Patents

Literature

142 results about "Basement floor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

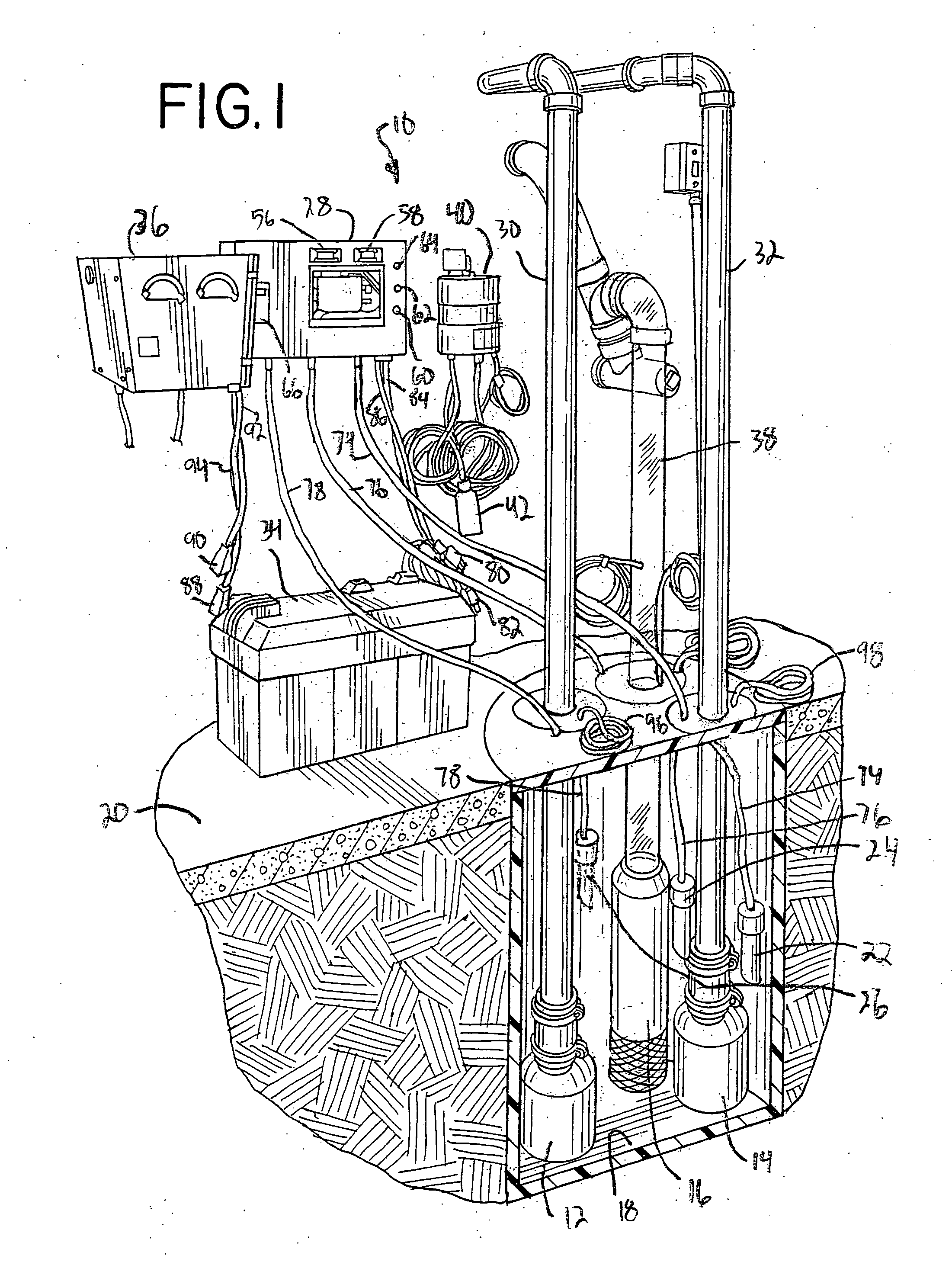

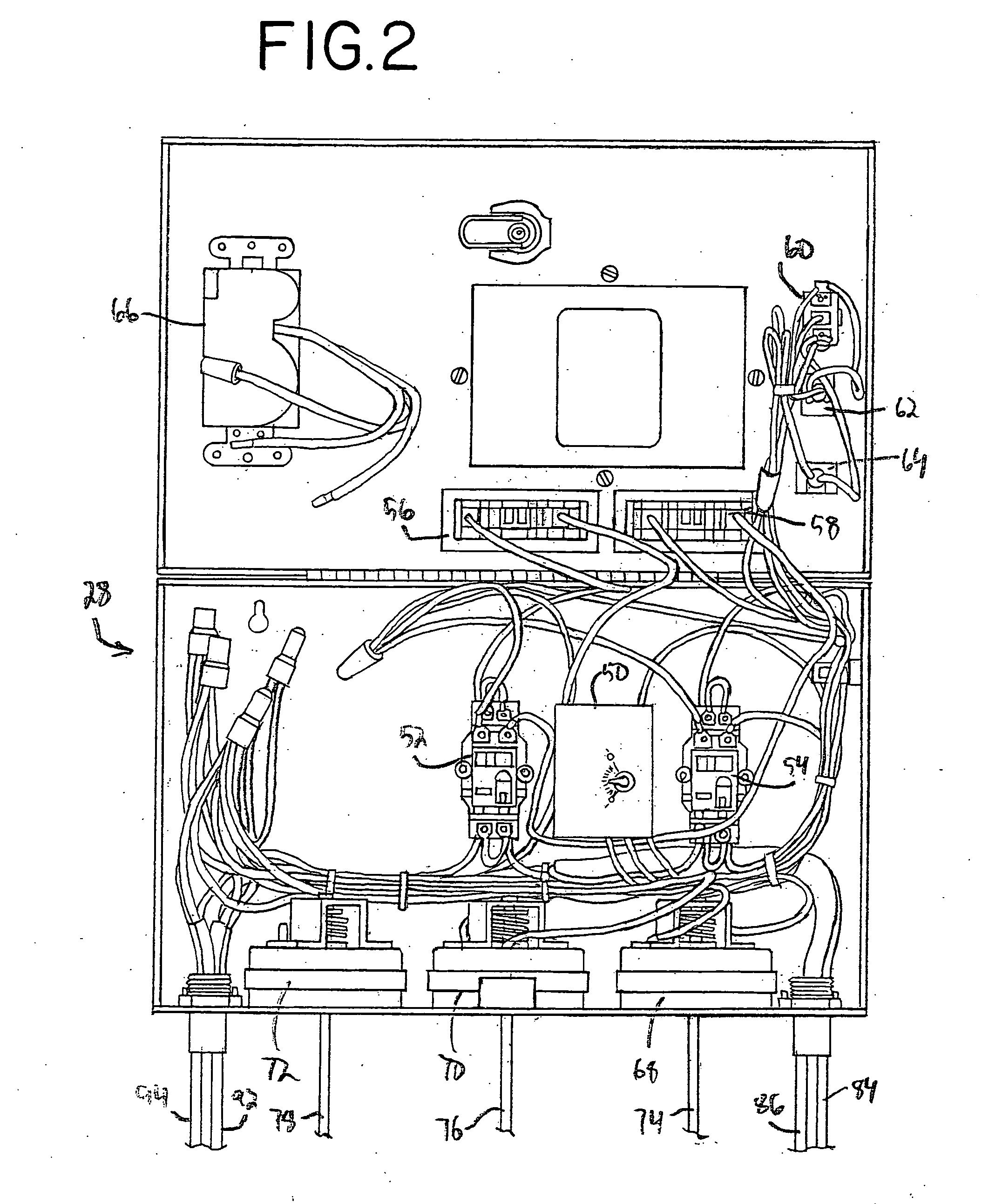

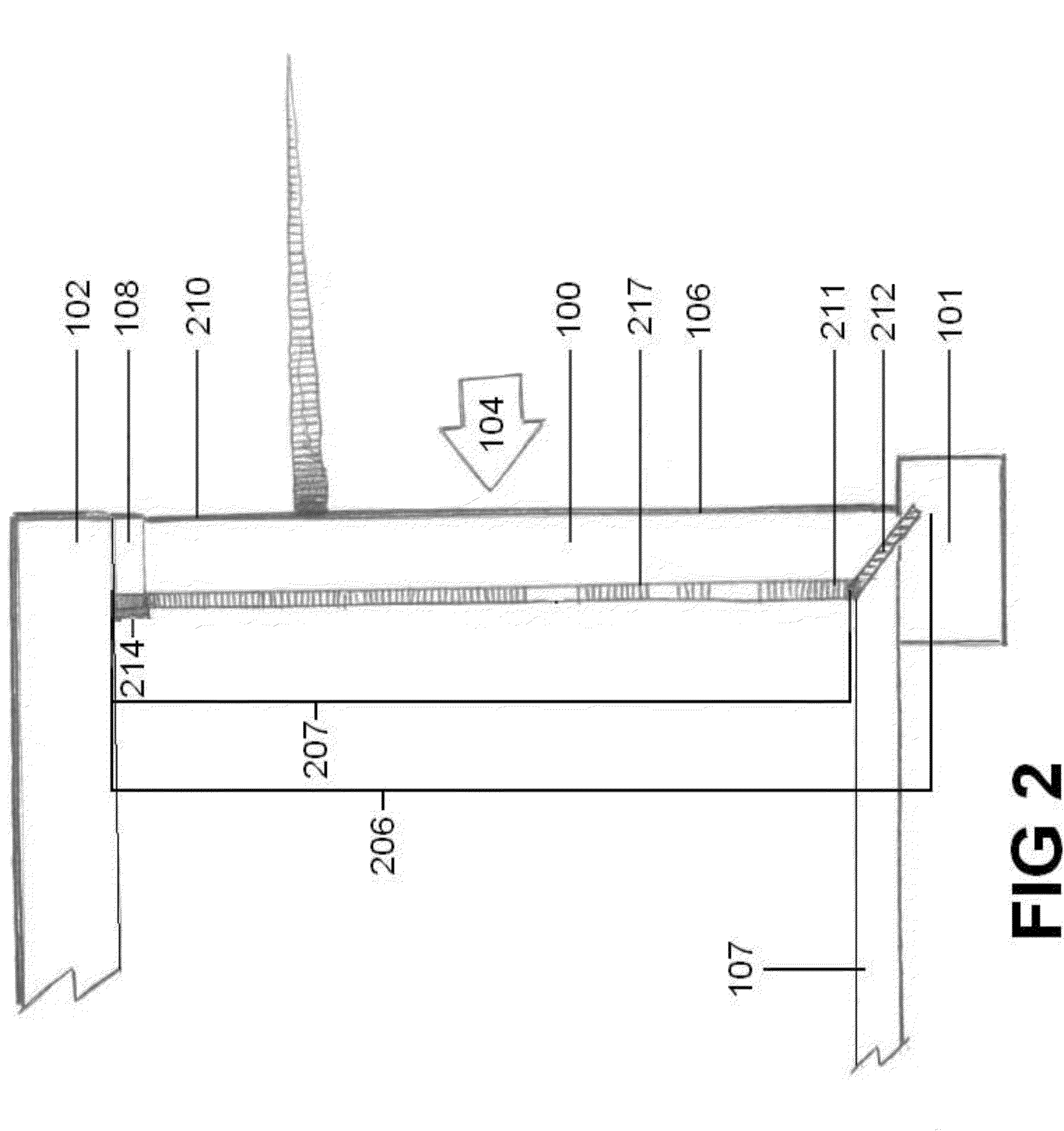

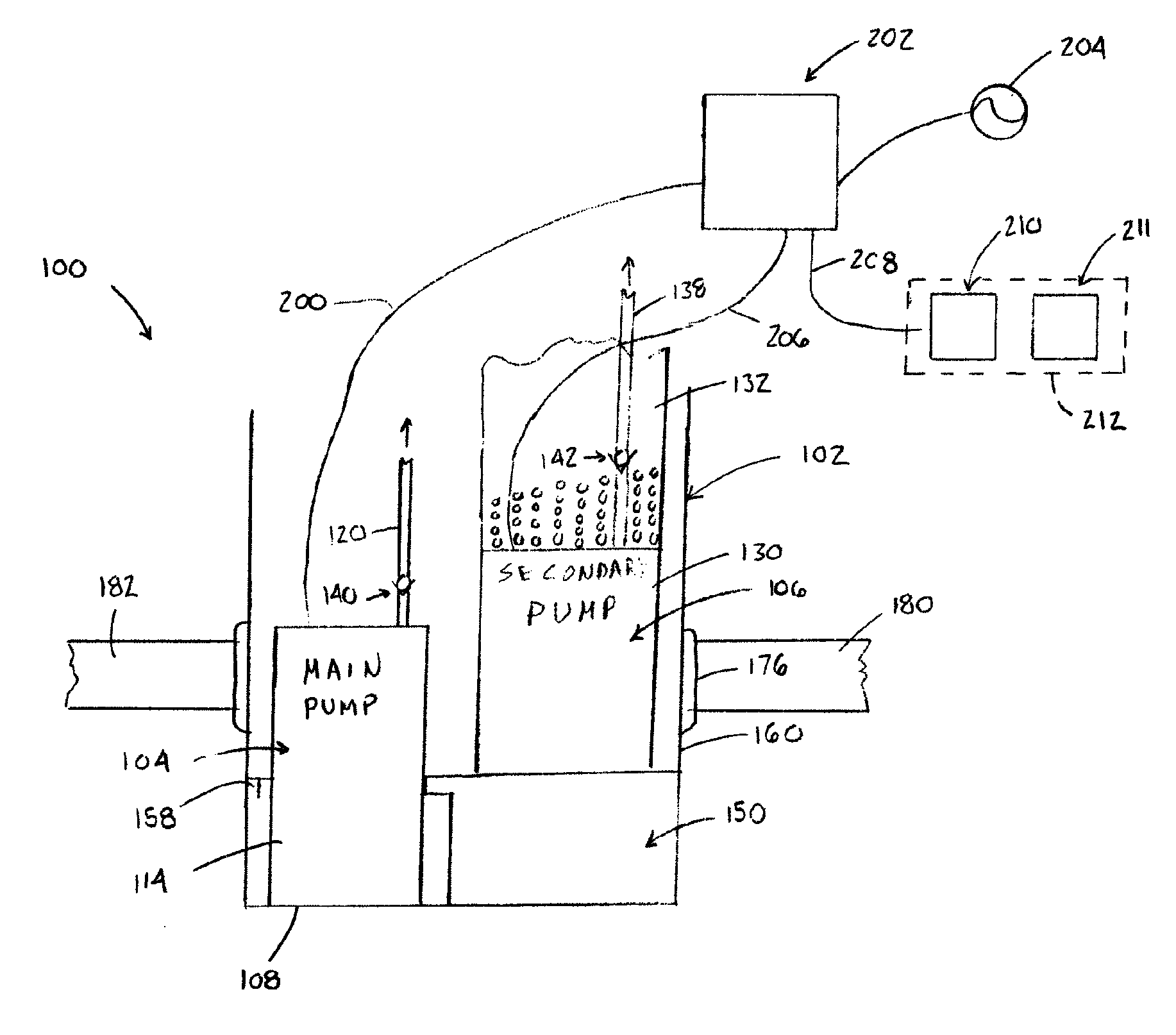

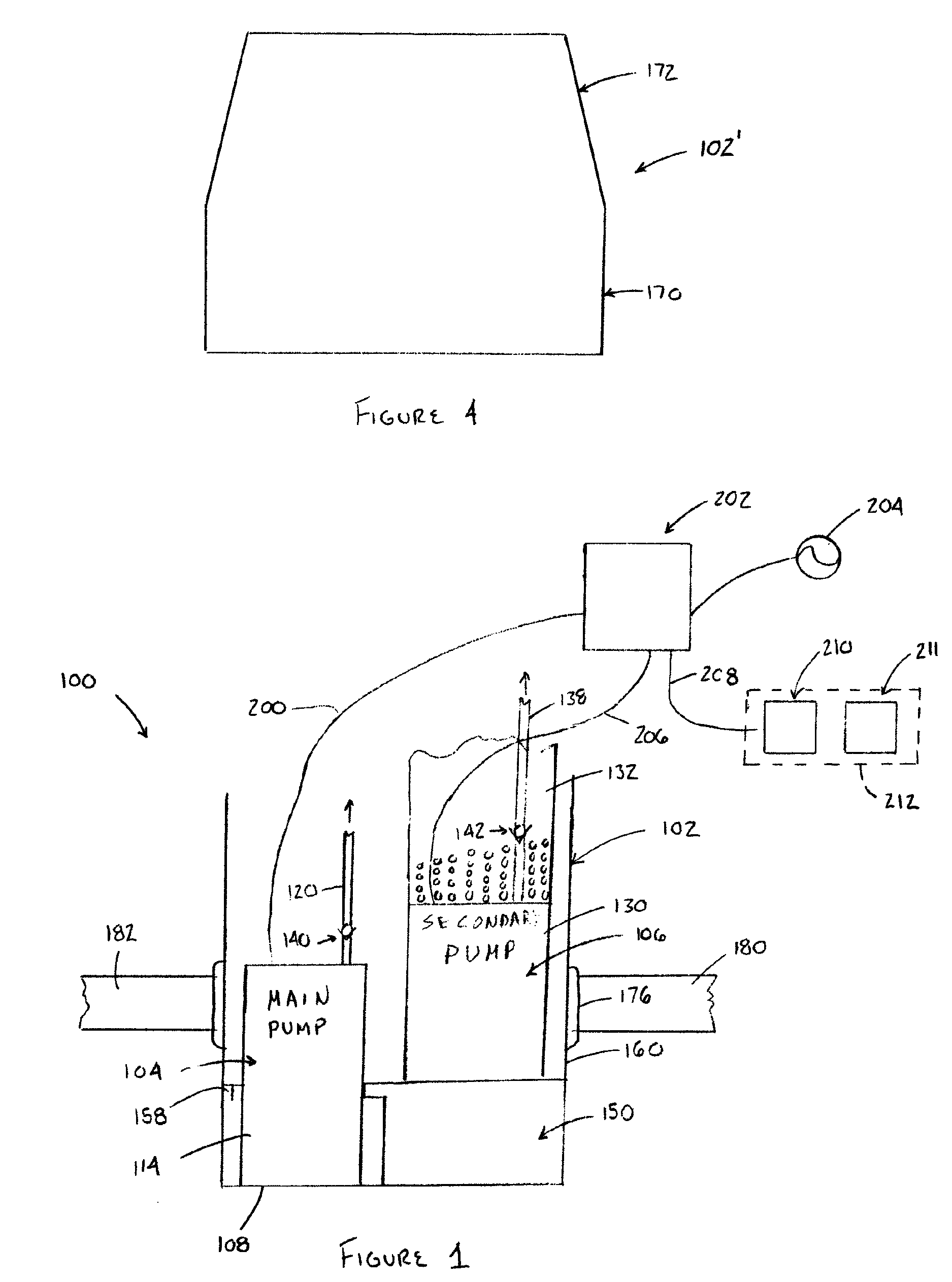

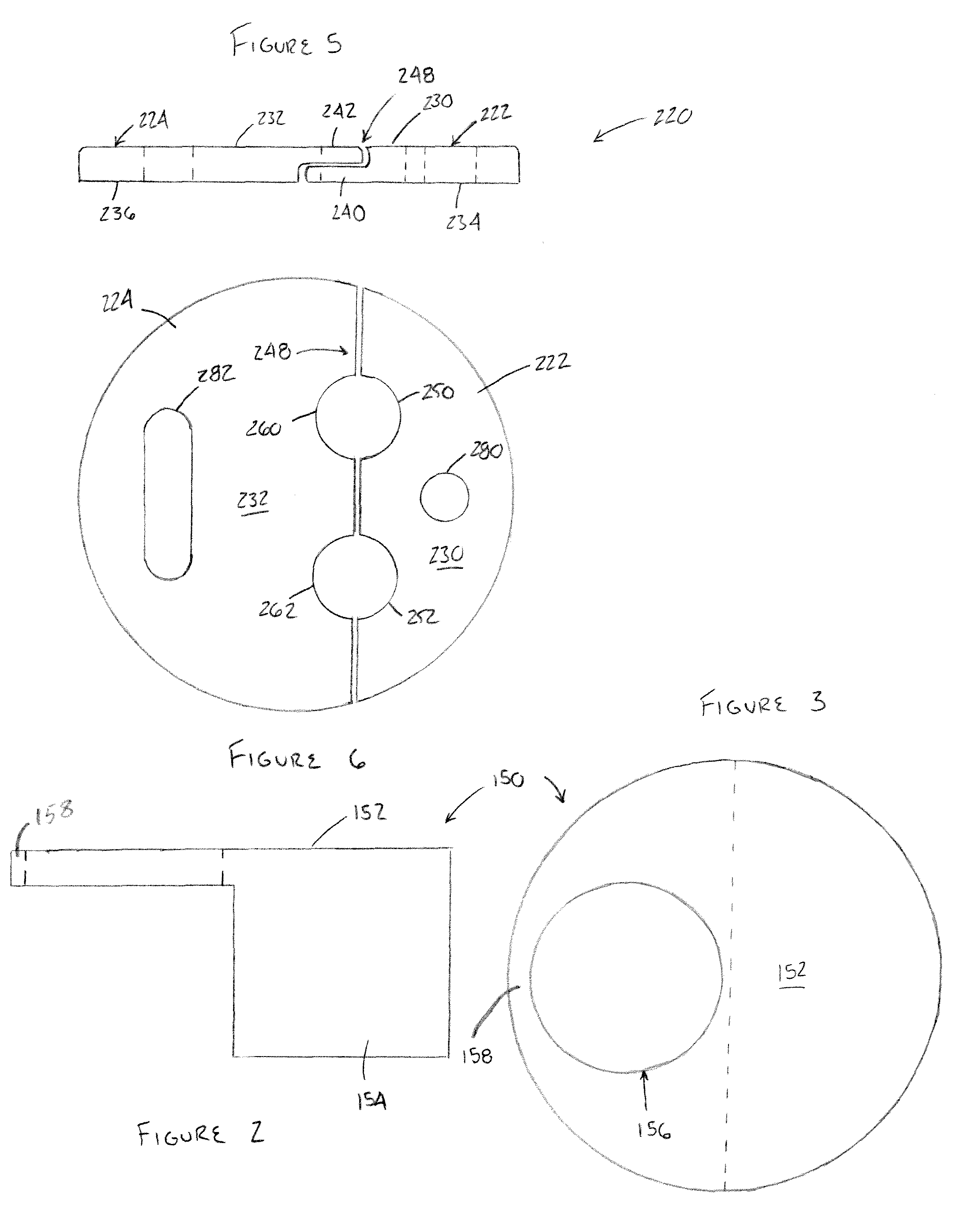

Sump pump with emergency backup system

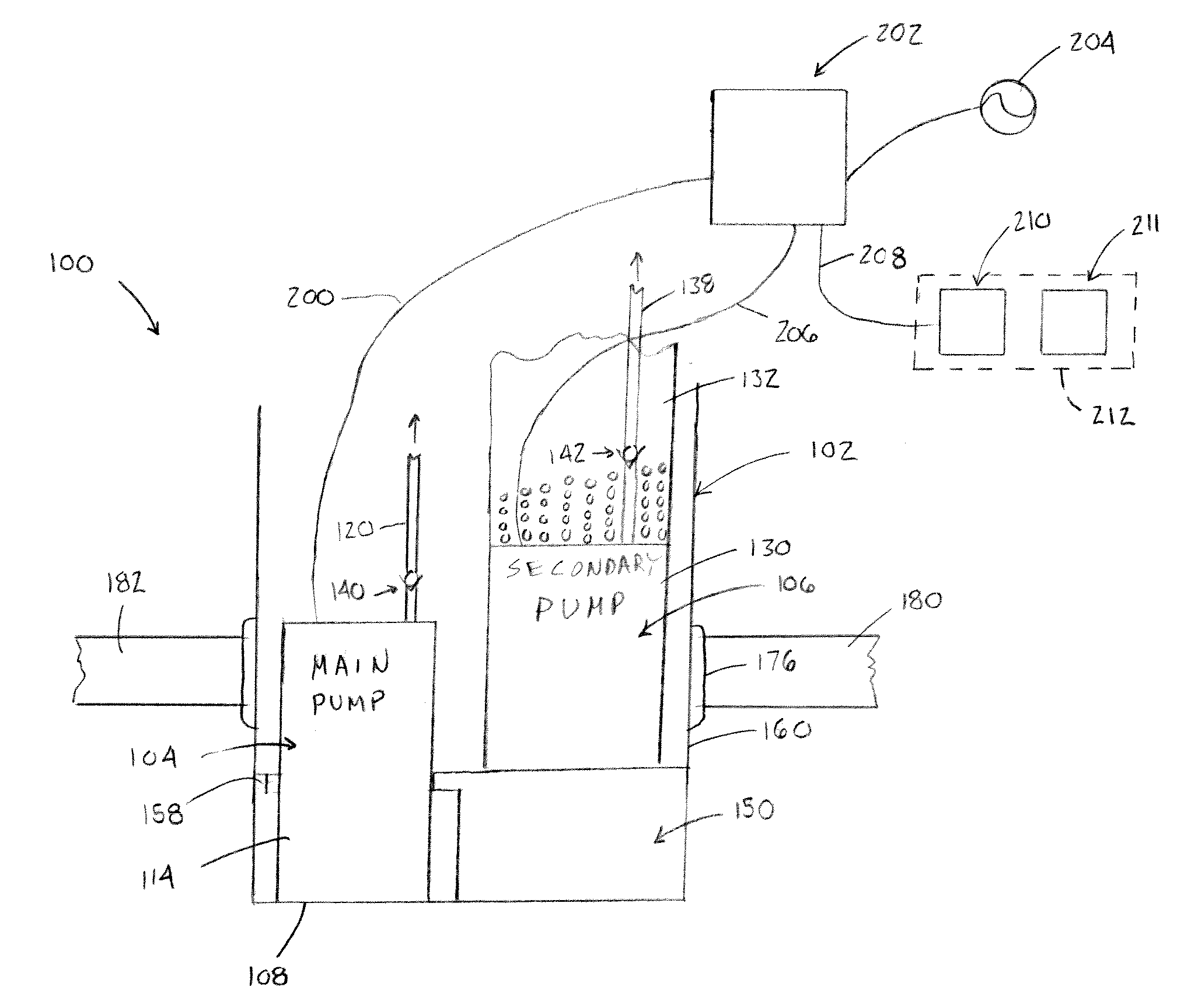

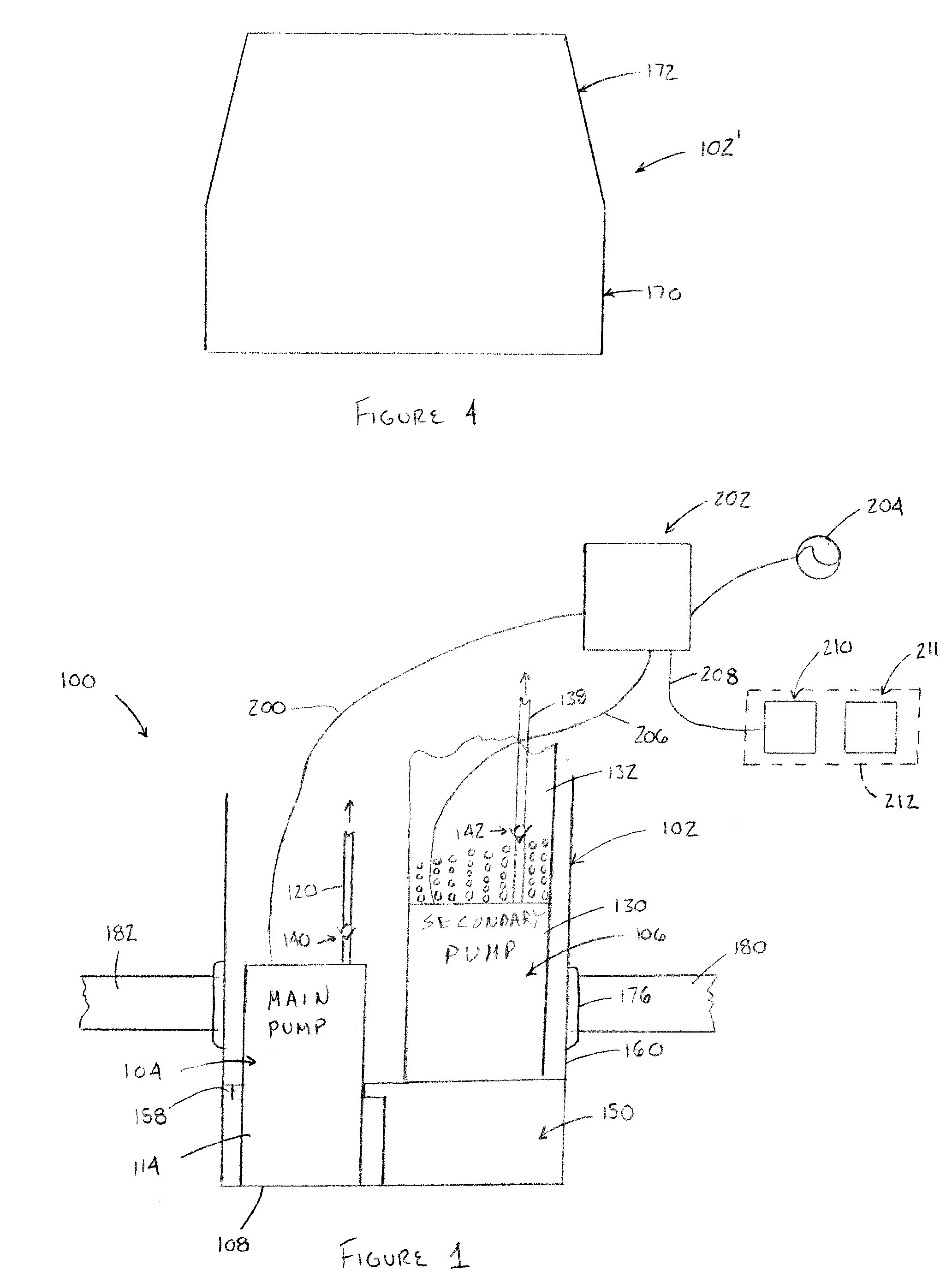

A flood control system for use in a structure having a basement floor below ground level is provided. The flood control system comprises a sump, a main pump positioned in the sump, and a secondary pump positioned in the sum. The secondary pump is raised relative to the main pump to a predetermined elevation. The main pump is energized when a height of water within the sump is at a first level. The secondary pump is energized when a height of water within the sump reaches a second, higher level and is de-energized when a height of water within the sump drops to a third level. A cover is releasably mounted to the sump. The cover includes a first section for covering the main pump and a separate second section for covering the secondary pump. At least one of the first and second sections is hingedly mounted to the sump. A controller is operatively connected to the main pump and the secondary pump. The controller is responsive to water level within the sump to selectively energize at least one of the main pump and the secondary pump.

