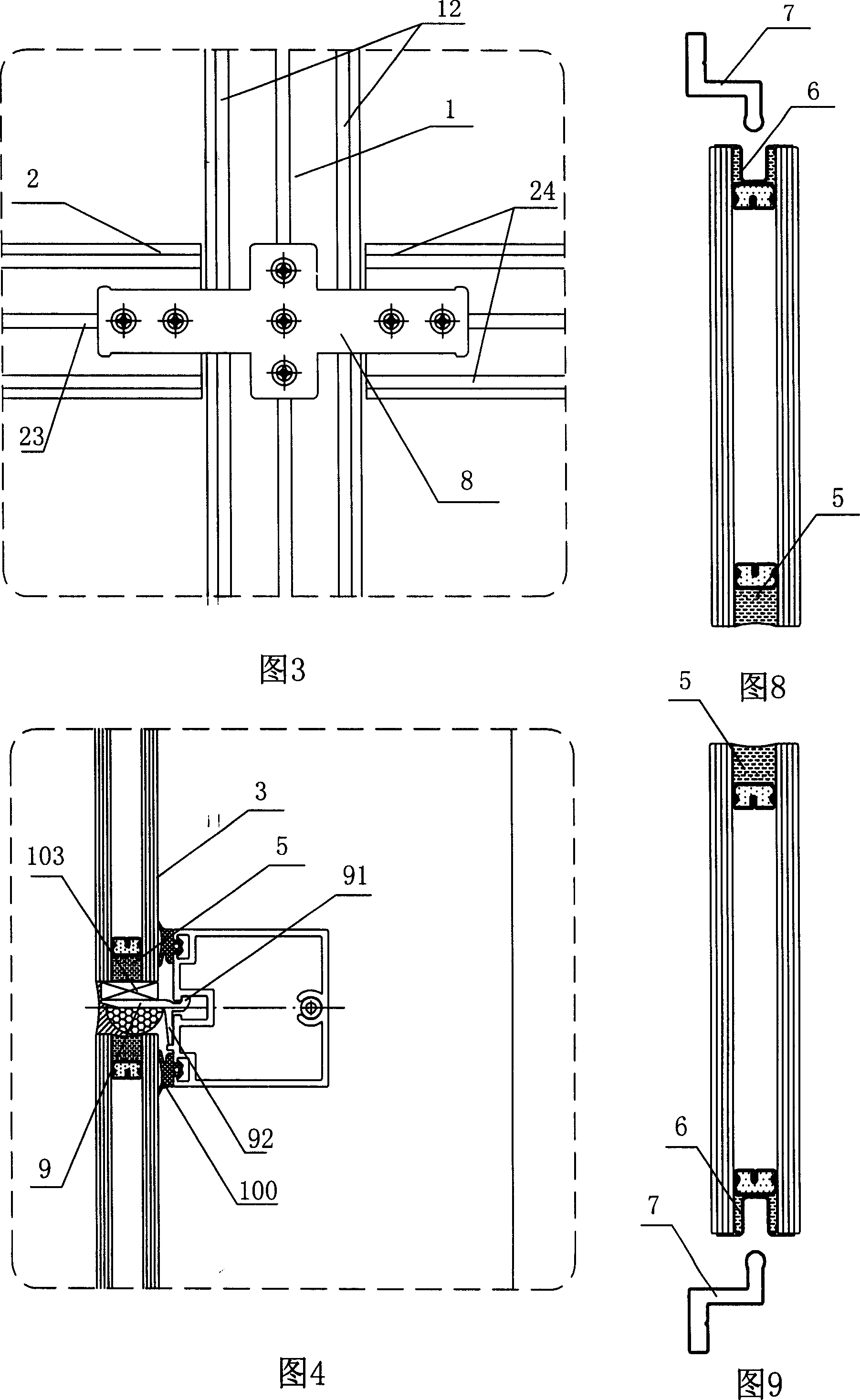

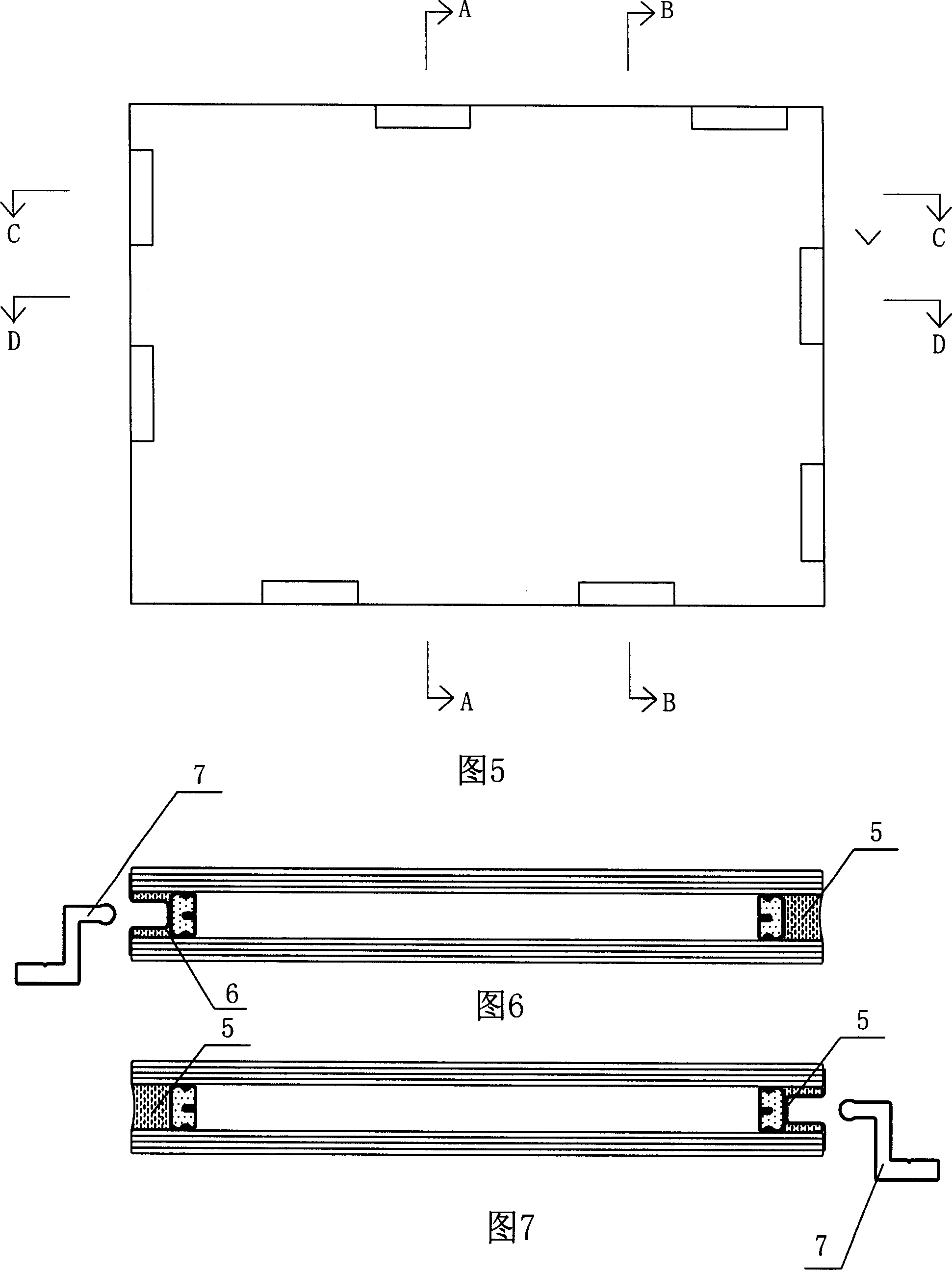

Hollow glass curtain wall with invisible frame and hollow glass plate for use in curtain wall

The invention provides a hidden framing hollow glass curtain wall, comprising upright pillar, cross beam and hollow glass block set on the upright pillar and cross beam. The hollow glass block contains inner glass plate and outer glass plate, round which there is structural glue used to connect inner and outer glass plates. There are inserting parts, whose length is far from less than the length of relative glass plate side, in the structural glue respectively. There are assembling slots in inserting parts and locating structure along the thickness direction of hollow glass plate. Connectors inserting into the assembling slots is set on said hidden framing hollow glass curtain wall and said connector is connected with upright pillar and cross beam. The invention changes the method that the glass of hidden framing glass curtain wall is formed to glass parts by structural glue necessarily and maintaining time for structural glue and relative machining procedure for structural glue and assistant frame is canceled so that unit cost is decreased largely. Construction process is quickened while quality danger generated by structural glue and assistant frame is reduced.

