Prefabricated assembly type tunnel inverted arch, tunnel structure and construction method of tunnel structure

A prefabricated assembly and tunnel structure technology, applied in the direction of tunnels, tunnel linings, shaft equipment, etc., can solve the problems of increasing labor intensity of workers, which cannot be effectively solved, and low degree of mechanization, so as to prevent uneven stress on the tunnel and avoid hidden dangers in quality , the effect of saving resources and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are only used to illustrate the present invention, but can not be used to limit the scope of the present invention.

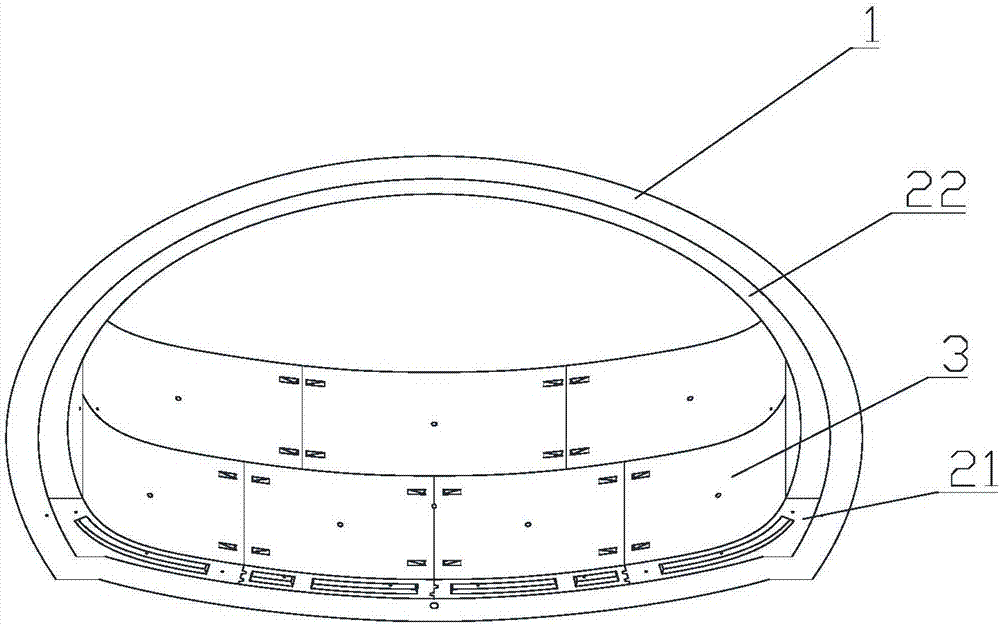

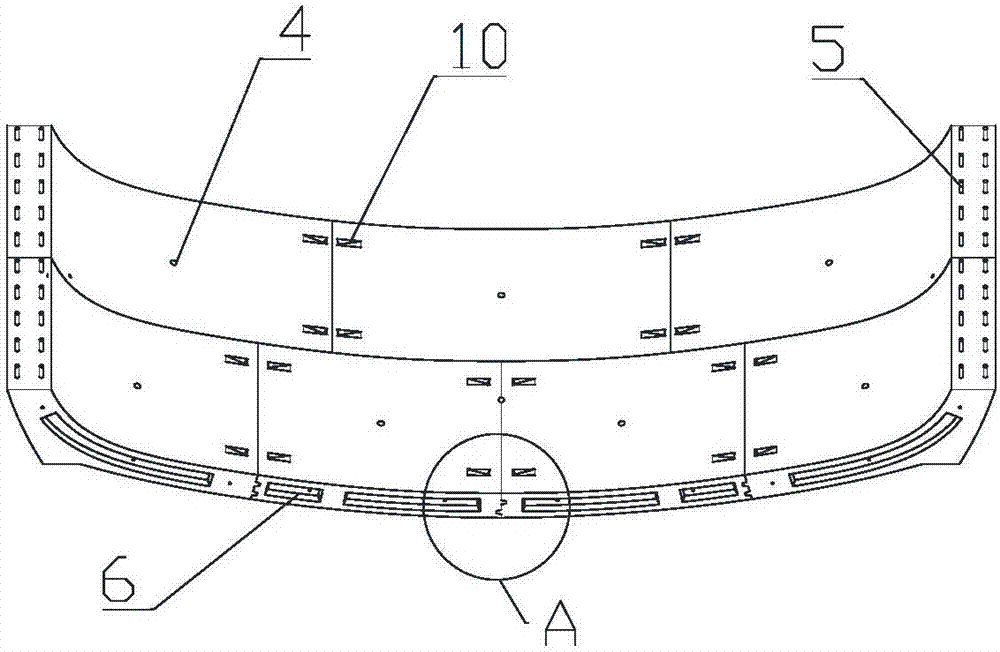

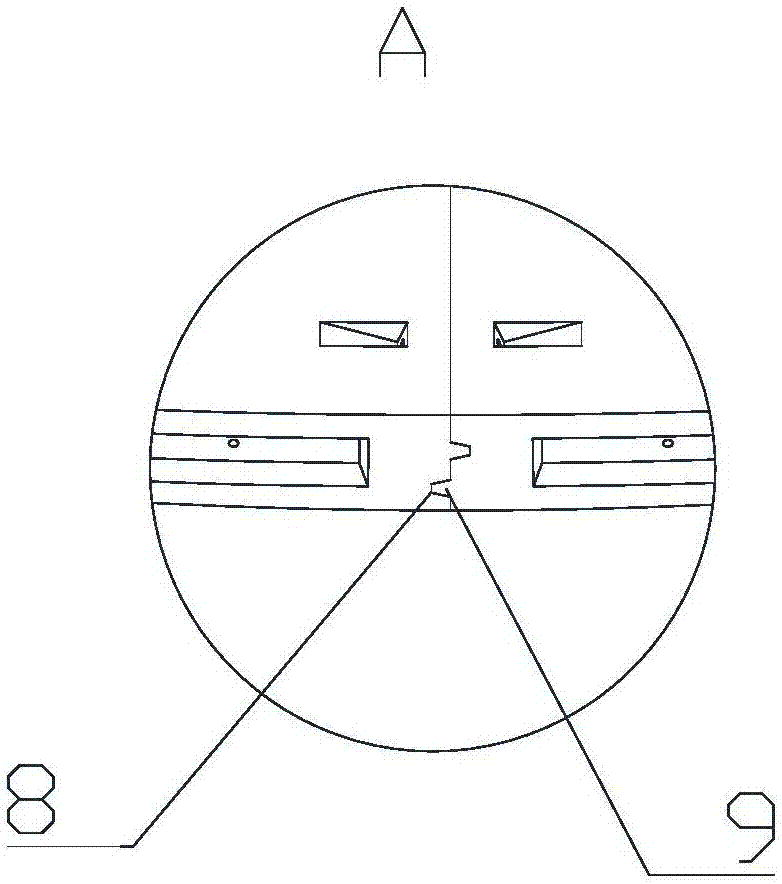

[0034] figure 1 A preferred embodiment of a tunnel structure according to the invention is shown. As shown in the figure, the tunnel includes primary support 1 and secondary lining 2, wherein the secondary lining 2 includes tunnel arch walls 22 and tunnel inverts 21, wherein the tunnel invert 21 is a prefabricated tunnel invert, which includes A plurality of rows of assembly units arranged in sequence along the extension direction of the tunnel, each row of assembly units includes a plurality of assembly blocks 3 with arc-shaped cross-sections, and the seams between adjacent assembly blocks 3 in each row of assembly units are consistent with the adjacent assembly The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com