Patents

Literature

133results about How to "Solve common quality problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Outer wall structure and construction and installation method

InactiveCN104018598AComplete and reliable quality assuranceSolve common quality problemsCovering/liningsSolid waste managementWater leakageArchitectural engineering

The invention relates to a building outer wall structure, in particular to an outer wall structure and a construction and installation method. The outer wall structure is sequentially provided with an inner decorative layer, a structural layer, a waterproof layer and an outer decorative layer from inside to outside. The construction and installation method of the outer wall structure includes the steps that wall battens and doors and windows are installed; the waterproof layer is constructed; construction and installation method of the outer wall structure are finished after the inner wall face and the outer wall face are decorated. The common quality problems such as empty drums, deformation, cracks and water seepage caused by thermal insulation construction on the outer wall are solved by using a self-heat-preservation system for the outer wall, so that an integral and reliable quality guarantee is provided for an outer wall engineering system; all the adopted materials are common combinations with light inorganic materials as carriers and are good in cosolvency, usability, cohesiveness, ageing resistance and the like; the construction procedure of outer wall engineering is simplified, construction period is shortened, unified management on construction sites is facilitated, management cost is lowered, and project management efficiency is improved; the self-heat-preservation function of the wall is achieved, and the problem that the outer wall is prone to water seepage or water leakage is solved.

Owner:江西昌南建设集团有限公司

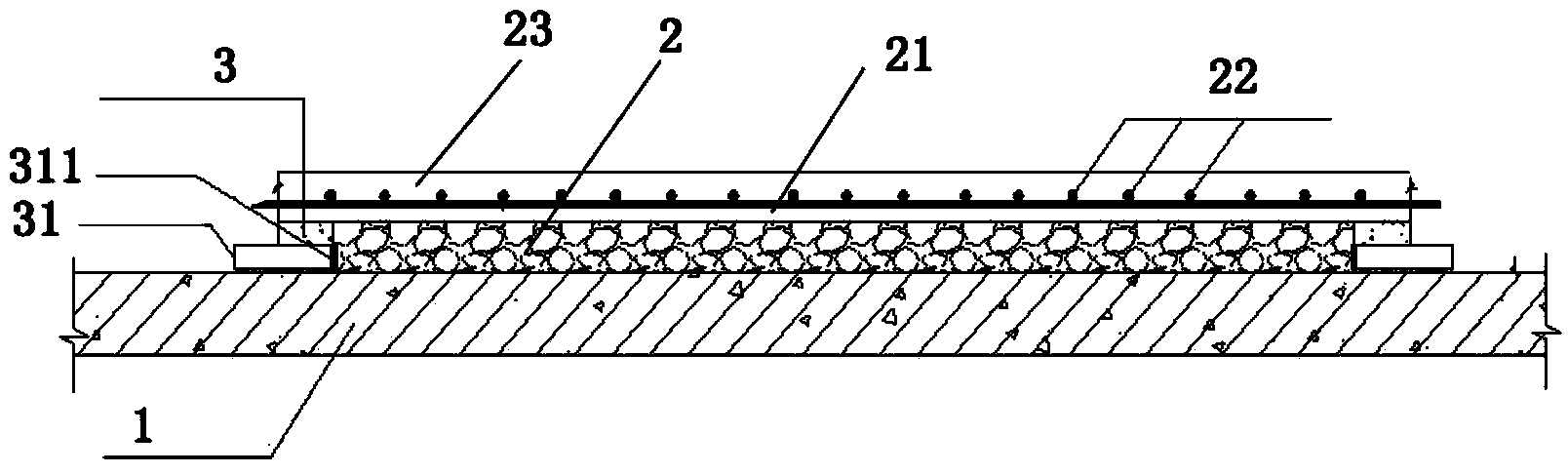

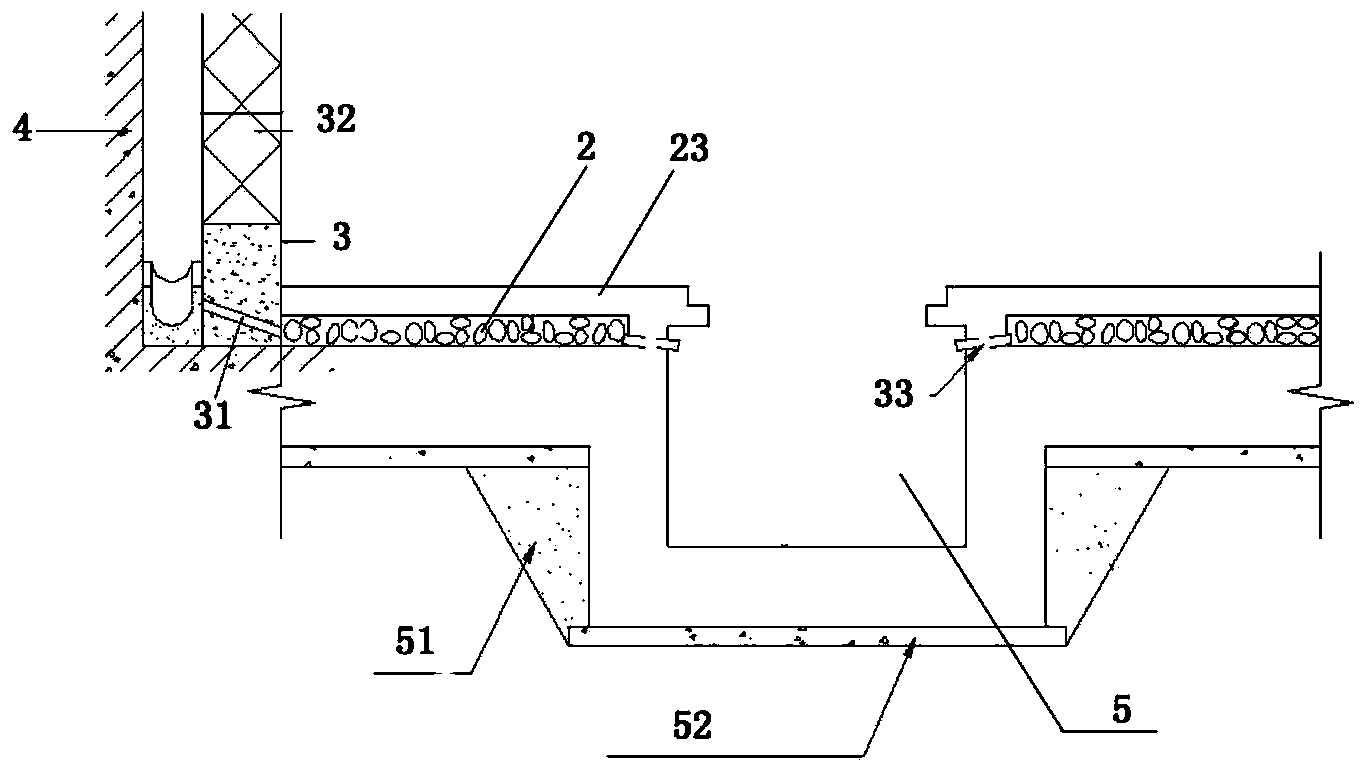

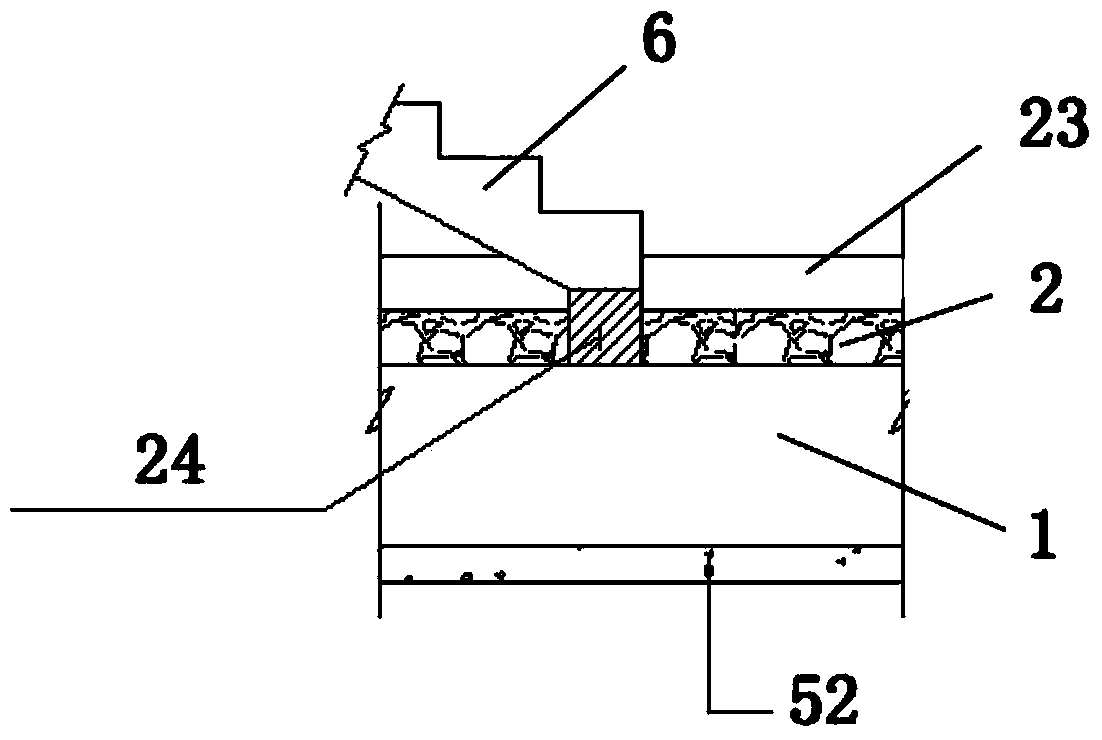

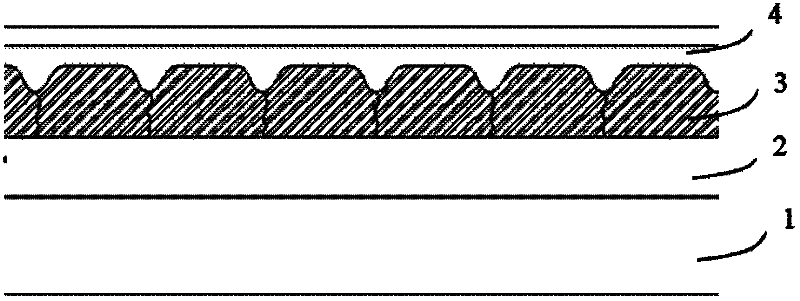

Basement bottom plate water drainage layer construction method

InactiveCN103821181ASolve common quality problemsEffective exportArtificial islandsProtective foundationBasementSurface layer

The invention discloses a basement bottom plate water drainage layer construction method. According to the method, a grait layer is paved at the basement bottom layer part, the self discharge function of the grait layer is utilized for realizing the water drainage, the traditional single water blocking mode is broken, water seeped from the outer wall and the bottom plate of the basement is firstly gathered to an anti-seeping wall water drainage ditch and is then gathered to a water collecting well through entering the water drainage layer to flow freely, and finally, the water is pumped and discharged into a municipal pipe network through an automatic water discharge pump. The water drainage layer is used as an isolation layer between the bottom plate structure and a decoration surface layer, seeped water can be effectively guided out, the dryness of the use surface layer is maintained, a good water drainage effect is reached, and the common quality problem of the basement outer wall and bottom plate seepage is effectively solved.

Owner:ZHONGTIAN CONSTR GROUP

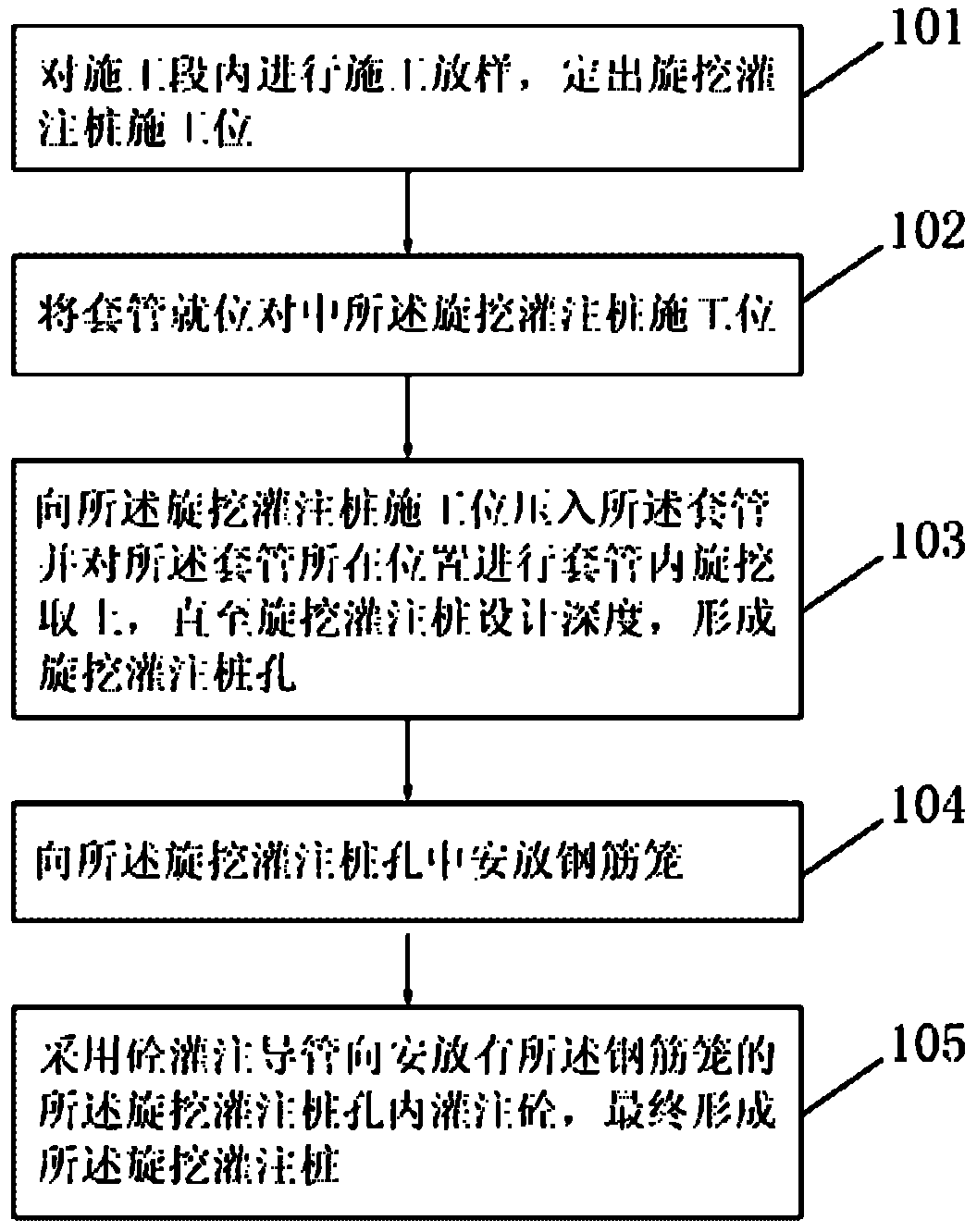

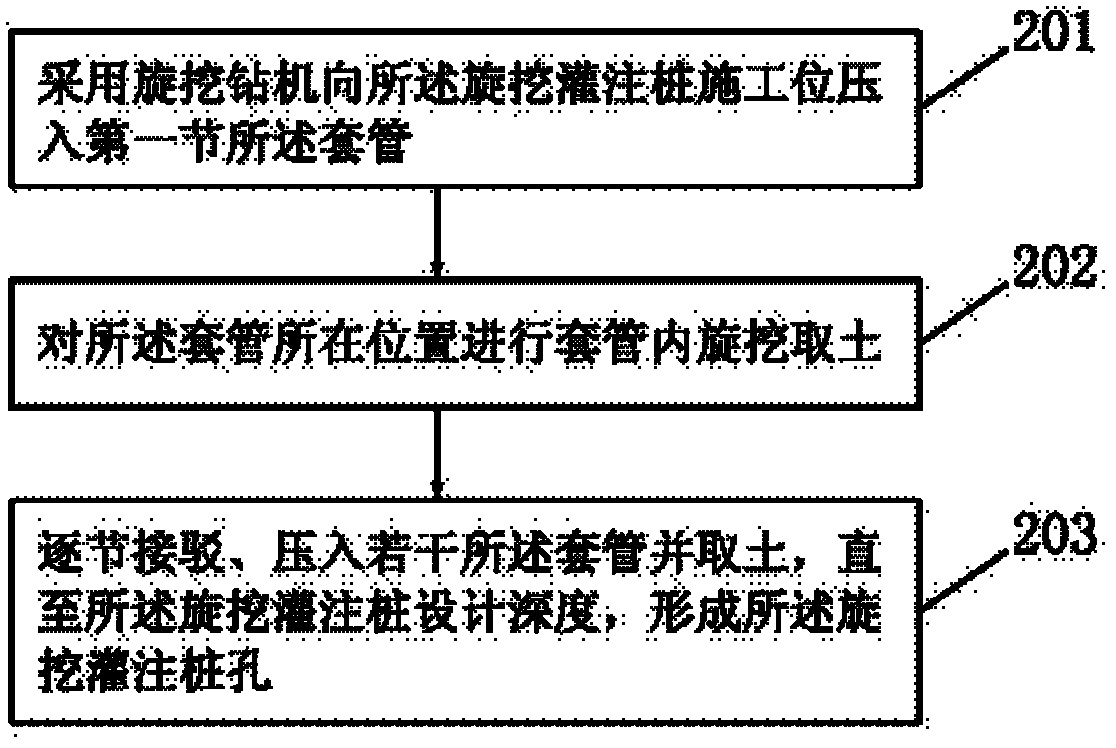

Construction method for revolving digging cast-in-place pile

An embodiment of the invention discloses a construction method for a revolving digging cast-in-place pile. A case pile is used for holing and protecting a wall, a revolving digging machine is used for taking soil and holing from the inside of the case pile, soil excavated volume of the construction method is lower as compared with a traditional wall protecting method by the aid of mud, a peripheral soil structure cannot be damaged, influences to surrounding environments and pollution due to construction are low, the speed for removing slag in end holes is fast, quality is high, and the problem that the mud skin on a side of a mud wall protecting and holing technical pile reduces bearing capacity of the engineering pile is avoided effectively. The construction method effectively stops common quality drawbacks of other types of punched and bored cast-in-place piles, such as hole collapse, necking and the like. Operation is safe, pile forming speed is faster, cost is lower, and construction efficiency and construction quality are greatly improved.