Owner:浙江中南幕墙科技股份有限公司

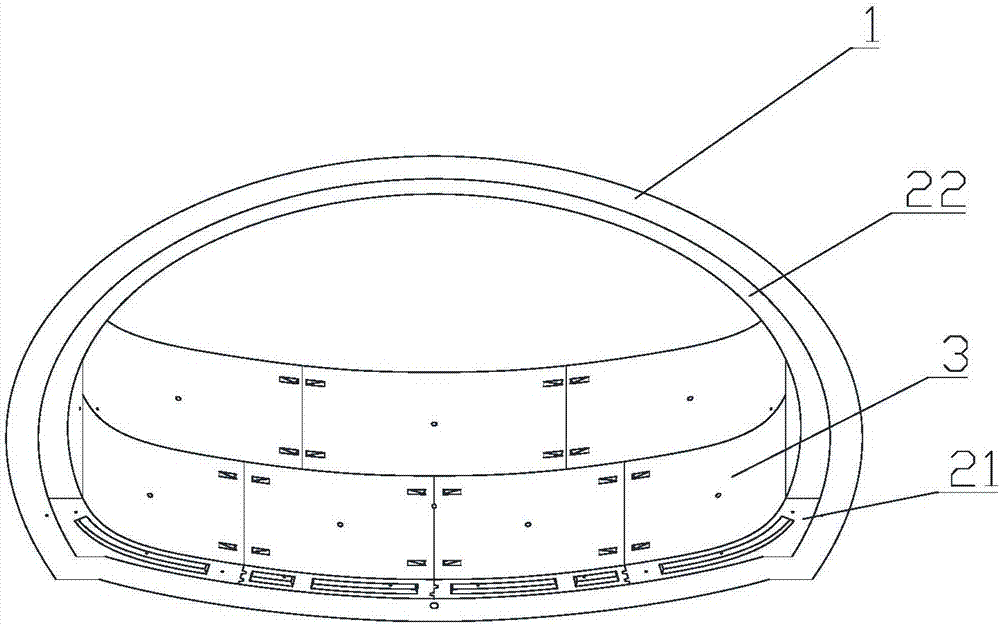

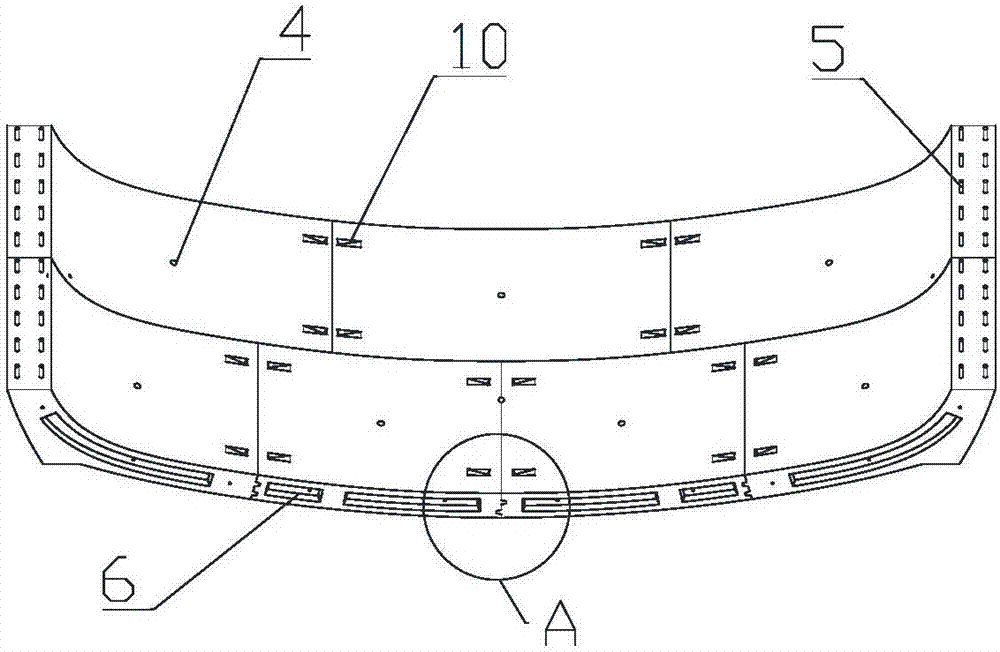

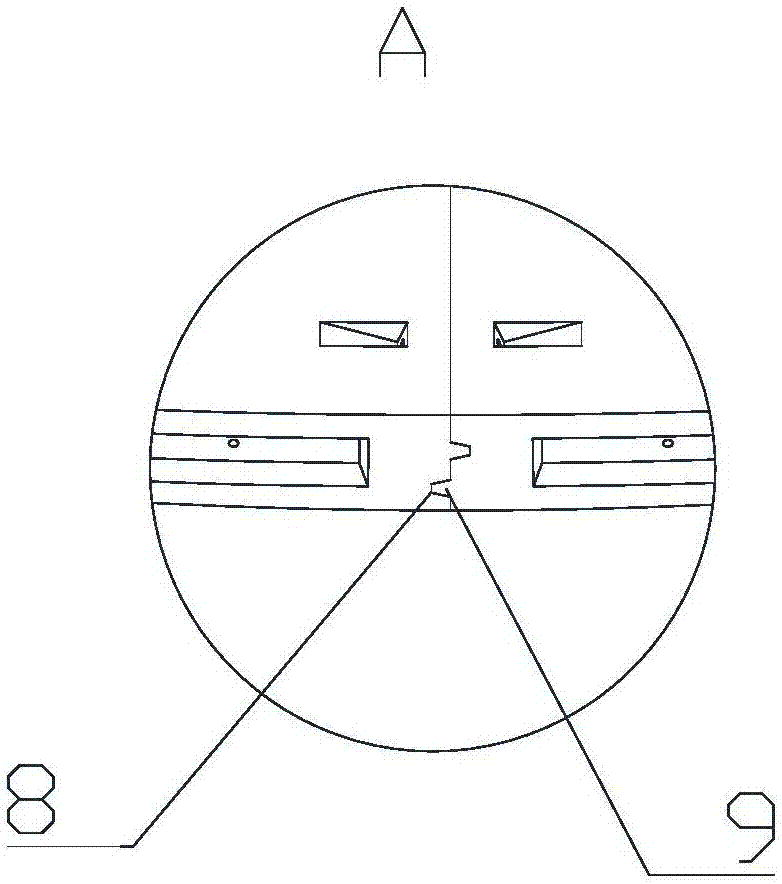

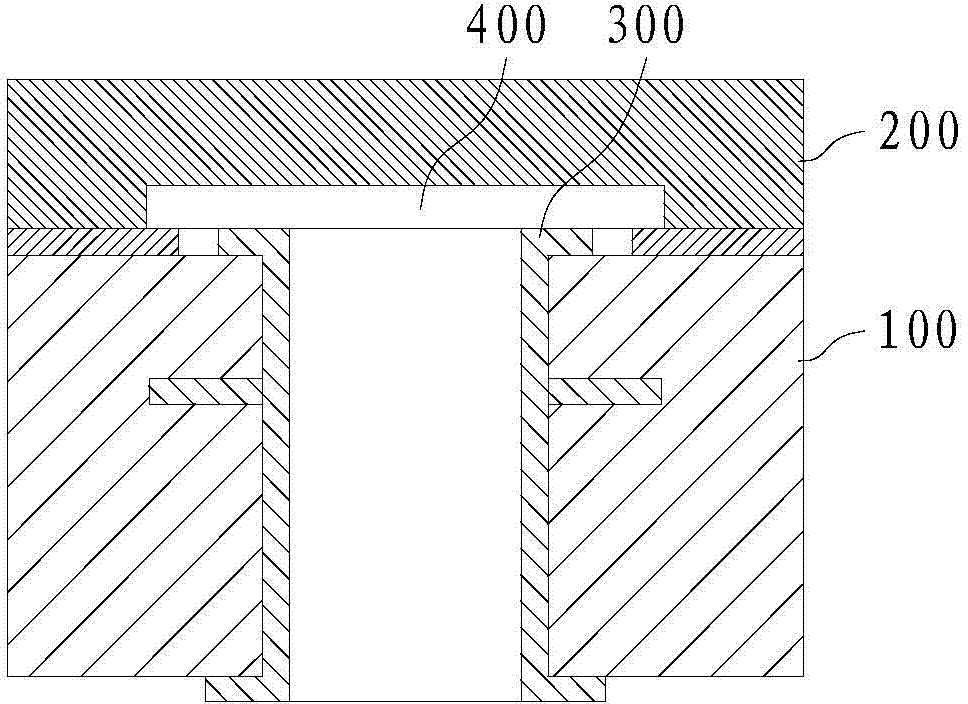

Prefabricated assembly type tunnel inverted arch, tunnel structure and construction method of tunnel structure

The invention relates to the technical field of tunnel engineering and discloses a prefabricated assembly type tunnel inverted arch. The prefabricated assembly type tunnel inverted arch comprises multiple rows of splicing units sequentially arranged in the extending direction of a tunnel. Each row of the splicing unit comprises multiple splicing blocks with arc-shaped cross sections. Joint seams of adjacent splicing blocks in the splicing units and joint seams of adjacent splicing blocks in the adjacent splicing units are staggered. Connecting rebars connected with a tunnel arch wall are reserved at the tops of the outer side faces of the prefabricated blocks on the two sides of each row of the splicing unit. In the building process of the prefabricated assembly type tunnel inverted arch and a trench structure, the prefabricated assembly type tunnel inverted arch has the beneficial effects that the resource energy is saved, the construction pollution is reduced, the labor production efficiency is improved, the labor intensity of workers is lowered, and the quality safety level is increased; and the potential hazards that the stress of the tunnel is not uniform, the deformation is likely to generate and the cracking is likely to generate can be prevented. The invention further discloses a tunnel structure with the prefabricated assembly type tunnel inverted arch and a construction method of the tunnel structure.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +3

Circuit board manufacturing method

InactiveCN103945651AAchieving Via InsulationEfficient detectionPrinted circuit aspectsPrinted element electric connection formationEngineeringAlkaline etching

The invention discloses a circuit board manufacturing method. The circuit board manufacturing method comprises the following steps of providing a cover plate, correspondingly forming a through hole corresponding to a plated-through hole of a circuit board in the cover plate and enabling the cover plate to cover the electroplated circuit board surface, wherein the through hole is aligned to the plated-through hole of the circuit board; providing a resin material with good copper face wettability and enabling the resin to be fully stirred under the vacuum condition; enabling the stirred resin to be coated on the cover plate surface, enabling the through hole of the cover plate to be full of the resin through a single stroke of a scraper of a silk-screen machine, wherein the rein flows into the plated-through hole through the through hole, and an oil return knife scrapes back the resin left on the cover plate surface; covering a pattern electrotinning layer on a electro-coppering layer required to be reserved, protecting patterns required to be reserved, enabling a copper ring at the hole opening position at at-least one end of the plated-through hole to be exposed, adopting alkaline etching liquid to perform etching to remove the copper ring protected by a tin-free layer, and performing etching for desired depth. The circuit board manufacturing method can remove the copper ring at the hole opening position of the plated-through hole, achieve through hole insulativity of the circuit board and effectively take the place of a backdrill technology.

Owner:DONGGUAN SHENGYI ELECTRONICS

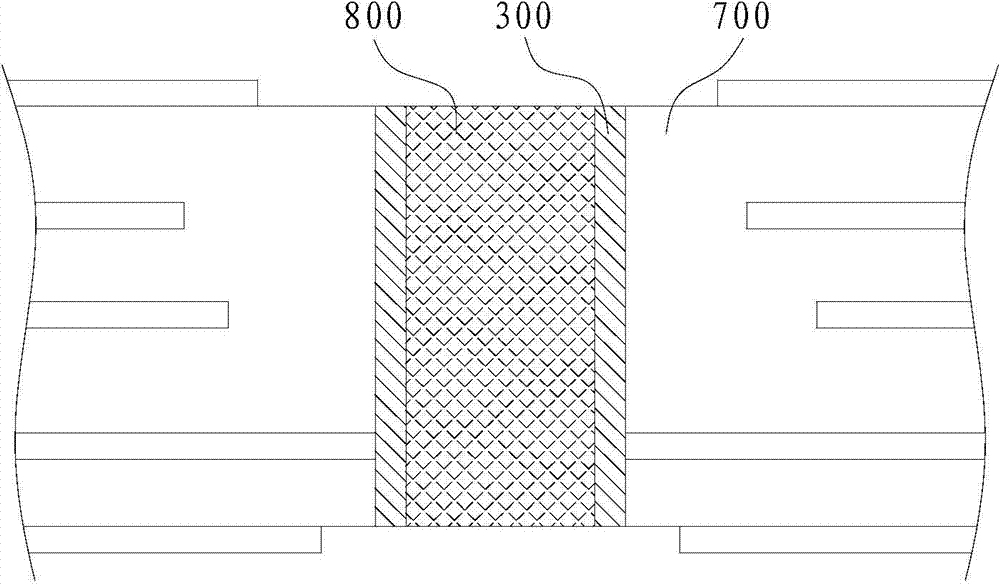

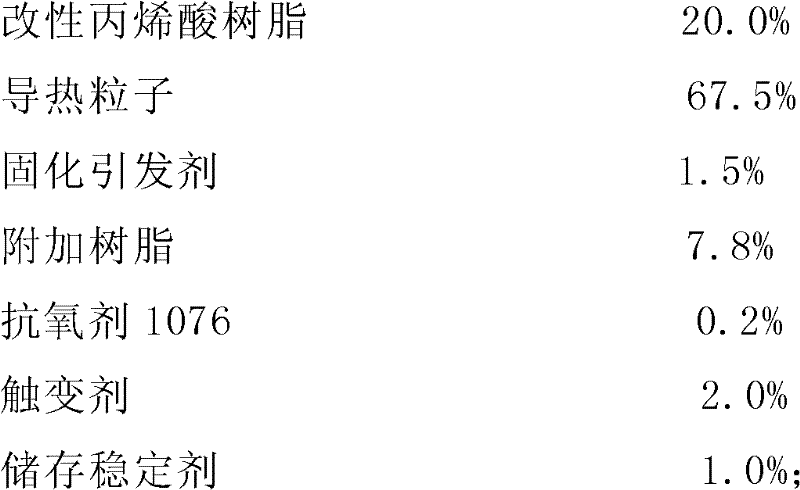

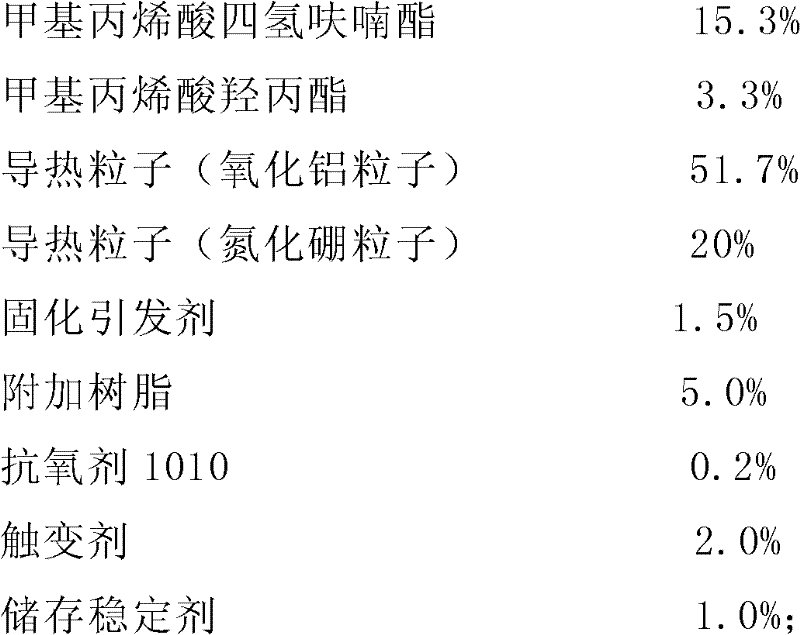

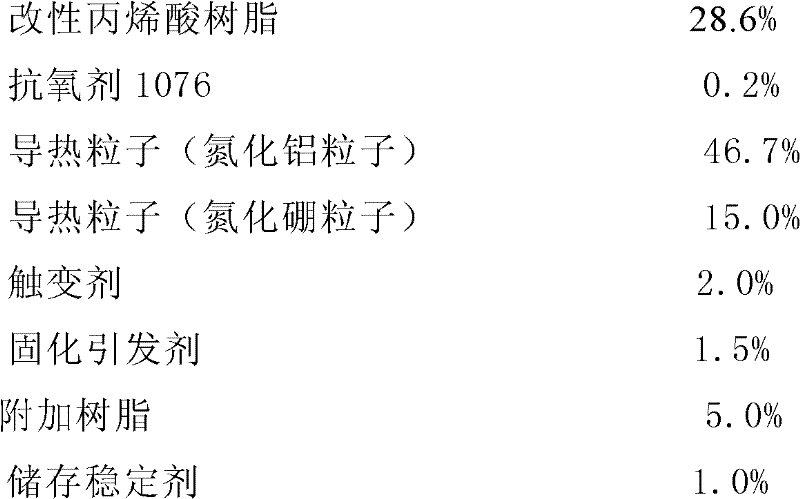

Fast cured thermal conductive adhesive and preparation method thereof

ActiveCN102504707AIncreased shear strengthFast curingNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAcrylic resinAdhesive

The invention relates to a thermal conductive adhesive and a preparation method thereof. The thermal conductive adhesive comprises 10 to 45 weight percent of modified acrylic resin, 50 to 85 weight percent of thermal conductive particles and 1 to 5 weight percent of curing initiator. Compared with the existing single-component thermal conductive adhesive, the thermal conductive adhesive disclosed by the invention can be suitable for surfaces of polar substrates such as metal, ceramic and glass, has high cutting speed after being cured and has high curing speed. Compared with the existing two-component thermal conductive adhesive, the thermal conductive adhesive disclosed by the invention has high curing speed and high cutting strength after being cured on one hand, and has no risk of incomplete curing caused by improper proportioning or nonuniform stirring on the other hand. The thermal conductive adhesive can be used for thermal conductive connection between various heat source generators and a radiator.

Owner:TIF ADVANCED MATERIALS SHANGHAI

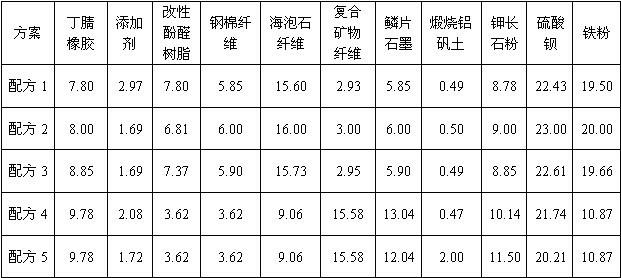

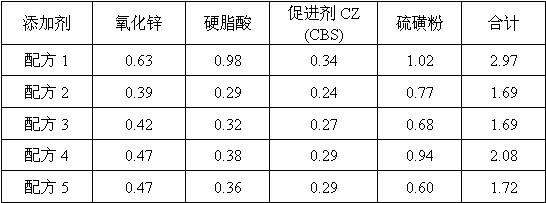

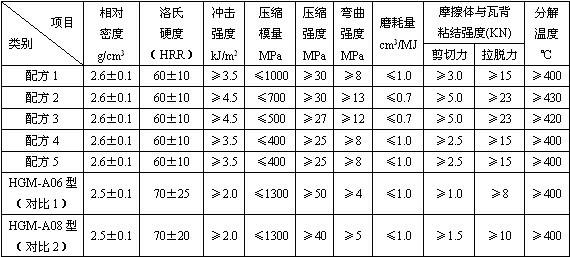

Composition brake shoe for railway freight car, and method for manufacturing same

ActiveCN102661340AHigh bonding strengthReduce wearOther chemical processesBraking membersCrazingSlag

The invention discloses a composition brake shoe for a railway freight car, and a method for manufacturing the same. A friction piece of the composition brake shoe for the railway freight car is synthetised by using following materials by weight parts: 6-10 parts of nitrile rubber, 2-8 parts of modified phenolic resin, 3-6 parts of steel wool fibers, 9-16 parts of sepiolite fibers, 2-16 parts of composite mineral fibers, 5-13 parts of graphite, 0.4-2 parts of calcined bauxite, 20-24 parts of barium sulfate, 8-12 parts of potassium feldspar powder, 10-20 parts of iron powder, and 1-3 parts of additives. The friction piece of the composition brake shoe is formed through the steps of dosing, banburying or mixing, crashing, hot press molding and curing forming, and thermal processing. The composition brake shoe is capable of well satisfying various performance indexes requested in PRC (People's Republic of China) railway industrial standard TB / T2403-2010, and can be applied to railway freight cars traveling at the highest speed of 120km / h and axle load of the composition brake shoe is not greater than 25 tons; besides, the composition brake shoe has stable friction properties and excellent friction resistance, and is low in attrition to wheels and low in braking noise; and as a result, potential quality hazards ( such as brake shoe body breakage, slag and block dropping, metal inlaying and hot cracks) endangering traveling safety are fundamentally solved.