Owner:EVERDRY MARKETING & MANAGEMENT

Basement flood control system

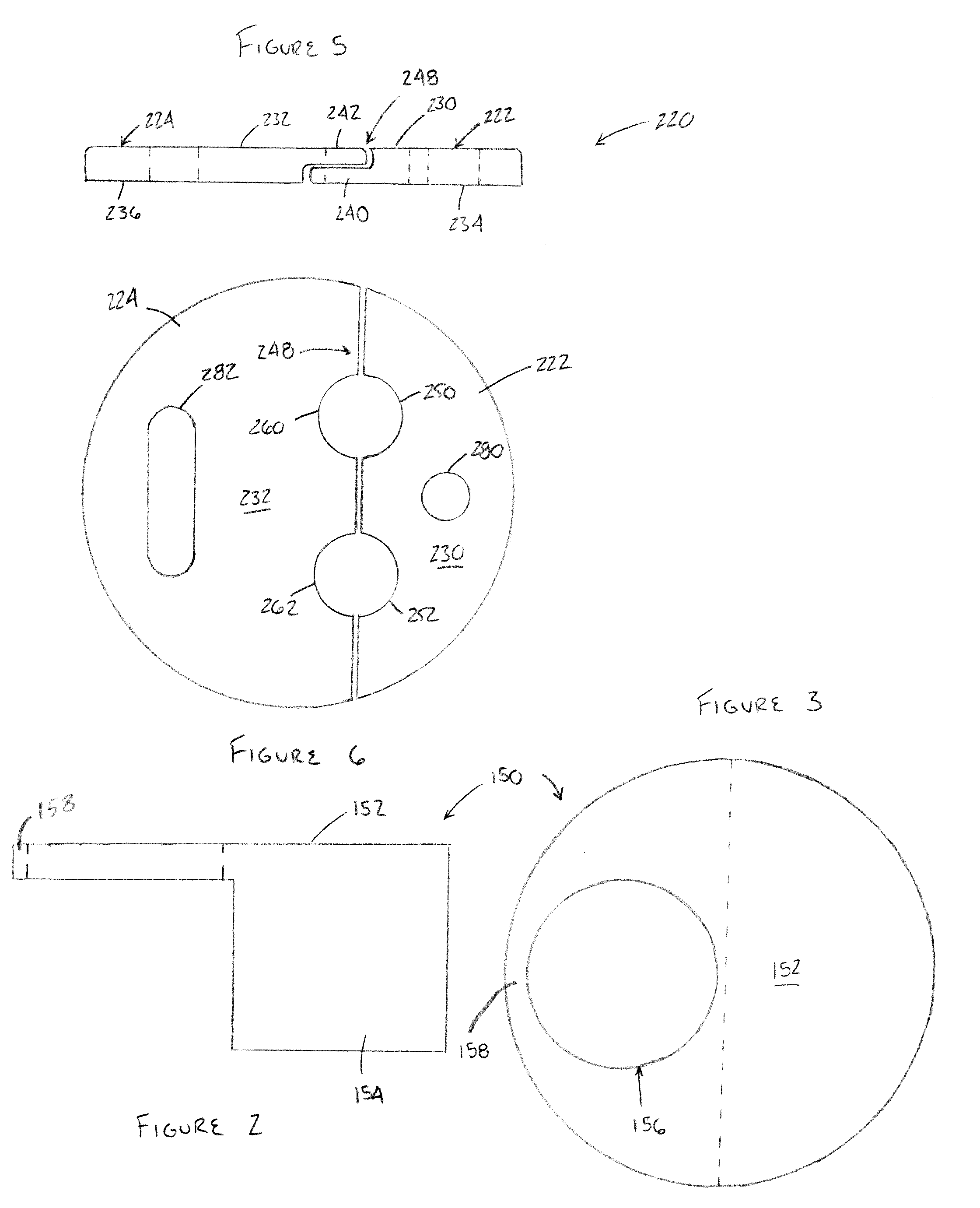

A basement flood control system for use in a structure having a basement floor located below ground level and having a sump pit or other collection basin for gathering subterranean water. The system has two primary pump units operated with line current, a battery-operated back-up pump unit, and a sensor arrangement for sensing water level in the collection basin. A controller is connected to the sensor arrangement and the pump units for variously activating the pump units singly or in any combination responsive to the water level detected by the sensor arrangement.

Owner:NIEDERMEYER KARL

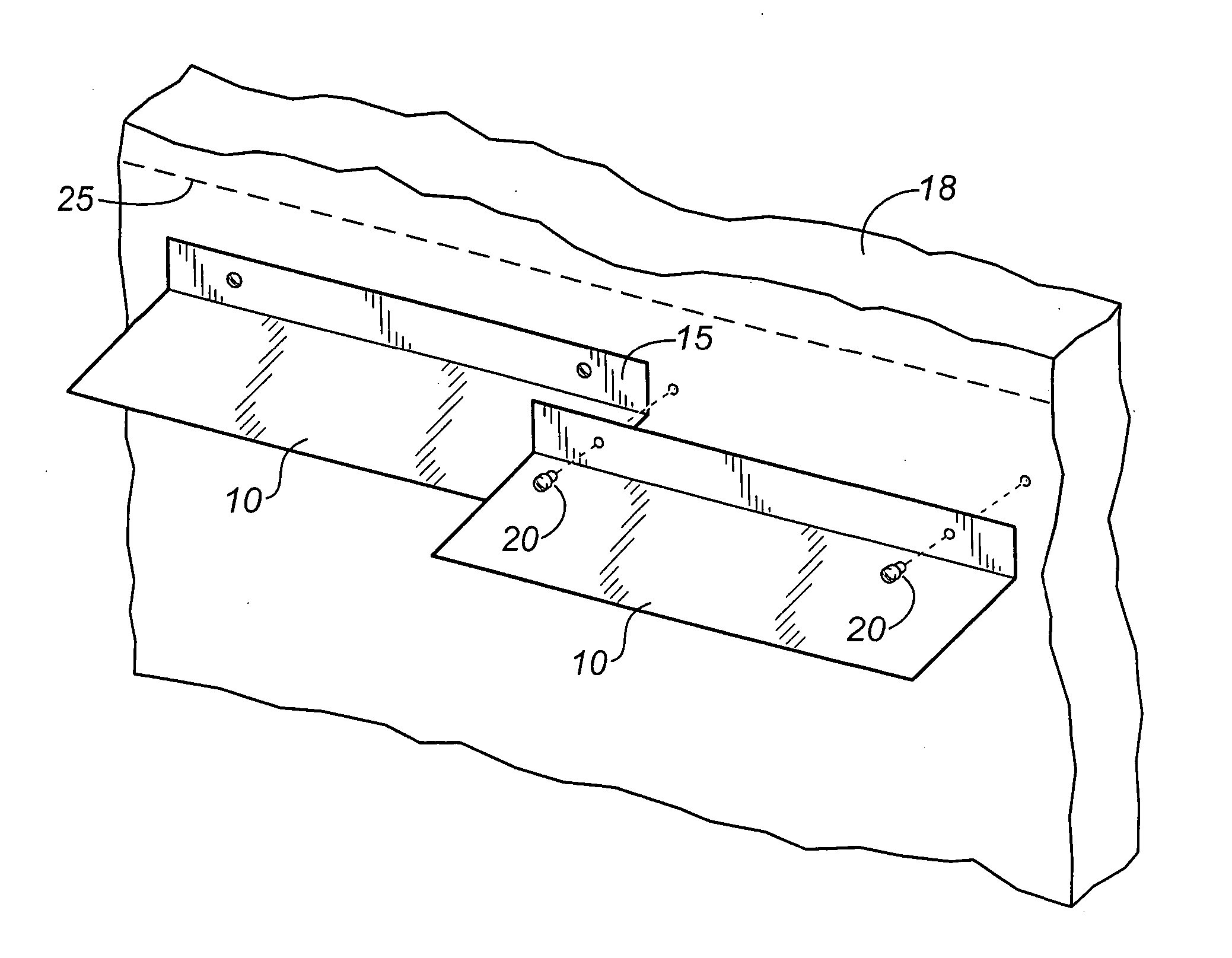

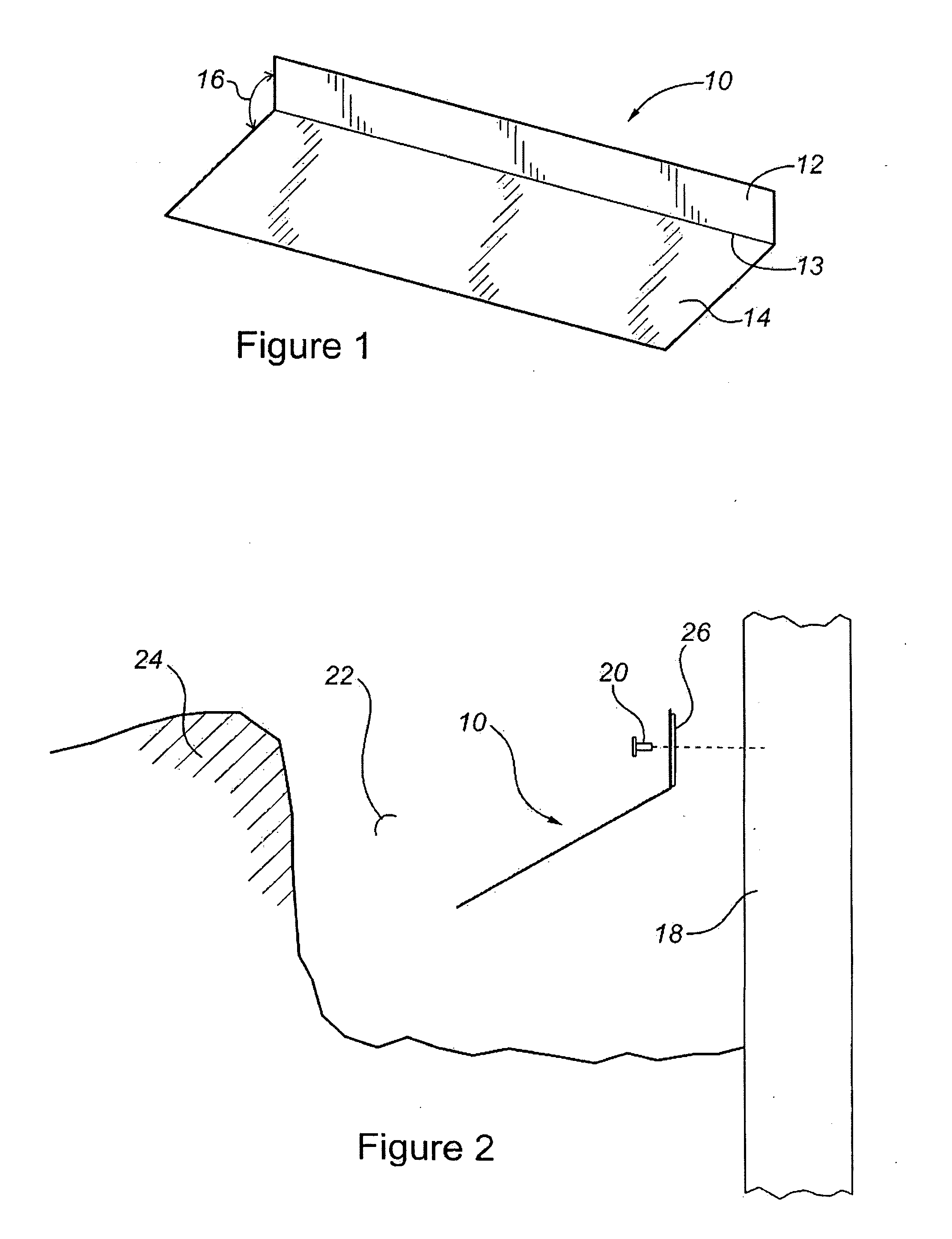

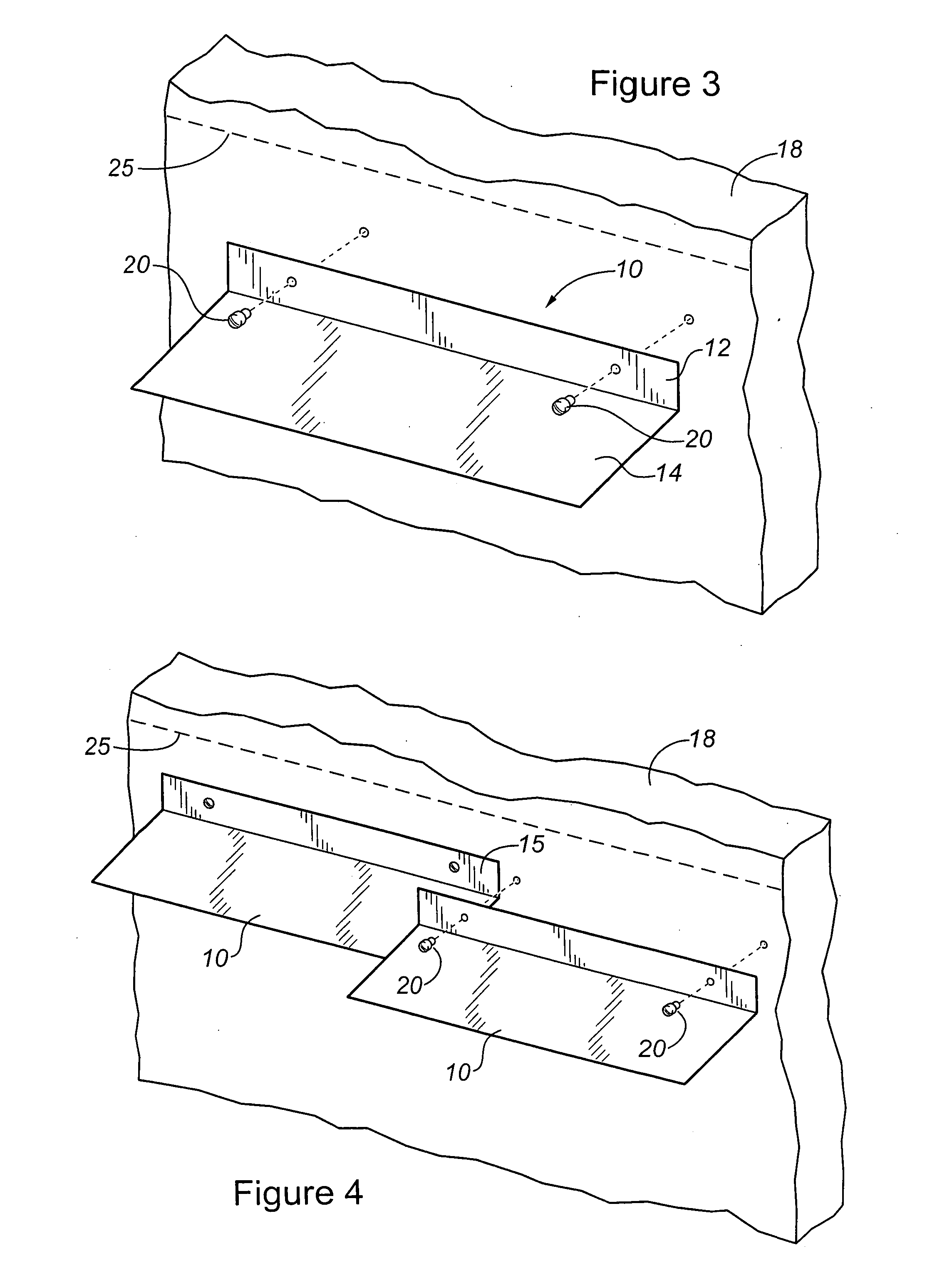

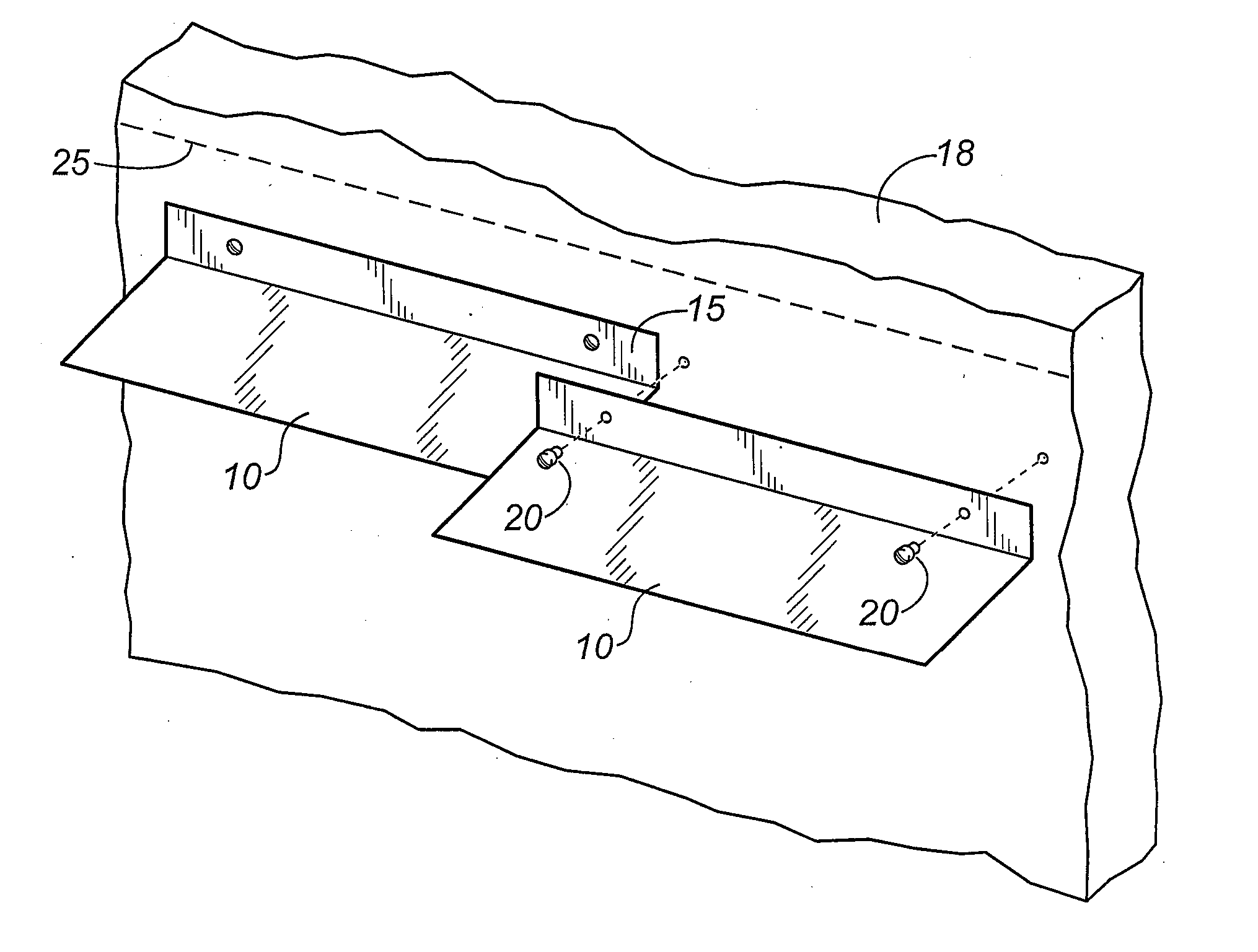

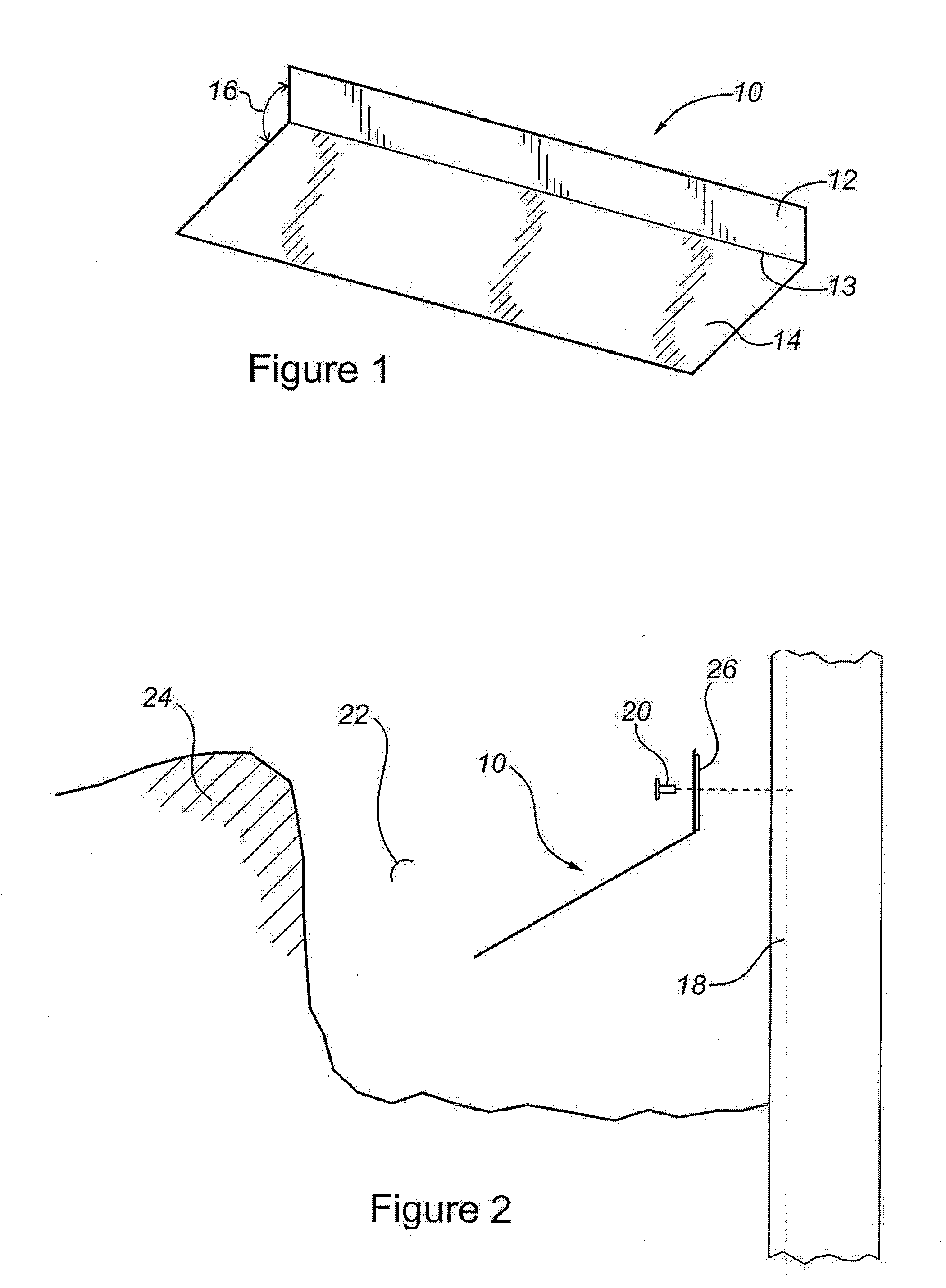

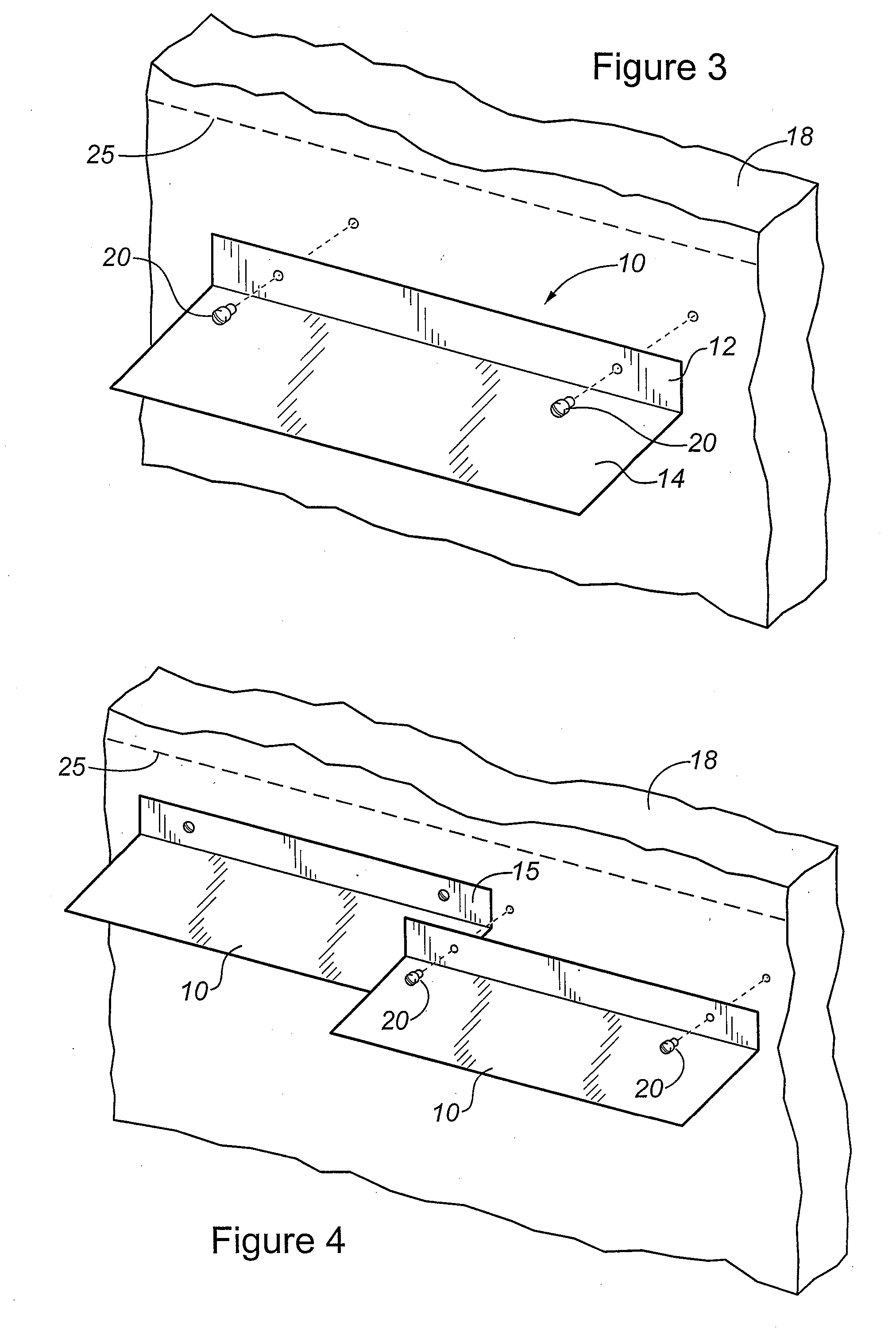

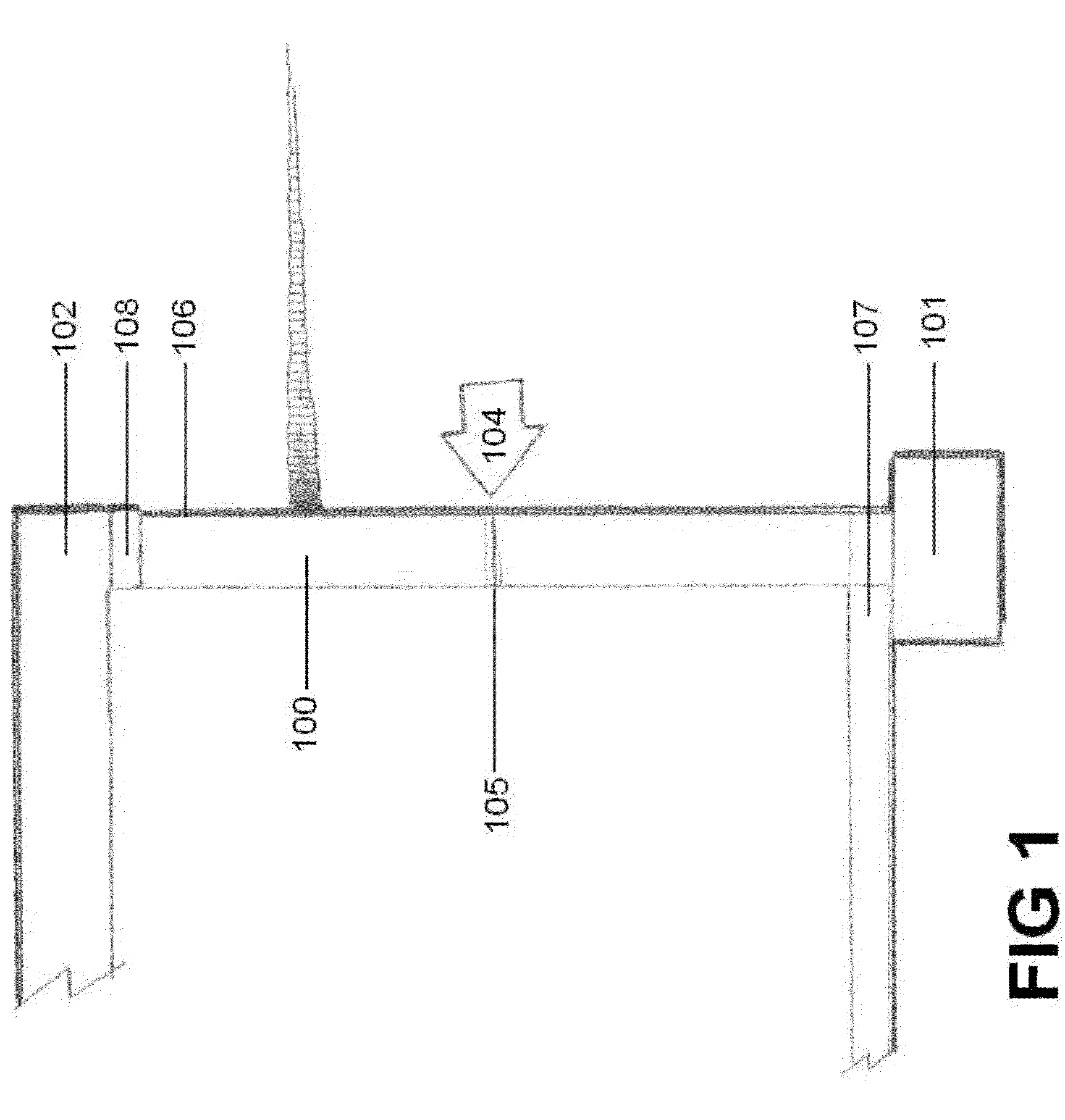

Method and apparatus for deflecting liquid from a foundation wall

InactiveUS20060032158A1Easy to moveAddressing Insufficient CoverageProtective foundationBuilding constructionsEngineeringStormwater

Rain water is deflected from the foundation wall of a building structure by a flashing of non-ferrous metal that is fastened to the foundation below the grade level of the soil. Soil is trenched and exposed about the foundation, and the flashing is installed in the trench around the perimeter of the foundation wall. After installation, the trench is backfilled with soil thereby covering the flashing and restoring grade. During heavy rains or floods, water seeping into the soil is deflected away from the foundation by the flashing. This prevents water from pooling at the bottom of the foundation and seeping up into the structure through the joint where the foundation meets the basement floor.