Owner:深圳市润信建设工程有限公司 +1

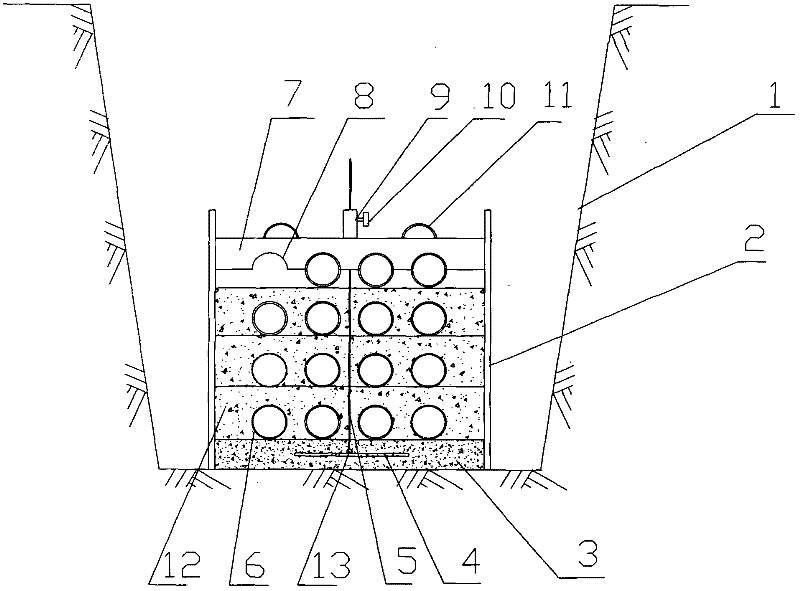

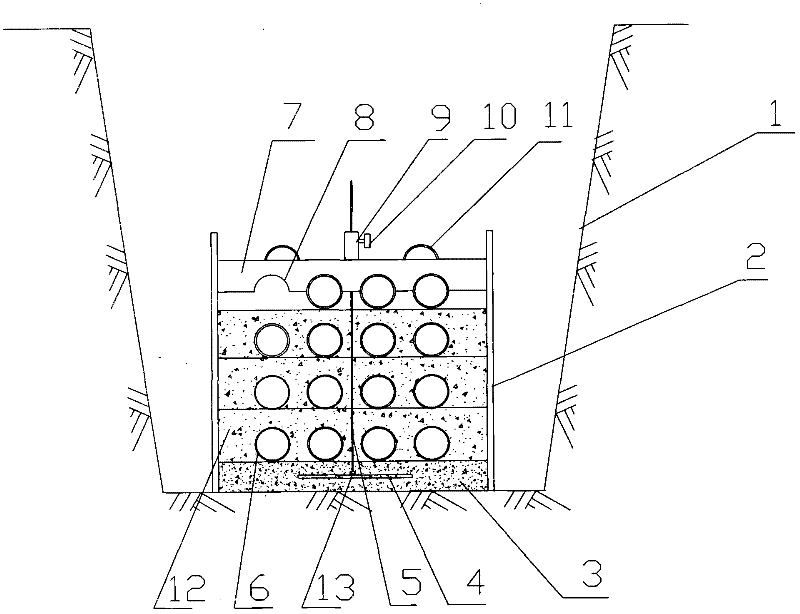

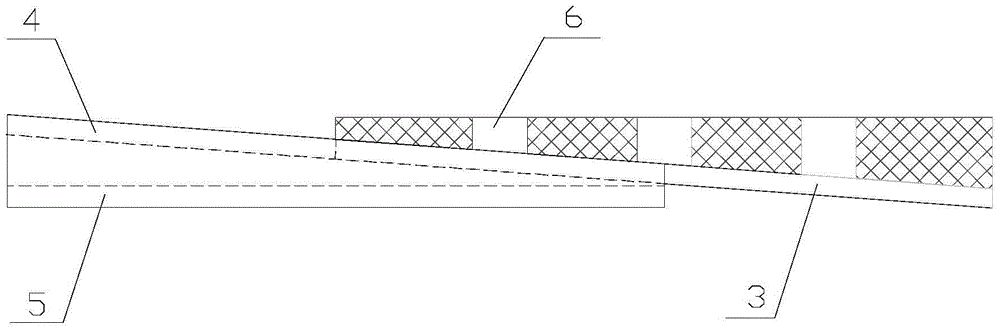

Cast-in-place concrete cable conduit construction method

InactiveCN102359123ASolve common quality problemsSmall footprintArtificial islandsUnderwater structuresReinforced concreteRebar

The invention provides a cast-in-place concrete cable conduit construction method. Layered laying of cable conduits and layered pouring of concrete are adopted; and the cable conduits are accurately positioned by adopting a cable conduit anti-floating positioning device when the concrete is poured, so that the cable conduits are prevented from floating and shifting, and the construction quality is effectively improved. The method comprises the following steps of: 1) measuring and paying off; 2) digging a foundation trench; 3) setting a pouring template; 4) pouring a reinforced concrete foundation, and arranging positioning steel bars on the concrete foundation piecewise; 5) positioning the laid cable conduits layer by layer by matching an anti-floating positioning bracket and the positioning steel bars, and pouring concrete layer by layer for fixing to the cable conduits between the positioning steel bars; 6) taking down the anti-floating positioning bracket and the positioning steel bars, and filling the holes at the positioning steel bars by using concrete; 7) checking passing of cables passing through the pipes to prevent blockage; 7) plugging pipe orifices by using plastic cloth to prevent sundries; and 8) backfilling soil to the foundation trench, and finishing the construction.

Owner:JINAN URBAN CONSTR GRP

Construction method for light steel keel partition wall

InactiveCN106168067AReduce wasteSimple and fast operationBuilding material handlingSocial benefitsFalsework

The invention discloses a construction method for a light steel keel partition wall. The technological process of the construction method comprises the steps of construction preparation, scaffold erection, surveying and lining, welding and fixation of galvanized steel components, sleeper wall construction, fixation of an uppermost keel, a bottommost keel and frame keels, staging of vertical keels, keel installation, gypsum face plate installation, joint treatment, wall decoration and acceptance check. The construction method is easy and convenient to implement, the installation speed is high, and the labor efficiency is improved; meanwhile, the stability of the partition wall and the shock resistance of the integral structure are enhanced, the sound insulation effect and the fireproof grade between every two rooms are better improved, the common quality problem of cracking of light steel keel partition wall bodies is solved, and remarkable economic benefits and social benefits are achieved.