Owner:CHONGQING YUHONG RAIL CAR ACCESSORIES CO LTD

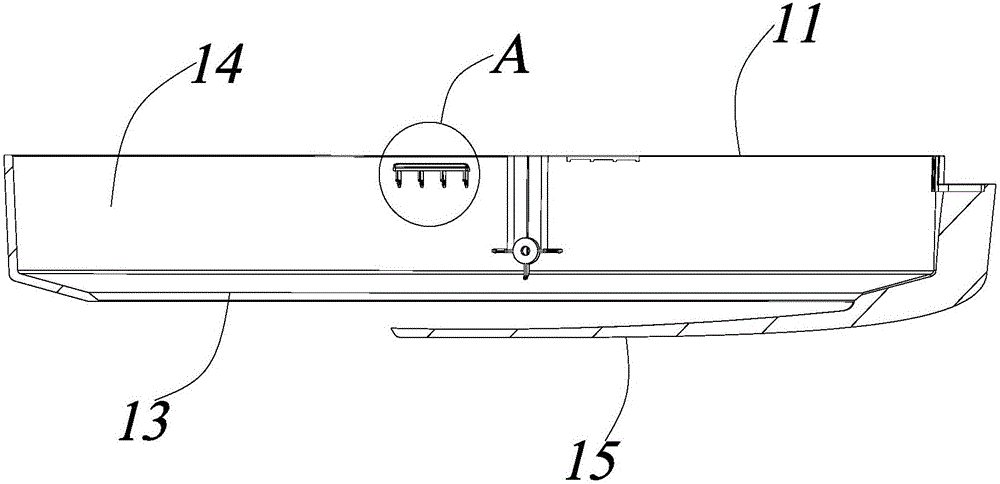

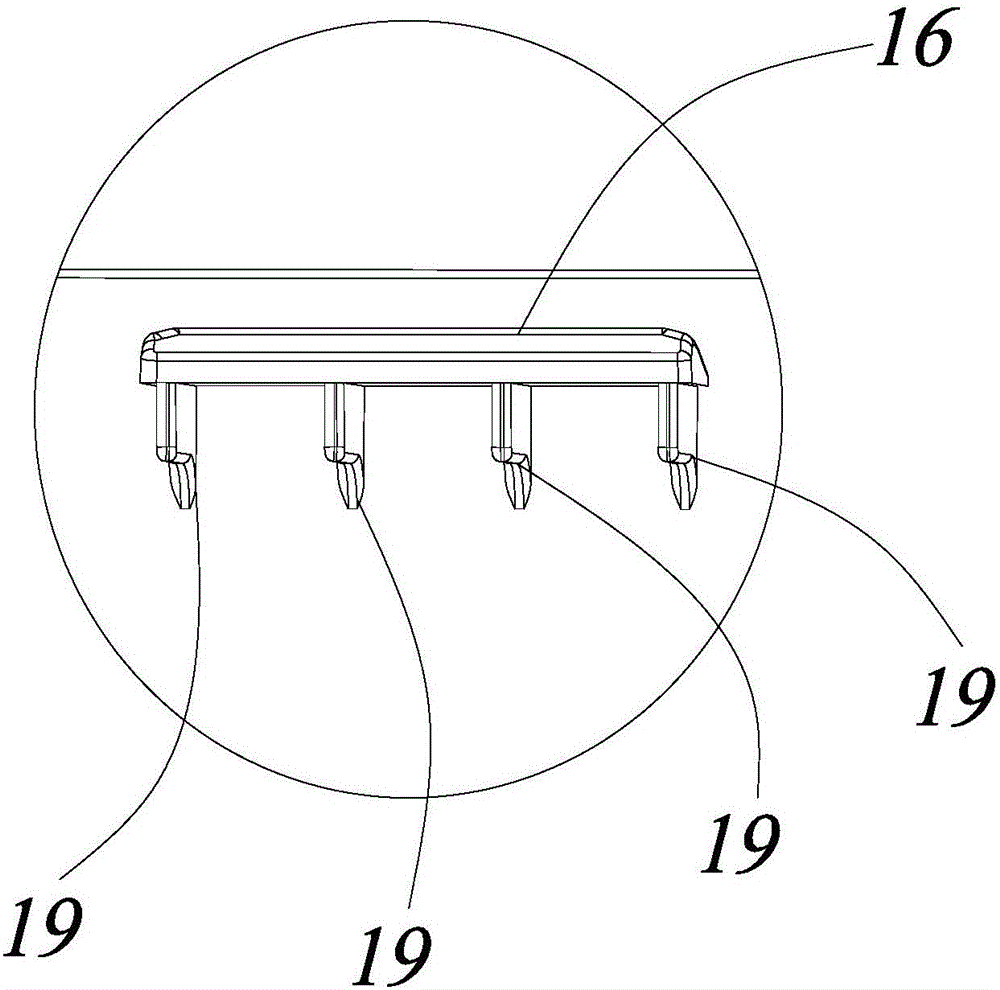

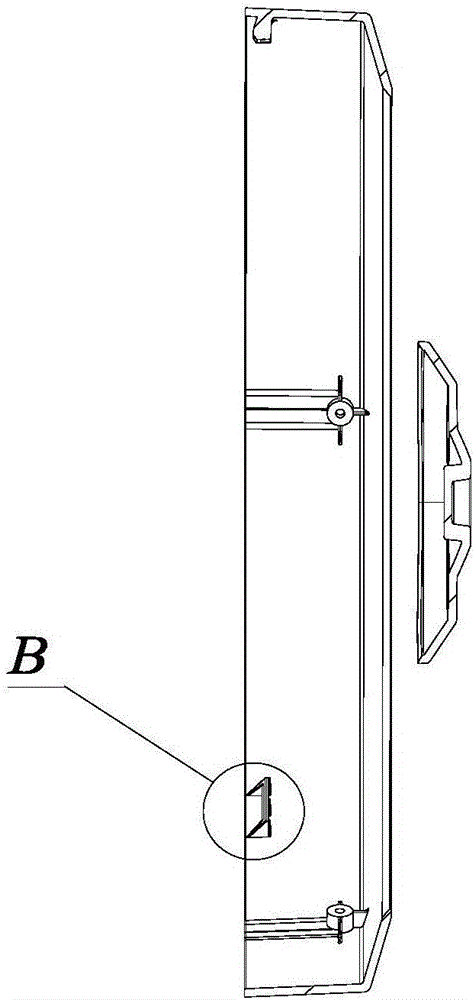

Assembly structure of pot cover and pot with assembly structure

ActiveCN106073519APrevent disengagementSimplify the assembly processCooking-vessel lids/coversPressure-cookersEngineeringAssembly structure

The invention discloses an assembly structure of a pot cover and a pot with the assembly structure. The assembly structure of the pot cover is used to assemble a face cover and a sealing cover together; a forward buckle and a backward buckle corresponding to pot teeth of the sealing cover are disposed on the outer edge facade of the face cover; and the pot teeth of the sealing cover can firstly stretch into the forward buckle, and then the sealing cover can generate elastic deformation to clamp the pot teeth into the backward buckle. In this way, the assembly structure of the pot cover provided by the invention can solve the problems that pot cover assembly is inconvenient, assembly efficiency is low, and hidden quality hazards exist on the premise of preventing separation between the face cover and the sealing cover.

Owner:GREE ELECTRIC APPLIANCES INC

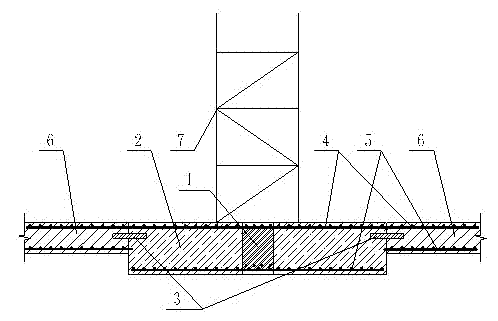

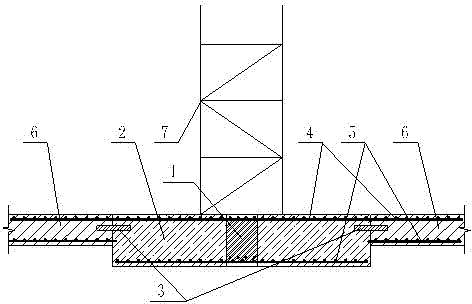

Tower crane foundation in building basement and manufacturing method of tower crane foundation

ActiveCN102677675AImprove stabilityGuaranteed safe operationProtective foundationBasementReinforced concrete

The invention discloses a tower crane foundation in a building basement and a manufacturing method of the tower crane foundation. The tower crane foundation is manufactured into an orthogonal beam slab type reinforced concrete tower crane foundation composed of an orthogonal beam and a slab. During manufacture, a pit of the tower crane foundation is dug in the building basement, and then the orthogonal beam is poured in a traditional mode of pouring reinforced concrete and the slab is poured on the orthogonal beam, and meanwhile, at least one circle of water retaining boards is fixedly inlaid around the slab; base plate surface ribs of basement base plates are embedded according to a traditional mode of pouring the basement base plates, and then the basement base plates are poured; and after the basement base plates are poured, the water retaining boards are inserted into the basement base plates around the slab, so that the orthogonal beam slab type reinforced concrete tower crane foundation is connected with the basement base plates into one. The tower crane foundation has the advantages of fastness, convenience and high efficiency in construction, low construction and operation cost, reliability in performance, safety in operation, convenience in operation and the like.

Owner:CHINA CONSTR FOURTH ENG DIV

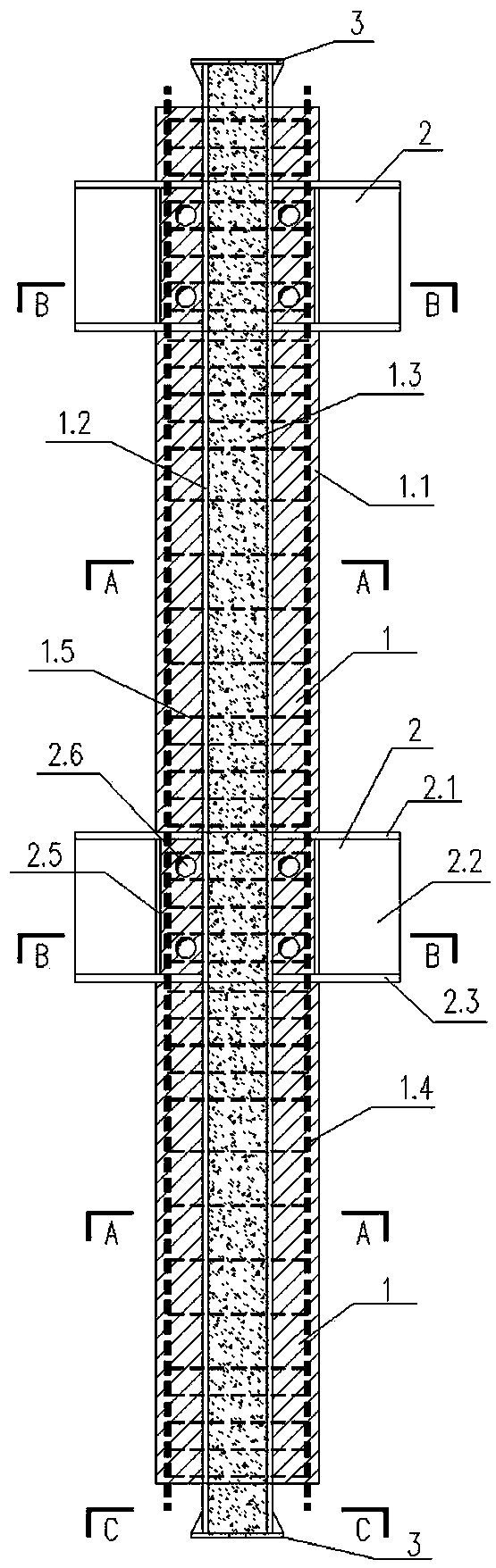

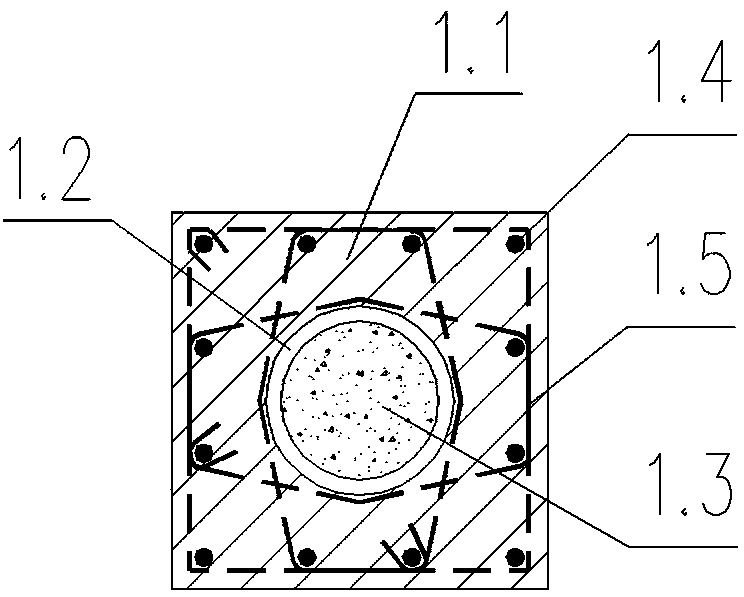

Fabricated frame strip steel bracket long column and construction method thereof

ActiveCN103556781AEasy to processEasy to installStrutsPillarsReinforced concrete columnEarthquake resistance

The invention discloses a fabricated frame strip steel bracket long column and a construction method of the fabricated frame strip steel bracket long column. The column body is a composite column consisting of three parts, namely steel pipe outer reinforced concrete, a steel pipe and steel pipe inner concrete; the steel pipe and the steel pipe inner concrete penetrate through the whole long column; the steel pipe inner concrete is subjected to primary prefabrication to form a steel pipe concrete column; concrete at a steel pipe outer joint or total concrete is poured in advance at the second time; a steel bracket is welded with the steel pipe. The long column has the advantages that 1, a multi-layer frame column is manufactured into a long column, the manufacture is simple, and the installation is convenient; 2, the column body is a composite column, the compression bearing capacity and shear capacity of the column are 2-4 times that of a reinforced concrete column with the same section, and the bearing capacity and anti-seismic property of the frame column are obviously improved; 3, the steel bracket is arranged and can be connected with a steel beam or a cast-in-place reinforcedconcrete beam, and the connection is convenient and reliable; and 4, high-strength concrete in the steel pipe is prefabricated in a factory, and the construction cost of the column is greatly reducedcompared with that of a conventional composite column. Therefore, the long column is suitable for various multi-story and high-rise prefabricated buildings and is wide in market prospects.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