Owner:ALL TERM FINANCING

Method and apparatus for deflecting liquid from a foundation wall

InactiveUS20070175113A1Easy to moveAddressing Insufficient CoverageProtective foundationBuilding constructionsStructural engineeringBasement floor

Rain water is deflected from the foundation wall of a building structure by a flashing of non-ferrous metal that is fastened to the foundation below the grade level of the soil. Soil is trenched and exposed about the foundation. Multiple sections of foundation flashing are installed in the trench around the perimeter of the foundation wall. Adjacent flashing sections overlap in a continuous manner. After installation, the trench is backfilled with soil thereby covering the flashing and restoring grade. During heavy rains or floods, water seeping into the soil is deflected away from the foundation by the flashing. This prevents water from pooling at the bottom of the foundation and seeping up into the structure through the joint where the foundation meets the basement floor.

Owner:ALL TERM FINANCING

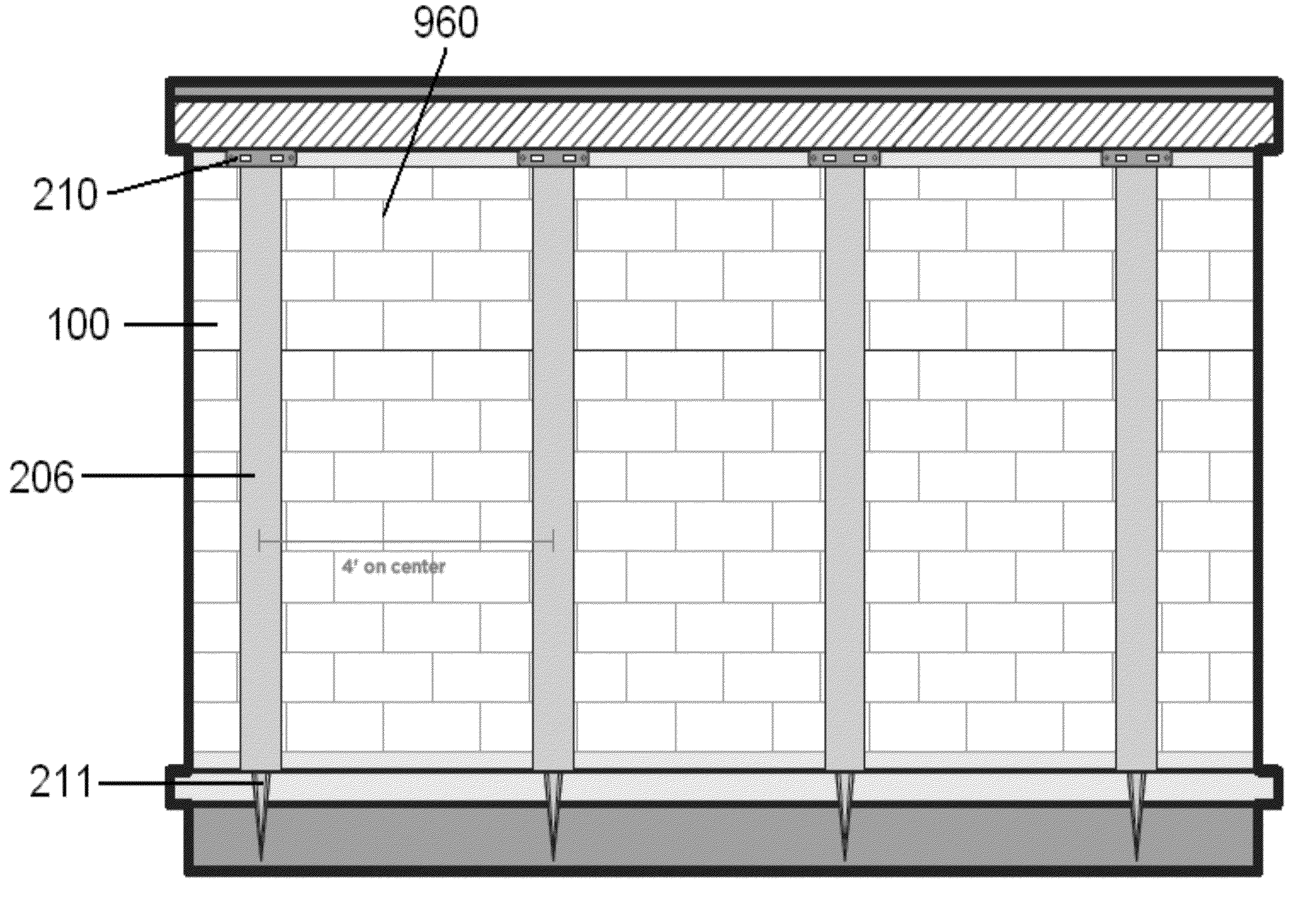

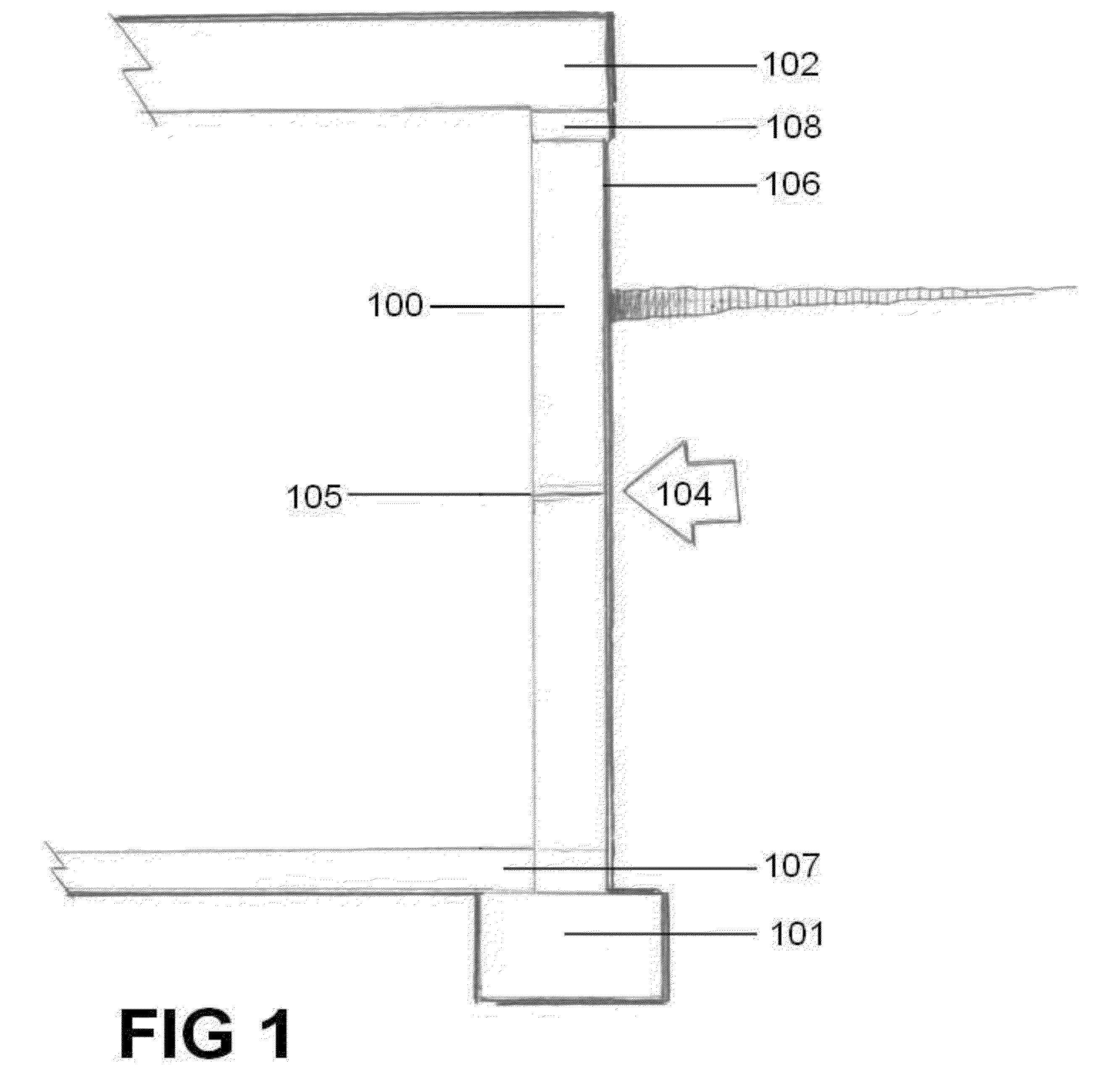

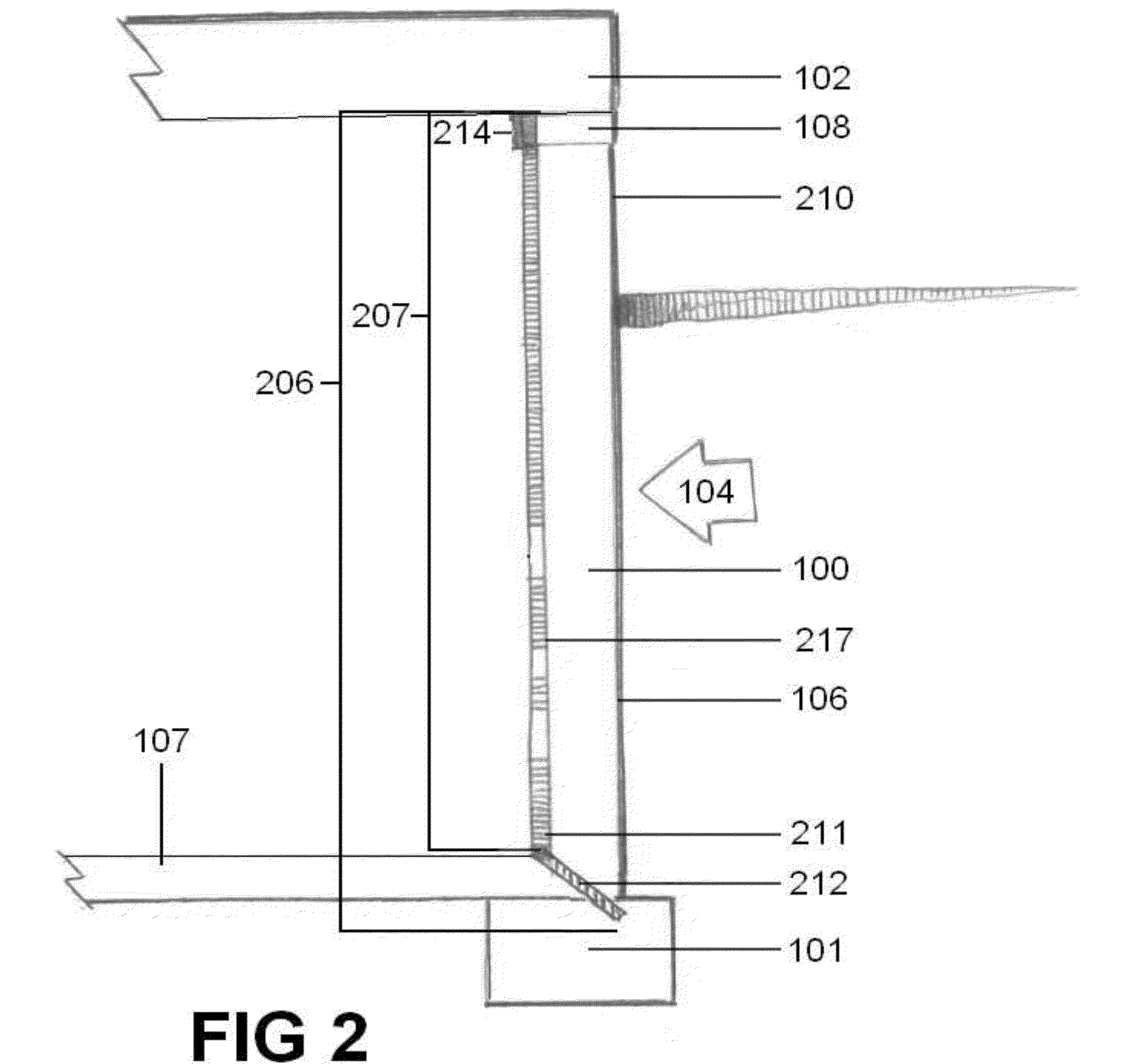

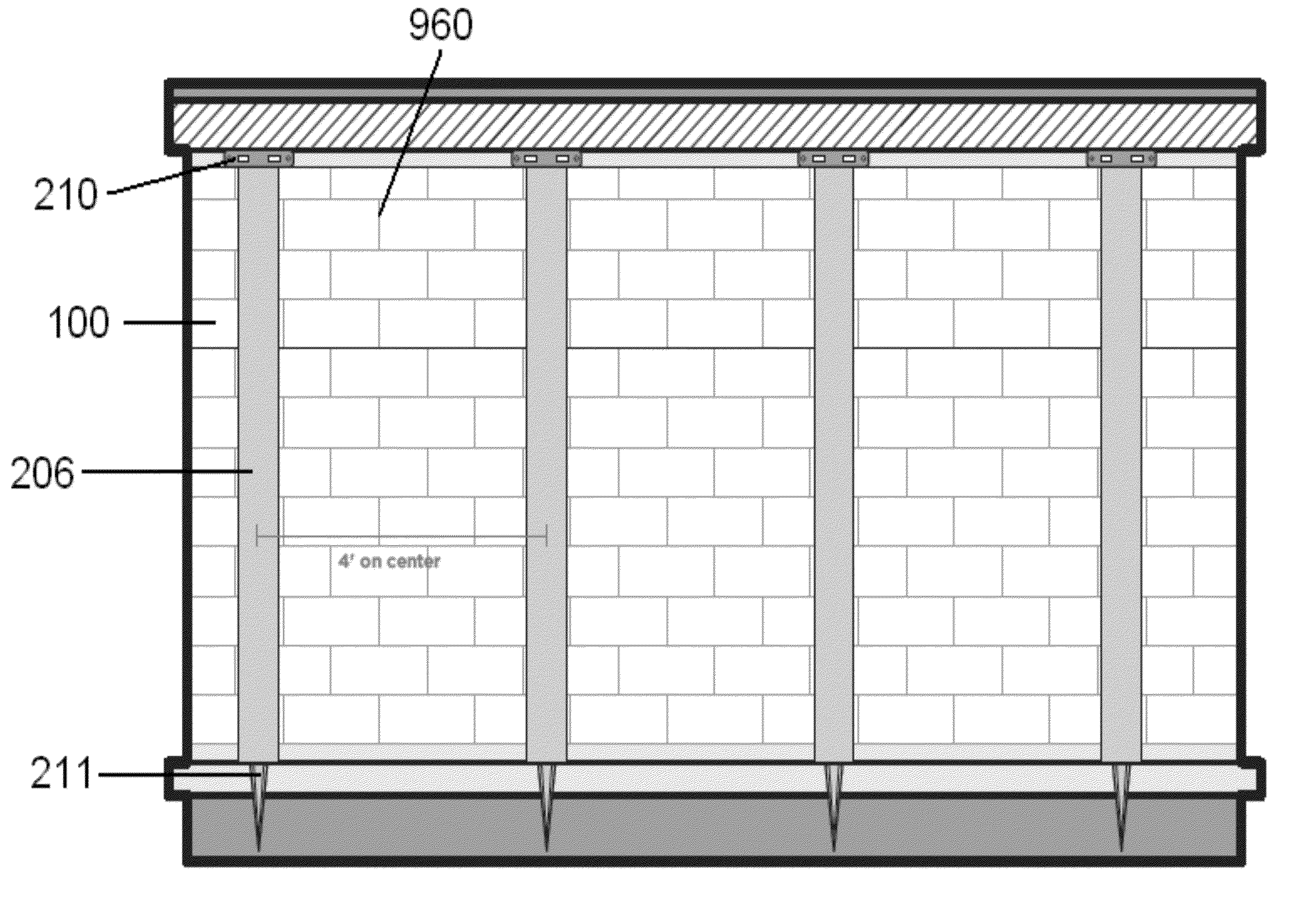

Carbon fiber wall reinforcement system and a method for its use

The basement wall reinforcement system comprises carbon fiber materials securely mounted to the wall being reinforced as well as to structural components at both the top and bottom of the wall. These additional connections at the top and bottom of the wall increase the capacity of the carbon fiber to prevent bowing and cracking by transferring lateral forces from the wall to these structural components. Such structural components can include foundations, basement floors, sill plates, rim joists and floor joists. The carbon fiber can be connected to these structural components by pins, epoxies and specially designed brackets.