Owner:上海闵轩钢结构工程有限公司

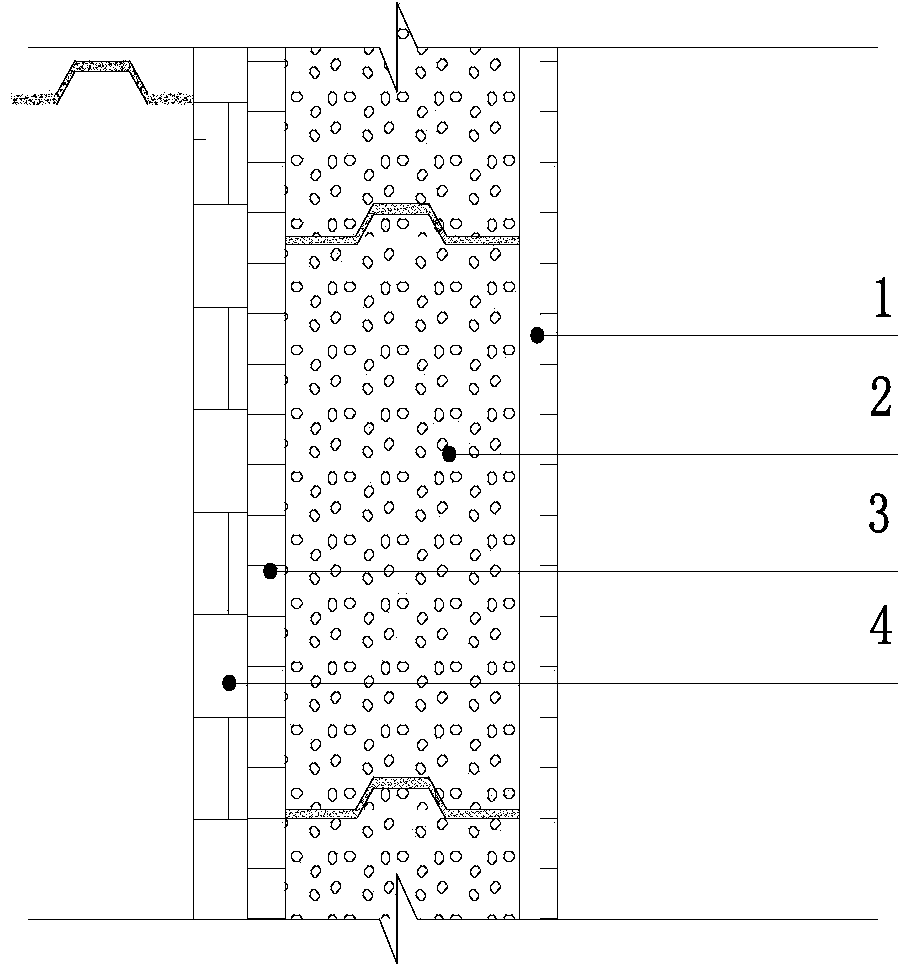

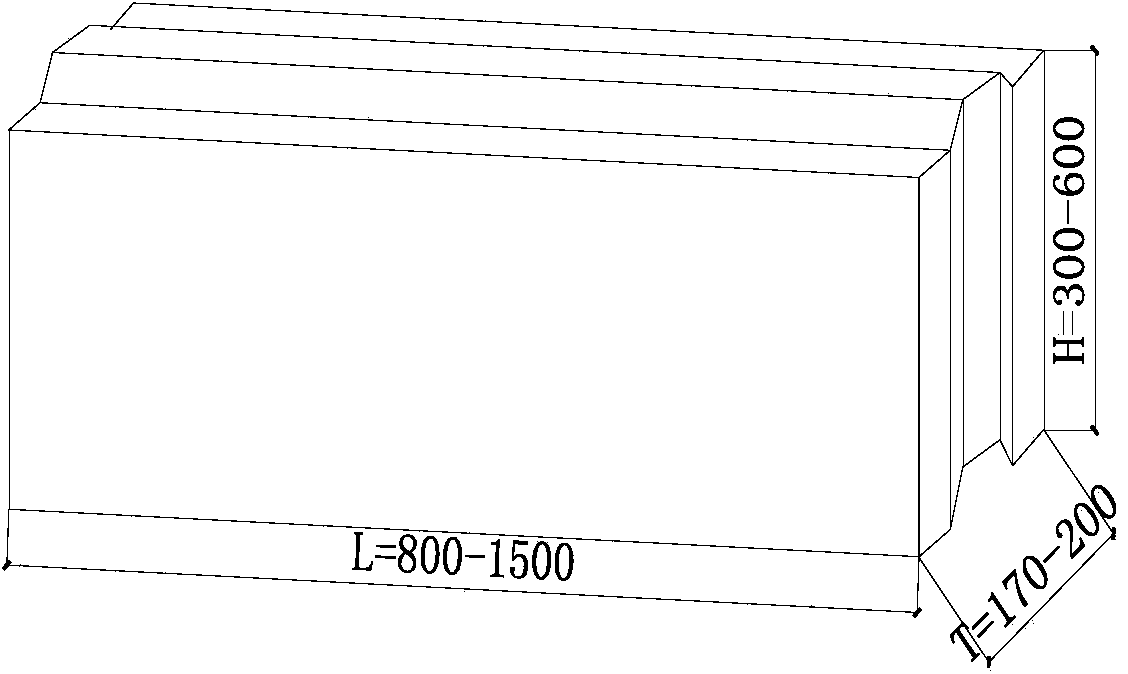

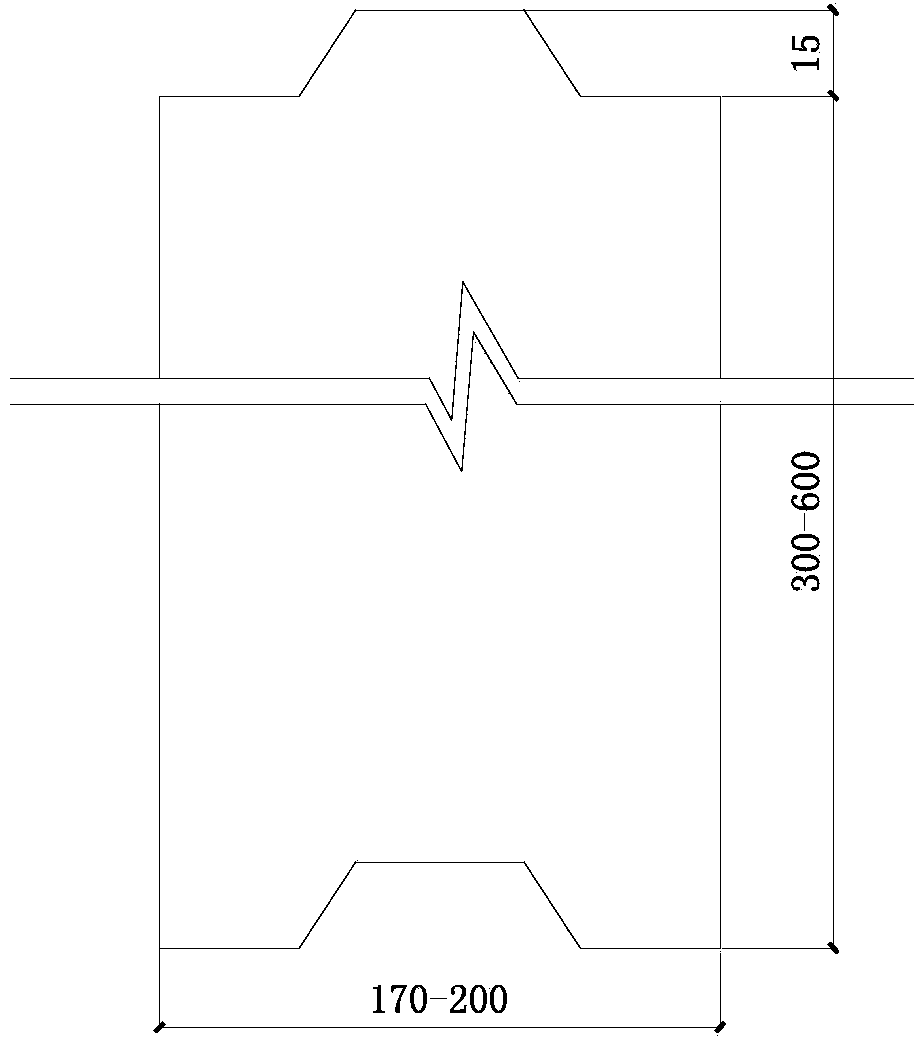

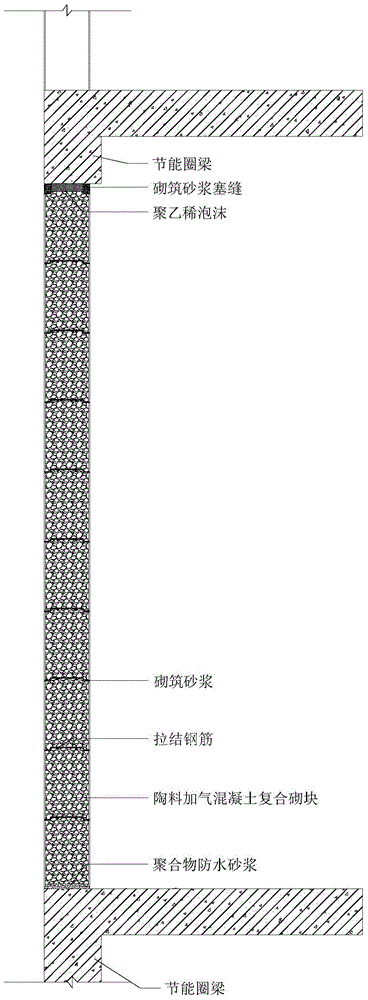

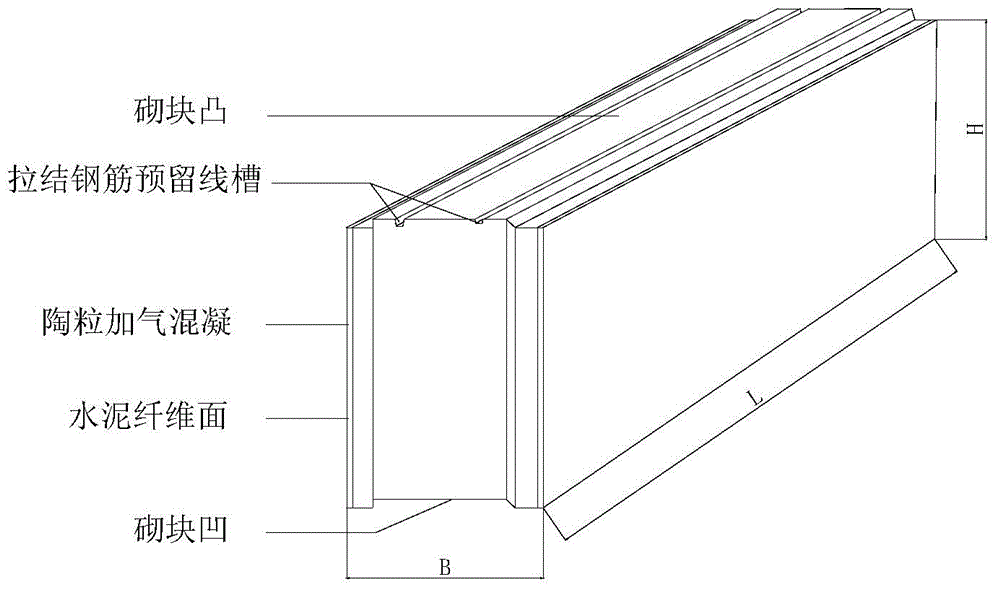

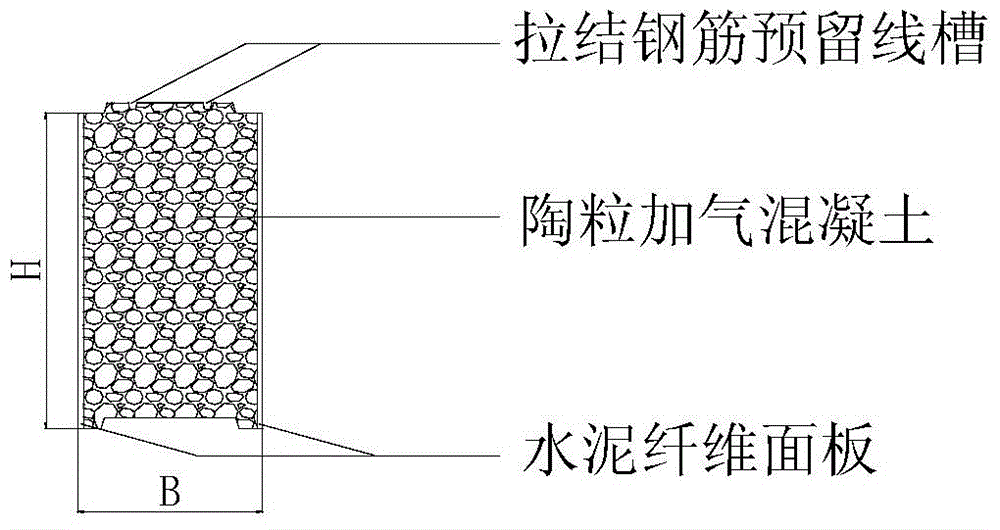

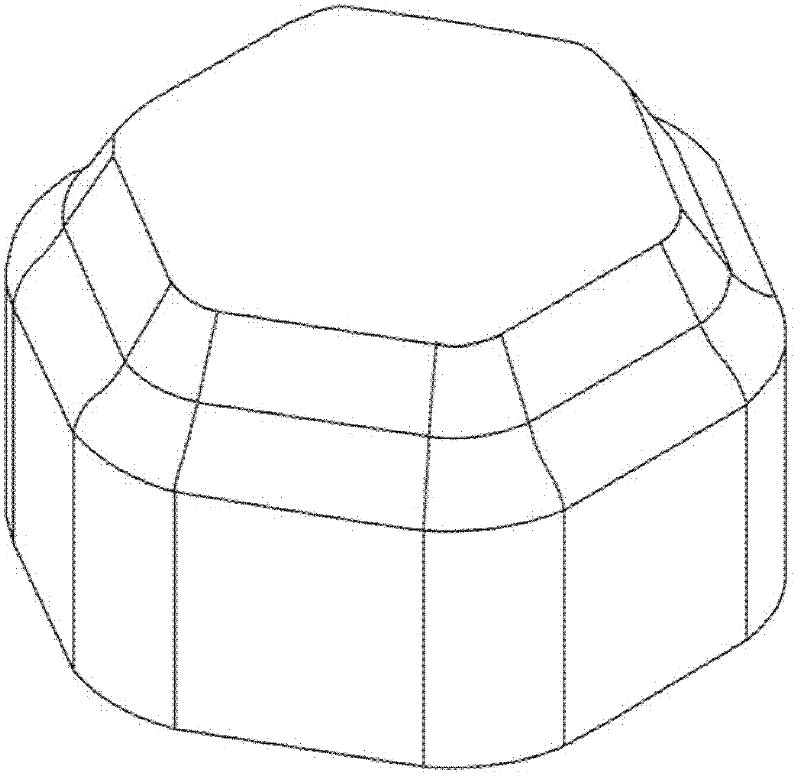

Building brickwork and masonry construction method of building brickwork

InactiveCN104358341AMeet the requirements of self-insulation systemSolve common quality problemsConstruction materialWallsMaterials scienceConcrete composites

The invention discloses a building brickwork and a masonry construction method of the building brickwork, and relates to a building brickwork of a building. The building brickwork is a brickwork which is built by light-weight aggregate concrete composite blocks; grooves and tongues are formed in the periphery of each light-weight aggregate concrete composite block; the light-weight aggregate concrete composite blocks are respectively 600-1200mm in length, 300-600mm in height and 80-200mm in thickness; the grooves are downward and the tongues are upward in field masonry; and the masonry construction method comprises the following steps: (1) building the brickwork by the blocks, namely building the first block on a foundation or floor ground, building the second composite block in a manner of being staggered with the first block, wherein the staggered-joint is 1 / 2 of the length of the block and is not smaller than 200mm at least; the composite block brickwork is connected with a building structure column and a concrete shear wall; the composite block brickwork is connected with building structure beams and plates; the building brickwork is subjected to deformation joint construction; a parapet wall is subjected to masonry construction; a switch socket is pre-buried and installed; and cable pipelines are laid; (2) fixing door frames and window frames; and (3) building a wall body corner structure by the light-weight aggregate concrete composite blocks.

Owner:FUJIAN MEIJINLAI GREEN BUILDING TECH +1

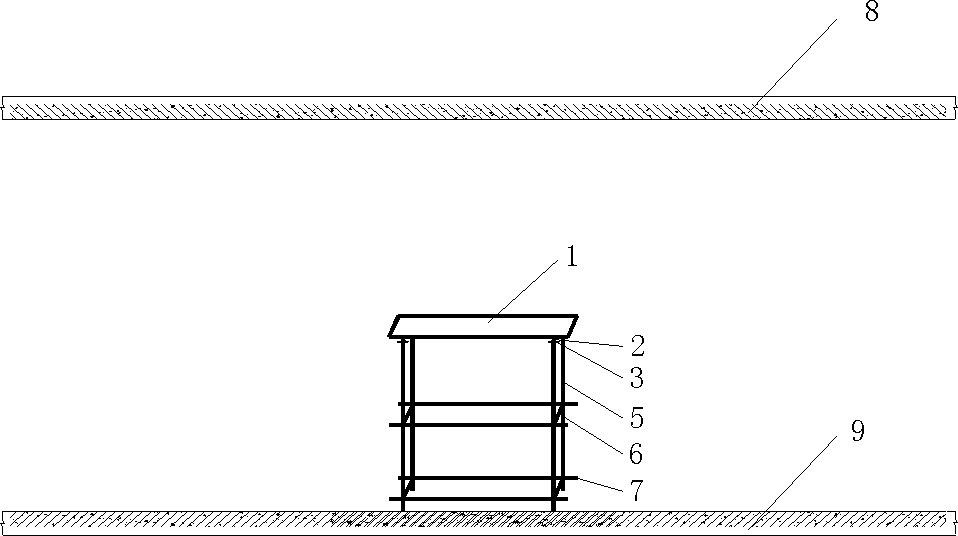

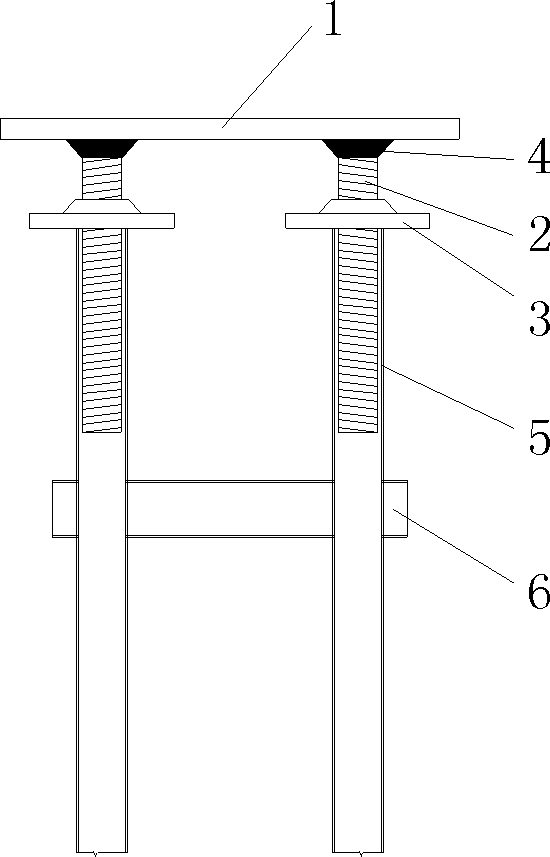

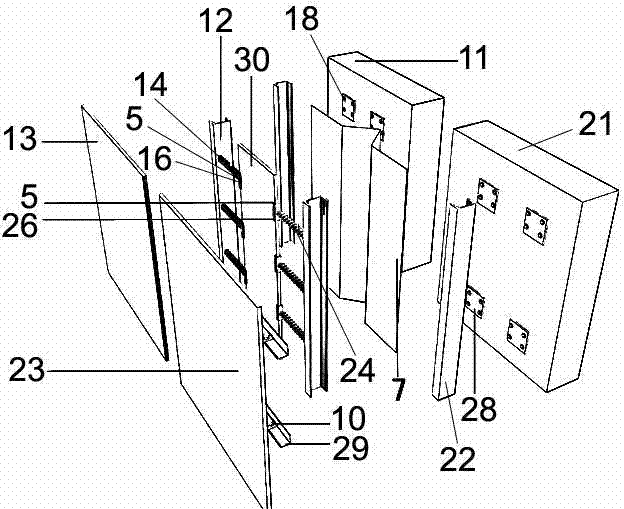

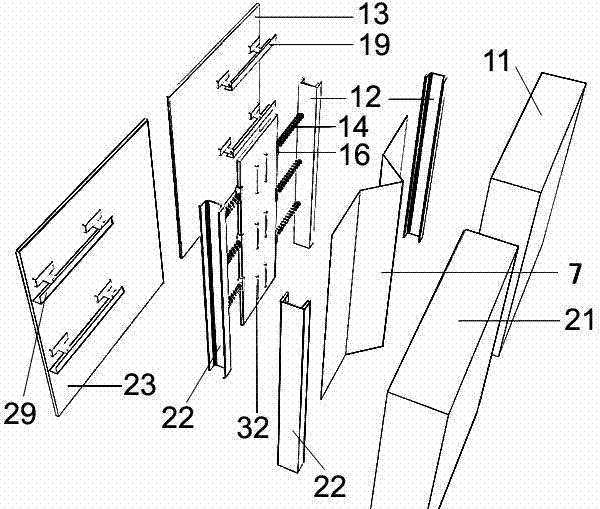

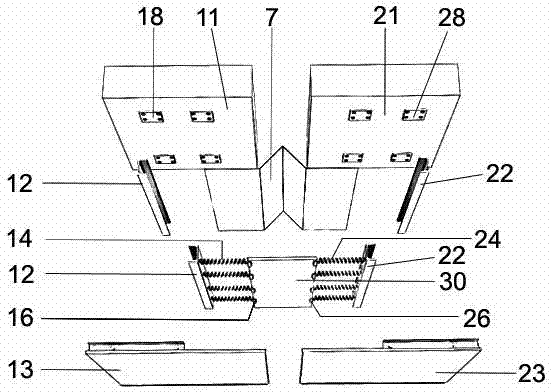

Pre-embedding construction method for distribution box with rows of pipes, and support device

ActiveCN102493648AEasy to fixImprove ergonomicsElectrical apparatusBuilding material handlingEngineeringRebar

The invention discloses a pre-embedding construction method for a distribution box with rows of pipes, and a support device, and relates to a pre-embedding construction method for distribution pipes and a distribution box of a masonry wall in building engineering. The construction method comprises the following steps of: fixing the distribution box at a design position by using a temporary platform; installing rows of distribution pipes on the upper part of the distribution box; suspending the distribution box by using the installed distribution pipes, removing the temporary platform, and installing distribution pipes on the lower part of the distribution box to ensure that the distribution box is fixed in the vertical direction; constraining the rows of distribution pipes and the distribution box in the horizontal direction by using steel bars which stretch into the masonry wall; controlling the degree of the distribution box stretching out of the wall by using a formwork fixing system; and pouring concrete to firmly fix the distribution pipes and the distribution box so as to fulfill the aim of accurately installing the distribution box in an embedded mode. The device is provided with a transverse steel pipe component, an upper steel pipe component, a lower steel pipe component, a lower supporting plate, a left supporting plate, an upper supporting plate and a right supporting plate.