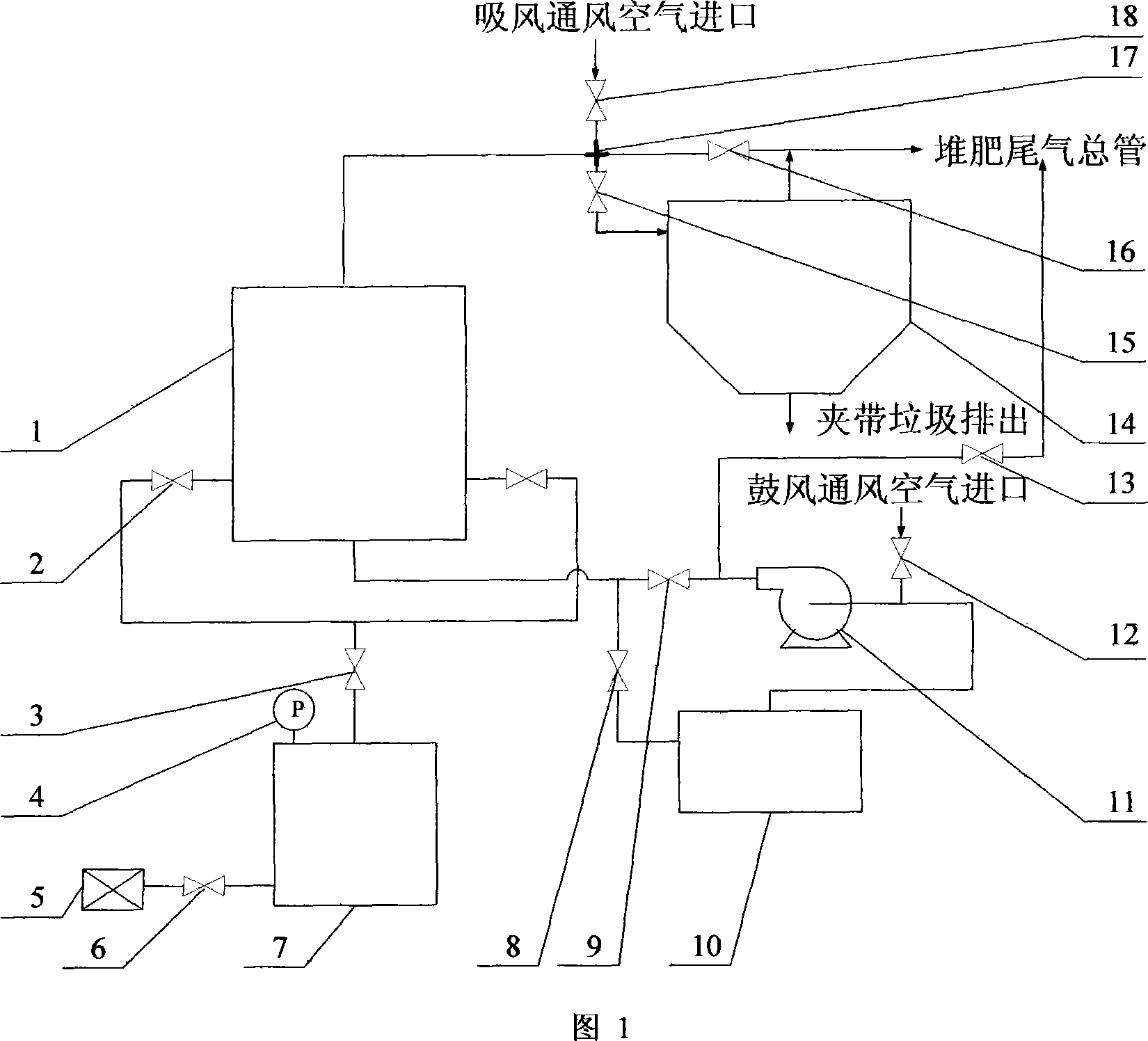

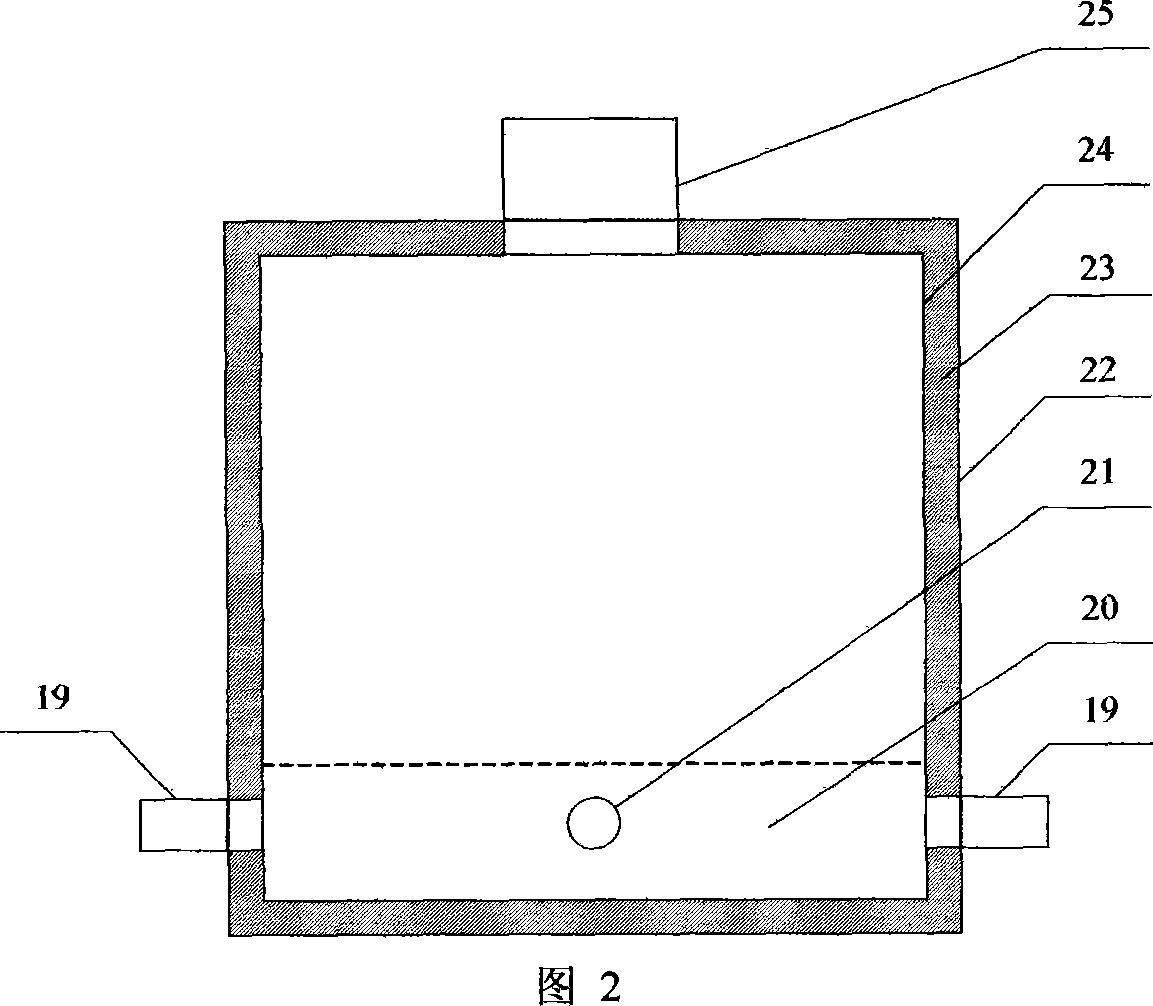

Bidirectional ventilation and pneumatic pile-turning composting process

ActiveCN101062872AControl layered non-uniform stateReduces the problem of entrainment out of the reactorBio-organic fraction processingClimate change adaptationAir volumeSludge

The invention discloses a bidirectional flow ventilation and air pressure composting method, which comprises the following steps: dwelling pile body with height at 2-2. 5m and upper margin at 0. 5-1. 0m in box compost reactor; inserting three heat indicators and three pile body gap gas sampling pipe into different height; adopting 0. 1-0. 2m3 / min fixing air quantity per m3 initial compost raw material and batch process; venting; changing the direction of ventilation when the biggest differential temperature more than 5 deg. c of the three heat indicators; turning over the pile at the second day for one time one day; compressing the air with impulse; discharging momentary; making the pile body float and drop; testing oxygen concentration of the gas in the pile body per 15 min; finishing the compost when the biggest differential value less than 1. 0% of adjacent twice. This invention possesses low operating cost without twice pollution, which can be used to the compost of life garbage, agricultural waste and sludge of the waste water treatment plant.

Owner:TONGJI UNIV

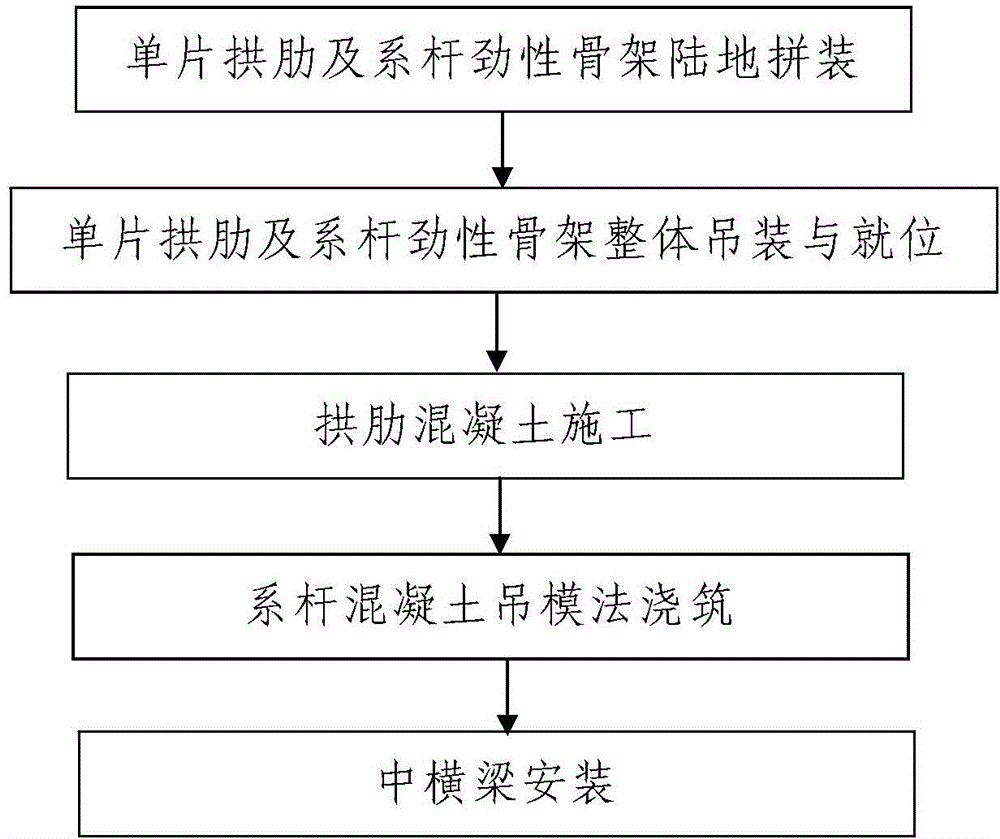

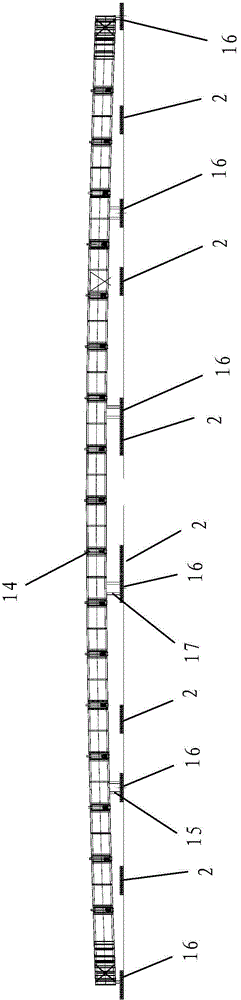

Large span steel tube arch bridge stents-free hoisting process

ActiveCN104404887AThe process steps are simpleReasonable designBridge erection/assemblyArch-type bridgeInsertion stentSpandrel

The invention discloses a large span steel tube arch bridge stents-free hoisting process, the large span steel tube arch bridge is the tied-arch bridge formed above the river and the bridge superstructure comprises arch ribs and a tie bar connected between two arch feet of the arch rib, a stiff skeleton is formed in the tie bar; the stents-free hoisting process for the large span steel tube arch bridge is as follows: 1, assembling the single arch rib with the stiff skeleton of the tie bar on the ground, on the assembling field at the bank side of one side of the river, assembling the arch steel tube stent of the arch rib with the stiff skeleton of the tie bar and obtaining the assembled single piece bridge superstructure; 2, integrally hoisting and positioning the single piece arch rib and the stiff skeleton of the tie bar; adopting floating crane shift platform for hoisting the assembled single piece bridge superstructure and transporting the structure to the bridge lower support structure. The large span steel tube arch bridge stents-free hoisting process is simple in technology process, reasonable in design, convenient in construction and good in construction effect; the large span steel tube arch bridge stents-free hoisting process can be finished simply and quickly, and the hoisting process is safe and reliable.

