Non-asphaltic base construction method for pre-paving type high-molecular self-adhesive film waterproofing membrane for basement floor

A basement floor, self-adhesive film technology, applied in building thermal insulation materials, building components, buildings, etc., can solve problems such as long cycle, achieve high work efficiency, significant economic benefits, and resource saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, the present invention is described further:

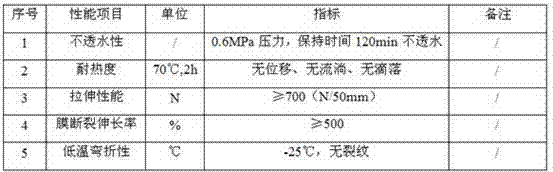

[0022] The coiled material used in the present invention comprises the polymer material layer as bottom layer, the polymer self-adhesive film layer positioned above the polymer material layer, and the release layer or release layer positioned above the polymer self-adhesive film layer. A lap edge is reserved on the molecular self-adhesive film layer next to the layer or the isolation layer.

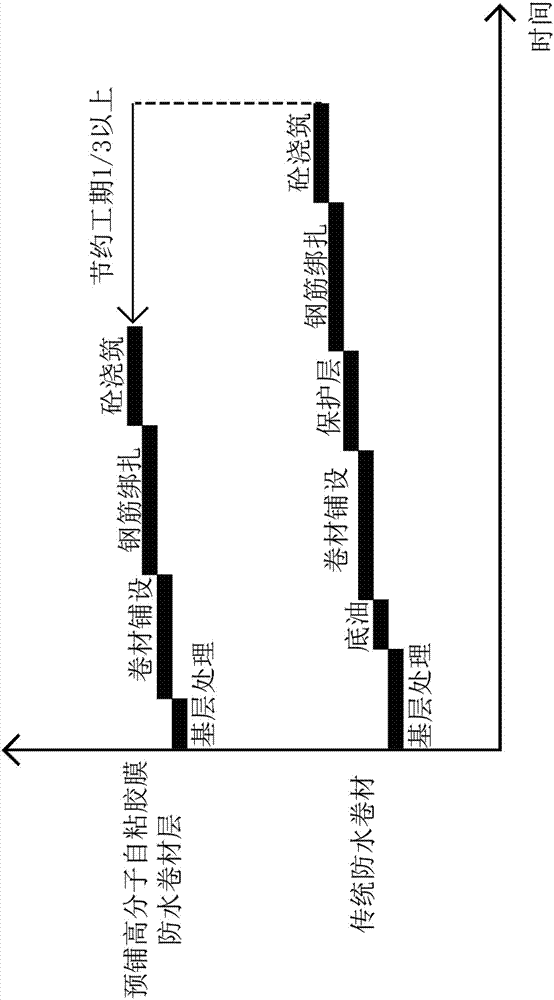

[0023] Basement floor pre-paved polymer self-adhesive membrane waterproofing membrane non-bituminous construction method, including the following steps 1): protective wall repair; 2), base treatment; 3), coil laying; 4), steel bar binding; 5 ), concrete pouring;

[0024] The above step 1) Repairing of the protection wall includes a. Laying out of the protection wall: after the construction of the cushion layer of the foundation floor of the building, release the position line of the protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com