Owner:XIAMEN YCUCG

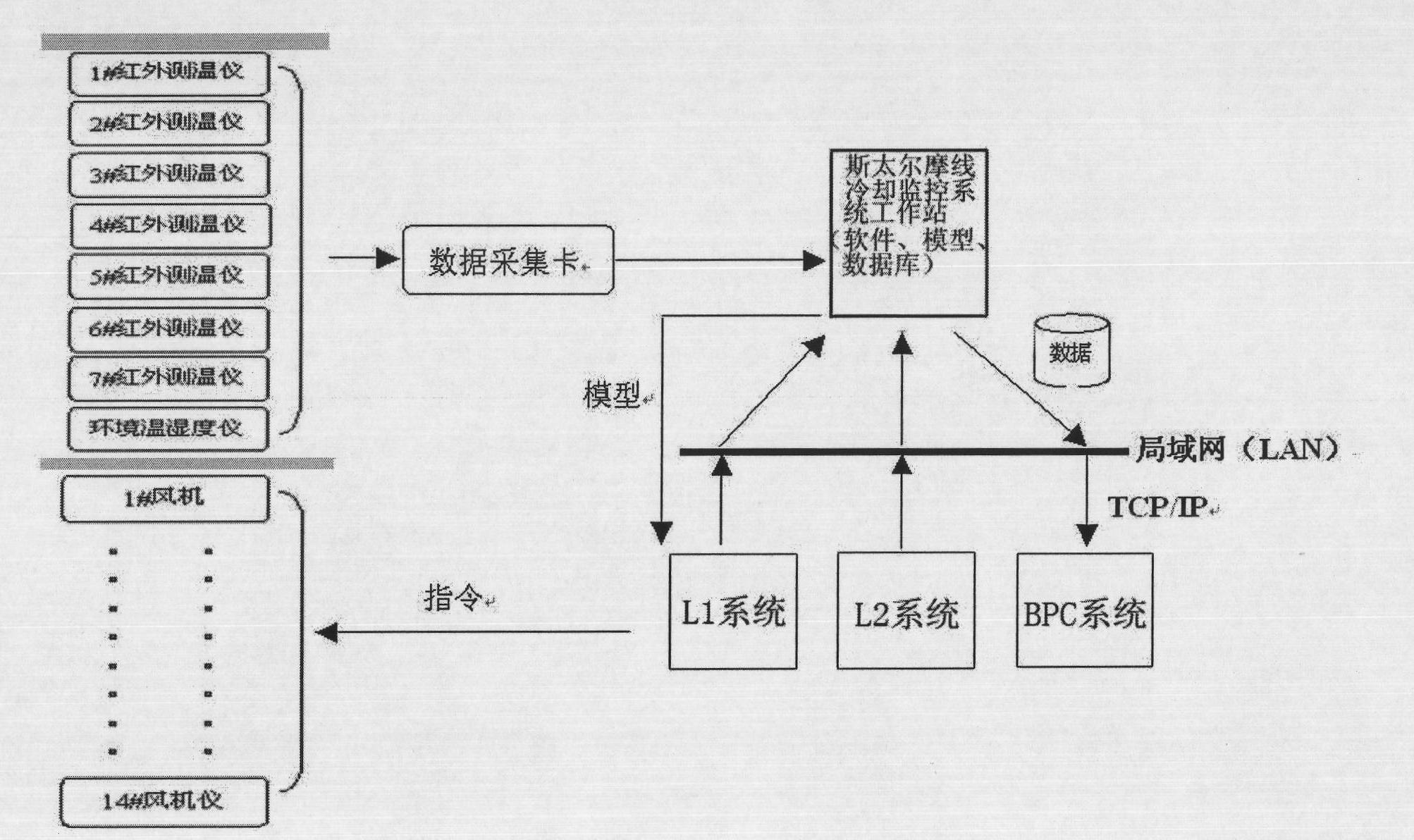

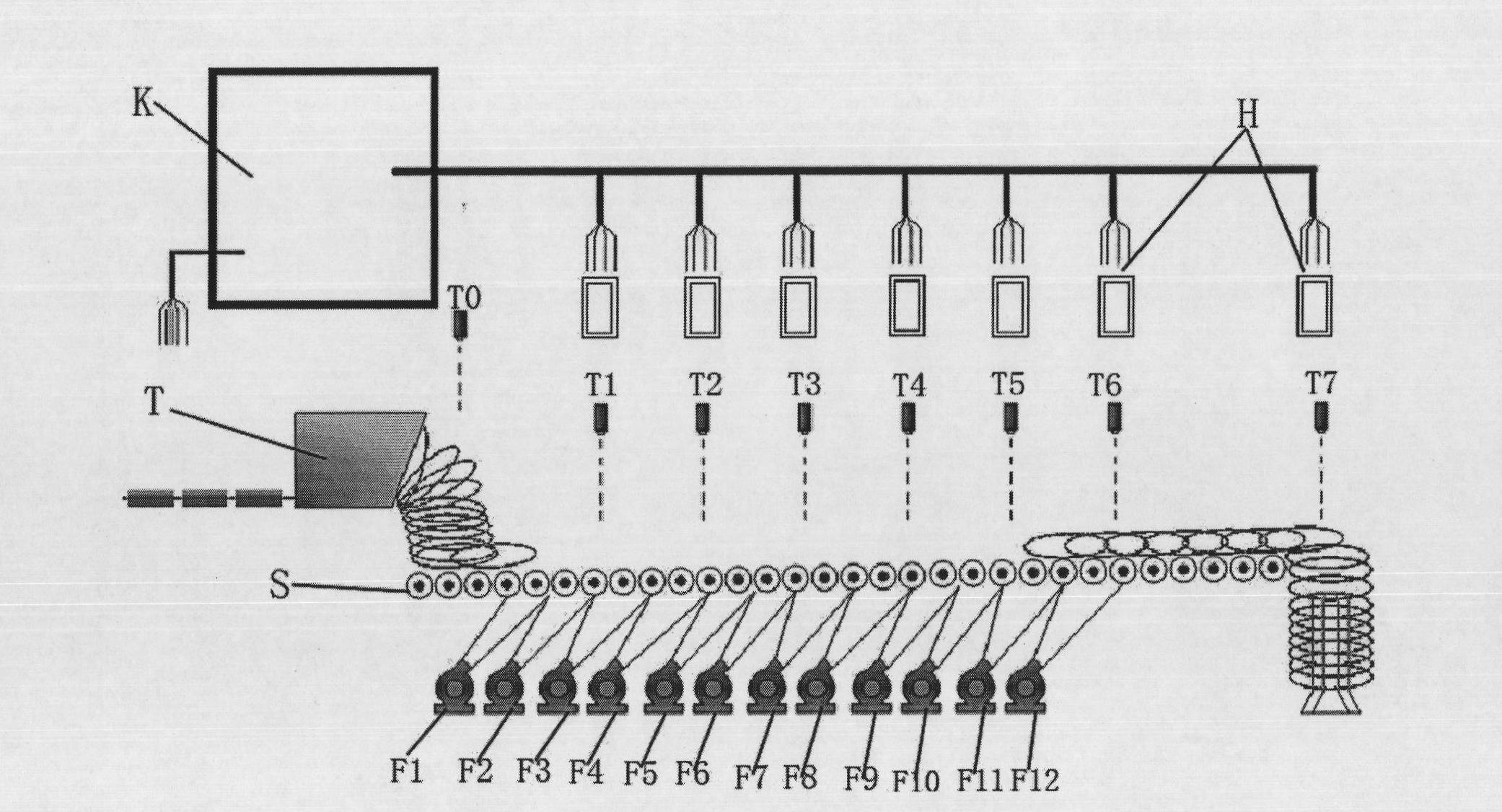

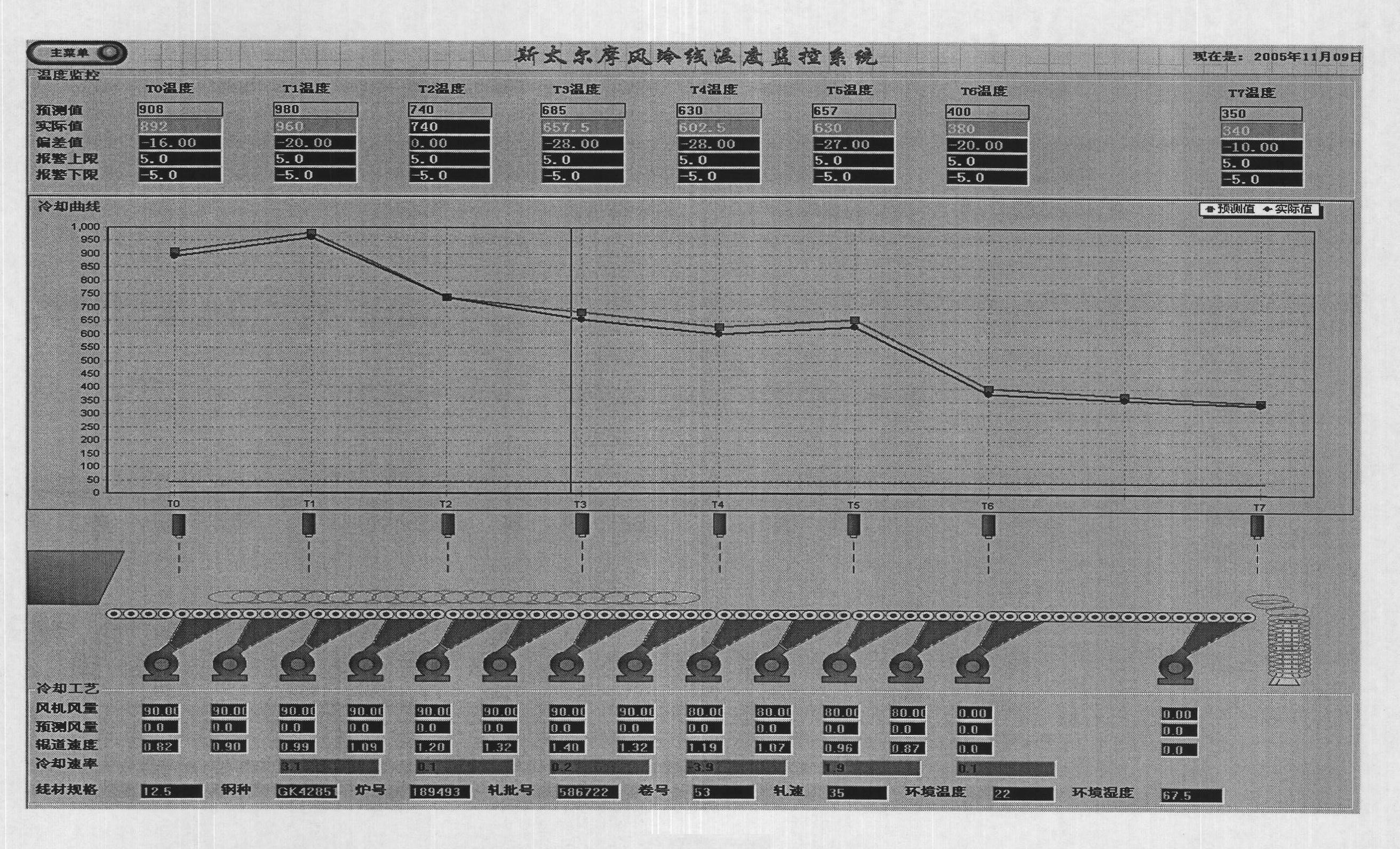

Stelmor line cooling method of high-speed wire by taking temperature as direct-control parameter

ActiveCN102151704AImprove tissue performanceReduce manufacturing costTemperature control deviceWork treatment devicesAir volumeData collector

The invention discloses a Stelmor line cooling method of a high-speed wire by taking temperature as a direct-control parameter, comprising the steps of: respectively arranging seven infrared thermo detectors at the first to sixth sections and a gathering coil of the Stelmor line and additionally arranging an environment temperature and humidity meter; additionally arranging a computer, an interface, a data collector, a cable and the like to realize integrally reasonable installation; establishing an assorted software system and forming a standard cooling curve and an actual cooling curve of the wire on the Stelmor line; establishing a Stelmor optimal cooling curve prediction model and a Stelmor line fan air volume set prediction model by using neural network technology; deriving the air volume set value of each fan; and eliminating the difference between the actual cooling curve and the standard cooling curve. By means of the invention, a Stelmor dynamic closed loop type cooling control system is established, the bad influences on the intensity caused by the chemical components and the fluctuation of the environment temperature are eliminated, the structure properties of various wire products can be optimized and the accurate control of the structure properties of the wire products is realized.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for constructing karren stratum shield tunnel

The invention relates to a technology for constructing a karren stratum shield tunnel, in particular to a method for constructing a karren stratum shield tunnel, aiming to overcome the defects of the traditional method. The method for constructing the karren stratum shield tunnel comprises the following steps: (1) optimizing tunnel entrance steel ring structures: arranging elastic rubber water stopping rings in tunnel entrance steel rings, rubber water stopping curtain fabric on the outmost end and slurry injection holes and slurry injection pipes at the periphery; (2) constructing enclosing and protecting structures of a station by adopting glass fiber reinforced bars so that a shield machine enters the shield tunnel by shearing; (3) during the construction of the body of the station, making the shield machine move forward rapidly so that folding plates outside the rubber water stopping curtain fabric are overlapped on cutter discs, and injecting shield machine tail grease between the two rubber water stopping curtain fabric through injection holes; and (4) splicing shield tunnel pipe pieces, connecting the shield tunnel pipe pieces into a whole by using I-shaped steel, and supplementing slurry for the second time after the tail of the shield machine enters between the rubber water stopping curtain fabric. The shied machine can enter the shield tunnel safely and rapidly, and the method for constructing the karren stratum shield tunnel has simple working procedures, adopts the advanced technology, is safe and reliable, fills the blank of the technology for constructing the non-reinforced shield tunnel and has good popularization prospect.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

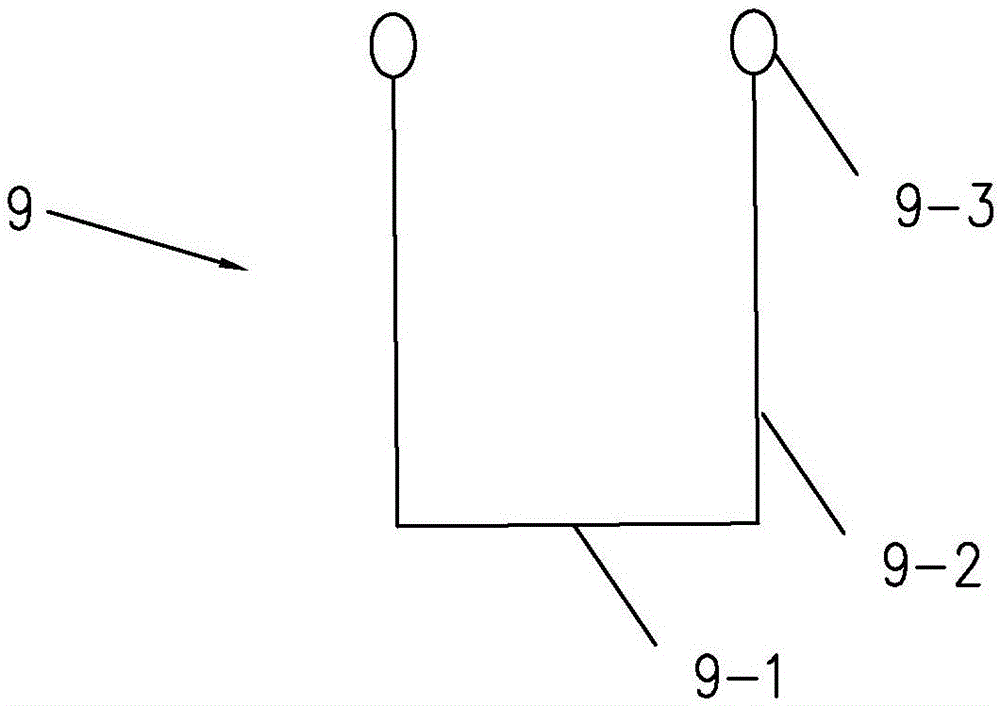

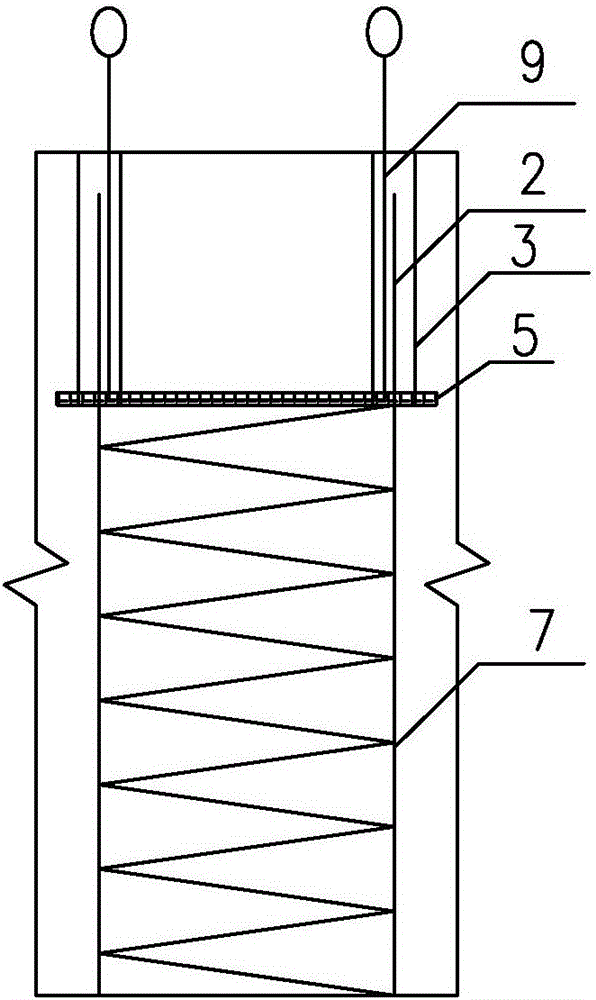

Integral quick lifting method for pile head of drilled pile during pre-embedding and drilling-free ring-cutting

ActiveCN106400802AReduce security risksReduce construction difficultyExcavationsBulkheads/pilesChinese charactersRebar

The invention discloses an integral quick lifting method for a pile head of a drilled pile during pre-embedding and drilling-free ring-cutting. The integral quick lifting method comprises the following steps of: mounting the drilled pile in front of a reinforcement cage after the drilling is ended, directly embedding foam sponge pipes into main ribs of an exposed supporting table of the reinforcement cage and an outer-end surface of a sounding pipe, fixing the foam sponge pipes by use of rubber bands to ensure that the foam sponge pipes do not slide; coating the foam sponge pipes outside a reinforcement positioning frame in the shape of Chinese character jing and a ring-shaped reinforcement positioning ring in advance; replacing drilling by use of a PVC tube every 40-50 cm along the perimeter of the pile body on the positioning frame, covering the foam sponge pipes for conveniently identifying positions during breaking construction; after foundation pit excavation is completed, lightly knocking at a position 10 cm above elevation of a pile top to expose the PVC tubes and the positioning ring, inserting a separating wedge into the PCV tubes, knocking with external force until the pile head is completely separated from the pile body; and utilizing lifting equipment to perpendicularly lift the upper pile head. The construction method is suitable for integral breaking and lifting construction of pile heads of foundation projects of highways, high speed railways, subways and high-rise buildings.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG

