Soft and weak wall rock tunnel advance reinforced support construction method

A construction method and technology for weak surrounding rock, applied in tunnels, tunnel linings, drilling equipment and methods, etc., can solve the problems of complex procedures, poor advance support effect, and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

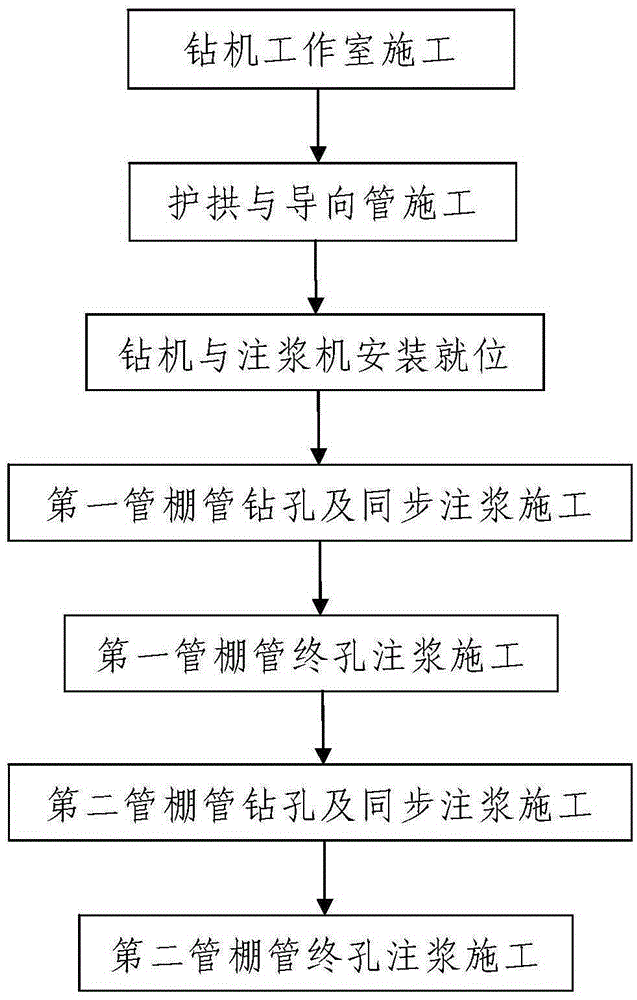

[0072] Such as figure 1 A construction method for advance strengthening support of tunnels with weak surrounding rocks is shown. The tunnel is divided into multiple sections from the back to the front along the longitudinal extension direction of the tunnel to carry out the advance support construction of the pipe shed. The construction methods for the advance support of the shed are the same; when performing the advance support construction of the pipe shed for any segment, the following steps are included:

