Chimney formwork turning construction device

A construction device and chimney technology, which is applied in the field of chimney mold-turning construction devices, can solve problems such as pulling cracks, chimney pockmarks, and large friction between the formwork and the chimney, achieve uniform stress, avoid excessive stress, and improve the flipping mold. Efficiency and the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

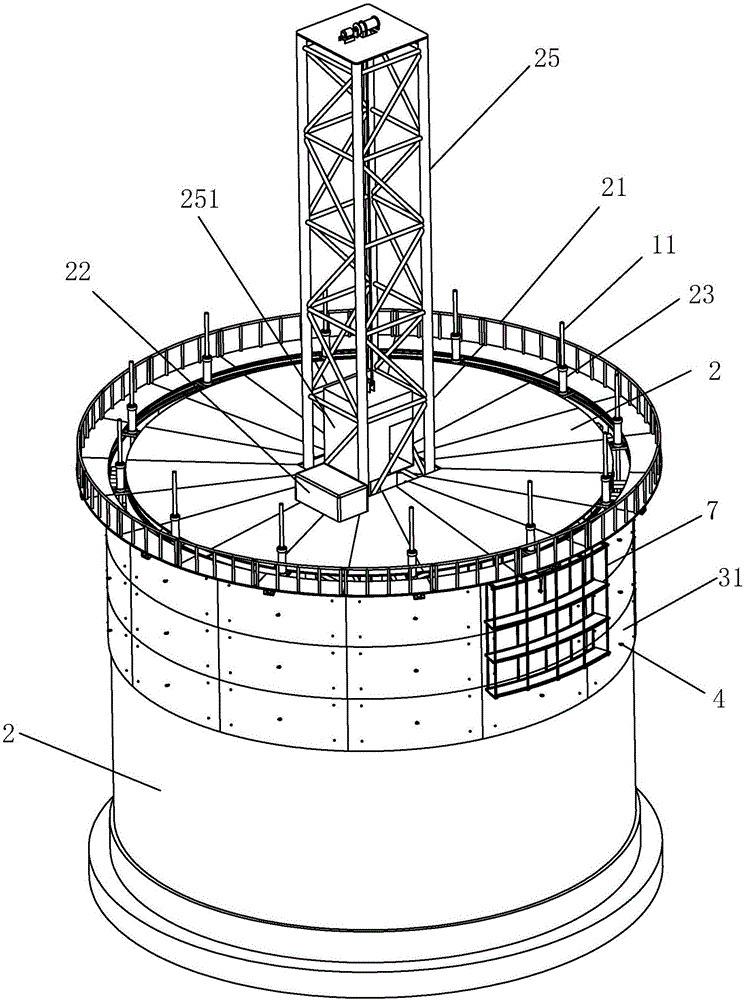

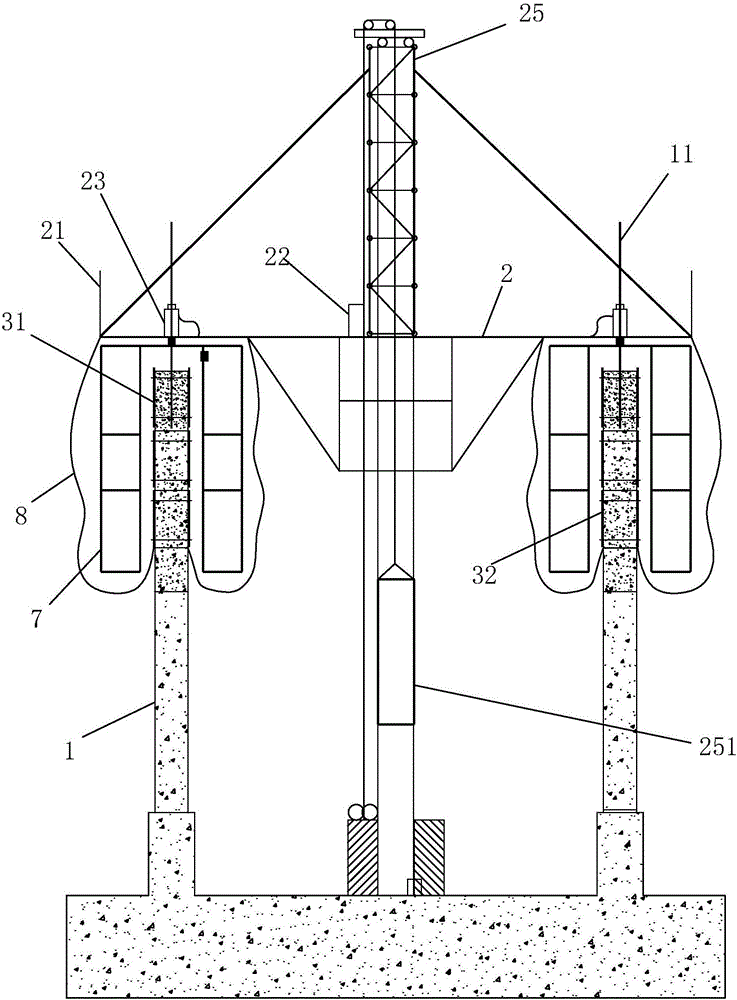

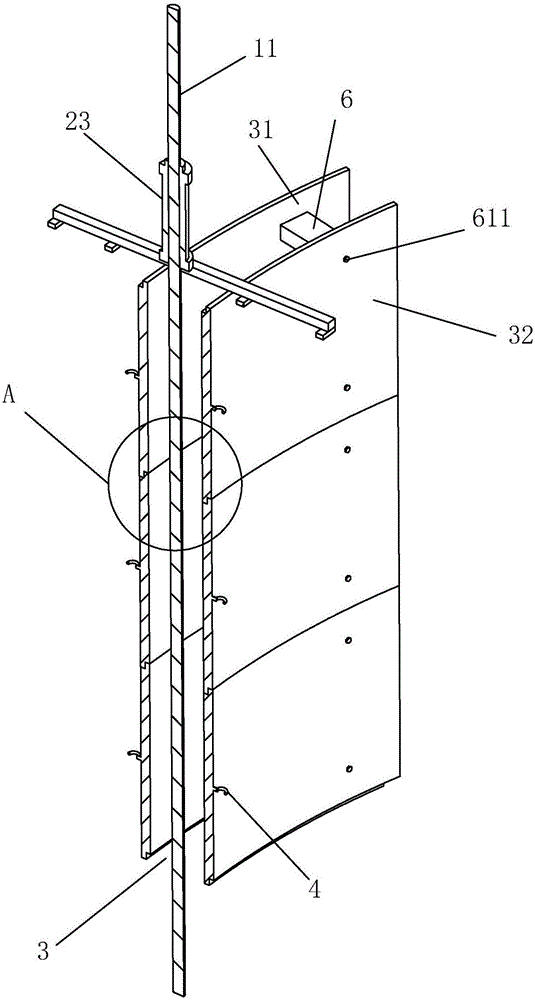

[0037] A kind of chimney turning form construction device, refer to figure 1 , figure 2 as well as image 3 , including the operating platform 2 and a lifting device that drives the operating platform 2 to move upward. The lifting device includes support rods 11 arranged in a circular array in the pouring cavity 3, the bottom of the support rods 11 is fixed on the top of the poured chimney 1, and the support rod 11 is covered with a through-hole jack 23, which is fixed on the operating platform 2, a hydraulic station 22 is provided at the center of the operation platform 2 to drive the action of the through-hole jack 23. During operation, the hydraulic station 22 pressurizes the inside of the through-hole jack 23, and the through-hole jack 23 can drive the operation platform 2 to support Climb on pole 11. In order to prevent people from falling from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com