Owner:RHINO PROD USA

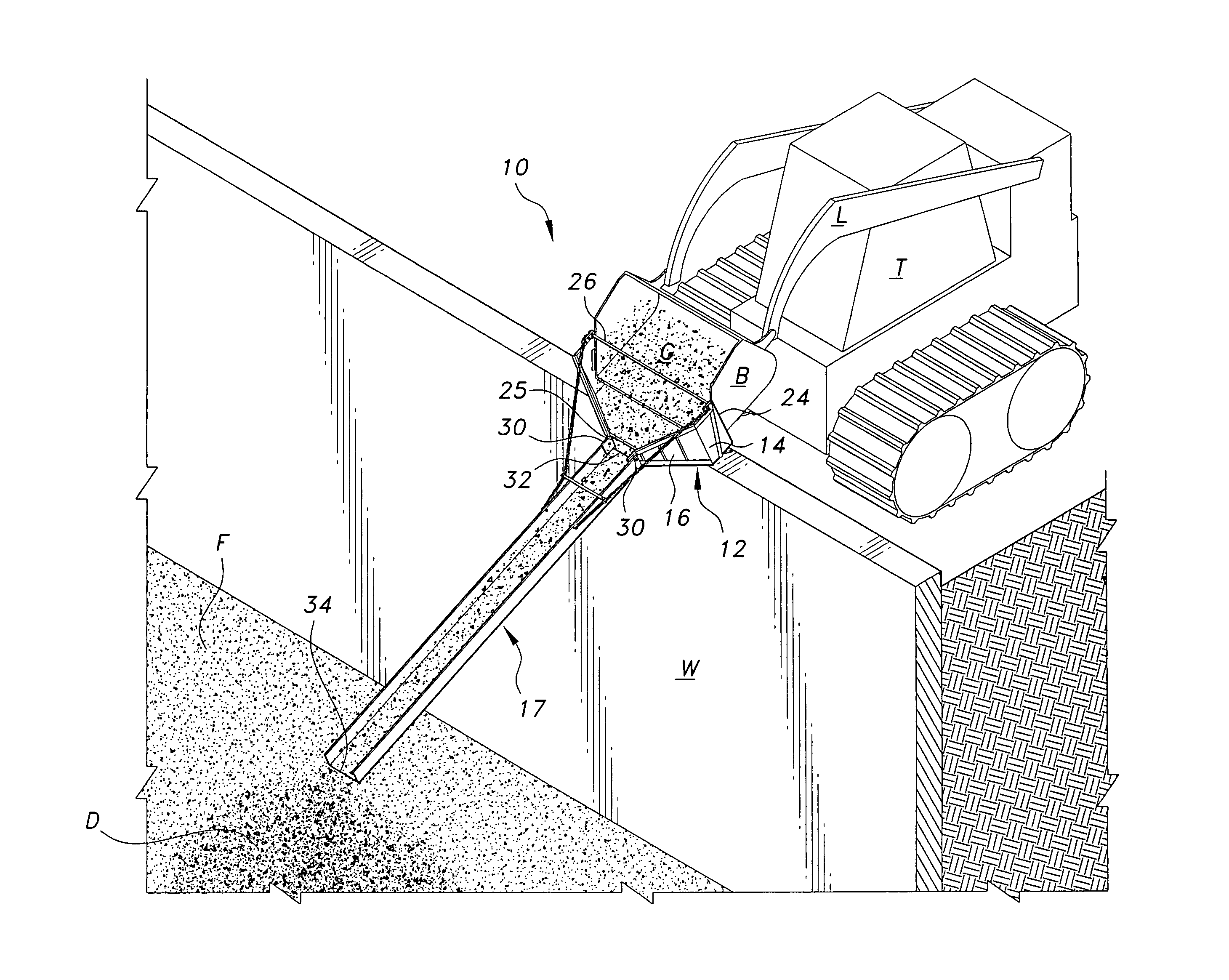

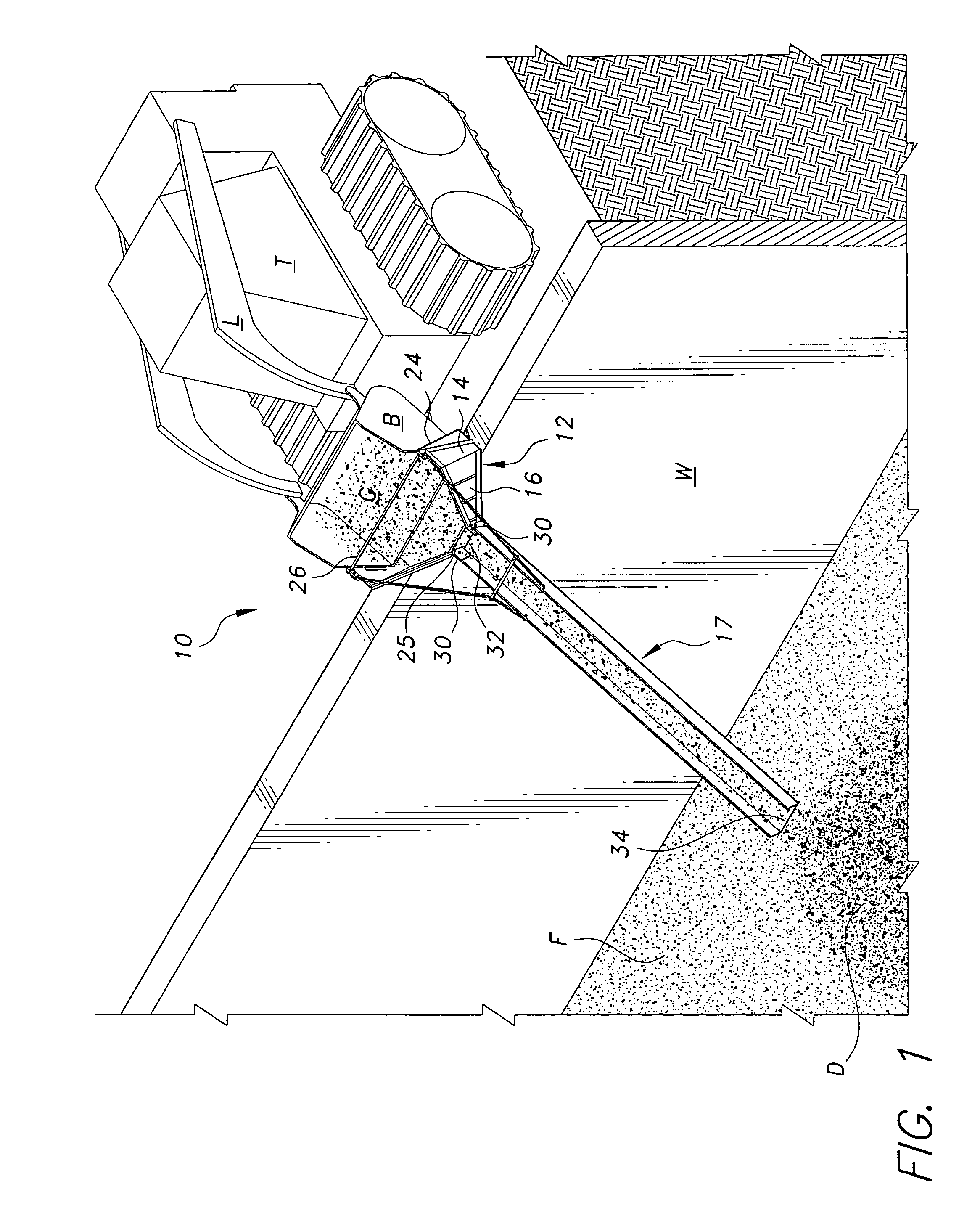

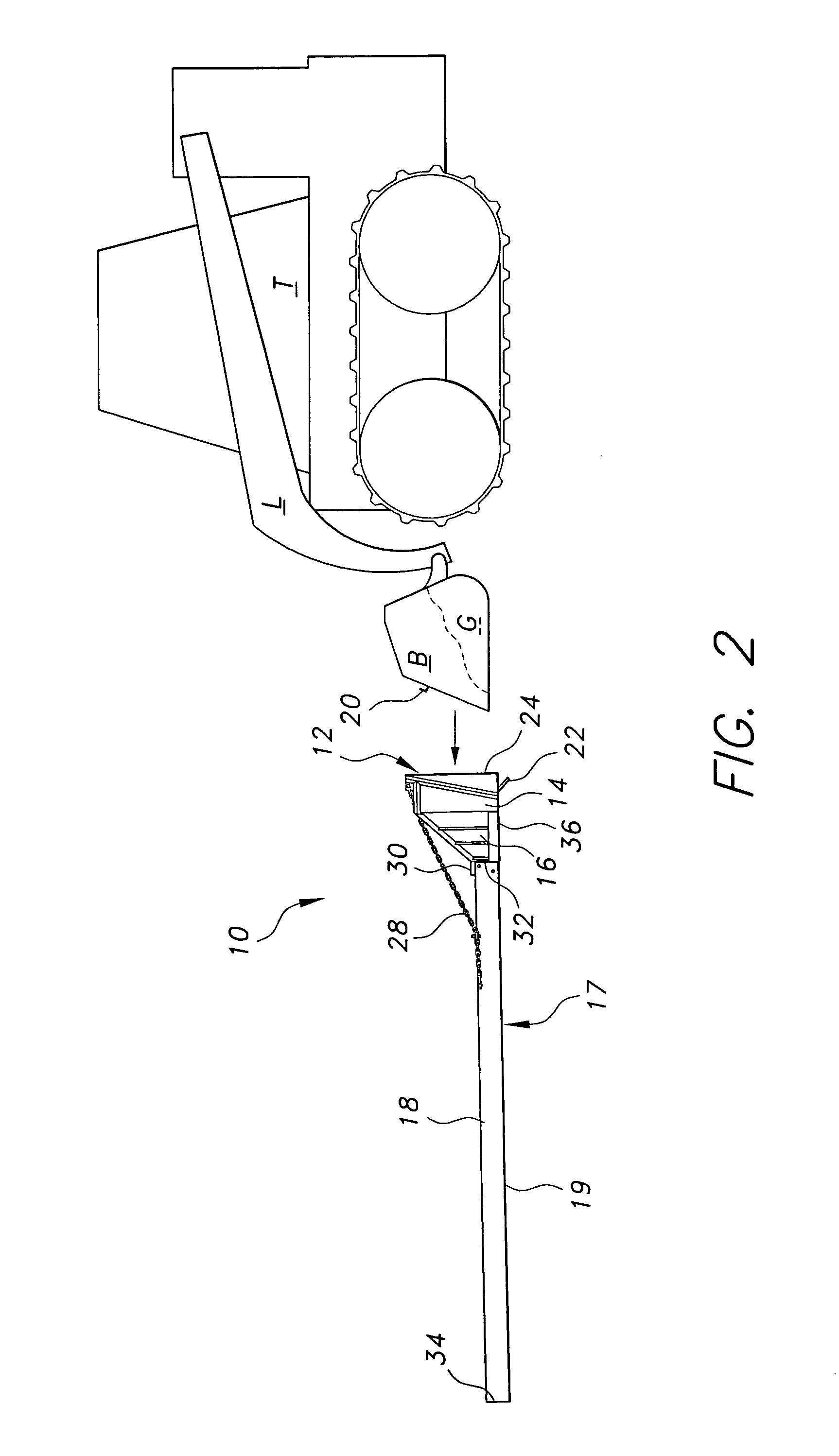

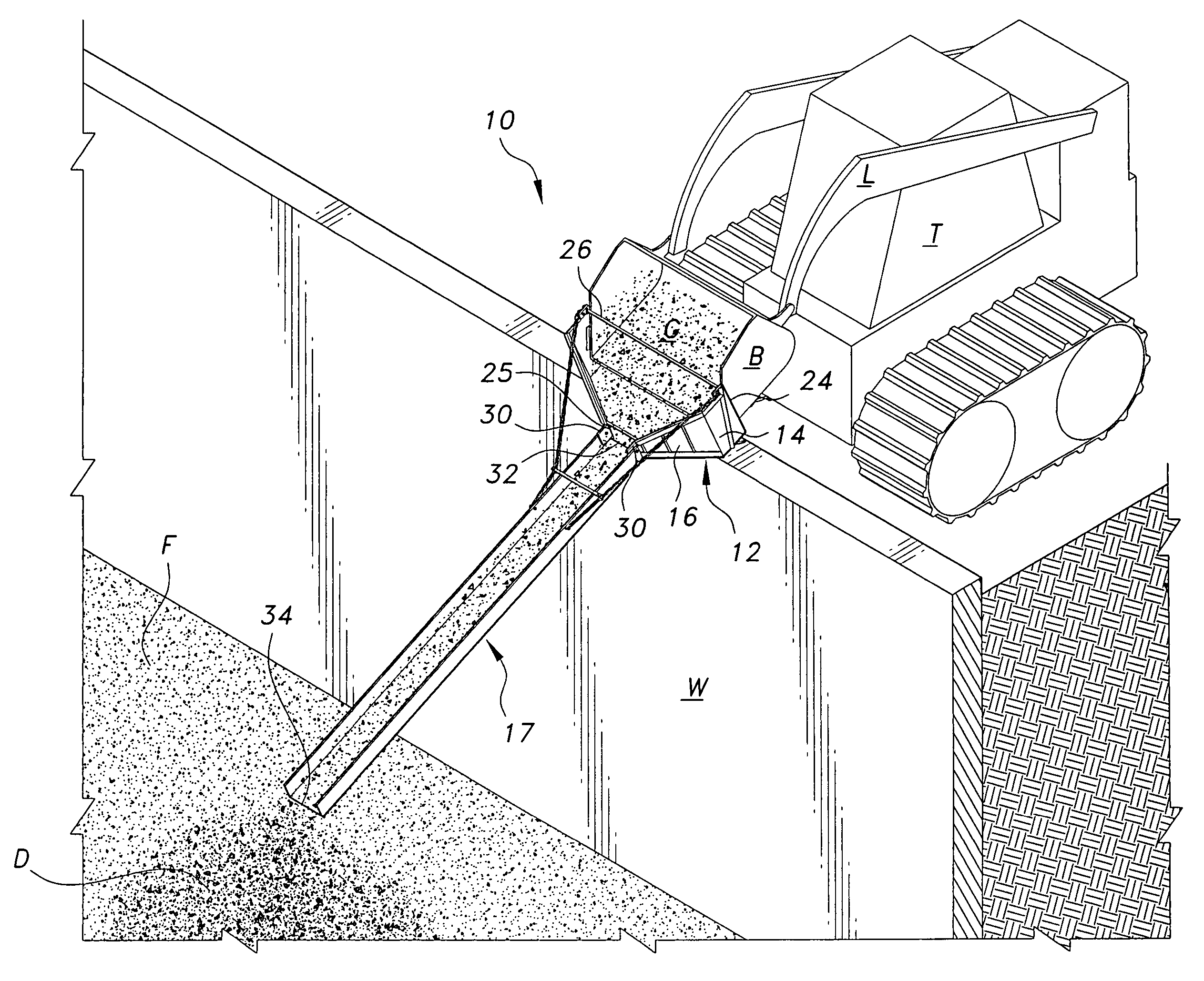

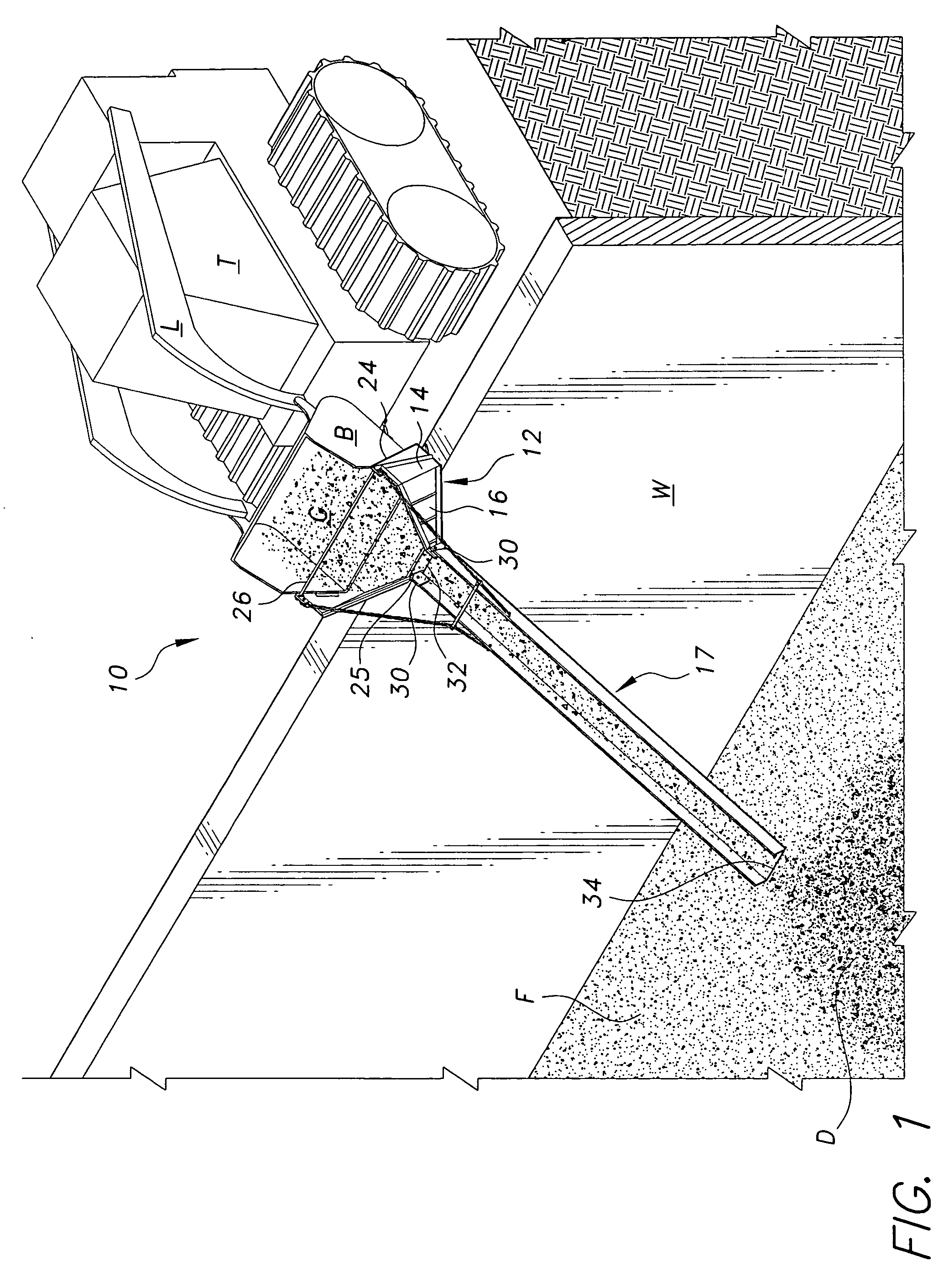

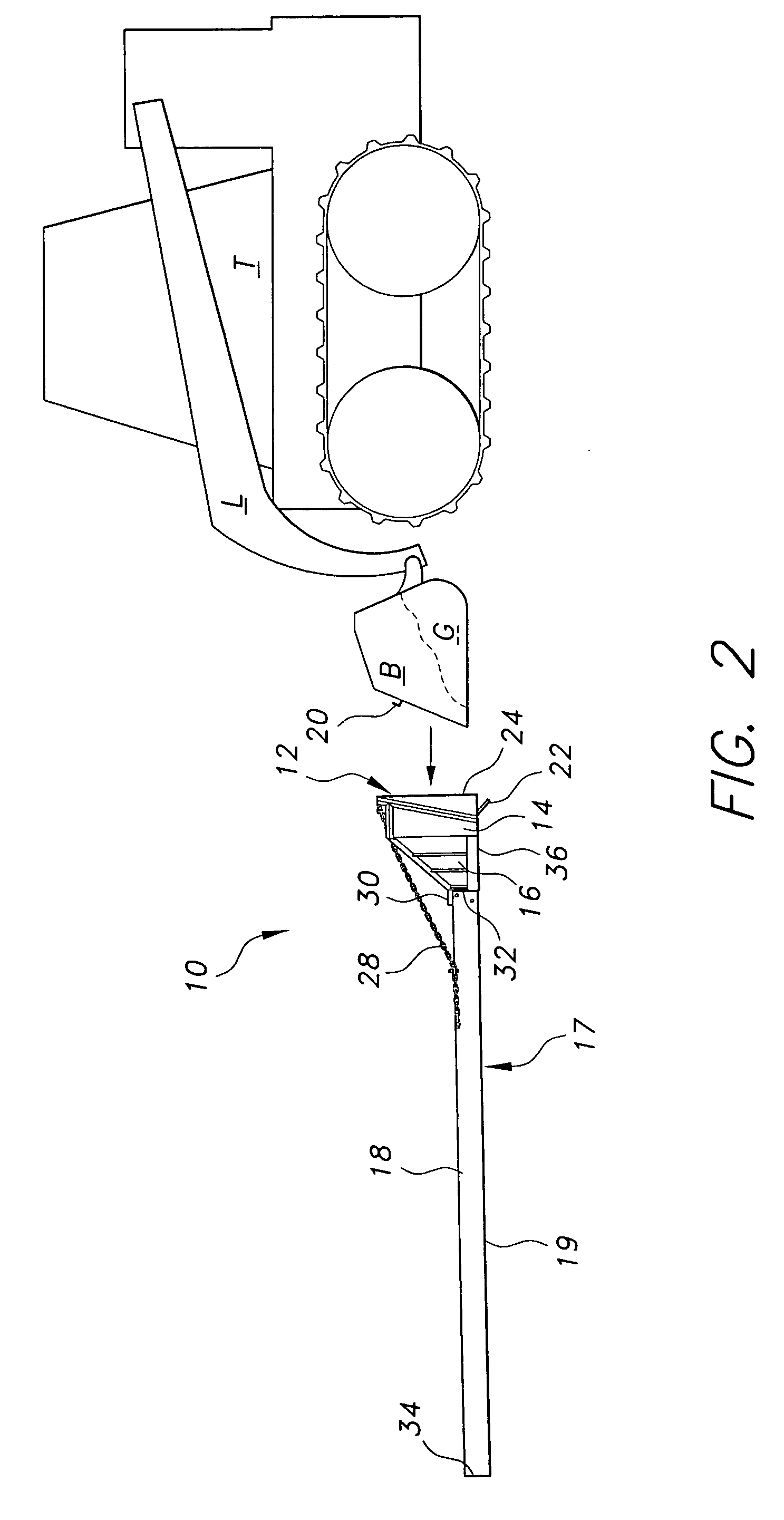

Front end loader bucket discharge funnel and distributor

A discharge funnel and distributor chute for sand and gravel or other disperse material which is removably attachable to the bucket of a front end loader. Funnel engaging hooks are attached along the front edges of the sides of the bucket and spaced upward from the bucket floor. The funnel has a floor and vertical sidewalls forming an open rear bucket receiving portion for receiving the front lower portion of the bucket. This portion has a floor and sides with a hook engaging bar extending between upper ends of the funnel sides forming a rear opening. Angled bucket guide bars are located along the inner sides of opposite walls. The funnel has a converging funnel portion connected to the engaging portion. The converging portion opens into a discharge chute. The chute allows the discharge of disperse material to a specific location such as a basement floor under construction.

Owner:RALEY THOMAS A

Carbon fiber wall reinforcement system and a method for its use

The basement wall reinforcement system comprises carbon fiber materials securely mounted to the wall being reinforced as well as to structural components at both the top and bottom of the wall. These additional connections at the top and bottom of the wall increase the capacity of the carbon fiber to prevent bowing and cracking by transferring lateral forces from the wall to these structural components. Such structural components can include foundations, basement floors, sill plates, rim joists and floor joists. The carbon fiber can be connected to these structural components by pins, epoxies and specially designed brackets.

Owner:RHINO PROD USA

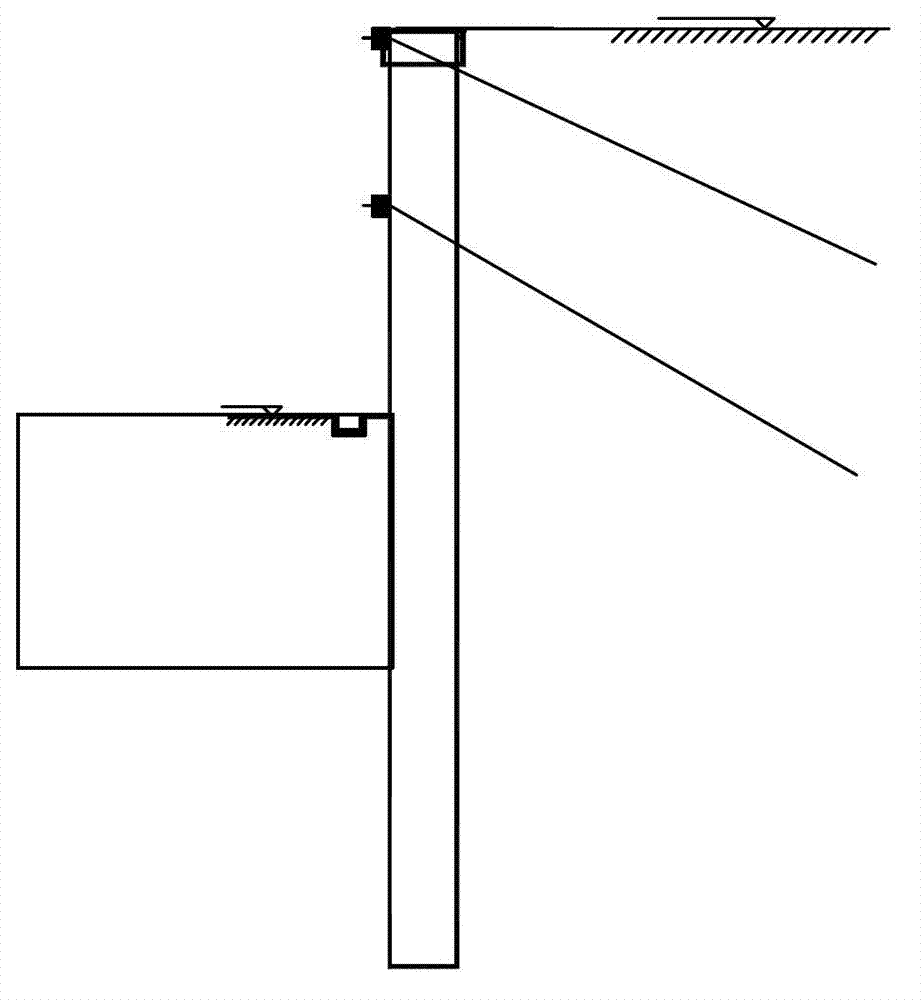

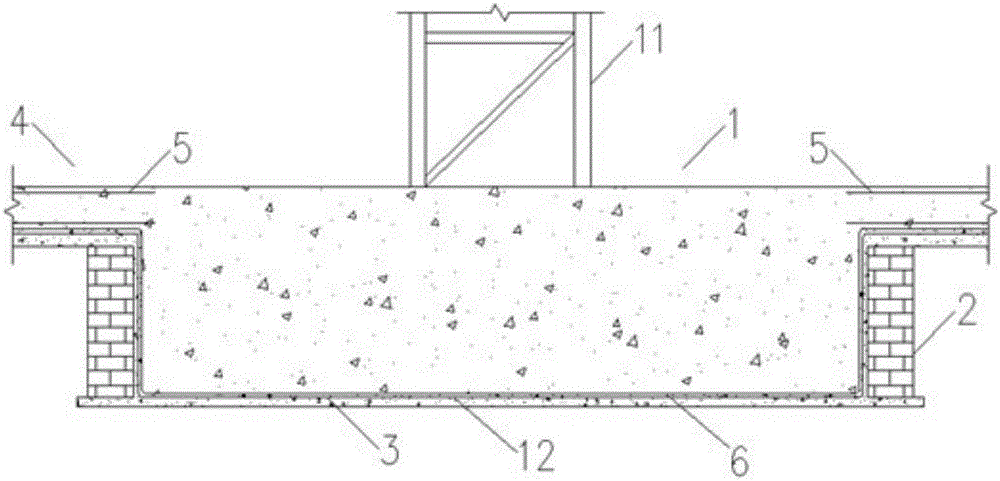

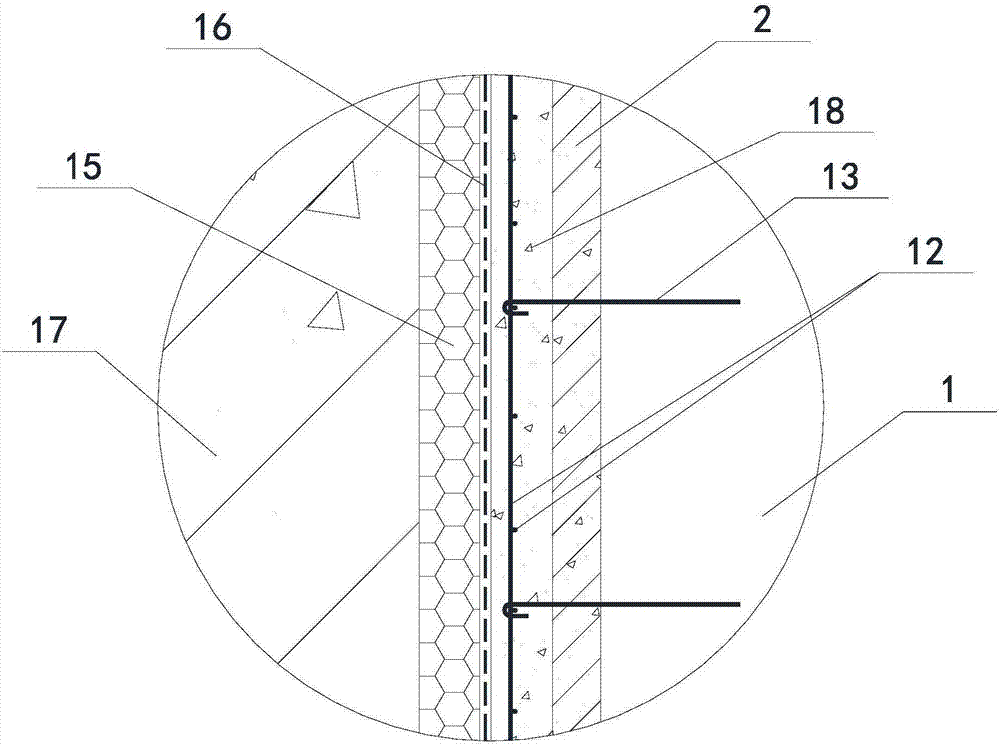

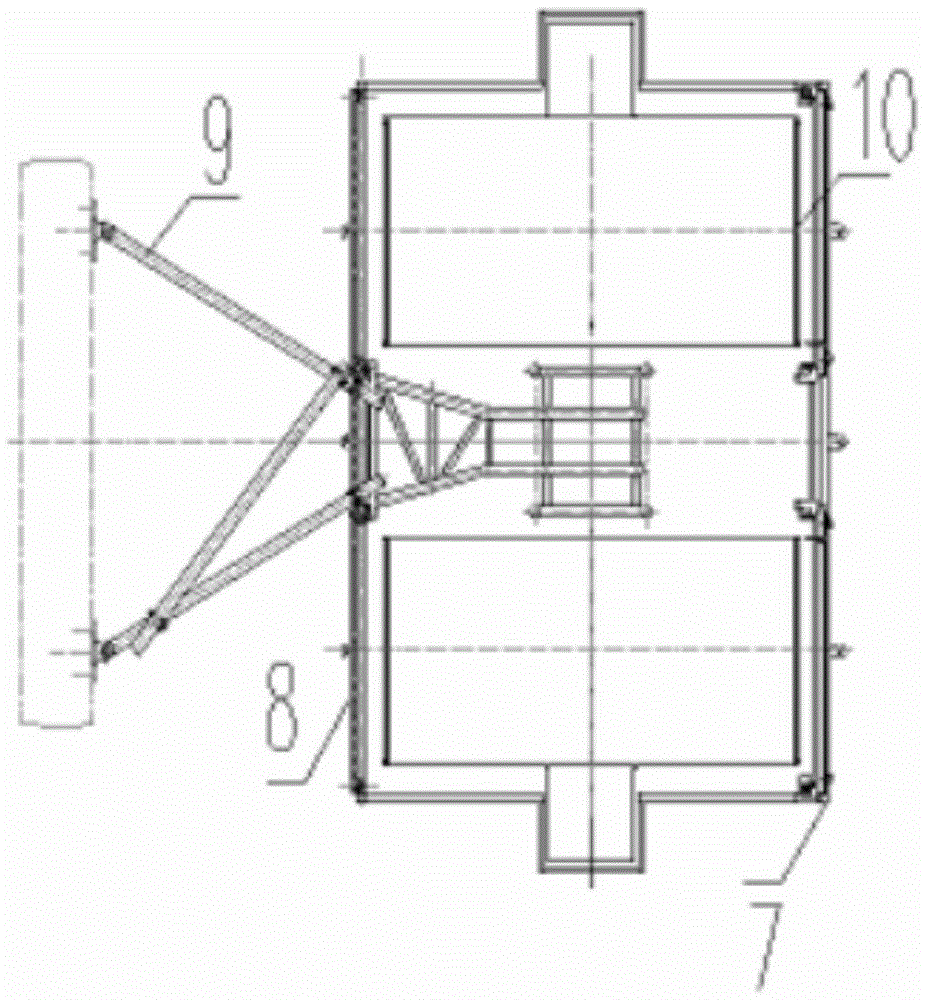

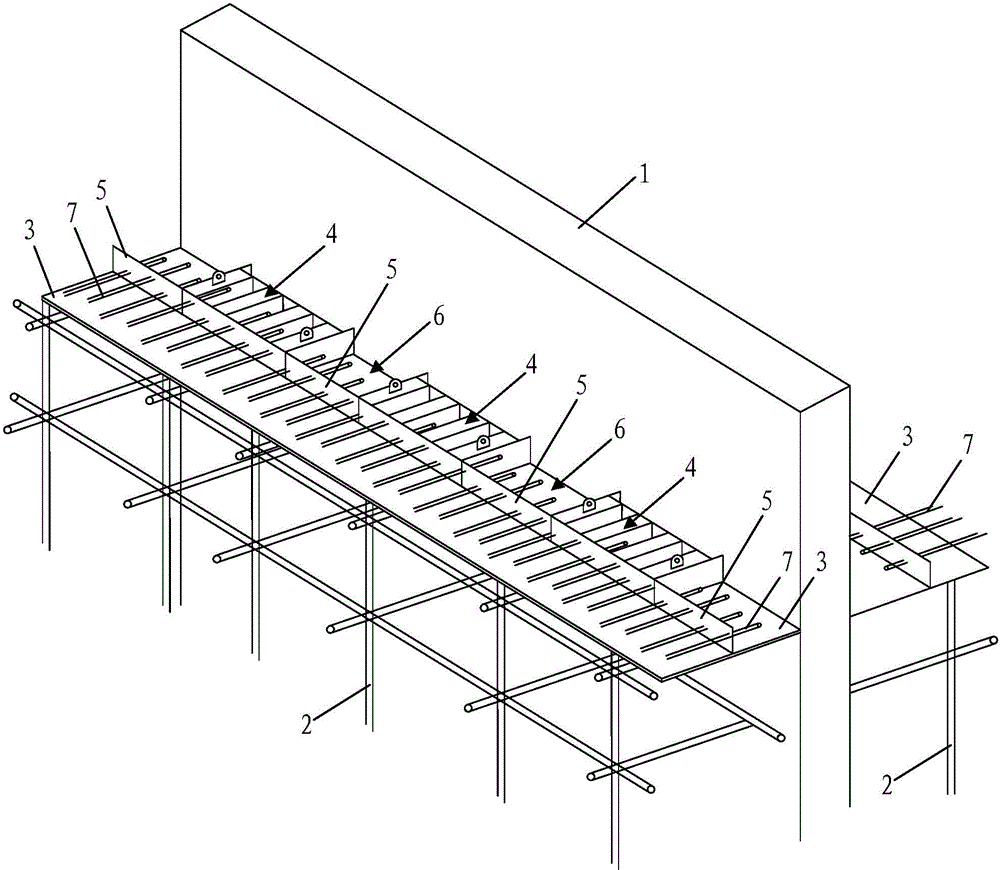

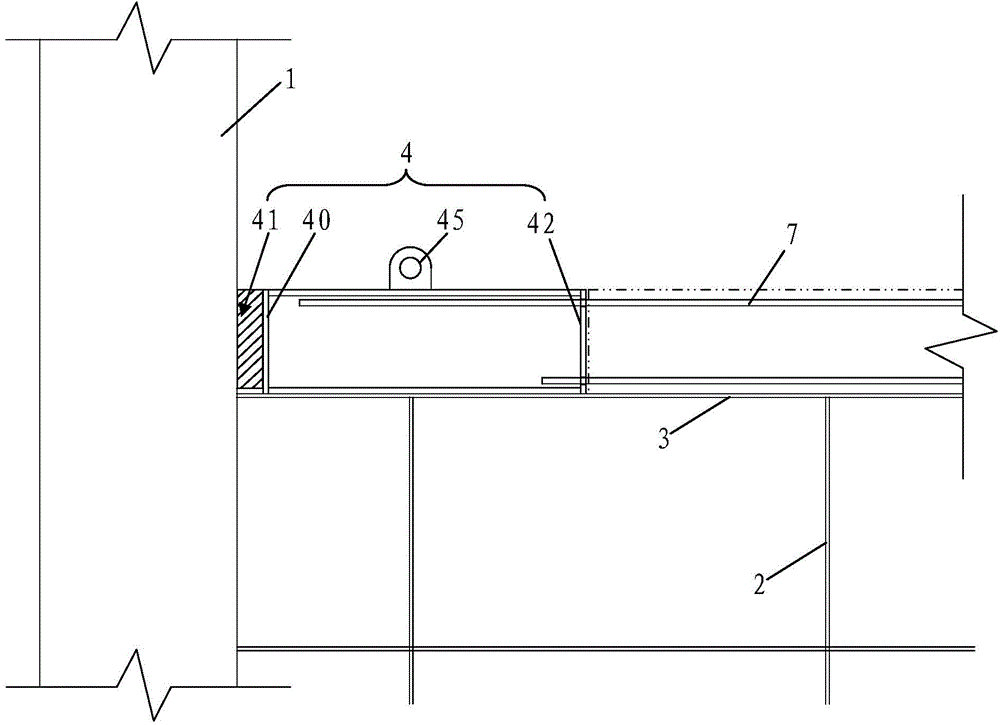

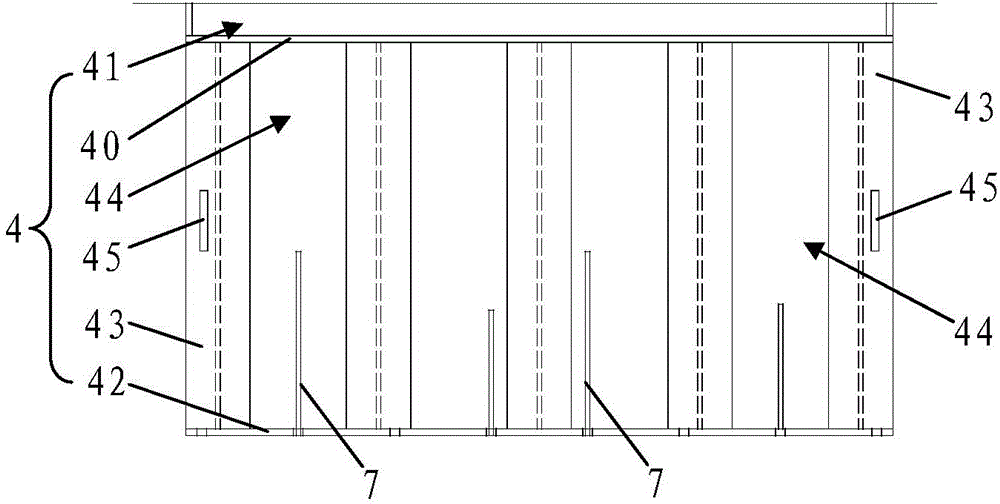

Support method and device of support pile preformed core-soil double-buttress inclined inner-strut foundation ditch

The invention relates to a support method of a support pile preformed core-soil double-buttress inclined inner-strut foundation ditch. An inclined strut mechanism is arranged between a support pile and a basement floor, core-soil is reserved in the position in the foundation ditch which is arranged on one side of the inclined strut mechanism, and the position is close to the support pile. A device of the support pile preformed core-soil double-buttress inclined inner-strut foundation ditch comprises a support pile, the inclined strut mechanism is arranged between the support pile and the basement floor, core-soil is reserved at the position in the foundation ditch which is arranged on one side of the inclined strut mechanism, and the position is close to the support pile. The method and the device of the support pile preformed core-soil double-buttress inclined inner-strut foundation ditch are suitable for geological conditions that an unknown cable, a pipe ditch or a cave exist in surrounding geology and geological conditions which are not suitable for utilizing ditch support of a piled anchor or a cantilever and a horizontal strut of anchor cable construction and the like and are convenient to construct and short in a project schedule.