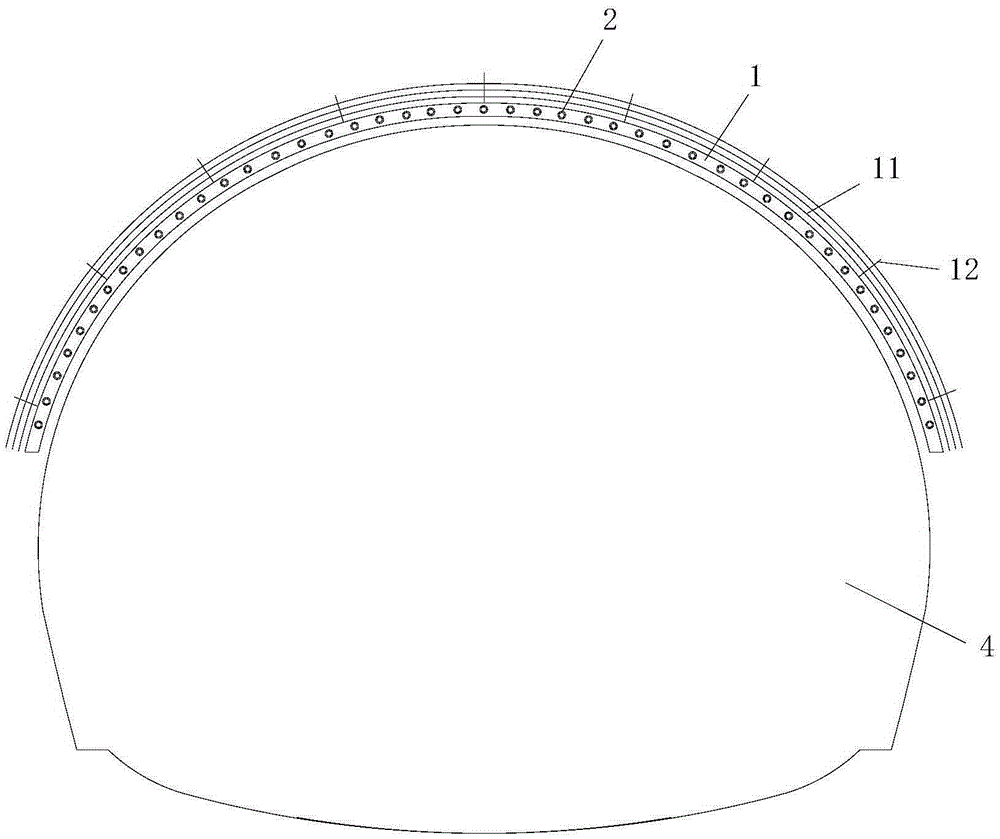

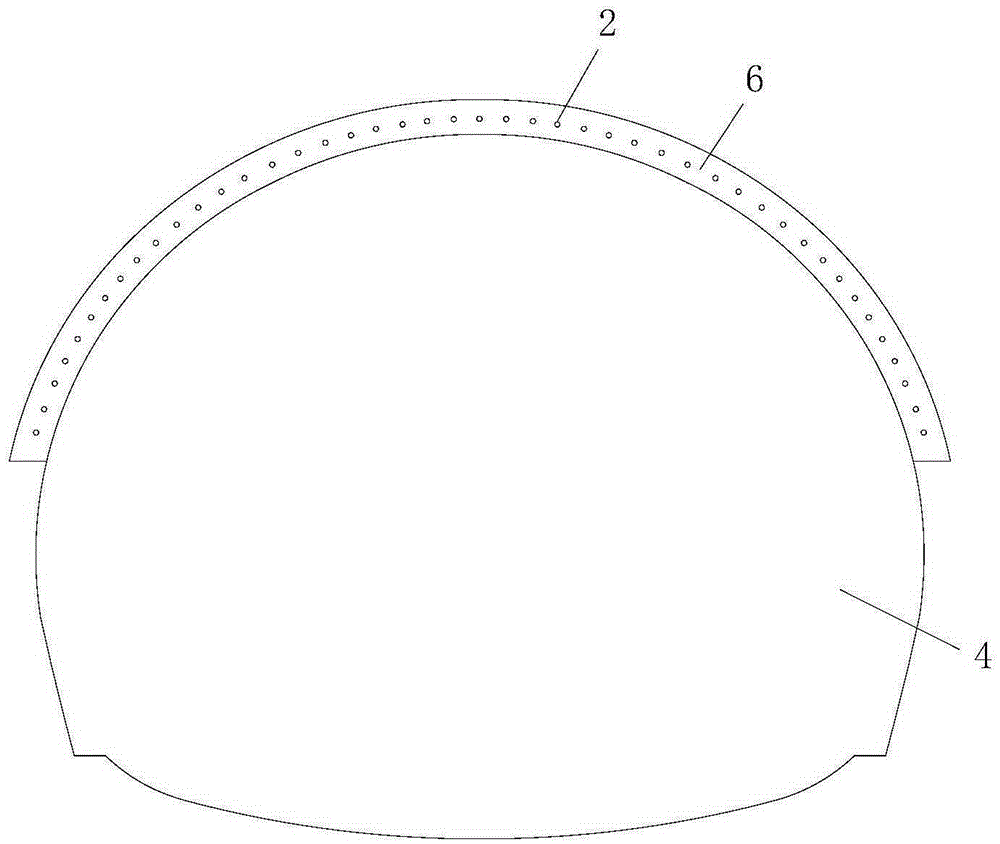

[0073] Step 1. Construction of guard arches and guide pipes: install a guard arch on the rear side of the face of the current construction section; The steel arch 1 is equipped with a plurality of guiding pipes 2 respectively guiding a plurality of pipe shed pipes 3, see figure 2 , diagram 2-1 and image 3 ;

[0074] The external insertion angles of the plurality of pipe shed pipes 3 are all 1° to 3°, and each of the pipe shed pipes 3 is arranged coaxially with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com