Owner:NO 1 ENG LIMITED OF CR20G

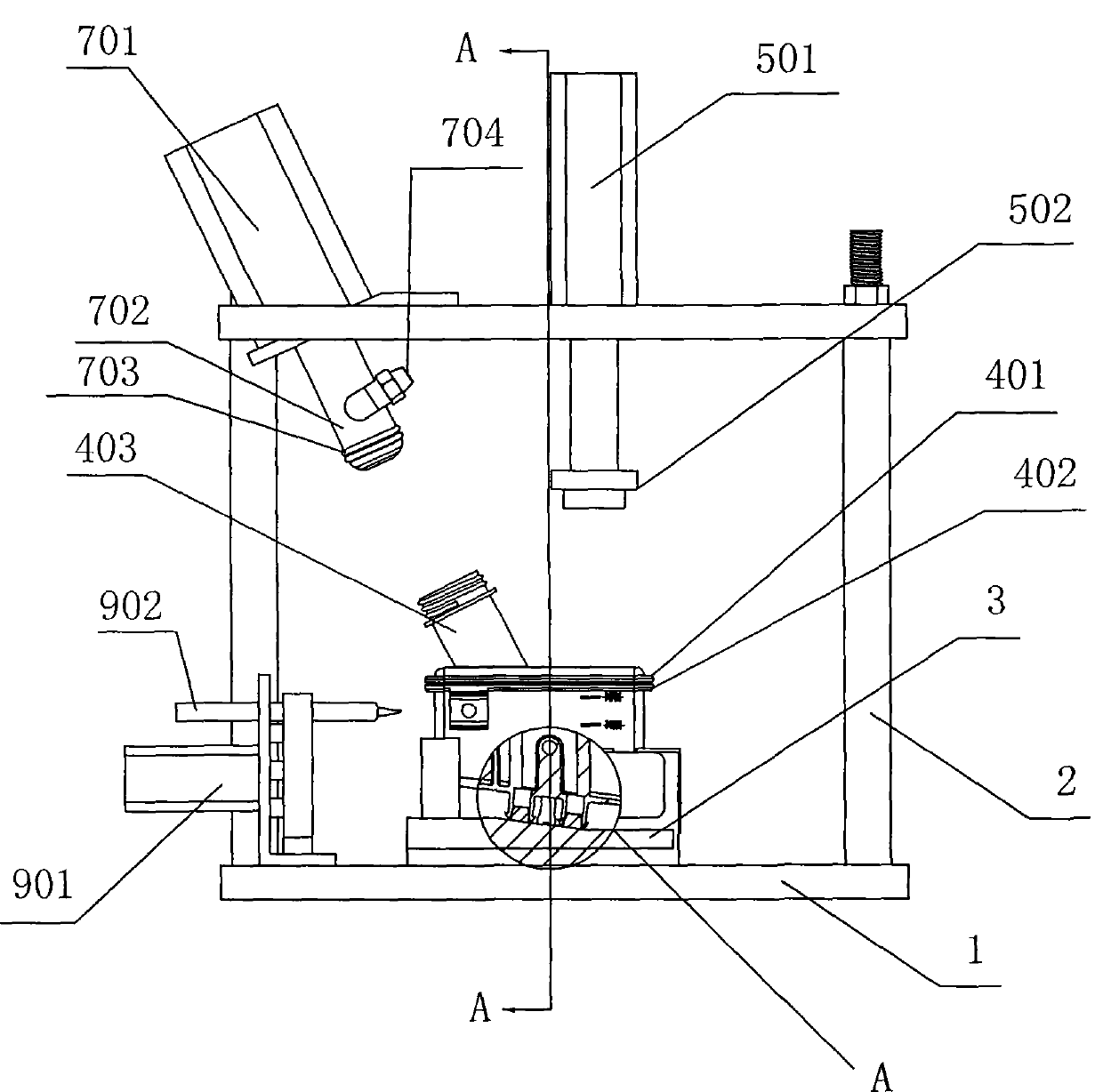

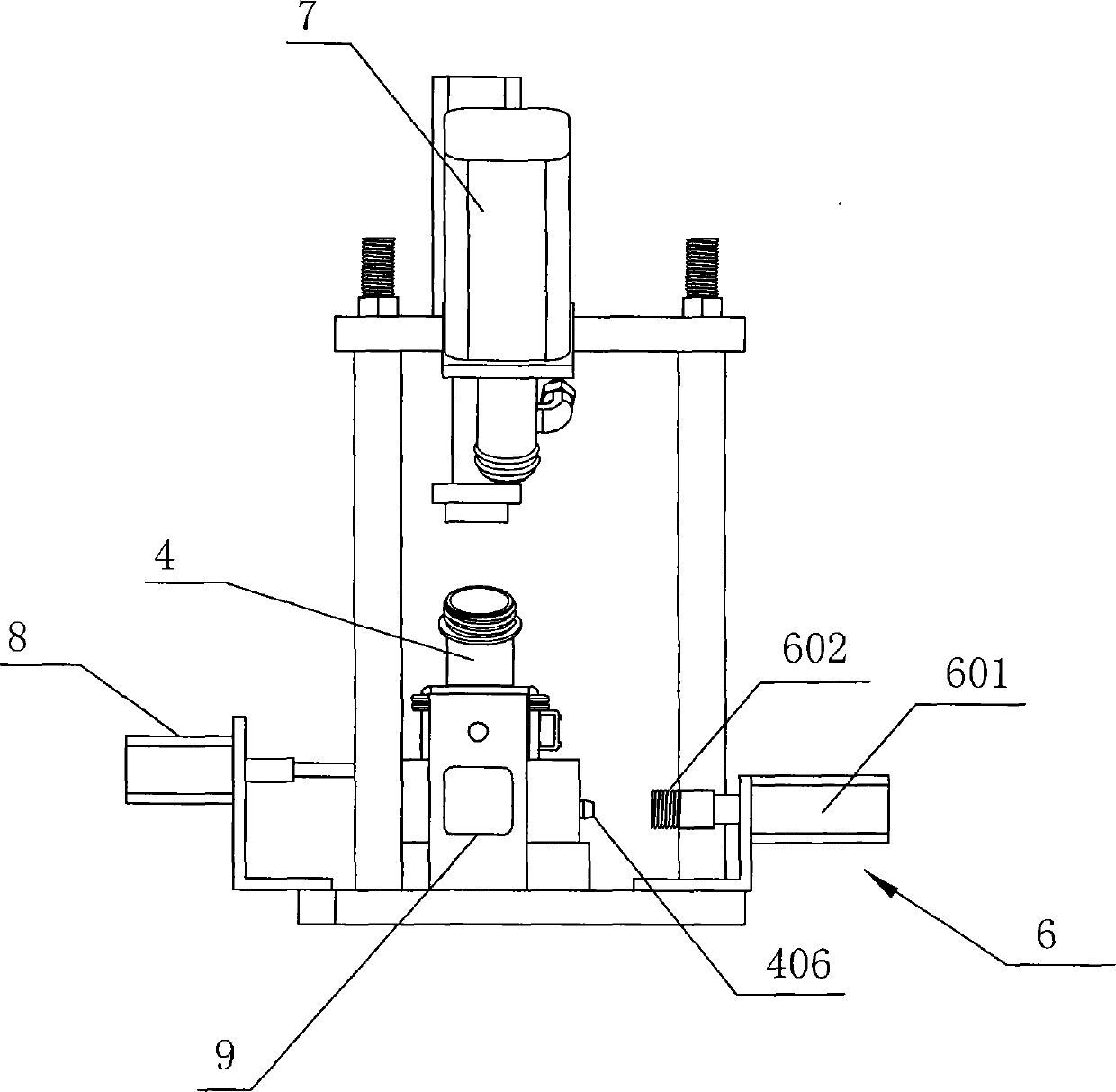

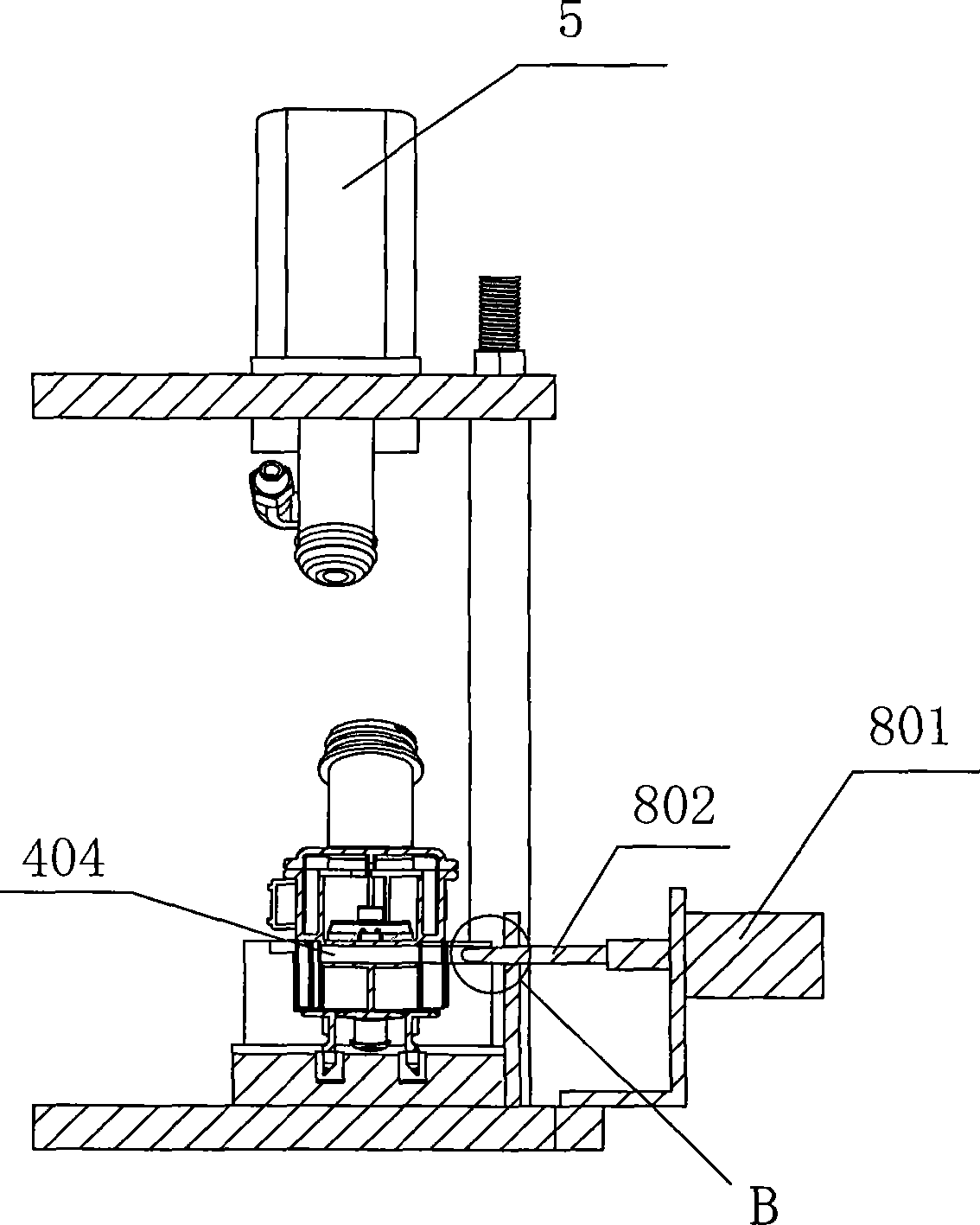

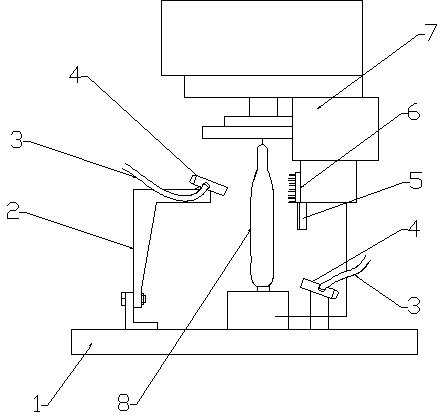

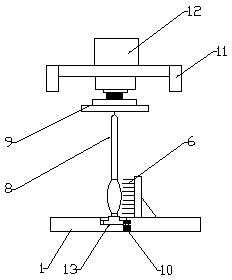

Leak detecting device of automotive brake liquid storage pot and leak detecting method of leak detecting device

ActiveCN103344389AAvoid quality hazardsFluid-tightness measurement using fluid/vacuumLiquid storage tankStructural engineering

The invention relates to a leak detecting device of an automotive brake liquid storage pot and a leak detecting method of the leak detecting device, and belongs to the technical field of hydraulic container leak detection testing. The leak detecting device comprises a base, a support, a leak detecting clamp, the liquid storage pot, a pressing structure, a sealing and blocking structure and a testing structure. A liquid level sensor fixing hole is transversely formed in the middle of a lower body, two bottom oil outlets are formed in the lower portion of the lower body, and two oil outlet choke plugs are arranged at the positions, corresponding to the two bottom oil outlets of the liquid storage pot, of the leak detecting clamp. The leak detecting device further comprises a plug pin fixing structure and an identification structure, the plug pin fixing structure is arranged behind the liquid storage pot and comprises a side fixing air cylinder and a plug pin, the plug pin is arranged at the front end of the side fixing air cylinder and arranged opposite to the liquid level sensor fixing hole, and when the side fixing air cylinder moves, the plug pin can be connected with the liquid level sensor fixing hole in an inserting mode after moving forwards. The leak detecting device of the automotive brake liquid storage pot further comprises the leak detecting method. The leak detecting device of the automotive brake liquid storage pot and the leak detecting method of the leak detecting device have the advantages that leak detection does not exist, the yield of products is improved, and the potential quality hazard of an automobile brake failure caused by the products is avoided.

Owner:浙江乔士智能工业股份有限公司

Wind turbine blade manufacturing method

The invention discloses a wind turbine blade manufacturing method. Rigid cushion blocks are embedded into a blade root pavement layer to inhibit the deformation of a soft fibre-reinforced fabric. The rigid cushion blocks are divided a bolt sleeve lower cushion block and a bolt sleeve upper cushion block because of different forms of the rigid cushion blocks; a lower rigid control cushion block is manufactured by taking a blade root cylindrical section of a blade mould as a mould, so that the obtained cushion block shape has good matching property with the blade mould; an upper rigid control cushion block is manufactured by adopting a special mould; through reasonable design of the mould, the fit property between the cushion block and a bolt sleeve upper pavement layer can be ensured. The cushion block is manufactured by adopting pouring resin and the fibre-reinforced fabric which are used for producing the blade, so that the compatibility between the cushion block and the blade can be effectively ensured; an interface problem is avoided. The cushion block surface is perforated, so that the resin can penetrate through the cushion block smoothly and permeate a fabric pavement layer below; the resin pouring process of the blade is not affected. The upper surface and the lower surface of the cushion block are both protected by de-moulding cloth, so that the pollution of dust can be effectively avoided, and the cushion block is beneficial to storing for a long time.