Owner:XIAMEN YCUCG

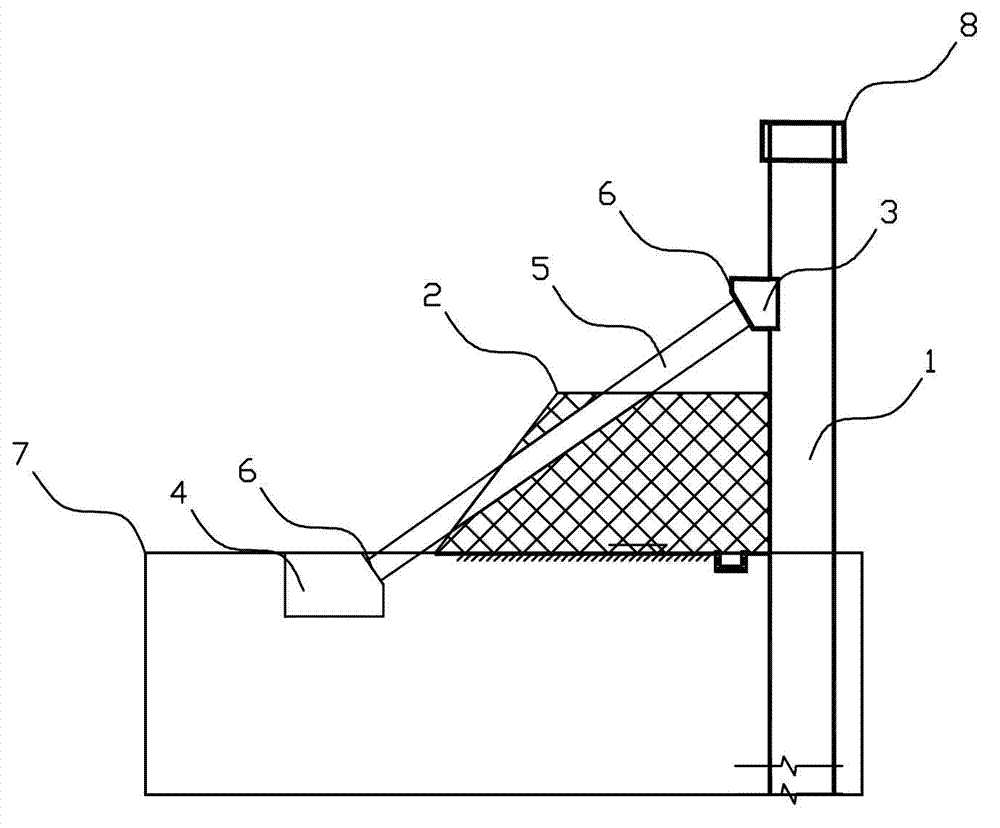

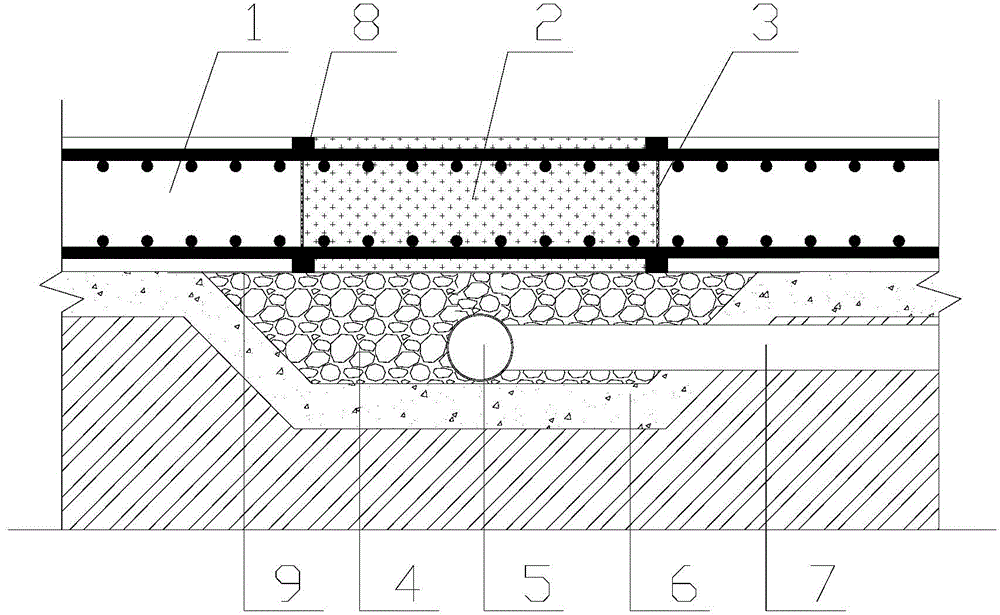

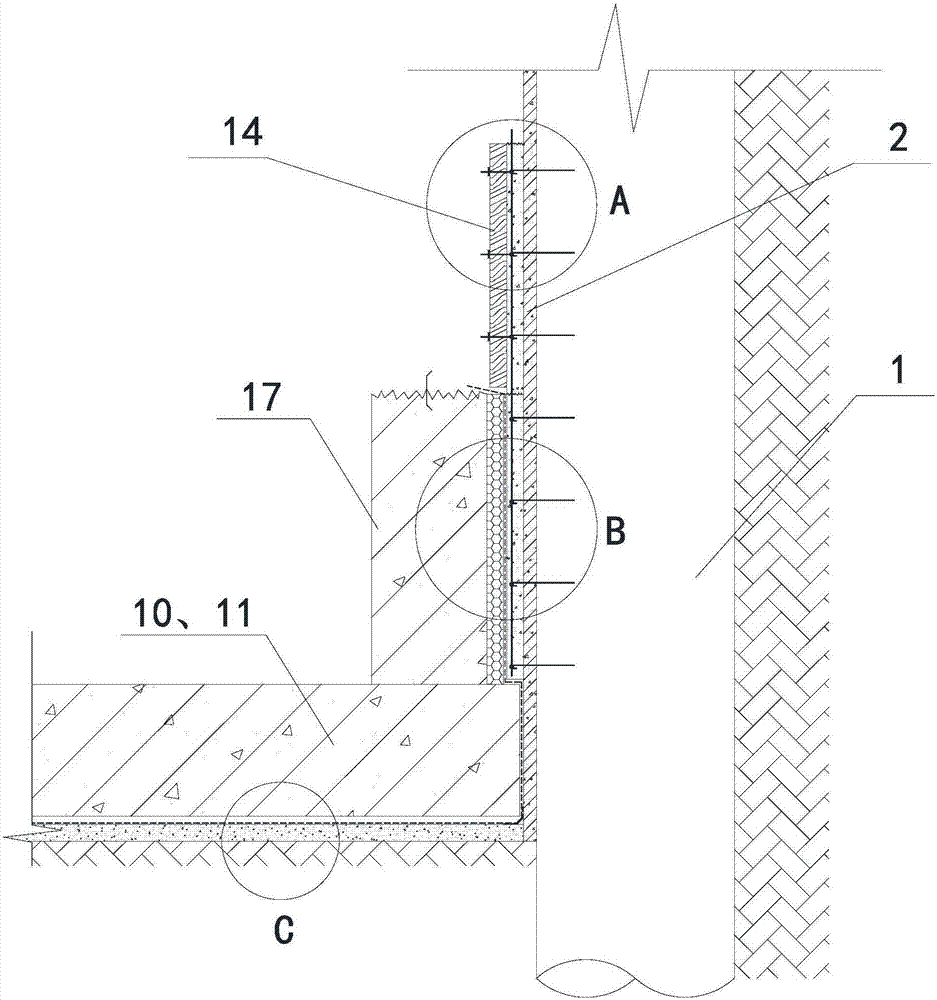

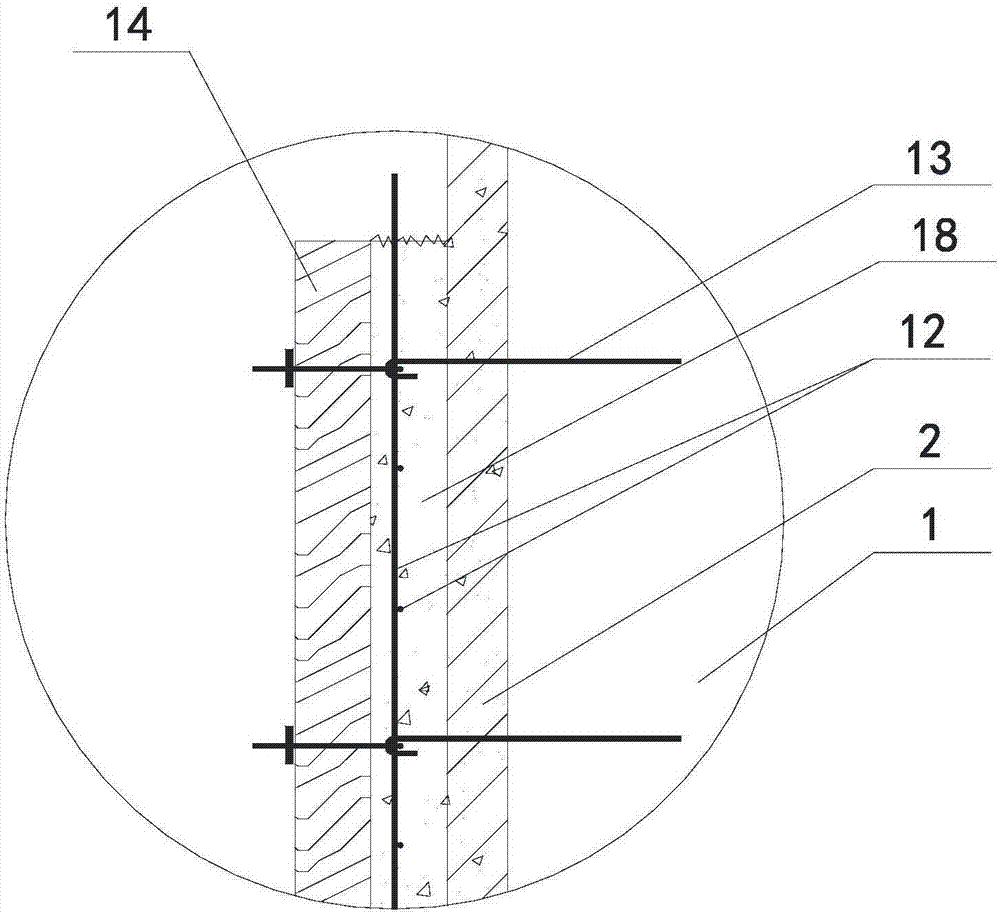

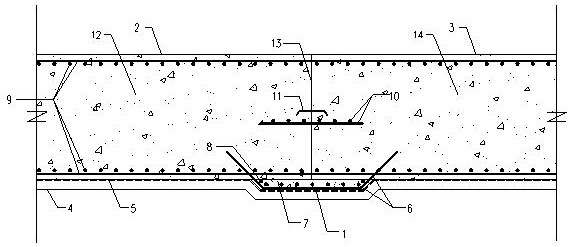

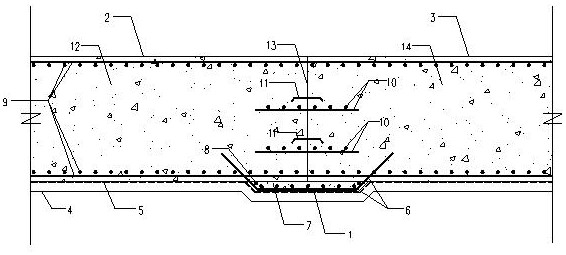

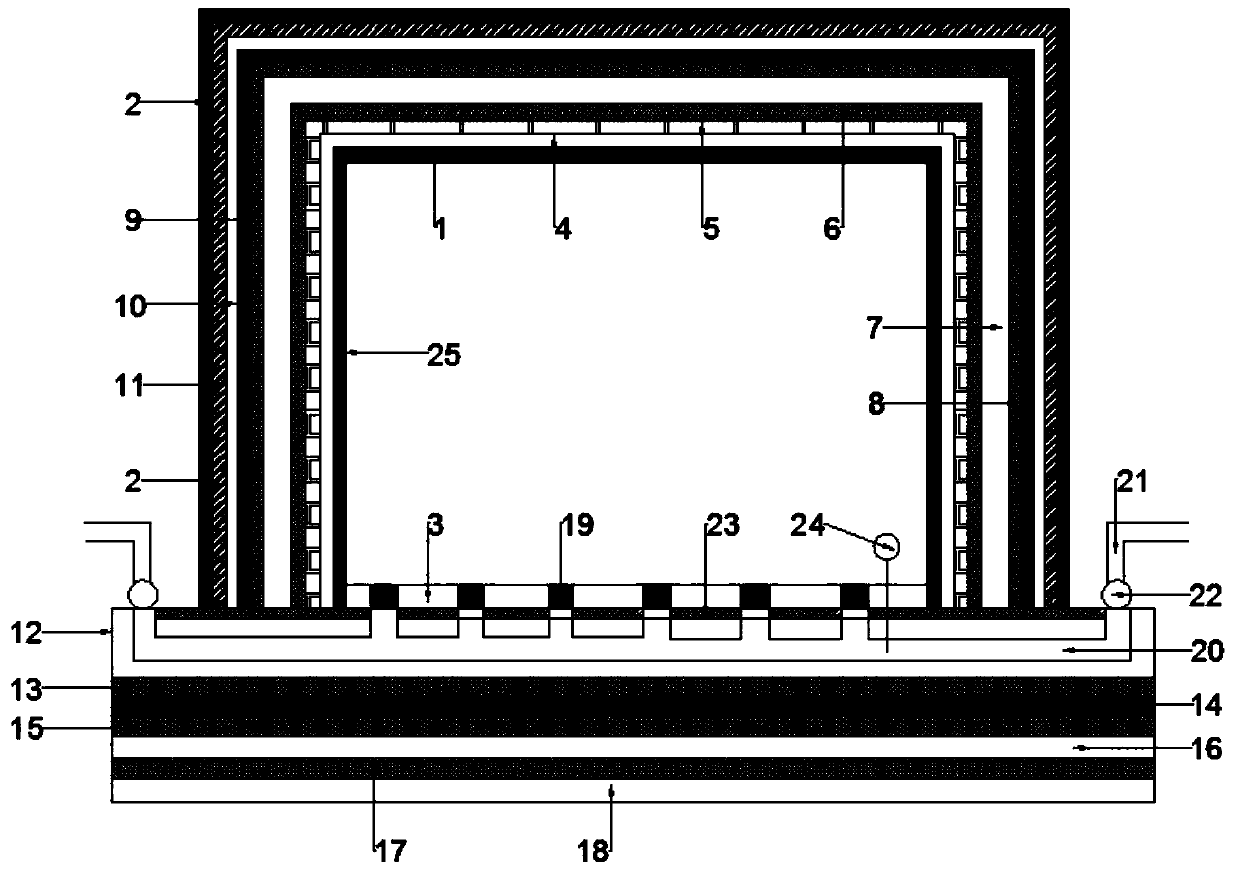

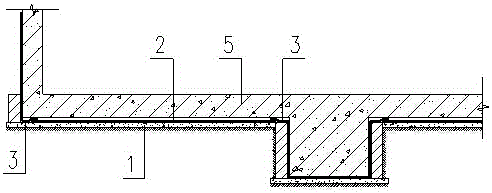

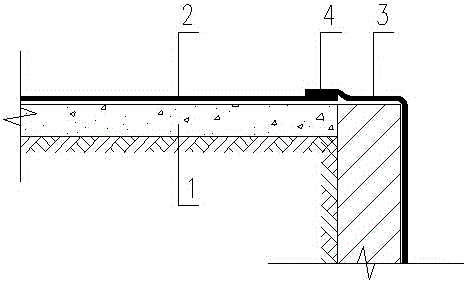

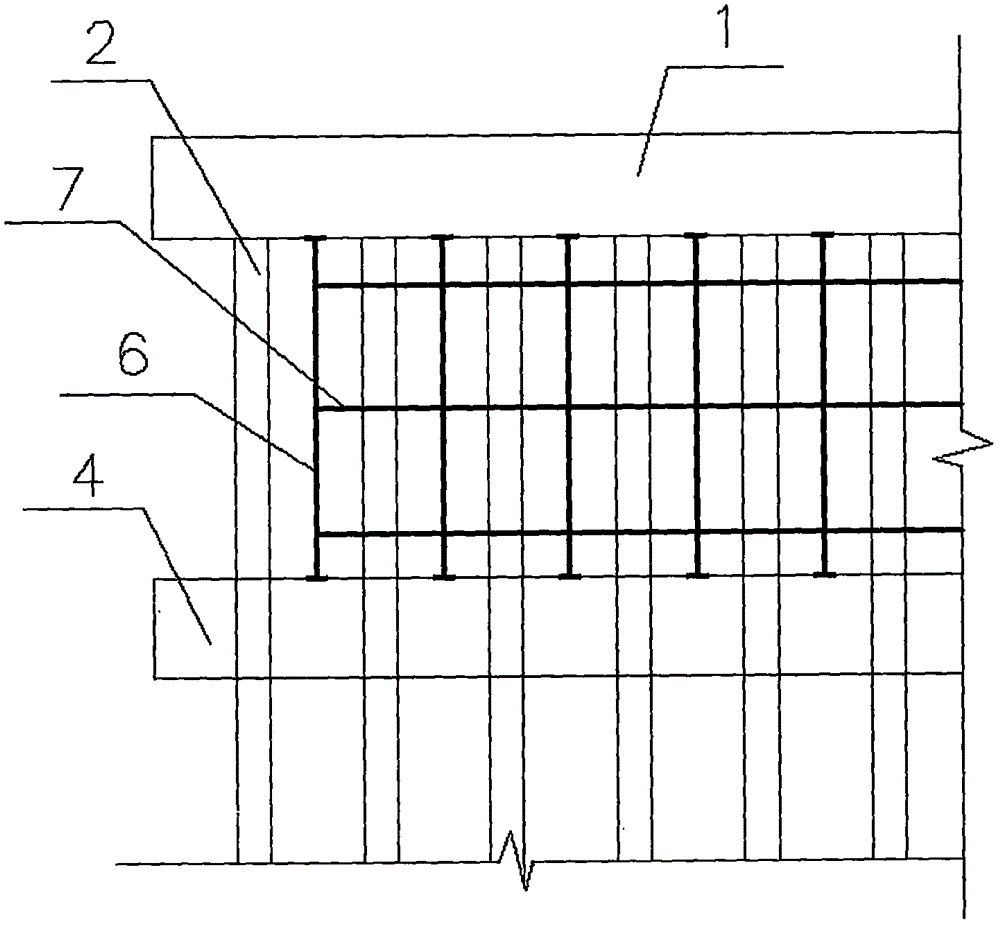

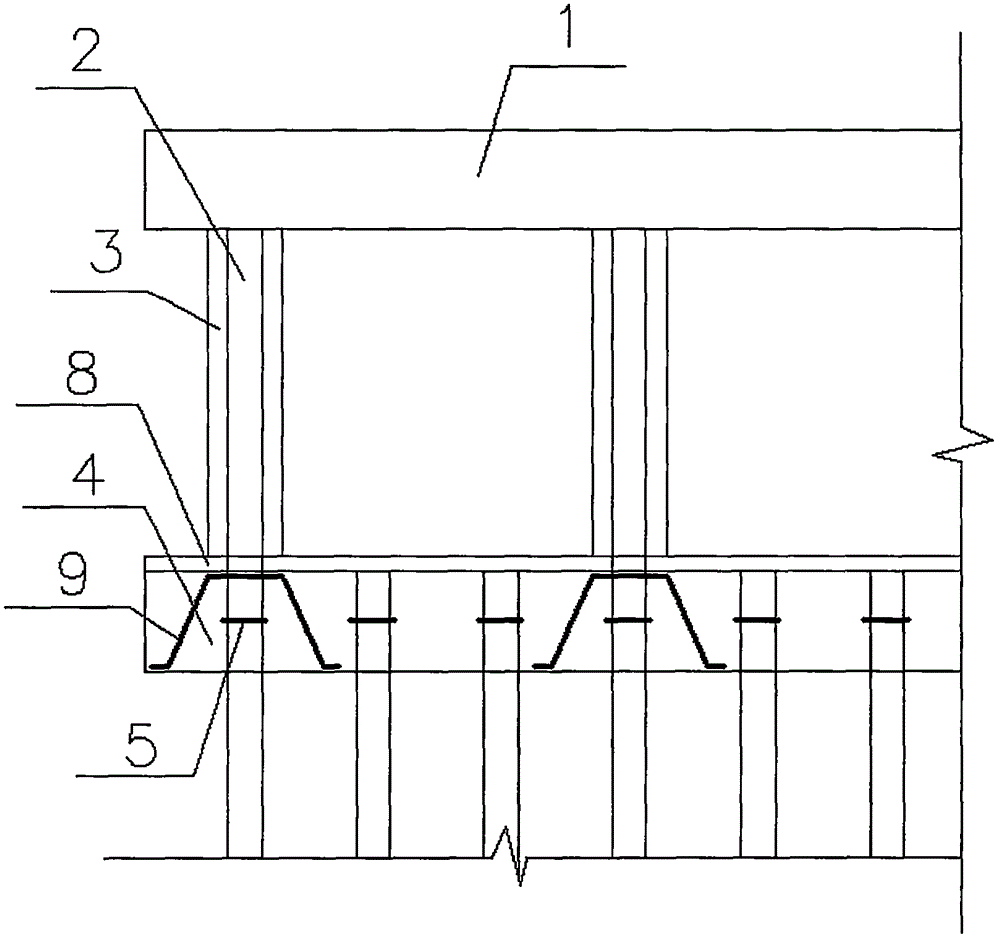

Construction method for basement floor post-cast strip waterproofing structure

ActiveCN104404985ASimple structureImprove the quality of operationArtificial islandsProtective foundationWater filterRebar

The invention discloses a construction method for a basement floor post-cast strip waterproofing structure and belongs to the technical field of waterproofing of buildings. The construction method comprises the following steps: laying a main drain pipe and a branch drain pipe in a water filtering tank to a floor sump, fully laying graded broken stone in the water filtering tank to form a broken stone water filtering layer, arranging mortar stop blocks on two sides at the lower part of a post-cast strip, and mounting floor reinforcing bars; mounting mortar stop blocks on two sides at the upper part of the post-cast strip after mounting a post-cast strip side form; and pouring post-cast strip concrete after pouring floor concrete on two sides of the post-cast strip, and curing concrete under a strip-film heat and moisture preservation condition for not less than 14 days. The construction method provided by the invention can reduce water pressure of a basement floor, realizes the waterproofing function of the basement floor post-cast strip and guarantees the pouring quality of concrete.

Owner:CHINA MCC17 GRP

Sump pump with emergency backup system

A flood control system for use in a structure having a basement floor below ground level is provided. The flood control system comprises a sump, a main pump positioned in the sump, and a secondary pump positioned in the sum. The secondary pump is raised relative to the main pump to a predetermined elevation. The main pump is energized when a height of water within the sump is at a first level. The secondary pump is energized when a height of water within the sump reaches a second, higher level and is de-energized when a height of water within the sump drops to a third level. A cover is releasably mounted to the sump. The cover includes a first section for covering the main pump and a separate second section for covering the secondary pump. At least one of the first and second sections is hingedly mounted to the sump. A controller is operatively connected to the main pump and the secondary pump. The controller is responsive to water level within the sump to selectively energize at least one of the main pump and the secondary pump.

Owner:EVERDRY MARKETING & MANAGEMENT

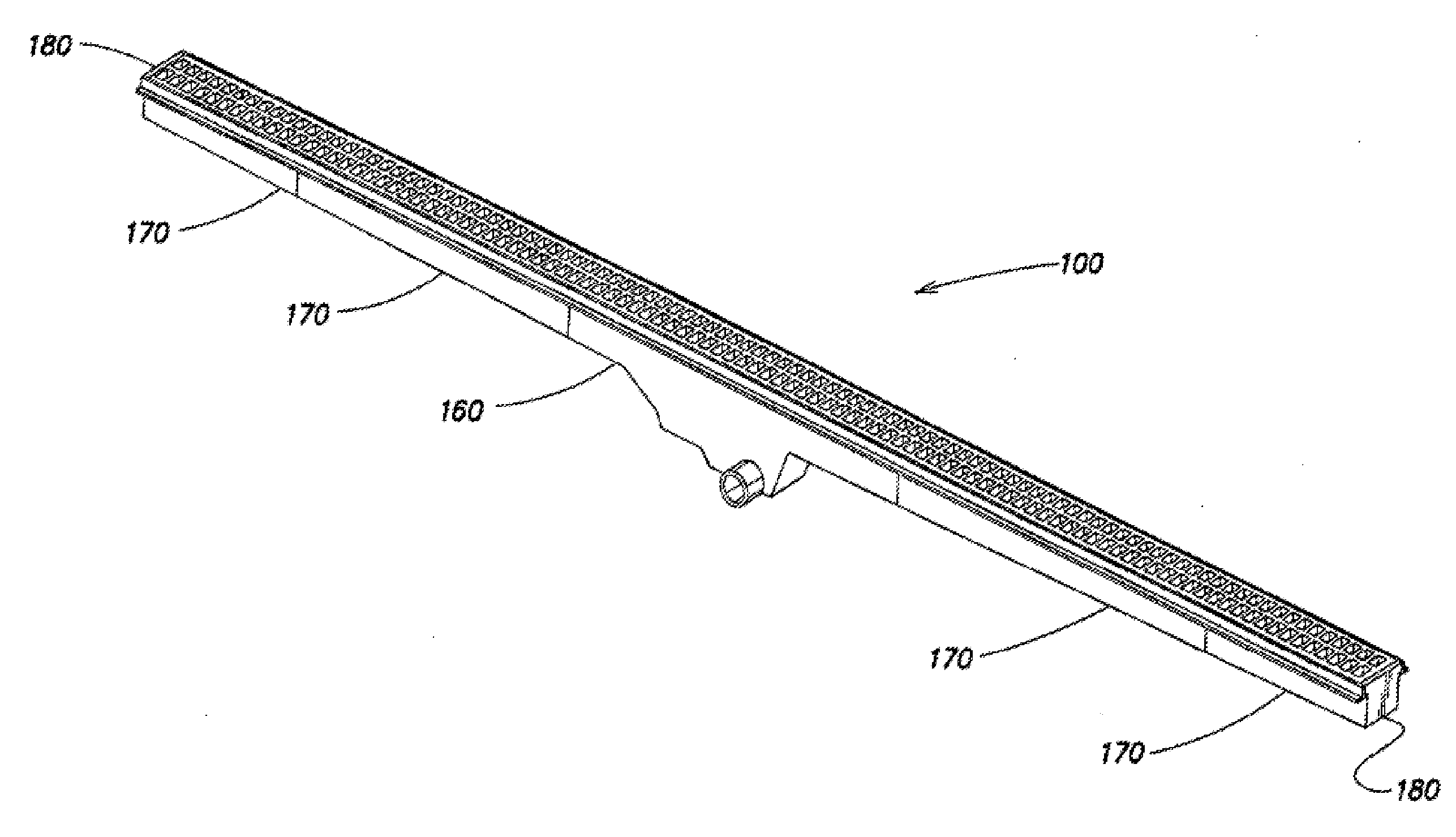

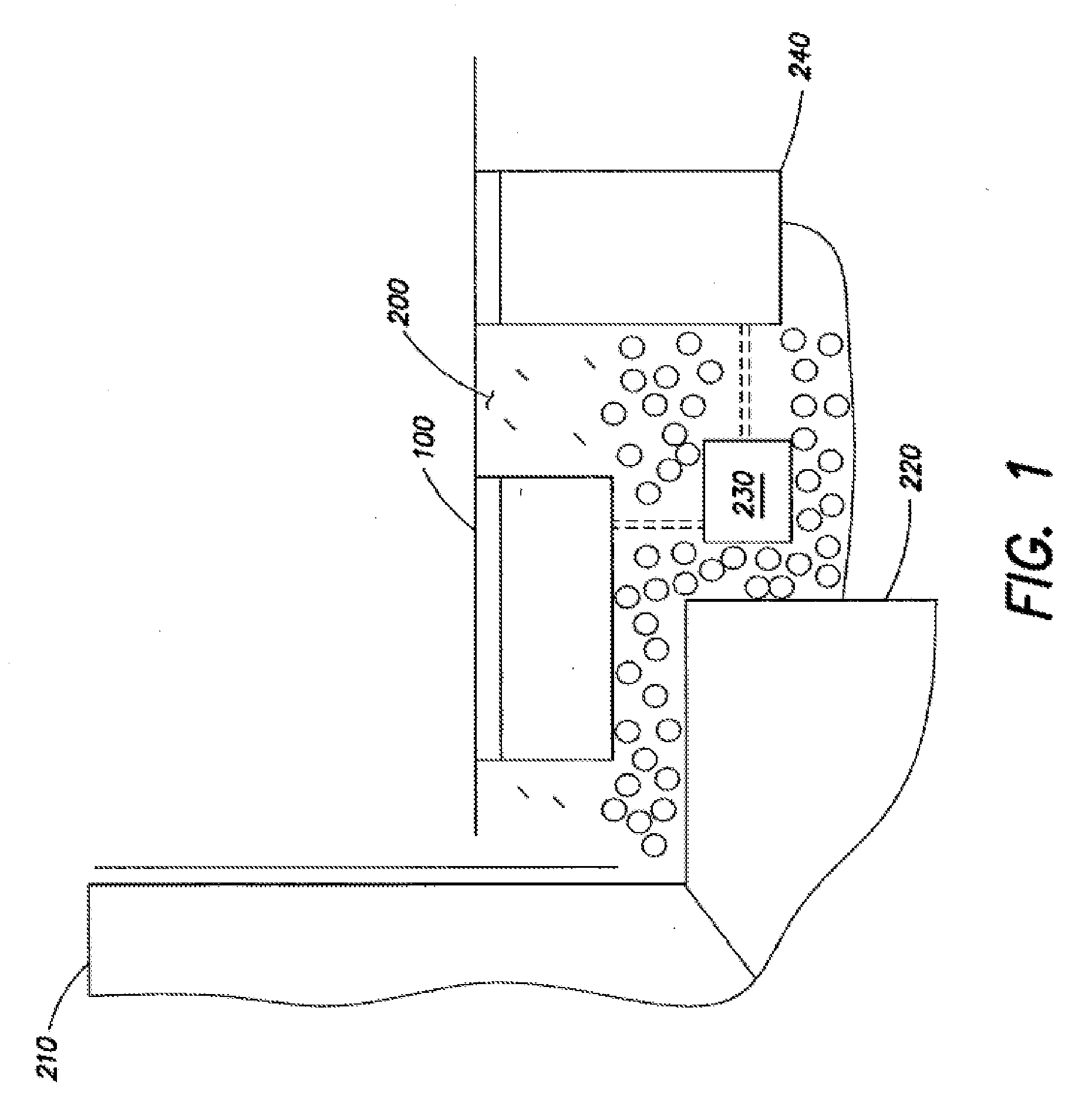

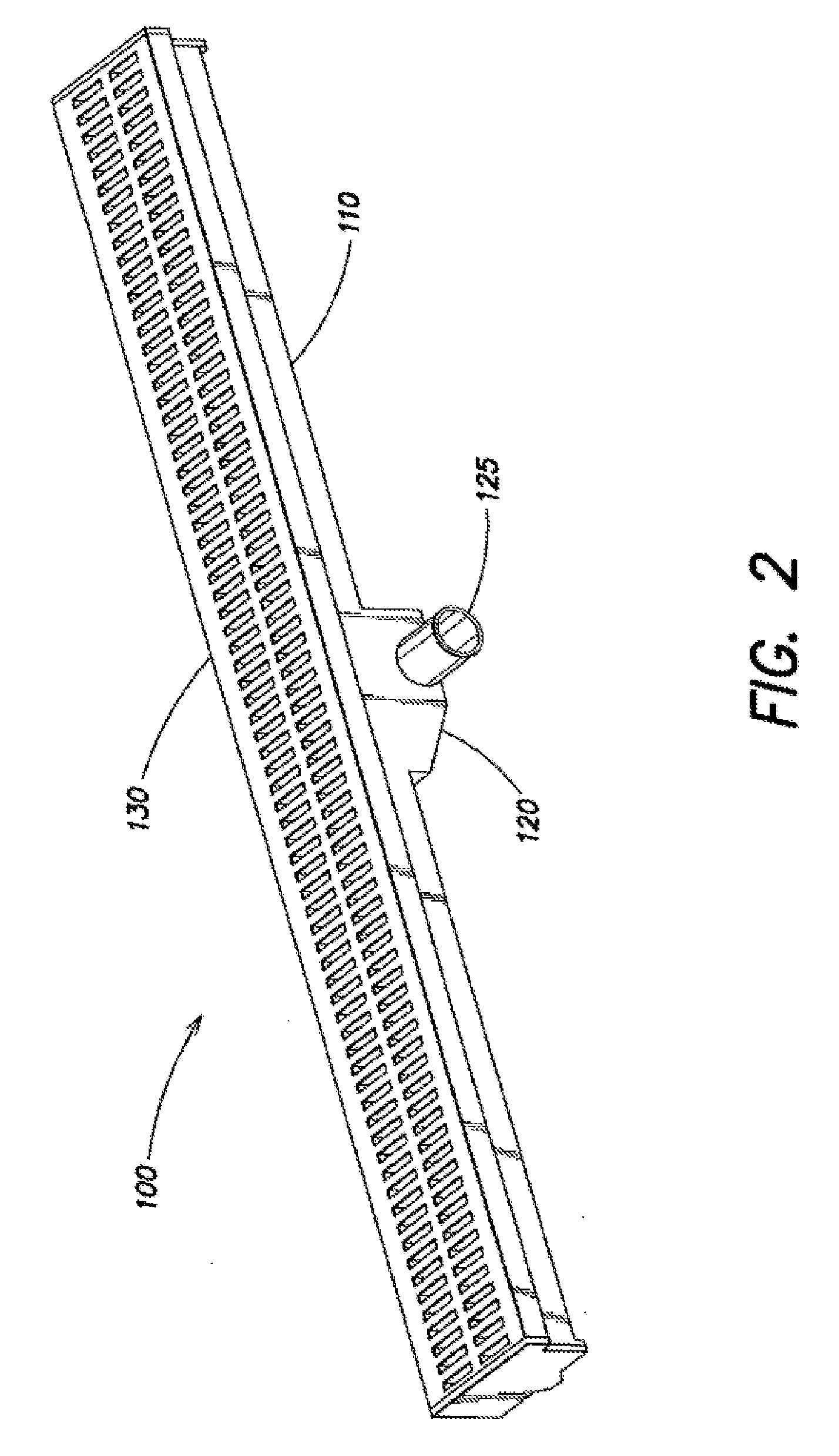

Front end loader bucket discharge funnel and distributor

A discharge funnel and distributor chute for sand and gravel or other disperse material which is removably attachable to the bucket of a front end loader. Funnel engaging hooks are attached along the front edges of the sides of the bucket and spaced upward from the bucket floor. The funnel has a floor and vertical sidewalls forming an open rear bucket receiving portion for receiving the front lower portion of the bucket. This portion has a floor and sides with a hook engaging bar extending between upper ends of the funnel sides forming a rear opening. Angled bucket guide bars are located along the inner sides of opposite walls. The funnel has a converging funnel portion connected to the engaging portion. The converging portion opens into a discharge chute. The chute allows the discharge of disperse material to a specific location such as a basement floor under construction.