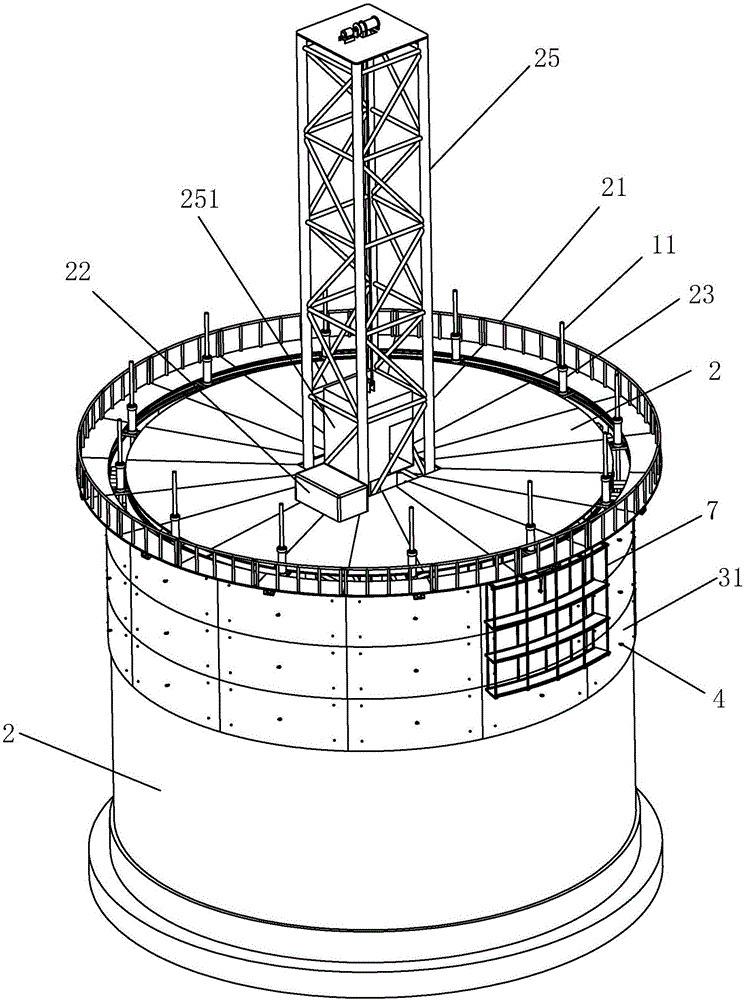

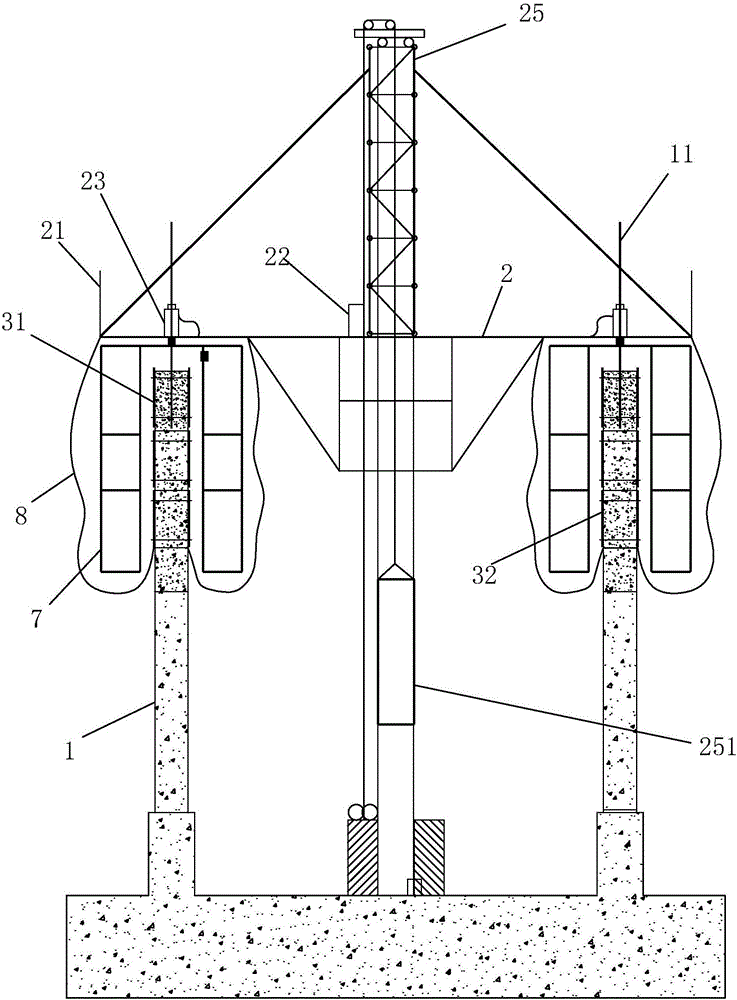

Chimney formwork turning construction device

The invention discloses a chimney formwork turning construction device. According to the technical scheme, the chimney formwork turning construction device is characterized in that the device comprises an operation platform, a lifting device for driving the operation platform to move upwards, at least two layers of inner formworks arranged on the inner wall of a chimney in a surrounding mode, and at least two layers of outer formworks arranged on the outer wall of the chimney in a surrounding mode; an annular casting cavity is defined by the inner formworks and the outer formworks; the inner formworks and the outer formworks are arranged in the vertical direction; fixing devices are arranged between the outer formworks and the inner formworks; and a hanging racket for allowing constructors to assemble or disassemble the inner formworks and the outer formworks is arranged below the operation platform. In the construction process, steel bars are bundled at first, the inner formworks and the outer formworks are assembled and fixed on the top of the chimney subjected to casting molding, an operator injects concrete into the casting cavity on the operation platform, the operation platform is lifted after the concrete is shaped, the steel bars continue to be bundled, then the inner formwork and the outer formwork on the lowermost portion are detached and installed to the position below the operation platform, another new casting cavity is formed, and the operations are conducted repeatedly till the required casting height is achieved.

Owner:黄晖

Large area super-flat reinforced concrete floor and colorful diamond sand surface layer one-step forming method

InactiveCN107060171ALow costSolve common quality problemsFloorsFlooringSurface layerReinforced concrete

The invention relates to a large area super-flat reinforced concrete floor and colorful diamond sand surface layer one-step forming method. The one-step forming method comprises the steps of template erection, steel bar binding, expansion reinforcing band arrangement, elevation measurement, steel bar elevation check, laser leveler adjustment, concrete pouring, laser leveler leveling, professional leveling, diamond sand spreading, grinding and flexible compacting, polishing, construction seam cutting, curing, finished product curing and upper structure construction. According to the one-step forming method, a structural floor is used as a base layer, a diamond sand floor surface layer and a structure are subjected to one-step pouring forming, the common quality problem that the floor surface layer is prone to forming hollow protrusions due to secondary pouring is avoided, meanwhile, one concrete base layer is reduced, and cost is greatly reduced. The floor is fully covered with recyclable materials such as plastic films and templates so that an upper main structure can continue to be conveniently constructed.

Owner:SHANGHAI SENXIN CONSTR ENG

Unstressed permeating washing scabbling technology

InactiveCN104372952AShorten the setting timeTo achieve a rough effectBuilding material handlingHigh pressure waterHigh pressure

The invention belongs to the technical field of concrete surface aggregate scabbling treatment, and particularly provides an unstressed permeating washing scabbling technology. The unstressed permeating washing scabbling technology comprises the main steps that (1) construction preparation is carried out, wherein concrete surface treatment retarder is mixed on the basis of traditional concrete construction preparation, and a formwork for construction is mounted; (2) the formwork is cleaned; (3) the concrete surface treatment retarder is brushed; (4) after the brushed concrete surface treatment retarder is air-dried, concrete starts to be poured; (5) the formwork is dismounted; (6) laitance is washed off with high-pressure water; (7) after the laitance is washed off with the water, whether missing happens in the brushing process of the concrete surface treatment retarder or not is checked. The face needing to be scabbled is smeared with the retarder, the concrete curing time of the scabbled face of 5 mm to 10 mm is slowed down, the concrete surface reaches the rough effect through washing and brushing after the formwork is dismounted, common quality problems of traditional scrabbling are effectively solved, and construction cost is saved.

Owner:中交二公局第五工程有限公司

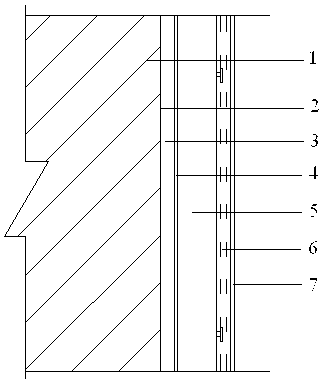

Thick plastered exterior wall outer heat-insulation system with double-layer gridding cloth compounded with foam cement boards

InactiveCN103276822AImprove wind pressureImprove system securityHeat proofingLoad resistanceCement board

The invention discloses a thick plastered exterior wall outer heat-insulation system with double-layer gridding cloth compounded with foam cement boards. The thick plastered exterior wall outer heat-insulation system comprises an interface layer, a leveling layer, an adhesion mortar layer, a heat-insulation layer with the foam cement boards, an anti-crack protective layer with the inlaid double-layer gridding cloth and a finishing layer. The interface layer, the leveling layer, the adhesion mortar layer, the heat-insulation layer with the foam cement boards, the anti-crack protective layer with the inlaid double-layer gridding cloth and the finishing layer are sequentially fixedly connected with one another from the inside to the outside on the basis of a base-layer wall, joint filling and leveling heat-insulation materials are embedded in gaps of the foam cement boards in the heat-insulation layer with the foam cement boards, and the anti-crack protective layer with the inlaid double-layer gridding cloth comprises first gridding cloth, anchoring parts, second gridding cloth and three layers of anti-crack mortar. The thick plastered exterior wall outer heat-insulation system has the advantages that common quality problems of plate marks, anchor bolt marks, cracks and the like of a thin plastered system can be solved, the anchoring parts are assuredly positioned on the outer side of the gridding cloth, performance indexes of the wind load resistance, water absorption, impact resistance and the like of the outer heat-insulation system are increased, and the safety of the system is improved.

Owner:JIANGSU NIGAO SCI & TECH +1

Process for preventing crack of frame, bent and short-leg shear wall filler wall

InactiveCN101333827ASolve common quality problemsImprove project qualityWallsBuilding insulationsPolystyreneEconomic benefits

The invention belongs to the industrial and civil construction forming field, in particular relates to the connection-formation field of the light material applied in the building wall body; the improvements of a prevention frame, a bent, a short-leg shear wall and the wall crack filling process method thereof include that the work procedures are as follows: (1) the line-putting in the construction; (2) the reinforced bars planting; (3) the substrate layer cleaning; (4) the polystyrene board cutting; (5) the mortar mixing of the polymers; (6) the polystyrene board sticking and (7) the net addition. when the decoration construction of the processed frame, the bent and the short-leg shear wall and the filling of the wall body are finished, the temperature crack is controlled effectively; the method is popularized and used completely in the group company; not only the engineering quality is improved comprehensively, but also the general quality problem that the cracks occur in the guard wall body so that good social and economic benefits are obtained.

Owner:ZHONGTAI CONSTR GROUP

New construction method of municipal road inspection well

InactiveCN106567410ASolve common quality problemsArtificial islandsUnderwater structuresSurface layerReinforced concrete

The invention discloses a new construction method of a municipal road inspection well. The method is characterized by comprising the following steps: 1) foundation pit soil of the inspection well is excavated; 2) the foundation is treated; 3) widened parts around the inspection well and empty parts between pipe foundations are treated for compaction and leveling; 4) the inspection well is built; and a bearing stratum is filled; 5) a water stabilization basic layer is paved; 6) an opening of the inspection well is temporarily and tightly covered by a wood cover or a steel plate; 7) a bottom layer in asphalt concrete is paved, leveled and rolled; 8) the bottom layer of the asphalt concrete paved around the inspection well is excavated out; 9) a reinforced concrete structural layer is cast at the reverse excavated part in situ; 10) a prefabricated well ring and a well lid are mounted; 11) an asphalt concrete surface layer is cast in situ; and 12) a road basic layer is covered for maintenance. The construction method can effectively reinforce the manual compaction and surface reinforcing treatment of the road foundation around the well to prevent the well periphery sedimentation and the well lid damage so as to achieve the effects of safety and beauty.

Owner:WENZHOU XINGYE MUNICIPAL CONSTR

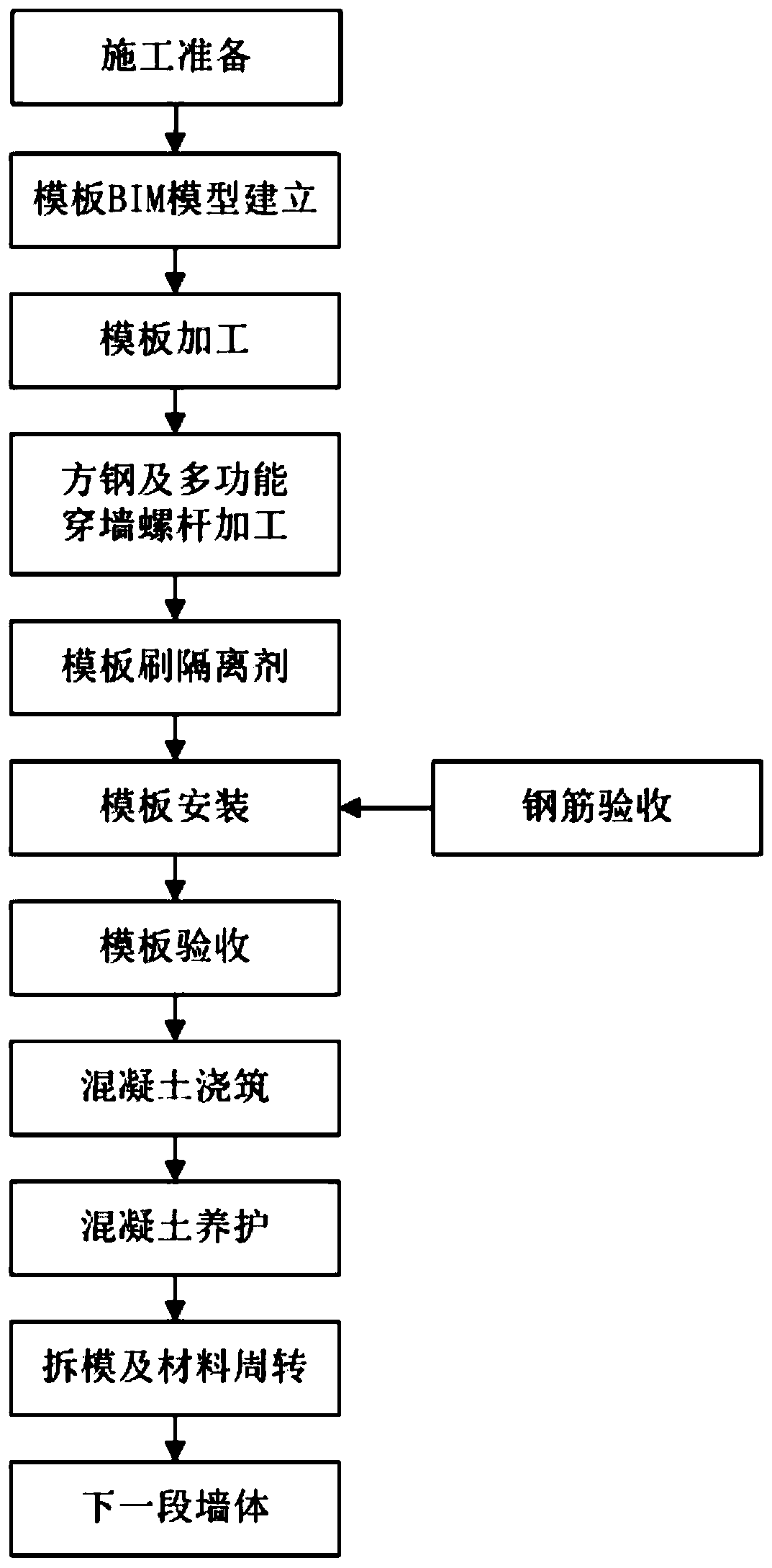

Faced concrete outer wall template construction method

InactiveCN111005557AEvenly distributedFacilitate customization in advanceGeometric CADForms/shuttering/falseworksSteel tubeScrew system

Owner:广东恒辉建设集团股份有限公司

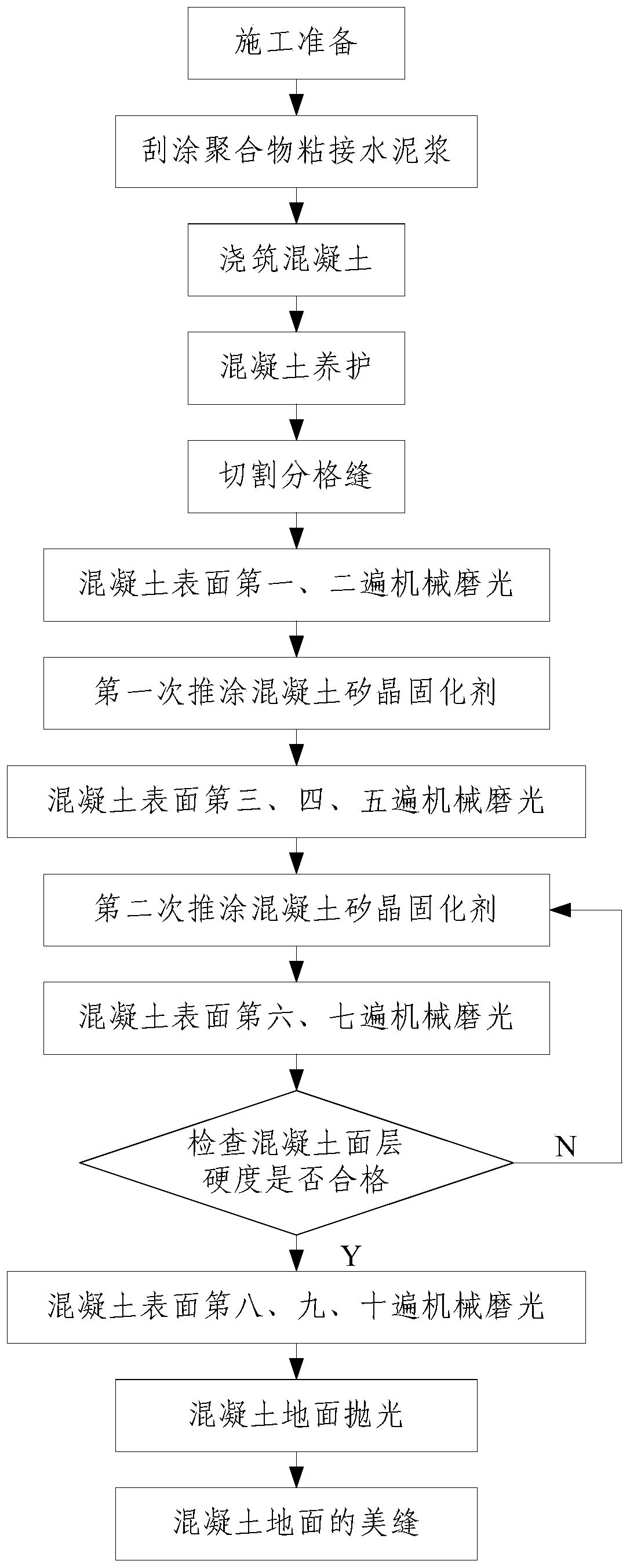

Abrasion-resistant concrete terrazzo floor construction method

InactiveCN109797945AImprove performanceVariety of colorsFlooringPlane surface grinding machinesCement pasteTerrazzo

The invention discloses an abrasion-resistant concrete terrazzo floor construction method. The abrasion-resistant concrete terrazzo floor construction method includes the steps of 1, construction preparation, 2, scrape coating of polymer binding cement paste, 3, concreting, 4, concrete curing, 5, dividing joint cutting, 6, first and second mechanical lapping of concrete surfaces, 7, first push coating of silicon-on-insulator curing agents, 8, third, fourth and fifth mechanical lapping of concrete surfaces, 9, second push coating of silicon-on-insulator curing agents, 10, sixth and seventh mechanical lapping of concrete surfaces, 11, concrete surface check, 12, eighth, ninth and tenth mechanical lapping of concrete surfaces, 13, concrete floor polishing, and 14, caulk sealing of concrete surfaces. The abrasion-resistant concrete terrazzo floor construction method has the advantages that the silicon-on-insulator curing agents permeate into the concrete surfaces by conducting push coatingtwice during multi-time concrete surface lapping, and therefore the concrete floor surfaces are reinforced, cured and hardened to form non-expansion shrinkproof high-strength compounds of smooth andabrasion-resistant structures.