Owner:保定华翼风电叶片研究开发有限公司

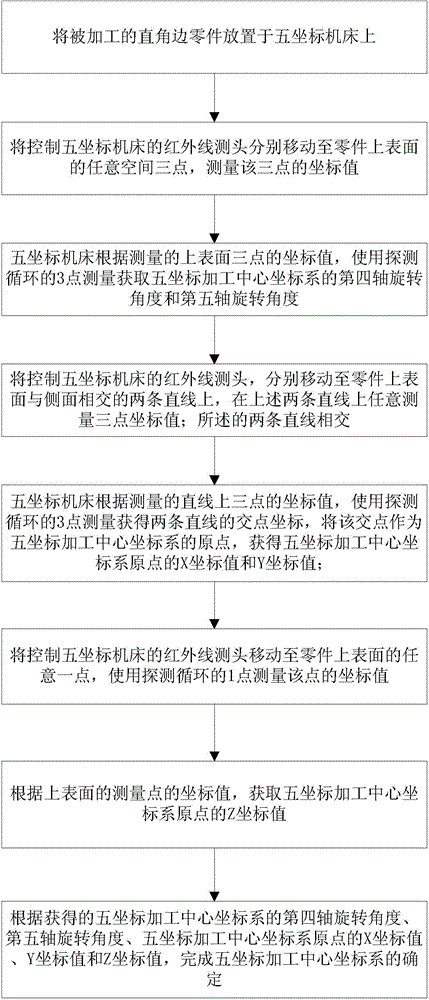

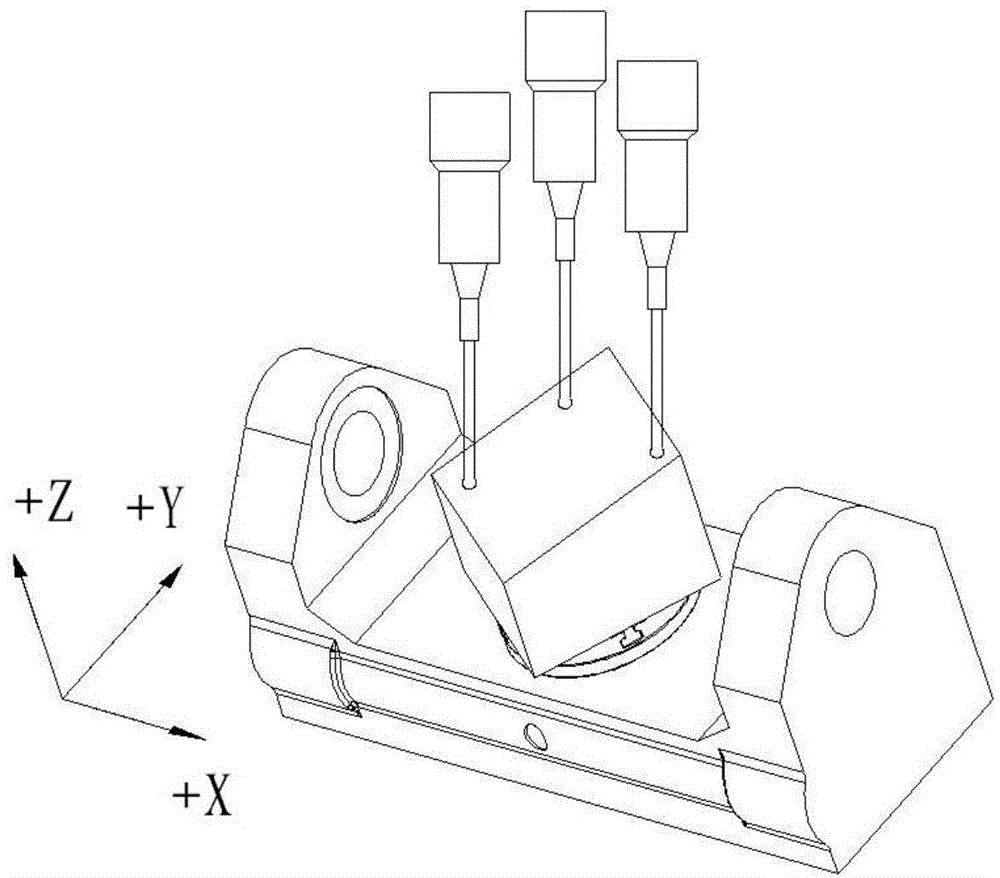

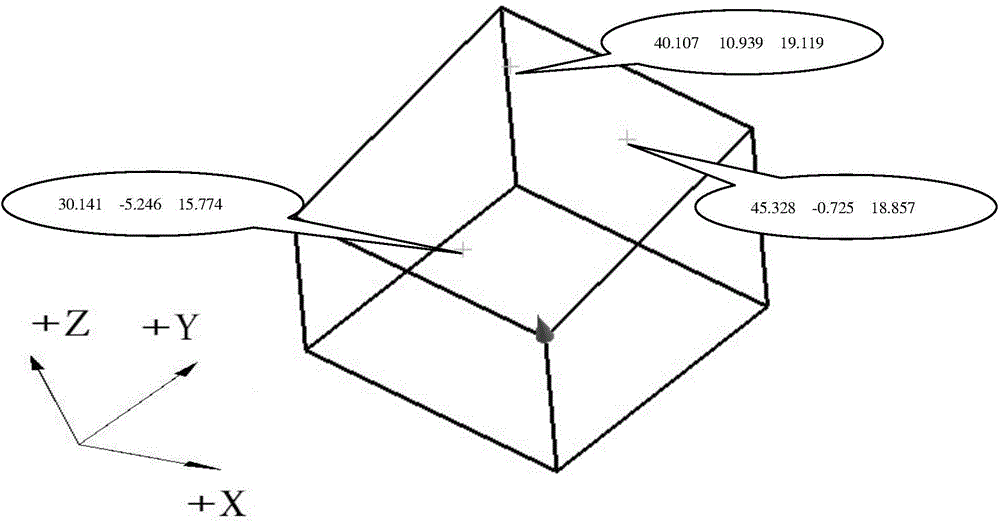

Five-axis machining center coordinate system determination method based on 7-point detection repetition

InactiveCN104476330AReduce processing timeAvoid quality hazardsMeasurement/indication equipmentsNumerical controlRational use

The invention discloses a five-axis machining center coordinate system determination method based on 7-point detection repetition and belongs to the field of online measurement of numerical control machining. The five-axis machining center coordinate system determination method based on the 7-point detection repetition changes the traditional manual coordinate system aligning and machining which waste time and labor, and the aligning quality is partial to the processing experience of an operator. The five-axis machining center coordinate system determination method based on the 7-point detection repetition includes that mounting an infrared measuring head at the five-axis machining center, using the infrared measuring head to measure and sample points, calculating according to mechanical coordinate data of the measured points to obtain the rotating angle and zero point position of each of the fourth axis and fifth axis, and writing in a zero point offset table to realize zero point set. The five-axis machining center coordinate system determination method based on the 7-point detection repetition is simple in application conditions and suitable for the five-axis machining center with two rotary axes at a working table; the machining and detection are integrated through reasonably using an online measurement technology, the automatic alignment of the system is effectively realized, the part machining time is shortened, the workload of the operator is reduced, the potential quality hazard due to the alignment of the part machining is avoided, and the non-intervention processing for the part during the whole process is effectively guaranteed.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

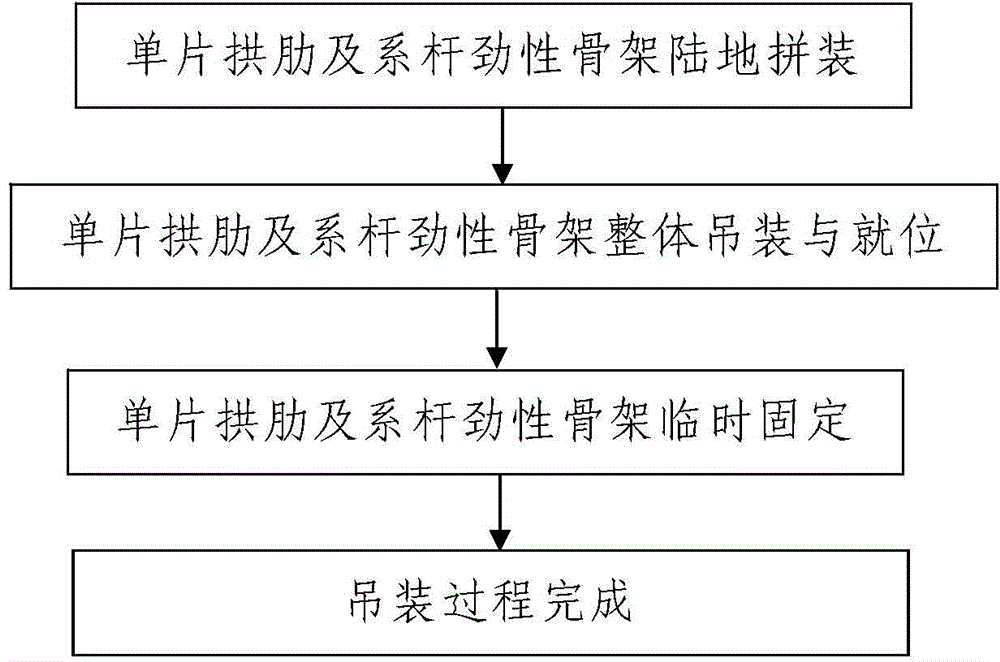

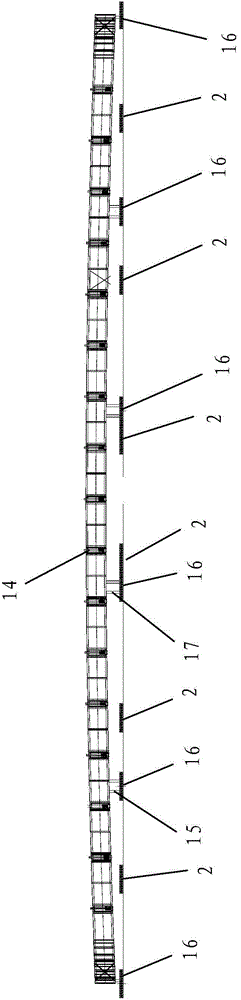

Construction process of large-span steel tube arch bridge without supports

ActiveCN104594197AThe process steps are simpleReasonable designBridge erection/assemblyArch-type bridgeSpandrelMarine navigation

The invention discloses a construction process of a large-span steel tube arch bridge without supports. The constructed large-span steel tube arch bridge is a tied-arch bridge erected on a river channel. A bridge upper structure of the tied-arch bridge comprises arch ribs and tie bars connected between every two arch pins of the arch ribs. Rigid frameworks are arranged in the tie bars. The construction process includes the following steps of firstly, splicing the single-piece arch ribs and the rigid frameworks of the tie rods on the land, wherein arch-shaped steel tube supports of the arch ribs and the rigid frameworks are spliced on a splicing field on a bank side of the river channel; secondly, hoisting the single-piece arch ribs and the rigid frameworks of the tie rods together and placing the arch ribs and the rigid frameworks in place; thirdly, constructing the arch ribs through concrete, wherein the arch pins and end beams are constructed, and concrete is symmetrically pressed and poured for the arch ribs; fourthly, conducting pouring through a tie rod concrete suspended form method; fifthly, installing middle beams. The construction process is simple in process step, reasonable in design, convenient to construct and good in construction effect; the construction process of the large-span steel tube arch bridge without supports can be easily, conveniently and rapidly completed without greatly influencing the navigation of the river channel.

Owner:NO 1 ENG LIMITED OF CR20G

Thrum finding device of automatic winding CBF thrum picker

InactiveCN104003253AImprove head find success rateReduce the number of times you handle gauzeFilament handlingWinding machineYarn

The invention relates to spinning equipment in the textile filed, in particular to a thrum finding device of an automatic winding CBF thrum picker. The device comprises an automatic winding machine. A yarn thrum lifting device and a smoothing brush are arranged below the thrum picker. When regular cop is on the winding machine, the yarn thrum lifting device comprises a right-angled support installed at the position of the thrum picker, one end of the right-angled support is fixed under the CBF thrum picker, and the other end of the right-angled support is provided with a compressed air blowing nozzle. A brush used for smoothing yarn is additionally arranged above a scraper of the thrum picker, and a blowing nozzle is additionally arranged below the brush. According to the thrum finding device of the automatic winding CBF thrum picker, the frequency of small yarn treatment can be reduced greatly for a tender, the labor intensity of the tender is relieved, abrasion of parts of equipment is reduced, repairing cost is reduced, and consumption is reduced.

Owner:SHANDONG WEIQIAO PIONEERING GROUP

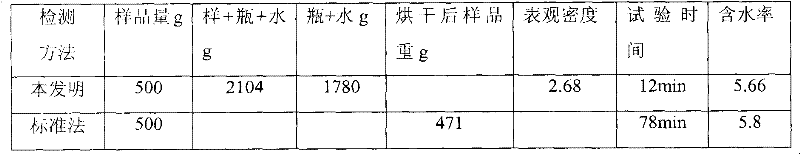

Quick detection method for fine aggregate water content

InactiveCN102346121AAvoid quality hazardsAdjust in timeWeighing by absorbing componentConstruction aggregateWater content

The invention relates to a concrete production quality detection method, in particular to a detection method for fine aggregate water content, comprising the following steps: step 1, carrying out sampling on fine aggregate to get fine aggregate m0 which represents a sample; step 2, putting the weighed fine aggregate of the step 1 in a container with a predetermined graduation line, adding water below the graduation line, stirring to eliminate bubbles, adding water again until reaching the graduation line, and weighing with a weight of m1; step 3, emptying and washing the container which has the graduation line and is filled with the fine aggregate, adding water again until reaching the graduation line, guaranteeing no bubble on the surface, and weighing with a weight of m2; step 4, calculating according to the following formula: fine aggregate water content (%) = ( m0-(m0+m2-m1)*gamma s ) * 100 % / m0; and step 5, simultaneously carrying out parallel test twice, taking the arithmetic average of the two results to obtain the fine aggregate water content. According to the invention, the detection of fine aggregate water content can be realized quickly, thereby being helpful for reducing concrete quality hidden troubles.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD

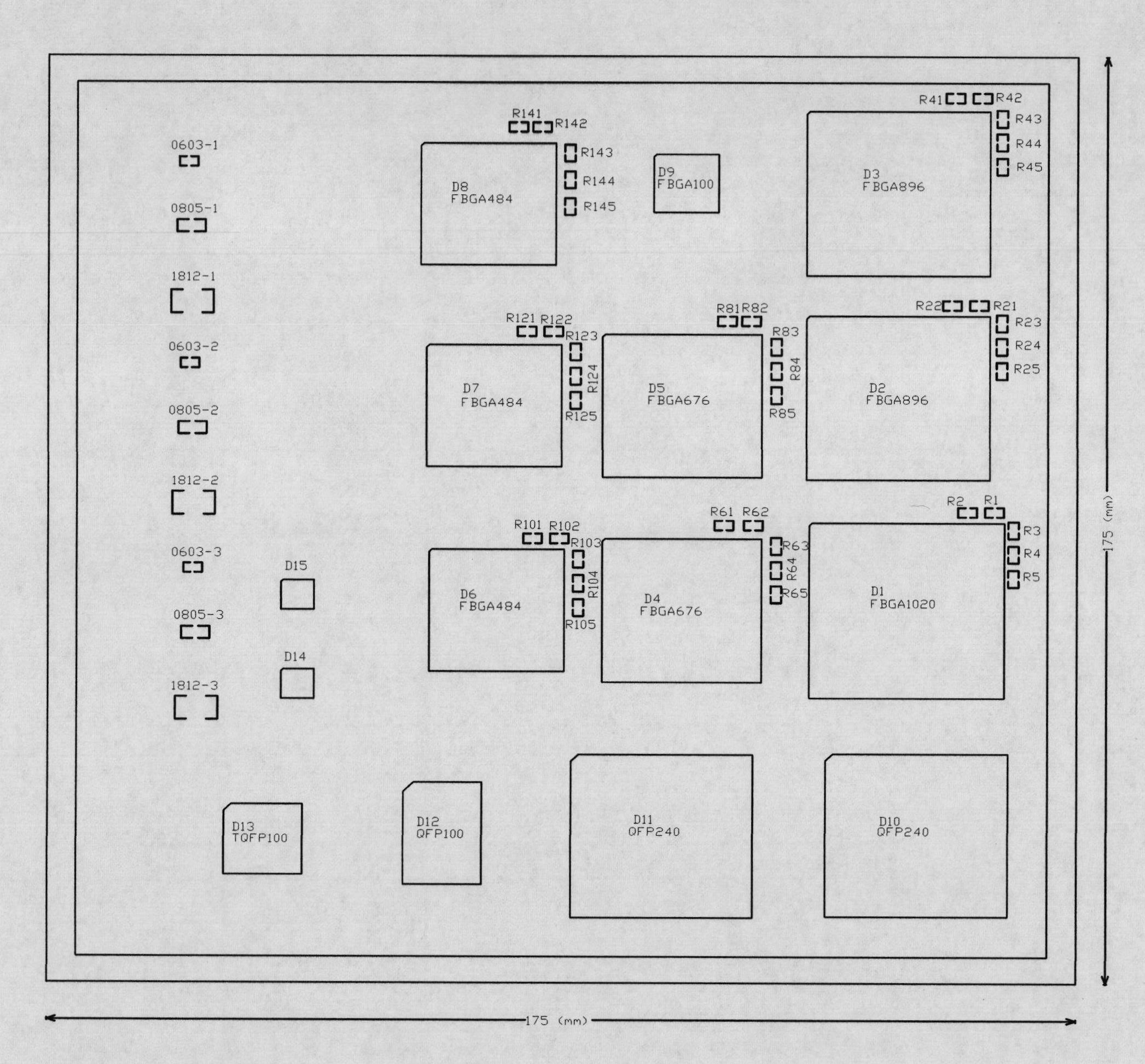

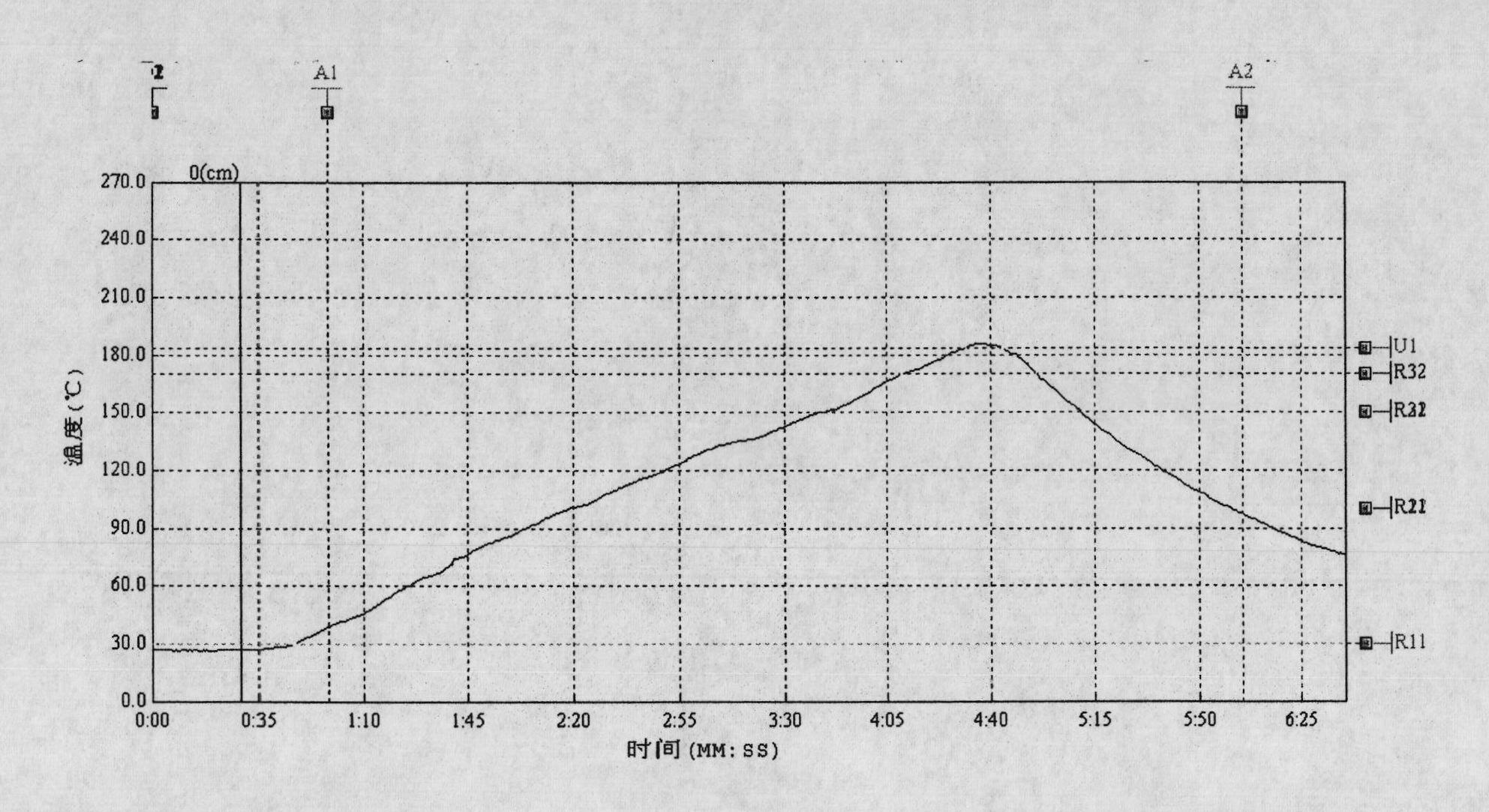

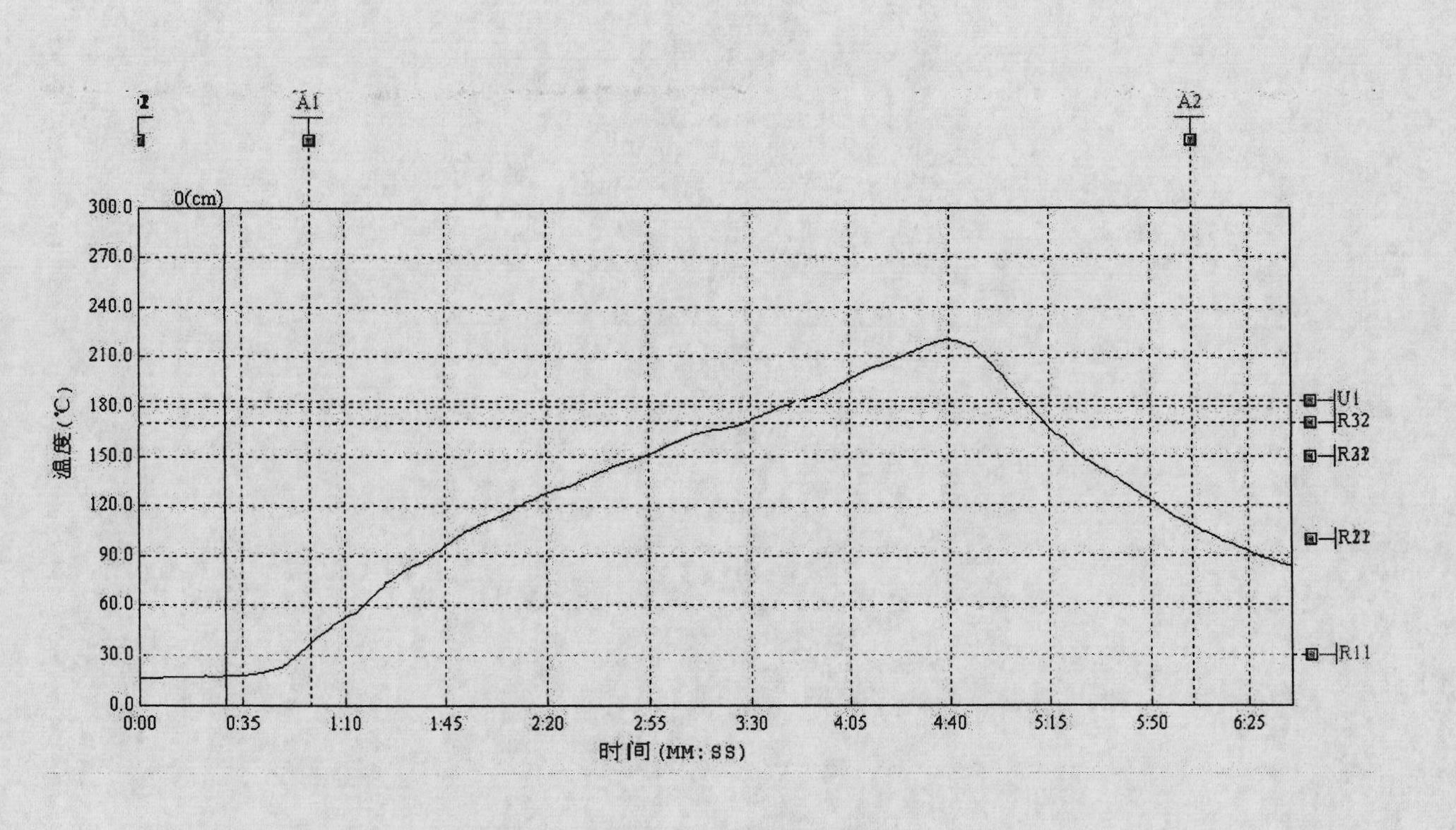

One-board welding process for printed circuit board components

InactiveCN102625597AFast simulation optimizationAddressing the increasing miniaturizationPrinted circuit assemblingProcess engineeringMonoboard

The invention relates to a one-board welding process for printed circuit board components. A large number of experiments conducted confirm that the welding spot temperature is mainly affected by thickness of bare boards of printed circuit boards and quality of elements of the printed circuit boards. Based on the law that when the set temperature of every temperature zone of a reflow oven is increased by a value, the obtained actual temperature curve and the original temperature curve are basically unchanged, a simulation optimization method of oven temperature setting-up parameters is summed up. When the one-board welding process for the printed circuit board components is applied to passage printed circuit board components, measured temperature curves of cold spots and hot spots of board surfaces of the passage printed circuit board components meet requirements of the lead-containing reflow welding, shapes of the welding spots are good, and electrical performance of the assembling unit before and after experiment is normal when temperature impact experiment is used for testing the quality of the welding spots. By the one-board welding process for the printed circuit board components, the rapid simulation optimization of process parameters is realized, the production efficiency of aerospace electronic products and the product percent of pass are greatly improved and the hidden quality dangers are eliminated, so that the one-board welding process for the printed circuit board components plays a very active role in guaranteeing the quality and the reliability of products.

Owner:BEIJING RES INST OF TELEMETRY

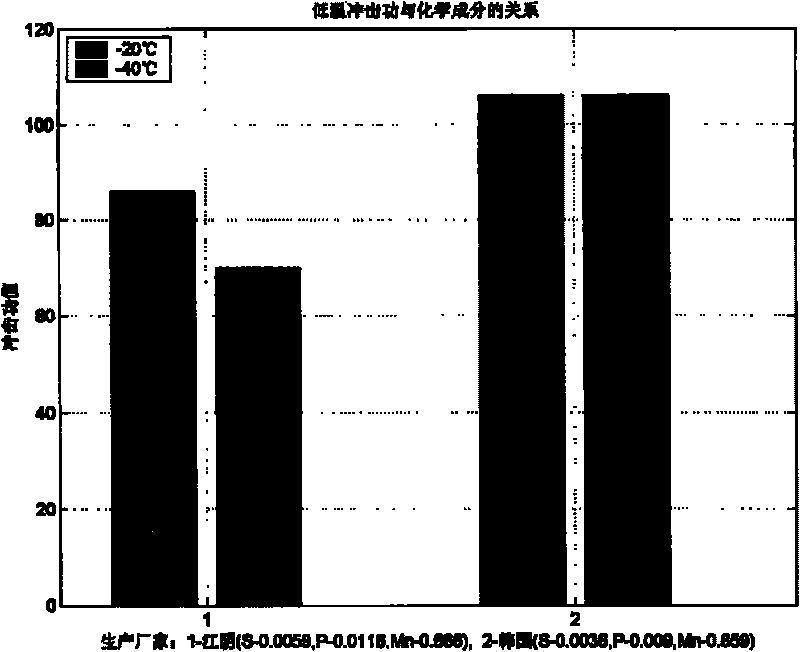

Heat treatment process for improving low-temperature impact work of 42CrMo bearing

InactiveCN101705342AHigh impact energy at low temperatureImprove reliabilityFurnace typesHeat treatment furnacesQuenchingHeating temperature

The invention belongs to the technical field of heat treatment processes, and discloses a heat treatment process for improving the low-temperature impact work of a 42CrMo bearing. The heat treatment process comprises the following quenching and tempering process parameters: the quenching heating temperature of quenching and tempering heat treatment is 840+ / -10 DEG C; the quenching soaking time (h) of the quenching and tempering heat treatment is 3.5 hours; the tempering heating temperature of the quenching and tempering heat treatment is 580+ / -10 DEG C; the tempering soaking time (h) of the quenching and tempering heat treatment is 8 hours; and a coolant adopted by the quenching and tempering heat treatment is F2000 with the concentration of 6 percent. The process solves the important technical problem that the low-temperature impact work cannot meet the requirement after a wind power bearing is treated by adopting a conventional heat treatment process; and the process greatly improves the low-temperature impact work of the wind power bearing, ensures that the wind power bearing has high reliability, and reduces hidden quality danger.

Owner:LUOYANG LYC BEARING

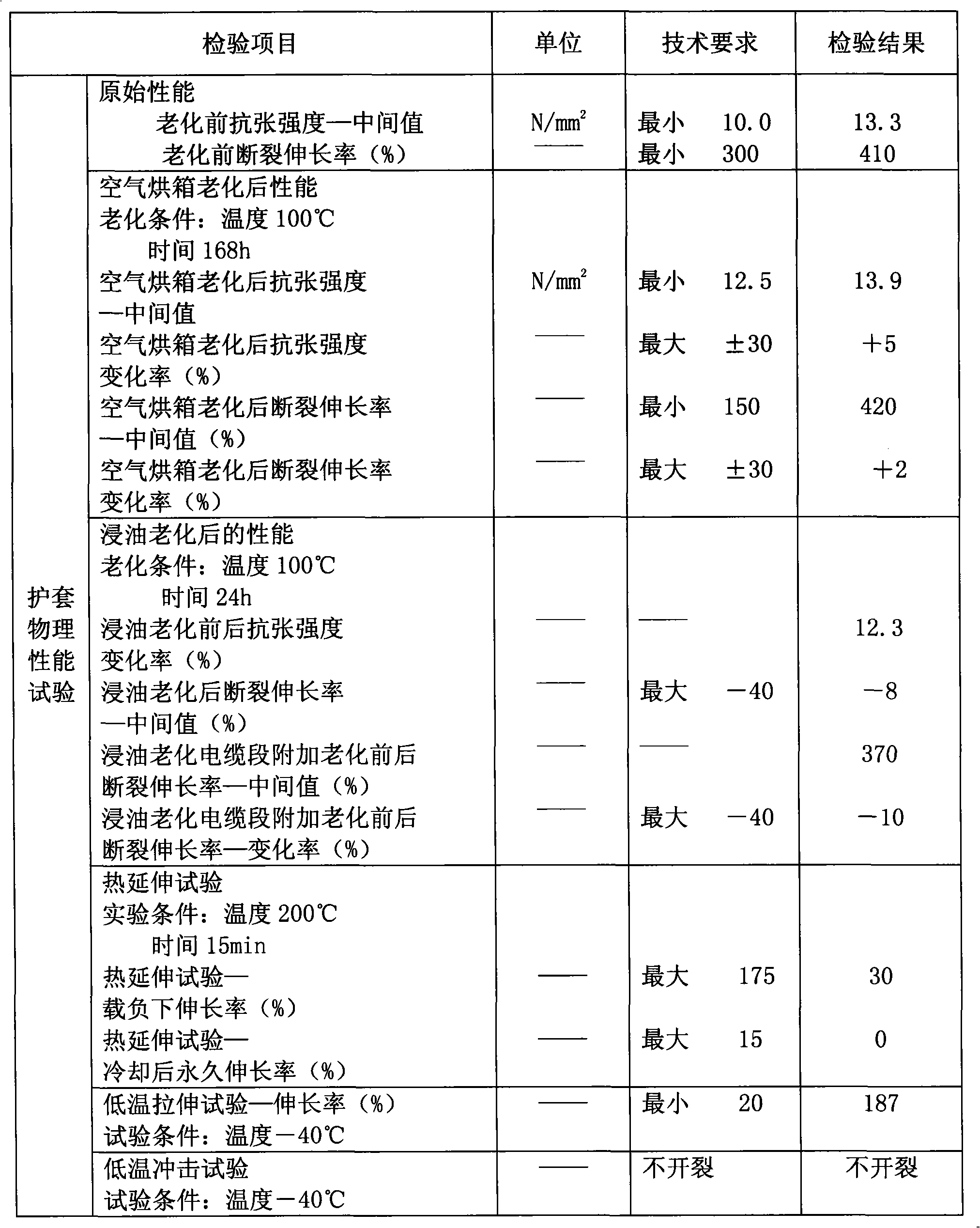

Chlorinated polyethylene used for preparation of low temperature wind energy cable and preparation method thereof