Owner:RALEY THOMAS A

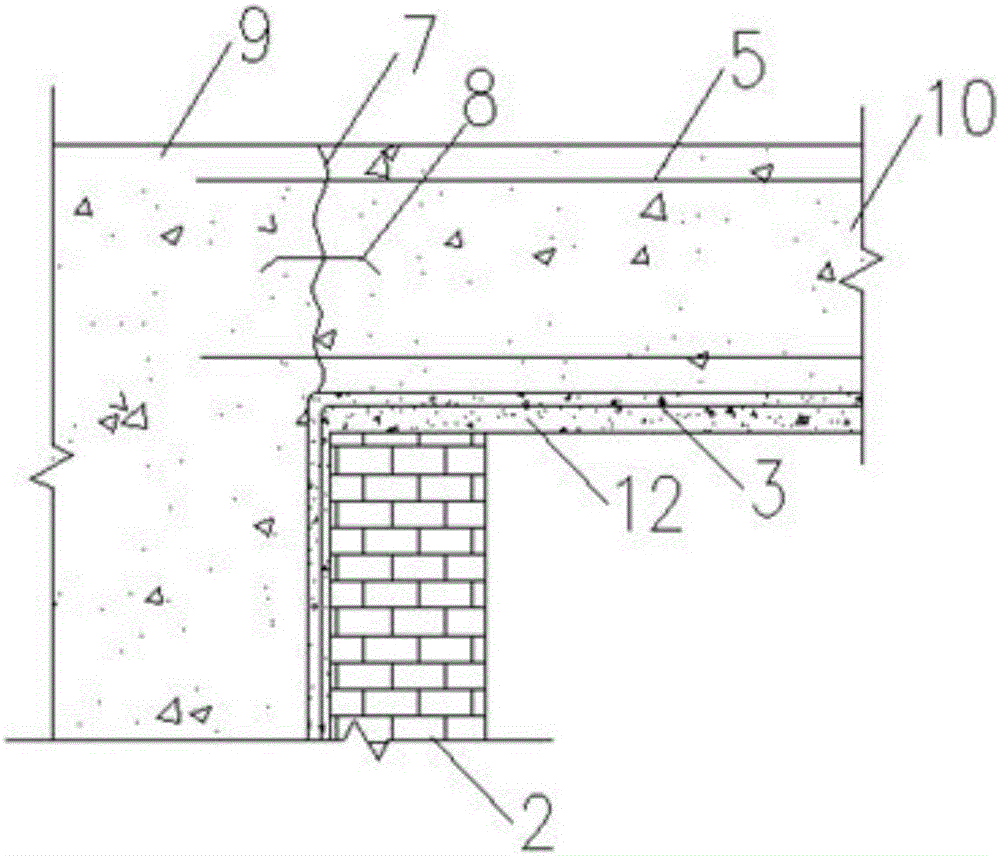

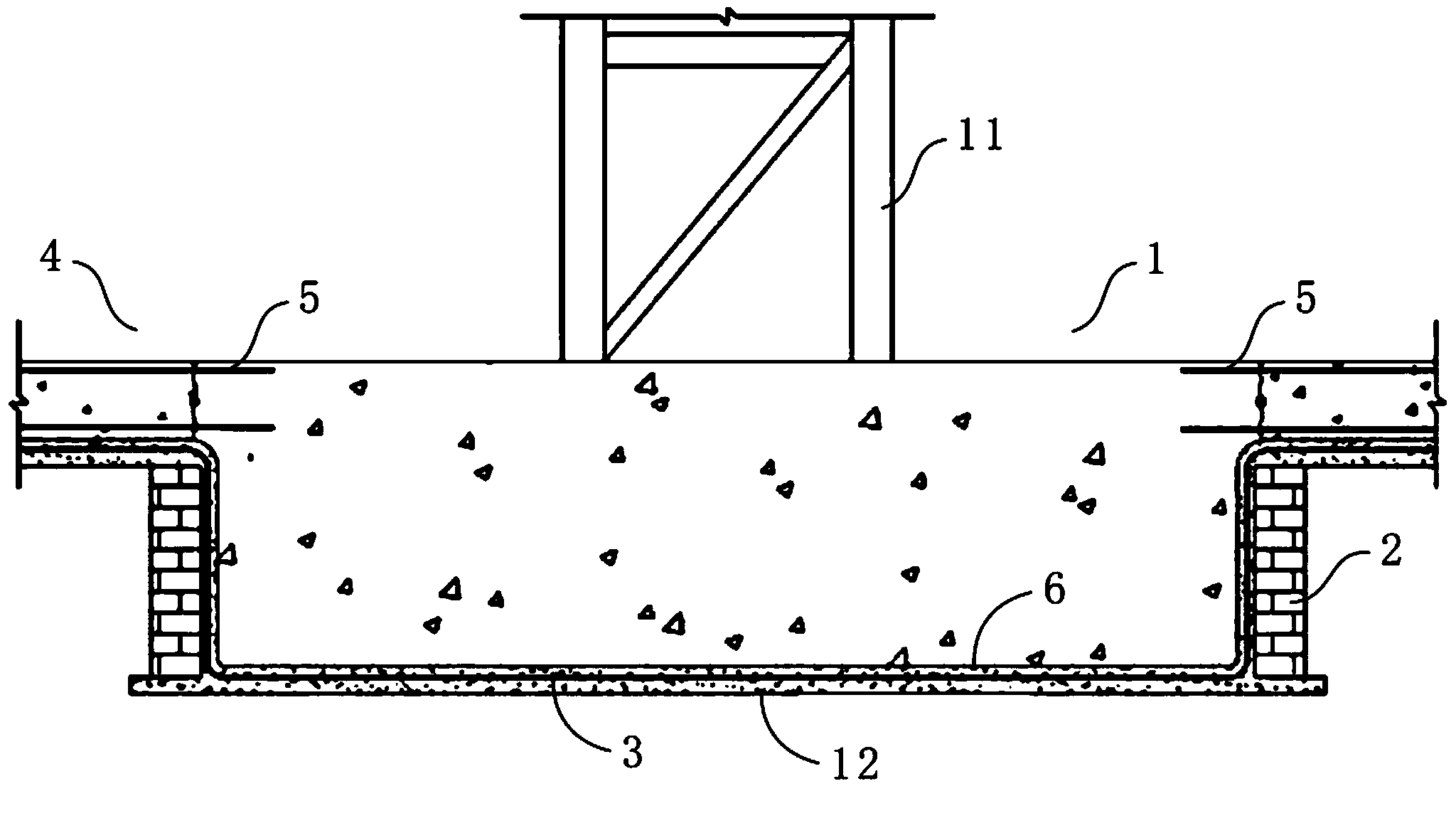

Leakage-proof construction method combining tower crane foundation and basement floor

InactiveCN106120872AEliminate potential safety hazards such as rustAvoid prolonged water accumulationProtective foundationProof constructionBrick

The invention discloses a leakage-proof construction method combining a tower crane foundation and a basement floor. The method comprises the following steps: excavating an earthwork groove and building a brick membrane along an inner wall of the earthwork groove, laying a waterproof material, distributing a foundation reinforcement cage, mounting supporting feet of a tower crane, mounting a grounding device, pouring concrete, mounting standard sections of the tower crane and the like. The leakage-proof construction method has the advantages that problems in a utilization process of the tower crane that the standard sections of a tower body are immersed in water for a long period to cause potential safety hazards including rusting and the like and the water is deposited in an installation position of the tower crane for a long period are effectively avoided, a dismounting procedure of the tower crane is simplified and the stability of connection between the earthwork groove and the basement floor is increased after the concrete is poured into the earthwork groove; and the leakage-proof construction method has very good leakage-proof effect and is suitable for being applied to a tower crane construction process of various types of mid-rise buildings and high-rise buildings.

Owner:TIANJIN 20 CONSTR

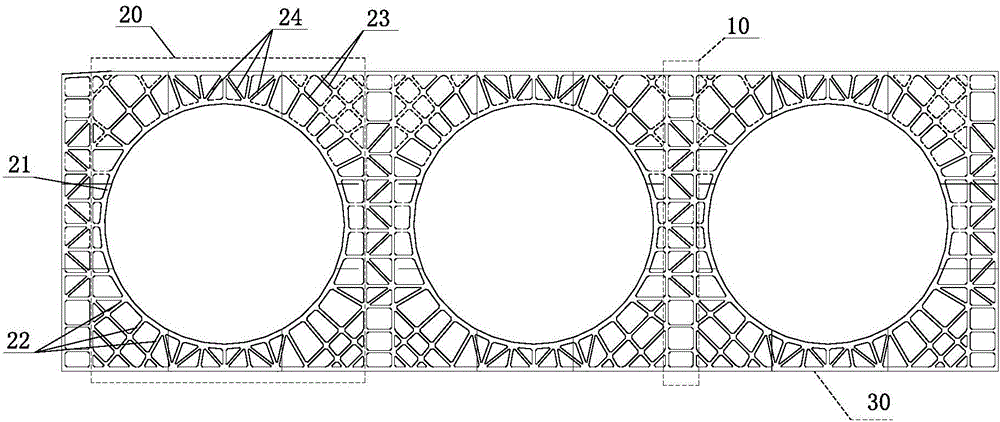

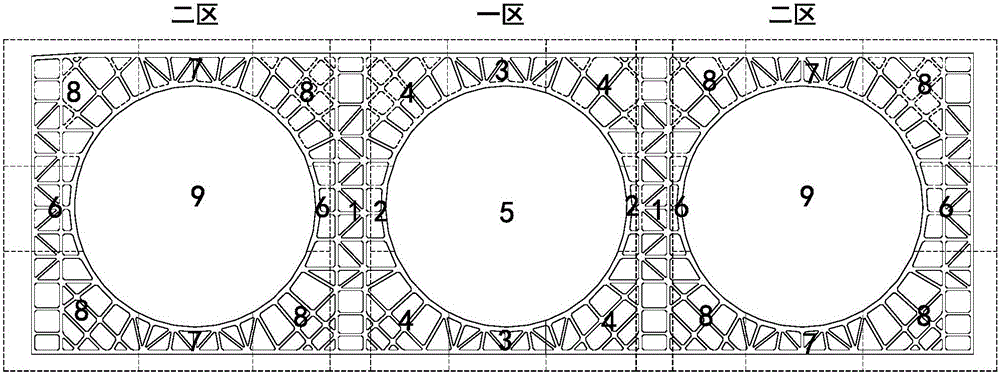

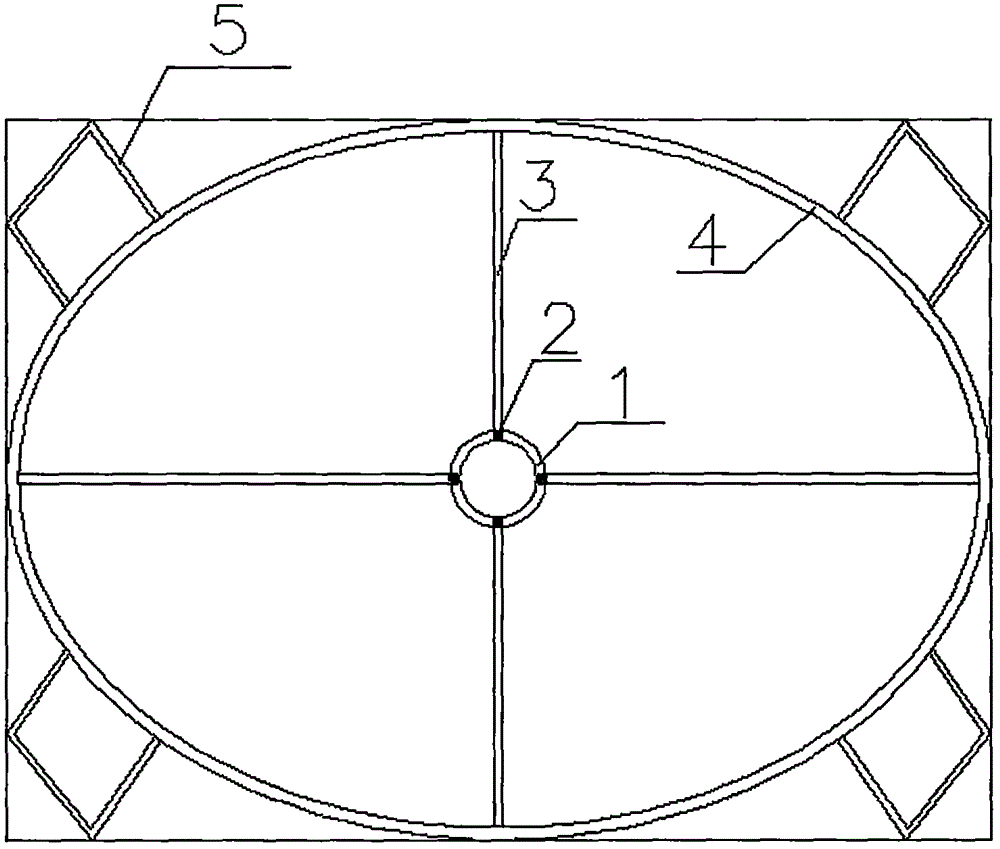

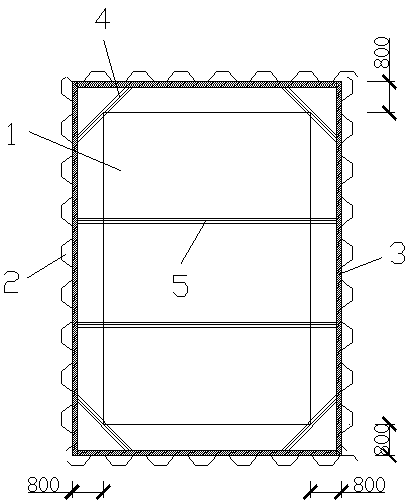

Partitioning supporting structure and method for large, long and deep foundation pit

InactiveCN106013167AImprove construction progressAvoid Staging Wall DemolitionExcavationsTowerBasement floor

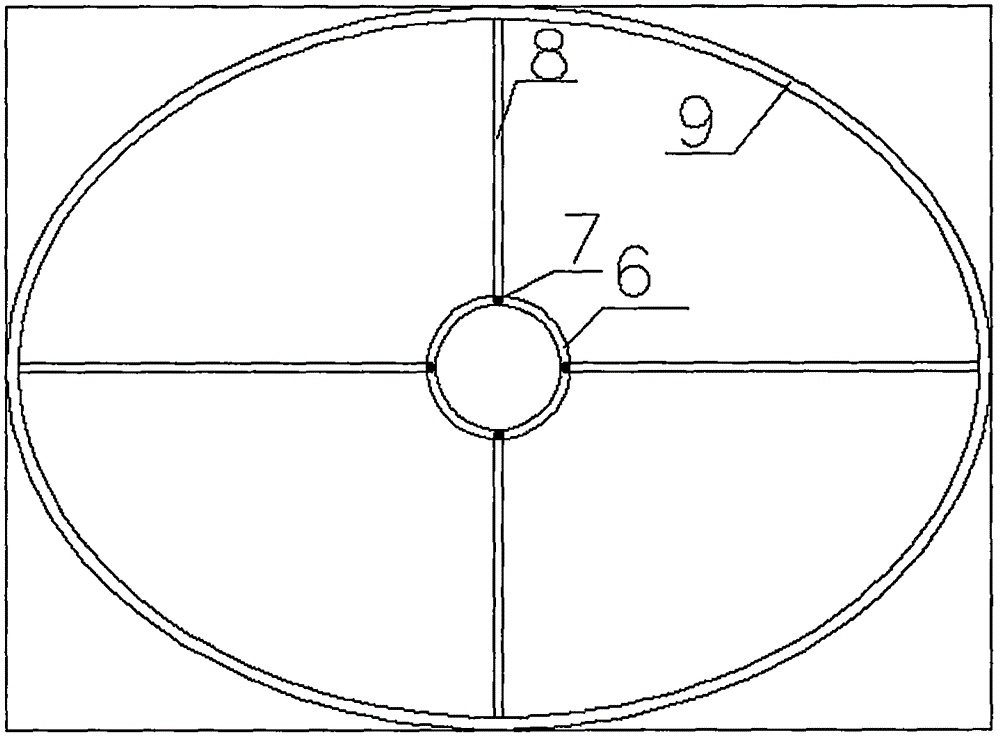

The invention discloses a segmented support structure and a support method for long and deep foundation pits. The structure includes a plurality of partition supports that divide the foundation pit into several partitions, and a ring brace is fixed in each partition, and the ring The inner edge of the brace is rounded, and the outer edge of the ring brace matches the edge of the partition in which it is placed. It can realize the one-time excavation of super long and super large foundation pits, which greatly speeds up the construction speed, reduces the waste of labor, materials and time, and meets the development requirements of green construction. And it can effectively reduce the number of internal supports, so that the tower can avoid the construction of the supporting structure. When the basement floor is completed, the tower can be constructed, which speeds up the overall construction progress. Different construction sequences will have an important impact on the deformation of the ring brace and the distribution of internal forces, and the poor control of the roundness of the ring brace will affect the safety of the foundation pit project. , effectively controlling the roundness of the ring brace, thereby improving the safety of the foundation pit project.

Owner:SHANGHAI CONSTR NO 1 GRP

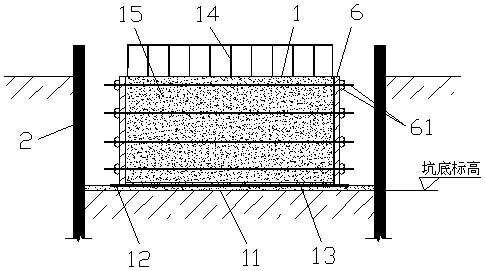

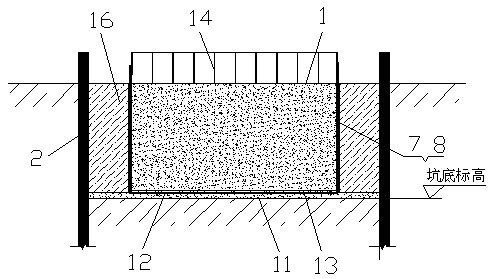

Deep basement supporting construction method

InactiveCN105887891AMeet the requirements of construction safety and stabilityControl Horizontal ShiftArtificial islandsExcavationsSteel columnsBasement floor

The invention discloses a deep basement supporting construction method. The deep basement supporting construction method is characterized by comprising the following construction steps of: (1) constructing a layer of steel column foundation piles, two layers of steel column foundation piles, a layer of steel columns and two layers of steel columns; (2) constructing basement supporting row piles; (3) constructing basement waterproof curtains, and using cement mixing piles as the basement waterproof curtains; (4) constructing a layer of basement inner ring ring-beams and a layer of basement outer ring ring-beams; (5) constructing a layer of diagonal braces and angle braces; (6) carrying out pit earth excavation till reaching the construction elevation of the bottoms of two layers of basement inner ring ring-beams; (7) constructing two layers of basement inner ring ring-beams and two layers of basement outer ring ring-beams; (8) constructing two layers of diagonal braces; (9) carrying out pit earth excavation till reaching the construction elevation of the bottoms of three layers of basement bottom plates; (10) constructing the basement bottom plates; (11) constructing the outer concrete wall of the basement; (12) dismantling the two layers of basement inner ring ring-beams, the two layers of basement outer ring ring-beams and two layers of diagonal braces; (13) constructing two layers of basement floors; (14) dismantling a layer of basement inner ring ring-beams and a layer of basement outer ring ring-beams; and (15) constructing a layer of basement floors.