Owner:陕西建工集团股份有限公司

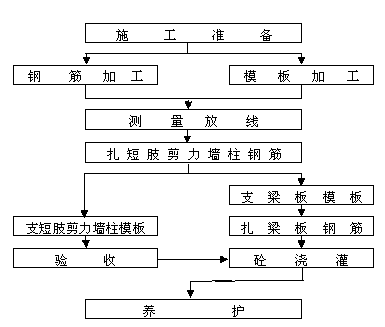

Main structure construction method by sequentially processing beam slab frameworks, short-leg shear wall and column frameworks

InactiveCN103266766AConstruction duration shortenedShorten the time intervalBuilding material handlingFloor slabConcrete beams

The invention relates to a main structure construction method by sequentially processing beam slab frameworks, short-leg shear wall and column frameworks. The method includes the following steps: a, strapping short-leg shear wall and column rebars; b, mounting the beam slab frameworks; c, calibrating the shear wall and column rebars before strapping beam rebars, immediately performing inspection after strapping the beam rebars, and then strapping floor slab rebars; d, mounting the short-leg shear wall and column frameworks when strapping the floor slab rebars; and e, simultaneously pouring concrete to beam slabs, floor slabs and short-leg shear walls and columns. In the method, mounting of the short-leg shear wall and column frameworks and strapping of the beam slab rebars and the floor slab rebars which are completely not in the same working face can be performed simultaneously, and the mounting of the short-leg shear wall and column frameworks becomes a non-critical work from a critical work and does not occupy construction periods, so that main engineering construction duration of the whole frame shear structure is reduced, and a main structure construction period and time intervals in shutdown and waiting of labor force are greatly shortened.

Owner:JIANGNAN CONSTR CO LTD DONGYANG ZHEJIANG

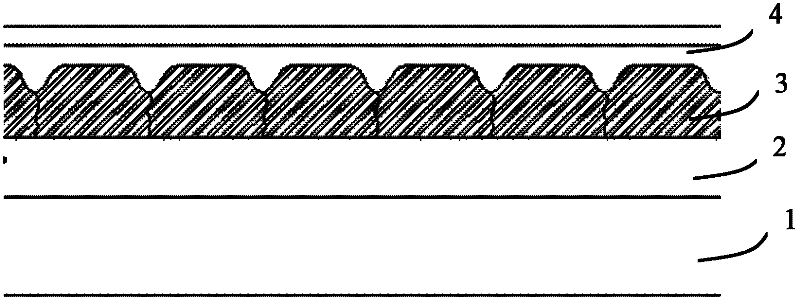

Rigid-flexible composite structural pavement and cast-in-place method and prefabricating method for manufacturing rigid-flexible composite structural pavement

ActiveCN102304885ASolve the puzzle of destructionAvoid stabilityIn situ pavingsPaving detailsConvex structureComposite construction

The invention relates to a rigid-flexible composite structural pavement and a cast-in-place method and a prefabricating method for manufacturing the rigid-flexible composite structural pavement. The rigid-flexible composite structural pavement comprises a roadbed layer, a cushion layer, a base layer, a rigid layer and a flexible layer, wherein the rigid layer comprises a plurality of regularly arranged rigid building blocks among which gaps are reserved; and the flexible layer comprises a flexible filling layer and a flexible surface layer. The top of the rigid layer is designed to a regular honeycomb concave-convex structure, and the flexible asphalt concrete layer is formed by using the property of the flexible asphalt concrete material and used for coating and filling the concave-convex gaps of the rigid building block structures, so that the pavement has the properties of rigid and flexible pavements and has the structural characteristic of rigid-flexible composite stress; and the construction cost of a road is greatly saved, the heavy-duty traffic impact resistance of the base layer of the road is greatly reinforced, the service life of the road is greatly prolonged, and the pavement is suitable for large-scale popularization and use.

Owner:杨光原 +2

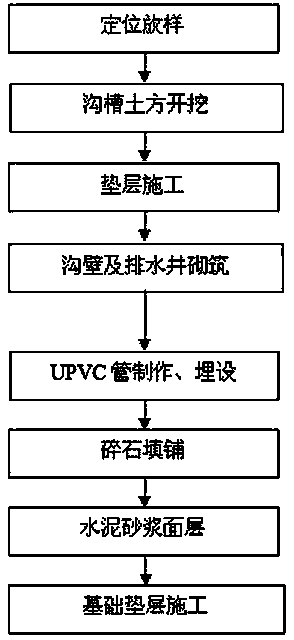

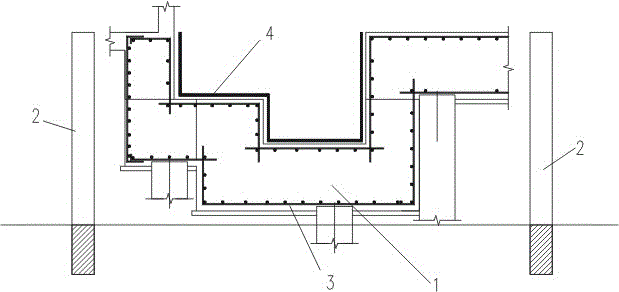

Construction method of hydrophobic structure of post-cast strip of bottom plate of basement

InactiveCN103469828AGuarantee the construction qualityTimely exclusionProtective foundationBasementPolyvinyl chloride

The invention provides a construction method of a hydrophobic structure of a post-cast strip of a bottom plate of a basement. The construction method comprises the following steps of (1) positioning and putting a sample; (2) carrying out groove earth excavation; (3) carrying out cushion layer construction; (4) building a trench wall and a draining well; (5) manufacturing and burying a rigid polyvinyl chloride (UPVC) pipe; (6) filling and laying gravels; (7) surfacing cement mortar; (8) constructing a basic cushion layer. The construction method has the advantages of being simple in construction, improving the quality, protecting the environment and the like, and is convenient for construction of the post-cast strip.

Owner:浙江天力建设集团有限公司

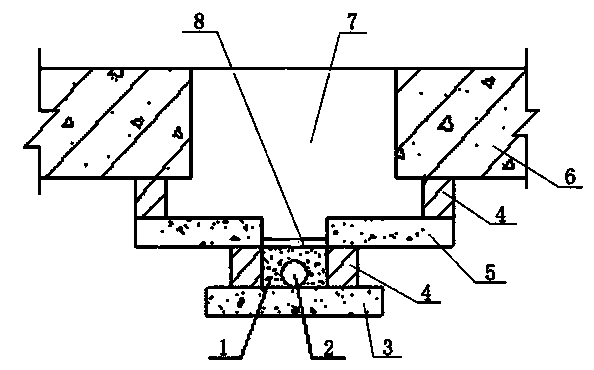

Settlement joint wall ground stone installation structure

ActiveCN102953518ASolve the problem of collision crackingAvoid safety hazardsCovering/liningsGround stoneStructural stability

The invention discloses a settlement joint wall ground stone installation structure, which comprises vertical structural members and horizontal structural members. The vertical structural members are fixedly arranged on a structural wall body. The horizontal structural members are fixedly connected with a face stone. The vertical structural members and the horizontal structural members are fixedly connected together. A movable stone panel assembly is arranged between the vertical structural members closest to the two sides of a settlement joint. The movable stone panel assembly comprises springs and a movable stone veneer. The vertical structural members on the two sides of the movable stone veneer and the two sides of the settlement joint are respectively connected with the movable stone veneer through the springs. The settlement joint wall ground stone installation structure provided by the invention has the advantages that the problem that stones collide and are cracked because a building body is displaced can be solved, the potential safety hazard that the stones fall off are avoided, the troubles in replacing the stones are reduced, the structural stability is improved.

Owner:GOLD MANTIS CONSTR DECORATION

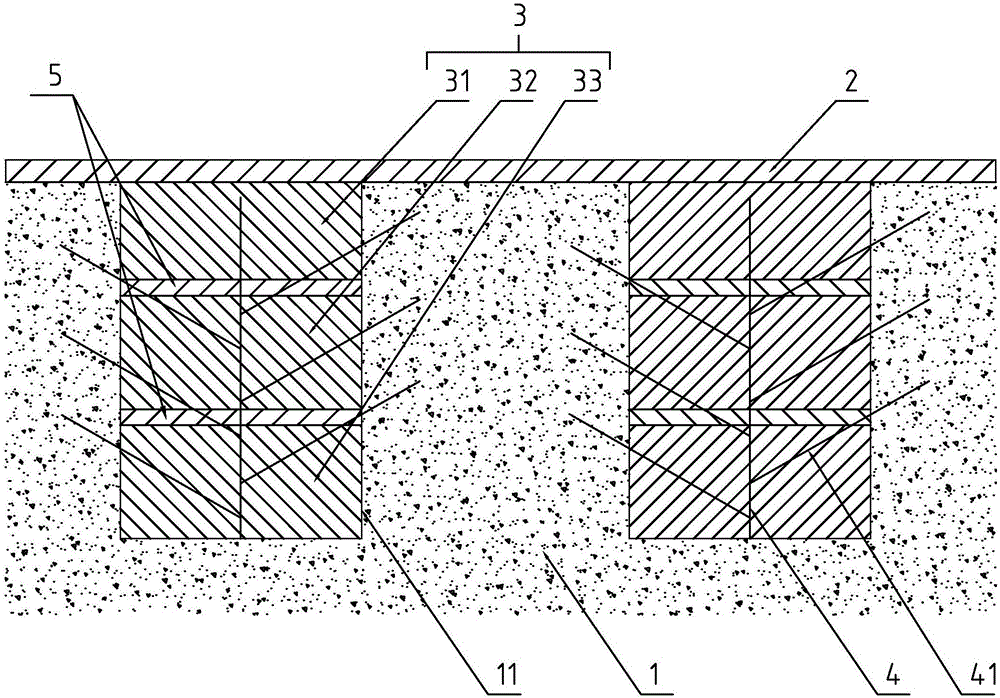

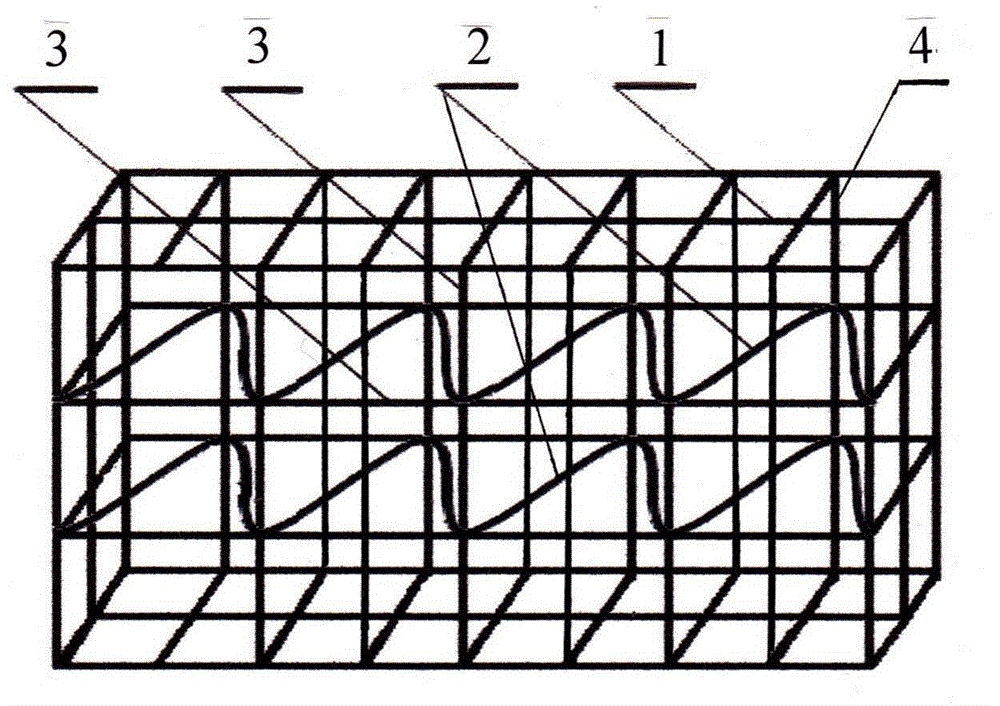

Steel wire framework heat preservation building block

InactiveCN104805950AHigh strengthImprove anti-theft functionConstruction materialUltimate tensile strengthWire mesh

The invention relates to a steel wire framework heat preservation building block and belongs to the technical field of building material products. The building block comprises a heat preservation building block body formed by combining steel wire frameworks, and is characterized in that the steel wire frameworks comprise rectangular steel wire mesh frames and Z-shaped web bars arranged in the rectangular steel wire mesh frames; and steel wires on two facades of the rectangular steel wire mesh frames are located 1-2cm beyond facades of the building block body. The block has the advantages that a wall built has high strength, an anti-theft function and very good safety performance. The block is mature in technology, good in environmental protection property and wide in application range and can replace the existing various wall building materials for use.