ActiveCN101643563AIncrease low temperature aging strengthHomogeneous catalysisPlastic/resin/waxes insulatorsParaffin waxDecabromodiphenyl oxide

The invention discloses chlorinated polyethylene used for the preparation of a low temperature wind energy cable and a preparation method thereof. The chlorinated polyethylene comprises the followingcomponents by weight percent: 36-42% of CPE rubber, 11.2-15.2% of carbon black, 16-20% of talcum powder, 6-10% of light calcium carbonate, 1.6-4.0% of accelerator, 17.2-21.6% of softener, 1.0-1.6% ofparaffin, 2-5% of antimonous oxide, 1.6-3.0% of magnesium oxide, 1.6-4% of decabromodiphenyl oxide and 1.8-3.6% of DCP vulcanizing agent. The preparation method comprises the following steps: mixing CPE rubber, carbon black, talcum powder and light calcium carbonate, then adding softener, banburying for 27-40min, then adding accelerator, mixing with paraffin, magnesium oxide, antimonous oxide anddecabromodiphenyl oxide, banburying continuously for 3min, and then adding DCP vulcanizing agent to banburying for 0.5min. The cable prepared from the material can not age and can maintain performances at -40 DEG C after a long time use.

Owner:江苏久立电缆有限公司

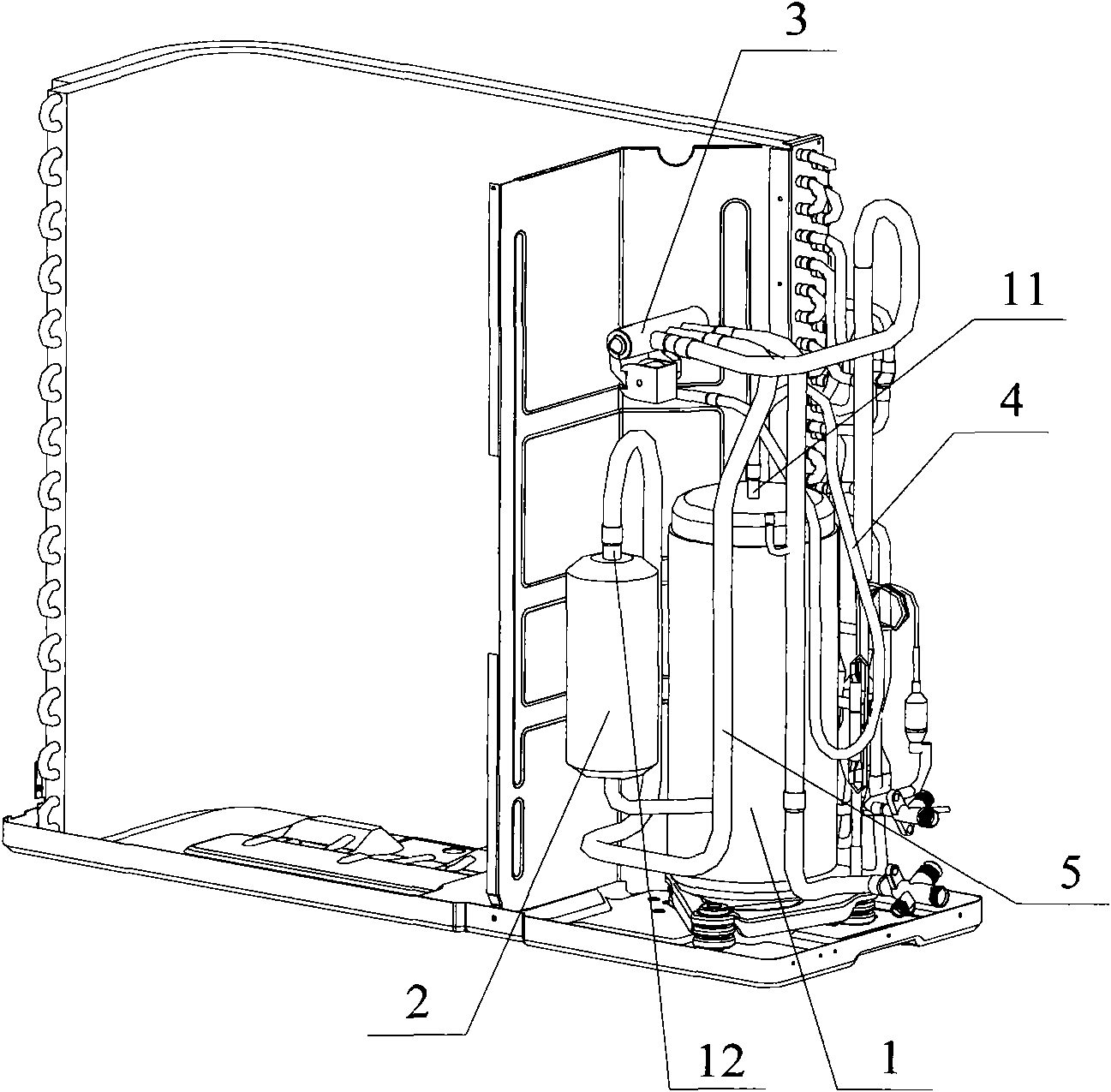

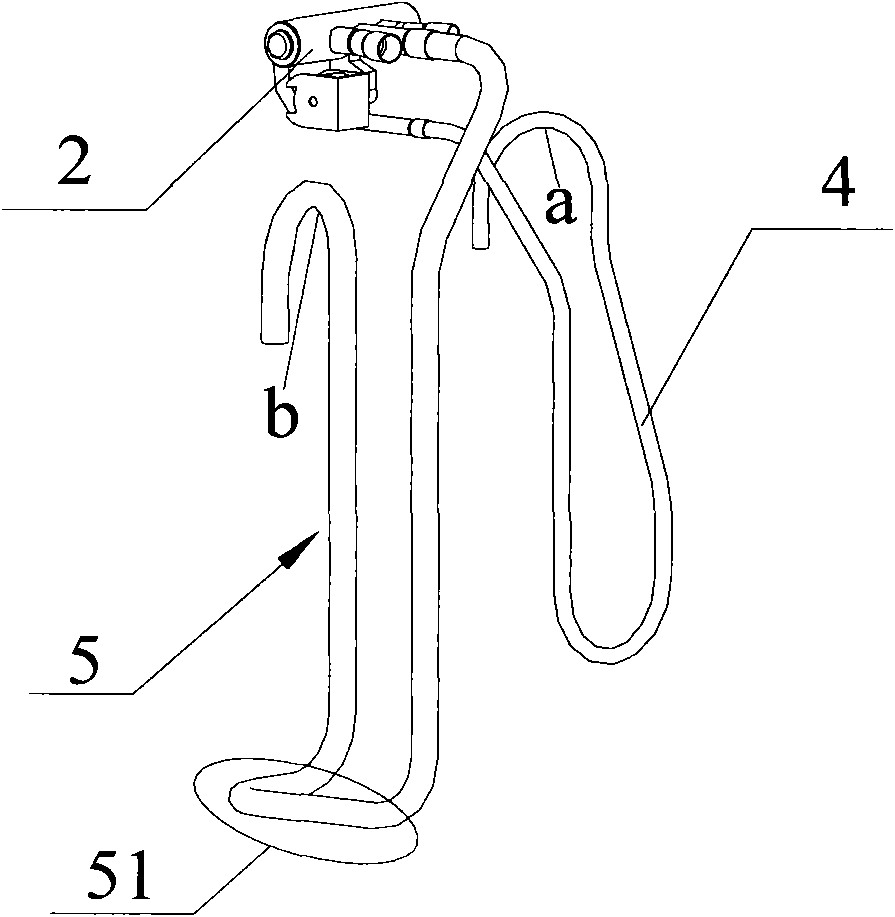

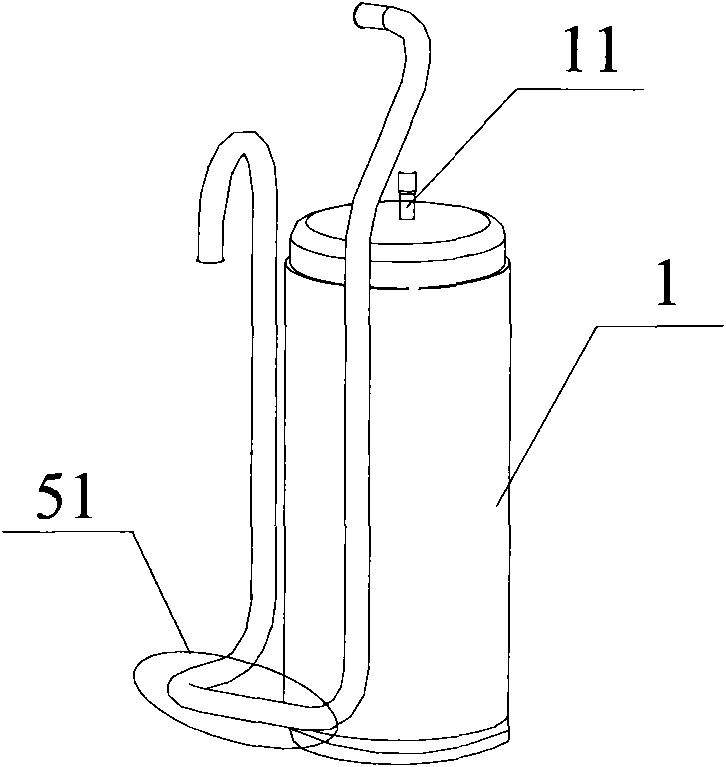

Pipeline distributing system of compressor and air conditioner with same

ActiveCN102062503AReduce weightIncrease stiffnessFluid circulation arrangementVibration attenuationGas pipeline

The invention discloses a pipeline distributing system of a compressor and an air conditioner with the same. The pipeline distributing system comprises an air discharging pipeline and an air returning pipeline, wherein the air returning pipeline is provided with an L-shaped bent pipeline section which is positioned at the bottom of the air returning pipeline. Without adopting additional balance weight, the pipeline distributing system has shorter distributed pipeline and favorable vibration attenuation.

Owner:HAIER GRP CORP +1

Method for manufacturing soft and hard combined board

The invention relates to a method for manufacturing a soft and hard combined board. The method comprises the following steps of: preparing the circuit of an inner-layer soft board; pre-cutting a gap on the surface of each inner-layer PP (Propene Polymer) film; adhering and pressing the inner-layer PP films onto the two sides of the inner-layer soft board; pre-cutting a gap on the surface of each FR-4 layer, pressing the FR-4 layers onto the inner-layer PP films through the pseudo-adhering and transferring processes; combining the inner-layer soft board and the FR-4 layers together through pressing, and then sequentially carrying out target hole punching, hole drilling, board copper depositing and electroplating processes; preparing the circuit of a secondary outer layer, combining the secondary outer layer with the FR-4 layers; pre-cutting a gap on the surface of each of PP films on the surfaces of the secondary outer layer, combining the PP films of the secondary outer layer and the secondary outer layer together by pressing and then sequentially carrying out target hole punching, hole drilling, board copper depositing and electroplating processes; preparing the circuit of an outer layer, combining the outer layer and the PP films of the secondary outer layer and then performing a green oil coating process; and removing the FR-4 layers out of a soft board area and then performing the subsequent processes, wherein the gap width is 0.01-0.05mm. According to the invention, a PAD is effectively prevented from being subjected to fretting corrosion, PI (polyimide) is ensured to have no chromatic aberration, and the surface of the board is flat, thereby being beneficial to the improvement of the yield of circuit boards.

Owner:HUIZHOU BLUEWAY ELECTRONICS

Numerical control machining method capable of guaranteeing machining command information to be correct

InactiveCN103149877AAvoid quality hazardsReduce economic lossProgramme controlComputer controlNumerical control system

A numerical control machining method capable of guaranteeing machining command information to be correct is based on a Siemens 810 D and 820 D numerical control system. The numerical control machining method capable of guaranteeing the machining command information to be correct is characterized in that a restriction link which allows the reasonable range of a cutter compensation value to be input is additionally set in the numerical control machining program of cutter compensation. The technique required in the method does not need additional investment. When the mistake proofing technique is adopted in numerical control machining, hidden quality problems caused by the fact that operators manually input radius compensation and length compensation values are avoided. Not only are economic losses caused by scrapped products or very poor products avoided, but also the production process can go on smoothly. Indirect losses caused by handling the very poor products are further avoided. The numerical control machining method has enormous foreseeable economic value and social value.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Large area super-flat reinforced concrete floor and colorful diamond sand surface layer one-step forming method

InactiveCN107060171ALow costSolve common quality problemsFloorsFlooringSurface layerReinforced concrete

The invention relates to a large area super-flat reinforced concrete floor and colorful diamond sand surface layer one-step forming method. The one-step forming method comprises the steps of template erection, steel bar binding, expansion reinforcing band arrangement, elevation measurement, steel bar elevation check, laser leveler adjustment, concrete pouring, laser leveler leveling, professional leveling, diamond sand spreading, grinding and flexible compacting, polishing, construction seam cutting, curing, finished product curing and upper structure construction. According to the one-step forming method, a structural floor is used as a base layer, a diamond sand floor surface layer and a structure are subjected to one-step pouring forming, the common quality problem that the floor surface layer is prone to forming hollow protrusions due to secondary pouring is avoided, meanwhile, one concrete base layer is reduced, and cost is greatly reduced. The floor is fully covered with recyclable materials such as plastic films and templates so that an upper main structure can continue to be conveniently constructed.

Owner:SHANGHAI SENXIN CONSTR ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com