Owner:朱奎

Basement floor drain and method

Owner:ANDRAS STEPHEN +1

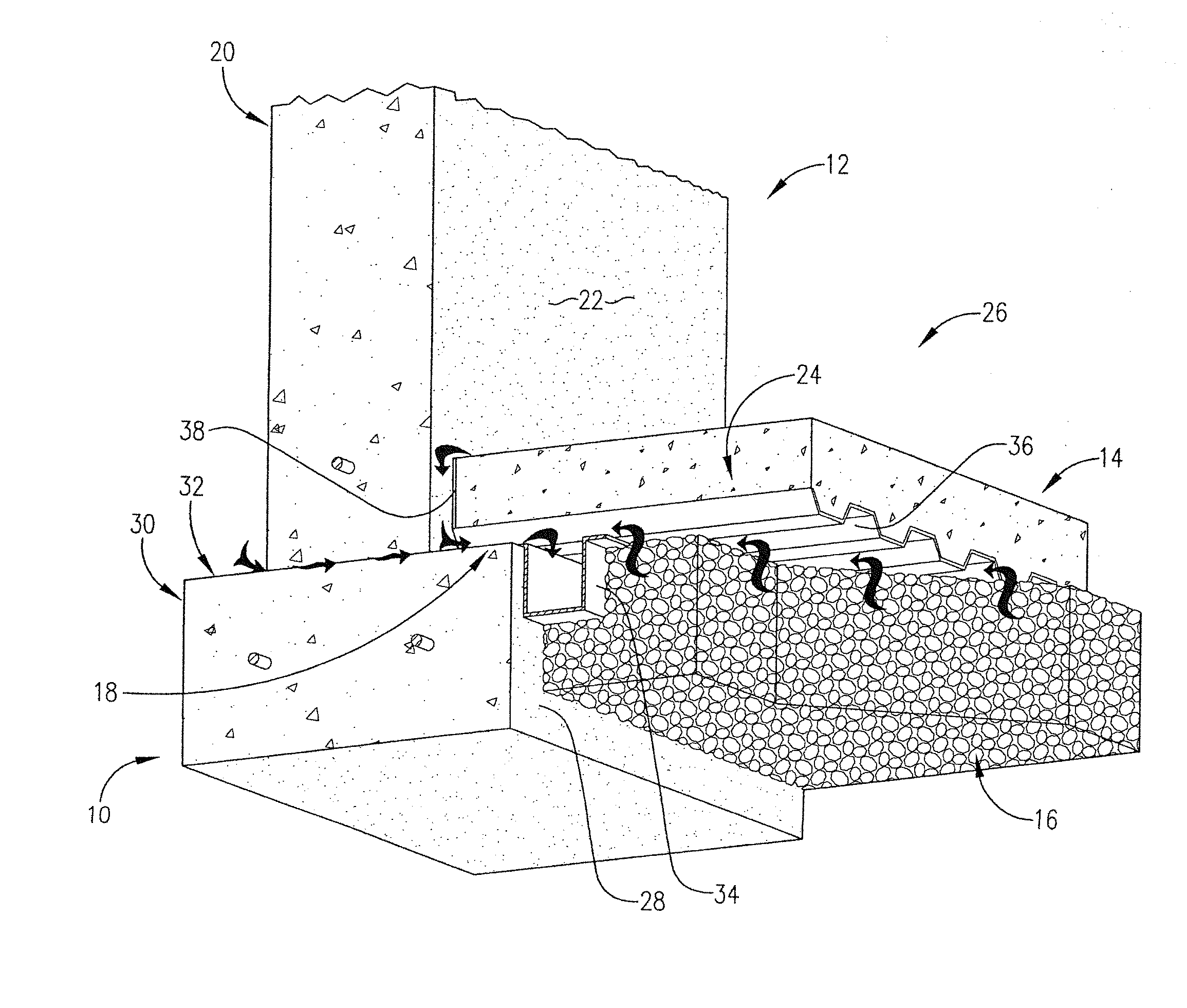

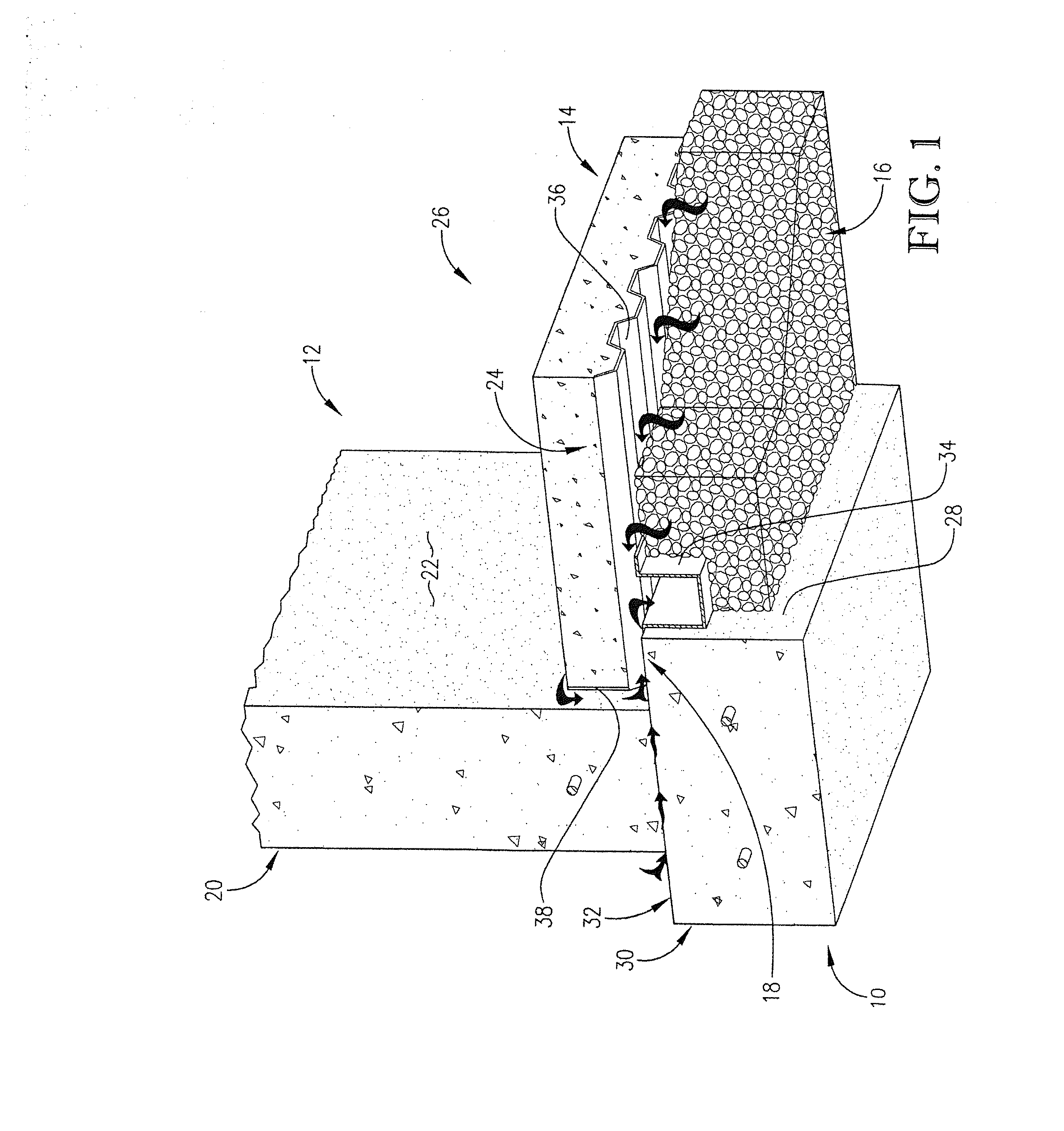

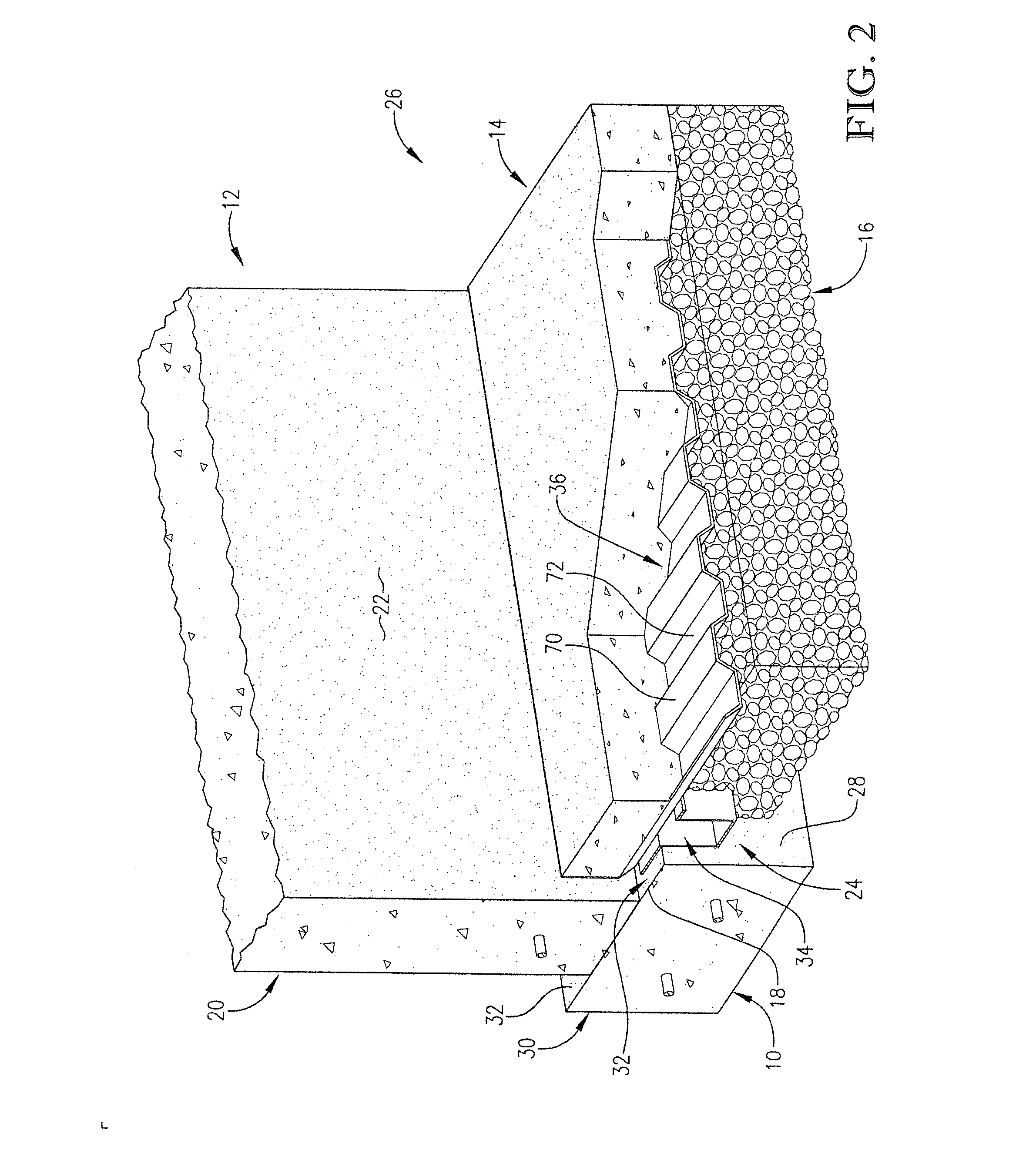

Apparatus and method for diverting water at basement joints

A water diverting system for diverting water from a building's foundation, where the foundation has a basement footing having an interior face oriented towards an interior of the foundation, a basement wall having an interior face oriented towards the interior of the foundation, and a basement floor slab. The system includes a channel for collecting water and configured to be installed adjacent the basement footing. The channel is overlaid with a corrugated track for directing water to the channel. A vertical water guide extends perpendicularly from the track and is positioned adjacent the interior face of the basement wall. The guide includes a plurality of spaced projections for directing water trickling down along the wall to the channel.

Owner:DRY BASEMENT

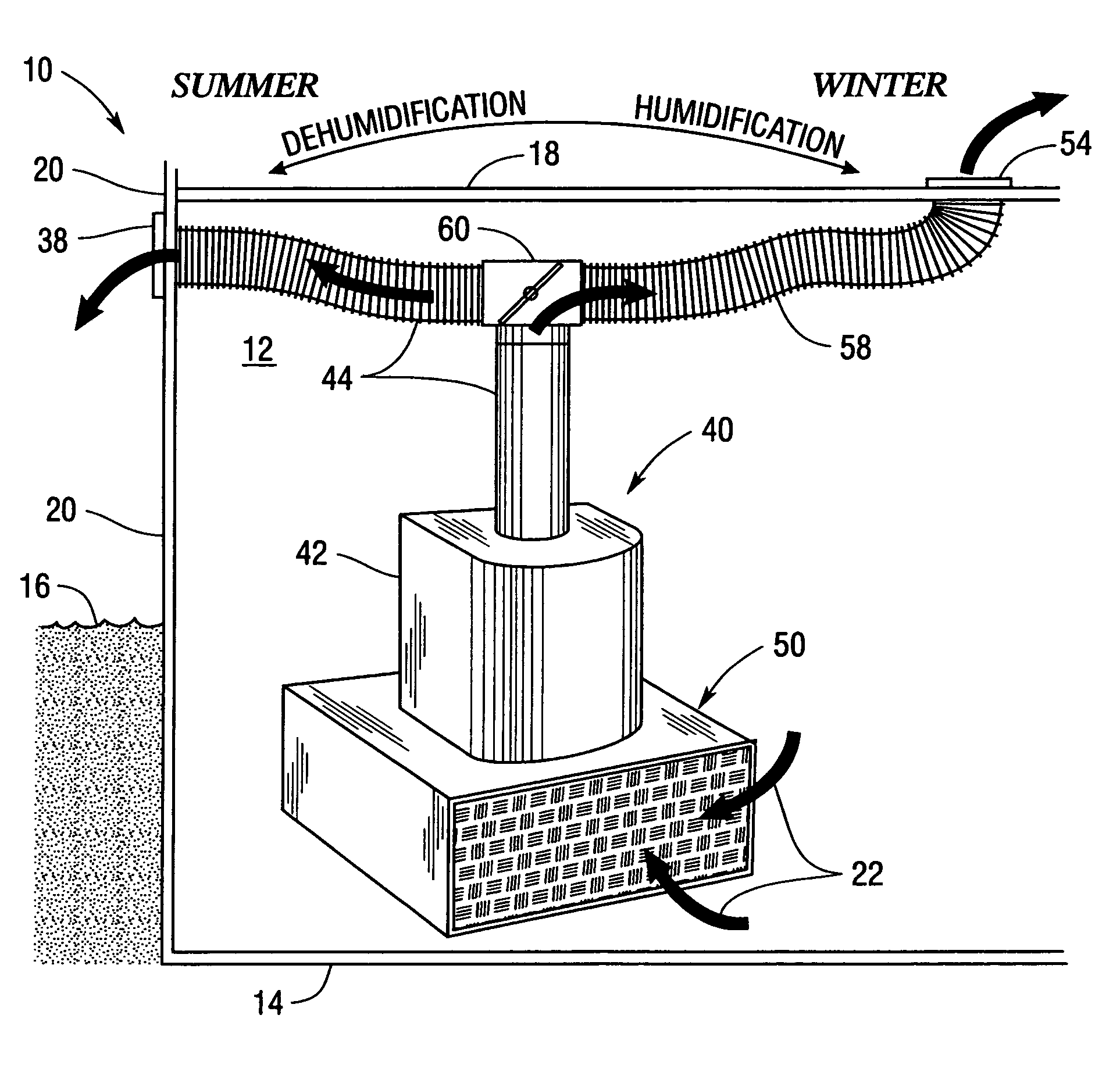

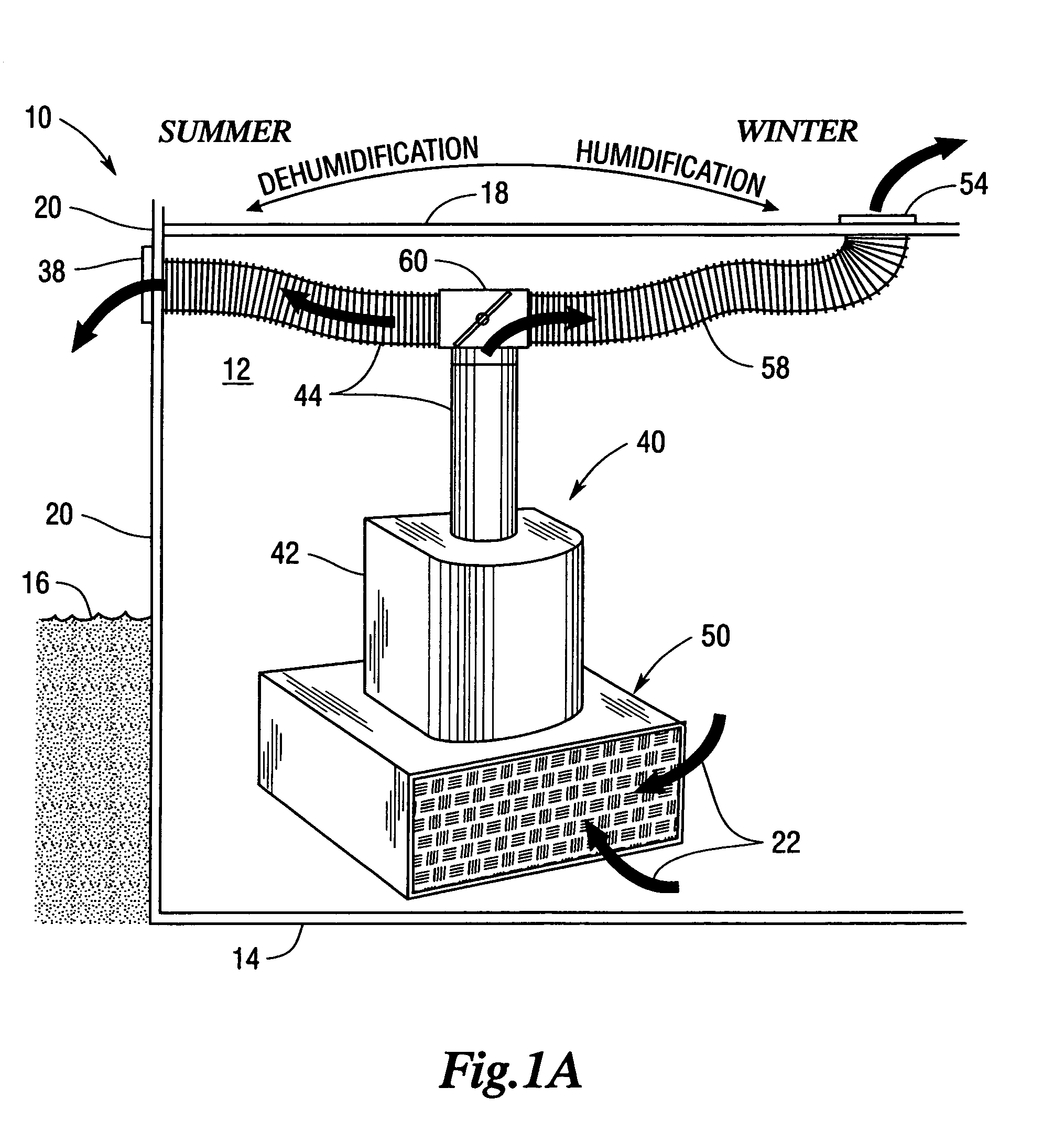

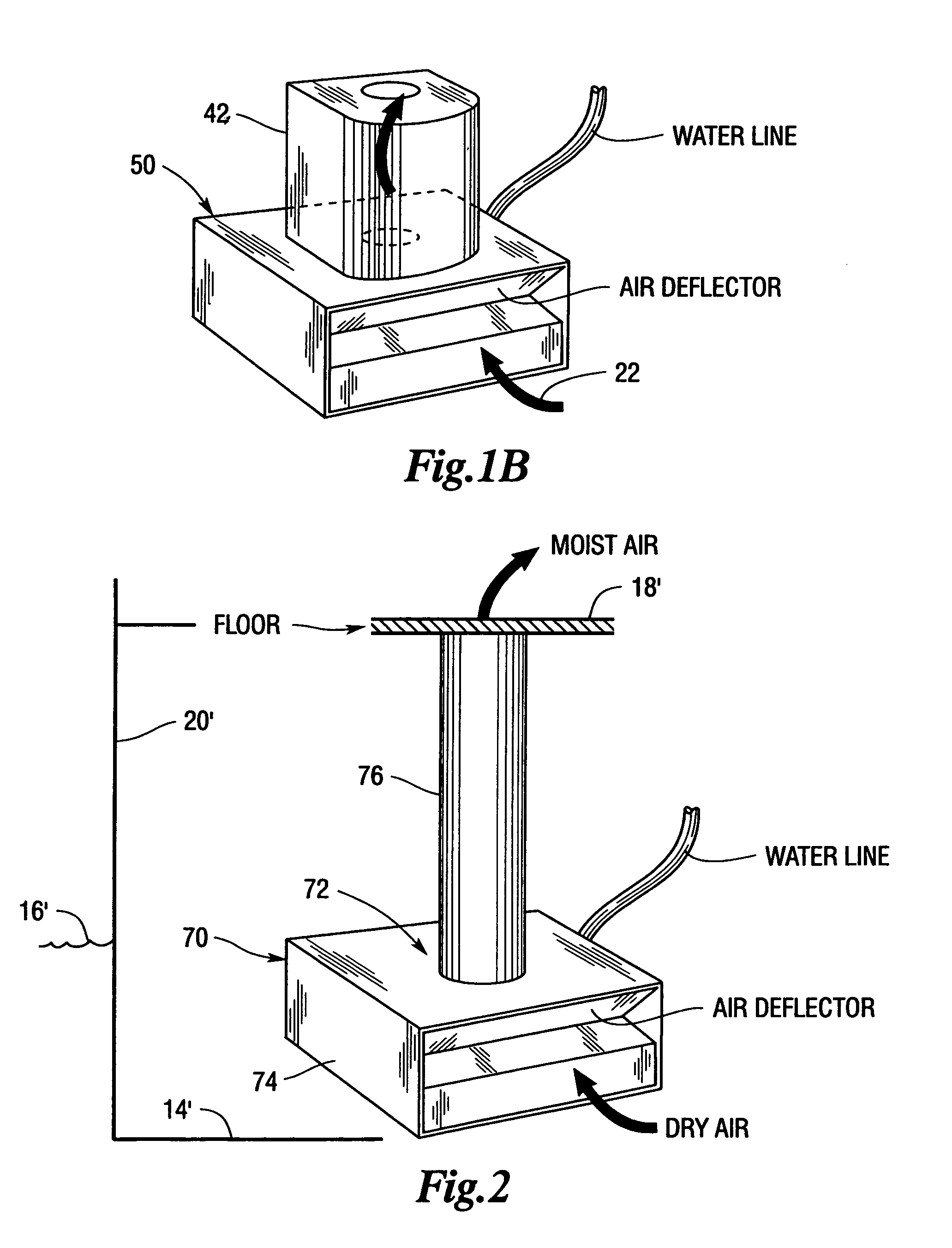

Year round selective dehumidifying and humidifying apparatus and method

InactiveUS6974382B1Space heating and ventilation safety systemsLighting and heating apparatusFresh airBasement floor

Apparatus which may be used year-round for dehumidifying air in the enclosed space of a building to comfortably allow a higher temperature during summer conditions, for exchanging air in the enclosed space year-round with fresh air to provide a more healthful environment within the building and for selectively humidifying the air when desired at certain times of the year. The apparatus includes a fan mounted on or otherwise adjacent the basement floor or other bottom floor and a conduit connecting the fan outlet to an opening in an outside wall for removing stale relatively damp air from the bottom floor level and discharging it out of the building. A humidifier is provided in flow communication with the fan and connected through another conduit to the enclosed space. A valve connected to both conduits provides selective humidifying of the air in the enclosed space.

Owner:SWAN ROSS M

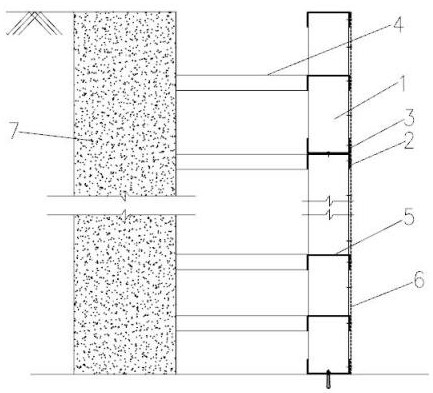

Operation frame body capable of canceling backfilling of basement outer wall and construction method

PendingCN107119695AWater resistance is not affectedDoes not affect other projectsProtective foundationCellarsInsulation layerBrick

The invention relates to an operation frame body capable of cancelling backfilling of a basement outer wall and a construction method. The construction method includes the steps that the operation frame body capable of cancelling backfilling of the basement outer wall is constructed firstly, then a series of construction of a basement bottom plate are conducted, and finally a thermal insulation layer and a waterproofing layer on the outer facade of a basement wall body are constructed and concrete of the outer facade of a basement and a basement floor face are poured at the inner side of the operation frame body. By adoption of the operation frame boy capable of cancelling backfilling of the basement outer wall and the construction method, the procedure of concrete backfilling in a traditional basement construction method can be canceled, meanwhile, no influence on construction of waterproof of the outer facade of the basement and other engineering can be guaranteed. By adoption of the construction method, land utilization of at least 0.3-1.2m basement perimeter can be enlarged, or earth-rock of 0.3-1.2m basement perimeter can be less excavated, so that unnecessary costs on a leveling layer, a waterproof protection layer, a brick protection wall, an external formwork, an external frame pipe, backfilling earth and the like of outdoor facades can be saved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Construction method of bearing platform and basement floor in deep soft soil area

InactiveCN109322320AEasy to recycleOvercome construction flawsArtificial islandsProtective foundationEngineeringRebar

The invention discloses a construction method of a bearing platform and a basement floor in a deep soft soil area. The method comprises the steps: excavating the bearing platform by a steel sheet pilesupporting mode; according to the depth of the bearing platform, setting waist beams, angle braces and opposite braces on steel sheet piles through calculation; after excavation is completed, pouringa cushion layer, constructing waterproofing and a waterproofing protection layer, binding a bearing platform reinforcement, and then erecting templates around the bearing platform reinforcement; pouring bearing platform concrete to the bottom level of the basement floor, and constructing waterproofing and a waterproofing protection layer for the side face of the bearing platform; after earth is backfilled and compacted, pulling out the steel sheet piles; and after the bearing platform construction of the designated construction section is completed, pouring a cushion layer for the basement floor, constructing waterproofing and a waterproofing protection layer for the floor, binding a floor reinforcement, pouring floor concrete, and thus completing basement floor construction. The method can be simple, efficient and safe to complete the excavation and support of the bearing platform and the construction of the basement floor in the soft soil area, ensures the safety of construction operation, facilitates the recovery and utilization of the steel sheet piles after being pulled out, and saves cost.

Owner:CHINA MCC20 GRP CORP

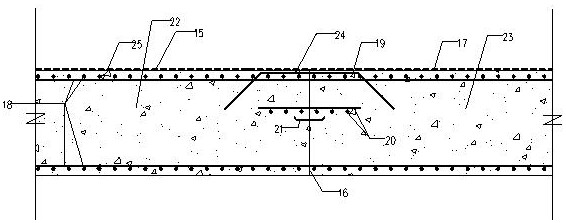

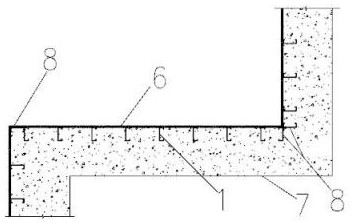

Construction joint waterproof construction method for combined design of water stop steel plate and anti-crack steel bars

InactiveCN111749279AWaterproofNo waterproof effectArtificial islandsUnderwater structuresWater stopArchitectural engineering

The invention relates to a construction joint waterproof construction method for combined design of a water stop steel plate and anti-crack steel bars of basement floors. The construction joint waterproof construction method is characterized by comprising the following steps of a, digging a foundation bottom plate pit to the designed elevation; b, pouring a concrete cushion layer at the bottom ofthe pit; c, laying a pre-laid anti-sticking waterproof coiled material; d, binding an anti-crack steel bar net; e, pouring waterproof concrete in an inclined pit; f, binding the reinforcing steel barson the left side of a construction joint; g, mounting a steel plate waterstop at the position of a concrete bottom plate; h, mounting a formwork at the construction joint; i, pouring waterproof concrete on the left side of the construction joint; j, pouring a concrete cushion layer of the bottom plate on the right side of the construction joint; and k, pouring waterproof concrete on the bottom plate of the right side of the construction part. The construction joint waterproof construction method for combined design of the water stop steel plate and the anti-crack steel bars has the advantagesthat the water stop steel plate and the anti-crack steel bars are combined to form a water stop area, so that the concrete has the anti-crack water stop function, the waterproof effect is good, an additional external anti-crack waterproof layer is arranged at the construction joint of the bottom plate, and the flow path of water is increased.

Owner:CHINA MCC5 GROUP CORP

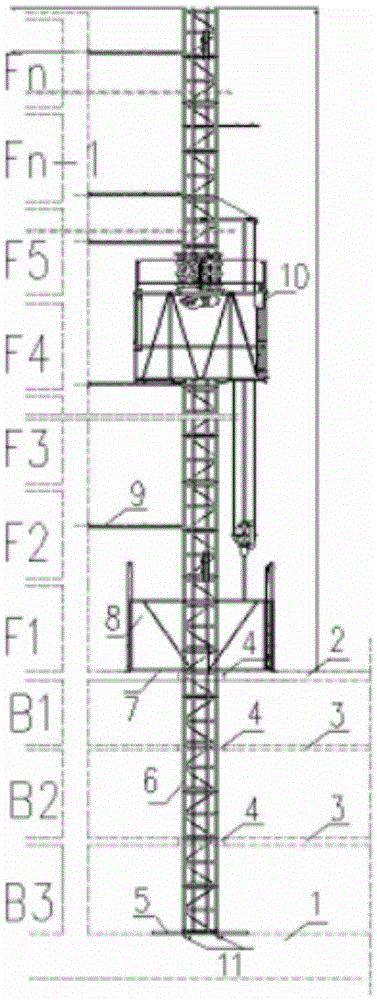

Plate penetrating installing method for installing construction lifting machine on basement top plate

ActiveCN105347142AClear forceEasy constructionElevatorsBuilding liftsArchitectural engineeringUltimate tensile strength

The invention relates to a plate penetrating installing method for installing a construction lifting machine on a basement top plate. The method comprises the following steps that during basement construction, bottom frame foundation bolts of the construction lifting machine are embedded in a bottom plate, and during basement floor plate and top plate construction, holes are reserved in guide frames; a basement bottom plate is utilized in a foundation of the construction lifting machine, a bottom frame is fixed to the foundation bolts, guide frames are directly installed on the bottom frame, every two layers of the guide frames are fixed with structural attached wall frames, and stability and strength of the guide frames are enhanced; a fence bottom frame is installed on the basement top plate, and a fence is installed on the fence bottom frame; the guide frames are provided with a construction lifting machine cage and other devices, the connecting strength among connecting pieces is checked, and it is ensured that construction is carried out after the requirement is met; and after construction is finished, the construction lifting machine cage and other auxiliary devices are dismounted, and the reserved holes in basement floor plates and the basement top plate are blocked through micro-expansion concrete. The holes are only reserved in the floor plates, stress is definite, construction is easy, and cost is reduced.

Owner:SHANGHAI ZHONGJIN CONSTR GRP

Construction method for narrow outer enclosure space of deep foundation

ActiveCN112962663AAvoid backfillReduce excavation and transportationArtificial islandsExcavationsSoil nailingKeel

The invention discloses a construction method for a narrow outer enclosure space of a deep foundation. The construction method comprises the steps that slope protection piles are driven in, a foundation pit is excavated, slope protection treatment is conducted through a soil nailing wall technology, a concrete foundation cushion layer is poured, and cushion layer waterproof treatment is conducted; a keel frame is arranged, an outer wall outer side structure formwork is prefabricated, the outer wall outer side structure formwork is arranged on the outer side of the keel frame, and then lightweight aggregate concrete is poured between the protection slope and the outer wall formwork; along with basement floor construction, the keel frame is heightened layer by layer by riveting ceiling keels of the keel frame and ground keels of the keel frame on the upper layer, the lightweight aggregate concrete is poured, and then waterproofing is conducted till the basement height requirement is met; and steel bars are bound along the side face of the waterproof deep foundation, concrete is poured on an inner side formwork, then the inner side formwork is detached, and the basement outer wall waterproof function is achieved. The construction defects that the reserved space between the deep foundation pit slope and a basement wall body is too narrow, the construction space is not enough, and the reserved space occupies the basement area can be effectively overcome.

Owner:司顺生

Construction method combining tower crane foundation and building basement floor

ActiveCN103510537AAvoid safety hazardsAvoid prolonged water accumulationArtificial islandsUnderwater structuresPondingBrick

The invention discloses a construction method combining a tower crane foundation and a building basement floor, and belongs to a building construction method. The method comprises the steps that an earthwork slot of a tower crane is excavated downwards in the building basement floor, and brick forming dies are built in the earthwork slot along the inner walls of the earthwork slot; waterproof materials are laid in the earthwork slot along the brick forming dies, and the waterproof materials are extended from the earthwork slot onto an adjacent building basement floor. Due to the fact that the construction technique combining the tower crane foundation and the building basement floor is adopted, potential safety hazards left in the detaching process of the tower crane are effectively eliminated; because the tower crane foundation is flush with the basement floor, the problem of long-term ponding of the installing position of the tower crane is avoided, and the working procedures of demounting and mounting the tower crane are simplified. Meanwhile, the construction method combining the tower crane foundation and the building basement floor has the advantages that construction procedures are simple, suitable for being applied to the construction process of the tower crane of various mid-rise buildings and high-rise buildings and easy to popularize.

