Tower crane foundation in building basement and manufacturing method of tower crane foundation

A technology of tower crane foundation and manufacturing method, which is applied in construction, infrastructure engineering, protection devices, etc., can solve problems such as poor handling, increased safety hazards, water soaking of tower crane foundation, etc., so as to save the amount of concrete and steel bars, and save pumping shifts Cost, simple and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below, the present invention will be further described in detail in conjunction with the accompanying drawings and embodiments.

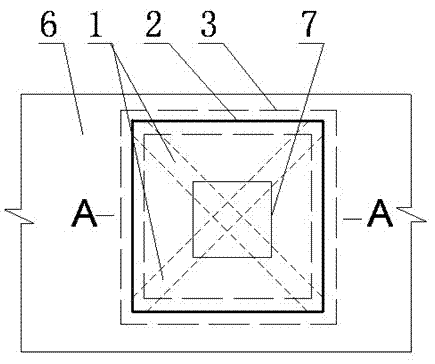

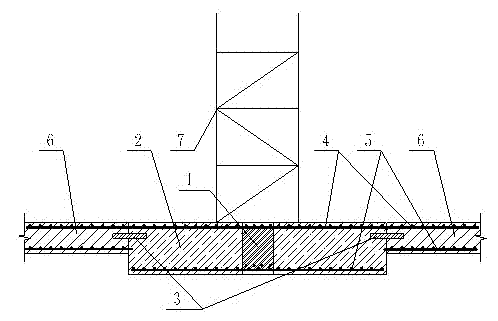

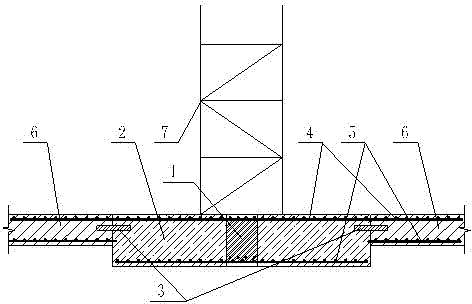

[0020] Embodiment of the present invention: when making tower crane foundation in building basement, make according to a kind of tower crane foundation making method in building basement of the present invention, be about to make tower crane foundation be made up of cross beam 1 and plate 2 For the tower crane foundation of cross-beam slab type reinforced concrete, when making it, the pit of the tower crane foundation is first dug in the basement of the building, and then the cross-beam 1 and the slab around the cross-beam 1 are poured according to the traditional method of pouring reinforced concrete. 2. Make the cross beam 1 and slab 2 poured as a whole; when pouring the reinforced concrete cross beam 1 and slab 2, the traditional floor gluten 4 and the bottom of the floor are also pre-embedded in the cross beam 1 and slab 2 Rib 5 (eg fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com