Owner:朱林军

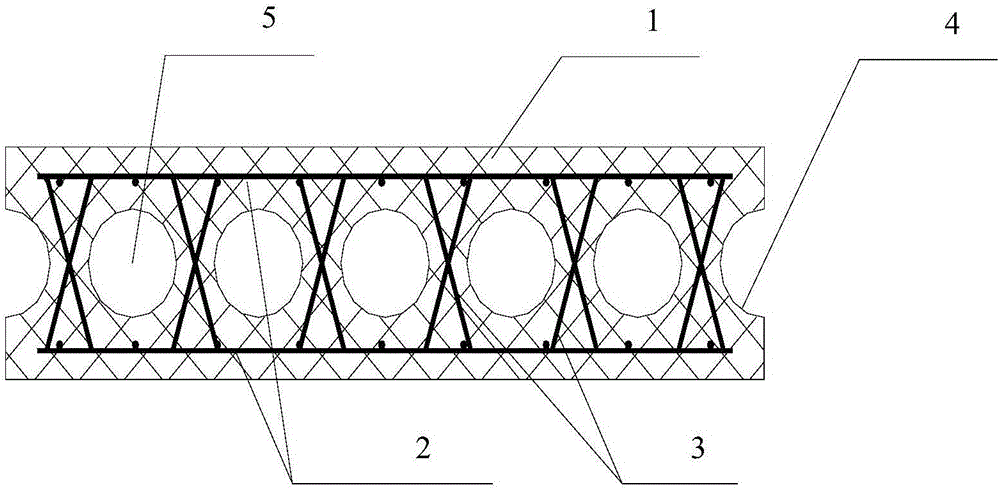

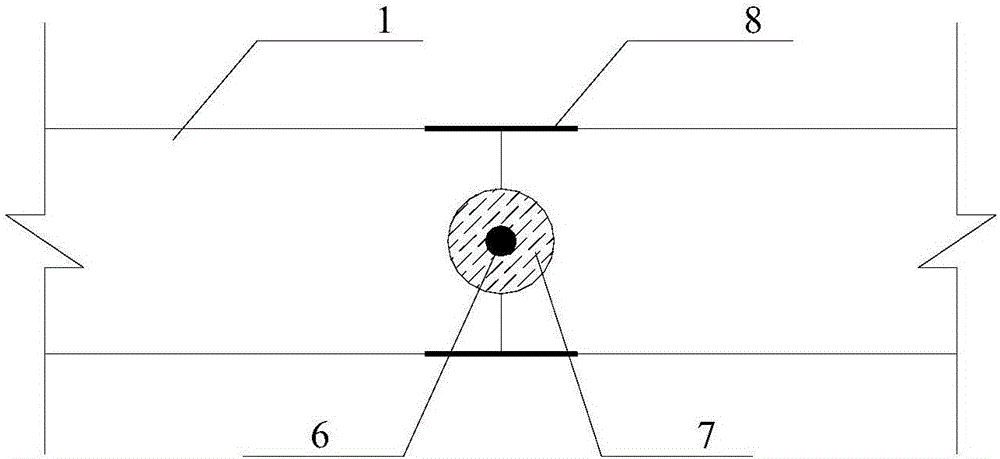

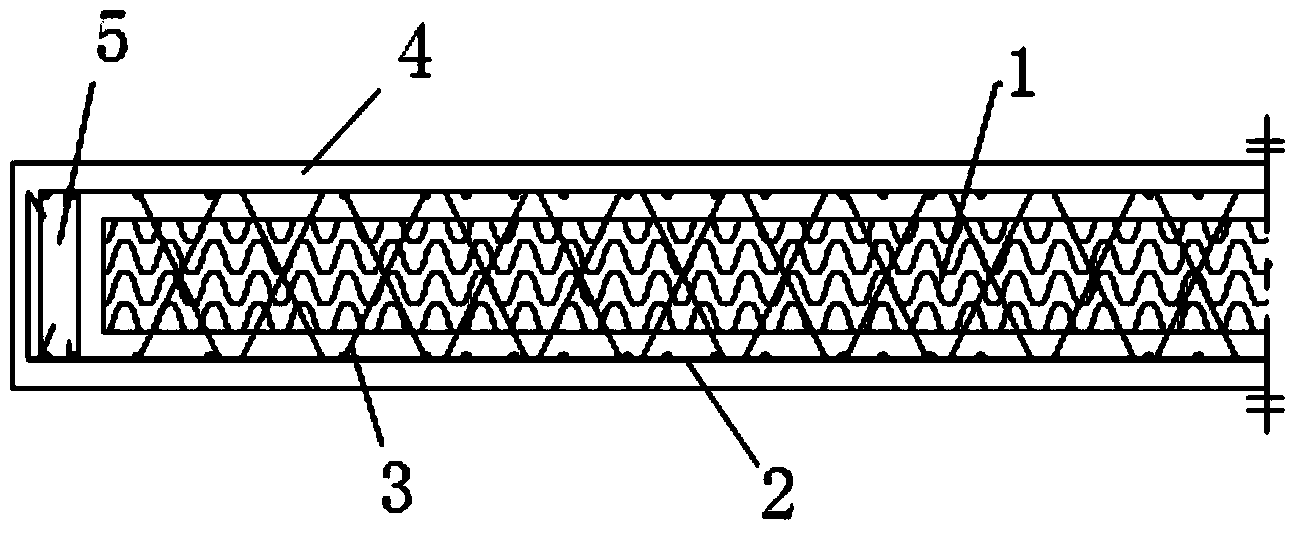

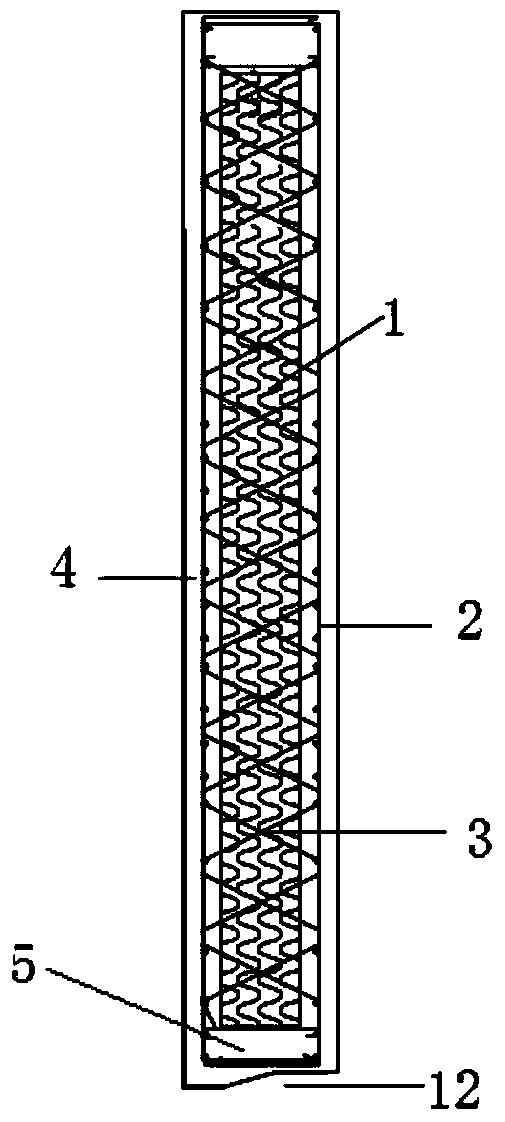

Lightweight partition board with net rack and fiber-reinforced hollows and splicing method thereof

InactiveCN105019597ASolve the adverse effects of earthquake resistanceEasy and flexible connectionBuilding componentsBuilding material handlingExpanded clay aggregateEngineering

The invention provides a lightweight partition board with a net rack and fiber-reinforced hollows and a splicing method thereof, and relates to the prefabricated partition boards of assembly type concrete structures in the field of architectural industrialization. The lightweight partition board comprises a board body, steel wire meshes, obliquely inserted bars, positioning grooves and cavities, wherein the obliquely inserted bars are fixedly connected with the upper steel wire mesh and the lower steel wire mesh to form the space net rack, the board body is formed by casting through ceramsite fiber concrete, and the upper surface and the lower surface of the board body are formed into natural rough surfaces through special formworks with foveolate protrusion structures. According to the lightweight partition board with the net rack and the fiber-reinforced hollows and the splicing method thereof, the problems that an existing partition board is prone to cracking, low in strength and high in water absorption are solved, the factory prefabrication can be achieved, the self weight is low, the flexible connection with a main body can be achieved, shock resistance can be better achieved, the construction is quick, the manufacturing cost is low, energy conservation and environment protection are achieved, safety and reliability are achieved, and sound insulation and heat preservation effects are good.

Owner:ANHUI XINHUA UNIV

Construction method for deep foundation pit of elevator shaft

ActiveCN105133619ANo standing waterSolve common quality problemsExcavationsVertical ductsWater levelWater collection

The invention provides a construction method for a deep foundation pit of an elevator shaft. The construction method comprises the following steps that construction of an auxiliary precipitation pit is firstly conducted; the depth of the auxiliary precipitation pit is 1-2 m larger than that of the deepest position of the deep foundation pit of the elevator shaft, and water drawing is conducted; then construction of the deep foundation pit of the elevator shaft is conducted, the deep foundation pit is made into a funnel-shaped water collection pit with the diameter of the bottom smaller than that of the top, and then water drawing is conducted; construction is conducted according to a drawing of the deep foundation pit of the elevator shaft, and water stop steel plates with the thickness of 3-5 mm are laid; construction is conducted on a waterproof layer of the surface of the elevator shaft; and finally concrete pouring is conducted. According to the construction method, construction is easy, the water level of a construction area of the elevator shaft can be lowered below the lowest point of the elevator shaft, it is guaranteed that no water is accumulated in the elevator shaft, then construction of the next procedure is conducted, and therefore water seepage risks are reduced, construction quality is improved, the construction period is shortened, and the aim of lowering cost is achieved.