Owner:成都建工雅安建设有限责任公司

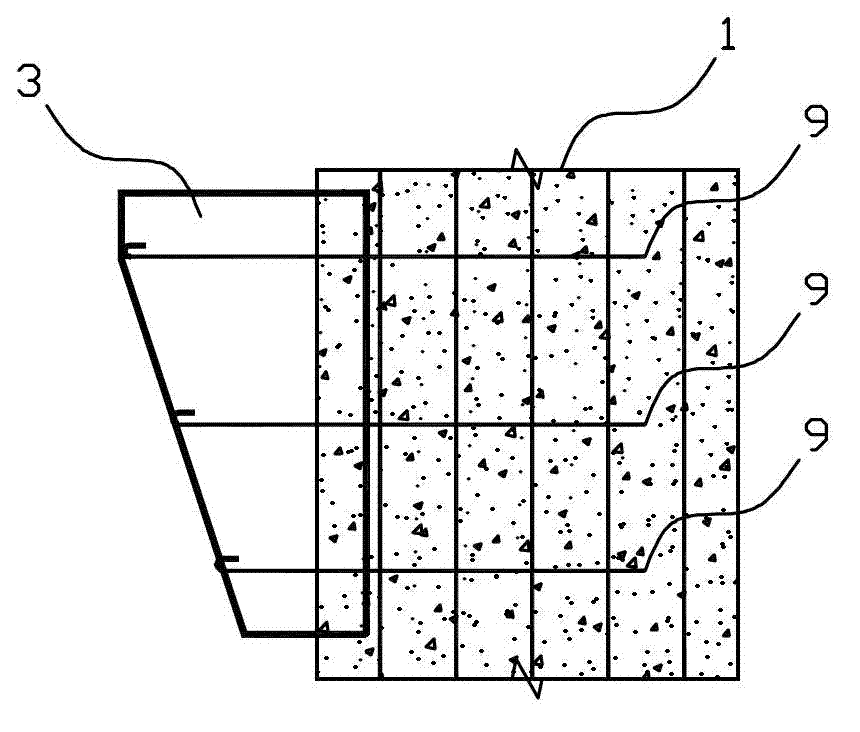

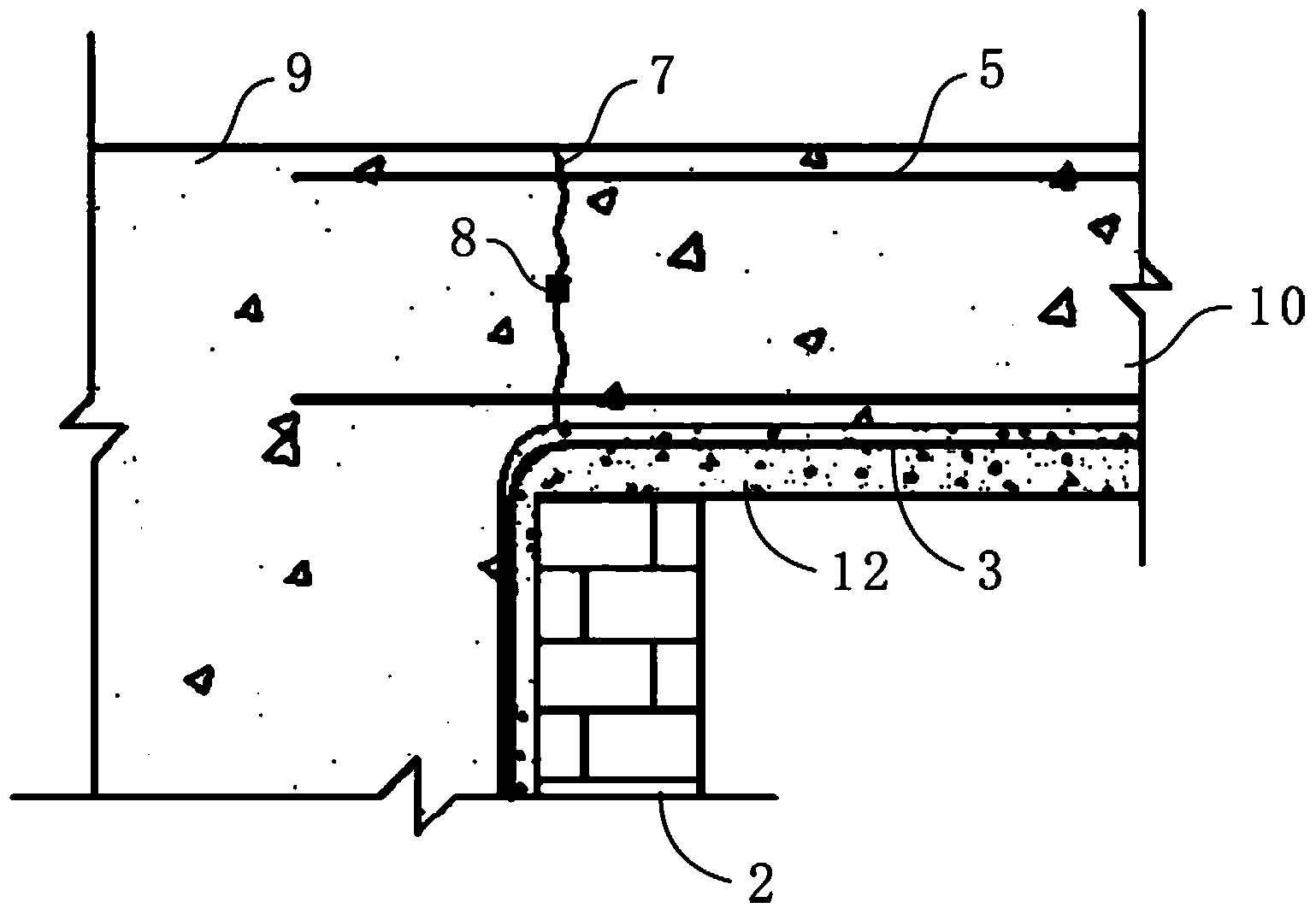

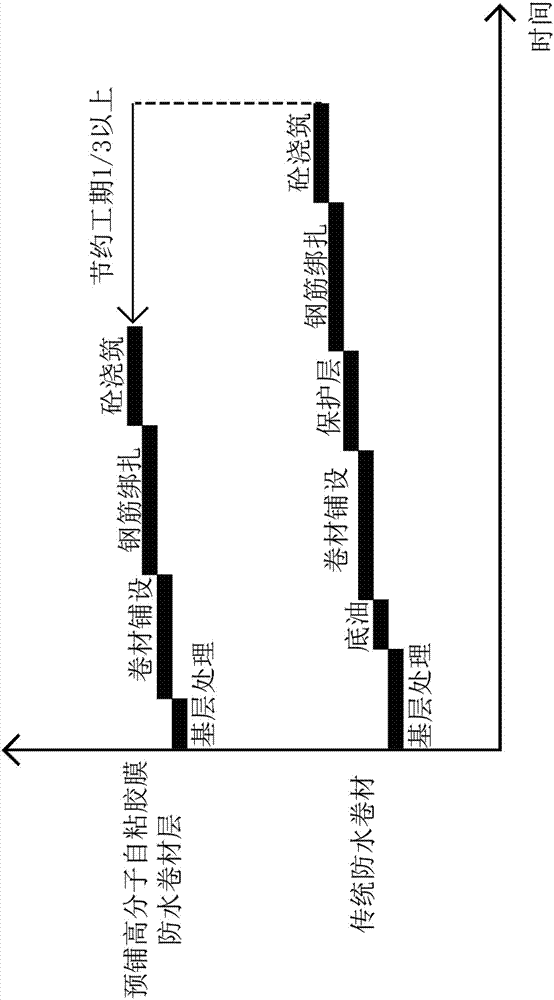

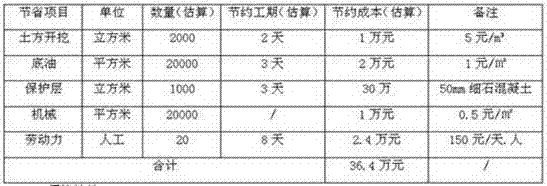

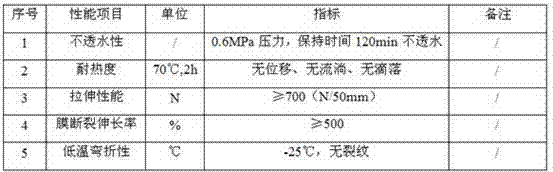

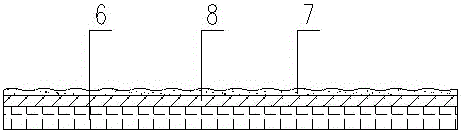

Non-asphaltic base construction method for pre-paving type high-molecular self-adhesive film waterproofing membrane for basement floor

InactiveCN107165290ASimplify the construction processImprove work efficiencyBuilding insulationsButt jointArchitectural engineering

The invention discloses a non-asphaltic base construction method for a pre-paving type high-molecular self-adhesive film waterproofing membrane for a basement floor. The method comprises the following steps of (1) repairing of a protection wall, (2) treatment of a foundation layer, (3) paving of the membrane, (4) bundling of reinforced bars and (5) concrete pouring. Compared with a traditional method, the construction procedures of the pre-paving type high-molecular waterproofing membrane are simple, requirements for treatment of the foundation layer are not high, primer treatment, a leveling layer and a protection layer are not required, the project efficiency is greatly improved, and the construction period is shortened; construction operation is convenient and flexible, the construction process is easy to master, pertinence is high, and the working efficiency is high; and the requirements for construction devices are low, proportioning can be conducted in advance, unnecessary waste during construction is reduced, and the economic benefits are remarkable. The pre-paving type high-molecular waterproofing membrane is low in weight is low and reliable in butt joint, has high tensile strength and good waterproof effect compared with a traditional waterproof membrane, can obviously improve the effect of a waterproof project, and reduces the expenses of later maintenance; and as no primer operation or fire operation exists during construction, potential safety hazards are eliminated, resources are saved, and the environment friendliness is improved.

Owner:SHANGHAI BAOYE GRP CORP

Basement waterproof novel structure and construction method

InactiveCN110439038APrevent water leakageGuarantee the environmentProtective foundationPolystyreneWater resources

The invention discloses a basement waterproof novel structure and a construction method, and relates to the technical field of waterproof structures. The basement waterproof novel structure comprisesan inner wall, an outer wall and a basement floor, and a first protective layer, a polystyrene foam layer, a first waterproof layer and a seepage gravel layer, a second waterproof layer, a first cement mortar layer, a concrete protective wall and a non-woven gauze layer are sequentially arranged between the inner wall and the outer wall. According to the basement waterproof novel structure and theconstruction method, a multi-layer waterproof effect is achieved through a simple structure, the problem of leakage of a basement is solved, the phenomenon of instability of a space waterproof structure is avoided, and water collected in a drain pipe is pumped through a water pumping pipe into an external water demand device connected with the water pumping pipe, the effect of fully utilizing water resources is achieved, the water is prevented from infiltrating into the basement floor or infiltrating into the basement from the wall surface, centralized drainage can be carried out, and materials and labor are saved.

Owner:CHINA MCC17 GRP

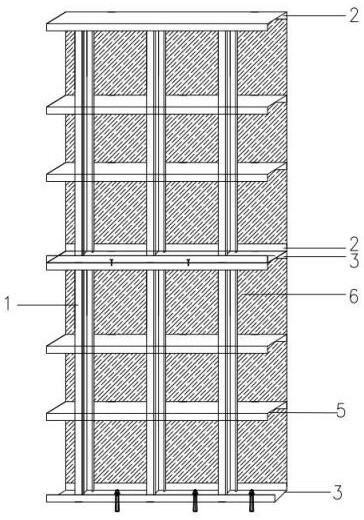

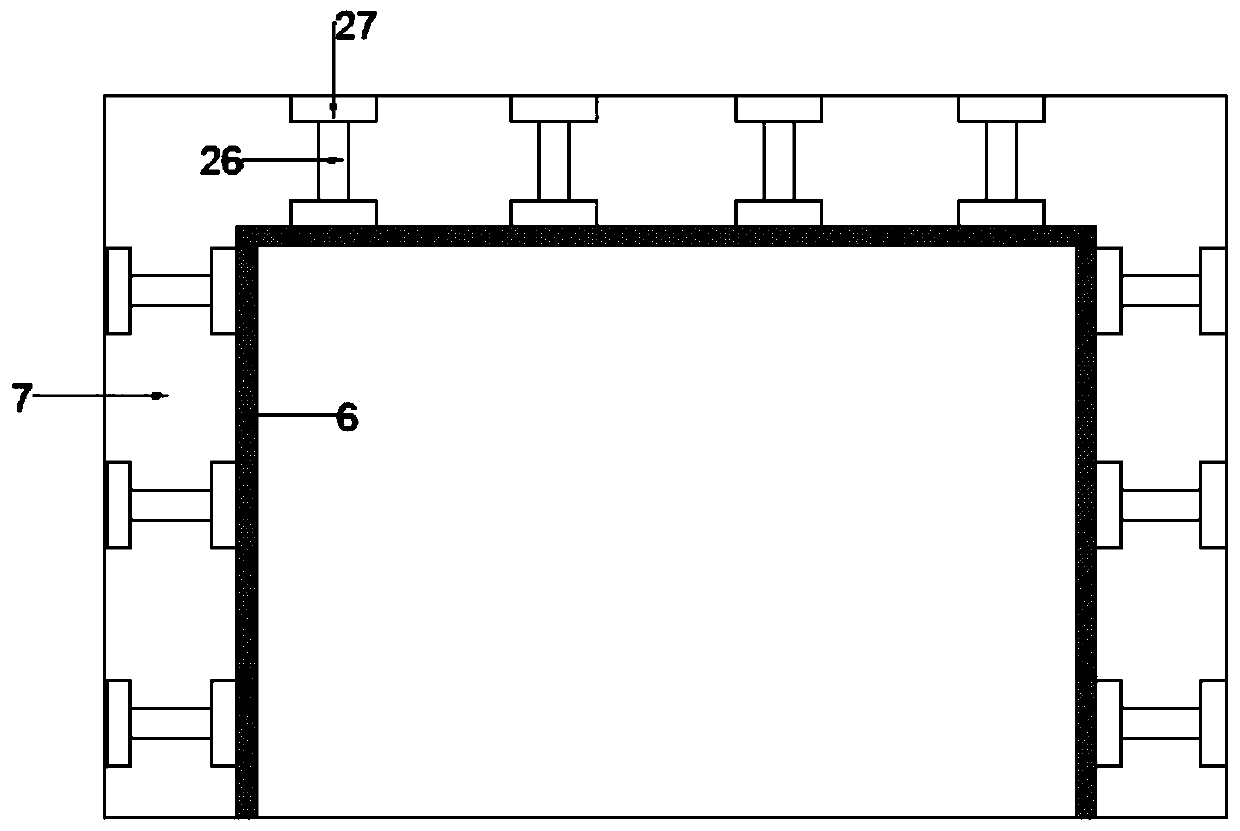

Underground continuous wall support replacement structure and construction method

ActiveCN104652474APrecise positioningWell formedArtificial islandsUnderwater structuresSlurry wallFloor slab

The invention provides an underground continuous wall support replacement structure and a construction method, wherein the underground continuous wall support replacement structure comprises an underground continuous wall, floor slab casting areas and support replacement units; the floor slab casting areas are located at the sides of the underground continuous wall, and each floor slab casting area comprises a formwork and floor slab rebars arranged on the formwork; the support replacement units are arranged on the formworks and located between the floor slab casting areas and the underground continuous wall, each support replacement unit comprises a plurality of support replacement bodies, and the support replacement bodies are arranged at intervals along the length direction of the underground continuous wall; each support replacement body comprises a first support end and a second support end, the first support end abuts against the underground continuous wall, an isolating strip is arranged between the second support ends of each two neighboring support replacement bodies, so that a side formwork of the floor slab casting area is formed, and at least part of the floor slab rebars run through the second support ends to form connecting sections. The invention utilizes the underground continuous wall to build supports and arranges the underground continuous wall support replacement structure, a basement floor slab is then formed by casting and the floor slab rebars are connected, consequently, the difficulty of support replacement construction is decreased, and the efficiency and quality of construction are further increased.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Integrated construction method and waterproof structure of basement bottom plate and waterproof coiled material

ActiveCN105544617BGuaranteed waterproof performancePrevent infiltrationProtective foundationEngineeringMoisture

The invention discloses an integrated construction method of a basement floor and a waterproof coiled material and a waterproof structure. The waterproof structure is laid with a pre-paved self-adhesive film waterproof coiled material on the horizontal surface of the basement floor cushion, and its structure has positive and negative angles. The self-adhesive modified asphalt waterproofing membrane is paved at the location, and the lap joint between the pre-paved self-adhesive film waterproofing membrane and the self-adhesive modified asphalt waterproofing membrane is coated with cement adhesive, and the basement floor is poured on the pre-paved On top of self-adhesive waterproof membrane and self-adhesive modified asphalt waterproof membrane, an integrated waterproof layer is formed. In the present invention, two different waterproof coiled materials are laid and pasted on the cushion layer of the basement floor for waterproofing construction, so that the coiled material waterproof layer and the base plate structure are closely combined to form an integral waterproof layer, which can completely prevent moisture from penetrating between the waterproof coiled material and the structure Clearance.

Owner:CCFED THE FIRST CONSTR & ENG

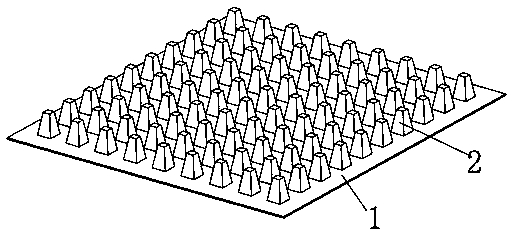

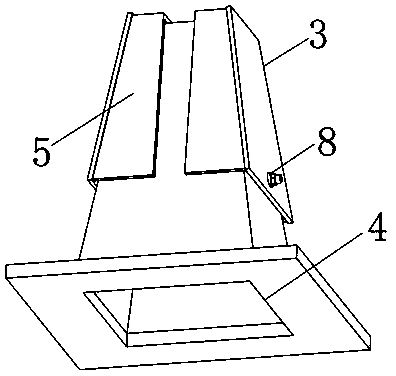

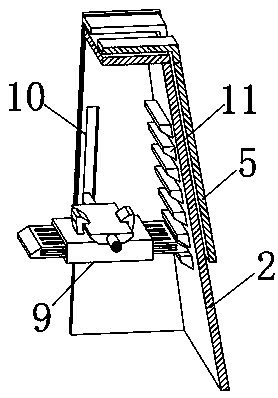

Basement floor drain board and construction process thereof

ActiveCN110130404AHigh strengthIncrease contact surfaceProtective foundationArchitectural engineeringRebar

The invention discloses a basement floor drain board and a construction process thereof. The basement floor drain board comprises a drain board body, a plurality of supporting frustums and an overheadprevention device, wherein the support frustums are distributed and fixed to the surface of the drain board body in a rectangular array mode; a plurality of mounting holes are formed in the position,corresponding to the supporting frustums, of the drain board body; and the overhead prevention device is installed outside the supporting frustums. A traditional drain board frustum-shaped support ischanged into prismatic support so as to increase the contact surface. The strength of the drain board is improved, and the overhead prevention device sleeves the outer side of the prismatic support which may be overhead, so that the overhead phenomenon is greatly reduced, the strength of the drain board is improved, and steel bar binding and concrete surface casting in the later period are more stable.

Owner:宁波建工建乐工程有限公司

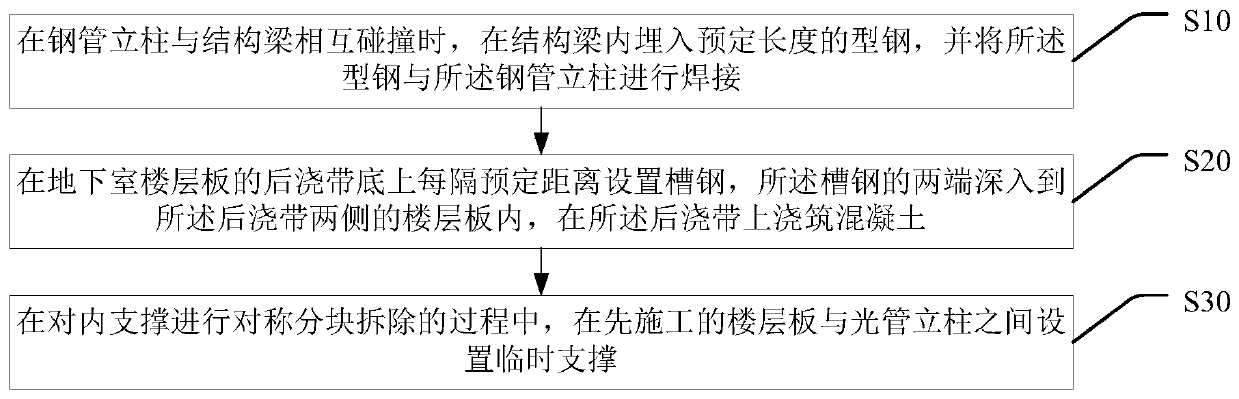

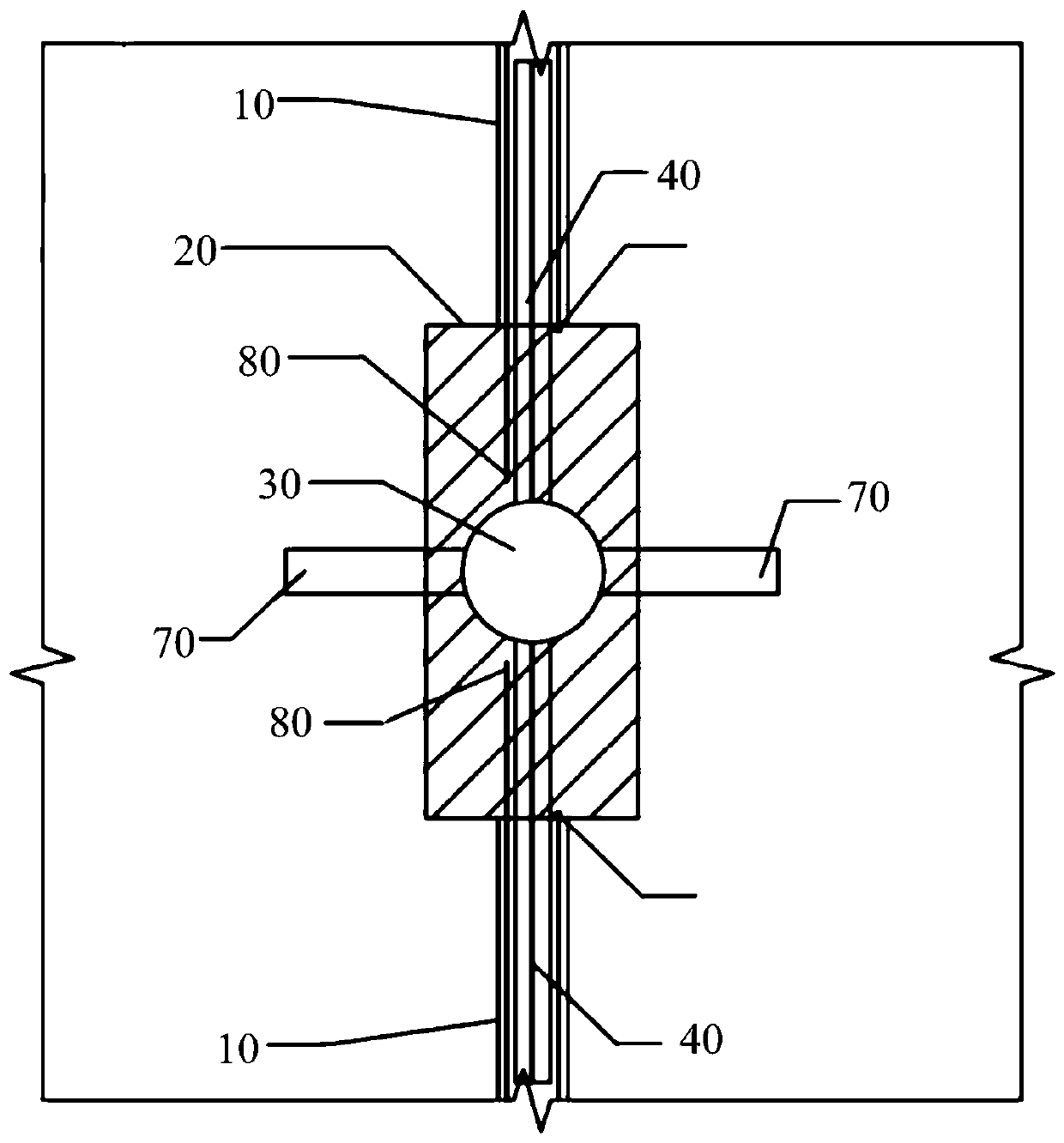

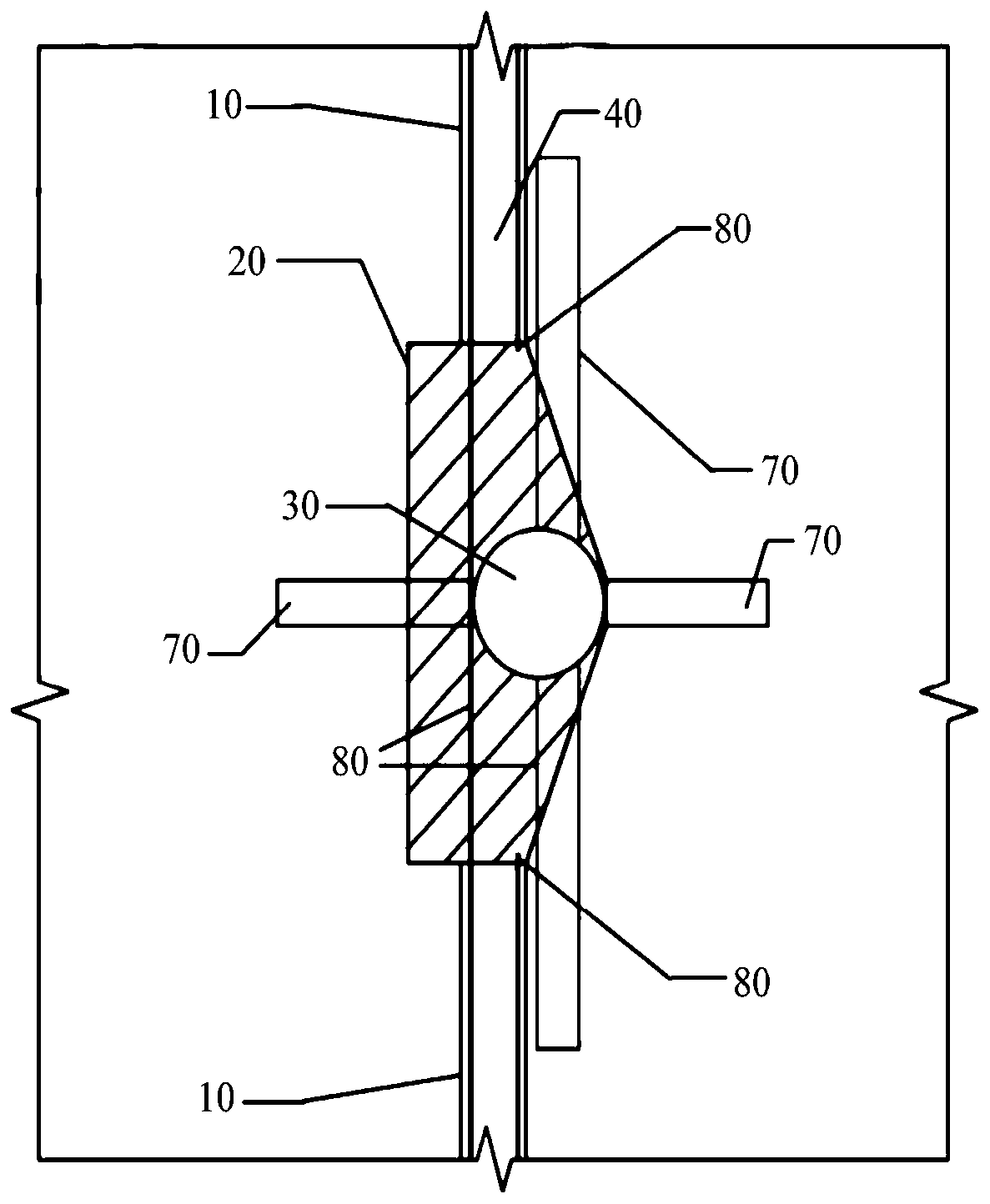

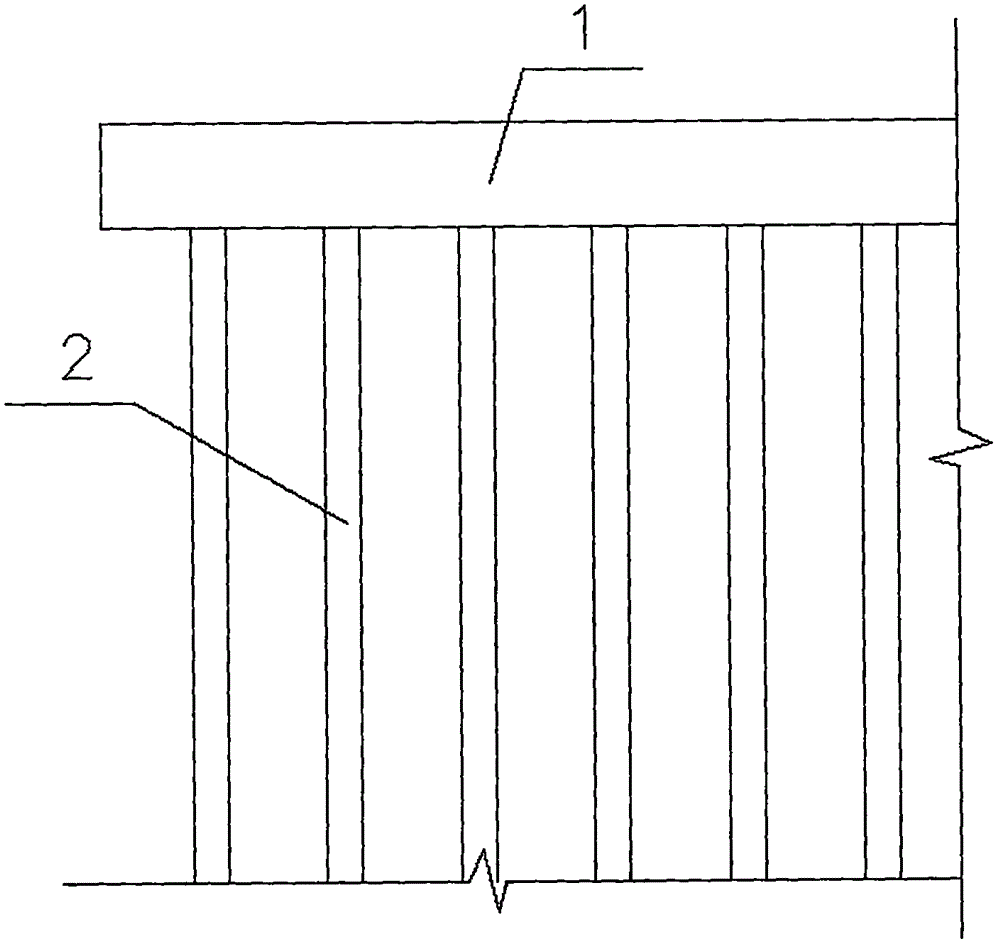

Method for dismantling and replacing inner support of foundation pit

ActiveCN111305221AGuaranteed stabilityGuaranteed continuityExcavationsArchitectural engineeringEconomic benefits

The invention discloses a method for dismantling and replacing an inner support of a foundation pit. The method comprises the following steps that when a steel pipe upright post and a structural beamcollide with each other, section steel with a preset length is embedded in the structural beam, and the section steel and the steel pipe upright post are welded; channel steel is arranged at the bottom of a post-cast strip of a basement floor plate at intervals of preset distances, the two ends of the channel steel penetrate into the portions, on the two sides of the post-cast strip, of the floorplate, and concrete is poured on the post-cast strip; and in the process of symmetrically partitioning and dismantling the inner support, a temporary support is arranged between the floor plate constructed in advance and the steel pipe upright post. The method for dismantling and replacing the inner support of the foundation pit ensures the stability of the floor plate and the structural beam andforce transmission continuity when the inner support of the foundation pit is dismantled, improves the safety stability of the structure, simultaneously improves the construction efficiency and the economic benefit, provides a reference value for dismantling the inner support of the foundation pit, and has wide applicability.

Owner:中建四局土木工程有限公司 +1

Basement reconstruction structure with raft foundation building

ActiveCN106285032AImprove structural performanceBuilding repairsCellarsRubber ringStructural engineering

The invention discloses a basement reconstruction structure with a raft foundation building. The basement reconstruction structure is characterized in that original piles are used as basement force bearing columns, part piles of a basement are removed, the original piles are reinforced to form the force bearing columns, and effective connection is conducted between the bearing columns and the original piles through special connection structures. The basement floor is provided with shear resistant ribs in the positions of the force bearing columns, and the shear resistant ribs are in a horse stool shape. Watertight rubber rings are arranged on the outer surfaces of the original piles and in the concrete floor, and the watertight rubber rings are arranged in the middle of the concrete floor. Annular watertight grooves are formed along the outer surfaces of the original piles and embedded into the watertight rubber rings. Polyurethane waterproof mortar is arranged on the concrete floor. The basement reconstruction structure is good in structural behavior, safe and reliable.

Owner:临沂杰创化工产业园有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com