Owner:CHINA FIRST METALLURGICAL GROUP

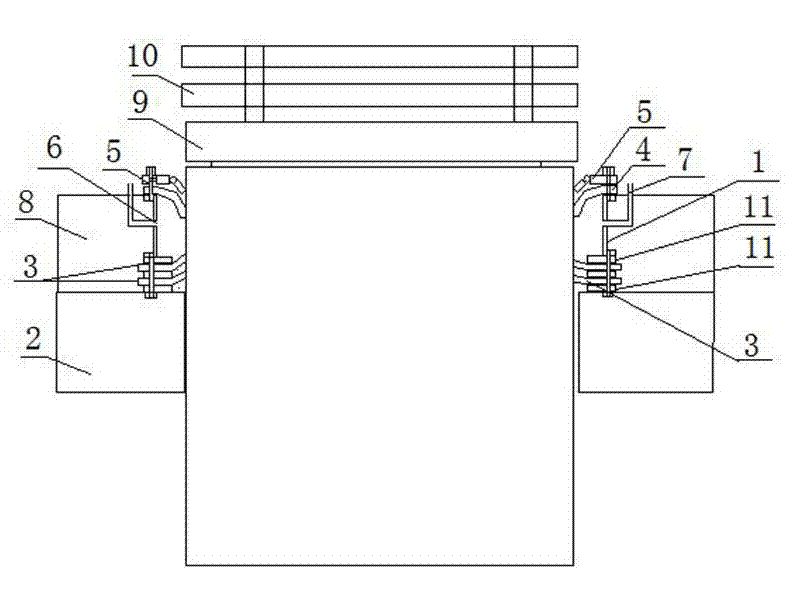

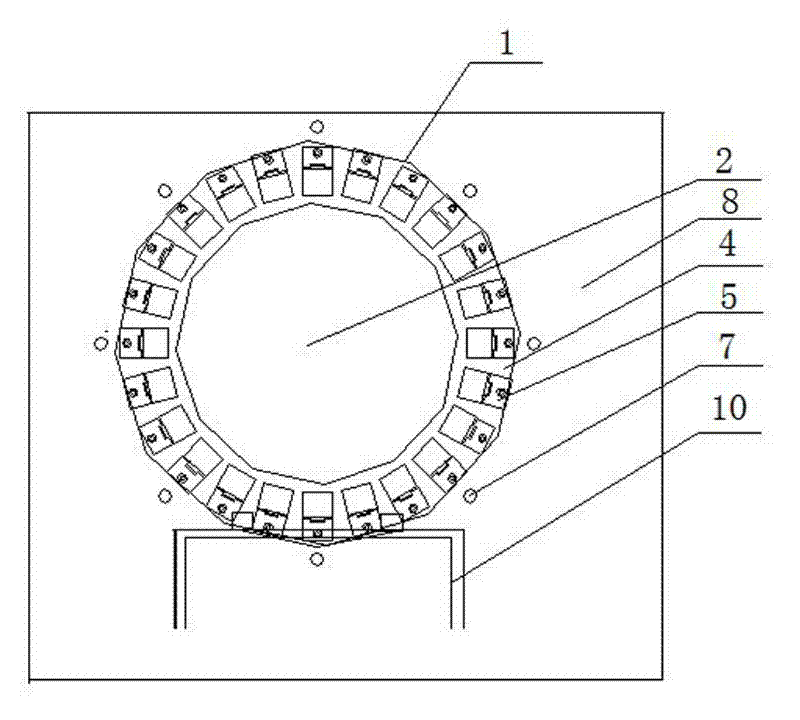

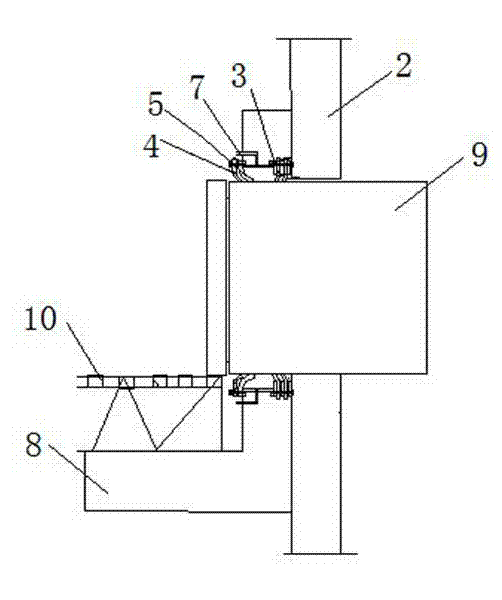

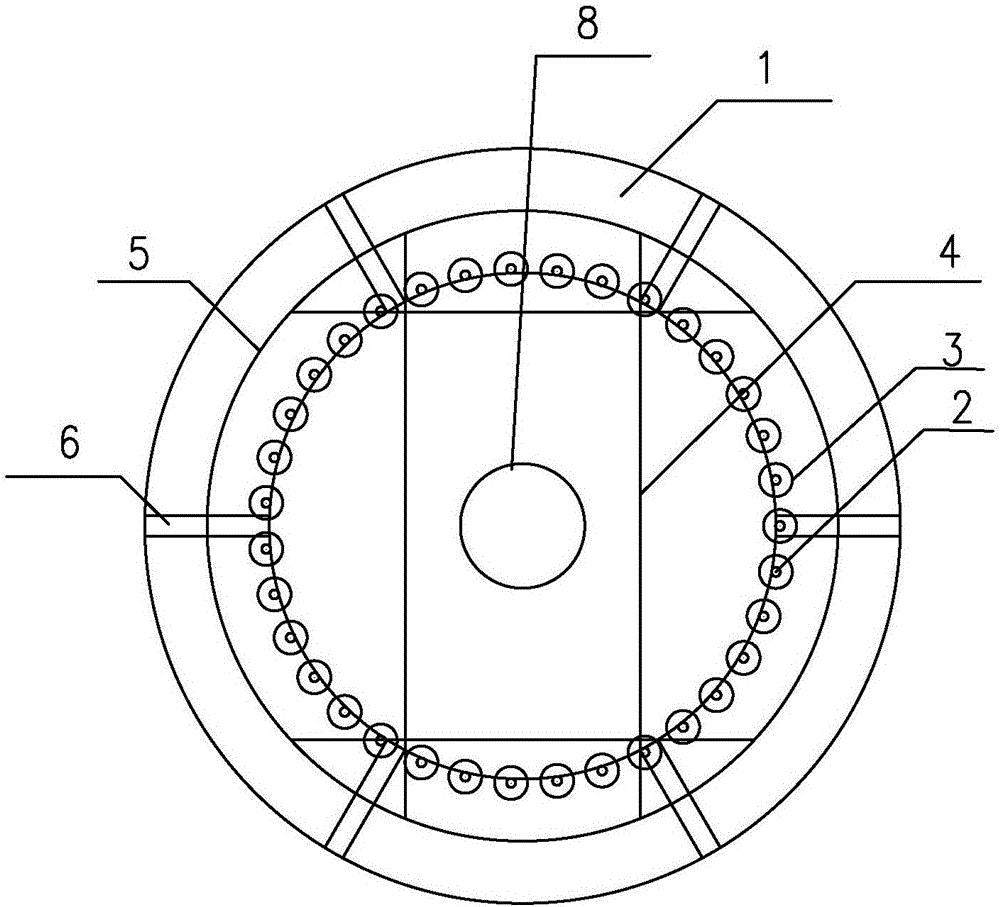

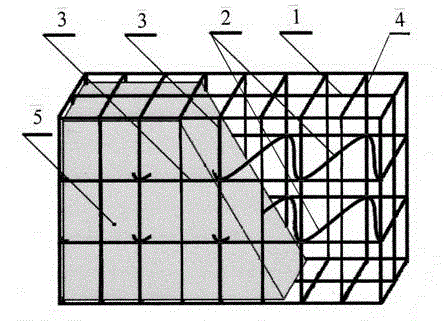

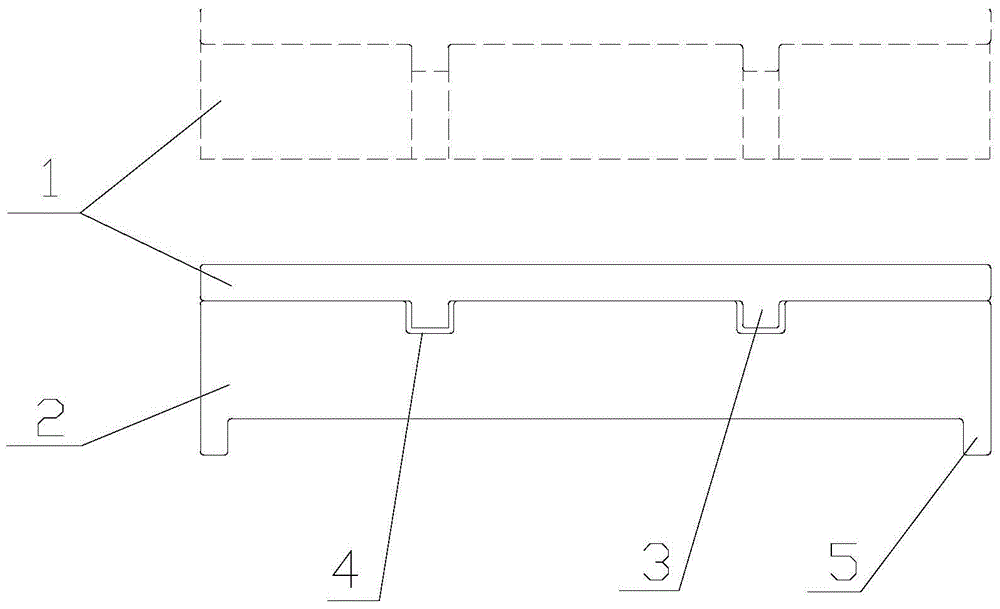

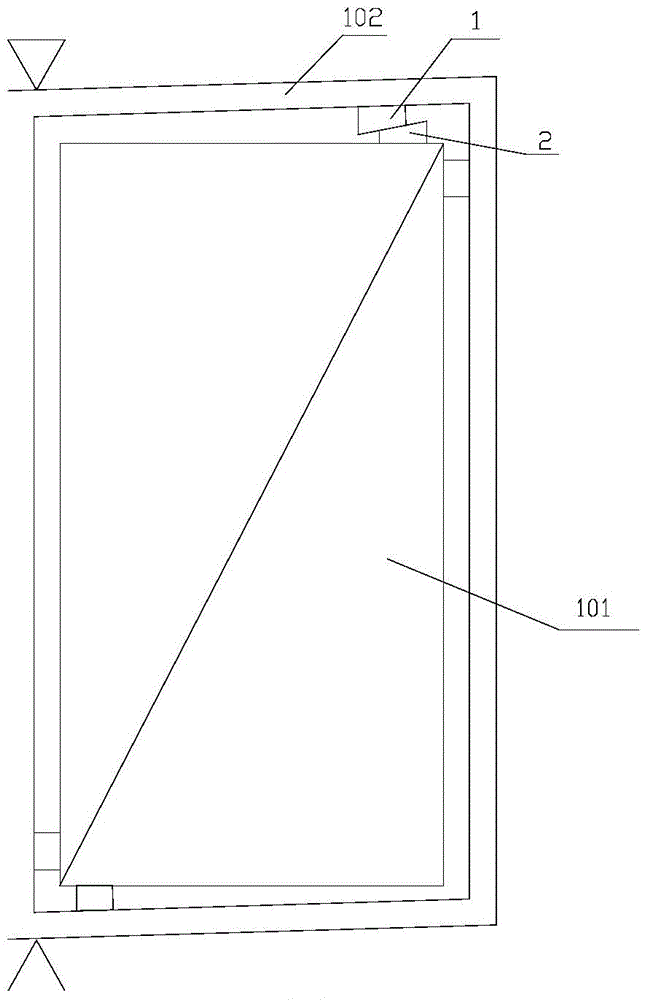

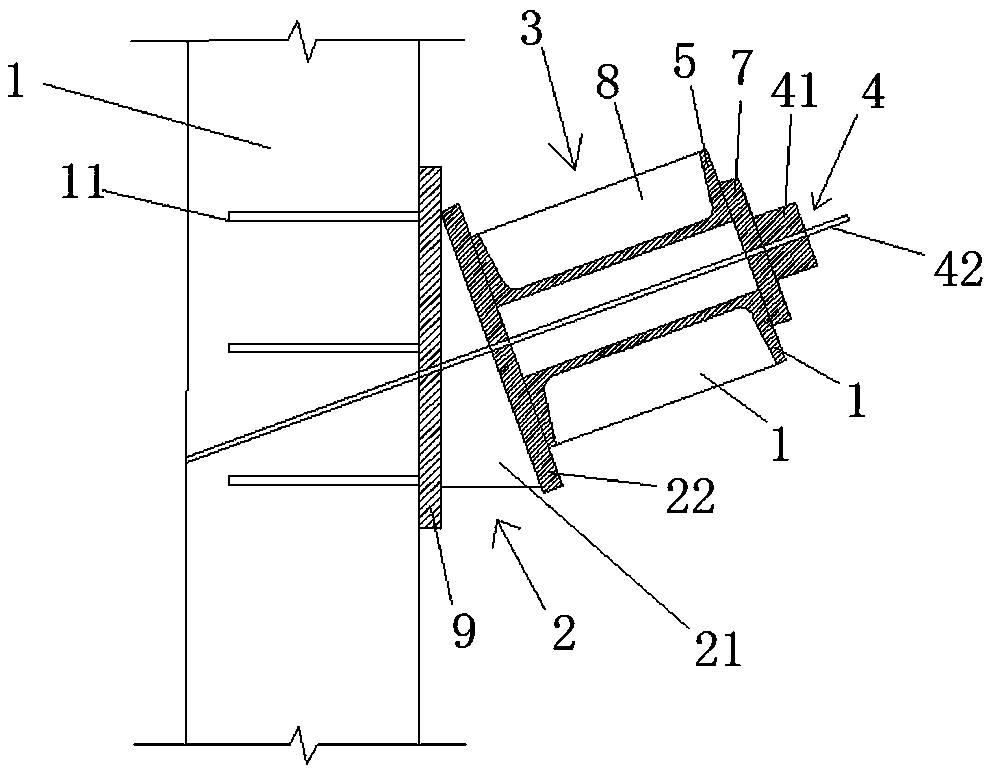

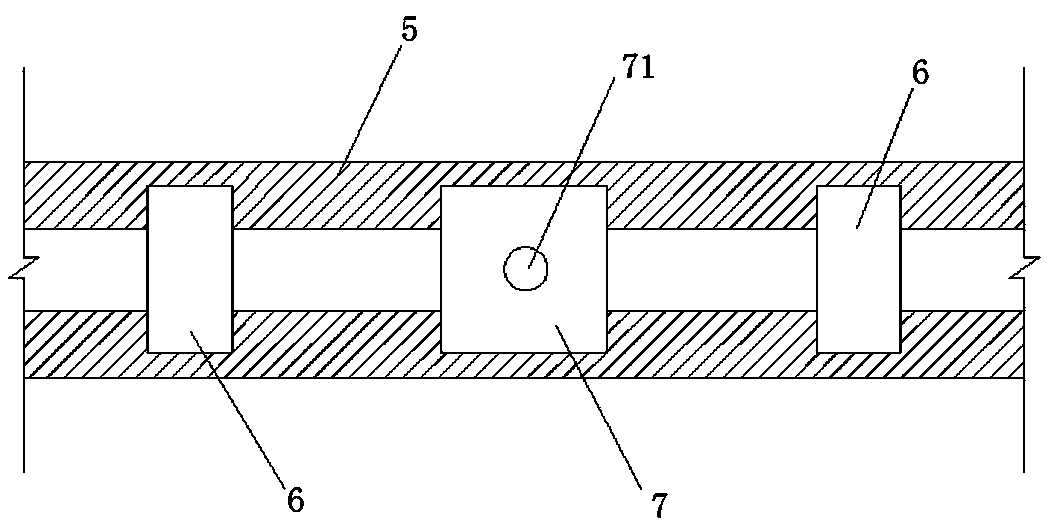

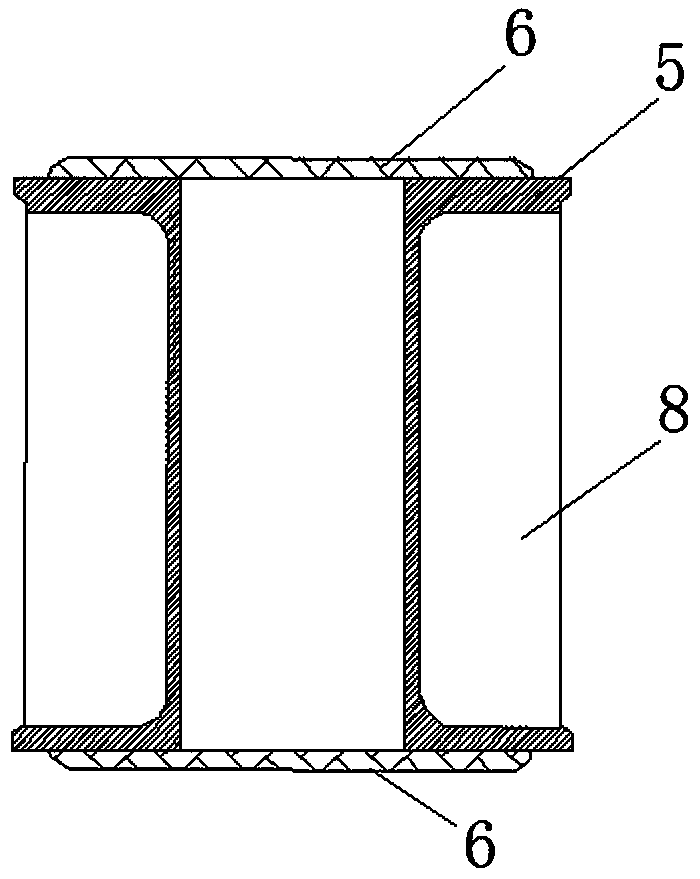

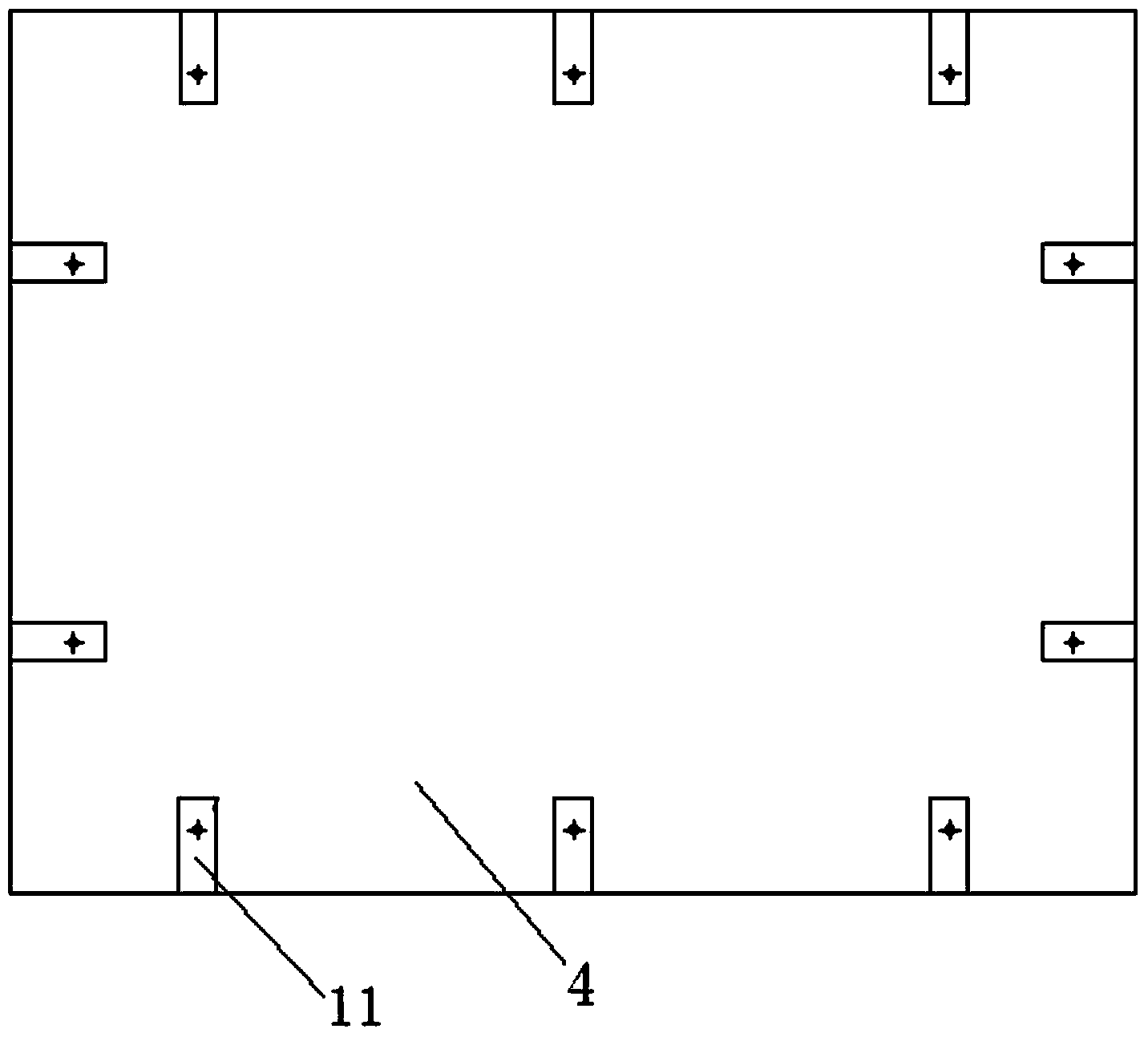

Light partition wall

The invention discloses a light partition wall which comprises unit brickworks (1), a fastener screw cap (2), a fastener bolt (3), an assembled fastener body (4) and an I-shaped metal frame (5), wherein the assembled fastener body (4) is a T-shaped structural part, a hole is arranged on the assembled fastener body (4), the fastener screw cap (2) is provided with an inner wire per se, the screw cap (2) and the fastener bolt (3) are matched with each other to fix the assembled fastener body (4) onto the I-shaped metal frame (5) so as to form into a plurality of spaces capable of independently containing the unit brickworks (1), and the plurality of unit brickworks (1) are filled into the spaces to form the light partition wall. The screw cap (2) and the fastener bolt (3) are matched with each other to be fixed on the I-shaped metal frame (5) so as to form a hooking and fastening end, and the assembled fastener body (4) is hooked and fastened to the hooking and fastening end through the hole on the assembled fastener body. According to the light partition wall, the cyclic utilization rate of the material can be improved, the facing construction difficulty on the surface of the light partition wall can be reduced, and the common quality problems of the conventional gypsum brickwork can be avoided.

Owner:GOLD MANTIS CONSTR DECORATION

Wedge-shaped combined glass cushion block

InactiveCN104088567ASolve common quality problemsElimination due to toleranceGlass pane fixingSash windowEngineering

The invention discloses a wedge-shaped combined glass cushion block and relates to the technical field of structural engineering. The wedge-shaped combined glass cushion block comprises a first cushion block and a second cushion block which are in fit with each other, both the first cushion block and the second cushion block are wedge-shaped, a guide strip is arranged on the first cushion block, and a guide groove matched with the guide strip is formed in the second cushion block. The wedge-shaped combined glass cushion block is combined through two wedge blocks with the same gradient, different cushion block heights can be produced by changing the positions of the wedge blocks, and the condition of adjusting the cushion blocks continuously in a changing manner is realized. Through the adoption of the wedge-shaped combined cushion, the tolerance can be eliminated completely, the deflection can be prevented, and the common quality problem of sash edge failure can be solved thoroughly. The deformation resisting capability of the glass cushion block in a plane can be enhanced.

Owner:SUZHOU GOLD MANTIS CURTAIN WALL CO LTD

Press-stressed anchor cable assembly type steel waist rail and construction method thereof

PendingCN111395356AReduce pollutionLight weight structureExcavationsBulkheads/pilesPre stressArchitectural engineering

The invention discloses a pre-stressed anchor cable assembly type steel waist rail. The pre-stressed anchor cable assembly type steel waist rail comprises a plurality of triangular steel inclined cushions which are fixedly arranged on a support pile, a steel waist rail body which is welded on inclined surfaces of the triangular steel inclined cushions and an anchor cable for keeping stability of the support pile, wherein the steel waist rail body comprises two pieces of channel steel which are the same, are symmetrical back to back and are arranged in a spaced mode, a plurality of connecting batten plates for connecting the two pieces of channel steel and a plurality of pressure-bearing plates which are symmetrically welded on left and right side surfaces of the two pieces of the channel steel; the connecting batten plates are arranged in the spaced mode; the two ends of each connecting batten plate are separately welded on the side surfaces of two pieces of channel steel; through holes are formed in positions, different from a welding area, on middle regions of the pressure-bearing plates; the anchor cable comprises an anchorage device, an anchor cable body and an anchor root, wherein the anchorage device is blocked outside the pressure-bearing plates; the anchor cable body sequentially passes through the through holes, the triangular steel inclined cushions and the support pile; and the anchor root at the tail end is fixedly arranged on a nearby rock body.

Owner:FUJIAN YONGTAI CONSTR ENG CO +1

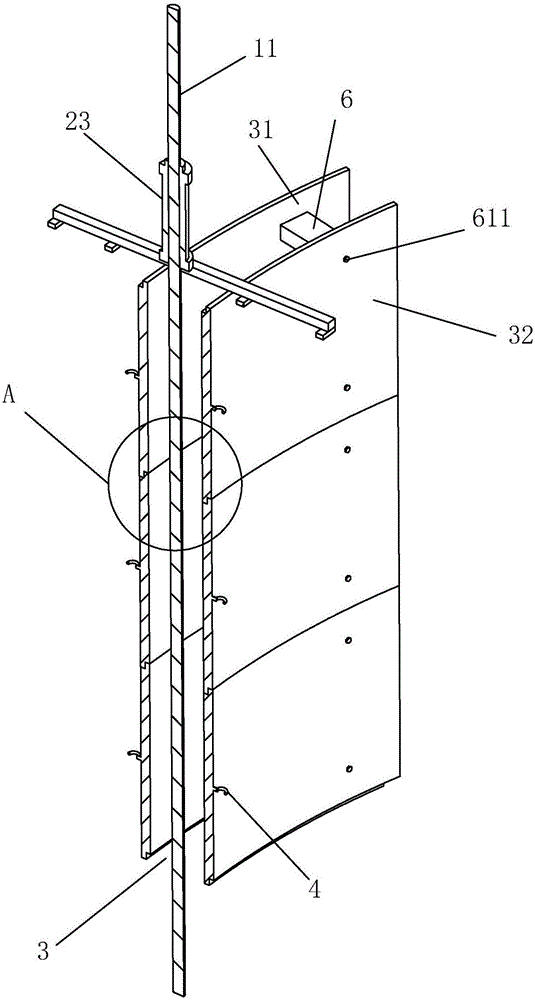

Self-heat-preservation prefabricated outer wall board with frame net rack

InactiveCN104234302AReduce the workload of insulationFast constructionBuilding componentsEngineeringSelf weight

The invention discloses a self-heat-preservation prefabricated outer wall board with a frame net rack. The prefabricated outer wall board comprises a heat-preservation sandwich board, steel wire net sheets and inclined inserting bars, wherein a space steel wire net rack is formed by the upper and lower steel wire net sheets and the heat-preservation sandwich board is arranged in the space steel wire net rack; the upper and lower steel wire net sheets are arranged at the peripheral edges along with the heat-preservation sandwich board, are bent inwards by two rows and are additionally provided with tie bars to form a frame steel bar cage; and lightweight concrete wall bodies are arranged on the upper and lower surfaces, and the peripheries of the space steel wire net rack. According to the self-heat-preservation prefabricated outer wall board, industrial prefabrication can be realized and the self weight is light; the periphery can be in flexible connection with a main body so that the anti-seismic effect is better; and meanwhile, the self-heat-preservation prefabricated outer wall board has the characteristics of rapid construction speed, low construction cost, energy conservation and environmental friendliness, safety and reliability and good heat preservation effect.

Owner:ANHUI YUTAI BUILDING TECH GRP

Double-column wave-dissipating body one-time prefabricating construction method

ActiveCN103171052ASimplify on-site construction proceduresImprove work efficiencyBreakwatersQuaysMaterials scienceBuilding construction

The invention discloses a double-column wave-dissipating body one-time prefabricating construction method which comprises the following steps: (1) prefabricating a concrete bottom tire; (2) paying off and bottoming; (3) binding steel bars; (4) erecting a template; (5) hoisting top steel bars; (6) reserving a lifting hole; (7) grouting the template; (8) concrete pouring; (9) removing the template; and (10) maintaining. According to the double-column wave-dissipating body one-time prefabricating construction method, by adoption of the one-time casting molding of set combined spliced steel template, the novel lifting design and the grouting method, the field construction process is simplified, various quality problems in the traditional prefabricating process for the double-column wave-dissipating body are solved, the working efficiency is improved, the cost is saved, and an obvious effect is achieved.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HARBOR ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com